Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491results about How to "Improve wear life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

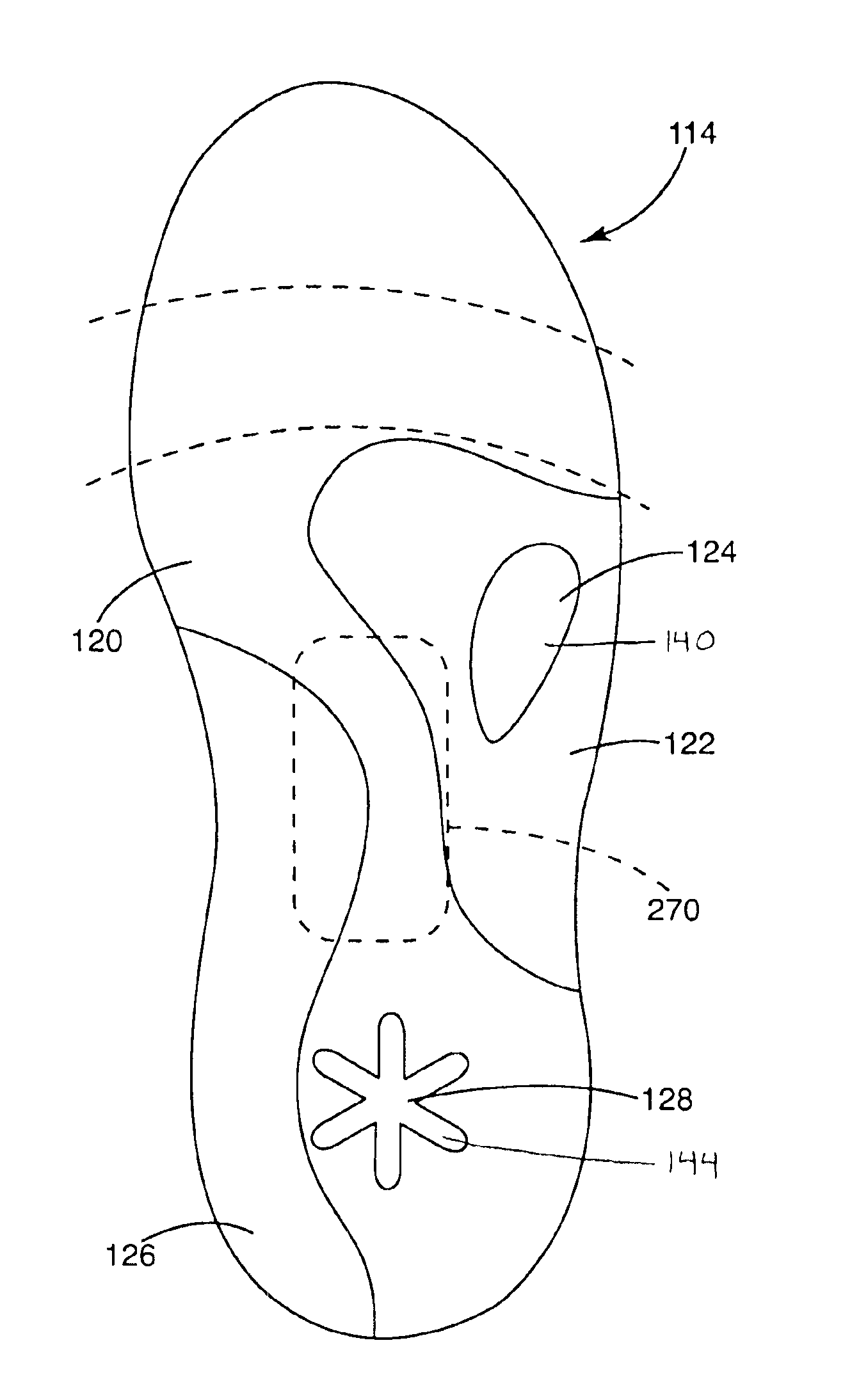

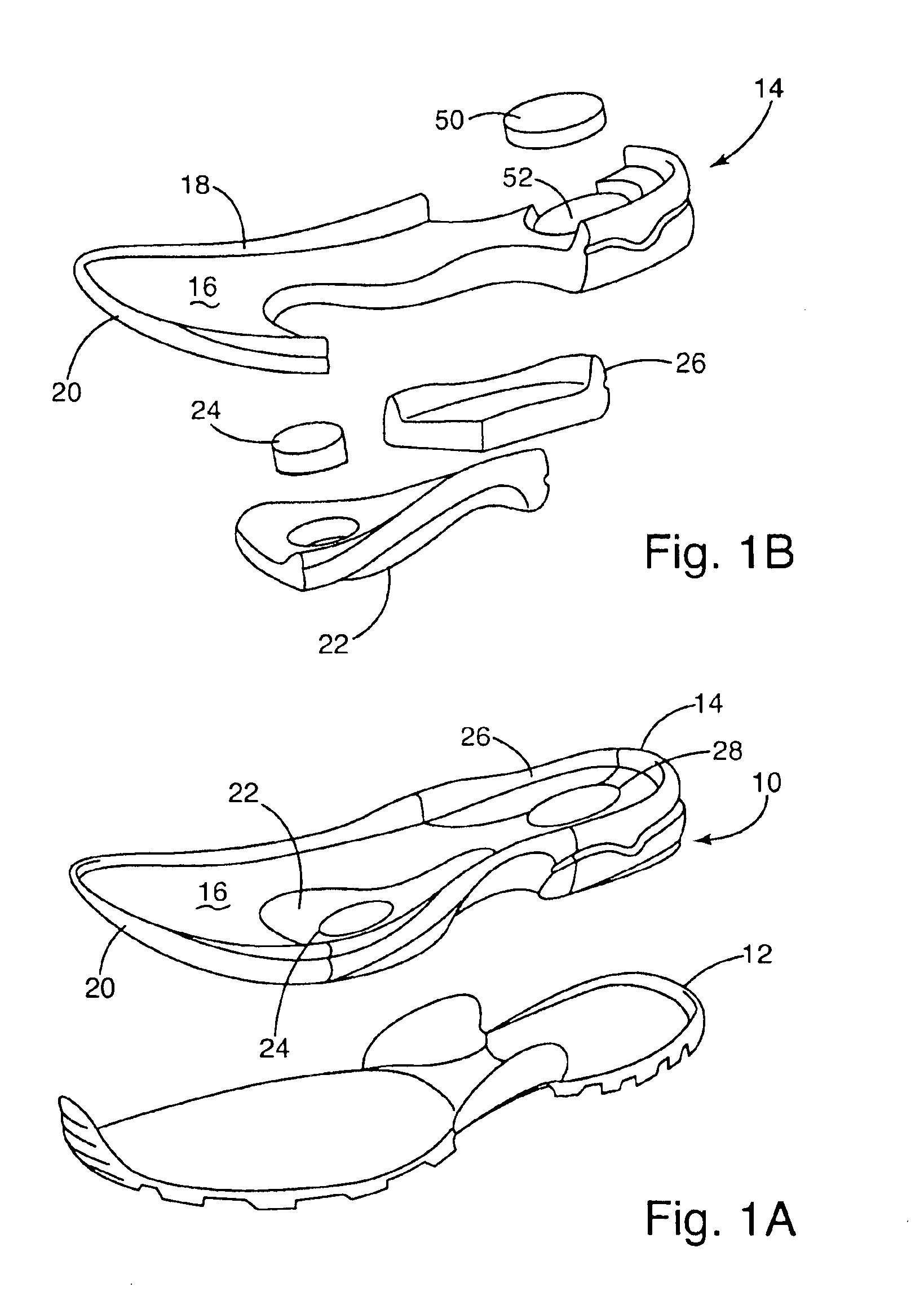

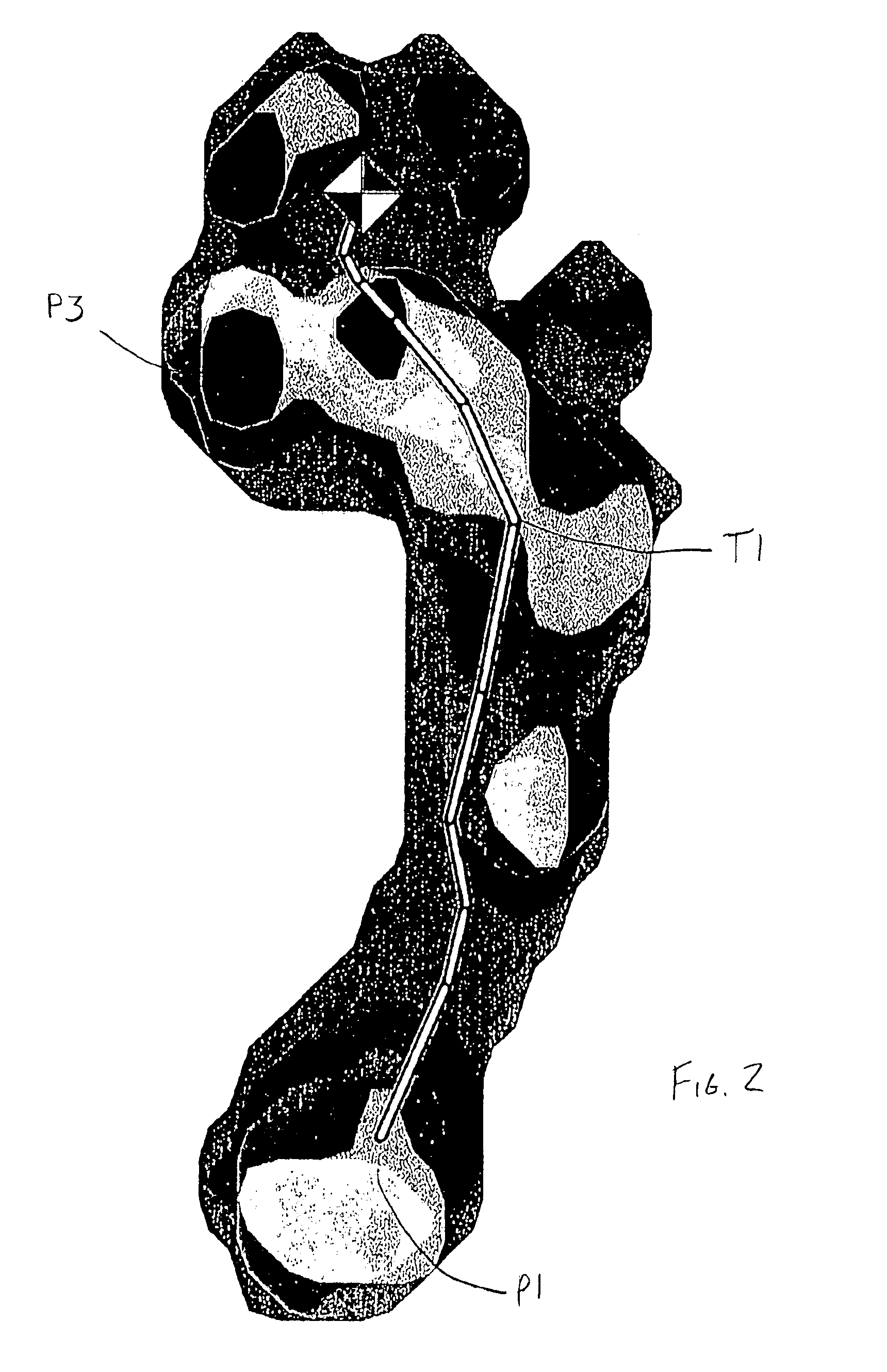

Footwear sole

A sole component for an article of women's footwear intended to address biomechanical characteristics unique to women. The sole component includes a lateral alignment portion underlying and extending through a region beneath the distal head of the second metatarsal, the distal head of the fifth metatarsal and the proximal head of the fifth metatarsal, and not into the flex zone ahead of the distal heads of metatarsals. The lateral alignment portion provides relatively firm resistance to compression. The sole component may further include a forefoot fixing portion underlying the distal head of the fifth metatarsal. The forefoot fixing portion provides relatively soft resistance to compression. In some embodiments, the sole component may also include a medial alignment portion extending along the medial side of the component from the heel through the arch.

Owner:WOLVERINE OUTDOORS

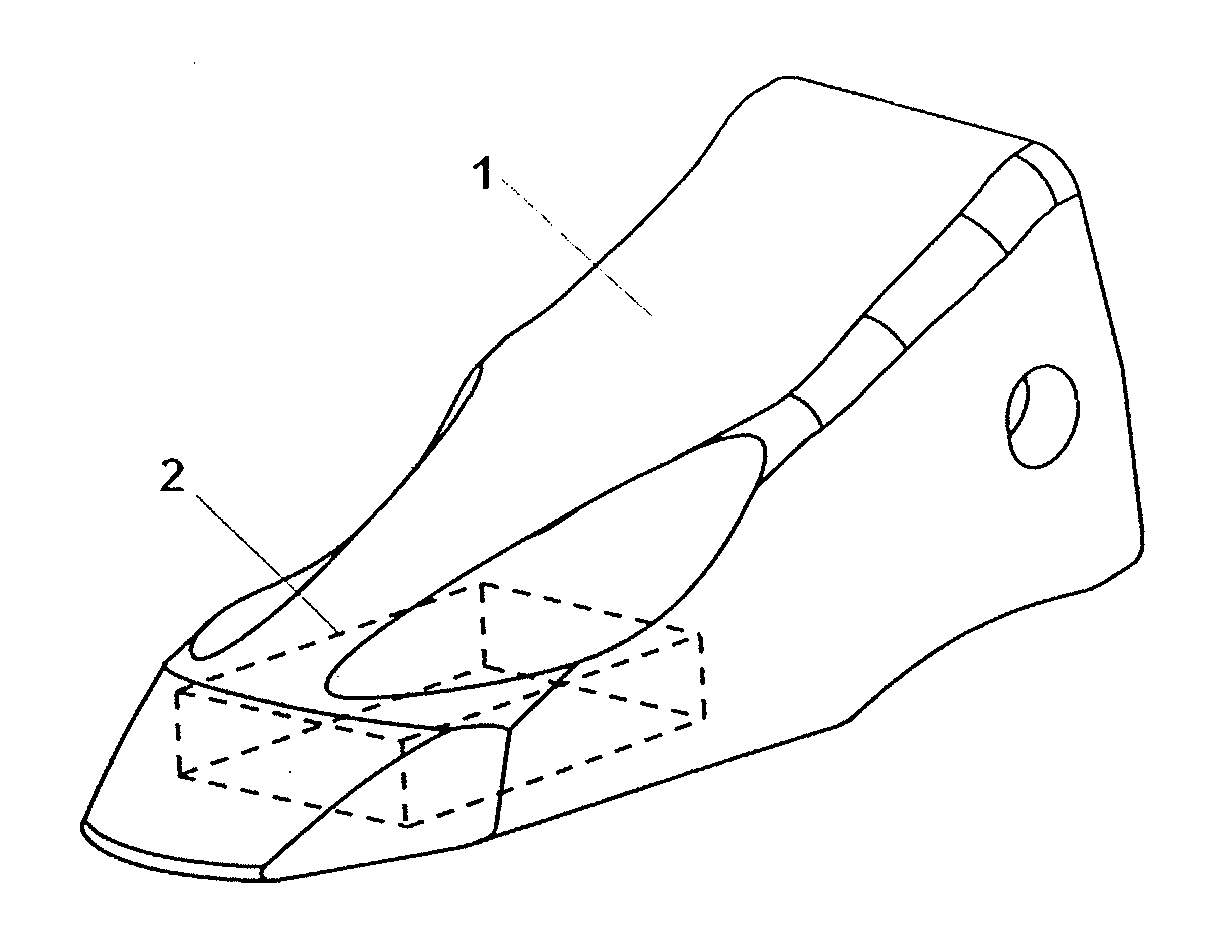

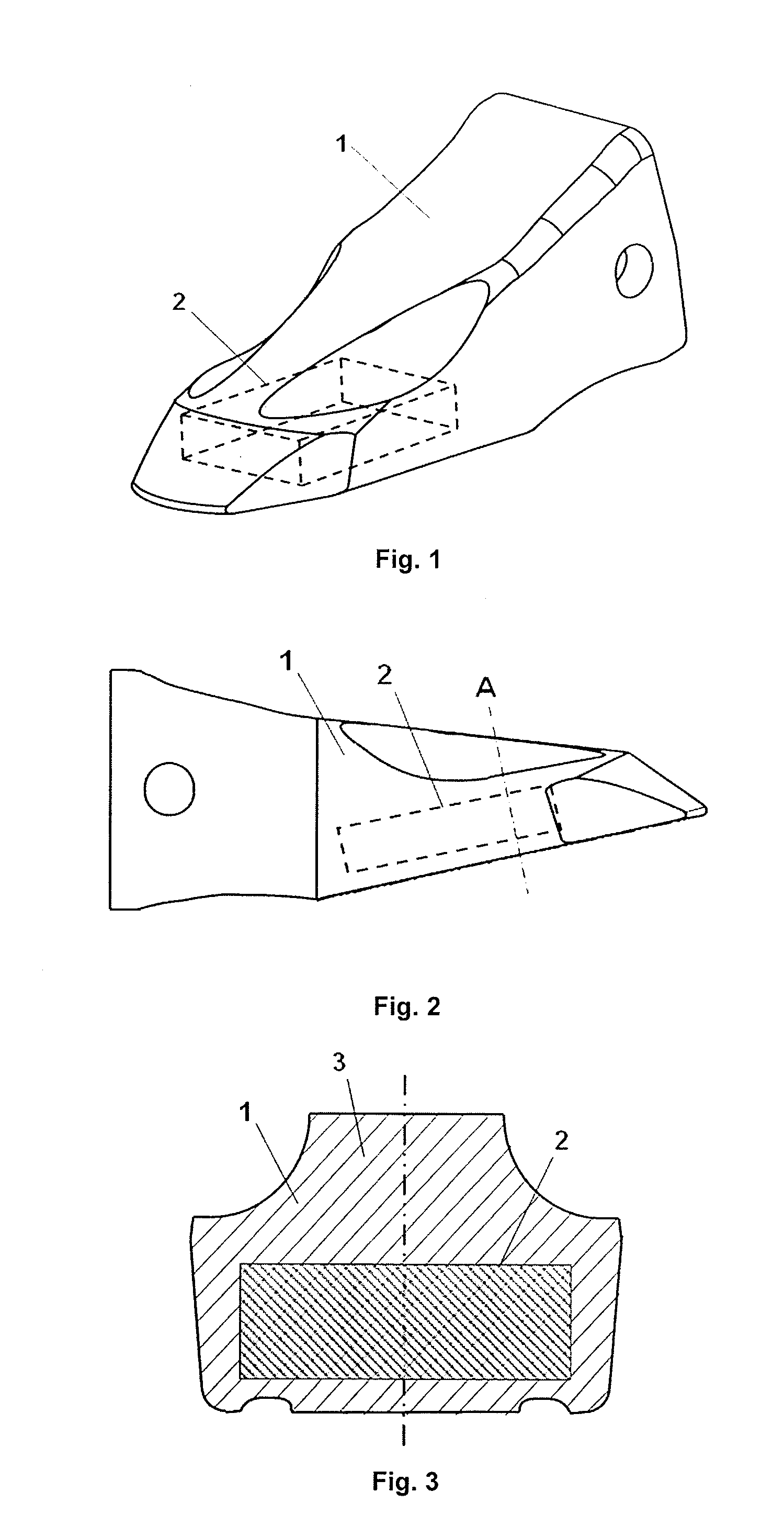

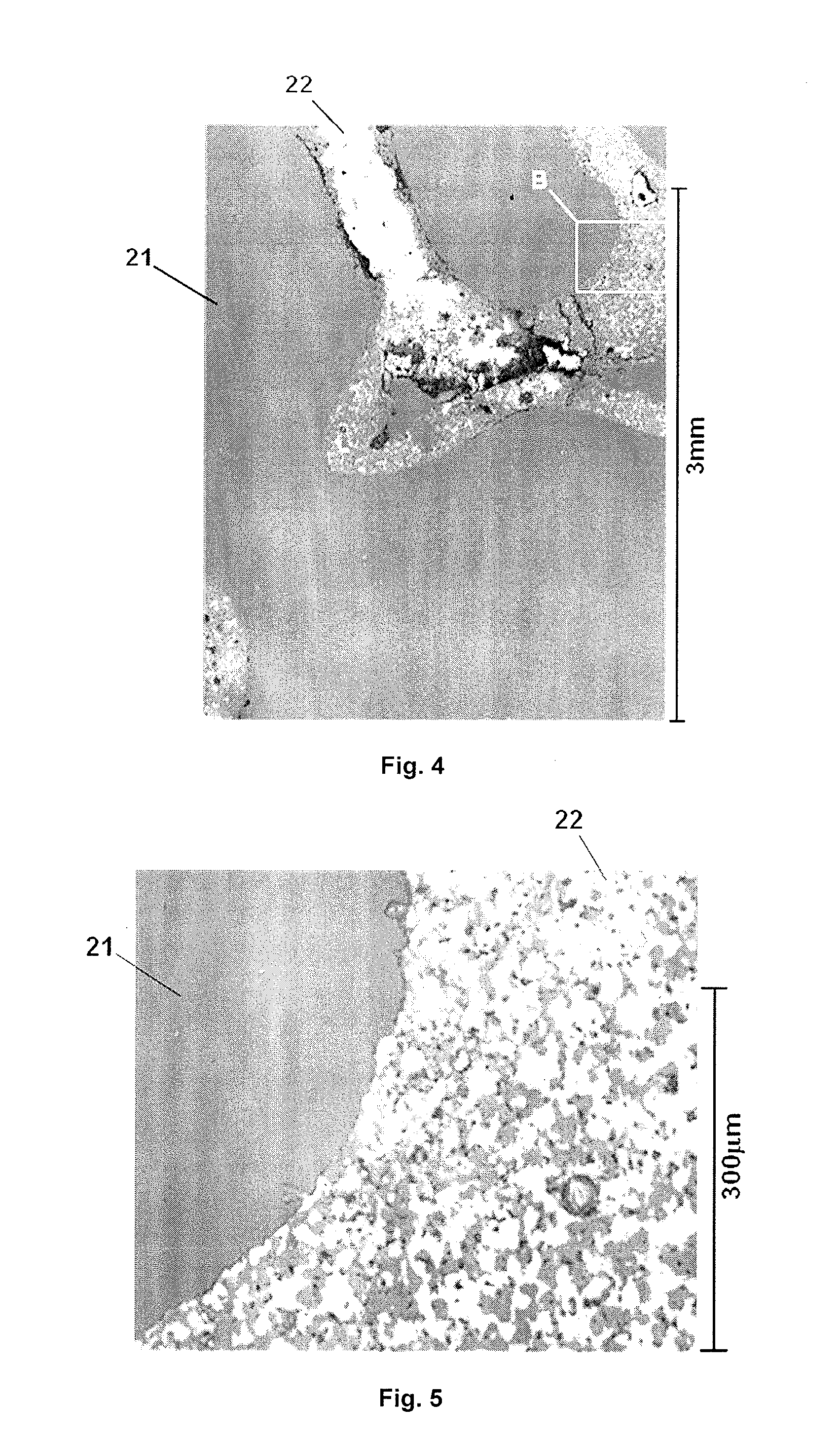

Wearing element with enhanced wear resistance

ActiveUS20120131821A1Improve wear lifeImprove wear resistanceDrill bitsSlitting machinesWear resistanceMaterials science

Wearing element with enhanced wear resistance related to wearing elements, such as cast steel teeth to be specially used in machinery for earth-moving, ground-engaging and / or rock-loading applications, as well as to inserts to be included within the wearing elements, to enhance their wear resistance thus prolonging their service life.

Owner:METALOGENIA SA

Diesel engine water pump with improved water seal

ActiveUS6884022B2Extended service lifeEasy constructionRotary bearingsEngine sealsImpellerWear particle

An improved diesel engine water pump includes three main features that aid in extending the maintenance-free life of the pump. The impeller shaft is carried by tapered roller shaft support bearings of which the impeller bearing has a floating outer race that is urged axially by a preload spring to provide a prescribed axial preload that maintains concentricity of the shaft with the axis and prolongs bearing life. An improved oil seal combines an oil slinger, a stationary deflector and a lip oil seal with a return passage to the engine to more effectively limit oil leakage from the pump. An improved water seal includes pressurized water jets fed from the pump volute that flush wear particles from the water seal surface and increase water seal life. Further details of these features are also disclosed.

Owner:ELECTRO-MOTIVE DIESEL

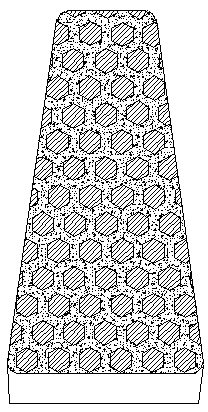

Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

The invention discloses a composite reinforced wear-resistant part of a metal-ceramic prefabricated member and a manufacturing method of the composite reinforced wear-resistant part. The manufacturing method comprises the steps as follows: uniformly mixing ceramic particles with self-fluxing alloy powder to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, pressing by pressure, forming and demoulding, and placing biscuits and gaskets into a drying box for drying; placing the dried biscuits and gaskets into a vacuum furnace for sintering, cooling and discharging to obtain the metal-ceramic composite prefabricated member; carrying out sand blasting on the prefabricated member, and spraying a layer of nickel-based self-fluxing alloy powder onto the surface of the prefabricated member; and placing the processed fabricated member onto the end surface of a cast cavity, and pouring metal liquid formed by smelting metal matrix materials into the bottom of the cast cavity to obtain the composite reinforced wear-resistant part of the metal-ceramic prefabricated member. According to the manufacturing method, the wear resistance and the impact resistance of the composite wear-resistant part are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

