Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205results about How to "Considerable time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

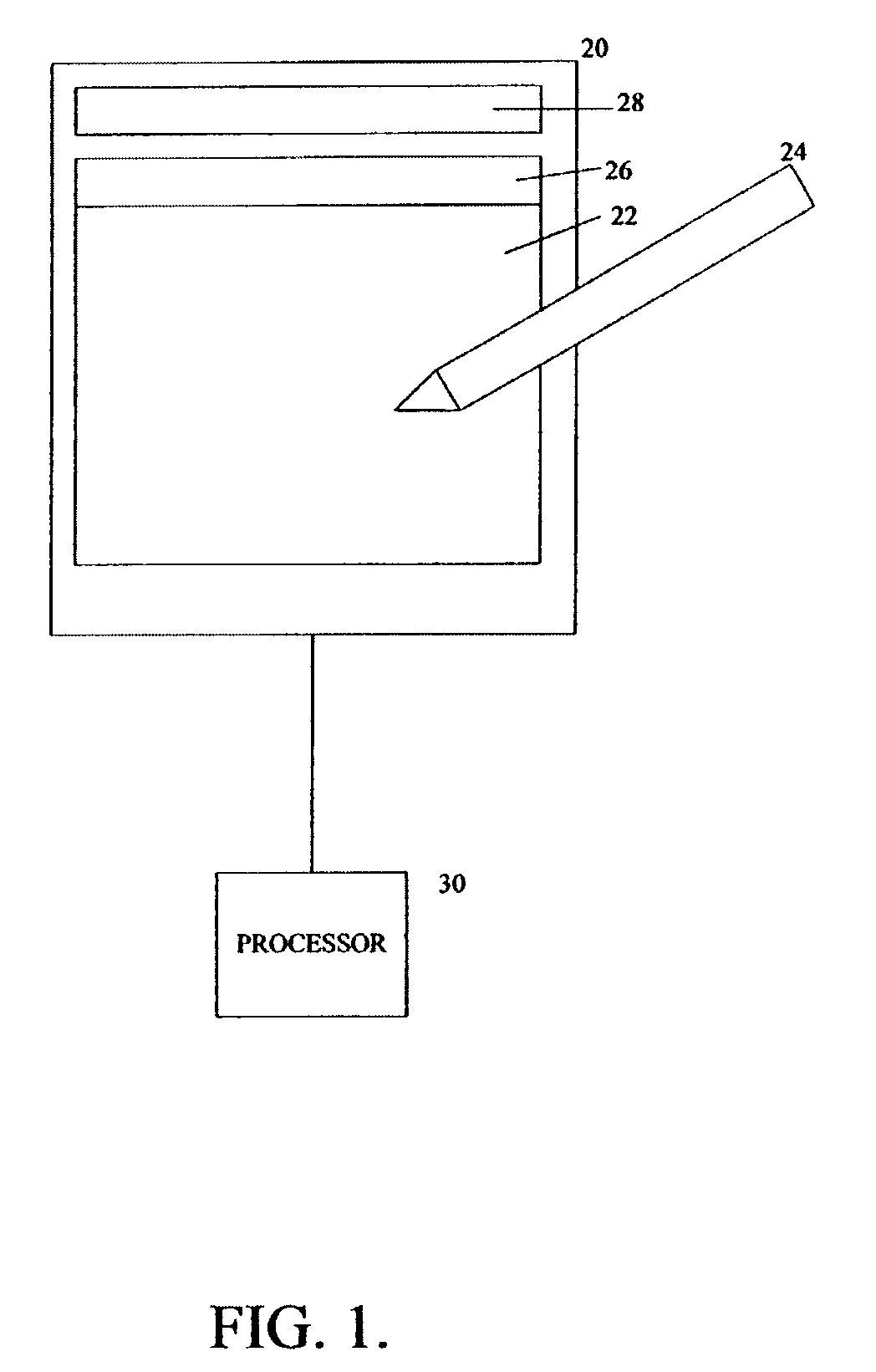

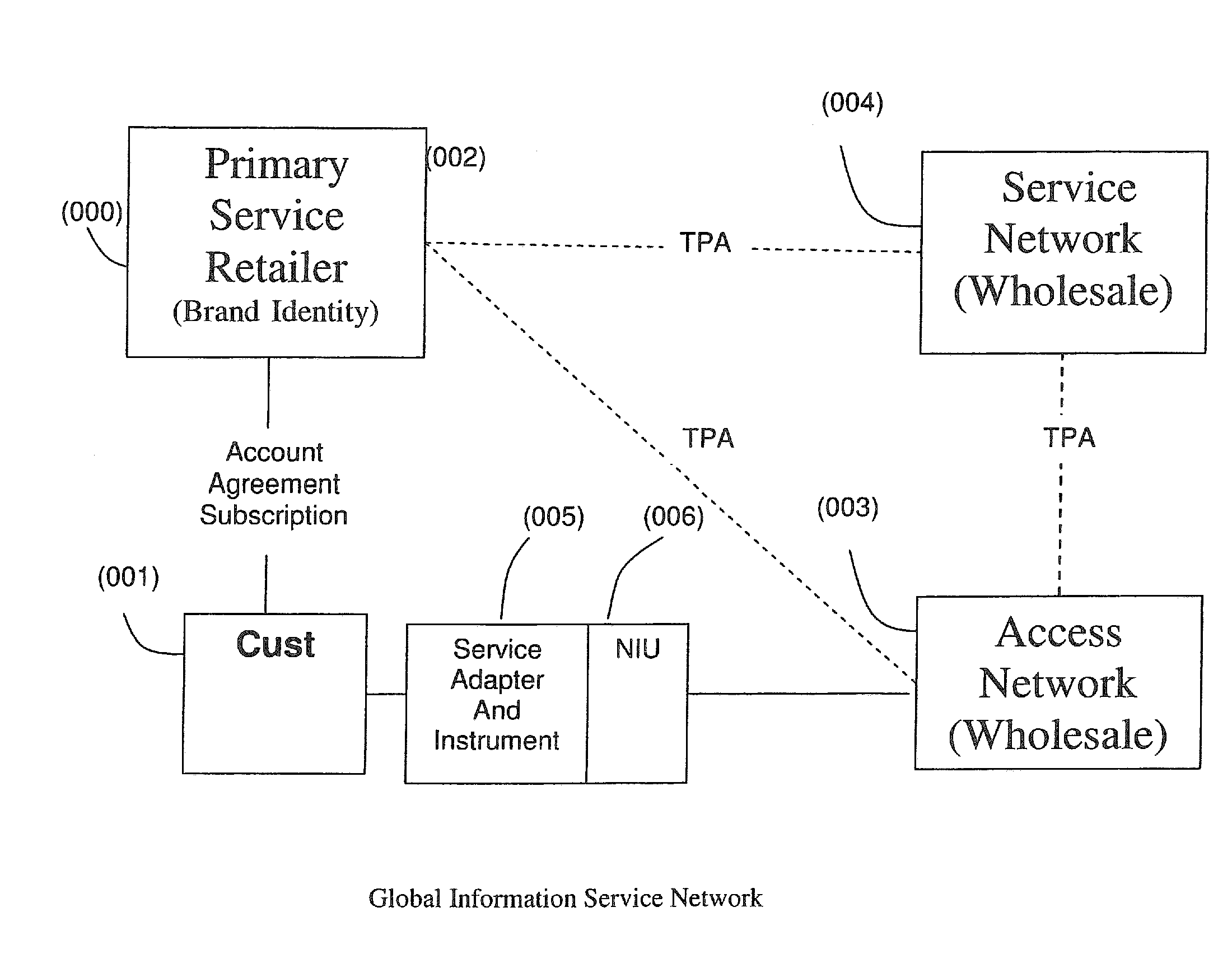

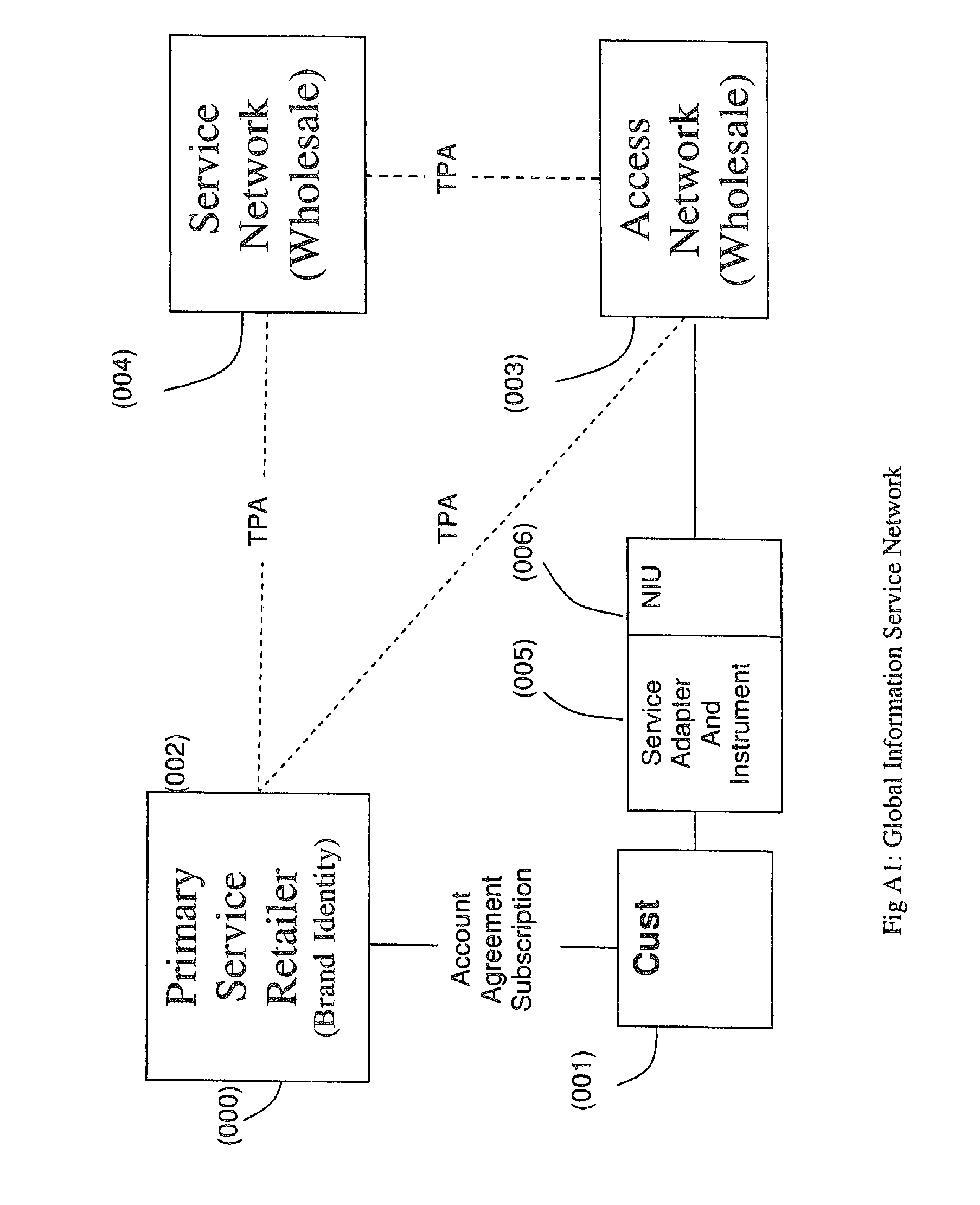

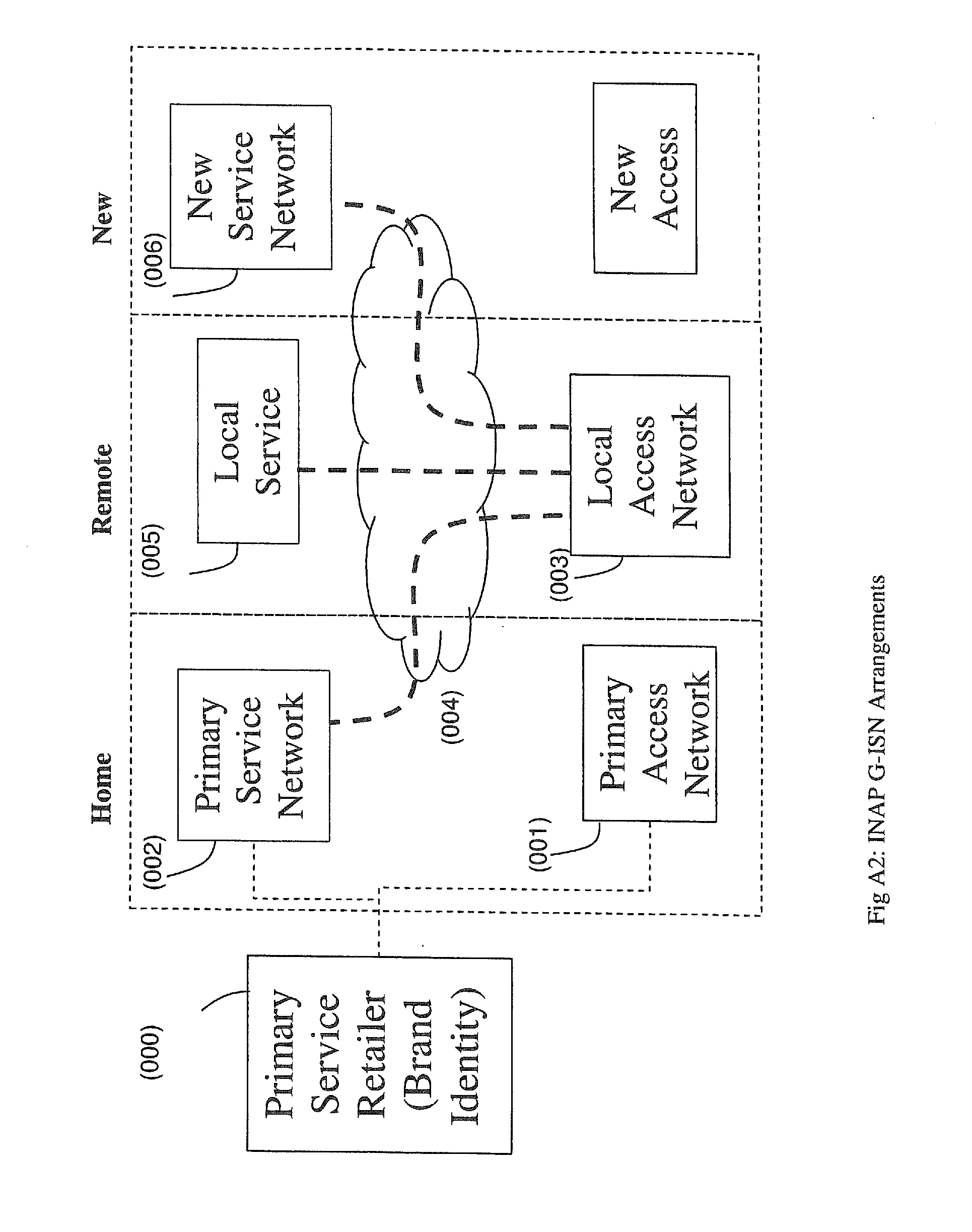

Intelligent network providing network access services (INP-NAS)

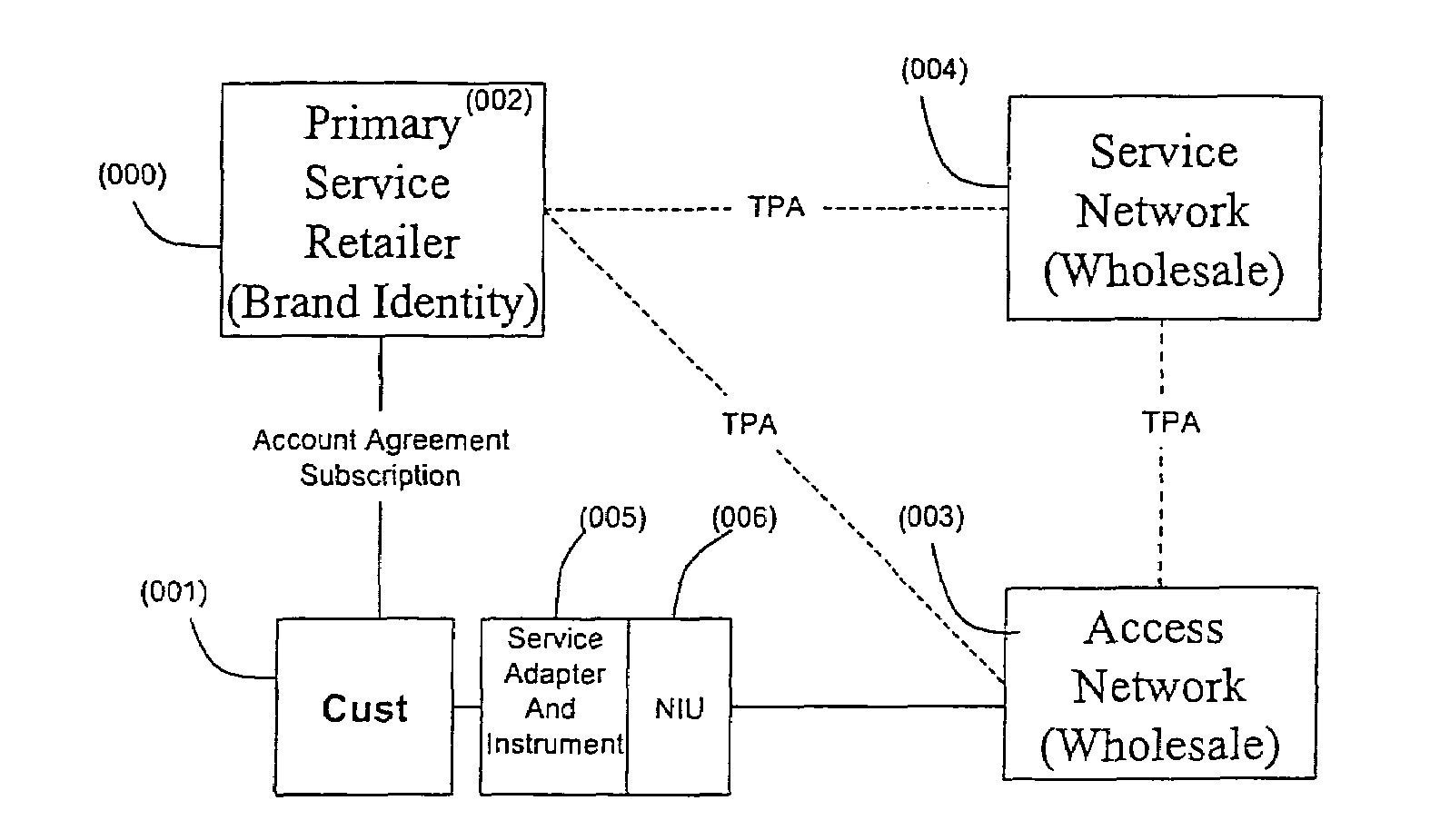

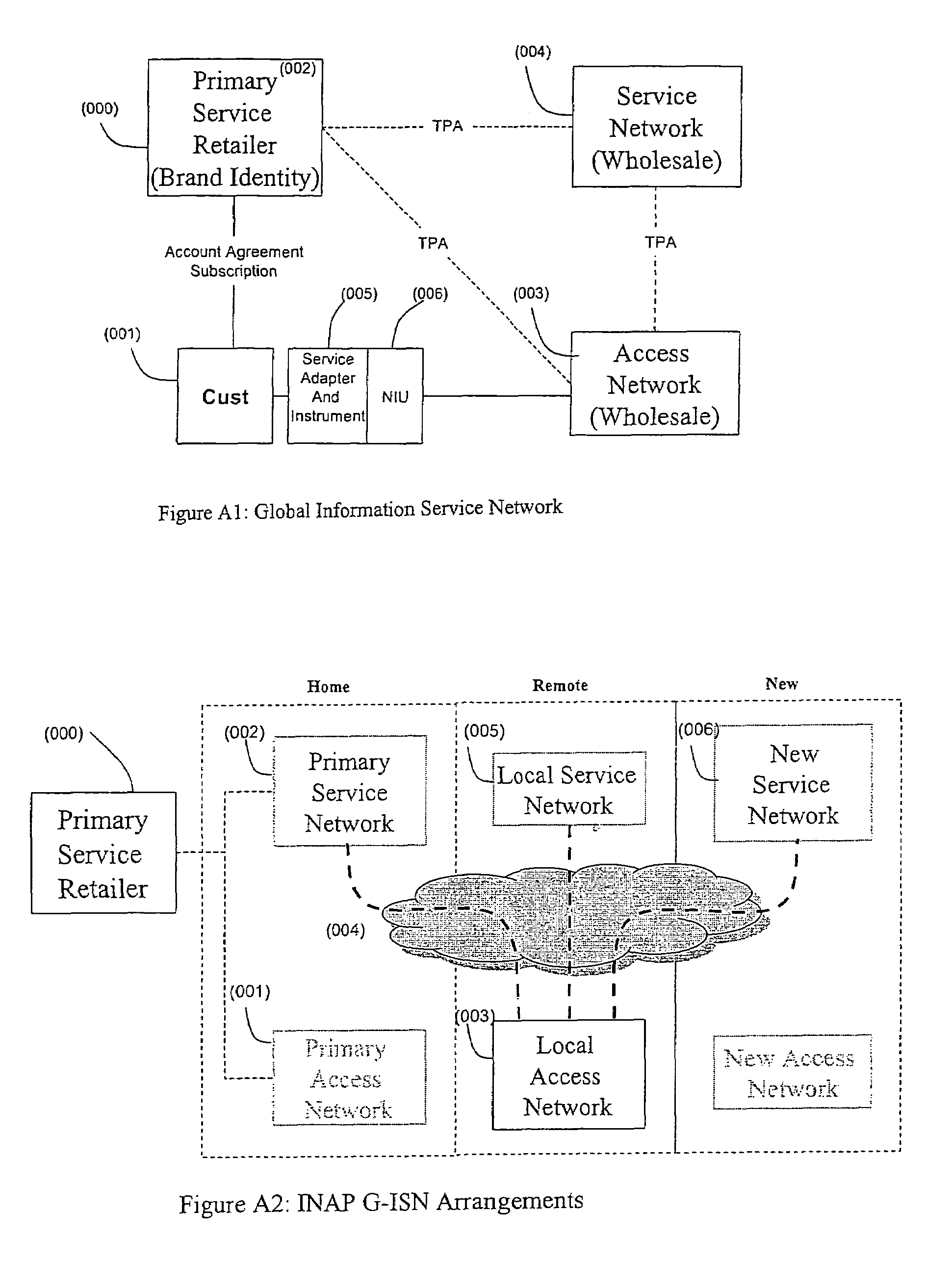

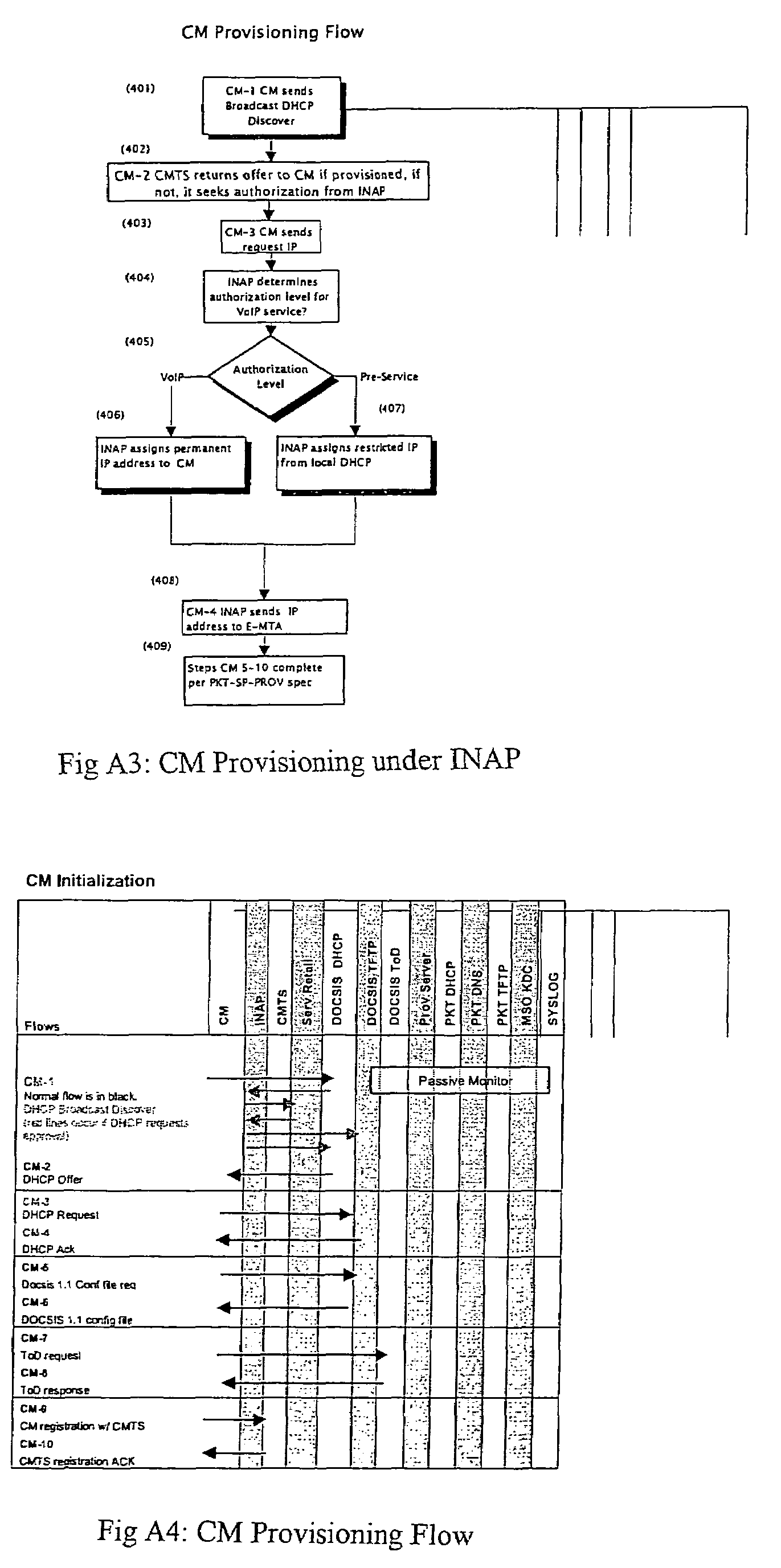

InactiveUS7496652B2Efficient use ofConsiderable timeBroadband local area networksMultiple digital computer combinationsIntelligent NetworkSmart network

An open Information Services network architecture is disclosed which enables multiple business entities to assume specialized roles of access provider, service provider, and service retailer. The disclosed technology provides instant plug-and-play service, decouples access and service networks and provides seamless (single step) access enabling customers to maintain a service account regardless of location. The benefits of the disclosed technology, among others, include: Multi-level and multi-service registration; Broker Services providing customers with a choice of provider; Security Services relating to distribution; Revenue Assurance services, Gentle Reminder / Gentle Touch; Revenue Assurance services pertaining to usage integrity verification upon registration; mobile services derived from G-ISN; and claim benefits pertaining to LNP services derived from G-ISN.

Owner:AI-CORE TECH LLC +1

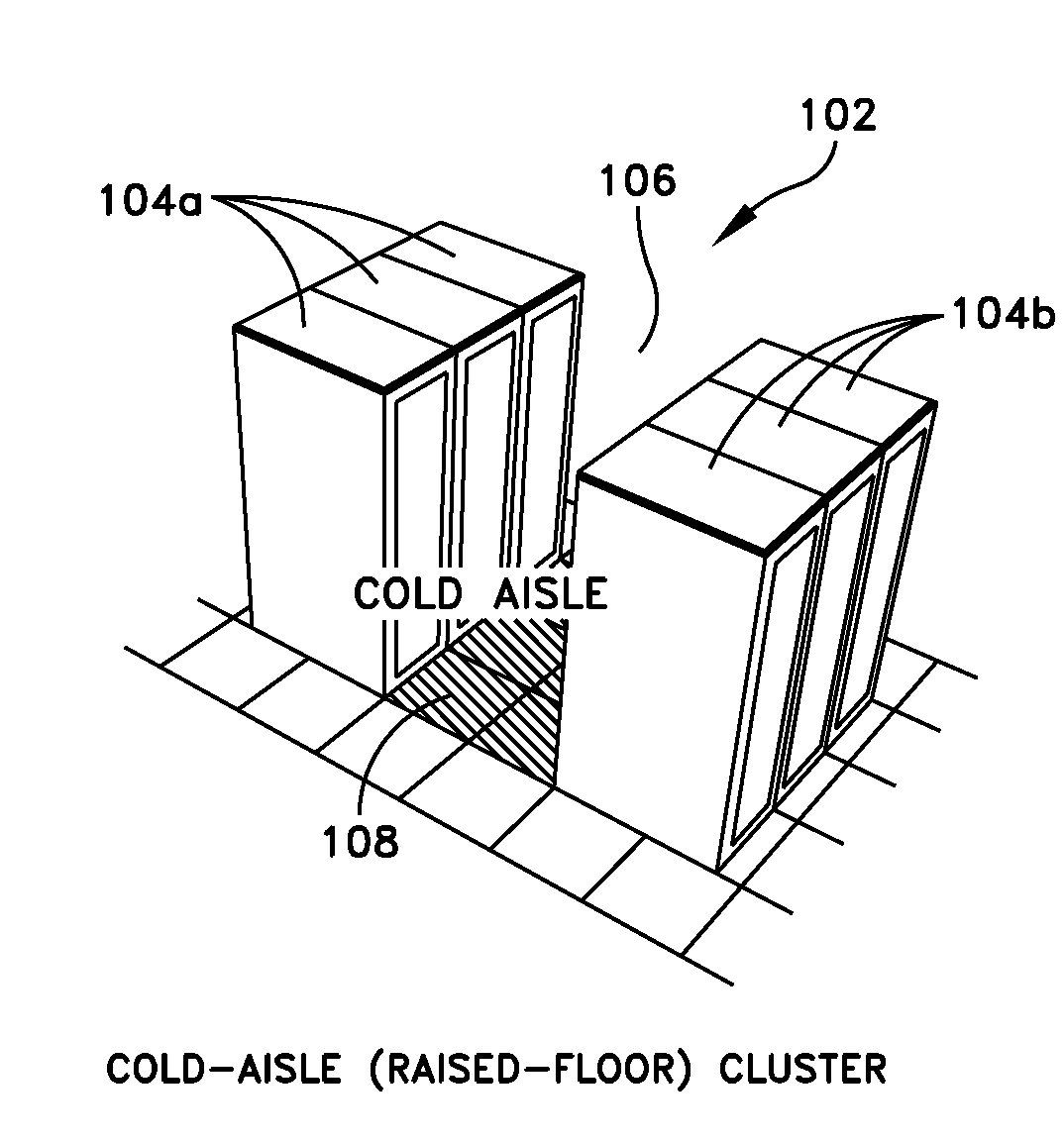

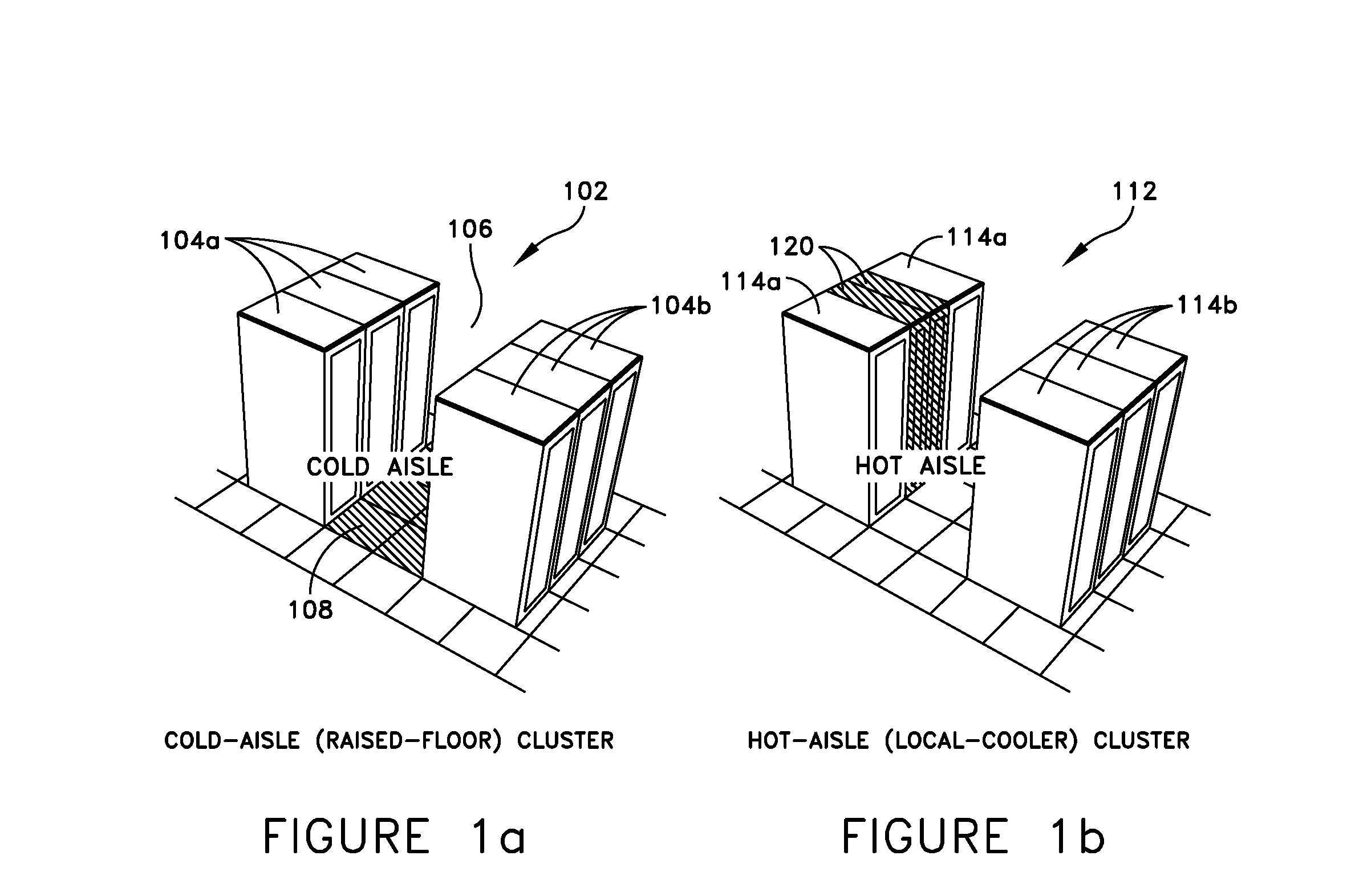

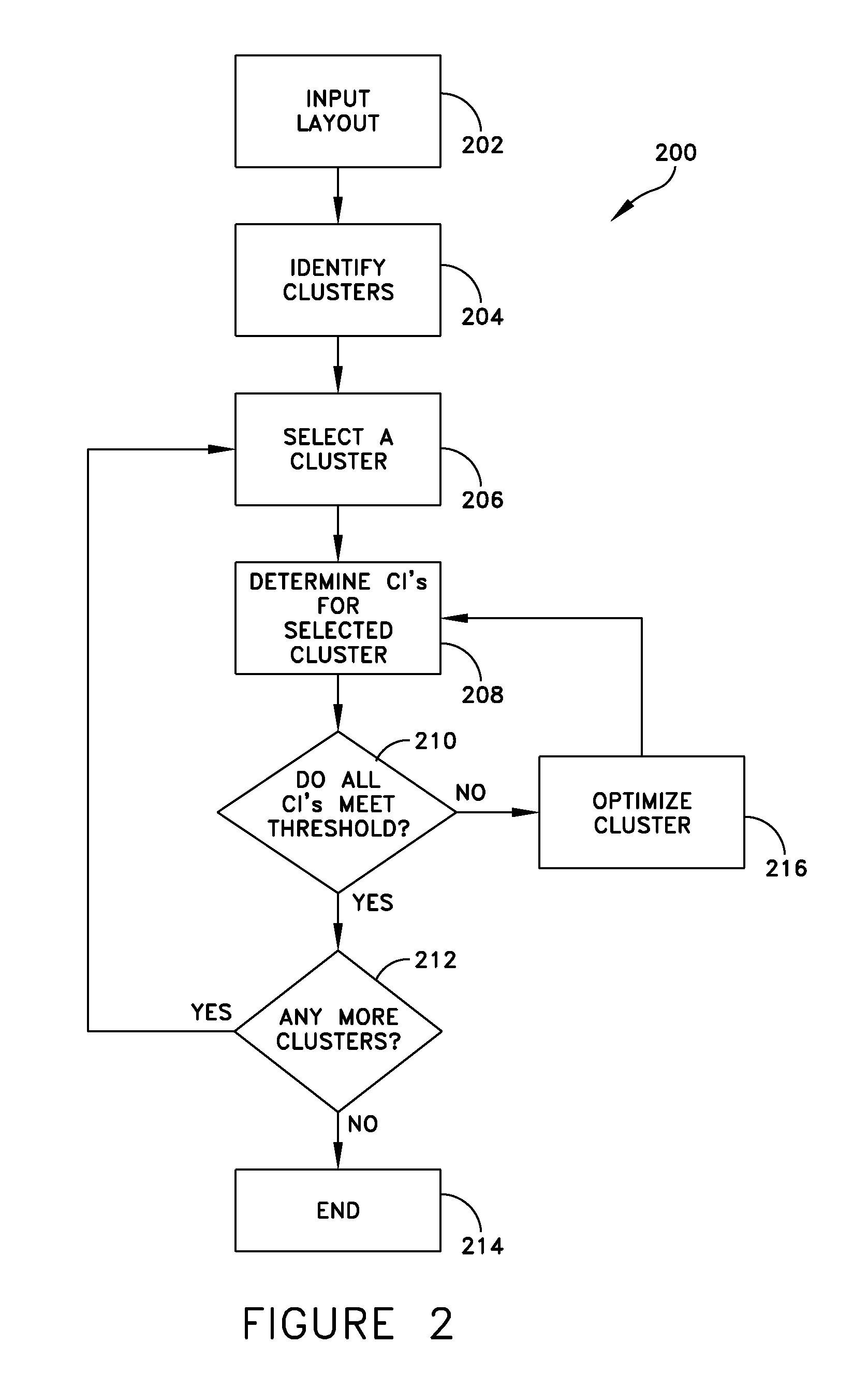

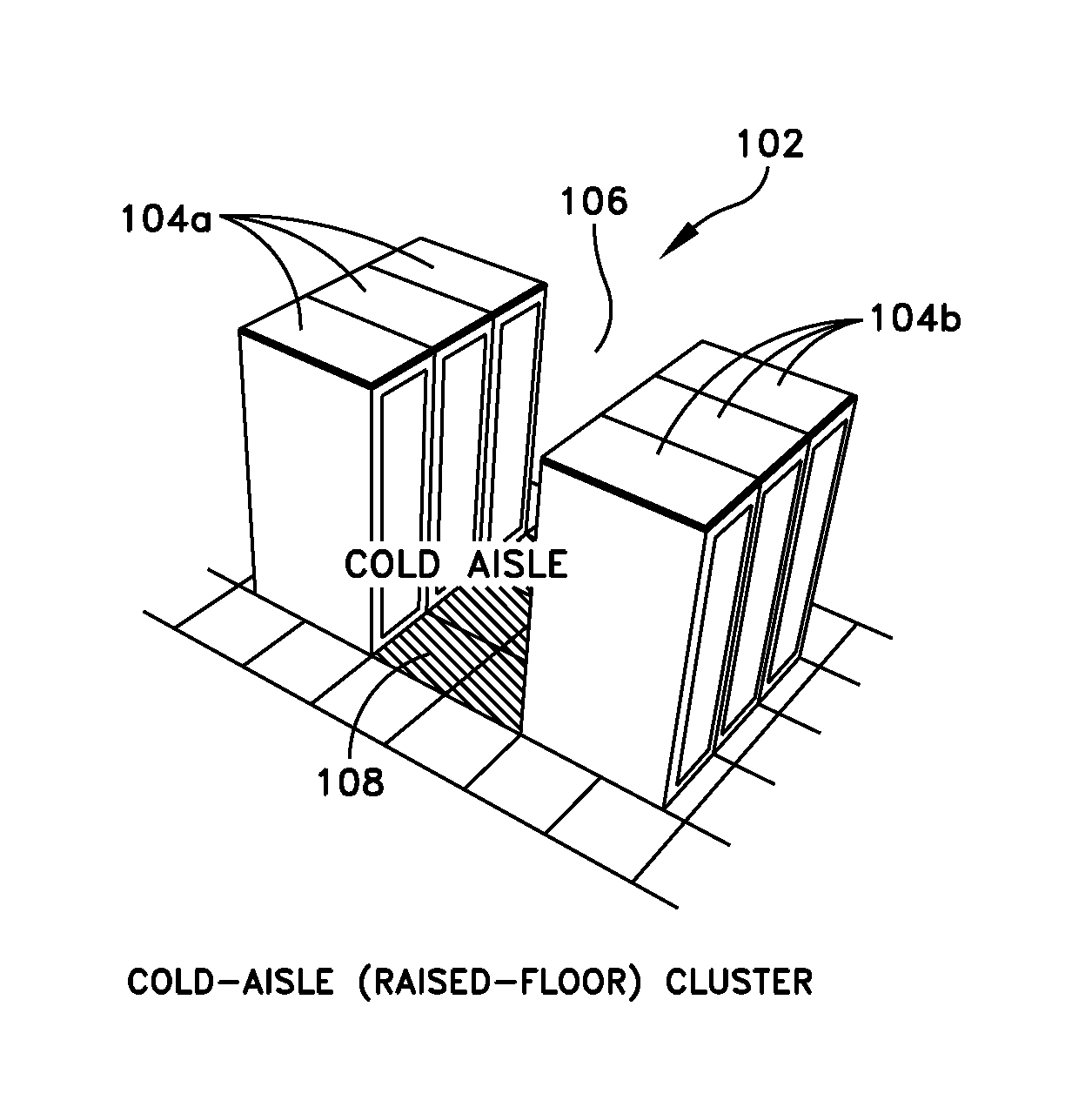

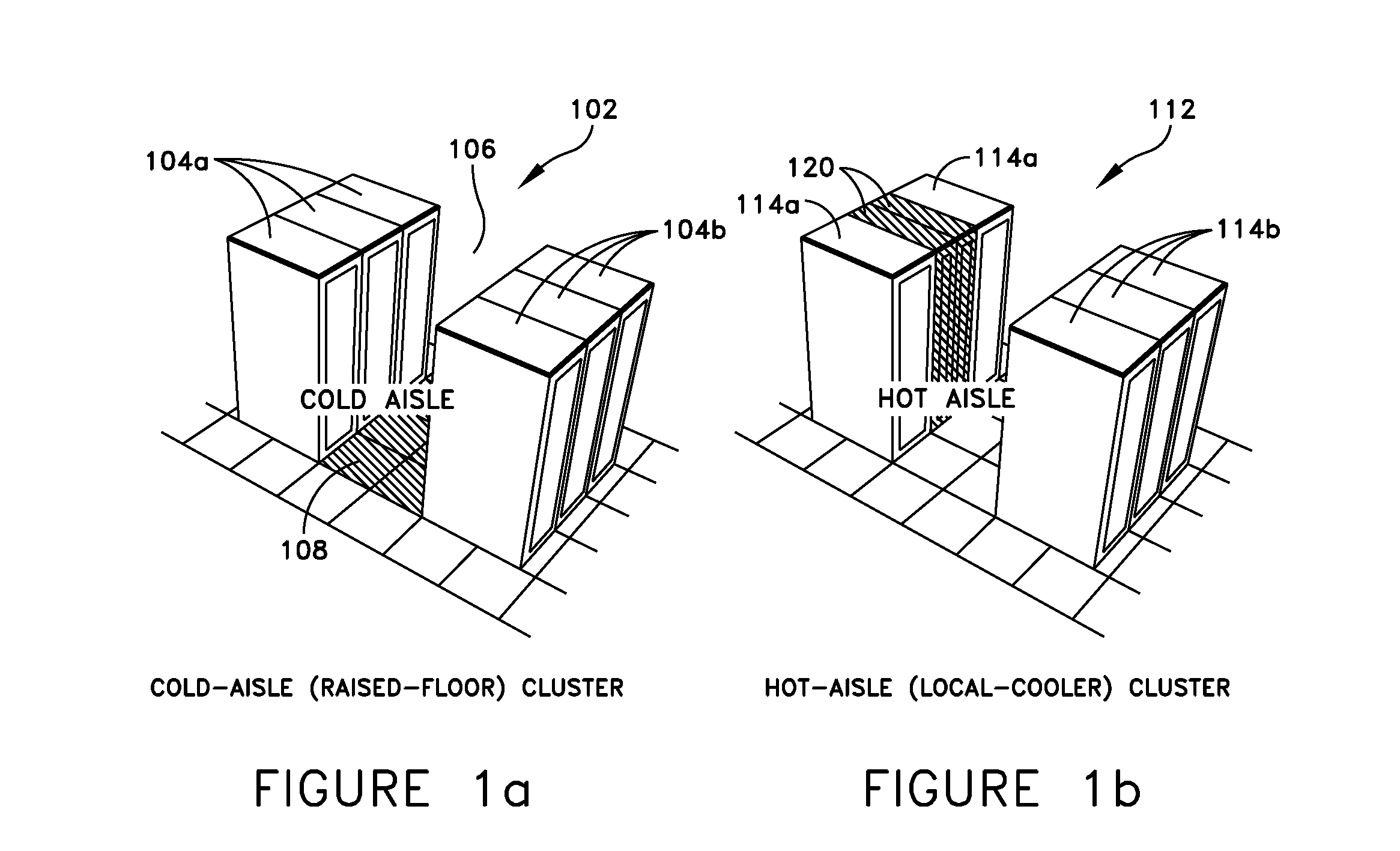

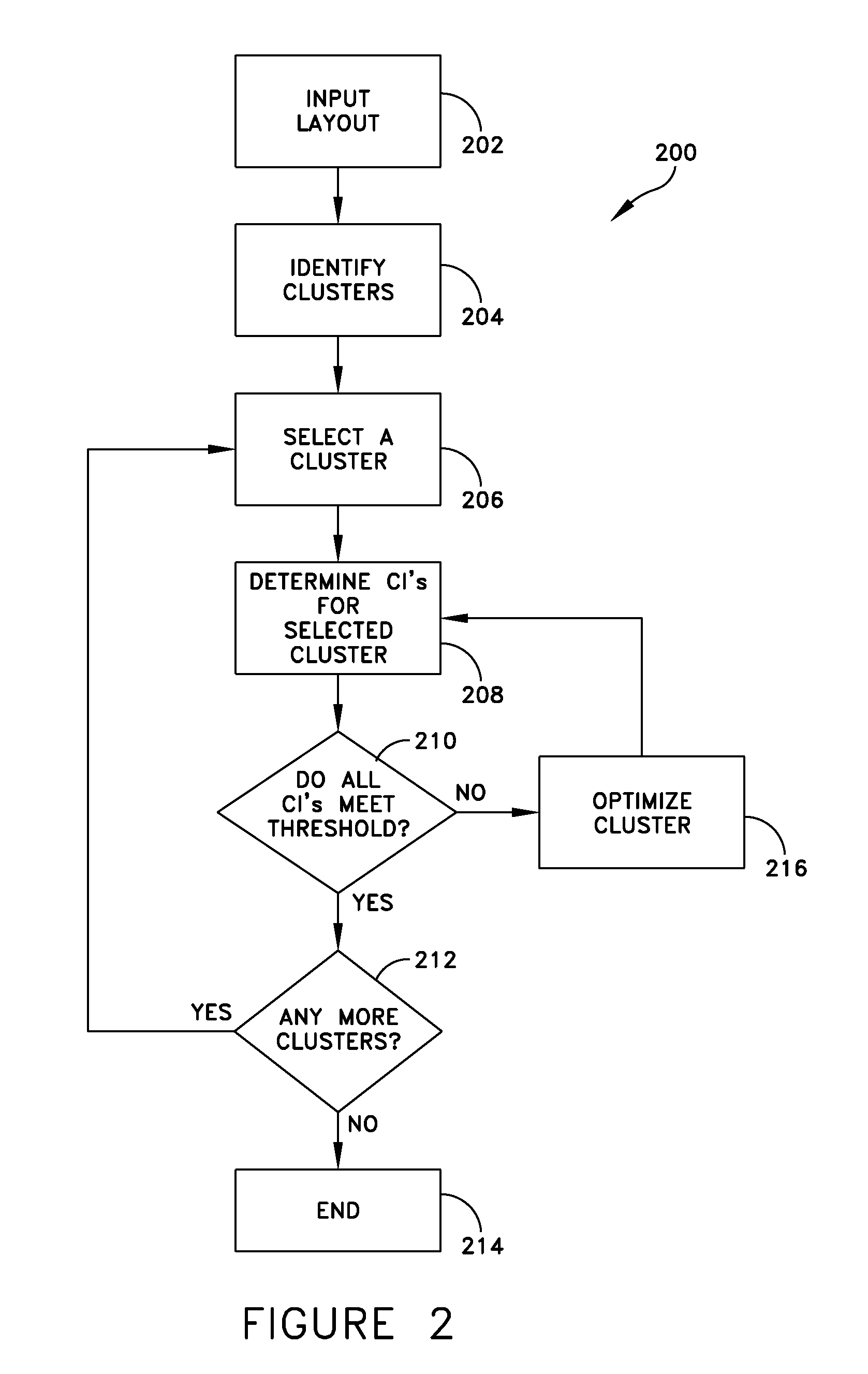

System and method for evaluating equipment rack cooling performance

ActiveUS20080174954A1Optimize layoutConsiderable timeThermometer detailsDigital data processing detailsData centerReliability engineering

Aspects of the invention are directed to systems and methods for designing and analyzing data centers. One aspect is directed to a method of determining cooling characteristics of a data center. The method includes receiving data related to a configuration of equipment in the data center, identifying rack clusters in the configuration of equipment, and determining a capture index for at least one equipment rack of at least one rack cluster.

