Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32393results about How to "Improve cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

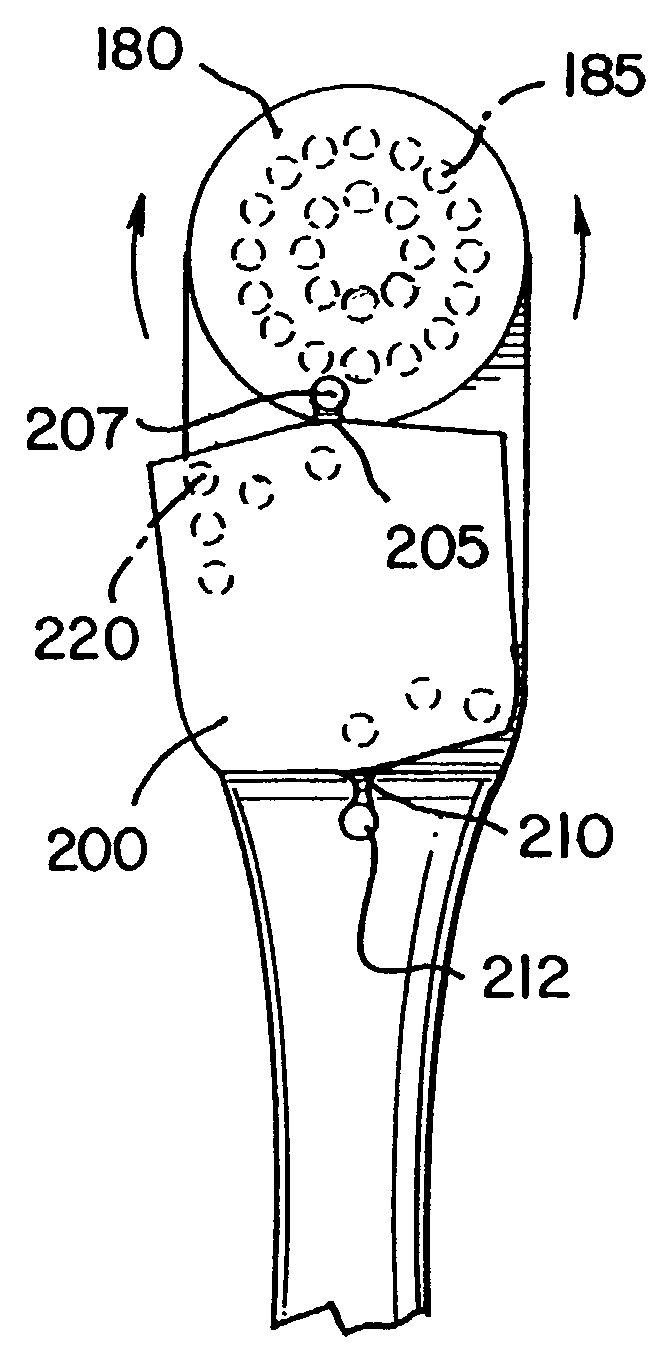

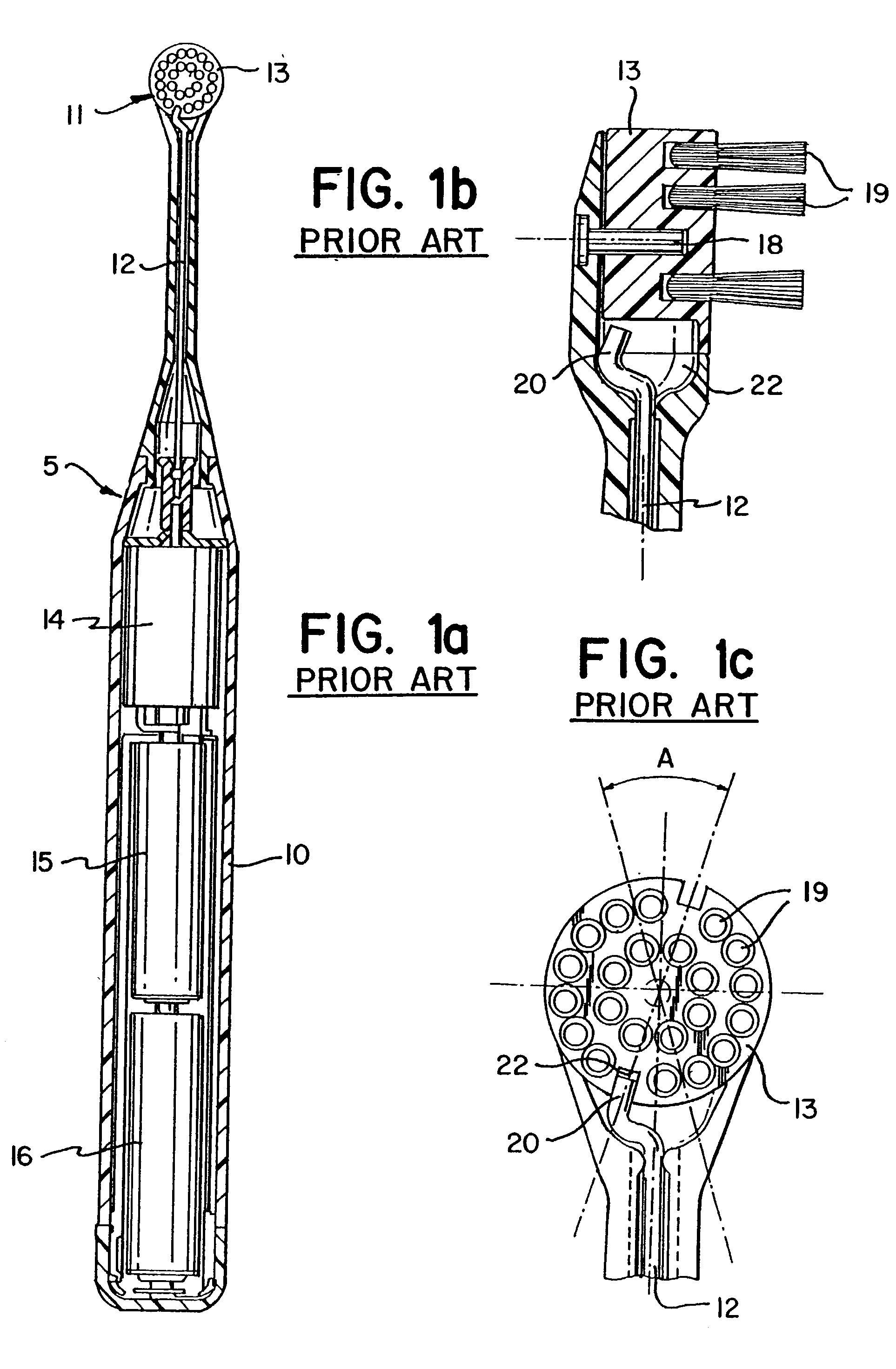

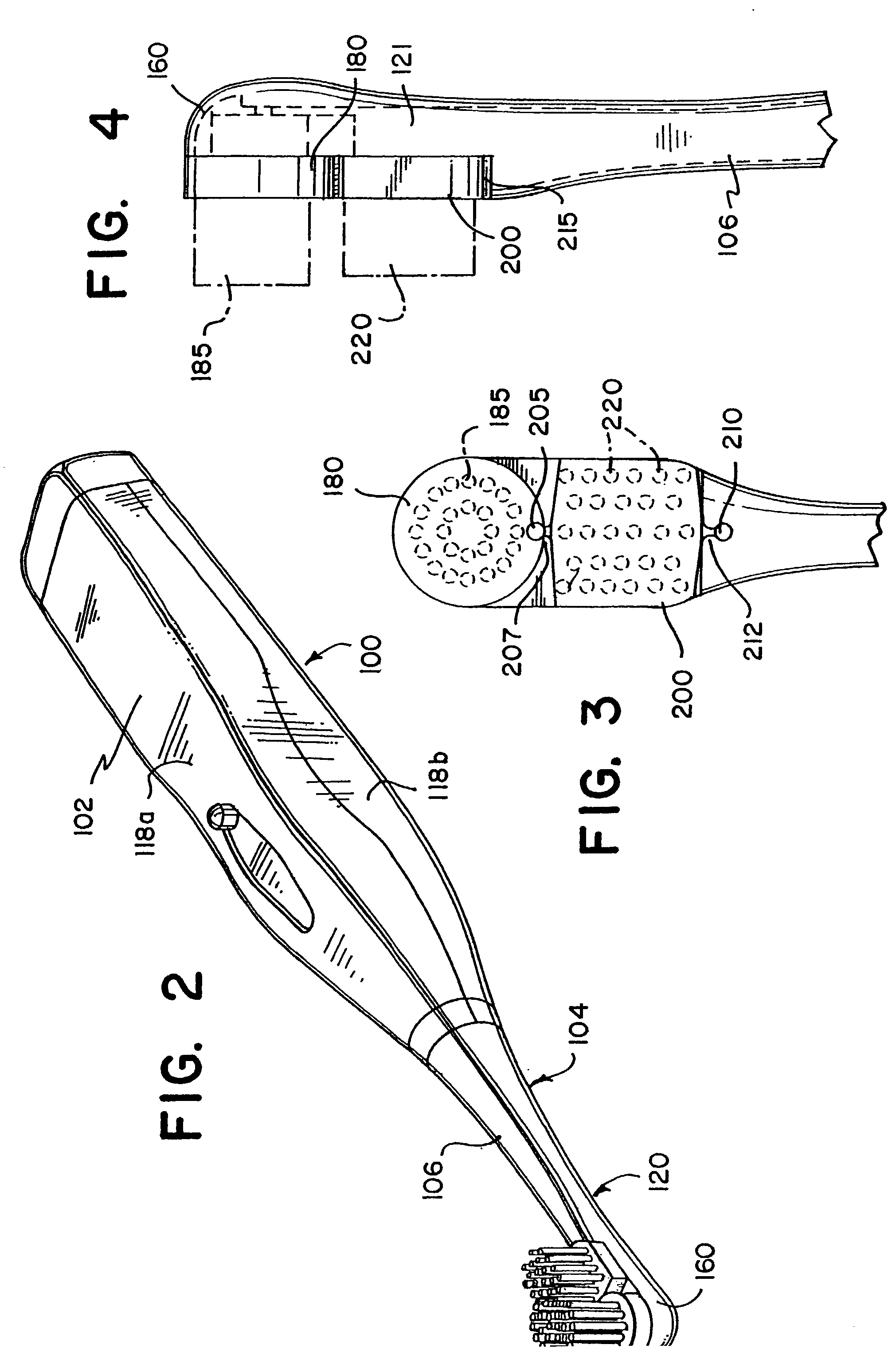

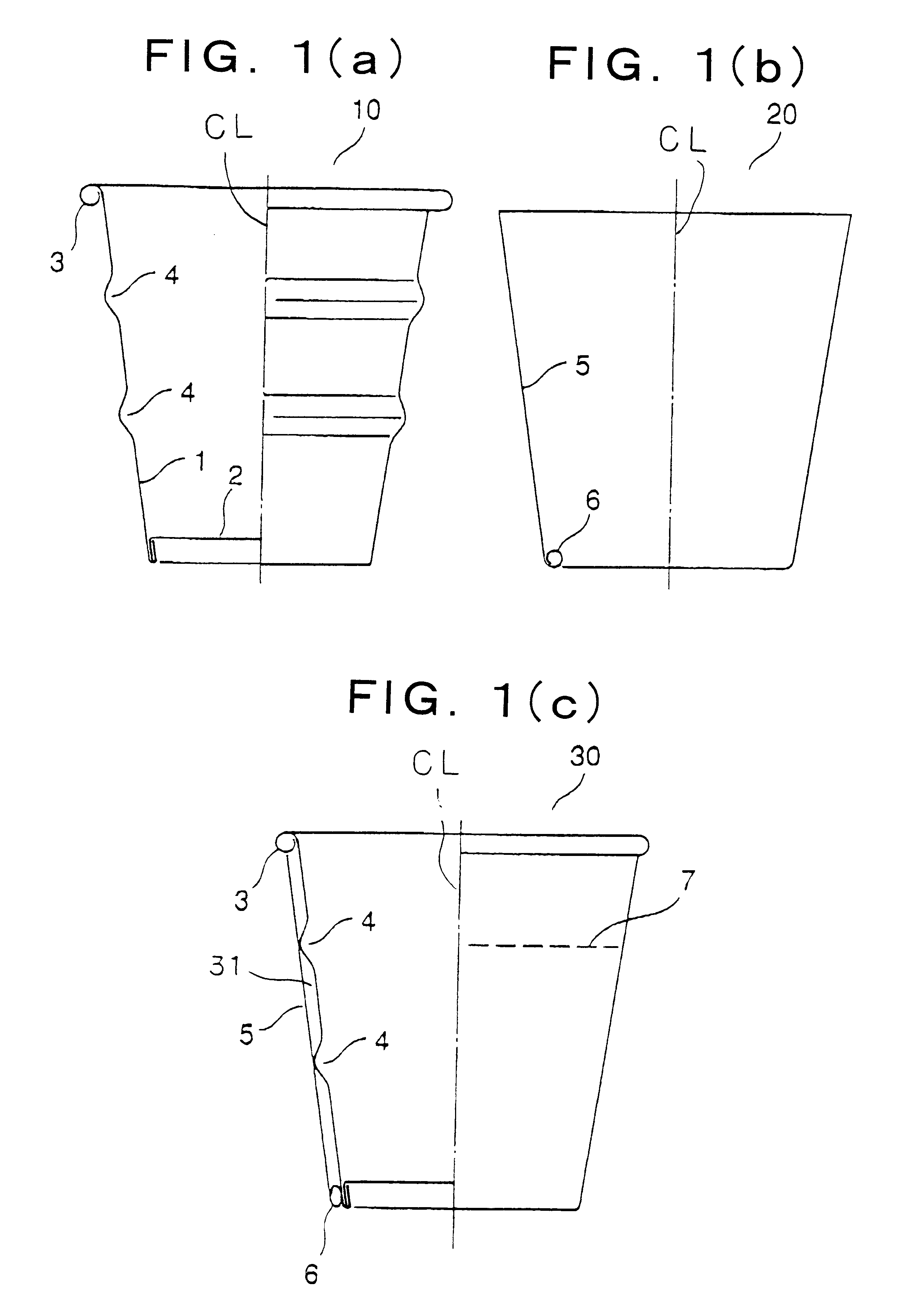

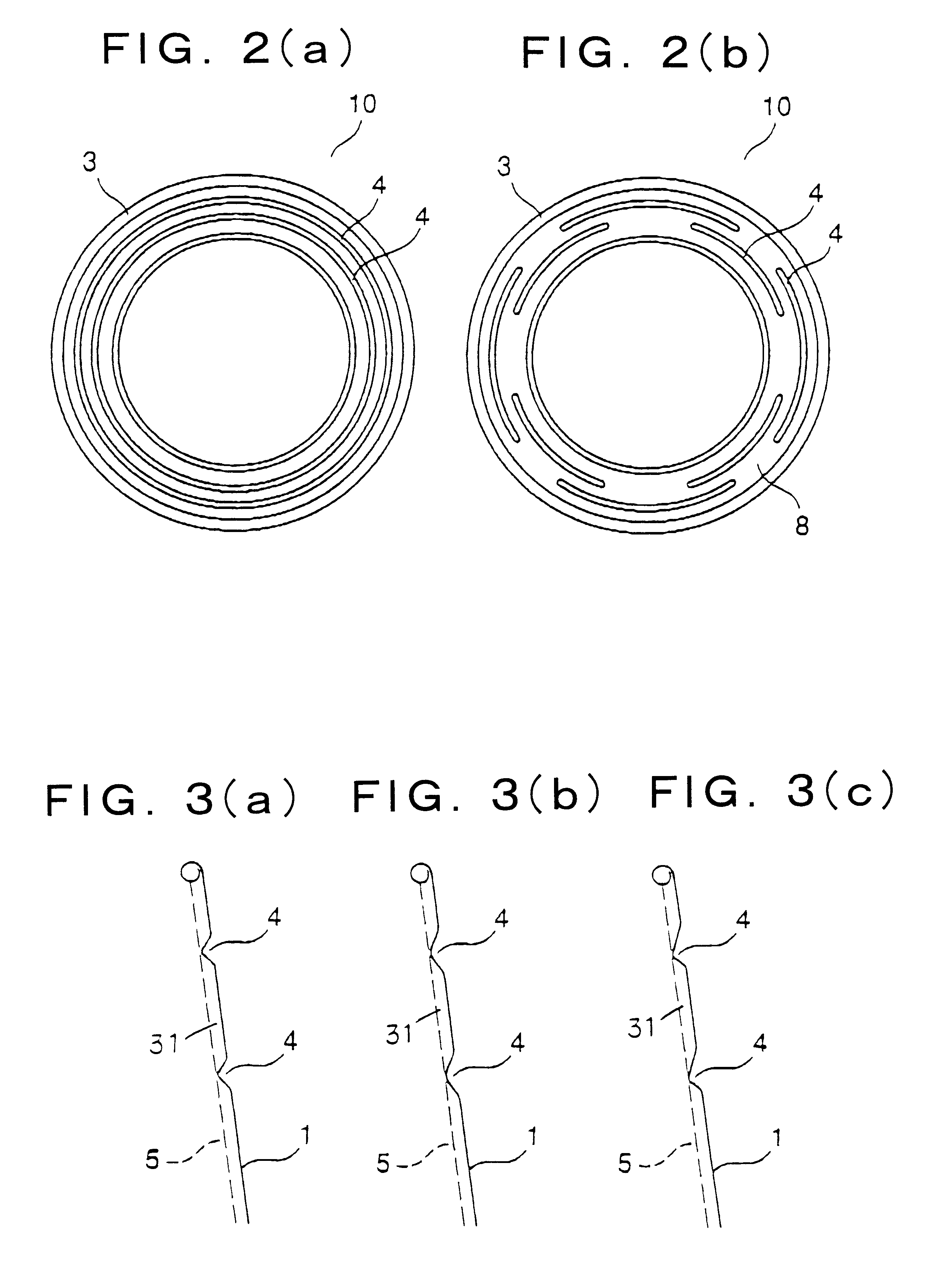

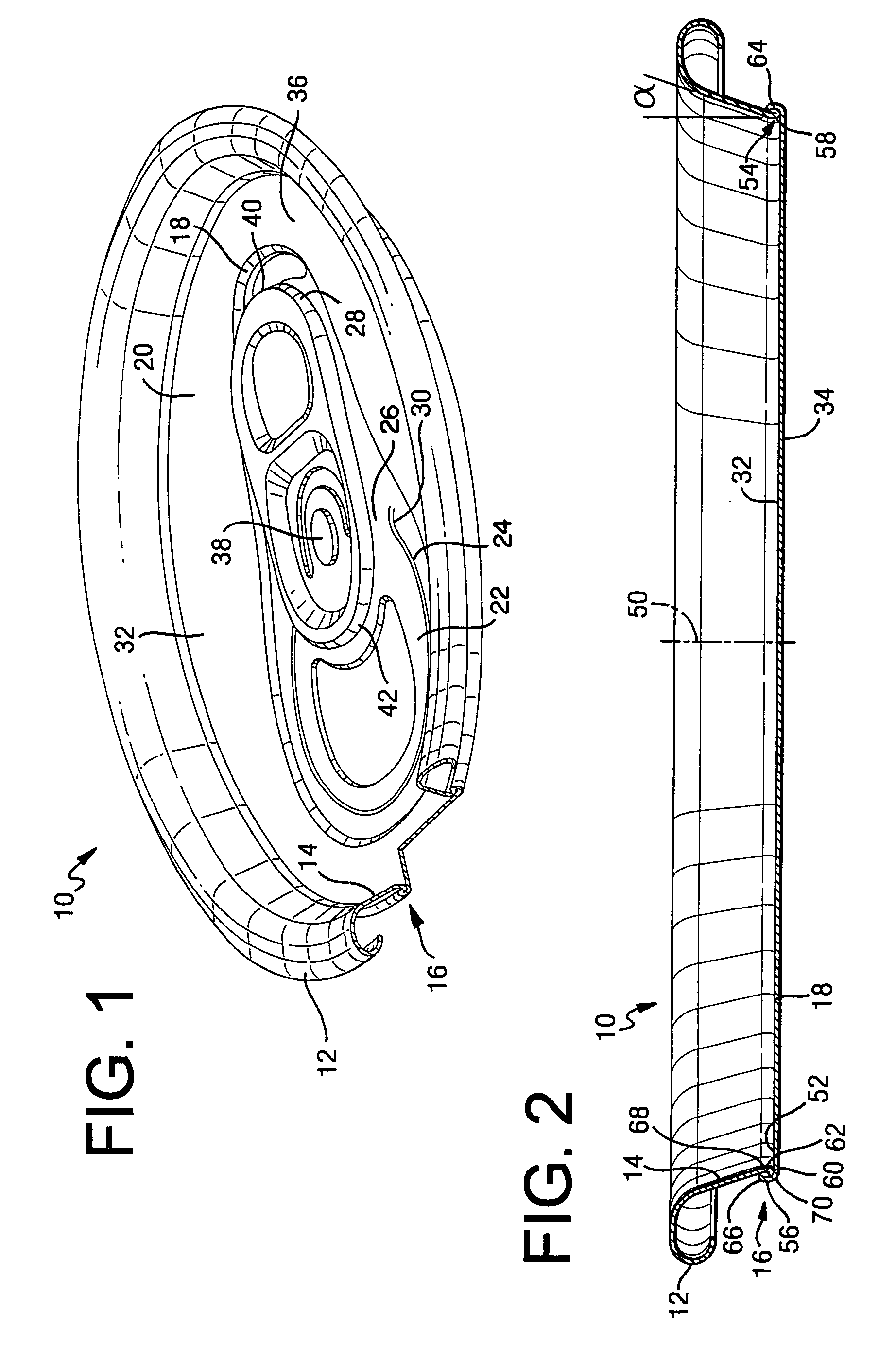

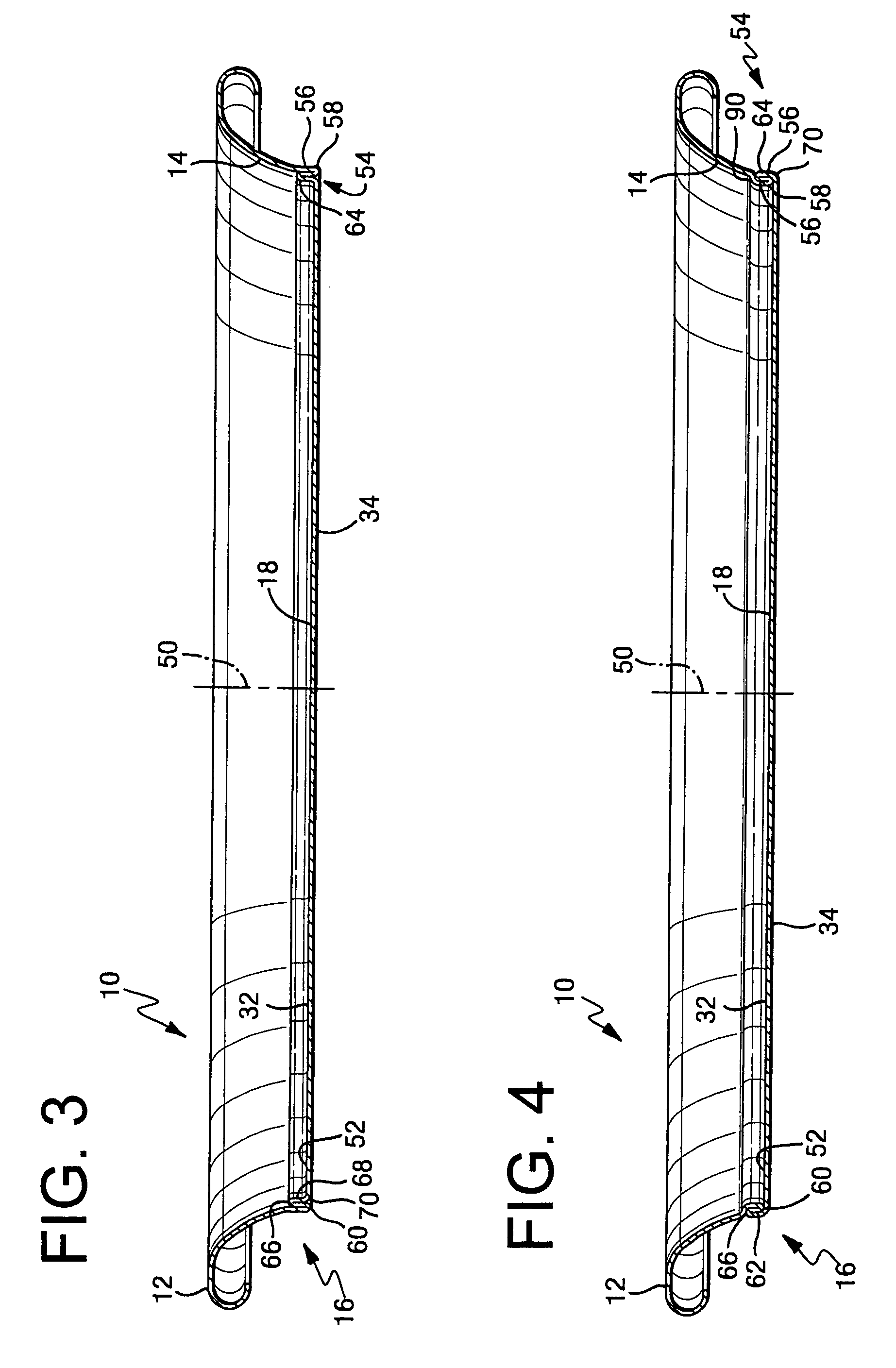

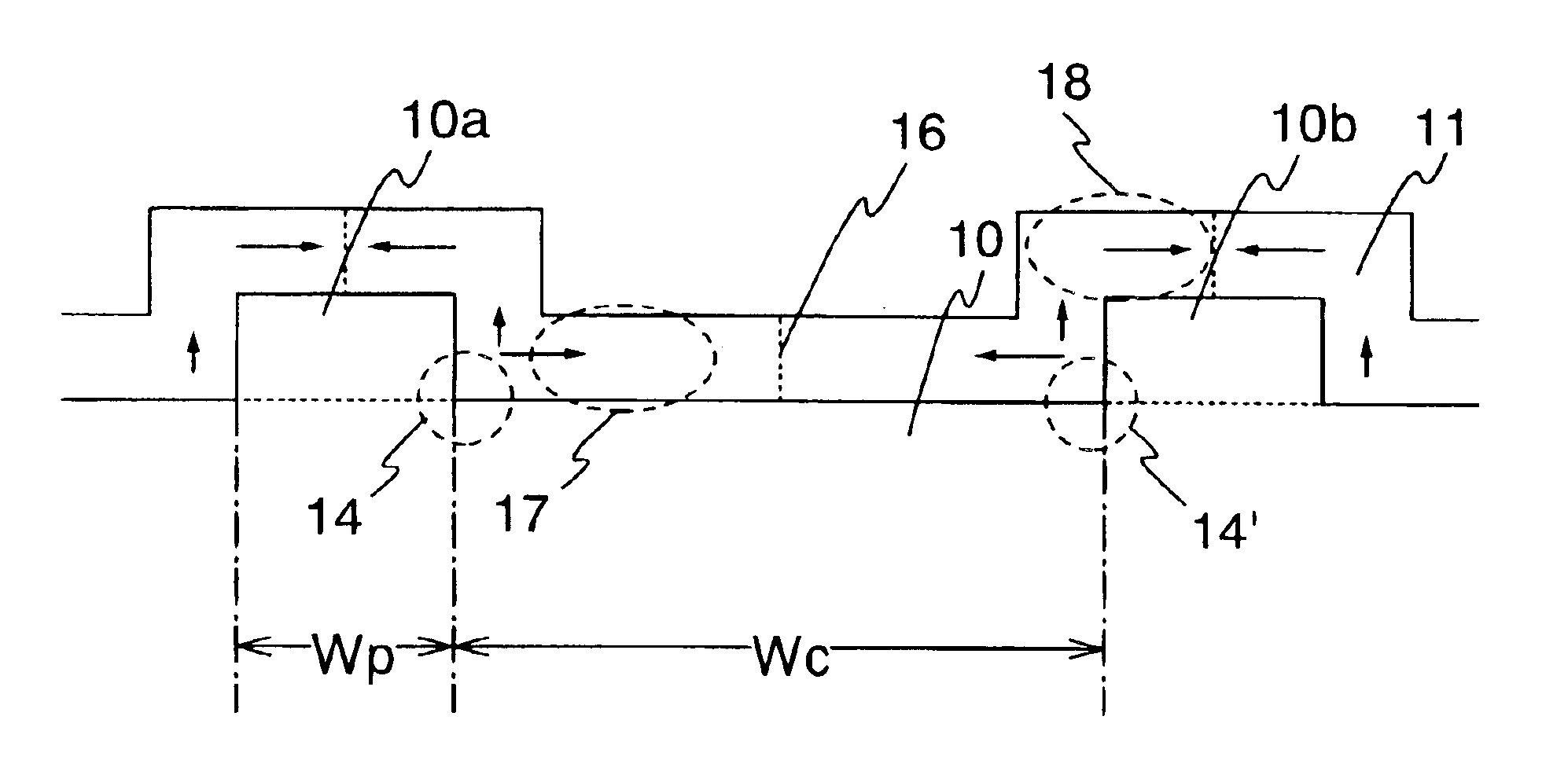

Toothbrush with sectorial motion

InactiveUS20040060137A1Increased moving bristle areaImprove cleanlinessCarpet cleanersKitchenware cleanersBristleEngineering

A powered toothbrush to provide oral hygiene having a brush section with a first bristle carrier that is powered and driven to rotate in an oscillating manner through a prescribed angle. A second bristle carrier is pivotally connected to the first bristle carrier and also pivotally connected to the brush section. The second bristle carrier oscillates in accordance with the oscillation of the first bristle carrier in a sectorial manner. The bristle carriers may include a variety of elastomeric and non-elastomeric bristles or combinations thereof to provide cleaning, polishing, whitening and stimulating to the teeth and gums.

