Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

727results about "Multi-walled nanotubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled patterning and growth of single wall and multi-wall carbon nanotubes

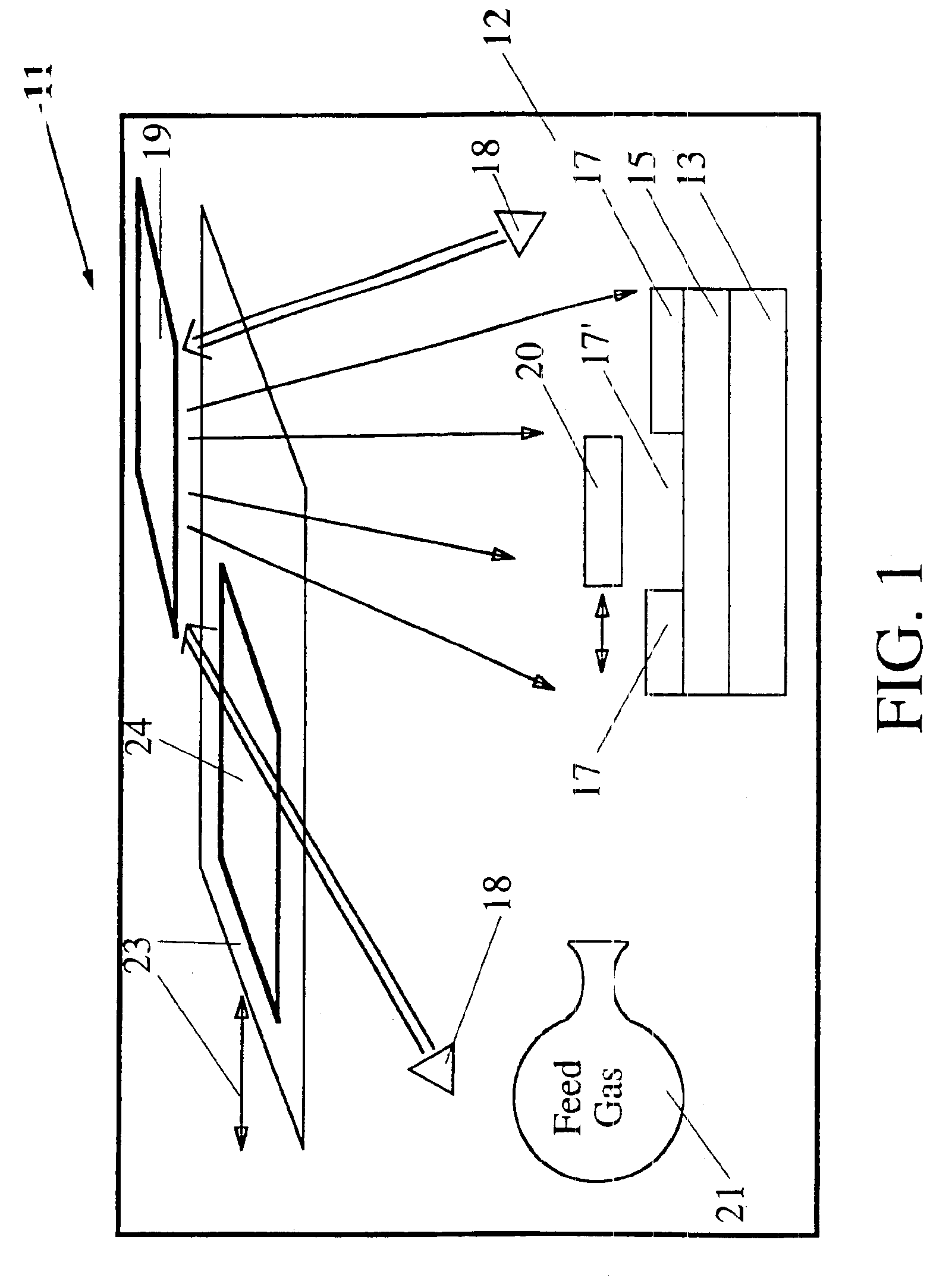

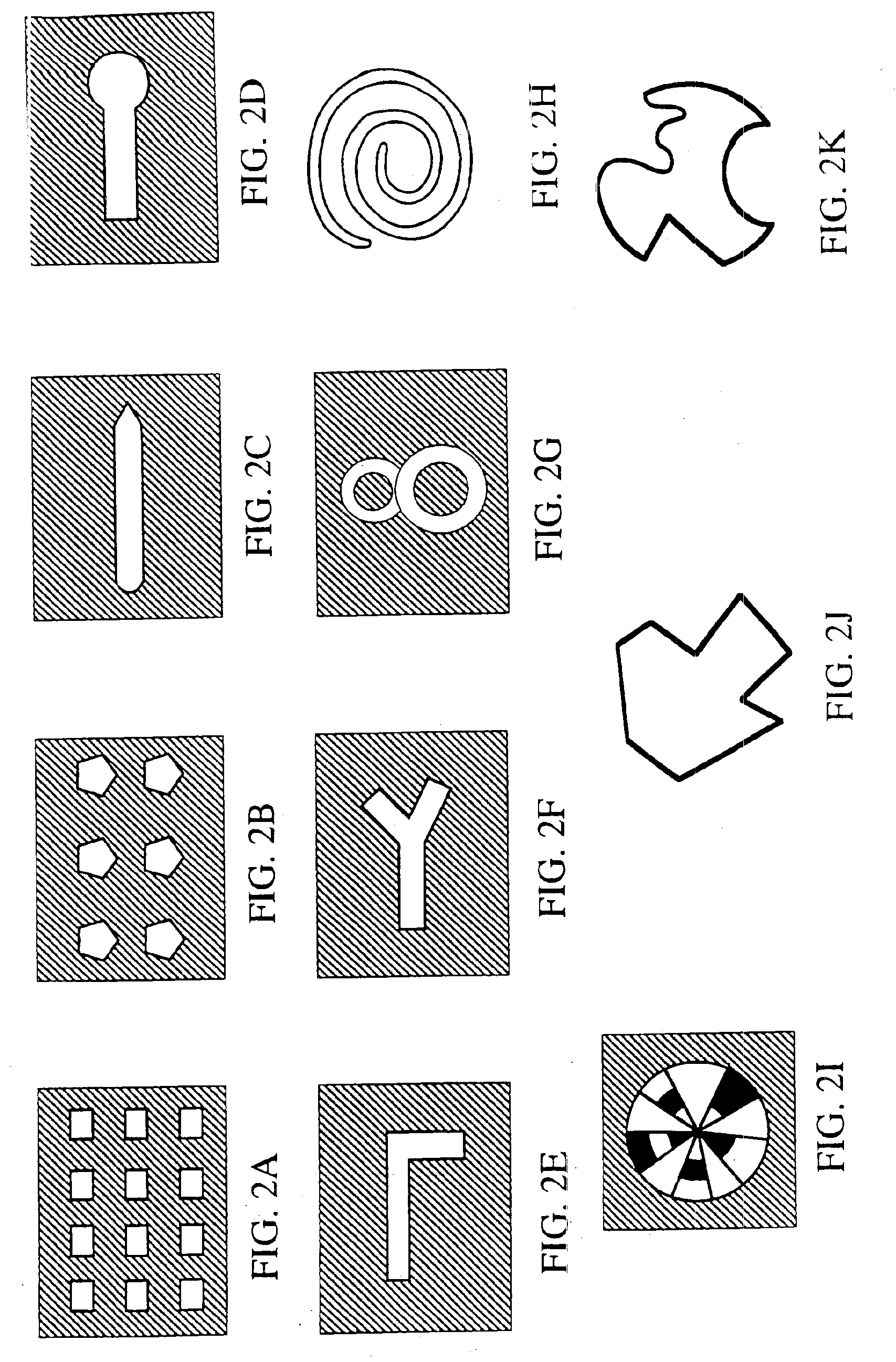

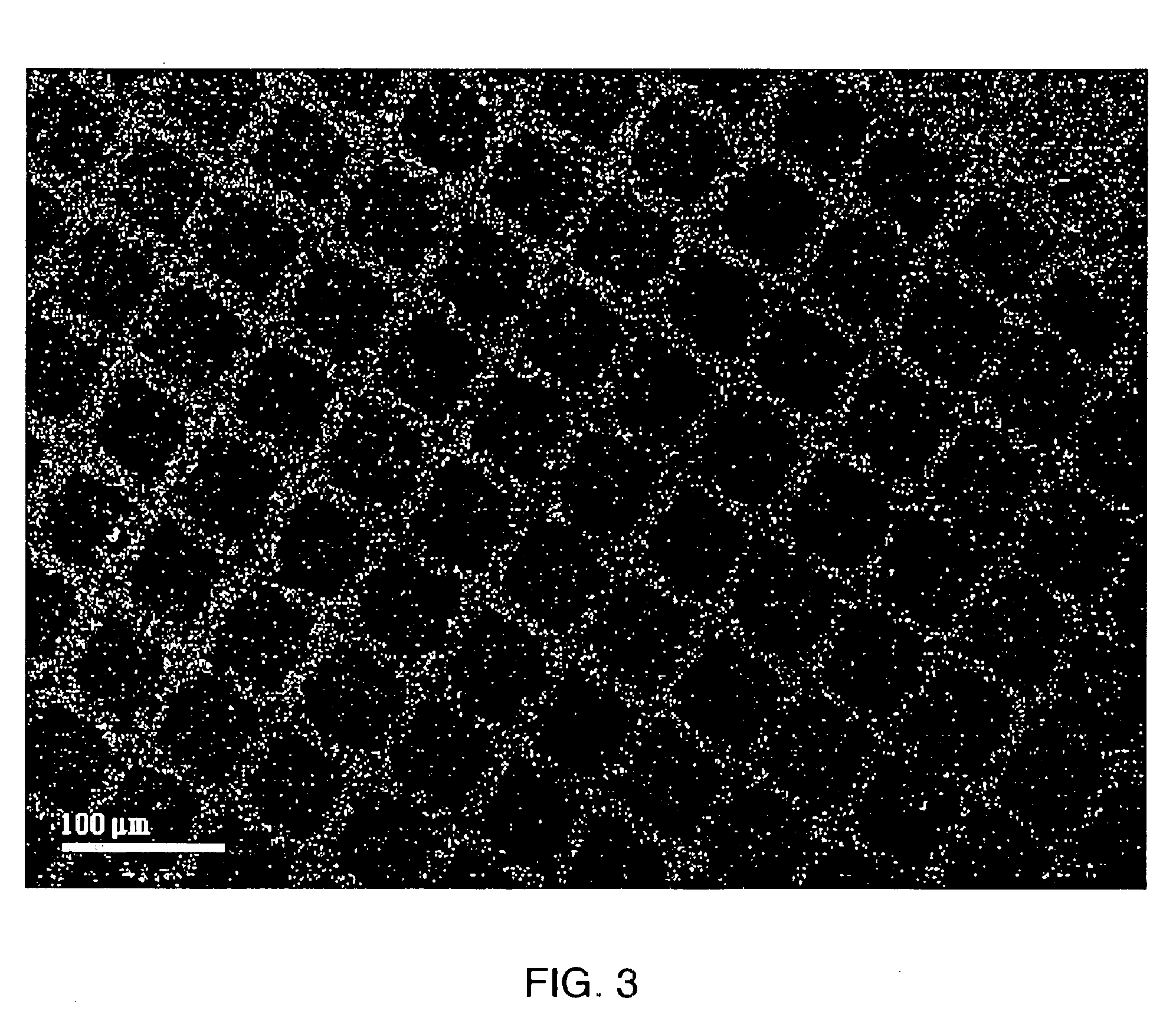

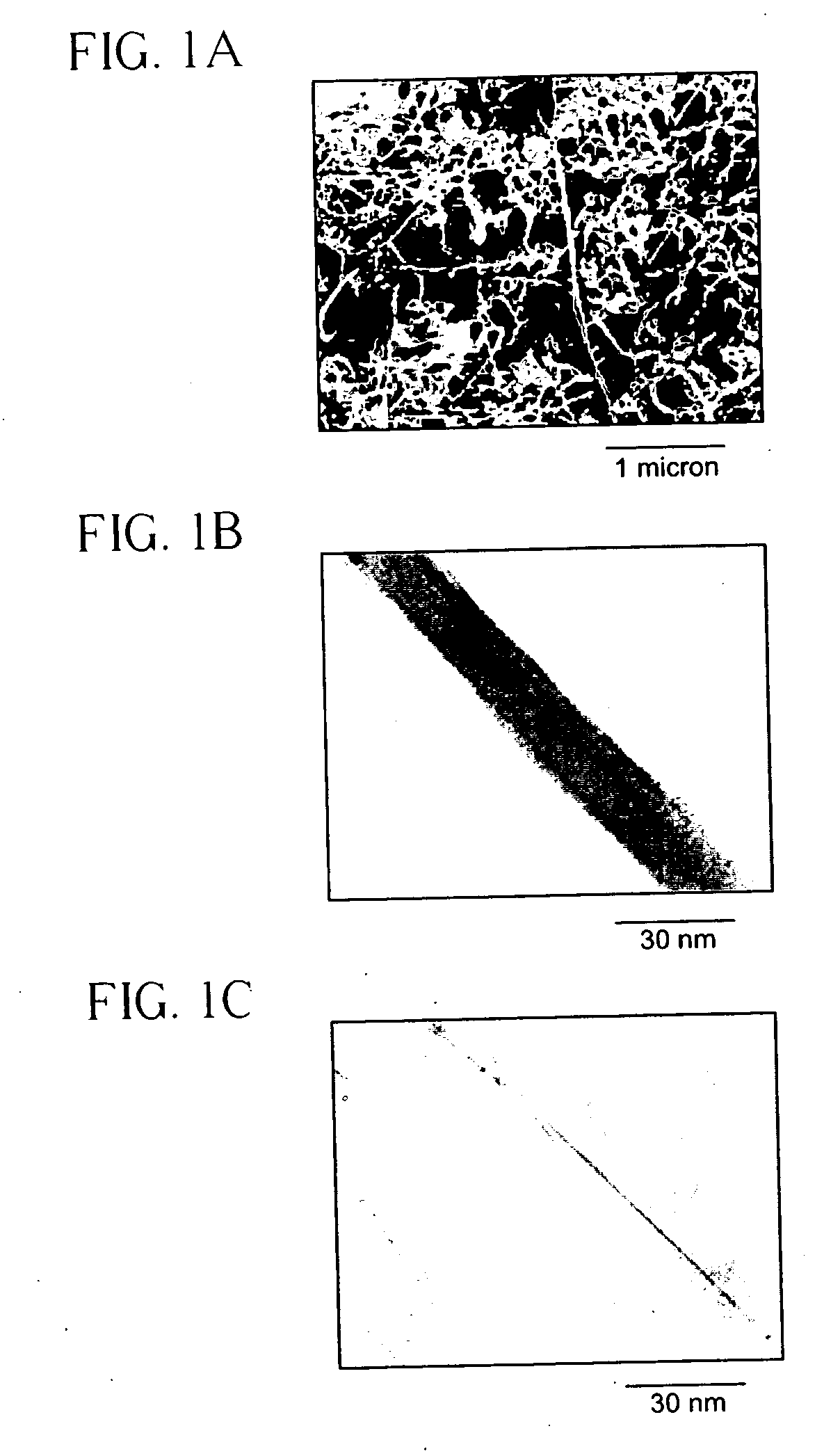

Method and system for producing a selected pattern or array of at least one of a single wall nanotube and / or a multi-wall nanotube containing primarily carbon. A substrate is coated with a first layer (optional) of a first selected metal (e.g., Al and / or Ir) and with a second layer of a catalyst (e.g., Fe, Co, Ni and / or Mo), having selected first and second layer thicknesses provided by ion sputtering, arc discharge, laser ablation, evaporation or CVD. The first layer and / or the second layer may be formed in a desired non-uniform pattern, using a mask with suitable aperture(s), to promote growth of carbon nanotubes in a corresponding pattern. A selected heated feed gas (primarily CH4 or C2Hn with n=2 and / or 4) is passed over the coated substrate and forms primarily single wall nanotubes or multiple wall nanotubes, depending upon the selected feed gas and its temperature. Nanofibers, as well as single wall and multi-wall nanotubes, are produced using plasma-aided growth from the second (catalyst) layer. An overcoating of a selected metal or alloy can be deposited, over the second layer, to provide a coating for the carbon nanotubes grown in this manner.

Owner:NASA +1

Production of agglomerates from gas phase

ActiveUS20050006801A1Avoid enteringImprove mechanical propertiesMaterial nanotechnologyMulti-walled nanotubesGas phaseReaction zone

A process for production of an agglomerate comprises the steps of: passing a flow of one or more gaseous reactants into a reactor; reacting the one or more gaseous reactants within a reaction zone of the reactor to form product particles; agglomerating the product particles into an agglomerate; and applying a force to the agglomerate to displace it continuously away from the reaction zone.

Owner:CAMBRIDGE ENTERPRISE LTD

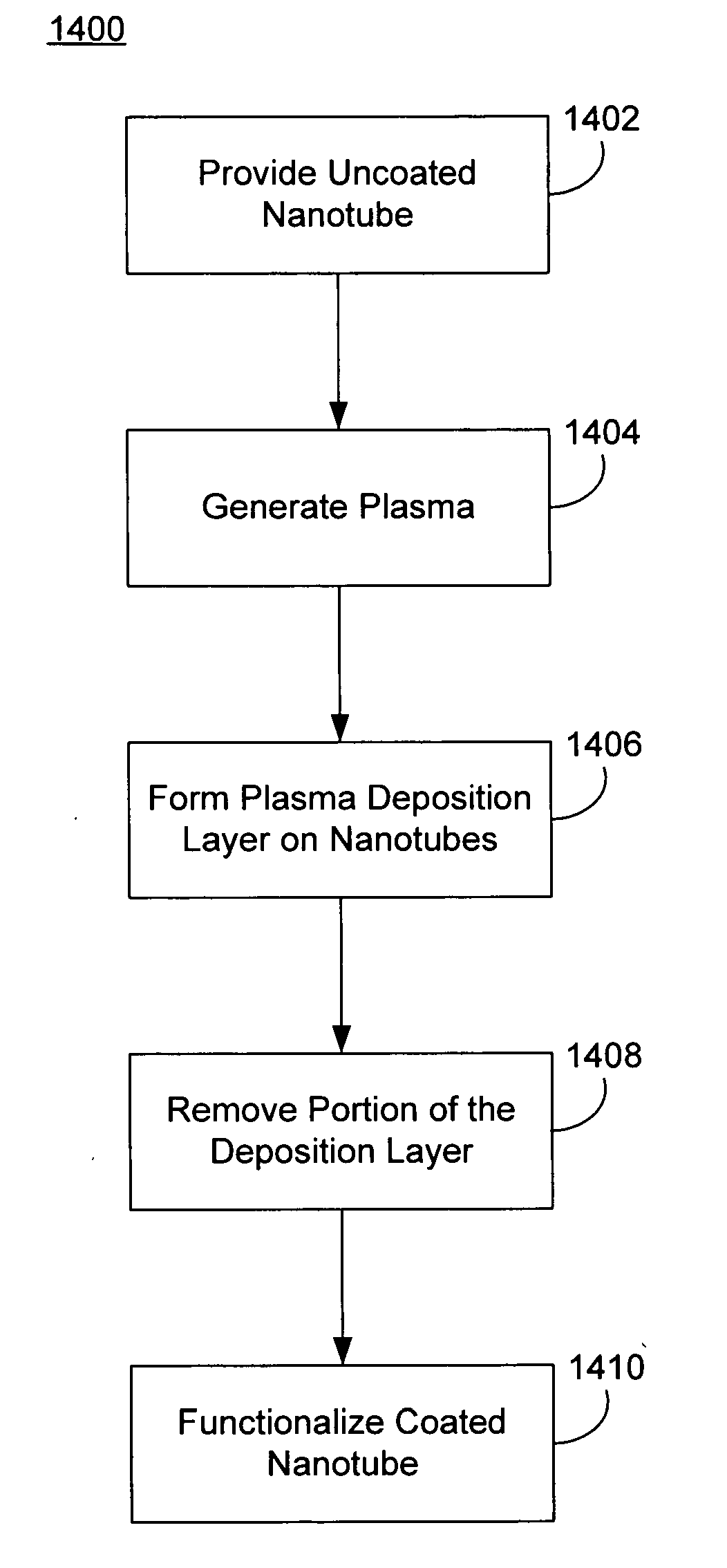

Coatings for carbon nanotubes

A coated nanotube that includes an inner nanotube having an exterior surface, and a plasma deposited layer covering at least part of the exterior surface of the inner nanotube. Also, a method of making a coated nanotube, the method where the method includes the steps of generating a plasma from a coating precursor, and exposing an inner nanotube to the plasma, where a plasma deposited layer is formed on at least a portion of the inner nanotube. Additionally, a method of making a coated nanotube that includes the steps of providing an inner nanotube, and evaporating a metal into the inner nanotube, where the metal forms a coating layer on at least a portion of the inner nanotube.

Owner:CALIFORNIA INST OF TECH

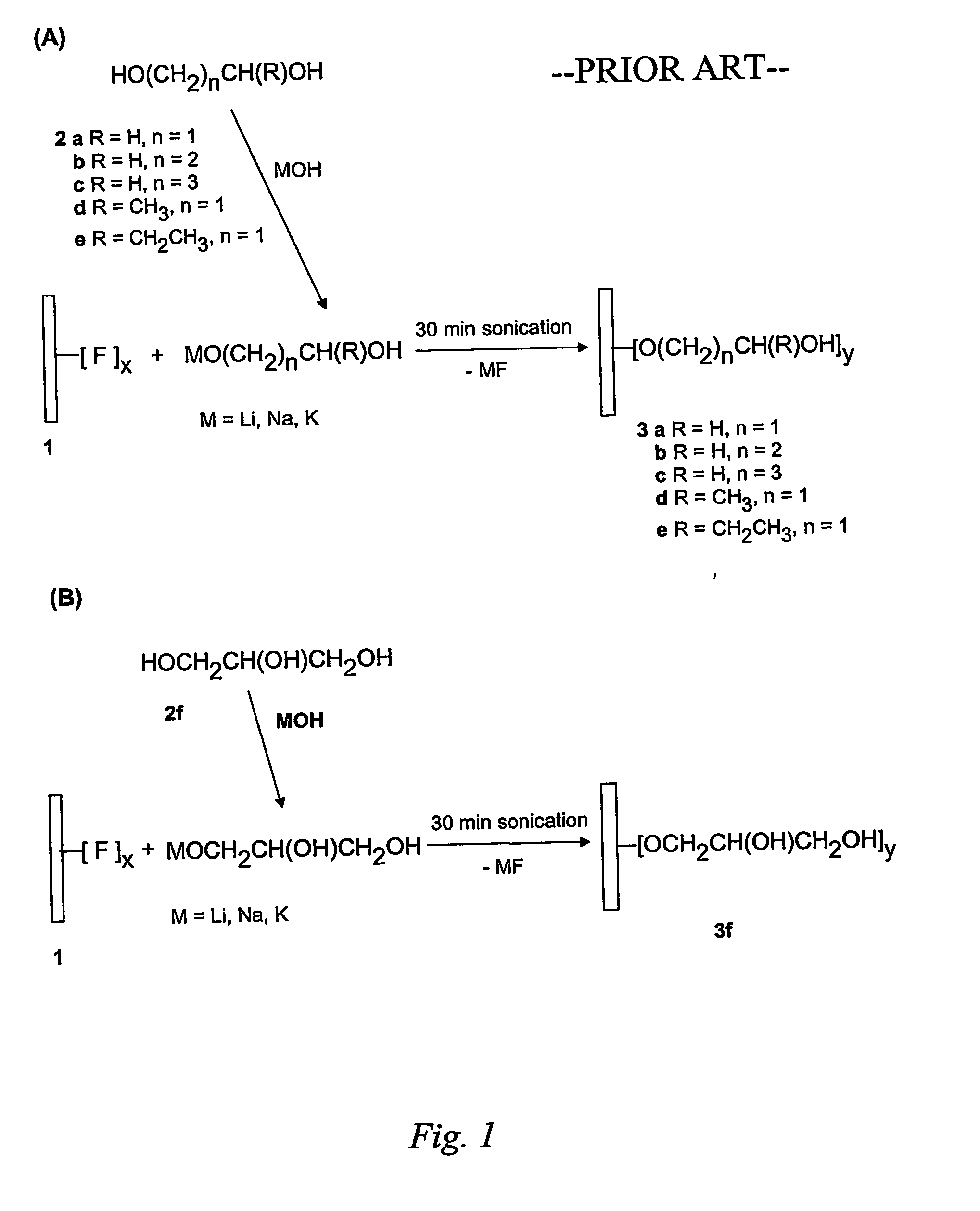

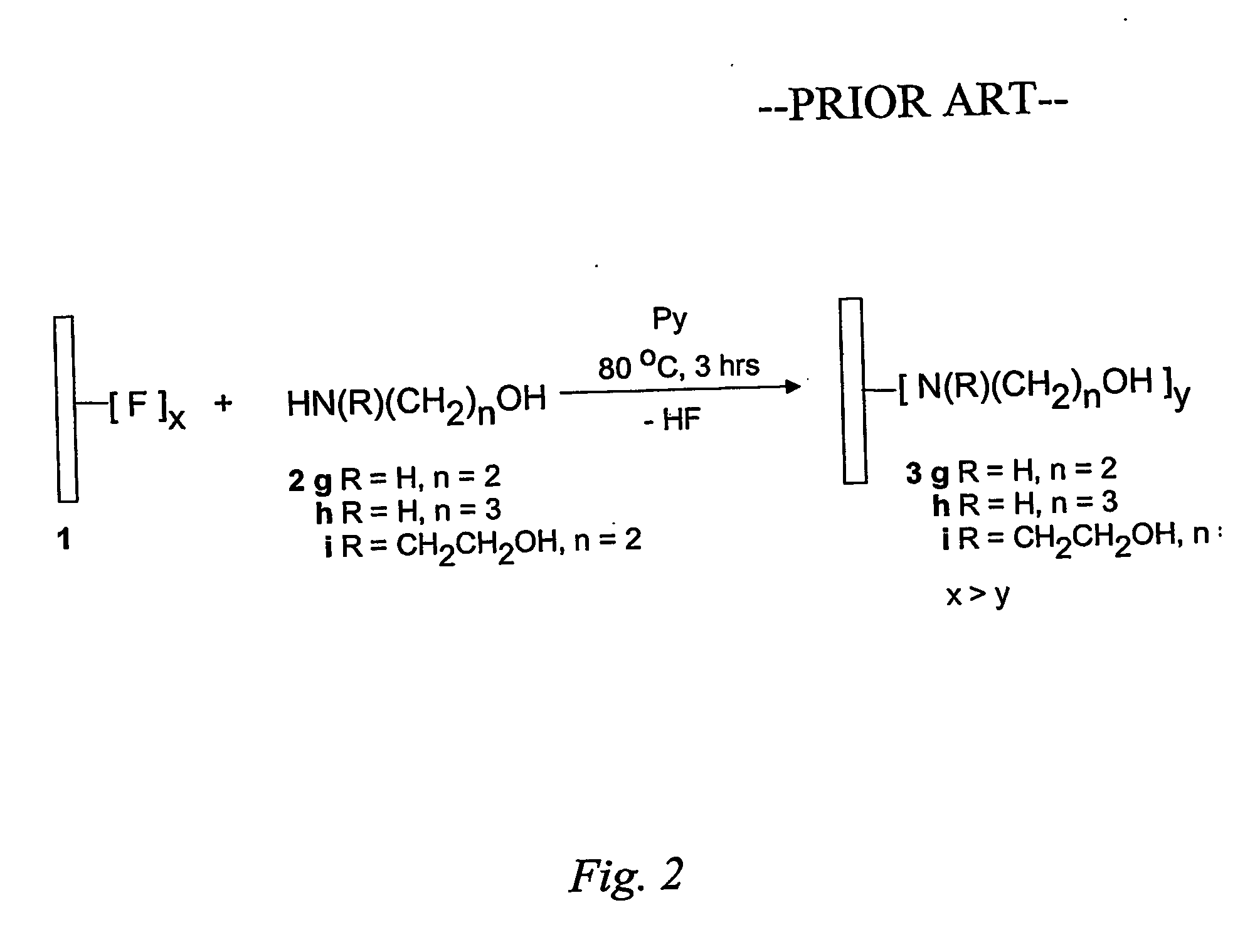

Methods of chemically derivatizing single-wall carbon nanotubes

InactiveUS6841139B2Increase resistanceHigh yieldMaterial nanotechnologyPigmenting treatmentFiberLithium

