Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1411 results about "Spark plasma sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), is a sintering technique. The main characteristic of SPS is that the pulsed or unpulsed DC or AC current directly passes through the graphite die, as well as the powder compact, in case of conductive samples. Joule heating has been found to play a dominant role in the densification of powder compacts, which results in achieving near theoretical density at lower sintering temperature compared to conventional sintering techniques. The heat generation is internal, in contrast to the conventional hot pressing, where the heat is provided by external heating elements. This facilitates a very high heating or cooling rate (up to 1000 K/min), hence the sintering process generally is very fast (within a few minutes). The general speed of the process ensures it has the potential of densifying powders with nanosize or nanostructure while avoiding coarsening which accompanies standard densification routes. This has made SPS a good method for preparation of ceramics based on nanoparticles with enhanced magnetic, magnetoelectric, piezoelectric, thermoelectric, optical or biomedical properties. SPS is also used for sintering of Carbon Nanotubes for development of field electron emission electrodes. While the term "spark plasma sintering" is commonly used, the term is misleading since neither a spark nor a plasma is present in the process. It has been experimentally verified that densification is facilitated by the use of a current.

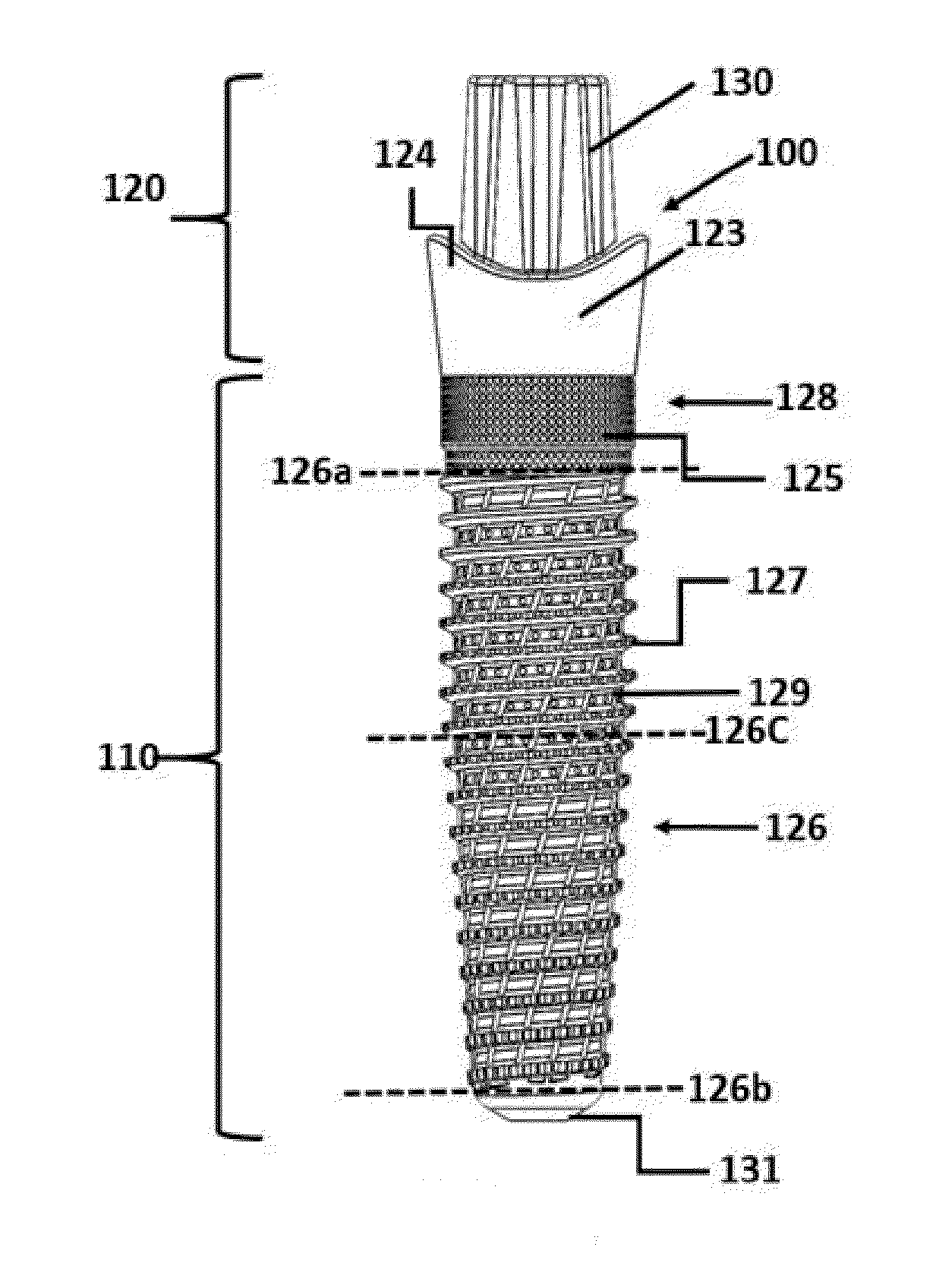

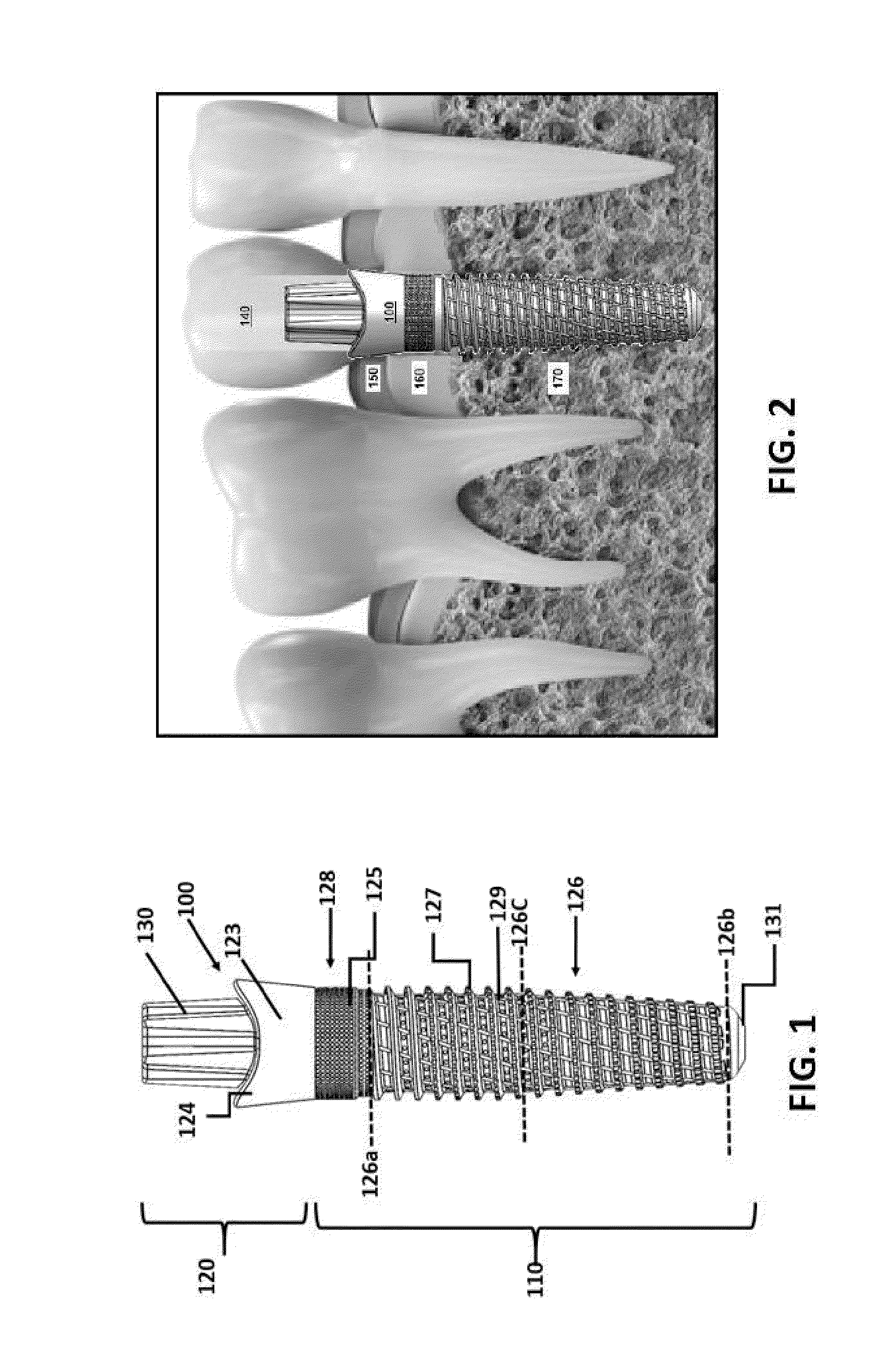

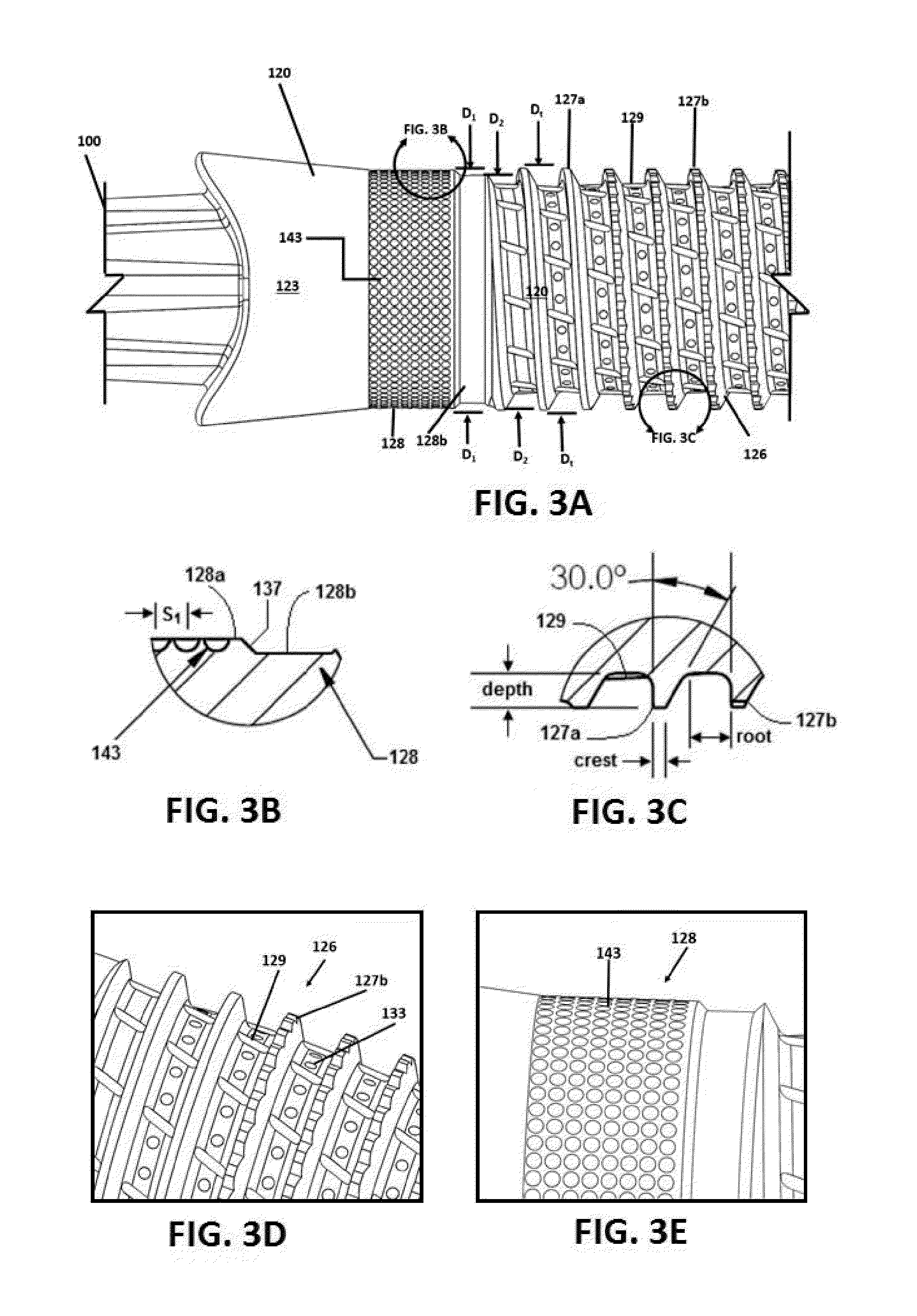

Osseointegrative surgical implant

InactiveUS20160015483A1Improve primary stabilityPromote healingSuture equipmentsDental implantsCeramic compositeSurgical implant

Embodiments of the present invention provide an osseointegrative implant and related tools, components and fabrication techniques for surgical bone fixation and dental restoration purposes. In one embodiment an all-ceramic single-stage threaded or press-fit implant is provided having finely detailed surface features formed by ceramic injection molding and / or spark plasma sintering of a powder compact or green body comprising finely powdered zirconia. In another embodiment a two-stage threaded implant is provided having an exterior shell or body formed substantially entirely of ceramic and / or CNT-reinforced ceramic composite material. The implant may include one or more frictionally anisotropic bone-engaging surfaces. In another embodiment a densely sintered ceramic implant is provided wherein, prior to sintering, the porous debound green body is exposed to ions and / or particles of silver, gold, titanium, zirconia, YSZ, α-tricalcium phosphate, hydroxyapatite, carbon, carbon nanotubes, and / or other particles which remain lodged in the implant surface after sintering. Optionally, at least the supragingival portions of an all-ceramic implant are configured to have high translucence in the visible light range. Optionally, at least the bone-engaging portions of an all-ceramic implant are coated with a fused layer of titanium oxide.

Owner:OSSEODYNE SURGICAL SOLUTIONS LLC

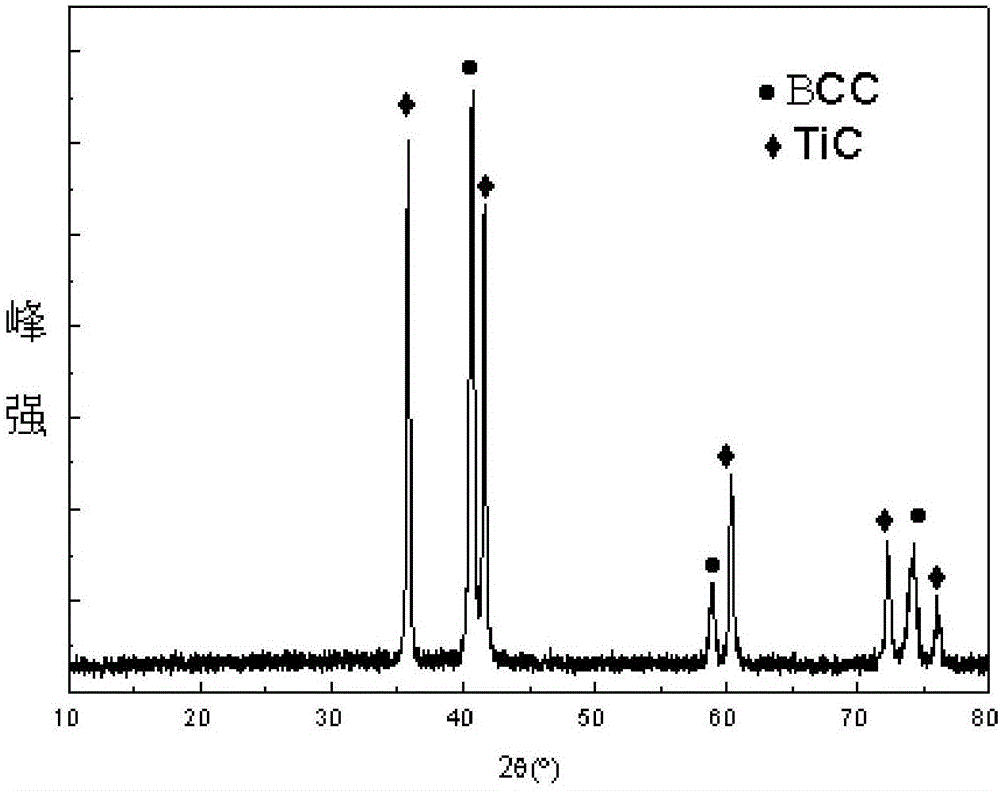

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

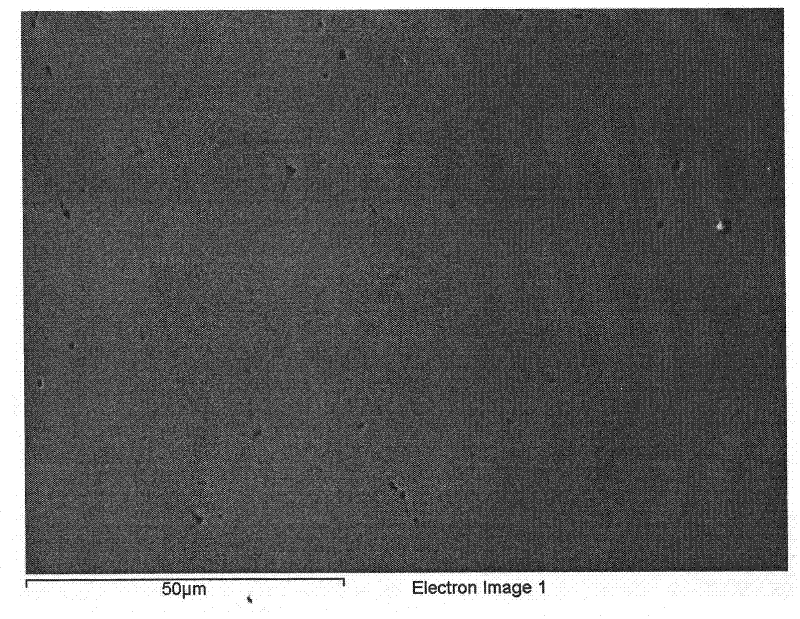

Method for improving graphene and copper basal body binding force in copper-based graphene composite material

The invention provides a method for improving graphene and copper basal body binding force in a copper-based graphene composite material; and the method prepares the composite material by a spark plasma sintering technology through adding a small amount of alloy elements in a copper basal body and mixing the alloy elements with graphene. Experiments prove that the method improves the interface binding force of the basal body and a graphene reinforcement phase in the composite material; and compared with a composite material prepared by adding no alloy element, high tensile resistance is achieved. In addition, the copper-based graphene composite material with excellent heat conductivity, electricity conductivity and wear resistance can be obtained by optimizing the adding quantity of the alloy elements and the mass of the graphene, so that excellent application prospect is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-strength and high-conductivity graphene copper-based composite material and preparation method thereof

The invention discloses a high-strength and high-conductivity graphene copper-based composite material and a preparation method thereof, wherein the graphene copper-based composite material comprises 0.01wt.%-6.0wt% of graphene and the balance of copper; the preparation method comprises the following steps: firstly, adding graphene oxide to a copper sulfate solution, adding a hydrazine hydrate solution to reduce nano-copper powder and graphene, drying and then reducing in H2 atmosphere, and finally, preparing the graphene copper-based composite material from the reduced composite powder by use of the Spark Plasma Sintering (SPS) technology. The graphene copper-based composite material shows excellent electric conductivity and thermal conductivity and outstanding wear resistance and corrosion resistance, and thus has a wide application prospect in the field of the frame leads and the electrical contact materials.

Owner:JIANGXI UNIV OF SCI & TECH

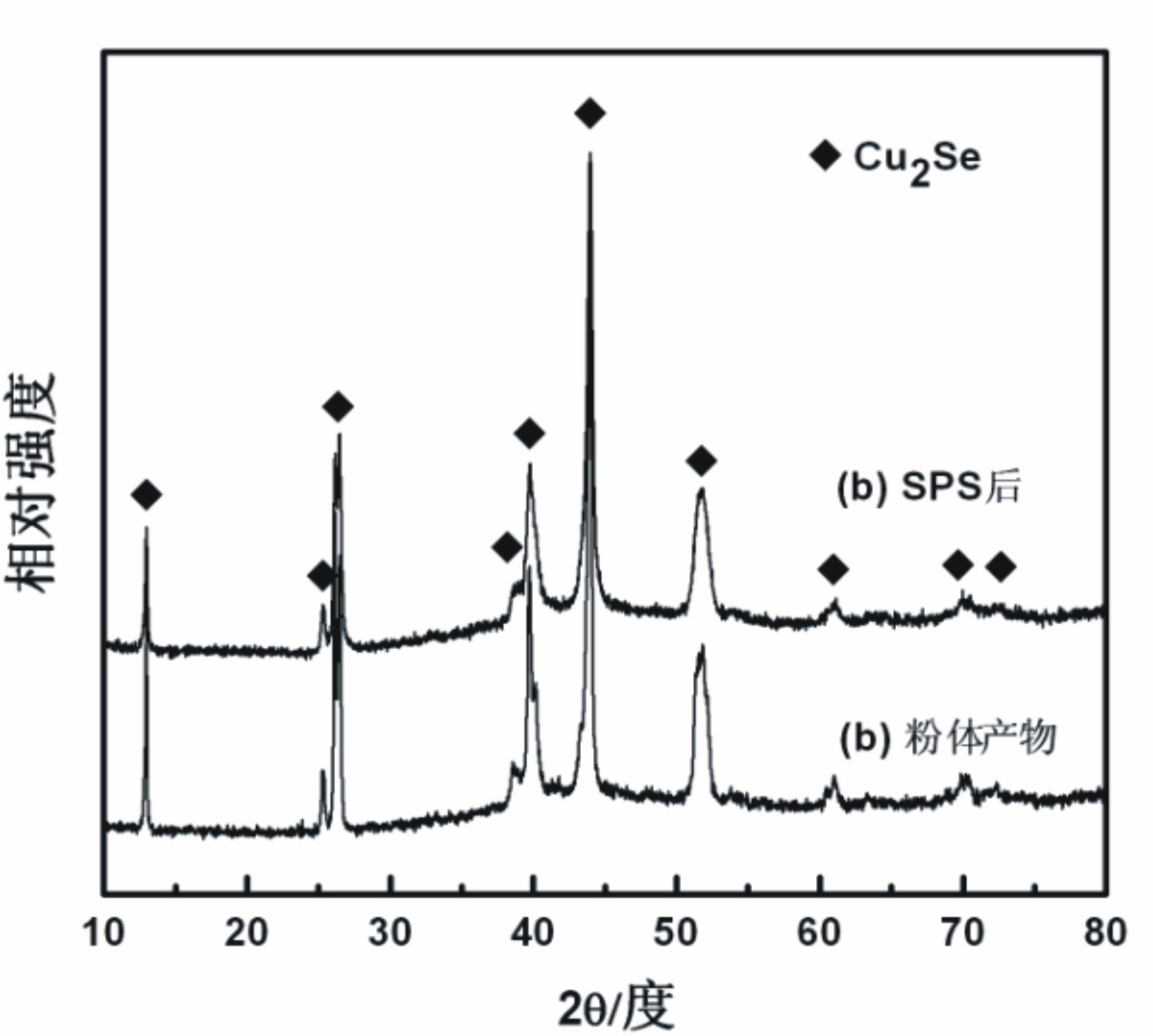

Method for preparing Cu2Se thermoelectric material by low-temperature solid-phase reaction

InactiveCN102674270ALow costControl compositionChemical industryBinary selenium/tellurium compoundsThermoelectric materialsMuffle furnace