Owner:SCHNEIDER ELECTRIC IT CORP

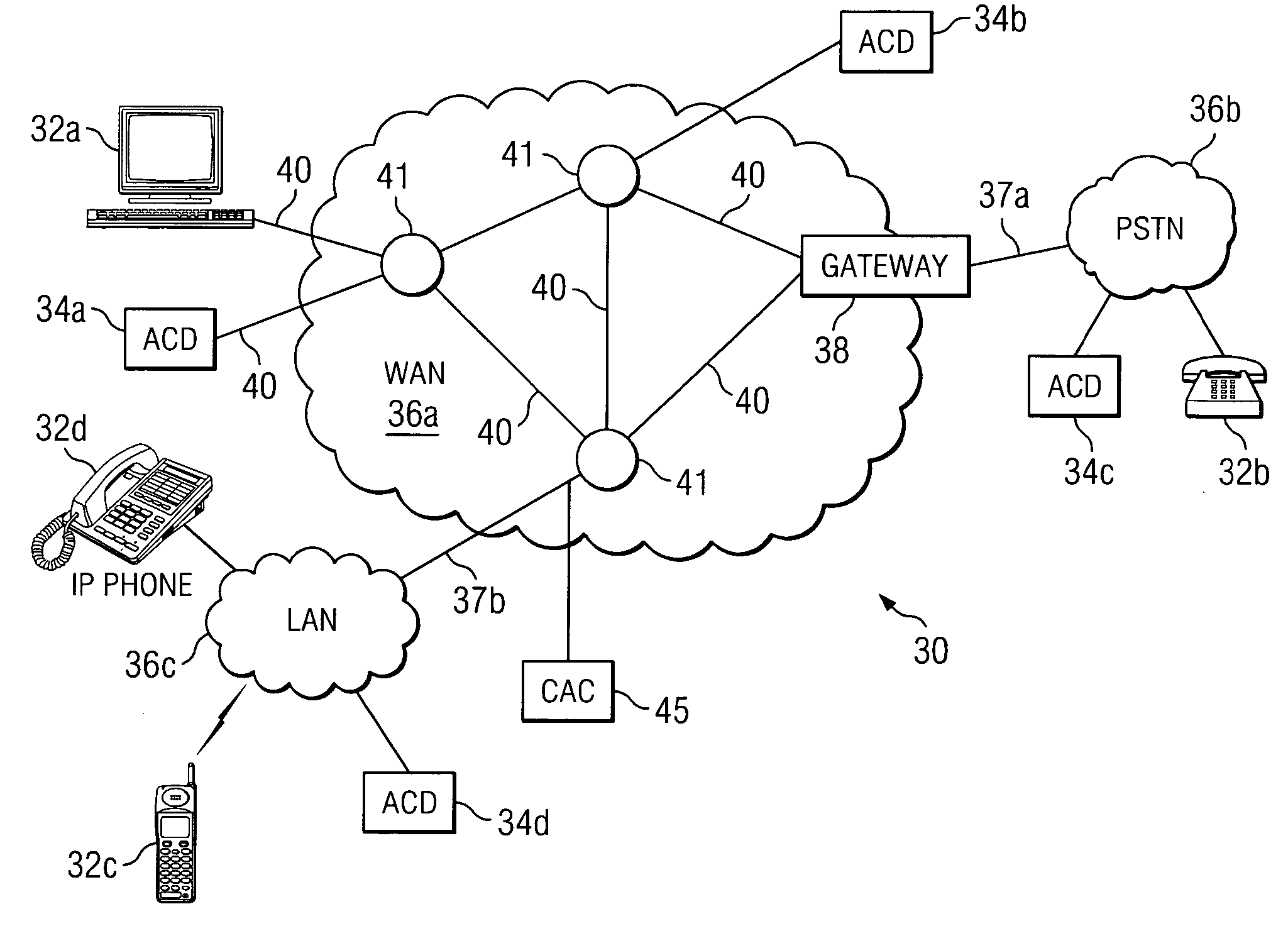

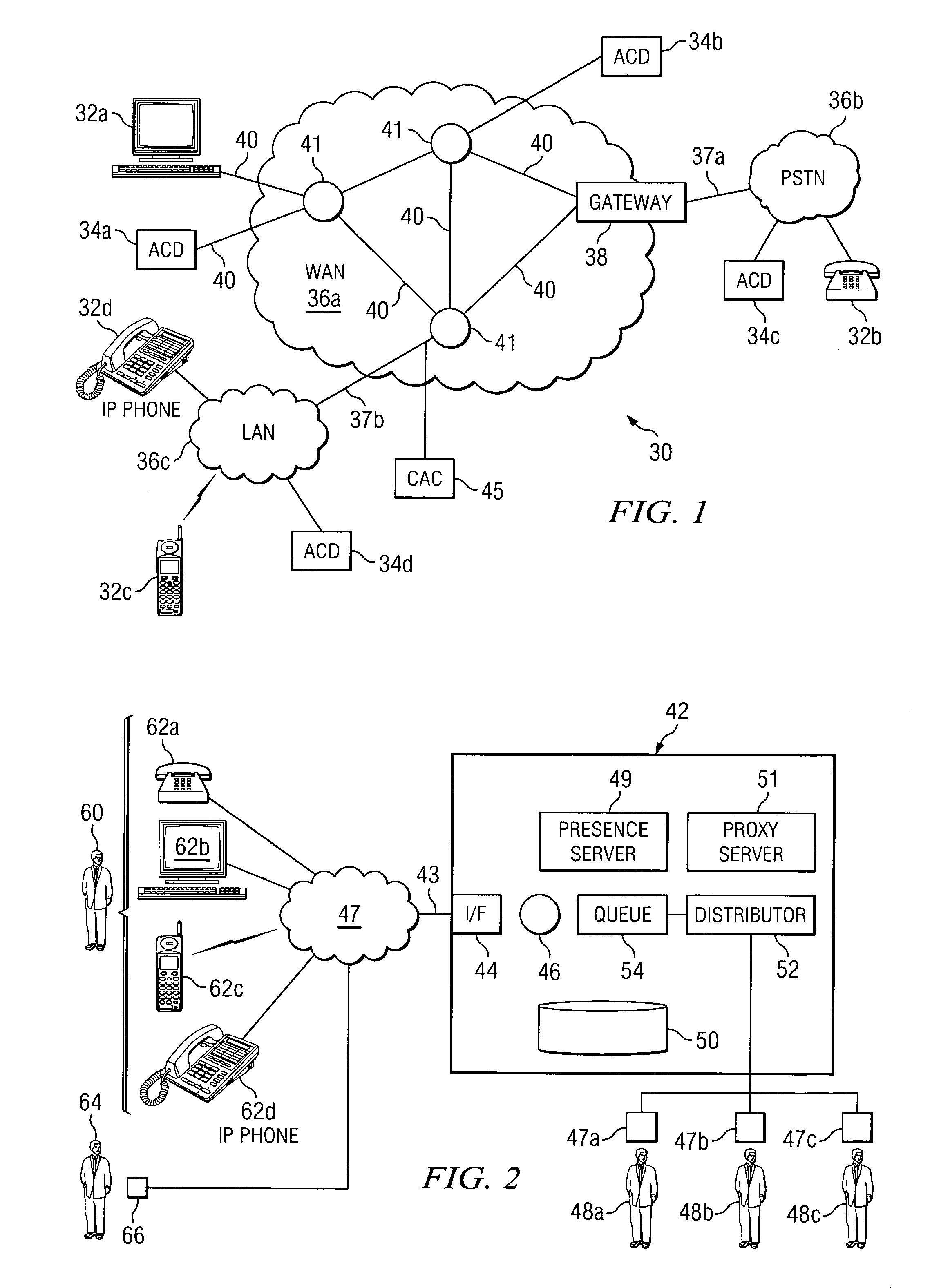

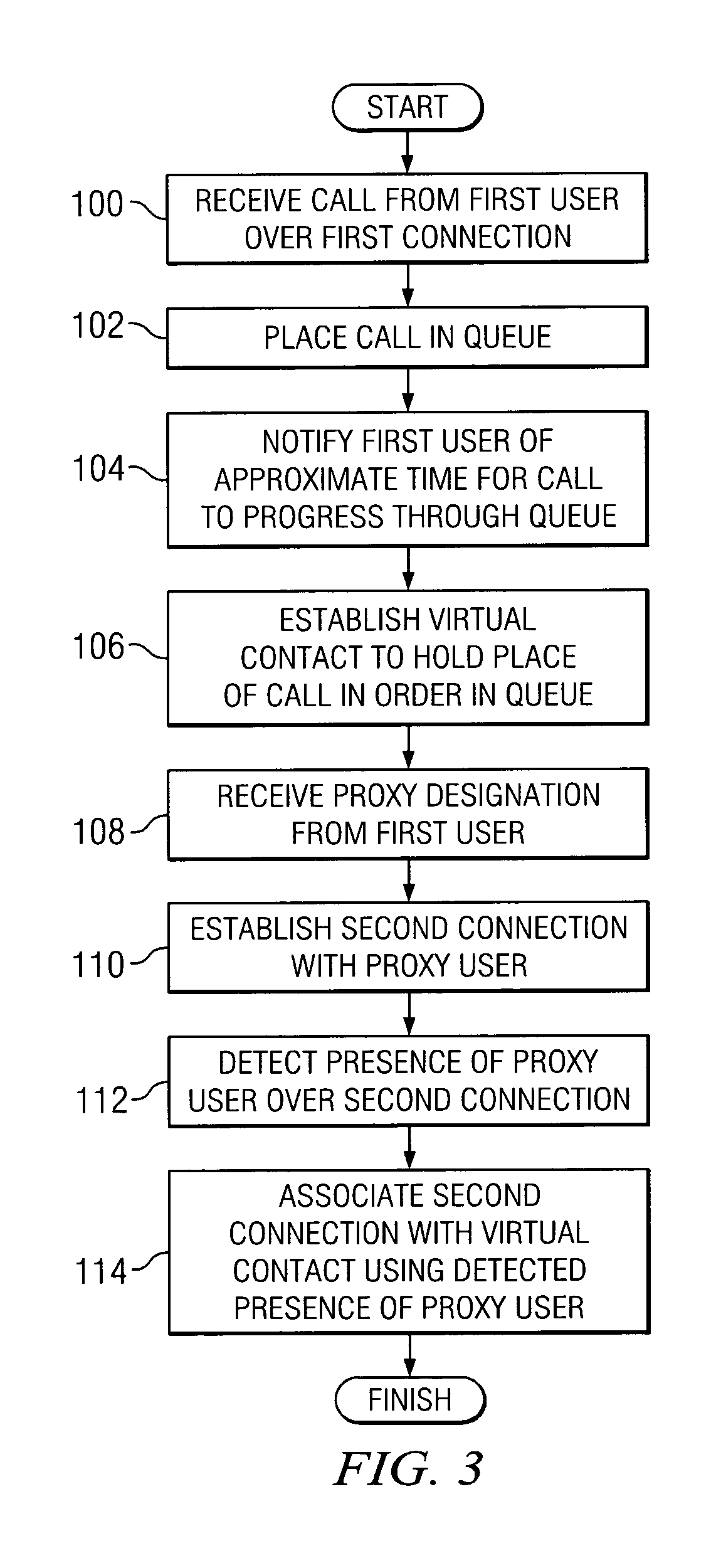

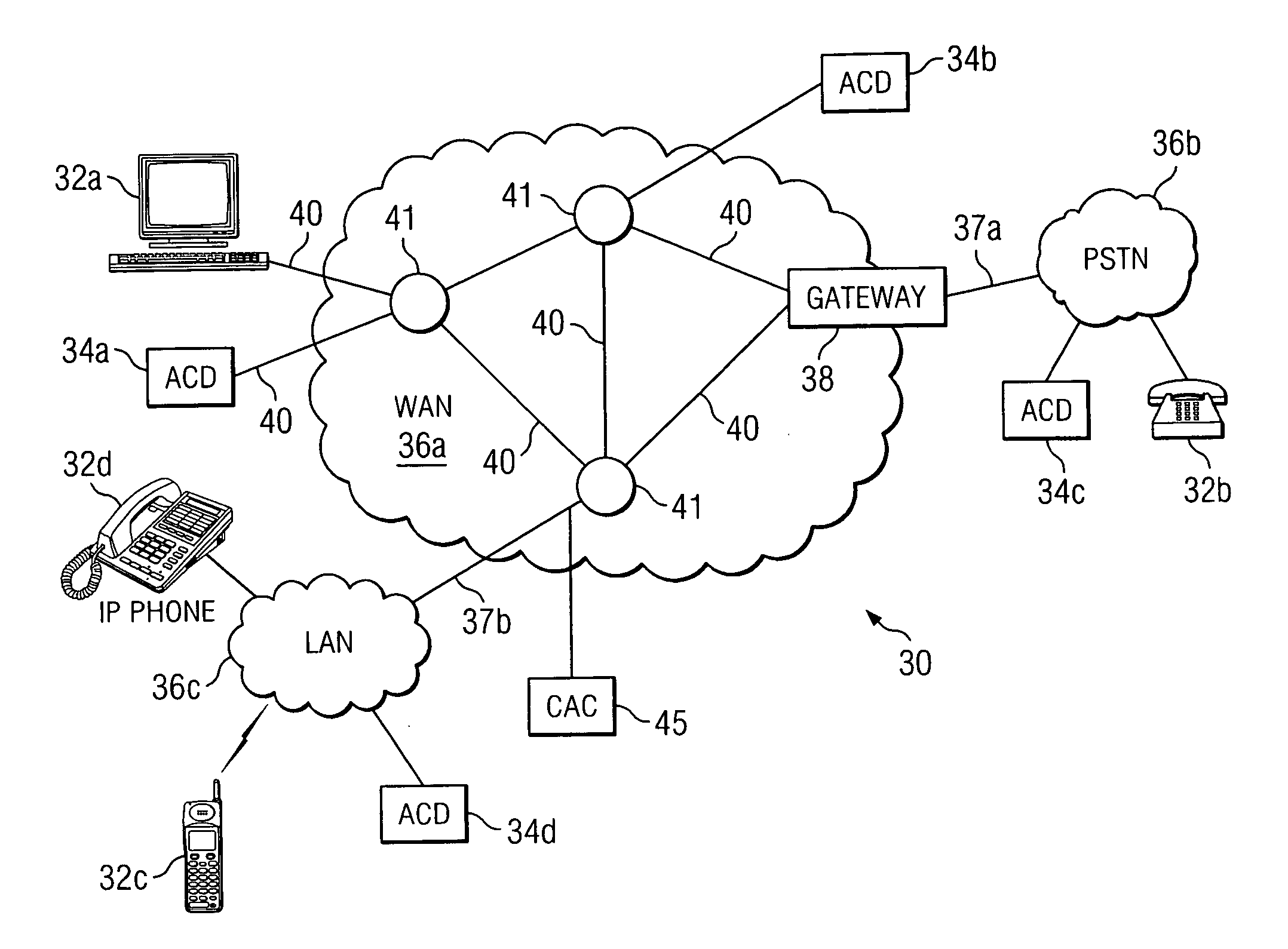

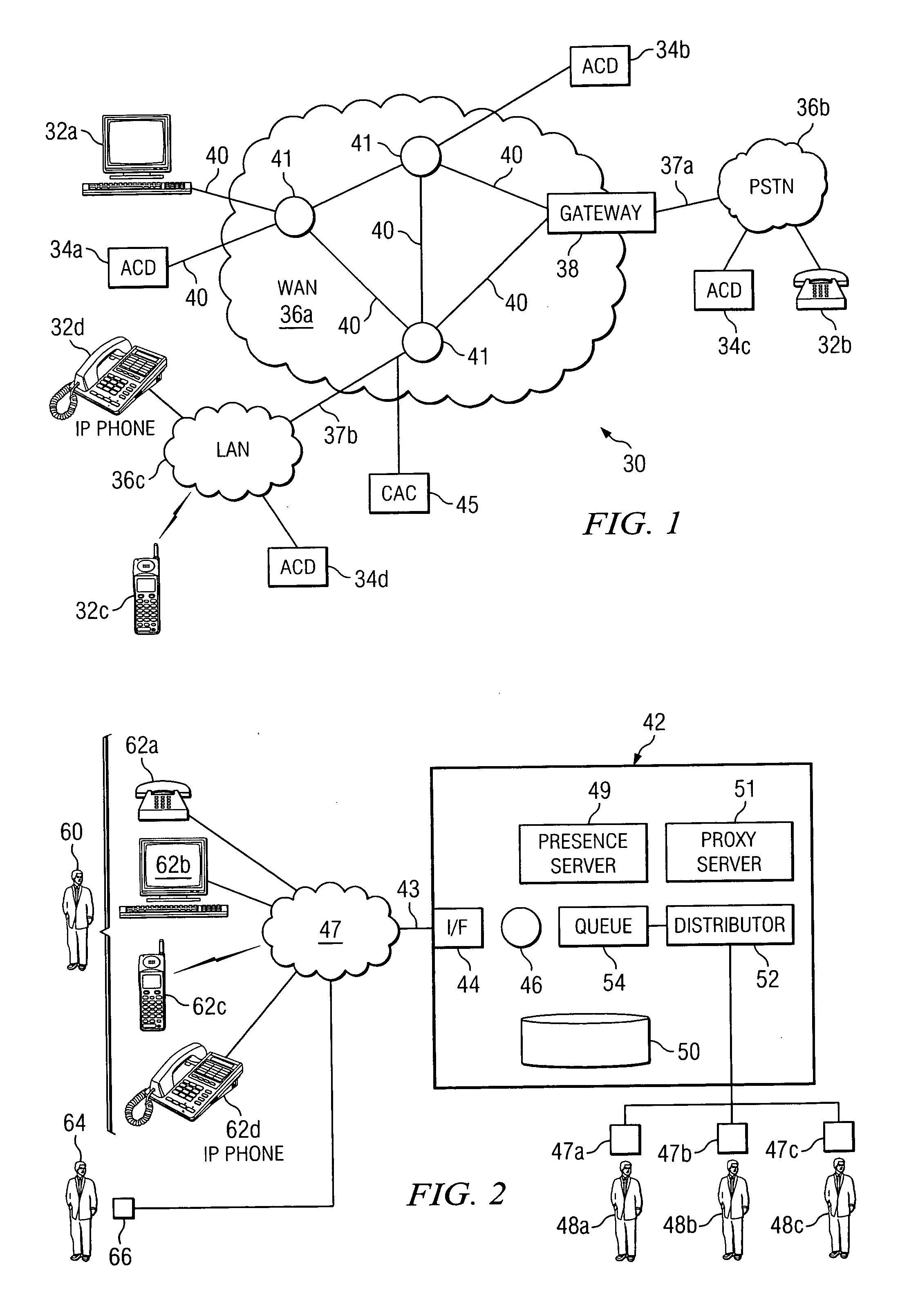

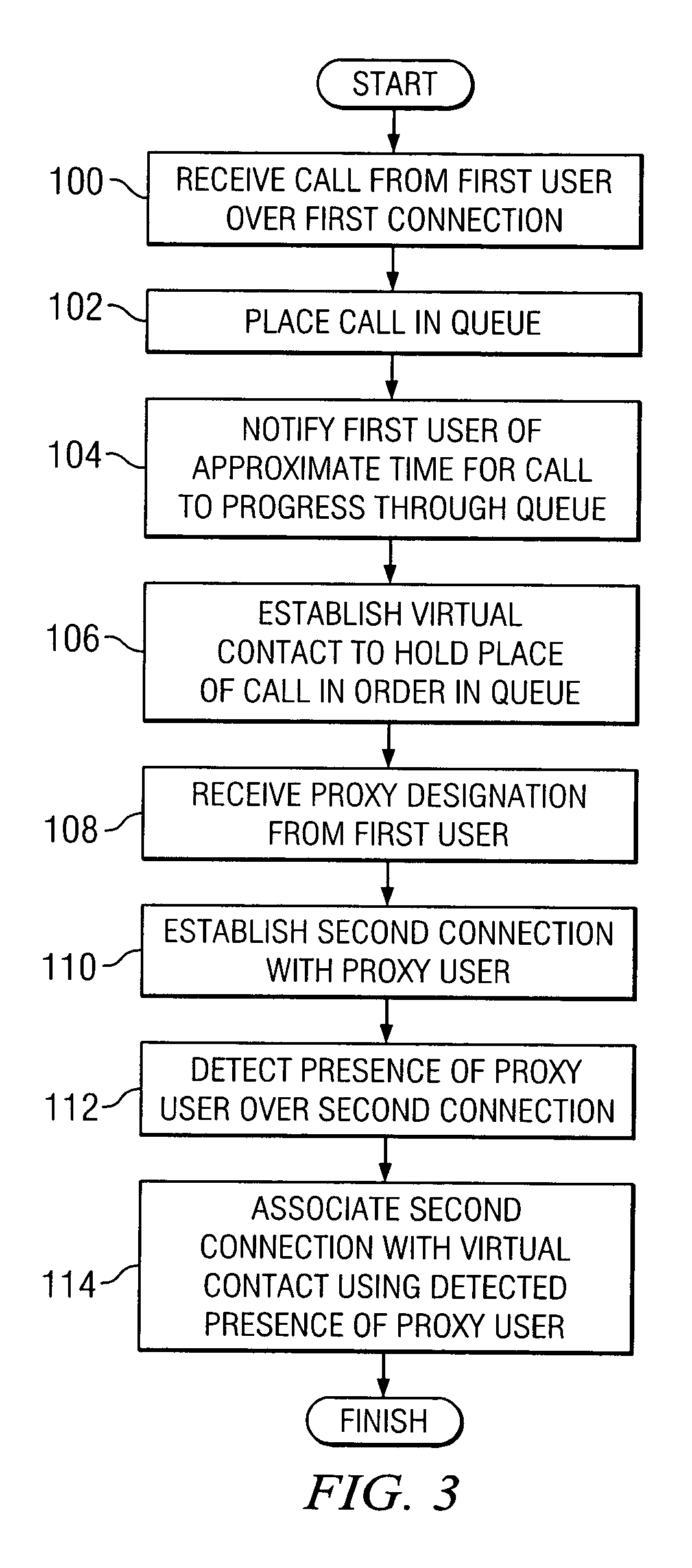

Method and system for utilizing proxy designation in a call system

ActiveUS20050047582A1Eliminates and reduces of disadvantageEliminates and reduces of and problemManual exchangesAutomatic exchangesComputer network

A method for utilizing proxy designation in a call system includes receiving a call from a first user over a first connection with a first endpoint of the first user. The method includes receiving a proxy designation from the first user. The proxy designation comprises a proxy user designated to handle the call for the first user. The method also includes establishing a second connection with the proxy user and detecting the presence of the proxy user over the second connection.

Owner:CISCO TECH INC

Method and system for managing calls of an automatic call distributor

ActiveUS20050047581A1Eliminates and reduces of disadvantageEliminates and reduces of and problemManual exchangesAutomatic exchangesTelecommunications

A method for utilizing proxy designation in a call system includes receiving a call from a first user over a first connection with a first endpoint of the first user. The method includes receiving a proxy designation from the first user. The proxy designation comprises a proxy user designated to handle the call for the first user. The method also includes establishing a second connection with the proxy user and detecting the presence of the proxy user over the second connection.

