Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1113results about How to "Increase burn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extinguishment combination with hot gas sol

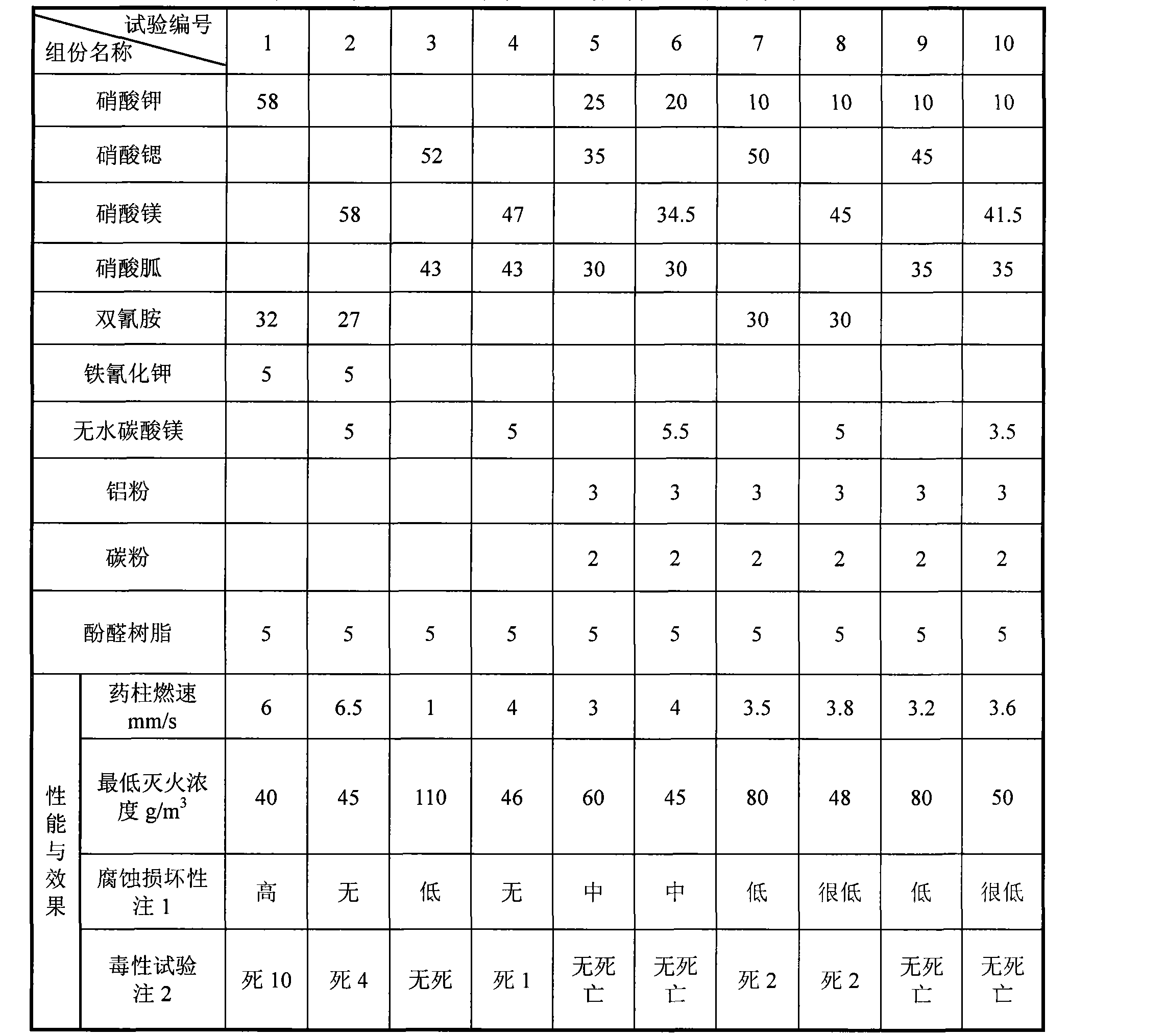

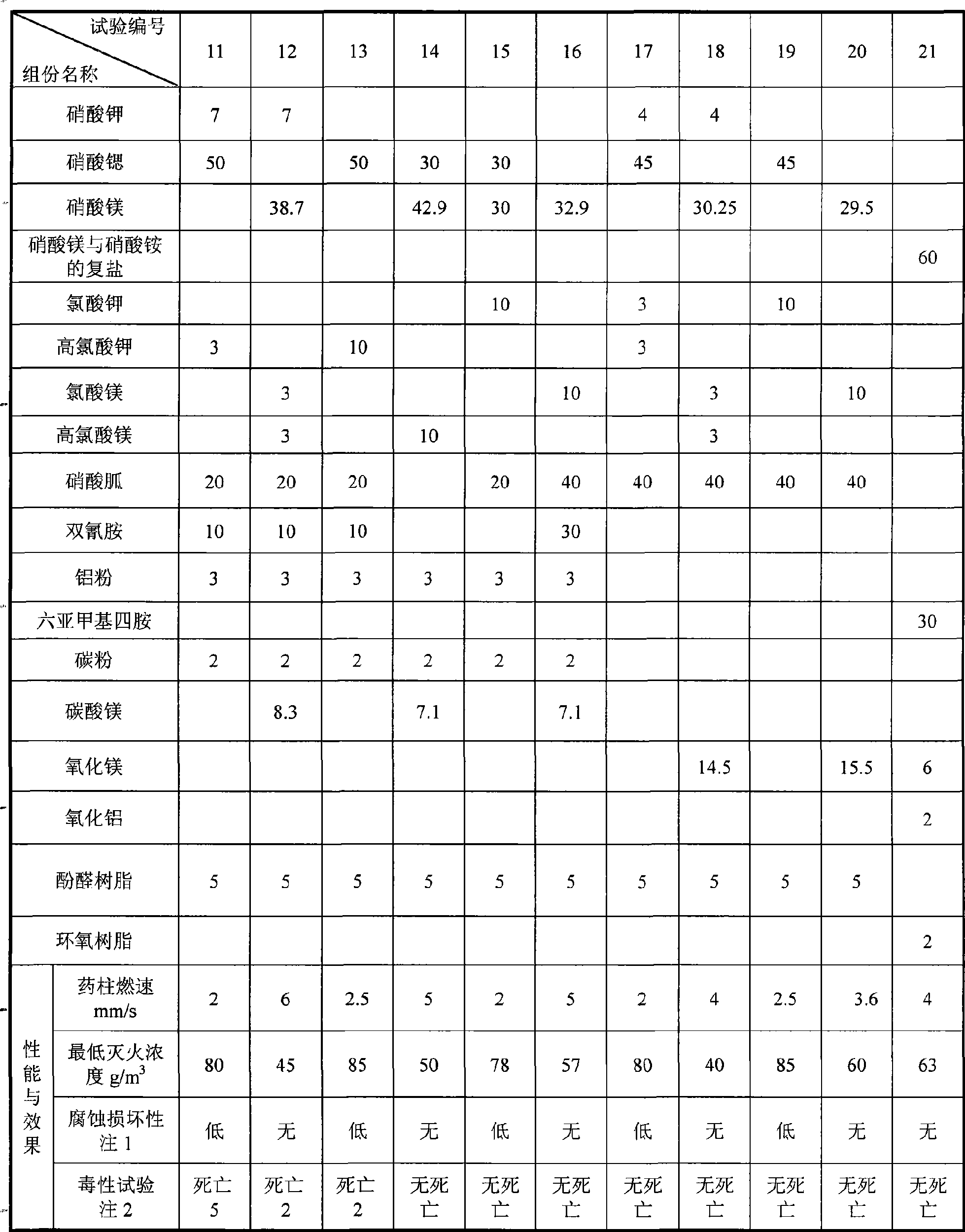

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274ALow ignition temperatureShorter ignition delay timeChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

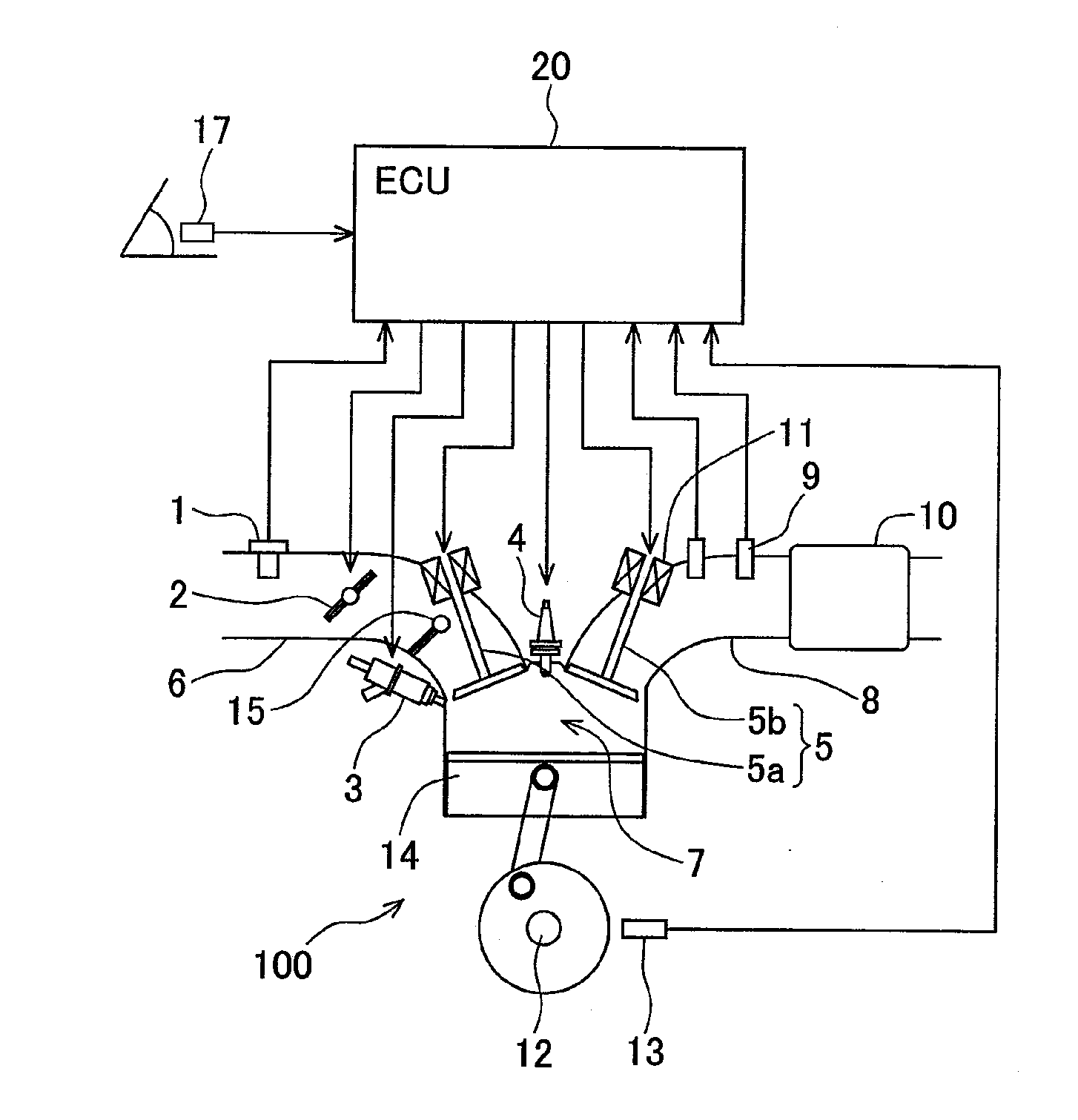

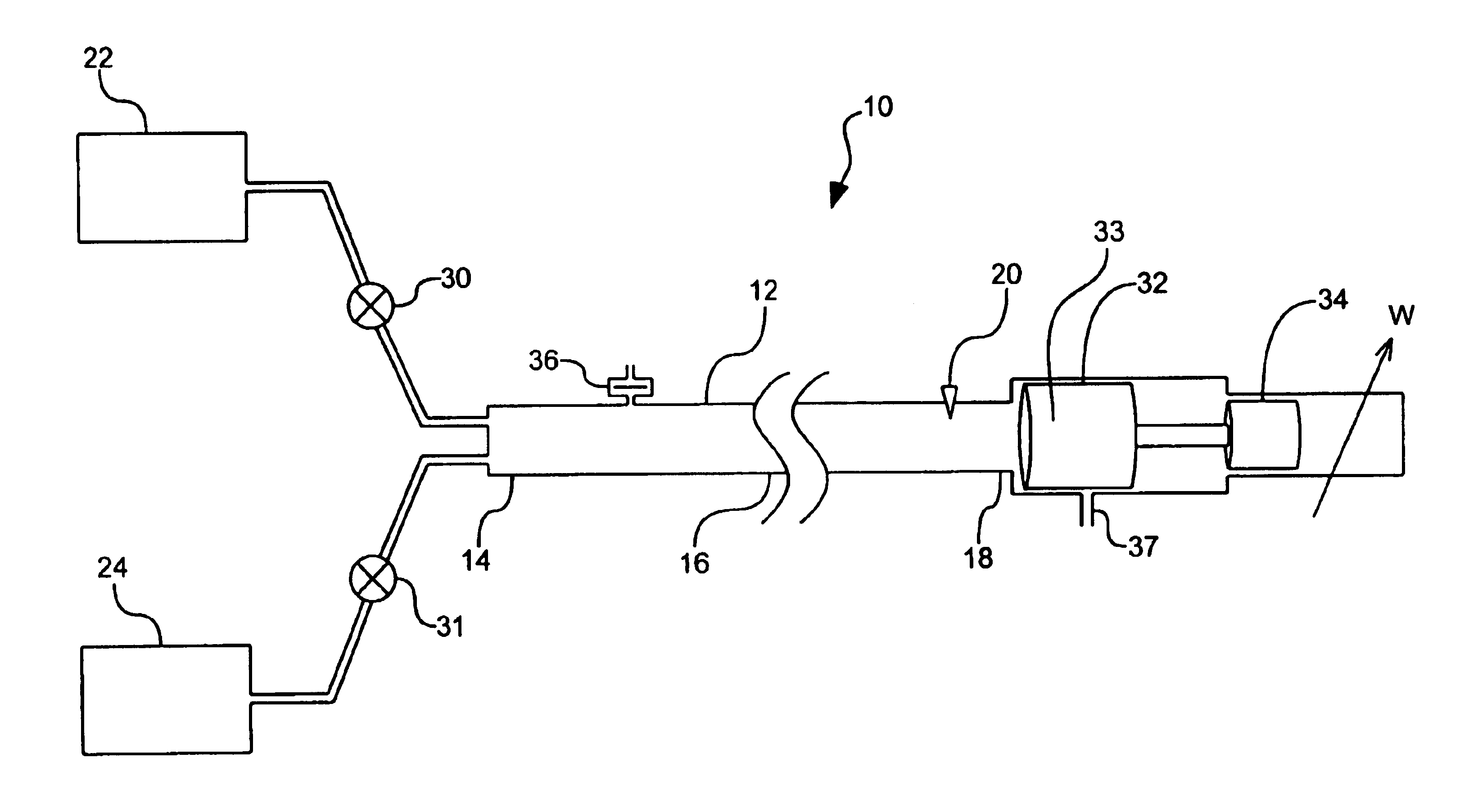

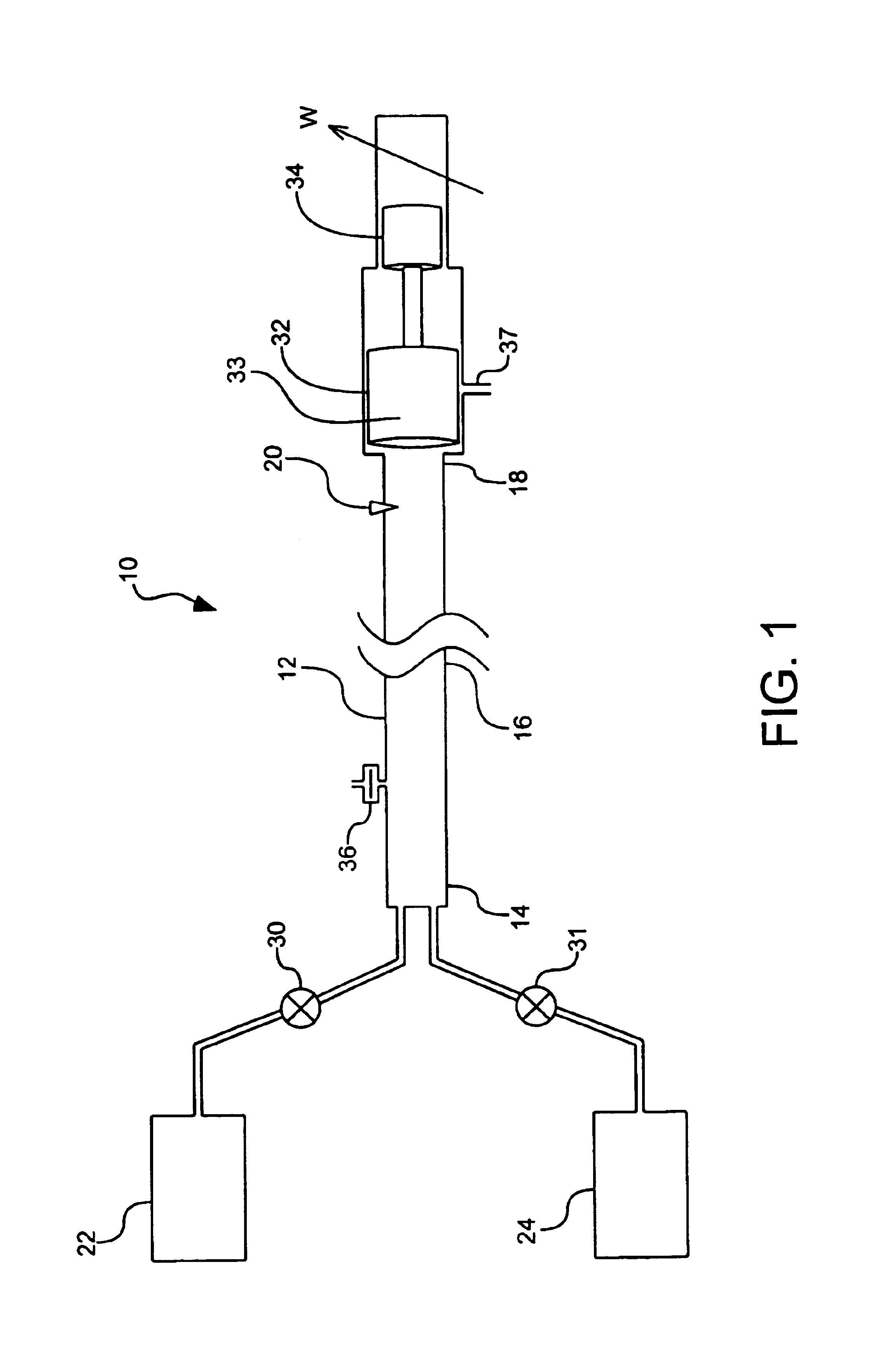

Engine combustion control via fuel reactivity stratification

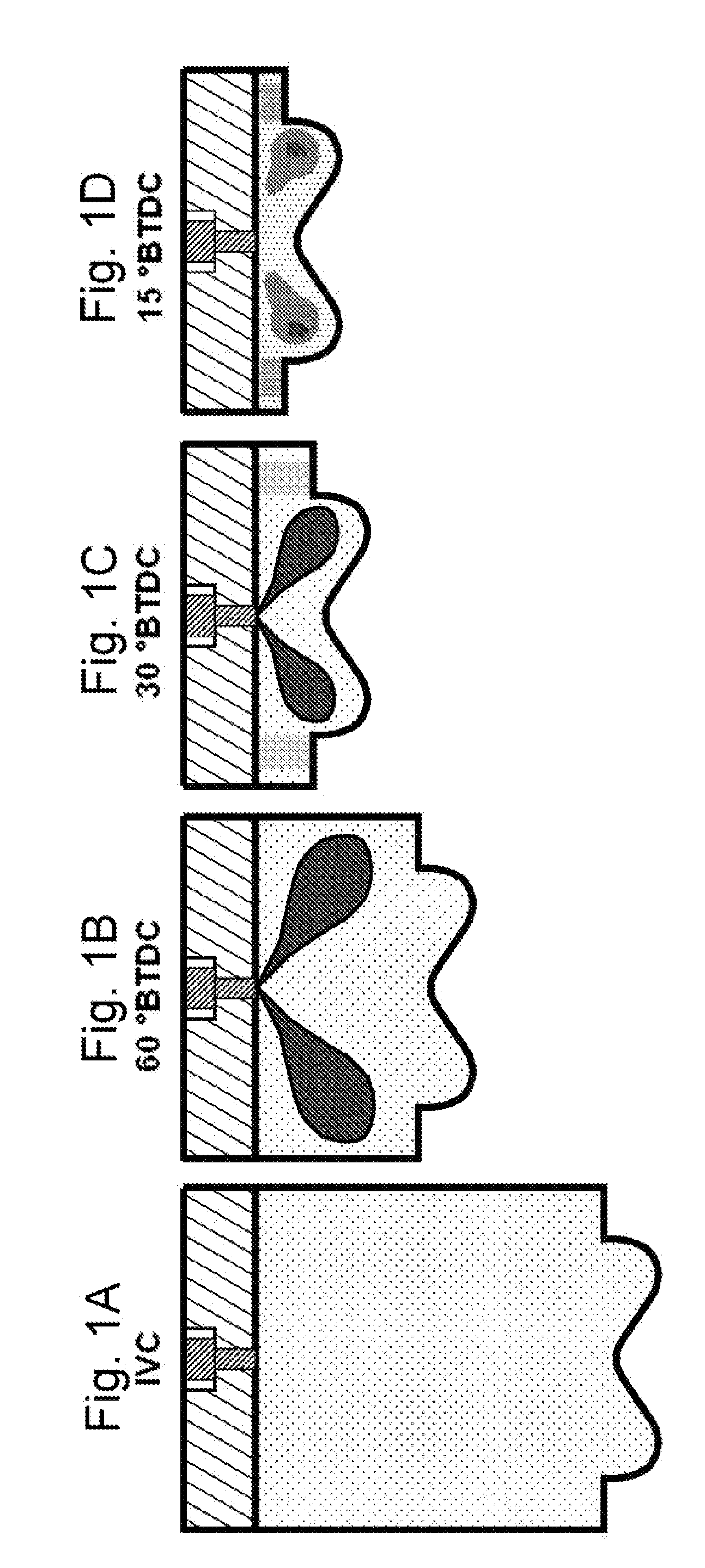

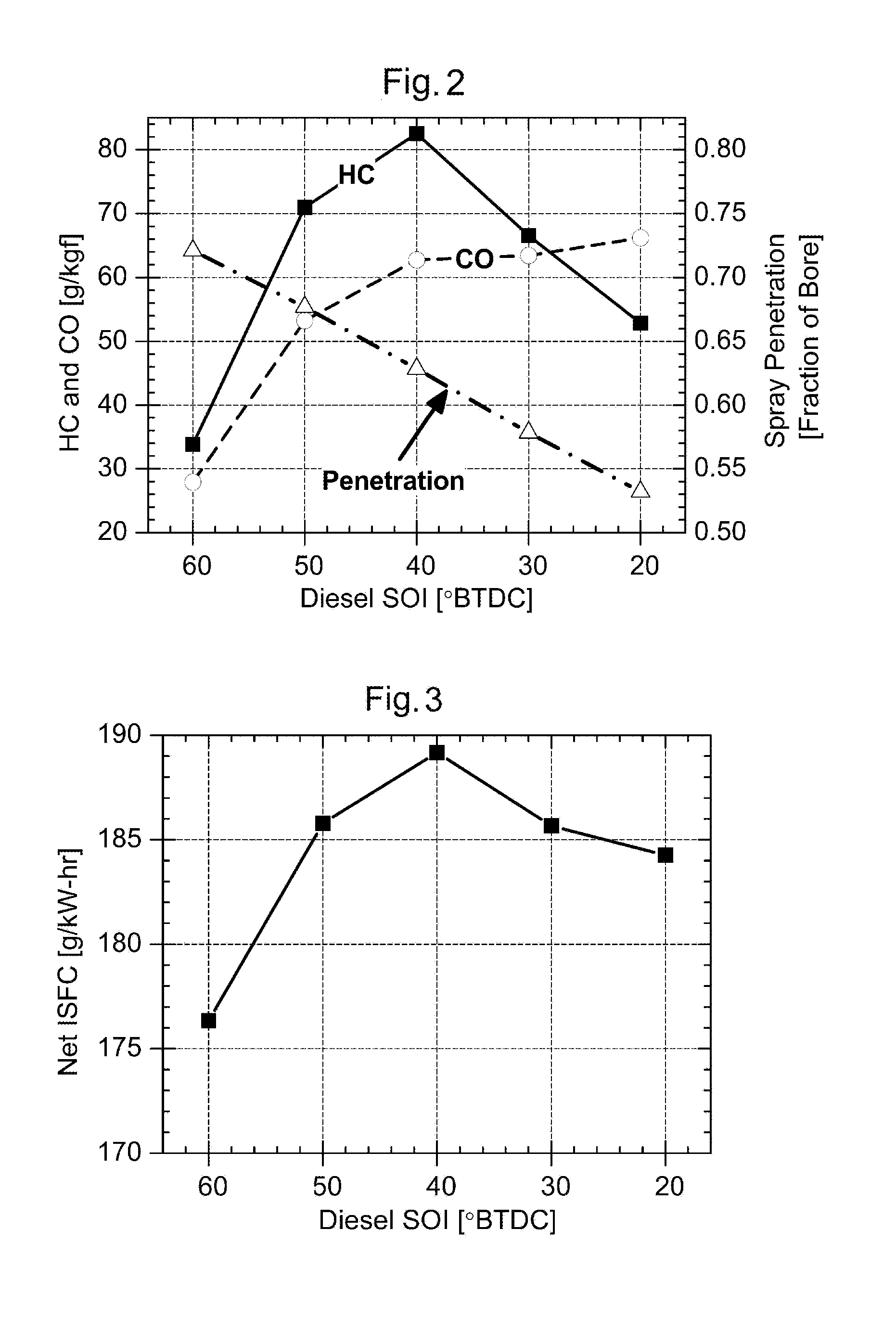

ActiveUS20110192367A1High and low reactivityConvenience to workElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

A compression ignition engine uses two or more fuel charges having two or more reactivities to control the timing and duration of combustion. In a preferred implementation, a lower-reactivity fuel charge is injected or otherwise introduced into the combustion chamber, preferably sufficiently early that it becomes at least substantially homogeneously dispersed within the chamber before a subsequent injection is made. One or more subsequent injections of higher-reactivity fuel charges are then made, and these preferably distribute the higher-reactivity matter within the lower-reactivity chamber space such that combustion begins in the higher-reactivity regions, and with the lower-reactivity regions following thereafter. By appropriately choosing the reactivities of the charges, their relative amounts, and their timing, combustion can be tailored to achieve optimal power output (and thus fuel efficiency), at controlled temperatures (and thus controlled NOx), and with controlled equivalence ratios (and thus controlled soot).

