Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

455results about How to "Burn quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

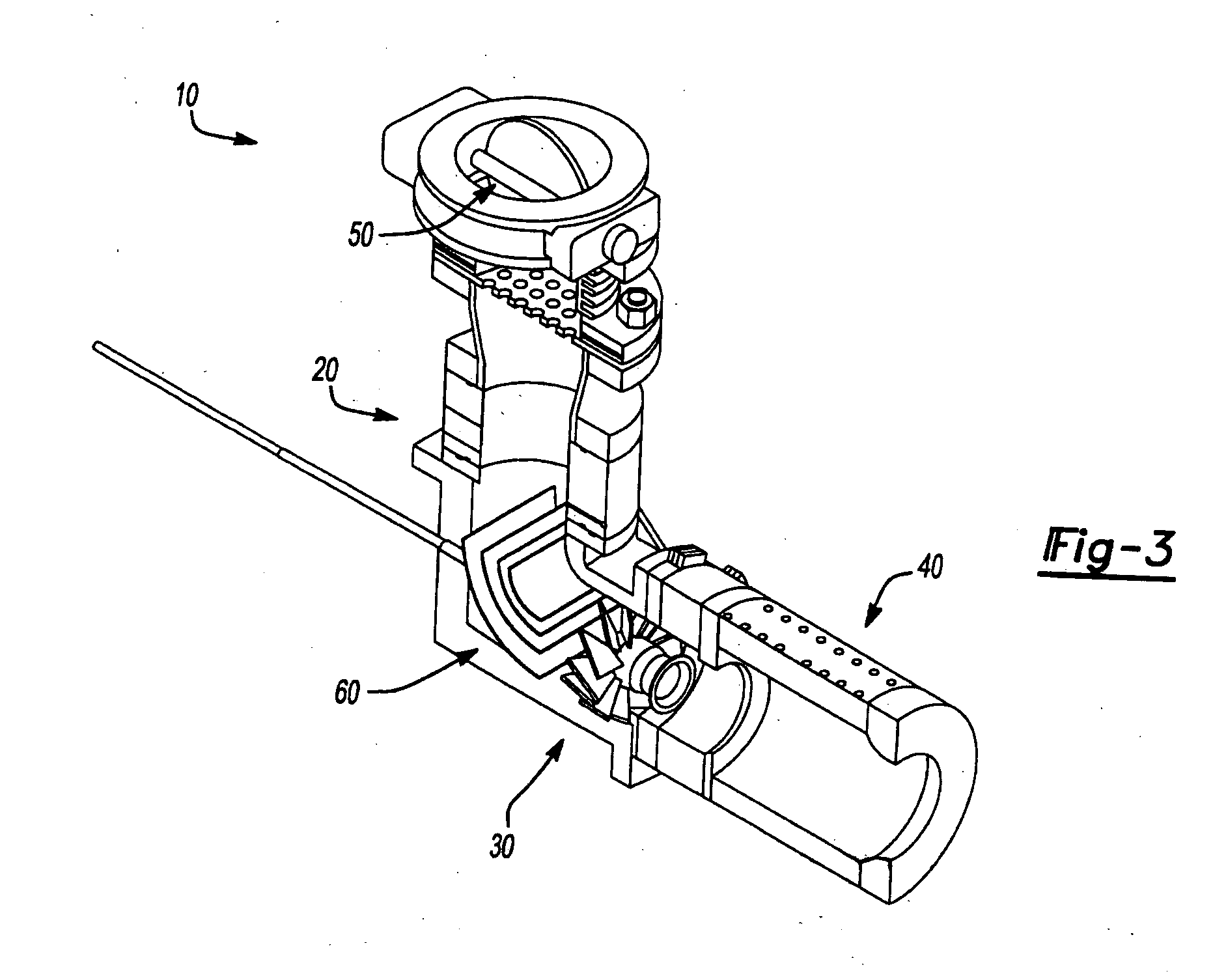

Method and apparatus for vaporizing a compound

ActiveUS7458374B2Heating fastBurn quicklyOther heat production devicesAerosol deliveryInhalationMedicine

Disclosed is a method and device for rapid heating of a coated substance which preferably includes a drug to vaporized for inhalation therapy. A device in accordance with the present invention preferably includes a substrate which has an interior surface surrounding an interior region and an exterior surface upon which the coated substance is to be adhered. Though the substrate is preferably metallic, it does not need to be. A combustible element is placed in the interior region of the rigid substrate and an igniter is connected to the combustible element. The igniter is for initiating oxidation of the combustible element. Preferably, the coated substance is vaporized inside of a housing to allow the vaporized drug to aerosolize and be inhaled by a user.

Owner:ALEXZA PHARMA INC

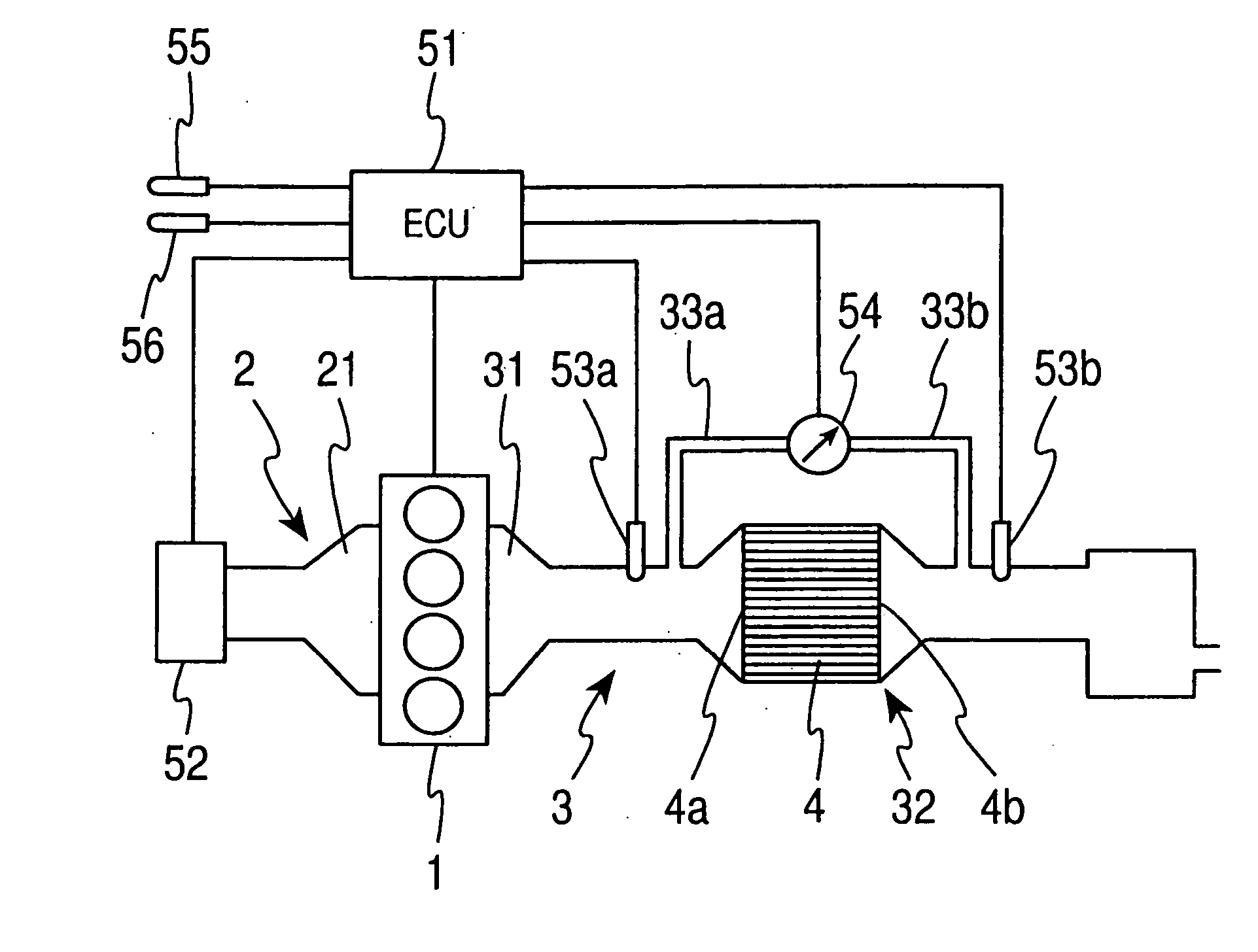

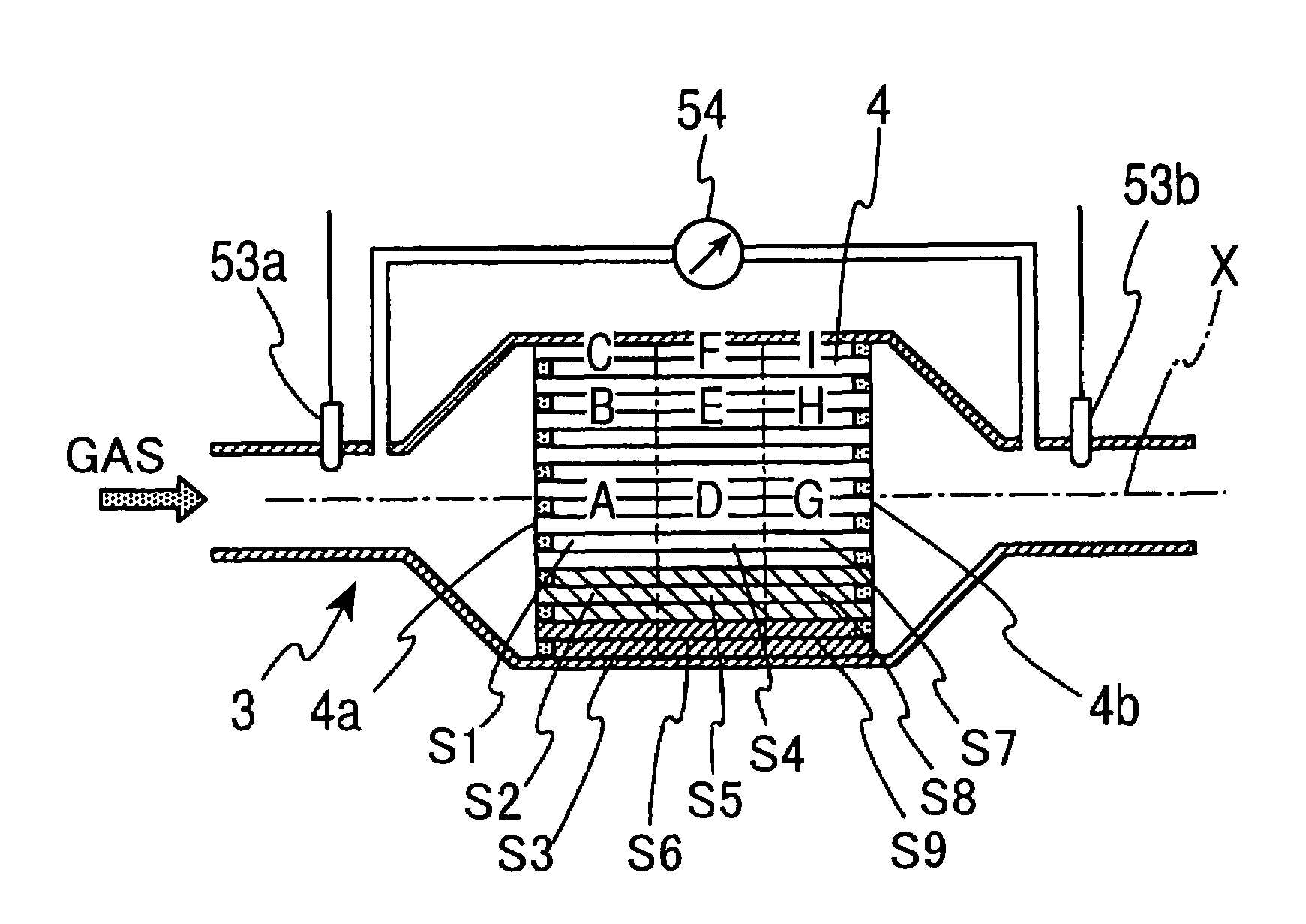

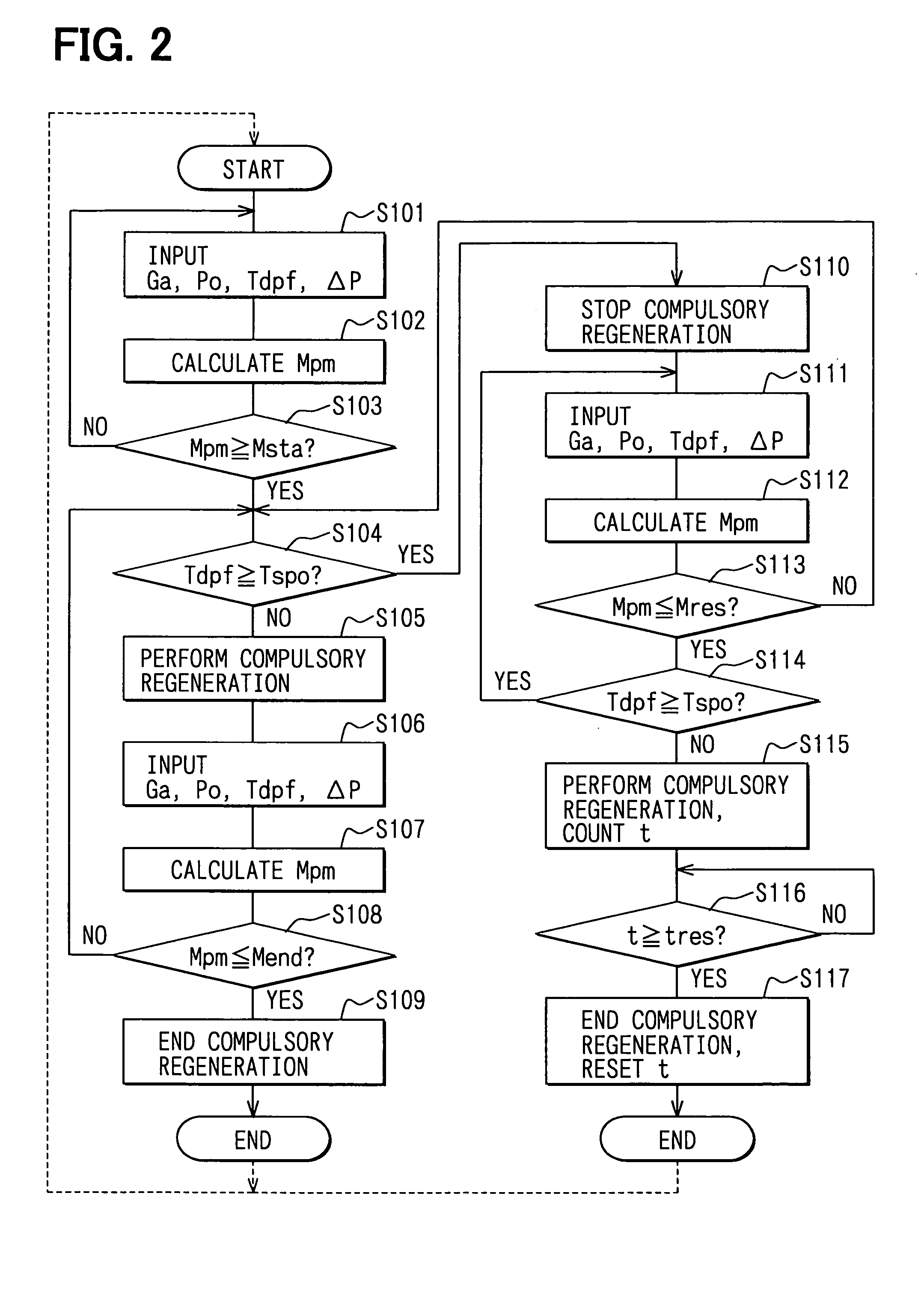

Exhaust gas purification system of internal combustion engine

ActiveUS20050198944A1Prevent occurrenceRapid combustionInternal combustion piston enginesDispersed particle filtrationDiesel particulate filterElectronic control unit

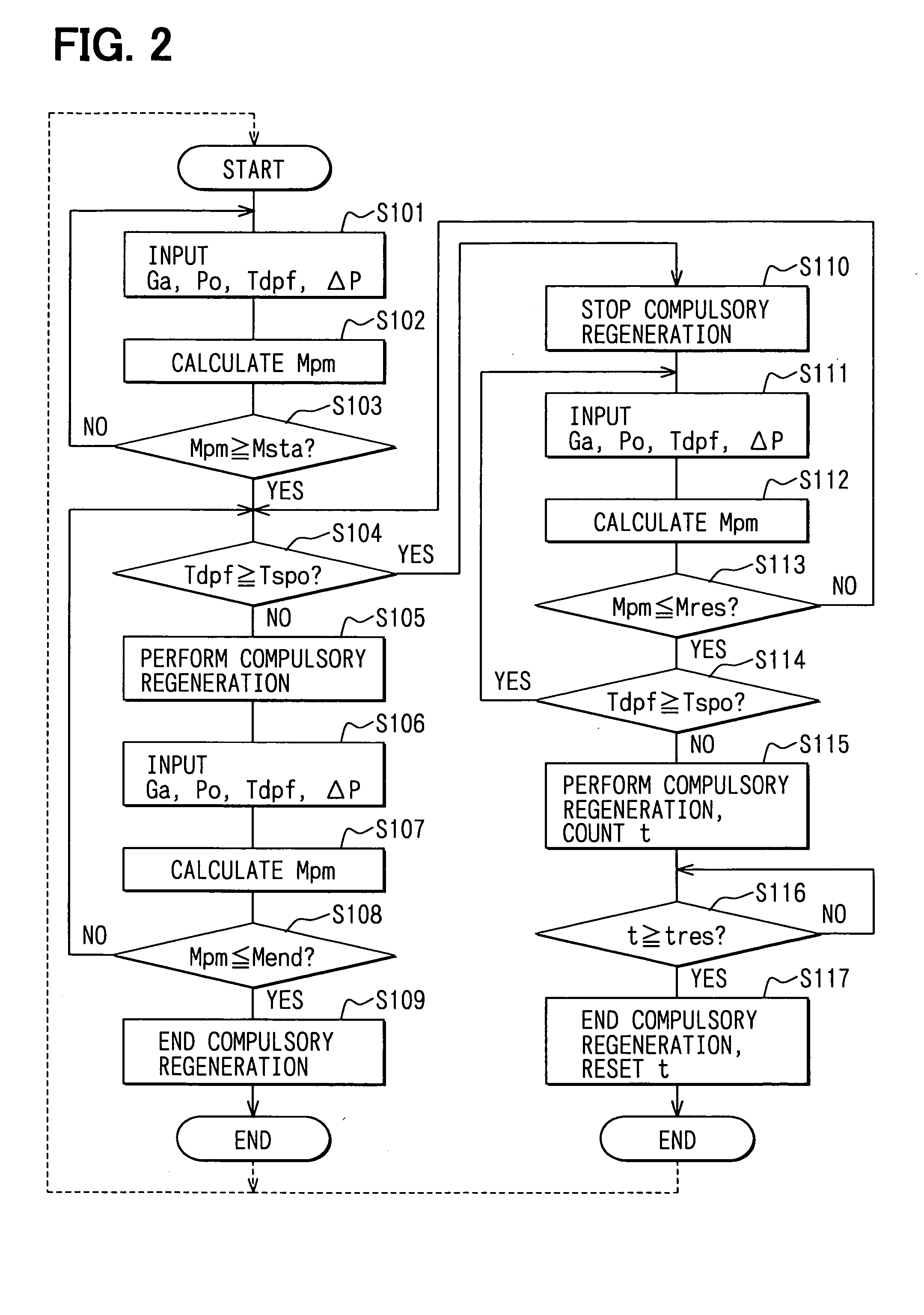

An electronic control unit (ECU) of an internal combustion engine calculates a present deposition quantity of exhaust particulate matters based on operating states of the engine such as a differential pressure of a diesel particulate filter (DPF). If the present deposition quantity exceeds a predetermined upper limit value, the ECU performs compulsory regeneration of the DPF to compulsorily combust and reduce the deposited exhaust particulate matters. The ECU determines that spontaneous regeneration occurs if a temperature of exhaust gas in the DPF is equal to or higher than a reference temperature. Thereafter, the ECU completes the compulsory regeneration to eliminate the deposited exhaust particulate matters if the ECU determines that the spontaneous regeneration stops and the deposition quantity becomes equal to or less than a predetermined lower limit value.

Owner:DENSO CORP

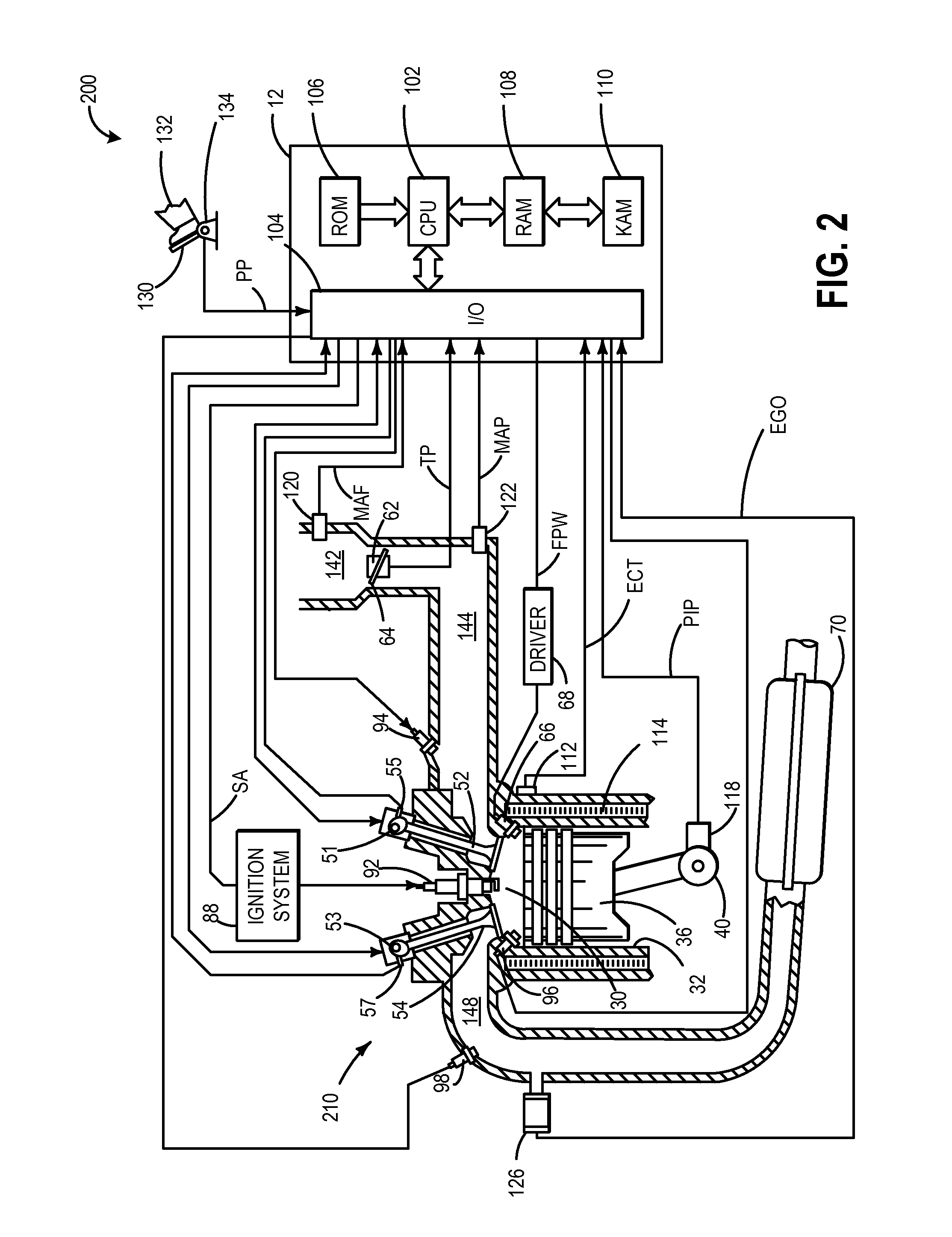

Reduction of cold-start emissions and catalyst warm-up time with direct fuel injection

InactiveUSRE36737E1Reduce decreaseReduce hydrocarbonElectrical controlInternal combustion piston enginesCombustion chamberInternal combustion engine

