Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Increase the degree of oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature SCR catalyst using nitrogen-dopped activated carbon as carrier and preparation technique thereof

InactiveCN101352681AIncrease the degree of oxidationEasy to handleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen

The invention discloses a low-temperature SCR catalyst which takes nitrogen mingled with active carbon as a carrier. The catalyst takes the nitrogen mingled with active carbon prepared by ammonia gas ignition as the carrier and one of the oxides loaded with metallic element of Mn, V, Fe, Co or Cu as an active ingredient. The invention also discloses a specific method for preparing the catalyst. The carrier of nitrogen mingled with active carbon increases the number of base sites on the surface of the active carbon, so as to improve the adsorptive capacity of NO and O2 and lead more NO to be oxidized into NO2. The load of the metal metallic oxides of Mn, V, Fe, Co and Cu forms a large amount of acid sites on the surface of the catalyst, which promotes the absorption capability of the catalyst to NH3. The measures effectively enhances the denitration activity of the low-temperature SCR catalyst which takes the nitrogen mingled with active carbon as the carrier and extends the activity temperature window of the reaction thereof.

Owner:ZHEJIANG UNIV

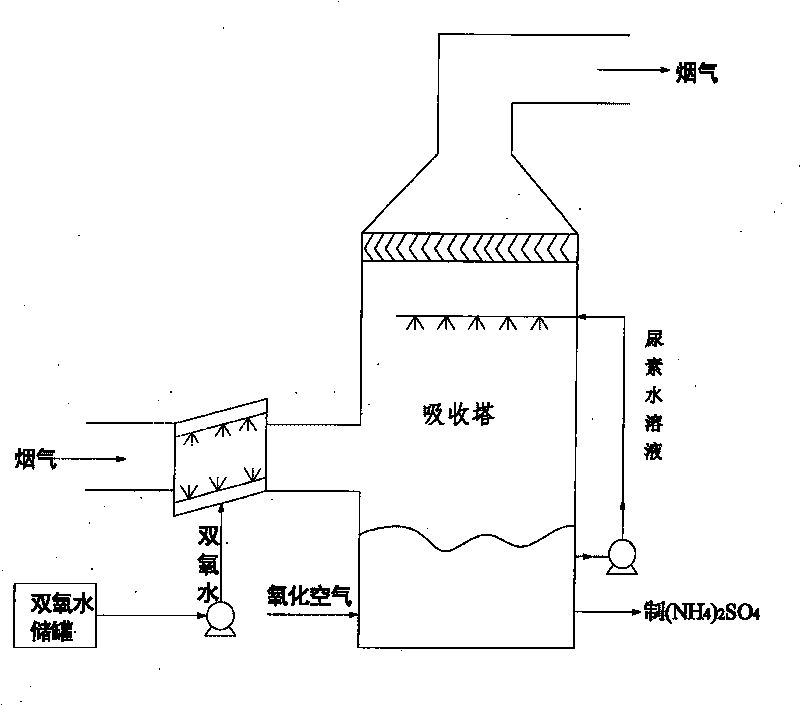

Chloric strong oxidant enhanced wet combined urea desulfurizing and denitrifying process

InactiveCN1986033AIncrease the degree of oxidationImprove denitrification efficiencyDispersed particle separationAir quality improvementNitrogen oxideSodium chlorite

The wet combined fume desulfurizing and denitrifying process with chloric strong oxidant enhanced urea has the fume to be treated contacted sufficiently with the mixed absorbent liquid containing urea and chloric strong oxidant inside the absorbing reactor so as to eliminate NOx and SO2 through absorption before being exhausted. The chloric strong oxidant is sodium chlorite, sodium hypochlorite, bleaching powder or their mixture. The process has high denitrifying efficiency, high fume purifying effect, simple structure, easy operation and small occupied land. The said process can reach NOx eliminating rate of 75-98 % and desulfurizing efficiency over 95 %.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

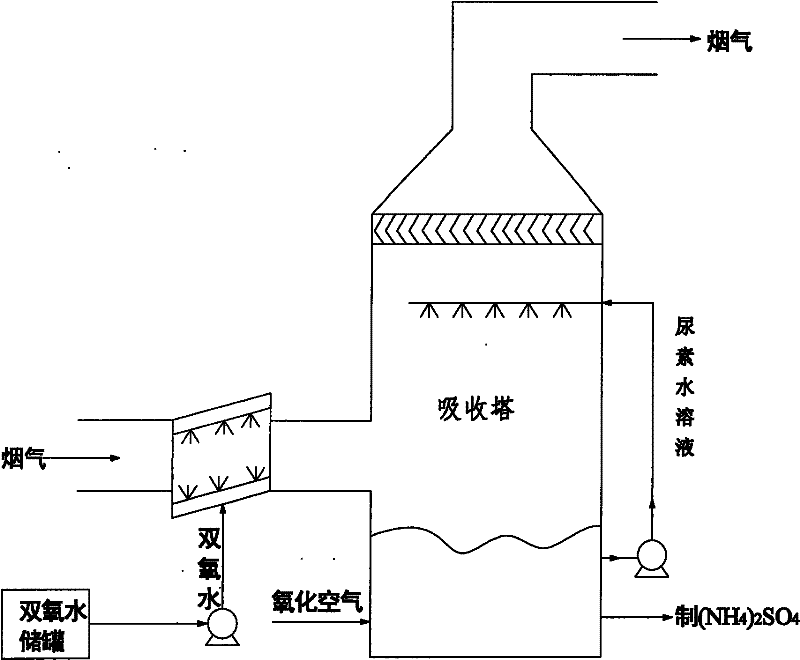

Coal-fired flue gas denitration and desulfurization method combined with urea wet method

ActiveCN101708419AImprove denitrification rateGood chemical stabilityLighting and heating apparatusDispersed particle separationUreaAqueous solution

The invention discloses a coal-fired flue gas denitration and desulfurization method combined with the urea wet method. The method comprises the following steps: spraying 50wt% of hydrogen peroxide at the coal-fired flue gas inlet of a absorption tower while keeping the molar ratio of H2O2 to NO to be 2-3, so as to oxidize NO in the coal-fired flue gas to NO2 and increase the oxidization degree of NOX; and perform denitration and desulfurization simultaneously by using the urea aqueous solution in the absorption tower. The method of the invention increases the denitration rate of the coal-fired flue gas denitration and desulfurization combination technology by increasing the oxidization degree of NOX and the temperature of the absorption solution. The method has simple technology, convenient operation and management, no secondary pollution and good environmental and economic benefits.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

