Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

454 results about "Diamondoid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, diamondoids are variants of the carbon cage molecule known as adamantane (C₁₀H₁₆), the smallest unit cage structure of the diamond crystal lattice. Diamondoids also known as nanodiamonds or condensed adamantanes may include one or more cages (adamantane, diamantane, triamantane, and higher polymantanes) as well as numerous isomeric and structural variants of adamantanes and polymantanes. These diamondoids occur naturally in petroleum deposits and have been extracted and purified into large pure crystals of polymantane molecules having more than a dozen adamantane cages per molecule. These species are of interest as molecular approximations of the diamond cubic framework, terminated with C−H bonds. Cyclohexamantane may be thought of as a nanometer-sized diamond of approximately 5.6×10⁻²² grams.

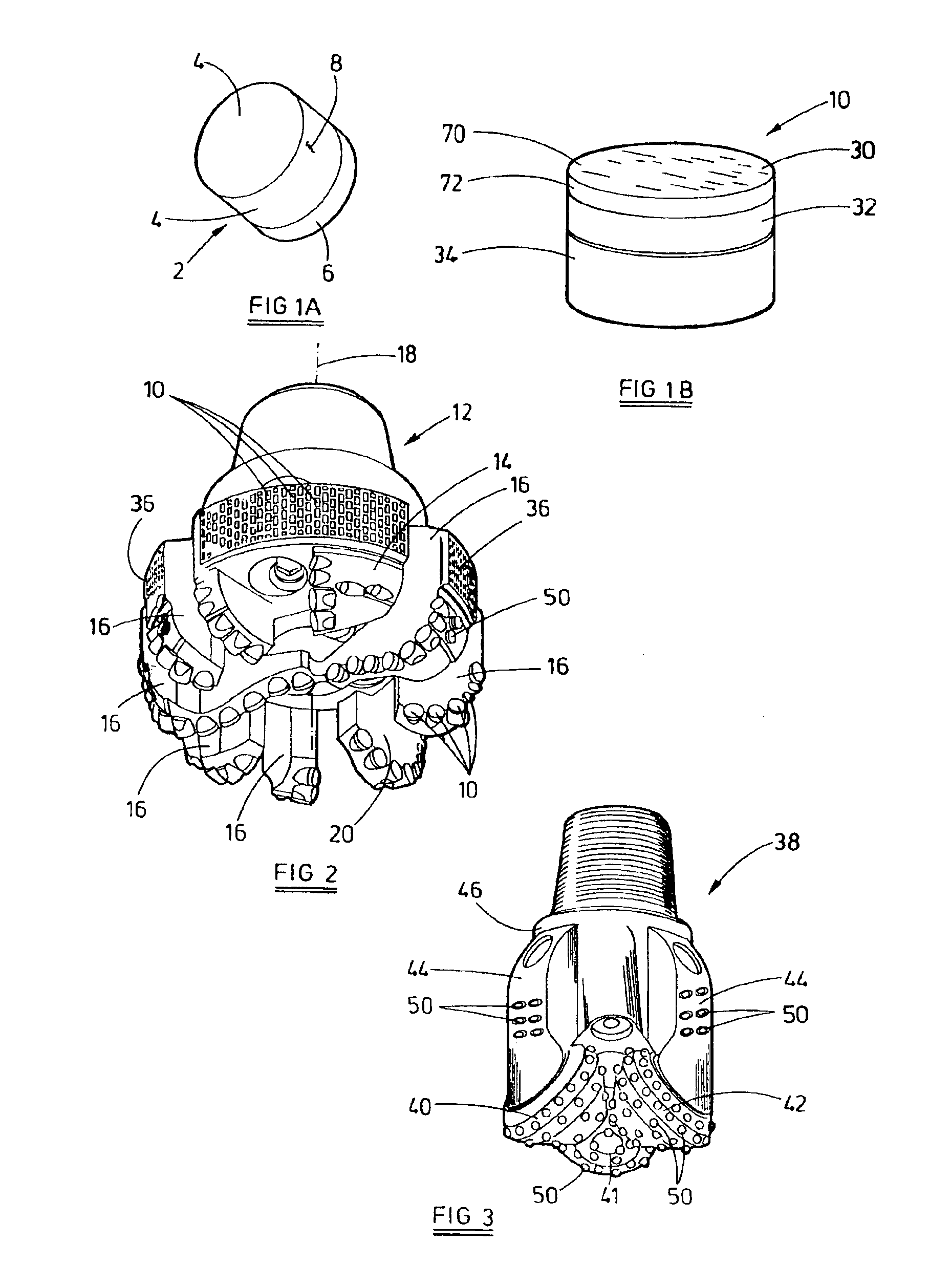

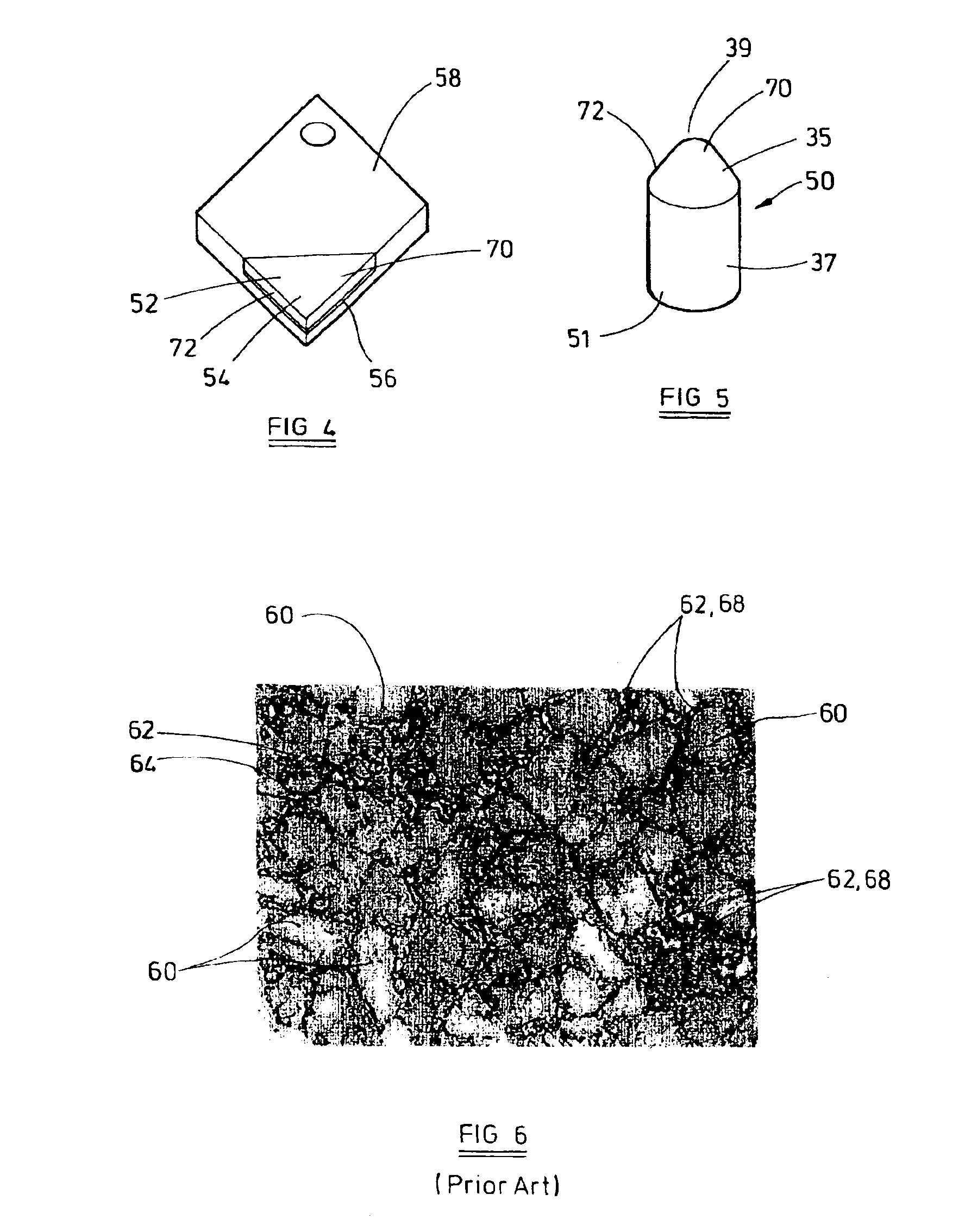

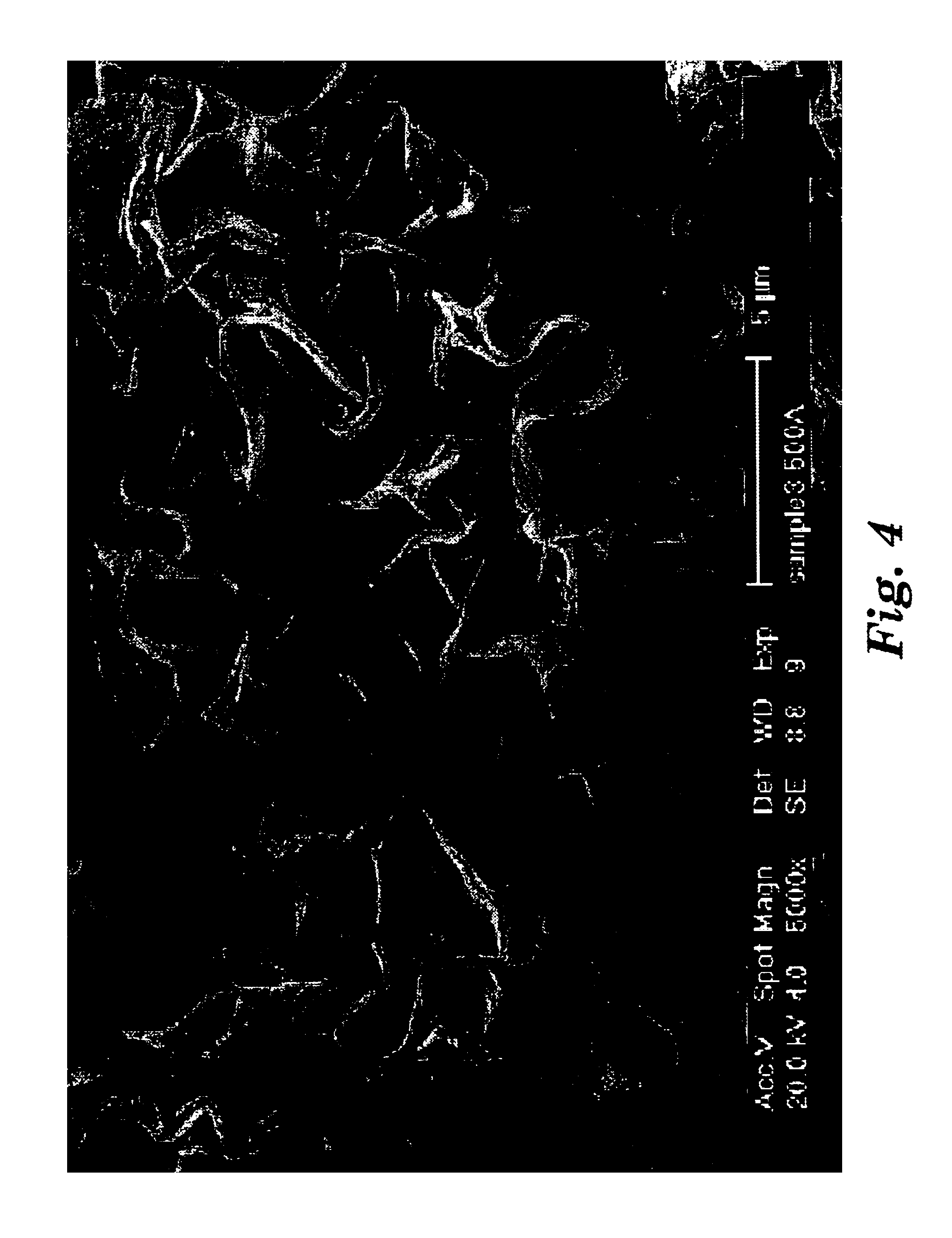

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

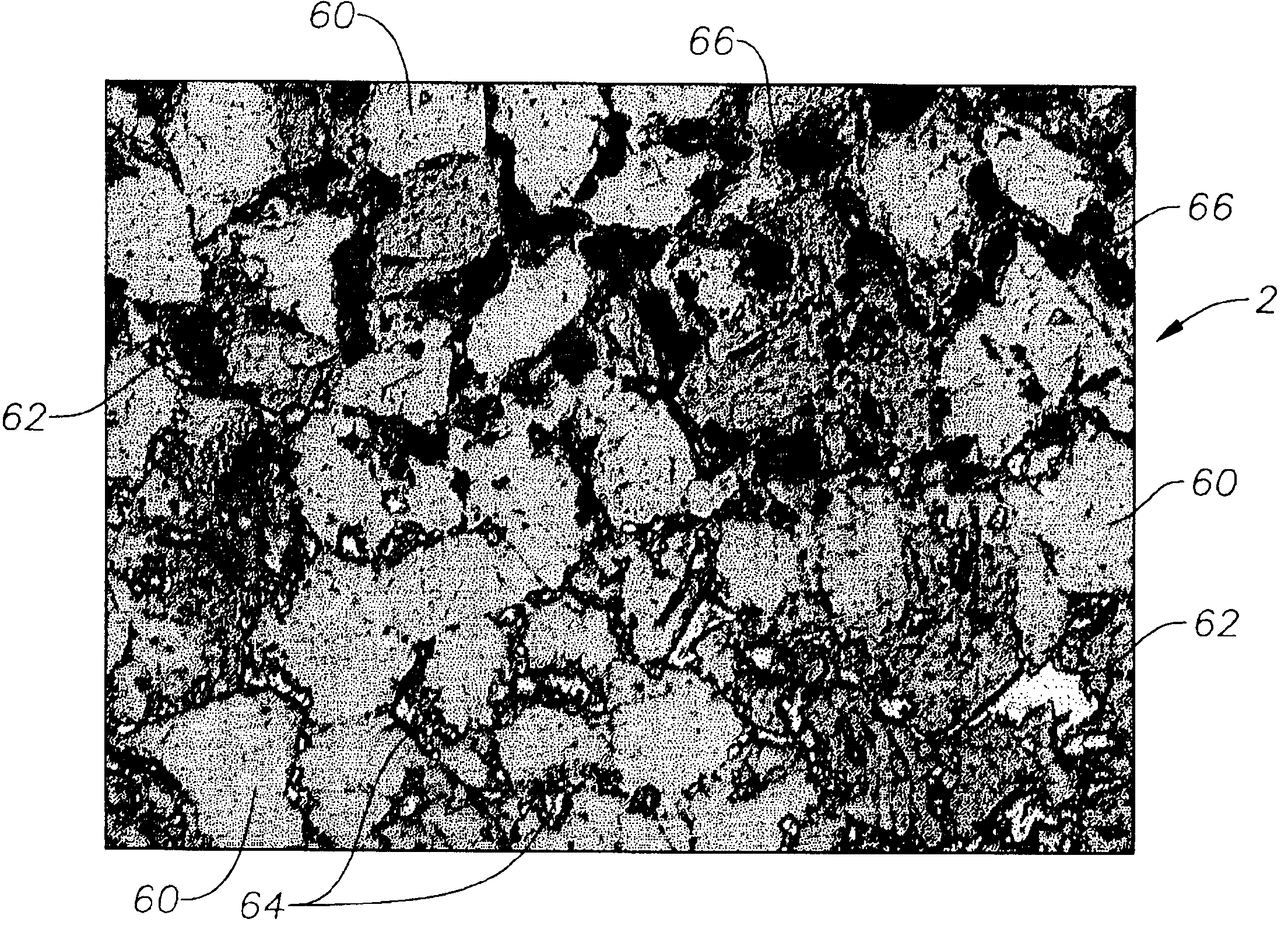

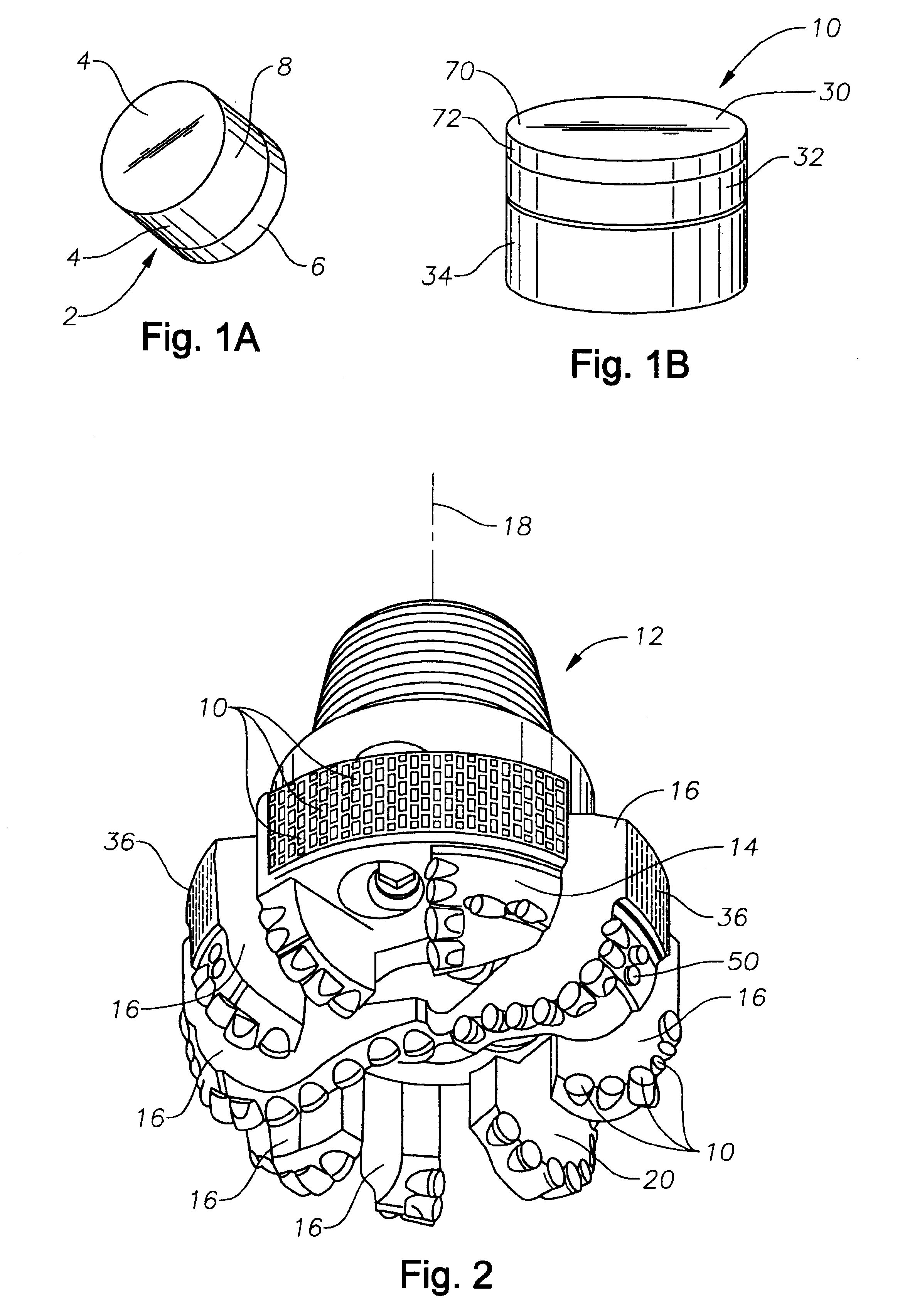

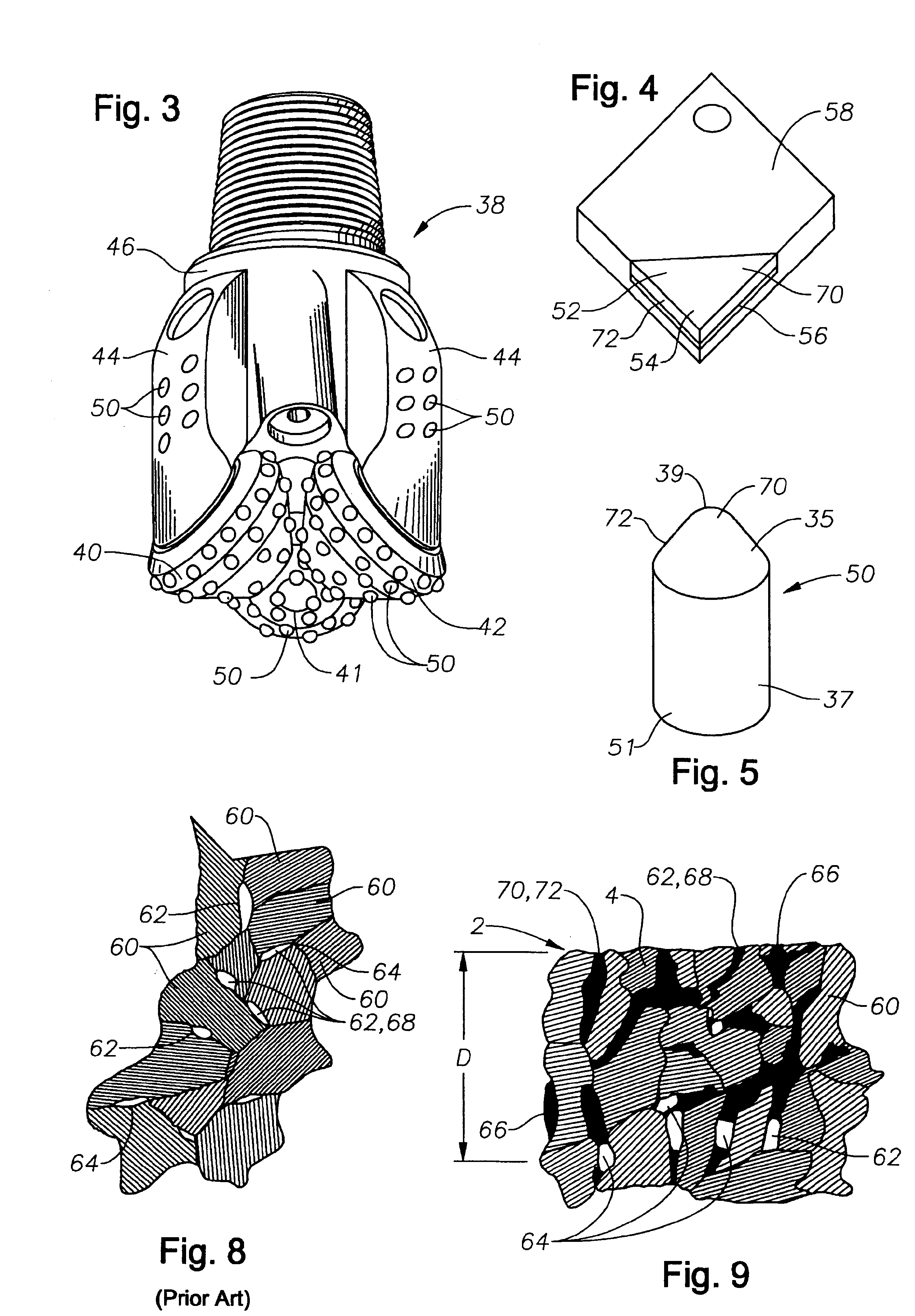

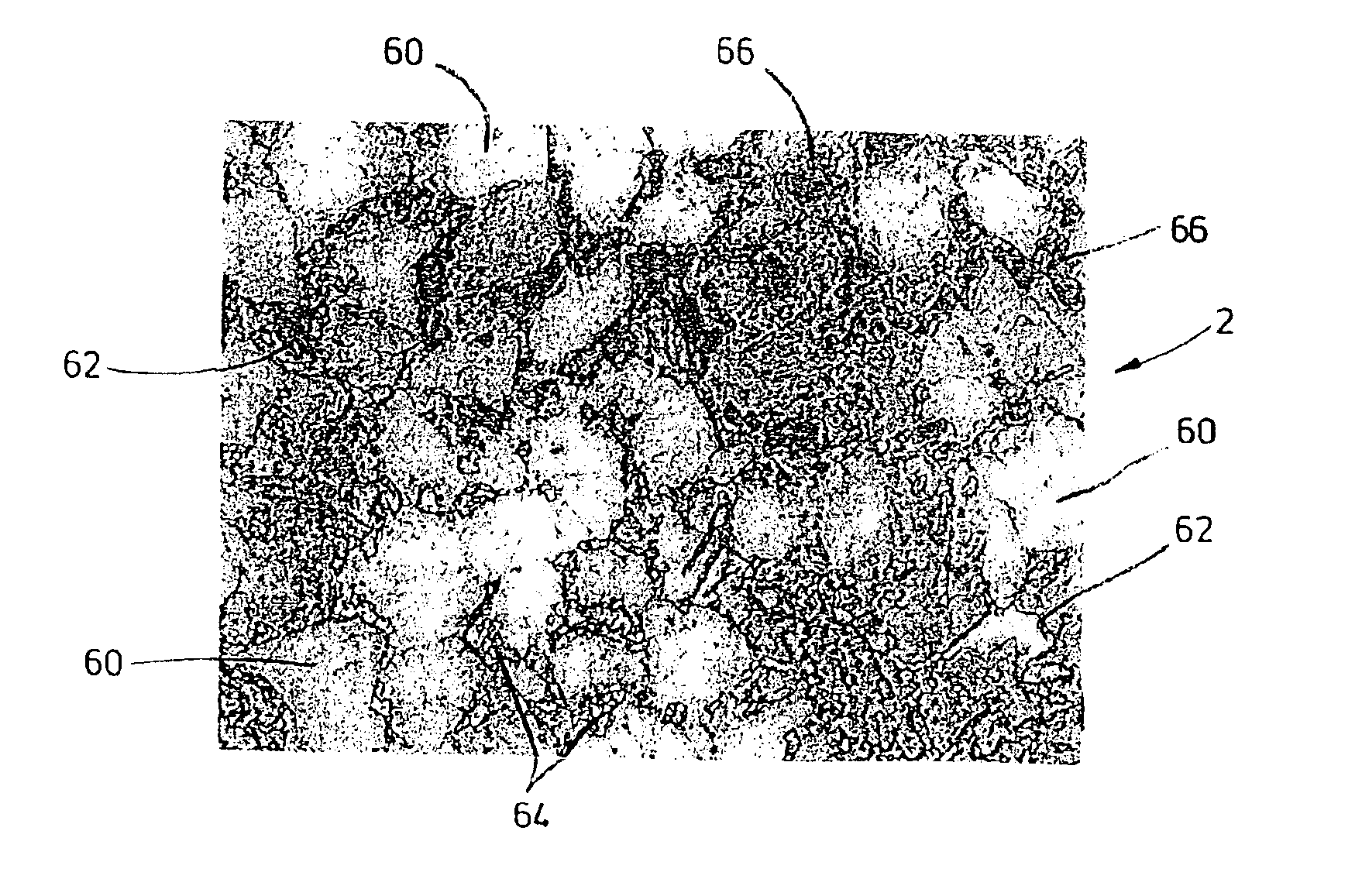

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

Polycrystalline diamond partially depleted of catalyzing material

Owner:REEDHYCALOG UK

Diamond-like nanocomposite compositions

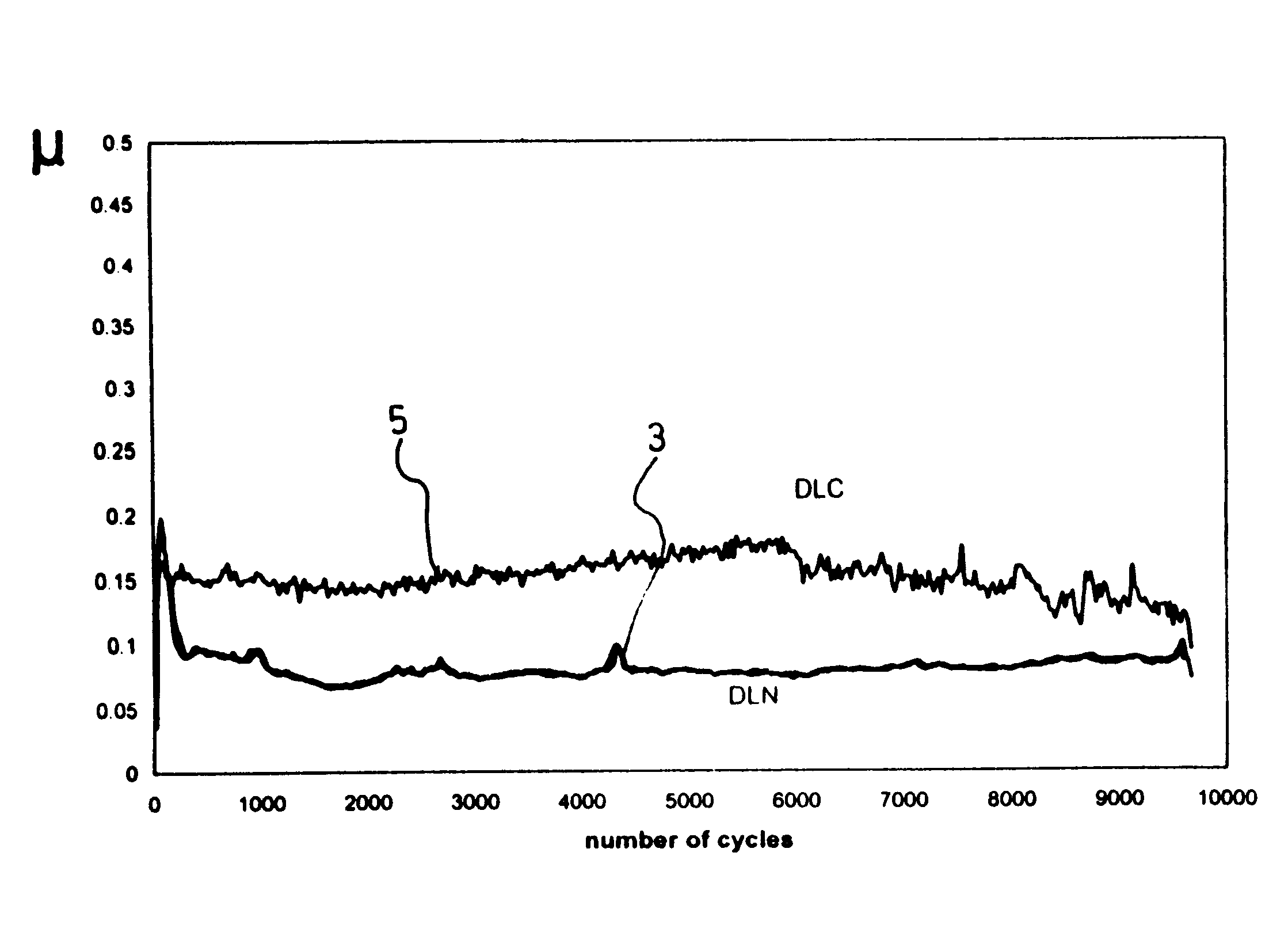