Owner:COLGATE PALMOLIVE CO

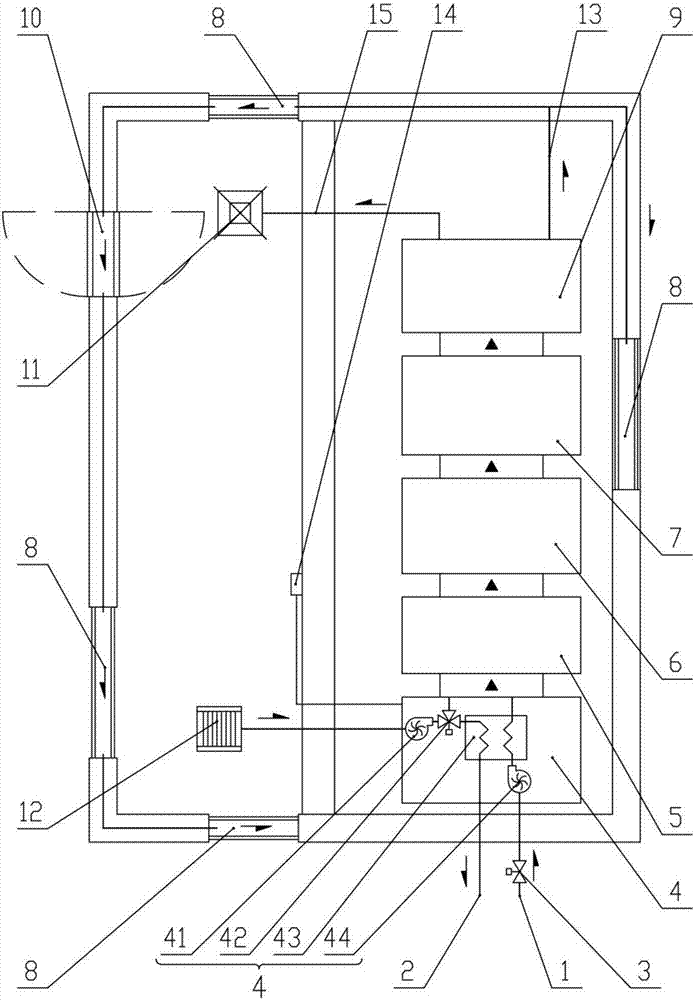

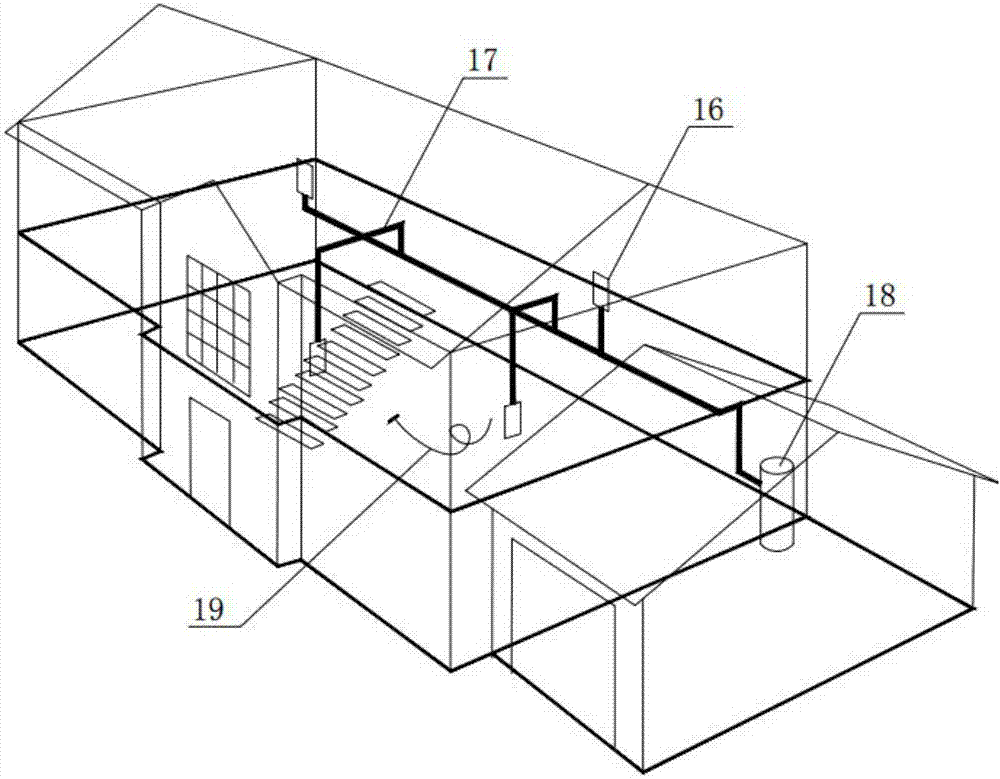

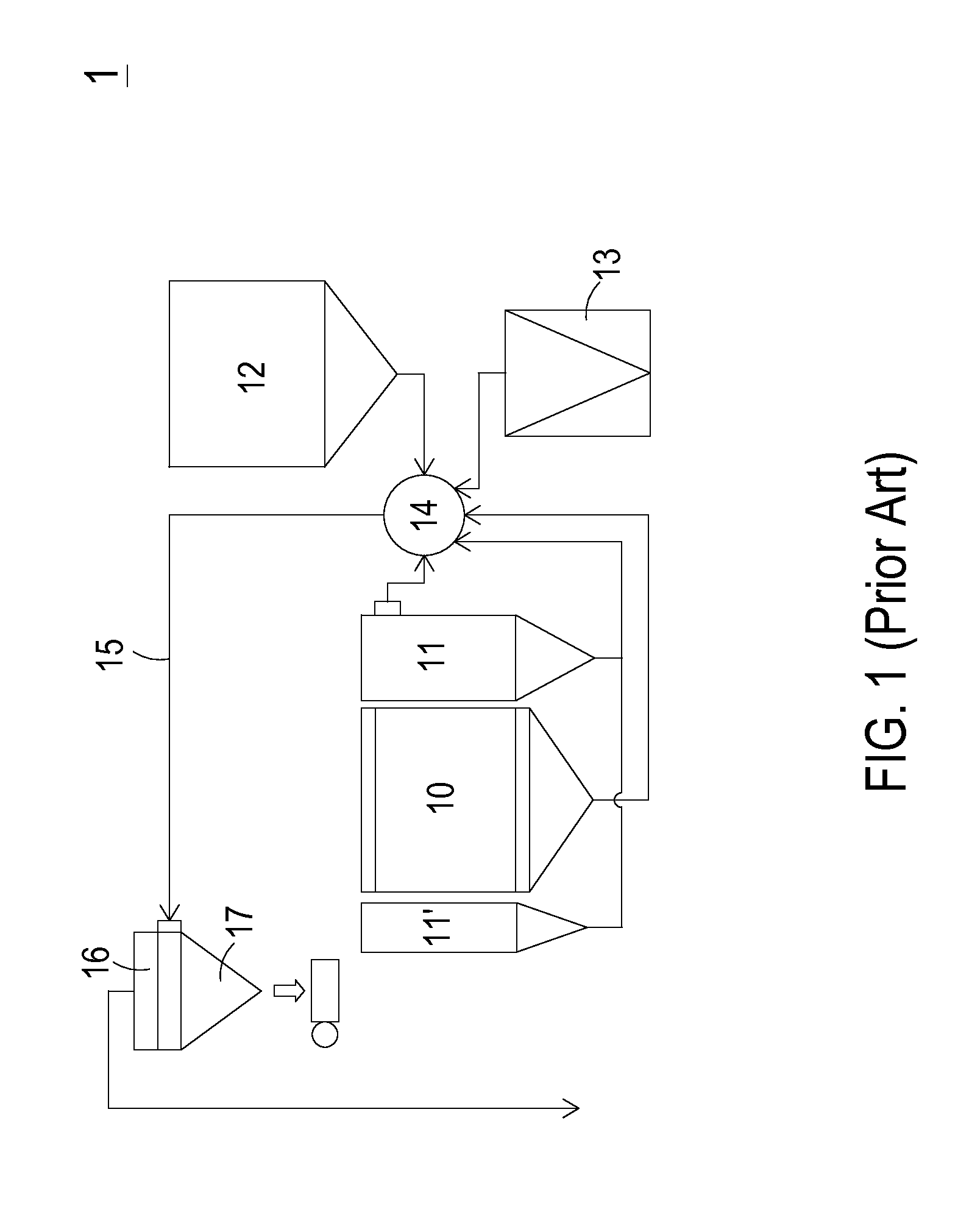

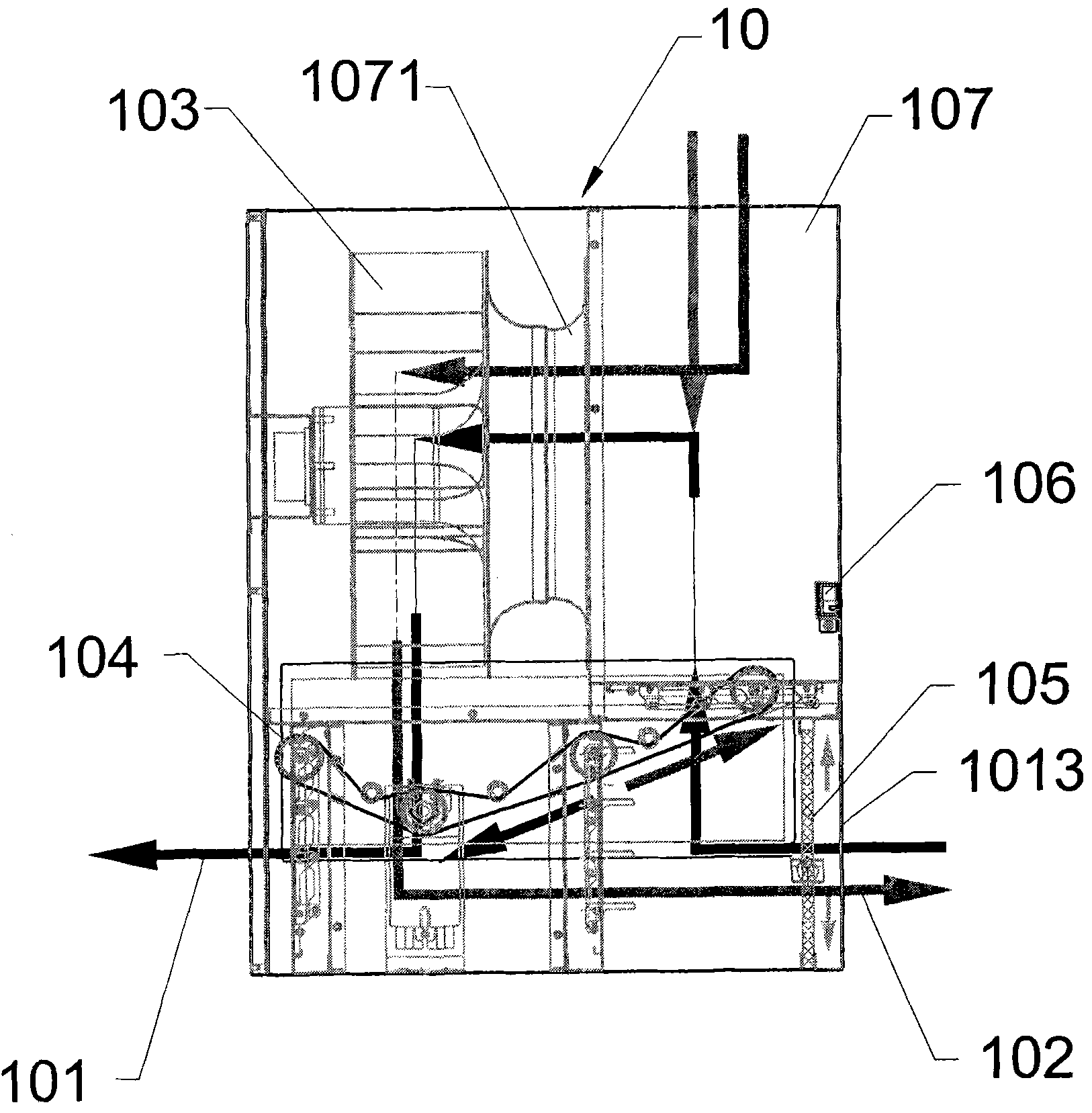

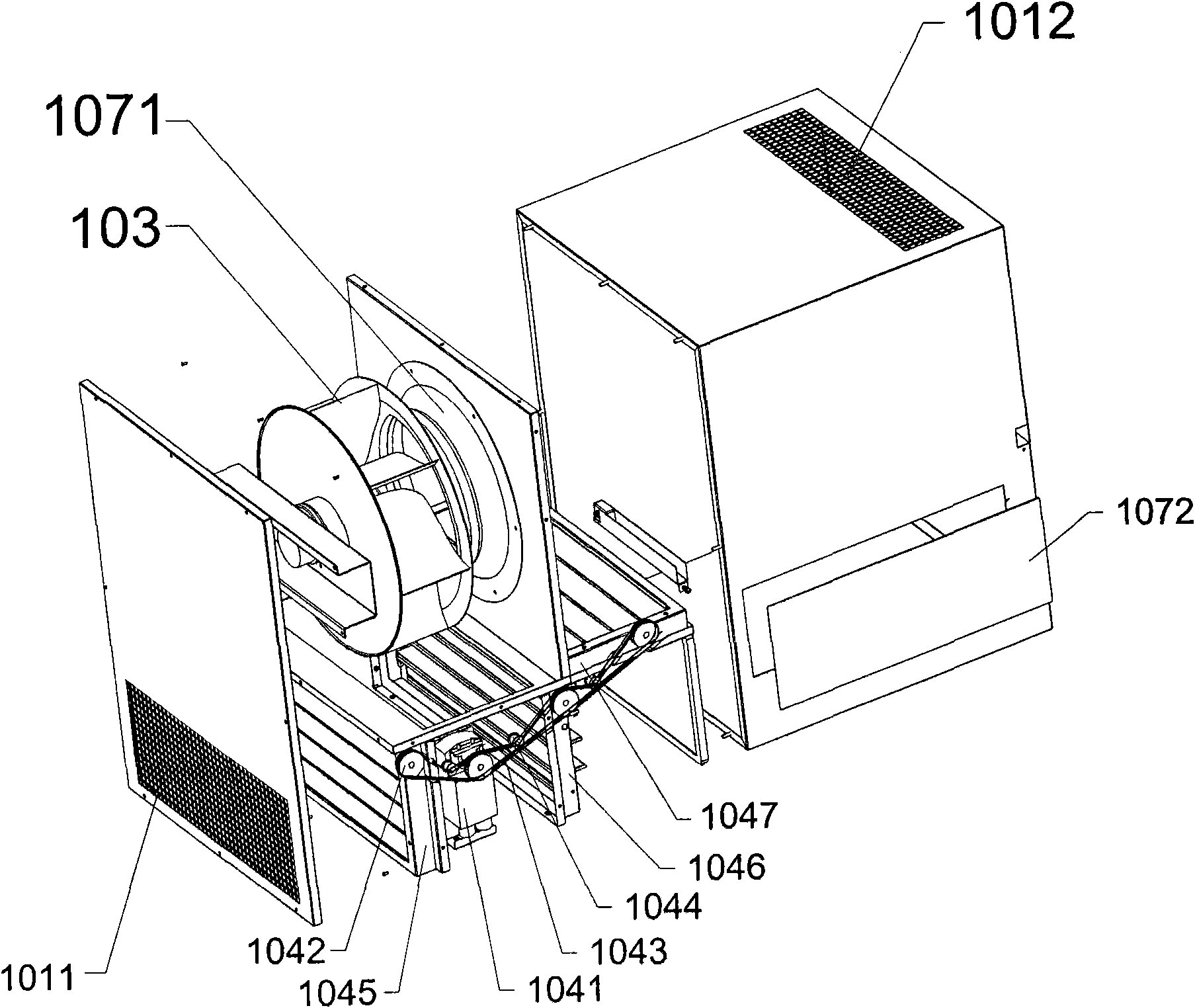

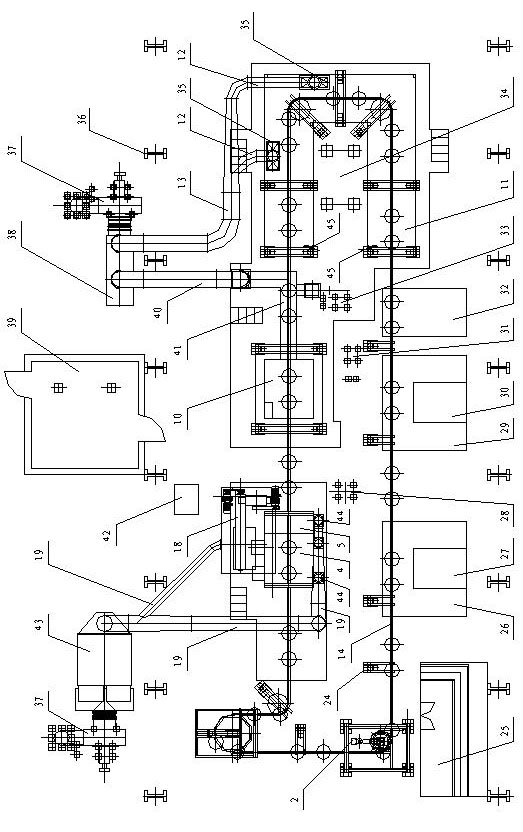

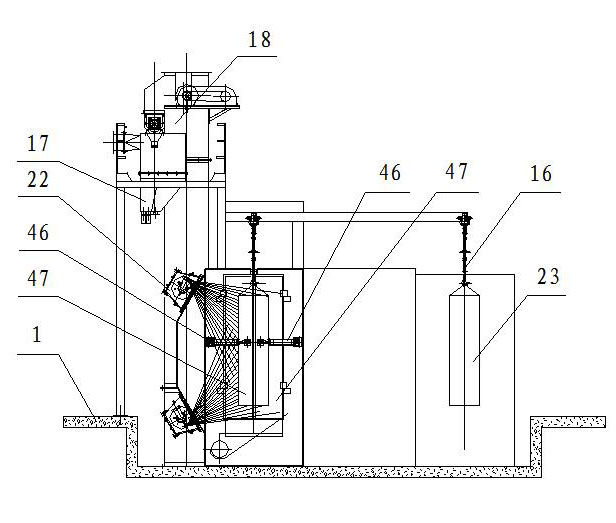

Constant-temperature, constant-humidity and constant-cleanliness silent indoor air system

InactiveCN106895521AAgainst intrusionAvoid damageMechanical apparatusSpace heating and ventilation safety systemsFiltrationFresh air

The invention provides a constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, belongs to the field of indoor intelligent adjustment, and relates to multiple techniques including indoor air pressure control, indoor air purification, an indoor central dedusting system, supercharging and compensation functions for interlayers of double windows and double doors, an outdoor haze isolating system, an indoor air internal-circulation cleaning method, air heat exchange, air heating, refrigeration, dehumidification and the like. According to the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, the pressure of fresh air is made positive through the interlayers of the double doors and the double windows, the air pressure in the interlayers of the double doors and the double windows is made higher than outdoor air pressure, and outdoor air is prevented from invading indoor air; a small primary-efficiency, medium-efficiency and high-efficiency filtering system is used for filtration, various types of automatic adjustment and control including heating, refrigerating, dehumidifying and the like are conducted on air, pollutant dust generated indoors is removed through the central dedusting system, and the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system is an omnidirectional intelligent air control system.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

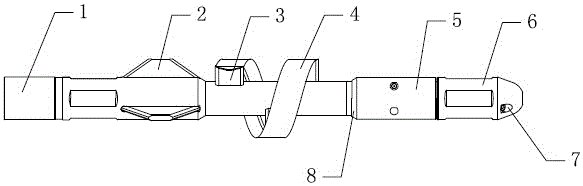

Oil and gas field coiled tubing paraffin removal and contaminant release process and tool thereof

PendingCN106761561AWill not artificially cause blockageImprove cleanlinessCleaning apparatusWaxCoiled tubing

The invention relates to an oil and gas field coiled tubing paraffin removal and contaminant release process and a tool thereof. Paraffin removal is performed by using coiled tubing, and removed paraffin can be recycled to the ground, and therefore a wellbore cannot be blocked due to human factors. A flushing port is designed at the upper end of a flushing tool, and then paraffin remaining on mechanical scraping portions can be cleared. The coiled tubing is connected with the paraffin removal and contaminant release tool for paraffin removal and contaminant release. The flushing tool at the front end of a pipe string can first perform 360 degree hydraulic cleaning on the wellbore, and then along with descending of the pipe string, a paraffin remover in the pipe string performs mechanical cleaning on the wellbore, and therefore dual cleaning mode combining the hydraulic cleaning with mechanical scraping is achieved, removal effects are greatly improved, cost is saved, and work efficiency is improved.

Owner:JEREH ENERGY SERVICES

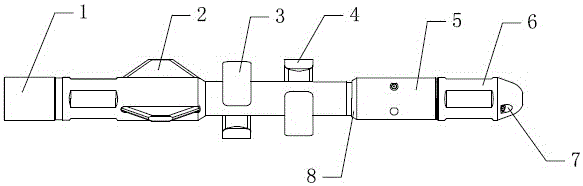

Preparation method for high-alkaline calcium naphthenate

ActiveCN101885677AAvoid aggregation and sedimentationHelps neutralize the reactionAdditivesCarboxylic acid salt preparationCalcium hydroxideAlkaline water

The invention relates to a preparation method for high-alkaline calcium naphthenate. In the method, calcium hydroxide and calcium oxide are taken as calcifying agents, pure water is replaced by alkaline aqueous solution, and a mode of multiple addition is adopted to prepare a calcium naphthenate product with the base number of more than or equal to 350 mgKOH / g. The product has the advantages of low viscosity and turbidity and better high temperature cleanliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

Insulating container

InactiveUS6193098B1Improve insulation performanceImprove securityBoxes/cartons making machineryDomestic cooling apparatusEngineeringPaper cup

