Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8292 results about "Ammonia gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonia is a strong, colorless gas. If the gas is dissolved in water, it is called liquid ammonia. Poisoning may occur if you breathe in ammonia.

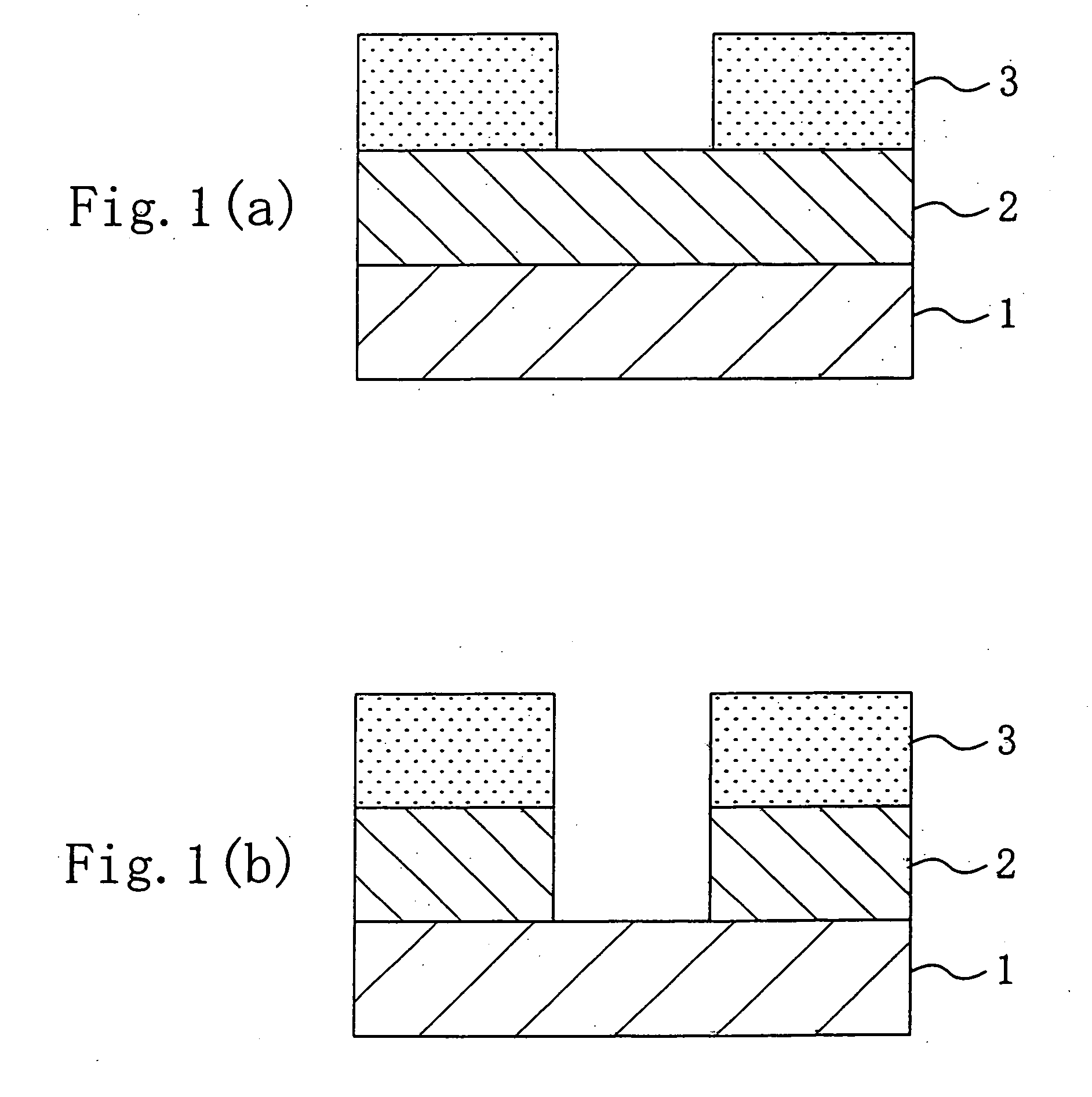

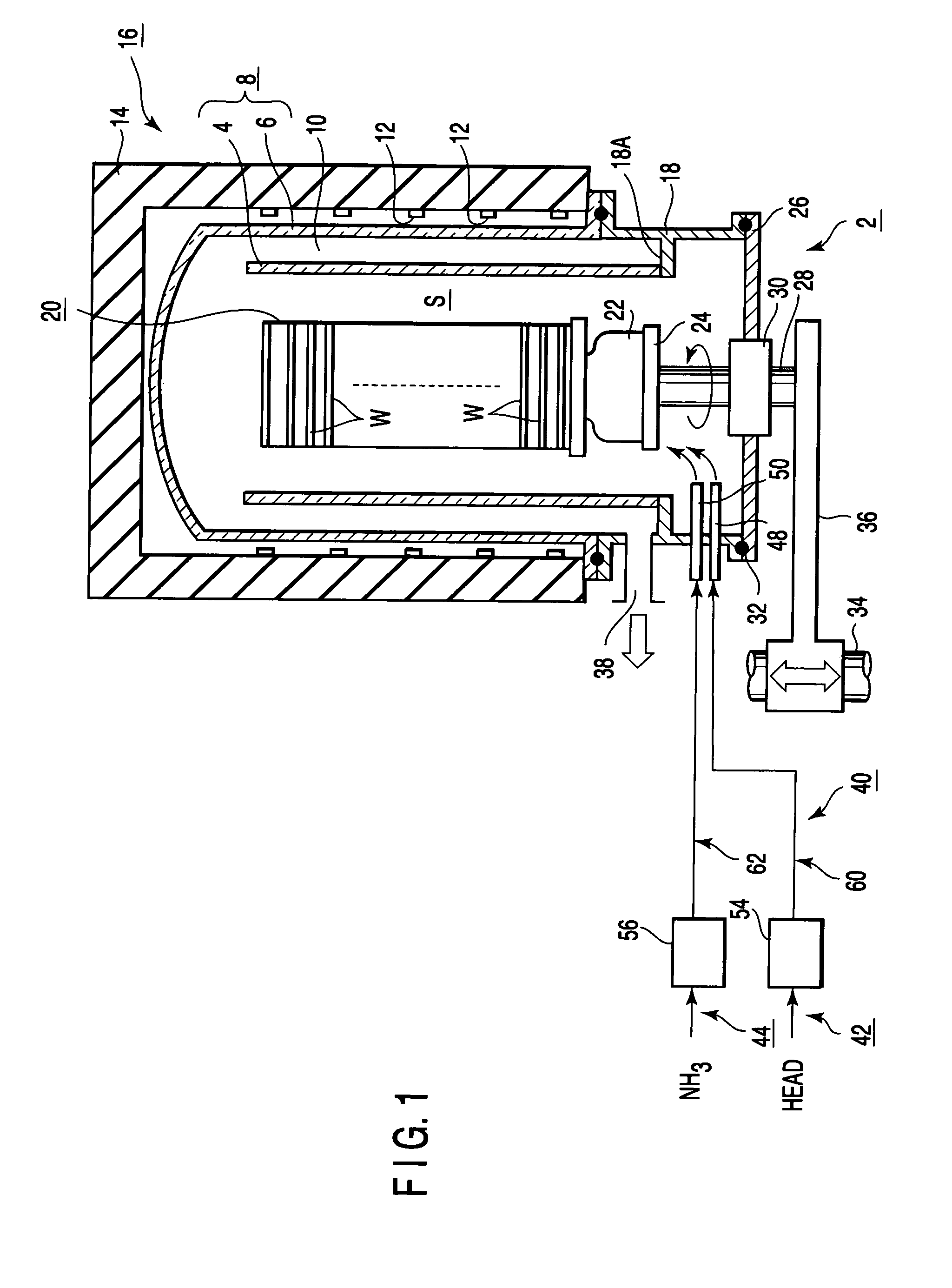

Cvd method for forming silicon nitride film

ActiveUS20060286817A1Low process temperatureImprove controllabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesAmmonia gas

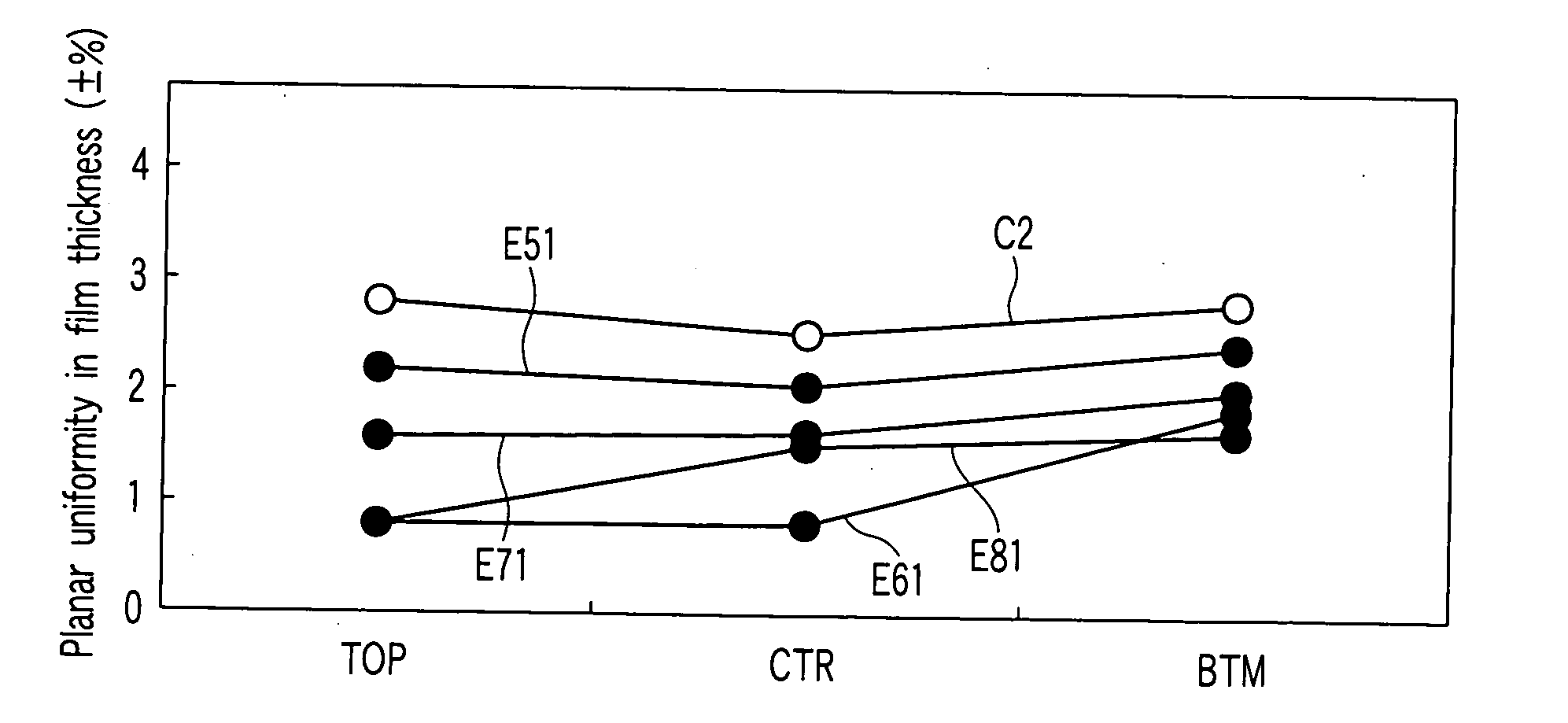

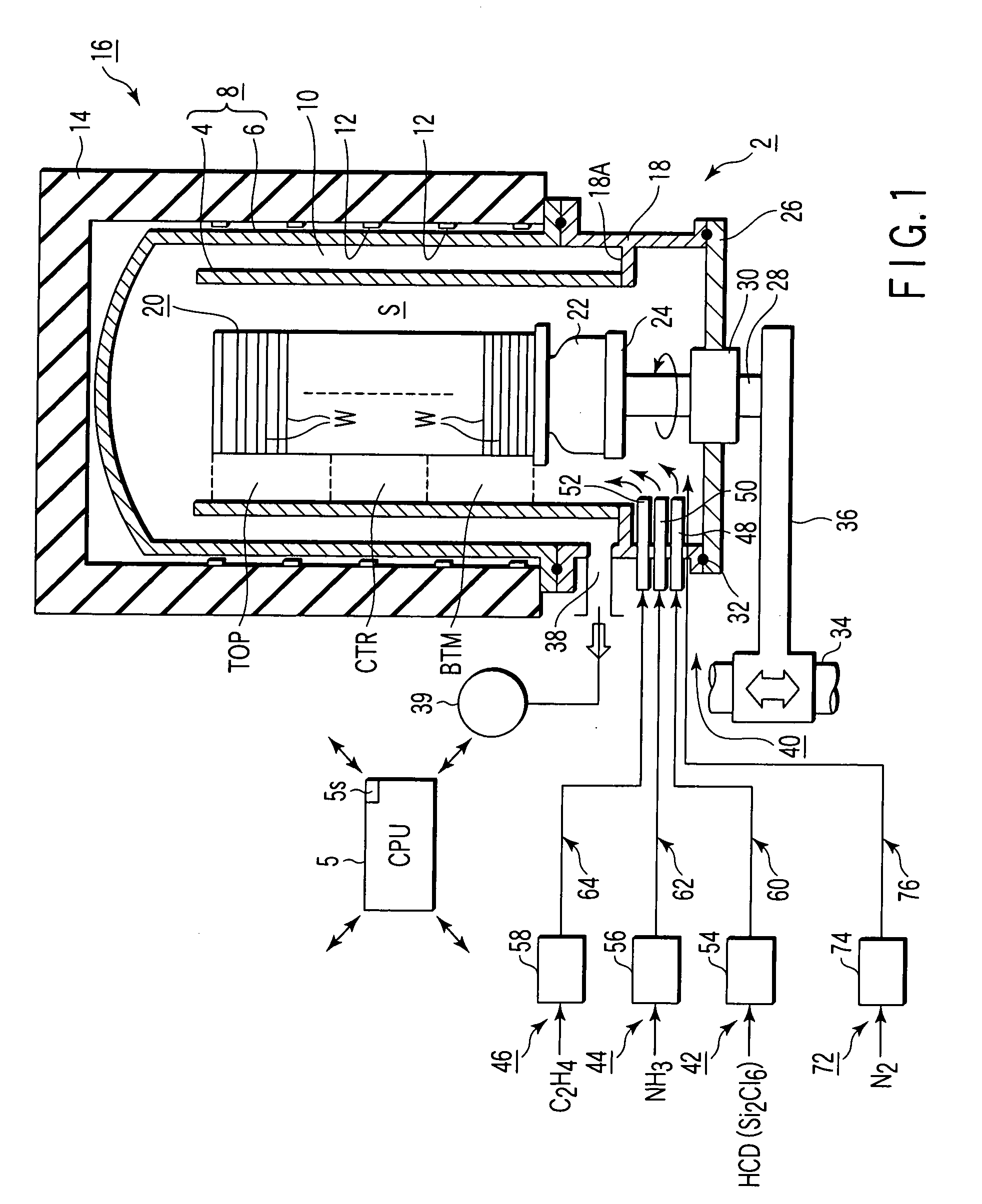

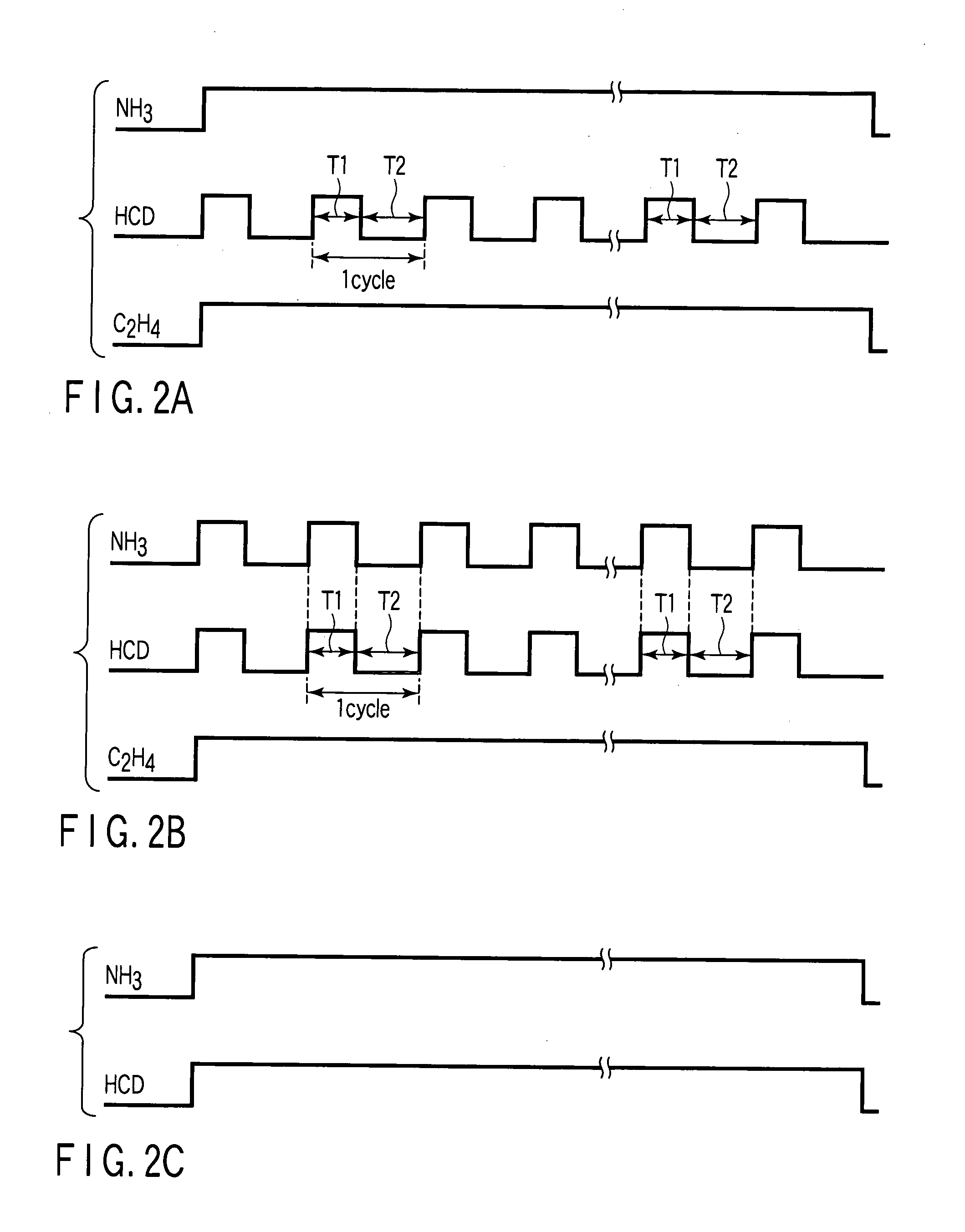

A CVD method for forming a silicon nitride film includes exhausting a process chamber (8) that accommodates a target substrate (W), and supplying a silane family gas (HCD) and ammonia gas (NH3) into the process chamber, thereby forming a silicon nitride film on the target substrate by CVD. Said forming a silicon nitride film on the target substrate alternately includes a first period of performing supply of the silane family gas (HCD) into the process chamber (8), and a second period of stopping supply of the silane family gas.

Owner:TOKYO ELECTRON LTD

Substrate processing method

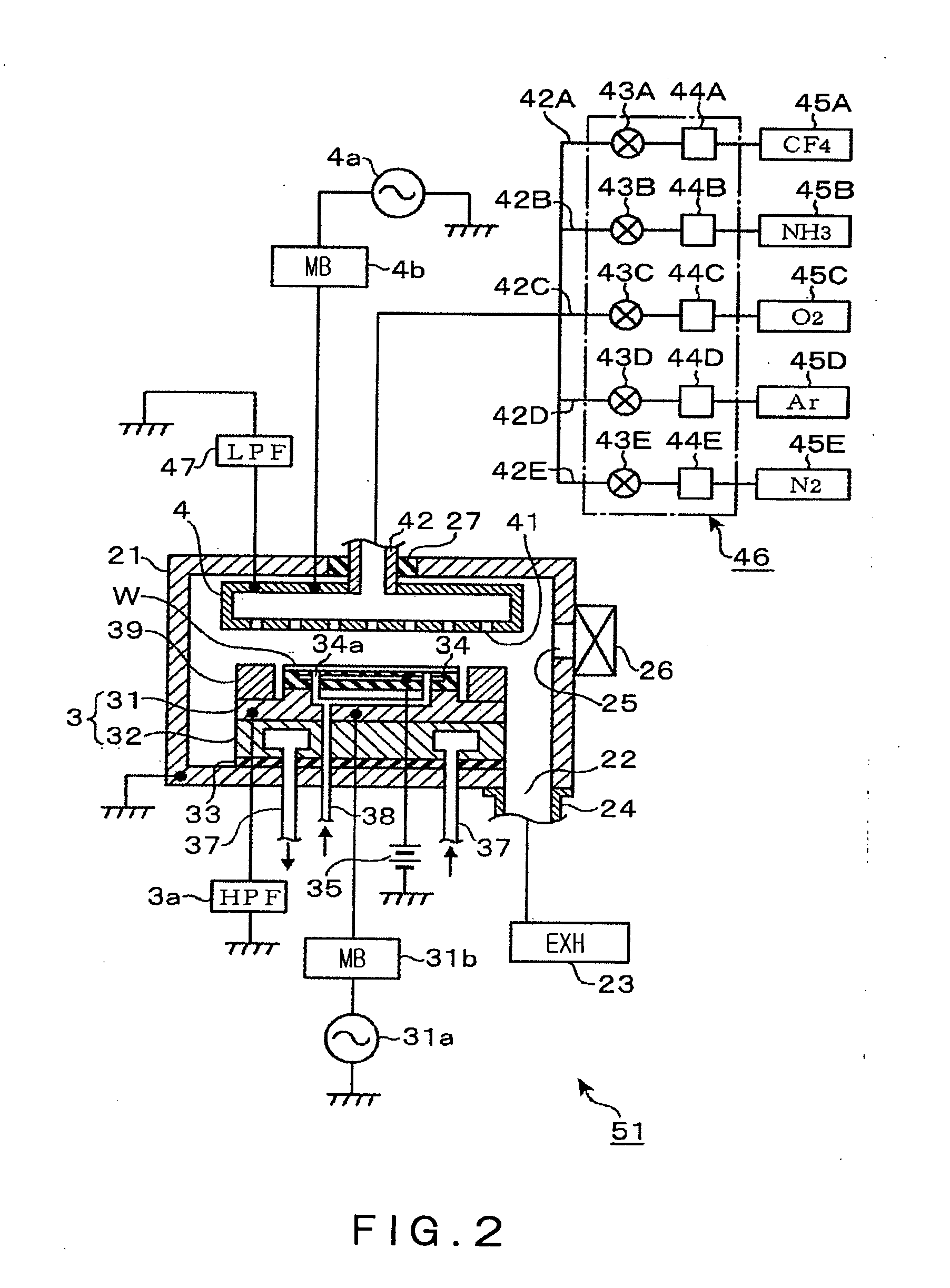

ActiveUS20110204025A1Decorative surface effectsPretreated surfacesDecompositionAMMONIUM SILICOFLUORIDE

