Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

757 results about "Potassium manganate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium manganate is the inorganic compound with the formula K₂MnO₄. This green-colored salt is an intermediate in the industrial synthesis of potassium permanganate (KMnO₄), a common chemical. Occasionally, potassium manganate and potassium permanganate are confused, but they are different compounds with distinctly different properties.

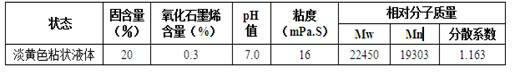

Preparation method of graphene oxide dispersion liquid

ActiveCN103787317AThe process steps are simpleReduce manufacturing costCarbon compoundsToxic gasSulfate radicals

The invention discloses a preparation method of a graphene oxide dispersion liquid, and the preparation method comprises the following steps: performing ultrasonic treatment so as to obtain a sulfate-intercalated graphite / sulfuric acid mixture; adding potassium permanganate into the obtained sulfate-intercalated graphite / sulfuric acid mixture for a medium-temperature oxidation reaction to obtain a preliminary graphite oxide; performing a high-temperature hydrolysis reaction to obtain a graphite oxide with a hydrophilic group; adding hydrogen peroxide and continuously performing an oxidation reaction to obtain luminous yellow graphite oxide turbid liquid; centrifuging or filtering to obtain claybank mud-like or cake-like object, and treating with a mixed solution of hydrogen peroxide and concentrated sulfuric acid to obtain graphite oxide with a great quantity of hydrophilic groups; washing and vacuum-drying to obtain pure graphite oxide, adding into a solvent and performing ultrasonic treatment to obtain graphene oxide dispersion liquid. The graphene oxide in the graphene oxide dispersion liquid has good dispersity, good stability and relatively large slice. By adopting the preparation method, the process steps are simplified, and the production cost and energy consumption are reduced; the emission of NO2 / N2O4 toxic gas is avoided in the reaction process, thereby being environment-friendly.

Owner:江苏超电新能源科技发展有限公司

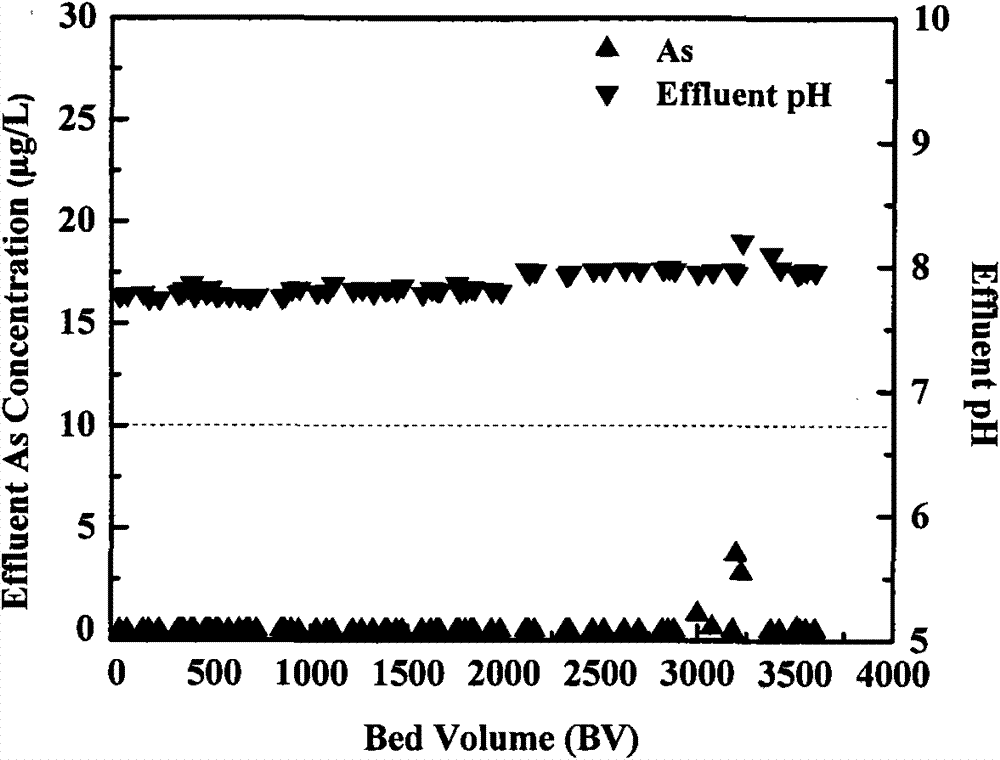

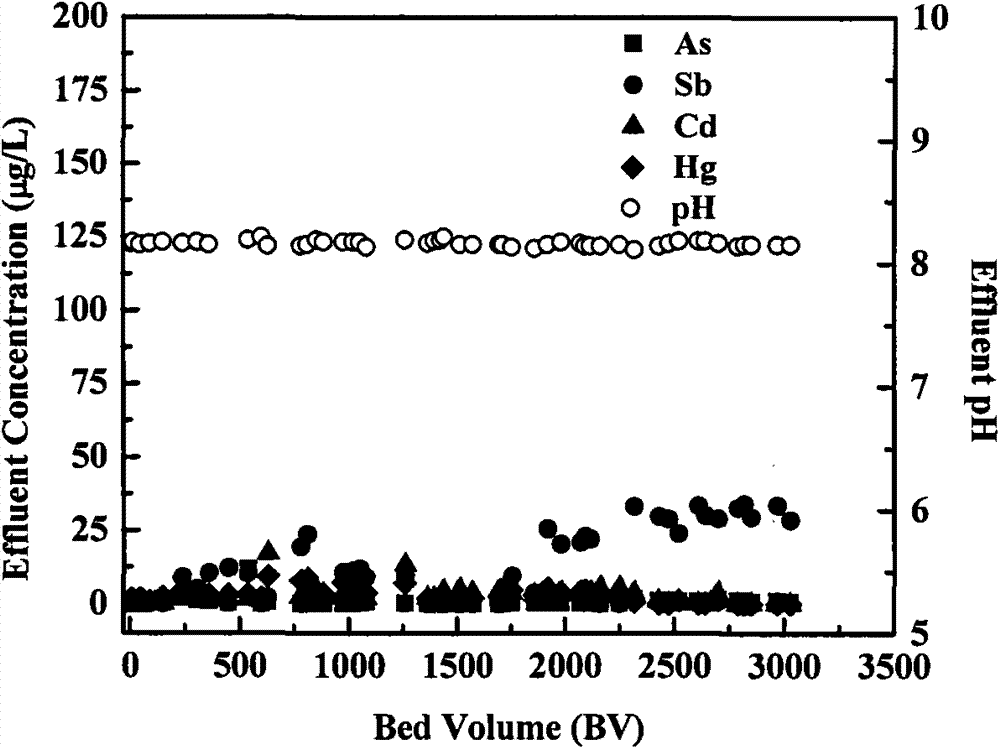

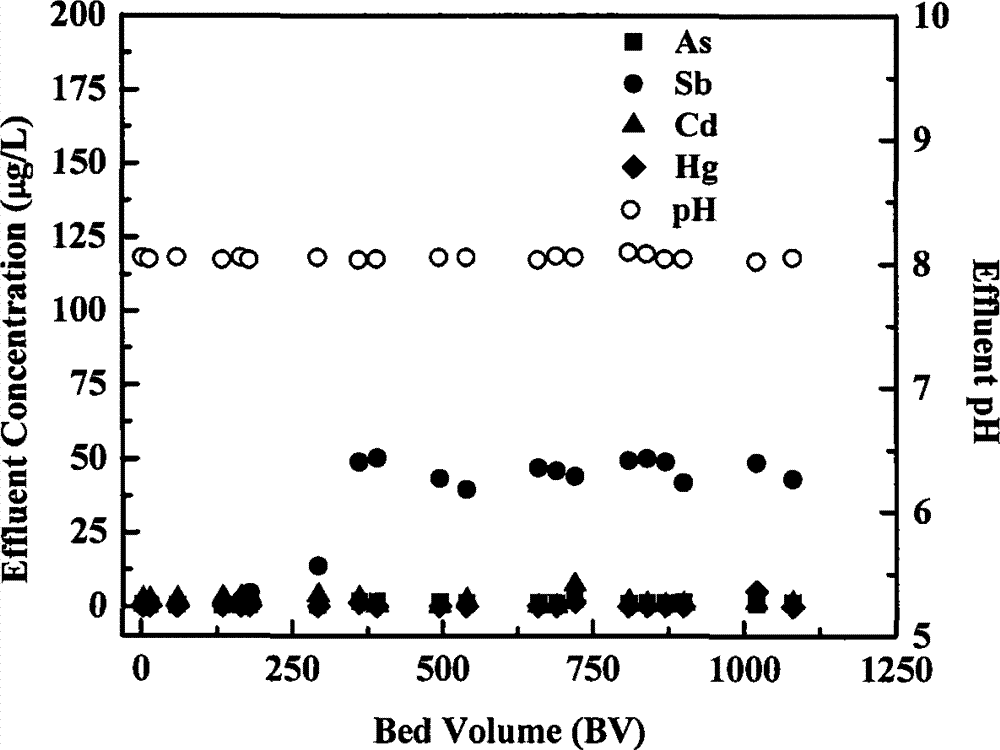

Method for quickly and efficiently removing heavy metals in water body

ActiveCN104276646AImprove cleanlinessGood chromaWater contaminantsMultistage water/sewage treatmentPotassium permanganatePrecipitation

The invention relates to a method for removing heavy metals in a water body, which is characterized in that common oxidizers for water treatment, such as hydrogen peroxide, sodium hypochlorite, potassium permanganate and the like, are utilized for oxidization to activate the zero-valent iron surface and continuously generate fresh iron (III) / (II) (hydro)oxide and other active components, thereby quickly and efficiently removing heavy metals in the water body, including As, Hg, Cd, Pb, Cr, Se, Sb, Cu, Zn and the like, in a mode of adsorption, precipitation, redox or the like.

Owner:BEIJING NORMAL UNIVERSITY

Method for rapidly preparing graphene in large quantities by utilizing graphite oxides

InactiveCN102502611ASimple processExcellent microwave absorbing mediumGrapheneNanotechnologyPotassium dichromatePotassium manganate

The invention aims at providing a preparation method for rapidly obtaining graphene in large quantities. On the basis of obtaining graphite oxides, the molecular thermodynamic movement of groups such as hydroxyl groups (-OH), carboxylic groups (-COOH) and the like which are generated on the surfaces of graphite oxide layers through oxidization can be induced and stimulated through microwave treatment so as to produce a momentary unsteady state, so that Van der Waals binding force between graphite layers is damaged, and graphene can be rapidly obtained in large quantities. The graphite oxides are obtained through the oxidization of metal salt such as potassium permanganate, potassium dichromate and the like as well as strong protonic acid such as concentrated sulphuric acid, concentrated nitric acid and the like, and then microwave irradiation is carried out under the conditions that the power ranges from 2 to 10 kW, the vacuum pressure ranges from 0.01 to 0.06 MPa and so on, so that microwave cleavage of the graphite oxides can be accomplished within 2 to 10 seconds, and graphene with less than ten layers can be obtained rapidly in large quantities. The preparation method can also control the layer number or the thickness of graphene products by controlling the concentration and the oxidation time of oxidizing mediums as well as the power, the degree of vacuum and the like of the microwave irradiation.

