Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2891 results about "Magnesium salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium Salts (technically called Magnesium Chloride), is the compound you find in all Magnesium supplements and it has a different molecular structure than Epsom Salts. The molecular structure of Magnesium Chloride is much more easily absorbed into the body than that of Epsom Salt.

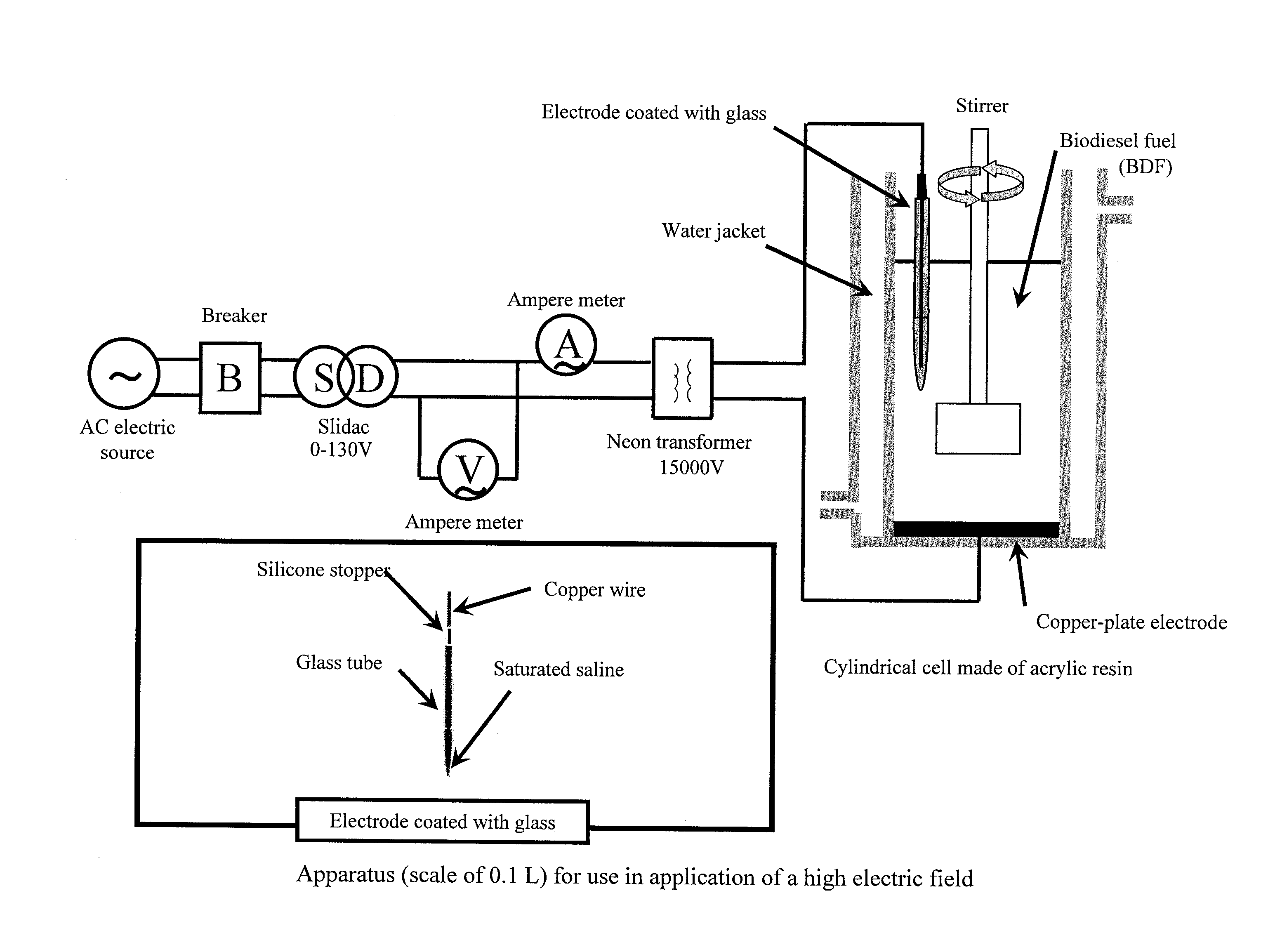

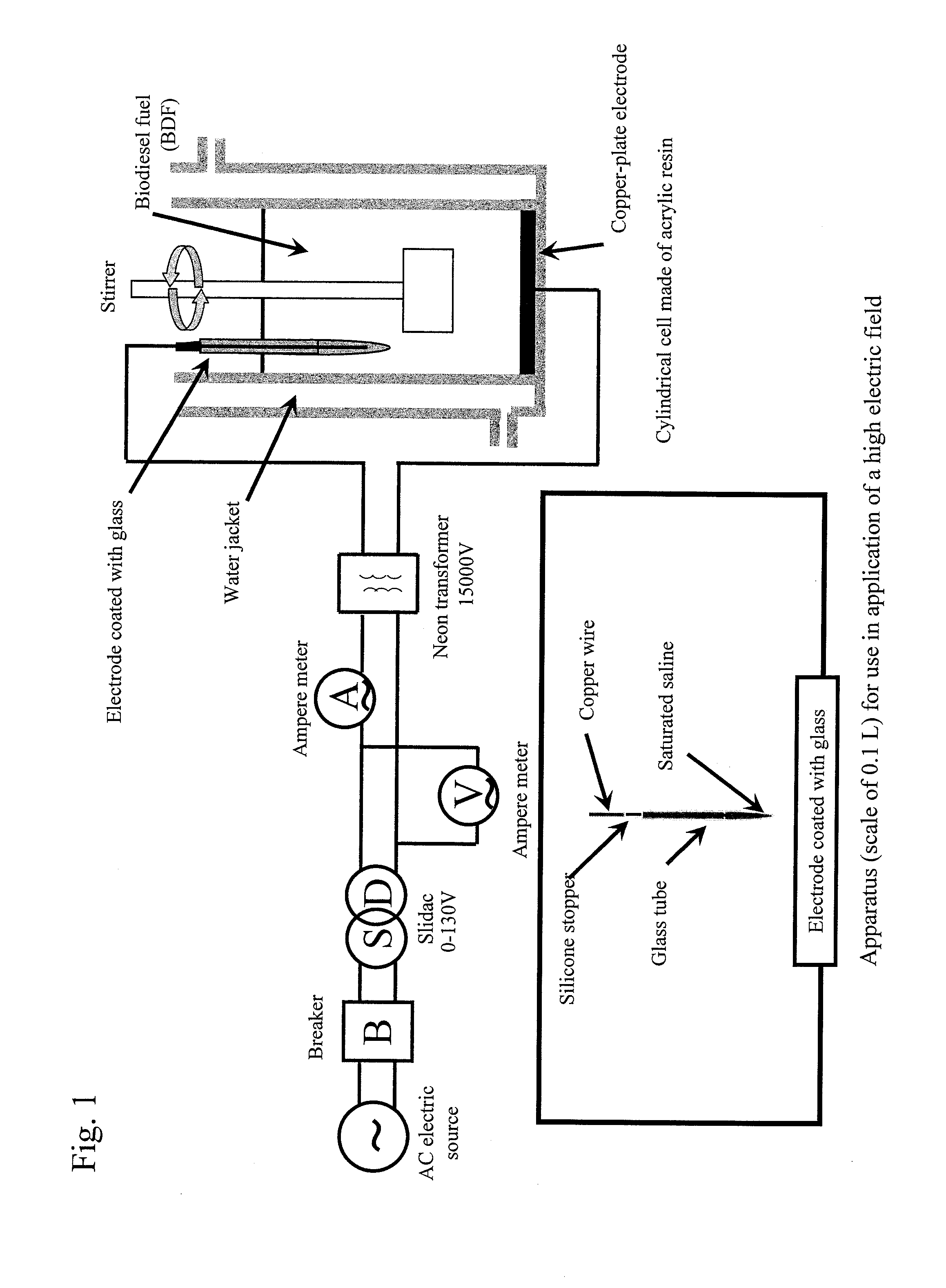

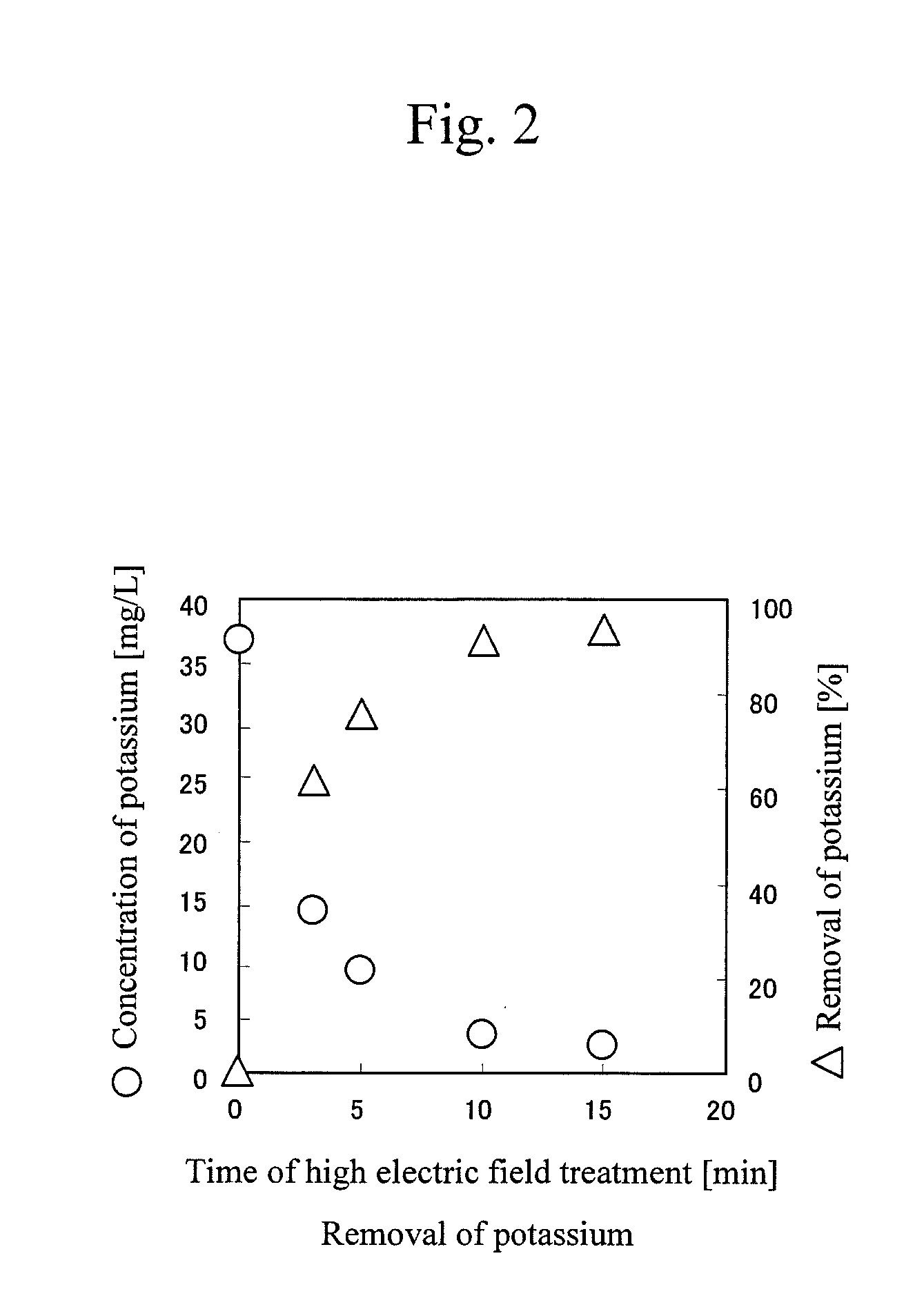

Method for purifying biodiesel fuel

InactiveUS20090025277A1Preventing and greatly reducing generationWater/sewage treatment by irradiationLiquid separation by electricityDemulsifierBiodiesel

Provided is a method for purifying a biodiesel fuel while completely preventing or greatly reducing generation of waste water. The present invention relates to a method for purifying a biodiesel fuel characterized by applying an electric field to or heating a crude biodiesel fuel and a method for purifying a biodiesel fuel characterized by adding water (preferably containing a demulsifier such as an inorganic calcium salt or a magnesium salt) to a crude biodiesel fuel to form W / O emulsion, and breaking the emulsion by application of an electric field or heating, etc.

Owner:KAGOSHIMA UNIV

Copper bismuth catalyst and preparation method thereof

ActiveCN102658158AImprove wear performanceExtended service lifeOrganic compound preparationHydroxy compound preparationCooking & bakingAlcohol

The invention relates to a copper bismuth catalyst for combining chemically into 1, 4-butynediol with formaldehyde and ethyne and a preparation method thereof. The preparation method comprises the following steps of: preparing mixed solution which contains copper salt, bismuth salt, magnesium salt and dispersant; dropping alcoholic solution with an organic silicon source into the mixed solution; adjusting a pH value of the mixed solution with alkaline solution to obtain mixed precipitate; and further aging, washing, drying and baking in inert atmosphere to obtain the copper bismuth catalyst with C-MgO-SiO2 a carrier, in the catalyst, the content of CuO accounts for 25-50 weight percent, and the content of Bi2O3 accounts for 2-6 weight percent. The catalyst is applied in a reaction of combining chemically into 1, 4-butynediol with formaldehyde and ethyne, and has high catalytic activity and high selectivity.

Owner:SHANXI UNIV

Pharmaceutical composition and method for the transdermal delivery of magnesium

InactiveUS20050196434A1Reduce disadvantagesBiocideAerosol deliveryAutonomic bladder dysfunctionMagnesium salt

The present invention relates to a method and transdermal pharmaceutical composition for preventing magnesium deficiency or imbalances associated with magnesium deficiency including diabetes, hypertension, high cholesterol, cardiac arrhythmias, acute myocardial infarction, arteriosclerosis, atherosclerosis, preeclampsia, dysautonomia, mitral valve prolapse, asthma, constipation, irritable bowel syndrome, migraines, muscle spasms and cramping, premenstrual syndrome, osteoporosis, kidney stones, chronic fatigue syndrome, and fibromyalgia. The transdermal pharmaceutical composition includes a therapeutically effective amount of a pharmaceutically acceptable salt of magnesium and a pharmaceutically acceptable carrier. A therapeutically effective amount of a pharmaceutically acceptable salt of zinc a vitamin such as B-complex vitamin, a carotenoid, a mineral, or a combination thereof may also be included in the transdermal pharmaceutical composition. A therapeutically effective amount of progesterone may also be included in the transdermal pharmaceutical composition. The transdermal pharmaceutical composition may be topically administered to prevent magnesium deficiency or imbalances caused by magnesium deficiency.