Owner:CISCO TECH INC

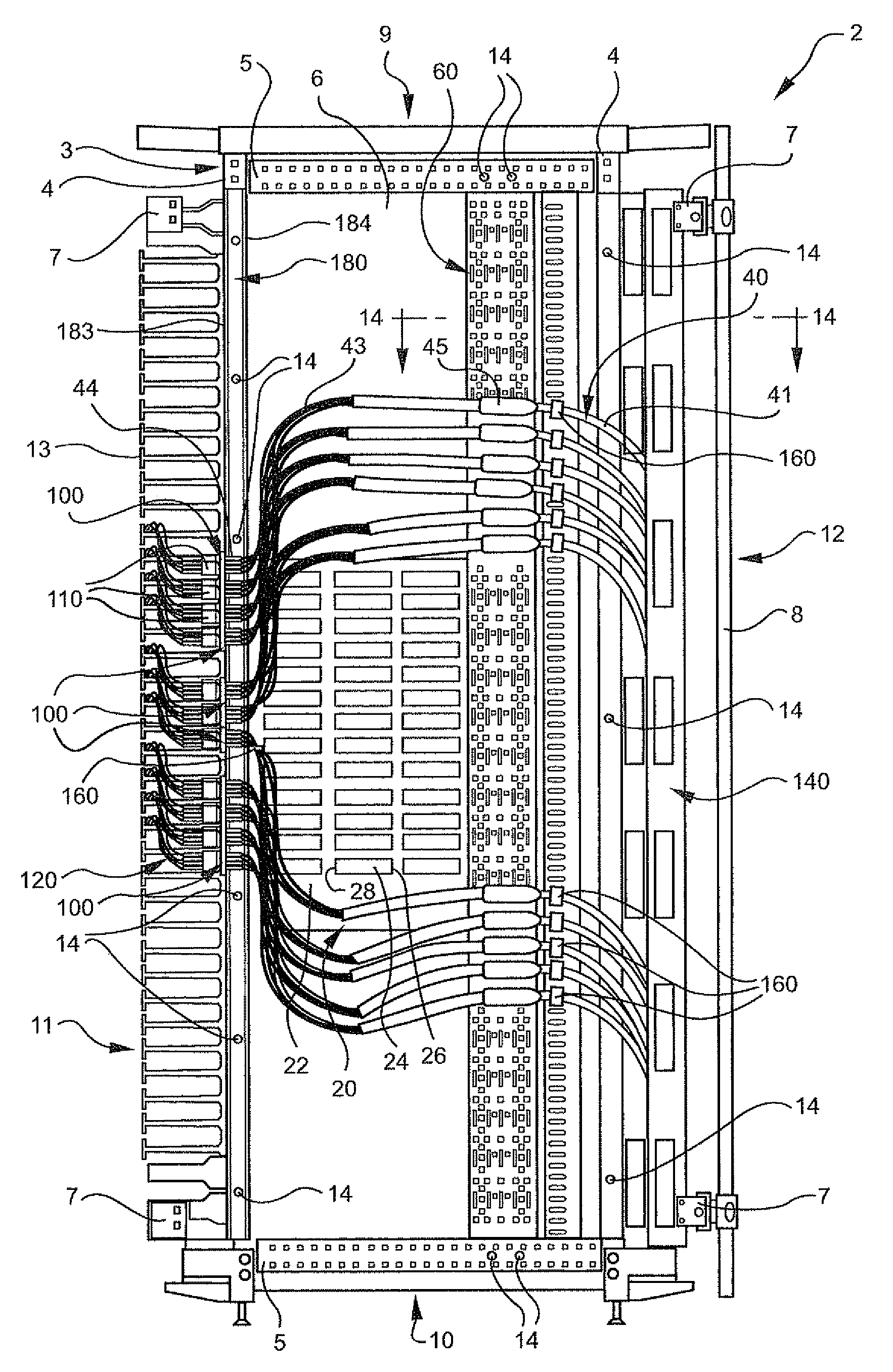

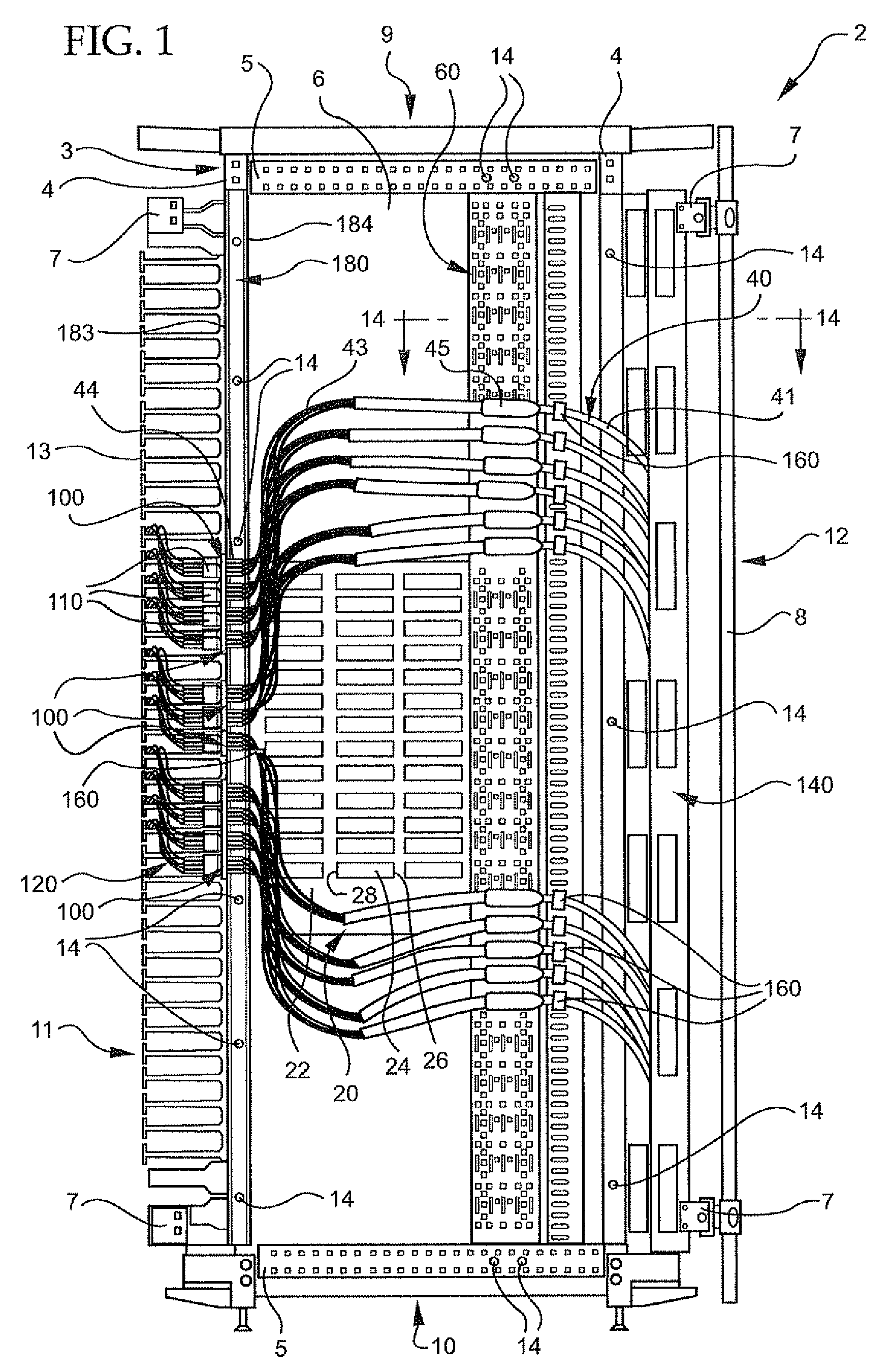

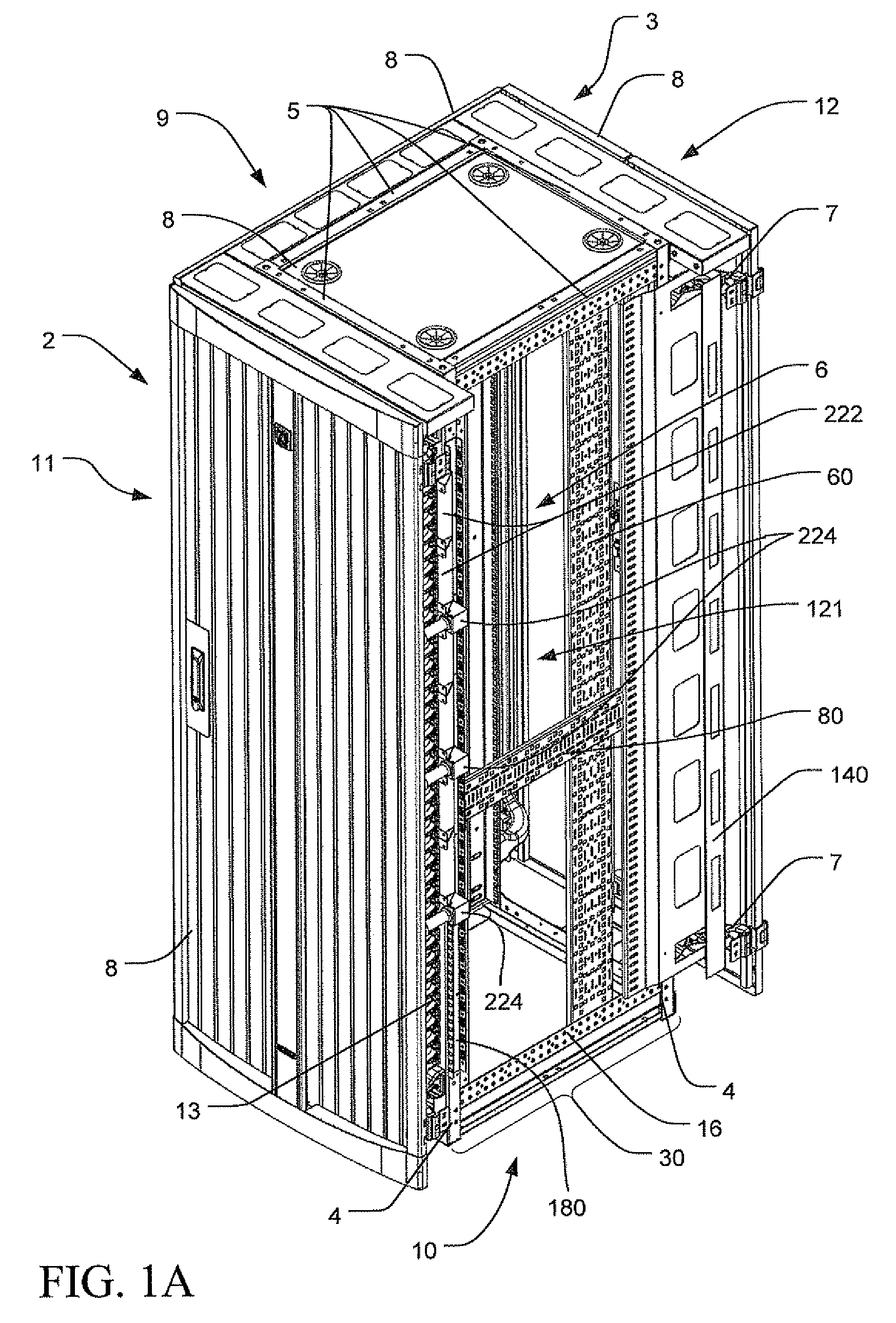

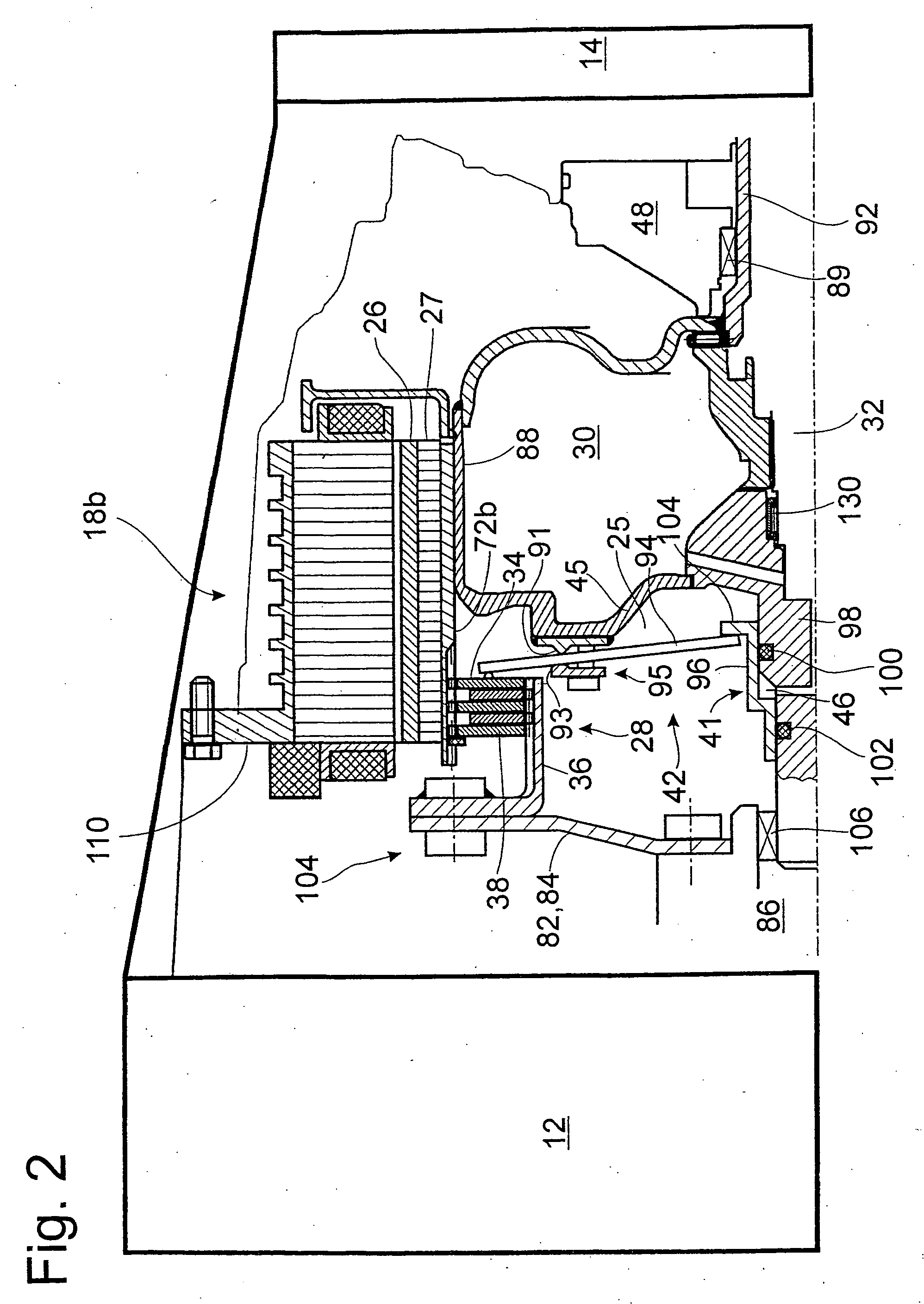

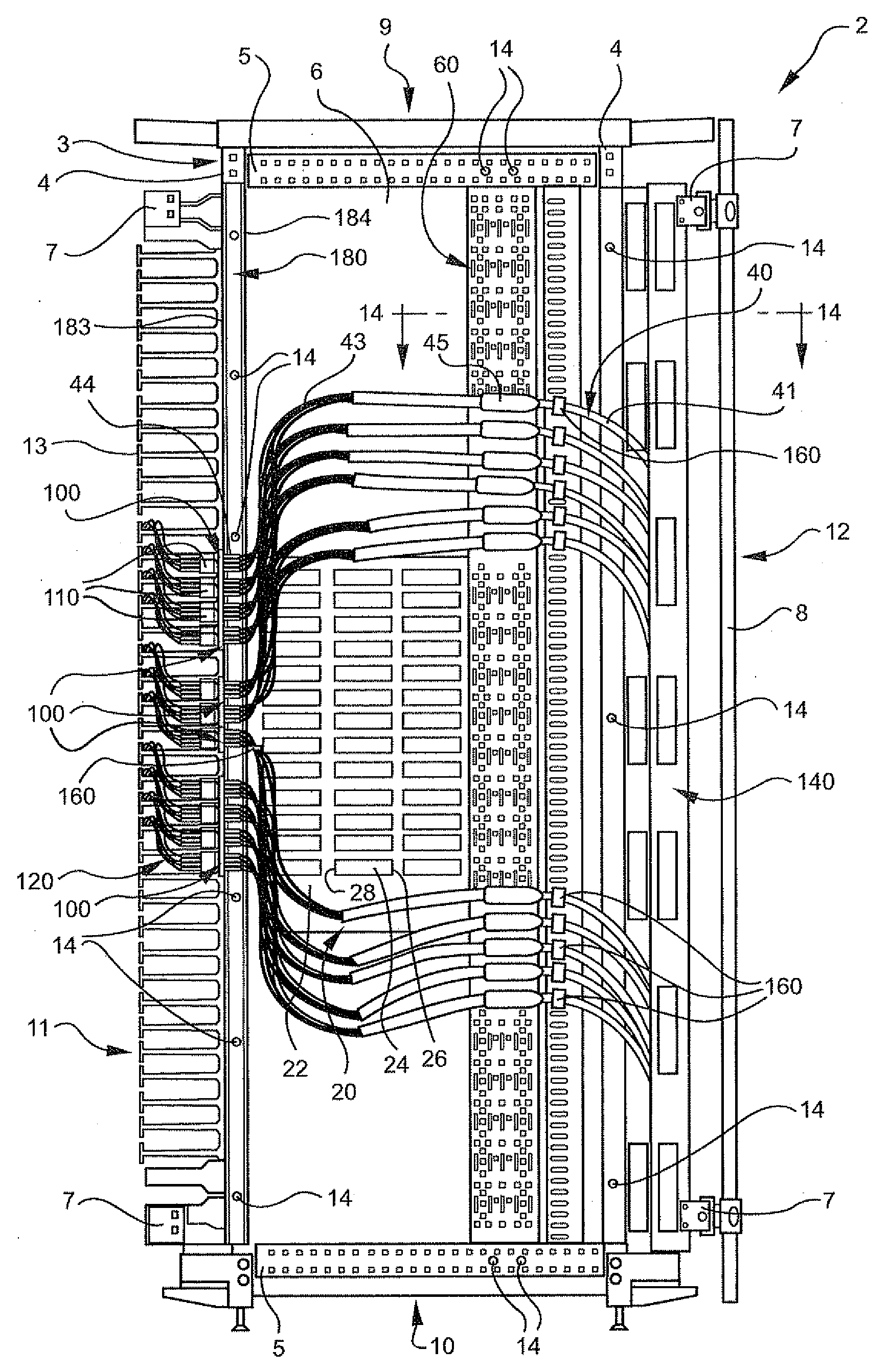

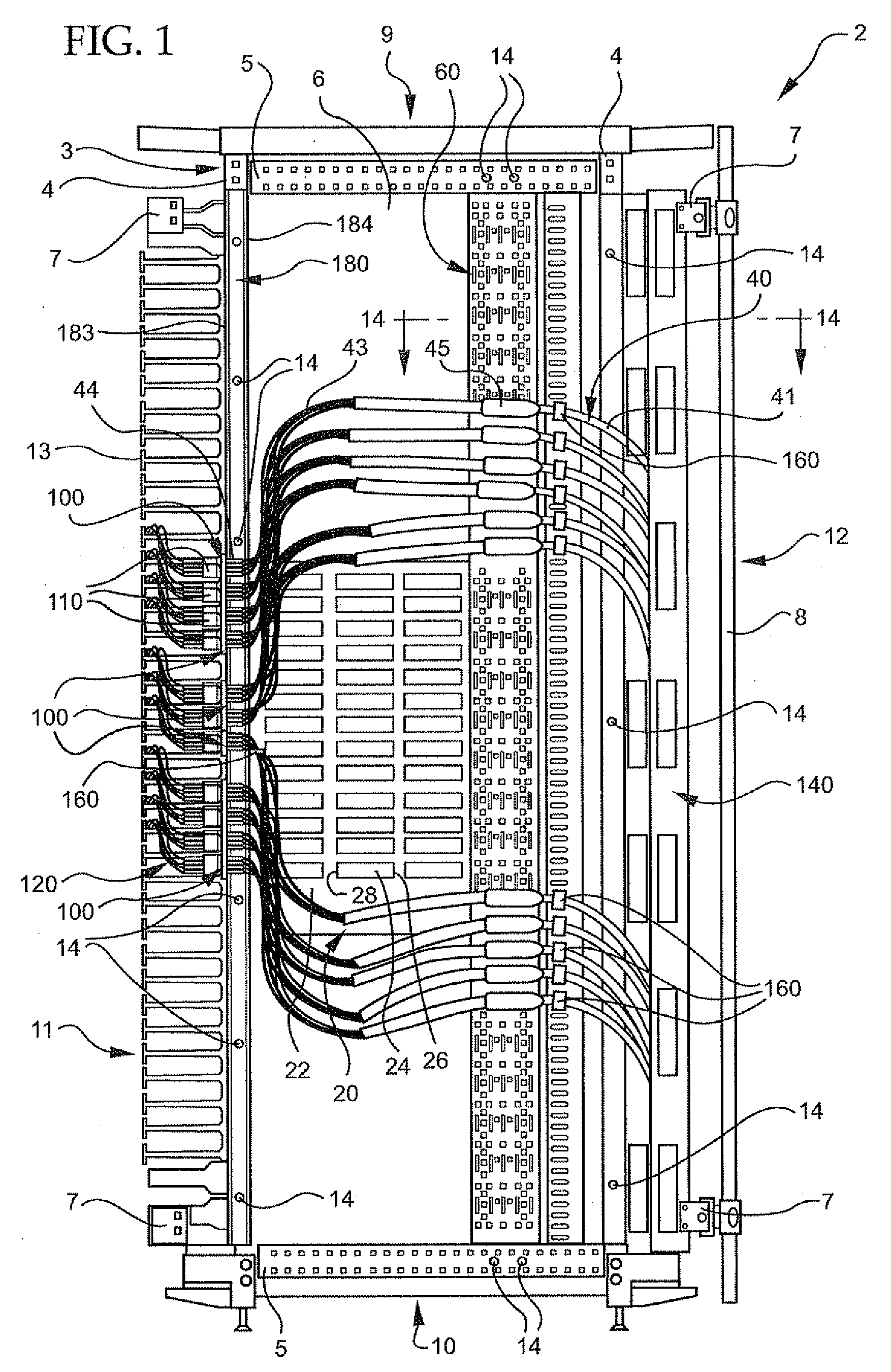

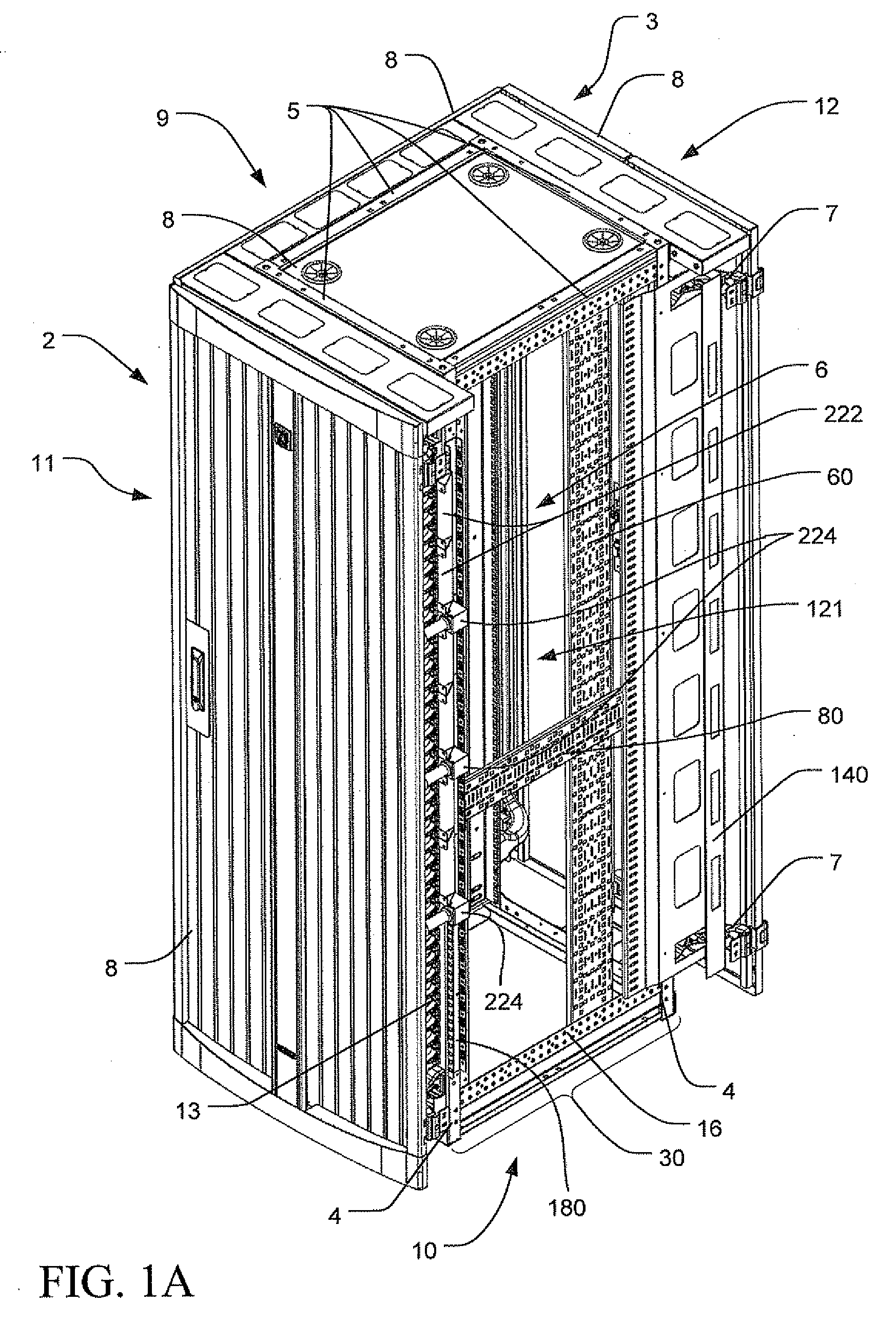

Apparatus and method for organizing cables in a cabinet

ActiveUS7974105B2Reduce hindranceEasy to installBus-bar/wiring layoutsOptical light guidesEngineeringCable management

An equipment cabinet (2) includes an equipment rack (3) for mounting equipment (20), and includes organizational elements for organizing cables within the cabinet. The cables may be organized to reduce impeding airflow to or from the equipment, and / or to reduce unwanted bending of the cables themselves. The organizational elements may include one or more of: a trunk cable (40) including a furcation plug (45) and universal clip (47); a furcation bracket—either vertical (60) or horizontal (80); a termination panel (100); a trunk cable manager (140, 200); and / or an accessory bracket (180). The organizational elements may be used in various combinations with one another, and may be provided in a kit.

Owner:CHATSWORTH PROD INC

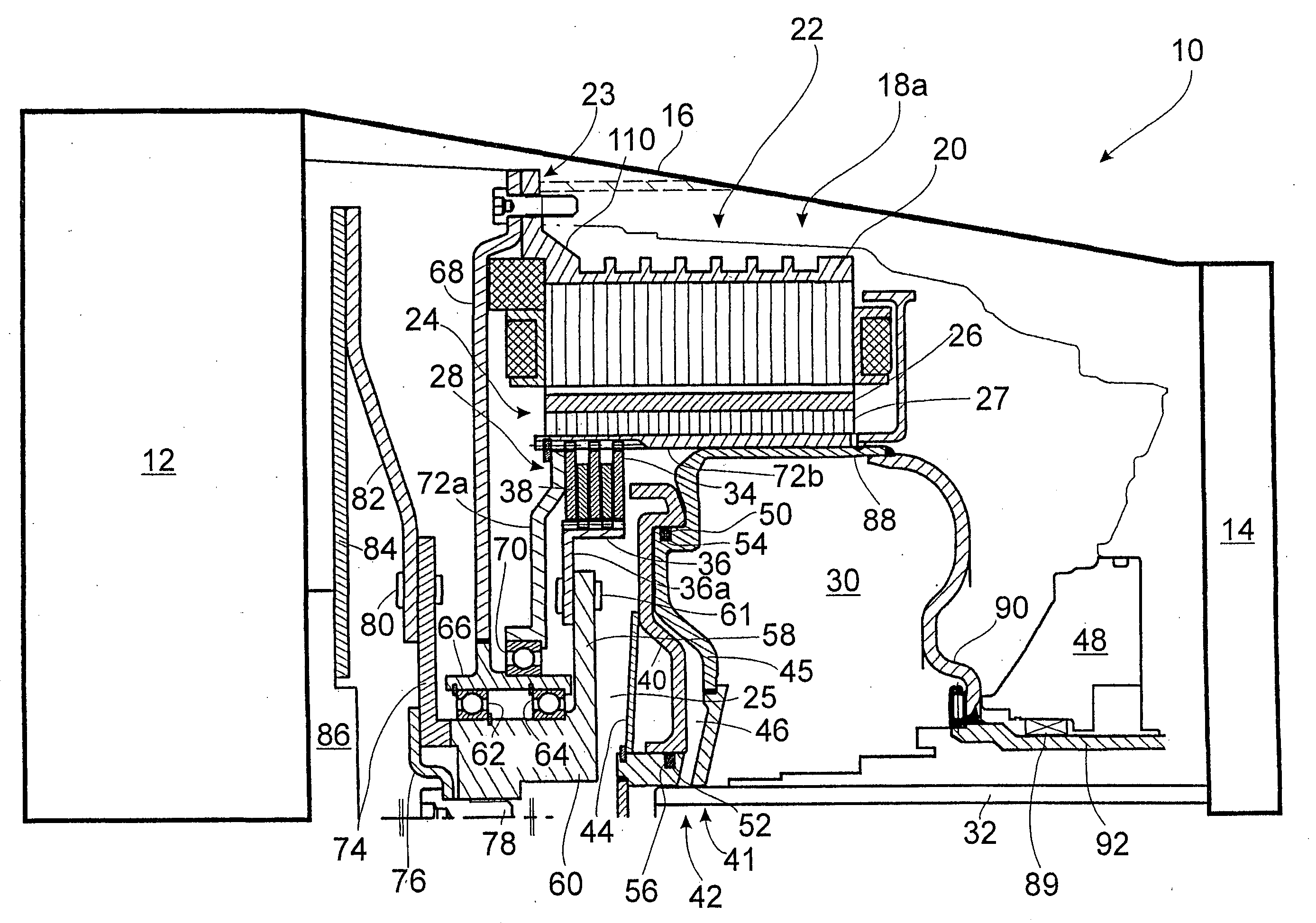

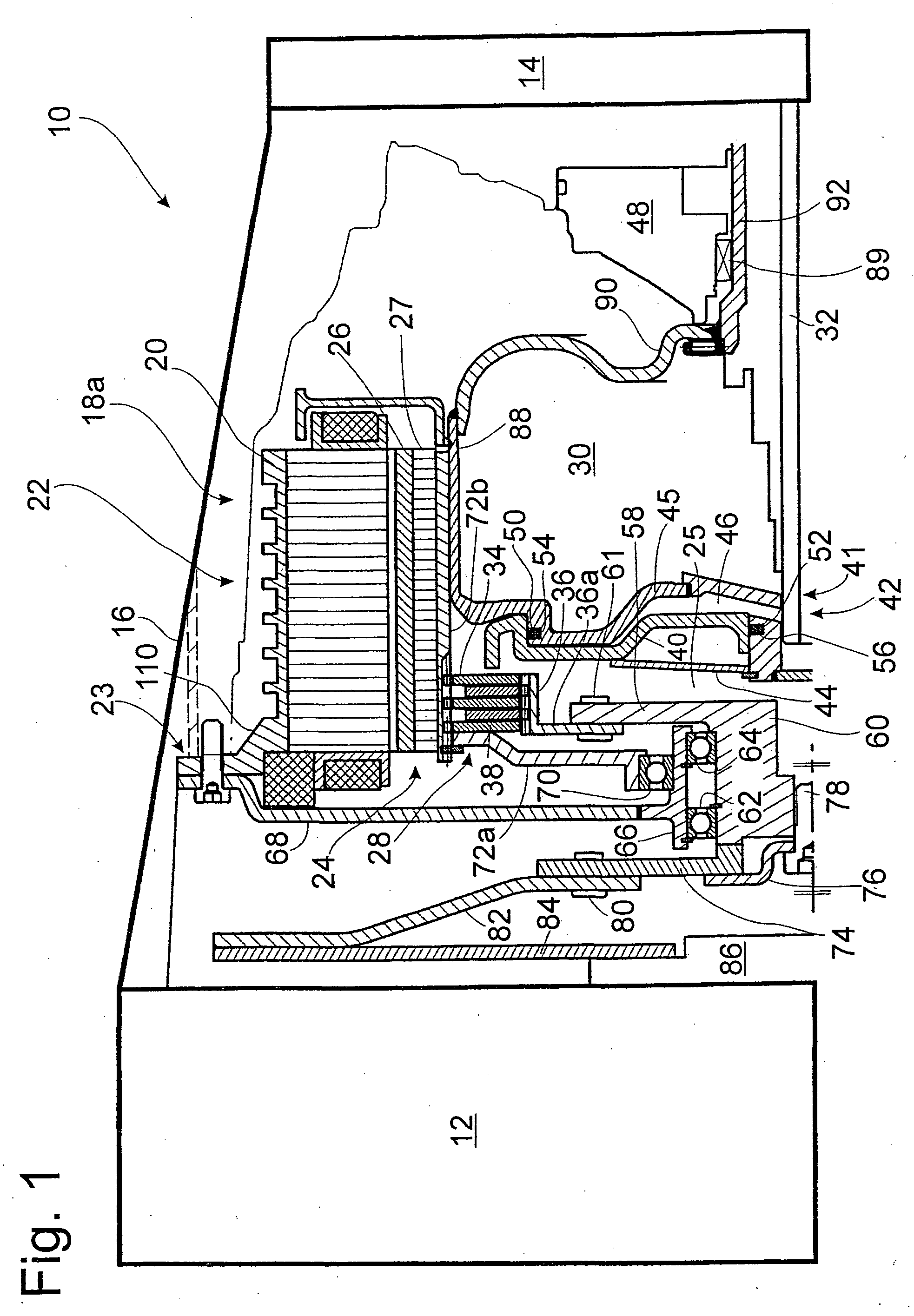

Electromotive drive module

InactiveUS20060289209A1Low costSave considerable assembly timeFluid actuated clutchesGas pressure propulsion mountingElectric machineExternal combustion engine

An electromotive drive module for installation in a housing between an internal combustion engine and a transmission of a motor vehicle power train. The drive module includes an electric machine with a stator and a rotor and first and second clutch devices, by means of which the rotor can be connected when desired to the internal combustion engine and / or to the transmission for the transmission of torque.

Owner:ZF FRIEDRICHSHAFEN AG

Apparatus and method for organizing cables in a cabinet

ActiveUS20090273915A1Improves optical fiber organizationReduces fiber congestionBus-bar/wiring layoutsOptical light guidesEngineeringCable management

An equipment cabinet (2) includes an equipment rack (3) for mounting equipment (20), and includes organizational elements for organizing cables within the cabinet. The cables may be organized to reduce impeding airflow to or from the equipment, and / or to reduce unwanted bending of the cables themselves. The organizational elements may include one or more of: a trunk cable (40) including a furcation plug (45) and universal clip (47); a furcation bracket—either vertical (60) or horizontal (80); a termination panel (100); a trunk cable manager (140, 200); and / or an accessory bracket (180). The organizational elements may be used in various combinations with one another, and may be provided in a kit.

Owner:CHATSWORTH PROD INC

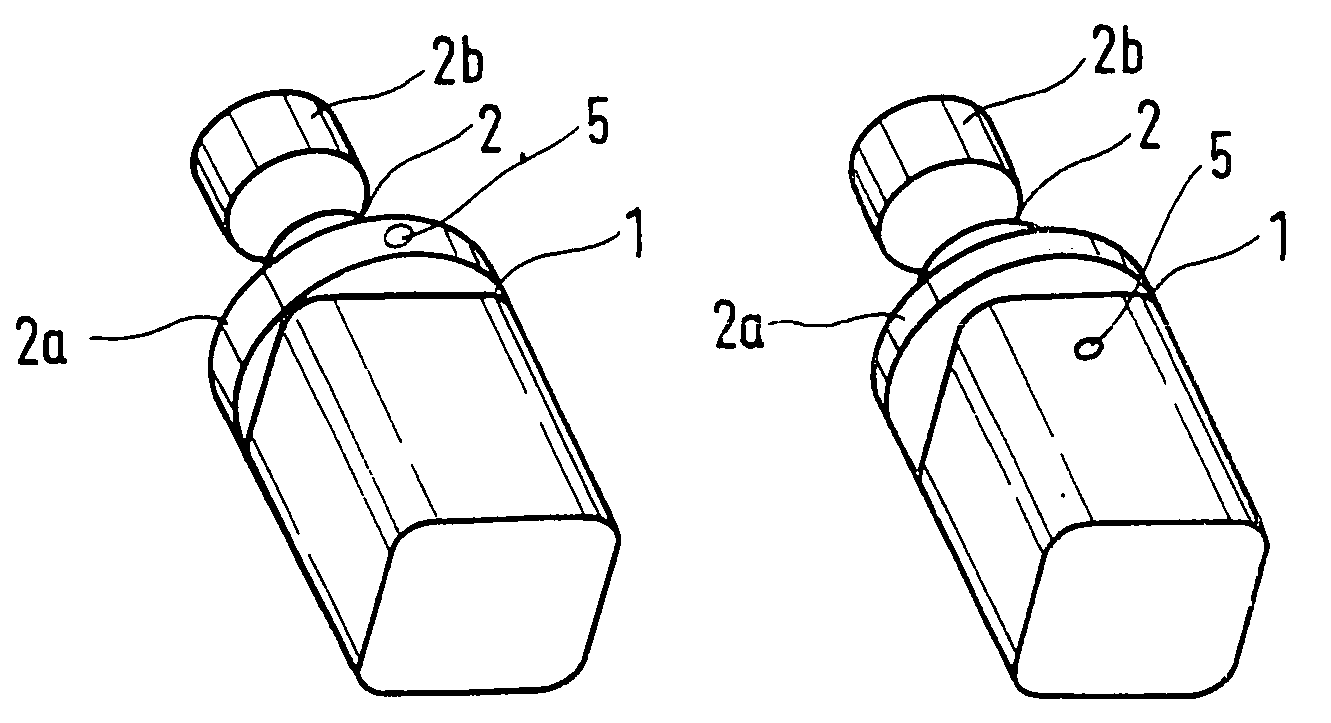

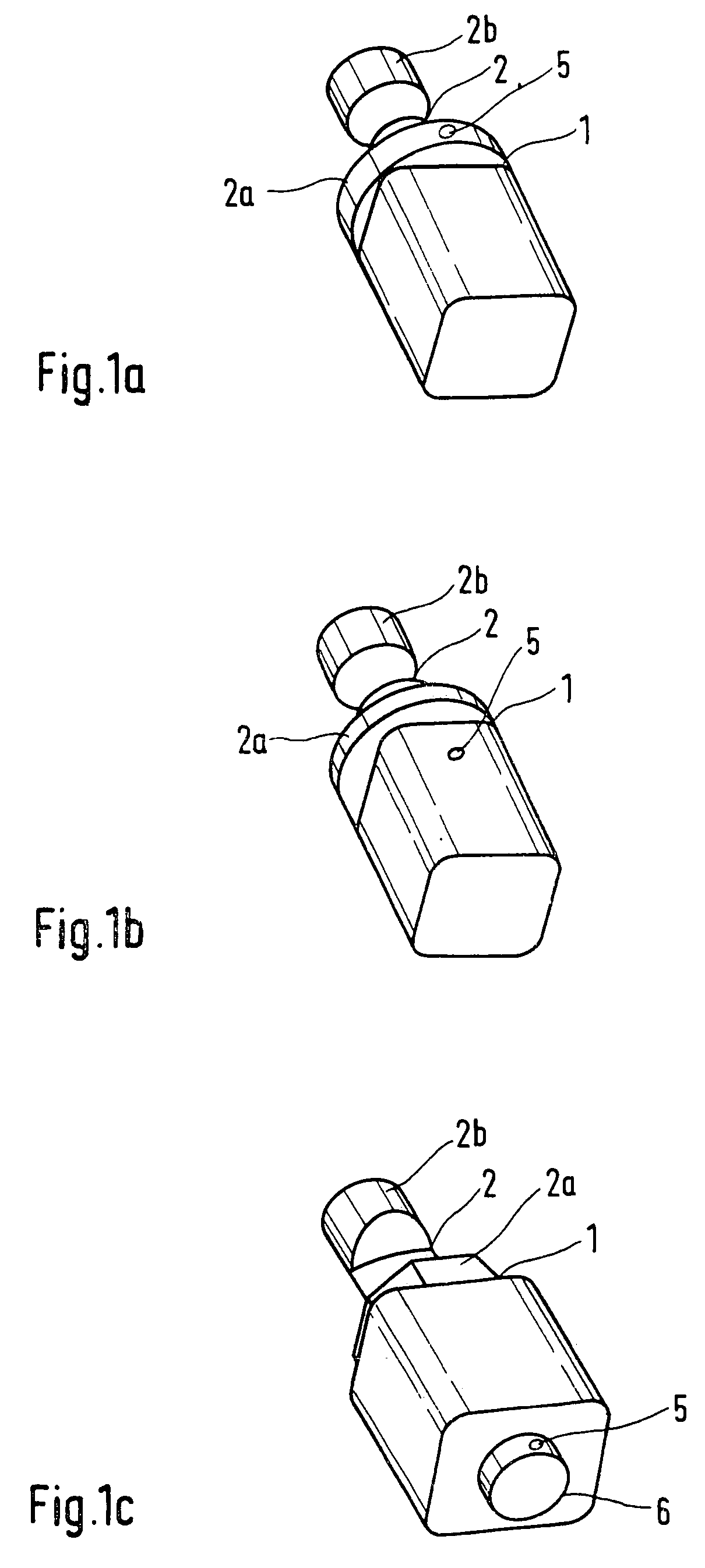

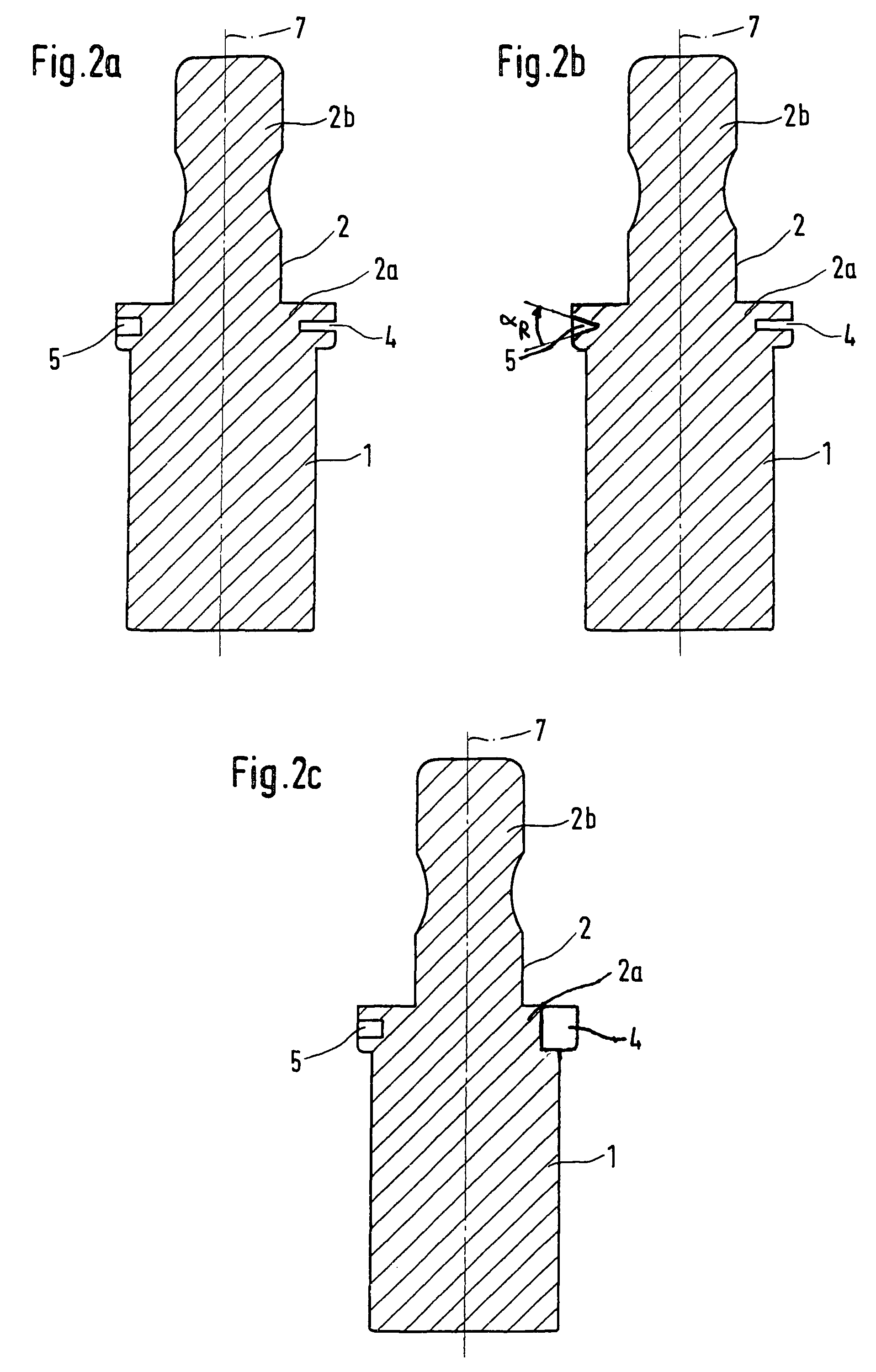

Blank for the production of a dental shaped body and method of producing said shaped body

ActiveUS7985119B2Considerable timeImprove shape qualityGrinding feed controlTooth crownsMaterial removalDental restorative materials

A blank and method for the production of dental shaped bodies in machining equipment having at least two tools located in the machining chamber of the machining equipment, including a corpus of tooth restoration material, from which the shaped body can be carved by means of at least one of at least two tools by material removal. The blank exhibits at least two gages, each of which is in the form of a recess, the geometry of which is such that the tool selected for the cutting operation can be recognized by means of at least one of the gages by reference to its outer contour, the at least two gages being disposed on the blank in such a way that they can be simultaneously engaged by the at least tools when the blank is clamped in the machining equipment for carving purposes.