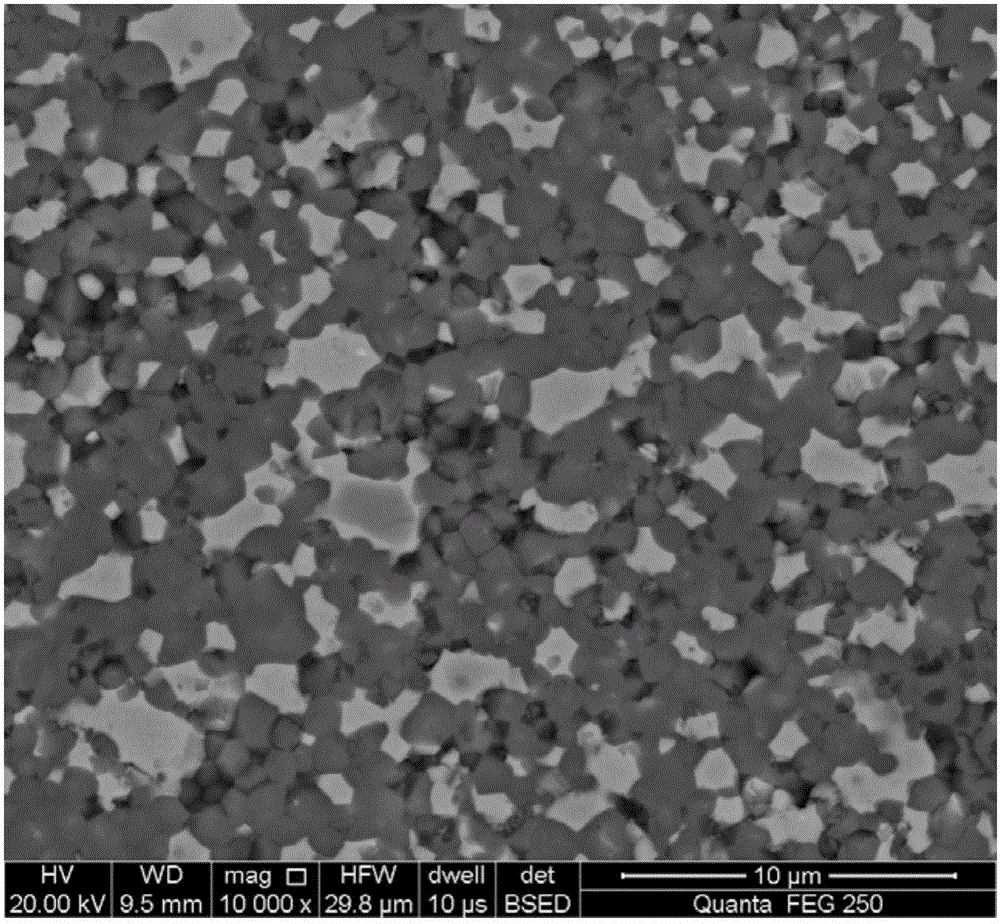

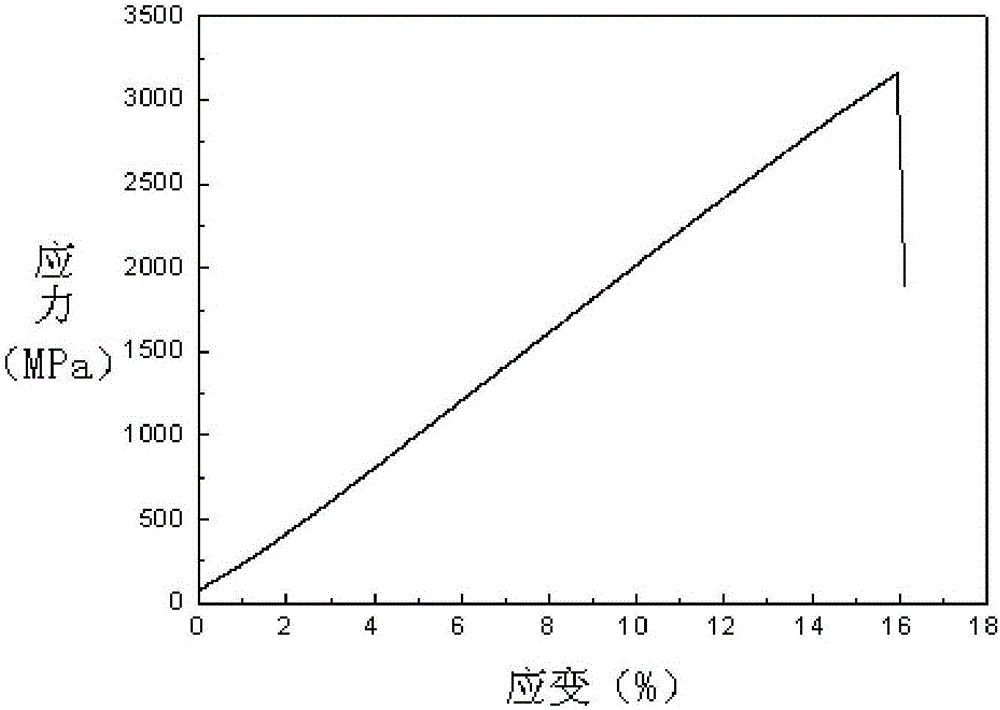

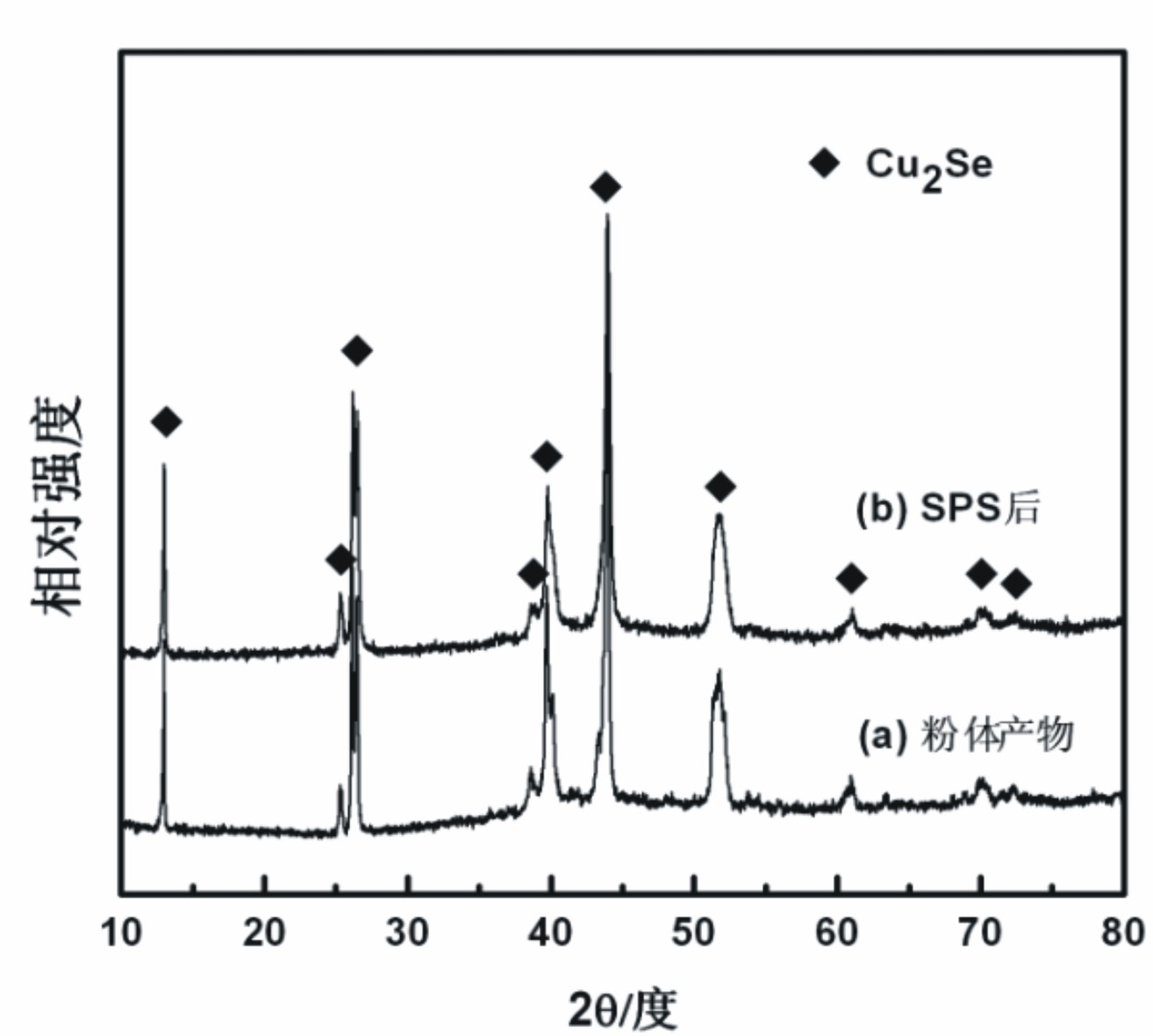

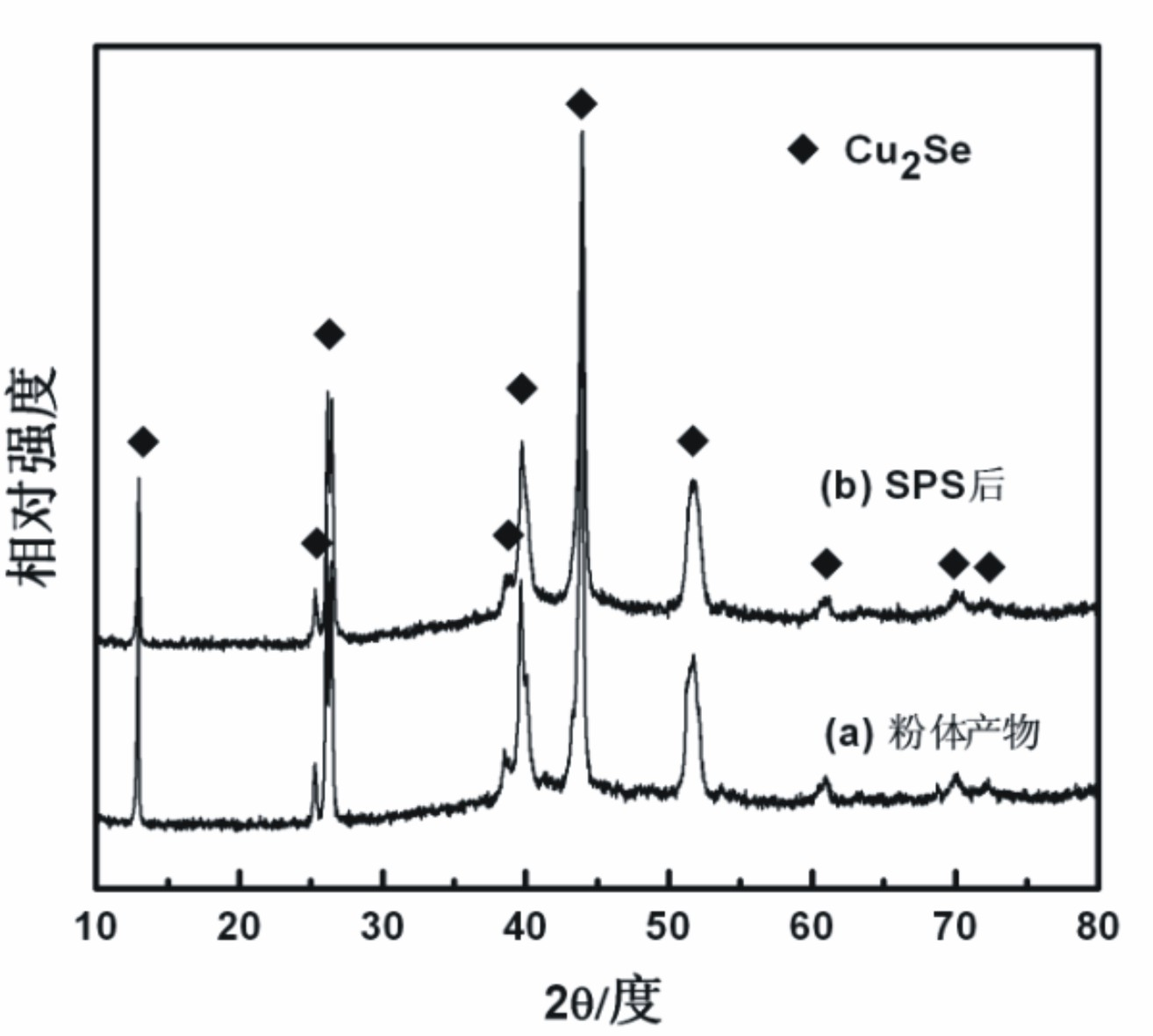

The invention relates to a method for preparing a Cu2Se thermoelectric material. The method for preparing the Cu2Se thermoelectric material by the low-temperature solid-phase reaction is characterized by comprising the following step: 1) weighing Cu powder and Se powder according to the molar ratio of 2:1 and mixing the Cu powder and the Se powder uniformly to obtain mixed powder, wherein the Cu powder and the Se powder serve as raw materials; 2) pressing the mixed powder into a block body by using tablet press, placing the block body into a graphite crucible, vacuumizing, sealing into a quartz glass tube, placing into a muffle furnace, performing solid-phase reaction at the temperature of between 650 and 750 DEG C for 12 to 24 hours, and grinding the obtained product into powder; and 3) performing spark plasma sintering on the powder obtained in the step 2) to obtain a compact block body, namely the Cu2Se thermoelectric material. By the method, the raw materials have low cost; the reaction temperature is low; energy is saved; and the materials are fed according to the stoichiometric ratio of the Cu2Se, so the product composition can be controlled precisely; and the repeatability is high.

Owner:WUHAN UNIV OF TECH

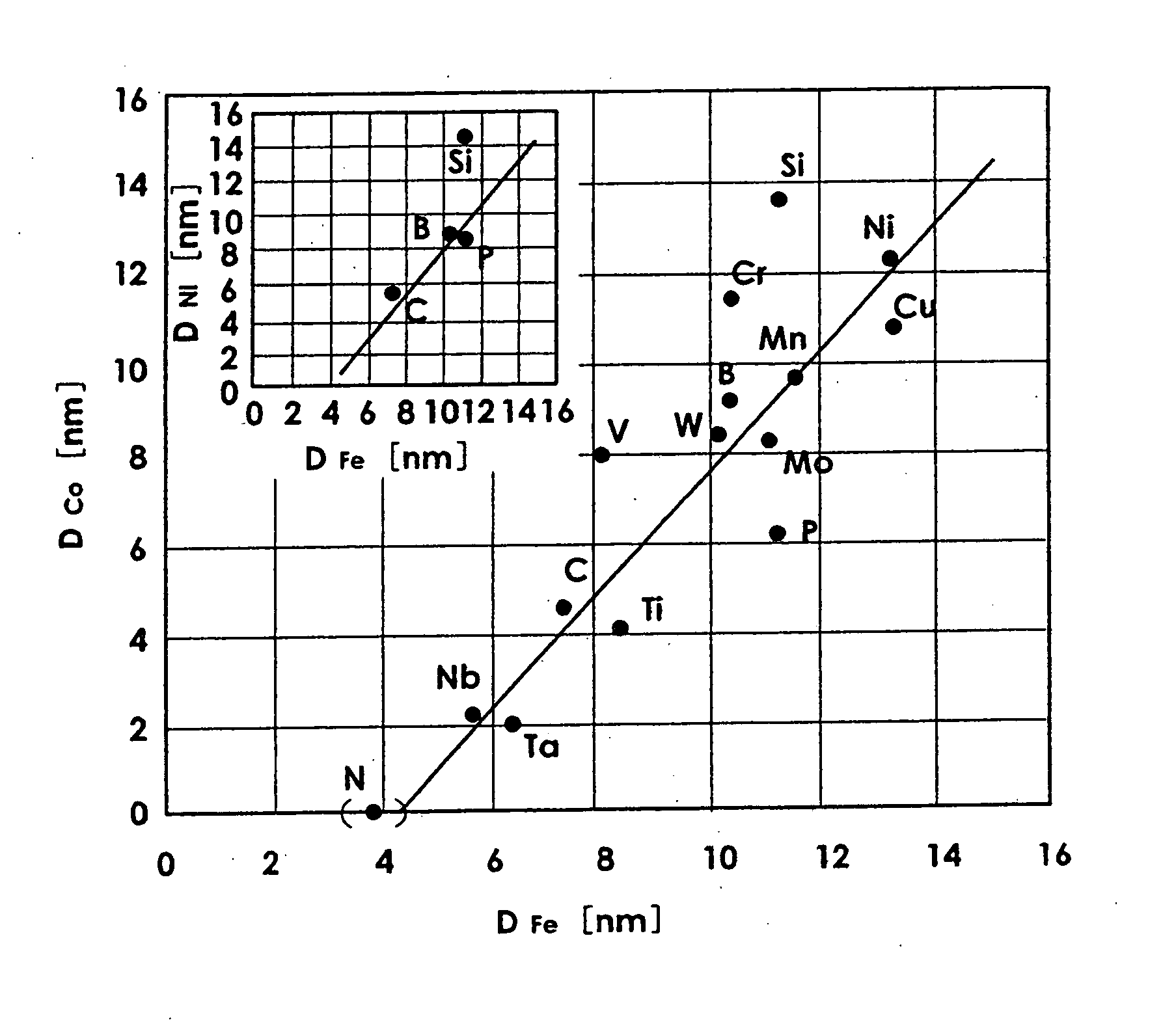

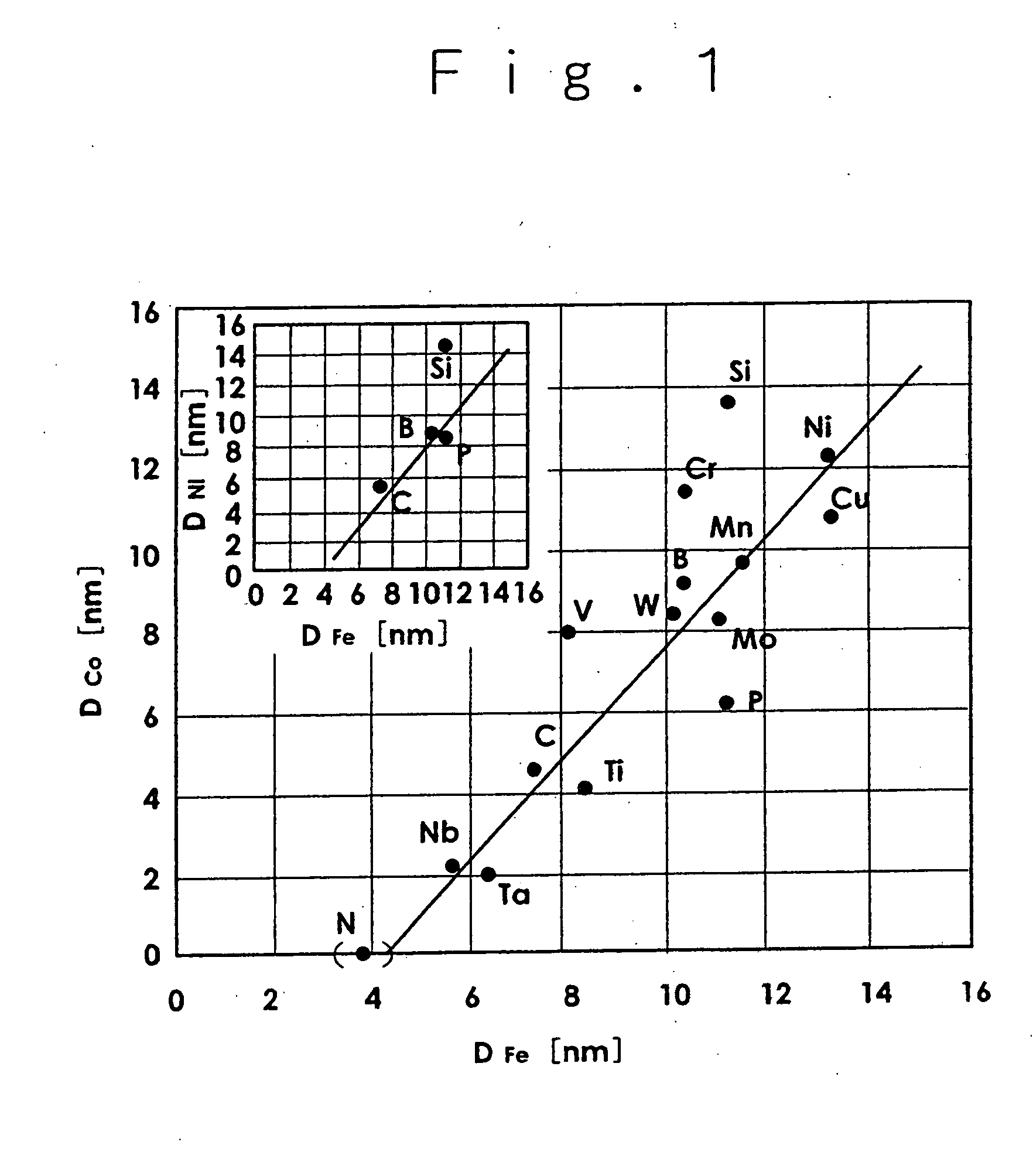

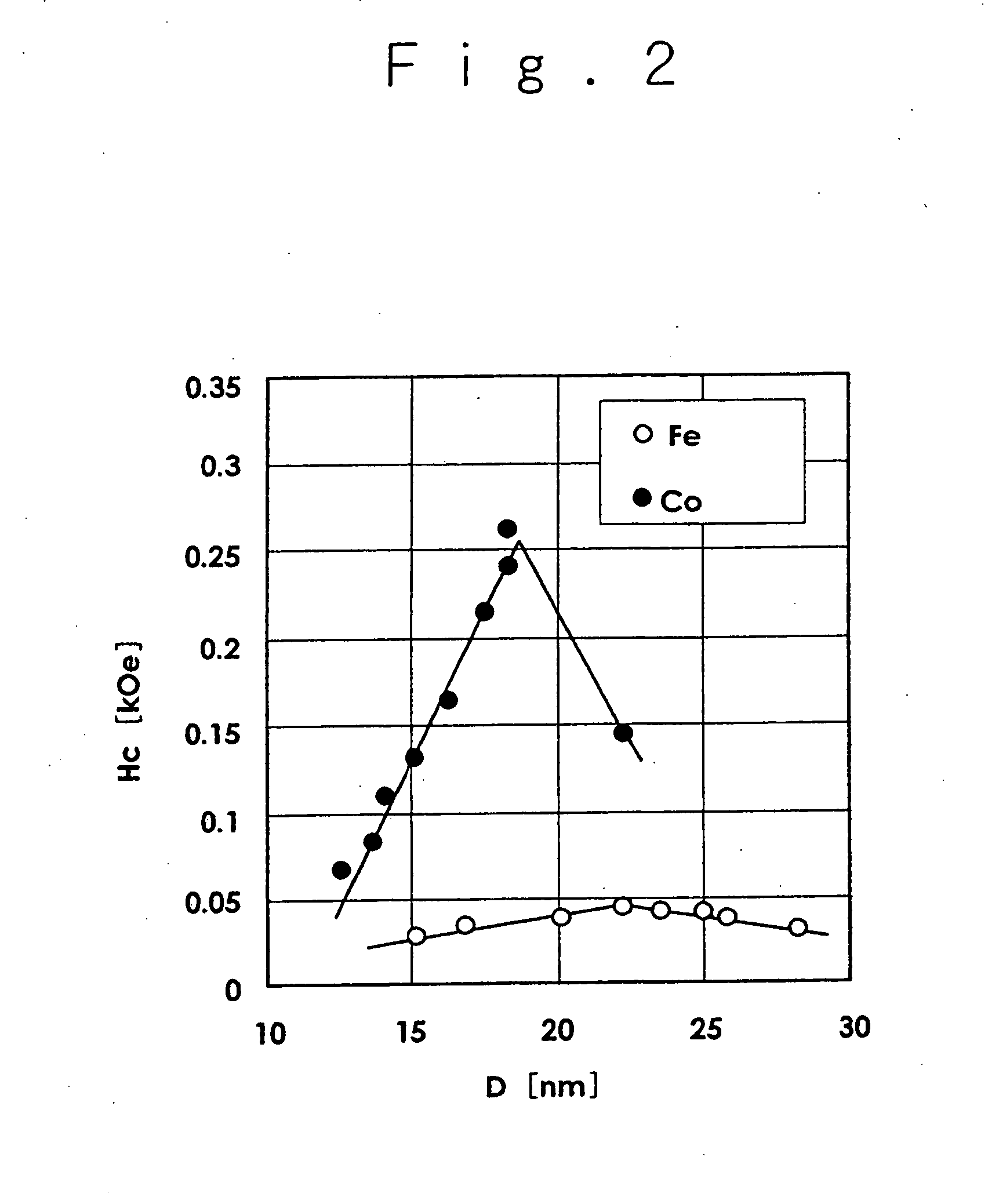

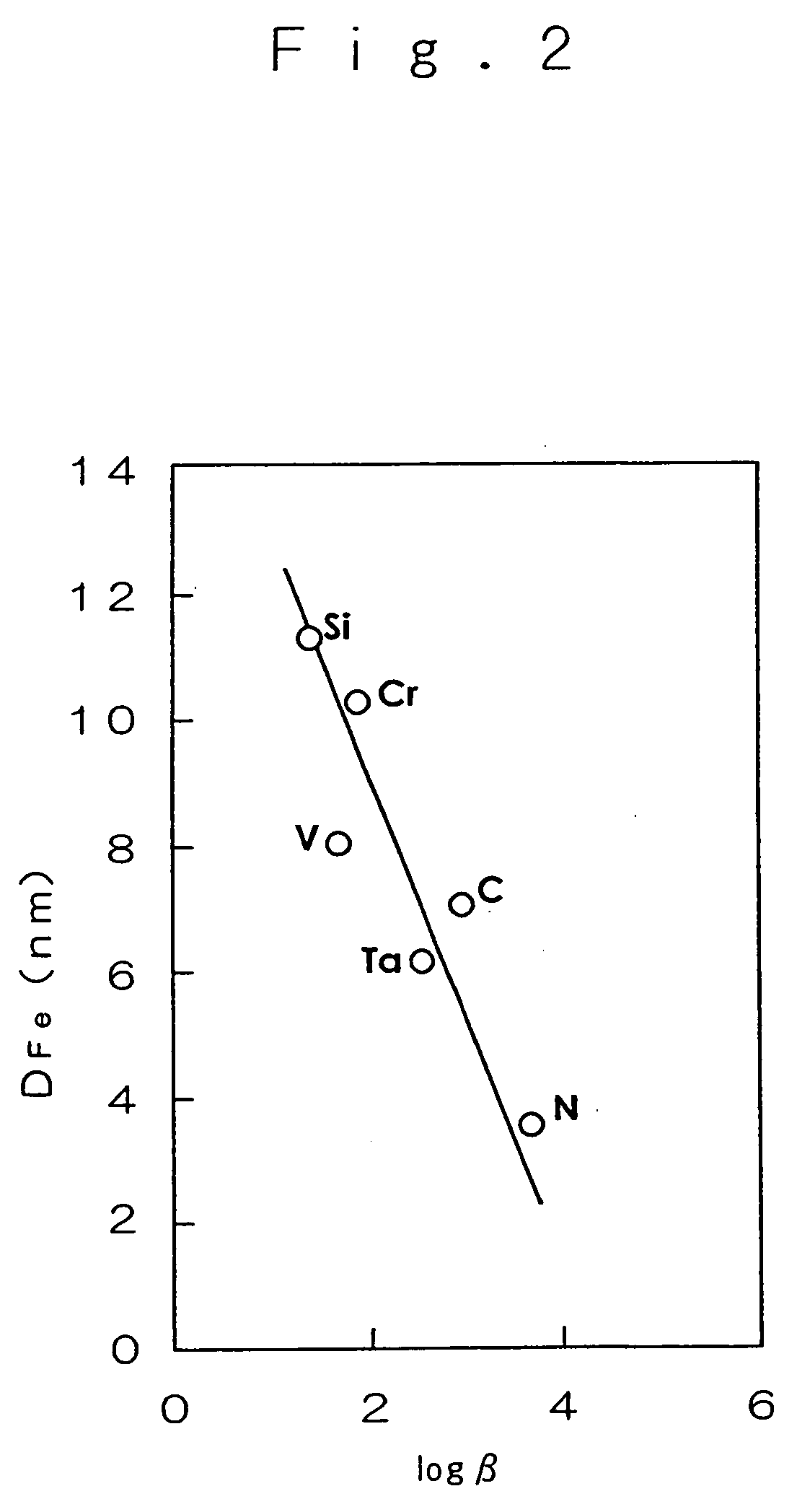

Nano-crystal austenitic steel bulk material having ultra-hardness and toughness and excellent corrosion resistance, and method for production thereof

InactiveUS20060193742A1Easy to prepareImprove corrosion resistanceTransportation and packagingMetal-working apparatusGrowth retardantManganese

The invention provides a super hard and tough, nano-crystal austenite steel bulk material having an improved corrosion resistance, and its preparation process. The austenite steel bulk material comprises an aggregate of austenite nano-crystal grains containing 0.1 to 2.0% (by mass) of a solid solution type nitrogen, wherein an oxide, nitride, carbide or the like of a metal or semimetal exists as a crystal grain growth inhibitor between and / or in said nano-crystal grains. For preparation, fine powders of austenite steel-forming components, i.e., iron and chromium, nickel, manganese, carbon or the like are mixed with a substance that becomes a nitrogen source. Mechanical alloying (MA) is applied to the mixture, thereby preparing nano-crystal austenite steel powders having a high nitrogen concentration. Finally, the austenite steel powders are consolidated by sintering by means of spark plasma sintering, rolling or the like.

