Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Equivalent hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost, high-strength, high-toughness and high-abrasion resistance cold-working die steel and preparation method thereof

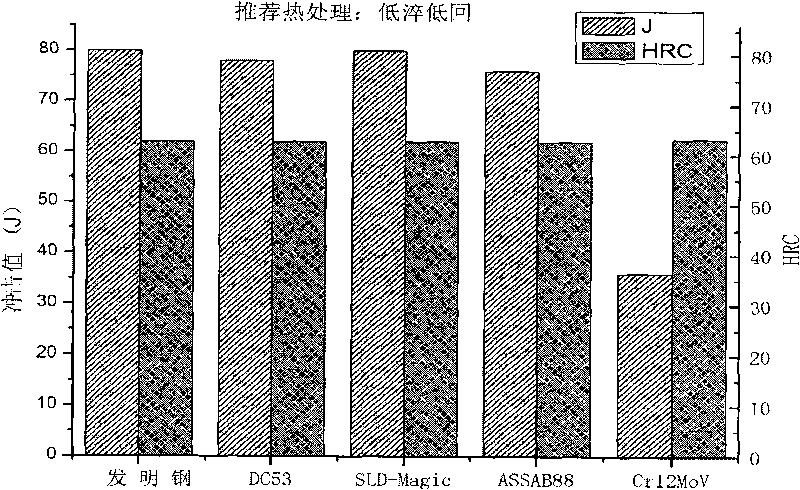

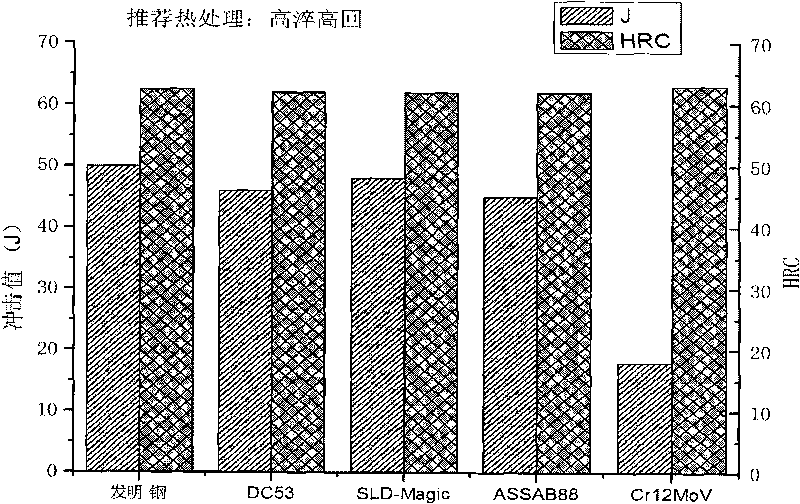

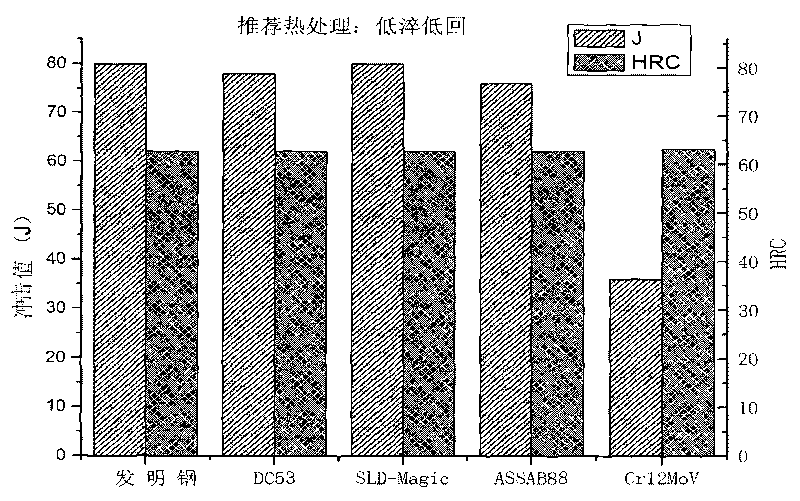

The invention relates to a low-cost, high-strength, high-toughness and high-abrasion resistance alloy steel and a preparation method thereof. The invention belongs to the technical field of preparation technologies of special alloy steel. The alloy steel comprises the following elements by weight percent: 0.88-1.10% of C, 0.45-0.65% of Si, 0.20-0.50% of Mn, 7.50-9.0% of Cr, 1.30-1.80% of Mn, 0.30-0.60% of V and the balance of Fe. The preparation process comprises the following steps: (1) preparing materials and melting by using the conventional method, wherein the melting temperature is 1500-1550 DEG C; (2) carrying out electro-slag re-melting; (3) annealing after the electro-slag re-melting; (4) forging; (5) annealing after the forging, and annealing at the temperature of 850-880 DEG C for 8 hours; (6) carrying out shpheroidizing annealing to 860-550 DEG C; and (7) carrying out the heat treatment technology, adopting the low temperature quenching and low temperature tempering or high temperature quenching and high temperature tempering technology for carrying out heat treatment, and finally preparing the high-strength, high-toughness and high-abrasion resistance cold-working die steel. The hardness of the die steel is 62-63HRC and the average impact toughness is 80J. Compared with the imparted steel, the alloy steel has the equivalent hardness and toughness, and can completely replace the imported high-strength, high-toughness and high-abrasion resistance cold-working die steel.

Owner:SHANGHAI UNIV

Metal-matrix composite ceramic liner plate and preparation method thereof

ActiveCN102618772AImprove interfacial bond strength and overall performanceImprove interface bondingGearingCylindersCeramic particleChromium

The invention discloses a metal-matrix composite ceramic liner plate. Zirconia aluminum oxide, high chromium iron powder and iron powder are electrically smelted and injected into a metal-matrix ceramic reinforcement with a plurality of communicated plug holes to form the metal-matrix composite ceramic liner plate; the upper and lower end faces of the metal-matrix ceramic reinforcement are provided with communicated plug holes, and four side faces of the metal-matrix ceramic reinforcement are provided with communicated grooves; after different reinforcements are spliced, grooves on edges of two adjacent reinforcements form complete plug holes, a metal liquid is poured into the plug holes and can infiltrate among ceramic particles of the reinforcements through the plug holes and uniformly coat the ceramic particles, so that a ceramic phase and a metal phase are uniformly distributed. Therefore, the toughness and wear resistance of the finished ceramic products are enhanced, and the thermal shock resistance of the finished ceramic products is improved.

Owner:洛阳鹏飞耐磨材料股份有限公司

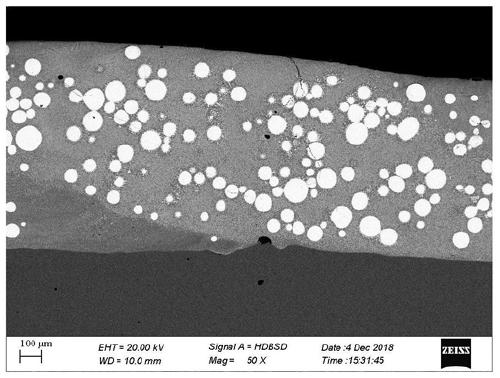

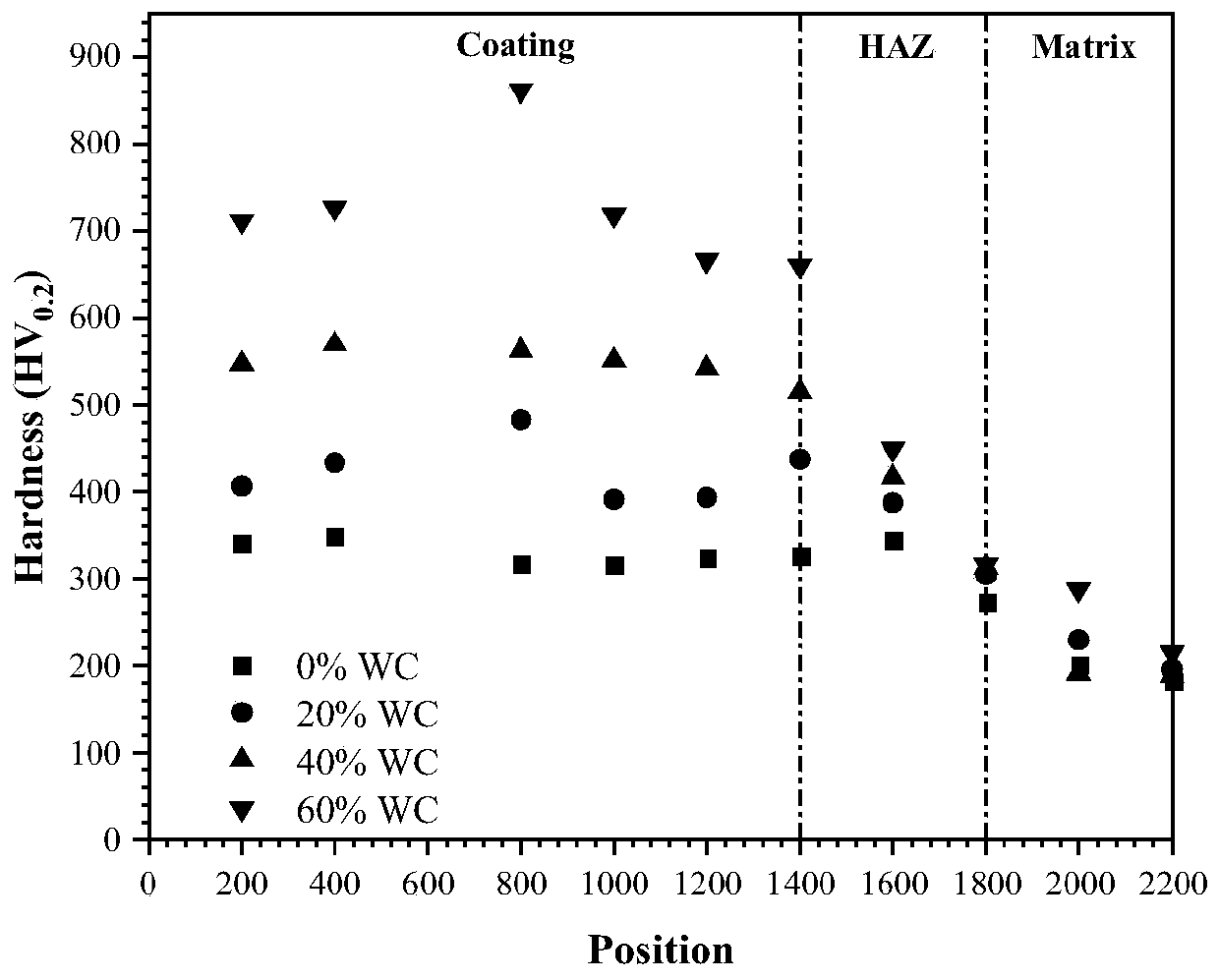

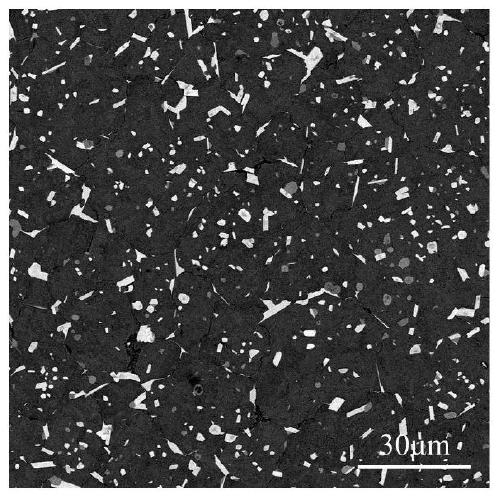

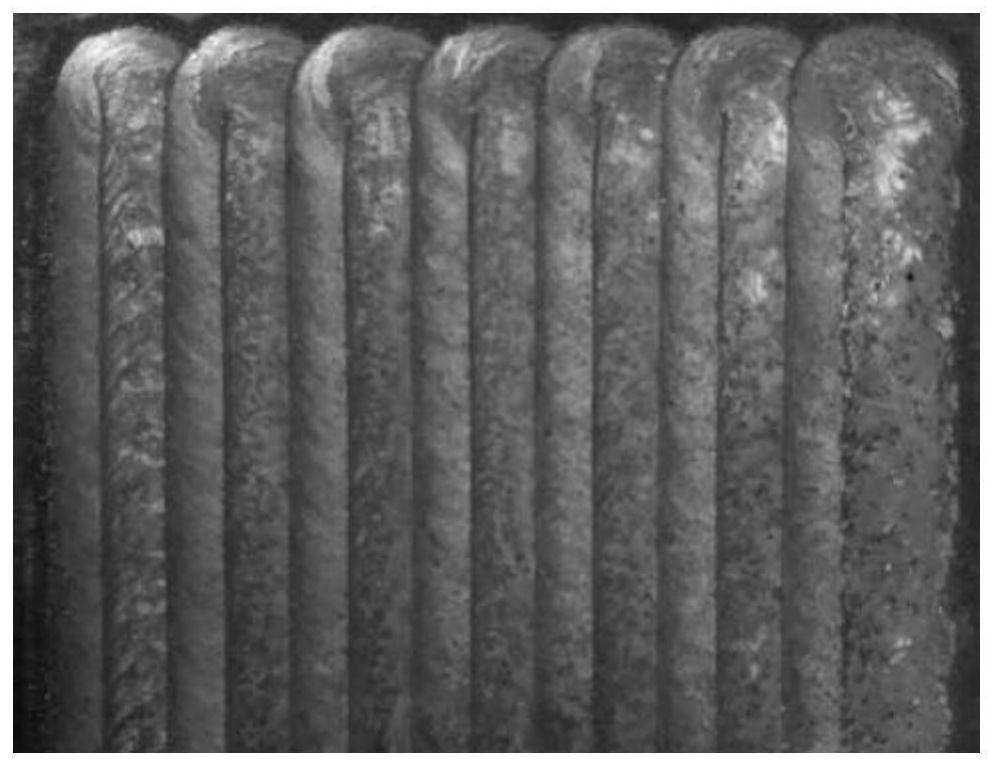

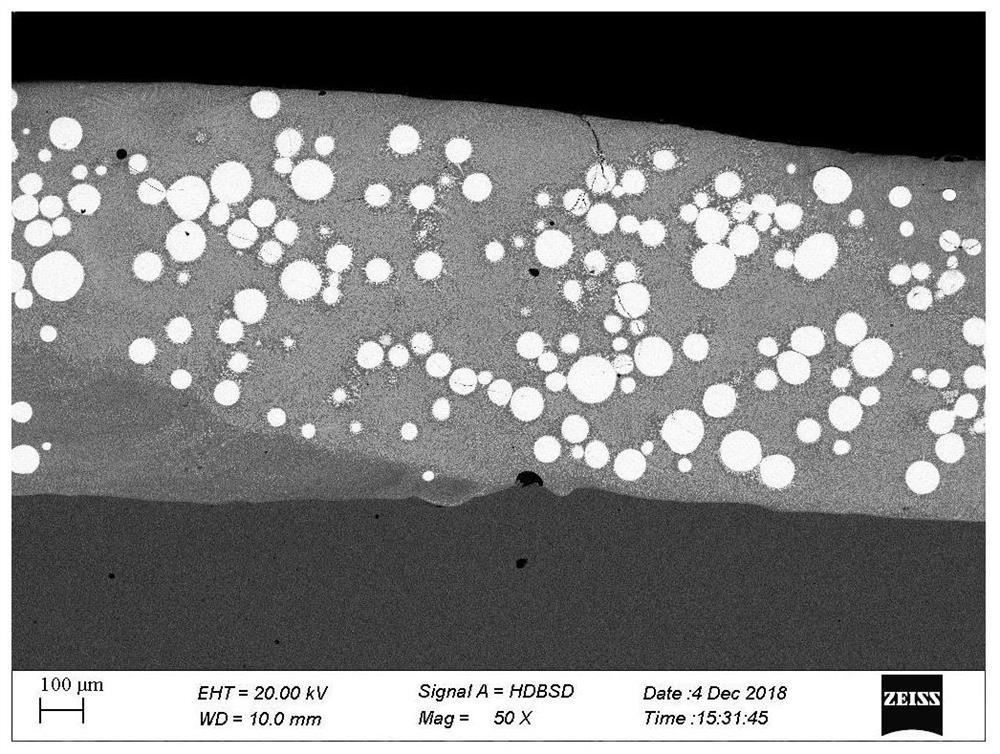

High-entropy alloy composite large-particle tungsten carbide composite coating as well as preparation method and application thereof

ActiveCN110331398AImprove performanceImprove bindingMetallic material coating processesHigh entropy alloysLarge particle

The invention belongs to the field of preparation of special composite coatings, and particularly relates to a high-entropy alloy composite large-particle tungsten carbide composite coating as well asa preparation method and application thereof. The composite coating is composed of a high-entropy alloy and tungsten carbide, wherein the tungsten carbide contains large-particle tungsten carbide, and the particle size of the large-particle tungsten carbide is 75-150 microns. The preparation method comprises the steps that high-entropy alloy powder and the large-particle tungsten carbide are prepared according to a set proportion; and the high-entropy alloy / the large-particle tungsten carbide is prepared through a laser cladding and rapid cooling method. The preparation process of the high-entropy alloy composite large-particle tungsten carbide composite coating is adopted, the high-entropy alloy / the large-particle tungsten carbide composite coating is prepared while protection matrices and the large-particle tungsten carbide are not damaged, so that the uniform distribution of the large-particle tungsten carbide particles in the composite coating is achieved, and various types of large-particle tungsten carbide particles and various types of laser cladding equipment are suitable.

