Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1059 results about "Phase reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase I Reactions: Phase I Reactions Phase I reactions (also termed nonsynthetic reactions) may occur by oxidation, reduction, hydrolysis, cyclization, and decyclization addition of oxygen or removal of hydrogen, carried out by mixed function oxidases, often in the liver.

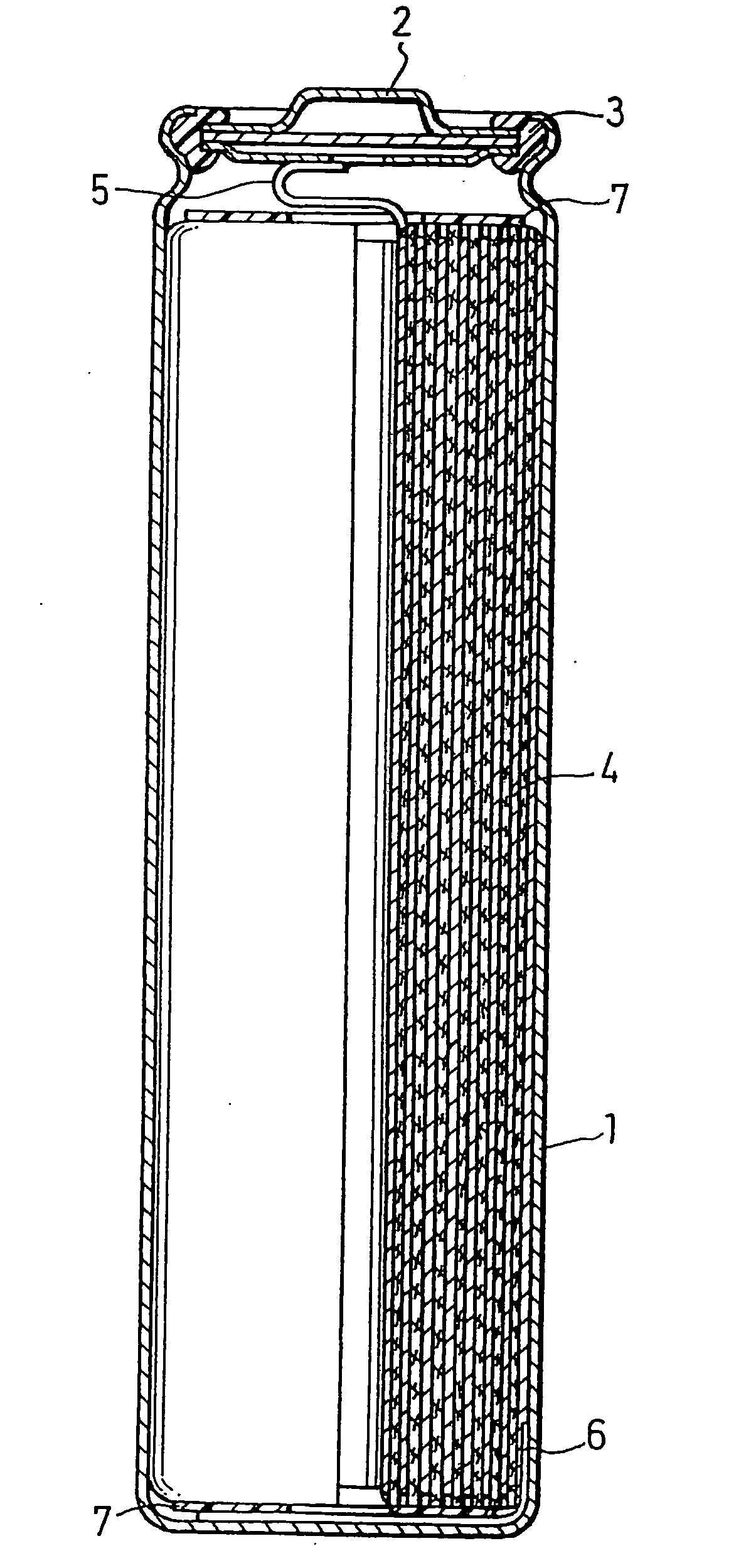

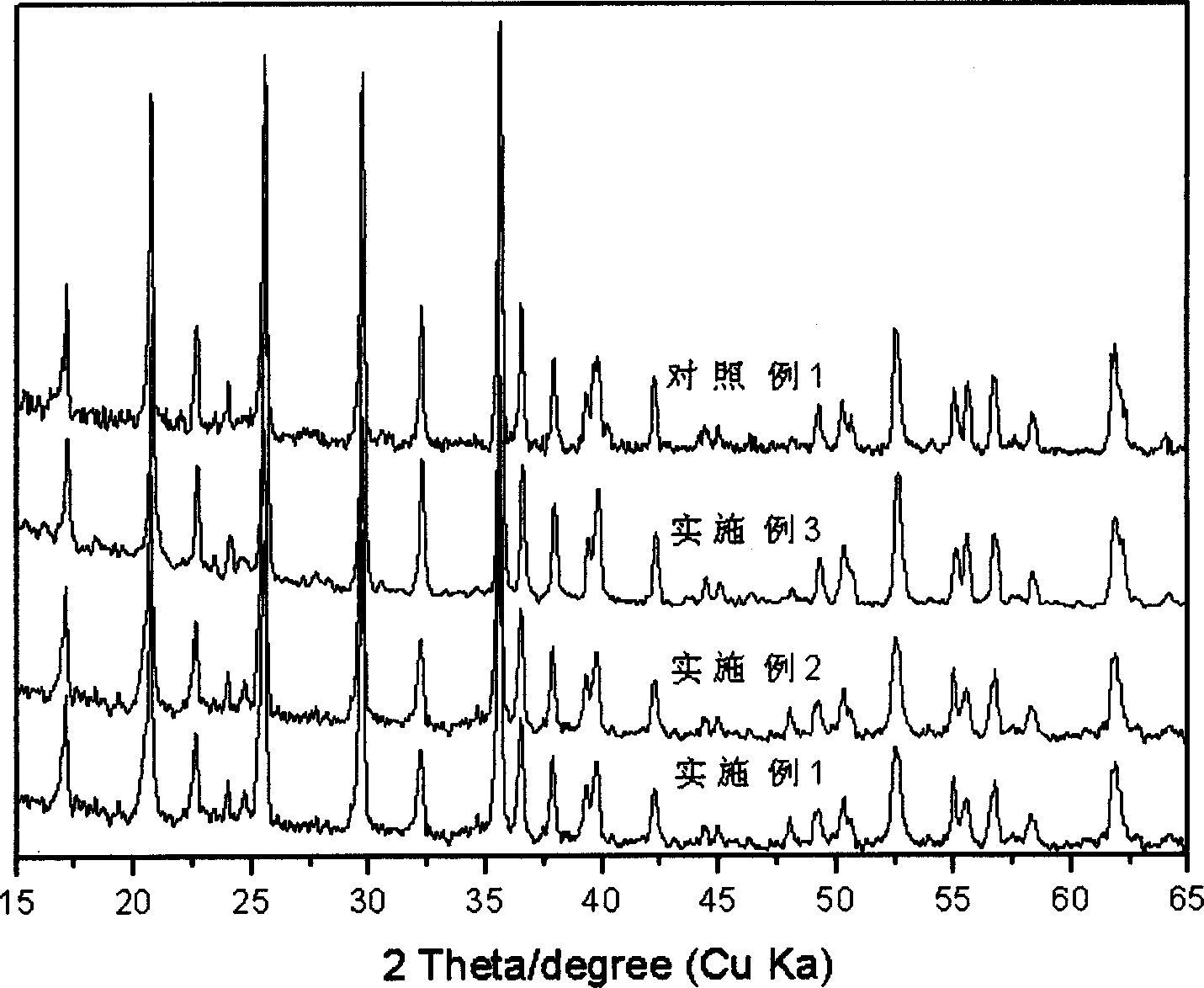

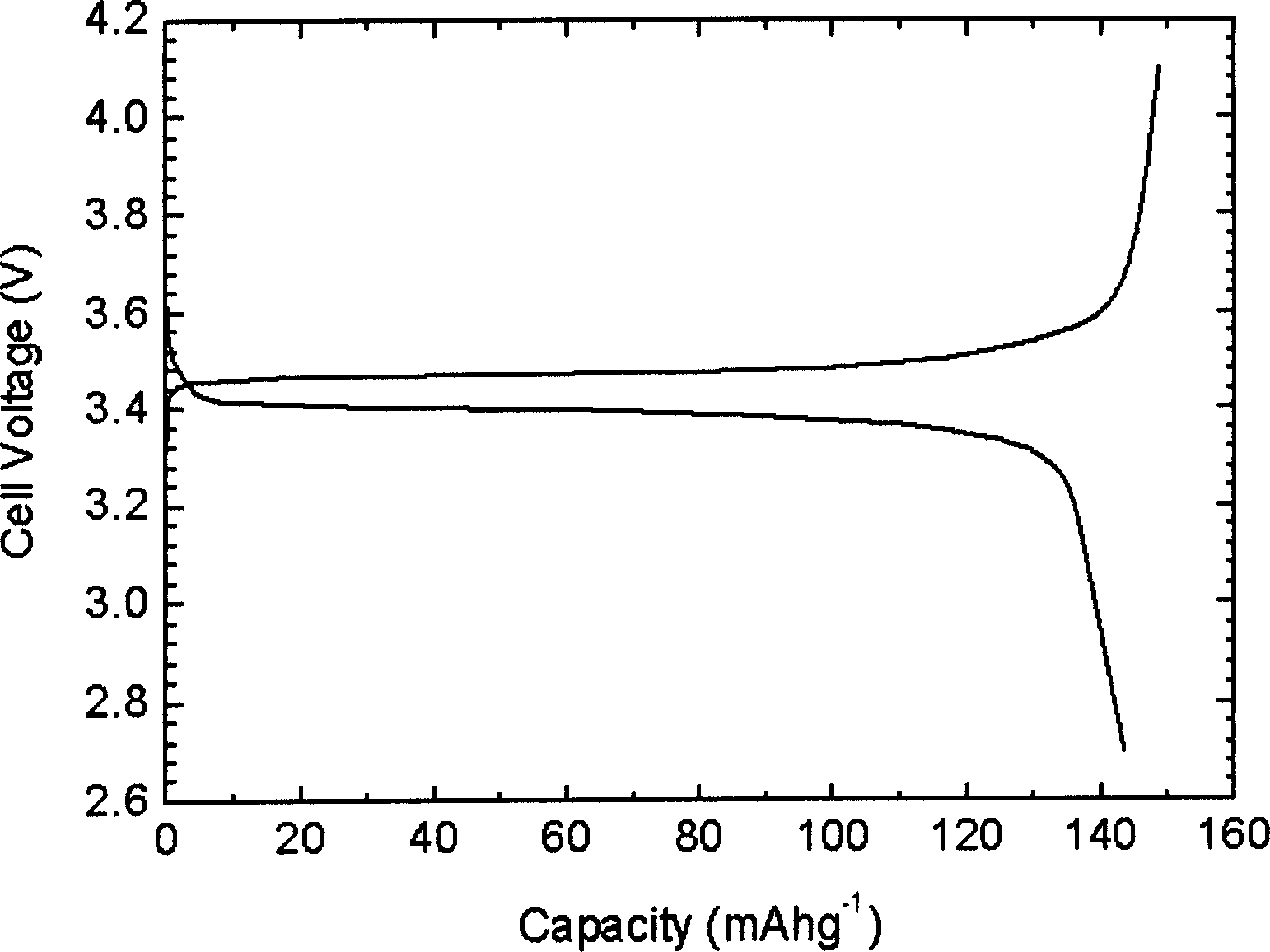

Anode active material, manufacturing method thereof, and non-aqueous electrolyte secondary battery

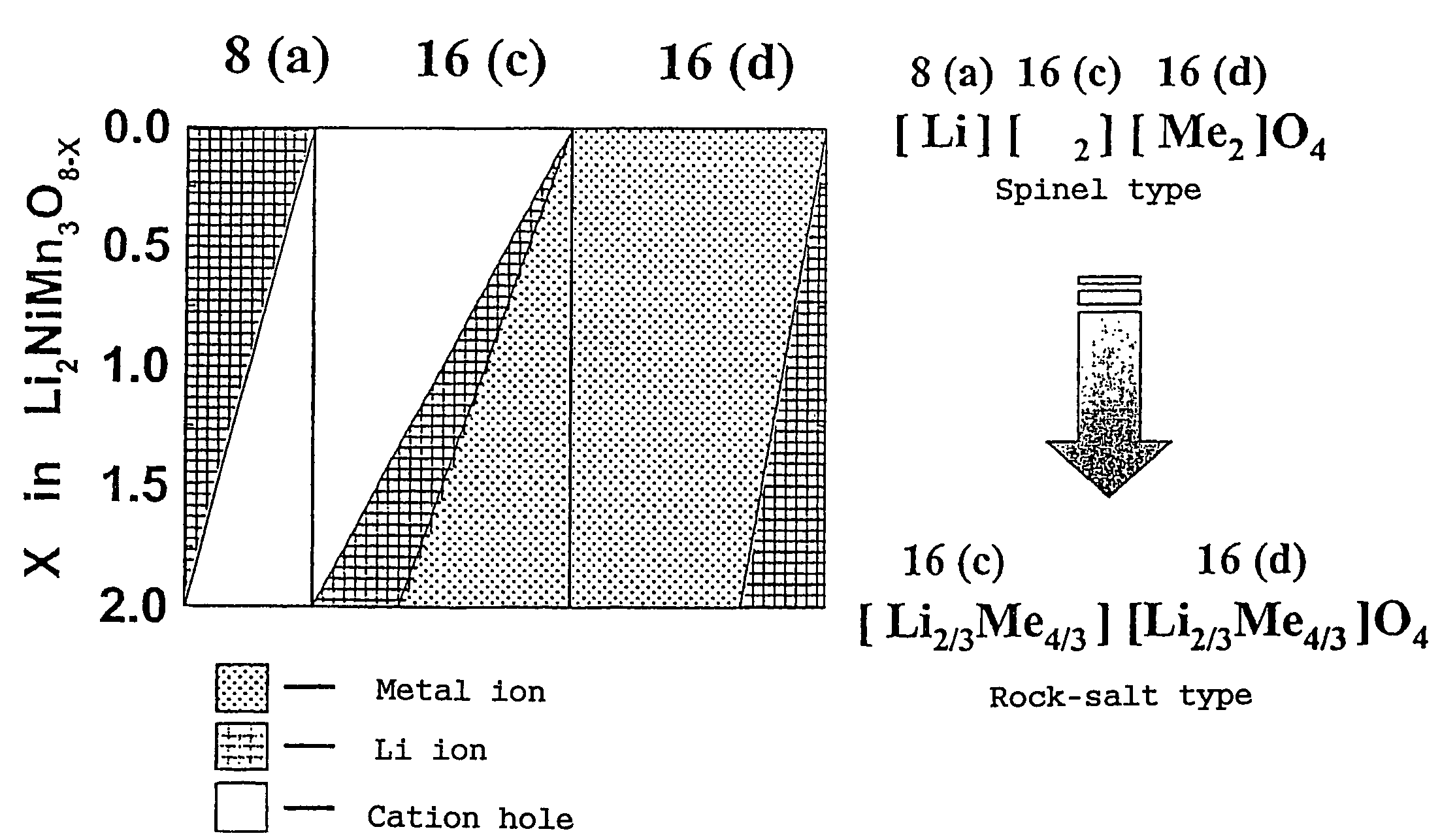

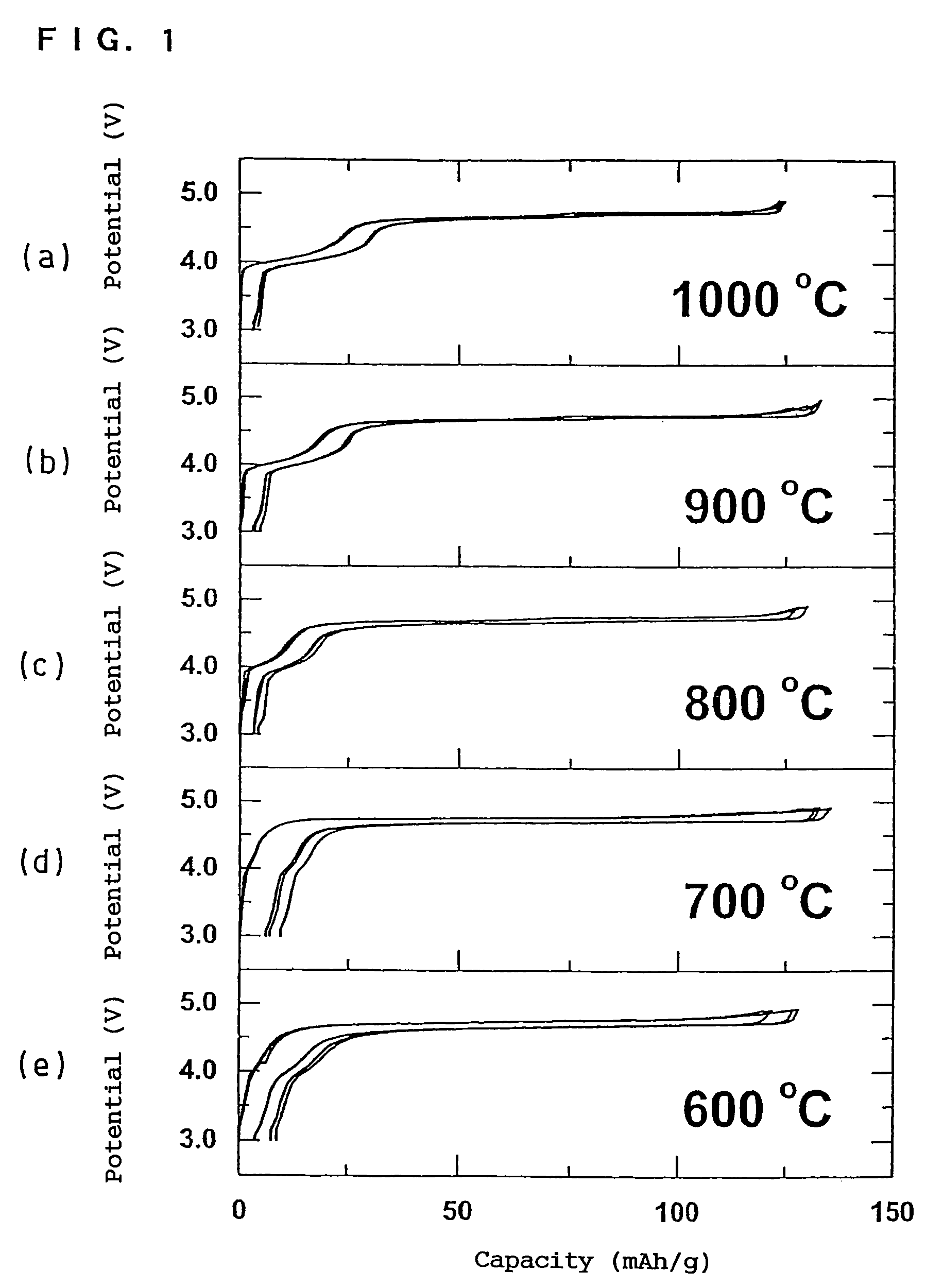

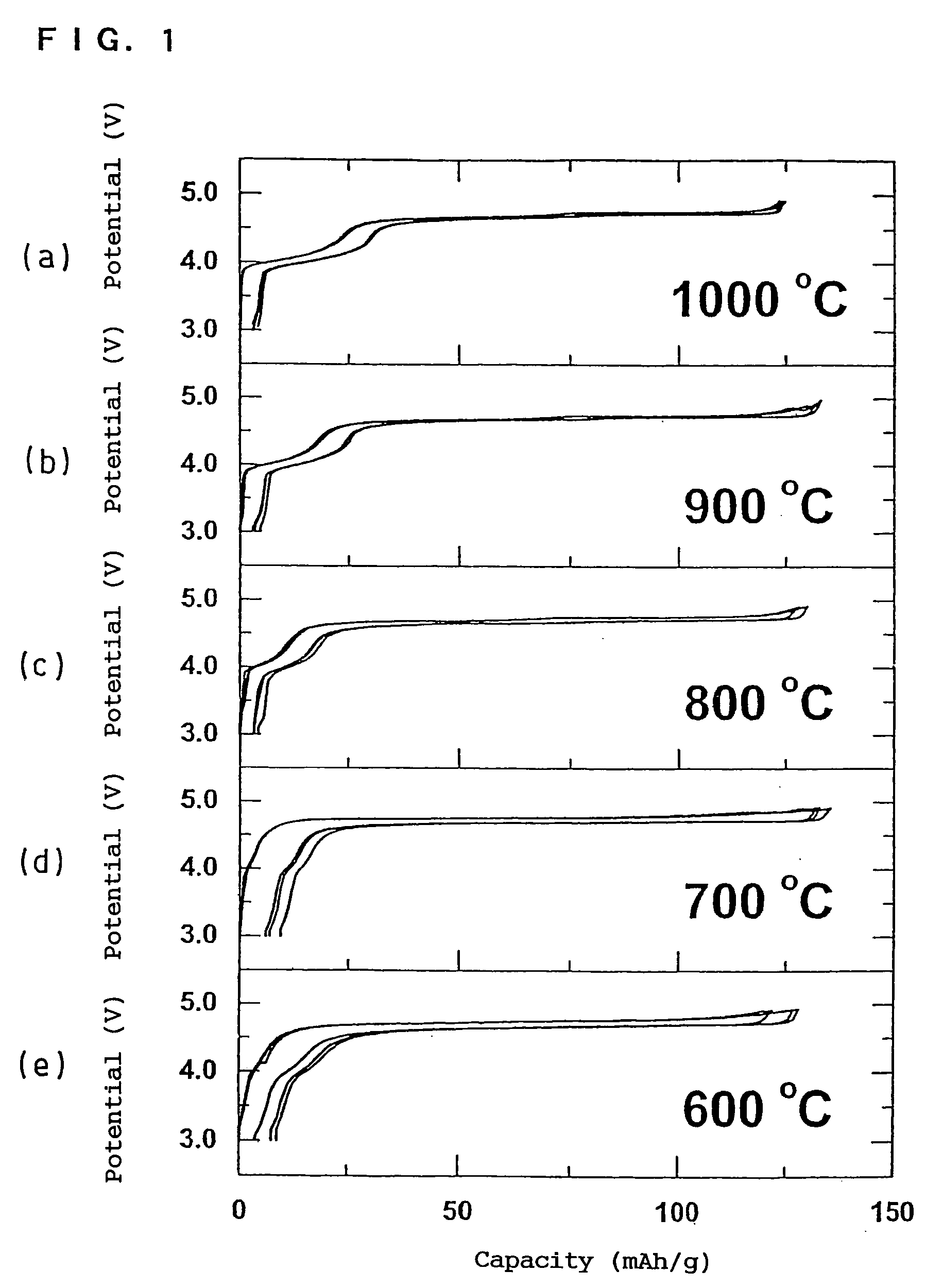

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:OSAKA CITY UNIV +1

Light emitting device, phosphor, and method for preparing phosphor

ActiveUS20060001352A1Solve the lack of lifeIncrease thermal resistanceGas-filled discharge tubesDischarge tube luminescnet screensRare-earth elementOxygen