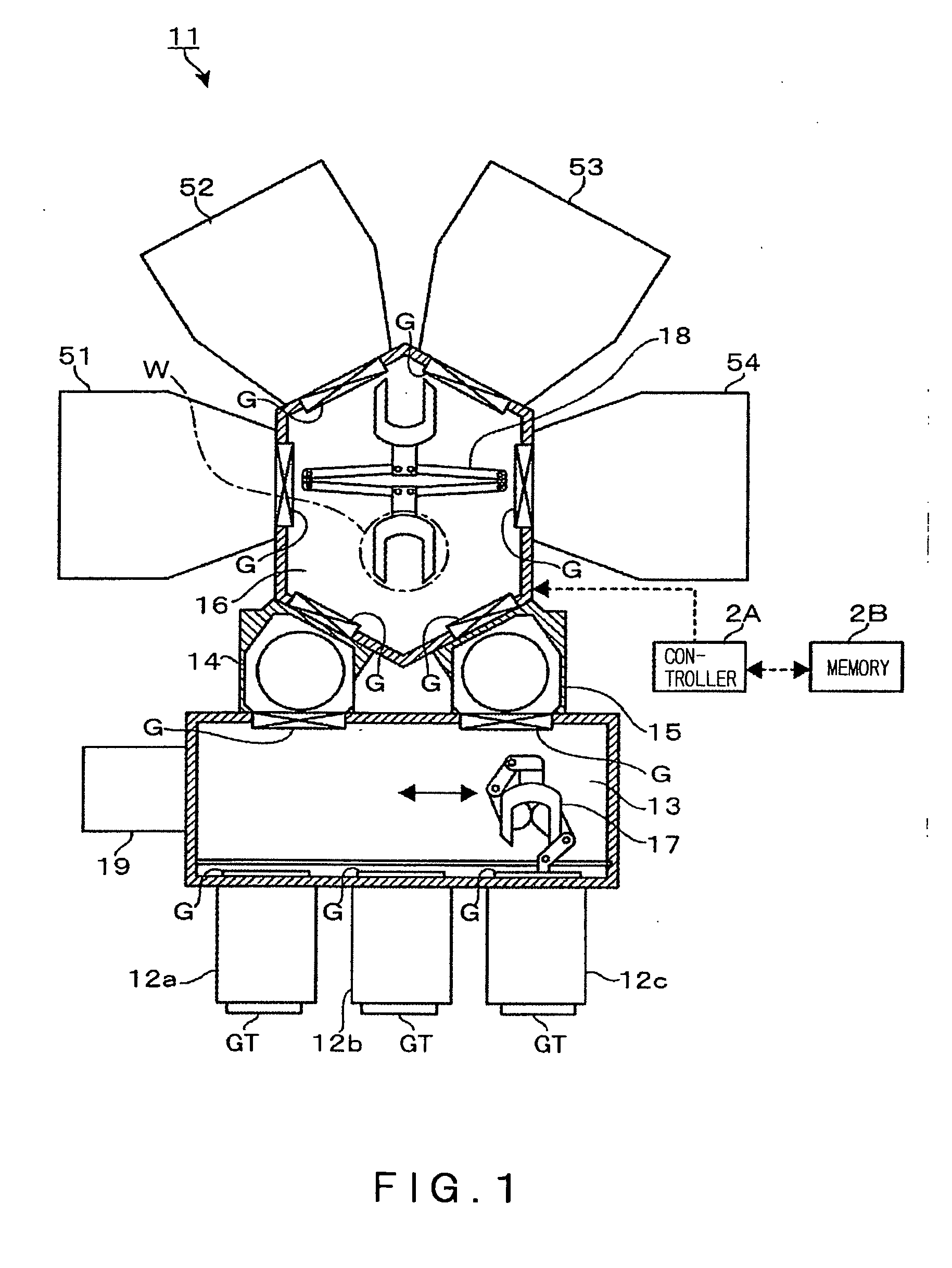

A silicon-containing film on a substrate is subjected to a plasma process using a process gas containing fluorine and carbon, and is thereafter subjected to plasma process using an ammonia gas, whereby ammonium silicofluoride having toxicity and hygroscopic property is adhered to the substrate. The harmful ammonium silicofluoride is removed by the inventive method. After conducting the plasma process using an ammonia gas, the substrate is heated to a temperature not lower than the decomposition temperature of the ammonium silicofluoride to decompose the ammonium silicofluoride in a process container in which the plasma process was conducted, or in a process container connected with the processing vessel which the plasma process was conducted therein and is isolated from a clean room atmosphere.

Owner:TOKYO ELECTRON LTD

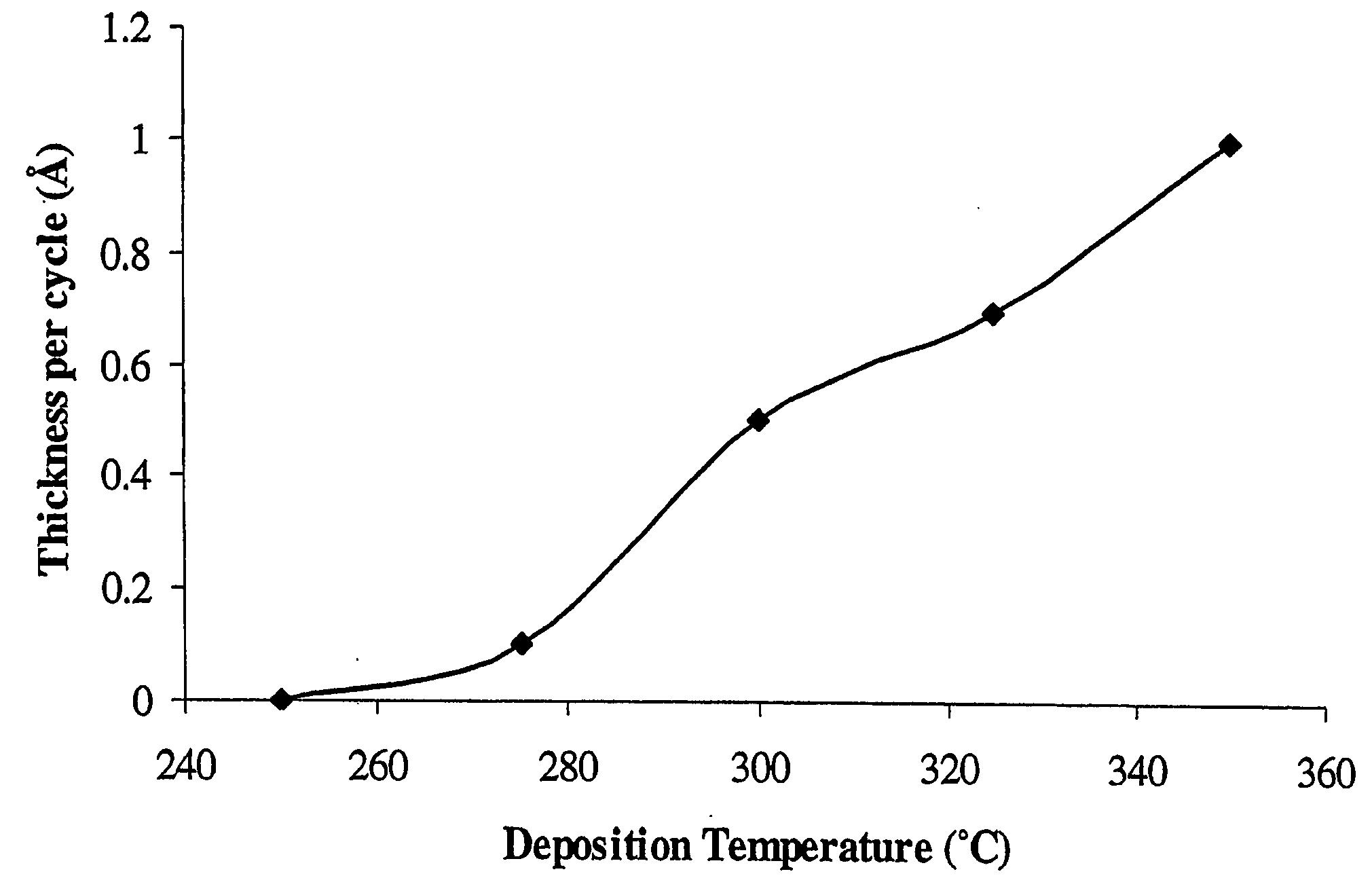

Vapor deposition of tungsten nitride

ActiveUS20060125099A1Uniform thicknessImprove efficiencyMirrorsSemiconductor/solid-state device detailsElectrical conductorGas phase

Tungsten nitride films were deposited on heated substrates by the reaction of vapors of tungsten bis(alkylimide)bis(dialkylamide) and a Lewis base or a hydrogen plasma. For example, vapors of tungsten bis(tert-butylimide)bis(dimethylamide) and ammonia gas supplied in alternate doses to surfaces heated to 300° C. produced coatings of tungsten nitride having very uniform thickness and excellent step coverage in holes with aspect ratios up to at least 40:1. The films are metallic and good electrical conductors. Suitable applications in microelectronics include barriers to the diffusion of copper and electrodes for capacitors. Similar processes deposit molybdenum nitride, which is suitable for layers alternating with silicon in X-ray mirrors.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Etching method

InactiveUS20060226121A1Improves anisotropic propertyIncrease ratingsDecorative surface effectsSemiconductor/solid-state device manufacturingSimple Organic CompoundsHydrogen

An interlayer insulating film composed of an organic compound film containing an organic component as a main constituent is deposited on a semiconductor substrate. Then, etching is performed with respect to the interlayer insulating film by using a plasma derived from an etching gas containing an ammonia gas as a main constituent. As a result, active hydrogen is generated in the plasma derived from the ammonia gas to decompose the organic component into hydrogen cyanide, whereby etching proceeds. Since a surface of the organic compound film is efficiently nitrided by nitrogen generated from the ammonia gas, the sidewalls of a depressed portion in the organic compound film are protected so that an excellent anisotropic property is provided. Since the etching gas does not contain a component which oxidizes the organic compound film, the problem does not occur that a gas is generated from the organic compound film in a subsequent heat treatment process.

Owner:PANASONIC CORP

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Coal Compositions for Catalytic Gasification

ActiveUS20090217590A1Drying solid materials with heatGaseous fuelsPtru catalystHydrocotyle bowlesioides

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

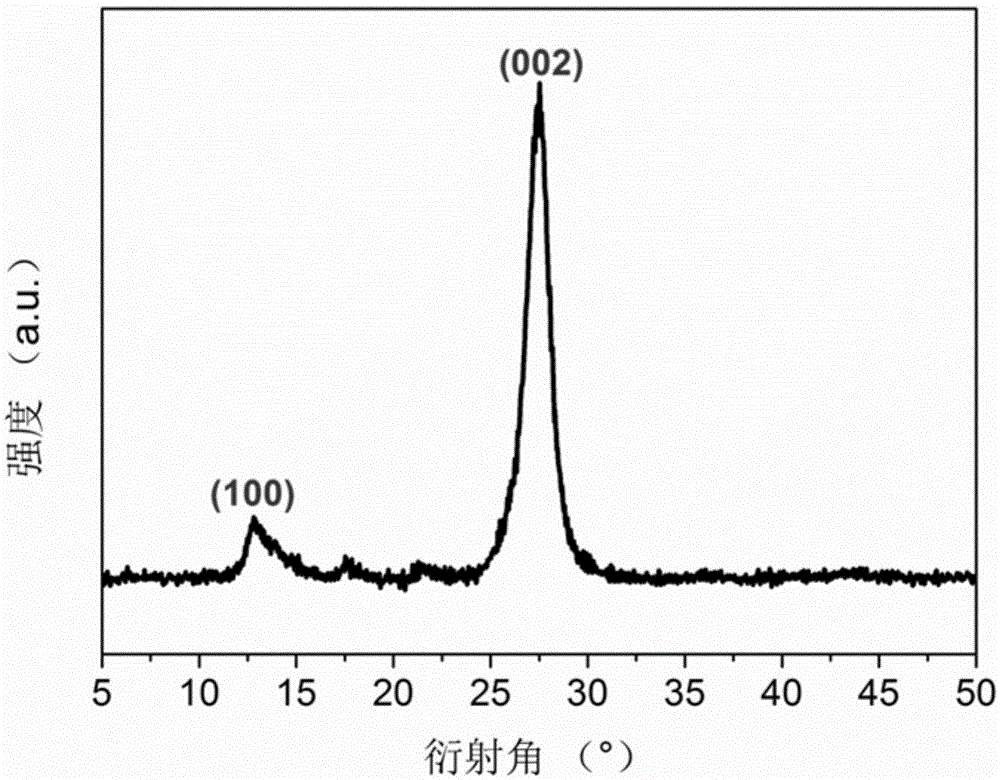

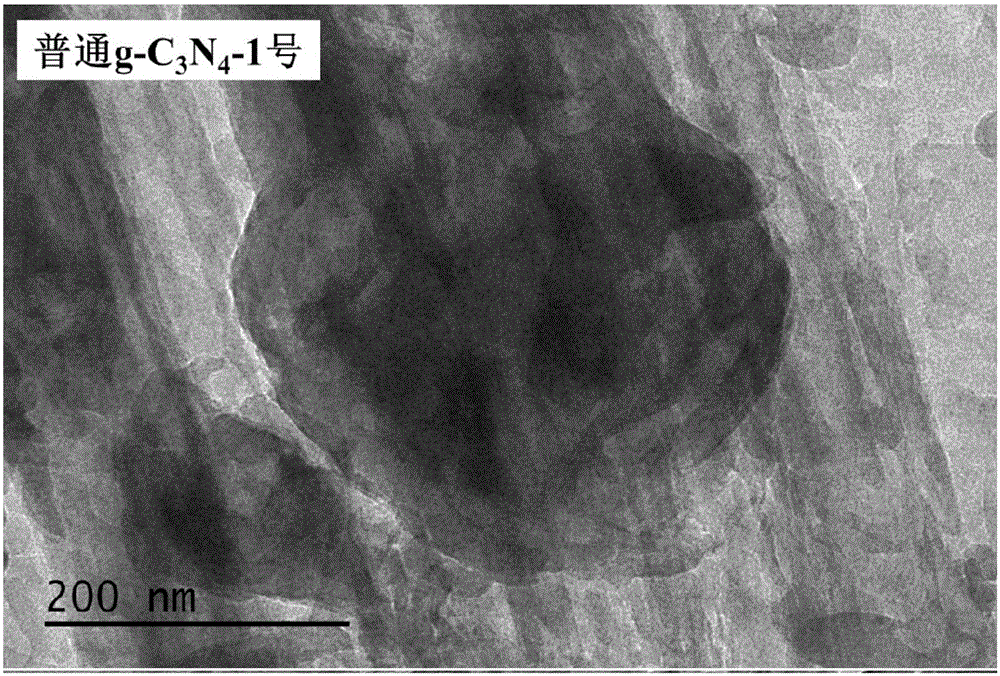

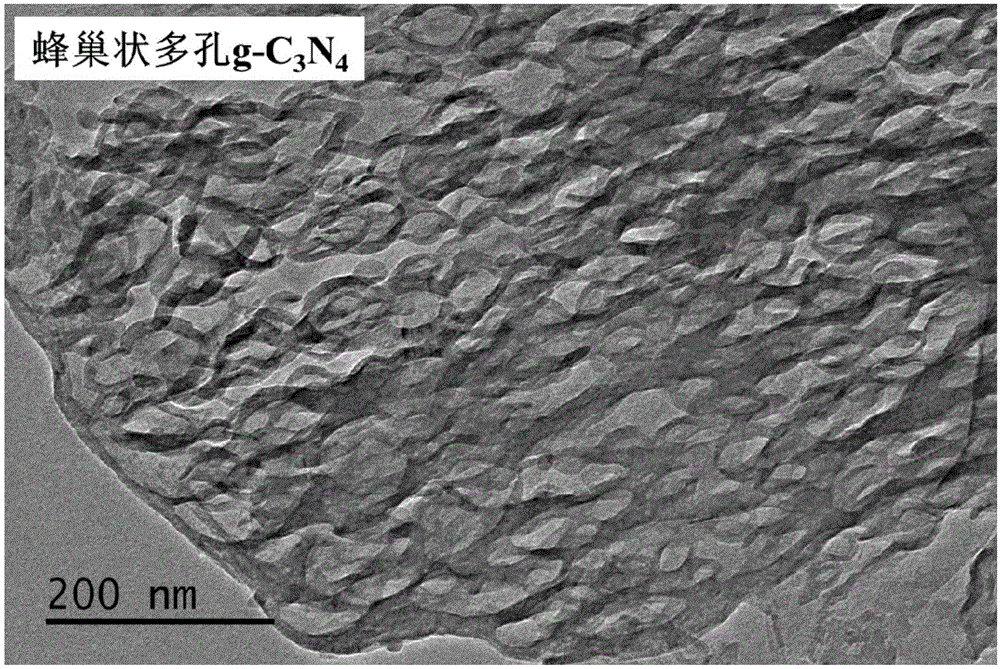

Graphite-phase carbon nitride (g-C3N4) material and preparation method and application thereof

ActiveCN105126893APlay a pore-forming roleAppropriate speedPhysical/chemical process catalystsWater/sewage treatment by irradiationCalcinationMaterials science

The invention relates to a method for preparing a graphite-phase carbon nitride (g-C3N4) material. The method includes the steps that a carbon nitride precursor and ammonium salt are evenly mixed, and then calcination is conducted so that the porous g-C3N4 material can be obtained. The ammonium salt is any one of ammonium base salts capable of generating ammonia gas through thermal decomposition or is the combination of at least two of the ammonium base salts. In the preparation process of the g-C3N4 material, the ammonium salt is added into the carbon nitride precursor to be mixed. In the high-temperature calcining process, the ammonium salt is subjected to pyrogenic decomposition to generate gas, a pore-forming effect on the g-C3N4 material is achieved, and the cellular porous g-C3N4 material is obtained. In the preparation process of the g-C3N4 material, template agents are not used, and thus the method is simple, efficient and environmentally friendly; the prepared g-C3N4 material is high in photocatalytic activity and can be used in the pollution control processes such as exhaust gas and wastewater treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