Owner:CENT SOUTH UNIV

Method for restoring surface defects of casting machine after machining

The invention discloses a method for restoring surface defects of a casting machine after machining, which comprises the following steps: painting a copper plating protection layer on the surface around the defect on the surface of the casting machine after machining and / or on the surface of the defect; then resurfacing welding the defect to cause a defect repair welding point to be higher than the surface of the casting machine; and carrying out plane milling and / or grinding processing at the part of the repair welding point higher than the surface of the casting machine until the repair welding point has the same process dimension with the surface of a basal body. The process is a composite type restoring technique expanded on a common restoring process, and the repair welding point is well combined with a parent material, has equivalent rigidity with the parent material, and has the basically same color and luster with the parent material. The method not only avoids the hazards of part deformation, cracking and the like easily caused by singly adopting an argon arc welding method, but also avoids the problems of long restoring time, weak combination with the parent material and the like caused by singly adopting an electric brush plating method.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE +1

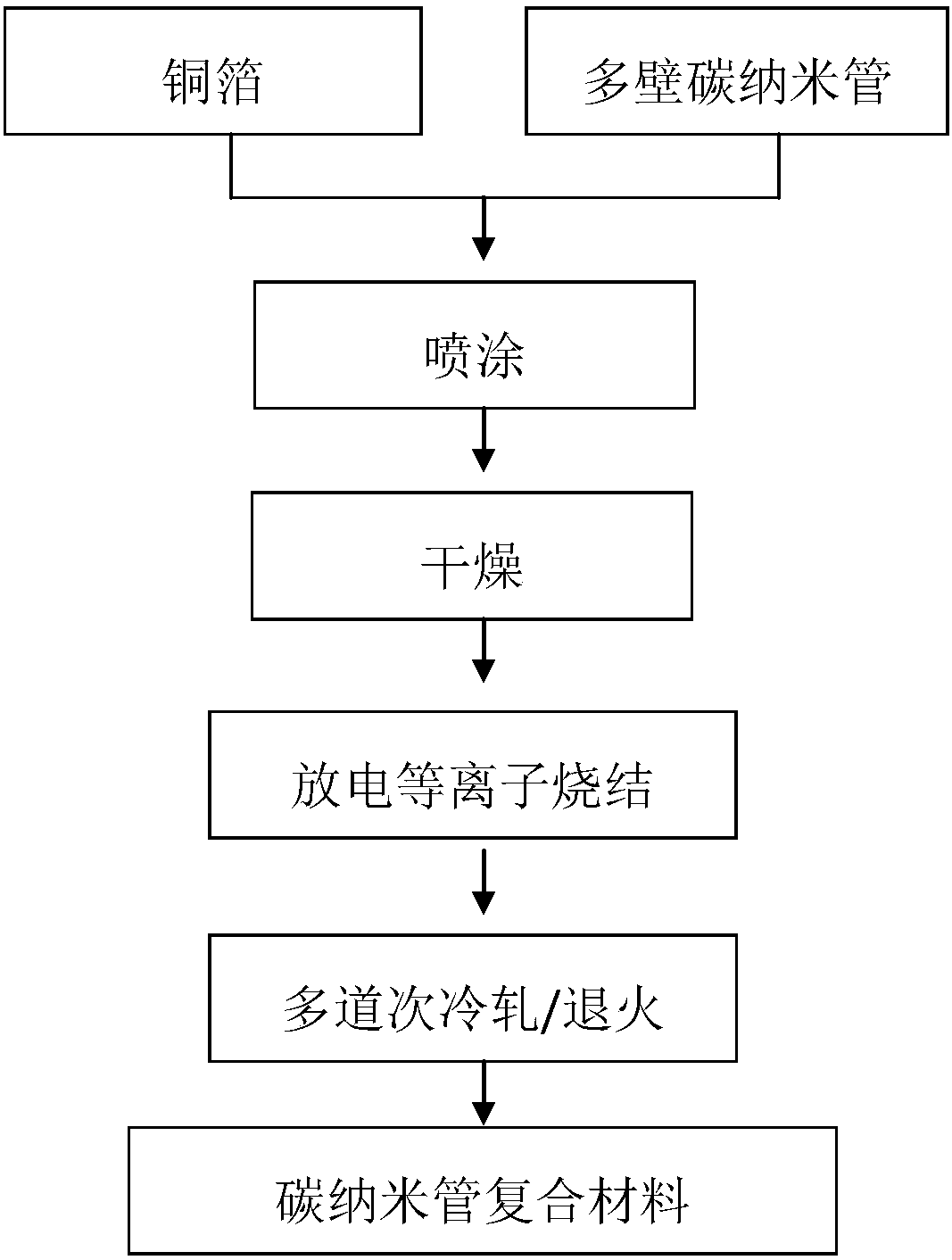

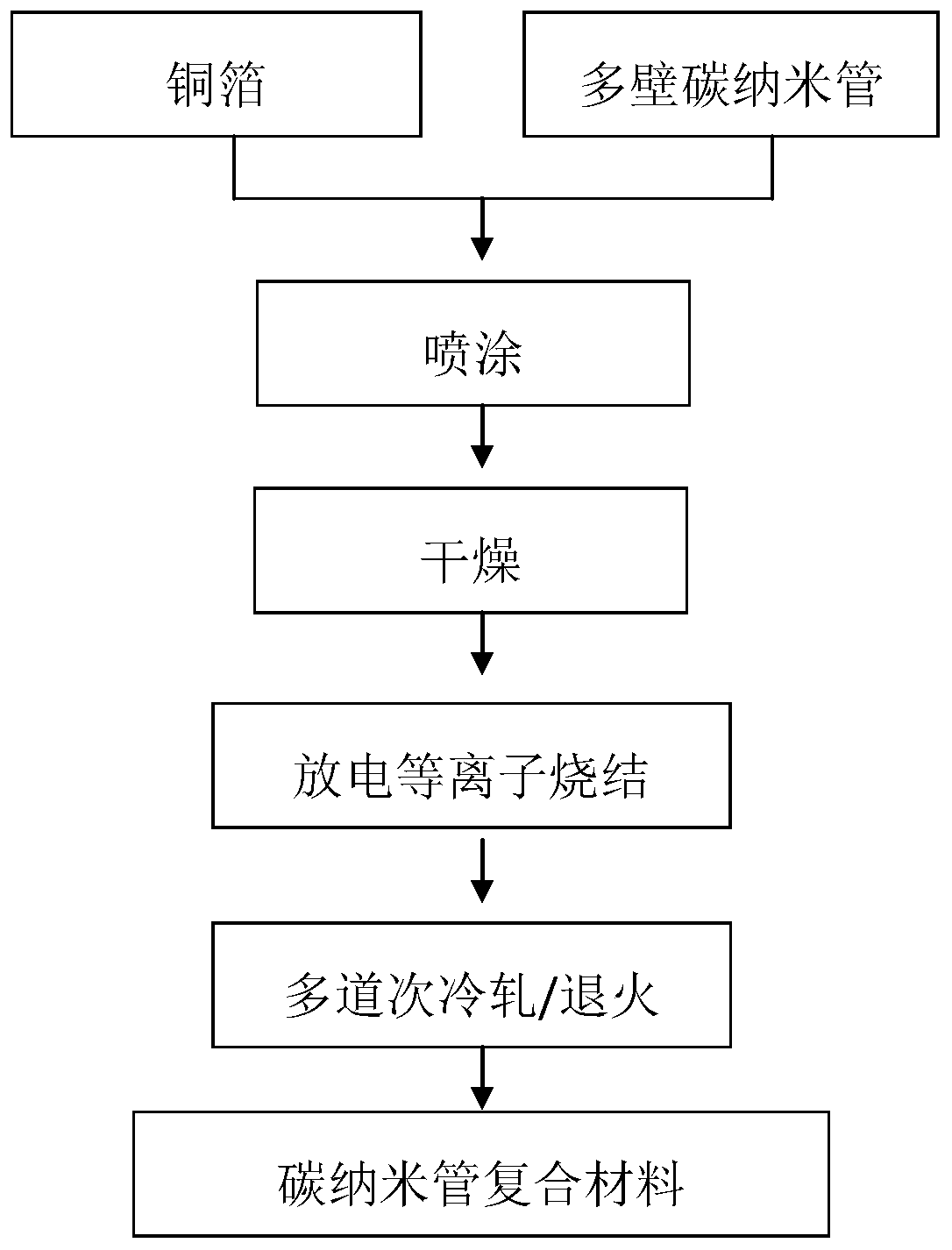

Preparation method of carbon nanotube enhanced copper-based composite material

The invention discloses a preparation method of a carbon nanotube enhanced copper-based composite material. The preparation method comprises the following steps: uniformly adding MWCNTs (Multi-walledCarbon Nanotubes) between copper foils; carrying out an SPS (Spark Plasma Sintering) and cold rolling technology to obtain a laminar MWCNTs / Cu composite material thin belt. The relative density of anobtained MWCNTs / Cu composite material is 94.3 to 98.6 percent. Compared with a traditional powder SPS MWCNTs / Cu composite material, the resistivity is reduced by 10 percent to 16 percent and the yieldstrength is equivalent.

Owner:CENT SOUTH UNIV

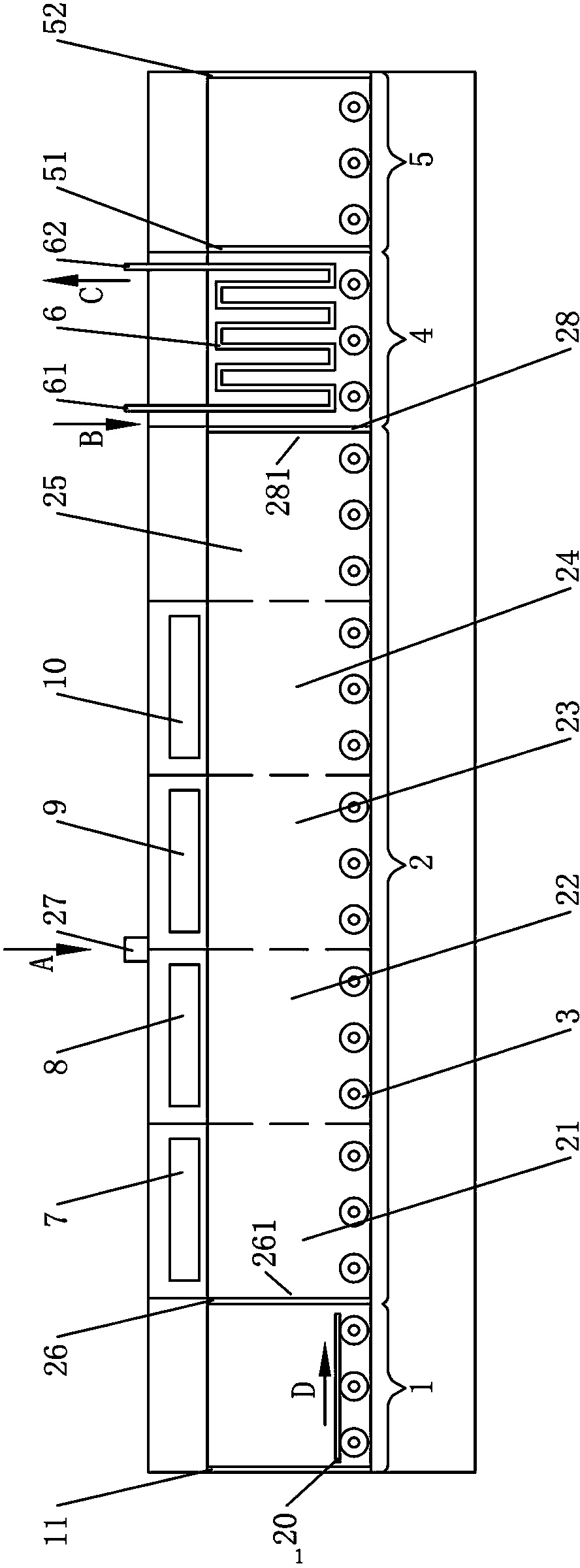

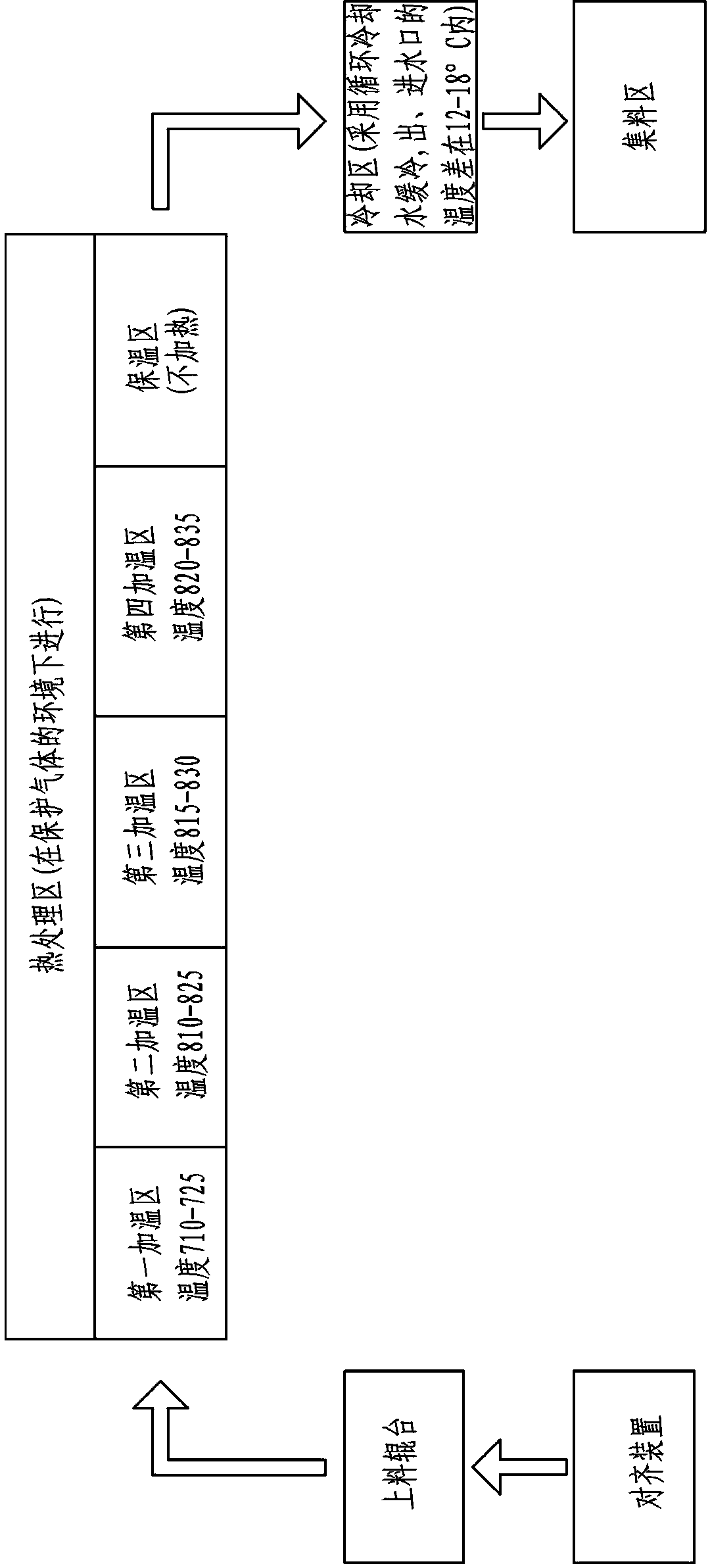

Steel pipe annealing equipment and steel pipe annealing technology

ActiveCN103710512AIncrease productivitySlow coolingFurnace typesHeat treatment furnacesShielding gasHardness

The invention relates to steel pipe annealing equipment and a steel pipe annealing technology. The steel pipe annealing equipment comprises the following technological processes: A. conveying a steel pipe to a feeding roller table through an alignment device, and conveying at the speed of 16-27m / h; B. enabling the steep pipe to enter a thermal treatment furnace via an inlet sealing box and carrying out closed heat treatment on the steel pipe, and continuing to move the steel pipe forwards in the thermal treatment furnace at the speed of 16-27m / h, wherein the steel pipe orderly passes through a first heating area, a second heating area, a third heating area, a fourth heating area and a heat preservation area inside the thermal treatment furnace; the heating temperatures of the first heating area, the second heating area, the third heating area and the fourth heating area are orderly increased, and the thermal treatment furnace is filled with protective gas in the closed thermal treatment process; C. slowly cooling the steel pipe by a cooling box adopting circulating cooling water to cool after the steel pipe is discharged from the thermal treatment furnace; and D. enabling the steel pipe to enter an aggregate area through an outlet sealing box to finish the overall process after the steel pipe is discharged from the cooling box. By adopting the technology, the inner stress of the material after pipe welding can be removed, the steel pipe is uniform in hardness, high in tensile strength and high in ductility, the yield strength is reduced, and the steel pipe is flexible.