Owner:SOUTHEAST UNIV

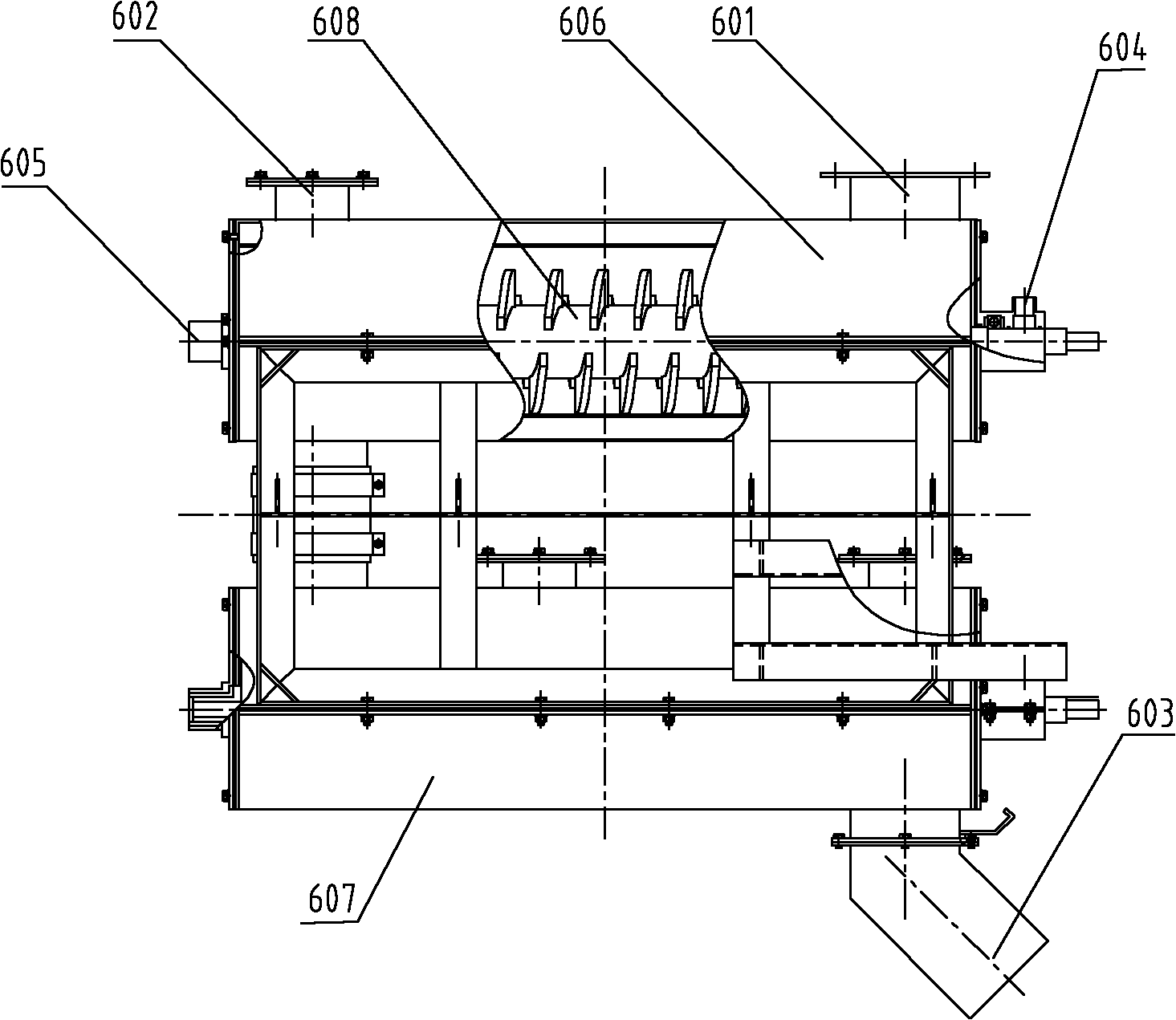

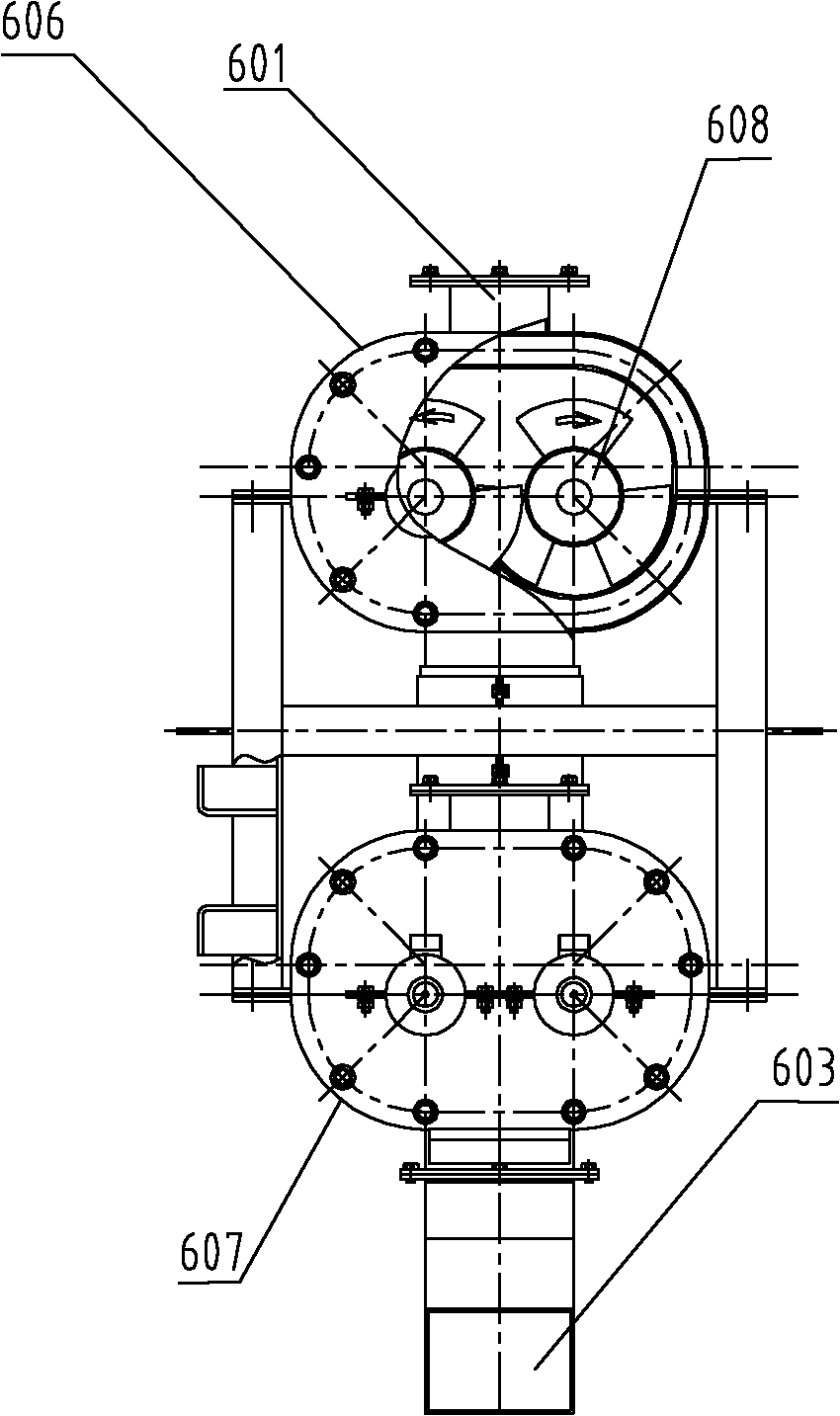

Sludge dehydrating and drying process method and device

InactiveCN101823825AGood effectLow costSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentAutomatic controlSlag

The invention belongs to the technical field of environmental engineering, in particular to a sludge dehydrating and drying process method and a device. The technical essential points of the invention are that: firstly, adding one or several of fly ash, fine manganese slag, calcined lime, ferric chloride solution and aluminum sulfate solution into sludge and dehydrating and conditioning the sludge; secondly, feeding the sludge into a pre-drying area and simultaneously adding a certain amount of calcined lime, potassium permanganate and finished product of dry sludge and uniformly mixing; feeding the sludge treated in the pre-drying area into a hollow paddle spiral indirect dryer; returning one part of finished product of dry sludge to the pre-drying area and carrying out drier back-mixing with wet sludge; supplying saturated heated steam to a drier by an electric boiler; and introducing steam tail gas from the drier to the pre-drying area for heating the wet sludge. The device is automatically controlled by a control center through a control bus. The process has the advantages of energy saving, environmental protection and high efficiency.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of organic-chain-segment-modified graphene oxide

InactiveCN102745672APreparation helpsPromote recombinationCarbon compoundsOrganosolvPotassium manganate

The invention discloses a preparation method of organic-chain-segment-modified graphene oxide. According to the invention, graphite is oxidized under the effects of strong oxidizing agents such as concentrated sulfuric acid, sodium nitrate and potassium permanganate; the oxidized graphite is subjected to ultrasonic dispersion in an organic solvent, such that a graphene oxide dispersion system is prepared; diisocyanate and dihydric alcohol are subjected to a reaction; hydroxyacrylate is used for sealing one end; and an NCO group in the organic chain segment is subjected to a reaction with the prepared graphene oxide, such that the organic-chain-segment-modified graphene oxide is prepared. The organic chain segment contains polymerizable double bonds, such that cross-linking polymerization of the modified graphene oxide and other organic materials can be promoted, and composite materials with special properties can be obtained.

Owner:SHENZHEN POLYTECHNIC

Graphene @Fe3O4 compound water base magnetorheological fluid and preparation method thereof

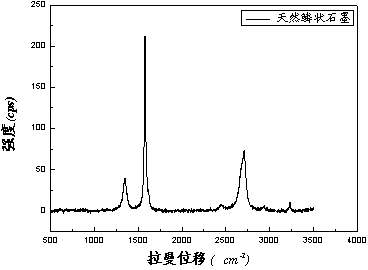

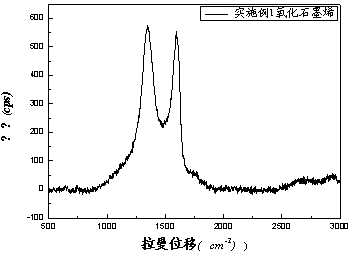

The invention relates to the field of intelligent magnetic materials and in particular relates to a graphene @Fe3O4 compound water base magnetorheological fluid and a preparation method thereof, solving the problems that existing magnetorheological fluids are easy to settle and the stability and magnetorheological effects of the magnetorheological fluids are difficult to optimize at the same time. The preparation method comprises the following steps: preparing a Fe3O4 water base magnetic fluid with FeCl2.4H2O and FeCl3.6H2O; sequentially adding concentrated sulfuric acid, potassium permanganate and hydrogen peroxide to natural flake graphite and sodium nitrate to prepare graphite oxide; and then carrying out ultrasonic dispersion on home-made graphite oxide to prepare graphene oxide, finally adding a surfactant, the Fe3O4 water base magnetic fluid and a reducing agent to graphene oxide, washing the solution with deionized water until the solution is neutral, and then dispersing graphene @Fe3O4 compound magnetic particles in the deionized water to undergo ultrasonic dispersion, removing the precipitates and taking the supernatant, namely the stable graphene @Fe3O4 compound water base magnetorheological fluid, wherein the magnetic particles are graphene @Fe3O4 and account for 5-35wt% of the whole. The method has the advantages of good stability, low zero field viscosity, high shear strain and wide operating temperature range.

Owner:ZHONGBEI UNIV

Chromium-free treating liquid for preparing erosion-resisting oxide film on aluminum alloy surface, treating and using method thereof

ActiveCN101054664AImprove corrosion resistanceGolden colorMetallic material coating processesSodium acetateChromium free

The present invention discloses a chromium-free treatment liquid for preparing corrosion resistant oxidation film at aluminium alloy surface as well as the processing and use method thereof, characterized in that said treatment fluid utilizes a cobalt (III) salt as a main salt and a hypermanganate and a nitrate as a composite oxidizing compound to prepare a composite Co-Mn oxidation film having favorable corrosion resistance performances at aluminium alloy surface. The formula for said treatment liquid is that each litre solution contains cobalt salt of 5 g / L(-1)-20 g / L(-1), kalii permangana of 1 g / L(-1)-4 g / L(-1), sodium nitrate of 1 g / L(-1)-4 g / L(-1), promotor (chlorides and fluorides) of 1 g / L(-1)-4 g / L(-1), sodium acetate of 20 g / L(-1)-50 g / L(-1) and wetting agents (sodium dodecylbenzene sulfonate, OP-10) of 0.5 g / L(-1)-1 g / L(-1). Saic processing and use method comprises (1)sanding the aluminium alloy until its surface is smooth and even; (2) pretreating the aluminium alloy surface; (3) performing a conversion processing by using the treatment fluid; (4) cleaning-up using water and atmospheric-drying naturally. Said treatment fluid in accordance with the present invention possesses the advantages of environmental protection due to its hexavalent chromium-free, fast film-forming speed, simple process, uniform rete, strong corrosion resistance, few environment pollution, and the like.

