Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Fluohydric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing magnesium alloy chemical conversion coating

ActiveCN1880503AEliminate hazardsImprove corrosion resistanceMetallic material coating processesSodium iodideFluohydric acid

The invention discloses a chemical transmission film preparing technology of magnesium alloy, which comprises the following steps: a. proceeding degreasing disposal for magnesium or magnesium alloy through sodium hydroxide or one or multiple hybrid solutions of sodium phosphate with sodium hydroxide, sodium carbonate and sodium silicate solution; b. proceeding acid cleaning disposal for degreased magnesium or magnesium alloy through hybrid solution of phosphoric acid and sodium phosphate; c. proceeding activating disposal for acid cleaned magnesium or magnesium alloy through hybrid solution of fluohydric acid and sodium phosphate; d proceeding chemical synthesizing disposal for activated magnesium or magnesium alloy through composite solution of calcium nitrate hydrate, sodium nitrite, sodium iodide and hydrogen dioxide solution; e. packing hole of synthetic magnesium or magnesium alloy through deionized water. The invention doesn't utilize chromic composition, which eliminates danger for environment.

Owner:靖江市华信科技创业园有限公司

Process for preparing patterning titanium dioxide inverse opal photonic crystal

InactiveCN1880519ASimple processFrom gel statePolycrystalline material growthFluohydric acidUltraviolet lights

The invention discloses a preparing method of pattern titanium oxide reverse-gelite photon crystal, which comprises the following steps: adopting quartz glass or silicon monocrystal as substrate; immersing single-dispersed silica globule solution; adopting vertical depositing method on the substrate to produce gelite film; immersing the heat gelite at 500-800 deg.c in the allocated ultraviolet photosensitive titanium oxide colossal; filling ultraviolet photosensitive titanium oxide colossal in the silica globule gap through capillary action; etching mask ultraviolet light after gelatinizing; cleaning gel part of non-illumination through organic solvent; proceeding heat disposal under 800-1000 deg.c; placing film in the 1-10 percent fluohydric acid solution to dissolve silica globule; drying under 100-150 deg.c to obtain the product.

Owner:SHAANXI UNIV OF SCI & TECH

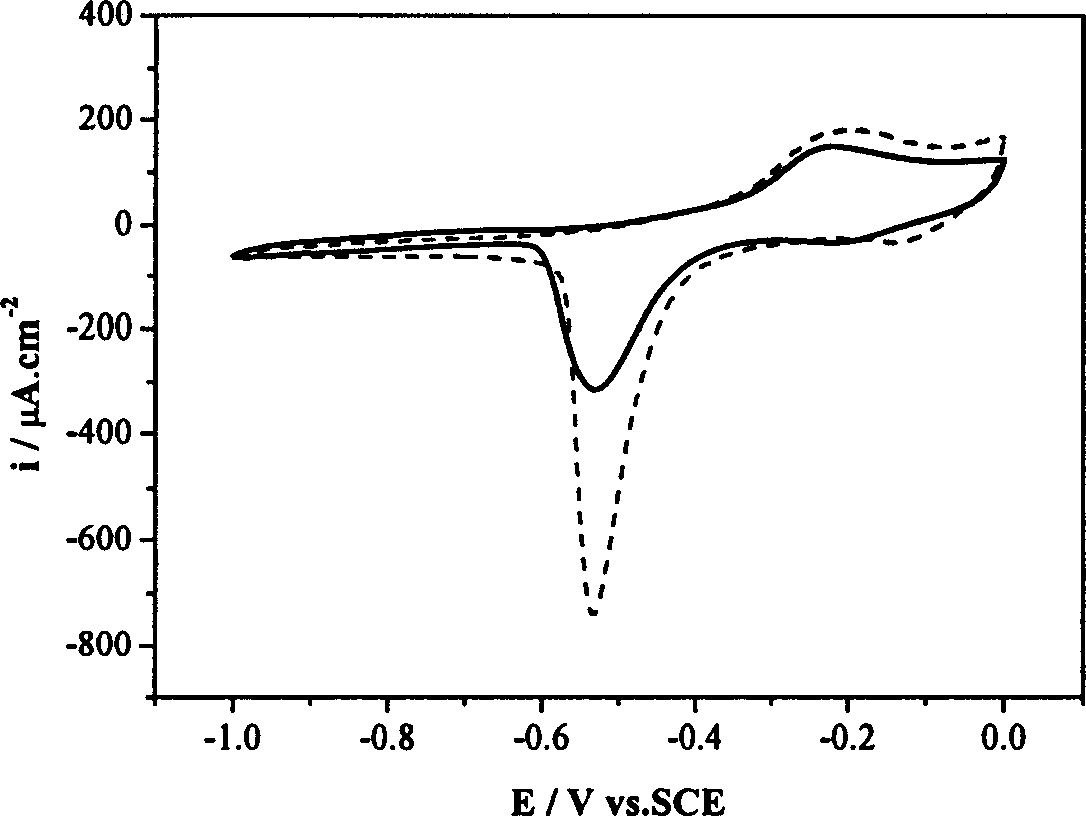

Quantitatively analyzing method for fluohydric acid in lithium ion battery electrolyte

InactiveCN1614406AHigh measurement accuracyEasy to judgeChemical analysis using titrationMaterial electrochemical variablesHydrofluoric acidAlcohol

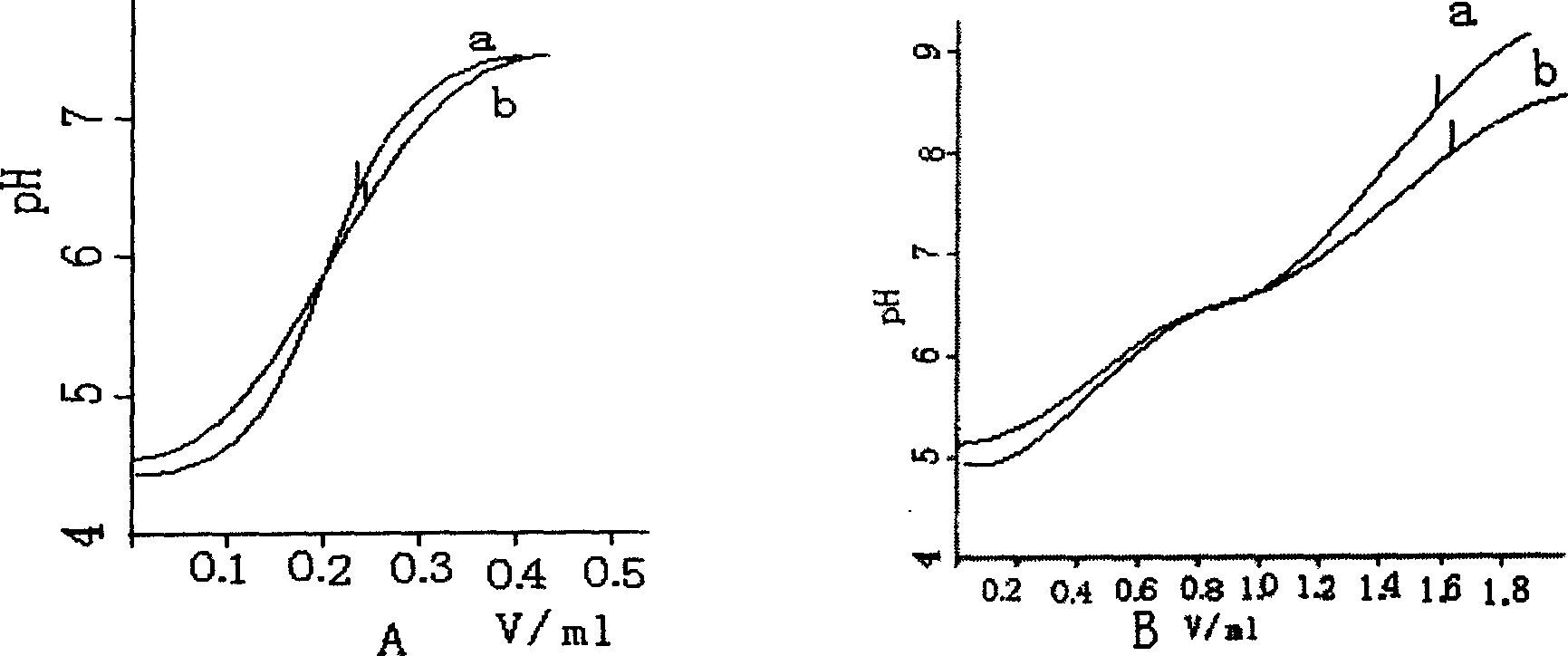

A quantitative analysis method includes diluting lithium ion cell electrolyte in absolute ethyl alcohol or methyl alcohol, using MOH as titrant, applying automatic potentiometric titration, using (CoXV20) / (1000XM) to confirm titrimetric curve as Co referring to tritrant concentration, V referring to consumed tritrant volume ml, 20 referring to HF molecular weight and M referring to electrolyte weight, using potentiometric titrator to carry out second order derivation of titrimetric curve for cnofirming titrimetric end point.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Analysis method for phosphor in high temperature alloy

InactiveCN1880946AEliminate the effects ofAnalytical results are reliableMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationDielectricFluohydric acid

The invention discloses a phosphor analyzing method in the high-temperature alloy, which is characterized by the following: heating to dissolve sample through compound acid such as azotic acid and hydrochloric acid or azotic acid, hydrochloric acid and hydrofluoric acid (or microwave sample-fusing furnace); adding perchloric acid to heat until smoke; dripping hydrochloric acid to remove chromium; adding complex citrate in the alkali dielectric; adding complex niobium, tantalum, zirconium, hafnium, titanium, vanadium, tungsten fluohydric acid in the azotic acid dielectric; extracting phosphor through butanol-chloroform composite agent and ammonium molybdate; reextracting organic phase through hydrochloric solution of tin chloride; testing absorbance of water phase at 680nm. The invention eliminates influence of high-content interference element, whose result is accurate and reliable with testing greatest lower limit as 0.0002%(m / m).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing diamond-like film by liquid-phase electro-deposition technology

InactiveCN1962958AIncrease coefficient of frictionImprove wear lifeElectrolytic inorganic material coatingPulsed DCFluohydric acid