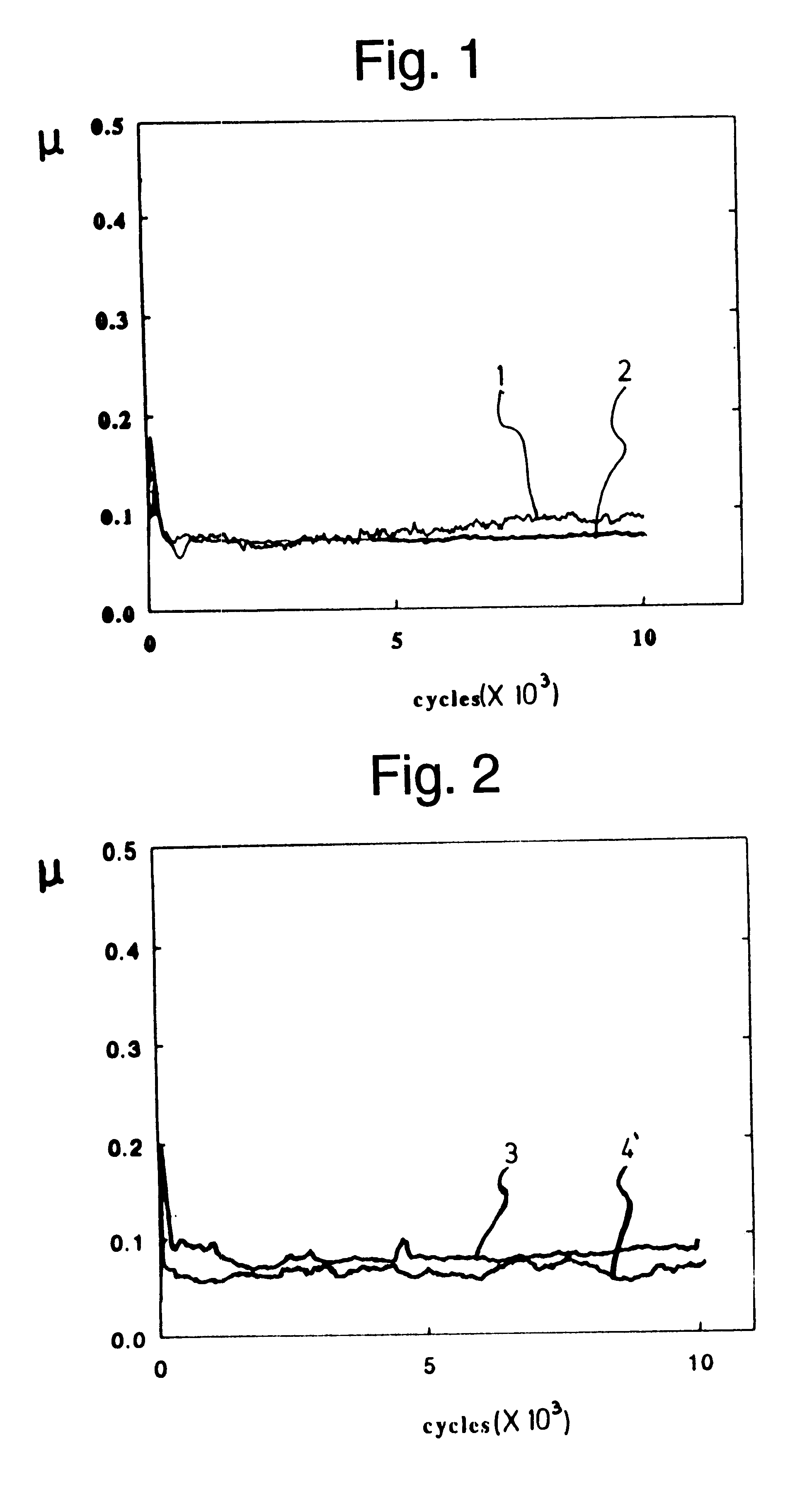

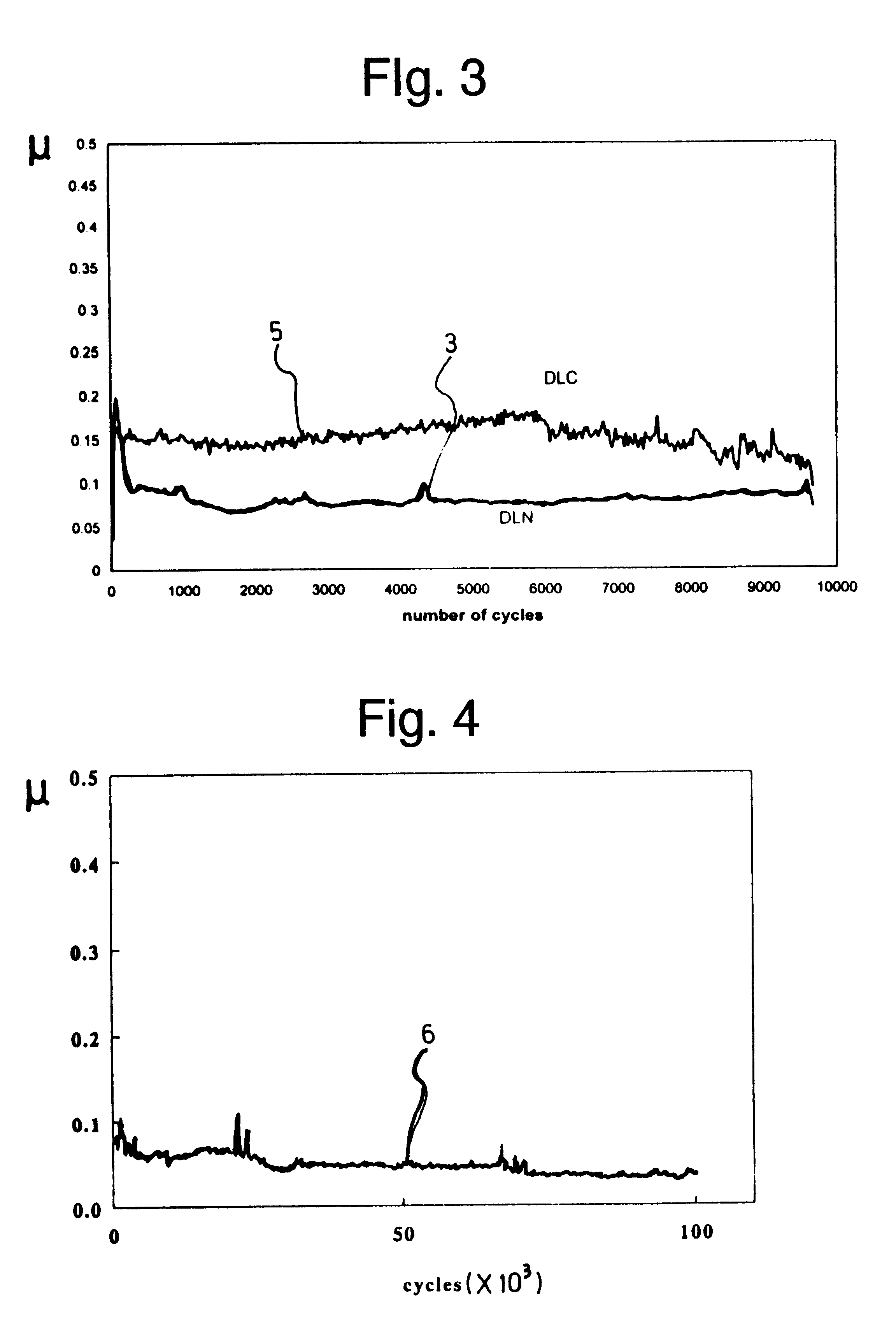

InactiveUS6200675B1Simple compositionHigh hardnessLayered productsVacuum evaporation coatingVacuum chamberRelative humidity

The invention relates to an improved diamond-like nanocomposite composition comprising networks of a-C:H and a-Si:O wherein the H-concentration is between 40% and 80% of the C-concentration and having a coefficient of friction against steel which is smaller than 0.1 in air with a relative humidity up to 90%, or in water. The invention relates also to a process for depositing the composition on a substrate in a vacuum chamber. The composition comprises preferably 30 to 70 at % of C, 20 to 40 at % of H, 5 to 15 at % of Si and 5 to 15 at % of O and can be doped with transition metals.

Owner:SULZER METAPLAS

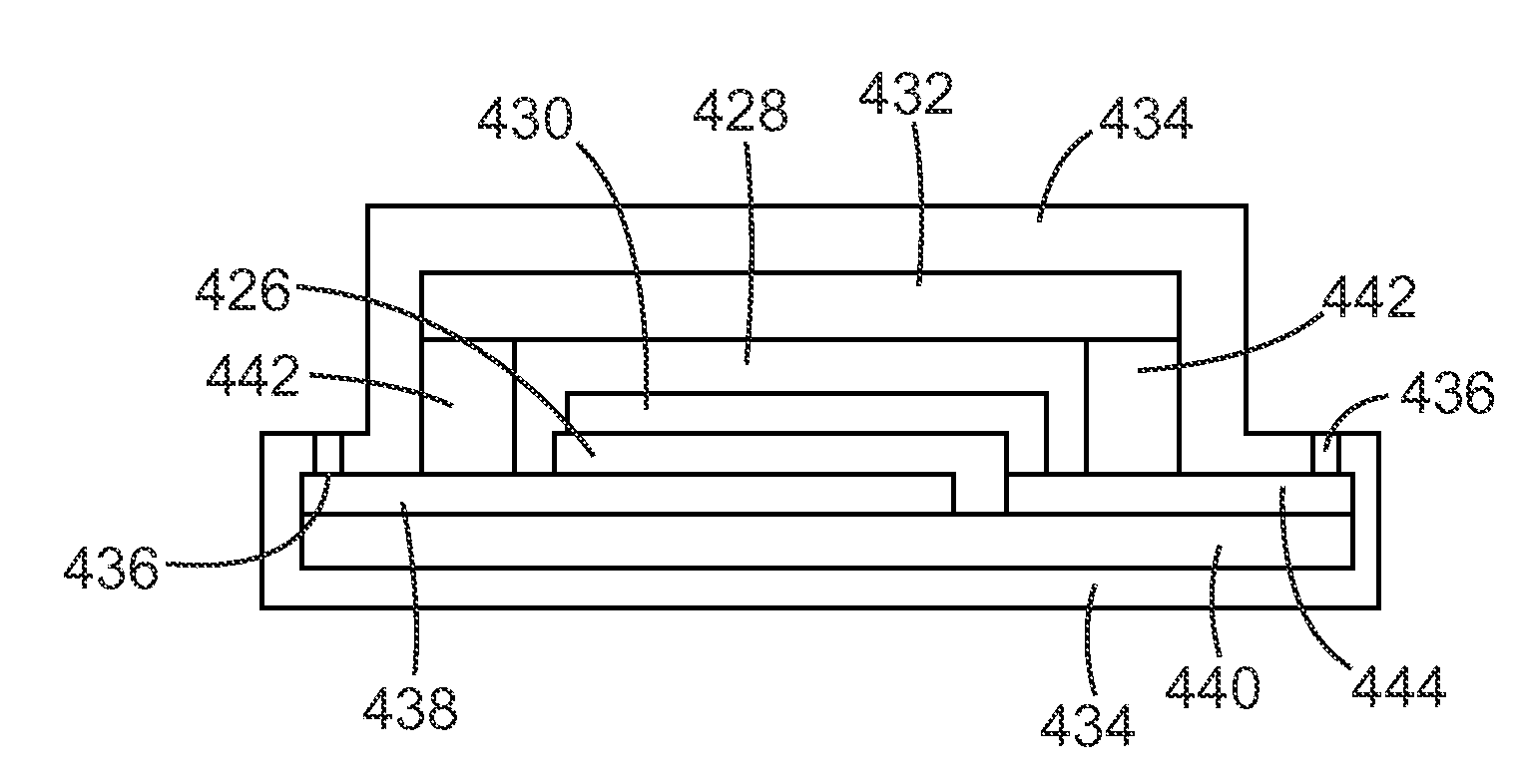

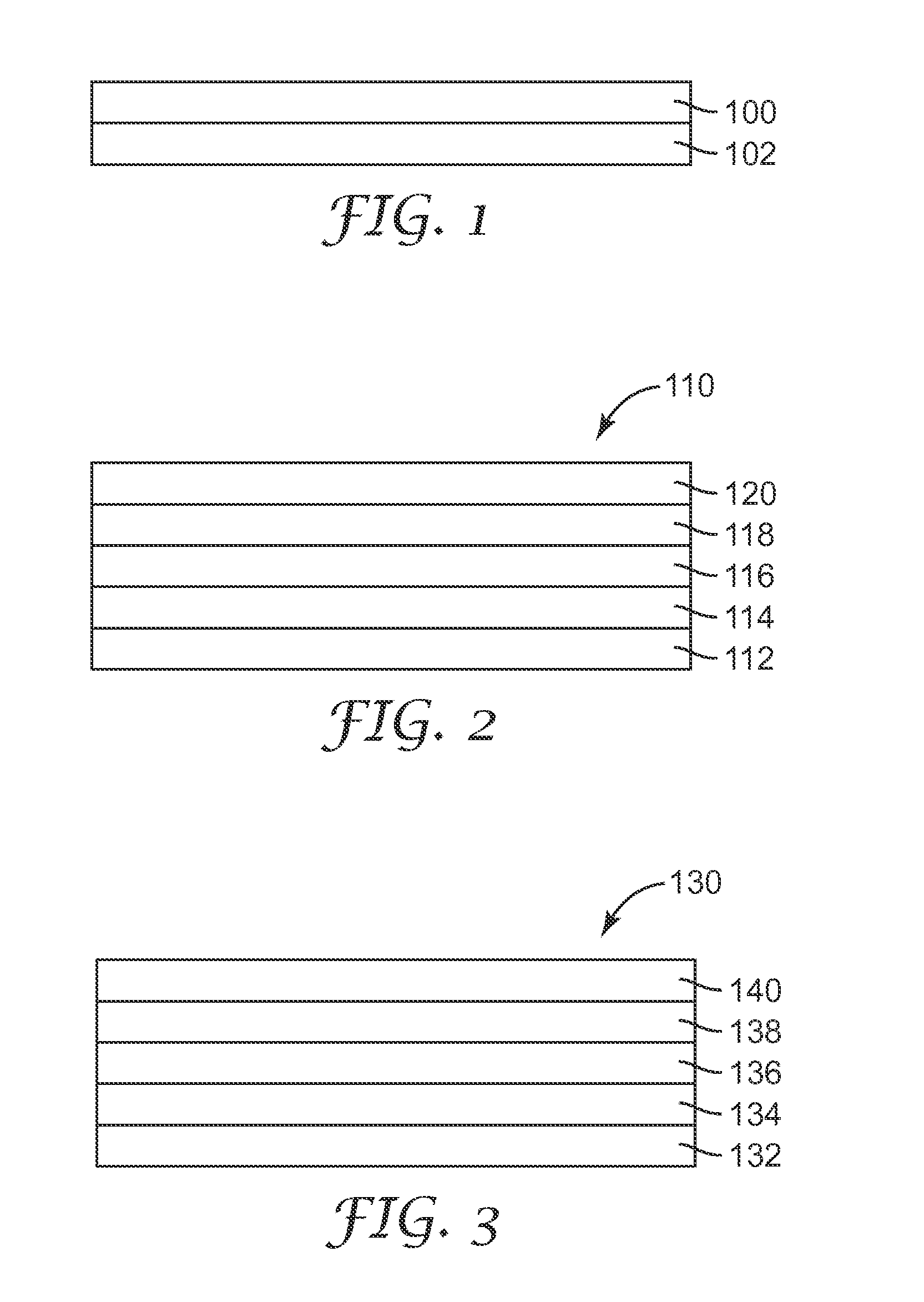

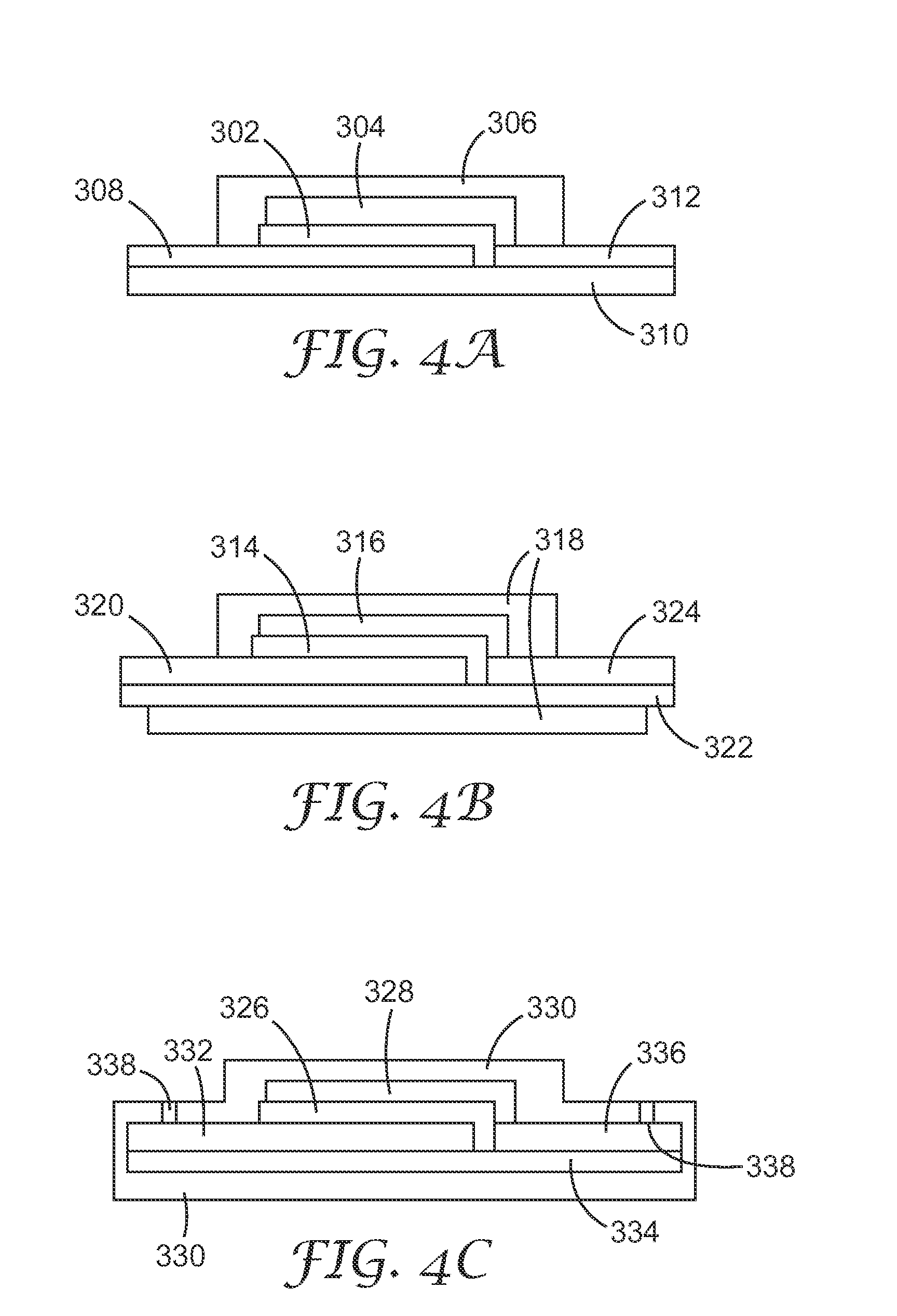

Moisture barrier coatings for organic light emitting diode devices

A barrier assembly having a flexible or rigid substrate, an organic electronic device, and one or more layers of diamond-like film. The diamond-like film layers can be used to mount, cover, encapsulate or form composite assemblies for protection of moisture or oxygen sensitive articles such as organic light emitting diode devices, photovoltaic devices, organic transistors, and inorganic thin film transistors. The diamond-like film layers can also provide for edge sealing of adhesive bond lines in the assemblies.