Owner:GUANGYA ALUMINUM

Method for constructing dual-chamber microbial fuel cell-type BOD (biochemical oxygen demand) sensor by using potassium permanganate as cathode electron acceptor

InactiveCN103207230AImprove performanceQuick checkMaterial analysis by electric/magnetic meansWater qualityEngineering

The invention provides a method for constructing a dual-chamber microbial fuel cell (MFC)-type BOD (biochemical oxygen demand) sensor by using potassium permanganate as cathode electron acceptor, which belongs to the field of waste water quality monitoring. The method specially comprises the steps of constructing a dual-chamber MFC reactor; enriching electricigenic microorganisms on an MFC anode plate, and adjusting an external resistor to obtain maximum MFC output power; respectively adding different concentrations of artificial sewage and potassium permanganate solution into an anode chamber and a cathode chamber of the MFC, calculating the generated electricity of the MFC corresponding to different BOD concentrations according to MFC output current and detection time; and processing the generated electricity and BOD by linear fitting to obtain a sensor detection limit and a linear equation. After a to-be-tested solution with unknown BOD value is added into the anode chamber of the MFC, the generated electricity of the MFC is calculated according to the MFC output current and the detection time; and the BOD value of the to-be-tested solution can be calculated according to the known linear equation. The MFC-type BOD sensor using potassium permanganate as cathode electron acceptor has the advantages that the BOD detection range is widened to be 500mg / L; the detection time is shortened by 50% or more; and the detection relative error is less than 10%. Accordingly, the MFC-type BOD sensor has a high application value.

Owner:BEIJING FORESTRY UNIVERSITY

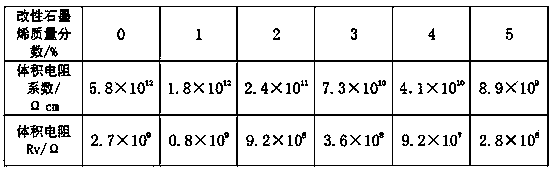

Highly hydrophobic antistatic composite coating and preparation method thereof

ActiveCN104130669AHigh strengthGood compatibilityPolyurea/polyurethane coatingsEpoxy resin coatingsSulfate radicalsPotassium manganate

The invention relates to a highly hydrophobic antistatic composite coating and a preparation method thereof. The hydrophobicity of a conventional hydrophobic material is improved mainly by adding fluorine-containing substances. The preparation method comprises the following steps: adding graphite powder and sodium nitrate into concentrated sulfuric acid, stirring in an ice bath, adding potassium permanganate, slowly dropwise adding distilled water, removing excessive potassium permanganate, filtering sulfate ions to obtain oxidized graphite, adding the oxidized graphite into an organic solvent, and ultrasonically processing to prepare an oxidized graphene solution; adding isocyanic acid, a long-chain modified substance and a reducer into the oxidized graphene solution in sequence to chemically modify oxidized graphene, washing and drying to obtain modified graphene; by taking resin as a base body, uniformly dispersing the resin and the modified graphene through ultrasonic blending or quick stirring to obtain the highly hydrophobic antistatic composite coating. The composite coating provided by the invention has hydrophobic and antistatic performances, does not contain the fluorine-containing substances, and is environment-friendly and excellent in durability.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method and application of nitrogen-doped graphene/nitrogen-doped carbon nanotube/zinc cobaltite composite material

ActiveCN105225844AIncrease contact areaIncrease usageHybrid capacitor electrodesCell electrodesCvd grapheneNitrogen doped carbon nanotube

The invention discloses a preparation method of a nitrogen-doped graphene / nitrogen-doped carbon nanotube / zinc cobaltite composite material. The method comprises the following specific steps: (a) adding potassium permanganate, hydrochloric acid and hydrogen peroxide to graphene oxide, and carrying out a stirring reaction to obtain porous graphene; (b) dialyzing the porous graphene for 8-12 days, carrying out ultrasonic dispersion, then adding a carbon nanotube, carrying out ultrasonic mixing and carrying out suction filtration to form a film; (c) drying the film, and then adding ammonium hydroxide for reaction for 24 hours; (d) adding zinc nitrate, cobalt nitrate, urea, ammonium fluoride, absolute ethyl alcohol and distilled water for reaction for 4 hours; and (e) transferring a mixture to a tube furnace, and sintering the mixture in a nitrogen atmosphere for 2 hours, so as to obtain the composite material. The composite material has relatively good flexibility; the electrochemical properties are barely changed after the composite material is bent into various angles; the specific capacitance value of the composite material can be up to 1802F / g; compared with relatively simple graphene, the carbon nanotube and most of composite materials of the graphene and the carbon nanotube, the composite material provided in the invention are significantly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Novel environment-friendly reagent for reducing leaching concentration of various heavy metals

InactiveCN103555340AReduce usage ratioSimplify the restoration construction processWater contaminantsOrganic fertilisersPhosphatePotassium manganate

The invention discloses a novel environment-friendly reagent for reducing leaching concentration of various heavy metals. The formula of the environment-friendly reagent comprises 0-30wt% of sodium polysulfide, 1-25wt% of sodium silicate, 0-15wt% of organic sulfur TMT-15, 0-20wt% of hydrazine hydrate, 1-20wt% of phosphate, 1-10wt% of sodium sulphide, 0-15wt% of ferrous sulfate, 0-5% of potassium permanganate, 0-5wt% of citric acid and 0-5wt% of edetic acid (EDTA). The novel environment-friendly reagent can be applied to ex-situ remediation of the traditional hazardous waste containing the heavy metals, and can also be applied to in-situ remediation of pollution site soil and underground water containing the heavy metals.

Owner:SHAOXING ENVIRONREM ENVIRONMENTAL TECH CO LTD

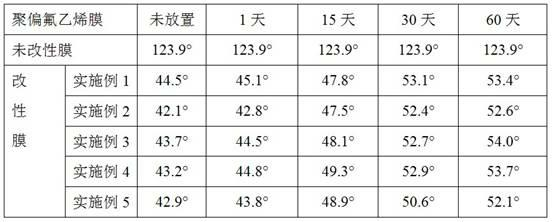

Method for performing hydrophilic modification on surface of polyvinylidene fluoride microporous membrane

The invention provides a method for performing hydrophilic modification on the surface of a polyvinylidene fluoride micro-porous membrane. The method is characterized by comprising the following specific steps of: cleaning a polyvinylidene fluoride micro-porous filter membrane with deionized water, dipping the cleaned filter membrane in solution of ethanol, dipping the dipped filter membrane in the deionized water, adding the polyvinylidene fluoride micro-porous membrane into solution of an alkali oxidant and reacting at the temperature of between 20 and 80 DEG C for 20 to 60 minutes, wherein the alkali oxidant contains alkali and potassium permanganate serving as an oxidant; dipping the polyvinylidene fluoride micro-porous membrane treated in the step one in solution of an acid reducing agent to remove the alkali and the potassium permanganate serving the oxidant on the surface, cleaning the dipped membrane with the deionized water and drying the cleaned membrane; and dipping the polyvinylidene fluoride micro-porous membrane treated in the step two in 5 to 20 volume percent solution of glycerin, reacting at normal temperature for 5 to 20 minutes, cleaning the membrane with the deionized water and drying the cleaned membrane. The method has the advantages of simple and efficient process, capability of improving the hydrophility of the polyvinylidene fluoride membrane and lasting effect.