Owner:BRIERRE BARBARA T

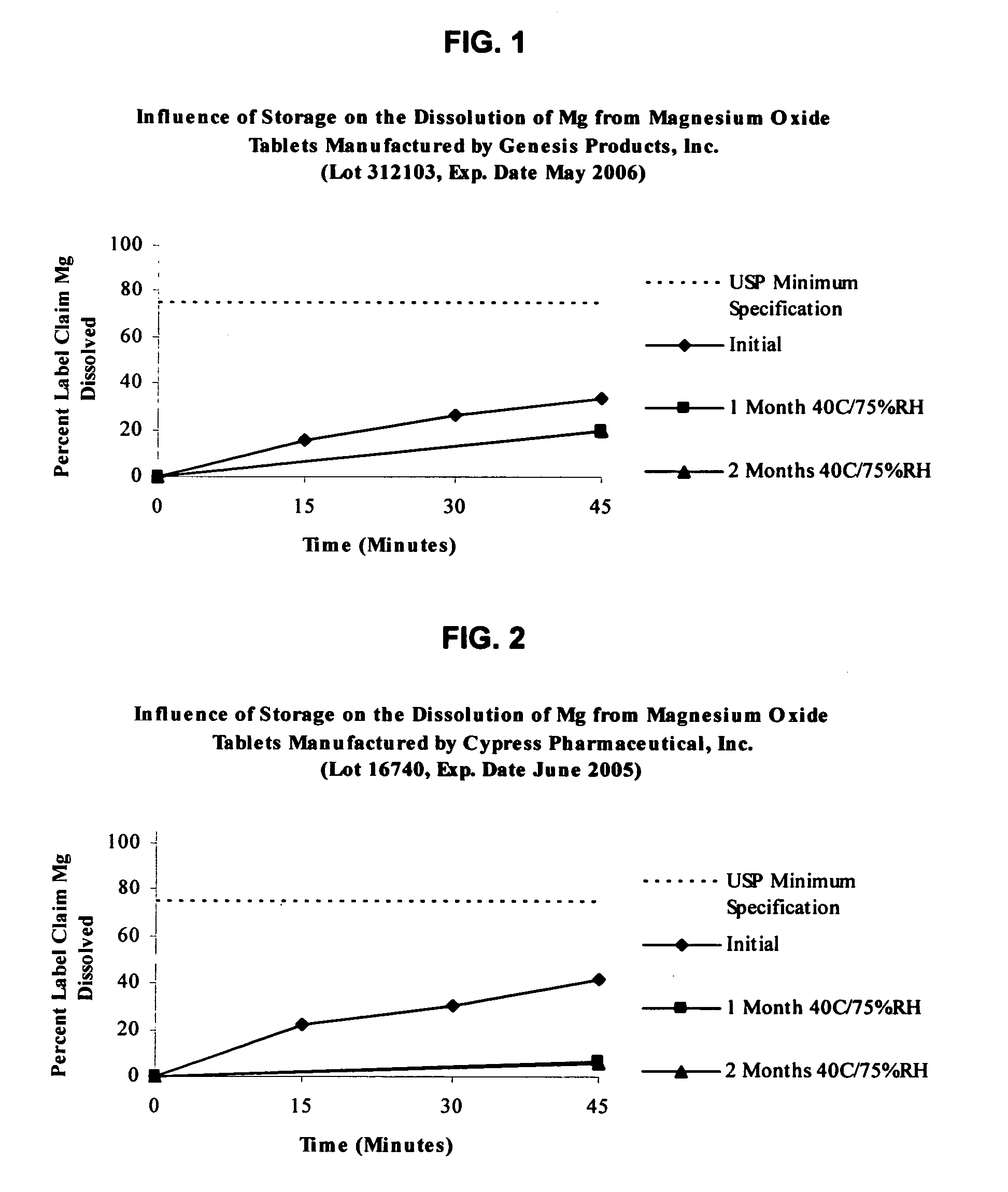

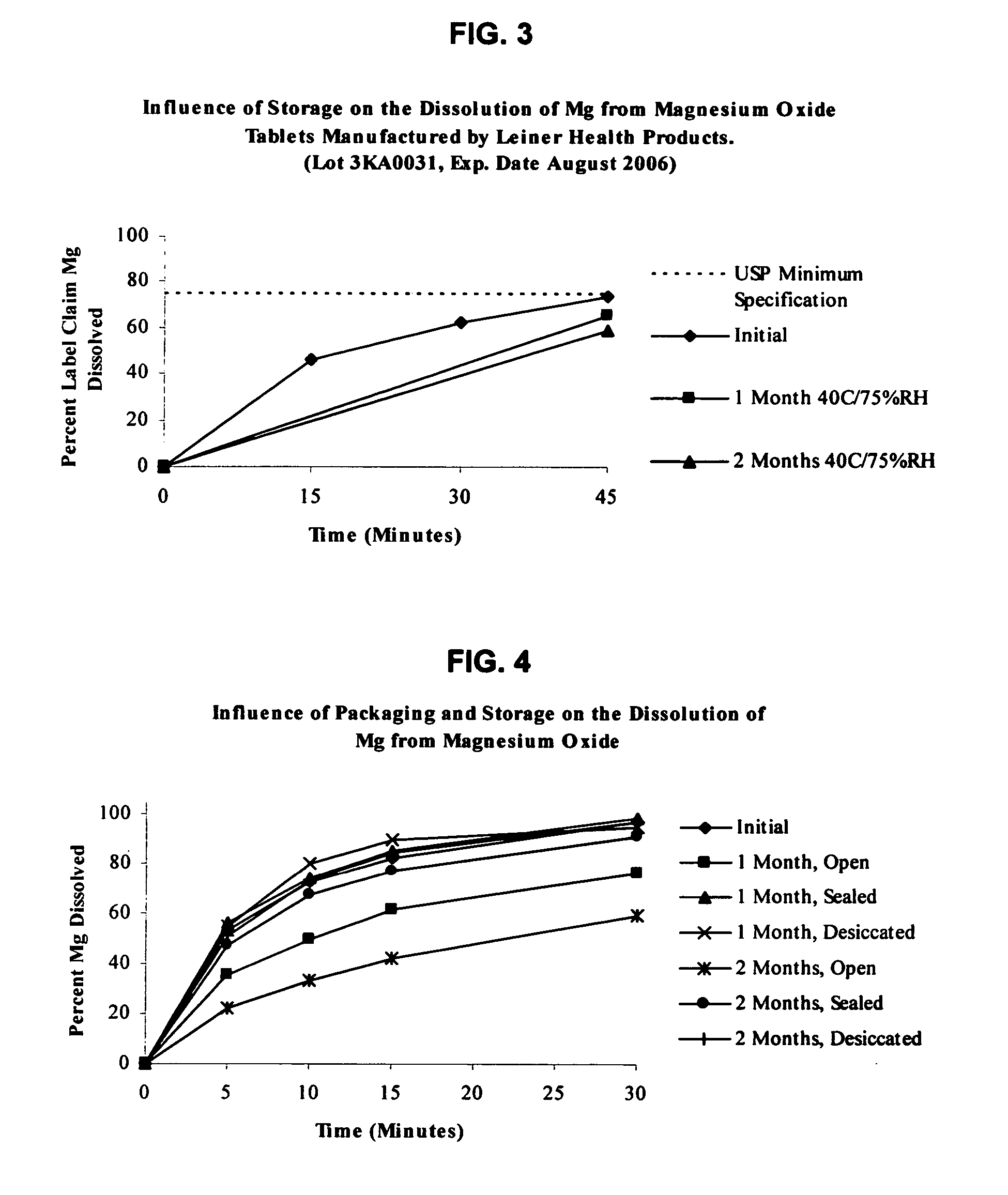

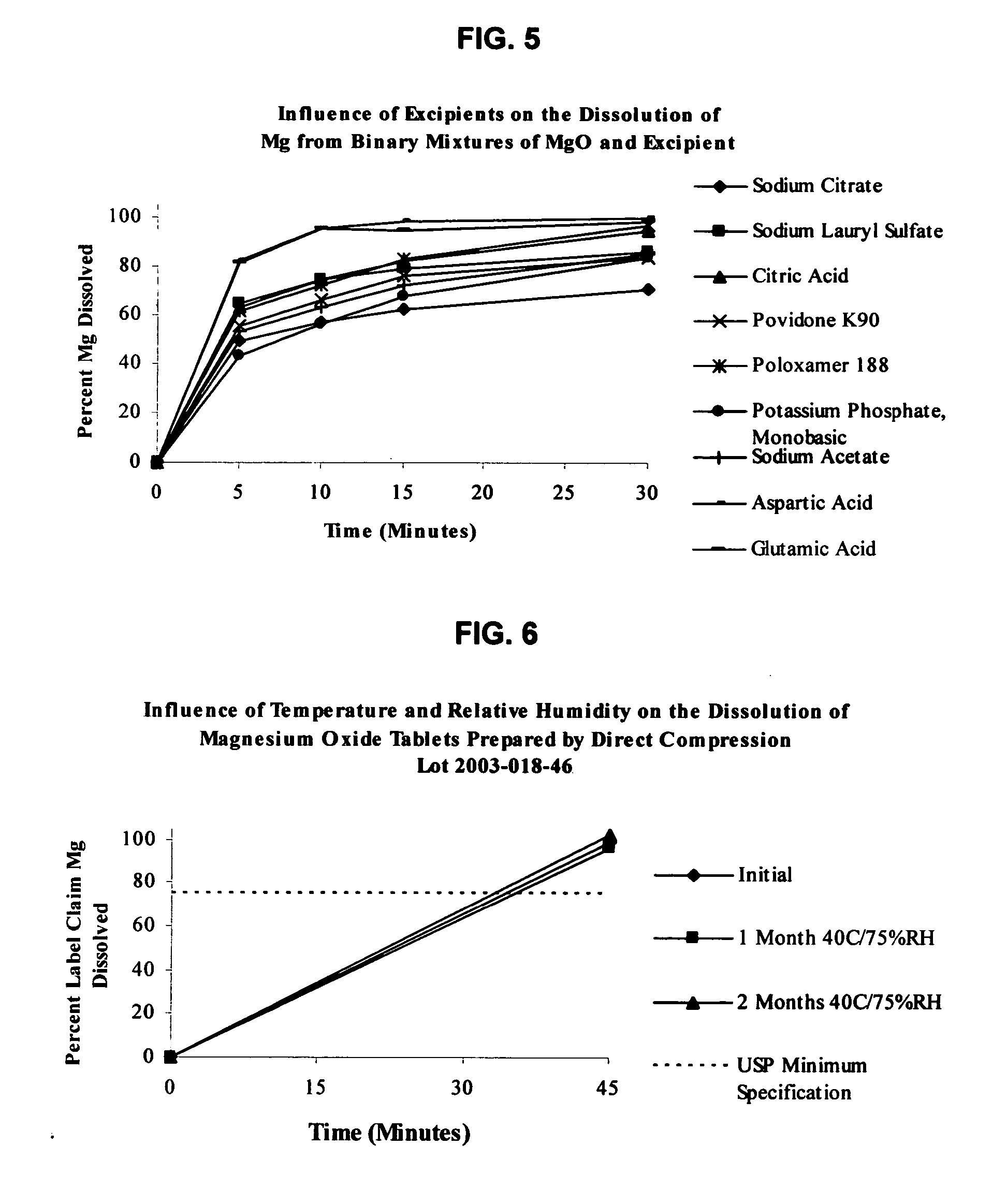

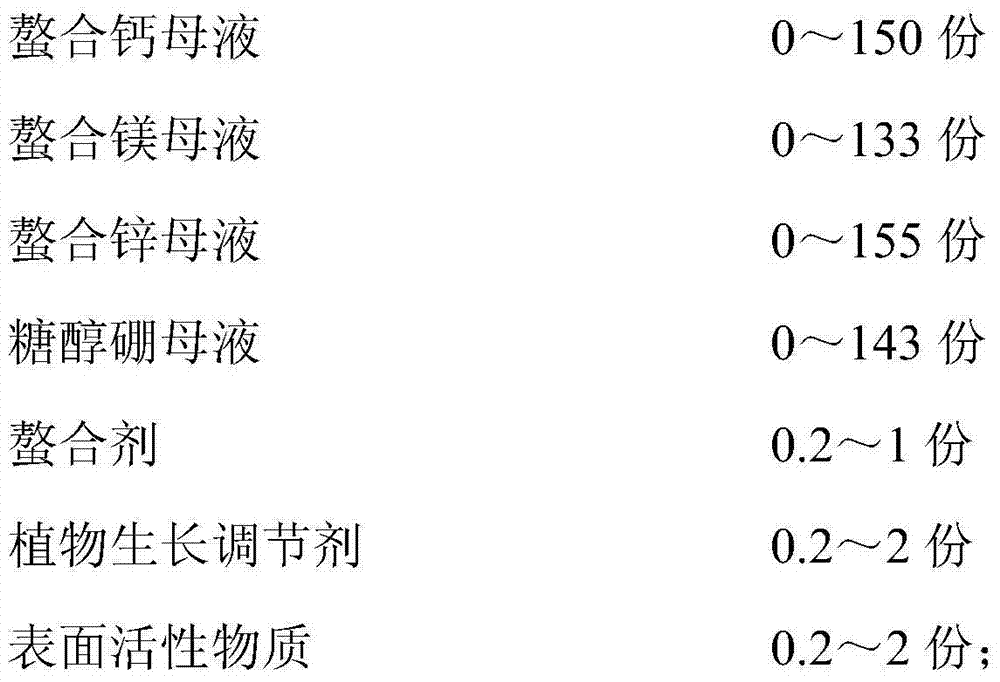

Compressed composition comprising magnesium salt

InactiveUS20050220865A1Stable dissolution profileDisintegrates quicklyBiocidePill deliveryInorganic saltsCellulose

An oral solid compress composition comprising a magnesium salt is provided. The composition provides a rapid dissolution of the magnesium salt, wherein not less than 75% of the magnesium salt dissolves within 45 minutes after placement in hydrochloric acid (0.1 N, 900 mL) as per USP Method <711>. In a particular embodiment, the magnesium salt is an inorganic salt such as MgO, Mg(OH)2, MgCl2, and others. The composition can be prepared by dry granulation, direct compression or another suitable process. The composition provides a substantially stable dissolution profile for the magnesium salt so that the dissolution profile changes only minimally even after an extended period of storage under pharmaceutically acceptable conditions when packaged in a sealed container-enclosure system. The solid composition may also exclude a cellulose-based composition. The compressed composition can be prepared and stored under anhydrous conditions.

Owner:BLAINE PHARMA

Electrolyte purgative

ActiveUS20050271749A1Reduce the amount requiredIncreased tonicityOrganic active ingredientsBiocideMagnesium saltPotassium

The invention relates to compositions for use in purgatives, to purgatives comprising such compositions, and to methods for inducing purgation of the colon. The composition may comprise at least one water-soluble sodium salt; at least one water-soluble minimally degradable sugar in an amount, by weight, of from about 1 to about 3 times the weight of sodium ions in said composition; at least one water-soluble potassium salt in an amount, by weight, of from about 0.05 to about 1 time the weight of said sodium salt in said composition; and at least one water-soluble magnesium salt, wherein the weight of magnesium ions in said composition is from 0.1 to about 10 times the weight of sodium ions in said composition.

Owner:RITE PREP PTY LTD AS TRUSTEE FOR THE RITE PREP UNIT TRUST

Sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and preparation method and applications thereof

ActiveCN103588564AAvoid reactionAchieve preparationFertilizer mixturesHigh concentrationMagnesium salt

The invention belongs to the field of agricultural production and discloses a sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and a preparation method and application thereof. The liquid fertilizer is prepared from various mother solutions, a chelating agent, a plant growth regulator and surface active materials. The preparation method comprises the following steps: causing sugar alcohol to respectively react with calcium salt, magnesium salt, zinc salt and boric acid to prepare calcium, magnesium, zinc and boron mother solutions, then mixing the mother solutions according to a certain ratio, and adding the chelating agent to cause the mother solutions to carry out secondary chelating reaction; after a while, adding the plant growth regulator and the surface active materials into reaction liquid, uniformly mixing, and cooling to the room temperature to obtain the high-concentration, stable and good-effect compound liquid fertilizer. The prepared liquid fertilizer provides adequate calcium, magnesium, zinc and boron and other nutrients for plants and can also carry out mixing of different elements and proportions according to the needs of different plants and different growth stages of plants.

Owner:SOUTH CHINA AGRI UNIV +1

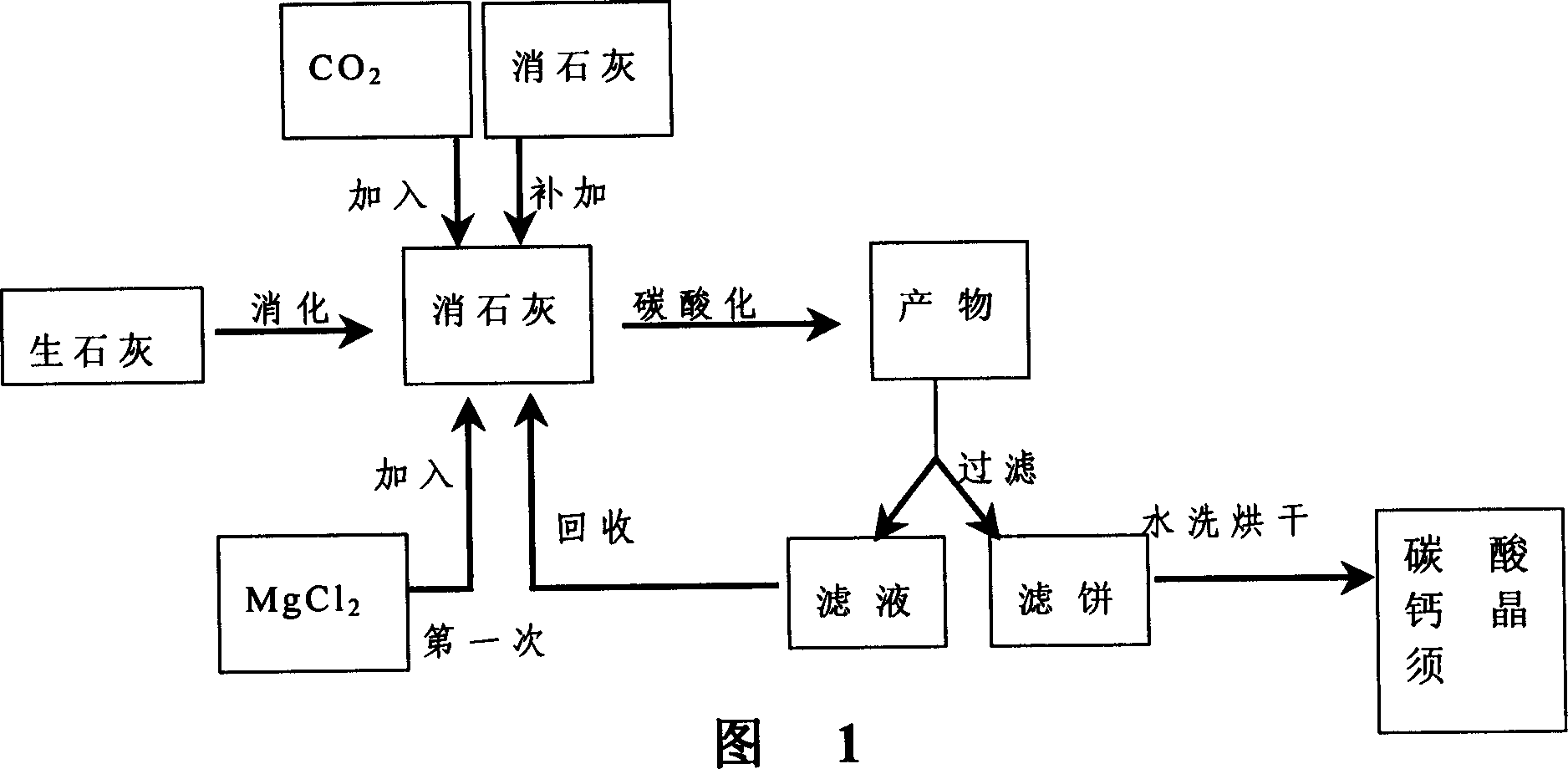

Method for preparing aragonite type calcium carbonate whisker

InactiveCN1641077AReduce manufacturing costReduce qualityCalcium/strontium/barium carbonatesPolycrystalline material growthMagnesium saltDiameter ratio

The present invention relates to the preparation process of high purity aragonite type calcium carbonate whisker. The present invention prepares aragonite type calcium carbonate whisker with lime or slaked lime as main material and magnesium salt as crystal salt controlling agent and through a CO2 carbonating process. The process features the repeated use of the magnesium salt solution and the homogeneous replenishment of lime slurry during carbonating reaction. The process has low production cost, less environmental pollution and high calcium carbonate whisker yield, and the prepared calcium carbonate whisker has high purity and high length / diameter ratio. The process is suitable for industrial production of calcium carbonate whisker.

