Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about "Nickel carbonyls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of fine-grained particles

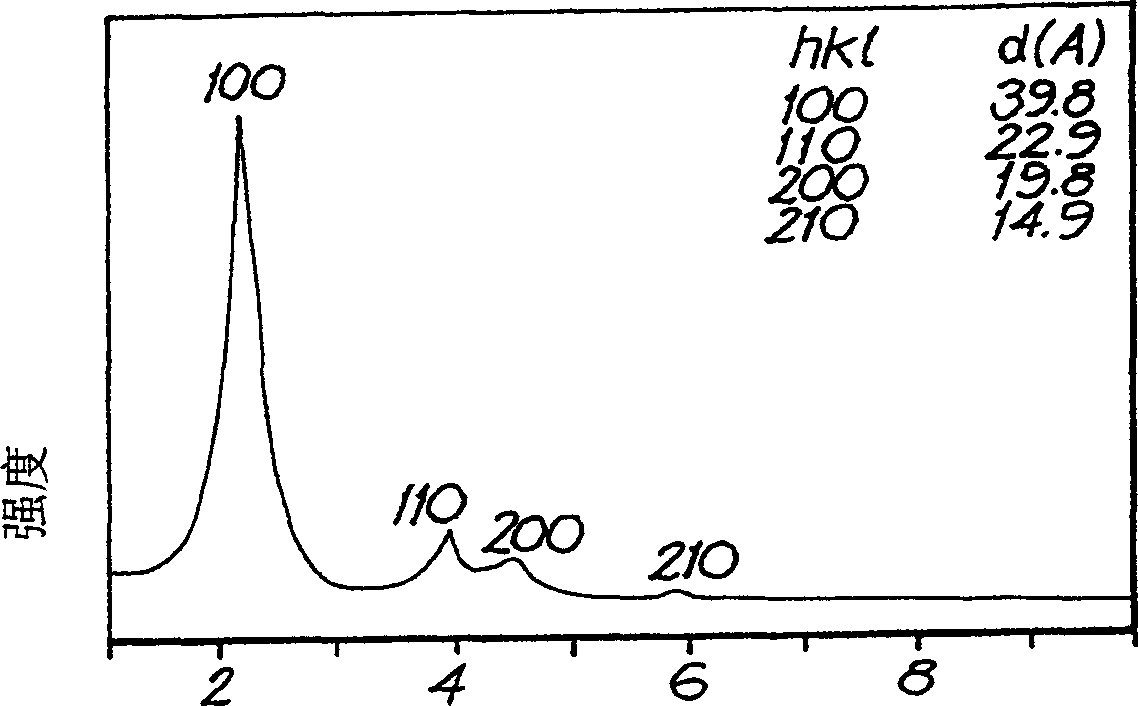

InactiveUS20050025698A1Heating fastMaterial nanotechnologyNanostructure manufactureMaterials scienceCrystallization

Particles of mixed metal oxide include at least two metal species. The particles have a grain size within the range of 1-100 nm. The particles are substantially crystalline. The particles contain only small or negligible amounts of amorphous material. The at least two metal species are uniformly dispersed in the particles.

Owner:VERY SMALL PARTICLE CO LTD

Production of fine-grained particles

InactiveCN1476413AImprove physical propertiesMaterial nanotechnologyNanostructure manufactureActive agentPhysical chemistry

Particles of mixed metal oxide include at least two metal species. The particles have a grain size within the range of 1-100 nm. The particles are substantially crystalline. The particles contain only small or negligible amounts of amorphous material. The at least two metal species are uniformly dispersed in the particles.

Owner:VERY SMALL PARTICLE CO LTD

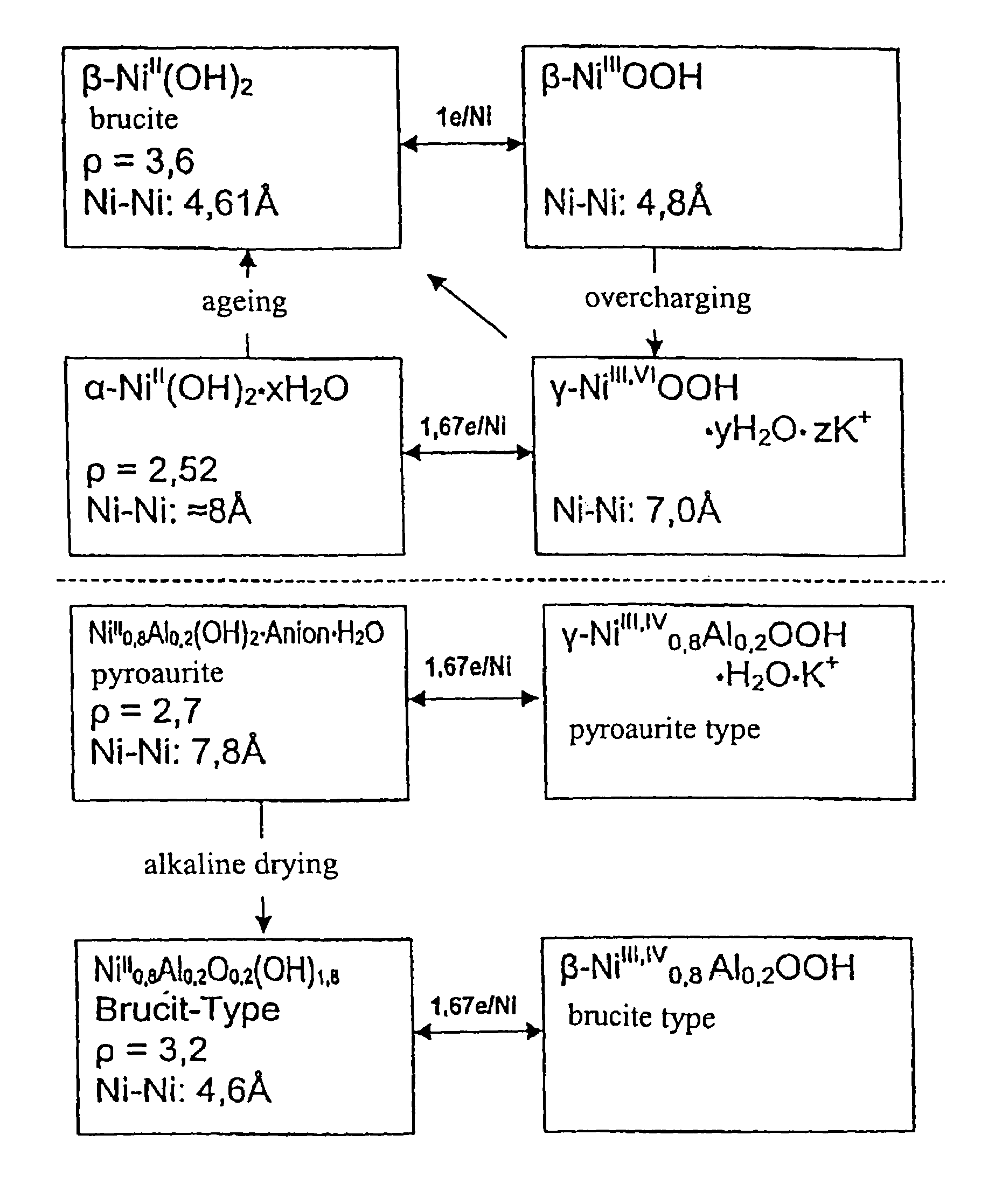

Active material for rechargeable batteries

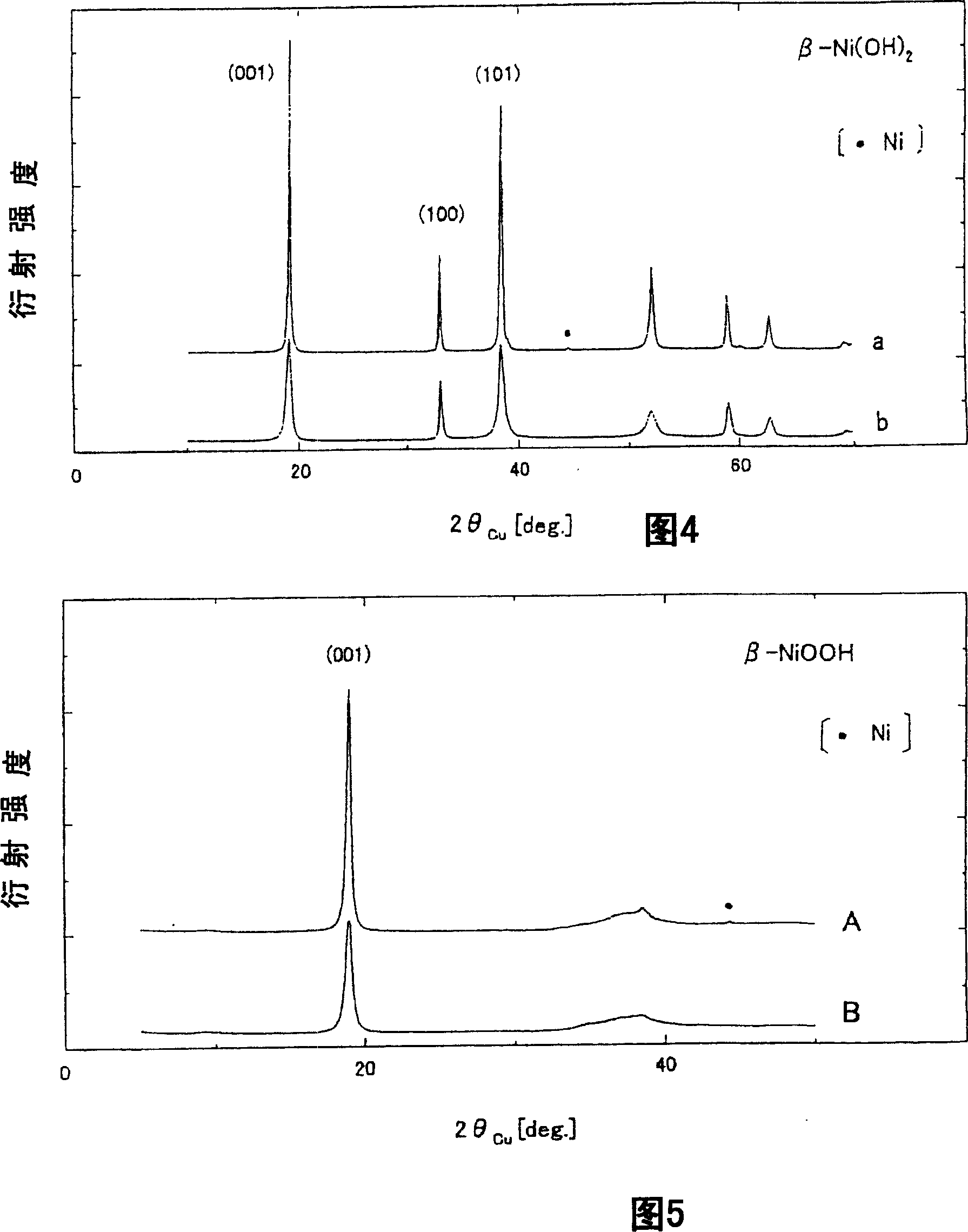

InactiveUS6958139B1Reduce spacingImprove storage densityNickel carbonylsAlkaline accumulator electrodesElectrical batteryNickel oxide hydroxide

A mixed metal hydroxide with brucite structure is described, which contains nickel hydroxide as its main component and at least one trivalent metal selected from the group consisting of Co, Fe, Al, Ga, In, Sc, Y and La in an amount of from about 12 to about 30 atom % relative to the sum of the metal components including Ni. The invention also relates to a rechargeable battery containing a mixed metal hydroxide according to the invention as an electrochemically active material as well as a secondary batter containing the mixed metal hydroxide. The invention also relates to a process for producing a mixed metal hydroxide having a brucite structure.