Owner:DONGHUA UNIV

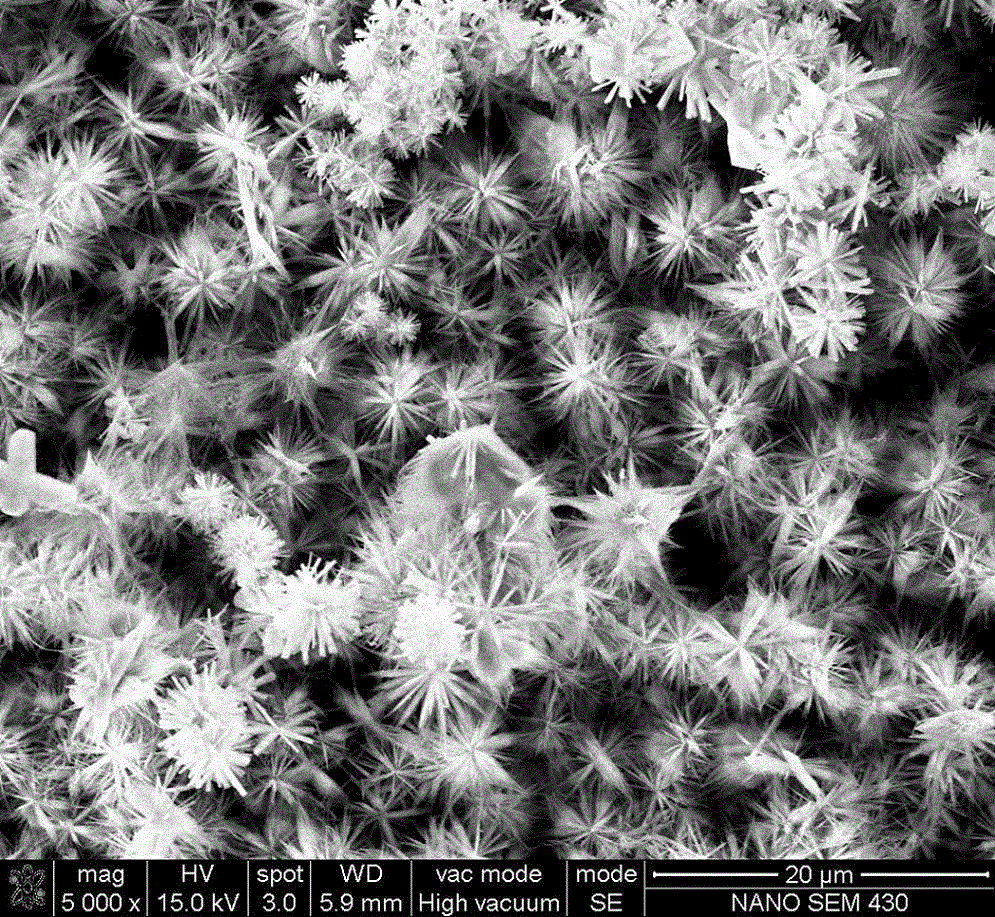

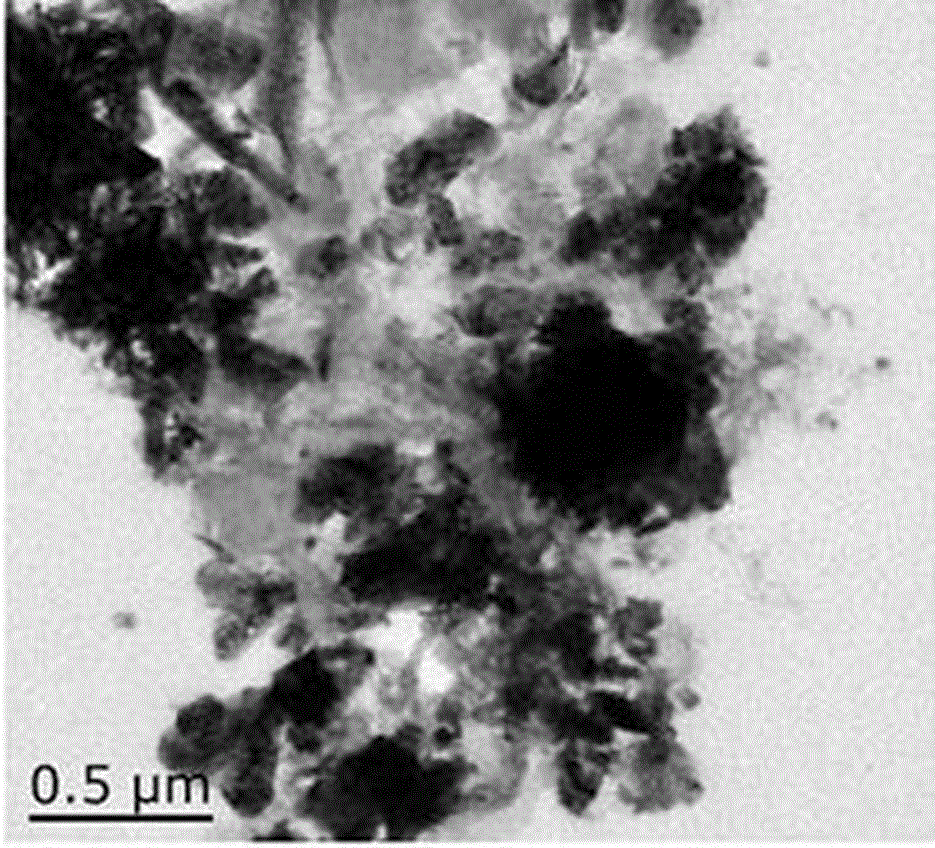

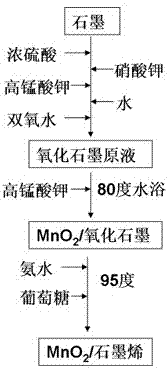

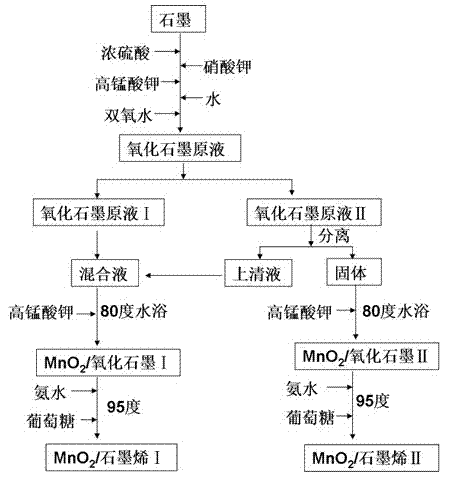

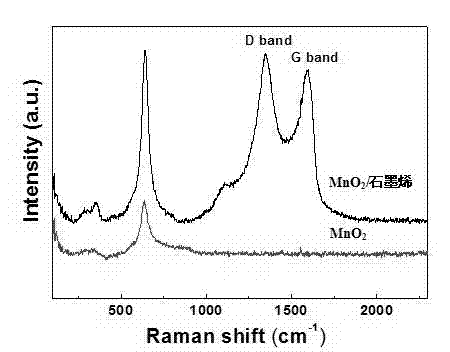

Lowcost preparation method of MnO2 / graphene composite electrode materials used for supercapacitor

InactiveCN103035417ATake advantage ofSimple processHybrid/EDL manufactureComposite electrodeSupercapacitor

The invention discloses a lowcost preparation method of MnO2 / graphene composite electrode materials used for supercapacitor. The graphite oxide stoste containing graphite oxide and divalent manganese ion which is obtained in a graphite oxidation process is directly used as a precursor of preparation of MnO2 / graphene compound, isolation of the graphite oxide is not needed, and the craft process is simplified. The divalent manganese salt in the graphite oxide stoste is used as one of manganese resources. Then potassium permanganate is added and manganese oxide is formed. Raw materials are effectively used and cost is lowered. Glucose which is of no influence to MnO2 structure is adopted as reducing agent to restore the graphite oxide to prepare grapheme, the condition is mild, green and environmental protection are achieved, and the method is suitable for mass production. The mass fraction of MnO2 in the MnO2 / graphene composite electrode materials is 56% to 94%. Electrochemistry volume reaches 100 F / g to 400 F / g.

Owner:LIAONING NORMAL UNIVERSITY

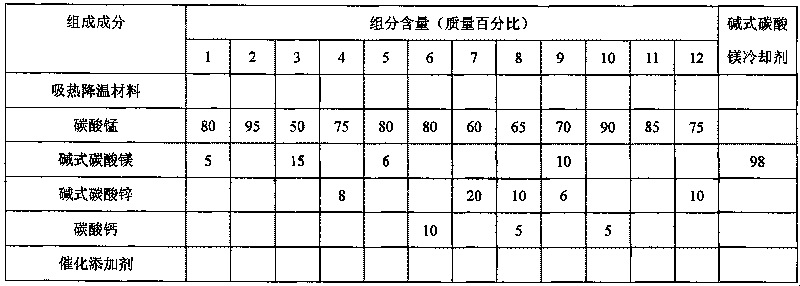

Catalytic chemical coolant for hot aerosol and preparation method thereof

InactiveCN101757760AImprove cooling efficiencyLow toxicityFire extinguisherHydroxyethyl celluloseFilm material

The invention relates to a catalytic coolant used in a hot aerosol fire extinguishing device and a processing technique of the catalytic coolant. As to the coolant, heat absorption cooling components mainly include manganese carbonate or manganese oxalate, manganese phosphate, potassium manganate, metal carbonate of a family I, a family II and a transition family, basic carbonate, oxalate and the like; a metal oxide or a hydroxide are adopted as a catalyst, an oxidant and a reinforcing filling; stearate, graphite and the like are adopted as a processing aid; composite solution of alkalis silicate and a water soluble polymer is adopted as an adhesive; and film materials such as hydroxymethyl or hydroxyethyl cellulose are adopted as a surface coating agent. The processing technique includes the steps of mould pressing, squeezing, pelletizing, coating and forming. Compared with the prior art, the catalytic coolant not only has high intensity and good cooling effect, but also can reduce secondary damage of an extinguishing agent and eliminate the content of poisonous gases in an extinguishing agent product so as to improve the environmental safety of the extinguishing agent.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

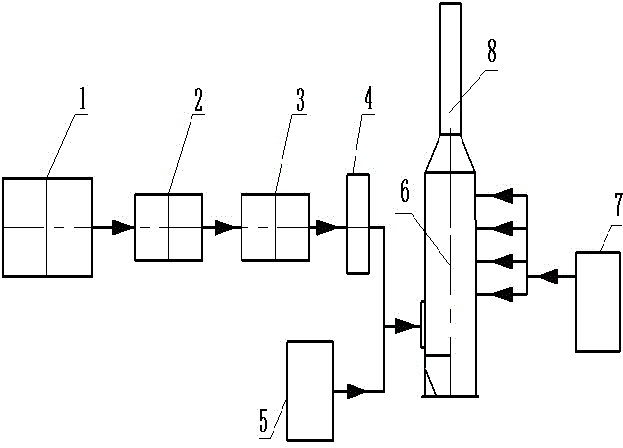

Gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process

InactiveCN104971594AEfficient removalReduce equipment costsDispersed particle separationAir quality improvementPotassium manganateSlurry

The invention discloses a gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process. According to the process, ozone is used as a gas-phase oxidant to oxidize one part of nitric oxide in flue gas into high-valence-state nitric oxide capable of being absorbed by slurry; any one or a mixture solution of more of hydrogen peroxide, sodium hypochlorite, sodium chlorite, sodium chlorate, sodium persulfate, potassium chlorate, potassium hypermanganate and potassium dichromate is sprayed to be used as a liquid-phase oxidant to oxidize the residual high-valence-state nitric oxide in the flue gas into the high-valence-state nitric oxide; and the flue gas enters an absorption tower and a magnesium hydroxide solution is sprayed to absorb the high-valence-state nitric oxide. Compared with the prior art, the process firstly adopts two times of oxidization of a gas phase and a liquid phase and a magnesium oxide wet process is used for absorbing so that a target of efficiently removing the nitric oxide is realized; and by virtue of the technical scheme, the use amount of the ozone is reduced, the equipment cost and operation cost are reduced and the denitration efficiency is improved and can reach more than or equal to 93%.

Owner:SHANGHAI SANQING ENVIRONMENTAL PROTECTION TECH

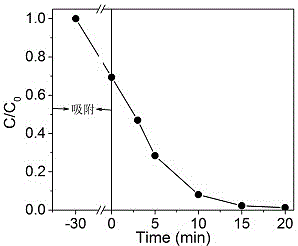

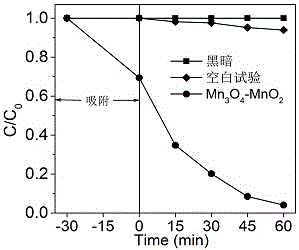

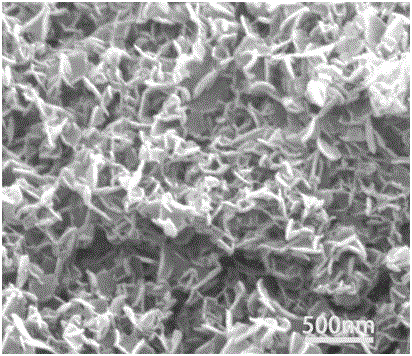

Preparation method of Mn3O4-MnO2 nano composite material and application thereof

InactiveCN106475090ASimple processEasy to operateMaterial nanotechnologyWater/sewage treatment by irradiationAlcoholRoom temperature

The invention relates to a preparation method of Mn3O4-MnO2 nano composite material and an application thereof; the preparation method includes steps of adding tetrahydrate manganese chloride and polyvinylpyrrolidone in de-ionized water, and adding the prepared mixing solution to the de-ionized water; adding sodium hydroxide and reacting; adding potassium permanganate in the reacted solution; keeping the stirring for 3-6 hours, and then cooling to room temperature; performing the centrifugal separation and obtaining precipitate; after alternatively washing the precipitate by de-ionized water and absolute ethyl alcohol, drying and obtaining the Mn3O4-MnO2 nano composite material, wherein the material thickness is 10-30 nm; the prepared nano composite material can be importantly applied to advanced oxidization technology. The process is simple in flow and free from pollution; the production and manufacturing costs of Mn3O4-MnO2 nano composite material can be reduced; meanwhile, the Mn3O4-MnO2 nano composite material prepared by the method can fundamentally degrade the organic pollutant in the water.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Method for preparing composite of grapheme with different oxidation degrees and manganese dioxide

InactiveCN102709057AHigh purityLess impurity elementsElectrolytic capacitorsPotassium manganateManganese oxide

The invention discloses a method for preparing composite of grapheme with different oxidation degrees and manganese dioxide. The method comprises the processes of: respectively carrying out low-temperature, intermediate-temperature and high-temperature subsection reactions on original graphite, and concentrated sulfuric acid with a mass concentration of 98% and potassium permanganate so as to obtain graphite oxide; dispersing the graphite oxide in de-ionized water, and reducing the prepared graphite oxide with hydrazine hydrate so as to obtain the grapheme oxide with different oxidation degrees by controlling reduction time; and mixing the grapheme oxide with MnCl2*4H2O in an isopropyl alcohol solution, and adding a water solution of the potassium permanganate to prepare the composite of the grapheme with the different oxidation degrees and the manganese dioxide through oxidation reduction. The method provided by the invention has the advantages as follows: materials used in the method are rich in storage amount and low in cost, so that the method is good in commercialization; an dispersing agent, a stabilizer and the like do not need to be added, and a pure chemical technology is used, so that simple operation, no pollution and low energy consumption can be realized; and the prepared composite material of the grapheme and the manganese dioxide has high purity and good stability.