Owner:SIRONA DENTAL SYSTEMS

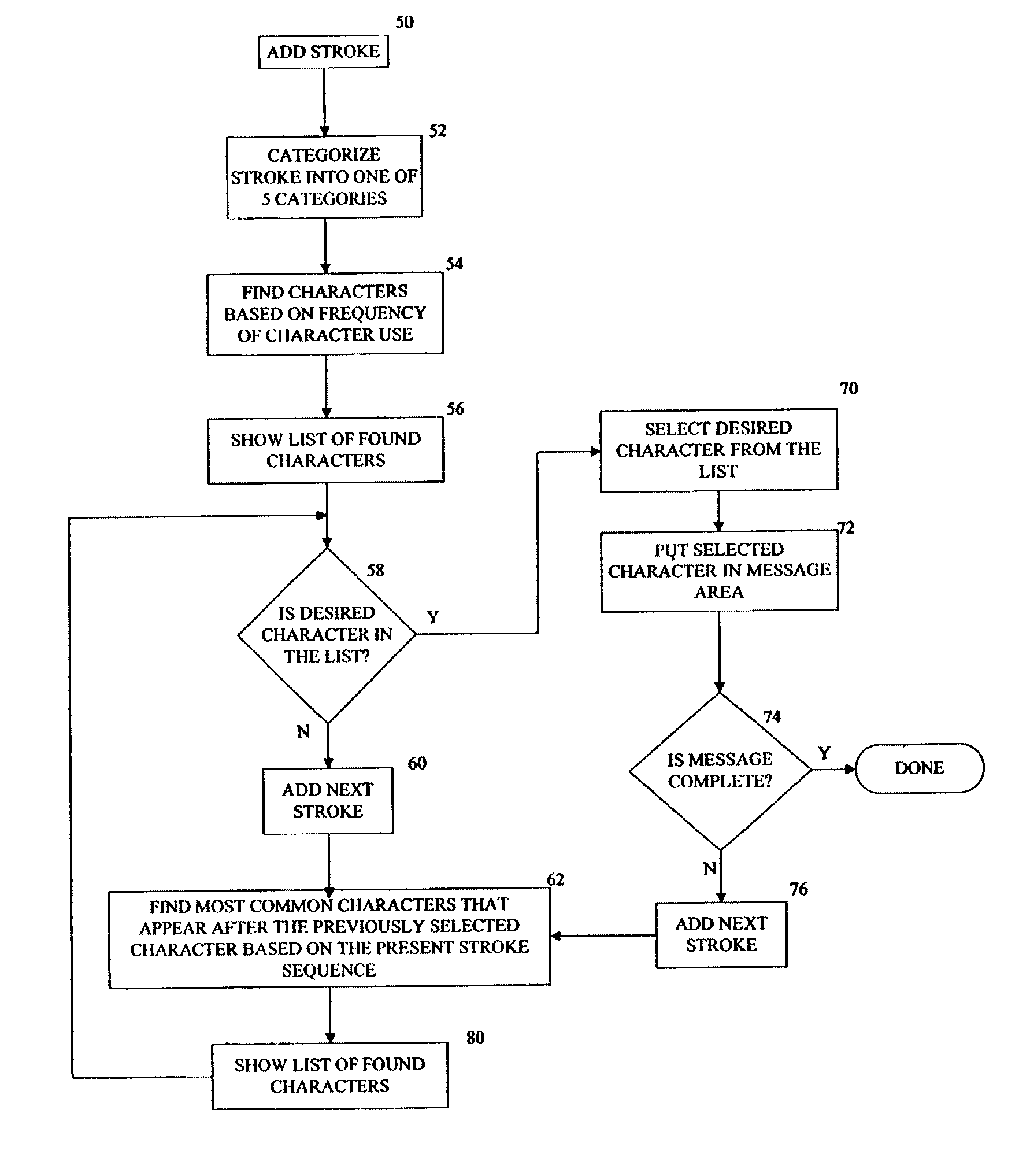

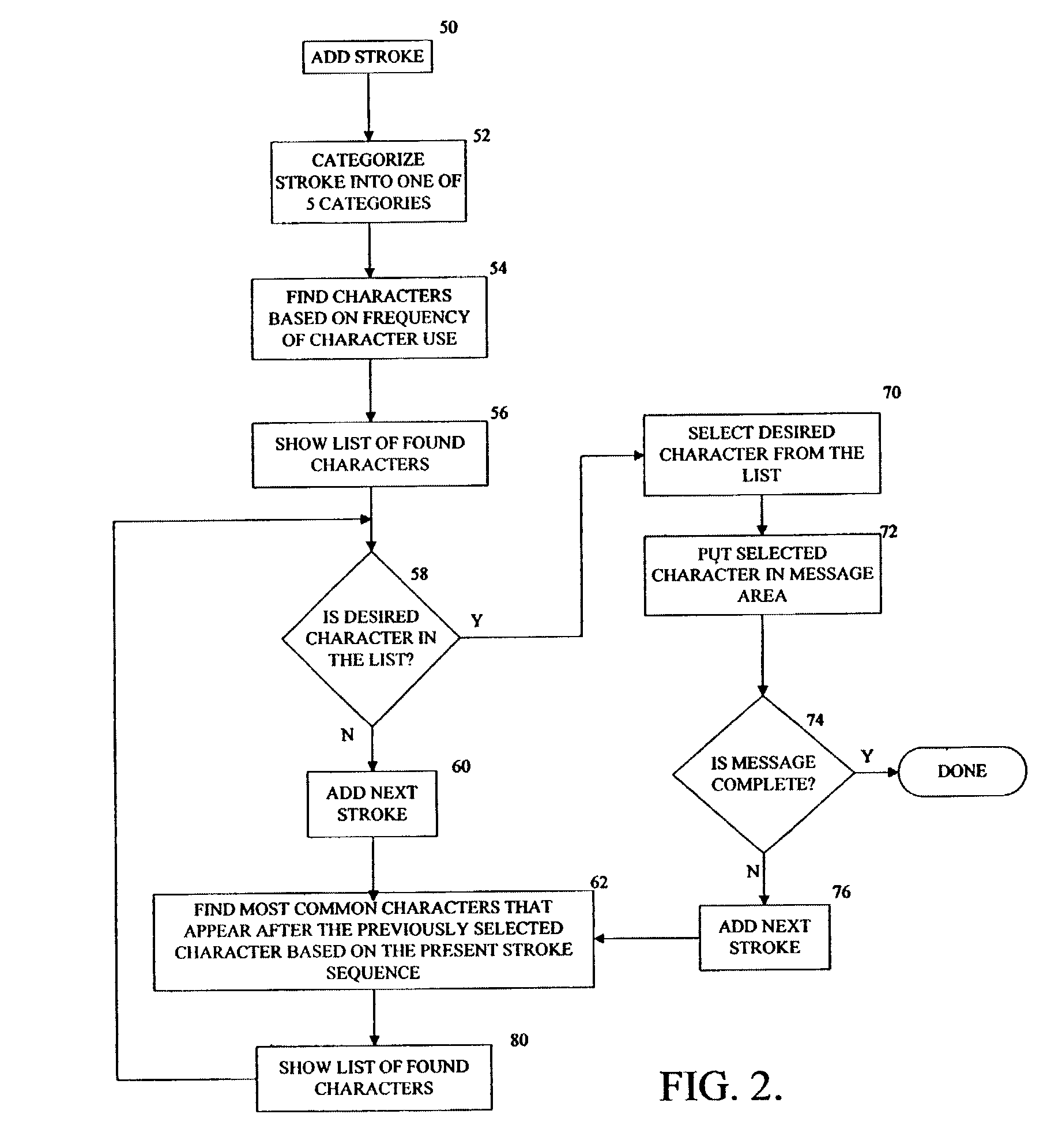

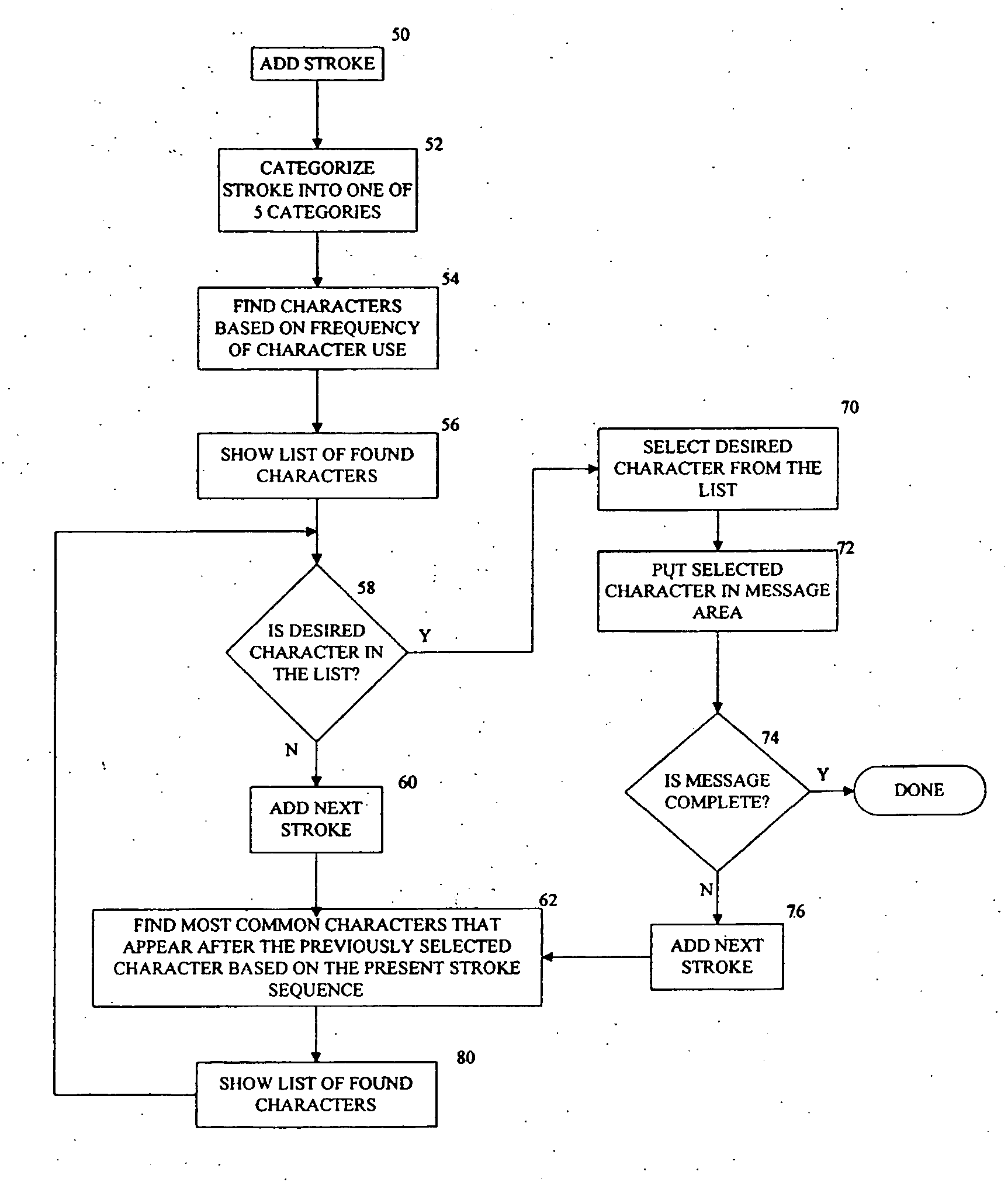

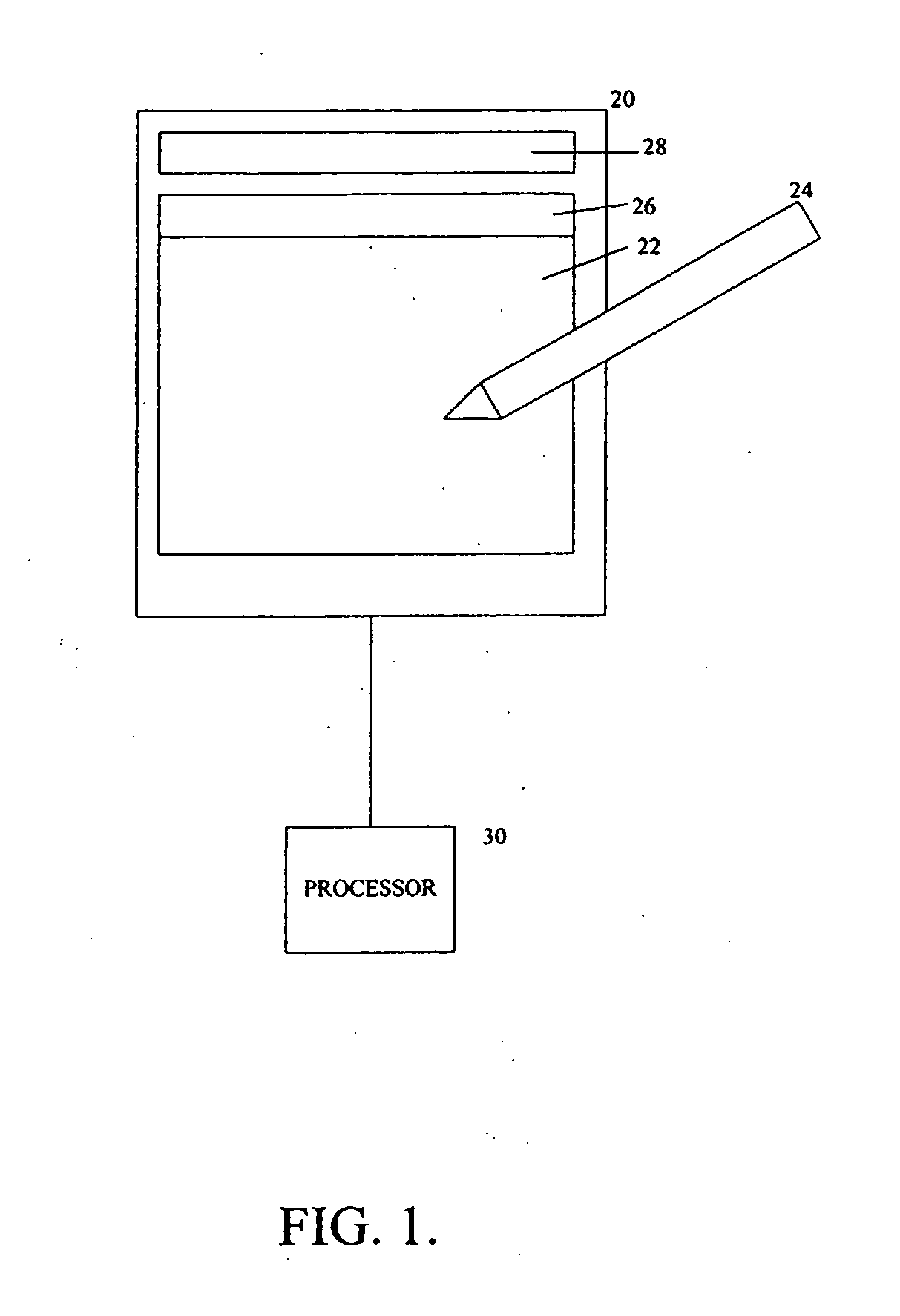

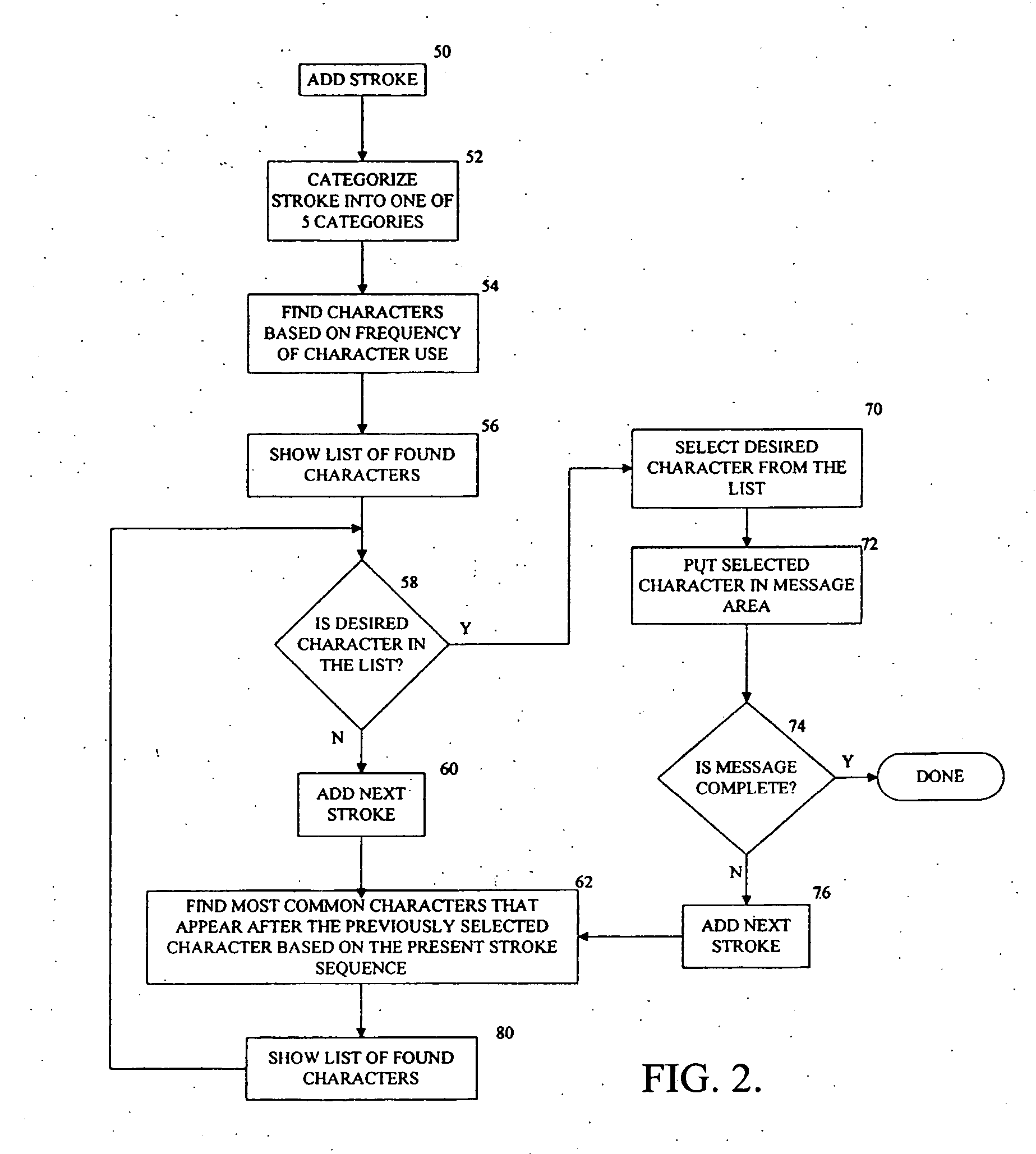

Chinese character handwriting recognition system

InactiveUS6970599B2Save timeConsiderable timeInput/output for user-computer interactionCharacter and pattern recognitionSpeech recognitionHandwriting recognition

A handwritten Chinese character input method and system is provided to allow users to enter Chinese characters to a data processor by adding less than three strokes and one selection movement such as mouse clicking or stylus or finger tapping. The system is interactive, predictive, and intuitive to use. By adding one or two strokes which are used to start writing a Chinese character, or in some case even no strokes are needed, users can find a desired character from a list of characters. The list is context sensitive. It varies depending on the prior character entered. Compared to other existing systems, this system can save users considerable time and efforts to entering handwritten characters.

Owner:TEGIC COMM

Intelligent Network Providing Network Access Services (INP-NAS)

ActiveUS20090238349A1Efficient use ofConsiderable timeBroadband local area networksTelephonic communicationIntelligent NetworkNetwork architecture

An open Information Services network architecture is disclosed which enables multiple business entities to assume specialized roles of access provider, service provider, and service retailer. The disclosed technology provides instant plug-and-play service, decouples access and service networks and provides seamless (single step) access enabling customers to maintain a service account regardless of location. The benefits of the disclosed technology, among others, include: Multi-level and multi-service registration; Broker Services providing customers with a choice of provider; Security Services relating to distribution; Revenue Assurance services, Gentle Reminder / Gentle Touch; Revenue Assurance services pertaining to usage integrity verification upon registration; mobile services derived from G-ISN; and claim benefits pertaining to LNP services derived from G-ISN.

Owner:AI CORE TECH LLC

Chinese character handwriting recognition system

InactiveUS20060062461A1Considerable timeInput/output for user-computer interactionCharacter and pattern recognitionFinger tappingChinese characters

A handwritten Chinese character input method and system is provided to allow users to enter Chinese characters to a data processor by adding less than three strokes and one selection movement such as mouse clicking or stylus or finger tapping. The system is interactive, predictive, and intuitive to use. By adding one or two strokes which are used to start writing a Chinese character, or in some case even no strokes are needed, users can find a desired character from a list of characters. The list is context sensitive. It varies depending on the prior character entered. Compared to other existing systems, this system can save users considerable time and efforts to entering handwritten characters.

Owner:TEGIC COMM

System and method for evaluating equipment rack cooling performance

ActiveUS7991592B2Considerable timeThermometer detailsDigital data processing detailsAnalysis dataData center

Owner:SCHNEIDER ELECTRIC IT CORP

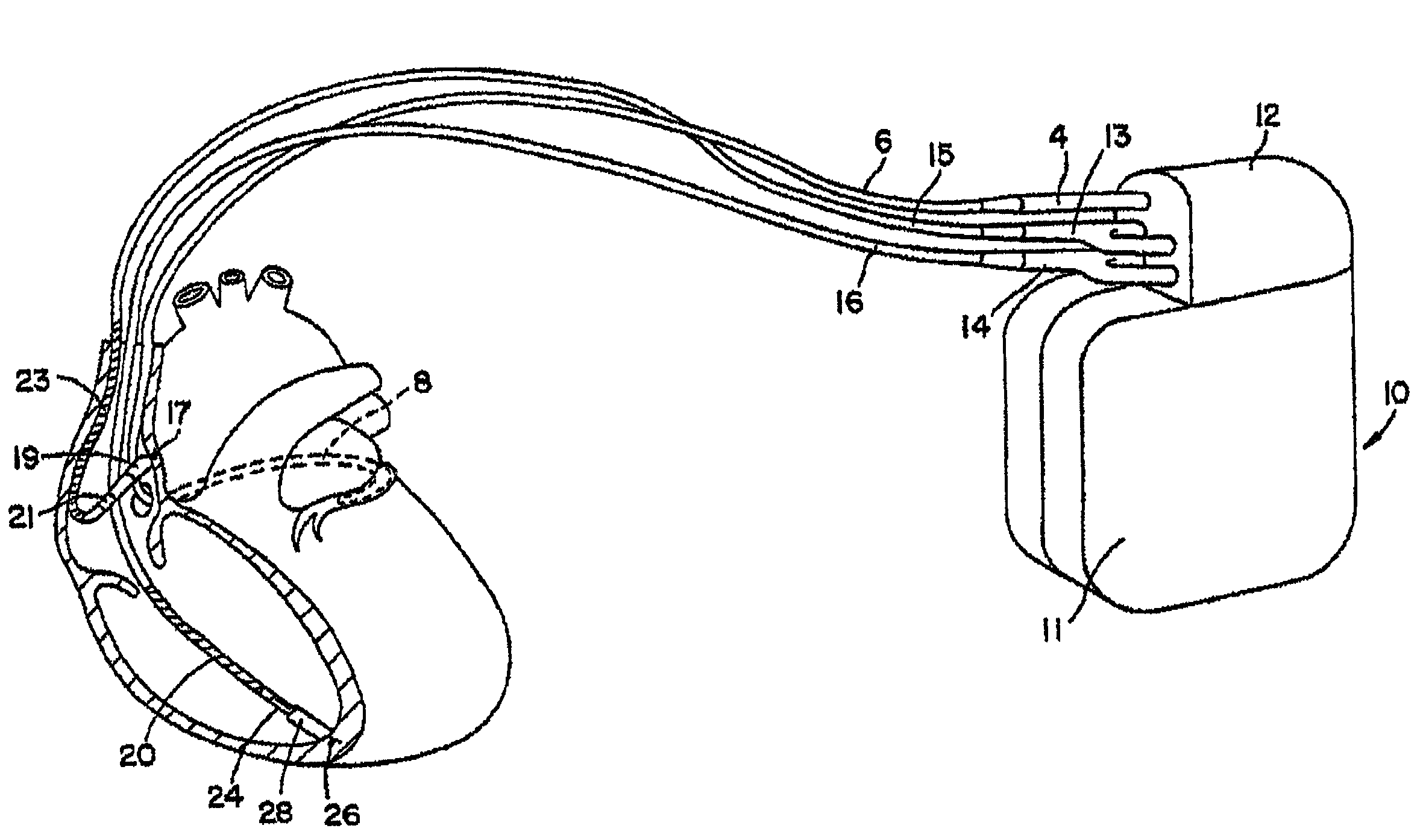

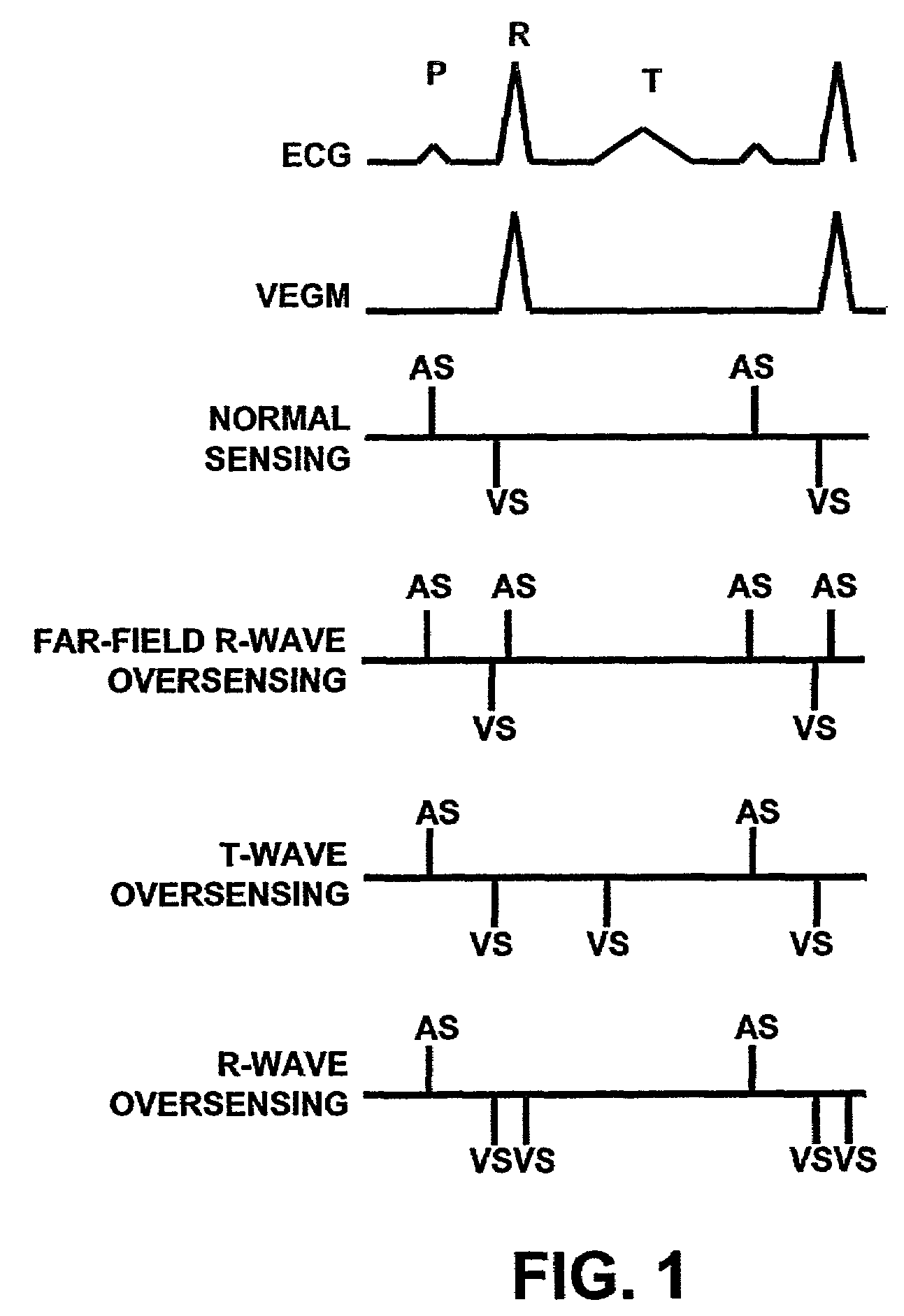

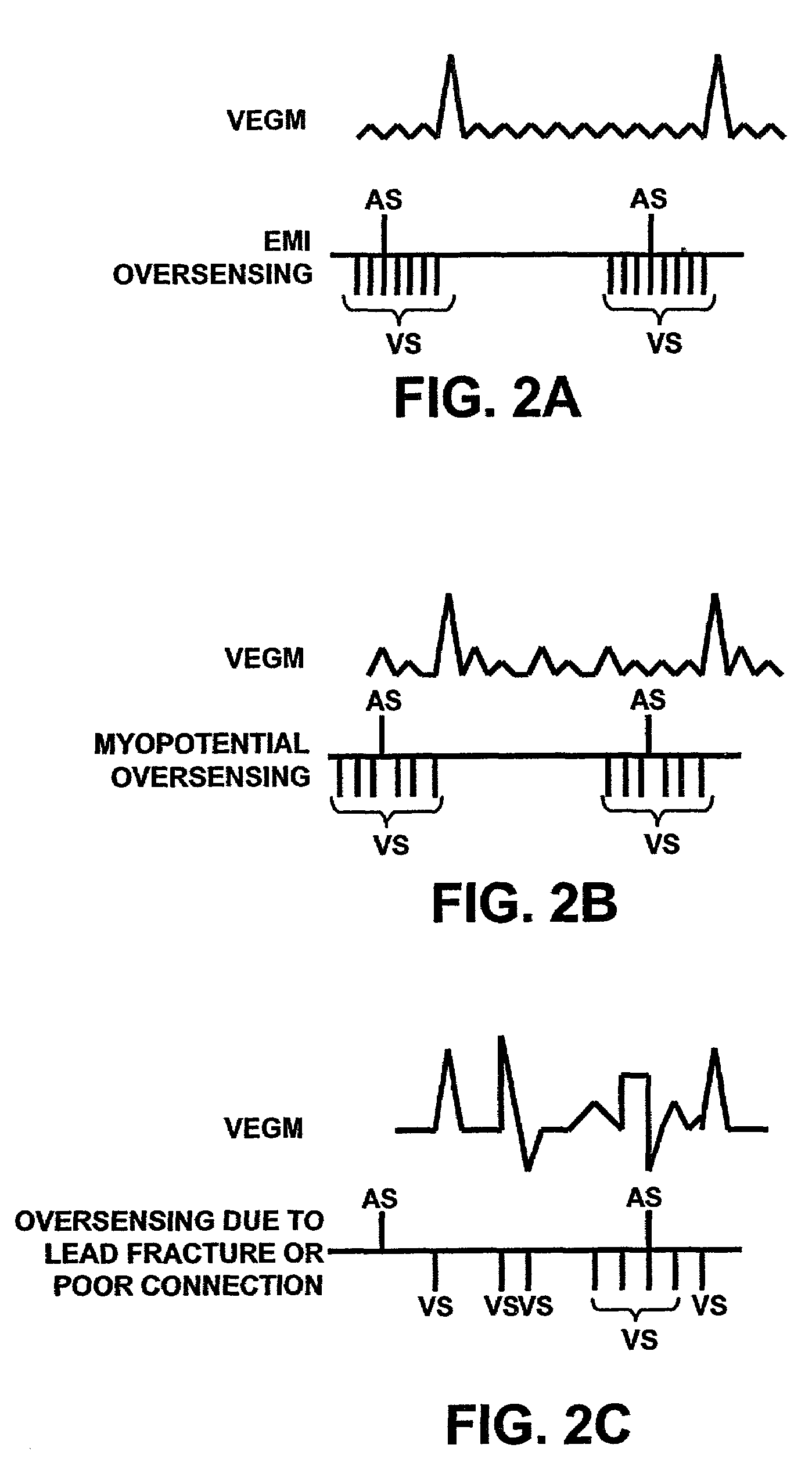

Method and apparatus for identifying cardiac and non-cardiac oversensing using intracardiac electrograms

ActiveUS7283863B2Eliminate oversensingConsiderable timeElectrocardiographyHeart defibrillatorsEngineeringElectromagnetic interference

A method and apparatus for automatically identifying various types of cardiac and non-cardiac oversensing is provided. EGM data, including time intervals between sensed and paced events and signal morphologies, are analyzed for patterns indicative of various types of oversensing, including oversensing of far-field R-waves, R-waves, T-waves, or noise associated with electromagnetic interference, non-cardiac myopotentials, a lead fracture, or a poor lead connection. Identification of oversensing and its suspected cause are reported so that corrective action may be taken.

Owner:MEDTRONIC INC

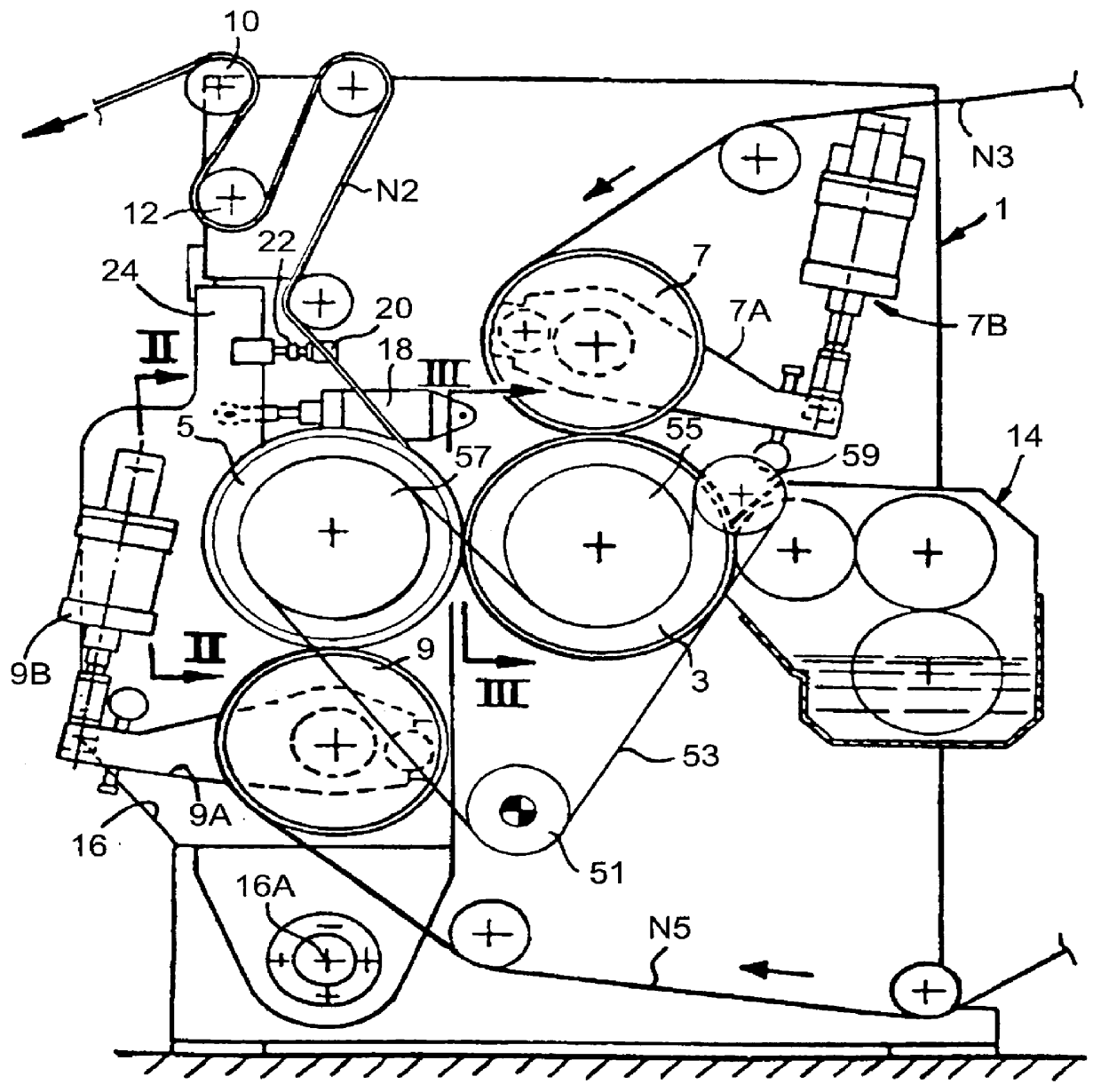

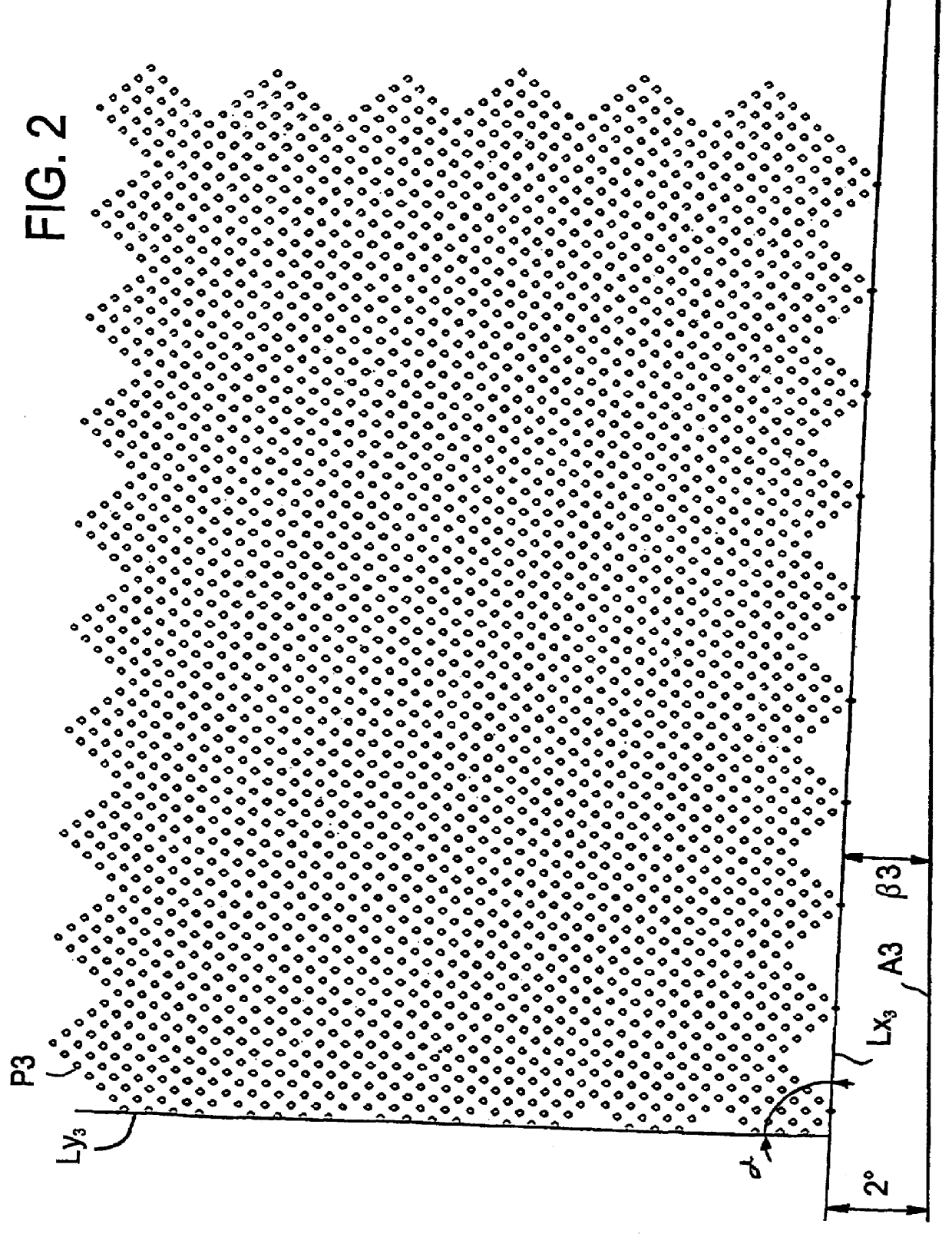

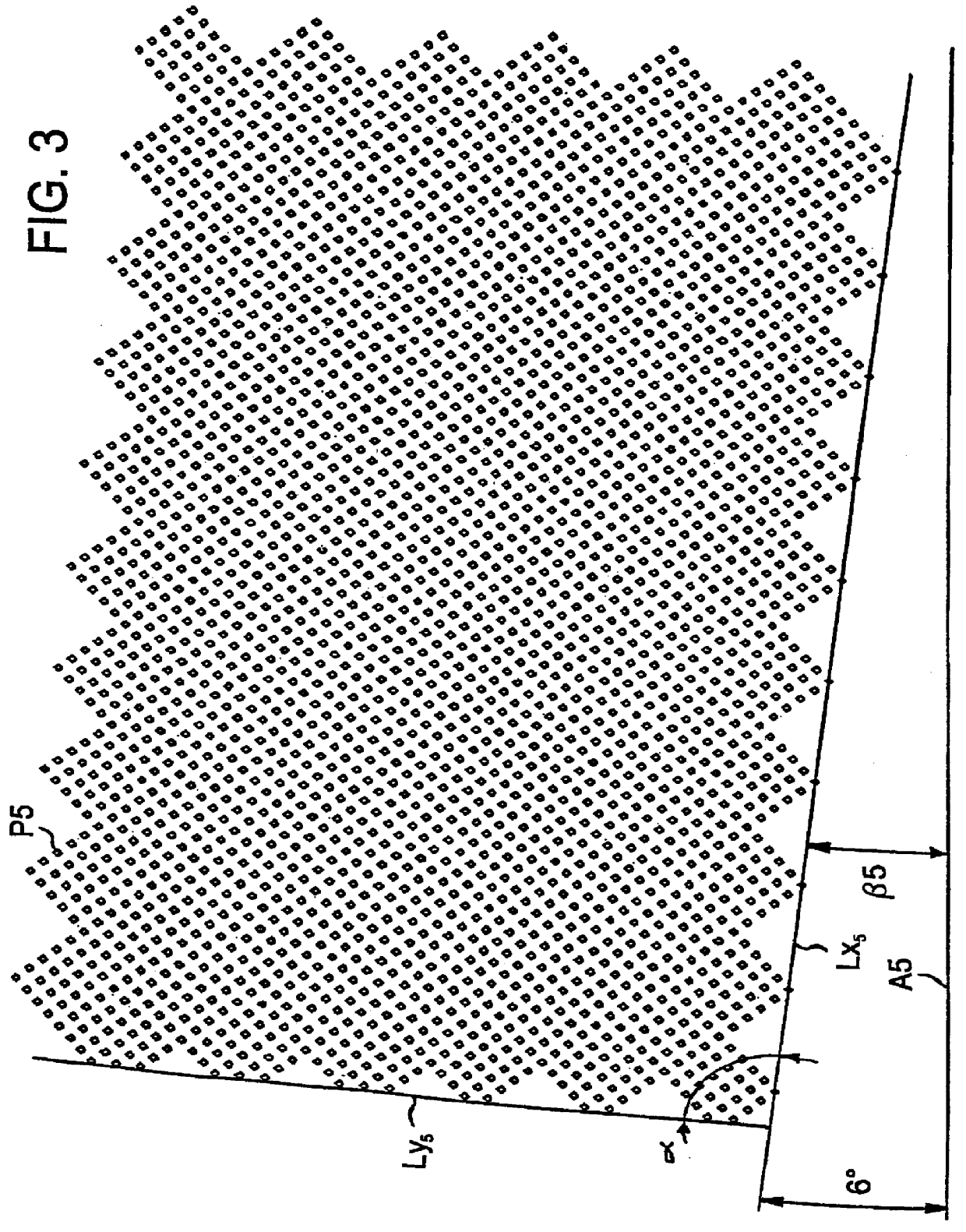

Embossing and laminating machine with embossing cylinders having different rotational speed

InactiveUS6053232AConsiderable timeReduce construction and maintenance costMechanical working/deformationWelding/cutting auxillary devicesEngineeringMechanical engineering

PCT No. PCT / IT96 / 00238 Sec. 371 Date Oct. 28, 1998 Sec. 102(e) Date Oct. 28, 1998 PCT Filed Dec. 2, 1996 PCT Pub. No. WO97 / 20687 PCT Pub. Date Jun. 12, 1997An embossing and laminating machine comprising a first embossing cylinder with a surface provided with a first set of protuberances, a second embossing cylinder with a surface provided with a second set of protuberances, said two embossing cylinders forming a nip, and a first and a second pressure roller interacting with said first and second embossing cylinders respectively; and in which said sets of protuberances are made in such a way that in said nip some of said first set of protuberances coincide with some of said second set of protuberances, while other protuberances of said first set are out of phase with corresponding protuberances of said second set, wherein said embossing cylinders are mechanically connected by a transmission which does not keep the cylinders in phase and which causes slight relative slippage between said embossing cylinders.

Owner:FABIO PERINI SPA

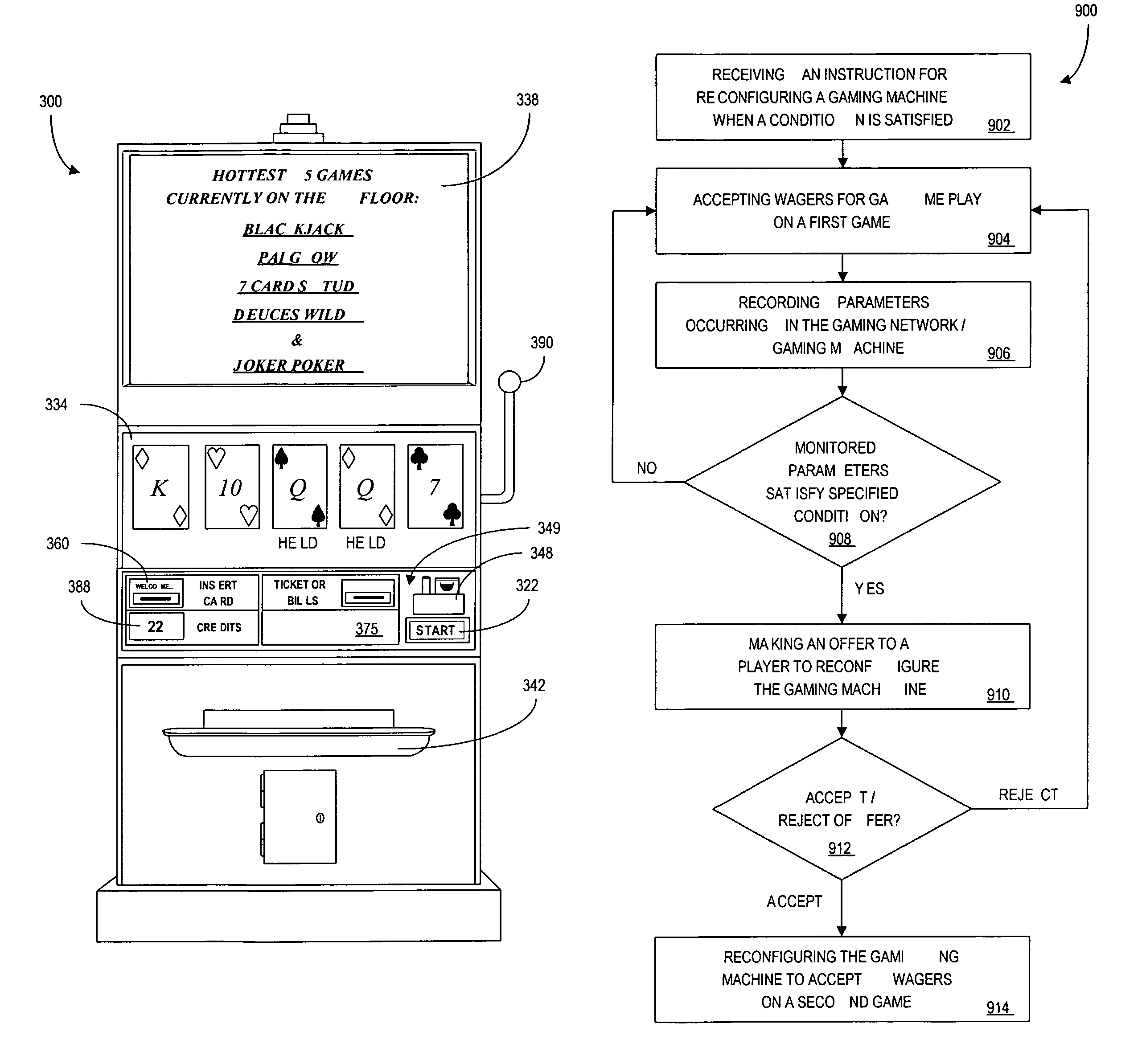

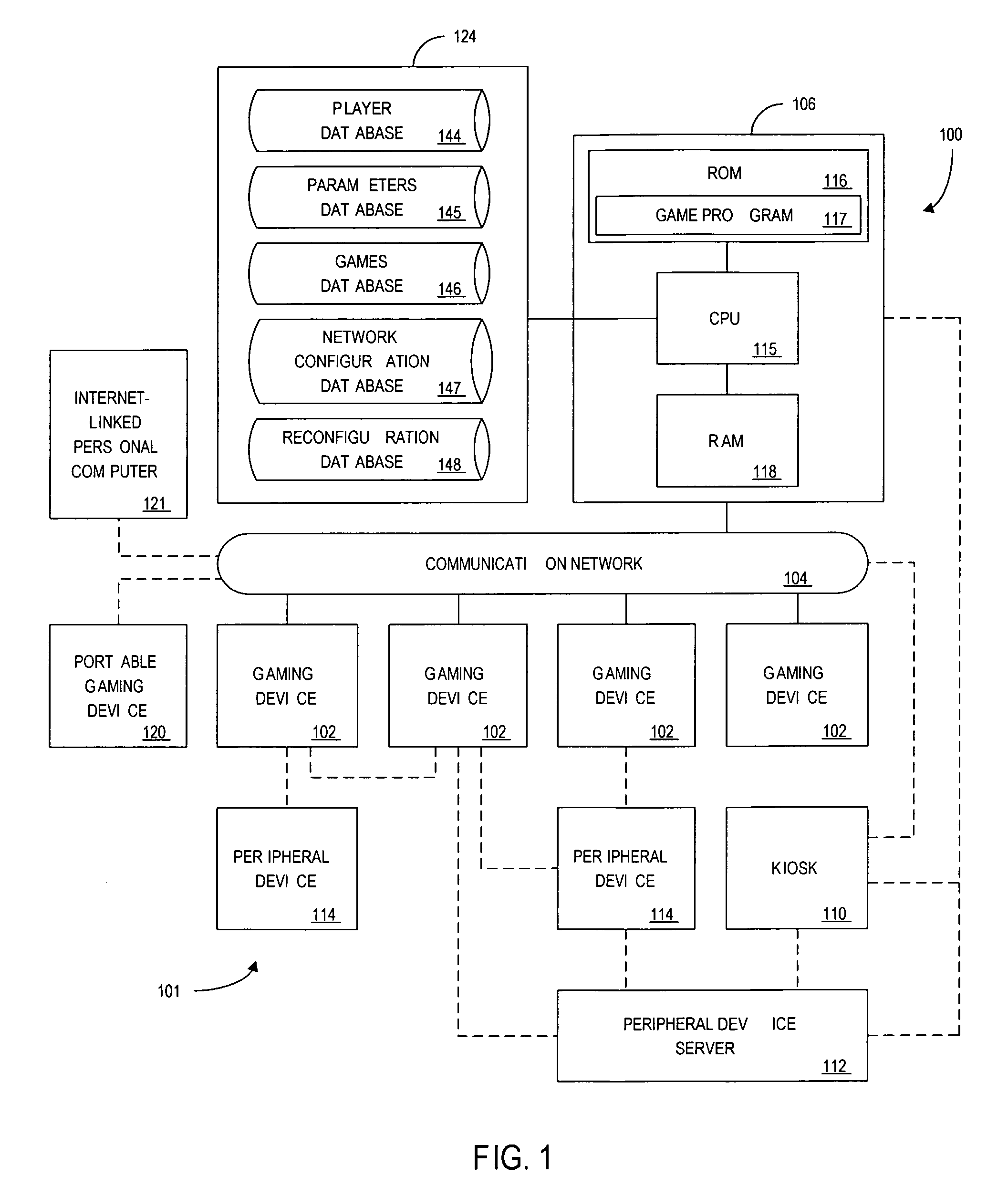

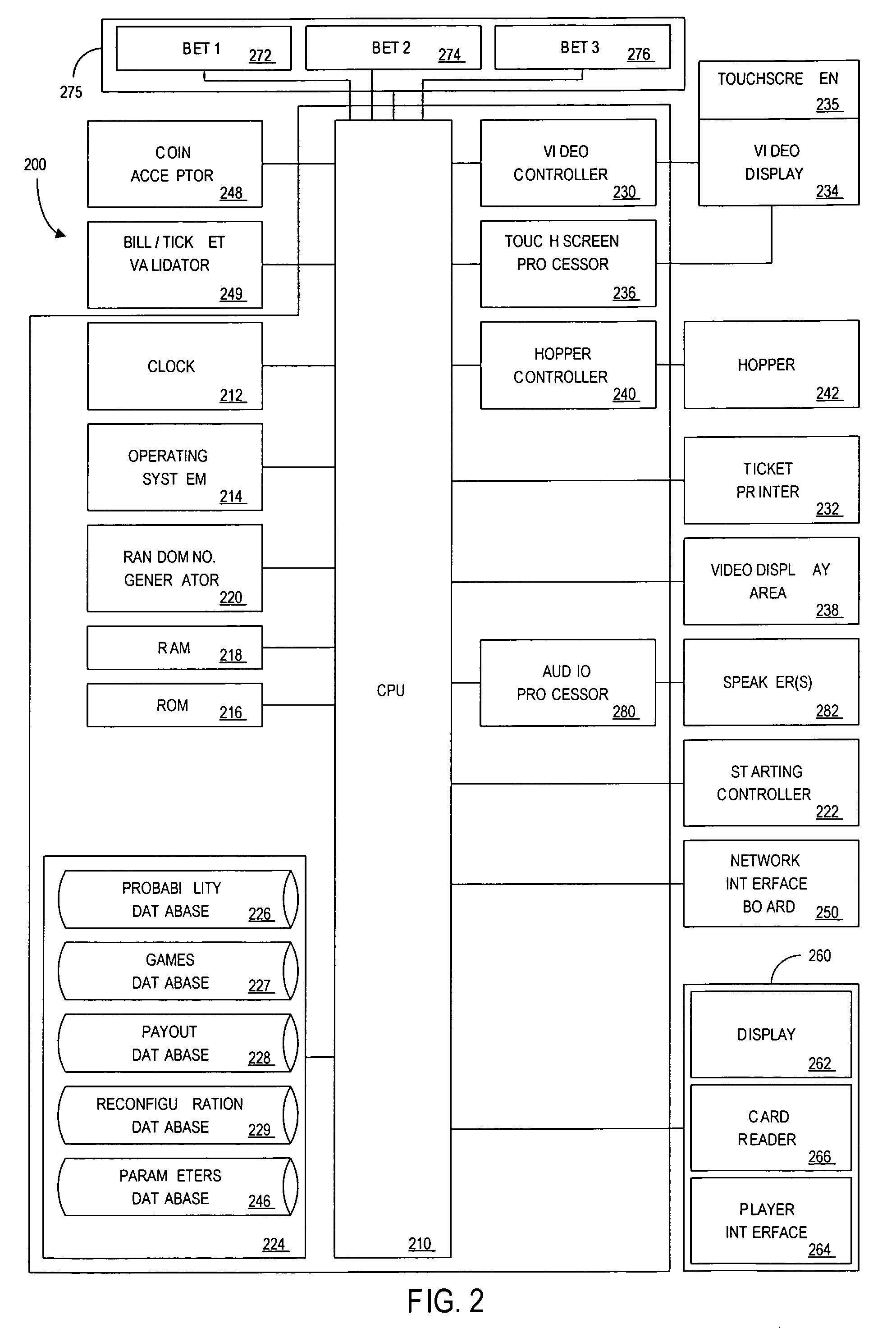

Method and apparatus for using conditional parameters to alternate between wagering games

ActiveUS7918736B2Considerable energyConsiderable timeApparatus for meter-controlled dispensingVideo gamesGame playParameter dependent

A wagering method is provided that allows players or gaming establishments to specify conditions which when satisfied, reconfigure the gaming device to change game play from a first game to a second game. The condition may depend upon the value of a parameter—generally related to game play—to determine if the condition is valid and triggers the reconfiguration. The second game may be selected from a game on the same gaming device, from a game on a different gaming device, or a game played by a specific player.