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

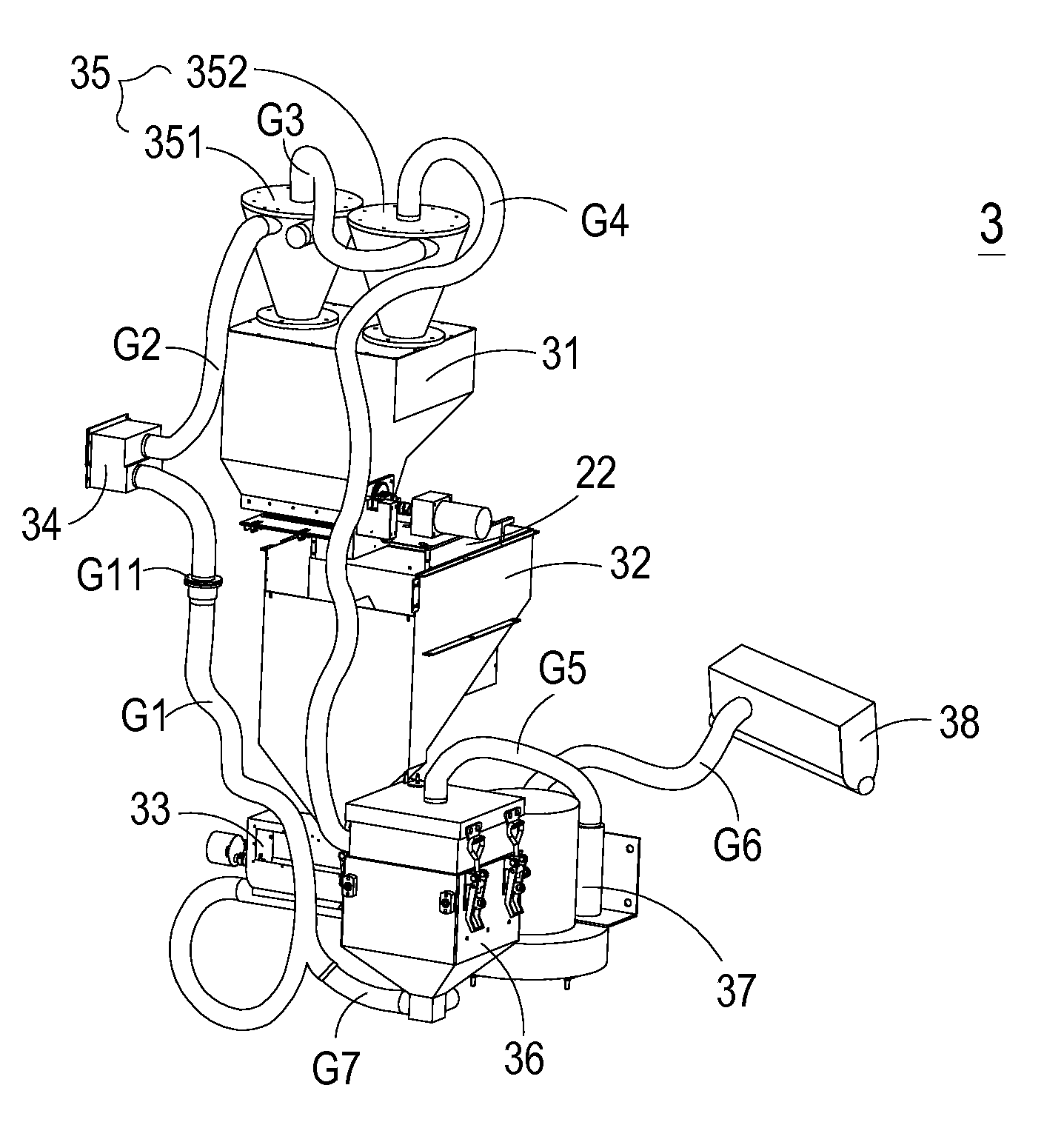

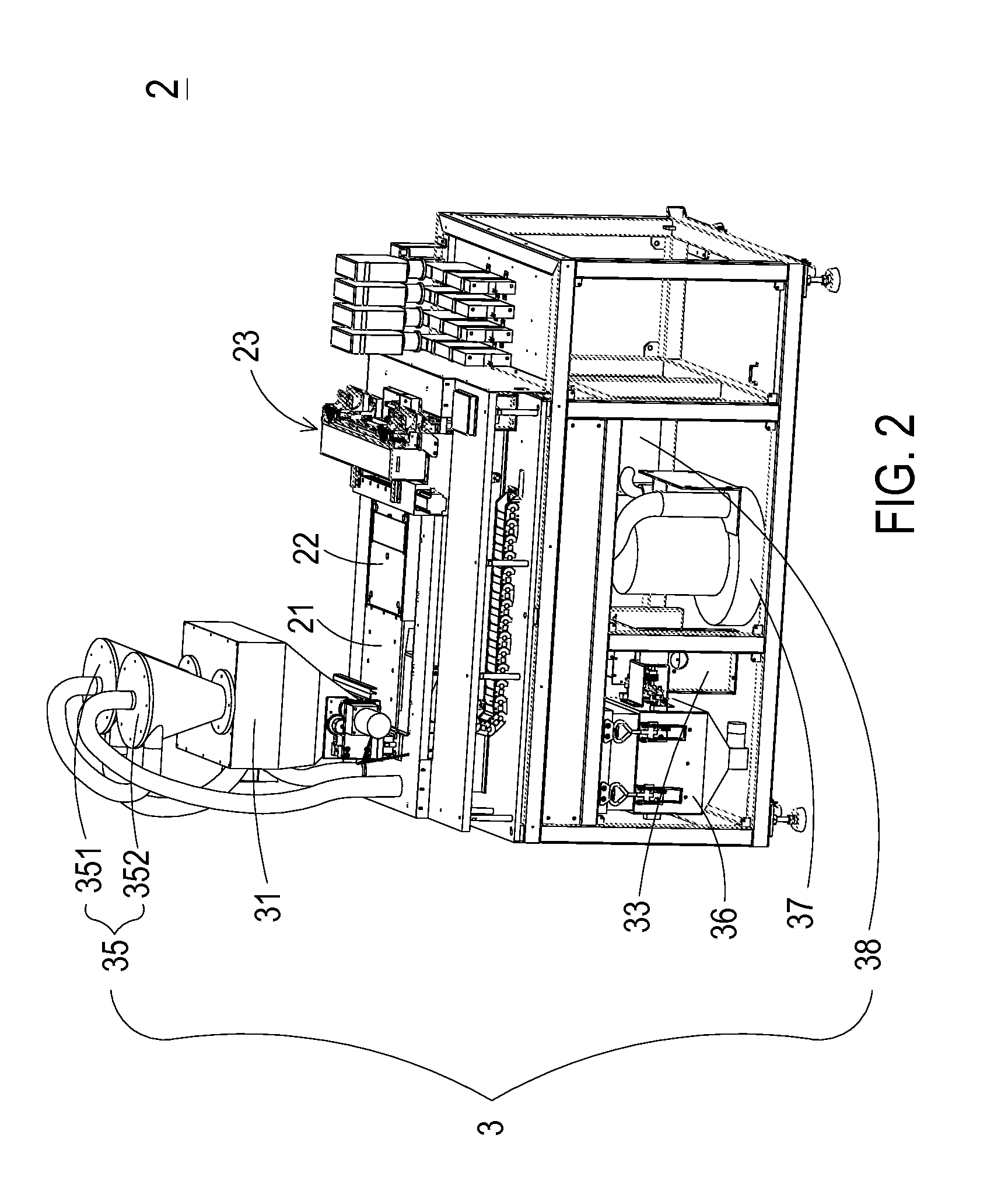

Powder recycling system

ActiveUS20150298397A1More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

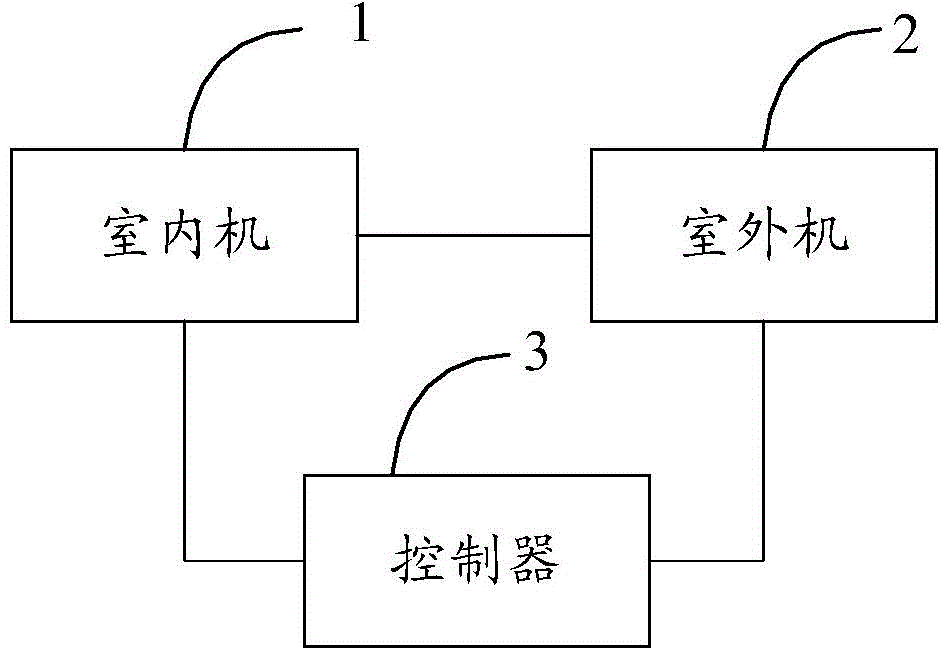

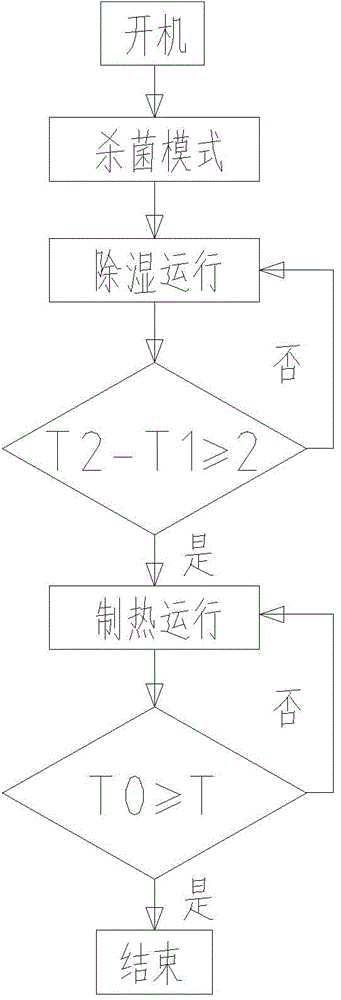

Method for sterilization of air conditioner and air conditioner

ActiveCN104913429AImprove cleanlinessImprove the bactericidal effectMechanical apparatusSpace heating and ventilation safety systemsOperation modeEngineering

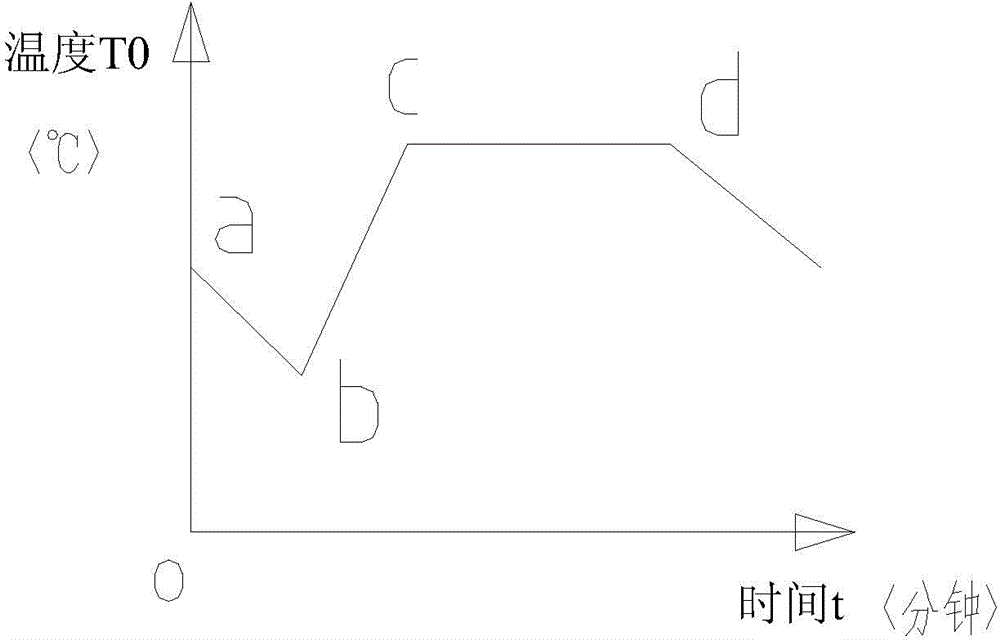

The invention relates to a method for sterilization of an air conditioner and the air conditioner. The method comprises the steps that the air conditioner is started, an indoor unit is in a heating operation mode, and the surface temperature T0 of a heat exchanger of the indoor unit is increased to be larger than a sterilization temperature threshold T, and is kept for the time t. According to the invention, after the air conditioner is started, the indoor unit conducts heating operation, and the surface temperature of the heat exchanger of the indoor unit is increased to be larger than the sterilization temperature threshold, and is kept for a certain time, so that bacteria in the air conditioner can be killed, and the cleanliness of the indoor unit of the air conditioner can be improved. In addition, in order to improve the sterilization effect of the air conditioner, before the indoor unit conducts heating operation, water can be added to the surface of the heat exchanger of the indoor unit, and / or the indoor unit can be in a dehumidification mode so as to generate condensation water on the surface of the heat exchanger of the indoor unit; and then the added water or the generated condensation water is converted into high-temperature steam in the indoor unit when the indoor unit conducts heating operation, and rapid sterilization is achieved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

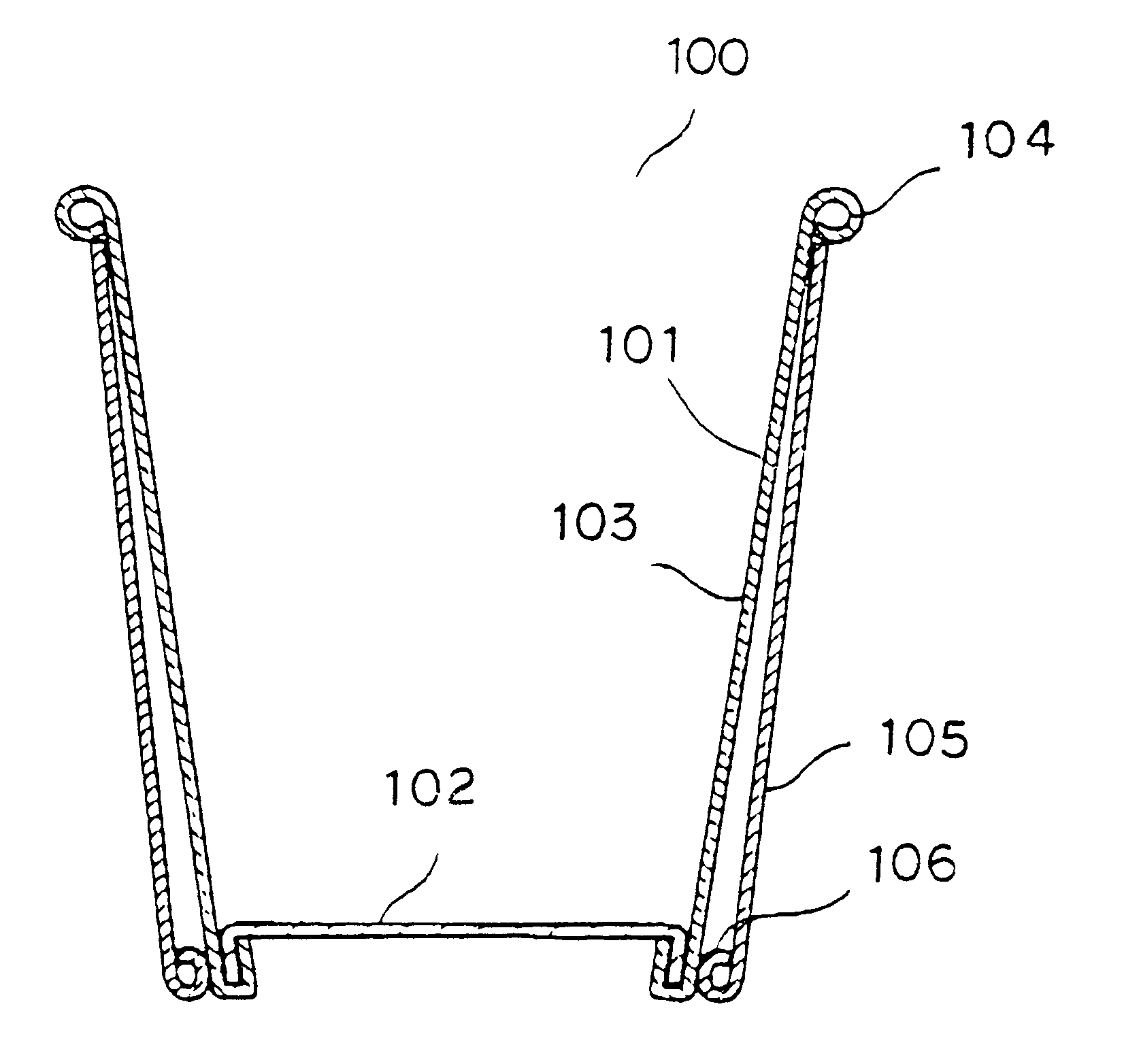

Handheld dust collector with bracket

InactiveCN105395132AImprove cleanlinessFirmly connectedSuction cleanersHand heldStructural engineering

