Cleanout method after tungsten CMP

A technology for cleaning pipelines and hydrofluoric acid, which is applied in the directions of cleaning methods, cleaning methods and utensils using liquids, chemical instruments and methods, etc., to achieve improved cleanliness and good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the cleaning technology of semiconductor silicon wafers, different chemical solutions are used for cleaning according to the defects of different characteristics, generally alkaline solution and acidic solution are used.

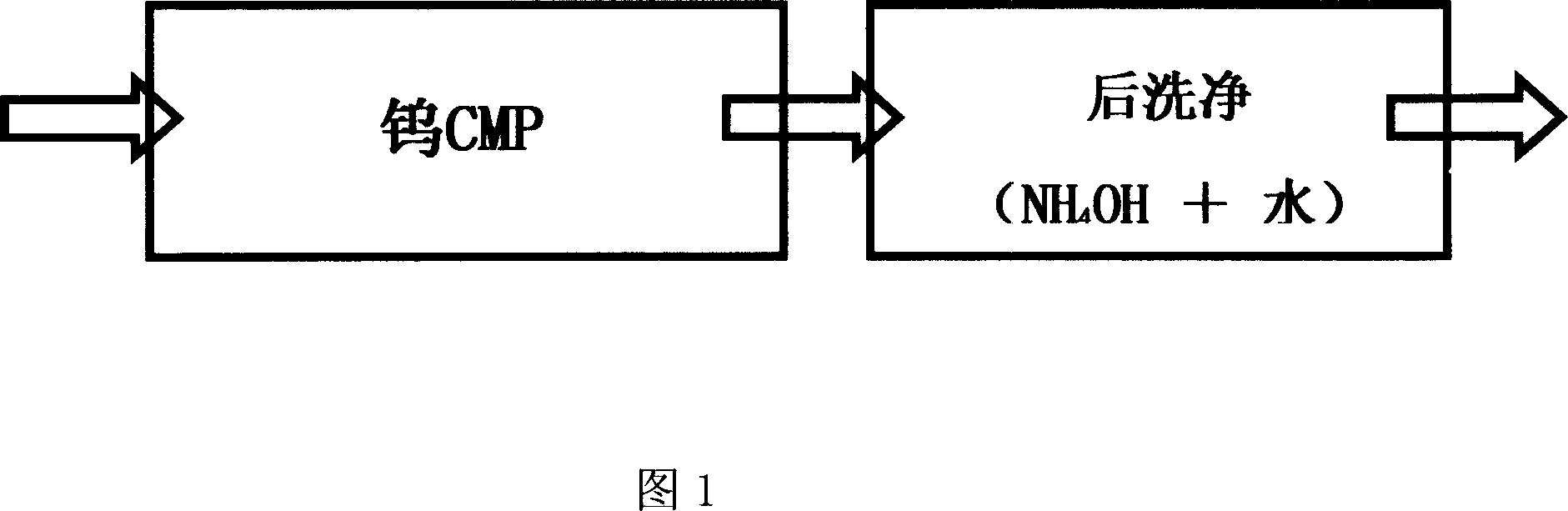

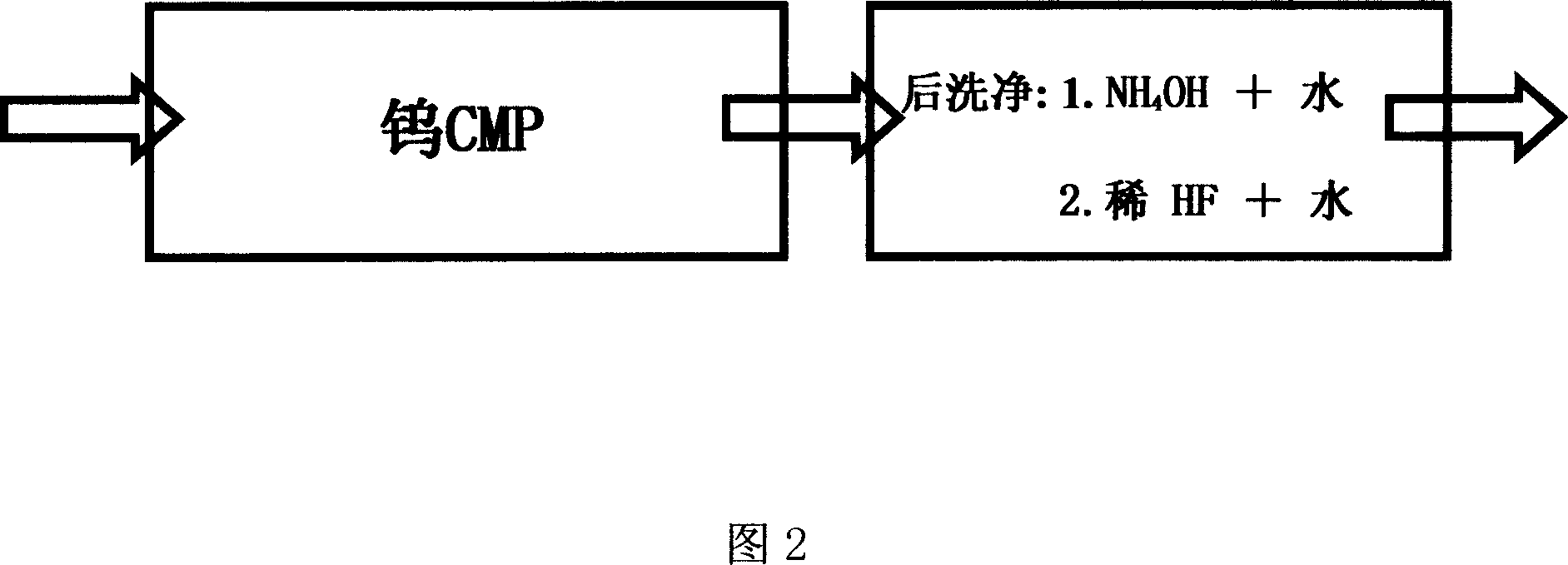

[0012] After the tungsten CMP process is completed, some defects will inevitably occur, including slurry remaining on the surface of the silicon wafer, micro scratches, small pits, and small holes formed on the surface of the silicon wafer. In order to overcome these defects, as shown in Figure 2, the cleaning method after the tungsten CMP of the present invention is that after the tungsten CMP process is completed, the existing ammonia water cleaning process steps are first used to clean the silicon wafer, and after that, use a concentration of <5 % dilute hydrofluoric acid in a short time, generally in the range of 10-20 seconds, to rinse the silicon wafer, then rinse with deionized water and spin dry.

[0013] When performing hydrofluoric acid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com