Owner:IGT

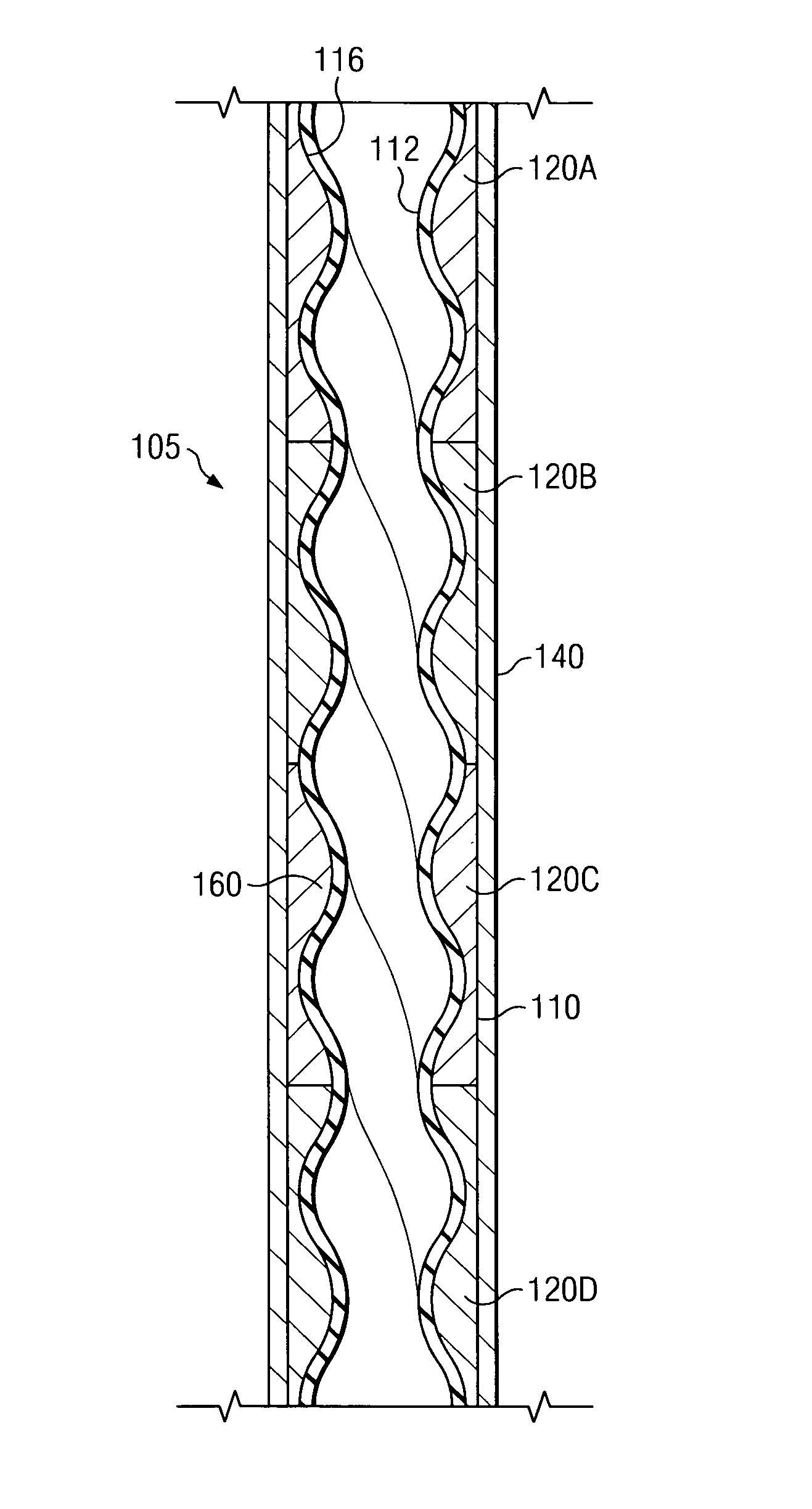

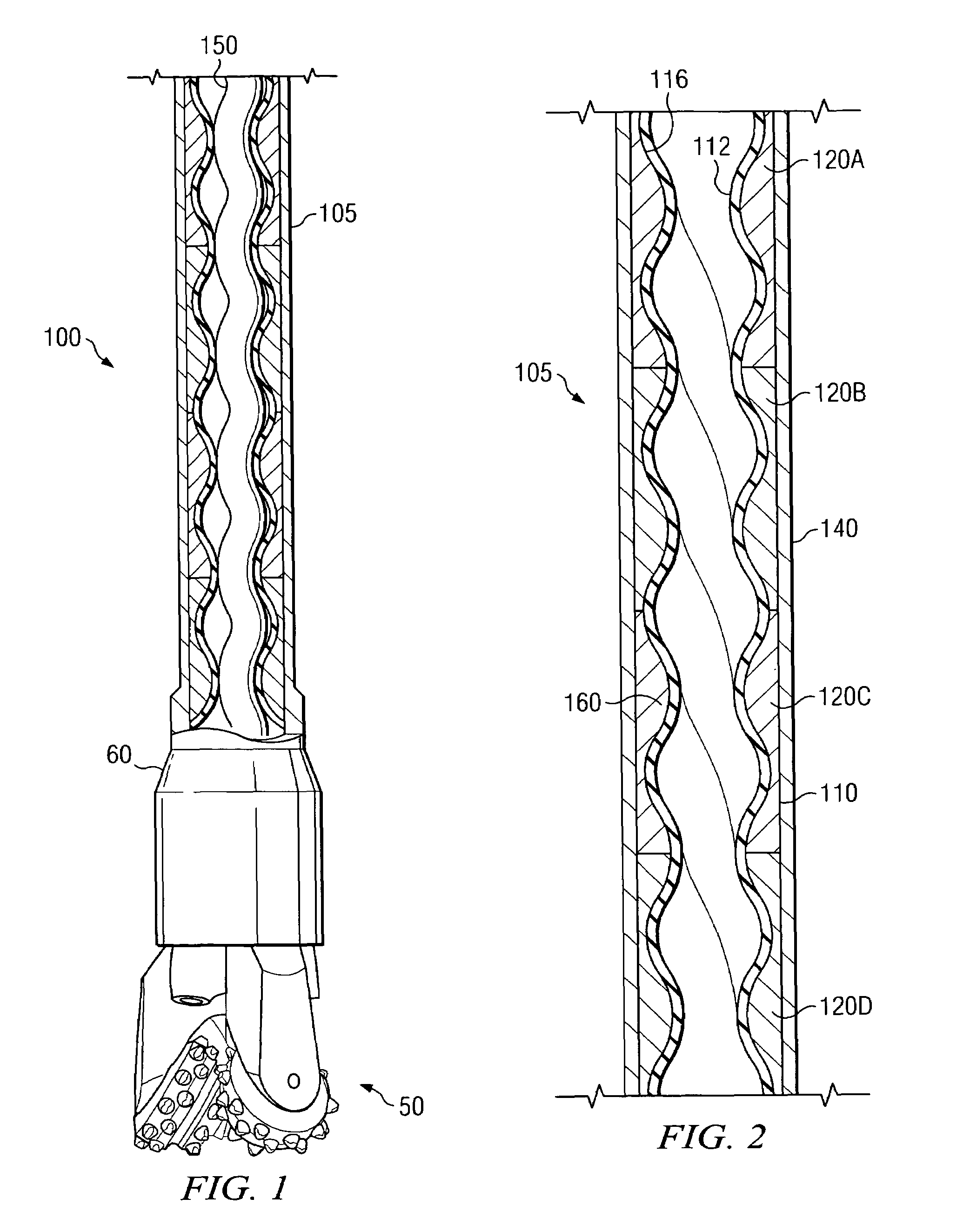

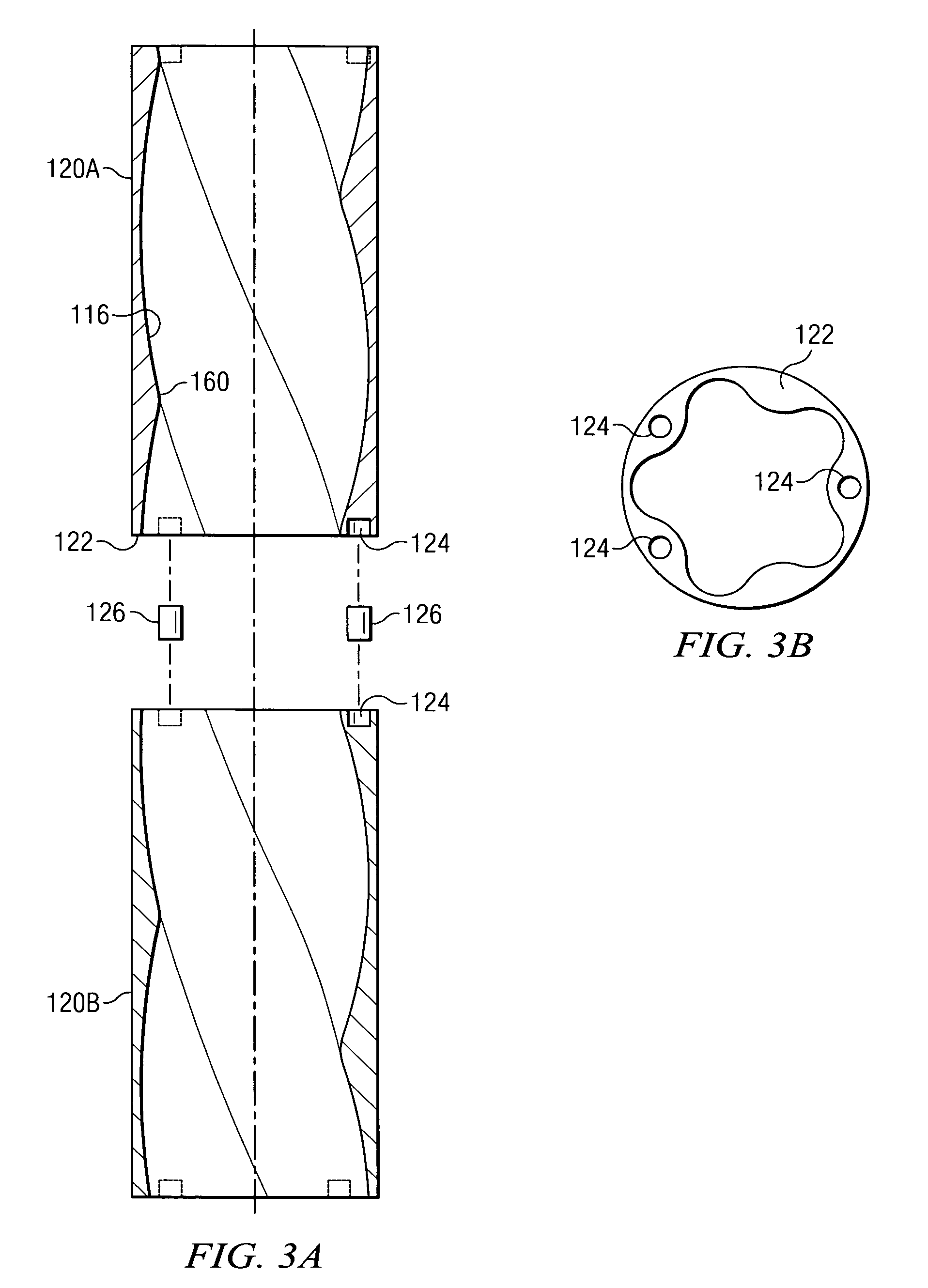

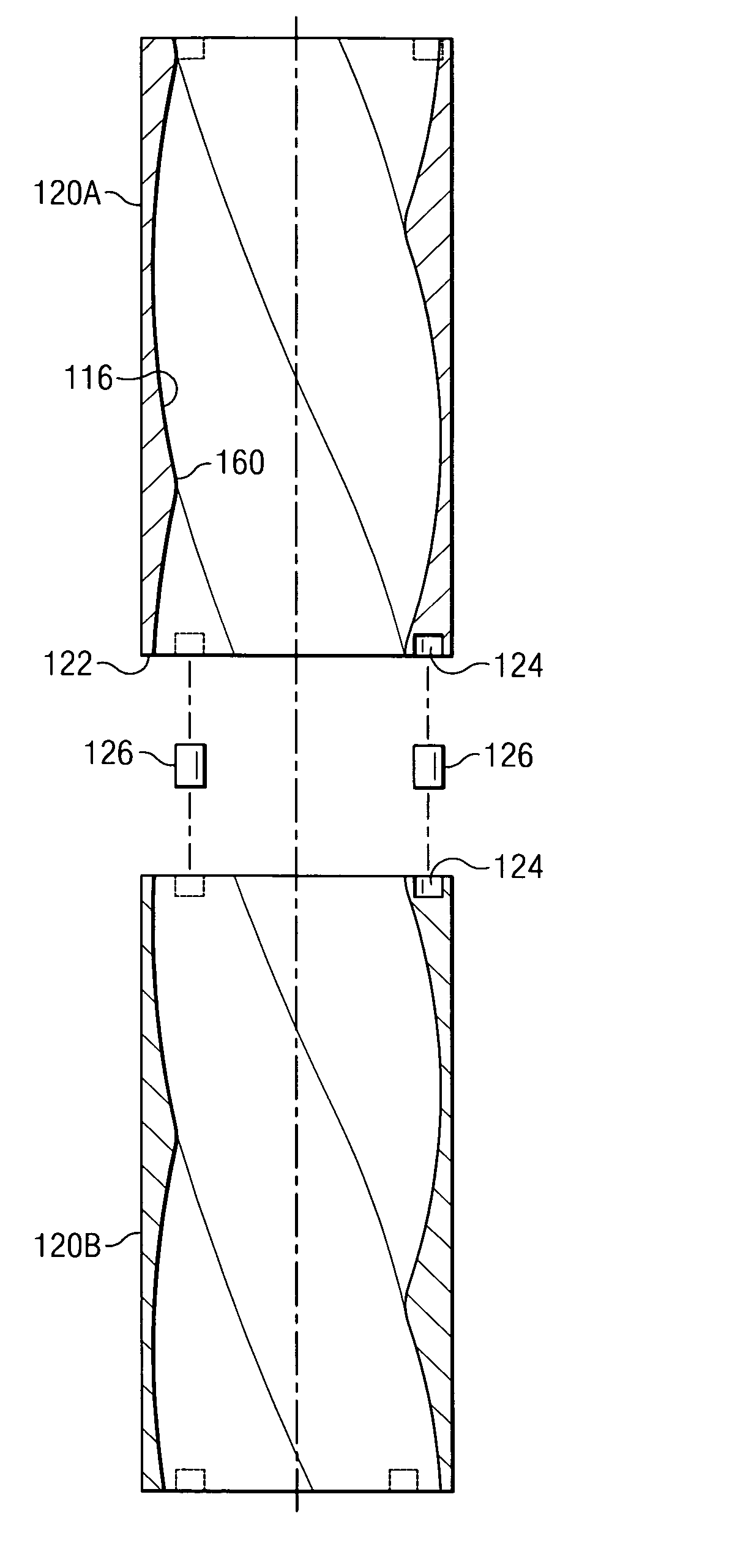

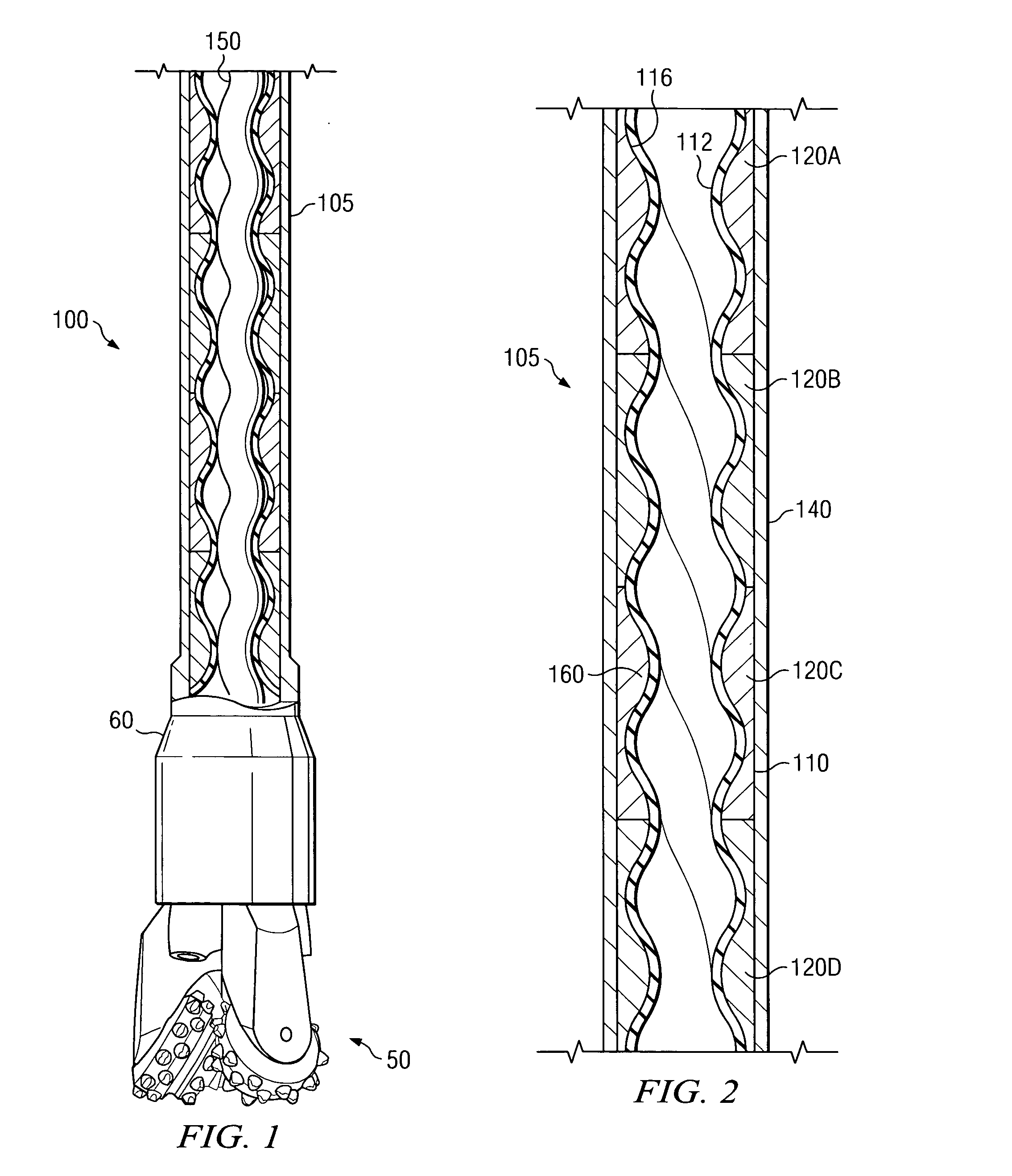

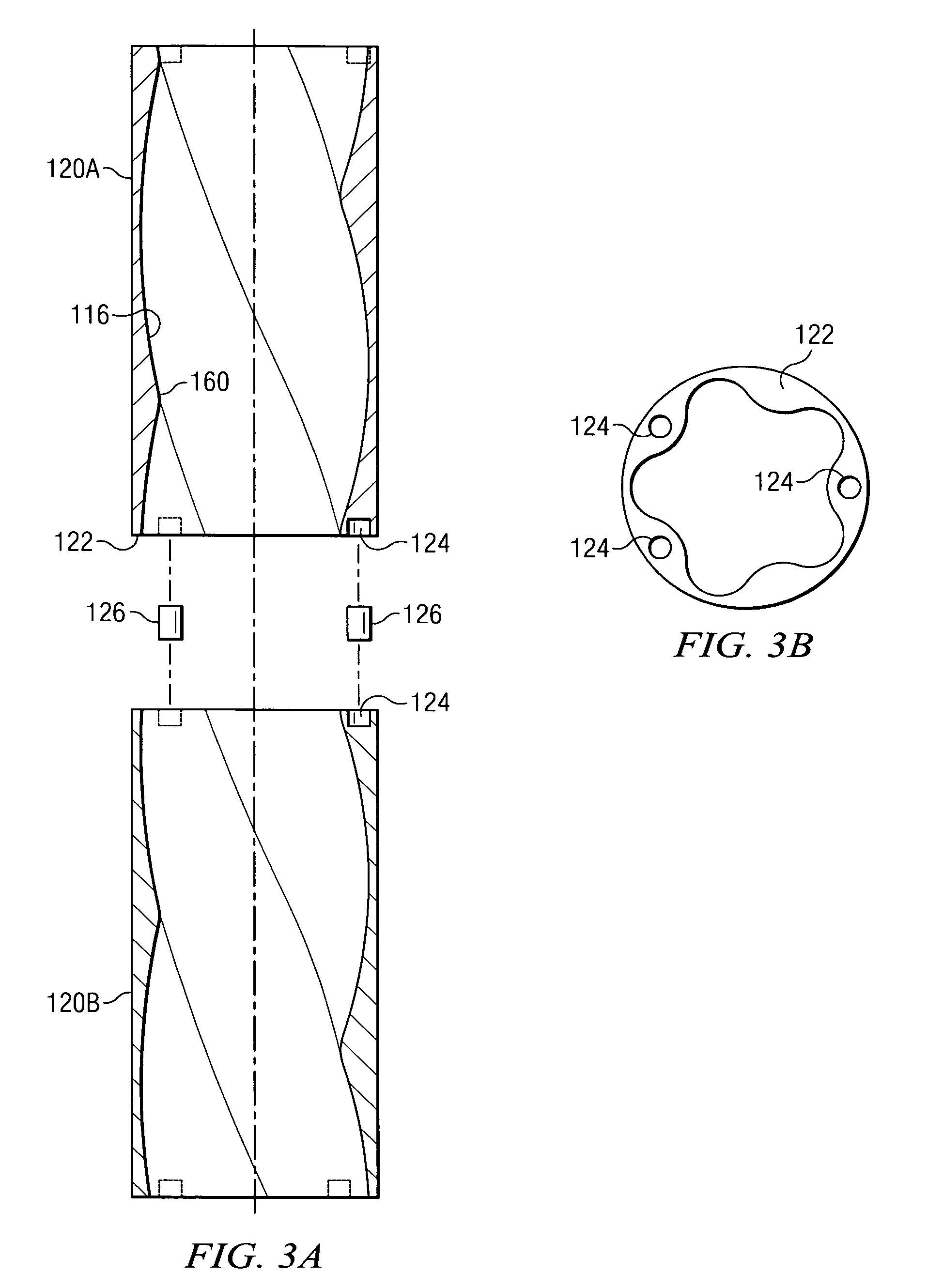

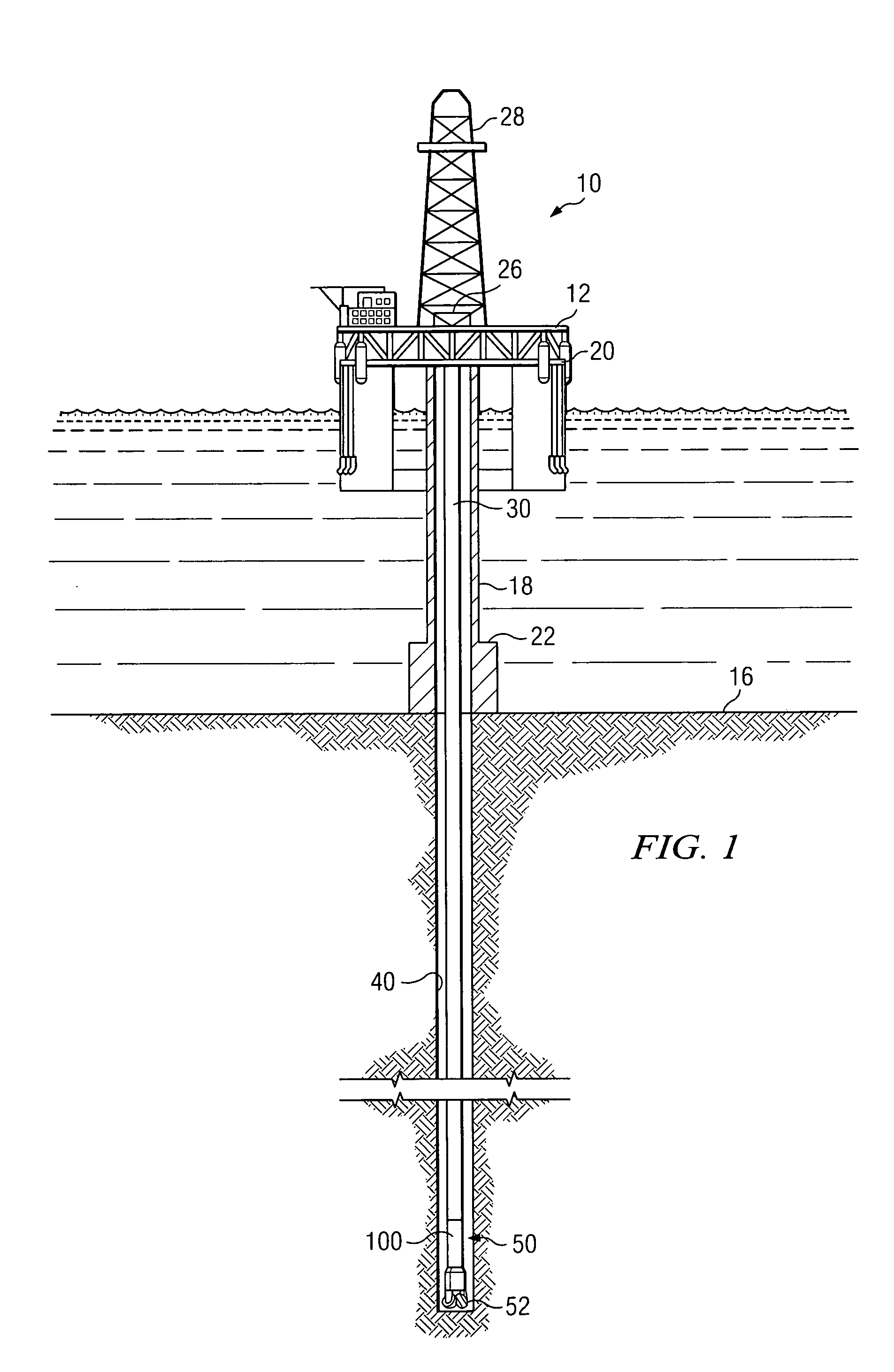

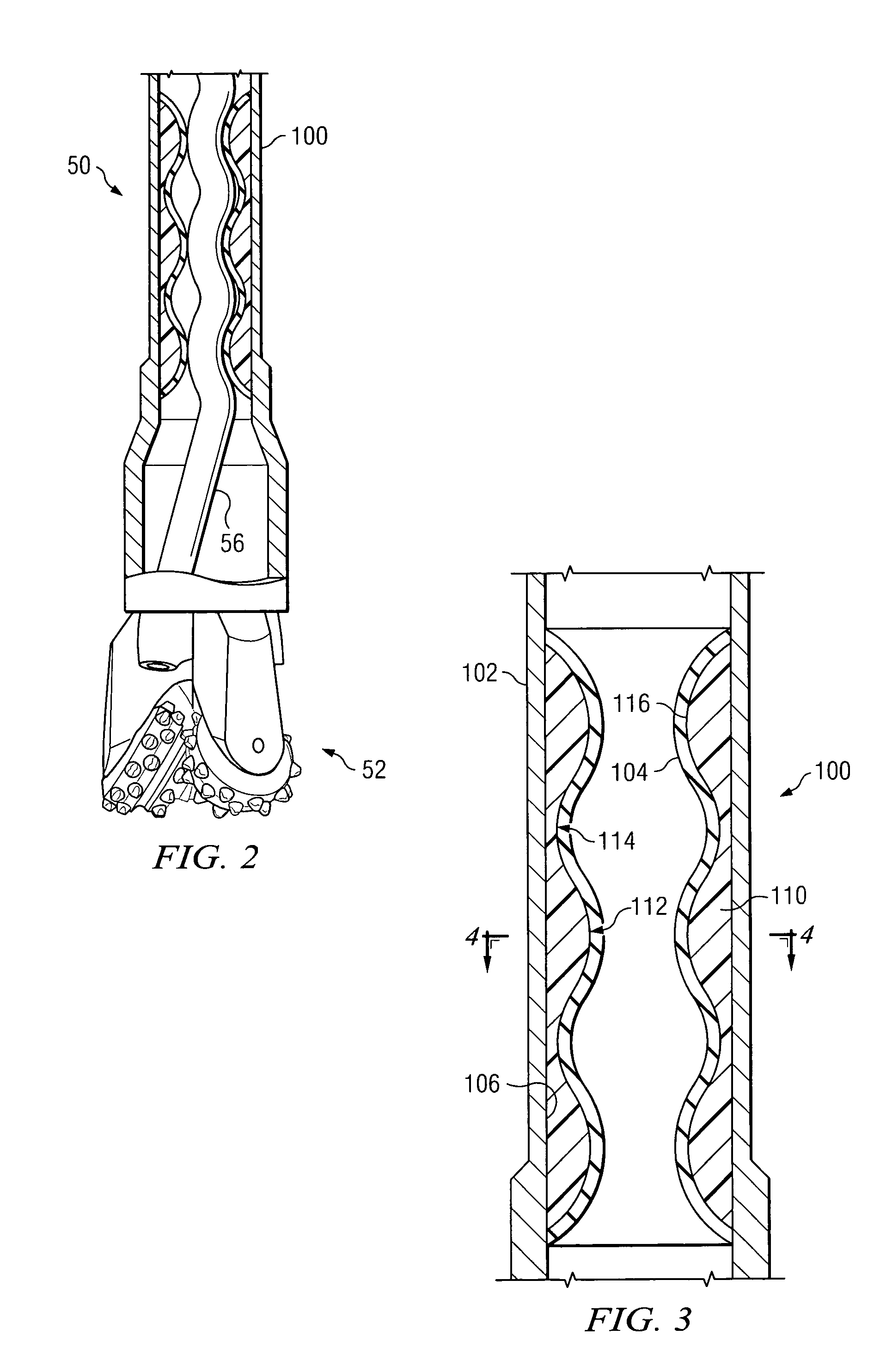

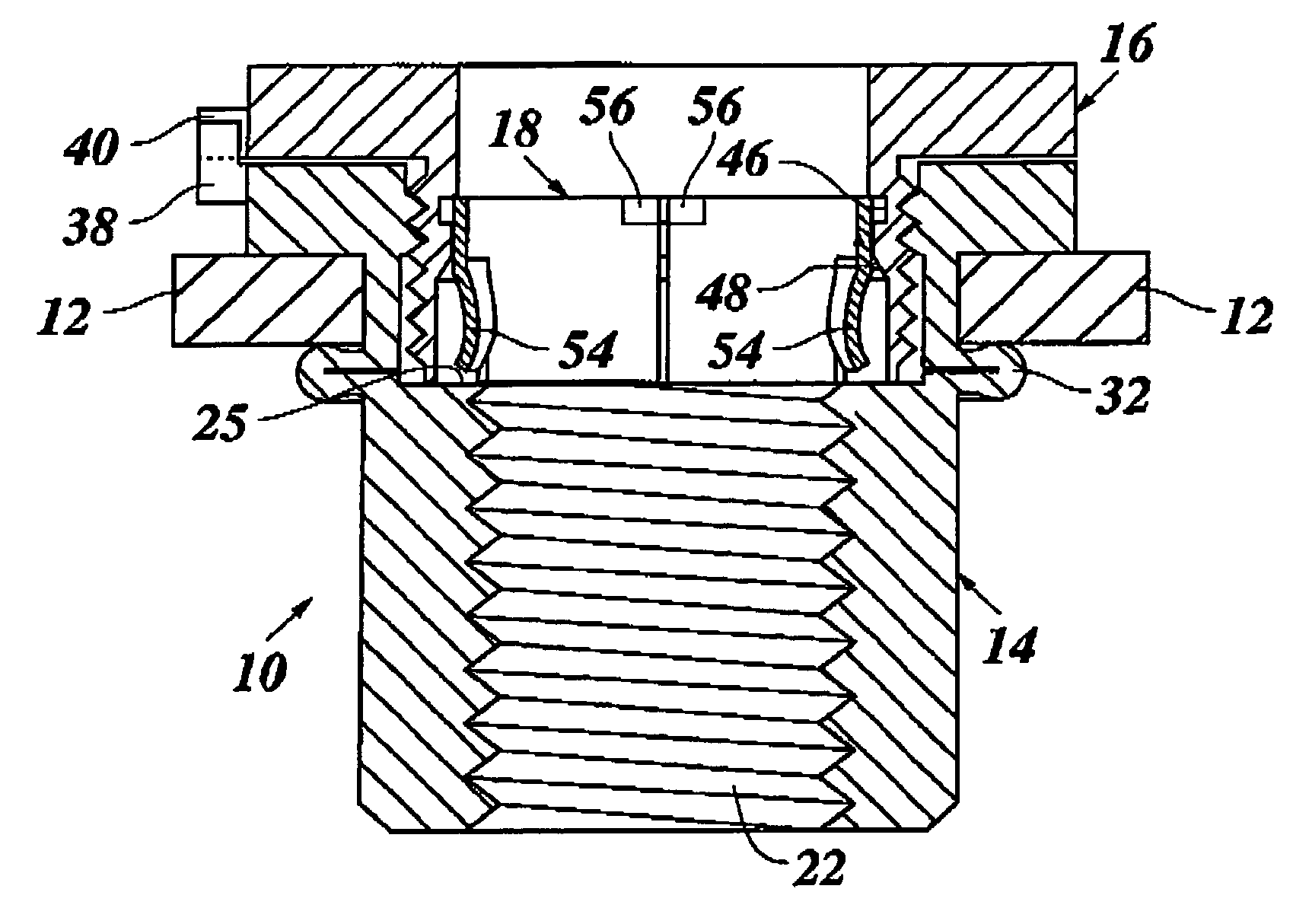

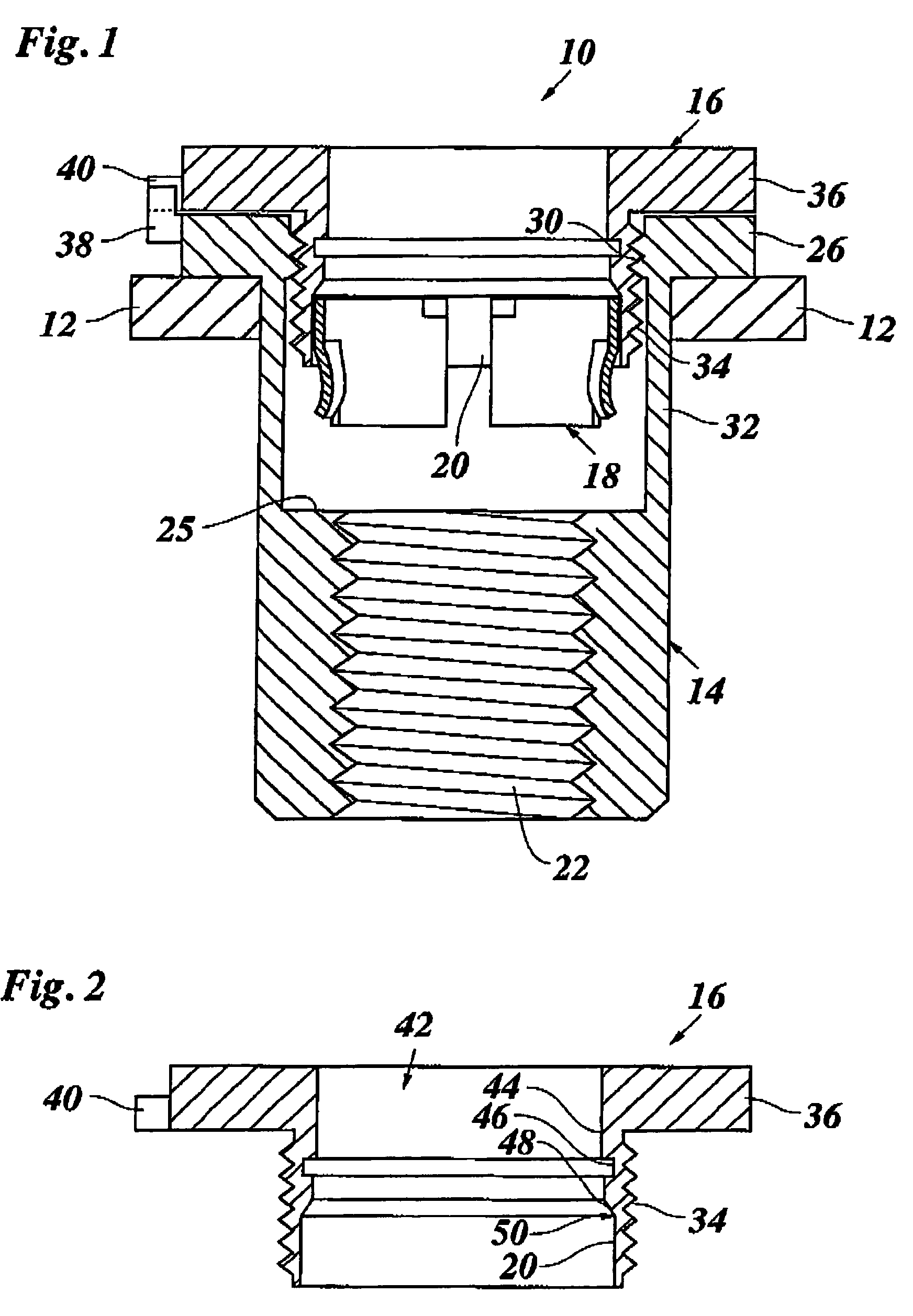

Progressing cavity stator including at least one cast longitudinal section

InactiveUS7396220B2Increased torque outputSimple and inexpensive to manufactureOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

Progressing cavity stator including at least one cast longitudinal section

InactiveUS20060182644A1Prevent rotationIncreased torque outputOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

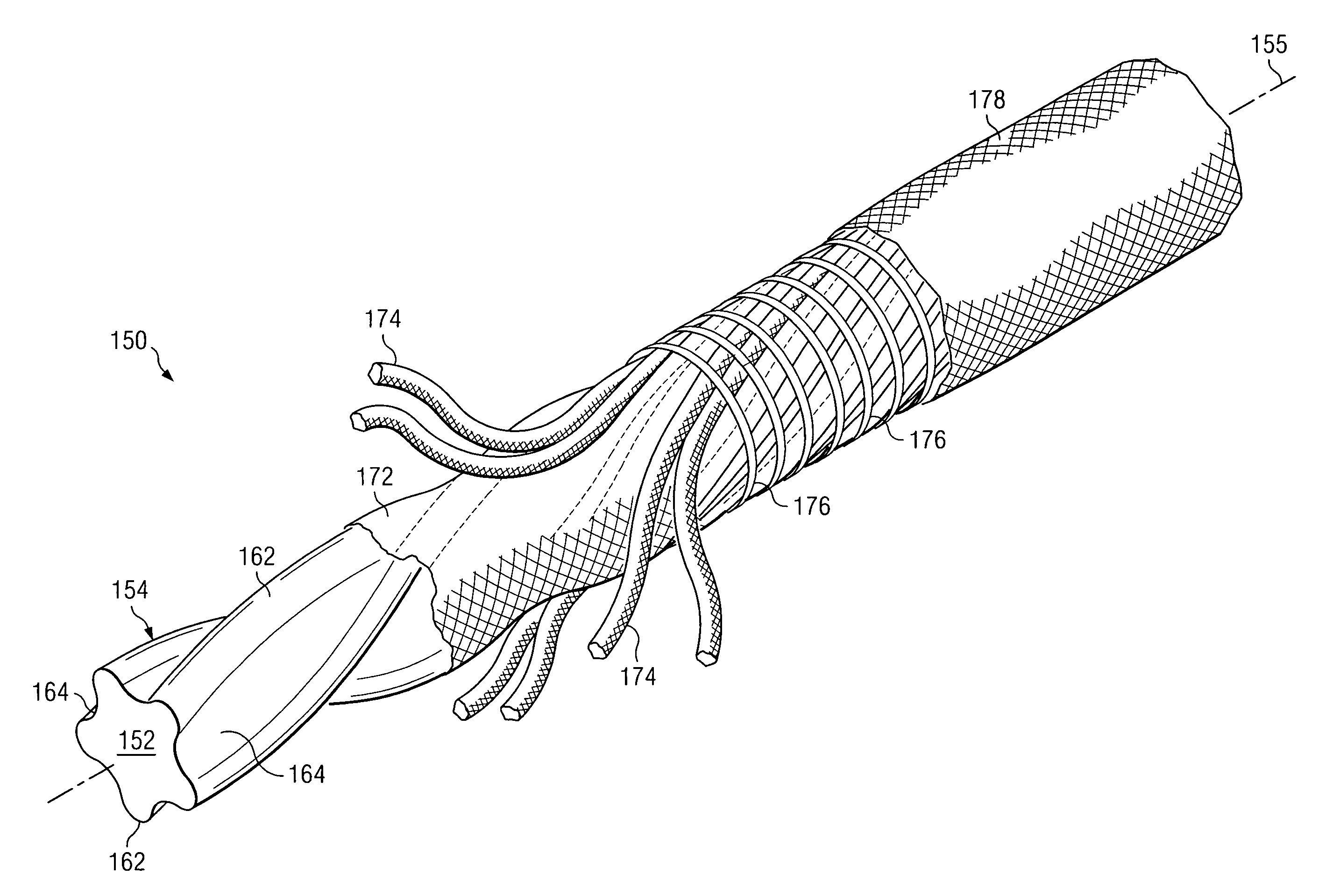

Composite material progressing cavity stators

InactiveUS20050089429A1Extended service lifeImprove reliabilityOscillating piston enginesEngine of intermeshing engagement typeElastomerFiber-reinforced composite

A progressing cavity stator is provided. The progressing cavity stator includes a fiber reinforced composite component providing an internal helical cavity having at least one helical groove and an elastomeric liner disposed on an internal surface of the fiber reinforced composite component. In various exemplary embodiments, the fiber reinforced composite component includes a plurality of fibers disposed in a matrix material, the plurality of fibers being disposed such that distinct portions thereof follow correspondingly distinct directions. Exemplary embodiments of this invention may advantageously exhibit a prolonged service life in downhole applications as compared to conventional progressing cavity stators. A replaceable progressing cavity insert for a stator is also provided. Methods for fabricating progressing cavity stators and progressing cavity inserts are also provided.