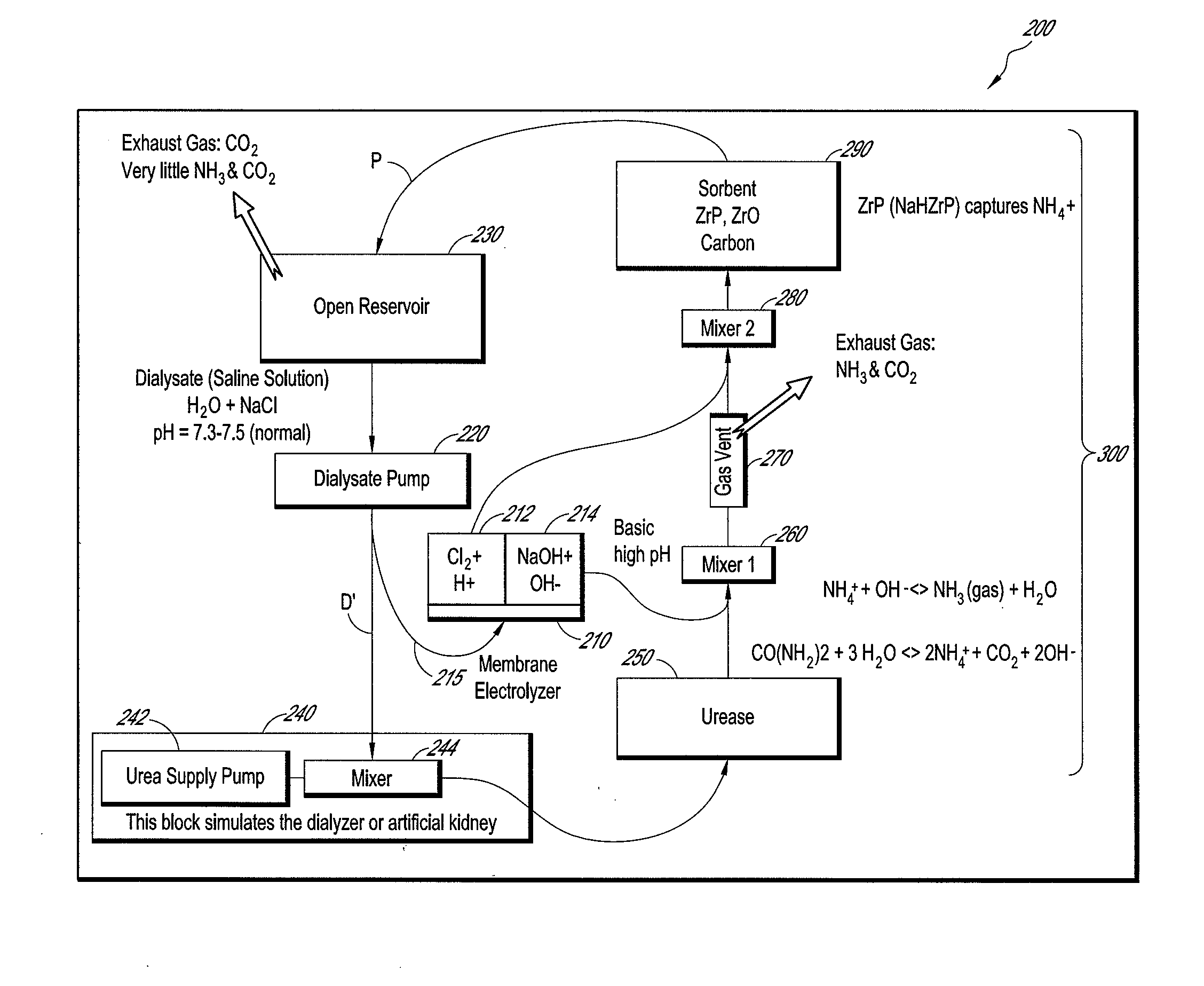

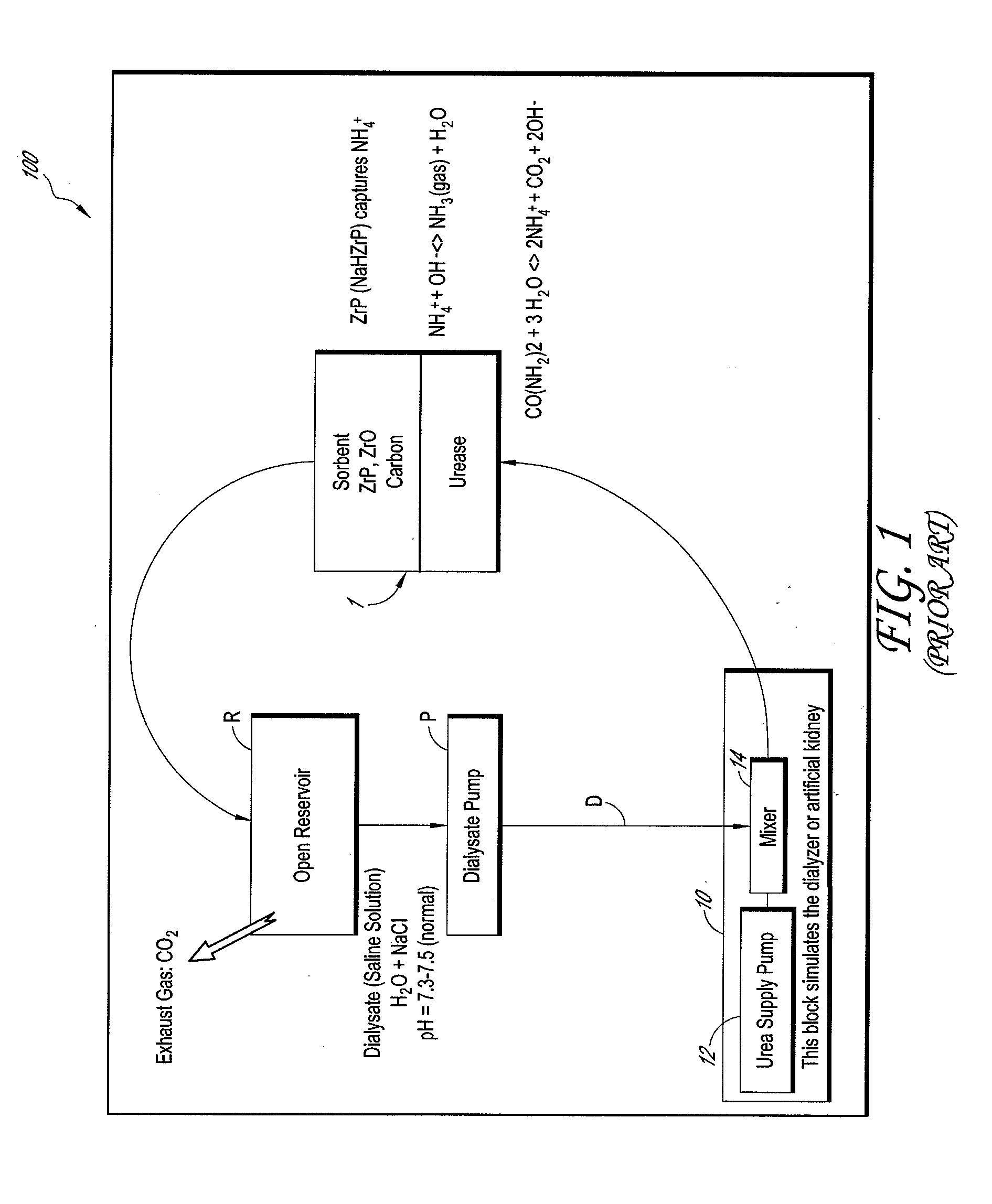

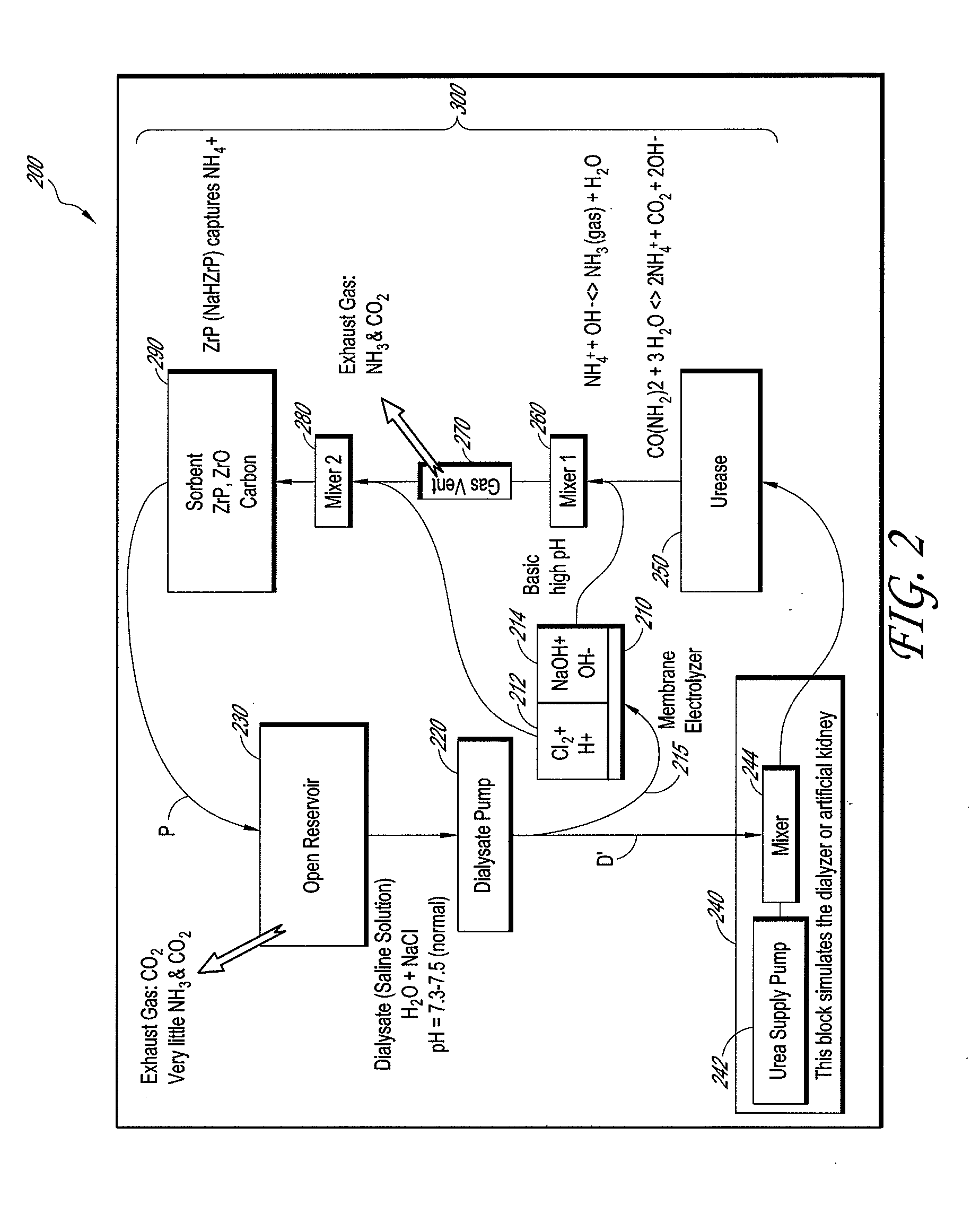

Membrane electrolyzer and hemodialysis system using the same

InactiveUS20110272352A1Raise the pHElectrolysis componentsApparatus sterilizationSorbentHaemodialysis machine

A sorbent hemodialysis system includes a dialyzer configured to receive a flow of clean dialysate from a reservoir and to output an unclean dialysate flow. The system also includes a sorbent component having a urease section and a sorbent section through which the unclean dialysate flow from the dialyzer passes, wherein the sorbent component removes urea from the dialysate. The system further comprises a membrane electrolyzer that receives at least a portion of said clean dialysate flow and separates the dialysate flow into an acidic component flow and a base component flow. A mixing conduit combines the base component flow from the membrane electrolyzer and an output dialysate solution from the urease section of the sorbent component to separate the dialysate solution into an ammonia gas amount and ammonia liquid amount. A gas vent is used to vent the ammonia gas amount, and the sorbent section with a suitable amount of zirconium phosphate (ZrP) removes the ammonia liquid amount from the unclean dialysate flow before flowing the clean dialysate to the reservoir. The system can further include a second mixing conduit upstream of the sorbent section of the sorbent component, the second mixing conduit combining the acidic component flow and the ammonia liquid amount in the dialysate solution to increase the pH of the dialysate solution to about 7.5 prior to returning to the reservoir.

Owner:C TECH BIOMEDICAL

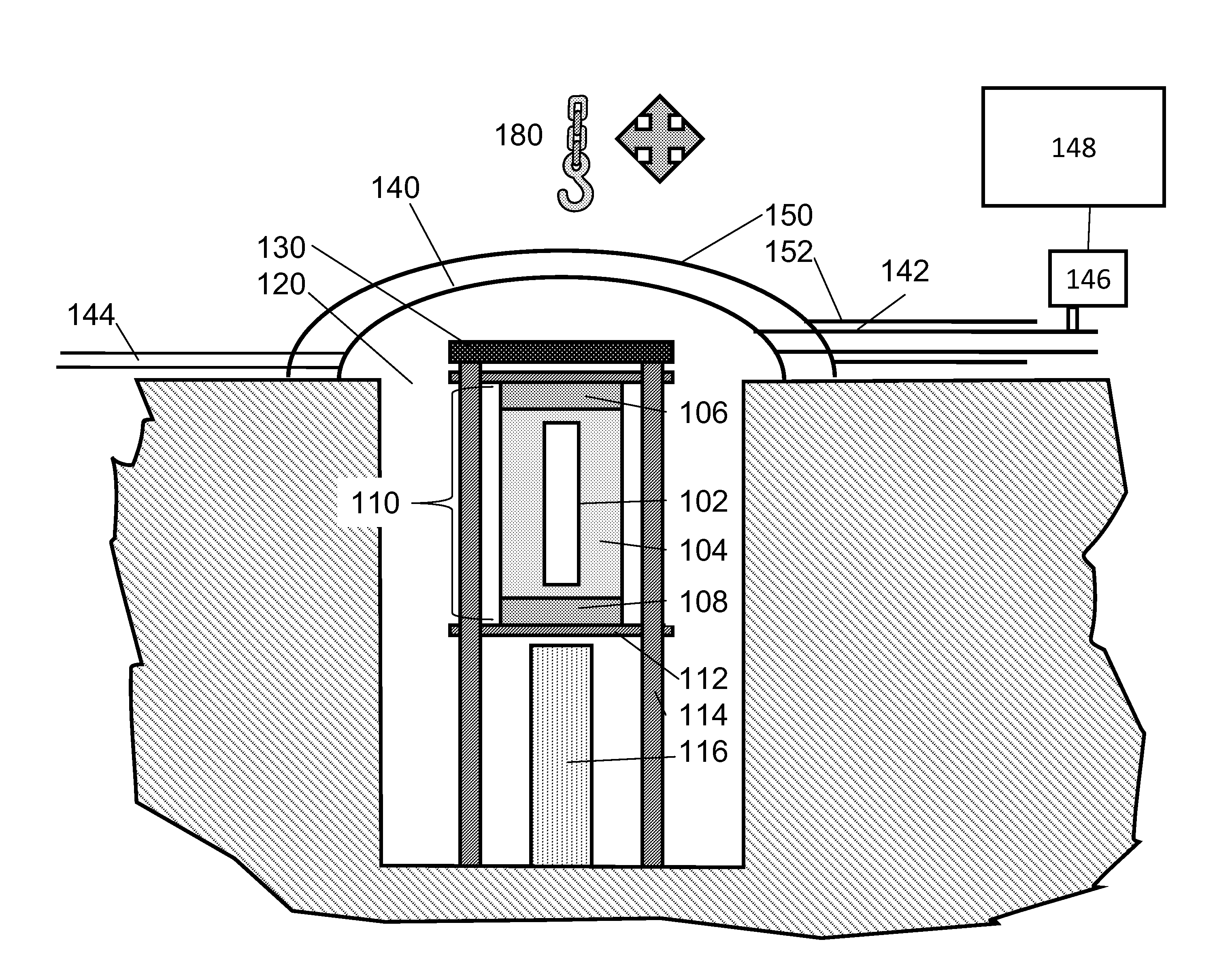

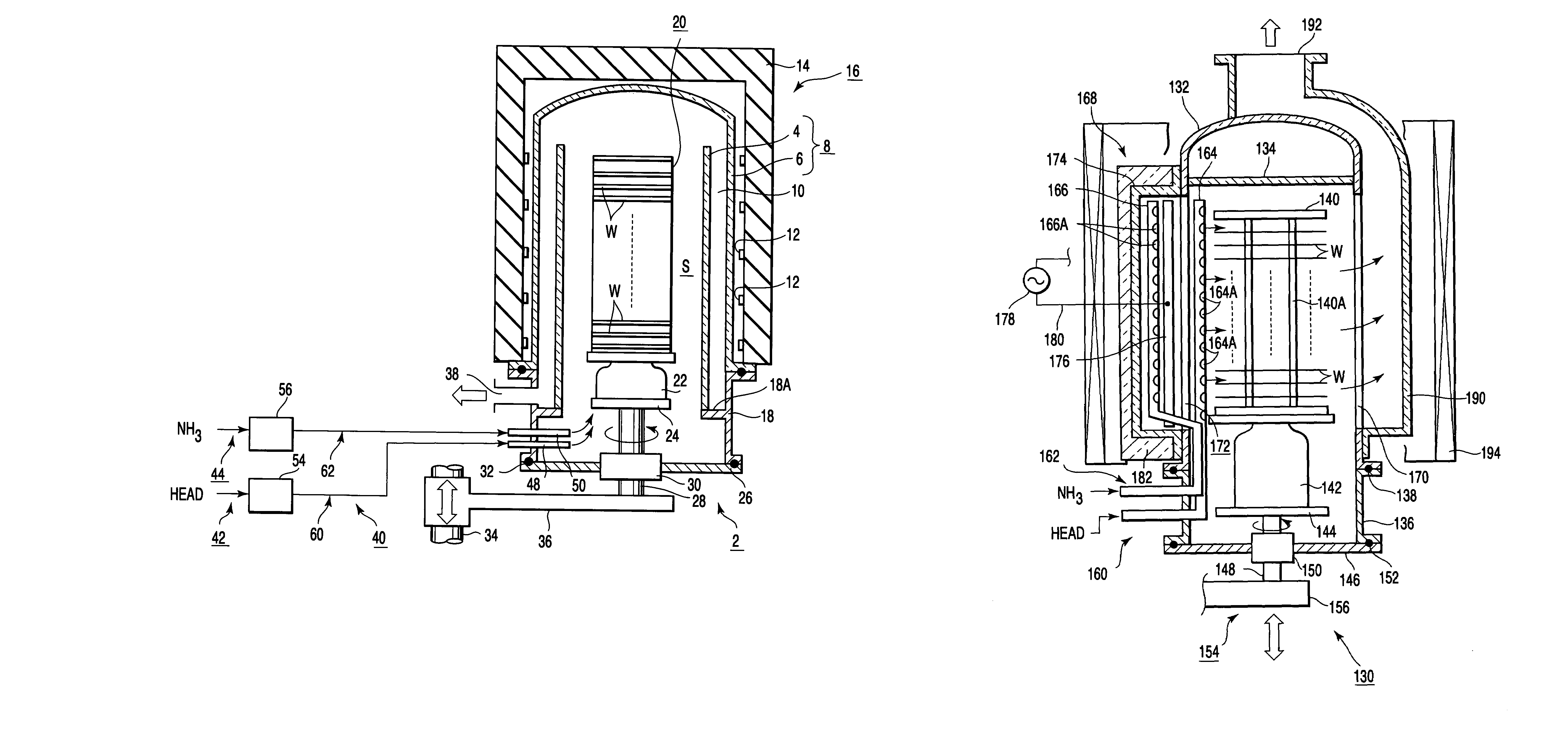

Plant and method for large-scale ammonothermal manufacturing of gallium nitride boules

InactiveUS20110100291A1Simple and cost-effective to manufactureSafe and cost-effectivePolycrystalline material growthFrom normal temperature solutionsNuclear engineeringGallium nitride

A method of operating a high pressure system for growth of gallium nitride containing materials. The method comprises providing a high pressure apparatus comprising a growth region and feedstock region. The high pressure reactor comprises a high pressure enclosure and is configured within a primary containment structure. The method includes operating an exhaust system coupled to the primary containment structure. The exhaust system is configured to remove ammonia gas derived from at least 0.3 liters of ammonia liquid.

Owner:SORAA

Composite oxide catalyst for cryogenic selective catalystic reductic oxide nitrogen

InactiveCN101028594AEasy to makeEasy to operateCatalyst carriersDispersed particle separationManganese oxideNitrogen gas

A composite oxide catalyst for removing NOx from the tail gas generated by combustion through low-temp selective catalytic reduction reaction in which ammonia gas or urea is used as reducing agent for reducing the NOx into N2 and H2O is prepared from a composite metallic oxide (whose main component is manganese oxide) and a porous inorganic oxide as carrier through citric acid complexing method.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

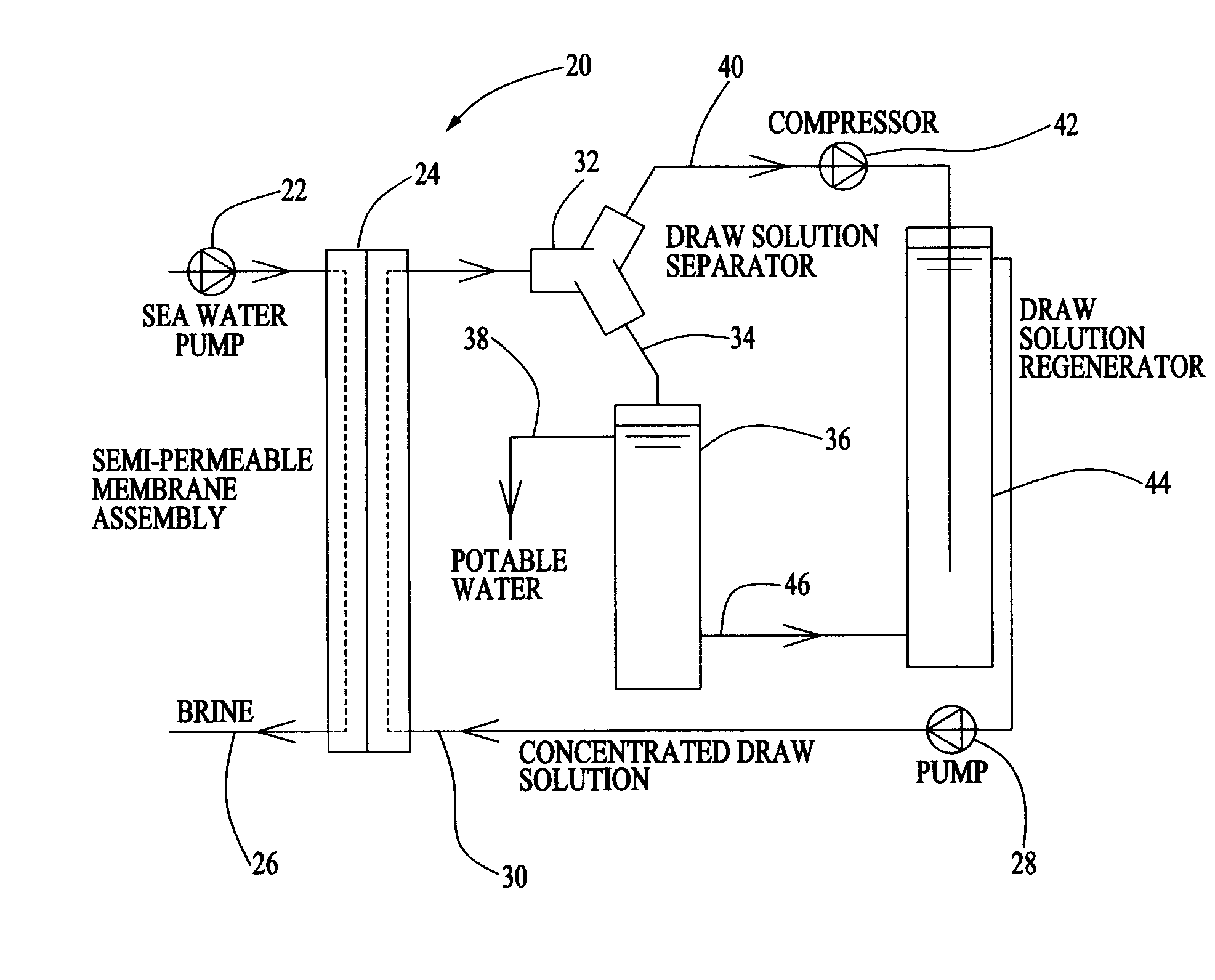

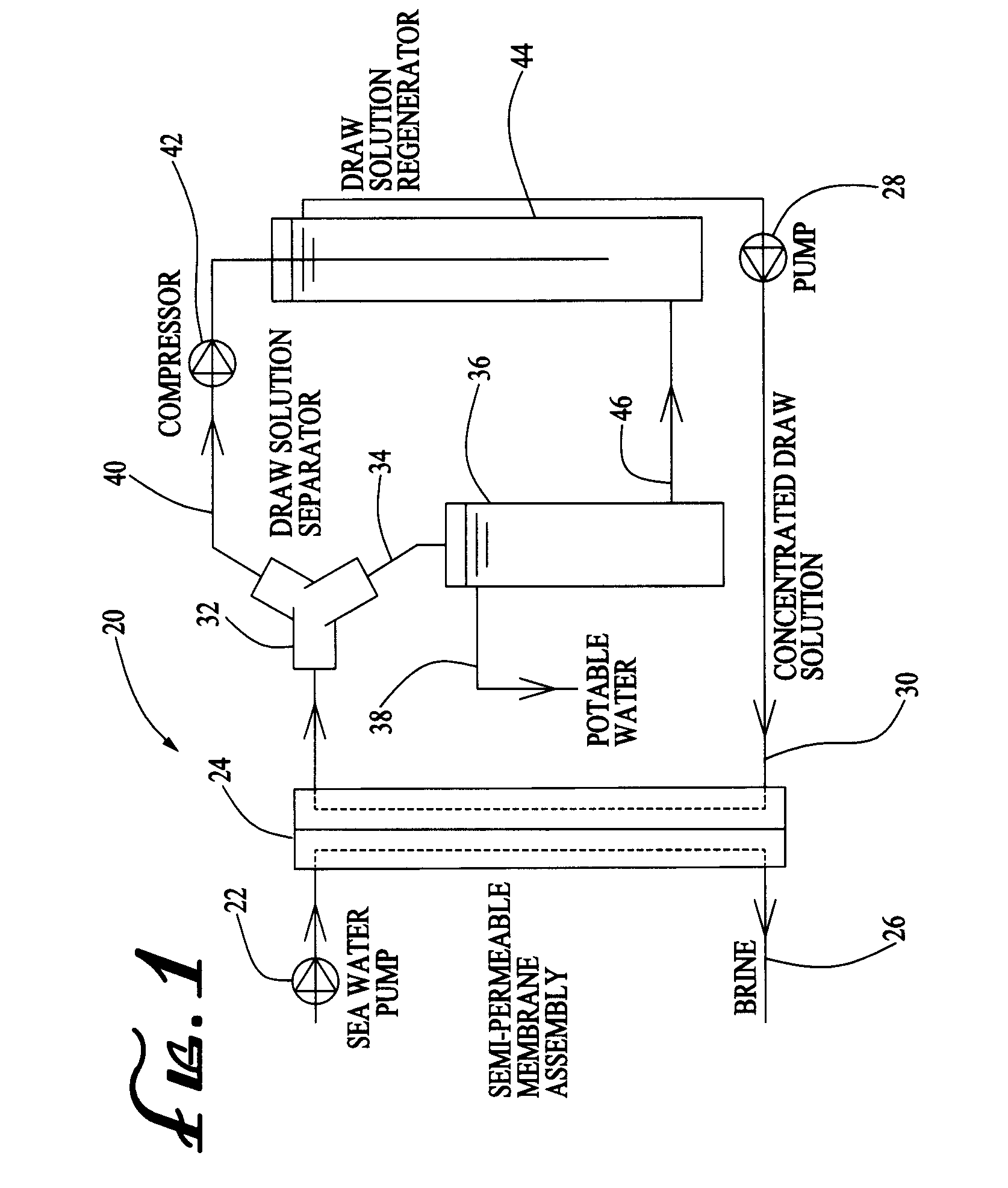

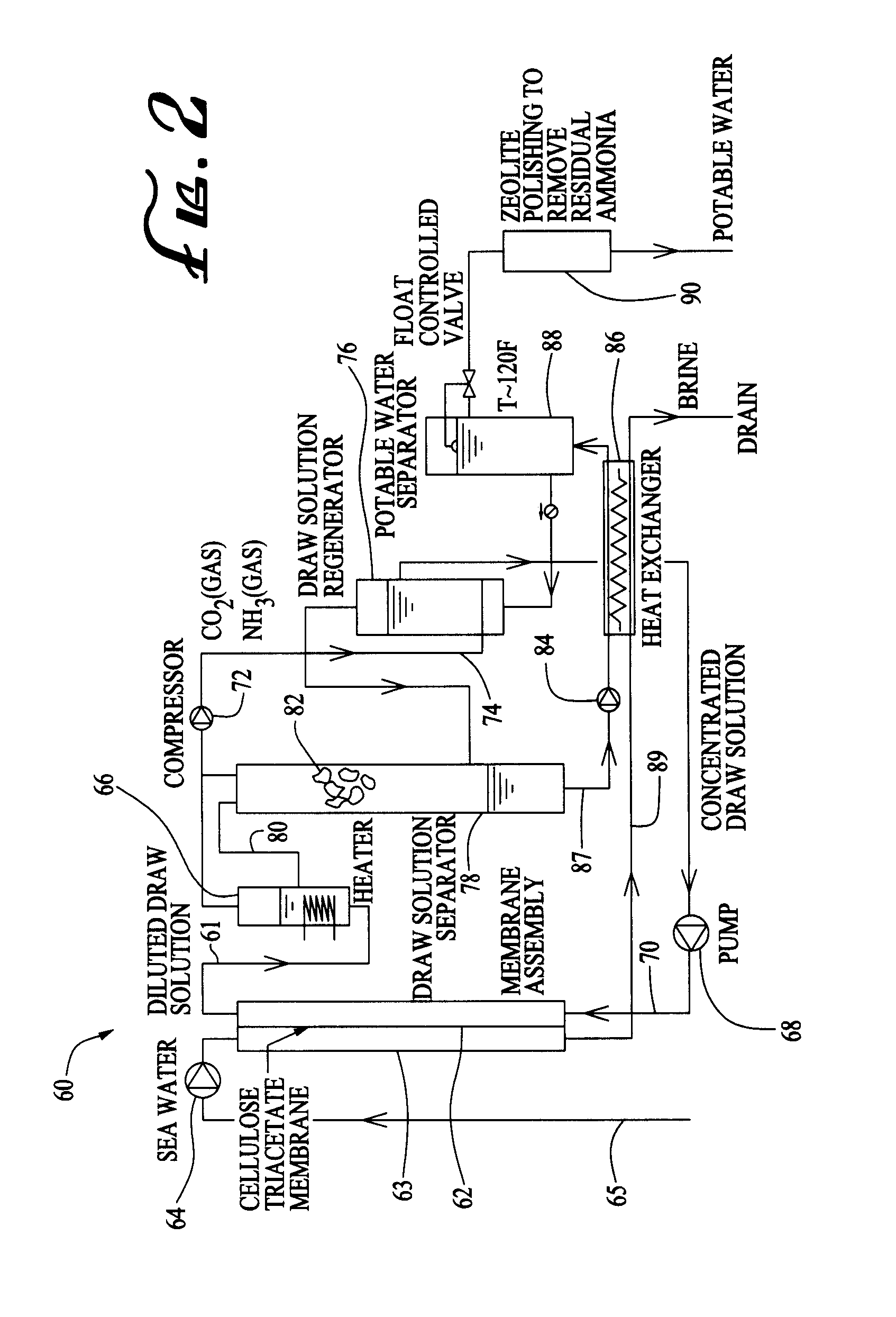

Method and Apparatus for Producing Potable Water from Seawater Using Forward Osmosis

