Diamond-like carbon composite molybdenum disulfide nano multilayer film and method for preparing same

A technology of compounding molybdenum disulfide and diamond film, which is applied in metal material coating technology, coating, ion implantation plating, etc., can solve the problems of brittleness, poor toughness, low friction, and low hardness of soft molybdenum disulfide film , to achieve the effect of good bearing capacity and anti-wear ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

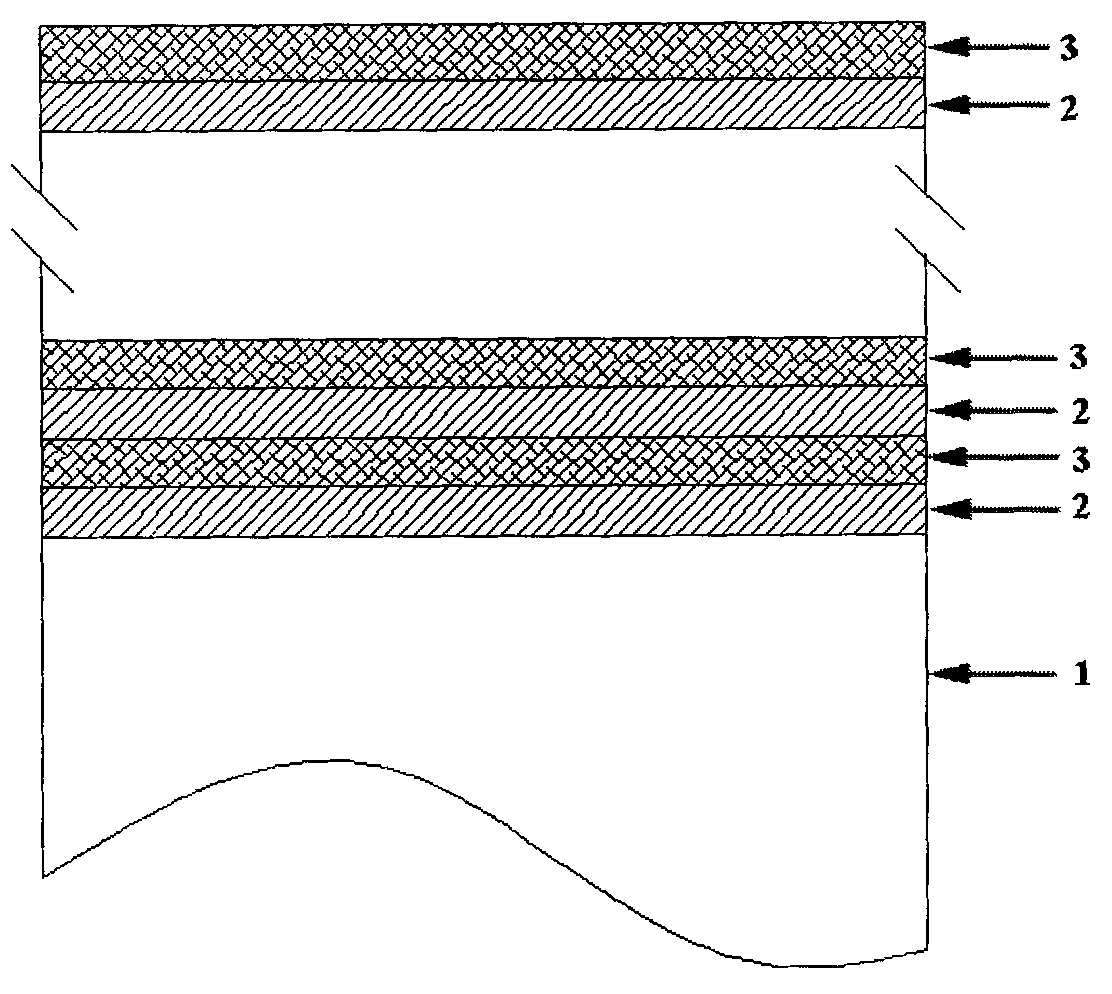

[0016] The substrate material is stainless steel (1Cr18Ni9Ti), and after ultrasonic cleaning, it is placed in a double-target magnetron sputtering vapor deposition system, and the following steps are followed: (a) Argon gas is introduced into the vacuum chamber, and the pressure is kept at 1-1.5Pa , turn on the bias power supply and adjust it to -1000V, perform argon ion discharge cleaning and activation on the surface of the stainless steel substrate, the time is 15-30min; (b) single-layer diamond-like film deposition, argon atmosphere, discharge pressure is 0.8Pa, using DC The current of the graphite target controlled by the power supply is 1.2A, the bias voltage applied to the stainless steel substrate is -300V, and the deposition time is 15min; (c) the single-layer molybdenum disulfide lubricating film layer is deposited, and the molybdenum disulfide target is controlled by a radio frequency power supply, and the power supply of the target is 500W. The deposition time is 3 ...

Embodiment 2

[0018] The substrate material is stainless steel (1Cr18Ni9Ti), and after ultrasonic cleaning, it is placed in a double-target magnetron sputtering vapor deposition system, and the following steps are followed: (a) Argon gas is introduced into the vacuum chamber, and the pressure is kept at 1-1.5Pa , turn on the bias power supply and adjust it to -1000V, perform argon ion discharge cleaning and activation on the surface of the stainless steel substrate, the time is 15-30min; (b) single-layer diamond-like film deposition, argon atmosphere, discharge pressure is 0.8Pa, using DC The current of the graphite target controlled by the power supply is 1.2A, the bias voltage applied to the stainless steel substrate is -300V, and the deposition time is 8min; (c) the single-layer molybdenum disulfide lubricating film is deposited, and the molybdenum disulfide target is controlled by a radio frequency power supply, and the power of the target power supply is 500W. The deposition time is 1.5...

Embodiment 3

[0020] The base material is stainless steel (1Cr18Ni9Ti). After ultrasonic cleaning, it is placed in a double-target magnetron sputtering vapor deposition system. The following steps are followed: (a) Argon gas is introduced into the vacuum chamber to keep the pressure at 1-1.5Pa, Turn on the bias power supply and adjust it to -1000V, and perform argon ion discharge cleaning and activation on the surface of the stainless steel substrate for 15-30 minutes; (b) single-layer diamond-like film deposition, argon atmosphere, discharge pressure of 0.8Pa, using DC power supply The graphite target current was controlled at 1.2A, the bias voltage applied to the stainless steel substrate was -300V, and the deposition time was 4 minutes; (c) single-layer molybdenum disulfide lubricating film was deposited, and the molybdenum disulfide target was controlled by radio frequency power supply, and the target power was 500W. The time is 1min; (d) Repeat the process (b) and (c) 50 times, after na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com