Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Equivalent tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

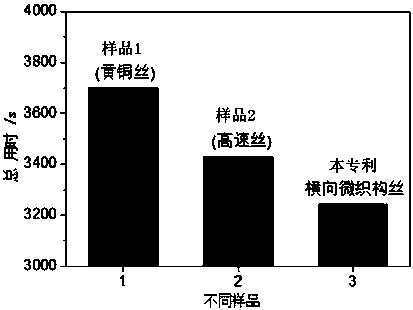

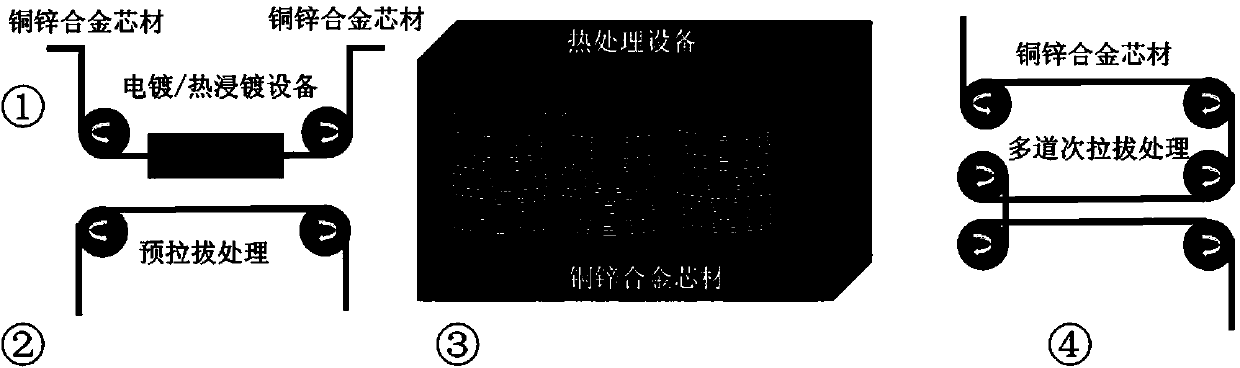

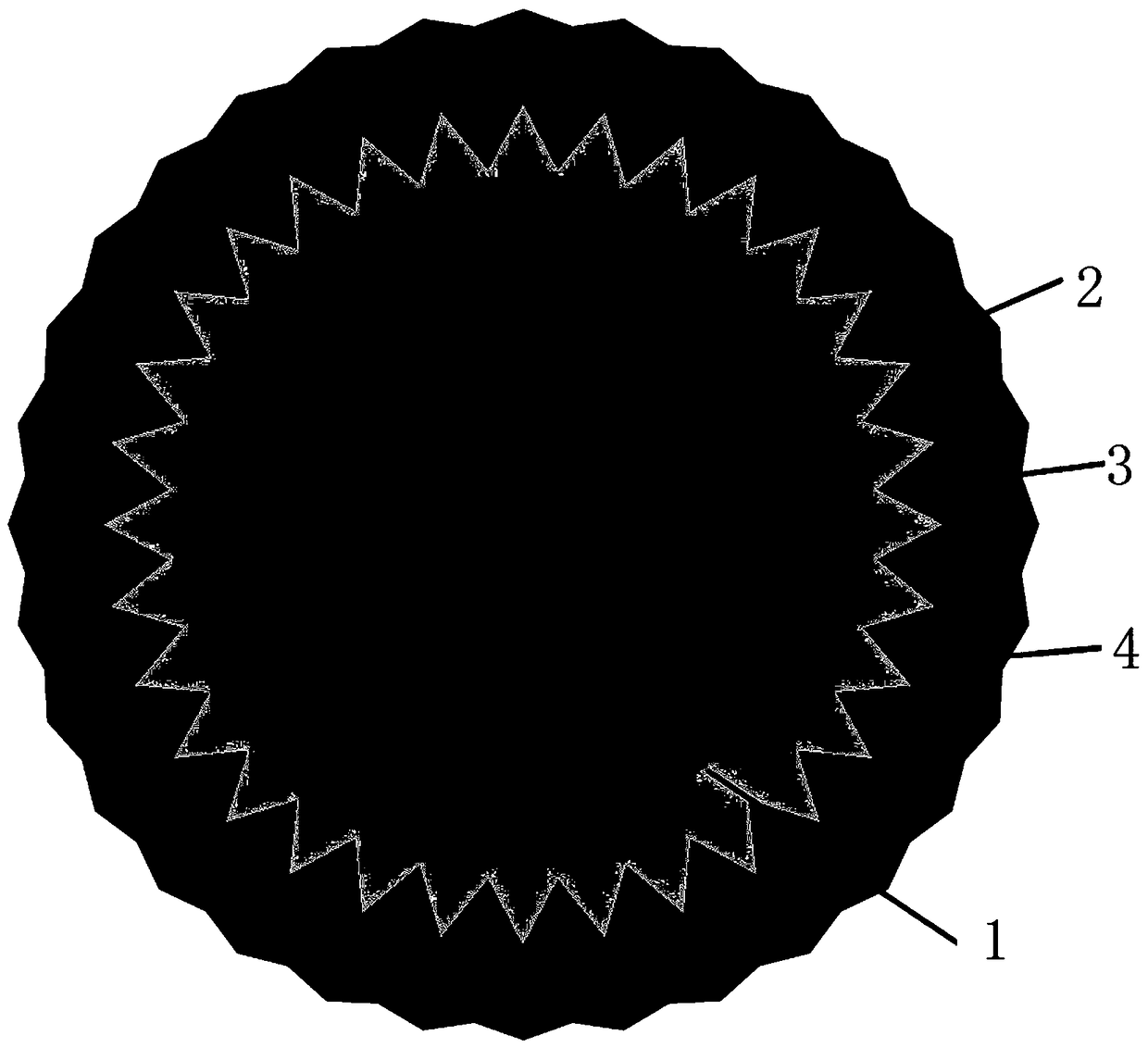

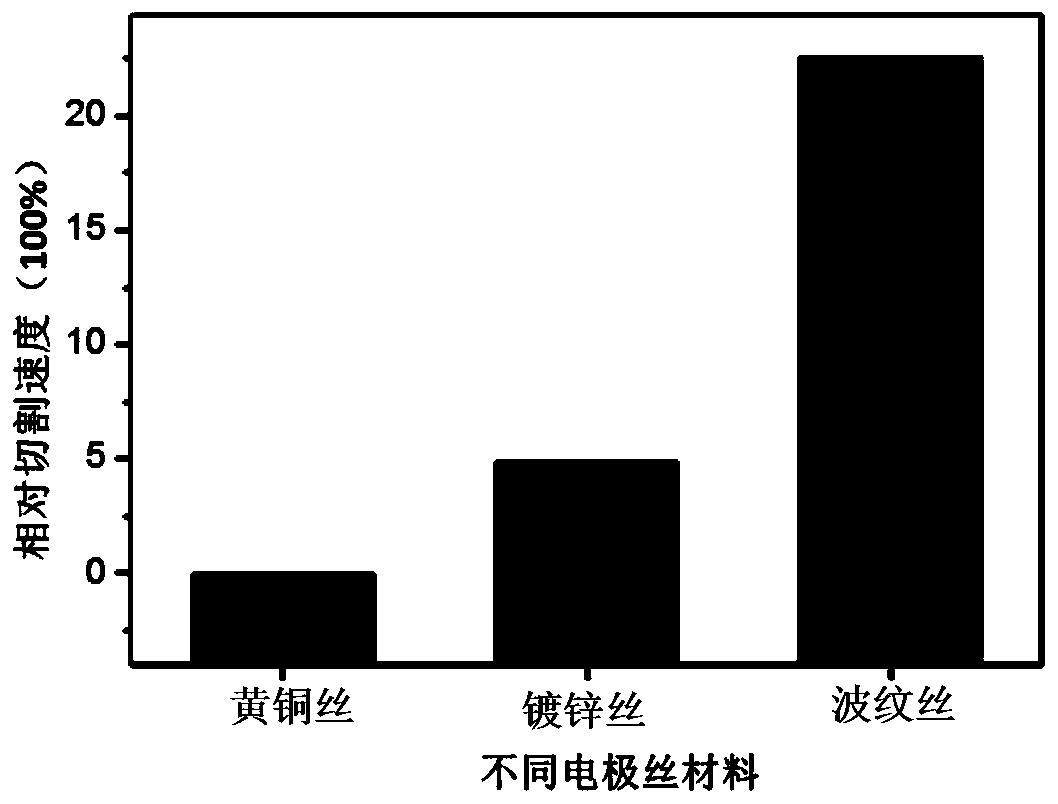

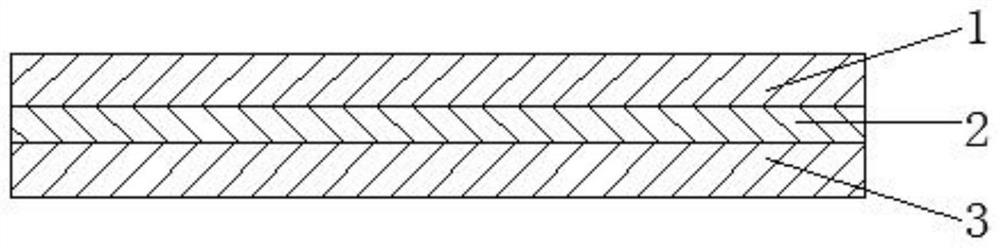

Preparation method of textured plating layer electrode wire

InactiveCN107671379AEasy to useImprove cooling effectHot-dipping/immersion processesElectrical-based machining electrodesZinc alloysStress relief

