Patents

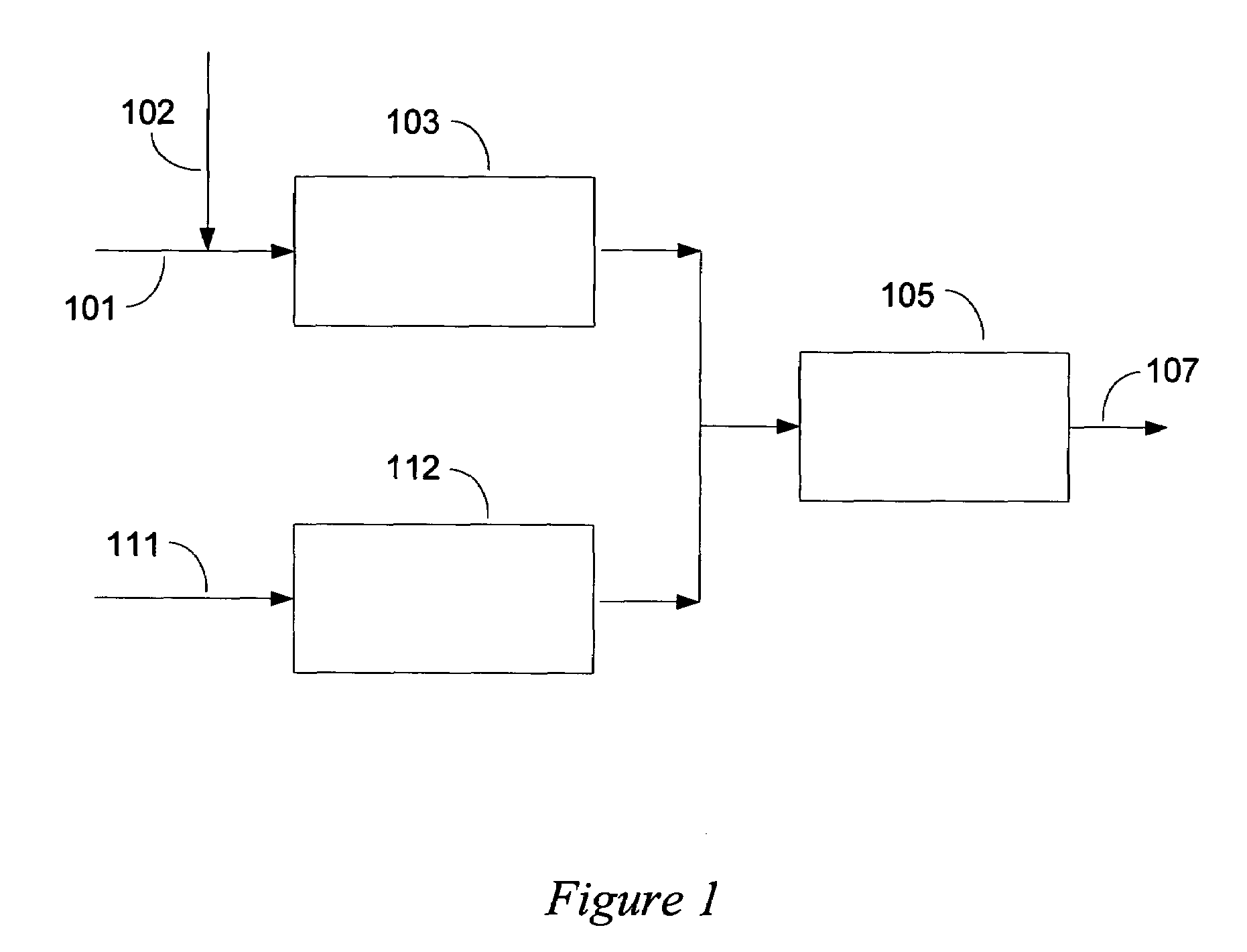

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

898results about "Single-walled nanotubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nanotube hybrid system using carbide-derived carbon, a method of making the same, an electron emitter comprising the same, and an electron emission device comprising the electron emitter

InactiveUS20080248310A1Improve uniformityLong life-timeMaterial nanotechnologyNanostructure manufactureHybrid systemHalogen

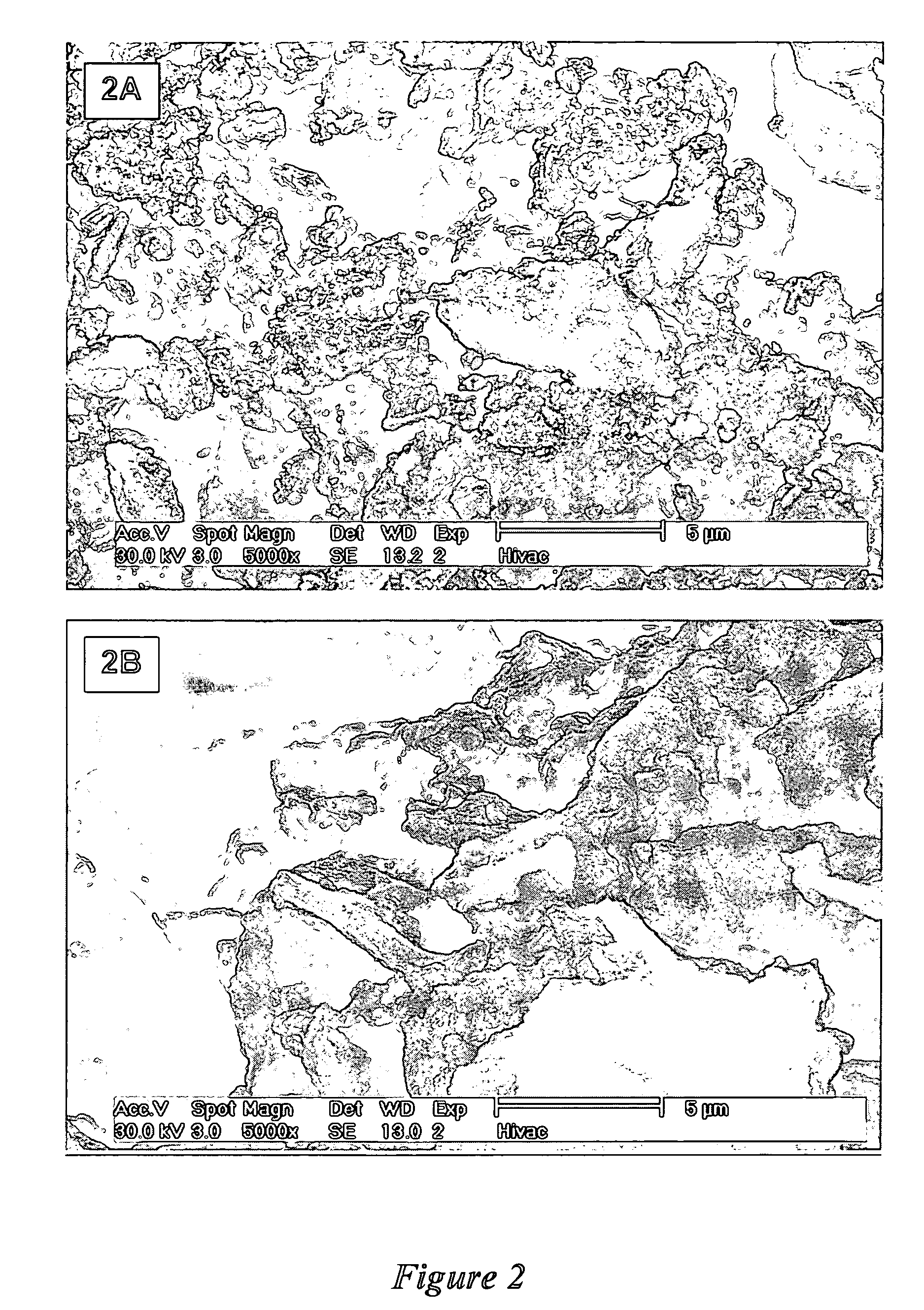

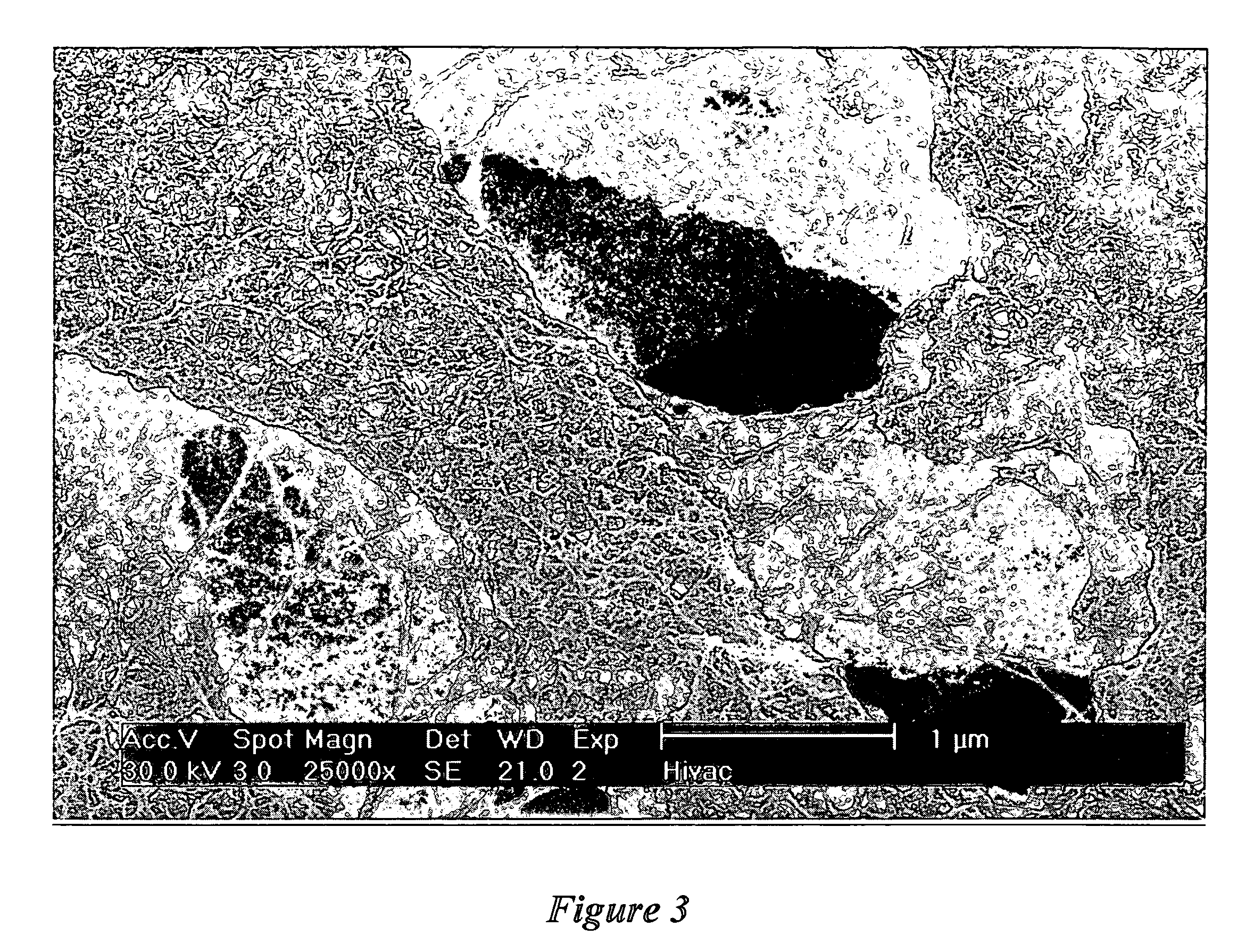

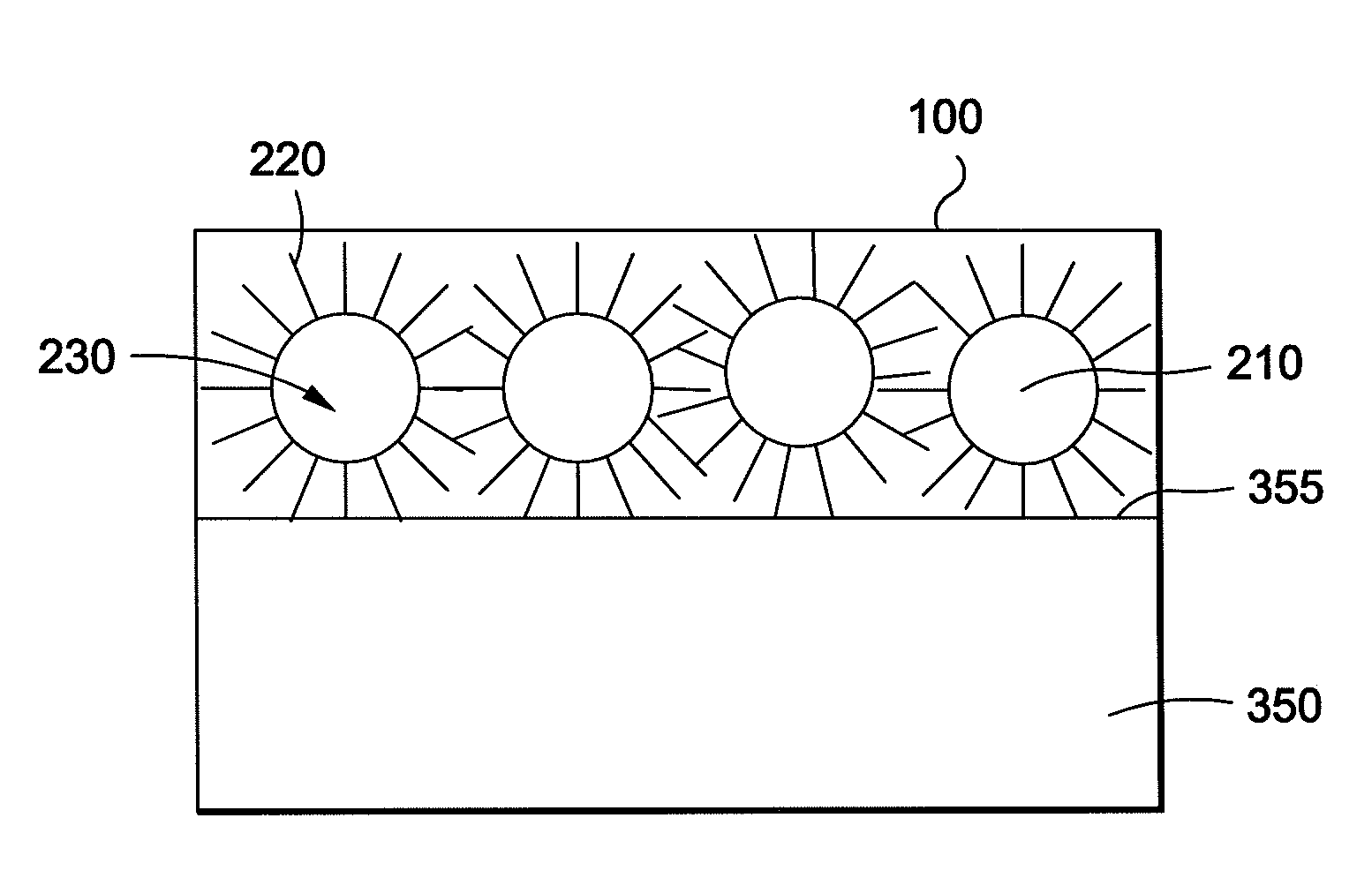

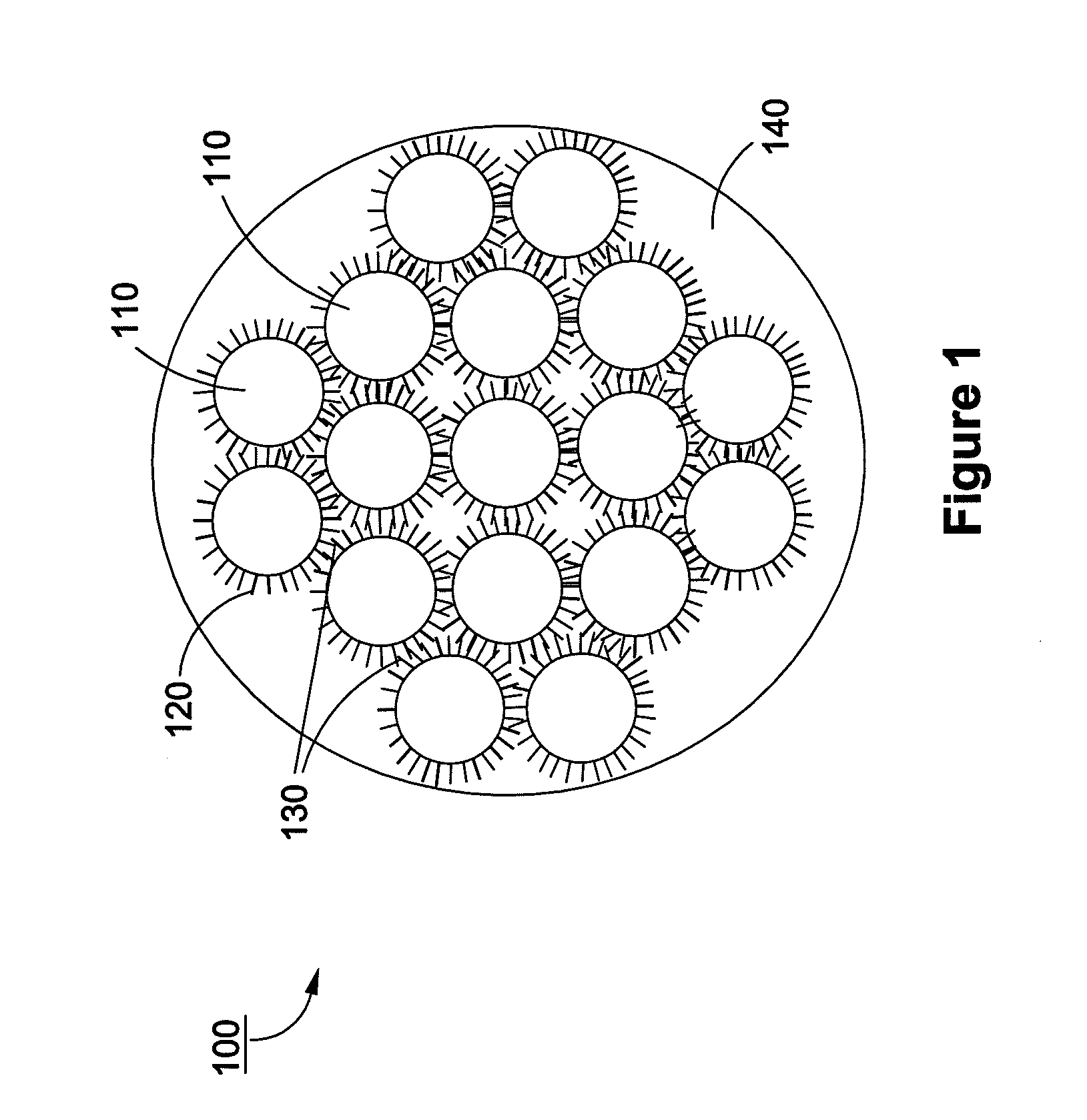

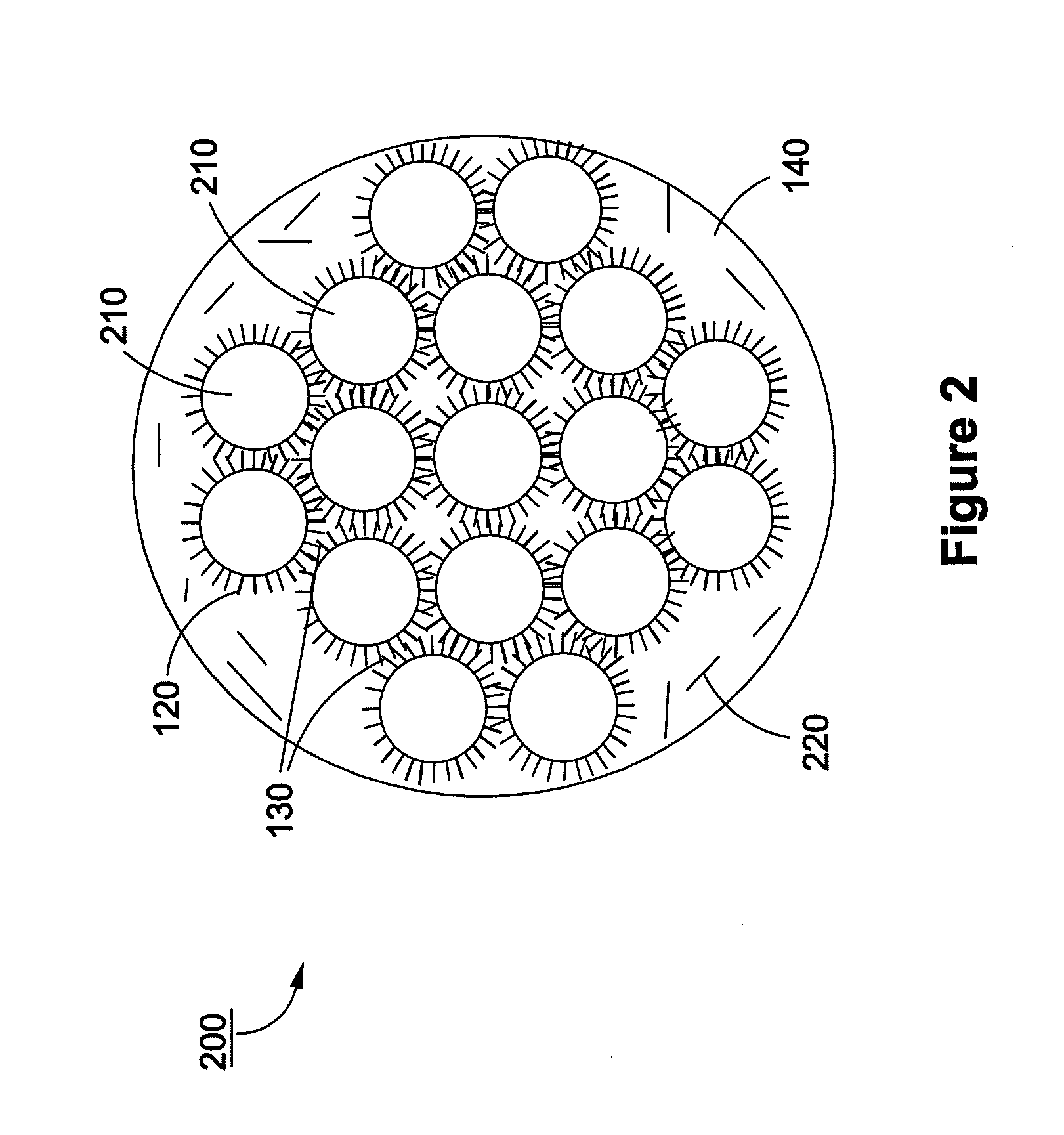

A carbon nanotube hybrid system includes: a carbide-derived carbon prepared by reacting a carbide compound and a halogen group containing gas to extract elements of the carbide compound except carbons; metals supported on the carbide-derived carbon or remaining in the carbide-derived carbon; and carbon sources from which carbon nanotubes are grown from the carbide-derived carbon. A method of preparing the carbon nanotube hybrid system includes preparing the carbide-derived carbon, extracting elements therefrom, and growing carbon nanotubes from the carbide-derived carbon. The carbon nanotube hybrid system has excellent uniformity and a long lifetime. An electron emitter having improved electron emitting properties can be inexpensively prepared using the carbon nanotube hybrid system compared to conventional carbon nanotubes. An electron emission device having excellent electron emitting properties can be prepared using the electron emitter.