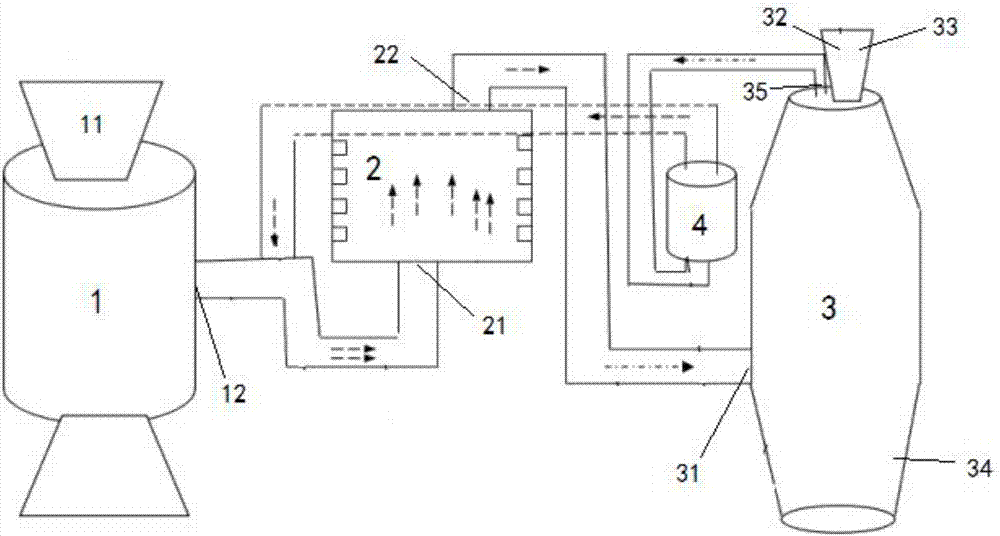

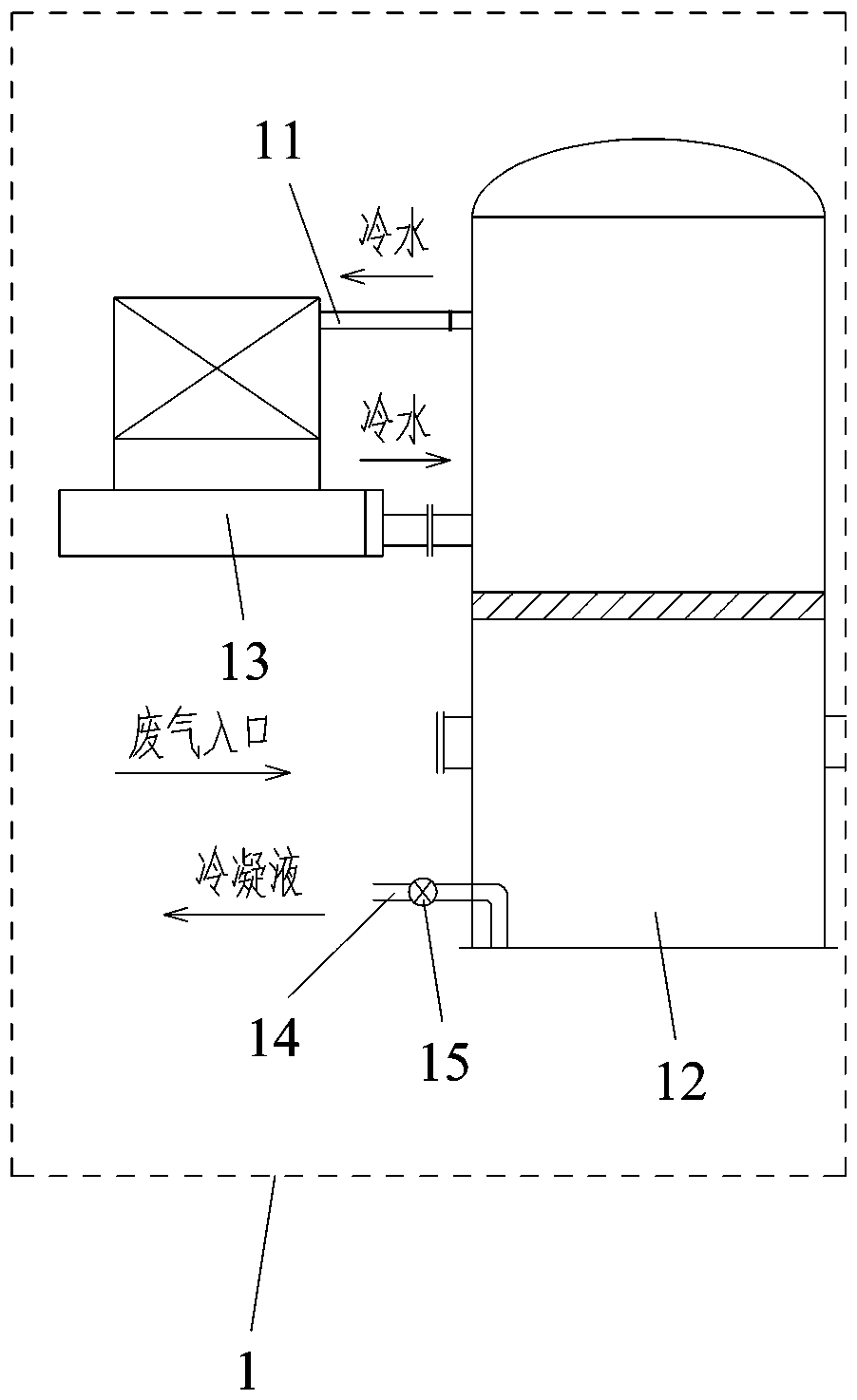

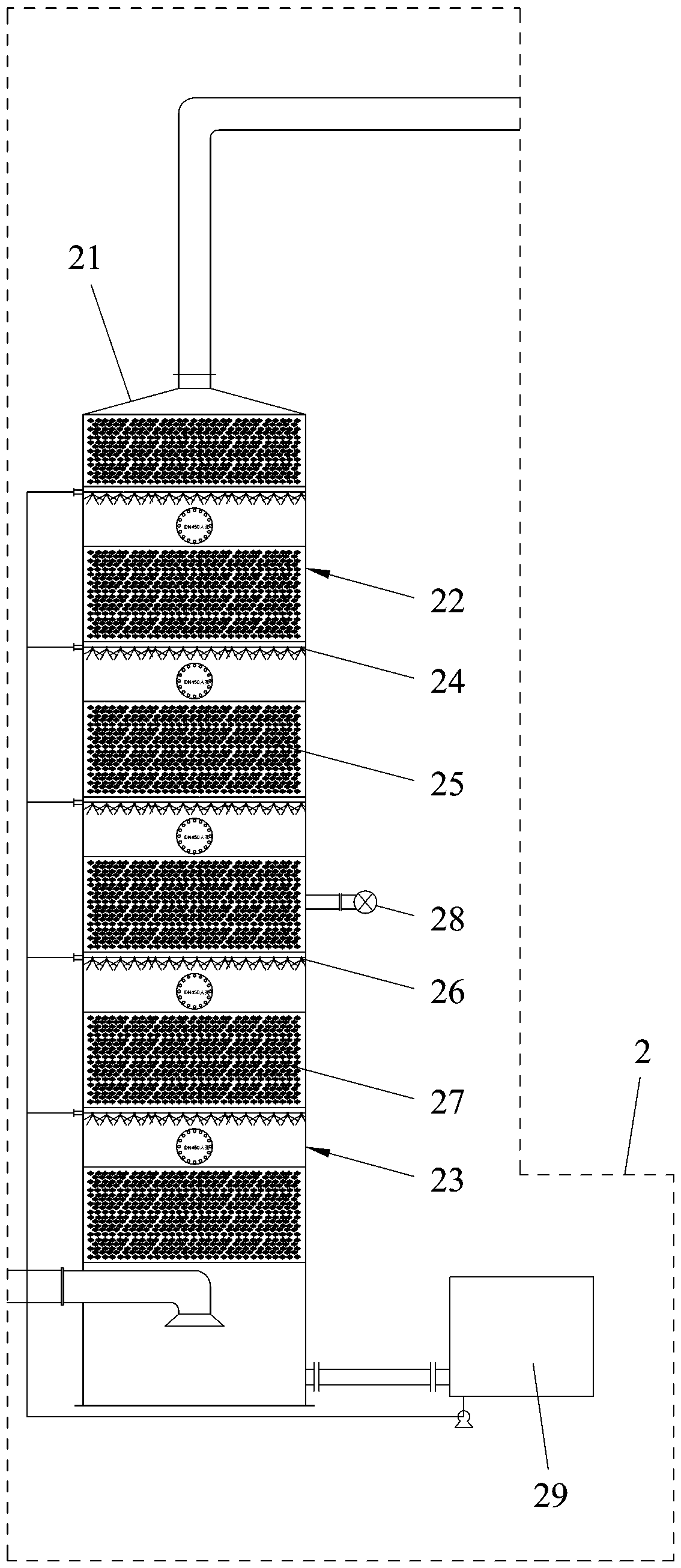

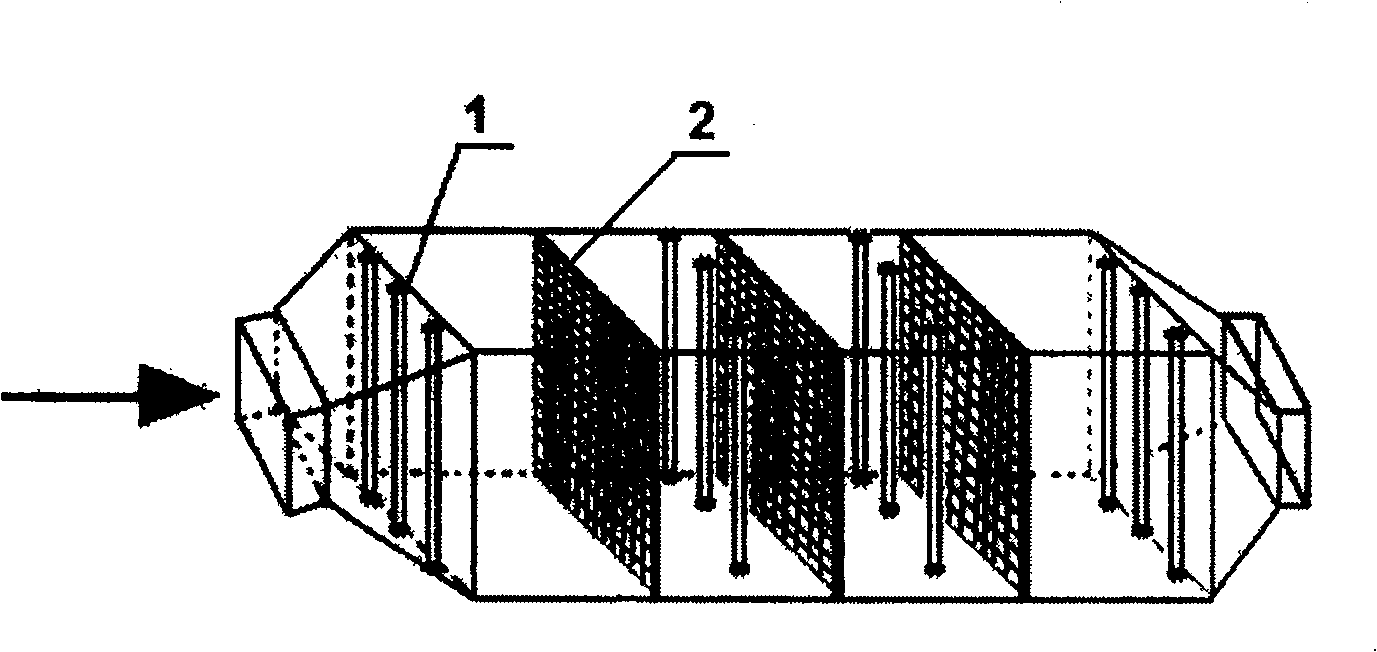

System device and method for deeply removing nitric oxide in industrial tail gas

ActiveCN103394279ASmall footprintReduce volumeDispersed particle separationGas phaseEmission standard