Owner:NAT UNIV OF DEFENSE TECH

Pharmaceutical Compositions and Methods of Treating Neurological Insults

InactiveUS20110318431A1Sufficient amountPromote functional recoveryBiocideNervous disorderMANNITOL/SORBITOLMagnesium salt

A pharmaceutical composition containing a magnesium salt and an osmotic hypertonic agent, like a mannitol, is disclosed. Also disclosed are methods of treating individuals who have suffered a neurological insult, such as traumatic brain injury.

Owner:ENDOGENX

Oxygen delignify treating method for grass group unbleached chemical pulp

ActiveCN101082187ALow percussionImprove water filtration performanceCellulosic pulp after-treatmentPulping with inorganic basesCelluloseMagnesium salt

The invention relates to an oxygen delignification processing method of grass unbleached chemical pulp. The oxygen delignification of the pulp is processed after cooking and before bleaching. Its rigidity before the oxygen delignification is potassium permanganate value 16-28 (equals to karber value 26-50). After pumping into the oxygen delignification reaction tower and inflating sodium hydroxide, magnesium salt and oxygen, the chemical pulp happen the oxygen delignification in the reaction tower. The chemical pulp with rigidity of potassium permanganate value 10-14 (equals to karber value 14-18) is achieved after the oxygen delignification. The invention can remove the lignin in the pulp effectively and the removal rate is 86-98%. It reduces the degradation of the cellulose to simplify the bleaching process and cut down the dosage of the chemicals. The bleached pulp has good rigidity and drainability. The breaking length of the pulp can reach 4500-8000m and its fold-resistant times can reach 20-70.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

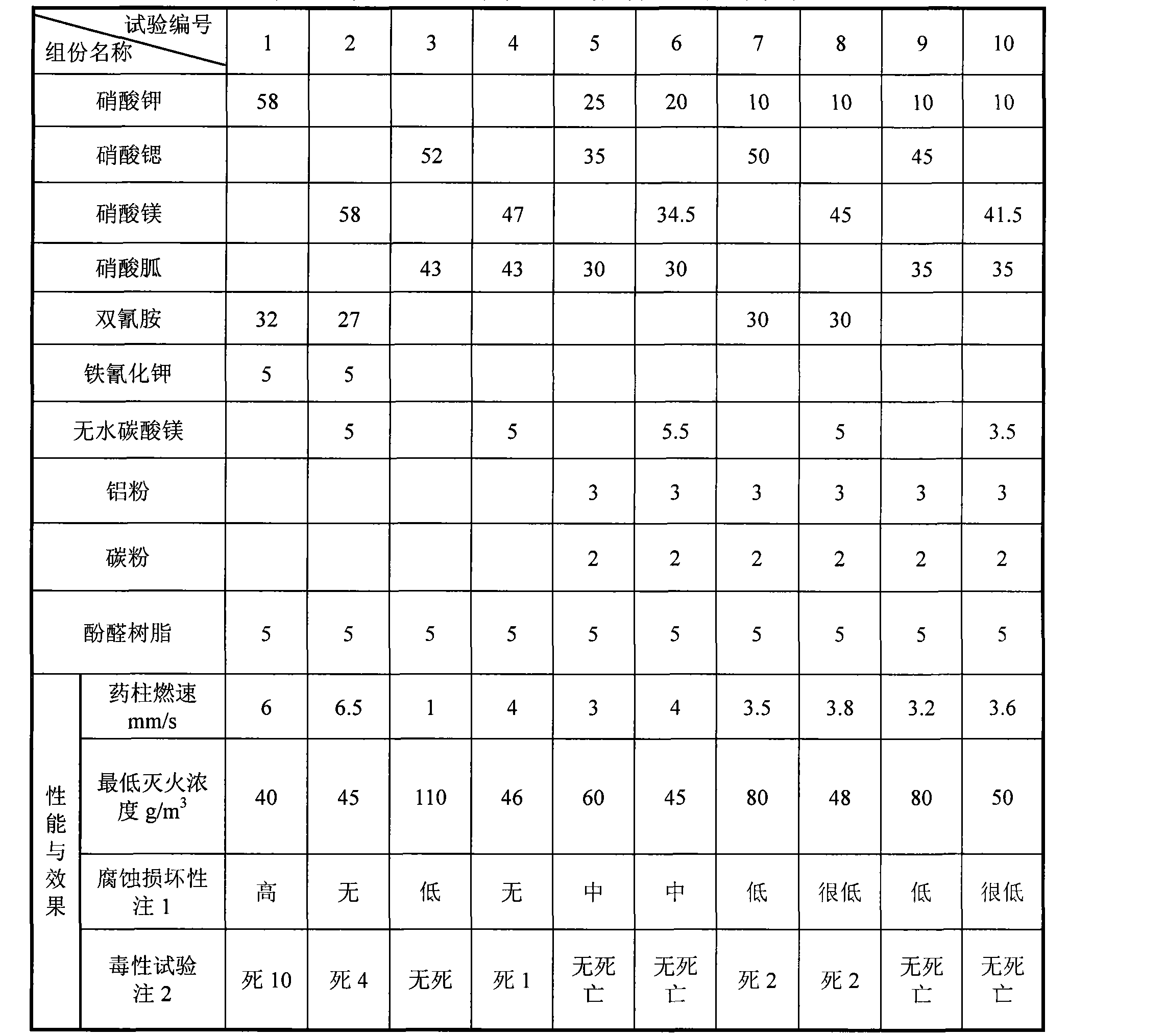

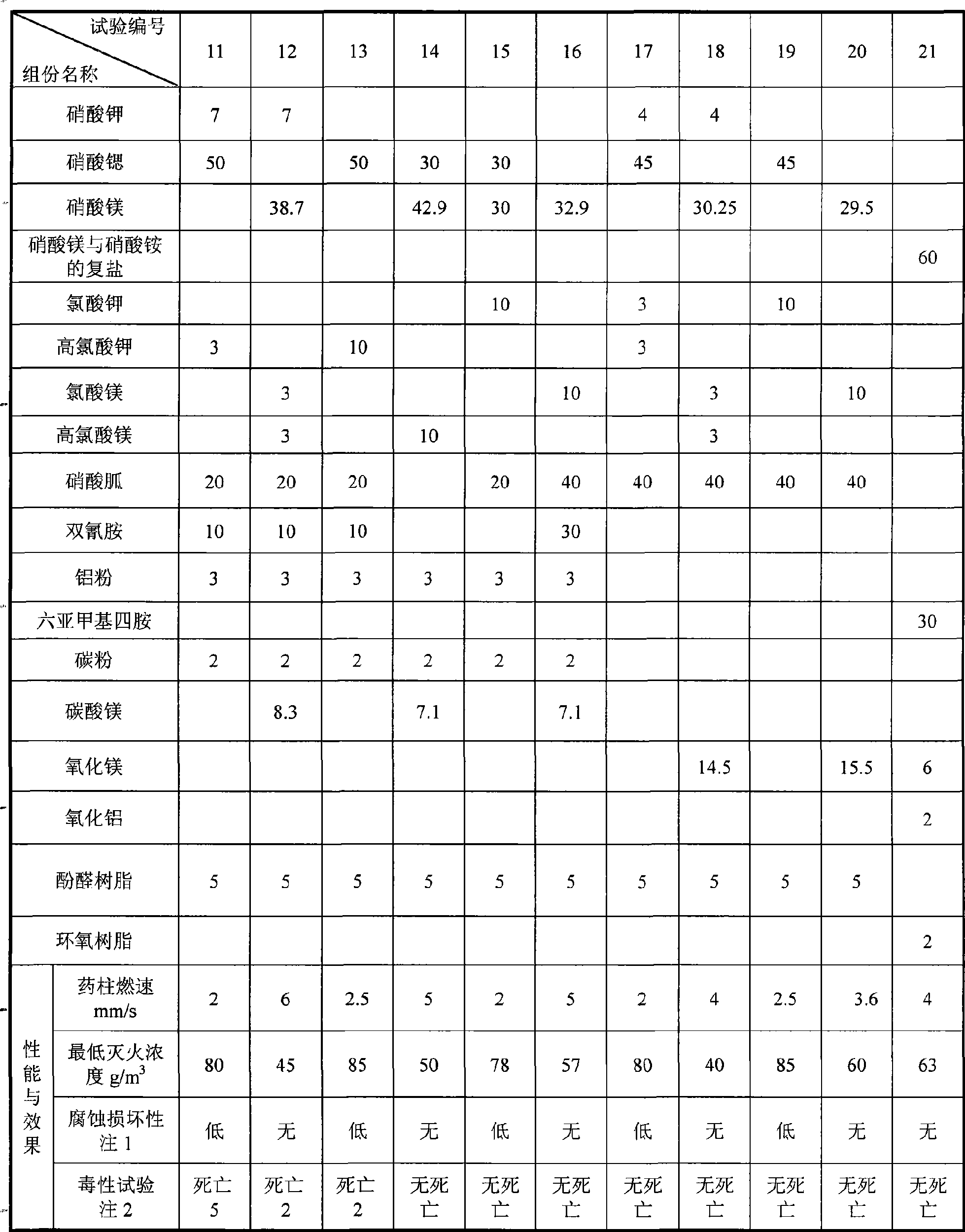

Extinguishment combination with hot gas sol

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Silica-magnesium fluoride hydrate composite sols and process for their preparation

InactiveUS6291535B1Low refractive indexEasy to prepareMagnesium fluoridesMaterial nanotechnologyOrganic solventMagnesium salt

A sol comprising silica-magnesium fluoride hydrate composite colloidal particles used in an anti-reflection coating material for forming an anti-reflection coating and a process for its preparation are provided. A sol comprising silica-magnesium fluoride hydrate composite colloidal particles having a ratio of silica to magnesium fluoride hydrate MgF2.nH2O, n being in the range between 0.25 and 0.5, in terms of a SiO2 / MgF2 weight ratio of from 0.01 to 5 and a primary particle size of 5 to 50 nm. A process for the preparation of an aqueous sol comprising silica-magnesium fluoride hydrate composite colloidal particles which comprises the steps of adding an aqueous fluoride solution to a mixture liquid of a silica sol and an aqueous magnesium salt solution to produce a slurry of an agglomerate comprising silica-magnesium fluoride hydrate composite colloidal particles and removing the salts formed as by-products. A process for the preparation of an organosol further comprising the step of replacing water in the aqueous sol with an organic solvent.