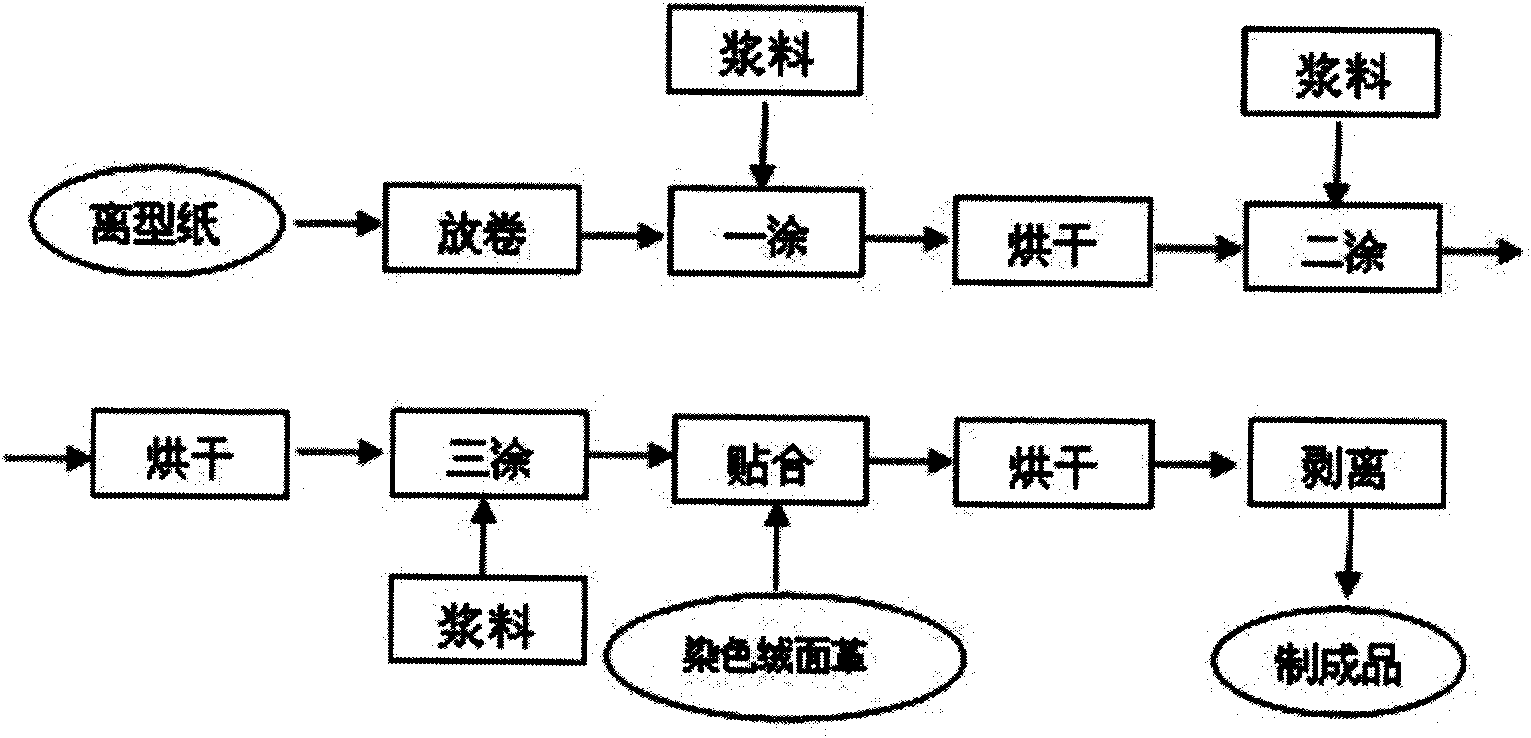

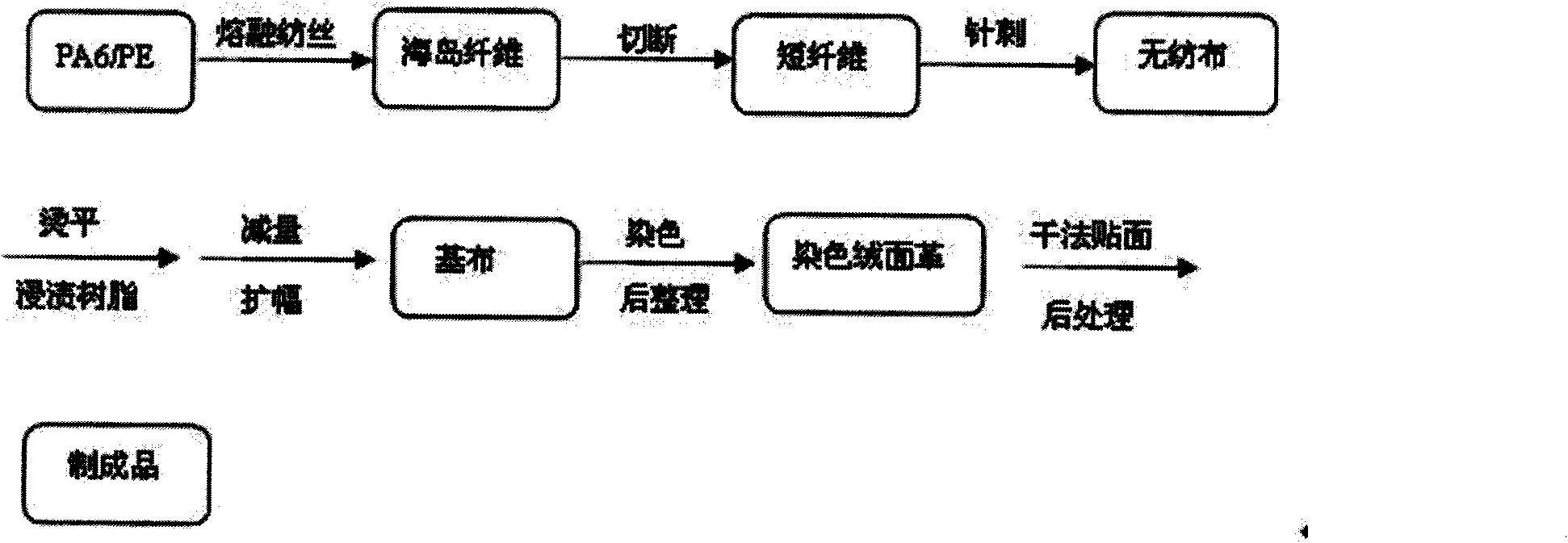

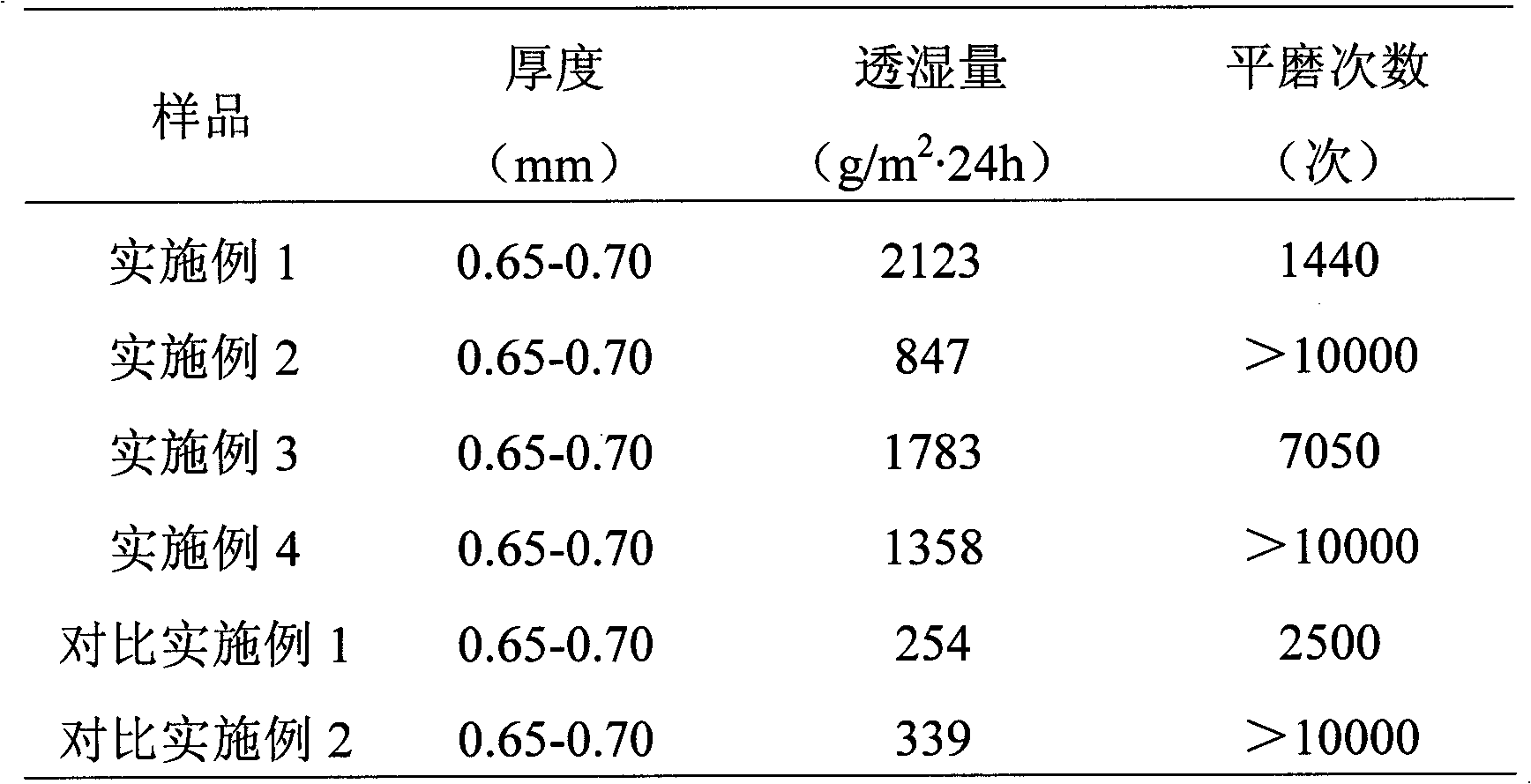

Superfine fiber leather and preparation method thereof

InactiveCN102102301AImprove comfortGood moisture permeabilitySynthetic resin layered productsTextiles and paperFiberWear resistant

The invention discloses a preparation method of superfine fiber leather, which comprises the steps of: coating a surface layer, a middle layer and an adhesive layer on a piece of release paper; laminating the release paper with dyed suede leather; drying; and removing the release paper to obtain the superfine fiber leather, wherein a sizing agent of the surface layer and the middle layer contains 100 parts of polyurethane resin, 10 to 60 parts of polar solvent, 1 to 6 parts of friction resistant additive and 0.5 to 5 parts of hydrophilic additive; a sizing agent of the adhesive layer contains 100 parts of polyurethane resin, 10 to 60 parts of polar solvent, 1 to 6 parts of friction resistant additive, 0.5 to 5 parts of hydrophilic additive and 70 to 90 parts of absorbent resin; a fluorine modified polyethylene wax substance is adopted as the friction resistant additive; and a hydrophilic organic silicon substance is adopted as the hydrophilic additive. The invention also discloses superfine fiber leather which has the moisture permeability higher than or equal to 850 grams per square meter for every 24 hours, which is higher than that of the natural leather. The preparation method disclosed by the invention can also improve the wear resistant time which is higher than 10000 times in the preferable embodiment of the invention.

Owner:HUAFON MICROFIBER SHANGHAI

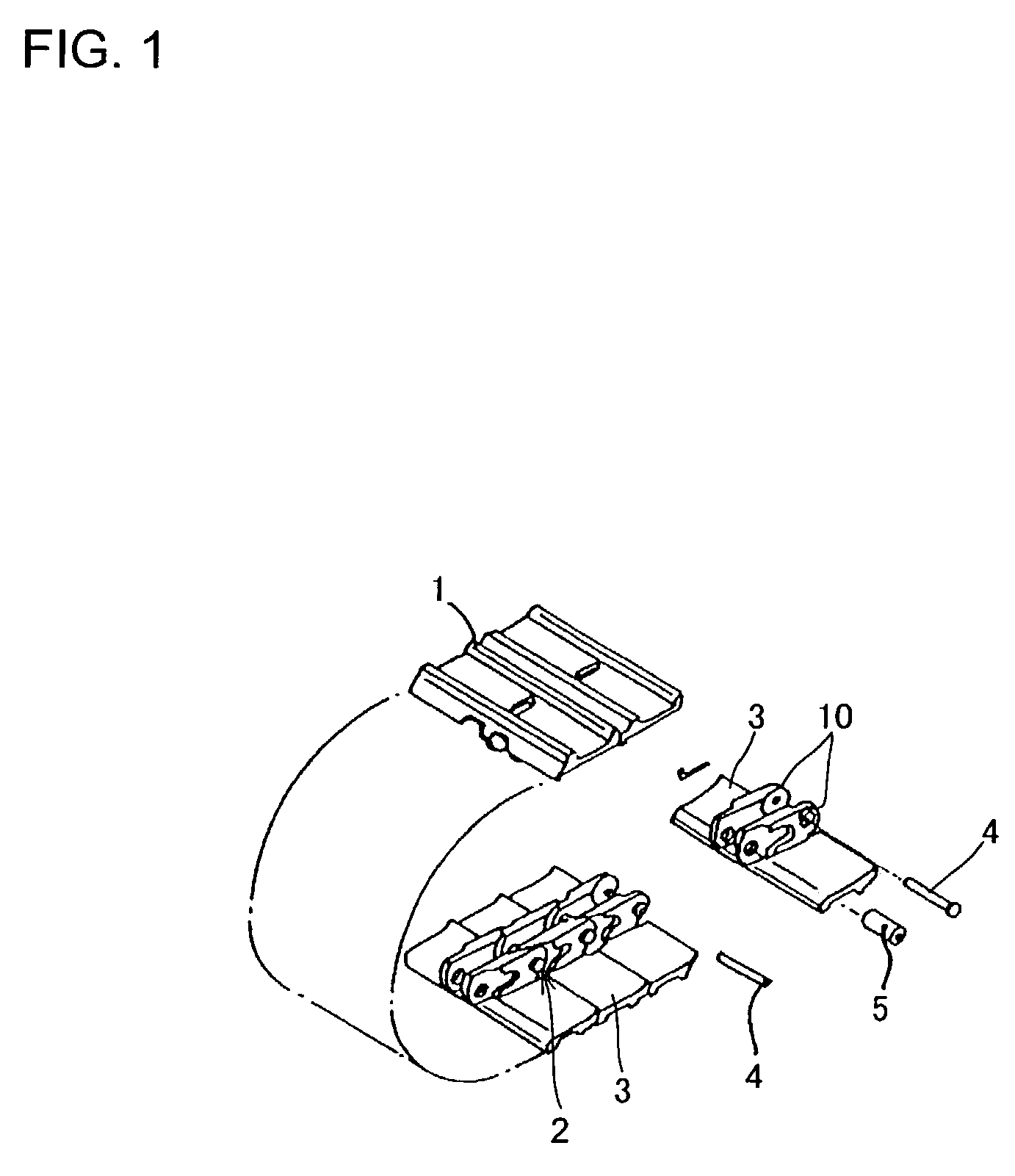

Track link production method and track link produced by the same

InactiveUS7040080B2Delayed failureIncrease pressureConnecting rodsMetal-working apparatusHigh dimensionalMachining process

There are proposed a track link production method capable of providing markedly improved wear life with good cost performance and a track link produced by this method. To this end, the track link production method includes a heat treatment process (Steps 4, 5) of applying quenching and low temperature tempering treatment to a whole link material after hot forging (Step 2), and is designed such that desired machining is applied to the link material (Step 3) before the heat treatment process (Steps 4, 5) and such that after the heat treatment process (Steps 4, 5), tempering (Step 6) and finish machining (Step 7) are sequentially applied to some of the parts which have undergone the machining process, the some parts including at least parts where high dimensional accuracy is required.

Owner:KOMATSU LTD

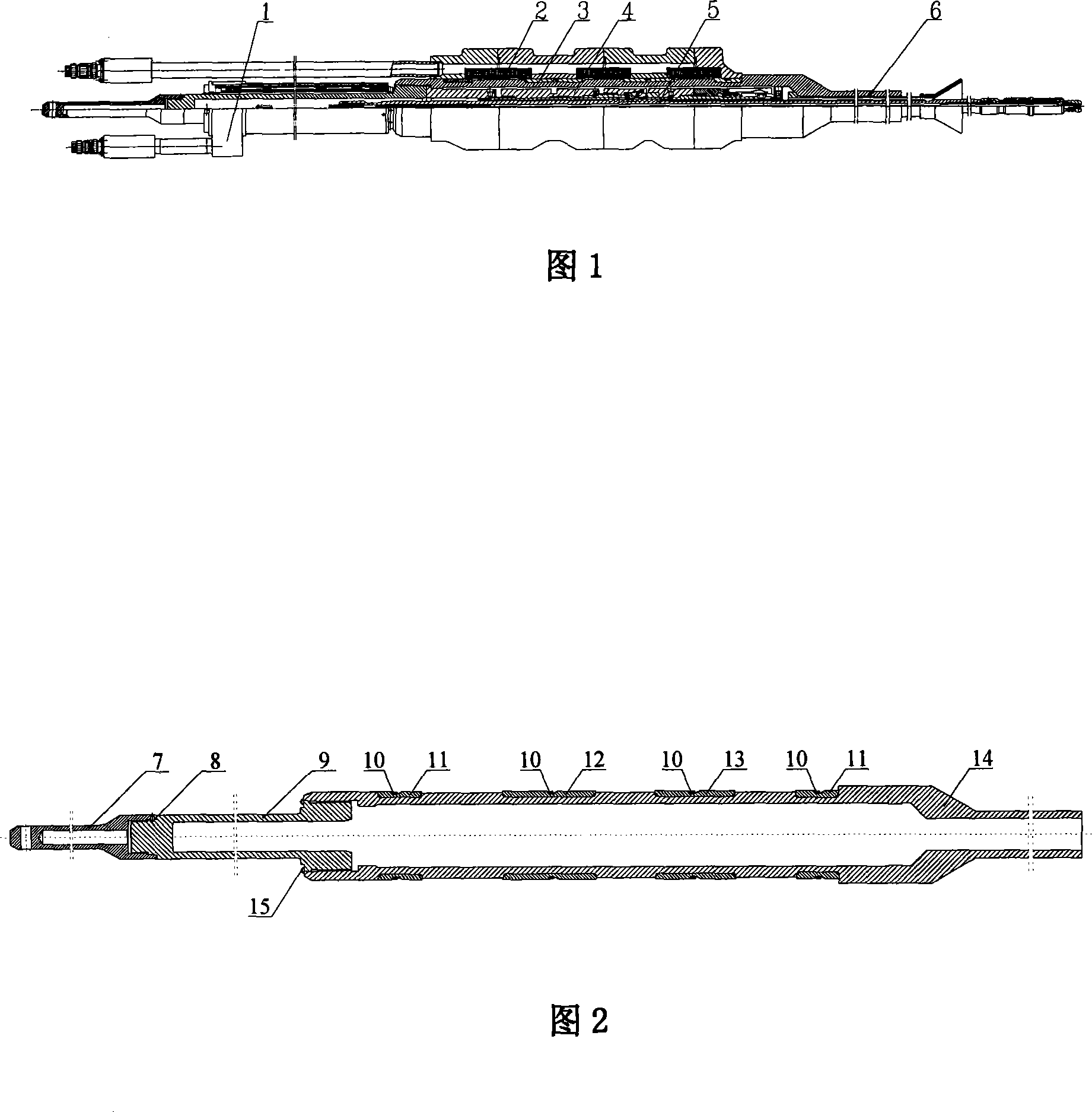

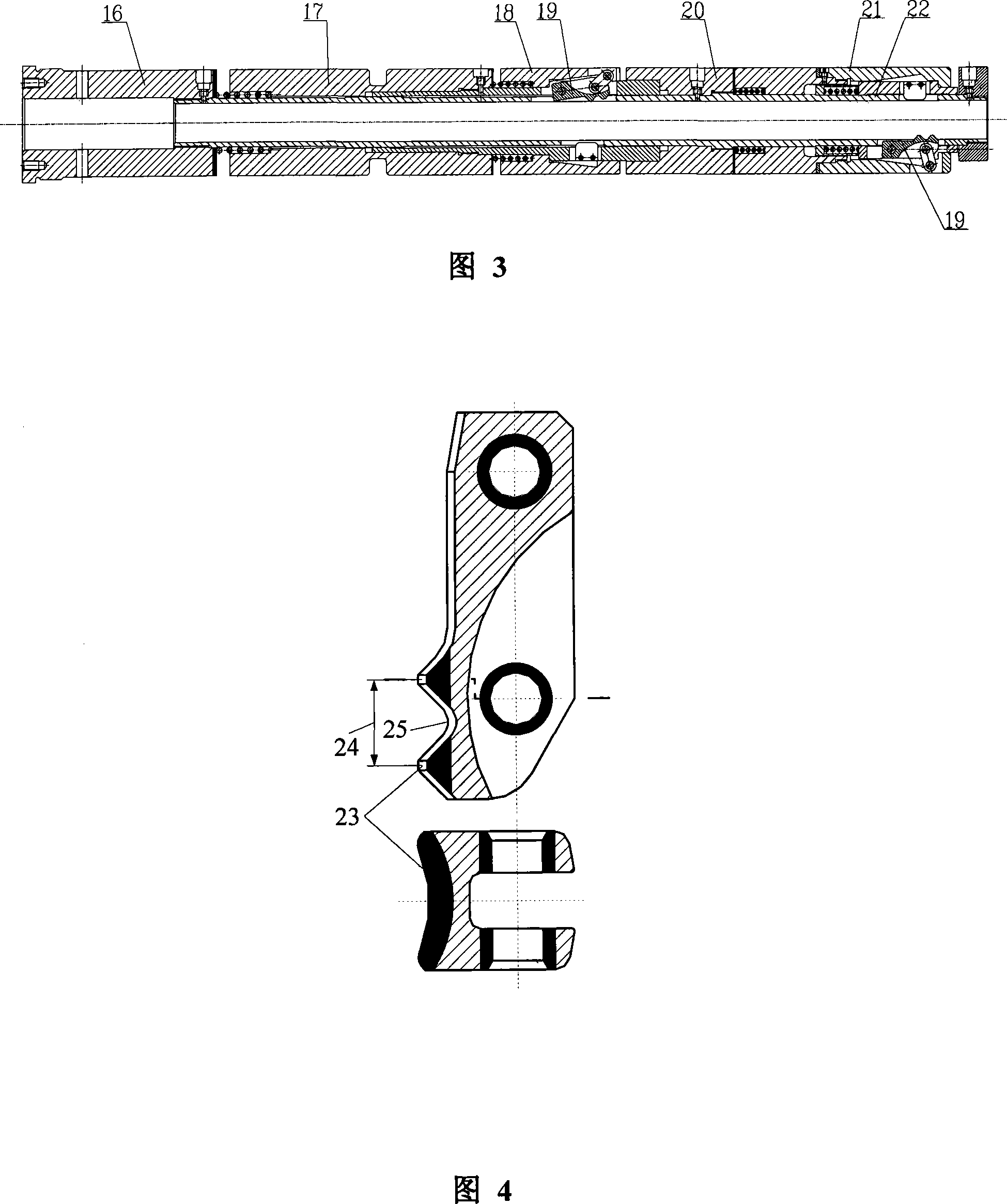

Stepwise magnetic force hoisting type reactor control rod driving mechanism

ActiveCN101178946AImprove wear lifeImprove wear resistanceNuclear energy generationNuclear reaction controlTube socketKnuckle

The invention provides a marching type and magnetic jacking reactor control rod drive mechanics, which comprises a rod position detector component, a coil component, a pressure shell component, a knuckle component, a driving rod component, a heatproof lagging component and the like. The whole mechanism is vertically mounted on a top cover of a reactor pressure vessel directly, wherein the pressure shell component consists of a hoisting connector, a travel sleeve and a hermetic case. The travel sleeve of the pressure shell component is an integral blind tube with a blocked upper end and the hermetic case is an integral structure composed of a tube socket of the driving mechanism on the top cover of the reactor pressure vessel, and the hermetic case. The knuckle component is composed of two identical knuckle teeth arranged side by side, the distance between the two knuckle teeth is equal to the teeth space of the driving rod component, and the two sides of the flute between the two knuckle teeth are of transitional circular arc shape. The invention greatly reduces the leakage possibility of the pressure shell of the reactor control rod drive mechanics, and greatly improves the wear resistance, the reliability and the service life of the reactor control rod drive mechanics.