Owner:WISCONSIN ALUMNI RES FOUND

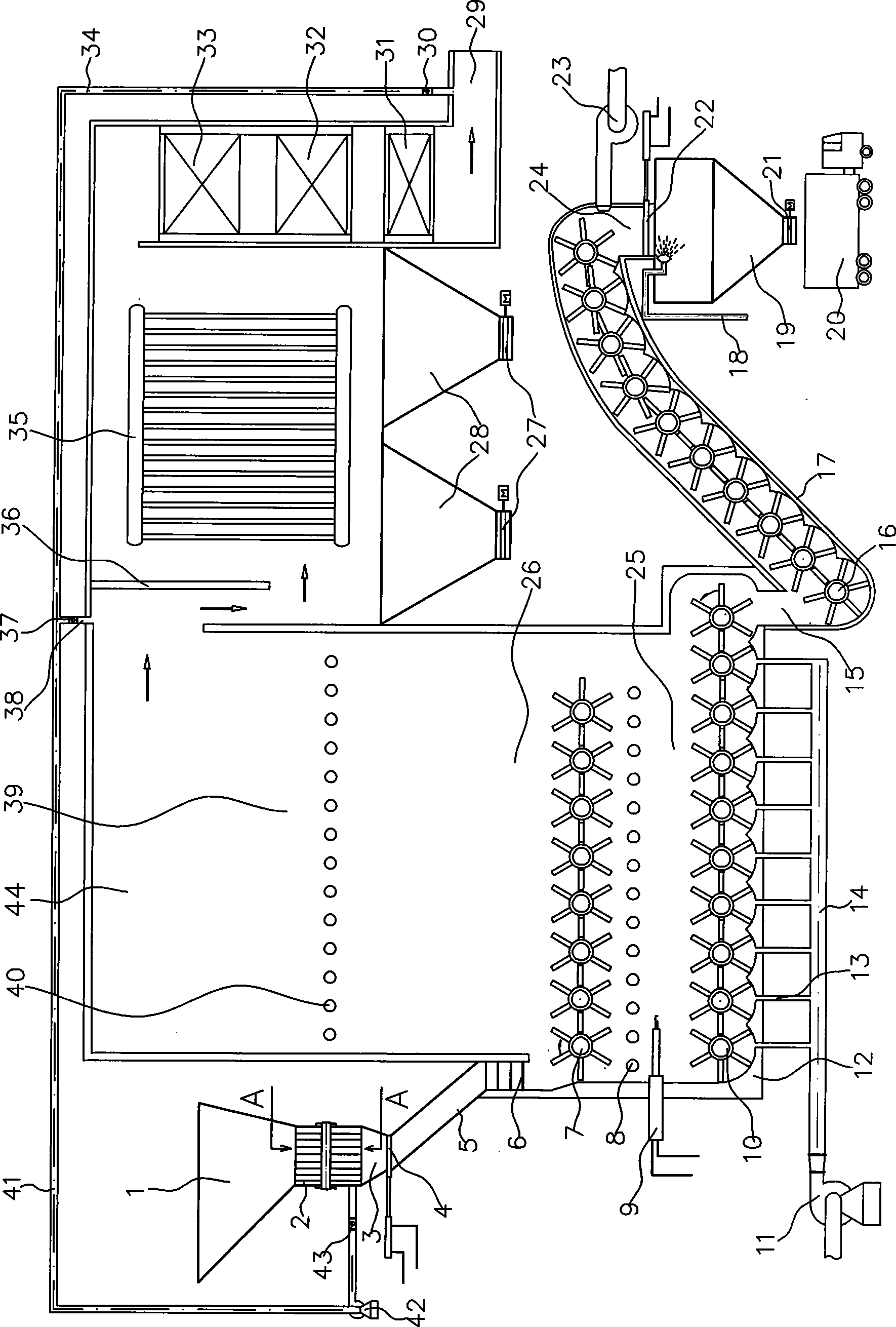

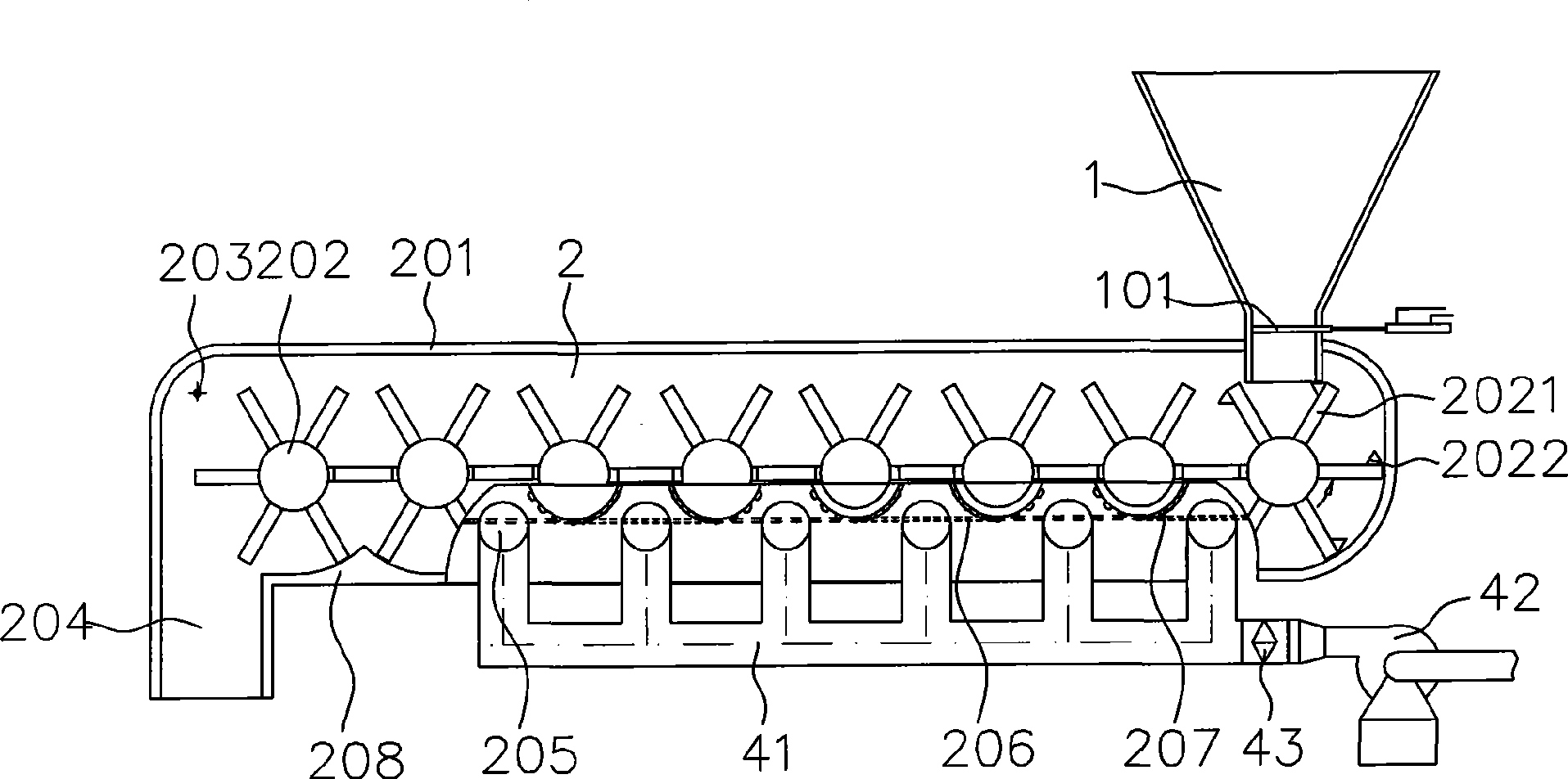

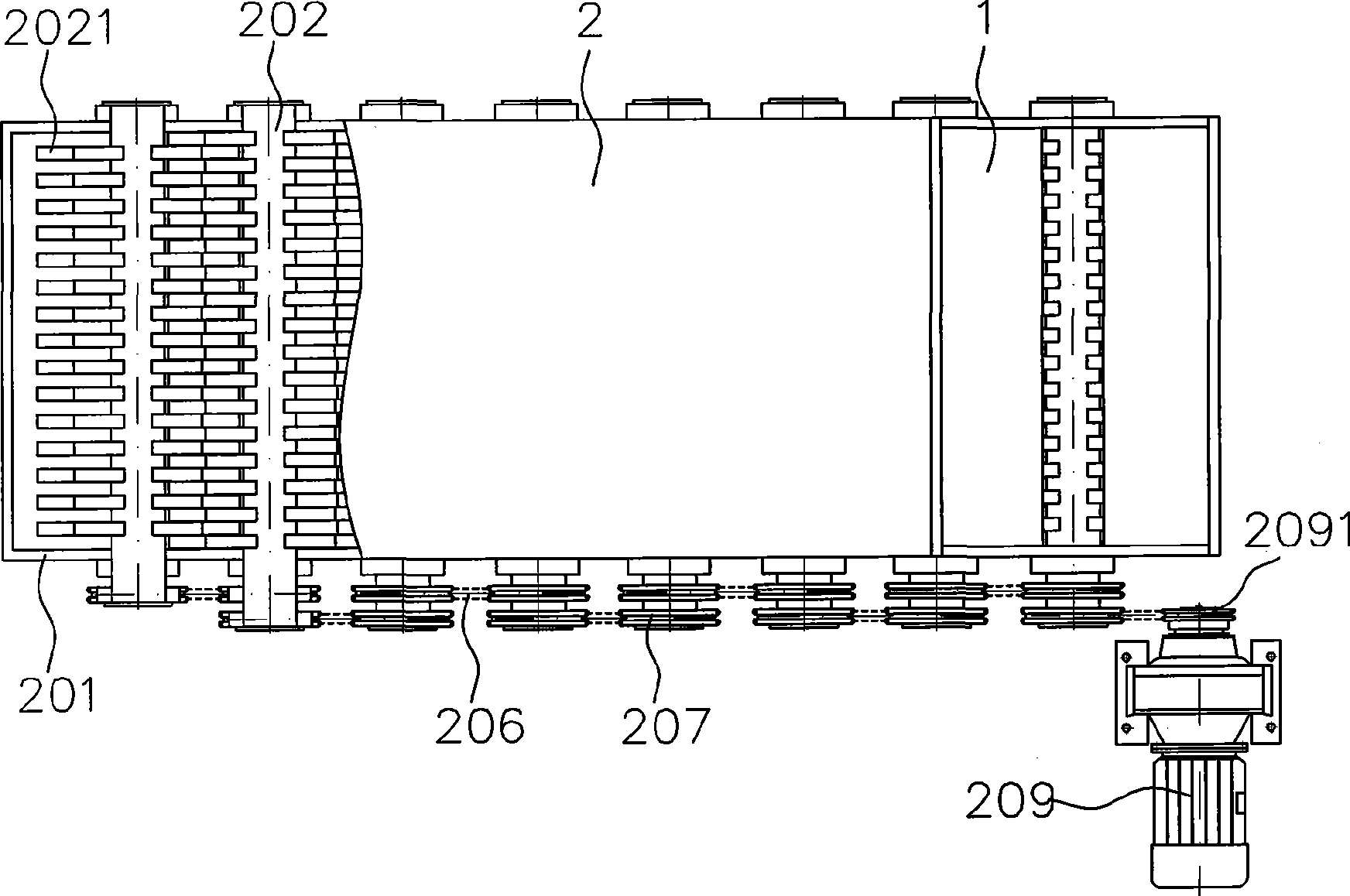

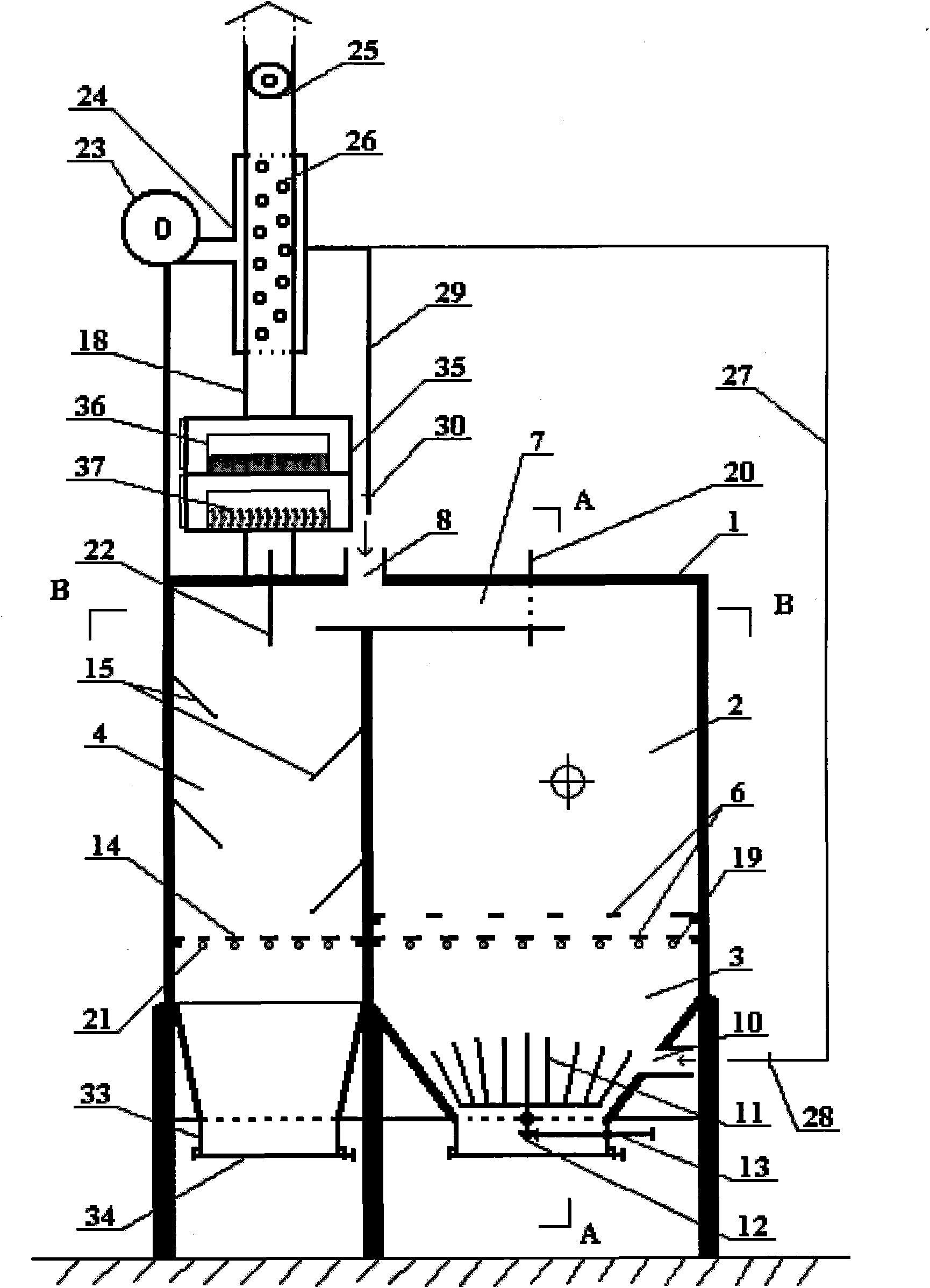

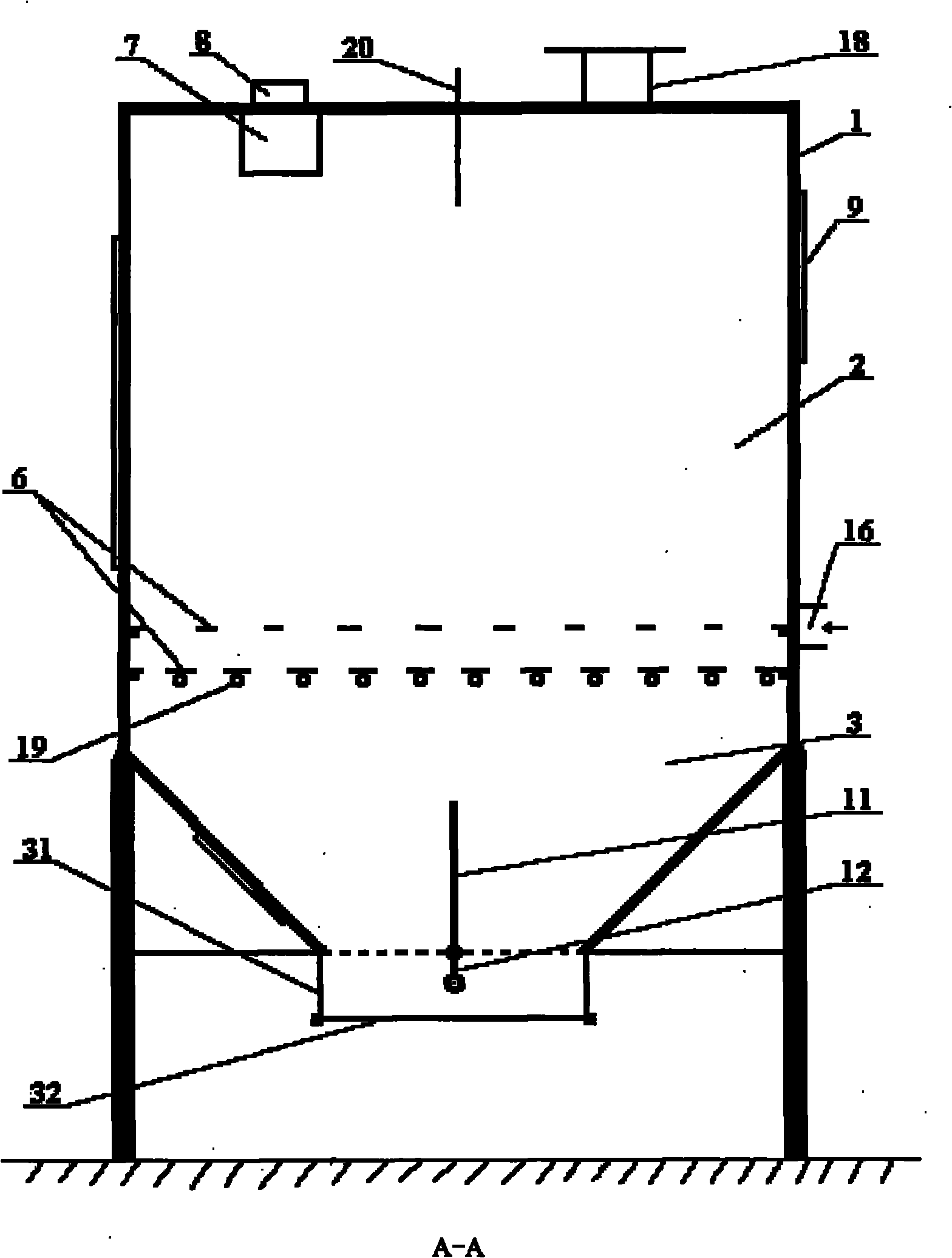

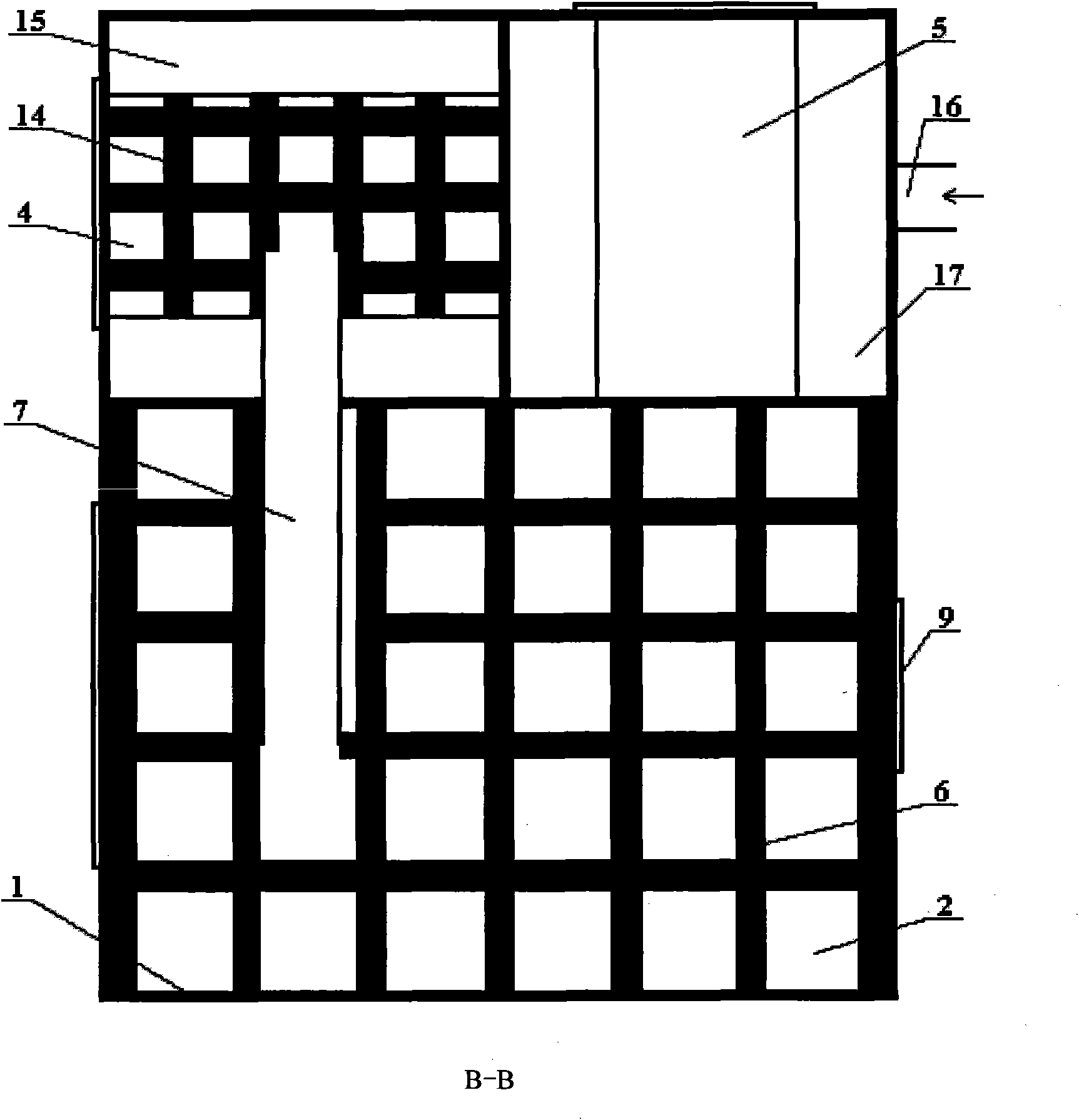

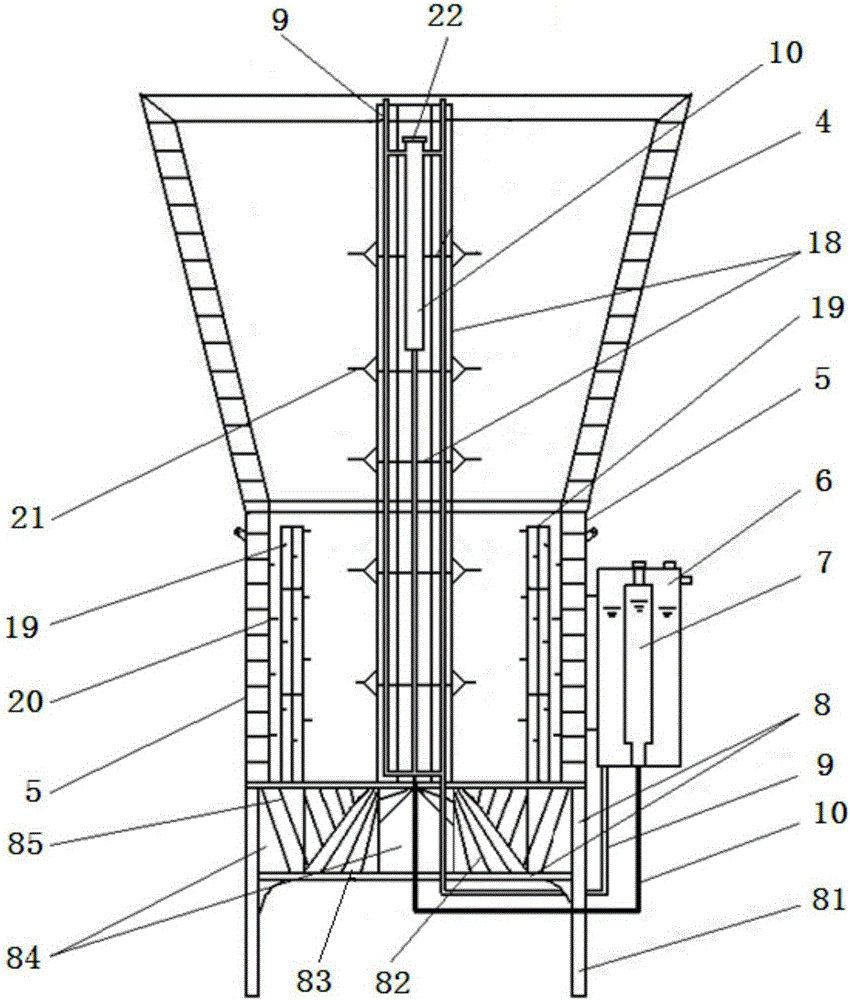

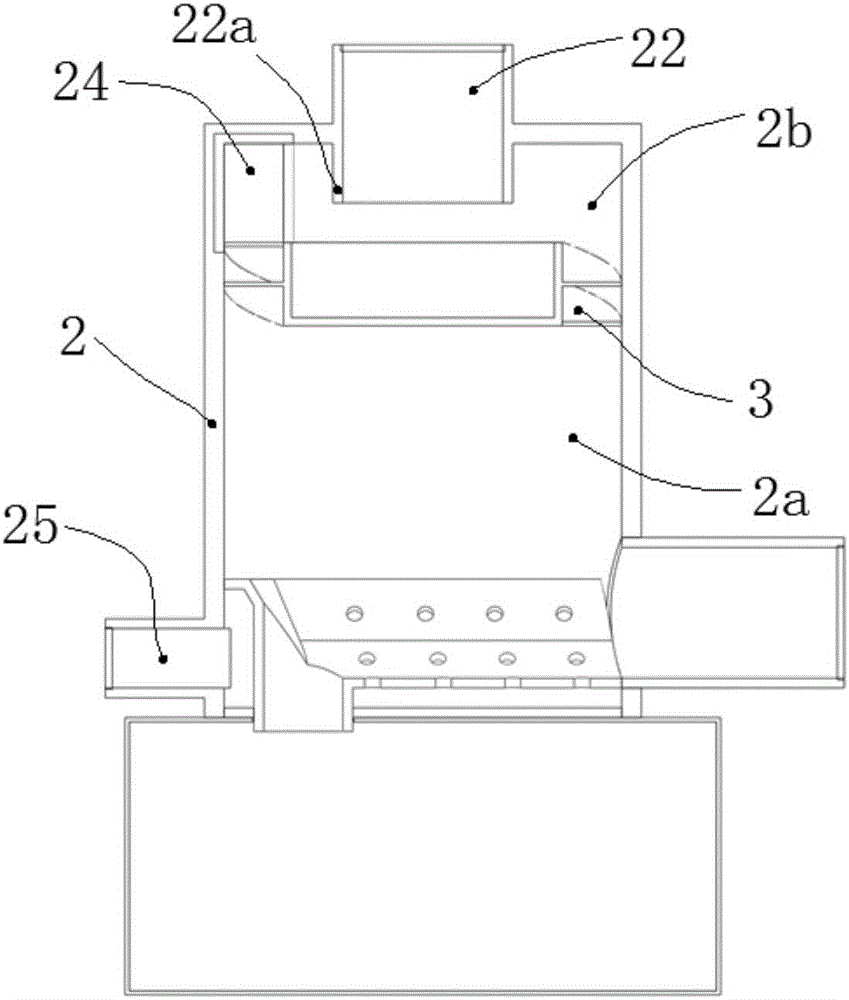

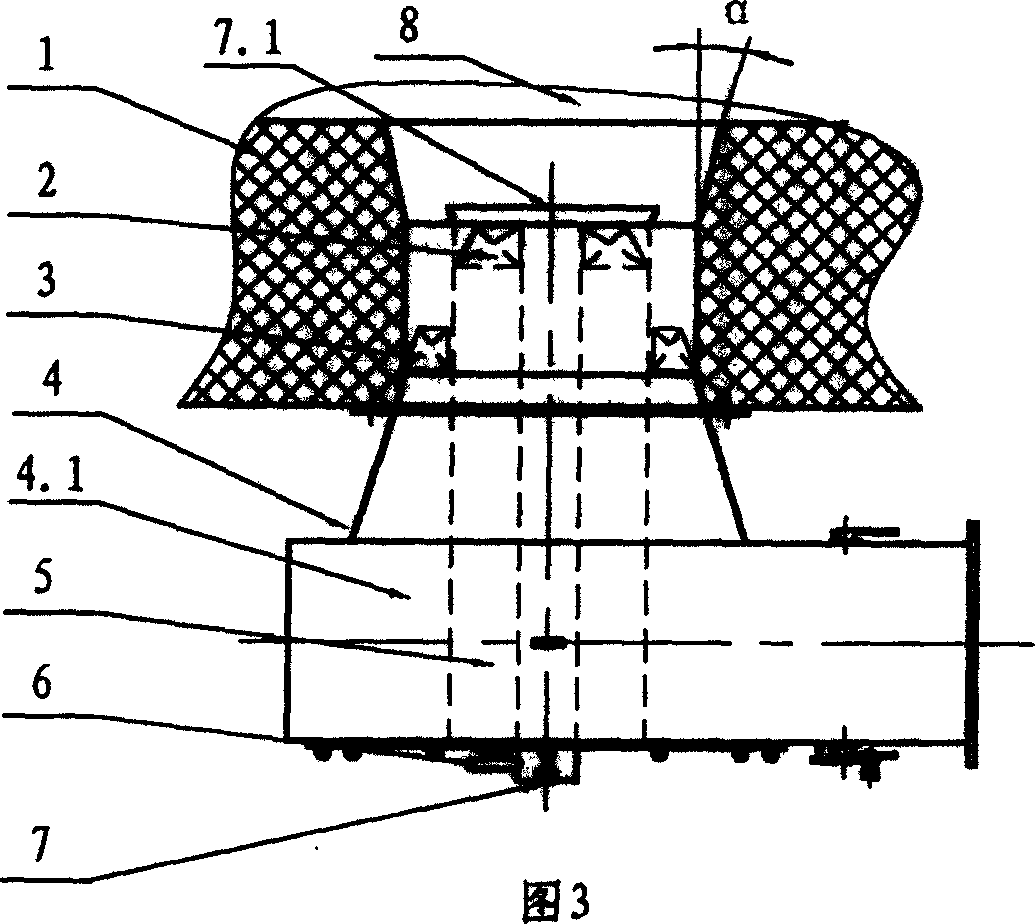

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

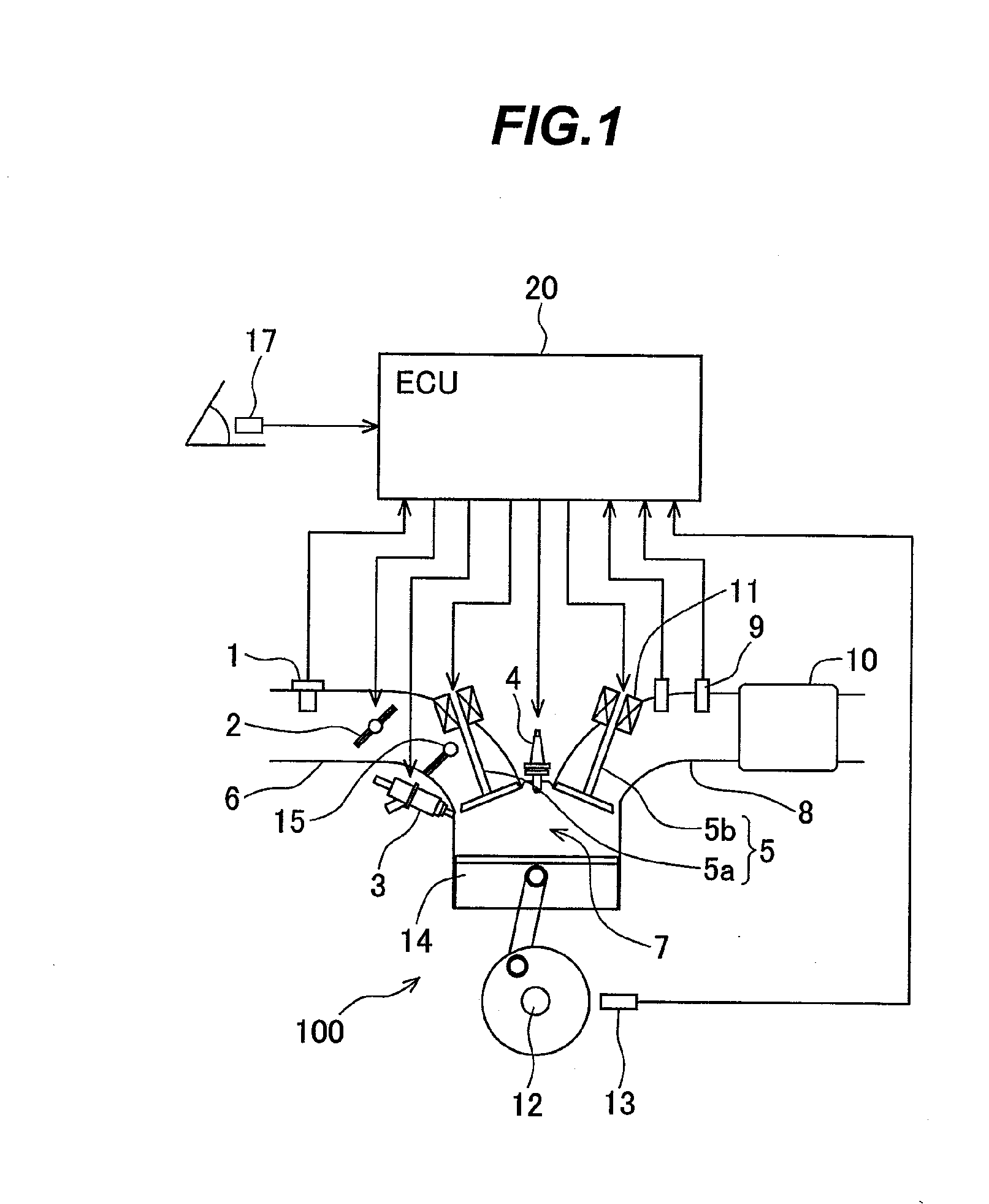

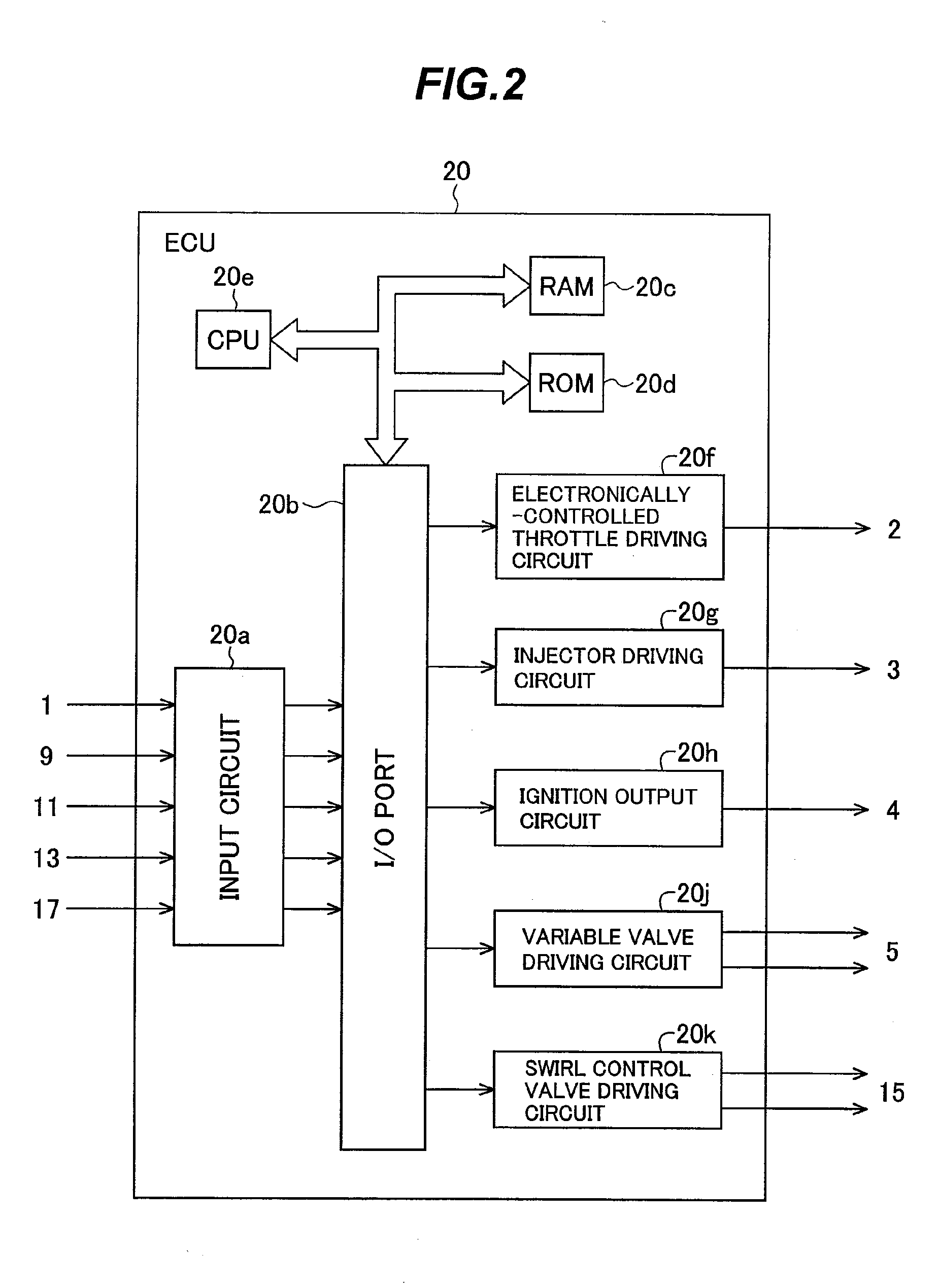

Apparatus and method for Controlling a Homogeneous Charge Compression-Ignited Internal-Combustion Engine

InactiveUS20090259387A1Reduce noiseReduce torque fluctuationElectrical controlInternal combustion piston enginesDiscriminatorHomogeneous charge compression ignition

In a homogeneous charge compression-ignited internal-combustion engine, based on information regarding the operational state of the engine, a combustion mode switching discriminator selects a homogeneous charge compression-ignited combustion mode if engine operating conditions allow homogeneous charge compression-ignited combustion. If not, the combustion mode switching discriminator selects a spark-ignited combustion mode. Immediately after switching from spark-ignited combustion to homogeneous charge compression-ignited combustion, a combustion mode switching corrector outputs switching correction values for operating quantities for homogeneous charge compression-ignited combustion. The correction values are used to adjust the operating quantities for homogeneous charge compression-ignited combustion, and new operating quantities obtained from the adjustments are output as control quantities from a combustion mode selector.

Owner:HITACHI LTD