Owner:DYNA DRILL TECH

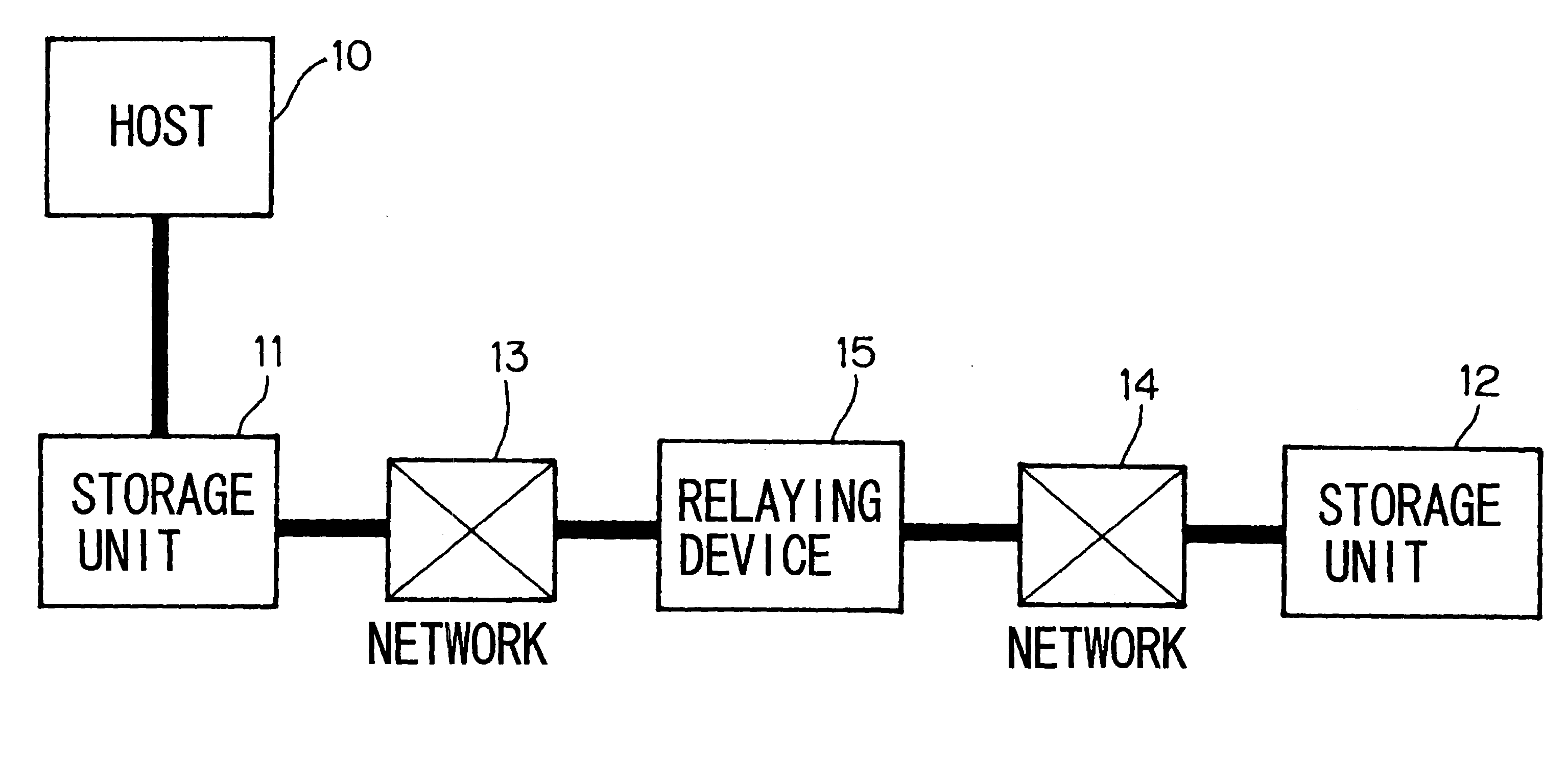

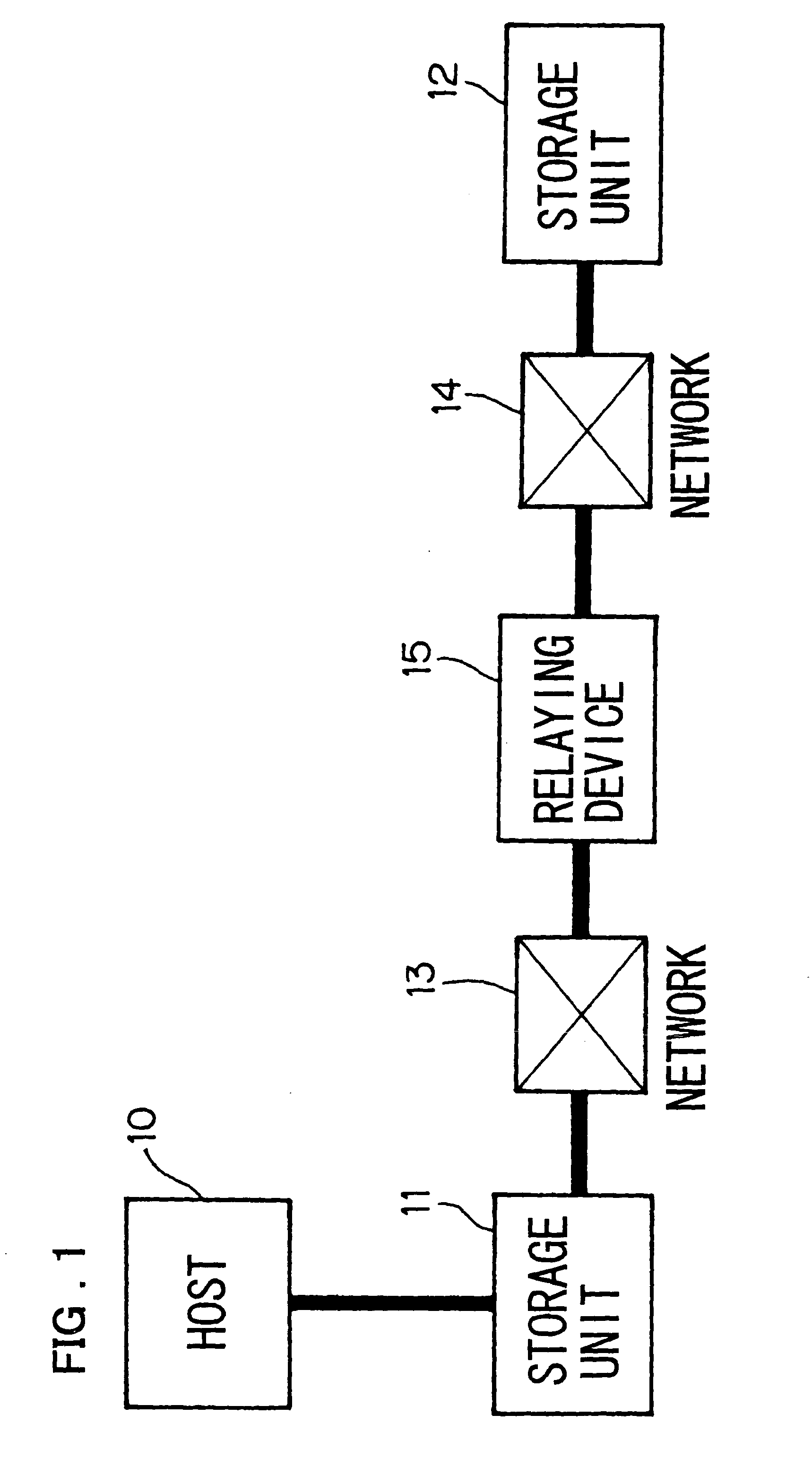

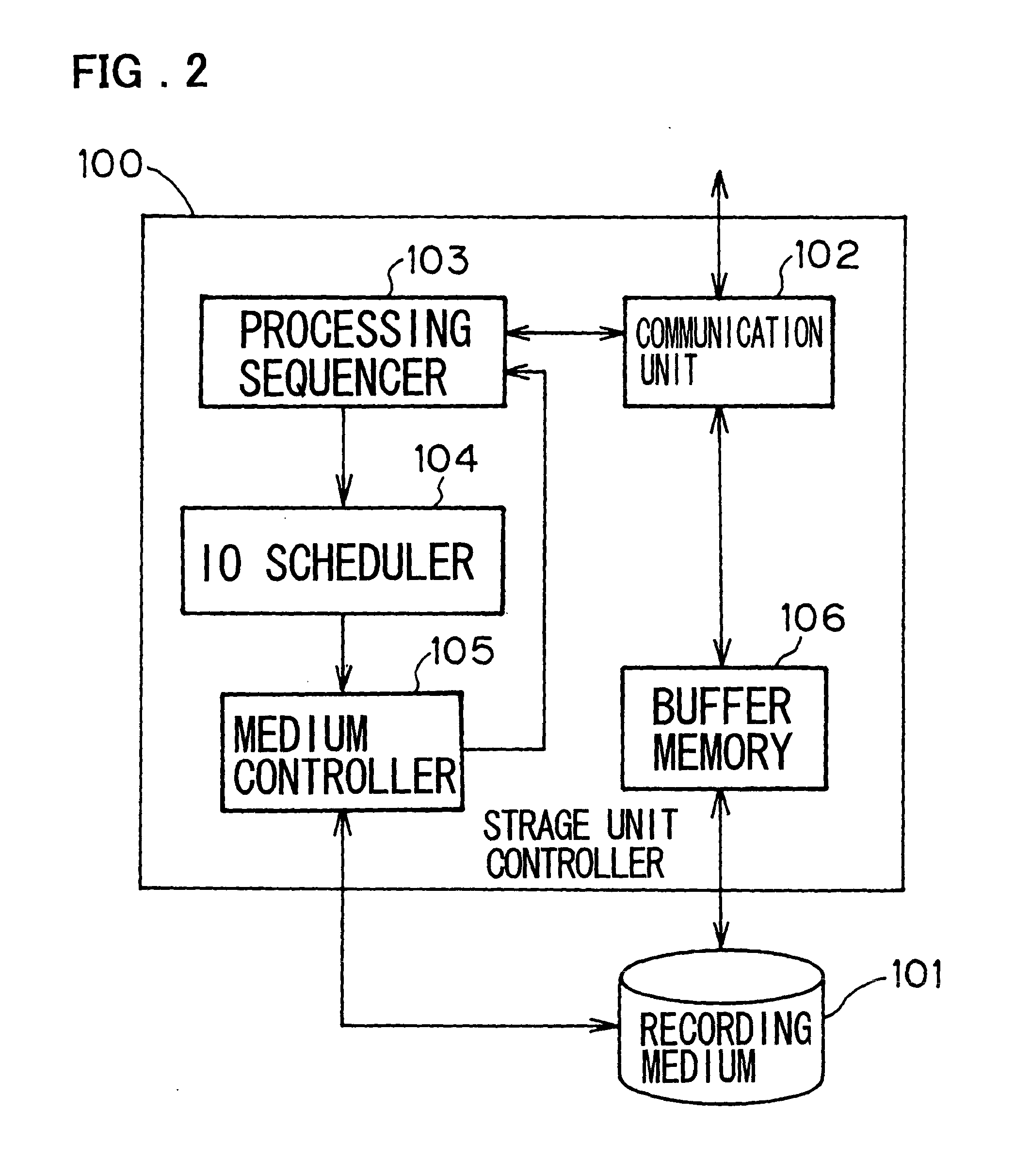

Data copying system, relaying device, data transfer/reception system and program for copying of data in storage unit

ActiveUS20040044649A1Considerable timeIncrease volumeInput/output to record carriersError detection/correctionComputer hardwareData transmission time

A relaying device for relaying data transferred from first storage unit to a second storage unit, is provided outside a range presumed to be affected by a disaster, when a disaster, such as an earthquake, has broken out in an installation site of a host of a normal system (host computer) and the first storage unit. Moreover, the relaying device is placed at such a location that the data transfer time between the first storage unit and the relaying device is shorter than the data transfer time in case the first and second storage units directly transfer data with each other. On receipt of data from the first storage unit, the relaying device notifies the first storage unit of the completion of reception of the data before completing transmission of the data to the second storage unit.

Owner:RAKUTEN GRP INC

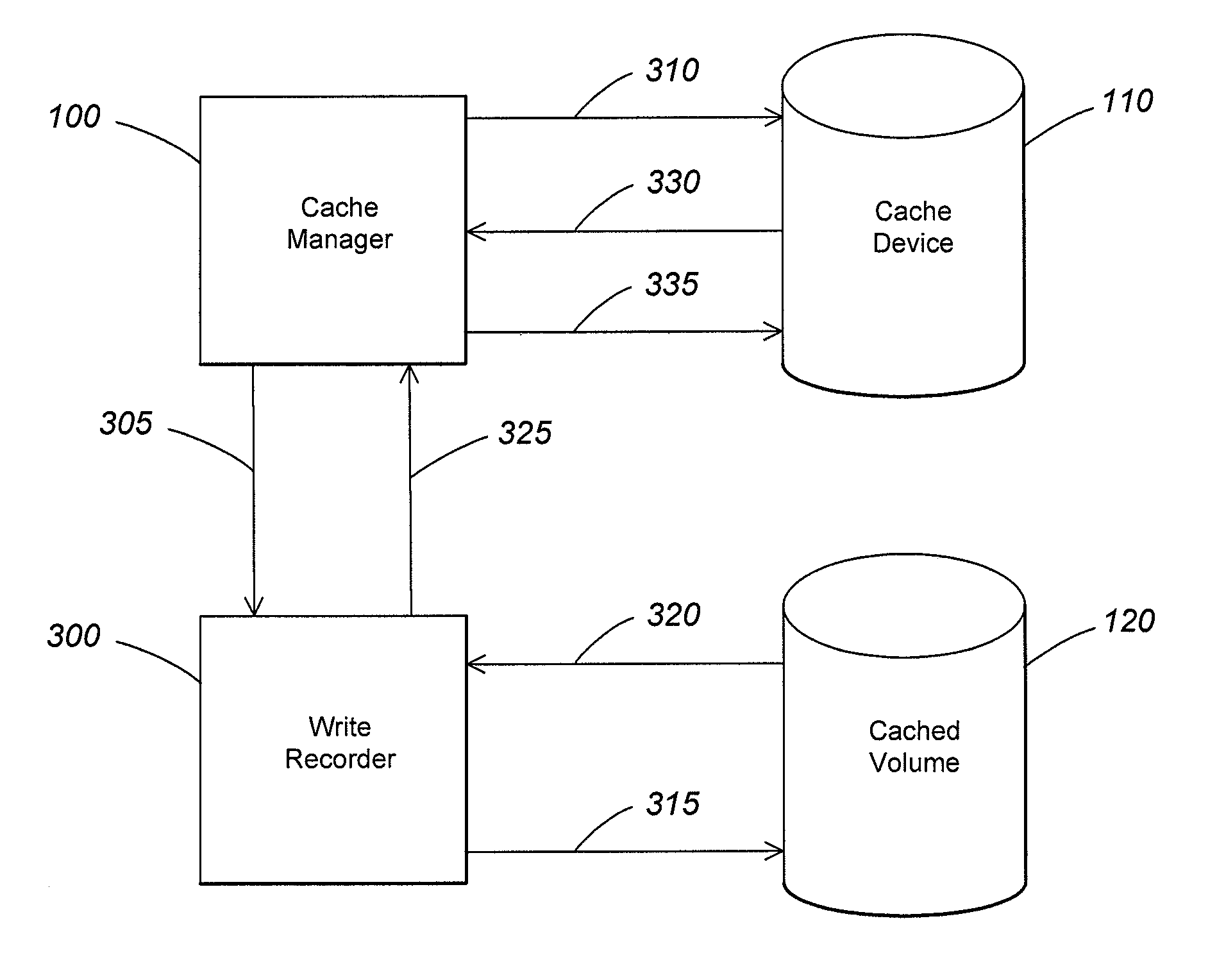

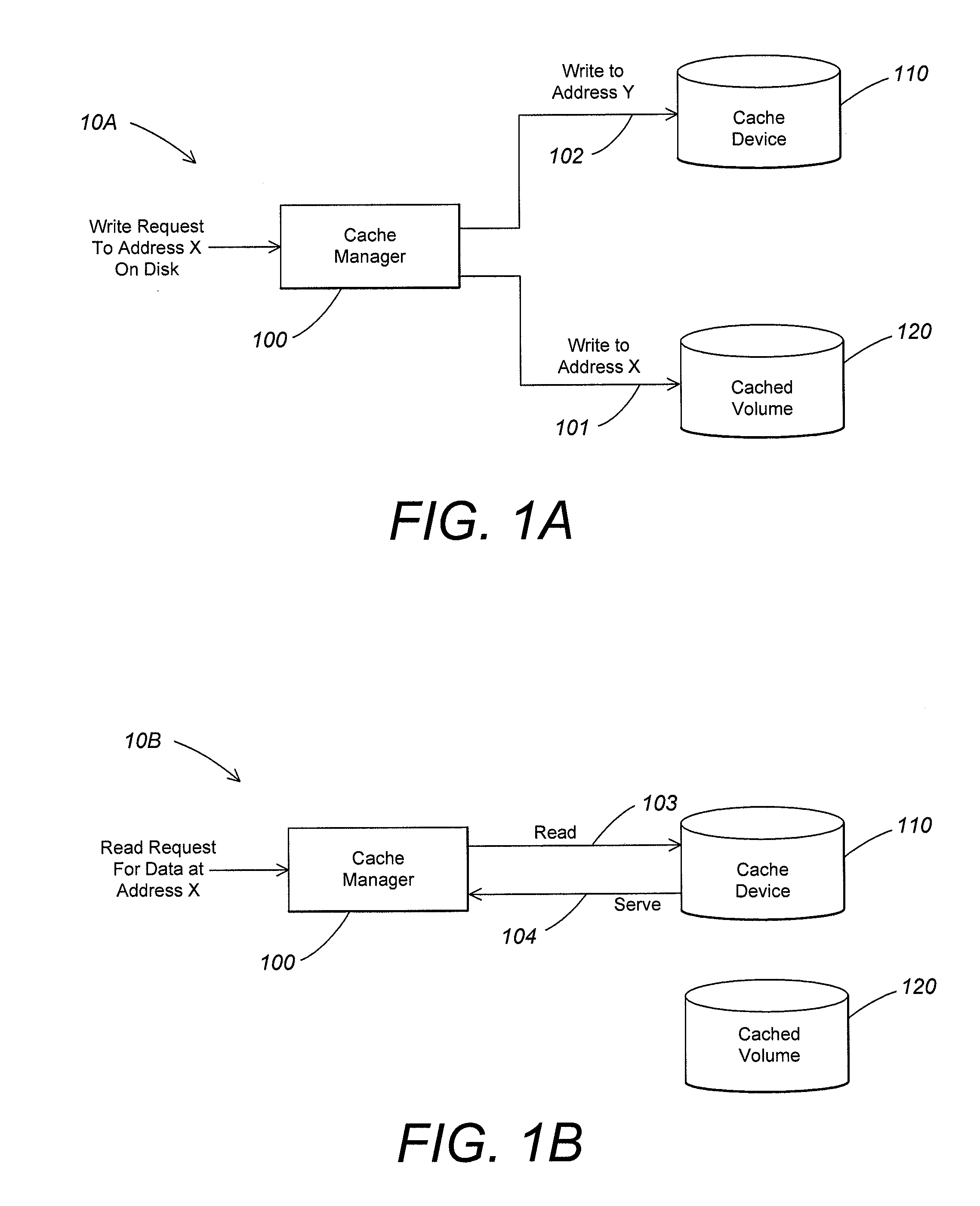

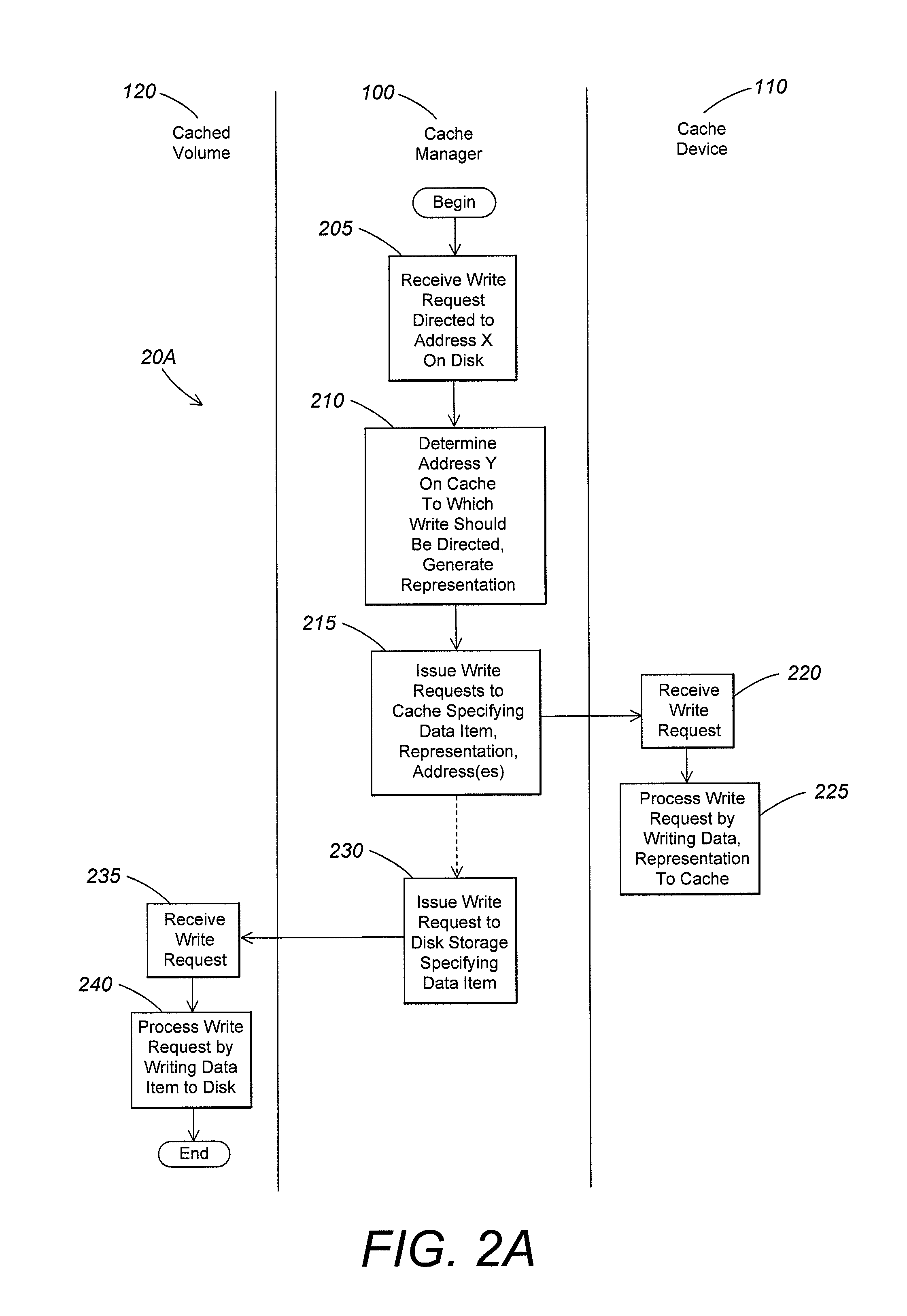

Managing cache data and metadata

ActiveUS20100070701A1Increase speedLarge storage capacityMemory architecture accessing/allocationEnergy efficient ICTData storingData store

Embodiments of the invention provide techniques for ensuring that the contents of a non-volatile memory device may be relied upon as accurately reflecting data stored on disk storage across a power transition such as a reboot. For example, some embodiments of the invention provide techniques for determining whether the cache contents and / or or disk contents are modified during a power transition, causing cache contents to no longer accurately reflect data stored in disk storage. Further, some embodiments provide techniques for managing cache metadata during normal (“steady state”) operations and across power transitions, ensuring that cache metadata may be efficiently accessed and reliably saved and restored across power transitions.

Owner:MICROSOFT TECH LICENSING LLC

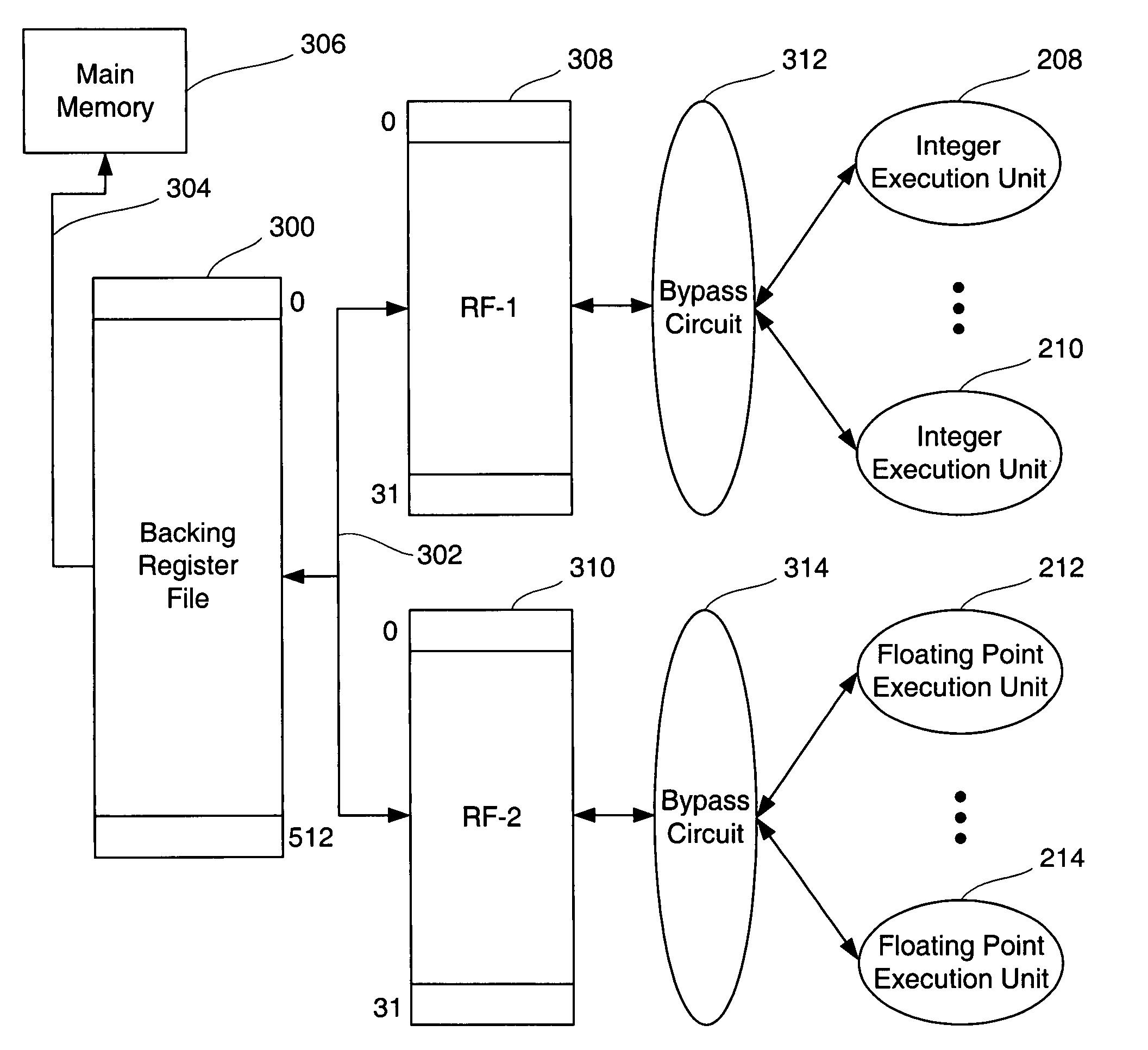

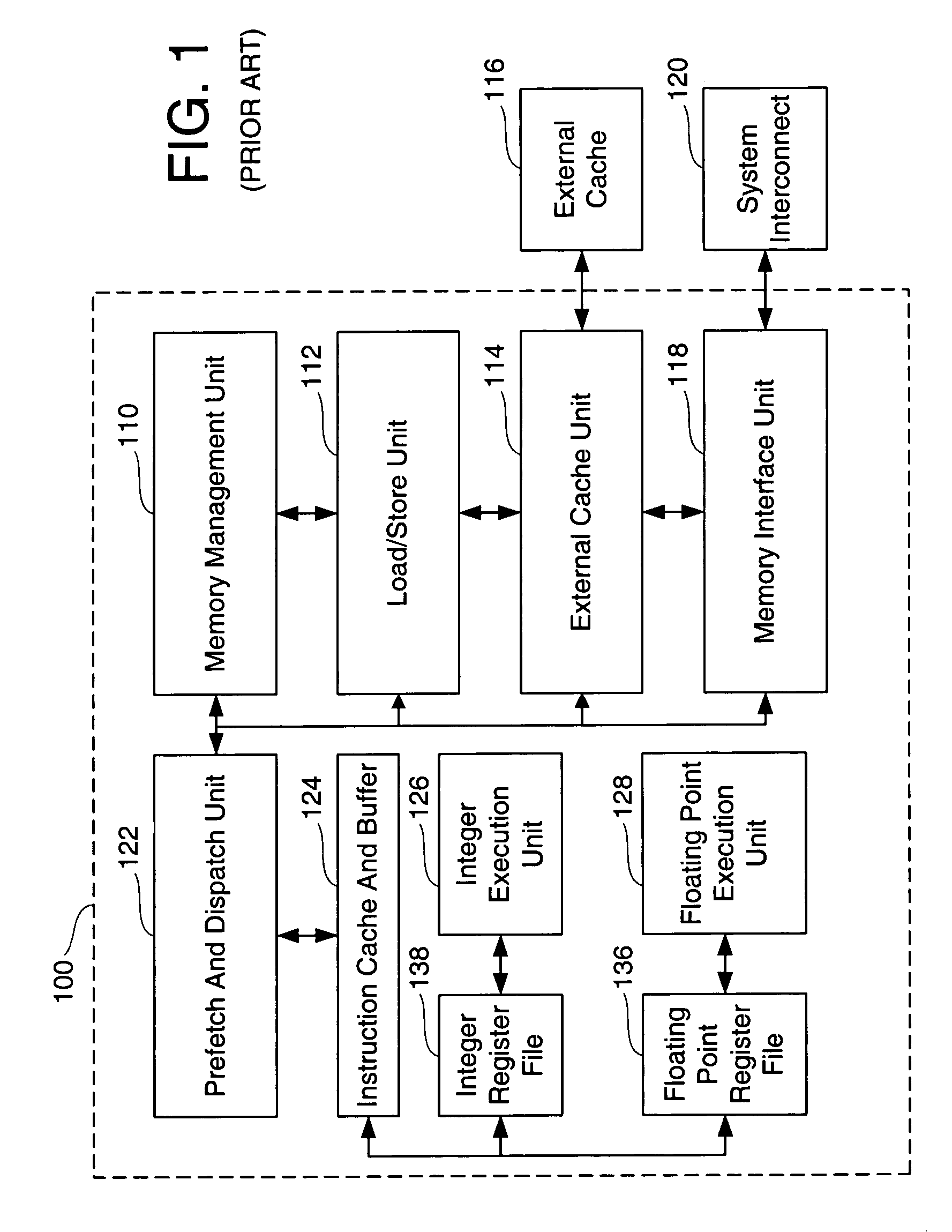

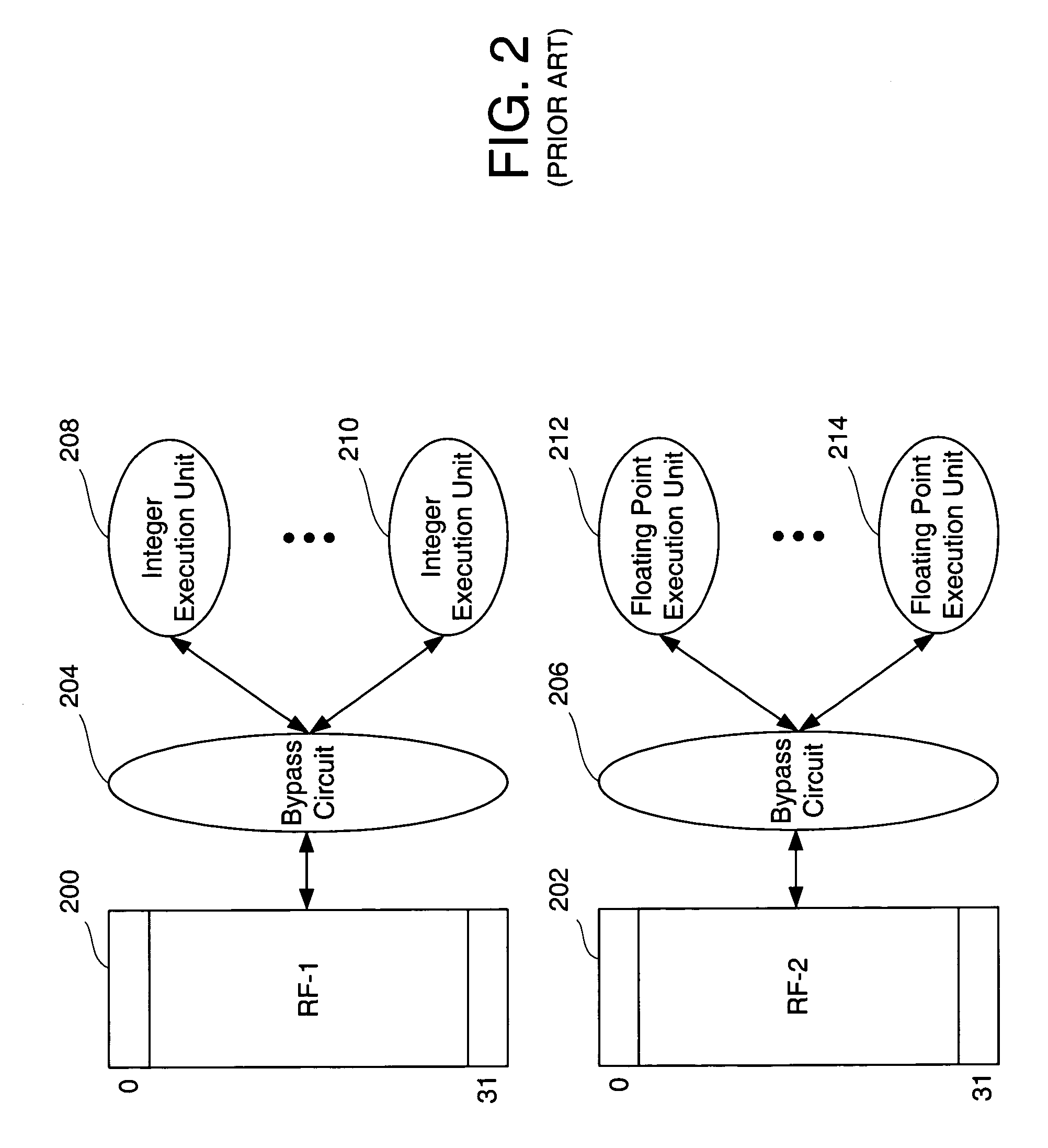

Backing Register File for processors

InactiveUS7206925B1Improve throughputConsiderable timeDigital computer detailsSpecific program execution arrangementsProcessor registerExecution unit

A processor is defined by a new architectural feature called a Backing Register File, where a Backing Register File is a set of randomly accessible registers capable of holding values, and further are directly connected to the processor's register files. The processor's register files are in turn connected to the processor's execution units. A Backing Register File is visible and controllable by users, allowing them to make use of a larger local address space increasing execution unit throughput thereby, while not changing the size of the processor's register files themselves.

Owner:ORACLE INT CORP

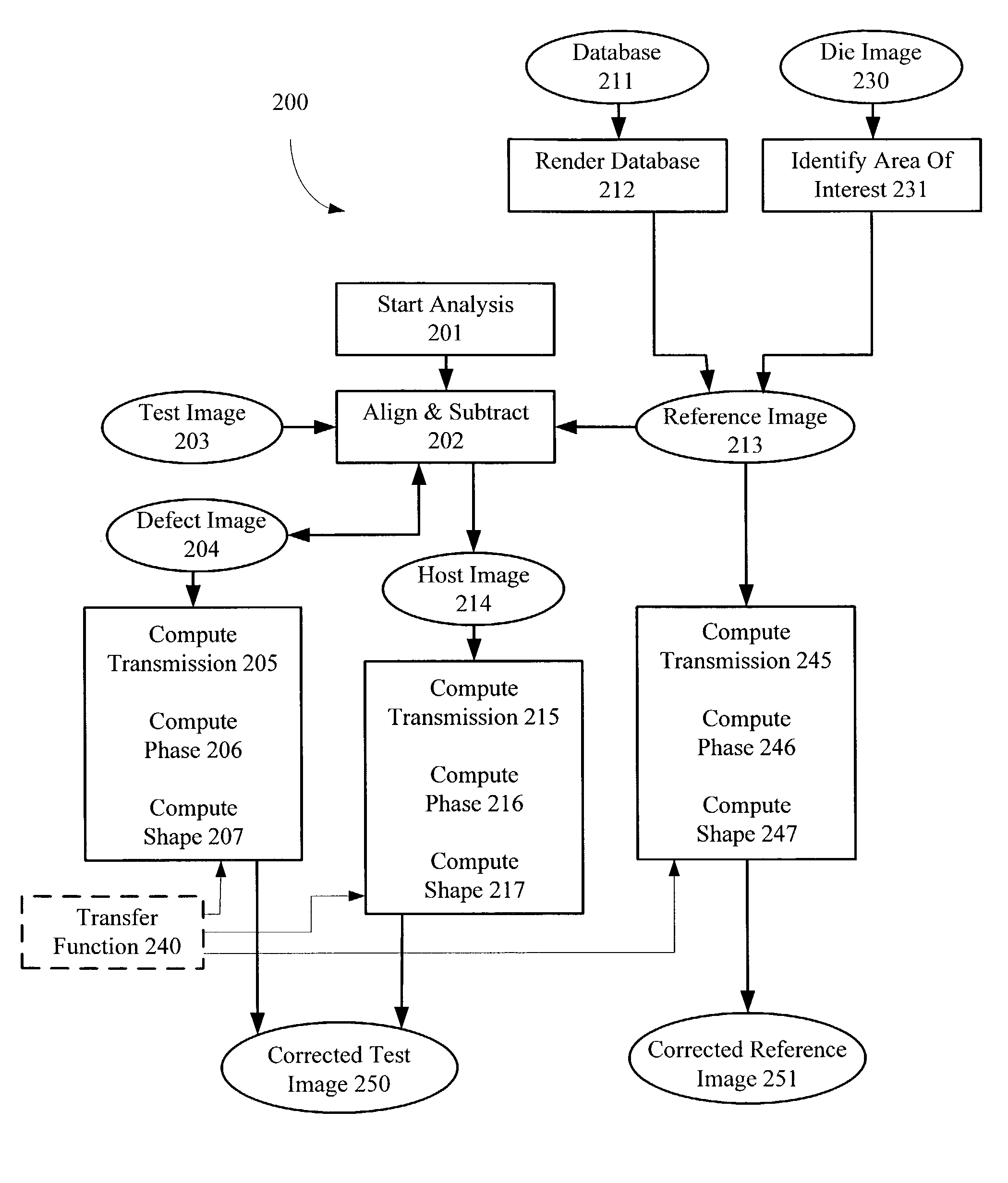

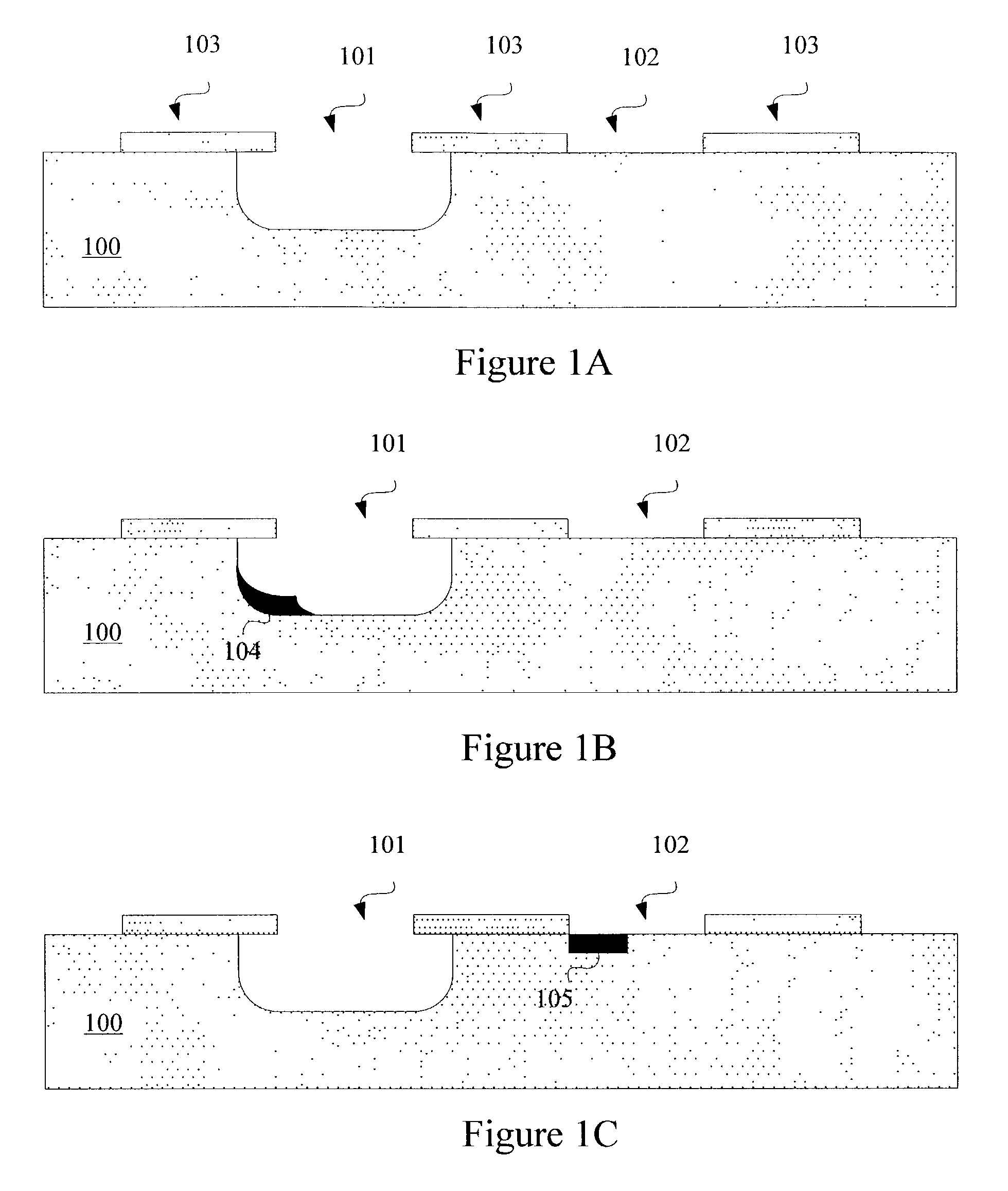

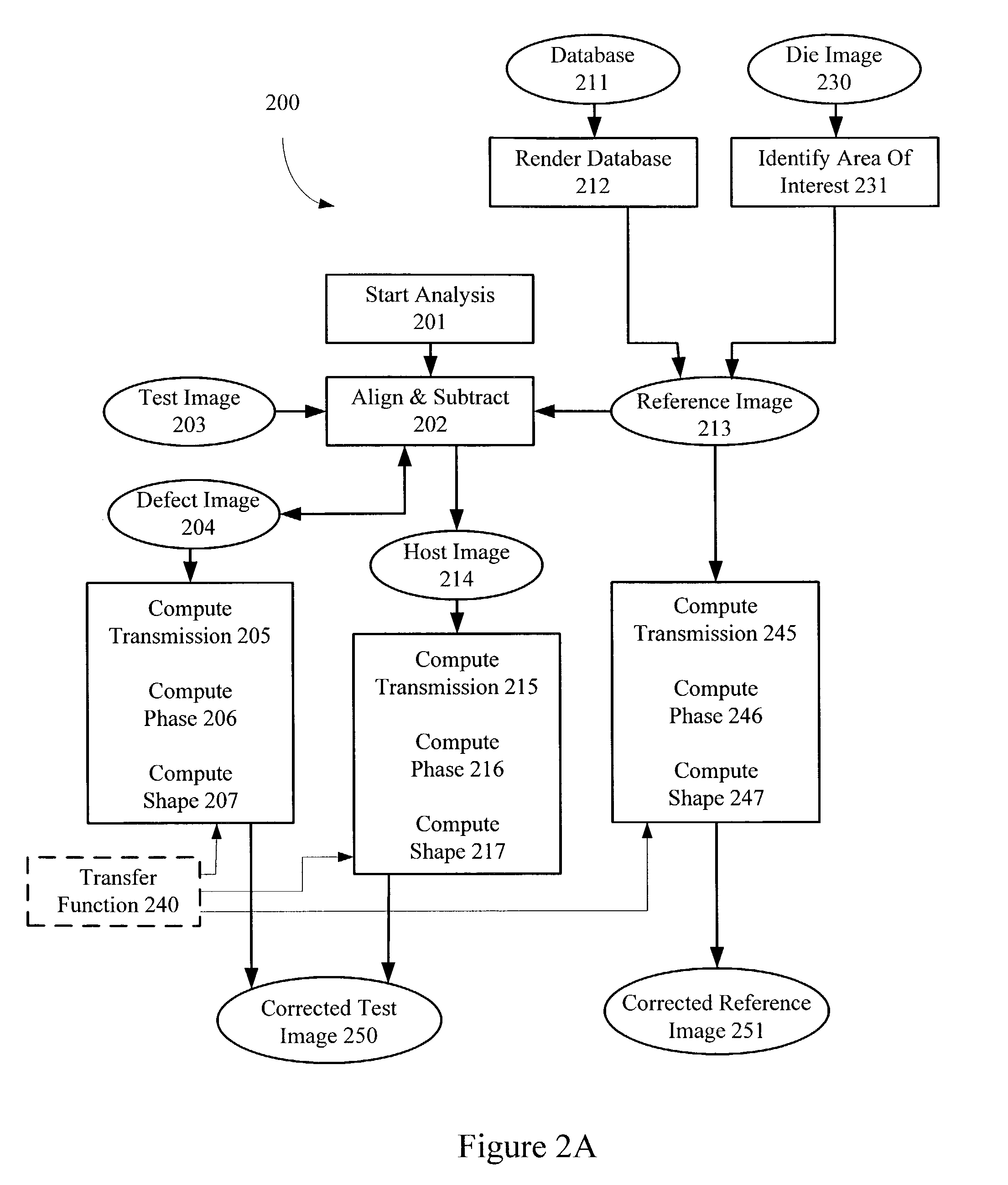

Soft defect printability simulation and analysis for masks

ActiveUS7043071B2Spread the wordGood decisionImage enhancementImage analysisEngineeringStandard test image

Masks that include optical proximity correction or phase shifting regions are increasingly being used in the manufacturing process. These masks, either initially or after repair, can have “soft” defects, e.g. phase and / or transmission defects. In accordance with one feature of the invention, soft defect information can be computed from standard test images of a mask. This soft defect information can be used to generate an accurate simulated wafer image, thereby providing valuable defect impact information to a user. Knowing the impact of the soft defect can enable a user to make better decisions regarding the mask. Specifically, a user can now with confidence accept the mask for the desired lithographic process, repair the mask at certain critical locations, or reject the mask, all without exposing a wafer.