Owner:SICHUAN HUADU NUCLEAR EQUIP MFR

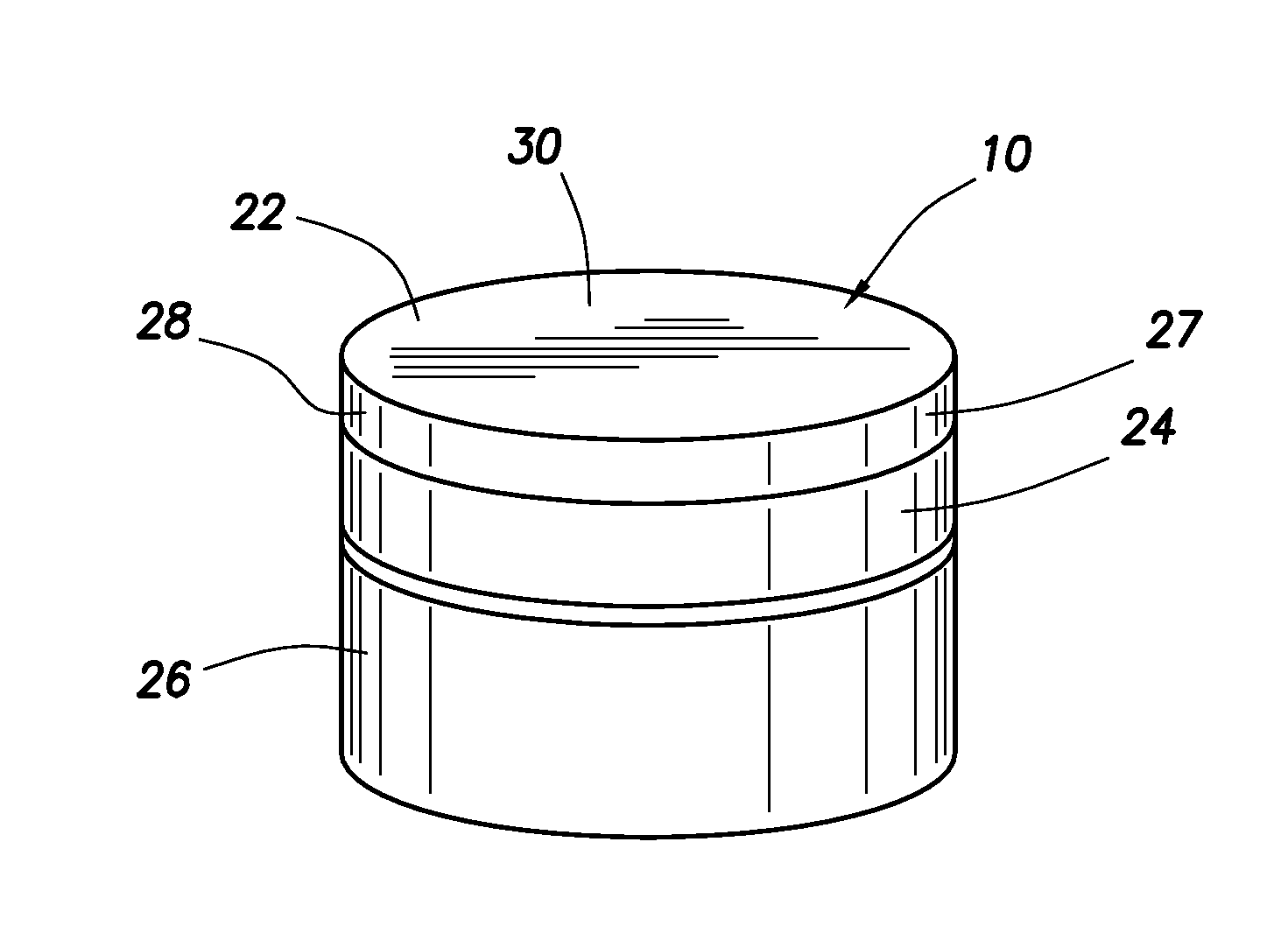

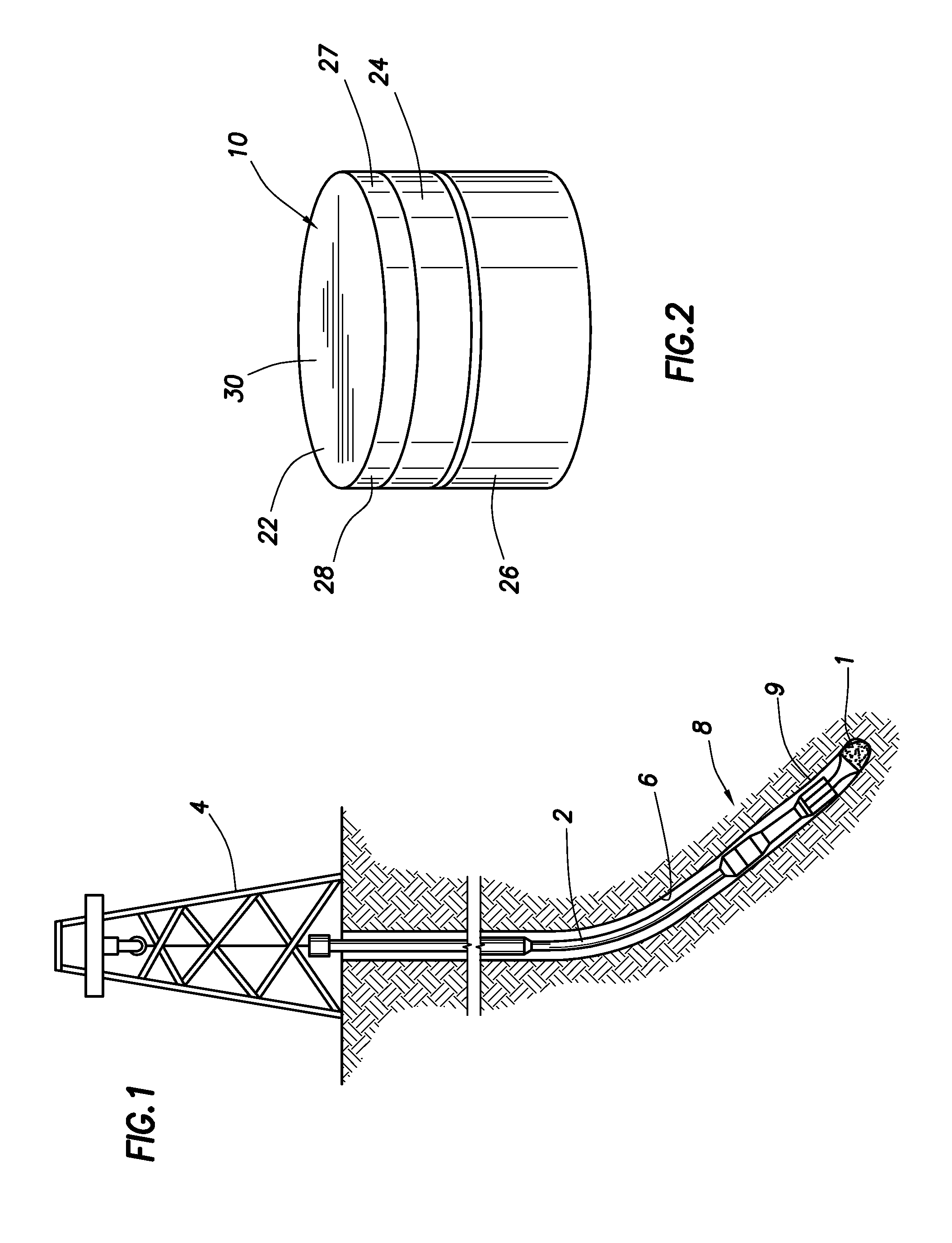

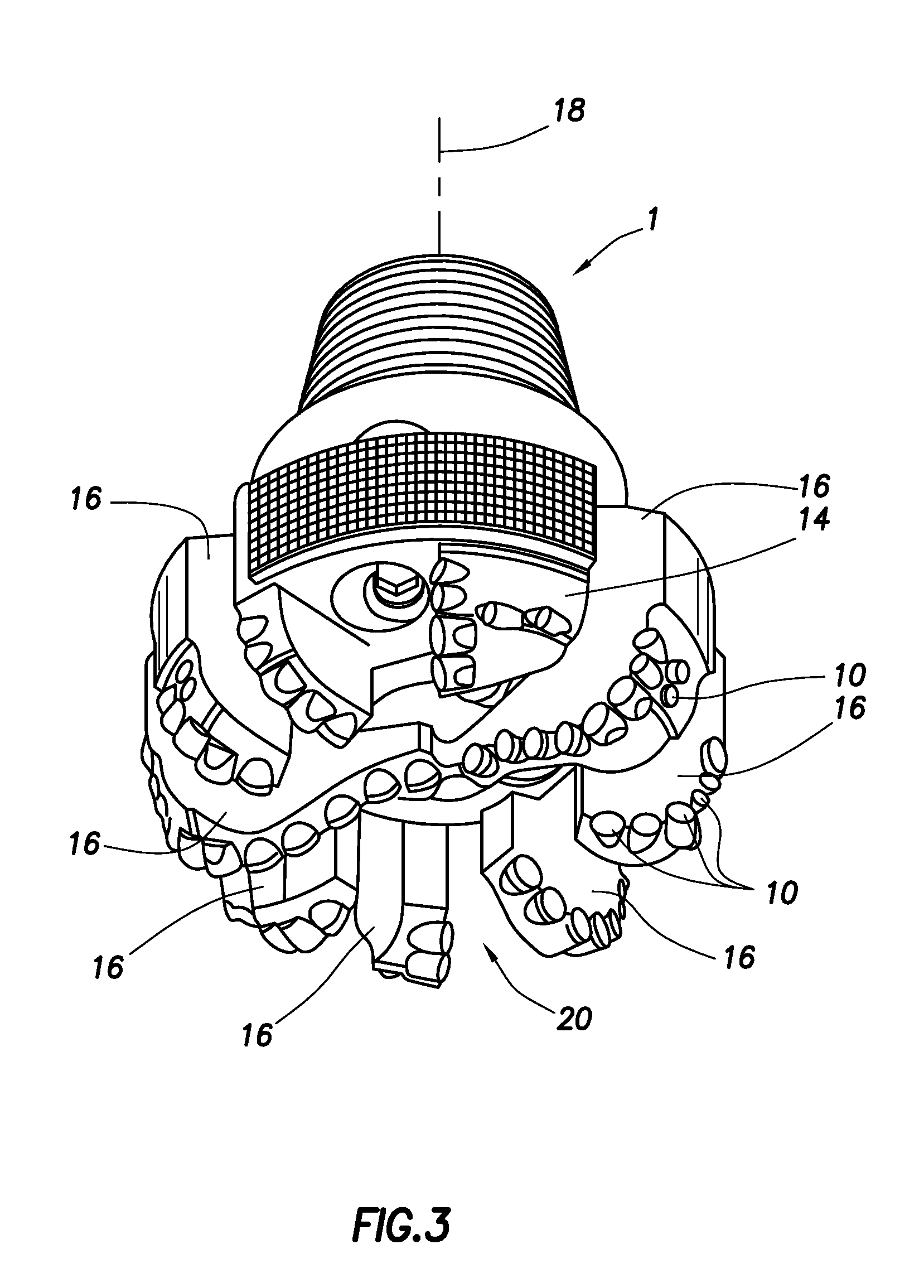

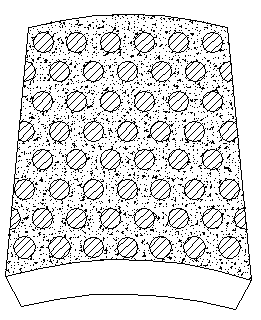

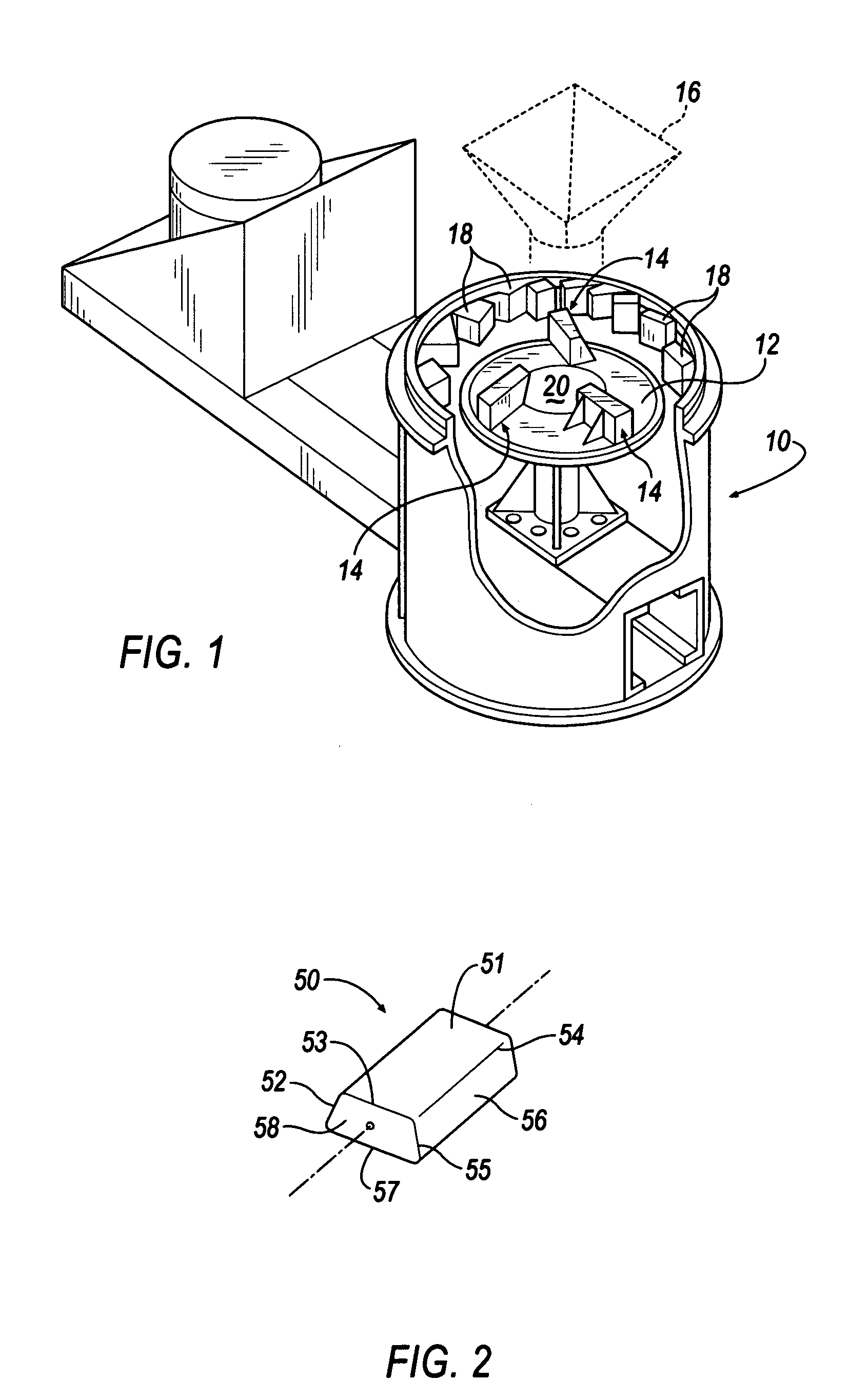

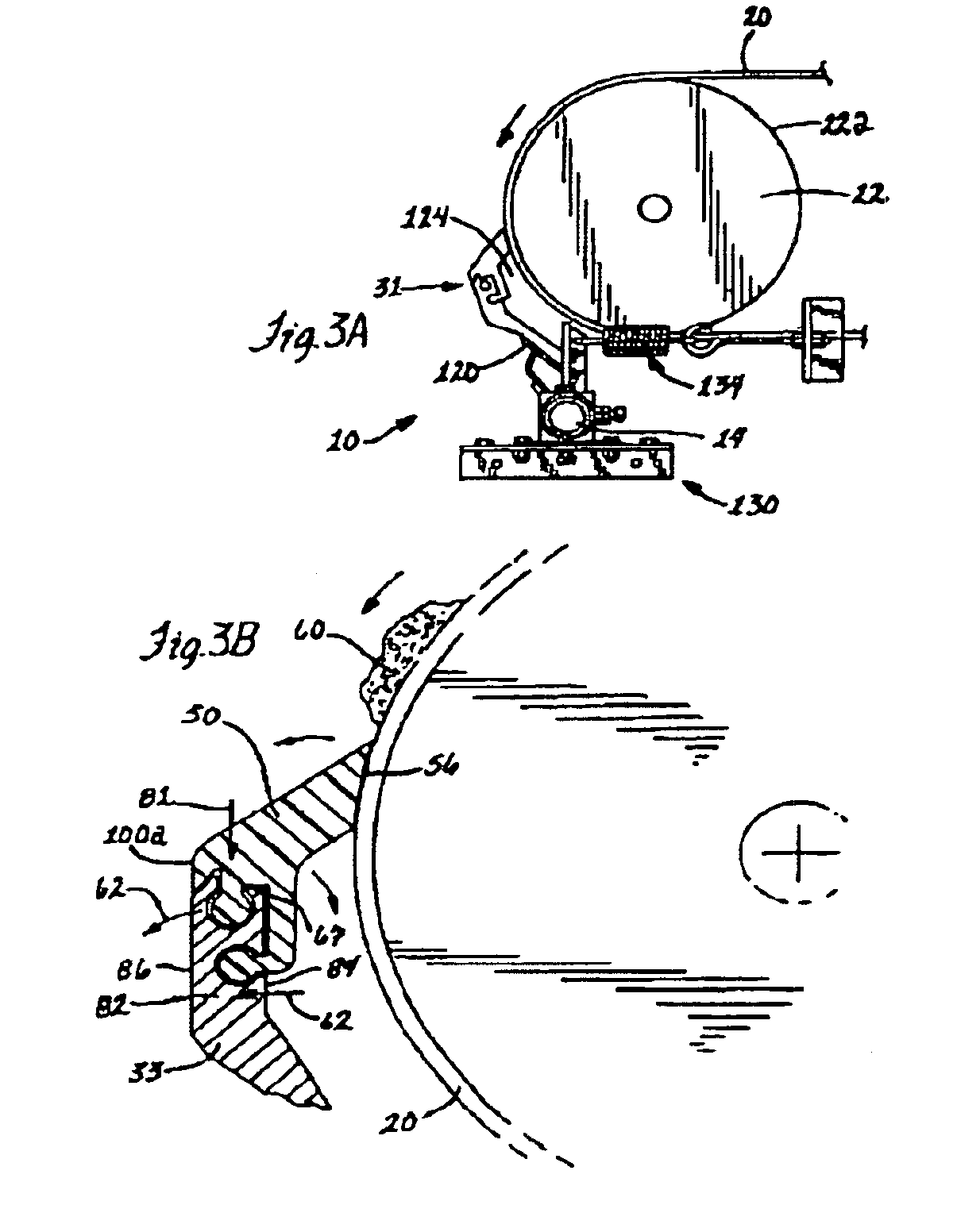

Polycrystalline diamond cutting element

ActiveUS20120097457A1Improve wear lifeImprove featuresDrill bitsConstructionsPolycrystalline diamondDrill bit

A polycrystalline-diamond cutting element for a drill bit of a downhole tool. The cutting element includes a substrate and a diamond table bonded to the substrate. The diamond table includes a diamond filler with at least one leached polycrystalline diamond segment packed therein along at least one working surface thereof. The cutting element may be formed by positioning the diamond table on the substrate and bonding the diamond table onto the substrate such that the polycrystalline diamond segment is positioned along at least one working surface of the diamond table. A spark plasma sintering or double press operation may be used to bond the diamond table onto the substrate.

Owner:NAT OILWELL DHT

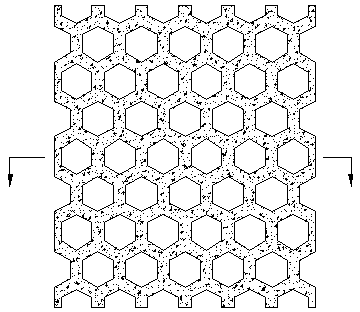

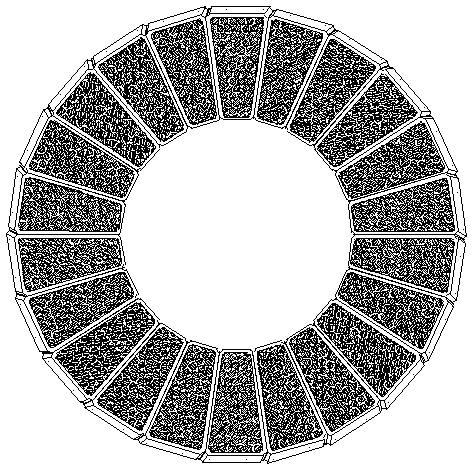

Ceramic grid enhanced metal matrix composite perform and preparation method thereof

The invention discloses a ceramic grid enhanced metal matrix composite perform and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing ceramic particles with the particle sizes of 8-30 meshes and self-fluxing alloy powder in polyvinyl alcohol to obtain a mixture; filling the mixture in a grid cavity, prepressing for preparing ceramic grids, filling the self-fluxing alloy powder into grid holes after the grids leave from a mold, wherein the monolithic material is pressed with 100-300 kilogram force, molding and demolding, placing and drying a biscuit and a mold cavity bottom plate in a 150 DEG C drying oven for 2 hours; placing the dried biscuit and the mold cavity bottom plate in a vacuum furnace, sintering for 30-90 minutes under the conditions that the temperature is 1000-1300 DEG C, and the vacuum degree is 0.1 Pa, and cooling and discharging to obtain the ceramic grid enhanced metal matrix composite perform. The ceramic grid enhanced metal matrix composite perform prepared by the method has the advantages of high density, uniform distribution of ceramic particles, good wear resistance and high grinding efficiency.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