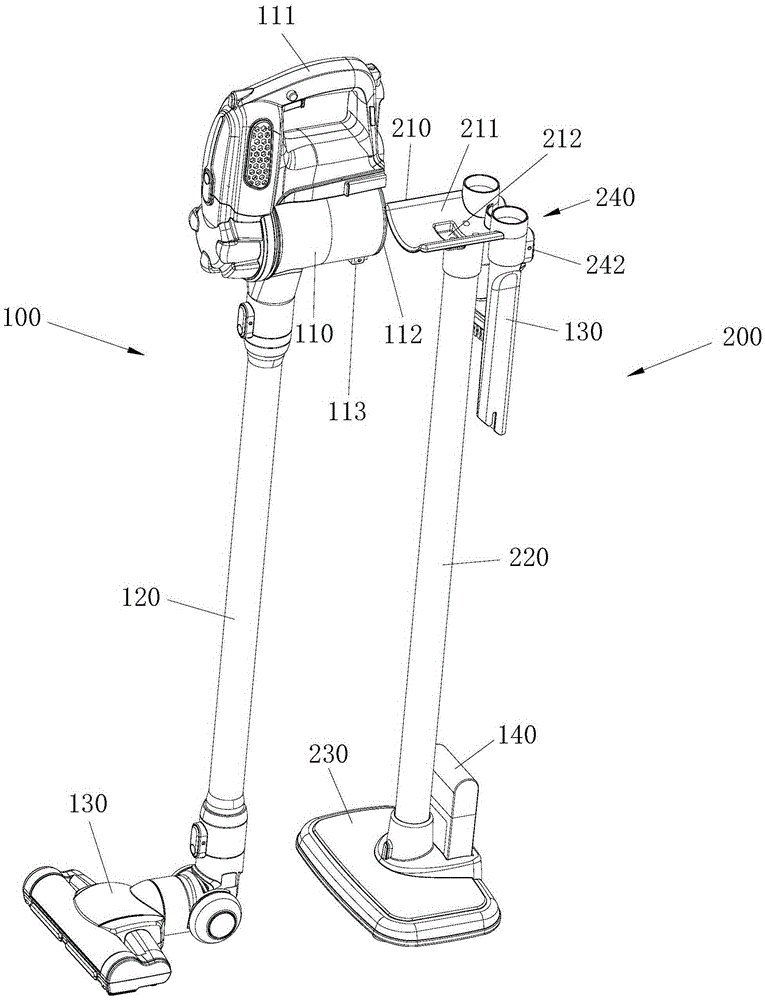

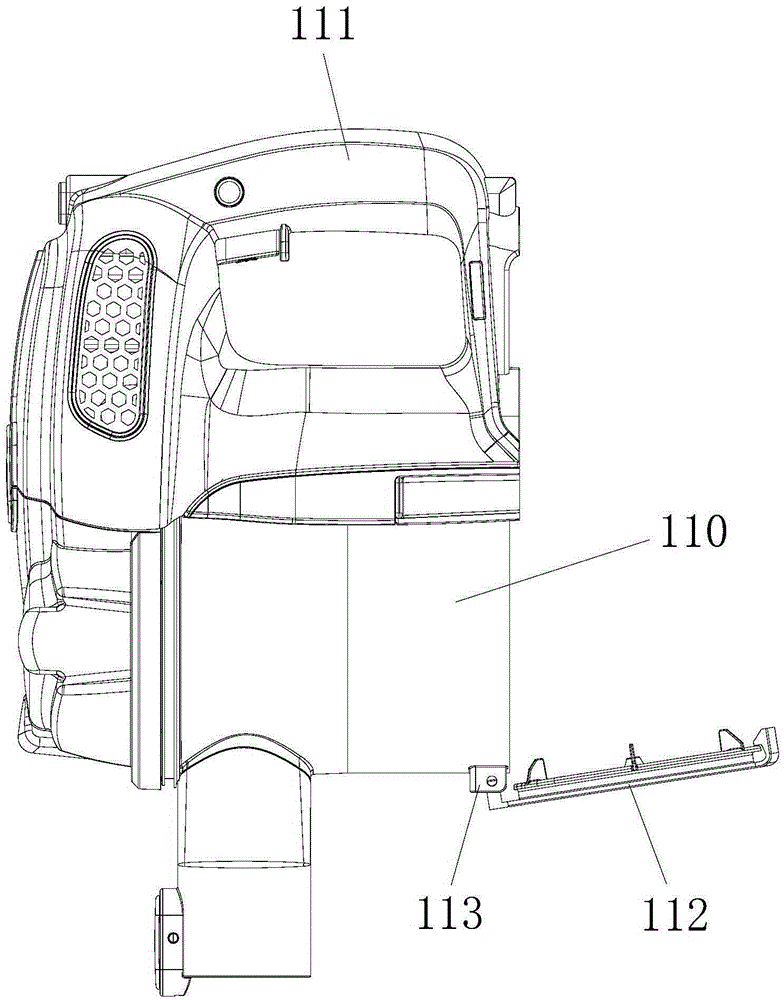

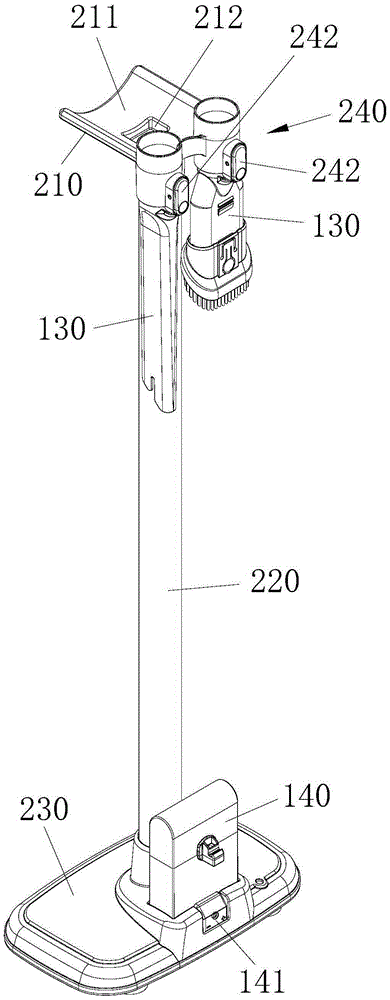

The invention discloses a handheld dust collector with a bracket. The dust collector comprises a handheld dust collection device and the bracket, wherein the handheld dust collection device comprises a shell provided with a handle, a suction fan and a dust collection box which are arranged inside the shell, and a dust suction head which is connected to the shell in a separated mode; a cover, which can be opened and closed, is connected to the shell, and the dust collection box can be taken out of the shell when the cover is opened; a convex connecting block is arranged on the outer wall of the shell; the cover is rotatably connected to the connecting block; the bracket comprises a base, a brace rod with lower end connected to the base and a supporting frame connected to the upper end of the brace rod; the shell and the supporting frame are connected in a separated mode; a locating groove, which is matched with the connecting block, is formed in the supporting frame; and the connecting block is located in the locating groove when the shell and the supporting frame are connected.

Owner:SUZHOU AIJIAN ELECTRIC APPLIANCE

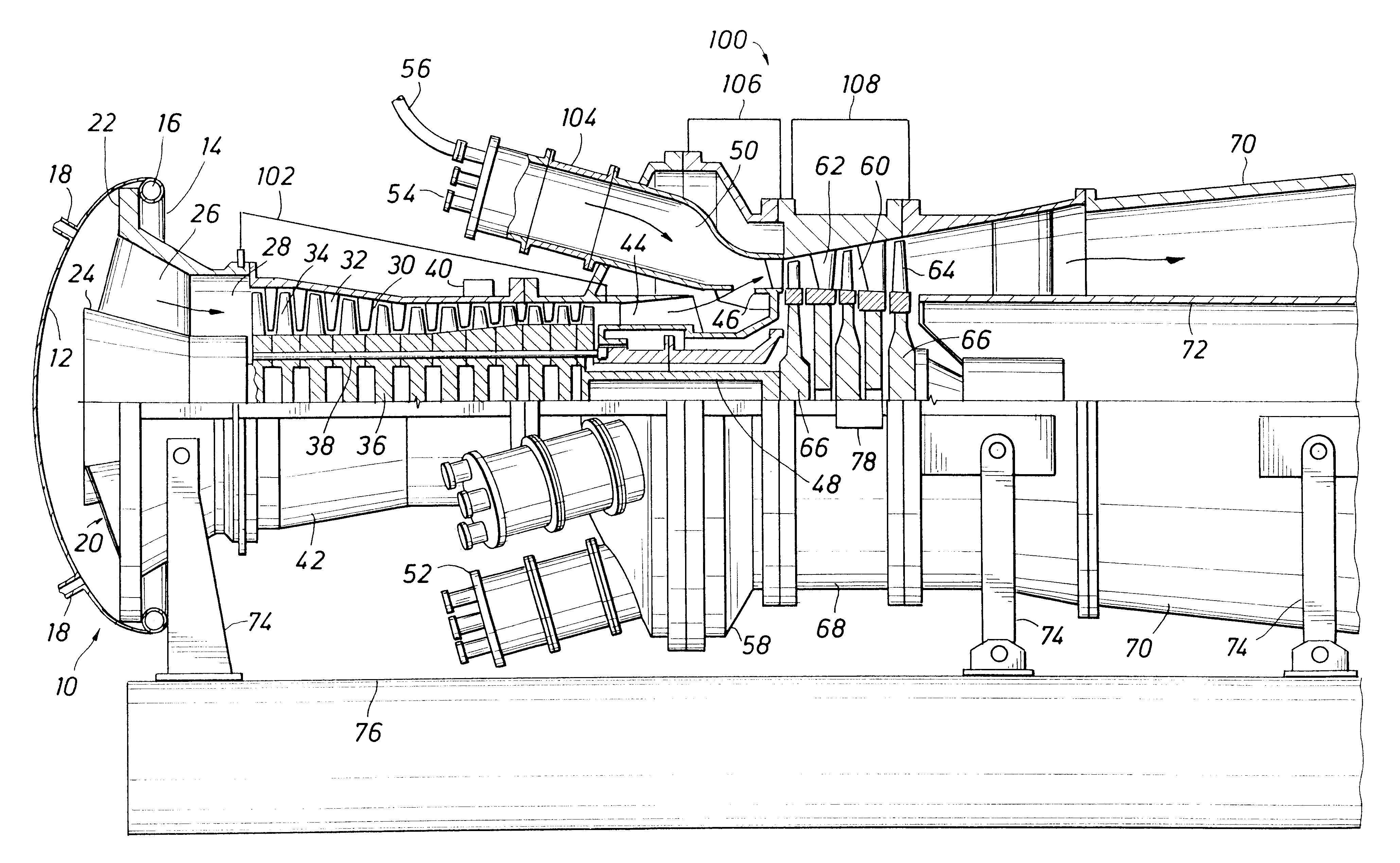

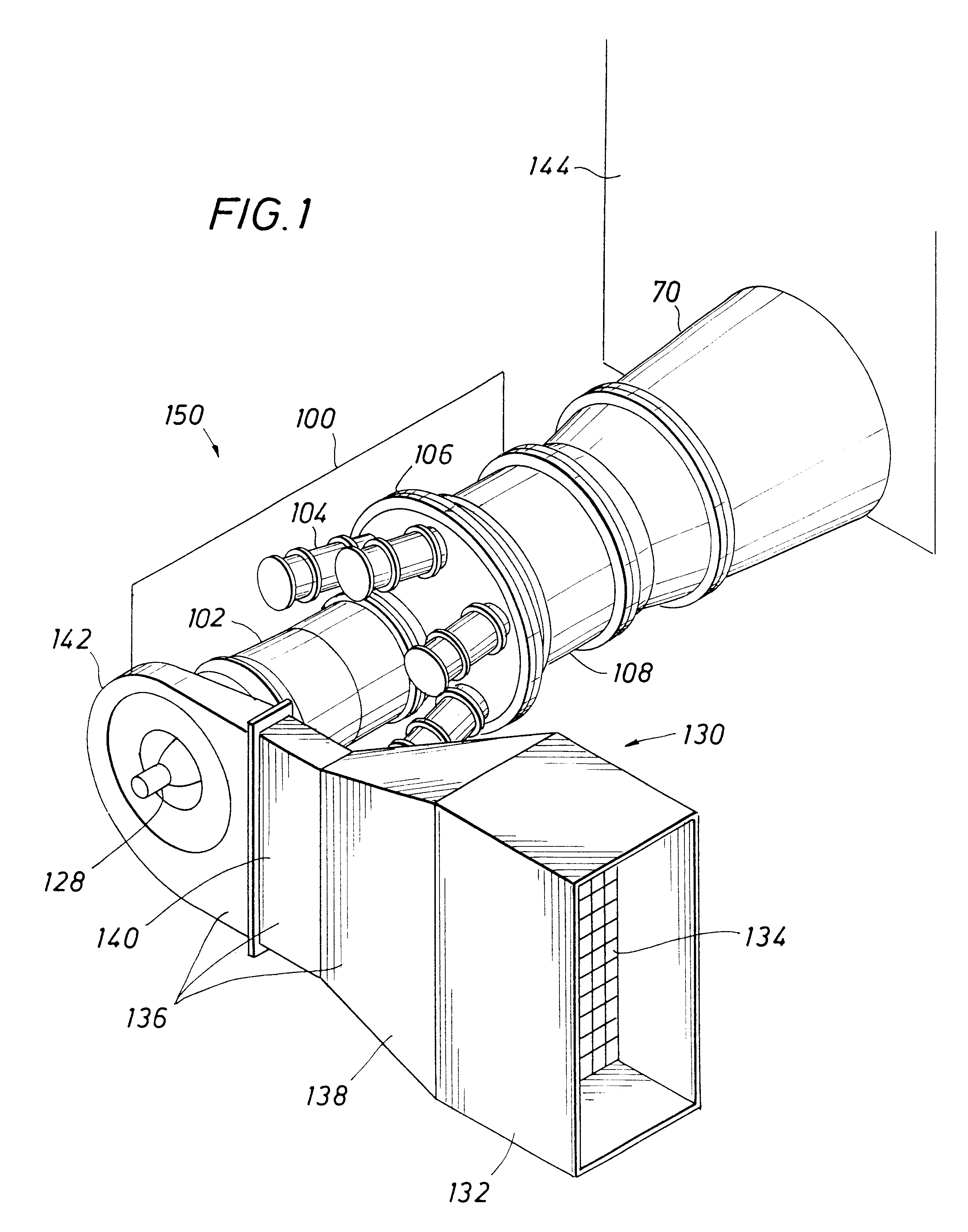

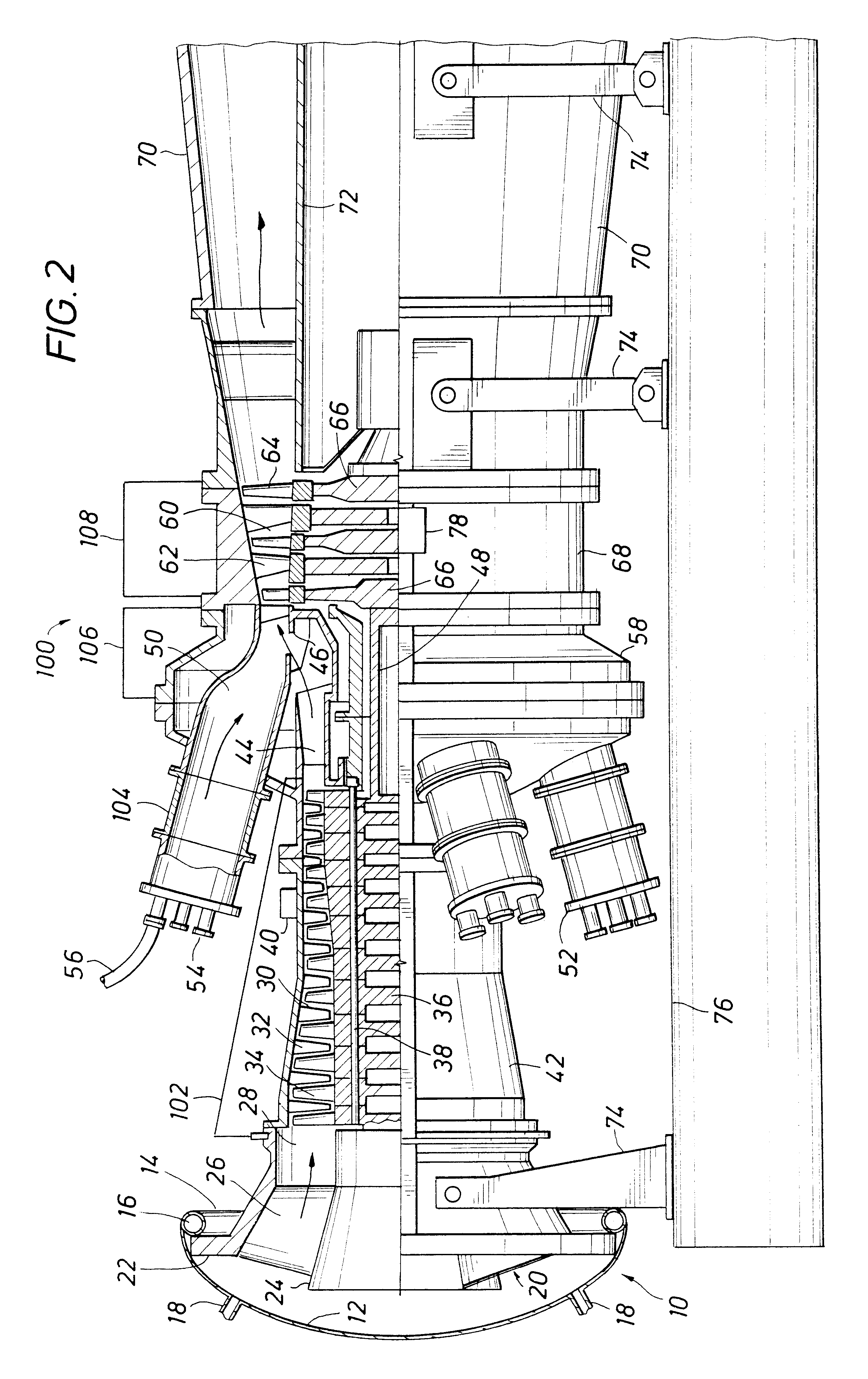

Manifold for use in cleaning combustion turbines

InactiveUS6491048B1Improve cleanlinessImprove effectivenessPump componentsElectrostatic cleaningParticulatesCombustion

The present invention is directed to a manifold for temporarily blocking the air intake of the compressor section of a combustion turbine to facilitate cleaning. A manifold suitable for providing a temporary seal about the air intake of the compressor section and through which a foamed cleaning solution can be pumped is disclosed. The manifold is conveniently provided as a flexible manifold body having an inflatable tubular member along the periphery thereof for sealing with the air intake and a plurality of hose connections through which a foamed cleaning solution can be delivered to the compressor section of the combustion turbine. Particulate films and contaminants adhering to the internal components of the compressor section of a turbine are readily removed by pumping a foamed cleaning solution such as a foamed, aqueous surfactant solution through the manifold and into the compressor section. Contaminants resulting from fuel combustion and deposited in the combustion and turbine sections are removed by pumping a second, foamed cleaning solution through those sections. The second solution typically comprises a foamed, aqueous acid solution optionally including a corrosion inhibitor. The compressor section must be isolated from such acid solutions, e.g. by pumping the foamed surfactant solution through the manifold and compressor section prior to and simultaneously with pumping the foamed acid solution through the combustion section.