The invention discloses a system device for deeply removing nitric oxide in industrial tail gas. The device is characterized by comprising two-stage serial connected equipment, wherein the two-stage serial connected equipment is formed by serial connection of an absorption tower and a single rotating packed bed or the serial connection of two rotating packed beds. The invention also discloses a method for removing by utilizing the device. The device and the method enable the nitric oxide emission to be lower 200mg / m<3> required by the national nitric oxide emission standard and are particularly suitable for upgrading and reconstructing factories with limited space; the removing rate of NO gas in the industrial tail gas can be effectively improved by a method for increasing the oxidation degree from the aspects of vapor phase and liquid phase; an optimal denitration effect can be achieved by using different combinations of absorbents according to different technical requirements; and the environmental pollution prevention and control of China can be greatly pushed and promoted by deep denitration of the two-stage serial connected equipment.

Owner:BEIJING UNIV OF CHEM TECH

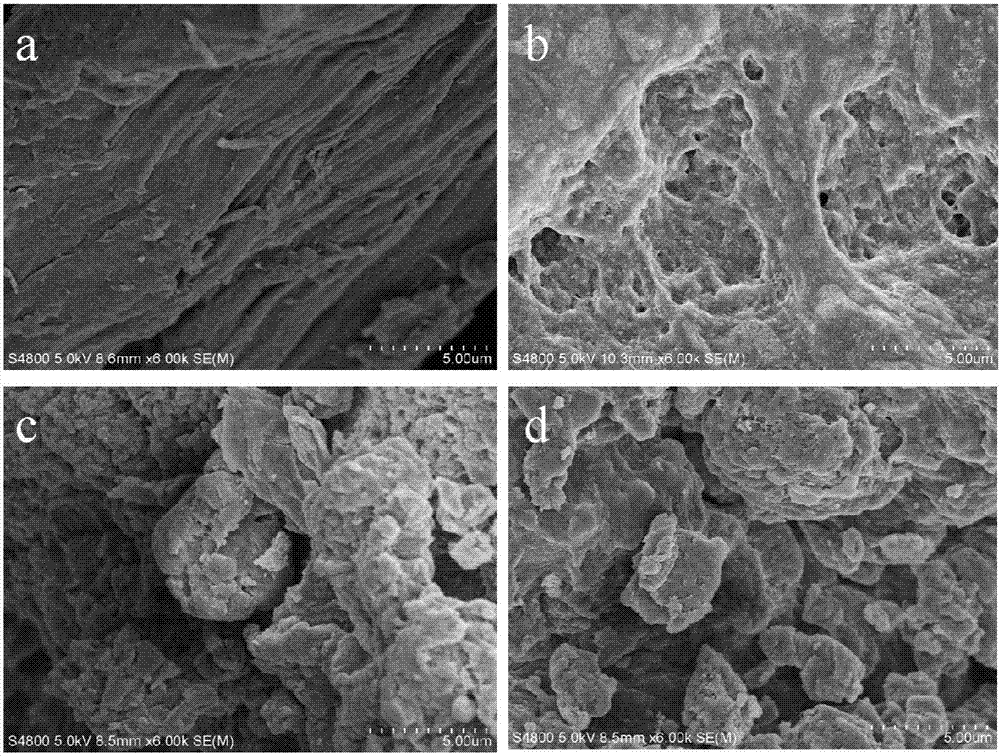

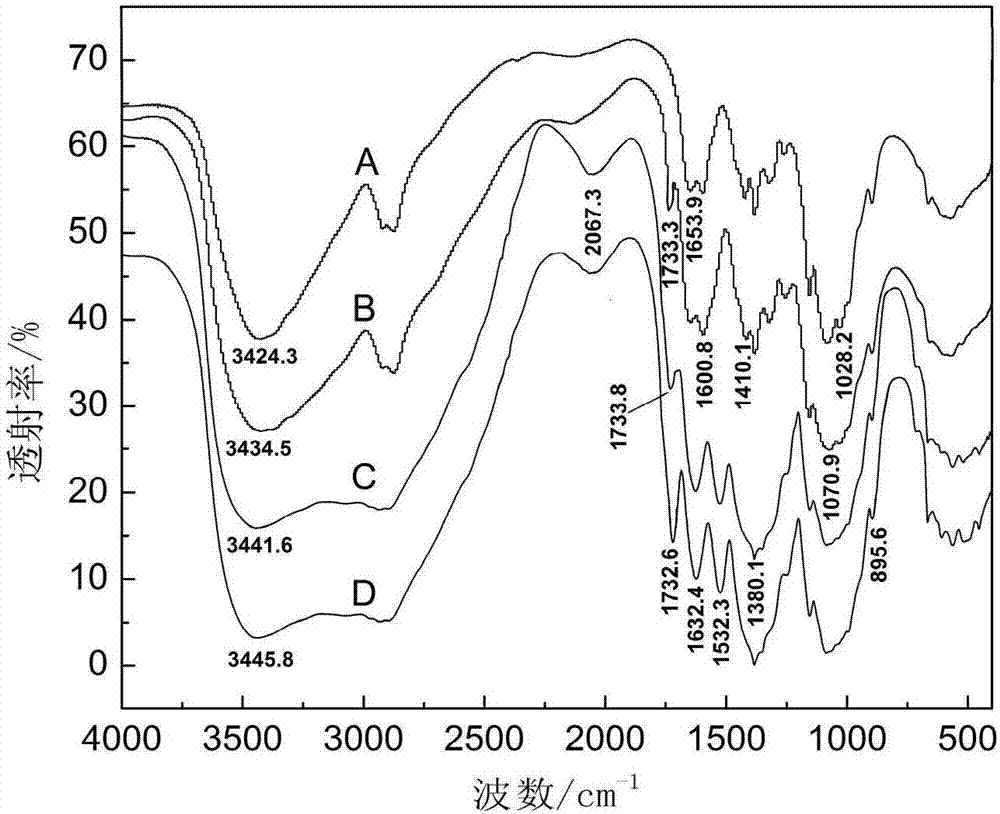

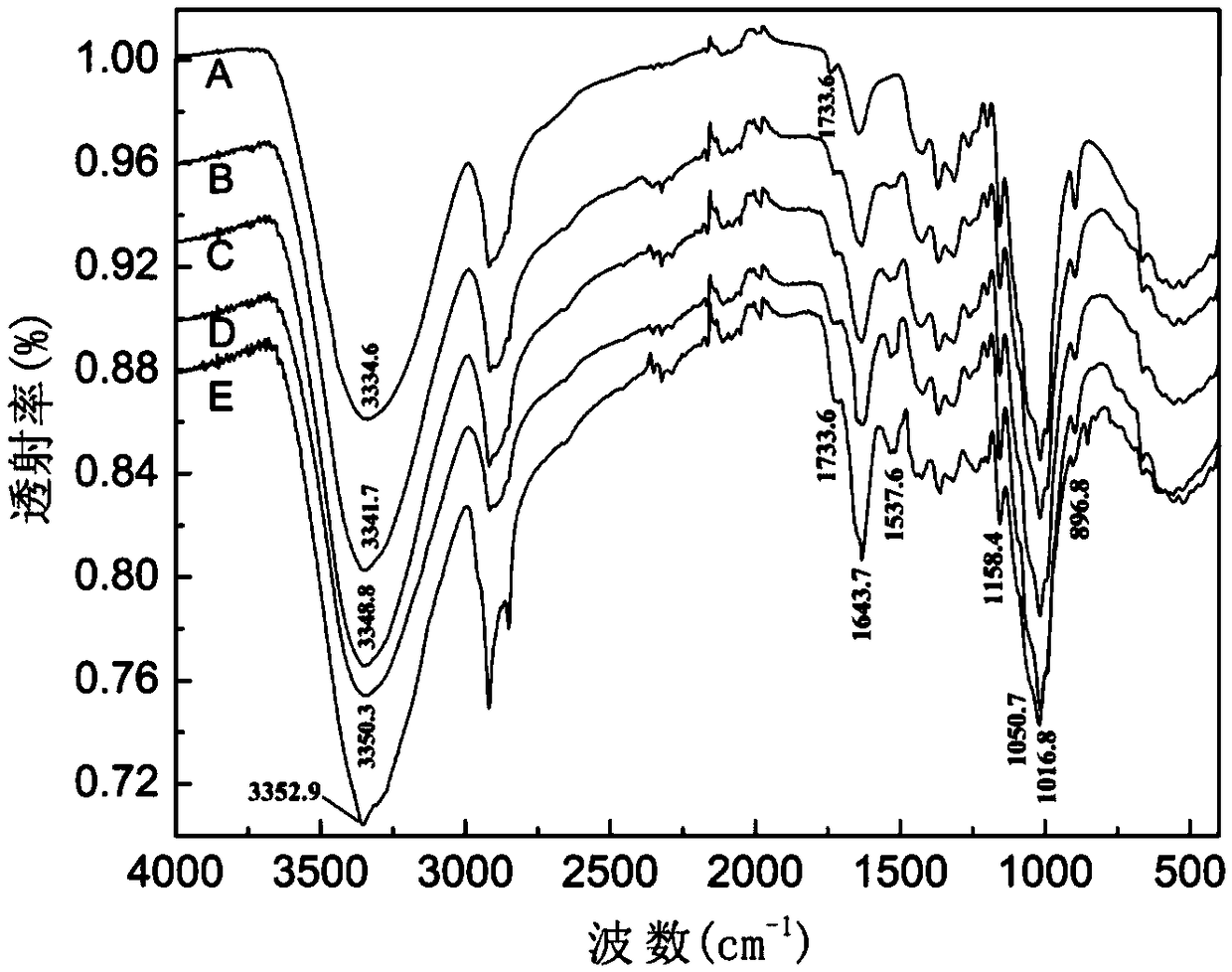

Selective-oxidized chitosan and heterogeneous preparation method thereof

The invention discloses a selective-oxidized chitosan and a heterogeneous preparation method thereof. The method is characterized in that according to preparation of the oxidized chitosan, macromolecular chitosan is dissolved in an ionic liquid, the chitosan is precipitated from the ionic liquid by adding absolute ethyl alcohol, and porous chitosan is obtained after the ionic liquid in a precipitation is fully replaced through absolute ethyl alcohol dipping and ultrasonic oscillation; the porous chitosan is moistened and expanded in the ionic liquid to form a semisolid gel with certain viscosity, and then partial or all hydroxyls at C6 position in pyranose rings of the chitosan are selectively oxidized into carboxyls in an ionic liquid medium to obtain the selective-oxidized chitosan with adoption of a concentrated nitric acid-concentrated phosphoric acid-sodium nitrite system. According to the method, operation is simple and convenient, the oxidation reaction rate is high, the oxidation degree of the chitosan is easily controlled, oxidation products are easy to separate, the yield of the products is high, the prepared carboxyl chitosan has good antibacterial activity and water solubility, and the ionic liquid can be recycled for cyclic utilization, which is environmentally friendly.

Owner:TAIHE KERUNGE GARMENT CO LTD

Method for preparing highly oxidized lead powder from waste battery lead plaster

ActiveCN103436702AHarm reductionReduce manufacturing costRed leadWaste accumulators reclaimingLead carbonateCooking & baking

The invention discloses a method for preparing highly oxidized lead powder from a waste battery lead plaster, which comprises the following steps: (1) grinding a waste lead plaster into powder; (2) adding a sulfuric acid solution and reducer into the lead plaster powder, sufficiently reacting, separating to remove the liquid, washing the solid material to neutral with water, and baking; (3) adding desulfurizer into the solid material obtained in the step (2), sufficiently reacting, separating to remove the liquid, washing the solid material to neutral with water, and baking; (4) adding an acid solution into the solid