Owner:NISSAN CHEM IND LTD

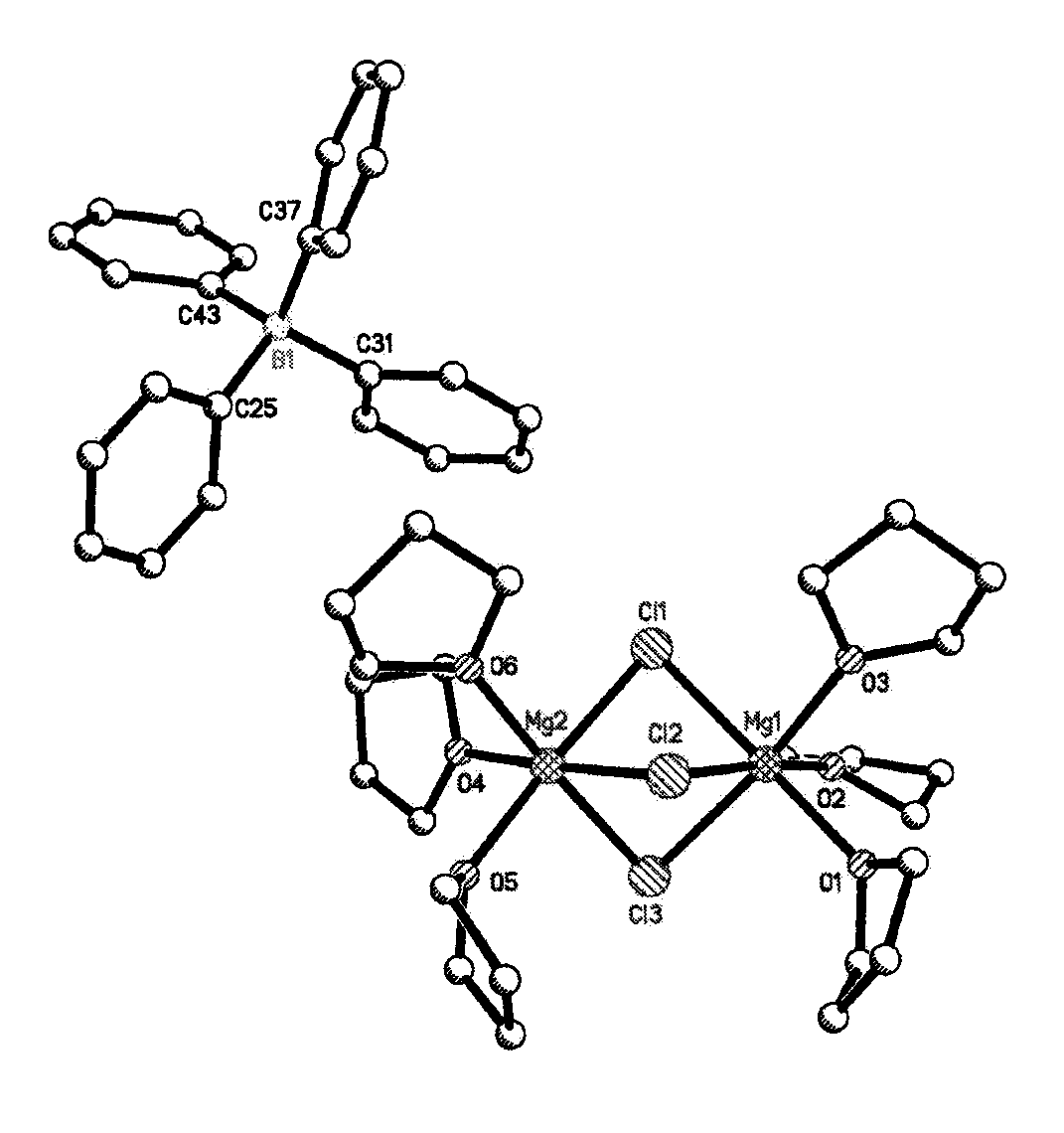

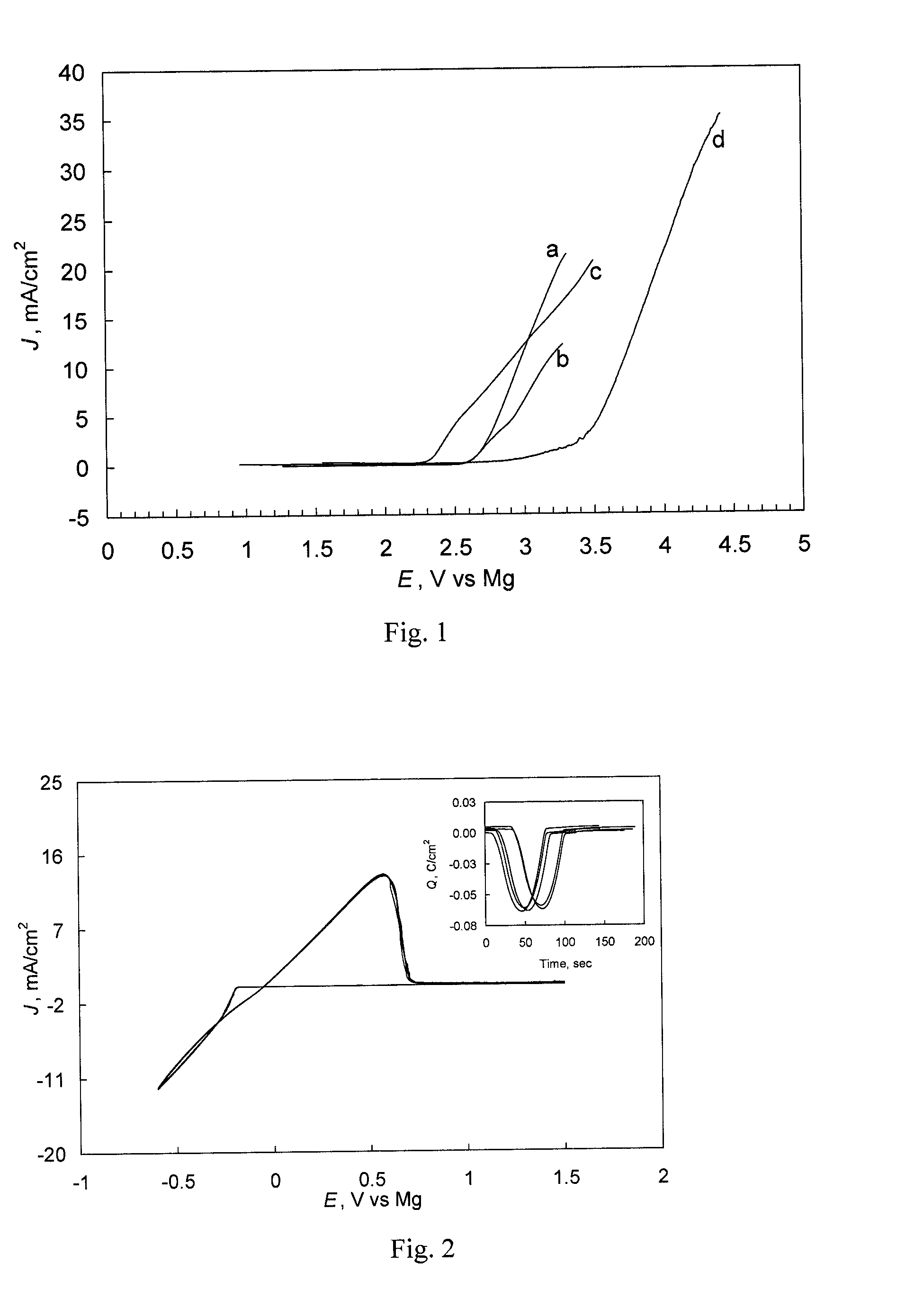

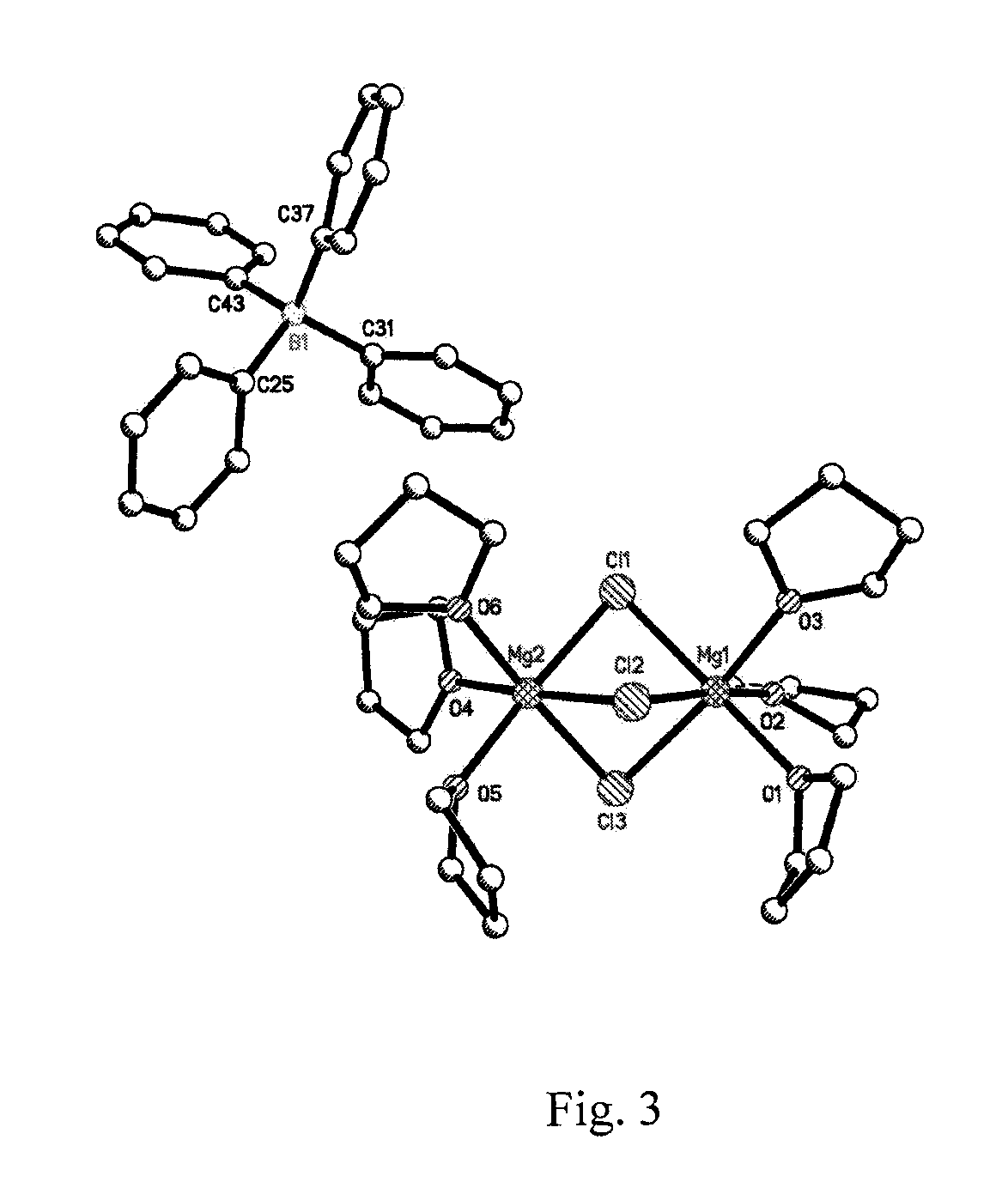

Electrolyte for magnesium battery

InactiveUS20130034780A1Safe handlingReduce environmental impactCell electrodesOrganic electrolyte cellsMagnesium saltGrignard reagent

A magnesium battery, having an anode containing magnesium; a cathode stable to a voltage of at least 2.6 V relative to a magnesium reference; and an electrolyte containing an electrochemically active magnesium salt obtained by reaction of a Grignard reagent or Hauser base with a boron compound of formula BR3 is provided. The electrolyte is stable to 2.6 E.V. vs. Mg in the presence of stainless steel.