Owner:NINGBO KANGQIANG MICRO ELECTRONICS TECH CO LTD

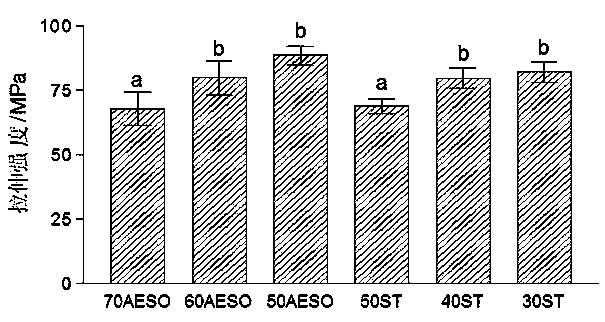

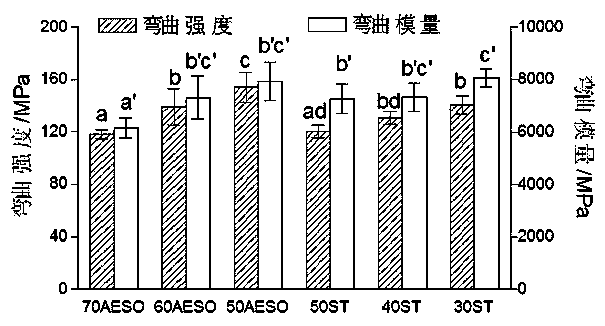

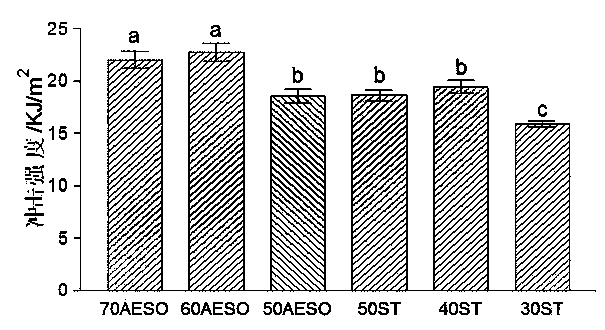

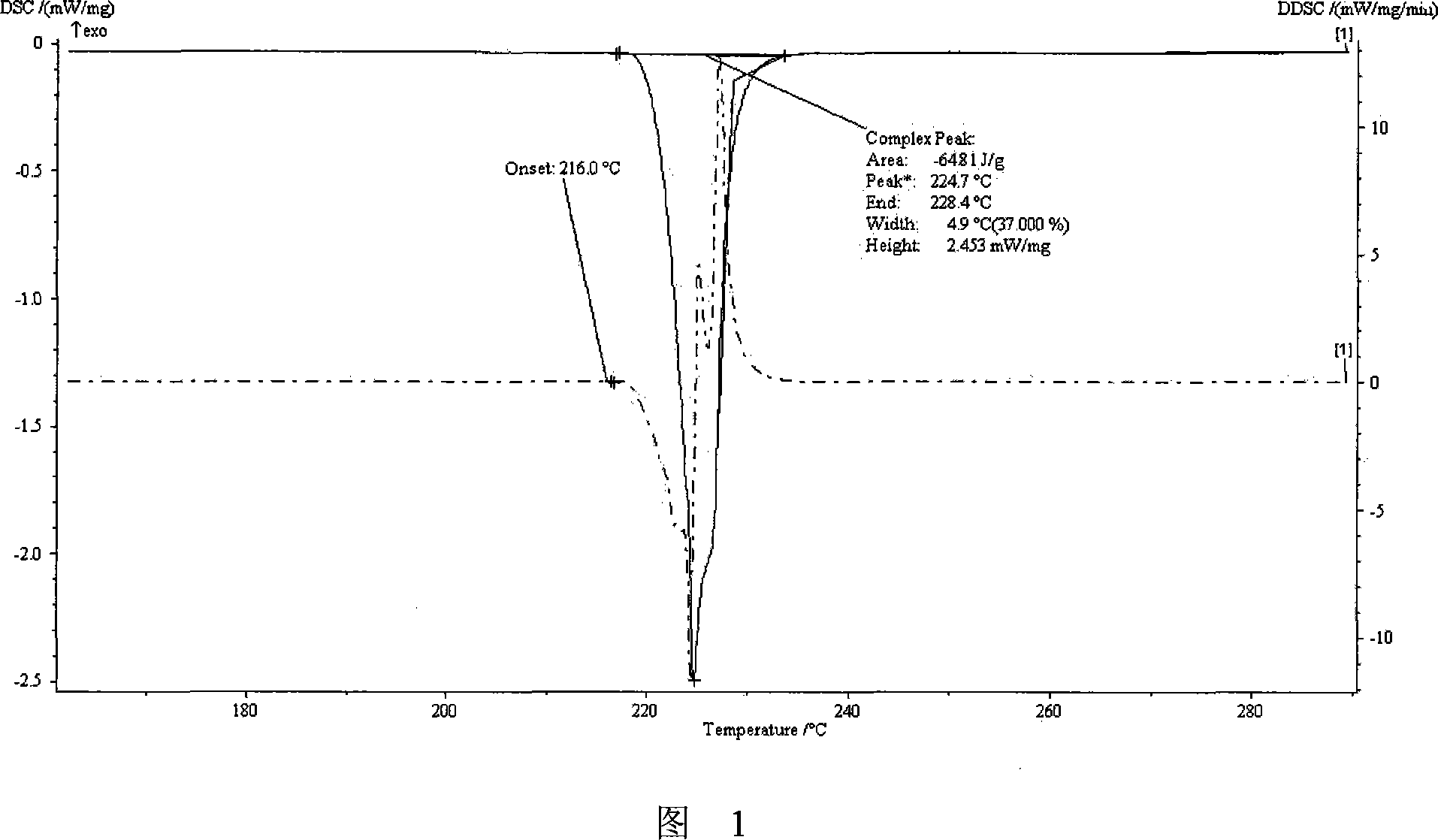

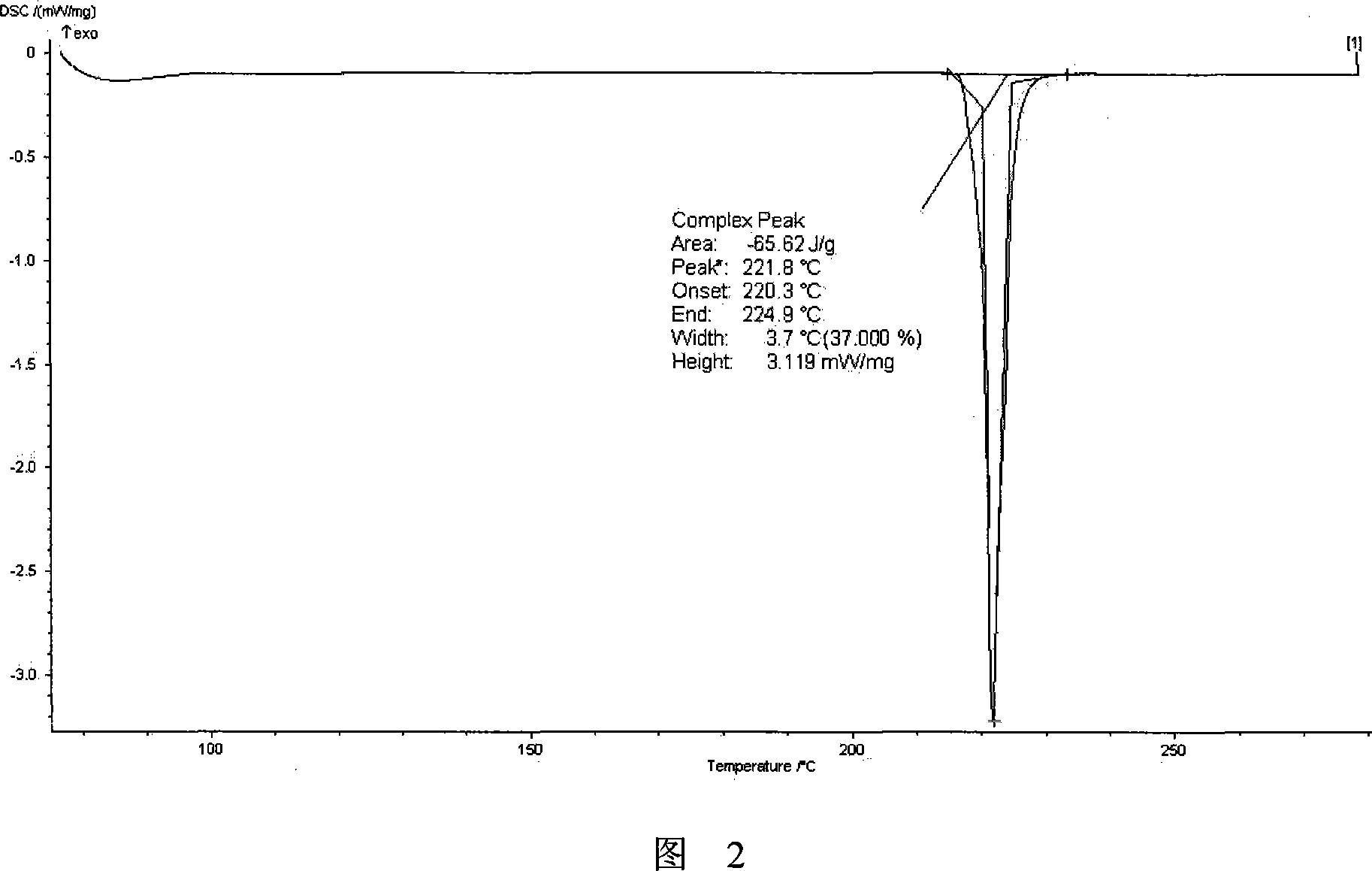

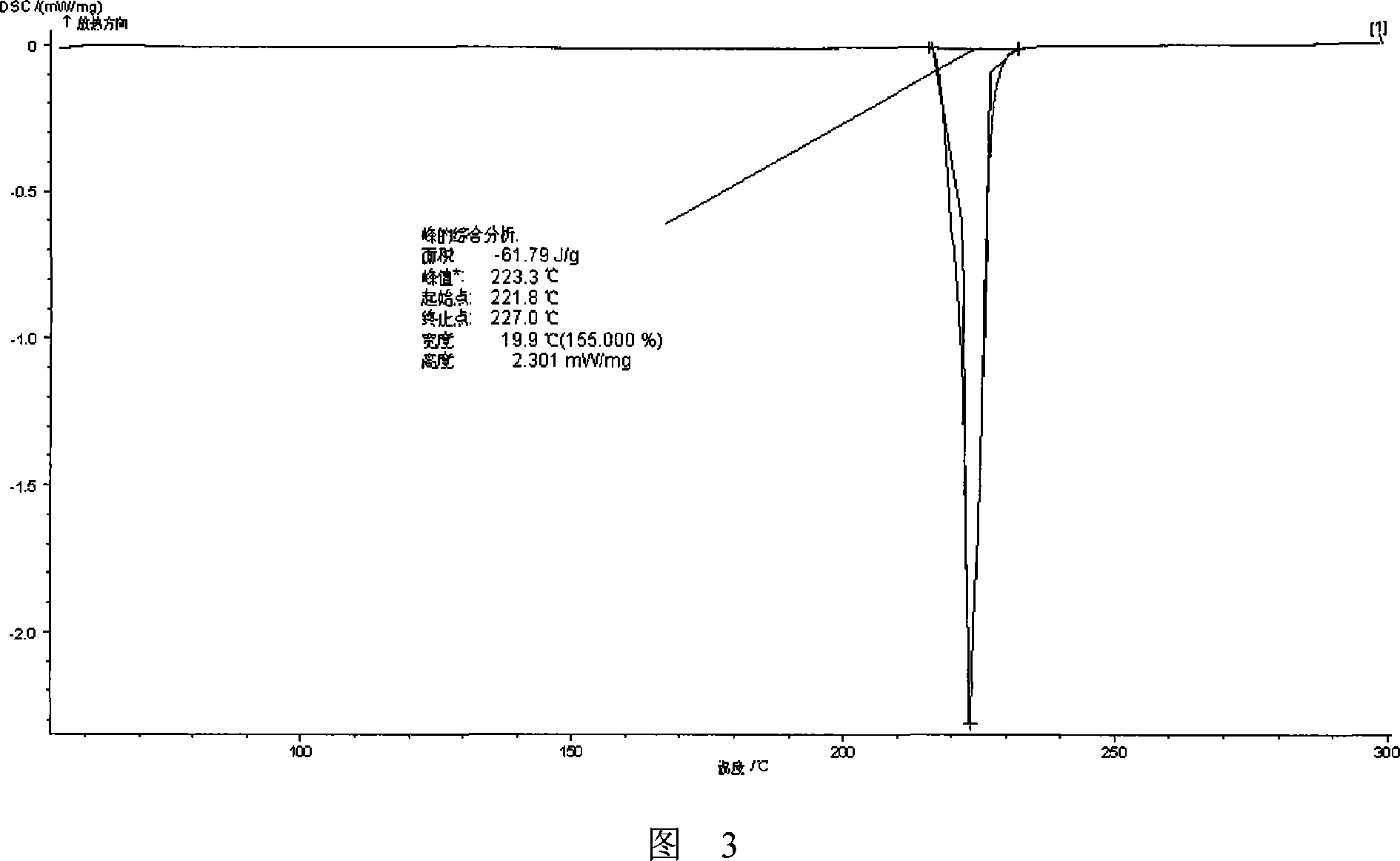

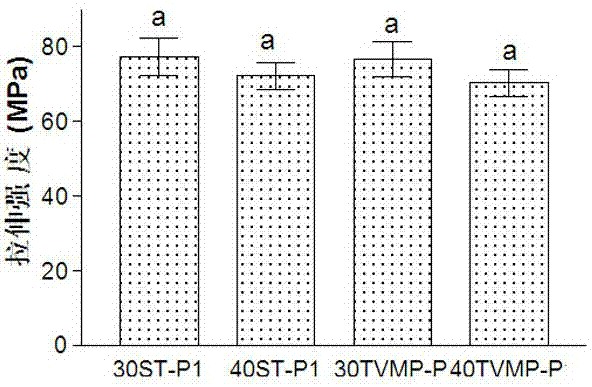

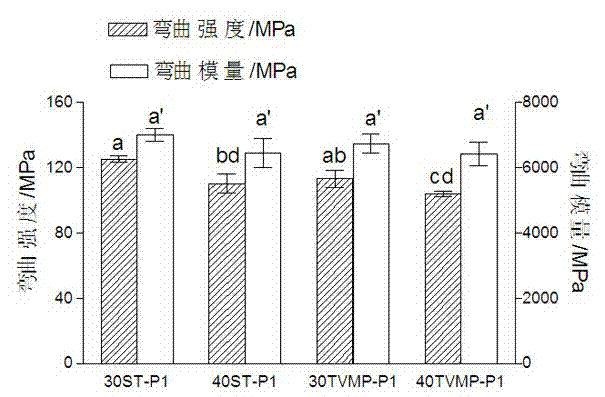

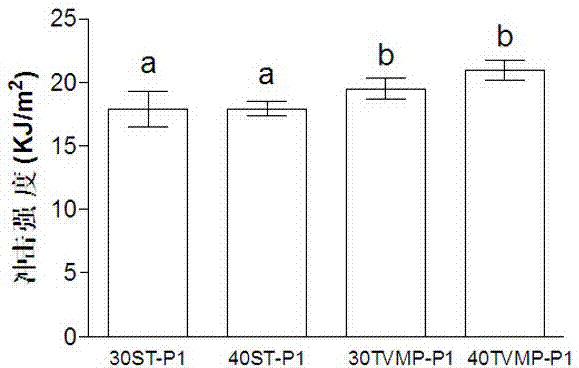

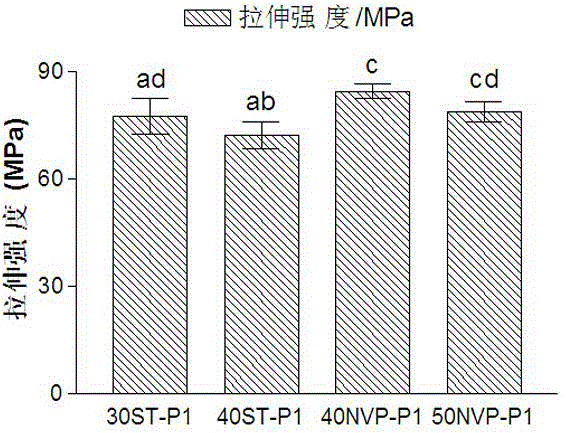

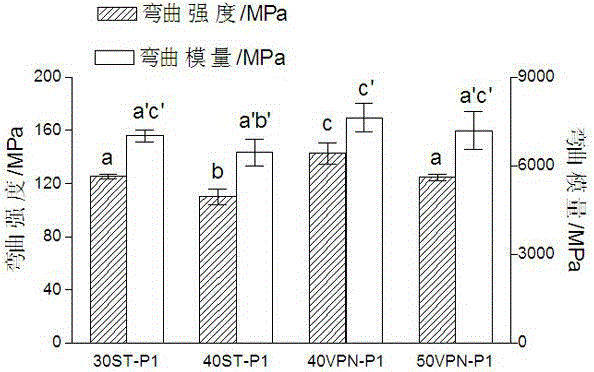

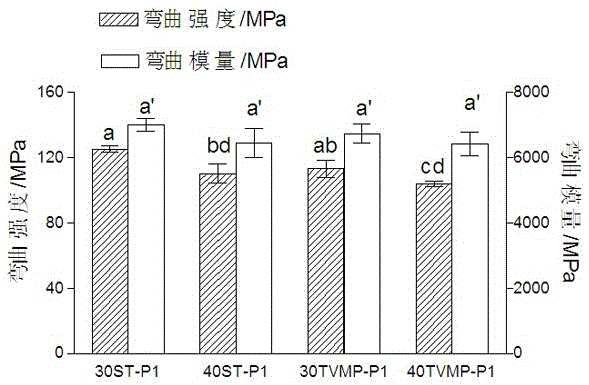

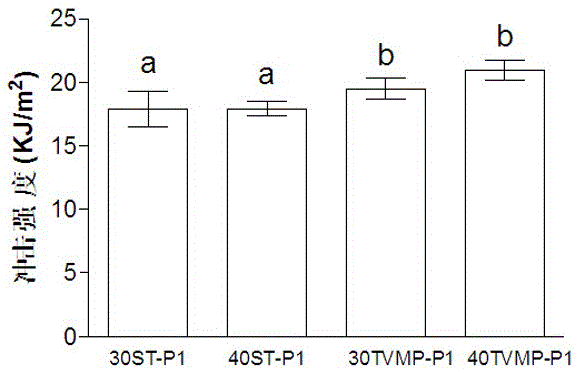

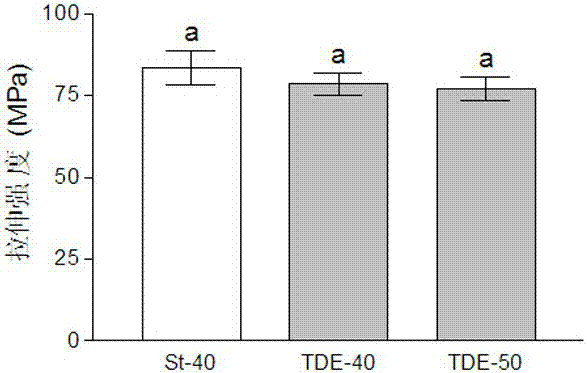

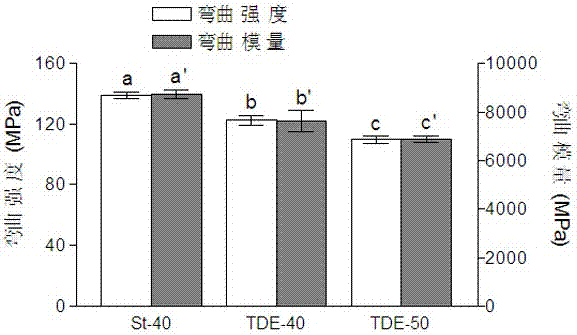

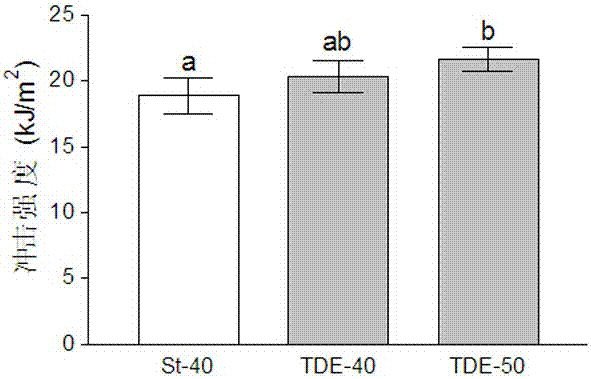

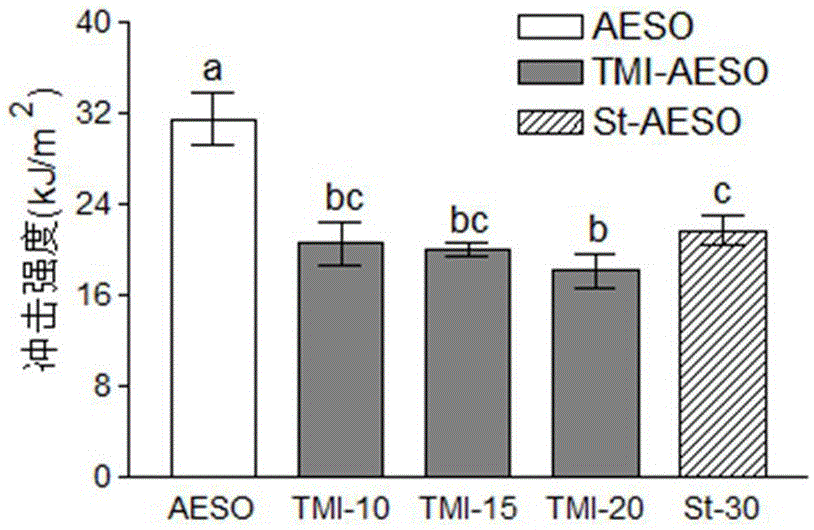

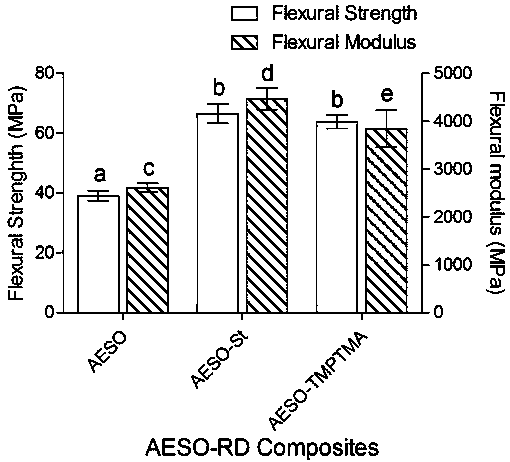

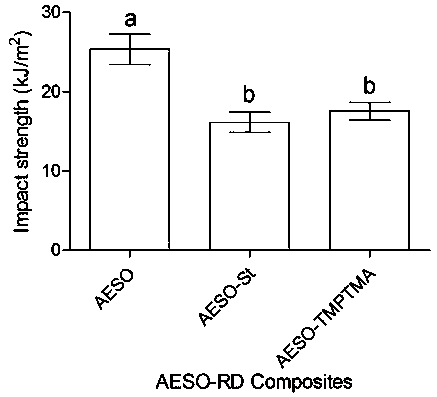

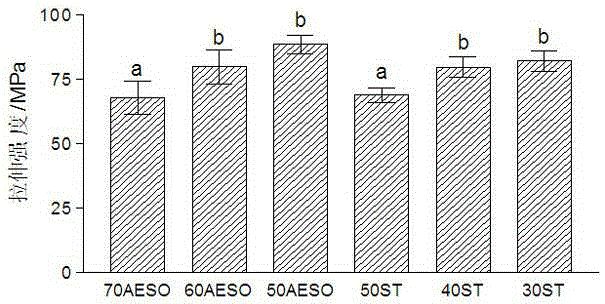

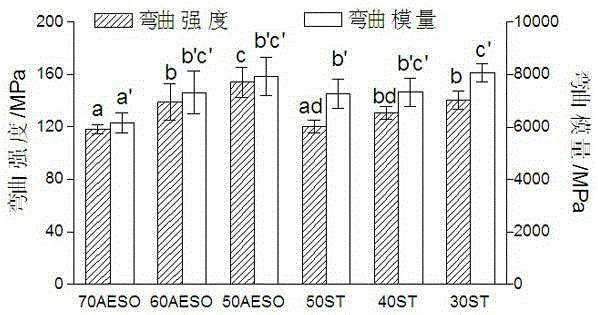

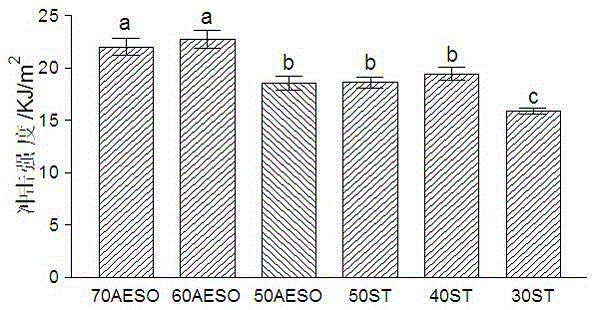

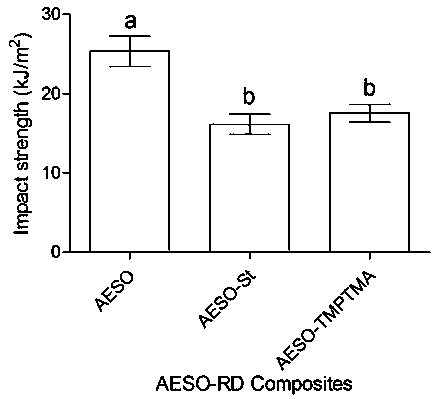

Bamboo-fibril-reinforced modified vegetable oil-base unsaturated polyester composite material

The invention provides a bamboo-fibril-reinforced modified vegetable oil-base unsaturated polyester composite material and a preparation method thereof. Acrylated epoxy soybean oil is used as the blend substance of the unsaturated polyester, and the bamboo fibrils are used as the reinforcer to prepare the composite material. The modified vegetable oil-base unsaturated polyester used by the composite material is free of the carcinogenic reactive solvent styrene, and therefore, has the characteristics of environment friendliness and low cost. The prepared composite material has very high tensile strength, bending strength, bending modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

SnAgCuNi series leadless soldering tin alloy

InactiveCN101058133AEquivalent tensile strengthImprove wettabilityWelding/cutting media/materialsSoldering mediaMelting pointMetallic Lead

The SnAgCuNi tinsel features n the weight composition of 1. 5-2. 5% Ag, 0. 1-0. 8% Cu, 0. 01-0. 5% Ni, 0. 001-0. 1% P, 0-0. 01% Bi with the rest being Sn and unavoidable impurities. The SnAgCuBi lead free solder alloy does not have any lead, being more environmental protective, with low fuse point, better moisture feature, with anti stretch, flexibility, expansion and creep resistance equal to the tinsel alloy.