Owner:3M INNOVATIVE PROPERTIES CO

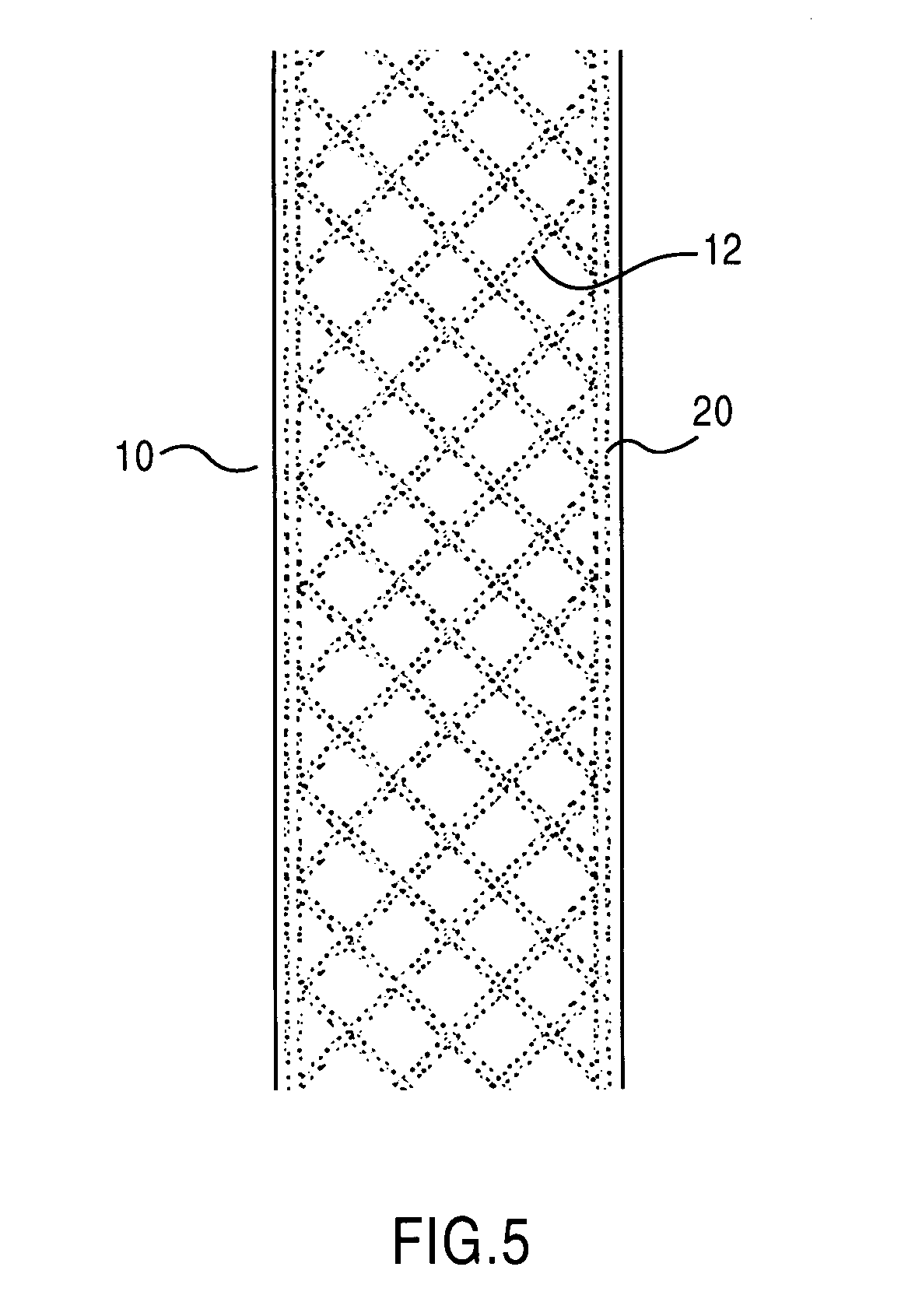

Medical devices having particle-containing regions with diamond-like coatings

InactiveUS20070106363A1Improve robustnessOuter surface is reduced and preventedMaterial nanotechnologySurgeryMedical deviceBiomedical engineering

Owner:BOSTON SCI SCIMED INC

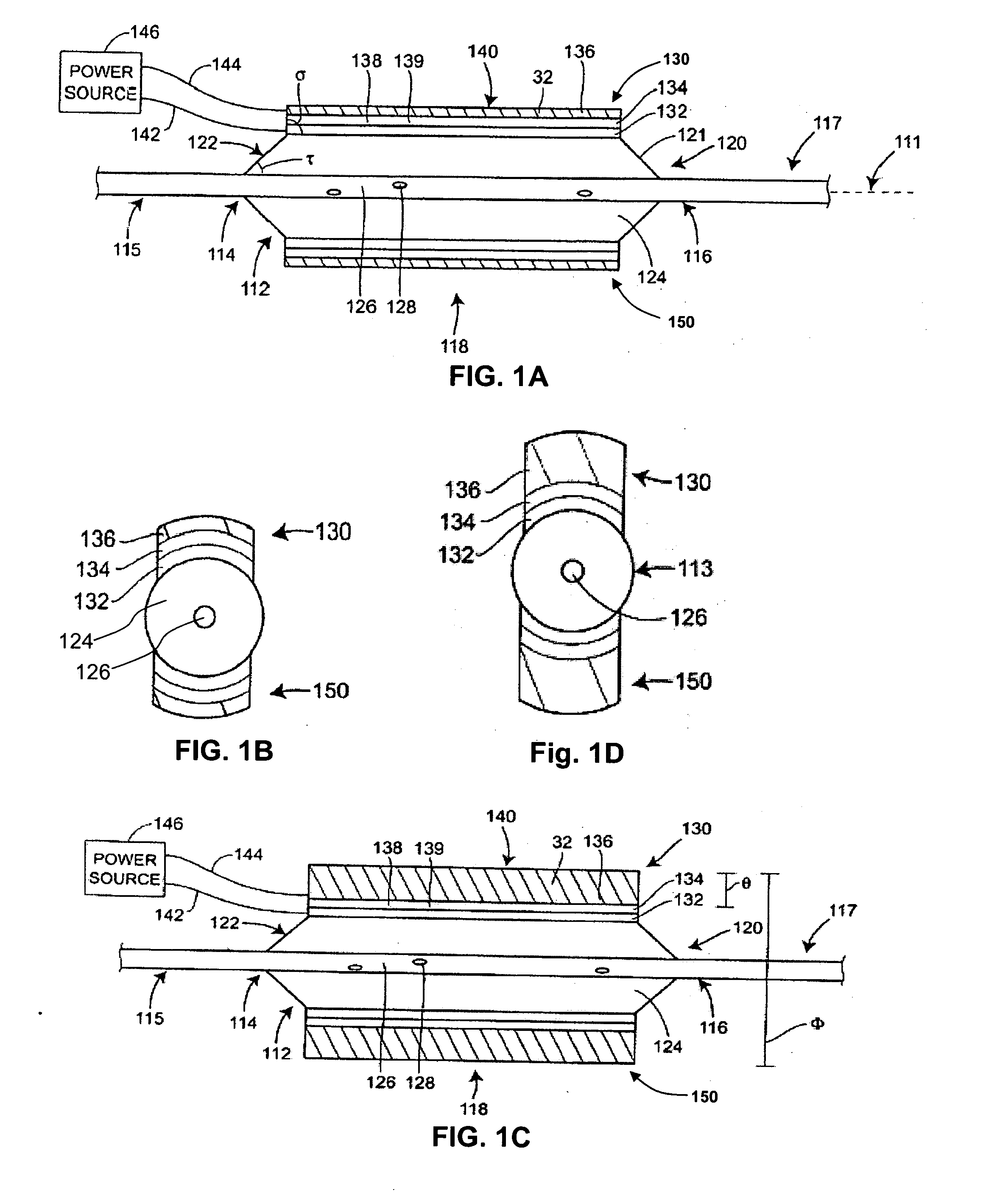

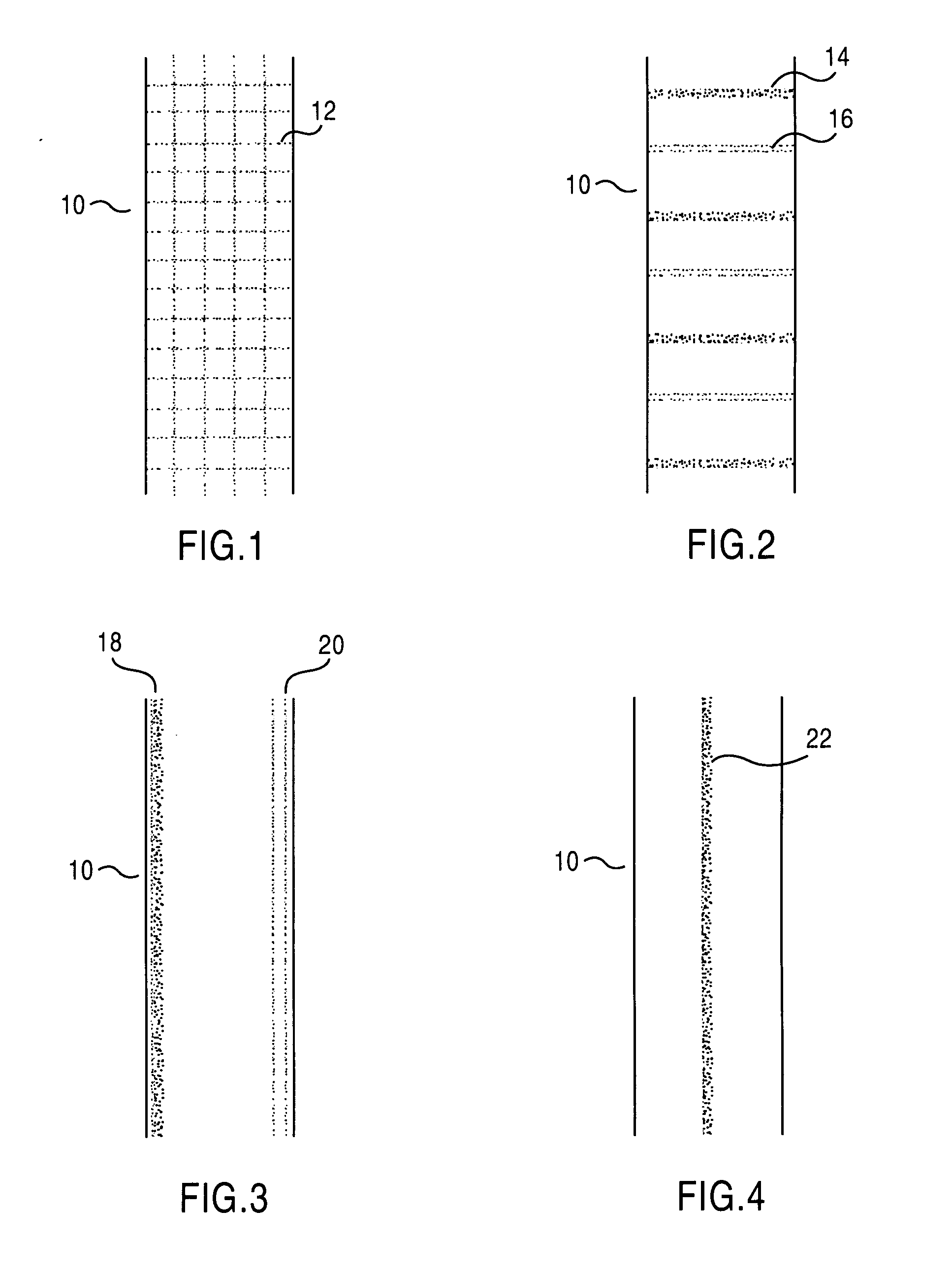

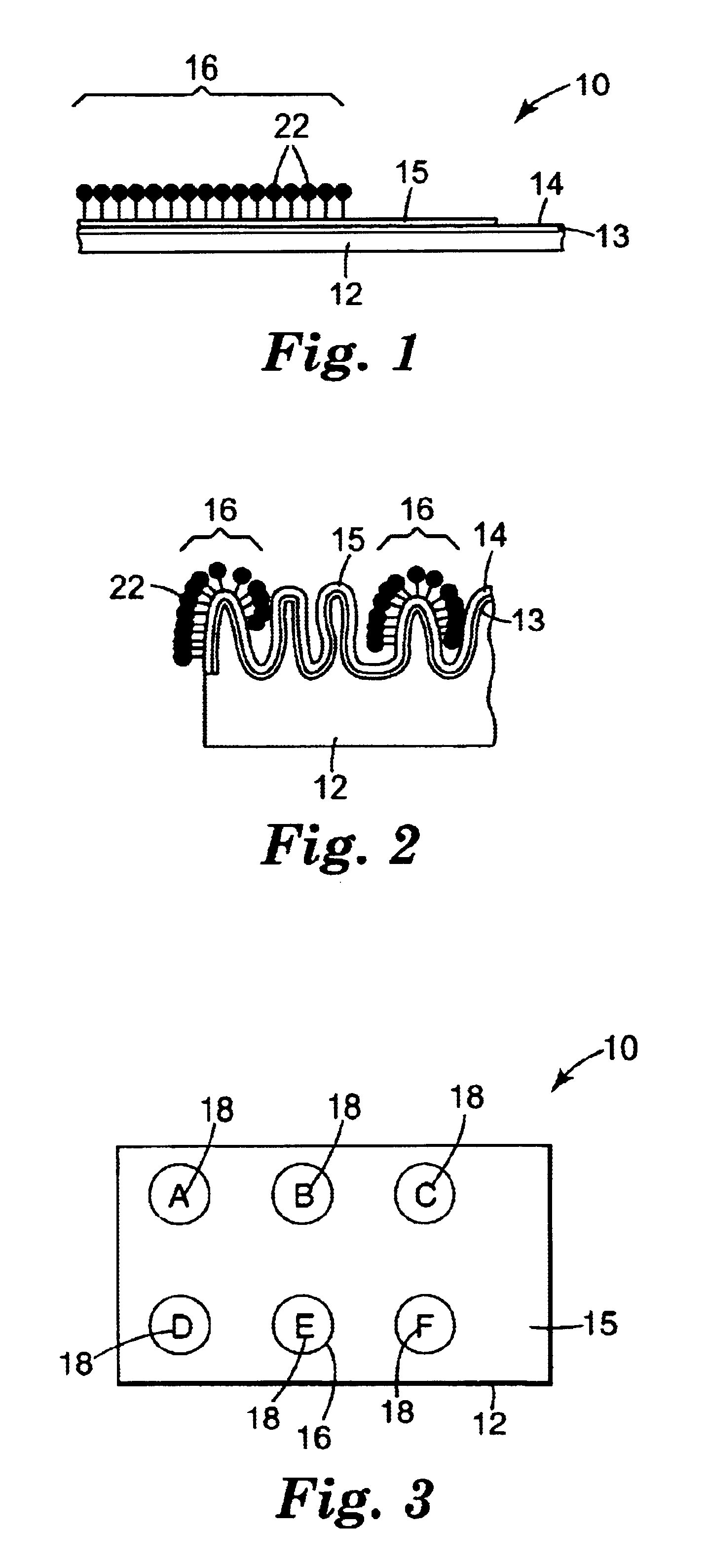

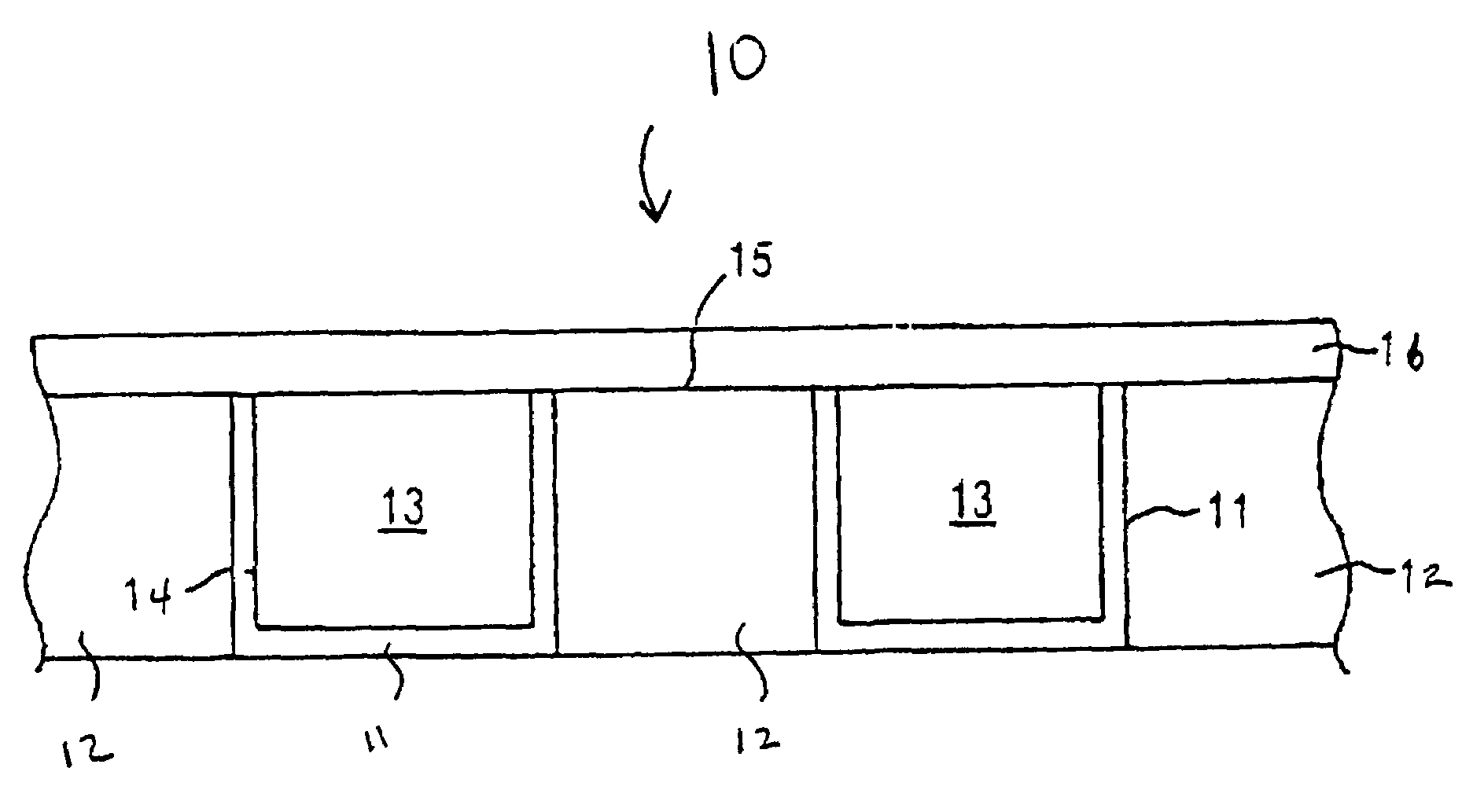

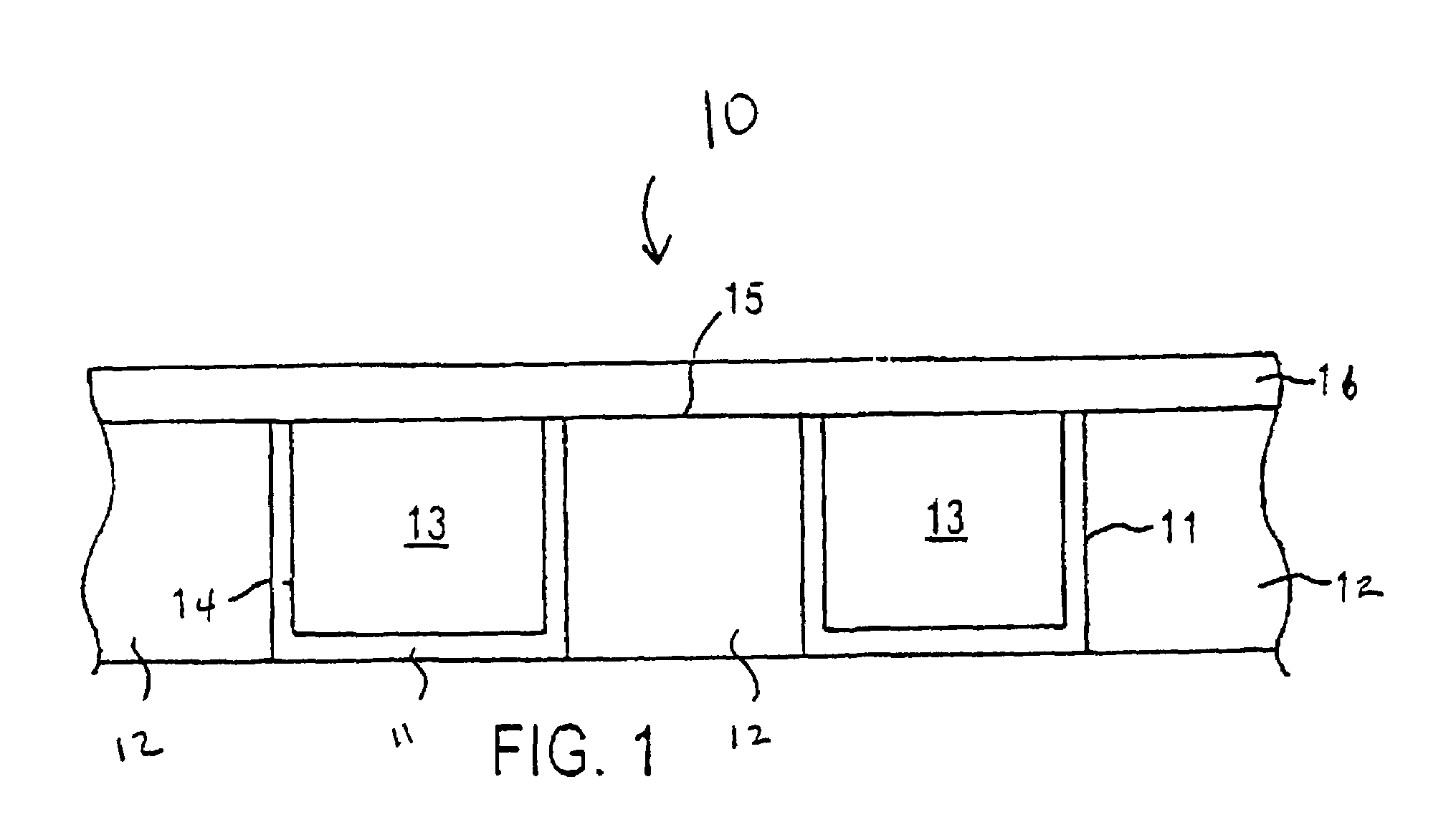

Patterning on surface with high thermal conductivity materials

ActiveUS20060234576A1Improve thermal conductivityHigh resistivityAdhesive articlesPaper/cardboardNanometreThermal transmittance

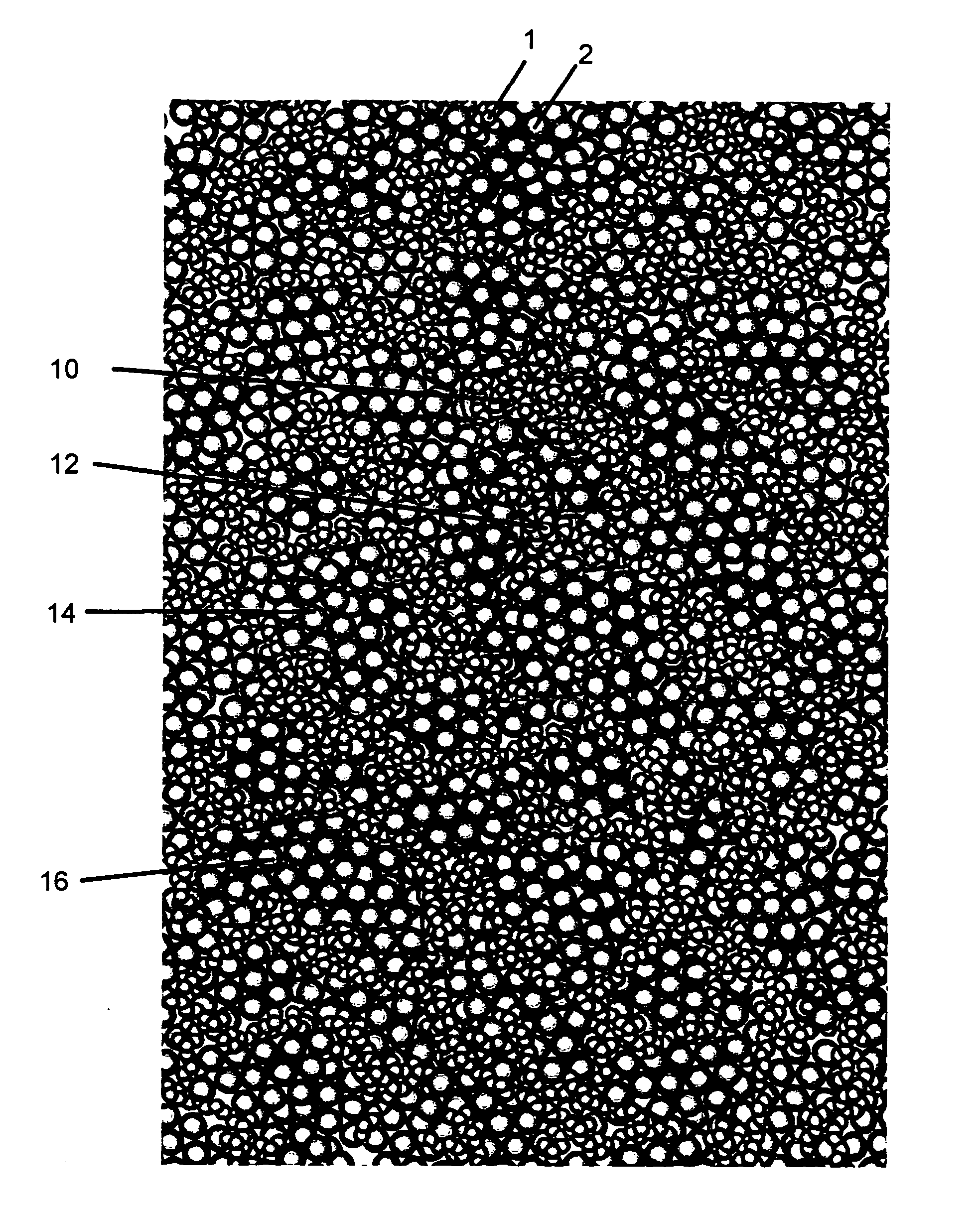

The present invention provides for high thermal conductivity paper that comprises a host matrix (10), and high thermal conductivity materials (12) added to a surface of the host matrix in a specific pattern (12). The high thermal conductivity materials are comprised of one or more of nanofillers, diamond like coatings directly on the host matrix, and diamond like coatings on the nanofillers. In particular embodiments the specific pattern comprises one or more of a grid, edging, banding centering and combinations thereof and the high thermal conductivity materials cover 15-55% of the surface of the host matrix. Multiple surfaces, including sub layers my have patterning.