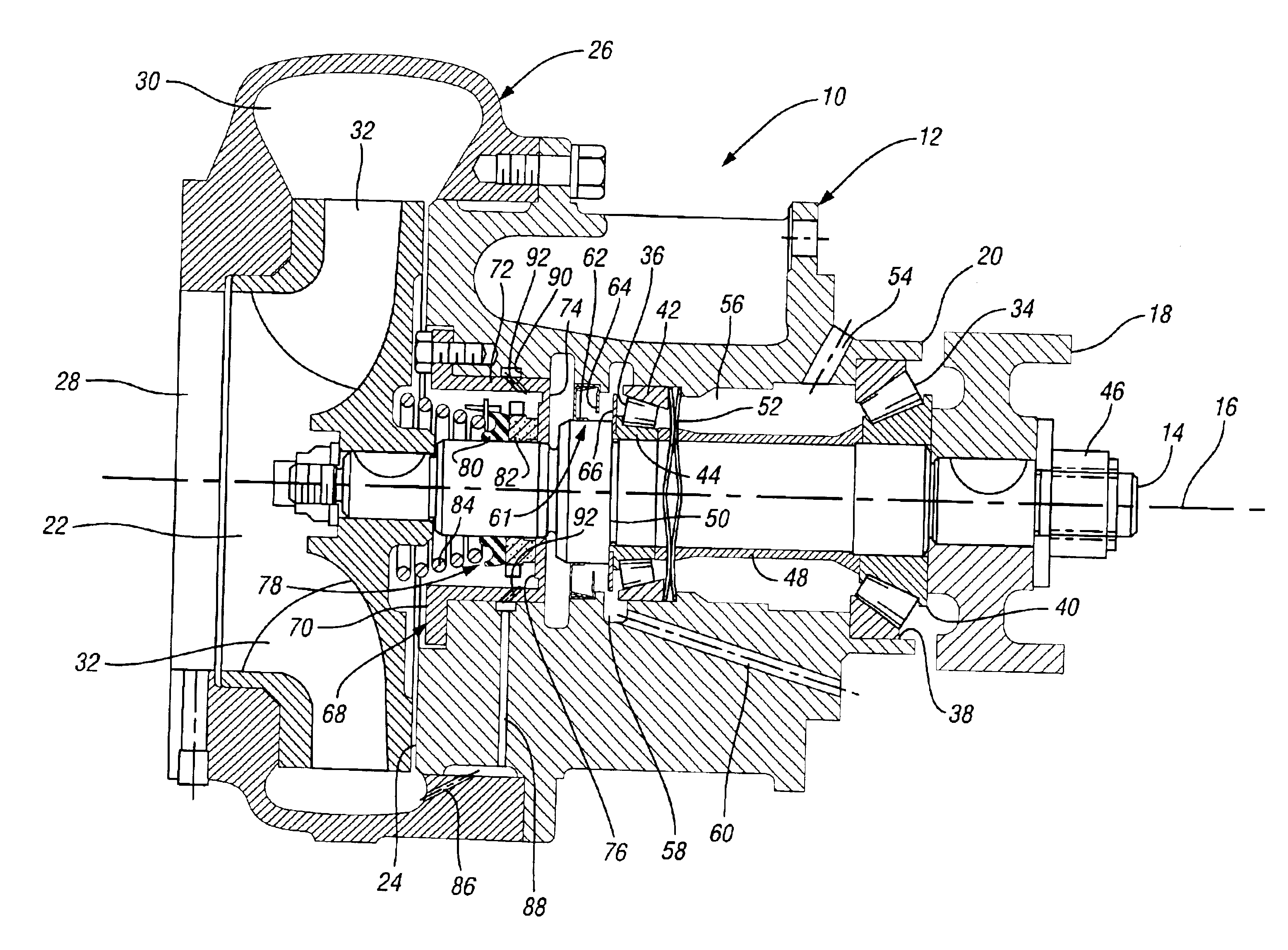

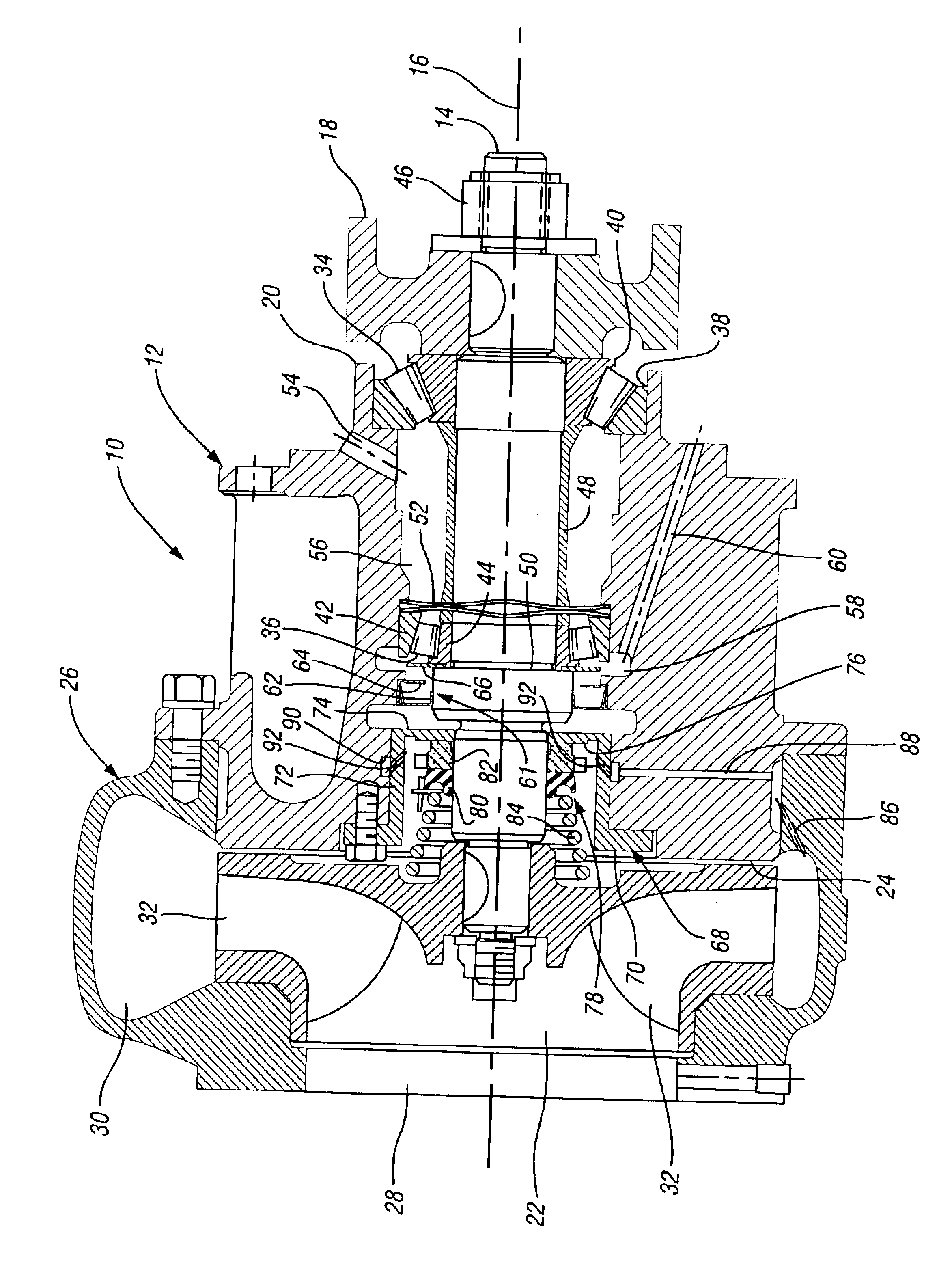

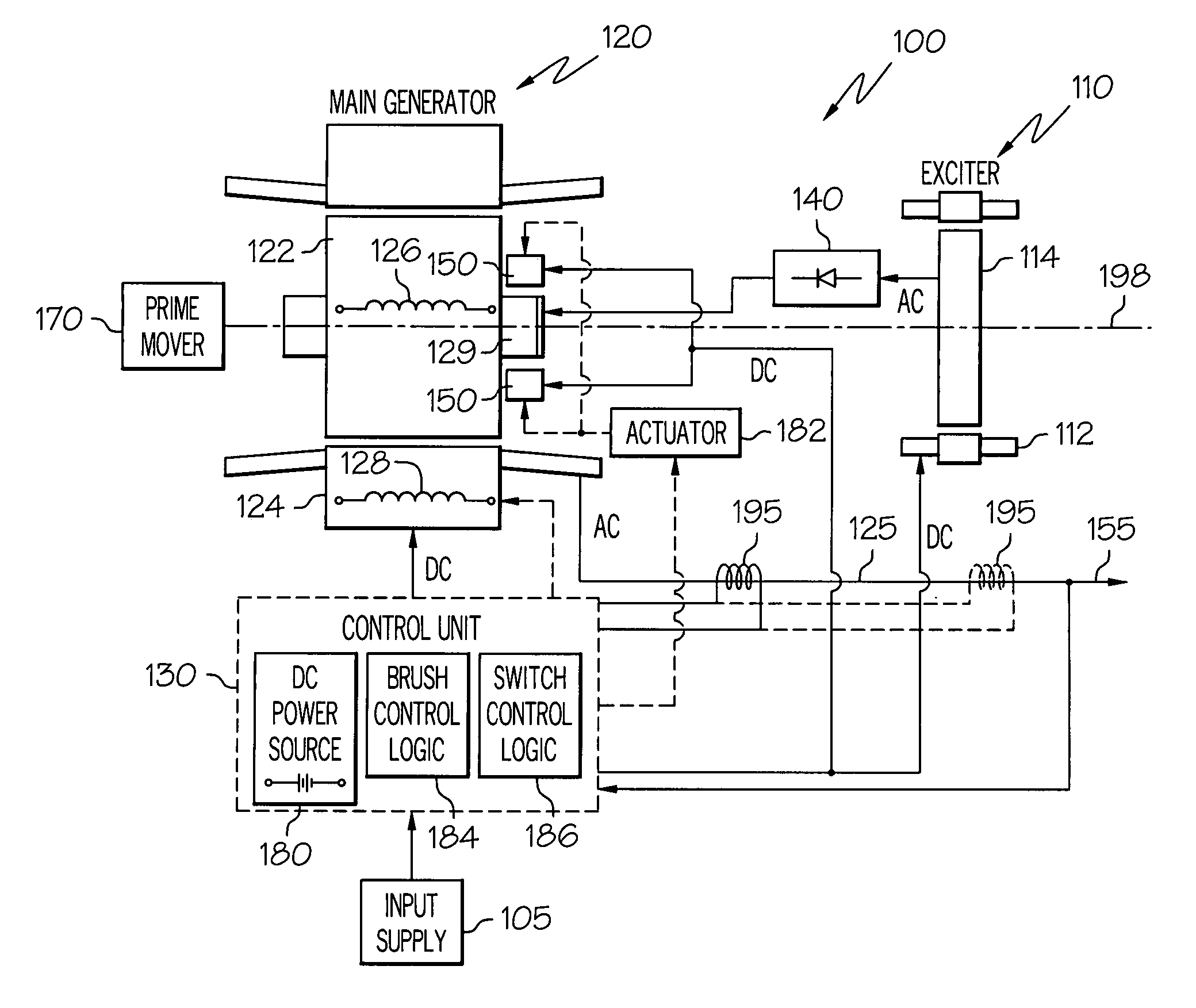

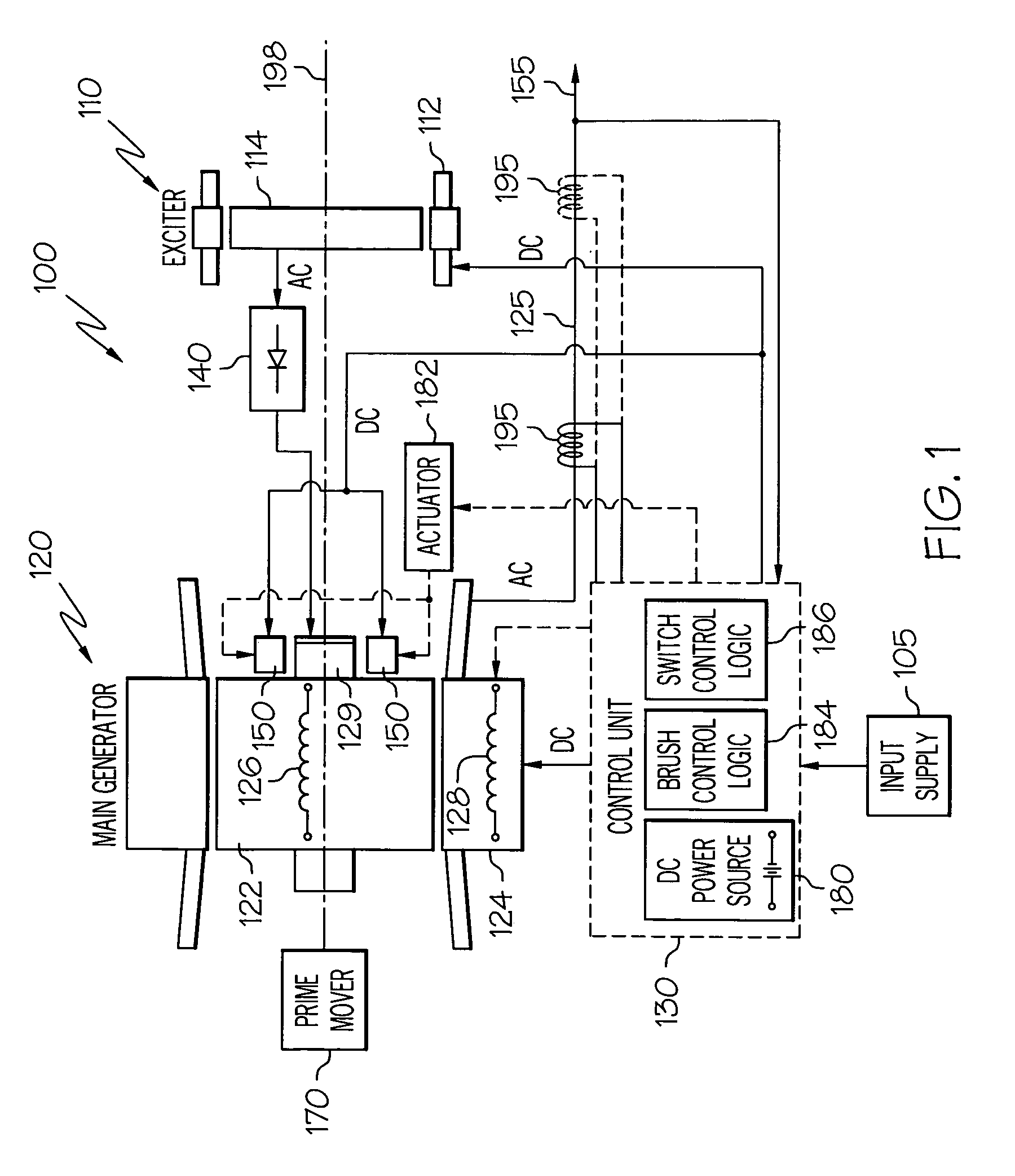

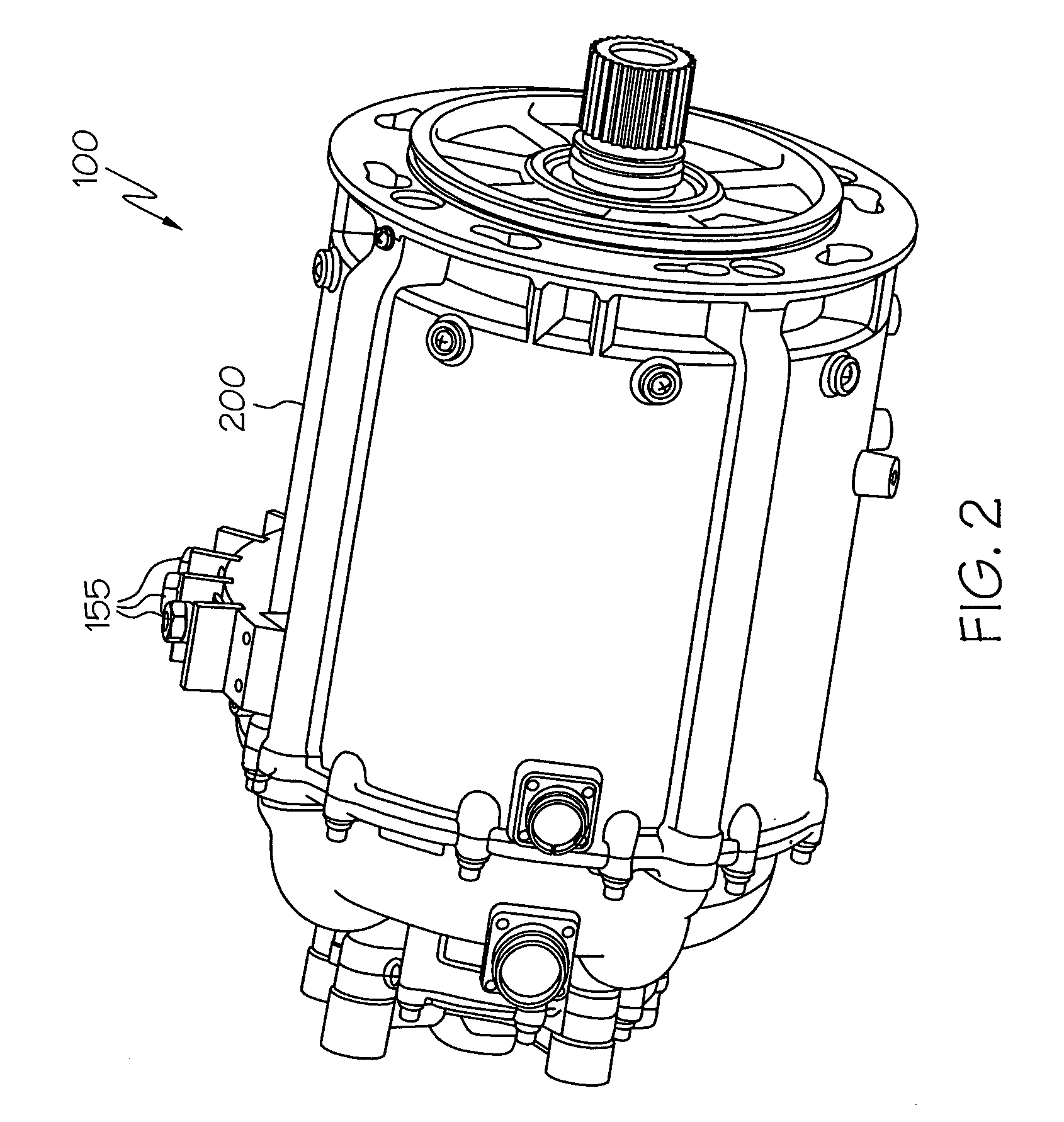

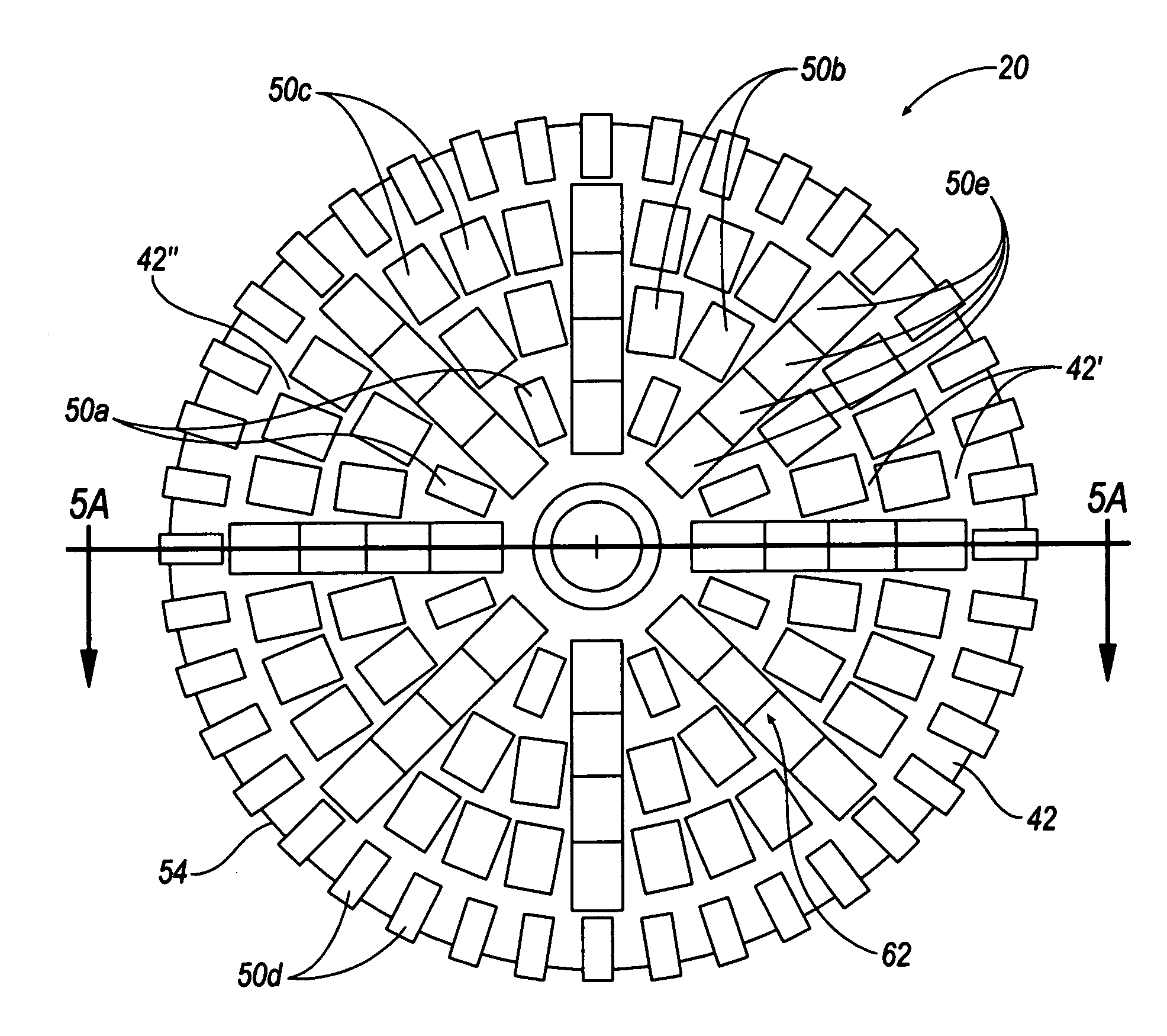

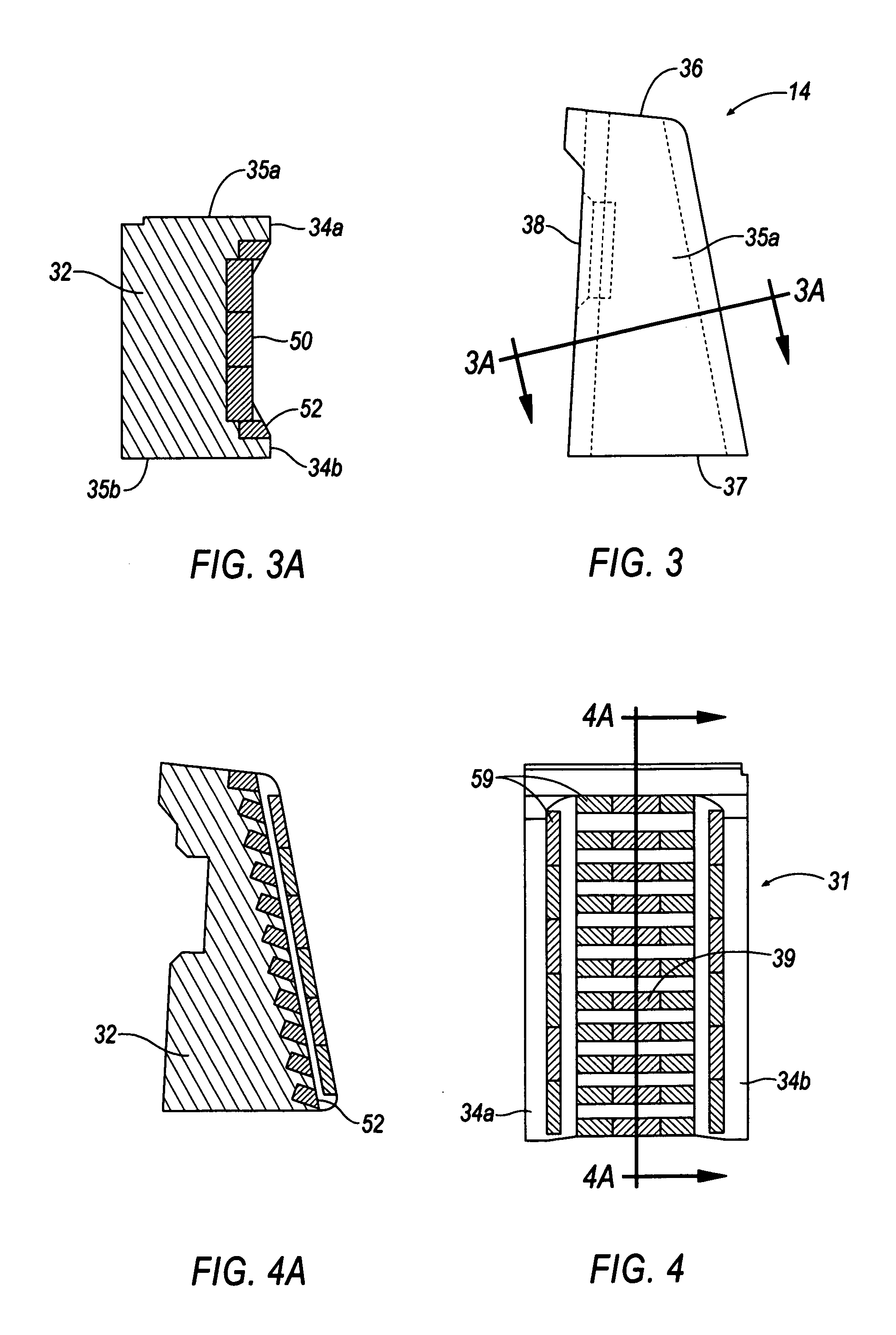

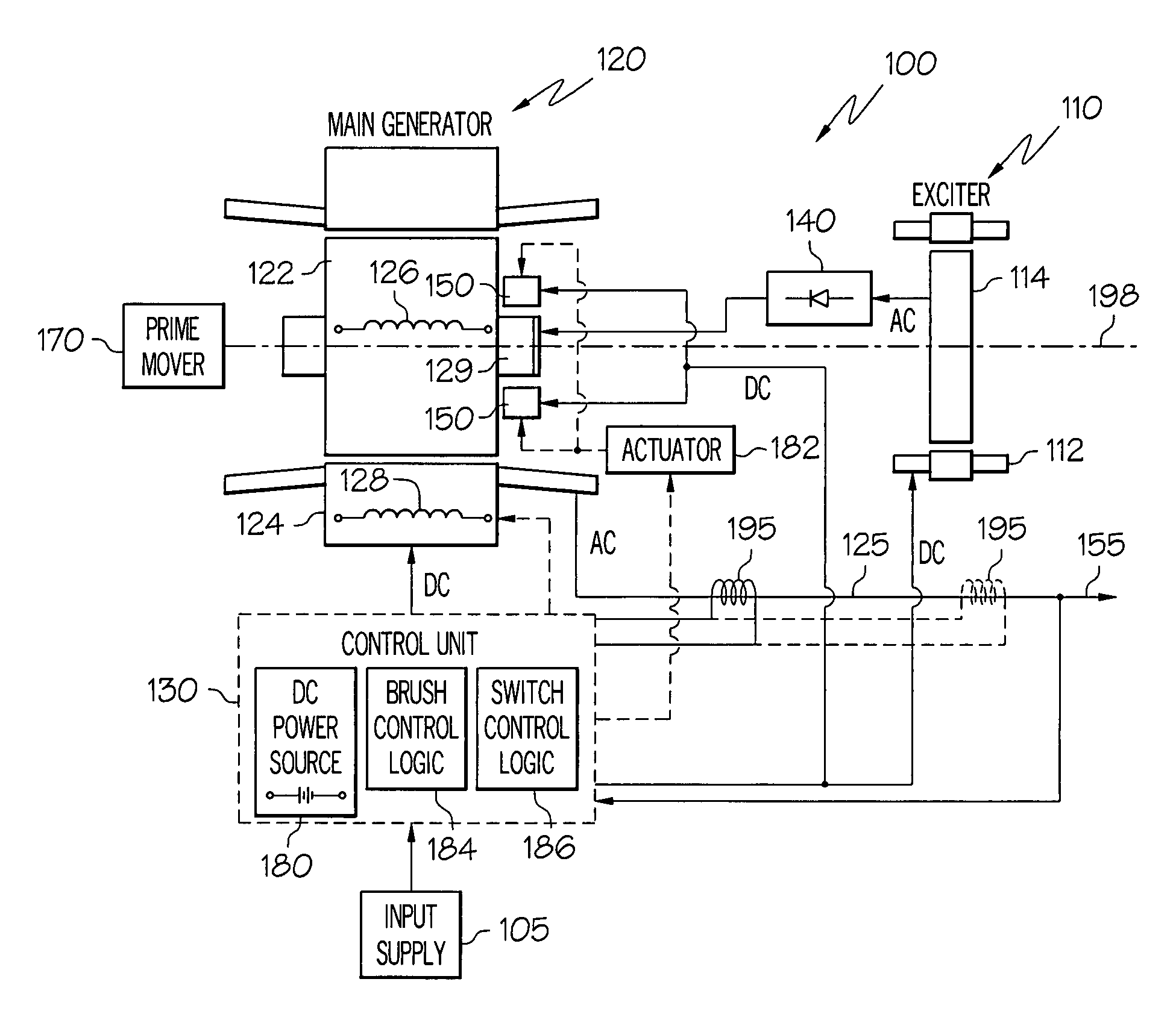

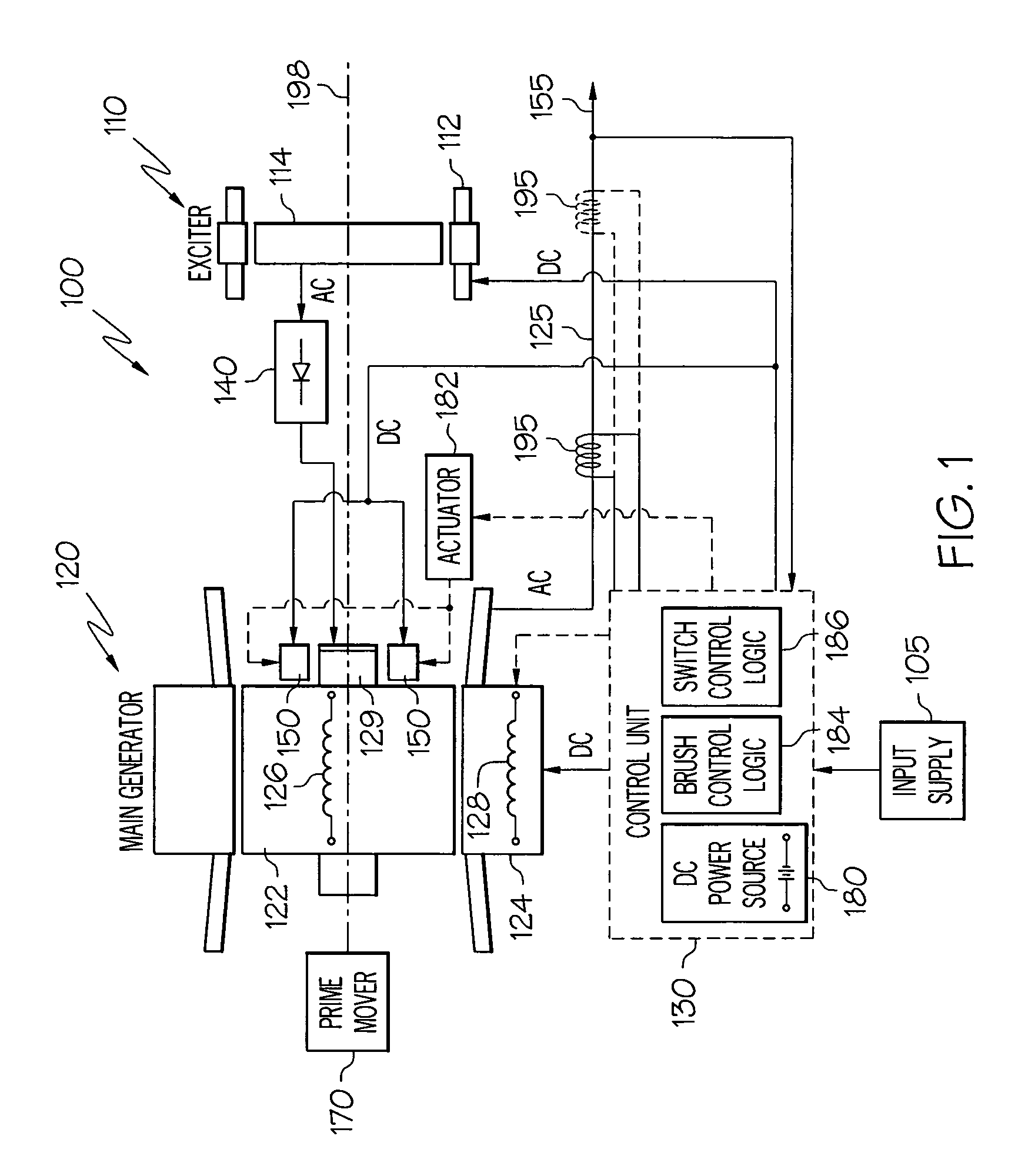

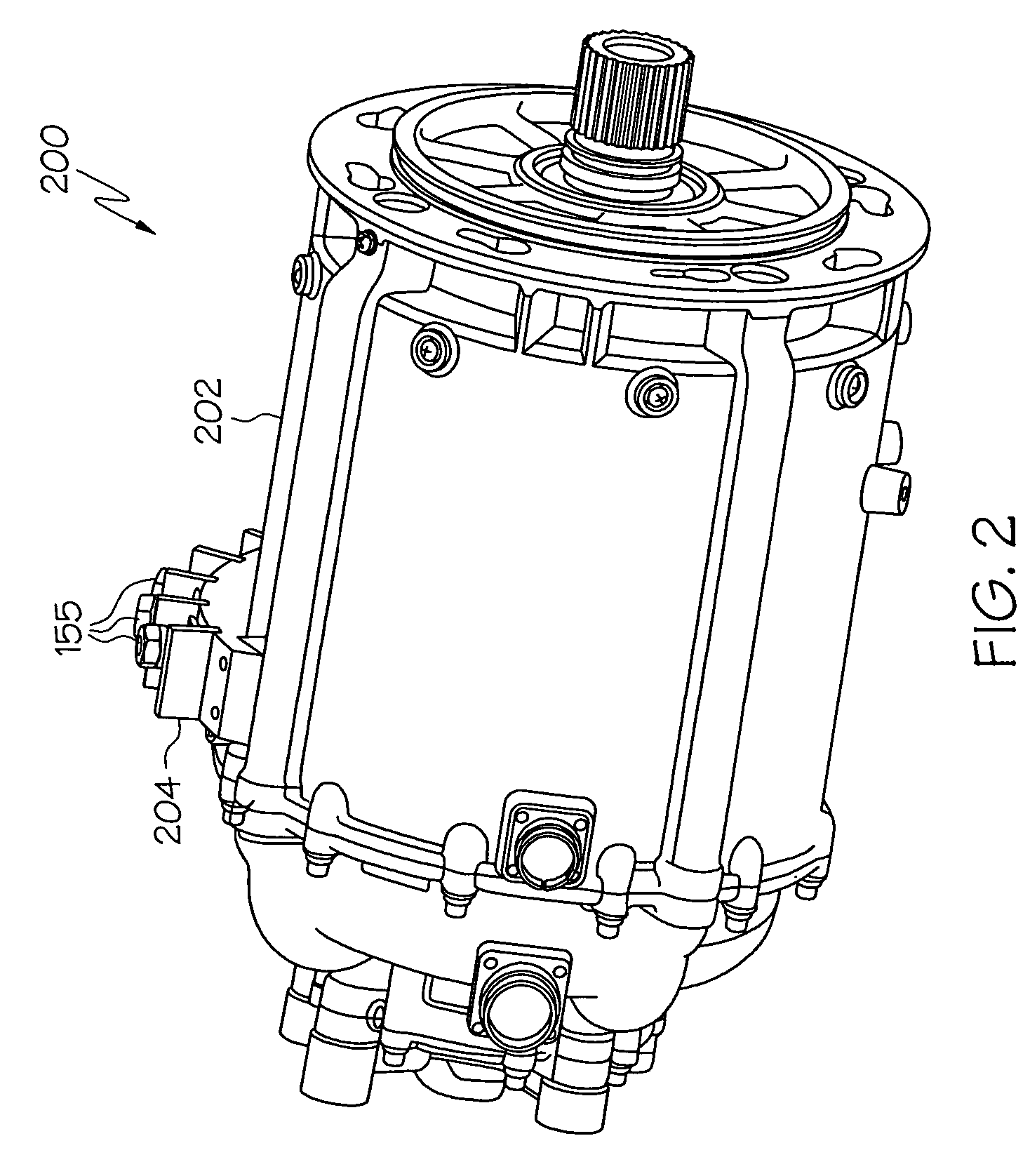

Hybrid gas turbine engine starter-generator

InactiveUS7078826B2Improve wear lifeLow costSynchronous generatorsAC motor controlElectricityStarter generator

A rotating electrical machine, such as an aircraft starter-generator, that may be operated in either a DC motor mode or an AC generator mode. The machine includes a conventionally wound main stator that is selectively configurable as a multi-pole AC stator and a multi-pole DC stator. The machine also includes rotor windings that are configured to be selectively coupled to either an exciter or a plurality of commutator segments, and DC brushes that are selectively moveable into, and out of, electrical contact with the commutator segments, to thereby electrically couple and decouple a DC power source to and from, respectively, the rotor windings.

Owner:HONEYWELL INT INC

CrNiMo series easily cut pinion steel and manufacturing method thereof

The invention relates to a CrNiMo series easily cut pinion steel and a manufacturing method thereof. The steel comprises the following chemical compositions by weight percent: 0.17-0.23% of C, 0.15-0.37% of Si, 0.60-0.95% of Mn, 0.35-0.65% of Cr, 0.35-0.75% of Ni, 0.15-0.25% of Mo, less than or equal to 0.030% of P, 0.010-0.040% of S, 0.005-0.050% of Al, 0.3-0.6% of Ca / S, and the balance of Fe and micro-impurities. The manufacturing method comprises the following steps: smelting in a primary refining furnace (electric furnace or converter); and carrying out LF+VD (ladle refining + vacuum degassing) or RH external refining, continuous casting and rolling, wherein through the external refining and vacuum degassing treatment, the content of the oxygen in the steel is not more than 15*16<-6>,the content of microelement S is controlled, the cutting property of the CrNiMo series pinion steel is improved, and the steel is suitable for speedily cutting and processing important precision parts.

Owner:SHANDONG IRON & STEEL CO LTD

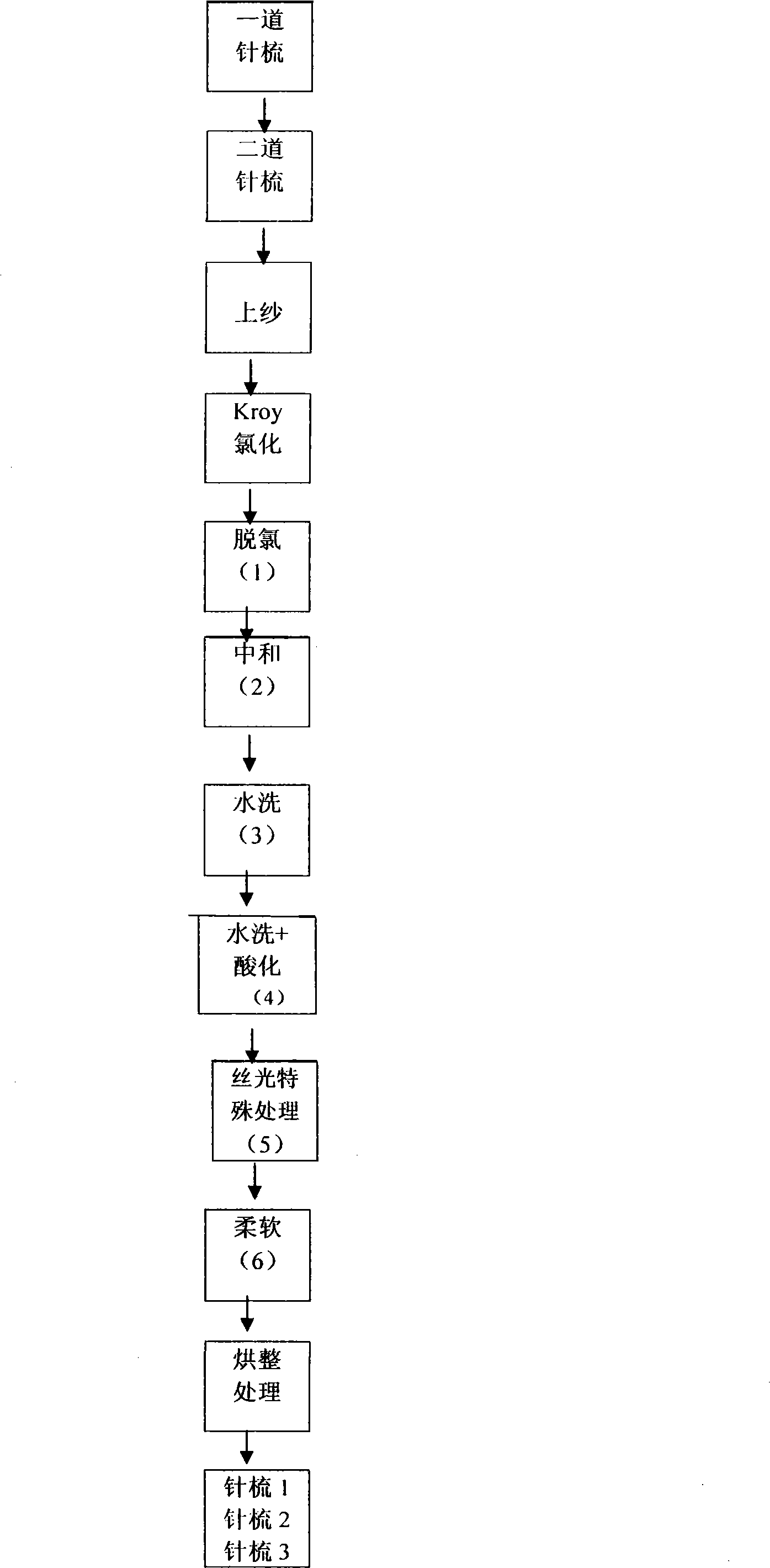

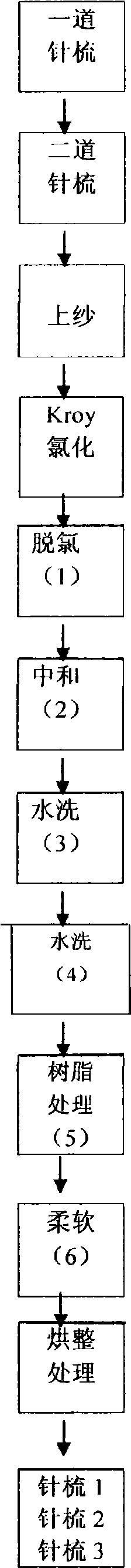

Wool shrinkproof mercerization method

ActiveCN101519838AGorgeous ingredientsRaw materials are simpleMercerising of sliversBiochemical fibre treatmentChlorinated solutionsEngineering

The invention provides a wool shrinkproof mercerization method which comprises the following steps: wools are combed by a needle, combed and opened again through secondary needle combing before chloriThe invention provides a wool shrinkproof mercerization method which comprises the following steps: wools are combed by a needle, combed and opened again through secondary needle combing before chloridization, and wetting agent is added during the needle combing for the chemical preliminary treatment; the secondary needle combing further ensures the opening and the fully and evenly wetting of thedization, and wetting agent is added during the needle combing for the chemical preliminary treatment; the secondary needle combing further ensures the opening and the fully and evenly wetting of thewools; chlorination scale stripping of chlorination solution is performed for the wools after the spraying of the wetting agent and the combing opening are performed, and the wools uniformly and sequewools; chlorination scale stripping of chlorination solution is performed for the wools after the spraying of the wetting agent and the combing opening are performed, and the wools uniformly and sequentially pass through a chlorination solution spraying device under the conditions of no tension and no twist number of each wool and are sprayed twice by adopting the chlorination solution. Compared wntially pass through a chlorination solution spraying device under the conditions of no tension and no twist number of each wool and are sprayed twice by adopting the chlorination solution. Compared with the technical level held by China, international fellow traders and international wool office at present, the product of the wools obtained by the wool shrinkproof mercerization method has the advith the technical level held by China, international fellow traders and international wool office at present, the product of the wools obtained by the wool shrinkproof mercerization method has the advantages of shrinkproof size stability, soft hand feeling, attractive cloth cover, stable coloring and other excellent properties, improves the coloring stability, expands the function of the wool prodantages of shrinkproof size stability, soft hand feeling, attractive cloth cover, stable coloring and other excellent properties, improves the coloring stability, expands the function of the wool product and prolongs the service life of the wool product for wearing.uct and prolongs the service life of the wool product for wearing.