Owner:上海华实纳米材料有限公司

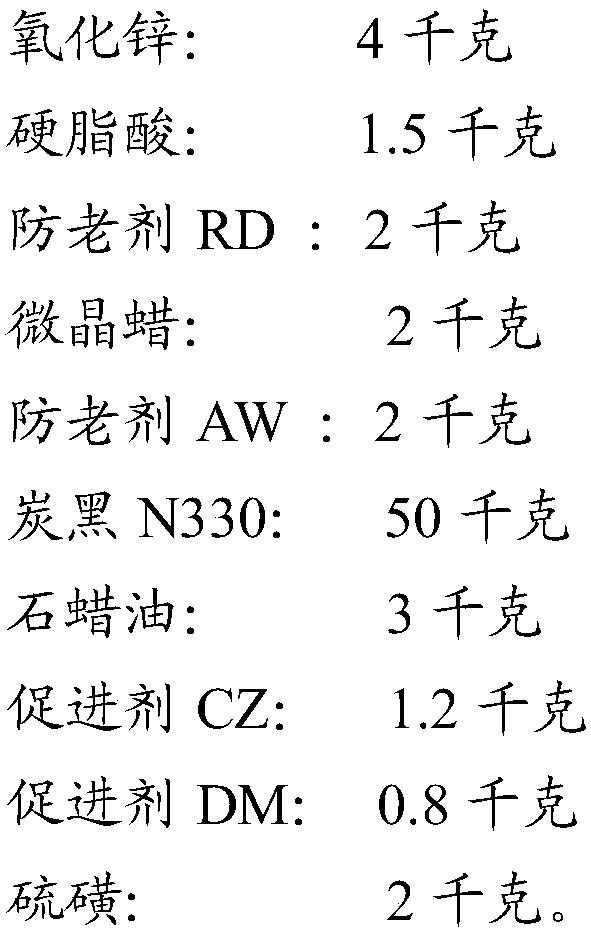

Rubber compound additive particle, preparation method thereof and application of particle

The invention provides a rubber compound additive particle, and belongs to the technical field of rubber. The rubber compound additive particle comprises, by weight, 20-30 parts of rubber, 5-8 parts of zinc oxide, 3-5 parts of stearic acid, 4-6 parts of anti-aging agents, 0.5-1 part of scorch retarders, 3-5 parts of accelerators and 2-4 parts of vulcanizing agents. The particle is cylindrical, thediameter of the particle is 2-5mm, and the height of the particle is 5-10mm. The rubber compound additive particle has functions of activating agents, the anti-aging agents, the accelerators, the vulcanizing agents and the scorch retarders, a small number of additives are used, the same effects can be achieved as compared with a traditional production process, the multifunctional rubber compoundadditive particle is a colloidal particle, on one hand, dispersion effects of various rubber additives in rubber can be effectively improved, on the other hand, matching is facilitated, weighing errors are reduced, environmental pollution caused by dust in production is decreased, and physical health of operators is facilitated.

Owner:河北省同创交通工程配套产品产业技术研究院

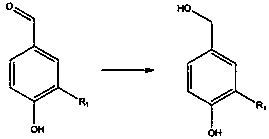

Bamboo fiber reinforced styrene-free unsaturated polyester composite material and preparation method thereof

The invention provides a bamboo fiber reinforced styrene-free unsaturated polyester composite material and a preparation method thereof. Acetylene and 3-hydroxymethyl phenylpropane are taken as raw materials, a monomer with multiple double bonds, namely 1, 1, 1-trivinyl methoxyphenylpropane is synthesized under alkaline conditions and used as a reaction solvent of unsaturated polyester, and the composite material is prepared by taking bamboo fiber as a reinforcing body. The unsaturated polyester used by the composite material prepared by the preparation method provided by the invention does not contain the carcinogenic reaction solvent, namely styrene, thereby having the characteristics of environmental friendliness and low cost; the prepared composite material has the advantages of very high tensile strength, flexural strength, flexural modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

