Method for separating lead and silver from manganese in anode sludge

A technology for anode slime and lead separation, applied in magnetic separation, solid separation, wet separation, etc., can solve problems such as no discovery, and achieve the effect of low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

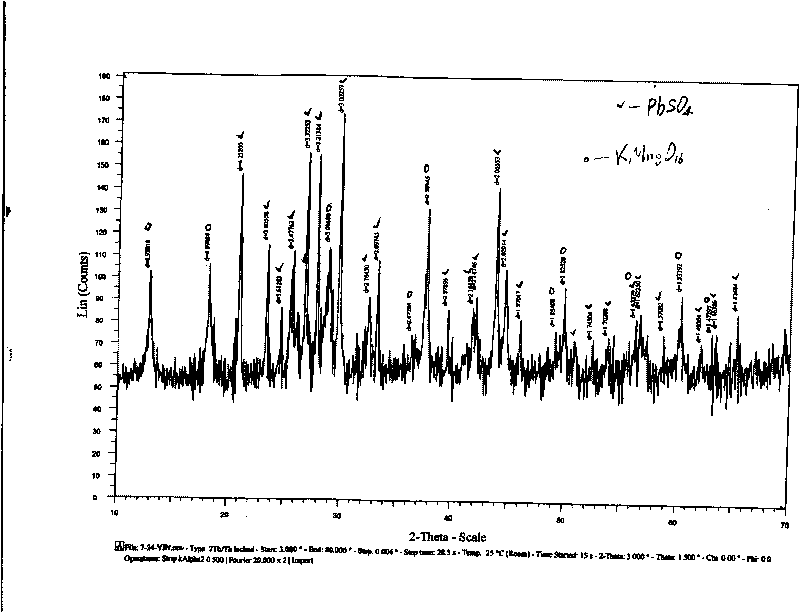

[0022] Example 1: Chemical analysis of an electrolytic zinc anode slime (see Table 1) shows that it contains 32.1% of Mn, 19.8% of Pb, and about 1223g / t of silver. XRD diffraction analysis results (see figure 1 ) shows that the lead in the anode slime is mainly PbSO 4 Existence, manganese mainly as KMn 8 o 16 exist. After the anode slime is countercurrently washed with water, the pH of the pulp changes from about 1 to about 5, and the solid-liquid separation obtains the filter residue and about three times the weight of the residue washing filtrate. The filter residue contains about 36% of manganese, about 21% of lead, and 1350g of silver. / t or so, the filtrate contains H 2 SO 4 28g / l 4 , containing 5.6g / l zinc and 2.1g / l manganese.

[0023] Table 1 Chemical analysis results of a certain zinc anode slime

[0024] project

mn

Pb

Ag(g / t)

Zn(water)

Mn(water)

h 2 o

h 2 SO 4 (water)

content(%)

32.07

19.76

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com