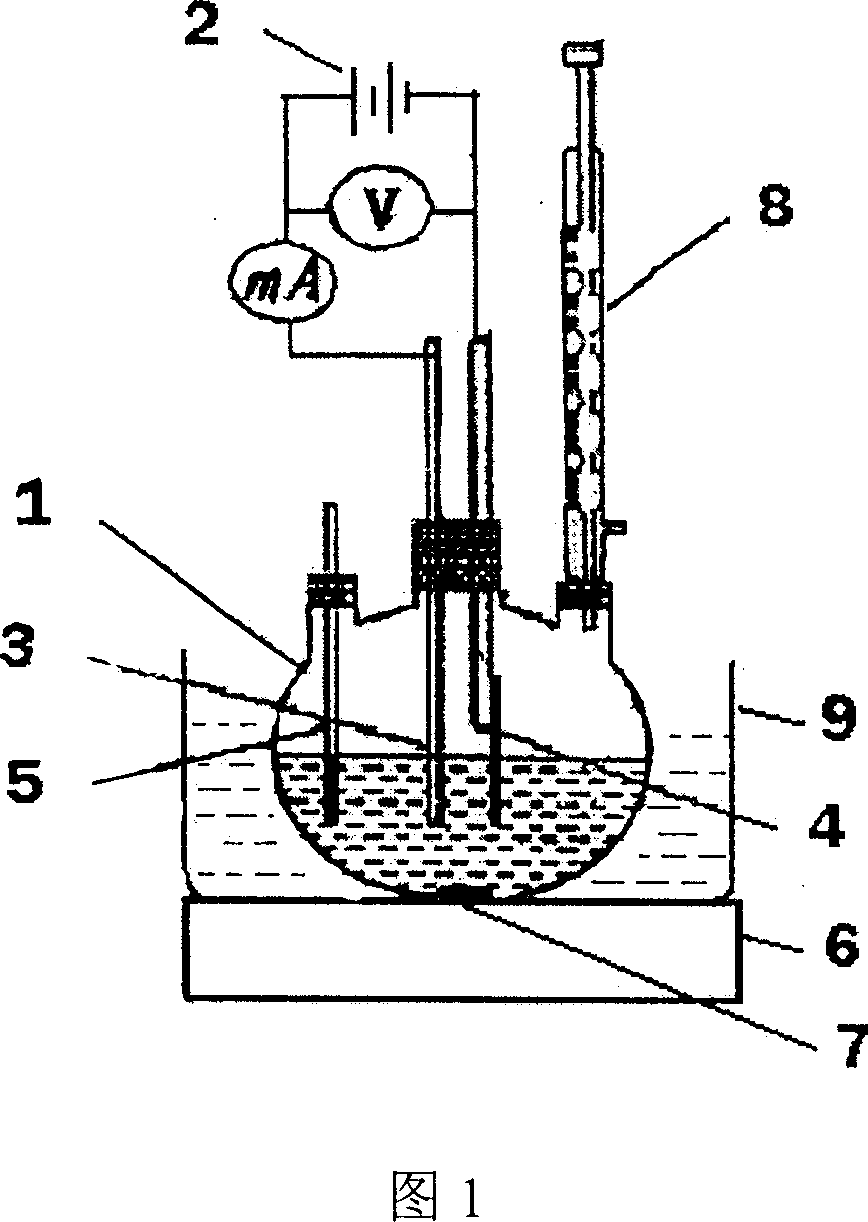

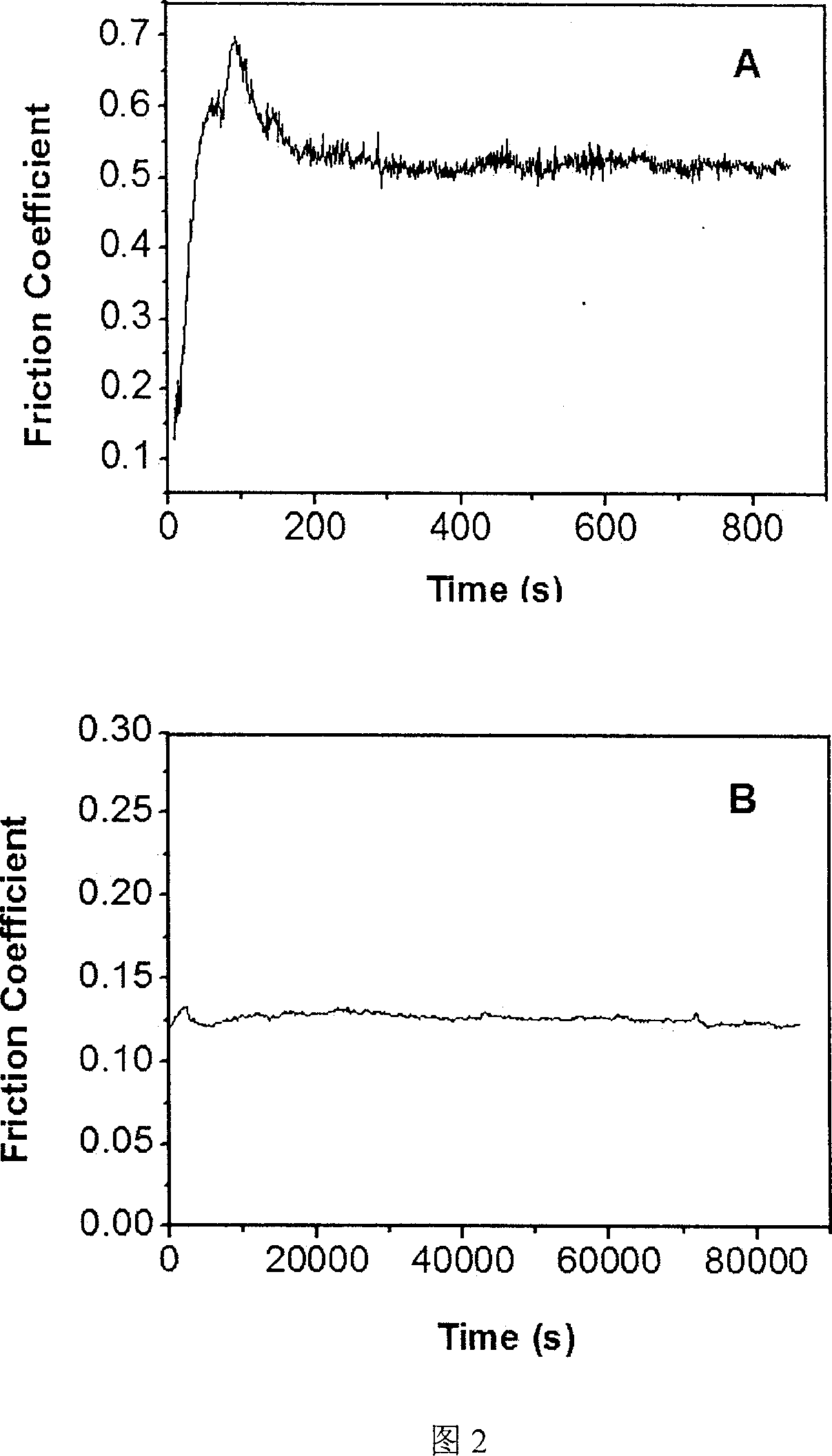

The invention discloses a preparing method of diamond film through liquid-phase electric sedimenting method in the diamond similar film preparing technical domain, which is characterized by the following: adopting demeso as electrolyte; setting the electrolyzing pressure at 50-500V high-frequency pulse DC pressure; sedimenting at 50-90 Deg C; refluxing vaporized electrolyte to sediment pond through condensing; selecting silica as base before sedimenting; disposing the silica in the acetone through ultrasound; immersing in the fluohydric acid solution; adopting high-purity graphite as anode in the sedimenting course; making disposed silica as cathode with the distance between two electrodes at 7mm; adopting demeso with high-dielectric constant and big dipole distance as electrolyte to prepare the product under lower pressure.

Owner:HENAN UNIVERSITY

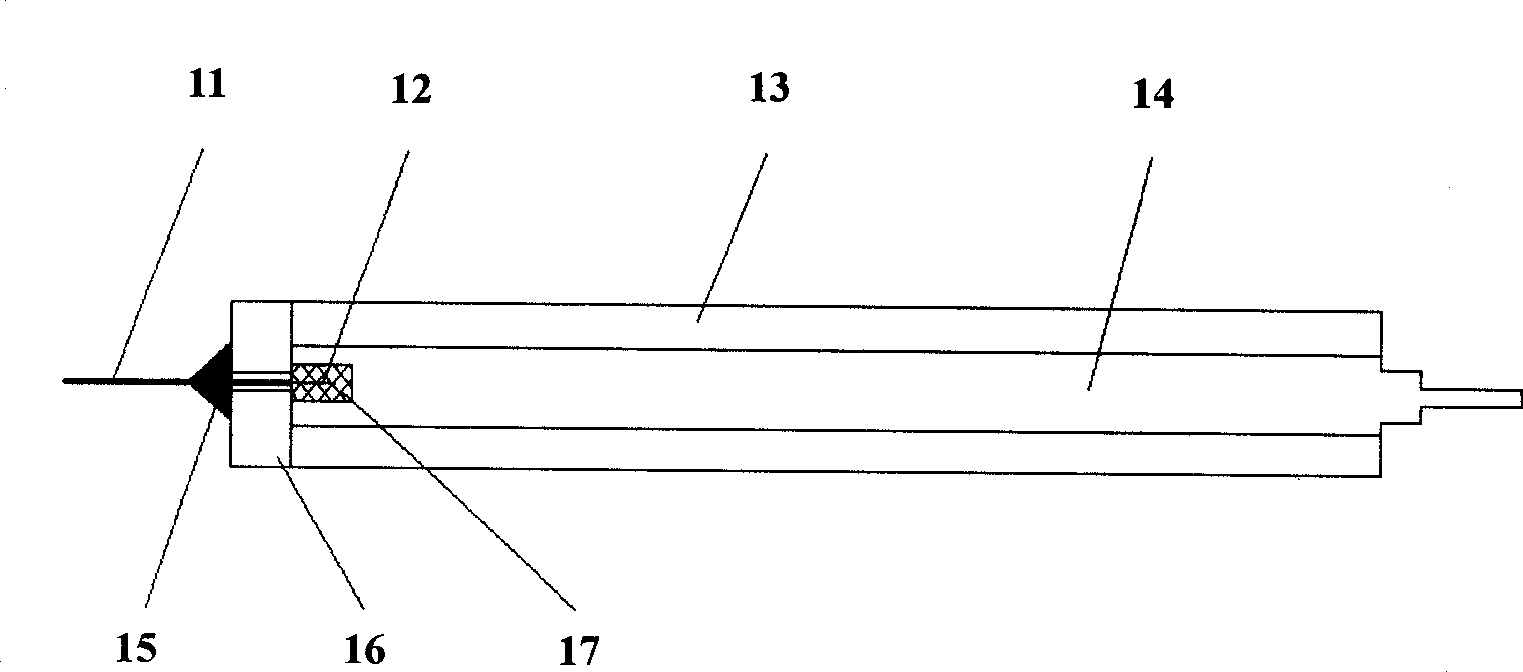

Method for producing optical fiber probe

The invention disclosed a way to make optical fiber transducer which includes the following steps: 1) treating the quartz glass optical fiber which contains fiber core, wrapper and covering layer to make the wrapper of one end outerop; 2) dipping the outeropped end and its connected section which contains covering layer into the 10-30wt% fluohydric acid and let them react with each other. After the reaction, the rested covering layer of the quartz glass optical fiber outerops to get the cone fiber transducer. The invention has many advantages: easy to operate, low cost, easy to produce in quantity; the transducer has very good repeatability.