Owner:浙江新中和羊毛有限公司

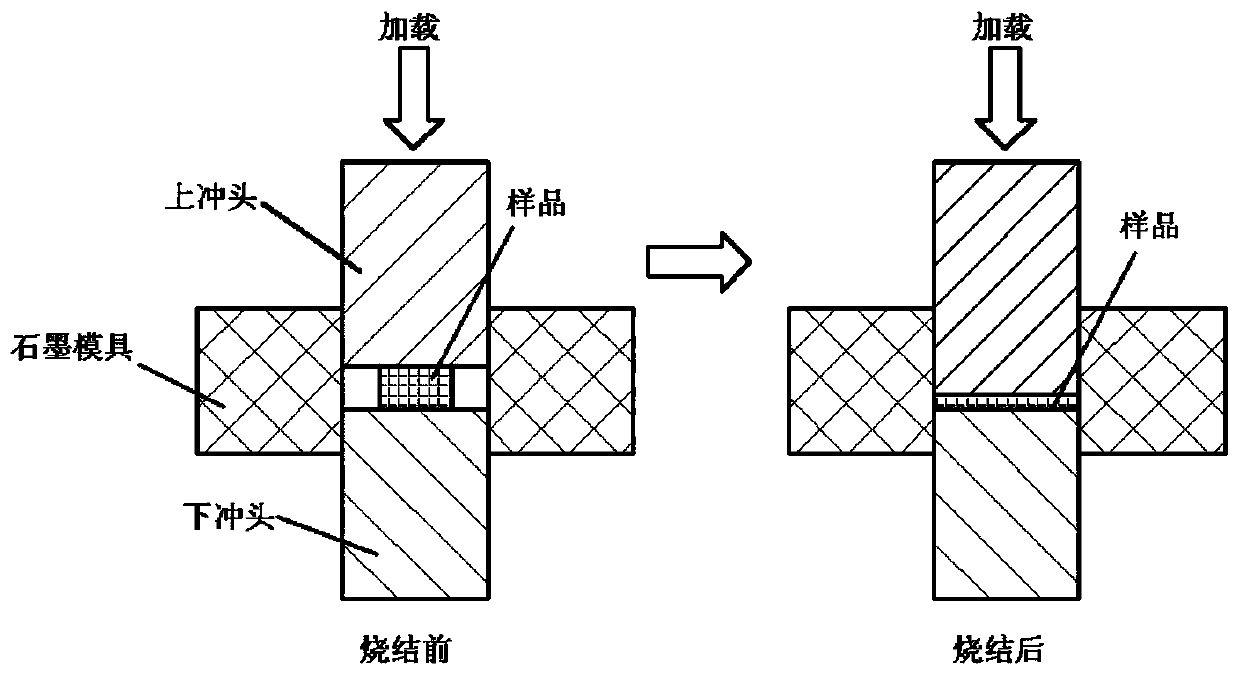

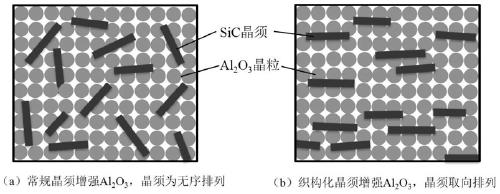

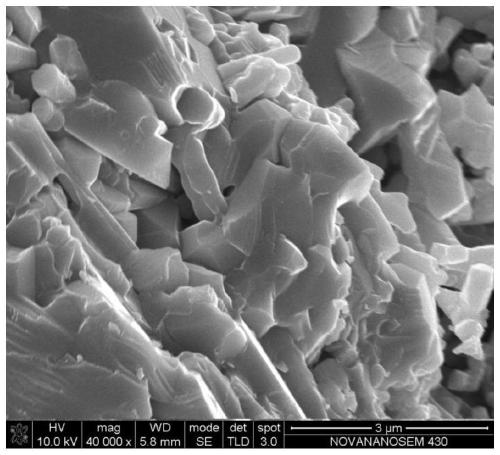

Whisker reinforced aluminum oxide composite ceramic as well as preparation method and application thereof

The invention relates to the technical field of ceramic materials, in particular to whisker reinforced aluminum oxide composite ceramic as well as a preparation method and application thereof. The composite ceramic is prepared from, by mass, 50-99.5 parts of aluminum oxide powder, 0.5-45 parts of whiskers, 0-20 parts of a sintering aid and 0-10 parts of a wear-resistant additive. The components are used as raw materials, a sample flows in a one-dimensional or two-dimensional direction in a mold by a hot-pressing flow sintering method, and the whiskers are directionally arranged to obtain the whisker-reinforced aluminum oxide composite ceramic. By texturing the whisker reinforced aluminum oxide composite ceramic, the toughness, strength, hardness and cutting performance of the aluminum oxide composite ceramic can be greatly improved. The whisker reinforced aluminum oxide composite ceramic prepared by the method is processed into a cutter which can be used for cutting a high-temperaturealloy at a high speed.

Owner:GUANGDONG UNIV OF TECH

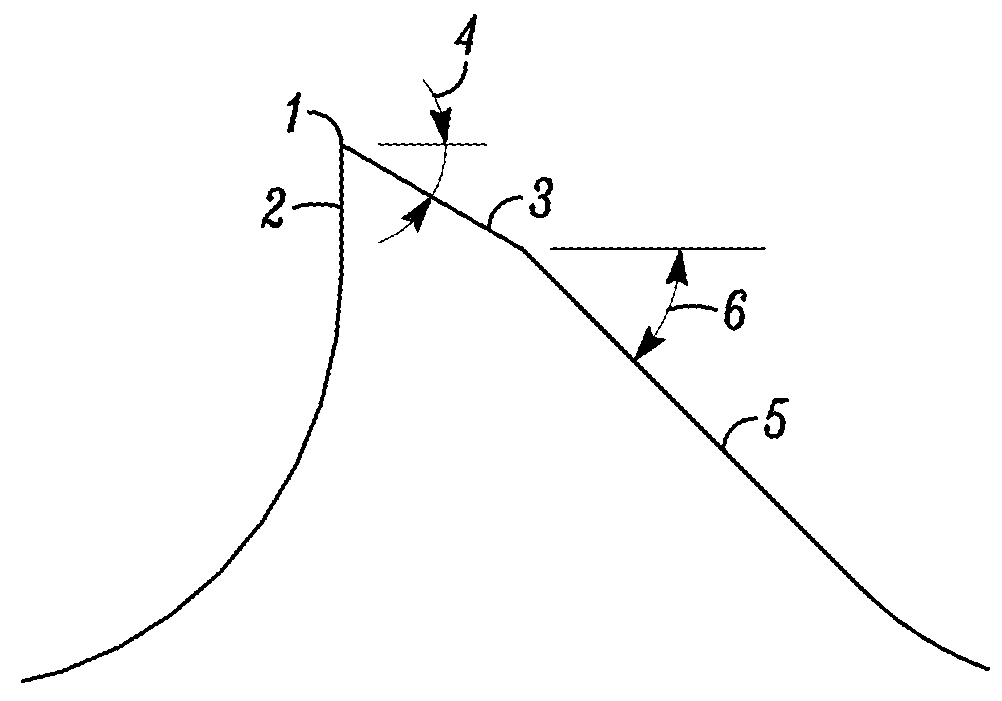

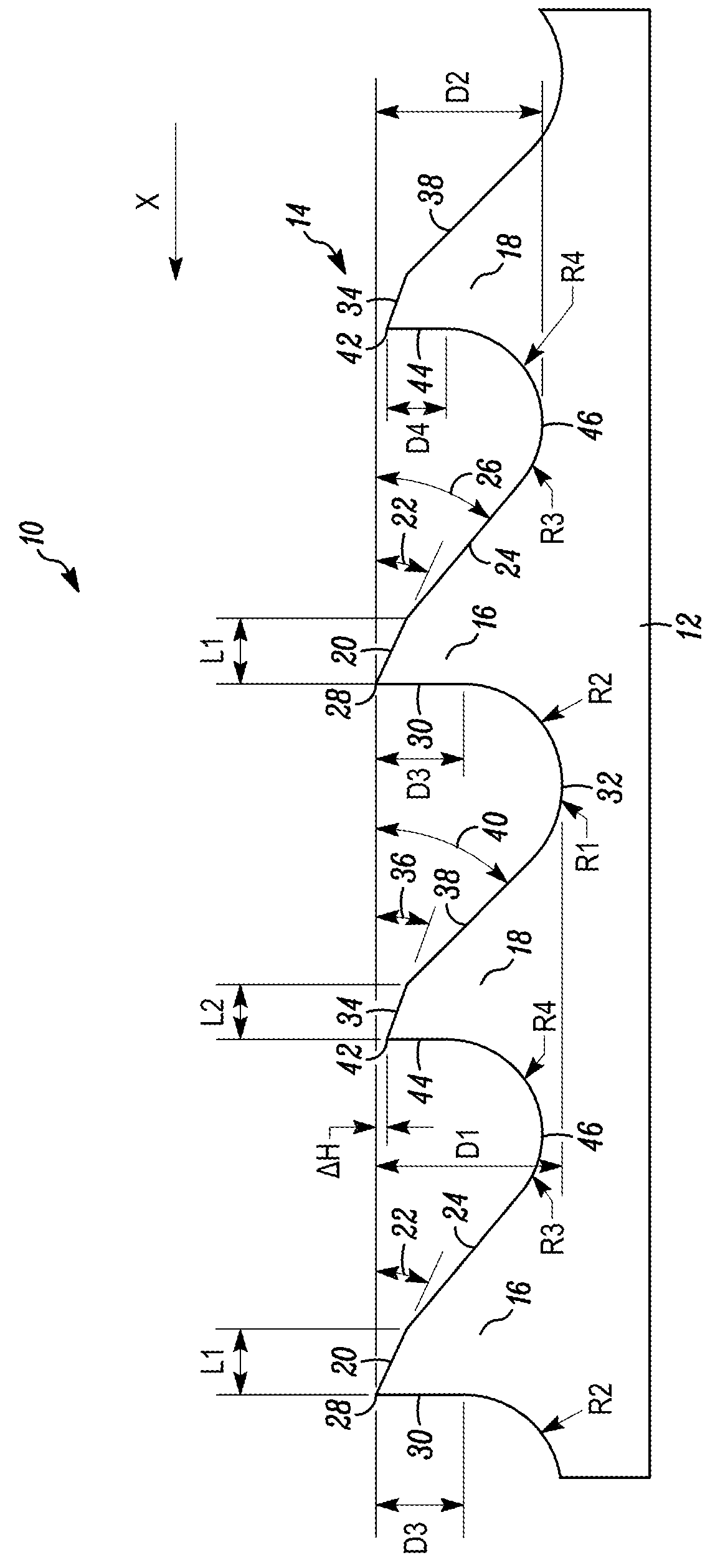

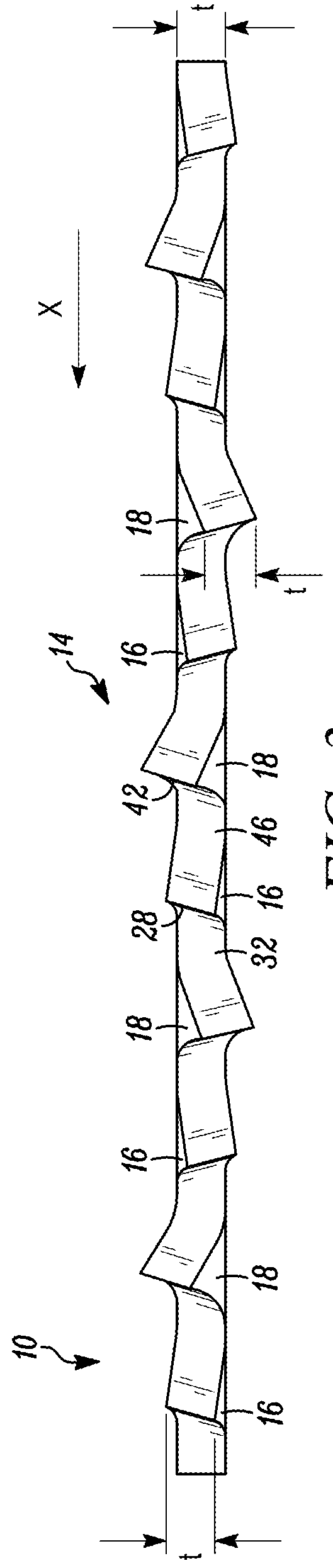

Saw blade tooth form for abusive cutting applications

ActiveUS9248518B2Impart toughnessIncreasing the blade's life spanMetal sawing devicesTransportation and packagingEngineeringLower tooth

Owner:BLACK & DECKER INC

Method for plating diamond film on surface of stainless steel metal

InactiveCN101082131AImprove wear lifeImprove adhesionVacuum evaporation coatingSputtering coatingTitanium carbideMetal

The present invention discloses process of plating diamond-like coating onto the surface of stainless steel, and features the adoption of pulse arc ionic plating technology. The diamond-like film plating process includes the following steps: activating ion in the surface of the metal workpiece, plating one transition titanium layer, plating one transition titanium carbide layer, and plating diamond-like coating on the transition titanium carbide layer. The present invention has raised adhesion of diamond-like coating, increased thickness and service life of the diamond-like coating and simple technological process, and is especially suitable for surface antiwear treatment of precise metal parts of 1Cr18Ni9Ti, Cr12, 9Cr18, 40Cr and other stainless steel.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

