Preparation method of Mn3O4-MnO2 nano composite material and application thereof

A technology of nanocomposite materials and mixed solutions, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high production cost, complicated process, energy loss, etc., and achieve easy operation, simple process flow and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

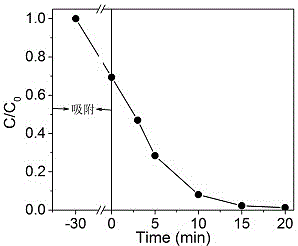

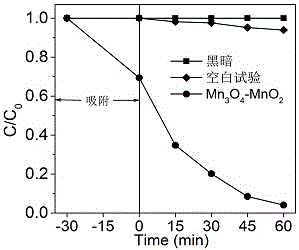

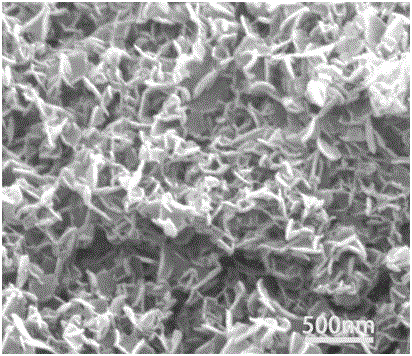

[0024] Embodiment 1: a kind of Mn 3 o 4 -MnO 2 A method for preparing a nanocomposite material, comprising the steps of:

[0025] Step 1, add 4.5mmol manganese chloride tetrahydrate (MnCl 2 4H 2 (2) and 1g polyvinylpyrrolidone (PVP), stirring to obtain a mixed solution of manganese chloride tetrahydrate and polyvinylpyrrolidone;

[0026] Step 2: Add the mixed solution of manganese chloride tetrahydrate and polyvinylpyrrolidone prepared in Step 1 into deionized water with a volume of 80ml and a temperature of 85°C, and then add 9mmol of sodium hydroxide (NaOH) to form a light brown precipitate. React 2min, obtain the solution after reaction;

[0027] Step 3, in the solution after the reaction that step 2 makes, add 2mmol potassium permanganate (KMnO 4), kept stirring at 85°C for 3 hours, cooled to room temperature, and centrifuged to obtain a precipitate;

[0028] In step 4, the precipitate obtained in step 3 was washed alternately with deionized water and absolute ethan...

Embodiment 2

[0029] Embodiment 2: a kind of Mn 3 o 4 -MnO 2 A method for preparing a nanocomposite material, comprising the steps of:

[0030] Step 1, add 9mmol manganese chloride tetrahydrate (MnCl 2 4H 2 (2) and 2g polyvinylpyrrolidone (PVP), stir to obtain manganese chloride tetrahydrate and polyvinylpyrrolidone mixed solution;

[0031] Step 2: Add the mixed solution of manganese chloride tetrahydrate and polyvinylpyrrolidone prepared in Step 1 into deionized water with a volume of 160ml and a temperature of 85°C, and then add 18mmol of sodium hydroxide (NaOH) to form a light brown precipitate. React for 1min to obtain the reacted solution;

[0032] Step 3, in the solution after the reaction that step 2 makes, add 4.5mmol potassium permanganate (KMnO 4 ), kept stirring at 85°C for 3 hours, cooled to room temperature, and centrifuged to obtain a precipitate;

[0033] In step 4, the precipitate obtained in step 3 was washed alternately with deionized water and absolute ethanol for ...

Embodiment 3

[0034] Embodiment 3: a kind of Mn 3 o 4 -MnO 2 A method for preparing a nanocomposite material, comprising the steps of:

[0035] Step 1, in 20ml deionized water, add 9mmol manganese chloride tetrahydrate (MnCl 2 4H 2 (2) and 1g polyvinylpyrrolidone (PVP), stirring to obtain a mixed solution of manganese chloride tetrahydrate and polyvinylpyrrolidone;

[0036] Step 2: Add the mixed solution of manganese chloride tetrahydrate and polyvinylpyrrolidone prepared in Step 1 into deionized water with a volume of 80ml and a temperature of 80°C, and then add 9mmol of sodium hydroxide (NaOH) to form a light brown precipitate. React 3min, obtain the solution after reaction;

[0037] Step 3, in the solution after the reaction that step 2 makes, add 7.2mmol potassium permanganate (KMnO 4 ), kept stirring at 80°C for 4 hours, cooled to room temperature, and centrifuged to obtain a precipitate;

[0038] In step 4, the precipitate obtained in step 3 is alternately washed twice with dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com