Owner:MIZUTANI MASARU

Highly heat-conductive composite material

InactiveUS8163060B2Improve the heating effectIncrease resistanceSingle layer grapheneAluminium powderAlloy

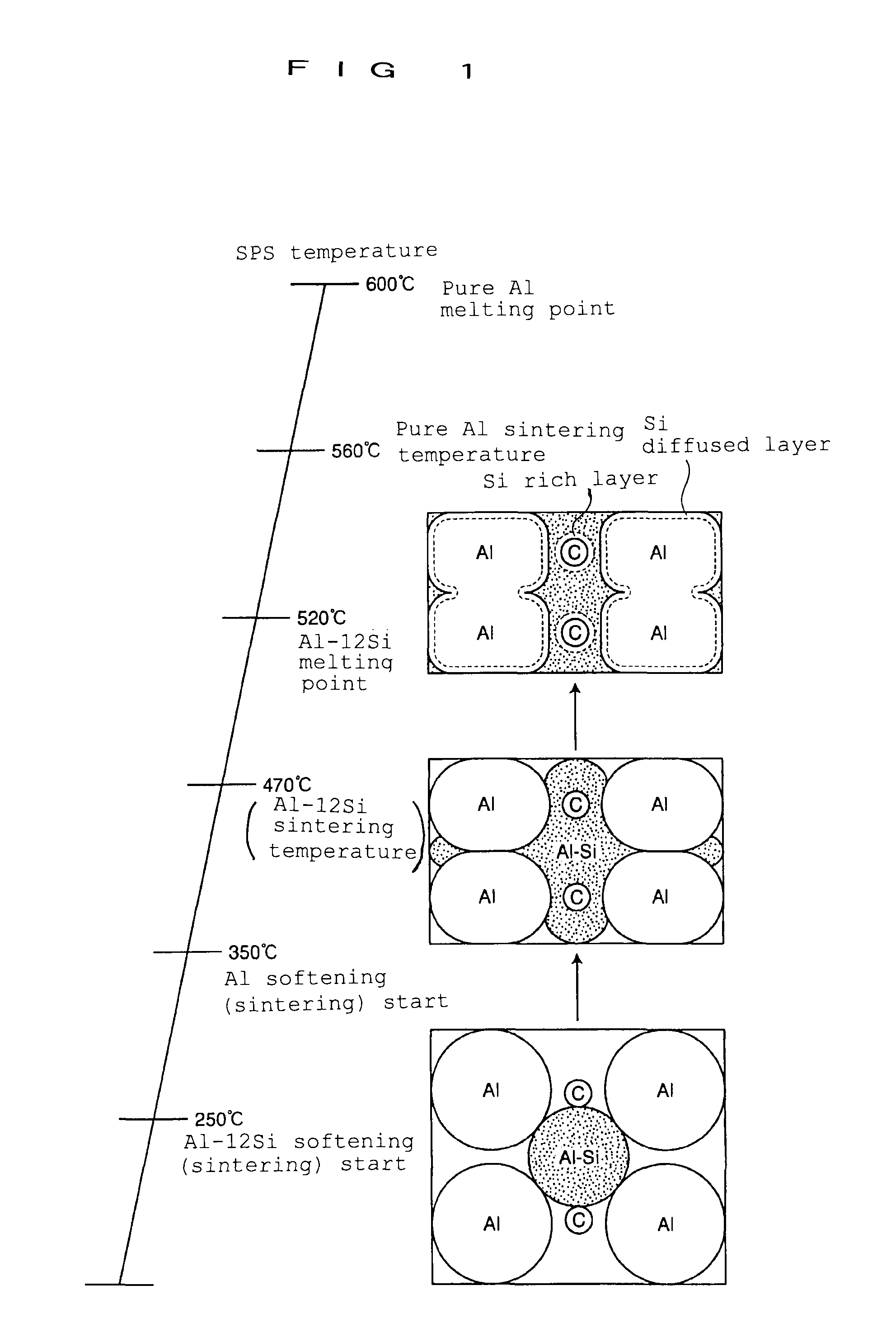

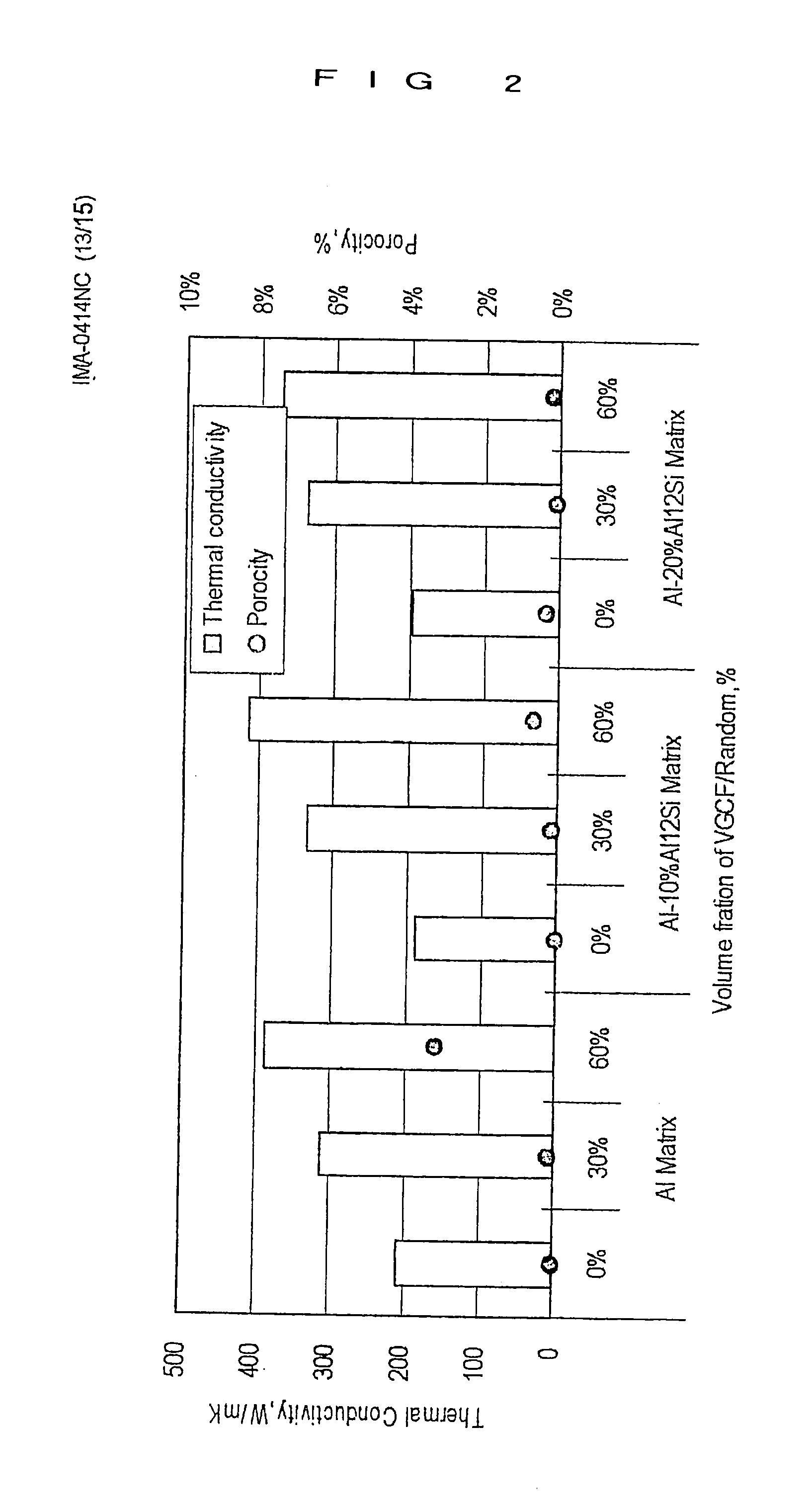

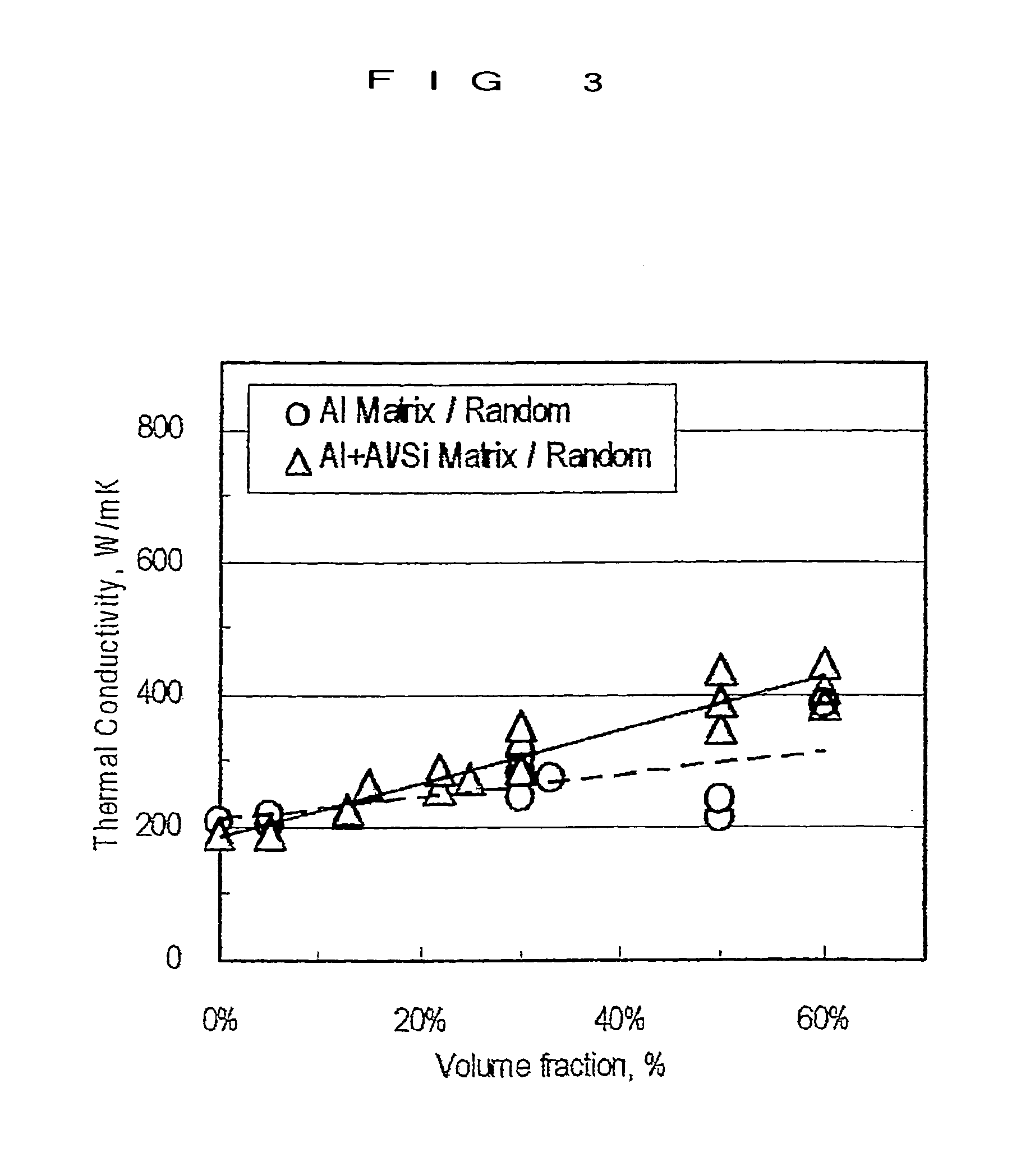

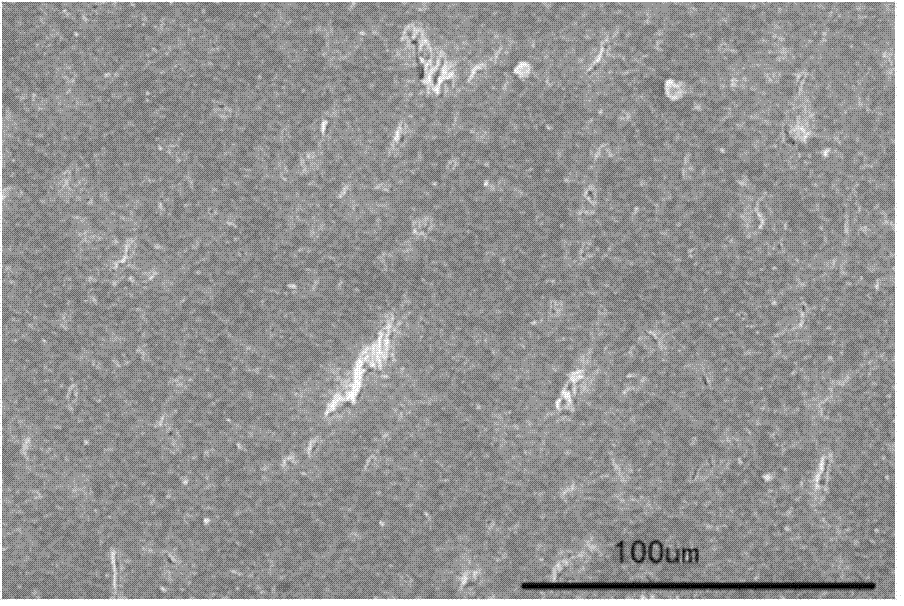

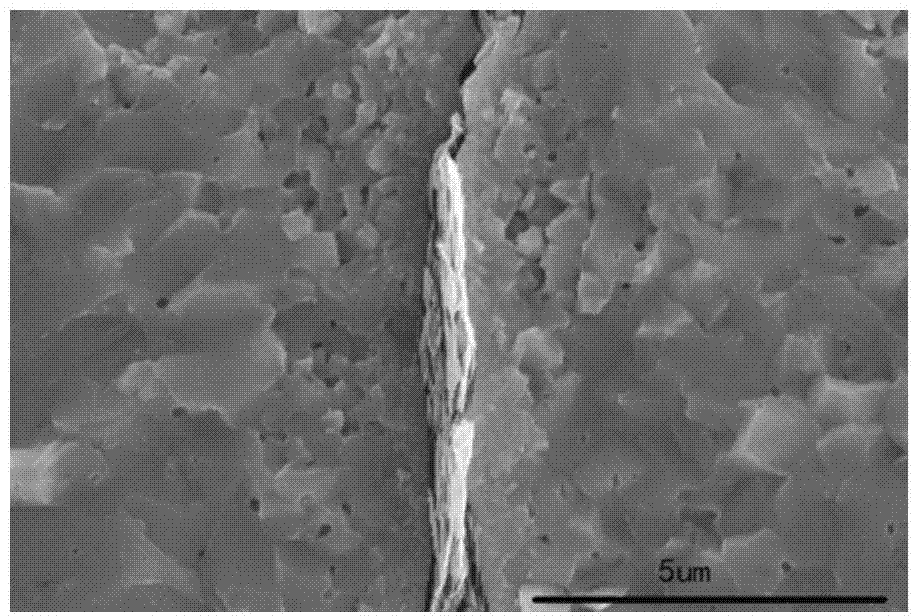

The heat conductivity of an aluminum composite material containing a fibrous carbon material is enhanced. In order to realize this, a spark plasma sintered body having a fibrous carbon material compounded in a metal matrix powder of aluminum or the like is fabricated. At the time of fabrication, an aluminum powder serving as a matrix mother material is compounded with an Al alloy powder such as an Al-12Si powder having a melting point lower than the sintering temperature of the mother material. During the process of sintering the aluminum powder, the Al alloy powder is melted, whereby the heat conductivity between the aluminum powder particles and between the aluminum powder particle and the fibrous carbon material is improved.

Owner:SUMITOMO PRECISION PROD CO LTD +1

High performance aluminum nanocomposites

InactiveUS20150252451A1Readily apparentTransportation and packagingMetal-working apparatusParticulatesNanoparticle

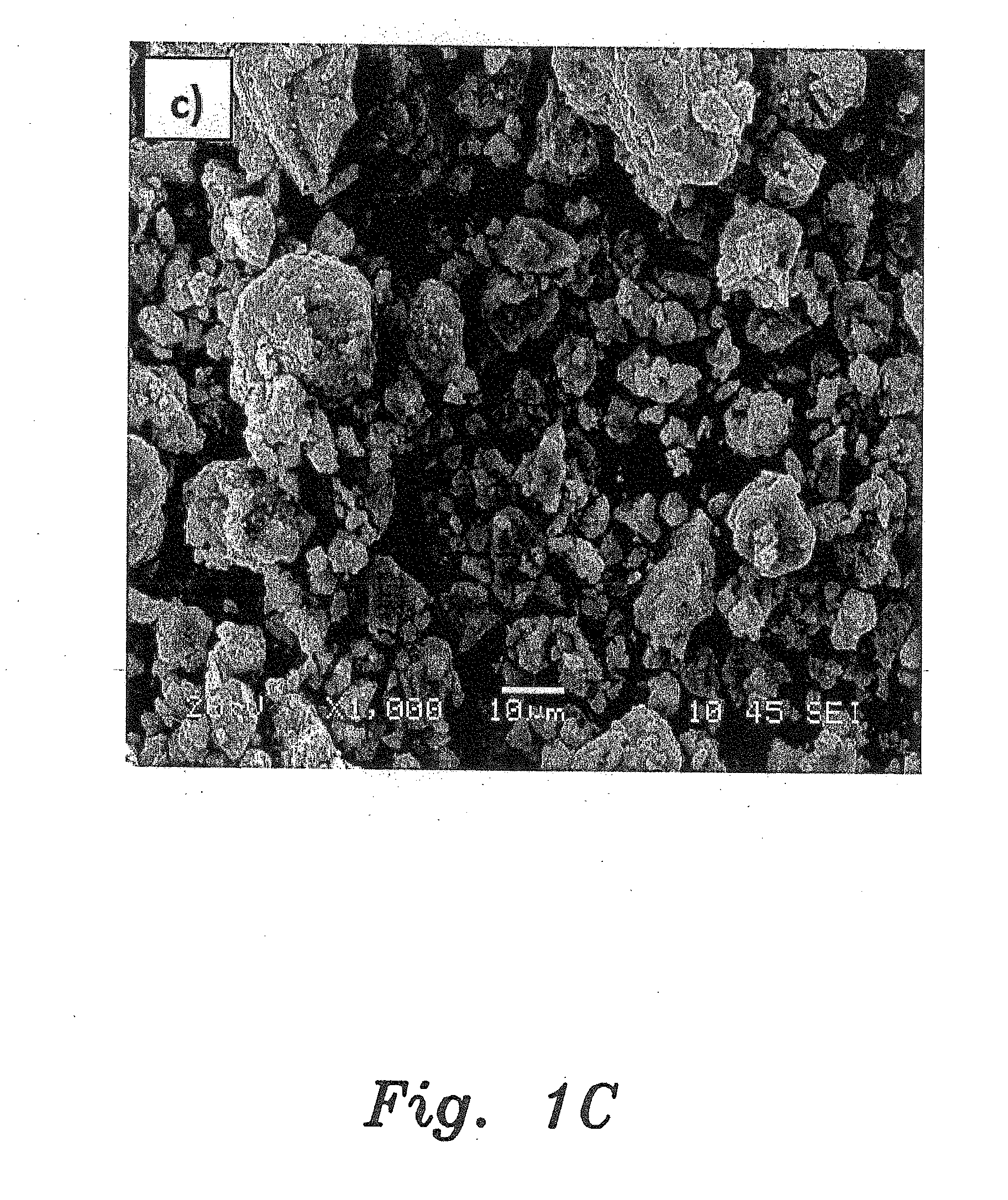

The high performance aluminum nanocomposites are formed by a combination of mechanical alloying and Spark Plasma Sintering (SPS) in order to obtain reinforced nanostrutured aluminum alloys, The nanocomposites are formed from aluminum metal reinforced with silicon carbide (SiC) particulates, wherein the SiC particulates have a particle diameter between about 20 and 40 nm. The nanocomposites are prepared by mixing aluminum-based metal, e.g., Al-7Si-0.3Mg, (Al=92.7%, Si-7% and Mg=0.3%), with SiC nanoparticles in a conventional mill to form a uniformly distributed powder, which is then sintered at a temperature of about 500° C. for a period up to about 20 hours to consolidate the silicon carbide particulates in order to obtain the reinforced aluminum metal-based silicon carbide nanocomposite.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Semi-passive control of solidification in powdered materials

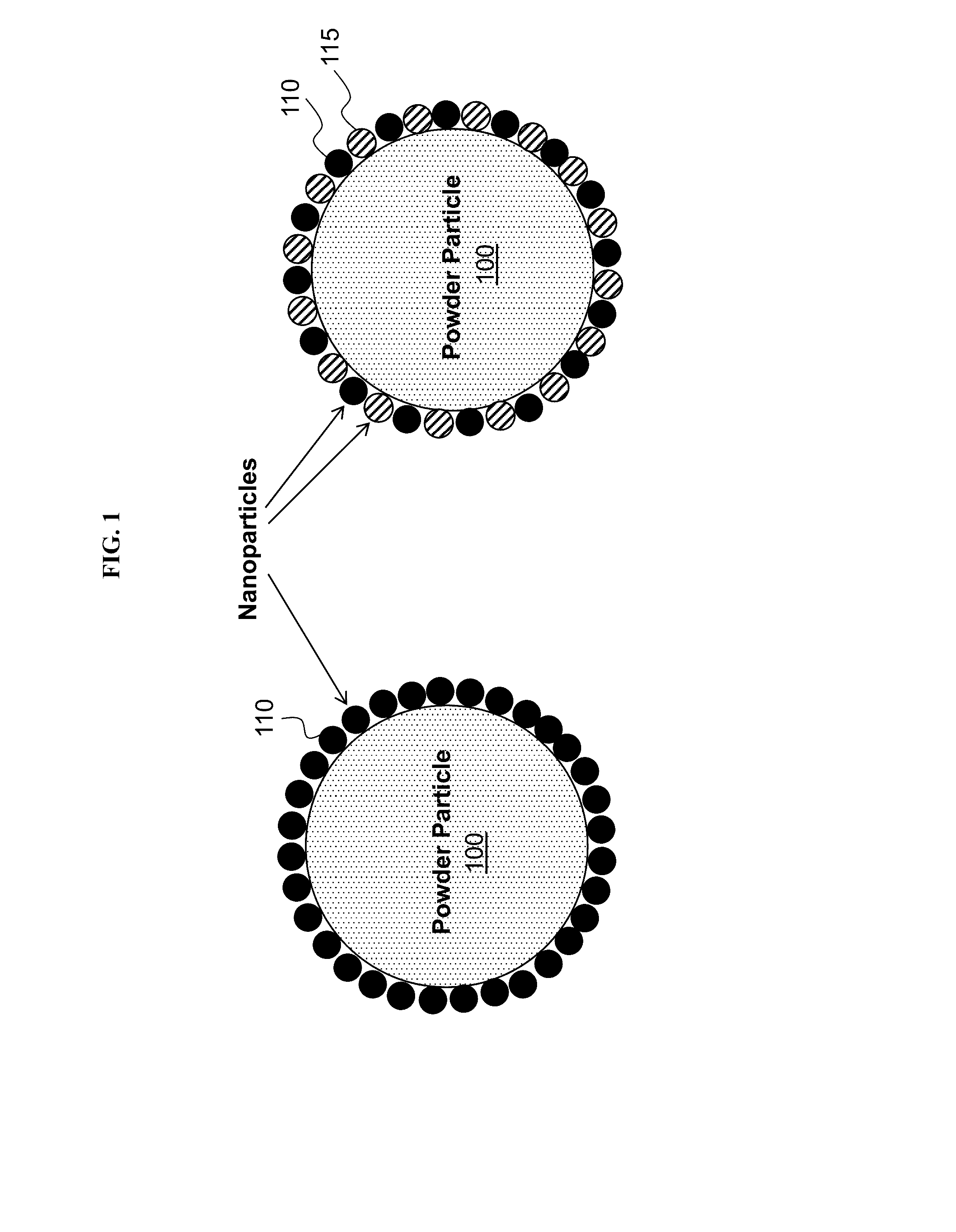

ActiveUS20170021417A1Additive manufacturing apparatusTransportation and packagingNanoparticleLiquid state

Disclosed herein are surface-functionalized powders which alter the solidification of the melted powders. Some variations provide a powdered material comprising a plurality of particles fabricated from a first material, wherein each of the particles has a particle surface area that is continuously or intermittently surface-functionalized with nanoparticles and / or microparticles selected to control solidification of the powdered material from a liquid state to a solid state. Other variations provide a method of controlling solidification of a powdered material, comprising melting at least a portion of the powdered material to a liquid state, and semi-passively controlling solidification of the powdered material from the liquid state to a solid state. Several techniques for semi-passive control are described in detail. The methods may further include creating a structure through one or more techniques selected from additive manufacturing, injection molding, pressing and sintering, capacitive discharge sintering, or spark plasma sintering.

