Graphene @Fe3O4 compound water base magnetorheological fluid and preparation method thereof

A magnetorheological fluid and graphene technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of difficulty in optimizing stability and magnetorheological effect at the same time, easy sedimentation of magnetorheological fluid, etc. Shear yield stress and magnetorheological effect, effect of high shear strain and low zero-field viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

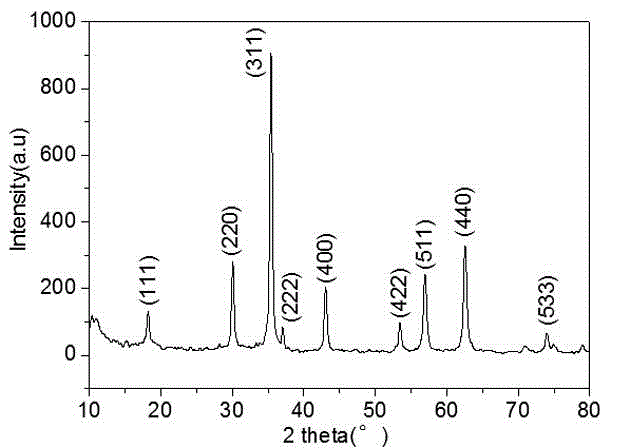

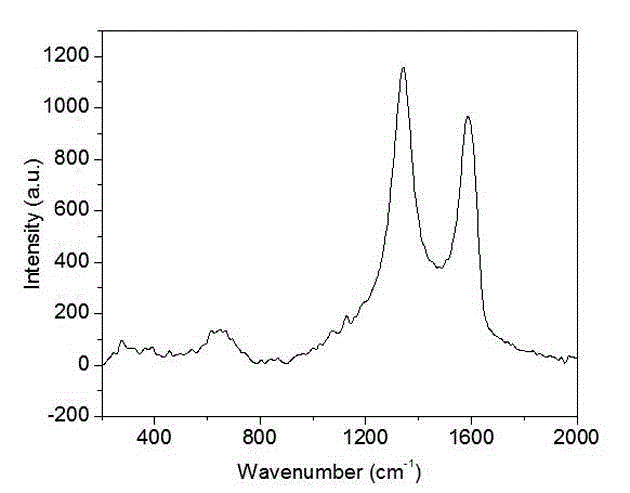

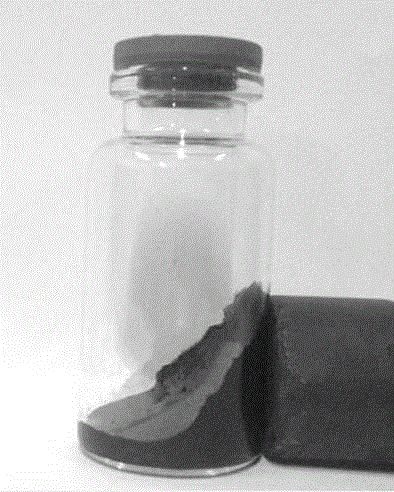

[0021] Graphene Fe 3 o 4 The preparation method of composite water-based magnetorheological fluid comprises the following steps:

[0022] 1) Preparation of stable Fe 3 o 4 Water-based magnetic fluid:

[0023] 3.0g FeCl 2 4H 2 O and 6.3 g FeCl 3 ·6H 2 Dissolve O in 90mL of deionized water, place in a constant temperature water bath at 50°C, stir evenly, and slowly add 85mL of NaOH solution with a concentration of 1.34mol / L dropwise at a rate of 2 drops / second under vigorous mechanical stirring at 500r / min After the dropwise addition, continue to react for 80min, stop, and cool to room temperature; the above-mentioned reaction liquid is magnetically separated to remove the supernatant, and the obtained Fe 3 o 4 The black magnetic particles were dispersed in a certain volume of deionized water by ultrasound for 30 minutes, then centrifuged at 2000 rpm for 10 minutes, and the upper layer was taken to obtain stable Fe with a concentration of 30 mg / mL. 3 o 4 Water-based m...

Embodiment 2

[0029] Graphene Fe 3 o 4 The preparation method of composite water-based magnetorheological fluid comprises the following steps:

[0030] 1) Preparation of stable Fe 3 o 4 Water-based magnetic fluid:

[0031] 4.5g FeCl 2 4H 2 O and 7g FeCl 3 ·6H 2 Dissolve O in 90mL of deionized water, place in a constant temperature water bath at 50°C, stir evenly, and slowly add 90mL of NaOH solution with a concentration of 1.34mol / L dropwise at a rate of 3 drops / second under vigorous mechanical stirring at 500r / min ; Stop after the dropwise addition and continue to react for 90min, and cool to room temperature; the above-mentioned reaction liquid is magnetically separated to remove the supernatant, and the obtained Fe 3 o 4 The black magnetic particles were dispersed in a certain volume of deionized water by ultrasound for 30 minutes, then centrifuged at 2000 rpm for 10 minutes, and the upper layer was taken to obtain stable Fe with a concentration of 20 mg / mL. 3 o 4 Water-based ...

Embodiment 3

[0037] Graphene Fe 3 o 4 The preparation method of composite water-based magnetorheological fluid comprises the following steps:

[0038] 1) Preparation of stable Fe 3 o 4 Water-based magnetic fluid:

[0039] 3.5g FeCl 2 4H 2 O and 7.5 g FeCl 3 ·6H 2 Dissolve O in 90mL of deionized water, place it in a constant temperature water bath at 50°C, stir evenly, and slowly add 80mL of NaOH solution with a concentration of 1.34mol / L dropwise at a rate of 1 drop / second under vigorous mechanical stirring at 500r / min ; Stop after the dropwise addition and continue to react for 85min, and cool to room temperature; the above-mentioned reaction liquid is magnetically separated to remove the supernatant, and the obtained Fe 3 o 4 The black magnetic particles were dispersed in a certain volume of deionized water by ultrasound for 30 minutes, then centrifuged at 2000 rpm for 10 minutes, and the supernatant was taken to obtain stable Fe with a concentration of 50 mg / mL. 3 o 4 Water-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com