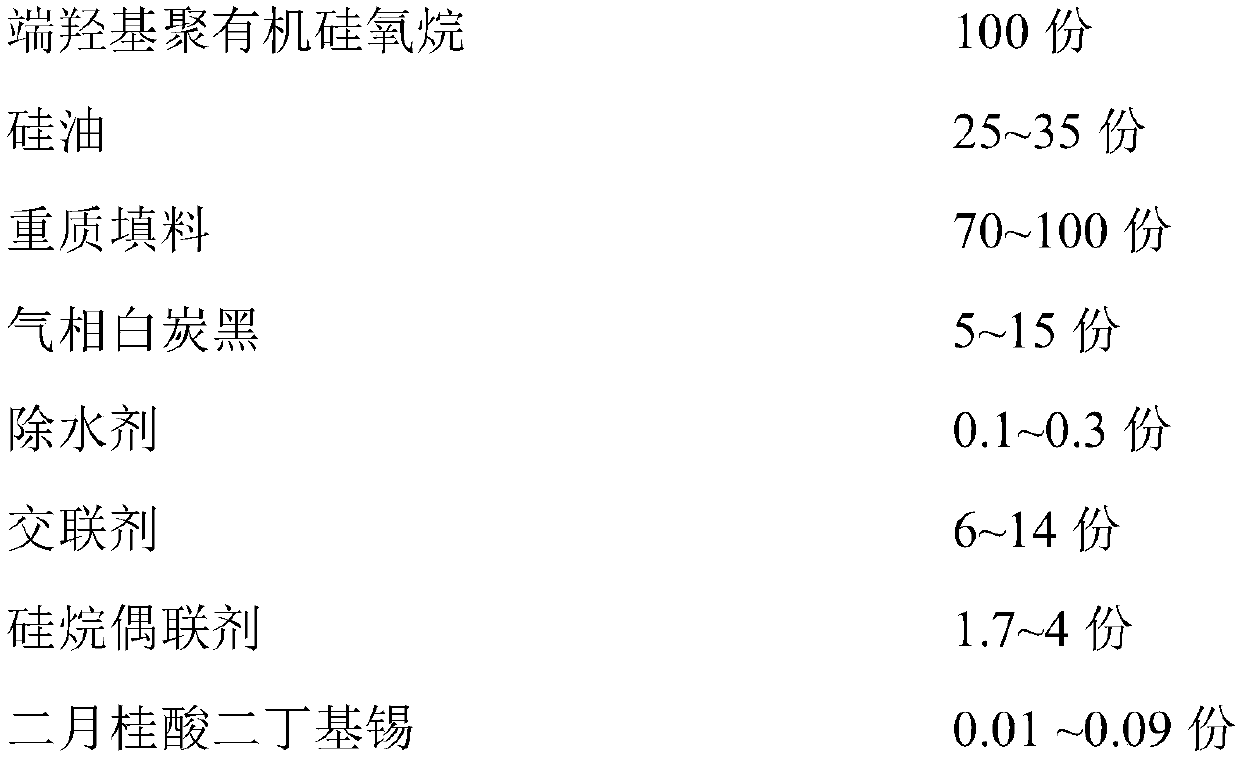

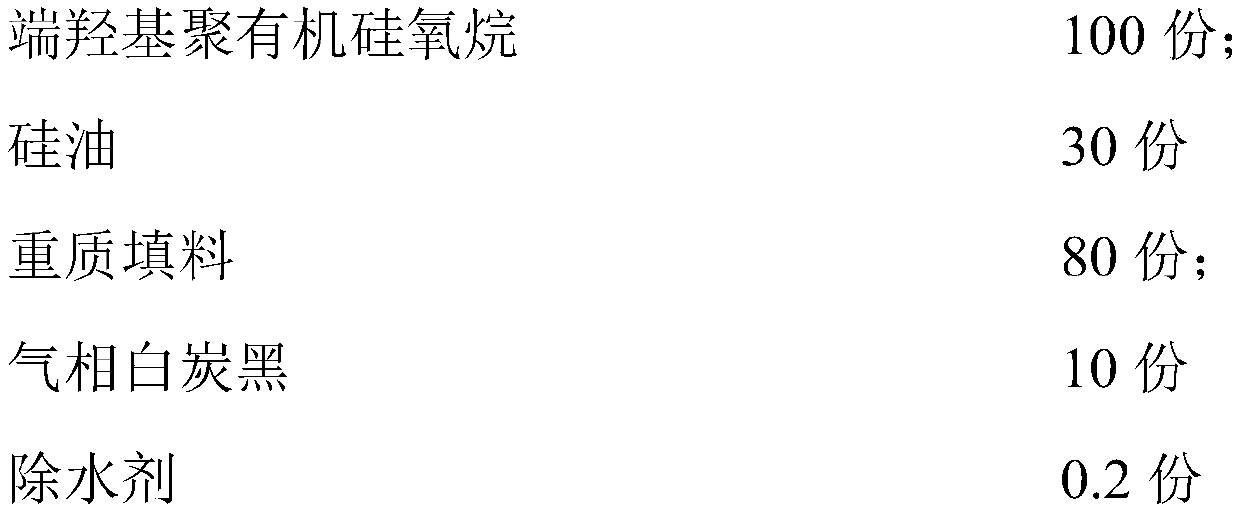

One-component room temperature vulcanized silicone rubber and preparation method

The invention discloses one-component room temperature vulcanization silicone rubber with a simple process and a preparation method thereof, and relates to the field of room temperature vulcanized silicone rubber. The one-component room temperature vulcanized silicone rubber is prepared from, by mass, 100 parts of hydroxyl terminated polyorganosiloxane alkane, 25-35 parts of silicone oil, 70-100 parts of a heavy filler, 5-15 parts of fumed silica, 0.1-0.3 part of a water remover, 6-14 parts of a cross-linking agent, 1.7-4 parts of a silane coupling agent and 0.01-0.09 part of dibutyl tin dilaurate. The preparation method of the one-component room temperature vulcanized silicone rubber adopts a formula design and raw material selection, uses powder with a low water content rate to interactwith the low-active cross-linking agent, and achieves high-temperature dehydration, the whole production process time is greatly shortened, the process is very simple, large-scale production is easilyachieved, and the storage stability is equal to a high temperature dehydration process.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

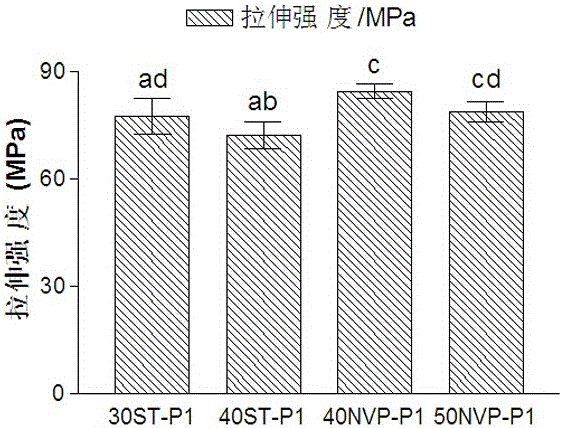

Unsaturated polyester and fiber reinforced composite material thereof based on environment-friendly reactive solvent

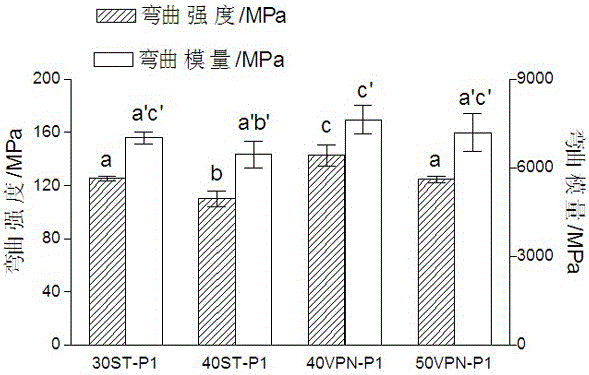

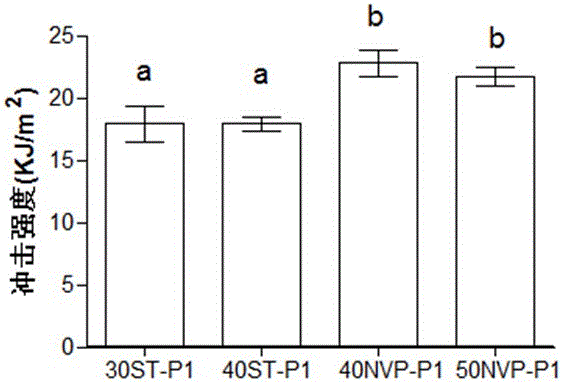

The invention discloses unsaturated polyester and a fiber reinforced composite material thereof based on an environment-friendly reactive solvent. A styrene-free unsaturated polyester resin matrix is synthesized by taking propylene glycol, isophthalic acid and fumaric acid as raw materials under certain conditions, and then the composite material is prepared by carrying out hot-press molding on the styrene-free unsaturated polyester resin matrix based on N-vinylpyrrolidone as a reactive solvent and raw bamboo fiber as a reinforcement body. Since the unsaturated polyester used in the composite material prepared by the method is free of the reactive solvent having carcinogenicity styrene, the unsaturated polyester has the characteristics of environment friendliness and low cost, and the prepared composite material has the advantages of very high tensile strength, flexural strength, flexural modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

Pectin preservative film and preparation method thereof

InactiveCN103772755AUniform thicknessEquivalent tensile strengthFlexible coversWrappersAdhesiveGlycerol

The invention discloses a pectin preservative film and a preparation method thereof. The pectin preservative film comprises the following components in parts by mass: 8-15 parts of pectin, 3-6 parts of polyvinyl alcohol, 0.5-0.8 part of adhesive, 0.8-1.3 parts of glycerol, 0.05-0.1 part of sodium hydroxide and 70-80 parts of water. The adhesive is gelatin or agar. The preparation method comprises the following steps: dissolving the pectin in water, adding the sodium hydroxide to regulate the pH value to 7-8, heating to 80-90 DEG C, stirring until the pectin is completely dissolved, adding the polyvinyl alcohol, adhesive and glycerol, stirring to obtain a viscous sol, pouring the sol into a double screw extruder, carrying out extrusion plastifying, and carrying out film blowing. The widely existent pectin used as the main film-forming material is degradable and can not cause environmental pollution; and the prepared preservative film has the advantages of uniform thickness, equivalent tensile strength and elongation at break to the commercially available common PE (polyethylene) film, and higher light transmittance, and can be used as a substitute of the common PE film.