Owner:HRL LAB

Graphene-reinforced titanium-based composite and preparation method thereof

The invention discloses a graphene-reinforced titanium-based composite and a preparation method thereof. The preparation method comprises the following steps: S1, weighing titanium powder and graphene nanoflake and carrying out ultrasonic dispersion; S2, subjecting the titanium powder and graphene nanoflake having undergone mixing and dispersion to ball milling; S3, drying and grinding mixed powder formed after ball milling; S4, putting the mixed powder obtained in the step S3 into a graphite die and placing the graphite die in a spark plasma sintering system; S5, carrying out spark plasma sintering on a compacted powder material in the graphite die; and S6, after completion of sintering, cooling a sintered sample to room temperature in a furnace and taking out the sample. The preparation method prepares the graphene-reinforced titanium-based composite with lightweight and high strength and toughness; and according to the method, ultrasonic dispersion and ball milling technologies are employed for powder mixing, then the composite is prepared from the uniformly mixed powder through spark plasma sintering technology, so the advanced composite with lightweight and high specific strength is obtained.

Owner:SUZHOU UNIV

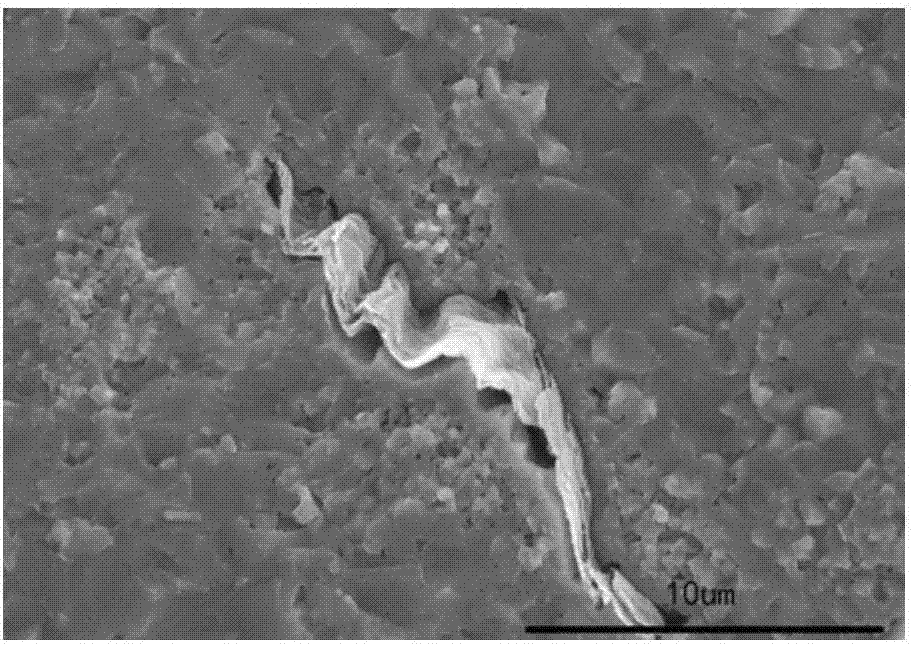

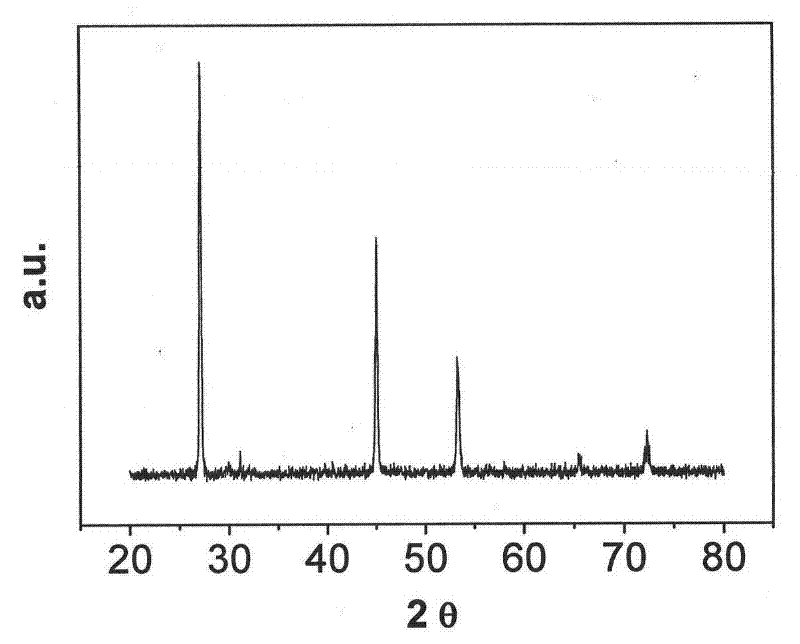

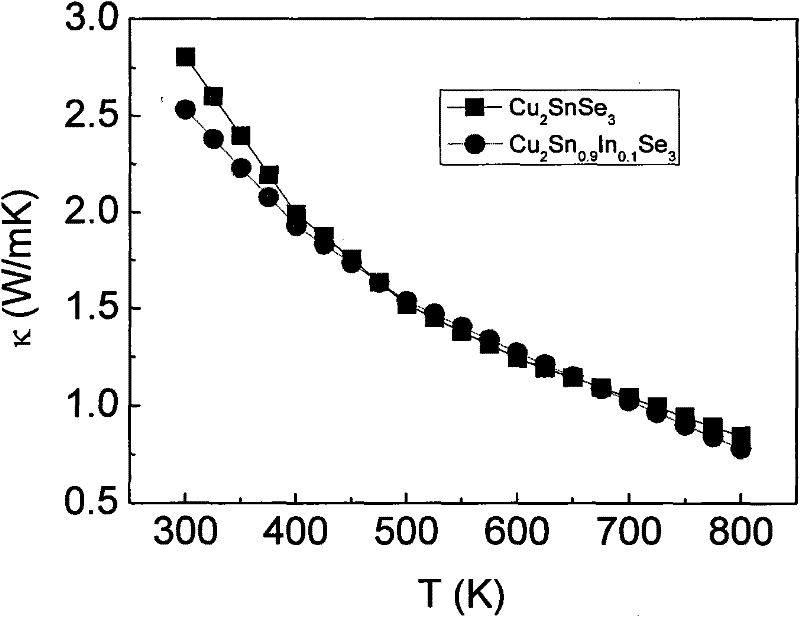

Method for preparing thermoelectric material of ternary diamond structure

ActiveCN102194989AExcellent thermoelectric performanceShort processing timeThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsAdamite

The invention relates to a method for preparing a thermoelectric material of a ternary diamond structure. The method comprises the steps of: raw material preparation, heat-preservation reaction, annealing treatment, spark plasma sintering and the like. In the invention, by applying a fusion-process preparation technology, rapid spark plasma sintering and other methods and controlling technological parameters, the method for preparing the thermoelectric material of the ternary diamond structure is realized and has the advantages of simple and convenient technology, short flow time, high feasibility and good thermoelectric performance, and the thermoelectric material of the ternary diamond structure, prepared with the method provided by the invention, has favorable thermoelectric performance and can be used as a p-type thermoelectric material. The method has the characteristics of simplicity, strong operability, low cost, good industrial prospect and the like.

Owner:中科西卡思(苏州)科技发展有限公司

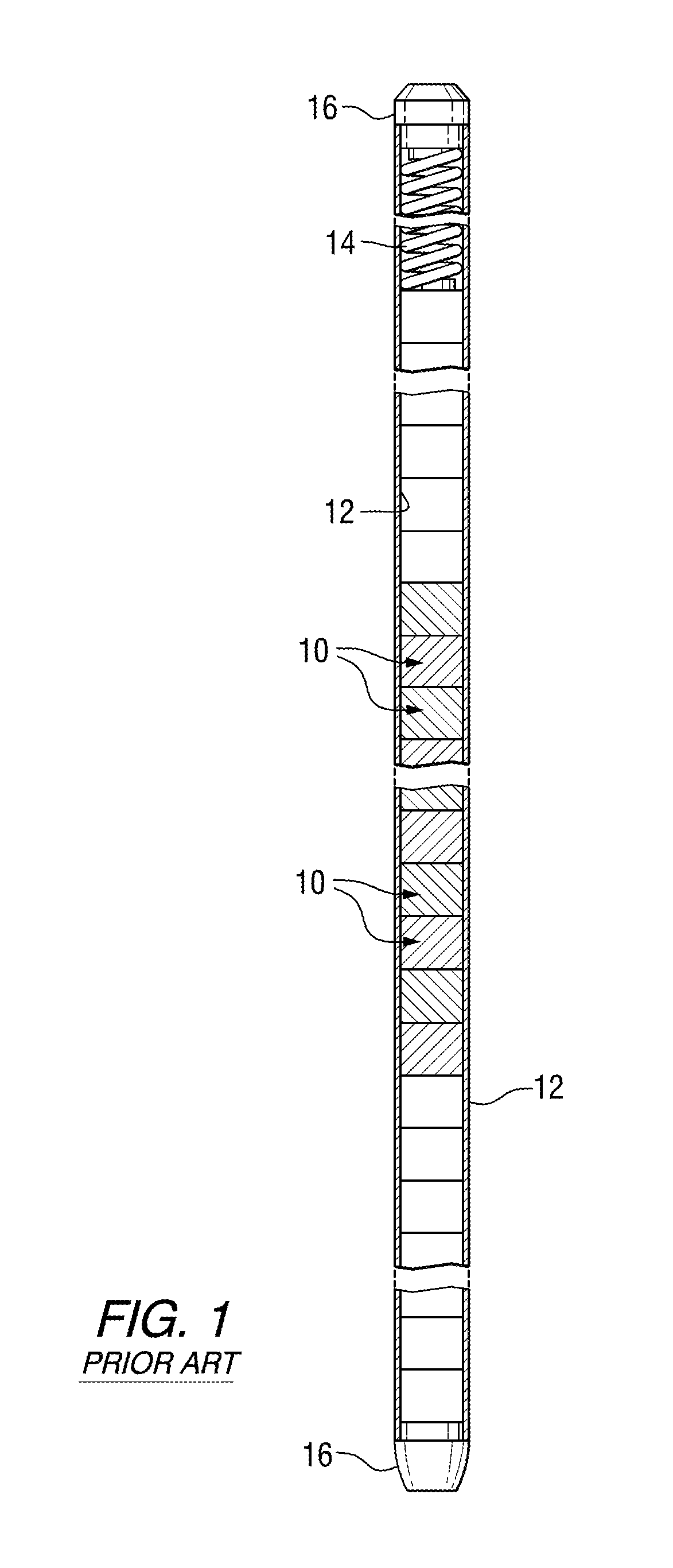

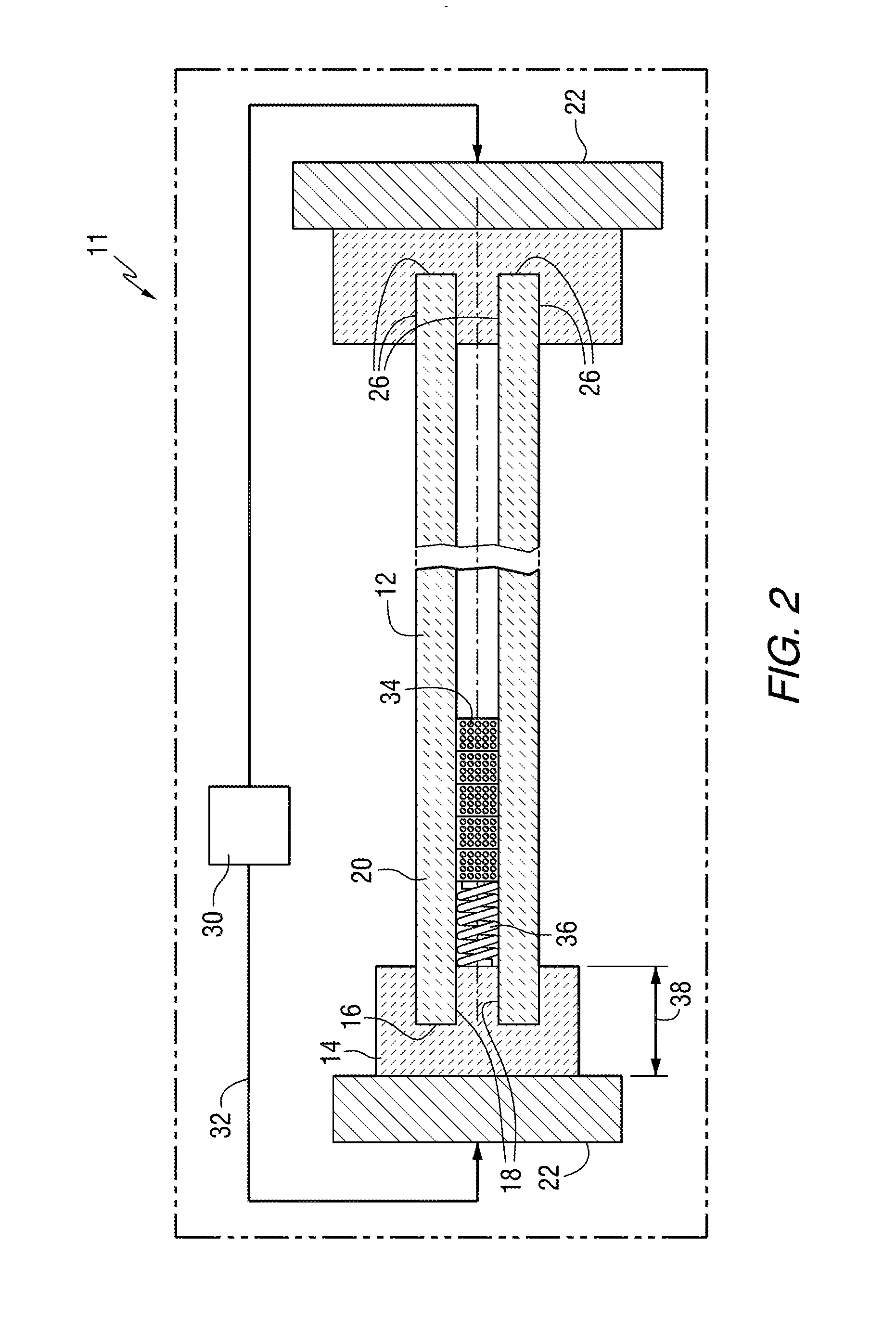

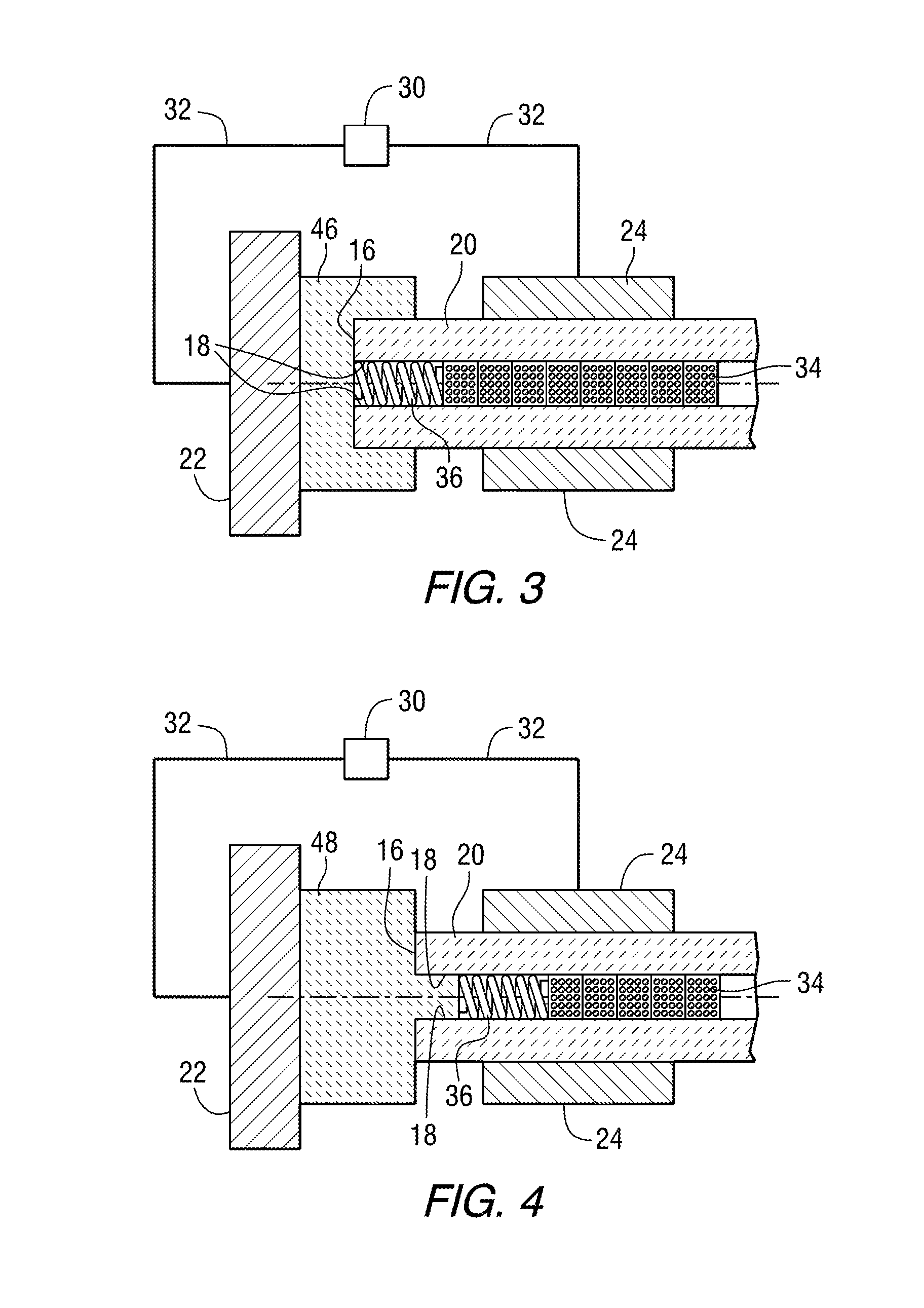

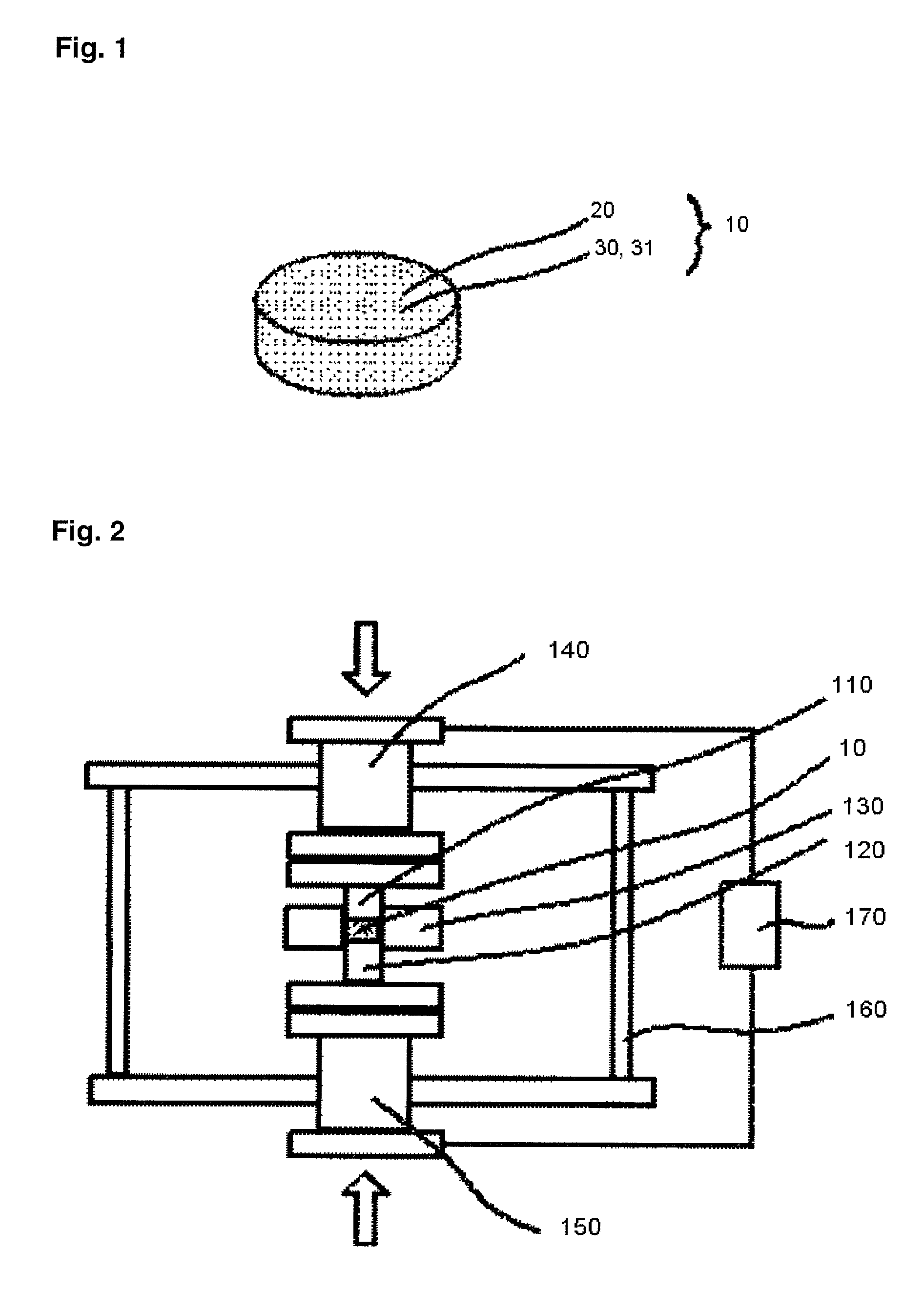

Sic matrix fuel cladding tube with spark plasma sintered end plugs

ActiveUS20150078505A1Increase temperatureResilient to flex and fractureFuel elementsNuclear energy generationCeramic compositeNuclear reactor

A method of providing an end-capped tubular ceramic composite for containing nuclear fuel (34) in a nuclear reactor involves the steps of providing a tubular ceramic composite (40), providing at least one end plug (14, 46, 48), applying (42) the at least one end plug material to the ends of the tubular ceramic composite, applying electrodes to the end plug and tubular ceramic composite and applying current in a plasma sintering means (10, 50) to provide a hermetically sealed tube (52). The invention also provides a sealed tube made by this method.

Owner:WESTINGHOUSE ELECTRIC CORP +1

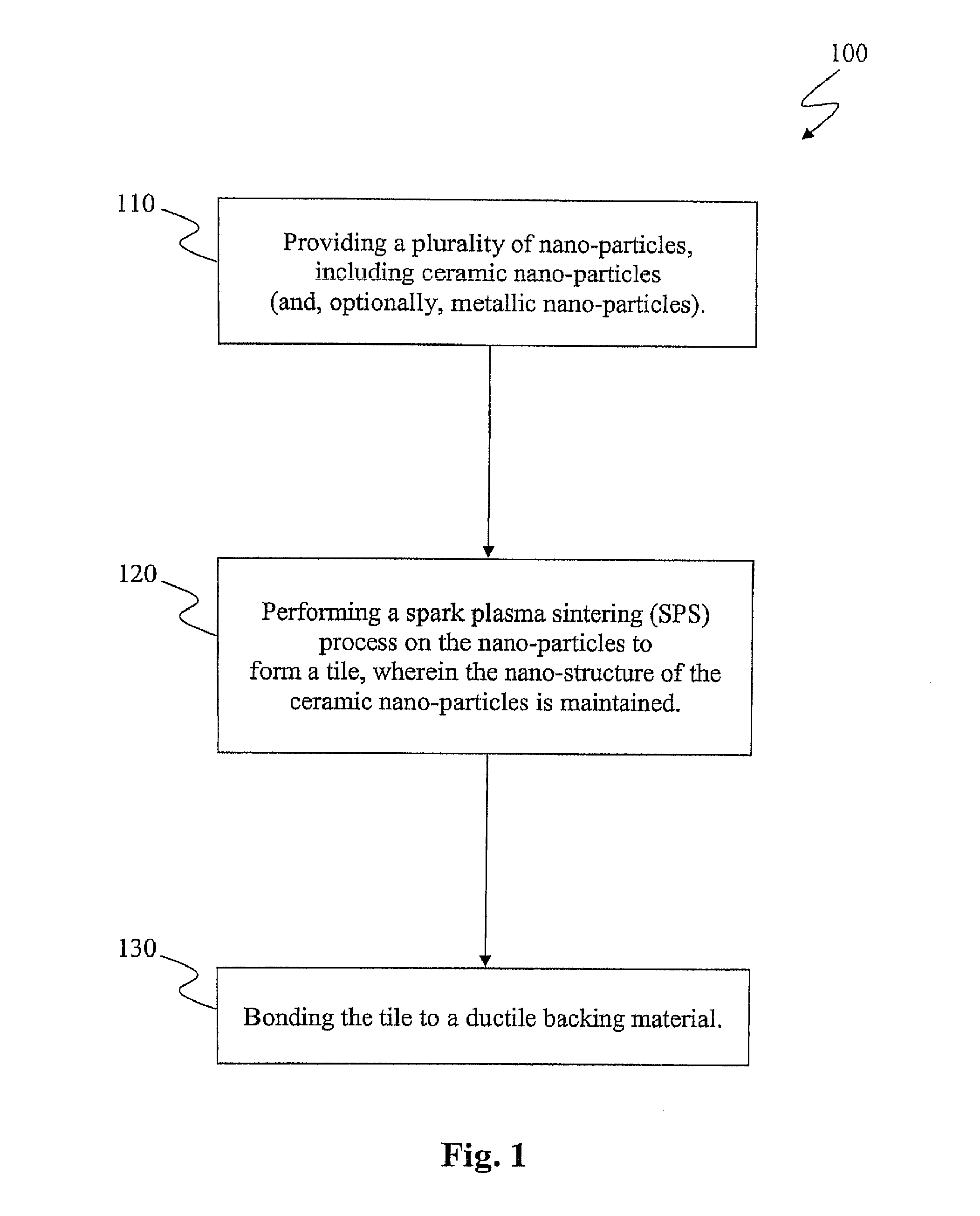

Impact resistant material

A method of making a tile, the method comprising: providing a plurality of nano-particles, wherein the plurality of nano-particles comprises a plurality of ceramic nano-particles; and performing a spark plasma sintering (SPS) process on the plurality of nano-particles, thereby forming a tile comprising the plurality of nano-particles, wherein the nano-structure of the nano-particles is present in the formed tile. In some embodiments, the tile is bonded to a ductile backing material.