Owner:SIEMENS ENERGY INC

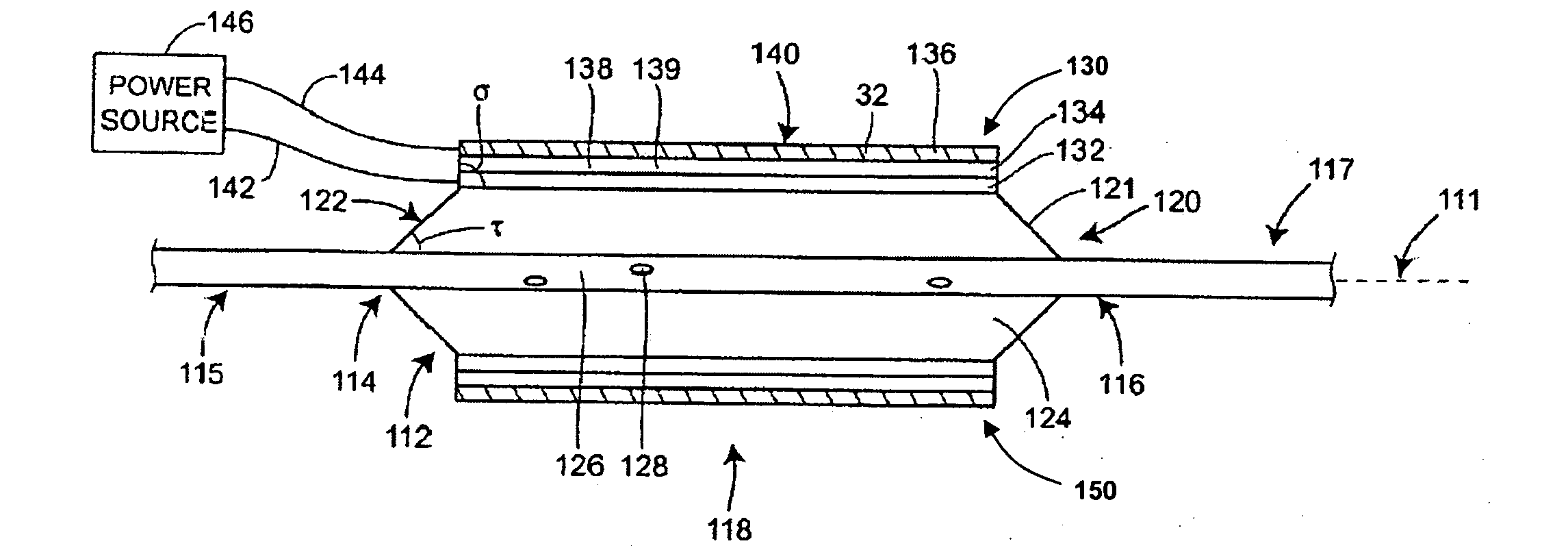

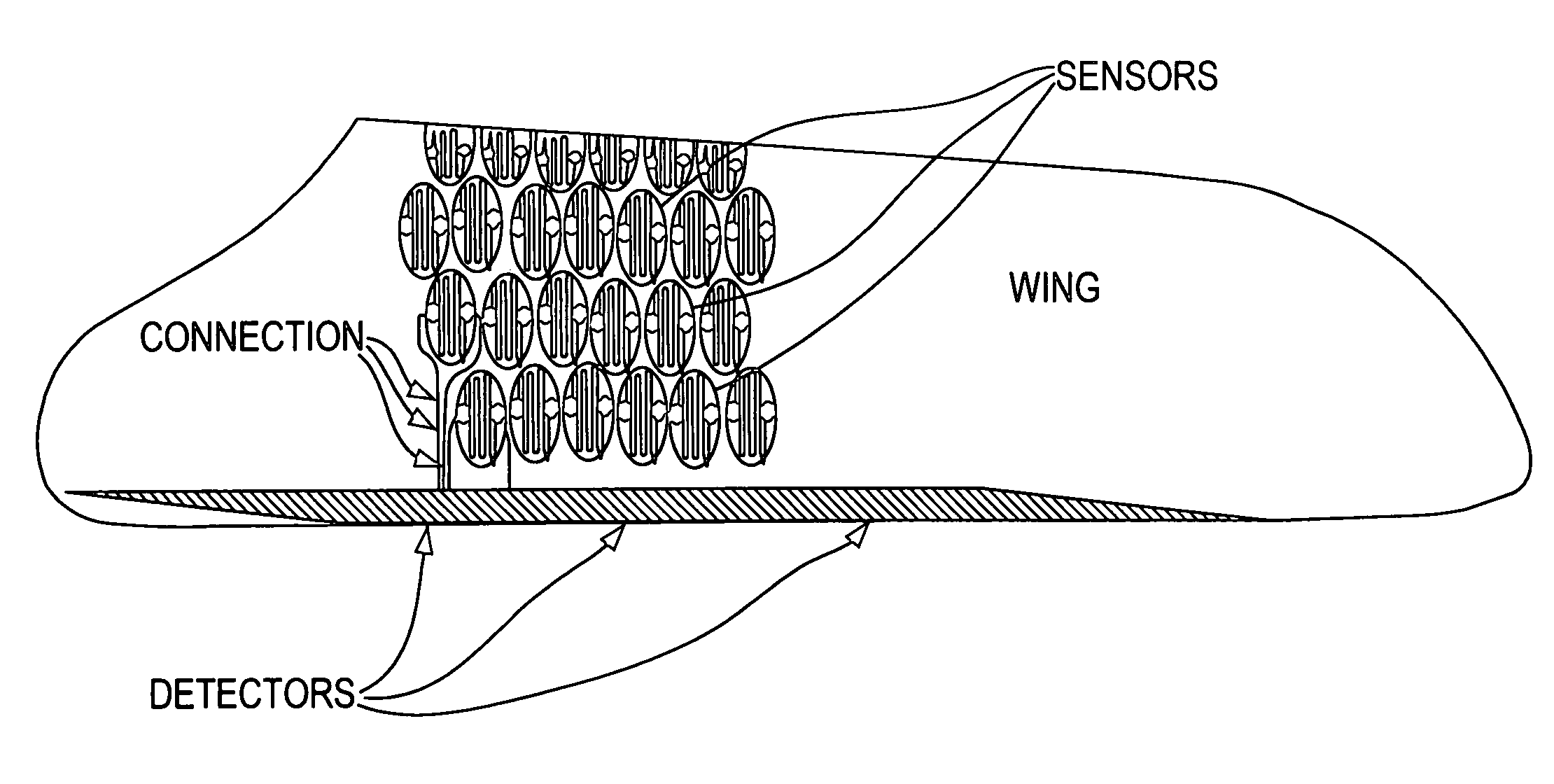

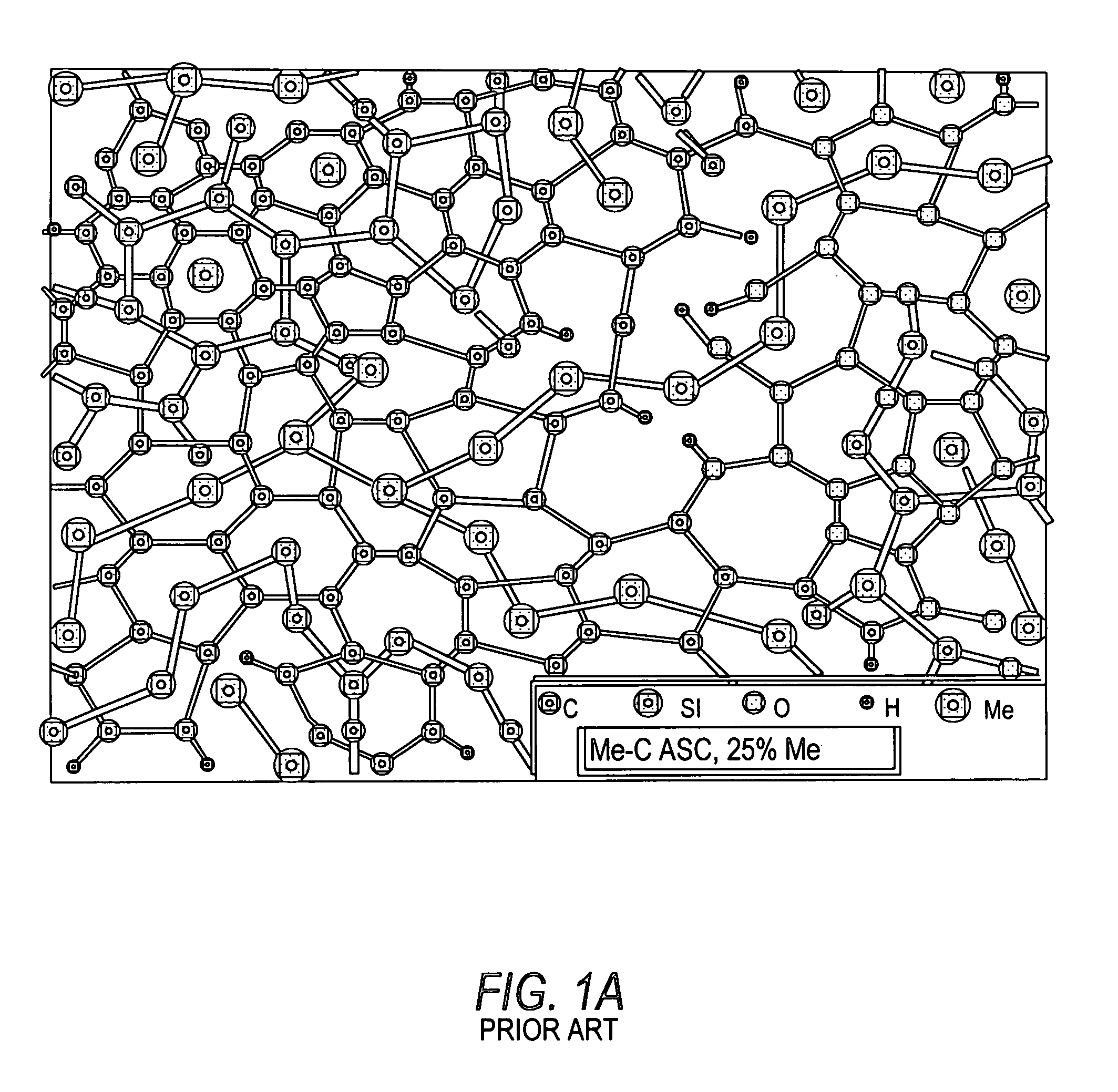

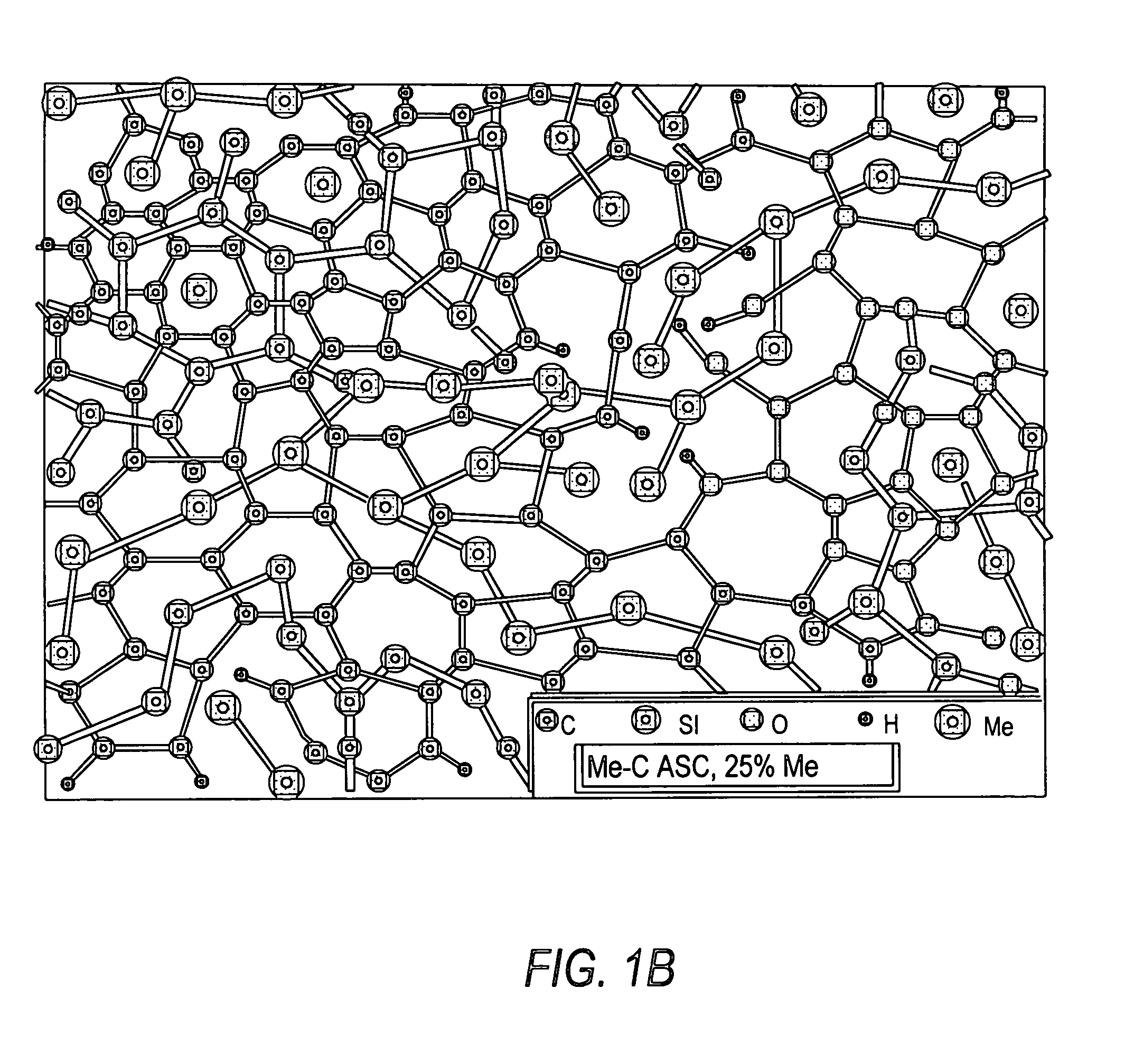

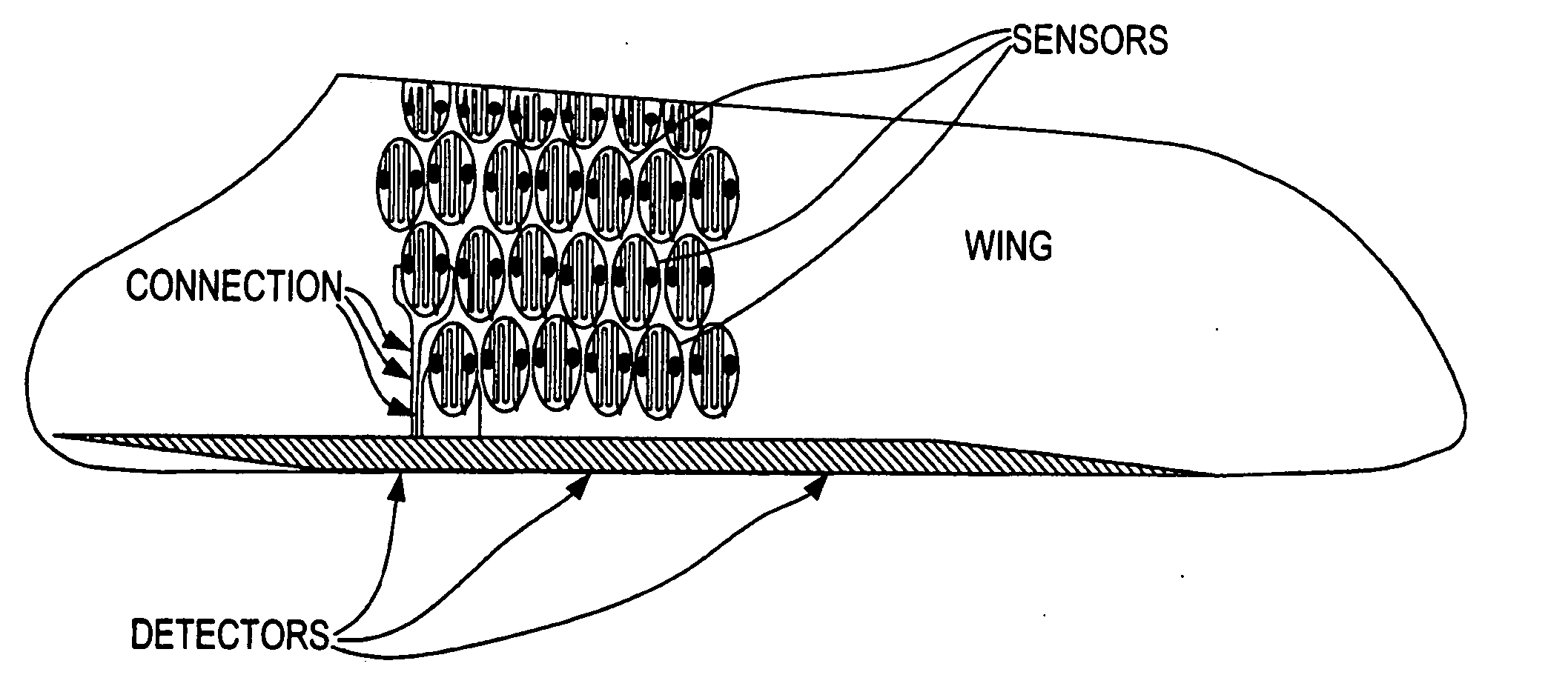

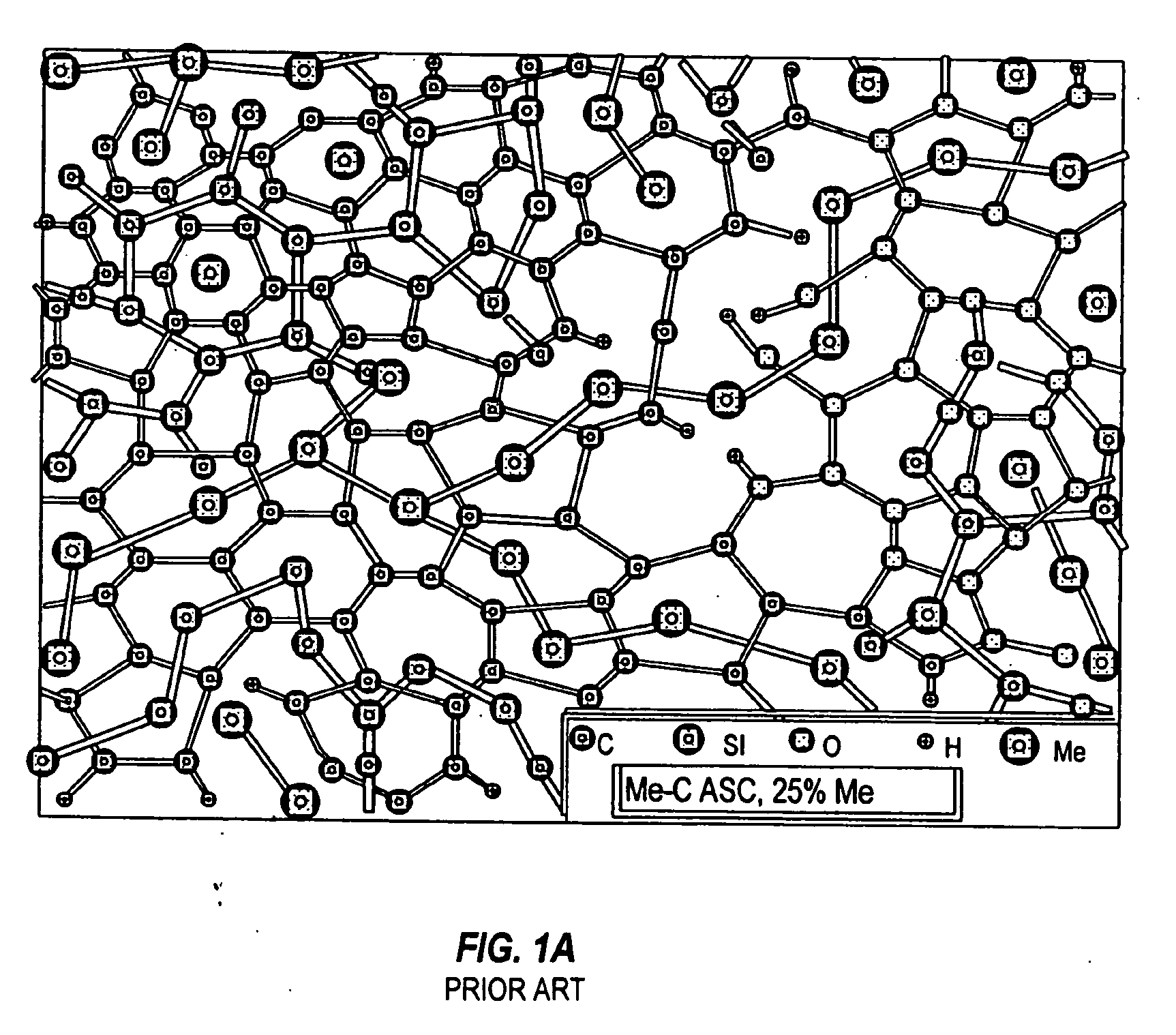

Method and apparatus for strain-stress sensors and smart skin for aircraft and space vehicles

InactiveUS6986287B1Wide rangeChange pressureForce measurementUsing electrical meansFine structureStress sensor

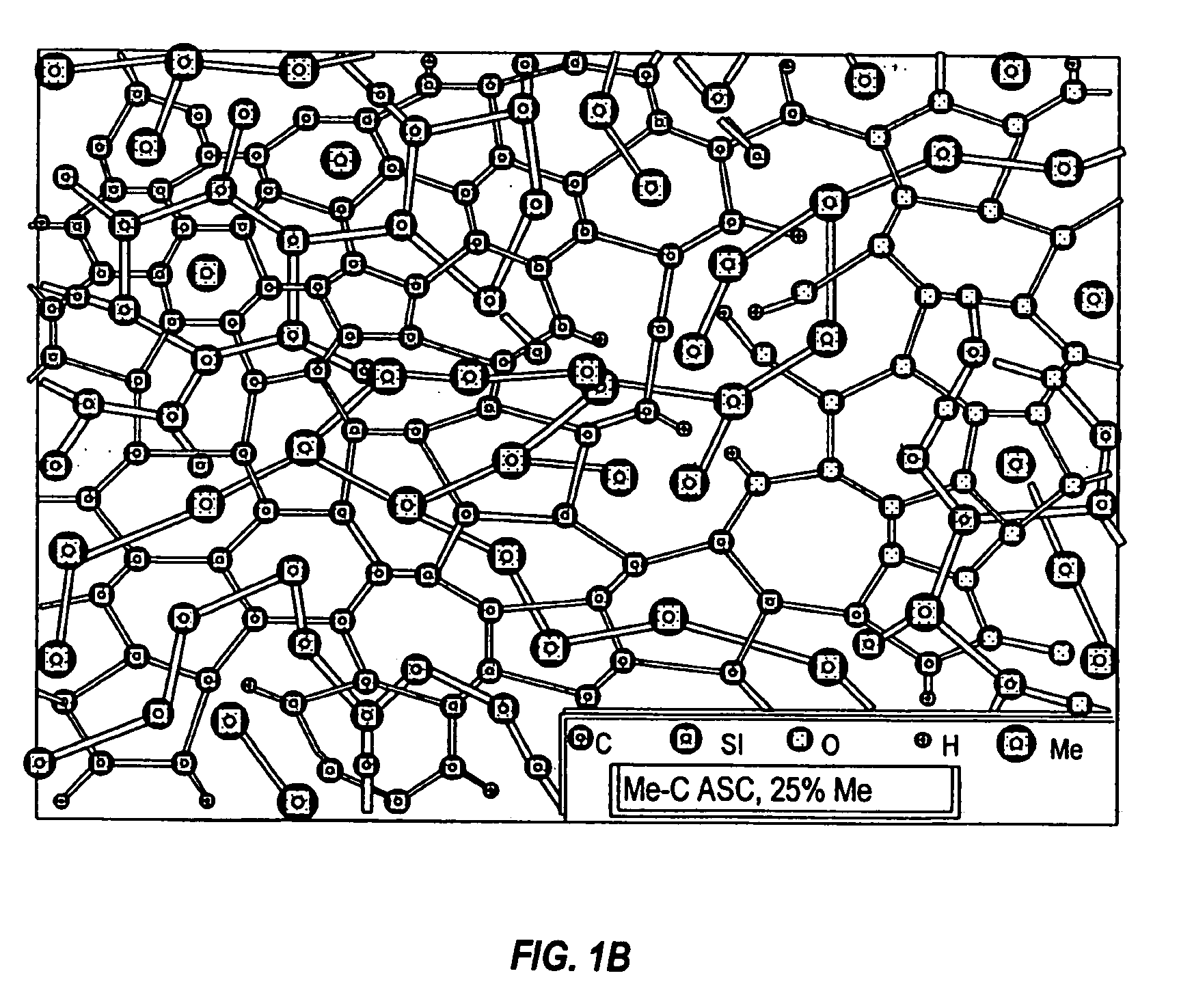

A new family of multifunctional smart coatings based on of stabilized diamond-like metal-carbon atomic scale composites and diamond-like atomic-scale composite (DL ASC) materials. Based on a unique combination of the coating fine structure, properties of the coating / substrate interface, and the mechanical and electrical properties of the coating, the disclosed smart coatings would integrate various high resolution sensors and interconnections, and the sensor would diagnose dangerous stress distribution in the coated subject with no distortion in real time, while these diamond-like coatings would simultaneously provide environmental protection of the coated surface and improve its aerodynamic quality.