Owner:TODA IND

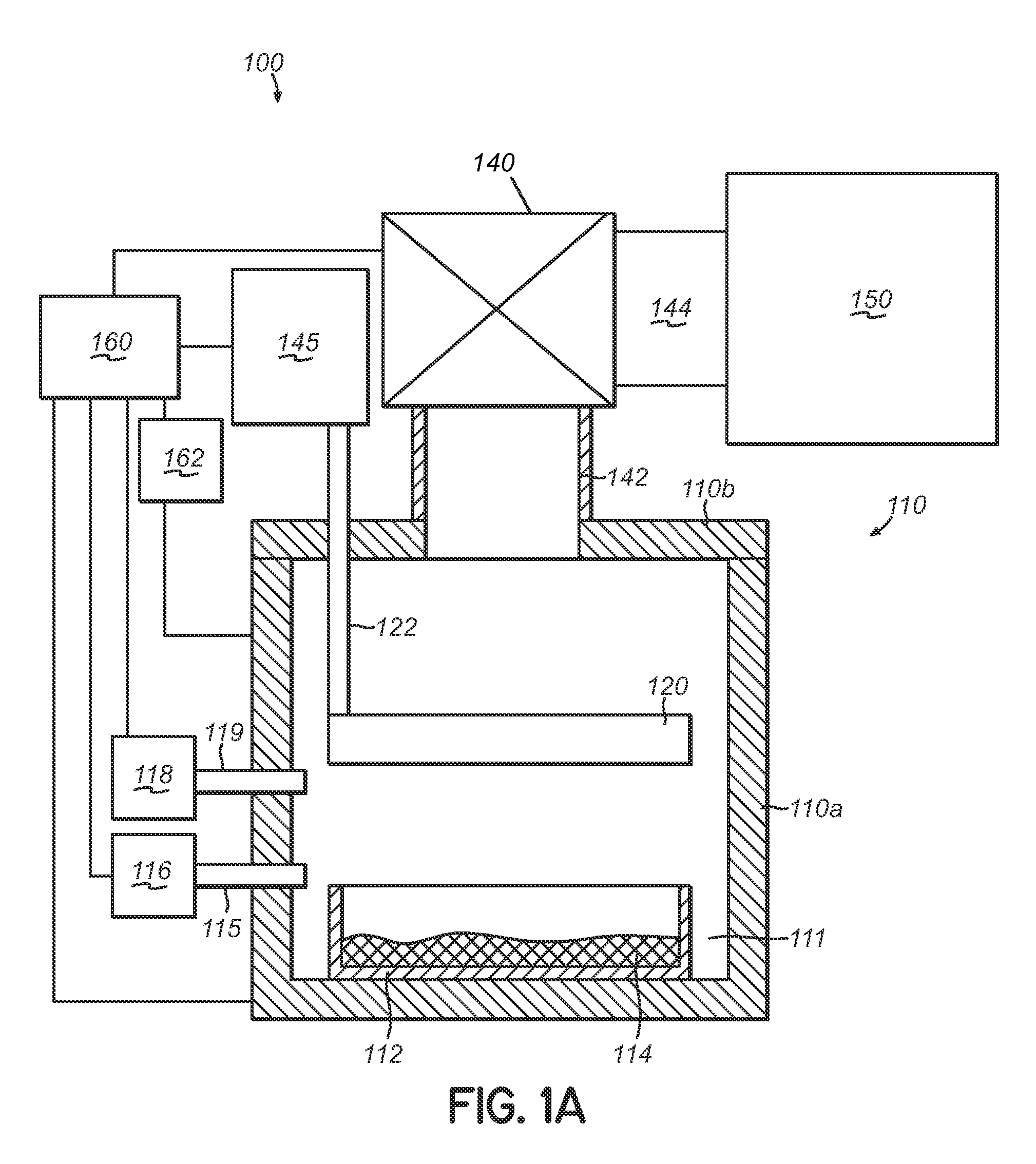

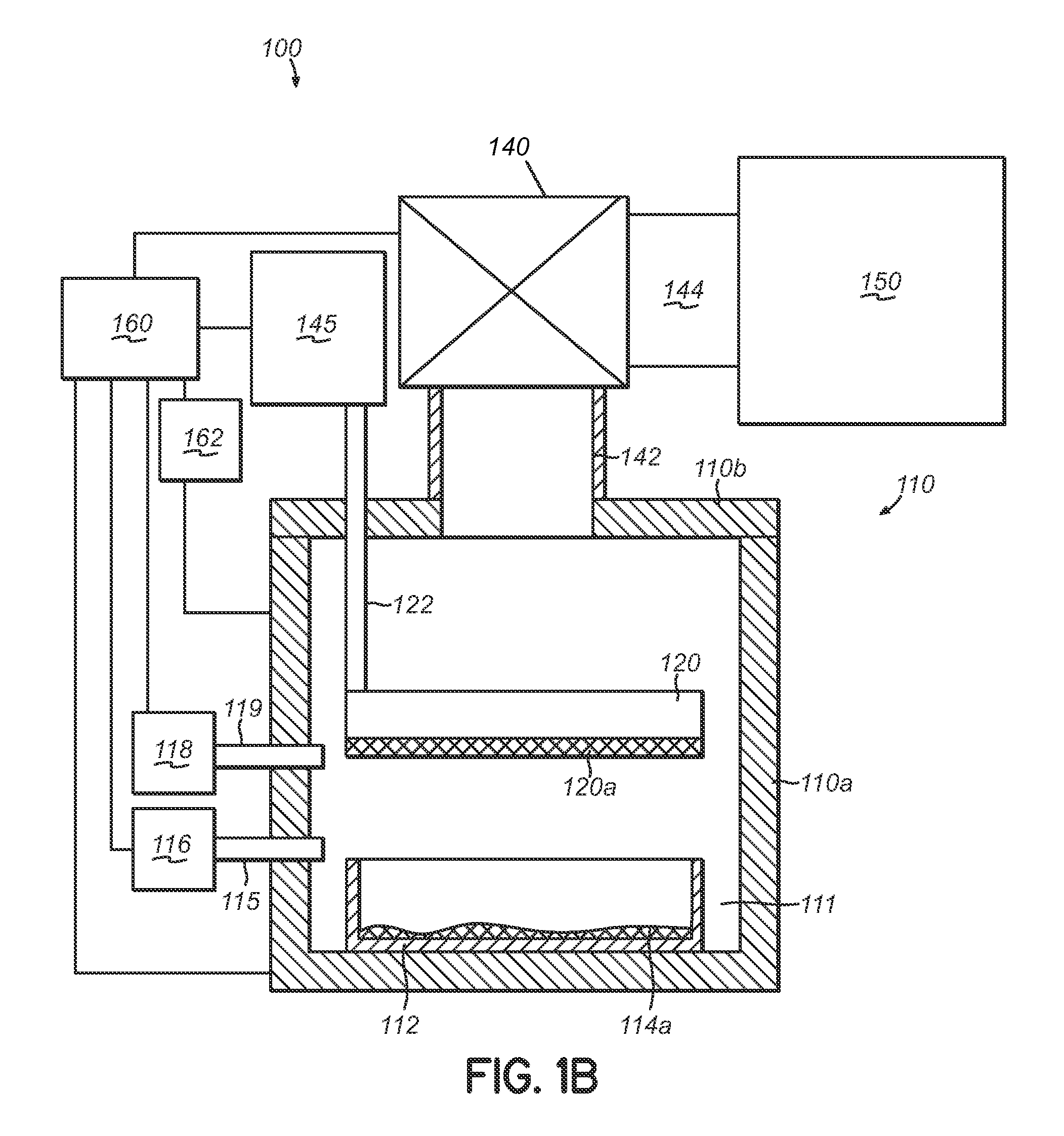

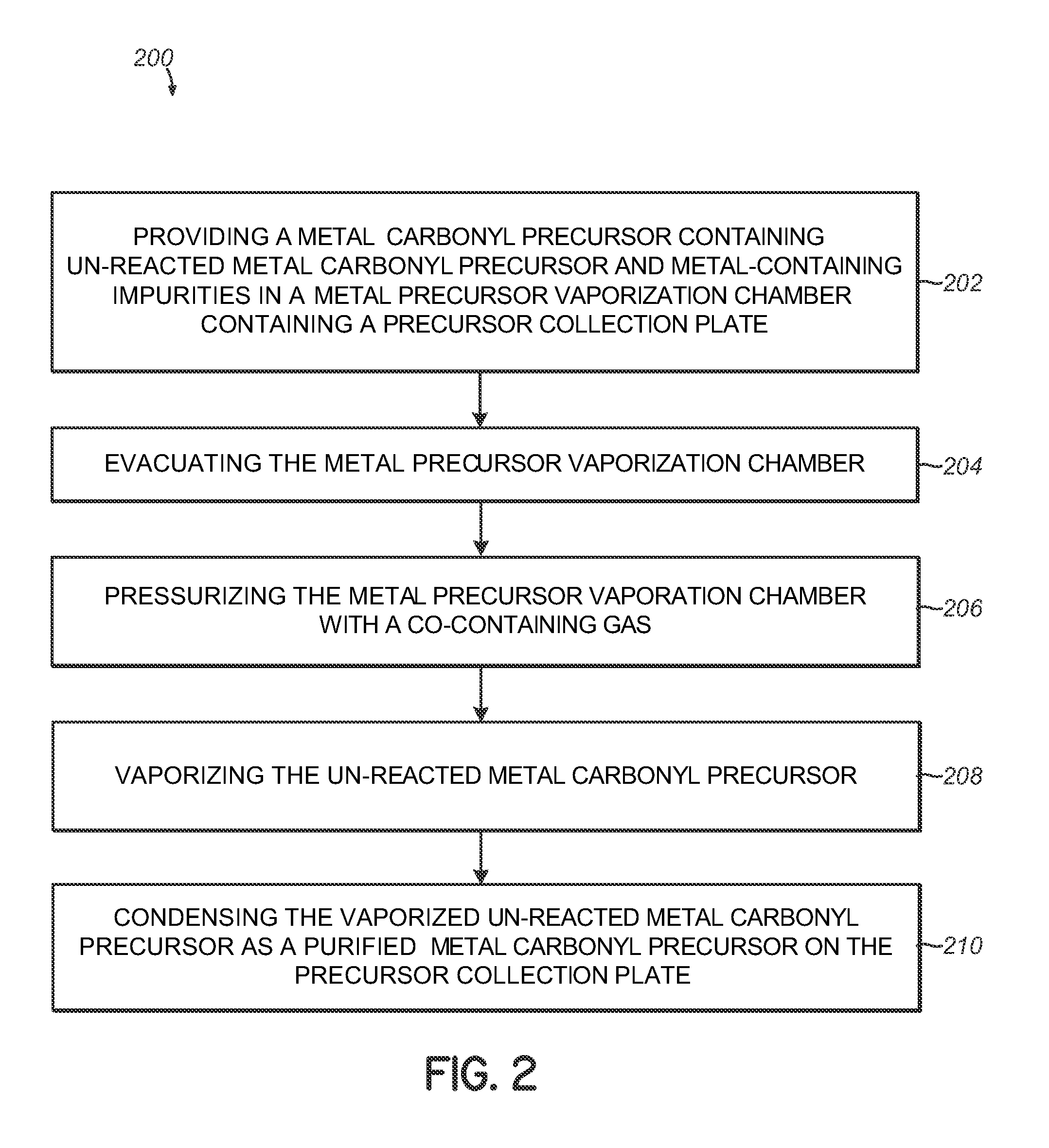

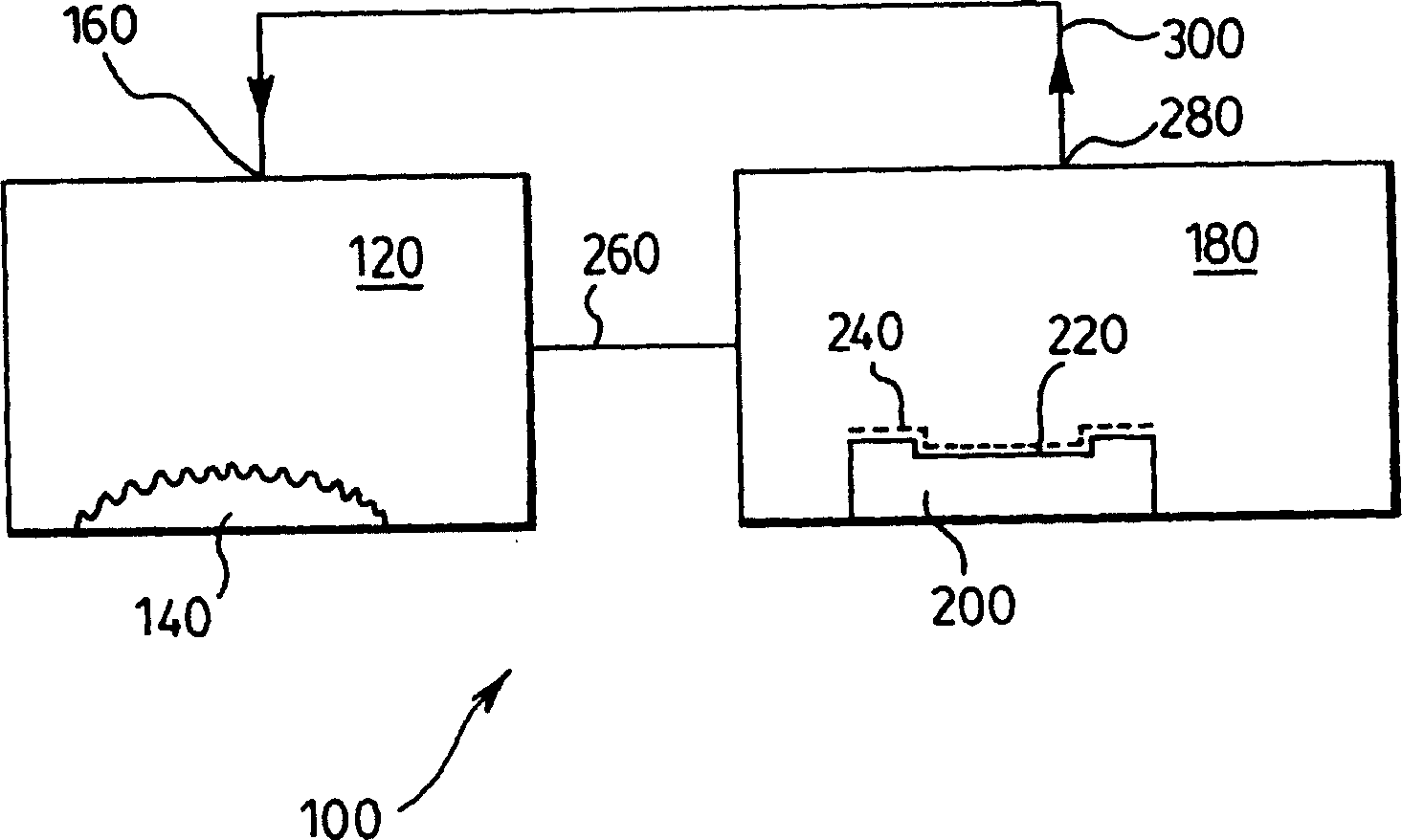

Method and integrated system for purifying and delivering a metal carbonyl precursor

InactiveUS20070231241A1Efficient deliveryOrganic compound preparationOxygen compounds preparation by reductionVaporizationMetal carbonyl

A method and integrated system are provided for purifying and delivering a metal carbonyl precursor utilized to process a substrate. The method includes providing the metal carbonyl precursor containing un-reacted metal carbonyl precursor and metal-containing impurities in a metal precursor vaporization chamber containing a precursor collection plate, evacuating the metal precursor vaporization chamber, pressurizing the metal precursor vaporization chamber with a CO-containing gas, vaporizing the un-reacted metal carbonyl precursor, and condensing the vaporized un-reacted metal carbonyl precursor as a purified metal carbonyl precursor on the precursor collection plate. The method may further include vaporizing the purified metal carbonyl precursor, and delivering a process gas containing the vapor of the purified metal carbonyl precursor by flowing a gas containing CO through the metal precursor vaporization chamber to a deposition system configured to expose a substrate to the process gas.

