Efficient burning furnace with rotary fluidization grate

A swirling flow and incinerator technology, applied in the direction of rotary grate, incinerator, grate, etc., can solve the problems of not forming fluidized combustion, consuming more auxiliary fuel, and high cost, and achieving the effect of preventing fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

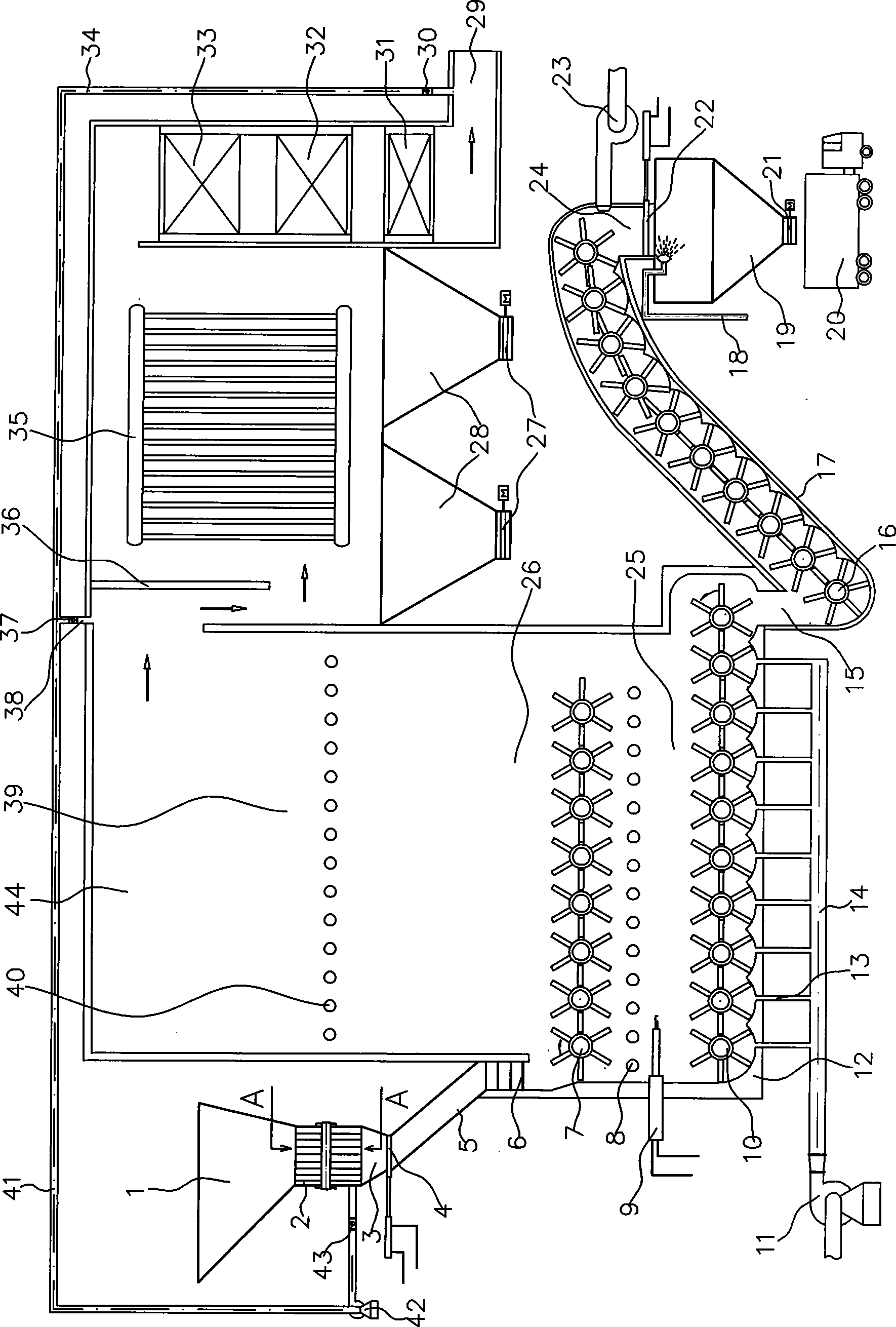

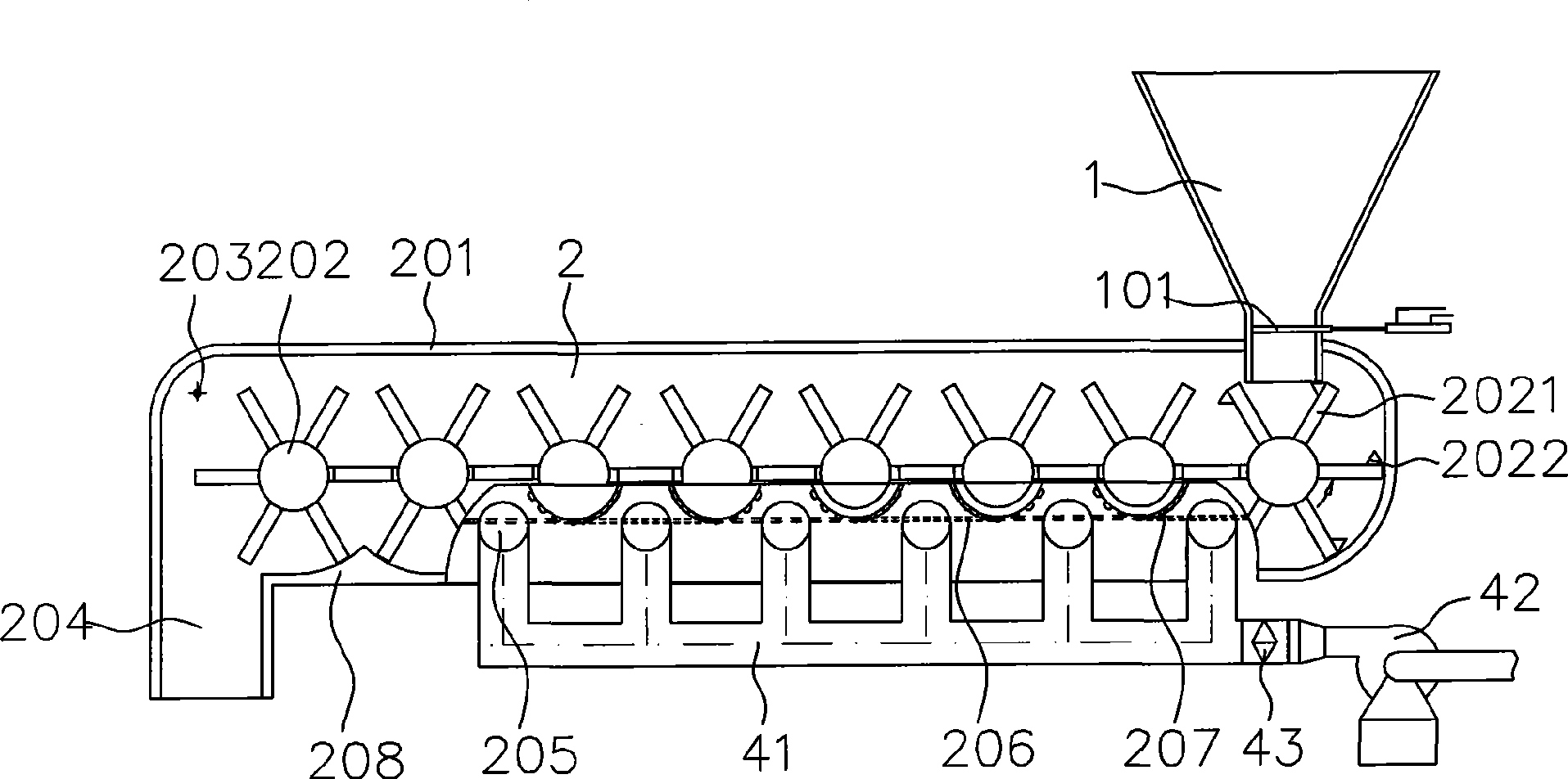

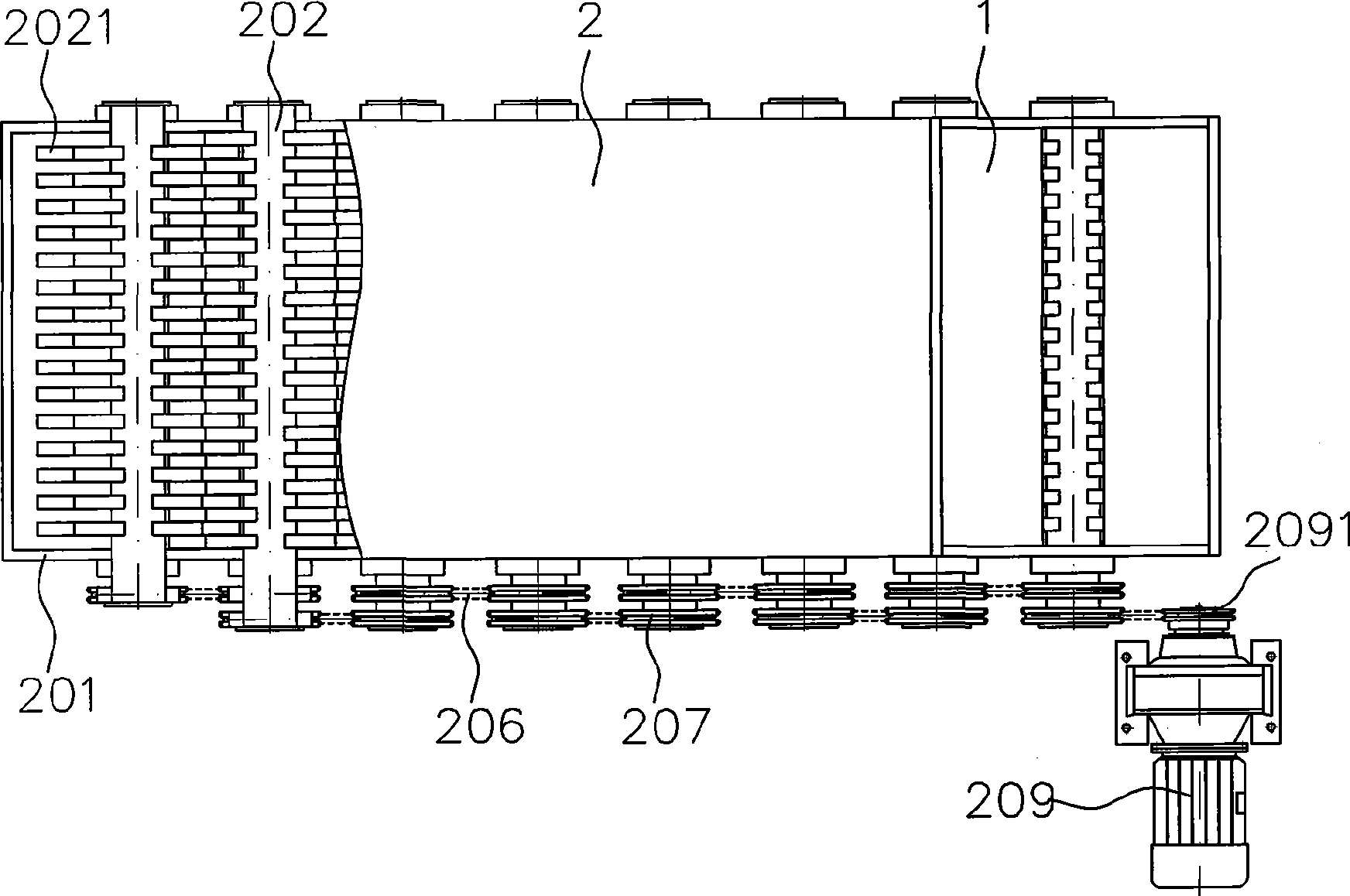

[0064] see Figure 1-Figure 11 Shown:

[0065] The rotary fluidized grate incinerator is composed of a feed system, a combustion system, and a slag discharge system. In addition, a waste heat boiler and a flue gas treatment system are connected with the incinerator to form a complete waste incineration power generation system.

[0066] Such as figure 1 As shown, the feeding system is composed of a feeding hopper 1, a pre-drying conveying device 2, a collecting hopper 3, a chute 5, and a distributor 6.

[0067] The feed hopper 1 is the receiving port where the garbage enters the incinerator, and is installed in the garbage storage pit near the side of the incinerator. The volume of the feed hopper 1 is suitable for accommodating the waste consumption of the incinerator for 900-1800 seconds. The feed hopper 1 is made of ordinary steel and treated with anticorrosion. The outlet of the feed hopper 1 is equipped with a pneumatic sliding door 101, which is in a normally open stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com