Owner:SAMSUNG SDI CO LTD

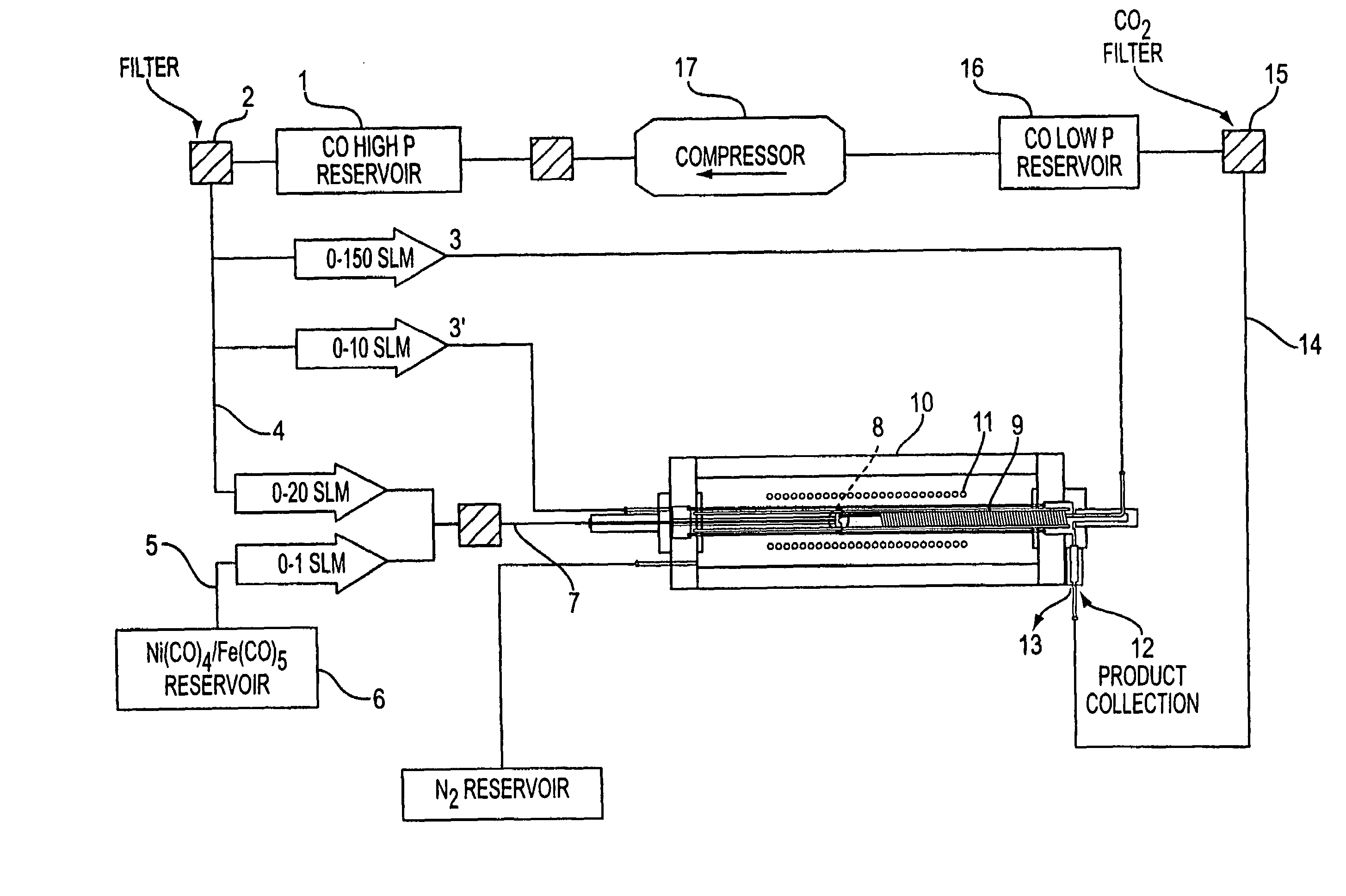

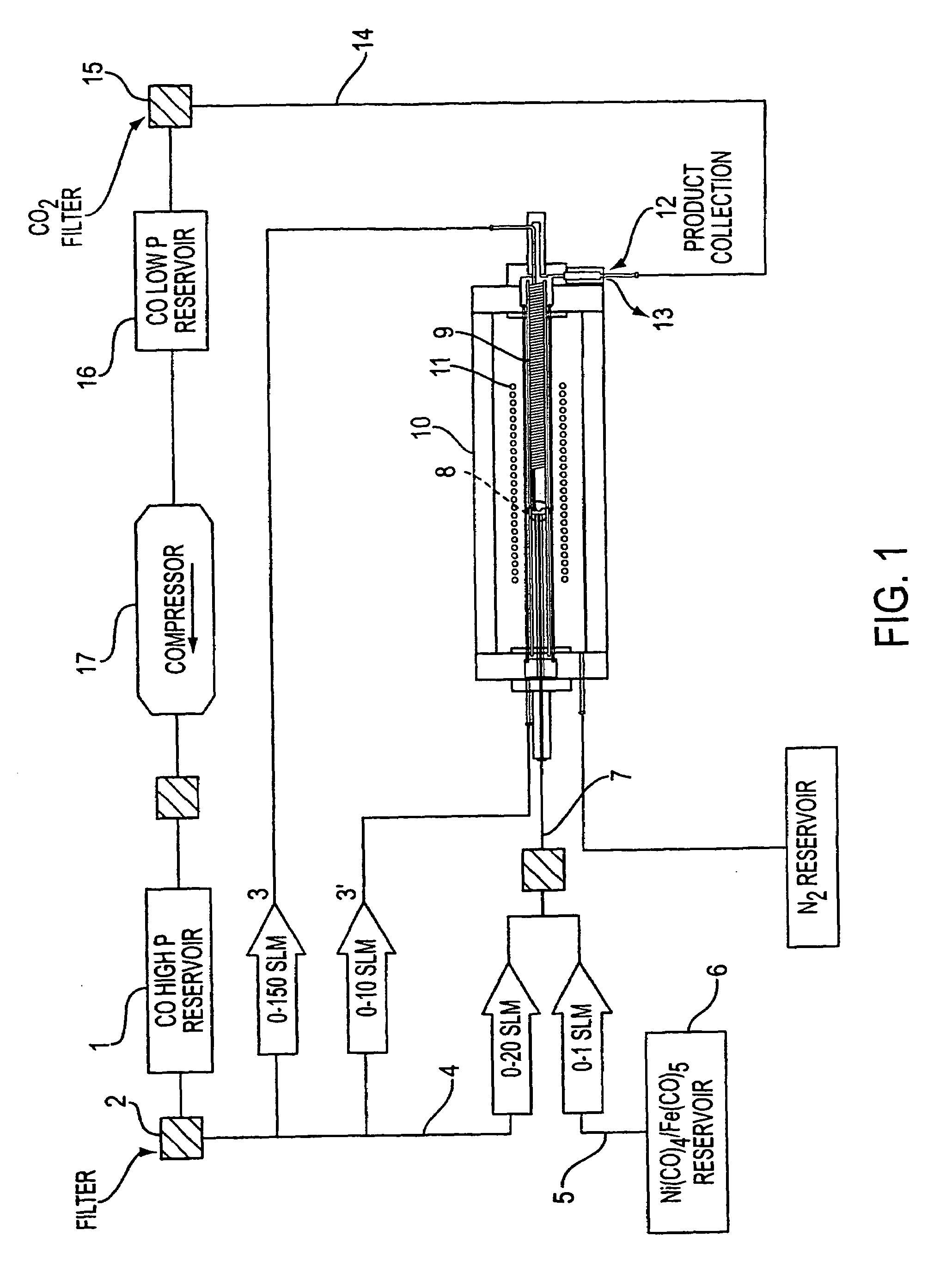

Process for producing single wall nanotubes using unsupported metal catalysts

InactiveUS6221330B1Continuous and efficient productionMaterial nanotechnologyFibre chemical featuresHydrogenGas phase

A process for producing hollow, single-walled carbon nanotubes by catalytic decomposition of one or more gaseous carbon compounds by first forming a gas phase mixture carbon feed stock gas comprising one or more gaseous carbon compounds, each having one to six carbon atoms and only H, O, N, S or Cl as hetero atoms, optionally admixed with hydrogen, and a gas phase metal containing compound which is unstable under reaction conditions for said decomposition, and which forms a metal containing catalyst which acts as a decomposition catalyst under reaction conditions; and then conducting said decomposition reaction under decomposition reaction conditions, thereby producing said nanotubes.