Owner:TIANJIN UNIV

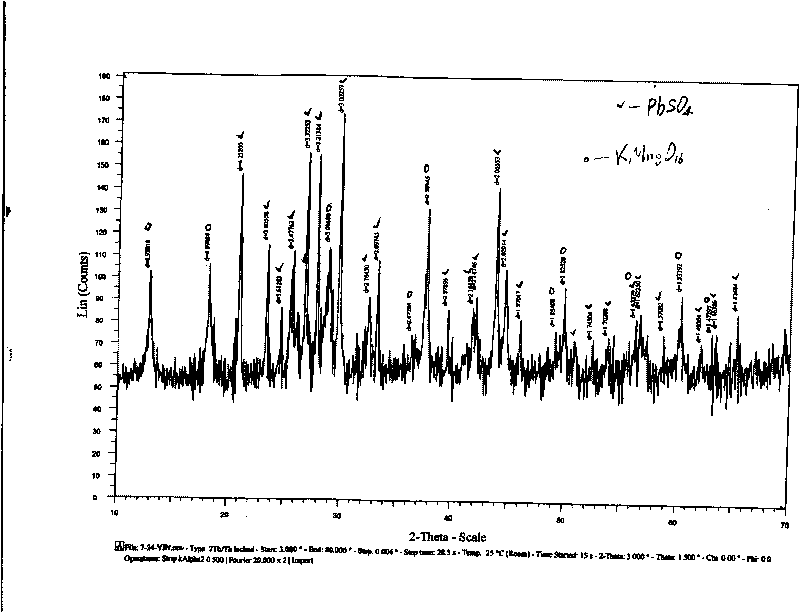

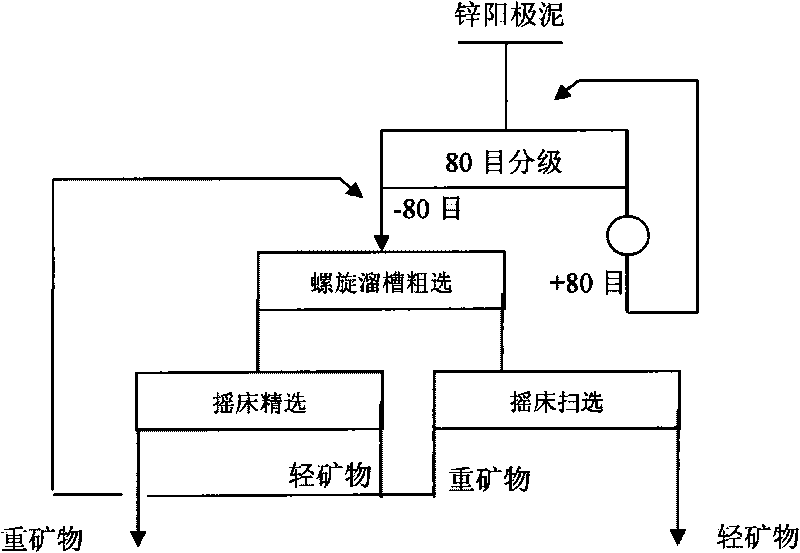

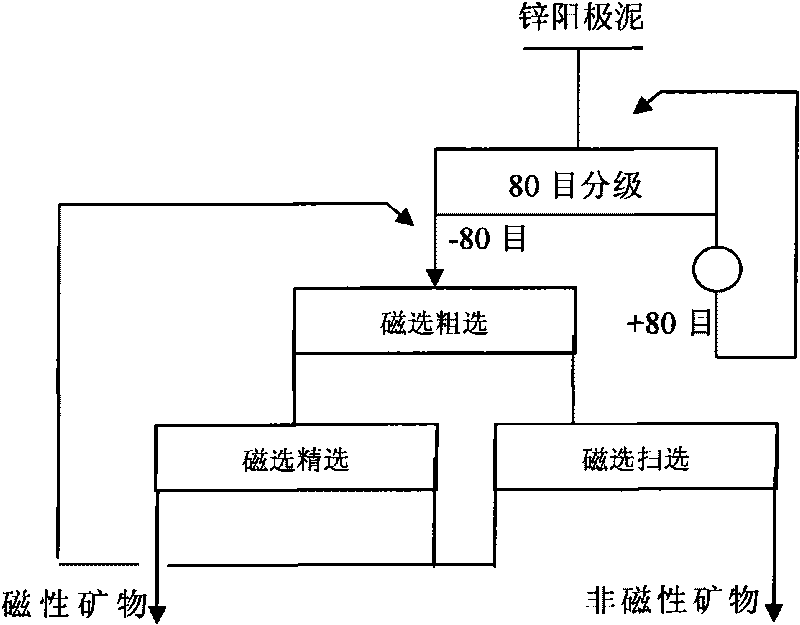

Method for separating lead and silver from manganese in anode sludge

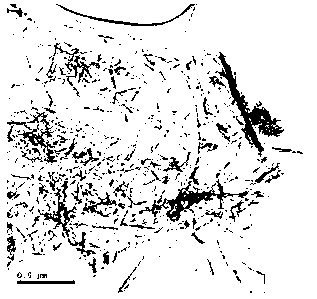

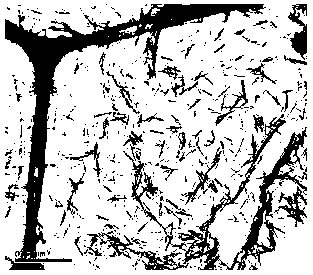

InactiveCN101690910ASimple processReduce manufacturing costFlotationMagnetic separationSludgePotassium manganate

The invention relates to a method for realizing the separation of lead and silver and the like from manganese in anode sludge. The method takes a physical benefication method, such as magnetic separation, reselection and flotation and the like as a main part, and comprises two steps: the first step: preprocessing the anode sludge, washing the anode sludge by water, removing reacted acid, water-soluble zinc or water-soluble manganese in the anode sludge; the second step: carrying out selective ore grinding on the anode sludge to a certain fineness, and processing by utilizing the physical benefication method, such as reselection, magnetic separation and flotation and the like to realize the separation of manganese from lead and silver. The invention has the following three characteristics: 1. the mode of existence of manganese in manganic concerntrate products is kept to be unchanged as quadrivalent manganese compound of manganese dioxide or potassium manganate with the same raw materials; 2. the physical benefication method adopting reselection, magnetic separation or flotation has simple process, lower manufacturing cost than the manufacturing cost generated by utilizing a wet process or a firing process; and 3. the physical benefication method adopting reselection, magnetic separation or flotation does not generate three waste pollution in the whole manufacturing process.

Owner:HUNAN HUAQI RESOURCES ENVIRONMENT SCI & TECH DEV CO LTD

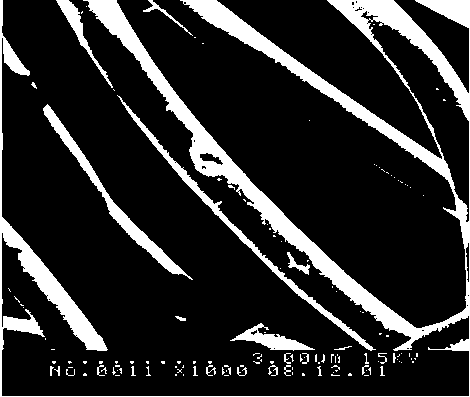

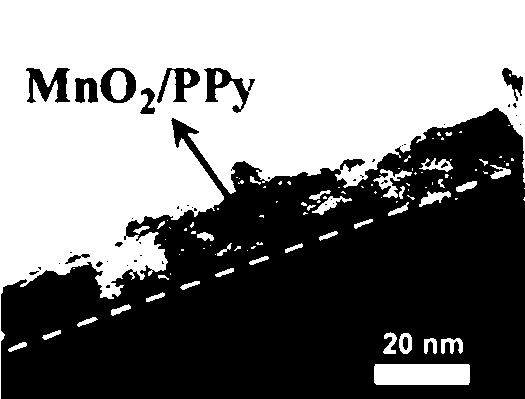

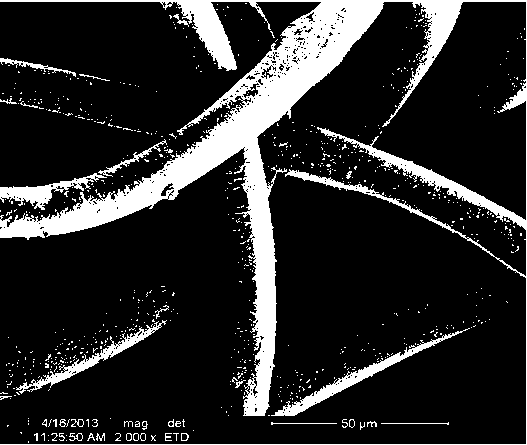

Dedusting filter material containing MnO2 catalyst, and preparation method and application thereof

ActiveCN103212245AImprove bindingGood dispersionNitrous oxide captureDispersed particle filtrationPtru catalystPolypyrrole

The invention discloses a dedusting filter material containing a MnO2 catalyst, and a preparation method and application of the dedusting filter material. A polyphenylene sulfide punched felt is taken as the filter material; potassium permanganate is reduced into an amorphous MnO2 denitrification catalyst, which is inserted and disperses into a polypyrrole matrix, through in-situ reaction of acidic potassium permanganate and pyrrole monomer on the surface of the punched felt, so that the MnO2 has a high denitration rate; and besides, the polypyrrole formed in situ is taken as a medium for connecting the catalyst and the filter material, and therefore, the catalyst is unlikely to drop. The catalytic filter material has a function of removing PM2.5 and NOx simultaneously, and can overcome the disadvantages of complexity, high treatment costs and the like of a tail flue gas purification system in the prior art.