Owner:广东志达精密管业制造股份有限公司

Locomotive-buffer-bar surface repairing and remanufacturing method

ActiveCN109079421AGuaranteed stabilityReduce welding heat inputWelding apparatusSand blastingEngineering

The invention discloses a locomotive-buffer-bar surface repairing and remanufacturing method. The locomotive-buffer-bar surface repairing and remanufacturing method includes the following steps that S1, repairable to-be-repaired buffer bars are screened out; S2, the abrasion loss of the to-be-repaired buffer bars is checked, to-be-repaired areas are determined on different-radius shaft segments ofthe buffer bars according to the size of the abrasion loss respectively, and to-be-repaired grooves are processed in the to-be-repaired areas; S3, the to-be-repaired buffer bars are sequentially subjected to sand blasting, cleaned and preheated; S4, one ends of the to-be-repaired buffer bars are fixed on a displacement device, and the to-be-repaired grooves are subjected to continuous annular welding through a CMT automatic welding system to complete repairing of the to-be-repaired buffer bars; S5, the repaired buffer bars obtained in the step S4 are welded to be subjected to slow cooling treatment; S6, the repaired areas of the repaired buffer bars are machined according to the size of an original-buffer-bar drawing, and then whole sand blasting is carried out. The locomotive-buffer-barsurface repairing and remanufacturing method is low in cost, high in efficiency and high in repairing quality, and the buffer bars after being repaired and remanufactured with the method can reach thequality standard of a new buffer bar.

Owner:SOUTHWEST JIAOTONG UNIV

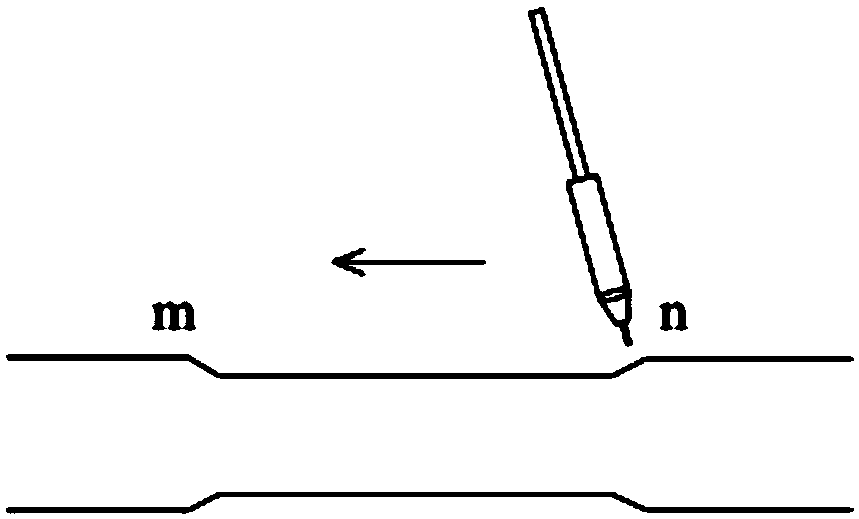

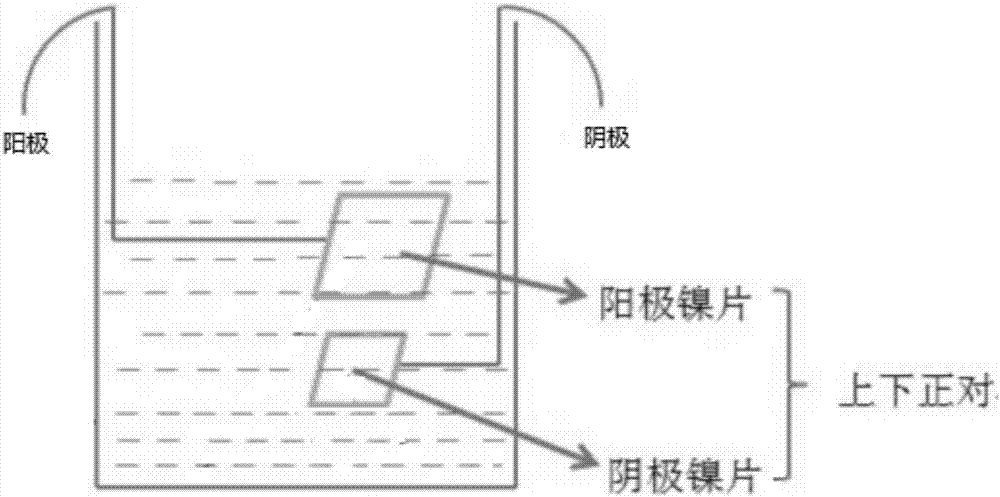

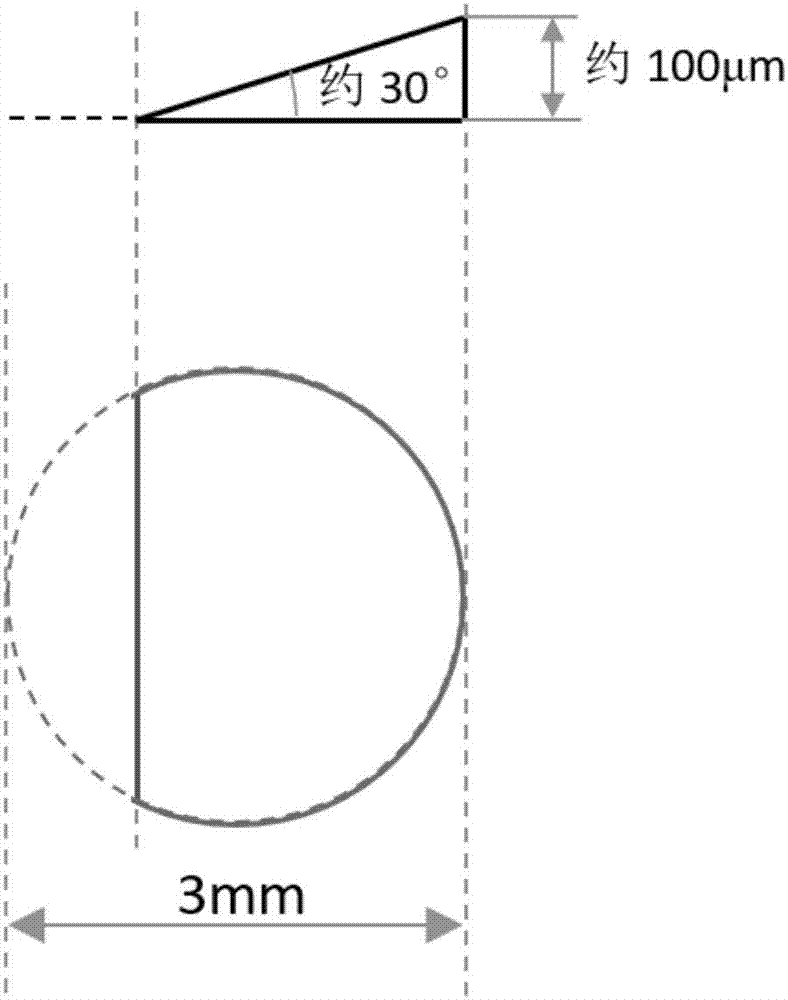

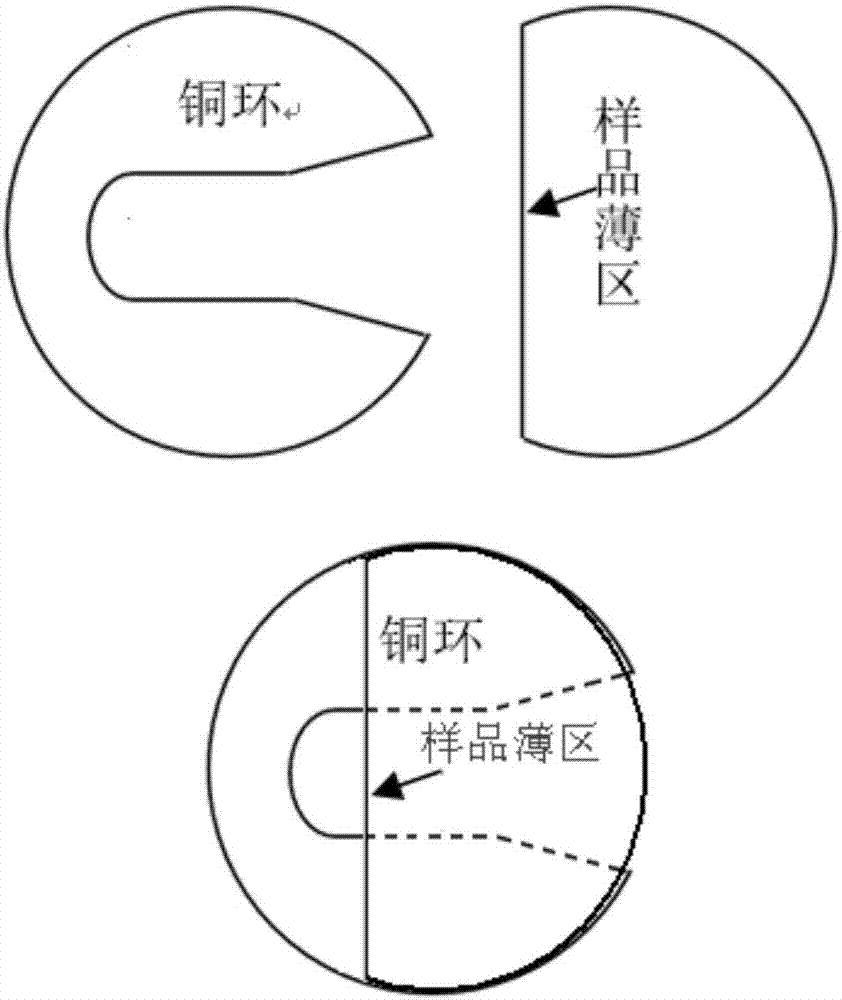

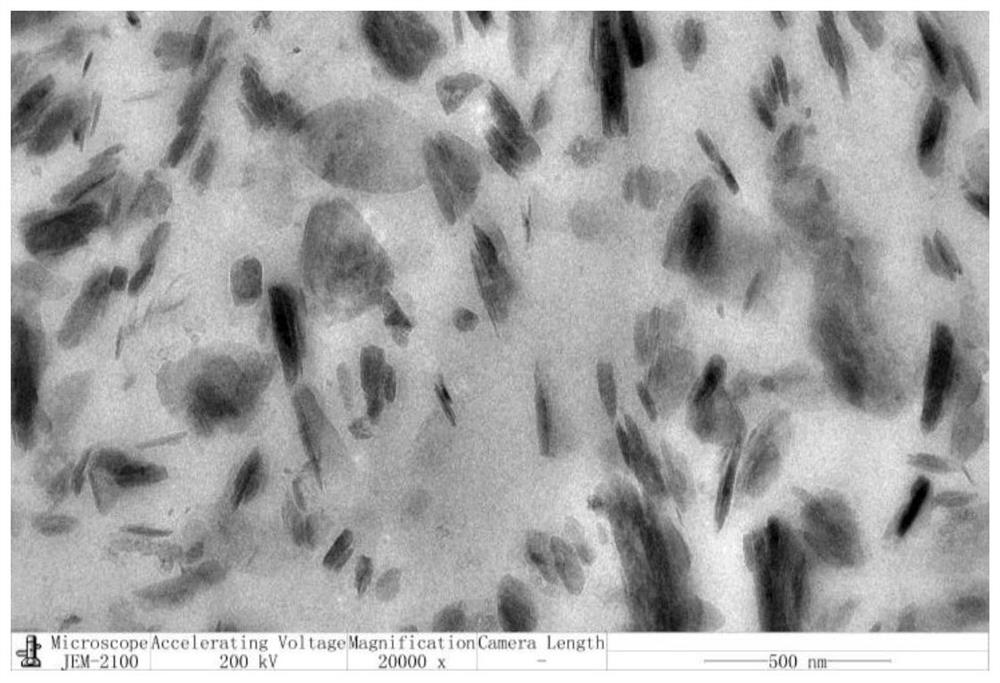

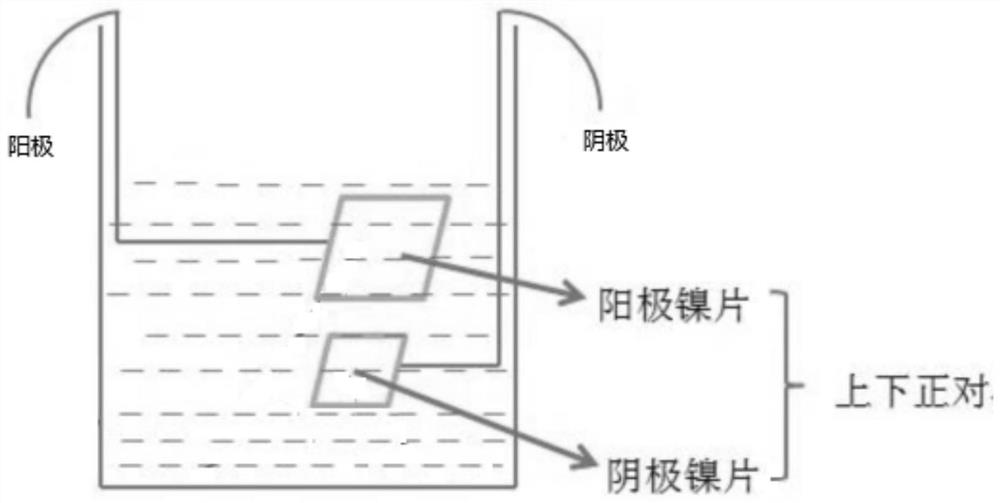

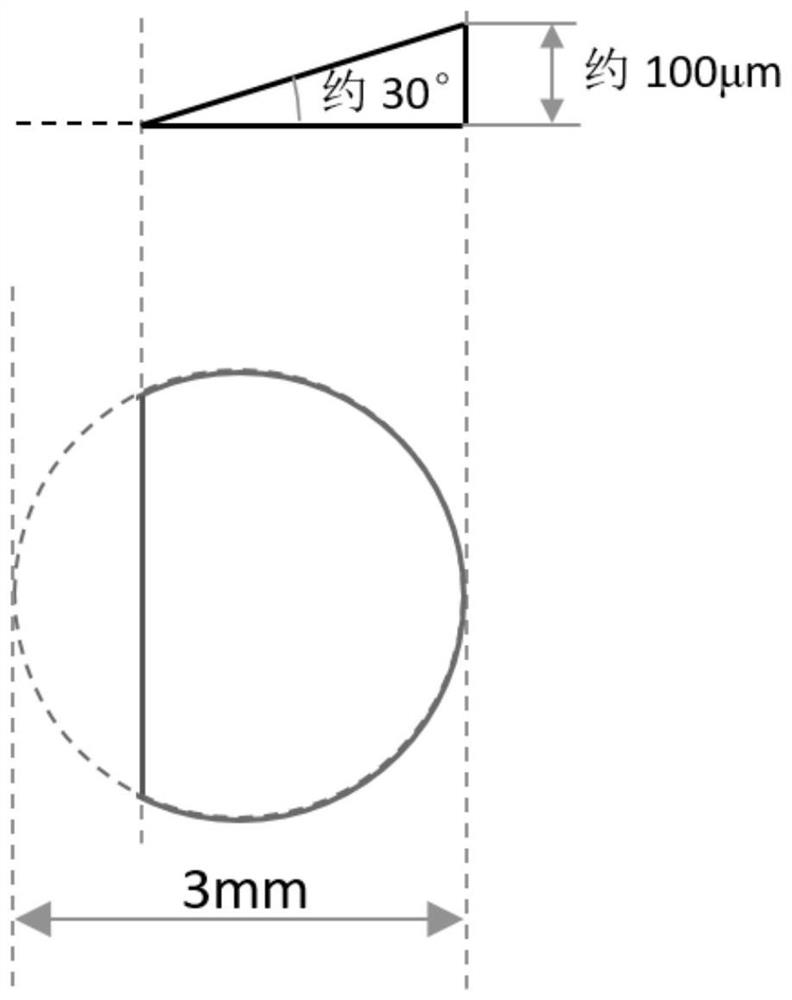

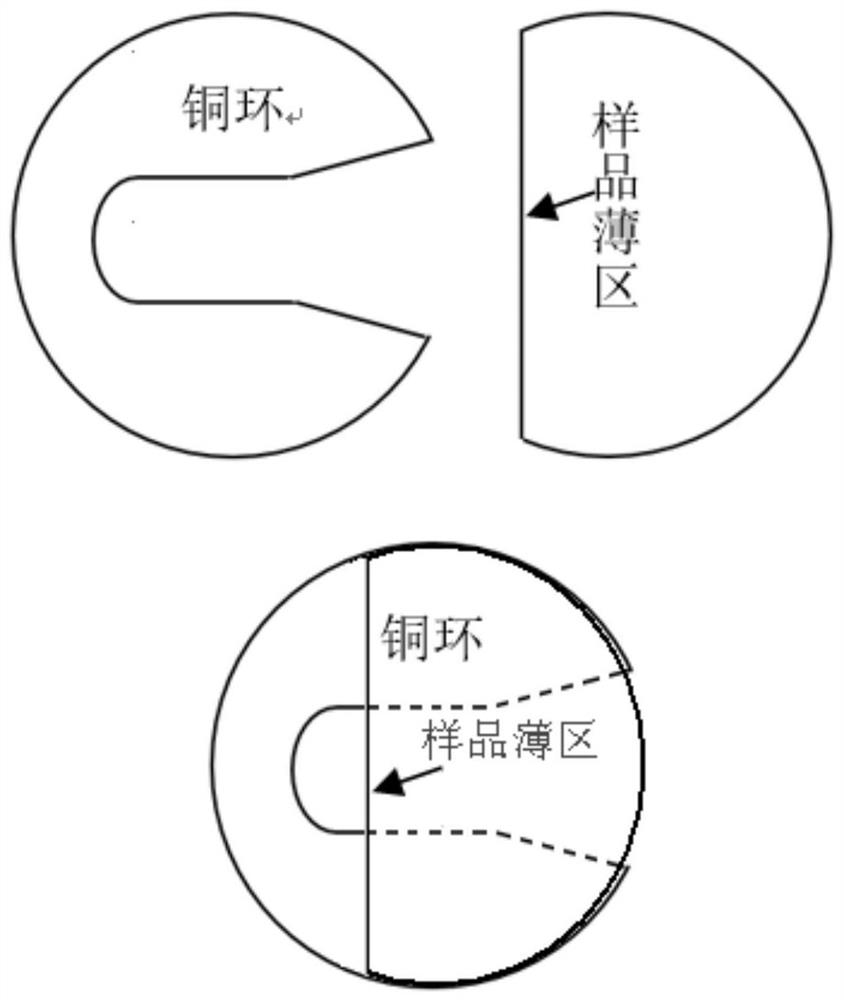

Method for preparing micron-order nickel-based high-temperature alloy powder transmission electron microscope film sample

