A composite coating of high-entropy alloy composite large-grained tungsten carbide and its preparation method and application

A high-entropy alloy and composite coating technology, which is applied in the coating process and coating of metal materials, can solve the problems of low friction coefficient, reduced self-corrosion potential, and reduced corrosion resistance, achieving improved wear resistance, The effect of coating hardness increase and macro hardness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0069] This embodiment includes the following steps:

[0070] (1) Select a commercially available elemental metal with a purity higher than 99.5% (mass percentage), weigh it with a molar ratio of Fe:Co:Cr:Ni=1:1:1:1, and use the smelting-gas atomization process Prepared into multi-principal alloy powder;

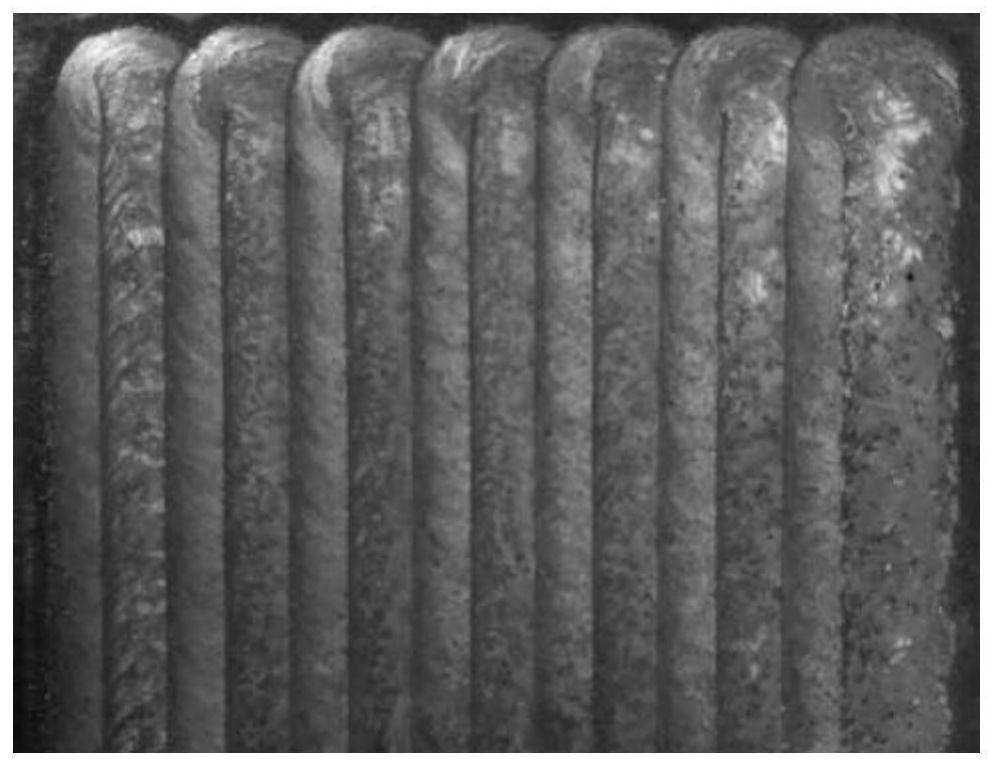

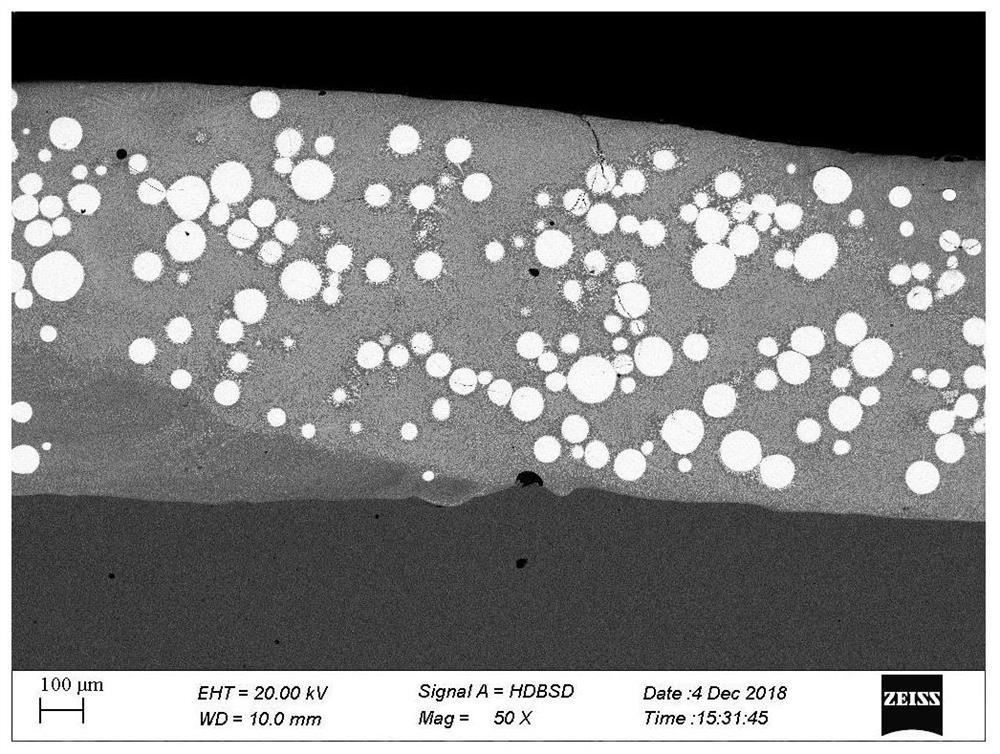

[0071] (2) According to the mass ratio of multi-principal alloy powder: WC particle = 4:1, weigh WC particles with a particle size between 75 and 125 μm and mix them with the ball-milled multi-principal alloy powder and preheat them. In the silo of the laser cladding equipment, the rust-removed and polished 42CrMo stainless steel surface is clad. The process parameters of laser cladding are: laser power P=1000w, v=4~15mm / s, spot diameter D is 4.5mm, protective gas flow rate is 10L / min. Finally, a multi-principal alloy / tungsten carbide composite coating (thickness is about 2 mm) is obtained.

[0072] In this example, the large-grain tungsten carbide is evenly distributed i...

Embodiment 3

[0074] The steps of this example are basically the same as those of Example 1, the only difference is that in step (1), the atomized powder is crushed to obtain irregular WC particles, which are used as tungsten carbide raw materials for cladding.

[0075] In this embodiment series, the tungsten carbide with large particles and irregular morphology is retained in the FeCoCrNi binder, and is closely combined with the binder; when the multi-principal alloy powder: WC particle=2:3 (mass ratio), the composite The average microhardness of the coating is about 698HV 0.2 , the volume wear rate is 0.154×10 ~5 mm 3 / (N·m), indicating that the high-entropy alloy / large particle tungsten carbide coating prepared by the present invention has good hardness and wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com