Owner:TSINGHUA UNIV

Process for cleaning silicon chip by using diluted fluohydric acid

InactiveCN101722159AOvercome deficienciesInorganic non-surface-active detergent compositionsCleaning using liquidsHydrofluoric acidFluohydric acid

The invention discloses a process for cleaning a silicon chip by using diluted fluohydric acid, which comprises the step that the diluted fluohydric acid is used in the step of chemical reagent cleaning, namely the last step of the cleaning flow, wherein the volume ratio (HF to H2O) of the fluohydric acid to water in fluohydric acid cleaning solution is 1:300-1:2,000, and the cleaning time of the diluted fluohydric acid cleaning solution is between 30 and 1,000 seconds. The process has the advantages that the surface of the silicon chip cleaned by the process still is a hydrophilic surface, so adsorption phenomena of particles and part of metals caused by the conventional hydrophobic surface cleaned by DHF do not occur. By using the process, the metal contamination of the surface of the silicon chip after being cleaned by the process is less than 1E10atoms / cm2, and simultaneously the particle contamination degree (more than or equal to 0.10 micron) of the surface of the silicon chip can be less than 15 per piece, so the defects of the conventional cleaning solution in RCA cleaning are further overcome.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Direct chromium stainless-steel pickling agent

A chromium stainless steel pickling agent consists of hydrochloric acid 30-80% with concentration 30%, fluohydric acid 17.2-69.7% with concentration 50-55%, hexamethine tetramine or Rhodin or LK corrosion inhibitor 0.3-3.8%. It can remove oxide skin directly, simplify process, and have excellent protection performance for chromium stainless steel surface. The surface is clean and smooth, and it can be used for heat-treatment chromium stainless steel wire stocks, rods, sections, pipe materials, silks and mechanical work pieces.

Owner:李青

Method for cleaning monocrystalline silicon chip

InactiveCN101590476AImprove quality and efficiencyImprove conversion efficiencyCleaning using liquidsHydrofluoric acidFluohydric acid

The invention discloses a method for cleaning a monocrystalline silicon chip, and aims to provide a method for cleaning the monocrystalline silicon chip. Residues of white spots, fingers, mortars and the like on the surface of the silicon chip are removed, and the phenomena of fingerprints and the white spots on the surface of the silicon chip are eliminated, so that the quality and the conversion efficiency of a solar-grade monocrystalline silicon chip are further improved. The method comprises the following steps: mortar pre-flushing, degumming, chip inserting, cleaning, spin drying and detection. Through the steps of the mortar pre-flushing, the degumming, the chip inserting, the cleaning, the spin drying and the detection, the method particularly adopts immersion of fluohydric acid solution and a conventionally different cleaning method, and a worker wears a corresponding glove during different process operations to clean the silicon chip through fluohydric acid immersion and cleaning solution to effectively eliminate the phenomena of the fingerprints and the white spots.

Owner:JIAXING WUSHEN OPTO ELECTRONICS MATERIAL

Injection pretreatment method for oil water well

InactiveCN1861980APlay the effect of reducing pressure and increasing injectionDelay energy declineFluid removalDrilling compositionPretreatment methodFluohydric acid

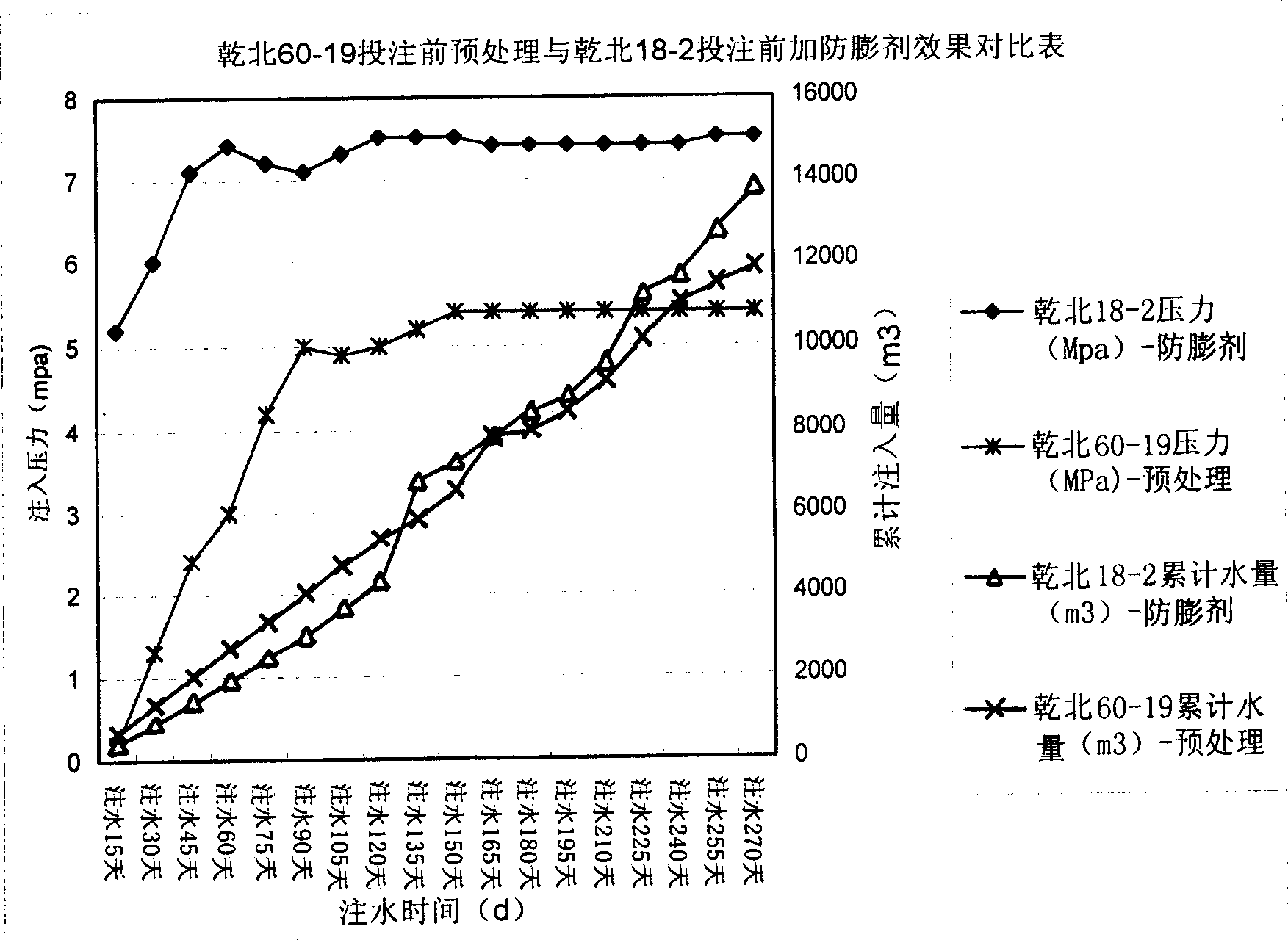

The present invention relates to an oil-water well shifting-in-injection pretreatment method, belonging to the field of oil field production technology. Said method includes the following steps: using pump truck to successively squeeze the prepad fluid formed from expansion-resisting expansion-reducing agent, visbreaking thickness-reducing agent and water-soluble demulsifying agent, aqueous solution-working solution composed of hydrochloric acid, fluohydric acid, corrosion inhibitor-mud acid, iron ion stabilizing agent-NTA, cleanup additive, expansion-resisting expansion-reducing agent, ethylene glycol butyl ether, and visbreaking thickness-reducing agent and clear water overflush fluid into the stratum, closing well and making reaction for 4-6 hr, making flowback, using pH test paper to determine pH, when the pH is equal to 7, stopping flowback, opening well to make normal production.