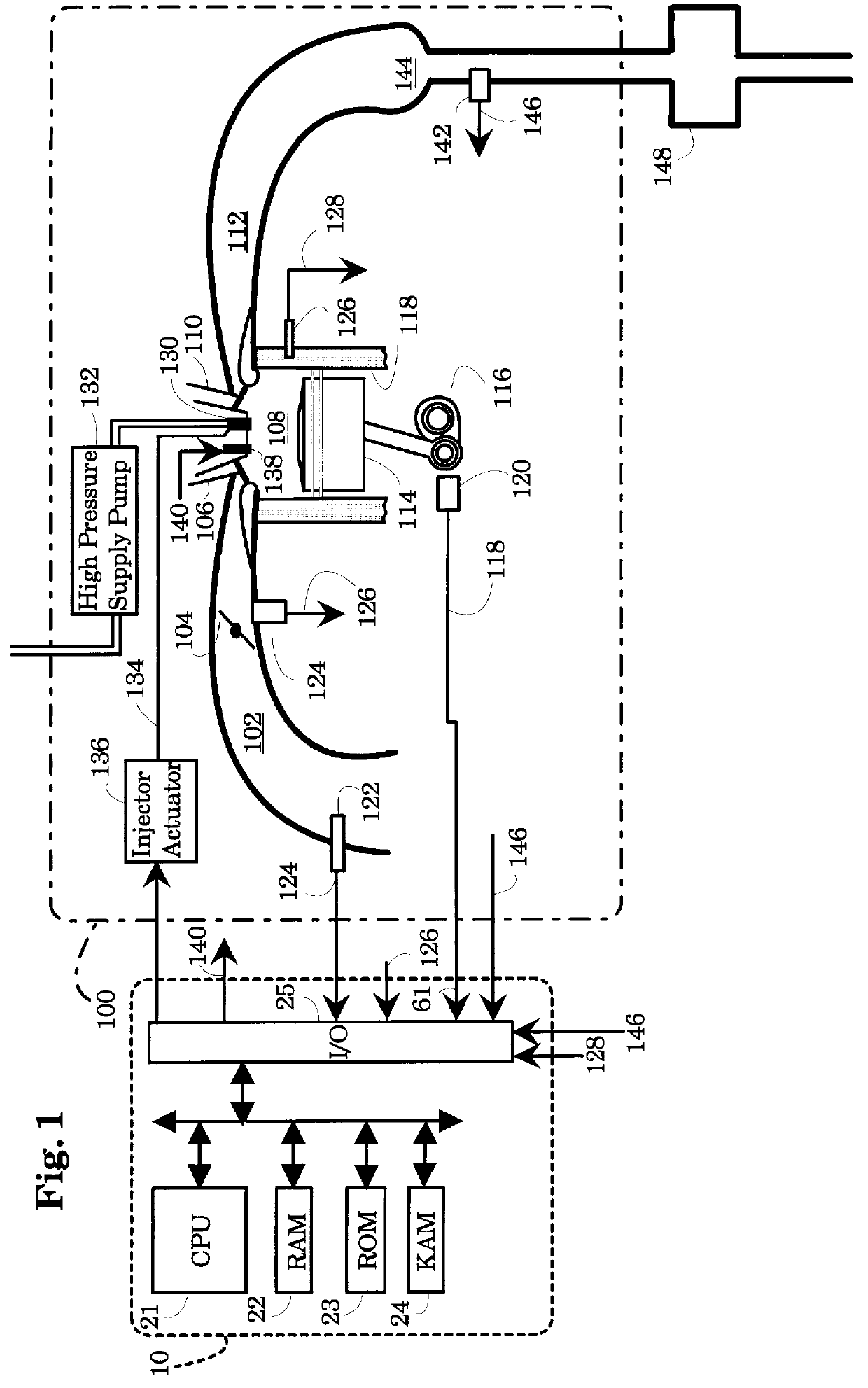

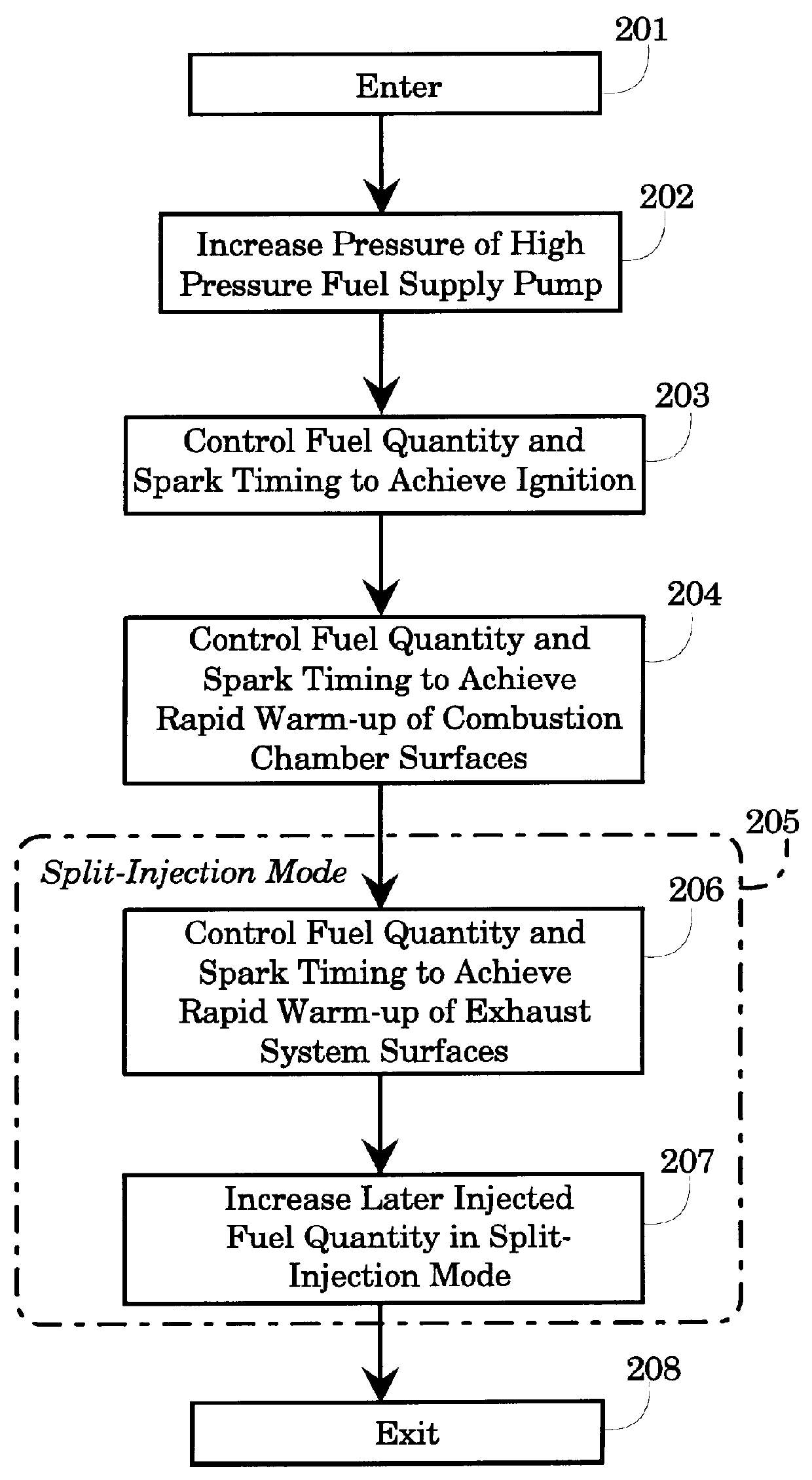

An internal combustion engine employs fuel injectors positioned to inject fuel directly into combustion chambers of the engine, and an electronic engine controller (EEC) to control operation of the engine. The EEC implements a cold start routine which controls the amount of fuel injected, the time at which the fuel is injected and spark timing to achieve a rapid increase in temperature of the engine and the exhaust system components, thereby decreasing tailpipe hydrocarbon emissions during cold start.

Owner:FORD GLOBAL TECH LLC

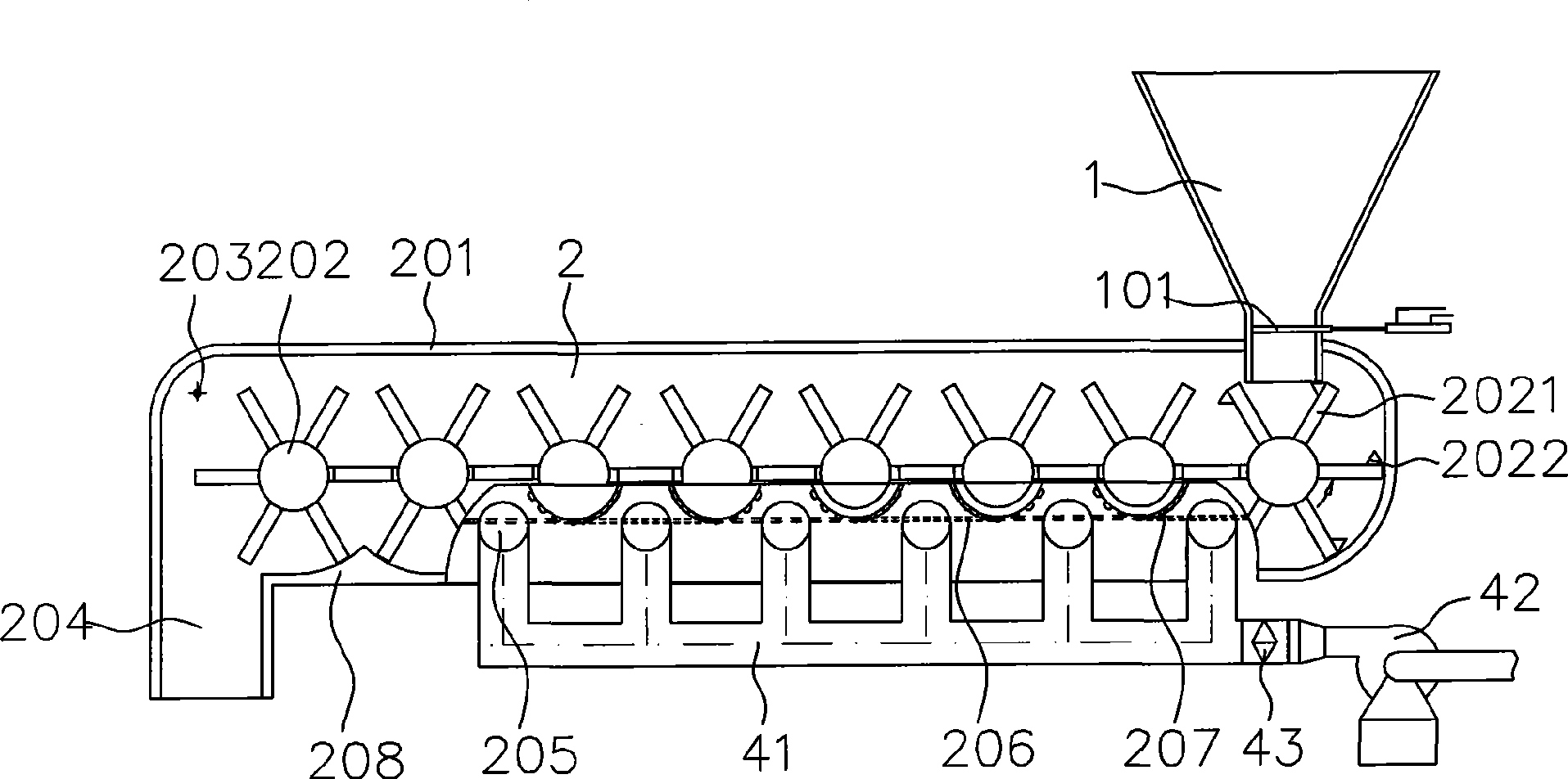

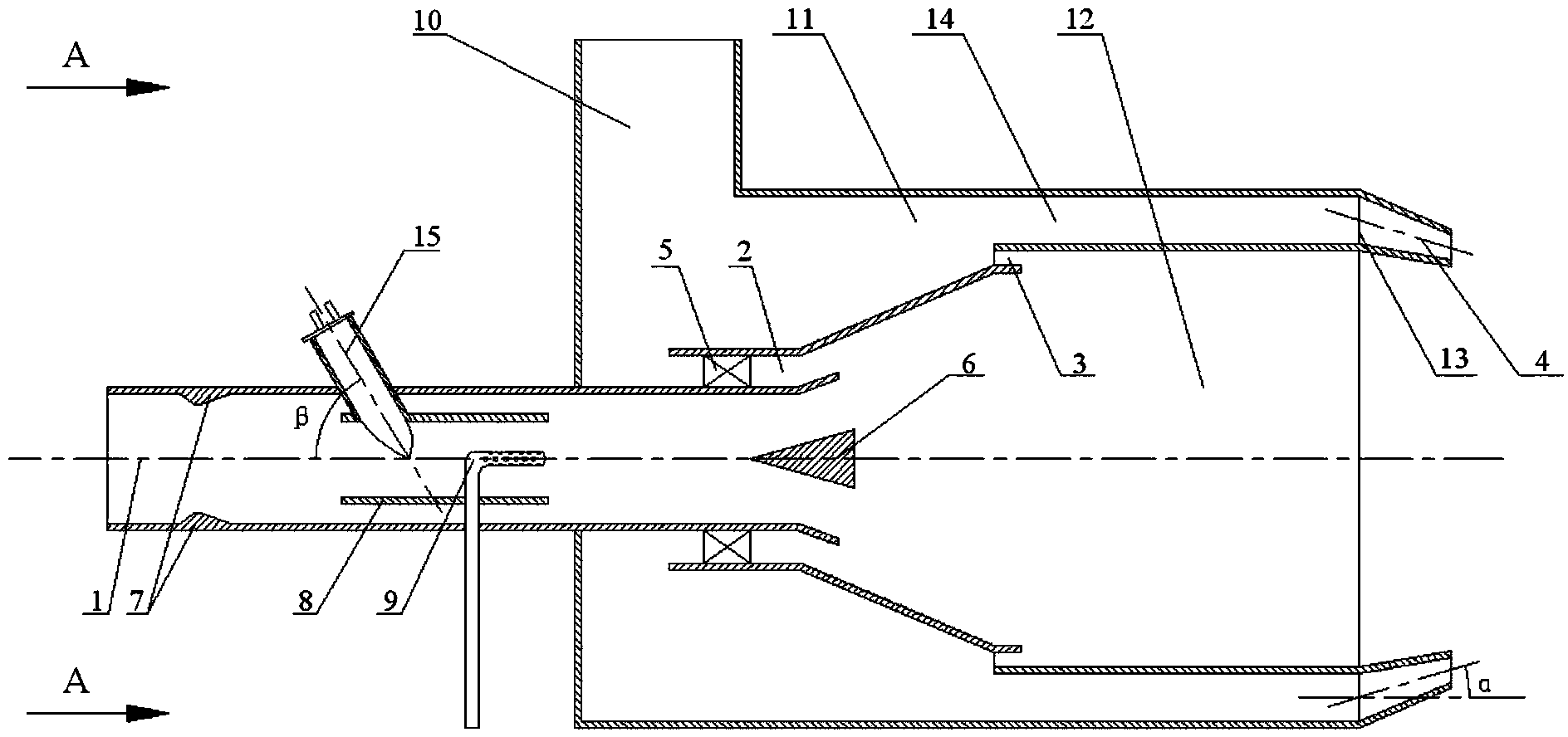

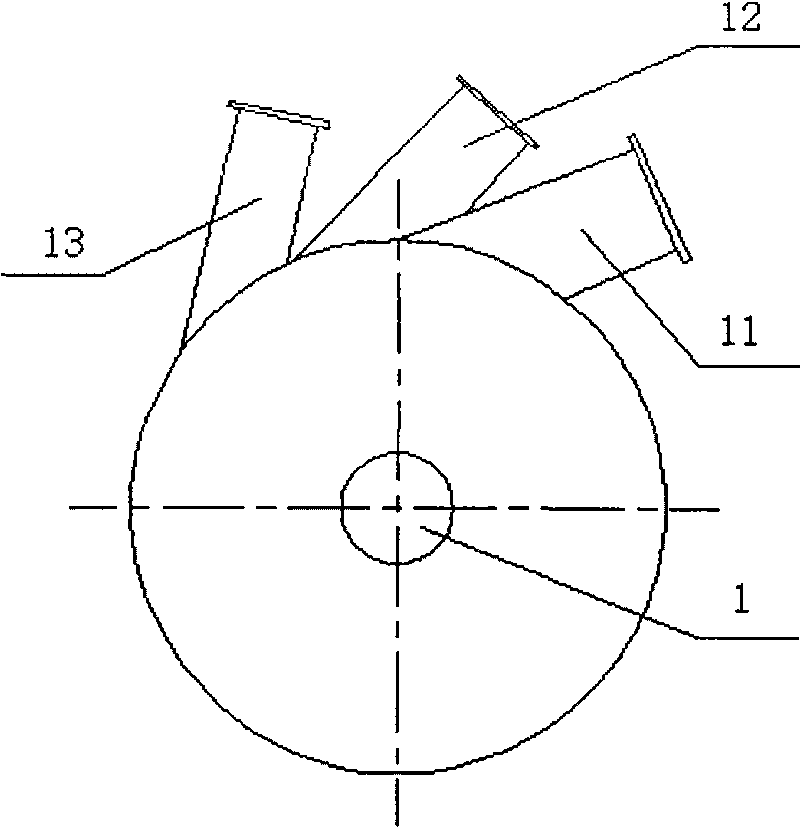

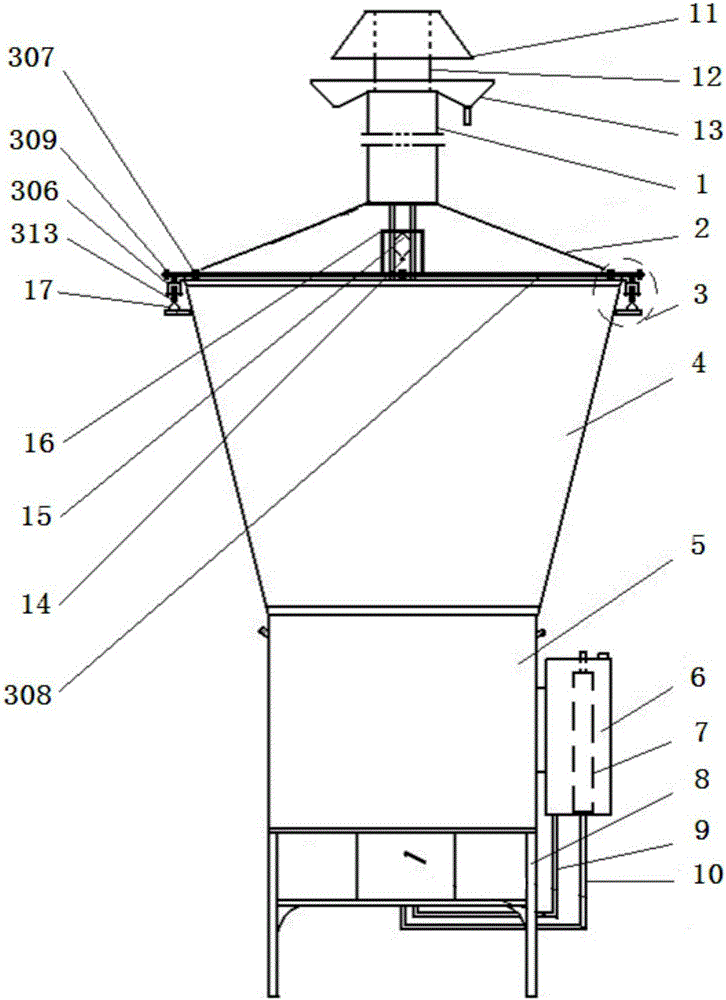

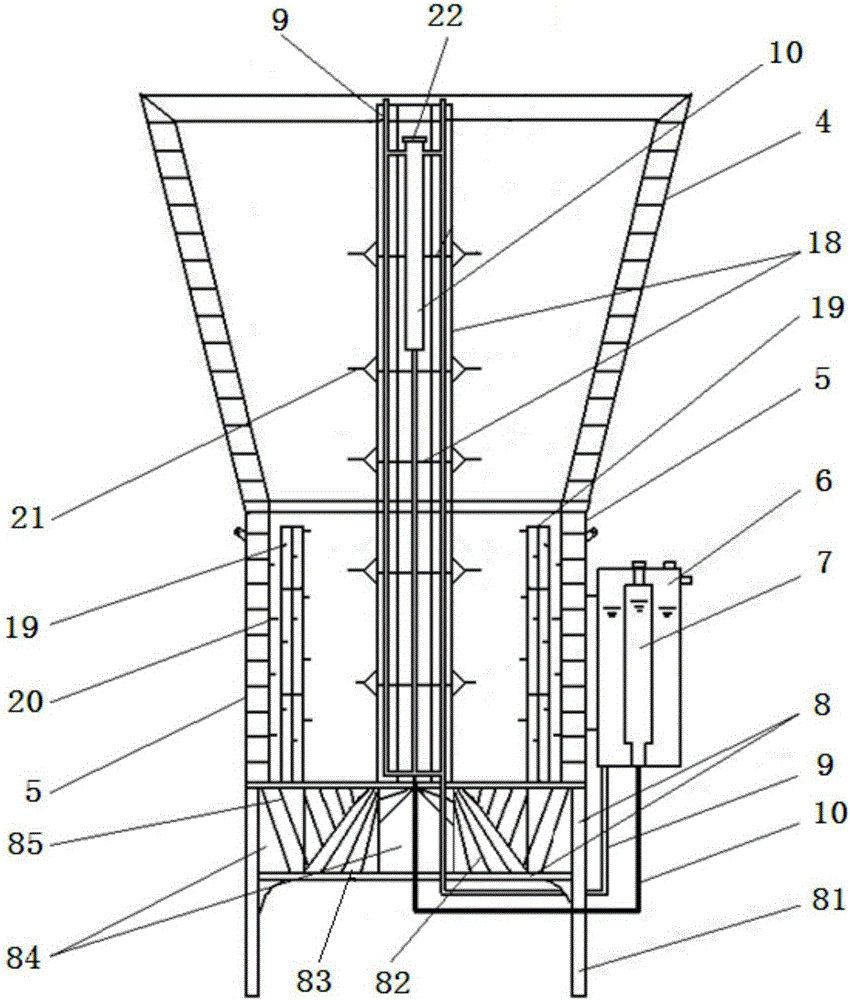

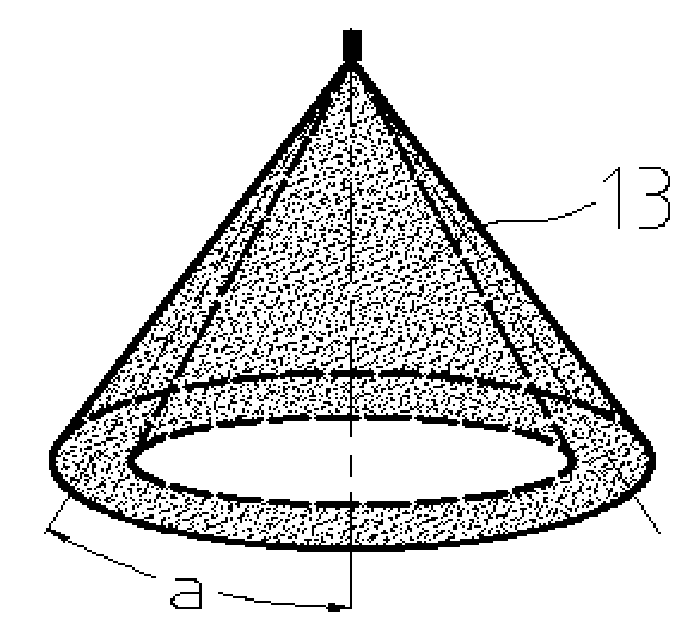

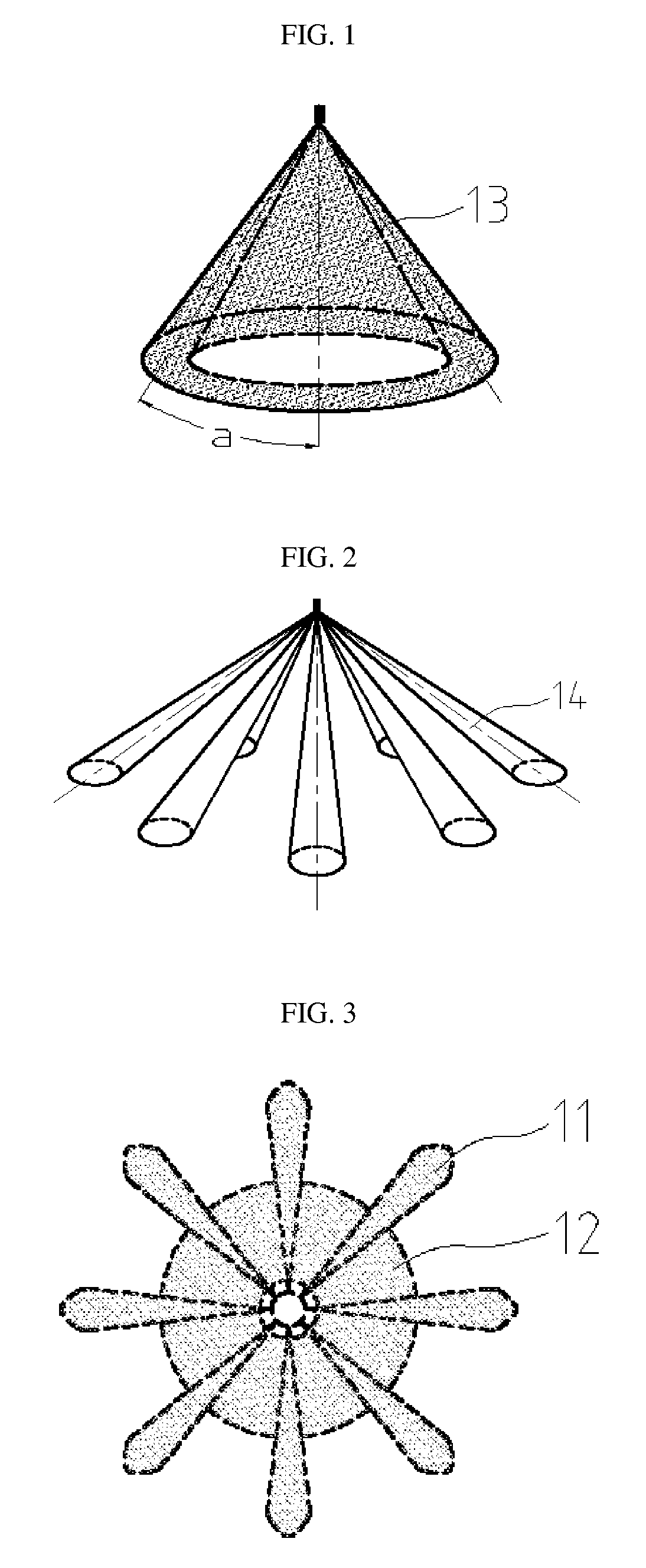

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

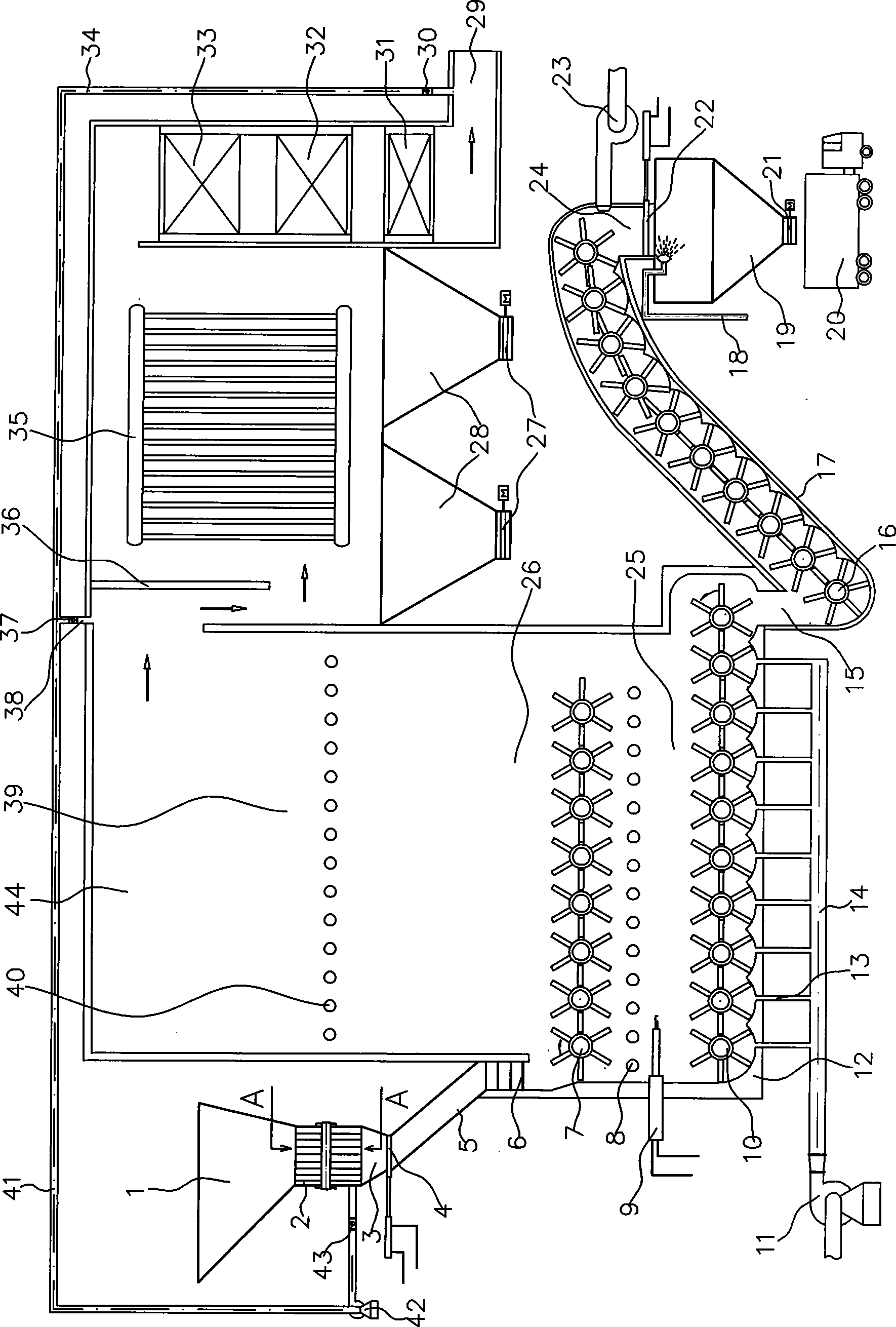

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

Compact swirl augmented afterburners for gas turbine engines

InactiveUS20060230764A1Promotes rapid and efficient atomization and mixingBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityFlame propagation

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel and an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:UNITED TECH CORP

Exhaust gas purification system of internal combustion engine

ActiveUS7254940B2Burn quicklyImprove variationInternal combustion piston enginesDispersed particle filtrationLower limitExternal combustion engine

An electronic control unit (ECU) of an internal combustion engine calculates a present deposition quantity of exhaust particulate matters based on operating states of the engine such as a differential pressure of a diesel particulate filter (DPF). If the present deposition quantity exceeds a predetermined upper limit value, the ECU performs compulsory regeneration of the DPF to compulsorily combust and reduce the deposited exhaust particulate matters. The ECU determines that spontaneous regeneration occurs if a temperature of exhaust gas in the DPF is equal to or higher than a reference temperature. Thereafter, the ECU completes the compulsory regeneration to eliminate the deposited exhaust particulate matters if the ECU determines that the spontaneous regeneration stops and the deposition quantity becomes equal to or less than a predetermined lower limit value.