Owner:TOKYO ELECTRON LTD

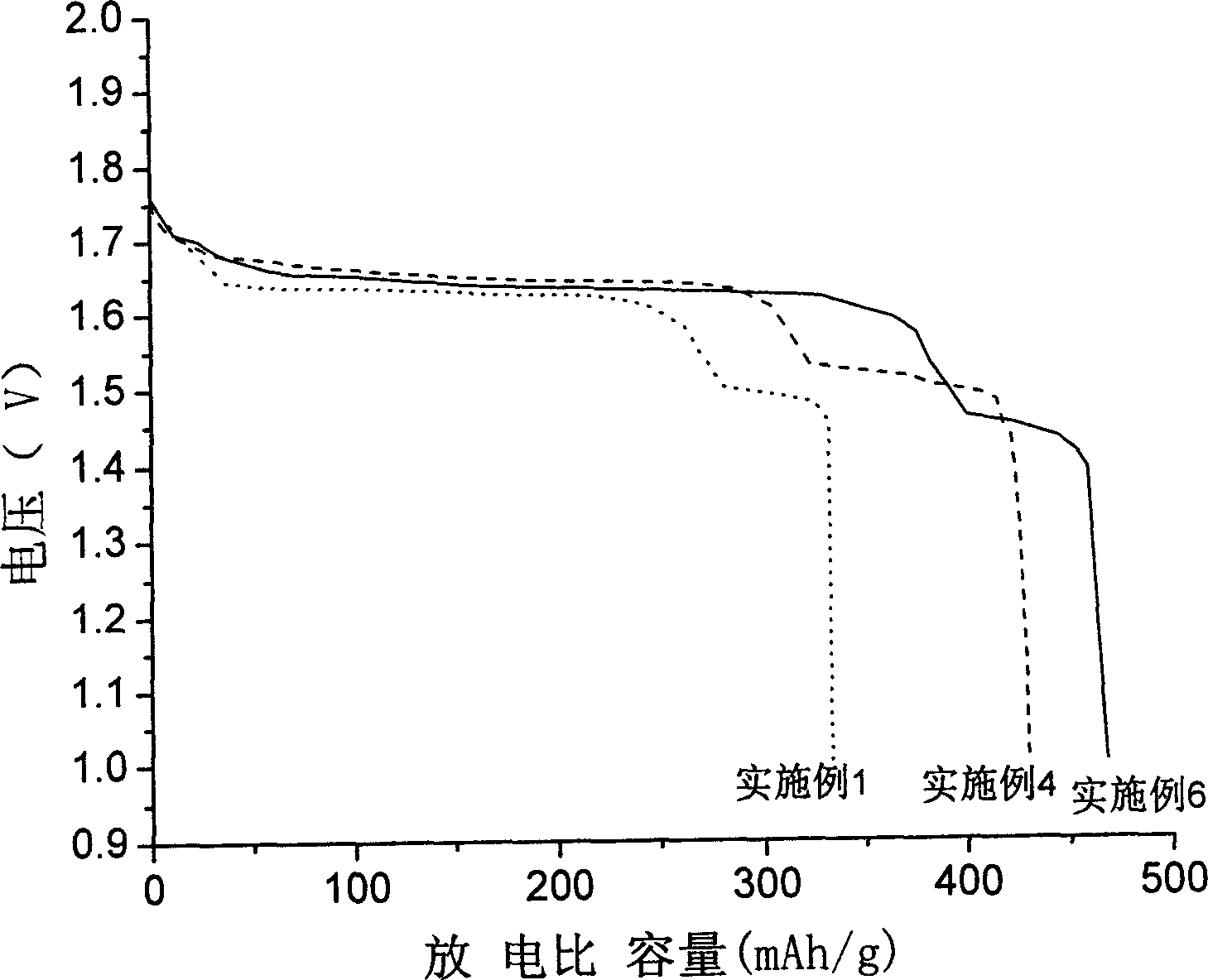

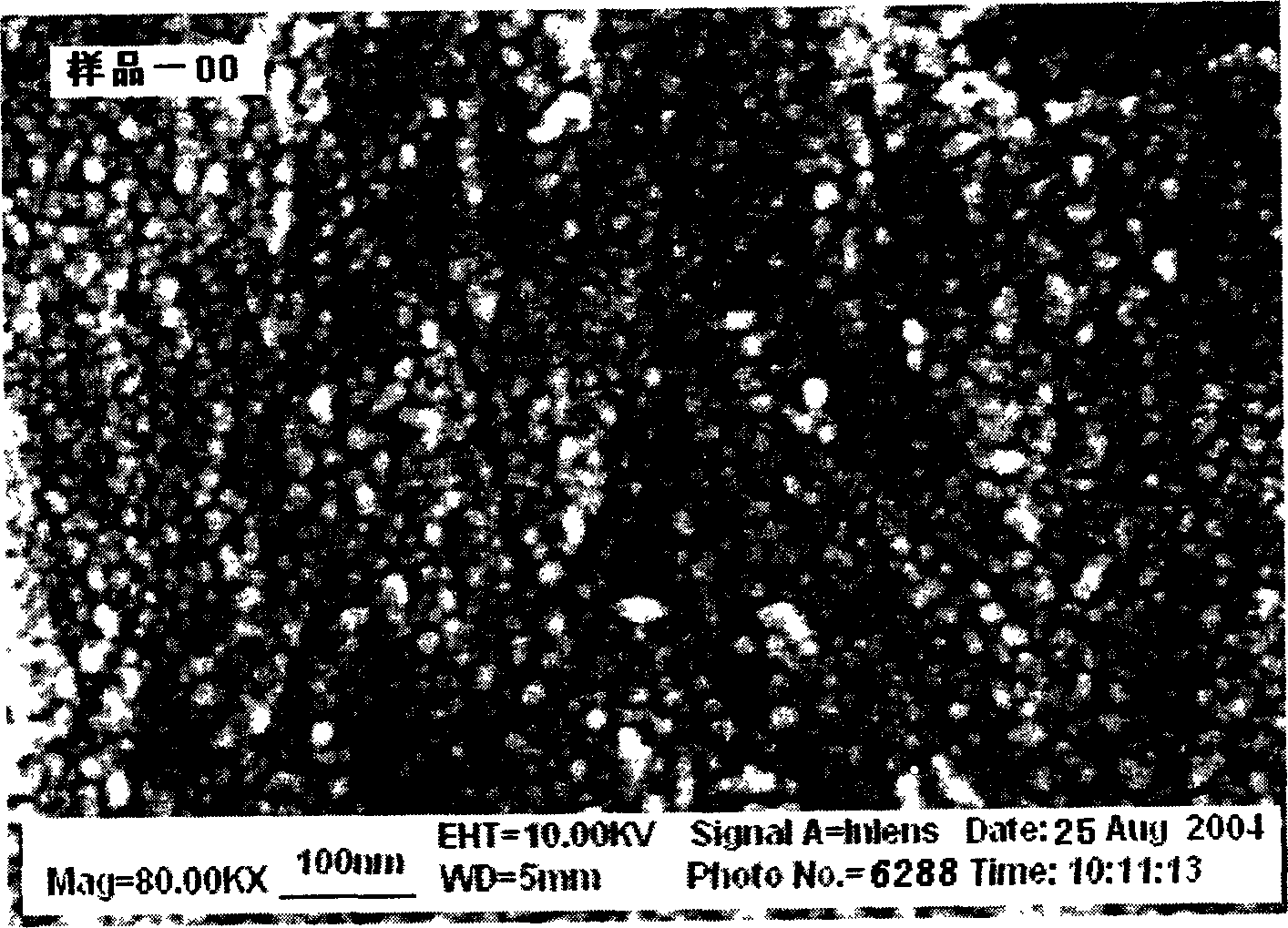

Nano grade nickel oxyhydroxide and process for preparing same

InactiveCN1433970ASmall and uniform particle sizeFully dispersed evenly dispersedCell electrodesNickel carbonylsPrimary cellPrimary battery

The present invention relates to the field of cell material, in particular, it relates to a method for preparing positive material nickel oxyhydroxide for zinc-nickel primary cell, zinc-nickel secondary cell and other cells using compound of nickel as active matter, such as cadmium-nickel cell, metal hydride nickel cell and Hawkins cell and nano grade nickel oxyhydroxide prepared by said method. The nano nickel oxyhydroxide is prepared by using nickeous salt as raw material, using sodium hypochlorite as oxidant; adopting precipitation reaction and oxidation reaction simultaneously in alkalineaqueous solution and adopting ultrasonic wave to make oscillation dispersion in the course of reaction. Said invented product is fine and uniform in grain size, large in specific surface area, high in initial discharge specific value, low in self-discharge rate and stable in electric performance.

Owner:SOUTH CHINA UNIV OF TECH

Nano-range nickel gamma-hydroxy oxide and preparing process thereof

A nano-class gamma-nickel hydroxyoxide is prepared through dissolving Ni salt in water, mixing with surfactant and Co (or Zn or Cd) salt, adding dropwise to the alkaline aqueous solution of oxidant, and oxidizing reaction while strong ultrasonic dispersing. Its advantages are low granularity, high specific surface area, high discharge cavacity, low self-discharge rate, high bulk density and high electric stability. It can be used as positive electrode of Zn-Ni battery.

Owner:SOUTH CHINA UNIV OF TECH

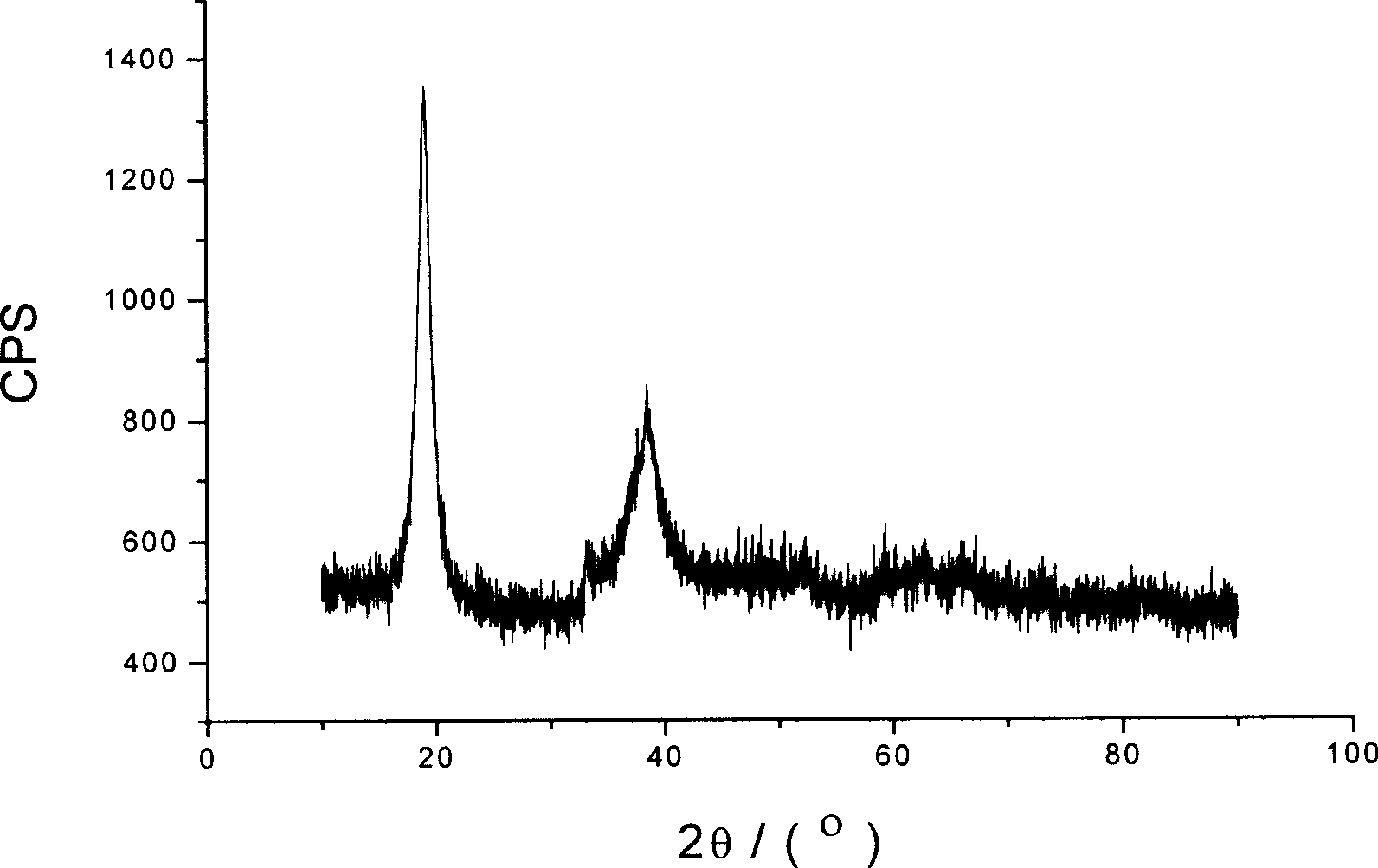

Preparation method of charged state beta-phase nickel oxyhydroxide

InactiveCN1444300ABest formulaStrong oxidation abilityElectrode manufacturing processesNickel carbonylsChemistryNickel oxide hydroxide

This invention discloses a method for preparing charging beta phase hydroxyl nickel oxide, applying NiOH after oxidation to prepare with uniform liquid phase method and select chloros as the main oxidant, attching electric field action the same time as the chemical oxidation to deeply oxidate the beta phase hydroxyl nickel oxide particles quickly in the electric field to form charging beta phase hydroxyl nickel oxide to be used as the nickel / zinc battery positive material with high discharging platform voltage.

Owner:轻工业化学电源研究所

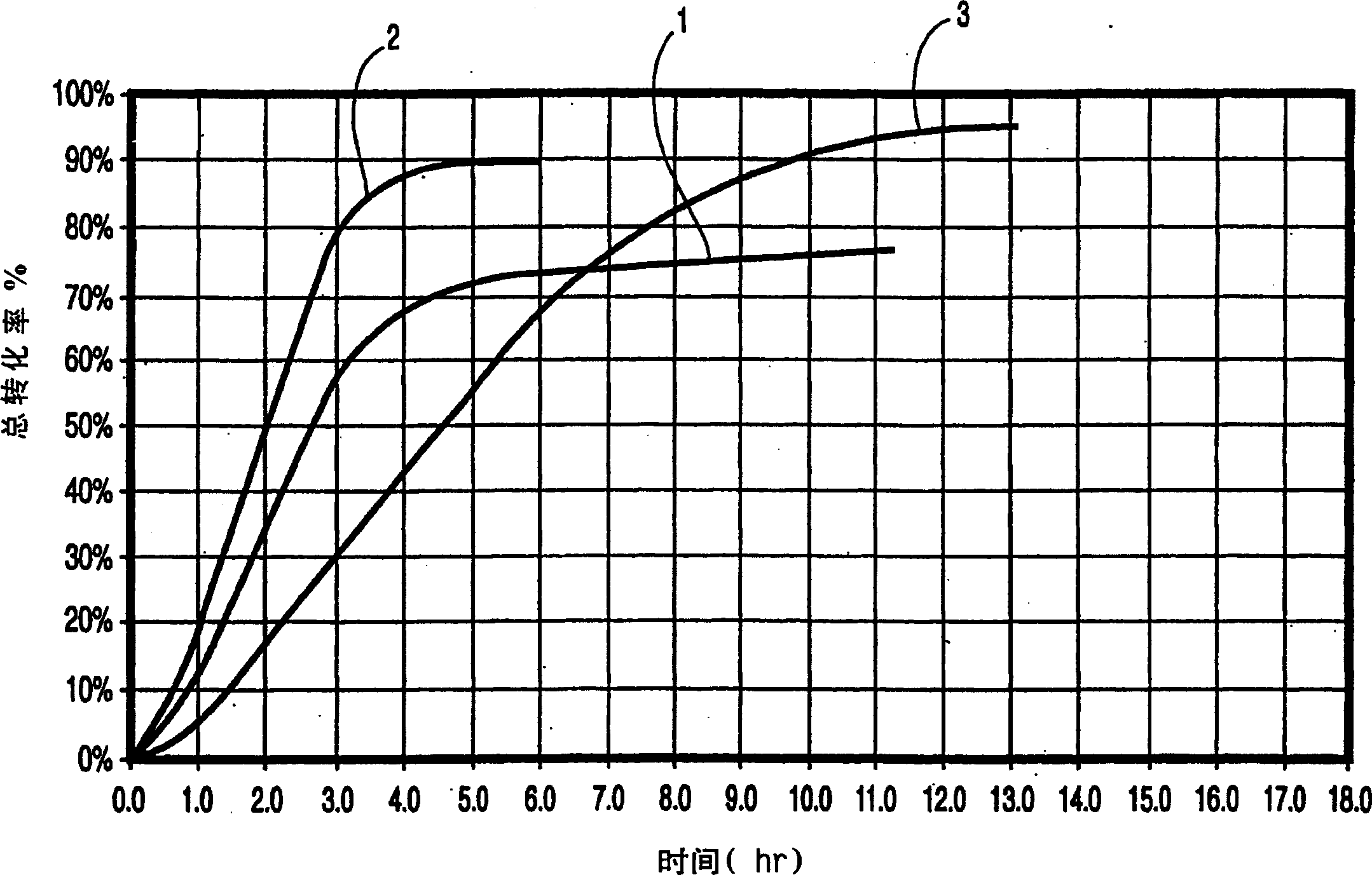

Oxo-process of preparing nickel carbonyl from coarse ore nickel

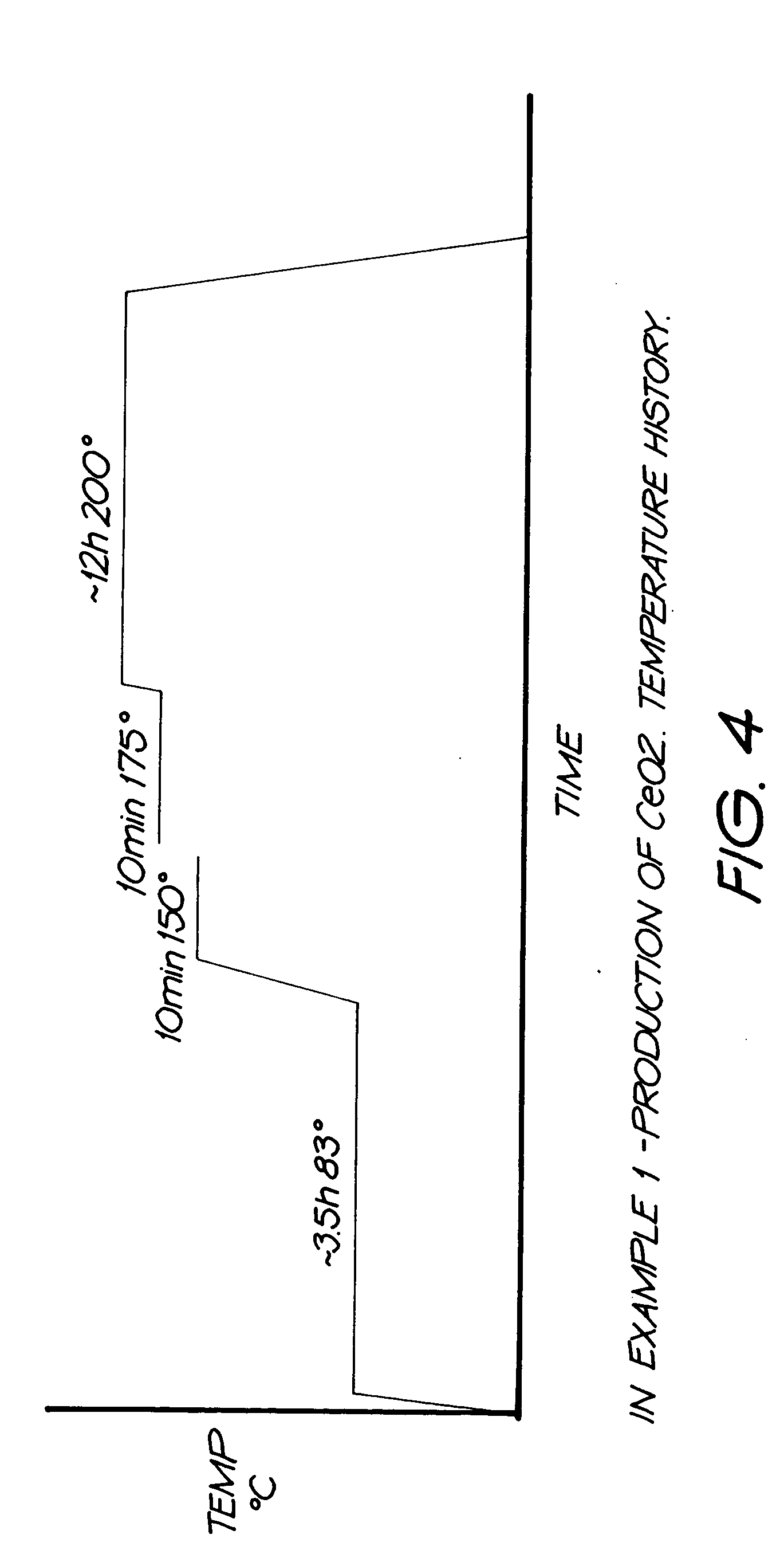

InactiveCN1398792AShort reaction timeImprove work efficiencyNickel carbonylsReaction temperatureNickel Carbonyl