Owner:SYNOPSYS INC

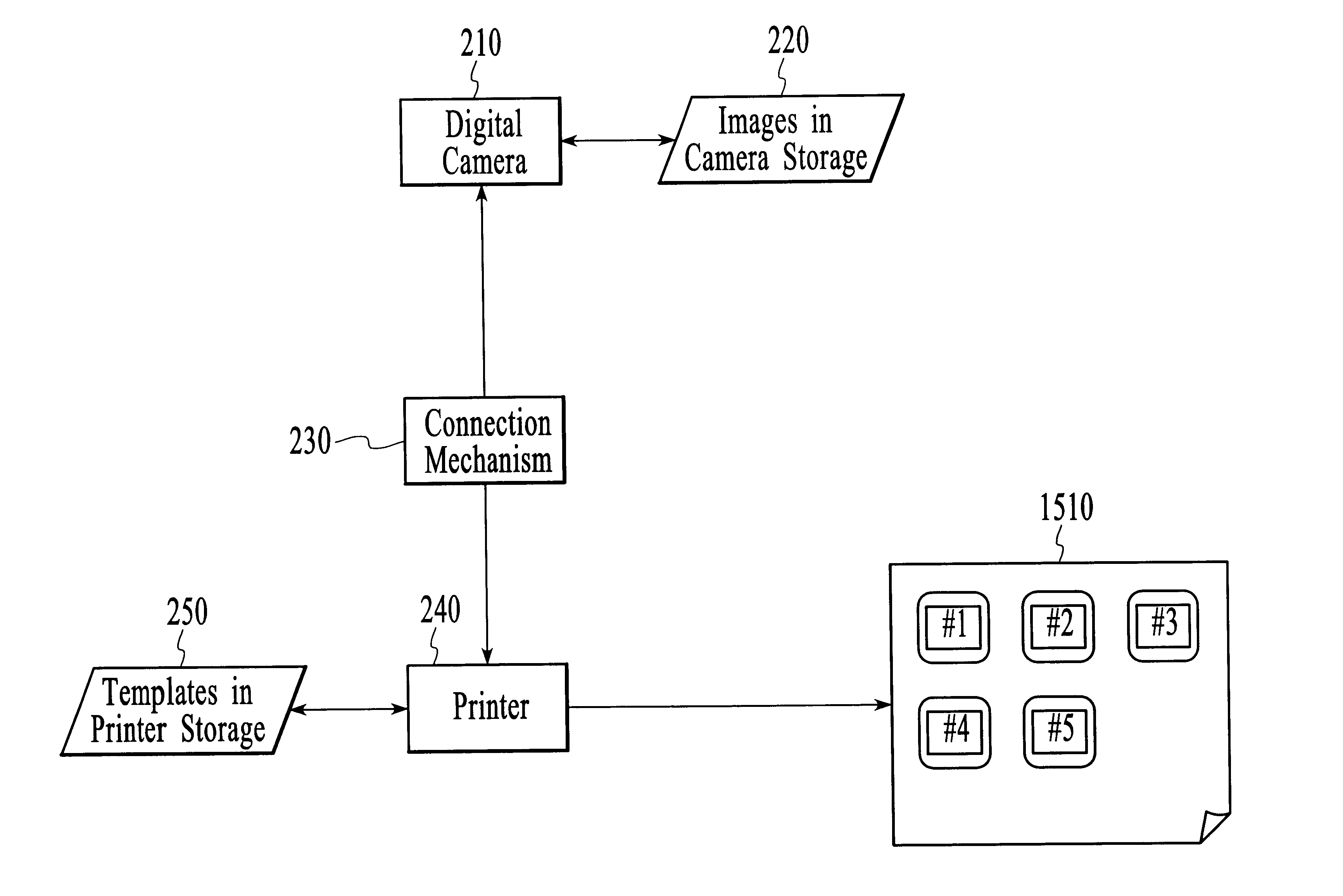

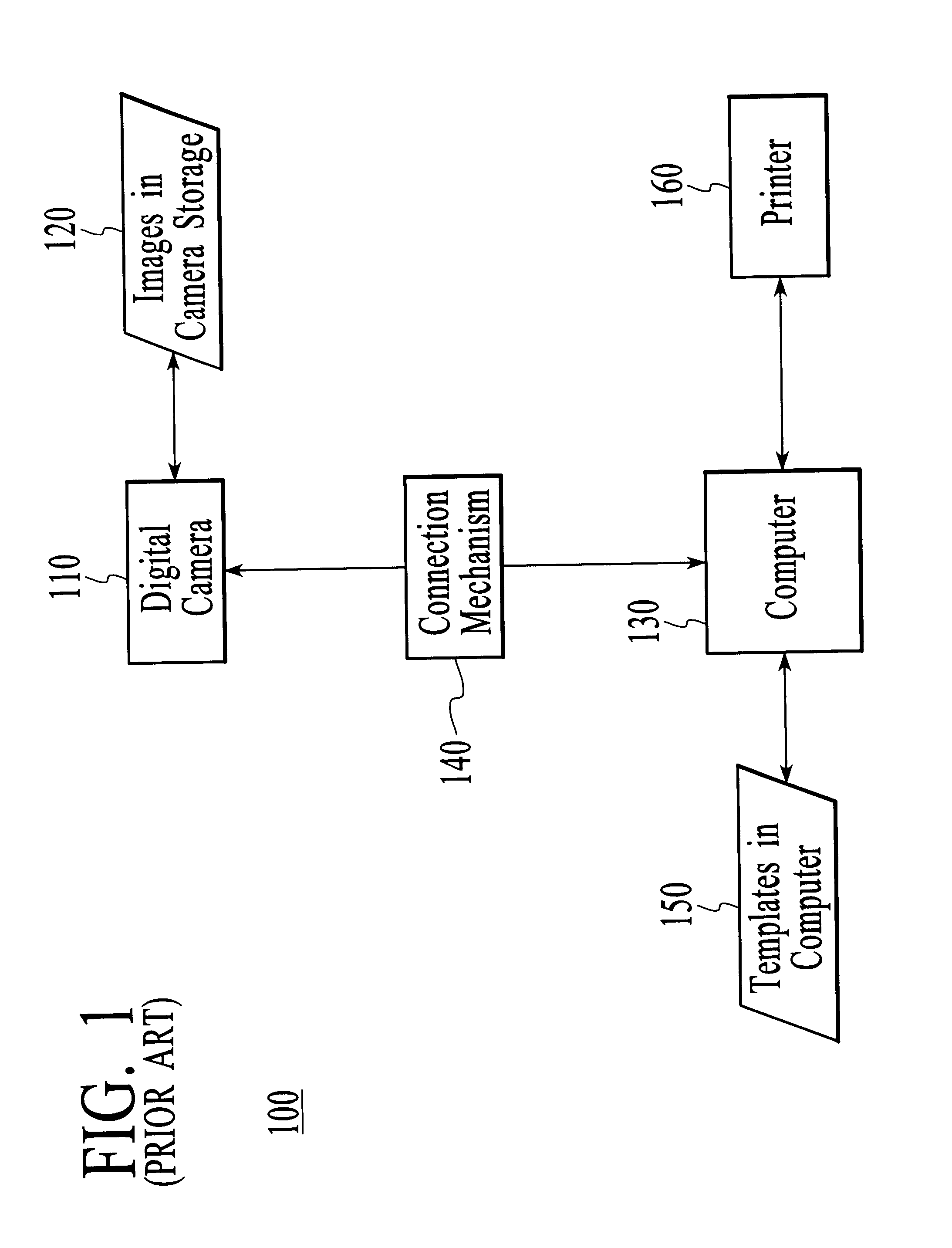

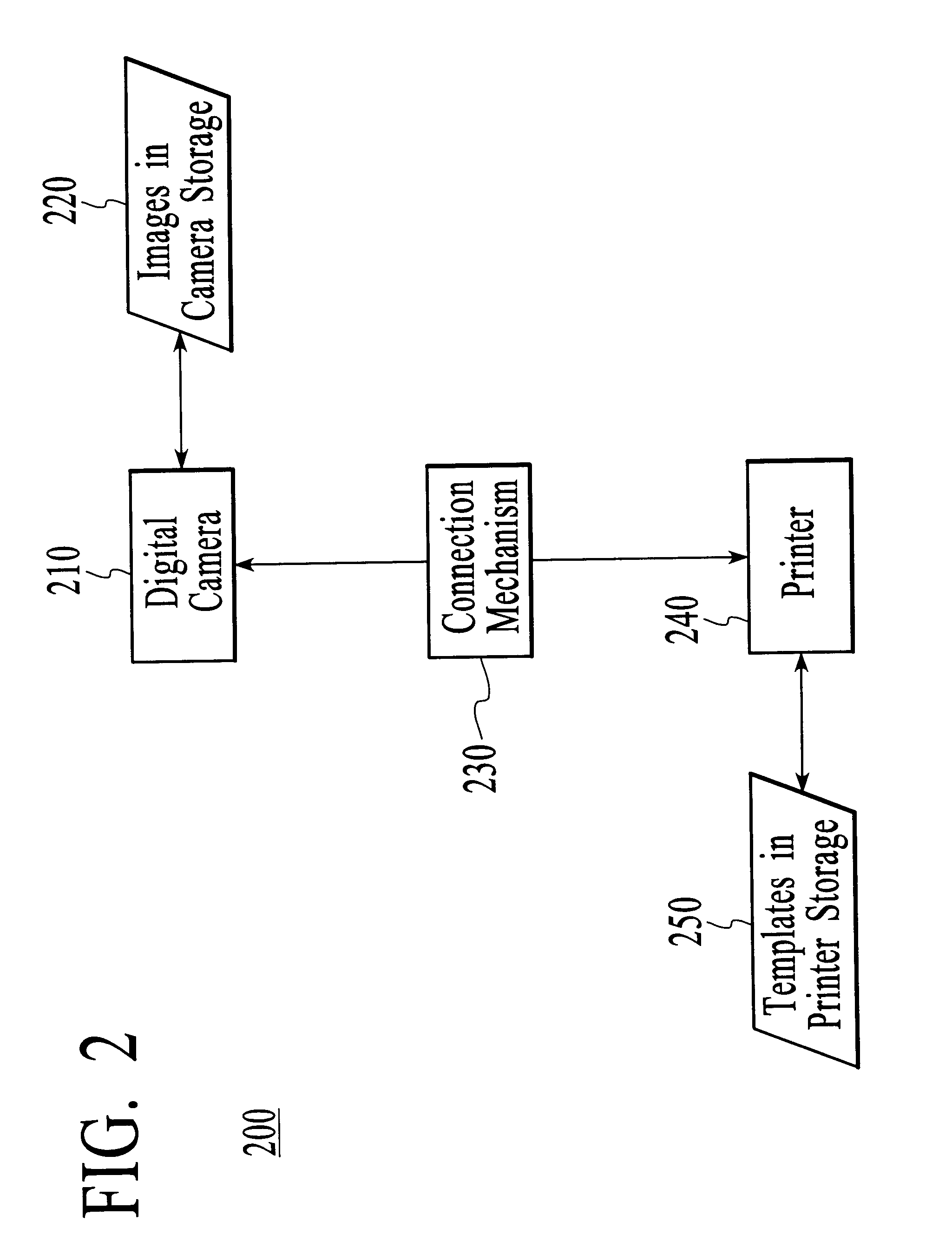

Creation and use of complex image templates

InactiveUS6912311B2Save timeLess processing timeDigital computer detailsVisual presentation using printersImage basedComputer engineering

The present invention provides a method and system for the creation and use of simple and complex templates. The system includes providing the template where the template contains a plurality of tags, and then applying the template to the image based on the tags. The plurality of tags provide instructions for the application of a plurality of plane files to be applied to the image. The method and system in accordance with the present invention automates the process of applying templates to images which reduces the required amount of user time for the interface. Its use of tags to store the template requires less storage space. The method and system in accordance with the present invention thus saves the user considerable time and effort in applying templates. It also require less processing time over manual template creation methods.

Owner:FLASHPOINT TECH

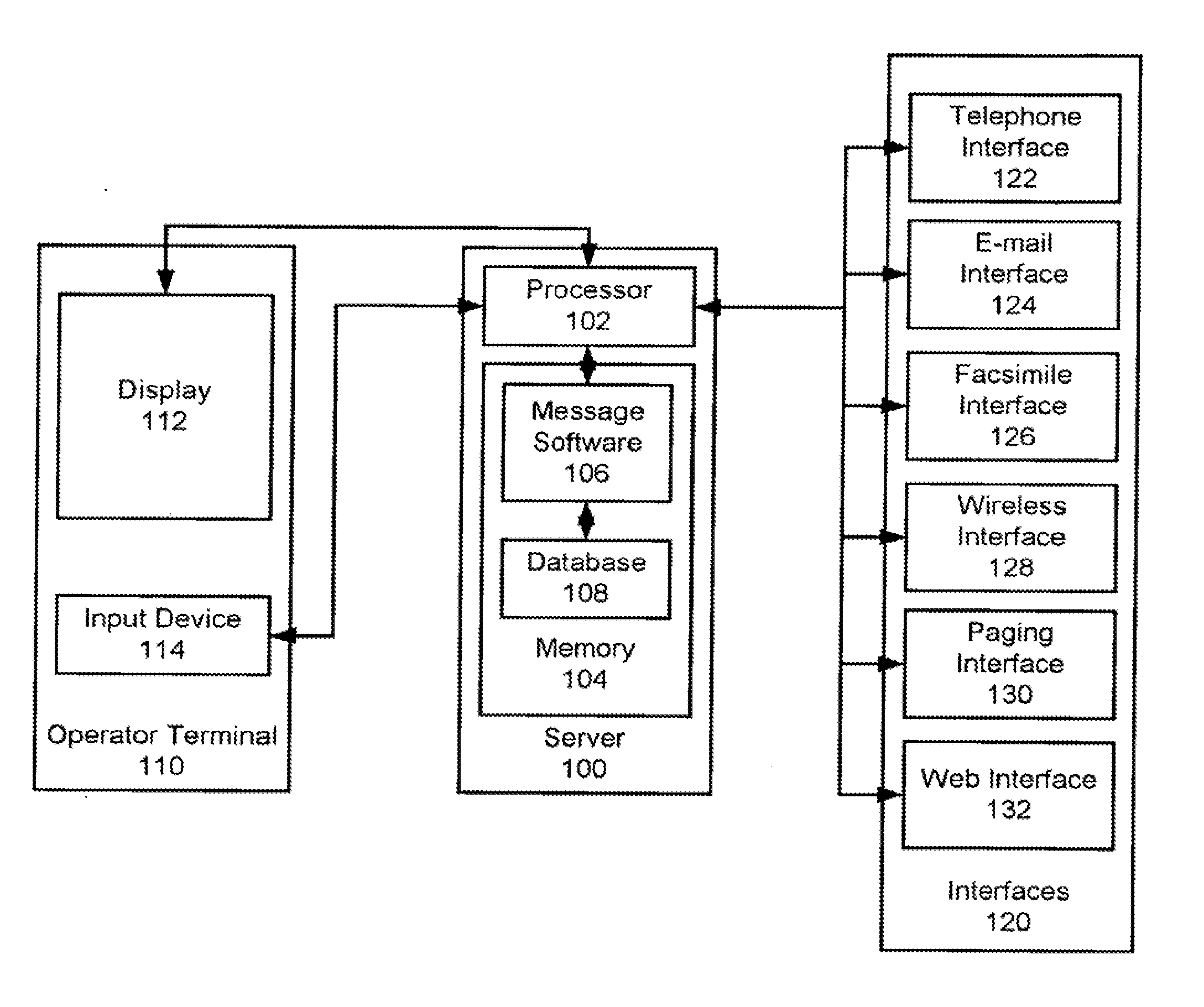

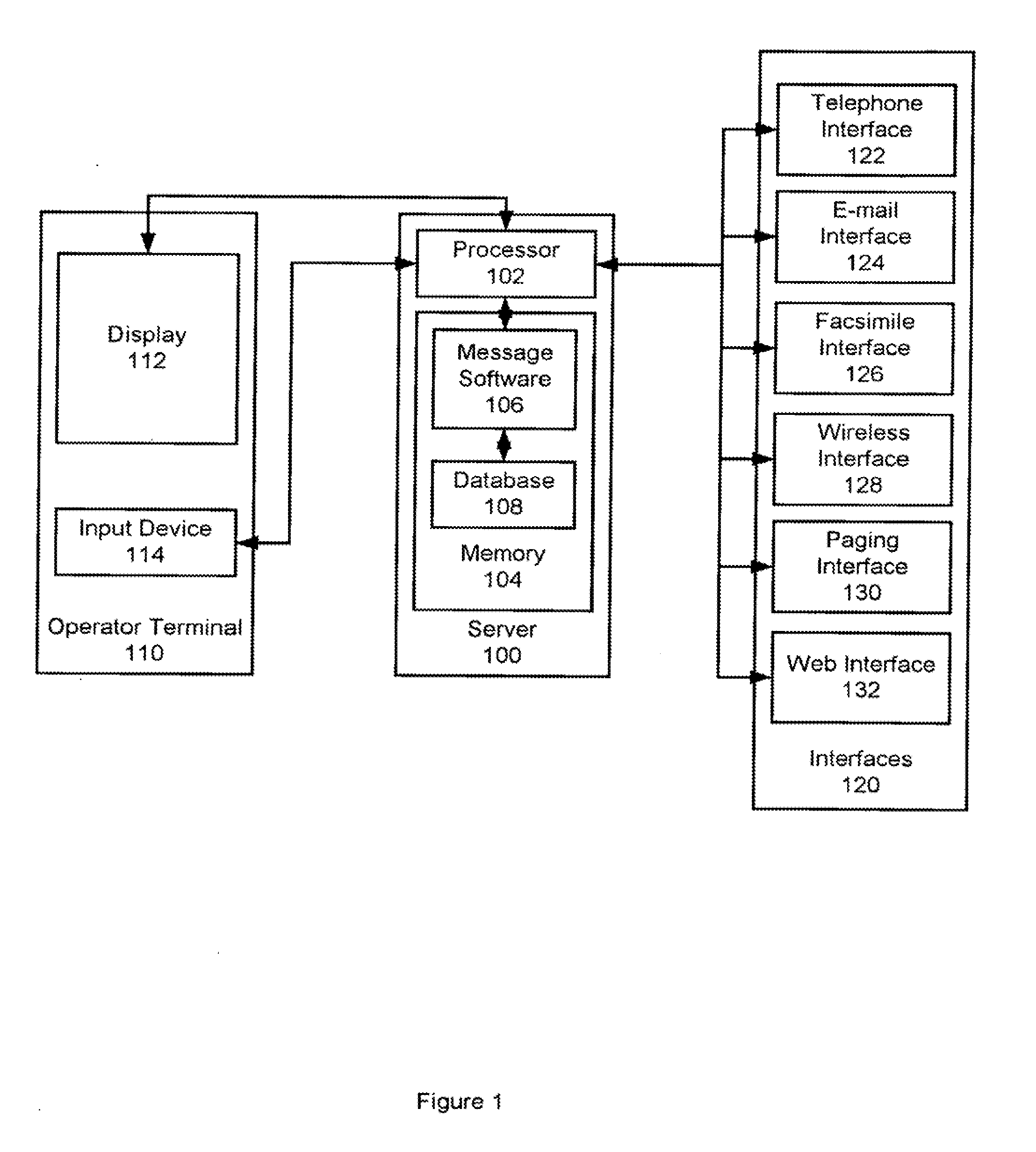

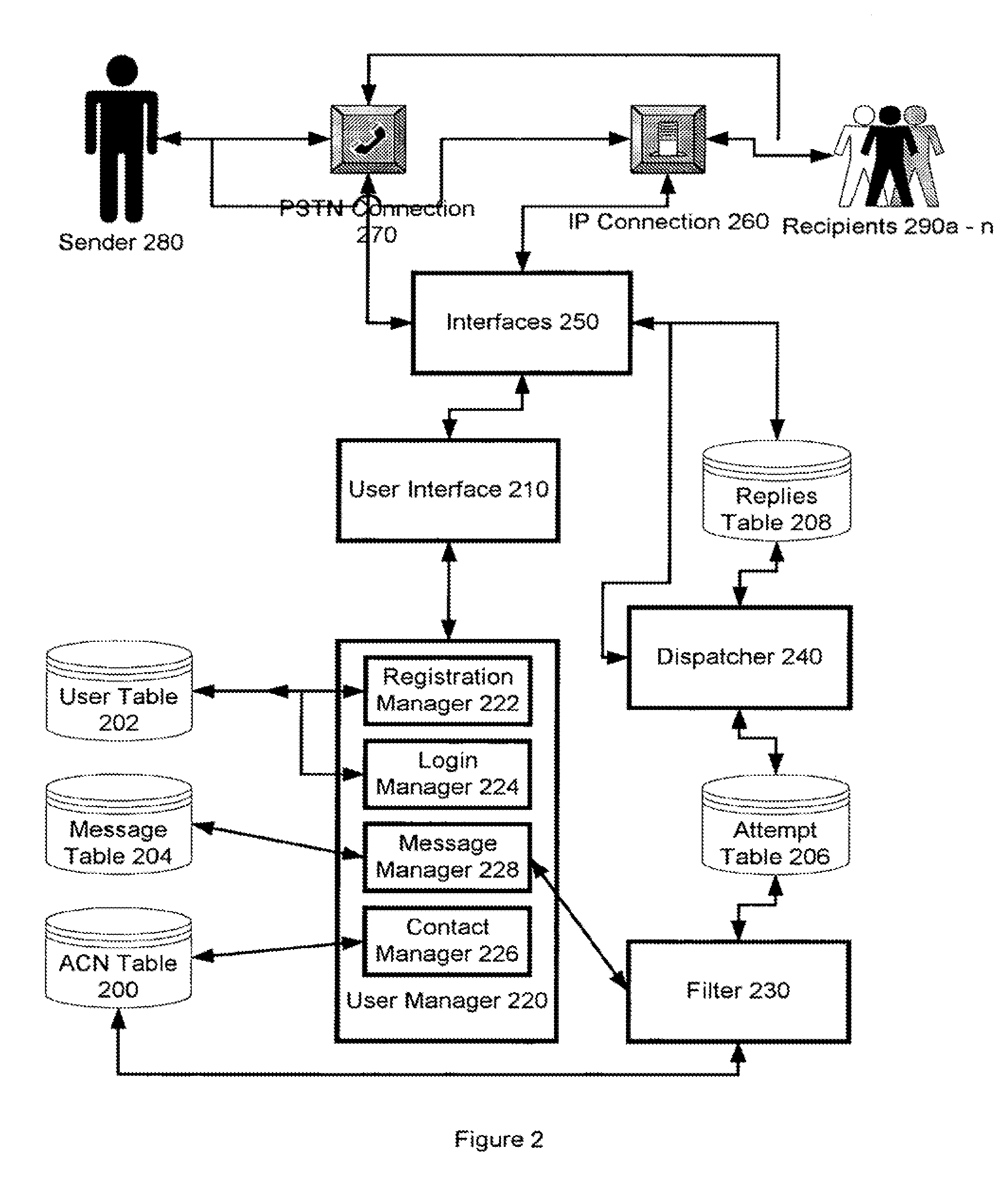

System and method for obtaining responses to tasks

InactiveUS20070280439A1Easily ignoringShorten the timeTelephonic communicationSpeech recognitionWorld Wide WebContact number

A method of automatically forwarding a response to a message to the sender of the message, wherein the sender is prompted to provide a message, the sender is prompted to identify a recipient, the recipient having a plurality of associated contact numbers, a user is prompted to rank the identified associated contact numbers relating to the recipient from highest to lowest, the message is sent to the highest ranked associated contact number to which the message has not yet been sent, the recipient of the message is prompted to provide a reply to the message, at least a predetermined amount of time is waited, until a response is received or the message has been sent to all associated contact numbers, the message is repeatedly sent to the next highest ranked associated contact number (and the recipient is prompted and the predetermined amount of time is waited), and the response is forwarded to the sender.

Owner:PRYWES NOAH

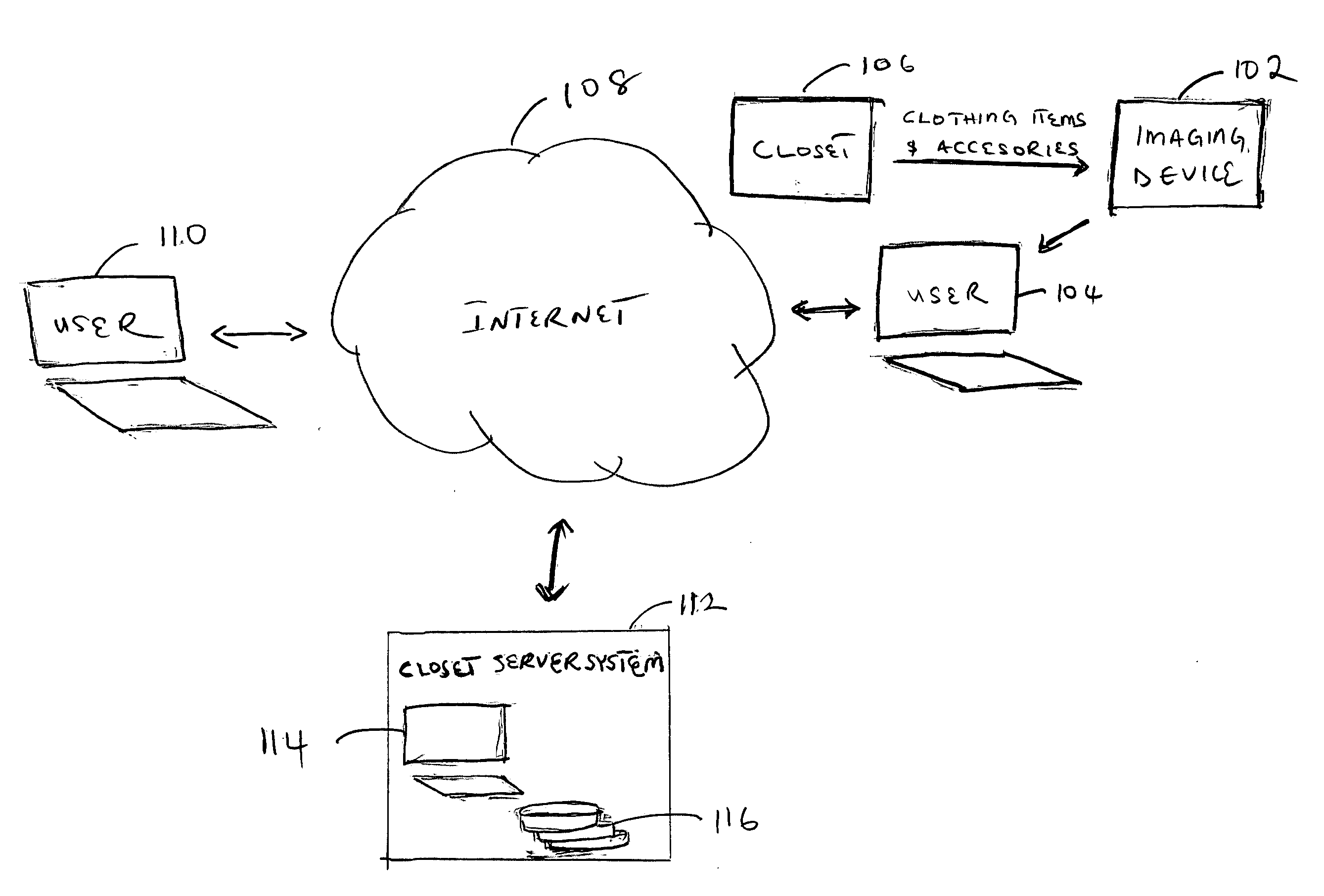

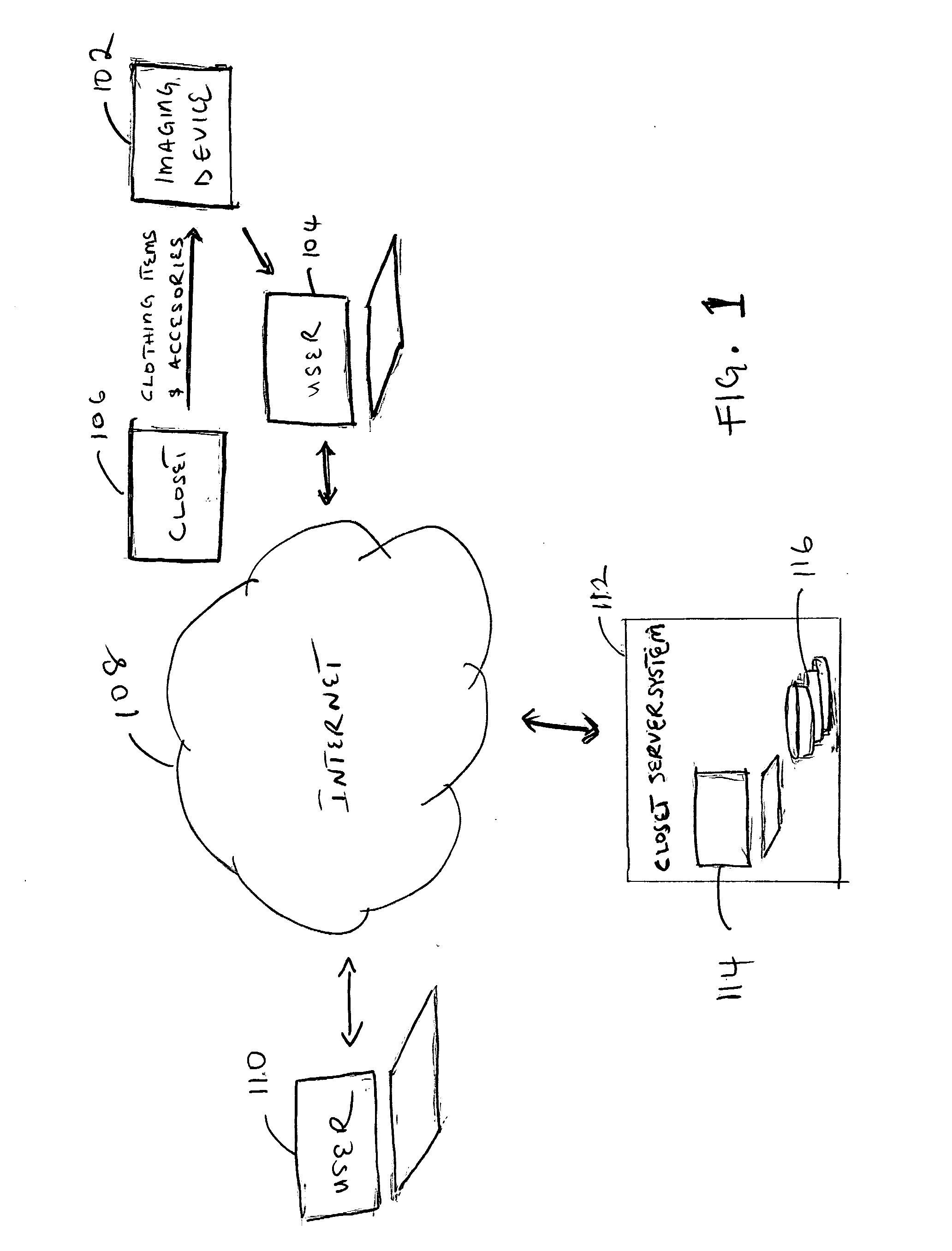

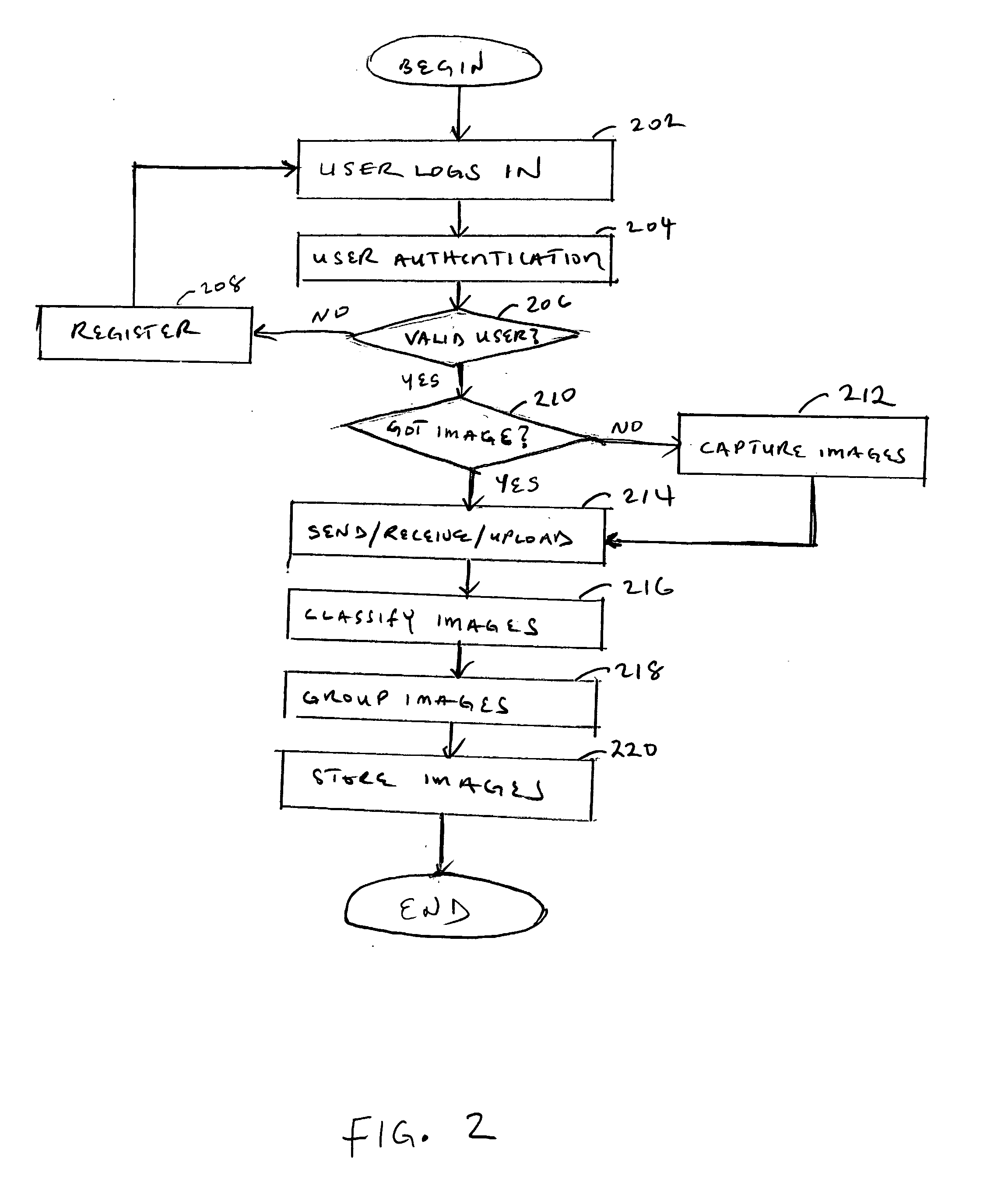

Online closet management and organizer system and method

InactiveUS20080126962A1Effective trackingSaving considerable timeDigital data processing detailsUser identity/authority verificationPersonal computerLibrary science

An online system and method for managing and organizing closets (i.e., “walk-in” closets and the like). The system and method uses captured images of clothing items and accessories stored in the closet for managing and organizing the closet. Images of the clothing items and accessories are first captured using a digital camera. The captured images are transferred to a PC (Personal Computer) or the like for uploading to an online server. After receipt, these captured images are then classified based on attributes or characteristics of the clothing items and accessories (or their corresponding images). An example of such attributes is the “Designer” of the clothing item and accessory. After classification, the captured images are stored for future retrieval by a user. The captured images can also be grouped into outfits representing combinations of the clothing items and accessories.