material obtained in the step (3), sufficiently reacting, removing the insoluble impurities to obtain a lead-containing solution, adding carbonate into the solution, sufficiently reacting, removing the liquid, washing the solid with water, and baking to obtain a pure lead carbonate solid; and (5) calcining the lead carbonate solid obtained in the step (4) in a muffle furnace to obtain the highly oxidized lead powder. The method has the advantages of low preparation cost, simple technical process and high lead recovery rate and quality, and can obviously lower energy consumption and reduce environmental pollution.

Owner:YANGZHOU APOLLO BATTERY

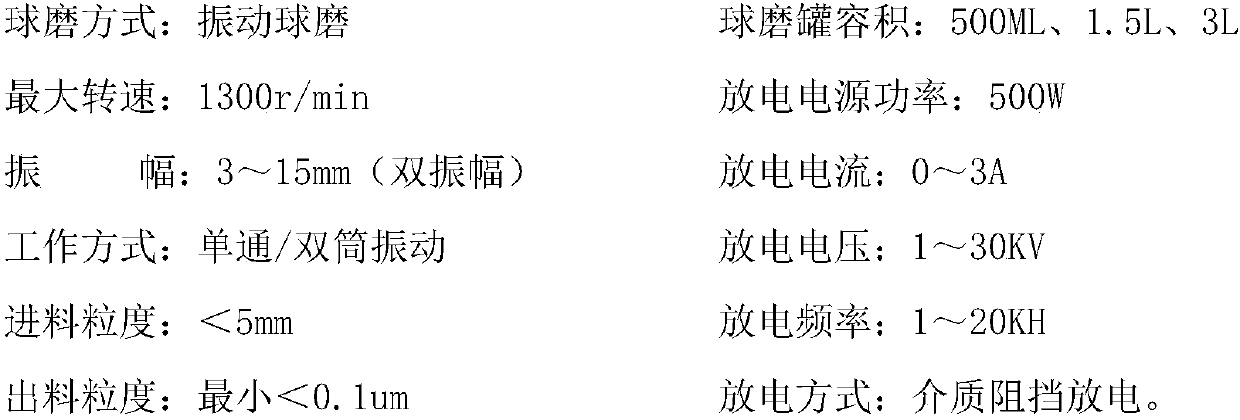

Method for preparing graphene nano-sheet based on crystalline flake graphite

The invention relates to the technical field of graphene nano-sheets, and discloses a method for preparing a graphene nano-sheet based on crystalline flake graphite. According to the preparation method, crystalline flake graphite serving as a raw material is oxidized by adopting low temperature, medium temperature and high temperature three stages, so that the side reaction in the graphite oxidizing process can be effectively controlled, and the graphite oxidizability can be improved; the graphite oxide is pre-stripped at a low temperature, which has lower cost in comparison with that for high-temperature stripping at about 1000 DEG C, and is applicable to industrial application. The ball mill method assisted with discharge plasma is adopted, the preparation method is simple in process andcan be produced in a large scale, has relatively small damage to graphite lamella, few-layer graphene nano-sheet with relatively good crystallinity can be easily obtained, and a good reduction effectcan be achieved for graphite by adding a solid-state ball mill medium, and the prepared graphene nano-sheet has high quality and a multi-fold translucent yarn structure.

Owner:郴州国盛新材科技有限公司

Normal-temperature gas-phase catalytic oxidation-absorption reduction two-stage type flue gas denitrification process

InactiveCN105561748AIncrease the degree of oxidationEfficient removalGas treatmentDispersed particle separationGas phaseCatalytic oxidation

The invention relates to the field of the flue gas purification treatment technology and in particular relates to a normal-temperature gas-phase catalytic oxidation-absorption reduction two-stage type flue gas denitrification process. The process can improve the oxidization degree of nitric oxide and can effectively remove nitrogen oxides under low power consumption. The normal-temperature gas-phase catalytic oxidation-absorption reduction two-stage type flue gas denitrification process comprises the following steps: (1) flue gas enters an oxidation tower after being desulfurized and dedusted; (2) NO in flue gas is subjected to plasma facilitated or enhanced gas phase catalytic oxidation at normal temperature to generate high-valence nitrogen oxide; (3) high-valence nitrogen oxide enters an absorption reduction tower along with flue gas, and reducing agent solution is sprayed into the absorption reduction tower to absorb and reduce the high-valence nitrogen oxide to generate nitrogen gas, carbon dioxide, water or sulphate; and (4) flue gas after nitrogen oxide removal is discharged.

Owner:WUXI BRIGHTSKY ELECTRONICS +1

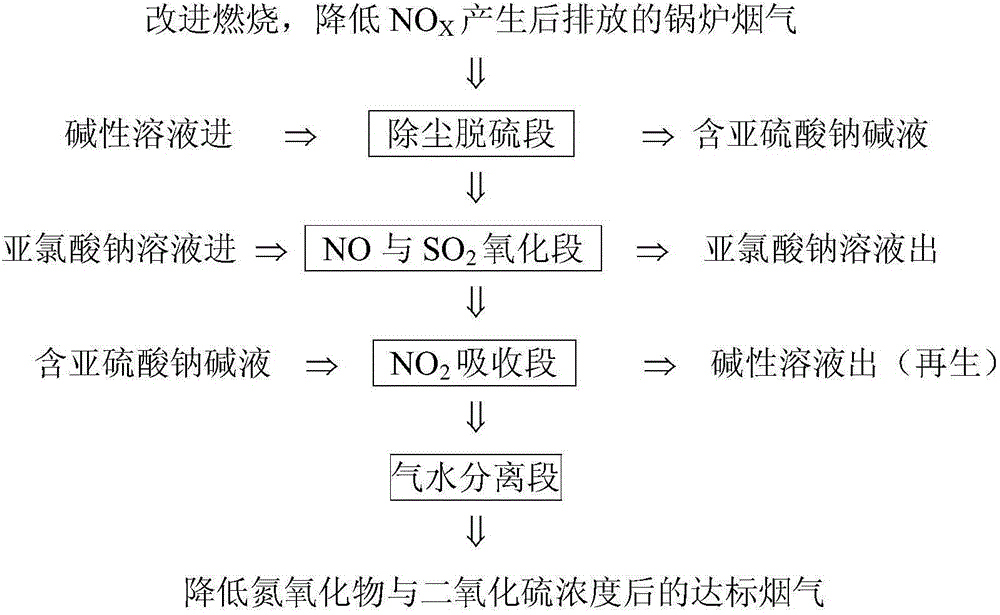

Method for reducing nitrogen oxides in flue gas of medium and small sized industrial coal burning boiler through combination with wet-method sulfur removing technology