The present invention is an oxo synthesis process of preparing cabonyl nickel from coarse nickel ore. The synthesis process has coarse nickel mineral as direct reactant, CO as reactant gas and H2S gas as catalyst, and in the operation conditions of 160-200 deg.C reaction temperature, 3.0-8.5 MPa reaction pressure and 8-12 hr reaction time, cabonyl nickel is produced with nickel extracting rate as high as 98%. The present invention has short reaction period, no need of treating reaction material and simple reaction process.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nickel carbonyl synthesizing method

The invention belongs to the field of powder metallurgy, especially relating to a method for synthesizing nickel carbonyl, including the following steps of: (1) preparing active carbonyl synthesizing raw material: firstly heating the alloy to melt at 1600 deg.C-1650 deg.C, then rapidly condensing the melt by 0.3-0.5 MPa high pressure water spray, where the water temperature is controlled at 10 deg.C-15 deg.C and the spraying speed is 4-5 kg / min, and the size of the obtained alloy particles is 0.5 mm-5 mm, and the proportion of the particles of 0.5 mm-2 mm is not less than 85% and that of the particles of 2mm-5mm is not greater than 15%; (2) synthesizing nickel carbonyl: placing the prepared alloy particles in a high pressure kettle of 10 liter, and the carbonyl synthesizing conditions: the CO content fed in the high pressure kettle >=92%; CO circulating speed in the carbonyl synthesizing system is 8-12 times / h, and the pressure is 5-12 MPa, the temperature is 100 deg.C-150 deg.C, and the synthesizing time is 24-32 hours. The invention has the advantages of simple technique, low equipment manufacturing cost, high carbonyl synthesis ratio as compared with the existing technique.

Owner:BEIJING CISRI GAONA TECH

Method for synthesizing nickel tetracarbonyl

The invention relates to a compound method for nickel carbonoxide. It sets thermalloy or ambrose first alloy onto fixed bed reactor and is continuously pumped into carbon monoxide with catalyst. The reaction pressure is controlled from 5.0Mpa to 15.0Mpa, and temperature is controlled from 150 degree centigrade to 250 degree centigrade. Thus, the carbonylation ratio of nickel in raw material is very high. And experiment safety factor is sharply increased.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Positive electrode material of alkaline battery and its preparation method

InactiveCN1405907ARaise the oxygen overpotentialInhibit or greatly slow down the oxygen evolution reactionAlkaline accumulatorsElectrode manufacturing processesElectrolysisOxygen

The invention discloses Beta-hydroxyl zinc-nickel oxide crystal, which is of hydrated oxide of nickel and zinc existed in eutectic form, and its preparing method. Comparing with prior art, the alkaline battery prepared by use of the said crystal as the material of the positive electrode, zinc as the negative electrode, the concentrated alkali solution as the electrolytic solution. The alkali battery provides higher discharge voltage and larger discharge current. With being even stored in high temperature, the battery still keeps excellent large load discharge characteristic and durability. Possessing the features of short preparation technological flow and simple operation, the invention is suitable for being as the material of the positive electrode of the alkali battery.

Owner:CHANGSHUN CHEM JIANGMEN CITY

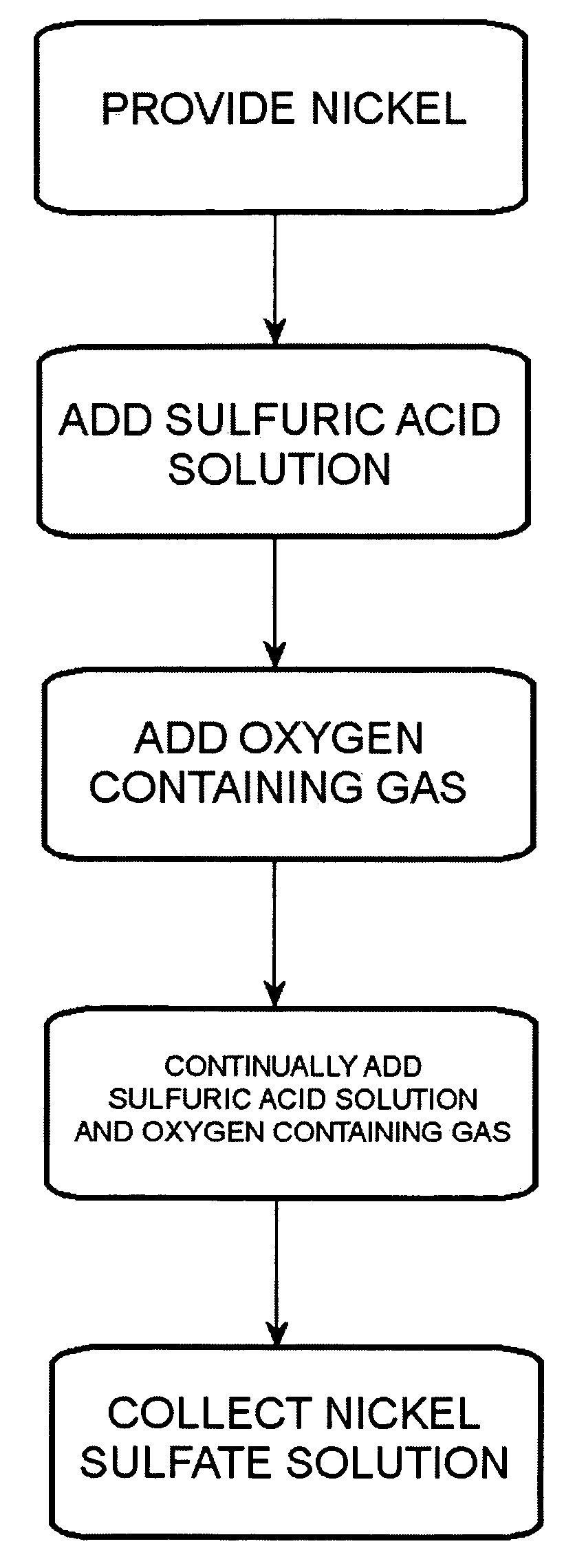

Method of producing a nickel salt solution

A method for converting nickel into a nickel salt solution. Nickel is dissolved and reacted in an oxygen-enriched acidic solution to produce a nickel salt solution as illustrated in the following chemical equation, wherein X is a conjugate base: Ni+H2X+½O2->NiX+H2O.

Owner:CHEVRON TEXACO TECH VENTURES

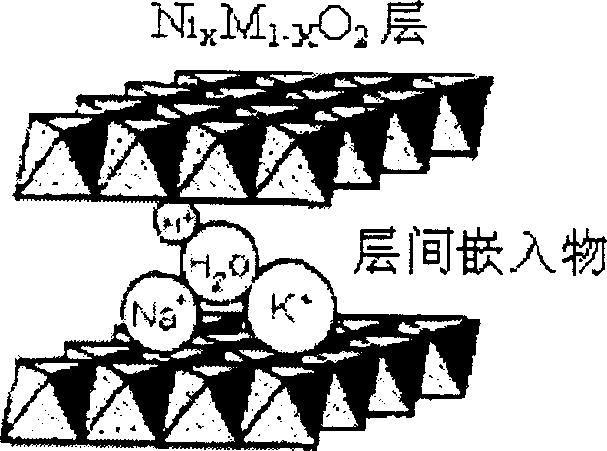

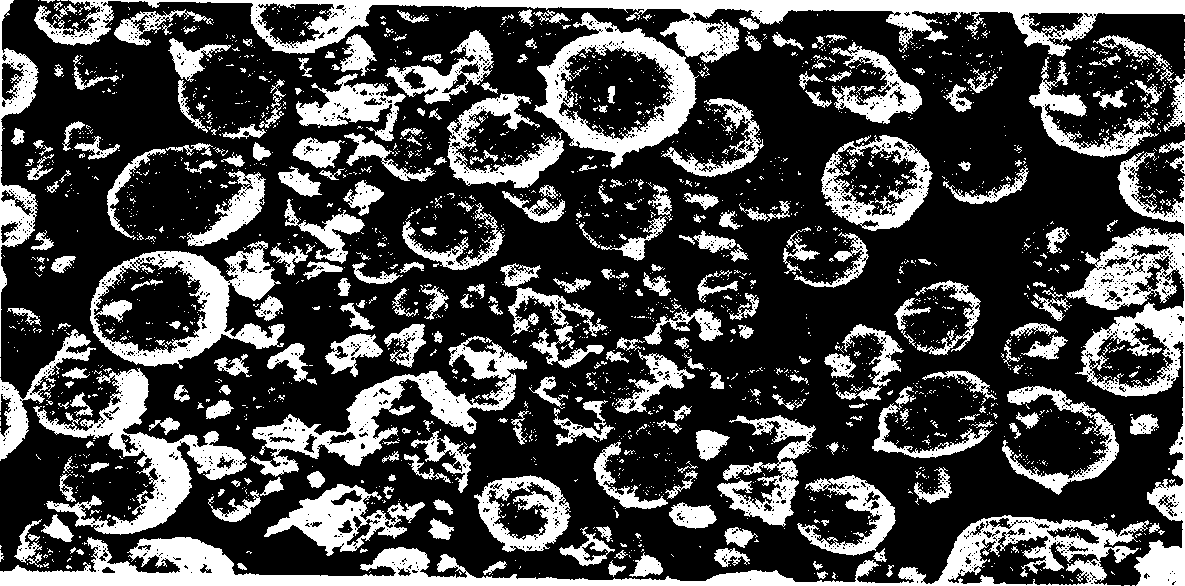

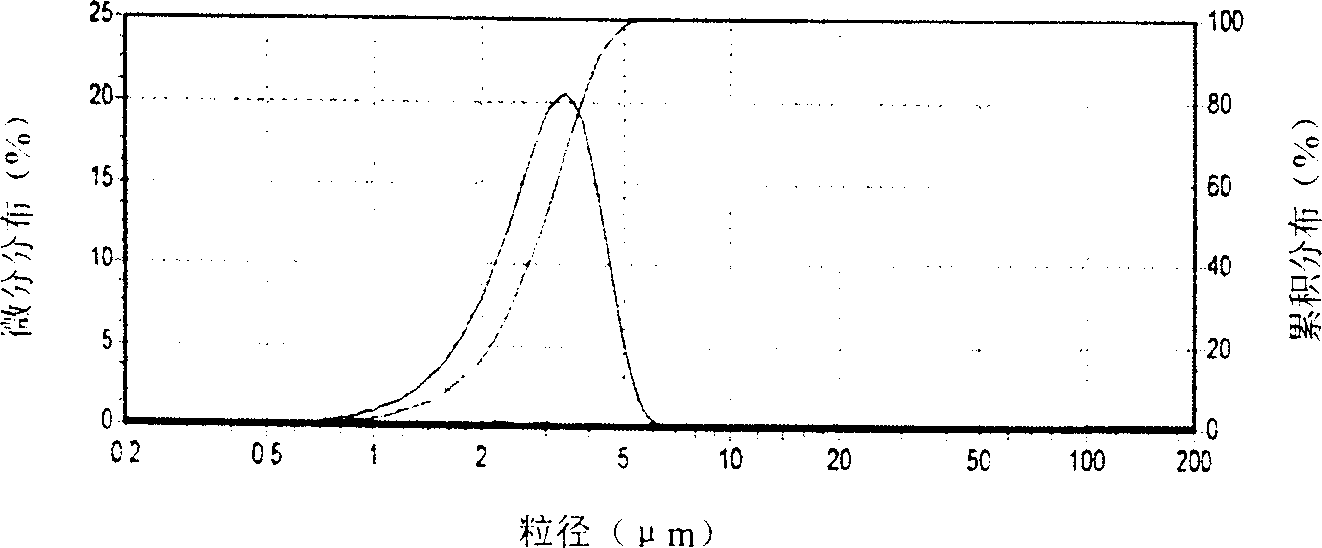

Spherical gamma nickel oxyhydroxide, preparation process and application thereof

InactiveCN1755969AEasy to storeImprove stabilityElectrode manufacturing processesNickel carbonylsNickel saltPotassium hydroxide

Disclosed a compound ball ª† hydroxyl nickel oxide, its preparing method and application, relates to a compound and a anode material of battery, while the compound has the advantages of better storage ability, high discharge capacity and high packaging density. Wherein, the chemical formula of said compound is ª†-HaKbNac(H2O)dNixM1-XO2 and the method comprises that mixing the nickel salt solution and at least one metal salt solution to attain the solution A; preparing caustic soda or caustic potash solution and adding sodium carbonate or potassium carbonate to attain the solution B; preparing the ammonia solution C; reacting the A, B, and C, processing the solid-liquid separation to attain the ball ª‡ nickel hydroxide; reacting with the oxidant in the solution of caustic soda or caustic potash to attain the black solid-liquid mixture and processing the solid-liquid separation to attain the ball ª† hydroxyl nickel oxide. The invention has better stability which avoids the easy discharge decompounded in lye; therefore, the invention can be used as anode material of battery to attain better storage ability, high discharge capacity, better crystal condition and density while the tap density can reach 1.9 g / cm3.

Owner:XIAMEN UNIV

Preparation method of carbonyl nickel powder

A preparation method of carbonyl nickel powder relates to a kind of carbonyl nickel powder, in particular to a preparation method of low-carbon carbonyl nickel powder. The preparation process is that carbonyl nickel vapor and carbon monoxide gas are used to form a mixed gas and the mixed gas passes through a decomposer and is heated and decomposed to prepare carbonyl nickel powder. The preparation method is characterized in that the disproportionation reaction of CO under high temperature is controlled in the heat decomposition process, thus the carbon content of the nickel powder is controlled. The preparation method of the carbonyl nickel powder comprises the following steps: the mixed gas consisting of carbonyl nickel vapor and carbon monoxide gas is introduced in the decomposer from the upper part of the decomposer, the carbonyl nickel in the mixed gas is heated and decomposed to generate metal nickel particles in the falling process, the disproportionation reaction of CO is limited under high temperature by controlling the decomposition conditions and the carbon content of the nickel powder is controlled to obtain the carbonyl nickel powder product with the carbon content of 0.01%-0.15% finally.