Owner:SDC MATERIALS

Phosphor-containing molded member, method of manufacturing the same, and light emitting device having the same

ActiveUS20090072700A1Compounding ratio of a phosphor with respect to a glass powder is highRaise the ratioDischarge tube luminescnet screensLamp detailsPhosphorMetallurgy

Owner:NICHIA CORP

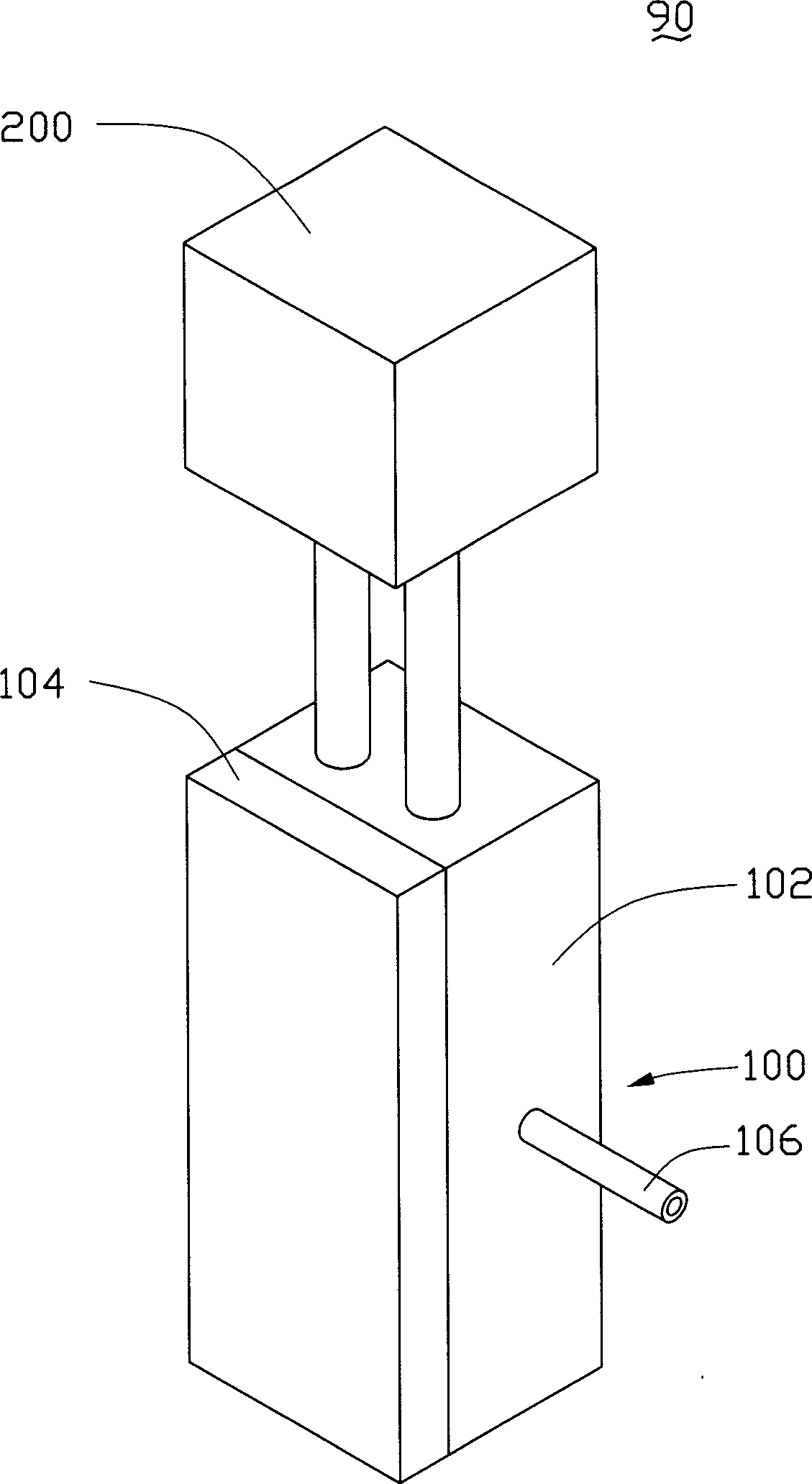

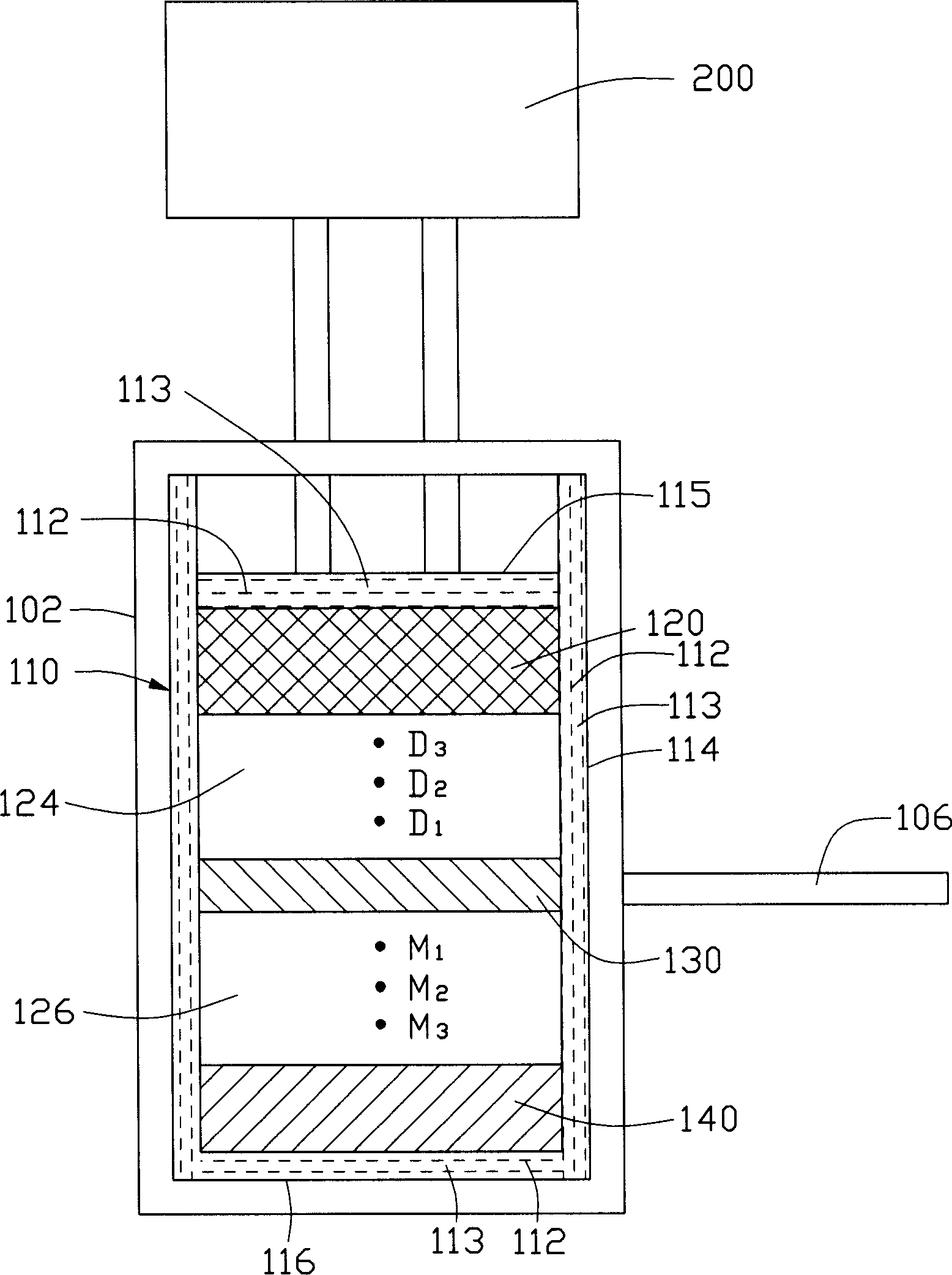

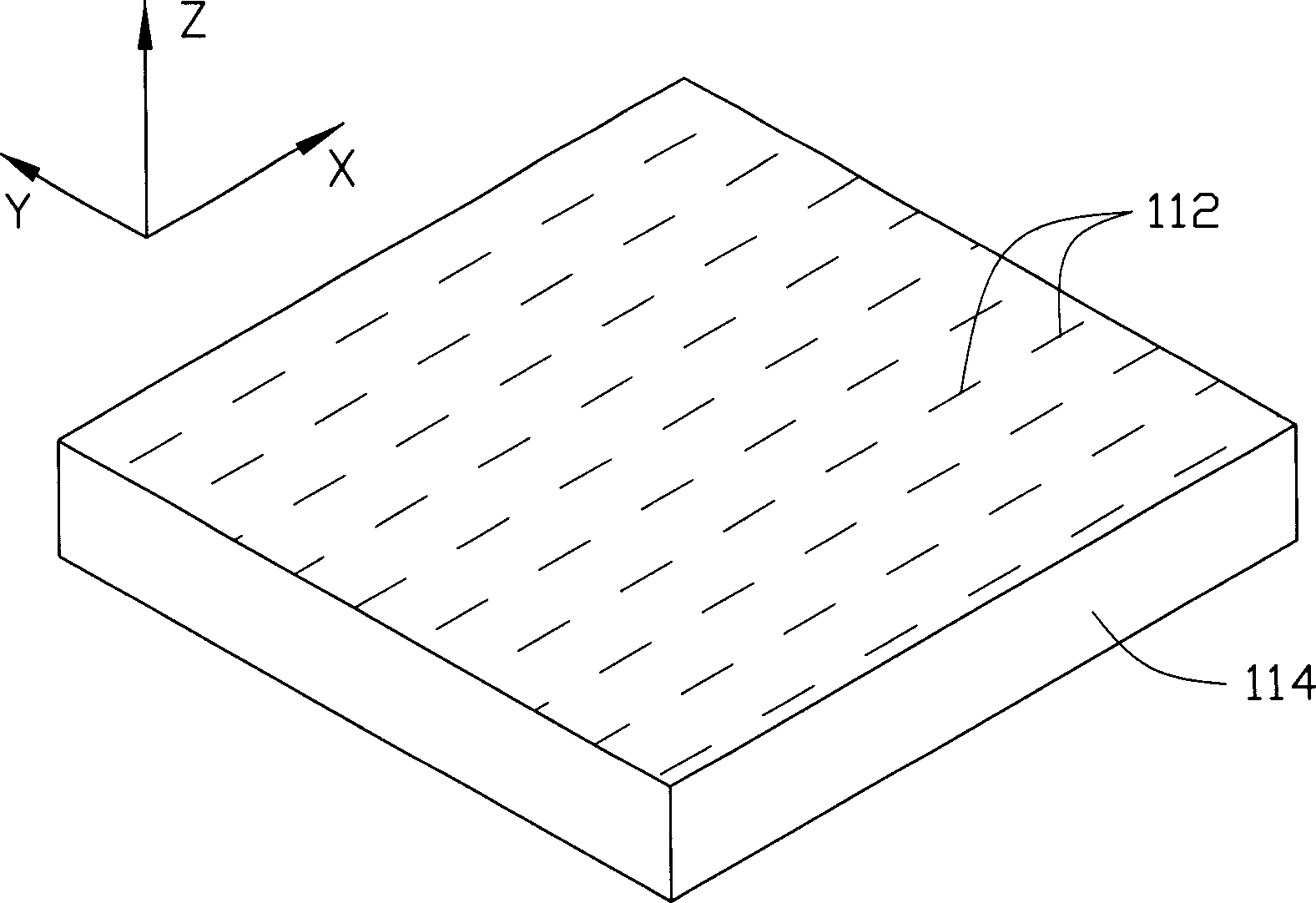

Device for measuring thermal coefficient

InactiveCN1657923AGuaranteed measurementGood insulation performanceMaterial heat developmentMeasurement deviceHeat conducting

The invention discloses a heat conducting coefficient measuring device which consists of a sealed heat insulation device and a vacuum system. The heat insulation device consists of heat source, two metal blocks, samples, a cooling device. The heat insulation device is made by spark-plasma sintering the aluminum oxide ceramic basal material with carbon nanometer tube uniformly arranged in with a intensity of 5 to 10 percent. The carbon nanometer tube distributes along the direction perpendicular to the direction which the heat travels. By pumping out the inner gas with the vacuum system, the adverse effect of the gas is eliminated which the carbon nanometer tube reflect the heat back in consequence that the carbon nanometer tube is radial heat insulation.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

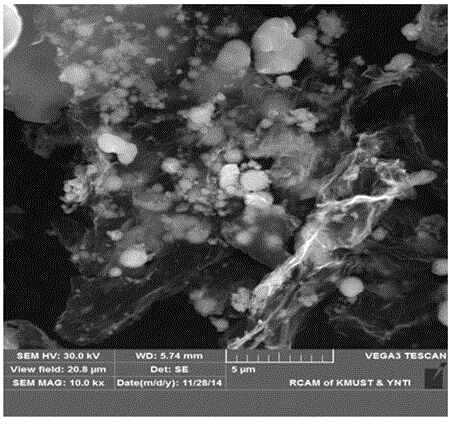

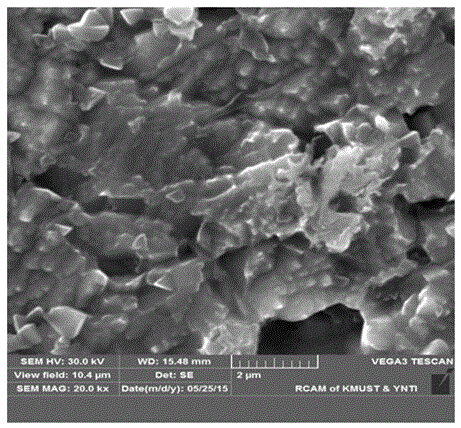

Preparation method of graphene-reinforced copper-based composite

ActiveCN105624445AImprove performanceEasy to organizeTransportation and packagingMetal-working apparatusSlurryCobalt

The invention discloses a preparation method of a graphene-reinforced copper-based composite and belongs to the field of preparation of high-strength and high-conductivity composites. The method comprises steps as follows: graphene, nano copper powder and cobalt powder in the required mass ratio are mixed in absolute ethyl alcohol, the mixture is physically dispersed under electromagnetic stirring, and then physically dispersed mixed slurry is added to a ball milling tank for mechanical ball milling; after evenly mixed slurry is centrifugally dried, obtained mixed powder is annealed and then subjected to hot-pressing SPS (spark plasma sintering) forming; an obtained block blank is annealed and then subjected to hot extrusion, and the graphene-reinforced copper-based composite is obtained. The graphene-reinforced copper-based composite prepared through the method has the good mechanical property, uniform structure and good heat and electricity conductivity.

Owner:KUNMING UNIV OF SCI & TECH

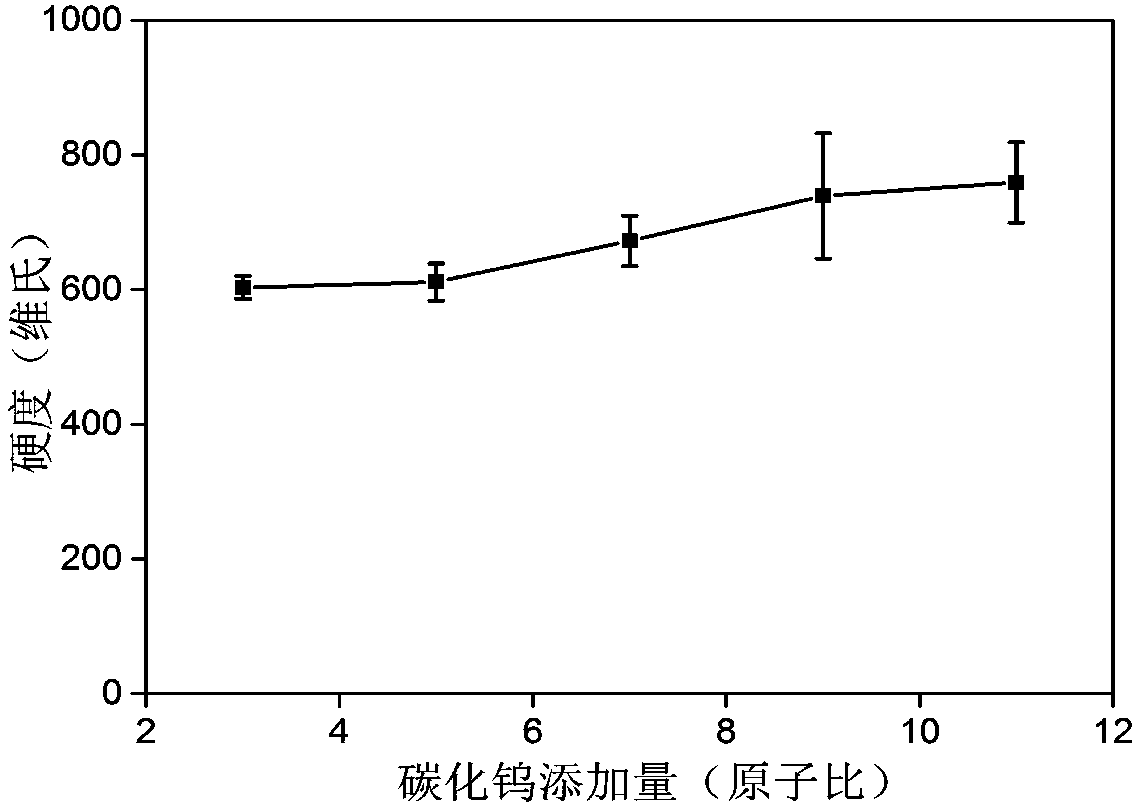

Tungsten carbide particle-enhanced iron-based powder metallurgy material and preparation method thereof

The invention relates to plastic forming technology and powder metallurgy technology, in particular to a tungsten carbide particle-enhanced iron-based powder metallurgy material and a preparation method thereof. According to a specific formula, the iron-based powder metallurgy material comprises the following components in percentage by mass: 85.0 to 90.0 percent of matrix material and 10.0 to 15.0 percent of enhanced phase tungsten carbide, wherein the matrix material comprises the following components in percentage by mass: 1.4 to 2.0 percent of copper, 1.7 to 2.0 percent of nickel, 0.9 to 1.2 percent of molybdenum, 0.7 to 1.6 percent of carbon and the balance of iron. In the invention, quick spark plasma sintering is adopted; and the obtained material has the characteristics of nearly full densification, high hardness, high indoor temperature bending strength, high high-temperature mechanical property and the like, can be used as a wear-resistant material, a tool material and the like, and can reduce the dependency of Chinese tool material production on import of precious metals such as vanadium, chromium and the like. The material has high cost performance and a good industrial production prospect.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing metal reinforced uranium dioxide nuclear fuel pellet

ActiveCN107256726ALow densityHigh strengthNuclear energy generationReactor fuel susbtancesMicro cellTwo step

The invention discloses a method for preparing metal reinforced uranium dioxide nuclear fuel pellets. The method mainly comprises two steps: firstly, preparing core-shell structure granules, namely performing low-temperature rapid pre-sintering on UO2 powder by using a Spark Plasma Sintering SPS technique, pelletizing, balling to obtain UO2 pellets, performing physical mixing on the UO2 pellets with metal (one of Mo, Cr, W and the like) micro powder to coat surfaces of the UO2 pellets by the metal micro powder, thereby obtaining metal coated uranium dioxide core-shell structure granules; secondly, preparing a nuclear fuel pellets, namely performing high-temperature liquidation on the metal powder on the surfaces of the UO2 pellets, thereby forming a micro cell structure continuous phase similar to a cytomembrane structure around the UO2 pellets, and obtaining the special metal reinforced UO2 nuclear fuel pellets with a UO2 substrate.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

NbMoTaW high-entropy alloy, and preparation method thereof

InactiveCN106167870AImprove performanceEliminate composition segregationHigh entropy alloysSolid solution

The invention belongs to the technical field of high-entropy alloy, and discloses a NbMoTaW high-entropy alloy, and a preparation method thereof. According to the preparation method, mechanical alloying and spark plasma sintering are combined for forming, alloying of Nb, Mo, Ta, and W which are high in melting points is realized at solid states, heating to the melting points is not necessary, block materials with excellent performance can be obtained via only one time of solid phase sintering ( the sintering temperature is 1600 DEG C or lower), a difficult problem that the melting temperature (>2900 DEG C) of smelting method is high is solved, processing temperature is reduced greatly, and technology is simplified. According to the microscopic structure of the NbMoTaW high-entropy alloy, dispersion distribution of a granular second phase in an isometric crystal substrate is observed, both the substrate phase and the second phase are BCC solid solution, the substrate average particle size is smaller than 6<mu>m, the second phase average particle size is smaller than 4<mu>m, the material crystal particles are small, the structure is uniform, no dendritic segregation is caused, and strength and hardness are high.

Owner:SOUTH CHINA UNIV OF TECH

High-efficiency soft magnetic composite material and preparation method thereof

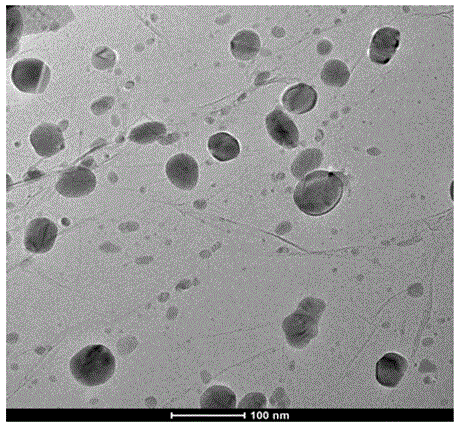

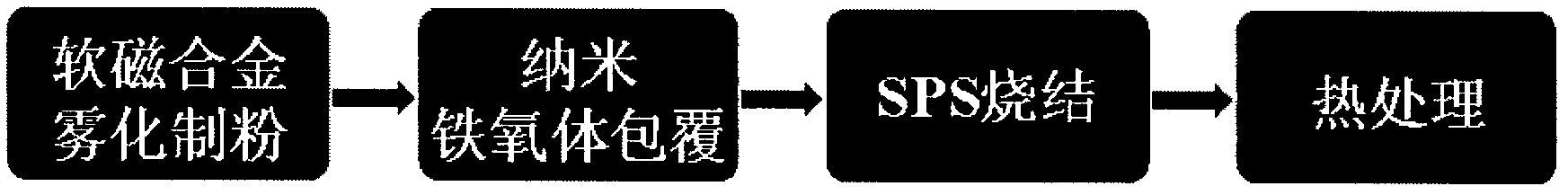

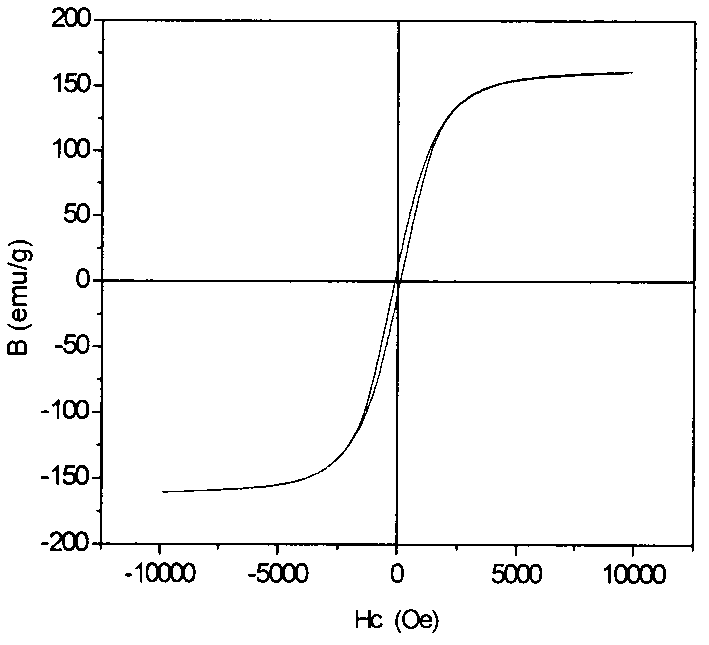

ActiveCN102136331AHigh resistivityHigh saturation magnetic inductionInorganic material magnetismMagnetic phaseAlloy

The invention discloses a high-efficiency soft magnetic composite material and a preparation method thereof. The material is in a nest wall structure composed of soft ferrite of high electrical resistivity; the ferrite in the nest wall structure completely isolates the soft magnetic metal in the nest or an alloy particle soft magnetic phase to cause the soft magnetic metal in the nest or the alloy particle soft magnetic phase to mutually isolate; the content of the soft magnetic metal or the alloy particle is 50-99wt%; and the balance is the soft ferrite. The preparation method comprises the following steps: mixing the soft magnetic metal or alloy particles and the soft ferrite powder at a ratio; causing the soft ferrite powder to completely and evenly coat the surface of the soft magnetic metal or the alloy particles; complexly sintering and shaping by spark plasma sintering densification; and finally, carrying out stress removal annealing heat treatment. The high-efficiency soft magnetic composite material has the characteristics of high-saturation induction density, high resistivity, high magnetic conductivity, low coercive force, low magnetic core loss and excellent comprehensive mechanical property. The high-efficiency soft magnetic composite material can be applied to occasions with higher working efficiency, high magnetic field and high stress. The preparation method issimple and the technological operation is convenient.