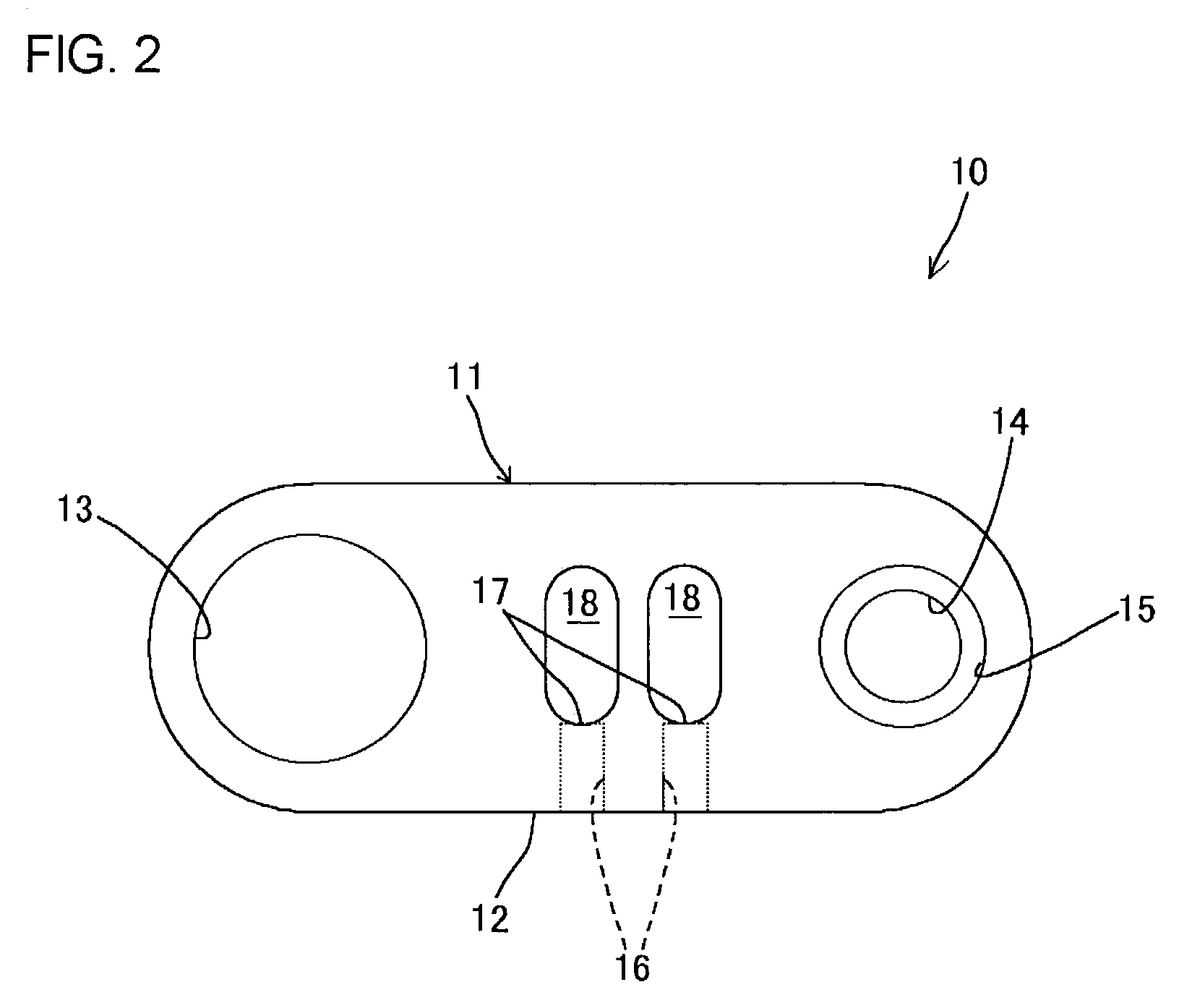

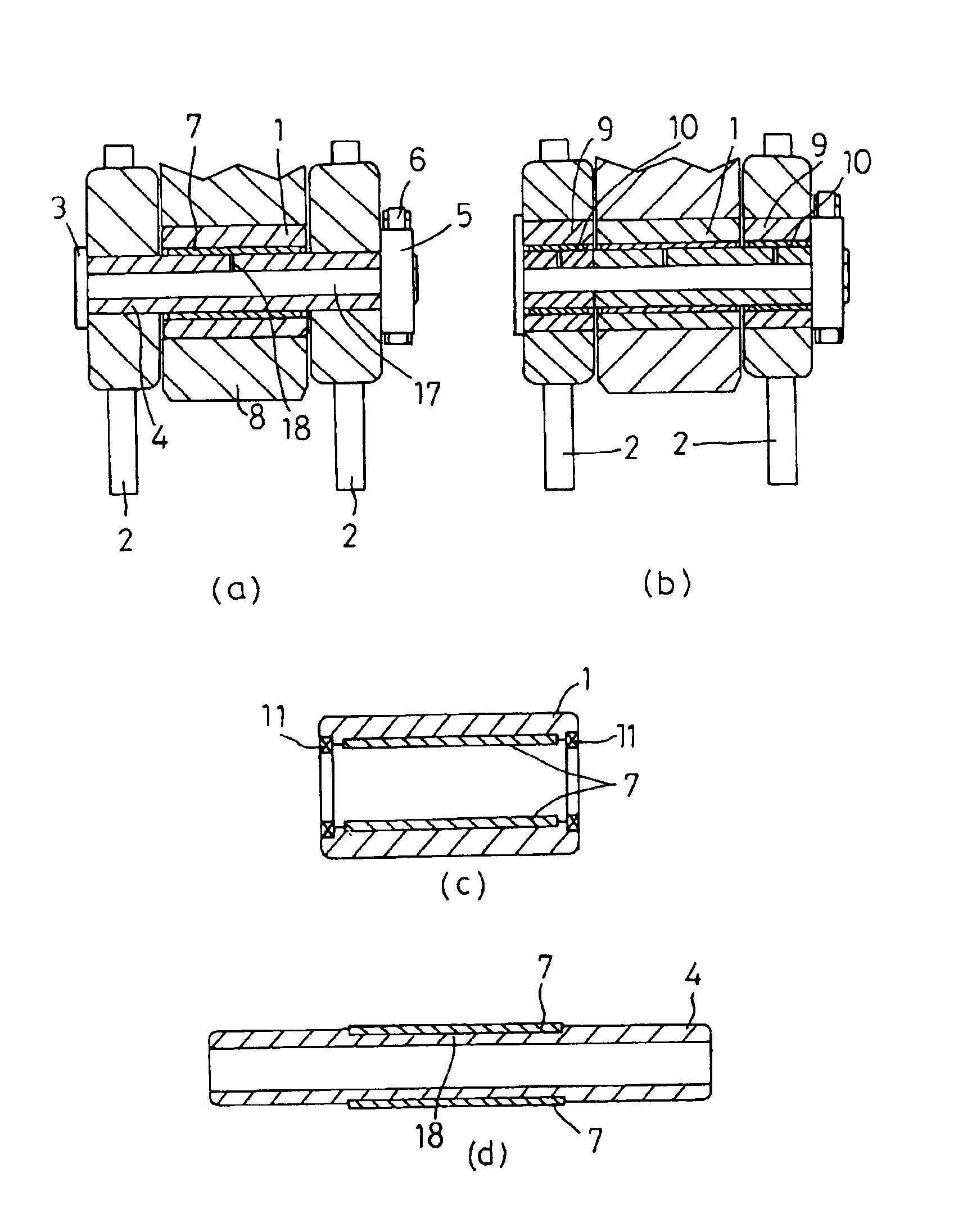

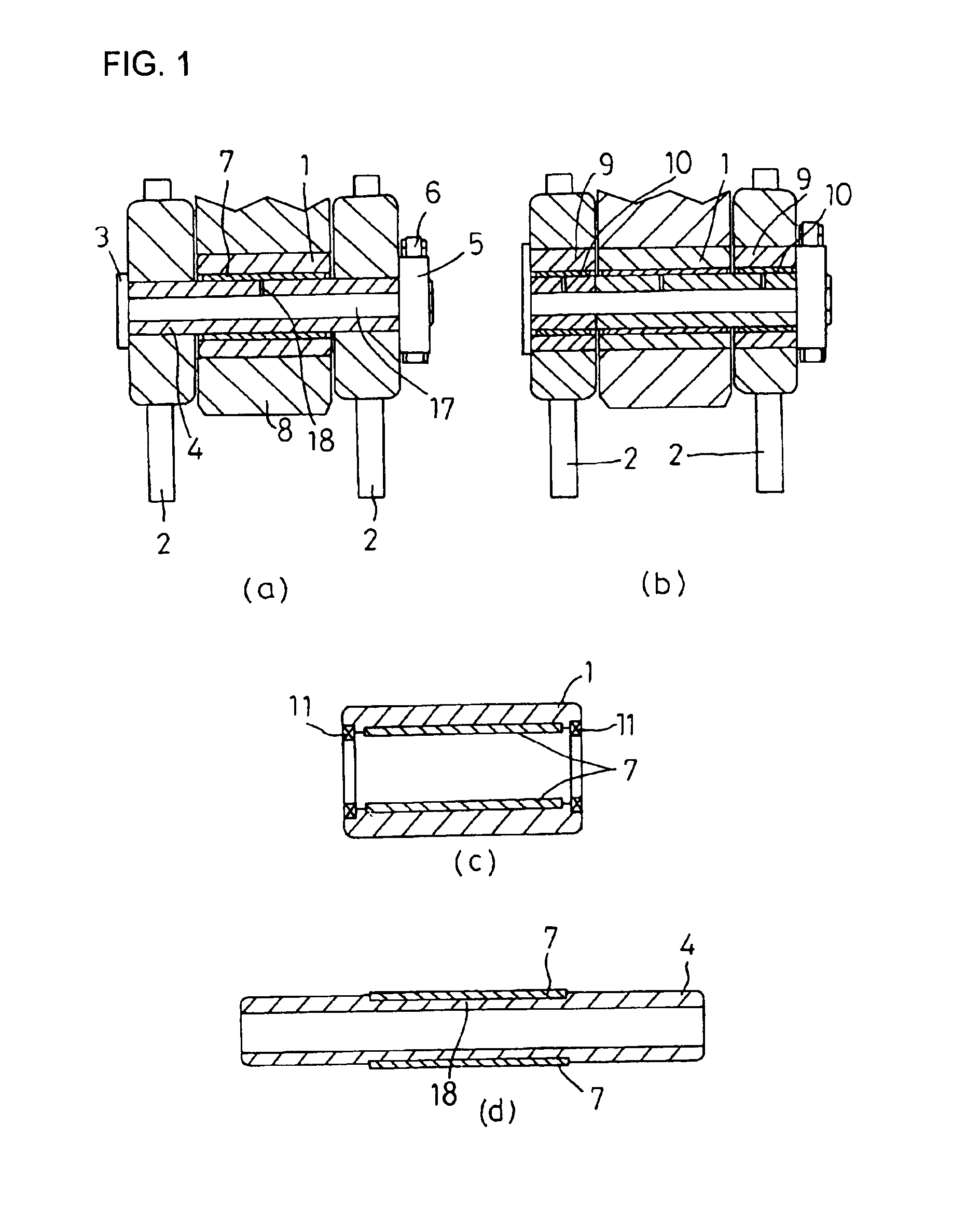

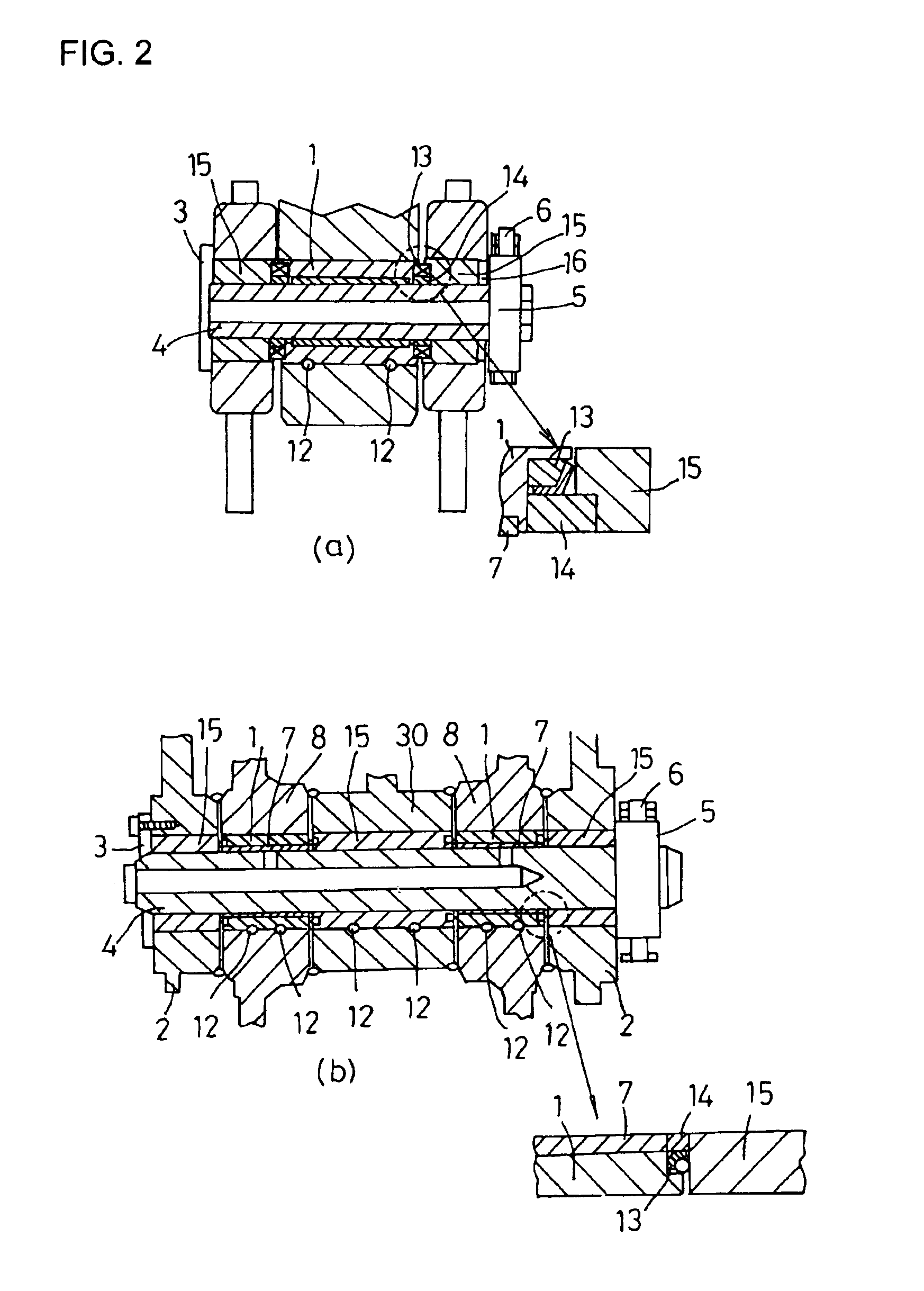

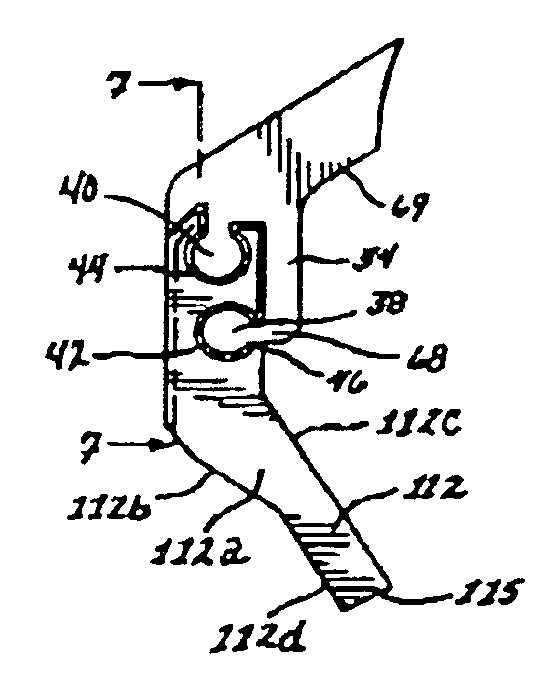

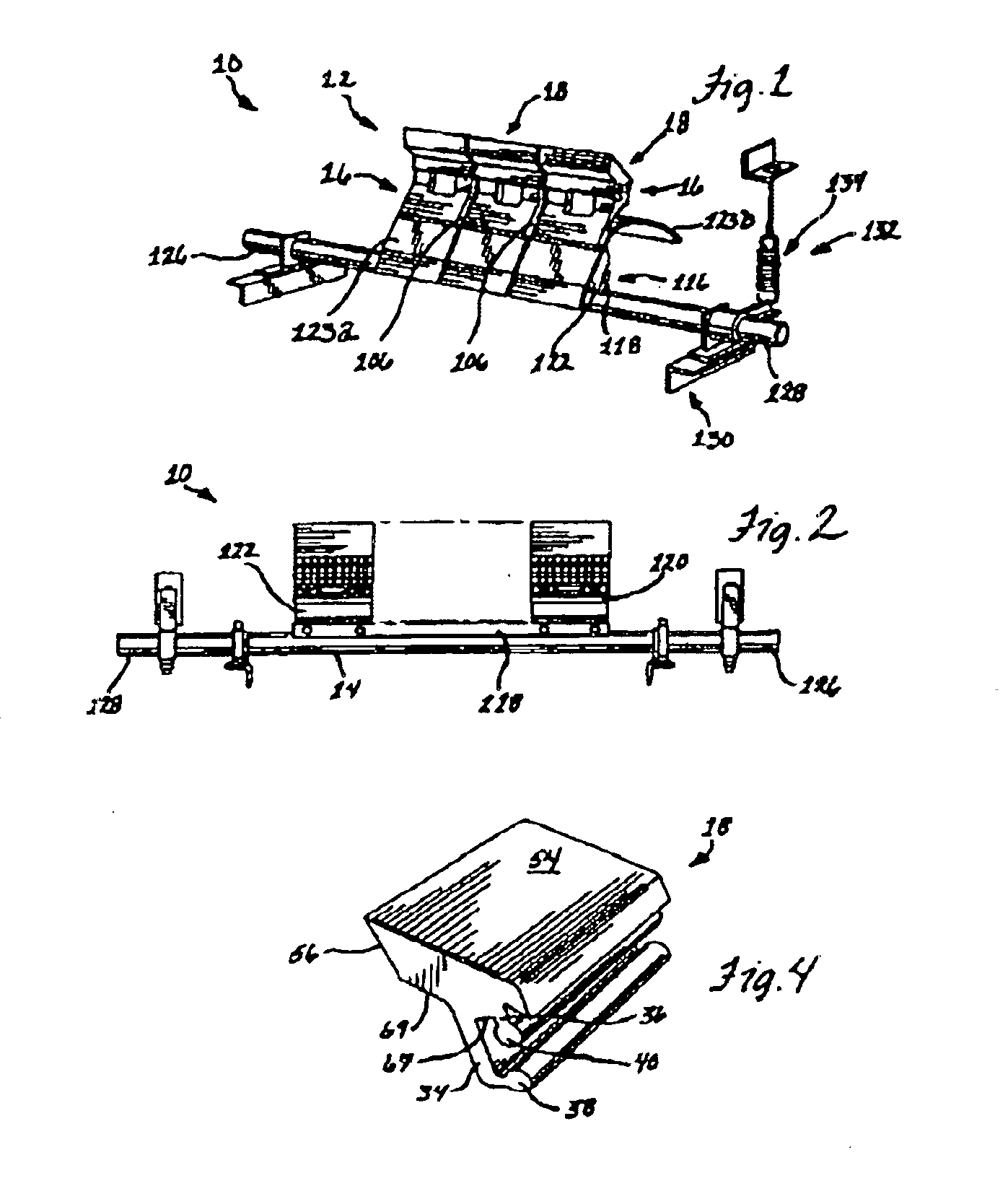

Coupling device for equipment implement

InactiveUS6962458B2Improve wear lifeNot impair lubricityYielding couplingFluid pressure sealed jointsLubricantLubricity

A coupling device for equipment implements is described, which coupling device does not impair the lubricity of bearing sections when the equipment is in service, does not cause seizure during rotation of bearings, does not need frequent feeding of grease to the bearing sections from outside, and provides good noise absorbability. The coupling device has such a structure that a metal based contact material 7 capable of storing a lubricating oil and / or lubricant is interposed between an implement bushing 1 made from steel and implement pin 4 of an implement for construction equipment.

Owner:KOMATSU LTD

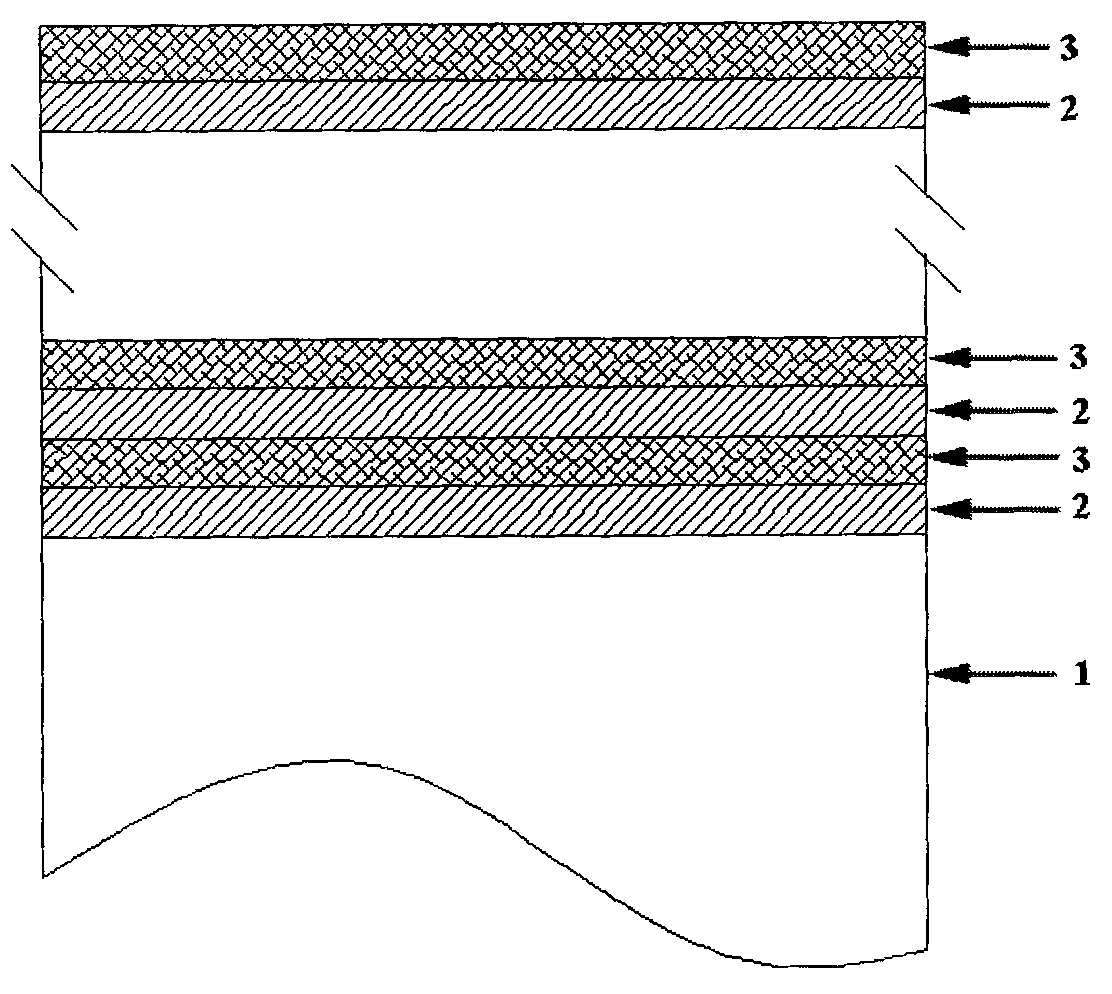

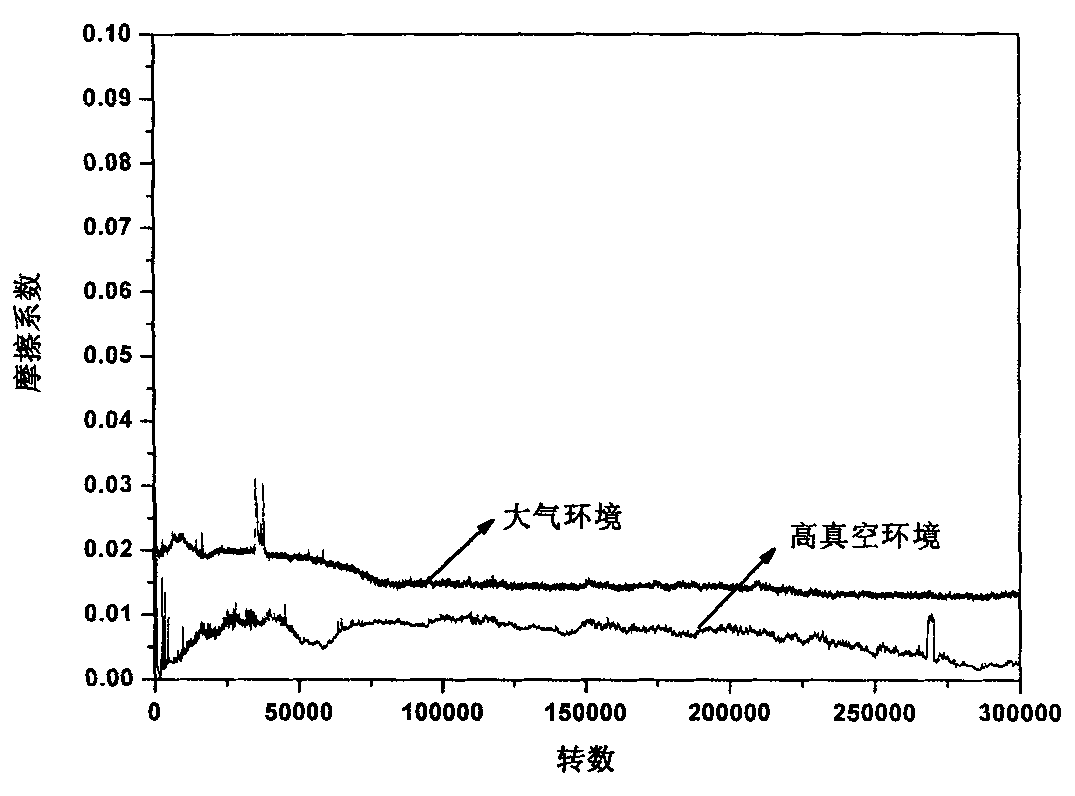

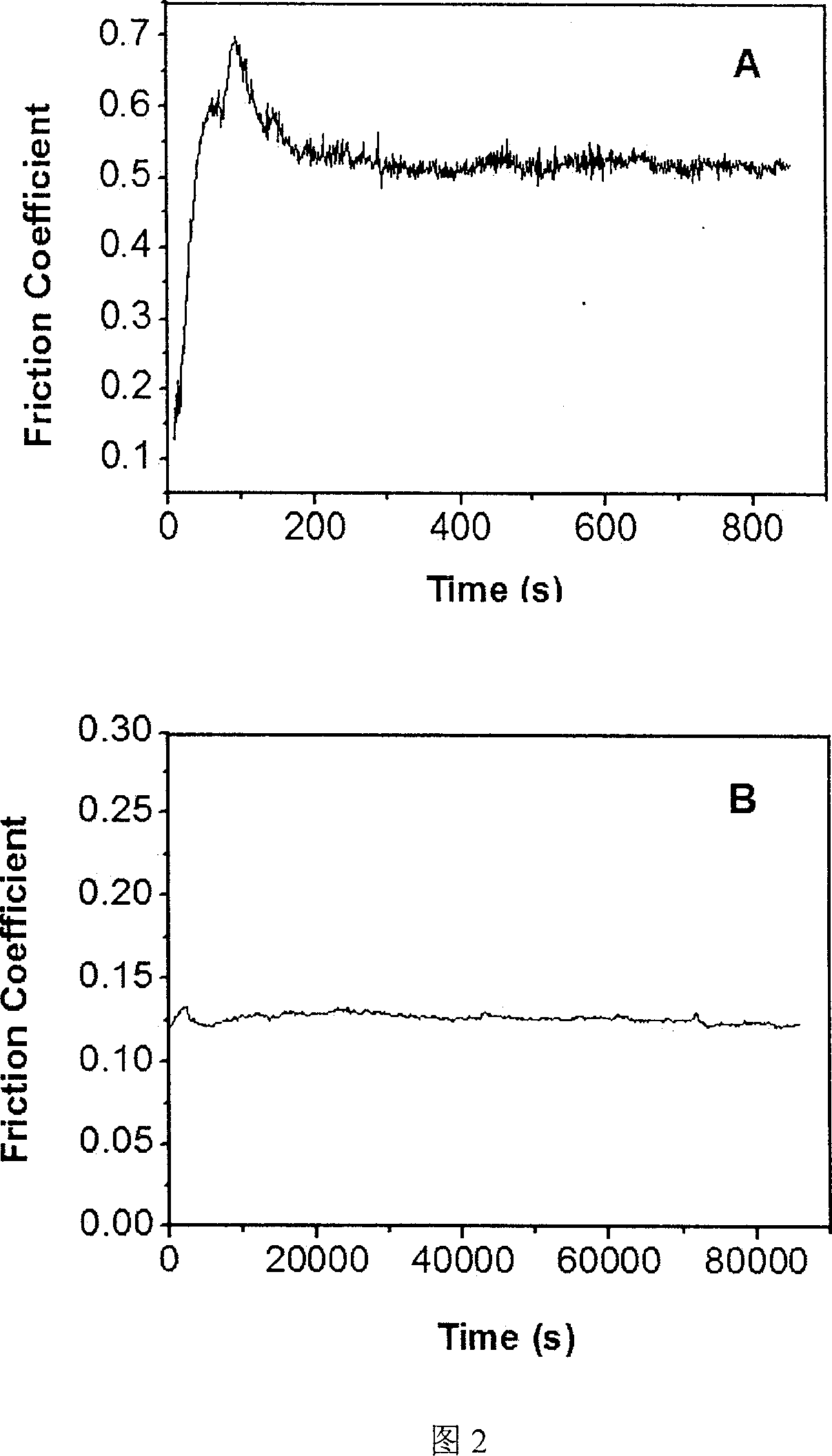

Diamond-like carbon composite molybdenum disulfide nano multilayer film and method for preparing same

ActiveCN102994947AReduce frictionImprove bearing capacityVacuum evaporation coatingSputtering coatingCarbon compositesDiamond-like carbon

The invention discloses a diamond-like carbon composite molybdenum disulfide nano multilayer film and a method for preparing the same. A double-target magnetron sputtering technology is adopted to alternatively deposit diamond-like carbon layers and molybdenum disulfide layers on a stainless steel base, so that the diamond-like carbon composite molybdenum disulfide nano multilayer film is obtained, wherein the thickness of a single diamond-like carbon layer is between 10 and 100 nanometers, the thickness of a single molybdenum disulfide layer is between 10 and 100 nanometers, and the total thickness of the diamond-like carbon composite molybdenum disulfide nano multilayer film is between 1.5 and 6 micrometers. By the prepared nano multilayer film, the wearing life defect and the problems of friction coefficient environment sensitivity of the molybdenum disulfide layer are improved, moreover, the problems of large brittleness, poor toughness and the like of a hard diamond-like carbon film are solved, so that the wear rate of the nano multilayer film in high vacuum environments is reduced by 1-2 orders of magnitude compared with the wear rate of a conventional molybdenum disulfide or diamond-like carbon film, and the perfect matching of ultralow friction and high hardness and toughness is realized.

Owner:徐州睿创智能科技有限公司

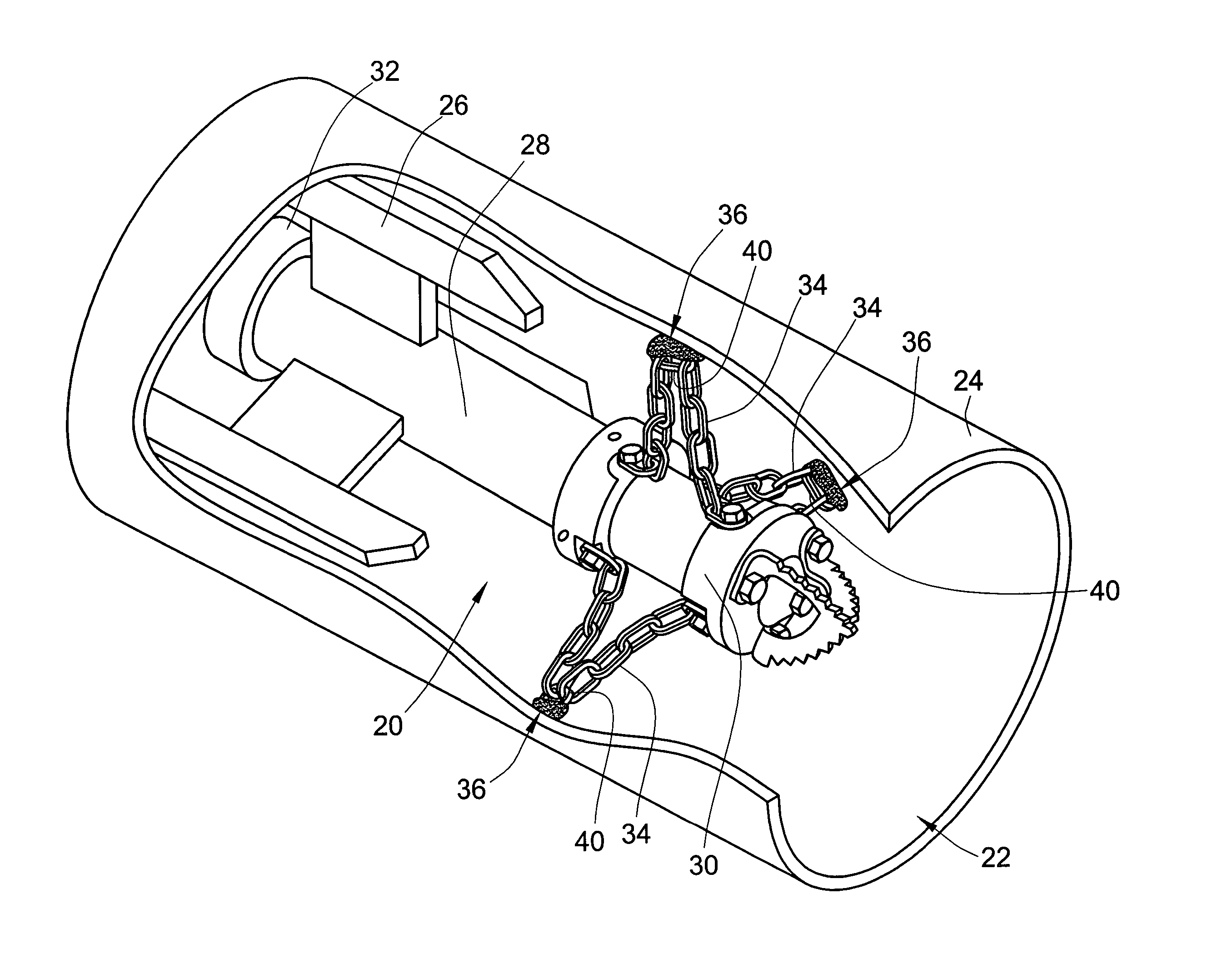

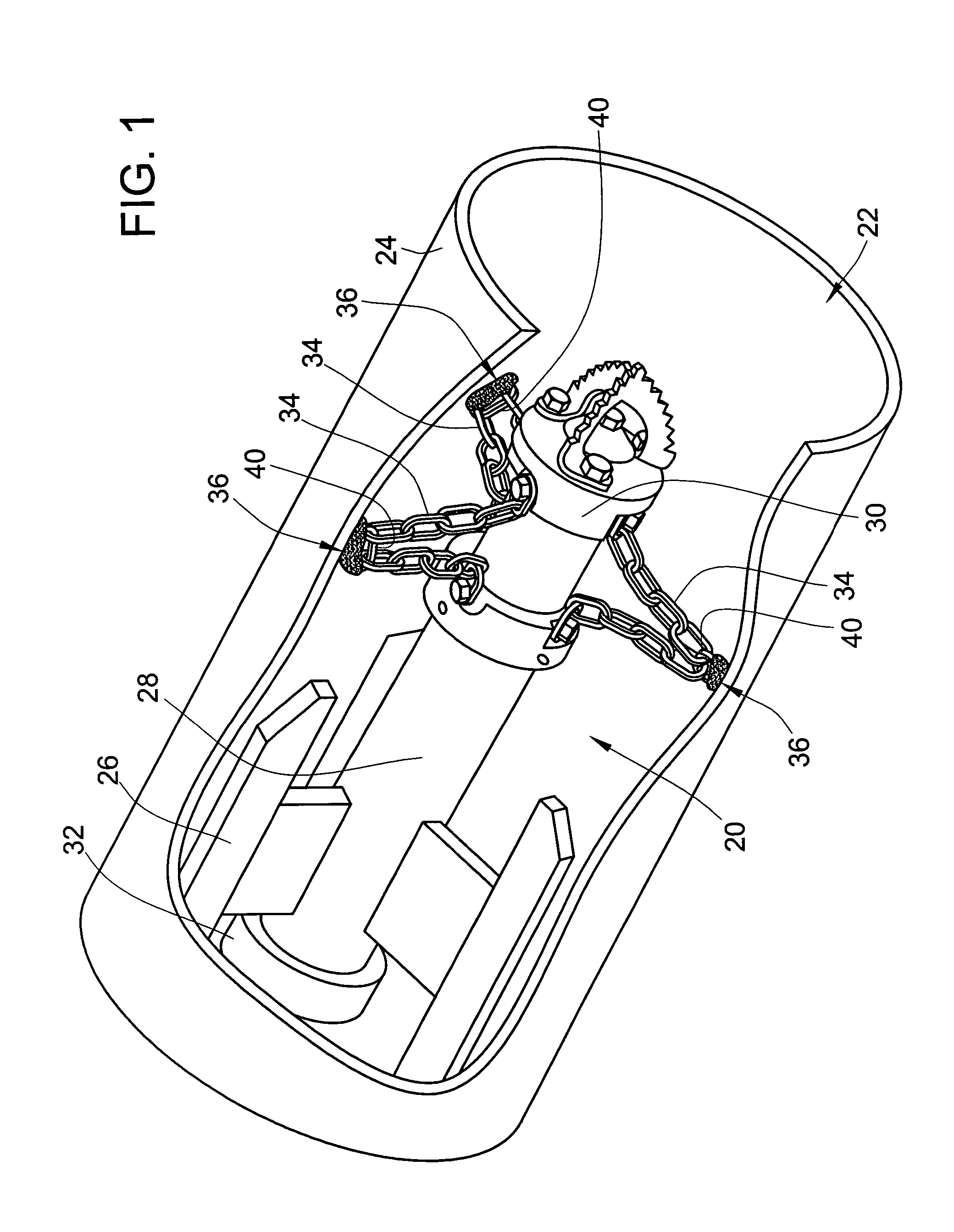

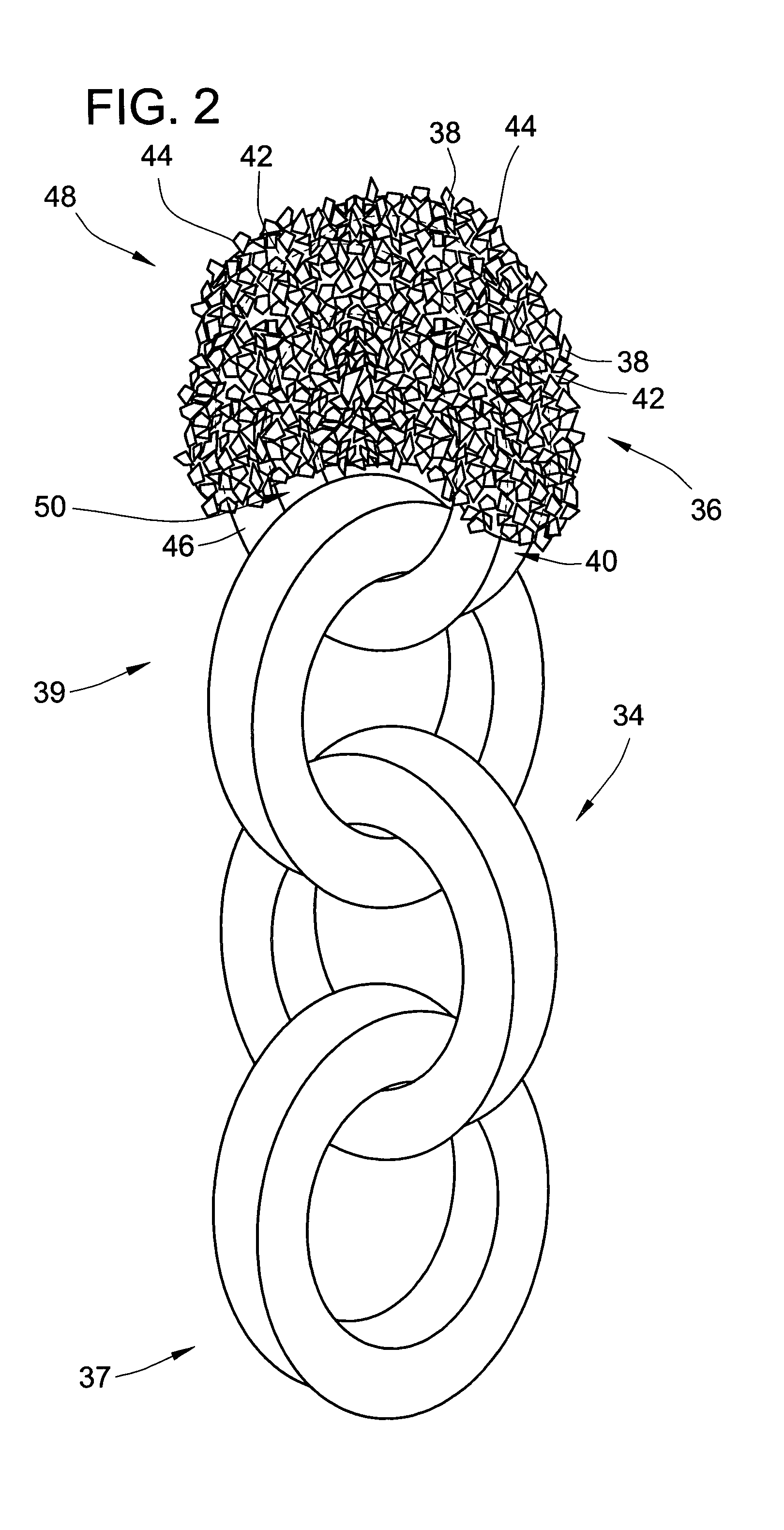

Apparatus and bit for cleaning pipes

InactiveUS20050028306A1Improve wear lifeEfficient removalSewer cleaningHollow article cleaningWear resistantEngineering

A rotary cutter and end bit therefore is provided for cleaning and clearing debris and roots from a pipe. The cutter comprises a support housing having a plurality of radially extending skid fins, which help position the chain root cutter in the center of the pipe. The support housing carries a rotor and the rotor rotates relative thereto. A motor supported by the support housing is adapted to rotate the rotor. A plurality of linkages extends radially from the rotor and attaches at least one end bit to the rotor of the chain root cutter. The end bit comprises a hard wear resistant material, such as carbide, that faces radially outward and increases the wear life of the end bit. The wear resistant material may comprise carbide chips that continuously provide sharp edges over the life of the end bit.