Owner:JINCHUAN GROUP LIMITED

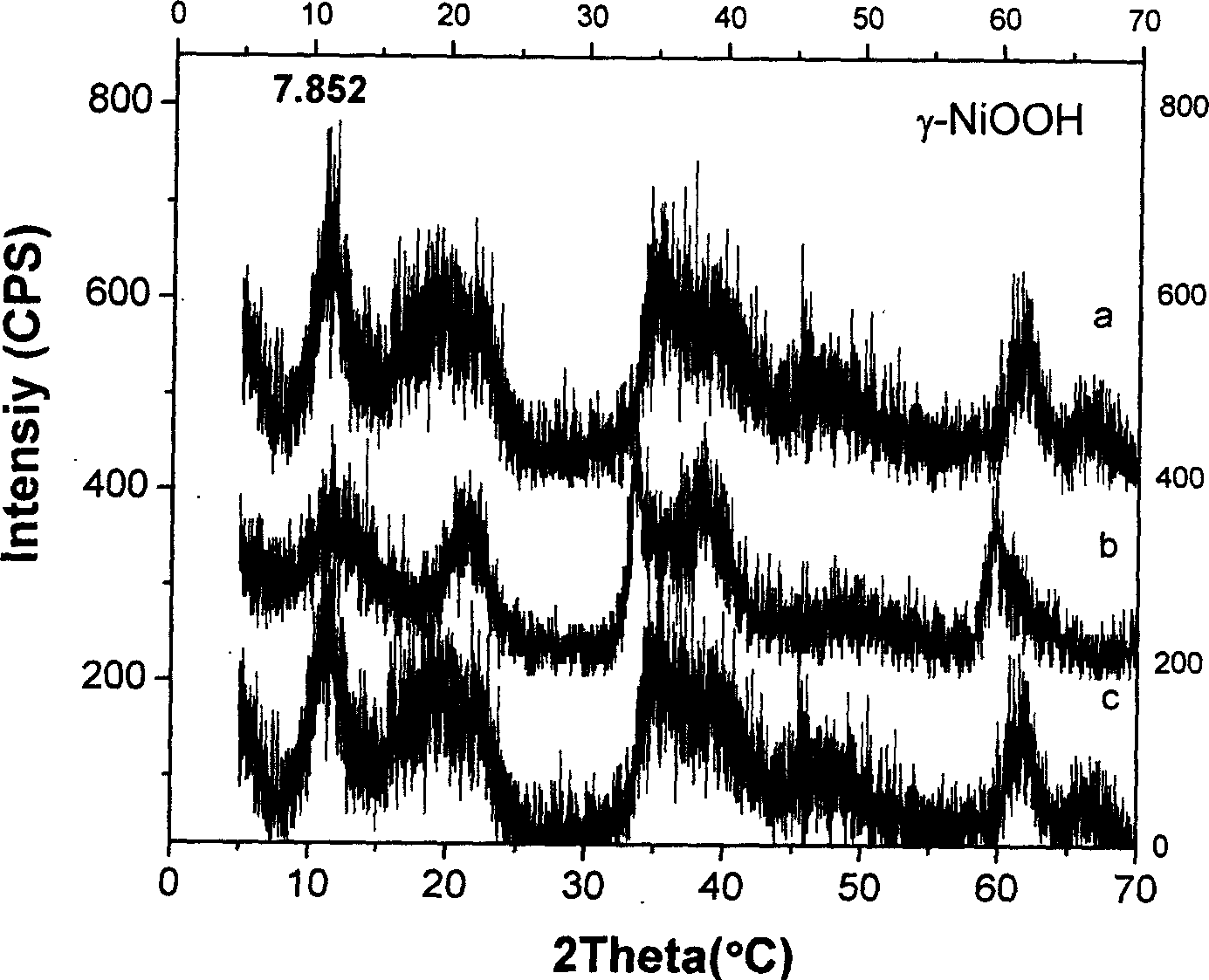

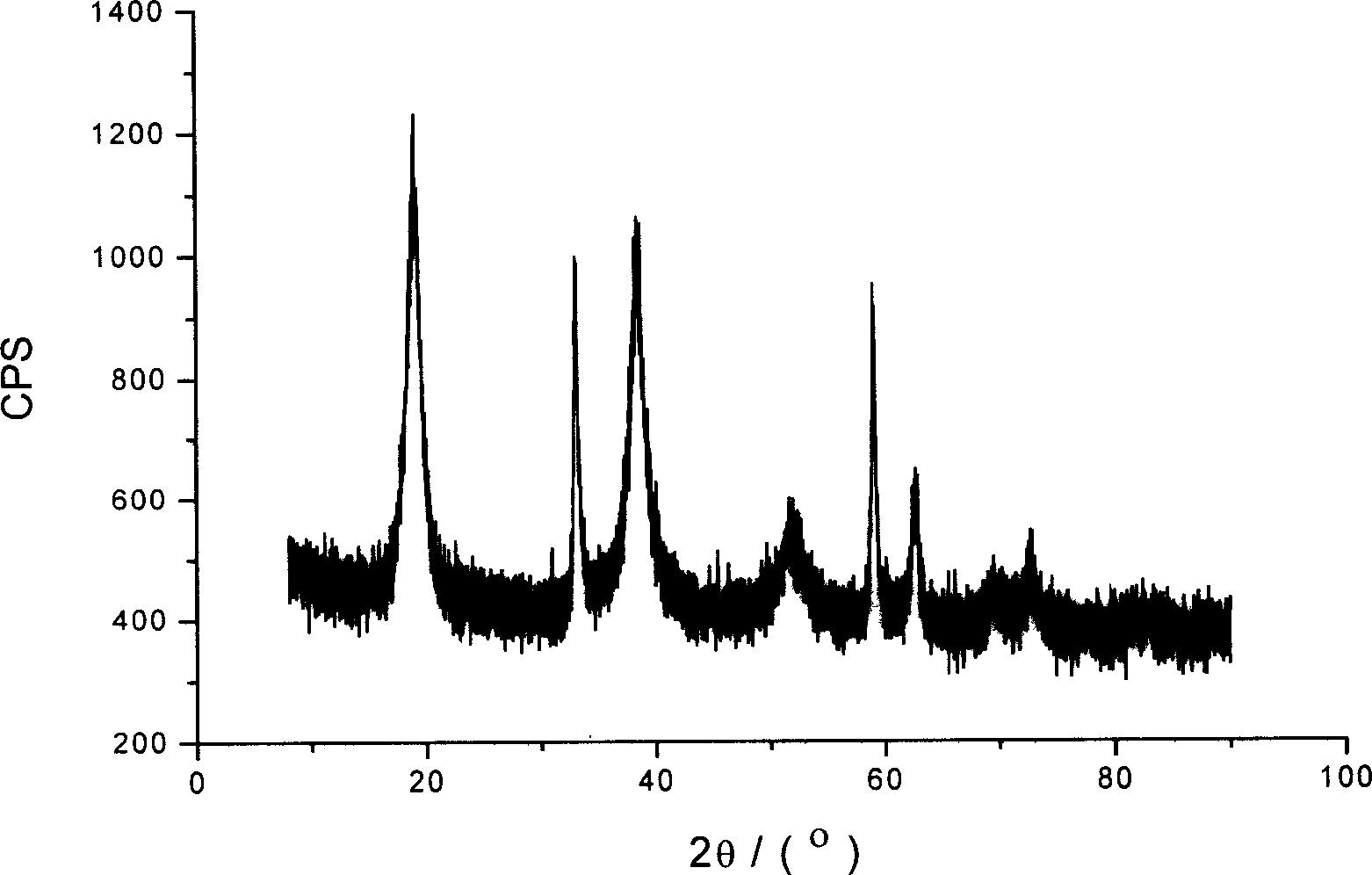

Gamma-hydroxyl nickel oxide and producing process thereof

InactiveCN1610150AHigh oxidation stateHigh specific capacityElectrode manufacturing processesNickel carbonylsNickel saltPotassium hydroxide

The present invention is gamma-hydroxy nickel oxide and its preparation process. The preparation process includes adding doping metal salt into bivalent nickel salt as main material to compound reaction solution; adding potassium hydroxide or sodium hydroxide into oxidant to compounding oxidant solution; adding the reaction solution into the oxidant solution under stirring and ultrasonic dispersion to obtain hydroxy nickel oxide; washing and drying to constant weight. The prepared gamma-hydroxy nickel oxide has small grain size, homogeneous grain, great specific surface area, high heat stability, high stability in alkali medium, high specific discharge capacity, and other advantages. The gamma-hydroxy nickel oxide may be used as the positive pole material for primary and secondary batteries.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing hydroxyl nickel from copper-nickel alloy

InactiveCN101209867AHigh activityIncrease the synthesis reaction rateNickel carbonylsNickel oxides/hydroxidesHydrogenSulfide

The invention relates to a method for producing hydroxyl nickel with copper nickel alloy, which is characterized in that: copper nickel alloy raw material to synthesize the hydroxyl nickel is first melted; selenium powder used as catalyst is added to activate the nickel in the raw material; the melt of the copper nickel alloy is water quenched into alloy particles; the alloy particles are reduced and activated by hydrogen, and then are subject to hydroxylation systemization to obtain the hydroxyl nickel. The method of the invention adds non-metallic elements which are conducive to hydroxylation systemization such as selenium powder in the primary copper nickel alloy, and electron migration happens between the simple substance selenium and Ni2S3 in the alloy to generate new metal center to improve the activity of nickel atom and the existing form of nickel is changed during the reactivation process by pumping in hydrogen to reduce the raw material, thus the existing form of nickel oxide and sulfide can be changed into a simple substance form conducive to oxonation, thereby accelerating synthesis reaction and reducing pressure required in the reaction.

Owner:JINCHUAN GROUP LIMITED

Alkaline battery positive pole material and preparing method

InactiveCN1901258AImprove storage performanceTight storageElectrode manufacturing processesNickel carbonylsOxidizing agentRadiochemistry

This invention relates to a positive material of alkali batteries and a preparation method, which provides a beta-alkyl Ni2O doped with Mg, the molecular formula is Ni(1-x) MgxO(1-x)OH(1+x), X is greater or equal to 3% and smaller than or equal to 15%, in preparation, solutions of Ni2SO4, NiNO3 or NiCl is mixed with solutions of MgSO4, MgNO3 or MgCl2 to NiMg solution then to parallel-flow with alkali solution and a complexing agent to be cleaned until SO32-, NO3-1 or Cl-1 can not be tested by solution then to be filtered and dried to get MgNi2(OH)2 which is added into KOH solution and oxidant is added to be cleaned till SO42- can not be tested by BaCl2 solution then to be filtered and dried.

Owner:XIAMEN UNIV

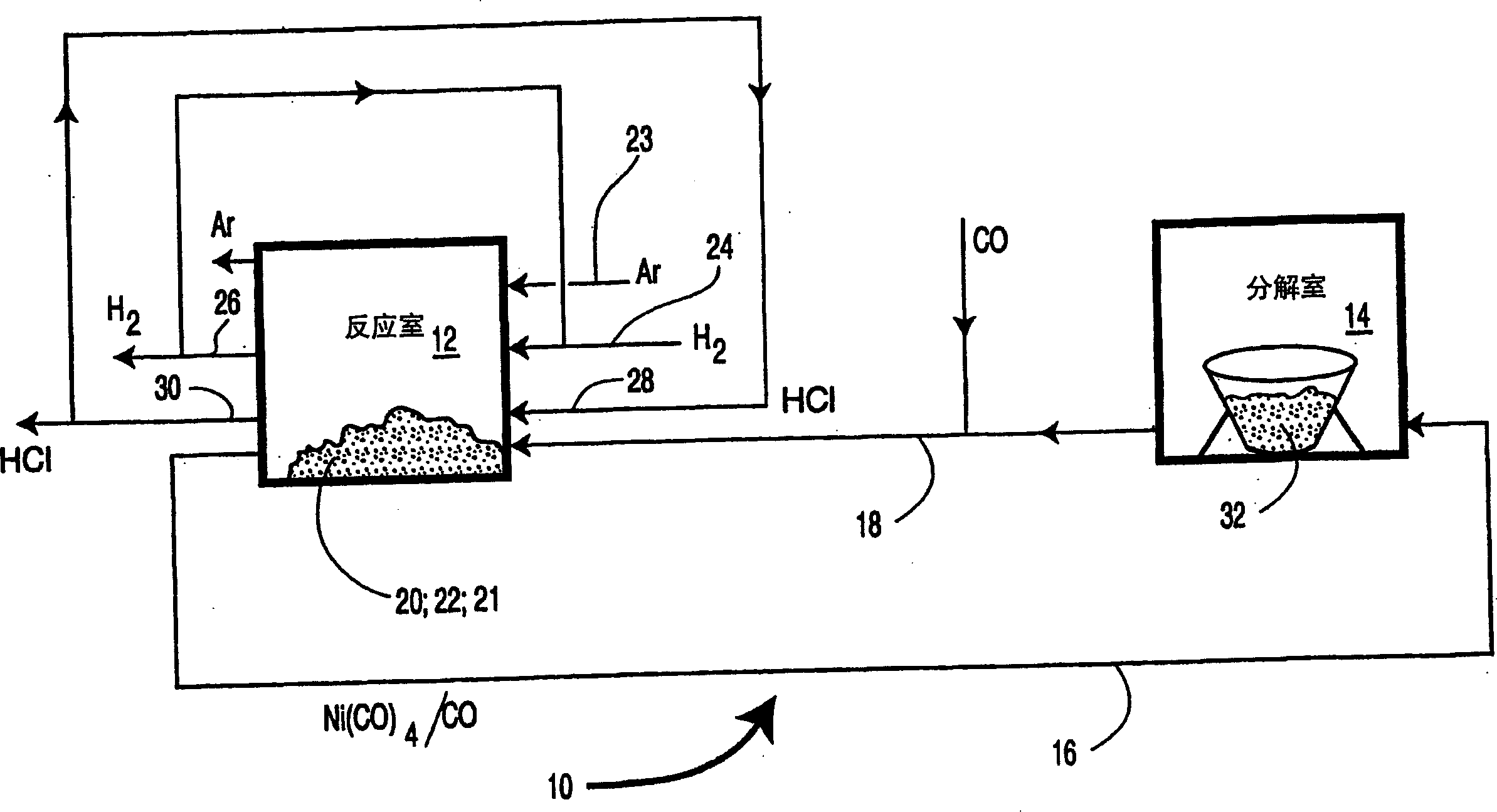

Preparation method of carbonyl nickel, nickel powder and its usage

A process for preparing Ni(CO)4 from CO and Ni source chosen from Ni, Ni compound and their mixture, which features that said Ni compound is not alone nickel chloride or the mixture of nickel chloride (50 W%) and nickel carbonate ore, includes such steps as treating said Ni source by H2 under existance of Cl anions to generate resultant Ni, reacting on CO to generate Ni(CO)4, and collecting Ni(CO)4.

Owner:CVMR CORP

Method for synthesizing nickel carbonyl under medium pressure in rotating kettle

InactiveCN103241782AReduce pressure requirementsShort reaction timeNickel carbonylsBurn treatmentNitrogen

The invention discloses a technology for synthesizing nickel carbonyl under medium pressure in a rotating kettle. The technology comprises the following preparation steps of: (1) preparing water-quenched copper-nickel alloy particles; (2) carrying out a carboxylation reaction; (3) separating; and (4) sterilizing residues in the kettle by using hot nitrogen replacement after the reaction is ended, feeding exhausted gas to an incinerator to be subjected to burning treatment, simultaneously recovering heat, opening a discharge hole and discharging the carbonylated alloy in the kettle after the nitrogen sterilization is finished, and then entering next circulation. According to the technology for synthesizing nickel carbonyl under medium pressure in the rotating kettle, the requirement on pressure is low and the pressure only needs 7.5-8.5MPa, the reaction time is greatly shortened by rotation of the rotating kettle, the yield is high, and the reaction speed can be controlled by means of the rotating speed of the rotating kettle if necessary. The rotating kettle is connected with a fixed airtight device through two groups of spiral flexible tube stacks, and therefore a dynamic and static conversion connection between the rotating kettle and other fixed pipelines is finished.