Owner:NANTONG TIANHE PACKING

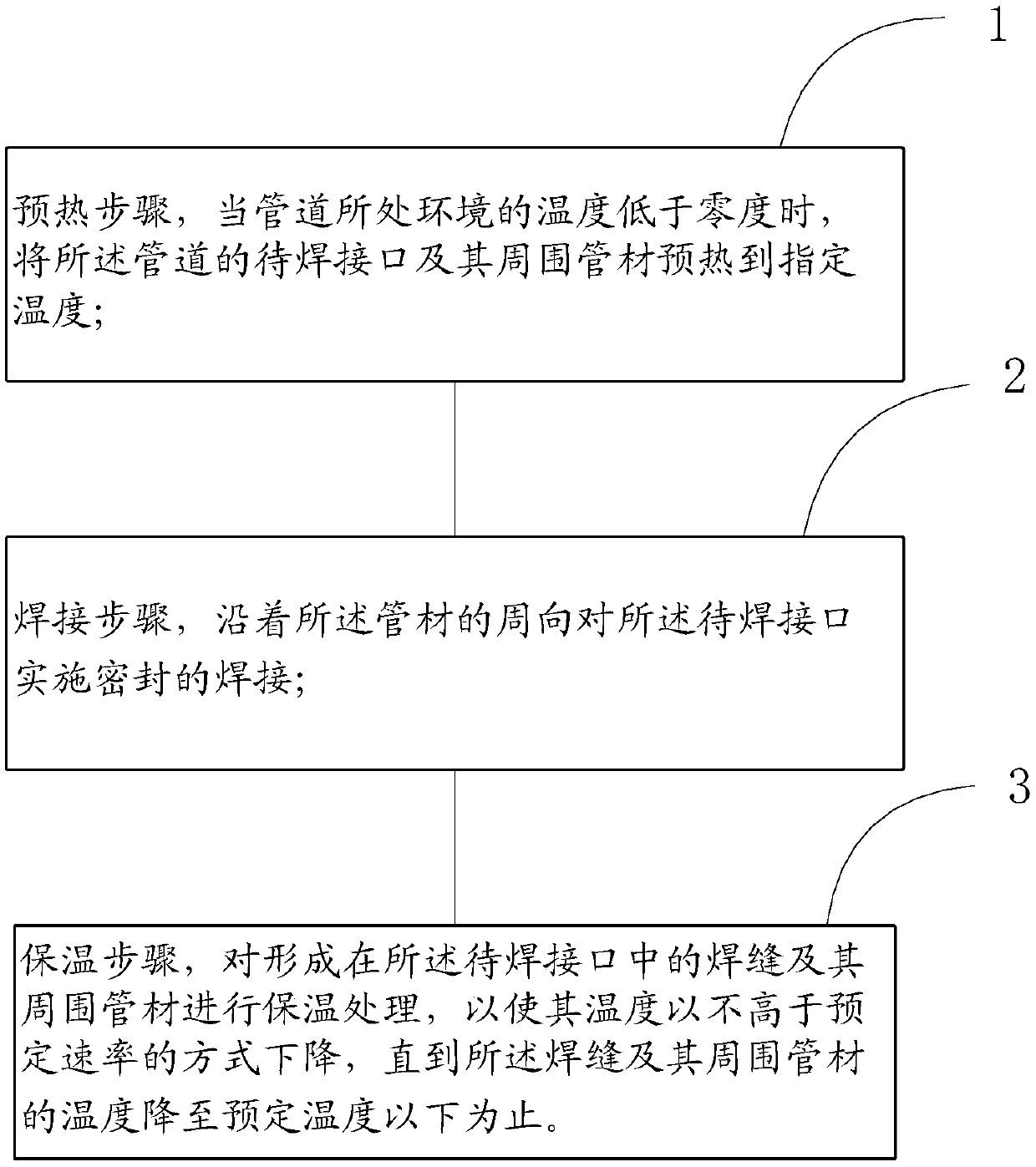

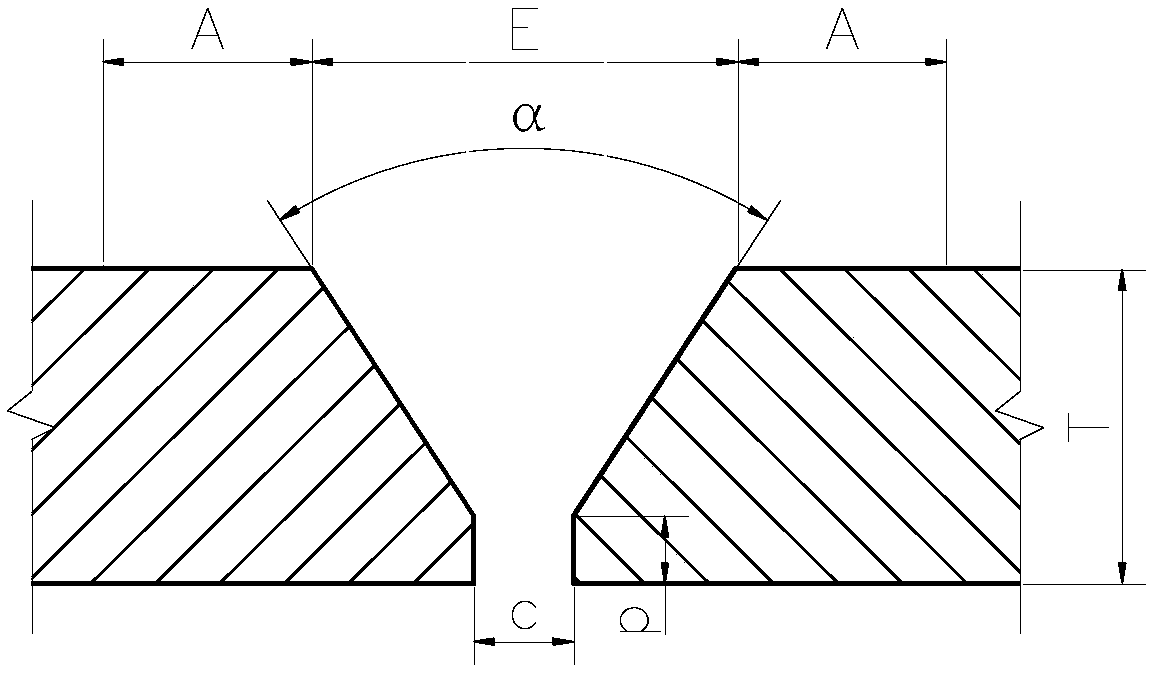

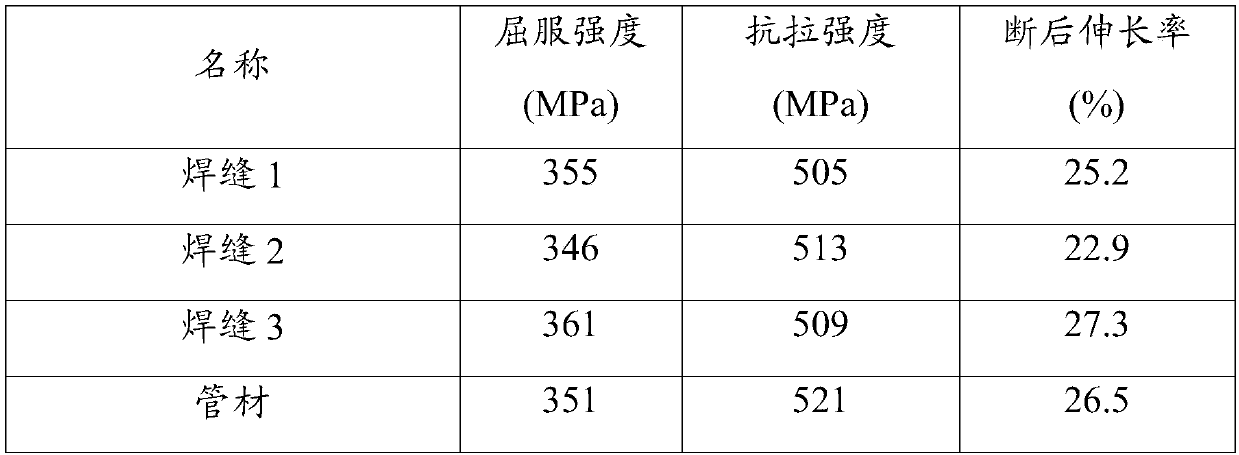

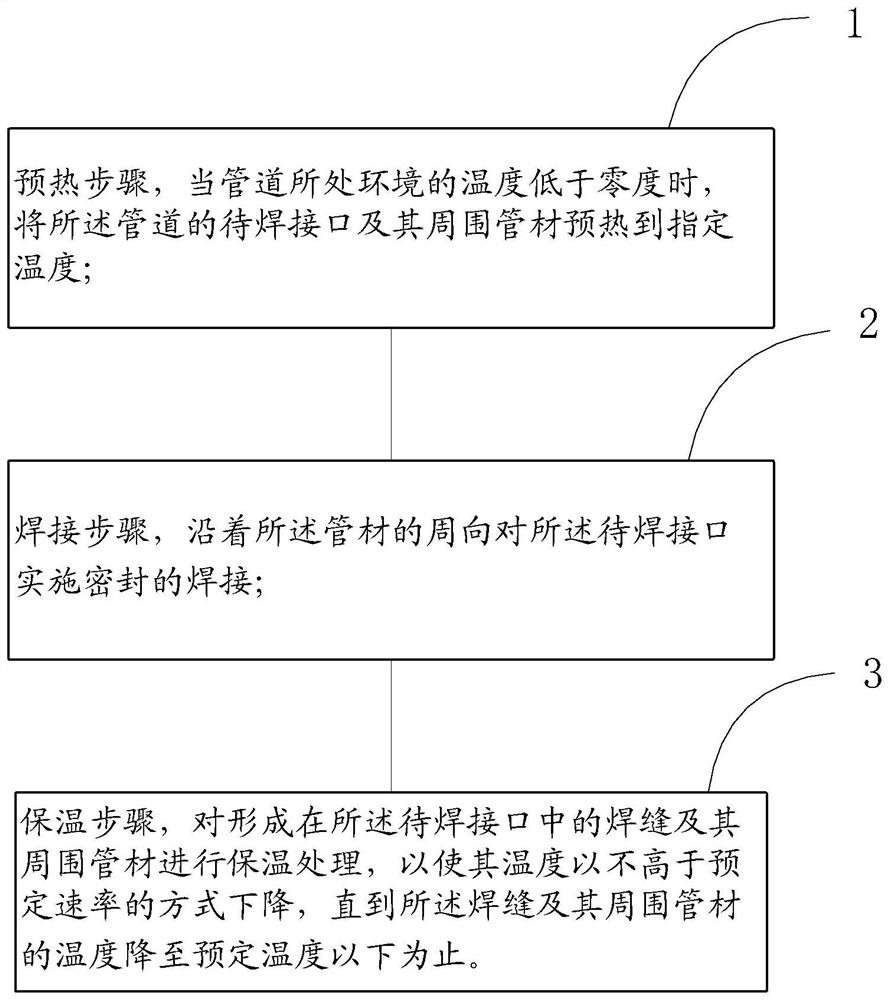

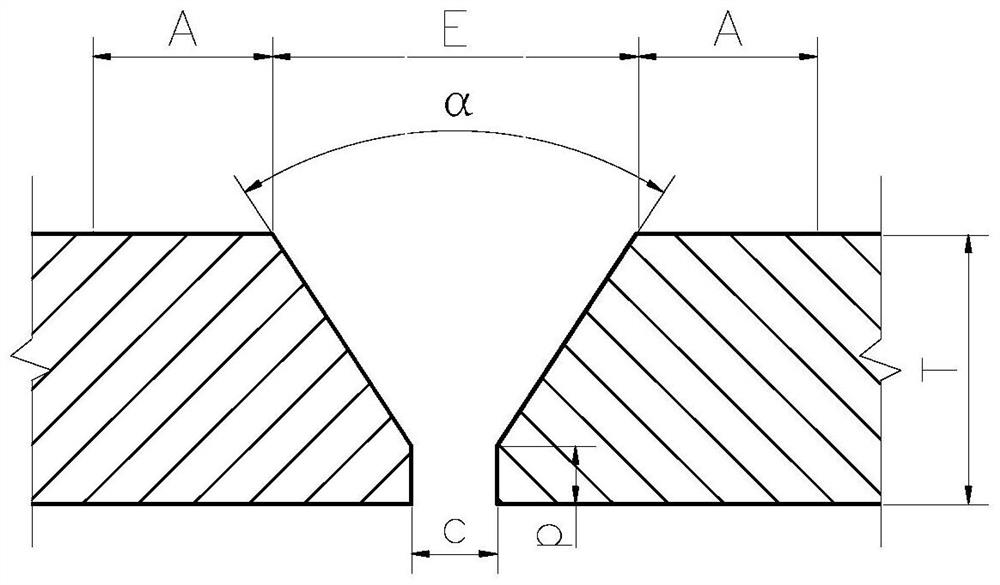

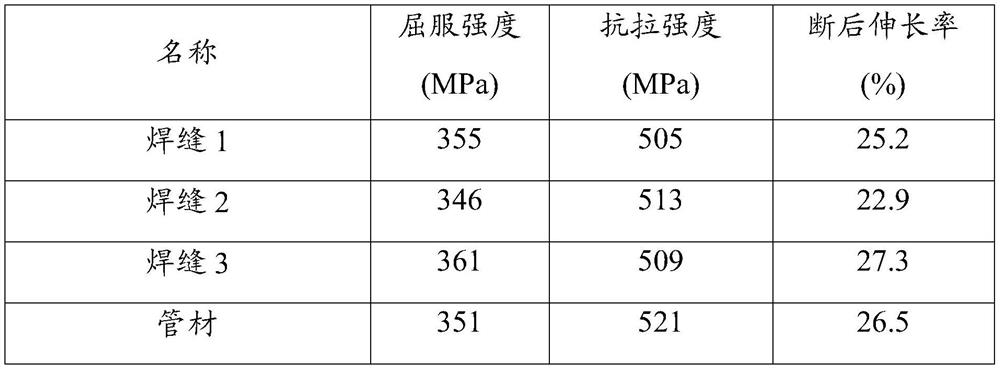

Welding method of pipelines

The invention relates to a welding method of pipelines. The welding method specifically comprises the following steps that preheating is performed as follows: when the temperature of the environment where the pipelines are located is lower than 0 DEG C, to-be-welded openings of the pipelines and surrounding pipes are preheated to the specified temperature; welding is performed as follows: sealed welding is performed on the to-be-welded openings in the circumferential directions of the pipes; and heat preservation is performed as follows: heat preservation treatment is performed on welding lines formed in the to-be-welded openings and the surrounding pipes, so that the temperature of the welding lines and the surrounding pipes is decreased at the rate not higher than the preset rate until the temperature of the welding lines and the surrounding pipes is decreased below the preset rate. According to the welding method, the temperature of the to-be-welded openings and the surrounding pipes is controlled by the aid of early waste heat and later heat preservation, and the residual stress of the to-be-welded openings and the surrounding pipes is reduced, so that the tensile strength of the welding lines is equivalent to that of the pipes, the problem that cracks appear easily after low-temperature welding is solved, the safe service performance of the heat supply pipelines is improved, and the work and the life of town residents are guaranteed.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

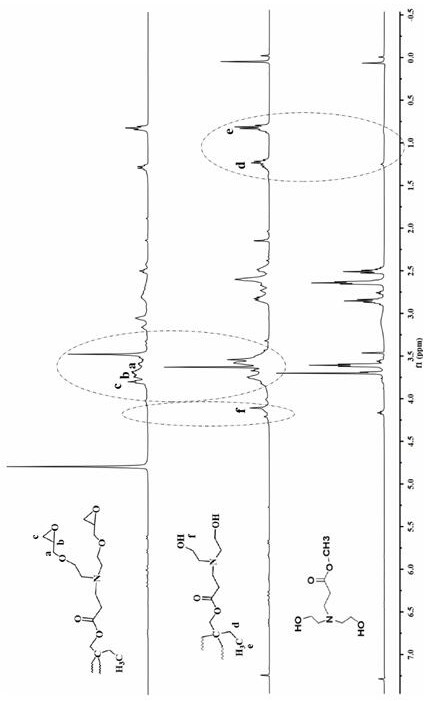

Degradable and thermoplastically processable epoxy thermosetting resin and preparation method thereof

The invention discloses degradable and thermoplastically processable epoxy vitrimers and a preparation method thereof, and belongs to the technical field of new material synthesis. The preparation method comprises the following steps: mixing an epoxy monomer with a beta-diketone structure with an amine curing agent in proportion, stirring the mixture, pouring the mixture into a mold, and heating the mixture until the curing is complete. The epoxy vitrimers obtained by the invention can be degraded in an acidic solution at the temperature of below 80 DEG C for 24 hours after being cured, and have a thermoplastic processing function; after being damaged, the epoxy resin can be self-repaired through hot pressing (10MPa, 10min) at 130-180 DEG C. The preparation process is simple, and the epoxyresin is expected to be used in the fields of recovery of reinforced fibers in epoxy composite materials, degradable or self-repairing epoxy coatings, degradable epoxy adhesives and the like.

Owner:FUZHOU UNIV

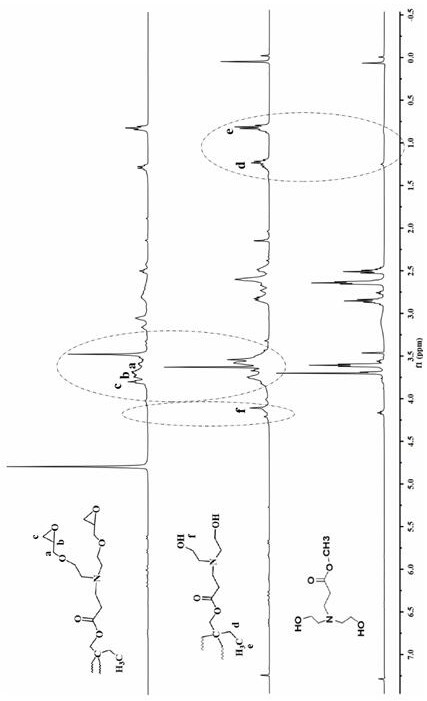

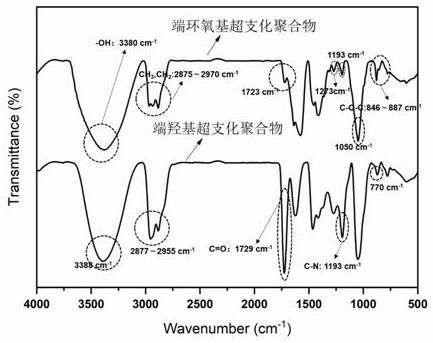

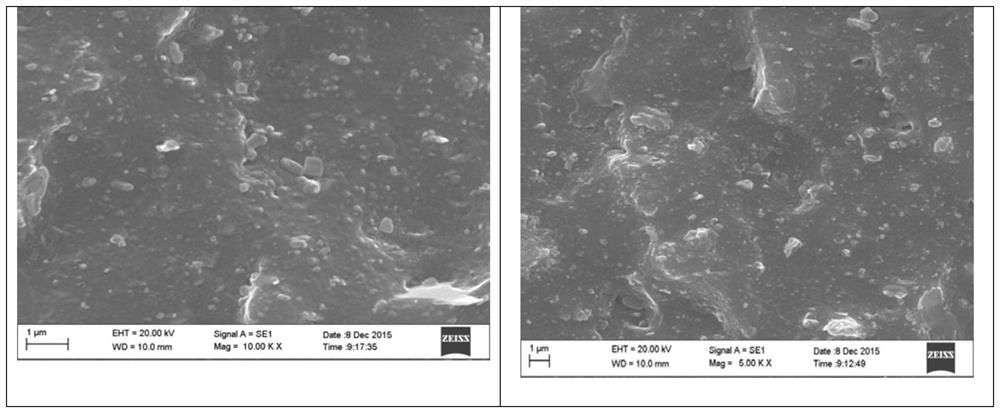

Hyperbranched epoxy polymer-nano silicon dioxide composite chrome-free tanning agent and preparation method thereof

ActiveCN112176127AMolecular weight controllableImprove antibacterial propertiesTanning treatmentEpoxyPolymer science

The invention relates to a preparation method of a hyperbranched epoxy polymer nano silicon dioxide composite chrome-free tanning agent, which comprises the following steps: reacting diethanol amine with methyl acrylate to obtain N,N-dihydroxyethyl-3-amidomethyl propionate; with trimethylolpropane as a reaction center core and N,N-dihydroxyethyl-3-amidomethyl propionate as a monomer (AB2 monomer),preparing hydroxyl-terminated hyperbranched poly (amine ester) by adopting a nucleated one-step method under the catalysis of p-toluenesulfonic acid pTSA; then, an epoxy chloropropane modification method is adopted for modification, and an epoxy-terminated hyperbranched polymer is synthesized; and finally, compounding the chrome-free tanning agent with nano silicon dioxide to obtain the compositechrome-free tanning agent. The hyperbranched epoxy polymer nano silicon dioxide composite chromium-free leather ecological tanning agent prepared by the invention has good water solubility, no toxicity and no pollution, the tanned leather is white and soft in color, fine in grain surface and good in extensibility, and the hyperbranched epoxy polymer nano silicon dioxide composite chromium-free leather ecological tanning agent has a wide application prospect as an environment-friendly leather chromium-free tanning agent.