Controllable combustion method and device

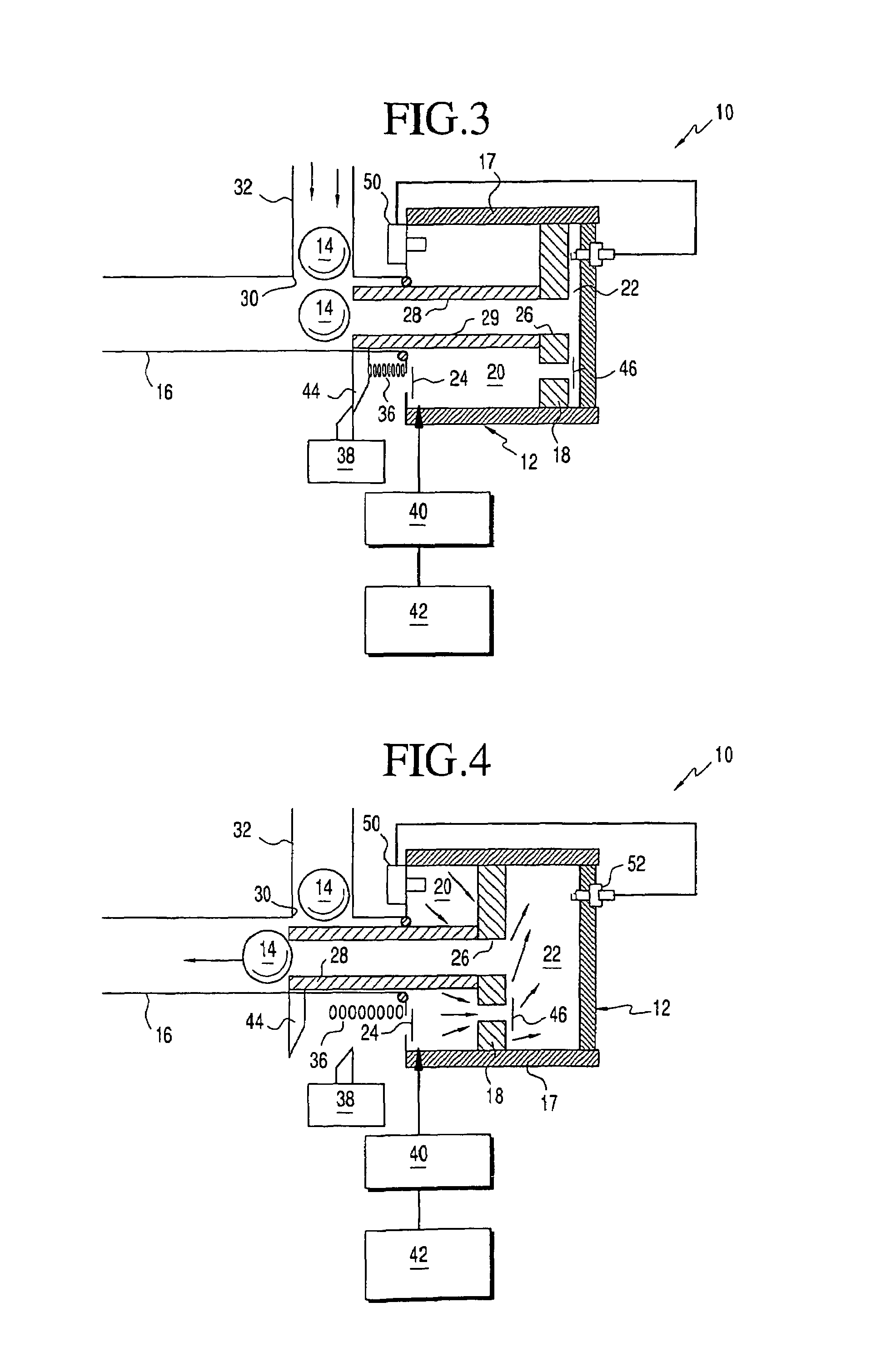

InactiveUS6938588B2High bandwidthFast energy extractionPulsating combustionFuel-injection pumpsCombustionEngineering

A method and device for controllably combusting combustible material, including a combustion device comprising an elongate combustion tube having an inlet section including an inlet for combustible material, an ignition section, including an igniter displaced along a length of the tube from the inlet section to ignite the combustible material, and at least one energy extraction device operatively coupled to the combustion tube and configured to extract energy from combustion of the combustible mixture.

Owner:SARCOS LC

Small efficient medicinal rubbish pyrolysis incinerator

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

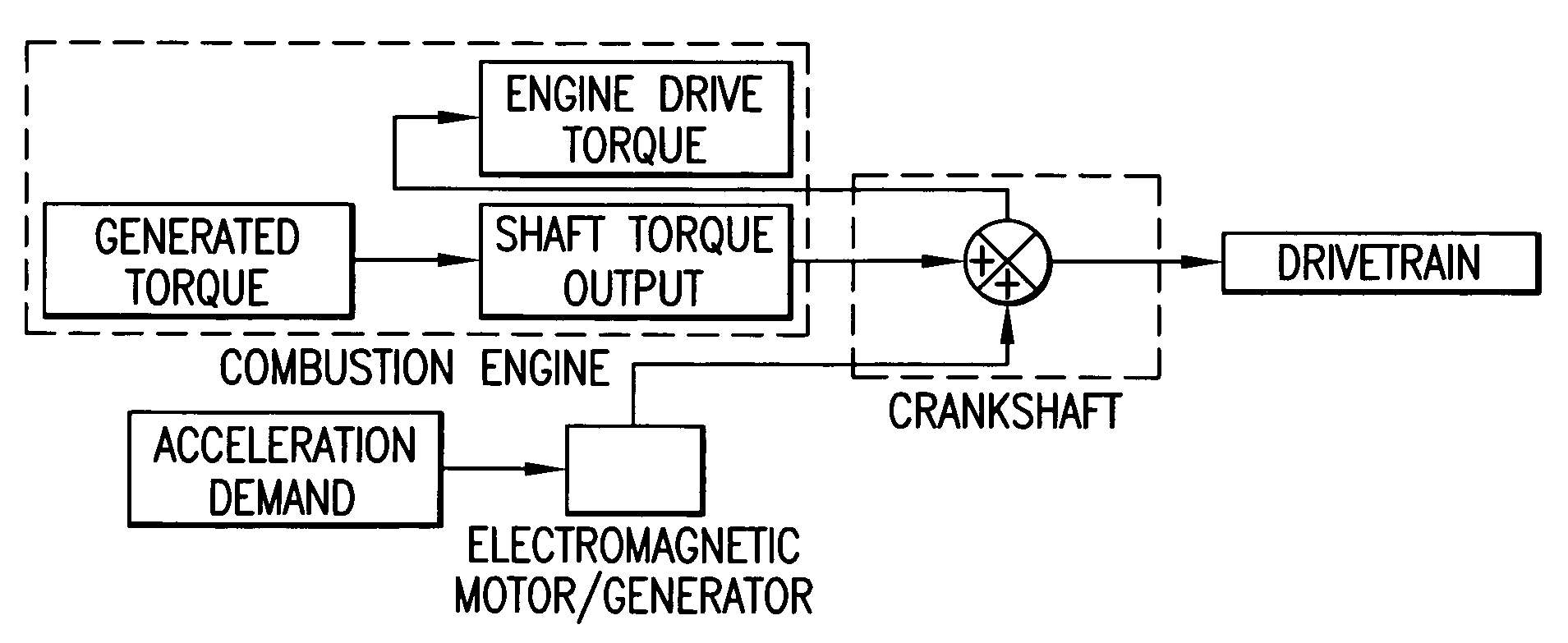

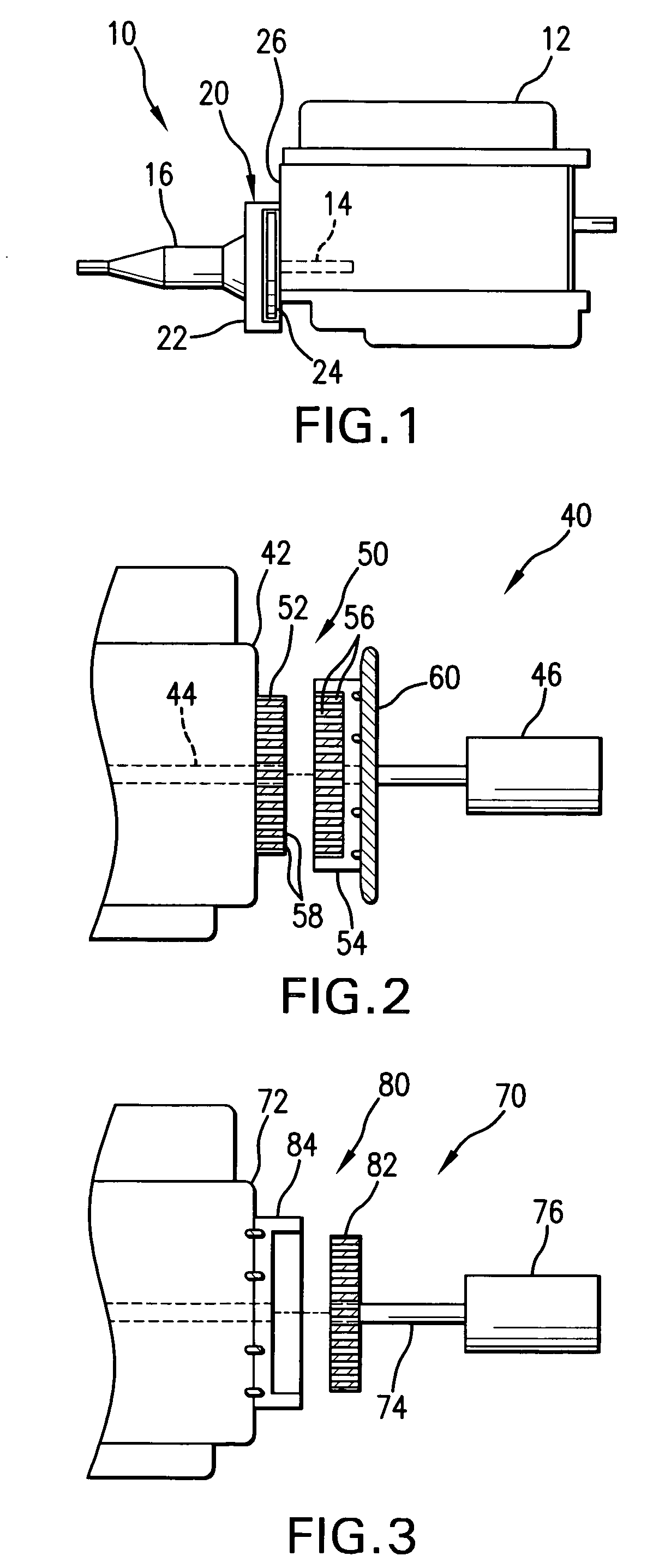

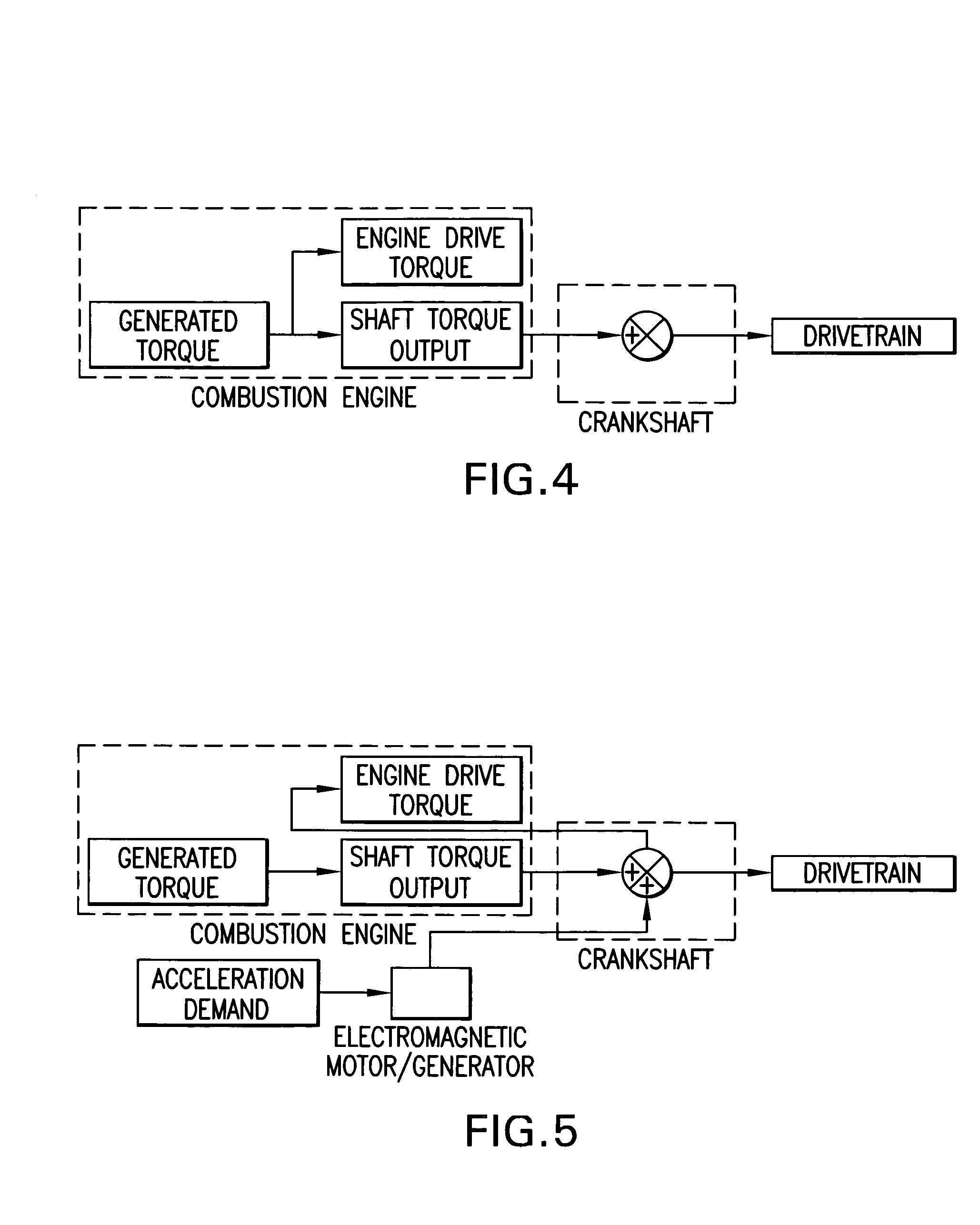

Combustion engine acceleration support using an integrated starter/alternator

ActiveUS7024859B2Increase probabilityImprove efficiencyReciprocating combination enginesCombination enginesAlternatorCombustion

A method of providing acceleration support to a combustion engine using an integrated starter / alternator. The integrated starter / alternator is in rotational combination with the crankshaft and connected to a battery system. The integrated starter / alternator is adapted to function at times as a power source adding torque to rotate the crankshaft to overcome friction and non-linear hydrodynamic forces within the engine. At other times the integrated starter / alternator functions as a power generator for subtracting torque from the crankshaft to provide electrical current to the battery system.