ActiveCN107121316ANot easy to come outEquivalent hardnessPreparing sample for investigationThinningMetallic Nickel

The invention belongs to the technical field of alloy material preparation and representation, and discloses a method for preparing a micron-order nickel-based high-temperature alloy powder transmission electron microscope film sample. The method comprises the following steps: adding nickel-based alloy powder into an electroplating liquid, and stirring so as to obtain a suspension; putting a cathode nickel piece and an anode nickel piece into the suspension so as to obtain uniform nickel-based alloy powder on the cathode nickel piece; connecting a power supply to implement electroplating, wrapping the nickel-based alloy powder with a nickel plated layer, performing mechanical thinning so as to obtain a circular piece of which the diameter is 3 mm, and further grinding so as to obtain a sample which takes the shape of a wedge in a thickness direction; and pasting the sample at the opening of an opened copper ring, enabling the thin end of the wedge to be close to the opening center of the copper ring, and putting the opened copper ring with the sample into an ion thinning instrument for ion thinning, thereby obtaining a film sample area for transmission electronic microscopy observation. The method provided by the invention has the advantages of being short in time, high in plated layer quality and good in wrapping effect of the nickel-based high-temperature alloy powder.

Owner:SOUTH CHINA UNIV OF TECH

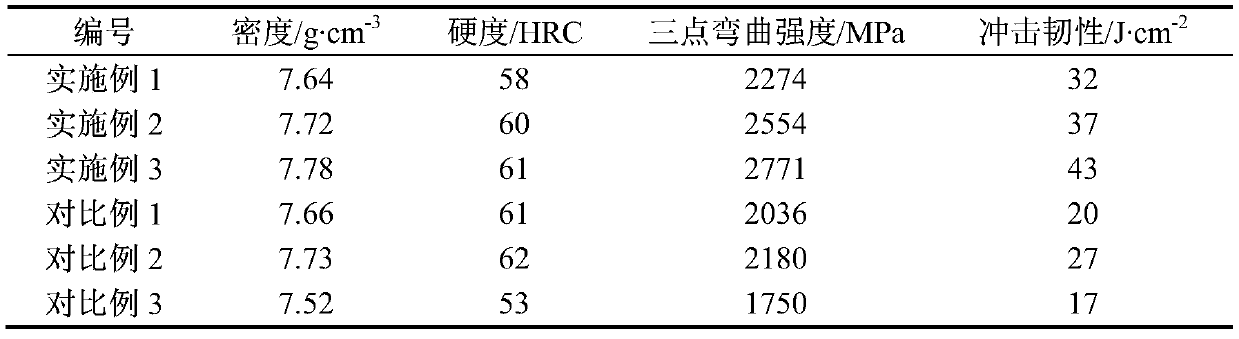

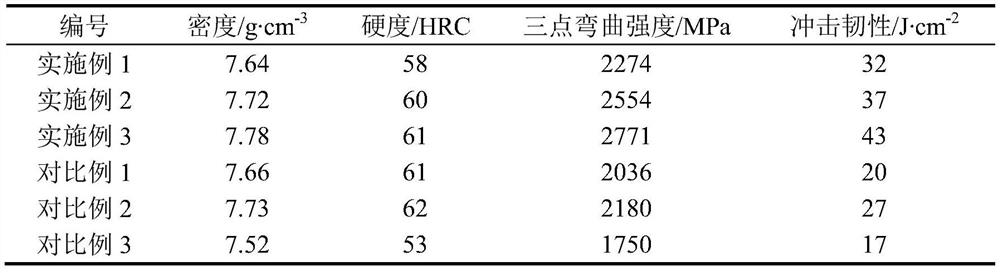

High-performance powder metallurgy pressing sintering type semi-high-speed steel and preparation method thereof

The invention discloses high-performance powder metallurgy pressing sintering type semi-high-speed steel and a preparation method thereof. Preparation of the high-performance powder metallurgy semi-high-speed steel is achieved by adopting carbonyl iron powder and carbide powder as raw materials through the processes of ball-milling mixing, cold pressing forming, thermal degreasing, vacuum sintering and the like. The prepared semi-high-speed steel is uniform in chemical component, fine in grain and capable of achieving overall dispersion distribution of carbides, the problems such as componentsegregation and thick carbides existing in a traditional casting method are avoided, and the strength and the toughness of the material are significantly improved. The high-performance powder metallurgy pressing sintering type semi-high-speed steel has the advantages that the technological process is simple, the production cost is low, and the components are easy to control. Compared with semi-high-speed steel prepared through a casting method, the semi-high-speed steel has the advantage that the bending strength and the impact toughness are obviously improved at the same compactness.

Owner:CENT SOUTH UNIV

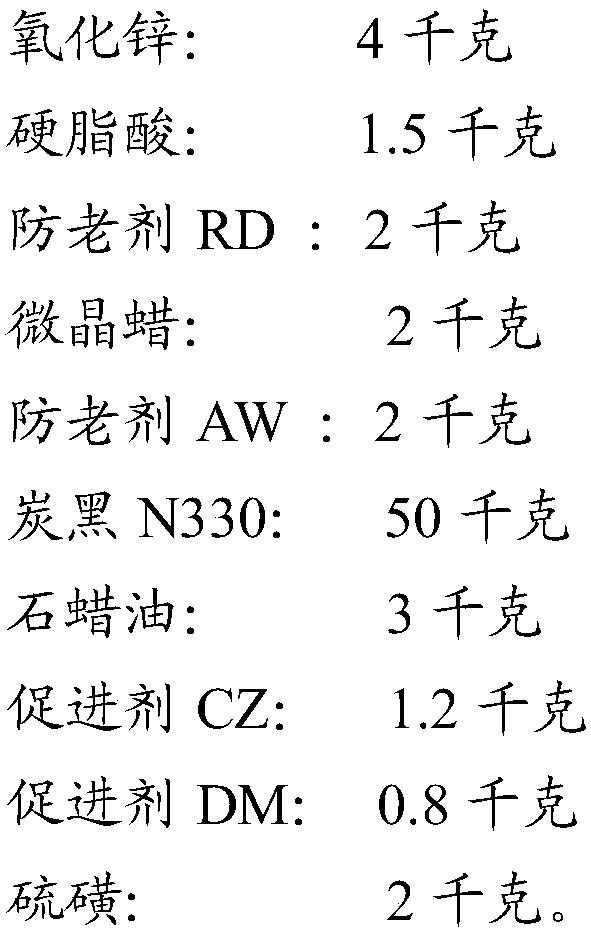

Rubber compound additive particle, preparation method thereof and application of particle

The invention provides a rubber compound additive particle, and belongs to the technical field of rubber. The rubber compound additive particle comprises, by weight, 20-30 parts of rubber, 5-8 parts of zinc oxide, 3-5 parts of stearic acid, 4-6 parts of anti-aging agents, 0.5-1 part of scorch retarders, 3-5 parts of accelerators and 2-4 parts of vulcanizing agents. The particle is cylindrical, thediameter of the particle is 2-5mm, and the height of the particle is 5-10mm. The rubber compound additive particle has functions of activating agents, the anti-aging agents, the accelerators, the vulcanizing agents and the scorch retarders, a small number of additives are used, the same effects can be achieved as compared with a traditional production process, the multifunctional rubber compoundadditive particle is a colloidal particle, on one hand, dispersion effects of various rubber additives in rubber can be effectively improved, on the other hand, matching is facilitated, weighing errors are reduced, environmental pollution caused by dust in production is decreased, and physical health of operators is facilitated.