Owner:FUZHOU UNIV

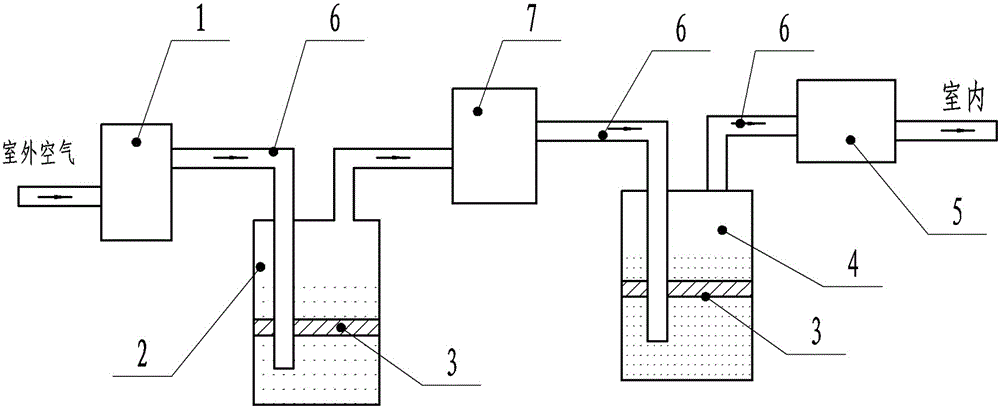

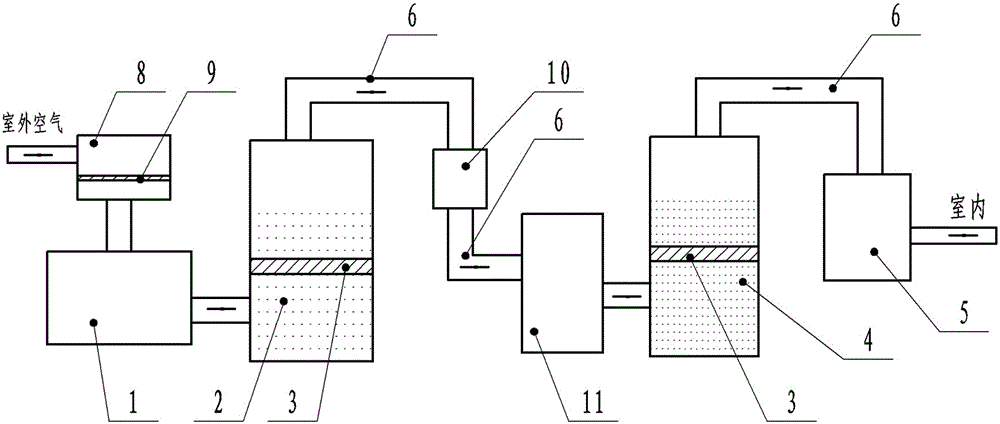

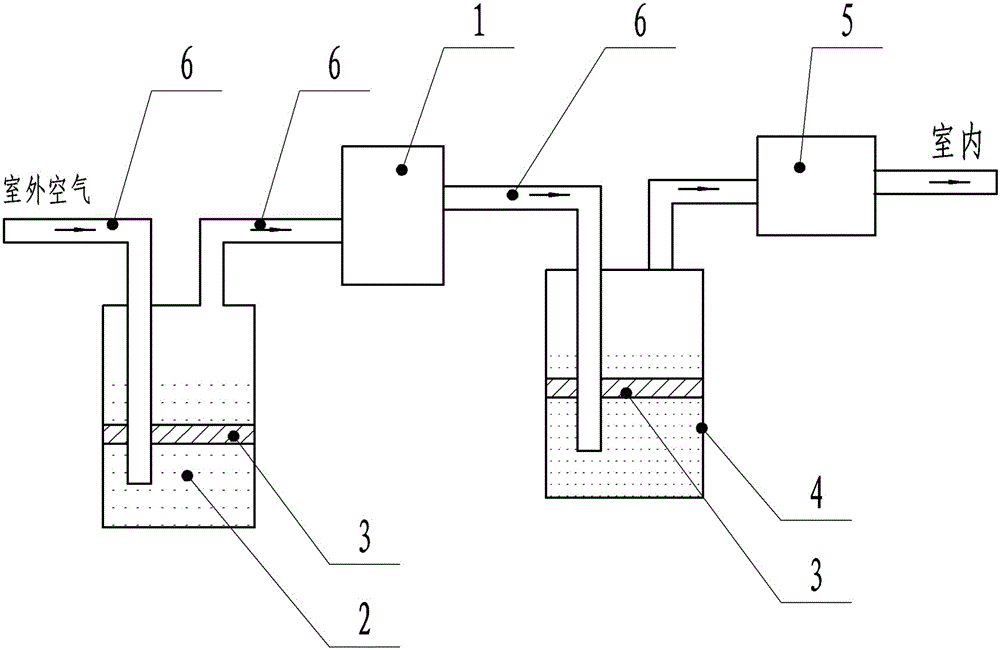

Air purification method and device

InactiveCN105032151AHighlight substantive featuresSignificant progressDispersed particle separationCalcium hydroxideProduct gas

The invention relates to an air purification method which purifies air by using a two-stage or multi-stage chemical agent solution absorption method. The two-stage or multi-stage chemical agent solution absorption method comprises: firstly absorbing vitiated air entering indoors to a first-stage absorption chamber; absorbing organic matter harmful gas by an acidic potassium permanganate solution and filtering the harmful gas; then introducing the gas to a second-stage absorption chamber by a fan; absorbing harmful gas with weak acidity output from the first-stage absorption chamber by using alkaline liquor, and filtering the harmful gas; and blowing the harmful gas indoors, wherein the acidic potassium permanganate solution in the first-stage absorption chamber is a mixed aqueous solution of potassium permanganate and diluted acid, and in the mixed aqueous solution, the potassium permanganate accounts for 0.5-3% by weight and the diluted acid accounts for 3-5% by weight; the alkaline liquor in the second-stage absorption chamber is an aqueous solution of sodium hydroxide or calcium hydroxide with the content of alkaline liquor being 2-5%.

Owner:黄国杰

Polishing solution for ultra-precise low-damage polish of large size diamond wafer and preparation thereof

InactiveCN101302403AImprove surface accuracyQuality improvementPolishing machinesAqueous dispersionsChromium trioxideSuperhard material

The invention belongs to the superhard material polishing technical field and discloses polishing solution used for ultraprecise and low-damage polishing of a large-scale diamond wafer and a method for preparing the same. The method is characterized in that: oxidants with strong oxidbillity including chromium trioxide, ammonium persulphate, potassium permanganate, potassium dichromate, oxydol, potassium ferrate, potassium perchlorate and so on are adopted as main compositions; a proper amount of abrasive material is added for preparing the polishing solution; and micro-removal of surface material of the diamond wafer can be realized by means of chemical and mechanical composite action at normal temperature or low temperature. Moreover, the polishing effect of the polishing solution can be improved by addition of proper amount of catalyst, stabilizer, dispersant and so on as well. The polishing solution and the method have the advantages that: the polishing solution prepared has the advantages of high polishing efficiency, good polishing quality, good stability and so on; and the ultraprecise and low-damage polishing of the large-scale diamond wafer can be realized at the normal temperature or the low temperature.

Owner:DALIAN UNIV OF TECH

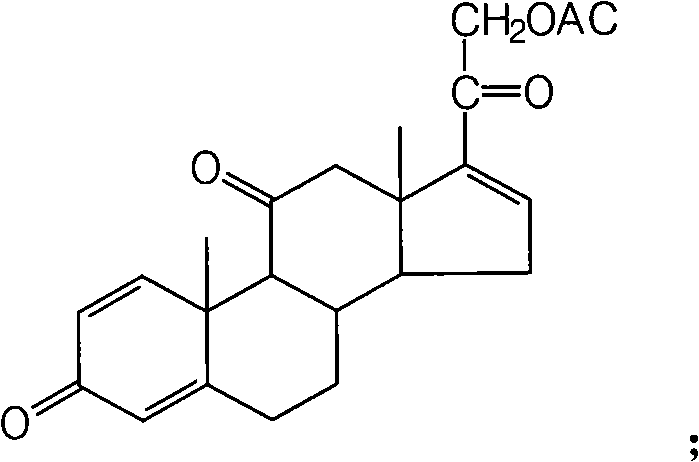

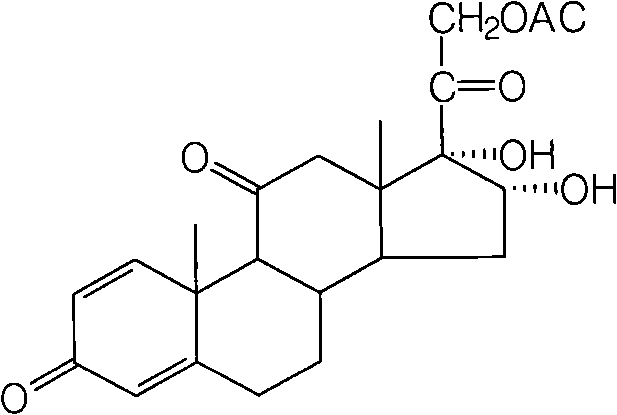

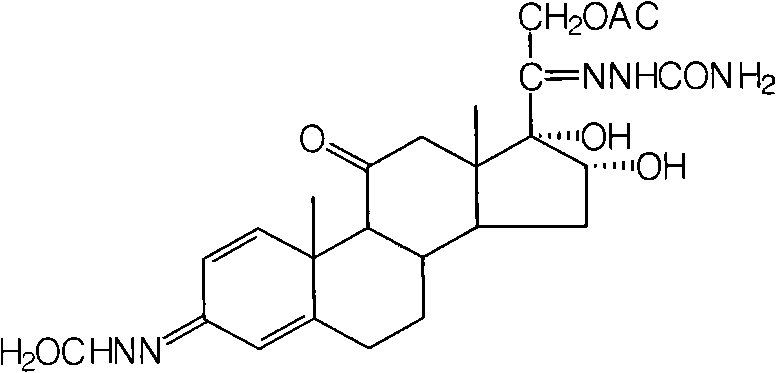

Method for synthesizing 16 alpha-hydroxy prednisolone

The invention relates to a method for synthesizing 16 alpha-hydroxy prednisolone, and belongs to the field of chemical technologies. In the method, prednisone is taken as an initiative raw material, and subjected to five-step reaction of elimination, oxidation, condensation, reduction and hydrolysis to form the 16 alpha-hydroxy prednisolone; the prednisone is taken as the raw material, organic weak base is taken as a retarder to inhibit the oxidation rate of potassium permanganate to reactants, a three-phase acid solvent is taken as a solvent, ketoxime is hydrolyzed by adding aqueous solution of nitrite, and refining is carried out by a multiphase separation crystallization technology. The method has the advantages of simple operation, mild reaction conditions, readily available raw material, low cost and light environmental pollution.

Owner:浙江东晖药业有限公司

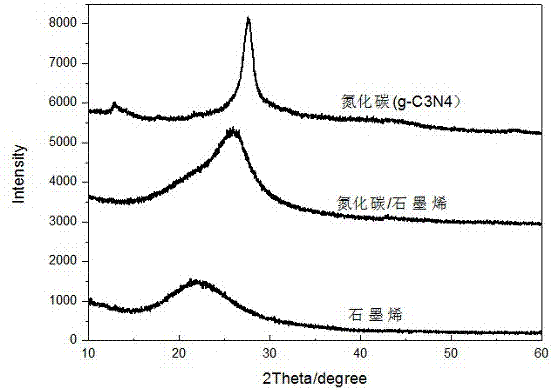

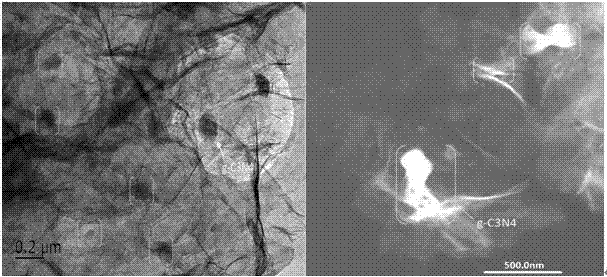

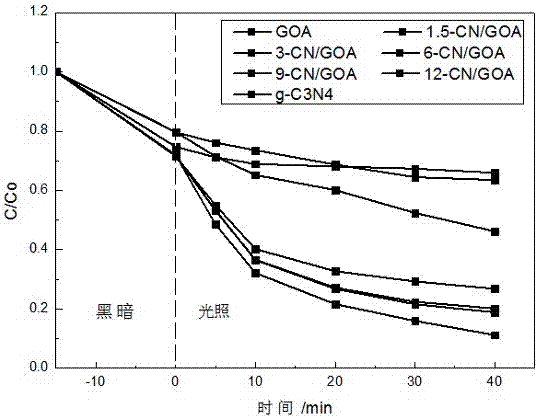

Preparation method of carbon nitride/graphene composite material with three-dimensional structure

InactiveCN107185576AAvoid reunionImprove photocatalytic performanceWater/sewage treatment by irradiationWater treatment compoundsEthylene diamineCarbon nitride

The invention discloses a preparation method of a carbon nitride / graphene composite material with a three-dimensional structure. The preparation method comprises the following steps: (1) preparing a graphene oxide solution by using a Hummers method; (2) putting dicyandiamide in a muffle furnace to prepare carbon nitride (g-C3N4); adding the carbon nitride (g-C3N4) into a concentrated sulfuric acid solution to stir and then adding sodium nitrate and potassium manganate under an ice bath to stir; diluting with deionized water and hydrogen peroxide, dialyzing after dilution and then drying at a temperature of 55 DEG C below zero to prepare carbon nitride (g-C3N4); (3) performing ultrasonic uniform mixing on the graphene oxide solution (GO) obtained in the step (1) and a carbon nitride (g-C3N4) nano sheet obtained in the step (2) according to the mass ratio of 5:3, then adding ethylene diamine and performing constant-temperature reaction at a temperature of 95 DEG C; adding a CTAB solution into the solution after reaction to react for 7 hours, taking out a product, washing, freezing and drying to obtain the carbon nitride / graphene composite material with the three-dimensional structure. The composite material with the three-dimensional structure has the benefit that as the ethylene diamine and CTAB are added as connecting agents, the flexibility and the stability of the composite material can be improved.