Owner:DENSO CORP

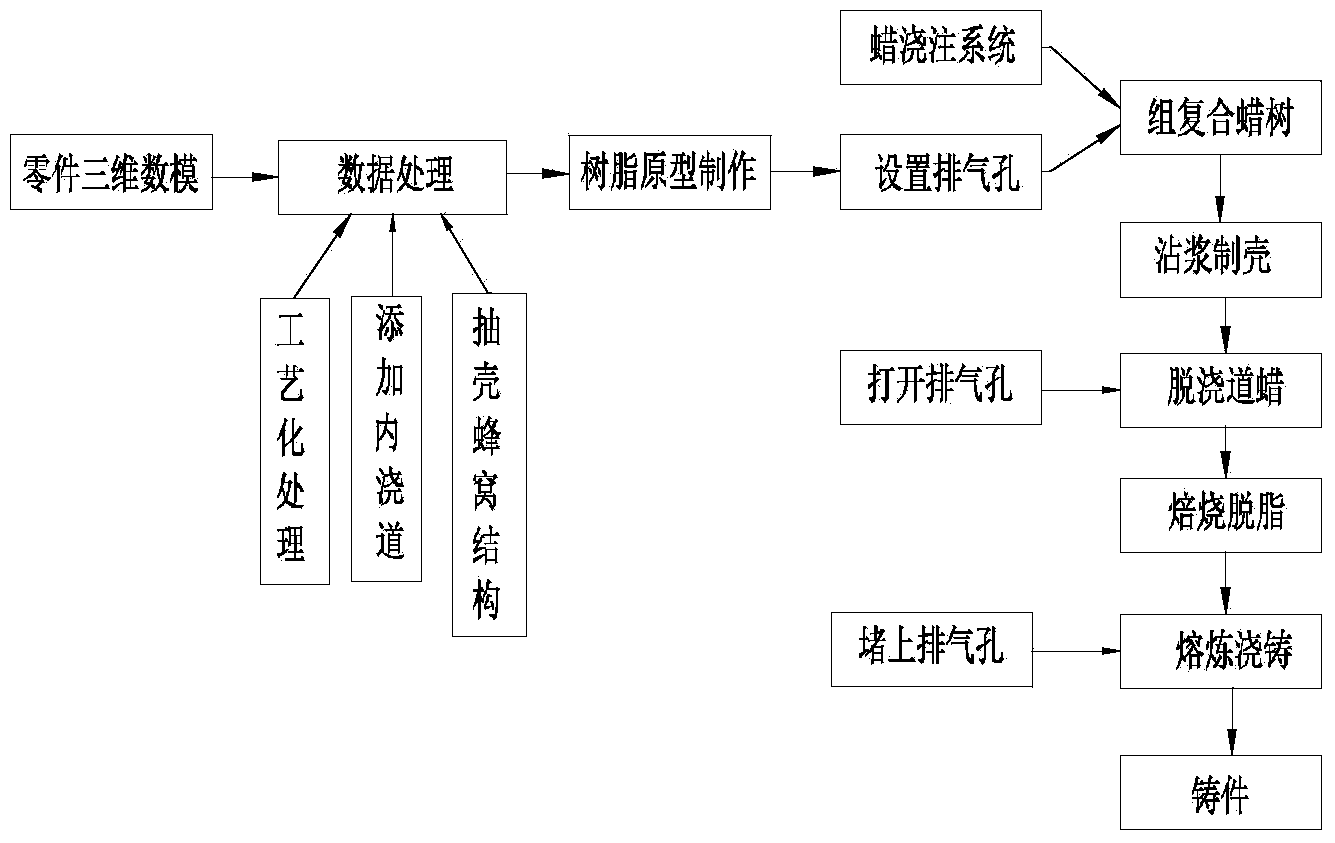

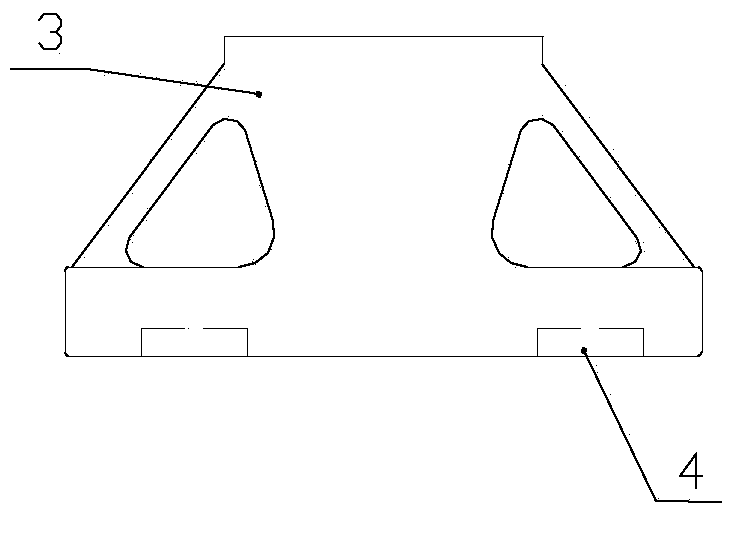

Rapid investment casting method based on stereolithography (SL)

Owner:无锡市交大增智增材制造技术研究院有限公司

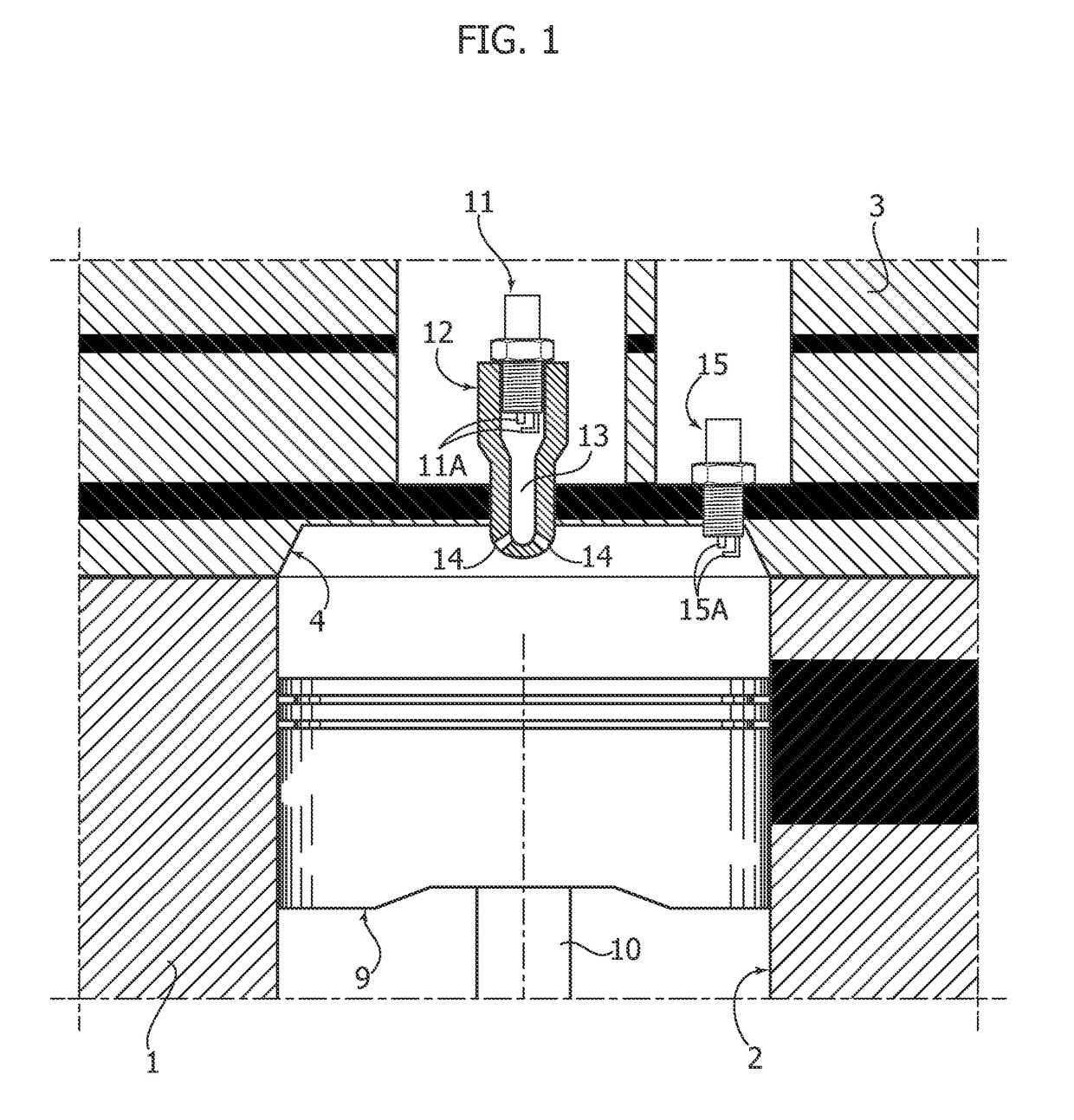

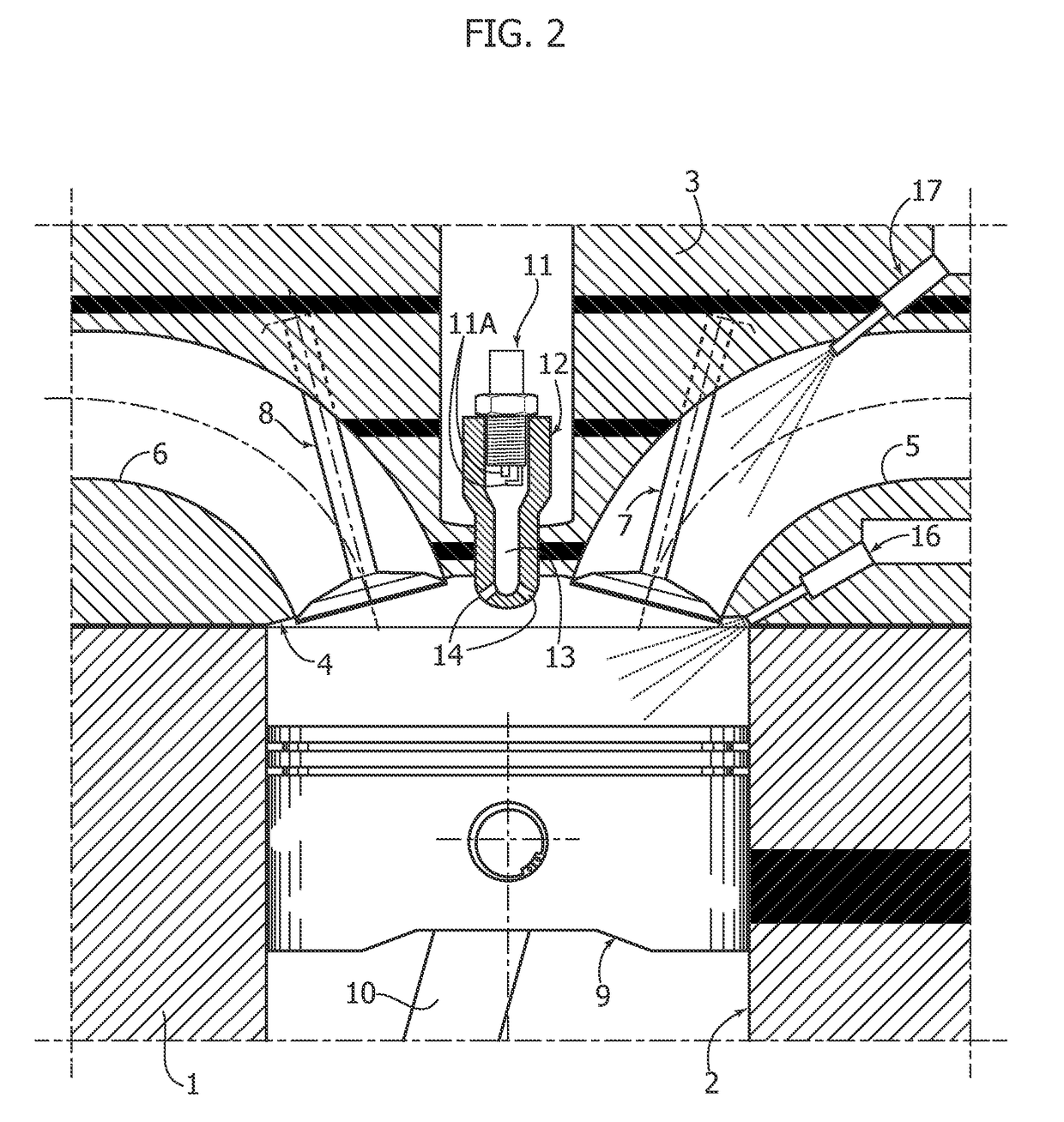

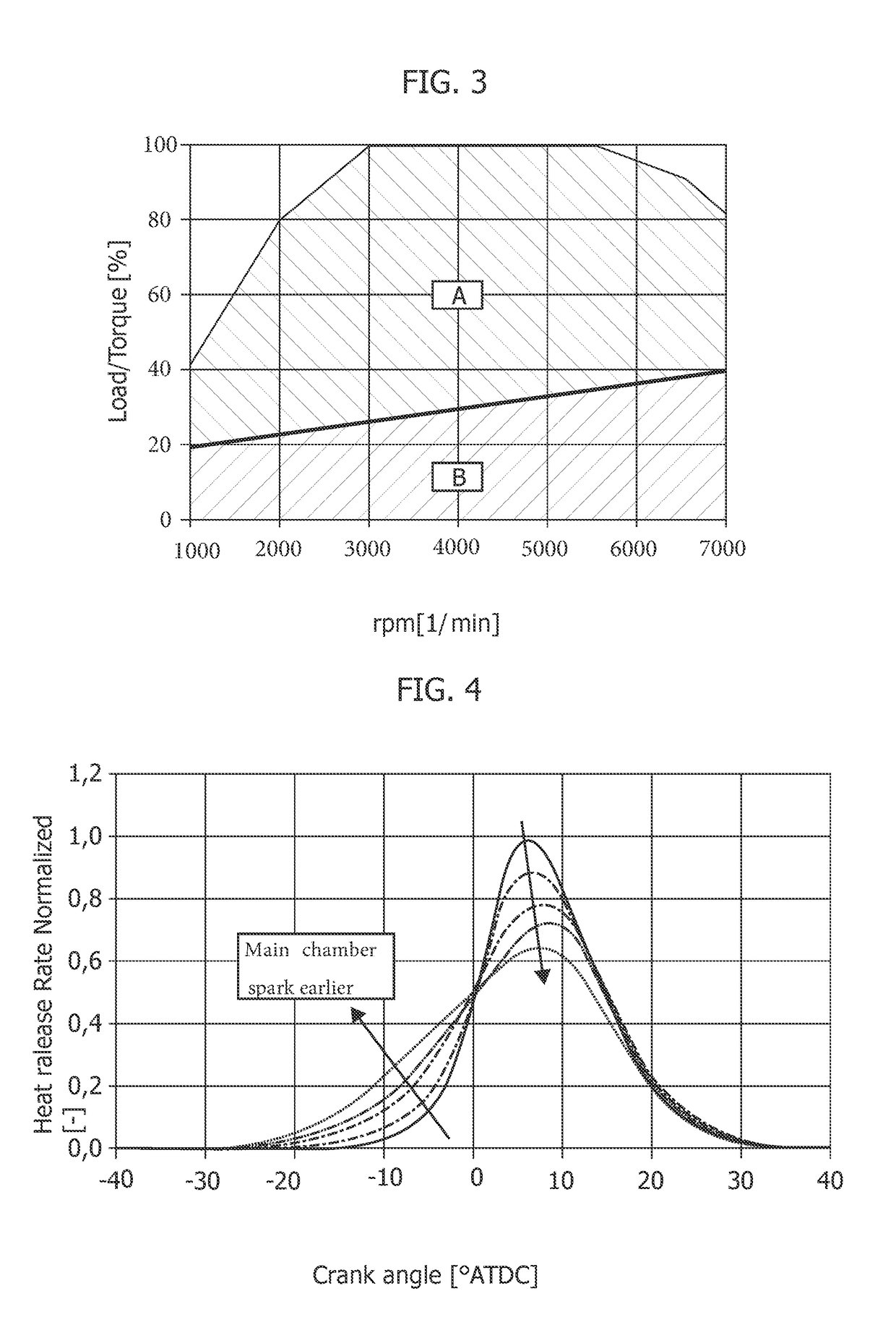

Gasoline internal combustion engine, with a combustion pre-chamber and two spark plugs

ActiveUS20190078498A1Increase resistanceReduce fuel consumptionSparking plugsInternal combustion piston enginesCombustion chamberDetonation

An engine has, for each cylinder, a combustion chamber and a combustion pre-chamber communicating with the combustion chamber. First and second spark plugs are associated with the pre-chamber and combustion chamber, respectively. Gasoline is injected by an injector device directly into the combustion chamber and / or by an injector device into a cylinder intake duct. There is no device for injecting gasoline, air or an air / gasoline mixture directly into the pre-chamber. The engine operates with an air / gasoline mixture substantially corresponding to stoichiometric for compatibility with an exhaust system having a trivalent catalyst. The pre-chamber is, not used for engine operation with poor dosing, but to increase resistance to engine detonation. The engine can thus be configured with a high compression ratio, with a significant reduction in fuel consumption at the same power level. The second spark plug is only activated at low and medium engine loads to stabilize combustion.

Owner:MASERATI

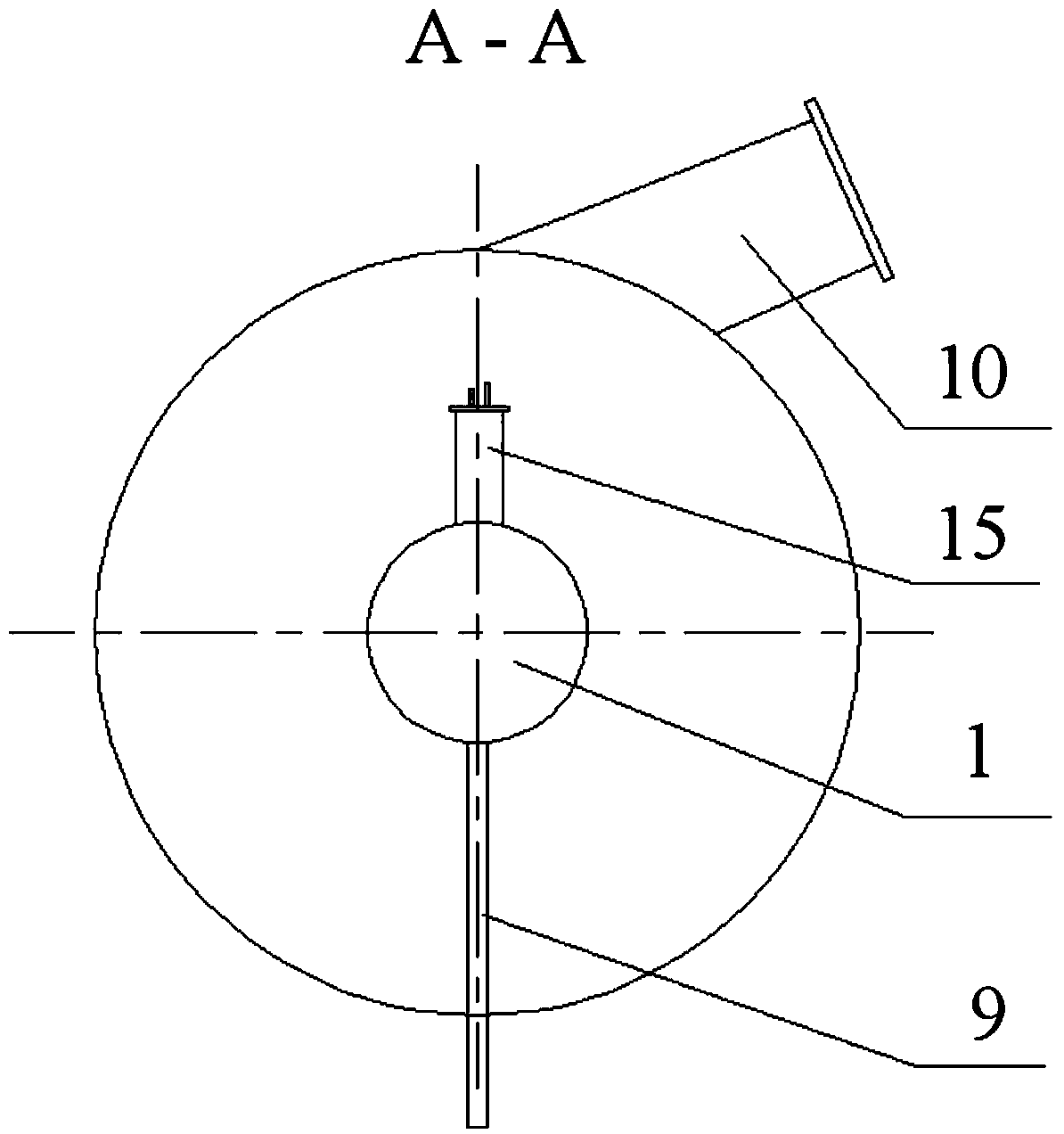

Novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor

ActiveCN103615717AWith low load stable combustion functionProvide in timePilot flame ignitersPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor. The novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor comprises an oxygen enrichment guide pipe, a primary air pipe, a cylindrical oil-coal mixed combustion chamber, a secondary air pipe, a secondary air box and a pre-combustion chamber, wherein the central axes of the primary air pipe, the cylindrical oil-coal mixed combustion chamber, the secondary air pipe, the secondary air box and the pre-combustion chamber coincide. A secondary air inlet inclining in the circumferential direction is formed in the pipe wall of the secondary air box; the primary air pipe penetrates through the secondary air box in the axial direction, the oil-coal mixed combustion chamber is coaxially arranged in the primary air pipe, and a high-energy tiny-oil ignition oil gun and the oxygen enrichment guide pipe are arranged in the oil-coal mixed combustion chamber; the secondary air pipe with a rotational flow impeller is coaxially arranged outside the primary air pipe in a sleeved mode and an outlet end is provided with a bluff body; the pre-combustion chamber is arranged in the secondary air box, the inlet end of the pre-combustion chamber is provided with a graded air duct, and a plurality of disturbance air nozzles are installed in an outlet of the combustor. The ignition fuel saving ratio reaches over 90% and the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the function of low load stable combustion and the function of ultralow load stable combustion; the technologies of oxygen enrichment, coal dust concentration, graded air feeding and the like are adopted, so that the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the advantages of being high in coal dust burn-off rate, low in NOx discharge and the like.