Owner:河北省同创交通工程配套产品产业技术研究院

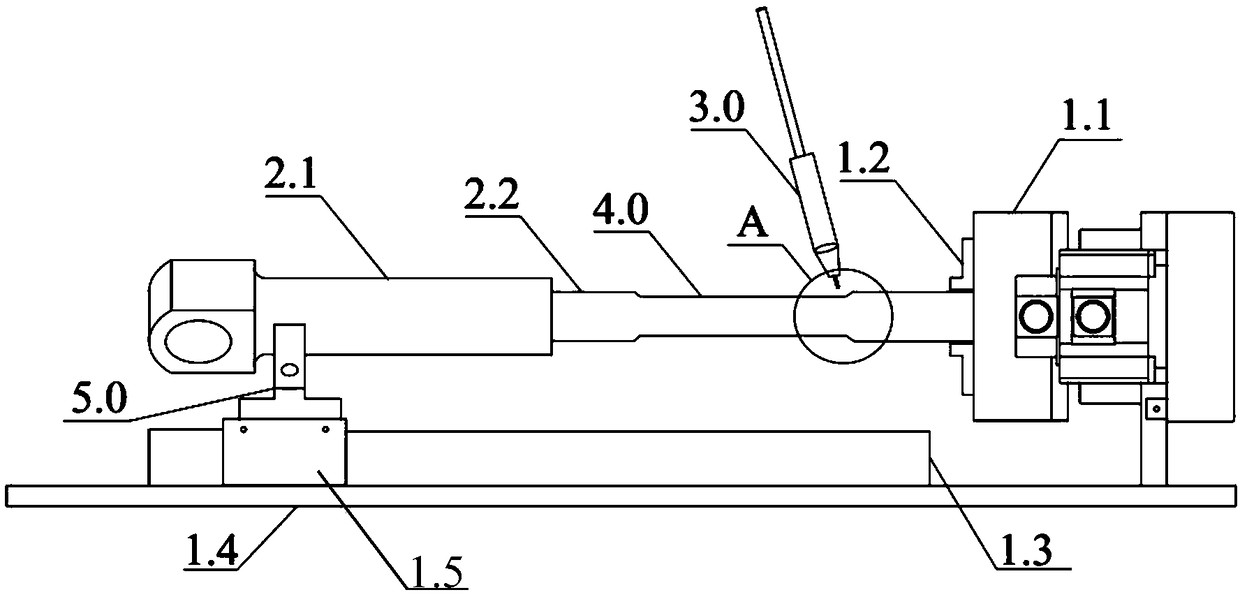

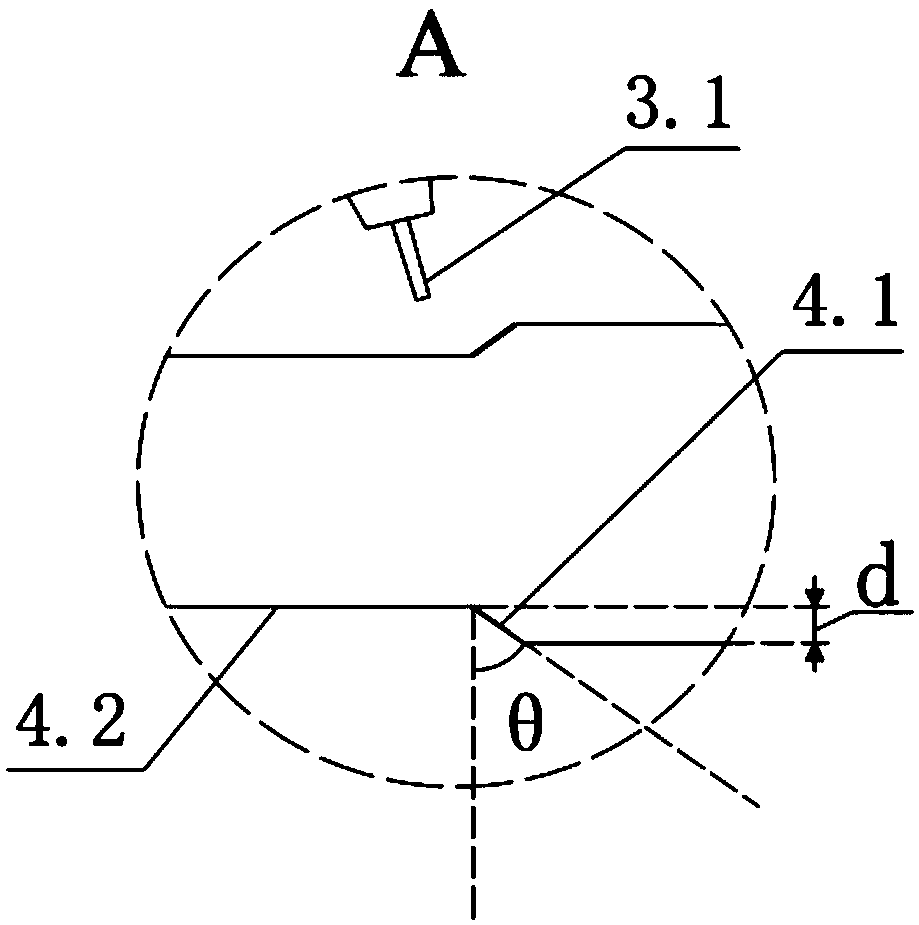

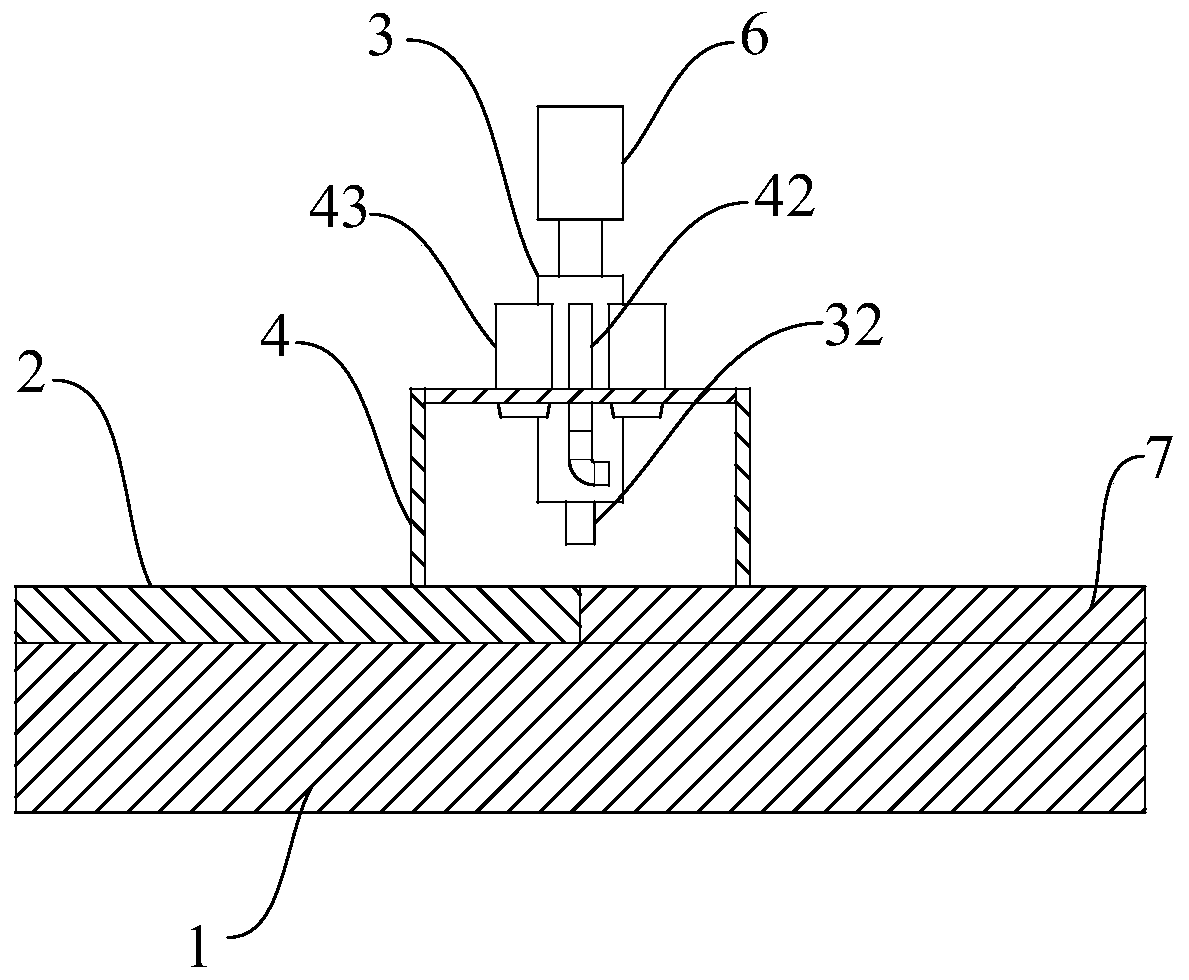

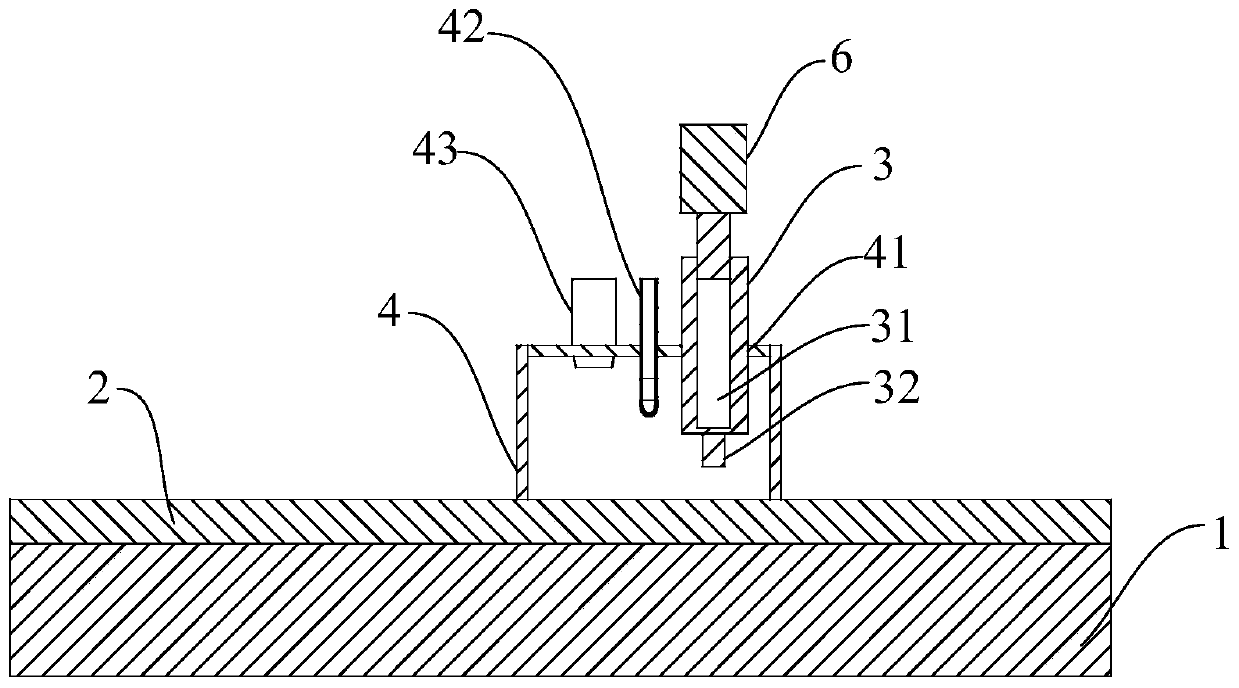

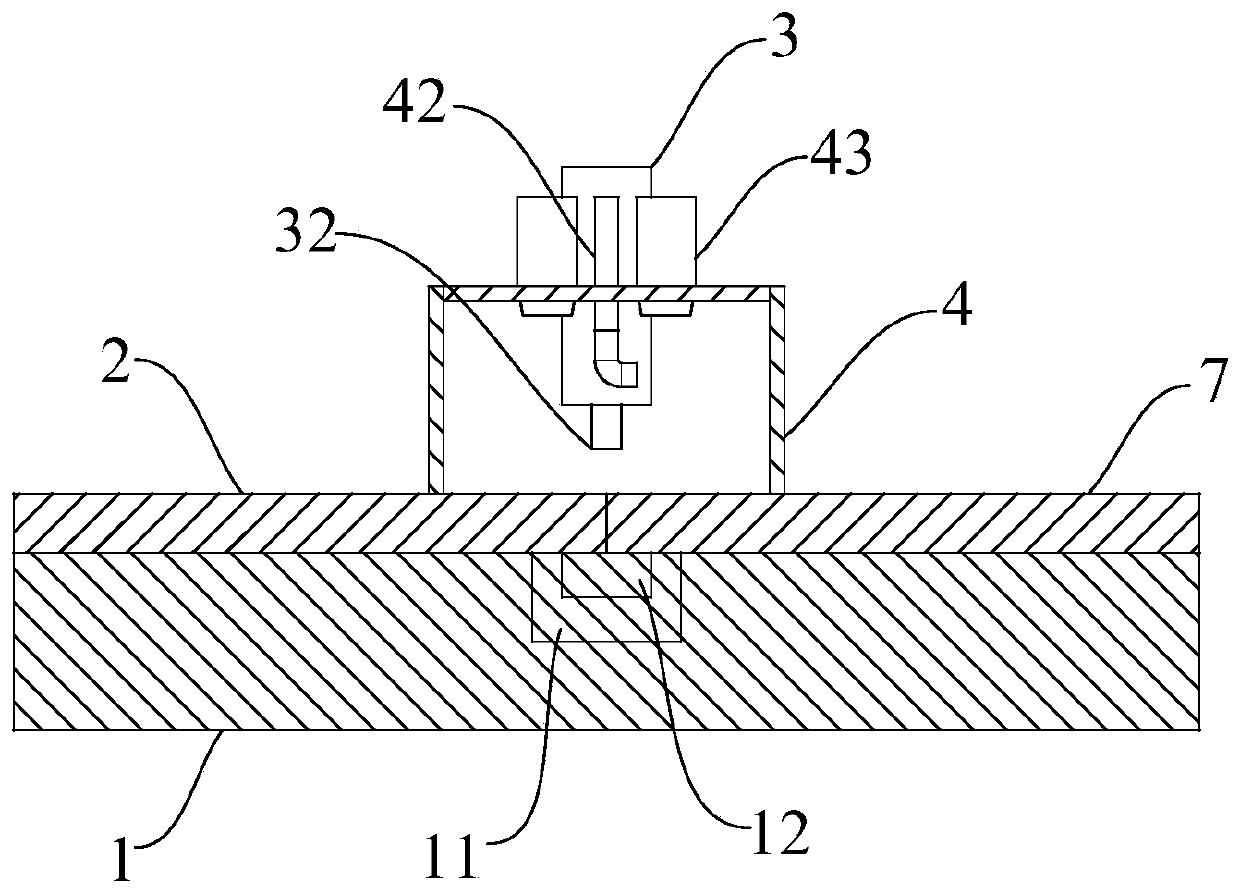

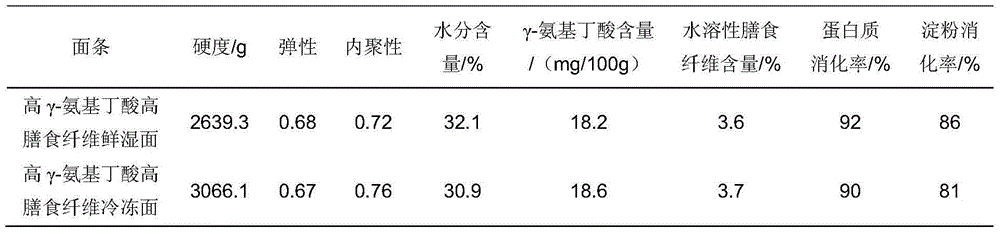

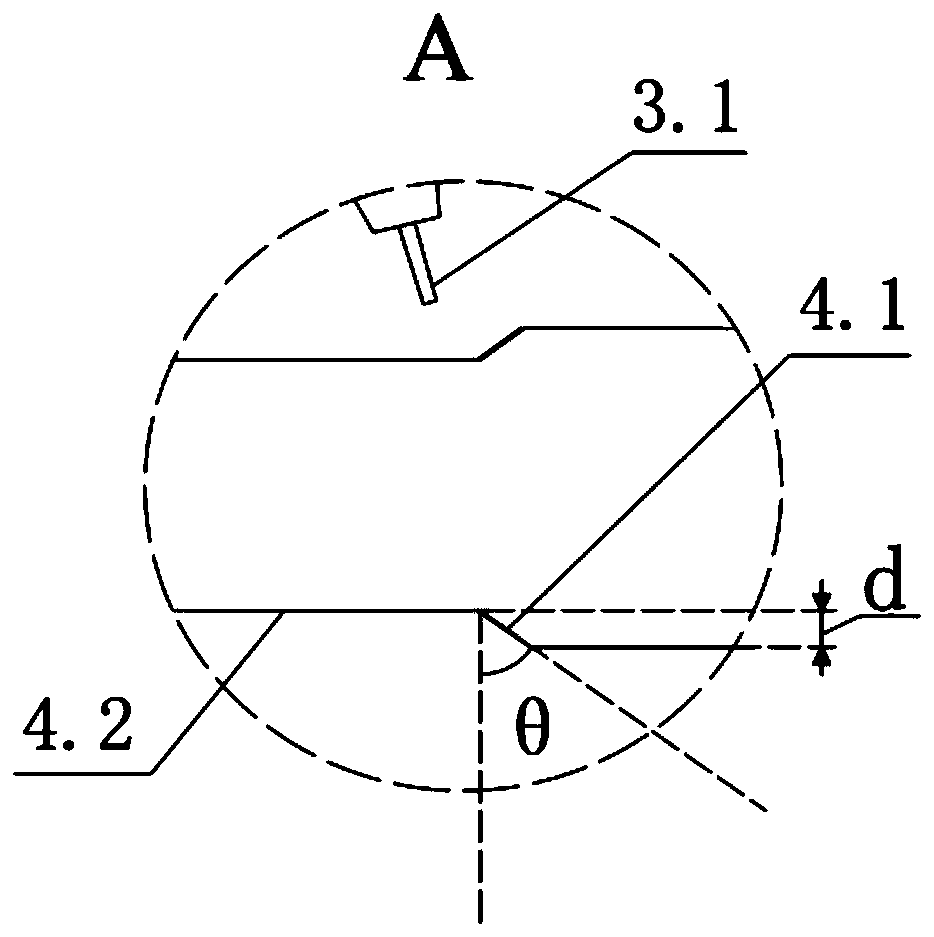

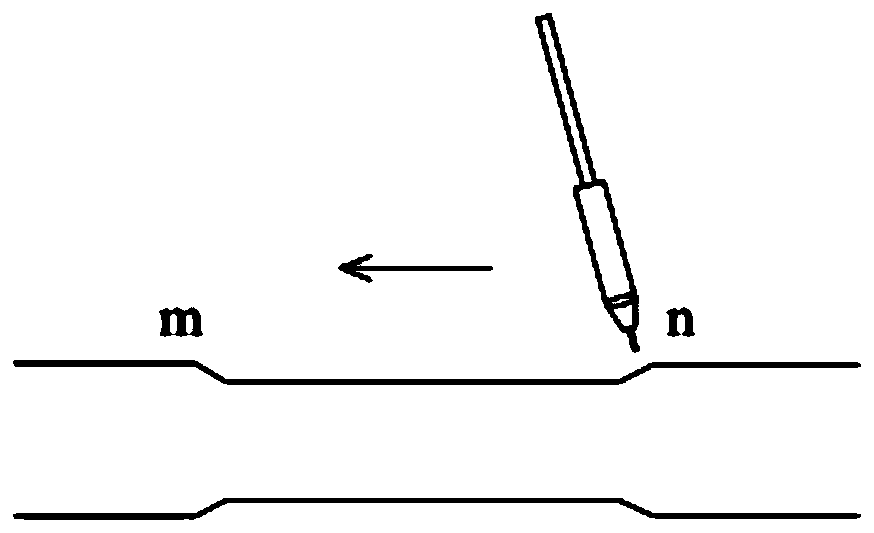

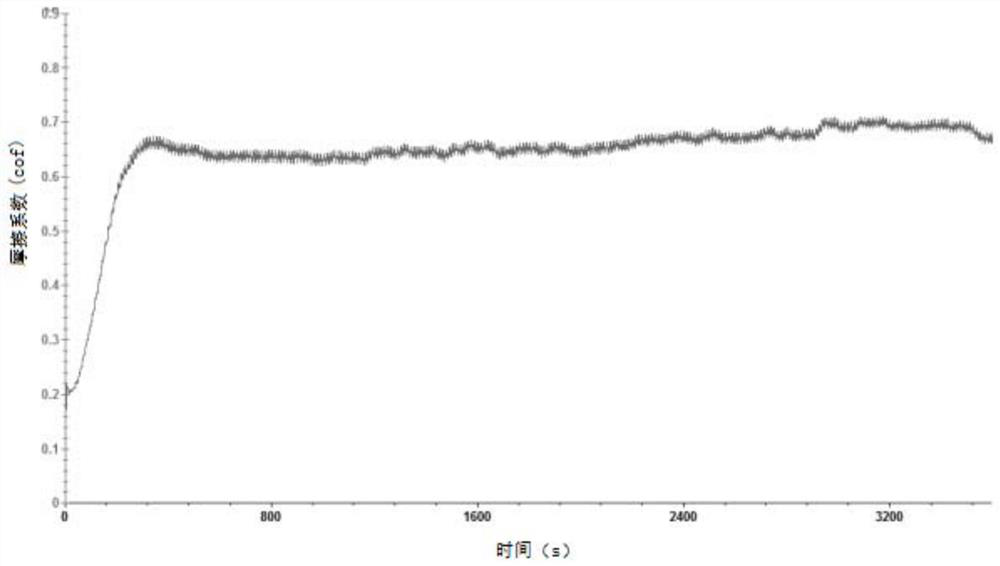

Friction stir butt welding device for large-thickness titanium-nickel dissimilar material and machining method of friction stir butt welding device

PendingCN111421222AReduce surface hardnessEquivalent hardnessWelding/soldering/cutting articlesNon-electric welding apparatusButt weldingAxial pressure

The invention relates to a friction stir butt welding device for a large-thickness titanium-nickel dissimilar material and a machining method of the friction stir butt welding device. The friction stir butt welding device comprises a workbench and a friction stir welding mechanism, the workbench comprises a fixed clamping device, the friction stir welding mechanism comprises friction stir weldingequipment, the output end of the friction stir welding equipment comprises a stirring head, and a gas protection mechanism is arranged at the stirring head; the friction stir butt welding device further comprises a laser output mechanism, the laser output mechanism comprises a plurality of second laser output mechanisms arranged on the upper portion of the gas protection mechanism; and a hollow placement groove is formed in the stirring head. By arranging the laser output mechanism, the gas protection mechanism or a current heating mechanism in the stirring head of conventional friction stir butt welding equipment, the problem of insufficient softening of the bottom of a to-be-welded area only during surface laser heating is solved, and the axial pressure of the stirring head in the welding process can be greatly reduced.