Owner:EAST CHINA ENG SCI & TECH

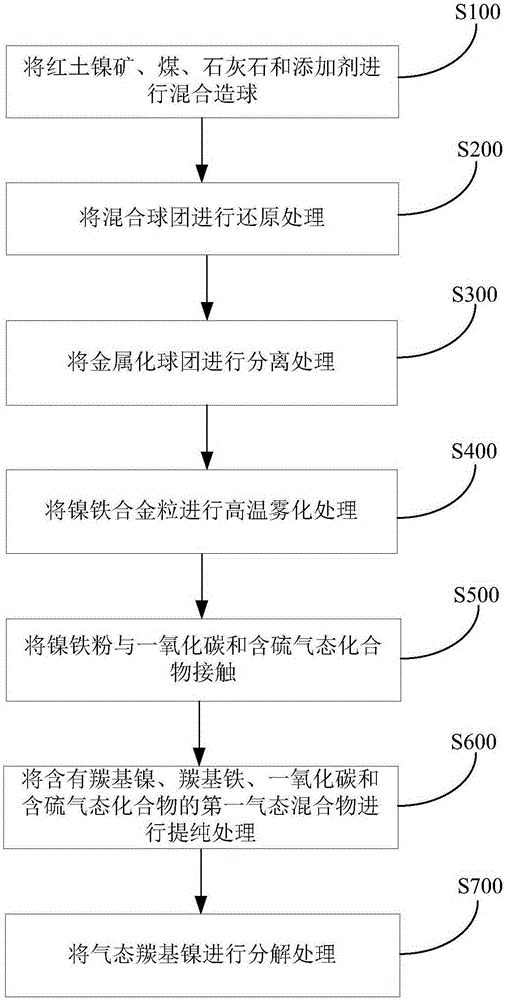

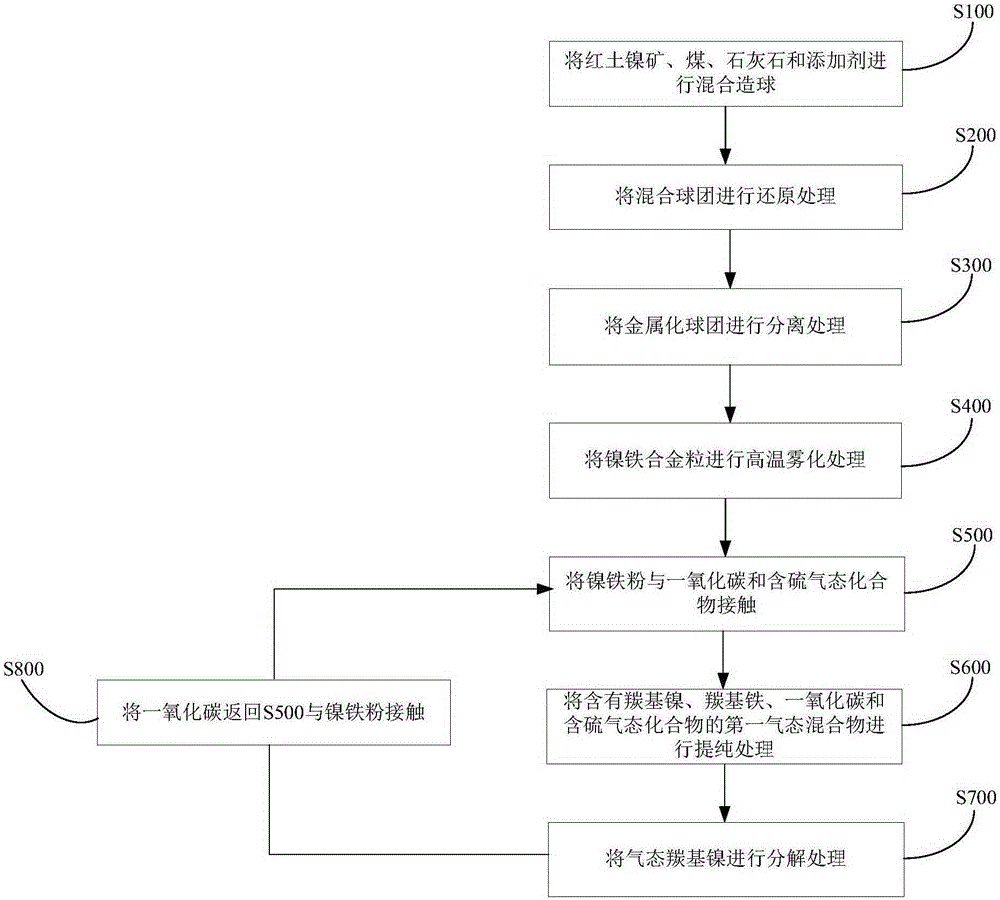

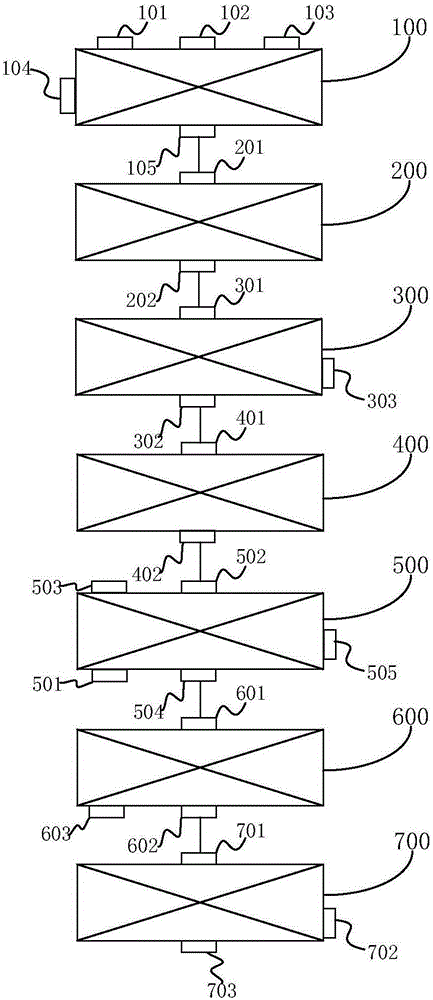

Method and system for preparing nickel carbonyl powder through laterite-nickel ore

ActiveCN105198008AHigh purityReduce manufacturing costNickel carbonylsReduction treatmentIron powder

The invention discloses a method and system for preparing nickel carbonyl powder through laterite-nickel ore. The method comprises the steps that 1, the laterite-nickel ore, coal, limestone and additives are mixed and pelletized; 2, reduction treatment is carried out on mixed pellets; 3, the metallized pellets are subjected to separation treatment, and ferro-nickel particles and tailings are obtained; 4, high-temperature atomization is carried out on the ferro-nickel particles, and ferronickel powder is obtained; 5, the ferronickel powder is in contact with carbon monoxide and sulfur-containing gaseous compounds, and a first gaseous compound containing nickel carbonyl, carbonyl iron, carbon monoxide and the sulfur-containing gaseous compounds, and iron powder are obtained; 6, the first gaseous compound is purified, and gaseous nickel carbonyl and a second gaseous mixture including the sulfur-containing gaseous compounds and carbon monoxide are obtained; 7, gaseous nickel carbonyl is decomposed, and the nickel carbonyl powder and carbon monoxide are obtained. According to the method, the cheap laterite-nickel ore can be effectively utilized for preparing the high-purity nickel carbonyl powder, and therefore production cost can be remarkably reduced.

Owner:SHENWU TECH GRP CO LTD

Method for producing carbonyl nickel by using copper-nickel alloy raw material

The process of producing carbonyl nickel with copper-nickel alloy as raw material includes the first adding Cu or S into the copper-nickel alloy to regulate the Cu / S to 4; the subsequent heating at 1400-1500deg.c to smelt, flowing the melt to quenching pond in the flow rate of 60-80 Kg / min and crushing the melt with sprayed water flow into 1-20 mm size active quenched copper-nickel alloy grains; and the final carbonyl nickel synthesizing process. The said production process converts nickel in the alloy into monomer form favorable to the carbonyl reaction so as to speed the synthesis reaction and realize the production of carbonyl nickel with copper-nickel alloy as raw material.

Owner:JINCHUAN GROUP LIMITED

Nickel oxide mixed with cobalt manganese hydroxy base and preparation method thereof

InactiveCN101000958AHigh tap densityThe process is simple and easy to controlCell electrodesNickel carbonylsManganeseNickel compounds

This invention discloses a nickel-oxhydroxide doped with cobalt-manganese and its preparation method, relating to a nickel compound, from which, the product prepared has high tap density. The technique program is the formula of Ni1-x-yCoxMnyOOH, in which, 1 / 5<=x<=2 / 5, 1 / 5<=y<=2 / 5. Its preparation method includes the following steps: (1) the mixed salt solution is prepared by Ni, Mn and Co, which molar ratio is 1:(1 / 5<=x<=2 / 5) :(1 / 5<=y<=2 / 5), and sodium hydroxide or potassium hydroxide solution is prepared, (2) precipitation reaction, (3) polyacrylamide is accessed into the above slurry for poly deposition, (4) the filter cake is washed, dried, crushed and sift out to get the product. This invention is used for the anode material of lithium battery.

Owner:HENAN NORMAL UNIV

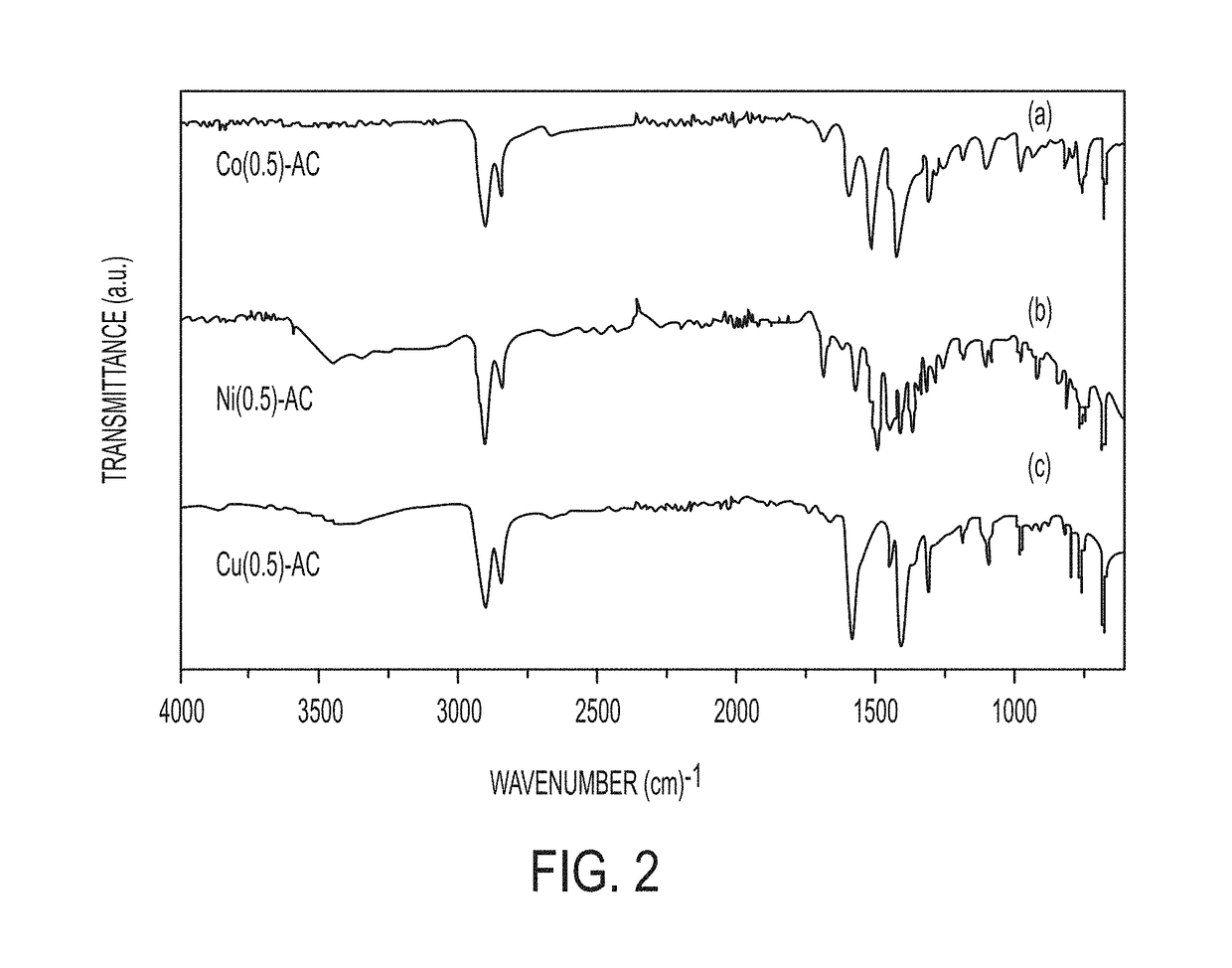

Synthesis of transition-metal adamantane salts and oxide nanocomposites, and systems and methods including the salts or the nanocomposites