ActiveUS20090308727A1Efficient and effectiveAuxillariesGeneral water supply conservationDesalinationPotable water

A method and apparatus for desalinating seawater which uses an ammonia bicarbonate forward osmosis desalination process. Seawater is pumped through one side of a membrane assembly. A draw solution is pumped through the other side of the membrane assembly. The draw solution withdraws water molecules from the seawater through the membrane into the draw solution. A draw solution separator receives a heated draw solution which then decomposes into ammonia, carbon dioxide and water. Potable water is separated from ammonia has and carbon dioxide gas. The ammonia gas and carbon dioxide gas are recombined with a portion of the potable water stream to reform the ammonium bicarbonate draw solution.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

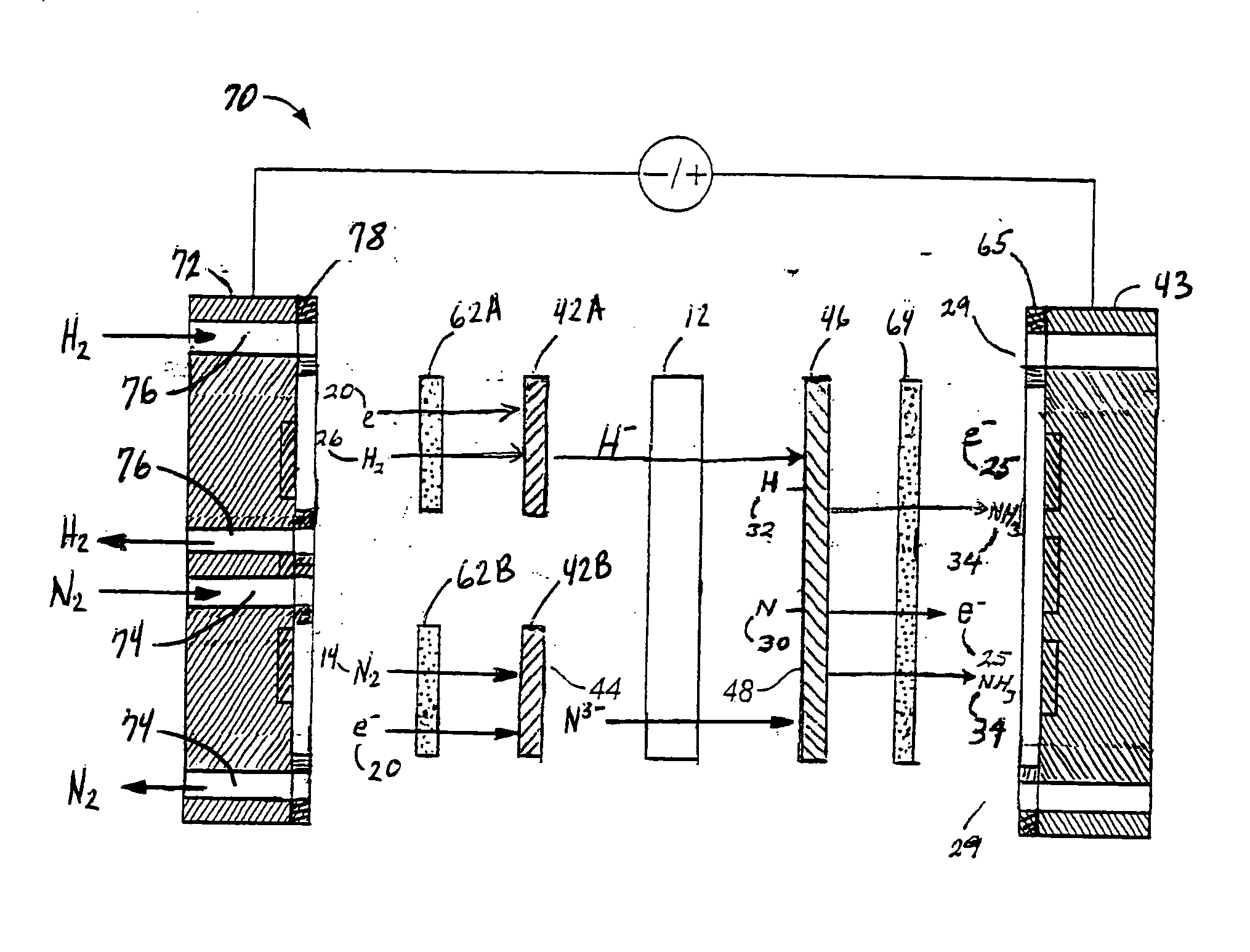

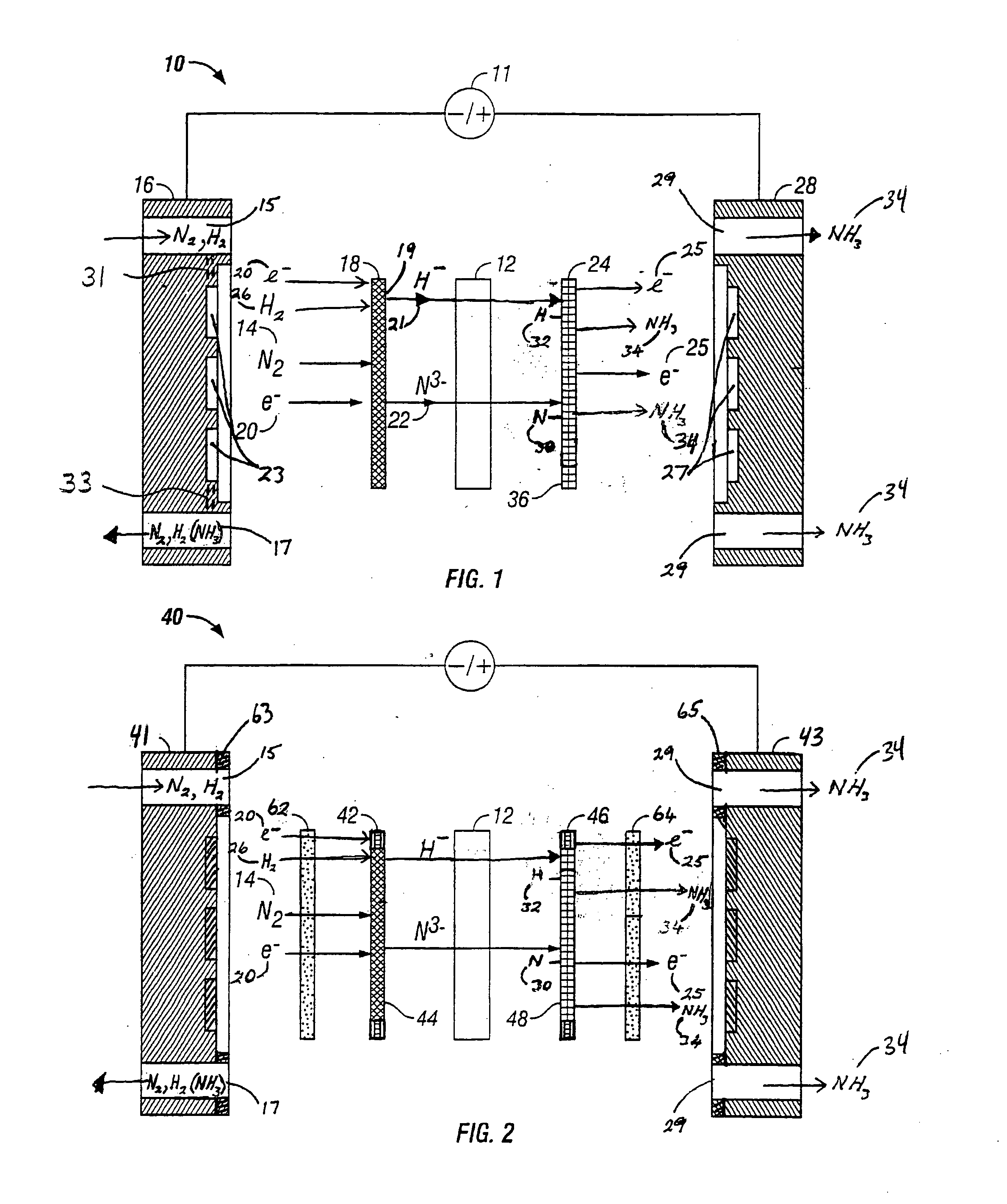

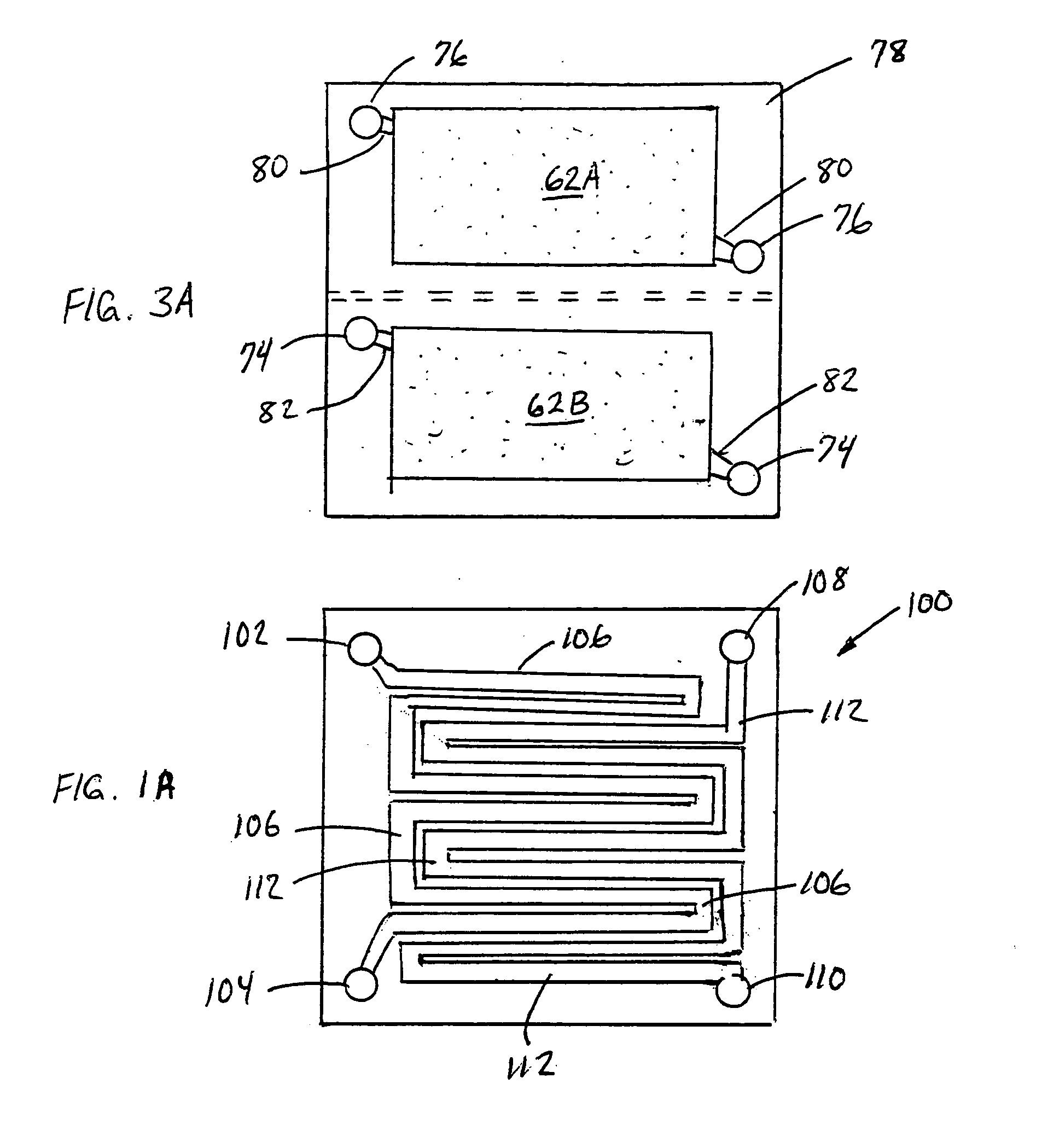

Electrochemical synthesis of ammonia

A method for the anodic electrochemical synthesis of ammonia gas. The method comprises providing an electrolyte between an anode and a cathode, providing nitrogen and hydrogen gases to the cathode, oxidizing negatively charged nitrogen-containing species and negatively charged hydrogen-containing species present in the electrolyte at the anode to form adsorbed nitrogen species and adsorbed hydrogen species, respectively, and reacting the adsorbed nitrogen species with the adsorbed hydrogen species to form ammonia. Nitrogen and hydrogen gases may be provided through a porous cathode substrate. The negatively charged nitrogen-containing species in the electrolyte may be produced by reducing nitrogen gas at the cathode and / or by supplying a nitrogen-containing salt, such as lithium nitride, into the molten salt electrolyte. Similarly, the negatively charged hydrogen-containing species in the electrolyte may be produced by reducing hydrogen gas at the cathode and / or by supplying a hydrogen-containing salt, such as lithium hydride, into the molten salt electrolyte.

Owner:LYNTECH INC

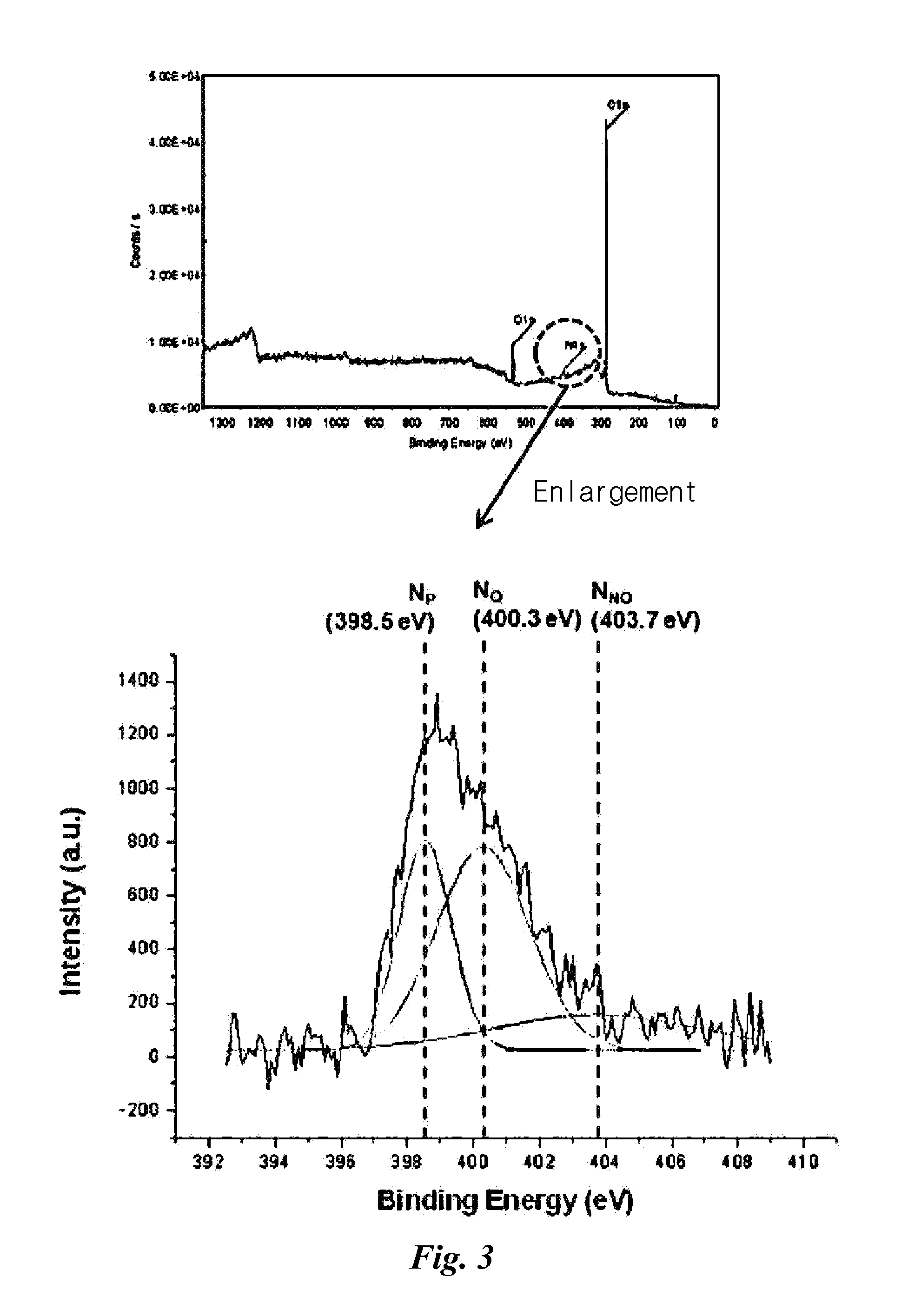

Low-temperature SCR catalyst using nitrogen-dopped activated carbon as carrier and preparation technique thereof

InactiveCN101352681AIncrease the degree of oxidationEasy to handleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen

The invention discloses a low-temperature SCR catalyst which takes nitrogen mingled with active carbon as a carrier. The catalyst takes the nitrogen mingled with active carbon prepared by ammonia gas ignition as the carrier and one of the oxides loaded with metallic element of Mn, V, Fe, Co or Cu as an active ingredient. The invention also discloses a specific method for preparing the catalyst. The carrier of nitrogen mingled with active carbon increases the number of base sites on the surface of the active carbon, so as to improve the adsorptive capacity of NO and O2 and lead more NO to be oxidized into NO2. The load of the metal metallic oxides of Mn, V, Fe, Co and Cu forms a large amount of acid sites on the surface of the catalyst, which promotes the absorption capability of the catalyst to NH3. The measures effectively enhances the denitration activity of the low-temperature SCR catalyst which takes the nitrogen mingled with active carbon as the carrier and extends the activity temperature window of the reaction thereof.