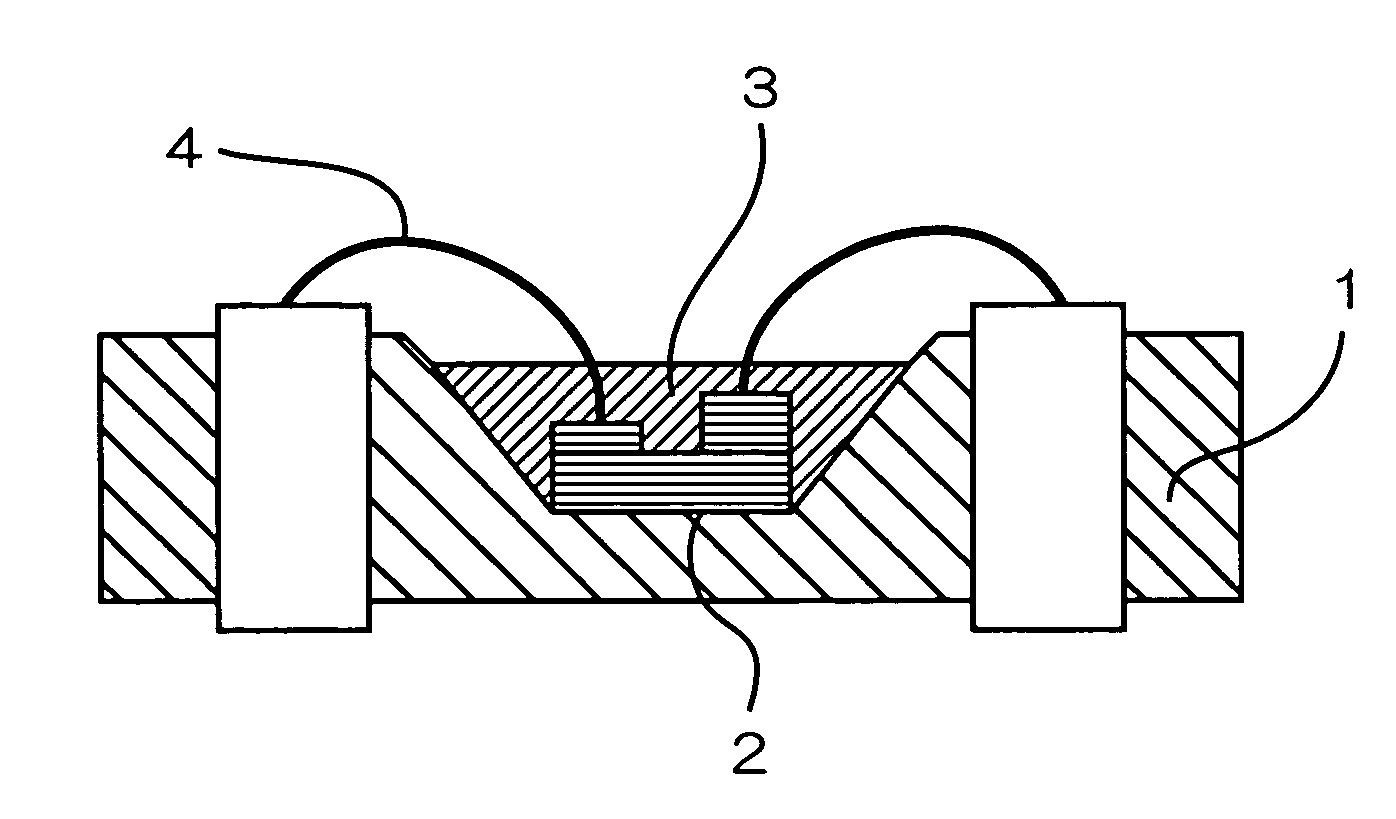

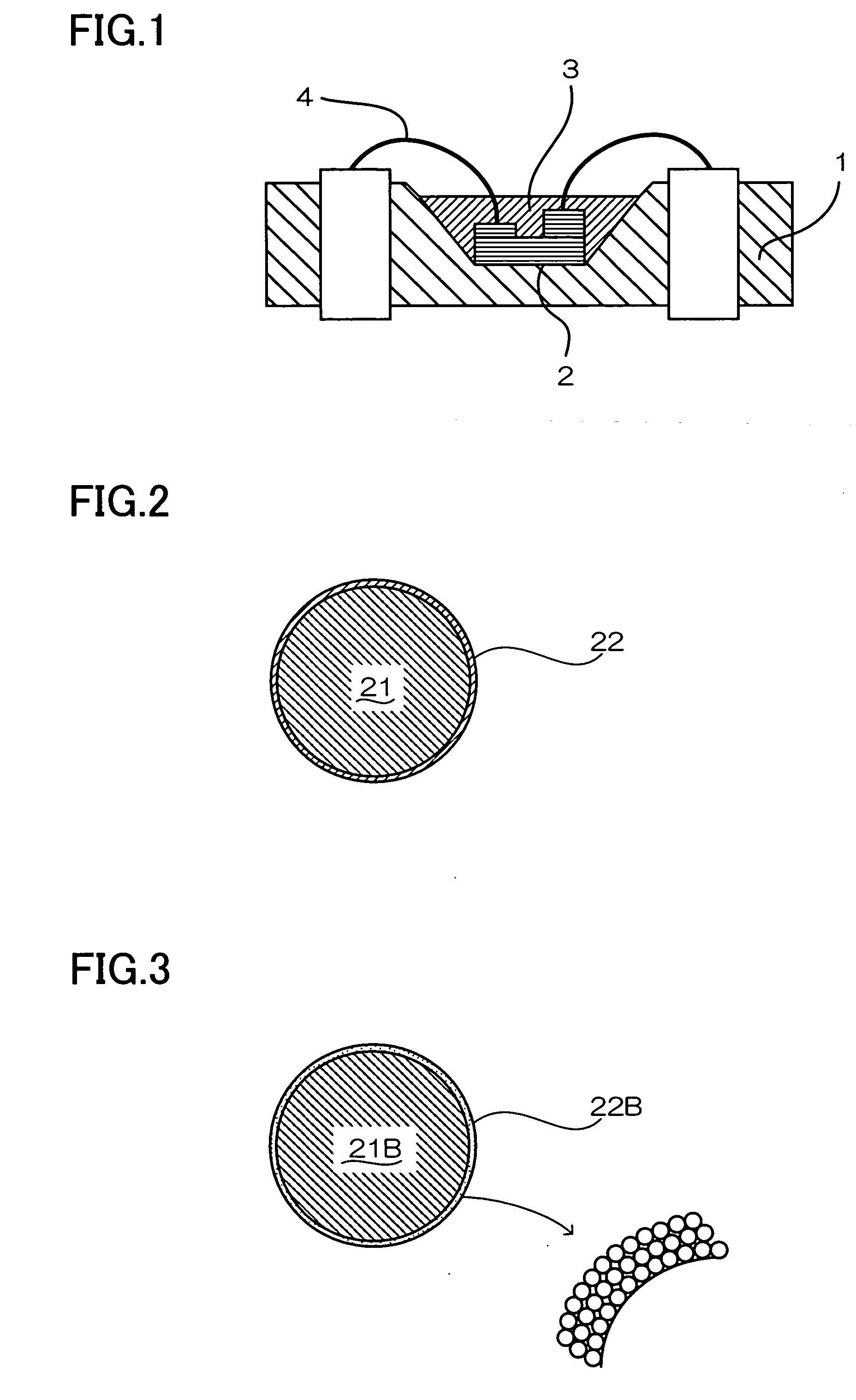

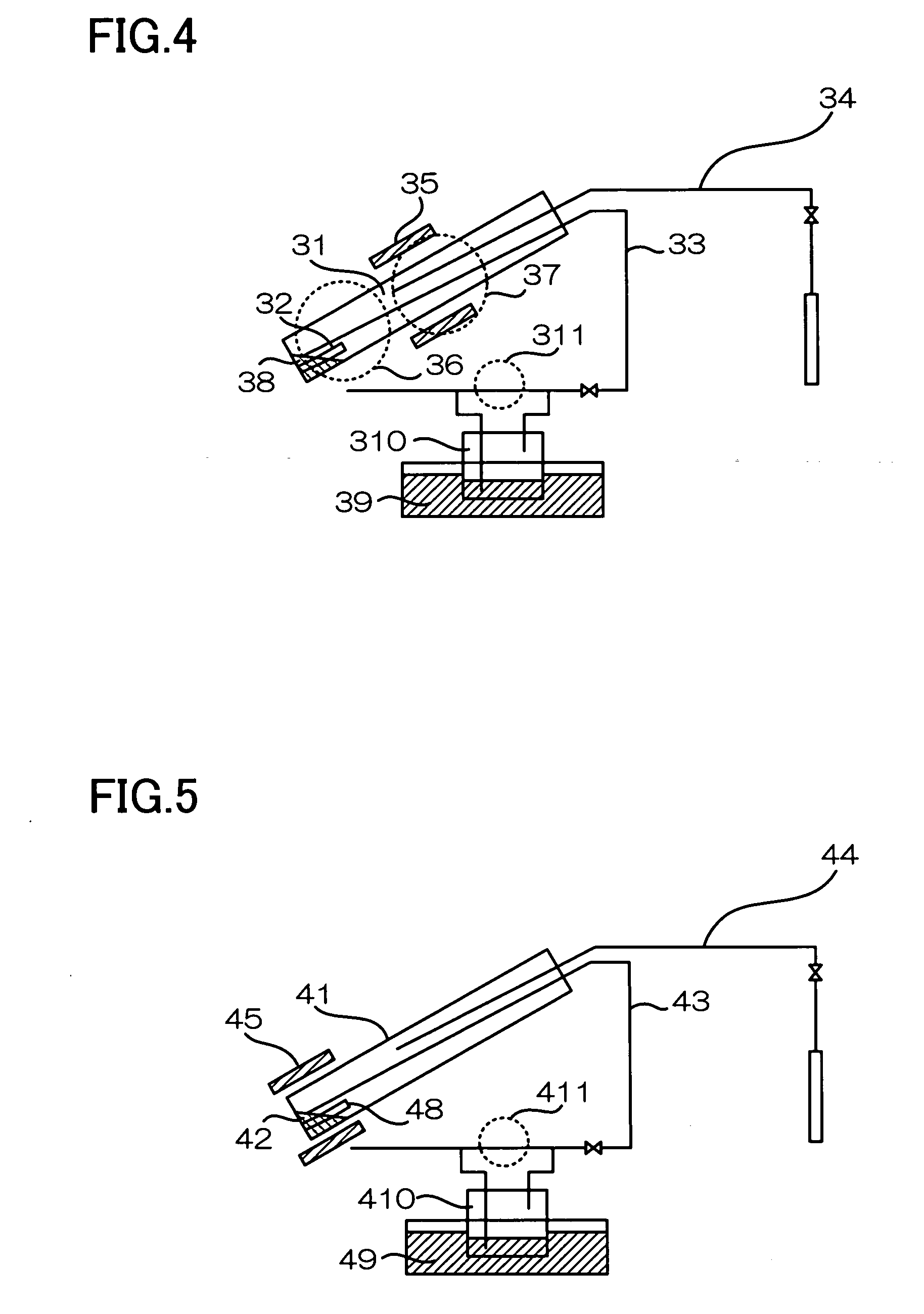

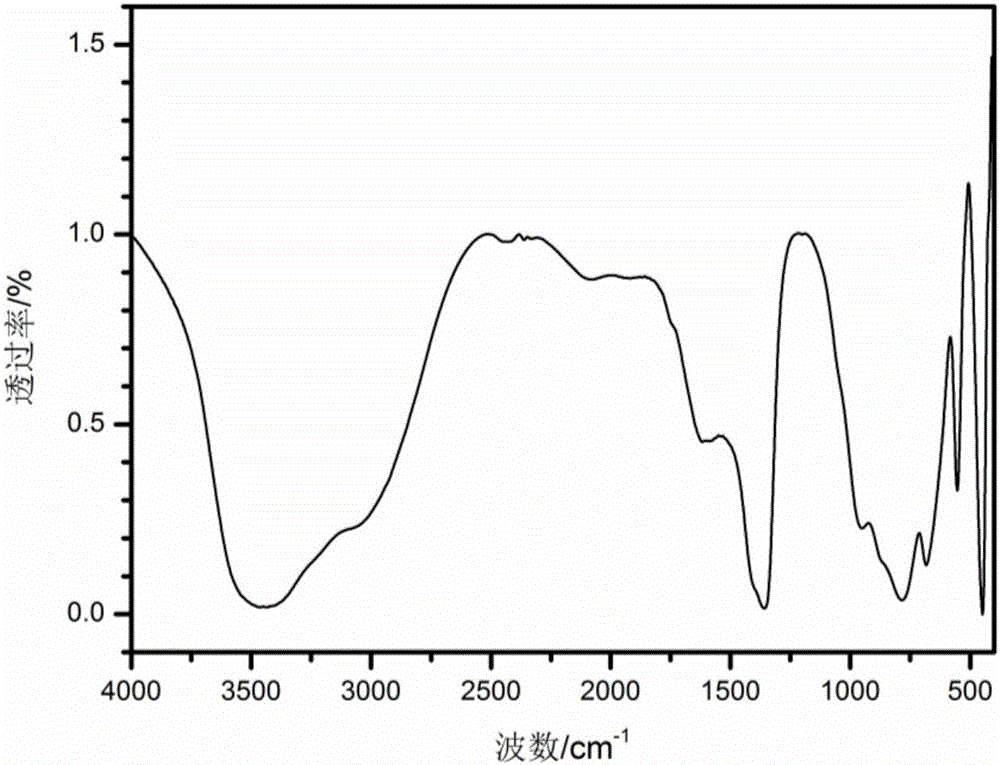

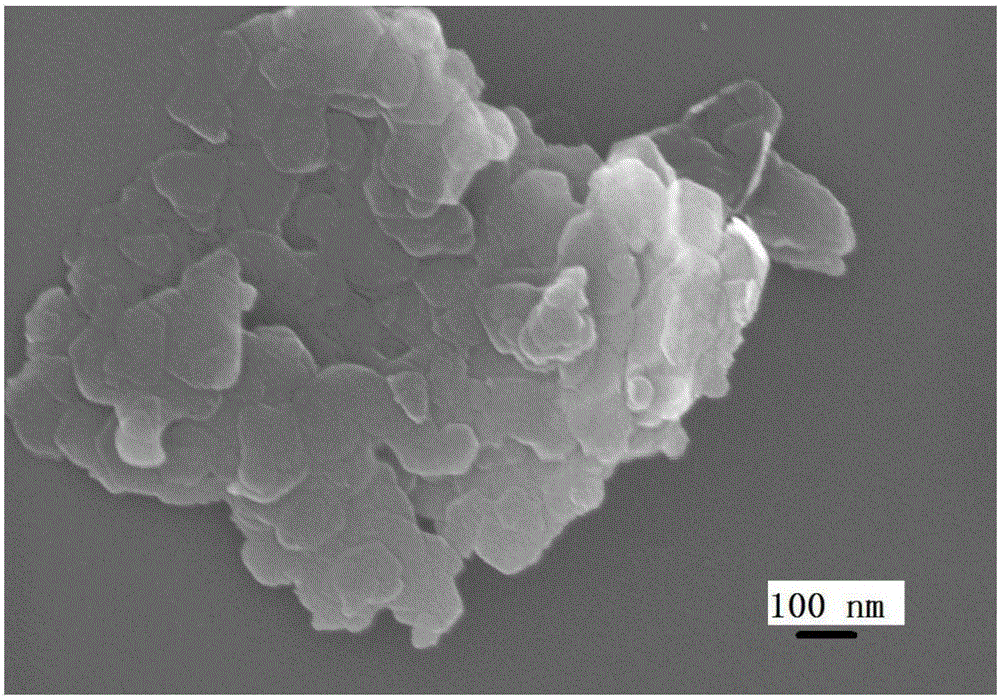

The surface of a phosphor is coated with a coating member made of a material different from the phosphor in chemical vapor-phase reaction. The coating member is made of any of metal oxide, metal nitride and metal oxynitride. The coating member coats the surface of the phosphor whereby having a substantially smooth film, or is formed such that a large number of fine particles relatively smaller than the phosphor aggregate to coat the whole surface of the phosphor. The coating member contains at least one metallic element selected from the group consisting of Al, Si, and rare earth elements. In addition, the phosphor is a transparent water-soluble phosphor and is an alkaline-earth silicon-nitride phosphor, an alkaline-earth silicon oxynitride phosphor, or the like. The BET value of the coated phosphor is 1.0 to 10 times the BET value before coating. The average thickness of the coating is 10 nm to 500 nm.

Owner:NICHIA CORP

Anode active material, manufacturing method thereof, and non-aqueous electrolyte secondary battery

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:OSAKA CITY UNIVERSITY +1

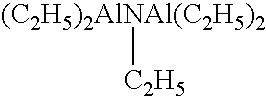

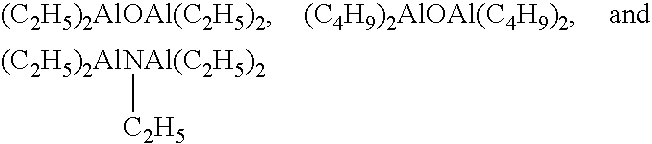

Alumoxane-enhanced, supported ziegler-natta polymerization catalysts, methods of making same, processes of using same and polymers produced therefrom

InactiveUS6124412AUseful and improved range of productivityGood physical propertiesOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationProduction rateAluminoxane

The present invention relates to a new olefin polymerization catalyst composition, and methods of preparing and methods of using the catalysts to polymerize various olefinic monomers in either gas or slurry phase reactions. The principal advance over the previous art of record involves using alumoxanes or combinations of alumoxanes as catalyst preactivators. Polymers prepared from these catalysts posses productivity increased as high as 40 percent. At the same time, the bulk density remains relatively constant. Additionally, the total amount of cocatalyst species needed to effectively practice the invention is relatively low.