Owner:GENERAL ELECTRIC CAPITAL AS AGENT

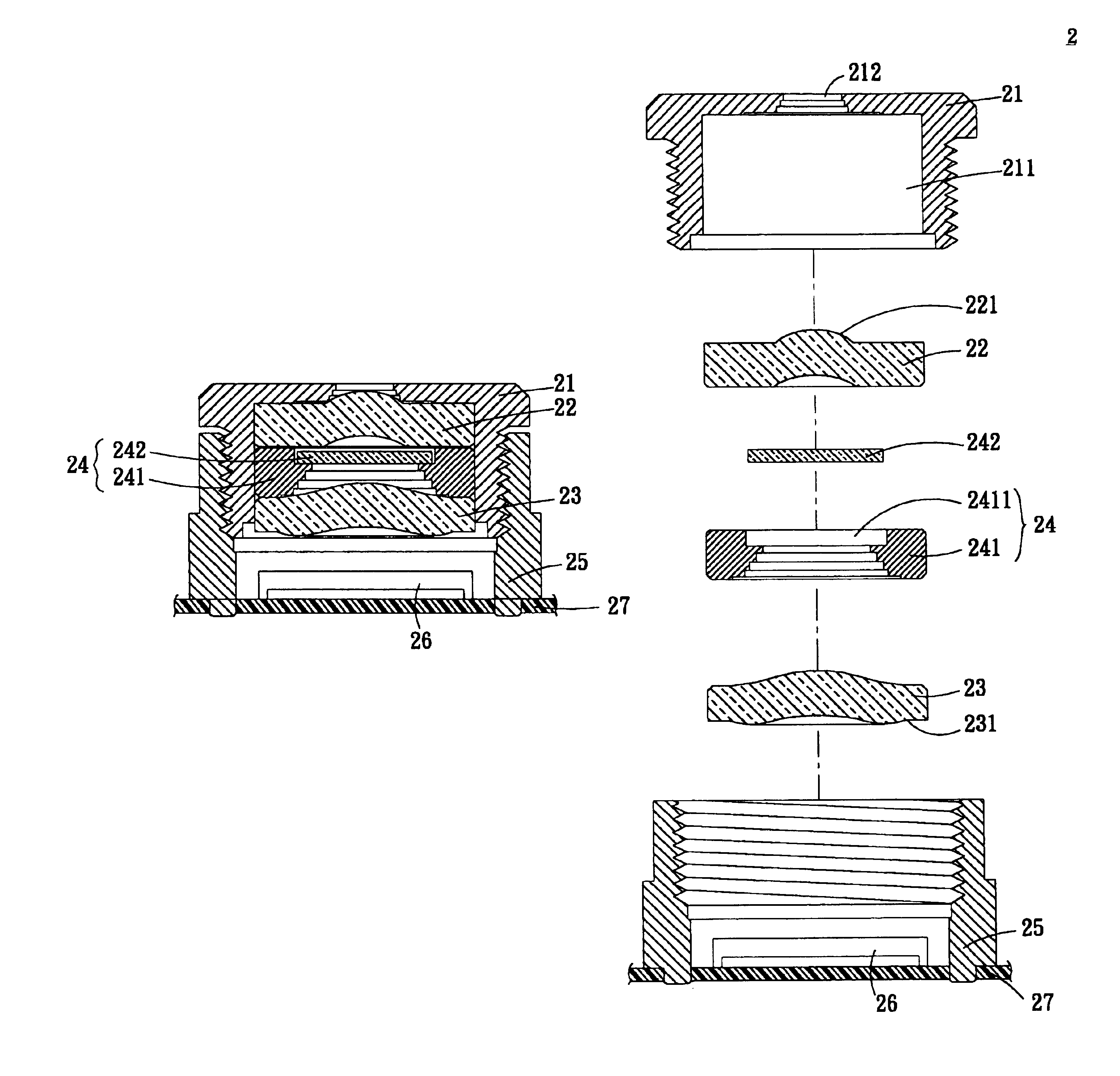

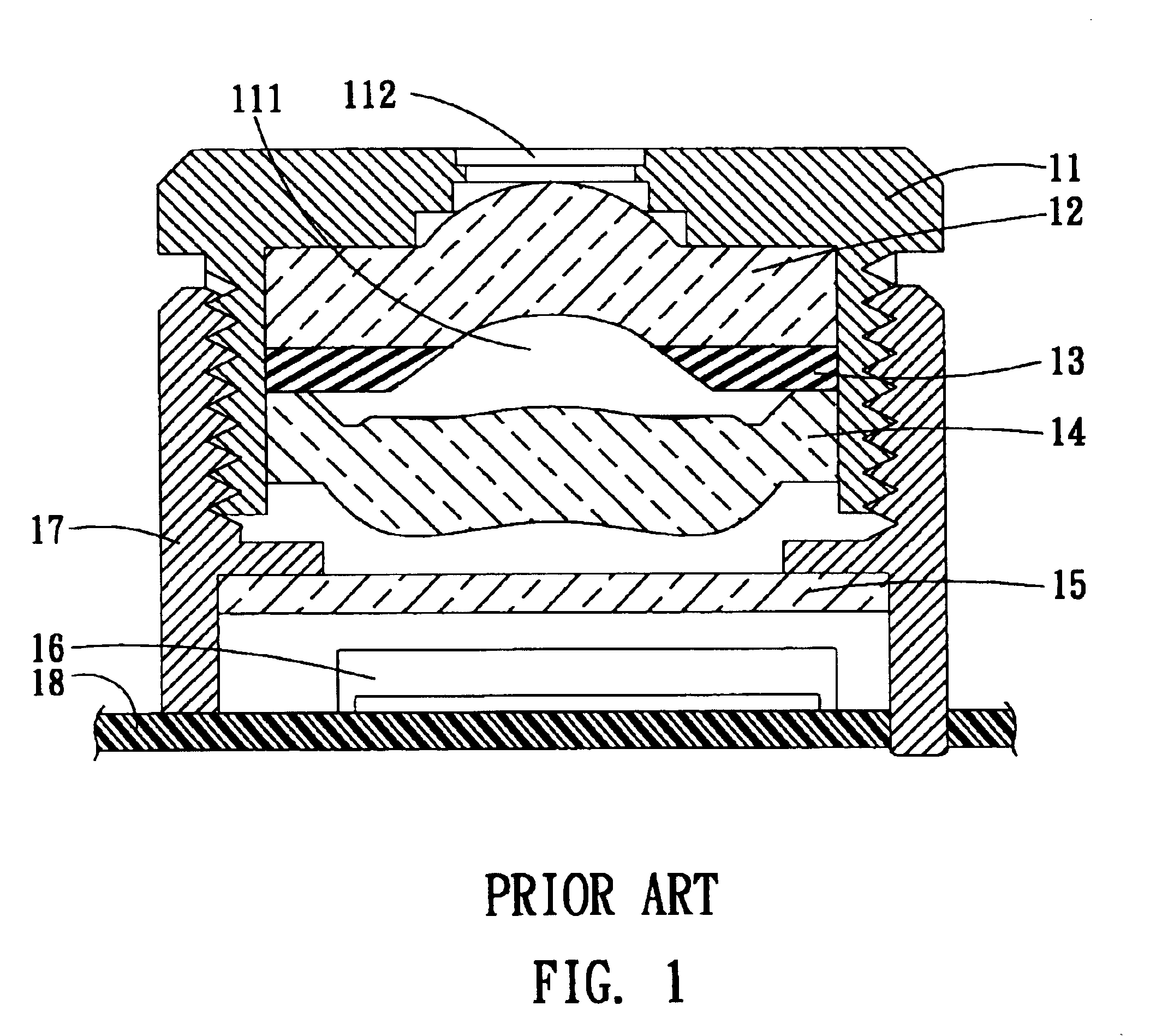

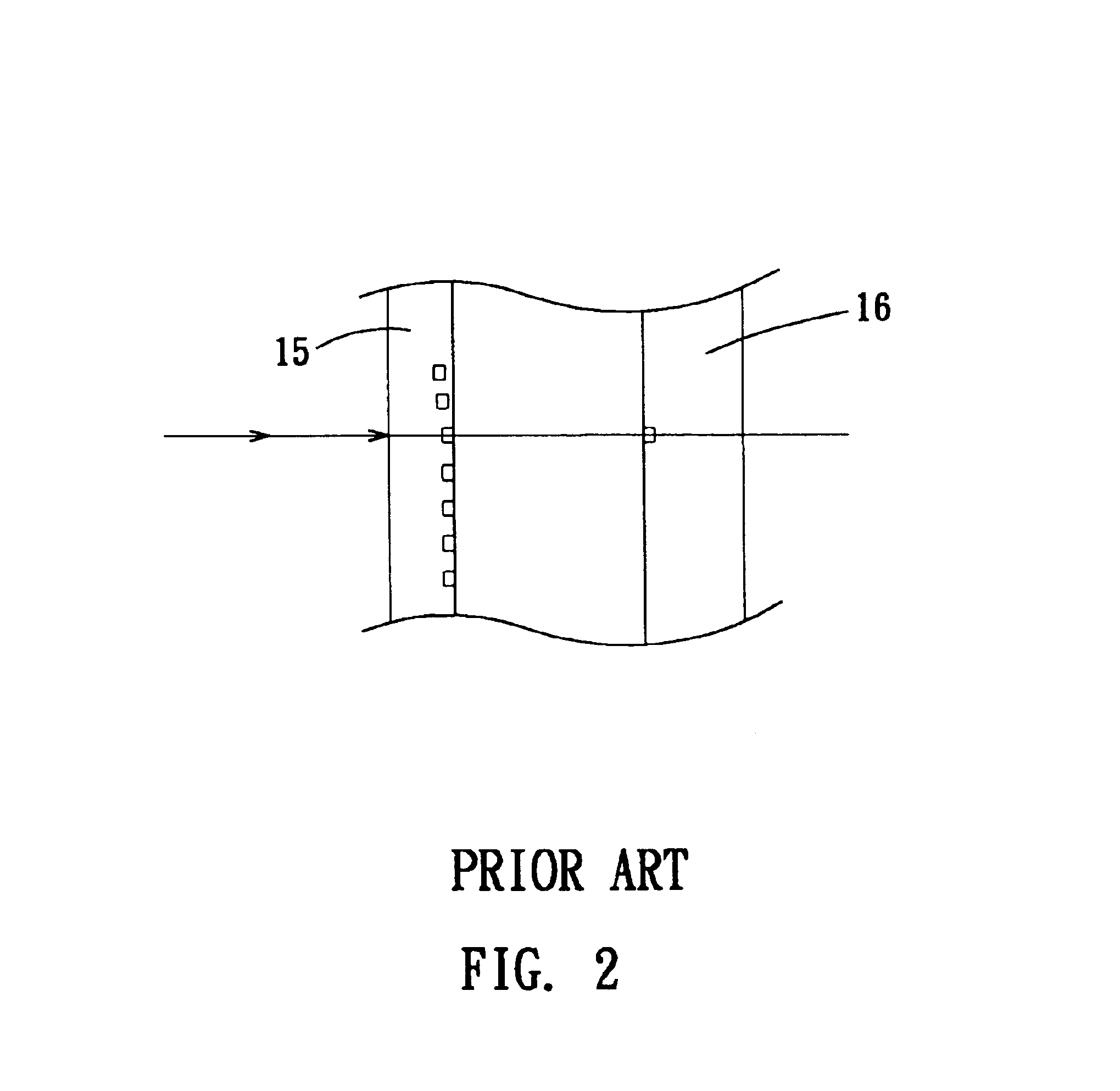

Camera lens assembly

ActiveUS6898030B1Improve cleanlinessIncrease productionMountingsCamera body detailsCamera lensOptical Module

A camera lens includes a barrel, a first lens, a second lens and an optical filter module. The barrel includes a first container and a diaphragm. The first lens is disposed in the first container next to the diaphragm. The second lens is disposed in the first container with a distance from the first lens. The optical filter module is disposed in the first container between the first and the second lenses.

Owner:CALLAHAN CELLULAR L L C

Can end

A can end member has a center panel, a circumferential chuck wall, and a transition wall. The center panel is centered about a longitudinal axis and has a peripheral edge. The center panel also has a step portion located radially outwardly from the longitudinal axis. The step portion has an annular convex portion joined to an annular concave portion and displaces at least a portion of the center panel vertically in a direction parallel to the longitudinal axis. The curl defines an outer perimeter of the end member. The circumferential chuck wall extends downwardly from the curl to the transition wall. The transition wall connects the chuck wall with the peripheral edge of the center panel. The transition wall has a folded portion extending outwardly relative to the longitudinal axis.

Owner:REXAM BEVERAGE CAN

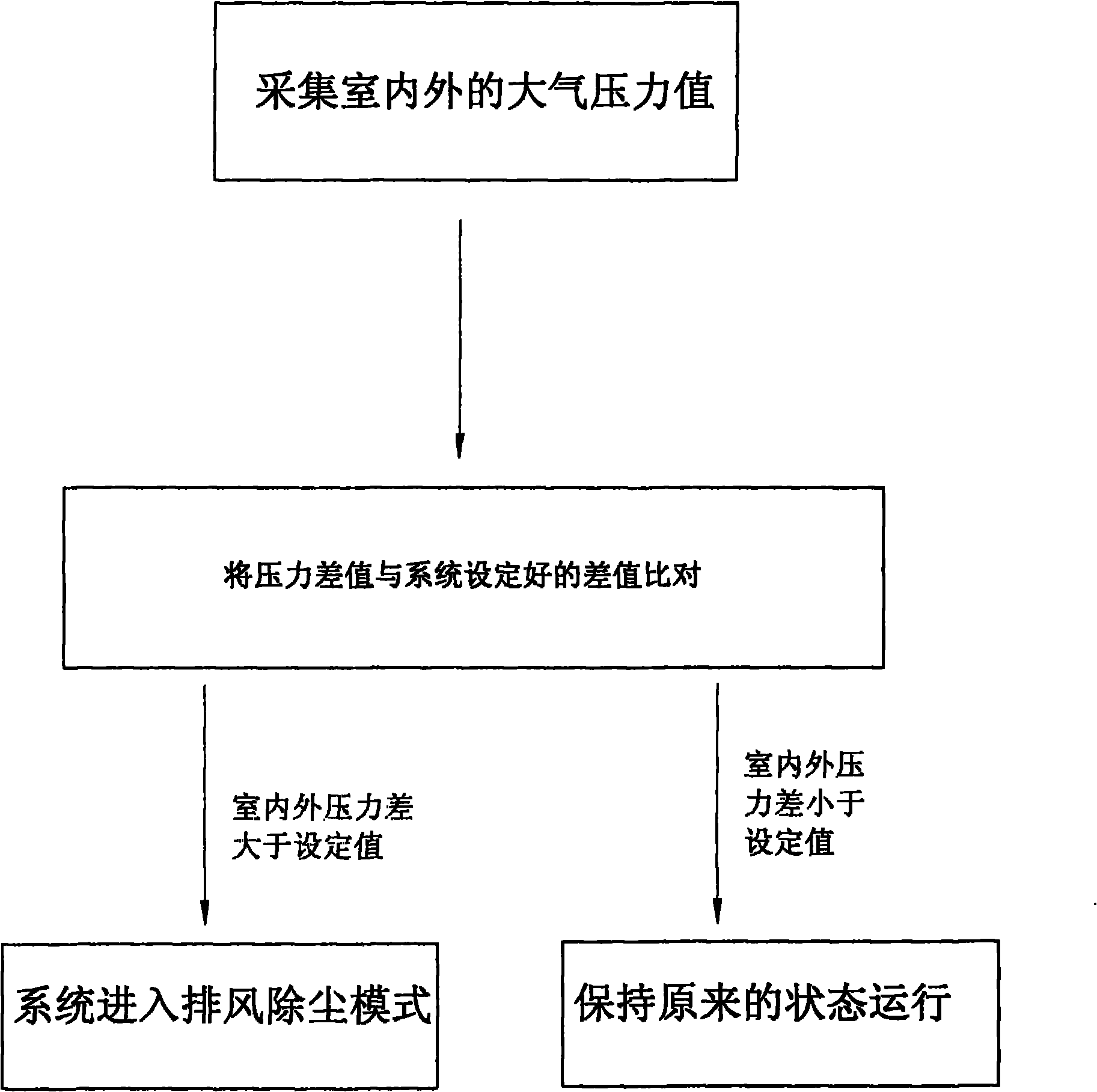

Efficient automatic dust-removing and intelligent ventilation system and automatic dust-removing method

InactiveCN101832612AGuarantee heat dissipation safetyImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTime-sharing

The invention relates to the ventilation system field, in particular to an efficient automatic dust-removing and intelligent ventilation system and an automatic dust-removing method. The system comprises an intelligent energy-saving ventilation system housing component and a fan, wherein the intelligent energy-saving ventilation system housing component comprises a dual duct, a dust-discharging duct, a throttle actuating mechanism, a dust screen, a temperature and humidity sensor and a distributed pressure sensor, wherein the temperature and humidity sensor and the distributed pressure sensor are connected with a control system, and the control system drives the throttle actuating mechanism to realize time-sharing and smooth transition of the dual duct and the dust-discharging duct. The beneficial effects of the invention are as follows: the fans of the air feeder unit can be used for several purposes such as air supply and dust removing, thus reducing the equipment cost; the self-cleaning of the filtering screen can be realized, thus prolonging the service life of the filtering screen, reducing replacement frequency and lowering maintenance cost; and by turning on / off the automatic dust-removing and intelligent ventilation system, the normal operation of the devices in an equipment room can be ensured.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