Owner:NANODYNAMICS INC

Method for preparing high-performance doped diamond-like film

InactiveCN101748381AImprove overall performanceImprove performanceChemical vapor deposition coatingIon beam depositionPhysics

The invention discloses a method for preparing a high-performance doped diamond-like film. The method is characterized by comprising the following steps: firstly, utilizing ultrasonic cleaning technology to remove a polluted layer on the surface of a substrate; utilizing ion beam assisted deposition technology to prepare a gradient transition layer; and finally utilizing ion beam deposition and magnetron sputtering to synthesize a multi-element doped DLC film, wherein except any one of carbonaceous gases, such as methane, acetylene, benzene, ethanol, acetone and the like, any gas containing non-carbon elements, such as silicon hydride, boron hydride, phosphorane, carbon tetrafluoride and the like, is simultaneously introduced, and a metal sputtering source is opened for the doping of metal elements. The method has the advantages of synthesizing the multi-element doped DLC film which is simultaneously doped with the metal elements and the nonmetal elements, fully developing the complementary advantages of the doped metal elements and the doped nonmetal elements and remarkably improving the combination properties of the DLC film.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Insulation paper with high thermal conductivity materials

InactiveUS20050274774A1Improve thermal conductivityHigh resistivityCooking-vessel materialsPlastic/resin/waxes insulatorsNanometreThermal transmittance

The present invention provides for a high thermal conductivity (HTC) paper that comprises a host matrix, such as mica, and HTC materials intercalated into the host matrix. The HTC materials are comprised of at least one of nanofillers, diamond like coatings directly on the host matrix, and diamond like coatings on the nanofillers.

Owner:SIEMENS ENERGY INC

Array comprising diamond-like glass film

InactiveUS6881538B1Increase signal strengthWide rangeBioreactor/fermenter combinationsSequential/parallel process reactionsSiliconMaterials science

Materials for use in miniaturized arrays, the arrays, and methods of manufacturing. Materials for making arrays described include a substrate with a silicon-containing layer, optionally with linking agents and reactants.

Owner:3M INNOVATIVE PROPERTIES CO

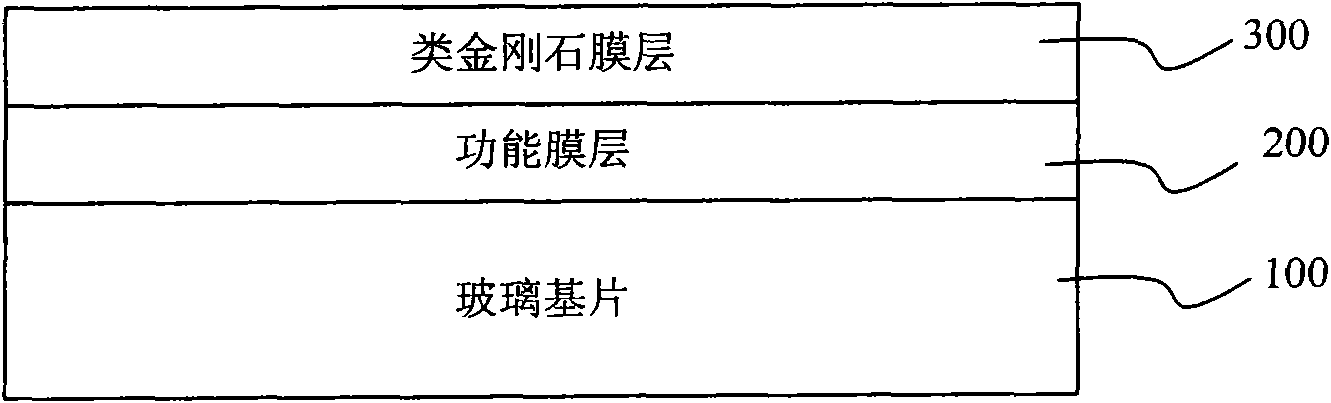

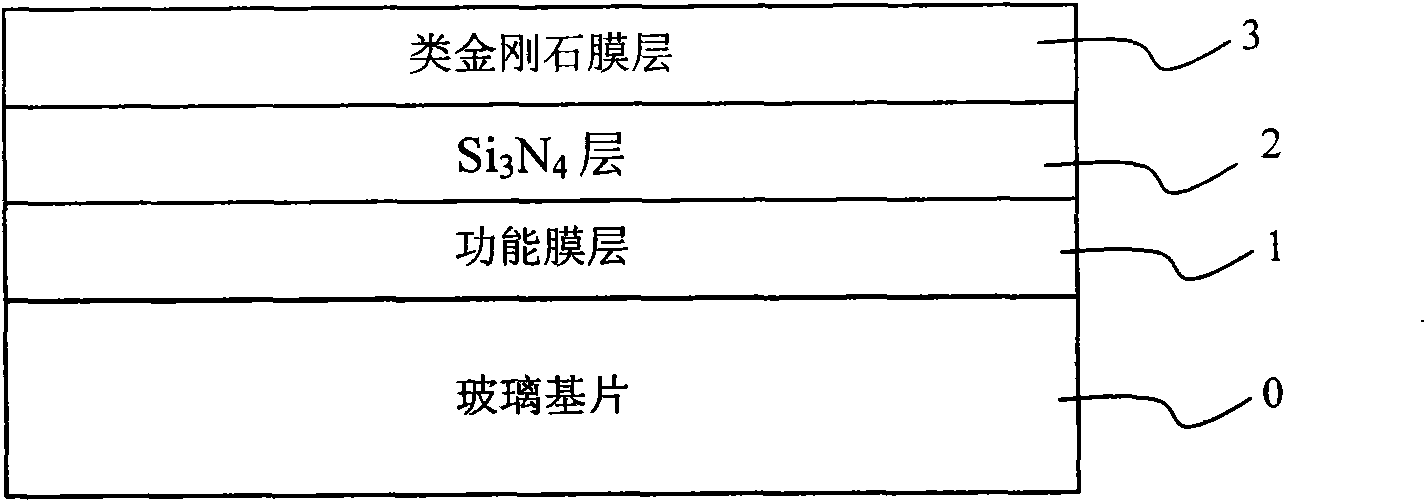

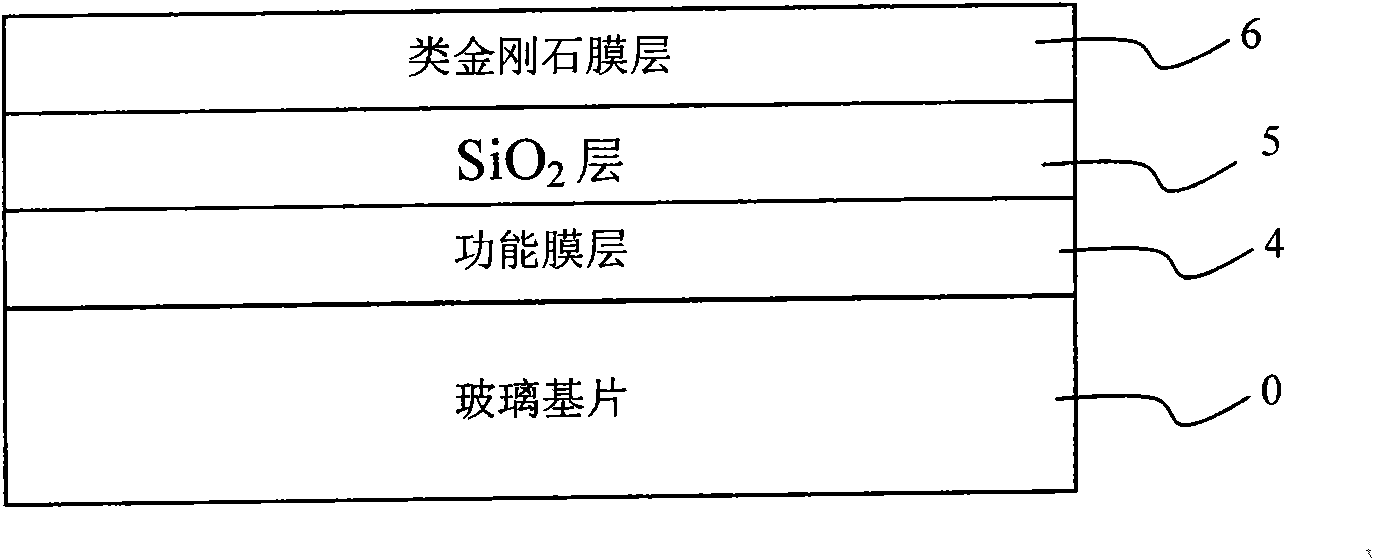

Diamond-like carbon coated glass and preparation method thereof

InactiveCN101602273AImprove antioxidant capacityHigh hardnessVacuum evaporation coatingSputtering coatingDiamond-like carbonOptoelectronics

The invention discloses diamond-like carbon coated glass and a preparation method thereof. The diamond-like carbon coated glass comprises a glass substrate, a functional film layer plated on the surface of the glass substrate, and a diamond-like carbon coated glass plated on the surface of the functional film layer, wherein the functional film layer is a low radiation film layer capable of being toughened, a low radiation film layer capable of not being toughening or a sunlight control film layer, wherein a substance on the outmost layer of the functional film is Si3N4, Ti3N4, TiO2, SnO2, SiO2, ZnO or SnZnO3. The diamond-like carbon film plated by the method has high stability, wear resistance and oxidative resistance, plays roles of preventing scratches and delaying oxidization in processes of glass transportation and storage, has good adhesion with the functional film layer, does not mutually erode and react with other film layers, and is volatilizable after a heat treatment process.

Owner:天津南玻节能玻璃有限公司 +1

Photolithographic patterning process using a carbon hard mask layer of diamond-like hardness produced by a plasma-enhanced deposition process

InactiveUS20050112506A1Optimum diamond-like hardness propertySemiconductor/solid-state device manufacturingPhotosensitive material processingHardnessLayer thickness

A carbon hard mask layer is applied to a substrate to be patterned by means of a plasma-enhanced deposition process in such a manner that it has a hardness comparable to that of diamond in at least one layer thickness section. During the production of this diamond-like layer thickness section, the parameters used in the deposition are set in such a manner that growth regions which are produced in a form other than diamond-like are removed again in situ by means of subsequent etching processes and that diamond-like regions which are formed are retained.

Owner:CHANGXIN MEMORY TECH INC

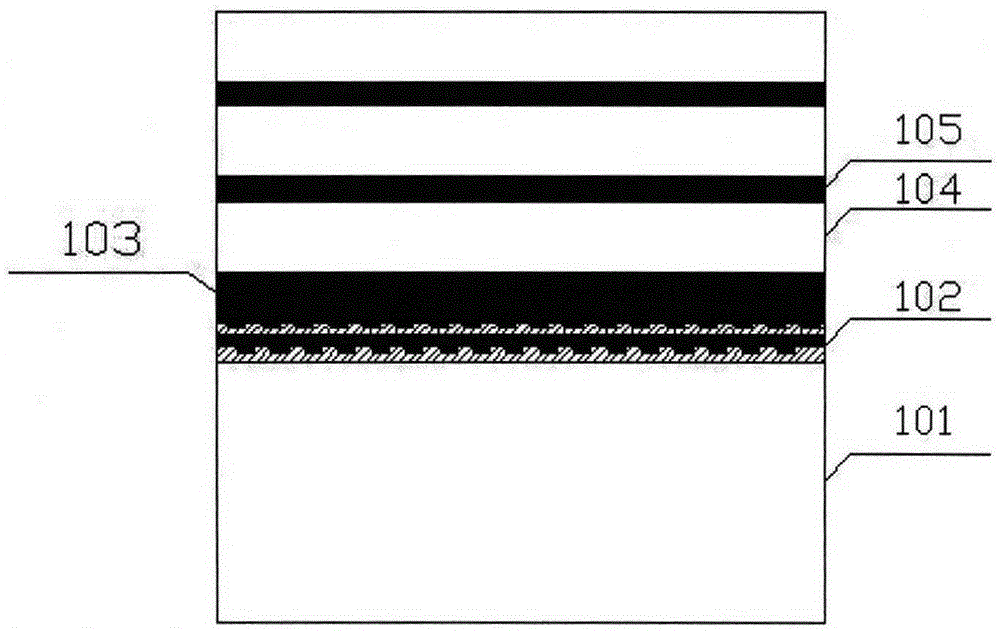

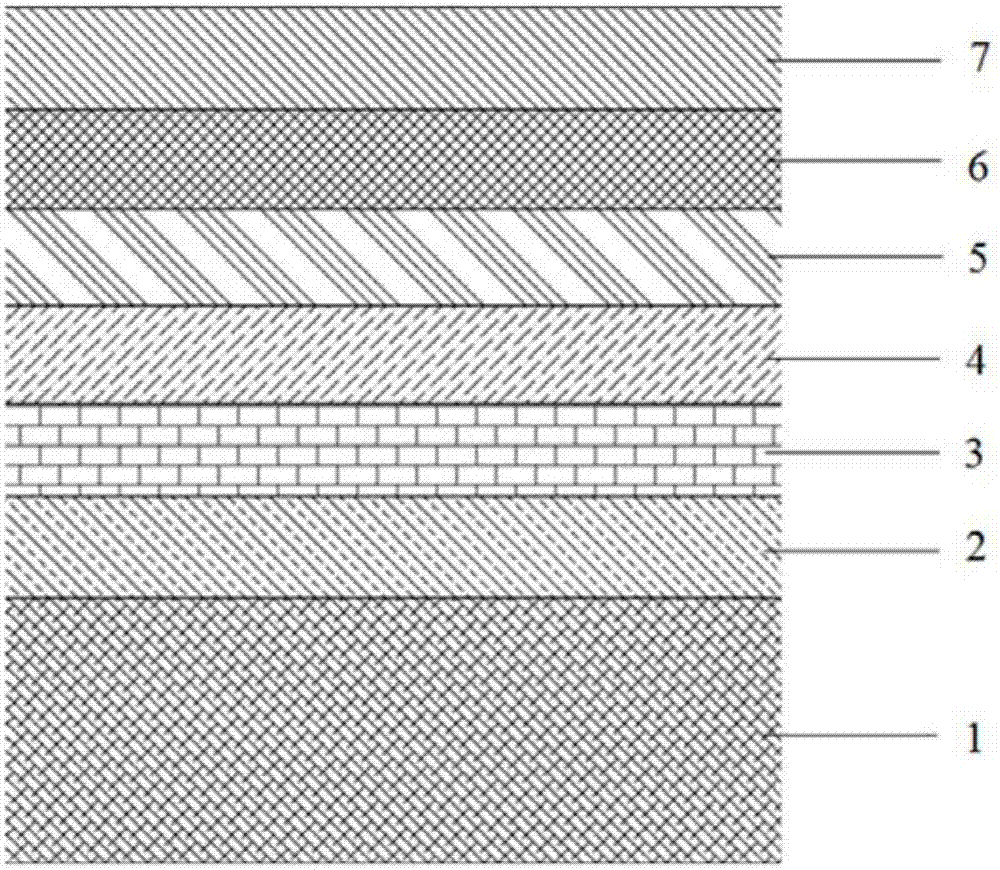

Multilayered gradient diamond like nano composite coating for aluminum alloy piston and preparation method thereof

InactiveCN102092166AOvercome stressOvercome adhesionLayered productsVacuum evaporation coatingDiamond-like carbonSurface layer

The invention discloses a multilayered gradient diamond like nano composite coating for an aluminum alloy piston and a preparation method thereof. The coating consists of a piston matrix, a bottom adhesive layer, a middle transition layer and a surface layer in turn, wherein the bottom is provided with a metal Ti or Cr adhesive layer; the middle transition layer is metal nitride and a Si layer; and the surface layer is a metal-doped diamond like carbon film. The wear life of the coating is improved by more than 40 times compared with that of a single-layer diamond like coating with the same thickness directly formed on the surface of aluminum alloy, and the friction coefficient under the oil lubricating condition is stabilized to be 0.05. The piston with the diamond like coating has better comprehensive performance than a piston of which the skirt is treated by MoS2, and can meet the requirements on high speed, high efficiency and low emission of a modern engine.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

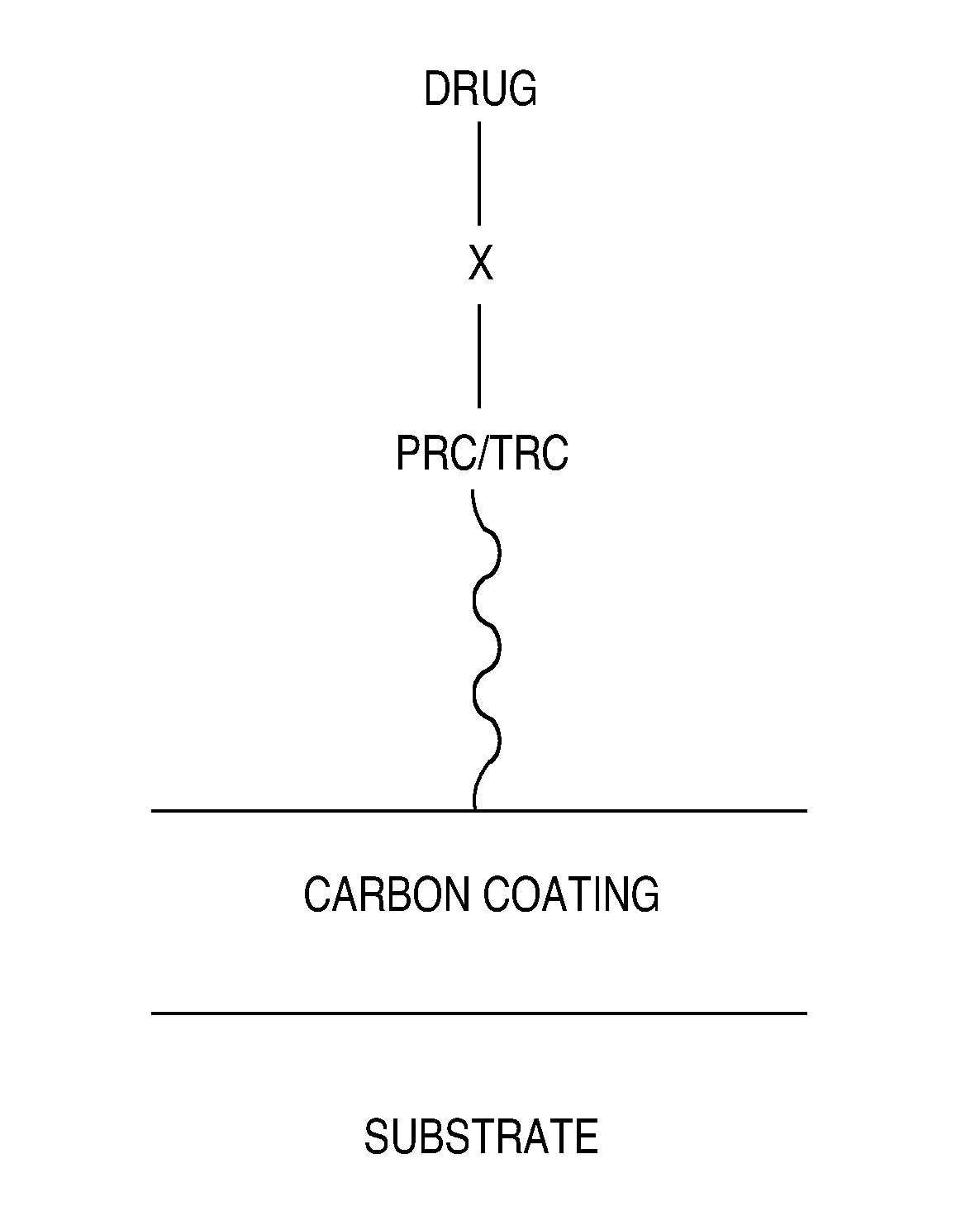

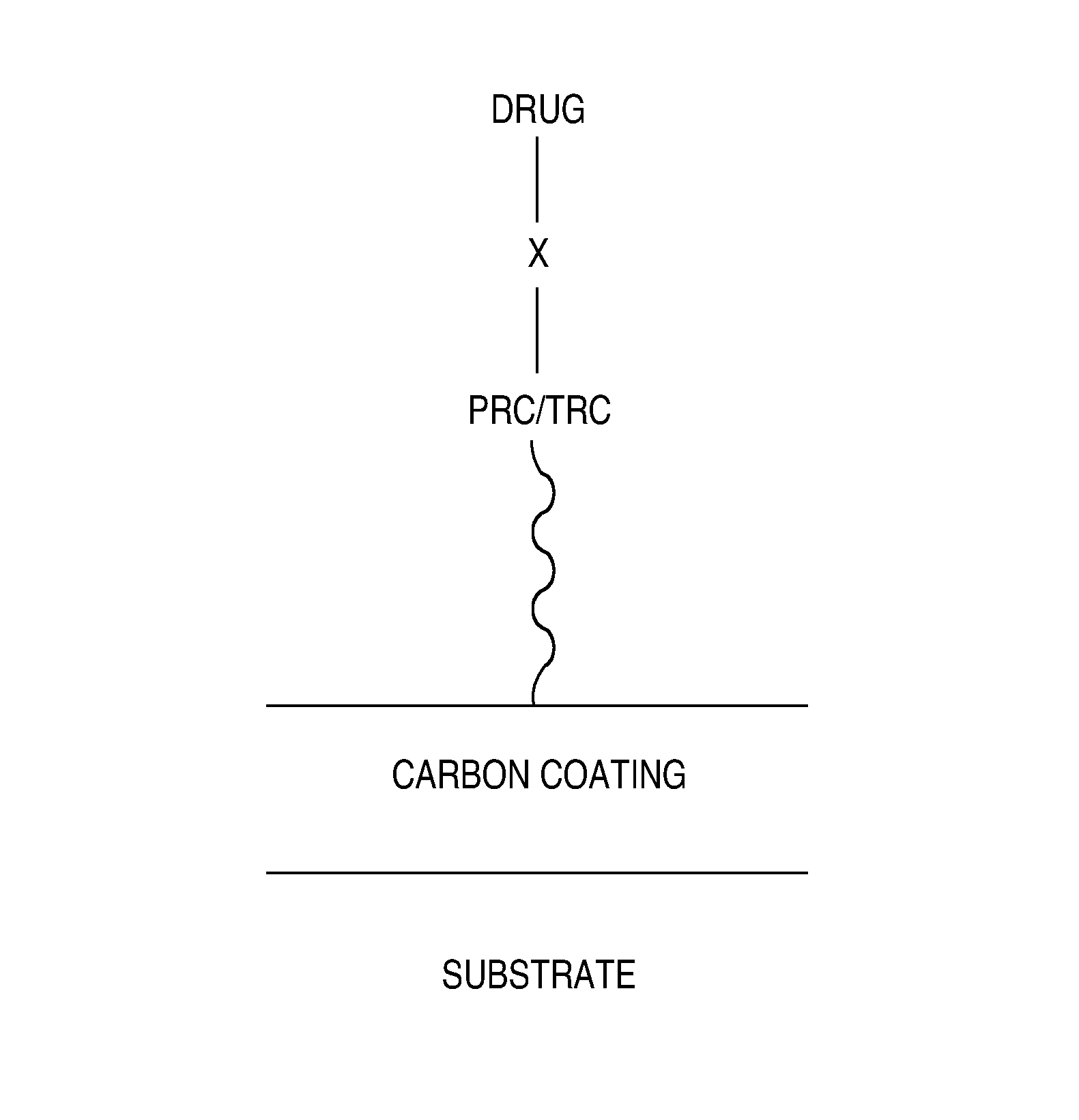

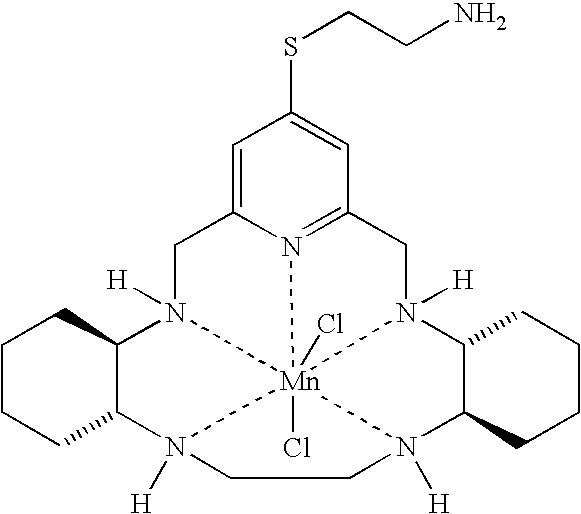

Carbon coating on an implantable device

InactiveUS8128688B2Reduce early or late thrombosisHigh degreeSurgeryPhotomechanical apparatusCarbon coatingActive agent