Owner:SAUDI BASIC IND CORP SA

Power storage device and charging method thereof

ActiveUS20140184172A1Reduced shutdown currentReduce power consumptionCharging stationsCell electrodesDecompositionEngineering

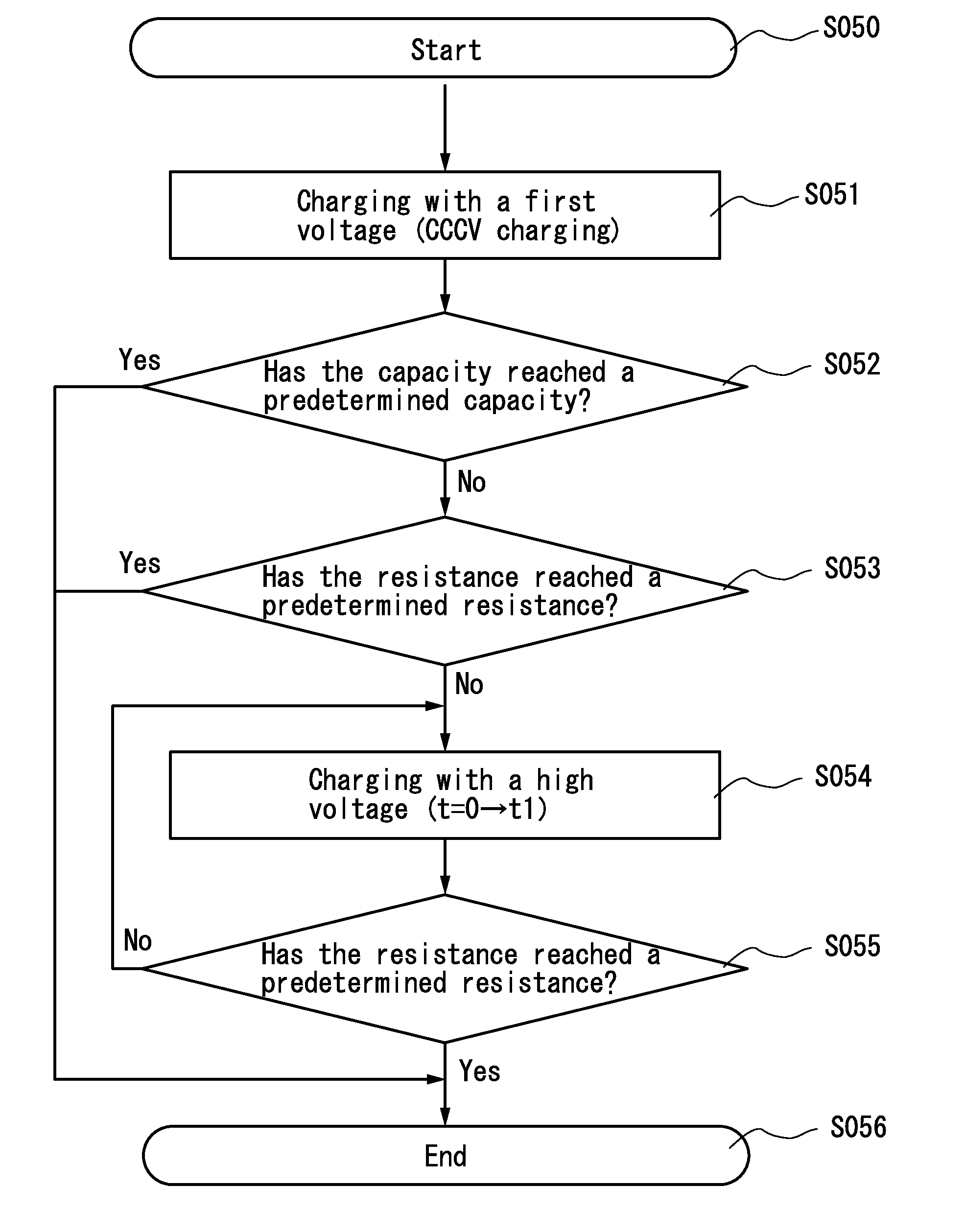

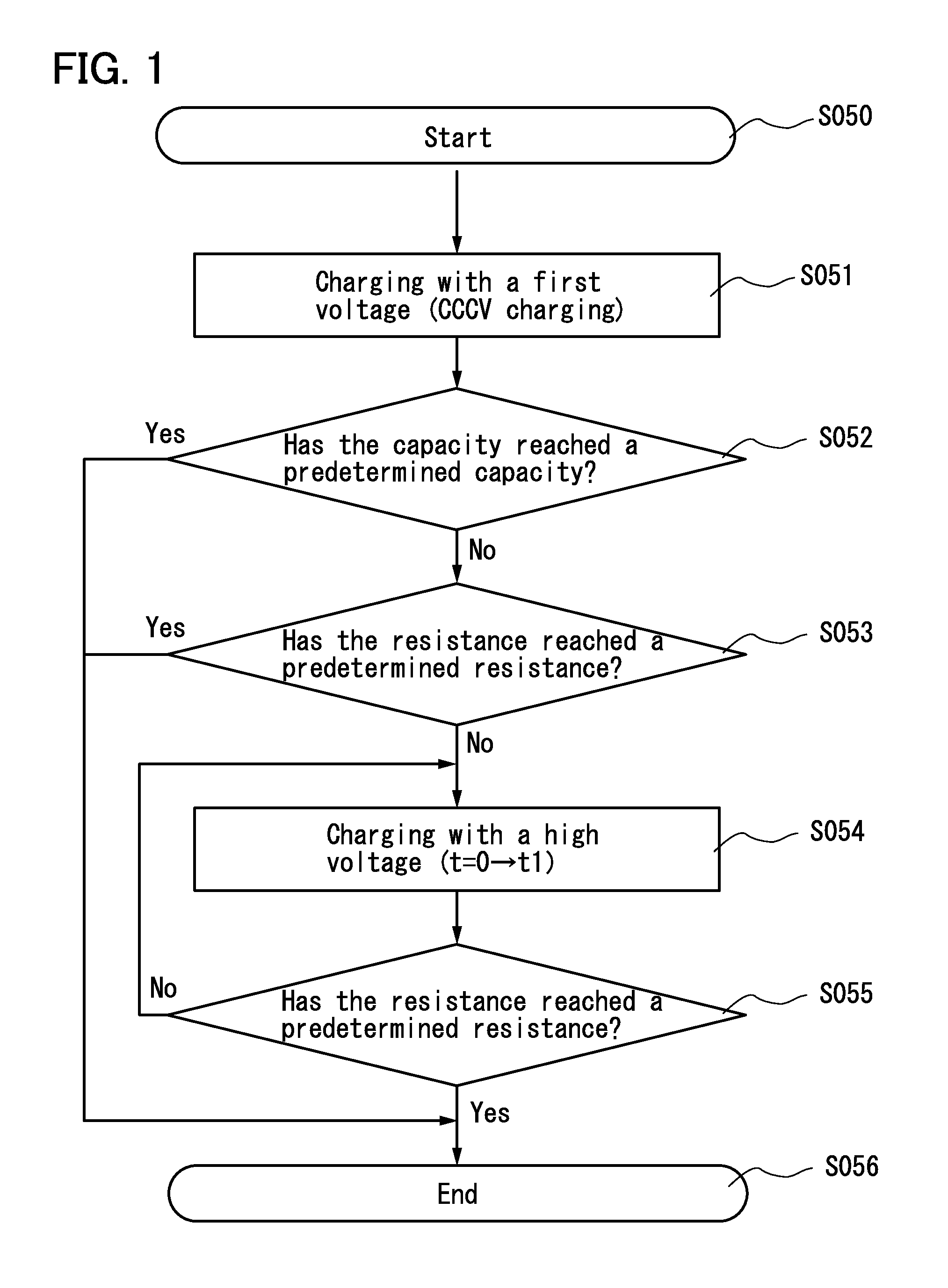

An object is to inhibit a decrease in the capacity of a power storage device or to compensate the capacity, by adjusting or rectifying an imbalance between a positive electrode and a negative electrode, which is caused by decomposition of an electrolyte solution at the negative electrode. Provided is a charging method of a power storage device including a positive electrode using an active material that exhibits two-phase reaction, a negative electrode, and an electrolyte solution. The method includes the steps of, after constant current charging, performing constant voltage charging with a voltage that does not cause decomposition of the electrolyte solution until a charging current becomes lower than or equal to a lower current value limit; and after the constant voltage charging, performing additional charging with a voltage that causes decomposition of the electrolyte solution until a resistance of the power storage device reaches a predetermined resistance.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing furfural compounds from biomass

The invention relates to a method for preparing furfural compounds from biomass. The method specifically comprises the preparation of a solid acid catalyst and a reaction process of the solid acid catalyst. The method disclosed by the invention can also be applied to biomass derivatives. The method comprises the steps of adding biomass or biomass derivatives and the solid acid catalyst to a reactor, filling with protective gas, and adopting an organic solvent / saturated inorganic salt aqueous-solution two-phase reaction system, thereby obtaining furfural and 5-hydroxymethylfurfural in a high yield manner under mild conditions. The method has the advantages that after the reaction is completed, the produced furfural and 5-hydroxymethylfurfural are efficiently extracted into an upper-layer organic phase, the solid acid catalyst and an unreacted substrate are retained in a bottom-layer water phase, the furfural, the 5-hydroxymethylfurfural or a mixture of the furfural and the 5-hydroxymethylfurfural can be obtained through simple separation, and fine chemicals and liquid fuels can be prepared in a manner that the furfural, the 5-hydroxymethylfurfural or the mixture of the furfural and the 5-hydroxymethylfurfural serves as a reaction intermediate; and the used catalyst is pollution-free and can be recovered and reused, so that the method has good industrial application prospects.

Owner:EAST CHINA UNIV OF SCI & TECH

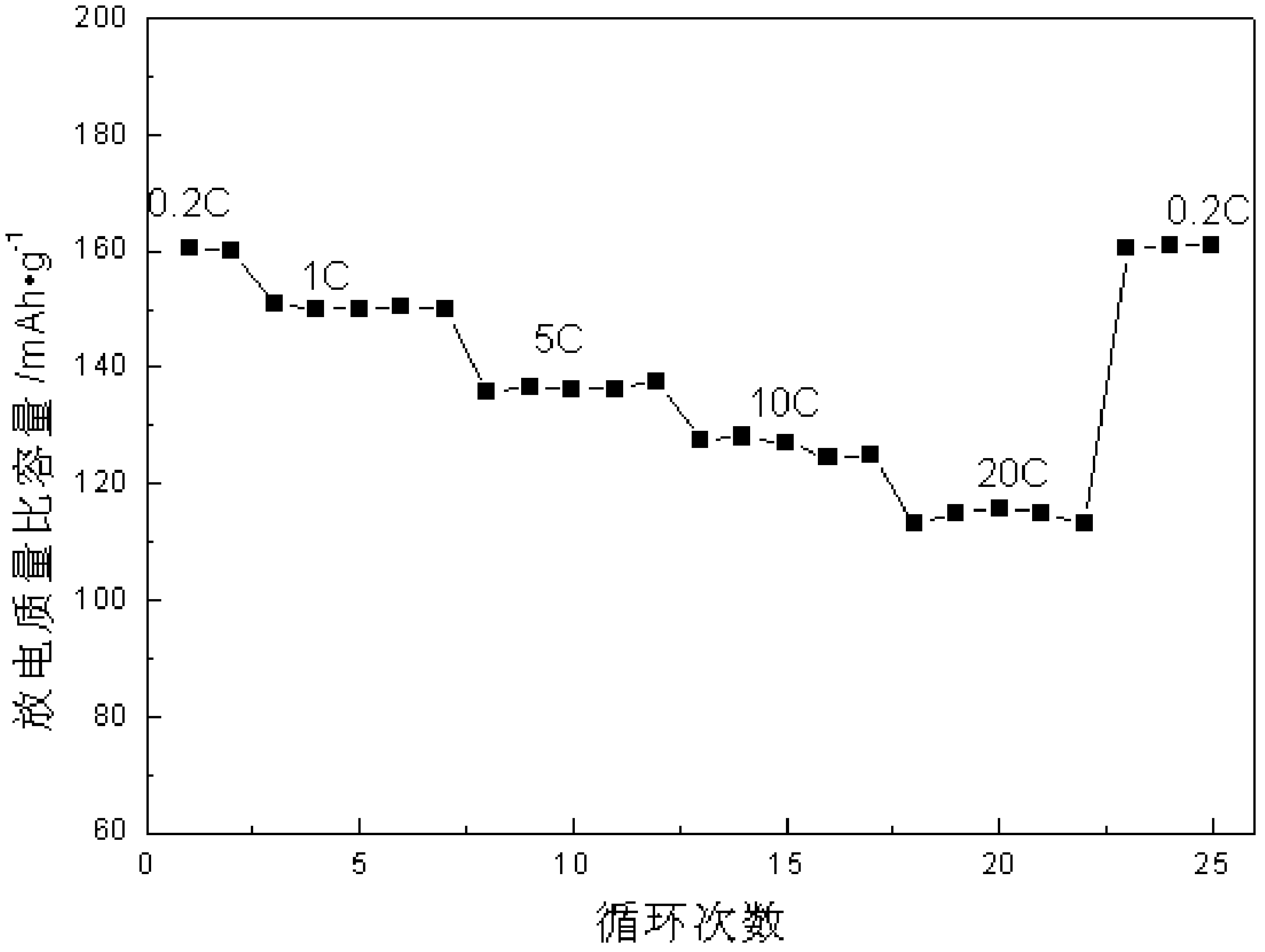

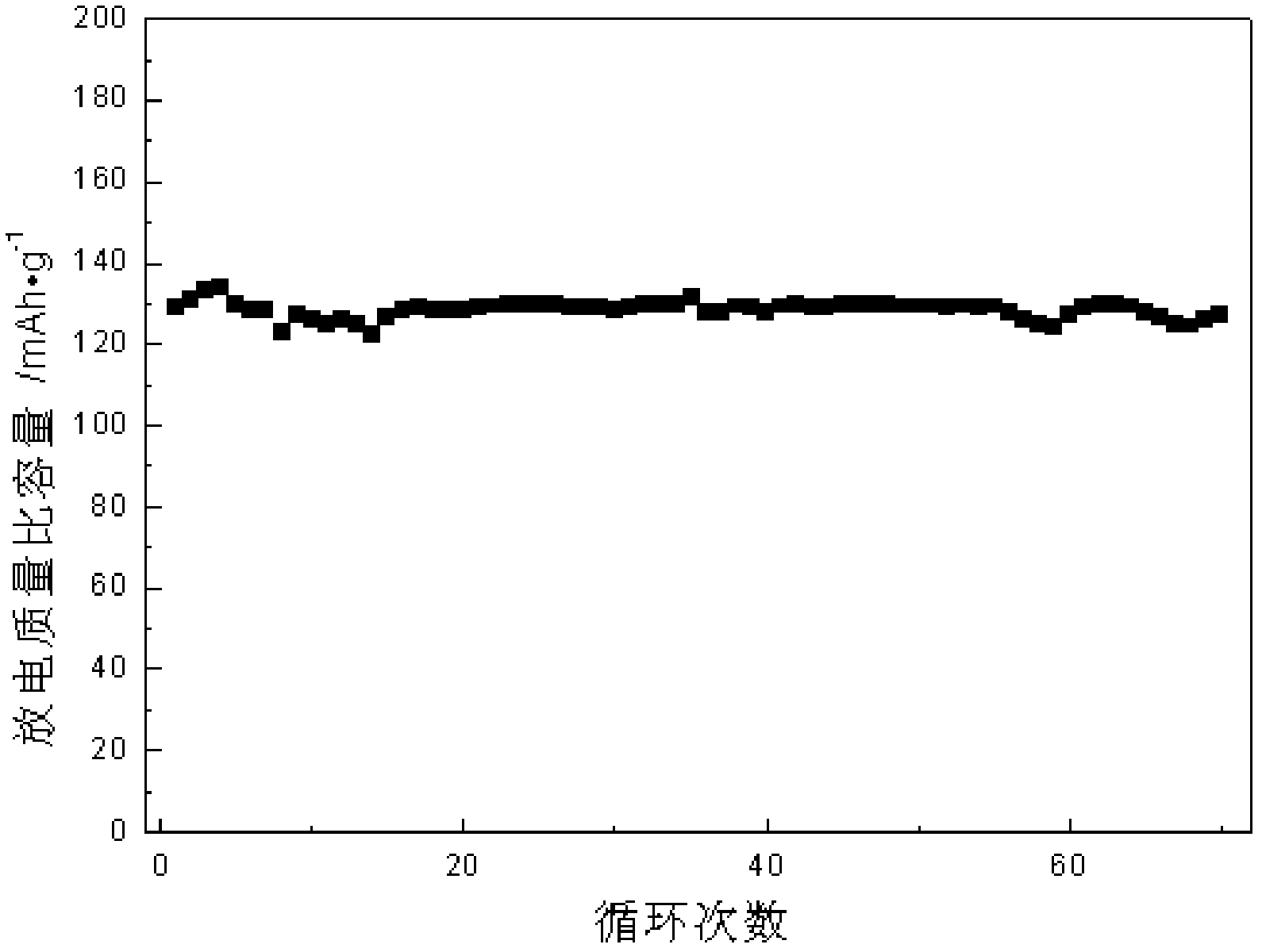

Multi-layer graphene/lithium iron phosphate intercalated composite material, preparation method thereof, and lithium ion battery adopting multi-layer grapheme/lithium iron phosphate intercalated composite material as anode material

InactiveCN102306783AImprove electronic conductivityReduced Diffusion ResistanceCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a lithium iron phosphate intercalated composite material, a preparation method thereof and a lithium ion battery adopting the multi-layer graphene / lithium iron phosphate intercalated composite material as an anode material. In the prior art, the electronic conductivity of the lithium iron phosphate material is poor, high-rate charging / discharging capacity of the lithium ion battery adopting the lithium iron phosphate material as the anode material is poor. The purpose of the present invention is to solve the problems in the prior art, and improve the rapid charging capacity of the power lithium ion battery so as to meet the requirements of the pure electrocar. The composite material is prepared through the following steps that: a rheological phase reaction method is adopted for multi-layer graphene, a trivalent iron salt, a phosphorus compound, a lithium compound and carbon source of small organic molecule to obtain a composite precursor, then the precursor is sintered to obtain the multi-layer graphene / lithium iron phosphate intercalated composite material. The anode slurry of the lithium ion battery anode plate comprises the composite material, a conductive agent and polyvinylidene difluoride. The composite material is an intercalated structure, wherein the lithium iron phosphate particles are intercalated between the multi-layer graphene to form the intercalated structure. The trivalent iron salt is adopted as the raw material, such that the cost is reduced. The lithium ion battery has good charging / discharging cycle performance, wherein the specific capacity is more than 60 mA.h.g<-1> at the rate of 20C.

