Fluidized activated carbon combined desulfurization and denitrification process

An activated carbon and process technology, applied in the field of fluidized activated carbon combined desulfurization and denitrification process, can solve the problems of high system operating cost, increased initial equipment investment, complex process equipment, etc. Promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

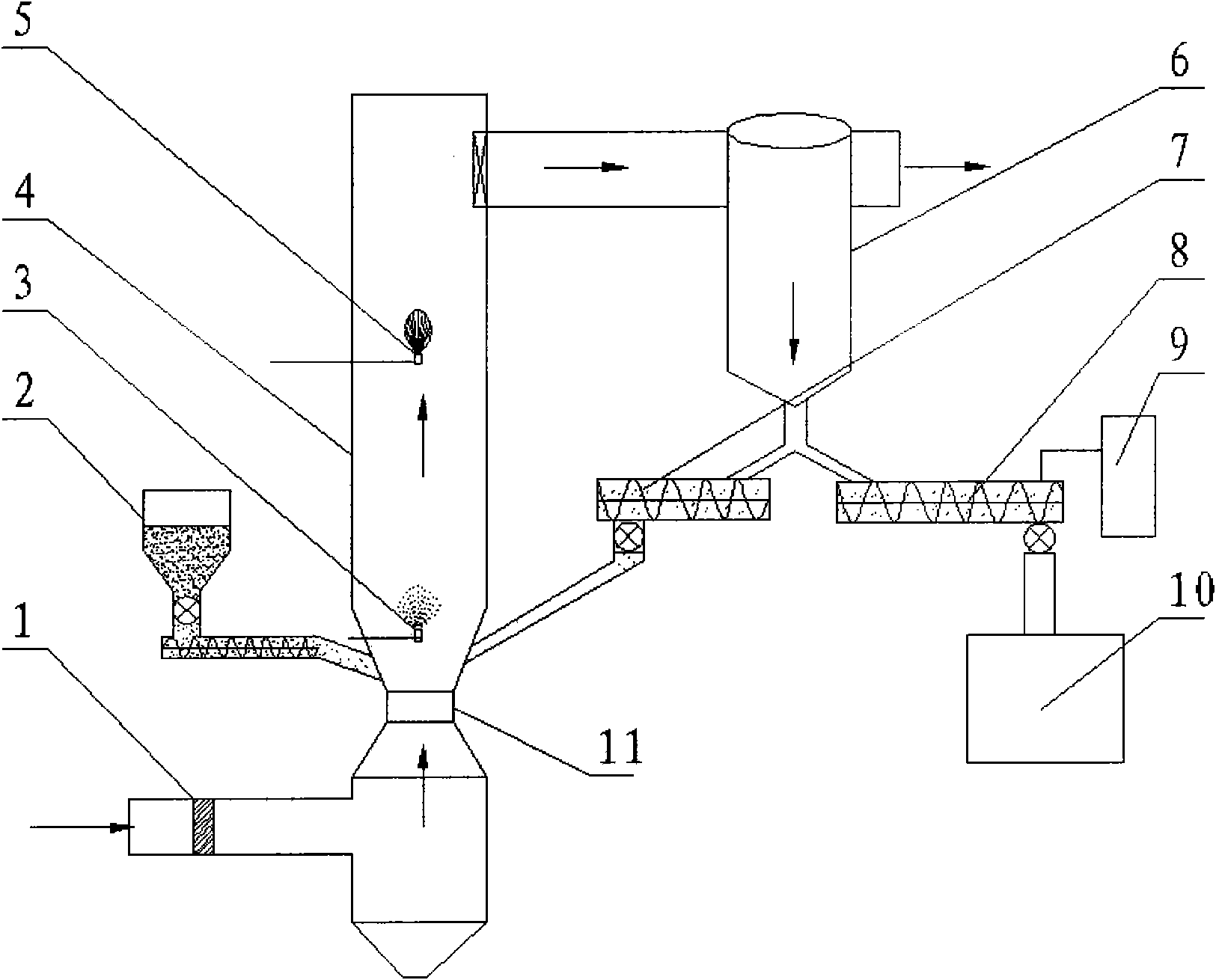

[0027] Attached below figure 1 A best implementation process of the present invention is given.

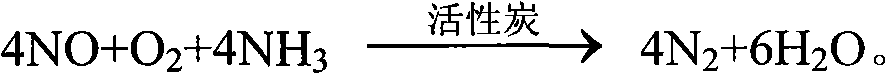

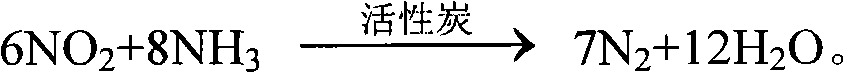

[0028] Fluidized activated carbon combined desulfurization and denitrification process such as figure 1 shown. The flue gas discharged from the boiler enters the circulating fluidized bed reaction tower 4 through the pre-dust removal device 1, and the flue gas is mixed and contacted with the activated carbon fed by the activated carbon feeding device 2 at the Venturi 11, and the temperature is adjusted by the water atomization system 3 , the activated carbon is mixed with the flue gas in a fluidized manner in the tower, and the SO in the flue gas 2 The lower part of the reaction tower is adsorbed and oxidized by activated carbon and removed; the ammonia injection device 5 sprays an appropriate amount of ammonia gas into the upper part of the reaction tower, and the NO in the flue gas x with NH 3 It is removed by catalytic reduction reaction.

[0029] The flue gas enters the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com