Owner:王洪新

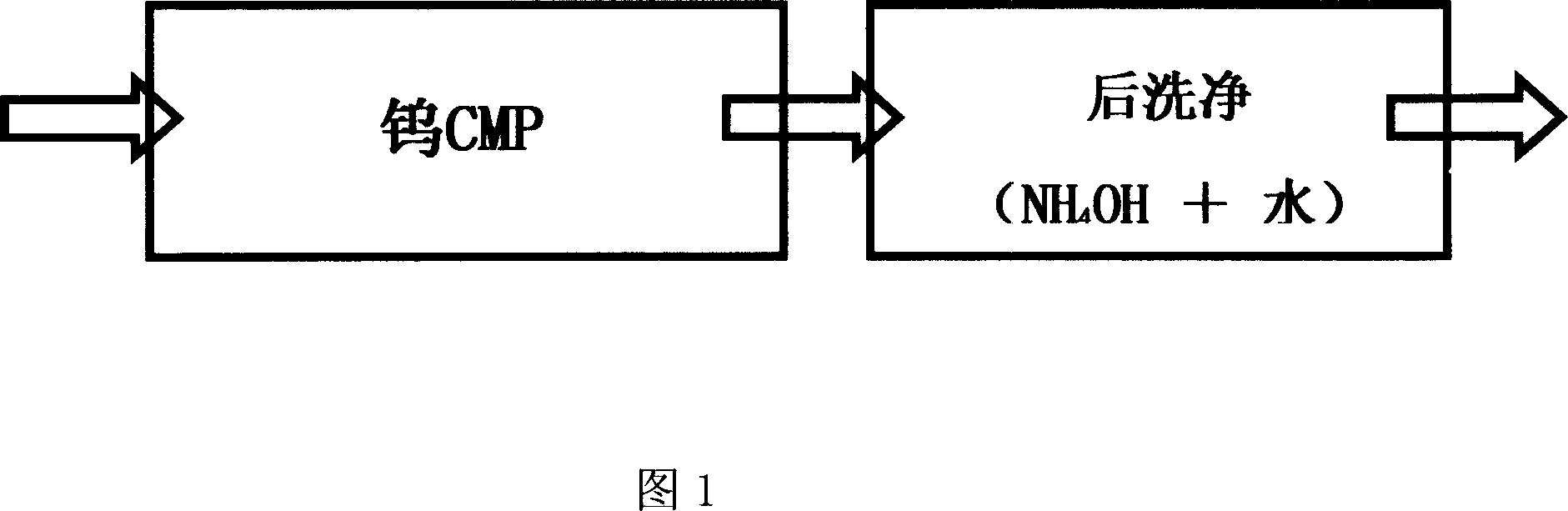

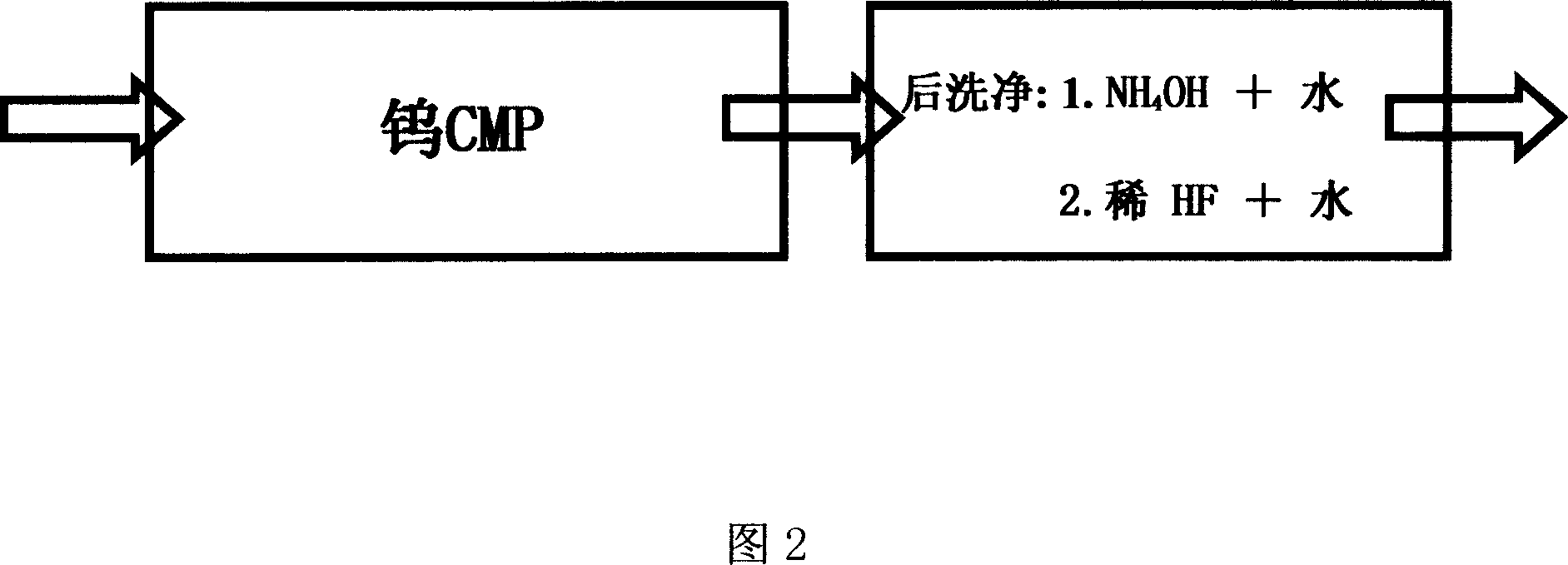

Cleanout method after tungsten CMP

InactiveCN1967788AAdded cleaning stepsEffective defectSemiconductor/solid-state device manufacturingCleaning using liquidsIonFluohydric acid

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

Process for electroless copper on silicon chip

InactiveCN1865500AReduce usageAvoid introducingLiquid/solution decomposition chemical coatingHydrofluoric acidCopper plating

The invention discloses a new copper plating method on the silicon plate, which is characterized by the following: introducing copper seed as catalyst on the silicon plate surface to proceed coating copper in the fluohydric acid solution; reducing copper to deposit on the substrate surface to produce fastening, bright and even copper coating. The method is convenient to operate with low cost, which improves the purity and conductivity of copper film.

Owner:FUDAN UNIV

Process for preparing silicon nitride nano material

The invention discloses a preparing method of silicon nitride nanometer material, which comprises the following steps: stirring molding agent and nitrate to dissolve; adding silicic carbethoxy and catalyst; hydrolyzing silicic carbethoxy into silica sol under indoor temperature; adding hardener to form sol gel; drying to obtain dried gel of silica; sintering to obtain porous silica; blending porous silica and silicon powder according to rate; aerating nitrogen or ammonia gas; heating to 1000-1500 deg.c; insulating for 2-30h; cooling to indoor temperature to obtain original product; oxidizing for 2-10h; immersing in the composite acid with alcaine and fluohydric acid or nitrate and fluohydric acid; washing; drying to obtain ladder-shaped, feather-shaped or wheat-shaped silicon nitride nanometer material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Etching solution composition for titanium and aluminium cascade metal films

The invention relates to an etching liquid compound, which can etch the metallic layered film made from titanium or the alloy whose main content is titanium or made from aluminum or the alloy whose main content is aluminum, that formed on glass insulated base plate, silicon base plate and compound semi-conductor base plate via splash method, without damaging the bottom base plate. And the invention can control taper degree in 30-90 degrees; the density of fluoride (fluohydric acid) is 0.01-5 mass%, nd the density of oxidant is 0.1-50 mass%.

Owner:KANTO CHEM CO INC

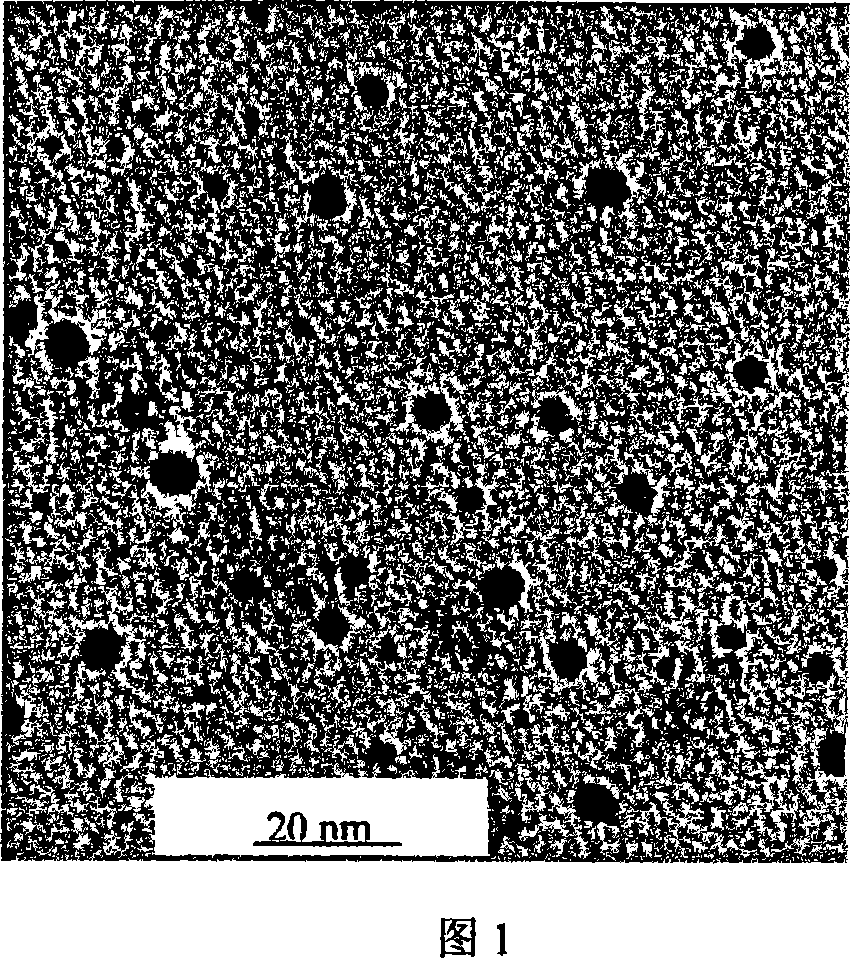

Method for preparing upcoversion nanocrystalline on rare-earth adulterating fluoride

InactiveCN101550593AEvenly dispersedWon't reunitePolycrystalline material growthFrom normal temperature solutionsFluohydric acidRare earth

The present invention relates to an improved method for preparing an upcoversion nanocrystalline on a rare-earth adulterating fluoride which includes steps as follows: weighing rare-earth nitrates Ln(NO3)3 or rare-earth chlorides LnCl3, adding de-ionized water for confecting combined stock solution with 0.05-0.2 mol / l concentration; adding mesoporous molecular screen powder into the solution, ultrasonic treatment, mixing continuously, filtering, deposition bathing, drying; adding the obtained solid powder into fluor oligosol or ammonium fluoride water solution, stirring for reacting thoroughly; moving the reaction mixer into a reactor, water heat treating 8-48 hours under temperature 100-180 deg c; placing the product into a fluohydric acid solution to soak for removing molecular screen forwork, bathing and vacuum drying for obtaining upcoversion irradiancy nanocrystalline of rare-earth adulterating fluoride with less than 10 nm size. The upcoversion irradiancy nanocrystalline does not agglomeration and can obtain globular shape particle with uniform decentralized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