Owner:HARBIN INST OF TECH

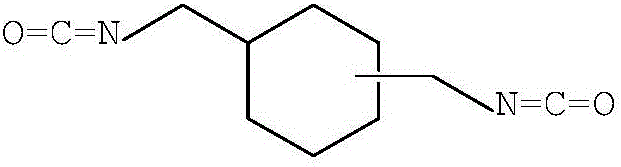

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

Positive electrode active material, production method thereof and non-aqueous electrolyte secondary battery

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:PANASONIC CORP +1

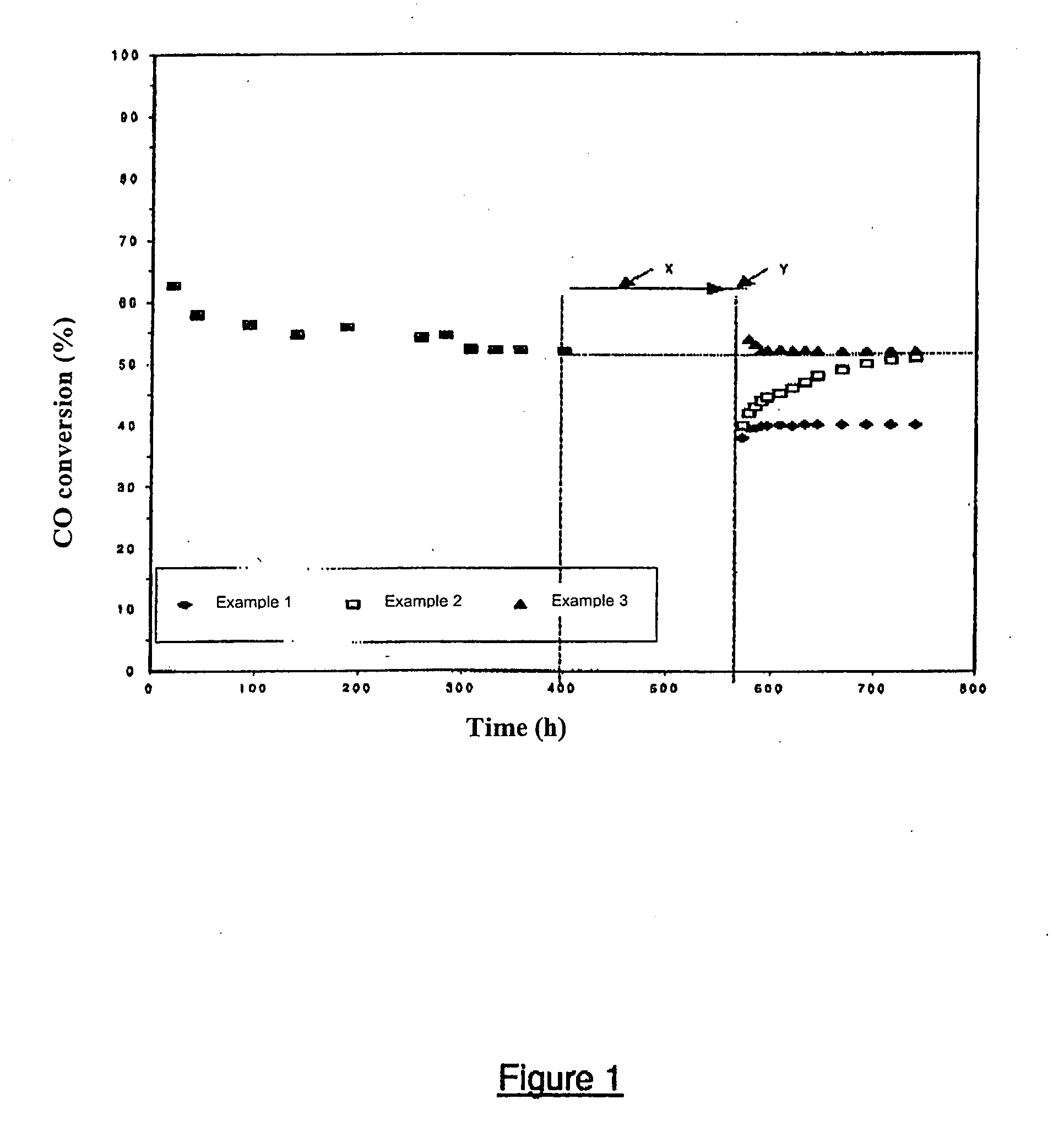

Method For Temporarily Interrupting A Fischer-Tropsch Reaction In A Three-Phase Bed Reactor

InactiveUS20080262112A1Quick restartMaintain performanceOrganic compound preparationOxygen compounds preparation by reductionPtru catalystFluid phase

A process for temporarily interrupting a Fischer-Tropsch type reaction carried out on a feed comprising at least carbon monoxide and hydrogen is carried out in a three-phase reaction zone comprising a liquid phase, a gas phase and solid catalyst particles maintained in suspension, said process comprising a step a) for interrupting the reaction and a step b) for restarting said reaction, during which the solid catalyst particles are maintained in suspension in the reaction zone;a) during the step for interrupting the reaction, supply of the feed is stopped, and a blanket of an inhibiting gas comprising less than 1% by volume of hydrogen and at least 5% by volume of at least one inhibiting compound selected from the group formed by carbon monoxide and water is established; andb) during the reaction restart step, in the reaction zone, a blanket of an activating gas with a hydrogen content of at least 20% by volume is established and supply of the feed is restarted.

Owner:INST FR DU PETROLE +1

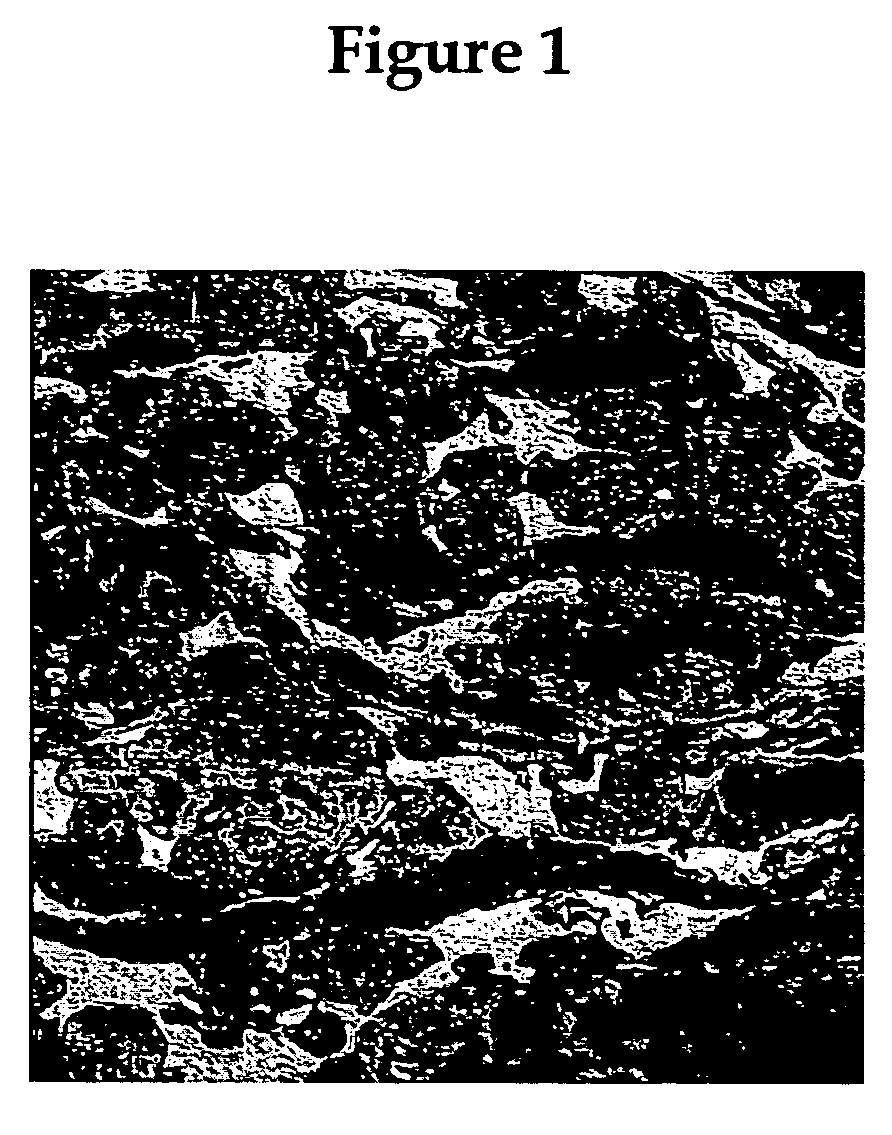

Textured catalysts and methods of making textured catalysts

InactiveUS7186668B2Maintain good propertiesGood dispersionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetalPhase reaction

A textured catalyst having a hydrothermally-stable support, a metal oxide and a catalyst component is described. Methods of conducting aqueous phase reactions that are catalyzed by a textured catalyst are also described. The invention also provides methods of making textured catalysts and methods of making chemical products using a textured catalyst.

Owner:BATTELLE MEMORIAL INST

Three-phase ultrasound light-catalyzed reaction device and method for CO2 reduction thereof

InactiveCN101138700AImprove photocatalytic efficiencyShort reaction timeDispersed particle separationEnergy based chemical/physical/physico-chemical processesWater bathsUltrasound - action

The present invention discloses a three-phase ultrasonic photo-catalyzed reaction device and a CO2 reducing method with the device. With the device, a photo-catalyst is placed in a photo-reactor, and the reactor is placed in a water bath of an ultrasonic generator. A light source is arranged above the photo-reactor. The method is that the CO2 gas to be reduced is mixed evenly with the photo-catalyst and a sodium hydroxide solution in the photo-reactor under the ultrasonic action, and reacts for 3-20 hours with radiation of the light source. Then the CO2 gas is reduced. The photo-catalyst is made from titanium dioxide or silicon dioxide and metal phthalocyanine. Metal phthalocyanine is supported on the surface of titanium dioxide in the way of in-situ synthesis, sol-gel, and immersion. The present invention promotes the photo-catalysis efficiency, reduces the reaction time, and saves the energy. Visible light can be used for reducing. Moreover, the phot-catalyst can be recycled, which reduces the pollution and the cost, sot the present invention is quite applicable for the three-phase ultrasonic photo-catalyzed reaction device and photo-catalyzed CO2 reducing.

Owner:TAIYUAN UNIV OF TECH

Process of making polymer blends

In a process for producing a polymer blend, at least one first monomer is polymerized in a first slurry phase reaction zone in the presence of a supported first catalyst to produce a thermoplastic first polymer having a crystallinity of at least 30%. At least part of said first polymer is then contacted with at least one second monomer different from said first monomer in a second solution phase reaction zone in the presence of a second catalyst and in the absence of polyenes under conditions to produce a second polymer having a crystallinity of less than 20%.

Owner:EXXONMOBIL CHEM PAT INC

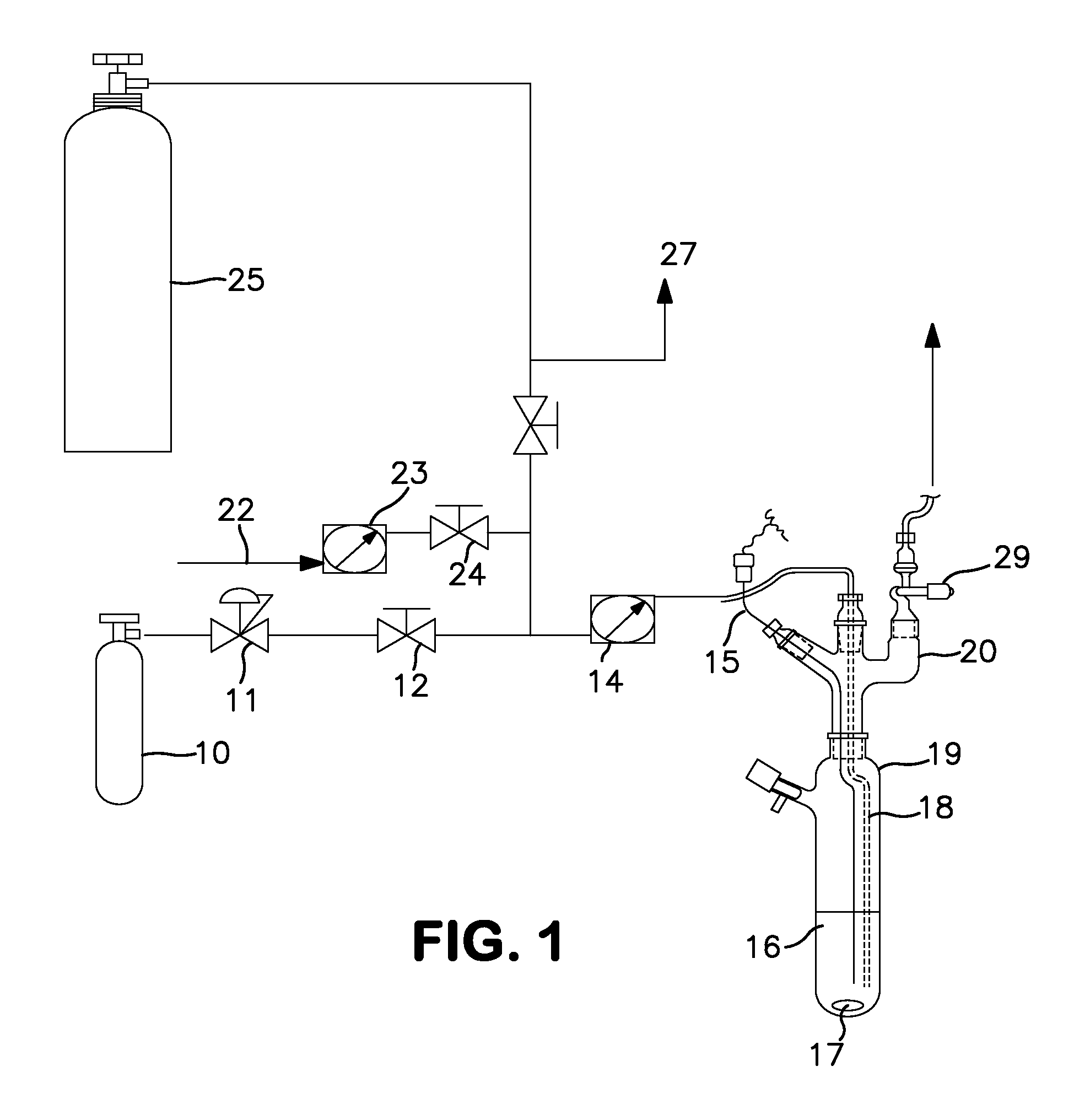

Apparatus and method for the condensed phase production of trisilylamine

ActiveUS20130089487A1Increased formationPromote formationSilicon compoundsNitrogen and non-metal compoundsDistillationSynthesis methods

The present invention is directed to a condensed phase batch process for synthesis of trisilylamine (TSA). An improved synthesis method that incorporates a solvent to help promote a condensed-phase reaction between ammonia gas (or liquid) and liquified monochlorosilane (MCS) in good yields is described. This method facilitates the removal of the byproduct waste with little to no reactor down time, substantial reduction of down-stream solids contamination and high-purity product from first-pass distillation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Process of making polymer blends

In a process for producing a polymer blend, at least one first monomer is polymerized in a first slurry phase reaction zone in the presence of a supported first catalyst comprising a Ziegler-Natta component to produce a thermoplastic first polymer having a crystallinity of at least 30%. At least part of said first polymer is then contacted with at least one second monomer different from said first monomer and at least one polyene in a second solution phase reaction zone in the presence of a second catalyst under conditions to produce and at least partially cross-link said second polymer such that said second polymer comprises at least a fraction which is insoluble in xylene and has a crystallinity of less than 20%.

Owner:EXXONMOBIL CHEM PAT INC

Method for synthesizing ethyl methyl carbonate through ester exchange

ActiveCN103483200AEasy to makeSimple process conditionsPreparation from organic carbonatesMolecular sieveAlcohol

The invention relates to a method for synthesizing ethyl methyl carbonate through ester exchange. The method comprises the following steps: filling a fixed bed reactor with catalysts, pumping dimethyl carbonate and ethyl alcohol into the fixed bed reactor according to the molar ratio of 0.5-2:1 after nitrogen purging is carried out, reacting at the air speed of 0.5-15h-1, the temperature of 100-240DEG C and the reaction operation pressure of 0-1MPa, and finally the ethyl methyl carbonate is obtained. The catalysts are modified molecular sieve based catalysts. The method is simple in technology condition, easy to control, capable of achieving continuous production due to the gas-solid phase reaction and low in cost of the adopted catalysts. The selectivity of the ethyl methyl carbonate can be higher than 90%, and the yield can be higher than 55%.