Owner:ABBOTT CARDIOVASCULAR

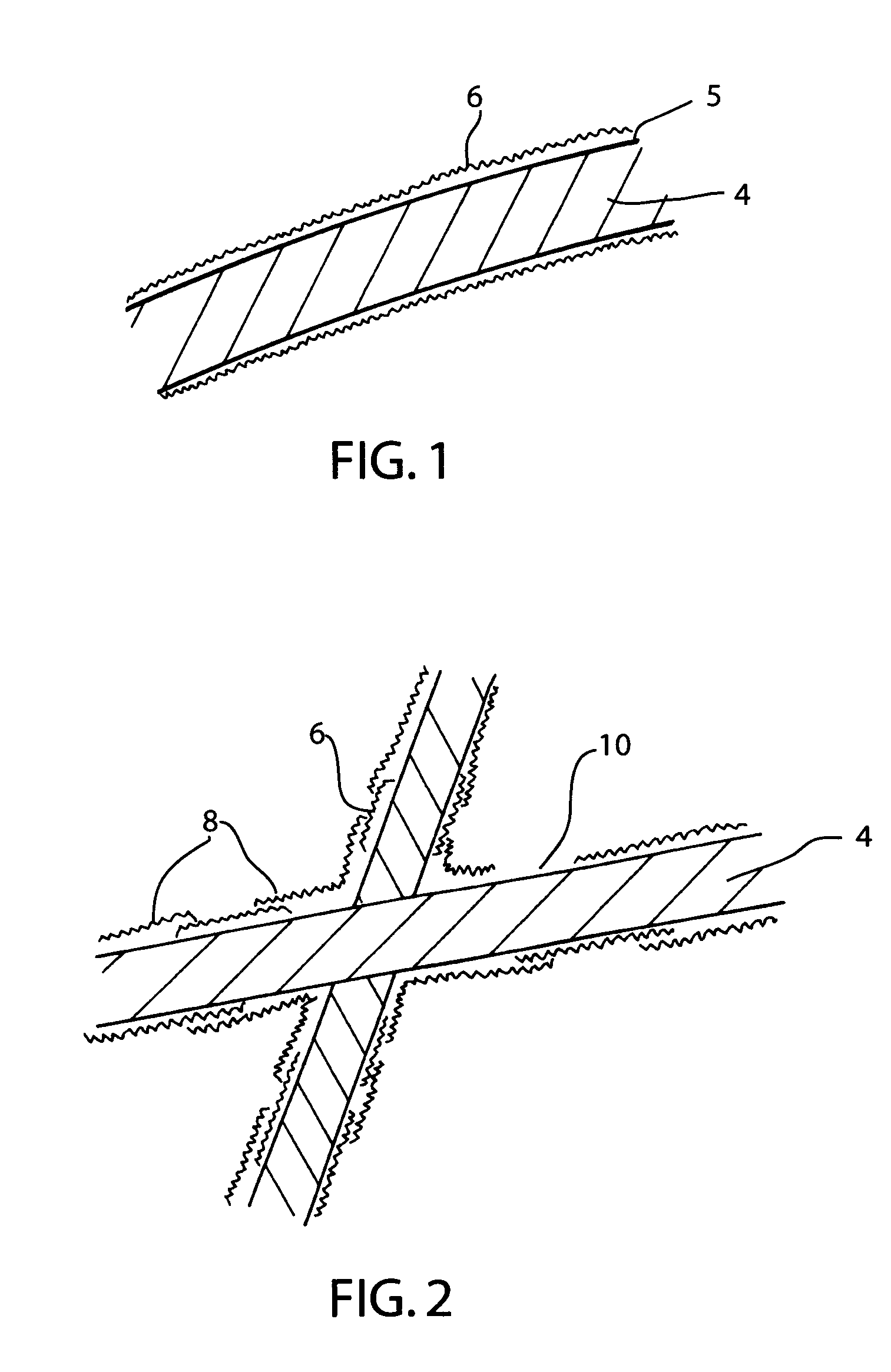

Fabrics with high thermal conductivity coatings

ActiveUS20050277350A1Improve thermal conductivityHigh thermal conductivity materialGlass/slag layered productsNatural mineral layered productsFiberCarbide

The present invention facilitates the thermal conductivity of fabrics by surface coating of the fabrics with high thermal conductivity materials 6. The fabrics may be surface coated when they are individual fibers or strands 4, bundles of strands, formed fabric or combinations therefore. A particular type of fibrous matrix used with the present invention is glass. Some fabrics may be a combination of more than one type of material, or may have different materials in alternating layers. HTC coatings of the present invention include diamond like coatings (DLC) and metal oxides, nitrides, carbides and mixed stoichiometric and non-stoichiometric combinations that can be applied to the host matrix.

Owner:SIEMENS ENERGY INC

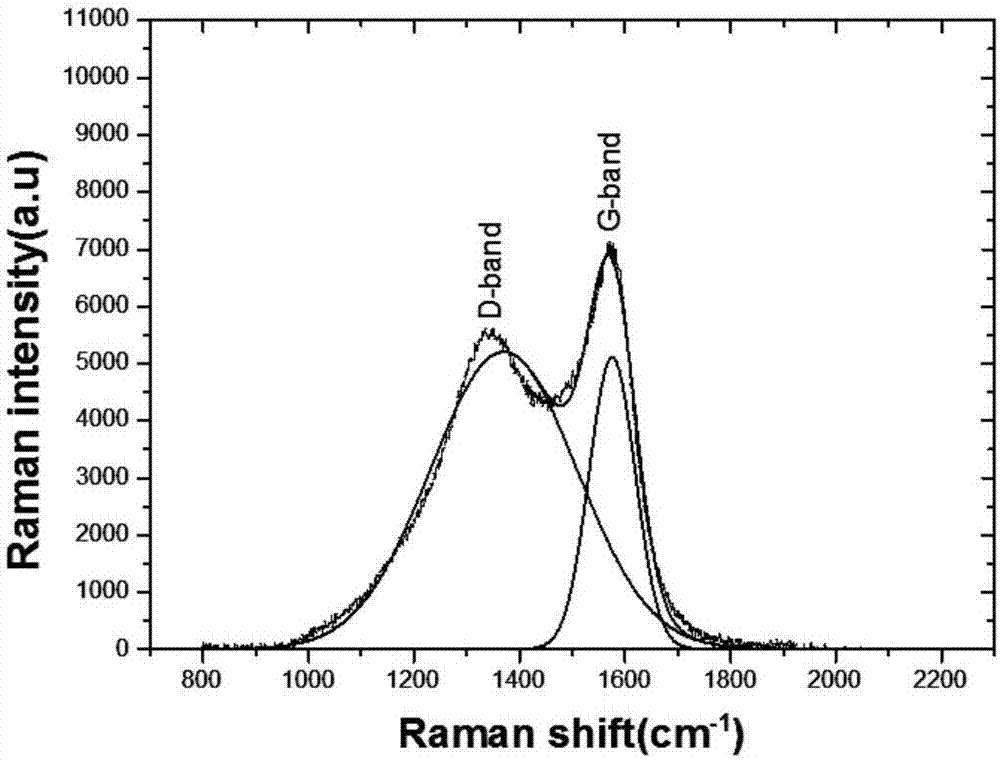

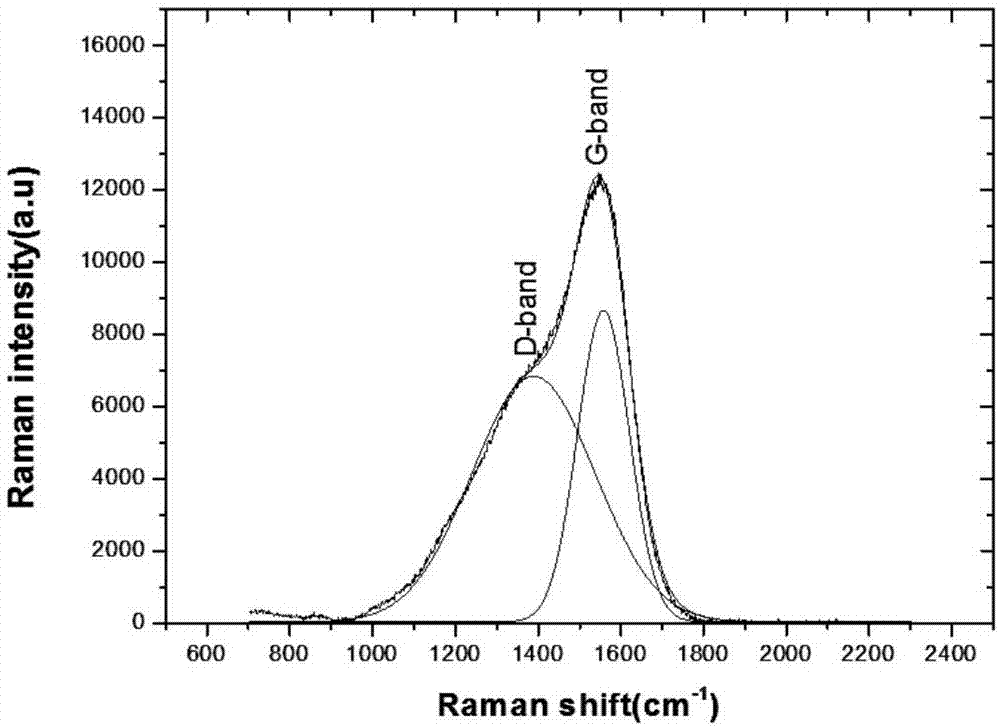

Method for producing amorphous carbon coatings on external surfaces using diamondoid precursors

InactiveUS20090029067A1Desirable mechanical and tribological propertyFast depositionChemical vapor deposition coatingPlasma techniqueGas phaseRefractive index

The invention relates to a method for forming high sp3 content amorphous carbon coatings deposited by plasma enhanced chemical vapor deposition on external surfaces. This method allows adjustment of tribological properties, such as hardness, Young's modulus, wear resistance and coefficient of friction as well as optical properties, such as refractive index. In addition the resulting coatings are uniform and have high corrosion resistance. By controlling pressure, type of diamondoid precursor and bias voltage, the new method prevents the diamondoid precursor from fully breaking upon impact with the substrate. The diamondoid retains sp3 bonds which yields a high sp3 content film at higher pressure. This enables a faster deposition rate than would be possible without the use of a diamondoid precursor.

Owner:CHEVROU USA INC

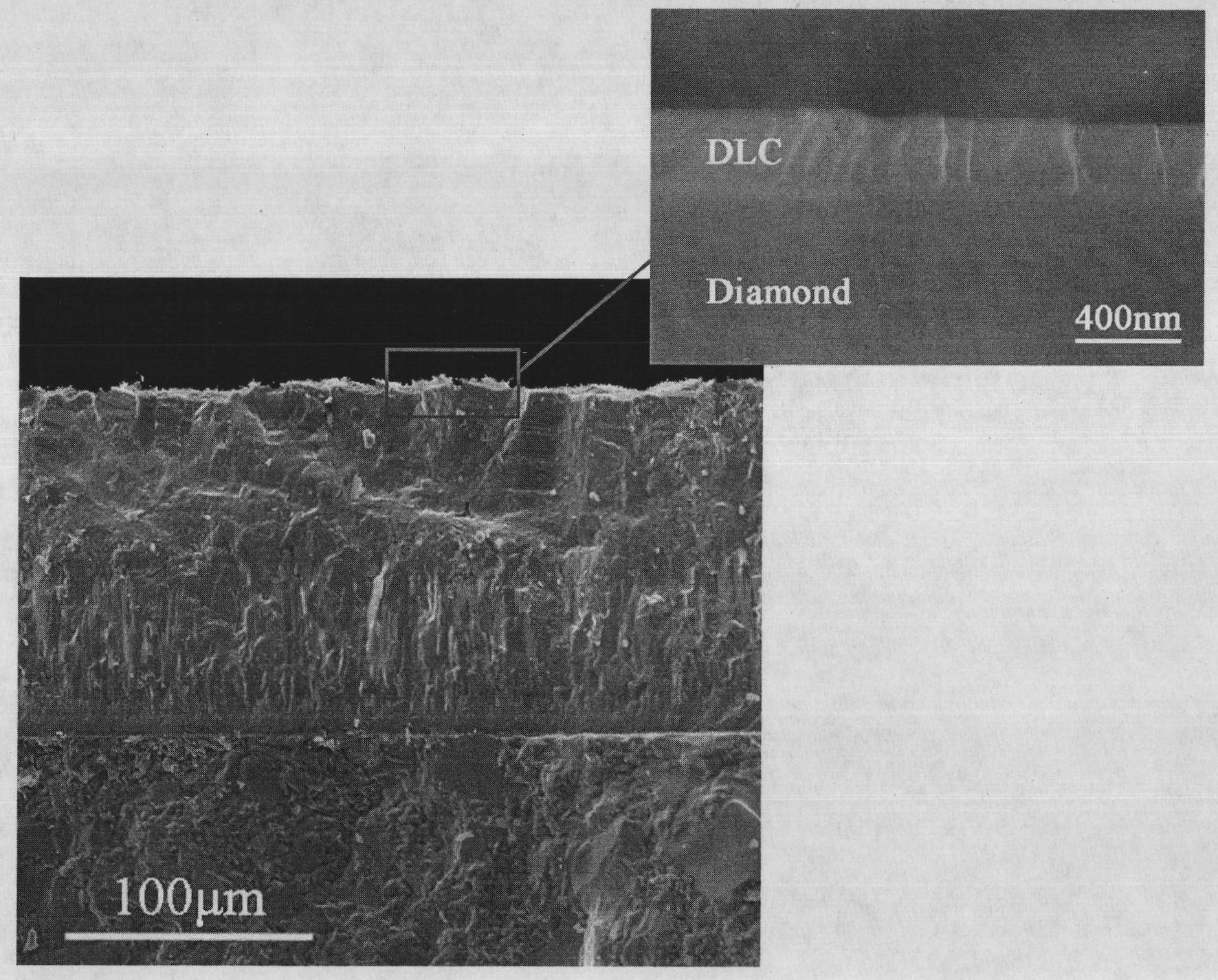

Super-hard self-lubricating diamond/diamond-like composite laminated coating material and preparation method thereof