Owner:CHINA JILIANG UNIV

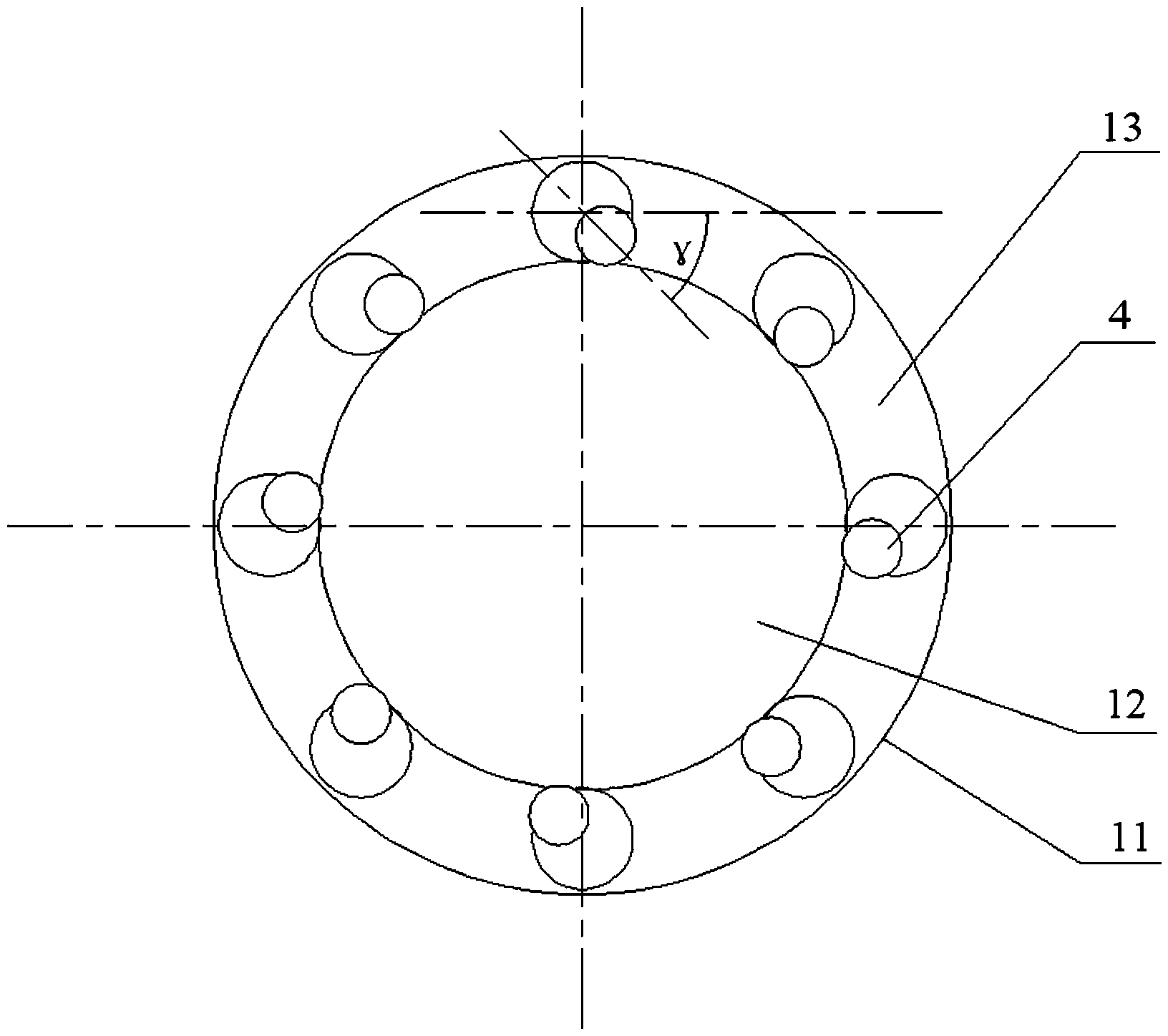

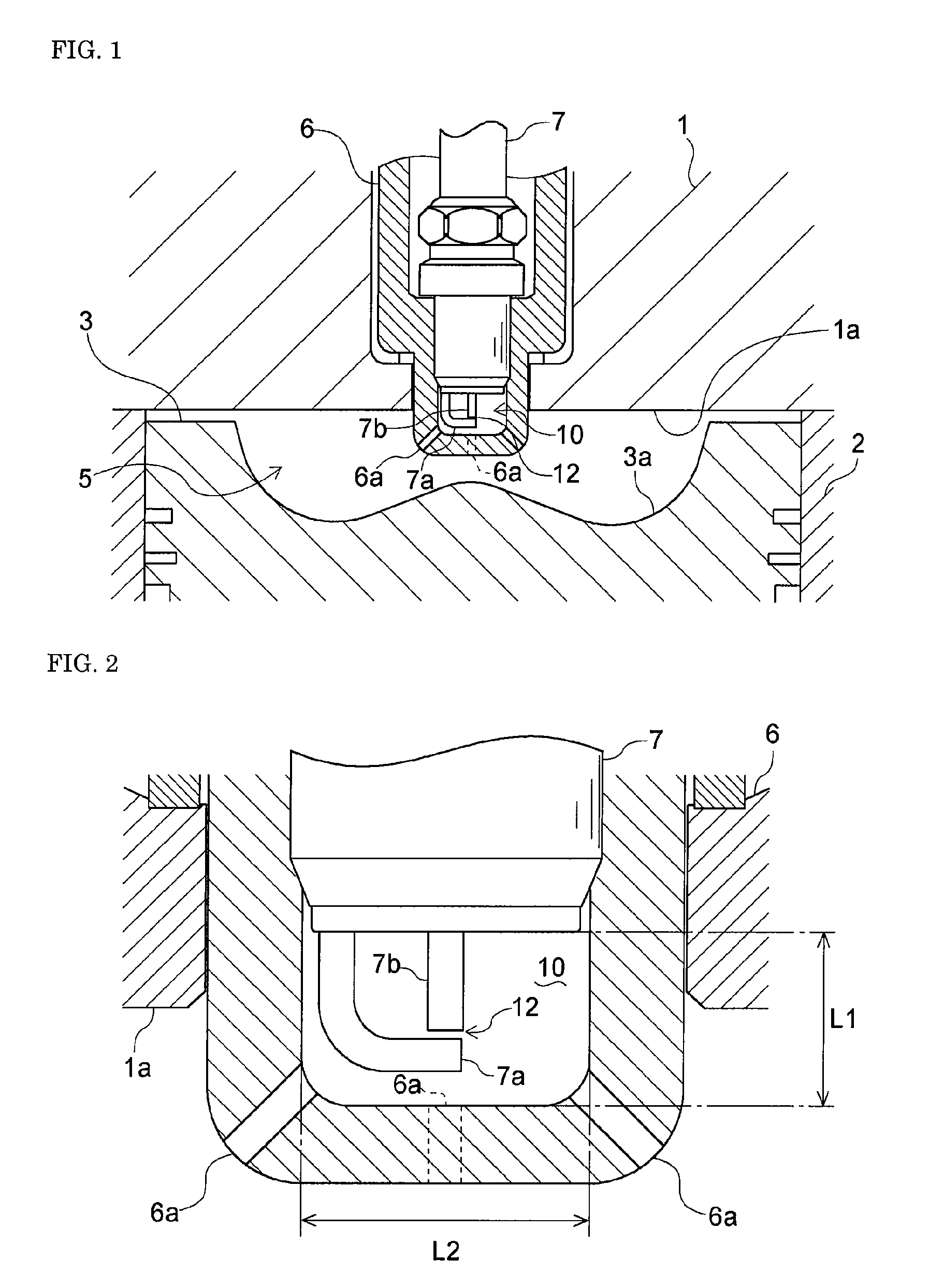

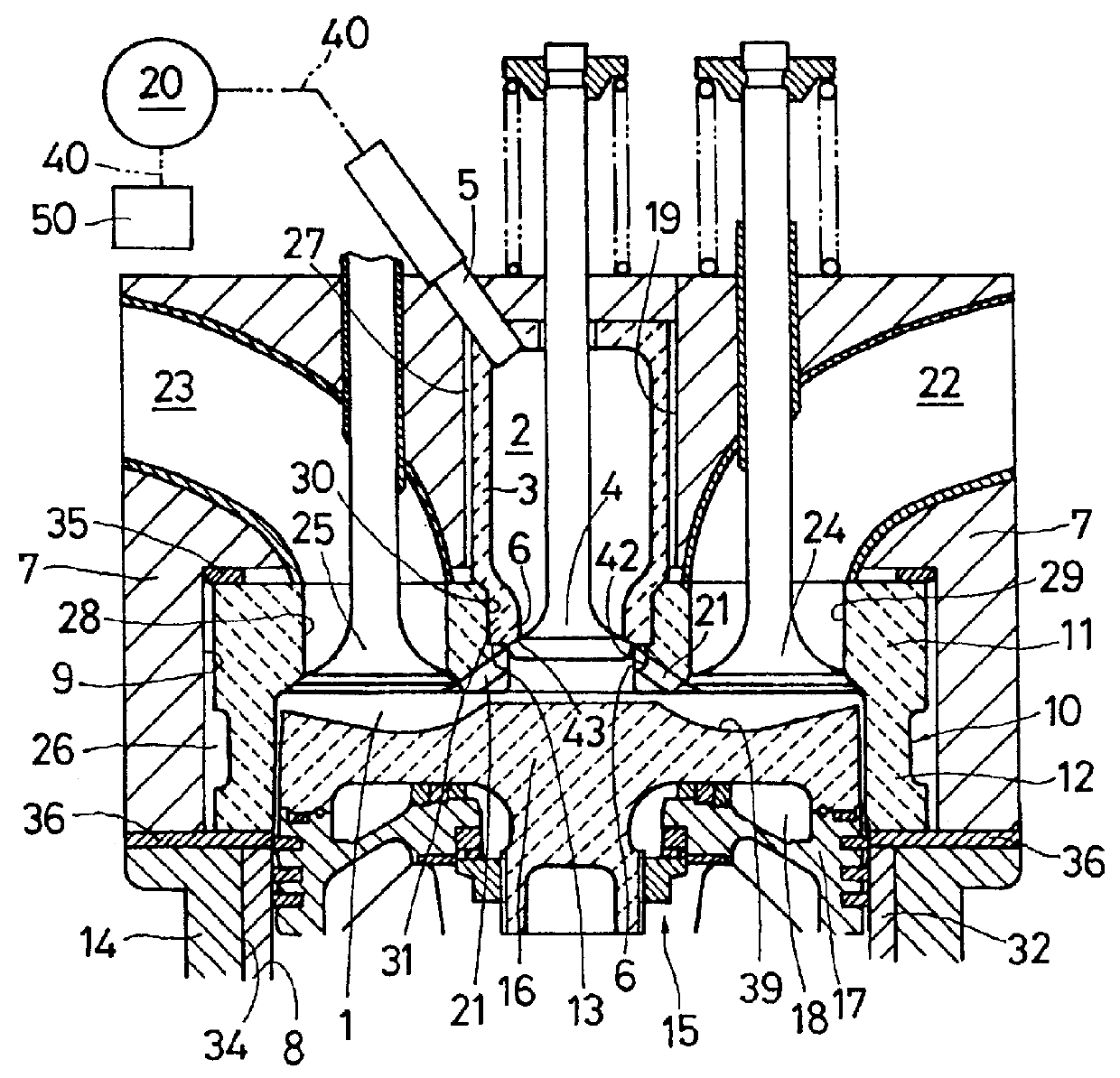

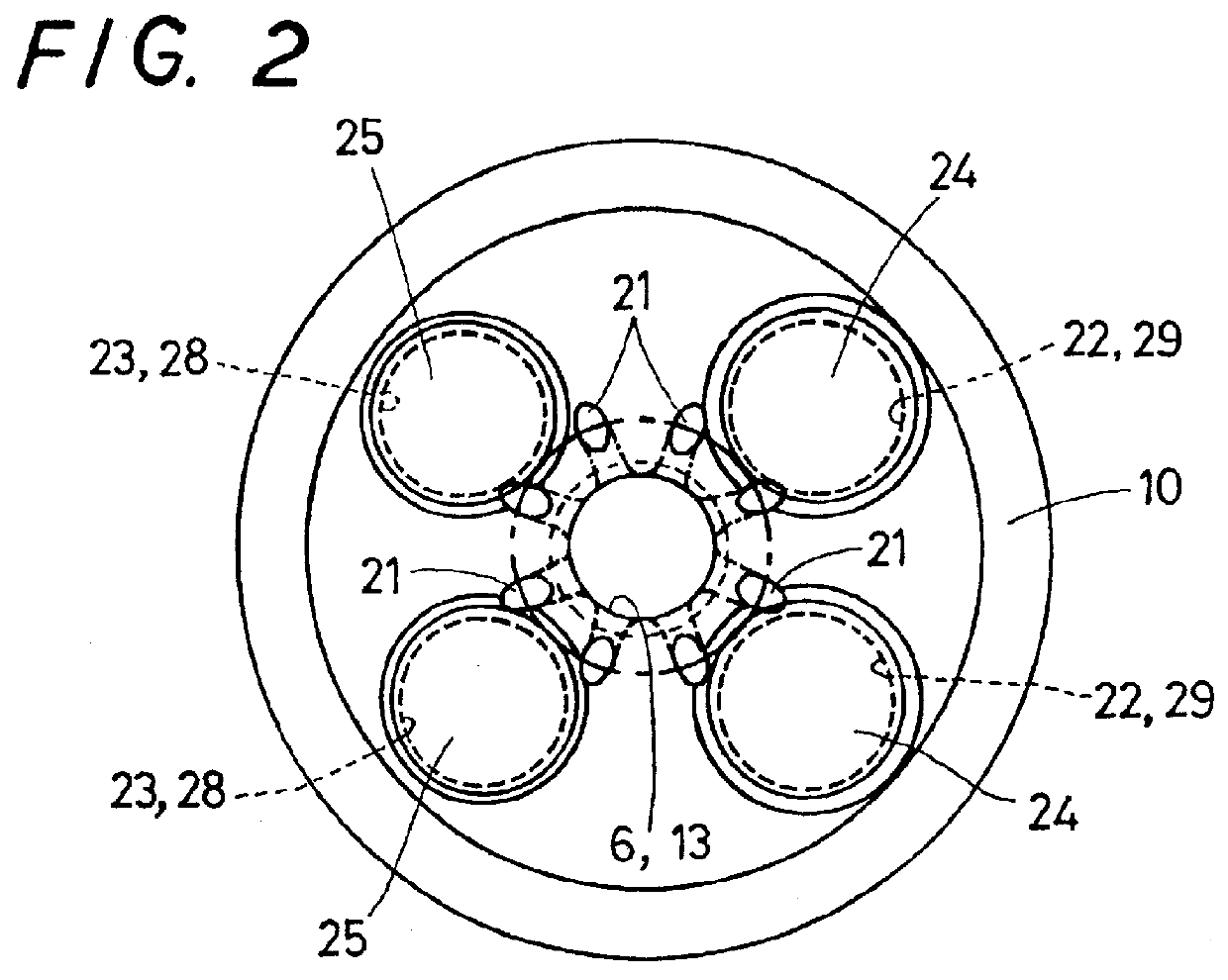

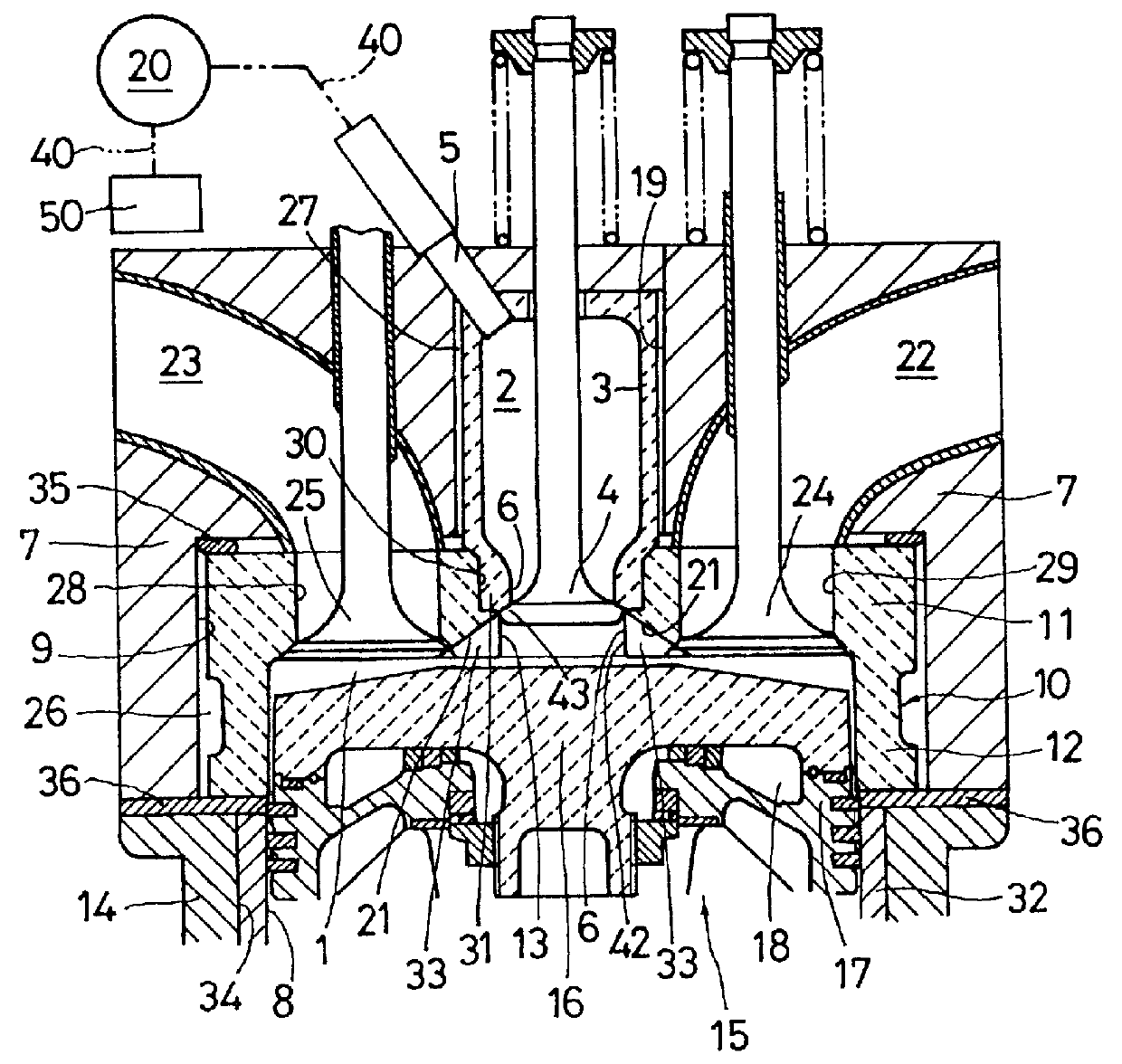

Multipoint ignition engine

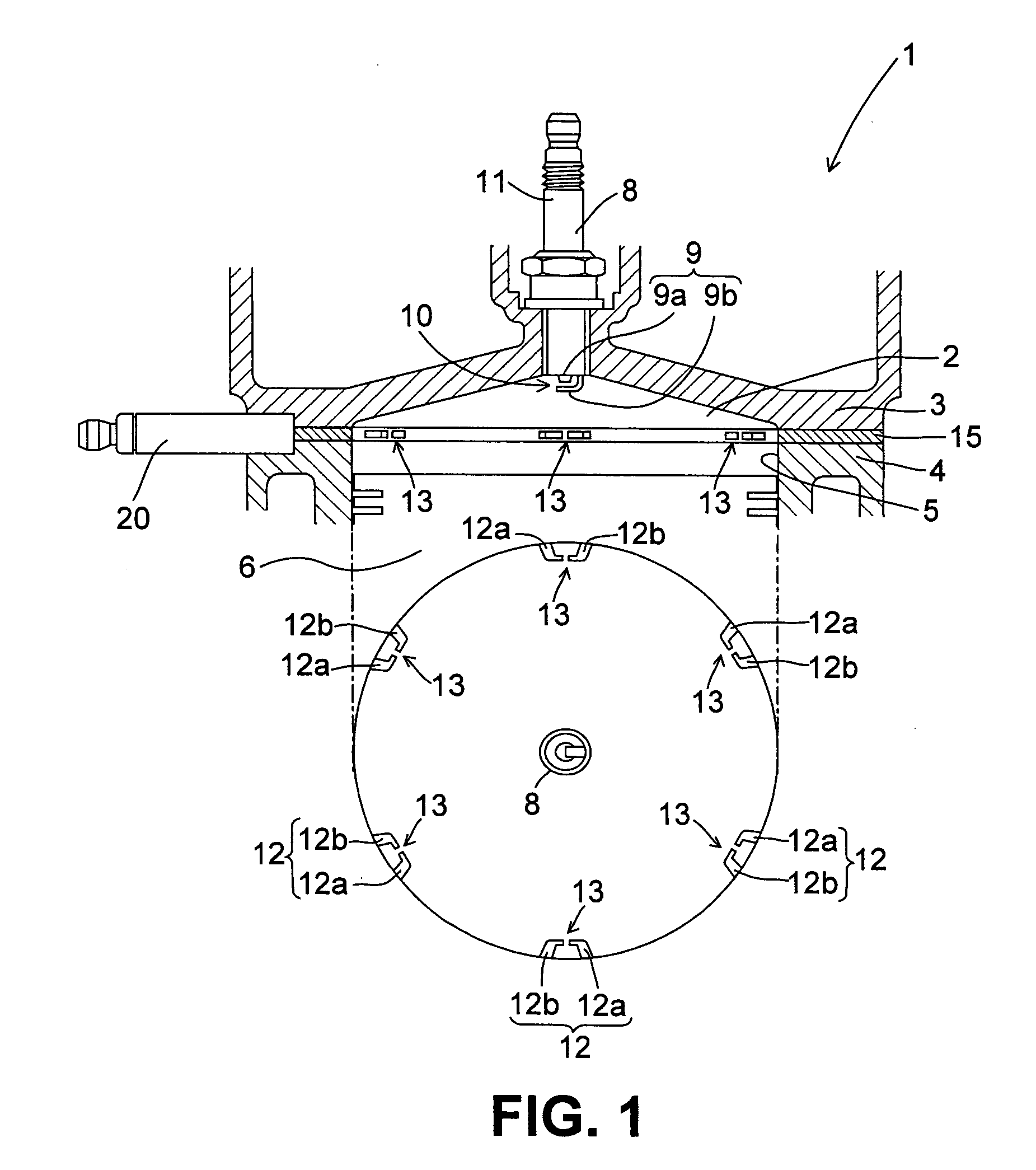

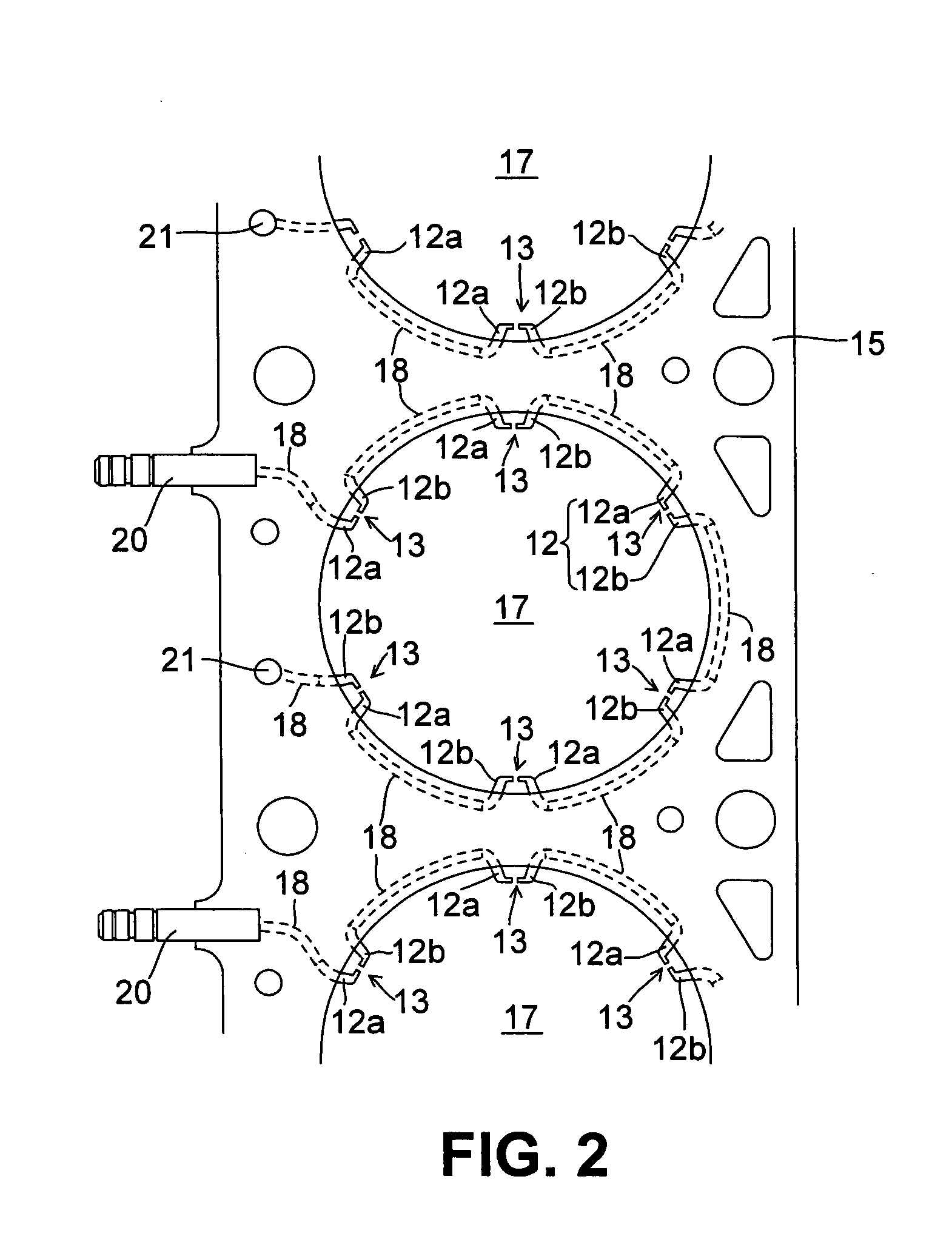

ActiveUS20070209634A1Burn fasterOutput and fuel efficiency can be improvedSparking plugsCombustion enginesHead gasketAir–fuel ratio

A multipoint ignition engine (1) includes a central electrode pair (9), disposed in the center of a combustion chamber (2), for forming a central spark gap (10), and a plurality of peripheral electrode pairs (12) held in a head gasket (15), which has an opening portion having a substantially identical diameter to an opening portion of a cylinder (5) in a position corresponding to the opening portion of the cylinder (5), for forming a plurality of peripheral spark gaps (13) around the inner periphery of the opening portion in the cylinder (5). An air-fuel mixture in the combustion chamber (2), which is obtained by mixing together fuel and air evenly to the stoichiometric air-fuel ratio or a richer / leaner air-fuel ratio than the stoichiometric air-fuel ratio, is ignited using both the central spark gap (10) and the plurality of peripheral spark gaps (13).