Owner:HEBEI UNIV OF TECH

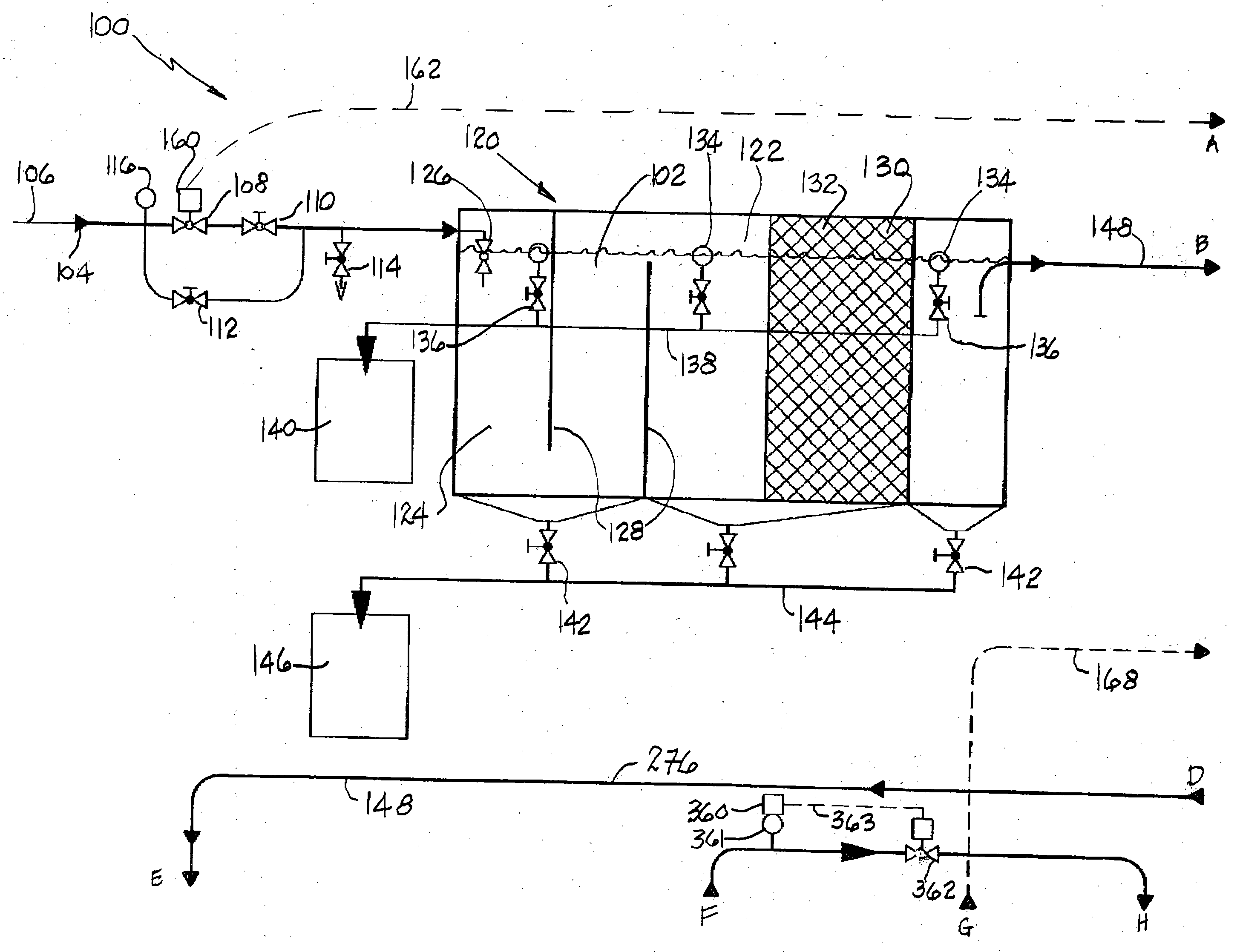

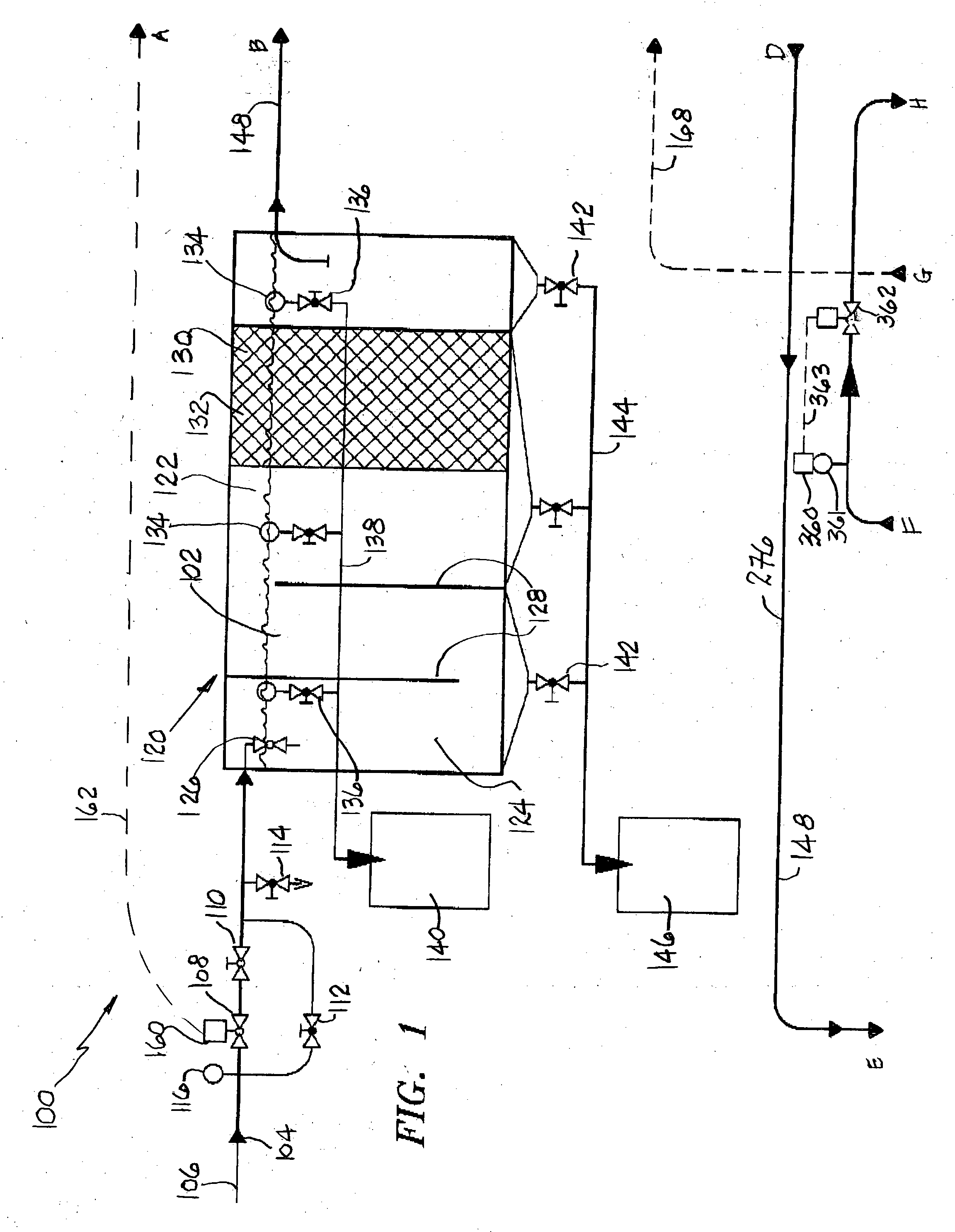

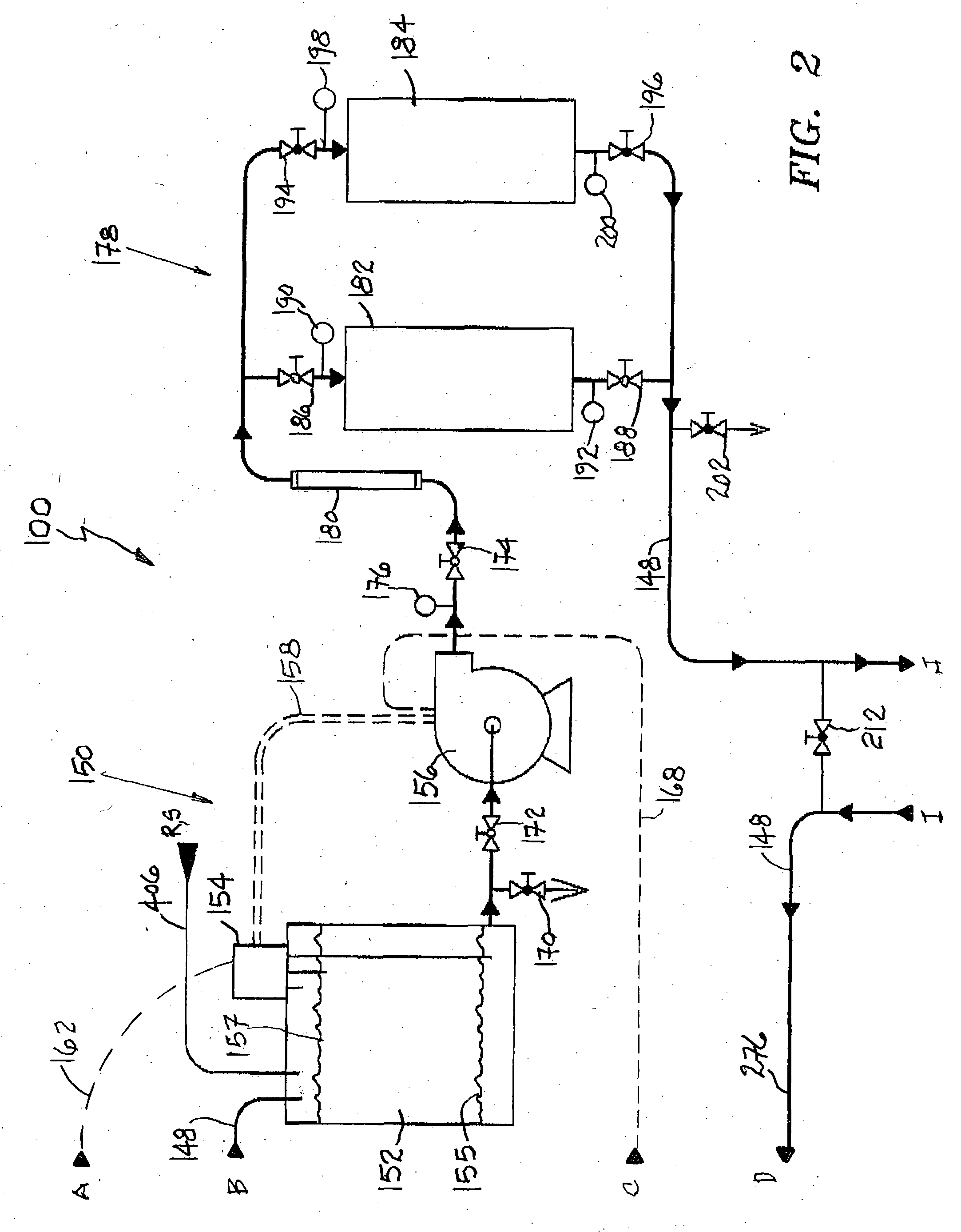

Multi-phase separation system

InactiveUS20050005772A1Minimizes probabilitySolid sorbent liquid separationVacuum distillation separationGas phaseLiquid state

A multi-phase separation system utilized to remove contaminants from fluids includes a pre-filtering module for filtering a contaminated fluid to provide a filtered contaminated fluid. A condenser module receives the filtered contaminated fluid and a contaminated gas phase for condensing the contaminated gas phase to a contaminated liquid. A phase reaction chamber converts the filtered contaminated fluid to a contaminated mist wherein the mist is subjected to a low energy, high vacuum environment for providing a first change of phase by separating into a contaminated gas phase and a liquid mist phase. The contaminated gas phase is carried out of the phase reaction chamber by a carrier air. A vacuum pump provides the low energy, high vacuum environment in the phase reaction chamber and delivers the contaminated gas phase to the condenser module for condensation providing a second change of phase.

Owner:LIQUID SEPARATION TECH & EQUIP

Method for preparing porzite porous honeycomb ceramic with needle-shaped crystal structure

InactiveCN101781124ALow costLow efficiencyExhaust apparatusDispersed particle separationAlkaline earth metalCrystal structure

The invention relates to a method for preparing a porzite porous honeycomb ceramic with a needle-shaped crystal structure. The method comprises the following steps: mixing various raw materials containing Al and Si, such as industrially pure kaoline, alumina, silicon oxide and the like according to the mol ratio of Al2O3 / SiO2 within the range of 3:2 to 2:1, and then adding a proper amount of nano-scale mineralizing agent which is formed by mixing one or more in an oxide MxOy containing a first transition element, alkali metal and alkaline-earth metal compounds or a raw mineral material containing the compounds; adding a proper amount of fluoride MFx or a catalyst containing an F raw mineral material, screening and mixing the raw materials, adding a proper amount of forming agent, forming a blank body, then drying and finally roasting by adopting a two-stage roasting synthesis technology. In the method of the invention, the raw materials with low price can be adopted, and a particular nano-scale catalyst and mineralizing agent composite can be self-manufactured and synthesized; the porzite porous honeycomb ceramic with the whole needle-shaped crystal structure can be continuously prepared through once roasting by utilizing the principle of a gas-solid phase reaction and adopting the two-stage roasting synthesis technology at lower temperature, and the porzite porous honeycomb ceramic has the characteristics of low cost and high efficiency.

Owner:JINGDEZHEN CERAMIC INSTITUTE

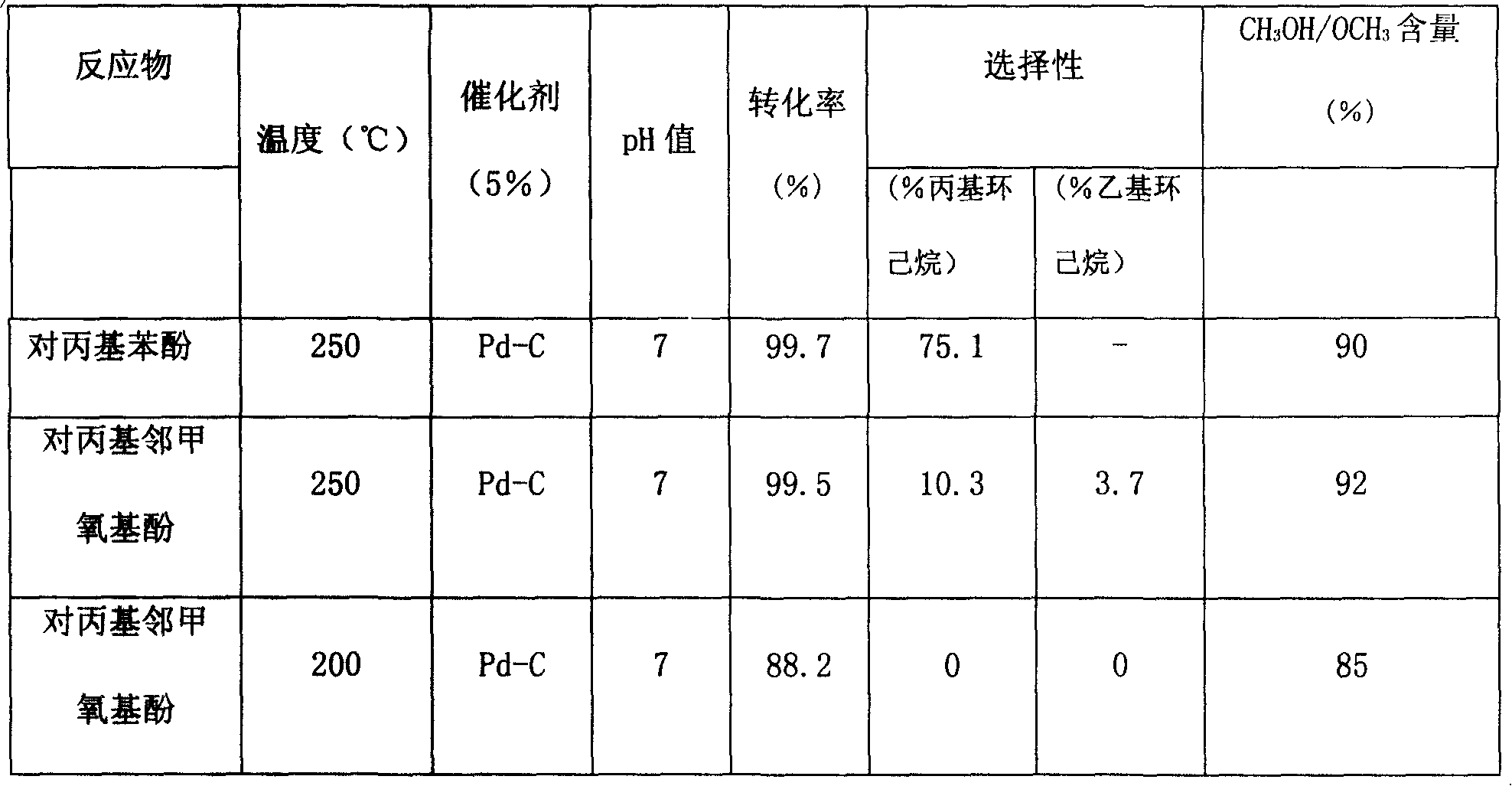

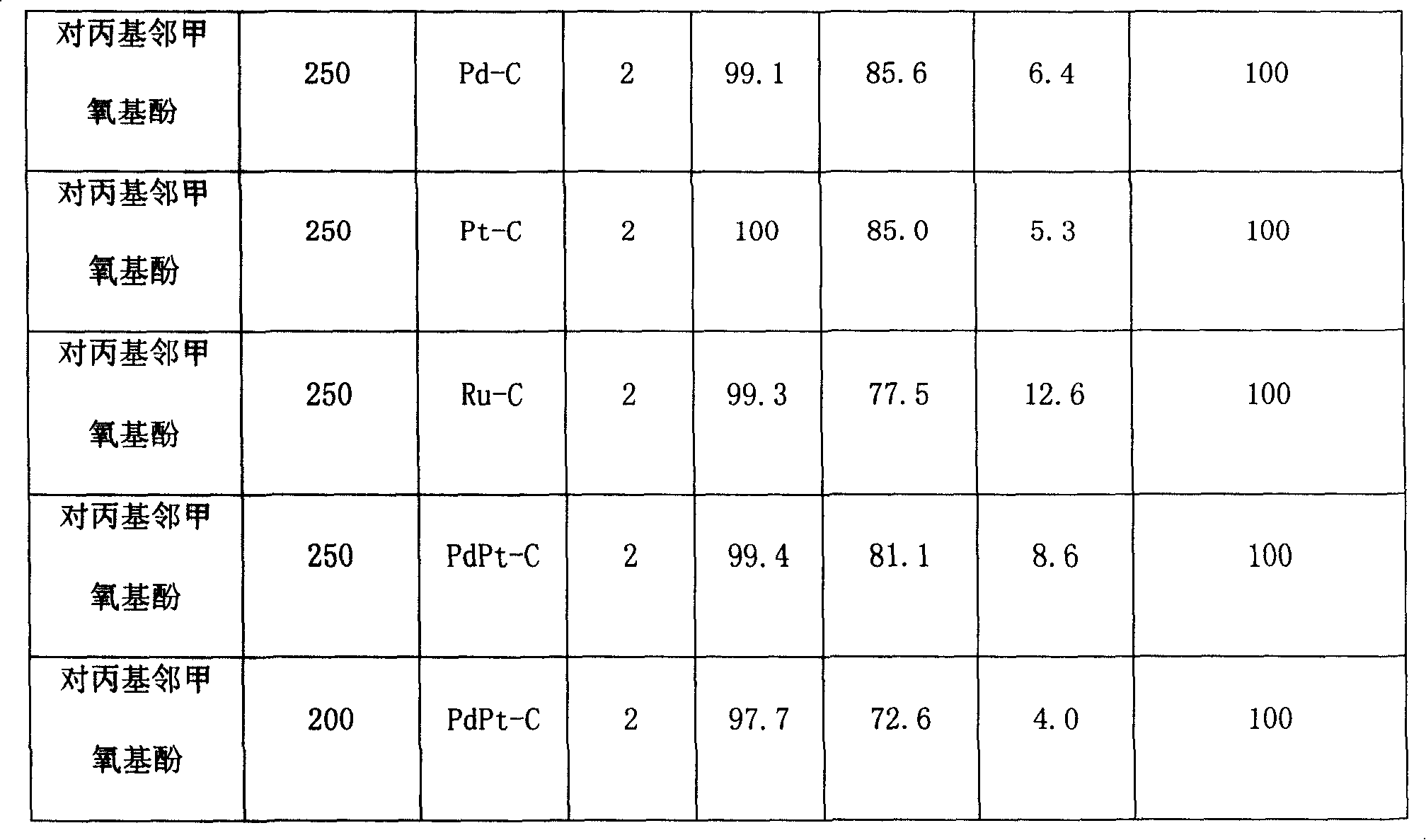

Method for preparing hydrocarbon fuel and methanol

InactiveCN101225319AIncrease profitHigh yieldOrganic chemistryLiquid carbonaceous fuelsHydrogenHigh pressure

The invention discloses a preparation method for hydrocarbon fuel and methanol, which is characterized in that a wood powder, a lignin, a lignin monomer and (or) a lignin monomer and / or dimer is used as a raw material, the raw material and a hydrogenation catalyst are filled into a high-pressure autoclave, the pH value of an aqueous phase reaction system is adjusted to 2 to 7, hydrogen is charged into the reaction system under the normal temperature, and the temperature is increased to 40 to 350 degree centigrade, the reaction is executed for 0.2 to 5 hours under 40 to 350 degree centigrade, and the product is divided into two phases after the reaction is completed and the temperature is decreased, the upper layer phase is the hydrocarbon fuel, the lower layer aqueous phase is a methanol solution; the molar ratio of the hydrogenation catalyst and the raw material is 1:10-10000. Compared to the traditional prepared hydrocarbon fuel and methanol, the preparation method for hydrocarbon fuel and methanol has the advantages of economy with wide resources of the raw material and low cost, environment protection, simplicity with simple process, high efficiency with high utilization ratio of the raw material and high productivity, which takes an important role in the utilization of the lignin, hydrocarbon fuel and methanol preparation field with a wide application prospect.