Owner:HYPERION CATALYSIS INT

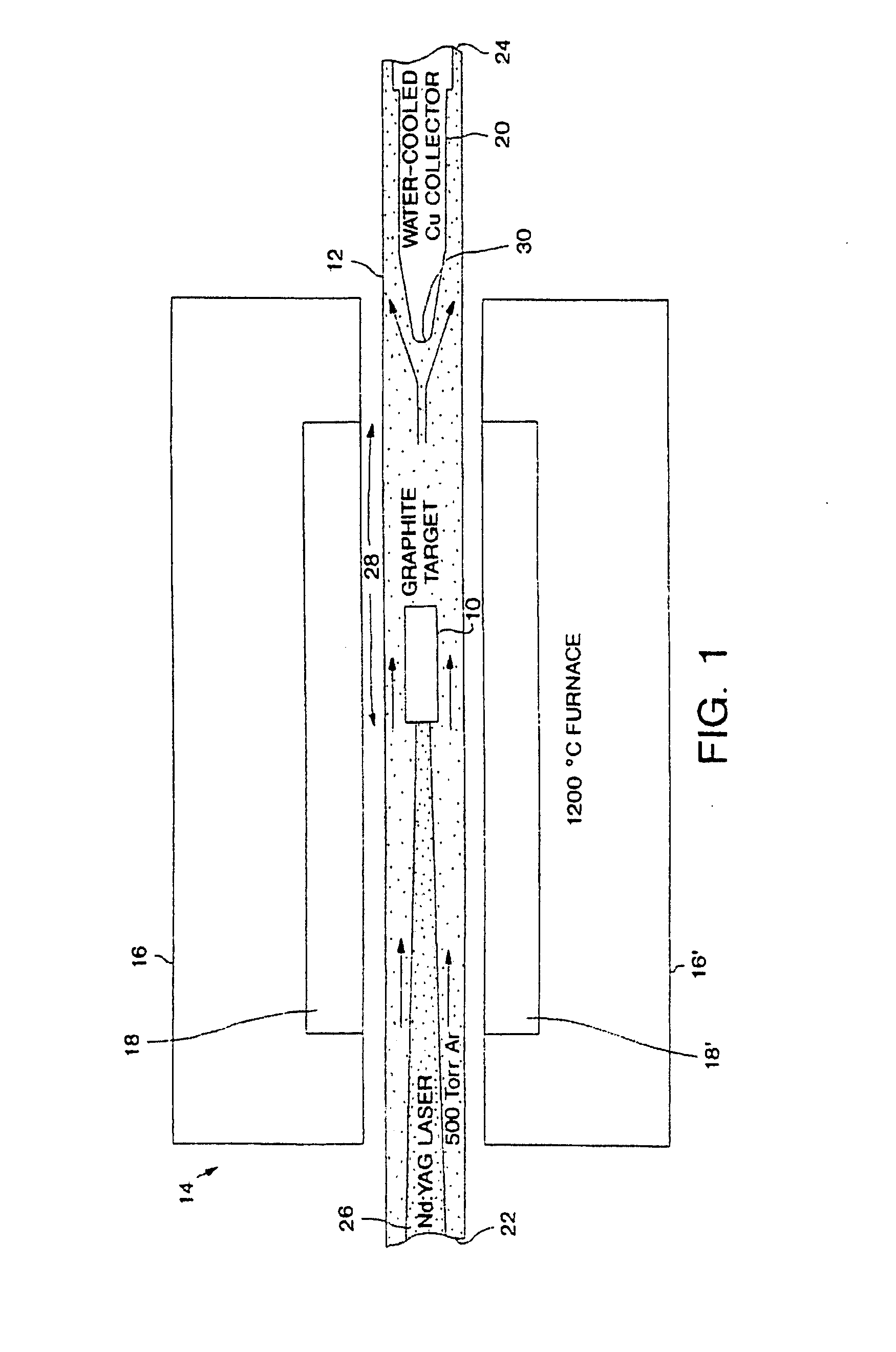

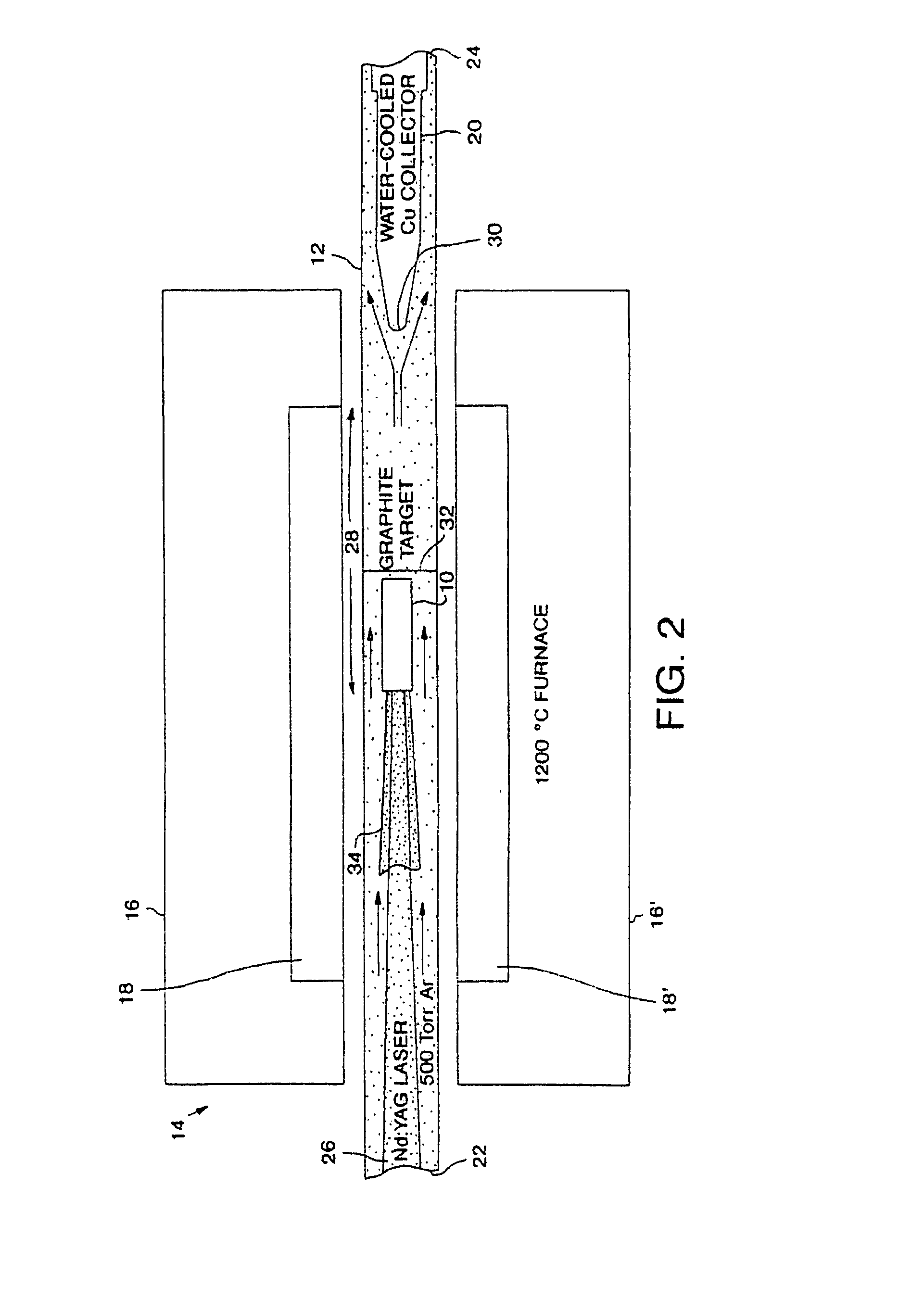

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

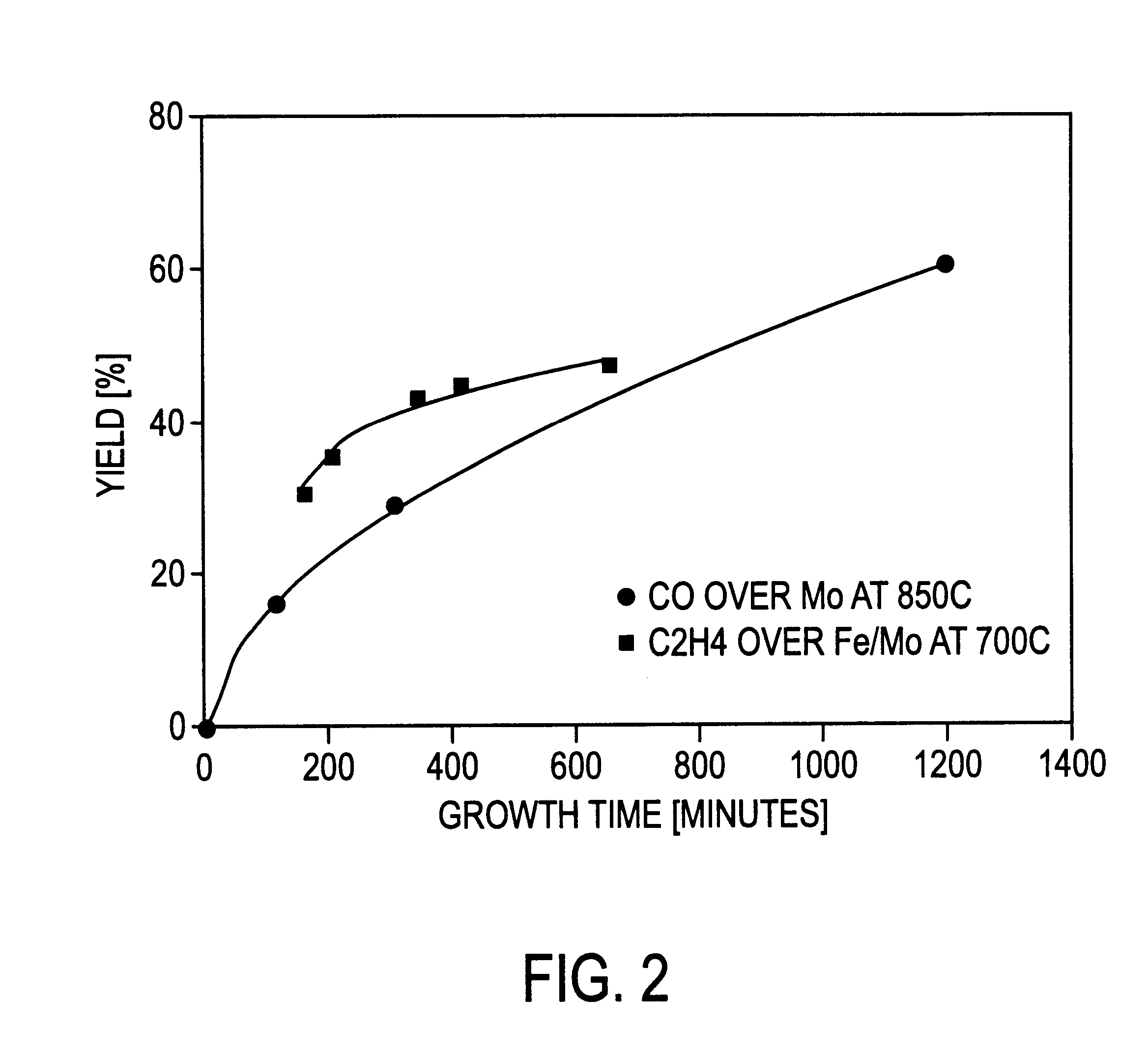

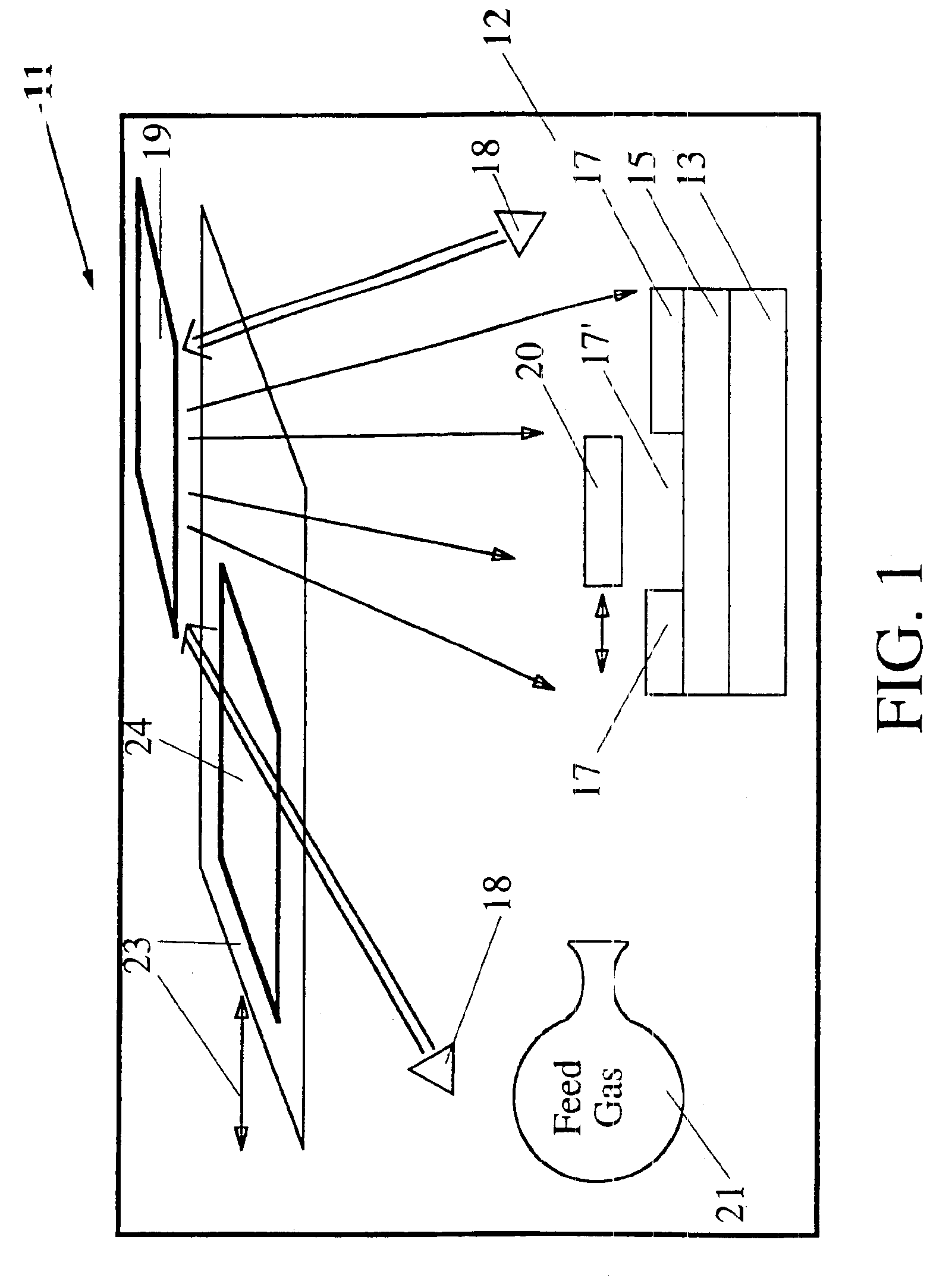

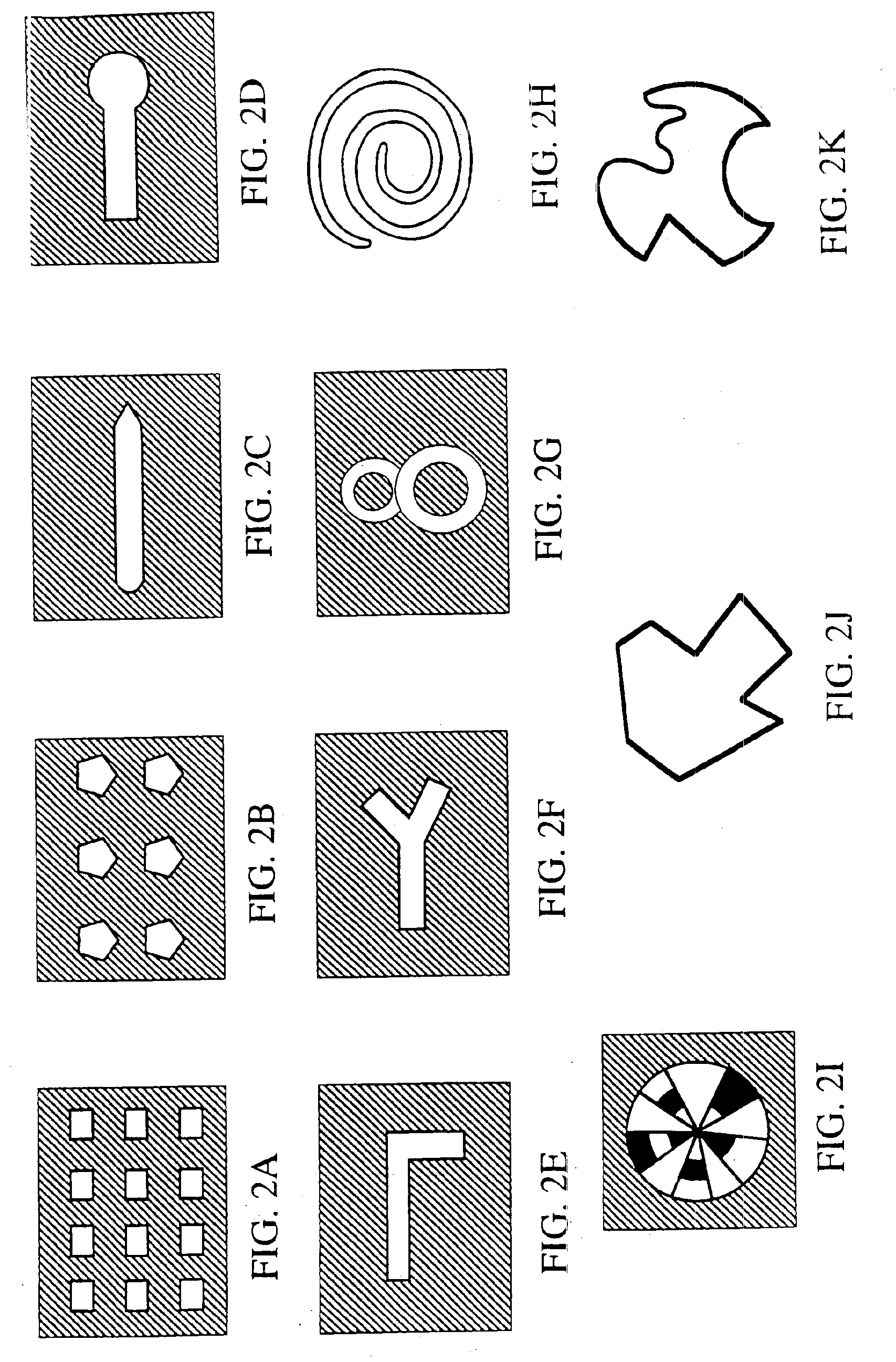

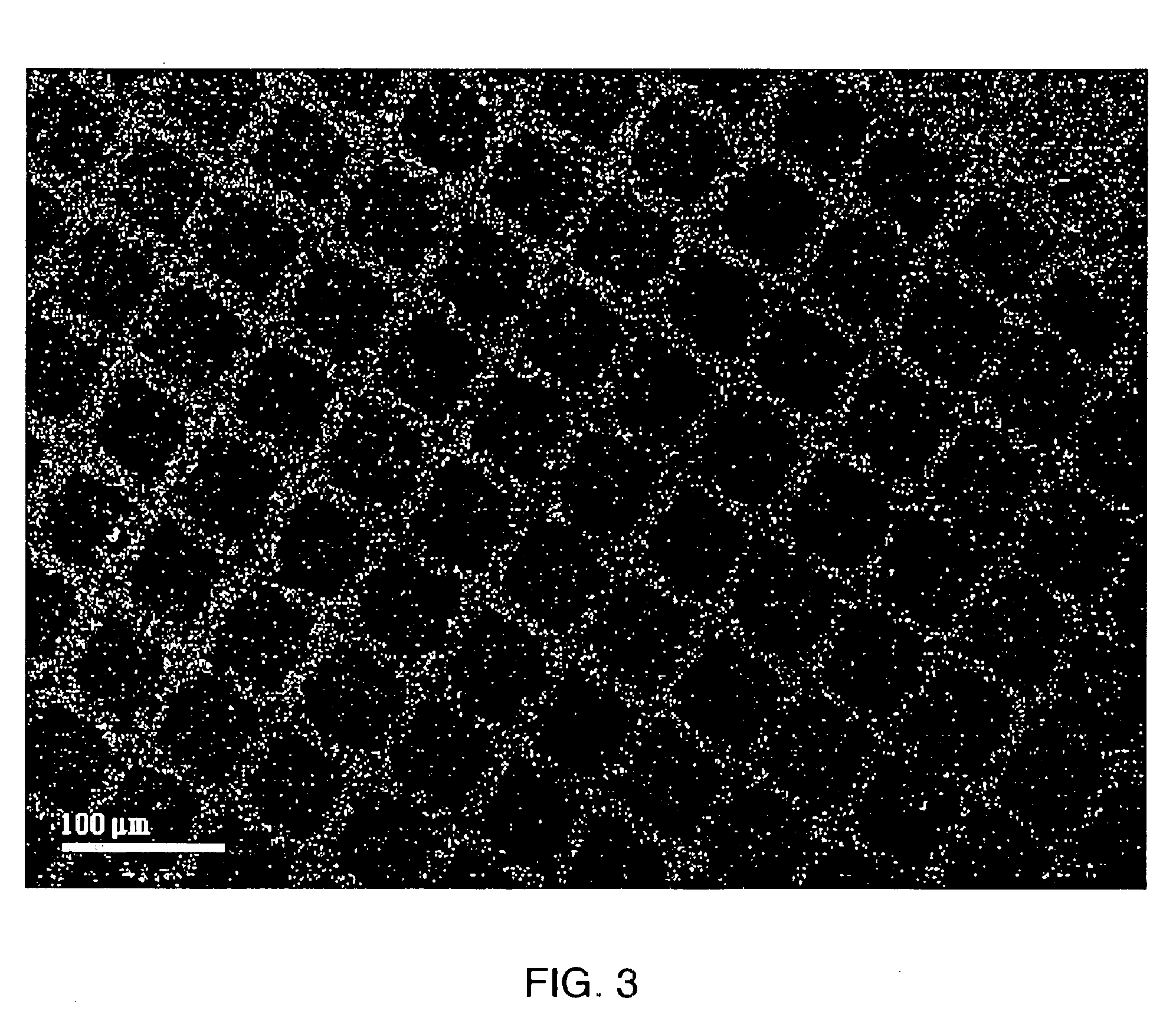

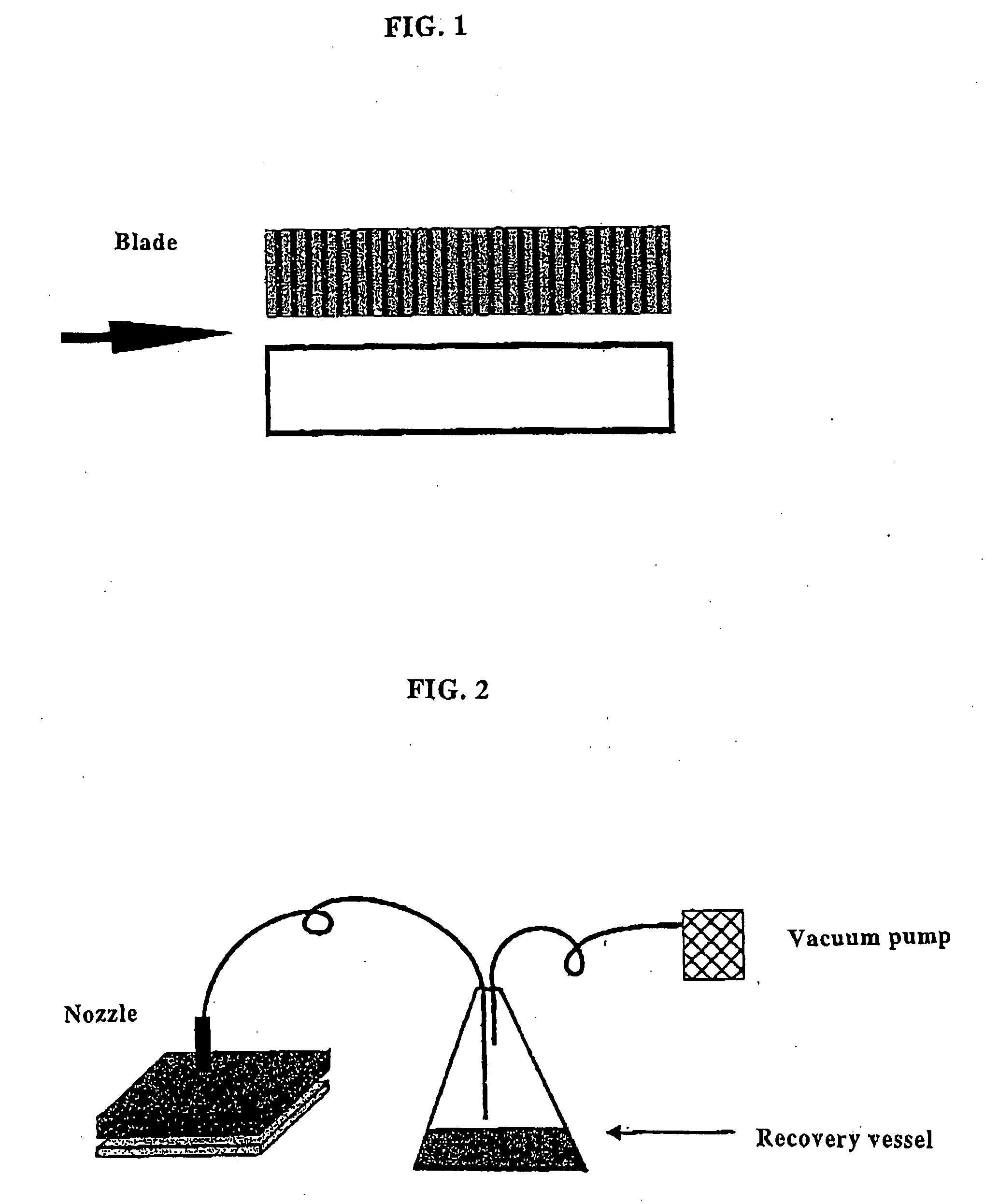

Controlled patterning and growth of single wall and multi-wall carbon nanotubes

Method and system for producing a selected pattern or array of at least one of a single wall nanotube and / or a multi-wall nanotube containing primarily carbon. A substrate is coated with a first layer (optional) of a first selected metal (e.g., Al and / or Ir) and with a second layer of a catalyst (e.g., Fe, Co, Ni and / or Mo), having selected first and second layer thicknesses provided by ion sputtering, arc discharge, laser ablation, evaporation or CVD. The first layer and / or the second layer may be formed in a desired non-uniform pattern, using a mask with suitable aperture(s), to promote growth of carbon nanotubes in a corresponding pattern. A selected heated feed gas (primarily CH4 or C2Hn with n=2 and / or 4) is passed over the coated substrate and forms primarily single wall nanotubes or multiple wall nanotubes, depending upon the selected feed gas and its temperature. Nanofibers, as well as single wall and multi-wall nanotubes, are produced using plasma-aided growth from the second (catalyst) layer. An overcoating of a selected metal or alloy can be deposited, over the second layer, to provide a coating for the carbon nanotubes grown in this manner.

Owner:NASA +1

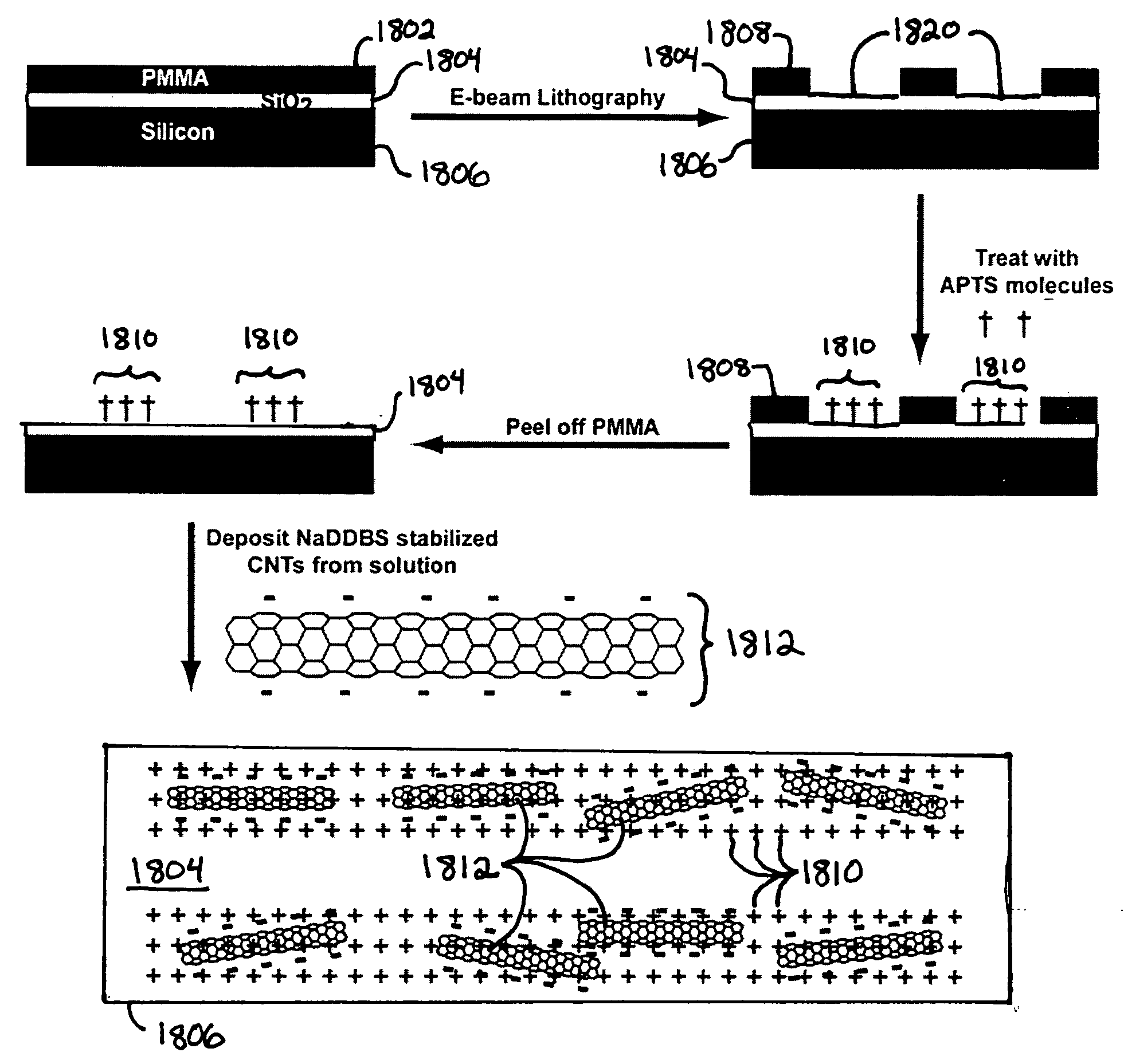

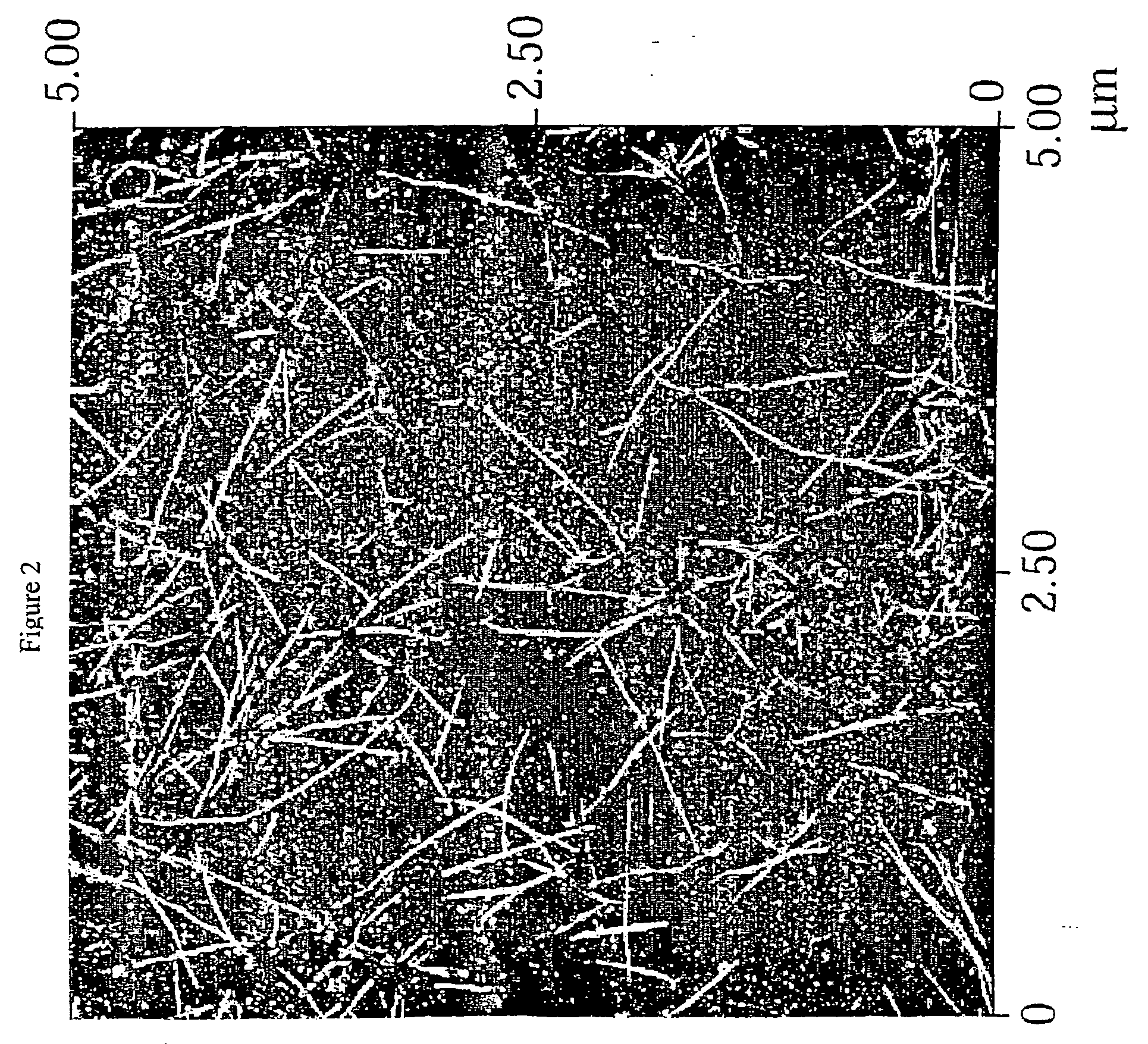

Process and applications of carbon nanotube dispersions

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Production of agglomerates from gas phase

ActiveUS20050006801A1Avoid enteringImprove mechanical propertiesMaterial nanotechnologyMulti-walled nanotubesGas phaseReaction zone

A process for production of an agglomerate comprises the steps of: passing a flow of one or more gaseous reactants into a reactor; reacting the one or more gaseous reactants within a reaction zone of the reactor to form product particles; agglomerating the product particles into an agglomerate; and applying a force to the agglomerate to displace it continuously away from the reaction zone.

Owner:CAMBRIDGE ENTERPRISE LTD

Mass production of carbon nanostructures

InactiveUS20060121279A1Improve mechanical stabilityPigmenting treatmentMaterial nanotechnologyGraphiteGraphene

Carbon nanostructures are mass produced from graphite. In particularly preferred aspects, graphene is thermo-chemically derived from graphite and used in numerous compositions. In further preferred aspects, the graphene is re-shaped to form other nanostructures, including nanofractals, optionally branched open-ended SWNT, nanoloops, and nanoonions.

Owner:PETRIK VIKTOR I

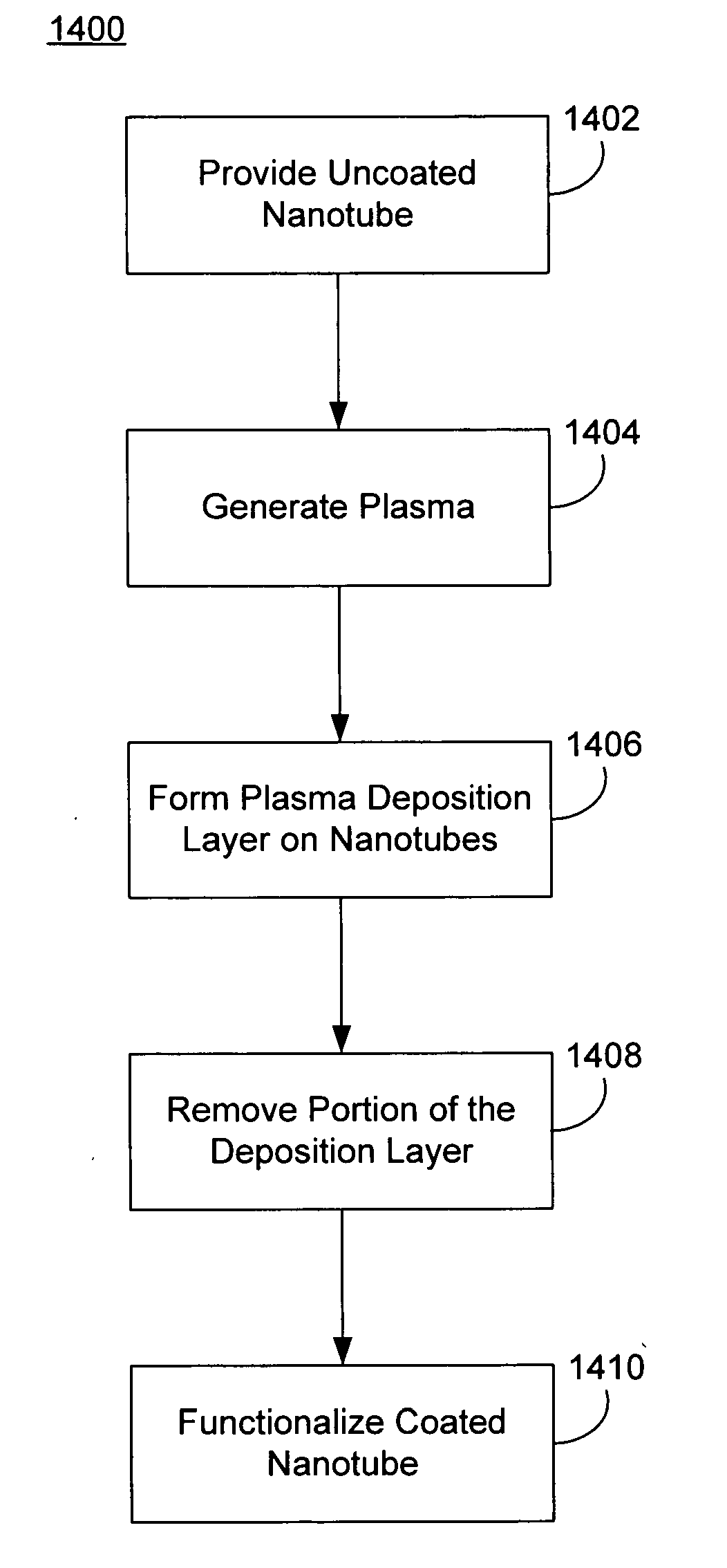

Coatings for carbon nanotubes

A coated nanotube that includes an inner nanotube having an exterior surface, and a plasma deposited layer covering at least part of the exterior surface of the inner nanotube. Also, a method of making a coated nanotube, the method where the method includes the steps of generating a plasma from a coating precursor, and exposing an inner nanotube to the plasma, where a plasma deposited layer is formed on at least a portion of the inner nanotube. Additionally, a method of making a coated nanotube that includes the steps of providing an inner nanotube, and evaporating a metal into the inner nanotube, where the metal forms a coating layer on at least a portion of the inner nanotube.

Owner:CALIFORNIA INST OF TECH

Method of purifying nanotubes and nanofibers using electromagnetic radiation

Disclosed are methods of purifying mixtures comprising nanofibers and / or nanotubes and residual catalyst particles that are covered by outer layers of the nanotube or nanofiber material. The mixtures are exposed to electromagnetic radiation, which induces localized heating in the residual catalyst particles. The localized heating creates breaches in the outer layers. Thereafter, the residual catalyst particles may be removed under relatively mild conditions that do not significantly affect the structural integrity of the nanotubes or nanofibers. The methods of the invention have been used to particular advantage in the purification of single wall carbon nanotubes (SWNTs) synthesized using metal catalysts. For these SWNTs, microwave radiation is preferably used to induce the localized heating, the outer layers are preferably removed at least in part by carrying out the localized heating under air, and the residual catalyst may be removed by exposure to relatively dilute aqueous acid.

Owner:PENN STATE RES FOUND

Methods of chemically derivatizing single-wall carbon nanotubes

InactiveUS6841139B2Increase resistanceHigh yieldMaterial nanotechnologyPigmenting treatmentFiberLithium

This invention is directed to making chemical derivatives of carbon nanotubes and to uses for the derivatized nanotubes, including making arrays as a basis for synthesis of carbon fibers. In one embodiment, this invention also provides a method for preparing single wall carbon nanotubes having substituents attached to the side wall of the nanotube by reacting single wall carbon nanotubes with fluorine gas and recovering fluorine derivatized carbon nanotubes, then reacting fluorine derivatized carbon nanotubes with a nucleophile. Some of the fluorine substituents are replaced by nucleophilic substitution. If desired, the remaining fluorine can be completely or partially eliminated to produce single wall carbon nanotubes having substituents attached to the side wall of the nanotube. The substituents will, of course, be dependent on the nucleophile, and preferred nucleophiles include alkyl lithium species such as methyl lithium. Alternatively, fluorine may be fully or partially removed from fluorine derivatized carbon nanotubes by reacting the fluorine derivatized carbon nanotubes with various amounts of hydrazine, substituted hydrazine or alkyl amine. The present invention also provides seed materials for growth of single wall carbon nanotubes comprising a plurality of single wall carbon nanotubes or short tubular molecules having a catalyst precursor moiety covalently bound or physisorbed on the outer surface of the sidewall to provide the optimum metal cluster size under conditions that result in migration of the metal moiety to the tube end.

