Highly hydrophobic antistatic composite coating and preparation method thereof

A highly hydrophobic, composite coating technology, applied in conductive coatings, epoxy resin coatings, chemical instruments and methods, etc., can solve problems such as environmental hazards, and achieve the effects of improved strength, environmental friendliness, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

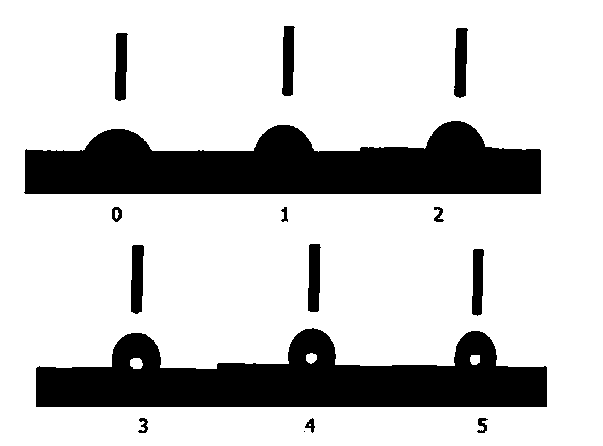

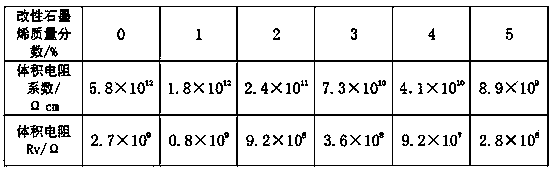

Image

Examples

preparation example Construction

[0043] The above-mentioned preparation methods of graphene oxide are not limited to the modified hummer method and Staudenmair et al.

[0044] Step 2: Modification of graphene:

[0045] Take graphite oxide and add it to an organic solvent (selected from acetone, N,N-pyrrolidone, N,N-dimethylformamide) to achieve a mass volume fraction of 2~10mg / ml, ultrasonic treatment for 1~3 hours, and prepare Graphene oxide solution;

[0046] Add isocyanate (selected from 4,4-dicyclohexylmethane diisocyanate, isophorone diisocyanate, 1,6-hexyl diisocyanate, dicyclohexylmethane diisocyanate, xylylene diisocyanate, isocyanate), the amount added is 100%~500% of the mass of graphene oxide, stirred and reacted for 10~24h under nitrogen protection, and the temperature is 70~90°C; then add long-chain modified substances (selected from octadecylamine, cetyl According to, dodecylamine, stearyl alcohol), the amount added is 2~4 times of the molar amount of isocyanate, and the reaction is continued ...

Embodiment 1

[0052] Step 1: the preparation of graphite oxide:

[0053] Take 2.0g of graphite powder and 1.0g of sodium nitrate and add it to 46ml of concentrated sulfuric acid (mass fraction 98%), and place the mixture in an ice bath and stir for 30min;

[0054] Weigh 6.0g of potassium permanganate and slowly add to the above mixture, and stir rapidly for 2 hours at a temperature not higher than 5°C;

[0055] Move the mixture into a warm water bath at 35°C and continue stirring for 3 h;

[0056] Slowly add 90ml of distilled water to the mixture, and control the temperature at 98°C for 30 minutes;

[0057] Cool to room temperature, add hydrogen peroxide with a mass fraction of 30%, remove excess potassium permanganate until the mixed solution turns bright yellow;

[0058]Add 150ml of distilled water to dilute and filter while it is hot, wash with hydrochloric acid with a molar concentration of 0.01mol / l, absolute ethanol, and deionized water in sequence until there is no sulfate ion in t...

Embodiment 2

[0068] Step 1: the preparation of graphite oxide:

[0069] Take 3.5g of graphite powder and 1.5g of sodium nitrate and add it to 53ml of concentrated sulfuric acid (mass fraction 98%), and place the mixture in an ice bath and stir for 45min;

[0070] Weigh 10.5g of potassium permanganate and slowly add to the above mixture, and stir rapidly for 3.5h at a temperature not higher than 5°C;

[0071] Move the mixture into a warm water bath at 35°C and continue to stir for 4.5 hours;

[0072] Slowly add 120ml of distilled water to the mixture, and control the temperature at 98°C for 45 minutes;

[0073] Cool to room temperature, add hydrogen peroxide with a mass fraction of 30%, remove excess potassium permanganate until the mixed solution turns bright yellow;

[0074] Add 225ml of distilled water to dilute and filter while hot, wash with hydrochloric acid with a molar concentration of 0.01mol / l, absolute ethanol, and deionized water in sequence until there is no sulfate ion in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com