InactiveCN104801160ALess investment in equipment transformationLow running costDispersed particle separationChemistryEnvironmental standard

The invention provides a method for reducing nitrogen oxides in flue gas of a medium and small sized industrial coal burning boiler through a wet-method sulfur removing technology. The method comprises the following steps: conducting dust removing and primary sulfur removing on flue gas generated by the coal burning boiler; collecting alkali liquor comprising sulfur removing product sodium sulfite of primary desulfuration according to a dual-alkali method; conducting oxidation treatment on the pretreated flue gas to integrally oxidize NO and residuary sulfur dioxide in the pretreated flue gas; utilizing the oxidized flue gas to get in contact with an alkali liquor, thereby removing nitrogen dioxide and sulfur oxide generated after oxidation in the oxidized flue gas to obtain purified flue gas; conducting gas-water separation to discharge flue gas which meets the environmental standard. Compared with the conventional dry-process flue gas denitration technology, the method provided by the invention has the advantages that desulfurization and denitrification can be simultaneously realized only by additionally arranging an oxidation reactor section in a conventional dual-alkali method absorbing system, so that the economic performance is very high.

Owner:BEIJING YANJING BREWERY

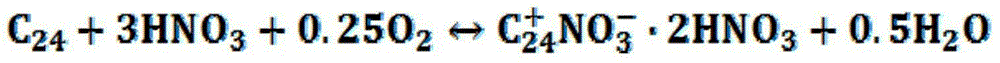

Method of production of graphite oxide and uses thereof

InactiveCN104817070AIncrease the degree of oxidationWell formedGraphiteThin material handlingEnvironmental effectMethods of production

Owner:BELENOS CLEAN POWER HLDG

Method for preparing high-intrinsic-degree graphene by electrolysis

The invention belongs to the technical field of inorganic material preparation, and particularly relates to a preparation method of high-intrinsic-degree grapheme. The preparation method comprises thefollowing steps that a graphite material is prepared into a positive electrode; sulfate is prepared into an electrolyte, firstly the electrode is pretreated under the condition of an applied voltage,then the pH of a solution is adjusted to be alkaline by adding ammonia water, and electrolytic stripping of the graphite positive electrode is performed at a certain temperature; and an electrolyzedproduct is subjected to solid-liquid separation and drying to obtain the high-intrinsic-degree grapheme. Lower oxidation activity of a solvent to the graphite material can be ensured by controlling the pH value of the electrolyte, the reduction of the oxidation degree of the product grapheme is facilitated, and the improvement of the quality of the grapheme is further facilitated. The grapheme isprepared form conventional chemical raw materials, the raw materials are low in cost and easy to obtain, and industrialization is convenient.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

Preparation method of high-strength formaldehyde-free wood fiber board, fiber board and application

PendingCN113146789APromote decompositionSpeed up hydrolysisDomestic articlesFlat articlesFiberSulfite salt

The invention belongs to the technical field of artificial boards, and particularly relates to a preparation method of a high-strength formaldehyde-free wood fiber board, the fiber board and application. The preparation method comprises the following steps of S1, wood pretreatment, wherein after poplar waste is crushed, two-step dipping with a mixed solution of potassium hydroxide and sodium sulfite and a calcium chloride solution, high-temperature treatment and drying for later use are carried out; S2, pre-pressing and forming; and S3, hot pressing for board forming. The mixed solution of potassium hydroxide and sodium sulfite is used for treating cellulose in wood waste residues, decomposition and hydrolysis of hemicellulose, lignin and the like are accelerated, TEMPO is used for oxidizing the cellulose, the oxidation degree is improved, calcium ions and cellulose nanofibers are crosslinked, the self viscosity is improved, and hot pressing forming of the fiber board is facilitated.

Owner:NANJING FORESTRY UNIV

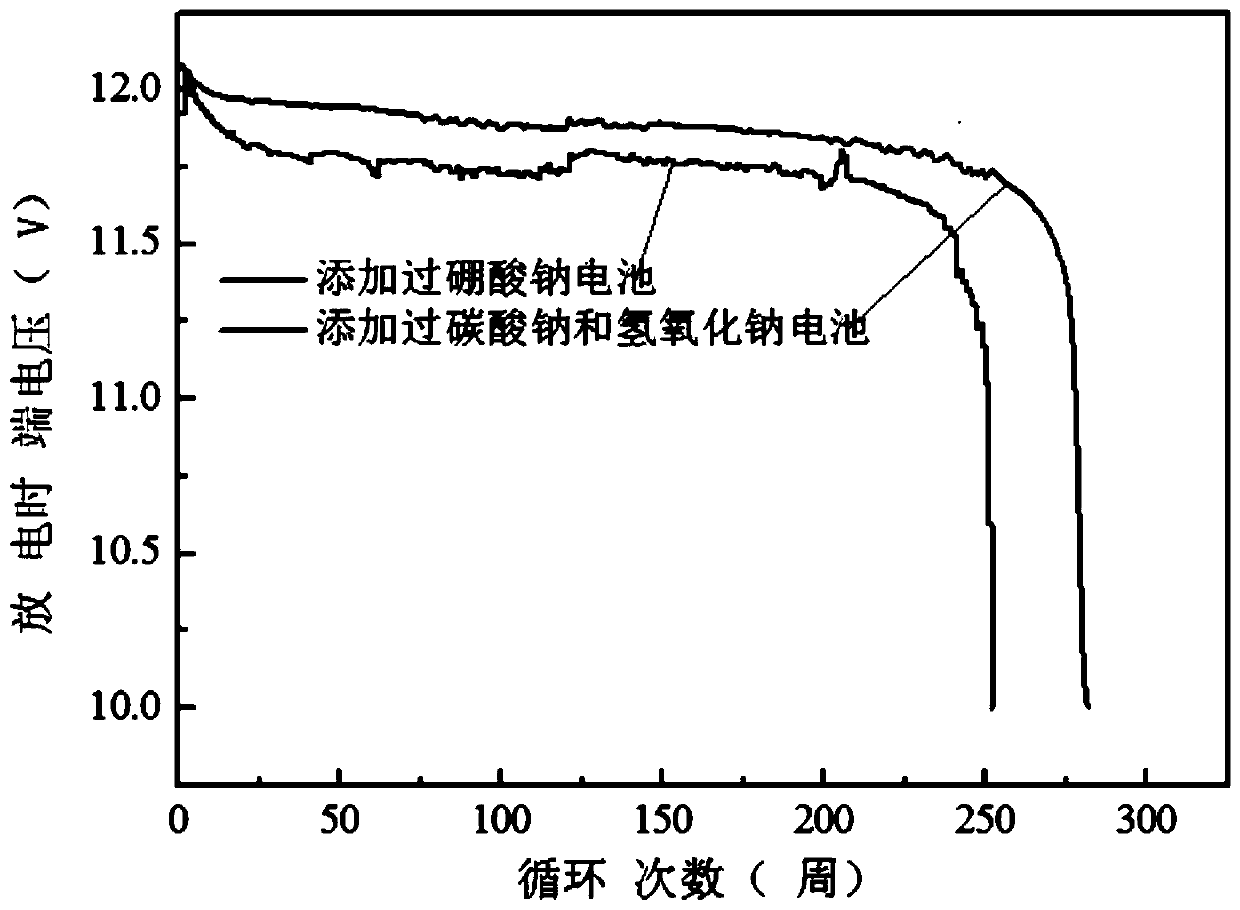

High-binding-force positive electrode lead paste for punching net grid and preparation method and application of positive electrode lead paste

ActiveCN111525126ALow priceImprove bindingFinal product manufactureElectrode carriers/collectorsFiberElectrical battery

The invention discloses positive electrode lead paste for a high-binding-force impact net grid and a preparation method thereof. The lead plaste is prepared from the following raw materials in percentage, by mass, 78%-84% of lead powder, 5%-8% of red lead, 5.4%-8.3% of sulfuric acid, 0.05%-0.06% of short fibers, 0.2%-0.3% of graphene oxide, 0.5%-0.7% of tetrabasic lead sulfate, 0.01%-0.03% of silicon dioxide, 0.01%-0.02% of zinc oxide, 0.05%-0.15% of sodium percarbonate, 0.1%-0.3% of solid alkali and the balance of deionized water. The lead plaste is advantaged in that through interaction of components, the binding force between the lead plaster and the grid and the binding force between the lead plaster and the grid are improved, and the binding force is greatly improved compared with traditional lead plaster and a traditional process; performance of a battery obtained by adopting the grid lead paste is obviously improved, low-temperature starting performance is good, and cycling stability is good; and the lead plaste is low in cost and environment-friendly.