Owner:RICE UNIV

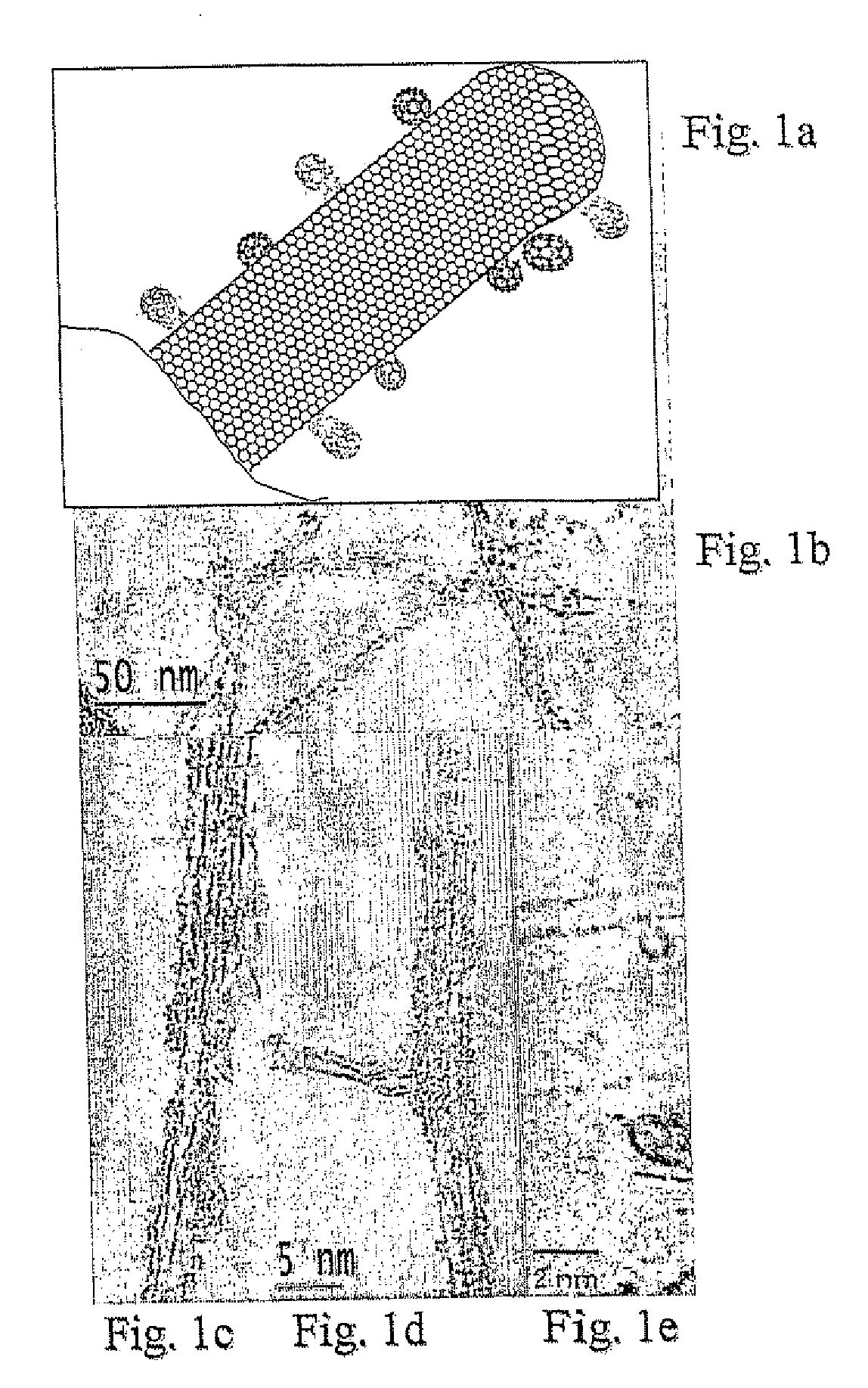

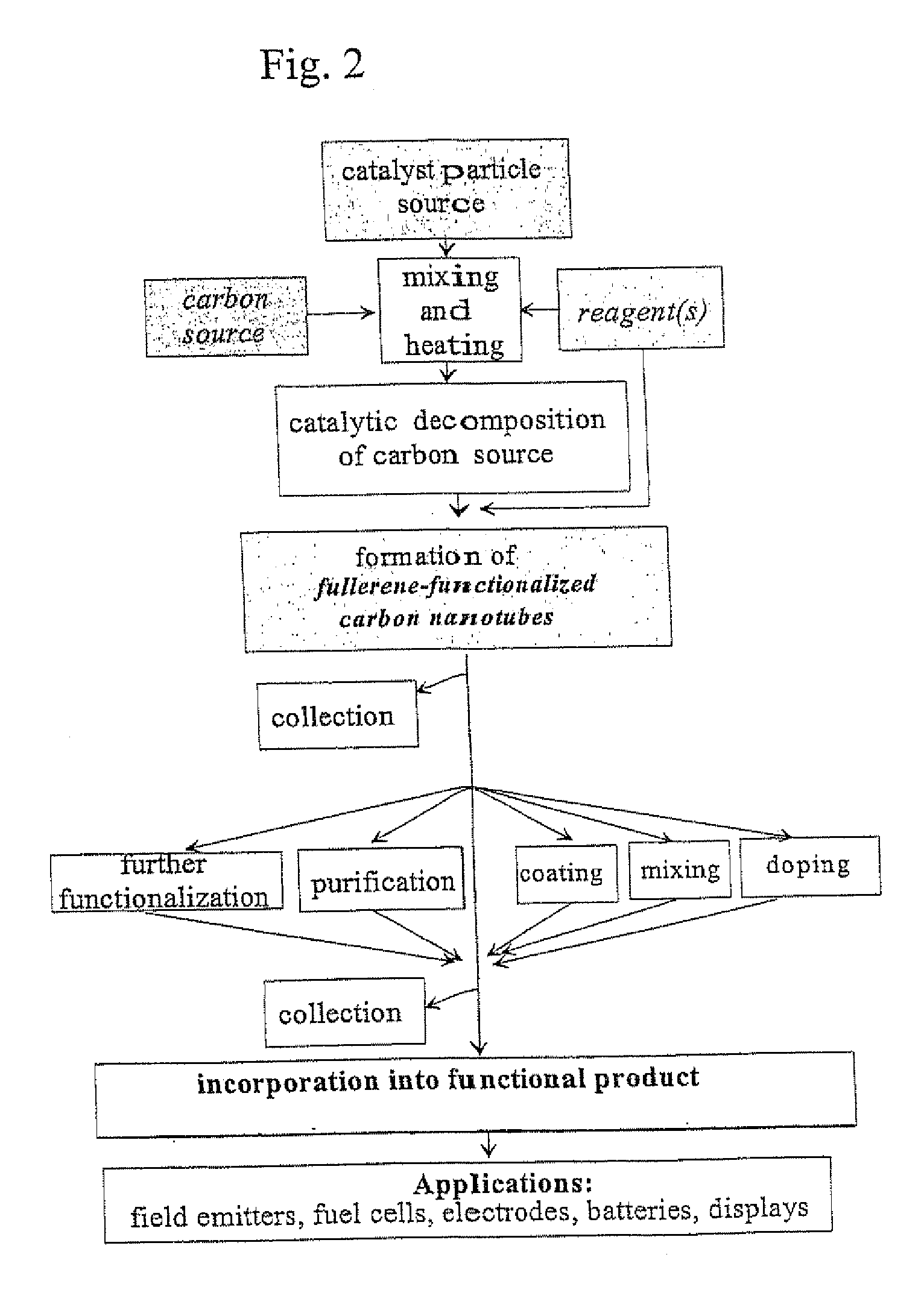

Carbon nanotubes functionalized with fullerenes

InactiveUS20090226704A1Enhancement in cold electron field emissionImprove mechanical propertiesSpecific nanostructure formationMaterial nanotechnologyC60 fullereneNanotube

The present invention relates to covalently bonded fullerene-functionalized carbon nanotubes (CBFFCNTs), a method and an apparatus for their production and to their end products. CBFFCNTs are carbon nanotubes with one or more fullerenes or fullerene based molecules covalently bonded to the nanotube surface. They are obtained by bringing one or more catalyst particles, carbon sources and reagents together in a reactor.

Owner:CANATU OY

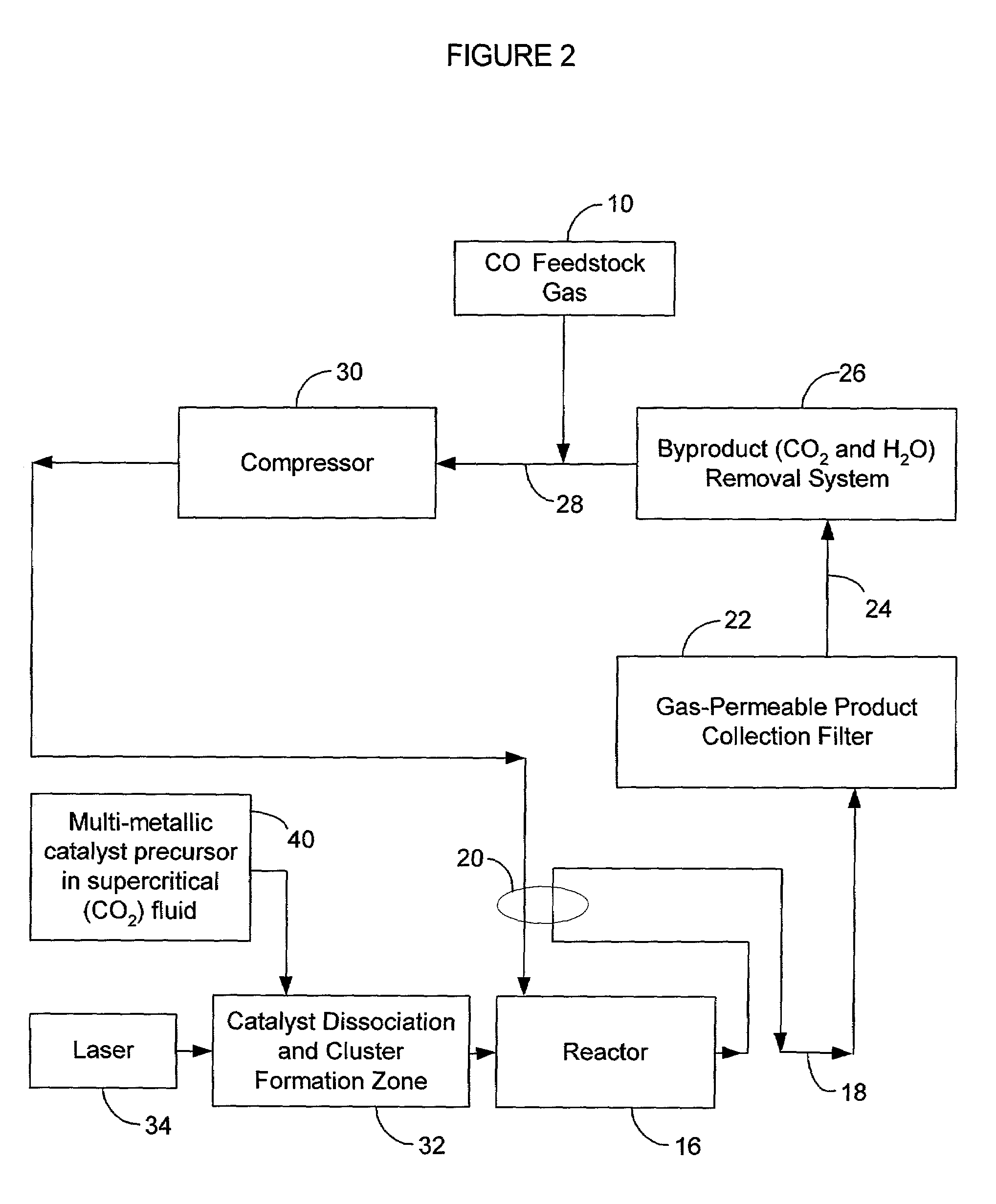

Process utilizing seeds for making single-wall carbon nanotubes

InactiveUS7052668B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFullerenesMetal catalystGas phase

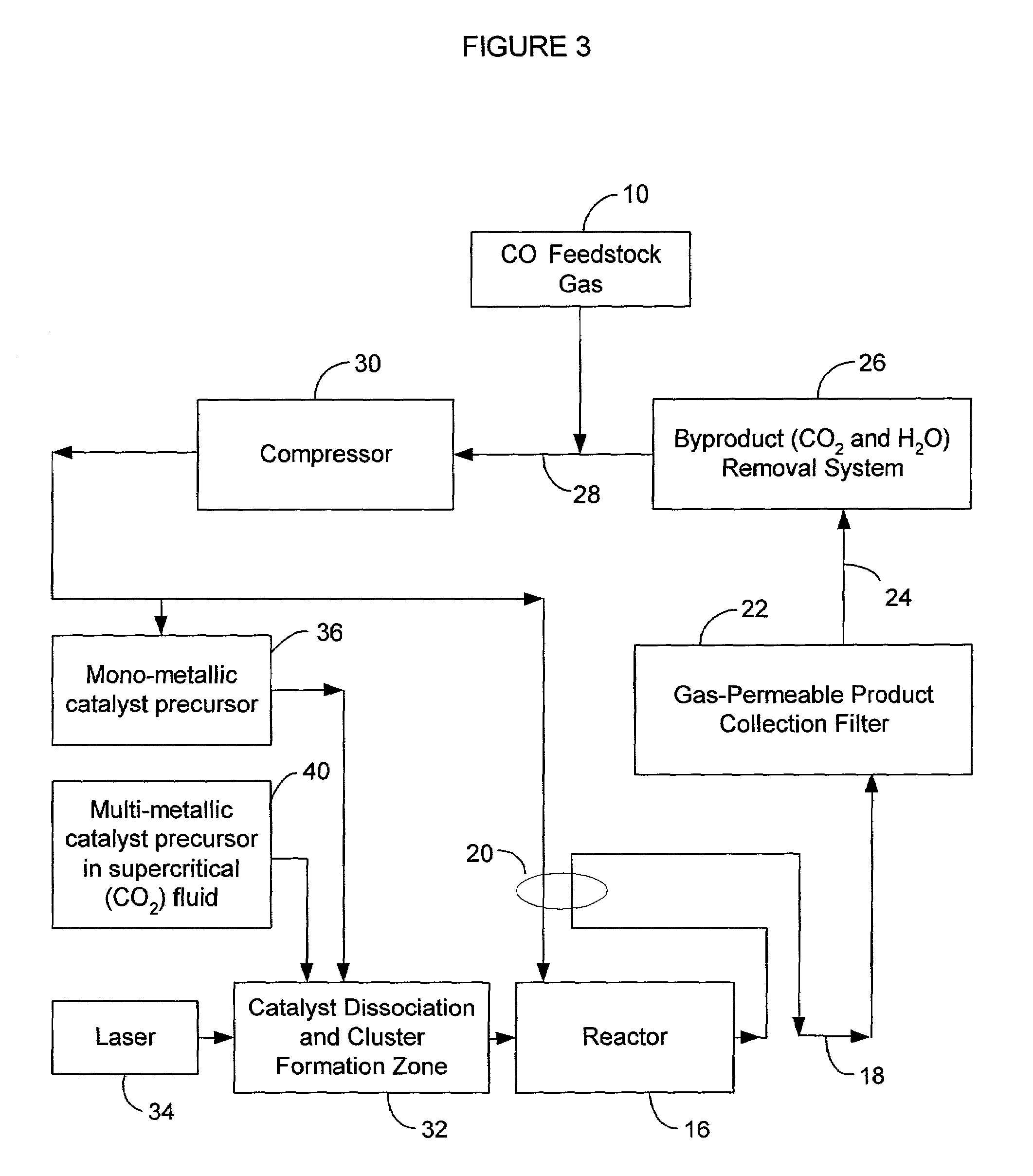

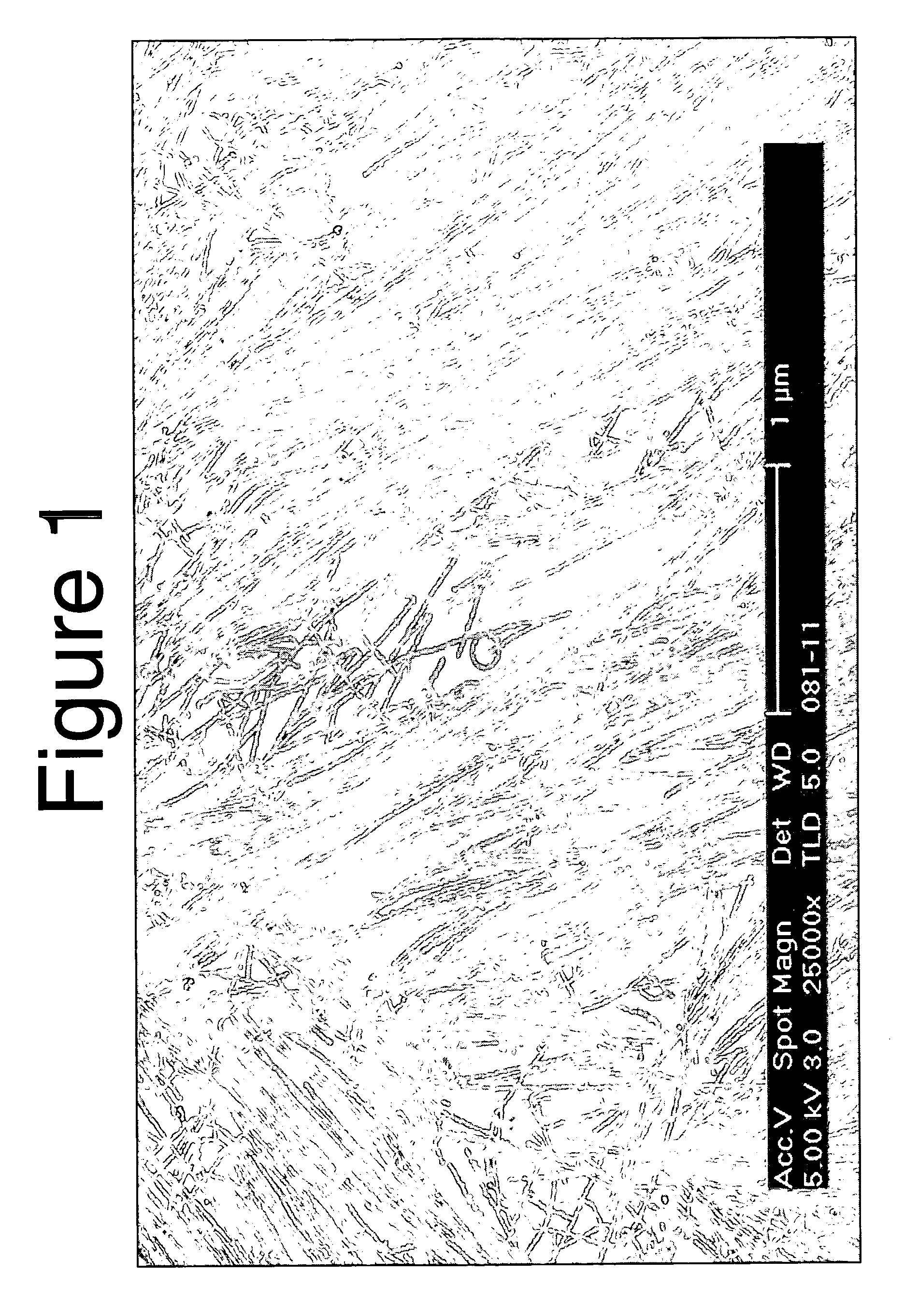

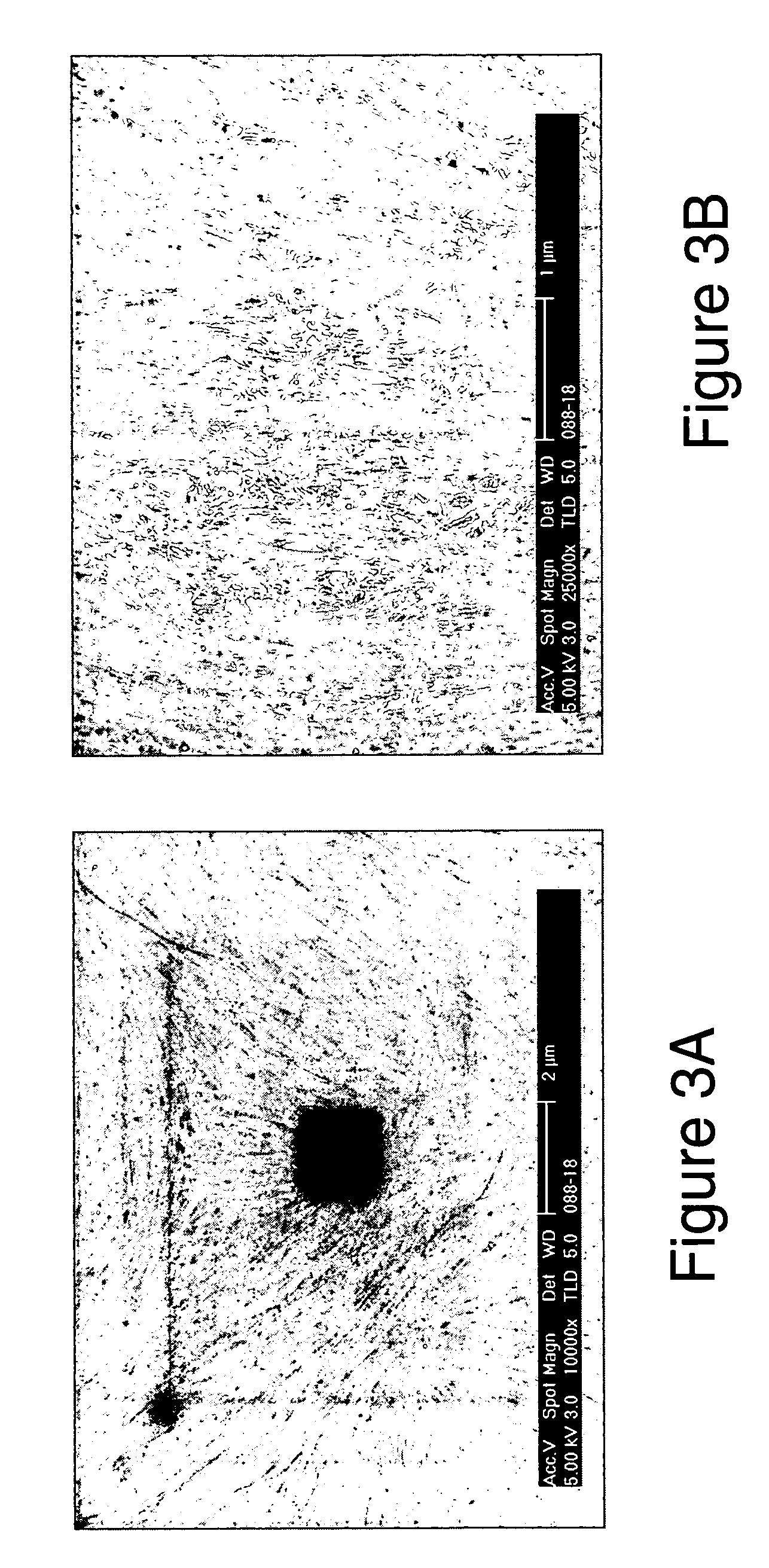

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

Aqueous carbon nanotube applicator liquids and methods for producing applicator liquids thereof

ActiveUS20060204427A1Low toxicityEasy to takeMaterial nanotechnologyCarbon fibresLiquid mediumVolumetric Mass Density

Certain applicator liquids and method of making the applicator liquids are described. The applicator liquids can be used to form nanotube films or fabrics of controlled properties. An applicator liquid for preparation of a nanotube film or fabric includes a controlled concentration of nanotubes dispersed in a liquid medium containing water. The controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity.

Owner:ZEON CORP

Fullerene nanotube compositions

InactiveUS20080063585A1High yieldModerate temperatureMaterial nanotechnologyFullerenesFullereneNanotube

This invention relates generally to a fullerene nanotube composition. The fullerene nanotubes may be in the form of a felt, such as a bucky paper. Optionally, the fullerene nanotubes may be derivatized with one or more functional groups. Devices employing the fullerene nanotubes of this invention are also disclosed.

Owner:RICE UNIV

Carbon nanotube particulates, compositions and use thereof

InactiveUS20050002851A1Suitable for useMaterial nanotechnologyNanoinformaticsParticulatesContact time

A method for making carbon nanotube particulates involves providing a catalyst comprising catalytic metals, such as iron and molybdenum or metals from Group VIB or Group VIIIB elements, on a support material, such as magnesia, and contacting the catalyst with a gaseous carbon-containing feedstock, such as methane, at a sufficient temperature and for a sufficient contact time to make small-diameter carbon nanotubes having one or more walls and outer wall diameters of less than about 3 nm. Removal of the support material from the carbon nanotubes yields particulates of enmeshed carbon nanotubes that retain an approximate three-dimensional shape and size of the particulate support that was removed. The carbon nanotube particulates can comprise ropes of carbon nanotubes. The carbon nanotube particulates disperse well in polymers and show high conductivity in polymers at low loadings. As electrical emitters, the carbon nanotube particulates exhibit very low “turn on” emission field.