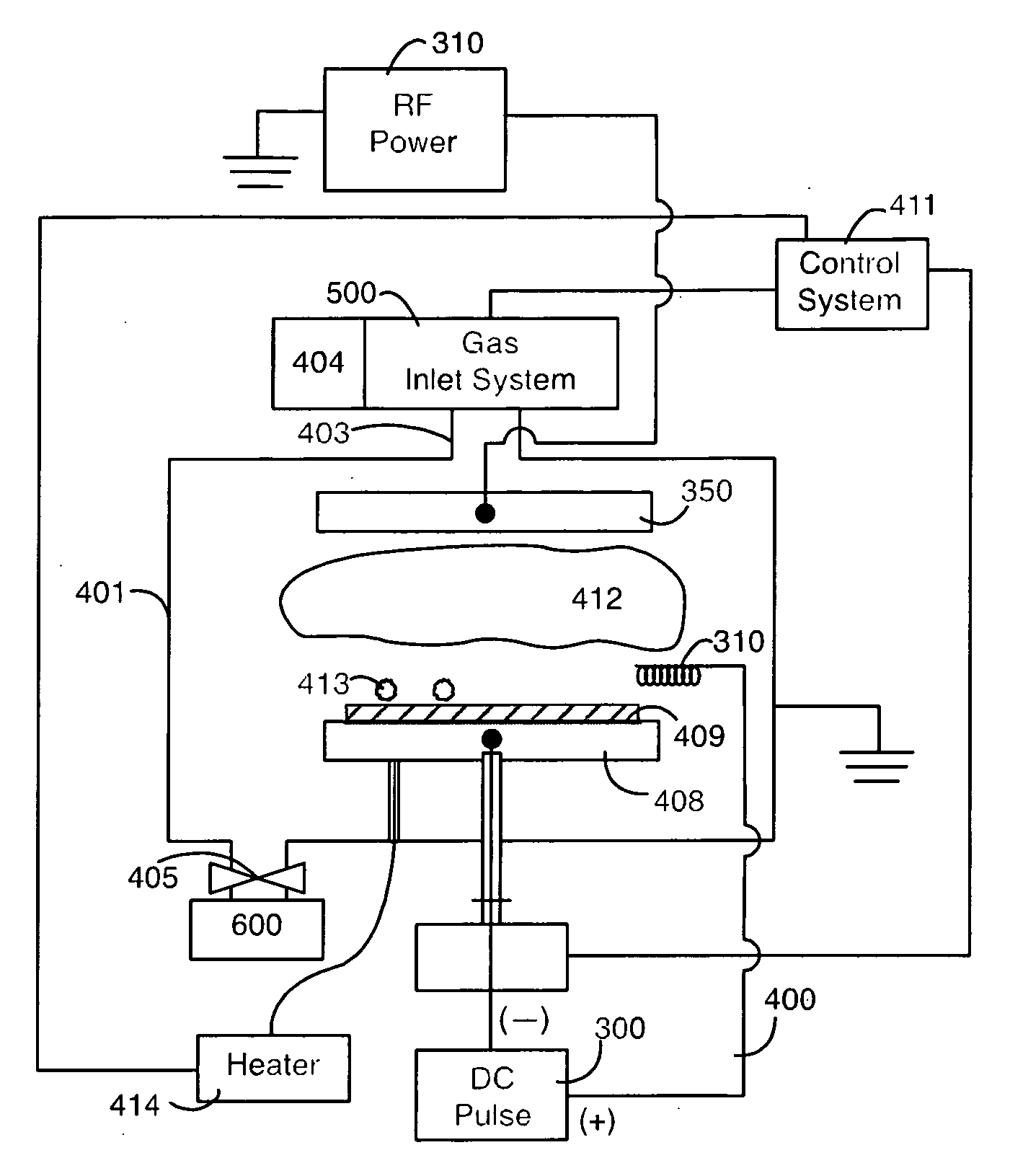

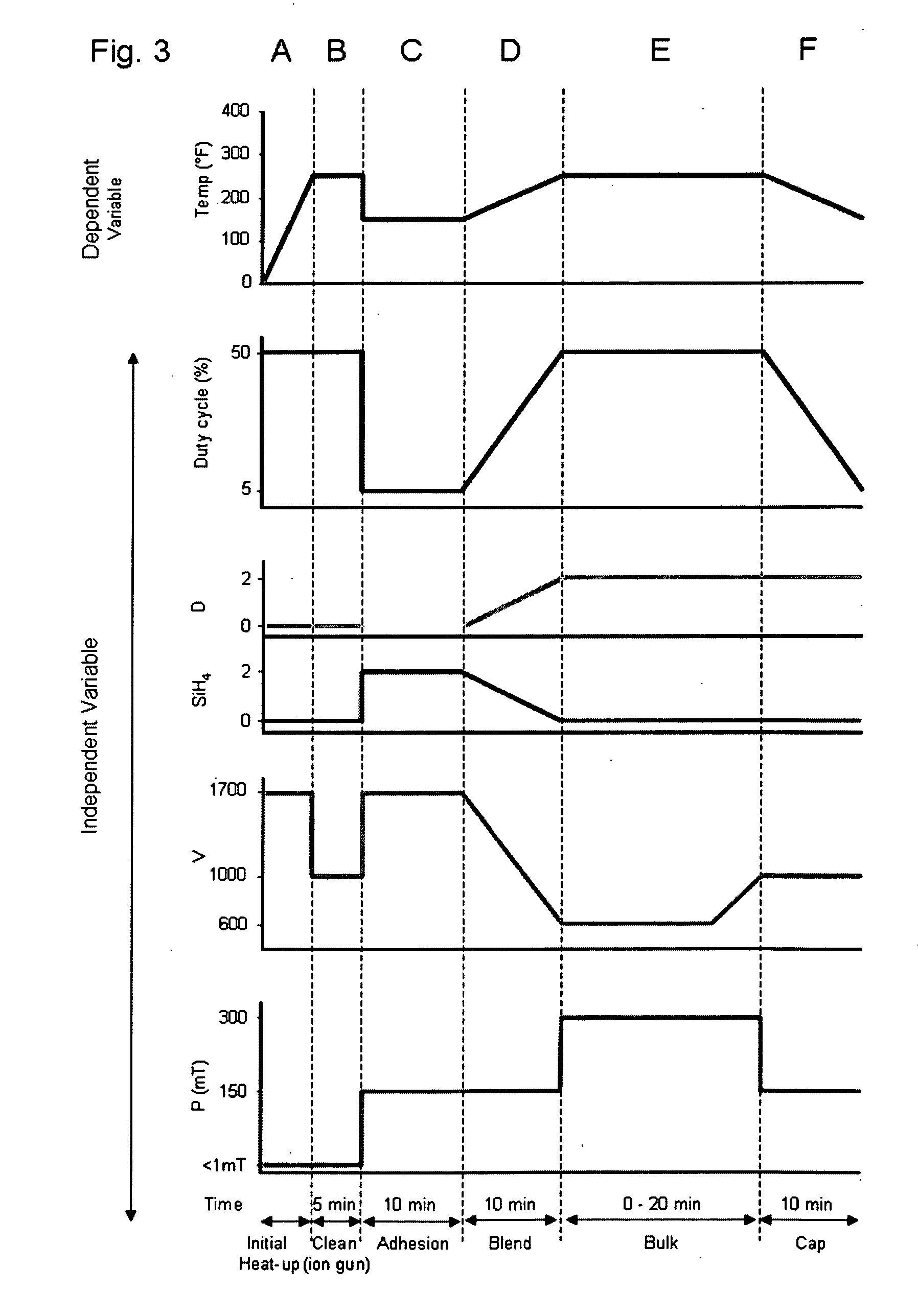

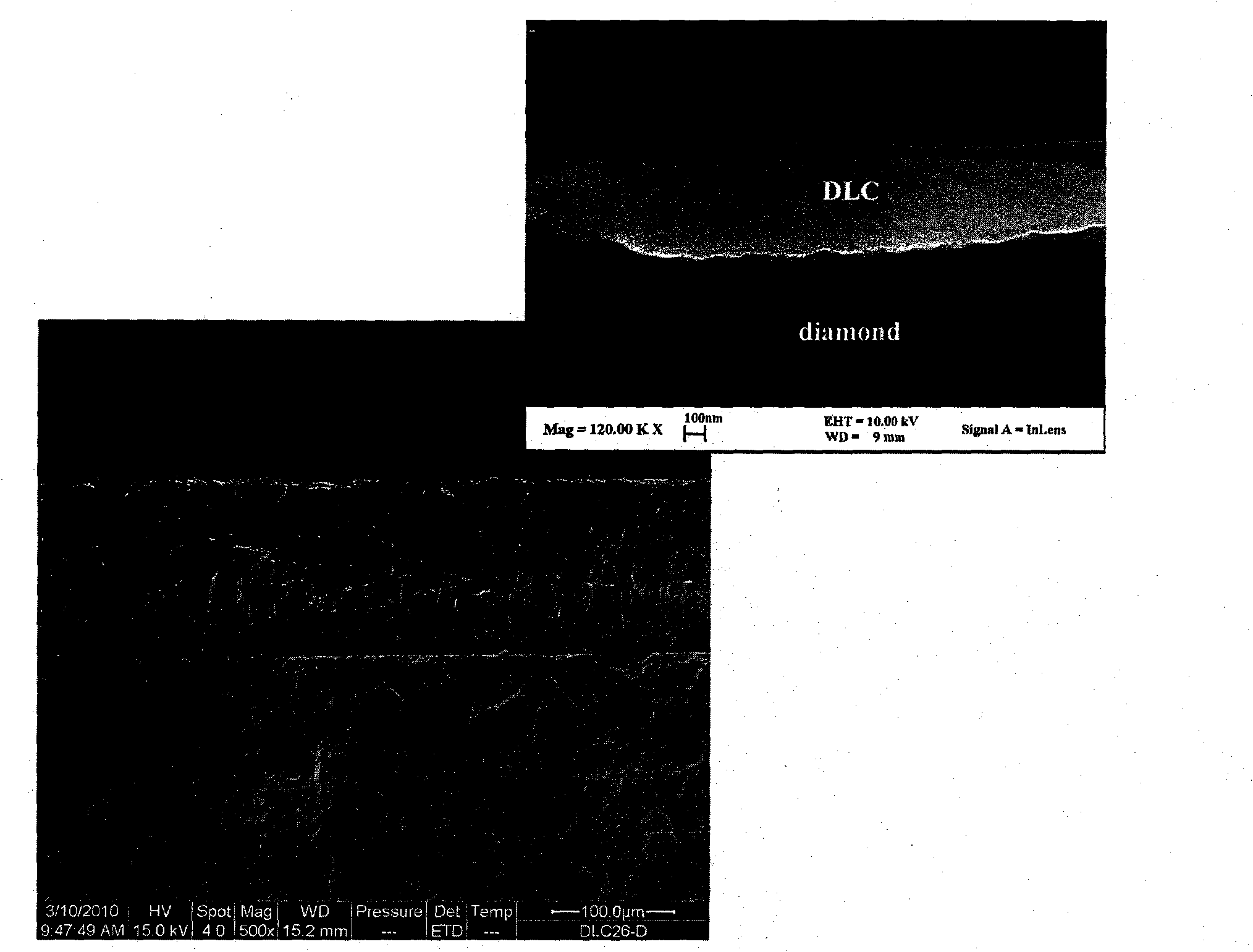

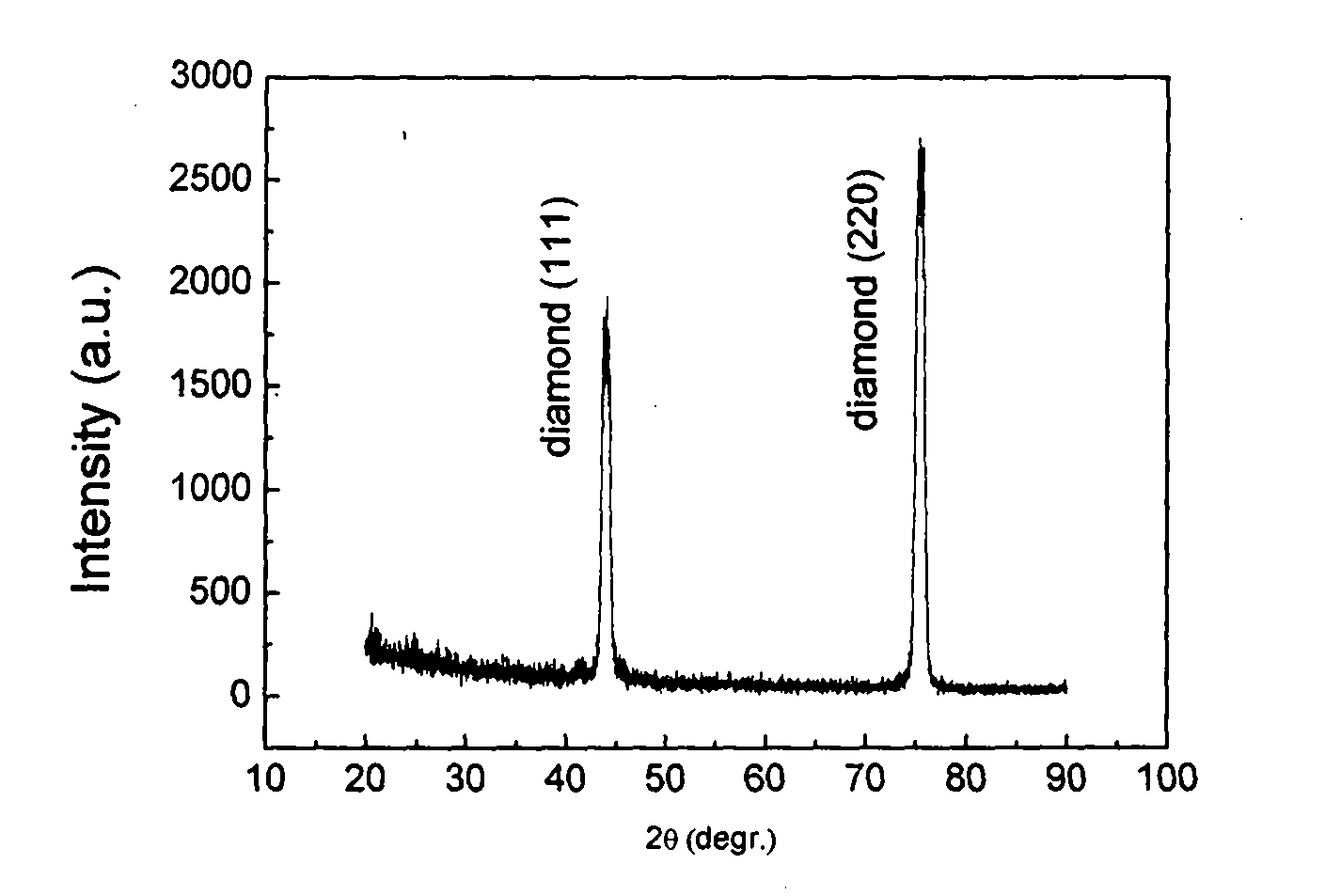

ActiveCN101818332AThe process steps are simplePrecise and controllable synthesis conditionsChemical vapor deposition coatingPolymer scienceMagnetic filtration

The invention relates to a tool coating material and a preparation method thereof, and belongs to the technical field of material preparation and application. The material is a diamond / diamond-like composite laminated coating material with super-hard self-lubricating property. The method for preparing the diamond / diamond-like composite laminated coating material is characterized by comprising the following steps of: firstly, pretreating a matrix by using mixed solution of acid and alkali respectively; secondly, synthesizing diamond with ultrahigh hardness and good crystalline form on the matrix, which serves as the main body of the composite coating, by adopting hot filament chemical vapor deposition; and finally, depositing a high-hardness diamond-like thin film on the main body of the diamond, which serves as a self-lubricating surface layer, by using magnetic filtration cathodic vacuum arc. In order to improve the binding force between the diamond thin film and the matrix and between the diamond-like thin film and the diamond thin film, a transition layer is coated between adjacent layers respectively. The method has the advantages of simple process, precise and controllable synthesis conditions, high film-forming quality, high product yield, low cost, and the like. The obtained diamond / diamond-like composite laminated coating material has ultrahigh hardness, extremely low friction factor and extremely low wear rate, shows excellent self-lubricating friction and wear resistance, and has significance for application of tools or molds under rigorous service conditions.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

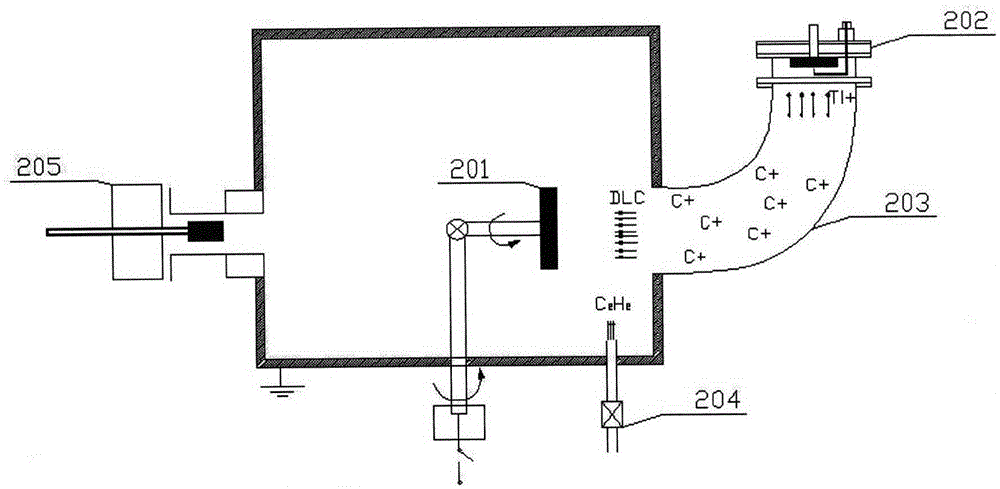

Method for preparing DLC (diamond-like carbon) thick films by means of efficient magnetic filter plasma deposition

ActiveCN105755442AEffective filteringFacilitate separate control of the ionization processVacuum evaporation coatingSputtering coatingCathodic arc depositionDiamond-like carbon

The invention discloses a method for preparing Metal carbide-inlaid Diamond-like Carbon (MC / DLC) films with the thicknesses larger than 30 micrometers, belongs to the field of preparation of hard abrasion-resistant coatings, and particularly relates to a technology for preparing MC / DLC thick films by the aid of magnetic filter plasma deposition processes.MC / DLC thick film structures comprise ion injection pinning layers, metal transition layers and the MC / DLC films.The method has the advantages that the DC / DLC films prepared by the aid of ion injection technologies, magnetic filter technologies and cathodic arc deposition technologies are high in binding force, the arc current intensity, the magnetic field intensity of bent pipes and the gas inflow of gas with carbon are controlled in deposition procedures, accordingly, the thicknesses, the hardness, the rub resistance and the abrasion resistance of the MC / DLC thick films can be optimized, and the high-quality MC / DLC thick films can be prepared by the aid of the method; magnetic filter plasma deposition equipment for implementing the method has proprietary intellectual property rights and is easy to operate, processes are mature, the MC / DC films can be produced on a large scale, and the method is suitable for deposition application to high-hardness abrasion-resistant coatings in all industrial components such as bearings of cutters.

Owner:BEIJING NORMAL UNIVERSITY

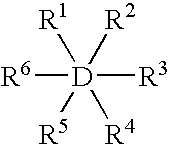

Functionalized higher diamondoids

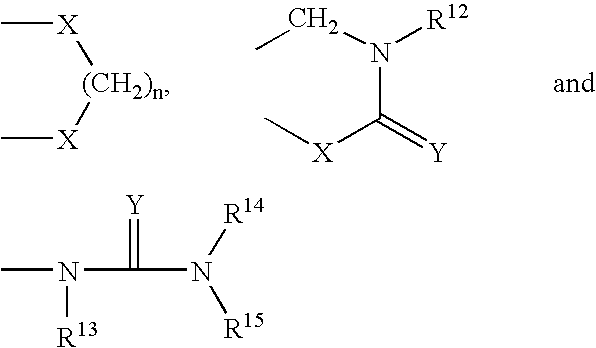

This invention is directed to functionalized higher diamondoids having at least one functional group. Preferably these derivatives have the following Formula I: wherein D is a higher diamondoid nucleus and wherein R<1>, R<2>, R<3>, R<4>, R<5 >and R<6 >are independently selected from a group consisting of hydrogen and functional groups, provided that there is at least one functional group on the derivative. The functionalized higher diamondoid compounds may also be of the formula D-L-(D)n wherein D is a higher diamondoid nucleus and L is a linking group and n is 1 or more. The functionalized higher diamondoid compouds additionally may be of the formula R<38>-D-D-R<39 >wherein D is a higher diamondoid nucleus and R<38 >and R<39 >are substituents.

Owner:CHEVROU USA INC

High-alloy metals reinforced by diamond-like framework and method for making the same

InactiveUS20060005900A1Improve corrosion resistanceImprove thermal stabilityVacuum evaporation coatingSputtering coatingDiamond-like carbonAlloy

A new class of high-alloy metals is invented. The metals possess an amorphous, nano crystalline, or combined amorphous-nano-crystalline structure and are reinforced, stabilized and hardened with a framework formed by predominantly sp3-bonded carbon, also known-as diamond like carbon. Optionally, other alloying nonmetallic elements selected from the group of Si, B, O, N may additionally stabilize the structure. The disclosed high-alloy metals comprise a metallic matrix which may include iron, nickel, chromium, refractory, and various other metals. These materials are very stable, and do not suffer a structural degradation up to relatively high temperatures. The disclosed high-alloy metals have the properties of high hardness, corrosion and wear resistance, and low friction. They have a wide range of applications as protective coatings on a wide variety of materials in various industries. They may be further applied as magnetic and electronic devices, such as field emission cathodes. Some of these alloys possess high emissivity, and their electrical conductivity may be varied in a relatively wide range.

Owner:DORFMAN BENJAMIN R

Method and apparatus for straining-stress sensors and smart skin for air craft and space vehicles

InactiveUS20070062300A1Detect directlyAerodynamic testingForce measurementFine structureStress sensor

A new family of multifunctional smart coatings based on of stabilized diamond-like metal carbon atomic scale composites and diamond-like atomic-scale composite (DL ASC) materials. Based on a unique combination of the coating fine structure, properties of the coating / substrate interface, and the mechanical and electrical properties of the coating, the disclosed smart coatings would integrate various high resolution sensors and interconnections, and the sensor would diagnose dangerous stress distribution in the coated subject with no distortion in real time, while these diamond-like coatings would simultaneously provide environmental protection of the coated surface and improve its aerodynamic quality.

Owner:NANODYNAMICS INC

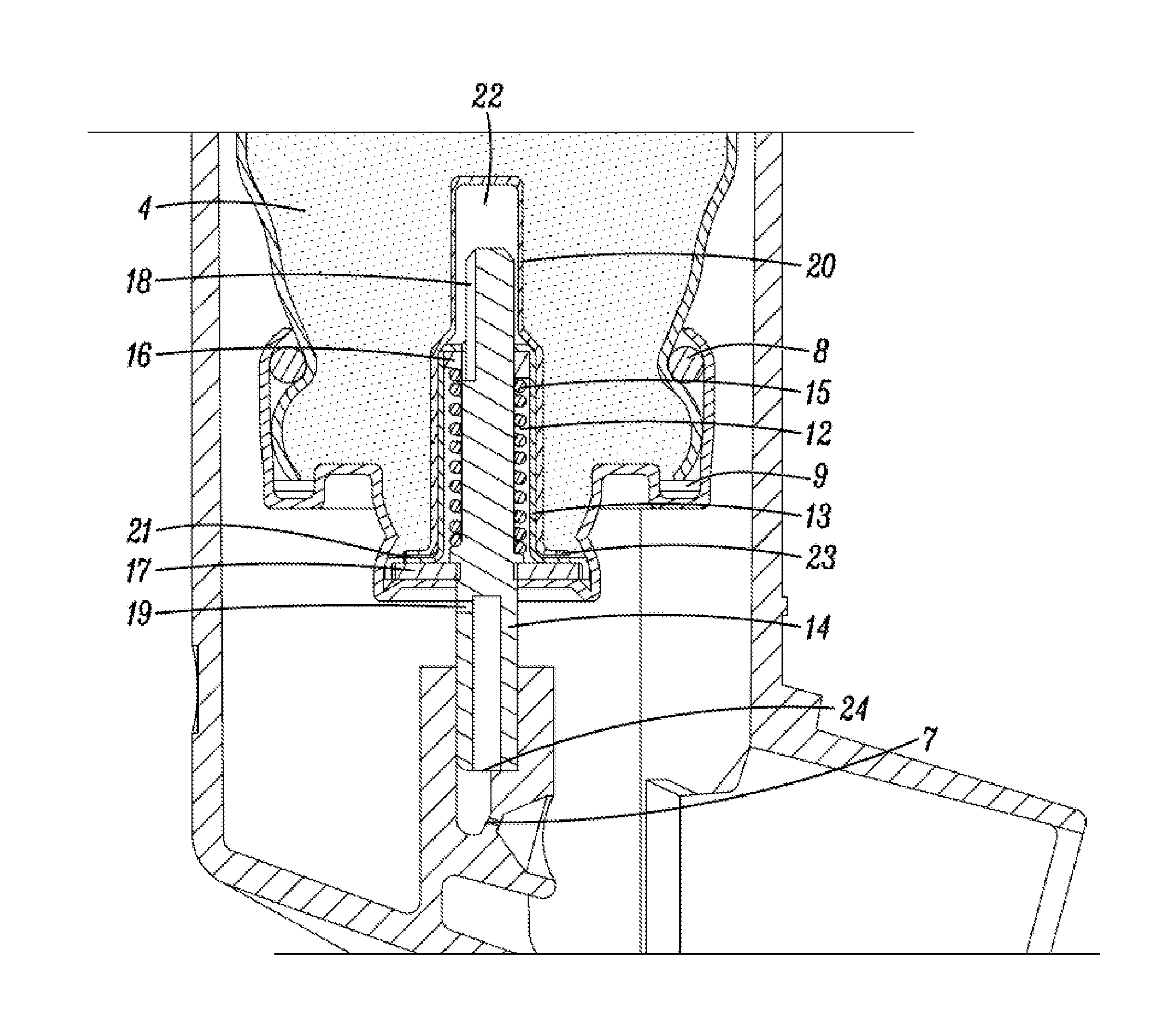

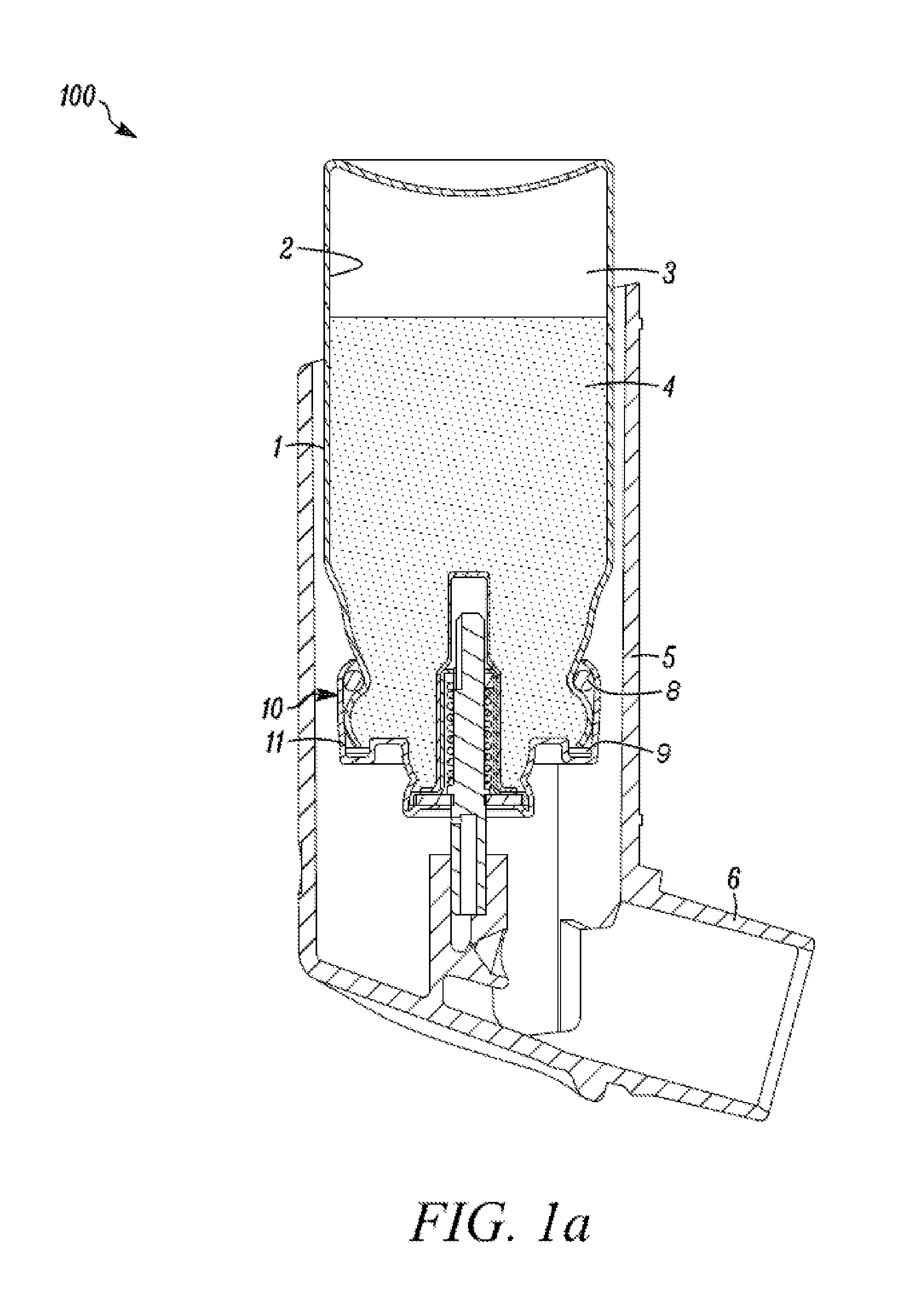

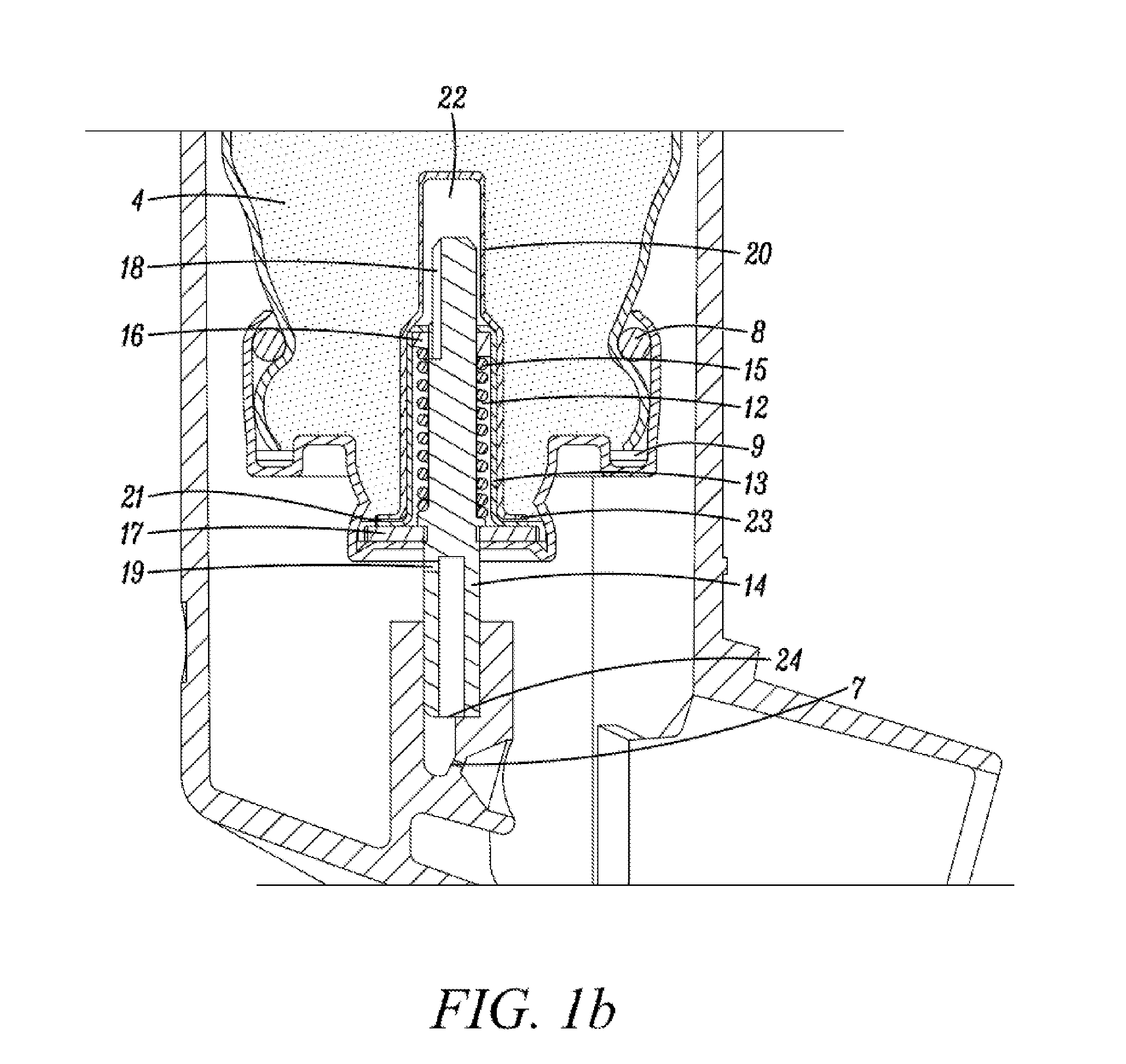

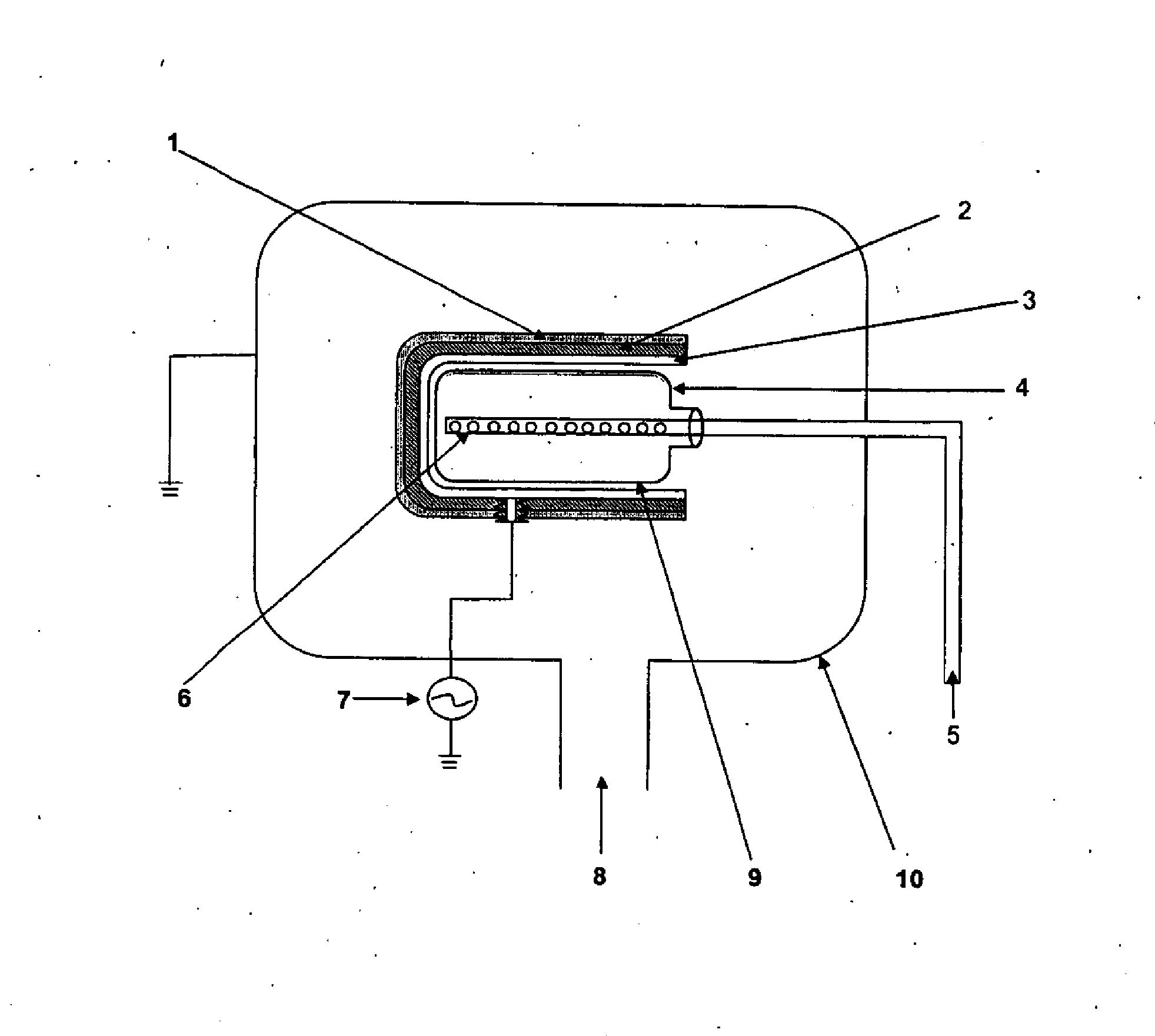

Medicinal inhalation device

InactiveUS20120103330A1Marked flexibilityAdvantageously low surface energyRespiratorsPharmaceutical containersHydrogenMedicine