Owner:PEKING UNIV

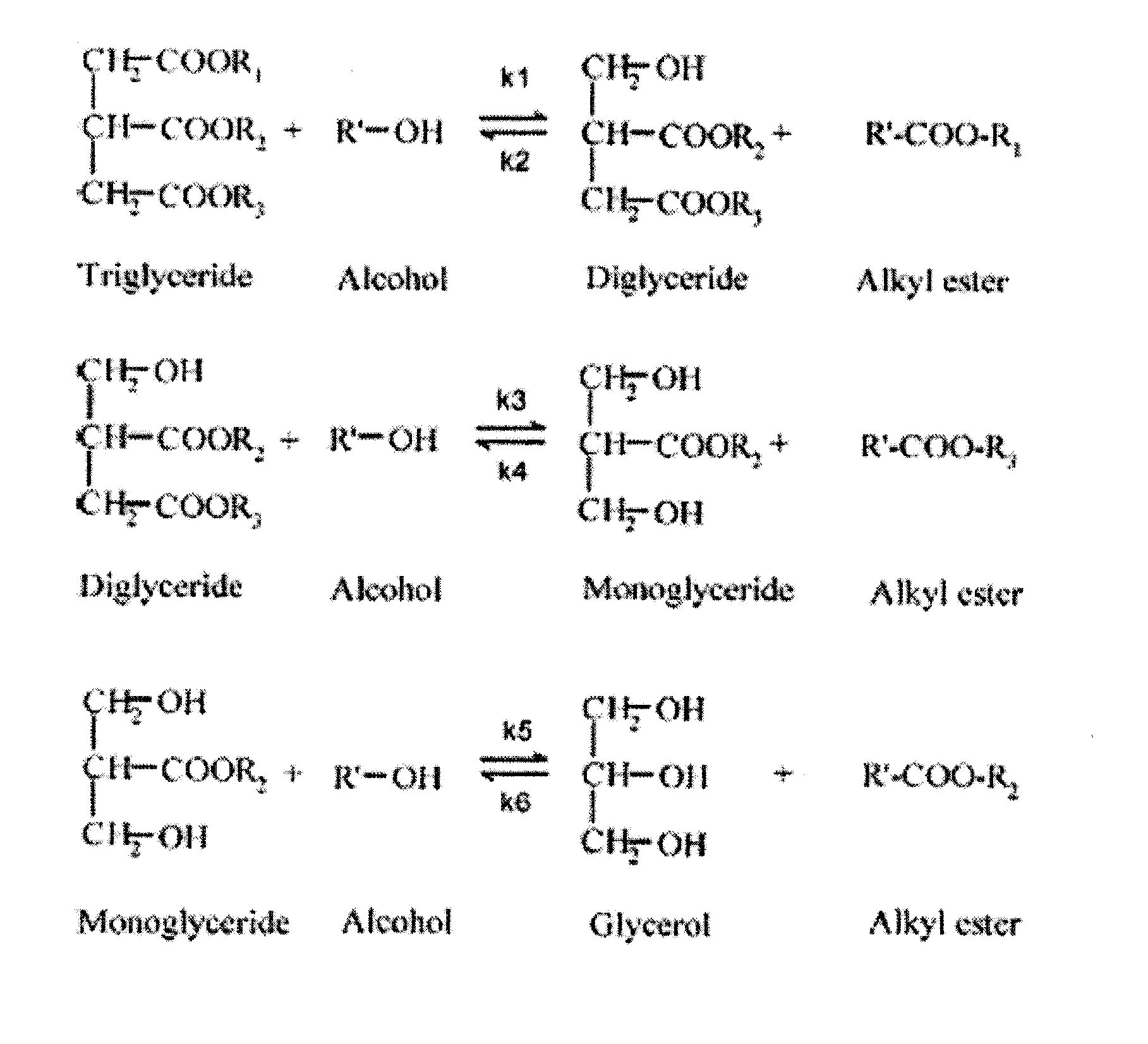

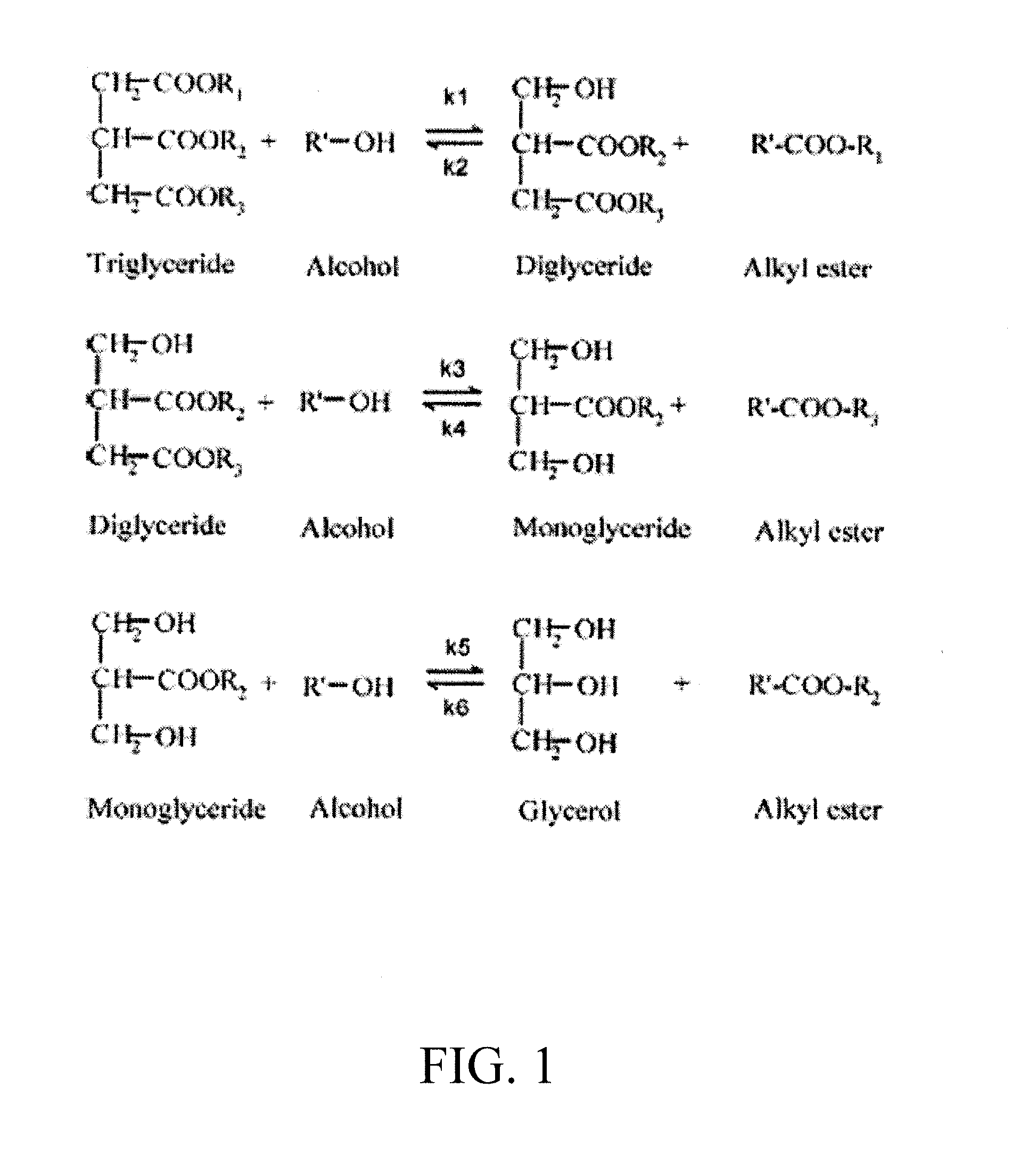

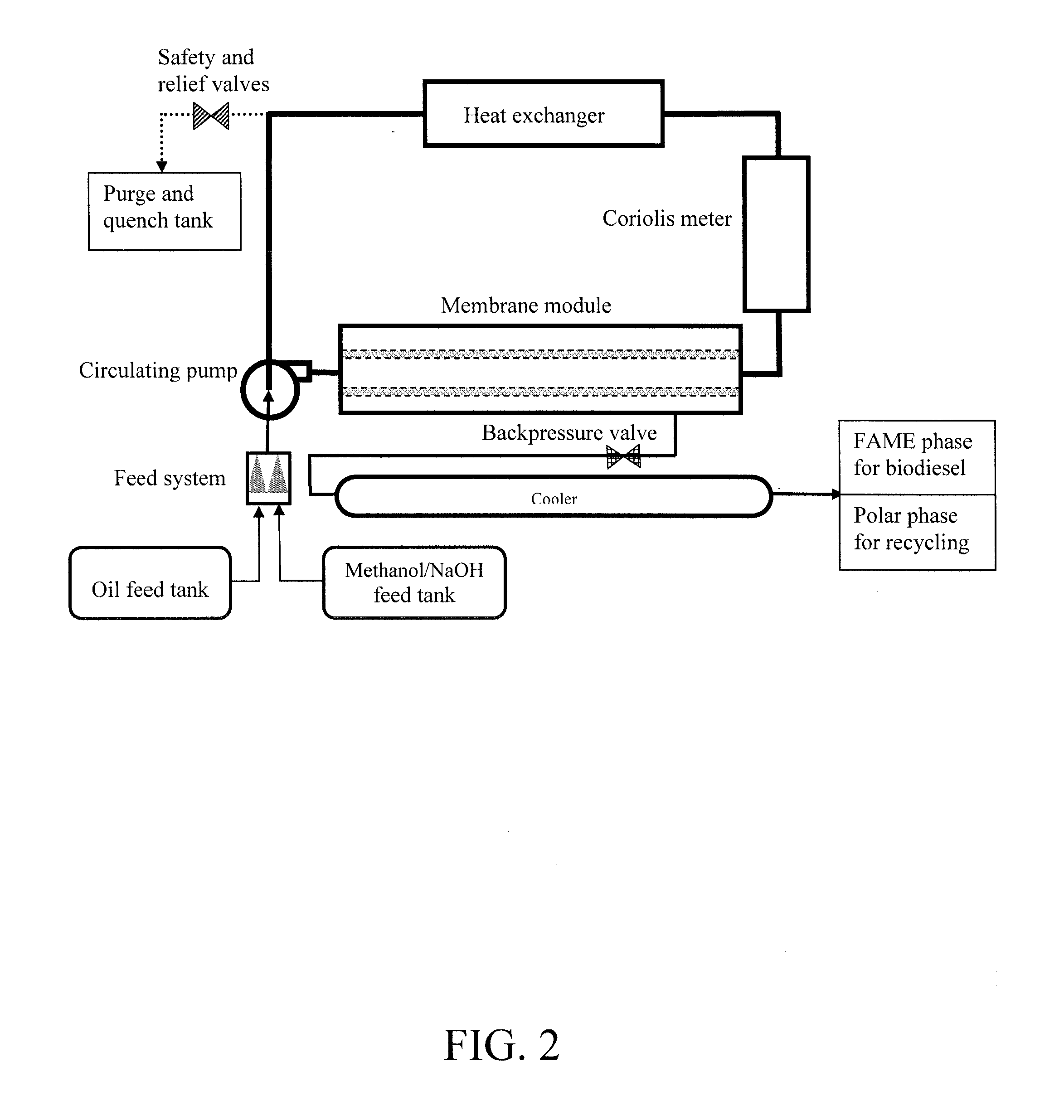

Biodiesel production using ultra low catalyst concentrations in a membrane reactor

InactiveUS20100307051A1Good colorReduce the amount requiredFatty oils/acids recovery from wasteFatty acid esterificationBiodieselEmulsion

A method for producing a fuel or fuel additive comprising providing a reaction mixture comprising oil and an alcohol in an oil-in-alcohol emulsion and a catalyst for converting the oil to the fuel or the fuel additive. The oil and the alcohol are reacted in the presence of the catalyst, at a concentration below that used in a conventional batch process, to produce the fuel or fuel additive. This low level of catalyst reduces the formation of diols and oxidation products that can diminish the quality of the fuel or fuel additive. The fuel or fuel additive produced is continuously removed during the reaction, effectively de-coupling the concentration of catalyst used from the rate of the two phase reaction.

Owner:UNIVERSITY OF OTTAWA

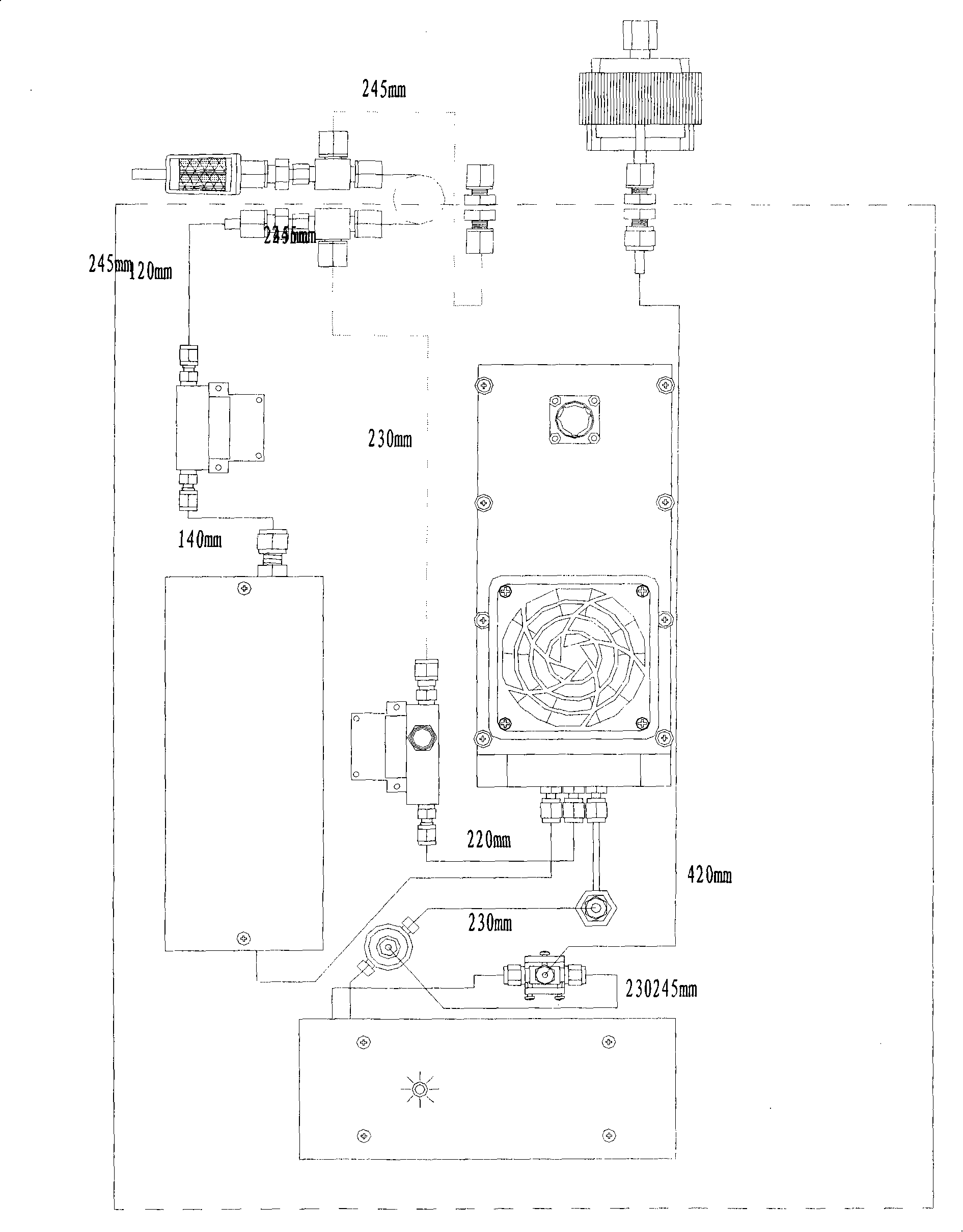

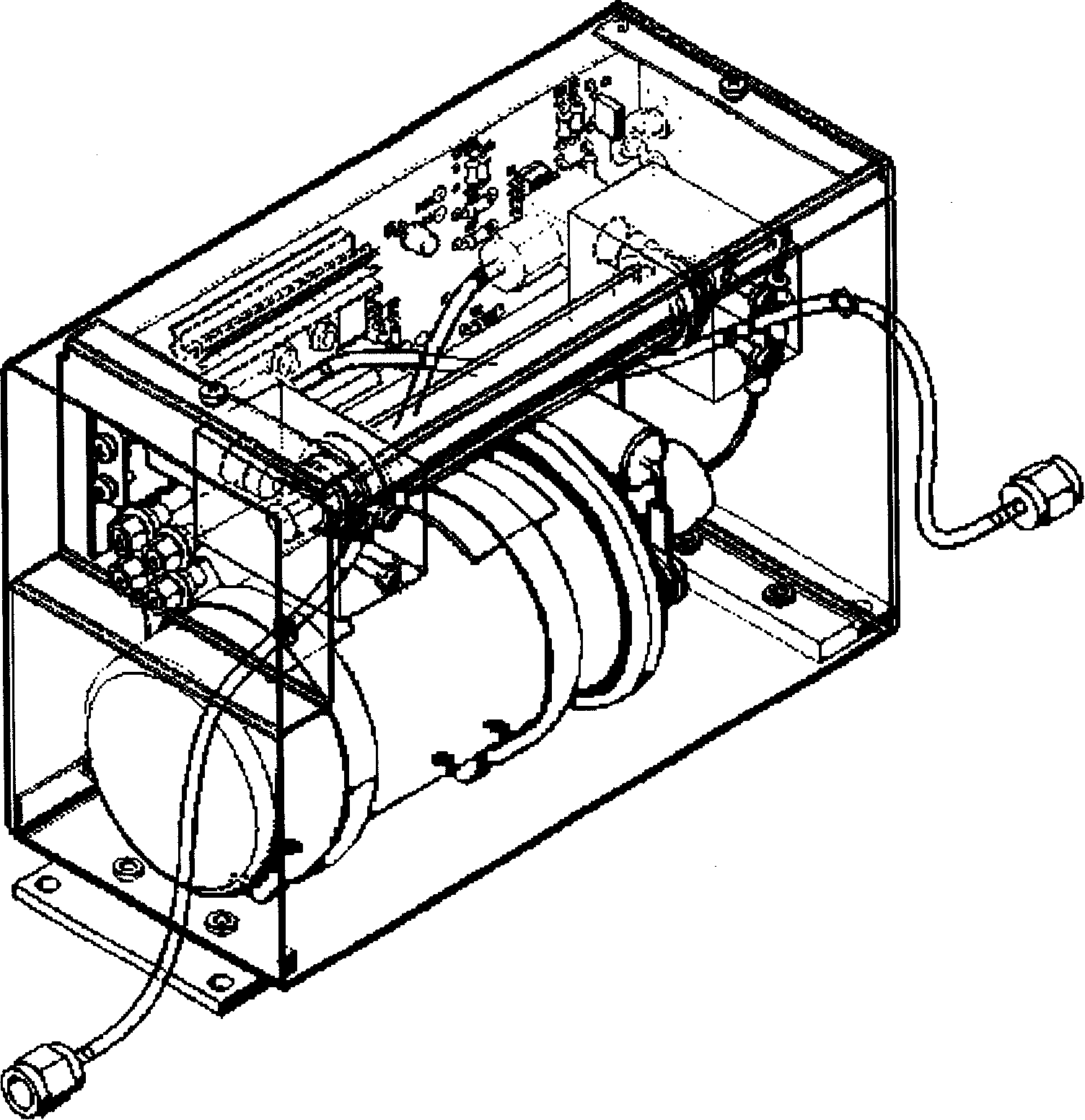

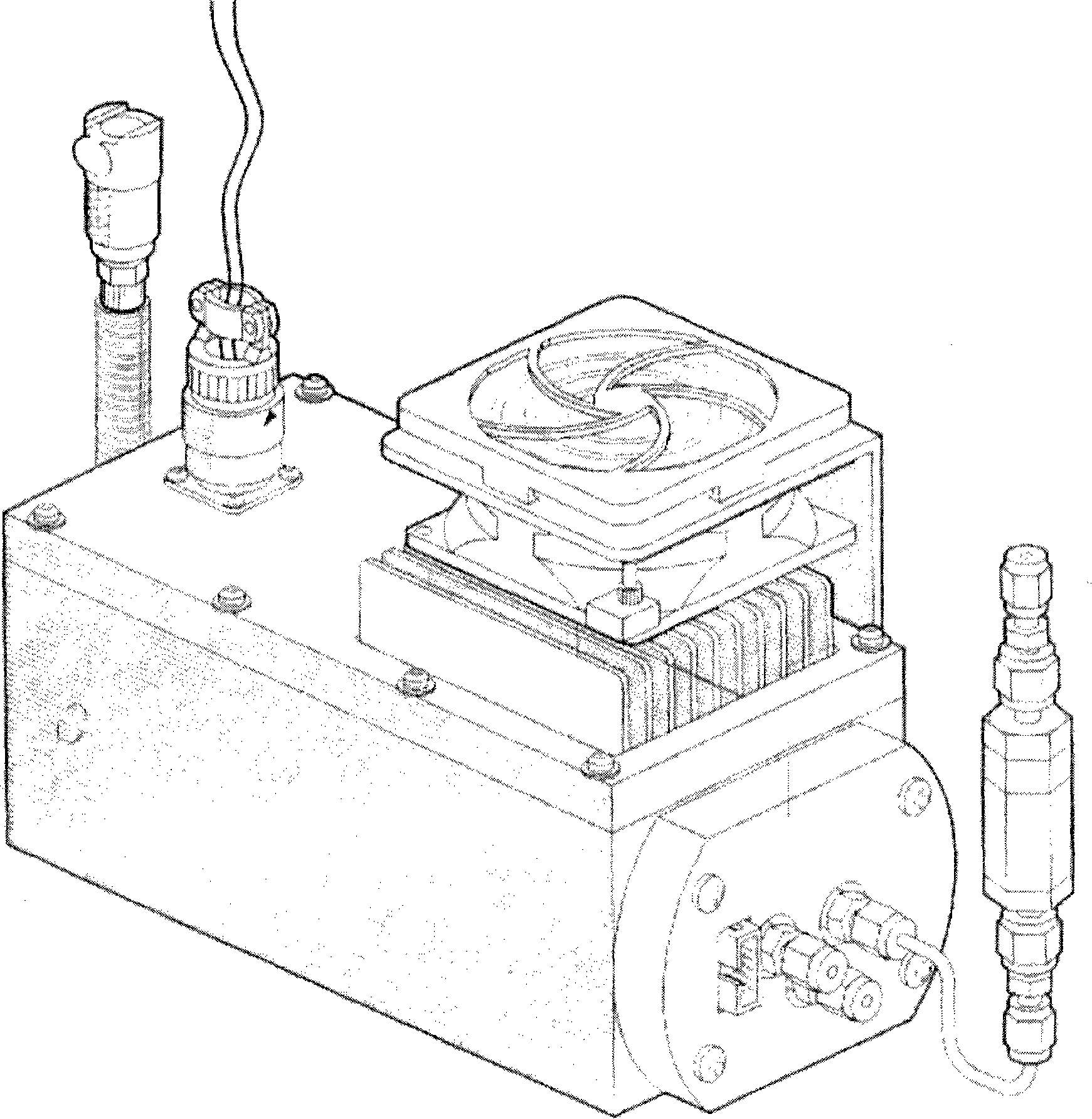

System using chemiluminescence method to execute nitrous oxides analysis

InactiveCN101162200AFast stabilityQuick responseChemiluminescene/bioluminescencePreparing sample for investigationGas analysisNitric oxide

The invention relates to a gas analysis system and belongs to the nitrogen oxide analysis field. The system detects the concentration of nitric oxide in the atmosphere by using the power of light generated in the gaseous phase reaction between O3 and nitric oxide (NO) gas. The method is called as a chemiluminescence method. The system is used to measure the concentration of NO, NO2 and the concentration NOX in the atmosphere continuously, reacts rapidly when the concentrations of NO, NO2 and NOX change and can measures stably for a long time; the system can be applied in many conditions of different temperatures and humidity without any impact on the measurement precision. All operation control can be accomplished on an operation panel. The concentration of gas is displayed on the LCD display screen on the operation panel. In addition to the display screen on the operation panel, terminals are also provided to provide measurement output signals. A filter and a sampling instrument are arranged at accessible positions and the whole system is reliable in design and convenient to maintain.