Owner:CHANGCHUN UNIV OF TECH

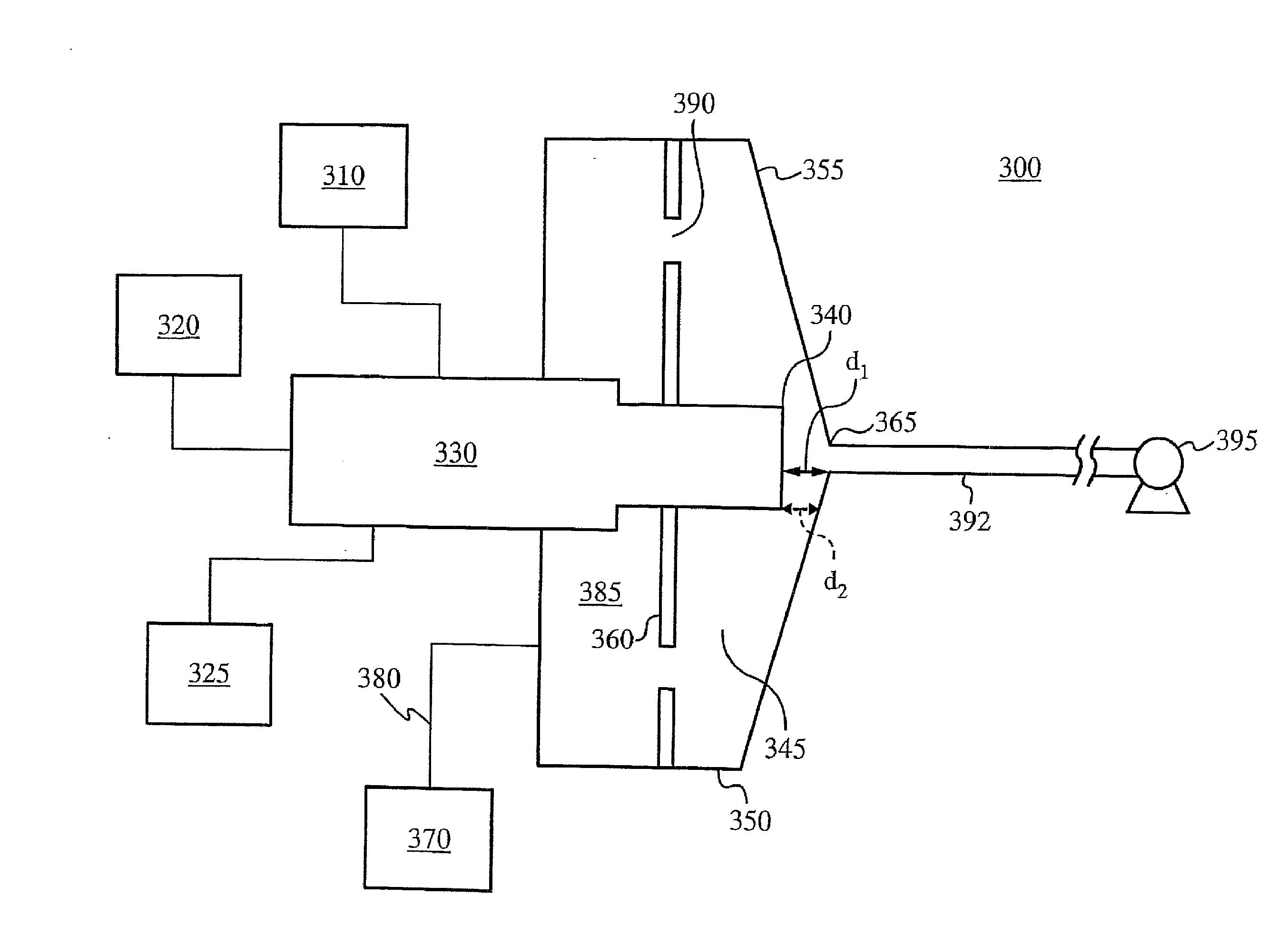

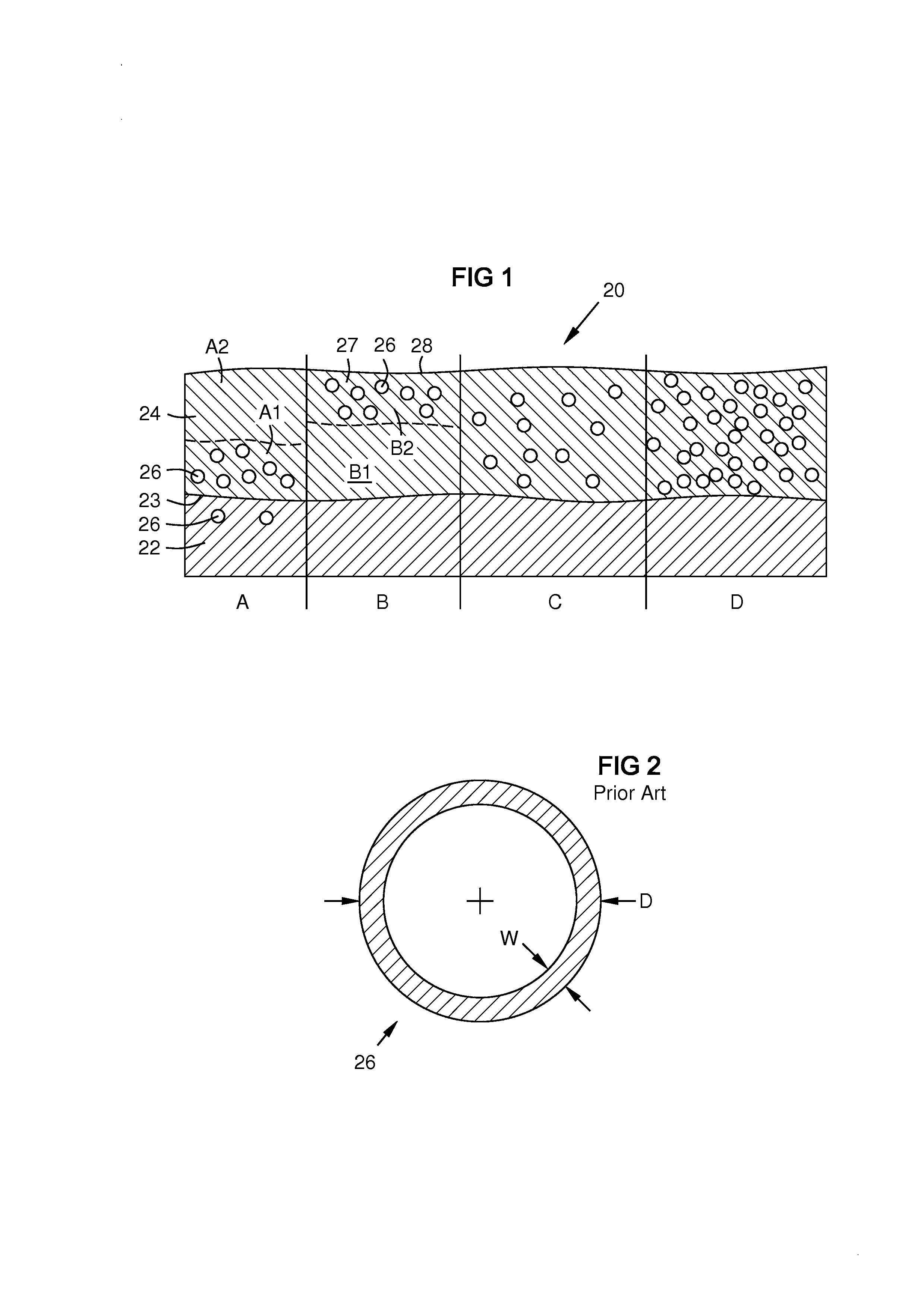

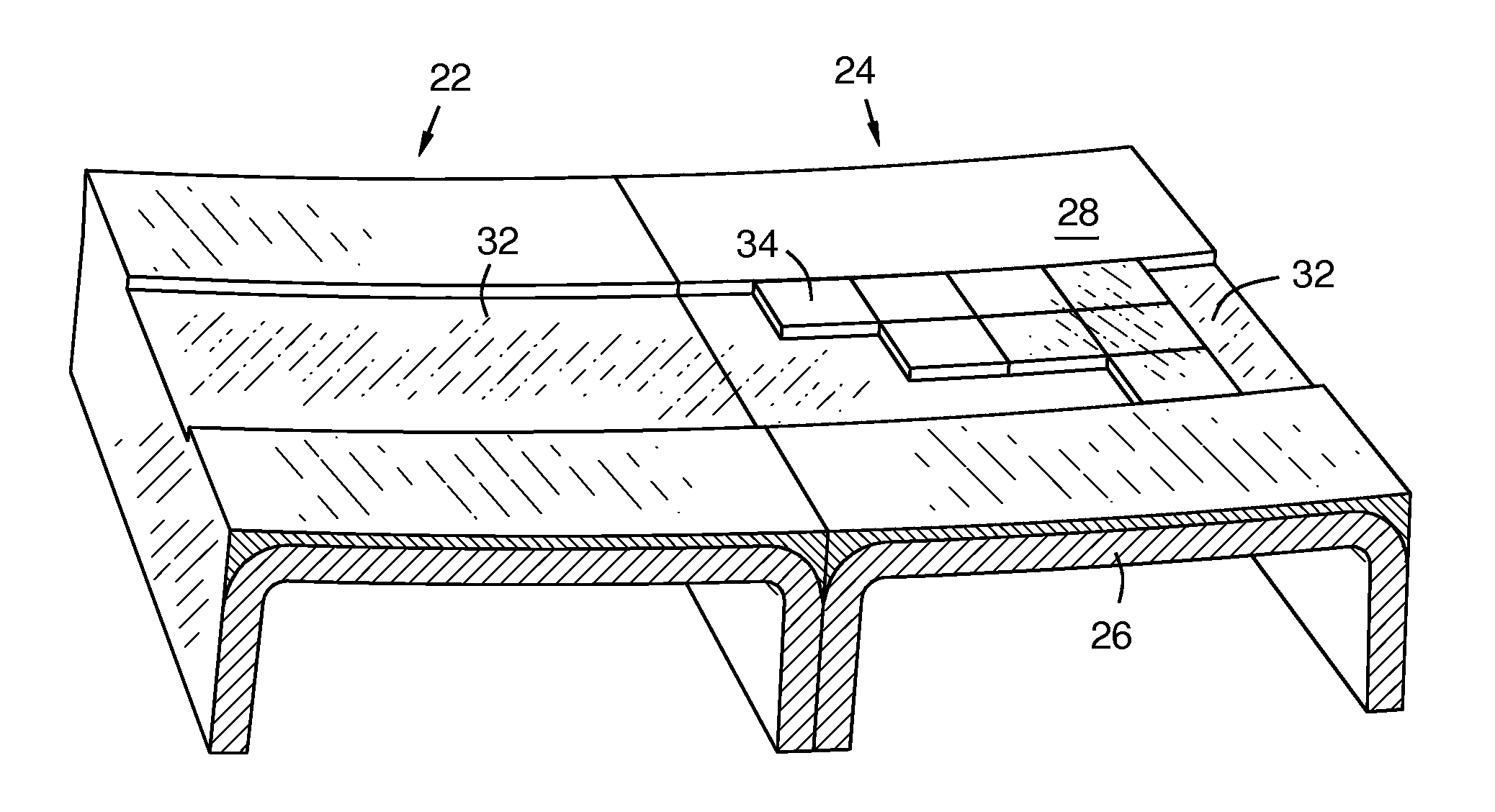

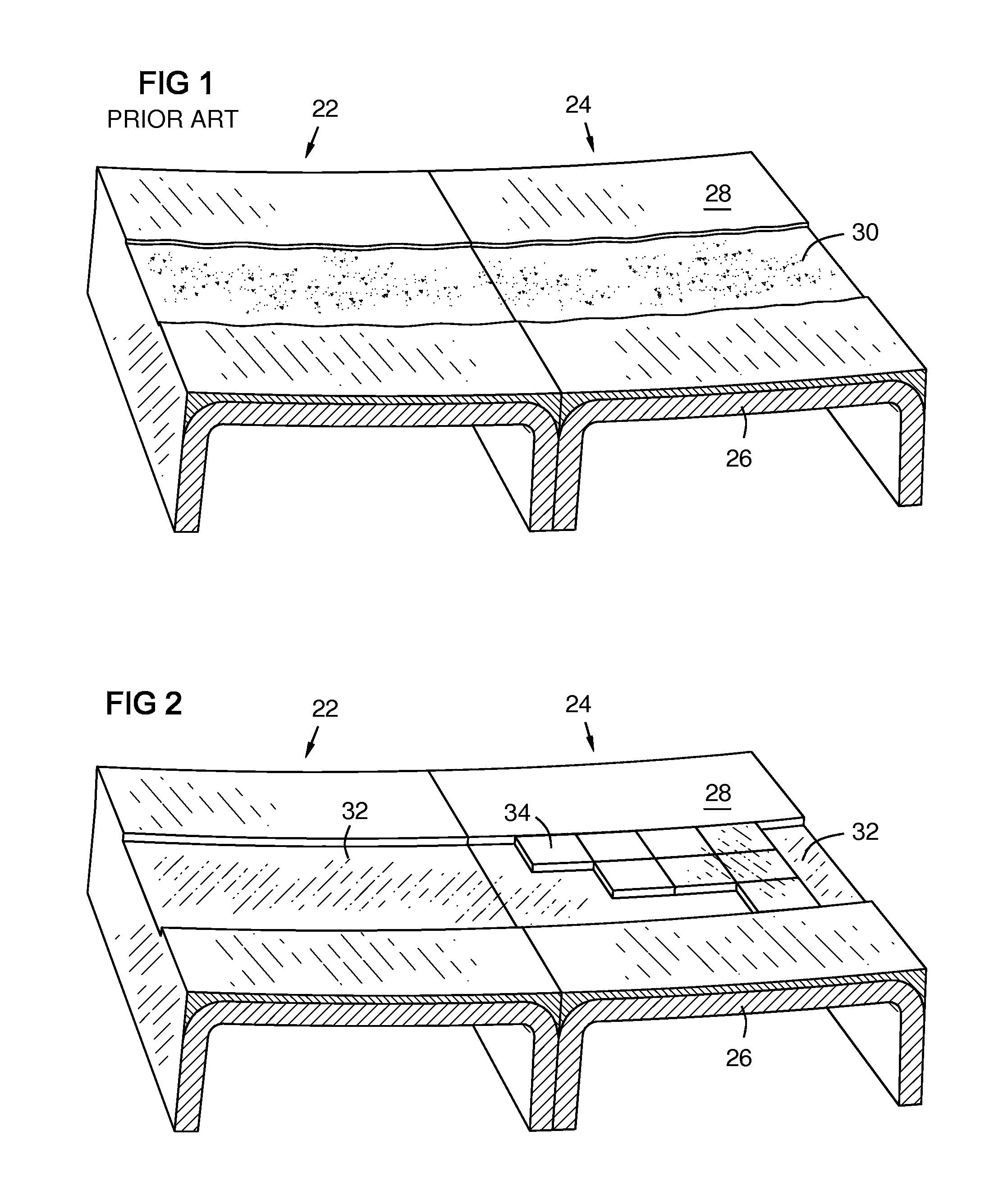

Powder-based material system with stable porosity

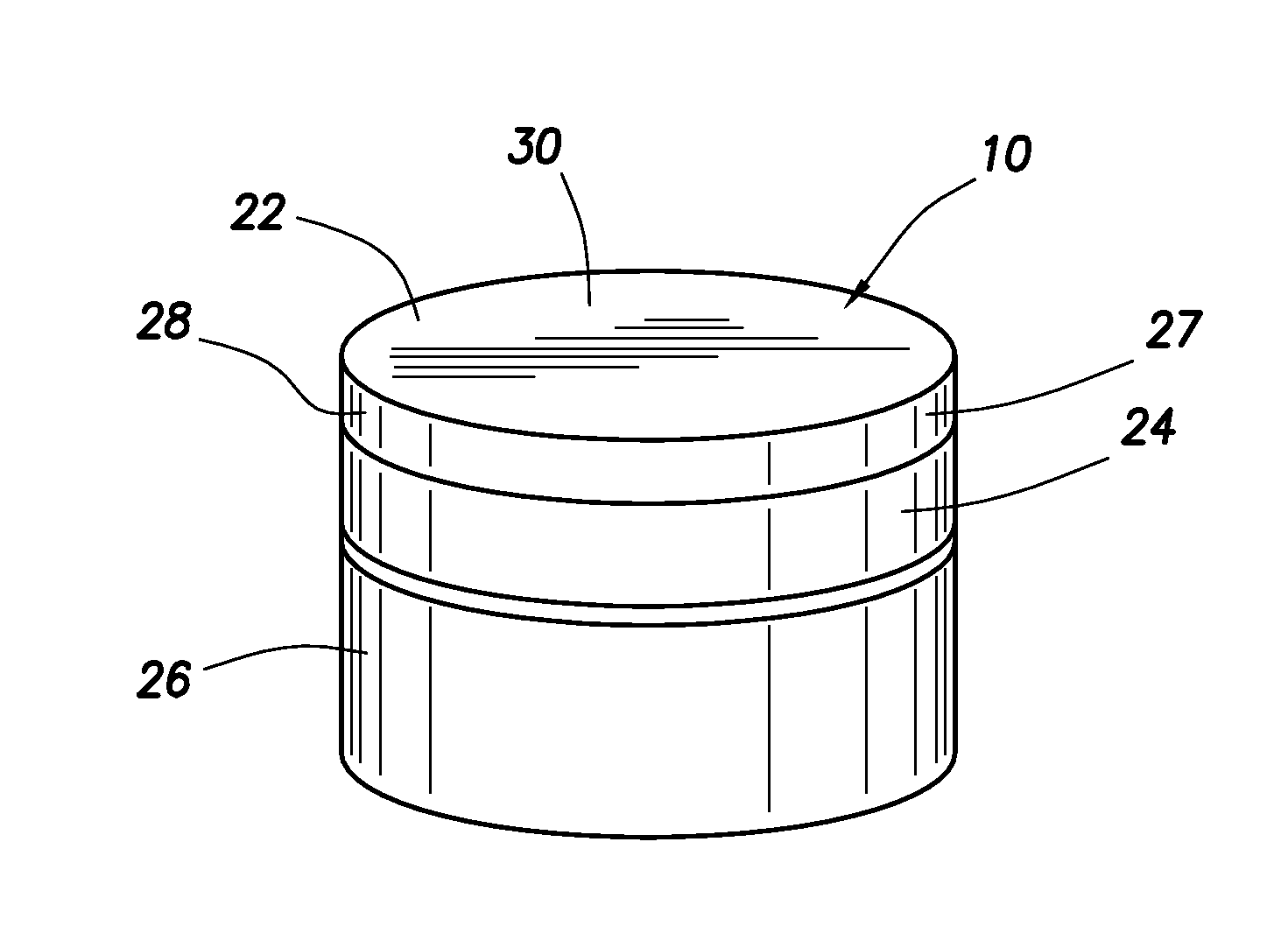

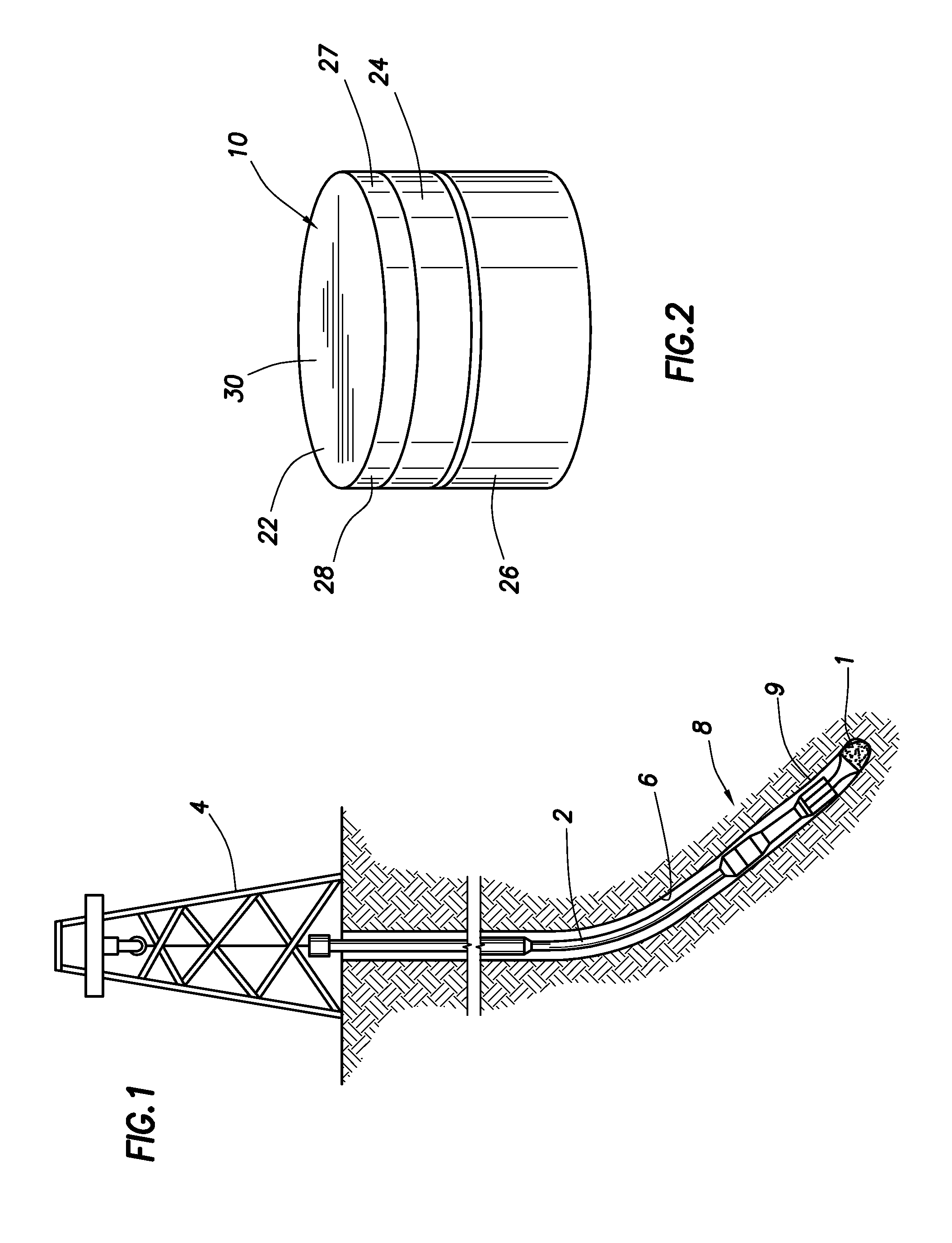

A powder-based material system having an intrinsic and stable degree of porosity provided by hollow ceramic spheres (26) in a fully dense matrix (27). A substrate (22) is formed from a metal powder (70), and may be partially sintered (60). A layer (24) of ceramic powder is arranged on the substrate including the pre-sintered hollow ceramic spheres plus a proportion of nano-sized ceramic particles effective to reduce the layer sintering temperature and to increase the sintering shrinkage of the layer to approximate that of the metal substrate during subsequent co-sintering. The substrate and layer are then co-sintered (61), such as with spark plasma sintering (32, 34, 36), at a temperature and for a duration to fully densify the ceramic powder matrix around the hollow spheres, thereby producing a metal / ceramic material system with low interface stress and with stable porosity during operational temperatures in a gas turbine engine.

Owner:SIEMENS AG

Nano-crystal austenitic metal bulk material having high hardness, high strength and toughness, and method for production thereof

InactiveUS20060127266A1Easy to prepareUltra-fine crystal grain structureTransportation and packagingMetal-working apparatusBorideExplosive forming

The invention provides a high hard, strength and tough nano-crystal metal bulk material and a preparation process thereof. The metal bulk material comprises an aggregate of metal nano-crystal grains, wherein an oxide, nitride, carbide, boride or the like of a metal or semimetal exists as a crystal grain growth inhibitor between and / or in the nano-crystal grains. The respective fine powders of nano-metal bulk material-forming components are mechanically alloyed (MA), using a ball mill or the like, thereby preparing nano-metal powders. Then, hot forming-by-sintering treatment such as spark plasma sintering, extrusion and rolling or explosive forming is applied to the powders to obtain a high hard, strength and tough nano-crystal metal bulk material.