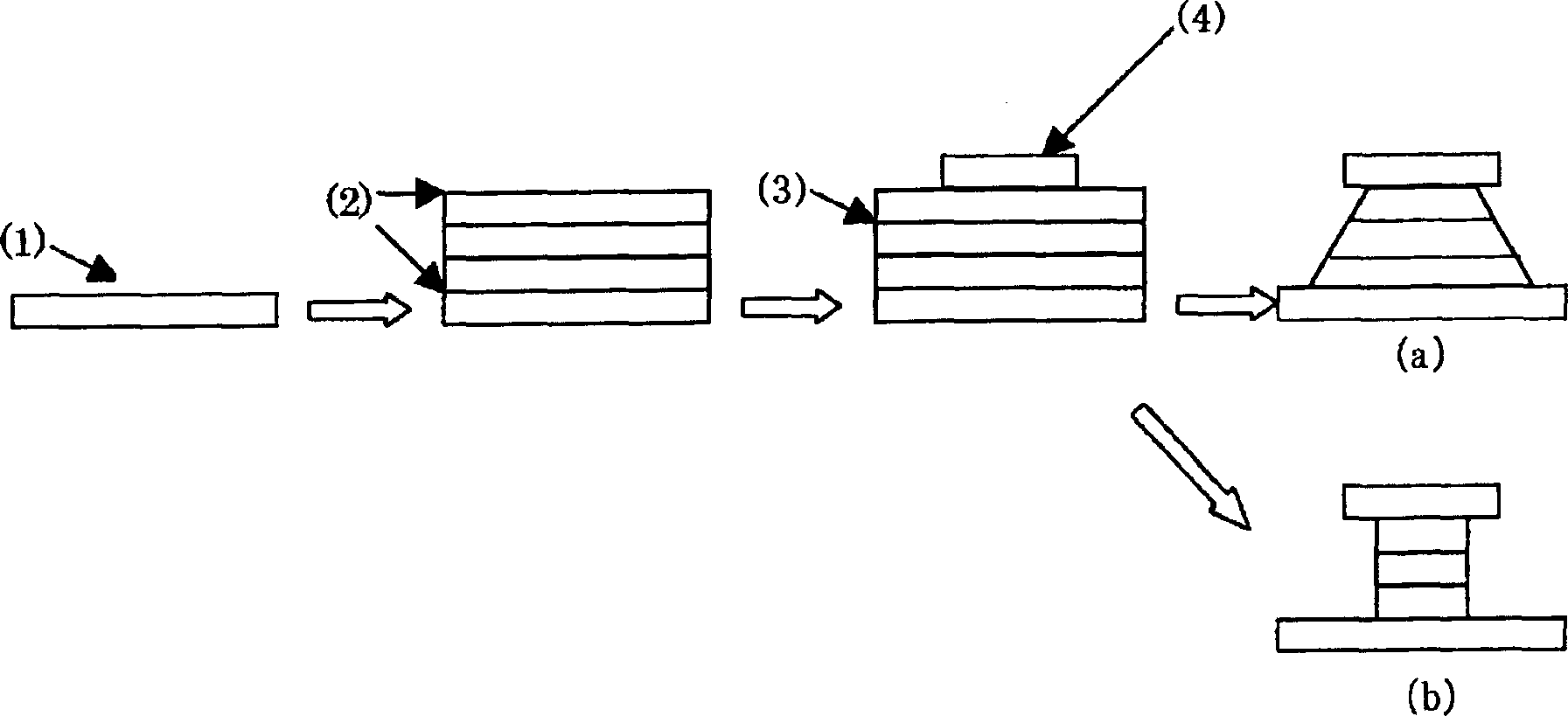

Cutting making process of silicon carbide boat for chip manufacture

InactiveCN1375383AIncrease productivityHigh precisionSemiconductor/solid-state device manufacturingMetal working apparatusHydrofluoric acidFluohydric acid

The linear cutting process for manufacturing carborundum boat for making wafer includes the following steps: (1). cutting carborundum tube to obtain blank material; (2) cutting blank to form and combing to produce comb gap; (3) cleaning primary product for several times, its cleaning liquor includes detergent, chlorylene, sulfuric acid and hydrogen peroxide, fluohydric acid and pure water, etc.; (4). annealing, heat treatment; (5) secondary cleaning; (6) polishing primary product by adopting oxyhydrogen H2O2; (7) more annealing heat treatment for eliminating stress produced by polishing step;(8). further cleaning; and (9) projecting and detecting primary product to obtain the invented finished product.

Owner:张彩根

Method of preparing TiO2 nano pipe array by anodic oxidation method

InactiveCN101016637AReduce energy consumptionSimple processPolycrystalline material growthSingle crystal growth detailsLight energyFluohydric acid

The invention discloses a preparing method of TiO2 nanometer pipe array with anodic oxidation method in photoelectric function film technical domain, which comprises the following steps: choosing dimethyl formamide and fluohydric acid as raw material; allocating organic electrolytic solution with mass percent of fluohydric acid at 0.1-5%; proceeding anodic oxidation reaction with the reacting time bigger than 5 h; growing the TiO2 nanometer pipe array with the length excesses 20 micrometer, pipe diameter excesses 100 nanometer and length-diameter ratio can reach above 200; setting the voltage at 10-40 volt; This method can be utilized to produce various photoelectron chemistry component, which possesses wide prospect in domains of light energy utilization, green energy development and waste water treatment.

Owner:TSINGHUA UNIV

Surface treatment method for zirconium oxide body, zirconium oxide veneering porcelain composite material and preparing method thereof

InactiveCN102432337AThe surface treatment method is simple and convenientHigh bonding strengthRough surfaceHydrofluoric acid

The invention provides a surface treatment method for a zirconium oxide body. The method comprises the following steps of: 1, fusing and attaching a ceramic layer on the surface to be treated of the zirconium oxide body; and 2, putting the zirconium oxide body on which the ceramic layer is sintered into a fluohydric acid solution to corrode the ceramic layer on the surface and expose a zirconium oxide substrate. The invention further provides a zirconium oxide veneering porcelain composite material and a preparation method thereof. Before veneering porcelain is sintered on zirconium oxide, the zirconium oxide surface is subjected to the mentioned treatment. The surface treatment method for the zirconium oxide body provided by the invention is simple and convenient; and due to the formation of a rough surface, hard materials such as zirconium oxide can be well bonded with an adhesive, and the bonding strength of the veneering porcelain can be increased greatly.

Owner:陈超 +1

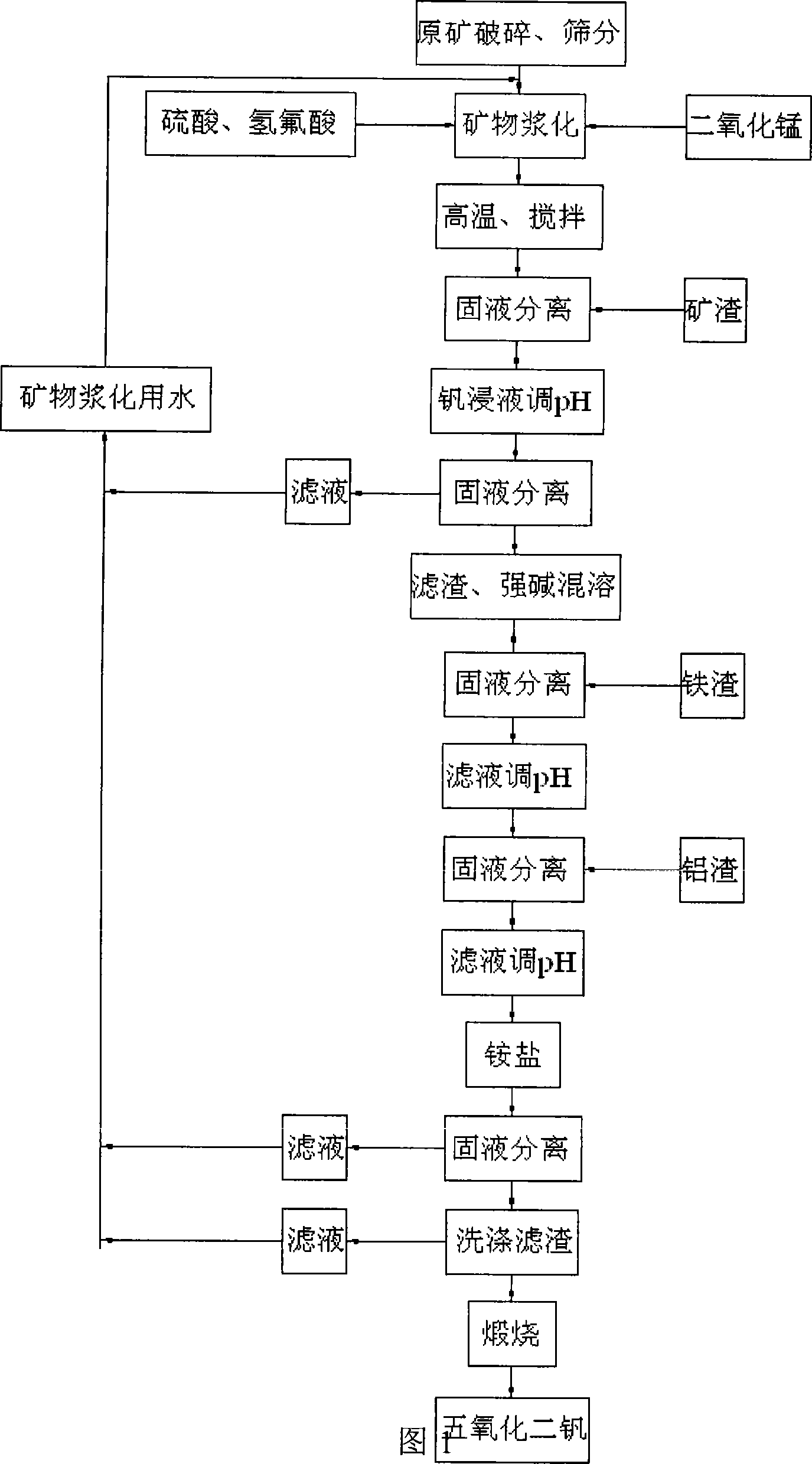

Alum extracting technique for clay ore by wet method

InactiveCN101215646AImprove use valueShort processVanadium oxidesProcess efficiency improvementFluohydric acidAmmonium metavanadate

The invention relates to a wet process vanadium extraction technology of clay ore, providing a valuable metal technology for extracting vanadium by wet process from vanadium clay ore, which belongs to the non-ferrous metal metallurgical technology field. The invention is characterized in that disintegrating clay ore, proceeding thermostatic mixing acid leaching reaction as adding sulfuric acid, fluohydric acid and oxidation agent under certain liquid solid volumetric ratio, separating solid and liquid, removing out iron and aluminum and recycling to utilize after leaching solution being treated by multistep pH value regulation and alkali deposition solubilization reaction, depositing vanadium by ammonium salt after purified vanadium being regulated pH value, filtering, drying and calcining ammonium metavanadate which is prepared to obtain vanadium pentoxide powder. The invention directly leaches clay ore mixing with acid, has high acid leaching rate, lower energy consumption, short technical process, easy operation and control, low productive cost, environment-friendly and safety, realizes zero discharge in the production process, has no waste gas generation, and recycles waste water and valuable metal, and the recycle rate of vanadium reaches 70-75%, purity of vanadium pentoxide of the product is larger than 99%.

