Rubber compound additive particle, preparation method thereof and application of particle

A rubber and particle technology, applied in the field of rubber auxiliaries, can solve problems such as the impact on the health of workers, flying dust, and increased product defect rate, and achieve the effects of benefiting health, reducing weighing errors, and improving dispersion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a preparation method for rubber compounding auxiliary particles described in the above technical solution, comprising the following steps:

[0028] (1) premixing zinc oxide, stearic acid, anti-aging agent, anti-scorch agent, accelerator and vulcanizing agent to obtain a premix;

[0029] (2) mixing the premixed material obtained in the step (1) with rubber to obtain a mixed material;

[0030] (3) extruding and granulating the kneaded material obtained in the step (2) to obtain rubber compounding aid granules.

[0031] The invention premixes zinc oxide, stearic acid, anti-aging agent, anti-scorch agent, accelerator and vulcanizing agent to obtain a premixed material. In the present invention, the premixing is preferably performed in a ball mill. In the present invention, the premixing time is preferably 5-10 minutes, more preferably 7-9 minutes. In the present invention, the rotational speed of the ball mill is preferably 800-1000 r / ...

Embodiment 1

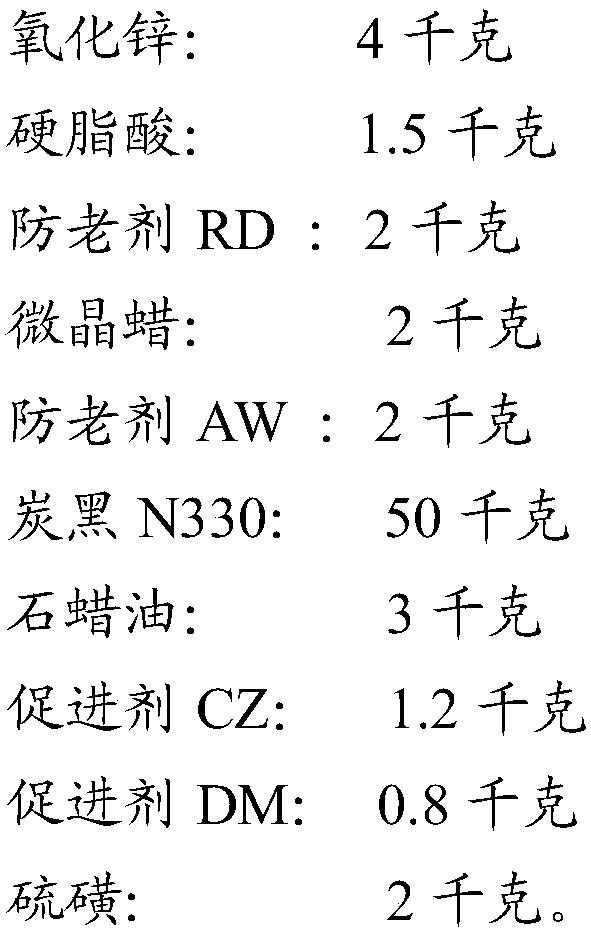

[0041] The ratio of each component of rubber compounding additive particles is as follows:

[0042] 25 parts of natural rubber, 6 parts of zinc oxide, 4 parts of stearic acid, 2 parts of anti-aging agent AW, 2 parts of anti-aging agent RD, 2 parts of microcrystalline wax, 0.6 parts of anti-scorch agent CTP, 1.5 parts of accelerator DM, and accelerator CZ 2 parts, sulfur 3 parts.

[0043] The preparation method comprises the following steps:

[0044] Accurately weigh the raw materials required for preparing the multifunctional compound additive according to the proportion.

[0045] Put the weighed raw materials (except natural rubber) into the ball mill, the weight ratio of ball to material is 2:1, the speed is 1000r / min, and grind for 8 minutes.

[0046] Put the natural rubber into the internal mixer for masticating, the internal mixer speed is 40r / min, masticate for 10min, then put the ground additives into the internal mixer for mixing, the internal mixer speed is 30r / min m...

Embodiment 2

[0055] The ratio of each component of rubber compounding additive particles is as follows:

[0056] 30 parts of EPDM rubber, 8 parts of zinc oxide, 3 parts of stearic acid, 6 parts of microcrystalline wax, 1 part of accelerator TMTD, 1 part of anti-scorch agent EC, 1.2 parts of accelerator BZ, 1.6 parts of accelerator CZ, 4 parts of dicumyl peroxide (DCP).

[0057] The preparation method comprises the following steps:

[0058] Accurately weigh the raw materials required for preparing the multifunctional compound additive according to the proportion.

[0059] Put the weighed raw materials (except natural rubber) into the ball mill, the weight ratio of ball to material is 2:1, the speed is 800r / min, and grind for 12 minutes.

[0060] Put the natural rubber into the internal mixer for masticating, the internal mixer speed is 30r / min, masticate for 20min, then put the ground additives into the internal mixer for mixing, the internal mixer speed is 40r / min min, the kneading temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com