Owner:SHENYANG DONGYU GRP CO LTD

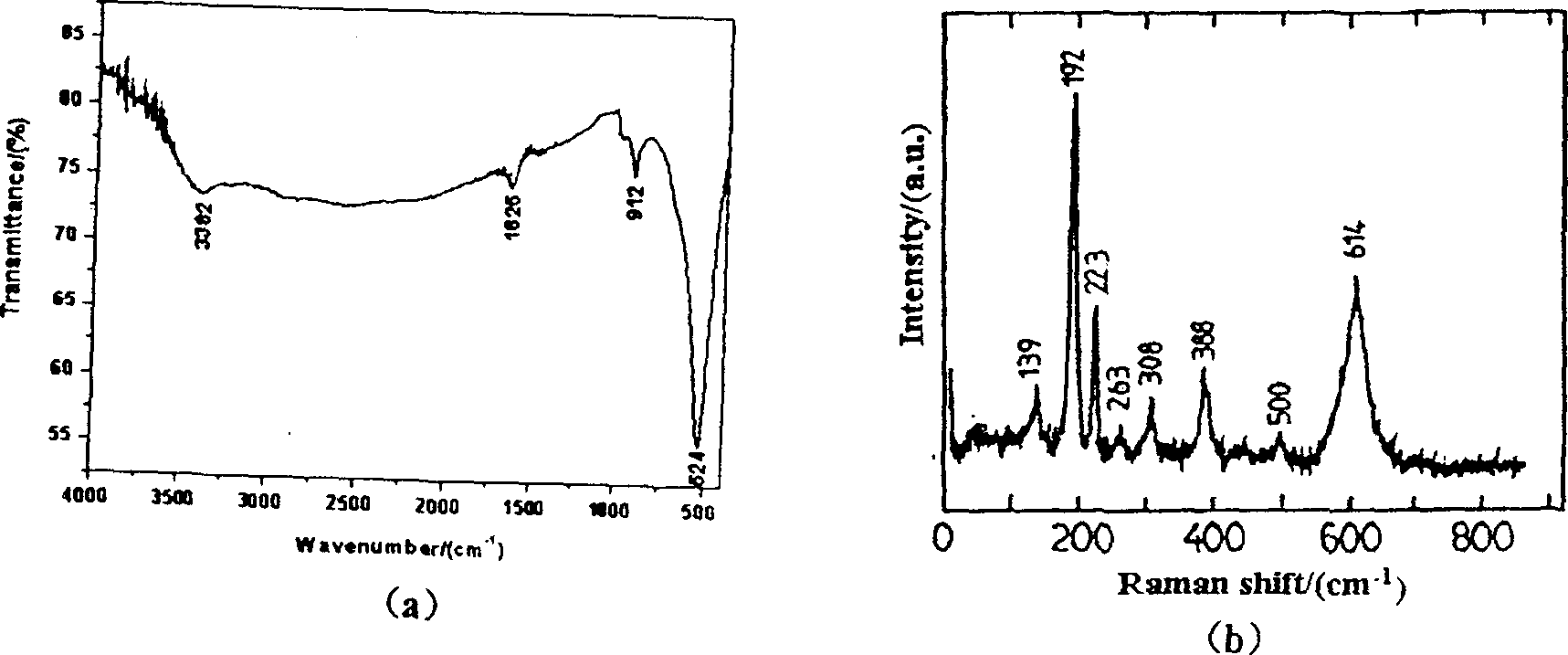

Vanadium dioxide nanometer rod and preparation method thereof

InactiveCN1522965AImprove surface activitySimple preparation processNanostructure manufactureVanadium oxidesVanadium dioxideHigh surface

The present invention provides a method for preparing B phase vanadium dioxide nano rod by means of rheological phase reaction and self-assembly process combination, and is characterized by that said method includes the following steps: mixing inorganic vanadium oxide powder and cationic surfactant according to the mole ratio of 2:1, magnetic stirring for 1 hr. in absolute ethyl alcohol medium, adding proper quantity of deionized water, stirring and ageing for 48 hr to form rheological product, moving it into the stainless reactor still with teflon lining bottom, making hydrothermal reaction for 6-8 days at 180 deg.C, water-washing and filtering for 3 times, drying for 12 hr at 80 deg.C so as to obtain B phasek vanadium dioxide nano rod product with high surface activity.

Owner:武汉理工力强能源有限公司

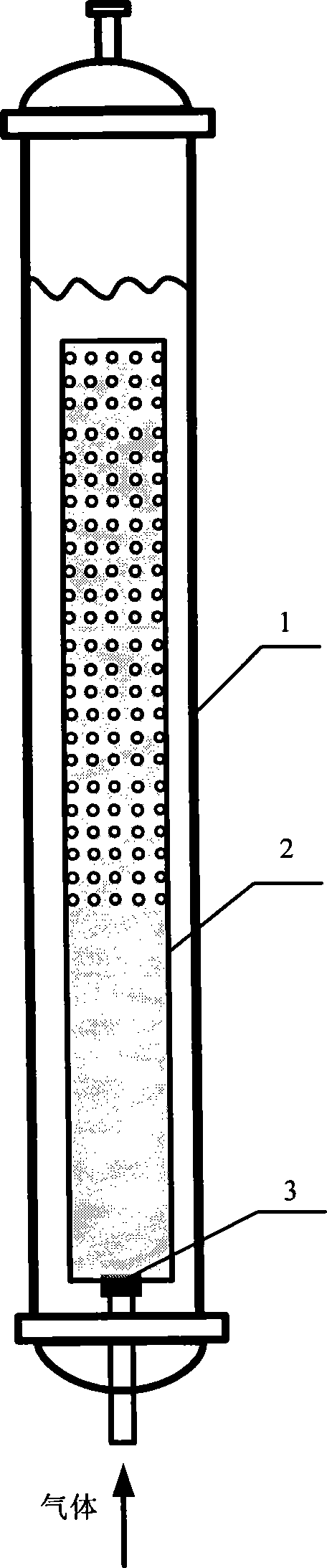

Air-lift type circular current reactor

InactiveCN101249405AIncrease gas holdupImprove efficiencyLiquid-gas reaction processesDiameter ratioEngineering

A loop reactor with a porous guide flow cylinder is applied in gas-liquid two-phase reaction or gas-liquid-solid three-phase reaction and belongs to chemical reaction engineering field. The guide flow cylinder is characterized in including an upper sealing section and a lower hole opened section. Distribution holes are opened on the hole opened section at a certain ratio, and both gas and liquid can flow out of the holes. After gas enters the guide flow cylinder through a gas distributor, gas and liquid flow out of the gas distribution holes of the hole opened section and the top of the guide flow cylinder and downwards into the guide flow cylinder from the bottom of the guide flow cylinder to form a circulation flow. Gas flowing out of the hole opened section is carried by fluid and descends to the reactor bottom. Even when the height / diameter ratio of the reactor is larger, the reactor bottom can have a high gas content. Therefore, the multi-hole guide flow cylinder breaks through a limit of a conventional circulation flow reactor on height / diameter ratio, and satisfies requirement of height / diameter ratio of a circulation flow reactor in industrial application.

Owner:SINOPEC YANGZI PETROCHEM

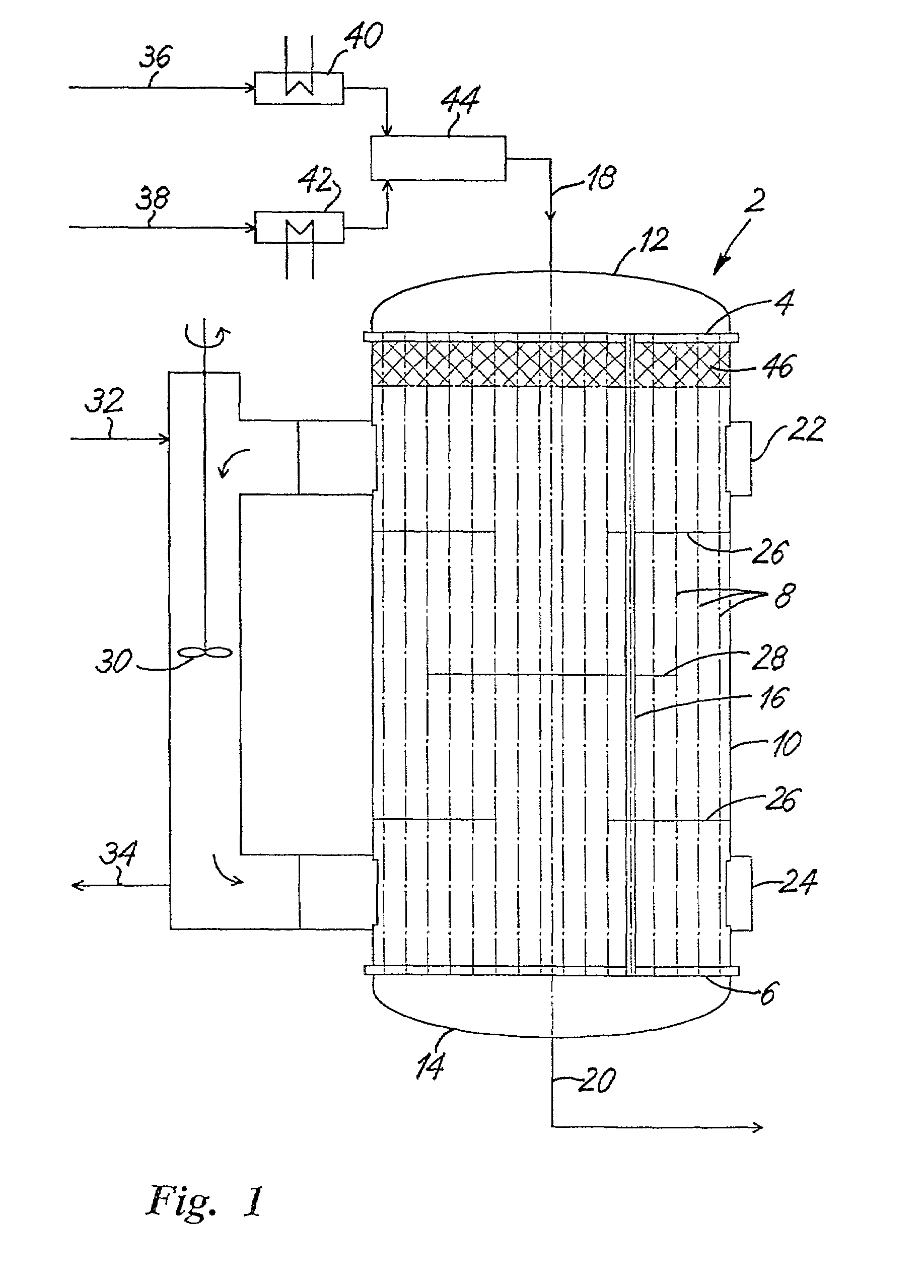

Tubular reactor for catalytic gas phase reactions

InactiveUS6932950B1Low temperature stressThermal insulationStationary tubular conduit assembliesHeat carrierProcess engineering

A tubular reactor (2) for catalytic reactions with a heat carrier that inside a reactor jacket (10) circulates around a contact tube bundle (8), which extends between a tube plate (4; 6; 80; 82) at the reaction gas inlet side and one at the reaction gas outlet side with gas inlet and gas outlet hoods (12, 14) spanning the face sides of the two tube plates and containing reaction-inhibiting media in the zone of the tube plate on the gas inlet side, characterize themselves in that the reaction-inhibiting media consist entirely or in part of a heat insulation layer (46; 50; 64; 80) with openings for the tube cross-sections on at least one of the two sides of the respective tube plate (4; 60; 82). In this manner, either the respective tube plate (4; 60; 82) is insulated against the hot heat carrier or the reaction gas entering into the reactor is prevented from having contact with the comparatively hot tube plate in order to prevent harmful secondary reactions at the reactor inlet.

Owner:MAN ENERGY SOLUTIONS SE

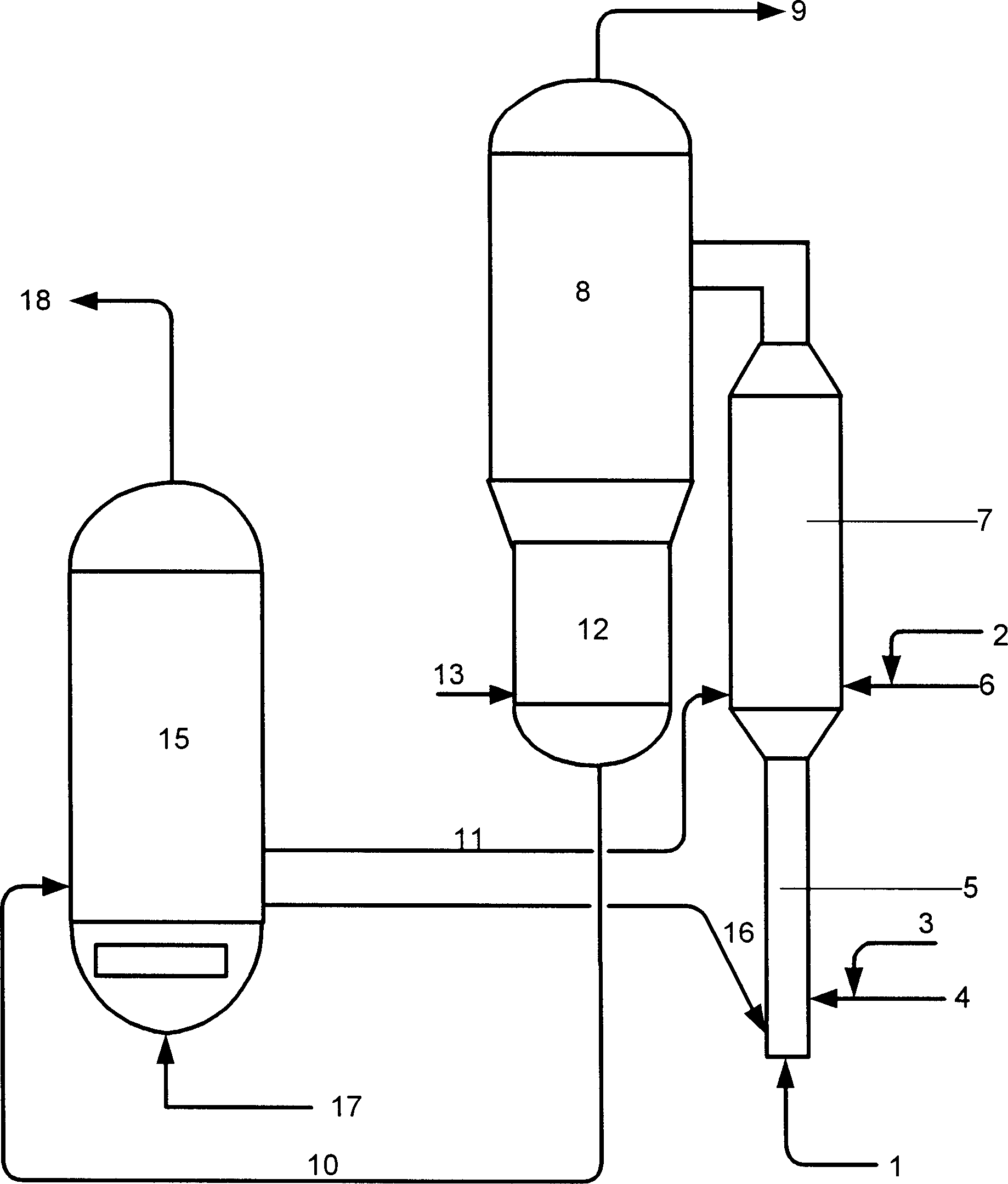

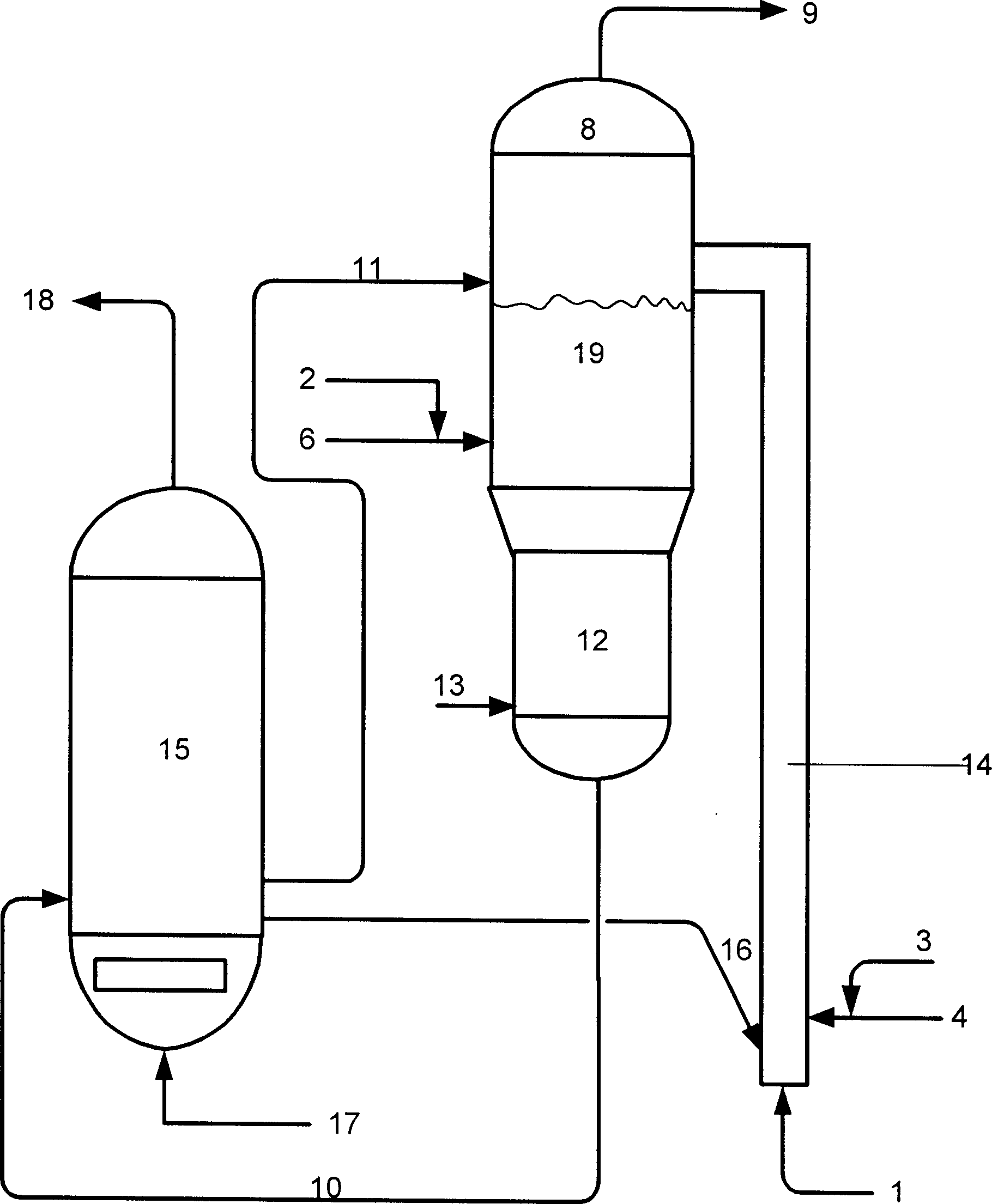

Catalytic conversion process of preparing ethylene and propylene

InactiveCN1403540AHigh yieldYield can be adjustedCatalytic naphtha reformingWater vaporReaction temperature