Owner:TOYOTA JIDOSHA KK

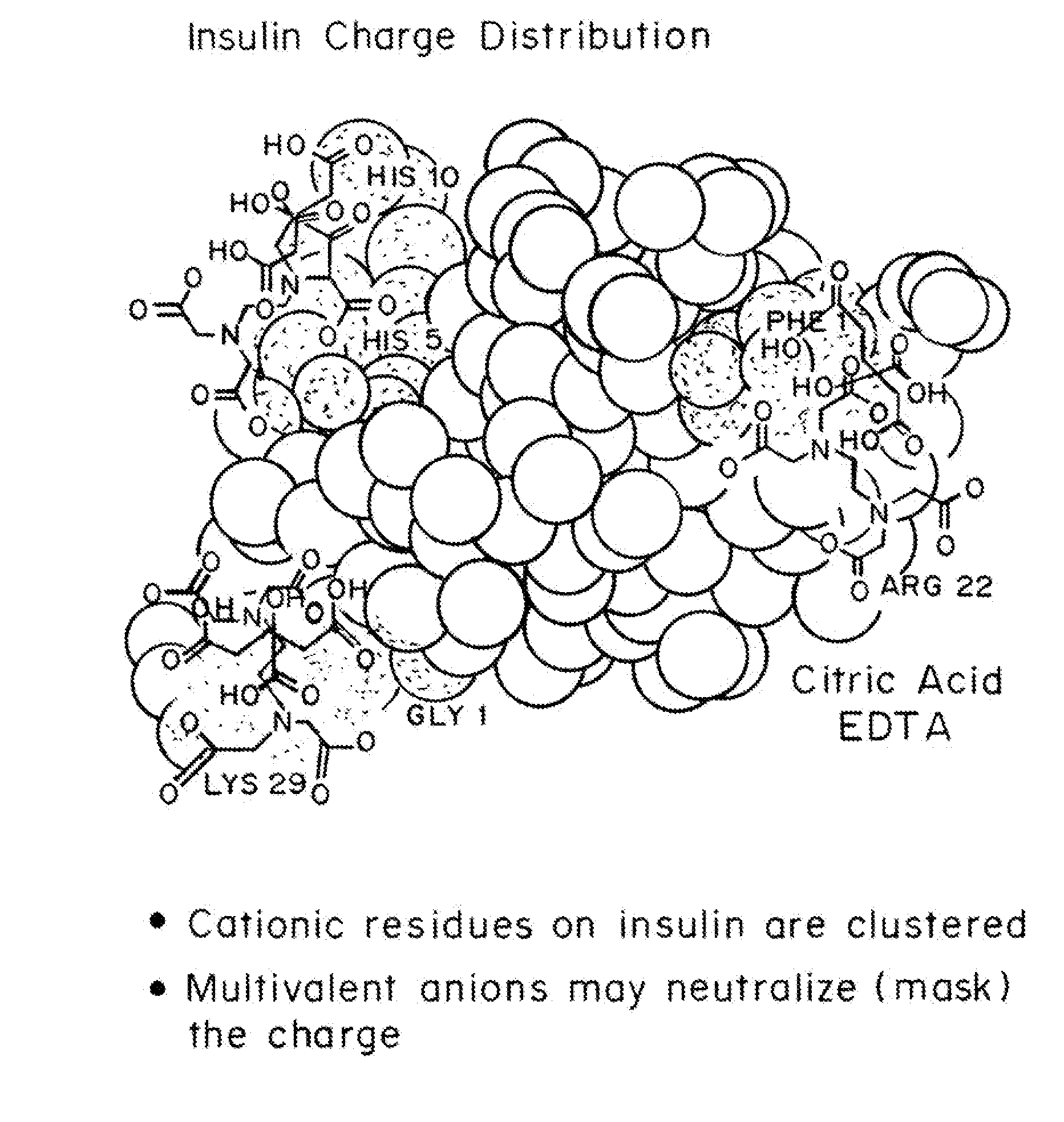

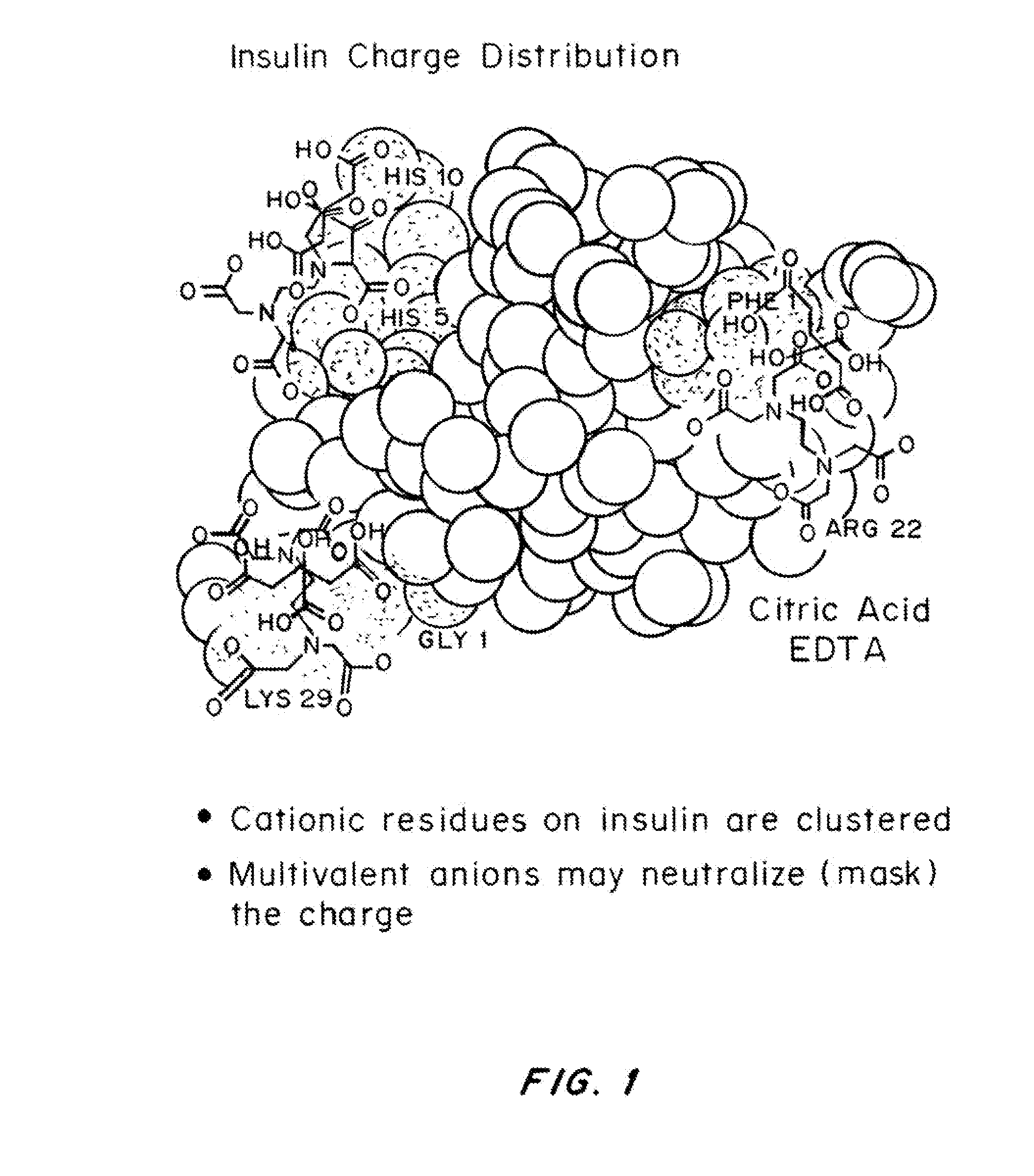

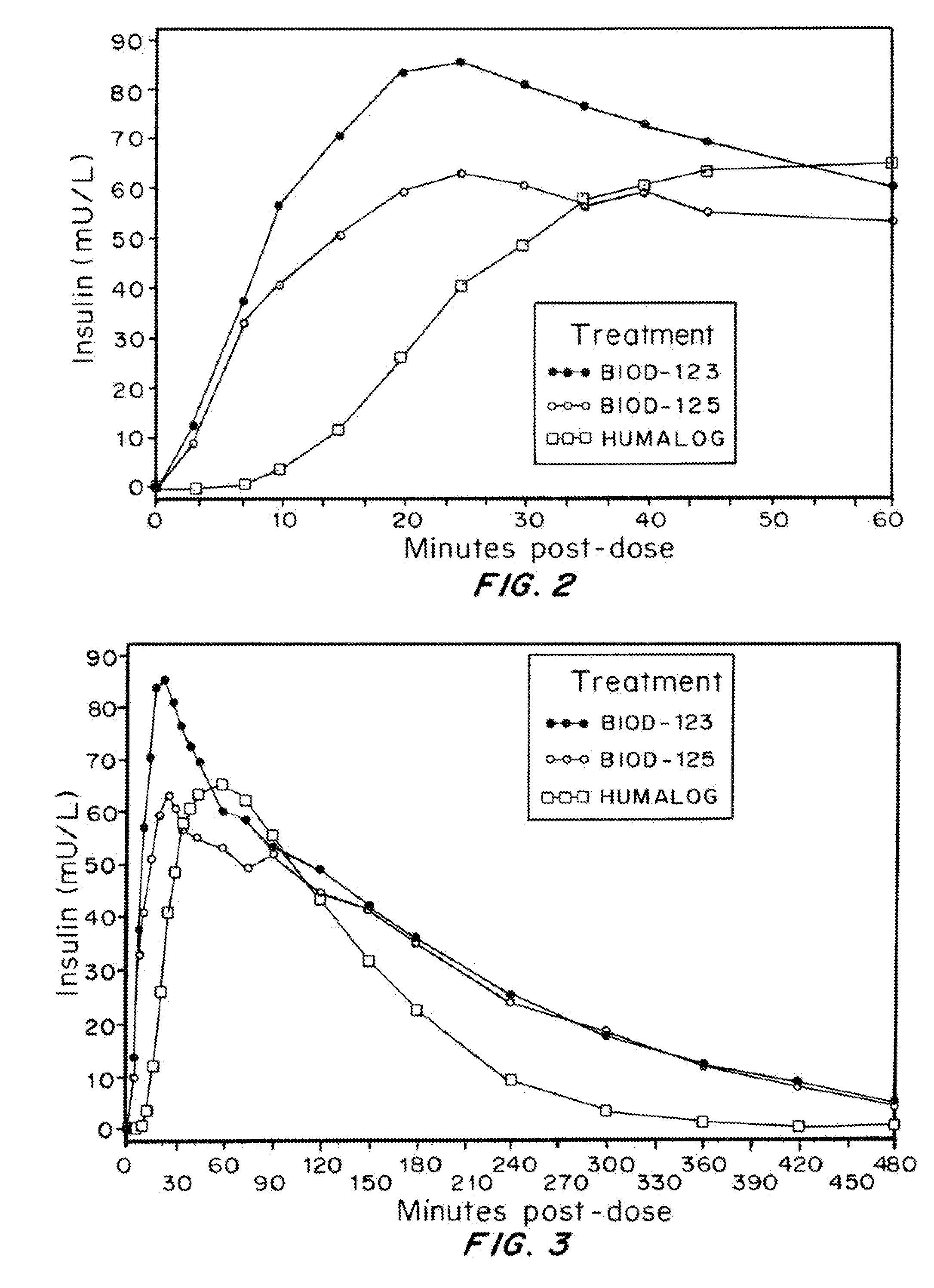

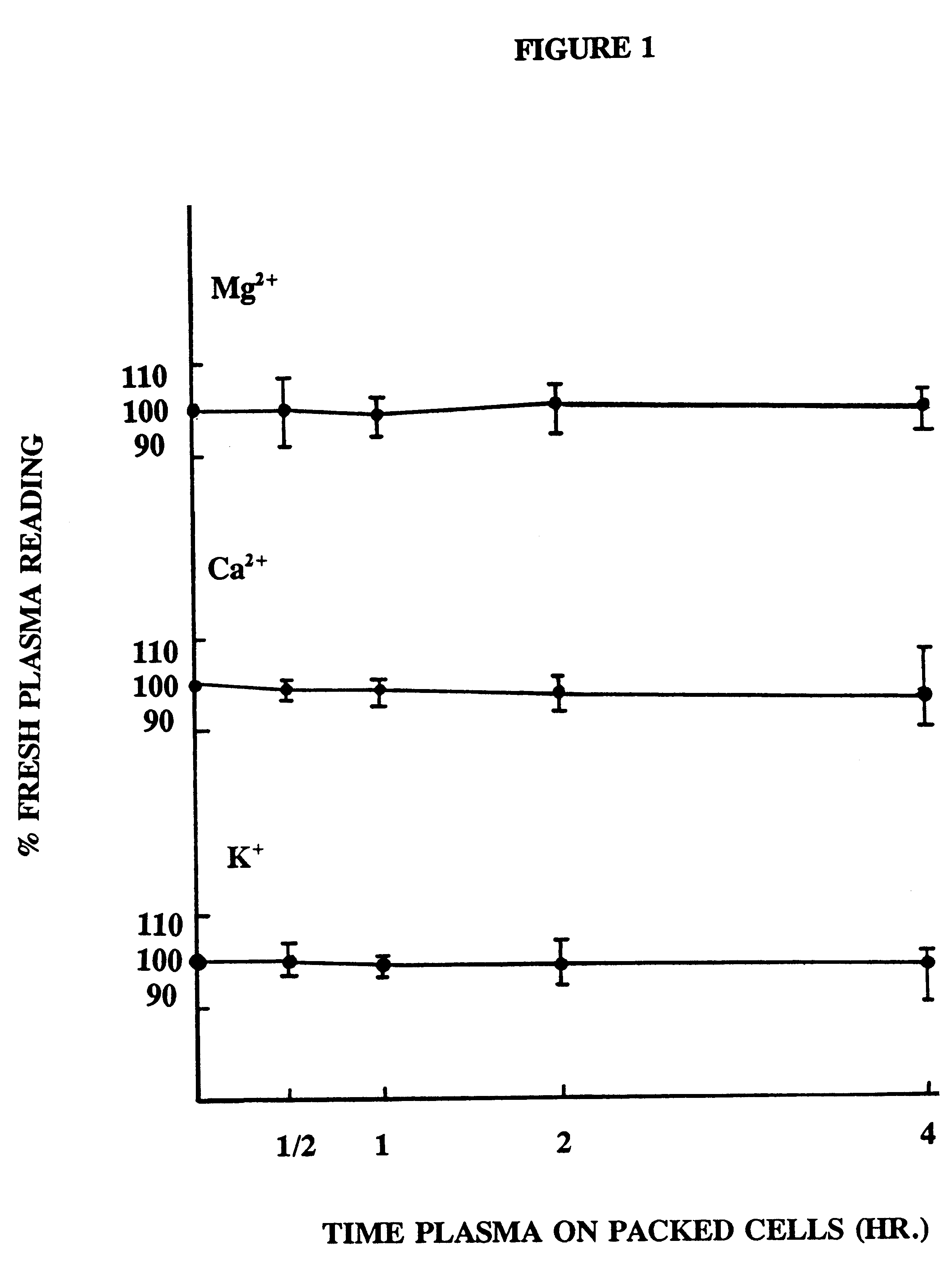

Magnesium Compositions for Modulating the Pharmacokinetics and Pharmacodynamics of Insulin and Insulin Analogs, and Injection Site Pain

ActiveUS20140113856A1Improved injection site tolerabilityPeptide/protein ingredientsMetabolism disorderEthylenediamineMagnesium salt

Compositions and methods for modulating injection site pain associated with rapid acting injectable insulin formulations have been developed for subcutaneous injection. The formulations contain insulin in combination with a zinc chelator such as ethylenediaminetetraacetic acid (“EDTA”), a dissolution / stabilization agent such as citric acid, a magnesium salt, and, optionally, additional excipients. New presentations include rapid acting concentrated insulin formulations and a way to enhance the absorption of commercially available rapid acting analog formulations by mixing them with a vial containing dry powder excipients that accelerate their absorption. Devices for mixing excipient and insulin together at the time of administration, while minimizing residence time of the mixture, are also described.

Owner:ELI LILLY & CO

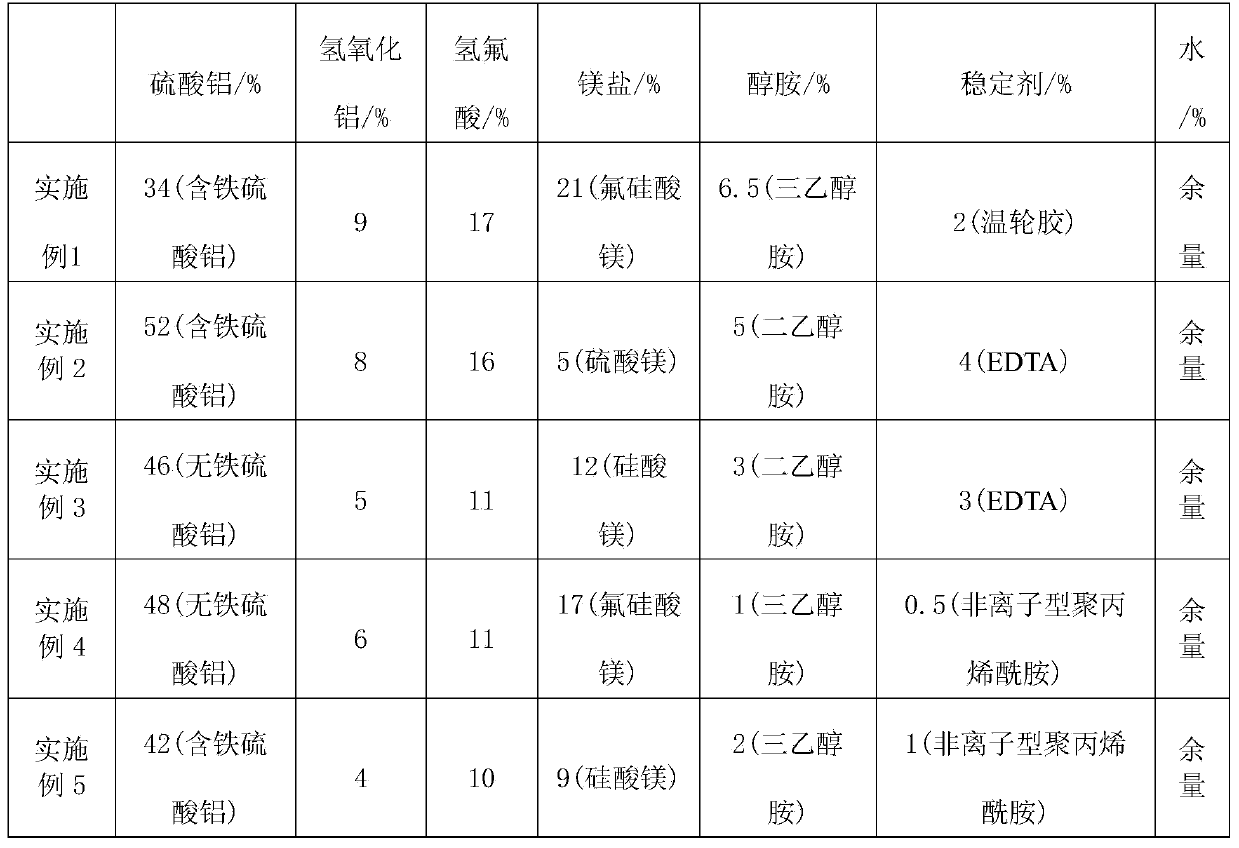

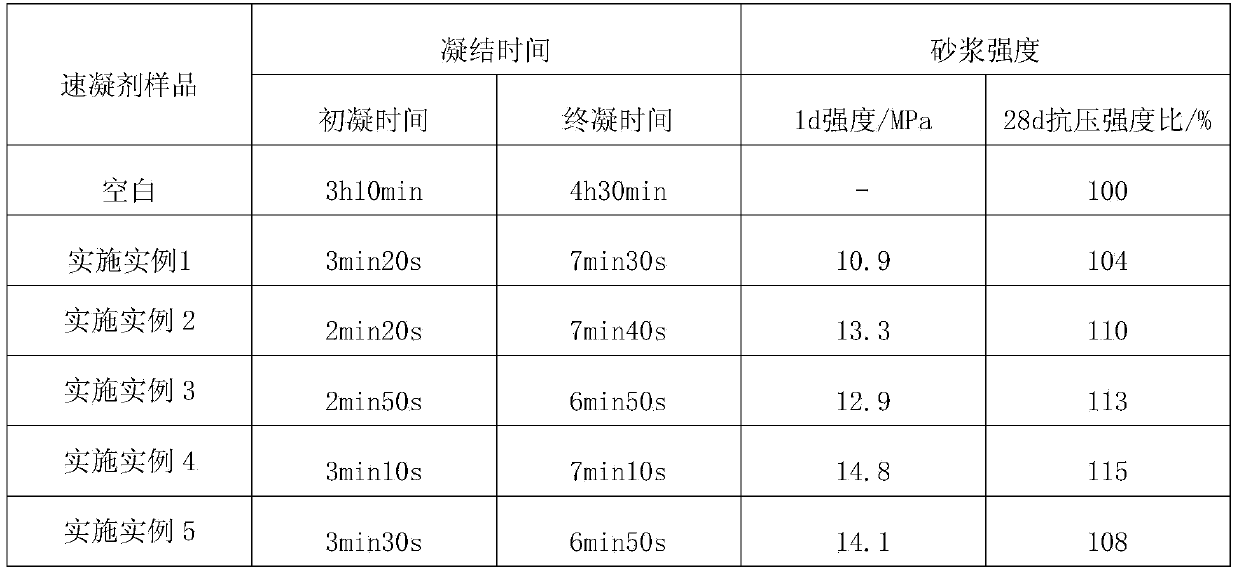

Heating-free non-alkali liquid accelerator for jetting concrete and preparation method of heating-free non-alkali liquid accelerator

The invention discloses a heating-free non-alkali liquid accelerator for jetting concrete and a preparation method of the heating-free non-alkali liquid accelerator. The liquid accelerator is prepared from the following components in percentage by mass: 30%-55% of aluminum sulfate, 3%-10% of aluminium hydroxide, 10%-18% of hydrofluoric acid, 8%-25% of magnesium salt, 1%-8% of alkylol amine, 0.5%-4% of a stabilizer, and 10%-33% of water. The preparation method is characterized by comprising the following processing steps: putting aluminium hydroxide into a reaction kettle; adding water to the reaction kettle, and stirring aluminium hydroxide into paste; slowly adding hydrofluoric acid, and when the temperature reaches 50-55 DEG C, adding aluminum sulfate to stir in batches; after hydrofluoric acid is completely added, adding residual aluminum sulfate and supplementing residual water, so as to obtain reaction liquid; adding the magnesium salt to the reaction liquid, and then adding the alkylol amine and the stabilizer, so that the solution becomes evenly mixed liquid. The accelerator disclosed by the invention has strong adaptability with cement, low energy consumption and good performance, and does not need to be heated in the use procedure.

Owner:刘翠芬 +1

Compositions including hardness ions and gluconate and methods employing them to reduce corrosion and etch

ActiveUS20080287334A1Reduce corrosionInorganic/elemental detergent compounding agentsOther chemical processesMagnesium saltHardness

The present invention relates to compositions including a water soluble magnesium salt, water soluble calcium salt, and gluconate, which have a beneficial effect on corrosion during cleaning. The present compositions can reduce corrosion of glass, aluminum, or steel. The present invention also relates to methods employing these compositions.