This invention is directed to making chemical derivatives of carbon nanotubes and to uses for the derivatized nanotubes, including making arrays as a basis for synthesis of carbon fibers. In one embodiment, this invention also provides a method for preparing single wall carbon nanotubes having substituents attached to the side wall of the nanotube by reacting single wall carbon nanotubes with fluorine gas and recovering fluorine derivatized carbon nanotubes, then reacting fluorine derivatized carbon nanotubes with a nucleophile. Some of the fluorine substituents are replaced by nucleophilic substitution. If desired, the remaining fluorine can be completely or partially eliminated to produce single wall carbon nanotubes having substituents attached to the side wall of the nanotube. The substituents will, of course, be dependent on the nucleophile, and preferred nucleophiles include alkyl lithium species such as methyl lithium. Alternatively, fluorine may be fully or partially removed from fluorine derivatized carbon nanotubes by reacting the fluorine derivatized carbon nanotubes with various amounts of hydrazine, substituted hydrazine or alkyl amine. The present invention also provides seed materials for growth of single wall carbon nanotubes comprising a plurality of single wall carbon nanotubes or short tubular molecules having a catalyst precursor moiety covalently bound or physisorbed on the outer surface of the sidewall to provide the optimum metal cluster size under conditions that result in migration of the metal moiety to the tube end.

Owner:RICE UNIV

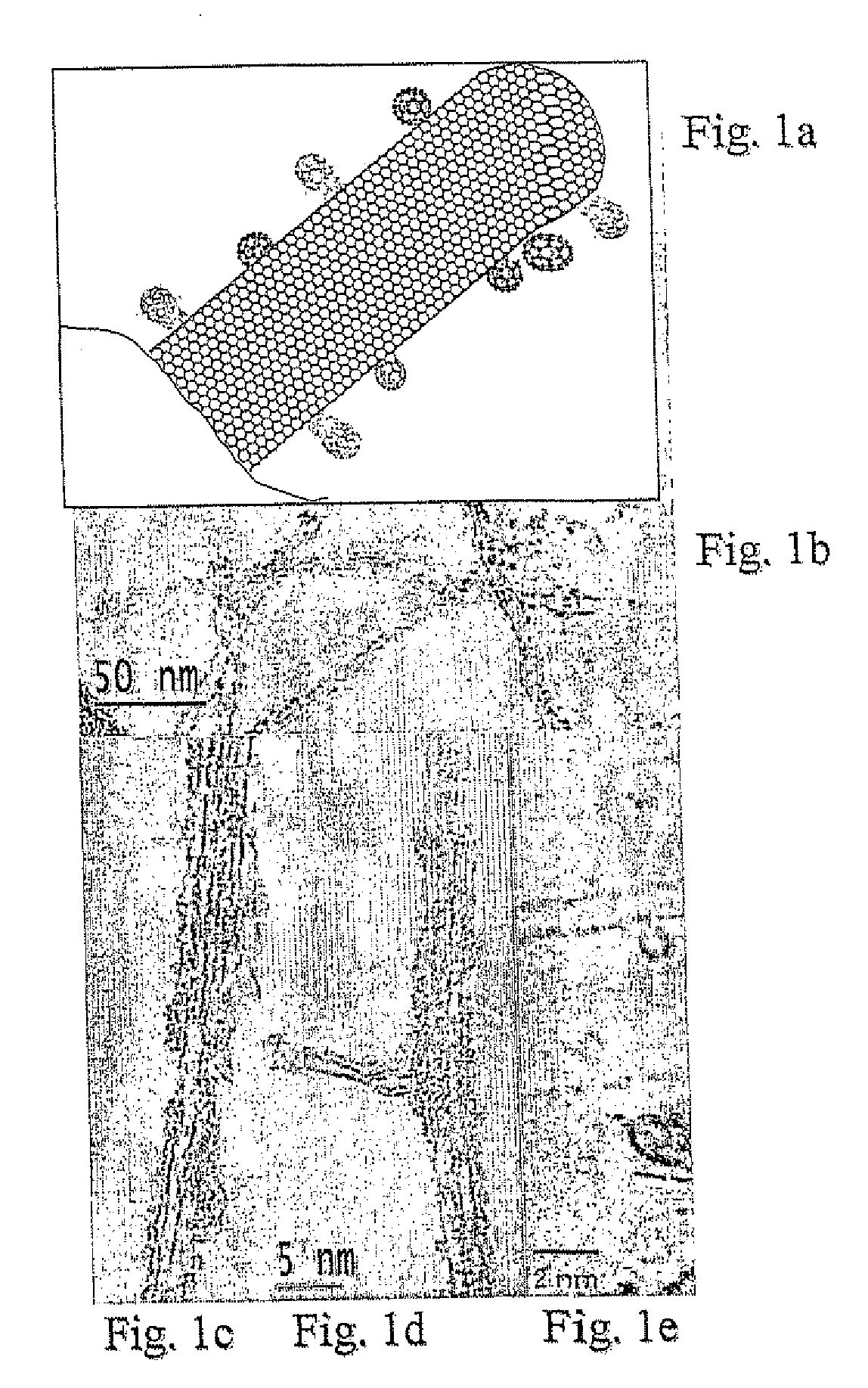

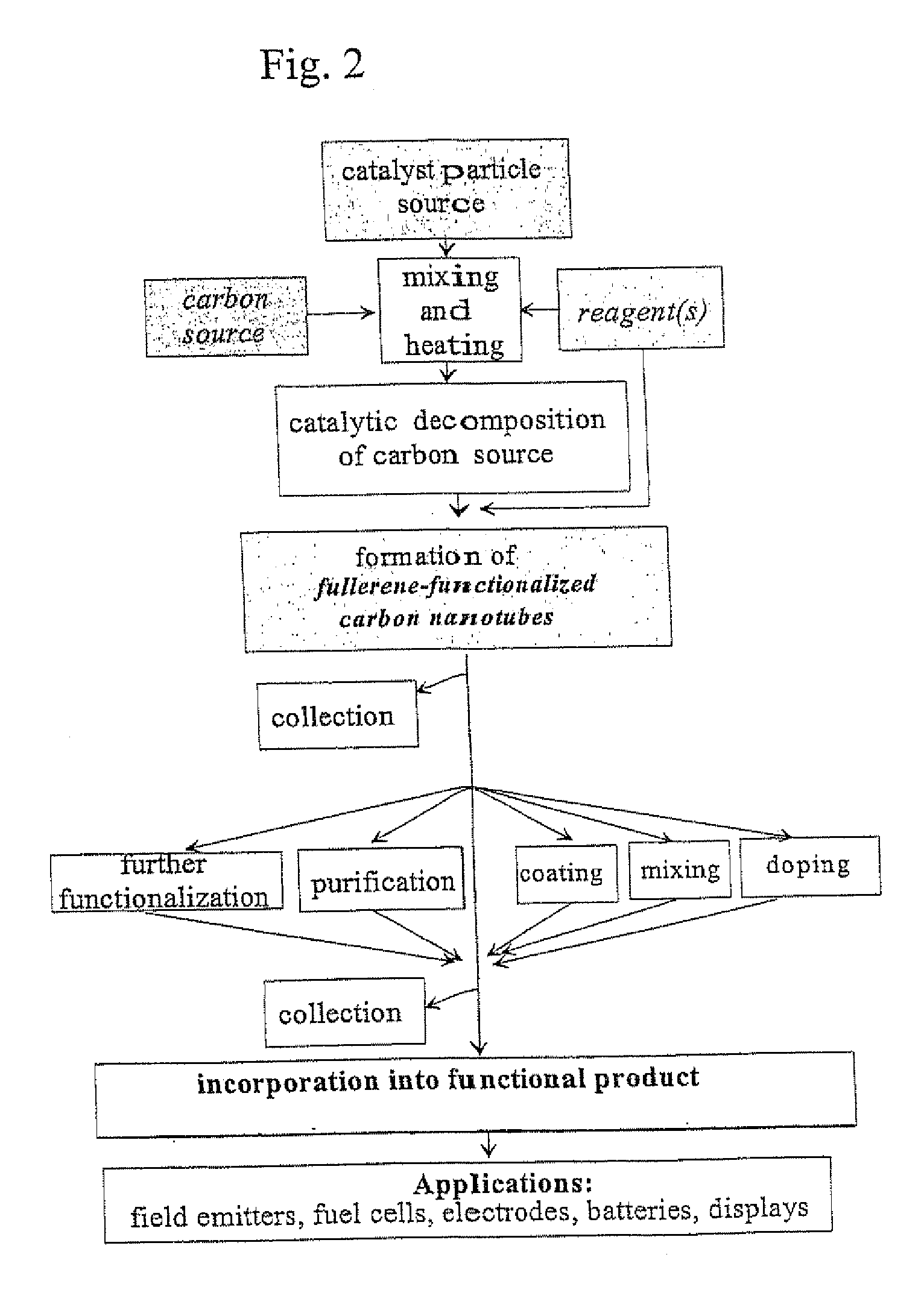

Carbon nanotubes functionalized with fullerenes

InactiveUS20090226704A1Enhancement in cold electron field emissionImprove mechanical propertiesSpecific nanostructure formationMaterial nanotechnologyC60 fullereneNanotube

The present invention relates to covalently bonded fullerene-functionalized carbon nanotubes (CBFFCNTs), a method and an apparatus for their production and to their end products. CBFFCNTs are carbon nanotubes with one or more fullerenes or fullerene based molecules covalently bonded to the nanotube surface. They are obtained by bringing one or more catalyst particles, carbon sources and reagents together in a reactor.

Owner:CANATU OY

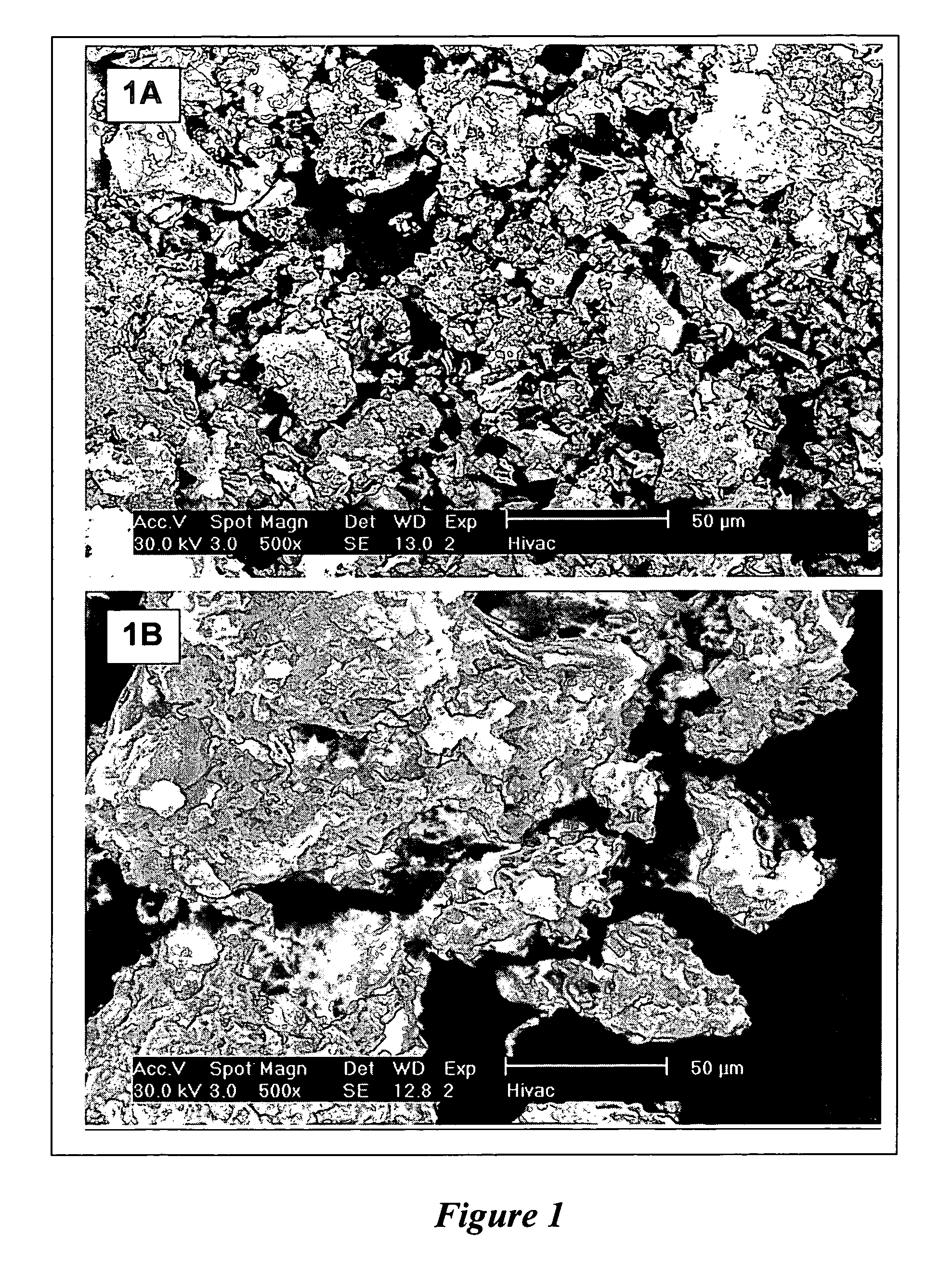

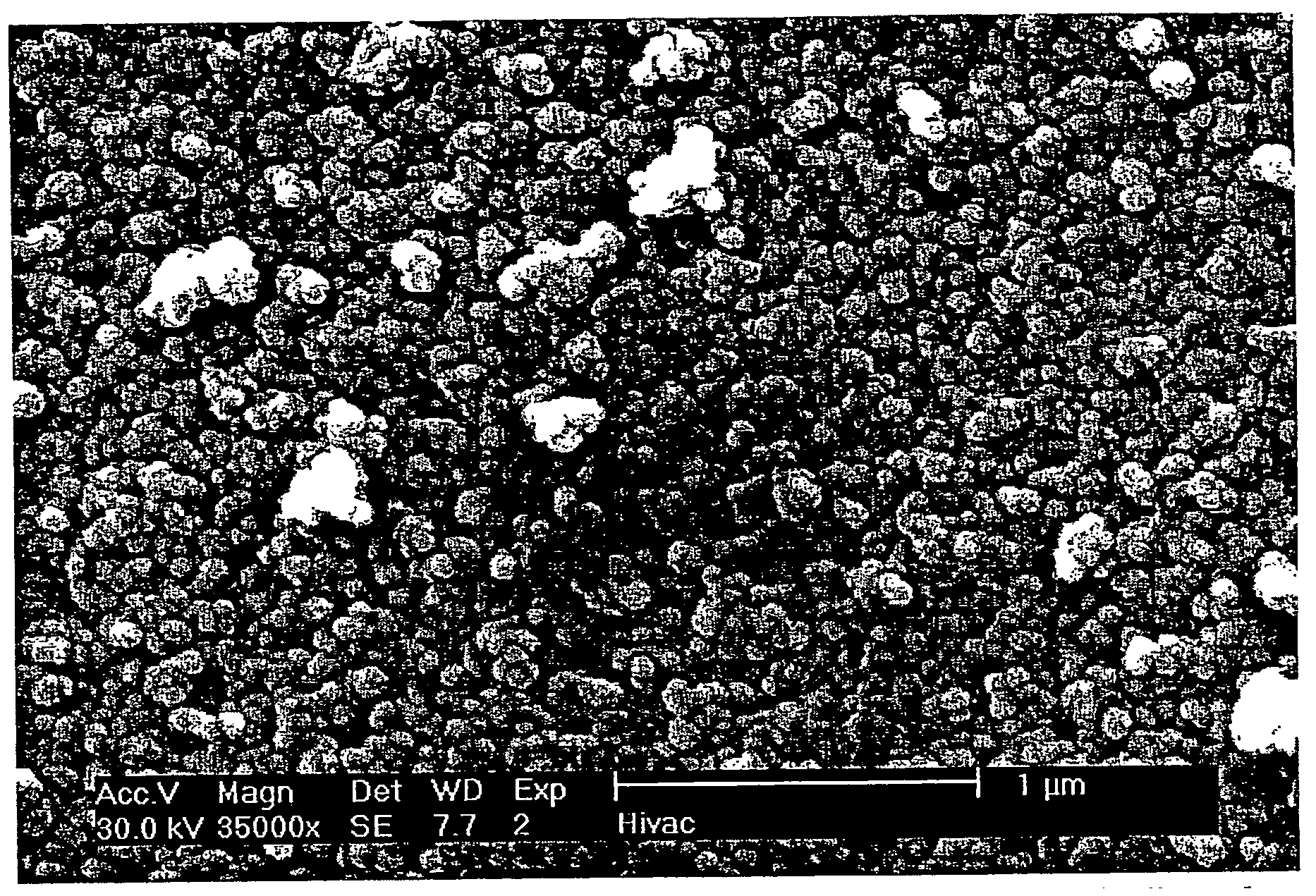

Carbon nanotube particulates, compositions and use thereof

InactiveUS20050002851A1Suitable for useMaterial nanotechnologyNanoinformaticsParticulatesContact time

A method for making carbon nanotube particulates involves providing a catalyst comprising catalytic metals, such as iron and molybdenum or metals from Group VIB or Group VIIIB elements, on a support material, such as magnesia, and contacting the catalyst with a gaseous carbon-containing feedstock, such as methane, at a sufficient temperature and for a sufficient contact time to make small-diameter carbon nanotubes having one or more walls and outer wall diameters of less than about 3 nm. Removal of the support material from the carbon nanotubes yields particulates of enmeshed carbon nanotubes that retain an approximate three-dimensional shape and size of the particulate support that was removed. The carbon nanotube particulates can comprise ropes of carbon nanotubes. The carbon nanotube particulates disperse well in polymers and show high conductivity in polymers at low loadings. As electrical emitters, the carbon nanotube particulates exhibit very low “turn on” emission field.

Owner:UNIDYM

Chemically modifying single wall carbon nanotubes to facilitate dispersal in solvents

InactiveUS6875412B2High yieldIncrease resistanceMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

Owner:RICE UNIV

Cnt-based resistive heating for deicing composite structures

ActiveUS20110024409A1Prevent freezingInhibition formationMaterial nanotechnologyLayered productsFiberCarbon nanotube