Owner:TURNTIDE TECH INC

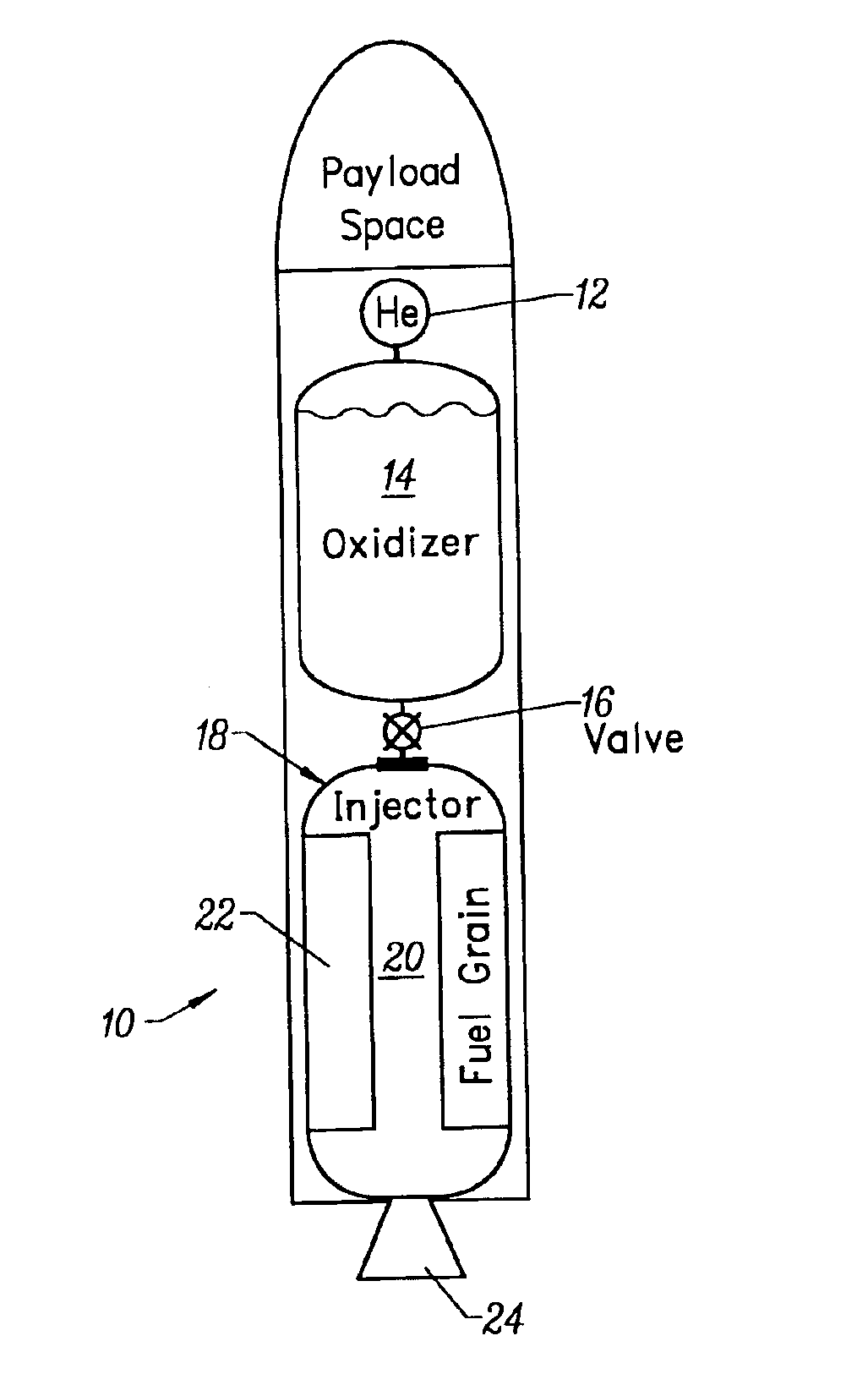

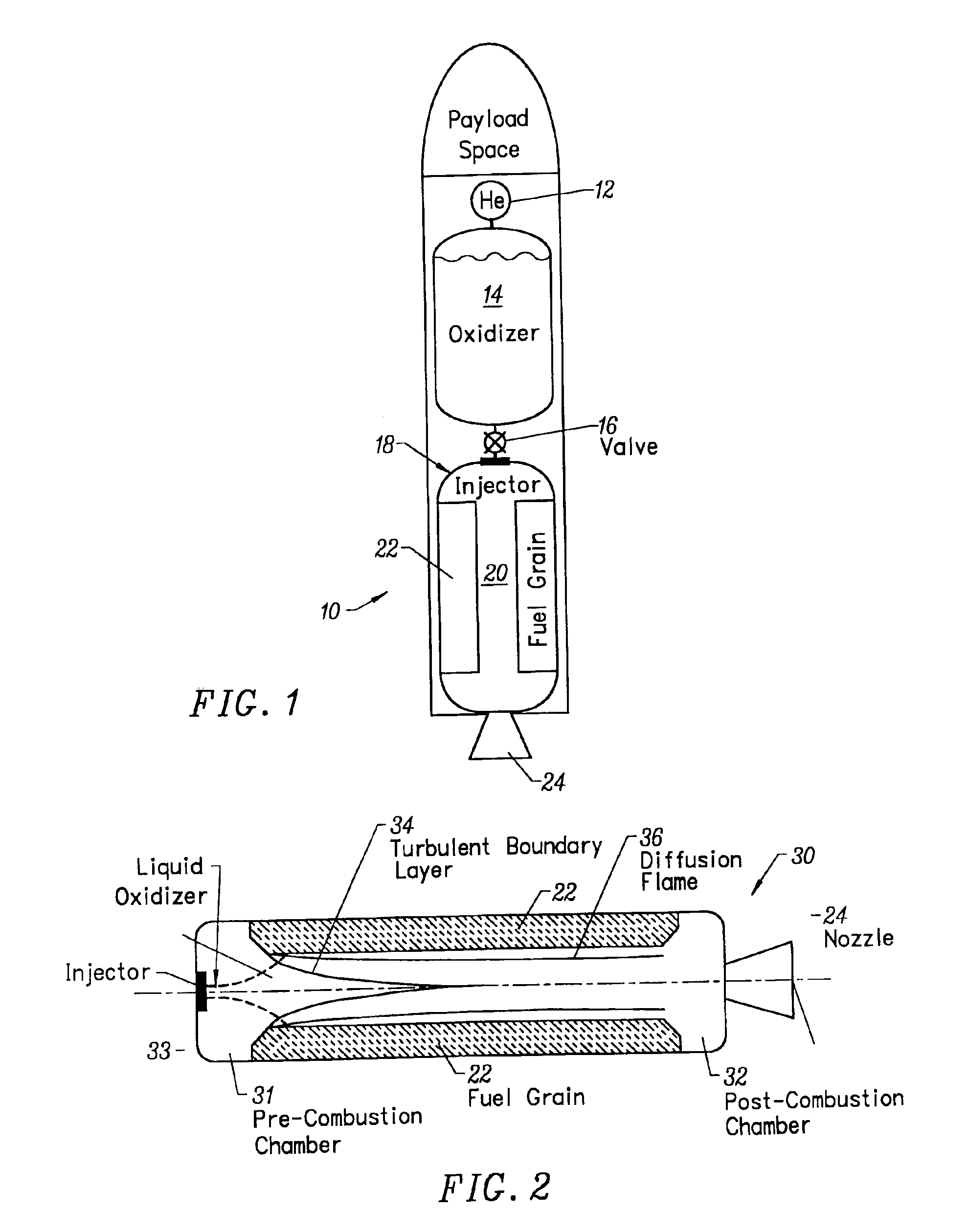

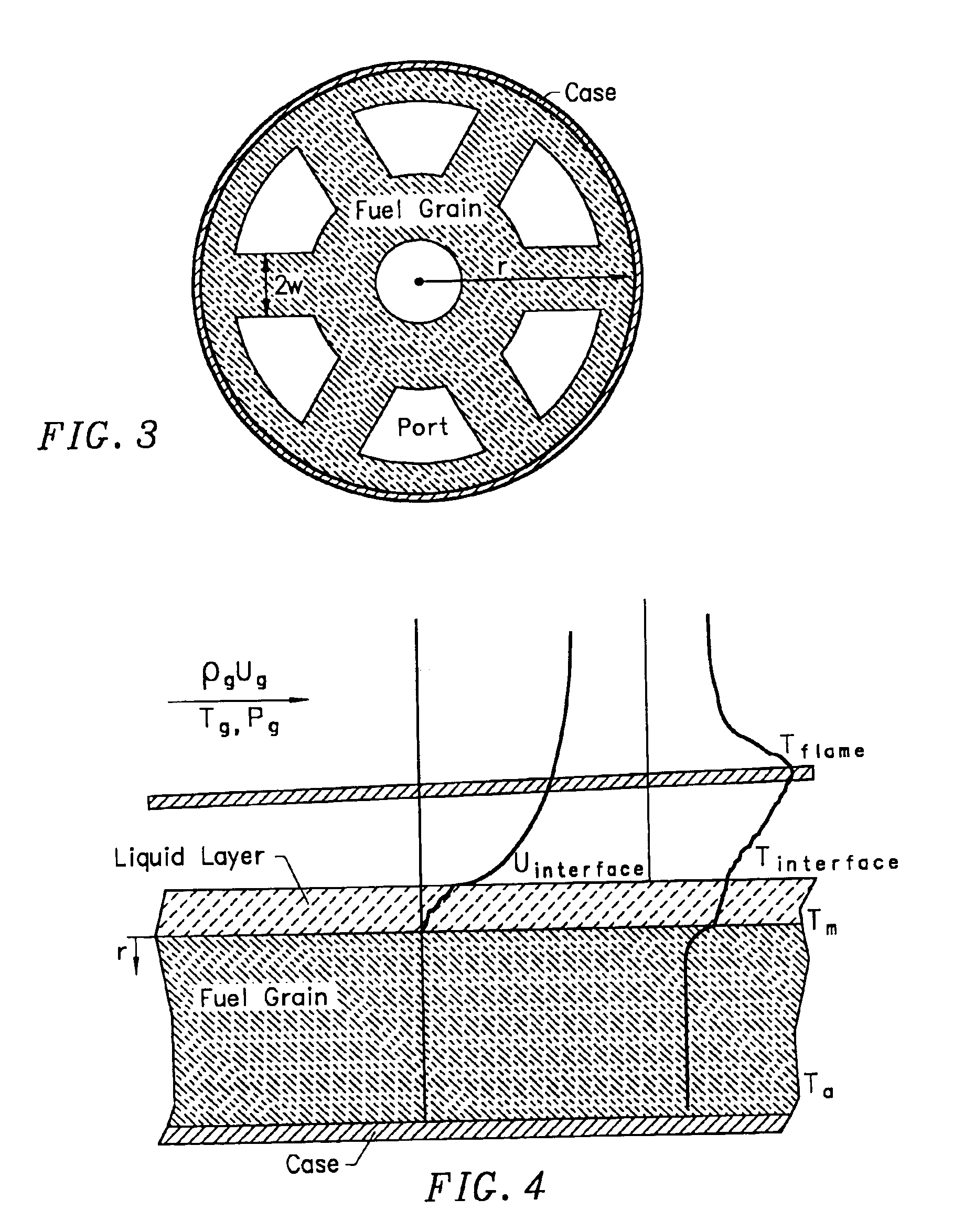

High regression rate hybrid rocket propellants and method of selecting

This invention comprises a new process for developing high regression rate propellants for application to hybrid rockets and solid fuel ramjets. The process involves the use of a criterion to identify propellants which form an unstable liquid layer on the melting surface of the propellant. Entrainment of droplets from the unstable liquid-gas interface can substantially increase propellant mass transfer leading to much higher surface regression rates over those that can be achieved with conventional hybrid propellants. The main reason is that entrainment is not limited by heat transfer to the propellant from the combustion zone. The process has been used to identify a new class of non-cryogenic hybrid fuels whose regression rate characteristics can be tailored for a given mission. The fuel can be used as the basis for a simpler hybrid rocket design with reduced cost, reduced complexity and increased performance.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

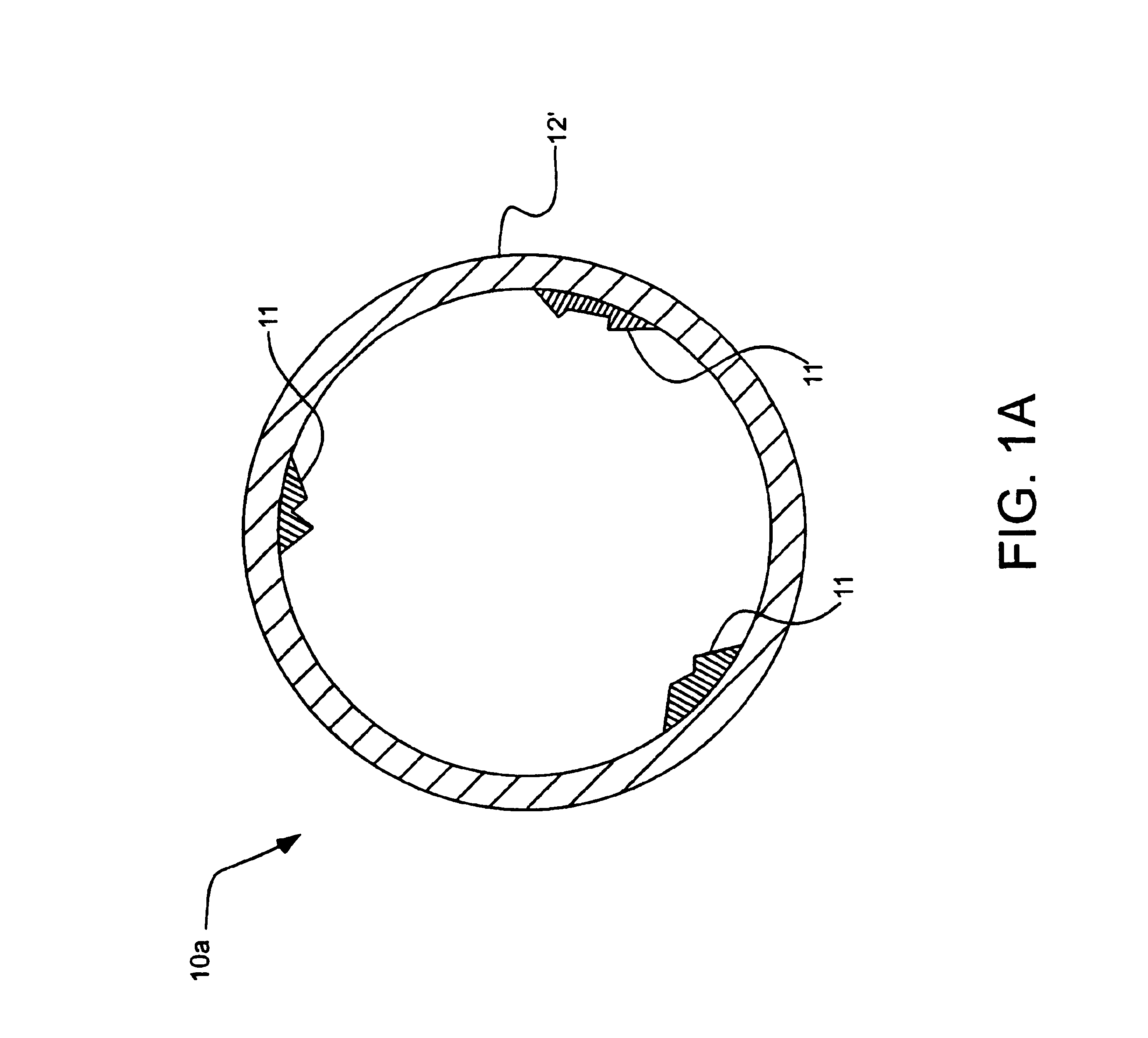

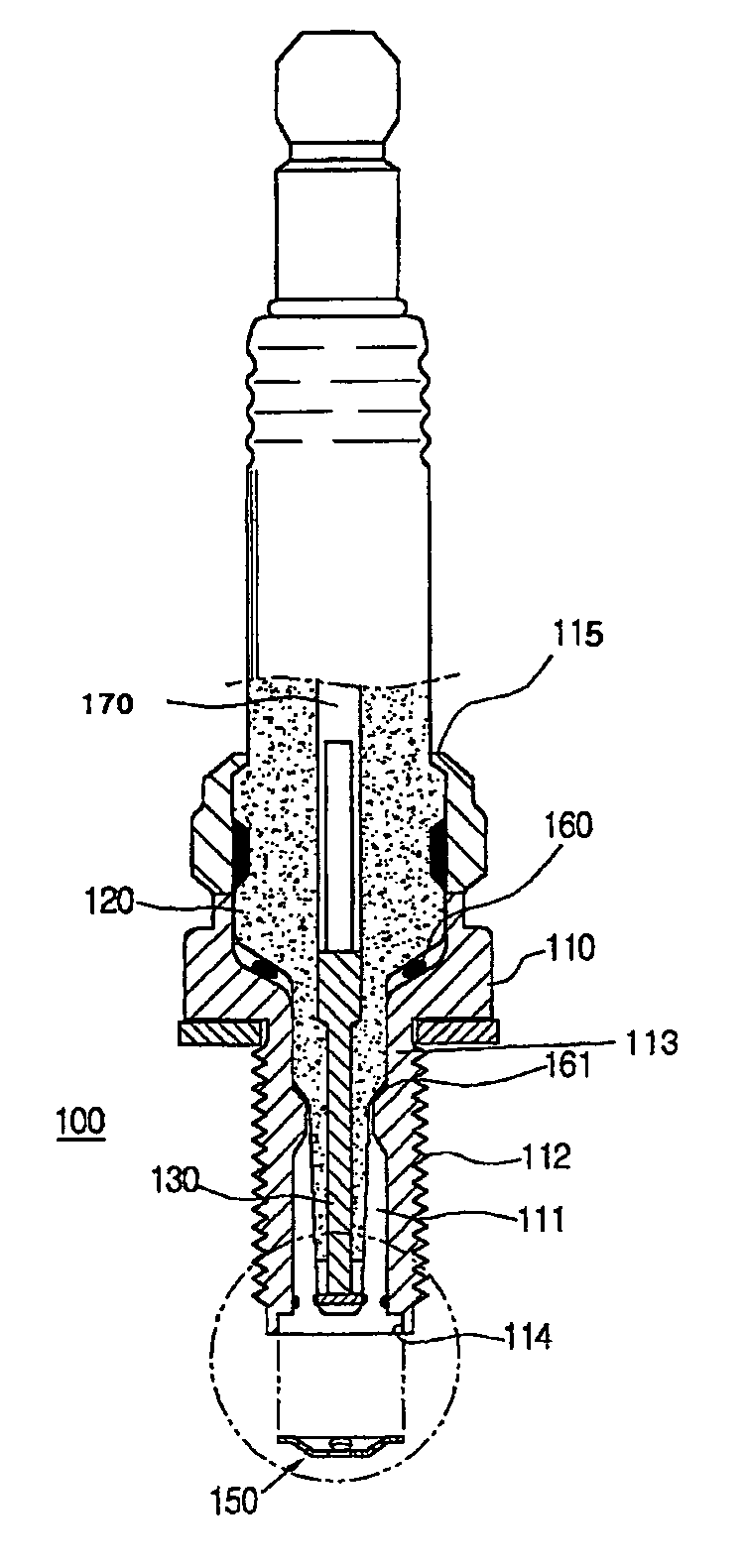

Ignition spark plug

InactiveUS7628130B2Extend your lifePrevent abnormal ignitionSparking plugsMachines/enginesCombustion chamberEngineering

An ignition plug is disclosed which includes a hollow main cell having a bendable extension part and a primary combustion chamber, an insulator mounted in the main cell, to insulate a terminal rod centrally embedded in the main cell, a central electrode having a first electrical contact arranged in the primary combustion chamber, the central electrode extending downwardly from the terminal rod while being surrounded by the insulator, a second electrical contact provided at a lower inner surface of the main cell while being arranged in the primary combustion chamber, the second electrical contact corresponding to the first electrical contact, and a cross flame ignition valve coupled to the main cell by the extension part in a bent state of the extension part, the cross flame ignition valve having a main ignition hole and auxiliary ignition holes for guiding flames from the primary combustion chamber to an interior of a cylinder.

Owner:JOHNG IN TAE

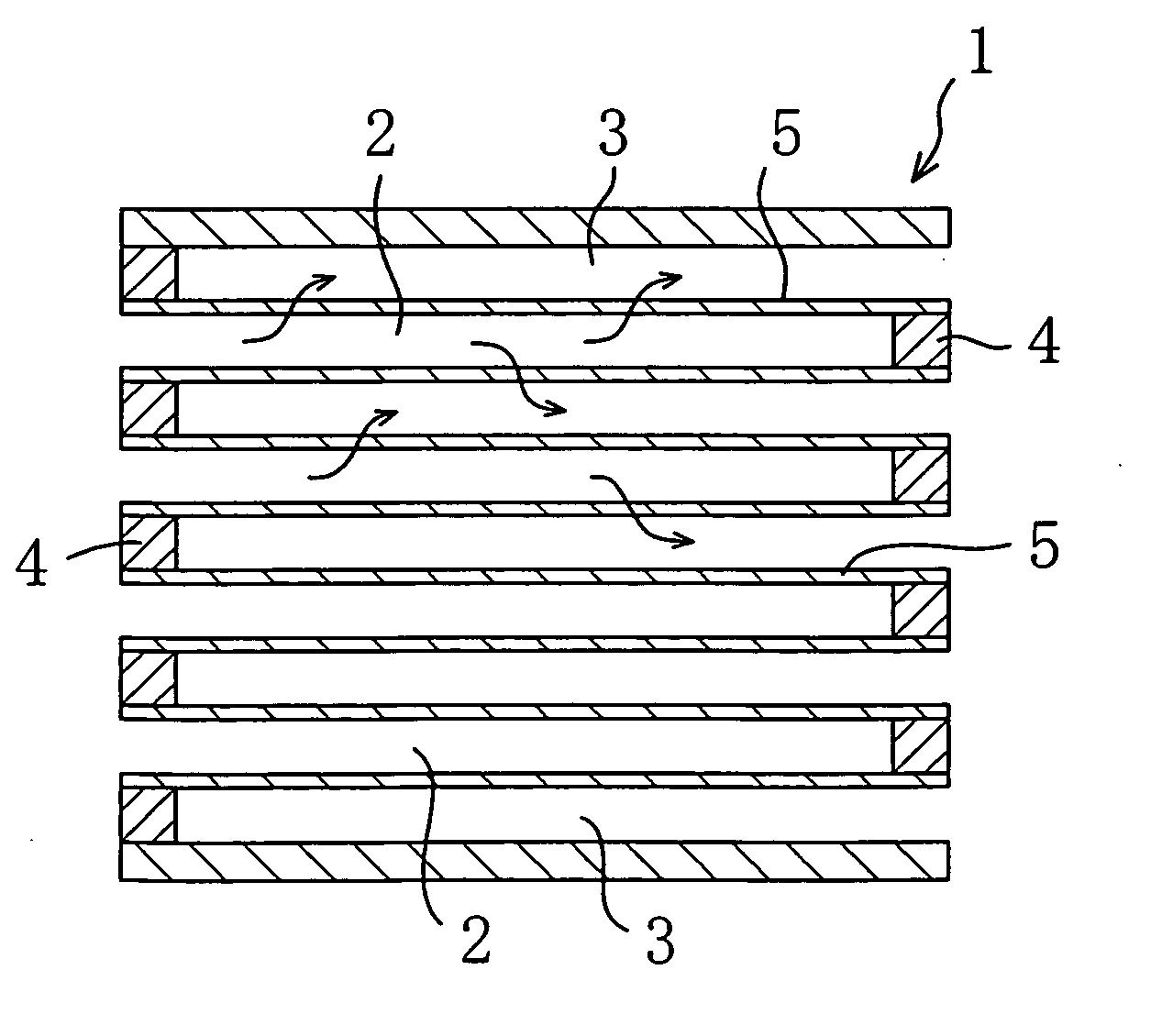

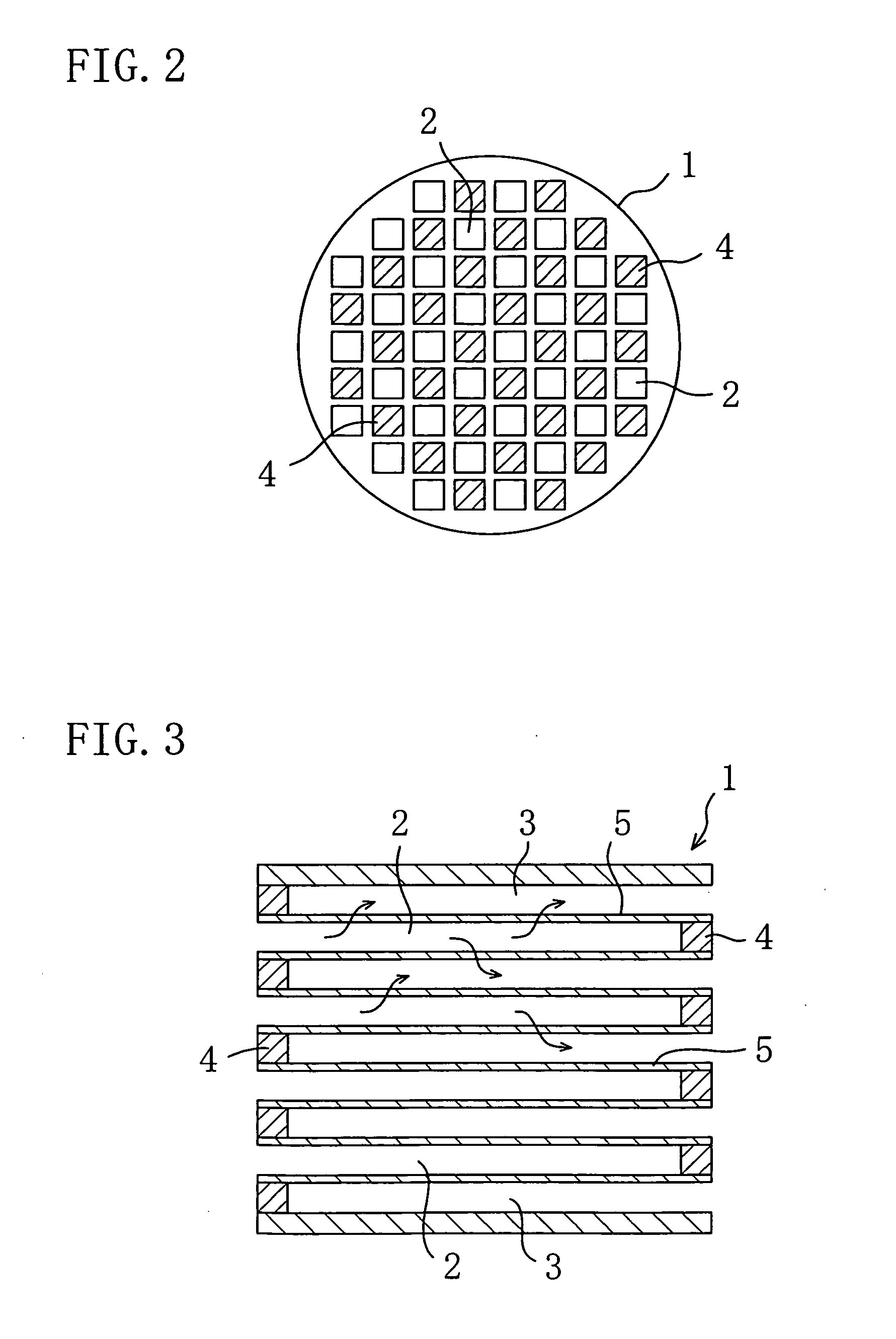

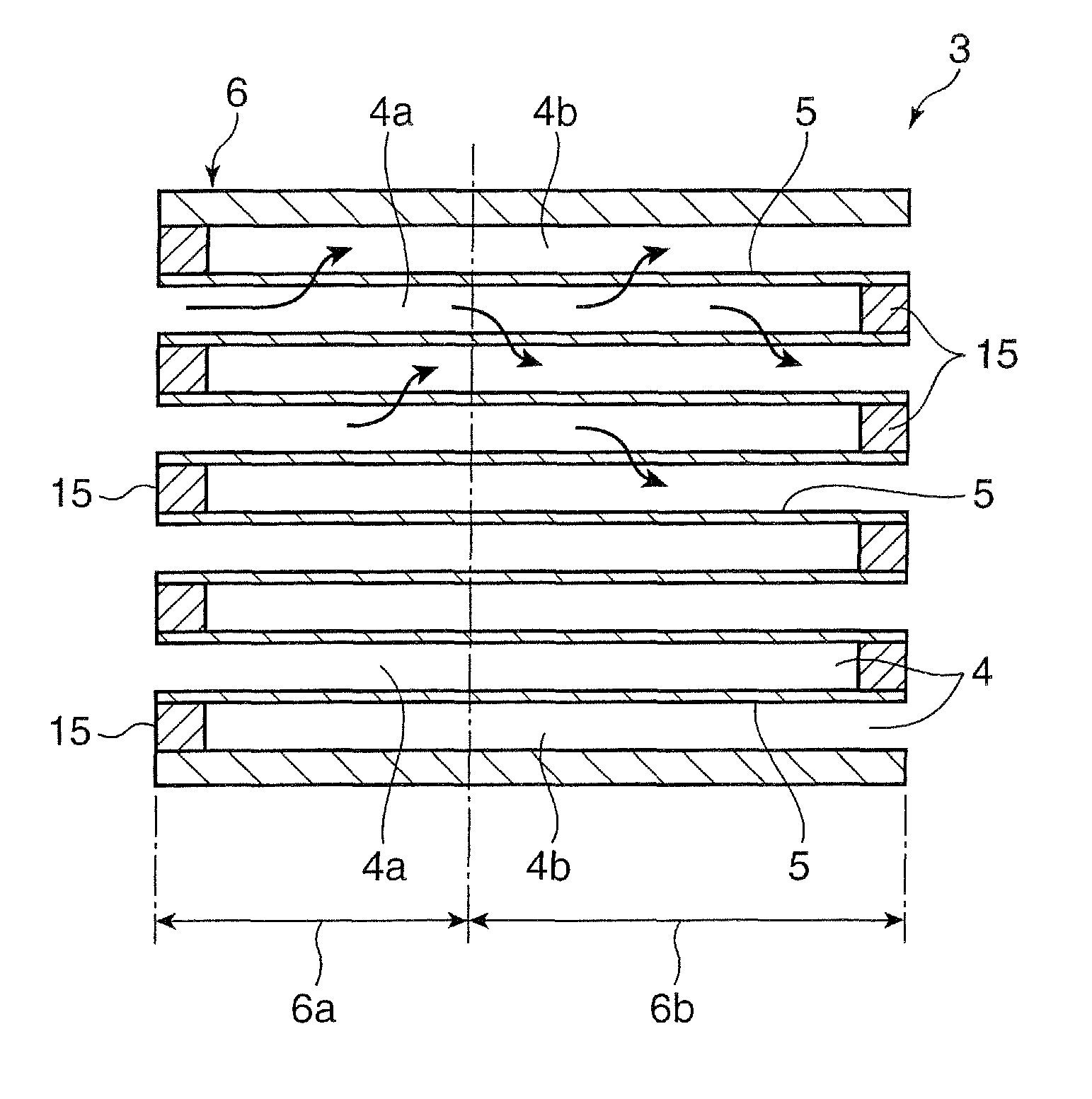

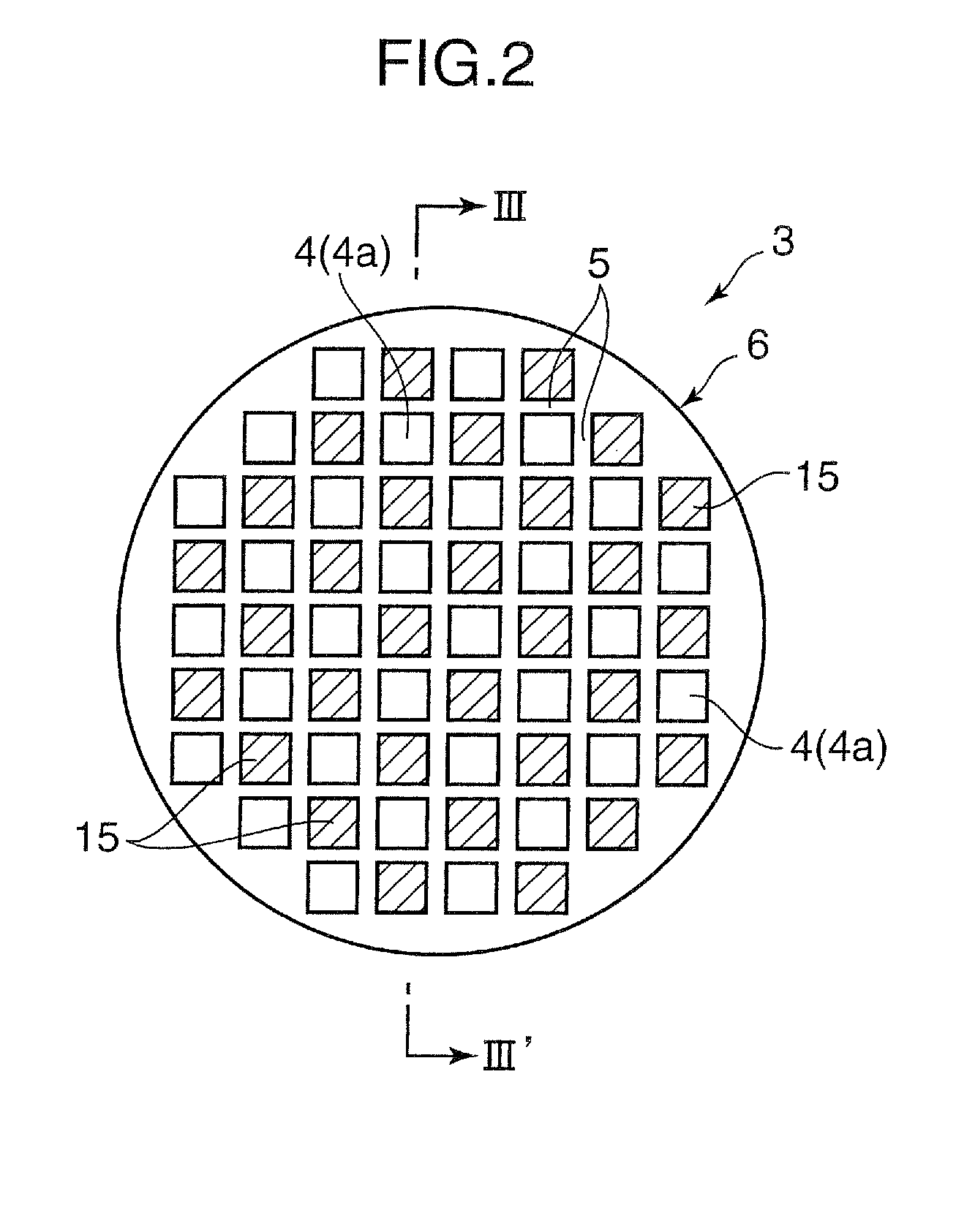

Diesel particulate filter

InactiveUS20060245985A1Increasing particulate burning rateEasy to oxidizeCombination devicesLoose filtering material filtersRare-earth elementMixed oxide

The present invention is intended to configure a diesel particulate filter to allow the burning rate of particulates to increase even with a small amount of catalytic metal or even without using any catalytic metal. In the diesel particulate filter, walls forming exhaust gas channels in a filter body on which the particulates are trapped are coated with a catalyst layer for promoting the burning of the trapped particulates. The catalyst layer contains a mixed oxide in which Ce, Zr and a rare earth element R other than Ce are contained in a Ce / (Ce+Zr) mole ratio between 10% and 90% both inclusive or between 20% exclusive and 80% inclusive.