Owner:BERGSTROM SKEGS

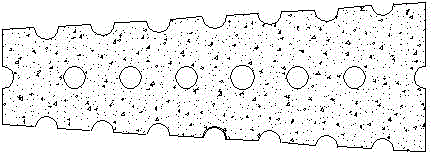

Wear bars for impellers

The present invention is particularly, but not exclusively, useful for reducing wear of component parts of impact-type rock-crushing machines caused by earth aggregate flows during operation of impact crushers. The present invention includes a central feed body and impeller shoe that has hard material insert bars fixed therein to reduce wear. The exposed top surface of the central feed body and front face of the impeller shoe are impregnated with a plurality of cemented carbide insert bars. The cemented carbide insert bars form an upper composite matrix that helps to reduce wear and the premature wash out of the hard material insert bars integrally cast within the central feed body.

Owner:KENNAMETAL INC

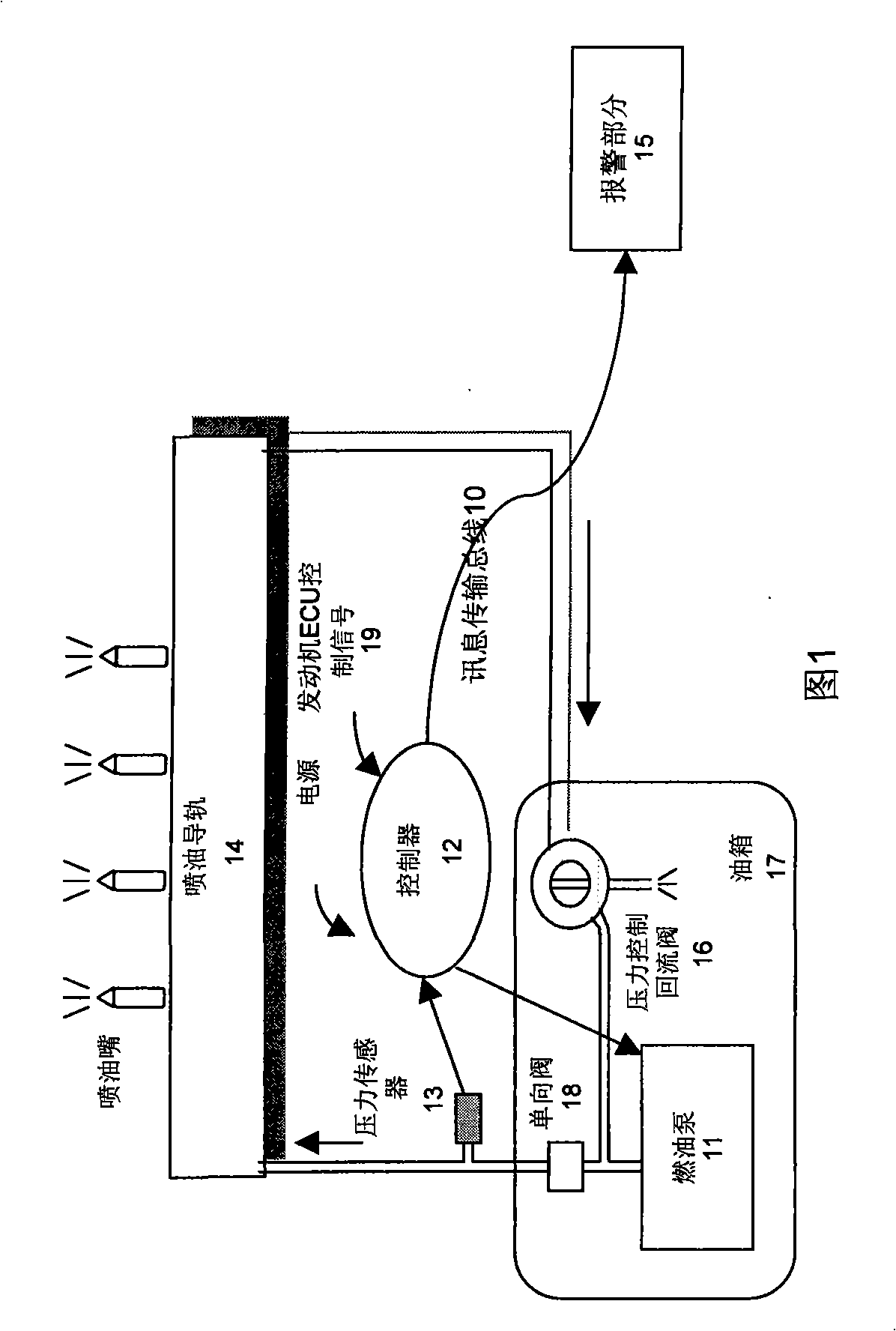

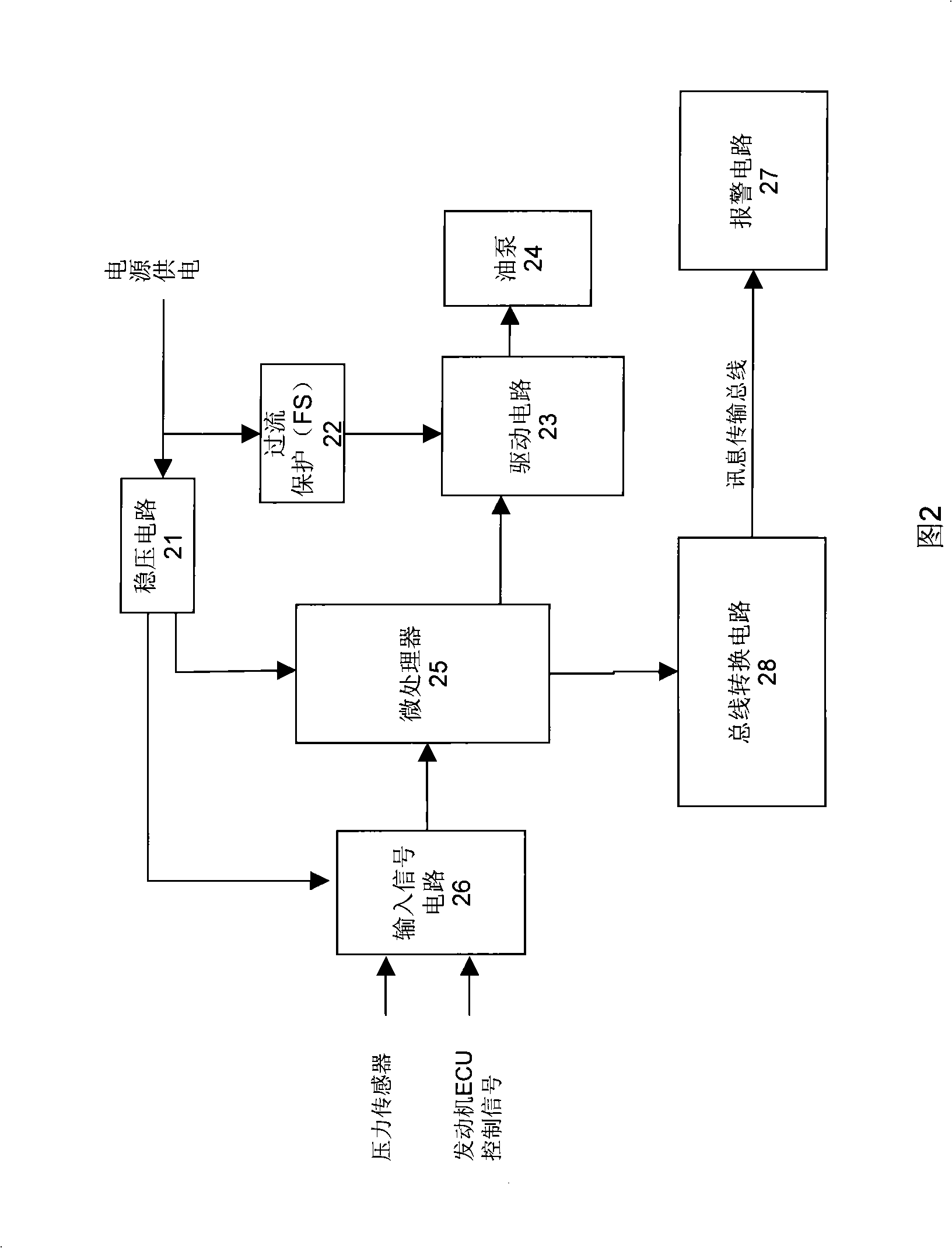

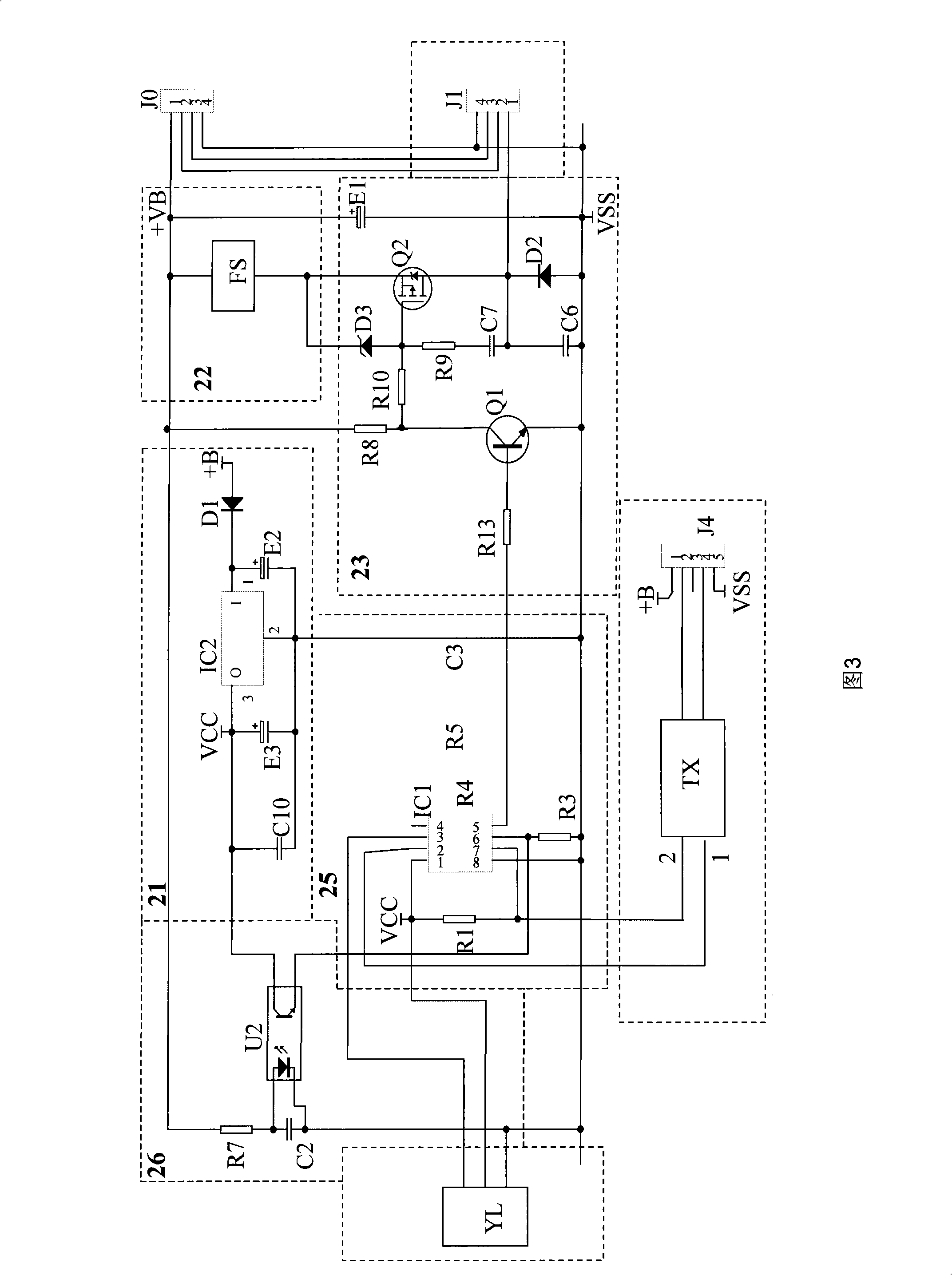

Supply method and system for intelligent control of gasoline engine fuel oil

InactiveCN101255836AAutomatic control of operating speedStable fuel pressureMachines/enginesLiquid fuel feedersActive safetySystem pressure

The present invention relates to a method and system for controlling intelligently fuel supply by gasoline engine. The fuel system comprises an oil pump, an injection guide, a pressure reflux valve, a gasoline tank, a check valve and an oil supply and return pipeline. Wherein, a pressure sensor and an intelligence controller, a transmitting bus, a sound and light alarm circuit are increased. After calculating and judging of control software of microprocessor of intelligence controller, outputs a certain pressure to the oil pump engine, at the same time, the microprocessor detects pressure signal of pressure sensor amends voltage transmitted to the oil pump motor at any moment according to the pressure signal to remain stabilization of system pressure, and detecting, judging problems resisted in fuel supply system to give off sound and light alarm in time. The present invention saves energy, reduces consume, can detect fuel supply system intelligently and determine faults and alarm, enhances the initiative safety of vehicle on moving.

Owner:尤永前 +1

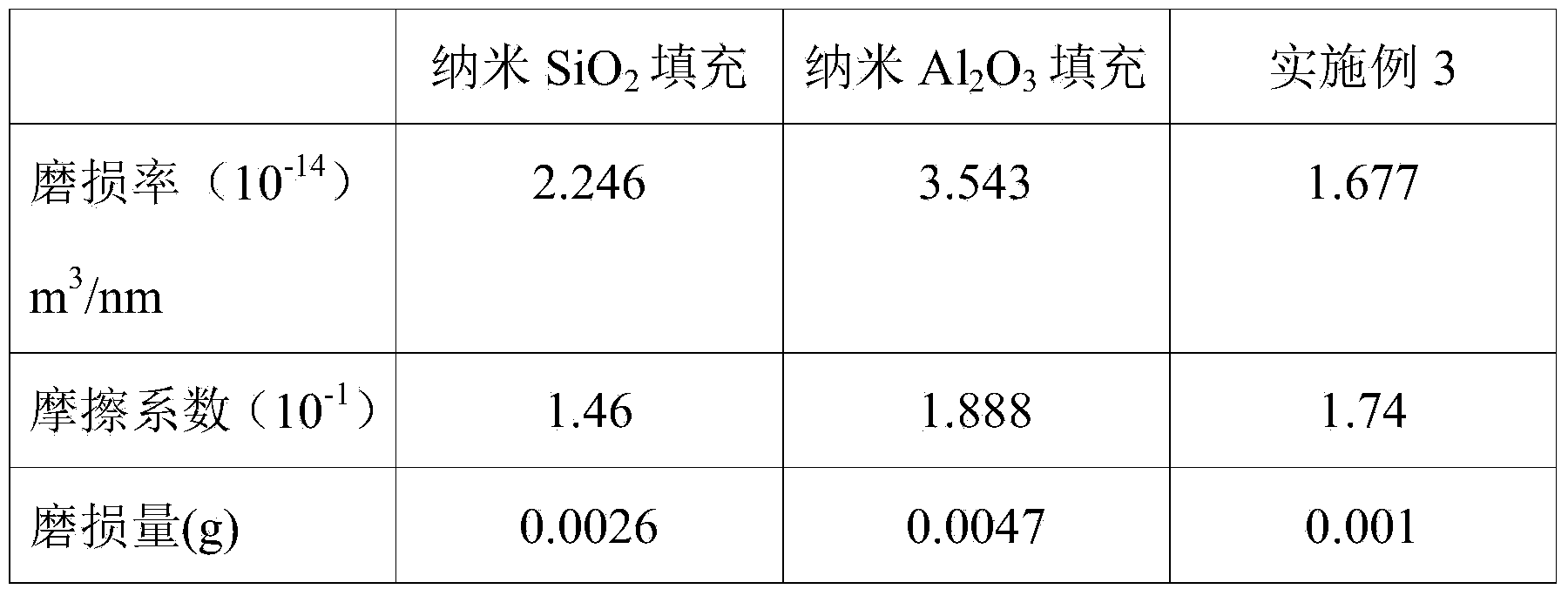

Nanometer filler cooperatively filling epoxy resin composite coating as well as preparation method and application thereof

The invention discloses a nanometer filler cooperatively filling epoxy resin composite coating. The composite coating is prepared from the following components in percentage by weight: 60-70 percent of epoxy resin, 26-34 percent of polyamide resin, 1-3 percent of modified nanometer Al2O3 and 1-3 percent of modified nanometer SiO2, wherein sum of the mass percent of the components is 100 percent. A preparation method comprises the following steps: respectively preparing the modified nanometer SiO2 and the modified nanometer Al2O3, respectively preparing the epoxy resin and the polyamide resin into solutions, adding the modified nanometer Al2O3 and the modified nanometer SiO2 in the epoxy resin solution, stirring, then adding the polyamide resin solution, soaking treated carbon fiber fabrics, and curing to obtain the composite coating. The nanometer filler cooperatively filling epoxy resin composite coating is applied to the surface of a steel block. With the adoption of the preparation method, the problem of poor abrasion resistance of a single nano particle filling epoxy resin composite coating is solved, and the prepared composite coating has good impact and abrasion resistances.

Owner:XIAN UNIV OF TECH

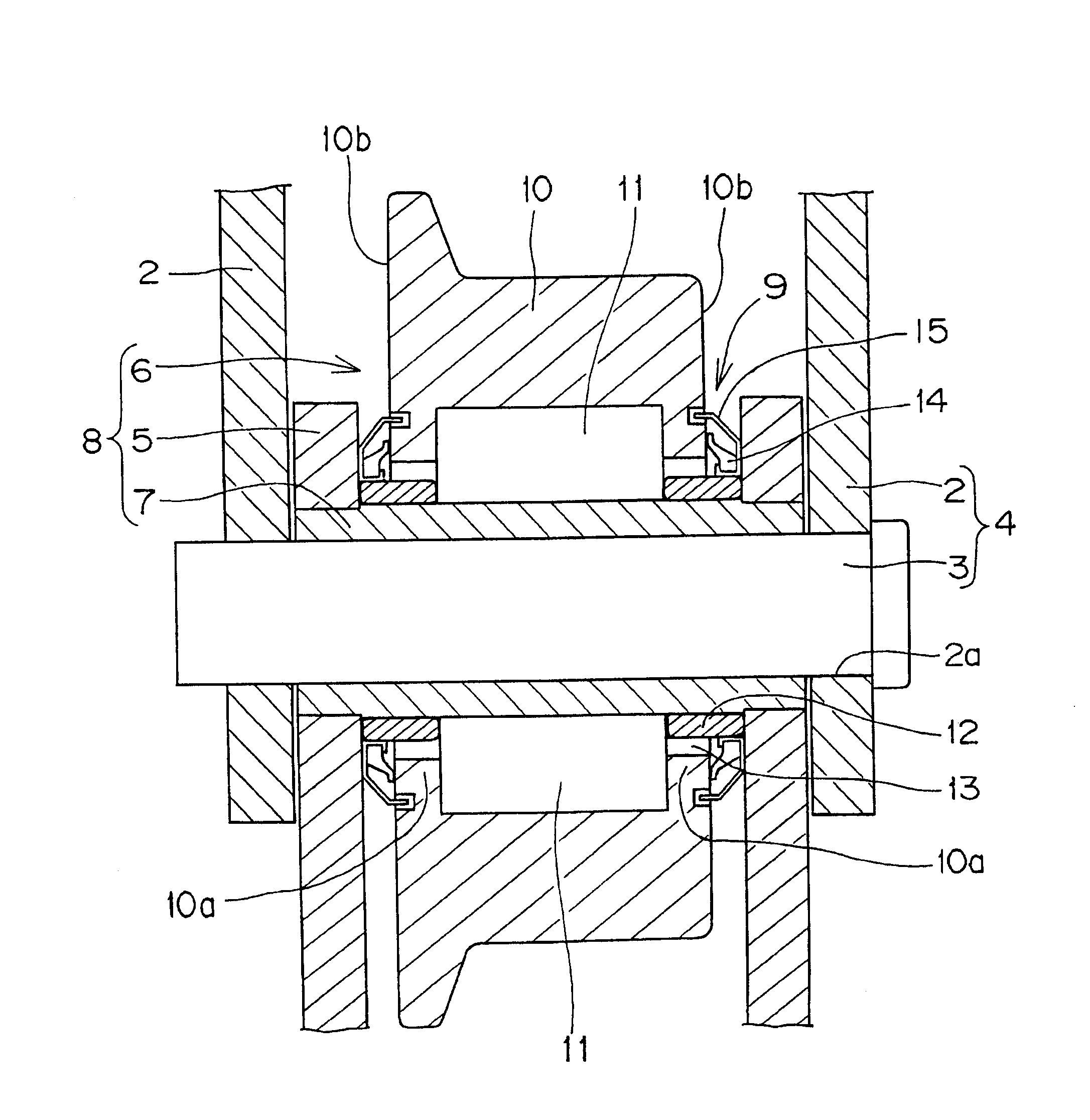

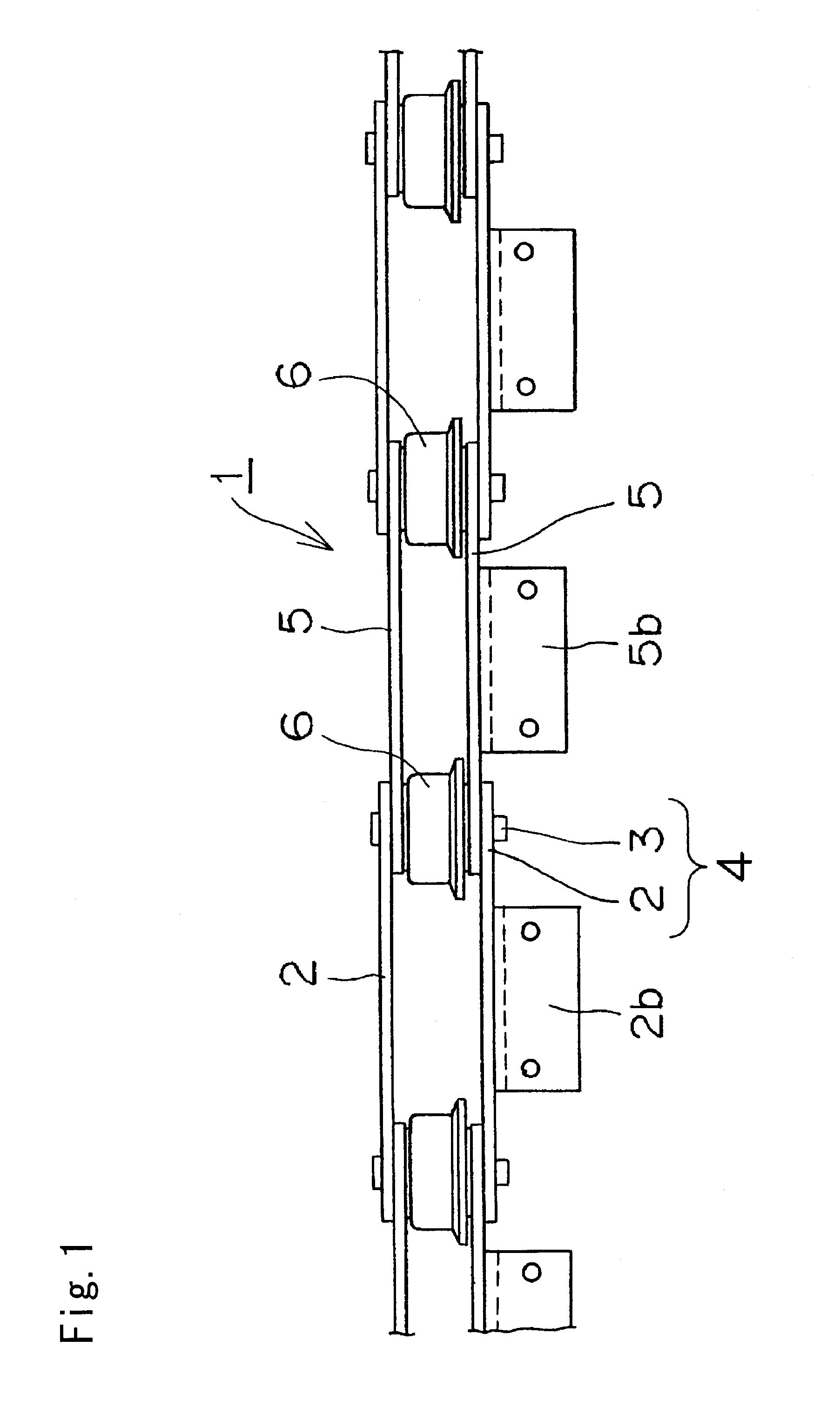

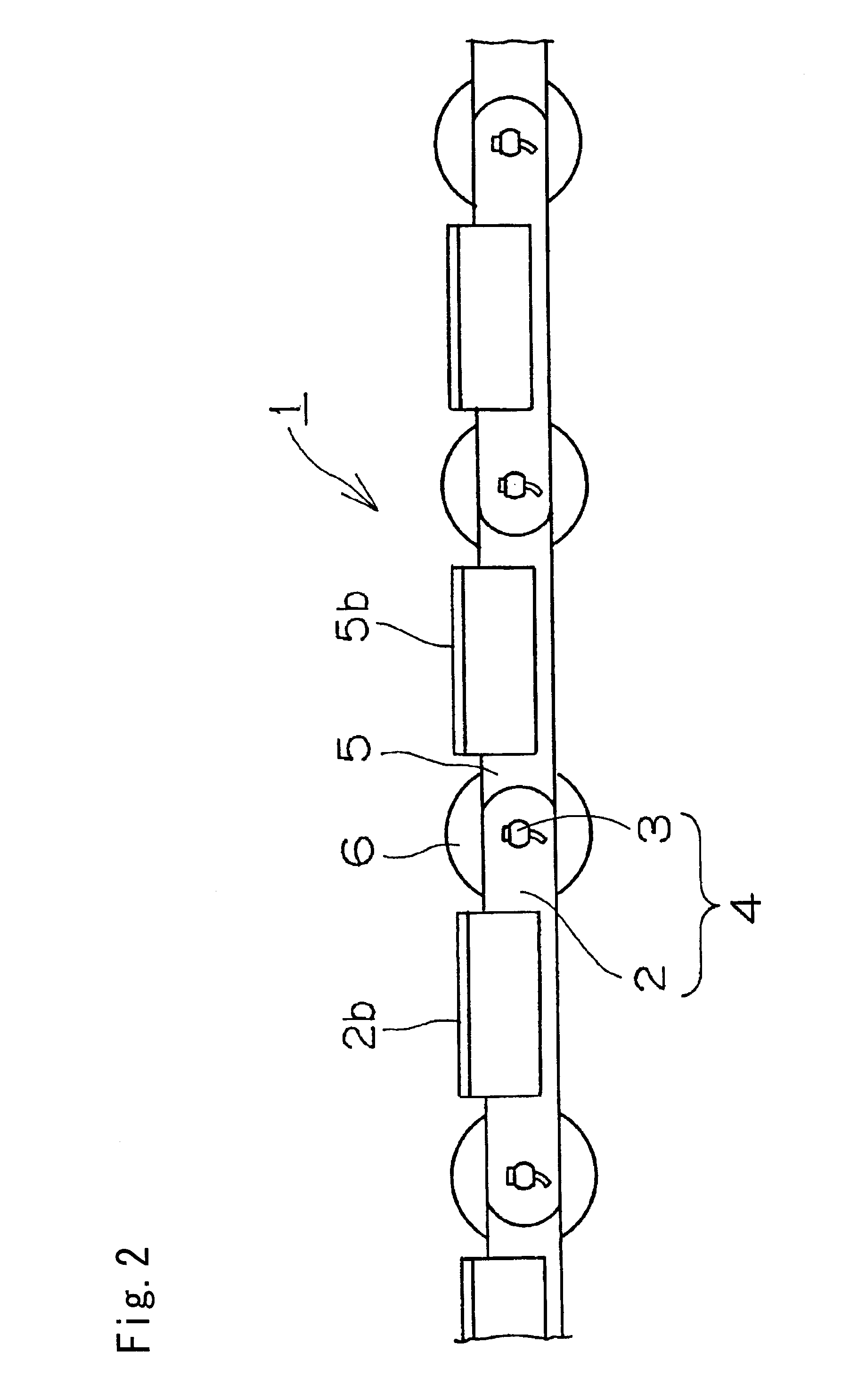

Bearing roller chain

InactiveUS20080124015A1Avoid Insufficient SealingSuppression of rotation failureEngine sealsRoller bearingsEngineeringRoller chain

A bearing roller chain having a seal mechanism preventing entry of foreign substance from the outside, and leaking of lubricating oil leakage to the outside and the like, thereby improving wear resistance of the bearing roller and reducing both the likelihood of rotation failure and the traveling resistance of the chain. The seal mechanism is provided between an inner link plate of the chain and the hollow bearing roller, which has a plurality of internal anti-friction rollers rotatable between the hollow bearing roller and a bush mounted between opposed inner link plates. The seal mechanism encloses the internal anti-friction rollers and comprises two parts, i.e a seal ring having an annular lip portion, which comes into close contact with an outer side surface of the bearing roller and an annular metallic seal member. The metallic seal member forms a labyrinth structure by providing a flange on an outer circumferential portion which loosely enters an annular concave groove in the outer side surface of the bearing roller. The seal mechanism provides a double sealing effect by virtue of the seal ring and the annular metallic seal member.