Owner:SHANGHAI UNIV

Preparation method of graphite oxide

The invention discloses a preparation method of graphite oxide. The preparation method comprises the steps: adding concentrated sulfuric acid in a dry beaker, cooling with ice water, adding a solid mixture of flake graphite and NaNO3 under constant stirring, and then slowly adding a potassium permanganate powder; after finishing addition of KMnO4, removing the water bath, and continuing stirring; slowly adding deionized water, stirring, then adding deionized water for dilution, carrying out a reaction under a condition of normal temperature, then adding hydrogen peroxide, reducing a residual oxidant until the solution becomes bright yellow, and then centrifuging to obtain a yellow-brown residue; respectively washing by an HCl solution and deionized water for 3 times, and centrifuging for one time after each washing until the filtrate is neutral; and finally placing the filter cake in a 60 DEG C drying box, and fully drying. The preparation method is safe and simple in operation and low in equipment requirements, can prepare graphite oxide with relatively high carbon-oxygen ratio; and moreover, the graphite oxide prepared by the method can be used for preparing graphene, and graphene is further applied in battery materials, composite materials, electronic devices, energy storage materials and other fields.

Owner:SUZHOU SHIYOUJIA ELECTRONICS TECH

Wet method smelting process of high silicon zinc oxide crude ore

InactiveCN101418377AEfficient use ofComplex compositionZinc oxides/hydroxidesCopper oxychloridesFlocculationSmelting process

The invention relates to a wet method smelting process for high silicon zinc oxide crude ore. The invention belongs to the field of wet method smelting, and provides a method for the direct leaching of high silicon, high-ferro zinc oxide crude ore. The method comprises the following steps: firstly the high silicon, high ferro zinc oxide crude ore is crushed and undergoes the wet mode ball milling and the acid leaching through the discarded electrolyte used in a zinc hydrometallurgy process; according to the content of ferrous iron ions during the acid leaching, potassium permanganate and / or manganese dioxide are / is added in an extracting stage; the dosage of the potassium permanganate and / or manganese dioxide is controlled 1 to 10 percent of the total weight of the ore; during the leaching, the temperature is controlled 40 to 90 DEG C, and the acidity pH value is 0.5 to 5.2; and a flocculant is added into the leached ore pulp for flocculation and concentration. According to the invention, the direct leaching of the high silicon zinc oxide ore can avoid the formation of silica sol, thereby effectively utilizing the high silicon zinc oxide ore resources. Compared with other high silicon ore treatment processes, the process has the advantages of low acid consumption, low production cost, simple technology, and the like.

Owner:云南金鼎锌业有限公司

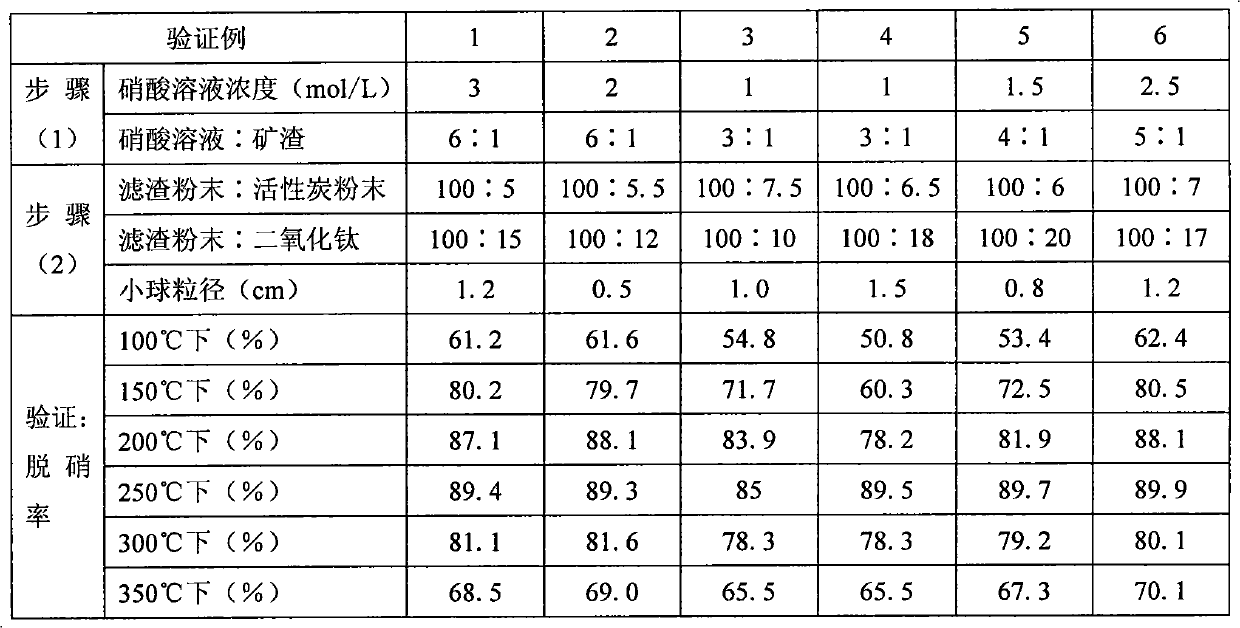

Method for preparing SCR (Selective Catalytic Reduction) denitration catalyst by slag and catalyst thereof

InactiveCN102000563ALow raw material costHigh low temperature activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated charcoal powderPtru catalyst

The invention relates to a method for preparing SCR (Selective Catalytic Reduction) denitration catalyst by slag and a catalyst thereof. The catalyst uses slag remained after potassium manganate is extracted as a main raw material. The preparation method comprises the following steps of: washing slag by a nitric acid solution, filtering the slag, drying and pulverizing; fully mixing filter slag powder with active carbon powder; then after adding titanium dioxide sol and deionized water for being adjusted into proper slurry, rubbing into strips and preparing small balls; and drying and roasting in sequence for activating. Compared with the prior art, the SCR denitration catalyst has catalytic activity in the range of smoke temperature of 150-350 DEG C and higher catalytic activity compared with the prior art within 200 DEG C and 300 DEG C (particularly 250 DEG C or so); and by applying the catalyst of the invention for carrying out SCR denitration, the denitration rate is high. The invention also has the advantages of raw material cost saving, elimination of pollution of high-valence manganese-contained wastes on environment and simple preparation process.

Owner:CHONGQING UNIV

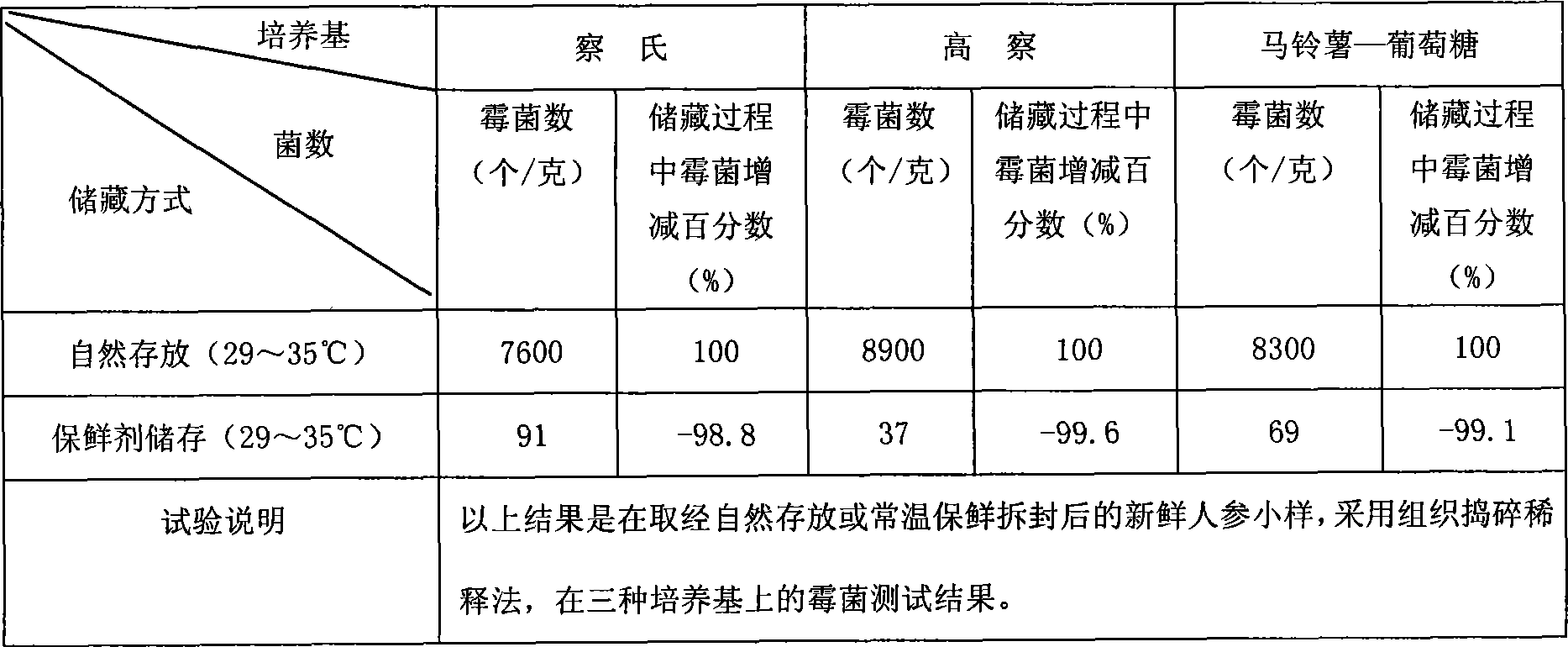

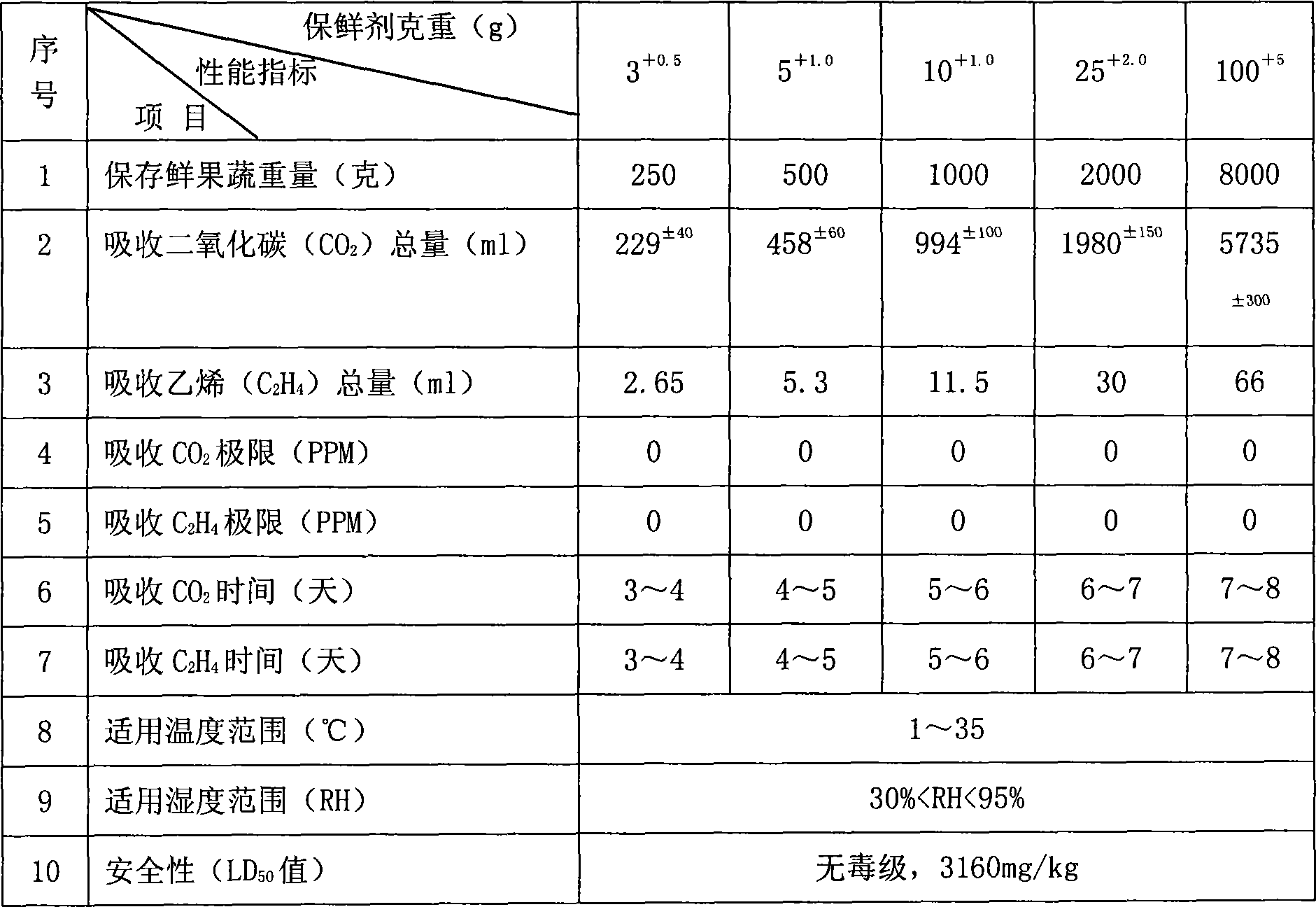

Organic composite type foodstuff, fruit and vegetables antistaling agent and preparation method thereof