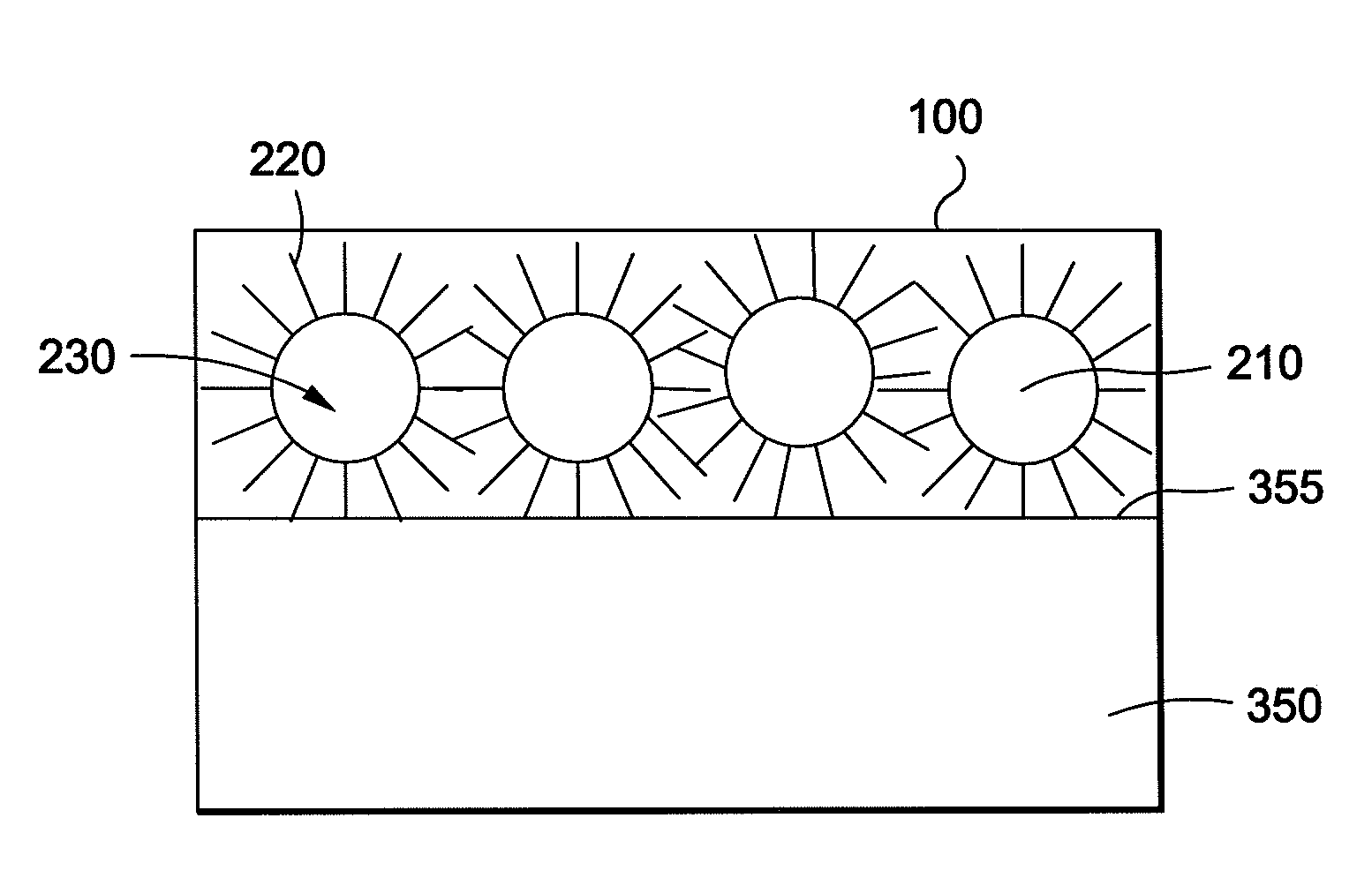

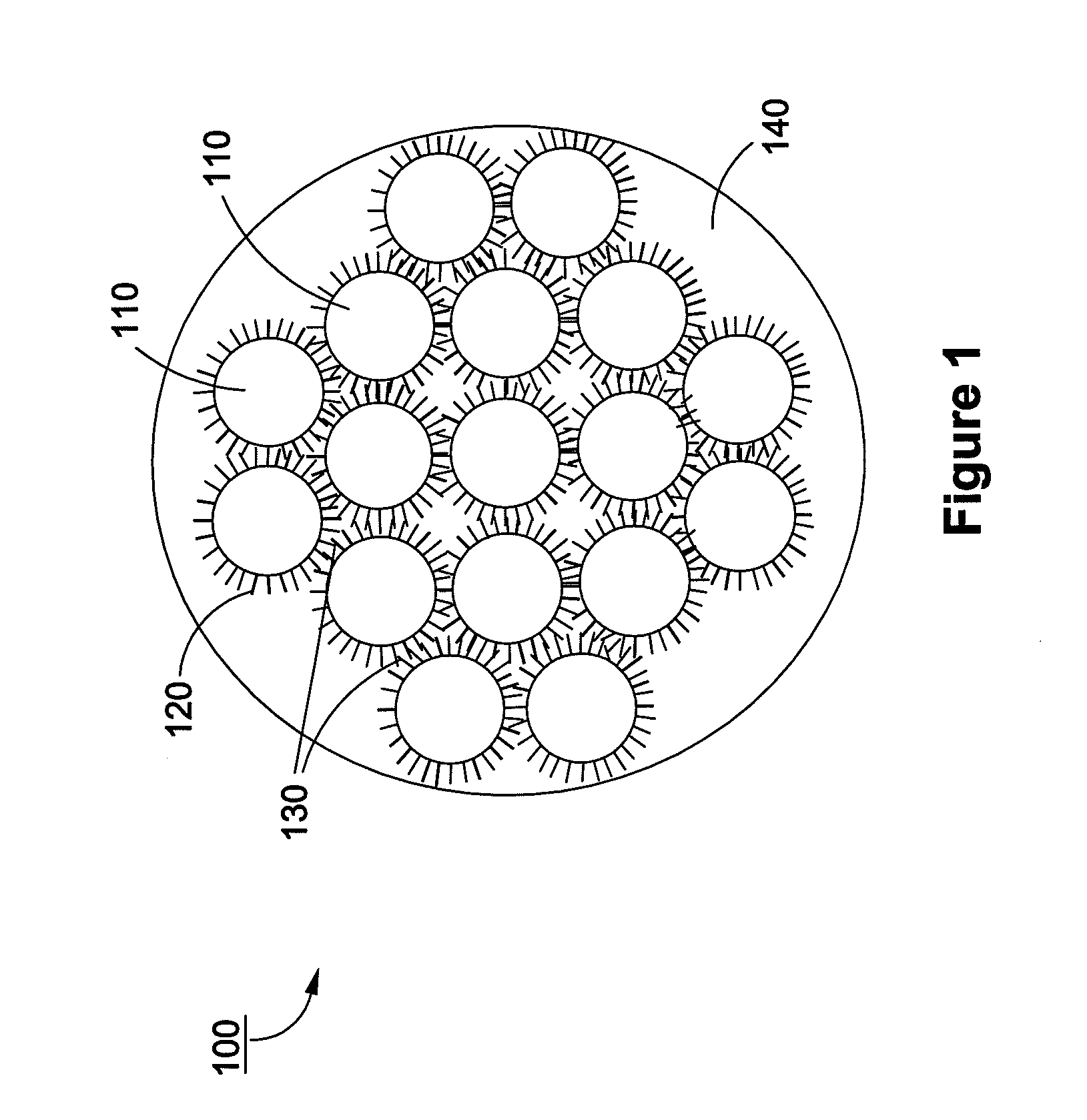

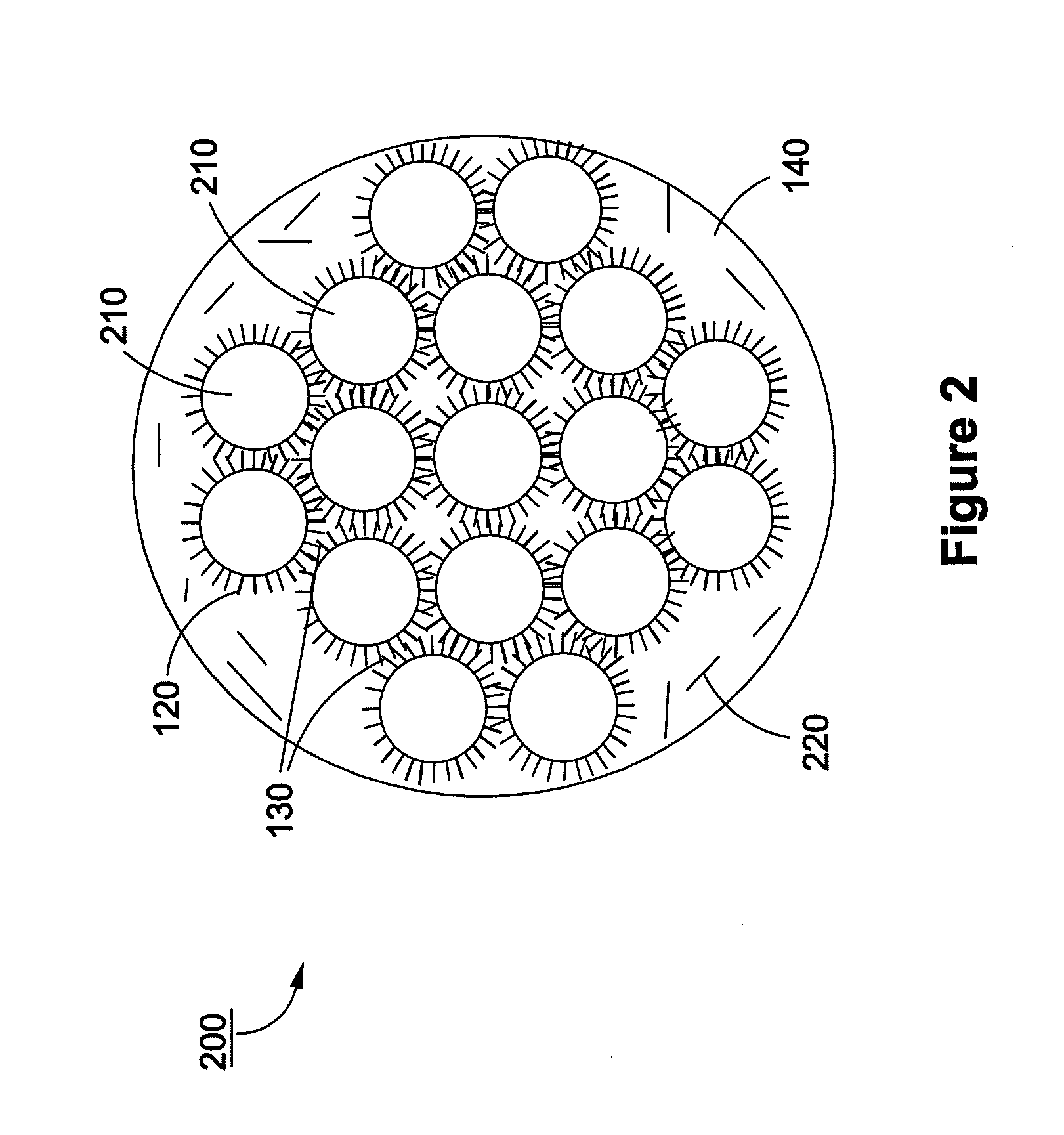

A composite structure includes a matrix material and a carbon nanotube (CNT)-infused fiber material that includes a plurality of carbon nanotubes (CNTs) infused to a fiber material. The CNT-infused fiber material is disposed throughout a portion of the matrix material. The composite structure is adapted for application of a current through the CNT-infused fiber material to provide heating of the composite structure. A heating element includes a CNT-infused fiber material includes a plurality of CNTs infused to a fiber material. The CNT-infused fiber material is of sufficient proportions to provide heating to a structure in need thereof.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

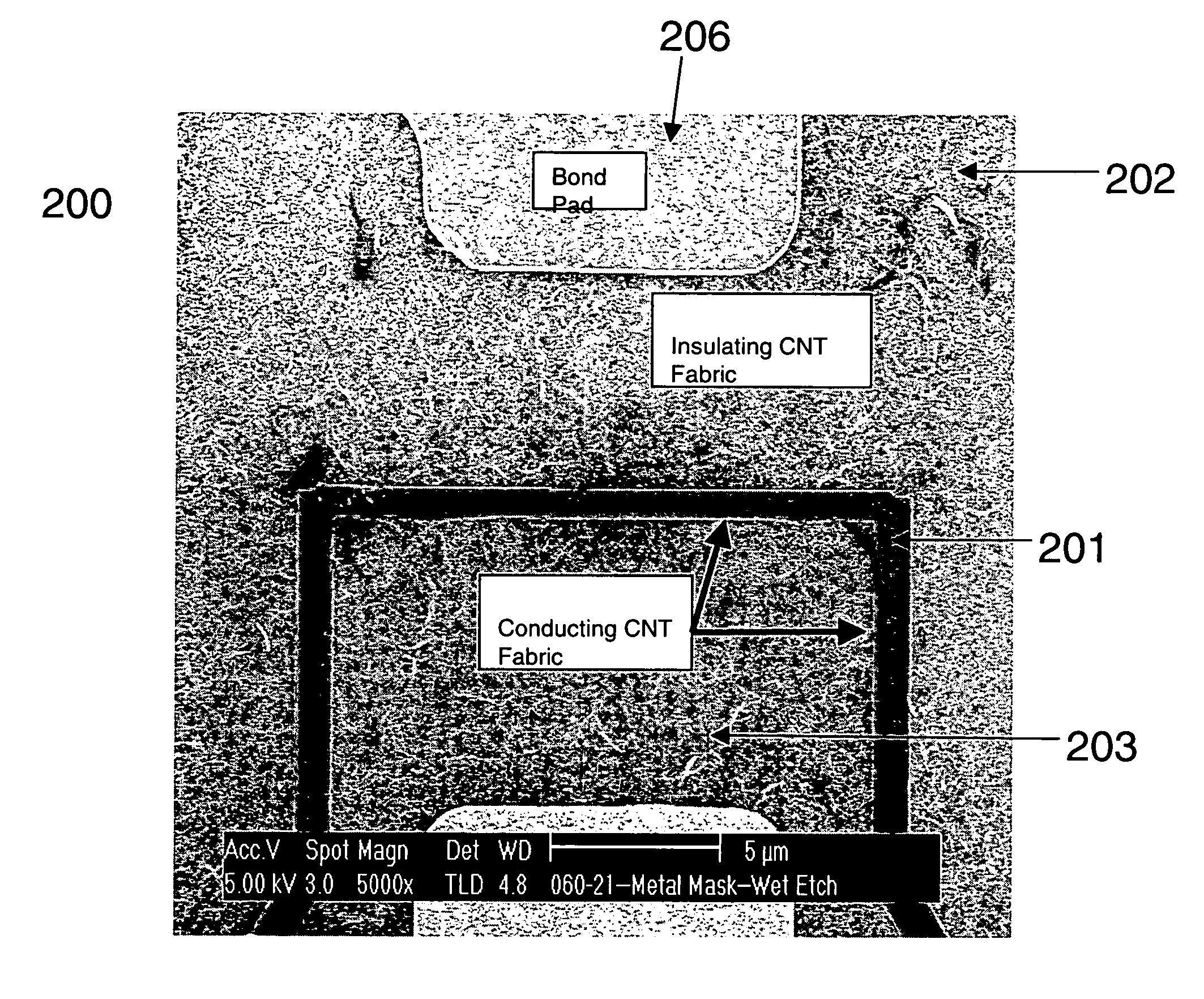

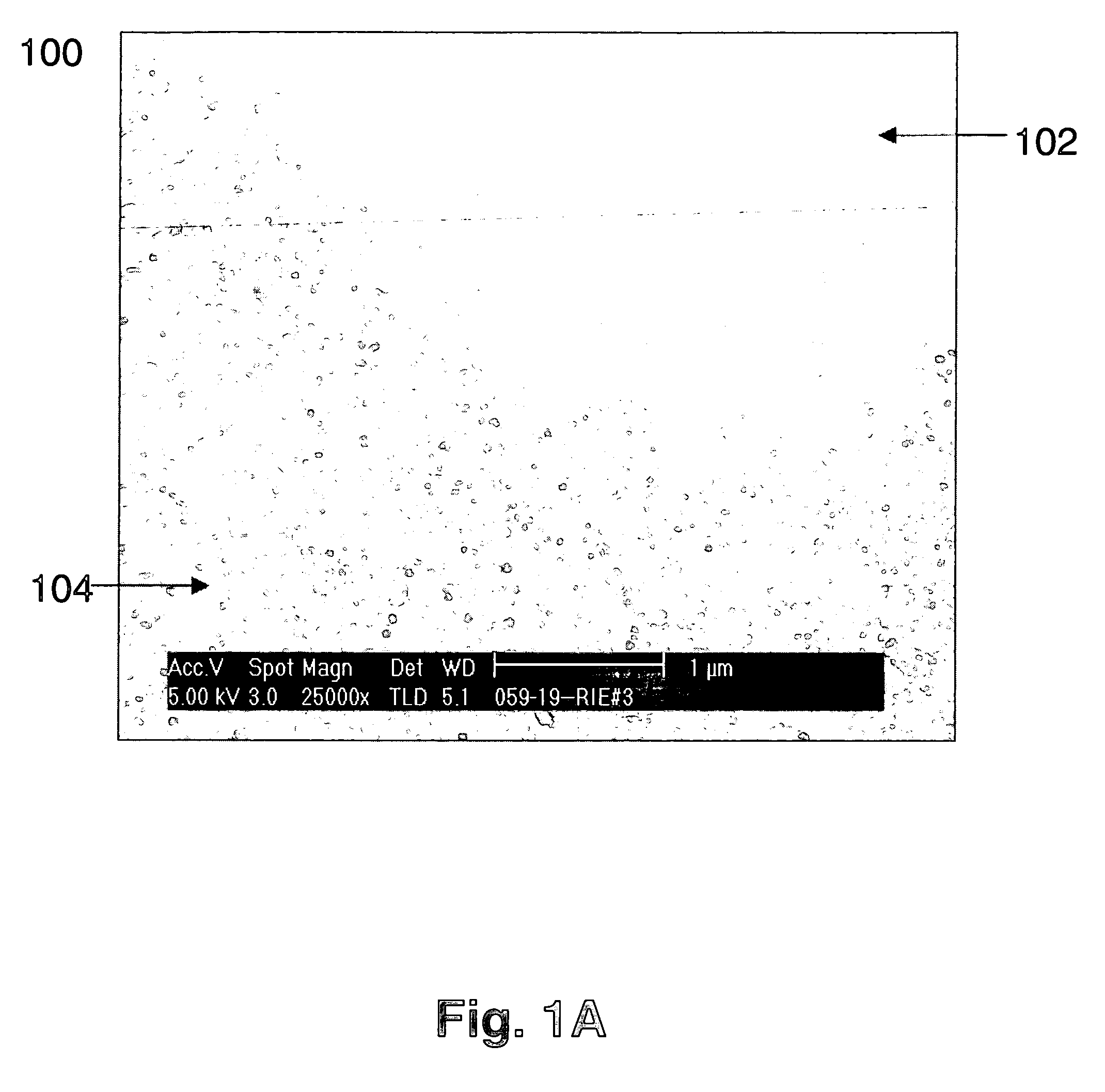

Nanotube articles with adjustable electrical conductivity and methods of making the same

InactiveUS20060276056A1Improve the immunityElectrical resistance increaseMaterial nanotechnologyFixed capacitor dielectricElectrical resistance and conductanceElectrical conductor

Nanotube articles having adjustable electrical conductivity, and methods of making the same. A patterned article includes conducting nanotubes that define a plurality of conductive pathways along the article, and also includes nanotubes of modified electrical conductivity. The modified nanotubes may electrically isolate the conducting nanotubes from other conductors. The nanotube segments may originally be semiconducting nanotubes, metallic nanotubes, nanotubes, single walled carbon nanotubes, multi-walled carbon nanotubes, or nanotubes entangled with nanotubes. The various segments may have different lengths and may include segments having a length shorter than the length of the article. A strapping material may be positioned to contact a portion of the plurality of nanotube segments. Such a strapping layer may also be used for making electrical contact to the nanotube fabric especially for electrical stitching to lower the overall resistance of the fabric.

Owner:NANTERO

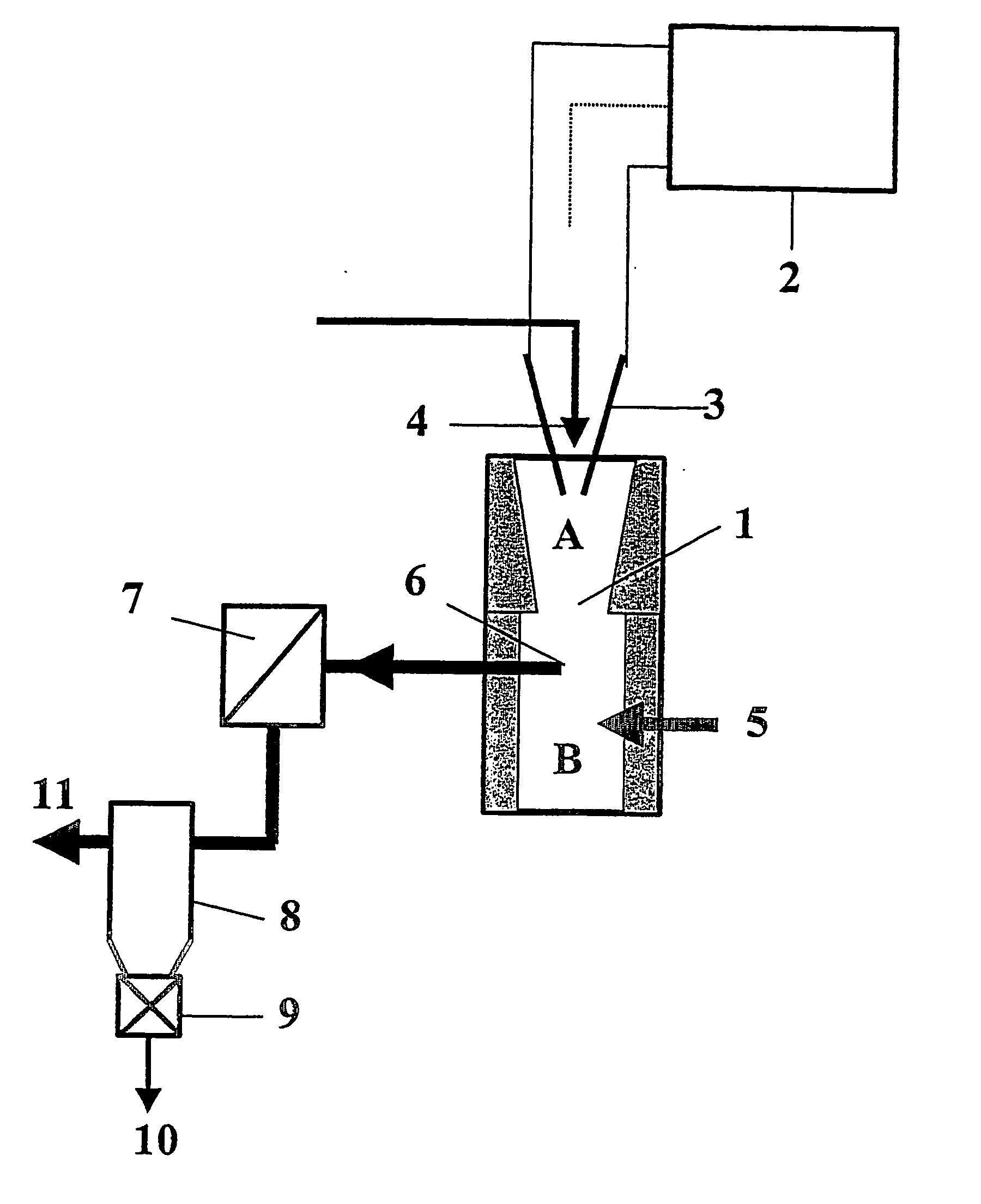

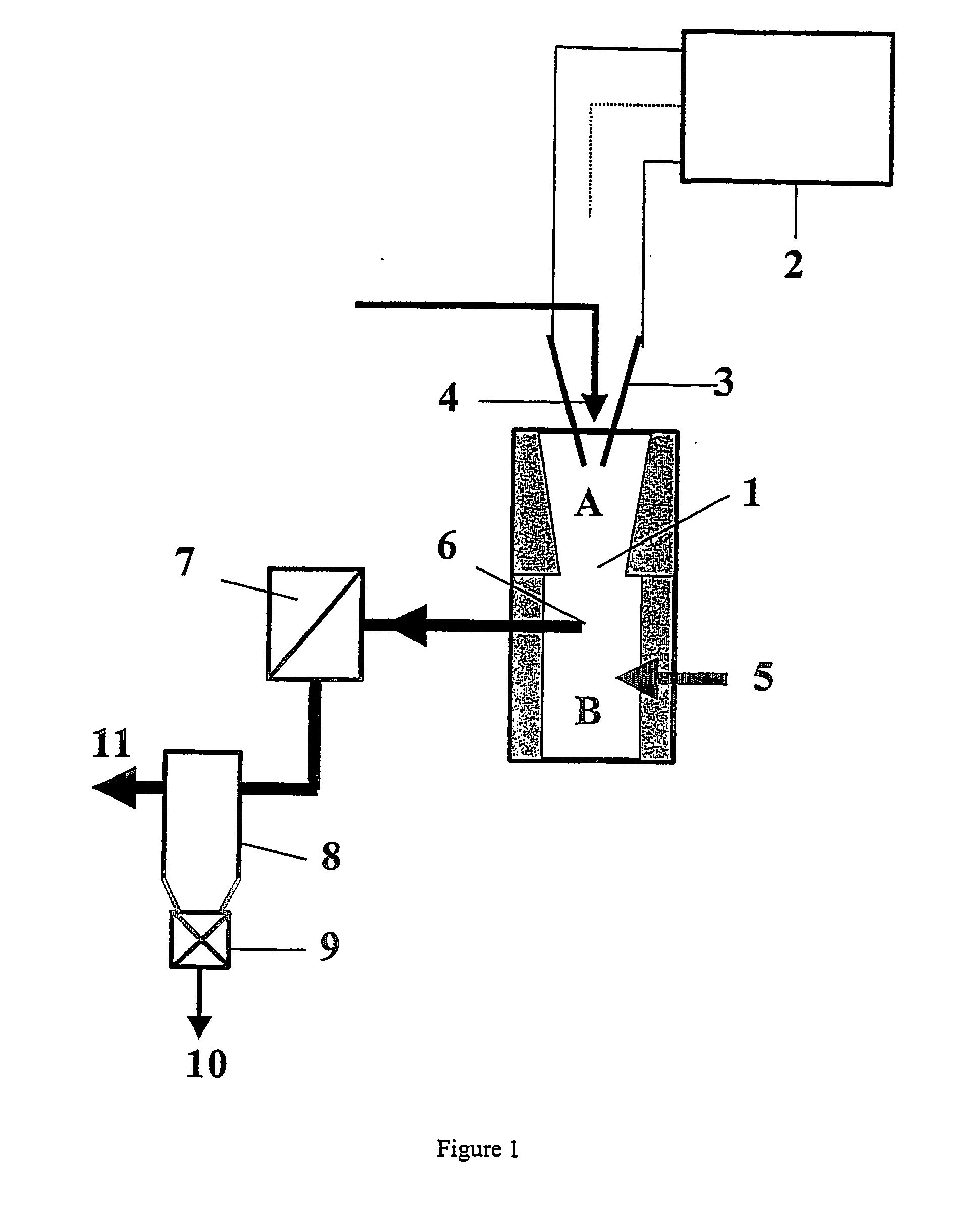

Carbon nanostructures and process for the production of carbon-based nanotubes, nanofibres and nanostructures

InactiveUS20070183959A1Enhanced interactionImprove mechanical propertiesMaterial nanotechnologyFullerenesThermal insulationNanostructure

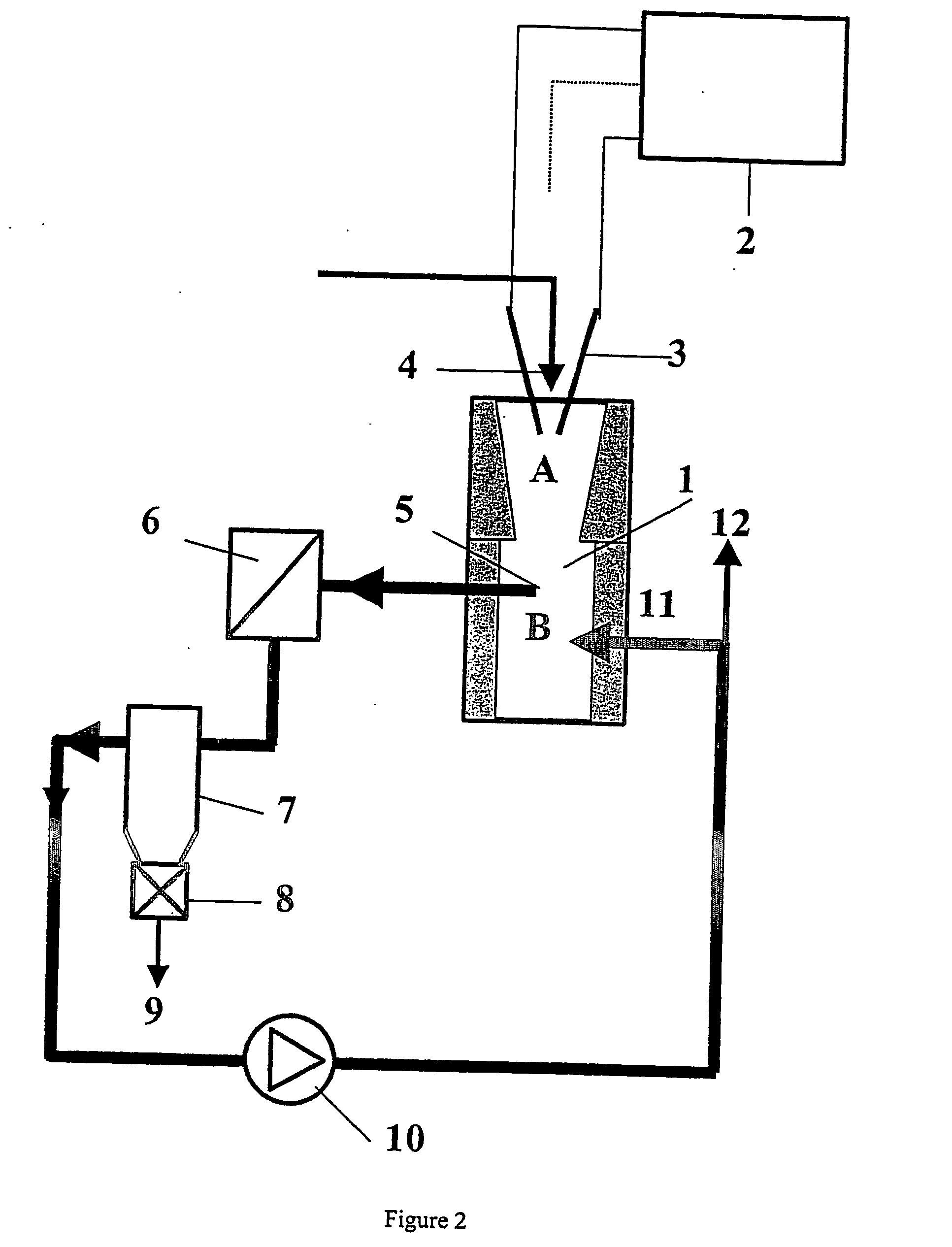

Continuous process for the production of carbon-based nanotubes, nanofibres and nanostructures, comprising the following steps: generating a plasma with electrical energy, introducing a carbon precursor and / or one or more catalysers and / or carrier plasma gas in a reaction zone of an airtight high temperature resistant vessel optionally having a thermal insulation lining, vaporizing the carbon precursor in the reaction zone at a very high temperature, preferably 4000° C. and higher, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyser through a nozzle, whose diameter is narrowing in the direction of the plasma gas flow, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyses into a quenching zone for nucleation, growing and quenching operating with flow conditions generated by aerodynamic and electromagnetic forces, so that no significant recirculation of feedstocks or products from the quenching zone into the reaction zone occurs, controlling the gas temperature in the quenching zone between about 4000° C. in the upper part of this zone and about 50° C. in the lower part of this zone and controlling the quenching velocity between 103 K / s and 106 K / s quenching and extracting carbon-based nanotubes, nanofibres and other nanostructures from the quenching zone, separating carbon-based nanotubes, nanofibres and nanostructures from other reaction products.