Owner:ZHEJIANG UNIV

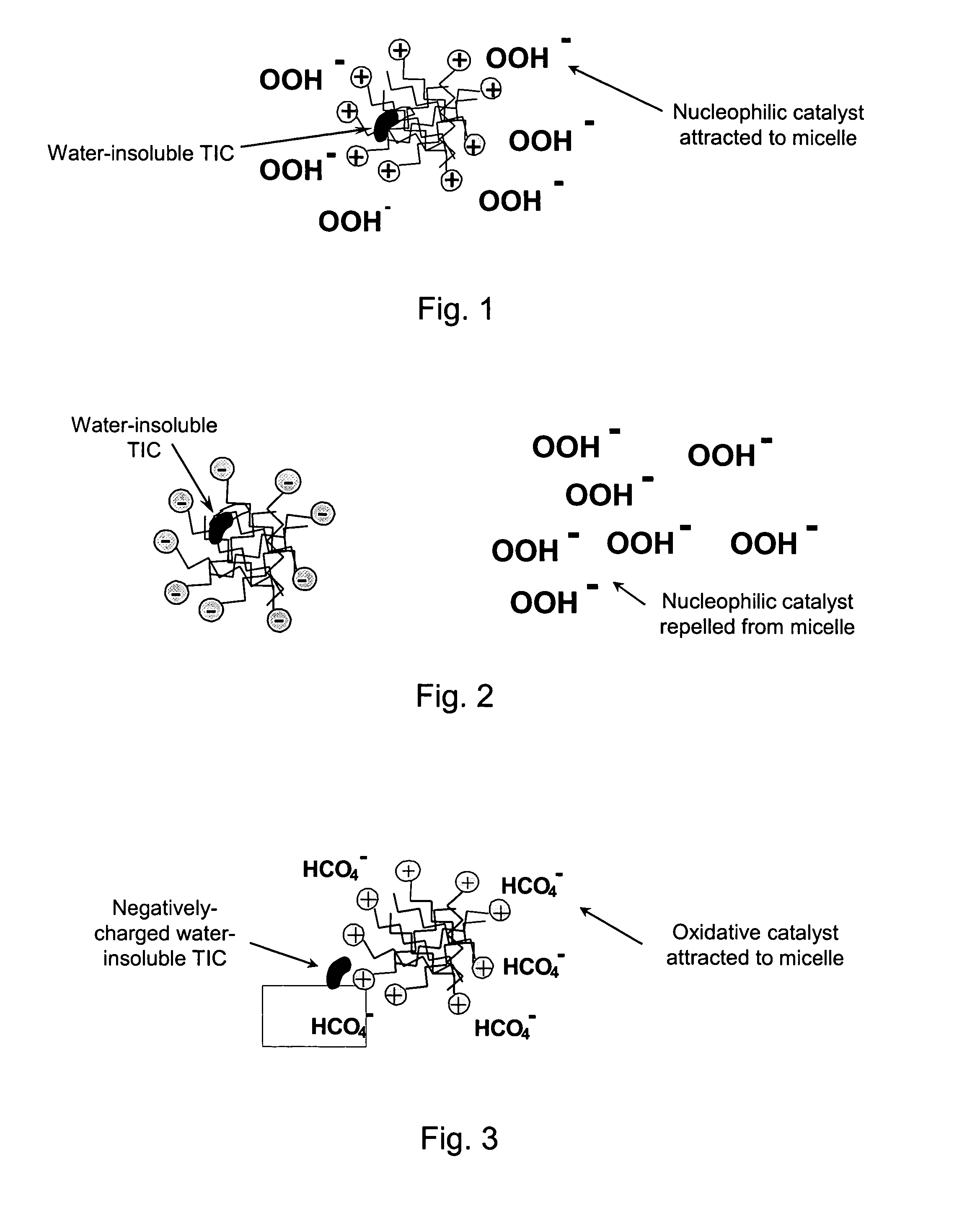

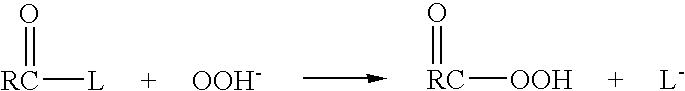

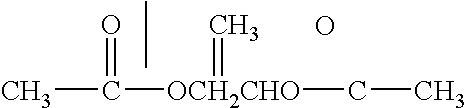

Reactive formulations for a neutralization of toxic industrial chemicals

InactiveUS7125497B1Efficiently neutralizedHydrogen peroxideLiquid degasificationBoron trichlorideMalathion

Decontamination formulations for neutralization of toxic industrial chemicals, and methods of making and using same. The formulations are effective for neutralizing malathion, hydrogen cyanide, sodium cyanide, butyl isocyanate, carbon disulfide, phosgene gas, capsaicin in commercial pepper spray, chlorine gas, anhydrous ammonia gas; and may be effective at neutralizing hydrogen sulfide, sulfur dioxide, formaldehyde, ethylene oxide, methyl bromide, boron trichloride, fluorine, tetraethyl pyrophosphate, phosphorous trichloride, arsine, and tungsten hexafluoride.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

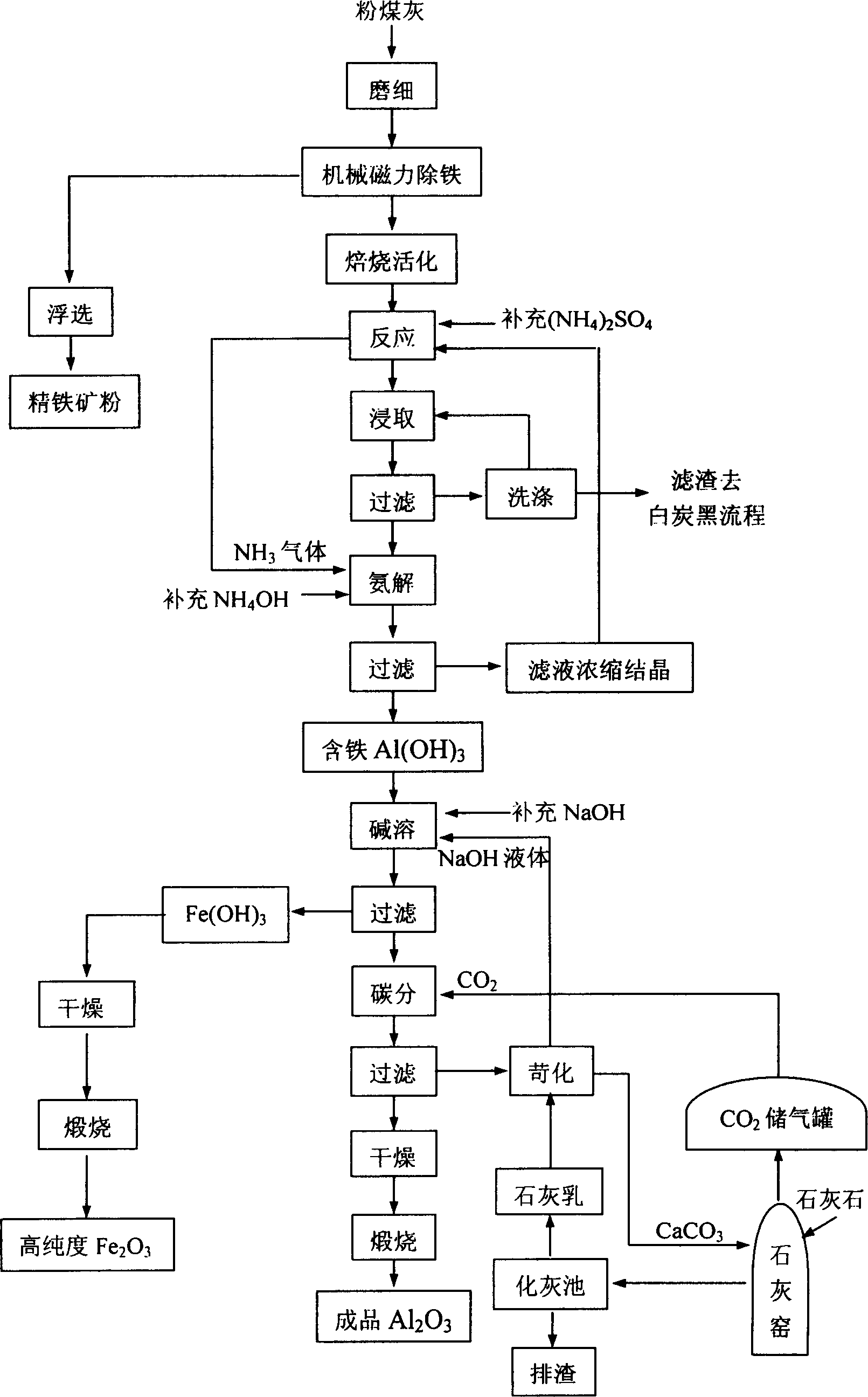

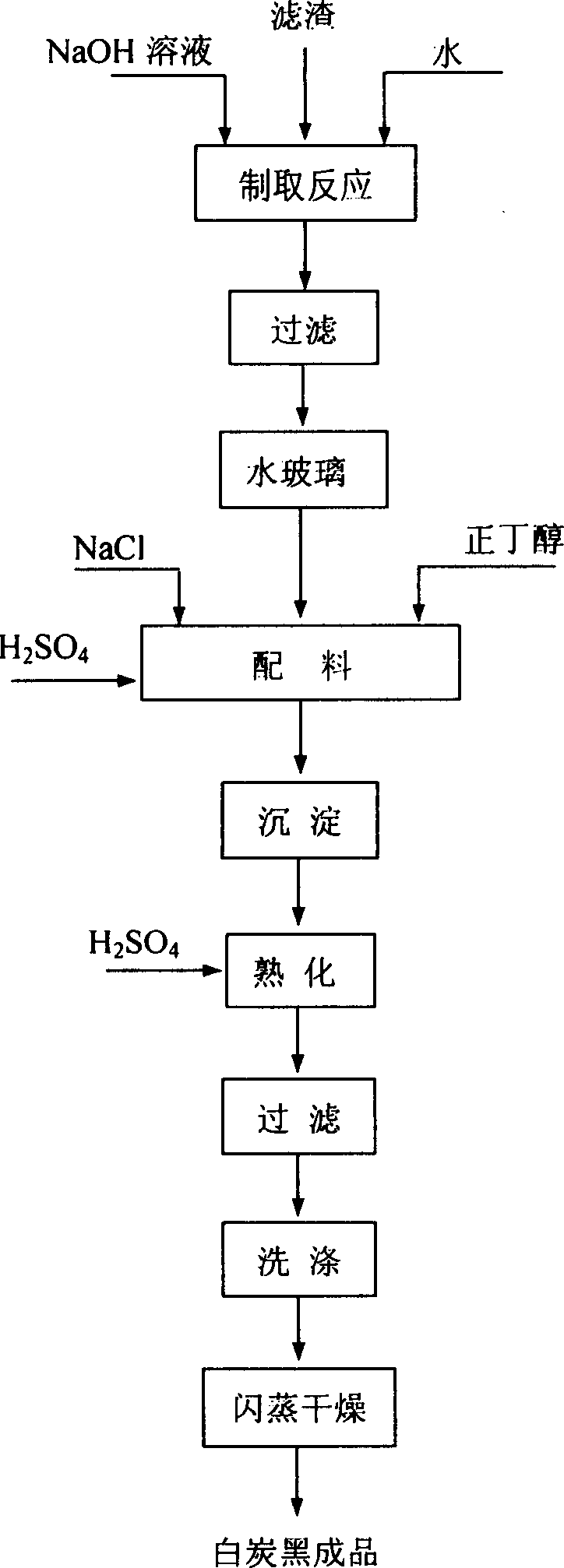

Method of extracting aluminium oxide from fly ash and simultaneously producing white carbon black

InactiveCN1868884AHigh activityUniform particle sizeSilicaAluminium oxides/hydroxidesAluminium hydroxideCoal

A process for extracting alumina from powdered coal ash while generating white carbon black includes such steps as grinding powdered coal ash, activating, adding ammonium sulfate, reacting, adding water, filtering, filling ammonia gas into the filtered liquid to obtain the deposited mixture of aluminum hydroxide and iron hydroxide, adding the solution of sodium hydroxide to dissolve the aluminum hydroxide deposit, adding carbon to obtain pure aluminum hydroxide, and calcining to obtain Al2O3.

Owner:NORTH UNITED POWER CO LTD

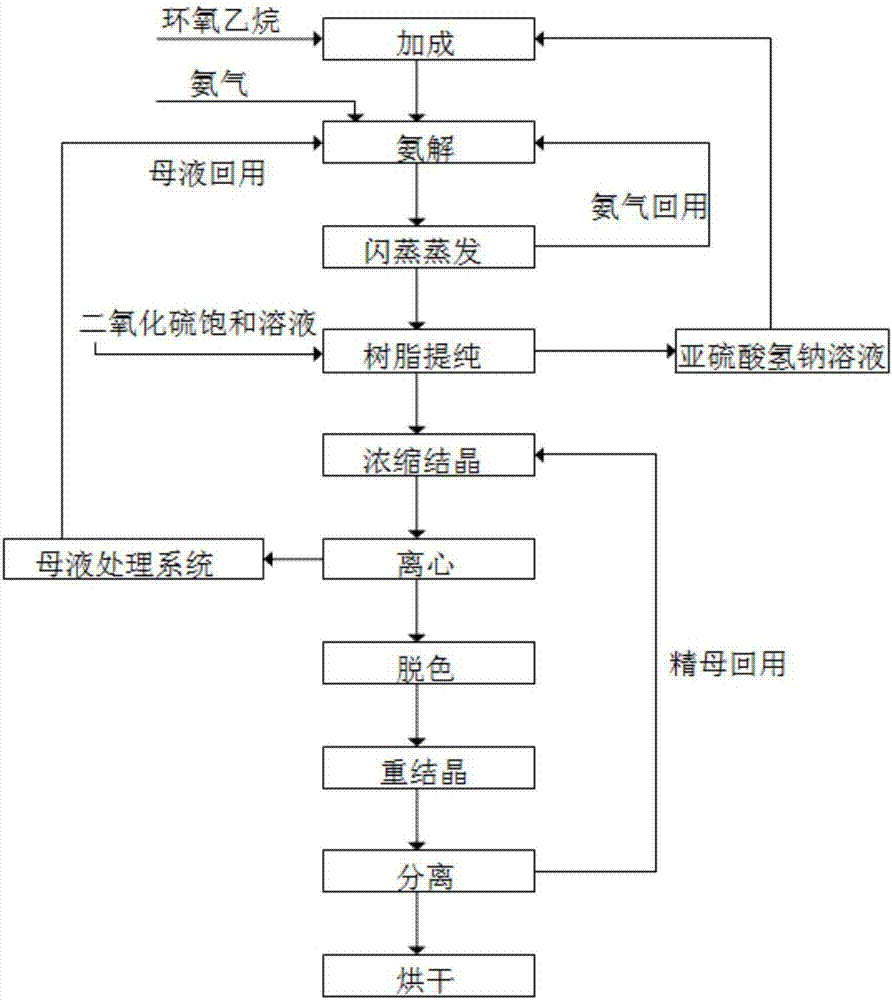

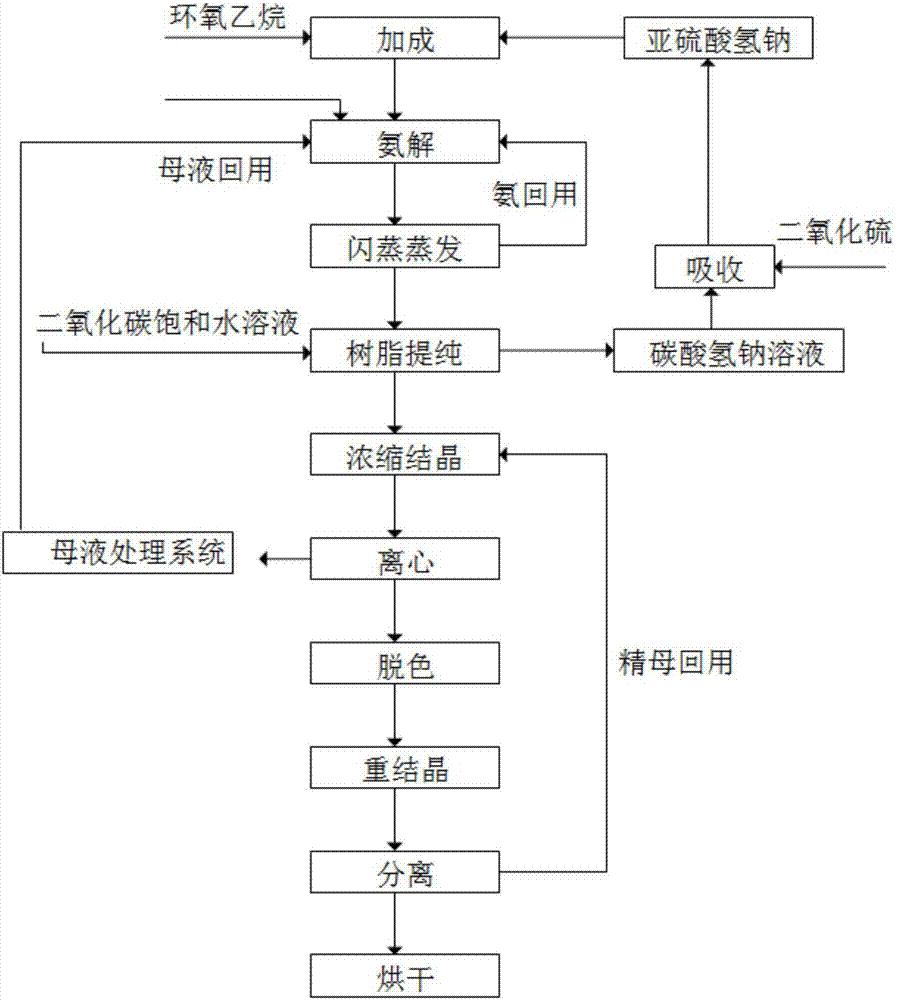

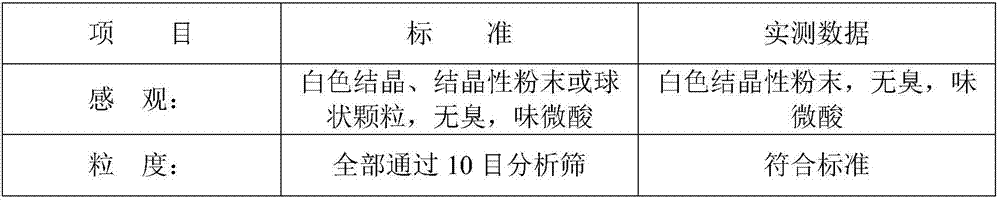

Method for cyclically producing taurine at high yield

ActiveCN107056659AReduce productionEfficient recyclingPhysical/chemical process catalystsOrganic compound preparationAfter treatmentHydrogen

The invention relates to a method for cyclically producing taurine at a high yield. The method includes the following steps that S1, ethylene oxide reacts with a sodium hydrogen sulfite solution to generate sodium hydroxyethyl sulfonate; S2, sodium hydroxyethyl sulfonate obtained in S1 is subjected to an ammonolysis reaction in ammonium hydroxide, flashing is carried out after the reaction is completed, and ammonia gas is recycled; S3, taurine-containing feed liquid of reaction liquid obtained after flashing in S2 is collected through an acid cation exchange resin column, the resin column is regenerated with a sulfur dioxide or carbon dioxide water solution after being inactivated, and eluant obtained during regeneration can be directly reused or reused after being treated with sulfur dioxide; S4, the feed liquid collected in S3 is subjected to after-treatment, and taurine is obtained. The method has the advantages that the generation amount of waste liquid in the whole process is small, part of substances are effectively and cyclically utilized in the process, the cost is reduced, the yield of taurine can reach 90% or above, meanwhile, the production process is relatively simple, and large-scale production is easy.

Owner:QIANGJIANG YONGAN PHARMA

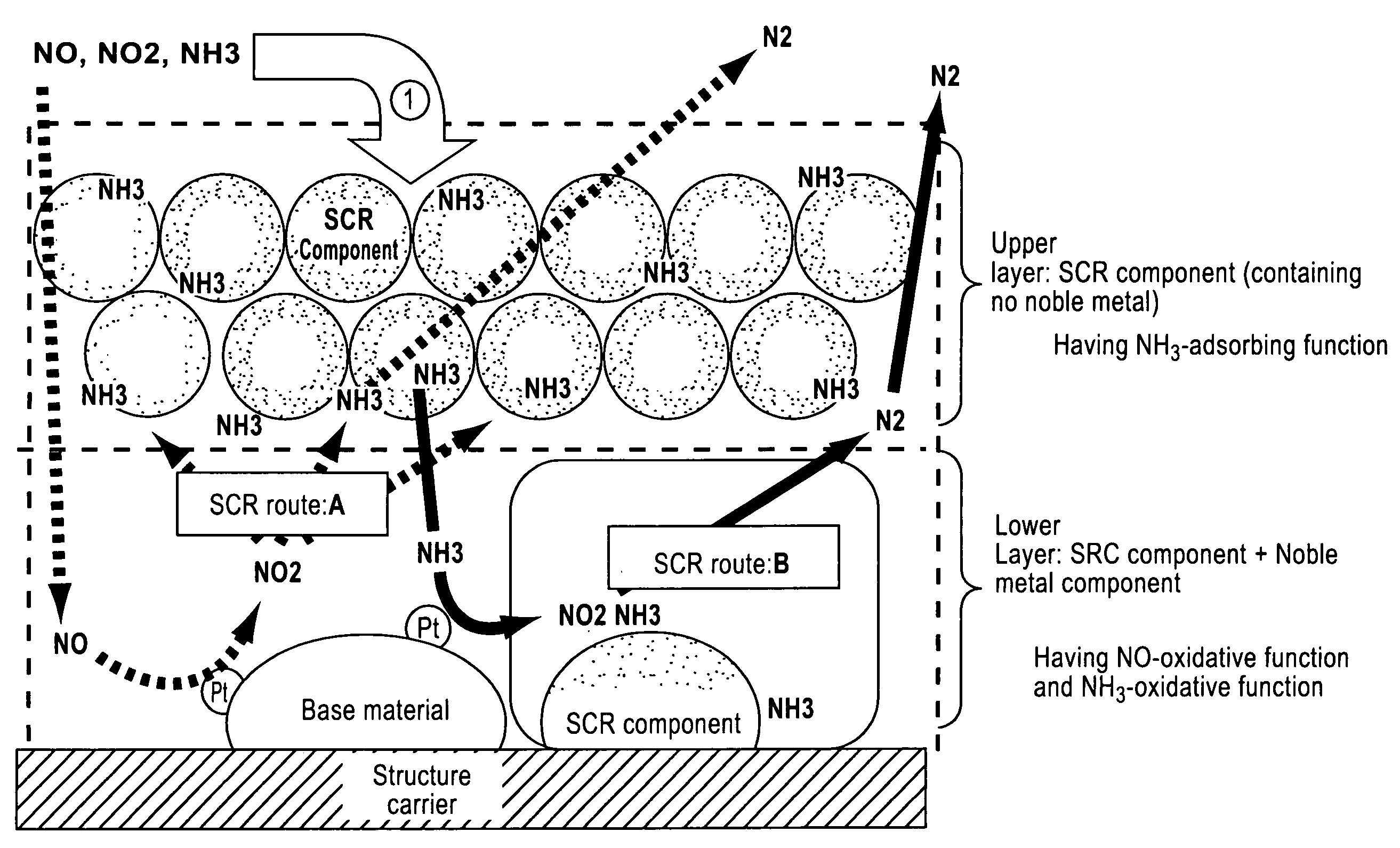

Selective catalytic reduction type catalyst, and exhaust gas purification equipment and purifying process of exhaust gas using the same

ActiveUS20080286184A1Improve purification effectImprove efficiencyGas treatmentNitrogen compoundsDiesel engineReducing agent