Owner:UNIDYM

Chemically modifying single wall carbon nanotubes to facilitate dispersal in solvents

InactiveUS6875412B2High yieldIncrease resistanceMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

Owner:RICE UNIV

Cnt-based resistive heating for deicing composite structures

ActiveUS20110024409A1Prevent freezingInhibition formationMaterial nanotechnologyLayered productsFiberCarbon nanotube

A composite structure includes a matrix material and a carbon nanotube (CNT)-infused fiber material that includes a plurality of carbon nanotubes (CNTs) infused to a fiber material. The CNT-infused fiber material is disposed throughout a portion of the matrix material. The composite structure is adapted for application of a current through the CNT-infused fiber material to provide heating of the composite structure. A heating element includes a CNT-infused fiber material includes a plurality of CNTs infused to a fiber material. The CNT-infused fiber material is of sufficient proportions to provide heating to a structure in need thereof.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

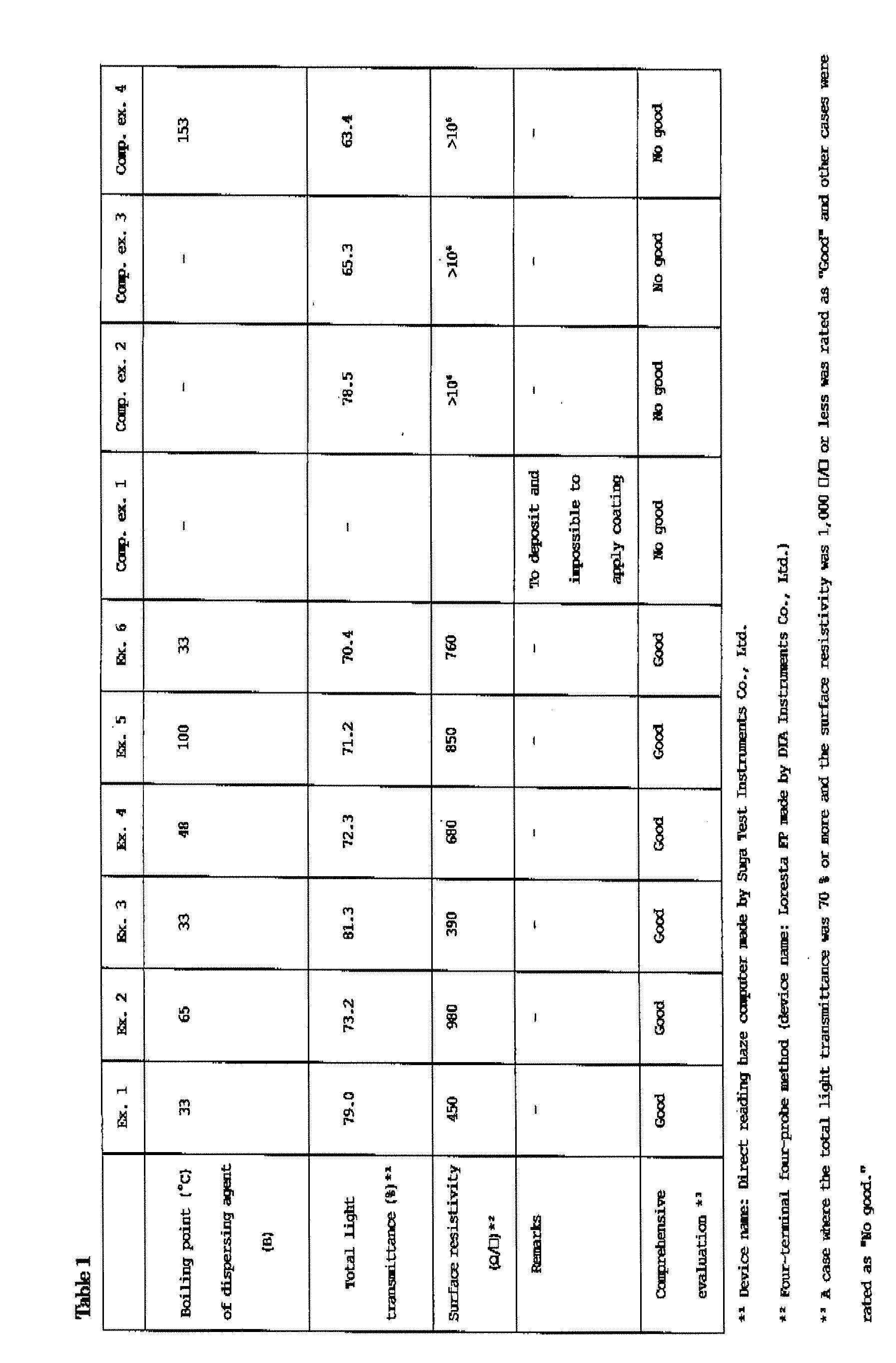

Carbon nanotube dispersion liquid and transparent conductive film using same

Disclosed is a carbon nanotube dispersion liquid which enables to easily form a transparent conductive film. Also disclosed is a transparent conductive film obtained by using such a carbon nanotube dispersion liquid. Specifically disclosed is a carbon nanotube dispersion liquid containing a carbon nanotube (A), a dispersing agent (B) composed of an organic compound containing one of a carboxyl group, epoxy group, amino group and sulfonyl group and having a boiling point of not less than 30˚C and not more than 150˚C, and a solvent (C). Also disclosed are a transparent conductive film containing a layer composed of a solid component of such a dispersion liquid, and a method for producing such a transparent conductive film.

Owner:KURARAY CO LTD

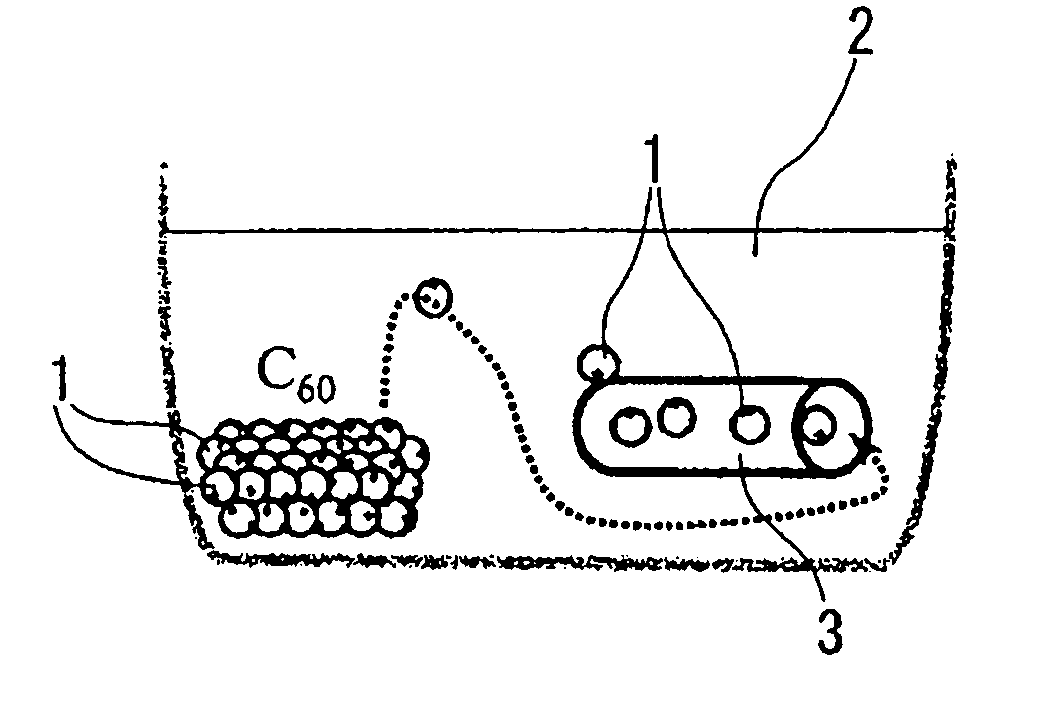

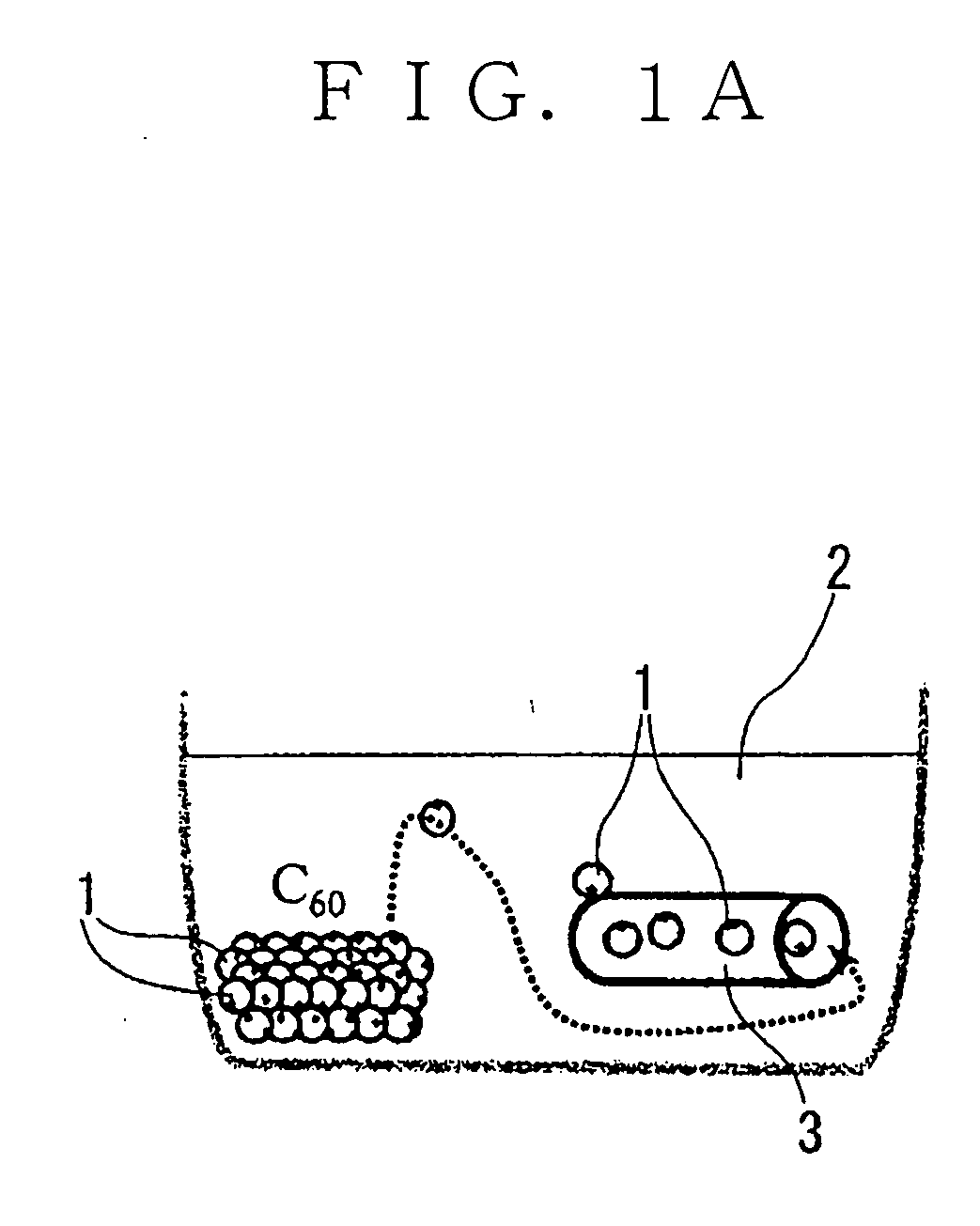

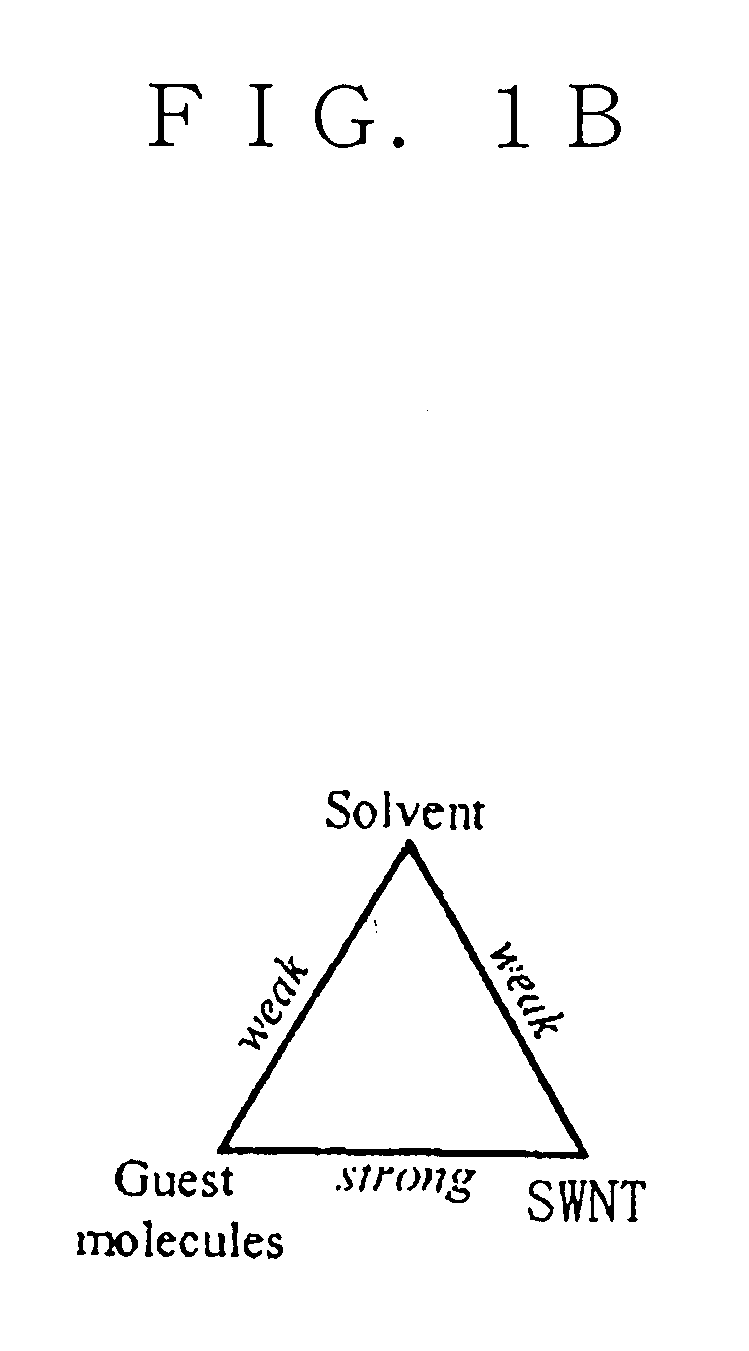

Nano-extraction method and nano-condensation methods for guest molecules incorporation into single-wall carbon nanotube

The objects of this patent application are to provide a new nano-extraction method for guest molecules to be incorporated into single-wall carbon nanotube (SWNT) comprising: putting guest molecules in solvent, wherein the guest molecules have a poor affinity to the solvent and a strong affinity to single-wall carbon nanotube (SWNT) and the attractive force between the guest molecules and SWNT is greater than that between the guest molecules and solvent molecules and that between the solvent molecules and SWNT, ultrasonicating the solution including the solvent and quest molecules, adding single-wall carbon nanotube (SWNT) or single-wall carbon nanotubes (SWNTs) with opened tips and wall-holes in the solution, and leaving the SWNT-guest molecules-solvent mixture until becoming stable with the guest molecules incorporated into SWNT at room temperature, and a nano-condensation method for guest molecules to be incorporated into single-wall carbon nanotube (SWNT) comprising: dropping saturated solution including solvent and guest molecules having a strong affinity to the solvent and a strong affinity to single-wall carbon nanotube (SWNT) onto SWNT or SWNTs placed on a grid disk laid on filtration paper for sucking up the excess solution as quickly as possible.