Owner:ТІМКАЛ SА +1

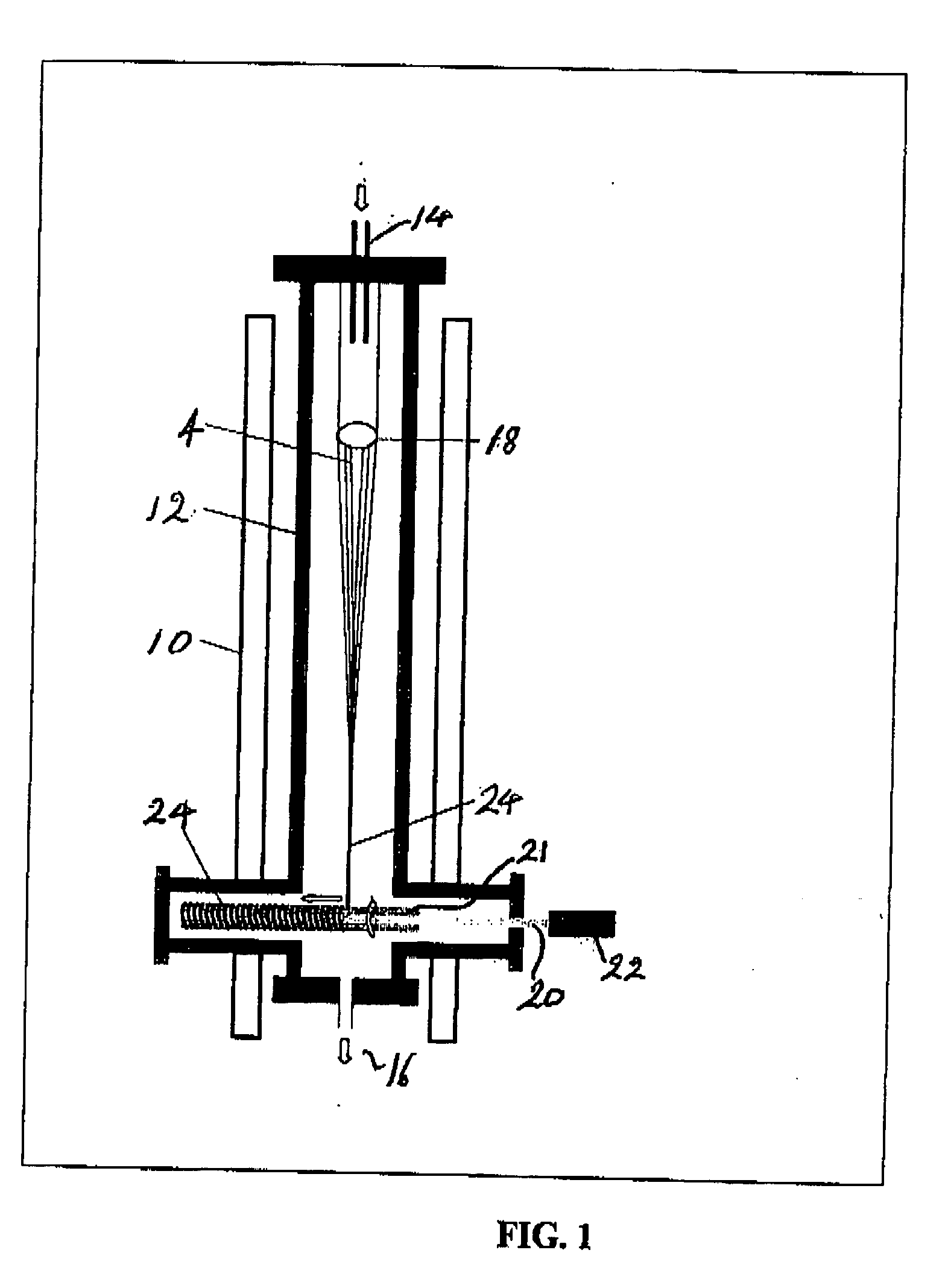

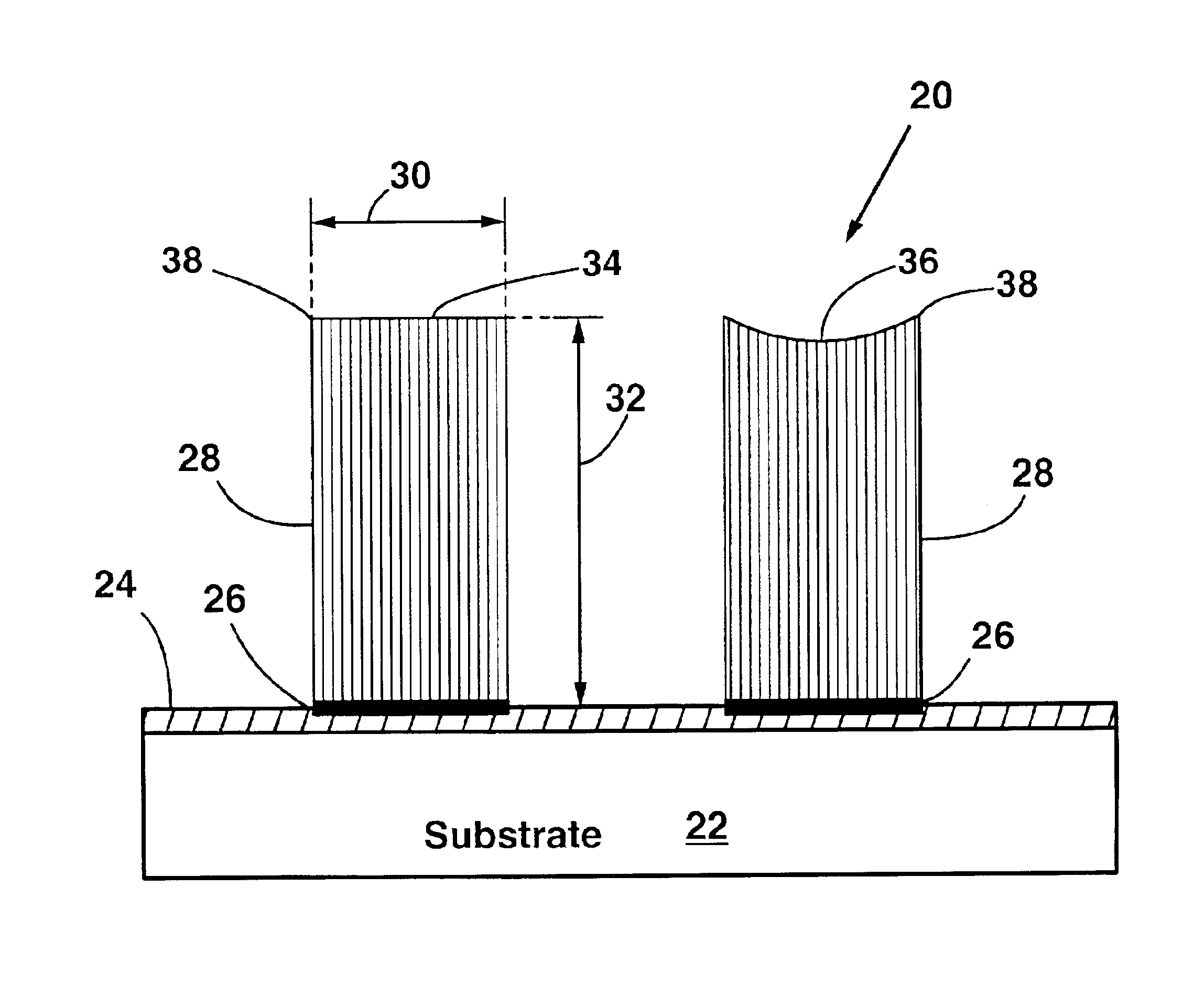

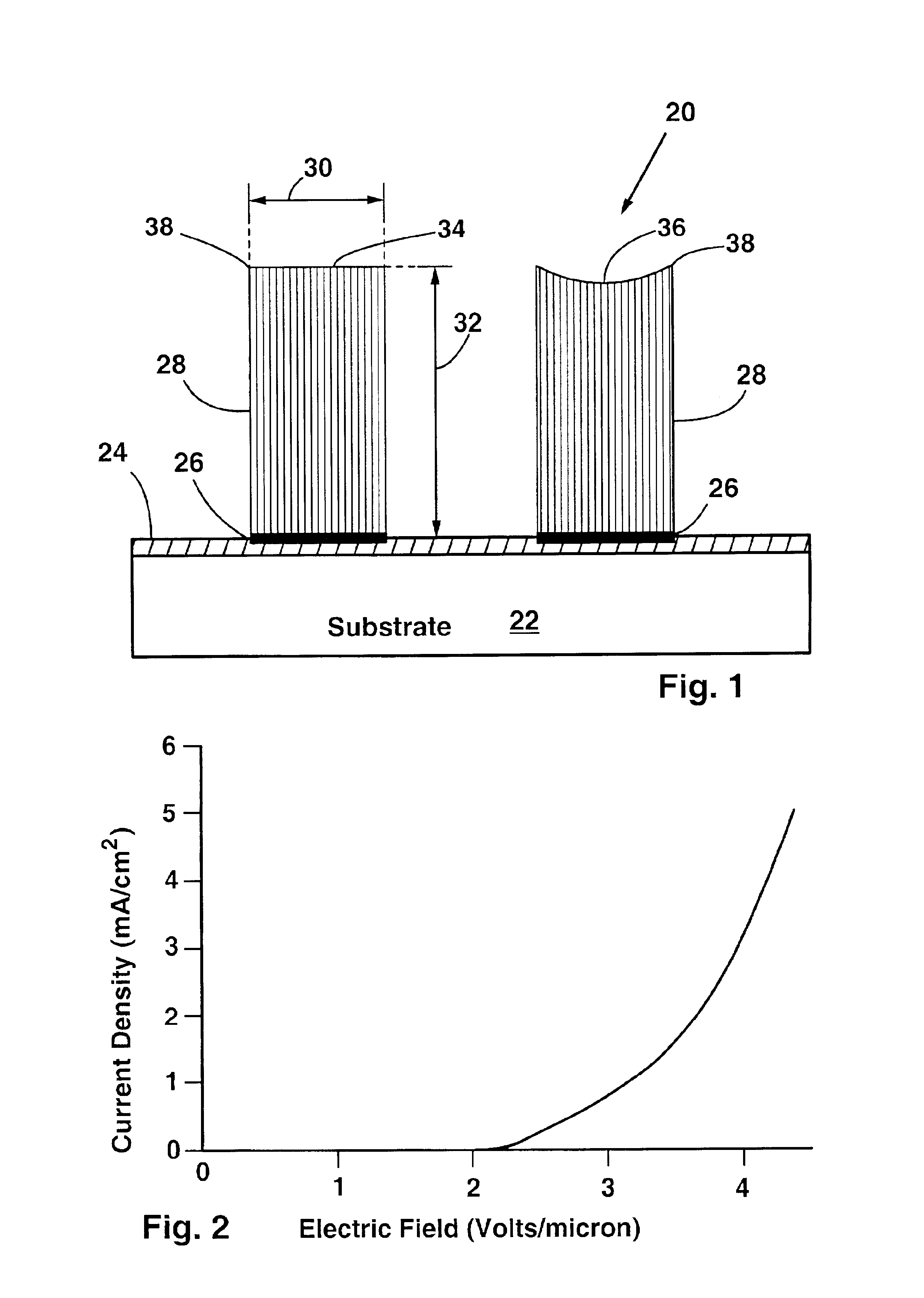

Self-oriented bundles of carbon nanotubes and method of making same

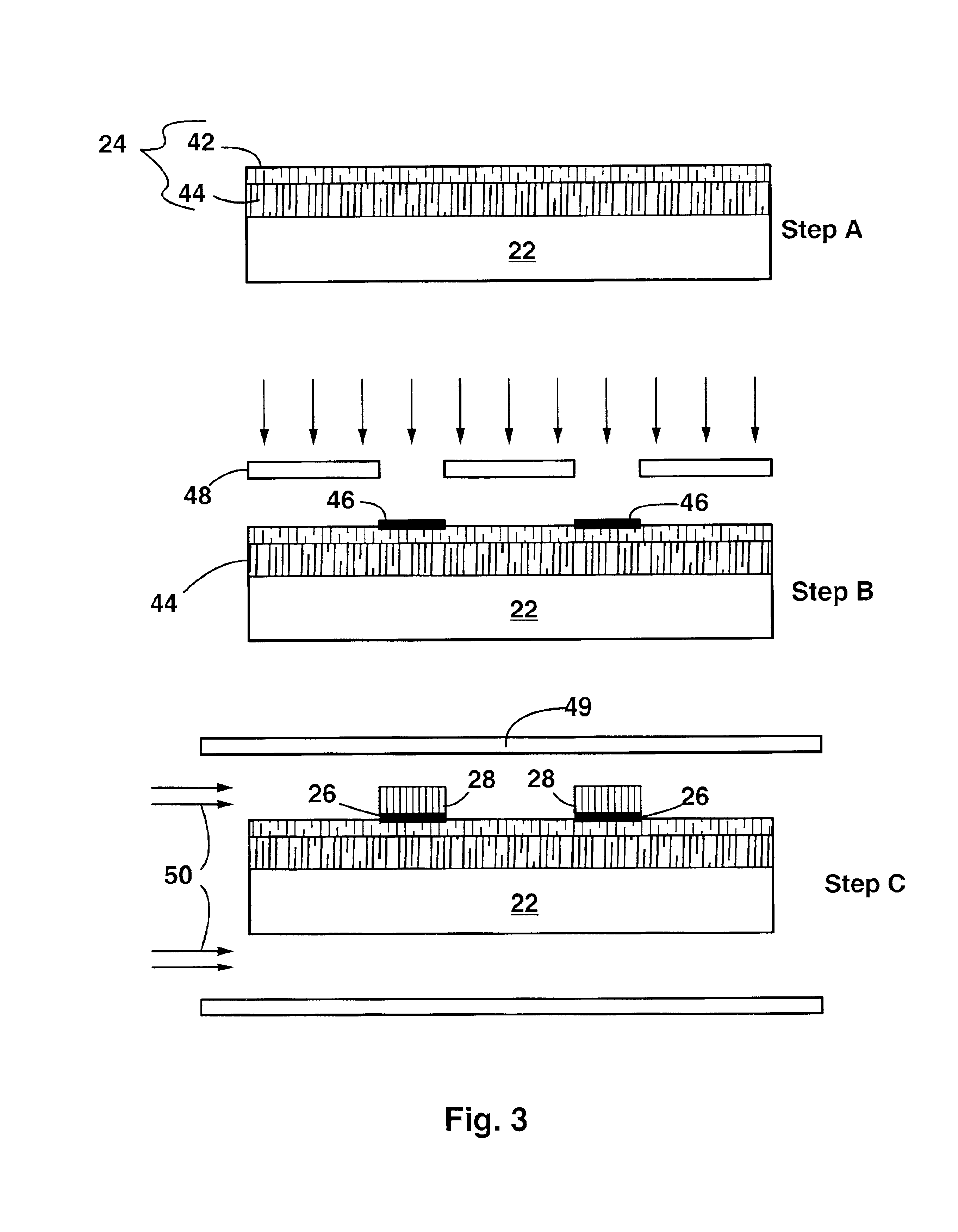

A field emission device having bundles of aligned parallel carbon nanotubes on a substrate. The carbon nanotubes are oriented perpendicular to the substrate. The carbon nanotube bundles may be up to 300 microns tall, for example. The bundles of carbon nanotubes extend only from regions of the substrate patterned with a catalyst material. Preferably, the catalyst material is iron oxide. The substrate is preferably porous silicon, as this produces the highest quality, most well-aligned nanotubes. Smooth, nonporous silicon or quartz can also be used as the substrate. The method of the invention starts with forming a porous layer on a silicon substrate by electrochemical etching. Then, a thin layer of iron is deposited on the porous layer in patterned regions. The iron is then oxidized into iron oxide, and then the substrate is exposed to ethylene gas at elevated temperature. The iron oxide catalyzes the formation of bundles of aligned parallel carbon nanotubes which grow perpendicular to the substrate surface. The height of the nanotube bundles above the substrate is determined by the duration of the catalysis step. The nanotube bundles only grow from the patterned regions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

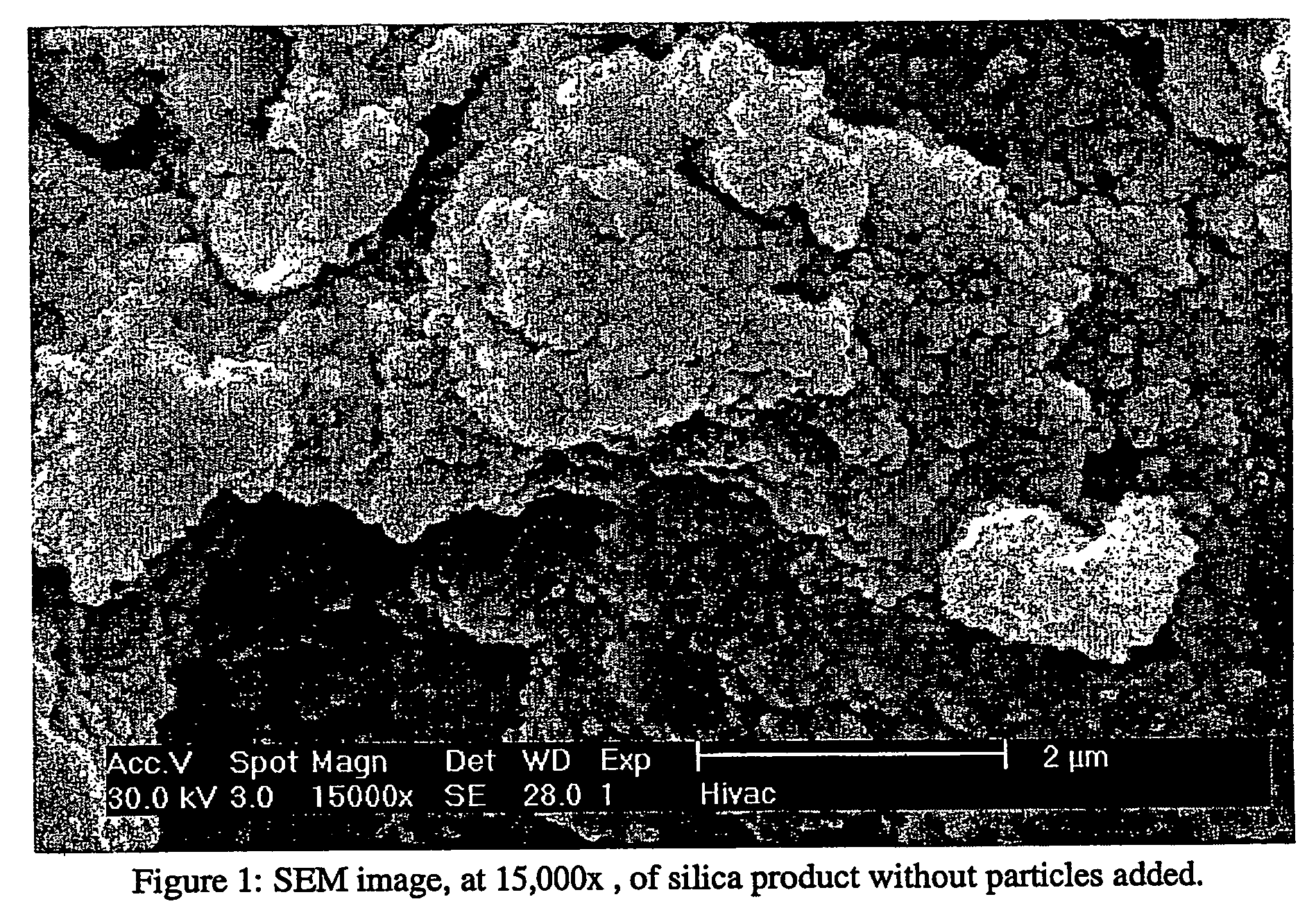

Transparent conductive film and coating composition therefor

InactiveUS20060263588A1High transparencyImproved and well controllable electrical propertiesMaterial nanotechnologyConductive layers on insulating-supportsPolymer scienceCarbon fibers

The disclosed is a transparent conductive film that includes a matrix and carbon fibrous structures added to the matrix, wherein the carbon fibrous structures comprise carbon fibers, each having an outside diameter of 15-100 nm, and wherein the carbon fibrous structures each comprise a granular part at which two or more carbon fibers are bound to each other, and wherein the granular part is concurrently produced in a growth process for the carbon fibers. When the transparent conductive film is formed at a thickness of 0.1-5 μm on a glass substrate, it shows a surface resistivity of not more than 1.0×1012Ω / □, and a total light transmittance of not less than 30%. A coating composition for the conductive transparent film is prepared by using a media mill equipped with beads having an average diameter of 0.05-1.5 mm to disperse the carbon fibrous structures into the liquid resinous composition.

Owner:MITSUI & CO LTD +1

Carbon nanotube containing materials and articles containing such materials for altering electromagnetic radiation

InactiveUS20050272856A1Reduce performanceImprove performanceMaterial nanotechnologyMagnetic/electric field screeningCarbon nanotubeElectromagnetic radiation

Disclosed herein is a material for altering electromagnetic radiation incident on the material. The material disclosed herein comprises carbon nanotubes having a length (L) that meets the following formula (1): L≧½λ (1) where λ is the wavelength of the electromagnetic radiation incident on the material. Also disclosed herein are methods of altering electromagnetic radiation, including mitigating, intensifying, or absorbing and re-transmitting electromagnetic radiation using the disclosed material.