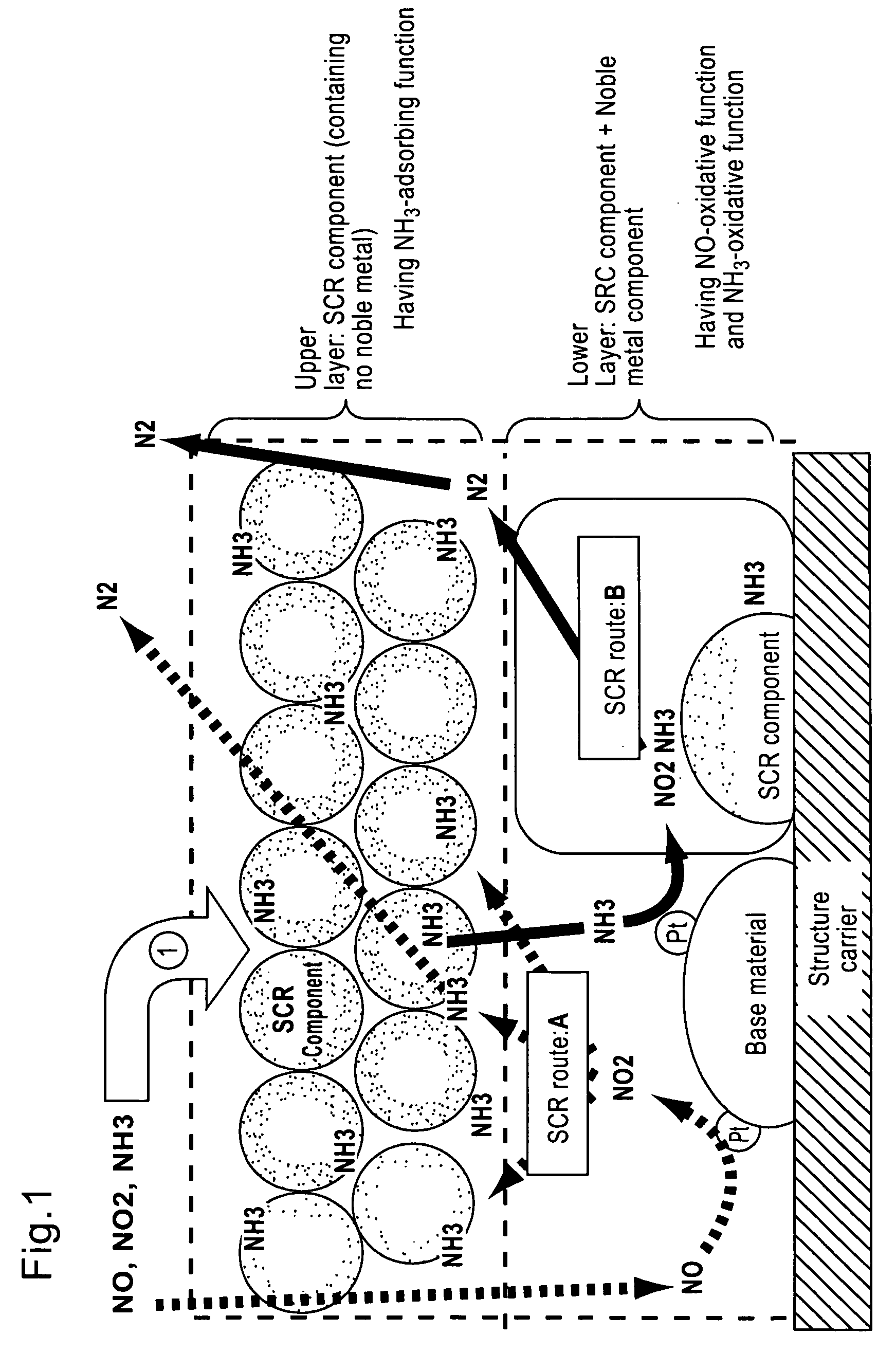

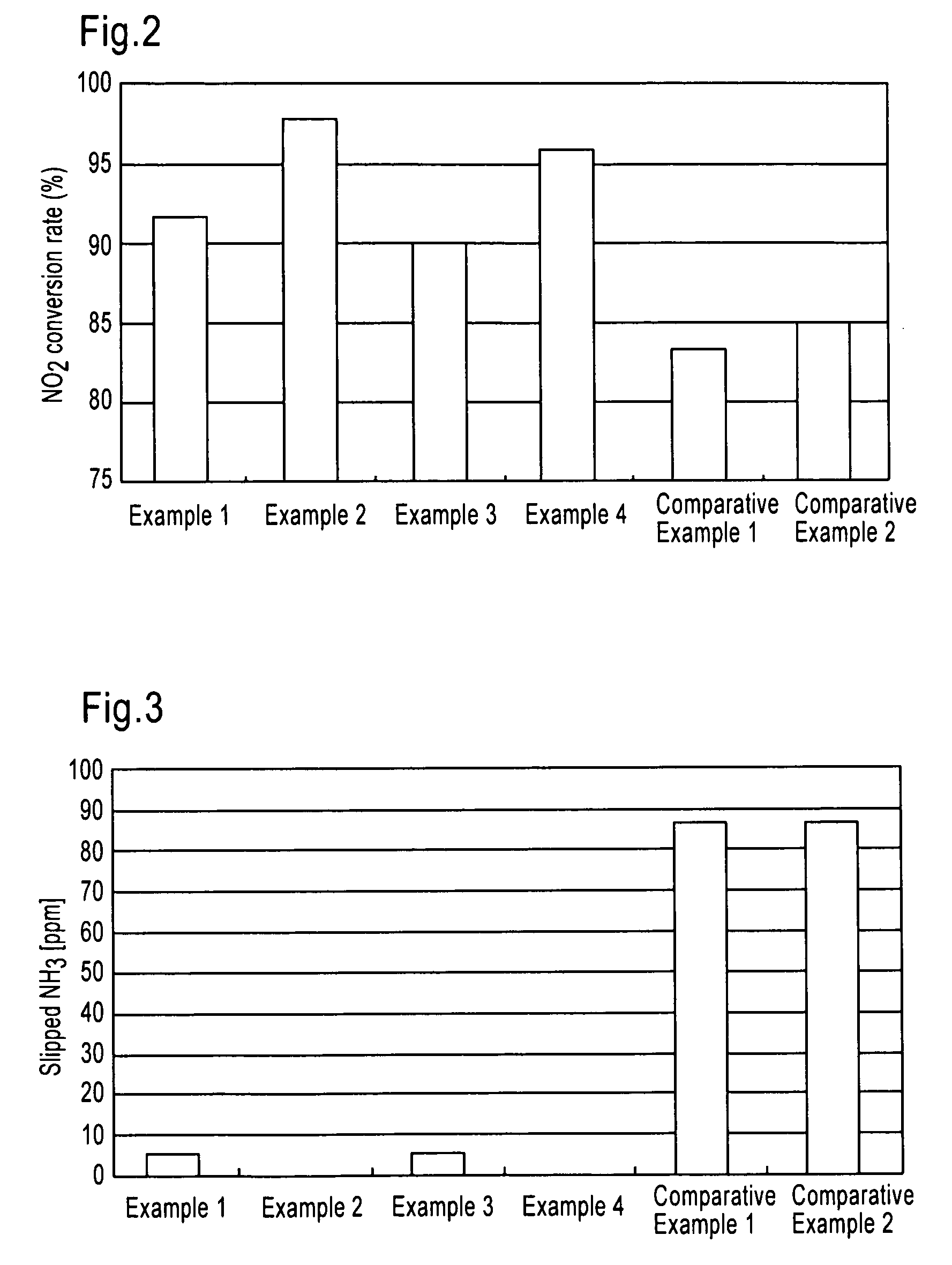

The present invention relates to a technology to purify nitrogen oxides contained in exhaust gas exhausted from lean combustion engines such as diesel engine with ammonia and a selective catalytic reduction type catalyst, and an object of the present invention is to provide a selective catalytic reduction type catalyst which can effectively purify nitrogen oxides even at a low temperature as well as inhibit leak of ammonia, and an exhaust gas purification equipment and a purifying process of exhaust gas using the same.The present invention is a selective catalytic reduction type catalyst for purifying nitrogen oxides in exhaust gas exhausted from lean combustion engines using ammonia or urea as a reducing agent, it is provided with a selective catalytic reduction type catalyst, characterized in that said catalyst comprises a lower-layer catalyst layer (A) having an oxidative function for nitrogen monoxide (NO) in exhaust gas and an upper-layer catalyst layer (B) having an adsorbing function for ammonia on the surface of a monolithic structure type carrier (C), and that the lower-layer catalyst layer (A) comprises a noble metal component (i), an inorganic base material constituent (ii) and zeolite (iii), and the upper-layer catalyst layer (B) comprises substantially none of component (i) but the component (iii).

Owner:N E CHEMCAT

Pork freshness intelligent detection device

InactiveCN101144780AFreshness identificationColor/spectral properties measurementsTesting foodDiagnostic informationLength wave

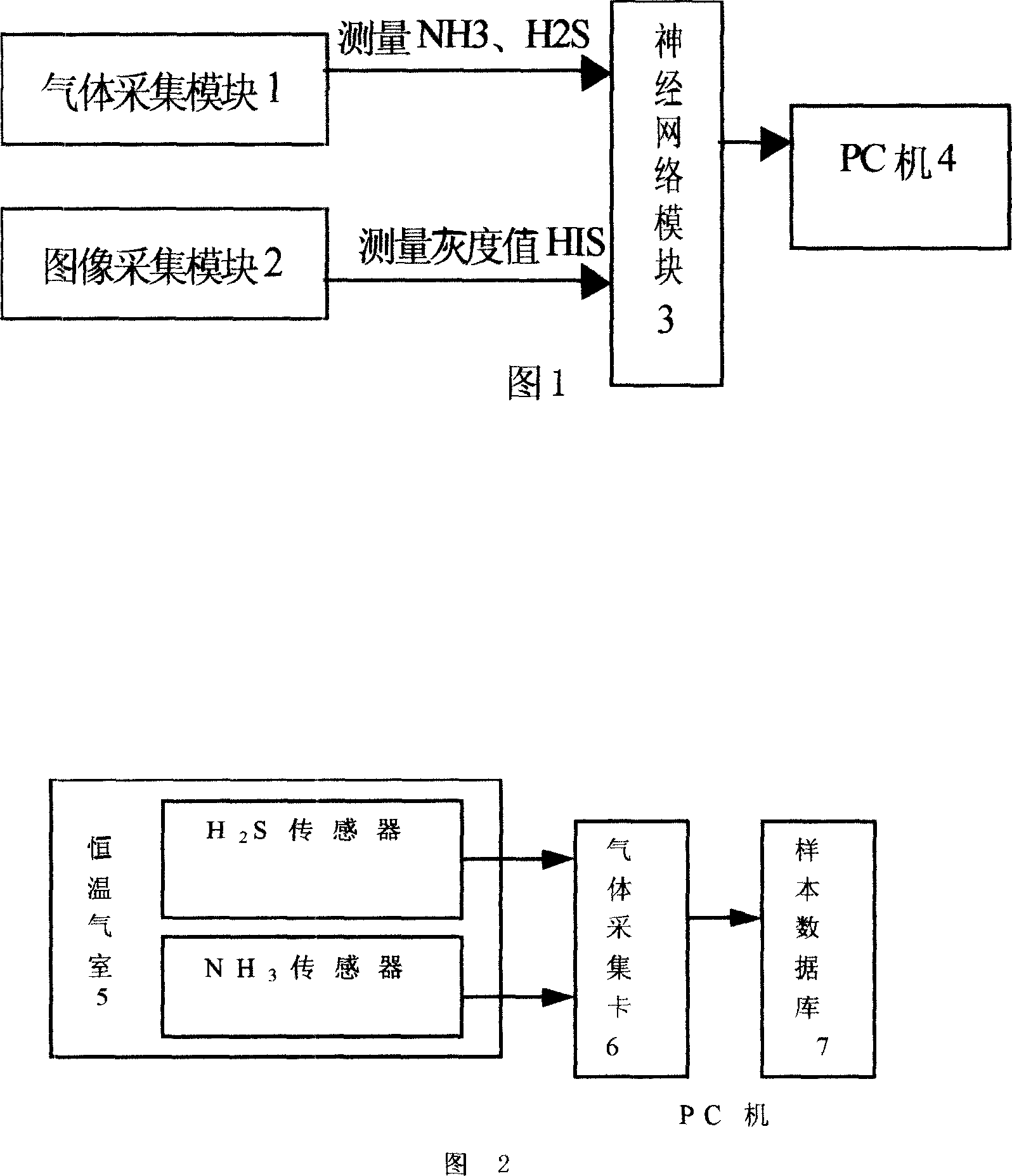

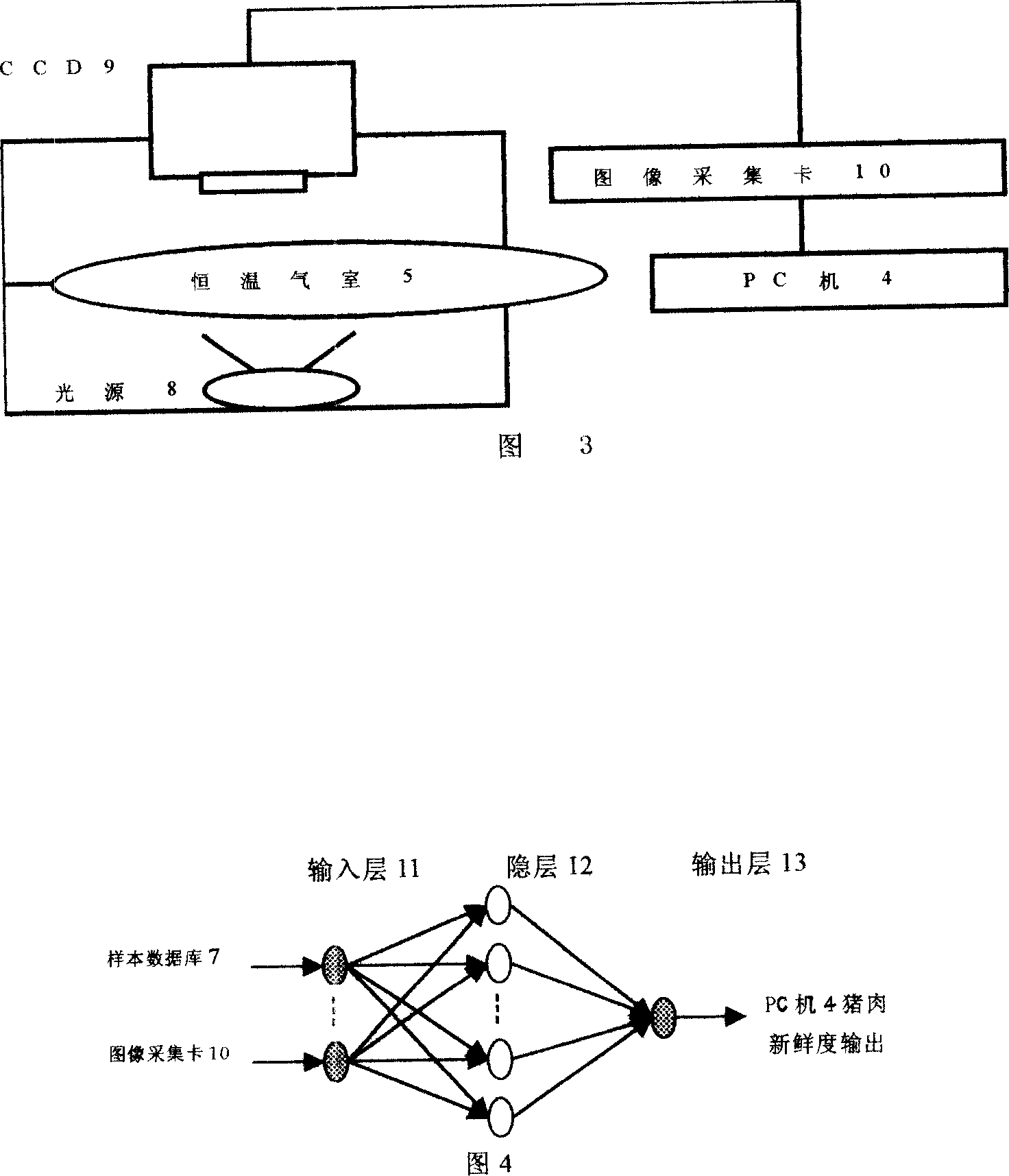

The invention discloses an intelligent pork freshness detecting device, and comprises a gas-collecting module (1), an image collecting module (2), a neural network module (3) and a computer (4), which are connected mutually through a leading wire. The gas-collecting module (1) collects a released ammonia gas (NH 3 ) and a hydrosulfuric acid gas (H 2 S) during the metamorphic process of the pork; the image collecting module (2) collects a diagnostic information of a relative gray-scale value (H, S, I) of a diagnostic wavelength of a specific element during the metamorphic process of the pork; H, S, and I are respectively a brightness, a chrominance and a saturation; the released ammonia gas and the hydrosulfuric acid during the metamorphic process of the pork, and the relative gray-scale value of H, S and I are inputted in the neural network module (3). The grade of the freshness of the pork is gained through the interfusion of a plurality of data, and can be displayed on the screen of the PC computer (4). The invention has the advantages that the fast detecting on site can be achieved, and the freshness of the pork can be identified expediently, quickly and effectively.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