Owner:COOK ROSALIND

Device for connecting component parts, comprising a blind rivet fastener

ActiveUS7226263B2Mounted easily and efficientlySimplify the installation processWashersNutsFastenerEngineering

A device for connecting component parts includes a blind rivet nut adapted to be anchored in one component part by a riveter which has a threaded stud; a spacer which is in threaded engagement with the blind rivet nut and, by being screwed-out, reaches a position in which it is supported at the other component part; a connecting screw adapted to be screwed into the blind rivet nut; and a torque transmitting intermediate member, which is accommodated in a receptacle of the spacer and transmits a torque onto the spacer when the connecting screw is screwed in. For anchoring the blind rivet nut in the one component part, the threaded stud is capable of being inserted into the intermediate member and the spacer and then being screwed into the blind rivet nut without causing the spacer to be rotated in its screw-out direction.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

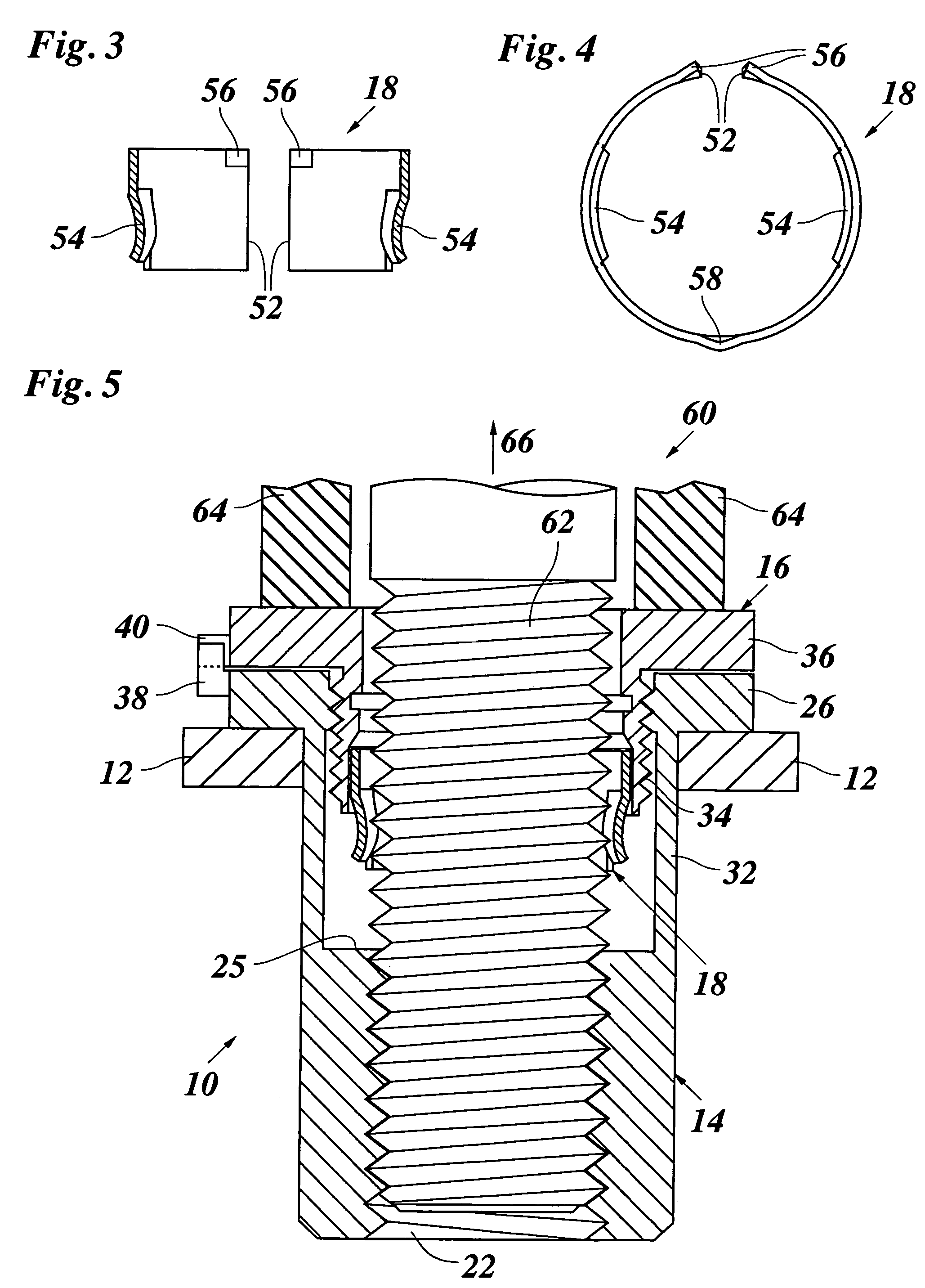

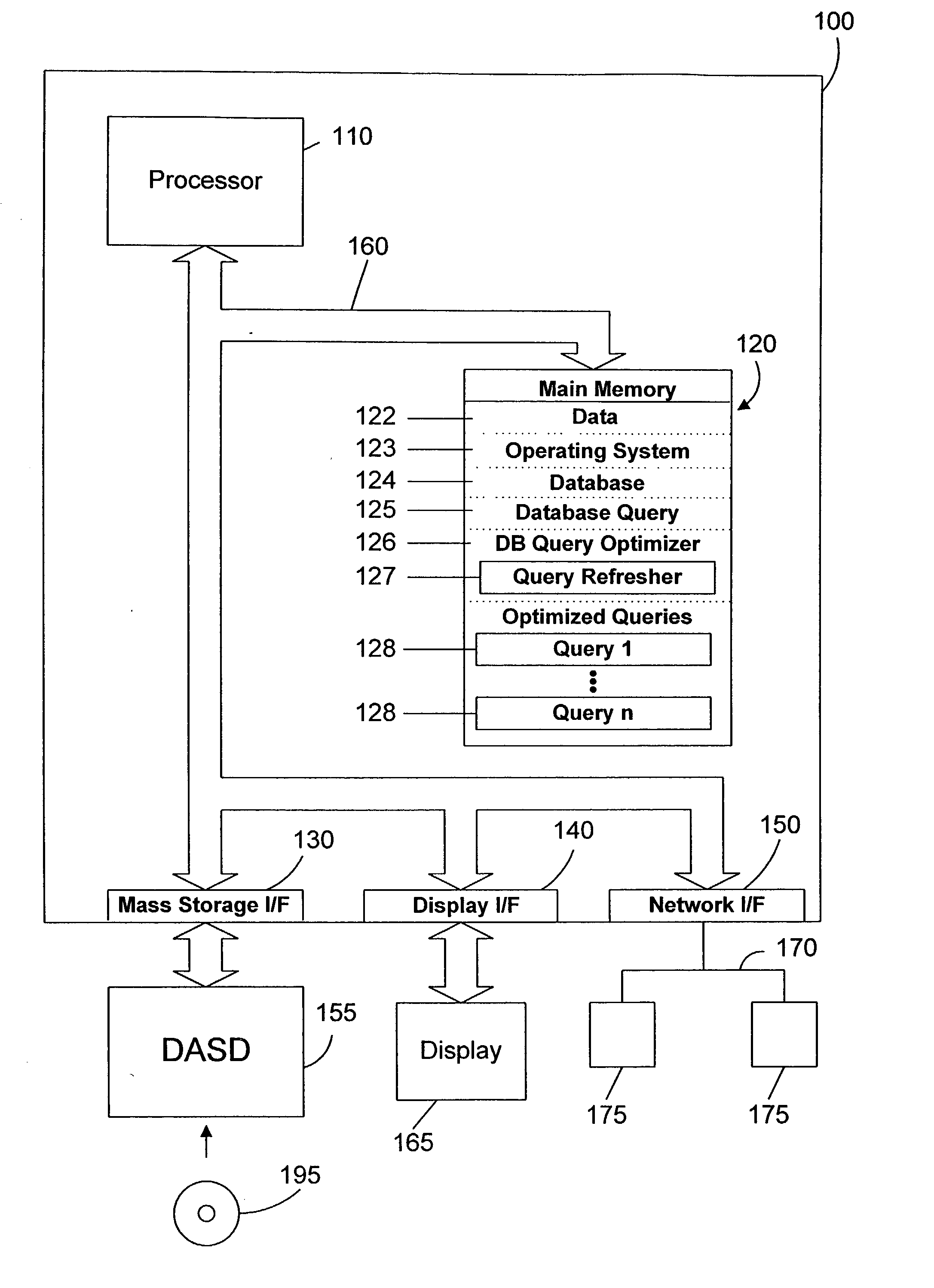

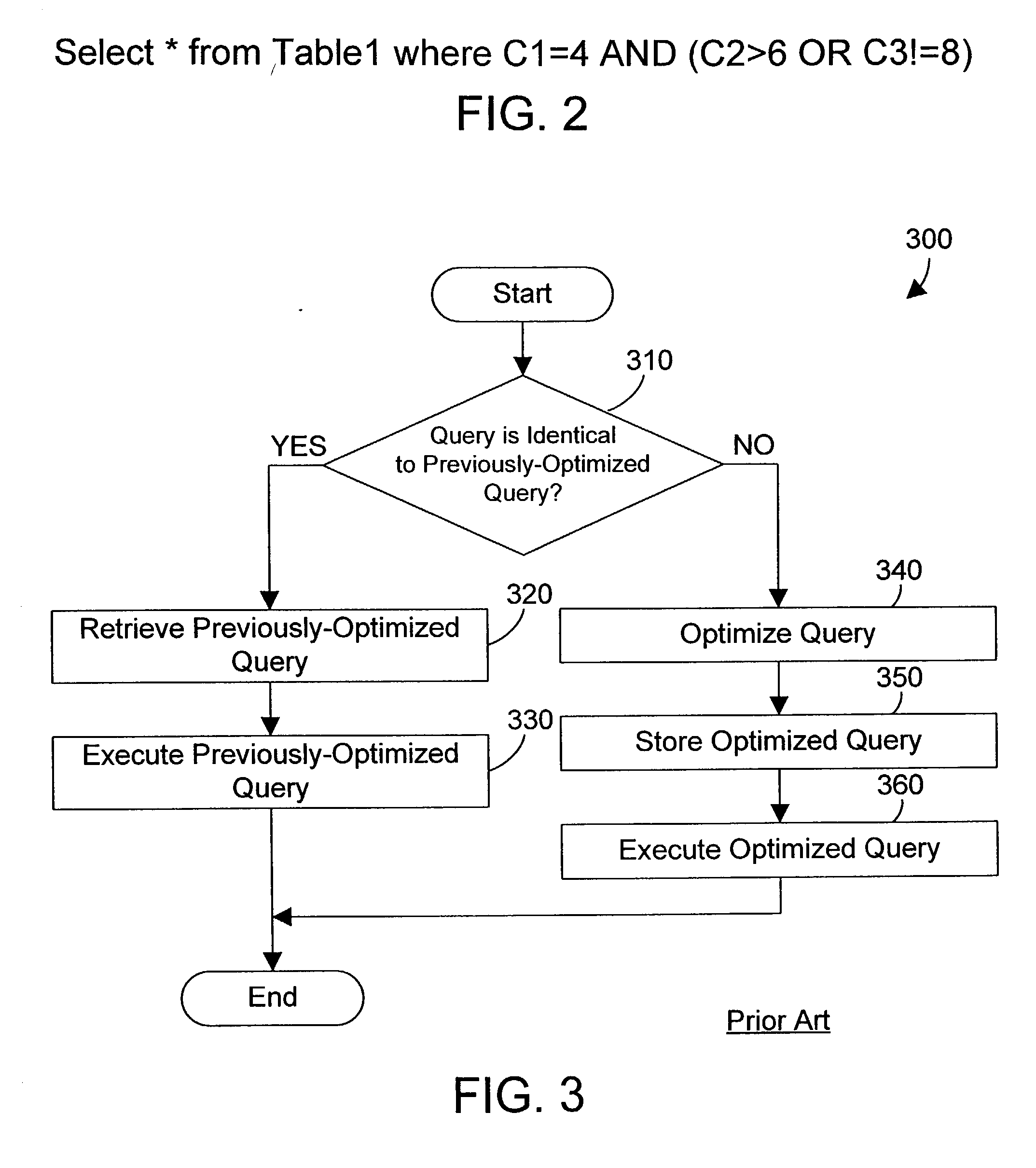

Apparatus and method for refreshing a database query

InactiveUS20030229621A1Improve query performanceImprove performanceData processing applicationsDigital data information retrievalDatabase queryData class

Previously-optimized database queries are stored in memory. When a new query needs to be optimized, the previously-optimized queries are examined to determine whether the new query has been previously optimized. If the new query has not been previously optimized, the previously-optimized queries are examined to determine whether any previously-optimized queries differ only in data type of one or more operands when compared to the new query. If a previously-optimized query that differs only in data type is located, the previously-optimized query is refreshed to reflect the different data type without the need of optimizing the new query from scratch. Portions of previously-optimized queries may thus be re-used even when a previously-optimized query is not identical to a new query to be optimized. As a result, the performance of query optimization in a database system is increased.

Owner:IBM CORP

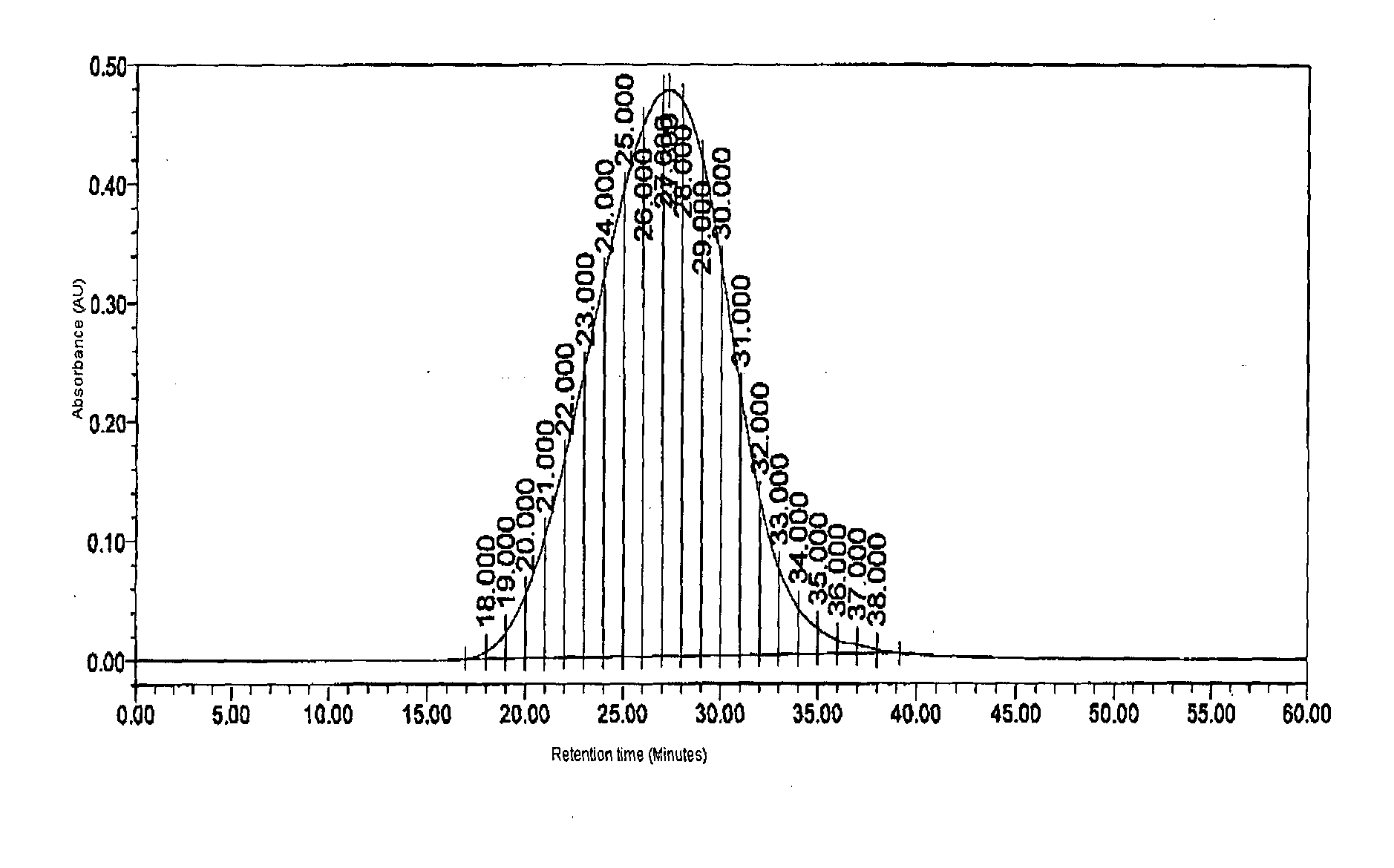

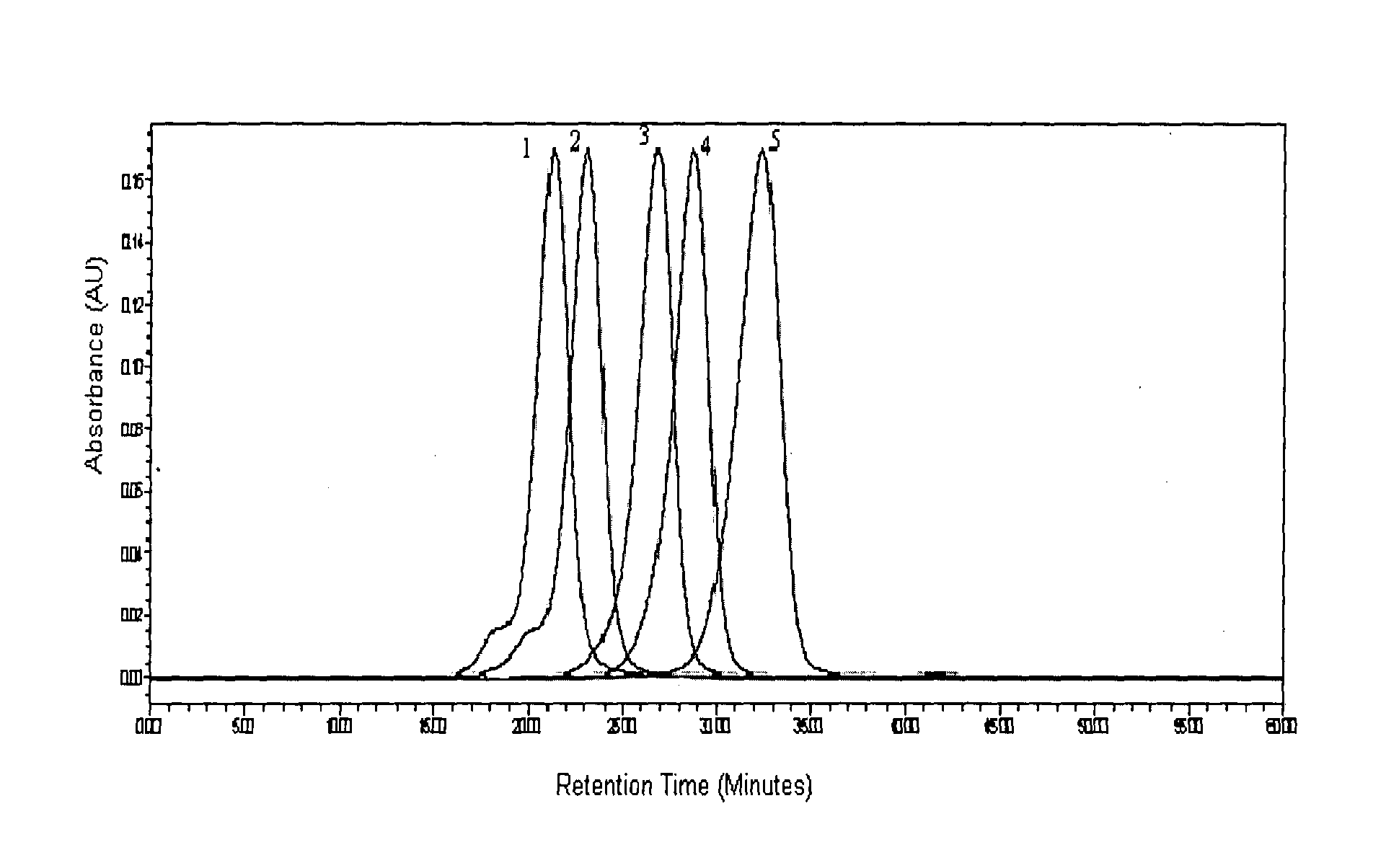

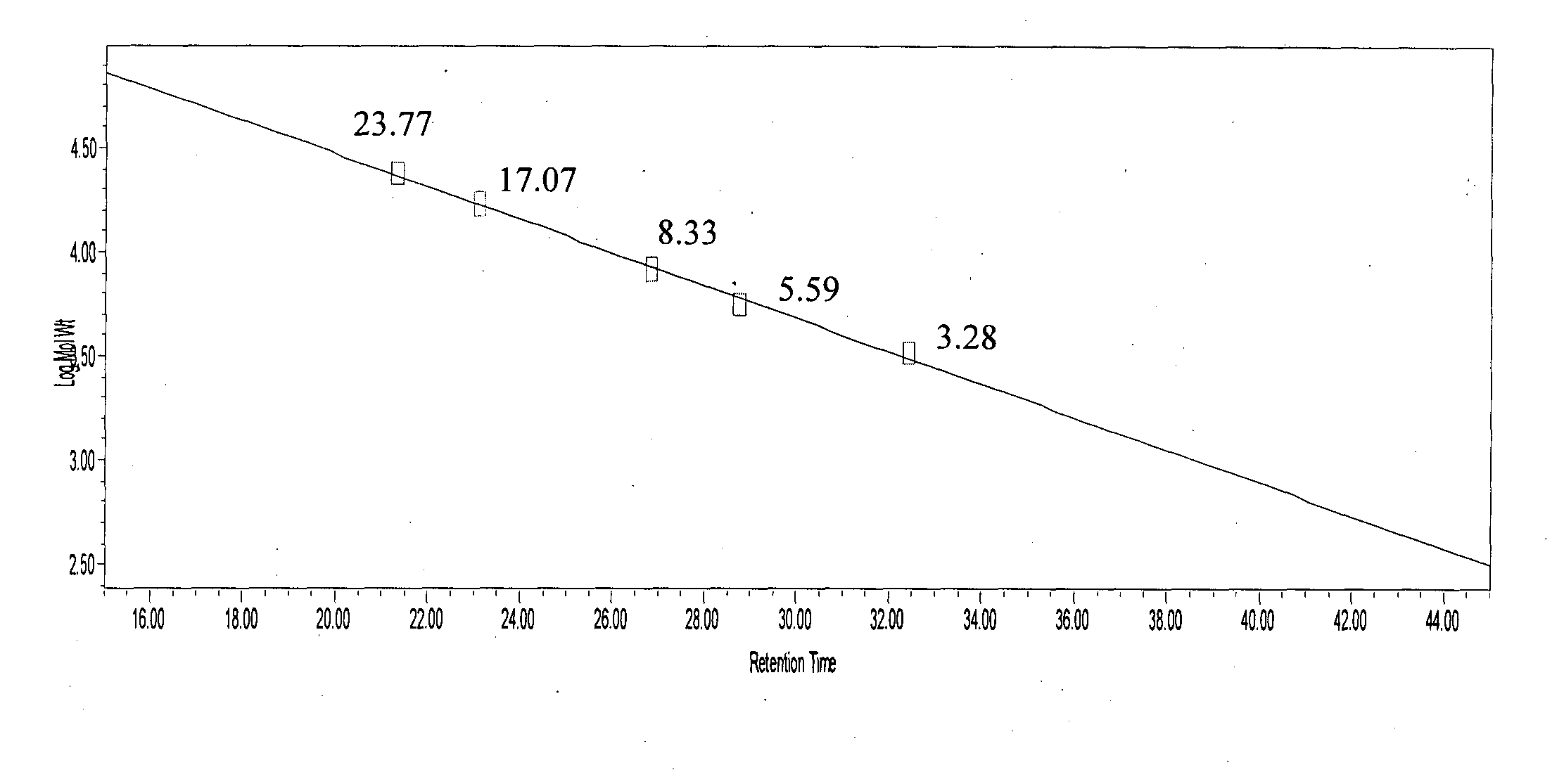

Copolymer-1, process for preparation and analytical methods thereof

InactiveUS20130323771A1Simple and cost-effectiveConsiderable timePeptide-nucleic acidsNervous disorderAnalysis methodCopolymer

The present invention relates to analytical methods such as molecular weight determination of polypeptide, in particular Glatiramer acetate. The present invention further relates to an improved process for preparation of polypeptides or pharmaceutically acceptable salts thereof, particularly Glatiramer acetate also known as Copolymer-1. The present invention further relates to characterization of Glatiramer acetate by peptide mapping.

Owner:USV LTD

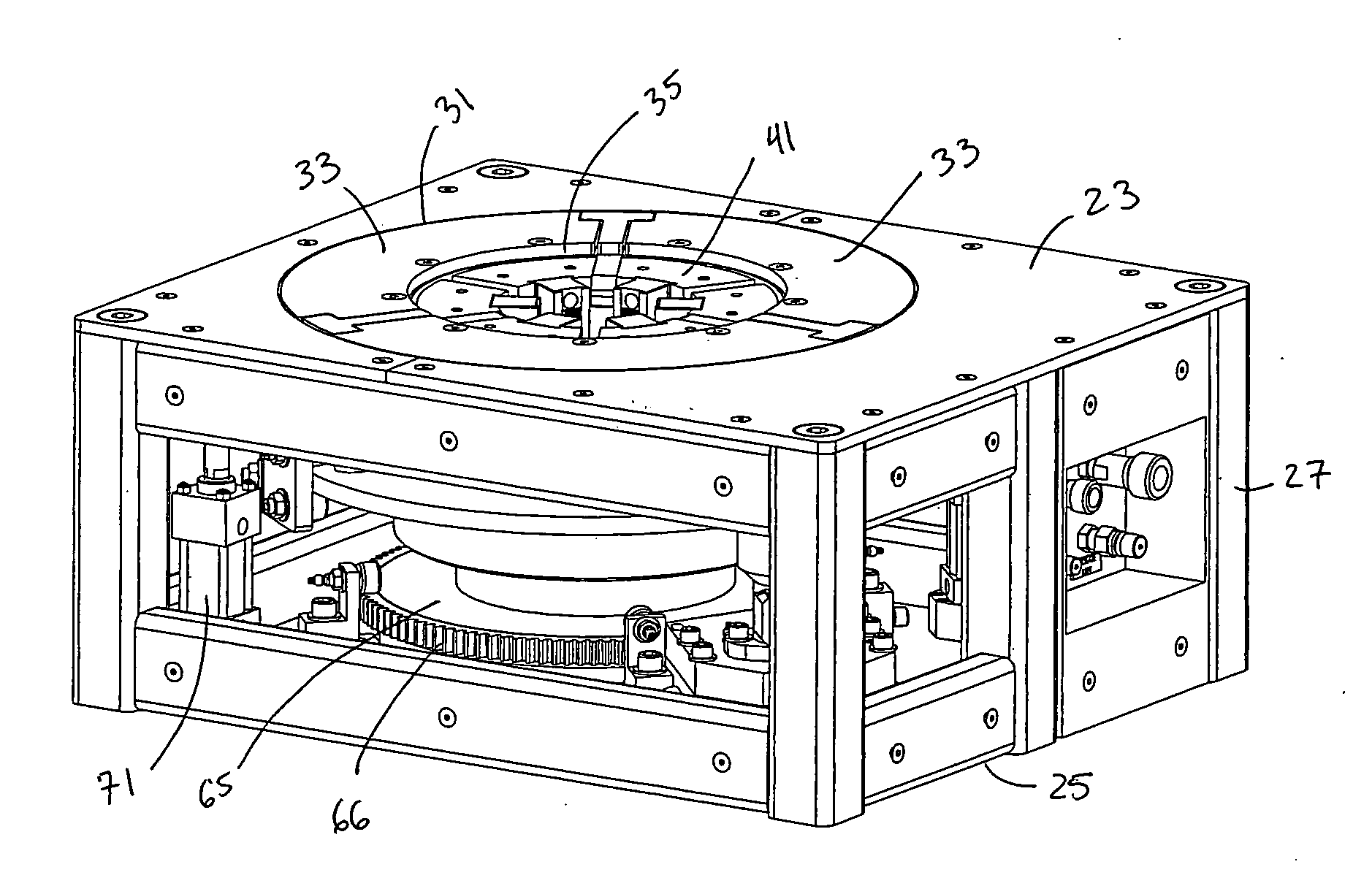

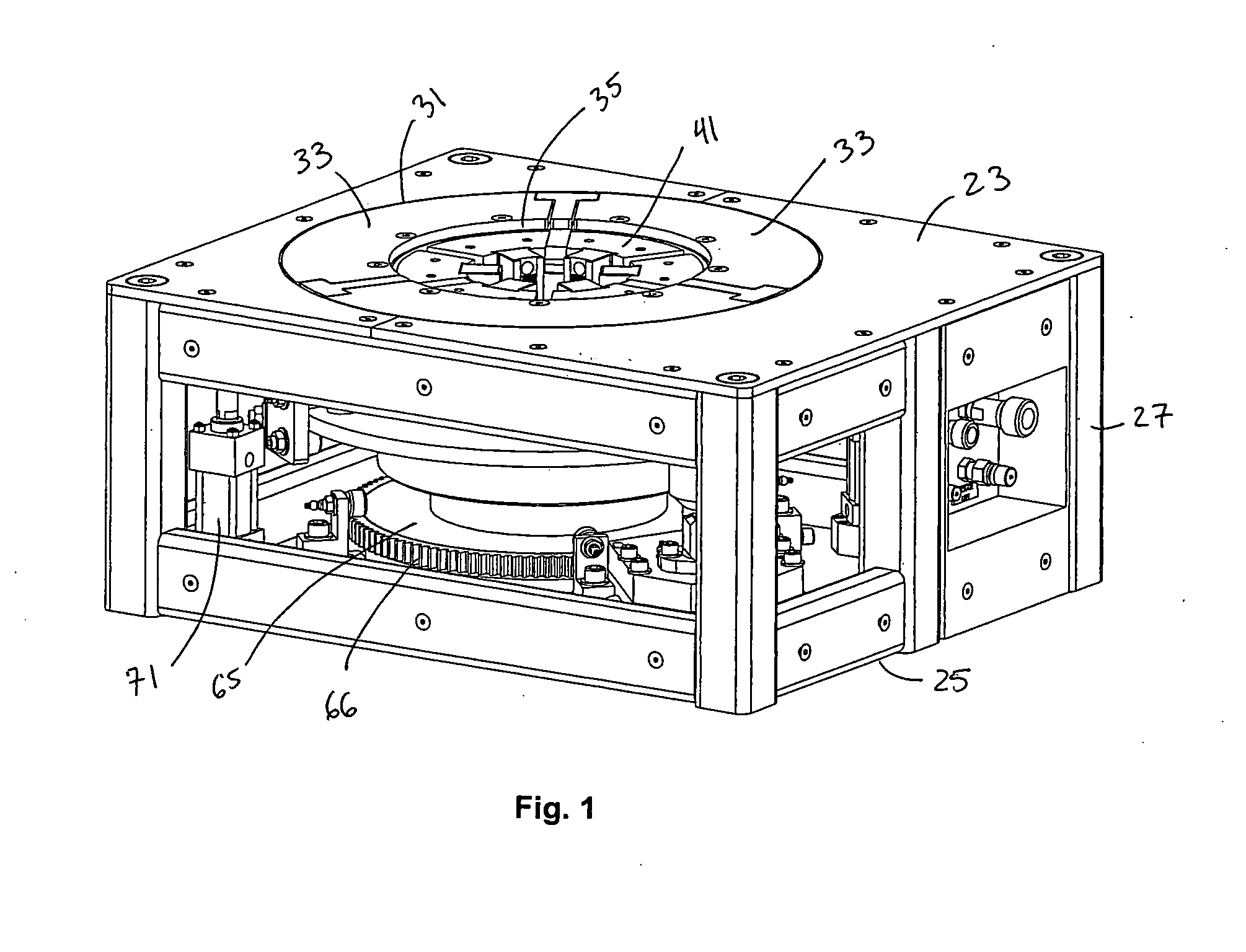

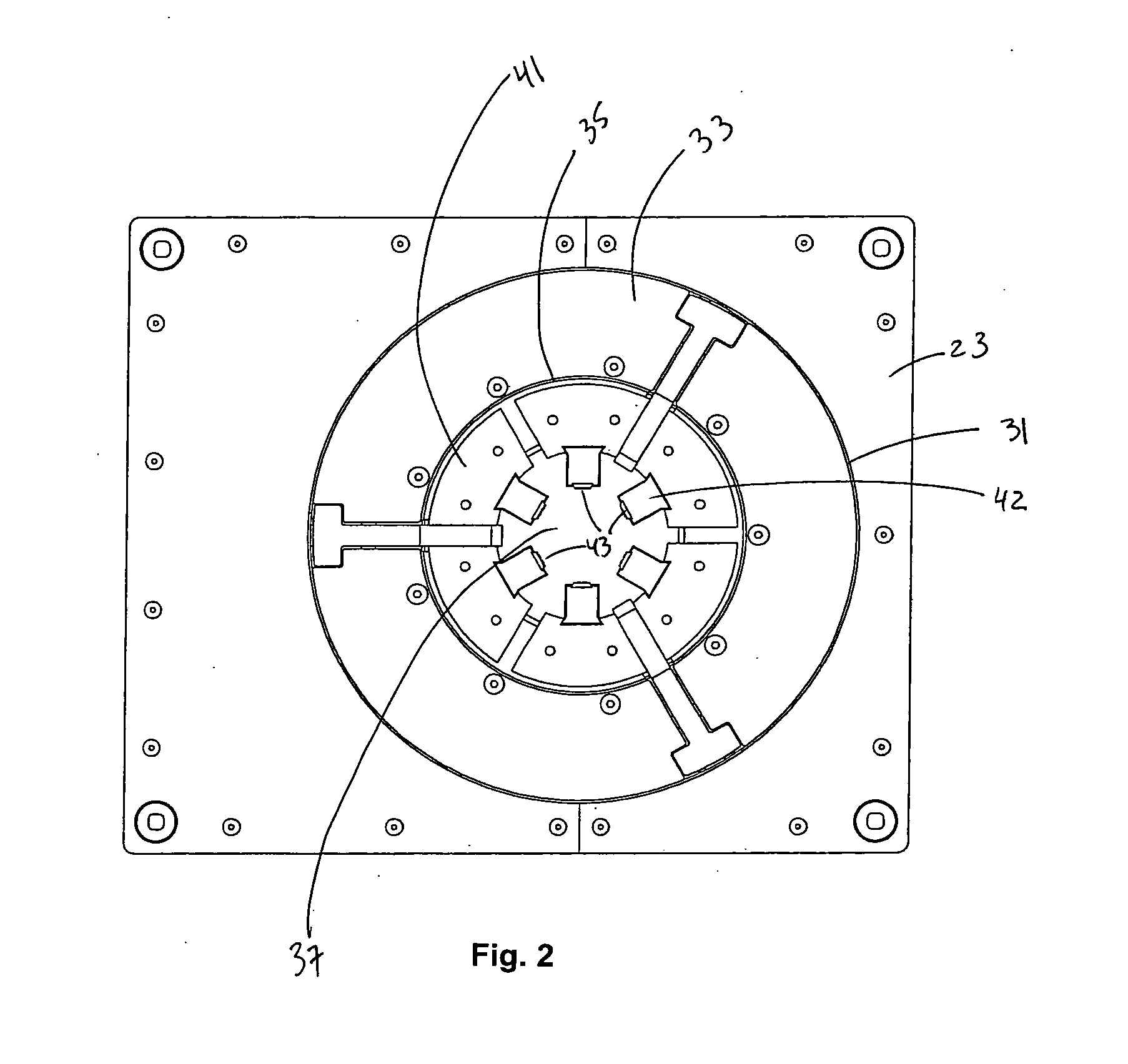

Mouse hole support unit with rotatable or stationary operation

InactiveUS20080202813A1Easy to set upConsiderable timeDrilling rodsConstructionsManual insertionDrill line

The present invention provides improved methods and apparatus for supporting and engaging drill pipe in a mouse hole that allows for multiple drill pipe sections to be attached together before being attached to an existing drill string. The present invention is designed to allow for engagement and disengagement of drill pipe sections of various diameters without the need for manually inserting or removing support shims or slips. Embodiments of the invention provide for rotation of the engaged drill pipe sections to assist in connection to another drill pipe section. These features allow for speedy set up and attachment of drill pipe sections during drilling operations. The support unit of the present invention is also portable, and may be retrofitted into an existing drill rig platform.

Owner:XTECH INDS

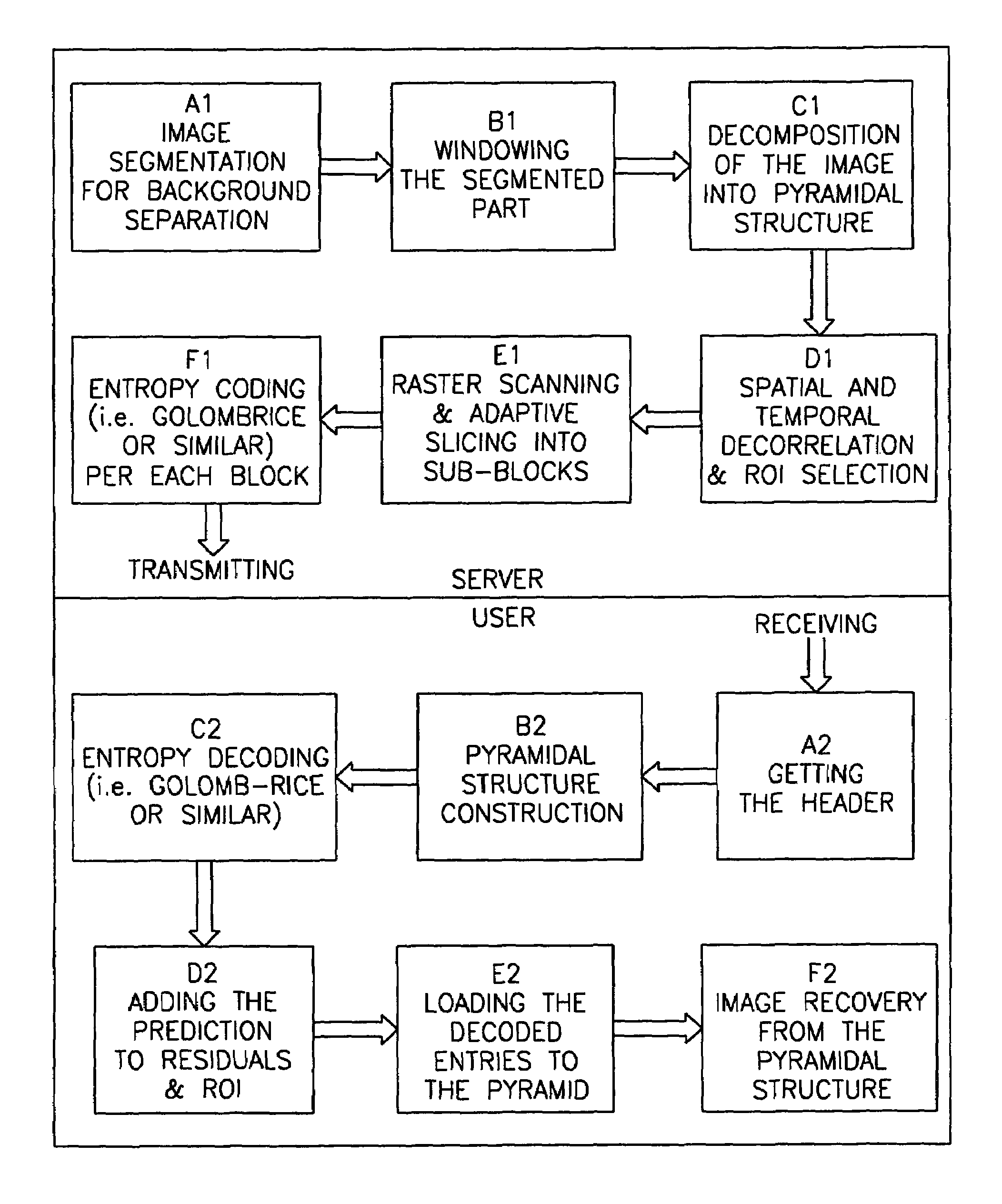

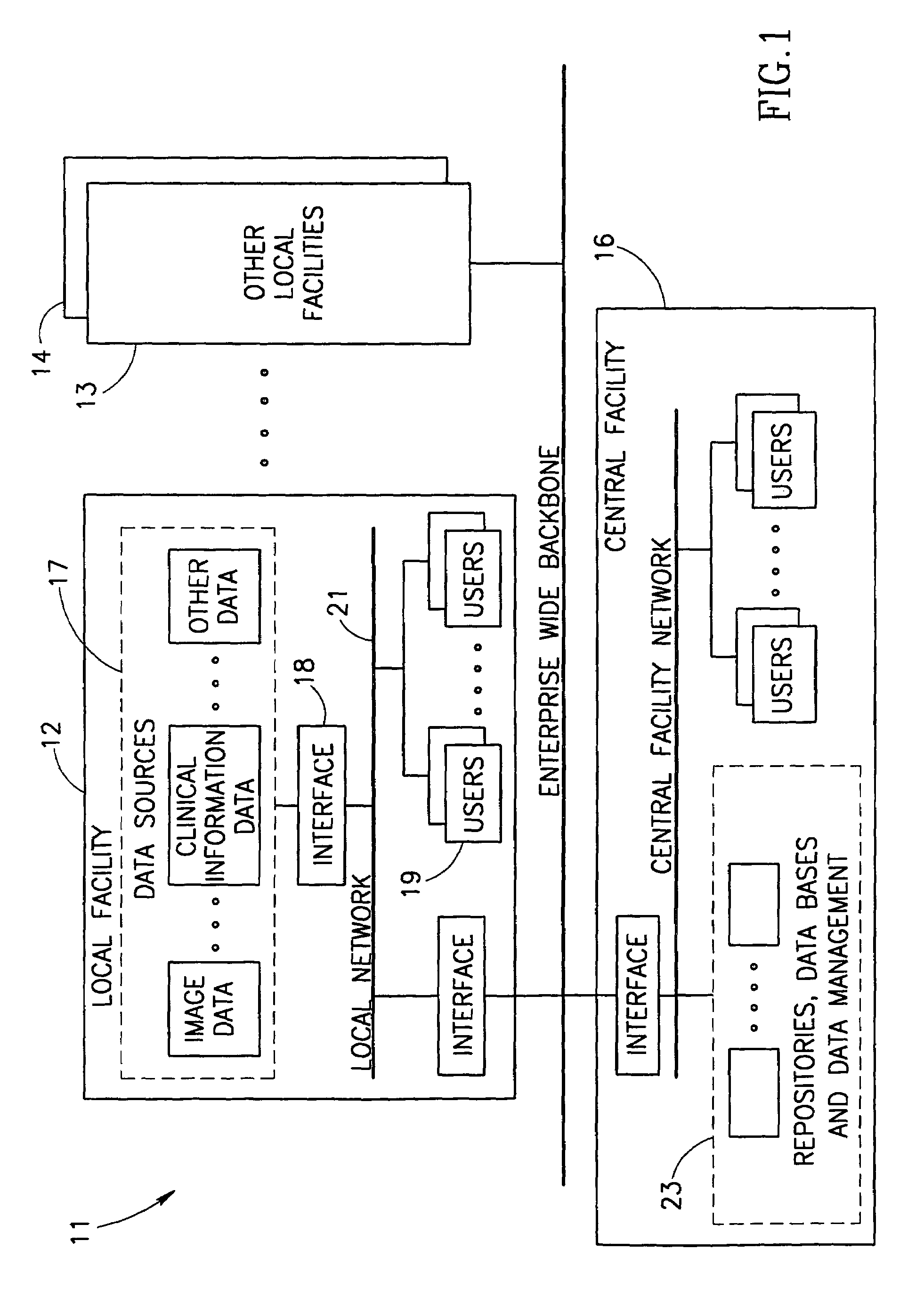

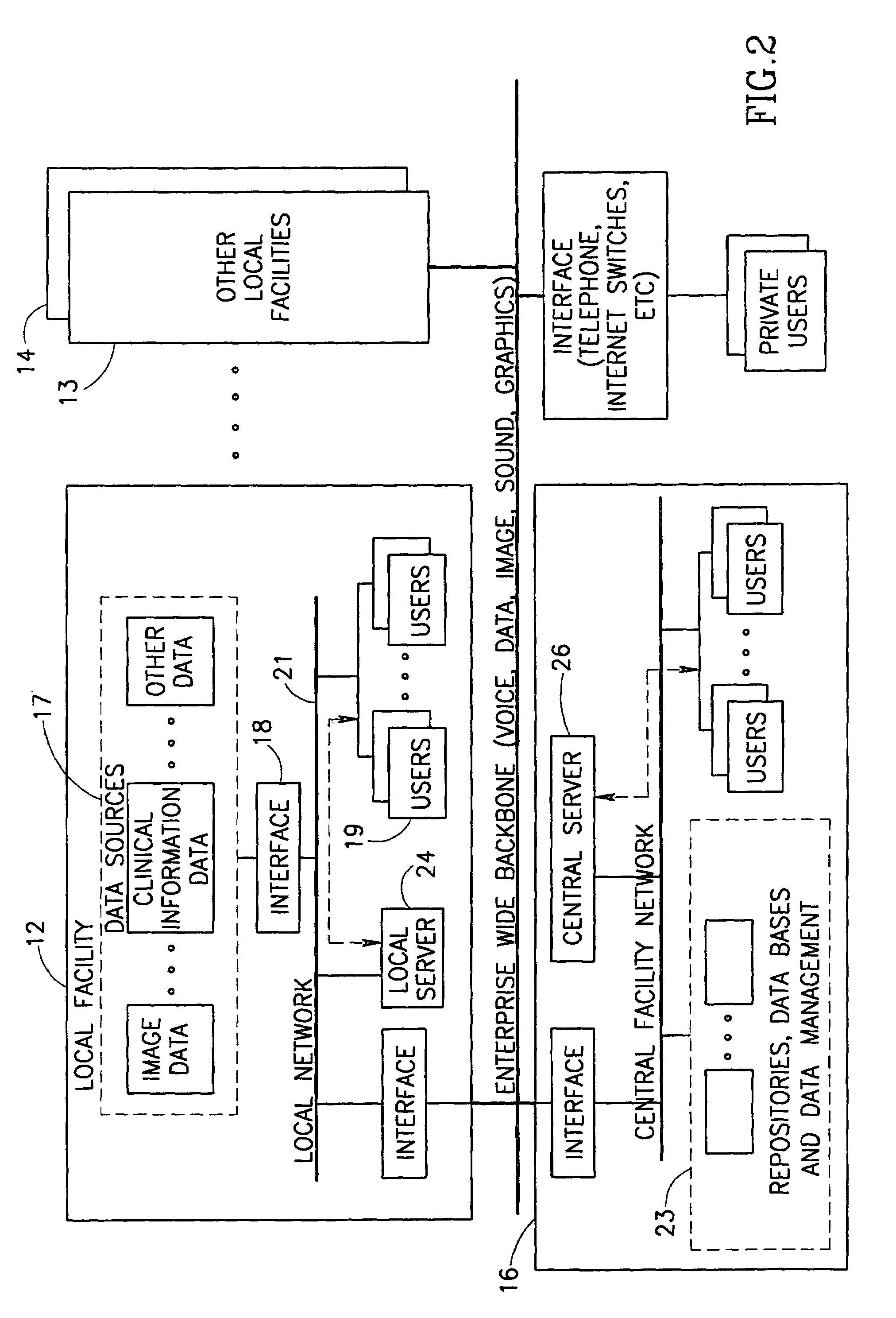

Data distribution system

InactiveUS7200858B1Reduce transfer timeShorten the timeAnalogue secracy/subscription systemsColor television detailsComputer networkDistribution system

An interactive system for obtaining data for diagnostic purposes from a server having access to stores of said data wherein the server supplies the data and software to a data requesting user that enables the user to receive the data progressively so as to decide during the receipt of the data what portions of the data are to be received thereby decreasing the time required to receive the data and that enables the user to load the software to process the supplied data.

Owner:ALGOTEC SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com