Owner:SHAANXI UNIV OF SCI & TECH

Corrugated electrode wire for electrical discharge machining and production method thereof

InactiveCN108857286AEasy to useImprove cooling effectElectrical-based machining electrodesBeta phaseWire cutting

The invention discloses a corrugated electrode wire for electrical discharge machining and a production method thereof. A core wire is made with corrugated stainless steel / carbon steel; a nickel layer, a copper layer and a galvanizing layer are deposited respectively on the surface of the core wire by means of electroplating; the coated wire material is then treated by means of resistance / radiation combined heating to obtain a base wire of triple-layer structure with alternating beta phase and gamma phase and with a zipper-zinc alloy layer, a nickel transition layer and a core wire layer; thetreated base wire is then drawn to obtain the corrugated electrode wire for electrical discharge machining which has a corresponding diameter. The corrugated electrode wire for electrical discharge machining having very small diameter and corrugated microstructure helps decrease resistance between the wire material and a chipping sample; discharging of wear debris occurred during cutting and circulation of a coolant are improved; wire cutting speed is increased; processing precision is kept stable.

Owner:NINGBO KANGQIANG MICRO ELECTRONICS TECH CO LTD

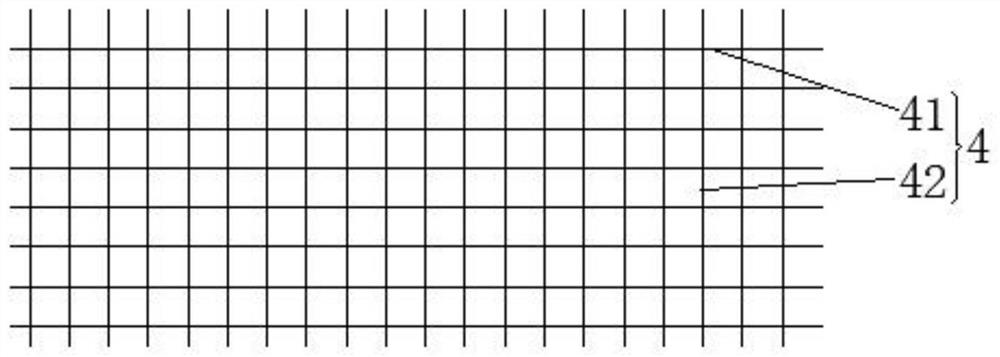

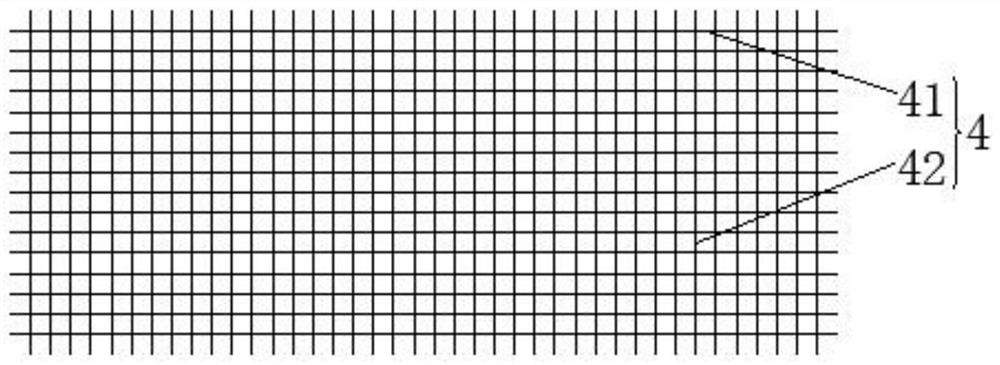

Dam air bag conveying belt

The invention discloses a dam air bag conveying belt, and belongs to the technical field of conveying belts. The dam air bag conveying belt comprises a first rubber covering layer, a framework layer and a second rubber covering layer, the framework layer is clamped between the first rubber covering layer and the second rubber covering layer, and the framework layer, the first rubber covering layer and the second rubber covering layer are combined into a whole through a vulcanization technology, wherein the framework layer is made of canvas. The dam air bag conveying belt has the beneficial effects that the framework layer made of the canvas is arranged between the first rubber covering layer and the second rubber covering layer, the canvas is formed by interweaving warps and wefts, the density of the warps and the wefts is 8-12 pieces per centimeter, and therefore the elasticity, softness and elongation of the dam air bag conveying belt are improved; and meanwhile, the equivalent tensile strength of the dam air bag conveying belt in the warp direction and the weft direction in the inflation process is ensured.

Owner:SHANDONG PHOEBUS RUBBER

A kind of bamboo fiber reinforced styrene-free unsaturated polyester composite material and its preparation

The invention provides a bamboo fiber reinforced styrene-free unsaturated polyester composite material and a preparation method thereof. Acetylene and 3-hydroxymethyl phenylpropane are taken as raw materials, a monomer with multiple double bonds, namely 1, 1, 1-trivinyl methoxyphenylpropane is synthesized under alkaline conditions and used as a reaction solvent of unsaturated polyester, and the composite material is prepared by taking bamboo fiber as a reinforcing body. The unsaturated polyester used by the composite material prepared by the preparation method provided by the invention does not contain the carcinogenic reaction solvent, namely styrene, thereby having the characteristics of environmental friendliness and low cost; the prepared composite material has the advantages of very high tensile strength, flexural strength, flexural modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

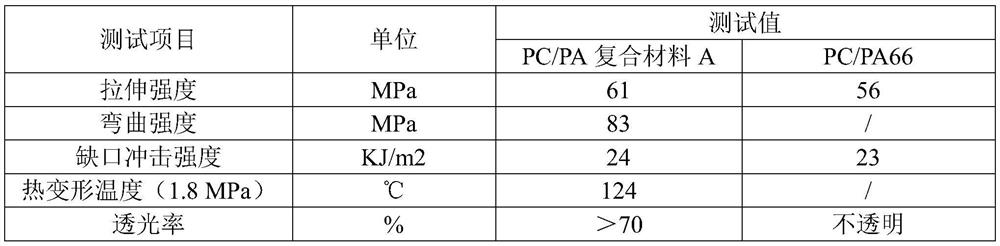

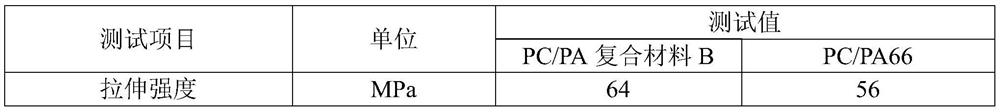

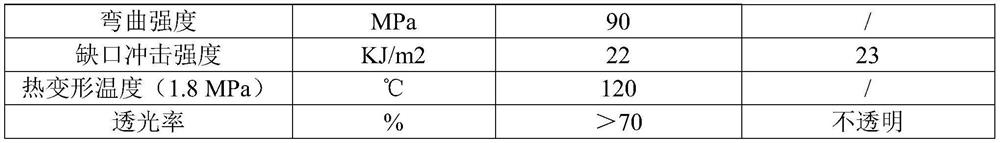

PC/PA composite material with relatively high light transmittance and preparation method thereof

The invention discloses a PC / PA composite material with relatively high light transmittance and a preparation method thereof. The composite material takes PC, PA10I and a copolymer thereof as main raw materials, a proper amount of an antioxidant and a lubricant are added, and compared with the existing PC / PA, the prepared product has the advantages that the tensile strength, bending strength, processing fluidity, heat resistance and other properties are basically equivalent; however, the product prepared by the method is good in transparency, and can be used for preparing products with transparent requirements.

Owner:SHANDONG DONGCHEN ENG PLASTIC

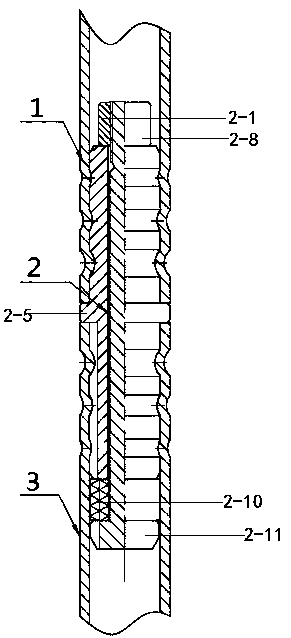

Lifting tool for sheared-off continuous oil tube and using method

InactiveCN111119779AHigh tensile strengthImprove construction efficiencyBorehole/well accessoriesCoiled tubingStructural engineering

The invention provides a lifting tool for a sheared-off continuous oil tube and a using method. The lifting tool comprises a mandrel, wherein a rolling slot sleeves outside the mandrel; a sealing rubber sleeve sleeves the mandrel below the rolling slot; a pressing part sleeves the mandrel above the rolling slot; the bottom end of the mandrel is connected to a stud head; a limiting lug boss is further connected in the middle of the rolling slot; and the rolling slot is divided into an upper rolling slot and a lower rolling slot through the limiting lug boss. Through the lifting tool, a continuous oil tube and a pre-arranged continuous oil tube are connected together, so that complex high-risk continuous oil tube crane lifting operation is converted into conventional continuous oil tube operation during lifting, and therefore, construction efficiency is greatly improved, and the safety risk is remarkably reduced. The lifting tool adopts an up-down symmetrical type three-rolling-slot design, adopts a gradual deepening type design for slot depth, has tensile load equivalent to tensile strength of the continuous oil tube, is simple in design and is high in tensile strength.

Owner:PETROCHINA CO LTD

A kind of plant fiber reinforced environment-friendly unsaturated polyester composite material

Owner:FUJIAN AGRI & FORESTRY UNIV

Unsaturated polyester and its fiber reinforcement based on environmentally friendly reactive solvents

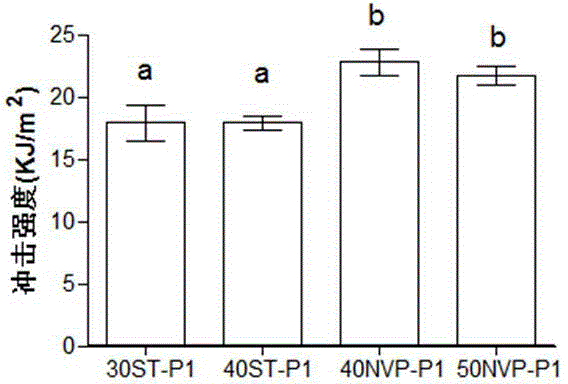

ActiveCN104479079BImprove mechanical propertiesEquivalent tensile strengthFlexural modulusResin matrix

The invention discloses unsaturated polyester and a fiber reinforced composite material thereof based on an environment-friendly reactive solvent. A styrene-free unsaturated polyester resin matrix is synthesized by taking propylene glycol, isophthalic acid and fumaric acid as raw materials under certain conditions, and then the composite material is prepared by carrying out hot-press molding on the styrene-free unsaturated polyester resin matrix based on N-vinylpyrrolidone as a reactive solvent and raw bamboo fiber as a reinforcement body. Since the unsaturated polyester used in the composite material prepared by the method is free of the reactive solvent having carcinogenicity styrene, the unsaturated polyester has the characteristics of environment friendliness and low cost, and the prepared composite material has the advantages of very high tensile strength, flexural strength, flexural modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

