A support structure and a moving coil gas proportional valve with the support structure

A gas proportional valve and bracket structure technology, which is applied in the direction of lift valve, valve details, valve device, etc., can solve the problem that the bracket rod and the sealing bowl cannot be processed separately, which affects the performance of the moving coil gas proportional valve, and the sealing bowl and valve port are sealed. Insufficient and other problems, to achieve the effect of good sealing, light structure, not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

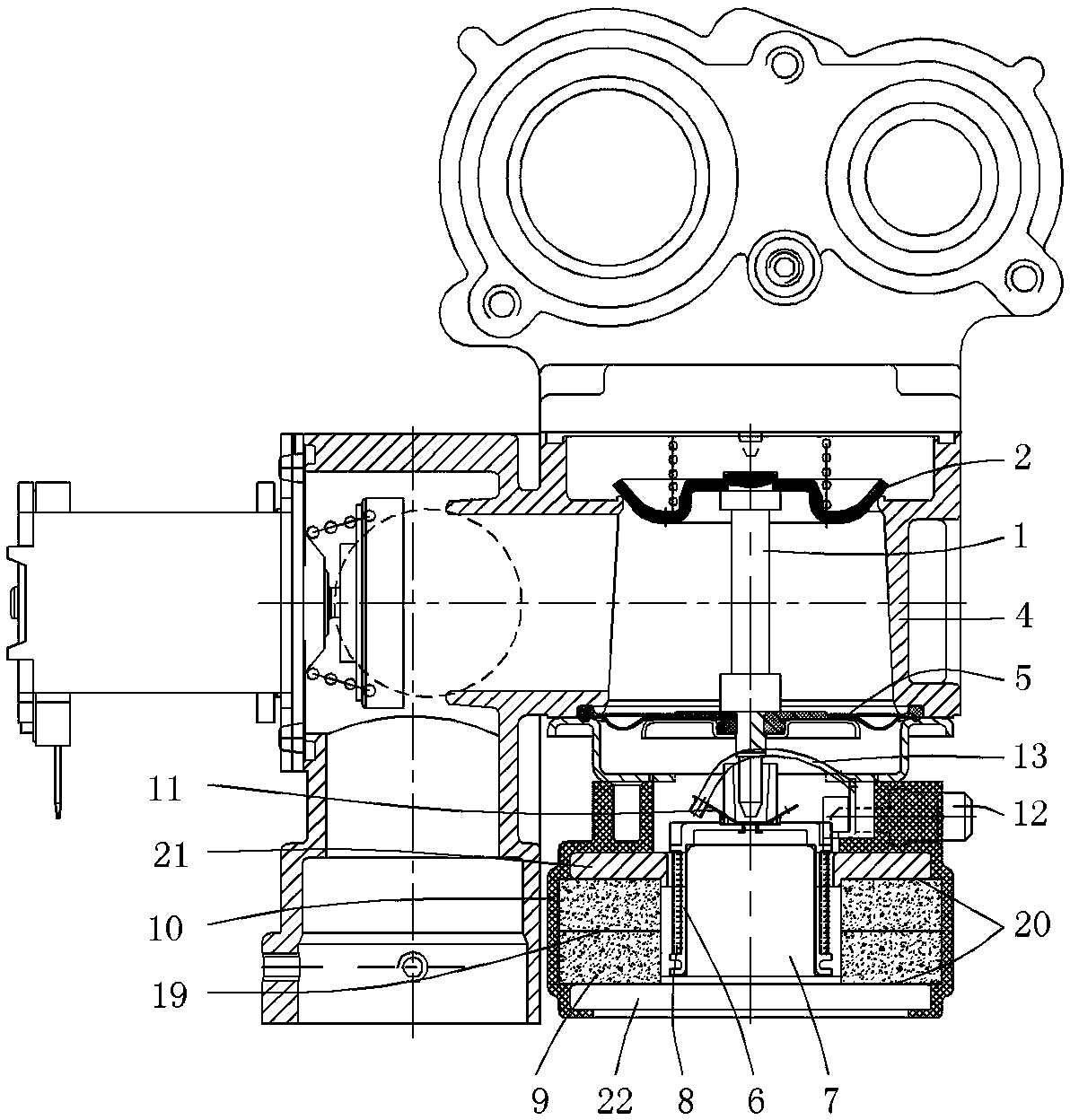

[0019] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

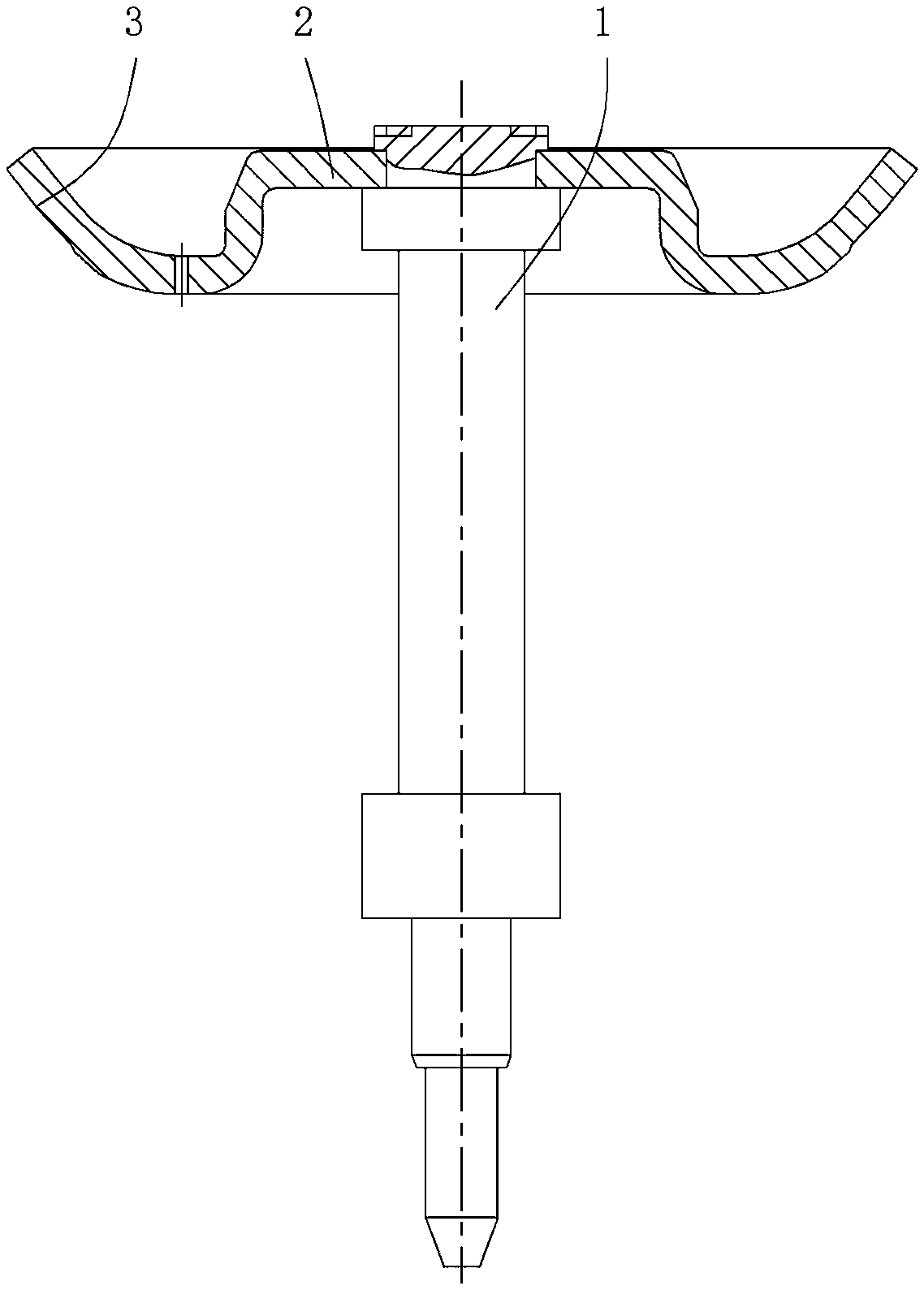

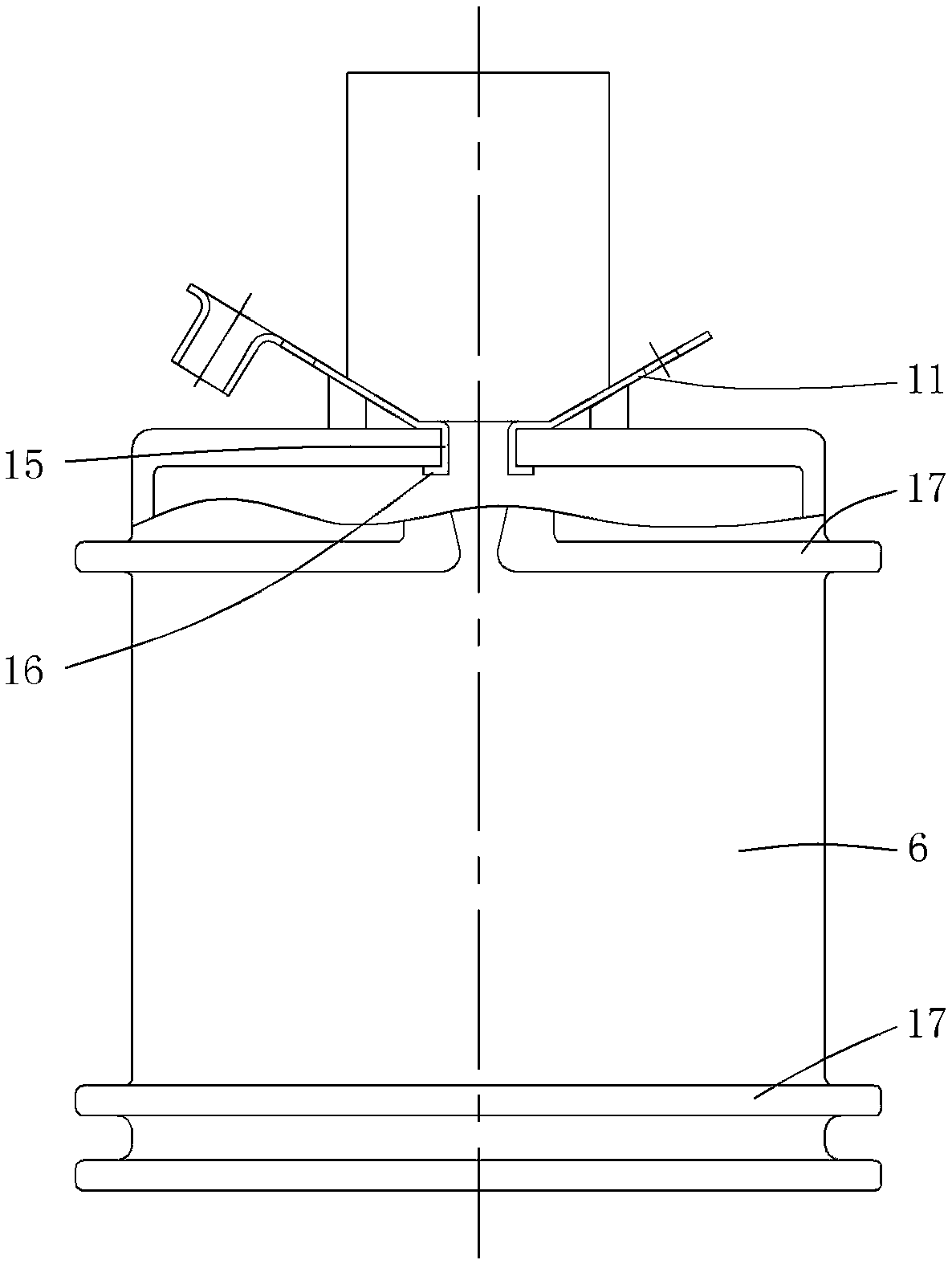

[0020] Reference figure 1 , A support structure, including a support rod 1, a sealed bowl 2 provided on one end of the support rod, the sealed bowl and the support rod are separate structures, the sealed bowl 2 and the support rod 1 can be processed separately , The processing is very convenient, the support rod 1 and the sealing bowl 2 are made of aluminum material, the structure is light and easy to control, the support rod 1 is generally stretched and formed of aluminum material, and the strength of the support rod is relatively high. It is not easy to break, and the service life is increased. The sealed bowl 2 is generally formed by die-casting aluminum material, which not only improves the density of the sealed bowl, but also has better sealing performance between the sealed bowl and the valve port, and the sealed bowl has good durability. High te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com