Owner:MULTIPURE INT

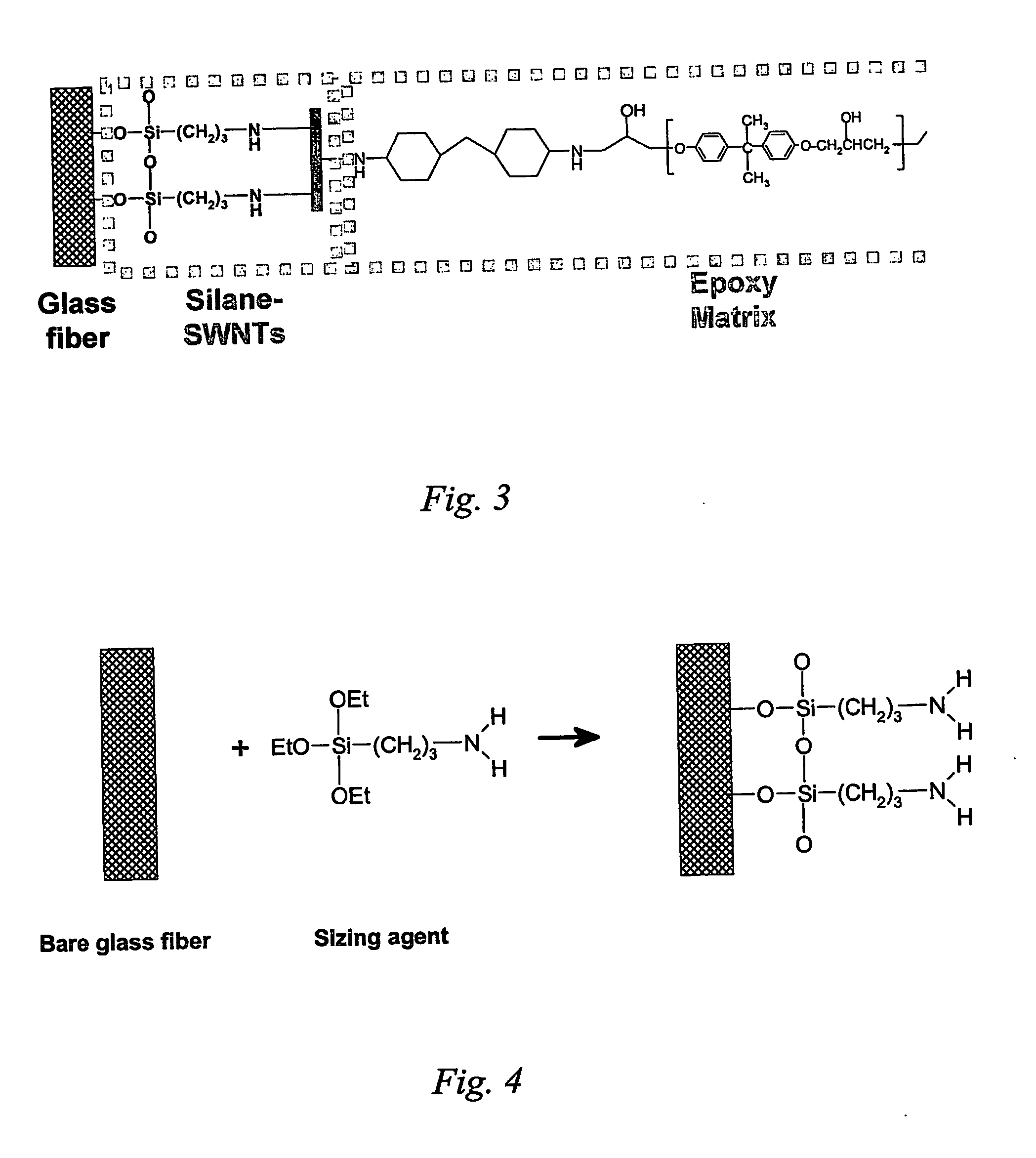

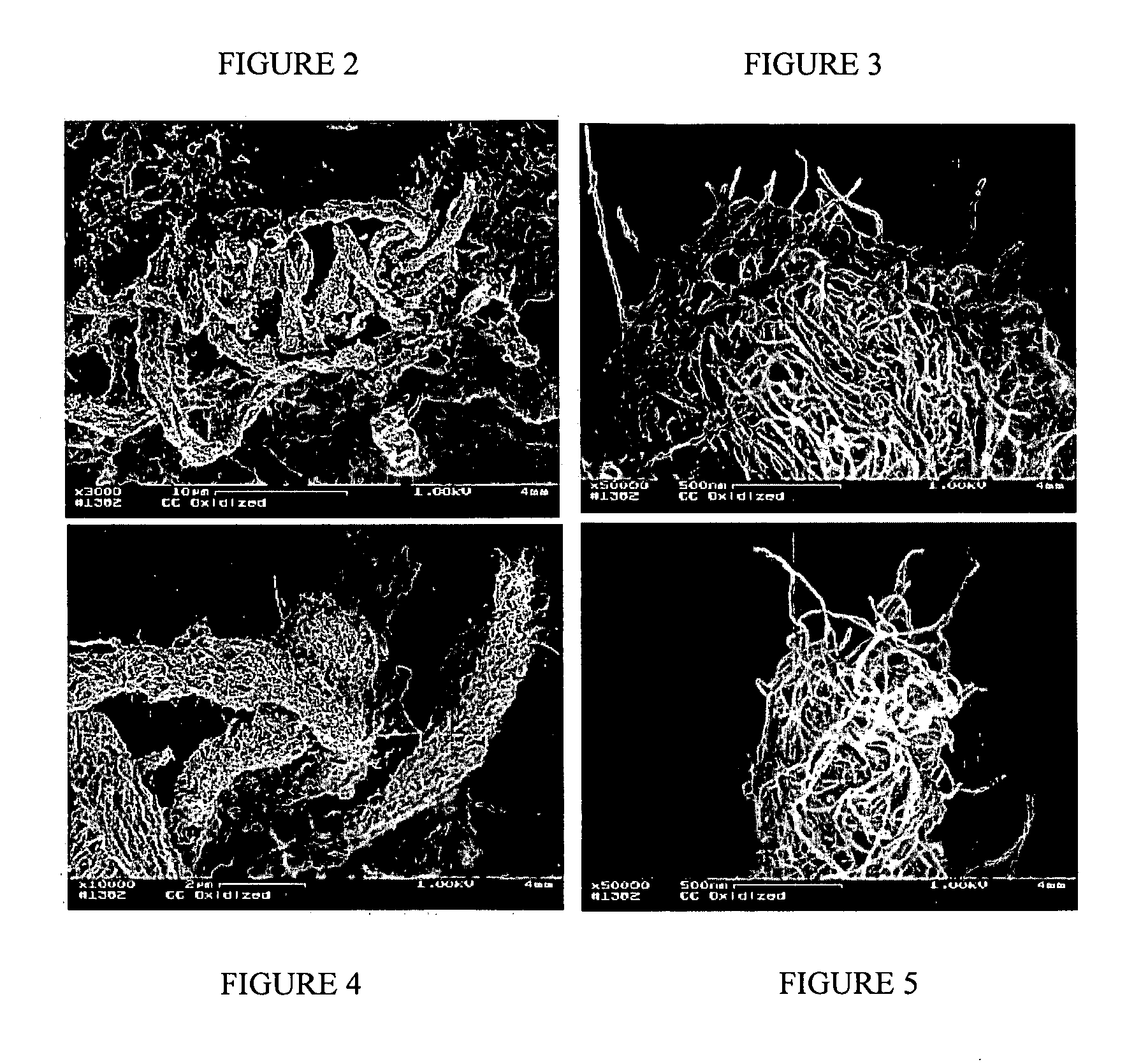

Sidewall Functionalization Of Carbon Nanotubes With Organosilanes For Polymer Composites

InactiveUS20070298669A1Improve the level ofStrong attachmentMaterial nanotechnologySilicon organic compoundsPolymer compositesPolymer chemistry

The present invention is directed to methods of functionalizing carbon nanotubes (CNTs), particularly single-wall carbon nanotubes (SWNTs), with organosilane species, wherein such functionalization enables fabrication of advanced polymer composites. The present invention is also directed toward the functionalized CNTs, advanced CNT-polymer composites made with such functionalized CNTs, and methods of making such advanced CNT-polymer composites.

Owner:RICE UNIV

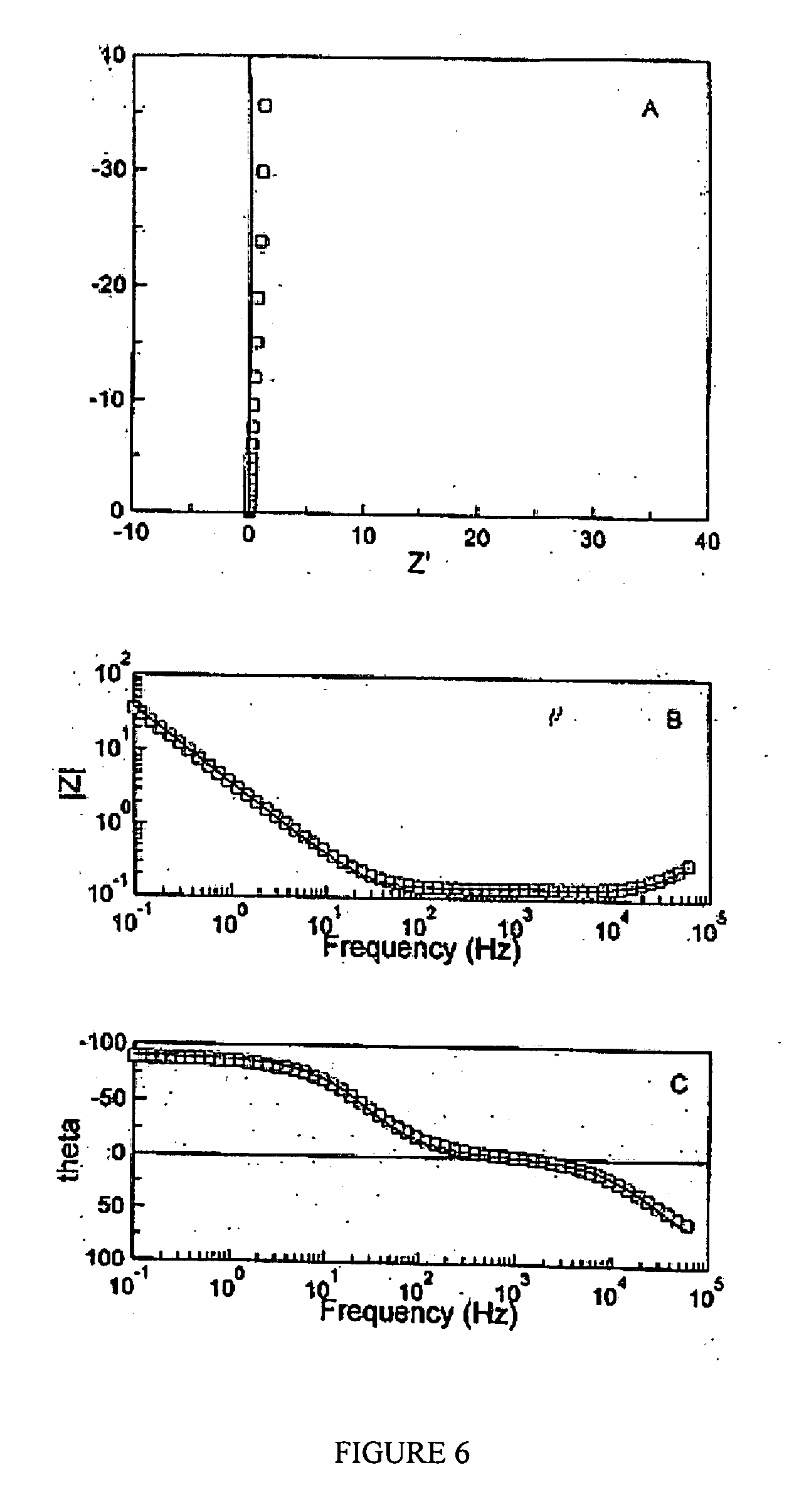

Methods of oxidizing multiwalled carbon nanotubes

InactiveUS20060239891A1Good electrochemical propertiesMaterial nanotechnologyHybrid capacitor electrodesMultiwalled carbonElectrochemistry

Methods of oxidizing multiwalled carbon nanotubes are provided. The multiwalled carbon nanotubes are oxidized by contacting the carbon nanotubes with gas-phase oxidizing agents such as CO2, O2, steam, N2O, NO, NO2, O3, and ClO2. Near critical and supercritical water can also be used as oxidizing agents. The multiwalled carbon nanotubes oxidized according to methods of the invention can be used to prepare rigid porous structures which can be utilized to form electrodes for fabrication of improved electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

Carbon nanotube adducts and methods of making the same

The invention provides an adduct comprising a carbon nanotube and a transitional metal coordination complex, wherein the metal of the complex is attached by a covalent linkage to at least one oxygen moiety on the nanotube.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

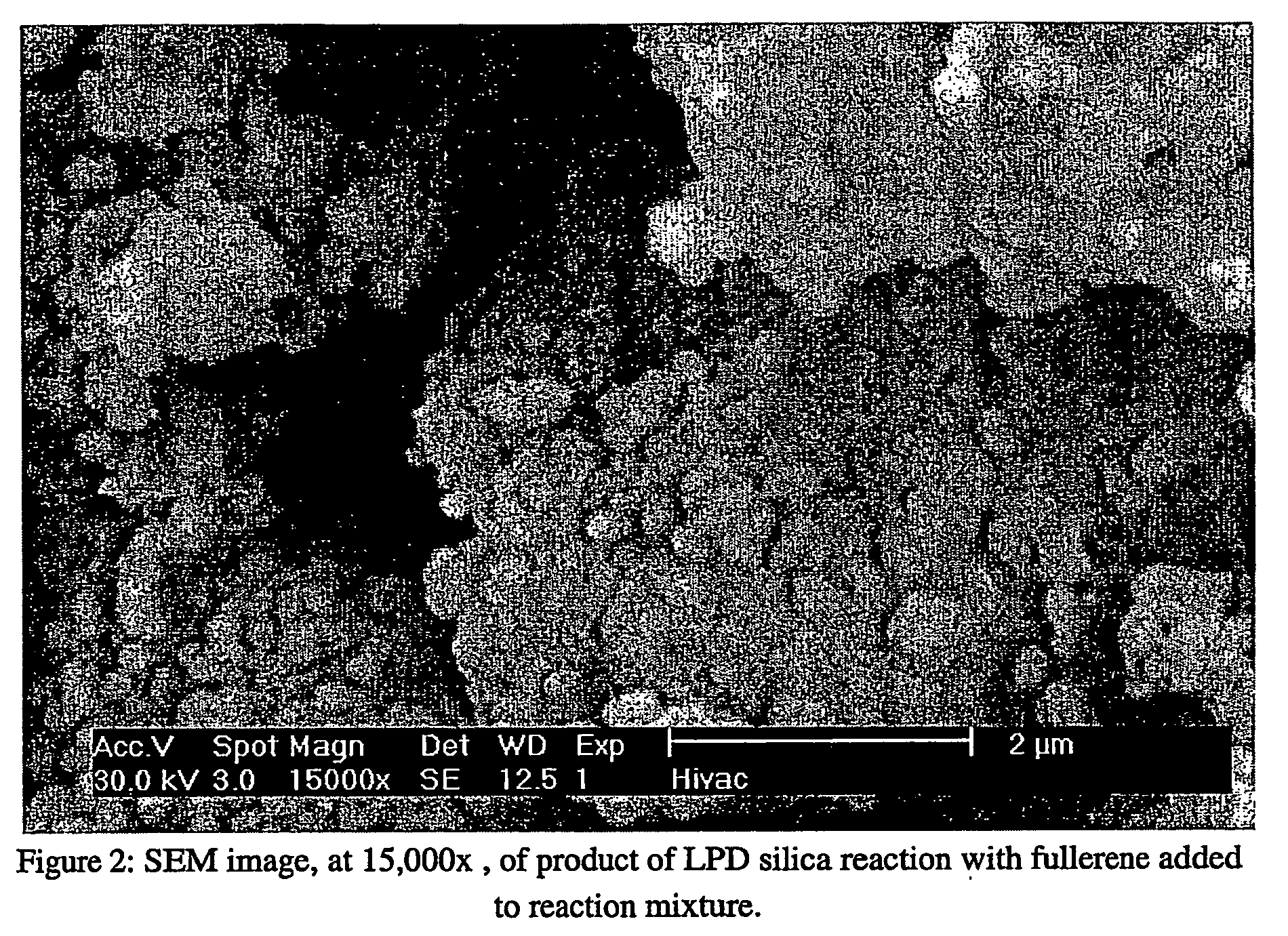

Coated fullerenes, composites and dielectrics made therefrom

InactiveUS20050089684A1Rate of formation is fasterFaster ratePigmenting treatmentMaterial nanotechnologyDielectricFullerene

The present invention relates to coated fullerenes comprising a layer of at least one inorganic material covering at least a portion of at least one surface of a fullerene and methods for making. The present invention further relates to composites comprising the coated fullerenes of the present invention and further comprising polymers, ceramics and / or inorganic oxides. A coated fullerene interconnect device wherein at least two fullerenes are contacting each other to form a spontaneous interconnect is also disclosed as well as methods of making. In addition, dielectric films comprising the coated fullerenes of the present invention and methods of making are further disclosed.