Owner:ECOLAB USA INC

Salt form of pantoprazole

Owner:TAKEDA GMBH

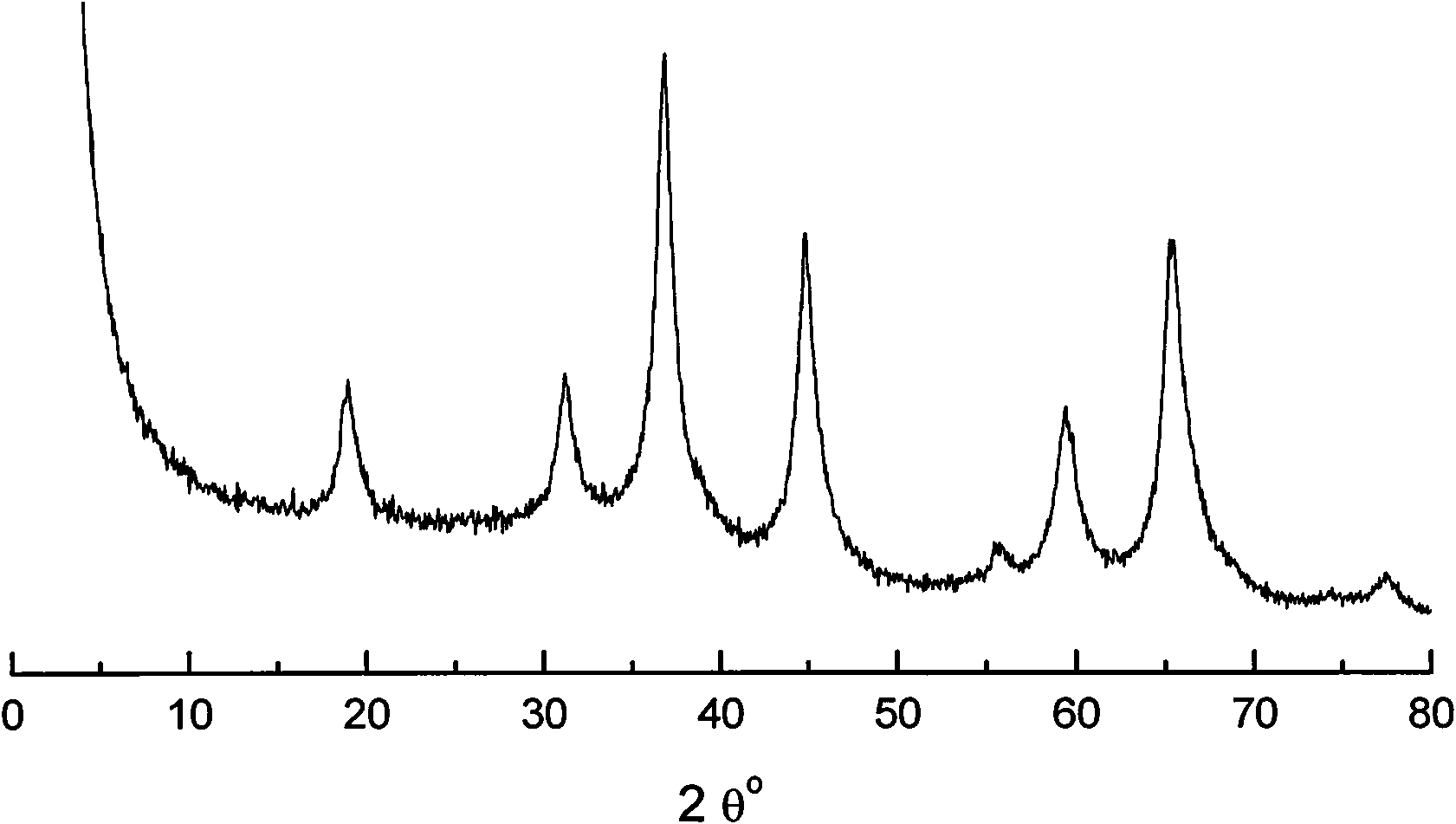

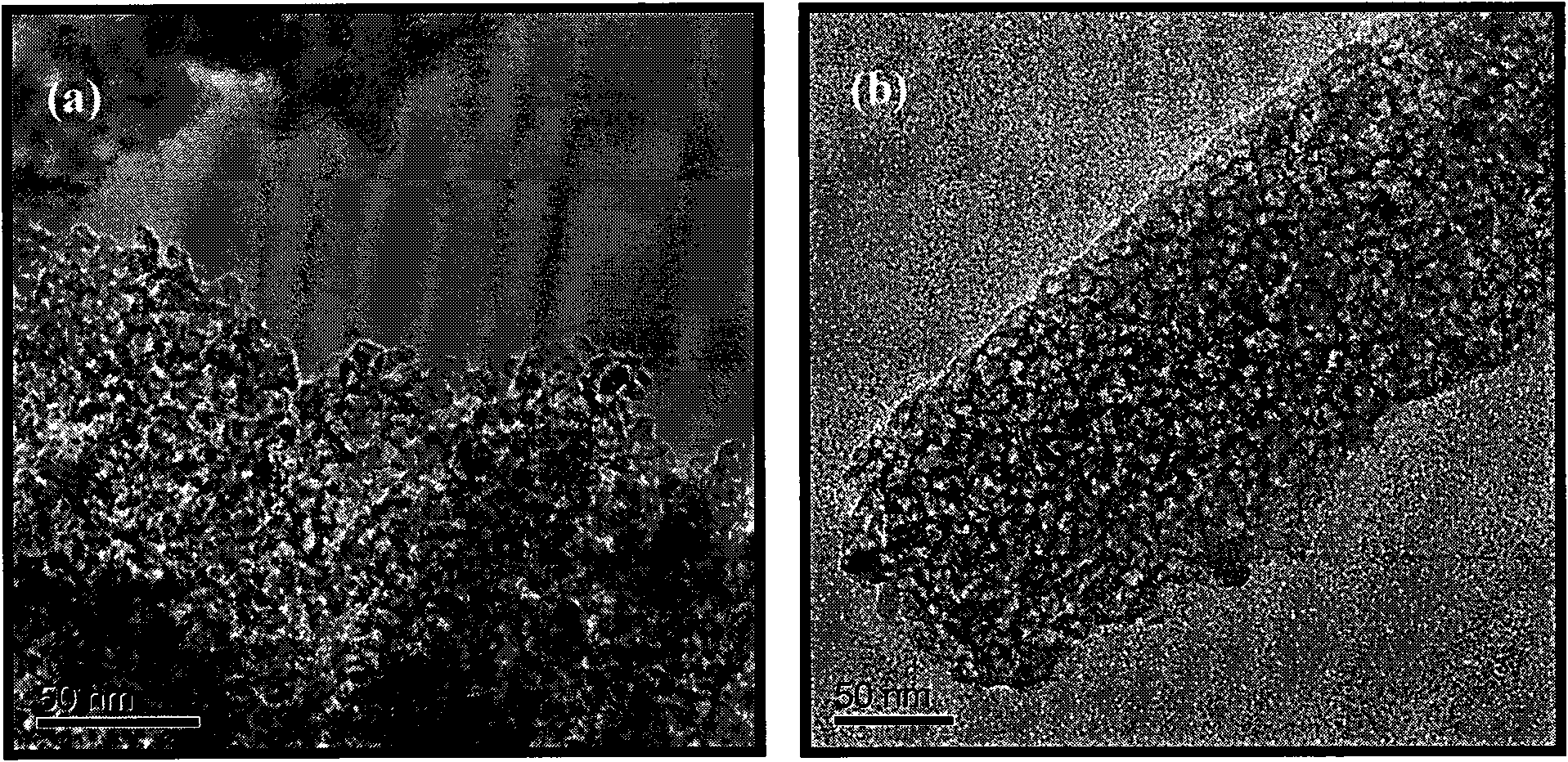

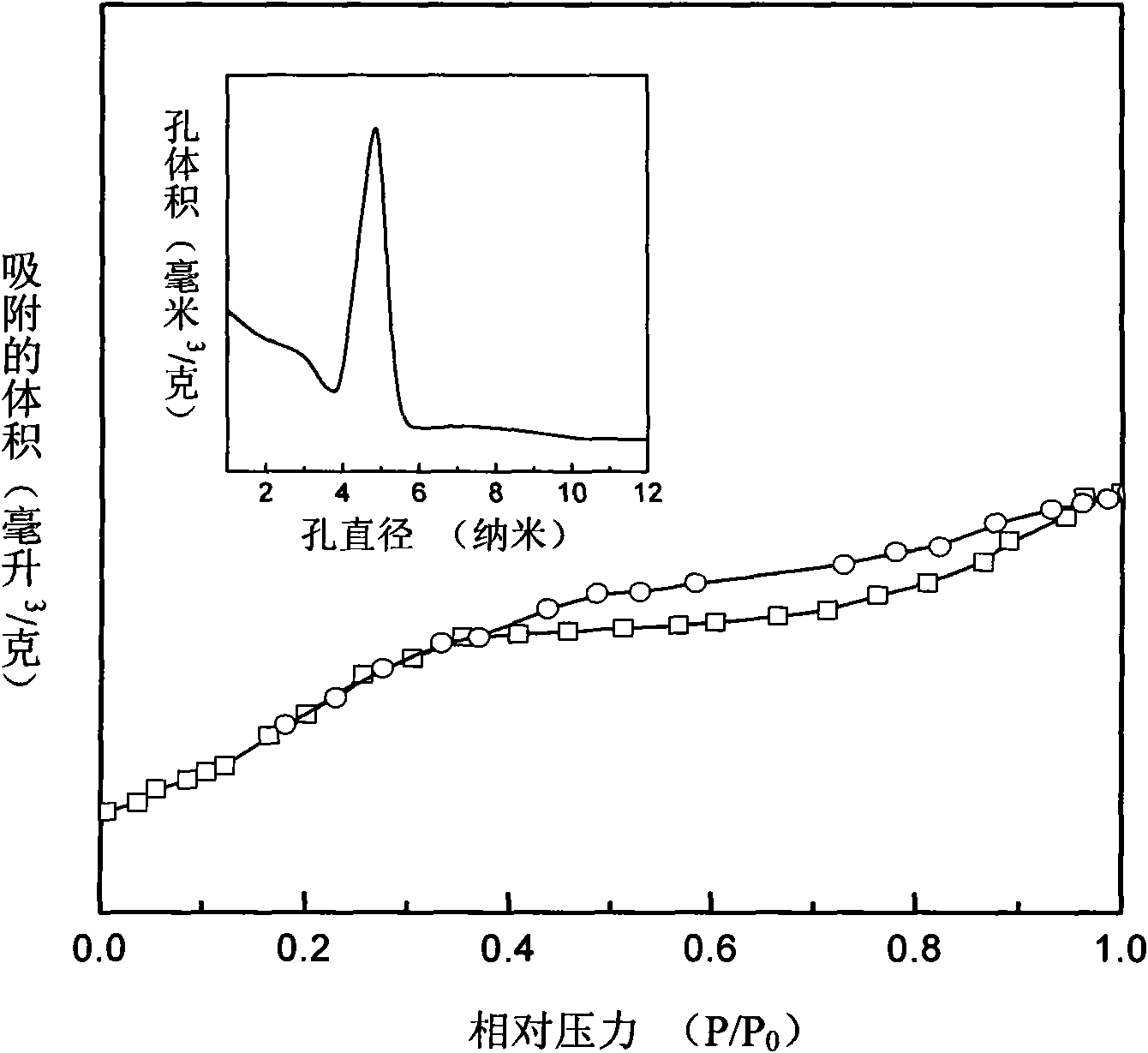

Method for preparing superfine mesoporous magnesium aluminate spinel

The invention discloses a method for preparing a superfine mesoporous magnesium aluminate spinel, which comprises the following steps: (1) adding an alkaline solution into a mixed solution of a soluble aluminum salt and a magnesium salt, and adding a surfactant into the mixture; (2) performing hydrothermal crystallization on the mixture after ageing at a temperature of between 120 and 180 DEG C for 4 to 72 hours; and (3) separating the mixture to obtain a solid product, and washing, filtering and drying the solid product to obtain magnesium aluminate spinel powder without baking or after baking at a temperature of between 500 and 700 DEG C for 4 to 6 hours. The particle size of the magnesium aluminate spinel prepared by the method is less than 100 nanometers, the specific surface area is between 200 and 400 m / gram, the pore volume is between 0.20 and 0.55 cm / gram, and the most probable pore diameter is between 3 and 6 nanometers.

Owner:NORTHWEST UNIV(CN)

Fire Fighting Foam Concentrate

InactiveUS20080196908A1Good foaming effectImproved foaming compositionFire rescueBoring toolsInorganic saltsCross-link

Fire fighting foam concentrates, expanded foam compositions, and processes of forming a foam composition using a composition comprising: a carbonised saccharide composition, a cross-linking agent or inorganic salt, a surfactant, and water. Augmented with urea or derivatives thereof and / or magnesium salts the disclosed compositions provide improved foaming compositions which also exhibit good biodegradability and environmental compatibility and have particular utility in addressing polar solvent fires such as those of methanol or acetone.

Owner:MCWANE LUXEMBOURG IP S A R L

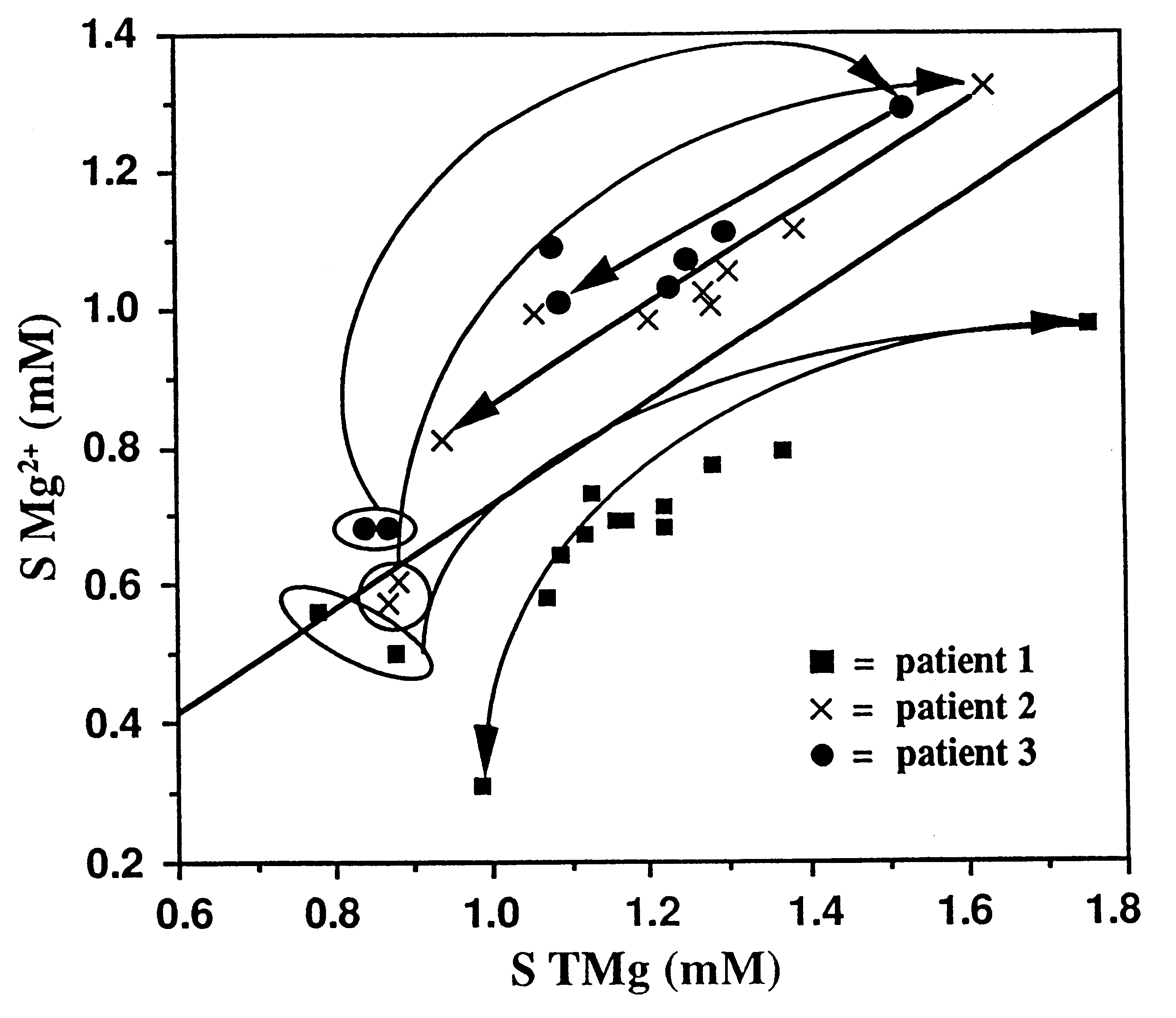

Method and composition for treatment of headache using magnesium

InactiveUS6218192B1Accurate concentrationBiocideInorganic phosphorous active ingredientsUnilateral painMagnesium salt

A method of treating headache is provided using a water soluble magnesium salt. Specifically, a method of treating a headache is provided for an individual having a serum ionized magnesium concentration of 0.44 mmoles / L to 0.53 mmoles / L and having at least one headache symptom by administering an amount of a water soluble magnesium salt sufficaent to inhibit at least one headache symptom in the individual within 24 hours and to raise the serum ionized magnesium concentration in the individual to within a normal ionized magnesium concentration range of 0.54 mmoles / L to 0.67 mmoles / L. Headache symptoms which may be inhibited include: pain, aura, photophobia, nausea, unilateral pain and phonophobia.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

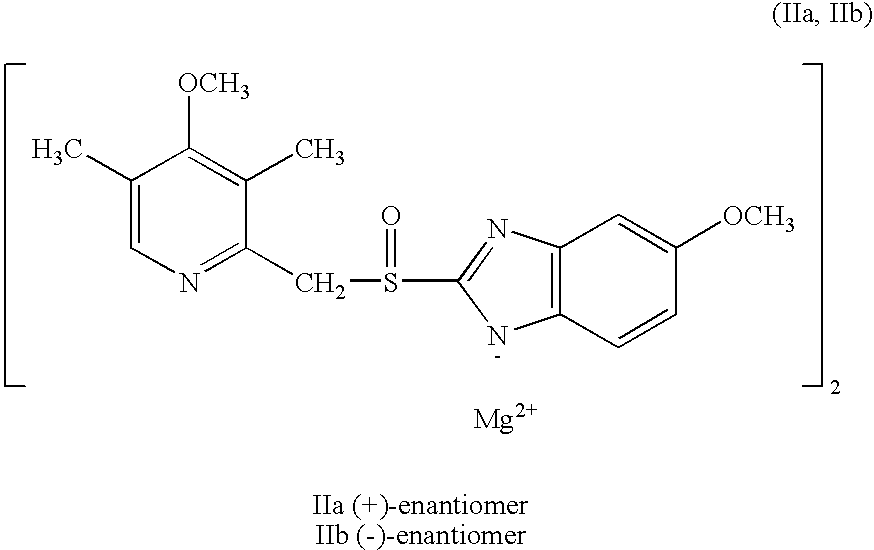

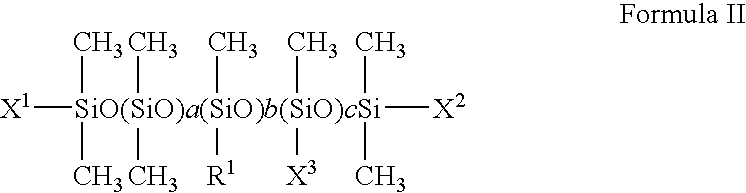

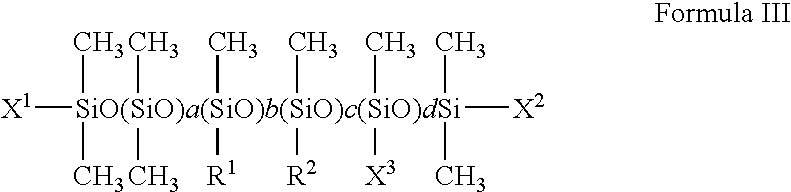

Process for the preparation of a magnesium salt of a substituted sulfinyl heterocycle

PCT No. PCT / SE97 / 00674 Sec. 371 Date Jul. 10, 1997 Sec. 102(e) Date Jul. 10, 1997 PCT Filed Apr. 22, 1997 PCT Pub. No. WO97 / 41114 PCT Pub. Date Nov. 6, 1997A novel process for the preparation of a magnesium salt of Formula I of a substituted sulfinyl heterocyclic compound containing an imidazole moiety. The process is carried out by mixing the substituted heterocycle of formula I with a weak and a magnesium source. The base and the magnesium source are selected to result in residues which are easy to remove during the reaction. The invention also relates to the use of the produced compounds in medicine.

Owner:ASTRAZENECA AB

Stable sodium-free or low-sodium aqueous solution of agreeable saltiness taste

A stable sodium-free aqueous seasoning solution of agreeable salty taste, adapted as a substitute for common salt in cooked and uncooked foodstuffs, containing purified water, an organic acid, a potassium salt, a calcium salt, and a magnesium salt. The mineral solution provides a dietary supplementation of magnesium, calcium, and potassium—indispensable minerals of a diet—to which colorants, natural essences and artificial essences (singly or in combination), and low concentrations of sodium chloride may be added.

Owner:REV

Enhanced activity hydrogen peroxide disinfectant

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:TRIKON TECH LTD +1

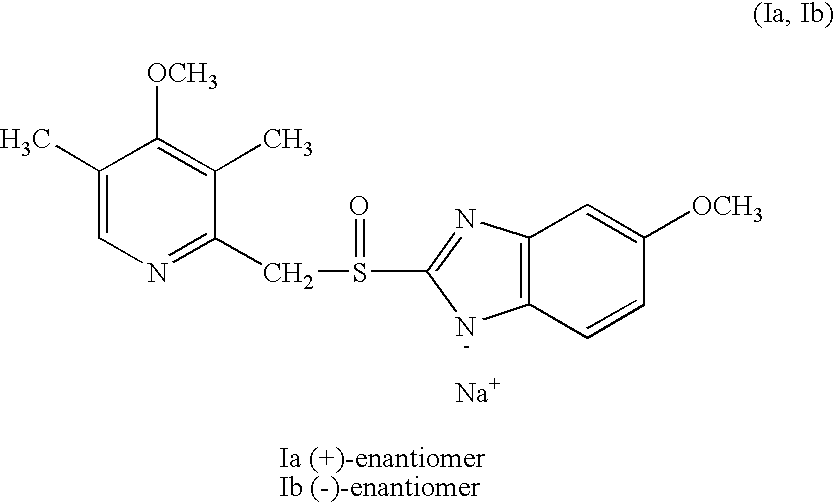

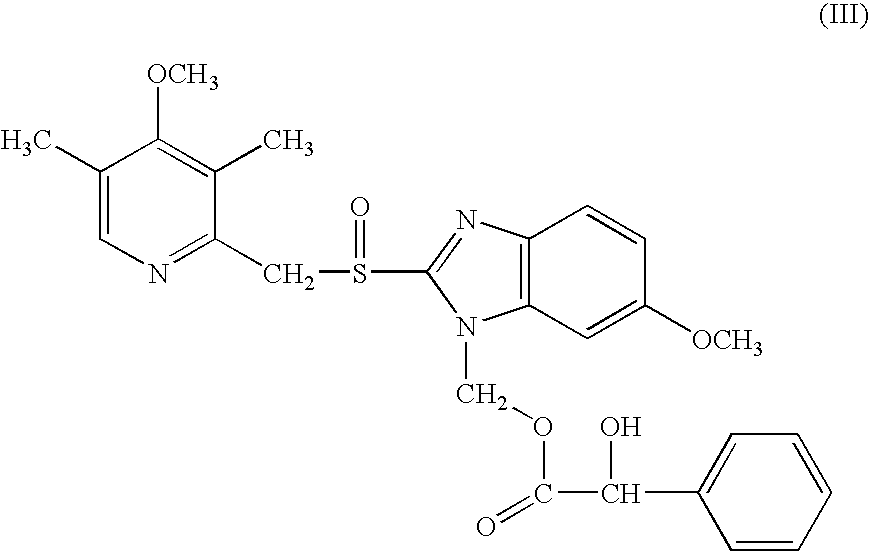

Compounds

InactiveUS6875872B1Inhibit gastric acid secretionPrevent acid aspirationBiocideOrganic chemistryMagnesium saltBULK ACTIVE INGREDIENT

The novel optically pure compounds Na+, Mg2+, Li+, K+, Ca2+ and N+(R)4 salts of (+)-5-methoxy-2-[[(4-methoxy-3,5-dimethyl-2-pyridinyl)methyl]sulfinyl]-1H-benzimidazole or (−)-5-methoxy-2-[[(4-methoxy-3,5-dimethyl-2-pyridinyl)methyl]sulfinyl]-1H-benzimidazole, in particular sodium and magnesium salt form thereof, where R is an alkyl with 1-4 carbon atoms, processes for the preparation thereof and pharmaceutical preparations containing the compounds as active ingredients, as well as the use of the compounds in pharmaceutical preparations and intermediates obtained by preparing the compounds.