Owner:NANO TECH INST

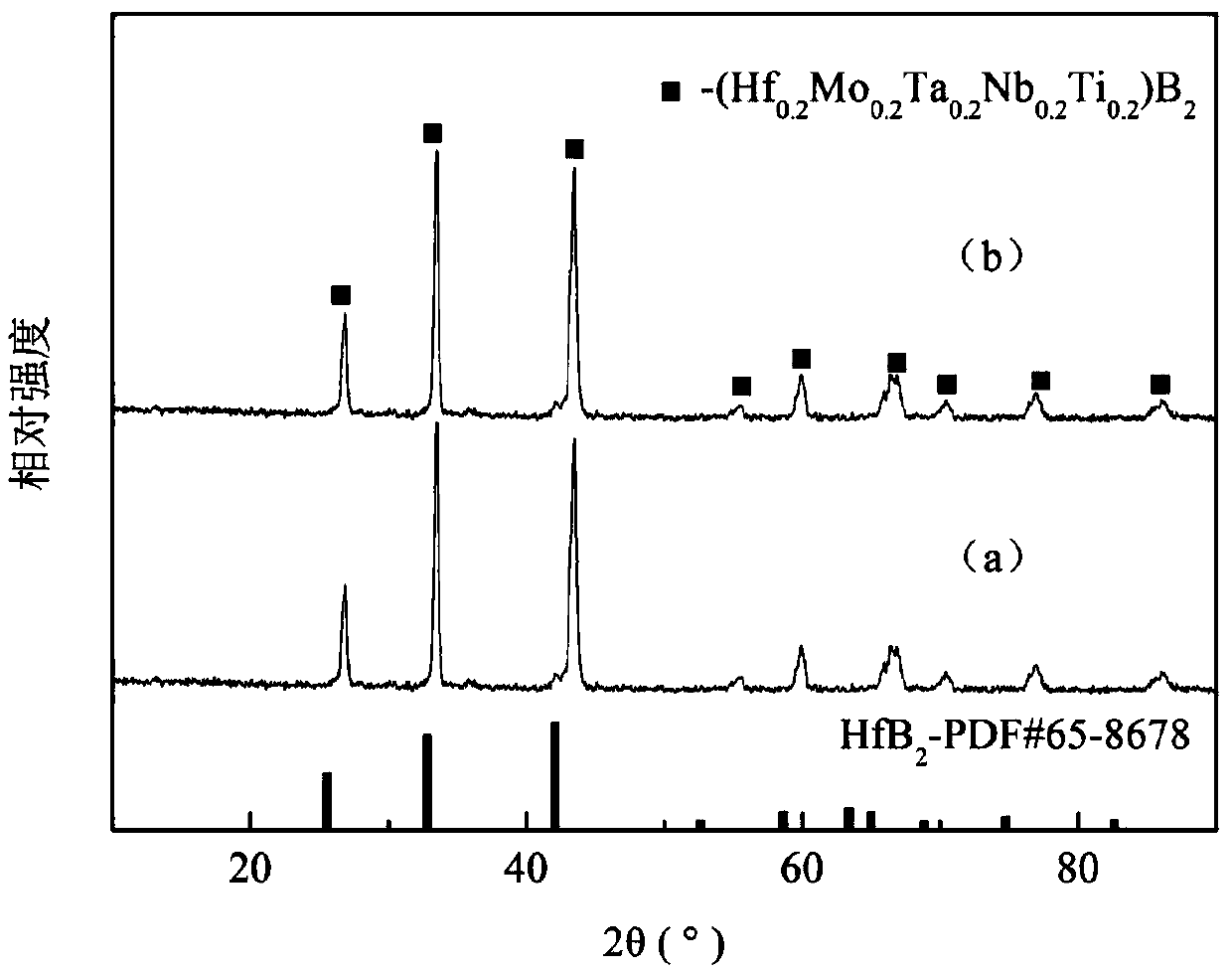

Ceramic with multi-element high entropy as well as preparation method and application of ceramic

The invention belongs to the technical field of ceramic materials and discloses a ceramic with multi-element high entropy as well as a preparation method and application of the ceramic. The ceramic isprepared by the following steps: taking an oxide of Me1, an oxide of Me2, an oxide of Me3, an oxide of Me4, an oxide of Me5 and amorphous boron powder as raw materials, performing ball milling, mixing and pressing into a green body; adding the green body into a graphite crucible, and performing vacuum heat treatment to obtain (Me1xMe2yMe3zMe4nMe5m)B2 solid solution powder; raising the temperatureof the solid solution powder to 1000-1400 DEG C by adopting spark plasma sintering, filling a protective atmosphere, and raising to a temperature of 1800-2200 DEG C for calcining, thereby obtaining the product. The prepared multi-element high-entropy ceramic has the relative density of more than 95%, the hardness of 25-35GPa, the breaking tenacity of 2-8MPa*m1 / 2 and the grain size of 0.1-1.1 microns, and after the heat treatment of 1000-1500 DEG C, the weight change rate is 0.3-1%.

Owner:GUANGDONG UNIV OF TECH

Tenacious metallic nano-crystalline bulk material with high hardness and high strength, and its manufacturing method

InactiveCN1685071AEasy to manufactureApplicable to solidification forming processTransportation and packagingMetal-working apparatusBorideExplosive forming

The invention provides a high hard, strength and tough nano-crystal metal bulk material and a preparation process thereof. The metal bulk material comprises an aggregate of metal nano-crystal grains, wherein an oxide, nitride, carbide, boride or the like of a metal or semimetal exists as a crystal grain growth inhibitor between and / or in the nano-crystal grains. The respective fine powders of nano-metal bulk material-forming components are mechanically alloyed (MA), using a ball mill or the like, thereby preparing nano-metal powders. Then, hot forming-by-sintering treatment such as spark plasma sintering, extrusion and rolling or explosive forming is applied to the powders to obtain a high hard, strength and tough nano-crystal metal bulk material.

Owner:NANO TECH INST

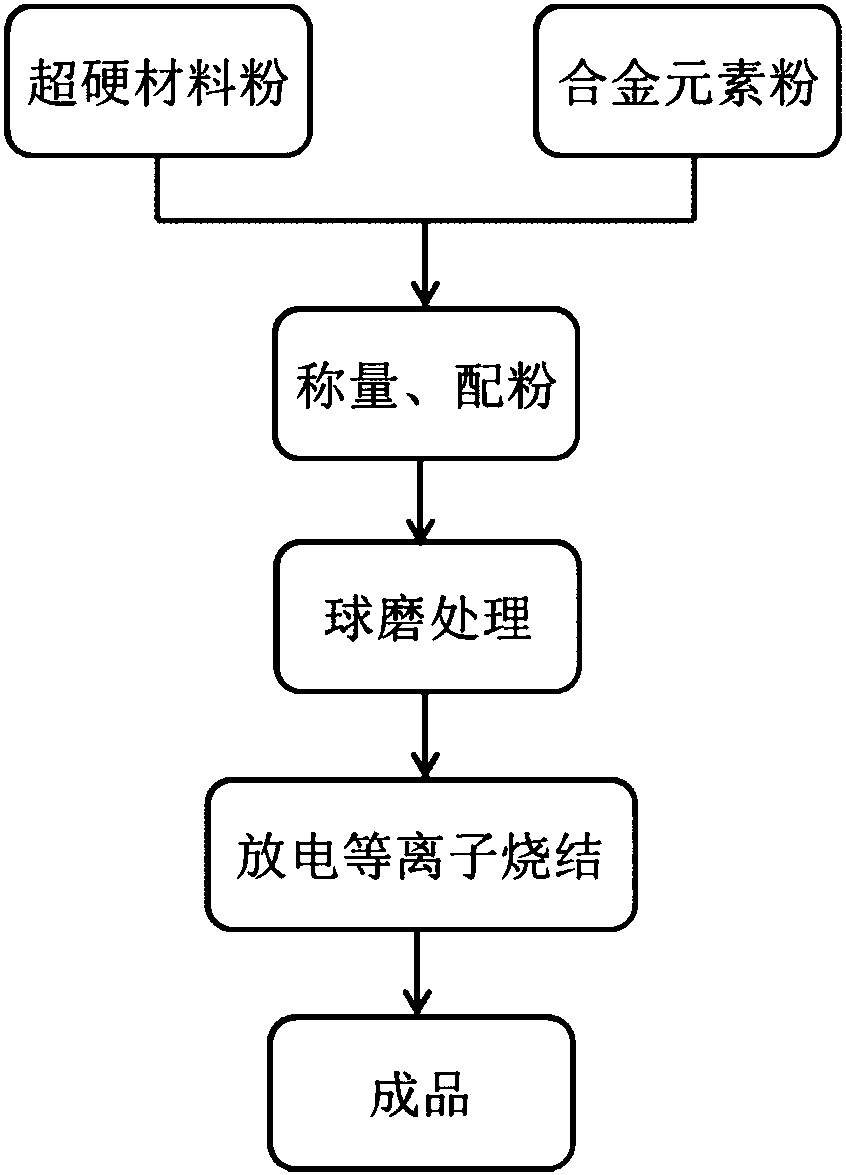

Preparation method for hard high-entropy alloy composite material

The invention discloses a preparation method for a hard high-entropy alloy composite material. The preparation method comprises the following steps that (1) superhard material powder and alloying element powder are selected as raw materials, wherein, the alloying element powder is selected from Fe powder, Co powder, Cr powder, Ni powder, Mn powder, and alloy powder composed of any three or more ofthe foregoing elements; the superhard material powder is selected from one or more of WC alloy powder, BN powder, and diamond powder; (2) the raw materials selected in step (1) is subjected to ball milling to obtain fine-grained powder; and (3) the fine-grained powder is subjected to spark plasma sintering and furnace cooling, and a agglomerate body is the hard high-entropy alloy composite material. According to the preparation method for the hard high-entropy alloy composite material, high-entropy alloys with excellent plasticity such as Fe, Co, Cr, Ni and Mn are adopted as matrices, and superhard particles such as WC and cubic BN are added as reinforcing phases, so that high hardness of products can be obtained, and the cost of hard high-entropy raw materials and the density and the preparation difficulty of products are reduced.

Owner:中科粉研(河南)超硬材料有限公司

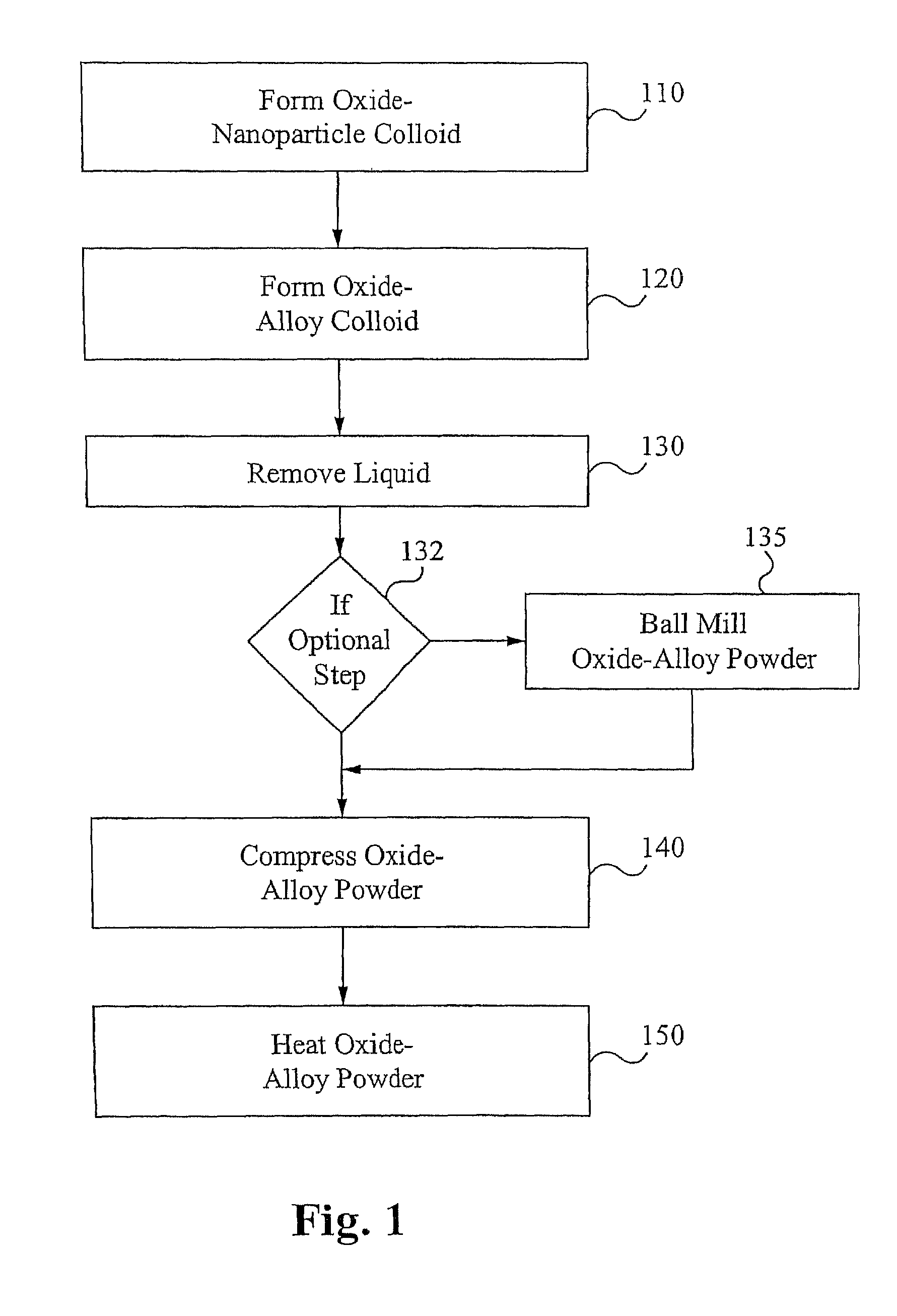

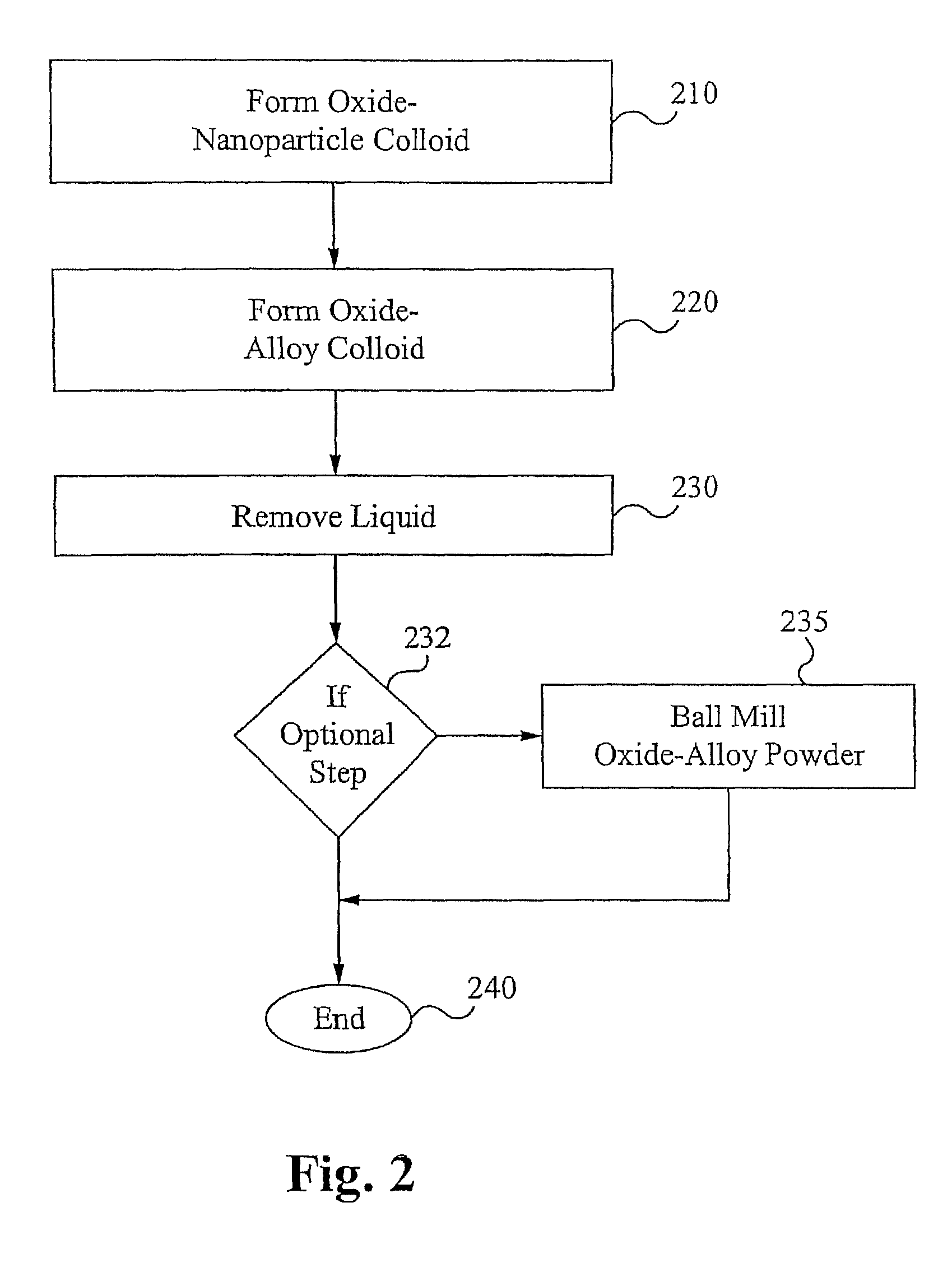

Method of forming oxide dispersion strengthened alloys

ActiveUS8821786B1Optimize allocationMaterial nanotechnologyMolten spray coatingNanoparticleOxide dispersion-strengthened alloy

A method of forming an oxide-dispersion strengthened alloy and a method for forming an oxide-alloy powder where the oxide-nanoparticles are evenly distributed throughout the powder. The method is comprised of the steps of forming an oxide-nanoparticles colloid, mixing the oxide-nanoparticles colloid with alloy-microparticles forming an oxide-alloy colloid, drying the oxide-alloy colloid solution to form an oxide-alloy powder, applying pressure to the oxide-alloy powder, and heating the oxide-alloy powder to a sintering temperature. The oxide-nanoparticles are sized to be between 1-10 nanometers in diameter. The ratio of oxide-nanoparticles to alloy-microparticles should be 1-5% by weight. Heating of the oxide-alloy powder can use a spark plasma sintering process.

Owner:SDC MATERIALS +1

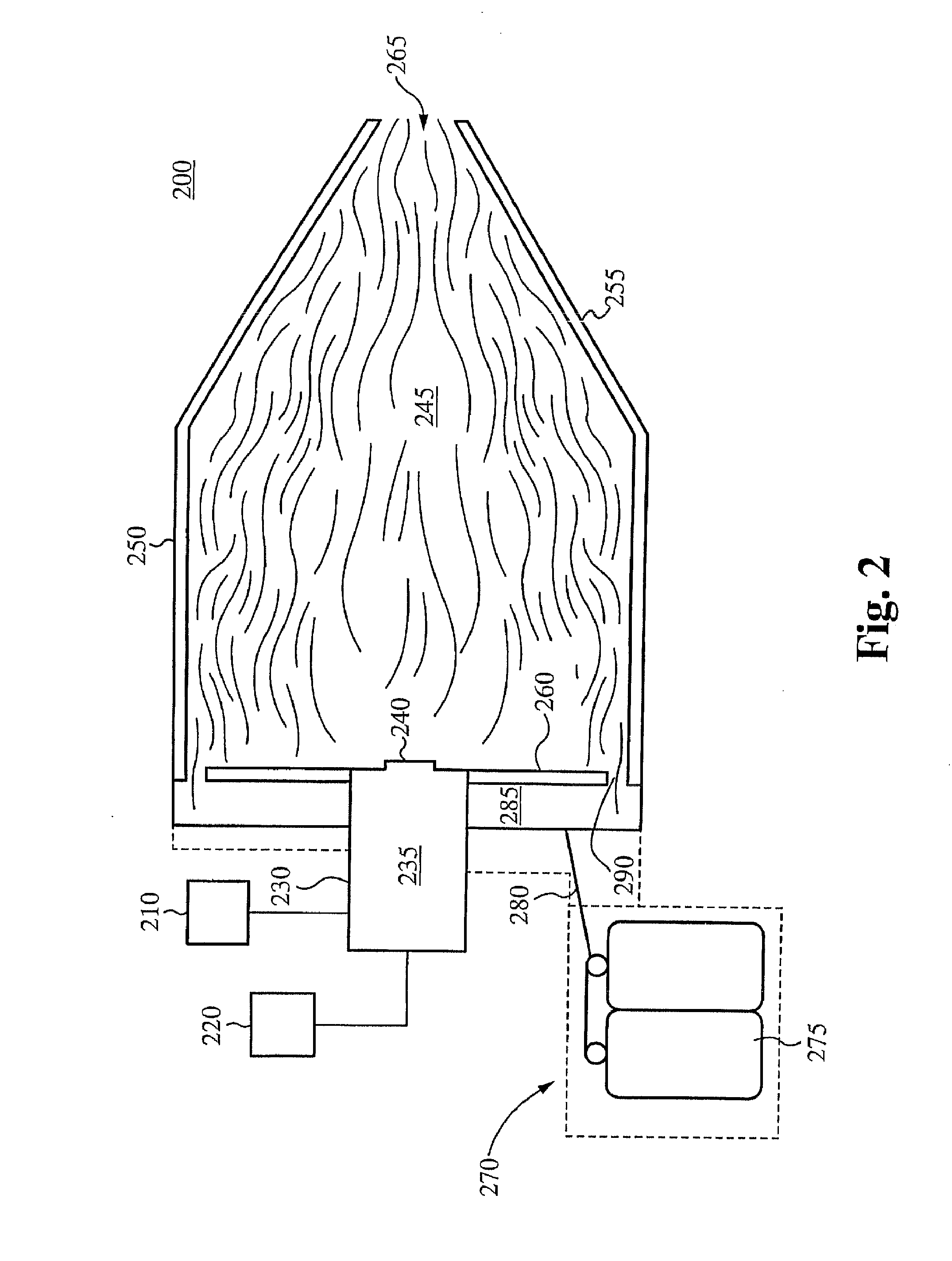

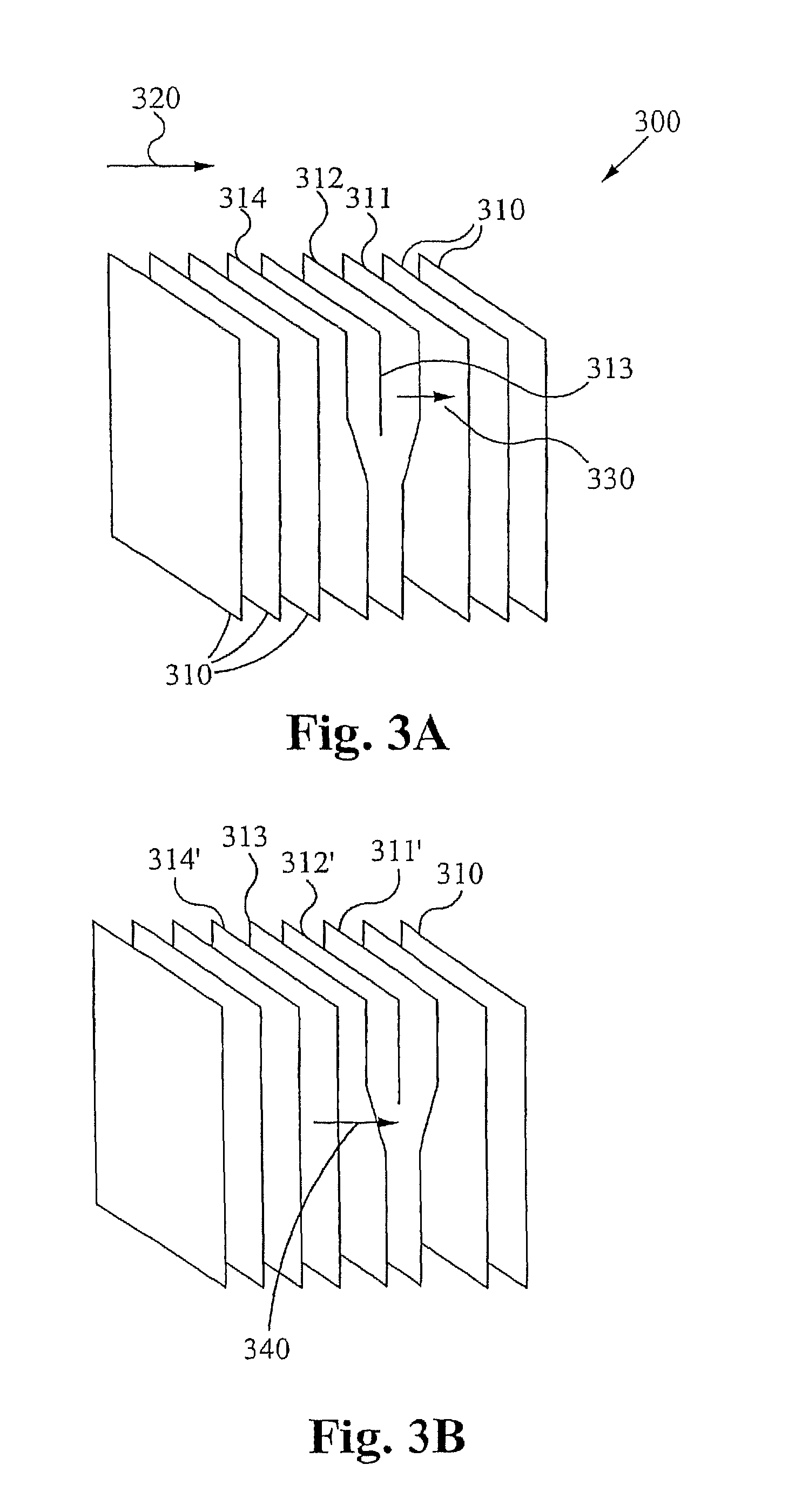

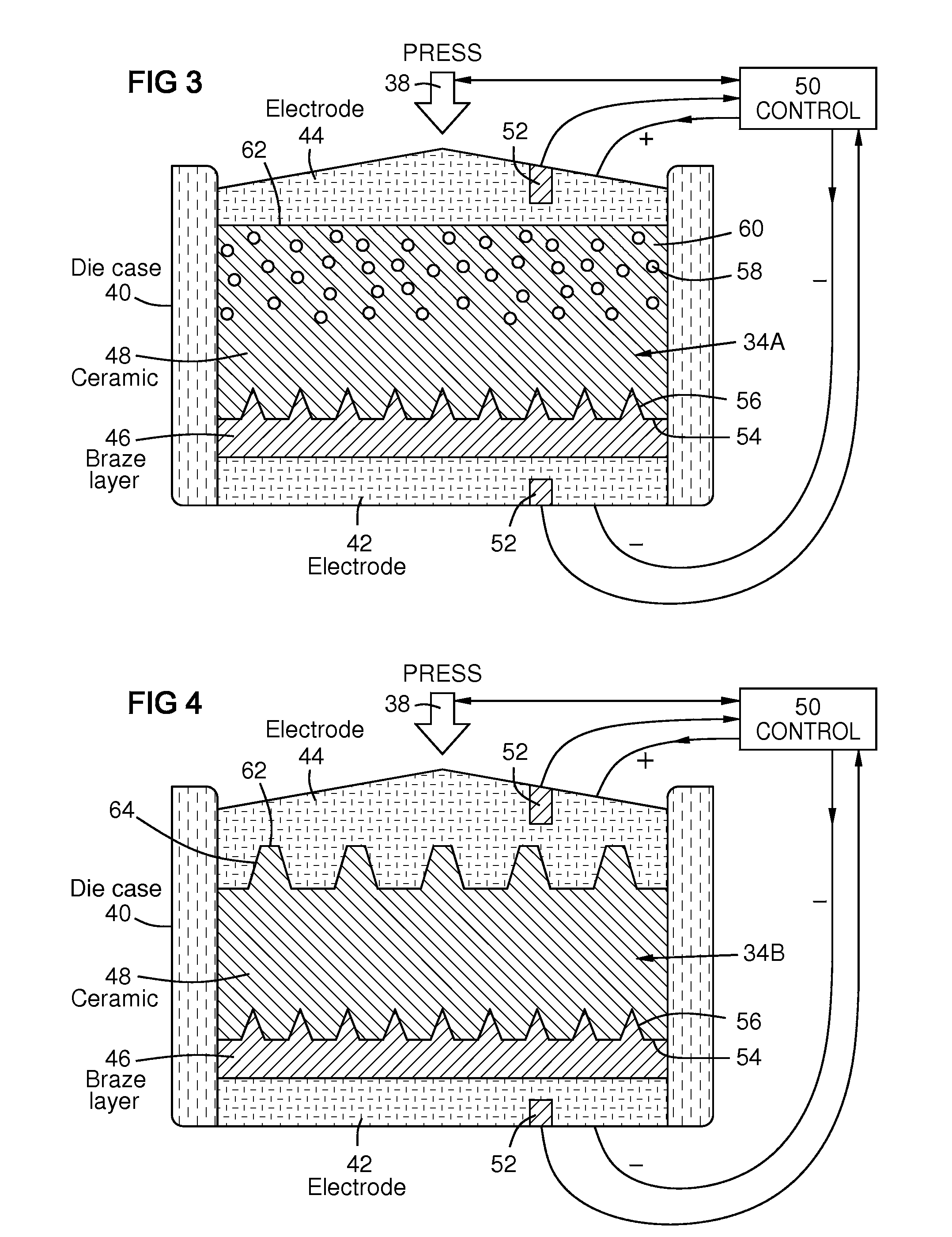

Method and apparatus for fabrication and repair of thermal barriers

A thermal barrier tile (34) with a braze layer (46) co-sintered to a ceramic layer (48) is brazed to a substrate (26) of a component for fabrication or repair of a thermal barrier coating (28) for example on a gas turbine ring segment (22, 24). The tile may be fabricated by disposing a first layer of a metal brazing material in a die case (40); disposing a second layer of a ceramic powder on the metal brazing material; and co-sintering the two layers with spark plasma sintering to form the co-sintered ceramic / metal tile. A material property of an existing thermal barrier coating to be repaired may be determined (90), and the co-sintering may be controlled (93) responsive to the property to produce tiles compatible with the existing thermal barrier coating in a material property such as thermal conductivity.