Owner:RICE UNIV +1

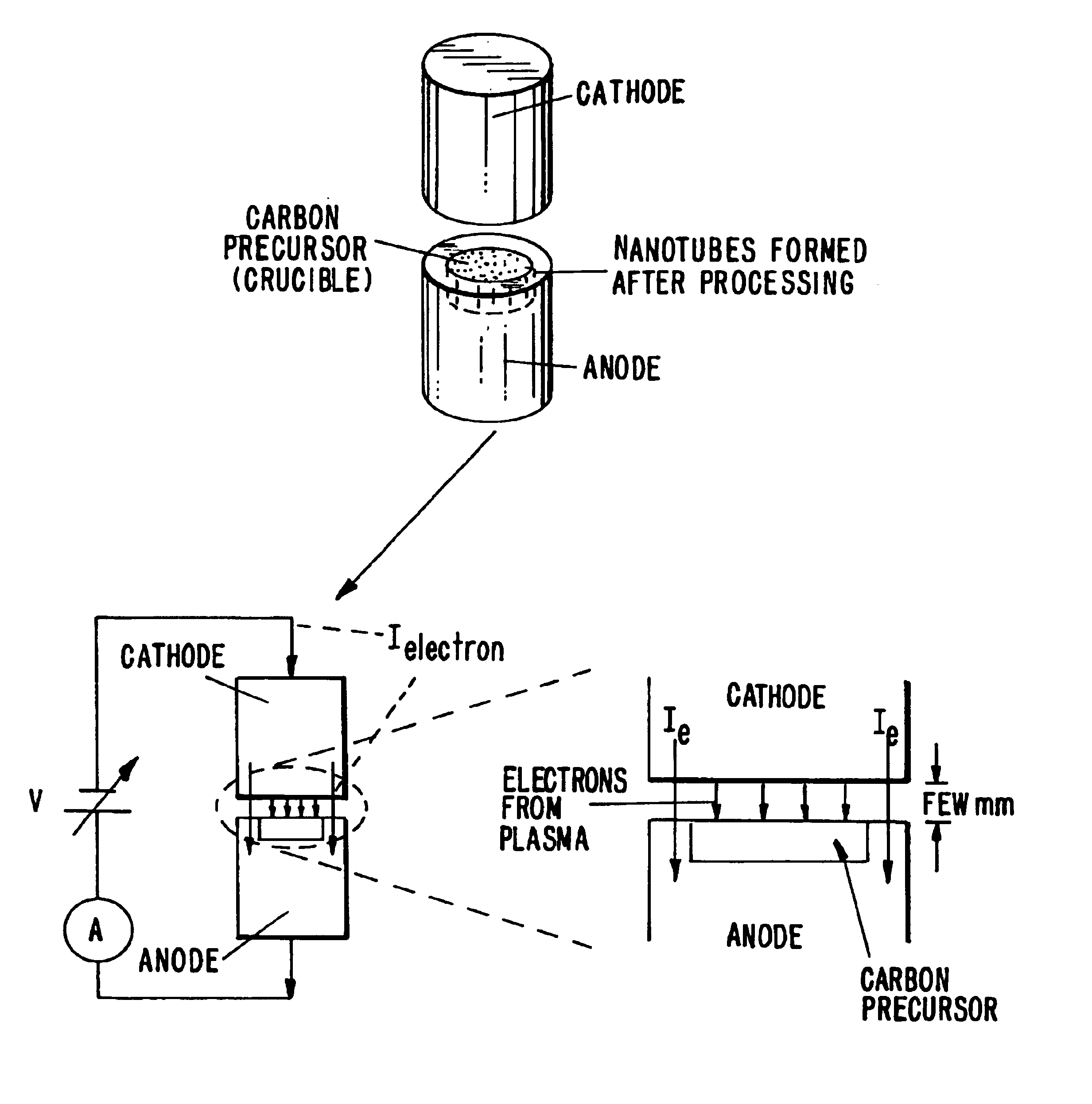

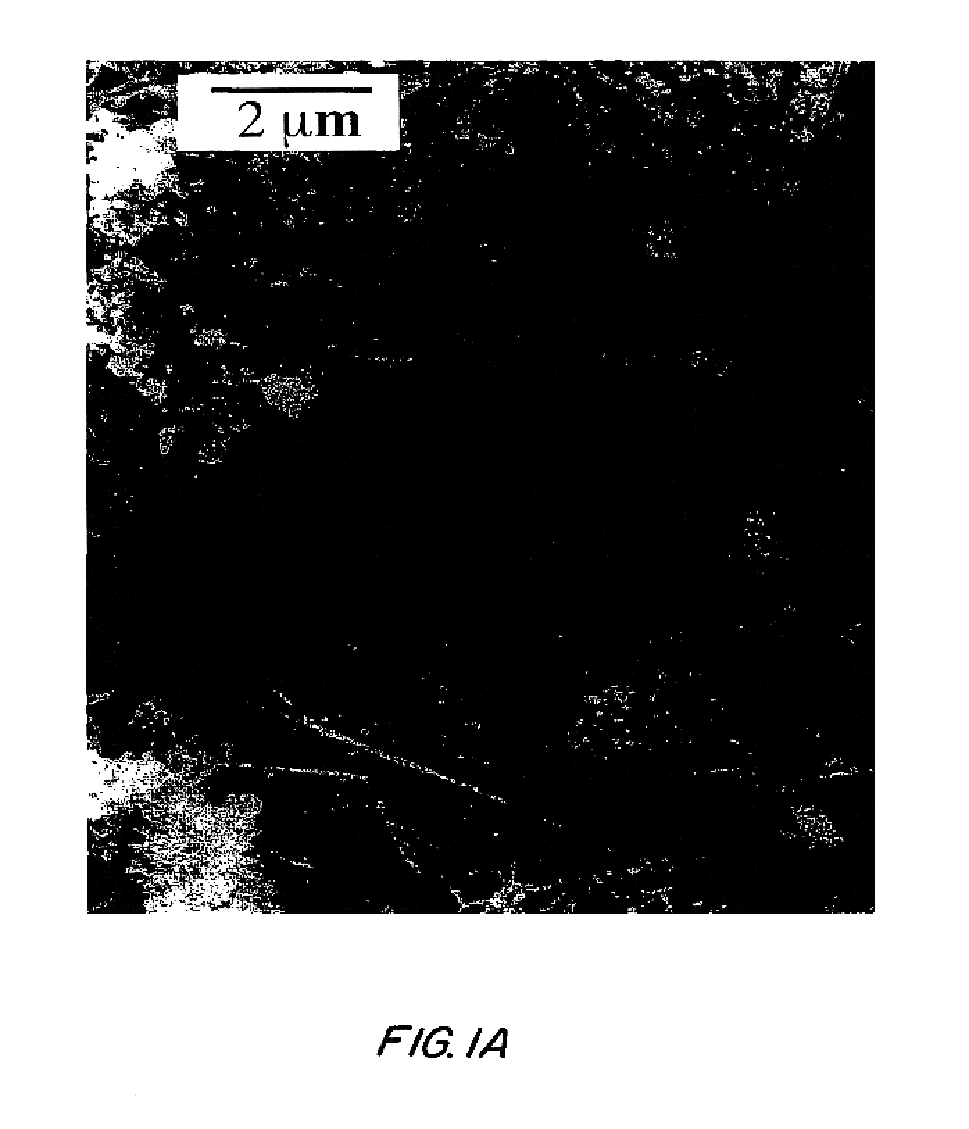

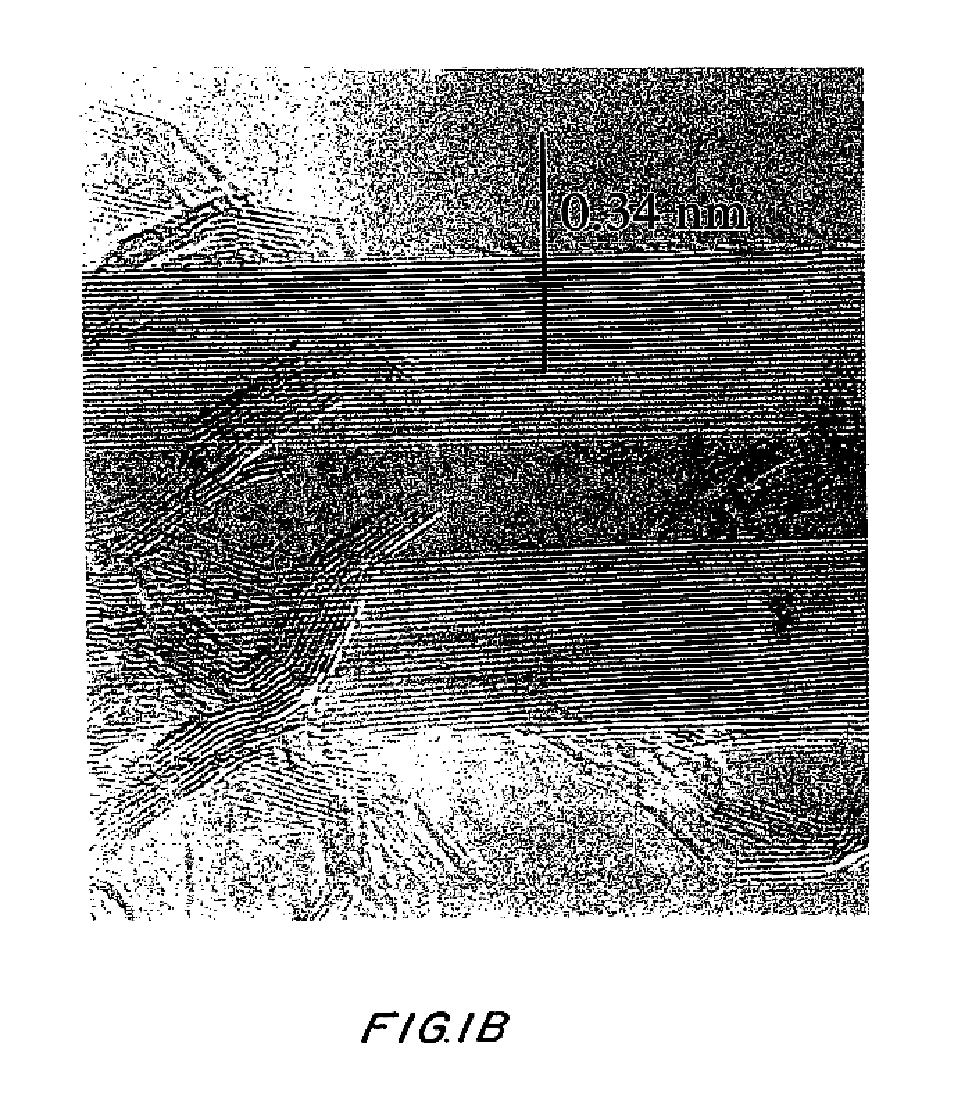

Carbon nanostructures and methods of preparation

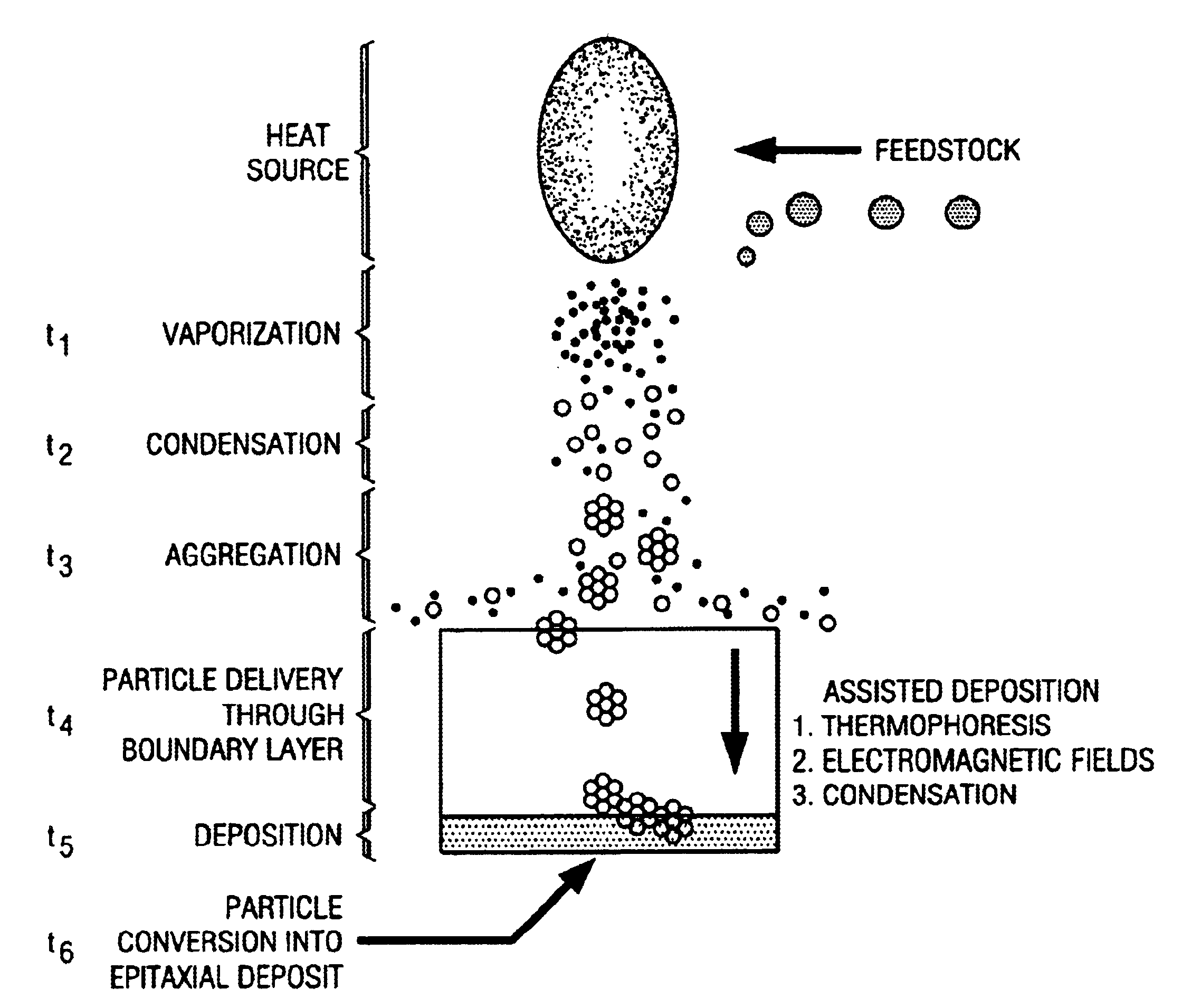

InactiveUS6765949B2Enhanced and superior structural and mechanical propertyImprove processing efficiencyMaterial nanotechnologyElectric discharge heatingSufficient timeElectric arc furnace

An electric arc furnace and method for forming tubular carbon nanostructures comprising a first electrode (cathode) and an a second electrode (anode) opposite the first electrode, sources of voltage (V) and current (A) to create charged particles (Ie) and produce an arch between the electrodes, a source of a gas to surround the arc, and a source of carbon precursor positioned adjacent the anode and within the arc, wherein the arc is maintained at a pressure and high temperature for a time sufficient to heat the carbon precursor to form carbon nonotubes upon the anode.

Owner:CHANG ROBERT P H

Divided solid composition composed of grains provided with continuous metal deposition, method for the production and use thereof in the form of a catalyst

This invention relates to a solid divided composition comprising grains whose mean size is greater than 25 μm and less than 2.5 mm, wherein each grain is provided with a solid porous core and a homogeneous continuous metal layer consisting of at least one type of transition non-oxidised metal and extending along a gangue coating the core in such a way that pores are inaccessible. A method for the production of said composition and for the use thereof in the form of a solid catalyst is also disclosed.

Owner:INST NAT POLYTECHNIQUE DE TOU LOUSE +1

Nanotube polymer composite and methods of making same

The invention relates to derivatized, well-dispersed CNTs that have enhanced miscibility with organic agents. Composite materials may be made using such CNTs. The composite materials, in turn, may be used in optical and electronic applications.

Owner:RENESSELAER POLYTECHNIC INST

Condensed phase conversion and growth of nanorods instead of from vapor

Compositions, systems and methods are described for condensed phase conversion and growth of nanorods and other materials. A method includes providing a condensed phase matrix material; and activating the condensed phase matrix material to produce a plurality of nanorods by condensed phase conversion and growth from the condensed chase matrix material instead of from vacor. The compositions are very strong. The compositions and methods provide advantages because they allow (1) formation rates of nanostructures necessary for reasonable production rates, and (2) the near net shaped production of component structures.

Owner:UT BATTELLE LLC

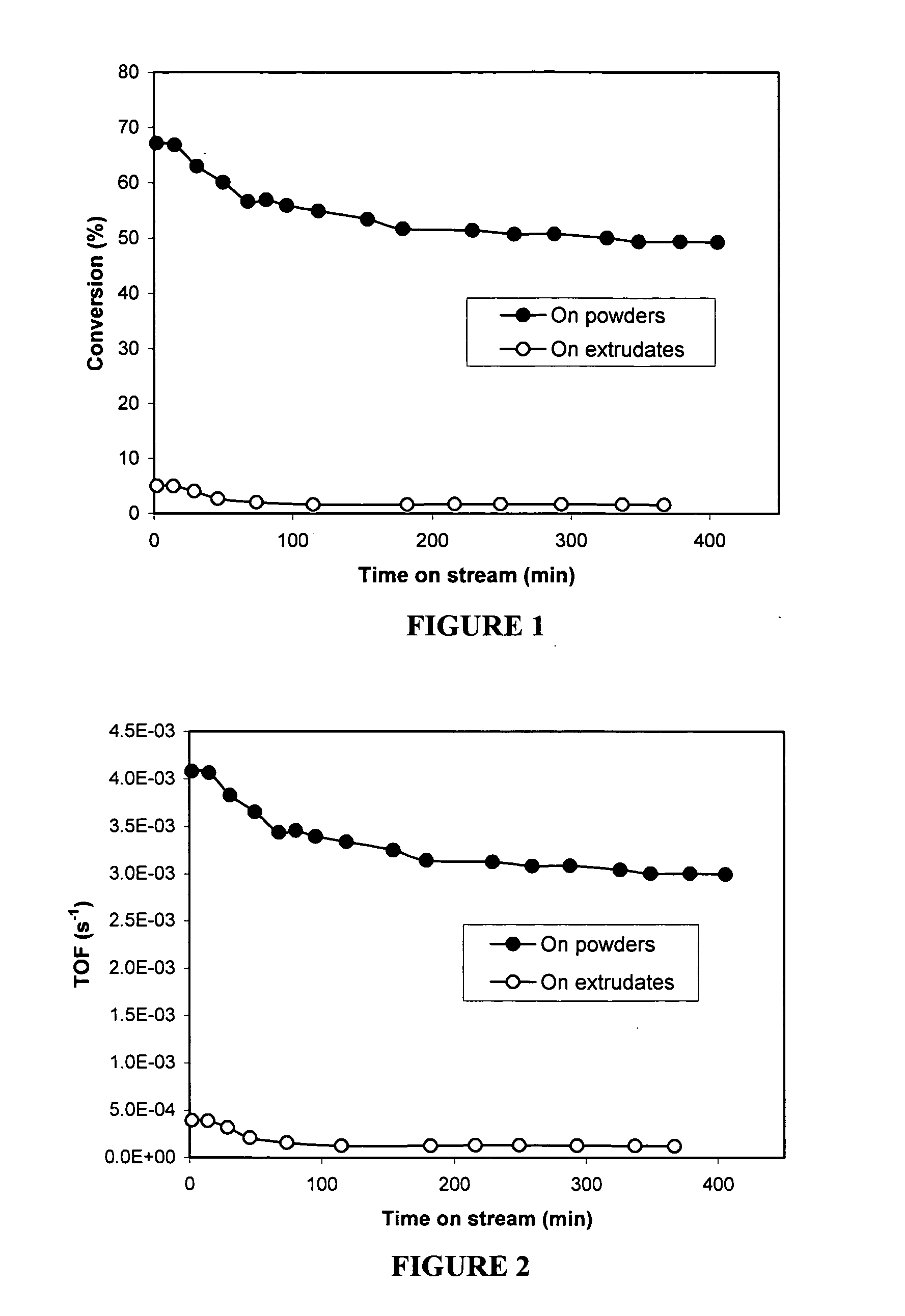

Method for preparing supported catalysts from metal loaded carbon nanotubes

InactiveUS20060142149A1Improves Structural IntegrityMaterial nanotechnologyOrganic compound preparationPtru catalystNanotube

A new method for preparing a supported catalyst is herein provided. Carbon nanotubes are functionalized by contacting them with an oxidizing agent to form functionalized carbon nanotubes. A metal catalyst is then loaded or deposited onto the functionalized carbon nanotubes. The mixture is then extruded to form the supported catalyst comprising a carbon nanotube structure containing metal catalyst more evenly dispersed within the internal structure of the carbon nanotube structure.

Owner:HYPERION CATALYSIS INT

Patterning carbon nanotube coatings by selective chemical modification

InactiveUS20060057290A1Efficient and rapid and cost-effective methodMaterial nanotechnologyLayered productsConductive coatingChemical modification

This invention is directed to a method of patterning carbon nanotubes transparent electrically conductive coating / films, by modification of the applied carbon nanotube (CNT) network through use of sidewall group functionalization to disrupt electrical conductivity of the nanotubes. The resulting areas which undergo chemical modification are rendered more or less conductive than those areas which where not altered. This results in a patterned film, wherein said pattern is shaped to form electrodes, pixels, wires, antenna or other electrical component. In addition, the areas of chemically modified CNT can be returned to their original conductive state (i.e. reversible and repeatable), or fixed to yield a permanent pattern.

Owner:EIKOS

Functionalization of Carbon Nanotubes in Acidic Media

InactiveUS20070280876A1Improve scalabilityEasy to functionalizePigmenting treatmentMaterial nanotechnologyCarbon nanotubeOrganic chemistry

The present invention is generally directed to methods of functionalizing carbon nanotubes (CNTs) in acidic media. By first dispersing CNTs in an acidic medium, bundled CNTs can be separated as individual CNTs, affording exposure of the CNT sidewalls, and thereby facilitating the functionalization of such CNTs, wherein functional groups are attached to the subsequently exposed sidewalls of these individualized CNTs. Once dispersed in this substantially unhundled state, the CNTs are functionalized according to one or more of a variety of functionalization processes. Typically, ultrasonication or non-covalent wrapping is not needed to afford such dispersion and subsequent functionalization. Additionally, such methods are easily scalable and can provide for sidewall-functionalized CNTs in large, industrial-scale quantities.

Owner:RICE UNIV

Polymeric compositions containing nanotubes

InactiveUS20100078194A1Improve flammability characteristicImprove thermal propertiesMaterial nanotechnologyConductive materialNanotubePolymer chemistry

A polymeric composition containing at least one polymer and carbon nanotubes is described. The polymeric composition can have carbon nanotubes that are multi-wall carbon nanotubes and / or single-wall carbon nanotubes. The compositions can also contain carbon black. Also described are various articles made from the polymeric compositions including cables and other articles.

Owner:CABOT CORP

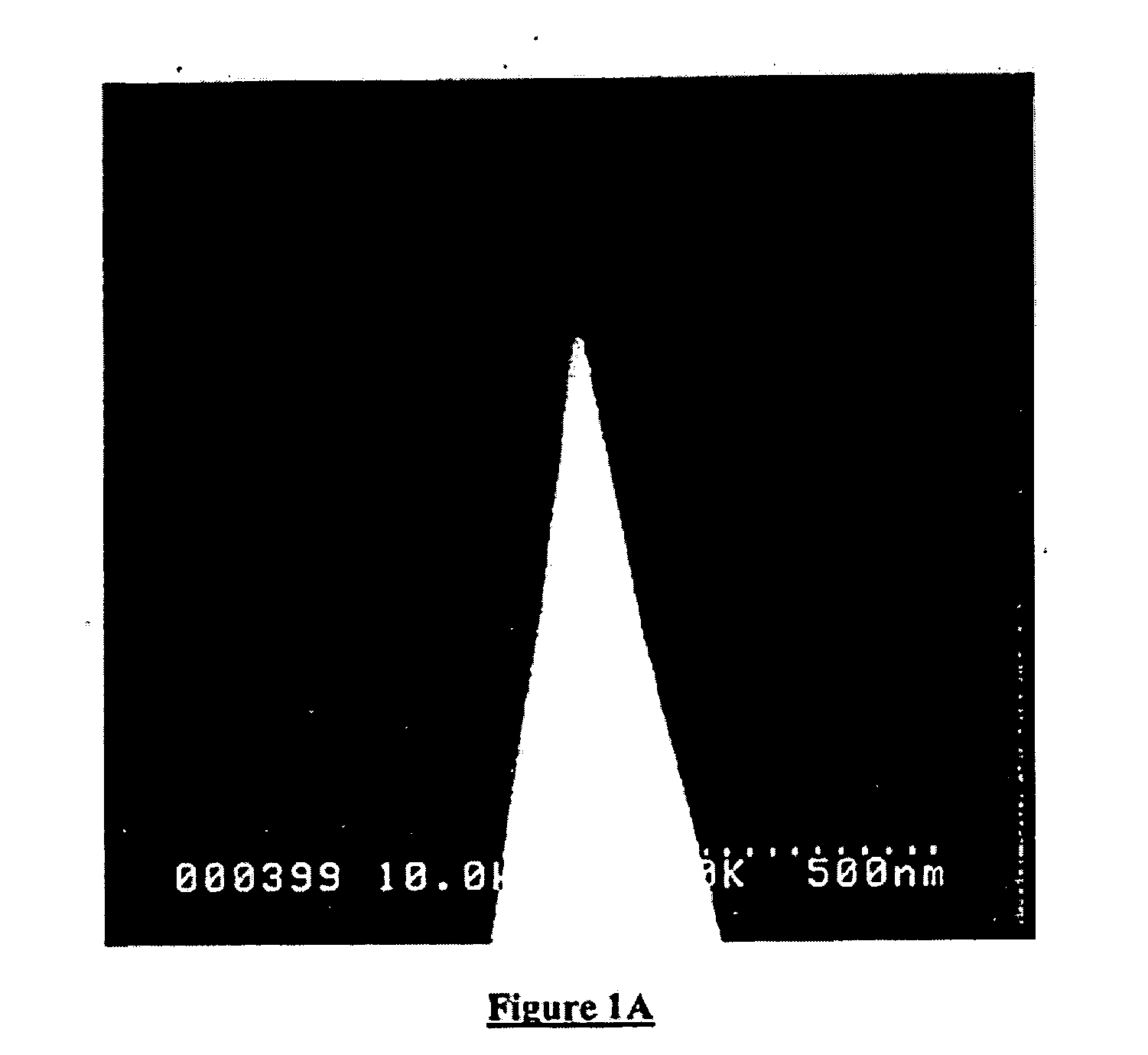

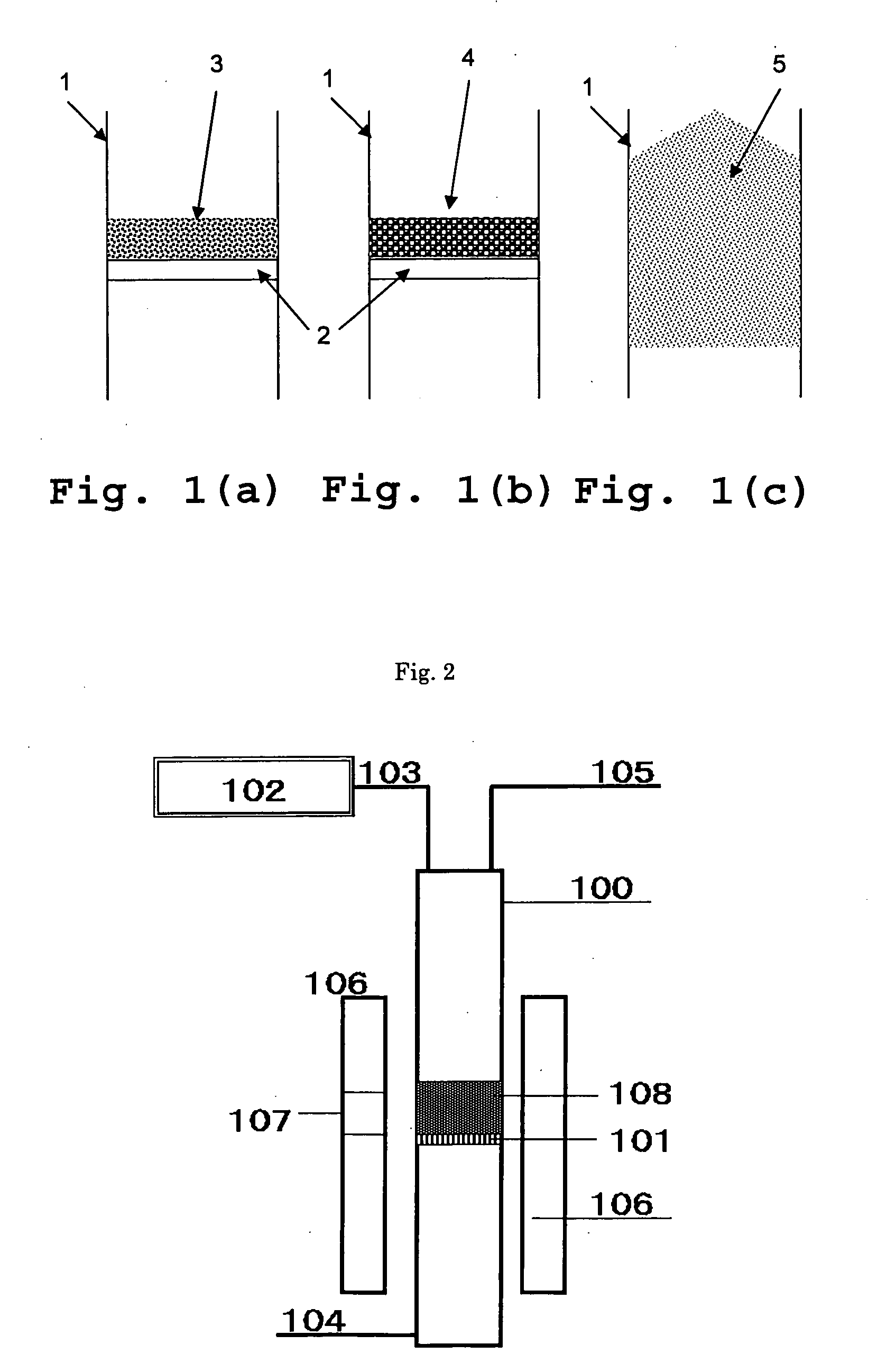

Catalyst-induced growth of carbon nanotubes on tips of cantilevers and nanowires

InactiveUS20020046953A1Easy to controlImprove performanceAnodisationMaterial nanotechnologyFiberNanowire