Owner:TONGLING UNIV

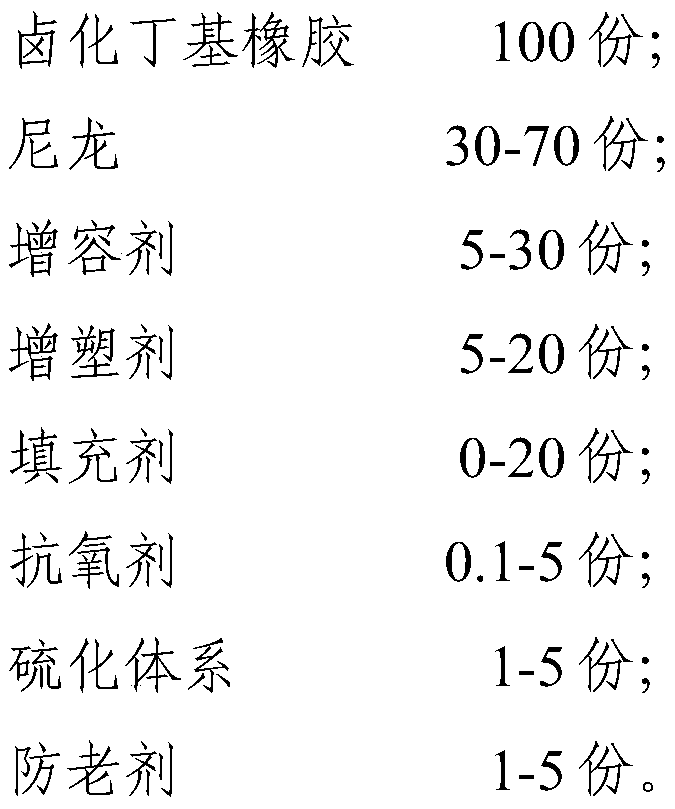

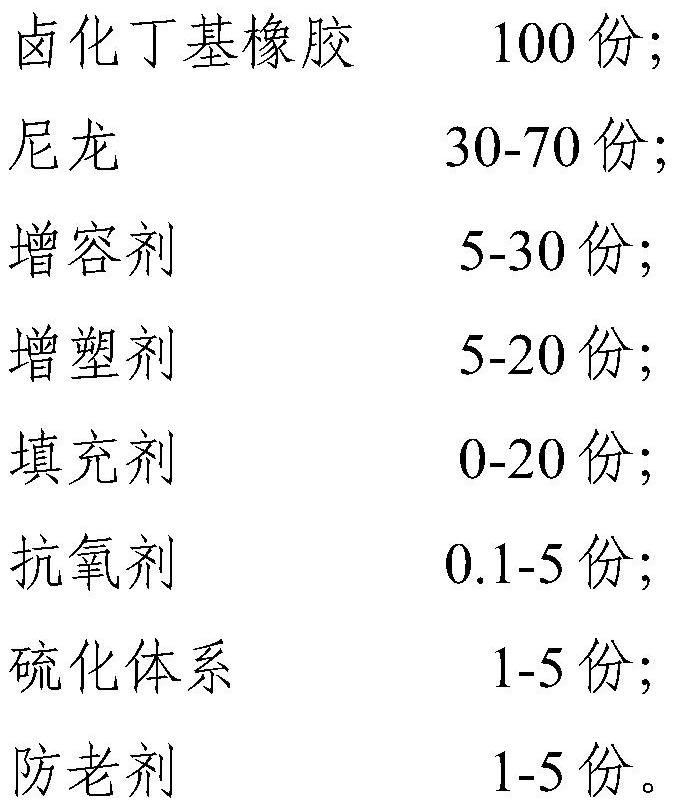

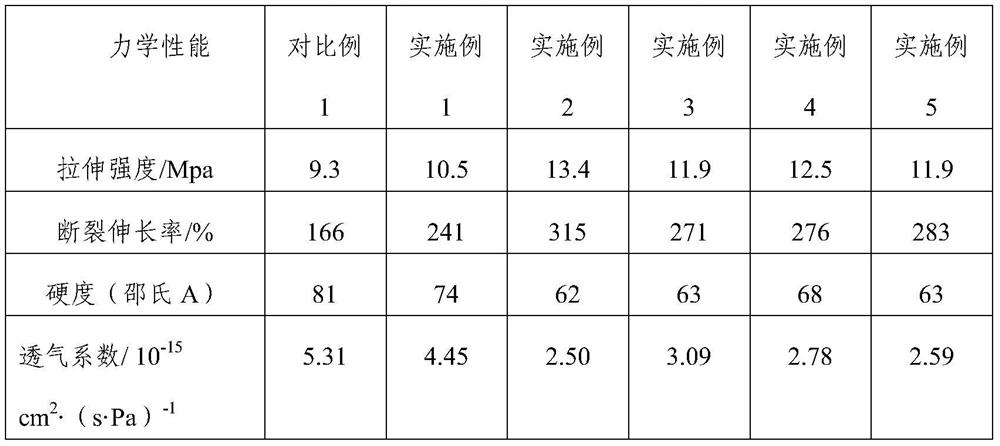

High-performance dynamically-vulcanized thermoplastic elastomer and preparation method thereof

The invention provides a high-performance dynamically-vulcanized thermoplastic elastomer and a preparation method thereof. The high-performance dynamically-vulcanized thermoplastic elastomer is prepared from the following raw materials in parts by mass: 100 parts of halogenated butyl rubber, 30-70 parts of nylon, 5-30 parts of a compatibilizer, 5-20 parts of a plasticizer, 0-20 parts of a filler,0.1-5 parts of an antioxidant, 1-5 parts of a vulcanization system and 1-5 parts of an anti-aging agent, wherein the filler is modified nano clay. The preparation method comprises the following steps:(1) mixing halogenated butyl rubber with the anti-aging agent, the plasticizer, part of the vulcanization system and the filler to prepare masterbatch; (2) placing the masterbatch in a drying box forcarrying out pre-vulcanization to obtain pre-vulcanized masterbatch; (3) adding the pre-vulcanized masterbatch, the nylon, the compatibilizer and the antioxidant into an internal mixer for uniformlymixing; and (4) adding the remaining vulcanization system into the internal mixer to prepare the dynamically-vulcanized thermoplastic elastomer. The prepared dynamically-vulcanized thermoplastic elastomer is excellent in mechanical performance, high in gas tightness and wide application range.

Owner:麒祥新材料(山东)有限公司

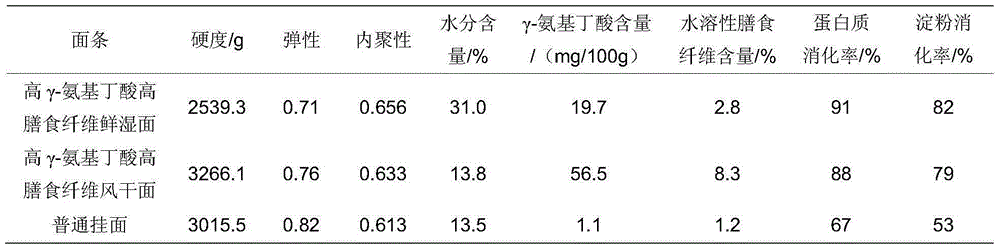

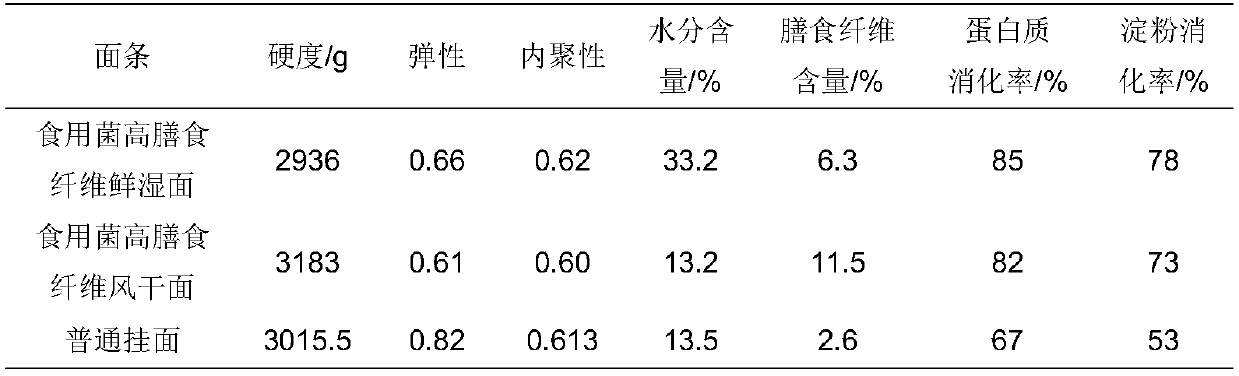

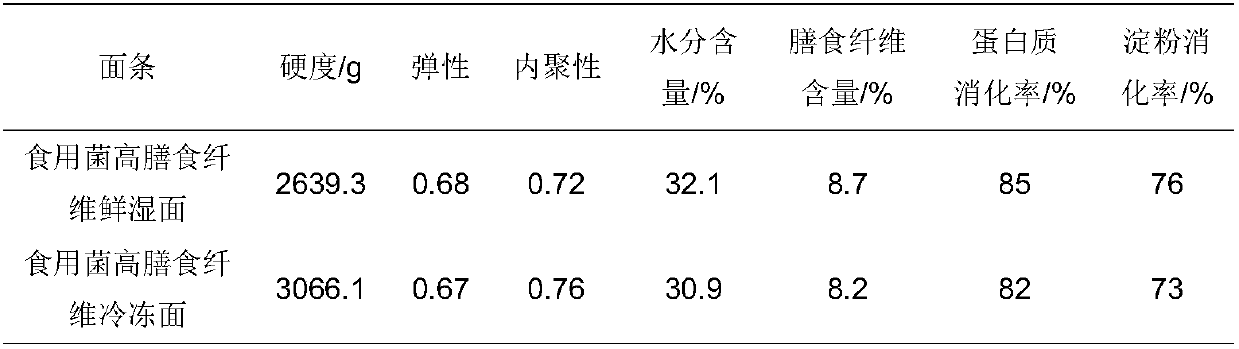

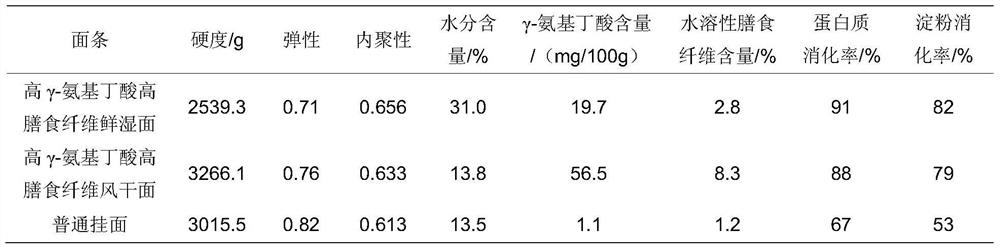

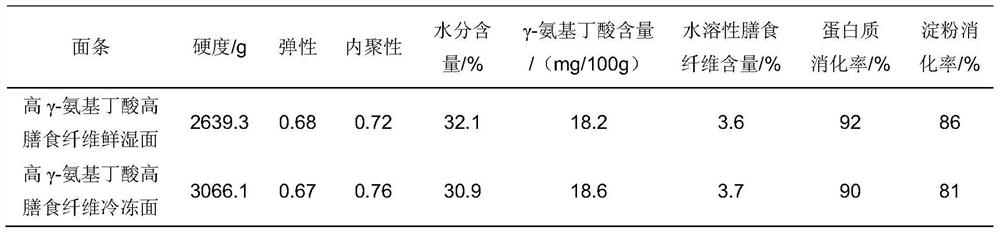

High-gamma-aminobutyric acid high-dietary-fiber noodles and preparation method thereof

ActiveCN104996908AHigh GABAIncrease the content of dietary fiberFood ingredient functionsFood preparationFlavorDietary fiber

The invention provides high-gamma-aminobutyric acid high-dietary-fiber noodles. The noodles have effects of improving intelligence, intestinal functions and the like, and have equivalent hardness, elasticity and cohesiveness with commercial common fine dried noodles. Furthermore, the invention provides a preparation method of the noodles. According to the preparation method, the taste of noodles can be improved by means of super-fine comminution; by means of germination, endogenous enzyme transformation, super-fine comminution and enzyme hydrolysis composition, the content and utilization of gamma-aminobutyric acid and water-soluble dietary fibers can be improved, the content of nutritional factors can be reduced, and the effect can be improved; and the noodles are prepared by utilizing raw stock of germination, so that tenacity and chewing performance of the noodles can be improved, the taste and flavor are good, and the nutritional digestive absorption rate of the noodles can be improved.

Owner:湖北金银丰食品有限公司

Triarrhena lutarioriparia mushroom shoot noodles and preparation method thereof

The invention provides triarrhena lutarioriparia mushroom shoot noodles. The triarrhena lutarioriparia mushroom shoot noodles comprise the following components in percentages by weight: 90%-93.5% of wheat flour, 3%-5% of triarrhena lutarioriparia mushroom powder, 2%-3% of triarrhena lutarioriparia shoot powder, and 1.5%-2% of edible salt. The noodles provided by the invention use the natural edible fungus triarrhena lutarioriparia mushrooms as one raw material, the triarrhena lutarioriparia mushrooms can provide edible fungus polysaccharides, and the noodles have the functions of improving immunity and strengthening physiques, and have a natural umami taste; and a culture material of the triarrhena lutarioriparia mushrooms is triarrhena lutarioriparia stalks, so that the method has no problems such as pesticide residues, and has the advantages of health and environmental protection.

Owner:湖南博大天能实业股份有限公司 +1

A method for repairing and remanufacturing the surface of a locomotive buffer bar

ActiveCN109079421BGuaranteed stabilityReduce welding heat inputWelding apparatusSand blastingEngineering

A method for repairing and remanufacturing the surface of a buffer rod of a locomotive, the steps of which are as follows: S1, screening out repairable buffer rods to be repaired; S2, inspecting the wear amount of the buffer rod to be repaired, respectively in the shaft sections of the buffer rods with different radii, Determine the area to be repaired according to the size of the wear amount, and process the groove to be repaired in the area to be repaired; S3, perform sandblasting, cleaning and preheating treatment on the buffer bar to be repaired in sequence; S4, fix one end of the buffer bar to be repaired on the variable On the positioner, continuous annular welding is performed on the groove to be repaired by the CMT automatic welding system to complete the repair of the buffer bar to be repaired; S5, post-weld slow cooling treatment is performed on the repair buffer bar obtained in step S4; S6, the repair area of the repair buffer bar is Machined to original drawing size and then sandblasted as a whole. The method of the invention has low cost, high efficiency and high repairing quality, and the quality standard of new parts can be reached after repairing and remanufacturing through the method of the invention.

Owner:SOUTHWEST JIAOTONG UNIV

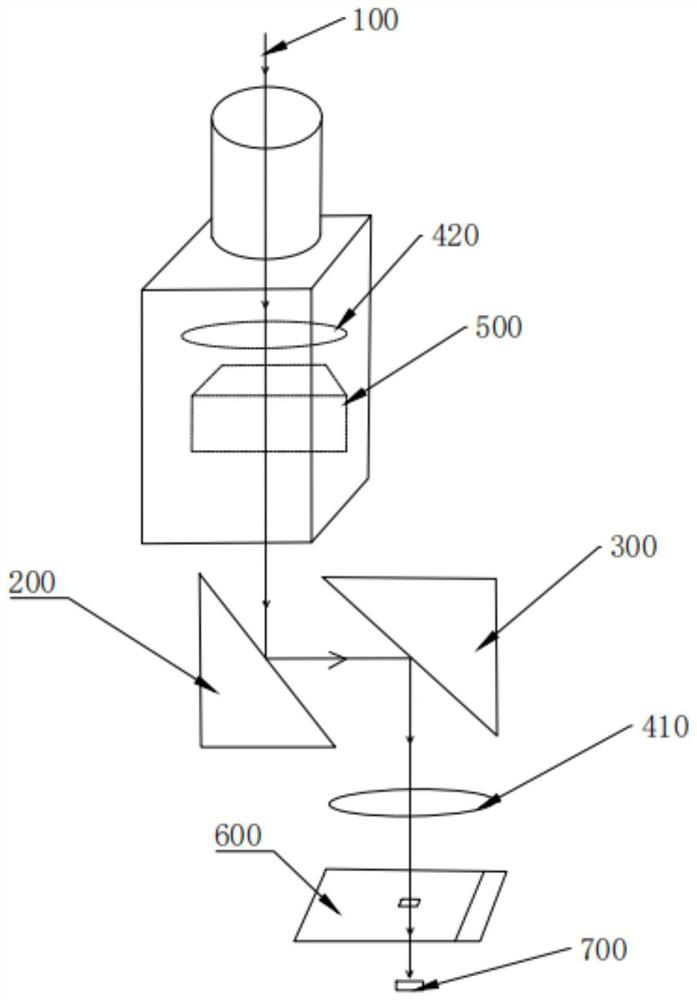

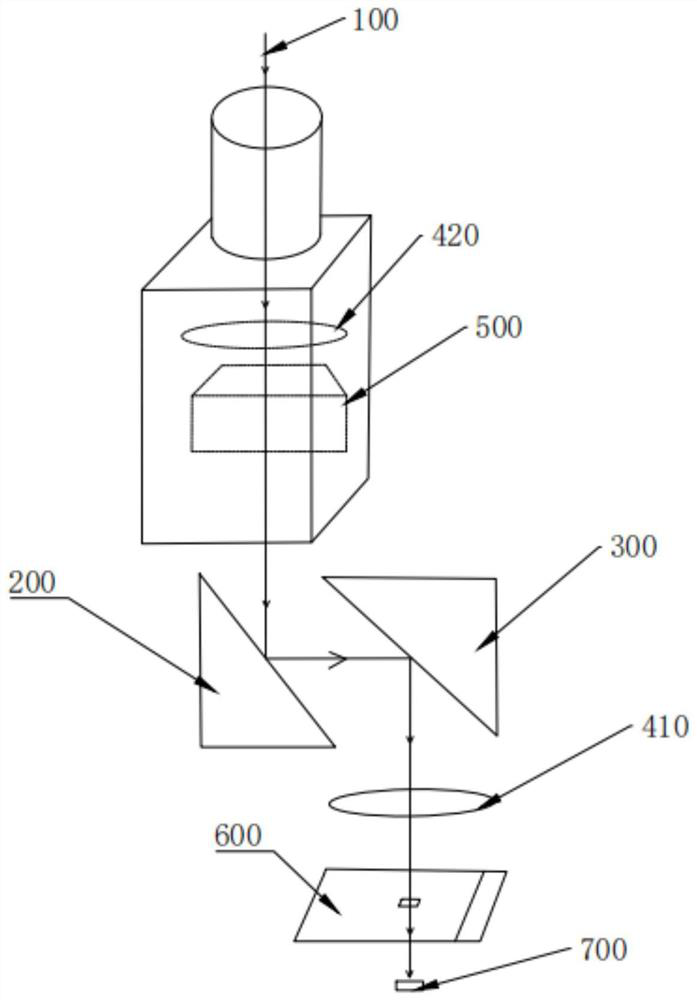

Fiber laser processing head and plate cladding process

ActiveCN112941505AImprove the quality of useExtended service lifeMetallic material coating processesLaser processingErbium lasers

The invention discloses an optical fiber laser processing head and a plate cladding process. The optical fiber laser processing head comprises a collimation integral mirror, a focusing integral mirror and a first protection lens which are sequentially arranged along a laser beam emission light path, a laser beam vertically enters the collimation integral mirror, then horizontally enters the focusing integral mirror, and then vertically enters the first protection lens. The collimation integral mirror and the focusing integral mirror are both copper integral mirrors. The plate cladding process comprises the following steps: directly outputting process parameters of a laser cladding plate based on a semiconductor, and preparing cladding coatings with different shapes by adopting an optical fiber laser; comparing cladding effect data obtained by cladding of the optical fiber laser and a semiconductor direct output laser based on the same cladding process parameters; and adjusting the cladding speed and the cladding step pitch of the optical fiber laser based on the comparison result, so that the cladding effect the same as that of the semiconductor direct output laser is obtained. The service life of the optical fiber laser is prolonged, and the cladding effect of the fiber laser is guaranteed.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD

A high-performance powder metallurgy pressed sintered semi-high-speed steel and its preparation method

The invention discloses a high-performance powder metallurgy pressed and sintered semi-high-speed steel and a preparation method thereof. The invention uses carbonyl iron powder and carbide powder as raw materials, and realizes the preparation of high-performance powder metallurgy semi-high-speed steel through processes such as ball milling, cold pressing, thermal degreasing and vacuum sintering. The prepared semi-high-speed steel has uniform chemical composition, fine grains, and overall dispersed distribution of carbides, which avoids the problems of composition segregation and coarse carbides in the traditional casting method, and significantly improves the strength and toughness of the material. The invention has the advantages of simple technological process, low production cost, easy control of components and the like. Compared with the semi-high-speed steel prepared by melting and casting, the provided semi-high-speed steel has significantly improved bending strength and impact toughness under the same density.