Owner:NEC CORP

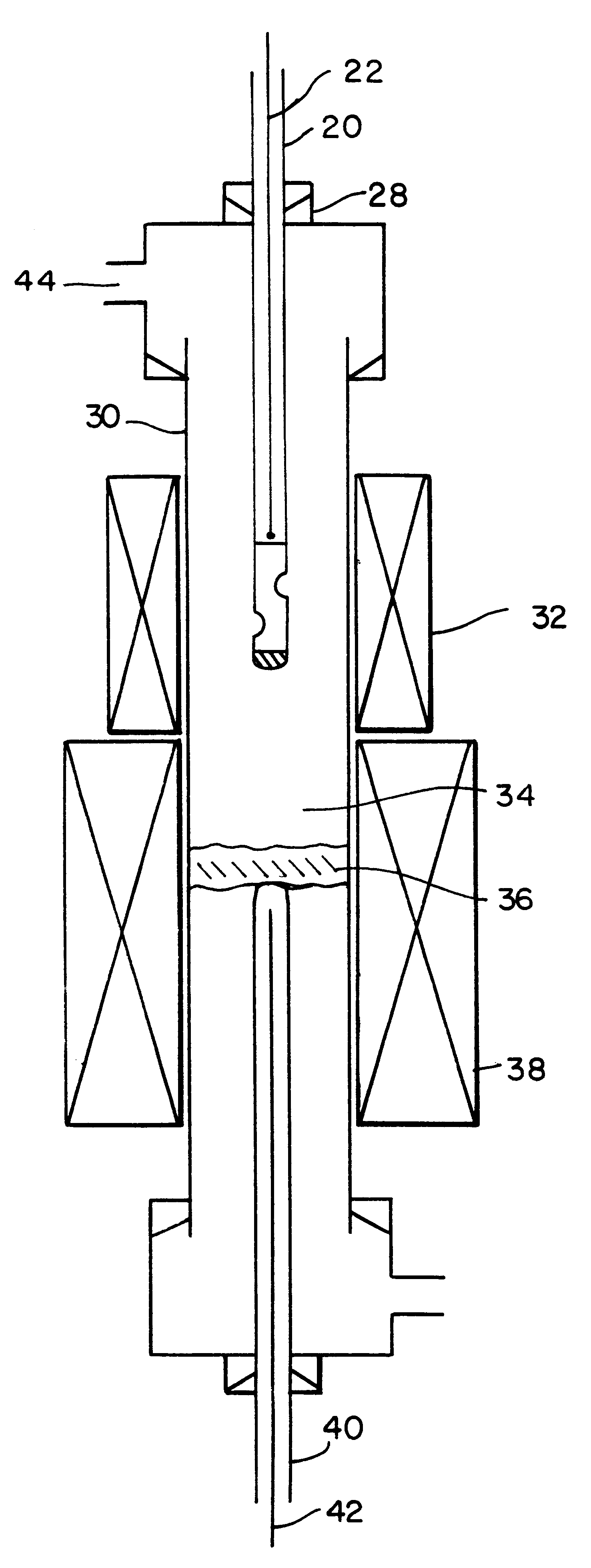

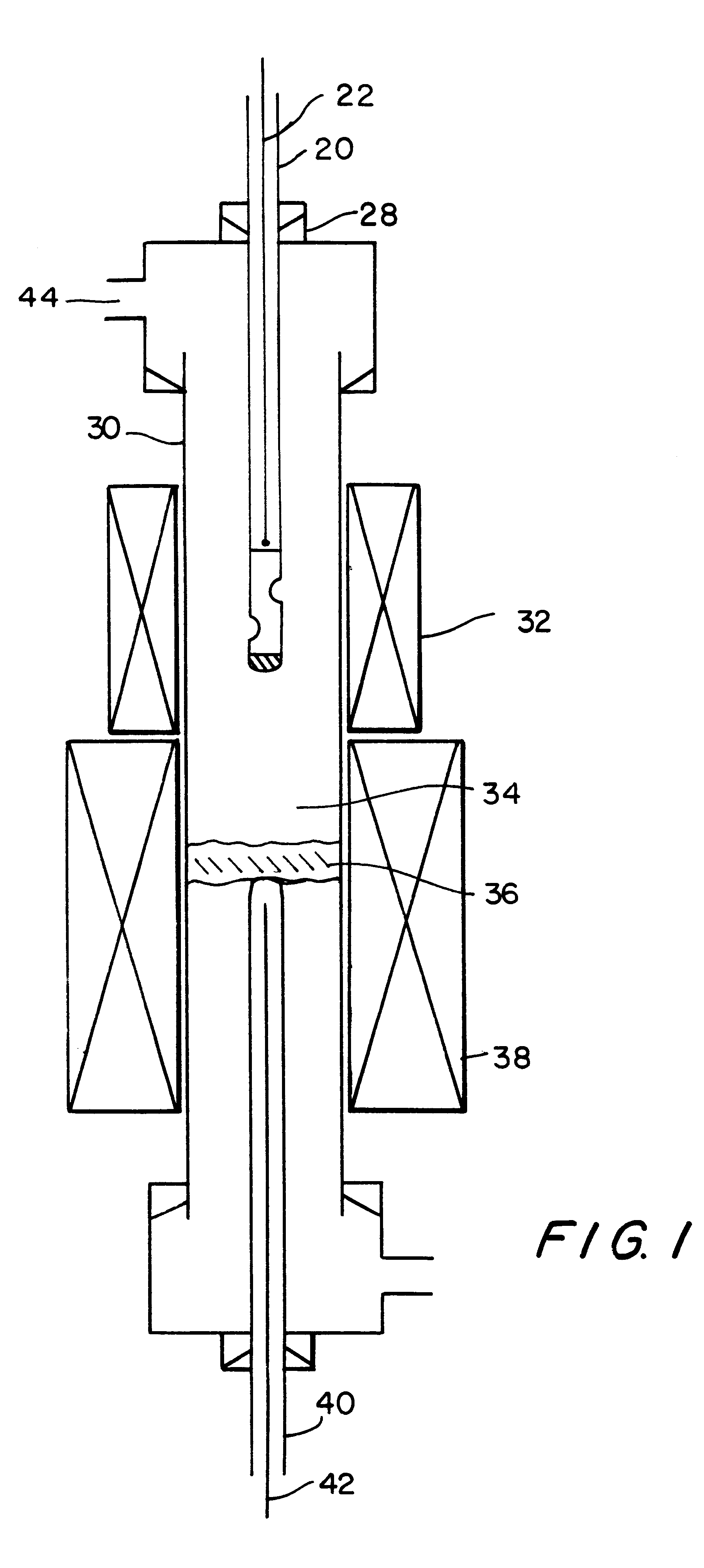

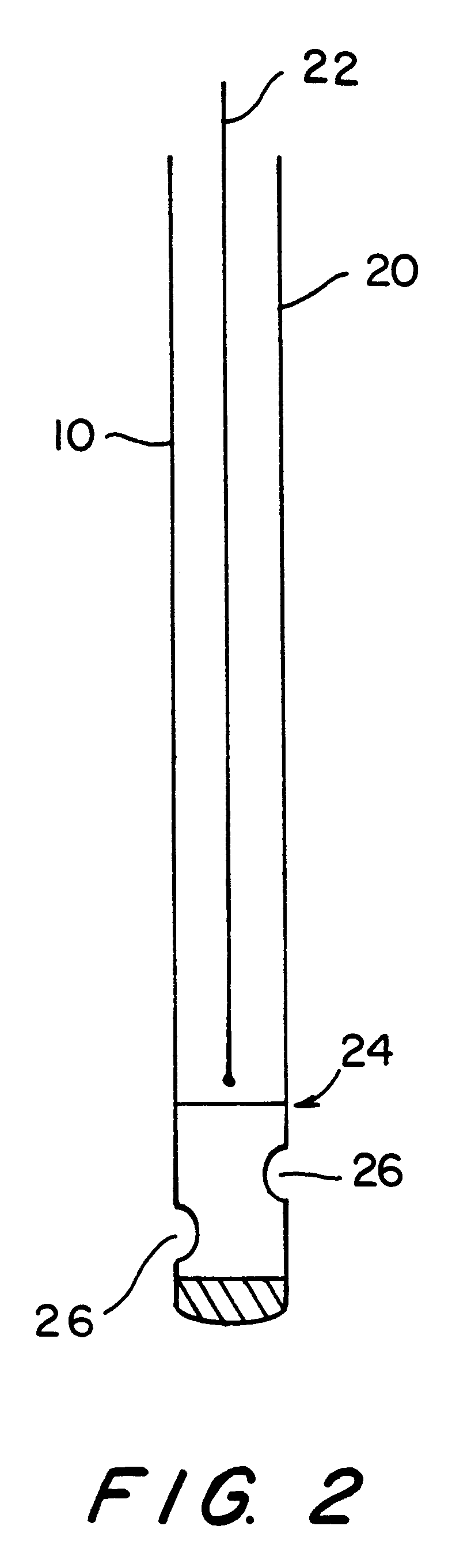

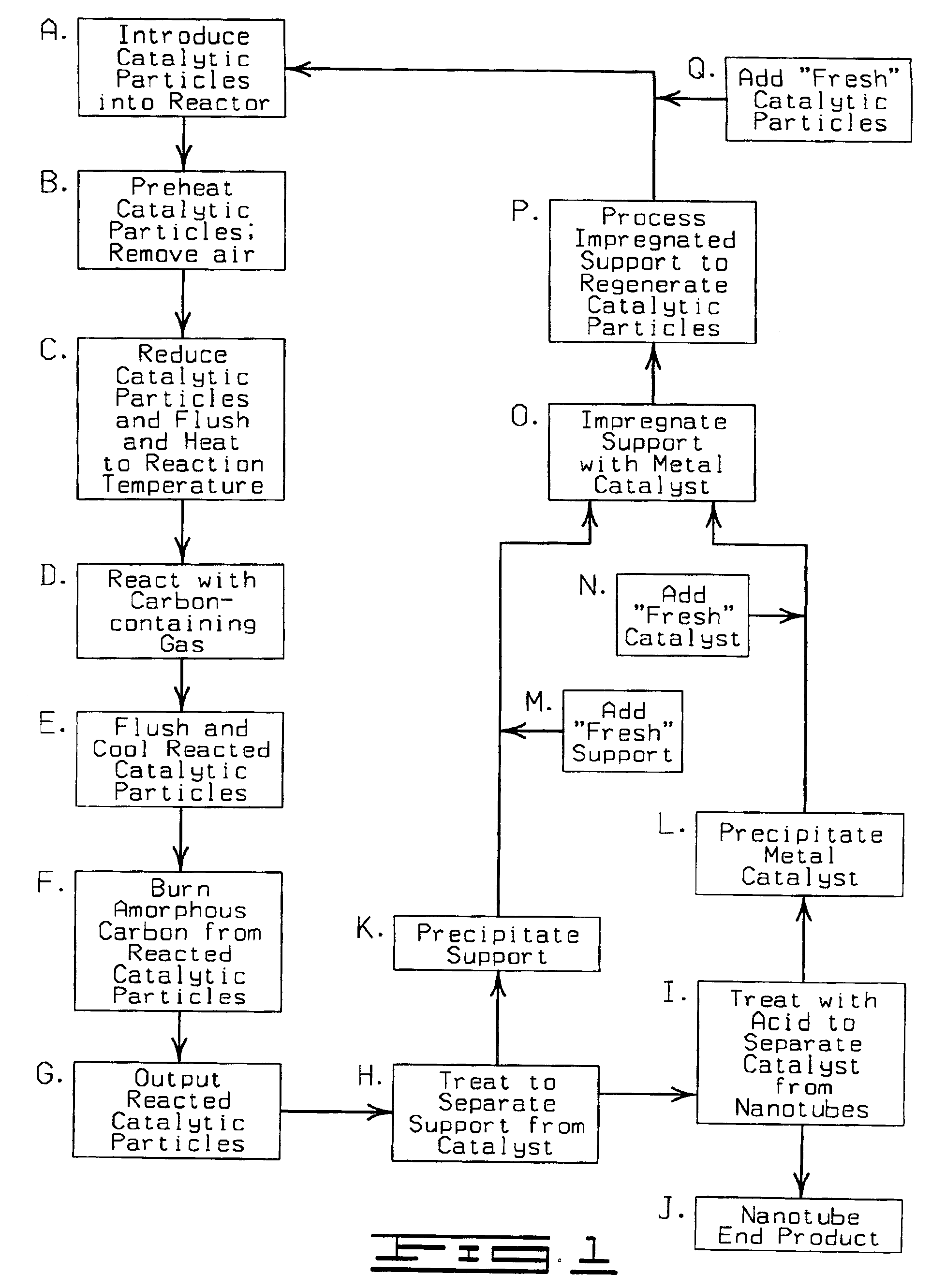

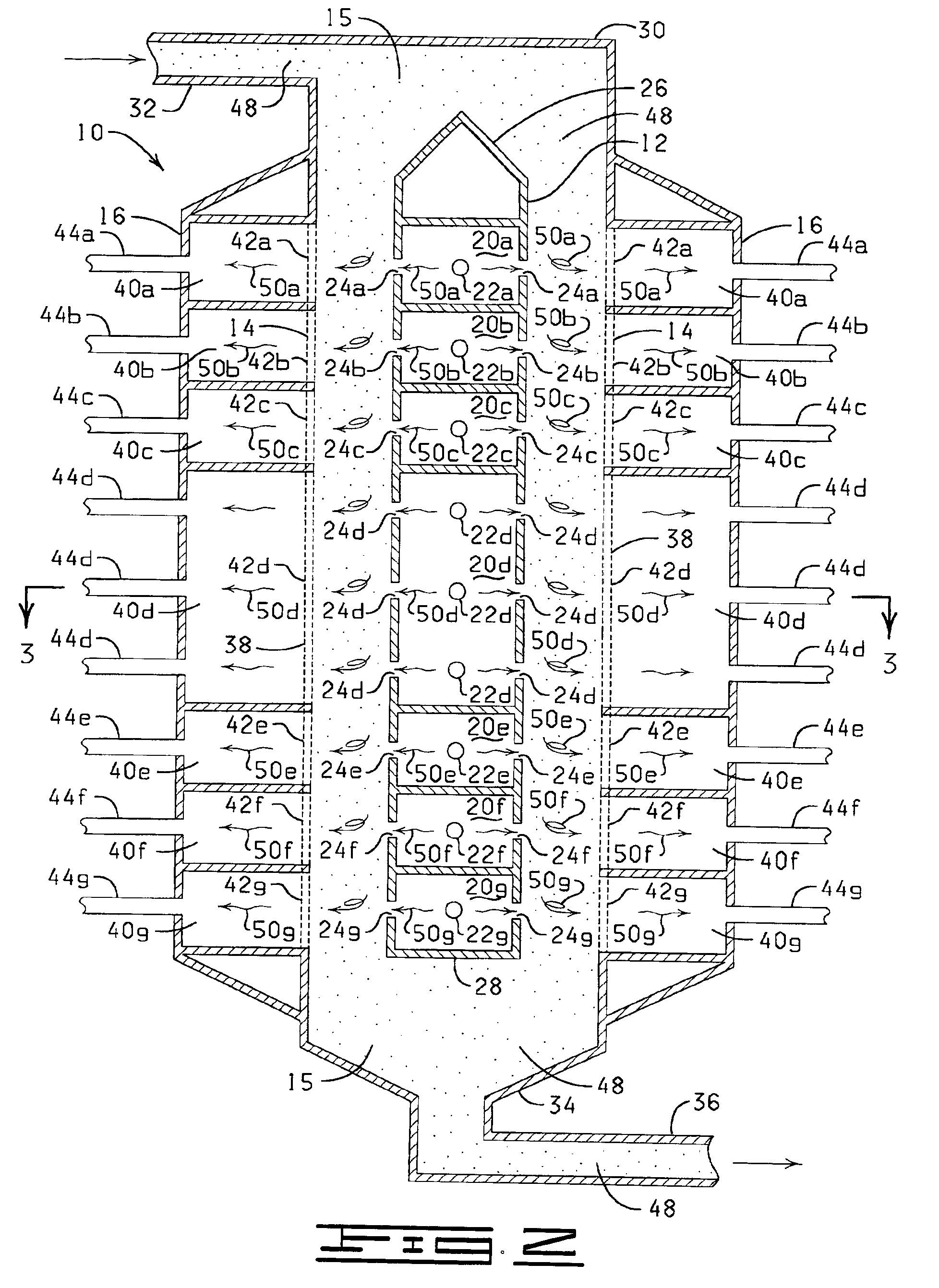

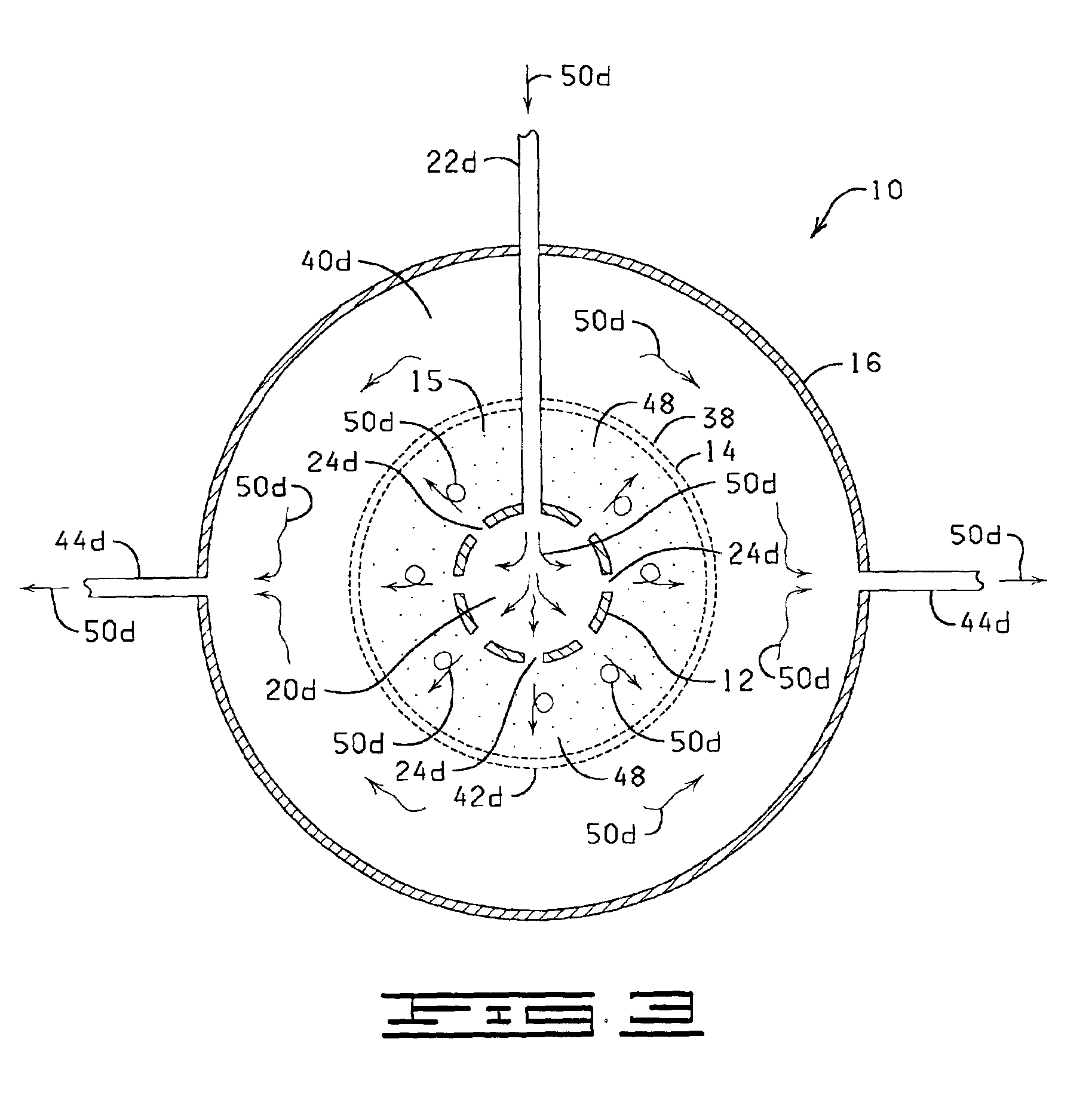

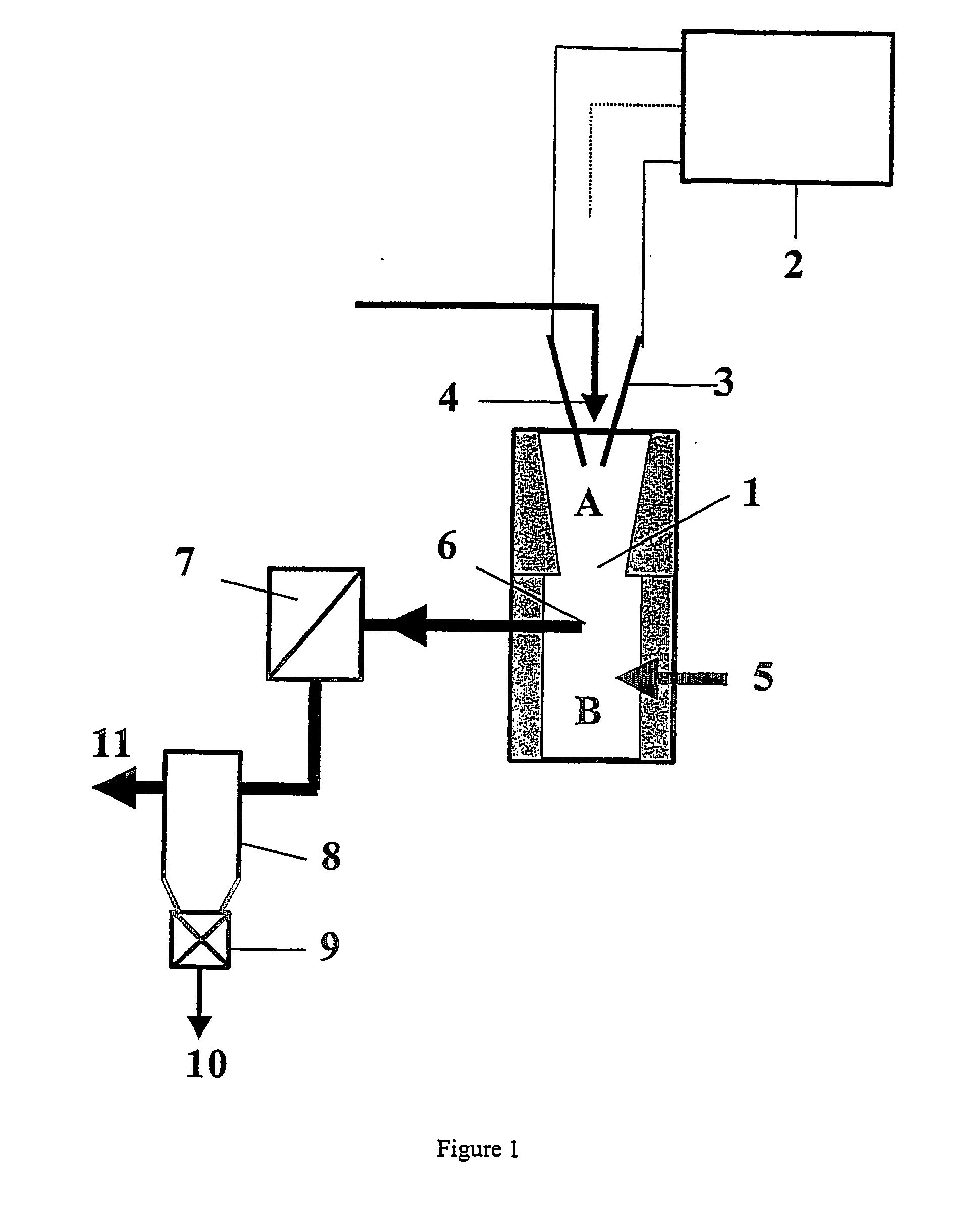

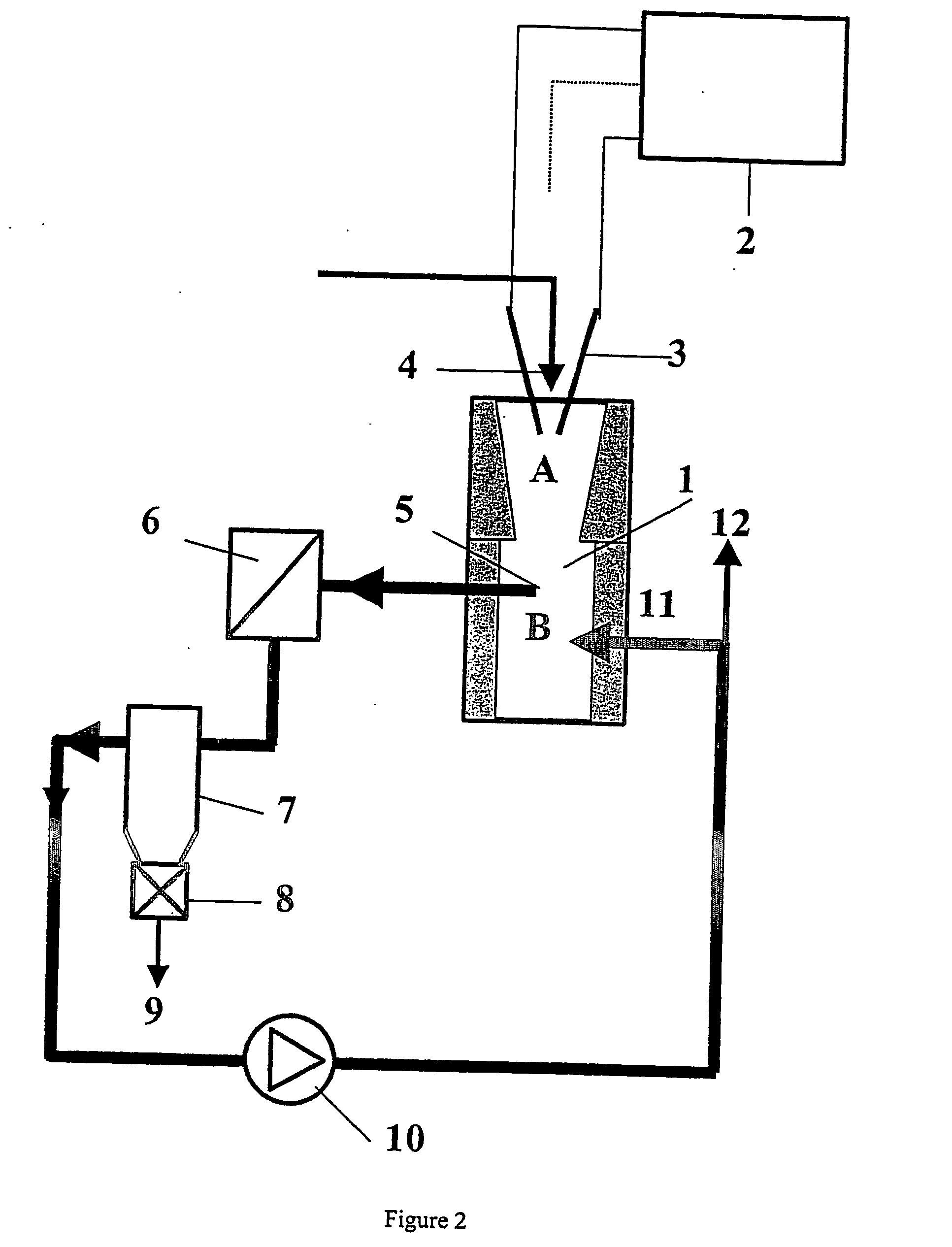

Method and apparatus for producing carbon nanotubes

InactiveUS6955800B2Avoid disadvantagesAvoid defectsMaterial nanotechnologyCatalyst regeneration/reactivationParticulatesCarbon nanotube

A method and apparatus for catalytic production of carbon nanotubes. Catalytic particles are exposed to different process conditions at successive stages wherein the catalytic particles do not come in contact with reactive (catalytic) gases until preferred process conditions have been attained, thereby controlling the quantity and form of carbon nanotubes produced. The method also contemplates methods and apparatus which recycle and reuse the gases and catalytic particulate materials, thereby maximizing cost efficiency, reducing wastes, reducing the need for additional raw materials, and producing the carbon nanotubes, especially SWNTs, in greater quantities and for lower costs.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

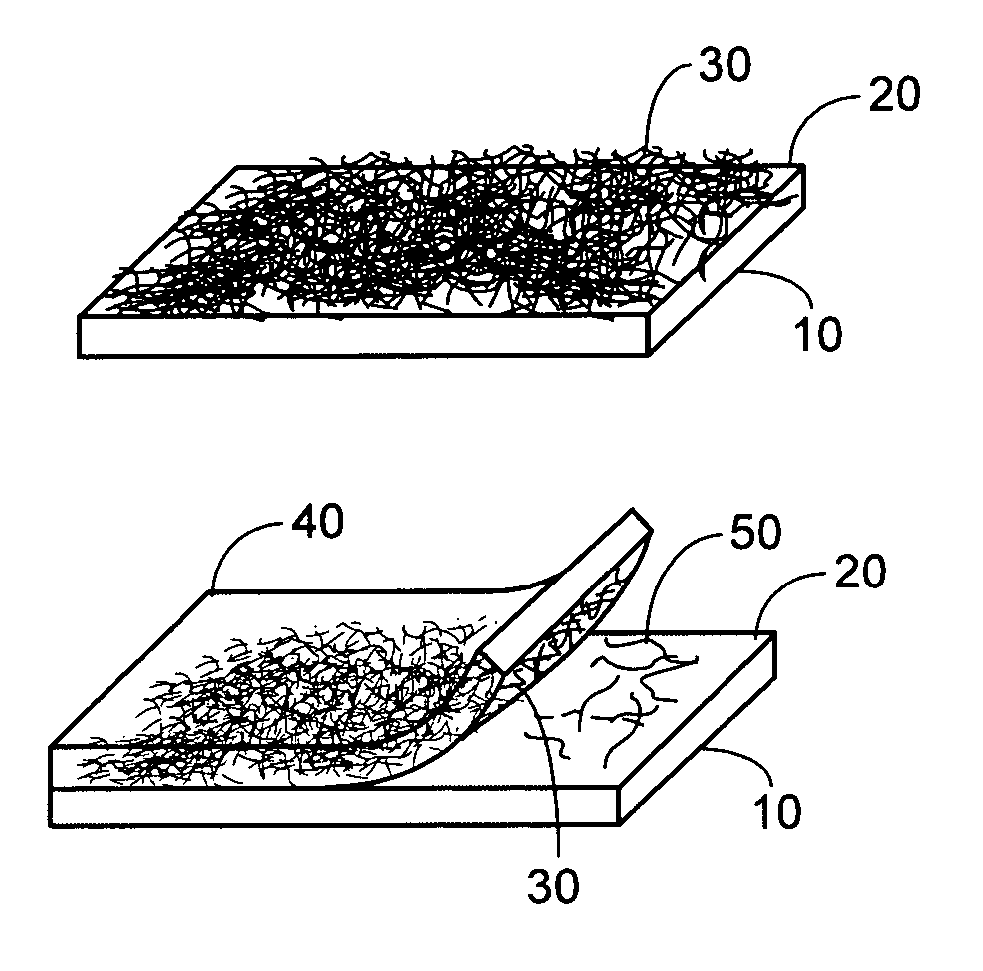

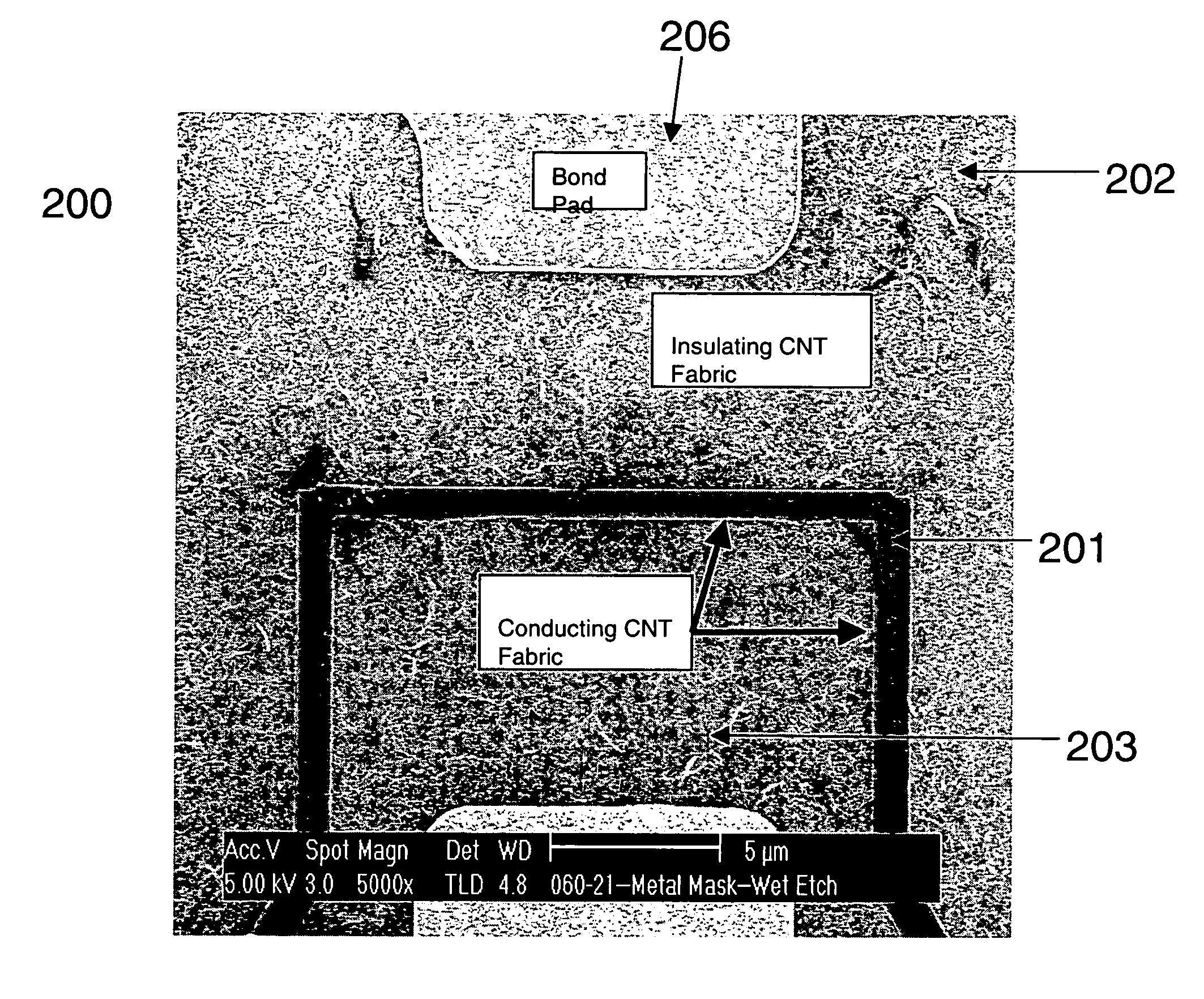

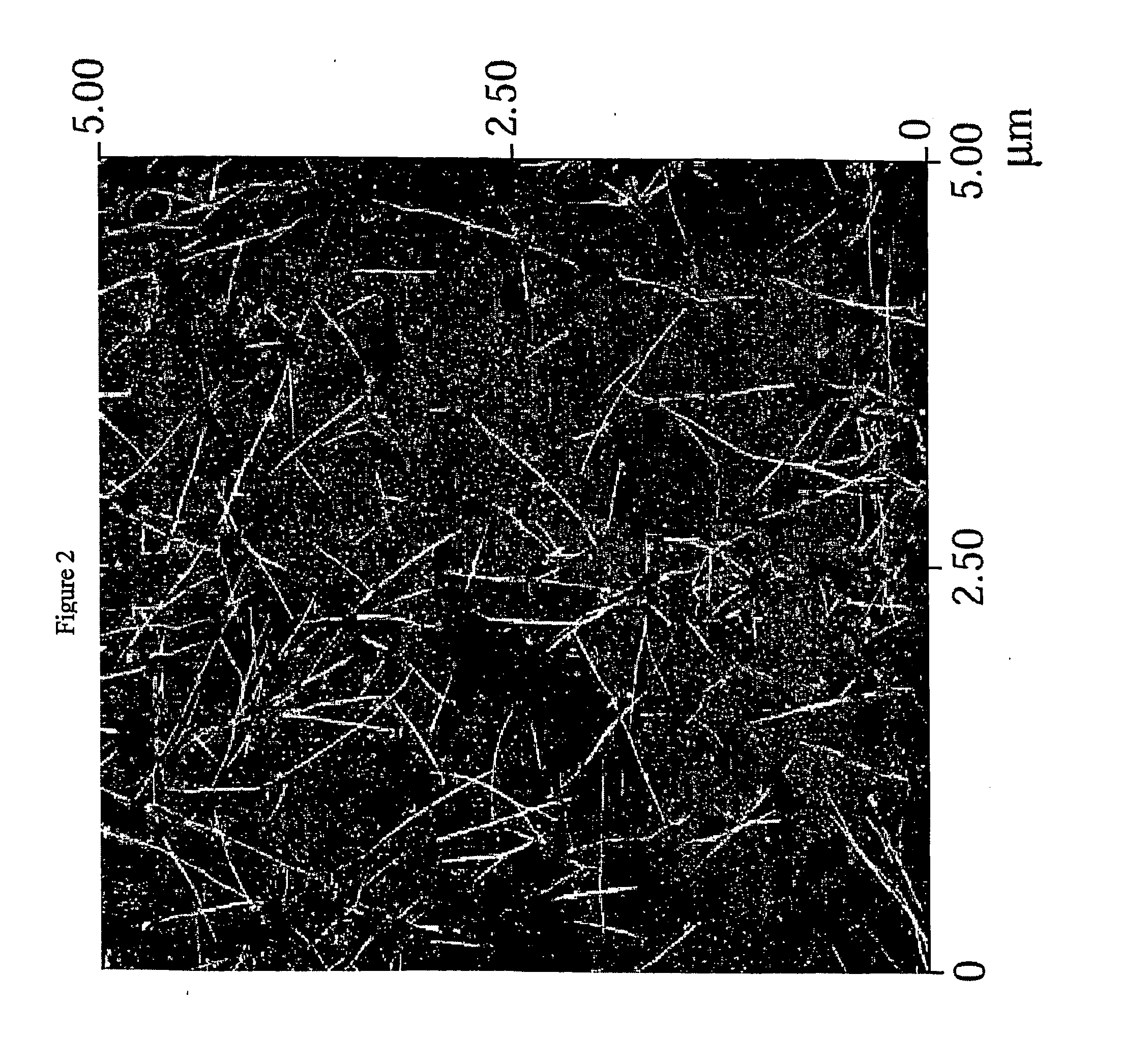

Nanotube articles with adjustable electrical conductivity and methods of making the same

InactiveUS20060276056A1Improve the immunityElectrical resistance increaseMaterial nanotechnologyFixed capacitor dielectricElectrical resistance and conductanceElectrical conductor

Nanotube articles having adjustable electrical conductivity, and methods of making the same. A patterned article includes conducting nanotubes that define a plurality of conductive pathways along the article, and also includes nanotubes of modified electrical conductivity. The modified nanotubes may electrically isolate the conducting nanotubes from other conductors. The nanotube segments may originally be semiconducting nanotubes, metallic nanotubes, nanotubes, single walled carbon nanotubes, multi-walled carbon nanotubes, or nanotubes entangled with nanotubes. The various segments may have different lengths and may include segments having a length shorter than the length of the article. A strapping material may be positioned to contact a portion of the plurality of nanotube segments. Such a strapping layer may also be used for making electrical contact to the nanotube fabric especially for electrical stitching to lower the overall resistance of the fabric.