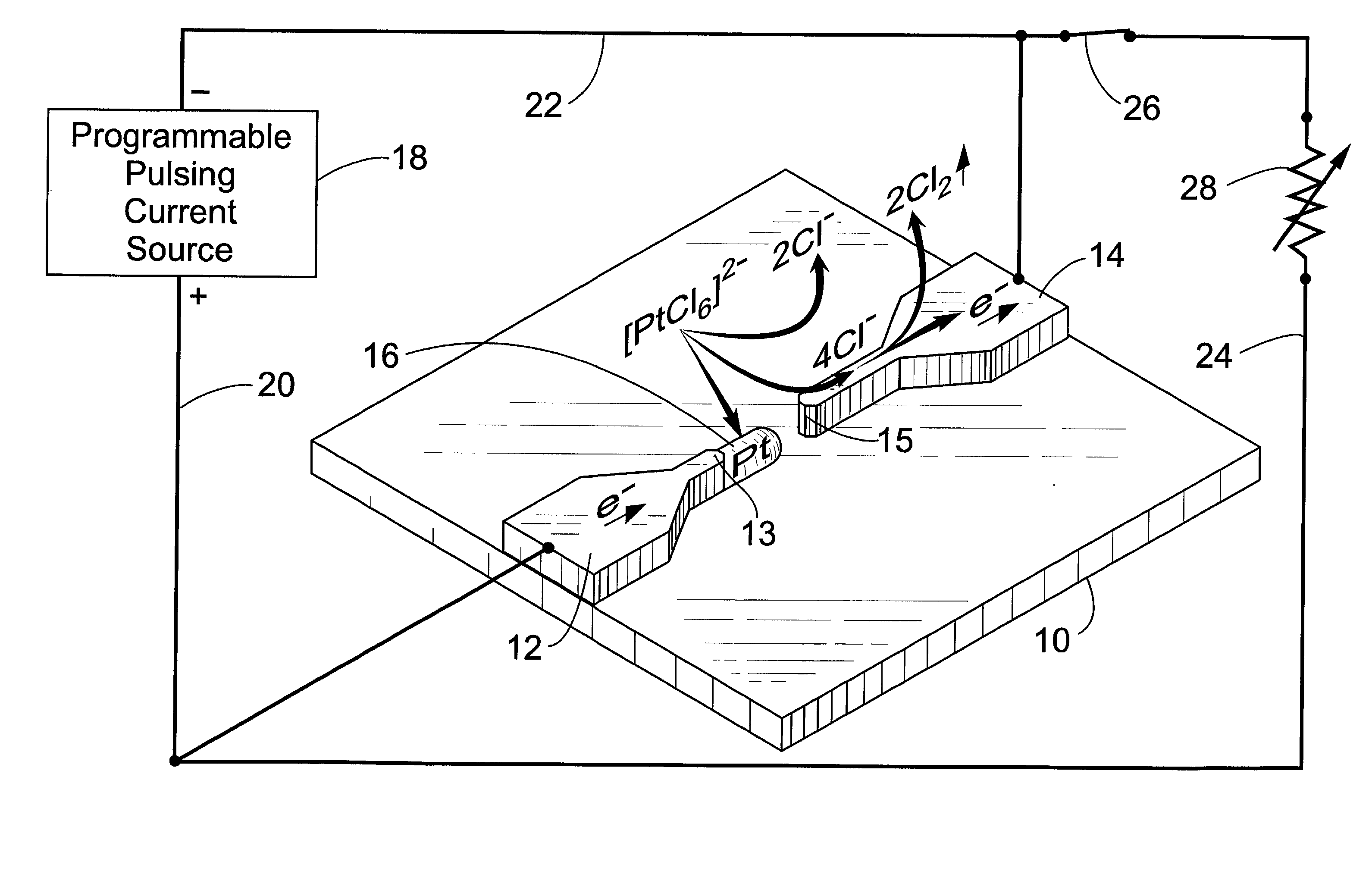

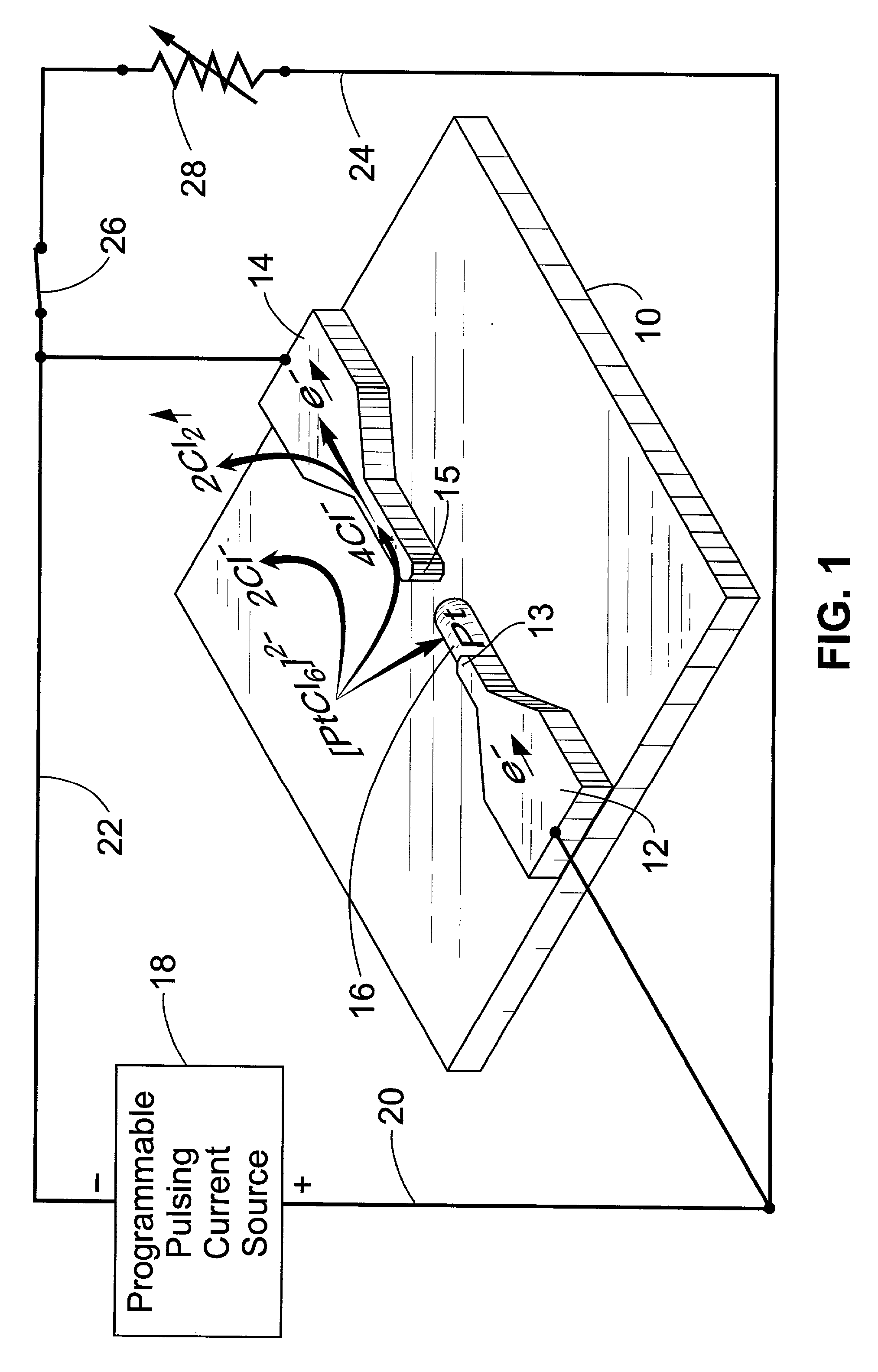

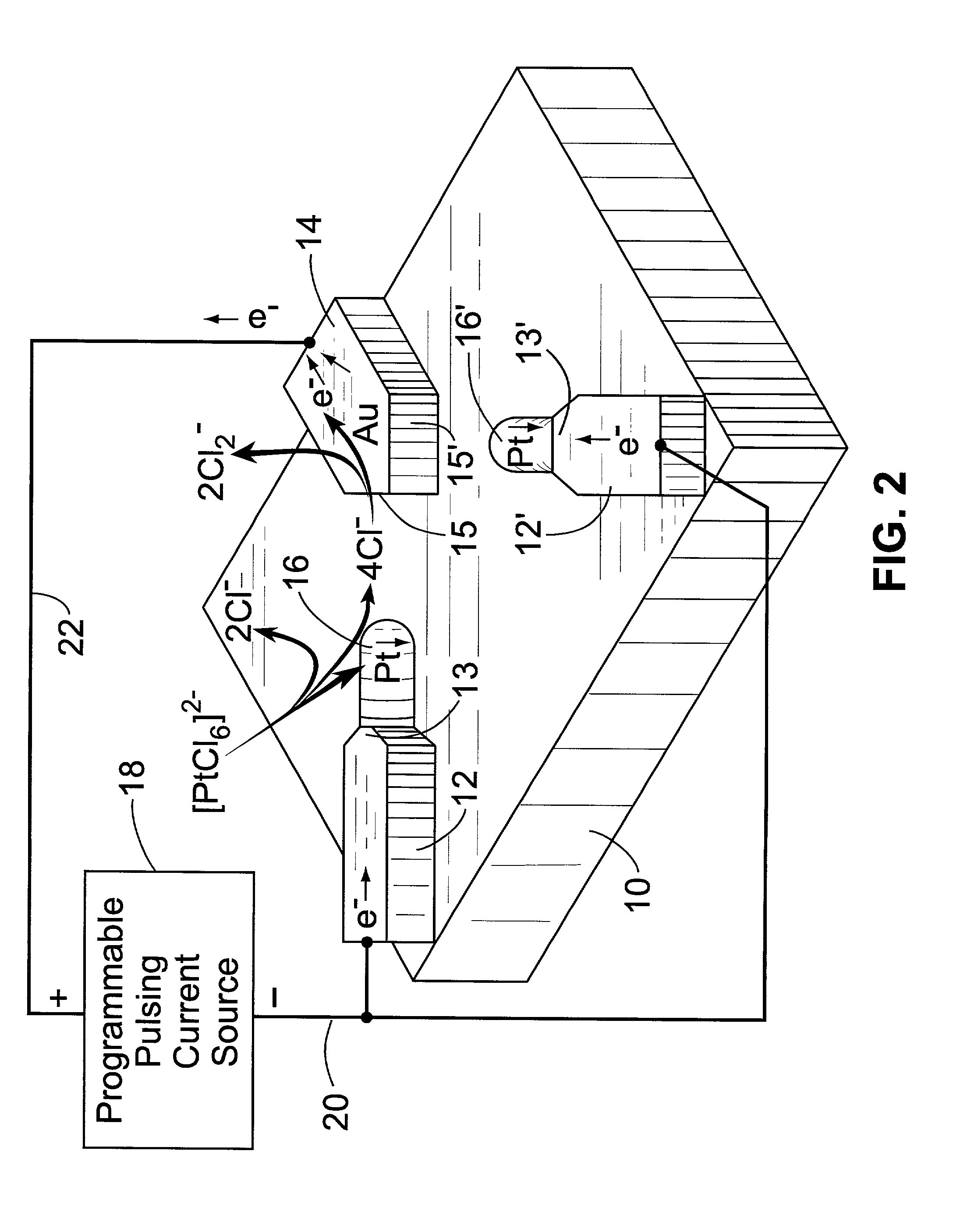

A method is described for catalyst-induced growth of carbon nanotubes, nanofibers, and other nanostructures on the tips of nanowires, cantilevers, conductive micro / nanometer structures, wafers and the like. The method can be used for production of carbon nanotube-anchored cantilevers that can significantly improve the performance of scaning probe microscopy (AFM, EFM etc). The invention can also be used in many other processes of micro and / or nanofabrication with carbon nanotubes / fibers. Key elements of this invention include: (1) Proper selection of a metal catalyst and programmable pulsed electrolytic deposition of the desired specific catalyst precisely at the tip of a substrate, (2) Catalyst-induced growth of carbon nanotubes / fibers at the catalyst-deposited tips, (3) Control of carbon nanotube / fiber growth pattern by manipulation of tip shape and growth conditions, and (4) Automation for mass production.

Owner:UT BATTELLE LLC +1

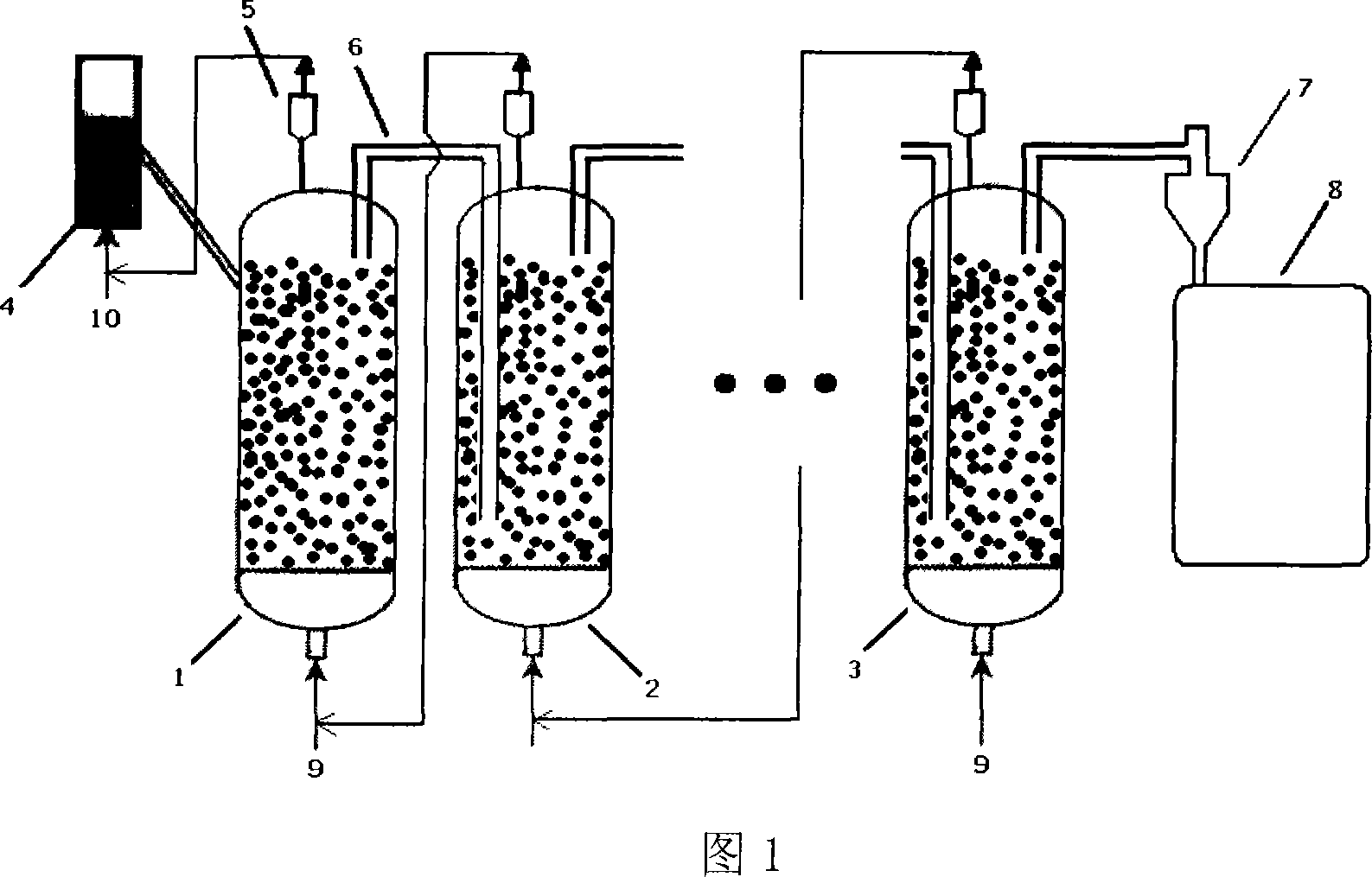

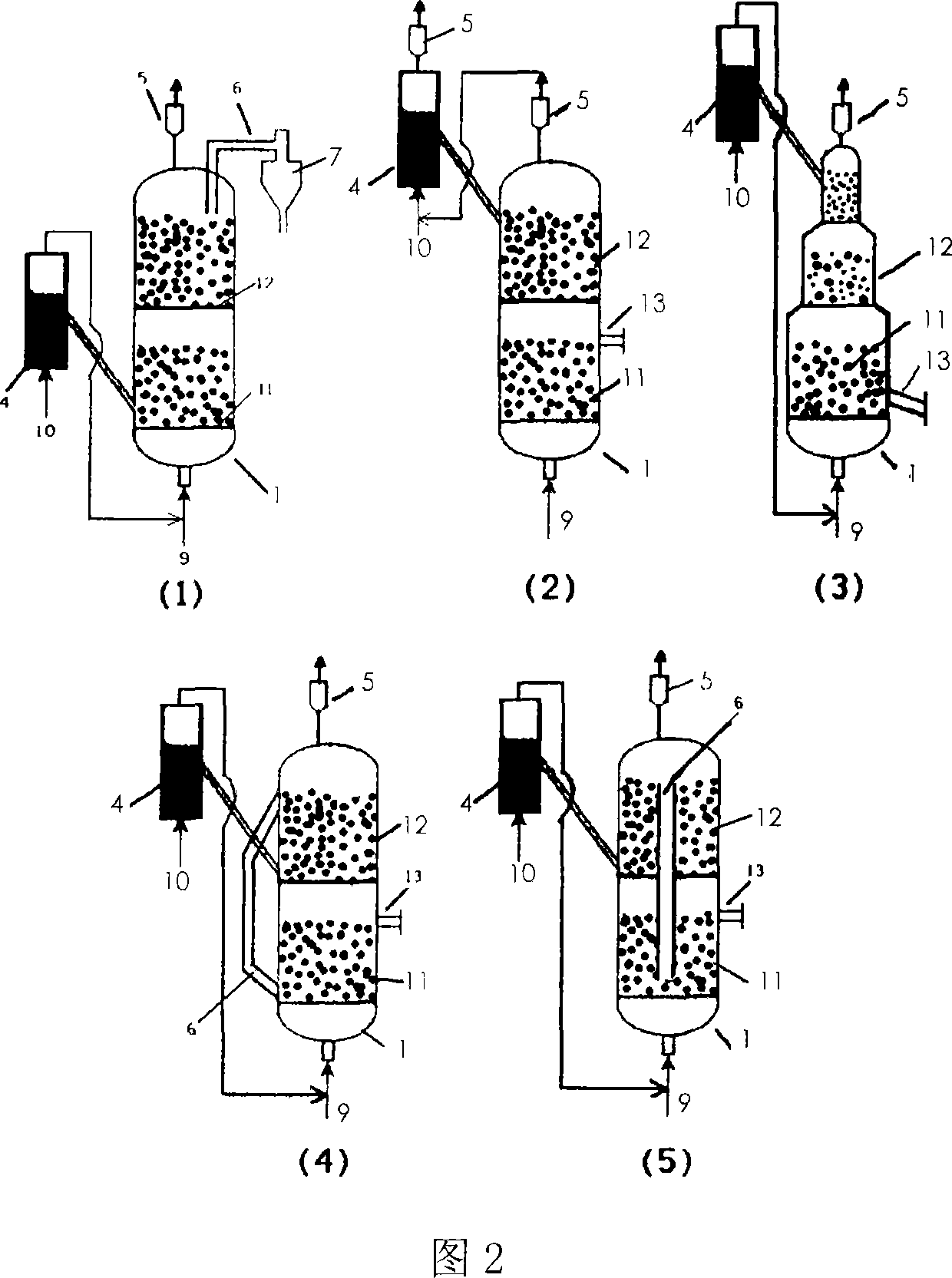

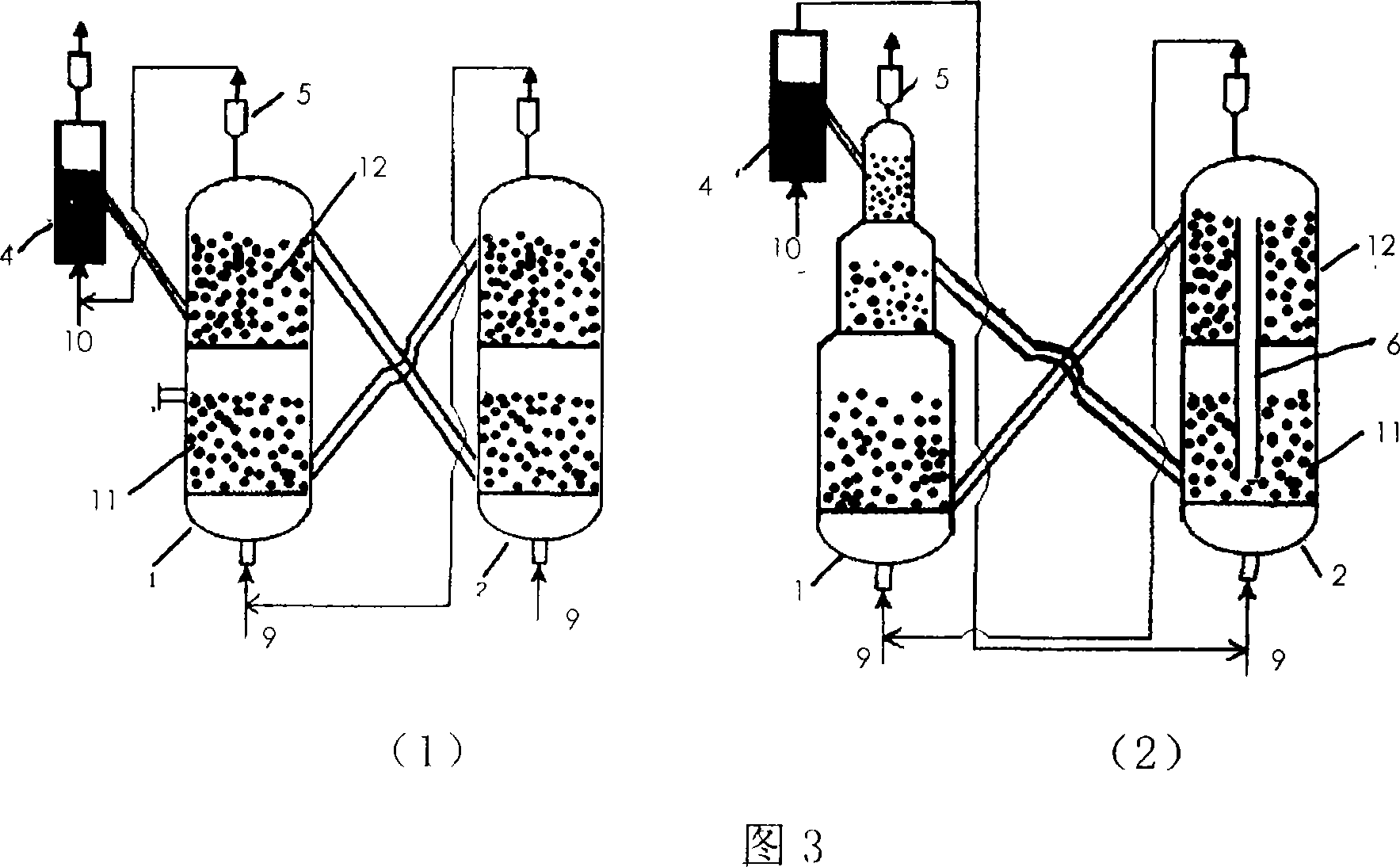

Method for producing Nano carbon tubes continuously and equipment

ActiveCN101049927AEfficient separationImprove stabilityMaterial nanotechnologyMulti-walled nanotubesCarbon nanotubeProduct gas

This invention discloses high-efficiency method and apparatus for continuously producing carbon nanotubes. The apparatus is a multi-stage counter-current reaction apparatus. The method comprises: placing the catalyst in the pre-reactor or the main reactor, introducing mixed gases of H2 or CO, and N2 or Ar, reducing, then introducing raw material gas, reacting to obtain carbon nanotubes, and sending the expanded solid raw material to the next stage reactor for reaction. The gas flow and the solid raw material are arranged in counter-current contact mode in the reactors, which can increase the conversion rate of the solid raw material. This invention has such advantages as simple apparatus and easy operation, and is suitable for industrial production on the scale of tens of thousands of tons per year.