Owner:MIYAMA

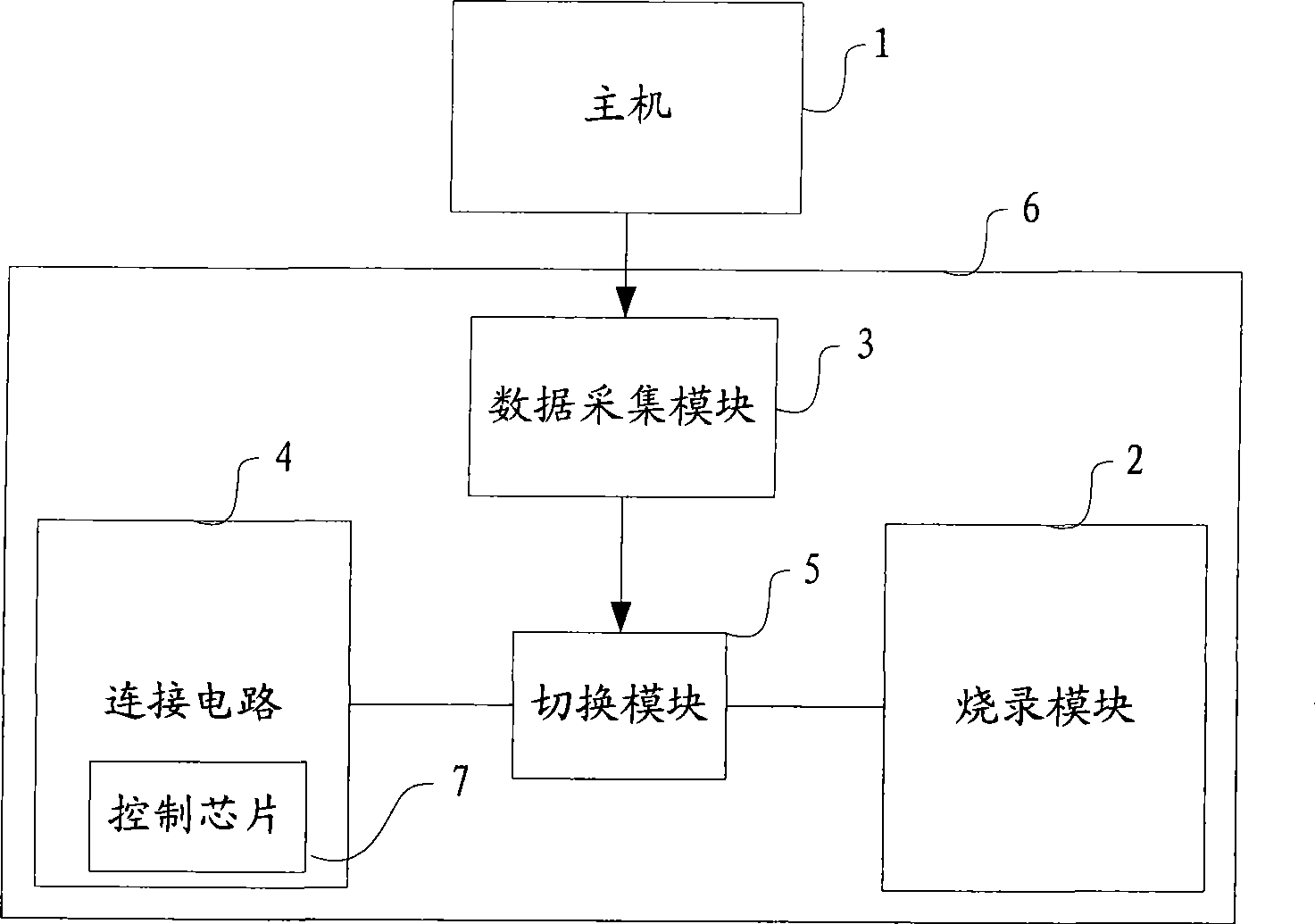

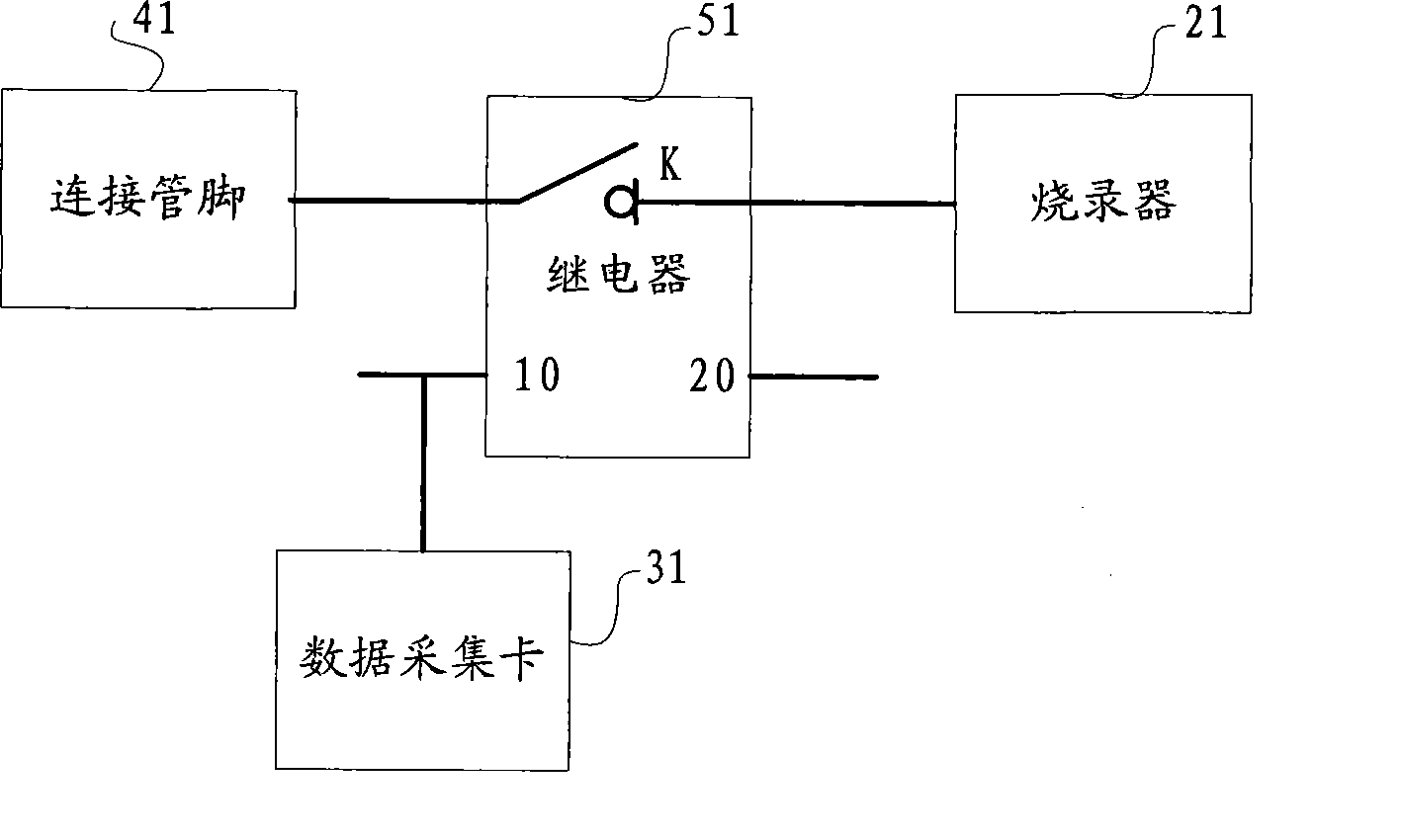

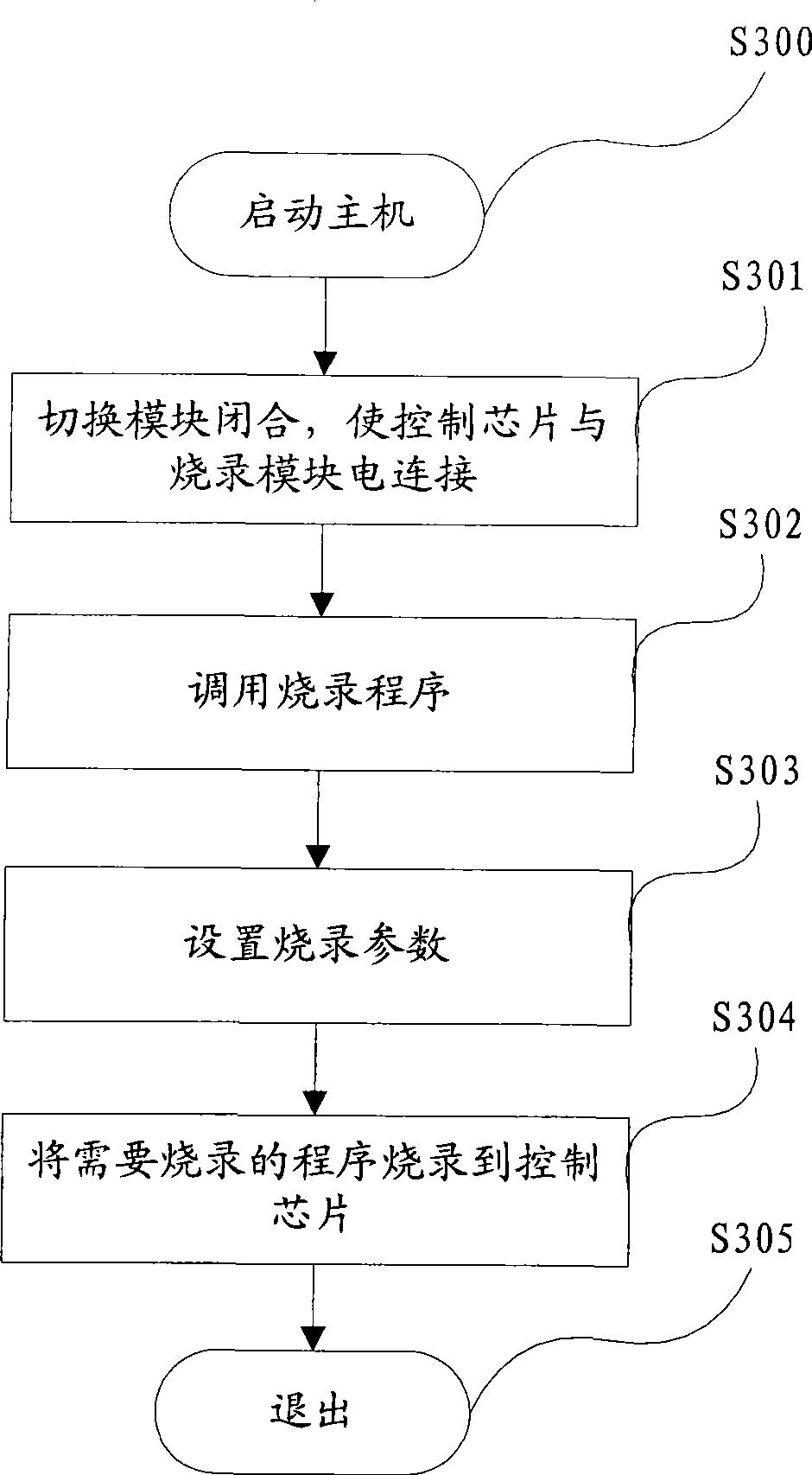

Burning apparatus and method for control chip

InactiveCN101470410AEasy maintenanceLow costProgramme controlComputer controlFile systemComputer module

The invention provides a control chip programming device, which comprises a programming module, a connection circuit and a switching module, wherein the programming module is used for programming programs required for the control chip, the connection circuit is connected with the control chip, and the switching module is respectively connected with the programming module and the connection circuit for controlling on and off of an electric signal between the connection circuit and the programming module. The programming module includes a programming program for programming the control chip. The invention further provides a control chip programming method. The control chip programming device and the method thereof require a programmer being embedded in a traditional chip programming test system, thereby saving the cost of programming equipment, and further the chip's program is automatically programmed according to the test file system, thereby reducing complexity of manual operation, reducing error rate, and increasing the production efficiency. For modifying the programming parameters, modification can be carried out by directly modifying the test files, which simplifies and speeds up the programming. The programming system realizes automatic operation, and thereby the whole system can be easily maintained.

Owner:BYD CO LTD

Removal of oils from solid surfaces and water with a substance having a high humate level

ActiveUS20090200241A1Lessen dangerRapid combustionSolid waste disposalContaminated soil reclamationChemistryOrganic chemistry

The present invention relates to a method for removing oil from water or a solid surface. This involves contacting the water or the solid surface with a substance in the form of a sheet and having a high humate level under conditions effective for the substance to absorb oil from the water or the solid surface. The substance, having absorbed oil, is then recovered from the water or solid surface. In an alternative embodiment this method can be carried out where the substance is manure which may or may not be in the form of a sheet.

Owner:NUTRIENT CONTROL SYST

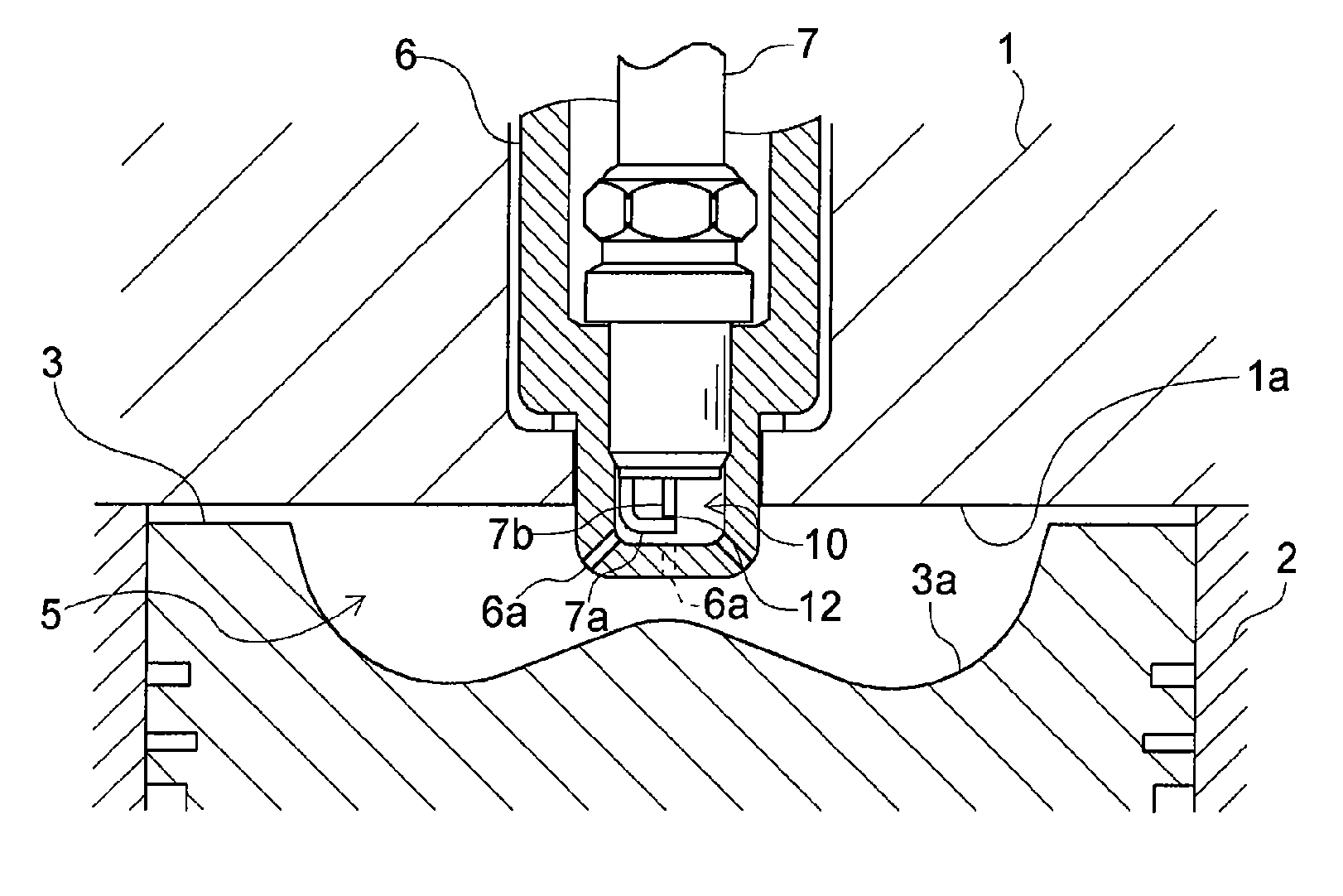

Spark ignition engine

InactiveUS7856956B2Low costBurn quicklySparking plugsInternal combustion piston enginesAutomotive engineeringSpark-ignition engine

A spark ignition engine capable of operating even with a leaner air-fuel mixture to achieve stable ignition and combustion performance. An ignition plug is fitted to a cylinder head through a sleeve, and the ignition electrode of the ignition plug is disposed in a cylinder, facing a single chamber type combustion chamber. The sleeve is formed in a blind cylindrical shape, an auxiliary chamber storing the ignition electrodes of the ignition plug is formed at the bottom part of the sleeve, and a nozzle hole allowing the auxiliary chamber to communicate with the combustion chamber is formed in the bottom part of the sleeve. The bottom part of the sleeve is projected from an explosion surface to the inside of the combustion chamber and the position of ignition by the ignition electrode is set near the explosion surface.

Owner:YANMAR POWER TECHNOLOGY CO LTD

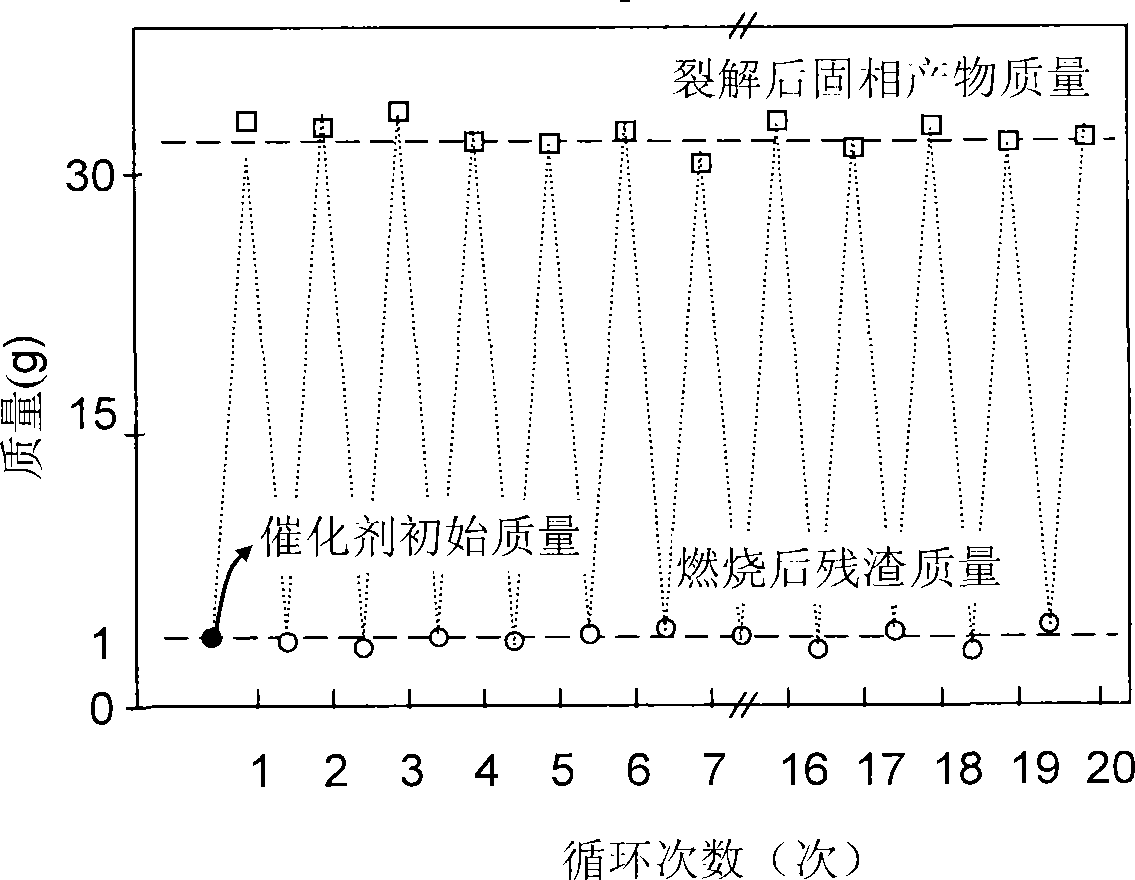

Technique for preparing hydrogen gas by hydrocarbons gases

The invention relates to a process for preparing hydrogen by hydrocarbon gases, which cracks the hydrocarbon gas to hydrogen and carbon / catalyst composite material by means of catalysis. The hydrogen is the product, and solid products are used as fuel to provide energy for the cracking process. Burned residue is recycled and cycled to be catalyst in the process of preparing the hydrogen. In the process of preparing the hydrogen of the invention, besides, the hydrogen with high purity and without CO and CO2 can be obtained, the catalyst is not consumed due to the recycling use of the catalyst, and problems that the catalyst losing activity results in an unstable system and the like are not existed.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