Owner:NANTERO

Carbon nanotubes: high solids dispersions and nematic gels thereof

InactiveUS20060099135A1Good dispersionMaterial nanotechnologyNanoinformaticsAqueous mediumSURFACTANT BLEND

Disclosed are high weight fraction carbon nanotube dispersions including an aqueous medium, carbon nanotubes, and at least one surfactant, the surfactant having an aromatic group, an alkyl group having from about 4 to about 30 carbon atoms, and a charged head group. Also disclosed are ultrasonication processes capable of providing stable dispersions of carbon nanotubes having reduced breakage of the carbon nanotubes. The preparation of nematic nanotube gels from the carbon nanotube dispersions are also disclosed. A variety of uses and applications of the carbon nanotube dispersions and nematic nanotube gels are provided.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

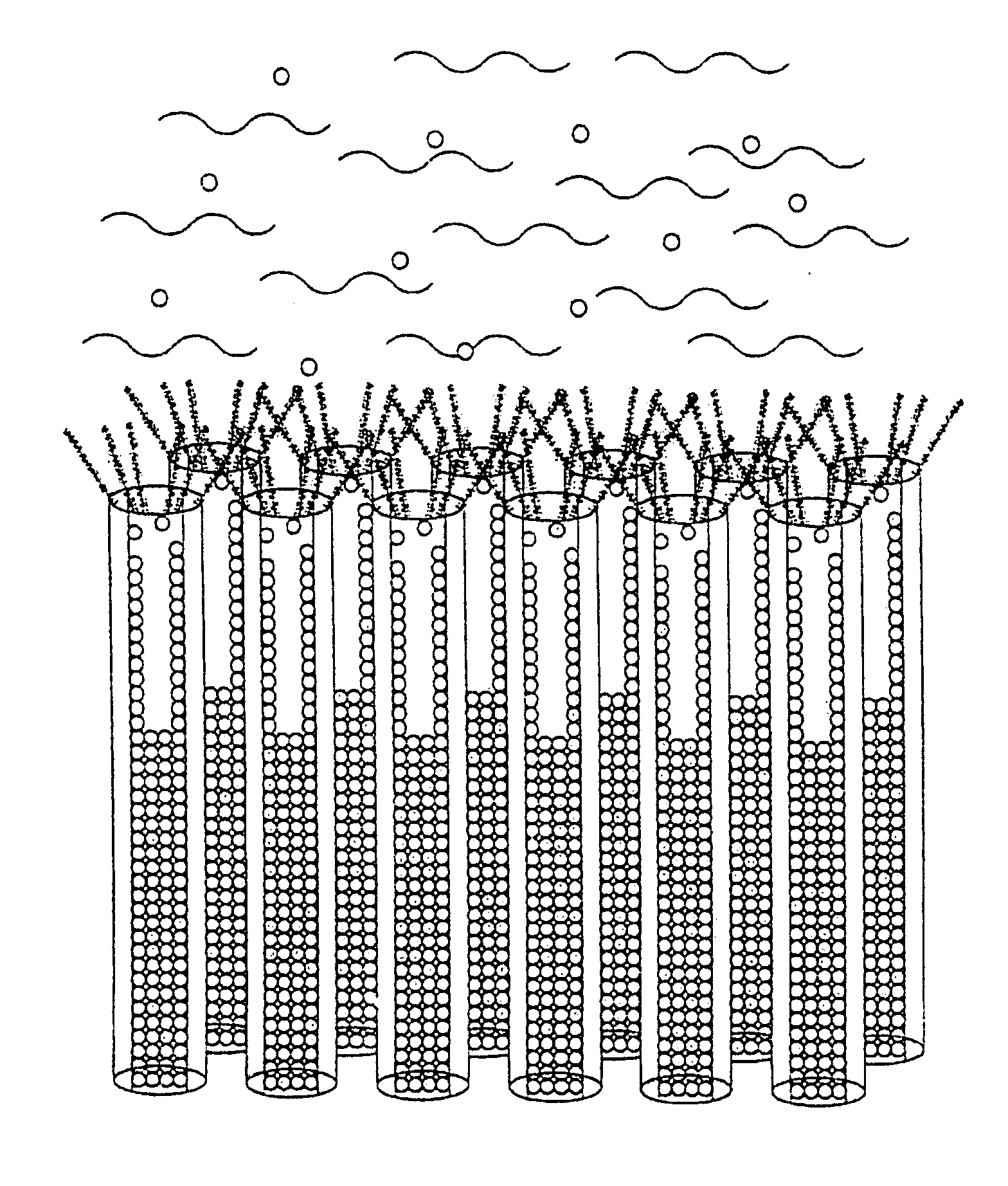

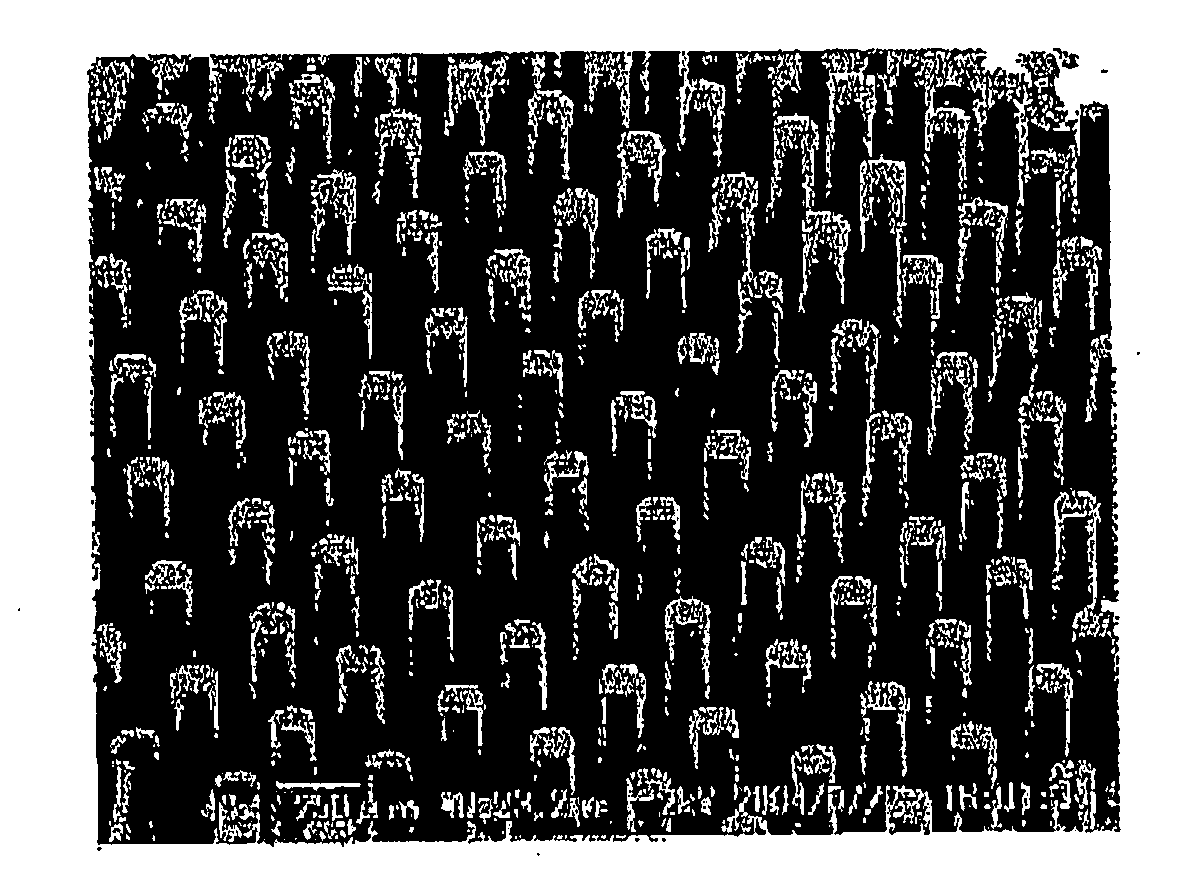

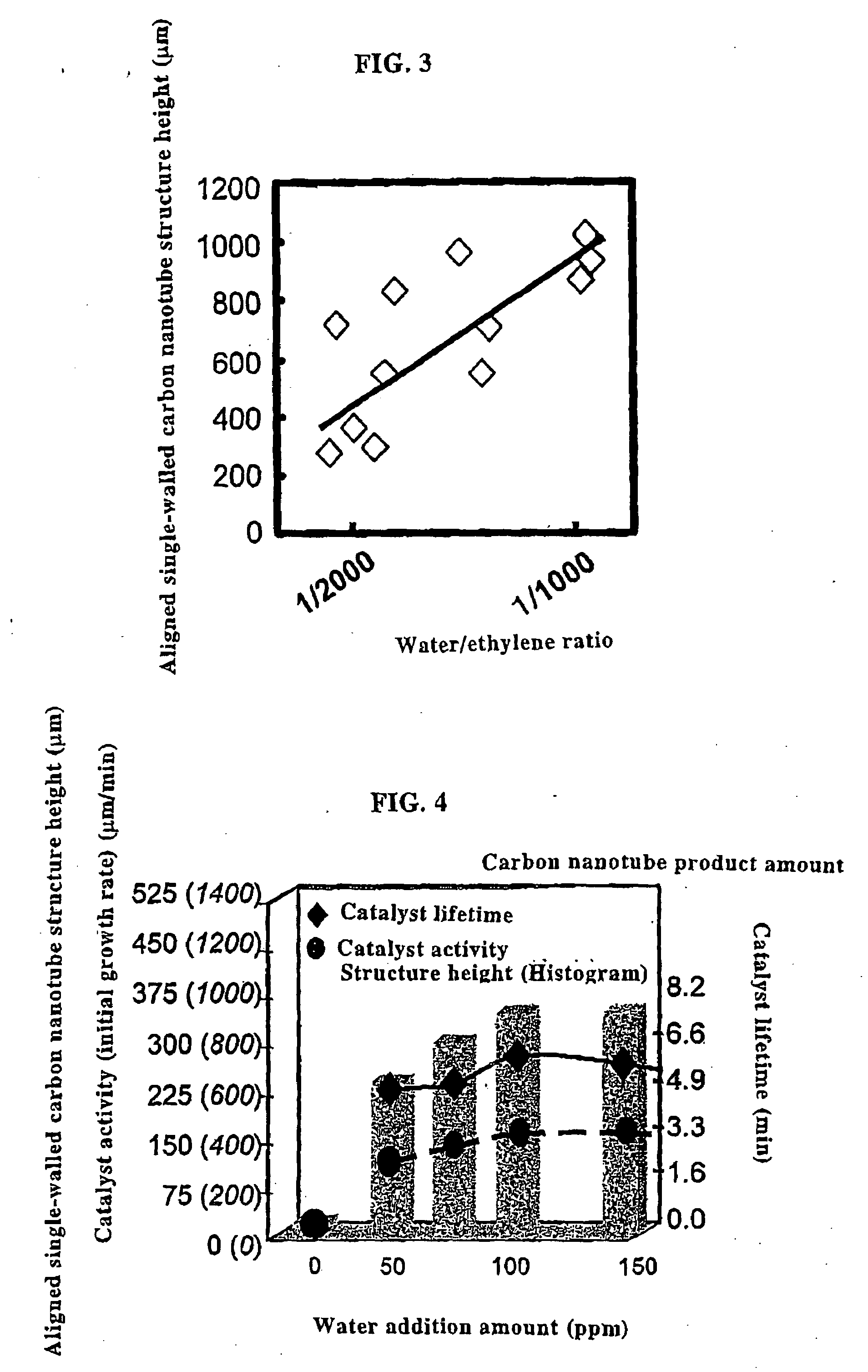

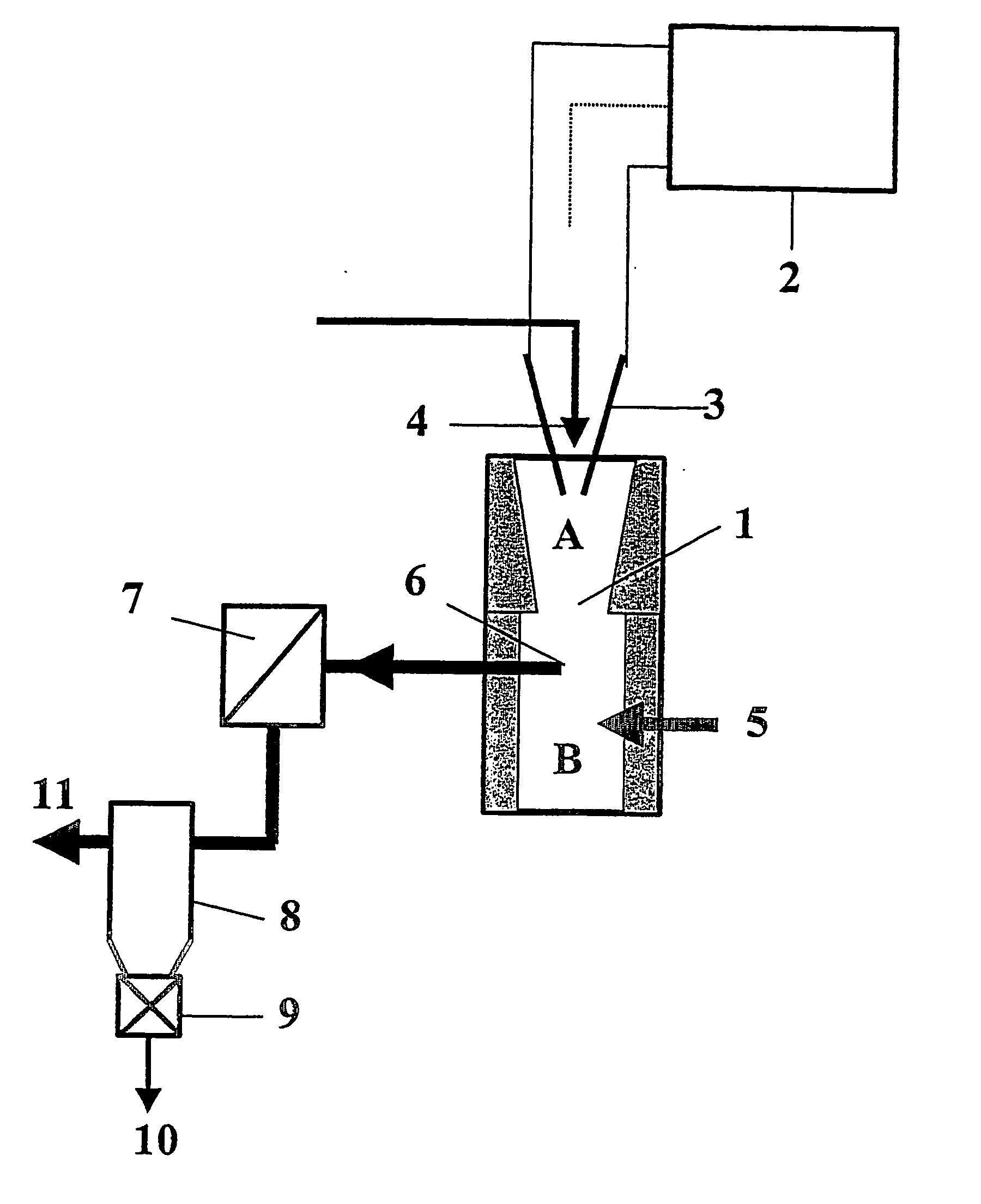

Single-Walled Carbon Nanotube and Aligned Single-Walled Carbon Nanotube Bulk Structure, and Their Production Process, Production Apparatus and Application Use

ActiveUS20080318049A1Efficient productionIncrease freedomMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Carbon nanostructures and process for the production of carbon-based nanotubes, nanofibres and nanostructures

InactiveUS20070183959A1Enhanced interactionImprove mechanical propertiesMaterial nanotechnologyFullerenesThermal insulationNanostructure

Continuous process for the production of carbon-based nanotubes, nanofibres and nanostructures, comprising the following steps: generating a plasma with electrical energy, introducing a carbon precursor and / or one or more catalysers and / or carrier plasma gas in a reaction zone of an airtight high temperature resistant vessel optionally having a thermal insulation lining, vaporizing the carbon precursor in the reaction zone at a very high temperature, preferably 4000° C. and higher, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyser through a nozzle, whose diameter is narrowing in the direction of the plasma gas flow, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyses into a quenching zone for nucleation, growing and quenching operating with flow conditions generated by aerodynamic and electromagnetic forces, so that no significant recirculation of feedstocks or products from the quenching zone into the reaction zone occurs, controlling the gas temperature in the quenching zone between about 4000° C. in the upper part of this zone and about 50° C. in the lower part of this zone and controlling the quenching velocity between 103 K / s and 106 K / s quenching and extracting carbon-based nanotubes, nanofibres and other nanostructures from the quenching zone, separating carbon-based nanotubes, nanofibres and nanostructures from other reaction products.

Owner:ТІМКАЛ SА +1

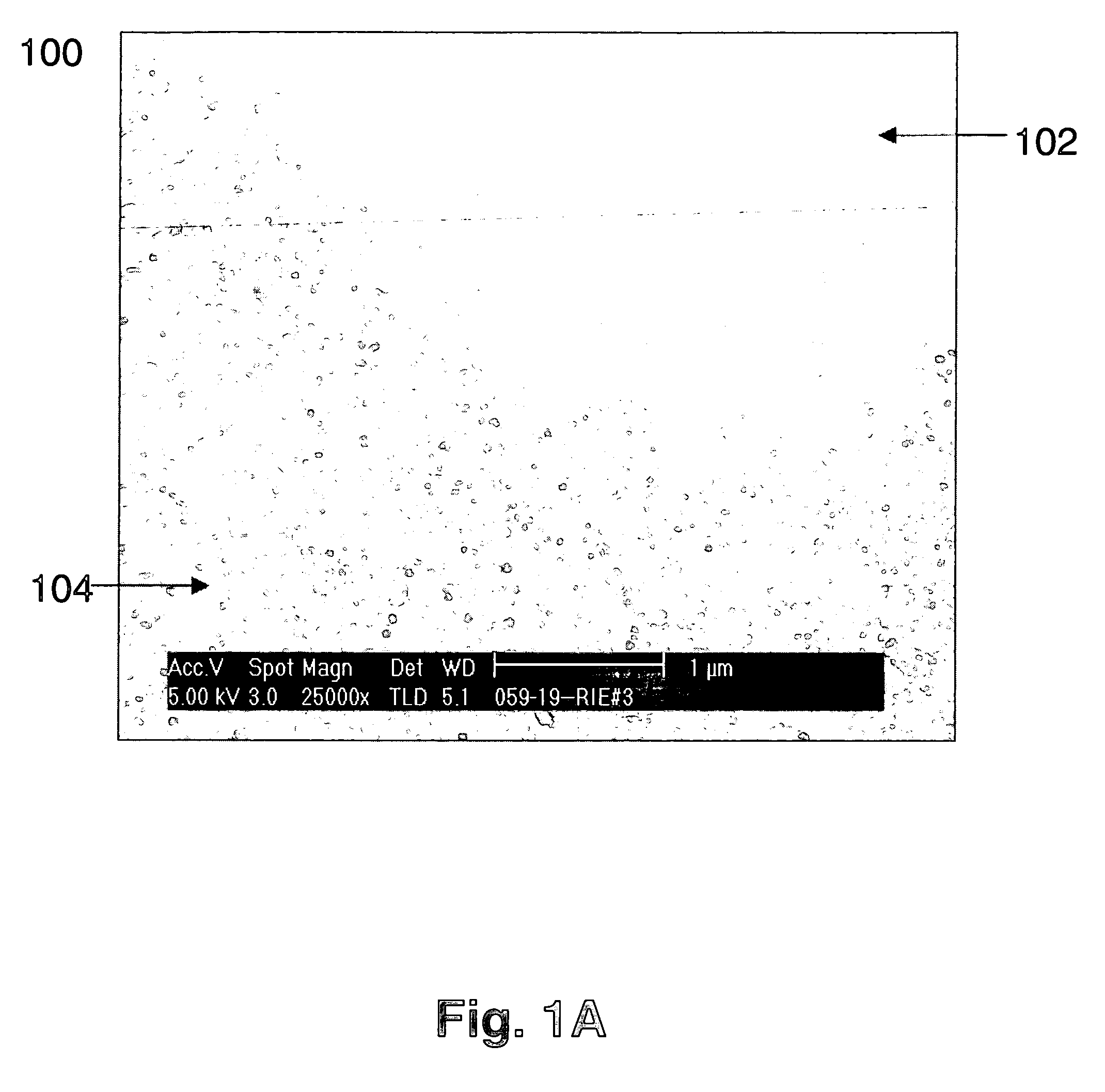

Spin-coatable liquid for formation of high purity nanotube films

ActiveUS20050058590A1Lower Level RequirementsPigmenting treatmentMaterial nanotechnologyLiquid mediumSpins

Certain spin-coatable liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. A spin-coatable liquid for formation of a nanotube film includes a liquid medium containing a controlled concentration of purified nanotubes, wherein the controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity, and wherein the spin-coatable liquid comprises less than 1×1018 atoms / cm3 of metal impurities. The spin-coatable liquid is substantially free of particle impurities having a diameter of greater than about 500 nm.