Owner:CENT SOUTH UNIV

Edible mushroom high dietary fiber noodles and its preparation method

The invention provides an edible fungus high dietary fiber noodle. Natural edible fungi are adopted as the raw and supplemental materials, which can provide edible fungus polysaccharide, and has the functions of enhancing immunity and strengthening constitution. Lentinus edodes and other edible fungi also contain abundant dietary fiber, thereby improving the dietary fiber content of the noodle. In addition, the invention also provides a preparation method of the noodle. Fresh lentinus edodes and other edible fungi are employed as the raw materials, by means of crushing and super-fine comminution enzymolysis, an edible fungus thick slurry can be prepared to replace water to knead dough, thus not only saving the energy consumption of drying during lentinus edodes powder preparation, but also reducing the loss of nutrition and flavor. Therefore, the technology has low energy consumption and high efficiency, and the product quality is good. Through crushing and super-fine comminution enzymolysis, the surface area of nutrient dissolution or degradation is increased, and the protein digestibility and starch digestibility are greatly enhanced. The noodle provided by the invention has hardness, elasticity and cohesiveness equivalent to those of commercially available ordinary fine dried noodles, but has dietary fiber content, protein and starch digestibility superior to ordinary fine dried noodles, and has better taste.

Owner:HUAZHONG AGRI UNIV

A kind of high-performance dynamically vulcanized thermoplastic elastomer and its preparation method

Owner:麒祥新材料(山东)有限公司

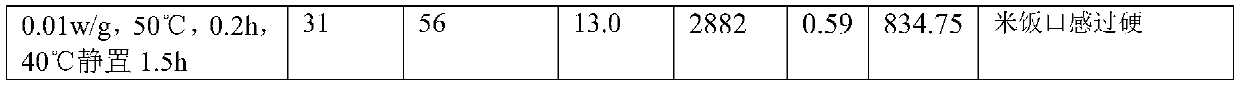

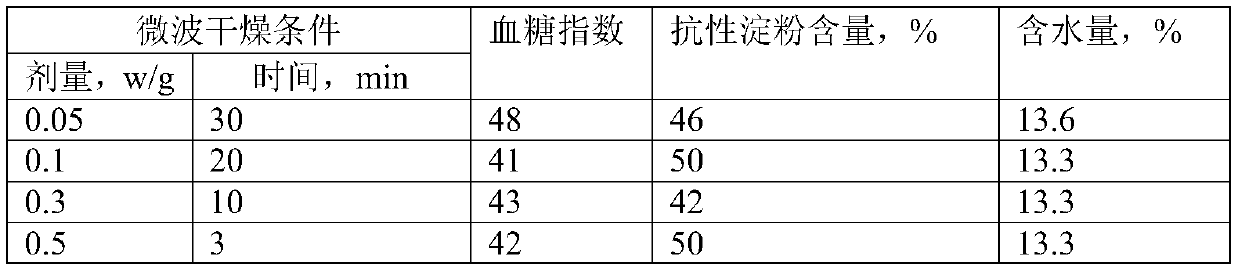

A kind of low glycemic index cereal rice and production method thereof

ActiveCN106490463BIncreased glycemic indexGreat tasteFood ingredient functionsBiotechnologyCereal grain

Owner:随州市金义米业有限公司

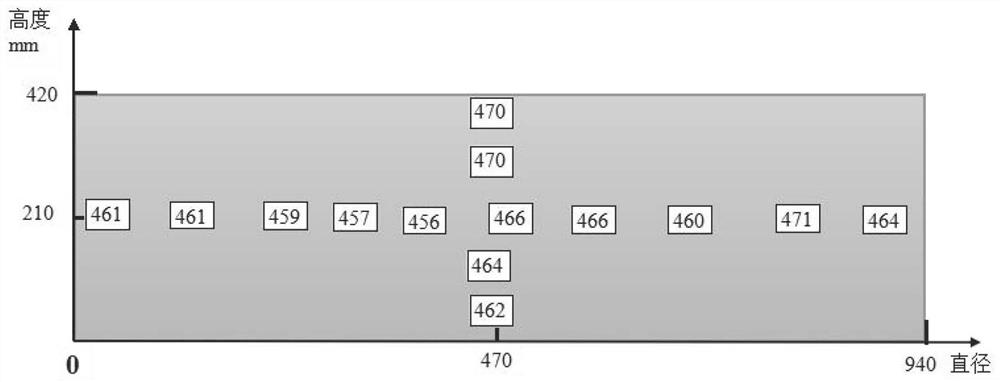

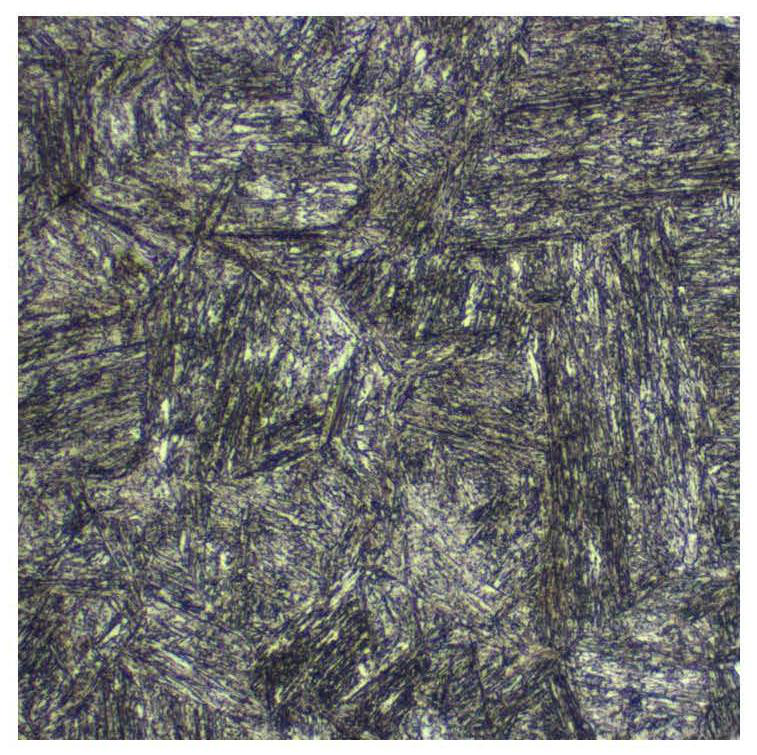

Flywheel rotor and preparation method thereof

InactiveCN113862566AMeet manufacturing requirementsImprove hardenabilityEnergy storageFlywheelsElectric arc furnaceTempering

The invention discloses a flywheel rotor and a preparation method thereof, and relates to the technical field of rotor energy storage. The flywheel rotor is made of high-strength steel, the high-strength steel is subjected to electric arc furnace smelting, external refining, electroslag remelting, controlled forging, normalizing, quenching and tempering, the yield strength ranges from 1150 MPa to 1700 MPa, the room-temperature V-shaped notch impact energy is larger than 27 J, the method is suitable for manufacturing an energy storage disc type flywheel rotor with the outer diameter being 600-2000 mm and the maximum height being smaller than or equal to 600 mm or a cylindrical flywheel rotor with the diameter being smaller than or equal to 1000 mm.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

Rubber composition and a sealing material for fuel cell separators

InactiveUS20200112036A1Improve cold resistanceLow production costSolid electrolyte fuel cellsSealing/support meansPolymer scienceFuel cells

A rubber composition comprising 1 to 10 parts by weight of an organic peroxide crosslinking agent having a one-hour half-life temperature of 110 to 130° C., based on 100 parts by weight of an ethylene-butene-non-conjugated diene copolymer. The ethylene-butene-non-conjugated diene copolymer can be used by being blended with EPDM in an amount of 50 wt % or less in the total amount of the ethylene-butene-non-conjugated diene copolymer and EPDM. A sealing material for fuel cell separators comprising a crosslinked molded article of the rubber composition has, in addition to functions required as a sealing material for separators, improved low temperature sealing properties.

Owner:NOK CORP

A fiber laser processing head and cladding plate technology

ActiveCN112941505BImprove the quality of useExtended service lifeMetallic material coating processesErbium lasersLaser beams

The invention discloses a fiber laser processing head and a cladding plate process. The fiber laser processing head includes a collimating integrator mirror, a focusing integrator mirror and a first protective lens arranged sequentially along the laser beam emitting optical path, and the laser beam enters the collimating mirror vertically. After the integrating mirror, it enters the focusing integrating mirror horizontally, and then vertically enters the first protective lens. Both the collimating integrating mirror and the focusing integrating mirror are copper integrating mirrors. The cladding plate process includes cladding plate based on the process parameters of semiconductor direct output laser, using fiber laser to prepare cladding coatings of different shapes; comparing the cladding of fiber laser and semiconductor direct output laser cladding based on the same cladding process parameters Effect data; based on the comparison results, adjust the fiber laser cladding speed and cladding step to obtain the same cladding effect as the semiconductor direct output laser. The invention improves the service life of the fiber laser and ensures the cladding effect of the fiber laser.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD