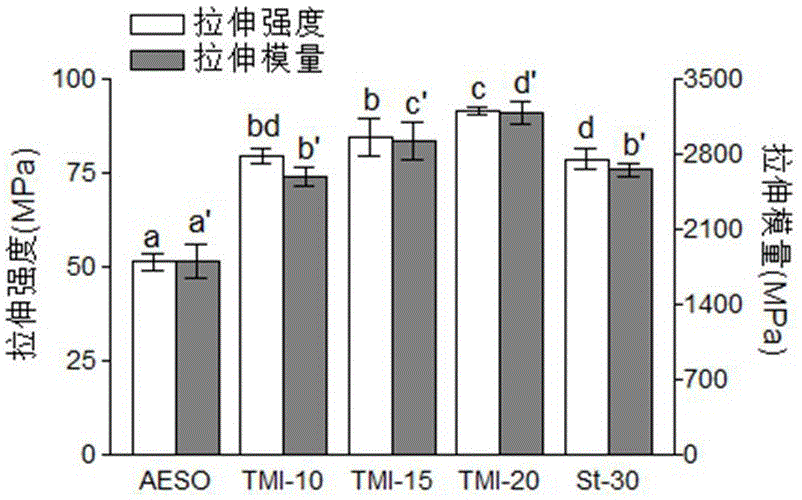

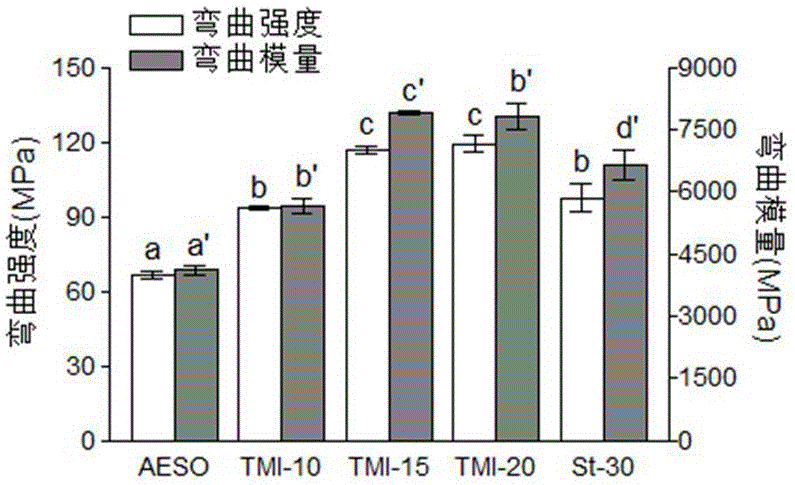

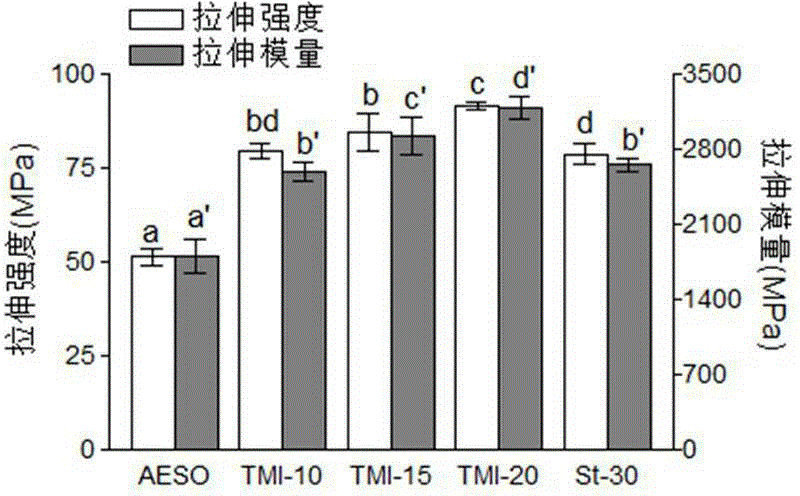

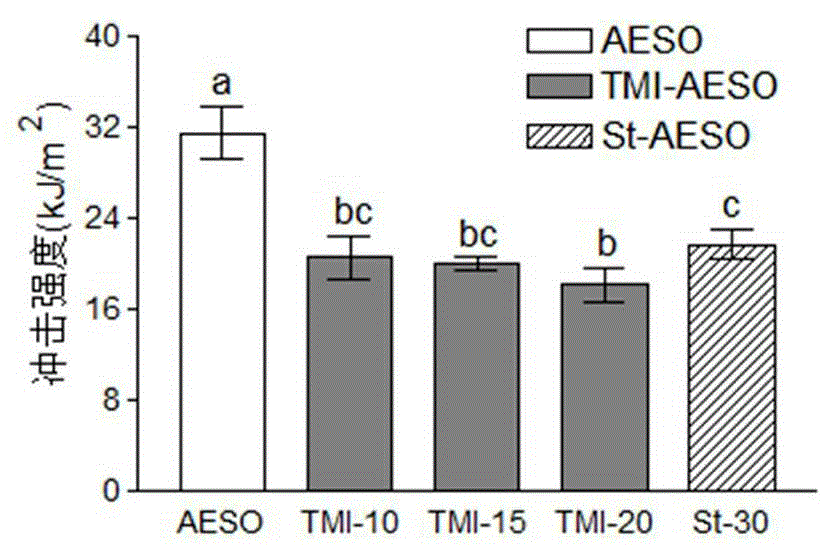

A kind of isocyanate cross-linked soybean oil-based resin/natural fiber composite material

The invention discloses an isocyanate-cross-linked soybean oil-based resin / natural fiber composite material and a preparation method thereof. The method comprises the following steps: adopting a di-functional group isocyanate monomer as a cross-linking agent of epoxy soybean oil acrylate, and preparing soybean oil-based thermosetting resin of which the degree of cross linking, the viscosity and the heat resistance are greatly improved; carrying out hot press molding for natural fiber, the isocyanate-cross-linked soybean oil-based resin and an initiator, and thus obtaining the natural fiber-reinforced soybean oil-based resin composite material. The prepared natural fiber-reinforced soybean oil-based thermosetting resin composite material has good tensile strength, tensile modulus, bending strength, bending modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

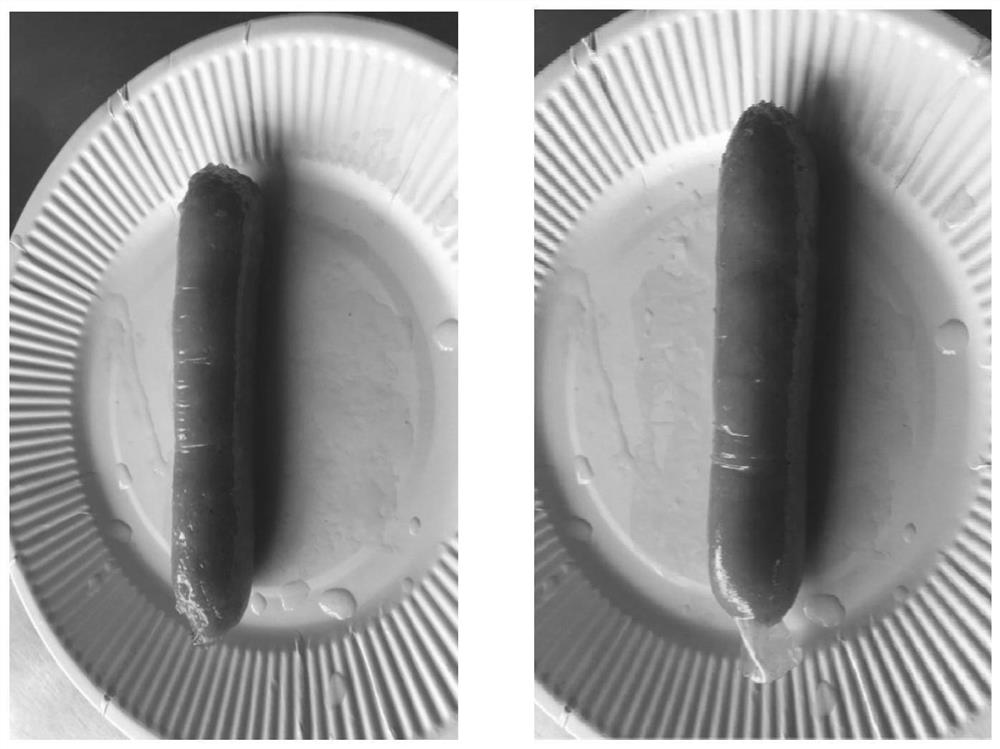

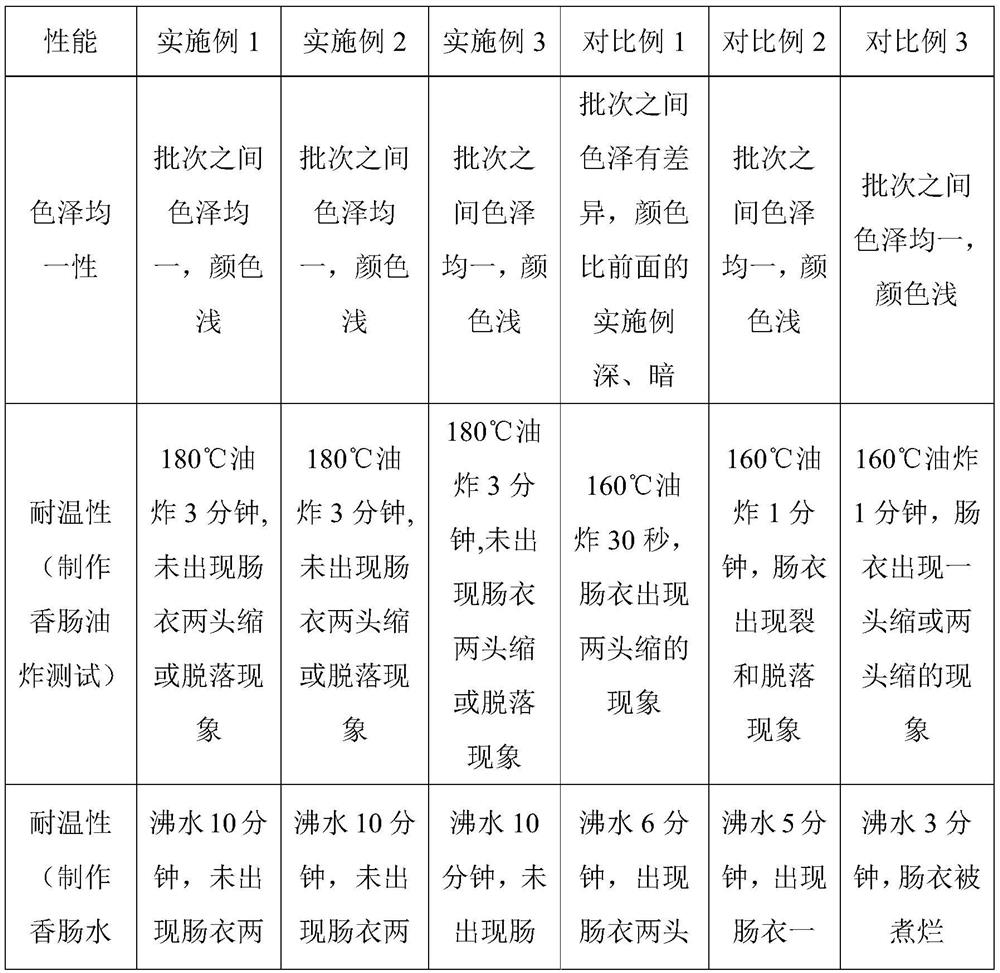

The Production Technology of Boiled/Fried Collagen Casing

ActiveCN110140747BIncrease the degree of cross-linkingWeave evenlyTextile casingsCellulosic sausage casingsFiberPolymer science

The invention relates to the technical field of casing production, in particular to a production process of boiled / fried collagen casings. In the extraction process of the collagen fiber, the present invention adds small molecule polyhydric alcohol, strong oxidant and ferric ion to the semi-finished product after ash washing for pretreatment, and then acidifies. The present invention increases the degree of cross-linking inside the collagen casing by pretreating the semi-finished product after ash washing; by adding suitable auxiliary materials and collagen fibers, the collagen group is prepared; by optimizing the process parameters, adjusting the process steps, and improving the The process of blowing sausage casings was improved; by optimizing the process parameters of the shrinkage and curing process, further cross-linking occurred between collagen molecules and within molecules. The invention is simple and easy to implement, and the prepared casing has good temperature resistance, pressure resistance and mechanical properties, the casing has uniform and beautiful color and stable quality, and is beneficial to industrial production.

Owner:山东海奥斯生物科技股份有限公司

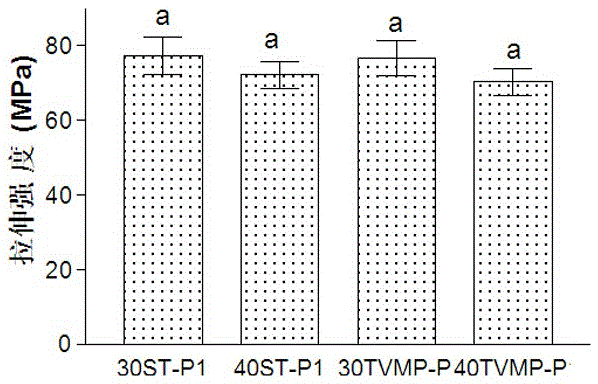

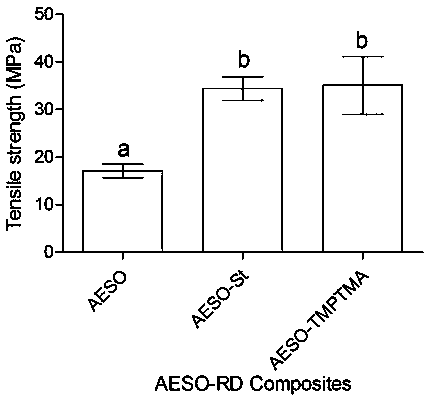

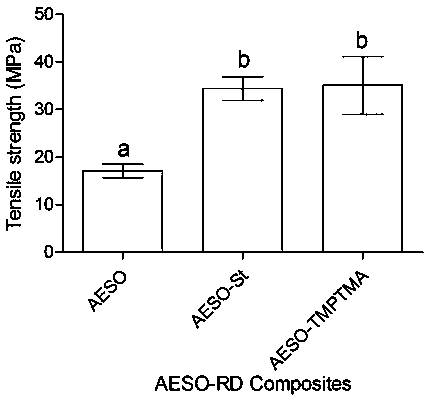

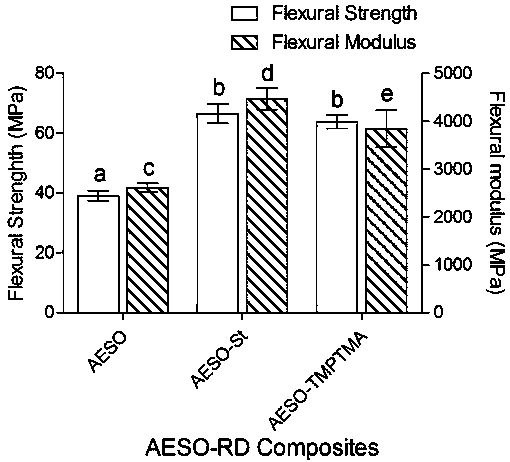

Plant fiber reinforced composite material based on methacrylate crosslinked soybean oil-based resin and preparation method thereof

ActiveCN107915811AHigh tensile strengthEquivalent tensile strengthCoatingsMethacrylateFlexural strength

The invention discloses a plant fiber reinforced composite material based on methacrylate crosslinked soybean oil-based resin and a preparation method thereof. Trimethylolpropane trimethacrylate and epoxidized soybean oil are blended for preparing soybean oil-based resin, and then plant fibers, soybean oil-based resin and an initiator are subjected to hot-press forming, so that the plant fiber reinforced composite material based on the methacrylate crosslinked soybean oil-based resin is obtained. The prepared plant fiber reinforced composite material based on the methacrylate crosslinked soybean oil-based resin is environment-friendly and has good tensile strength, bending strength and bending modulus, and soybean oil-based resin composite material crosslinked with styrene has equivalent impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

A kind of degradable and thermoplastically processable epoxy thermosetting resin and its preparation method

The invention discloses a degradable and thermoplastically processable epoxy vitrimers and a preparation method thereof, belonging to the technical field of new material synthesis. It is obtained by mixing an epoxy monomer with a β-diketone structure and an amine curing agent in proportion, stirring it, pouring it into a mold, heating it, and curing it completely. The epoxy vitrimers obtained in the present invention can be degraded in acidic solution below 80°C in 24 hours after curing, and have the function of thermoplastic processing; after being damaged, they can be repaired by hot pressing (10MPa, 10min) at 130‑180°C, and The preparation process is simple, and it is expected to be used in the fields of recycling of reinforcing fibers in epoxy composite materials, degradable or self-repairing epoxy coatings, and degradable epoxy adhesives.