Owner:UNIV OF SCI & TECH BEIJING

Purification and preparation method for solar energy polycrystalline silicon raw material

InactiveCN101054722AReduce energy consumptionIncrease production capacityPolycrystalline material growthSingle crystal growth detailsHydrofluoric acidProcess equipment

A process for purifying and preparing solar (radiation) energy polycrystalline silicon raw material comprises the following steps: firstly, pulverizing metallic silicon after a deoxidize processing, then acid cleaning it with aqua regia and fluohydric acid, and transferring it into a monocrystalline silicon extraction-tensile furnace for a extraction-tensile after the acid cleaning, separating air for a purification by utilizing the monocrystalline silicon extraction-tensile furnace for creation of vacuum, after a coarse extraction, transferring the polycrystalline silicon material into a zone founding furnace wherein a interval temperature grads form, eliminating white slime impurity by adopting heat extruding method. And then, a polycrystalline silicon raw material with a purity high than 99.9999%is obtained. Said invention possesses the advantages as follows: the energy consumption is reduced for vast scale and the deliverability is raised greatly by taking full advantage of traditional process equipment such as monocrystalline silicon extraction-tensile furnace and zone founding furnace, without needing reconstructions; the less process steps and the simplicity of operation is suitable for monocrystalline silicon extraction-tensile furnace of any type.

Owner:晶湛(南昌)科技有限公司

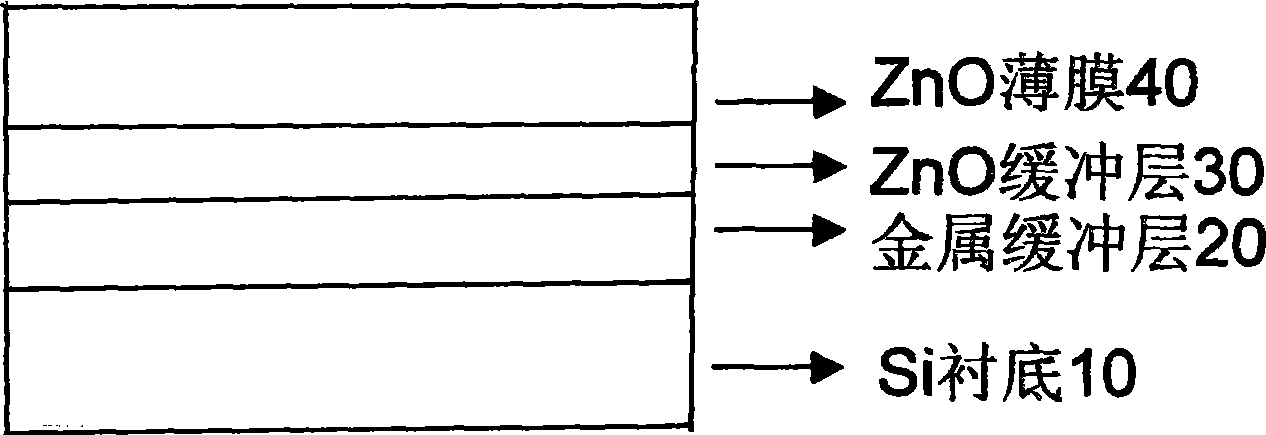

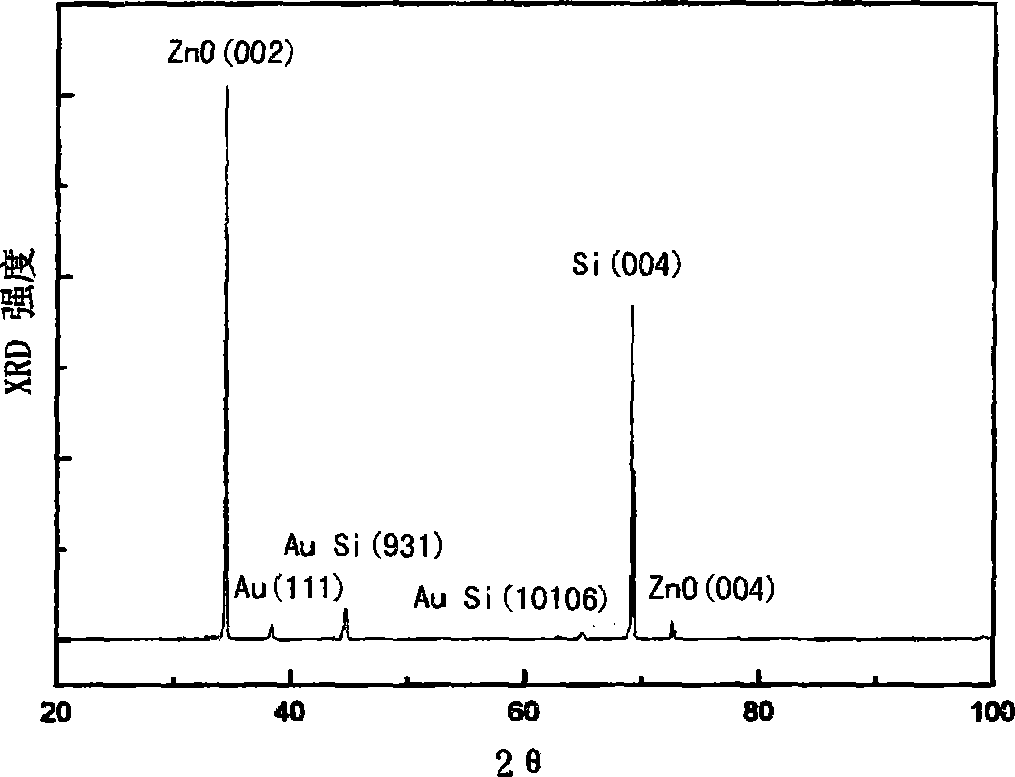

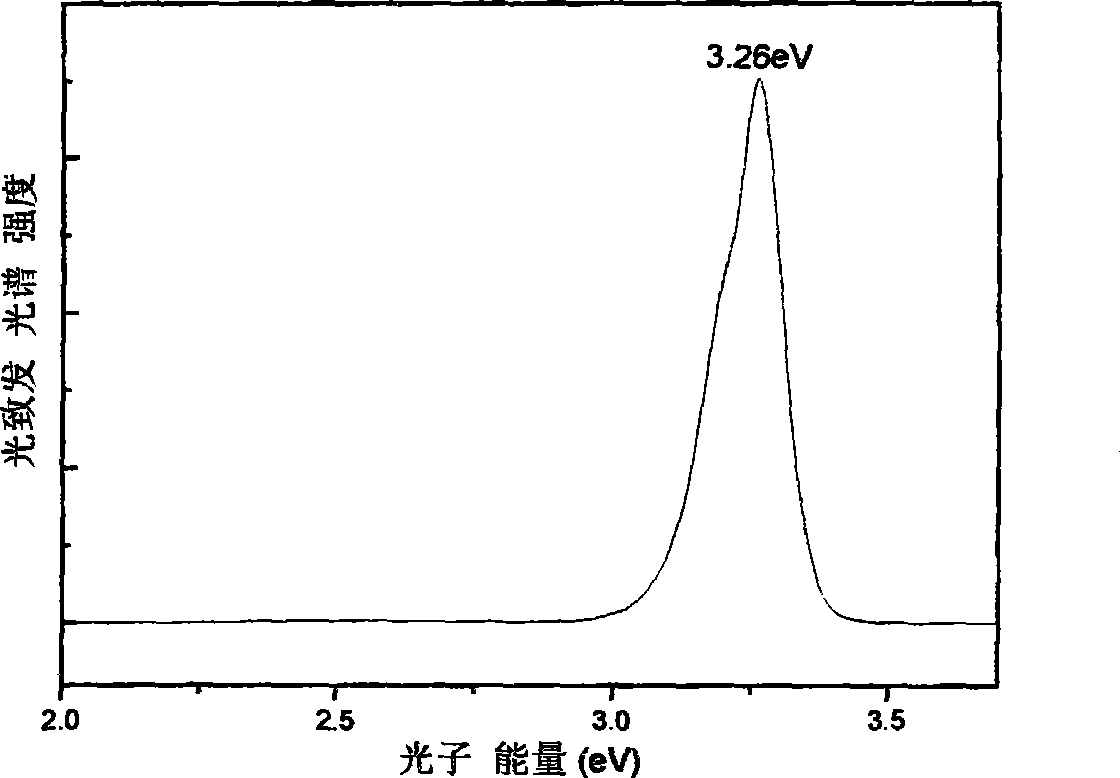

Process for growing ZnO thin-film on Si substrate

InactiveCN101388346AImprove cooling effectSolve the cooling problemSemiconductor/solid-state device manufacturingSemiconductor devicesHydrofluoric acidEtching