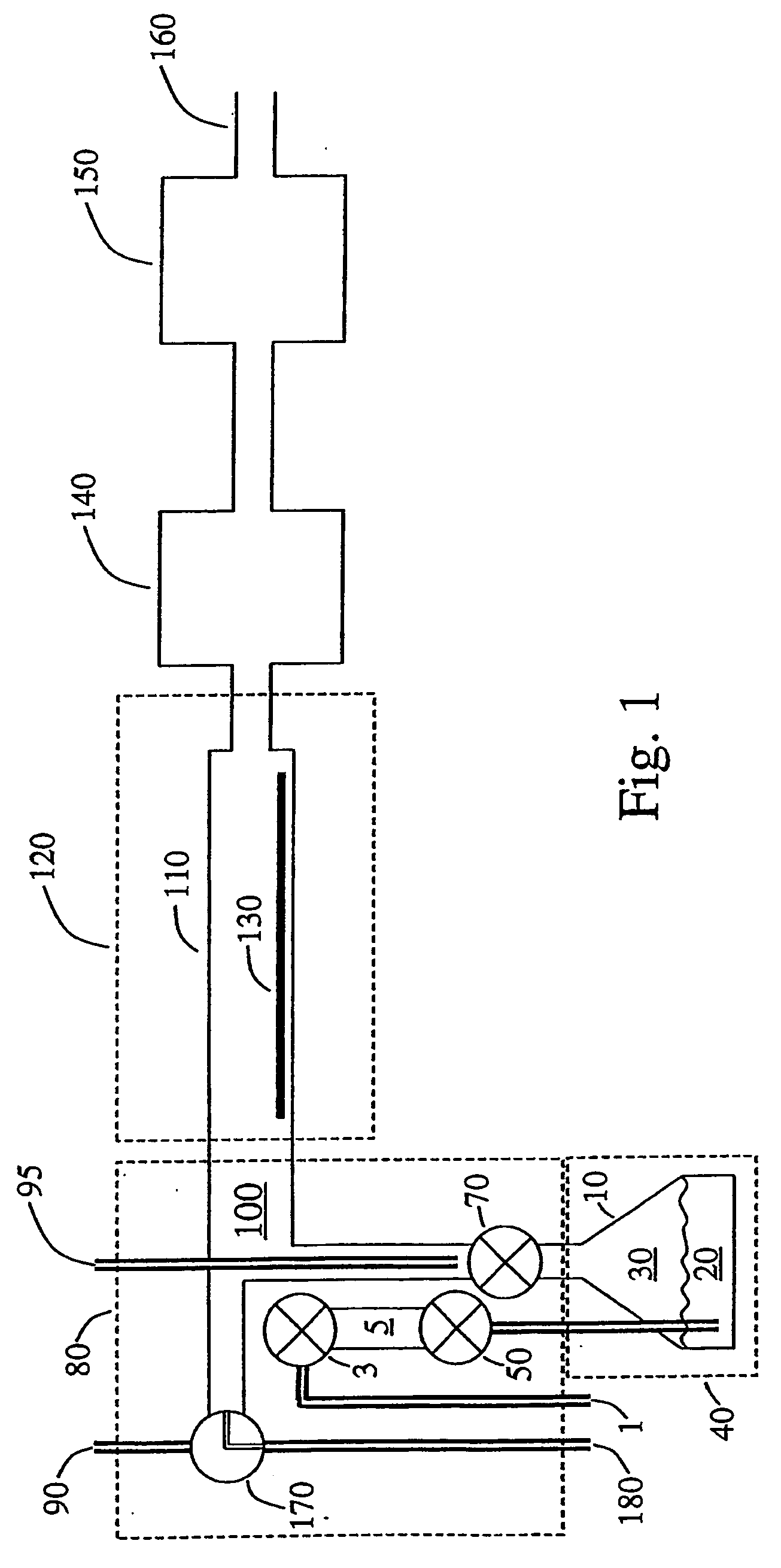

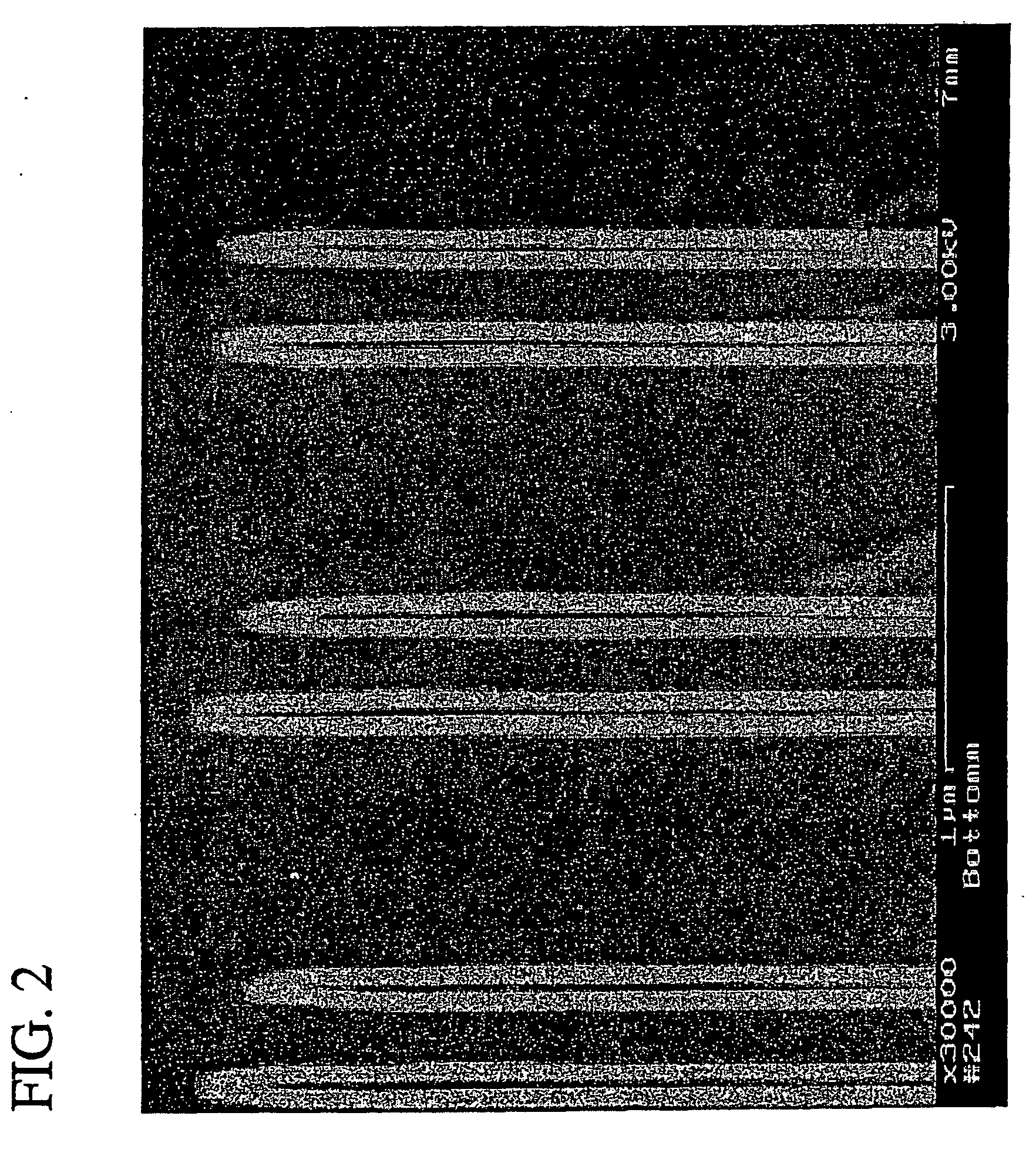

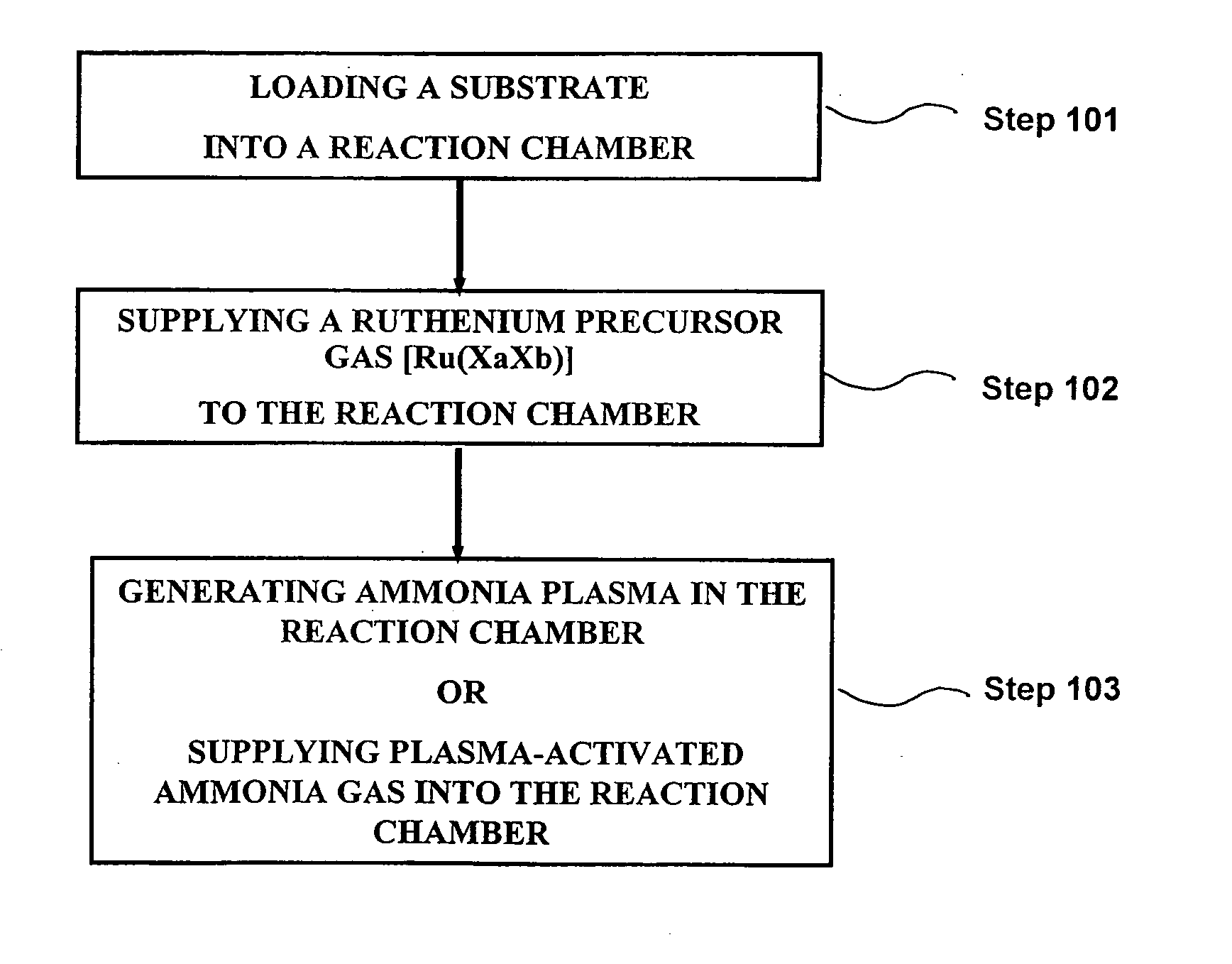

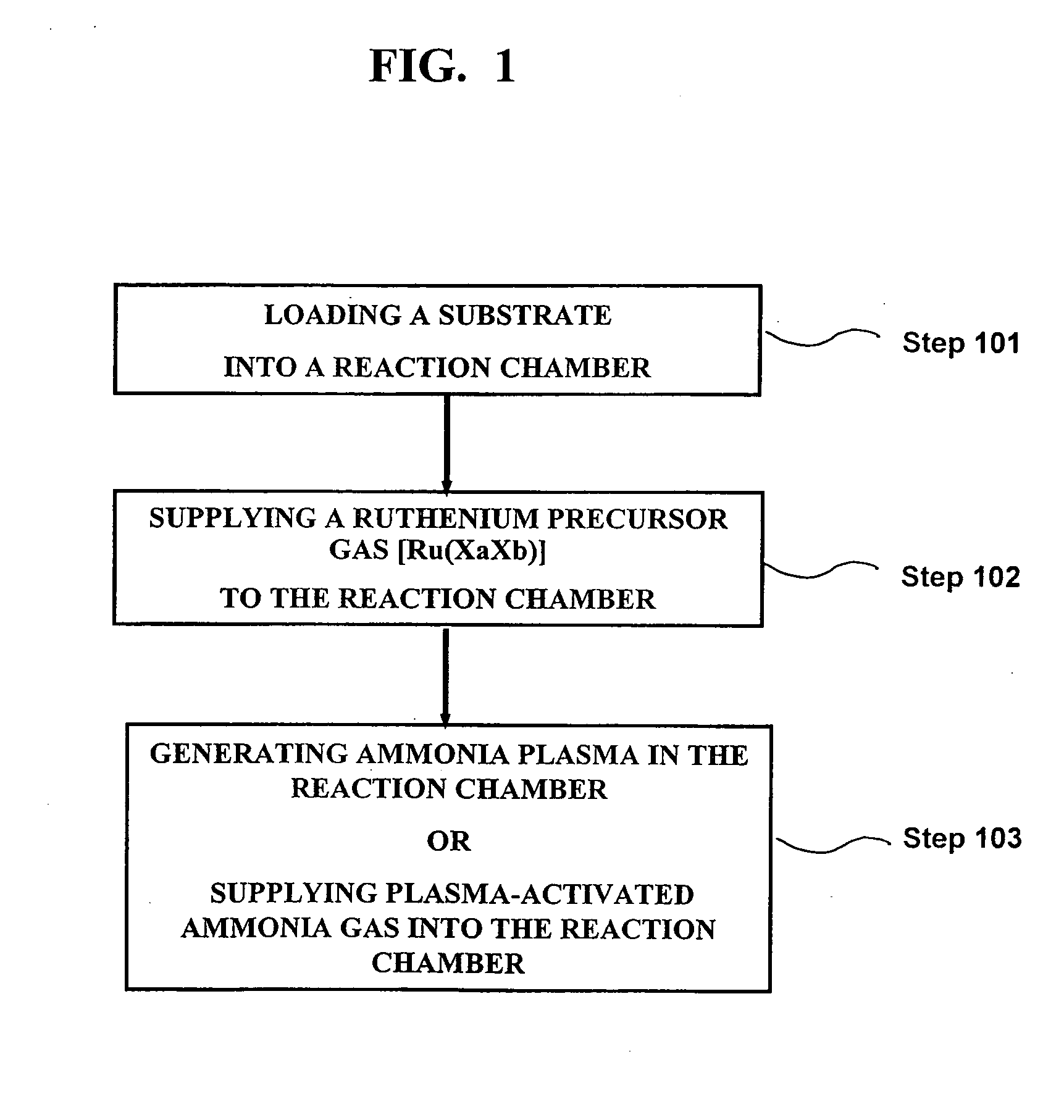

Method of forming a ruthenium thin film using a plasma enhanced atomic layer deposition apparatus and the method thereof

A method of depositing a ruthenium(Ru) thin film by using readily available ruthenium precursors such as Ru(CP)2 and Ru(EtCP)2, ammonia gas(NH3) as a reactant gas or a purge gas or both, and a plasma enhanced atomic layer deposition(PEALD) apparatus and the method thereof, according to the present invention, is disclosed. Also a gas mixture of nitrogen gas(N2) and hydrogen(H2) is used as a reactant gas or a purge gas or both in addition to ammonia gas in depositing a ruthenium thin film according to the present invention. A ruthenium(Ru) thin film of high density, very pure, very smooth on the film surface and uniform is deposited even at the temperature of the reaction chamber below 400° C. using ammonia gas and a gas mixture of nitrogen gas and hydrogen gas, respectively, as a reactant gas under plasma.

Owner:ASM GENITECH KOREA +1

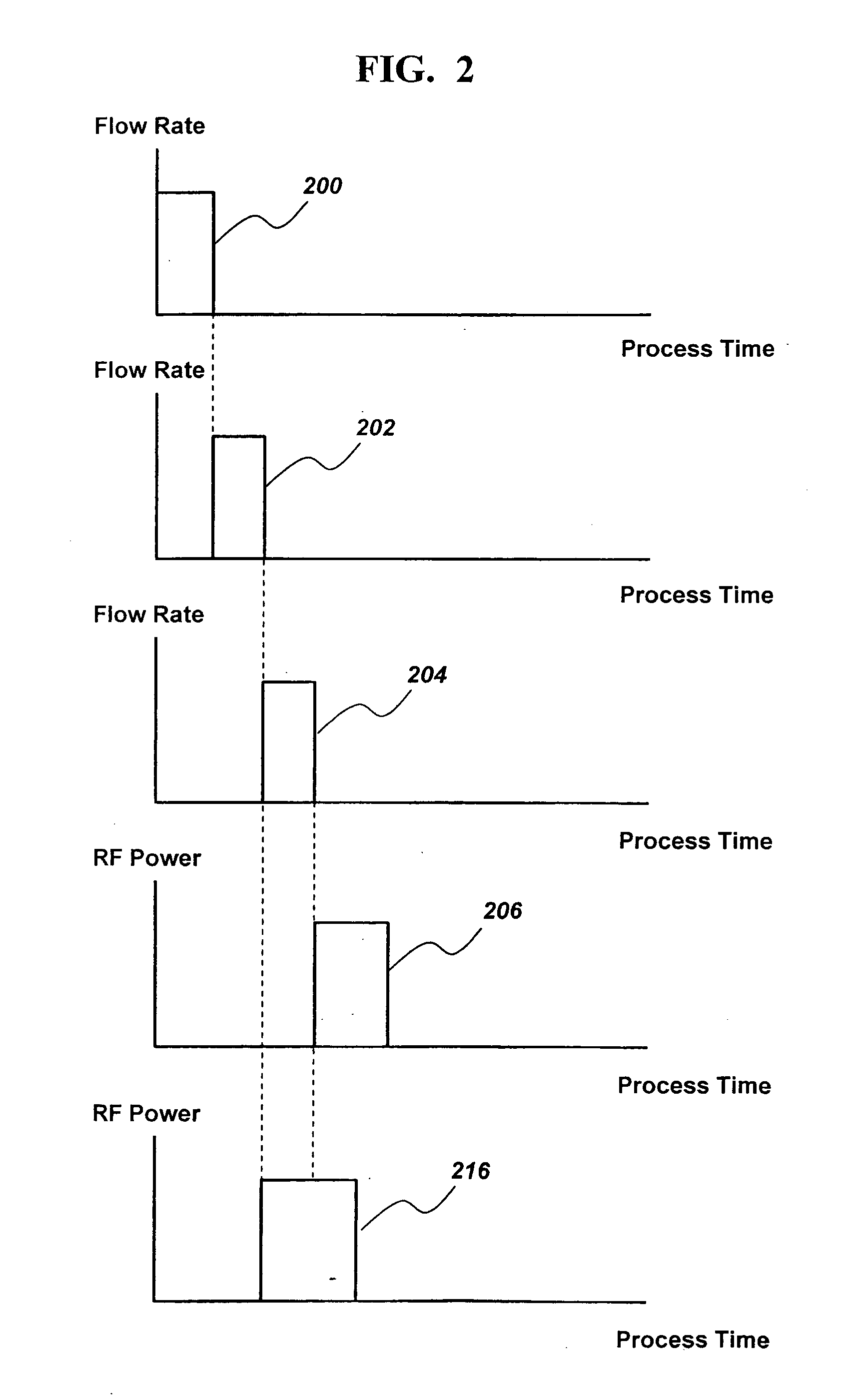

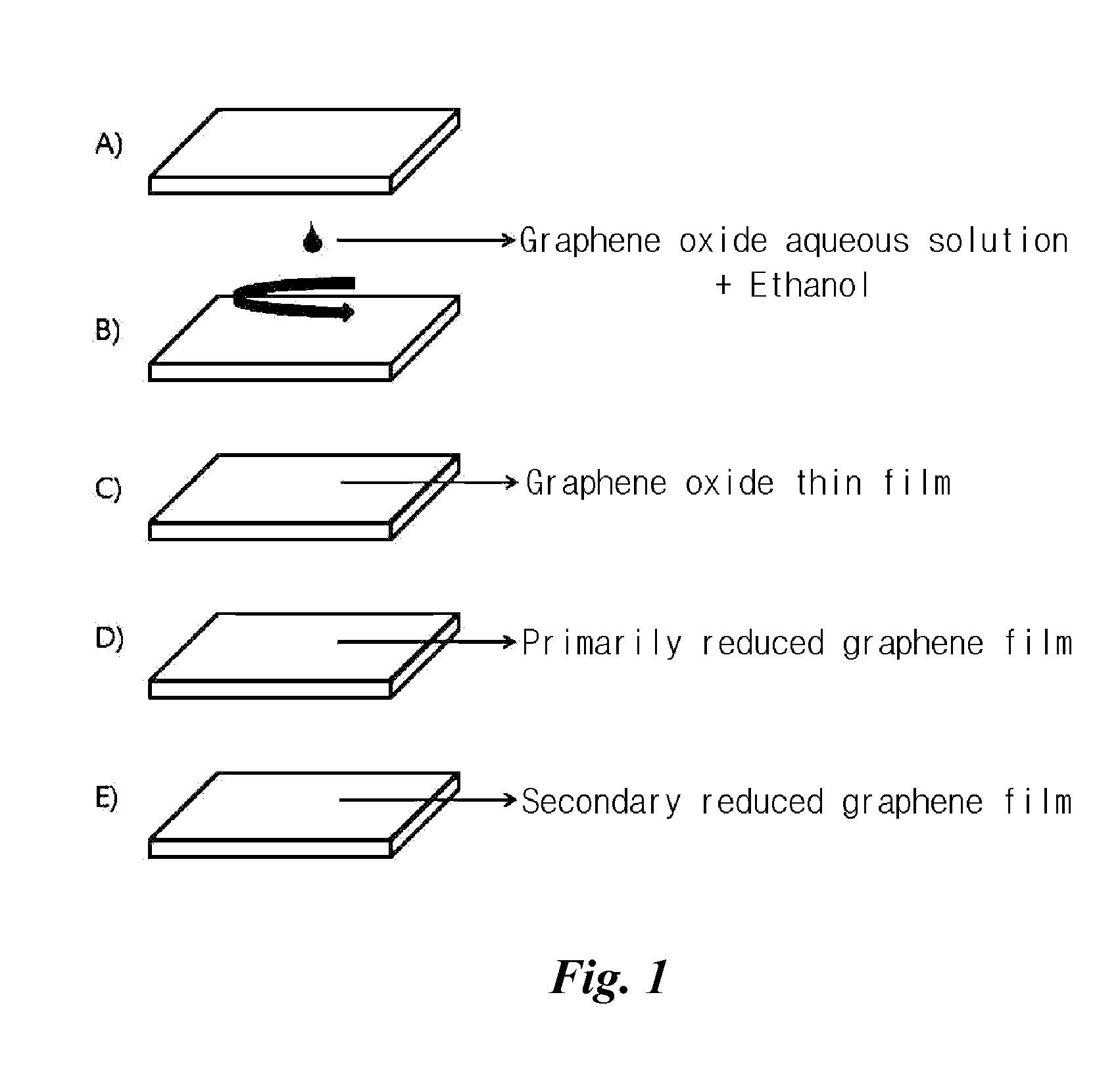

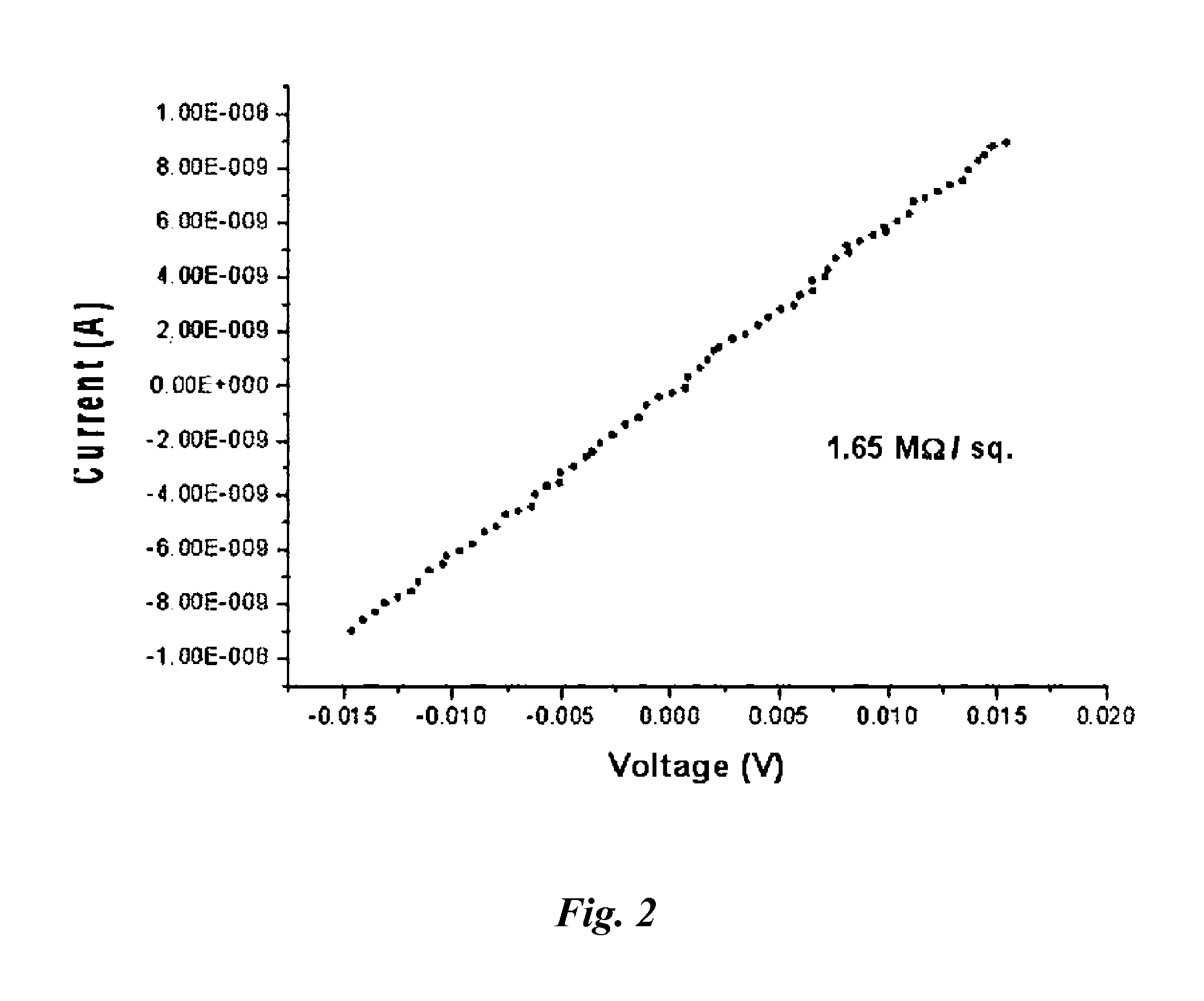

Nitrogen-doped transparent graphene film and manufacturing method thereof

ActiveUS20120161192A1Increase flexibilityGood electrical propertiesMaterial nanotechnologySynthetic resin layered productsHydrogenWork function

Provided is a transparent graphene film which is prepared by maintaining the primary reduced state of a graphene oxide thin film via chemical reduction, reducing the graphene oxide thin film with chemical vapor deposition, and doping nitrogen, thereby enhancing the conductivity and enabling the control of work function and a manufacturing method thereof. According to the present disclosure, a flexible, transparent, electrical conductivity-enhanced, and work function controllable graphene film can be large area processed and produced in large quantities so that can be applied in real industrial processes by forming a graphene oxide thin film on a substrate, performing the primary chemical reduction using a reducing agent, and performing further the secondary thermal reduction and nitrogen doping by injecting hydrogen and ammonia gas through chemical vapor deposition equipment.

Owner:KOREA ADVANCED INST OF SCI & TECH

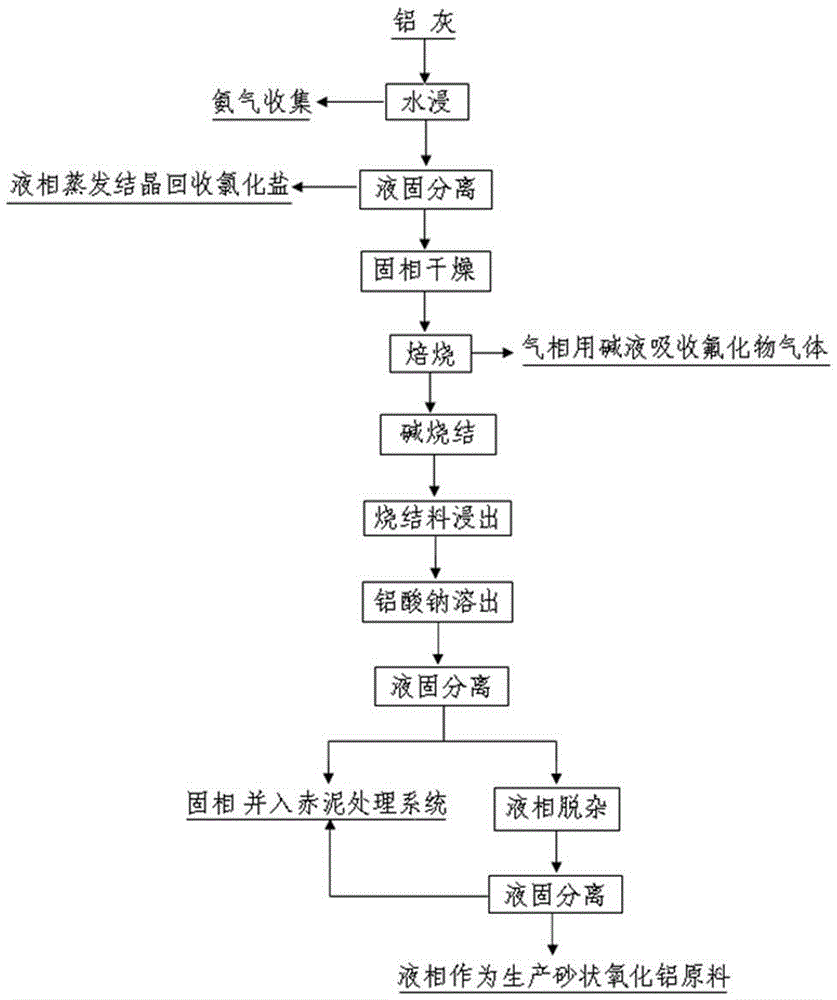

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

Preparation method of composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions

ActiveCN104294583ASimple methodGood antibacterial, anti-ultraviolet and deodorizing propertiesLight resistant fibresWrinkle resistant fibresStaphylococcusHydrogen

The invention discloses a preparation method of a composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions. The preparation method comprises the steps of preparing an activated modified treatment liquid, preparing a nano-titania dispersion liquid, processing fabrics by virtue of the activated modified treatment liquid, processing the fabrics by virtue of the nano-titania dispersion liquid, and the like. After the composite functional fabric is processed, the UPF value is more than 100, the deodorization rate is more than 95%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 96.7%, and the antibacterial rate (to staphylococcus) is 98.6%; after the composite functional fabric is washed for ten times in families, the UPF value is more than 50, the deodorization rate of the composite functional fabric to substances (including ammonia gas, formaldehyde, acetaldehyde, sulfureted hydrogen, nicotine and trimethylamine) is more than 90%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 93.9%, and the antibacterial rate (to staphylococcus) is 95.8%.