Owner:FUZHOU UNIV

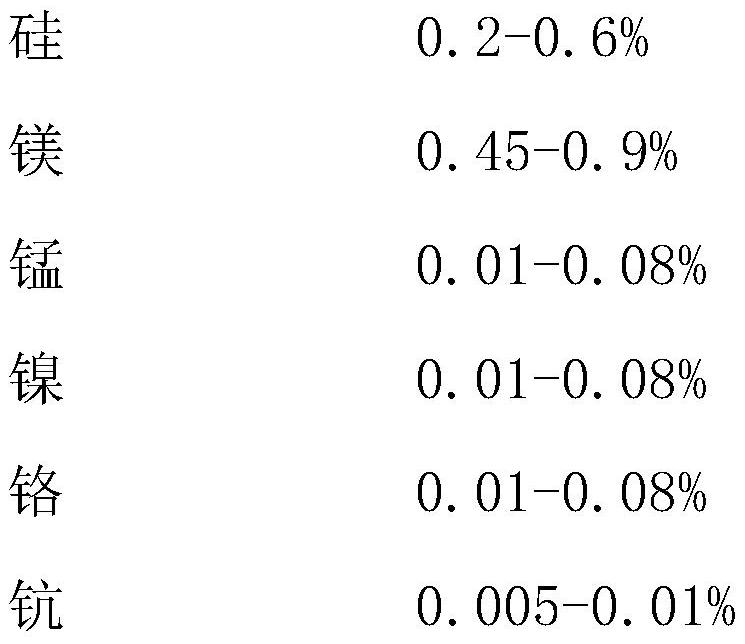

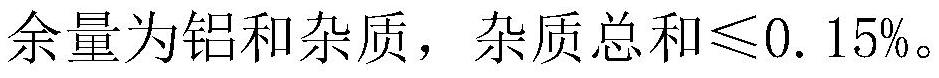

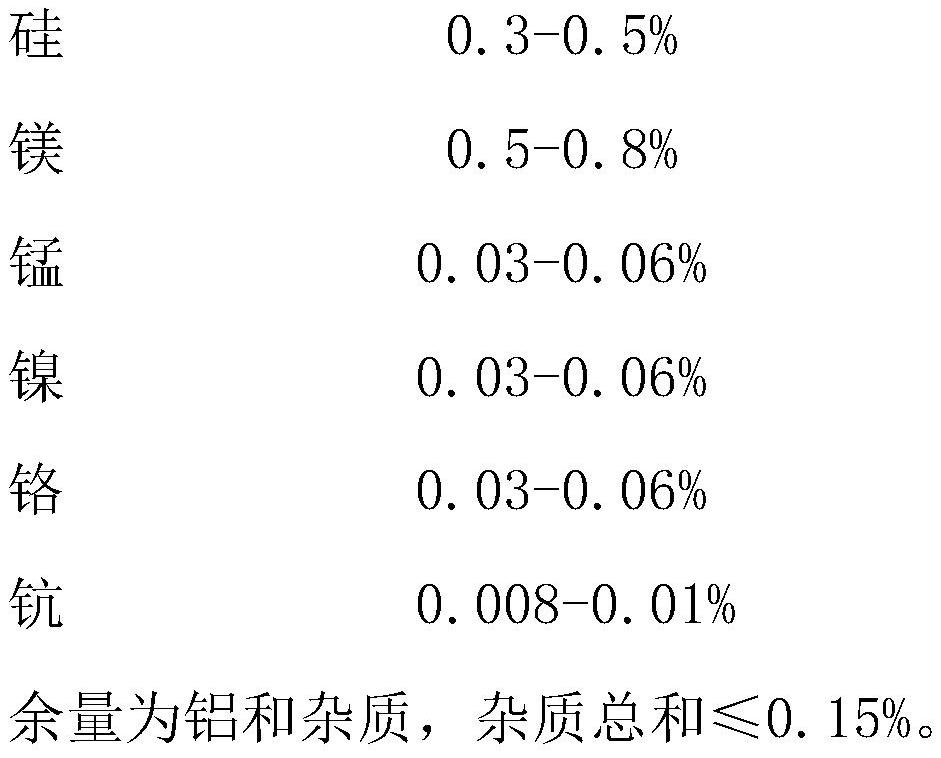

A kind of aluminum alloy material and preparation method thereof

The invention relates to the technical field of secondary aluminum, in particular to an aluminum alloy material and a preparation method thereof. The aluminum alloy material is prepared from waste aluminum and a component A in a weight ratio of 8: 1. In the waste aluminum, the iron content is less than 1.0 wt% of the total amount of the waste aluminum, the zinc content is less than 0.3 wt% of thetotal amount of the waste aluminum, the copper content is less than 0.3 wt% of the total amount of the waste aluminum, and the aluminum content is more than 80.0 wt% of the total amount of the waste aluminum. The component A comprises the following raw materials in percentage by weight: 0.2-0.6% of silicon, 0.45-0.9% of magnesium, 0.01-0.08% of manganese, 0.01-0. 08% of nickel, 0.01-0.08% of chromium, 0.005-0.01% of scandium, and the balance of aluminum and impurities, wherein the sum of impurities is less than or equal to 0.15%. Compared with the existing primary aluminum alloy, the aluminumalloy material has equivalent tensile strength, yield strength and glossiness, and is lower in production cost.

Owner:广东润盛科技材料有限公司

A kind of bamboo fiber reinforced modified vegetable oil-based unsaturated polyester composite material

The invention provides a bamboo-fibril-reinforced modified vegetable oil-base unsaturated polyester composite material and a preparation method thereof. Acrylated epoxy soybean oil is used as the blend substance of the unsaturated polyester, and the bamboo fibrils are used as the reinforcer to prepare the composite material. The modified vegetable oil-base unsaturated polyester used by the composite material is free of the carcinogenic reactive solvent styrene, and therefore, has the characteristics of environment friendliness and low cost. The prepared composite material has very high tensile strength, bending strength, bending modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

Isocyanate-cross-linked soybean oil-based resin/natural fiber composite material

The invention discloses an isocyanate-cross-linked soybean oil-based resin / natural fiber composite material and a preparation method thereof. The method comprises the following steps: adopting a di-functional group isocyanate monomer as a cross-linking agent of epoxy soybean oil acrylate, and preparing soybean oil-based thermosetting resin of which the degree of cross linking, the viscosity and the heat resistance are greatly improved; carrying out hot press molding for natural fiber, the isocyanate-cross-linked soybean oil-based resin and an initiator, and thus obtaining the natural fiber-reinforced soybean oil-based resin composite material. The prepared natural fiber-reinforced soybean oil-based thermosetting resin composite material has good tensile strength, tensile modulus, bending strength, bending modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

Plant fiber reinforced composite material based on methacrylate crosslinked soybean oil-based resin and preparation method thereof

ActiveCN107915811BHigh tensile strengthEquivalent tensile strengthCoatingsMethacrylateFlexural strength

The invention discloses a plant fiber reinforced composite material based on methacrylate crosslinked soybean oil-based resin and a preparation method thereof. Trimethylolpropane trimethacrylate and epoxidized soybean oil are blended for preparing soybean oil-based resin, and then plant fibers, soybean oil-based resin and an initiator are subjected to hot-press forming, so that the plant fiber reinforced composite material based on the methacrylate crosslinked soybean oil-based resin is obtained. The prepared plant fiber reinforced composite material based on the methacrylate crosslinked soybean oil-based resin is environment-friendly and has good tensile strength, bending strength and bending modulus, and soybean oil-based resin composite material crosslinked with styrene has equivalent impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

A pipe welding method

ActiveCN109514051BReduce temperature differenceCool evenlyArc welding apparatusThermal insulationEngineering

The invention relates to a pipeline welding method, which specifically includes: a preheating step, when the temperature of the environment where the pipeline is located is lower than zero, preheating the joint to be welded of the pipeline and the surrounding pipe materials to a specified temperature; the welding step, Carry out sealed welding on the joint to be welded along the circumference of the pipe material; heat preservation step, heat preservation treatment is carried out on the weld seam formed in the joint to be welded and its surrounding pipe materials, so that the temperature thereof is not higher than a predetermined The speed decreases until the temperature of the weld and its surrounding pipes drops below a predetermined temperature. The invention controls the temperature of the joint to be welded and its surrounding pipes through the early waste heat and post-insulation, and reduces the residual stress of the joint to be welded and its surrounding pipes, so that the tensile strength of the weld is equivalent to that of the pipe, and solves the problem of low temperature welding Cracks are prone to occur in the end, improve the safe service performance of heating pipes, and protect the work and life of urban residents.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

A kind of hyperbranched epoxy polymer-nanometer silicon dioxide composite chrome-free tanning agent and preparation method thereof

ActiveCN112176127BMolecular weight controllableMeet the needs of tanningTanning treatmentEpoxyPolymer science

A kind of preparation method of hyperbranched epoxy polymer-nanometer silicon dioxide composite chrome-free tanning agent, first prepare N, N-dihydroxyethyl-3-aminopropionate methyl ester with diethanolamine and methyl acrylate reaction ; Taking trimethylolpropane as the reaction center core again, and N, N-dihydroxyethyl-3-aminopropionic acid methyl ester as a monomer (AB 2 monomer), under the catalysis of p-TSA with p-toluenesulfonic acid, the hydroxyl-terminated hyperbranched poly(amine-ester) was obtained by a one-step method with nuclei; Oxygen hyperbranched polymer; finally, compound it with nano silicon dioxide to obtain a composite chrome-free tanning agent. The hyperbranched epoxy polymer-nanometer silicon dioxide composite chrome-free leather ecological tanning agent prepared by the present invention has good water solubility, non-toxicity, and no pollution. After tanning, the leather is white in color, soft, fine in grain, and good in extensibility. , as an environmentally friendly leather chrome-free tanning agent has broad application prospects.

Owner:SHAANXI UNIV OF SCI & TECH

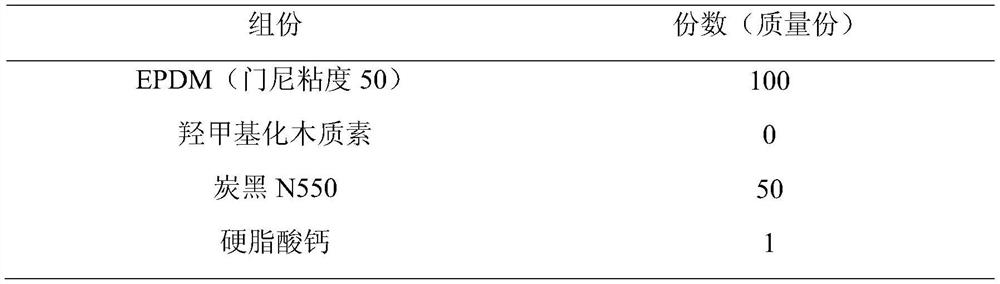

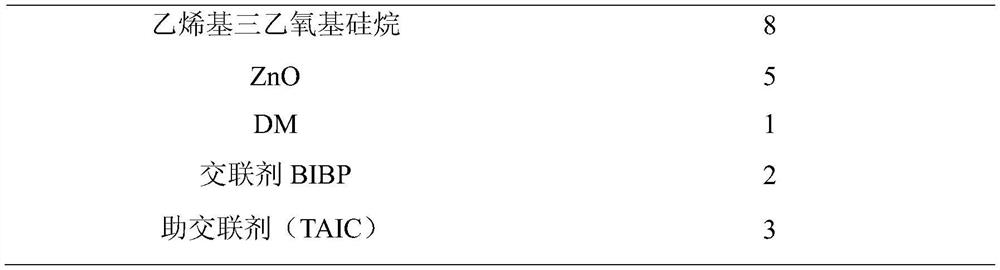

A kind of environment-friendly wear-resistant epdm material and preparation method thereof

ActiveCN109796686BImprove interface compatibilityPrevent dehydration and agglomerationRubber materialEPDM rubber

The invention belongs to the technical field of rubber materials, and discloses an environment-friendly wear-resistant EPDM material and a preparation method thereof. The environmentally friendly wear-resistant EPDM material is prepared from the following components in parts by weight: 100 parts of EPDM rubber, 30-80 parts of hydroxymethylated lignin, 1-3 parts of calcium stearate, 3-6 parts of zinc oxide, DM 1-3 parts, modifier 2-8 parts, cross-linking agent 1-3 parts, auxiliary cross-linking agent 2-5 parts. The invention uses hydroxymethylated lignin to play the role of nano reinforcement, adds vinyl siloxane to modify, improves the interfacial compatibility of lignin in EPDM and further improves the strength of the composite material. The obtained composite material not only has good tensile strength, but also has excellent wear resistance. The tensile strength and abrasion resistance of the EPDM compound prepared with carbon black N550 are equivalent, and it can replace the use of carbon black N550 in EPDM.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com