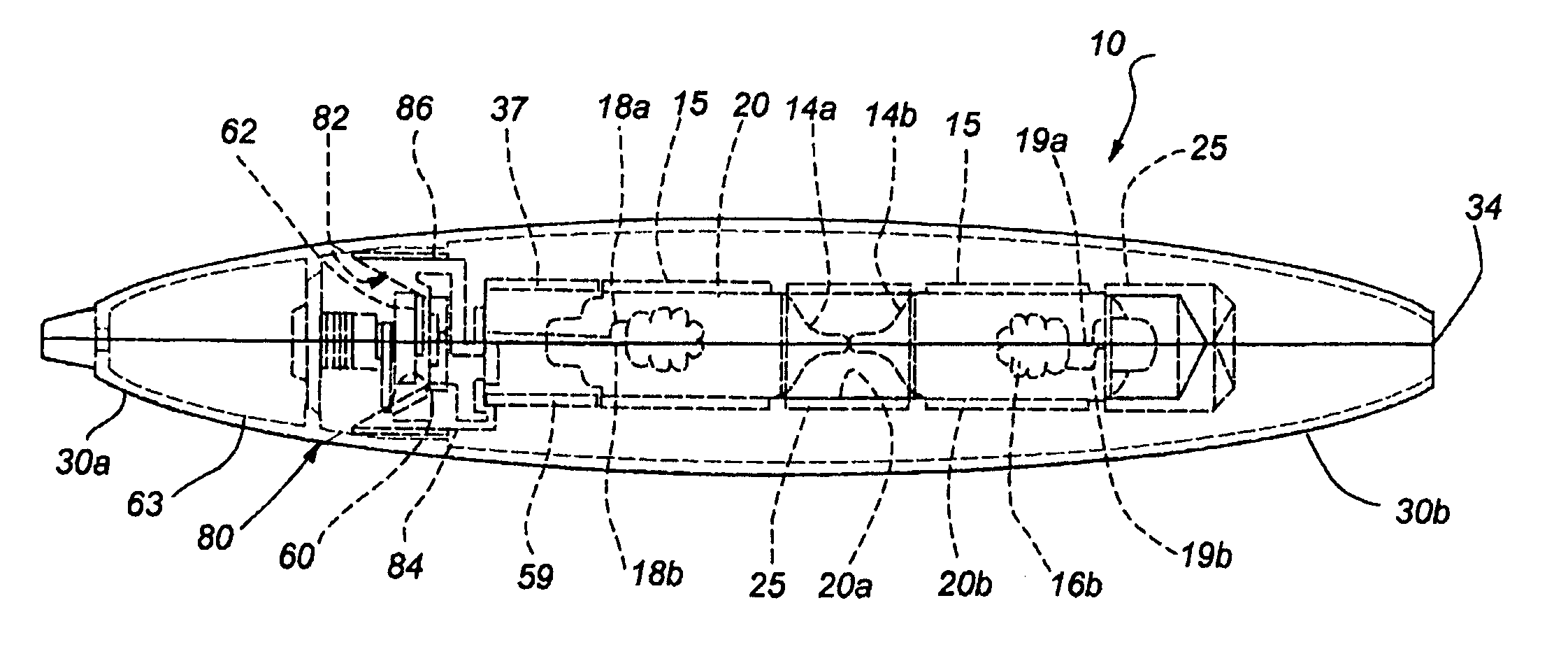

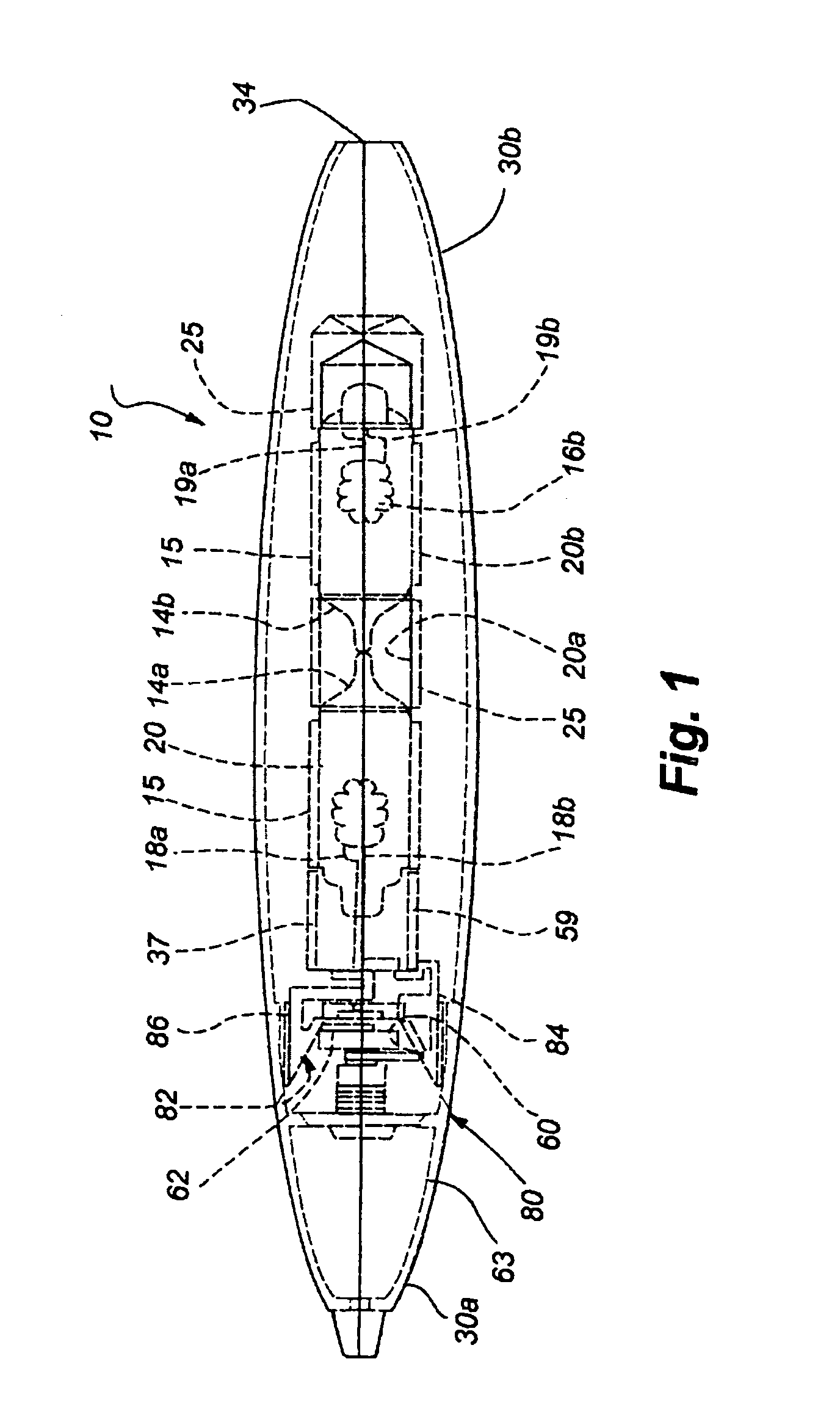

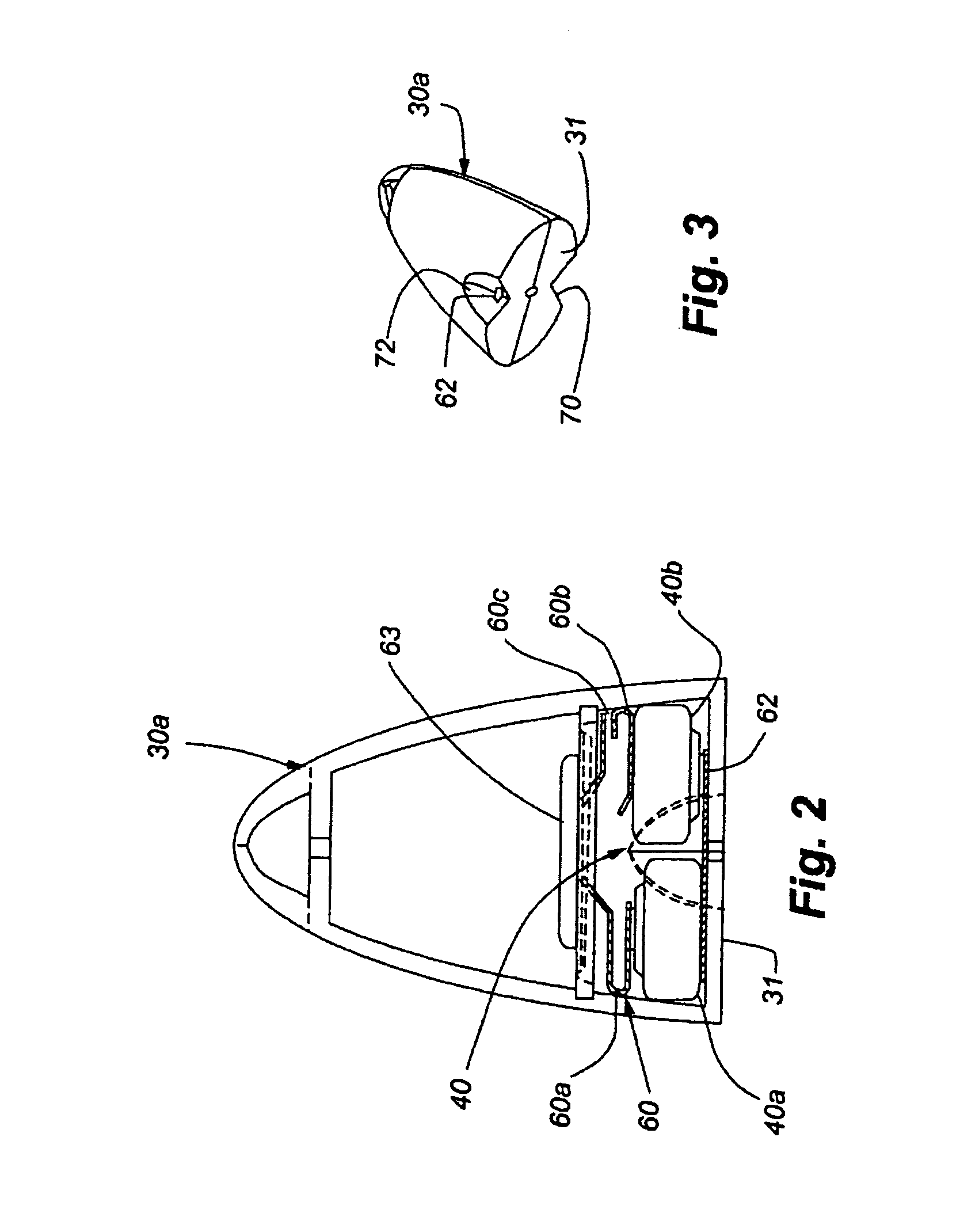

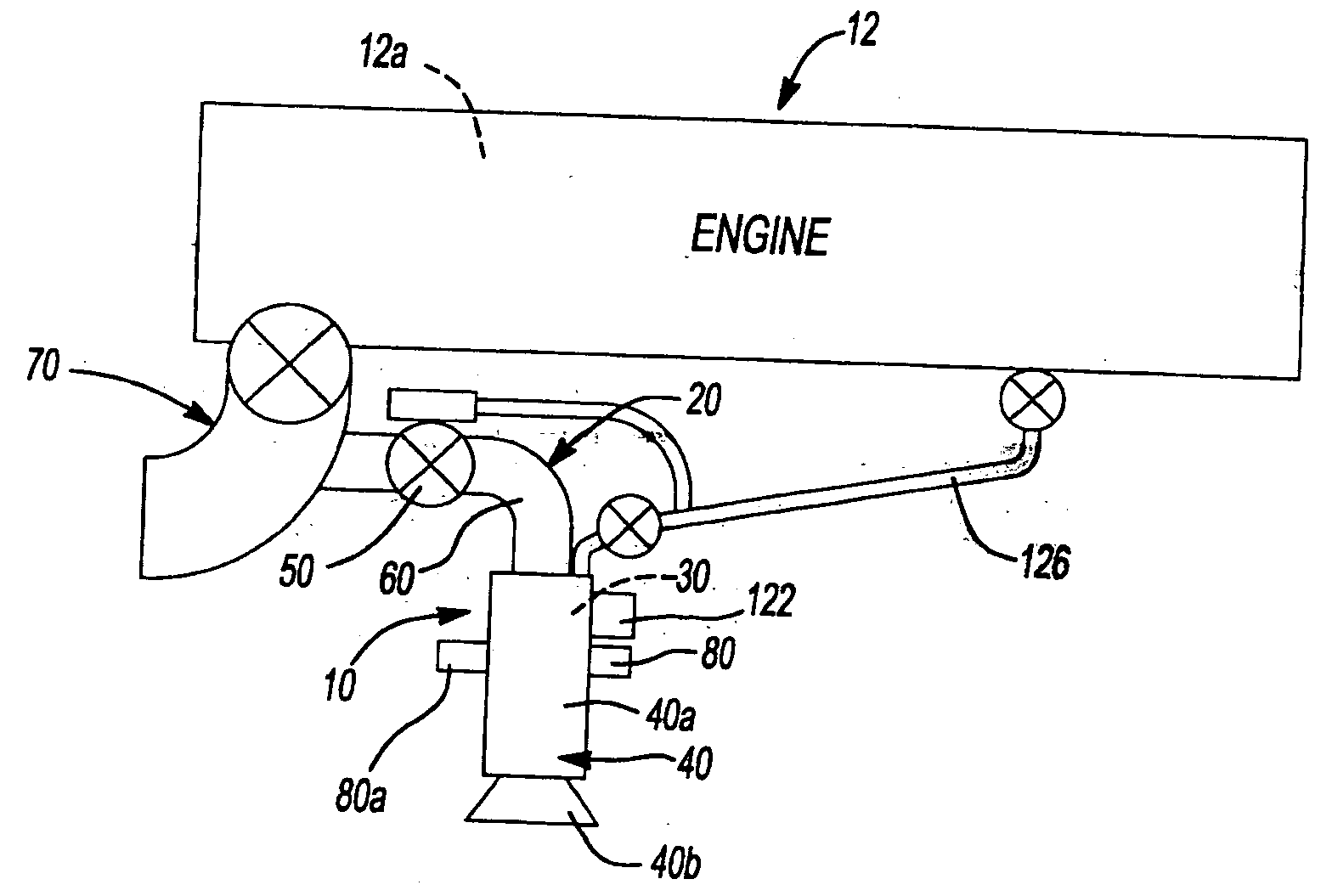

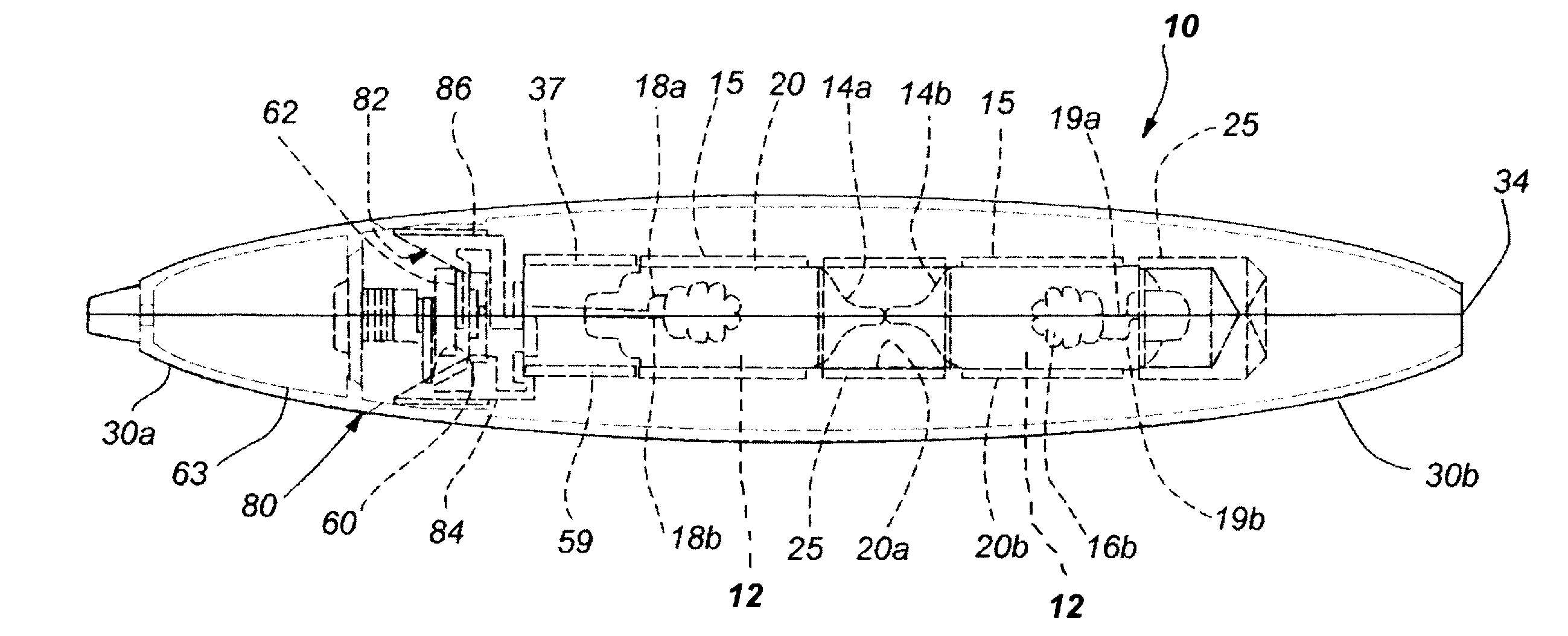

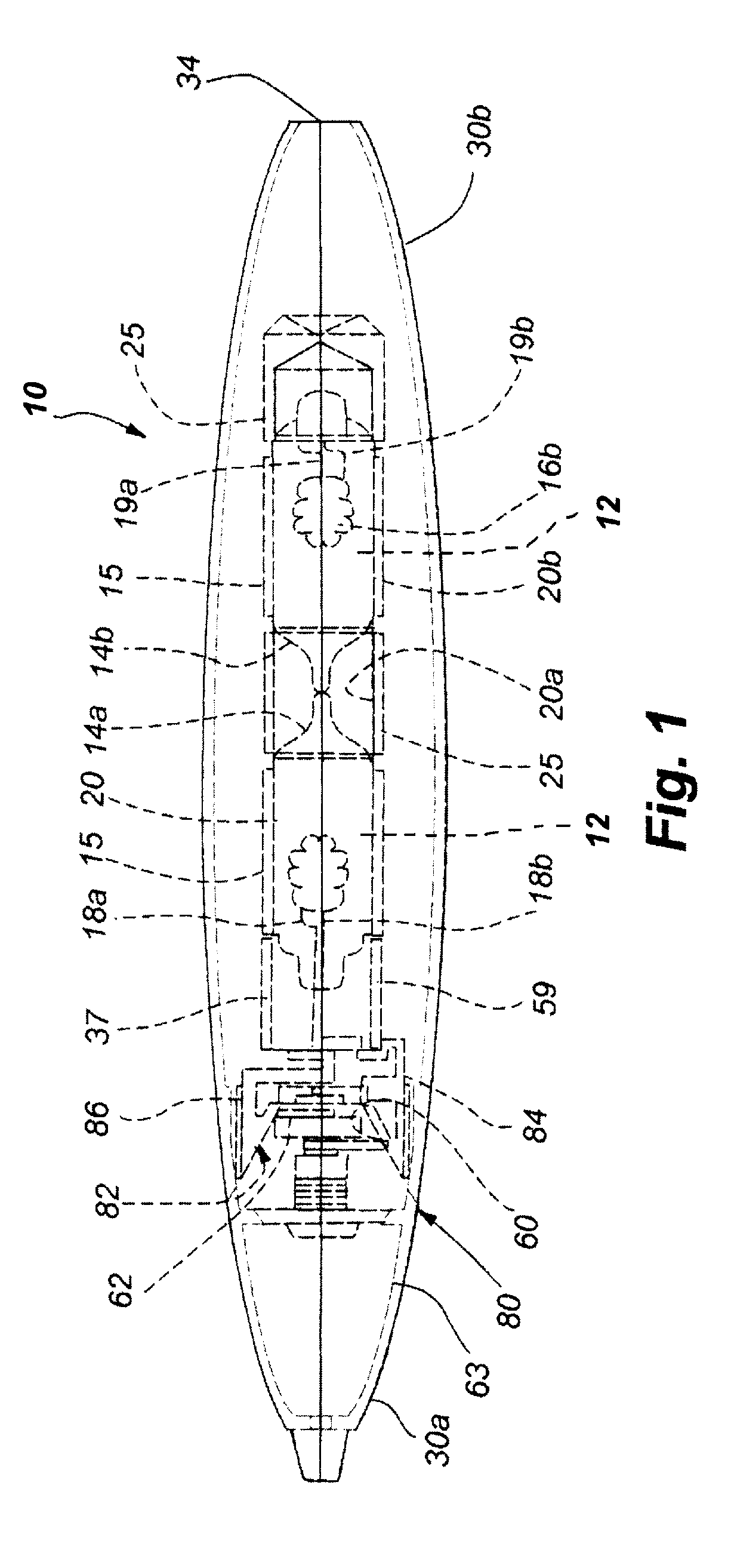

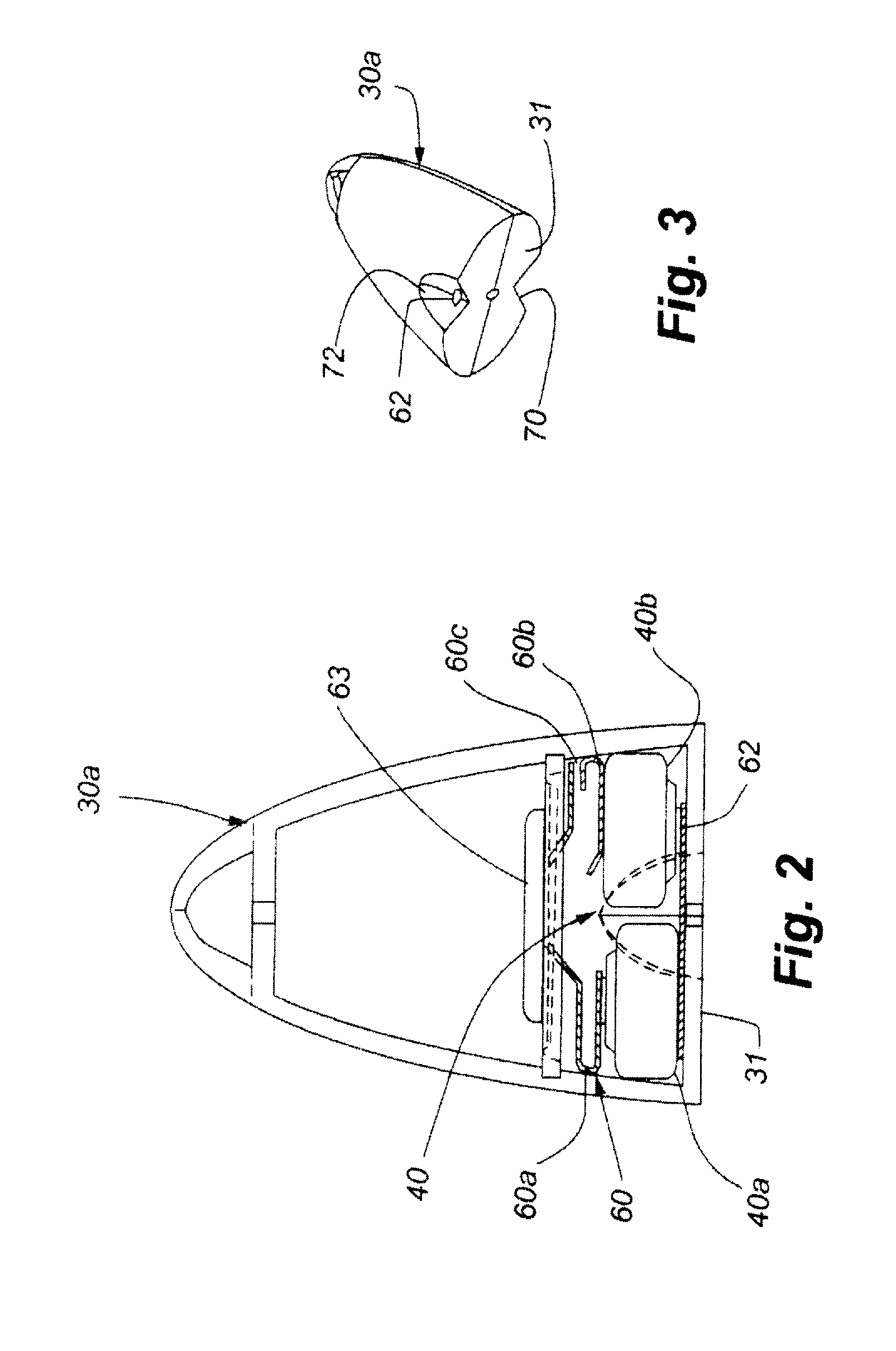

Method And Apparatus For Vaporizing A Compound

InactiveUS20090071477A1Heating fastBurn quicklyRespiratorsExothermal chemical reaction heat productionFuel cellsInhalation

Disclosed is a method and device for rapid heating of a substance. One embodiment includes a substance including a drug to be vaporized for inhalation therapy. A sealed fuel cell containing a combustible filament is placed in a heat exchange relationship with the substance. An igniter is operatively associated with the combustible element. The substance may be vaporized inside of a housing to allow the vaporized drug to aerosolize and be inhaled by a user.

Owner:ALEXZA PHARMA INC

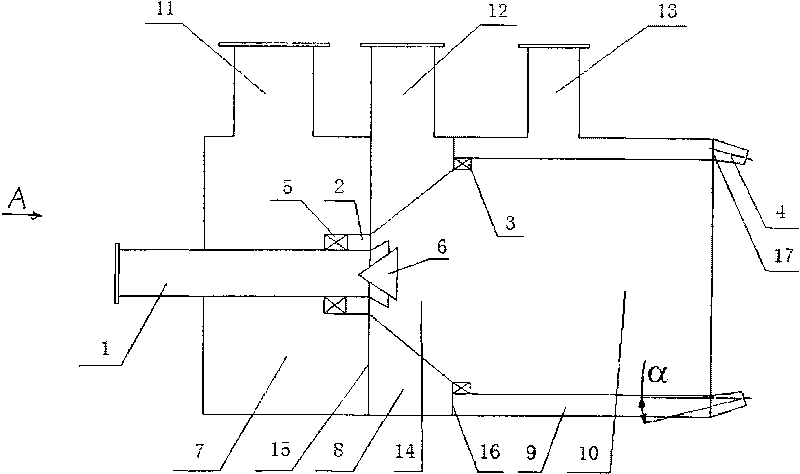

Gas engine with pre-combustion chamber

InactiveUS6073605AImprove performanceIncrease speedInternal combustion piston enginesFuel supply apparatusCombustion chamberCylinder head

This gas engine with pre-combustion chambers. effectively uses ejection energy of flames and air-fuel mixtures ejected from the pre-combustion chambers into the main combustion chambers to shorten the combustion duration and thereby enhance performance. Installed in the cylinder head at the central part of the cylinders are pre-combustion chamber structures. that form pre-combustion chambers; Combustion chamber structures are formed with communication port that communicate the pre-combustion chambers with the main combustion chambers. Control valves are provided to open and close the communication ports. The communication ports comprise main communication ports and sub-communication ports formed around the main communication ports. The sub-communication ports are formed in the combustion chamber structures so that they extend radially toward the cylinder periphery.

Owner:ISUZU MOTORS LTD

Low-NOx pulverized coal burner

The invention discloses a low-NOx pulverized coal burner, which comprises an inner secondary air box, a hierarchical air box and a disturbed air box. The inner secondary air box, the hierarchical air box and the disturbed air box are separated by a first clapboard and a second clapboard sequentially; the centers of the first clapboard and the second clapboard are provided with circular holes; each pipe wall of each of the three air boxes is correspondingly provided with an air inlet which inclines towards the circumferential direction; a primary air pipe axially passes through the inner secondary air box; an inner secondary air pipe with a swirl vane is coaxially sleeved outside the primary air pipe; the inner secondary air pipe is hermetically connected with the first clapboard; the inner secondary air pipe expands conicity and extends outwards to form a conical cylinder at the circular hole of the first clapboard; the conical cylinder is arranged in the hierarchical air box; the disturbed air box is coaxially provided with a precombustion chamber with two open ends; an annular channel is formed between the wall of the disturbed air box and the wall of the precombustion chamber; an annular end face is arranged at an outlet of the annular channel; a disturbed air nozzle is fixed at an opening of the annular end face; the inlet end of the precombustion chamber is hermetically connected with the second clapboard; an annular hierarchical air channel is formed at the root of the inlet of the precombustion chamber; and the conical cylinder is hermetically fixed with the inner wall of the hierarchical air channel.