Owner:江苏巧雅纺织科技有限公司

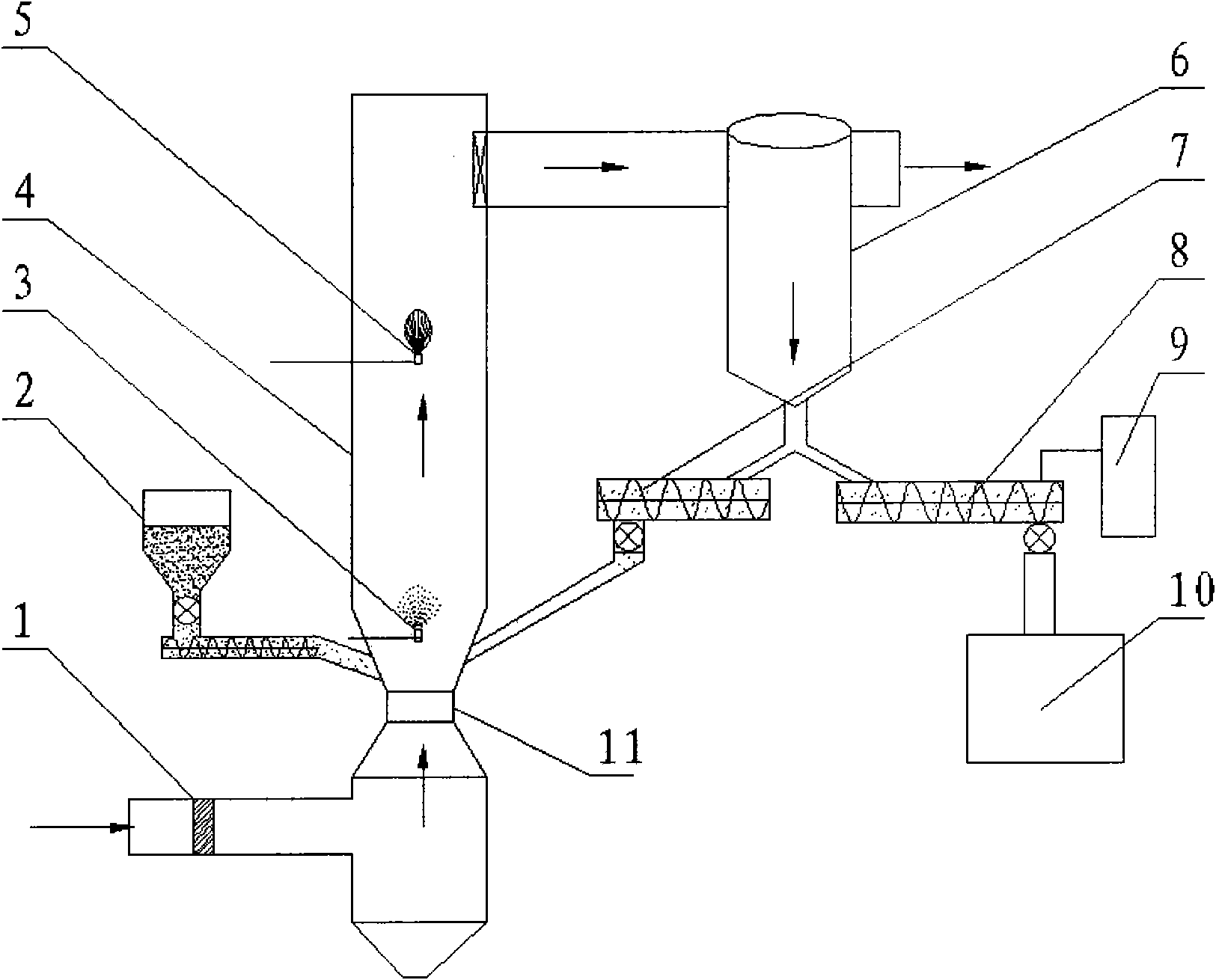

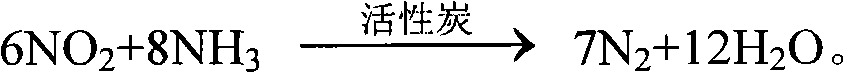

Fluidized activated carbon combined desulfurization and denitrification process

InactiveCN101856587AEfficient use ofSimple processDispersed particle separationAir quality improvementActivated carbonMicrowave

The invention relates to a fluidized activated carbon combined desulfurization and denitrification process, which comprises the following steps that: flue gas containing SO2 and NOx is mixed with activated carbon in a fluidized state, the temperature of the flue gas is adjusted by temperature-regulating and humidifying water, and SO2 is absorbed, oxidized and removed at the lower part of a circulating fluidized bed reaction tower; ammonia gas is injected into the upper part of the reaction tower and is reacted with NOx in the flue gas to realize the removal of the NOx; the purified flue gas passes through a gas-solid separation device which separates the activated carbon, part of the activated carbon is sent into the circulating fluidized bed reaction tower, and part of the activated carbon flows into a spiral microwave regeneration unit, so that the activated carbon is regenerated to realize the recycling of the activated carbon. The fluidized activated carbon combined desulfurization and denitrification process of the invention realizes the efficient recycling of the activated carbon and improves the reliability of a system.

Owner:SHANDONG UNIV

Method for harmless disposal and recycling of aluminum ash

ActiveCN105271327ATo achieve the purpose of comprehensive recycling of resourcesGreat social valueAmmonia preparation/separationAluminium oxides/hydroxidesMetallic aluminumSodium aluminate

The invention discloses a method for harmless disposal and recycling of aluminum ash. The method comprises steps of raw material water immersion nitrogen and chlorine removal, calcination fluorine removal, alkali fusion sintering, sintering material dissolving-out and purifying impurity removal. Aluminum ash generated in metal aluminum smelting process is employed as a raw material, after metal aluminum is recycled through secondary processing, nitrides are removed through water immersion, fluorides are removed through calcinations, alkali fusion sintering is carried out, the sintering materials are dissolved out, impurities are removed through a sodium aluminate solution, the processed aluminum ash is employed as a raw material for producing sand-shaped aluminum oxide. Ammonia gas generated in the aluminum ash harmless disposal process can be employed as an ammonium production raw material, a chlorination liquid generated can be employed as a chlorate production raw material, and silicon fluoride gas generated in the calcination process is absorbed by an aqueous solution. The method is simple and practical, environmental protection benefits are high, the production efficiency is high, the device investment is low, and energy consumption is low. Harmless and recycling disposal of hazardous wastes can be achieved. The obtained product can be applied in practical production.

Owner:YUNNAN WENSHAN ALUMINUM

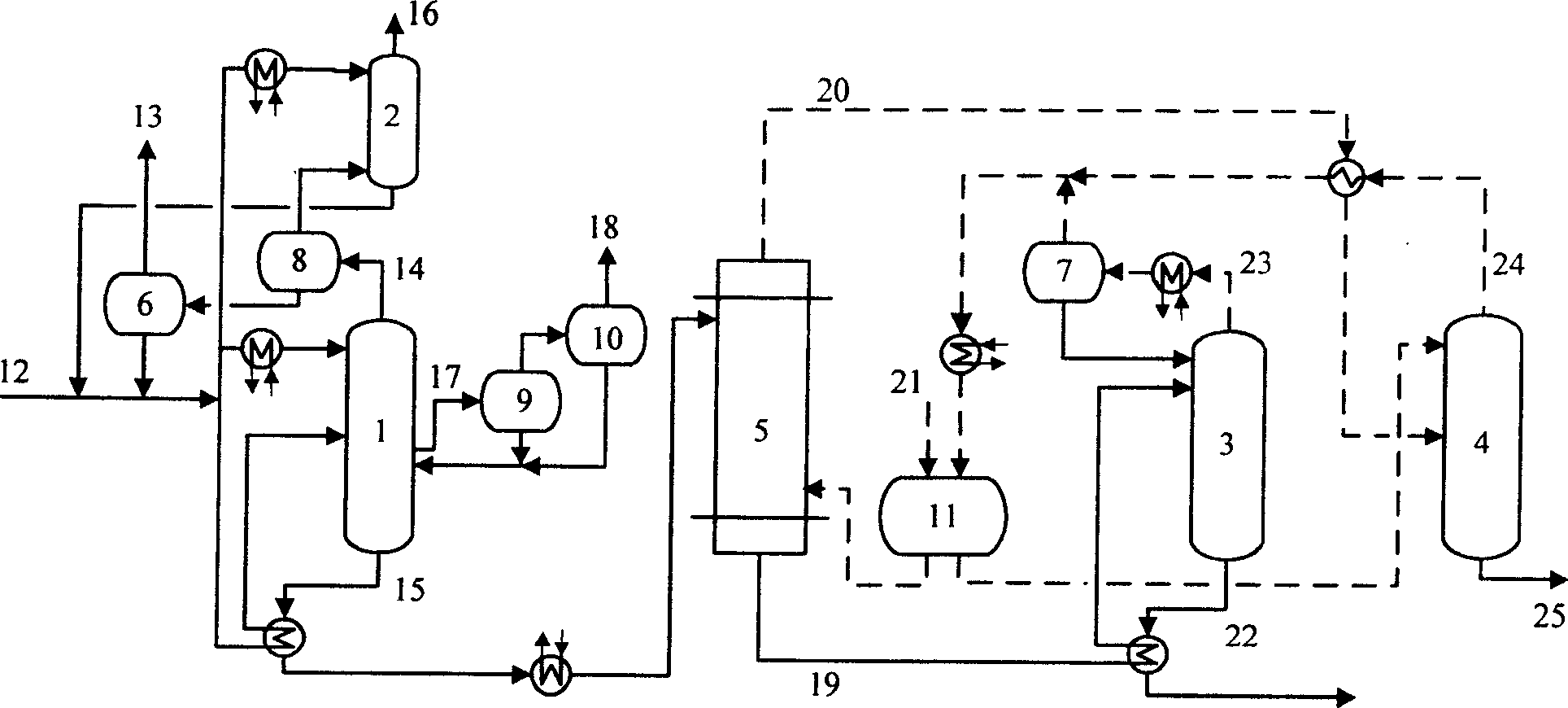

Method for treating coal gasification wastewater by single-tower pressurization stripping and device therefor

InactiveCN1884150AHigh removal rateReduce crystallizationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentCoal gasification wastewaterOrganic solvent

The invention discloses a gasification wastewater disposing method and device through single-tower pressurizing stripping, which comprises the following steps: entering the extracted of acid gas or ammonia gas of cold and hot coal gasification wastewater from band lateral line in the stripping tower from top and upper top; blending gas; dividing phases; washing; separating light oil and acid gas; preparing liquid ammonia through two-grade concreting and refining; separating crude phenol and organic solvent from bottom of tower through inversed-extracting autoclave liquid and organic solvent; recycling organic solvent through stripping. The gasification disposing device contains oil acid gas / ammonia stripping tower, extracting tower, acid gas washing tower, solvent stripping tower, solvent recycling tower, oil-water separator, dephlegmator, pump and reservoir.

Owner:SOUTH CHINA UNIV OF TECH

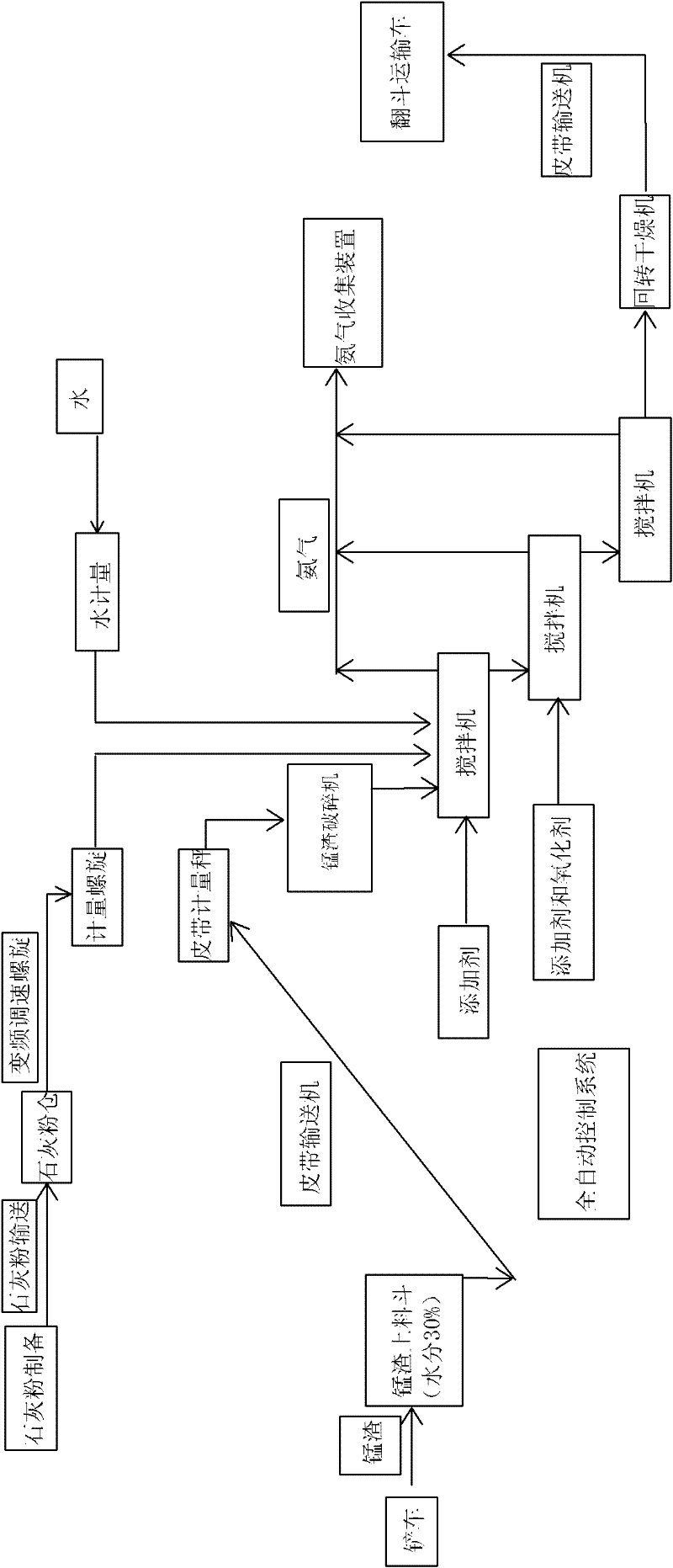

Innocent treatment method of electrolytic manganese slag

InactiveCN102161048AInhibition releaseAvoid diversionSolid waste disposalTreatment effectElectrolysis

The invention discloses an innocent treatment method of electrolytic manganese slag. The method comprises the following steps of: (1) weighing manganese slag accurately with metering equipment and crushing the manganese slag; (2) adding the crushed manganese slag into a blender; adding calcium oxide powder and water into the manganese slag, adding a certain amount of silicate additives into the mixture, stirring the mixture to form a uniform mixed material, and recovering ammonia gas; (3) after unloading the mixed material, transferring the mixed material into another blender, adding a certain amount of water soluble resin sulfosalt additives and ferric chloride, stirring again and recovering the ammonia gas; and (4) after stirring and unloading the material, transferring the material into a third blender, fully stirring, recovering the ammonia gas, drying the material in a turnover dryer, controlling the water content of the mixed material, and performing landfill treatment after drying. The method has a wide raw material source, an excellent treatment effect, a simple technical technology, high product strength and high durability; an environmental potential hazard caused in a manganese slag stacking process is eliminated; and the investment cost of an enterprise is reduced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

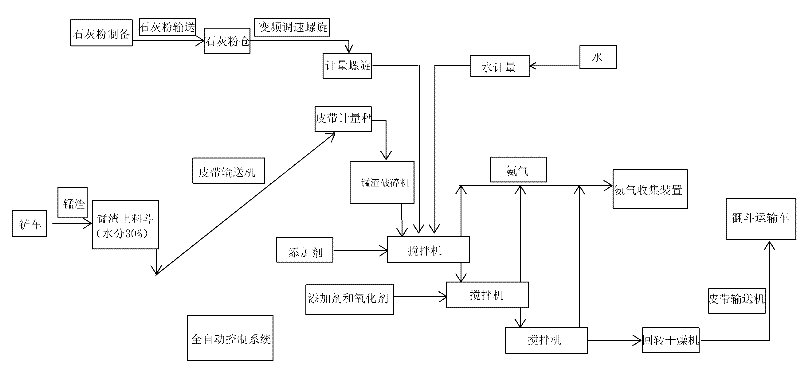

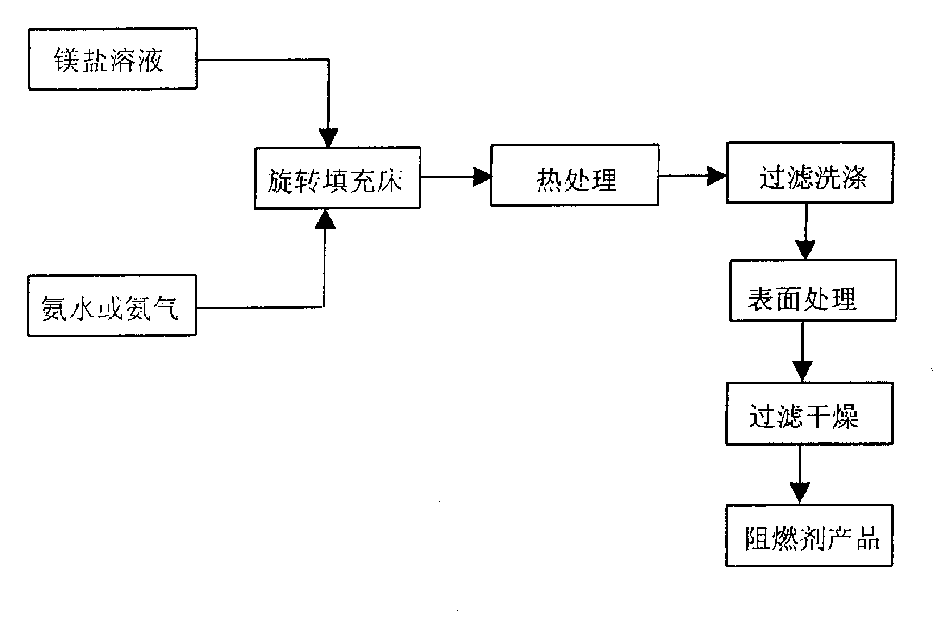

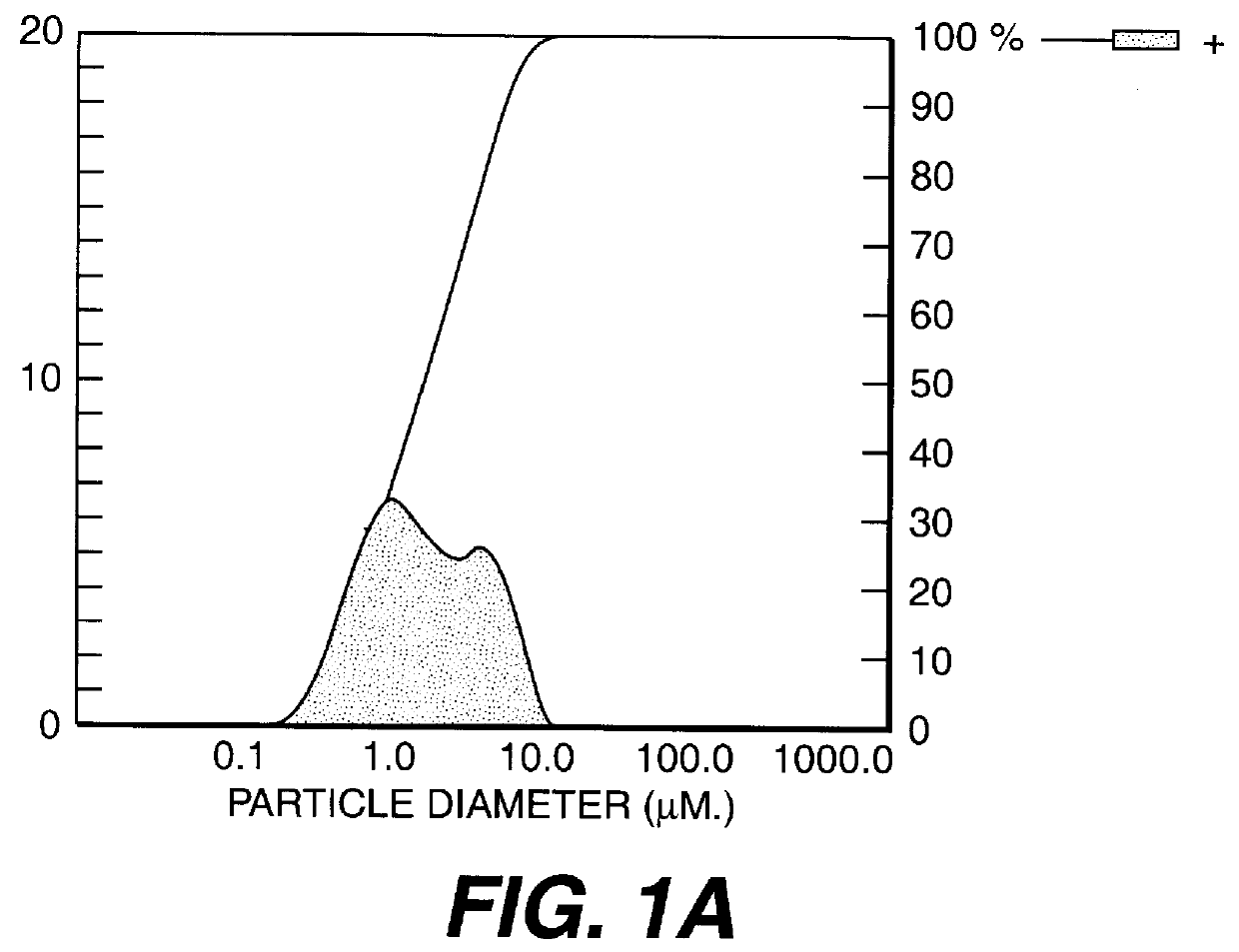

Preparation process of magnesium hydroxide fire-retarding nanomaterial

The present invention mainly is characterized by that it uses the magnesium chloride solution obtained by utilizing old bitter or magnesite through a refining process and industrial ammonia water or ammonia gas as raw material, or utilizes magnesium sulfate solution and industrial ammonia water or ammonia gas as raw material. Ultragravity (rotaryl filled bed) technology is adopted and utilizes liquid-liquid phase reaction or gas-liquid phase reaction mode is utilized to prepare nanometer magnesium hydroxide fire-retardant material. Said invention solves the defects of traditional process, such as complex process, high cost, non-uniform grain size and difficult control, etc.

Owner:BEIJING UNIV OF CHEM TECH

Calcium carbonate precipitation method

InactiveUS6036933ACalcium/strontium/barium carbonatesMagnesium carbonatesNitratePrecipitated calcium carbonate

PCT No. PCT / GB96 / 00488 Sec. 371 Date Oct. 22, 1997 Sec. 102(e) Date Oct. 22, 1997 PCT Filed Mar. 1, 1996 PCT Pub. No. WO96 / 26902 PCT Pub. Date Sep. 6, 1996A method for producing precipitated calcium carbonate by reacting an aqueous solution of calcium nitrate [Ca(NO3)2] with an aqueous solution of ammonium carbonate [(NH4)2CO3] and allowing calcium carbonate to precipitate from the resultant mixture containing nitrate [NH4NO3] in the mother liquor, the process being characterized in that: (i) the calcium nitrate [Ca(NO3)2)] solution utilized in the processes is prepared by slaking lime [CaO] in water in the presence of ammonium nitrate [NH4NO3] to form calcium nitrate [Ca(NO3)2] and ammonium hydroxide [NH4OH] in solution, filtering the solution to render it solids free, and heating the filtrate to dissociate the ammonium hydroxide [NH4OH] and to drive ammonia gas [NH3] from the solution; (ii) the ammonium carbonate (NH4)2CO3 solution utilized is prepared by absorbing ammonia gas [NH3] and carbon dioxide gas [CO2] in water, the ammonia gas preferably being derived from the step in (i) above in which the Ca(NO3)2 solution is heated; and (iii) the ammonium nitrate used is derived from the precipitation phase during which calcium carbonate is precipitated from the mother liquor containing ammonium nitrate.

Owner:PRETORIA PORTLAND CEMENT COMPANY +1

Method for determining deleterious bacterial growth in packaged food utilizing hydrophilic polymers

InactiveUS6149952AMaximize likelihoodMaximize possibilityMicrobiological testing/measurementConfectioneryHydrophilic polymersHydrophobic polymer

The present invention relates to a method for determining the presence or absence of contaminating bacteria in a packaged food sample comprising storing food in a package having as a lining a hydrophilic polymeric composition, said composition preferably being permeable to water and at least one gas dissolved in water or water vapor and being selected from the group consisting of carbon dioxide, carbon monoxide, hydrogen sulfide, sulfur dioxide, hydrogen and ammonia gas and containing an indicator for detecting the presence or abscence of said gas; said indicator being polymerized or dispersed throughout said polymeric composition or coated onto a hydrophobic polymeric composition.

Owner:INDICATOR SYST INT

Method of CVD for forming silicon nitride film on substrate

InactiveUS7094708B2Improve controllabilityLow process temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyAmmonia gas

A CVD method is to form a silicon nitride film on a target substrate (W). The method includes heating the substrate (W) accommodated in a process container (8), at a process temperature, and supplying a process gas including hexaethylamino-disilane gas and ammonia gas onto the substrate (W) heated at the process temperature, thereby depositing a silicon nitride film on the substrate (W).

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com