Owner:HENAN CHILWEE GENSHORE POWER

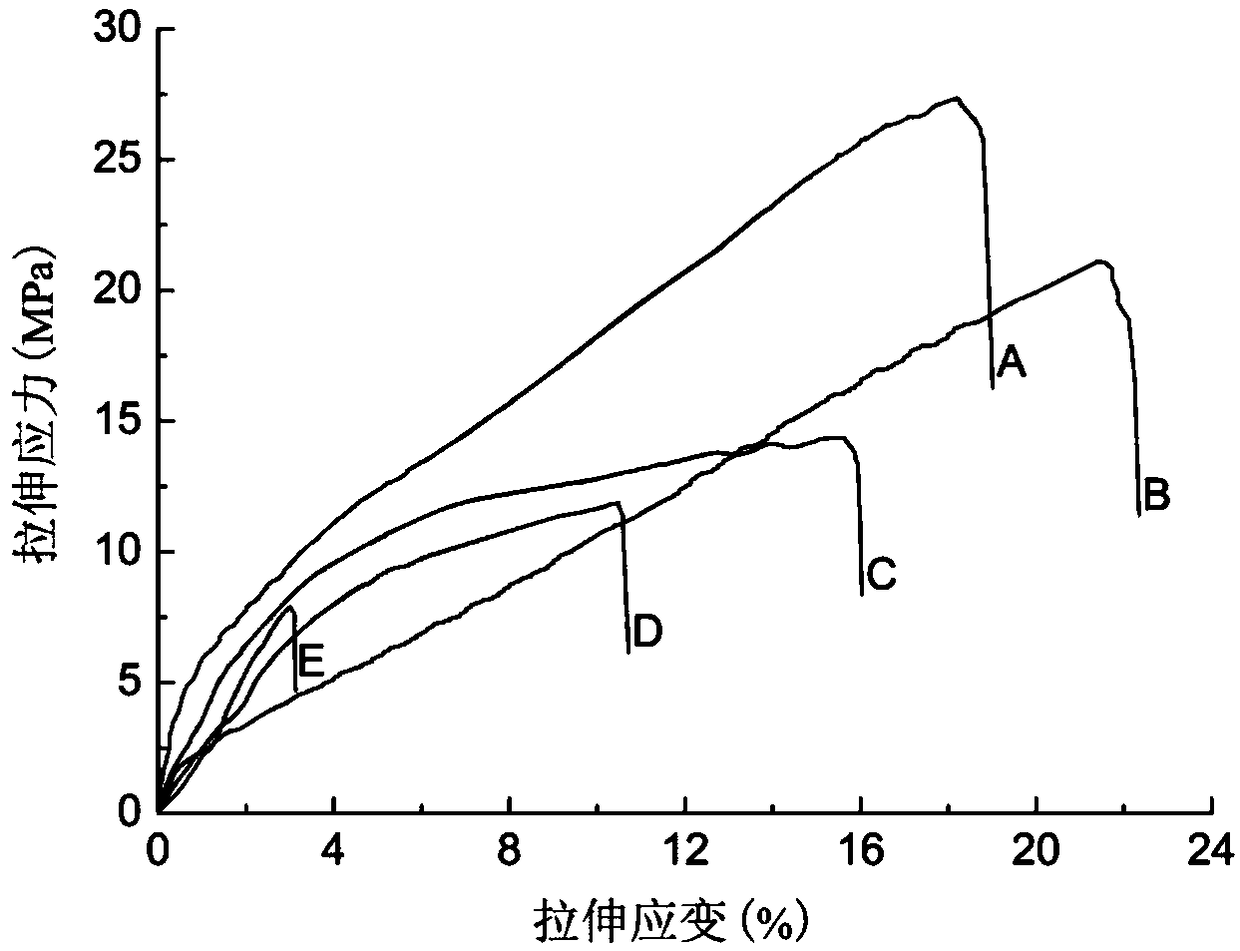

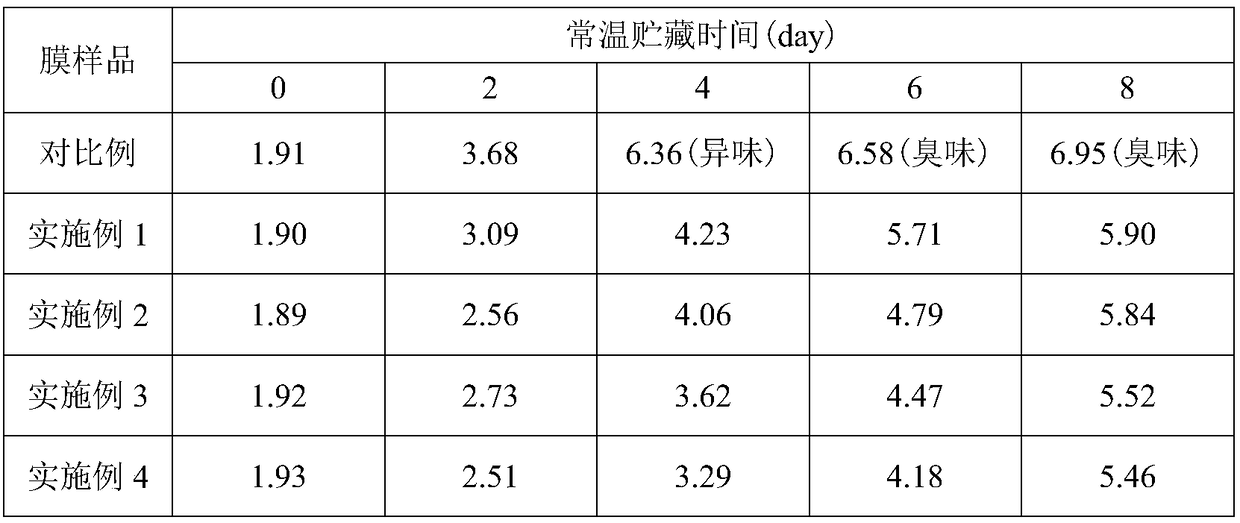

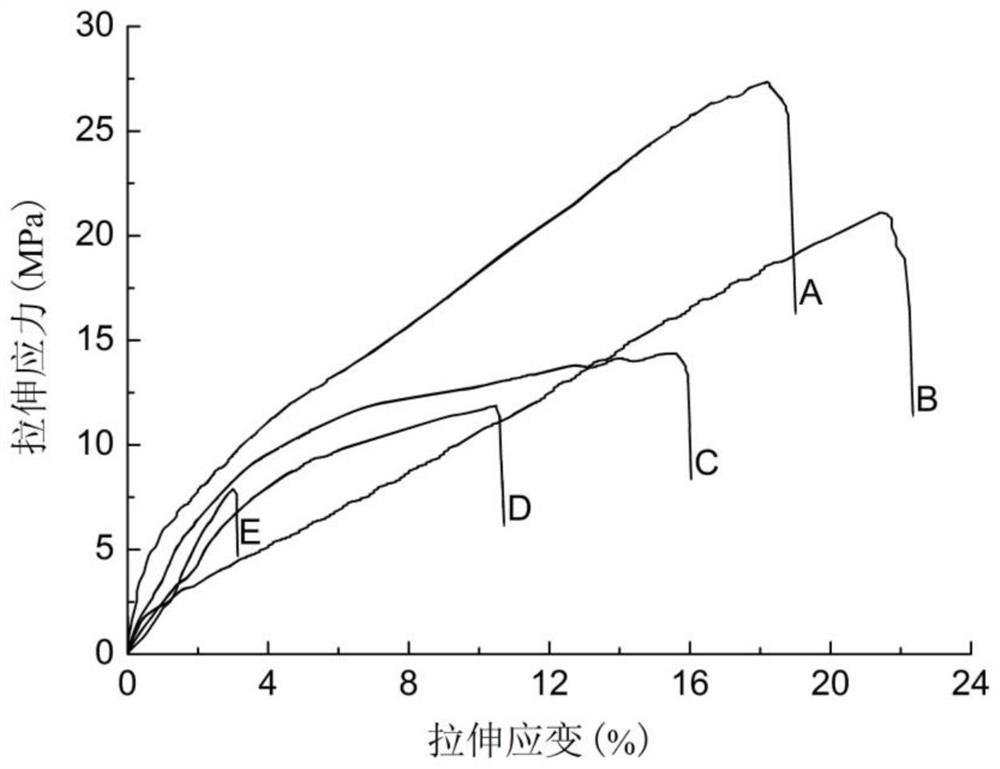

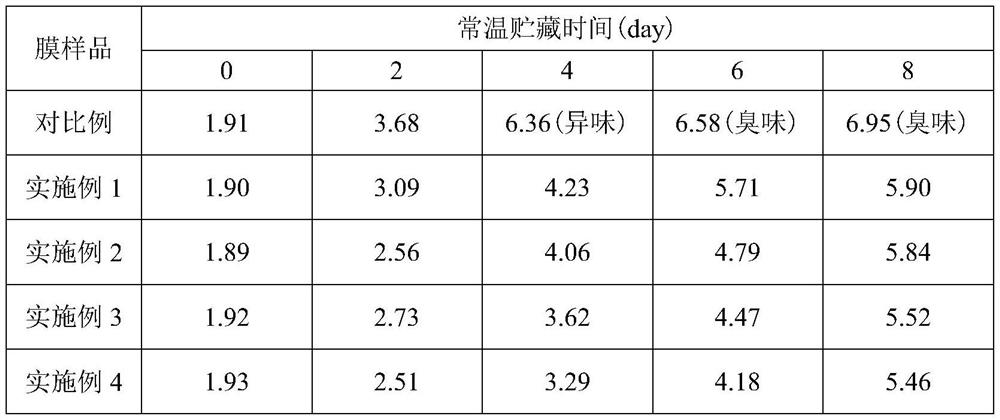

Tea leaf residue modified oxidized cellulose composite film, and preparation method and application thereof