Owner:ZHEJIANG JINGUO BOILER

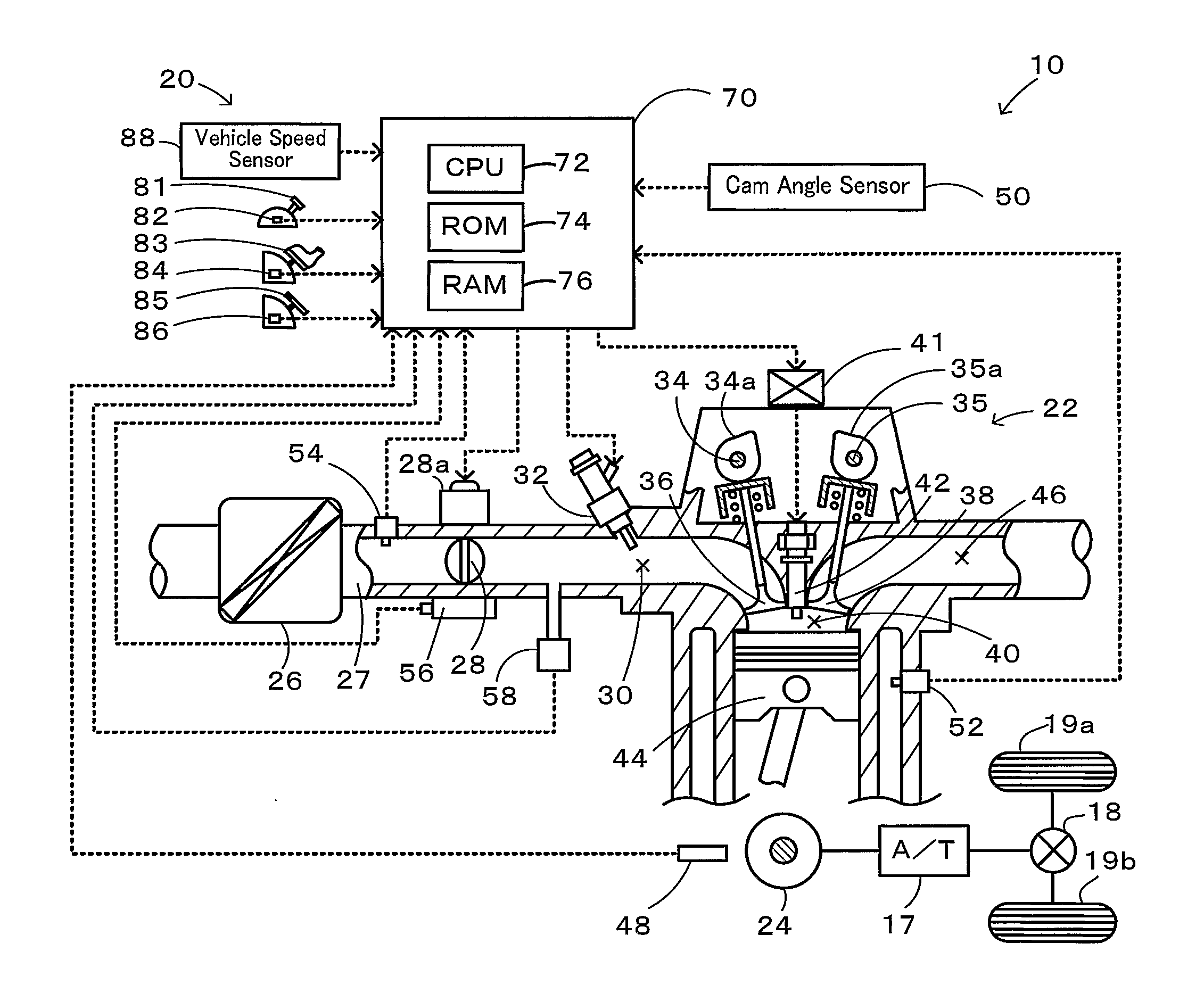

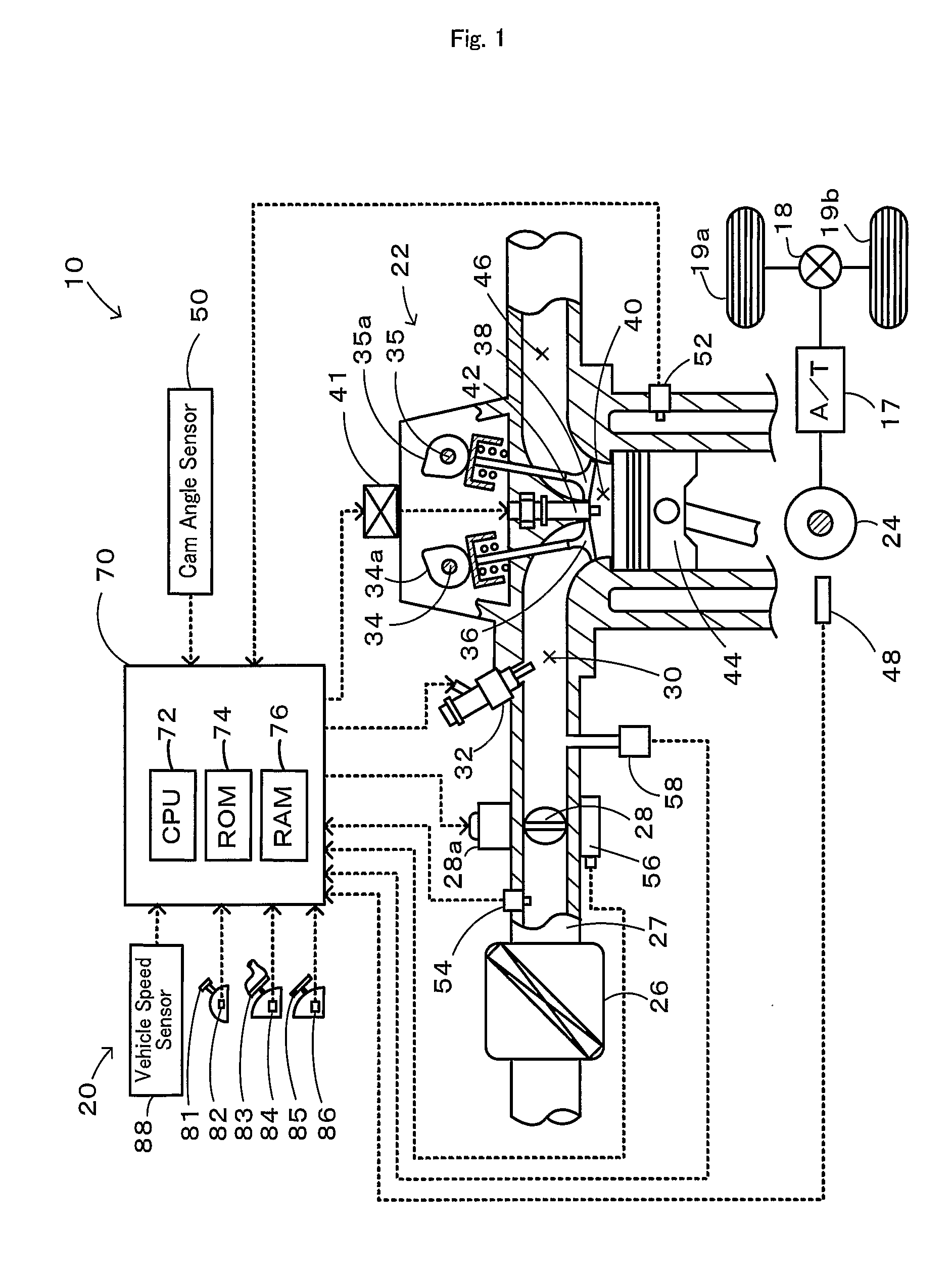

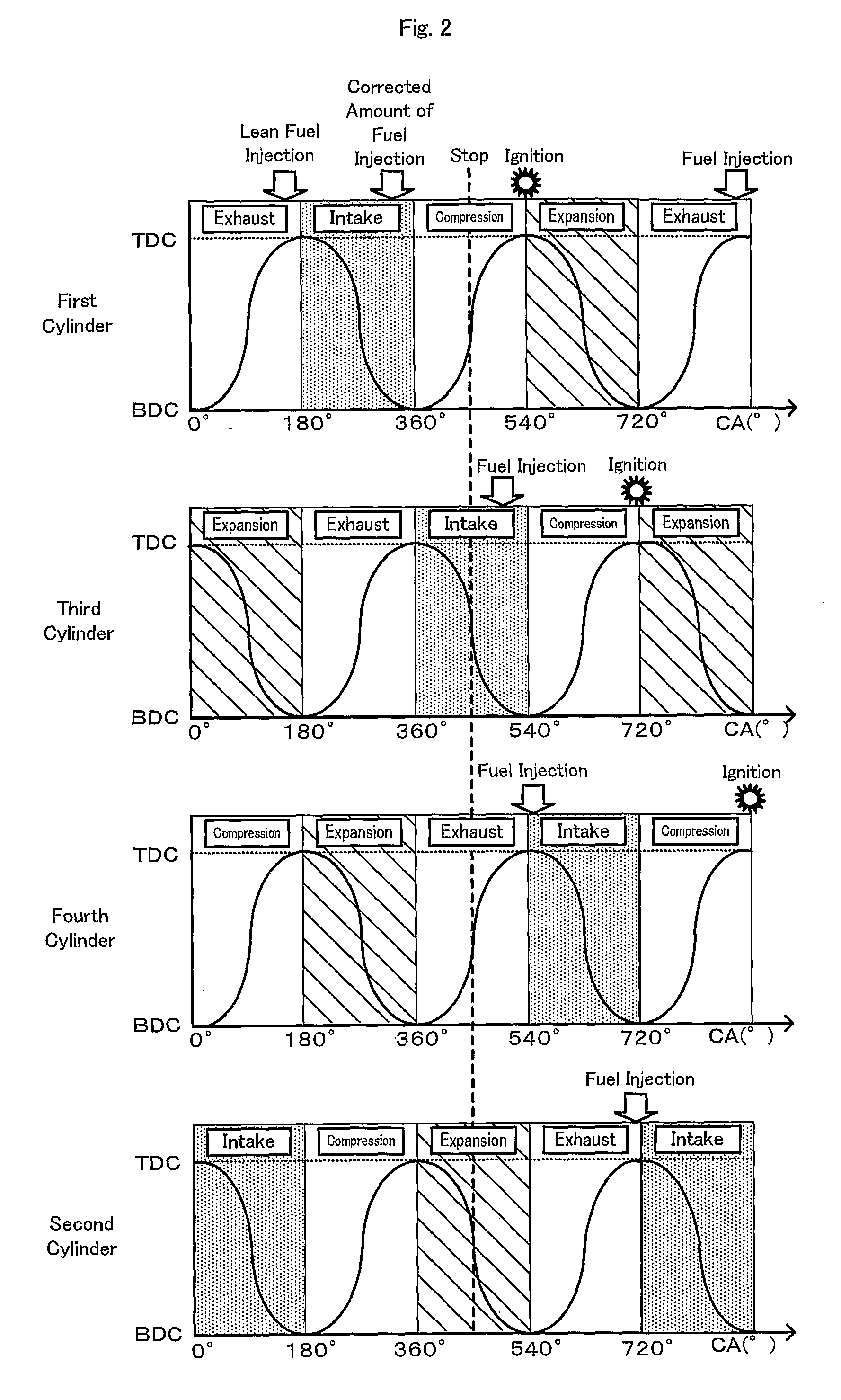

Internal Combustion Engine System and Internal Combustion Engine Control Method

ActiveUS20080091328A1Avoid vibrationStart fastAnalogue computers for vehiclesPower operated startersCombustionTop dead center

The internal combustion engine control technique of the invention computes a TDC pass rotation speed Ntdc, which represents the rotation speed of an engine when one of multiple cylinders of the engine passes over a top dead center TDC (step S110). The control technique estimates an engine stop crank angle CAs from a map that is experimentally or otherwise obtained to represent a variation in TDC pass rotation speed Ntdc against the stop position of the engine (step S120), and specifies a fuel injection cylinder that stops in a preset cycle range including part of a compression stroke at a stop of the engine (step S130). The specified fuel injection cylinder receives lean fuel injection at a specific fuel injection timing (step S170). When the specified fuel injection cylinder is later presumed not to pass over a top dead center TDC of the compression stroke, a corrected amount of fuel is injected into the specified fuel injection cylinder (step S240). When the specified fuel injection cylinder is later presumed to pass over the top dead center TDC of the compression stroke, on the other hand, the control technique ignites an air-fuel mixture of the intake air and the injected fuel for combustion in the compression stroke, synchronously with fuel injection into a next cylinder that goes into the compression stroke after the specified fuel injection cylinder (step S270).

Owner:TOYOTA JIDOSHA KK

Environment-friendly efficient waste incinerator

The invention discloses an environment-friendly efficient waste incinerator. The environment-friendly efficient waste incinerator comprises a lower incinerator body part, an upper incinerator body part, an internal chimney, a base, an incinerator cover and an external chimney. The upper incinerator body part and the lower incinerator body part of an incinerator body are welded into a whole. The internal chimney is arranged in the middle of the lower incinerator body part and the middle of the upper incinerator body part. A combustion chamber is formed by the lower incinerator body part and the internal chimney. Refractory bricks are arranged on the periphery of the lower incinerator body part and the periphery of the upper incinerator body part. The bottom end of the lower incinerator body part is connected with the base. Both the upper surface and the lower surface of the base are open. The incinerator cover is arranged on the upper incinerator body part. The external chimney is arranged at the top of the incinerator cover in a connected mode. A water tank is arranged outside the lower incinerator body part. An oil tank is further arranged in the water tank. A water pipe and an oil pipe are arranged in the internal chimney. The water pipe is communicated with the water tank. The oil pipe is communicated with the oil tank. According to the environment-friendly efficient waste incinerator, oil in the oil pipe can be gasified by means of heat generated during waste combustion, so that waste on the upper portion of the incinerator body can be combusted for the second time, continuous waste combustion is achieved, incineration is thorough and rapid, and the incineration effect is good; pollution to the environment is small, and the environment-friendly efficient waste incinerator is suitable for waste treatment in village and town communities, schools and hospitals.

Owner:都安通达环保设备制造厂(普通合伙)

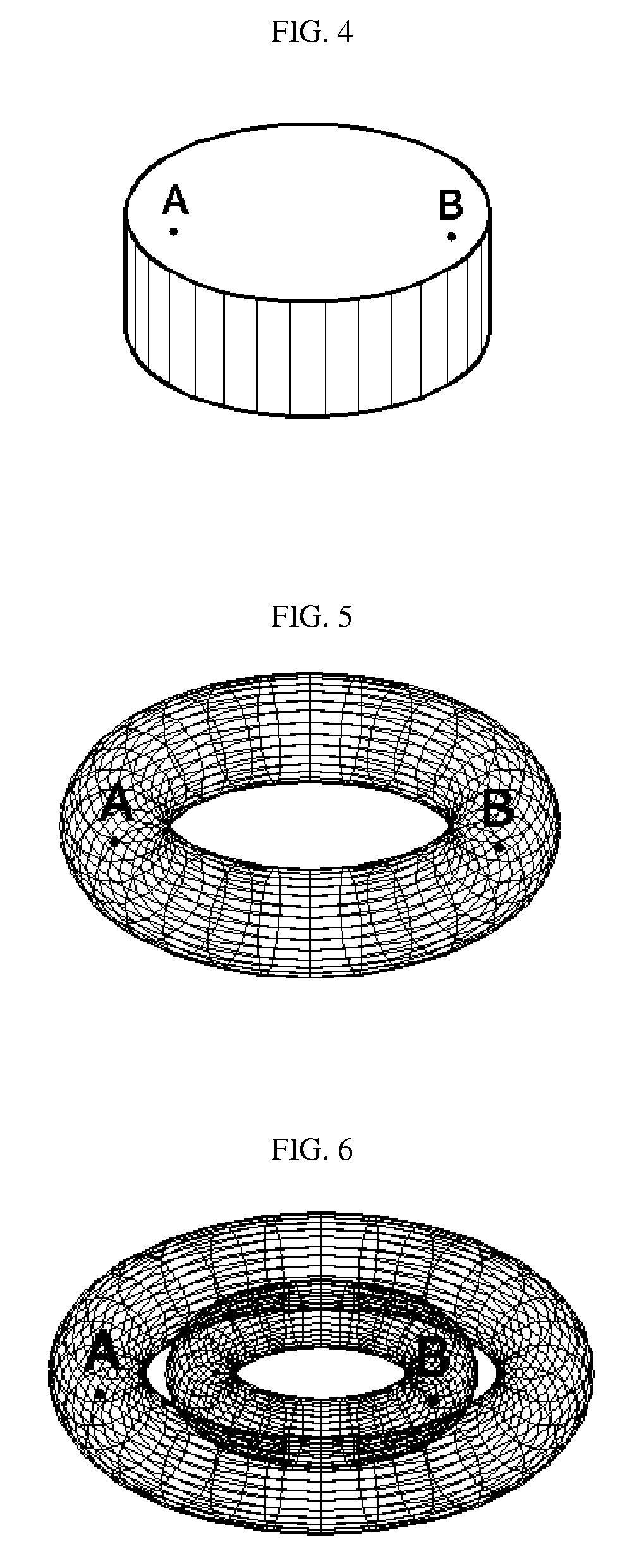

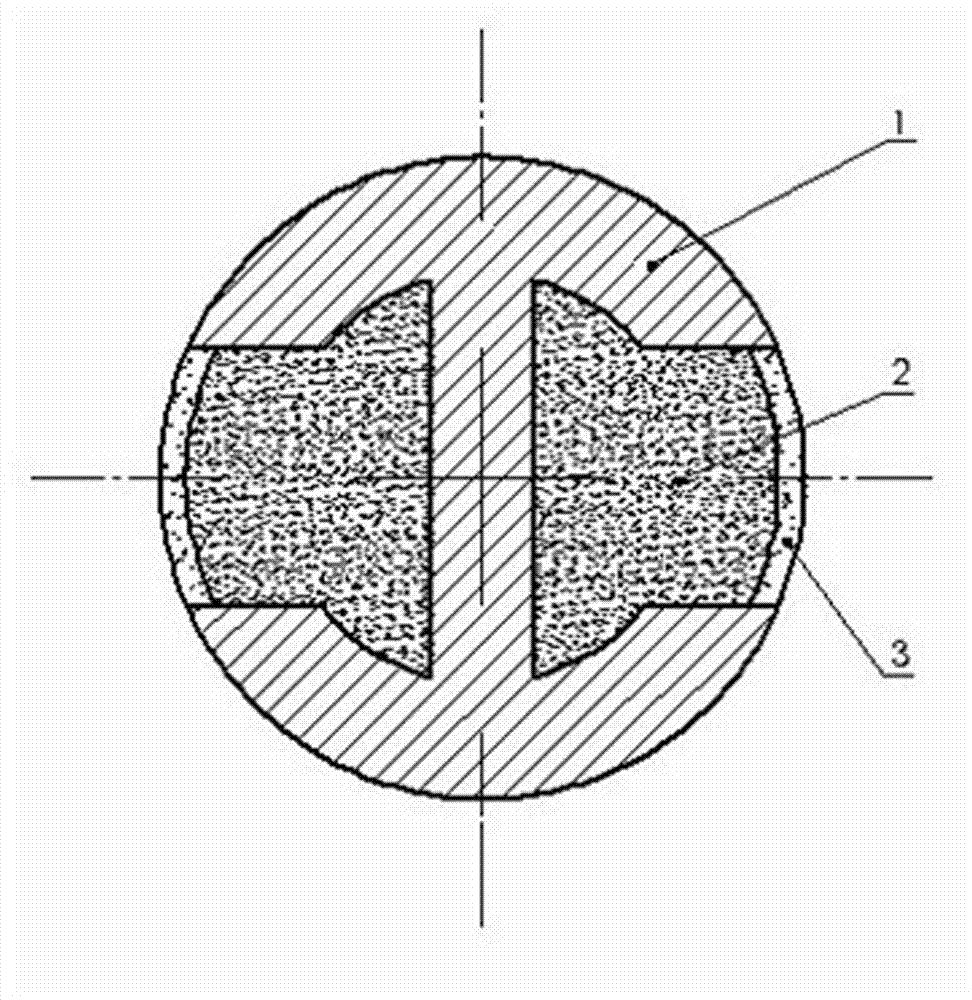

Premix Combustion Methods, Devices and Engines Using the Same

InactiveUS20080314360A1Reduce intensityHigh strengthElectrical controlInternal combustion piston enginesPressure riseCombustion chamber

This invention discloses a combustion method, which is for internal combustion engine, which utilizes a variable spray fuel injection wherein it has (i) a variable spray angle with smaller angles for earlier fuel injection and larger angles for later fuel injection, and (ii) variable spray patterns varying from hollow conical shapes for earlier injection to multi-jet shapes for later injection, wherein it has adaptive means to distribute fuel into combustion chamber space based on background pressure and injection timing. A combustion method, which utilizes a combustion chamber which has plural number of annular inner spaces resembling the space inside an automotive tire, which provides means to control propagation paths of combustion reaction radicals and control pressure rise rate, which also provides means to promote stratification of premixed charges. An internal combustion engine utilizing the said combustion methods is also disclosed.

Owner:HOU DEYANG

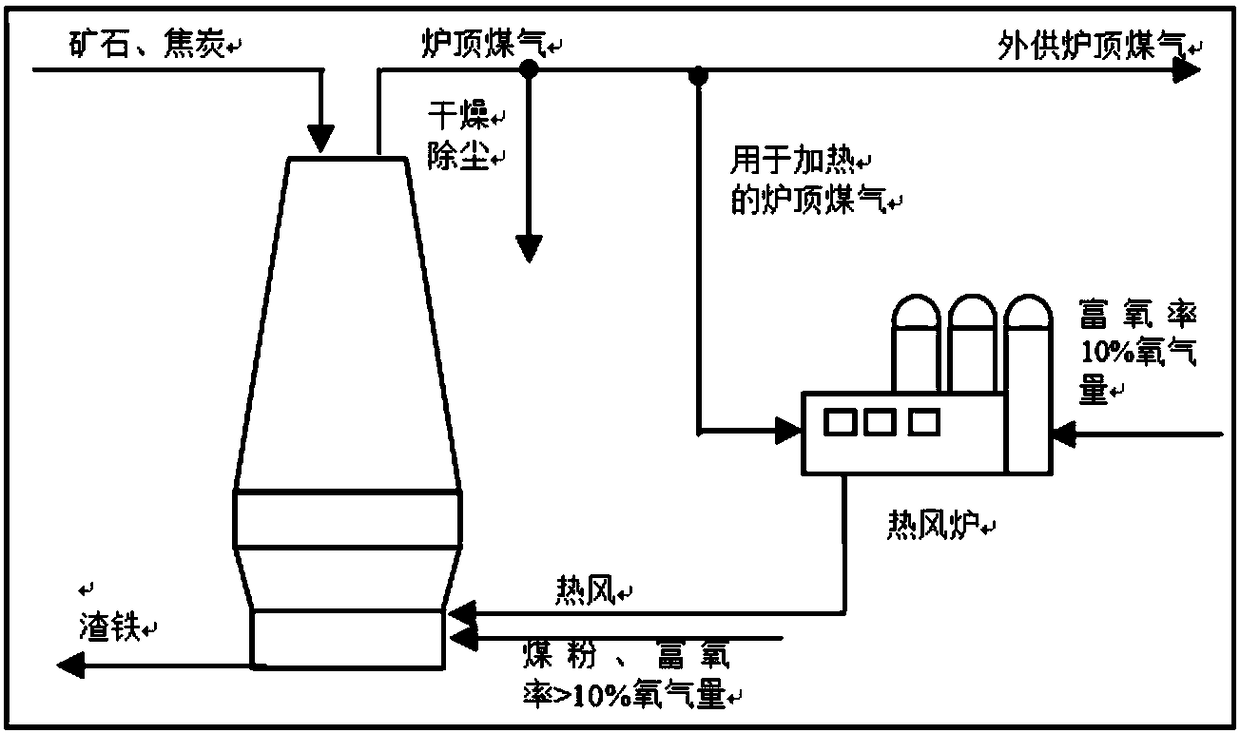

Blast furnace vanadium-titanium magnetite smelting method by utilizing ultra-high oxygen enriching air blasting

ActiveCN108330238AImprove combustion efficiencyIncrease profitBlast furnace detailsBlast furnace smeltingHigh oxygen

The invention relates to the technical field of vanadium-titanium magnetite smelting, and provides a blast furnace vanadium-titanium magnetite smelting method by utilizing ultra-high oxygen enrichingair blasting. The content of oxygen in hot air of a blast furnace is increased to 26-41% level, the corresponding air blasting oxygen enrichment rate is 5-20%, and the combustion rate of coal powder at the front end of a tuyere is increased; the coal gas reducing potential is increased; the reducing, soft melting, dripping and slag forming process of the vanadium-titanium magnetite in the blast furnace is optimized, breathability of the blast furnace is improved, and it is guaranteed that production of the blast furnace is stably and smoothly performed; and the problems that in the process ofsmelting the vanadium-titanium magnetite through the blast furnace process, the coal ratio is low, the energy consumption is high, furnace slag is viscous and thick, breathability is poor and intensified smelting is difficult are solved. According to the method, it is adopted that high-concentration oxygen is extra added in the hot air of the blast furnace, the oxygen content in the hot air is increased, the coal spraying ratio can be increased, the coke ratio is reduced, the iron making energy consumption of the blast furnace is reduced, the smelting strength is improved, production of the blast furnace is stabilized, and the blast furnace smelting cost of the vanadium-titanium magnetite is reduced.

Owner:UNIV OF SCI & TECH BEIJING

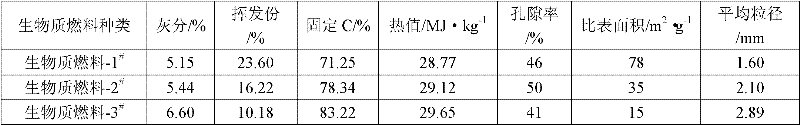

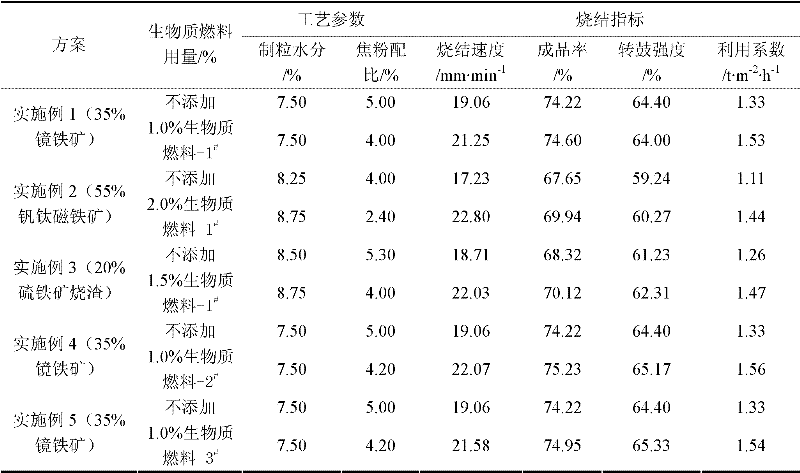

A method of using biomass fuel to strengthen the sintering of refractory iron ore

ActiveCN102296177AMeet the requirements of fast burningMeet caloric requirementsPorosityTitanomagnetite

The invention relates to a method for reinforcing the sintering of iron ores (vanadic titanomagnetite, specularite, secondary iron-containing resources and the like) difficult to pelletize by biomass fuel. By applying the biomass fuel with high burning velocity to the sintering of the iron ores difficult to pelletize, the sintering speed and the utilization coefficient can be improved. The reinforcing method comprises the following steps of: adding 1 to 4 percent of biomass fuel into a sinter mixture containing the iron ores difficult to pelletize, wherein the biomass fuel is required to have 65 to 85 percent of content of fixed carbon, 10 to 25 percent of volatile matter, more than 24 to 30MJ / kg of calorific value, 40 to 60 percent of porosity, 10 to 100m2 / g of specific surface area and 1 to 4mm of average particle size; after weighing the iron ores difficult to pelletize, a flux, sintering return fines and the biomass fuel according to the weight ratio, sufficiently mixing the raw materials and pelletizing; distributing the mixture, igniting and sintering to obtain agglomerates. After the biomass fuel is adopted to reinforce the sintering of the iron ores difficult to pelletize, the sintering speed can be improved by 2 to 5mm / min, the utilization coefficient can be improved by 0.2 to 0.4t / (m2.h) and meanwhile, low intensity variation of an agglomerate revolving drum is ensured.