ActiveCN101185460ARegulate physiological metabolismGrowth inhibitionFruit and vegetables preservationWater activityPack material

The invention discloses an organic compound fresh-keeping agent of food, fruit and vegetable and a preparation method thereof. The components and contents of the fresh-keeping agent are: 20-80 percent of calcium oxide, 5-20 percent of potassium permanganate, 10-30 percent of buldymite, 1-10 percent of high water-absorbing resins and 2-20 percent of diatomite. The preparation method is that the calcium oxide and the potassium permanganate are grinded and mixed, and the buldymite, the high water-absorbing resins and the diatomite are put into the mixture in sequence and packed in paper-plastic wrappage after mixed and stirred evenly. The fresh-keeping agent has unique formula, wide raw materials sources, simple technique, low cost and no pollution, and can effectively eliminate gases such as ethylene produced by packed materials as well as absorb free water and free grease produced by the wrappage and peculiar smell, and inhibit the growth of mould, naerobe and microzyme, thus being particularly suitable for fresh-keeping, storage and transportation of succulent food with a water content of 30 percent to 58 percent or water activity value of more than 0.75, fresh fruit and vegetable, meat products, plant raw medicinal materials and oleaginous food.

Owner:江苏中鲜保鲜科技有限公司

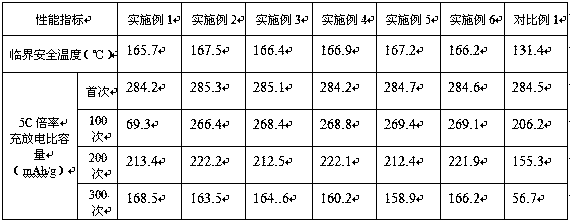

Spherical lithium iron phosphate coated lithium nickelate-cobaltate-manganate battery material and preparation method

InactiveCN109360967AImprove securityImprove cycle performanceSecondary cellsPositive electrodesLithium hydroxidePorous carbon

The invention provides a spherical lithium iron phosphate coated lithium nickelate-cobaltate-manganate battery material and a preparation method. Nickel sulfate, cobalt sulfate, manganese sulfate, potassium permanganate, lithium hydroxide and porous carbon nanospheres are added into deionized water in sequence, a lithium nickelate-cobaltate-manganate precursor is obtained after the reaction, thenwet gel obtained after a lithium source, an iron source, a phosphorus source and a chelating agent are added into water is added, high-temperature sintering is carried out after spray drying is completed, and the spherical lithium iron phosphate coated lithium nickelate-cobaltate-manganate battery material is obtained. By means of the method, the charge and discharge capacity and the structural stability of a positive electrode material are improved, the electrochemical capacity of the material is improved, the sizes of single-crystal particles in material particles are increased, the densityof the particles is improved, the firm micro structure change of the particle materials with uniform granularity and good sphericity is formed, the compaction density of a lithium nickelate-cobaltate-manganate ternary material is improved, the high-magnification stability is enhanced, meanwhile,, the preparation flow is simple, the production period is short, the raw material source is wide, and the cost is low.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

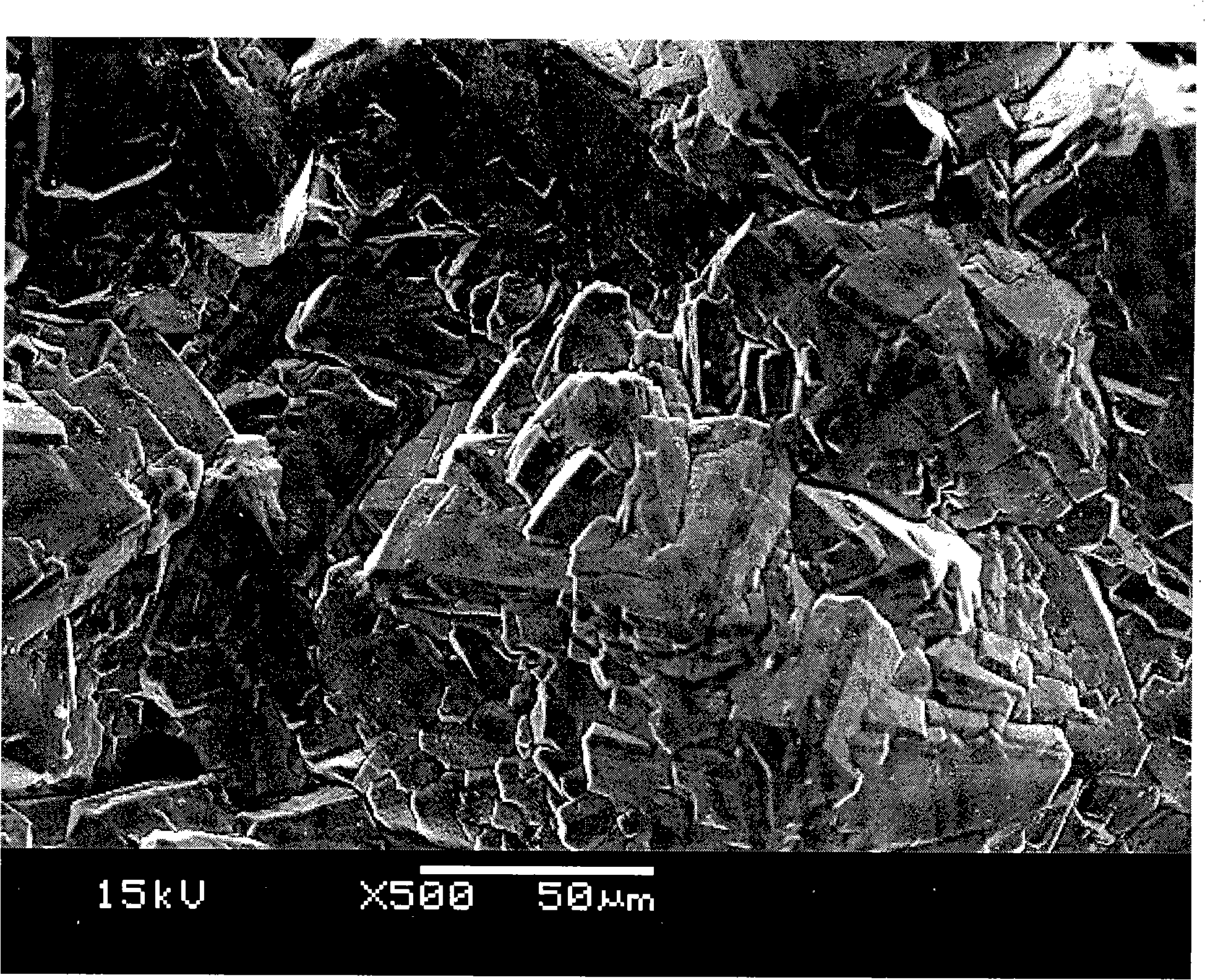

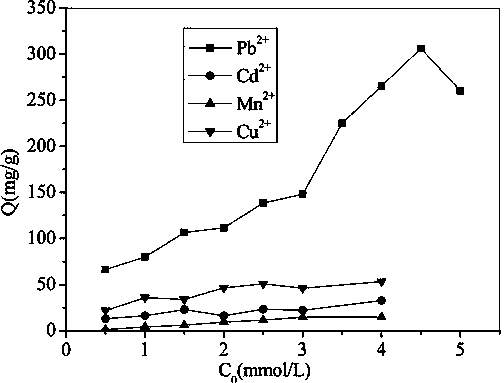

Preparation of graphene oxide adsorption material modified by dendritic polymer

InactiveCN103861564AOvercoming adjustmentOvercome applicabilityOther chemical processesWater/sewage treatment by sorptionWater bathsFiltration

The invention provides a preparation method of a new adsorbent, the method uses a dendritic polymer to modify a graphene oxide adsorption material, and the graphene oxide adsorption material modified by the dendritic polymer can effectively adsorb lead ions, cadmium ions, manganese ions, copper ions and other heavy metal ions in wastewater. The method is as follows: first using graphite powder as a raw material to prepare multilayer graphene oxide by concentrated sulfuric acid, potassium permanganate and hydrogen peroxide oxidation, fully dissolving the graphene oxide in ethanol with the aid of ultrasonic, then adding a certain amount of the dendritic polymer for water bath reaction at 30-80 DEG C for 6 to 48 hours, performing vacuum suction filtration of an obtained product, then washing with the ethanol, and then drying at 50-100 DEG C to obtain a heavy metal adsorption material. SEM (scanning electron microscope) pictures show that the adsorbent has a loose structure, and the adsorbent has a good application prospect in heavy metal adsorption field. Adsorption experiments show that, under the condition of normal temperature, the adsorbent has a good adsorption capacity to the lead ions, cadmium ions, manganese ions and copper ions, and especially has a strong adsorption capacity to the lead ions, and the maximum adsorption amount can reach 300mg / g above.

Owner:JISHOU UNIVERSITY

Method for preparing acrylic resin modified graphene oxide leather tanning agent

InactiveCN102586507AEquivalent tensile strengthEquivalent tear strengthTanning treatmentLeather industryAcrylic resin

The invention relates to a method for preparing an acrylic resin modified graphene oxide leather tanning agent. Pollution becomes a main problem that hampers the sustainable development of leather industry, wherein a chrome tanning agent is one of leading pollution sources. The method comprises the following steps of: adding concentrated sulfuric acid into a mixture of graphite powder and sodium nitrate, adding potassium permanganate, raising the temperature, reducing the temperature, washing, and dispersing by using ultrasonic waves to obtain an aqueous solution of graphene oxide; and adding methacrylic acid and acrylic acid into the aqueous solution of graphene oxide, treating by using ultrasonic waves, heating, dripping an initiator solution, keeping the temperature, reacting, and controlling the solid content to be 15 percent to obtain a product. The leather tanning agent can be used as a main tanning agent and is used for tanning leather; the tensile strength, the tearing strength and the breaking elongation of the tanned leather are equivalent to those of chrome tanned leather, and the tanned leather has soft and smooth handfeel; the leather tanning agent can substitute pollutional tanning agents such as a chrome tanning agent, an aldehyde tanning agent and the like, so that the pollution of the chrome tanning agent is reduced or eliminated from the source; and the leather tanning agent has a good application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com