ActiveCN109293959AWide variety of sourcesLow priceMeat/fish preservation using chemicalsChemical reactionComposite film

The invention discloses a tea leaf residue modified oxidized cellulose composite film, and a preparation method and an application thereof. The tea leaf residue modified oxidized cellulose composite film is obtained by an imine chemical reaction of an aldehyde group in a selectively oxidized cellulose molecule and an amino group in tea leaf residue. The tea leaf residue modified oxidized cellulosecomposite film prepared in the invention has good mechanical strength, biodegradability and anti-oxidation performance, is safe and sanitary, can be used for fresh-keeping of fresh pork at room temperature, and can prolong the shelf life of foods.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Device and method for treating NOX tail gas in nitric acid metal dissolving process and terminal

InactiveCN111068476AImprove absorption and utilizationHigh reuse rateDispersed particle separationTemperature controlAutomatic control

The invention provides a device for treating NOX tail gas in a nitric acid metal dissolving process. A gas-liquid mixing module is used for mixing gas and liquid in a kettle body, and a liquid phase forms negative pressure relative to other spaces in the kettle body through a mixing effect; an oxygenation control sensor collects an oxygen redundancy detection signal in the kettle body and sends the oxygen redundancy detection signal to an automatic control system; a pressure sensor and a temperature sensor respectively collect a pressure signal and a temperature signal of the kettle body and send the signals to the automatic control system; the automatic control system respectively controls a nitric acid control metering module, an oxygenation control module, a safety pressure relief module and a temperature control module to adjust the nitric acid adding speed, the oxygenation speed and the temperature in the kettle body according to the oxygen redundancy detection signal, the pressure signal and the temperature signal. The invention further provides a treatment method and a control terminal. The preparation process of nitrate and the absorption and the reuse of NOx gas are uniformly treated, and production, conversion, absorption and reuse of NOx are realized in one step in the reaction kettle.

Owner:汪子夏

Integral purification device for ship tail gas, and application thereof

ActiveCN109316931AIncrease the degree of oxidationSmall footprintGas treatmentUsing liquid separation agentGas phaseNitrogen oxide

The invention discloses an integral purification device for ship tail gas. The integral purification device for the ship tail gas comprises a motor and a purification device shell, wherein the purification device shell comprises a sprinkling device, a rotary silk screen liquid atomization and dispersion device and a rotary demister. In the device, the sprinkling device can be applied to a pipelineto sprinkle liquid phase oxidizing agent, the degree of oxidation of nitric oxide is improved in the pipeline, and land occupation is reduced so as to bring convenience in being subsequently adsorbedby absorbent in the rotary silk screen liquid atomization and dispersion device; in the rotary silk screen liquid atomization and dispersion device, gas flows along an axial direction, centrifugal resistance does not need to be overcome, and gaseous phase resistance is reduced; liquid is sprayed out from a liquid distributor to collide with a rotary silk screen, then, the liquid is cut into smalldrops by the multilayer silk screen to be evenly distributed in a fog shape, the cross flow contact area of the gaseous phase and the liquid phase is increased, and the mass transfer of the gaseous phase and the liquid phase is reinforced. The rotary demister utilizes the silk screen which rotates at a high speed to keep the surface of the demisting silk screen to be updated, gas-liquid separation is realized, and entrainment and the waste of absorbent are avoided.

Owner:BEIJING UNIV OF CHEM TECH

Method and system for reducing schreyerite through coal pyrolysis gas

PendingCN107447068AHigh quality half focusHigh Metallization Rate Metallized PelletsShaft furnaceHeating furnaceGas heating

The present invention proposes a method and system for reducing vanadium-titanium ore with coal pyrolysis gas. The method includes the steps of: coal pyrolysis: adding raw coal from the coal pyrolysis furnace silo to the coal pyrolysis furnace, at a temperature of 700-900°C , pyrolysis to generate solid semi-coke and pyrolysis gas; pyrolysis gas heating: the pyrolysis gas enters the heating furnace through the pipeline to be heated to obtain a high-temperature reducing gas of 1000‑1100 °C; vanadium-titanium ore reduction: the high-temperature reducing gas is transported After entering the shaft furnace, react with semi-coke, and reduce vanadium-titanium ore to obtain reduced vanadium-titanium metallized pellets; wherein, the pressure of reducing gas entering the shaft furnace is 0.45MPa-0.9MPa, and the temperature is 950-1050 ℃. The invention organically combines coal chemical industry with metallurgical production, effectively utilizes H2O and CO2 in coal pyrolysis gas to oxidize semi-coke, so as to increase the content of reducing gas and reduce the production cost and energy consumption of vanadium-titanium direct reduction iron.

Owner:SHENWU TECH GRP CO LTD

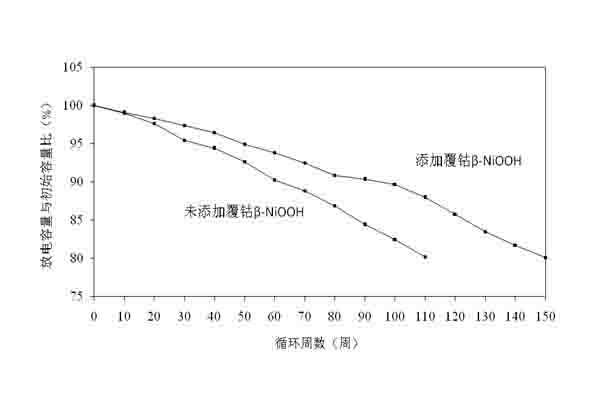

Method for preparing cobalt clad beta-NiOOH by liquid phase oxidation method

ActiveCN102040251ASimple processIncrease the degree of oxidationCell electrodesNickel carbonylsChemistryFluid phase

The invention relates to a method for preparing cobalt clad beta-NiOOH by a liquid phase oxidation method. In the technical scheme of the invention, the method for preparing the cobalt clad beta-NiOOH by the liquid phase oxidation method comprises the following steps of: preparing a NaOH aqueous solution, adding cobalt clad Ni(OH)2 and evenly stirring; adding an oxidizing agent at the temperature of 15-45 DEG C, stirring for 1-3h at the temperature of 40-85 DEG C, and standing for 0.5-1h; removing supernatant liquid; precipitating and washing; and drying. The molar ratio of the NaOH to the cobalt clad Ni(OH)2 to the oxidizing agent is 1: (0.7-1.0): (0.35-0.6). The method is simple to operate and improves the oxidizability of the Ni(OH)2, and the percent conversion of the cobalt clad beta-NiOOH is at least 95 percent; the cobalt clad beta-NiOOH prepared by the method is used as a secondary battery nickel electrode additive, and a manufactured secondary battery discharge plateau is high and has long cycle life.

Owner:LIAONING JIUYI ENERGY TECH

Coal-fired flue gas denitration and desulfurization method combined with urea wet method

ActiveCN101708419BIncrease the degree of oxidationGood chemical stabilityLighting and heating apparatusDispersed particle separationFlue gasEconomic benefits

The invention discloses a coal-fired flue gas denitration and desulfurization method combined with the urea wet method. The method comprises the following steps: spraying 50wt% of hydrogen peroxide at the coal-fired flue gas inlet of a absorption tower while keeping the molar ratio of H2O2 to NO to be 2-3, so as to oxidize NO in the coal-fired flue gas to NO2 and increase the oxidization degree of NOX; and perform denitration and desulfurization simultaneously by using the urea aqueous solution in the absorption tower. The method of the invention increases the denitration rate of the coal-fired flue gas denitration and desulfurization combination technology by increasing the oxidization degree of NOX and the temperature of the absorption solution. The method has simple technology, convenient operation and management, no secondary pollution and good environmental and economic benefits.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

Preparation method of microcrystalline graphite oxide

The invention relates to the field of inorganic nonmetallic materials, and in particular relates to a preparation method of microcrystalline graphite oxide. In the presence of a nitrate additive, microcrystalline graphite oxide with a high oxidation degree is obtained by virtue of staged reaction between a strong oxidant and microcrystalline graphite in a sulfuric acid solution. The preparation method provided by the invention has the following advantages: a technology of temperature programming and staged reaction is adopted, so that the happening of side reaction during the preparation of microcrystalline graphite oxide by oxidizing microcrystalline graphite can be effectively controlled, and then the purity and oxidation degree of a microcrystalline graphite oxide product are improved; and by virtue of the application of the additive, the time for intercalation of microcrystalline graphite can be effectively shortened, and then the reaction time of the whole process flow is shortened. Therefore, the preparation method provided by the invention has the characteristics of short reaction time and simple process, and is beneficial for realizing scale production and application of microcrystalline graphite; and the preparation of microcrystalline graphite oxide has not been reported at present.