Owner:CENT SOUTH UNIV

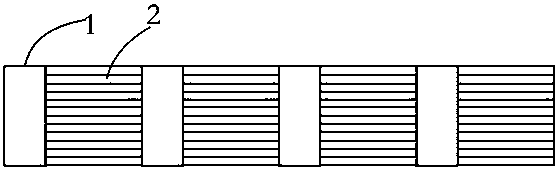

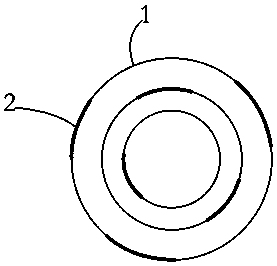

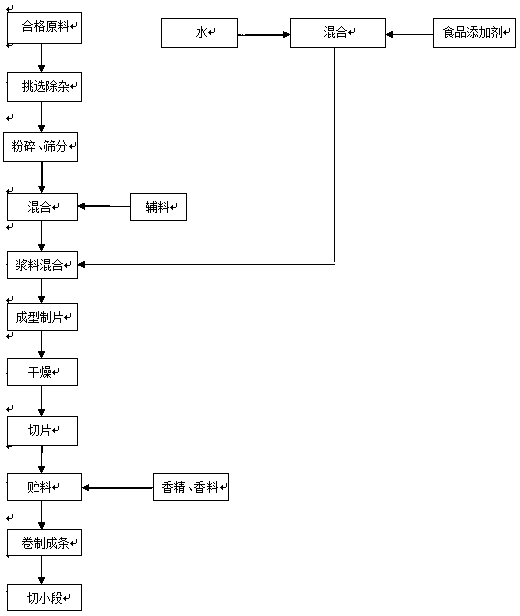

Tea healthy suction substance and preparation method of tea healthy suction substance

PendingCN108606362AAntioxidantRefreshingTobacco treatmentPre-extraction tea treatmentSmokeCatechinic acid

The invention provides a tea healthy suction substance and a preparation method of the tea healthy suction substance. The tea healthy suction substance comprises a smoke body, the smoke body comprisesexternal cigarette paper and a suction substance body arranged in the cigarette paper, the suction substance body is rolled into a cylindrical shape by a suction substance slip, the suction substanceslip comprises a plurality of connecting segments and loosening segments arranged between the connecting segments, and the connecting segments wrap the loosening segments during rolling of the connecting segments and loosening segments. The invention further provides a preparation method. The method comprises the steps that active ingredients extracted from tea slices are made into slips and assembled after being cut, the ingredients mainly comprise tea polyphenol (catechinic acid) and the like and have the effects of resisting oxidation and scavenging free radicals and the like, menthol is adopted and has the effects of cooling and refreshing and can completely replace tobacco.

Owner:东莞市香草生物工程有限公司

Smokeless propellant powder with safe, environmental-friendly and porous structure for fireworks

ActiveCN102924193AEnsure safetyBurn quicklyInorganic oxygen-halogen salt explosive compositionsEnvironmental resistanceFoaming agent

Owner:浏阳象形精品烟花出口造有限公司

Composite aluminum-base brazing wire for continuously brazing aluminum alloy and method for manufacturing composite aluminum-base brazing wire

InactiveCN103203560AReasonable structureThe joint performance is stable and goodWelding/cutting media/materialsSoldering mediaFiller metalSilicon

The invention discloses a composite aluminum-base brazing wire for continuously brazing aluminum alloy and a method for manufacturing the composite aluminum-base brazing wire. The aluminum-base brazing wire comprises a section of aluminum-base brazing filler metal, non-corrosive brazing fluxes for aluminum and silicon powder coating layers; the section of the aluminum-base brazing filler metal is provided with grooves, the non-corrosive brazing fluxes for the aluminum are composited in the grooves of the section, and the silicon powder coating layers are coated on surfaces of the brazing fluxes; and the section side of the section of the brazing filler metal can be provided with one groove or two grooves or three grooves. The method includes smelting and casting the brazing filler metal of the brazing wire during manufacture and squeezing a blank which is a rod; manufacturing the section of the brazing filler metal of the brazing wire by means of rolling and squeezing; compositing the section of the brazing filler metal with the non-corrosive brazing fluxes for the aluminum; and coating the silicon powder coating layers on the surfaces of the composite brazing fluxes. The composite aluminum-base brazing wire and the method have the advantages that the local composite aluminum-base brazing wire for continuously brazing the aluminum alloy is suitable for intelligent brazing equipment provided with a laser brazing system, so that the intelligent brazing equipment can be used for continuously brazing various medium and large aluminum alloy structural parts with over-burning temperatures higher than 580 DEG C, the quality of brazing seams is stable, and the efficiency is high.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

Internal combustion engine system and internal combustion engine control method

ActiveUS7587270B2Improve accuracyBurn quicklyAnalogue computers for vehiclesPower operated startersTop dead centerCombustion

The internal combustion engine control technique of the invention computes a TDC pass rotation speed Ntdc, which represents the rotation speed of an engine when one of multiple cylinders of the engine passes over a top dead center TDC (step S110). The control technique estimates an engine stop crank angle CAs from a map that is experimentally or otherwise obtained to represent a variation in TDC pass rotation speed Ntdc against the stop position of the engine (step S120), and specifies a fuel injection cylinder that stops in a preset cycle range including part of a compression stroke at a stop of the engine (step S130). The specified fuel injection cylinder receives lean fuel injection at a specific fuel injection timing (step S170). When the specified fuel injection cylinder is later presumed not to pass over a top dead center TDC of the compression stroke, a corrected amount of fuel is injected into the specified fuel injection cylinder (step S240). When the specified fuel injection cylinder is later presumed to pass over the top dead center TDC of the compression stroke, on the other hand, the control technique ignites an air-fuel mixture of the intake air and the injected fuel for combustion in the compression stroke, synchronously with fuel injection into a next cylinder that goes into the compression stroke after the specified fuel injection cylinder (step S270).

Owner:TOYOTA JIDOSHA KK

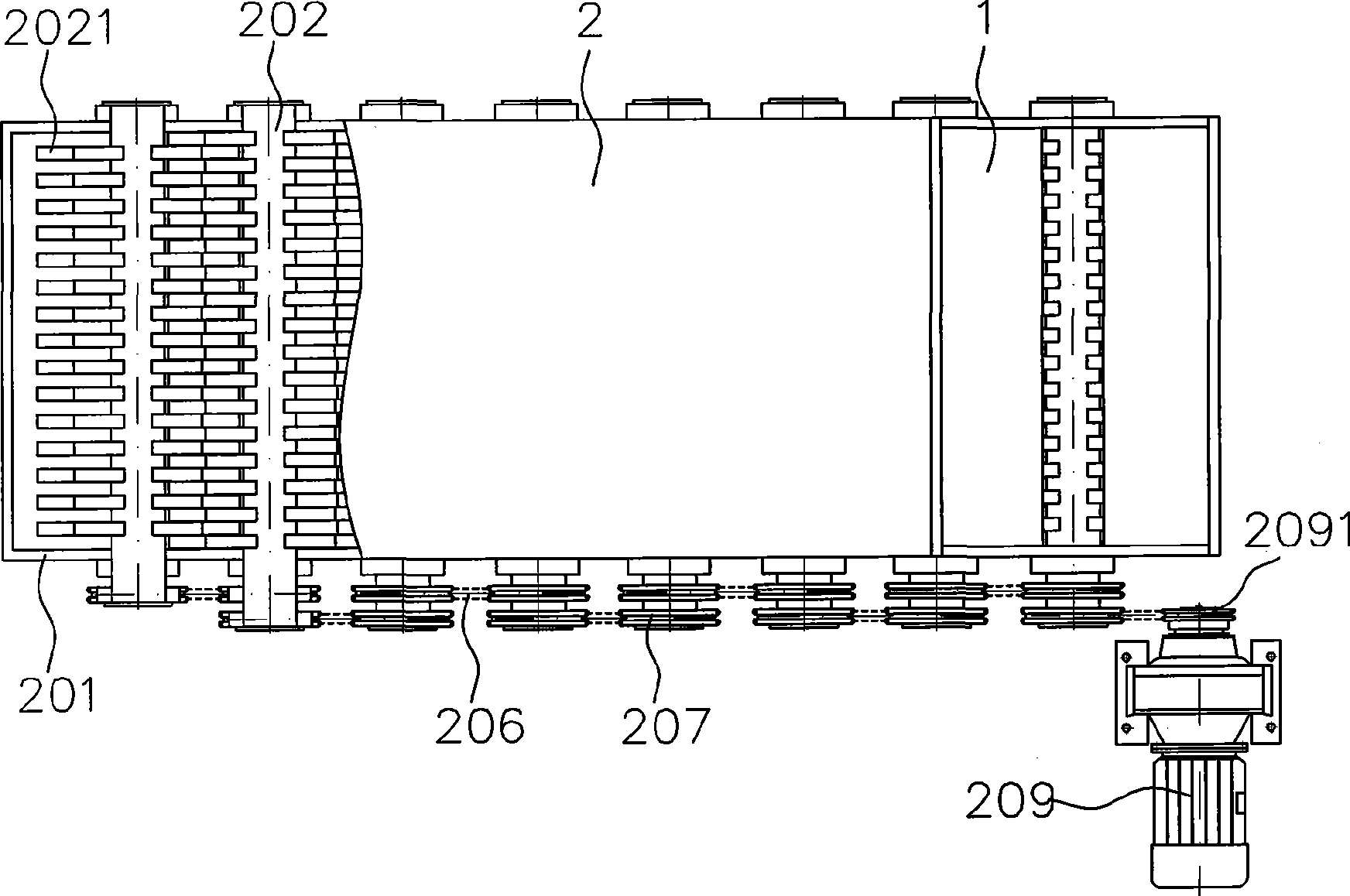

Unit modular large household refuse incineration furnace

The invention discloses a unit modular large household refuse incineration furnace and relates to household refuse incineration treatment equipment. The unit modular large household refuse incineration furnace comprises an incineration grate mechanism, air chambers and air supply systems, wherein the incineration grate mechanism comprises a drying section grate, a burning section grate, a burnout section grate and a rack; the drying section grate, the burning section grate and the burnout section grate respectively comprise two groups of grate units; each group of grate units comprises a spindle, a partition plate, a front wall plate, a rear wall plate and a grate with stepped drop; each grate comprises two groups of edge modules and at least one group of middle modules; each edge module and each middle module respectively consist of a plurality of grate sheets; each group of edge modules is fixed on the corresponding rack through a sidewall protection plate device; each air chamber is formed below each middle module and each edge module; an air inlet is formed at the lower end of each air chamber and connected with the corresponding air supply system; and each air supply system comprises a drying section air supply system, a burning section air supply system and a burnout section air supply system. The unit modular large household refuse incineration furnace is stable in operation, low in energy consumption and long in service life.

Owner:江苏楹能环保科技发展有限公司

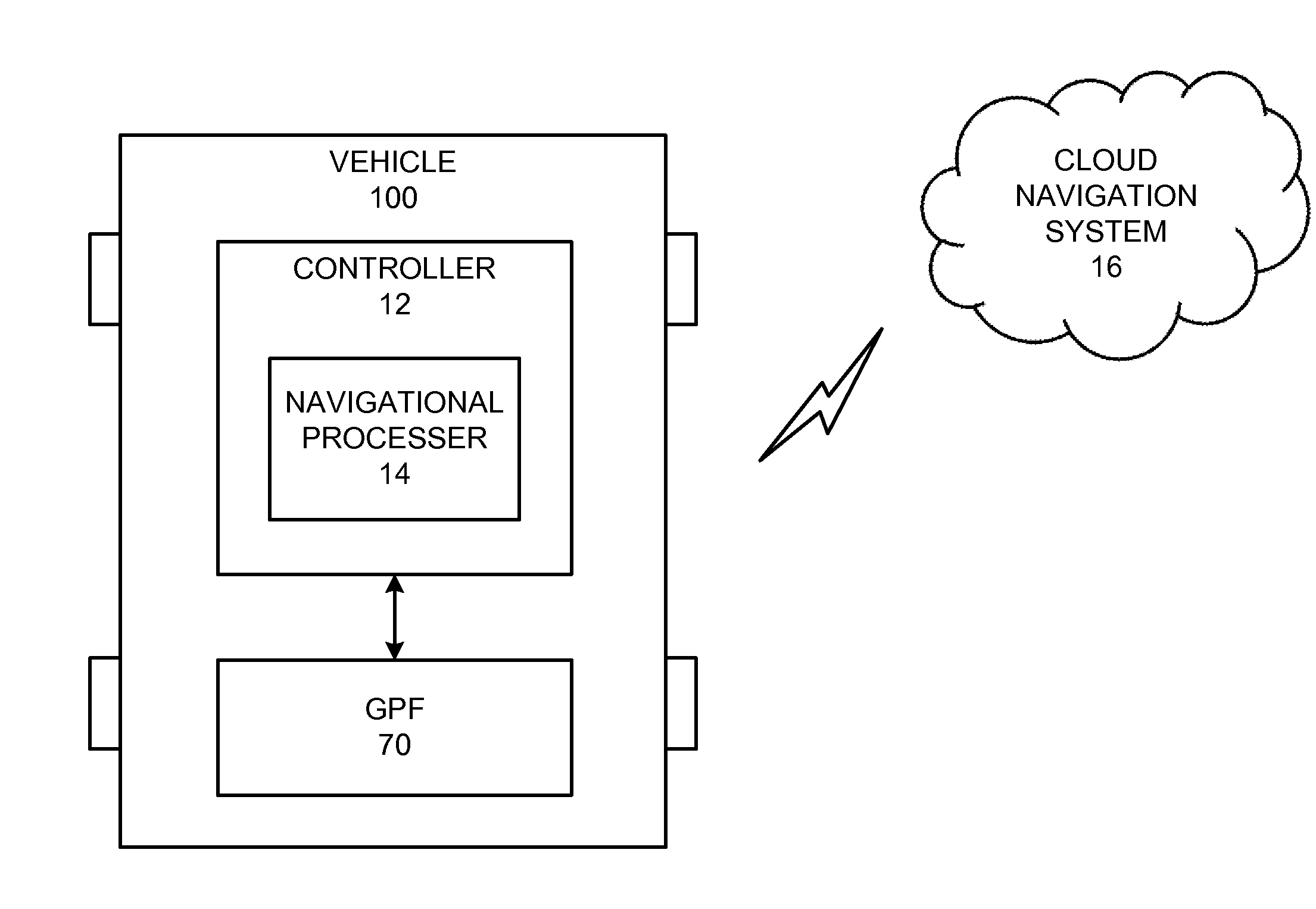

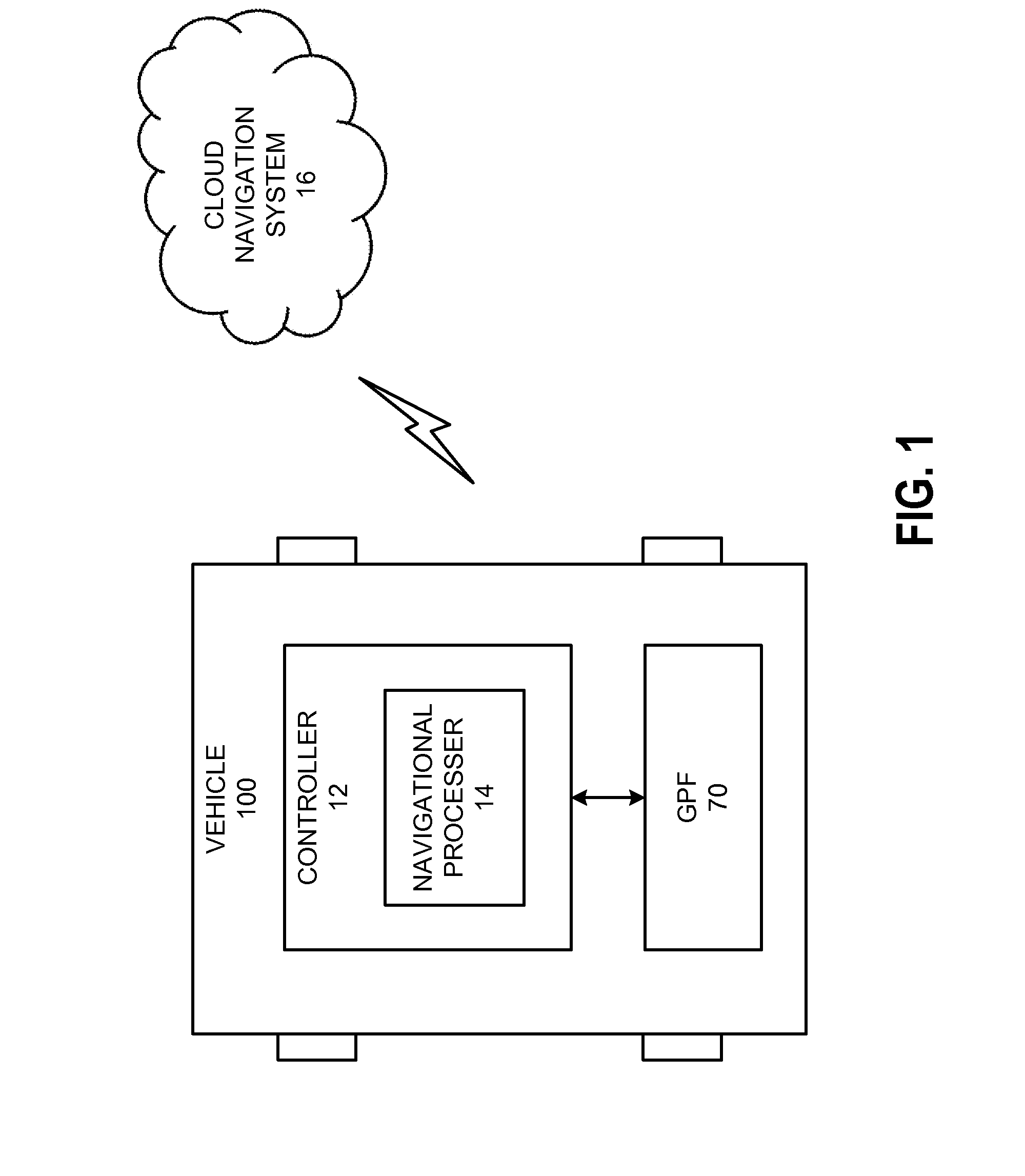

Idle speed gpf regeneration

ActiveUS20160201532A1Reduces soot loadPrevent releaseElectrical controlInternal combustion piston enginesMicro particlesElectrical and Electronics engineering

Systems and methods are described for coordinating the regeneration of a gasoline particulate filter to a time duration when engine output falls below a predetermined load threshold selected to indicate a low power state of the engine. In one particular example, the engine is configured to adjust engine operations to regenerate the particulate filter responsive to engine output falling below a predetermined low power threshold, the regeneration further based on an estimated duration that the output falls continuously below the low power threshold. The system and methods described advantageously allow for either full or partial regeneration events to be performed based on the estimated duration of the engine output below the low power threshold.

Owner:FORD GLOBAL TECH LLC

Ammonia-hydrogen fusion type hybrid power system and engine

ActiveCN114412668AStable combustionBurn quicklyInternal combustion piston enginesFuel supply apparatusCombustion chamberThermodynamics

The invention relates to the technical field of ammonia fuel engines, and provides an ammonia-hydrogen fusion type hybrid power system and an engine. The ammonia-hydrogen fusion type hybrid engine includes: a fuel tank for storing liquid ammonia, the fuel tank including a discharge port; the ammonia catalysis hydrogen production device is used for catalyzing ammonia gas to form hydrogen and comprises an ammonia inlet and a hydrogen outlet, and the ammonia inlet is connected with the discharge port; the ammonia fuel engine comprises a main combustion chamber, a jet ignition cavity and an ignition device, the main combustion chamber is connected with the discharge port, the hydrogen discharge port is connected with the jet ignition cavity, the ignition device is arranged in the jet ignition cavity, and the jet ignition cavity is communicated with the main combustion chamber. Combustion hydrogen can form jet flames and enter the main combustion chamber, and ammonia mixed gas is stably ignited. The hydrogen flame jet flow has multiple ignition sites and can form free radicals such as OH <-> with high concentration in the main combustion chamber, the combustion speed of ammonia mixed gas can be increased, and therefore stable ignition and rapid combustion of ammonia gas are achieved.

Owner:TSINGHUA UNIV

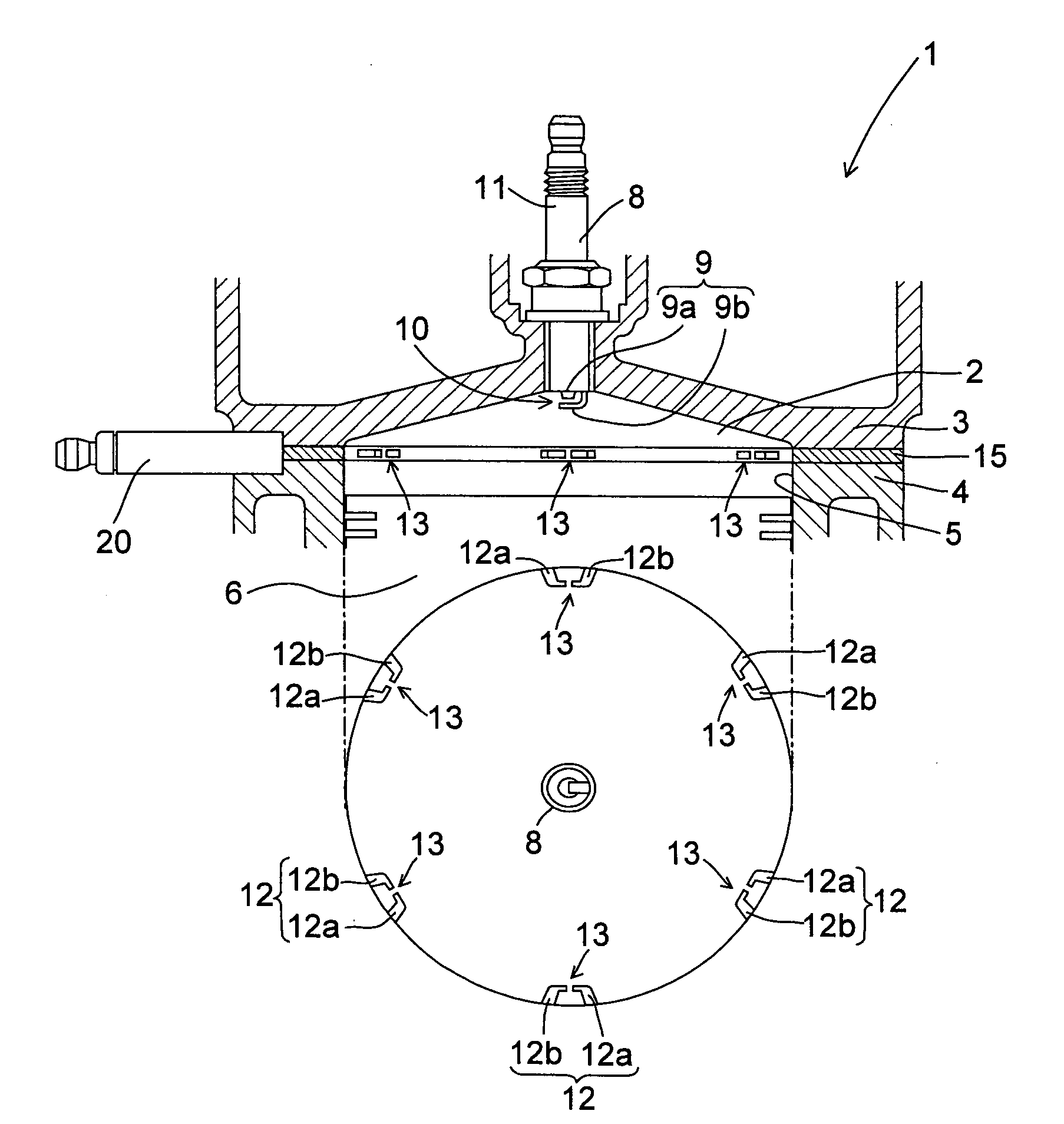

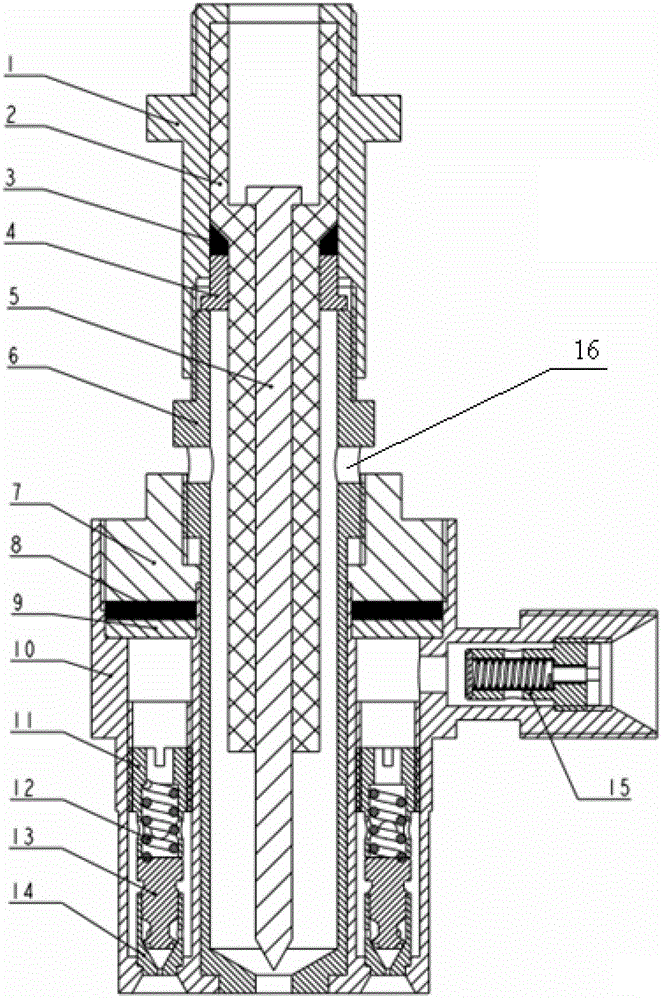

Fuel-atomizing integrated igniter

InactiveCN102980204AGuaranteed to igniteImprove fuel atomization effectCombustion ignitionThermal energyEngineering

The invention provides a fuel-atomizing integrated igniter which comprises an air plasma igniter and a fuel-atomizing jetting component, wherein the air plasma igniter is mainly composed of an inner electrode, a grounding electrode, an insulating medium and a power supply connector; the fuel-atomizing jetting component is mainly composed of a fuel-atomizing component shell and fuel-atomizing components; each of the fuel-atomizing components comprises a swirler shell and a swirler mounted in the swirler shell; the fuel-atomizing component shell is of annular shape; the plurality of fuel-atomizing components are uniformly distributed in the annular fuel-atomizing component shell; the annular fuel-atomizing component shell is provided with a fuel inlet; a fuel filter is arranged on the fuel inlet; the air plasma igniter is located in the annular fuel-atomizing component shell; an air guiding hole is formed on the grounding electrode; and the fuel-atomizing component shell and the grounding electrode are integrally connected through a pressing cover. The fuel-atomizing integrated igniter is applied to the field of thermal energy and power engineering; the generation of the conditions, such as, retrocession of an ignition source, flame blow-out, and the like, caused by horizontal jetting is avoided; and the reliability of ignition is increased.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com