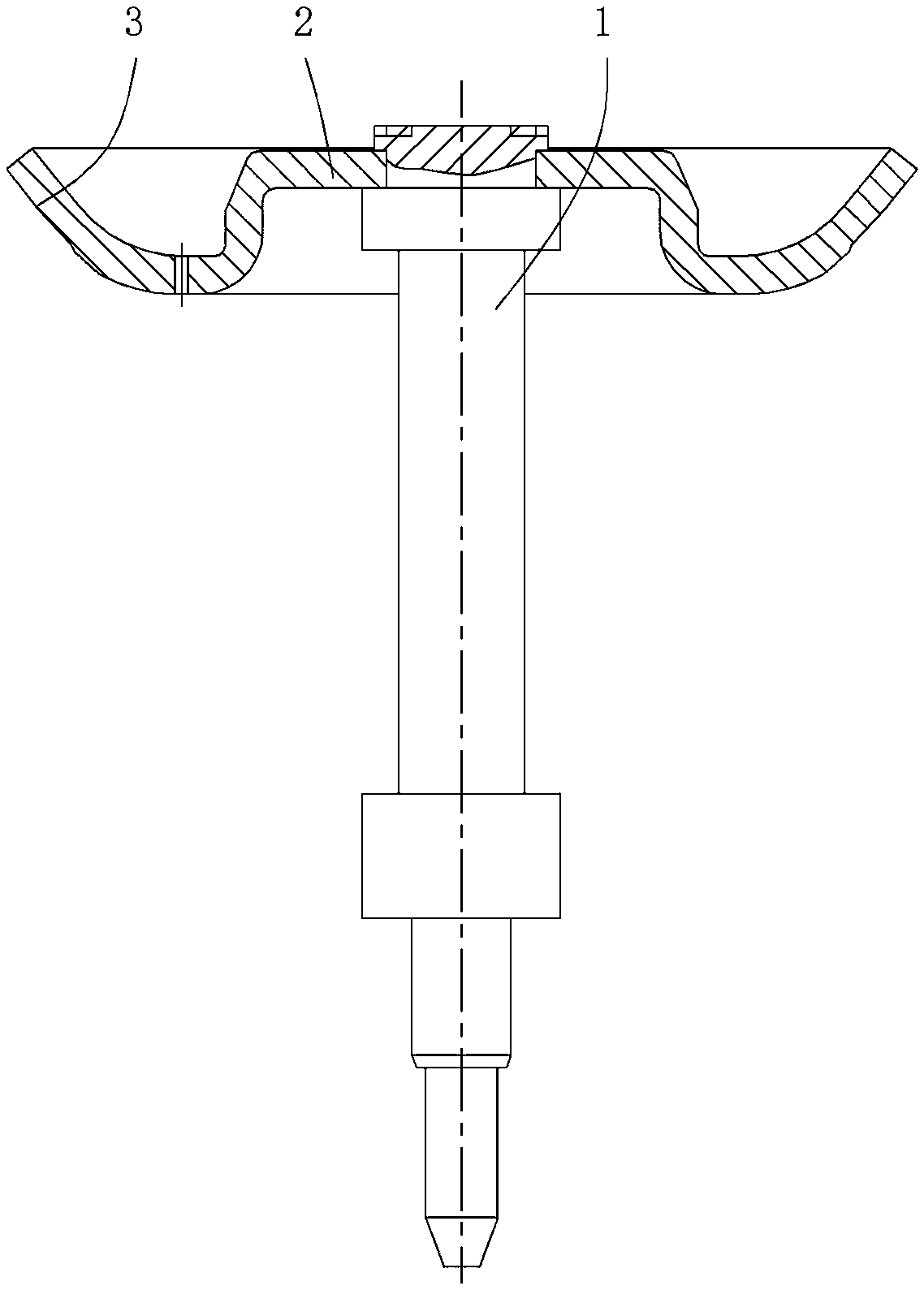

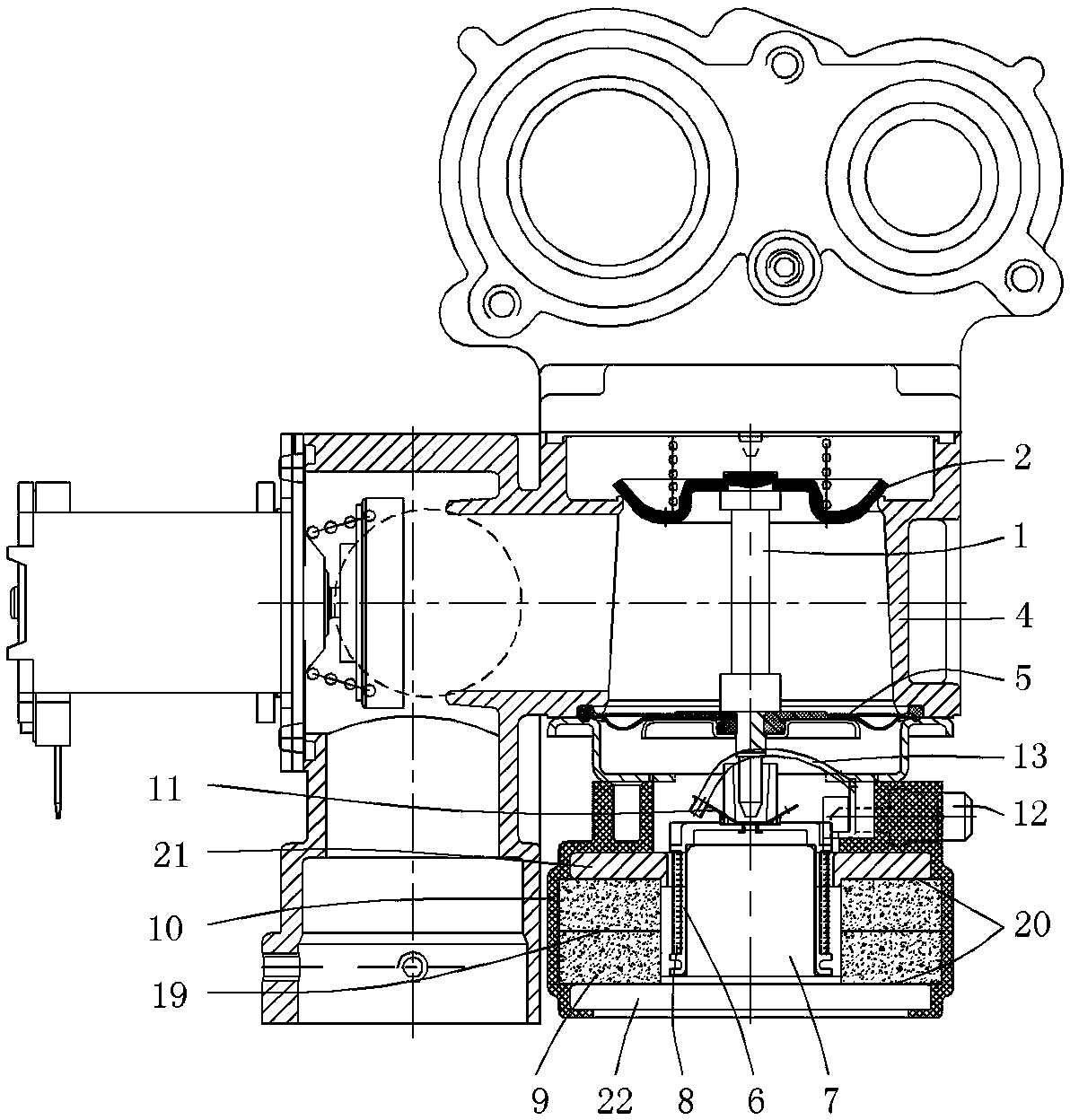

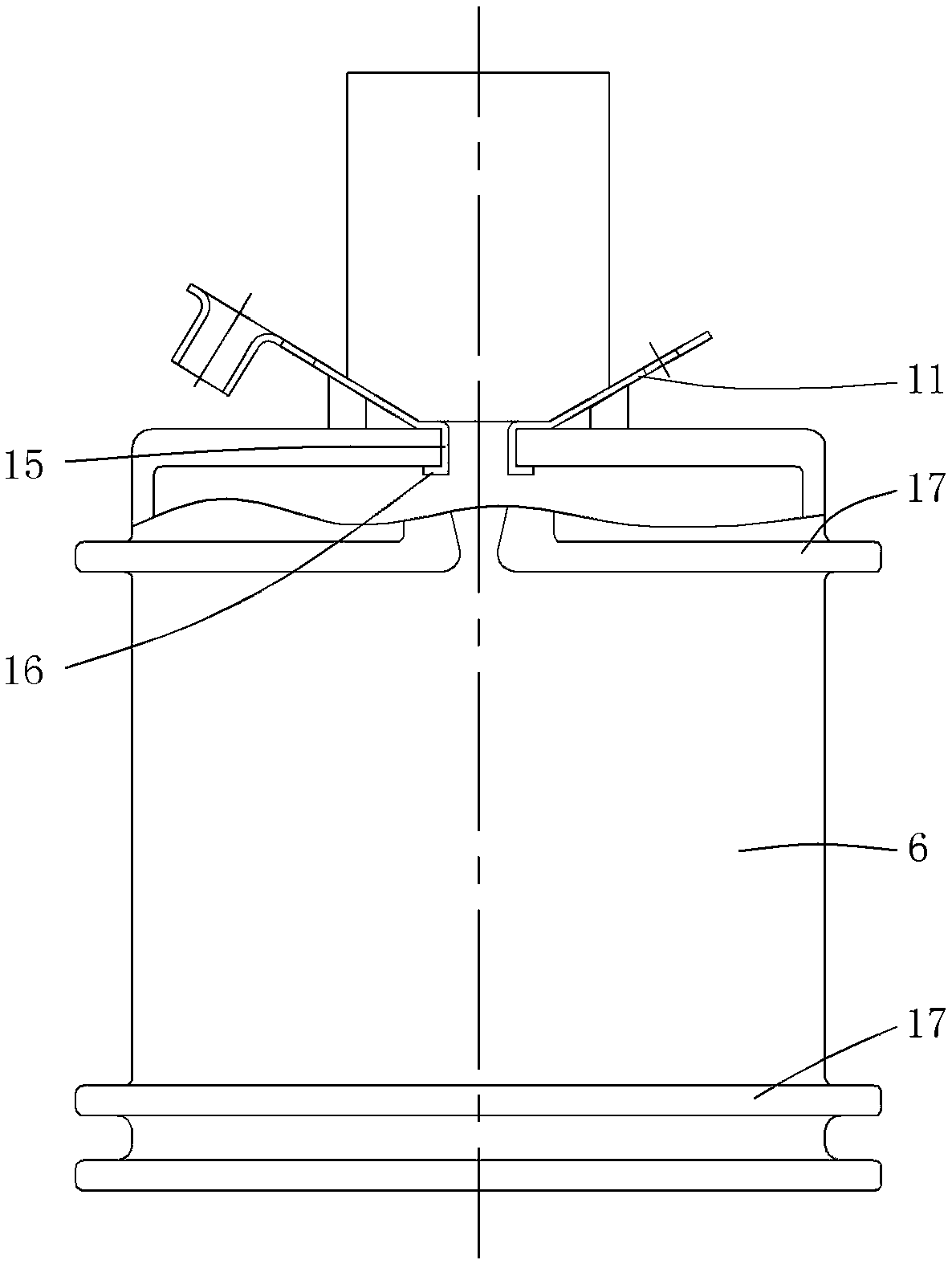

A support structure and a moving coil gas proportional valve with the support structure

ActiveCN105952917BHigh densityImprove high temperature resistanceOperating means/releasing devices for valvesLift valveInterference fitProportional valve

The invention provides a support structure. The support structure comprises a support rod and a sealing bowl arranged at one end of the support rod. The sealing bowl and the support rod are of a split structure. The support rod and the sealing bowl are each made of an aluminum material. The sealing bowl is mounted outside the end of the support rod in a sleeving manner and is in interference fit with the support rod. A conical plane is arranged at the sealing position outside the sealing bowl. The invention further provides a moving coil type fuel gas proportional valve. The moving coil type fuel gas proportional valve comprises a proportional valve body, a support assembly which is arranged in the proportional valve body in a sliding manner and can be sealed on a valve port of the proportional valve body, a moving coil assembly for driving the support assembly to move and an induction membrane for isolating the support assembly from the moving coil assembly. The support assembly is the support structure. The support structure and the moving coil type fuel gas proportional valve have the beneficial effects that the structure is light, control is easy, machining is quite convenient, strength and sealing performance are good, and the service life is long.

Owner:CIXI TIANXING ELECTRIC

Steel pipe annealing equipment and its annealing process

ActiveCN103710512BIncrease productivitySlow coolingFurnace typesHeat treatment furnacesShielding gasHardness

The invention relates to steel pipe annealing equipment and a steel pipe annealing technology. The steel pipe annealing equipment comprises the following technological processes: A. conveying a steel pipe to a feeding roller table through an alignment device, and conveying at the speed of 16-27m / h; B. enabling the steep pipe to enter a thermal treatment furnace via an inlet sealing box and carrying out closed heat treatment on the steel pipe, and continuing to move the steel pipe forwards in the thermal treatment furnace at the speed of 16-27m / h, wherein the steel pipe orderly passes through a first heating area, a second heating area, a third heating area, a fourth heating area and a heat preservation area inside the thermal treatment furnace; the heating temperatures of the first heating area, the second heating area, the third heating area and the fourth heating area are orderly increased, and the thermal treatment furnace is filled with protective gas in the closed thermal treatment process; C. slowly cooling the steel pipe by a cooling box adopting circulating cooling water to cool after the steel pipe is discharged from the thermal treatment furnace; and D. enabling the steel pipe to enter an aggregate area through an outlet sealing box to finish the overall process after the steel pipe is discharged from the cooling box. By adopting the technology, the inner stress of the material after pipe welding can be removed, the steel pipe is uniform in hardness, high in tensile strength and high in ductility, the yield strength is reduced, and the steel pipe is flexible.

Owner:广东志达精密管业制造股份有限公司

A kind of preparation method of carbon nanotube reinforced copper matrix composite material

The invention discloses a preparation method of a carbon nanotube enhanced copper-based composite material. The preparation method comprises the following steps: uniformly adding MWCNTs (Multi-walledCarbon Nanotubes) between copper foils; carrying out an SPS (Spark Plasma Sintering) and cold rolling technology to obtain a laminar MWCNTs / Cu composite material thin belt. The relative density of anobtained MWCNTs / Cu composite material is 94.3 to 98.6 percent. Compared with a traditional powder SPS MWCNTs / Cu composite material, the resistivity is reduced by 10 percent to 16 percent and the yieldstrength is equivalent.

Owner:CENT SOUTH UNIV

Metal-matrix composite ceramic liner plate and preparation method thereof

ActiveCN102618772BImprove the bonding strength of the interfaceEnhanced interface bindingGearingCylindersIron powderComposite ceramic

The invention discloses a metal-matrix composite ceramic liner plate. Zirconia aluminum oxide, high chromium iron powder and iron powder are electrically smelted and injected into a metal-matrix ceramic reinforcement with a plurality of communicated plug holes to form the metal-matrix composite ceramic liner plate; the upper and lower end faces of the metal-matrix ceramic reinforcement are provided with communicated plug holes, and four side faces of the metal-matrix ceramic reinforcement are provided with communicated grooves; after different reinforcements are spliced, grooves on edges of two adjacent reinforcements form complete plug holes, a metal liquid is poured into the plug holes and can infiltrate among ceramic particles of the reinforcements through the plug holes and uniformly coat the ceramic particles, so that a ceramic phase and a metal phase are uniformly distributed. Therefore, the toughness and wear resistance of the finished ceramic products are enhanced, and the thermal shock resistance of the finished ceramic products is improved.

Owner:洛阳鹏飞耐磨材料股份有限公司

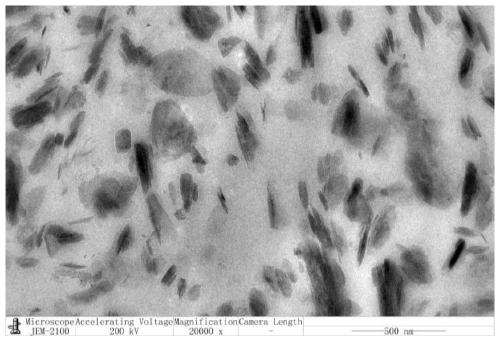

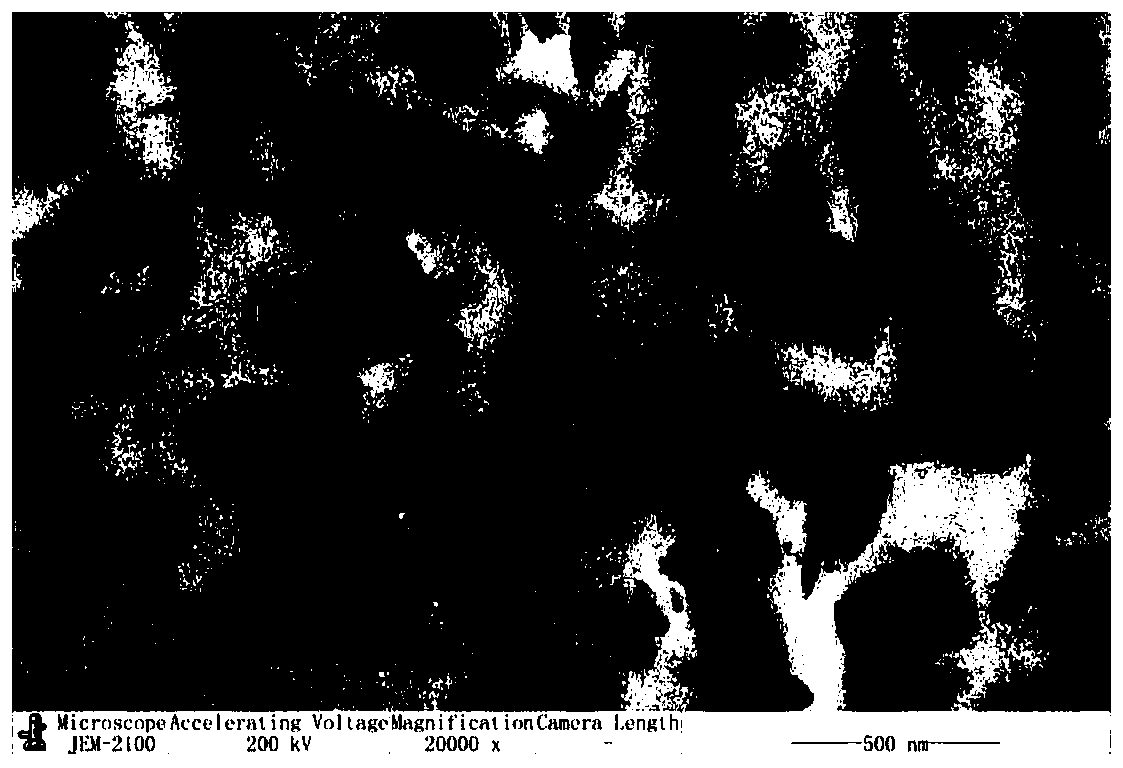

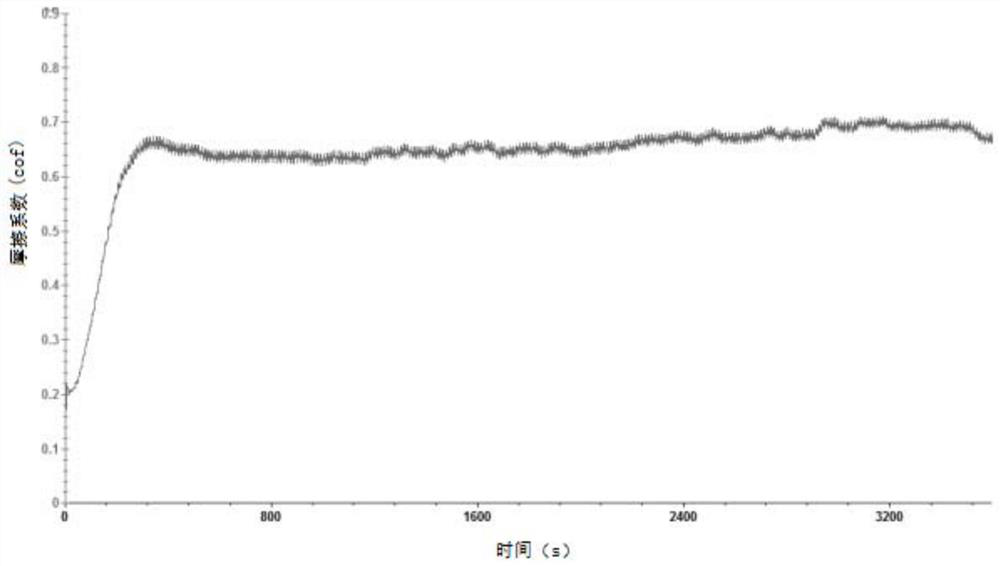

A composite coating of high-entropy alloy composite large-grained tungsten carbide and its preparation method and application

ActiveCN110331398BSubstrate hardness equivalentEquivalent hardnessMetallic material coating processesHigh entropy alloysAlloy composite

The invention belongs to the field of preparation of special composite coatings, and in particular relates to a composite coating of high-entropy alloy composited with large-grain tungsten carbide and its preparation method and application. The composite coating is composed of high-entropy alloy and tungsten carbide, and the tungsten carbide contains large particle tungsten carbide; the particle size of the large particle tungsten carbide is 75-150 microns. The preparation method is as follows: mixing high-entropy alloy powder and large-grain tungsten carbide according to a set ratio; preparing high-entropy alloy / large-grain tungsten carbide by laser cladding and rapid cooling. By adopting the preparation process of the present invention, the high-entropy alloy / large-grain tungsten carbide composite coating is prepared while protecting the matrix and the large-grain tungsten carbide from damage, so as to realize the uniform distribution of the large-grain tungsten carbide particles inside the composite coating, And it is suitable for large tungsten carbide particles of various qualities and various types of laser cladding equipment.

Owner:CENT SOUTH UNIV

High γ-aminobutyric acid high dietary fiber noodles and preparation method thereof

ActiveCN104996908BHigh GABAIncrease the content of dietary fiberFood ingredient functionsBiotechnologyNutrition

The invention provides a high γ-aminobutyric acid high dietary fiber noodle, which has the effects of improving intelligence and improving intestinal function, and the noodle hardness, elasticity and cohesion are comparable to those of ordinary dried noodles on the market. In addition, the present invention also provides a preparation method thereof, which can improve the taste of noodles through ultra-micronization; can improve γ-aminobutyric acid and water-soluble diet through germination and endogenous enzyme transformation, as well as the combined action of ultra-micronization and enzymatic hydrolysis The content and utilization of fiber can reduce the content of anti-nutritional factors and improve the efficacy; the use of sprouted puree to make noodles can improve the toughness and chewing performance of the noodles, the taste and flavor are good, and the nutrient digestion and absorption rate of the noodles can be improved.

Owner:湖北金银丰食品有限公司

Preparation method of micron-scale nickel-based superalloy powder transmission electron microscope thin film sample

ActiveCN107121316BNot easy to come outEquivalent hardnessPreparing sample for investigationMicron scaleThin membrane

The invention belongs to the technical field of preparation and characterization of alloy materials, and discloses a method for preparing a micron-sized nickel-based superalloy powder transmission electron microscope film sample. The method is as follows: adding nickel-based alloy powder into the electroplating solution and stirring to obtain a suspension; then placing the cathode nickel sheet and the anode nickel sheet in the suspension to obtain uniform nickel-based alloy powder on the cathode nickel sheet; The power supply is electroplated, the nickel-plated layer embeds the nickel-based alloy powder, and then it is mechanically thinned and punched into a disc with a diameter of 3mm, and then ground into a wedge-shaped sample in the thickness direction; it is attached to the opening of the open copper ring , the thin end of the wedge is close to the center of the opening of the copper ring, and then the open copper ring with the sample attached is placed in the ion thinning instrument for ion thinning to obtain a thin film sample area that can be observed by the transmission electron microscope. The method of the invention has the advantages of short time consumption, good coating quality and good embedding effect of nickel-based superalloy powder.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com