Carbon nanotubes: high solids dispersions and nematic gels thereof

a technology of carbon nanotubes and solids, applied in nanoinformatics, instruments, transportation and packaging, etc., can solve the problems of chemically modified carbon nanotubes less desirable, difficult to keep individually dispersed in solution, and easy aggregate of nanotubes,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

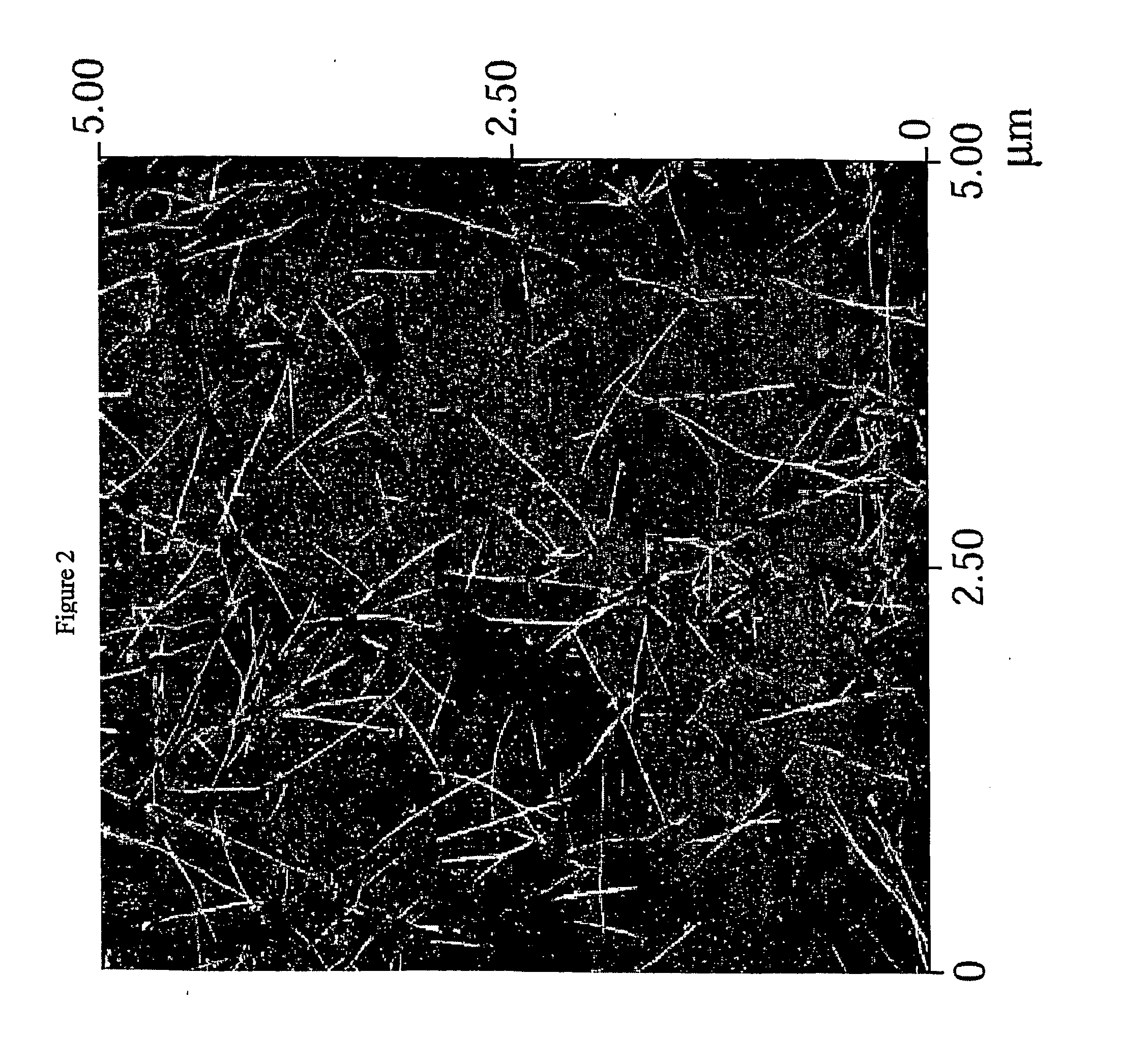

[0108] High Weight-Fraction Carbon Nanotube Dispersions. A method to disperse high weight-fraction carbon nanotubes in water is provided in these examples. A novel surfactant for this purpose, sodium dodecylbenzene sulfonate (NaDDBS), having a benzene ring moiety, a charged head group, and an alkyl chain, dramatically enhanced the stability of carbon nanotubes in aqueous dispersion compared to commonly used surfactants, e.g. sodium dodecyl sulfate (SDS) and Triton X-100 (TX100); dispersion concentrations were improved by approximately a factor of one hundred compared to the commonly used surfactants. The method used herein eliminates the need for high power tip- or horn-sonication and repeated centrifugation and decanting. A single step process is used, which includes mixing SWNTs with surfactant in a low-power, high-frequency sonicator. This sonication procedure enhances disaggregation of bundles of aggregated SWNTs with dramatically less tube breakage. Diameter distributions of na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com