Owner:SIEMENS ENERGY INC

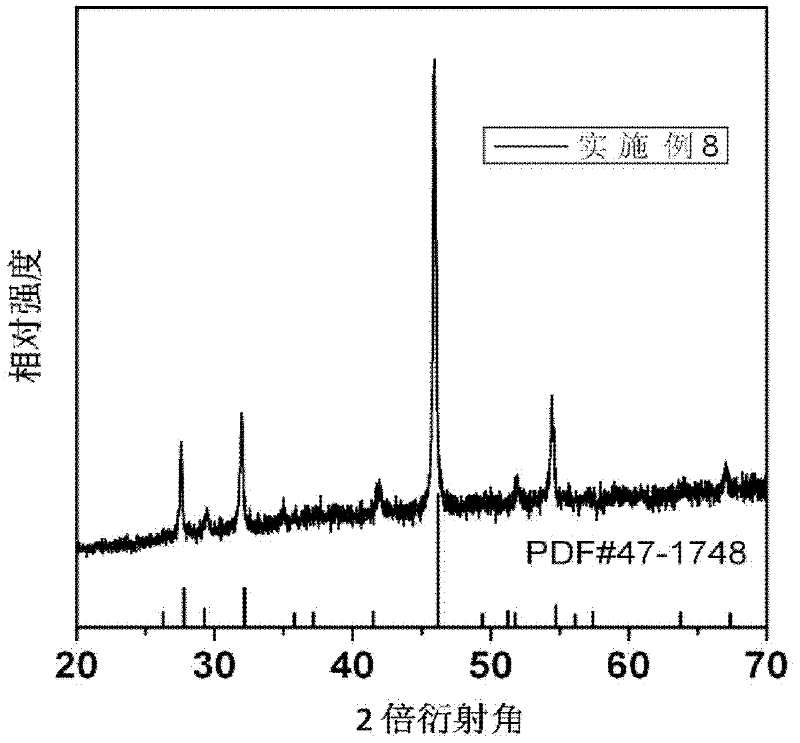

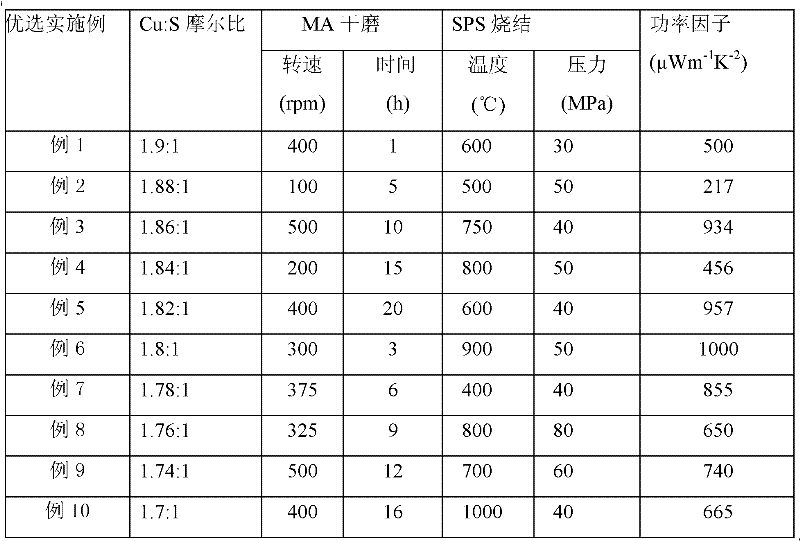

Preparation method of Cu1.8+xS binary thermoelectric material

InactiveCN102363530AShort preparation processShort timeNanotechnologyCopper sulfidesThermoelectric materialsSulfur

A preparation method of a Cu1.8+xS binary thermoelectric material belongs to the technical field of energy materials, and is characterized by comprising the following steps of: using an elemental copper powder (its mass fraction is greater than 99.9%) and an elemental sulfur powder (its mass fraction is greater than 99.8%) as raw materials, preparing a compound powder by a mechanical alloying method according to the ratio of Cu1.8+xS (x is less than or equal to 0.1 and greater than or equal to minus 0.1), and preparing the Cu1.8+xS bulk thermoelectric material which has a rhombohedral structure at room temperature by the adoption of a spark plasma sintering technology. The thermoelectric material has high conductivity and good mechanical properties. The raw materials required by the preparation method are cheap and easily available. The preparation method has advantages of no pollution and short technological process, and is convenient and fast.

Owner:UNIV OF SCI & TECH BEIJING

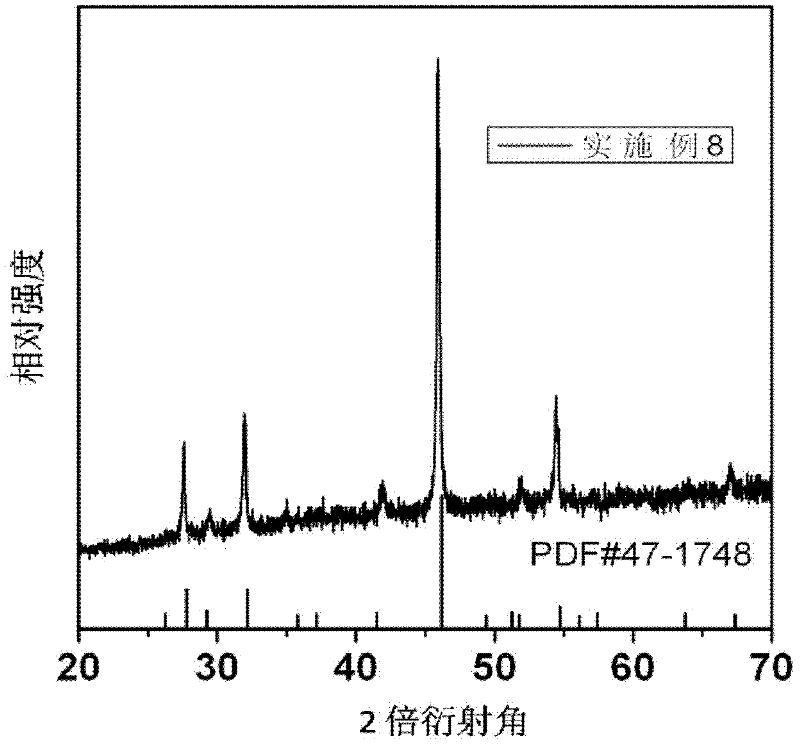

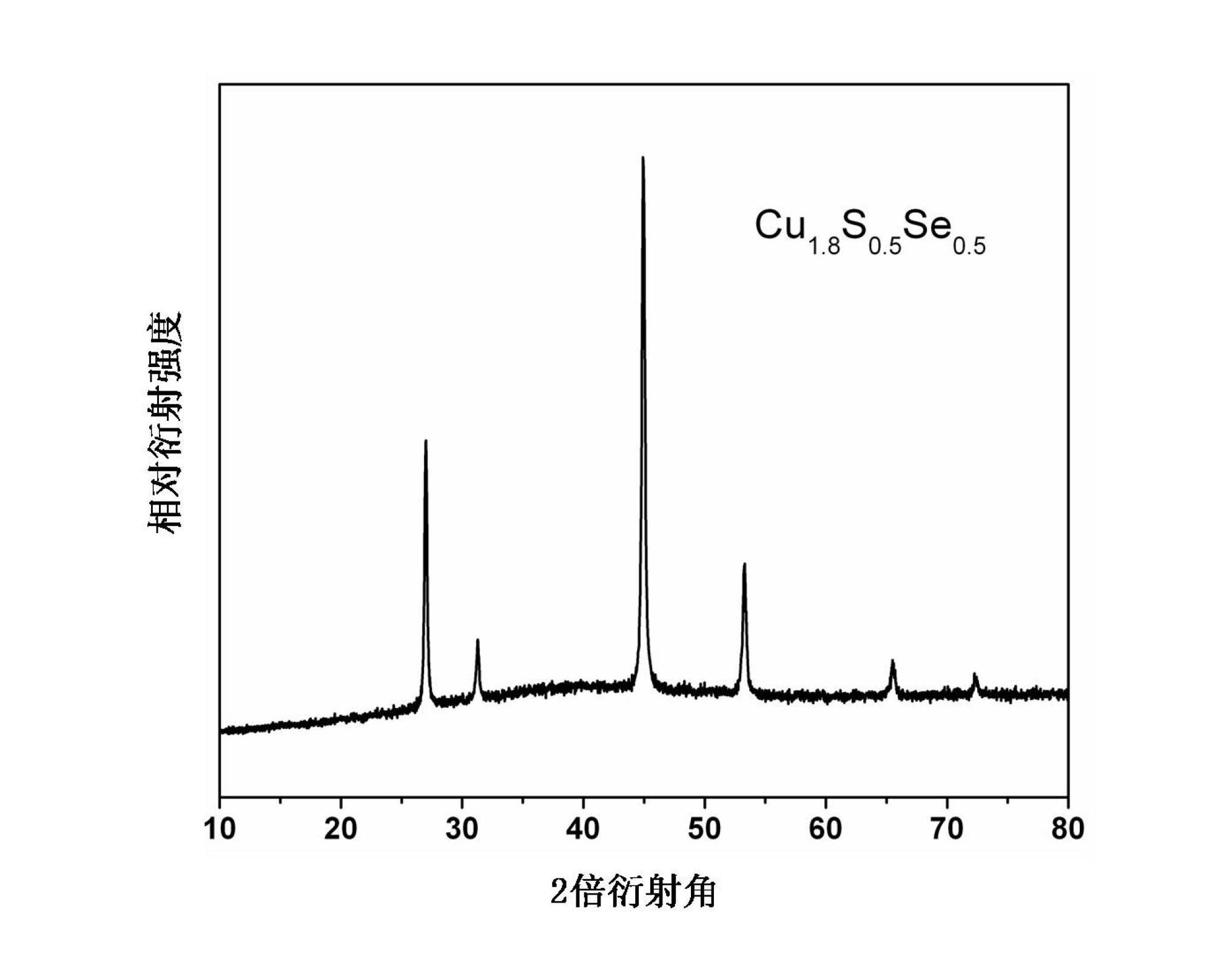

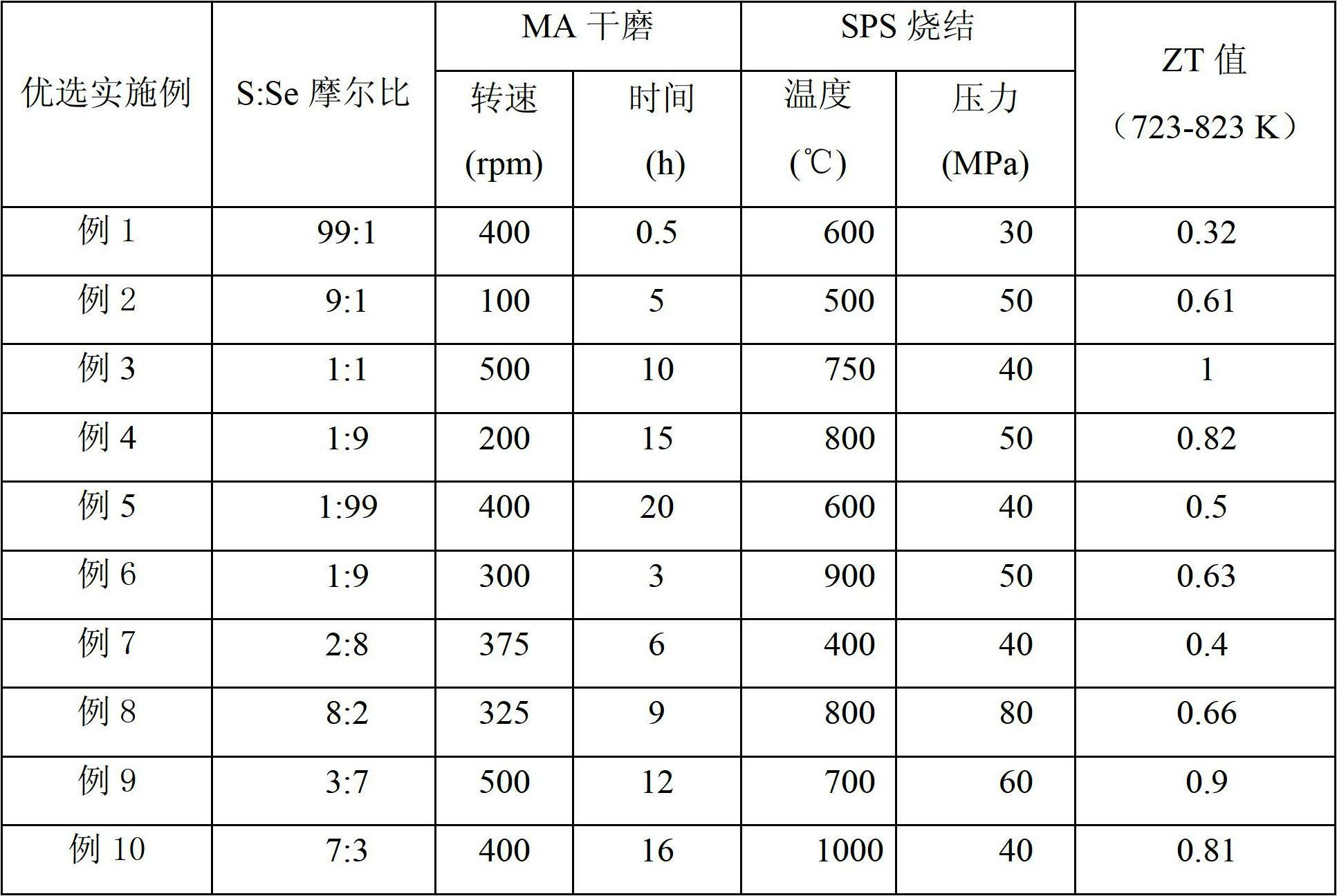

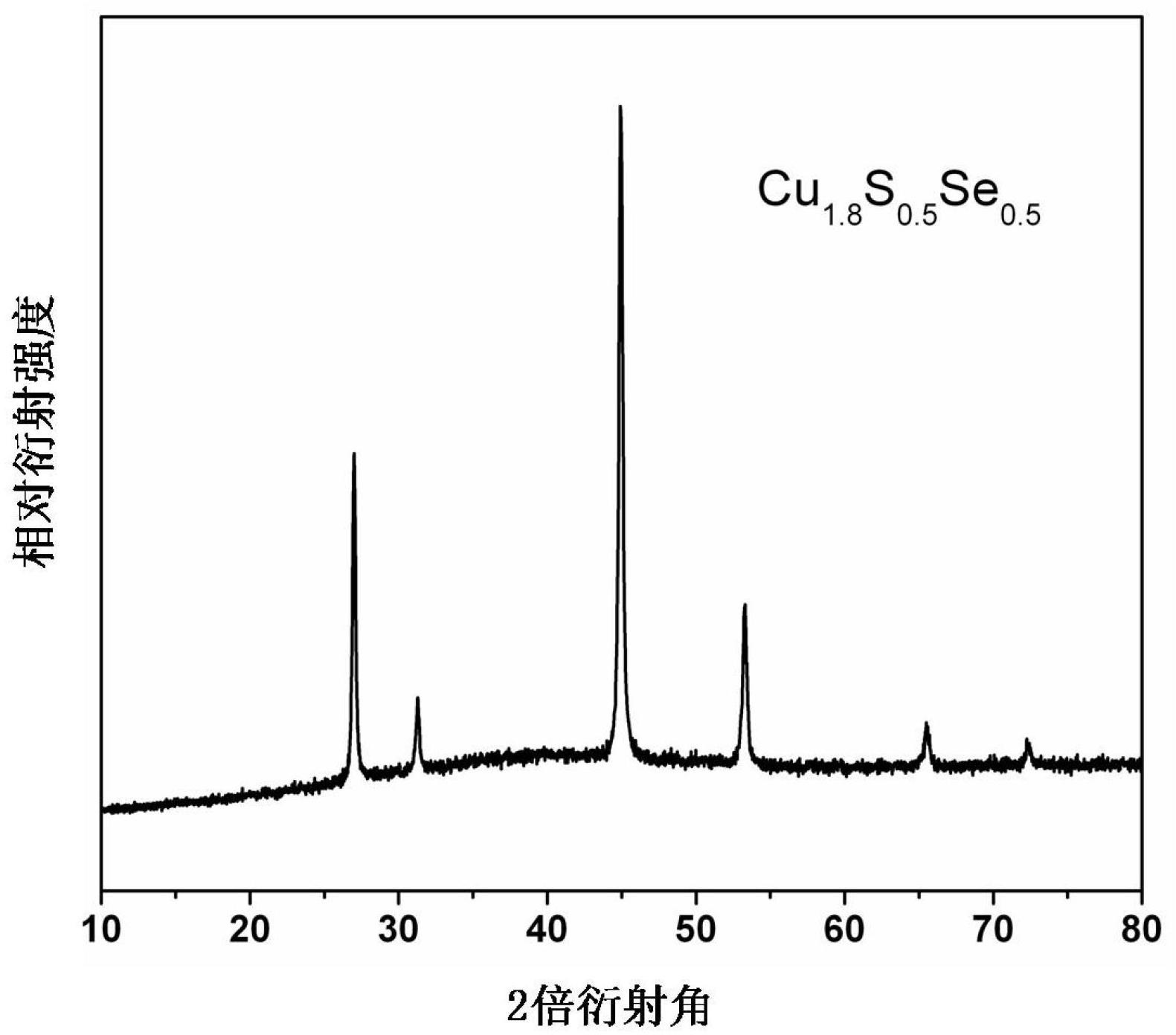

Cu-S-Se ternary thermoelectric material and preparation method thereof

InactiveCN102674842ARaise the average atomic massExcellent thermoelectric performance in the middle temperature regionThermoelectric materialsEnergy materials

The invention relates to a Cu-S-Se ternary thermoelectric material and a preparation method of the material, belonging to the technical field of energy material. The method for preparing the Cu-S-Se ternary thermoelectric material is characterized in that high-pure metal simple substance Cu powder, high-pure Se powder and high-pure S powder are taken as raw materials and are proportioned according to the chemical general formula Cu 1.8 S 1-x Se x (wherein x is the mole fraction of Se component element and is more than or equal to 0.01 and less than or equal to 0.99); and the compound powder is synthesized by a mechanical alloying method, and a block is prepared by spark plasma sintering. The method can be used for preparing the Cu-S-Se ternary thermoelectric material simply, conveniently and accurately, and the Cu-S-Se ternary thermoelectric material has the excellent thermoelectric property at the medium temperature area.

Owner:UNIV OF SCI & TECH BEIJING

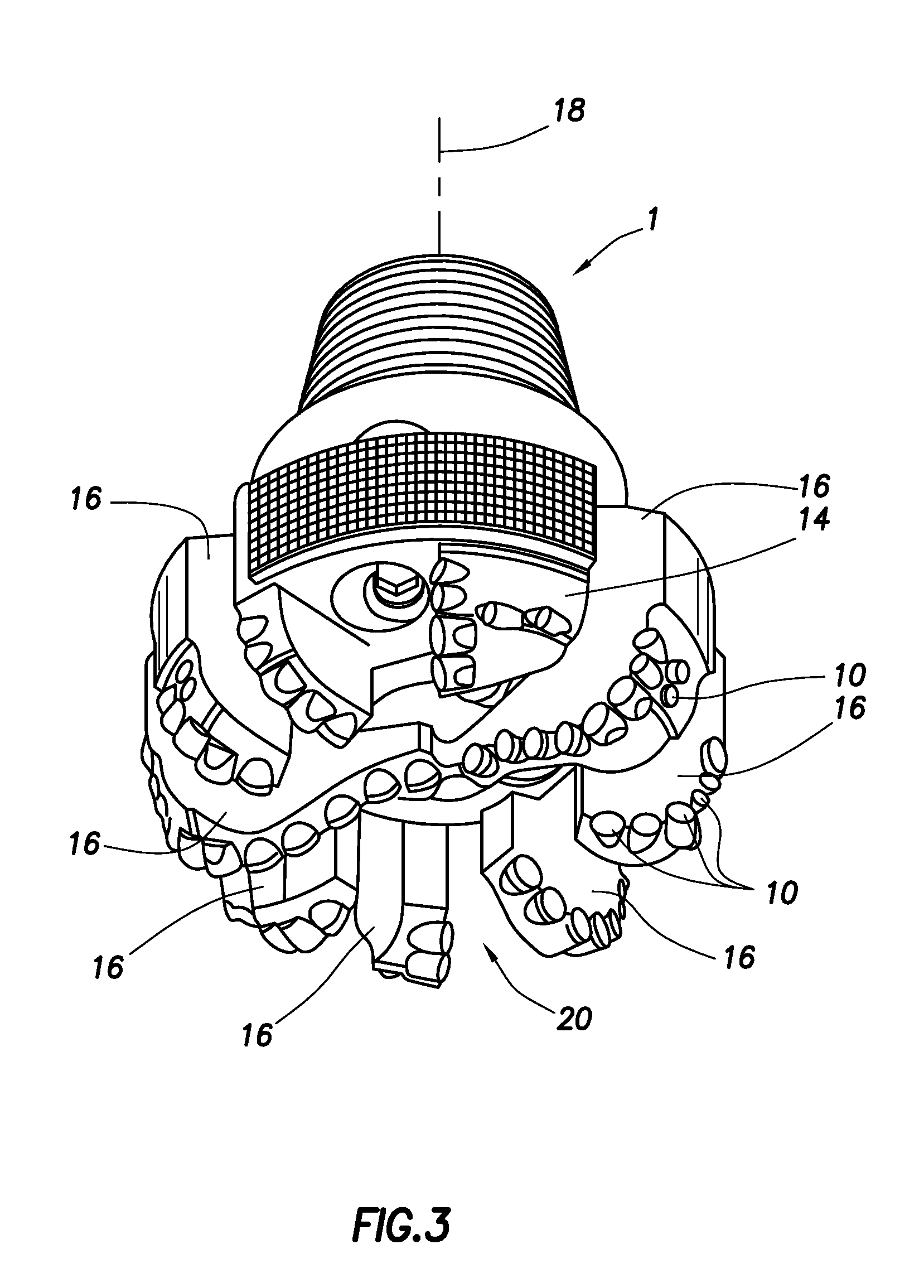

Polycrystalline diamond cutting element

ActiveUS20120097457A1Improve wear lifeImprove featuresDrill bitsConstructionsPolycrystalline diamondDrill bit

A polycrystalline-diamond cutting element for a drill bit of a downhole tool. The cutting element includes a substrate and a diamond table bonded to the substrate. The diamond table includes a diamond filler with at least one leached polycrystalline diamond segment packed therein along at least one working surface thereof. The cutting element may be formed by positioning the diamond table on the substrate and bonding the diamond table onto the substrate such that the polycrystalline diamond segment is positioned along at least one working surface of the diamond table. A spark plasma sintering or double press operation may be used to bond the diamond table onto the substrate.

Owner:NAT OILWELL DHT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com