Owner:ASTRAZENECA AB

Method for separating and extracting tungsten-molybdenum from mixed solution of tungstate-molybdate

InactiveCN101880780AEfficient separationRealize recyclingProcess efficiency improvementMagnesium saltDecomposition

Owner:CENT SOUTH UNIV

Treatment agent for elastic polyurethane fibers and elastic polyurethane fibers treated therewith

Owner:OPELONTEX CO LTD 50

Water soluble magnesium compounds as cleaning agents and methods of using them

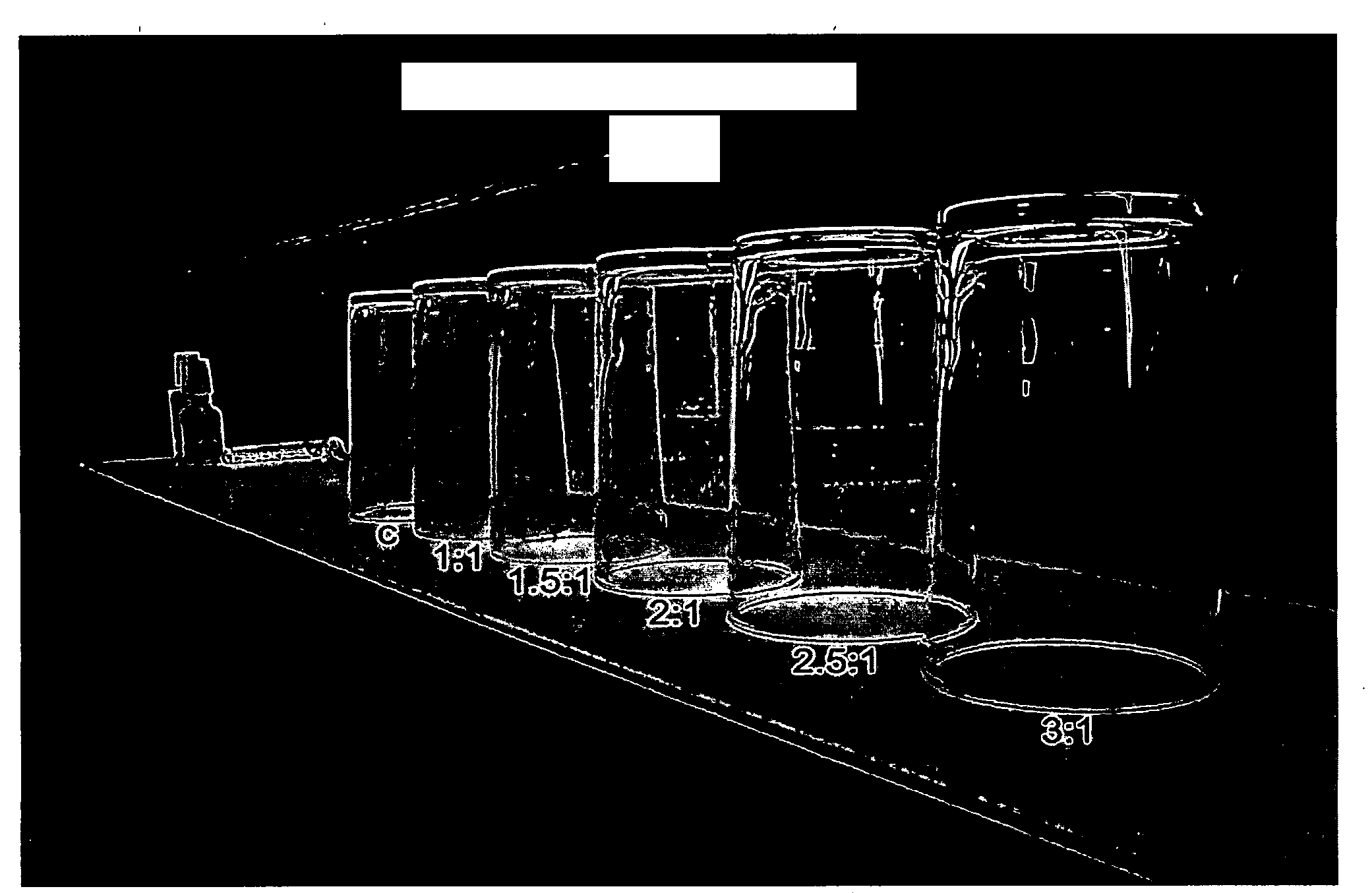

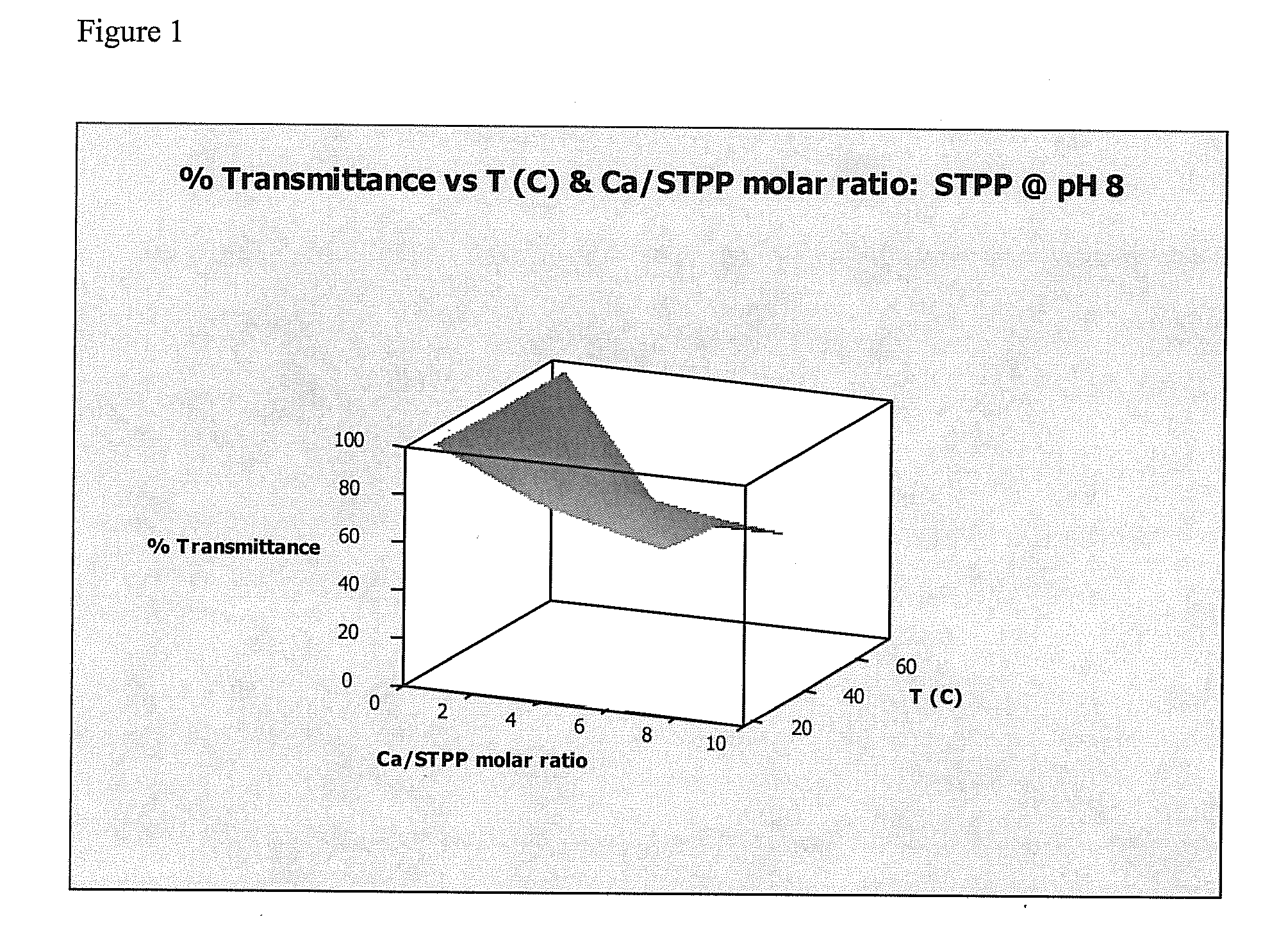

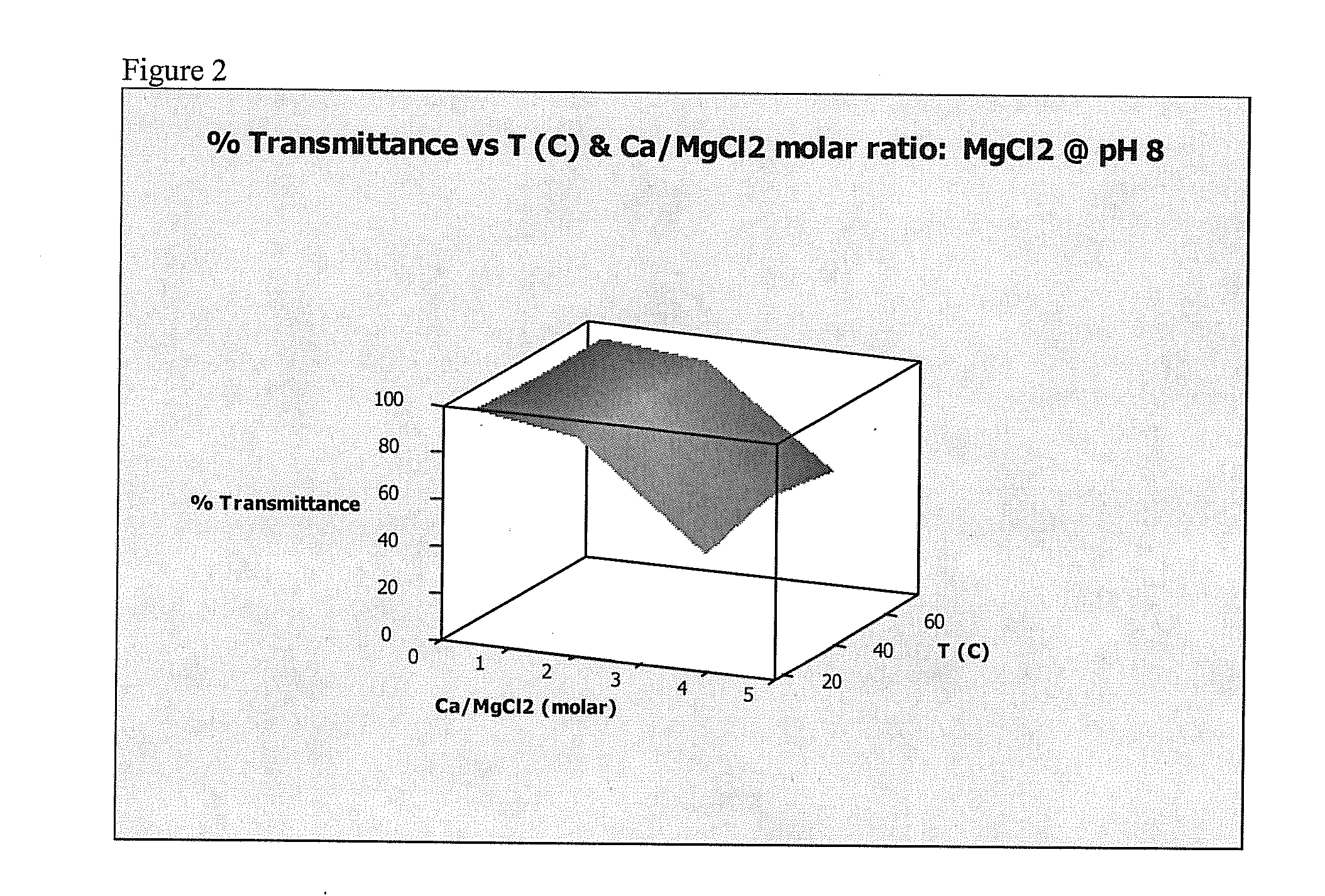

InactiveUS20080274928A1Reduce and prevent formationImprove solubilityInorganic/elemental detergent compounding agentsSpecific water treatment objectivesMagnesium saltWater insoluble

The present invention relates to compositions and methods employing a water soluble magnesium compound. In certain embodiments, the composition includes water and water soluble magnesium compound, but lacks other materials commonly used in cleaning compositions. The methods and compositions can provide magnesium ion at predefined ratios to calcium ion in water, such as magnesium ion in a molar amount equal to or in excess over a molar amount of calcium ion. A water soluble magnesium salt including an anion of a water soluble calcium salt is more effective than a magnesium salt with an anion of a water insoluble calcium salt. These compositions can be used for reducing lime scale or precipitate formation from hard water, removing soap scum, or the like.

Owner:ECOLAB USA INC

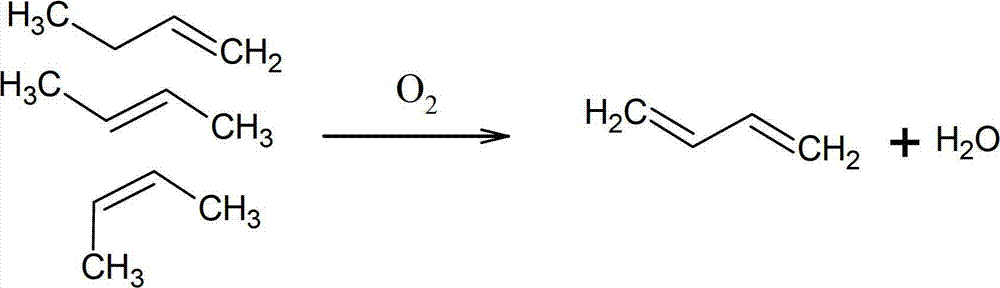

Catalyst and method used for preparing 1,3-butadiene by oxidative dehydrogenation of n-butene

ActiveCN102824914AHigh catalytic activityImprove catalytic selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsMagnesium saltDehydrogenation

The invention discloses a catalyst and a method used for preparing 1,3-butadiene by oxidative dehydrogenation of n-butene. The catalyst is a cobalt and magnesium modified zinc ferrite catalyst which is obtained by proportioning a ferric salt, a zinc salt, a cobalt salt, a magnesium salt and a deionized water in a mole ratio, regulating pH value with ammonia water, concentrating, filtering, drying, roasting, cooling, grinding and screening. The method for preparing 1,3-butadiene by utilizing the catalyst comprises the following steps of: with C4 fraction produced by MTO (methanol to olefin) as a raw material, carrying out catalytic oxidative dehydrogenation reaction on a reaction mixture which is formed by the C4 fraction, air and vapour under the action of the cobalt and magnesium modified zinc ferrite catalyst so as to efficiently prepare1,3-butadiene, wherein the main ingredient of the C4 fraction is n-butene. The method disclosed by the invention has the advantage that the C4 fraction is not required to be refined to remove impurities such as oxygenated chemicals, thus the method disclosed by the invention is a simple and efficient method for preparing a high-additional-value product by utilizing C4 resource of the MTO.

Owner:SHAANXI COAL & CHEM TECH INST

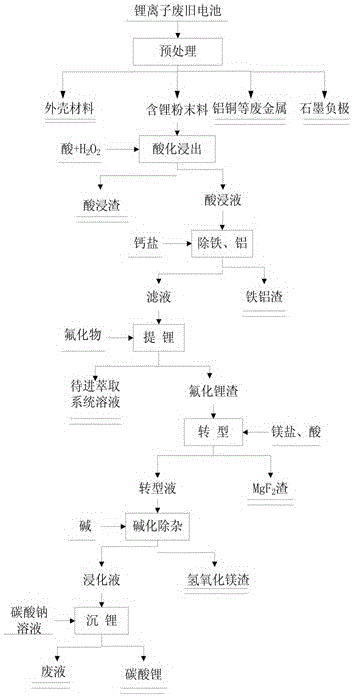

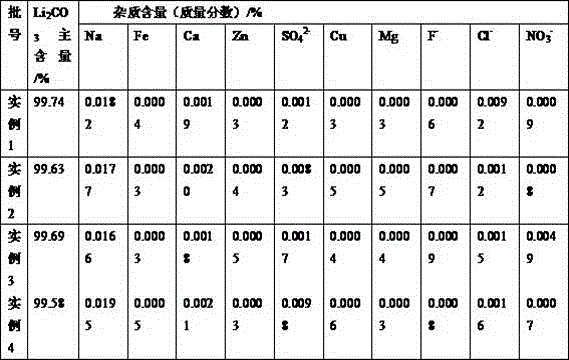

Method for recovering lithium from waste lithium battery to prepare battery grade lithium carbonate

InactiveCN106505225AHigh recovery rateReduce lossesReclaiming serviceable partsWaste accumulators reclaimingMagnesium saltLithium carbonate

The invention discloses a method for recovering lithium from a waste lithium battery to prepare battery grade lithium carbonate. Lithium is extracted from the waste lithium battery as a raw material to prepare the battery grade lithium carbonate. The method mainly comprises the following steps of (1) battery dismantling; (2) acidifying and leaching; (3) iron and aluminum removal; (4) fluorinating lithium deposition; (5) magnesium salt transformation; (6) alkalifying impurity removal; and (7) lithium deposition employing sodium carbonate. The lithium is recovered from the waste lithium battery to prepare the battery grade lithium carbonate, so that the battery grade lithium carbonate has the advantages of being high in lithium recovery rate, small in losses of other metal elements, friendly to environment and high in product purity; the main content of a product exceeds 99.5%; the requirements of battery grade products are met; and the method is simple in process, low in production cost and suitable for industrial production.