Owner:WUHAN UNIV OF TECH

Low-temperature SCR catalyst using nitrogen-dopped activated carbon as carrier and preparation technique thereof

InactiveCN101352681BIncrease the degree of oxidationEasy to handleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen

Owner:ZHEJIANG UNIV

Iron oxide red pigment two-step oxidation process waste gas treatment method

InactiveCN108176203AIncrease the degree of oxidationImprove absorption efficiencyDispersed particle separationAir quality improvementTwo stepWaste treatment

The invention relates to an iron oxide red pigment two-step oxidation process waste gas treatment method, which comprises: 1, removing steam and iron red particles from waste gas by using a heat exchange cooling method to generate first-stage waste gas; 2, oxidizing NO in the first-stage waste gas into NO2 by using N2O4 removed concentrated nitric acid to generate second-stage waste gas; 3, removing NO2 and NO from the second-stage waste gas by using N2O4 removed dilute nitric acid to generate third-stage waste gas; 4, further removing NO2 and NO from the third-stage waste gas by using a sodium hydroxide solution to generate fourth-stage waste gas; and 5, reducing NO2 in the fourth-stage waste gas into N2 by using a urea solution so as to generate fifth-stage waste gas, wherein the fifth-stage waste gas achieves the discharge standard. According to the present invention, with the iron oxide red pigment two-step oxidation process waste gas treatment method, the oxidation degree of the waste gas treatment can be increased, the absorption efficiency of the waste gas treatment can be increased, and the final waste gas can meet the discharge standard.

Owner:TAIKANG KITCHEN SCI TECH SUZHOU CITY

Method for graphene oxide synthesis

ActiveCN110734057AIncrease the degree of oxidationIncrease contentMaterial nanotechnologyCarbon compoundsPhysical chemistryDry ice

The invention relates to the field of carbon structure production and, in particular, to a method for synthesis of graphene oxide which is widely used in electronics, medicine, pharmacology and construction industries. Provided is a method for synthesis of graphene oxide that includes oxidizing ground graphite with sulfuric acid and at least one oxidizer in a medium of supercritical fluid, whereinthe method includes providing a mixture of sulfuric acid and dry ice in an amount sufficient for the mixture to solidify, and a mixture of at least one oxidizer and dry ice, wherein at least one of said mixtures contains ground graphite; introducing the provided mixtures into a high pressure autoclave; and further mixing the reagents. Thus, the claimed invention is a method for synthesis of graphene oxide that allows achieving the technical result consisting in safe production of high quality graphene oxide, wherein the time cost is relatively low and the consumption of sulfuric acid is significantly reduced.

Owner:矿物股份有限公司

Method for preparing oxidized chitosan and derivatives thereof by electrolytic method

The invention discloses a method for preparing oxidized chitosan and derivatives thereof by an electrolytic method. According to the method, a small amount of sodium iodate is adopted in an electrolytic tank to selectively oxidize chitosan and derivatives thereof under a dark condition, and after dialysis separation, oxidized chitosan containing aldehyde groups with high chemical reaction activityand derivatives thereof are obtained. Compared with a traditional method, the method has the advantages of being small in oxidant dosage, controllable in oxidation degree, green and environmentally friendly, and is a novel environmentally-friendly preparation method of oxidized chitosan and derivatives thereof.

Owner:SICHUAN UNIV

System device and method for deeply removing nitric oxide in industrial tail gas

ActiveCN103394279BSmall footprintReduce volumeDispersed particle separationGas phaseEmission standard

The invention discloses a system device for deeply removing nitric oxide in industrial tail gas. The device is characterized by comprising two-stage serial connected equipment, wherein the two-stage serial connected equipment is formed by serial connection of an absorption tower and a single rotating packed bed or the serial connection of two rotating packed beds. The invention also discloses a method for removing by utilizing the device. The device and the method enable the nitric oxide emission to be lower 200mg / m<3> required by the national nitric oxide emission standard and are particularly suitable for upgrading and reconstructing factories with limited space; the removing rate of NO gas in the industrial tail gas can be effectively improved by a method for increasing the oxidation degree from the aspects of vapor phase and liquid phase; an optimal denitration effect can be achieved by using different combinations of absorbents according to different technical requirements; and the environmental pollution prevention and control of China can be greatly pushed and promoted by deep denitration of the two-stage serial connected equipment.

Owner:BEIJING UNIV OF CHEM TECH

Power Battery

ActiveCN104332633BImprove corrosion resistanceHigh strengthElectrode carriers/collectorsPower batteryPower flow

The invention discloses a ternary non-aggregated power battery. The ternary non-aggregated power battery comprises positive and negative pole plates composed of plate grids and active substances, wherein the active substances are composed of lead powder and sulfuric acid; each plate grid is a ternary non-aggregated alloy plate grid; a positive pole plate grid is prepared from the following components in parts by weight: 0.02%-0.03% of Ag, 0.05%-0.06% of Ti, 0.9%-1.5% of Sn, 0.06%-0.08% of Ca and the balance of Pb; and a negative pole plate grid is prepared from the following components in parts by weight: 0.08%-0.09% of Ca, 0.02%-0.05% of Al, 1.0%-1.6% of Sn and the balance of Pb. According to the ternary non-aggregated power battery, Sn, Al and Ti elements are added into the plate grids and an alloy interface presents an amorphous-state polymer; the resistance of a resistance layer is obviously reduced; the circulating service life of the battery is prolonged and large-current charging and discharging performances of the battery are improved; and the corrosion resistance of the plate grids in sulfuric acid is improved and the service life of the battery is greatly prolonged.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU NEW ENERGY

Chloric strong oxidant enhanced wet combined urea desulfurizing and denitrifying process

InactiveCN100425327CIncrease the degree of oxidationImprove denitrification efficiencyDispersed particle separationAir quality improvementNitrogen oxideSodium chlorite

The wet combined fume desulfurizing and denitrifying process with chloric strong oxidant enhanced urea has the fume to be treated contacted sufficiently with the mixed absorbent liquid containing urea and chloric strong oxidant inside the absorbing reactor so as to eliminate NOx and SO2 through absorption before being exhausted. The chloric strong oxidant is sodium chlorite, sodium hypochlorite, bleaching powder or their mixture. The process has high denitrifying efficiency, high fume purifying effect, simple structure, easy operation and small occupied land. The said process can reach NOx eliminating rate of 75-98 % and desulfurizing efficiency over 95 %.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Flue gas combined desulfurization and denitration method

InactiveCN100534586CRealize joint desulfurization and denitrificationEffective oxidationDispersed particle separationAir quality improvementPhotocatalytic reactionFlue gas

Owner:ZHEJIANG UNIV

Ship tail gas integrated purification device and its application

ActiveCN109316931BIncrease the degree of oxidationSmall footprintGas treatmentUsing liquid separation agentNitrogen oxidesFluid phase

The invention discloses an integrated purification device for ship tail gas, which includes a motor and a housing of the purification device; the housing of the purification device includes a spray device, a rotating wire mesh liquid atomization dispersion device and a rotary demister; in the device, the spray The shower device can be applied in the pipeline to spray the liquid phase oxidant, increase the oxidation degree of nitrogen oxides in the pipeline, reduce the floor space, and facilitate subsequent absorption by the absorbent in the rotary screen liquid atomization dispersion device; In the rotating screen liquid atomization dispersion device, the gas flows in the axial direction without overcoming the centrifugal resistance, which reduces the gas phase resistance; the liquid is ejected from the liquid distributor, collides with the rotating screen, and is cut into The small droplets are evenly distributed in the form of mist, which increases the contact area of the gas-liquid two-phase cross-flow and strengthens the mass transfer of the gas-liquid two-phase. The rotary demister uses a high-speed rotating wire mesh to keep the surface of the demister mesh updated, realize gas-liquid separation, and avoid mist entrainment and waste of absorbent.

Owner:BEIJING UNIV OF CHEM TECH

Tea dregs modified oxidized cellulose composite film and its preparation method and application

ActiveCN109293959BWide variety of sourcesLow priceMeat/fish preservation using chemicalsPolymer sciencePork meat

The invention discloses a tea dregs modified oxidized cellulose composite film and its preparation method and application, which is obtained by imine chemical reaction between the aldehyde group in the selective oxidized cellulose molecule and the amino group in the tea dregs. The tea dregs modified oxidized cellulose composite film prepared by the invention has good mechanical strength, biodegradability and oxidation resistance, is safe and hygienic, can be used for keeping fresh pork at room temperature, and can prolong the shelf life of food.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com