Owner:ZEON CORP

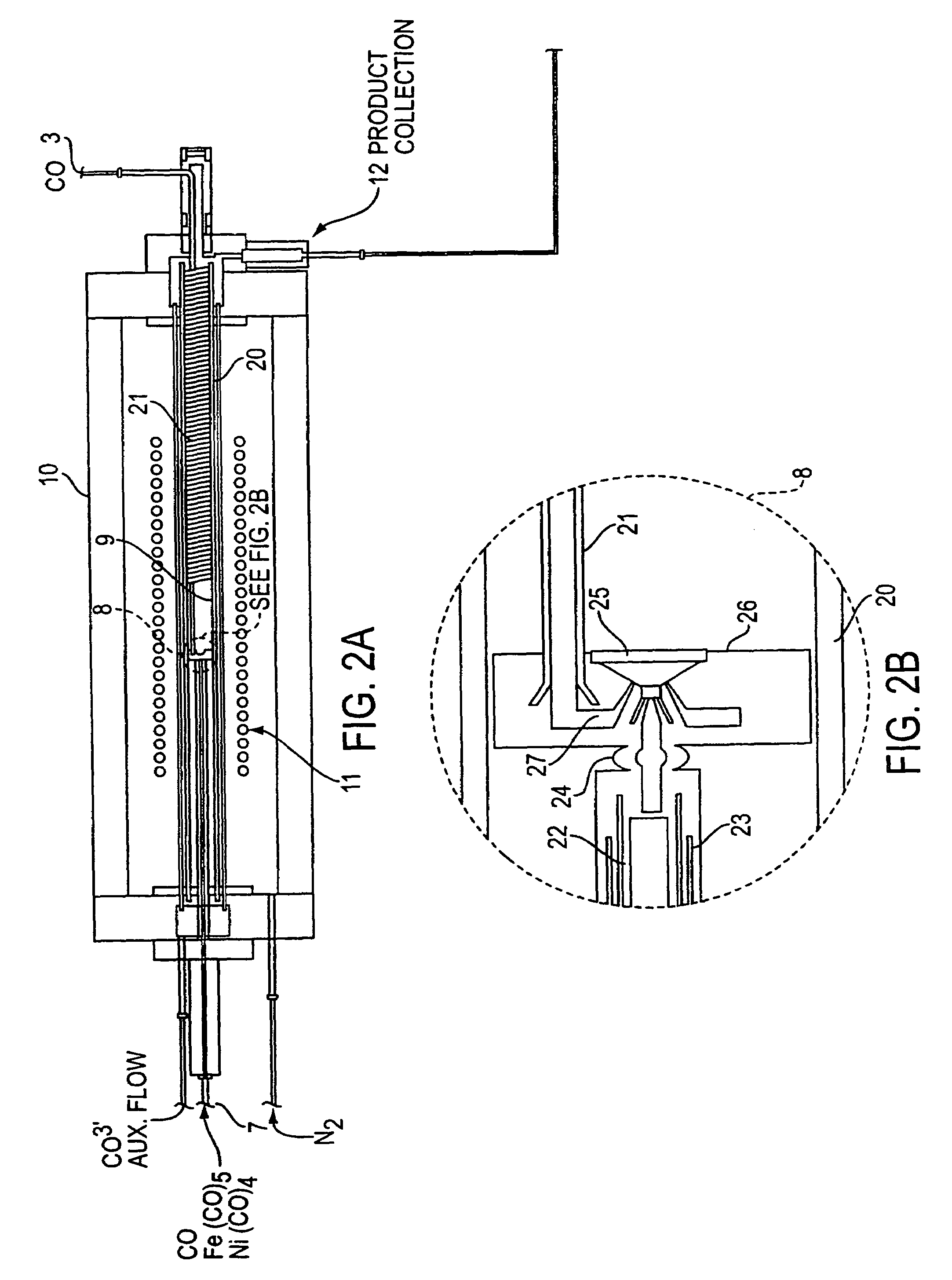

Single-wall carbon nanotubes from high pressure CO

InactiveUS7204970B2Promote rapid formationIncrease pressureMaterial nanotechnologyNanostructure manufactureDecompositionCarbon nanotube

The present invention discloses the process of supplying high pressure (e.g., 30 atmospheres) CO that has been preheated (e.g., to about 1000° C.) and a catalyst precursor gas (e.g., Fe(CO)5) in CO that is kept below the catalyst precursor decomposition temperature to a mixing zone. In this mixing zone, the catalyst precursor is rapidly heated to a temperature that results in (1) precursor decomposition, (2) formation of active catalyst metal atom clusters of the appropriate size, and (3) favorable growth of SWNTs on the catalyst clusters. Preferably a catalyst cluster nucleation agency is employed to enable rapid reaction of the catalyst precursor gas to form many small, active catalyst particles instead of a few large, inactive ones. Such nucleation agencies can include auxiliary metal precursors that cluster more rapidly than the primary catalyst, or through provision of additional energy inputs (e.g., from a pulsed or CW laser) directed precisely at the region where cluster formation is desired. Under these conditions SWNTs nucleate and grow according to the Boudouard reaction. The SWNTs thus formed may be recovered directly or passed through a growth and annealing zone maintained at an elevated temperature (e.g., 1000° C.) in which tubes may continue to grow and coalesce into ropes.

Owner:RICE UNIV

Method for making single-wall carbon nanotubes using supported catalysts

InactiveUS7250148B2Suitable for growthAppropriate densityMaterial nanotechnologyFibre chemical featuresCarbon nanotubeMoving bed

A method for growing single-wall carbon nanotubes involves preparing a catalyst comprising catalytic metals, iron and molybdenum, and magnesium oxide support material and contacting the catalyst with a gaseous carbon-containing feedstock at a sufficient temperature and for a sufficient contact time to make single-wall carbon nanotubes. The weight ratio of iron and molybdenum can range from about 2 to 1 to about 10 to 1 and the metals loading up to about 10 wt % of the MgO. The catalyst can be sulfided. Methane is a suitable carbon-containing feedstock. The process can be conducted in batch, continuous or semi-continuous modes, in reactors, such as a transport reactor, fluidized bed reactor, moving bed reactors and combinations thereof. The process also includes making single-wall carbon nanotubes with catalysts comprising at least one Group VIB or Group VIIIB metal on supports such as magnesia, zirconia, silica, and alumina, where the catalyst is sulfided.

Owner:UNIDYM

Carbon nanotube containing materials and articles containing such materials for altering electromagnetic radiation

InactiveUS20050272856A1Reduce performanceImprove performanceMaterial nanotechnologyMagnetic/electric field screeningCarbon nanotubeElectromagnetic radiation

Disclosed herein is a material for altering electromagnetic radiation incident on the material. The material disclosed herein comprises carbon nanotubes having a length (L) that meets the following formula (1): L≧½λ (1) where λ is the wavelength of the electromagnetic radiation incident on the material. Also disclosed herein are methods of altering electromagnetic radiation, including mitigating, intensifying, or absorbing and re-transmitting electromagnetic radiation using the disclosed material.

Owner:MULTIPURE INT

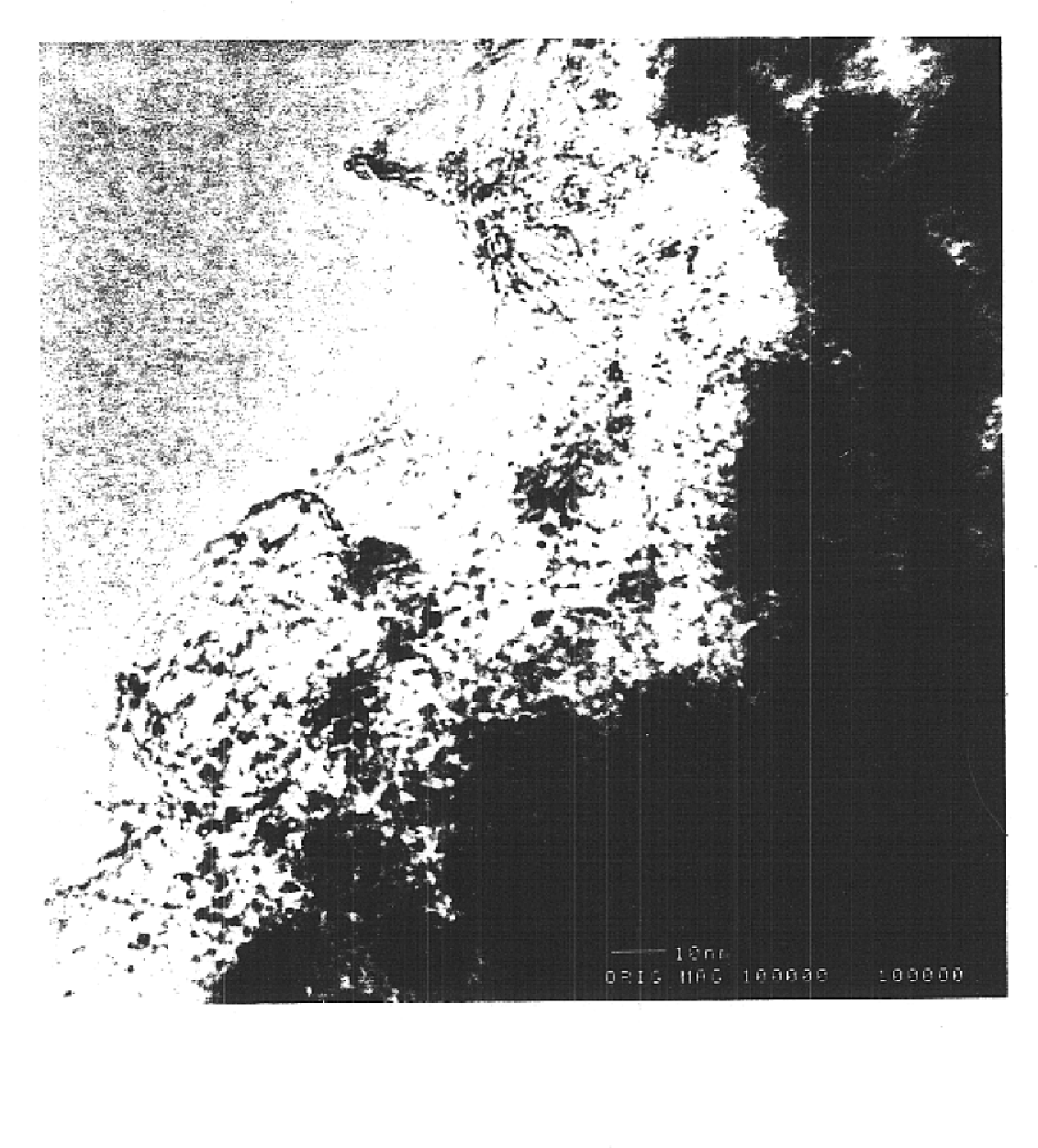

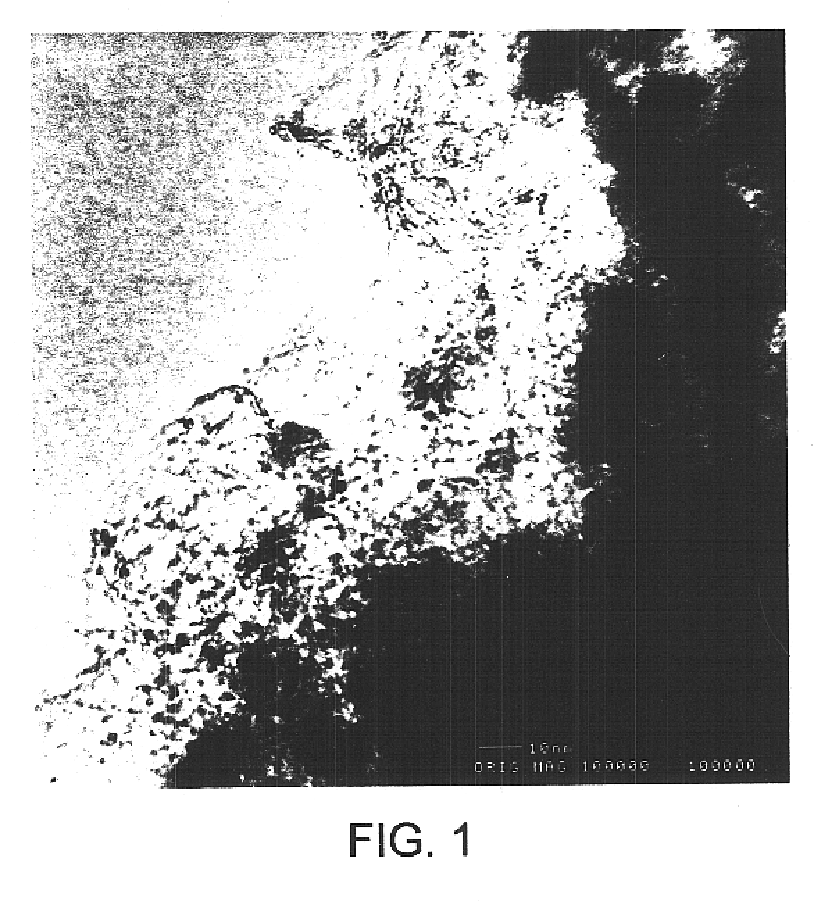

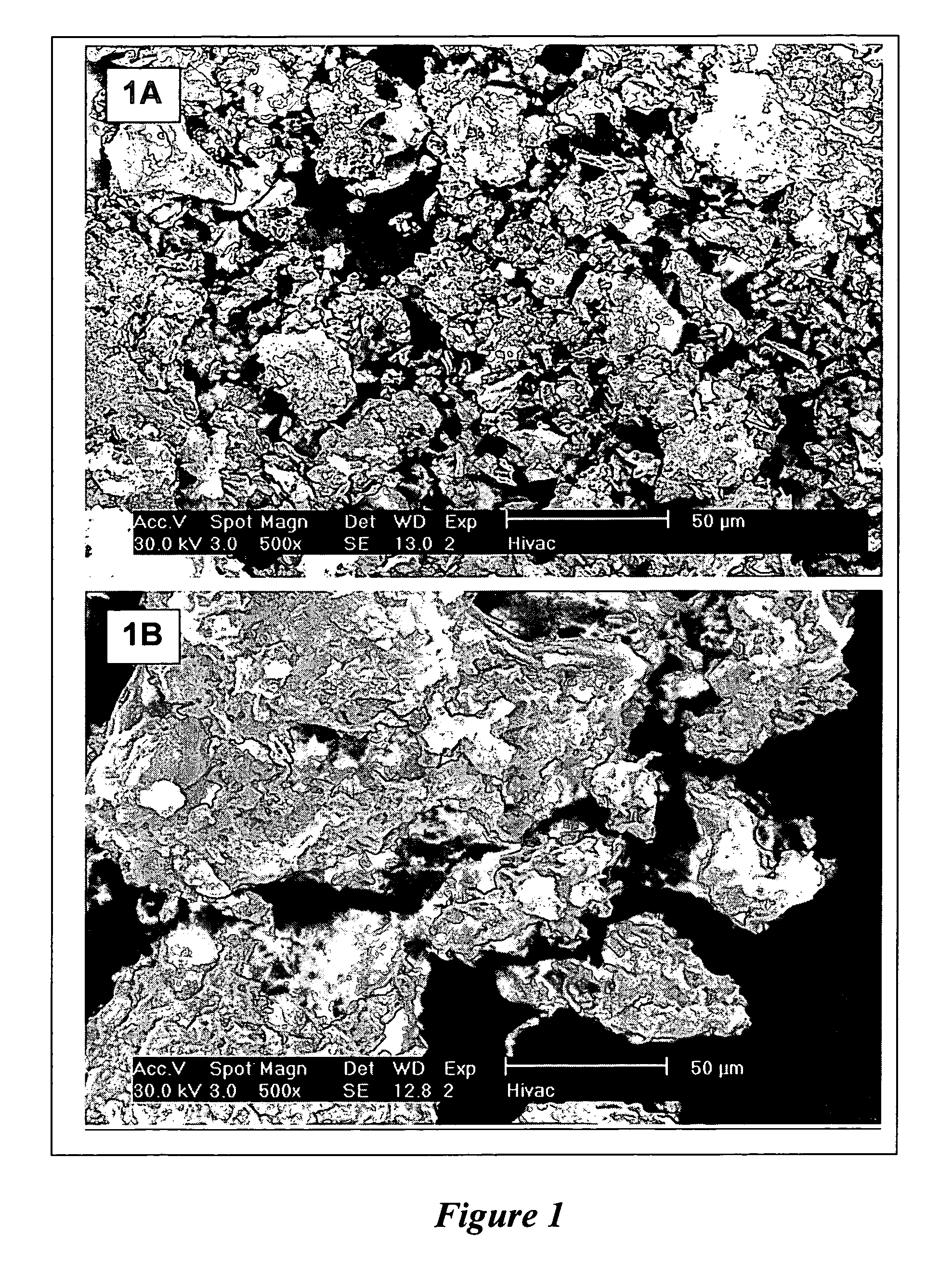

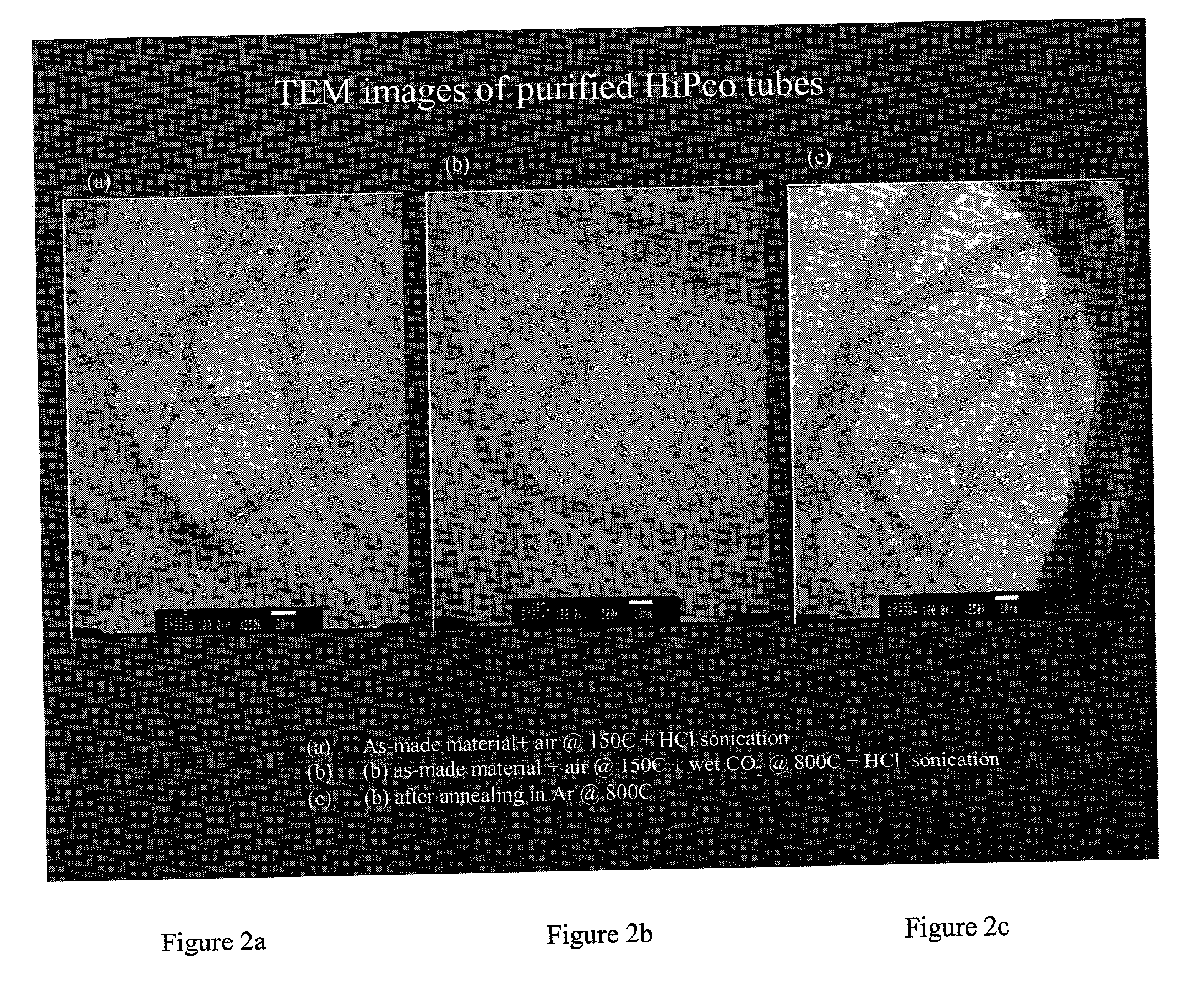

Process for purifying single-wall carbon nanotubes and compositions thereof

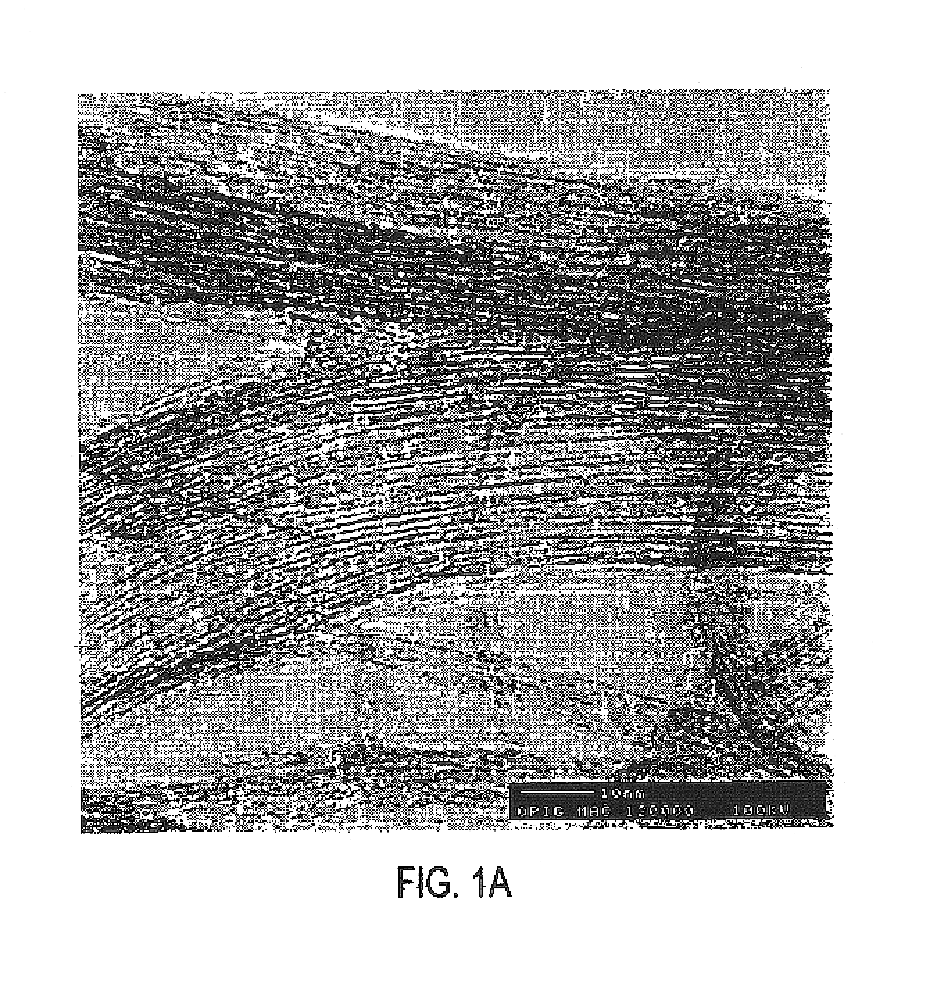

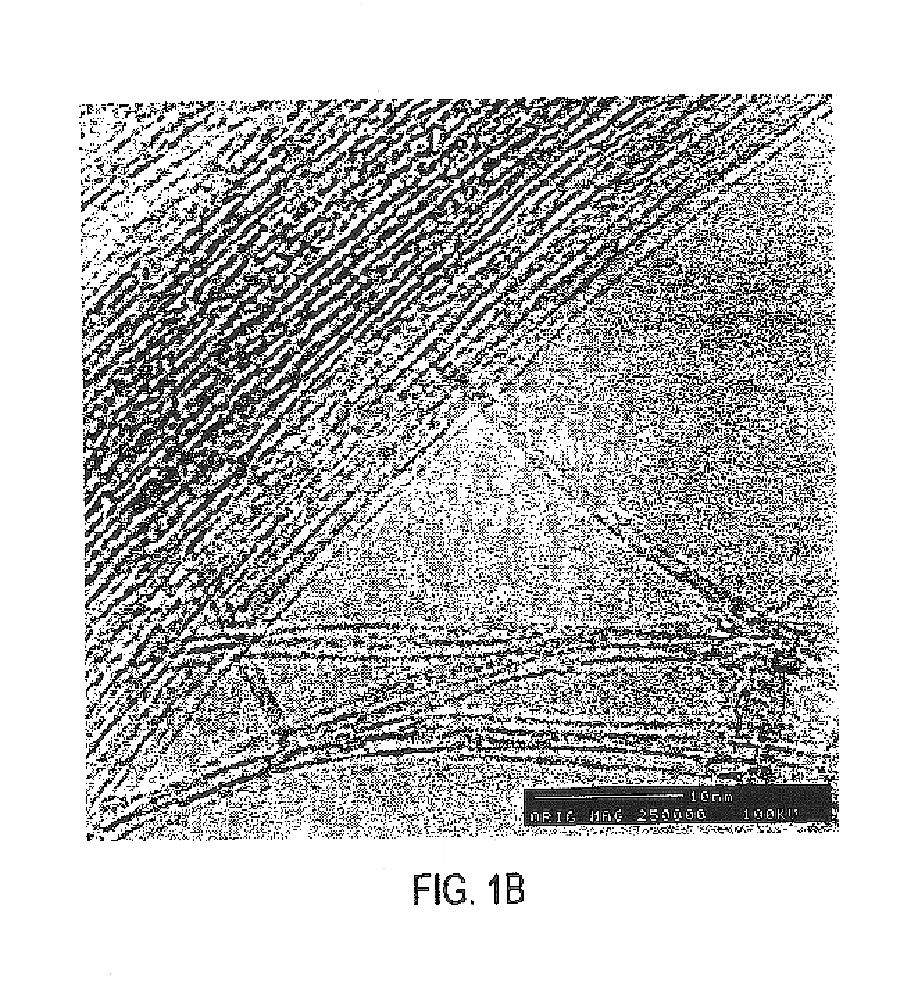

The present invention relates to a process for the purification of single-wall carbon nanotubes and the purified single-wall carbon nanotube material. Known methods of single-wall carbon nanotube production result in a single-wall carbon nanotube product that contains single-wall carbon nanotubes in addition to impurities including residual metal catalyst particles and amounts of small amorphous carbon sheets that surround the catalyst particles and appear on the sides of the single-wall carbon nanotubes and "ropes" of single-wall carbon nanotubes. The purification process removes the extraneous carbon as well as metal-containing residual catalyst particles. The process employs steps including a gas-phase oxidation of the amorphous carbon and subsequent liquid-phase reaction of a halogen-containing acid with the metal-containing species. Optionally, the single-wall carbon nanotube material may be annealed dry or in the presence of moisture. The present invention provides a scalable means for producing high-purity single-wall carbon nanotube material.

Owner:RICE UNIV

Popular searches

Electric discharge tubes Discharge tube/lamp details Single-walled nanotubes Thin material handling Cold cathode manufacture Chemical/physical/physico-chemical nozzle-type rreactors Energy based chemical/physical/physico-chemical processes Carbonsing rags Pressure vessels for chemical process Aligned nanotubes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com