A method for growing ZnO film on Si substrate is characterized by comprising the following steps: firstly cleaning the surface of the Si substrate through chemical cleaning method, and removing the oxide layer thereof through utilizing fluohydric acid etching method, secondly placing the cleaned Si substrate into a deposition device to evaporate a metal buffer layer, thirdly placing the Si substrate which covers the metal buffer layer into a growing device to grow a ZnO homo-buffer layer, finally growing a ZnO film on the ZnO homo-buffer layer, thereby finishing the preparation of the ZnO film on the Si substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

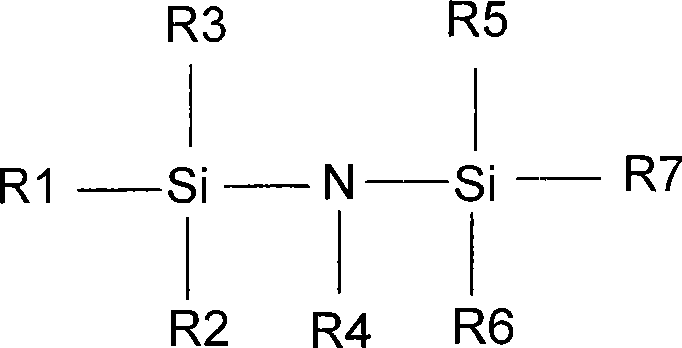

Method for stabilizing color and luster, moisture and fluohydric acid content of non-aqueous electrolyte

InactiveCN101442144AMoisture stableStabilized Hydrofluoric Acid ContentFinal product manufactureElectrolyte accumulators manufacturePhosphorous acidHydrofluoric acid

The invention provides a method for stabilizing the color and luster, the water content and the hydrofluoric acid content of a nonaqueous electrolyte at a high temperature of between 50 and 70 DEG C. The method is to add a silicon amine compound and a phosphorous acid ester compound into the nonaqueous electrolyte, wherein the addition of the silicon amine compound and the phosphorous acid ester compound is 0.01 to 3 percent of the weight of the electrolyte. The compounds can effectively inhibit increase of the water content and the hydrofluoric acid content of the electrolyte and maintain stable quality of the electrolyte.

Owner:BEIJING INST OF CHEM REAGENTS

Method of preparing 3C-SiC nano particles by chemical corrosion method

InactiveCN101058725AEasy to getStrong and stable blue light emissionLuminescent compositionsHydrofluoric acidAlcohol

The invention discloses a making method of 3C-SiC nanometer particle, which comprises the following steps: adopting the composite liquid of fluohydric acid, nitric acid to etch common 3C-SiC powder; using the size of original powder more than micrometer magnitude's; making the density of etching acid at 35%-45% and the density of nitric acid at 60%-70% with bulk rate at 2. 0-3. 0:1. 0; heating to 80-100 deg. c for 0. 5-2. 0h; cooling; blending reated acid liquid and powder in the high-speed centrifuger to centrifuge; pouring the upper-layer acid liquid; fetching the lower-layer powder; drying in the baker at 70-90 deg. c; adding centrifugal or anhydrous alcohol in the powder; cavitating through ultrasound for 30-60min; fetching the upper supernatant layer with 3C-SiC nanometer particle with size less than 8nm in the deionized water and anhydrous alcohol.

Owner:NANJING UNIV

Liquid and device for harnessing coal-mine gas

InactiveCN1594837AAvoid explosionReduce the temperatureDust removalDispersed particle separationFluohydric acidPhosphoric acid

A liquid for harnessing coal-mine gas is composed of water solution of phosphoric acid three (2, 3-) ester, fluohydric acid, sodium hypochlorite. The liquid can be heated and volatilized to the mine, can reduce the mine temperature, prevent gas from burning and explosion, reduce mine dust concentration, and effectively harness the gas in the mine and improve the mine safety.

Owner:山西潞华集团公司一厂 +1

Method for activating treatment of tourmaline and high activity tourmaline boric fertilizer made thereby

The invention discloses a tourmaline activating disposing method, which comprises the following steps: adding fluohydric acid or silicofluoridein or fluorescent stone and hydric sulphate in the tourmaline; releasing boron. The preparing method of high-activity tourmaline boron fertilizer is characterized by the following: activating tourmaline to dissolve boron element; increasing boron releasing quantity of tourmaline by 22 times than original ore; keeping tourmaline illuminating infrared negative ion; accelerating plant root growth.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Process for producing fluohydric acid

The present invention relates to one kind of hydrofluoric acid producing process. Ammonium fluoride or ammonium bifluoride and sulfuric acid in the molar ratio of 2 to 1 are mixed and reacted in a reaction furnace at 150-250 deg.c for 2-5 hr, the resultant gas is condensed and purified or absorbed to obtain anhydrous hydrofluoric acid or watered hydrofluoric acid, and the resultant solid is ammonium sulfate product. The present invention adopts side product from phosphate production as material, and has the advantages of rich material and low cost.

Owner:DO FLUORIDE CHEM CO LTD

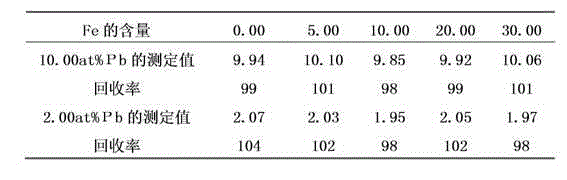

Method for measuring high content lead in iron-containing dust and mud

InactiveCN102914533AAccurate measurementHigh precisionAnalysis by thermal excitationHydrofluoric acidPerchloric acid

The invention relates to a method for measuring high content lead in iron-containing dust and mud and belongs to the technical field of analytical chemistry. The method comprises the following steps of: heating and decomposing a sample in a polytetrafluoroethylene beaker at a low temperature by using hydrochloric acid, nitric acid and hydrofluoric acid until perchloric acid is fuming; slightly cooling, adding dilute nitric acid dissolving salt, supplementing hydrochloric acid when insoluble substances are present, fixing the volume to a specified volume, and measuring the lead content by employing an inductive coupling plasma atomic emission spectrometer under the optimized instrument conditions. The method has the advantages of short measurement time, easy and convenient operation and high precision and accuracy and is particularly suitable for routine analysis of lots of samples.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method for determination of rare-earth content in nodularizer

InactiveCN1924559AImprove stabilityGood reproducibilityMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationRare-earth elementFluohydric acid

This invention discloses one nodularizer rare earth content testing method, which comprises the following steps: making test liquid and silicon, and the specimen liquid process steps are composed of aqua fortis and fluohydric acid specimen resolving, using boracic acid resolving over fluohydric acid to resolve the generated dinitrogen tetroxide by to process weak acid specimen liquid; the silicon process steps comprises the following steps: forming blue complex compound with azophosphon and rare earth element with largest absorption wavelength as 680nm with iron, titanium and calcium as mask with oxalic acid and with other metal element independent to measure the rare earth content by spectrophotometer.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

Processing method of tungsten filament and additive thereof

The invention involves a tungsten filament production method and it special additives, the method includes the following steps: weighing certain tungsten oxide and putting into reactor, adding additives which weight percentage is 0.8 ~ 1.2% relative to tungsten oxide, adding aluminum nitrate; adding water and mixing uniform, drying; hydrogen gas deacidizing and preparing doping tungsten powder in multi-pipe furnace, the dew-point of hydrogen gas <=-40DEG C, the hydrogen gas flow is 1.5-1.7 m3 / h, load-canoe amount is 400-500 g, push-canoe velocity is 1.5-2.5 canoe / h, the first deacidizing temperature is 600-650DEG C and the second deacidizing temperature is 800-900DEG C, the prepared doping tungsten powder is produced to tungsten strip through profiling and one time incipient fusion sintering, then is produced to thermos table tungsten wire through pressure processing; the invention has advantages of high production efficiency, high content of potassium in tungsten filament, good resistant temperature property and free-fluohydric acid pollution.