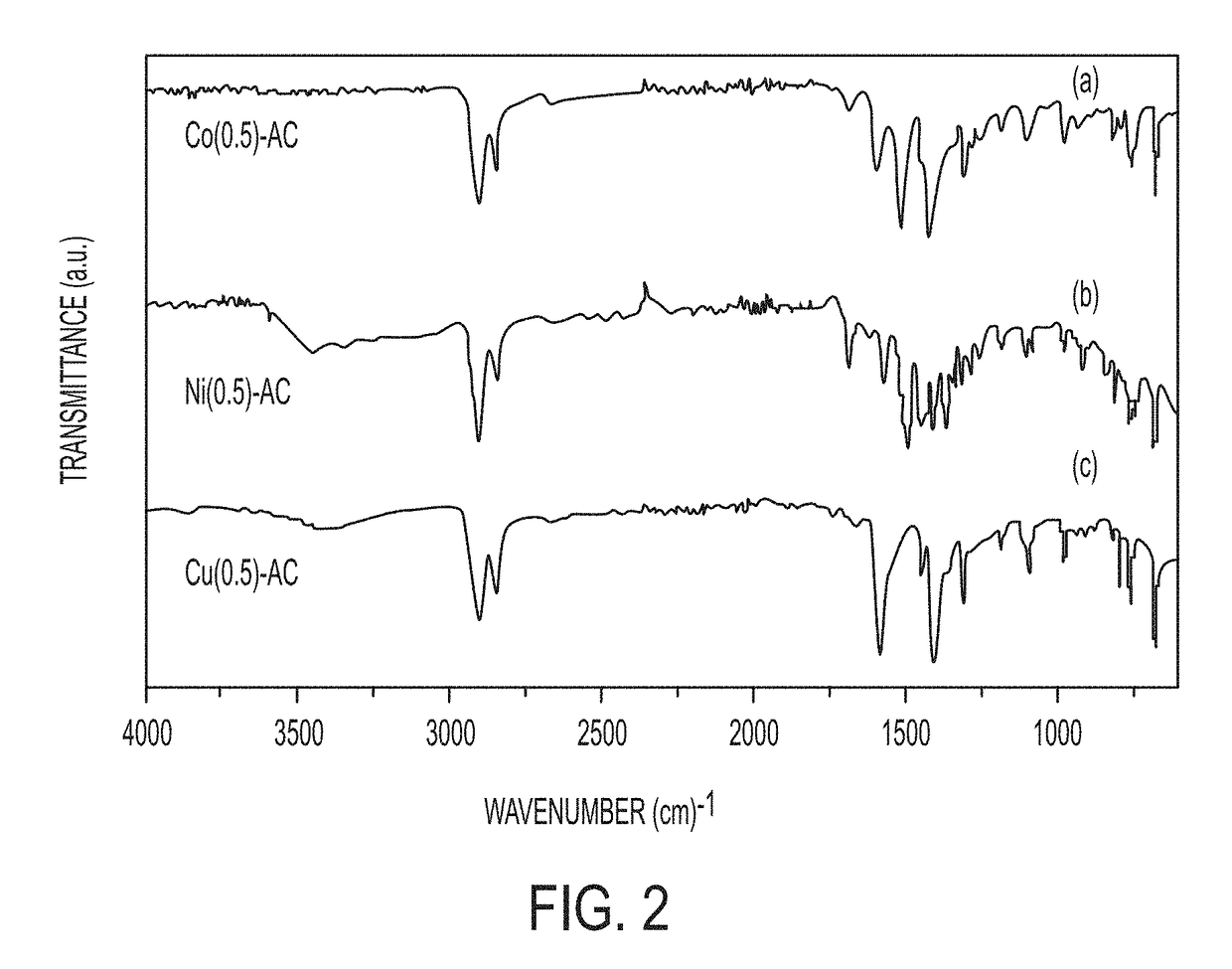

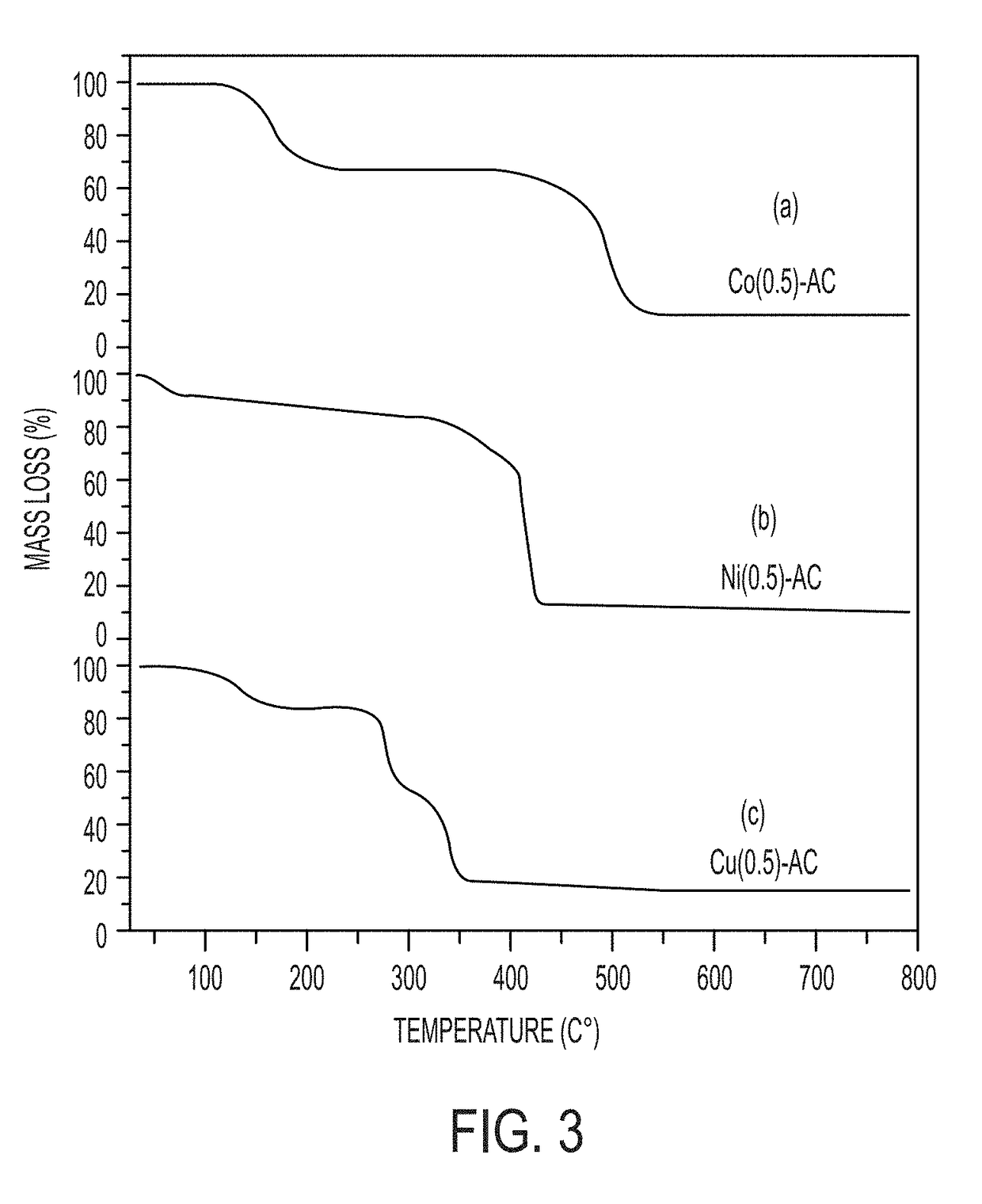

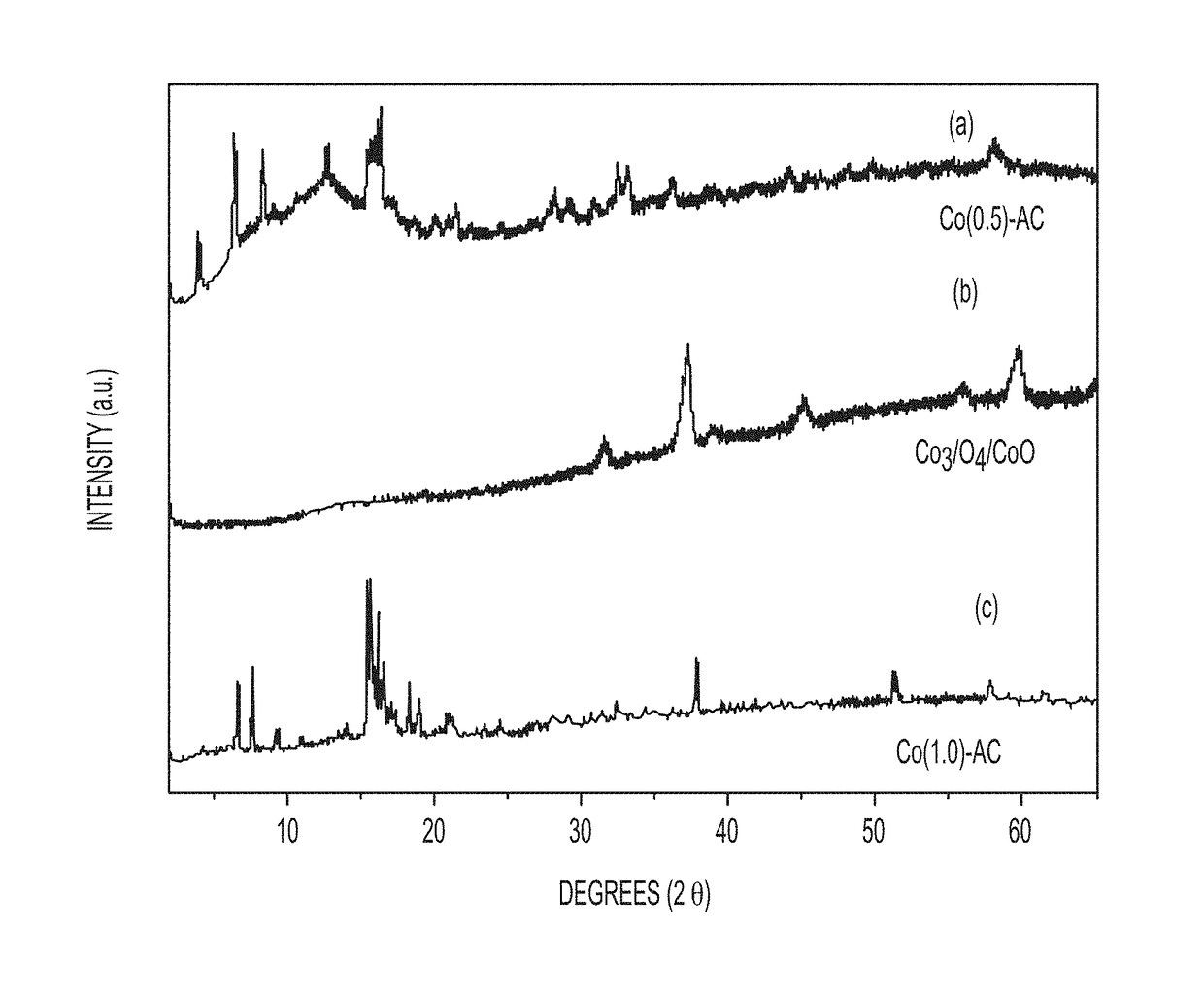

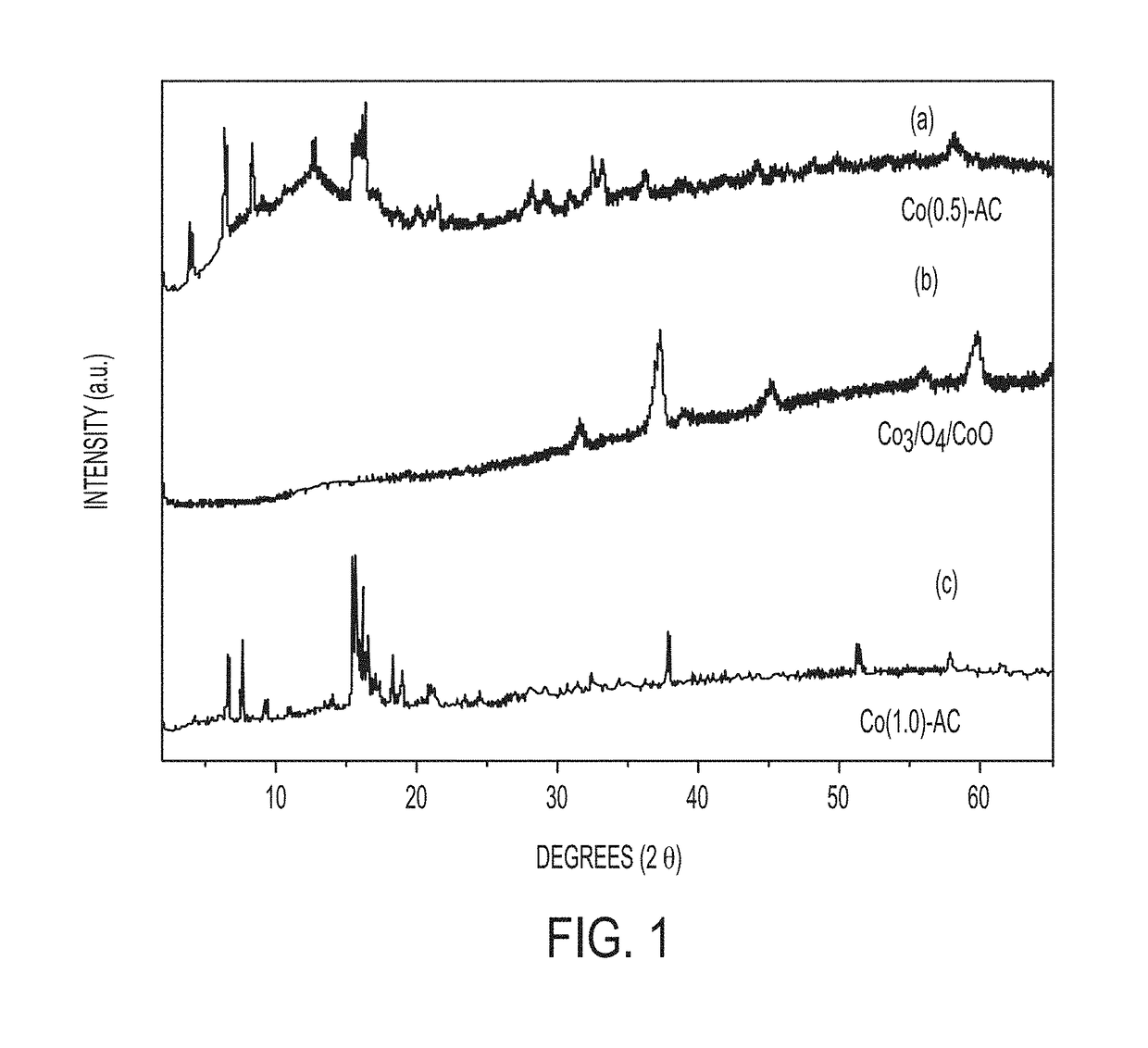

ActiveUS20170266643A1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureCarboxylic acid

A method for preparing a transition-metal adamantane carboxylate salt is presented. The method includes mixing a transition-metal hydroxide and a diamondoid compound having at least one carboxylic acid moiety to form a reactant mixture, where M is a transition metal. Further, the method includes hydrothermally treating the reactant mixture at a reaction temperature for a reaction time to form the transition-metal adamantane carboxylate salt.

Owner:SAUDI ARABIAN OIL CO +1

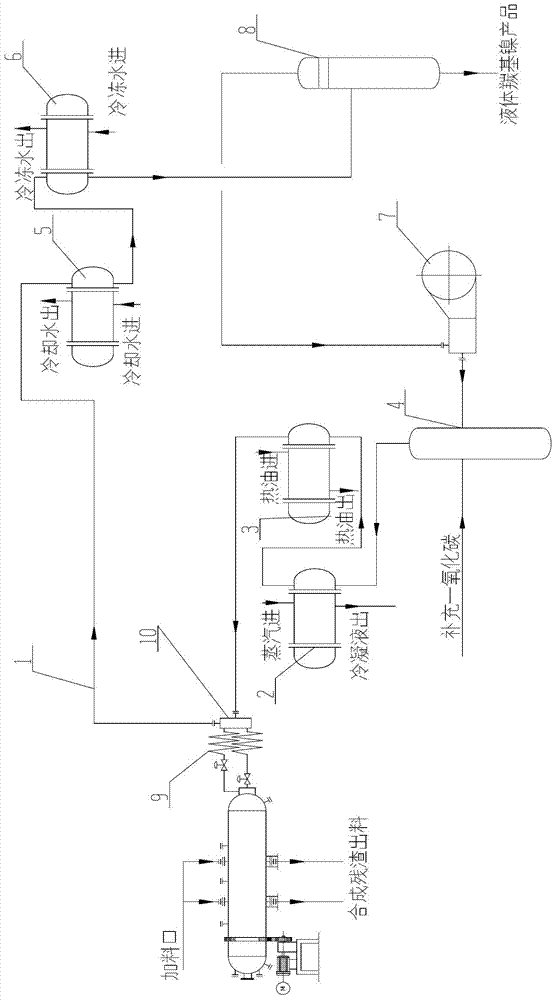

Preparation method of carbonyl ferronickel alloy powder

InactiveCN105948138AImprove stabilityGuaranteed working conditionNickel carbonylsIron carbonylsAlloyFerric

The invention discloses a preparation method of carbonyl ferronickel alloy powder. The method comprises the following steps: respectively introducing CO gas into a carbonyl nickel evaporator and a carbonyl iron evaporator, uniformly mixing the carbonyl-nickel-entrained CO gas and carbonyl-iron-entrained CO gas, introducing the gas mixture into a decomposer, and carrying out thermal decomposition, wherein the temperature of the CO gas introduced into the carbonyl nickel evaporator is 50-60 DEG C, and the temperature of the CO gas introduced into the carbonyl iron evaporator is 75-90 DEG C. The preparation method can enhance the stability of the mixed raw gas components and effectively maintain the operating state of the evaporators and feed pipeline.

Owner:JINCHUAN GROUP LIMITED

Synthesis of transition-metal adamantane salts and oxide nanocomposites, and systems and methods including the salts or the nanocomposites

ActiveUS10105684B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureCarboxylic acid

A method for preparing a transition-metal adamantane carboxylate salt is presented. The method includes mixing a transition-metal hydroxide and a diamondoid compound having at least one carboxylic acid moiety to form a reactant mixture, where M is a transition metal. Further, the method includes hydrothermally treating the reactant mixture at a reaction temperature for a reaction time to form the transition-metal adamantane carboxylate salt.

Owner:SAUDI ARABIAN OIL CO +1

Method for removing sulfureted hydrogen from mixture containing iron pentacarbonyl or nickel tetracarbonyl

The invention discloses a method for removing sulfureted hydrogen from mixture containing metal carbonyl (nickel carbonyl or iron carbonyl). The method includes that the catalyst is loaded in a fixed bed reactor; at the temperature of 5-250 DEG C, the CO mixed gas containing the nickel carbonyl or the iron carbonyl is added to the fixed bed reactor; under the air speed of 800-4000h-1, the sulfureted hydrogen in the mixed gas can be removed to below 0.1ppm.

Owner:吉林卓创新材料有限公司 +1

Process for synthesizing nickel carbonyl under normal pressure

The invention discloses a nickel tetracarbonyl synthesizing method through nickel and CO under normal pressure, which comprises the following steps: grinding nickel material; sintering the grinded material; reducing sulfur content; leaching the sintered slag to separate the copper in the sintered slag; reducing the slag through water gas; synthesizing the product through reduced material and CO.

Owner:JINCHUAN GROUP LIMITED

Method for preparing carbonyl nickel iron powder

InactiveCN101209865AQuality improvementSimple and fast operationNickel carbonylsIron carbonylsIron powderFerric

The invention relates to a method for preparing carbonyl ferronickel powder, which is characterized by the preparation course that: carbonyl nickel liquid and carbonyl iron liquid are heated respectively in two evaporators and then mixed with CO gas to be decomposed. The method for preparing carbonyl ferronickel powder of the invention has simple operation and obtains ferronickel powder with design ratio stably by adjusting the mixture ratio of carbonyl nickel to carbonyl iron. The content ratio of ferronickel powder can be adjusted at will according to need. The detection on the obtained carbonyl ferronickel powder shows that the ferronickel content in the product is stable, which realizes stable quality of the produced carbonyl ferronickel powder.