Owner:TSINGHUA UNIV

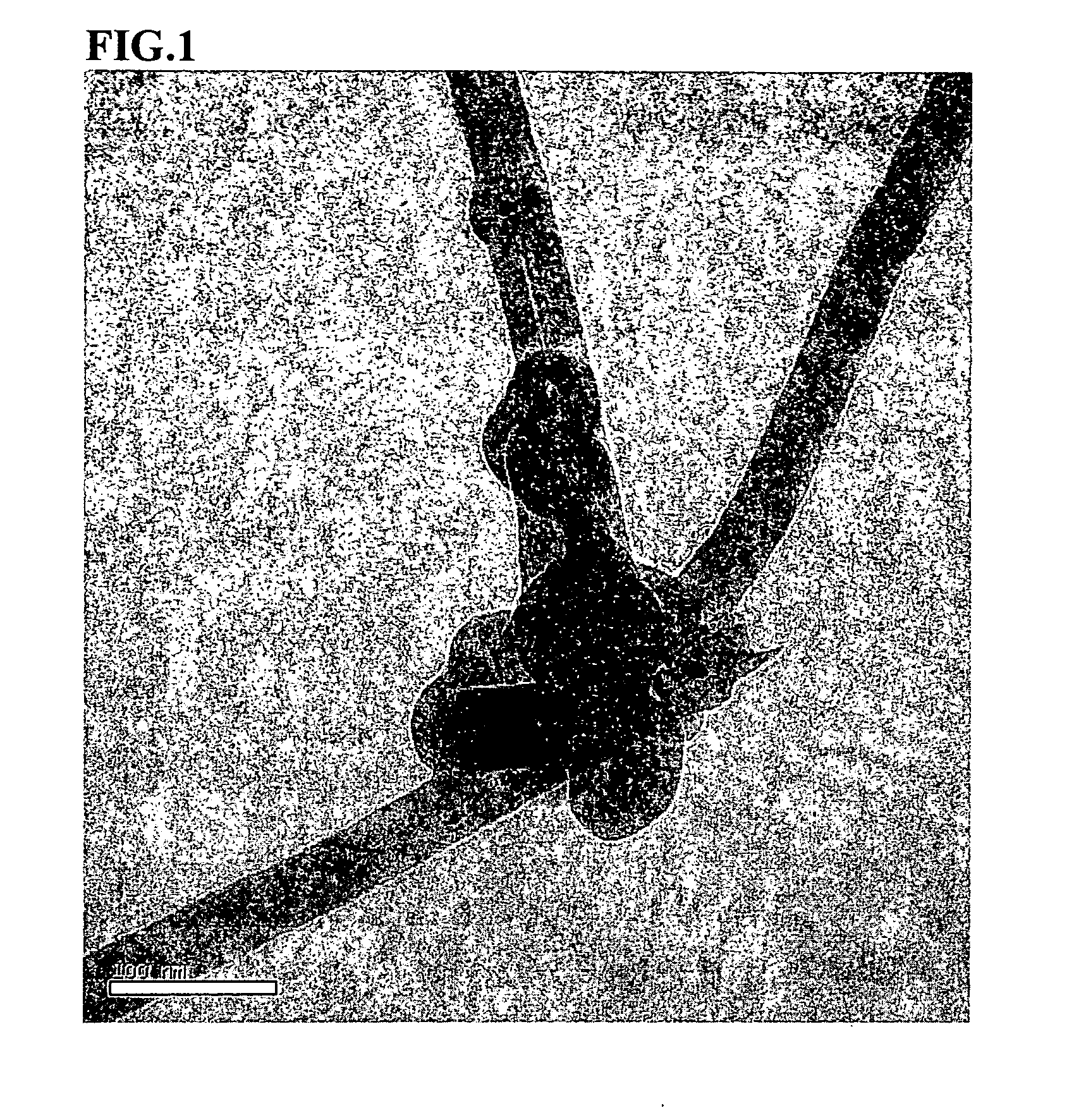

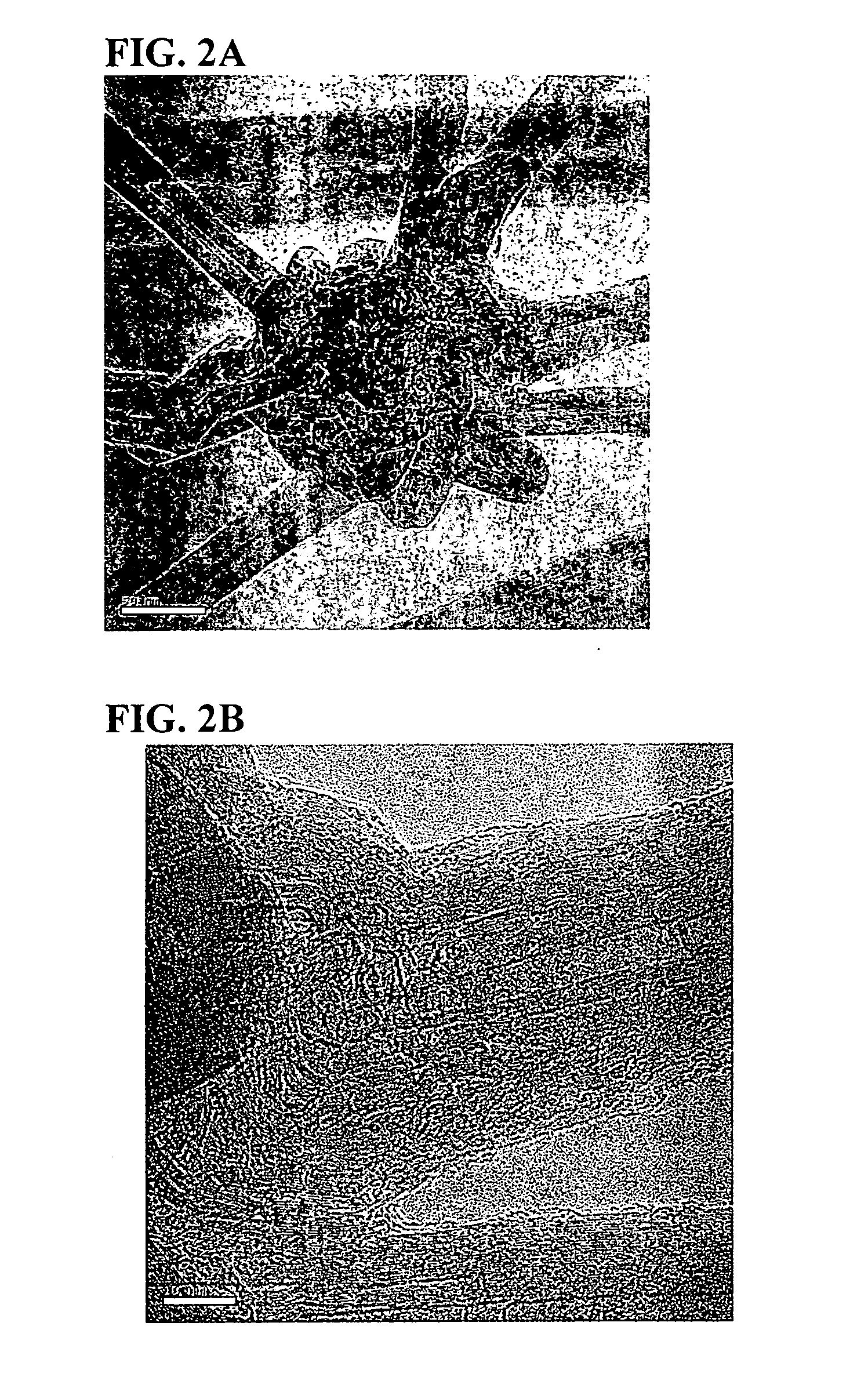

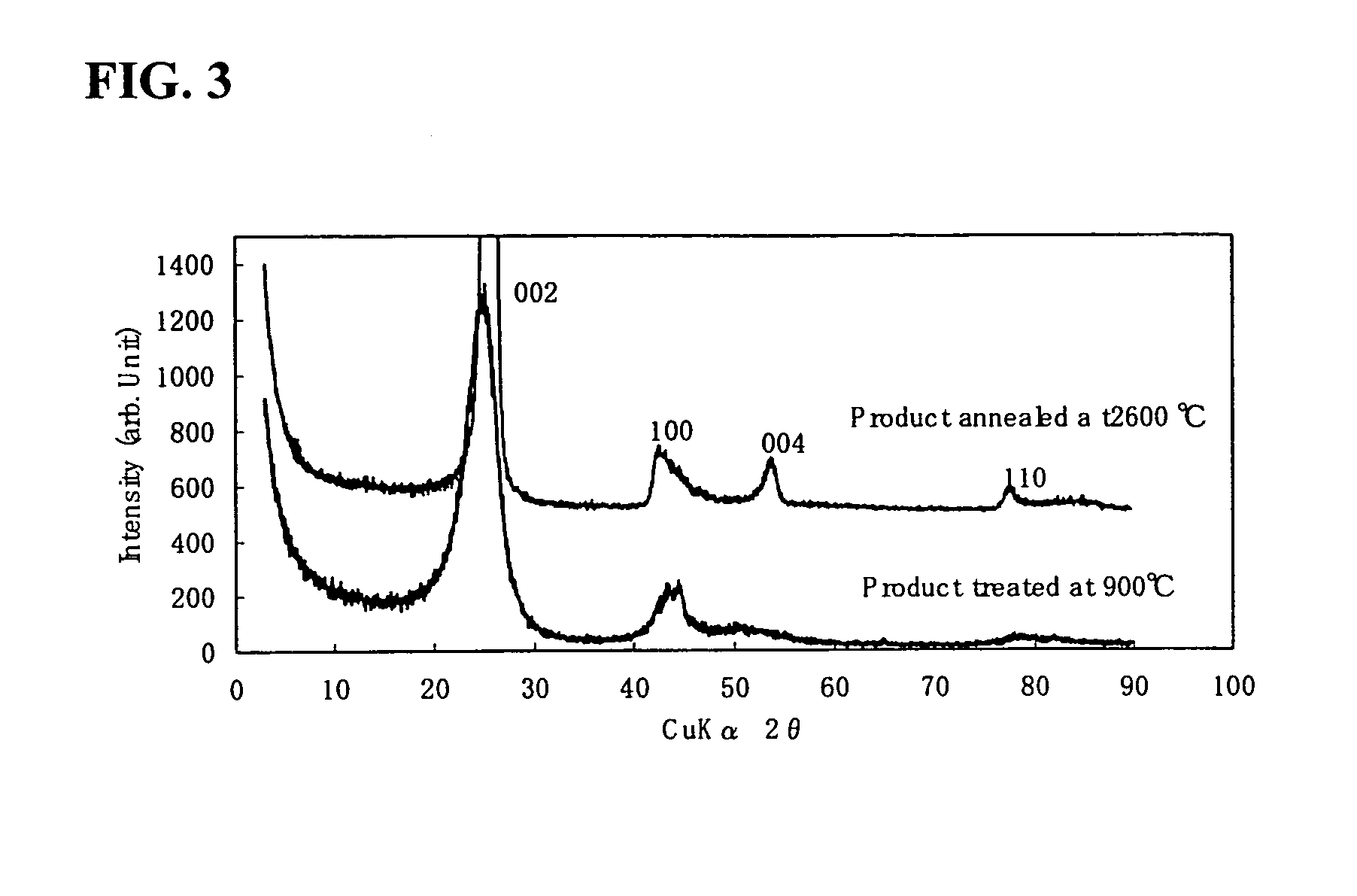

Aggregate of carbon nanotubes, dispersion thereof and conductive film using the same

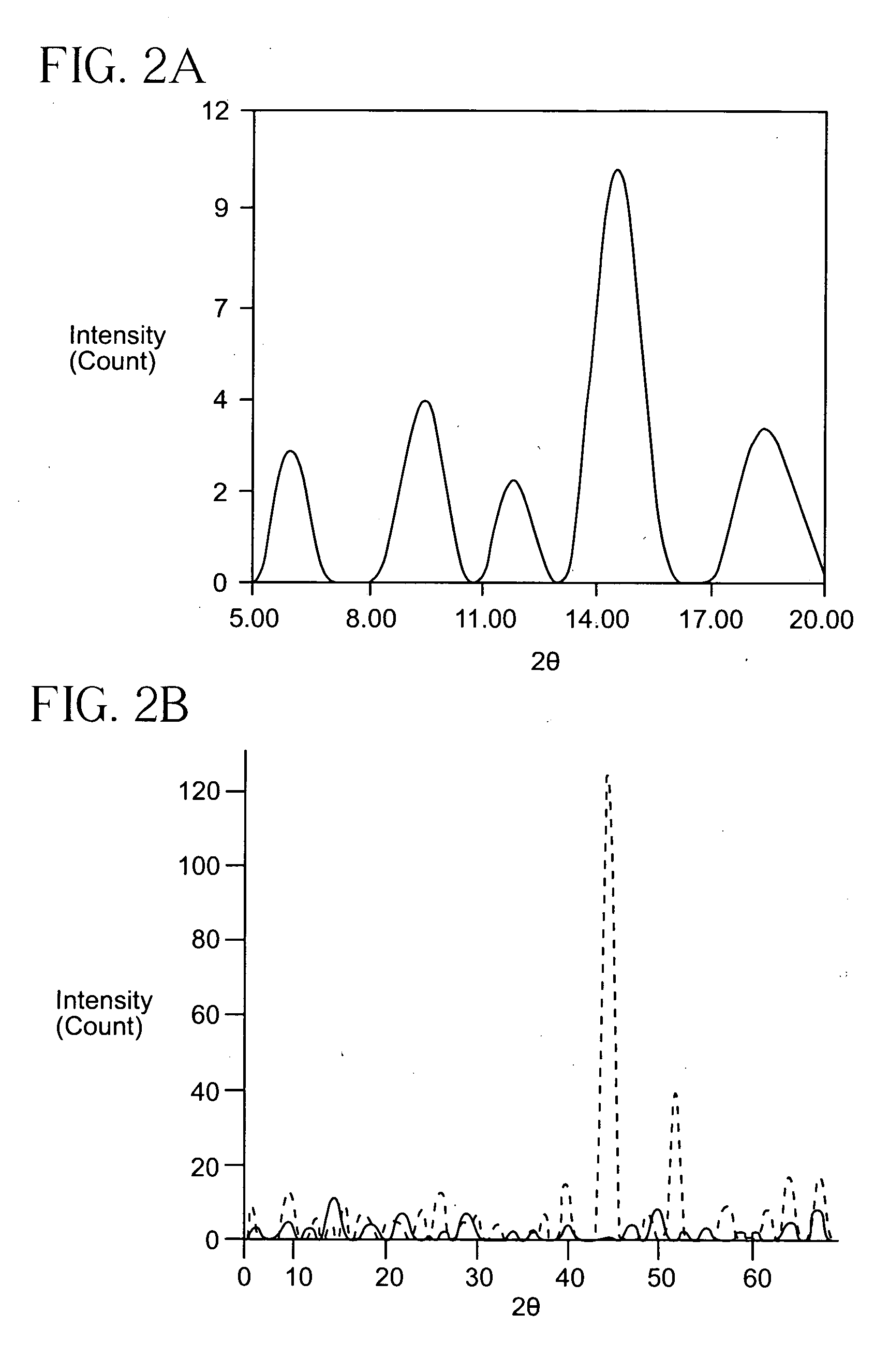

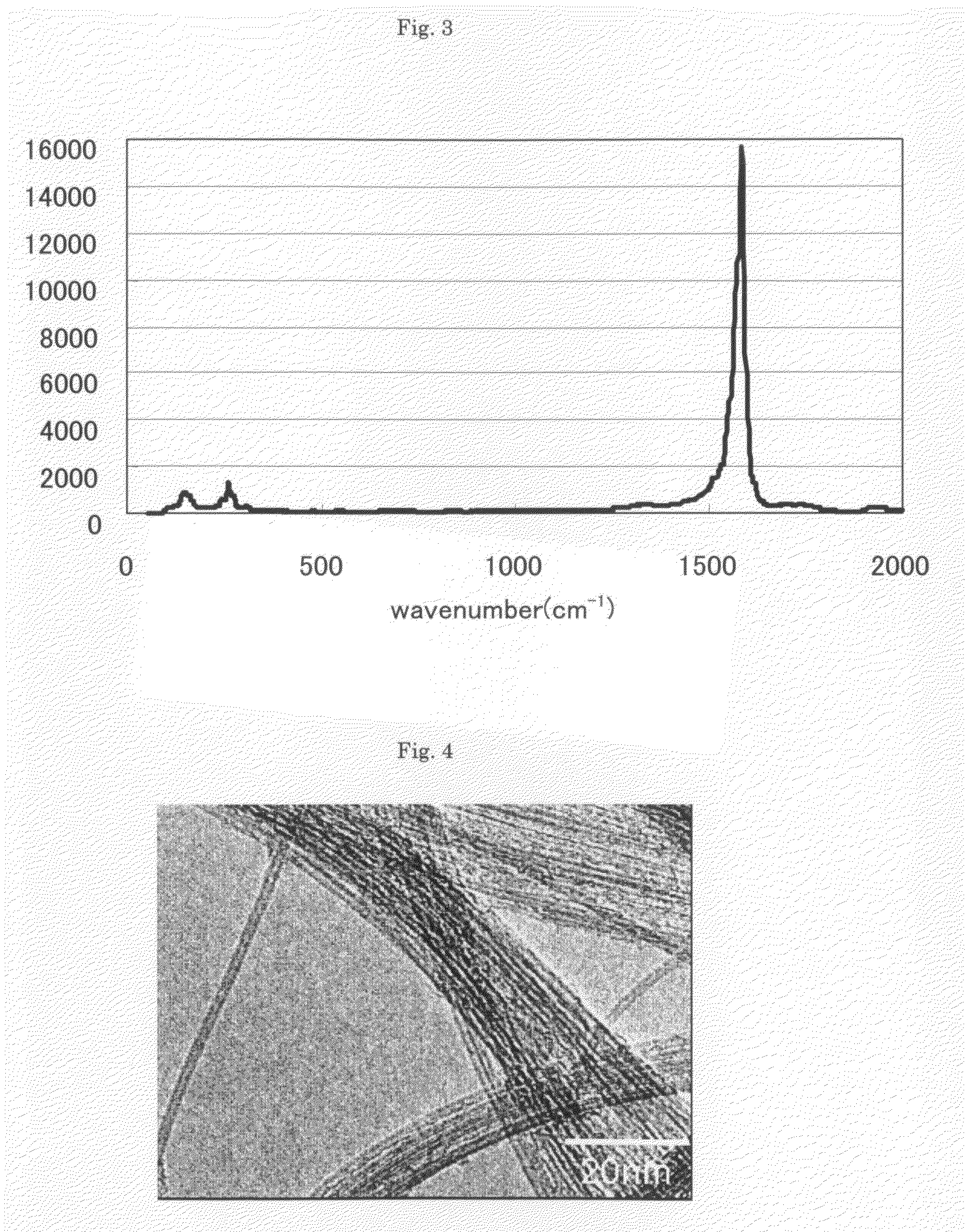

InactiveUS20090001326A1Good dispersionQuality improvementMaterial nanotechnologyNon-metal conductorsCombustionX-ray

Provided is an aggregate of carbon nanotubes satisfying (1) there is a 2θ peak at 24°±2° by X-ray powder diffraction analysis; (2) a height ratio (G / D ratio) of G band to D band by Raman spectroscopic analysis of wavelength 532 nm is 30 or more; and (3) a combustion peak temperature is 550° C. or more, and 700° C. or less. The present invention provides an aggregate of carbon nanotubes excellent in dispersibility while high quality, giving a film, molded article, membrane or the like having excellent characteristics

Owner:TORAY IND INC

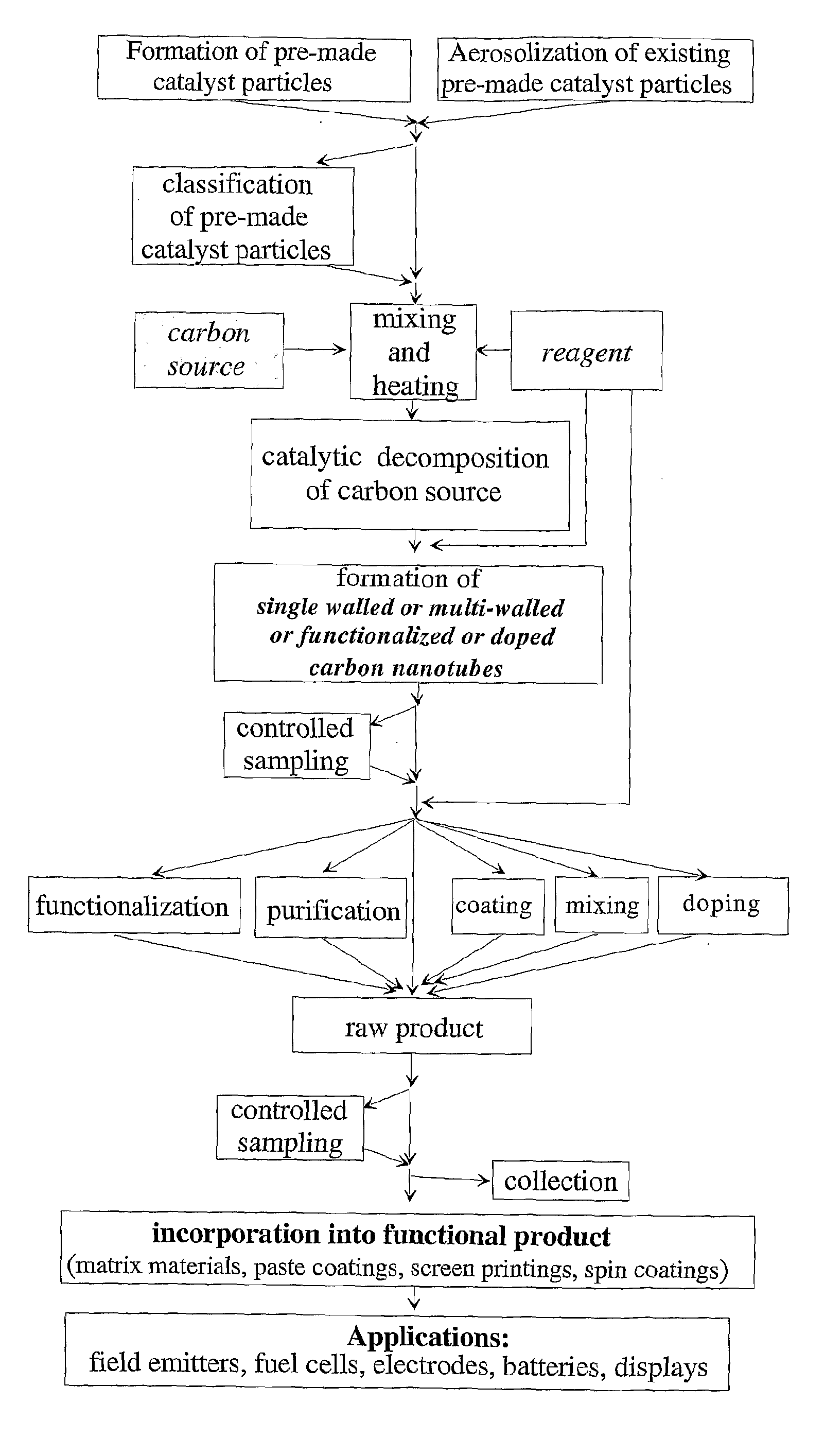

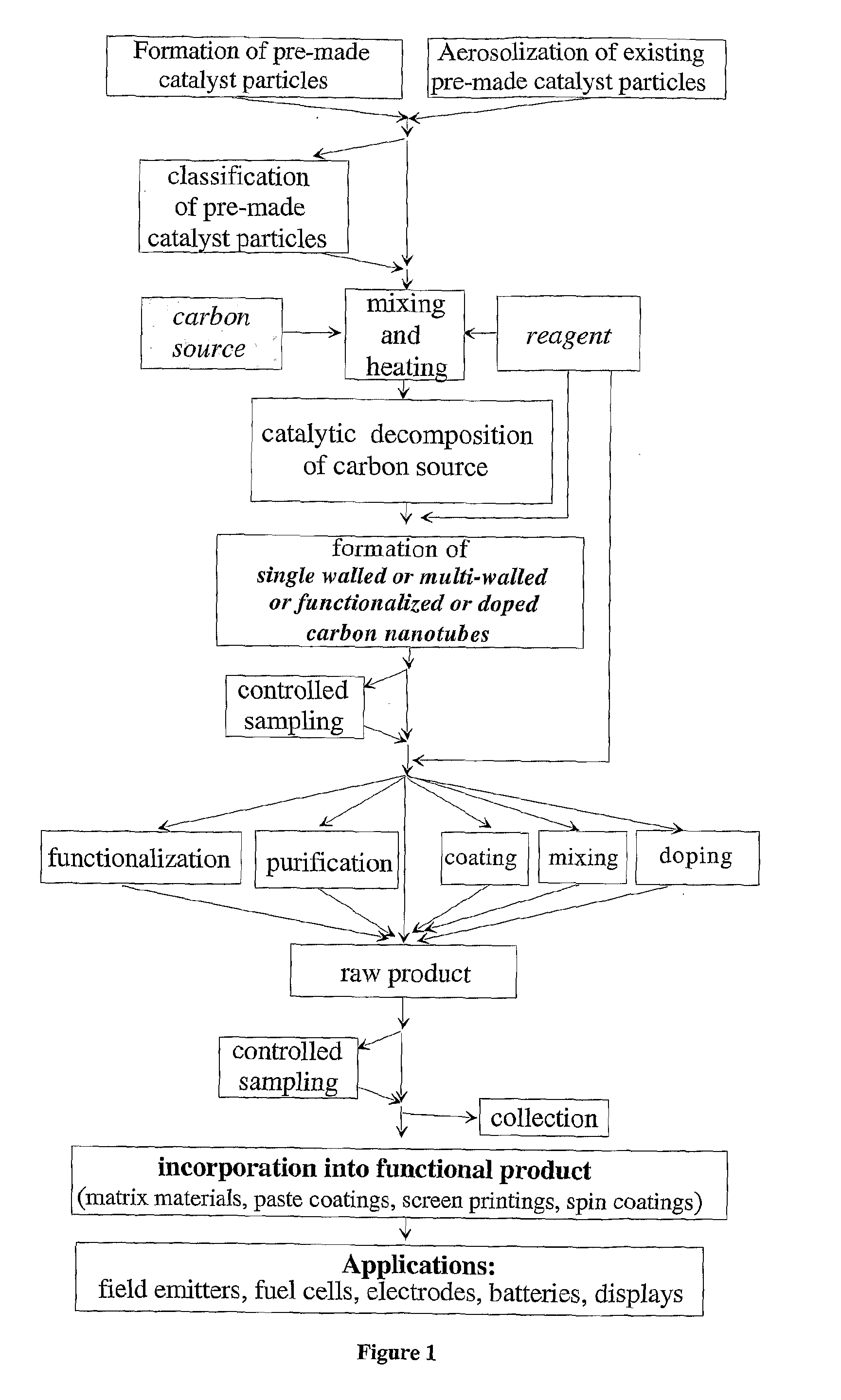

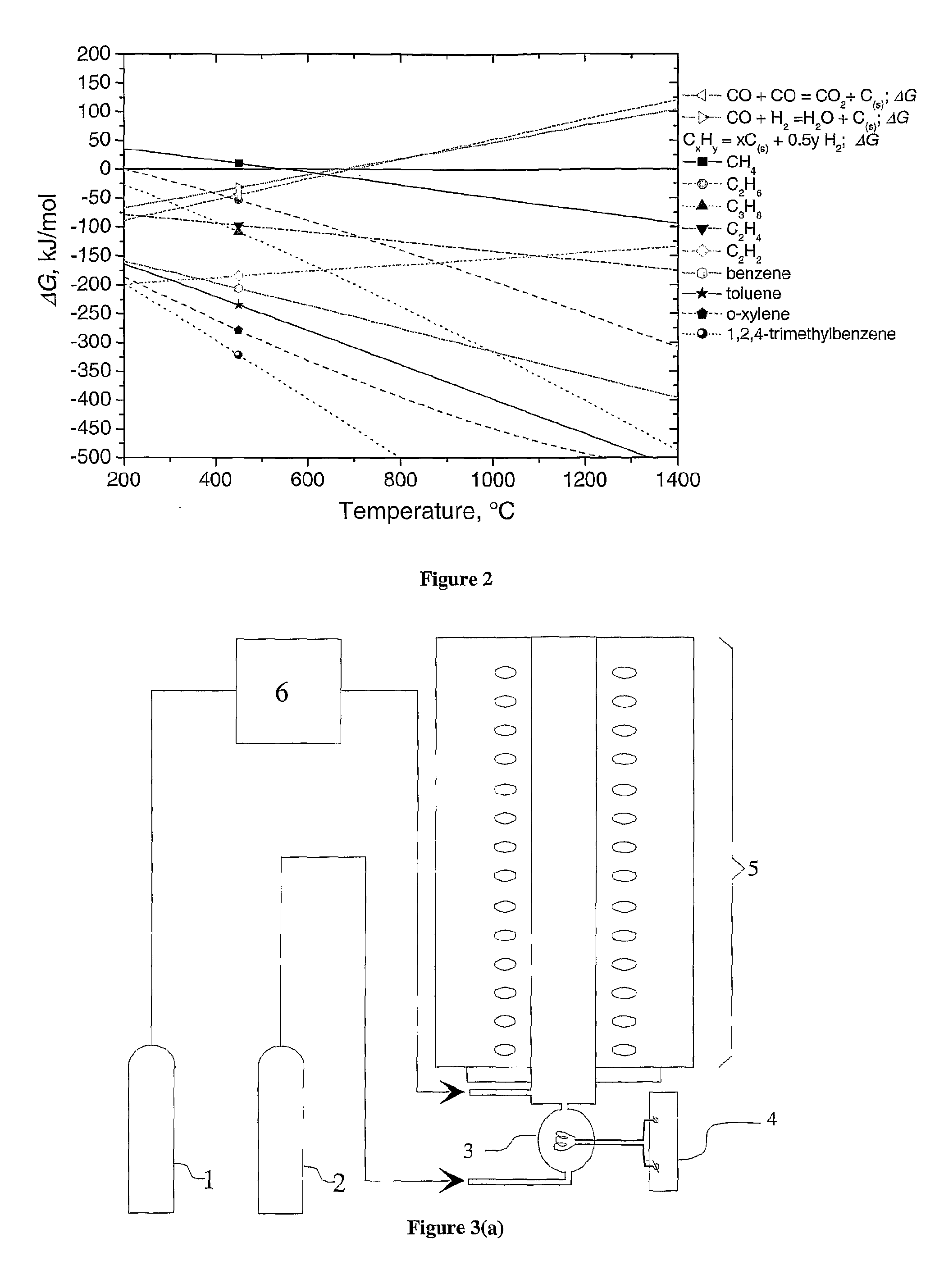

Single, multi-walled, functionalized and doped carbon nanotubes and composites thereof

The present invention relates to single walled and multi-walled carbon nanotubes (CNTs), functionalized CNTs and carbon nanotube composites with controlled properties, to a method for aerosol synthesis of single walled and multi-walled carbon nanotubes, functionalized CNTs and carbon nanotube composites with controlled properties from pre-made catalyst particles and a carbon source in the presence of reagents and additives, to functional, matrix and composite materials composed thereof and structures and devices fabricated from the same in continuous or batch CNT reactors. The present invention allows all or part of the processes of synthesis of CNTs, their purification, doping, functionalization, coating, mixing and deposition to be combined in one continuous procedure and in which the catalyst synthesis, the CNT synthesis, and their functionalization, doping, coating, mixing and deposition can be separately controlled.

Owner:CANATU OY

Composite and method of manufacturing the same

InactiveUS20070145335A1High mechanical strengthGood electrical and thermal conductivityMaterial nanotechnologyIndividual molecule manipulationCross-linkNetwork structure

To provide a composite excellent in mechanical strength or in electric conductivity and obtained by combining a carbon nanotube structure and ceramics, and a method of manufacturing the same. The composite is composed of the carbon nanotube structure and the ceramics, and, in the carbon nanotube carbon nanotube structure, functional groups bonded to multiple carbon nanotubes are chemically bonded to mutually cross-link to construct a network structure.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com