Owner:MAZDA MOTOR CORP

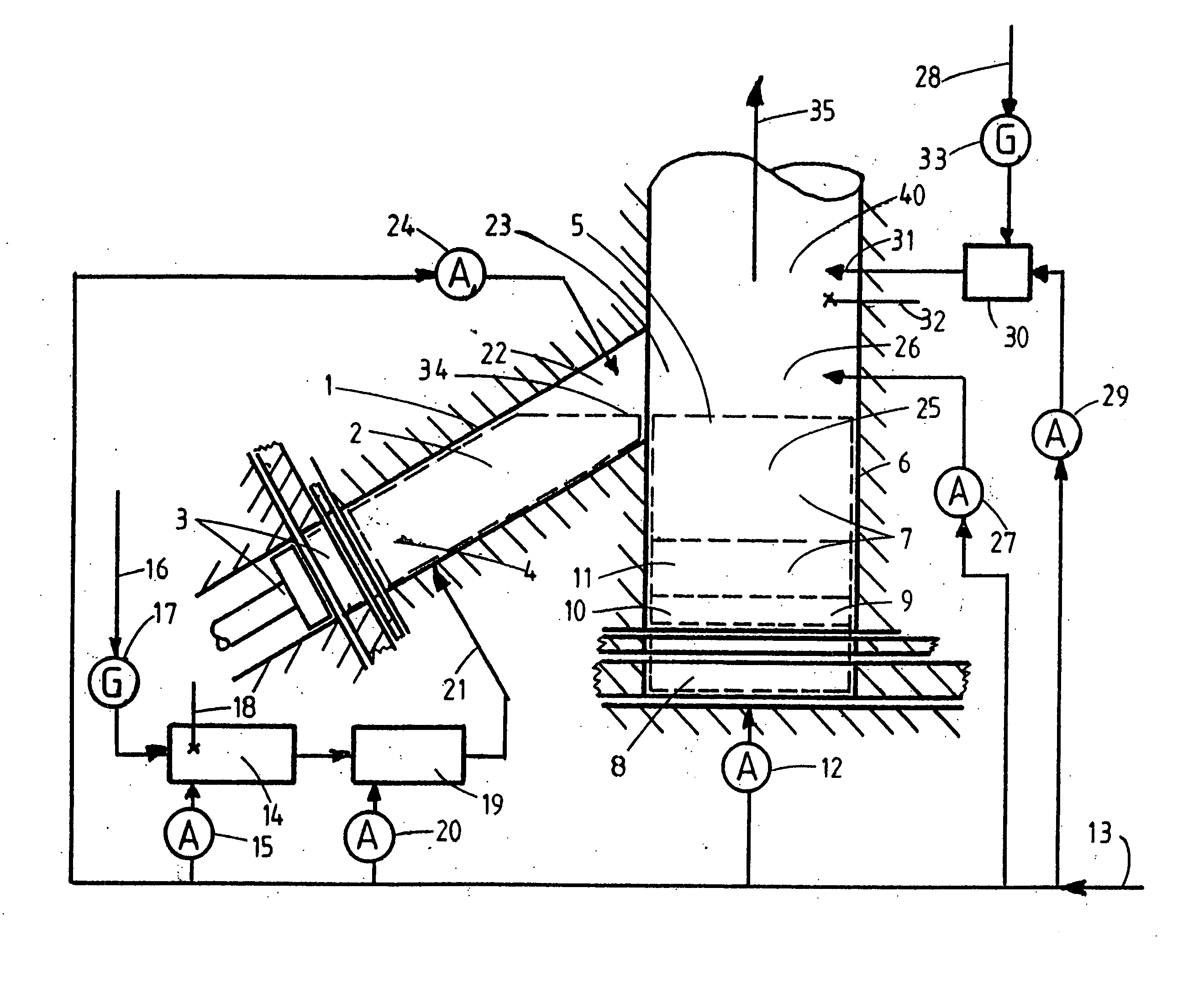

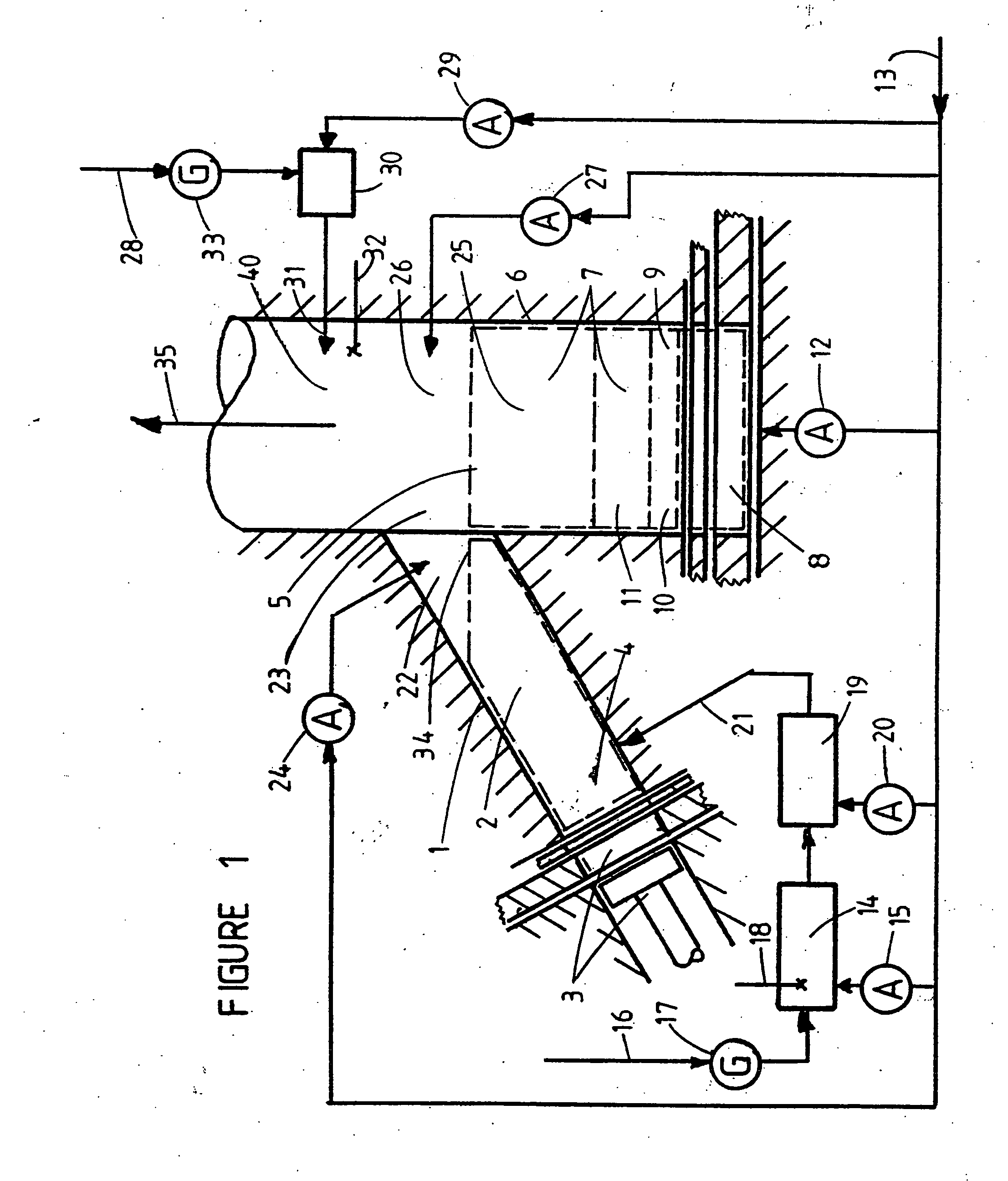

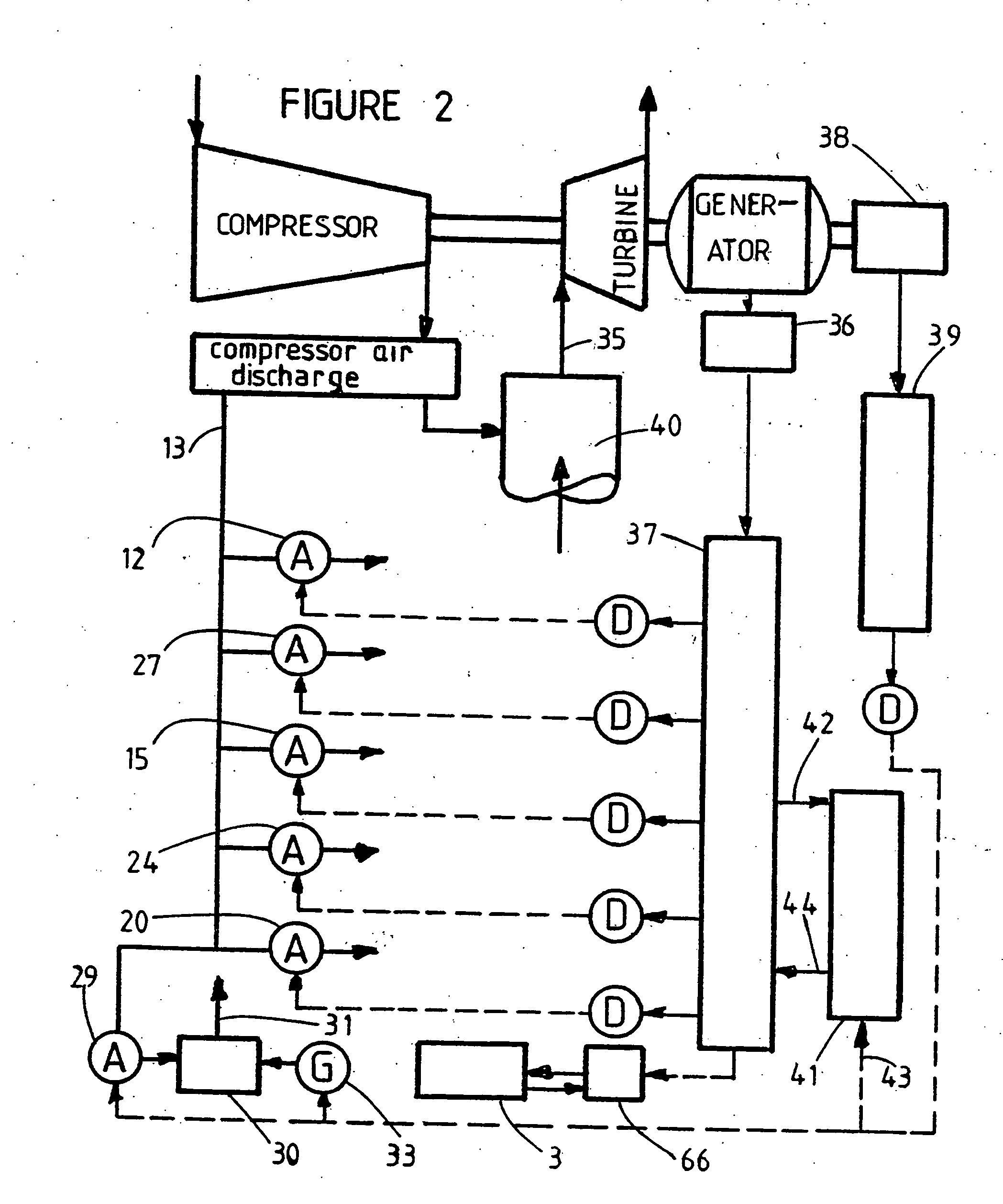

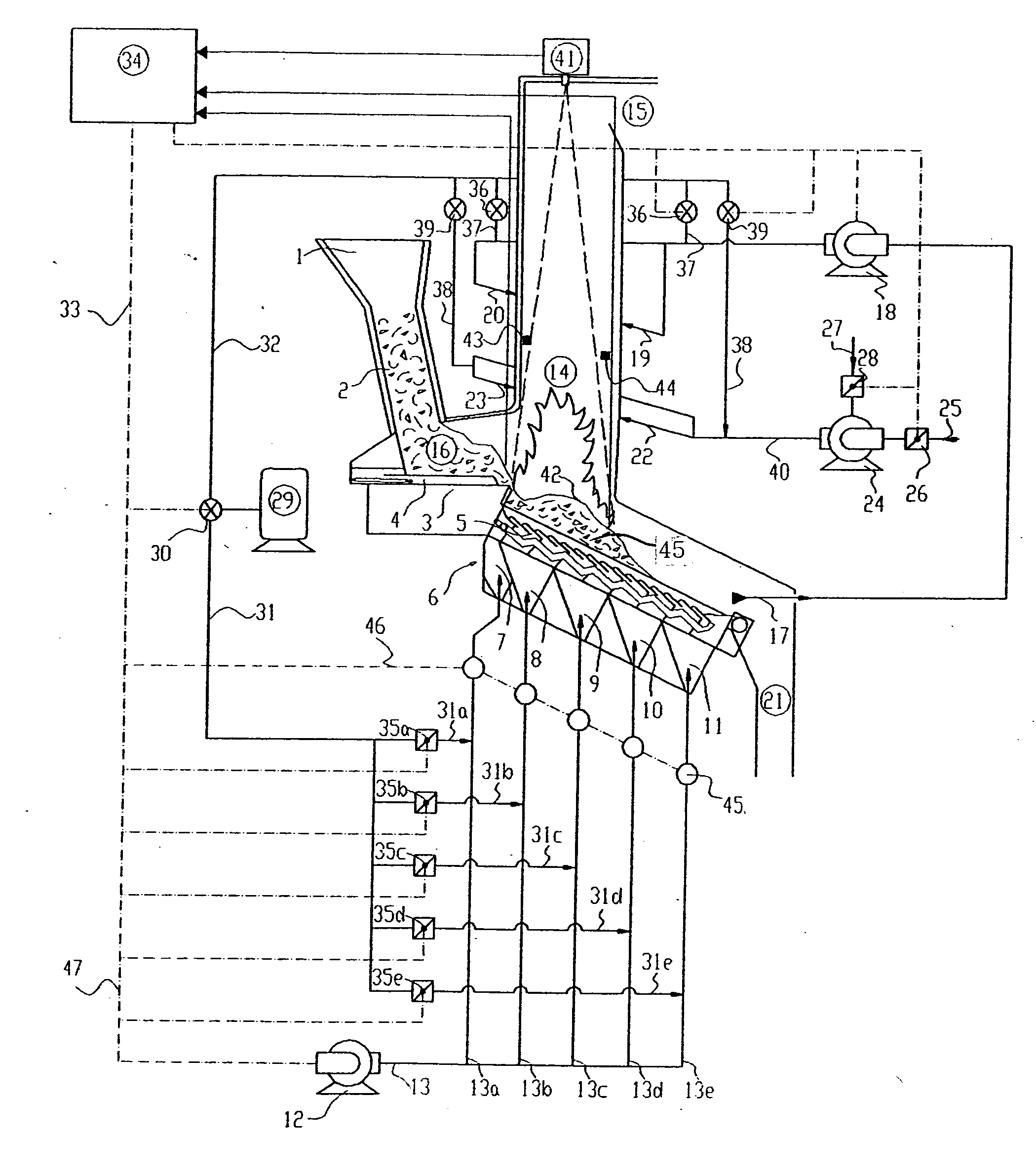

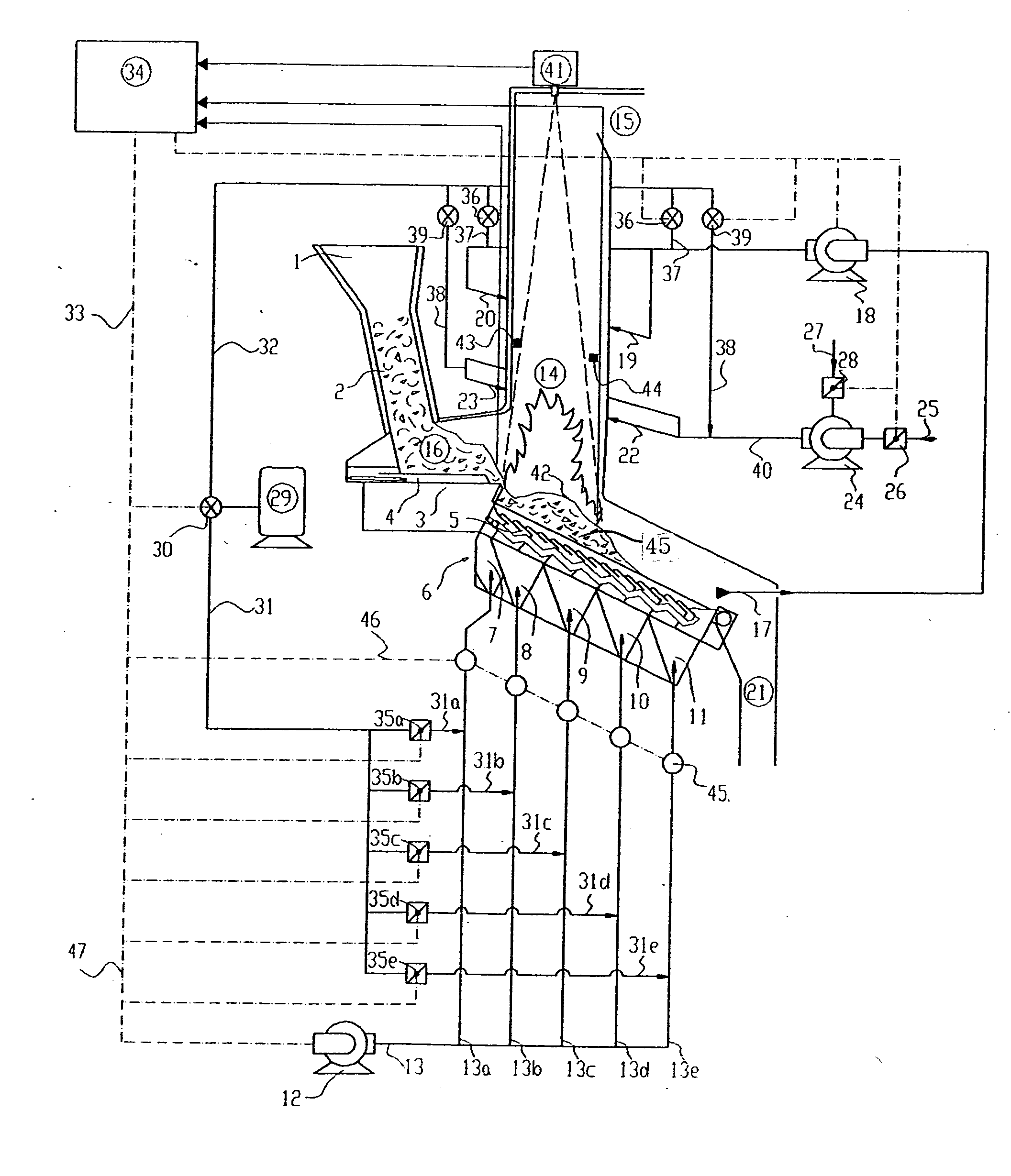

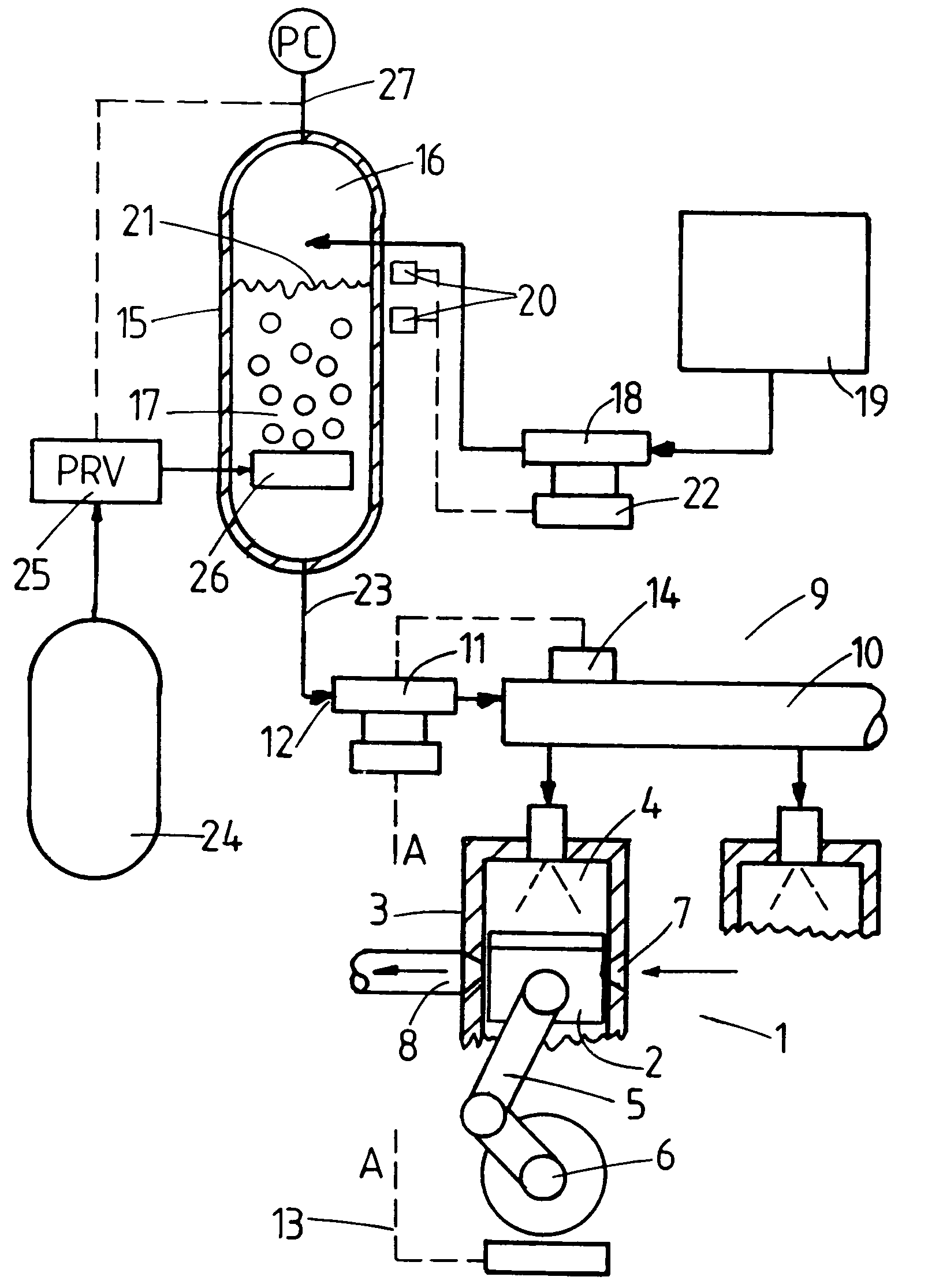

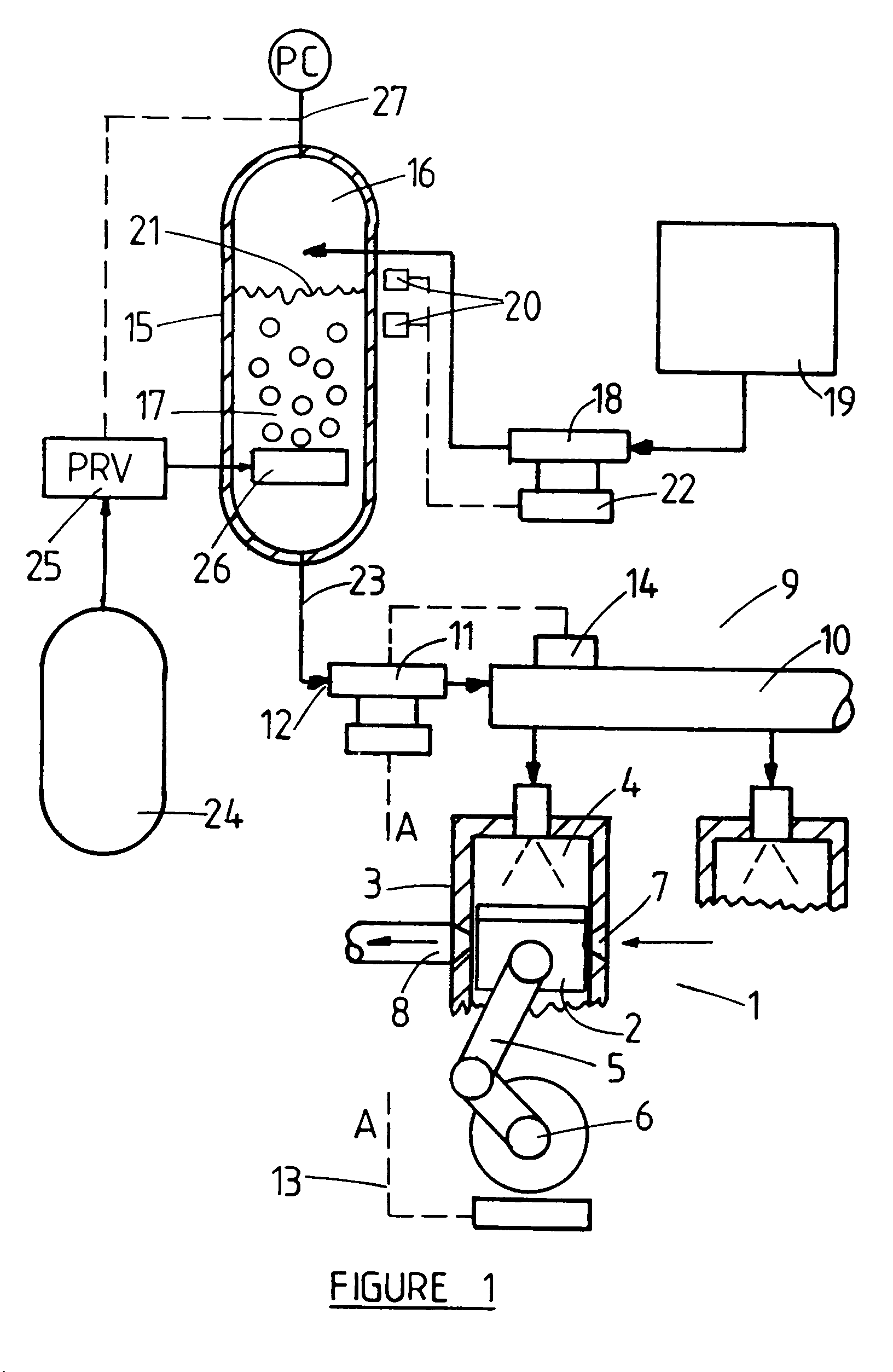

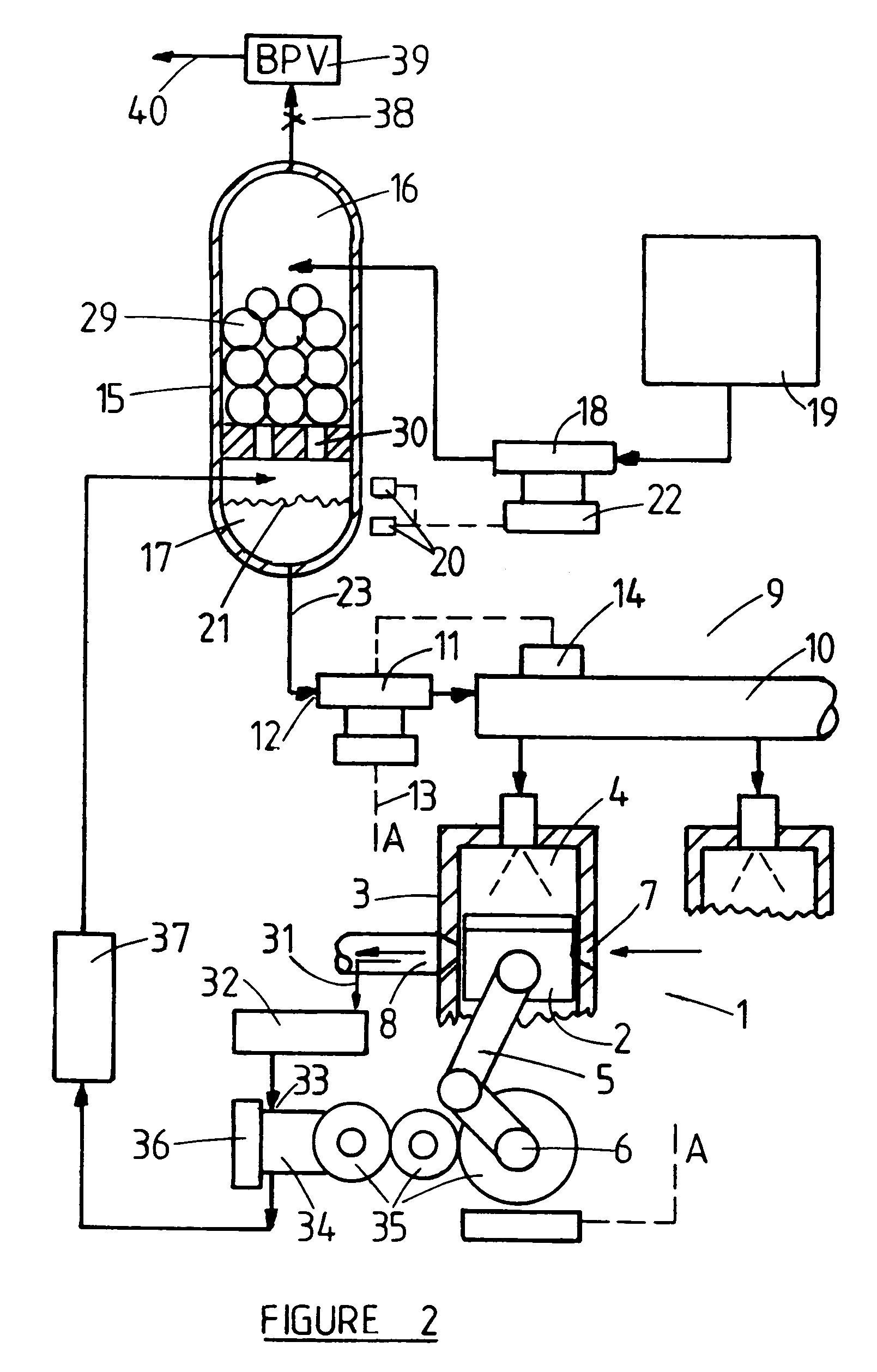

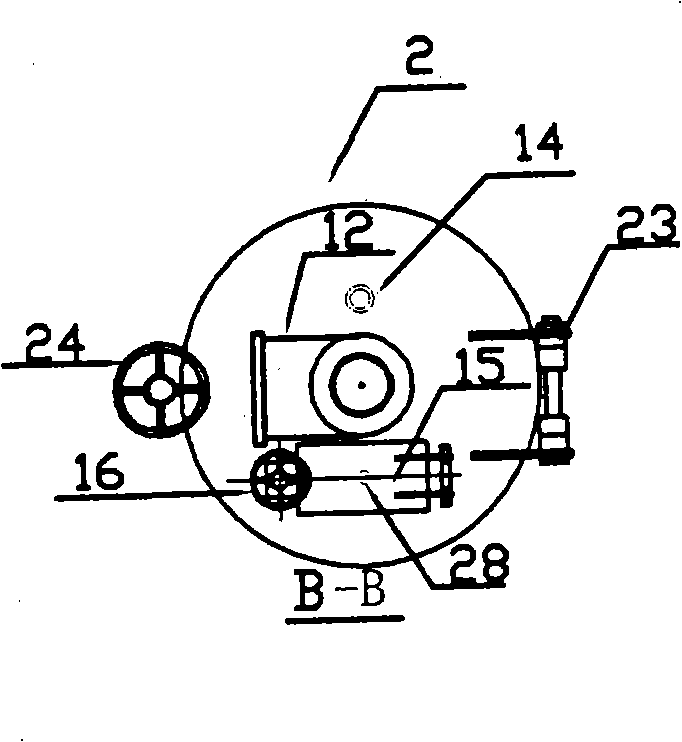

Mixed fuel coal burner for gas turbines

InactiveUS20070079594A1Reduce creationClean burningCombustion enginesGas turbine plantsPartial oxidationCombustion chamber

As shown schematically in FIG. 1, hot gases, containing molecular oxygen, from generator elements, (14) and (19), pass through a bed of coal chunks in an ODD reactor chamber (2). The molecular oxygen content of these hot gases is less than stoichiometric, relative to the coal volatile matter content, so that partial oxidation of only the volatile matter occurs within the ODD reactor chamber, (2), during devolatilization therein. Two products are thusly created, a partially oxidized, and hence cleaner burning, volatile matter fuel gas, and a solid devolatilized coke. The hot coke is transferred, by overfeed, into a coke reaction chamber, (7), where counterflowing primary air, via air meter, (12), gasifies the coke into carbon monoxide with some carbon dioxide. Finally, the carbon monoxide and the partially oxidized volatile matter, are admixed with overfire air, and burned fully to carbon dioxide in overfire burner chambers, (23), (26). The resulting hot burned gases flow into the nozzle inlet, where, after mixing with bypass air, they expand through the expander portion of a gas turbine engine. Coal ashes accumulate at the bottom, (9), of the coke reaction chamber, (7), where the overlying coke chunks prevent ash particle carryover into the turbine blades. Low cost coal can thus be cleanly used as an energy source for gas turbine engines.

Owner:FIREY JOSEPH CARL

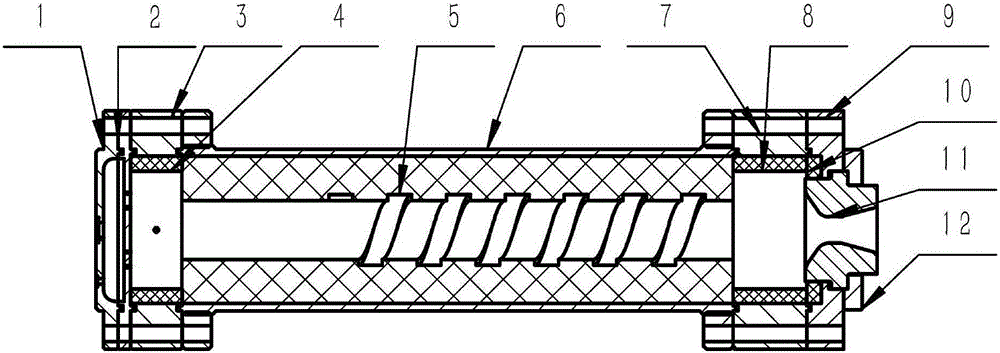

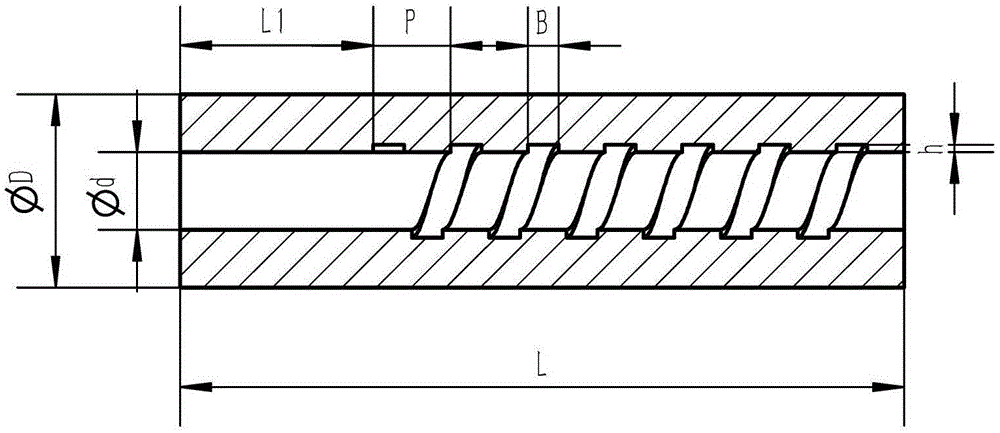

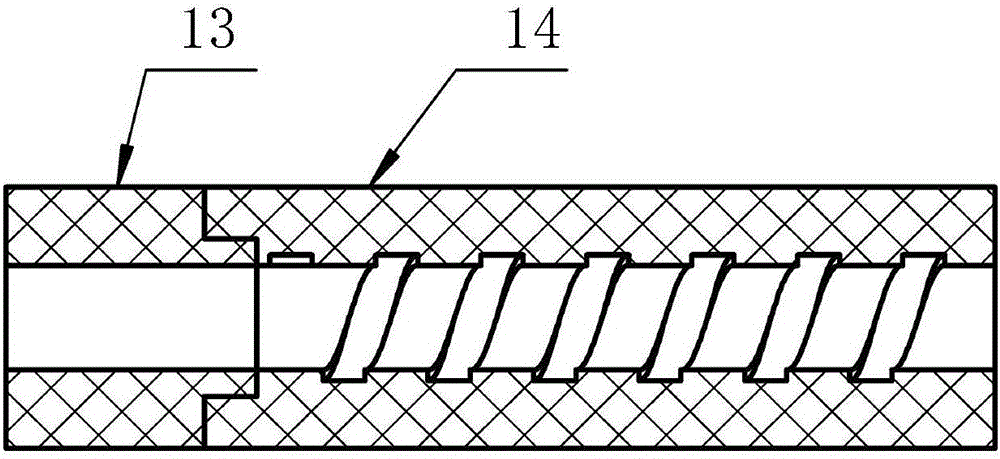

Spiral grain type solid-liquid rocket engine

InactiveCN106194501AImprove performanceIncrease burn rateRocket engine plantsCombustion chamberRocket engine