Owner:刘占波

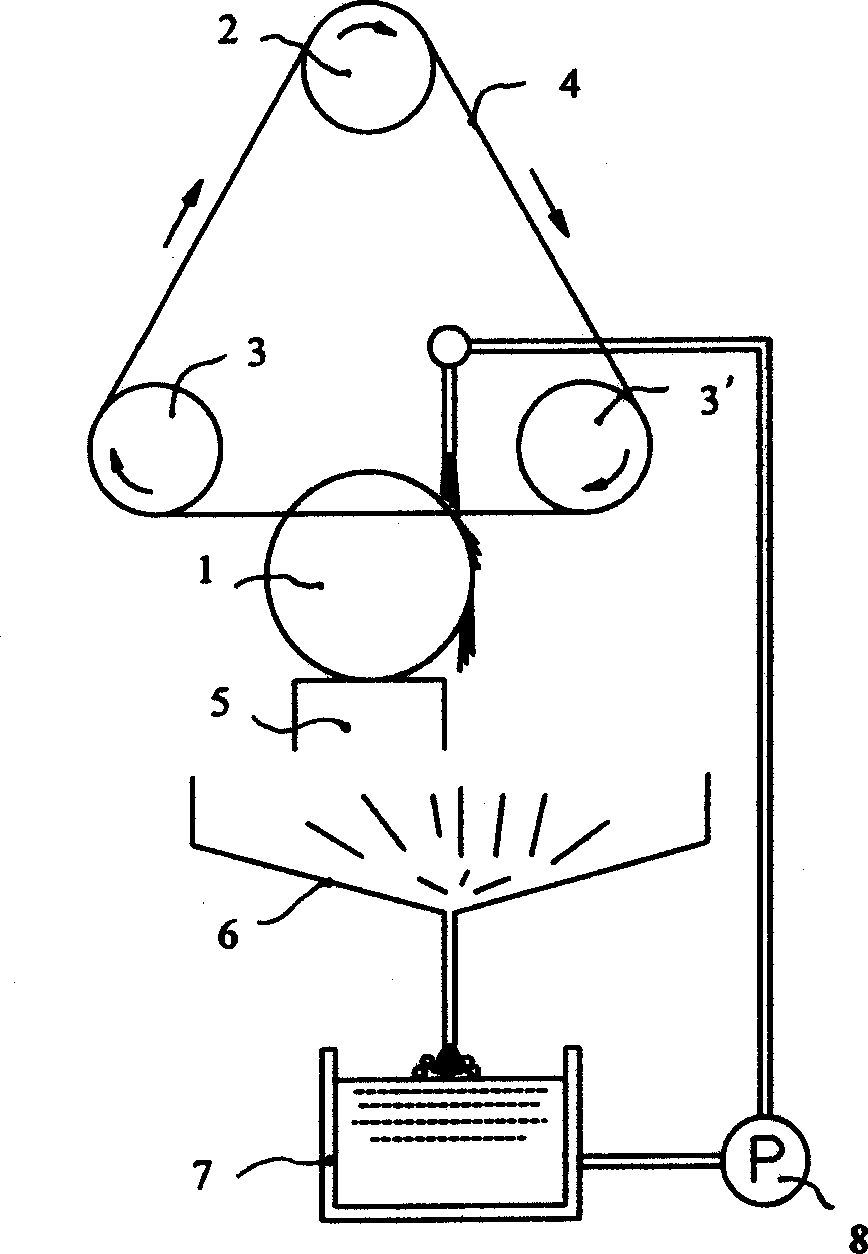

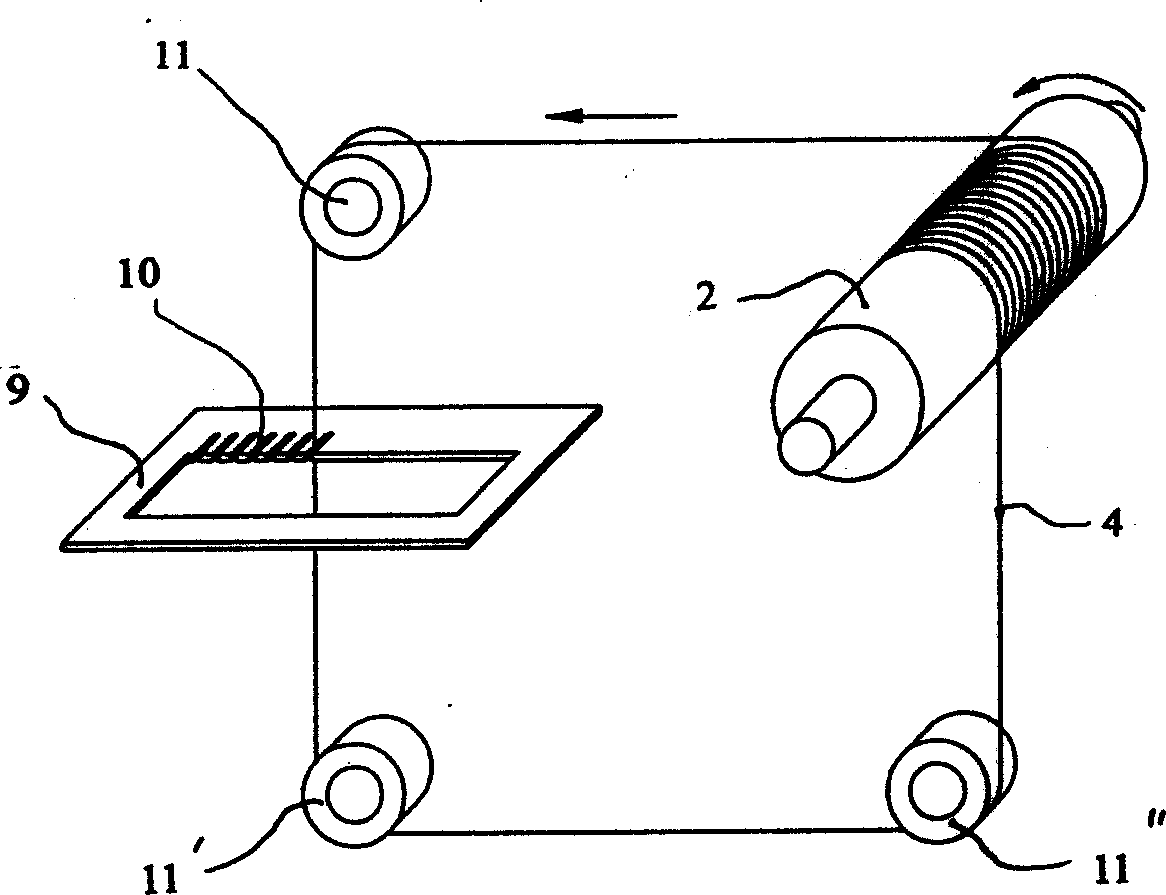

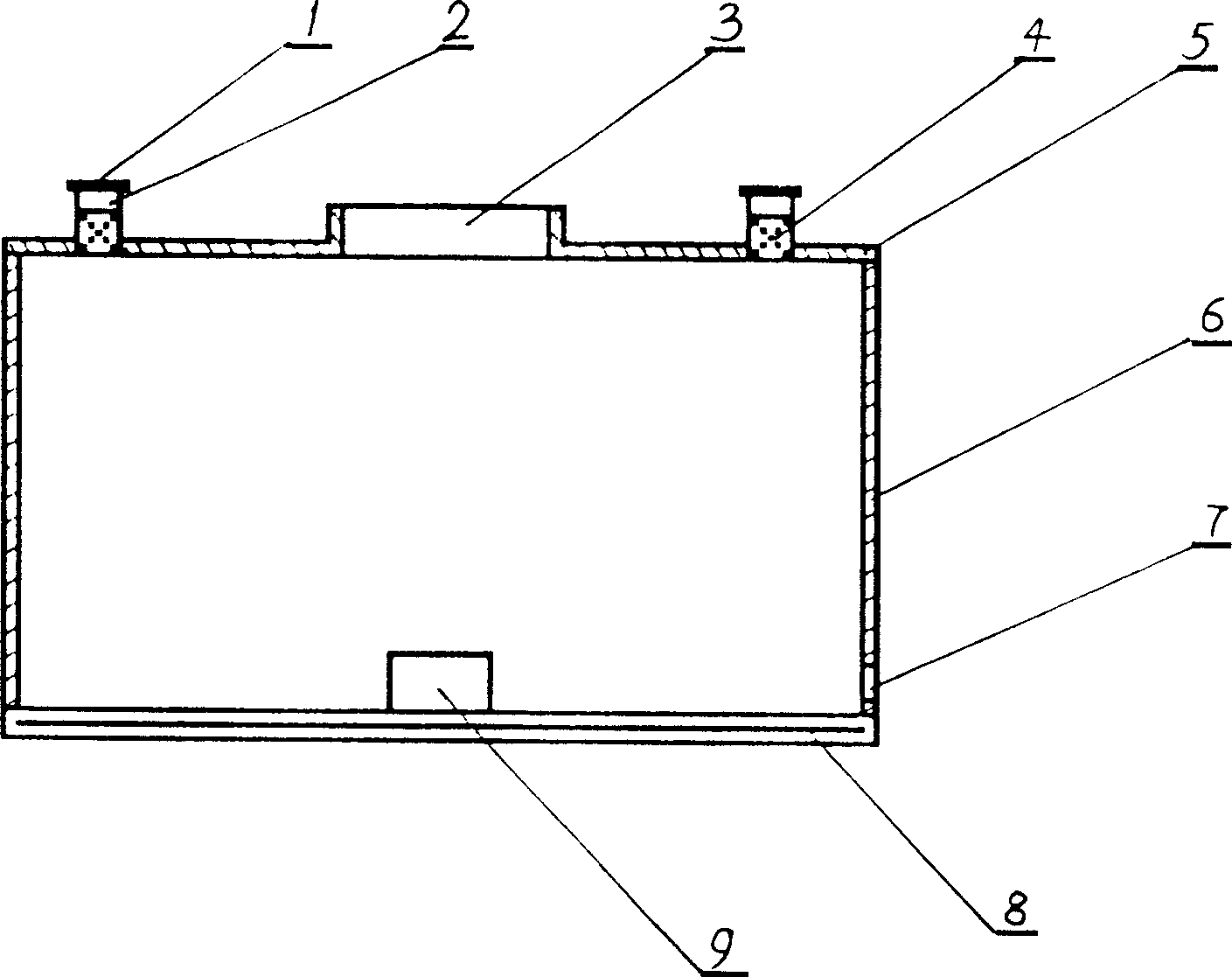

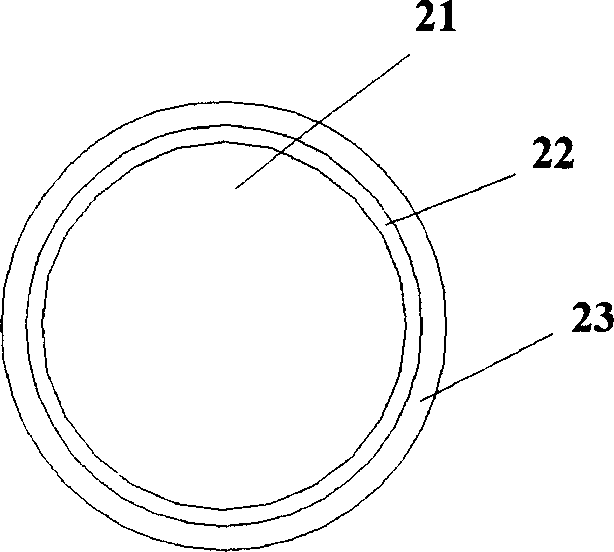

Ultra-micro ring electrode and preparation method thereof

InactiveCN1789997AMiniaturizableRealize mass productionMaterial electrochemical variablesElectrodesHydrofluoric acidFluohydric acid

The invention discloses a super-microring electrode and preparing method, which comprises the following steps: first, taking the naked optical fiber as the filamentary insulation substrate of super-microring electrode; adapting RF magnetic sputtering technology to deposit a layer of metal film as electrode film on the optical fiber surface; second, adapting plasma reinforced chemical gas-phase deposition technology to deposit silica film as electrode insulation film on the metal film; then, corroding the silica film on one end of optical fiber through fluohydric acid to make the optical fiber covered by metal film only; adapting aluminum powder conductive glue to connect the optical fiber and copper lead; finally, assembling the copper lead of super-microring electrode in the plastic liner; adapting optical fiber knife pen to cut the super-microring electrode surface on the other end of optical fiber covered by metal film and silicon nitride film.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com