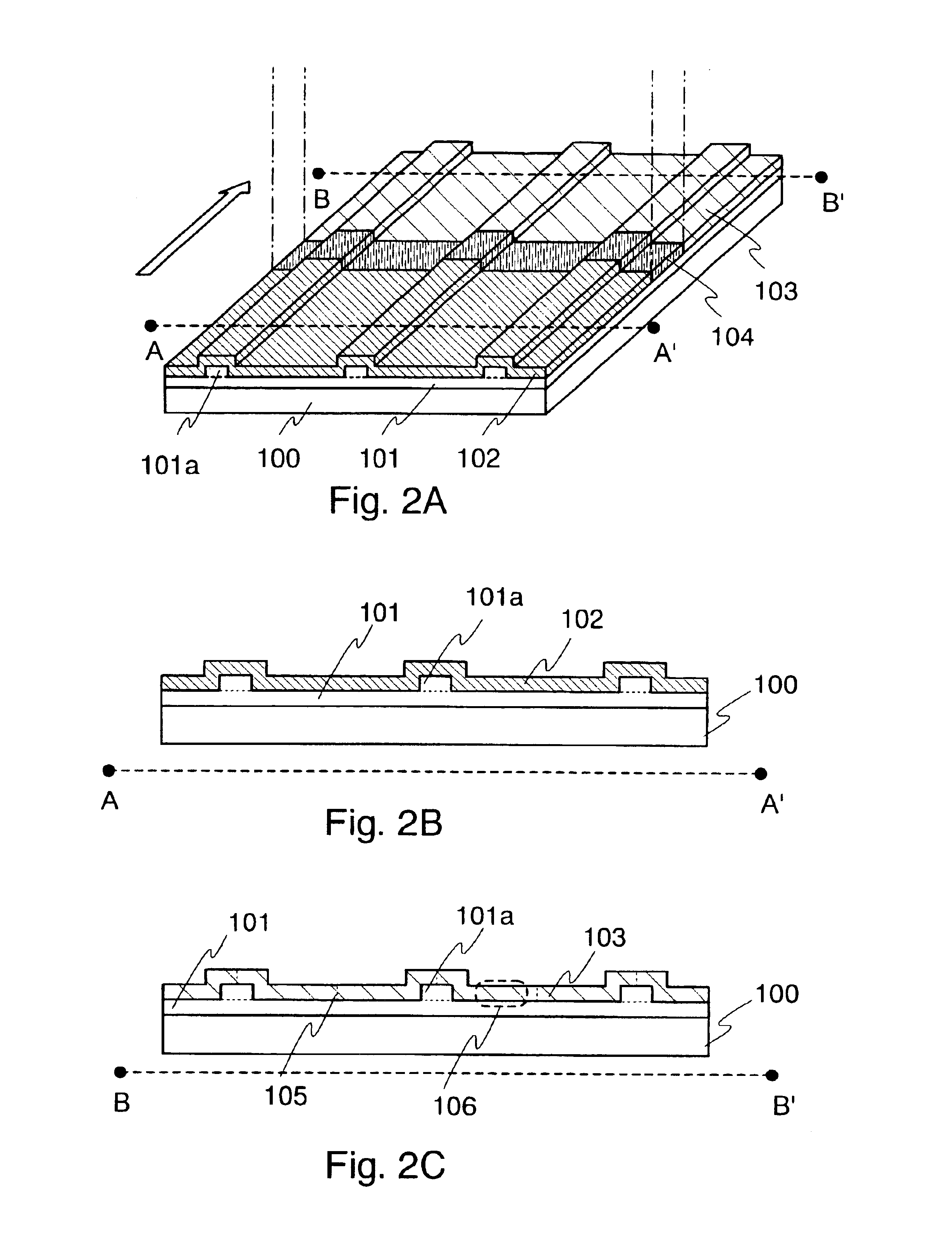

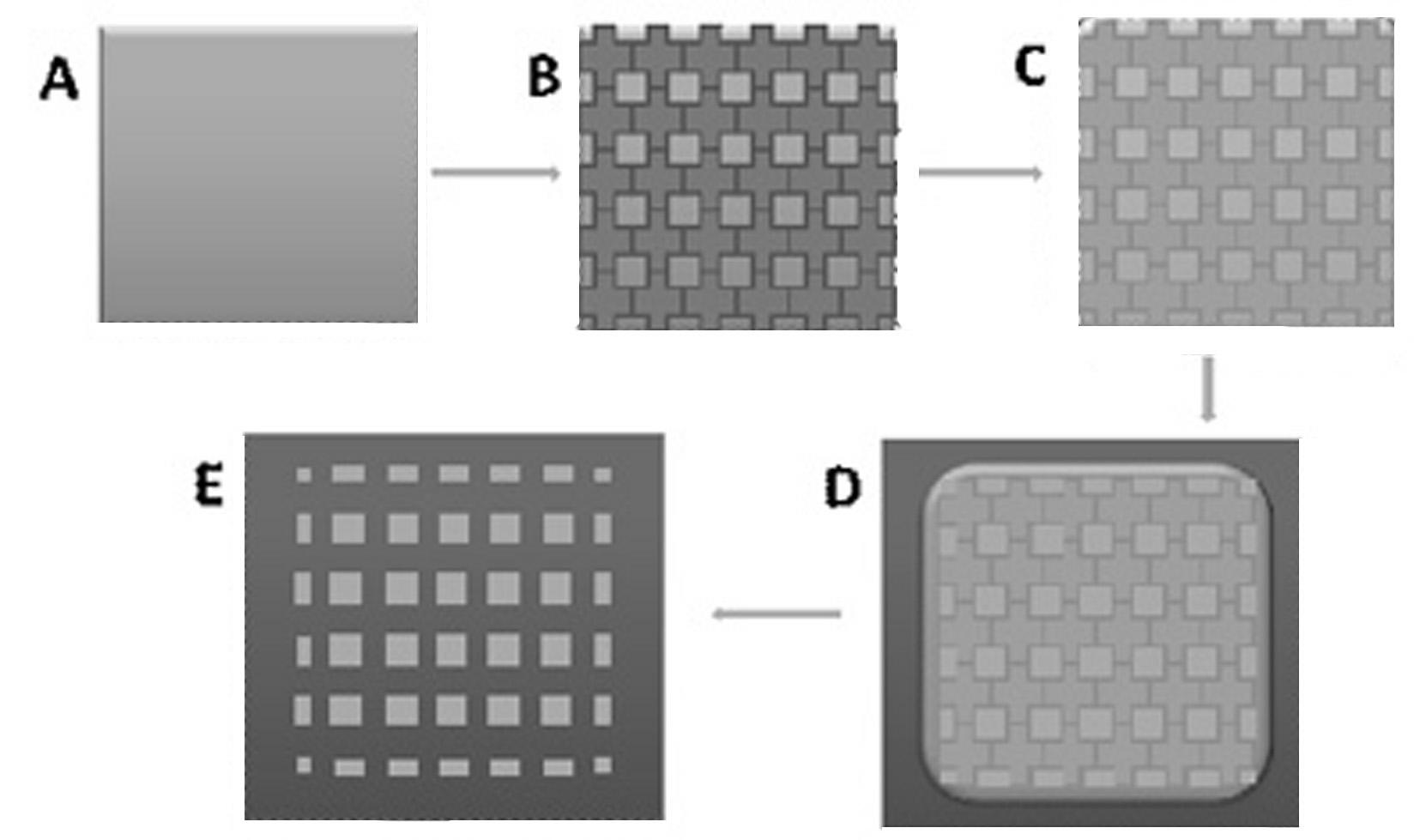

Semiconductor device formed over a surface with a depression portion and a projection portion

InactiveUS6841797B2Lower ON currentLow mobilityTransistorSolid-state devicesLaser lightSemiconductor

A semiconductor device production system using a laser crystallization method is provided which can avoid forming grain boundaries in a channel formation region of a TFT, thereby preventing grain boundaries from lowering the mobility of the TFT greatly, from lowering ON current, and from increasing OFF current. Rectangular or stripe pattern depression and projection portions are formed on an insulating film. A semiconductor film is formed on the insulating film. The semiconductor film is irradiated with continuous wave laser light by running the laser light along the stripe pattern depression and projection portions of the insulating film or along the major or minor axis direction of the rectangle. Although continuous wave laser light is most preferred among laser light, it is also possible to use pulse oscillation laser light in irradiating the semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

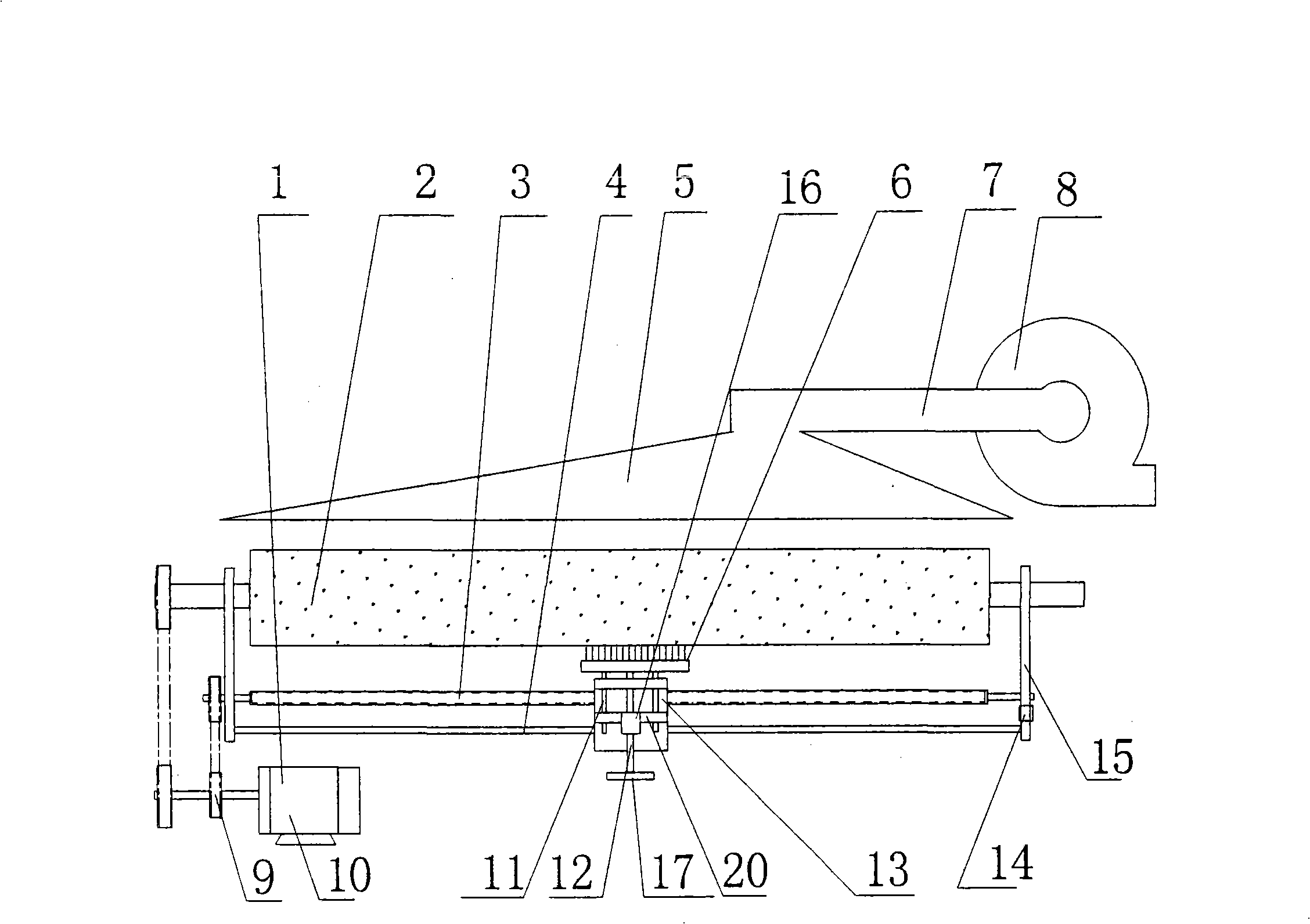

Automatic cleaning device for bristle roll of combing machine and cleaning method thereof

InactiveCN101285222AReduce damageImprove self-cleanlinessCombing machinesCleaning using toolsBristleEngineering

The invention provides an automatic cleaning device of a brush roller of a combing machine and a method for cleaning the same. The method comprises the following steps that: the upper side of the brush roller of the combing machine is provided with a dust hood which is connected with a draft fan through an air duct; the front part of the brush roller of the combing machine is provided with a brush roller cleaning mechanism; sundries which are attached on the brush roller of the combing machine are cleaned by contacting the brush roller cleaning mechanism with the surface of the brush roller of the combing machine. The automatic cleaning device of the brush roller of the combing machine and the method for cleaning the same are designed based on the principles of automation, cleaning and actual effect, which improve greatly work efficiency of an equipment maintainer so that the work must be done originally by two persons, but now the work can be done by one person after the brush automatic cleaner is used. Compared with the brush which is cleaned by persons, the brush which is cleaned by the brush automatic cleaner is cleaner, and the brush hair is straighter; and after the brush is operating, the state of cleaning the circular comb by the brush is improved greatly.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD +1