The invention discloses a spiral grain type solid-liquid rocket engine. The spiral grain type solid-liquid rocket engine comprises a head cover, a jetting panel, a front combustion chamber, a combustion chamber shell, a grain, a rear combustion chamber, a rear sealing head, a spraying pipe and a spraying pipe pressing plate. A threaded groove is designed in the inner wall of the grain, and therefore the combustion speed of the grain can be effectively increased, and the performance of the solid-liquid rocket engine is improved. For the solid-liquid rocket engine in which the specific value of the length of the grain to the inner diameter of the grain ranges from 5 to 15 and the ratio of the inner diameter of the grain to the outer diameter of the grain ranges from 1 / 6 to 1 / 2, the grain is subjected to optimization design. The spiral grain type solid-liquid rocket engine has the beneficial effects that the combustion speed of the solid-liquid rocket engine can be better increased, and the performance of the solid-liquid rocket engine is improved.

Owner:BEIHANG UNIV

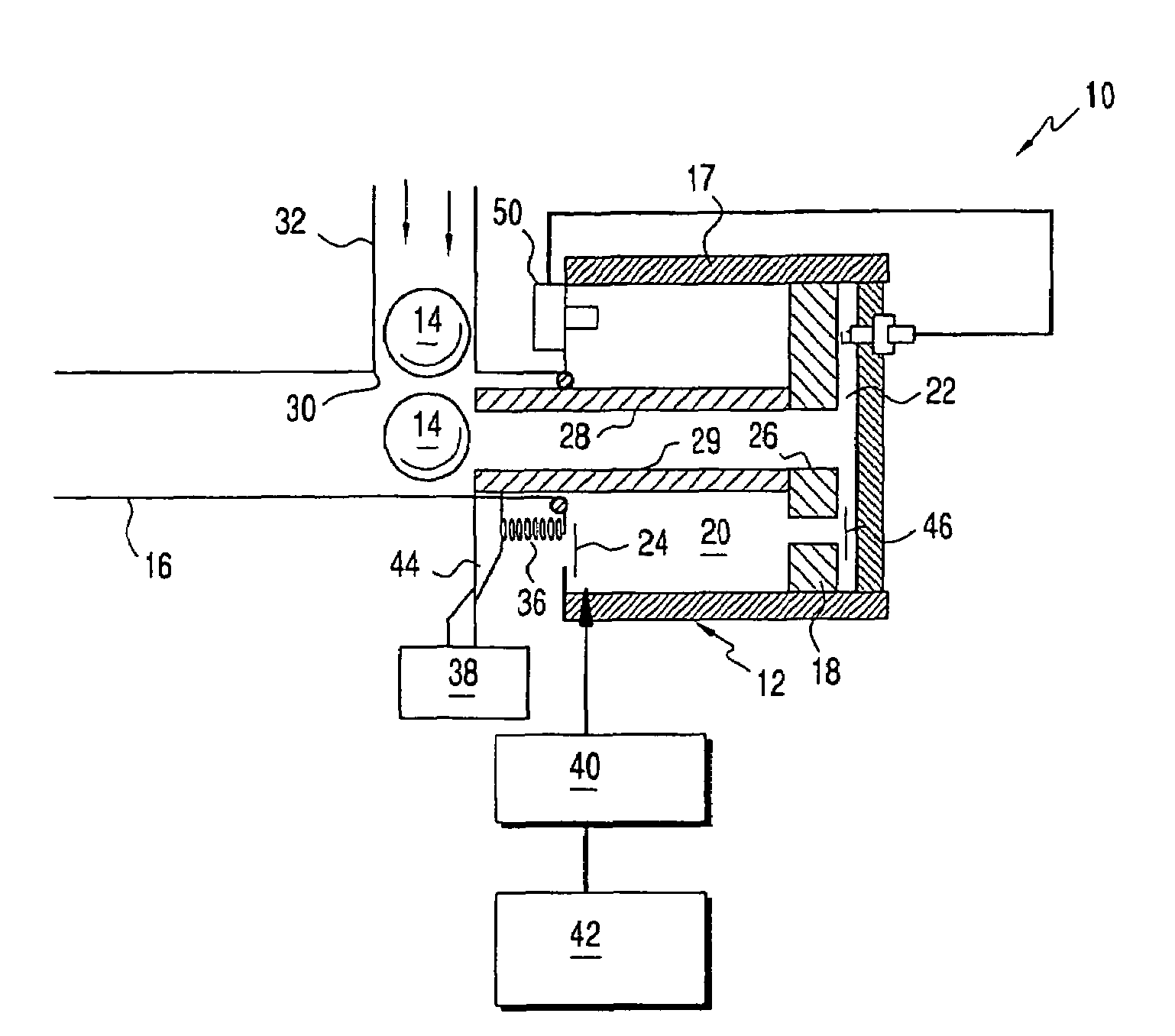

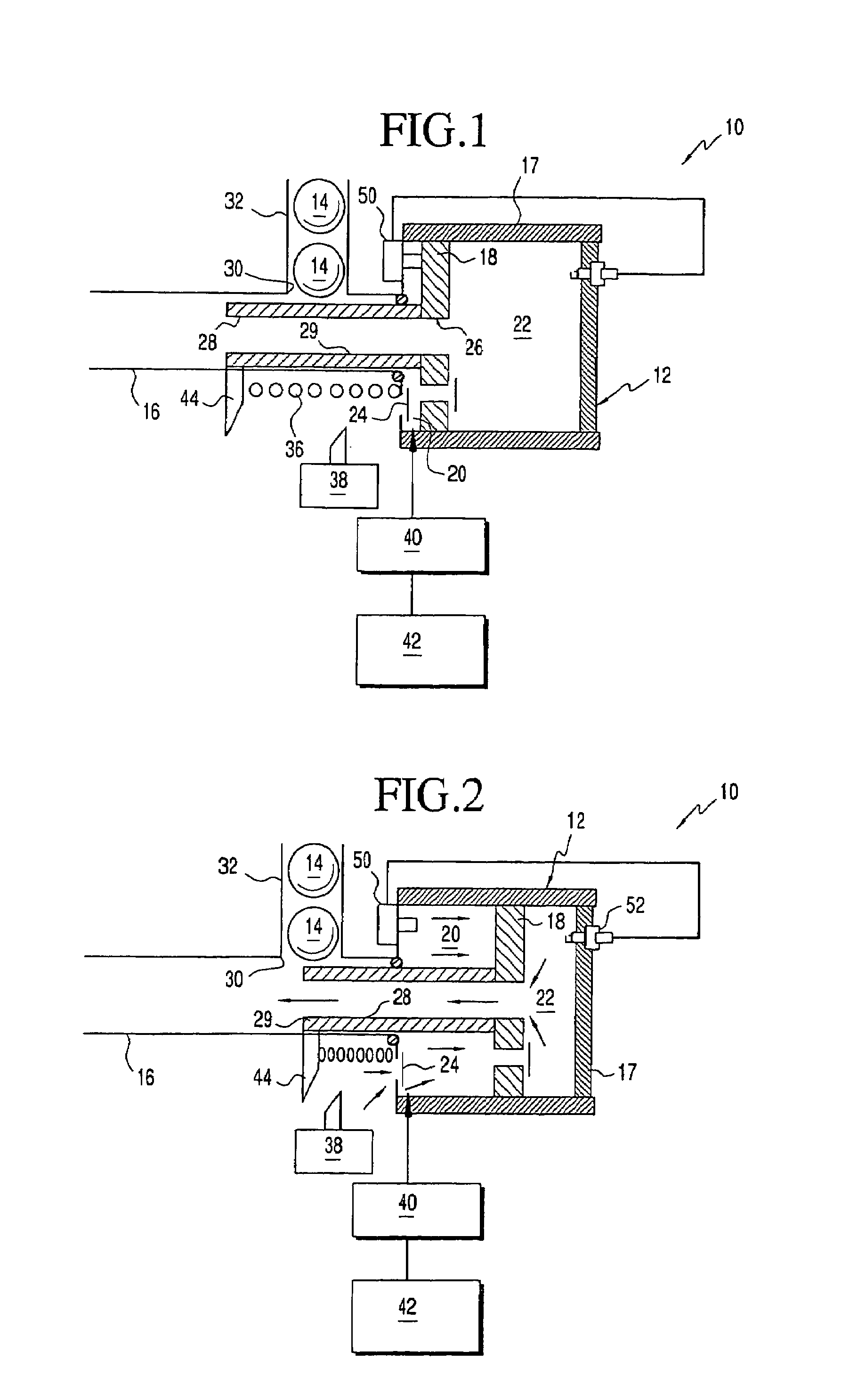

Process for combusting fuels, in particular waste

ActiveUS20060196400A1Reduce gas flowIncrease airflowAir supply regulationFlame sensorsCombustionReaction rate

A process for combusting fuels, in particular waste, includes reducing the oxygen mass flow of the underfire combustion gas and increasing the oxygen mass flow of the overfire combustion gas in the event of an increase in the reaction rate or combustion intensity.

Owner:MARTIN GMBH FUR UMWELT UND ENERGIETECHNIK +1

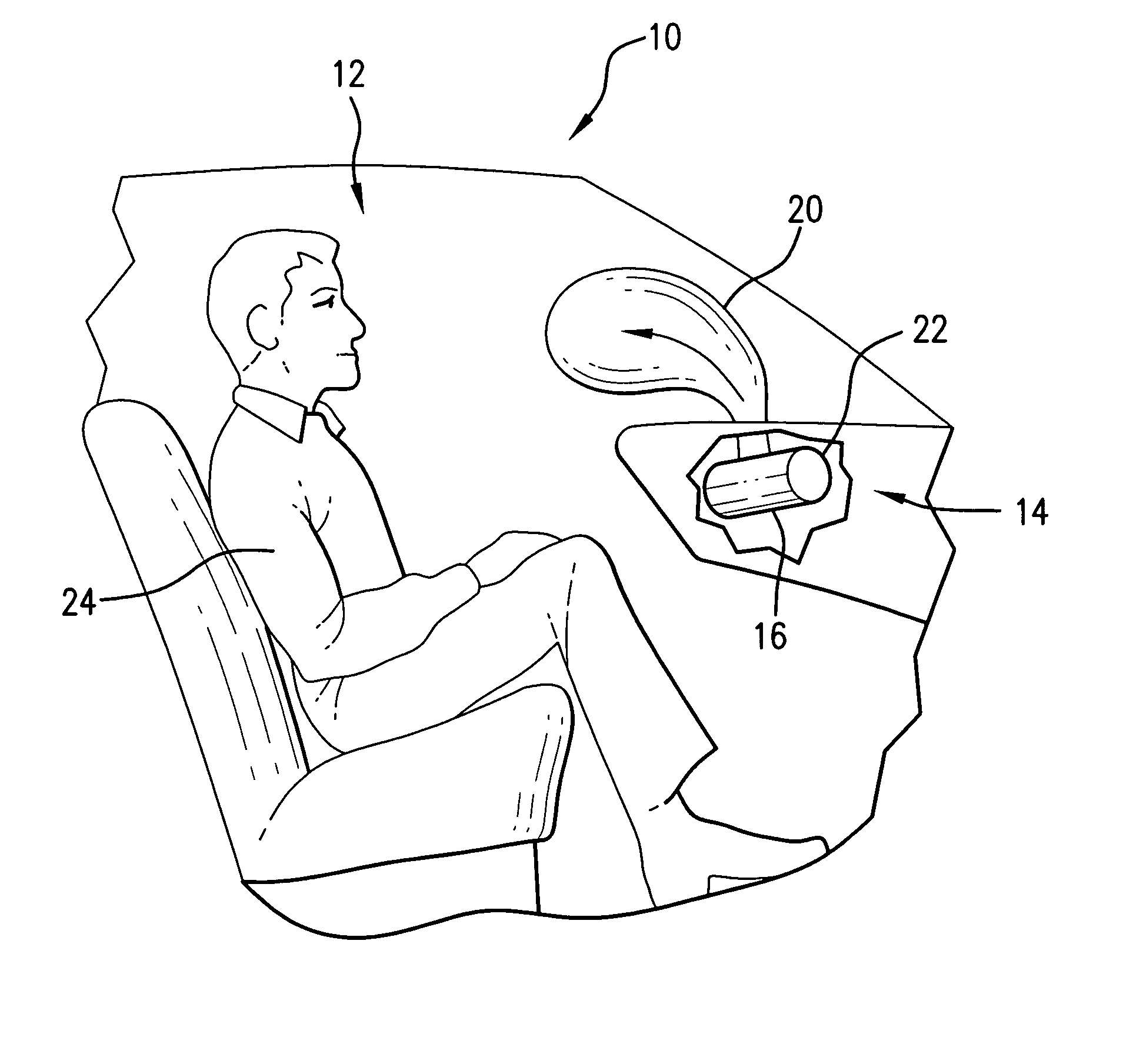

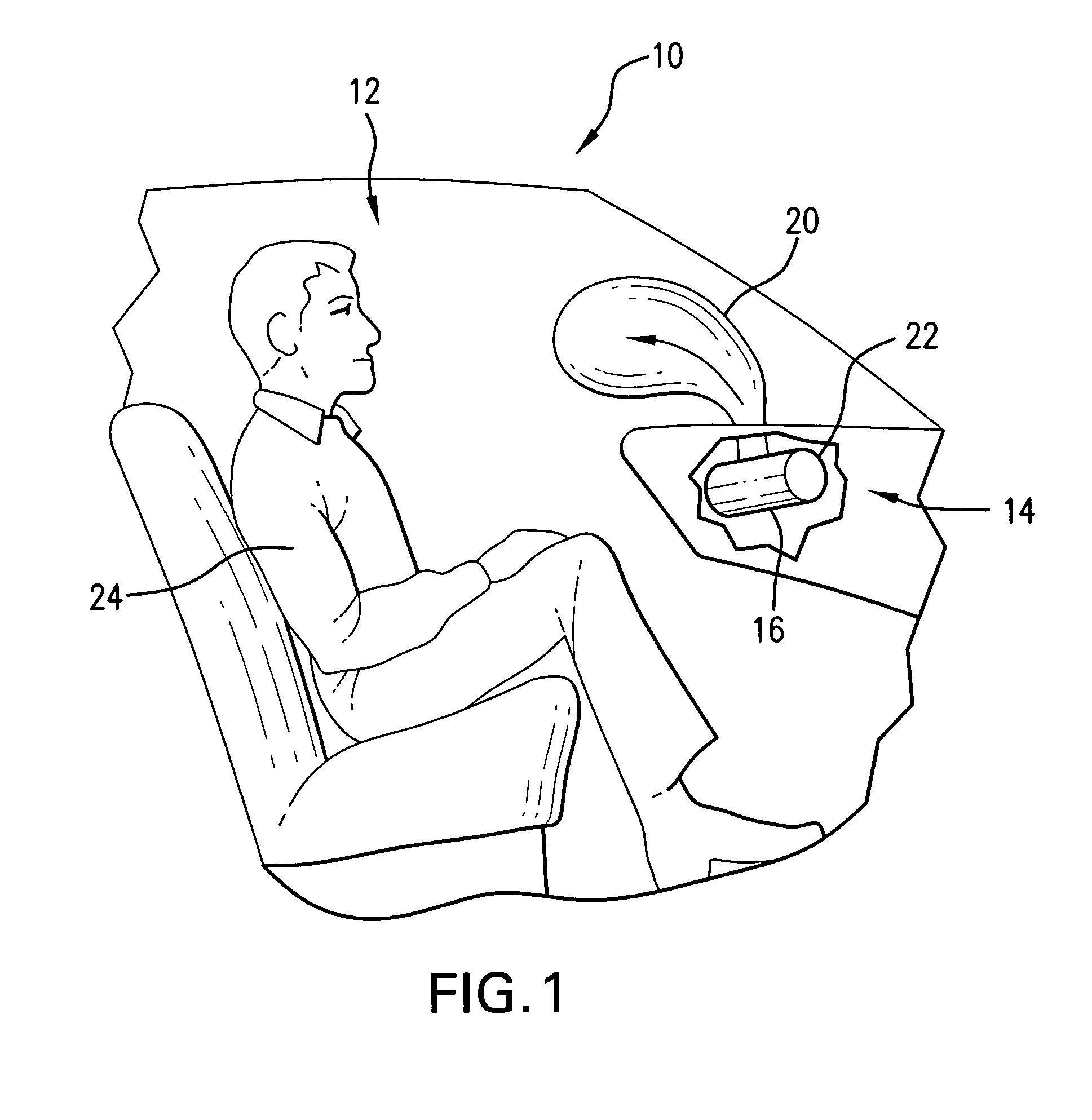

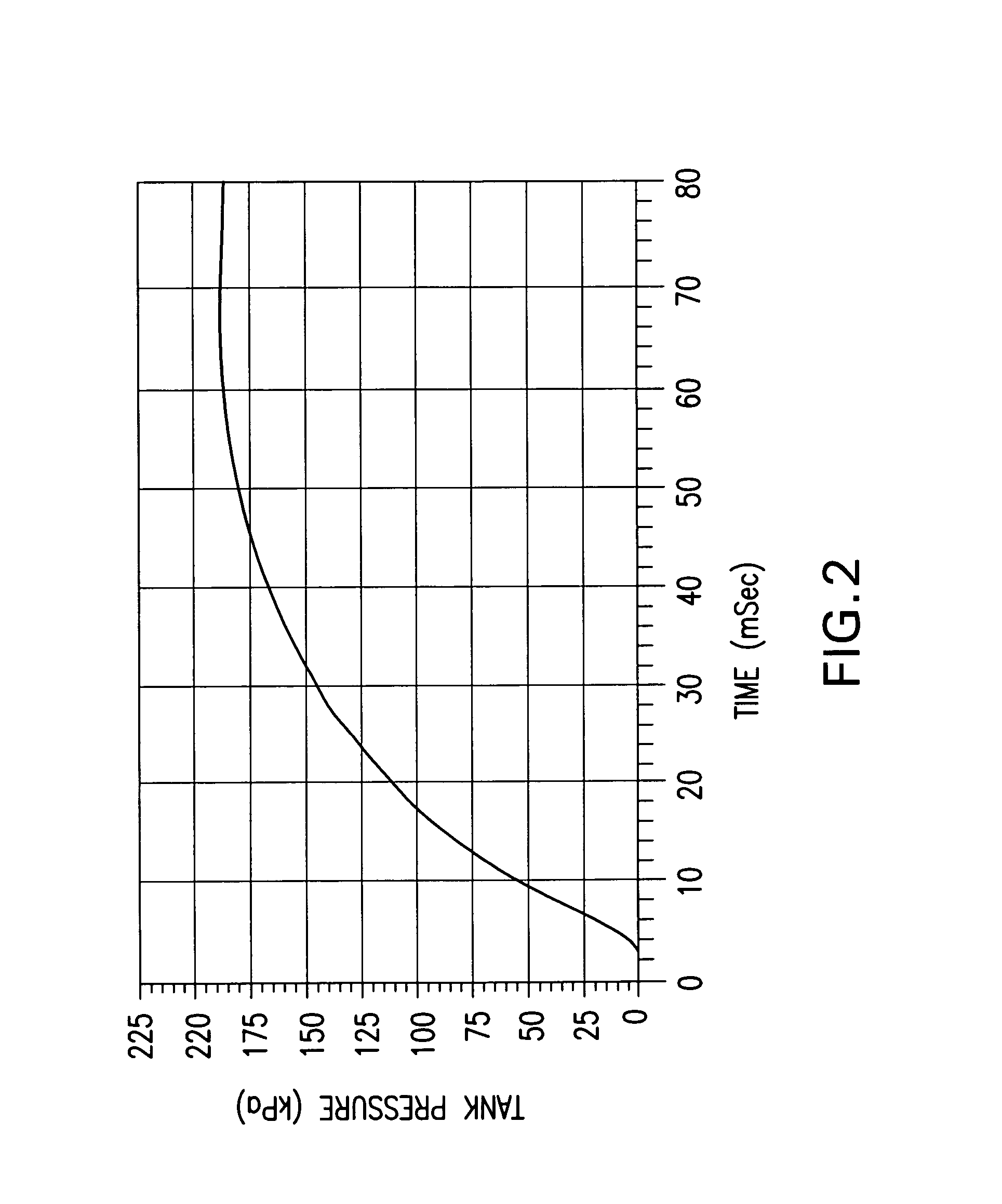

Combustion-gas-powered paintball marker

InactiveUS7686005B2Increase burn rateShort timeMissile propulsionCompressed gas gunsCombustionEngineering

An onboard combustion-gas-powered engine supplies power to a paintball marker or other projectile launcher by generating gas pressure pulses for propelling paintballs and other projectiles. The combustion gases produced by the engine can be allowed to rise in pressure within a confined volume of space before being released through a valve into a barrel for applying enhanced pressure pulses to the projectiles. A loading system is linked to a combustion accelerating system for automatically loading projectiles into the launcher.