Owner:3M INNOVATIVE PROPERTIES CO

Process to Deposit Diamond Like Carbon as Surface of a Shaped Object

InactiveUS20120045592A1Accurate frequencyMinimize and completely avoid damageElectric discharge tubesLinings/internal coatingsDiamond-like carbonCompanion animal

A plasma based deposition process to deposit thin film on the inner surfaces of the shaped objects such as plastic or metallic object like bottles, hollow tubes etc. at room temperature has been developed. In present invention uniform hydrogenated amorphous carbon (also called Diamond-Like Carbon, DLC) films on inner surfaces of plastic bottles is successfully deposited. Applications of such product include entire food and drug industries. There is a huge demand of polyethylene terephthalate (PET) or polyethylene naphthalate (PEN)) bottles, meant for the storage of potable water, carbonated soft drinks, wines, medicines etc. However, the higher cost prohibits their wide, spread use. The cheaper alternative is to use plastic bottles inside coated with chemically inert material such as Diamond-Like Carbon (DLC) will be commercially viable. Inventor process can be scaled up for mass production. This process can also be used for coating on inner surface of metallic cane or tube with a carbide forming interlayer (like hydrogenated amorphous silicon) to get the DLC films with better adhesion to inner surface of metals.

Owner:COUNCIL OF SCI & IND RES

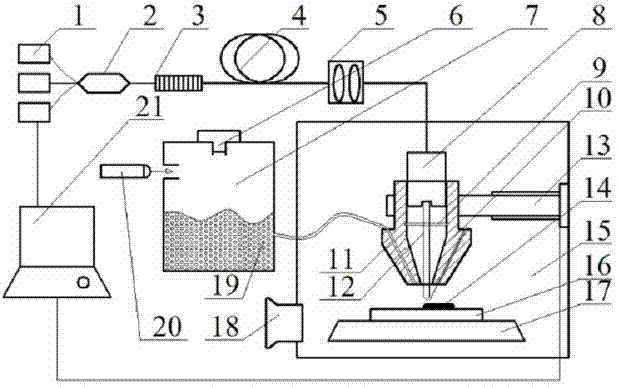

Method and device for preparing diamond-like carbon coating by cladding fiber laser

ActiveCN102409339AShort reaction timeFast binding strengthMaterial nanotechnologyMetallic material coating processesCarbon coatingDiamond-like carbon

The invention relates to a method and device for preparing a diamond-like carbon coating by cladding a carbon nanotube with fiber laser. The carbon nanotube is cladded with a fiber laser; the carbon nanotube is molten quickly by absorbing laser energy to form liquid carbon, and is cooled at an extremely high cooling speed; a diamond core grows, and undergoes phase change within an extremely short period of time; a part of carbon nanotube phases turn into diamond phases; the slightly-molten surface layer of a substrate material undergoes molecular level and atomic level diffusion, so that a strong metallurgically-bonded diamond-like carbon coating is formed; unbalanced condensation is led by an extremely high cooling speed; and an obtain diamond structure is fine and is approximate to a nanostructure. A used fiber laser head is coaxially connected with a powder spray head; processing is performed in a vacuum cavity; a laser beam is fully superposed with a carbon nanotube beam; and preparation of diamond-like carbon coatings of any shape and three-dimensional processing can be performed in cooperation with a flexible processing system of a six-degree-of-freedom robot.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

Wolframium (W) doped diamond-like coating and preparation method thereof

InactiveCN103451608AHigh coating hardnessImprove bindingVacuum evaporation coatingSputtering coatingChemical stabilityMaterials science

The invention provides a wolframium (W) doped diamond-like coating and a preparation method thereof. The coating comprises a Cr bottom layer, a CrC transition layer and a W doped diamond-like layer, wherein the Cr bottom layer is deposited on the surface of a substrate, the CrC transition layer is prepared on the Cr bottom layer, and the W doped diamond-like layer is prepared on the CrC transition layer. The preparation method comprises the following steps: firstly carrying out plasma cleaning on the substrate, opening a column electric arc Cr target to prepare the Cr bottom layer on the surface of the substrate, opening a plane magnetron sputtering C target to prepare the CrC transition layer on the Cr bottom layer, and finally closing the column electric arc Cr target and opening a plane magnetron sputtering W target to prepare the W doped diamond-like layer on the CrC transition layer. According to the preparation method provided by the invention, the electric arc and magnetron sputtering composite coating technology is adopted, so that the prepared coating is smooth and compact in surface, high in hardness, high in film bonding strength, low in friction coefficient and good in oxidization resistance and chemical stability, and can meet relatively high requirements for oxidization resistance, wear resistance and antifriction performance, therefore the coating has wide application prospects.

Owner:XI AN JIAOTONG UNIV

Diamond-like carbon (DLC) thin film and preparation method thereof

Owner:TRITREE METAL SHENZHEN

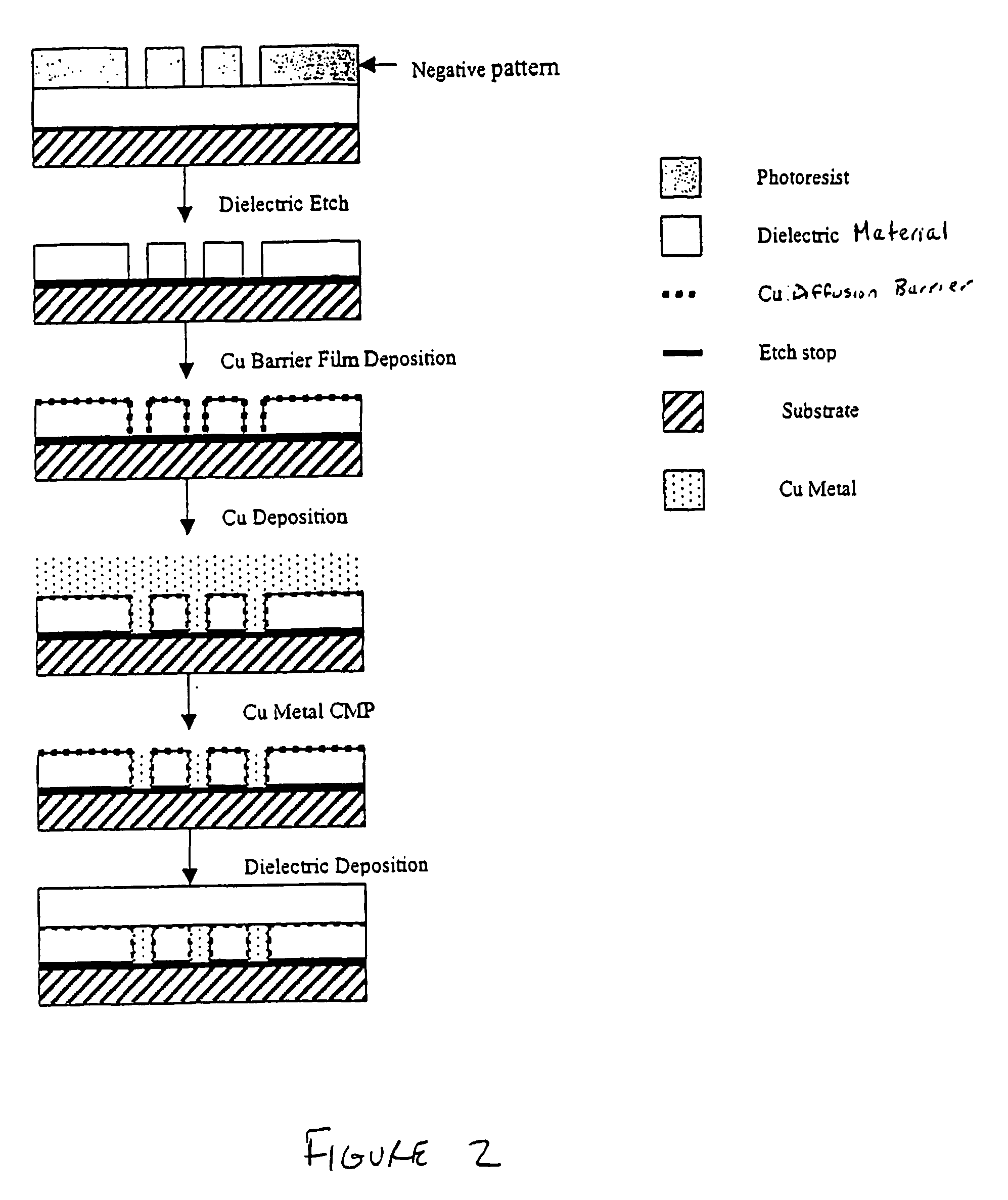

Copper diffusion barriers made of diamond-like nanocomposits doped with metals

InactiveUS7019399B2Semiconductor/solid-state device detailsSolid-state devicesDiffusionCopper interconnect

The invention relatse to a copper diffusion barrier which includes a diamond-like material includes carbon, hydrogen, silicon, oxygen and a metal and is a copper diffusion barrier. Another aspect of the invention relates to an integrated circuit which includes a copper interconnect, a dielectric material and the copper diffusion barrier.

Owner:SULZER METAPLAS

Preparation method of textured diamond-like carbon composite film for water lubrication

ActiveCN101748370AImprove stabilityImprove anti-friction and anti-wear propertiesVacuum evaporation coatingSputtering coatingDiamond-like carbonComposite film

The invention discloses a preparation method of a textured diamond-like carbon composite film for water lubrication. In the invention, by adopting a laser surface micro-processing technology, a microtexture appearance molding can be obtained on the surface of a workpiece, and a film can be obtained on the surface of the workpiece by plating a titanium transition layer and doping a diamond-like carbon film of titanium after the workpiece is plasma-cleaned by a magnetic control sputtering deposition technology. The film greatly enhances the stability and the antifriction and abrasion resistance performance of the conventional diamond-like carbon film under the condition of water lubrication with the friction coefficient reduction reaching up to 40 percent and the abrasion resistance enhanced by 1-3 times. The invention is suitable for surface protection and strengthening of a transmission friction pair of a mechanical sealing ring, a thrust bearing and other machines under the water-consuming environment, and the service life is prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

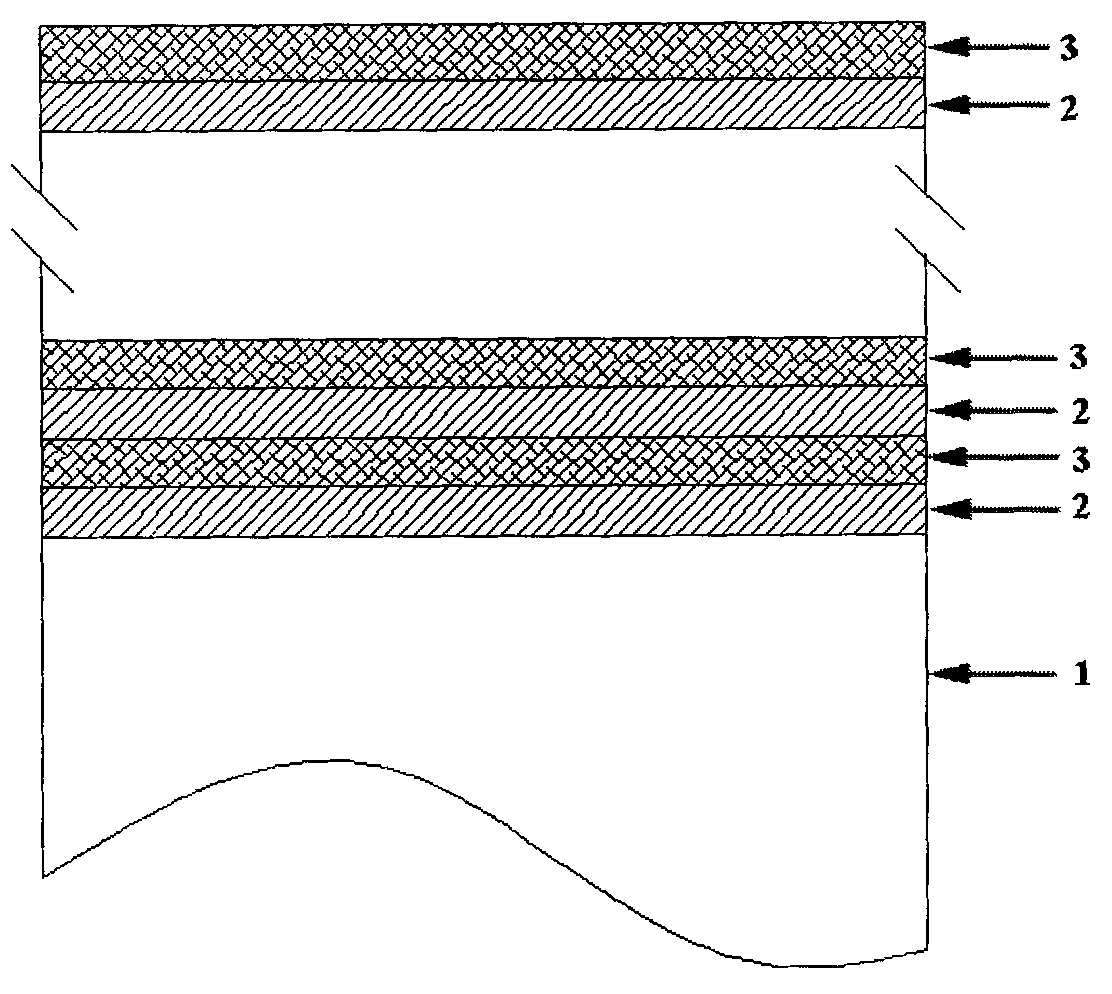

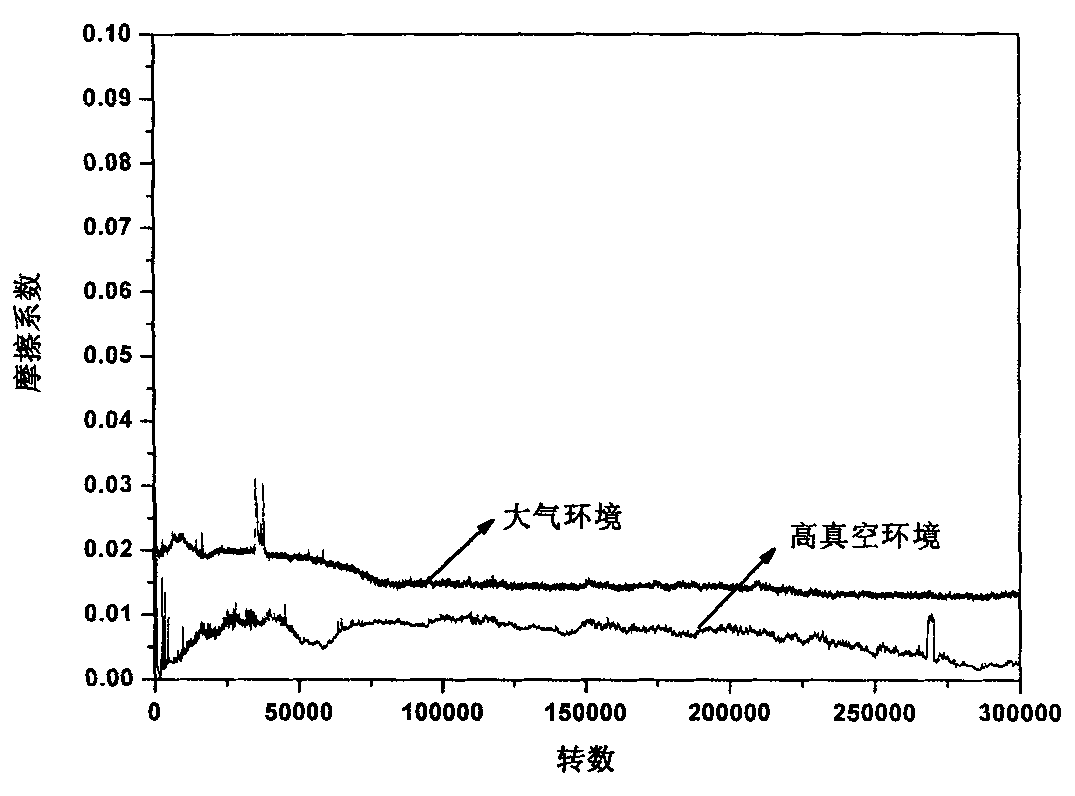

Diamond-like carbon composite molybdenum disulfide nano multilayer film and method for preparing same

ActiveCN102994947AReduce frictionImprove bearing capacityVacuum evaporation coatingSputtering coatingCarbon compositesDiamond-like carbon

The invention discloses a diamond-like carbon composite molybdenum disulfide nano multilayer film and a method for preparing the same. A double-target magnetron sputtering technology is adopted to alternatively deposit diamond-like carbon layers and molybdenum disulfide layers on a stainless steel base, so that the diamond-like carbon composite molybdenum disulfide nano multilayer film is obtained, wherein the thickness of a single diamond-like carbon layer is between 10 and 100 nanometers, the thickness of a single molybdenum disulfide layer is between 10 and 100 nanometers, and the total thickness of the diamond-like carbon composite molybdenum disulfide nano multilayer film is between 1.5 and 6 micrometers. By the prepared nano multilayer film, the wearing life defect and the problems of friction coefficient environment sensitivity of the molybdenum disulfide layer are improved, moreover, the problems of large brittleness, poor toughness and the like of a hard diamond-like carbon film are solved, so that the wear rate of the nano multilayer film in high vacuum environments is reduced by 1-2 orders of magnitude compared with the wear rate of a conventional molybdenum disulfide or diamond-like carbon film, and the perfect matching of ultralow friction and high hardness and toughness is realized.

Owner:徐州睿创智能科技有限公司

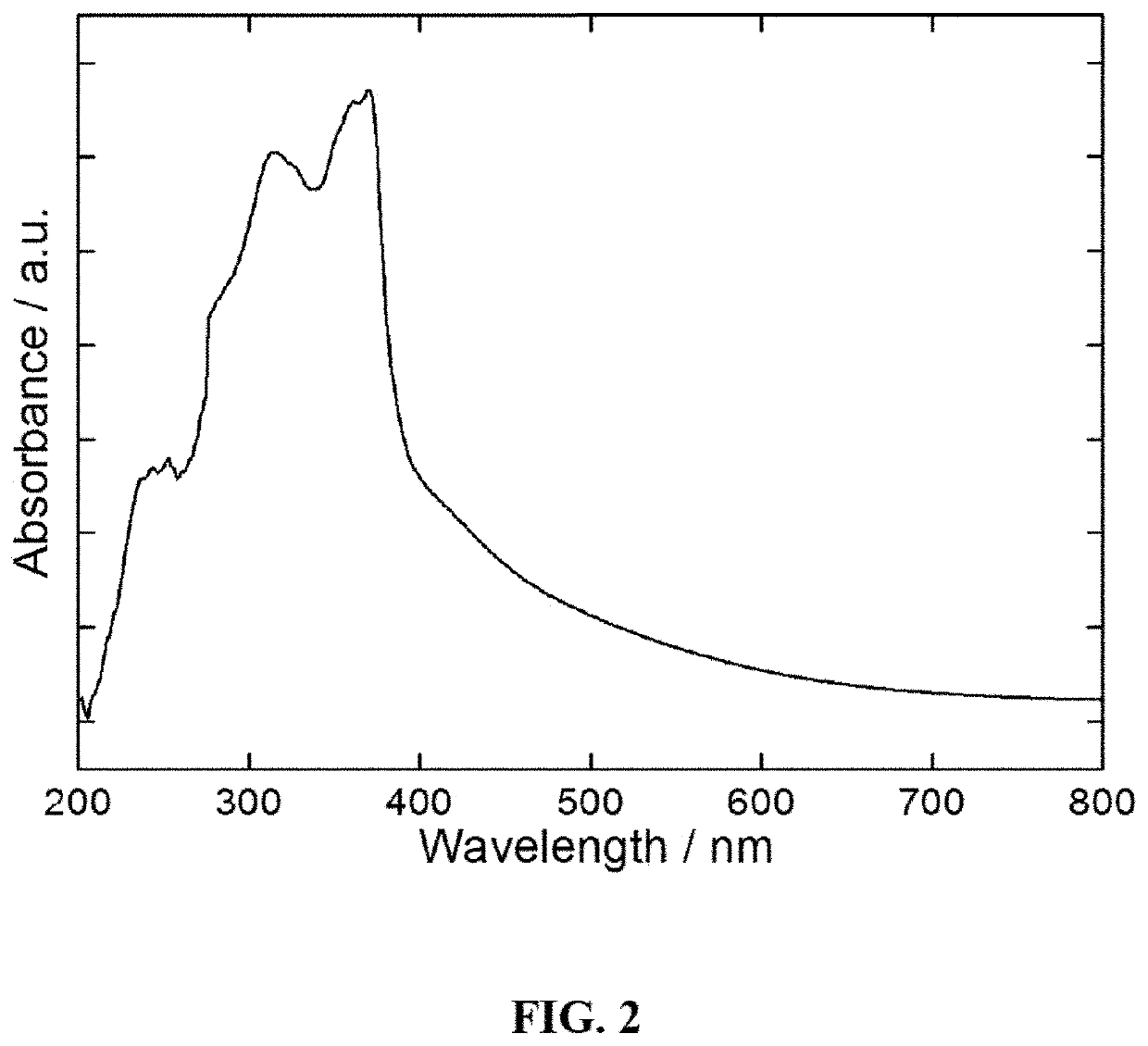

Water stable zinc-based metal organic framework and method of use

ActiveUS20200190114A1Organic-compounds/hydrides/coordination-complexes catalystsEnergy inputMetal-organic frameworkEngineering

A zinc-based metal organic framework and method of making is described. The zinc-based metal organic framework is in the form of an interpenetrating diamondoid framework where each Zn2+ ion center is linked with four other Zn2+ ion centers in a distorted tetrahedral geometry. The linking occurs through diamine and dicarboxylic acid linkers. The zinc-based metal organic framework may be deposited on a transparent conducting film and used as a photoelectrode for photoelectrochemical water splitting.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com