Owner:FUJIWARA MAKOTO +2

Scraper blade for conveyor belts

ActiveUS6926133B2Abrasion resistance is improvedImprove wear lifeConveyorsCleaningEngineeringMechanical engineering

A two piece scraper blade is provided that includes a scraper member that is releasably connected to a base member. The scraper member can be of a different material than the base member to provide various advantages including with respect to its wear resistance. Further, a toolless interconnection is provided for ease in attaching the scraper member to the base member. When worn, the scraper member can be replaced with a new scraper member in an easy and quick fashion.

Owner:FLEXIBLE STEEL LACING

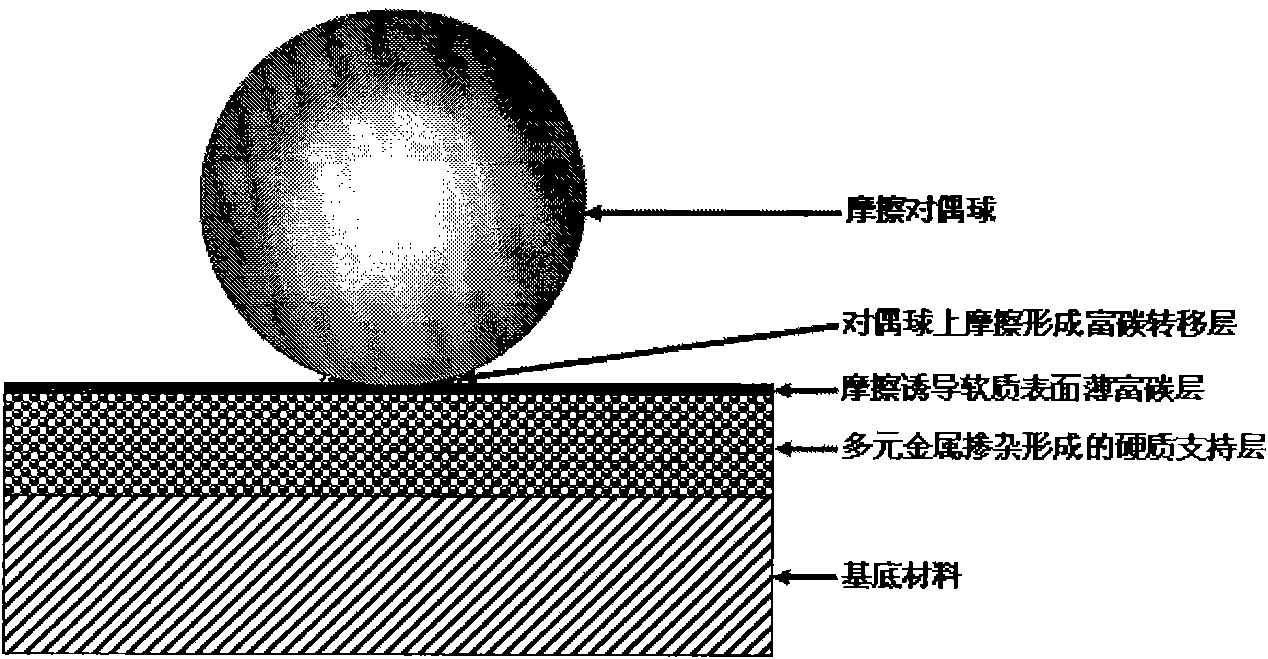

Method for preparing multi-element doped carbon-based nano composite film integrating functions of antiwear and lubrication

InactiveCN102337497AHigh hardnessReduce coefficient of frictionVacuum evaporation coatingSputtering coatingComposite filmDiamond-like carbon

The invention discloses a method for preparing a multi-element doped carbon-based nano composite film integrating functions of antiwear and lubrication. The carbon-based solid lubrication film is obtained on the surface of a metal workpiece by using a physical vapor deposition technology, the film thickness is 2.0-3.0 micrometers. Compared with a single metal doped diamond-like carbon-based composite film, the multi-element doped carbon-based nano composite film of the invention has high hardness (higher than 20GPa), low friction coefficient (the friction coefficient is 0.05-0.08), ultra low internal stress (lower than 1GPa) and excellent wear resistance (the wear resistance can be raised by 4-7 times). The multi-element doped carbon-based nano composite film can be used as a protective film integrating functions of antiwear and self lubrication, and is widely used in the precise machinery industry (bearings, gears, blades), engine industry (piston rings, piston pins, injection nozzles and the like), precise dies industry and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

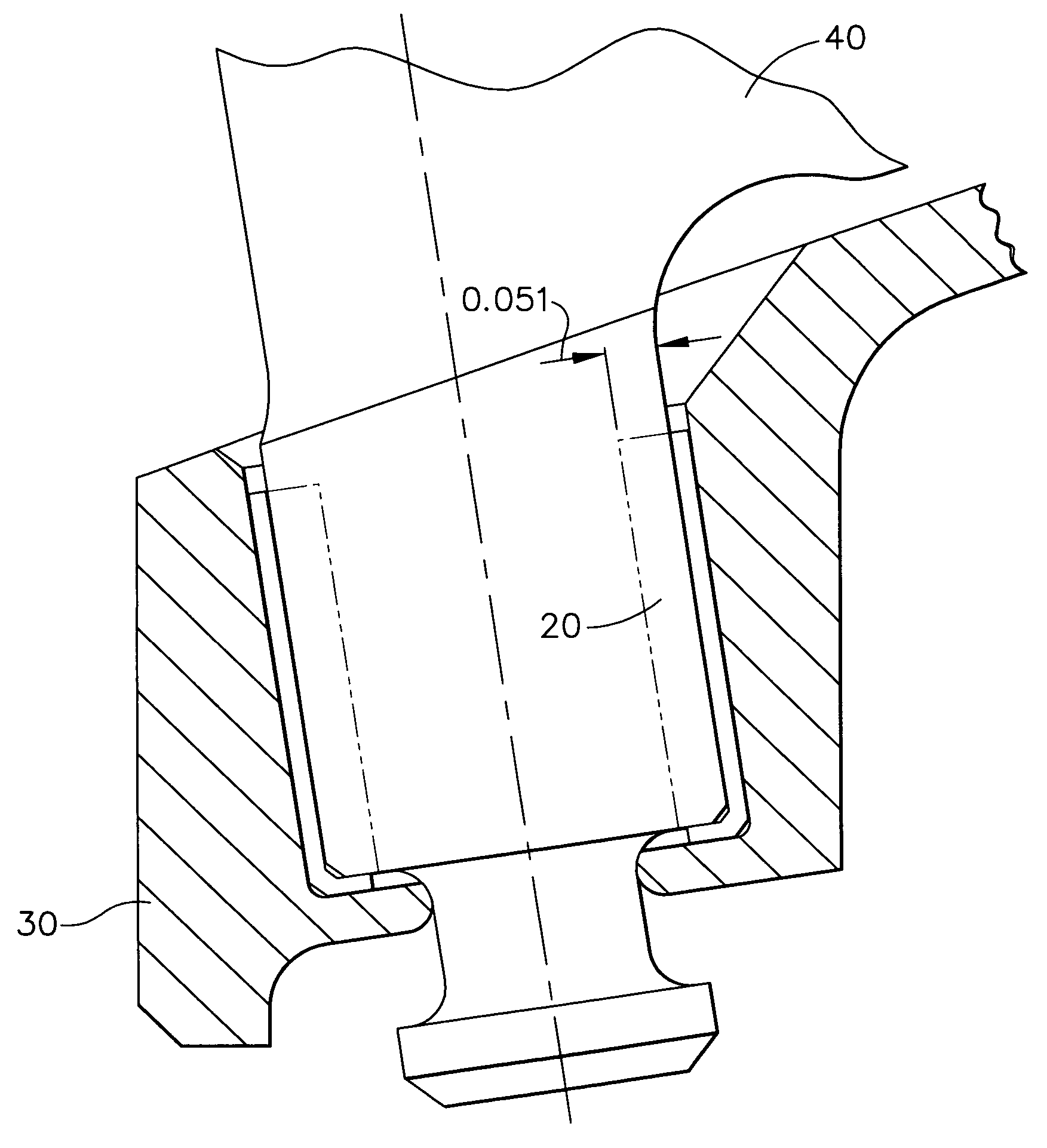

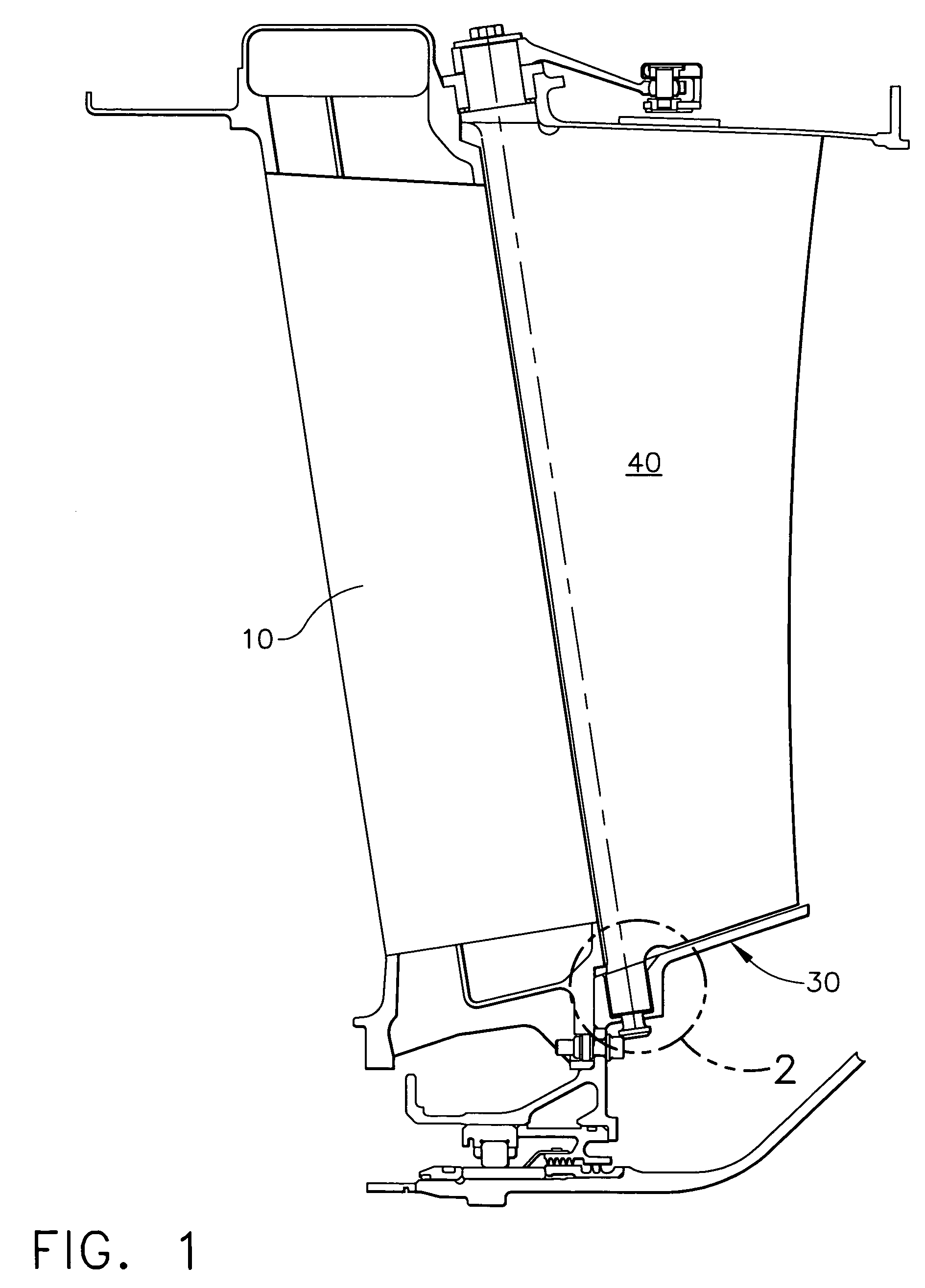

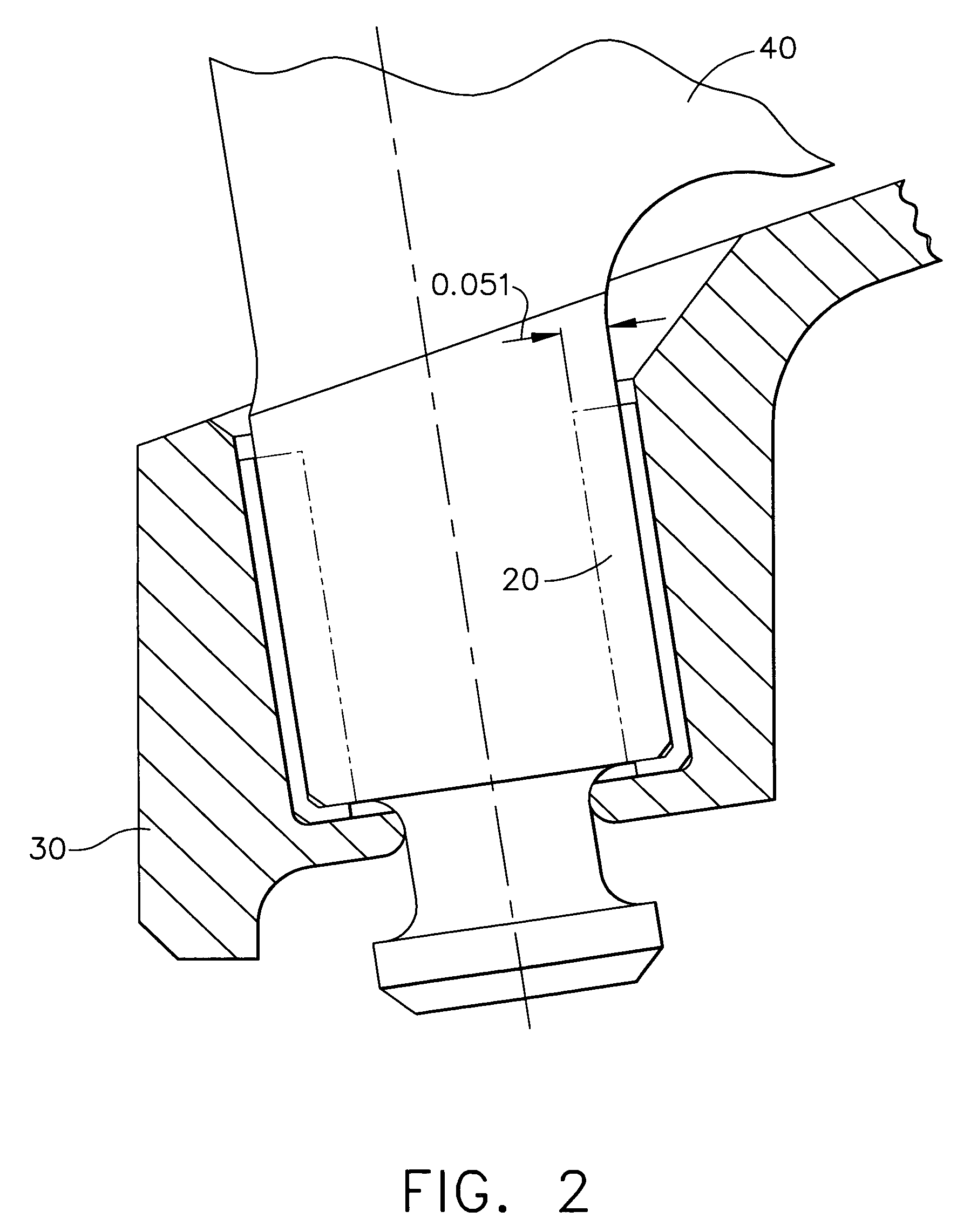

Inlet guide vane bushing having extended life expectancy

InactiveUS7121727B2Improve wear lifeReduce maintenanceEfficient propulsion technologiesBearing componentsEngineeringGas turbines

Owner:GENERAL ELECTRIC CO

Aluminium nitride and copper mixed nanometer lubricating grease additive and application thereof

The invention relates to preparation of an aluminium nitride and copper mixed nanometer lubricating grease additive and an application thereof, and belongs to the technical field of lubrication. The nanometer lubricating grease additive disclosed by the invention is prepared from nanometer AIN and nanometer Cu in a mixing manner, wherein the particle size ranges of the AIN powder and the Cu powder are 50-200nm. The obtained additive is added to base lubricating grease, so that not only can the anti-wear antifriction performance of the base lubricating grease be improved, but also the base lubricating grease can act on the surface of a friction pair, the roughness of the surface of the friction pair is improved, and a polishing scratch on the surface is repaired, so that the abrasion loss of the friction pair is reduced, the friction pair and the accuracy are effectively ensured, meanwhile, accumulation of heat on the friction surface is reduced, and the service life of the friction pair is prolonged. The test data show that compared with the lubricating grease to which the additive disclosed by the invention is not added, the friction coefficient of the lubricating grease to which the additive disclosed by the invention is added is reduced by 23.6-15.8%, and the friction durability is prolonged by 6-7 times.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Gas turbine engine starter generator that selectively changes the number of rotor poles

InactiveUS6995478B2Improve wear lifeLow costSynchronous generatorsGas turbine plantsStarter generatorGas turbines

A rotating electrical machine, such as an aircraft starter-generator, that may be operated in either a motor mode or an generator mode. The machine includes a main rotor that is selectively configurable as an M-pole rotor or an N-pole rotor. The machine can also include DC brushes that are selectively moveable into, and out of, electrical contact the main rotor, to thereby electrically couple and decouple a DC power source to and from, respectively, the rotor windings.

Owner:HONEYWELL INT INC

Preparation method for wear-resisting metal ceramic composite material

The invention discloses a preparation method for a wear-resisting metal ceramic composite material. The preparation method comprises the steps of uniformly mixing ceramic particles or ceramic particles being subjected to surface preprocessing with self-fluxing alloy powder by polyvinyl alcohol to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, wherein a 2-10mm common steel gasket is arranged at the bottom of the cavity in advance, and the mixture bears 50-70MPa from the pressing machine; after molding and demolding, putting both a biscuit and the gasket into a drying box of 150 DEG C to be drying for 2 hours; putting the dried biscuit and the gasket into a vacuum furnace to be sintered for 30-90 minutes, wherein the temperature of the vacuum furnace is 1000-1300 DEG C, and the vacuum degree is 0.1-1.0Pa; and cooling down and taking out of the furnace to obtain the wear-resisting metal ceramic composite material. The composite material is prepared by pressing and has the relatively high compactness after being sintered; if being compounded on the surface of a wear-resisting part, the wear-resisting part has the relatively long friction durability; the mixture does not contain an adhesive agent, so that the composite material does not generate slag inclusion and pores after being sintered.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

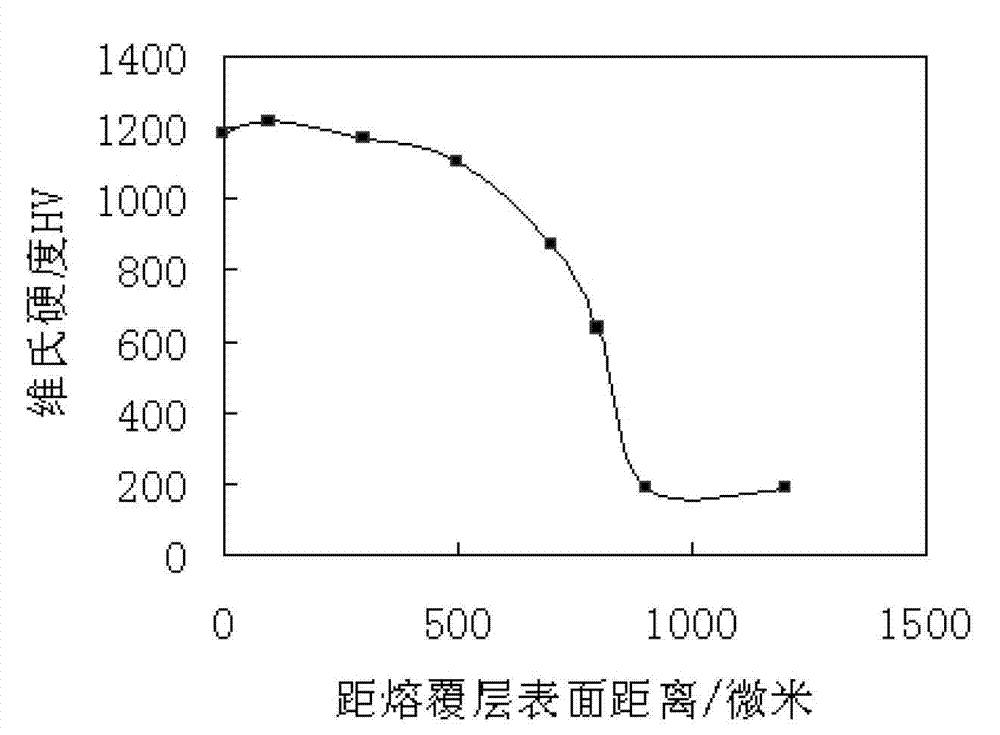

Powdered material used for preparing high-temperature wear-resistant cladding layer and preparation method thereof

InactiveCN102965665AImprove wear lifeLow dilution rateMetallic material coating processesSurface engineeringImpeller

The invention discloses a powdered material used for preparing a high-temperature wear-resistant cladding layer and a preparation method thereof, belonging to the technical field of surface engineering. The powdered material comprises the following components by weight percent: 6-28% of TiB2, and the balance of Ni-Cr-Mo-Fe-Nb-B-Si-C alloy powder, wherein the Ni-Cr-Mo-Fe-Nb-B-Si-C alloy powder comprises the following ingredients by weight percent: 23-28% of Cr, 1-3% of Mo, 2-4% of Fe, 0.5-1% of Nb, 3-4.5% of B, 3.5-4.5% of Si, 0.5-1.3% of C and the balance of Ni. The preparation method comprises the steps of preparing powdered raw materials and mixed powder, and preparing the mixed powder to be the cladding layer used for the anti-abrasion treatment of a water cooling wall tube of a circulating fluidized bed boiler, or used for the anti-abrasion treatment of mill exhausters in a thermal power plant or an impeller of an induced draft fan. A TiB2 ceramic particle reinforced wear-resistant cladding layer is prepared by adopting a laser cladding technology, the surface microhardness ranges from 1000-1200HV, the technical requirements of high temperature and wear resistance of the water cooling wall tube of the circulating fluidized bed boiler are met, and the service life of the water cooling wall tube can be prolonged obviously.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

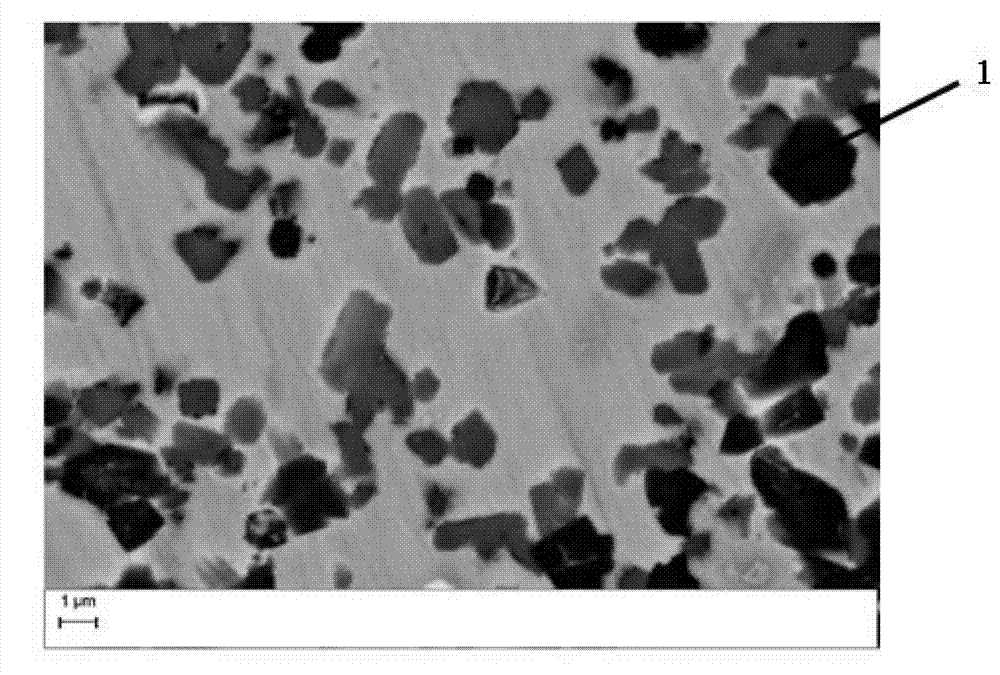

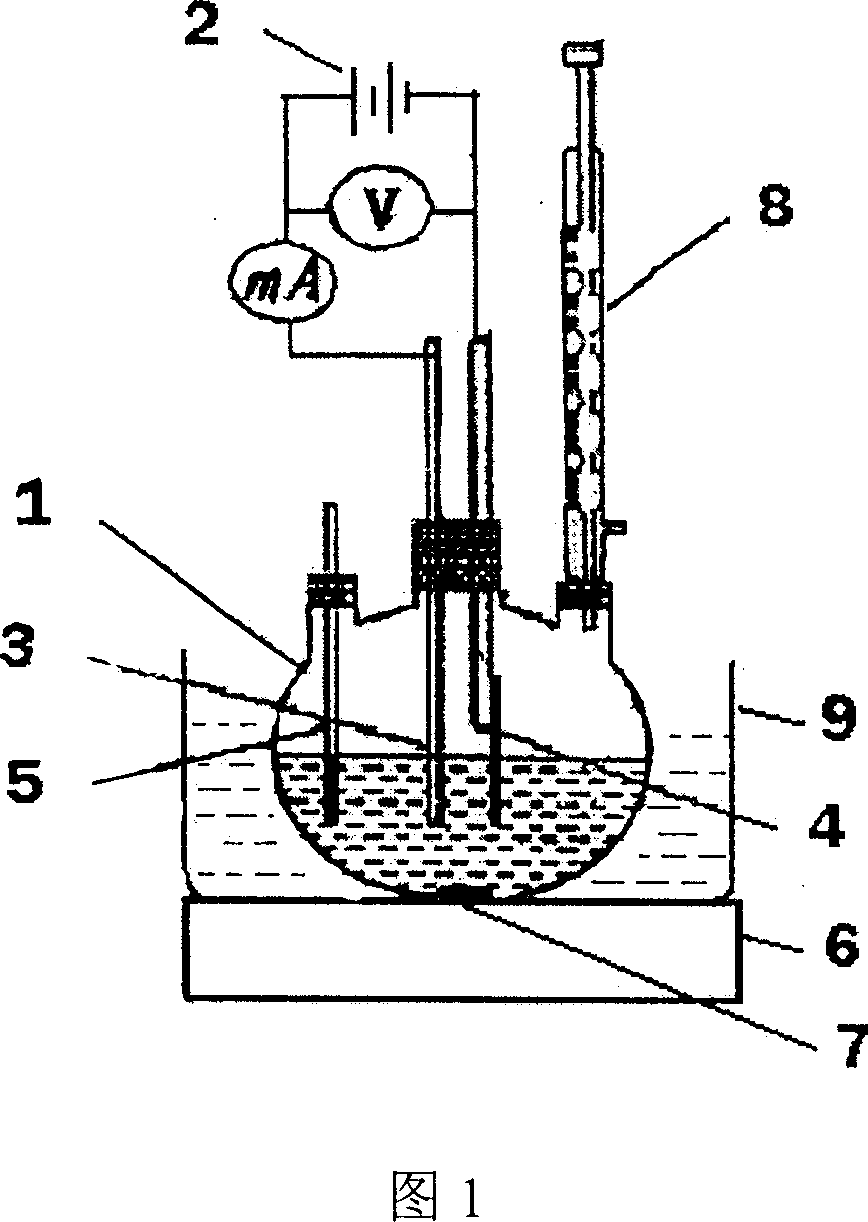

Method for preparing diamond-like film by liquid-phase electro-deposition technology

InactiveCN1962958AIncrease coefficient of frictionImprove wear lifeElectrolytic inorganic material coatingPulsed DCFluohydric acid

The invention discloses a preparing method of diamond film through liquid-phase electric sedimenting method in the diamond similar film preparing technical domain, which is characterized by the following: adopting demeso as electrolyte; setting the electrolyzing pressure at 50-500V high-frequency pulse DC pressure; sedimenting at 50-90 Deg C; refluxing vaporized electrolyte to sediment pond through condensing; selecting silica as base before sedimenting; disposing the silica in the acetone through ultrasound; immersing in the fluohydric acid solution; adopting high-purity graphite as anode in the sedimenting course; making disposed silica as cathode with the distance between two electrodes at 7mm; adopting demeso with high-dielectric constant and big dipole distance as electrolyte to prepare the product under lower pressure.

Owner:HENAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com