Owner:ADAMS JOSEPH S

Particulate filter

Disclosed is a particulate filter, which is adapted to be disposed in an exhaust passage of an engine to trap particulate matter contained in exhaust gas discharged from the engine. The particulate filter comprises a filter body having a porous partition wall which defines a plurality of exhaust gas channels allowing the exhaust gas to pass therethrough, and a catalyst layer formed on a surface of the porous partition wall. The catalyst layer includes a Zr-based composite oxide which contains zirconium (Zr), and a rare-earth metal except cerium, wherein a content ratio of an oxide of the non-cerium rare-earth metal to a total amount of ZrO2 and the oxide of the non-cerium rare-earth metal in the Zr-based composite oxide is set in the range of greater than 33 mol % to less than 40 mol %. The particulate filter of the present invention can achieve a higher PM burning rate to burn PM within a shorter period of time. In addition, the higher PM burning rate makes it possible to provide enhanced fuel economy performance in an engine designed to perform a post-injection control.

Owner:MAZDA MOTOR CORP

Environment-friendly efficient waste incinerator

The invention discloses an environment-friendly efficient waste incinerator. The environment-friendly efficient waste incinerator comprises a lower incinerator body part, an upper incinerator body part, an internal chimney, a base, an incinerator cover and an external chimney. The upper incinerator body part and the lower incinerator body part of an incinerator body are welded into a whole. The internal chimney is arranged in the middle of the lower incinerator body part and the middle of the upper incinerator body part. A combustion chamber is formed by the lower incinerator body part and the internal chimney. Refractory bricks are arranged on the periphery of the lower incinerator body part and the periphery of the upper incinerator body part. The bottom end of the lower incinerator body part is connected with the base. Both the upper surface and the lower surface of the base are open. The incinerator cover is arranged on the upper incinerator body part. The external chimney is arranged at the top of the incinerator cover in a connected mode. A water tank is arranged outside the lower incinerator body part. An oil tank is further arranged in the water tank. A water pipe and an oil pipe are arranged in the internal chimney. The water pipe is communicated with the water tank. The oil pipe is communicated with the oil tank. According to the environment-friendly efficient waste incinerator, oil in the oil pipe can be gasified by means of heat generated during waste combustion, so that waste on the upper portion of the incinerator body can be combusted for the second time, continuous waste combustion is achieved, incineration is thorough and rapid, and the incineration effect is good; pollution to the environment is small, and the environment-friendly efficient waste incinerator is suitable for waste treatment in village and town communities, schools and hospitals.

Owner:都安通达环保设备制造厂(普通合伙)

Method for preparing biodiesel with vegetable oil

InactiveCN101328418AIncrease burn rateEnough heat to burnFatty acid esterificationBiofuelsBiodieselVegetable oil

The invention relates to a method for manufacturing biodiesel from vegetable oil. The method particularly comprises the following steps that: the vegetable oil is used to form fatty acid ester under the action of an acid catalyst or a basic catalyst through reacting with low molecular alcohol; and the biodiesel is obtained by using a glycollic acid substance through centrifugal separation. The method can reduce the discharge degree of atmospheric environmental pollutants, and the biodiesel belongs to a renewable and available resource.

Owner:烟台波德斯化工有限公司

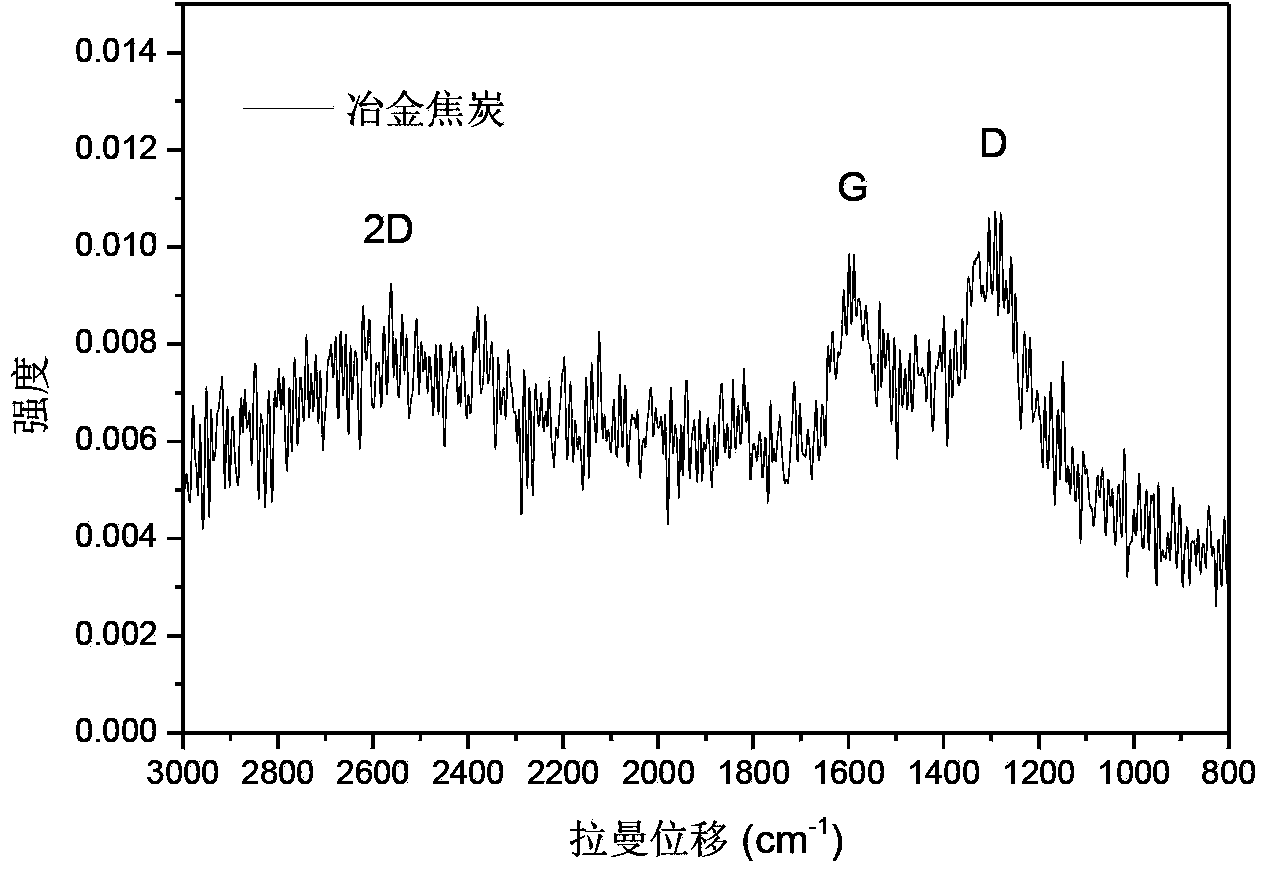

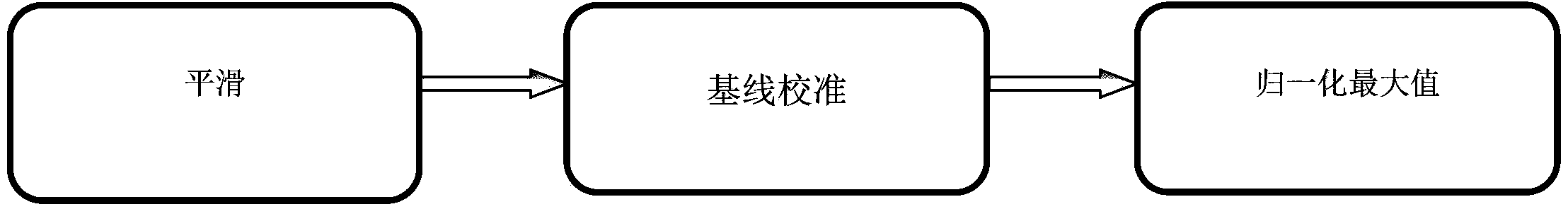

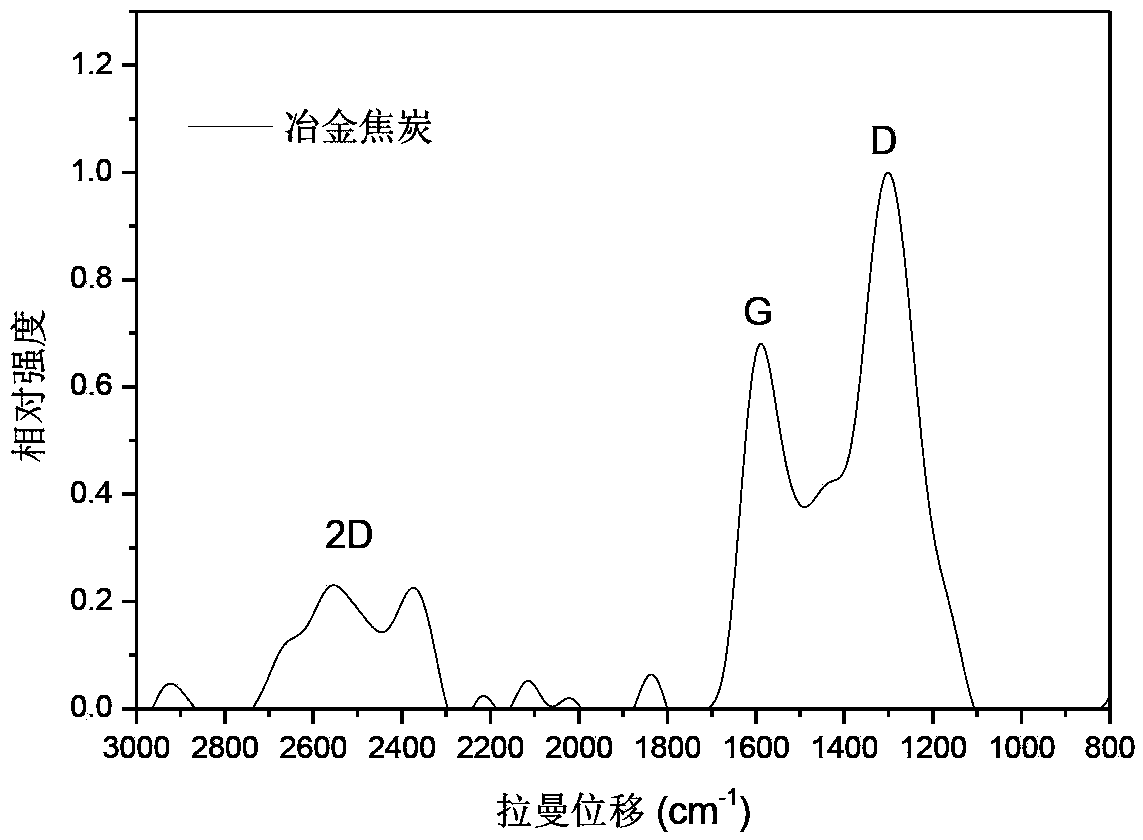

Raman spectrum quantitative determination method applicable to carbon sources in blast furnace gas dust

InactiveCN103529012AHigh measurement accuracyImprove applicabilityRaman scatteringMass ratioQuantitative determination

The invention provides a quantitative determination method for carbon sources in blast furnace gas dust. The quantitative determination method comprises calibration and detection steps, wherein the calibration step comprises the steps: obtaining Raman spectrums of various coke samples with different coke mass ratios and determining a D peak and G peak strength ratio ID / IG according to the Raman spectrums, and a trough lowest point V peak and G peak strength ratio IV / IG between a D peak and a G peak, and taking the D peak and G peak strength ratio ID / IG and the trough lowest point V peak and G peak strength ratio IV / IG as evaluation indexes to establish a mapping relation between the ratio of carbon-containing substances in coal of the sample or a coke sample and the evaluation indexes; the detection step comprises the steps: carrying out a Raman spectrum analysis on the blast furnace gas dust to be detected and determining the ID / IG and the IV / IG; matching on the established mapping relation according to the two strengths; and determining the ratio of the carbon-containing substances of the coal or the coke of the blast furnace gas dust to be detected so as to obtain the carbon sources. According to the quantitative determination method for the carbon sources in the blast furnace gas dust, the ratio of the carbon-containing substances of the coal or the coke can be quantitatively analyzed based on the Raman spectrum analysis; the method is reliable, simple and rapid to operate, strong in applicability and low in cost.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Non-nitrine gas generating agent and production thereof

ActiveCN1644574AReduce dosageReduce generationExplosivesPressure gas generationParaffin waxGas composition

A non-laminated gas producing agent and its production are disclosed. The non-laminated gas producing agent consists of oxygen-enriched carbamidine nitrate 40-60% with granularity 0.5-6mu, basic copper nitrate 10-28% as oxidant with granularity 0.5-6mu, copperon oxide of catalyst with primary oxidant 15-30% with granularity 0.1-6mu, and clay or paraffin wax 0.1-3% as process assistant with granularity 1-20mu. The production is carried out by: breaking the materials, adding into mixer by proportioning, mixing, sieving by screen, adding water 10-30%, agitating, drying, sieving the dried materials by screen with 20-80 mesh to obtain medicine particles, pressing into tablets, and drying the tablets under 100-120deg.C for 1.5-2.5hrs with water content <0.4%. It achieves wide regulating range, high gas output efficiency, and clean gas composition.

Owner:HUBEI HANGPENG CHEM POWER TECH

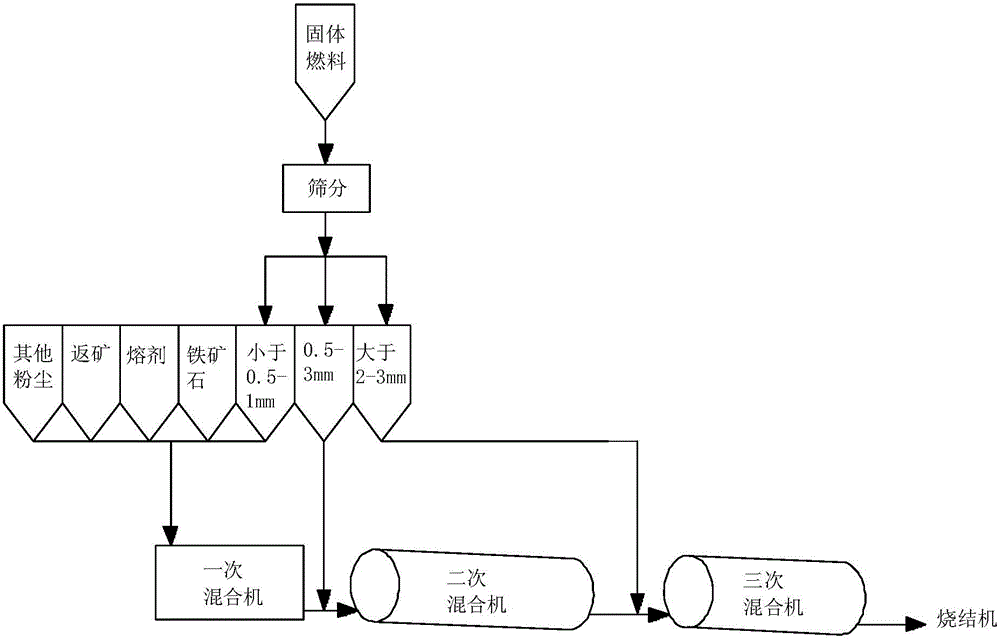

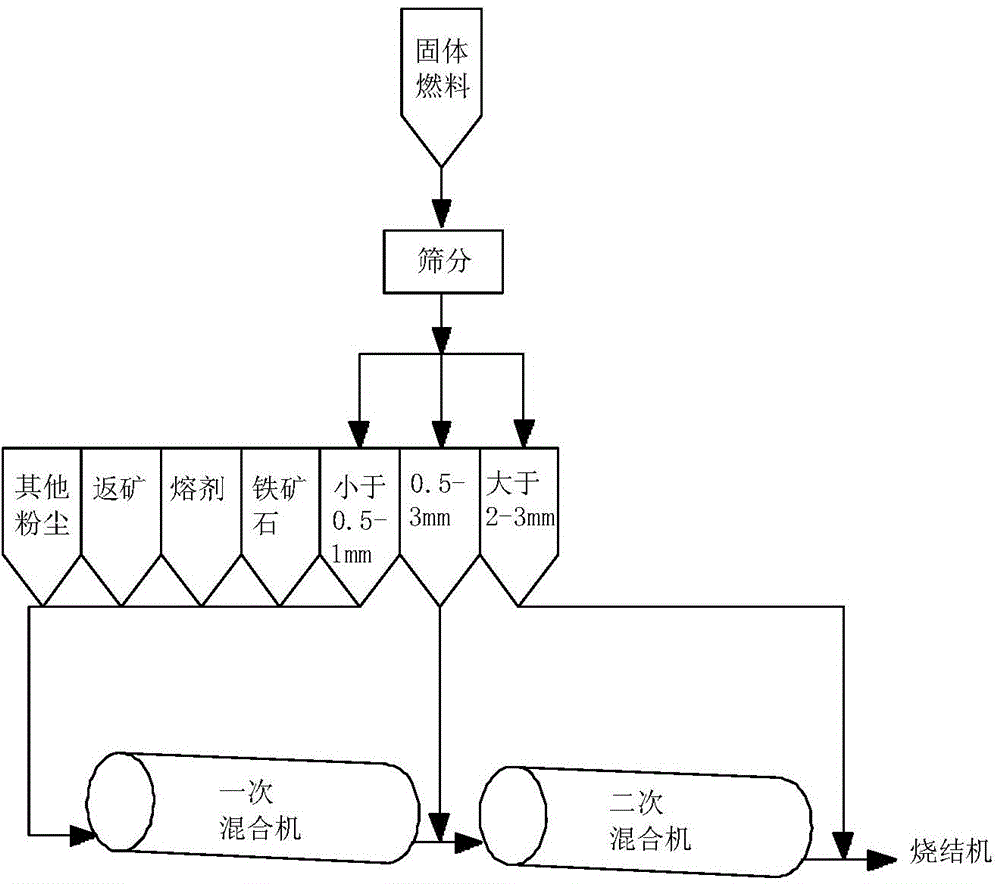

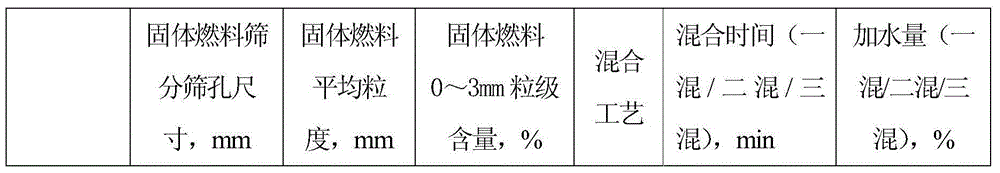

Method for reducing sintered solid fuel consumption

The invention discloses a method for reducing solid fuel consumption. The method comprises the following steps: 1) a solid fuel for sintering is screened to three particle grades of 2.0-3.0 mm, 0.5-3.0 mm and less than 0.5-1.0 mm; 2) the solid fuel with the particle grade of less than 0.5-1.0 mm is mixed with such sintered raw materials as iron ore, flux, return mines and other dust; and the above materials are added in a primary mixing machine for mixing; 3) the mixture and the solid fuel with the particle size of 0.5-3.0 mm are conveyed to a secondary mixing machine for mixed pelletization; and 4) the obtained mixture and the solid fuel with the particle size of 2.0-3.0 mm are input to a tertiary mixing machine, and are mixed and conveyed to a sintering machine for distribution, ignition and sintering. The method can improve the combustion speed and efficiency of the solid fuel, improves the pelletization effect of the sintered mixture, improves the material layer permeability in the sintering process, improves the sintered mineral product quality, and reduces the environmental pollution.

Owner:BAOSHAN IRON & STEEL CO LTD

Flame retarded polyolefin composition

InactiveUS6518344B1Easy to keepGood colorAluminium compoundsSynthetic resin layered productsScavengerPolyolefin

The present invention provides a new and improved flame retarded polyolefin composition that displays good retained physical properties upon aging. The composition also exhibits excellent moldability and it may be easily colored. In a preferred embodiment the composition includes a polyolefin, a halogen-containing flame retardant additive, from at least about 1.00% by weight to about 2.5% by weight of a stabilizer package, and from about 0% to about 1.0% by weight of an acid / halogen scavenger. The stabilizer package includes by weight from about 20% to about 80% of a hindered phenolic antioxidant, from about 20% to about 80% of a phosphite containing antioxidant, and from about 0% to about 40% of a thio-ester antioxidant. In addition to displaying excellent color and physical property development and retention characteristics, the composition of the present invention displays an improved UL94 vertical burn rating.

Owner:FERRO CORP

Gas generation with copper complexed imidazole and derivatives

InactiveUS20070240797A1Improve combustion effectImprove flammabilityNon-explosive/non-thermic compositionsPressure gas generationNitrogenBurn rate

A compound including at least one copper II complex of a material selected from the group of imidazole and imidazole derivatives is provided for use in a gas generant composition. An associated burn rate enhanced gas generant composition, in addition to such copper complex-containing compound, also includes a nitrogen-containing non-azide fuel. Additionally provided are methods for improving the combustion performance of a non-azide gas generant composition in at least one aspect selected from the group consisting of ignitability, burn rate and burn rate pressure sensitivity, through the addition of such copper complex-containing compound to the non-azide gas generant composition.

Owner:AUTOLIV ASP INC

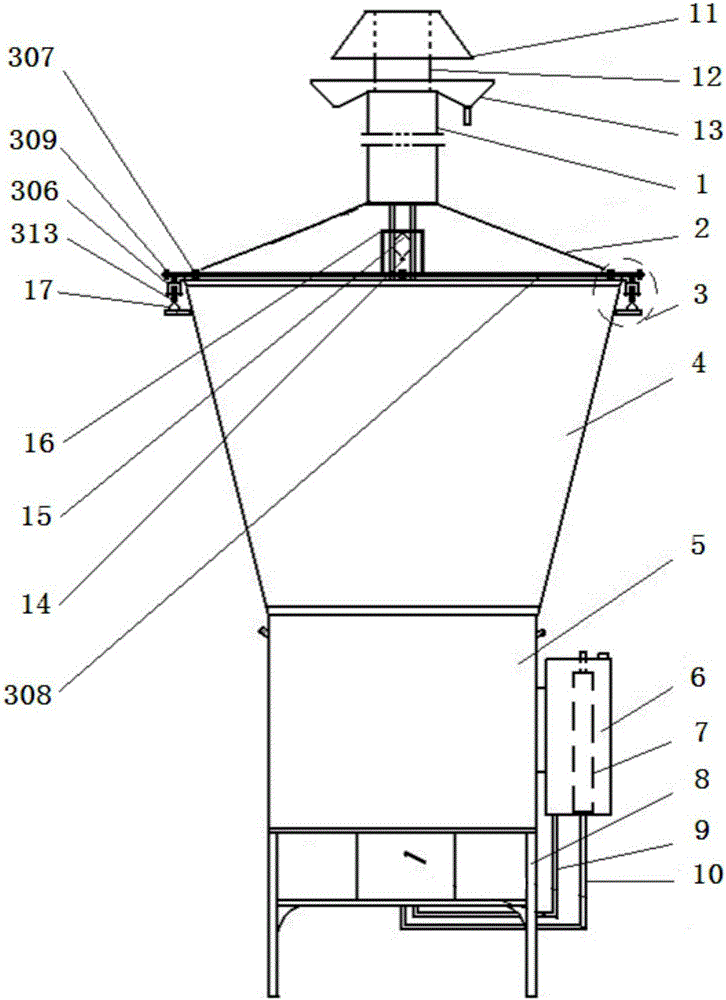

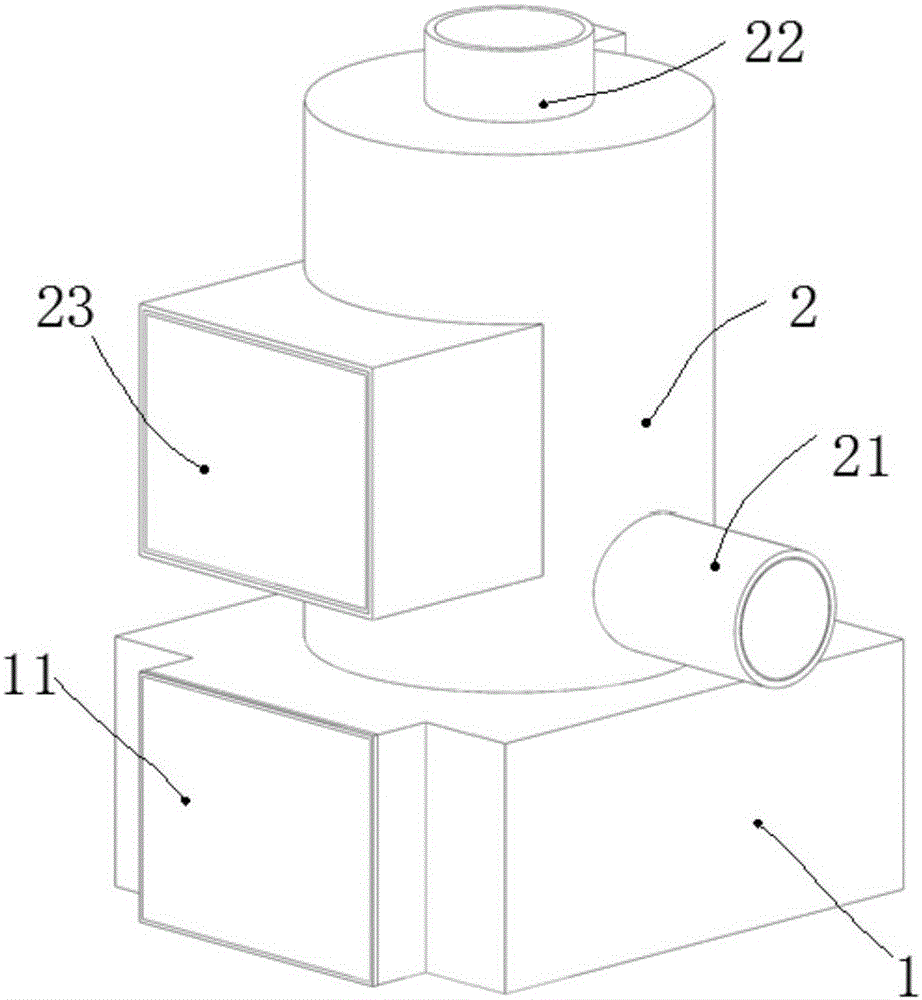

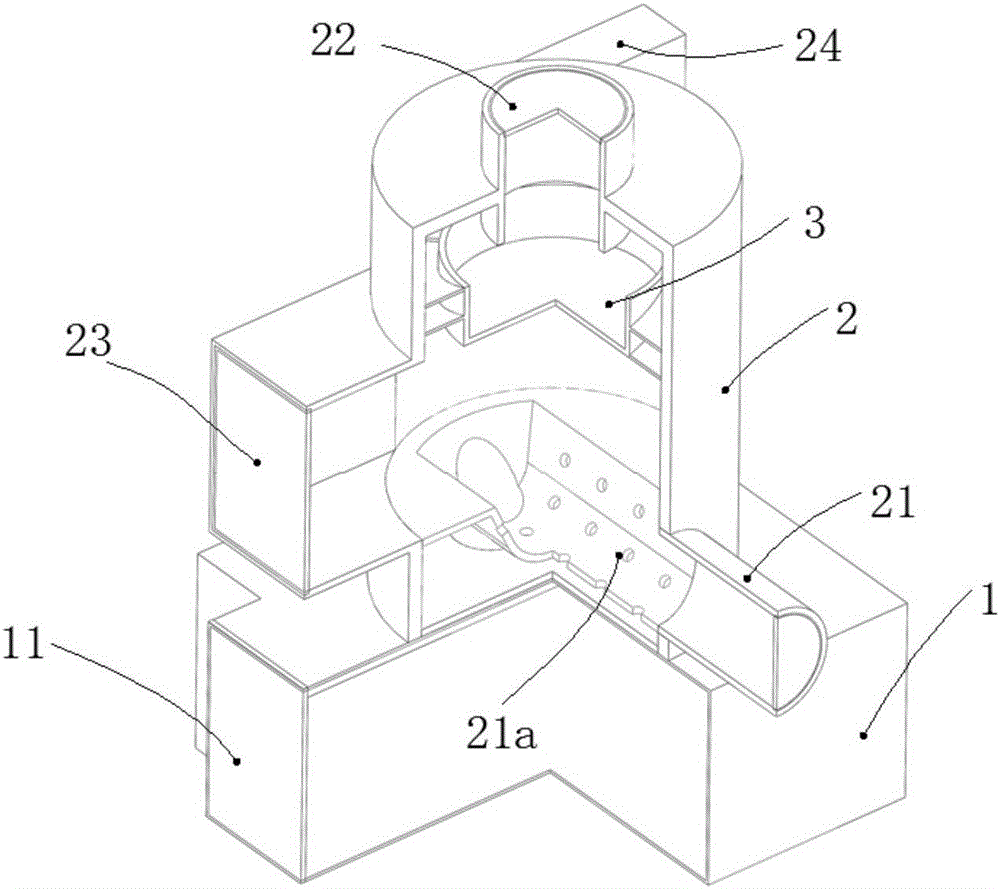

Biomass cyclone dust removal burner

ActiveCN105864745AIncrease burn rateImprove combustion effectSolid fuel combustionAir/fuel supply for combustionCycloneCombustion chamber

The invention discloses a biomass cyclone dust removal burner. The biomass cyclone dust removal burner is characterized in that a cyclone dust removal burner is arranged at the upper part of a furnace body and at the lower end of a furnace body fire outlet, the cyclone dust removal burner divides the furnace body into a lower burning chamber and an upper burning chamber, a secondary air supply tube consistent with the spiral direction of the cyclone dust removal burner is arranged in the upper burning chamber, the cyclone dust removal burner consists of a concave barrel and S-shaped helical blades arranged outside the concave barrel, the head ends and the tail ends of the S-shaped helical blades are connected at intervals, and the helical angles of the S-shaped helical blades are 15-30 degrees. The biomass cyclone dust removal burner can keep dust particles formed after burning in the upper burning chamber and further enhances the wall-attaching dust collection effect under the centrifugal action, so that the burning effect, the dust removal performance and the fire purity of the burner are remarkably improved, the dust emission concentration is less than or equal to 5 mg / m<3>, the fume blackness reaches Ringelmann 0 grade, dust larger than 30 micrometers cannot overflow, a smoke-free and dust-free effect can be basically achieved, and the specifications of the biomass cyclone dust removal burner are higher than those of like products in the prior art.

