Preparation method for hard high-entropy alloy composite material

A high-entropy alloy and composite material technology, which is applied in the field of preparing hard high-entropy alloy composite materials, can solve the problems of reducing the mechanical properties of materials, low mechanical properties of finished products, and high porosity of green bodies, and achieve short sintering time and good comprehensive performance , good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

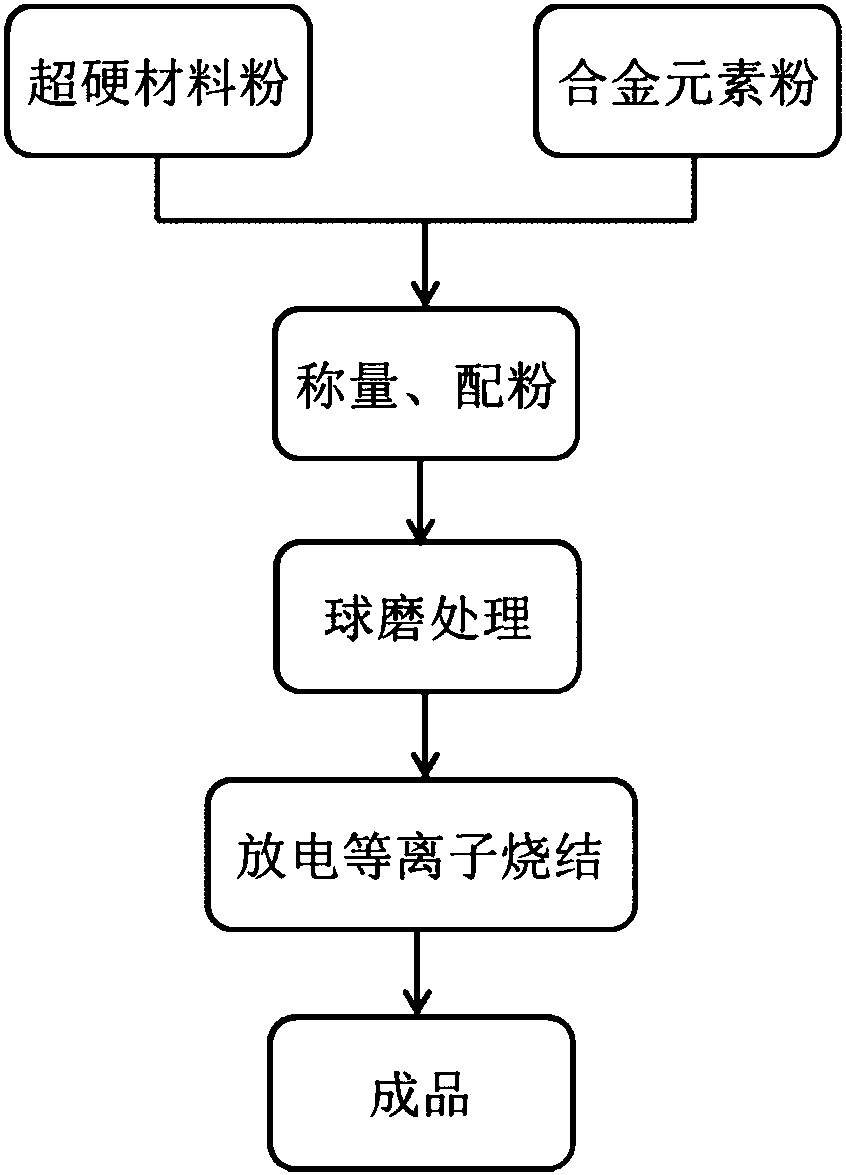

[0027] A kind of preparation method of hard high entropy alloy composite material of the present invention, its process flow chart is as figure 1 shown, including the following steps:

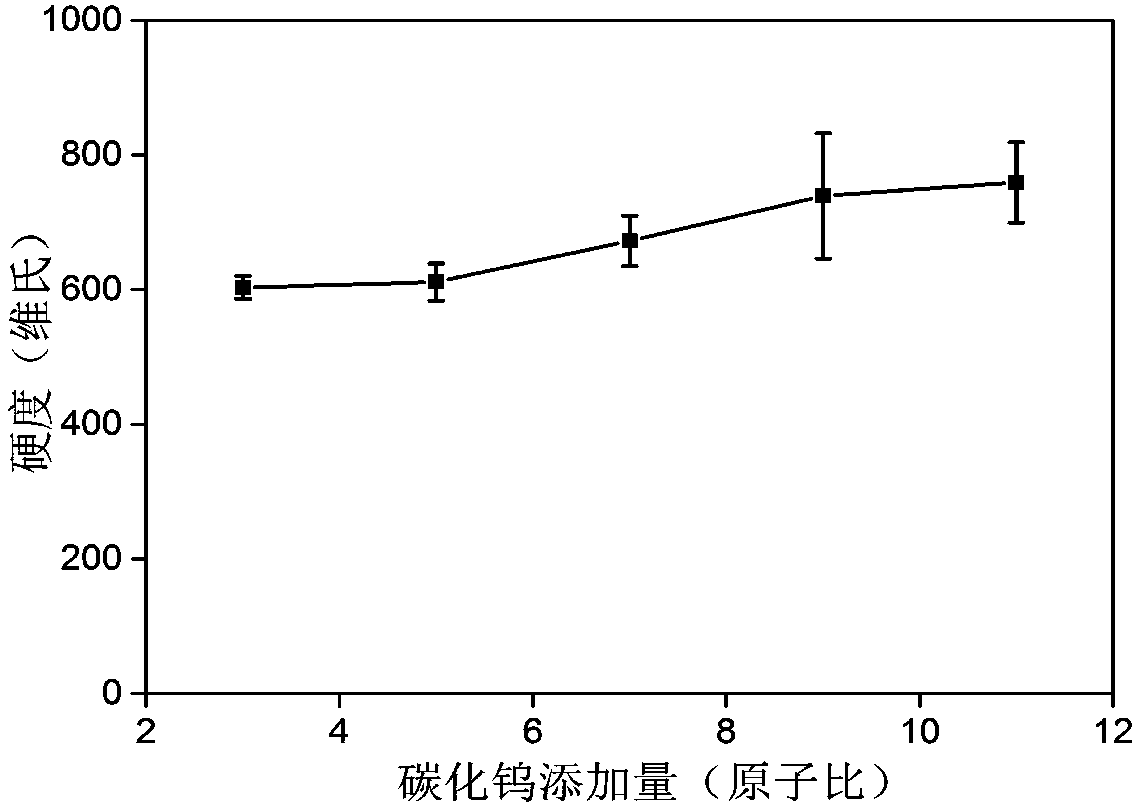

[0028] (1) Choose WC powder with a particle size of -280 mesh and alloy element powder (oxygen content less than 0.3%) with a particle size of -300 mesh as raw materials, the atomic ratio of WC powder and metal element powder is 3: 7, Fe in the metal element powder The atomic ratio of Cr powder, Ni powder, and Co powder is 1:1:1:1; among them, the alloy element powder does not contain other impurities except a small amount of unavoidable impurity oxygen, and the raw materials do not contain WC powder, Elemental components other than Fe powder, Cr powder, Ni powder, and Co powder;

[0029] (2) The raw material powder that step (1) is obtained is packed in the ball mill jar, adopts planetary ball mill and cemented carbide ball mill jar, ball mills at the speed of 250r / s 5 hours, obtains fine-gra...

Embodiment 2

[0035] A kind of preparation method of hard high entropy alloy composite material of the present invention, its process flow chart is as figure 1 shown, including the following steps:

[0036] (1) choose particle size as -600 mesh cubic BN powder and particle size as -300 mesh alloy element powder (oxygen content is lower than 0.3%) as raw material, the atomic ratio of BN powder and metal element powder is 4: 6, in the metal element powder The atomic ratio of Fe powder, Cr powder, Ni powder and Co powder is 1:1:1:1; Among them, the alloy element powder does not contain other impurities except a small amount of unavoidable impurity oxygen, and the raw materials do not contain BN powder , Fe powder, Cr powder, Ni powder, Co powder other elemental components;

[0037] (2) The raw material powder that step (1) is obtained is packed in the ball mill jar, adopts planetary ball mill and cemented carbide ball mill jar, ball mills 7 hours under the speed of 240r / s, obtains fine-graine...

Embodiment 3

[0042] A kind of preparation method of hard high entropy alloy composite material of the present invention, its process flow chart is as figure 1 shown, including the following steps:

[0043] (1) Choose diamond powder with a particle size of -400 mesh and alloy element powder (oxygen content lower than 0.3%) as raw materials with a particle size of -300 mesh, the atomic ratio of diamond powder and metal element powder is 2: 8, Fe in the metal element powder The atomic ratio of Cr powder, Ni powder, and Co powder is 1:1:1:1; among them, the alloy element powder does not contain other impurities except a small amount of unavoidable impurity oxygen, and the raw materials do not contain diamond powder, Elemental components other than Fe powder, Cr powder, Ni powder, and Co powder;

[0044] (2) The raw material powder obtained in step (1) is packed into a ball mill jar, and ball milled at a speed of 260r / s for 6 hours by using a planetary ball mill and a cemented carbide ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com