In the catalytic conversion process of preparing ethylene and propylene, preheated hydrocarbon oil A is injected into the dilute phase reaction area to contact with high-silicon zeolite catalyst for reaction in the reaction conditions of 630-750 deg.c temperature, 0.15-0.40 MPa pressure, 0.2-3 second reaction time, catalyst-to-material oil weight ratio of 15-40 and water vapor-to-material oil weight ratio of 0.3-1.2; the reactant flow is then introduced into the dense phase reaction area to contact with injected hydrocarbon oil B for further reaction in the reaction conditions of 500-600 deg.c temperature, 0.15-0.40 MPa pressure, 3-20 second reaction time, catalyst-to-material oil weight ratio of 7-20 and water vapor-to-material oil weight ratio of 0.15-0.6.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bulk phase-doped modified lithium ion battery positive electrode material and its preparation method

InactiveCN1794497AImprove electrochemical performanceEasy to achieve uniformityCell electrodesPhosphorus compoundsRoom temperatureLithium compound

This invention relates to a Li ionic battery positive material lithium ferrous orthophosphate after doping and modifying the bulk phase and a preparation method for the applied rheo-phase reaction, in which, the positive material of the Li ionic battery is composed of: LixFeyMzPO4, in which, M is selected from the following elements: Mg, Al, Ca, Ni, Zn, Cu, Ti, Mn and Zr and a compound with Fe, a doped element compound and a compound with P are mixed in proportion to be added with ethanol, water or their mixture to be milled to form a rheo-phase to be kept at the constant temperature of 60-100deg.C for 0.5-20 hours to be moved to a high temperature furnace and pre-processed for 2-20 hours under 200-500deg.C and baked processed for 5-48 hours under 550-900deg.C in inert gas and the temperature is reduced to room temperature to get the product.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

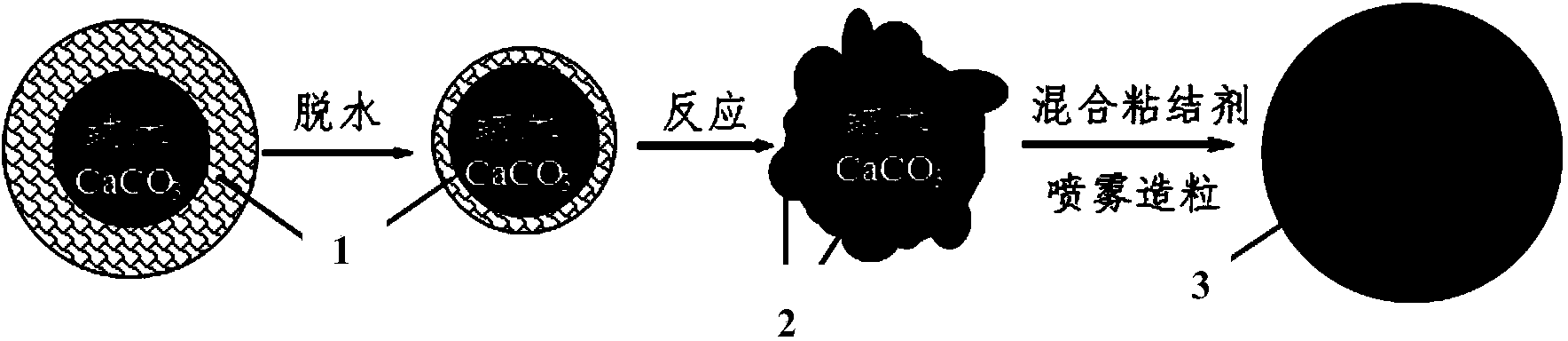

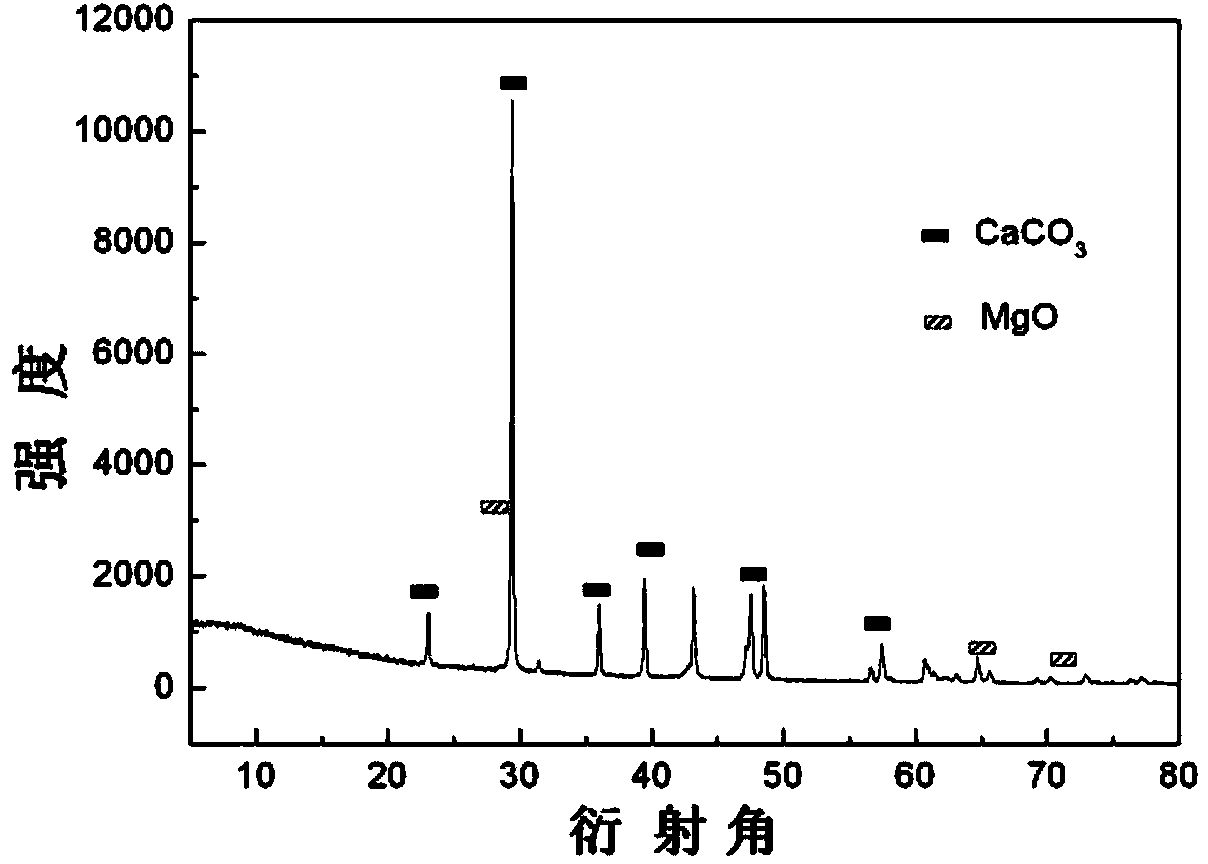

Surface coating modified nano calcium oxide based CO2 adsorbing agent and preparation method thereof

ActiveCN103962087AControl UniformitySimple methodOther chemical processesDispersed particle separationReaction fieldSorbent

The invention discloses a surface coating modified nano calcium oxide based CO2 adsorbing agent which is composed of internal nano calcium oxide and an external surface coating layer; the surface coating layer is prepared from at least one of Al2O3, Ca12Al14O33 and MgO. The invention further discloses a preparation method of the surface coating modified nano calcium oxide based CO2 adsorbing agent. An adsorption phase reaction method is utilized, and thickness and uniformity of the surface coating layer are controlled by controlling a reaction field, the method is simple and regulation and control are facilitated; according to the invention, the prepared surface coating modified nano calcium oxide based CO2 adsorbing agent has high CO2 adsorption capacity and obvious stability in adsorption ability in manifold cycles, can be in long-term recycling, and is an ideal adsorption agent in the adsorption process of high-temperature CO2.

Owner:ZHEJIANG UNIV

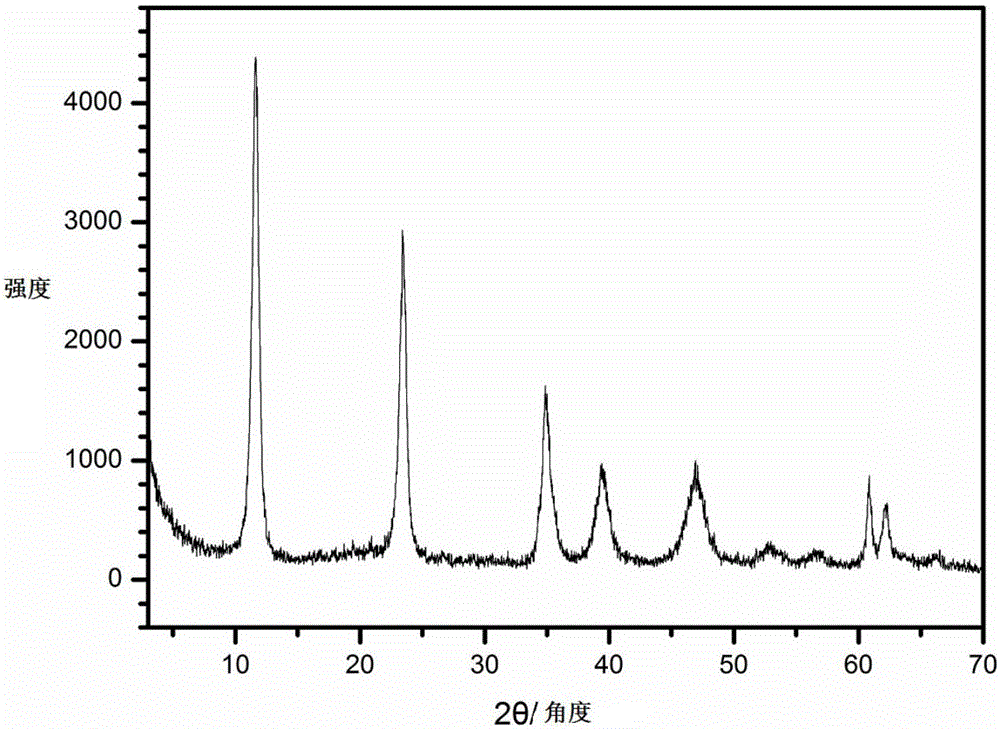

Preparation method of LDHs (magnesium-based layered double hydroxides)

ActiveCN105753022ARich sourcesLow priceAluminium-carbonate compoundsZinc compoundsMagnesium saltCalcium magnesium

The invention provides a preparation method of LDHs (magnesium-based layered double hydroxides). According to the method, calcium oxides or calcium magnesium oxides are used as an alkali source, calcium oxides or calcium magnesium oxides and a magnesium salt are subjected to a precipitation reaction, magnesium hydroxide precipitates are produced, then the magnesium hydroxide precipitates and divalent and trivalent soluble metal nitrates or chlorides are used as raw materials, LDHs are prepared through a liquid-solid phase reaction, and byproducts, namely, magnesium chlorides or magnesium nitrates, can be used as raw materials. The method has the advantages that the raw materials are rich in source, the price is low, the preparation process is simple, reaction conditions are mild, industrial production is facilitated and the like, and prepared LDHs can be widely applied to fields of catalysis, adsorption, environmental protection, high-polymer plastic and the like.

Owner:BEIJING UNIV OF CHEM TECH

Aldol condensation reaction solid base catalyst and application

ActiveCN102019177AReduce usageReduce Disposal EmissionsOrganic compound preparationCarbonyl compound preparationAlkali metal oxideGas phase

The invention relates to an aldol condensation reaction solid base catalyst and application. A composite oxide is used as a carrier which carries at least one alkali metal oxide in the catalyst, the composite oxide is a titanium oxide-aluminum oxide composite oxide or a zirconium oxide-aluminum oxide composite oxide, the mass percentage of Ti or Zr in the composite oxide is 0.1 to 30 percent, thealkali metal oxide is calcium oxide or magnesium oxide, and the mass percentage of the alkali metal in the catalyst is 0.1 to 40 percent; a fixed bed reactor is adopted, aliphatic aldehyde is contacted with the catalyst under a liquid phase condition at the temperature of between 60 and 260 DEG C to generate unsaturated aldehyde by reaction, and the catalyst is solid, so alkali aqueous solution is avoided, treatment and discharge of organic waste water are reduced, and the catalyst has excellent catalytic performance for the aldol condensation reaction; and particularly, the catalyst has goodstability, the reaction temperature is low compared with gaseous phase reaction, and the reaction result is superior to the reaction result under the gaseous phase reaction condition.

Owner:PETROCHINA CO LTD

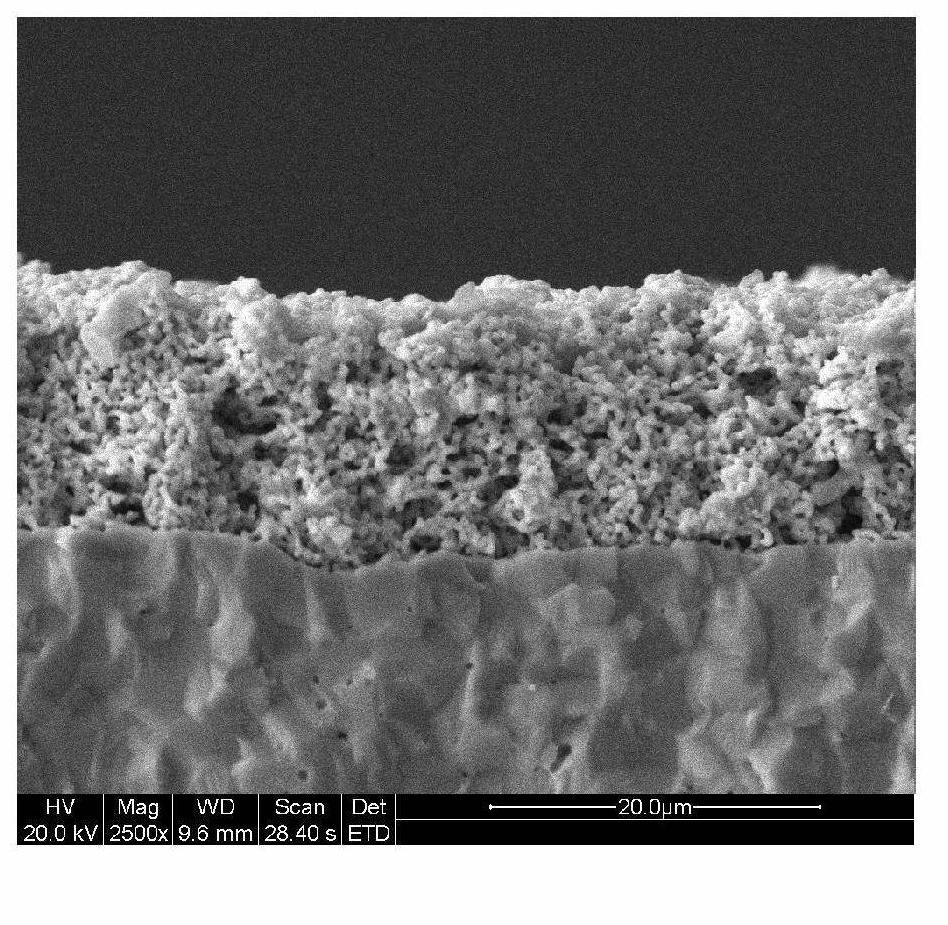

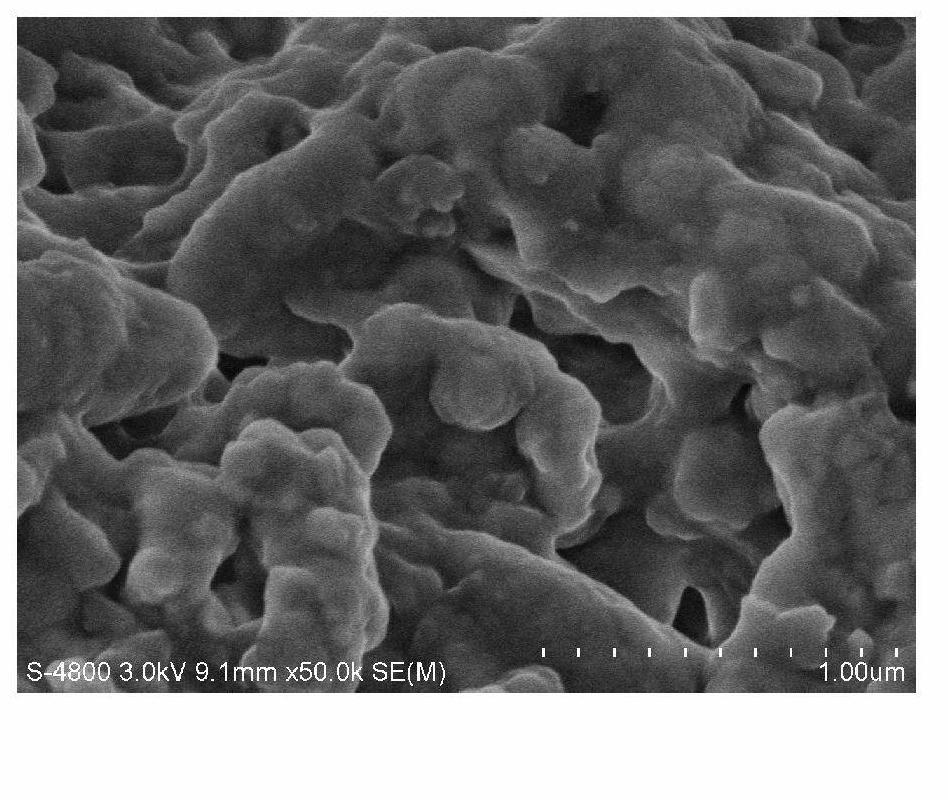

Solid oxide fuel cell composite cathode and preparation method thereof

InactiveCN102683722AHigh porosityImprove thermal stabilityCell electrodesAir atmosphereComposite cathode

The invention belongs to the field of solid oxide fuel cells and particularly relates to a solid oxide fuel cell composite cathode and a preparation method thereof, wherein the solid oxide fuel cell composite cathode has a high electrochemistry performance and is stable in long-time operation. The preparation method includes the following steps of step one, preparing a three-dimensional porous skeleton made of electrolytic materials at a high temperature; step two, preparing a powder suspension or a nitrate solution of a cathode material; step three, impregnating the powder suspension or the nitrate solution into the porous skeleton and then calcinating the porous skeleton; step four, repeating the operation of the step 3 for a plurality of times until the impregnating quantity reaches the requirement; step five, performing high temperature sintering under an air atmosphere to obtain the three-dimensional composite cathode with a core-shell structure. According to the solid oxide fuel cell composite cathode and the preparation method thereof, the process is simple, expensive experiment apparatuses are not required, the obtained composite cathode is of the core-shell structure, a core is the electrolytic skeleton, a shell is a phase reaction layer with a stable nano thin film structure, and the problem that the performance is attenuated due to the fact that nano particles of the solid oxide fuel cell composite cathode prepared by an impregnating method are low in stability and easy to sinter is solved.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com