Owner:JINCHUAN GROUP LIMITED

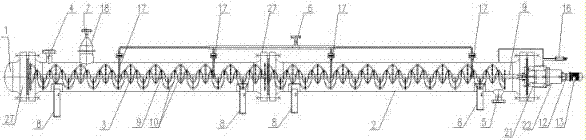

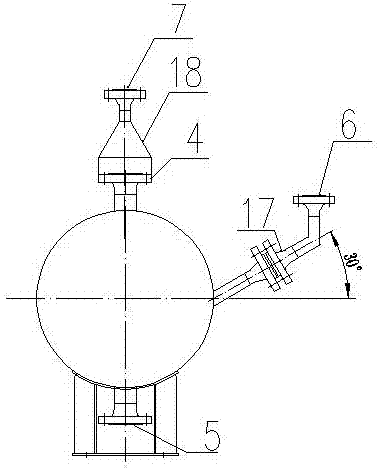

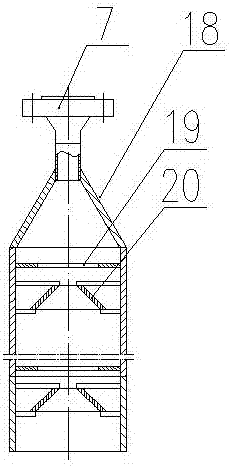

Continuous carbonylation reactor

PendingCN107243302AAvoid lostReduce lossesNickel carbonylsChemical/physical/physico-chemical stationary reactorsElectric machineryNickel Carbonyl

The invention discloses a continuous carbonylation reactor, belongs to the technical field of vapometallurgy, and aims to solve the problems of non-continuous reaction and low efficiency of synthesis of nickel carbonyl. The reactor comprises a sealing head, at least two barrel bodies and a stirring propulsion device, wherein the sealing end is connected with the barrel bodies through flanges; the barrel bodies are connected with each other through flanges; a material inlet, a residue outlet, a gas inlet and a gas outlet are formed in each barrel body; at least two supports are arranged below each barrel body; a stirring shaft, a sealing device, a speed reducer and a motor are arranged on the stirring propulsion device; stirring blades are arranged on the stirring shaft. As gas-solid two-phase reaction is continuous without stopping, the continuous carbonylation reactor is full in reaction, high in efficiency, high in sealing property and convenient to maintain.

Owner:JINCHUAN GROUP LIMITED +1

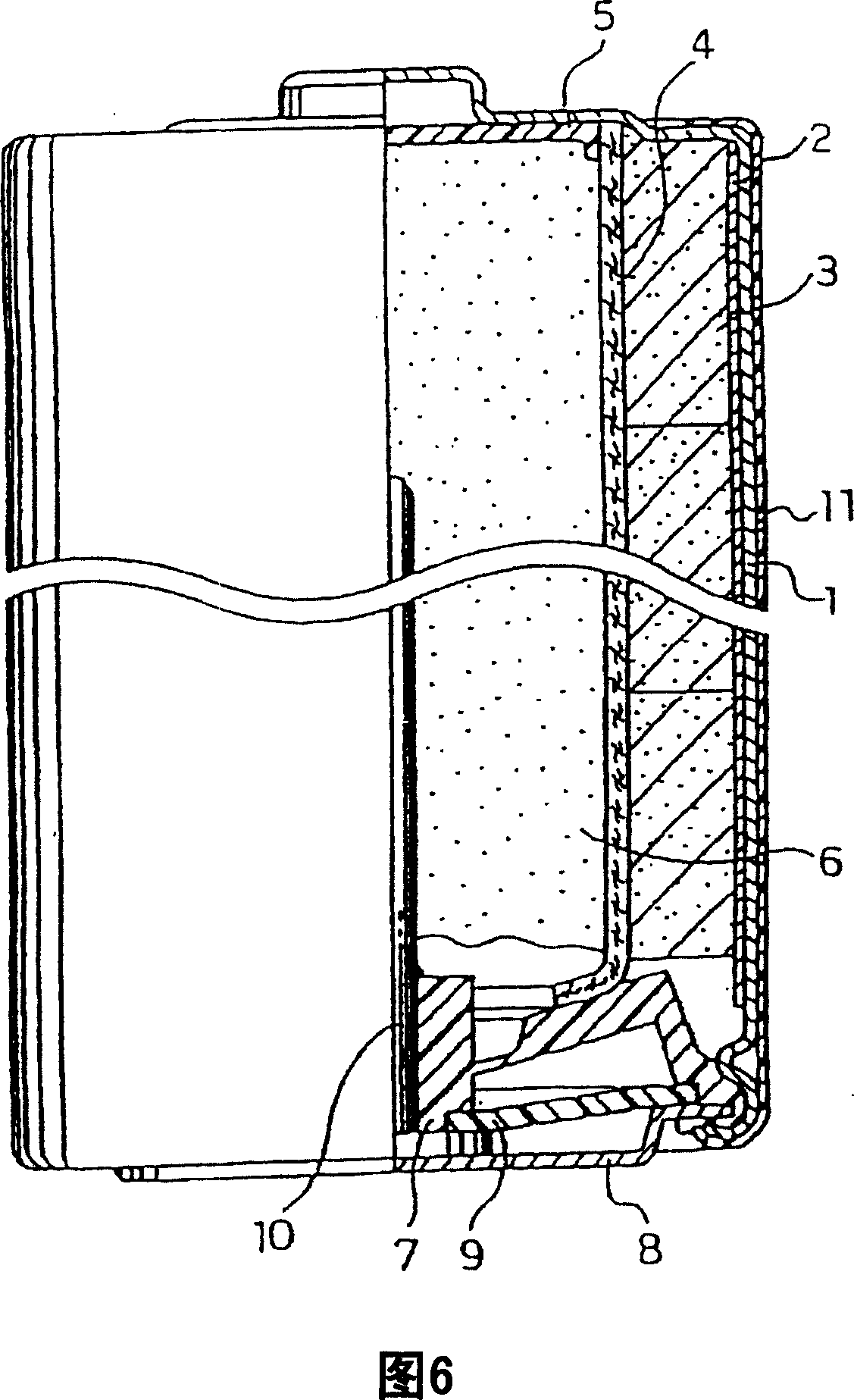

Nickel oxyhydroxide, manufacturing method therefor, and alkaline primary battery

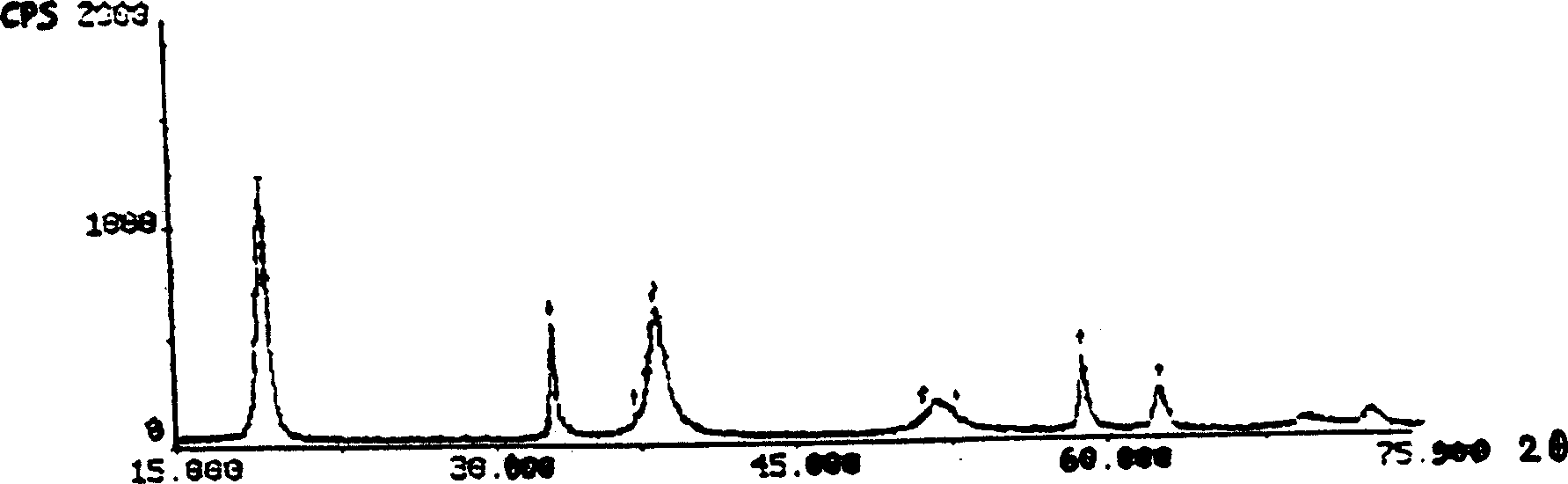

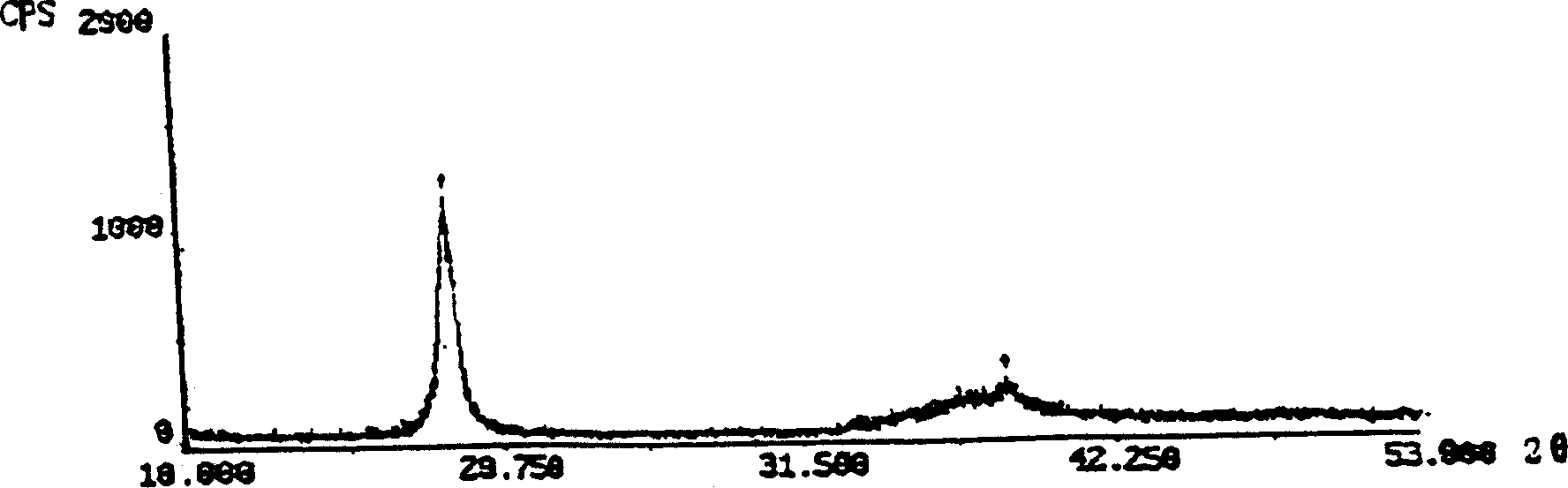

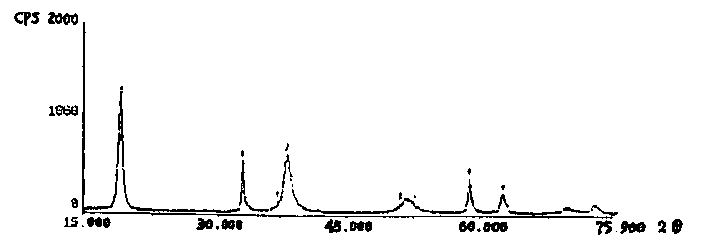

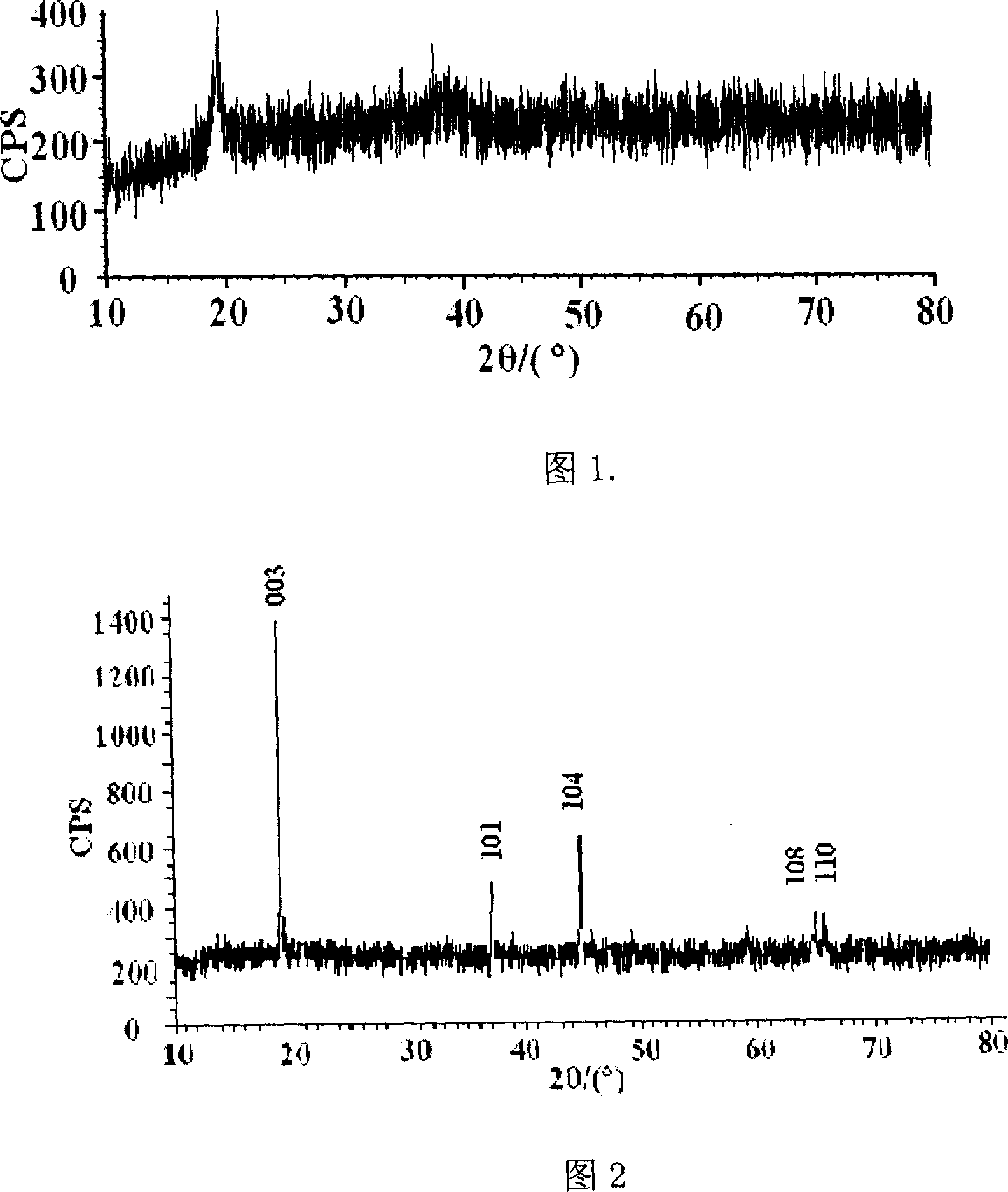

InactiveCN1982222APeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesNickel carbonylsX-rayPulse discharge

A nickel oxyhydroxide having a beta-type structure is used to greatly improve low-temperature discharge performance and pulse discharge performance under high-load of an alkaline primary battery including a positive electrode containing nickel oxyhydroxide. In the nickel oxyhydroxide having beta-type structure, a half-width of a peak of the (001) plane is 0.2 to 0.49 DEG in a powder X-ray diffraction, an average particle size (D50) based on the secondary particle volume is 5 to 10 mum, and an average valence of nickel is 2.9 to 3.0.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com