Owner:郭征旭 +1

Supplementary slurry fuel atomizer and supply system

InactiveUS7281500B1Low costSave on fuel costsNon-fuel substance addition to fuelInternal combustion piston enginesCommon railProduct gas

A supplementary slurry fuel atomizer of this invention, when used on a piston internal combustion engine, equipped with a common rail fuel injection system, improves slurry atomization, following injection, by expansion of gases, previously dissolved in the water phase of the slurry. This gas expansion separates the several fuel particles in each slurry droplet formed first during fuel injection. The thusly separated fuel particles subsequently burn more rapidly and completely, due to this fuel particle separation improving air access to the fuel. Apparatus is described for dissolving atomizing gas into the water phase of the slurry, in a contactor chamber at a pressure greater than the pressure prevailing in the engine cylinder volume, at the time of slurry injection.

Owner:FIREY JOSEPH CARL

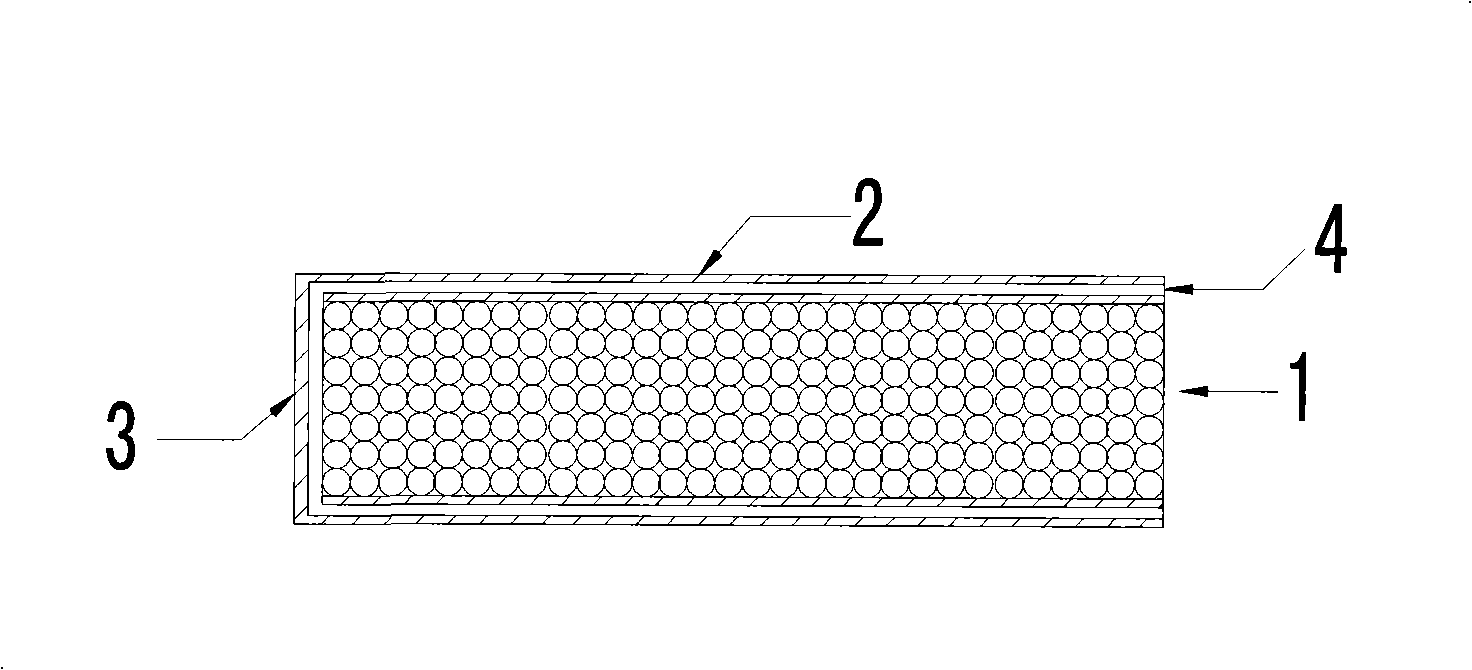

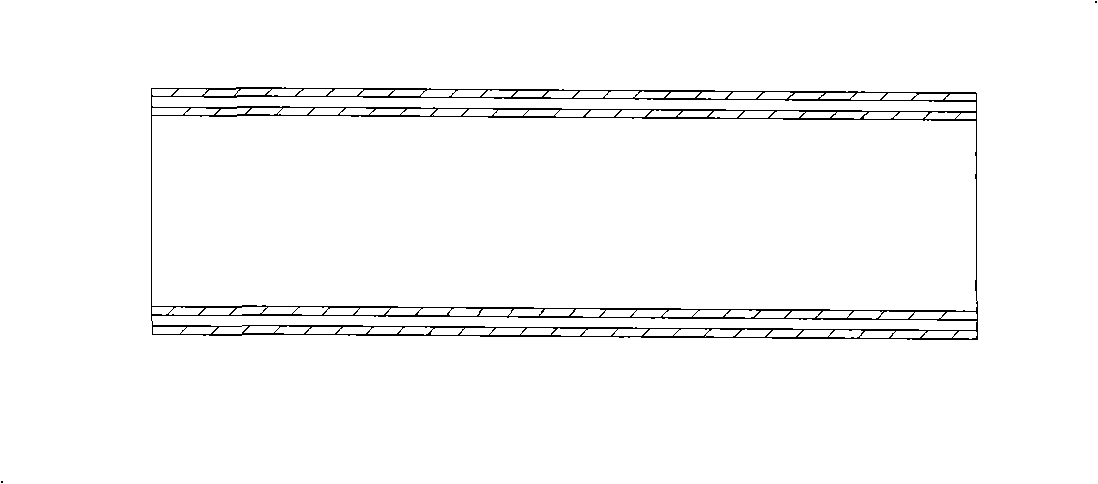

High-efficiency porous media combustor for minitype heat optoelectronic system

InactiveCN101354132AImprove temperature distributionStable and efficient workGaseous fuel burnerExhaust gasProduct gas

The invention provides a high-efficiency porous medium burner used in a micro thermo photovoltaic system, relating to the technical field of combined combustion of a two-phrase gas. SiC ceramic spherules with diameter of 0.3mm to 0.35mm are filled in a shell of the burner in the form of oblique parallelepiped and then sintered with the shell to form a porous medium structure with porosity epsilon equal to 26 percent to 27 percent and a tail gas discharging channel is arranged on the external wall of the burner. The shell of the burner is processed first and then a bottom cover (3) of the burner is processed and sintered with the shell, and finally, in the interior of which the screened SiC ceramic spherules with diameter of 0.34mm are filled, after sintering, the porous medium structure is formed and the tail gas discharging channel is arranged in the interior of the shell (2) of the burner. The porous medium burner reduces the heat loss brought by increase of surface to volume ratio due to microscale, greatly improves the temperature distribution on the external wall of the burner, promotes combustion efficiency and combustion stability, lowers gas discharging temperature and heightens the temperature of the external wall, thus greatly advancing the efficiency of the whole micro thermo photovoltaic system.

Owner:JIANGSU UNIV

Anti-slagging biomass solid granular fuel

The invention discloses an anti-slagging biomass solid granular fuel and solves a problem that a biomass solid granular fuel in the prior art is liable to slag and is low in combustion efficiency. The anti-slagging biomass solid granular fuel is prepared from following raw materials, by weight, 60-70 parts of crop straws, 10-15 parts of wood chips, 5-10 parts of bagasse, 3-5 parts of a combustion-promoting agent and 1-3 parts of an anti-slagging agent. The anti-slagging biomass solid granular fuel is simple in components, reasonable in formula, low in cost, high in combustion efficiency and low in slagging rate.

Owner:江山华隆能源开发有限公司

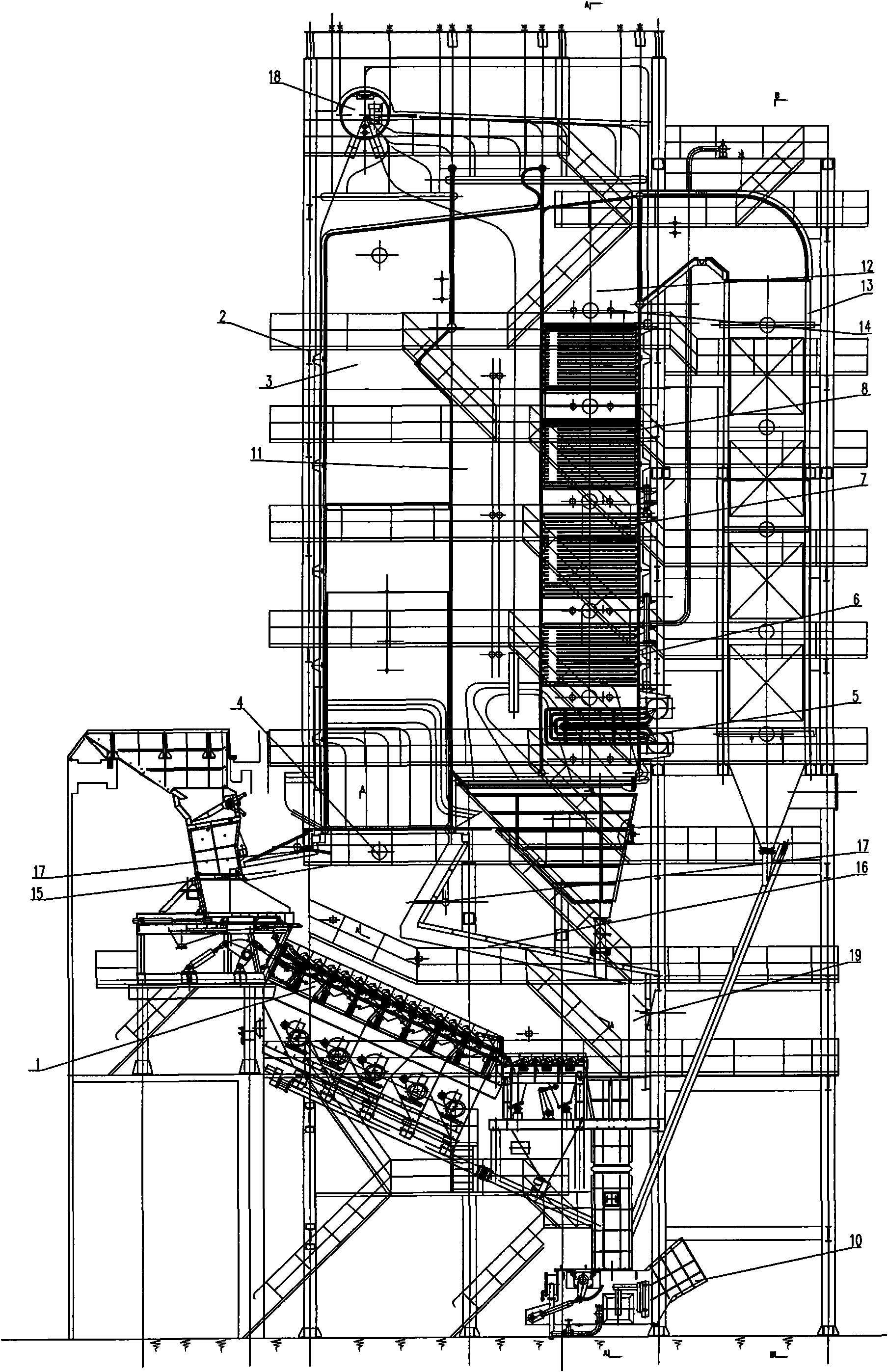

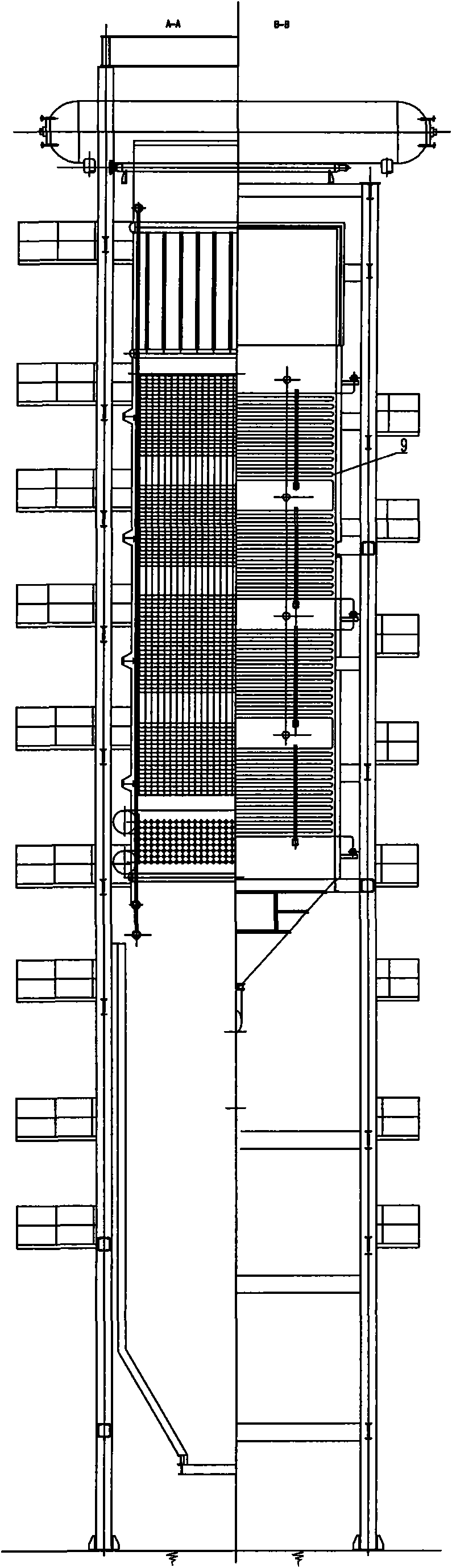

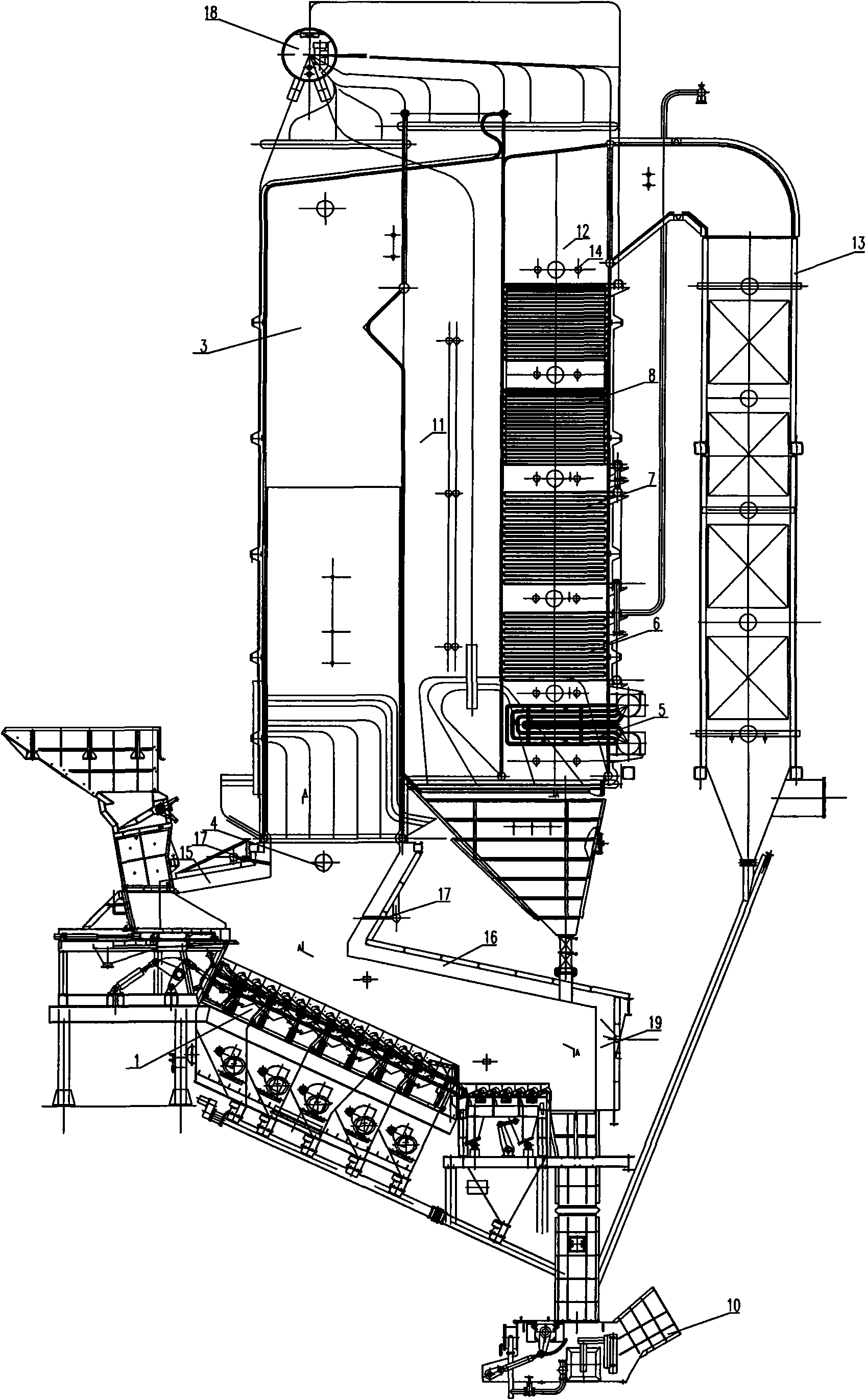

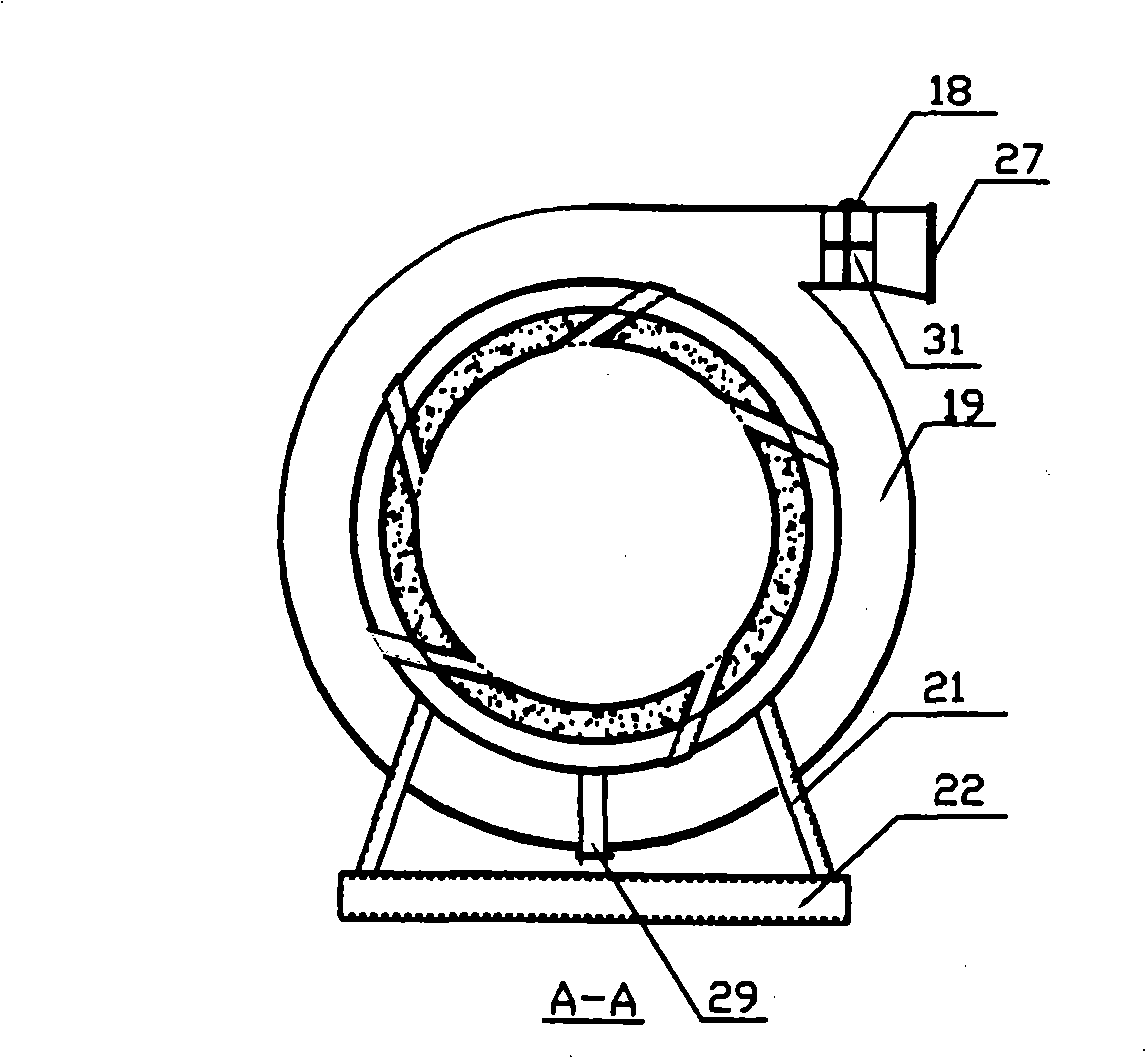

Waste incineration boiler

InactiveCN101852438ASuitable for a wide range of calorific valueGreat load adjustment capabilityIncinerator apparatusAir preheaterCombustion chamber

The invention discloses a waste incineration boiler. The waster incineration boiler mainly comprises a hearth and a combustion chamber, three flues and a tail flue which are connected to the hearth sequentially, wherein the upper part of the hearth is provided with a boiler barrel, and the lower part of the hearth is provided with a grate; and a slag and ash discharging device is arranged on the lower part of the grate. The waste incineration boiler is characterized in that the grate is a reciprocating multi-row grate; an auxiliary burner is arranged on the side wall on the lower part of the hearth; a start-up burner is arranged on the rear wall on the lower part of the hearth; and a high-temperature gas-air preheater and a superheater are respectively arranged in the three flues from bottom to top sequentially. The invention makes household waste with low heating value, high moisture content and high ash content sufficiently combusted and burnt out in the waste incineration boiler. The waste incineration boiler can effectively inhibit generation of harmful gas. Steam generated by the boiler is used for generating electricity and supplying steam. The waste incineration boiler realizes reduction, hazard-freetreatment and recycling of waste treatment furthest.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

Method for disposing urban sludge through combustion

InactiveCN1632377ADon't waste energyReduce processing timeIncinerator apparatusMunicipal sewageBuilding material

The invention discloses a combustion treatment method of urban sludge, which is provided for overcoming the disadvantages of the existing incineration treatment of urban sludge, such as low burn-out rate, poor treatment of urban sludge, high energy consumption, and long treatment time. The pump pressurizes the ignition fuel into the furnace and ignites it in an atomized state; stirs and mixes the municipal sludge and finished coal-water slurry in a certain proportion to form a liquid fuel, pressurizes it with a slurry pump and injects it into the furnace through the burner, and sends the compressed air to The nozzle makes the liquid fuel in an atomized suspension state and is ignited by the ignition fuel, and the urban sludge can be disposed of. Using the above-mentioned process to treat municipal sludge does not require dehydration and drying treatment, and does not waste energy; liquid fuel burns fully and quickly in the state of atomization and suspension, with less residue and can be used as building materials, so municipal sludge can be thoroughly processed Clean, recycle the heat, turn waste into treasure, and dispose of the largest amount of urban sludge with the least amount of finished coal-water slurry fuel.

Owner:QINGDAO HAIZHONG ENVIRONMENTAL PROTECTION BOILER

Low NOx liquid state slag-off double-eddy flow coal-powder combustor

ActiveCN101324334ABurn fastReduce smoke and dust emissionsPulverulent fuel combustion burnersSlagCoal

The invention relates to a low-NOx slag tapping double-swirl pulverized coal burner, which is suitable for 2-35 ton steam and hot water boiler and burning devices desired for heat energy for various kinds of industrial productions such as furnace, forging, steel making, road and bridge mixing station, and cold aggregate heating. The low-NOx slag tapping double-swirl pulverized coal burner comprises an adjustable burning device and a cylindrical burning chamber and is characterized in that the housing of the burning chamber is a heat insulating layer; a cooling water channel or a secondary air heat exchange fin is arranged between the housing the burning chamber and a secondary air chamber; a cooling water outlet pipe and a cooling water inlet pipe are respectively arranged on the upper and the lower ends of the cooling water channel; and a primary gas axial flow generator is arranged on the top of the jacket of an adjusting screw. The low-NOx slag tapping double-swirl pulverized coal burner has the advantages of sufficient burning and improved service life.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com