Owner:GANFENG LITHIUM CO LTD

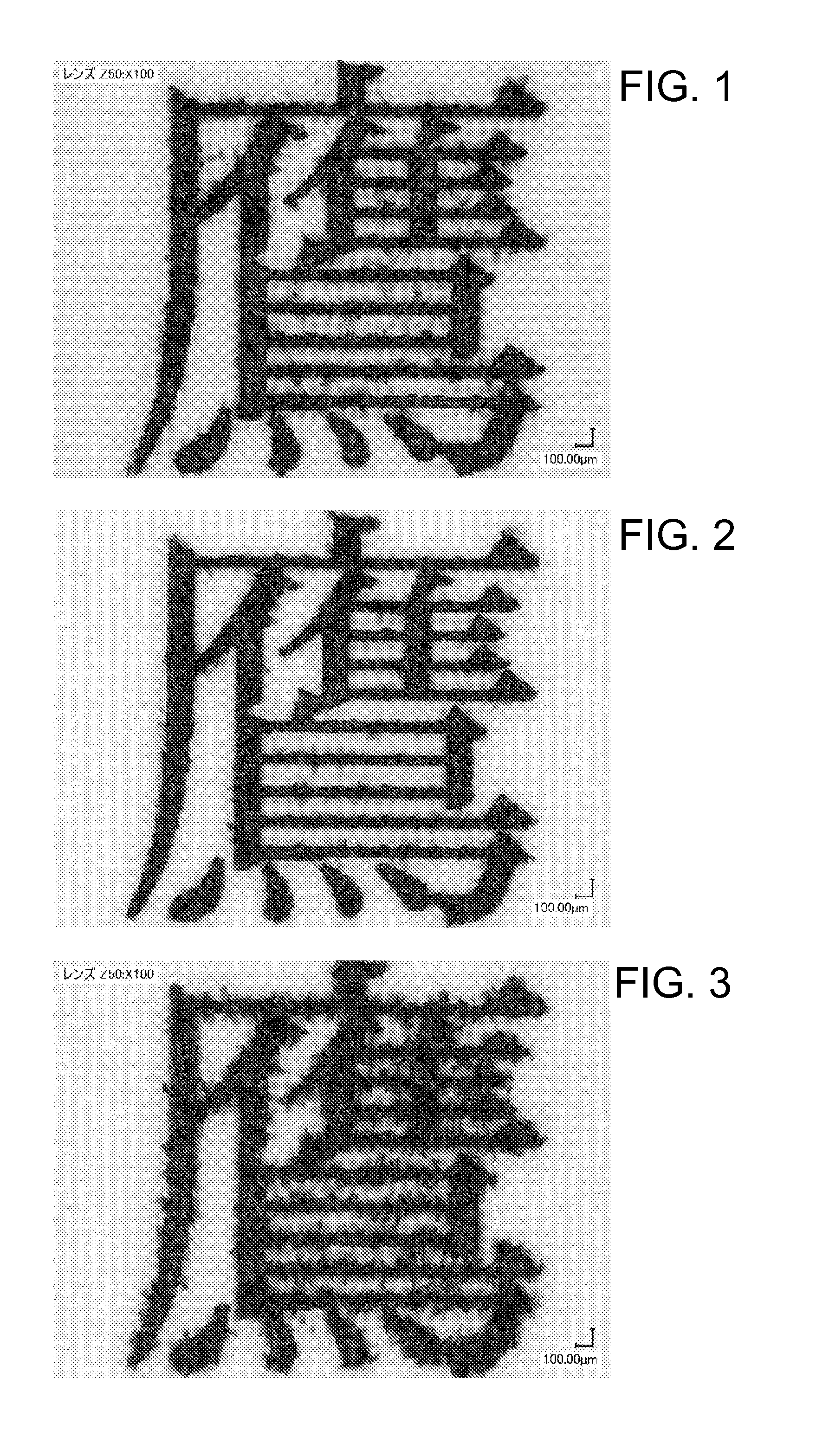

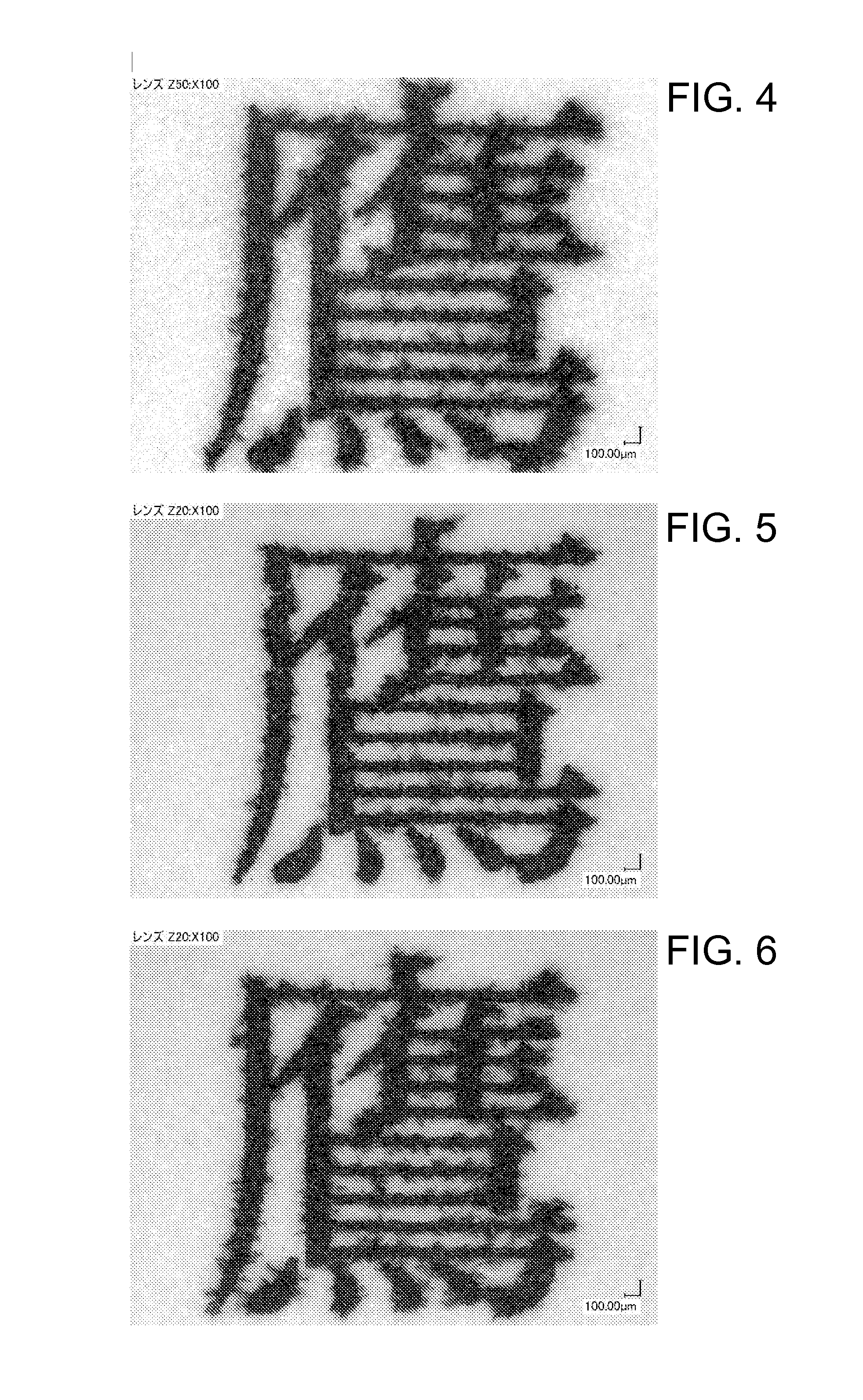

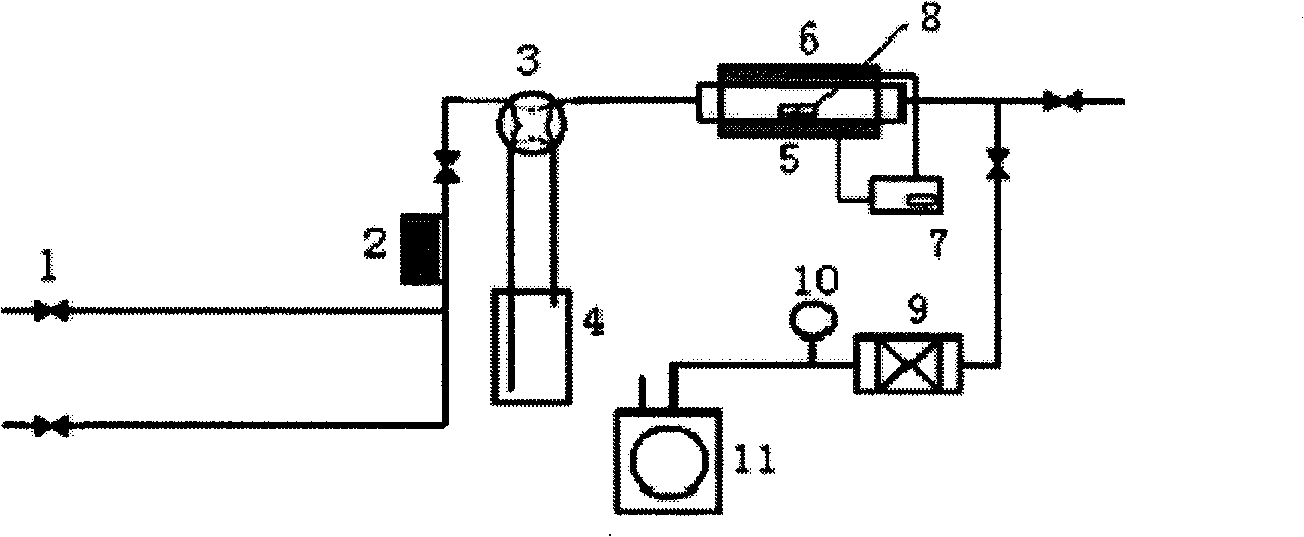

Inkjet recording method

InactiveUS20140055520A1Achieving fixabilitySuppressing featheringDuplicating/marking methodsInksSolubilityNickel salt

An inkjet recording method which suppresses feathering and color bleeding and is excellent in fixability to a recording medium. The inkjet recording method includes the steps of applying an ink-receiving solution prepared by dissolving in an aqueous solvent at least one metal salt having a water solubility of 0.1 mol / l or more, selected from calcium salts, magnesium salts, nickel salts and zinc salts having a valence of 2 or more, to at least the surface to be printed by using an inkjet ink or the entire surface of a recording medium; and printing on the metal salt adhered part by using the inkjet ink comprising at least a pigment, a resin emulsion and an aqueous solvent containing a surfactant. Further, a phosphorus-containing group having at least one P—O or P═O bond is bound to the surface of the pigment.

Owner:DNP FINE CHEMICALS CO LTD

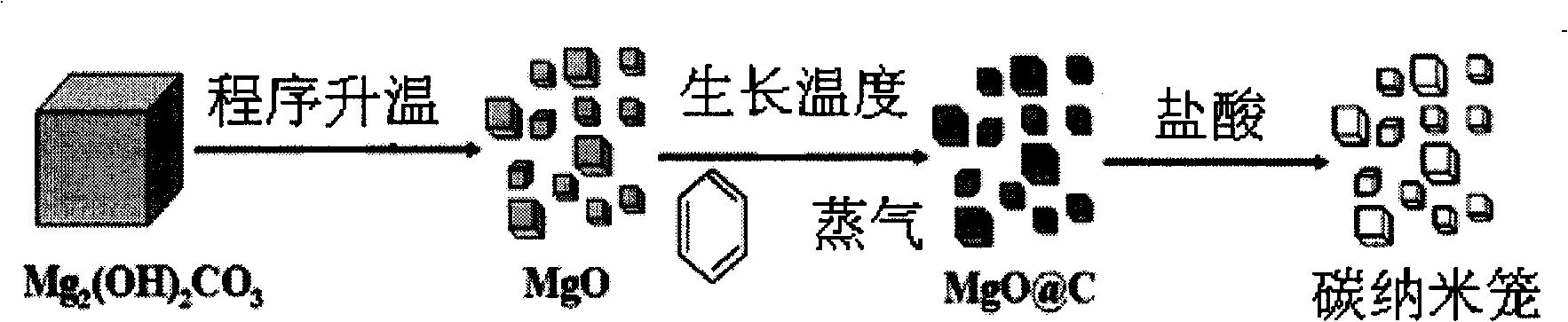

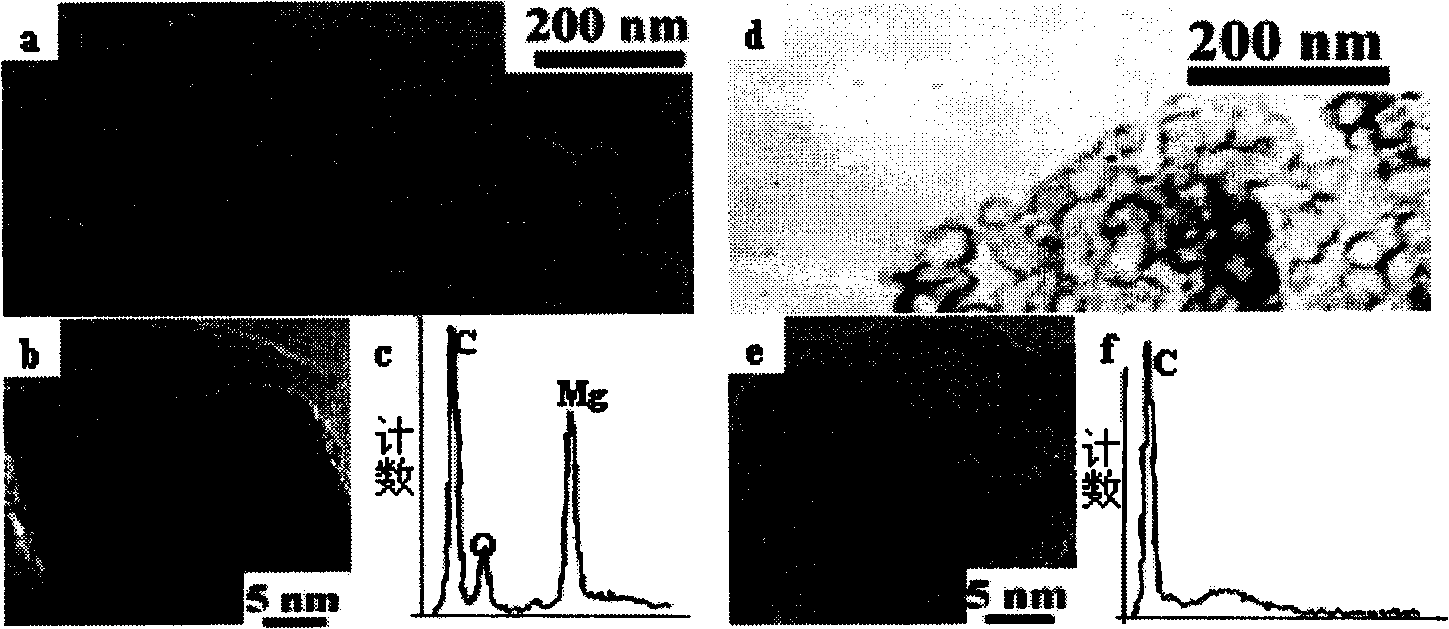

Method for mass preparing hollow nano cages in high quality

InactiveCN101284663AHigh purityHigh mesoporosityIndividual molecule manipulationMagnesiaMagnesium saltReaction temperature

A method for mass production of high-quality hollow carbon nanocages comprises the following steps: 1) light magnesium carbonate or magnesium carbonate is added into a reaction tube and spread evenly, the tube is put into a tubular furnace, air is pumped out of the tube, inert gas such as N2 and Ar is injected; the reaction temperature is increased to 670 DEG C-900 DEG C, (C) source vapor is introduced, and reaction is carried out for 5 to 240 minutes under the protection of 10-500sccm inert gas atmosphere; the (C) source gas is led to the reaction area of the tubular furnace by the inert gas flow, carbonized on the surfaces of nano particles generated in situ, and covered to form a MgO@C structure; after the reaction, the temperature inside the reaction tube drops to the room temperature under the protection of the inert gas; 2) powder is collected from the reaction tube, dipped in sufficient hydrochloric acid or sulphuric acid for 5 to 720 minutes to remove the kernel of MgO, filtered, washed to neutrality by using deionized water, and dried to obtain the hollow carbon nanocages; and 3) the magnesium salt filtrate is recycled. The nanocages prepared by the method have high purity, and the price for the precursor is low, thereby facilitating recovery and reuse.

Owner:NANJING UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com