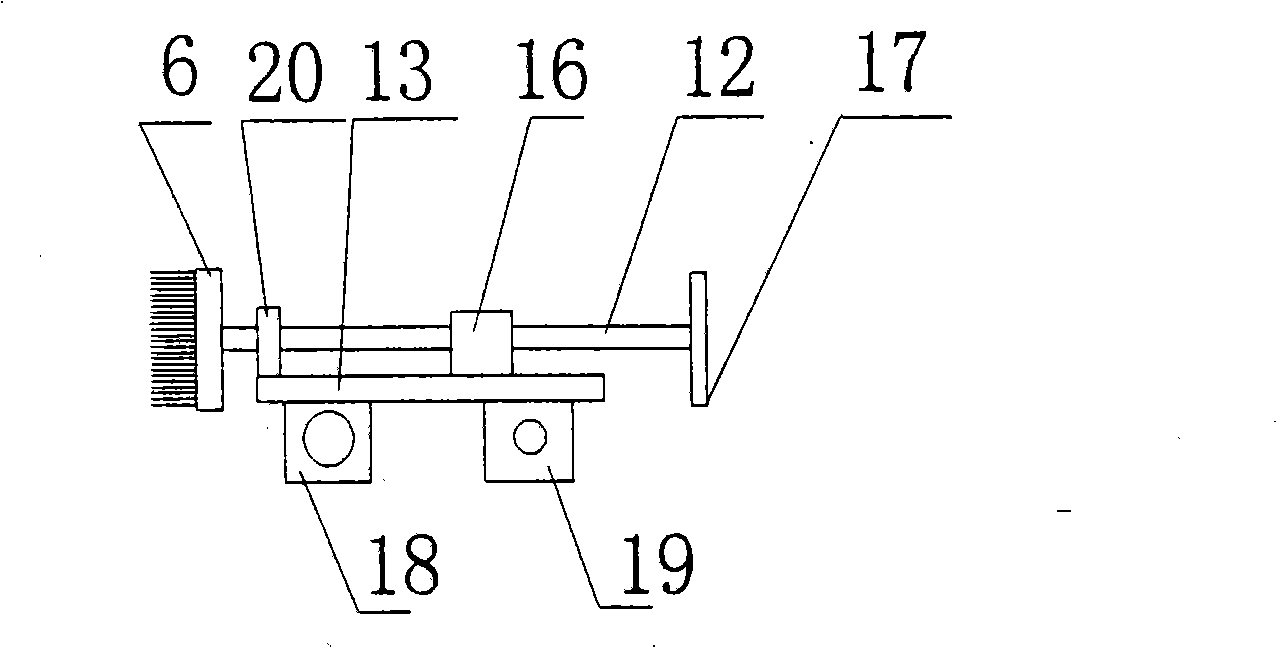

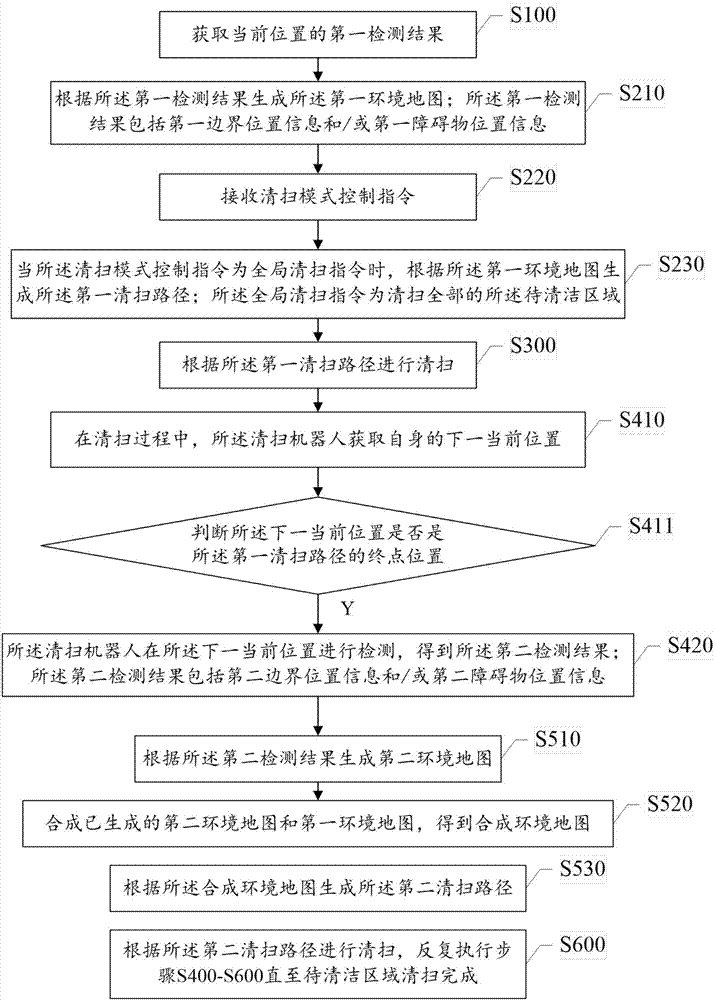

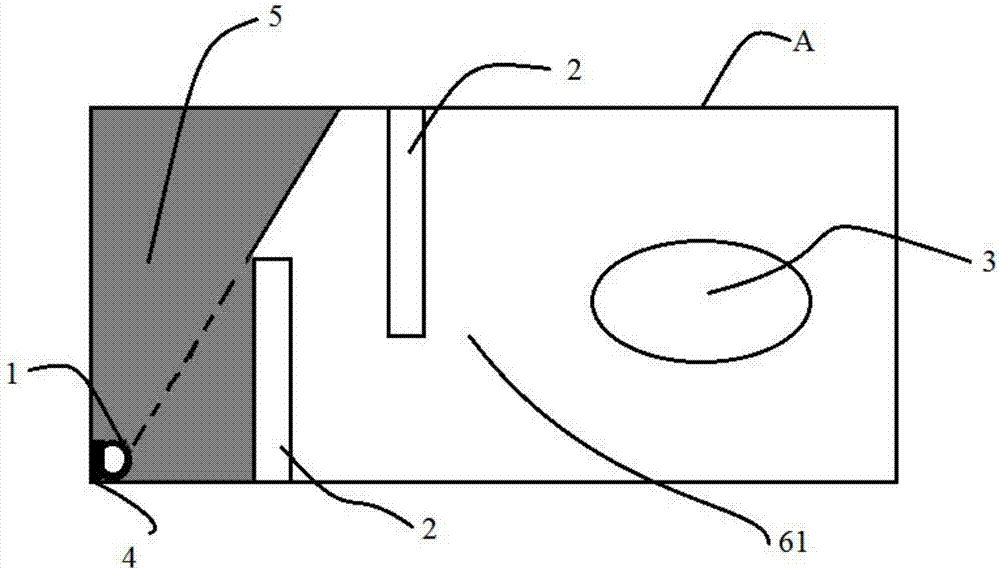

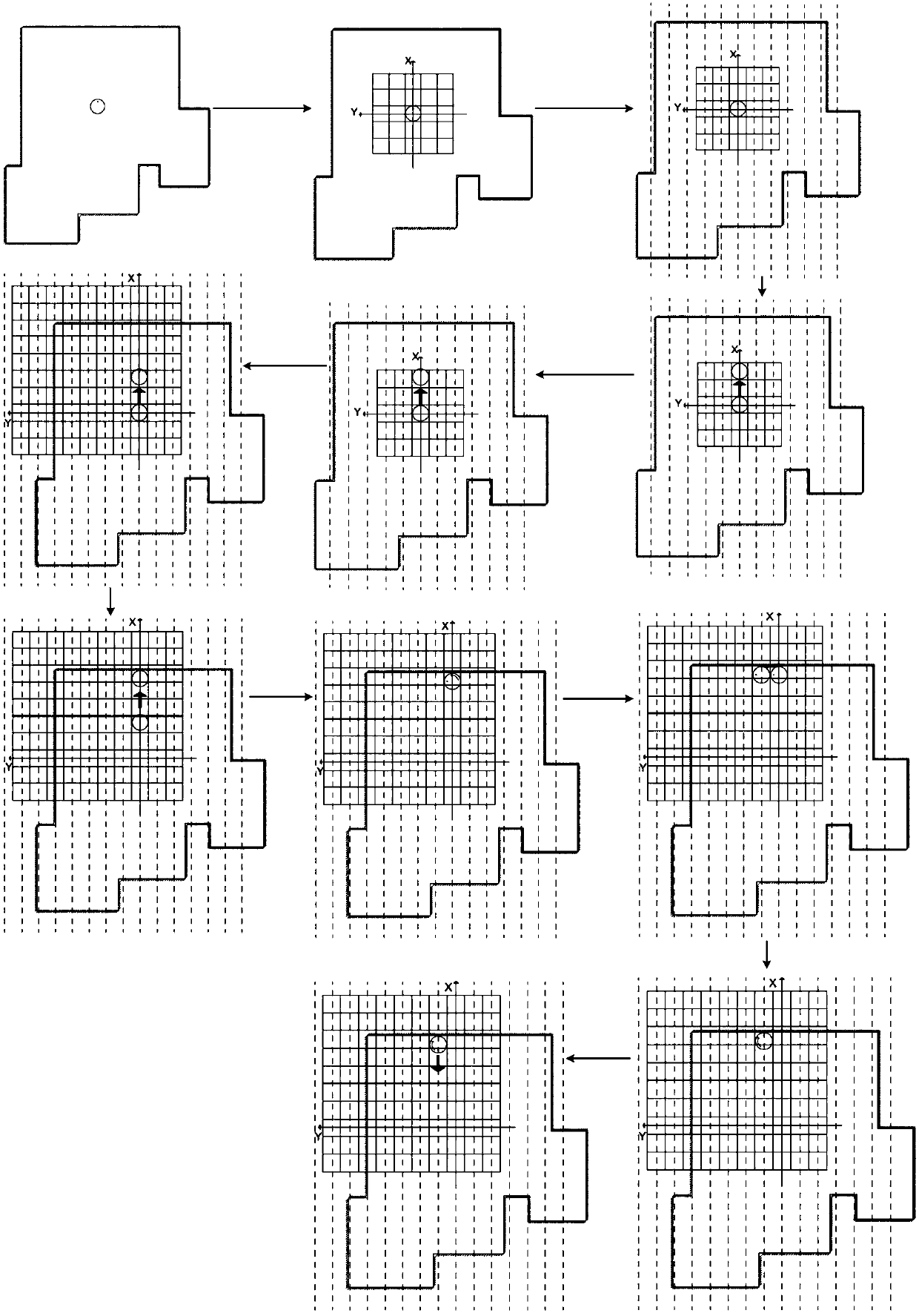

Planning method of cleaning robot cleaning route and cleaning robot

InactiveCN107328419AImprove cleanlinessShorten movement timeNavigational calculation instrumentsFloor sweeping machinesEngineeringPlanning method

The invention provides a planning method of a cleaning robot cleaning route and a cleaning robot. The planning method comprises the steps as follows: S100, a first detection result of a current location is acquired; S200, a first environment map is generated according to the first detection result, and a first cleaning route is generated according to the first environment map; S300, the cleaning robot performs cleaning according to the first cleaning route; S400, a second detection result of a next current position is acquired in a cleaning process; S500, a second environment map is generated according to the second detection result, and a second cleaning route is generated according to the first environment map and the second environment map; S600, cleaning is performed according to the second cleaning route, and the steps S400-S600 are executed repeatedly until cleaning of a to-be-cleaned area is completed. According to the planning method and the cleaning robot, cleaning and detecting are executed simultaneously by the cleaning robot, the cleaning route is updated in real time, cleaning efficiency is improved, and resources are saved.

Owner:台州市吉吉知识产权运营有限公司

Method for cleaning glass substrate

InactiveUS6568995B1High smoothnessIncrease degreeInorganic/elemental detergent compounding agentsPigmenting treatmentChemistryAqueous solution

After a polishing process of polishing a glass substrate with an abrasive containing lanthanoid oxides, the glass substrate is subjected to the first and second washing processes. In the first washing process, the polished substrate is washed with a washing solution containing acid and a reducing agent, wherein the acid includes at least nitric acid. In the second washing process, the washed substrate is treated with an aqueous solution of an alkaline detergent. The substrate is suitable for a recording medium.

Owner:HOYA CORP

Producing method of clean steel

The invention discloses a producing method of clean steel, which can further enhance the cleanliness and comprise the following steps of: pretreating with molten iron for desulfurizing until [S] is not more than 0.010%; then delivering to a converter for smelting; dephosphorizing and controlling sulfur; controlling finished molten iron in the converter to be with [P] of not more than 0.0080% and [S] not more than 0.010%; adding a ladle slag modifying agent to ladles in a steel tapping process for regulating and modifying the ladle slag, wherein after treating, in the molten iron, [P] is not more than 0.0060% to 0.0080%, [S] is not more than 0.0080% and roughing slag quantity is not more than 0.5%; controlling refined finished slag components in LF (Low Frequency) refining, wherein soft argon blowing time of the molten iron is not less than 5 minutes after LF refining, and the composition is qualified when [S] is not more than 0.0020%; carrying out VD (Vacuum Degassing) refining to ensure that [H] is not more than 1.5ppm; and continuously casting, wherein a double-layer high-alkalinity covering agent is adopted as a middle ladle, a seal ring and a long water gap are additionally arranged for argon-blowing protective casting, which is carried out at constant speed, and overheat delta T of the molten iron ranged from 15 DEG C to 30 DEG C. Under the condition that the producing cost is not increased basically, the cleanliness of the clean steel is further enhanced by the control of each procedure junction point, and the clean steel comprises the following components by weight percent: S not more than 20ppm, P not more than 100ppm, TO not more than18ppm, H smaller than 2.0ppm, N not more than 35ppm, and A, B, C and D types of impurities not more than 0.5 grade.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

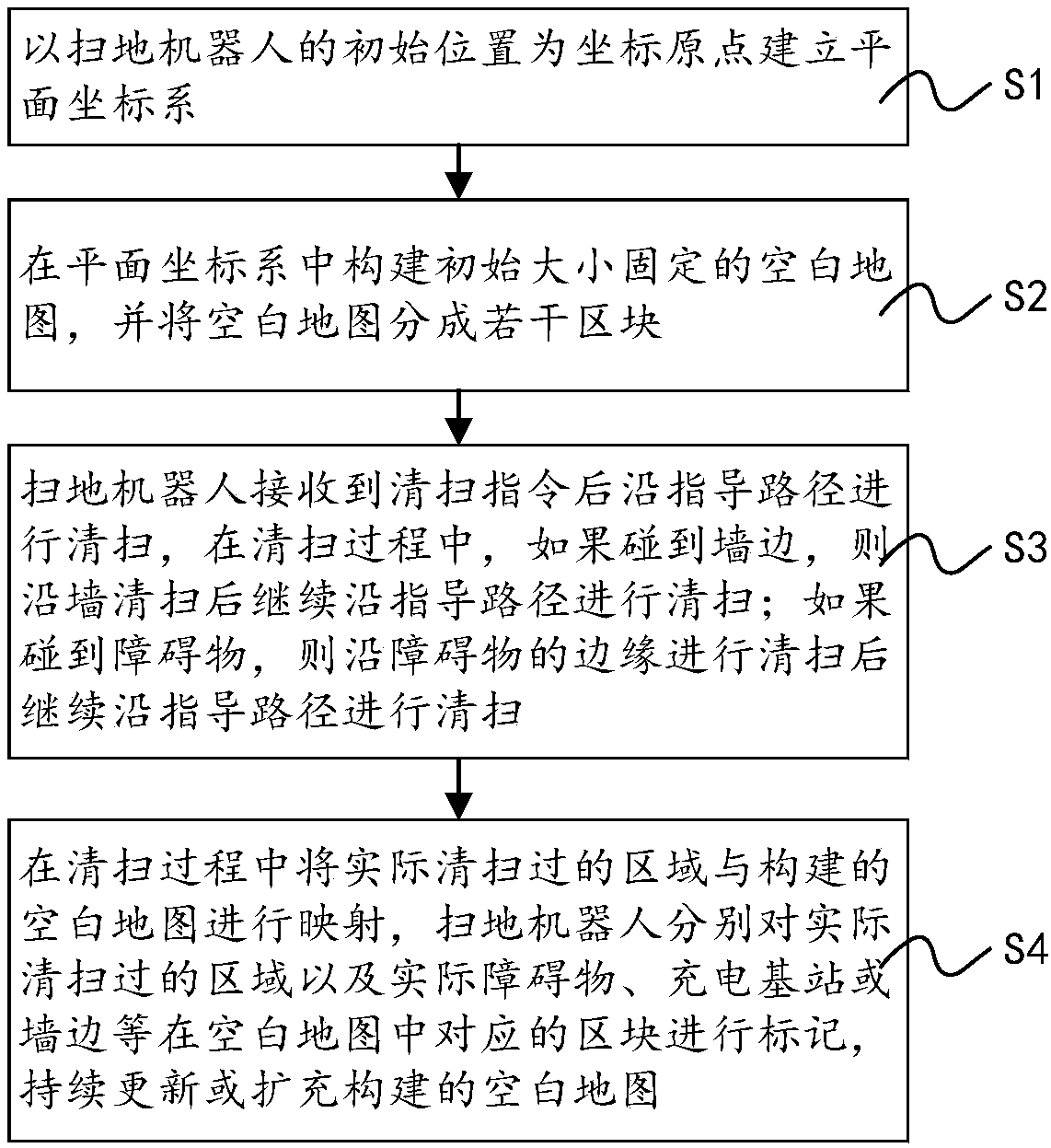

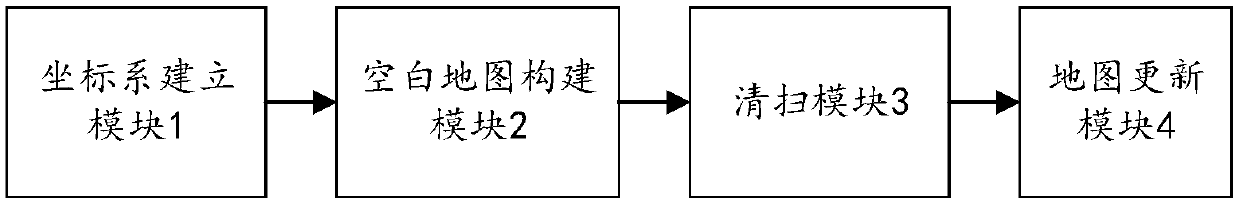

Floor mopping robot and cleaning path programming method

InactiveCN107943058AImprove experienceImprove performancePosition/course control in two dimensionsEngineeringProgramming method

The invention relates to a floor mopping robot and a cleaning path programming method. The cleaning path programming method comprises the following steps: establishing a plane coordinate system with the initial position of the floor mopping robot being a coordinate origin; establishing a blank map, the initial size of which is fixed but can be expanded, in the plane coordinate system, and dividingthe blank map into a plurality of areas, the size of each area being fixed; after the floor mopping robot receives a cleaning instruction, carrying out cleaning along a guide path, and in the cleaning process, if the robot encounters a wall, continuing to clean along the guide path after cleaning along the wall; if the robot encounters an obstacle, continuing to clean along the guide path after cleaning along the edge of the obstacle; and in the cleaning process, mapping the actually cleaned area and the established blank map to update a map. The floor mopping robot and the cleaning path programming method can enter an efficient cleaning mode directly at the beginning of cleaning, and then, update the map in the cleaning process, thereby preventing most of the repeated work, reducing cleaning repetition rate and improving cleaning coverage rate.

Owner:北京面面俱到软件有限公司

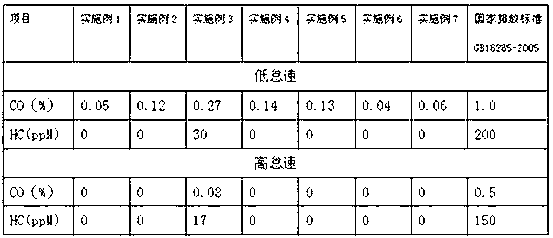

High-cleanness environment-friendly alcohol ether fuel for car

ActiveCN103275769AHigh chemical activityImproves resistance to phase separationLiquid carbonaceous fuelsFuel additivesMechanical engineeringMethanol

The invention provides a high-cleanliness environment-friendly alcohol ether fuel for a car. The fuel provided by the invention consists of the following raw materials: 600-800 parts of methanol, ethanol or a mixture of methanol and ethanol, 100-350 parts of an ether stabilizer, 1-6 parts of an anti-oxygen and anti-gum inhibitor, 2-5 parts of a metal deactivator, 1-3 parts of a corrosion inhibitor, 1-40 parts of a catalytic combustion improver, 2-4 parts of an antistatic agent, 10-100 parts of an antiknock stabilizer, 1-6 parts pf a purification dispersant, 1-6 parts of an anti-wear repair agent, 1-6 parts of a metal corrosion inhibitor, 2-6 parts of a rubber and plastic part corrosion and swelling inhibitor, 10-50 parts of a modified alcohol cosolvent, 0.2-0.8 part of a bactericide and 0.04-0.1 part of a recognition agent. The fuel provided by the invention has the advantages of stable performance, strong power, sufficient combustion, good seismic performance, good acceleration, easiness for starting up, no air lock, no separated layer, reduced fuel consumption, cleaner tail gas emission and no need of changing the structure of a spark ignition engine in the prior art and can be separately used, used instead of regular gasoline or used together with regular gasoline by co-combustion.

Owner:鲁家政

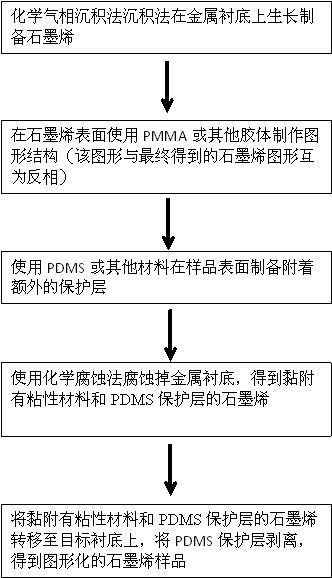

Transfer preparation method of patterned graphene

InactiveCN102637584ACause structural damageImprove cleanlinessSemiconductor/solid-state device manufacturingCvd grapheneAdhesive materials

The invention discloses a transfer preparation method of patterned graphene, which comprises the following steps: coating an adhesive material on a graphene surface, which grows on a catalytic metallic substrate, according to a designed pattern; coating a PDMS (polydimethylsiloxane) layer on the graphene surface, and thermosetting; soaking the obtained sample in an etching solution to remove the catalytic metallic substrate, so that the graphene with the adhesive material and the PDMS floats in the solution; transferring the graphene with the adhesive material and the PDMS onto a target substrate; and stripping the PDMS from the target substrate to obtain the patterned graphene. The method disclosed by the invention does not limit the use of materials of the target substrate; when stripping the PDMS, an expected pattern can be obtained without causing additional structure damage on the graphene, and meanwhile, the graphene surface is kept clean; and the invention can be used for preparing patterned graphene without expensive etching equipment.

Owner:LANZHOU UNIVERSITY

Method for polishing and grinding hydrant drill end and special polishing grinder

ActiveCN101073876AImprove processing efficiencyImprove qualityEdge grinding machinesConvex sideEngineering

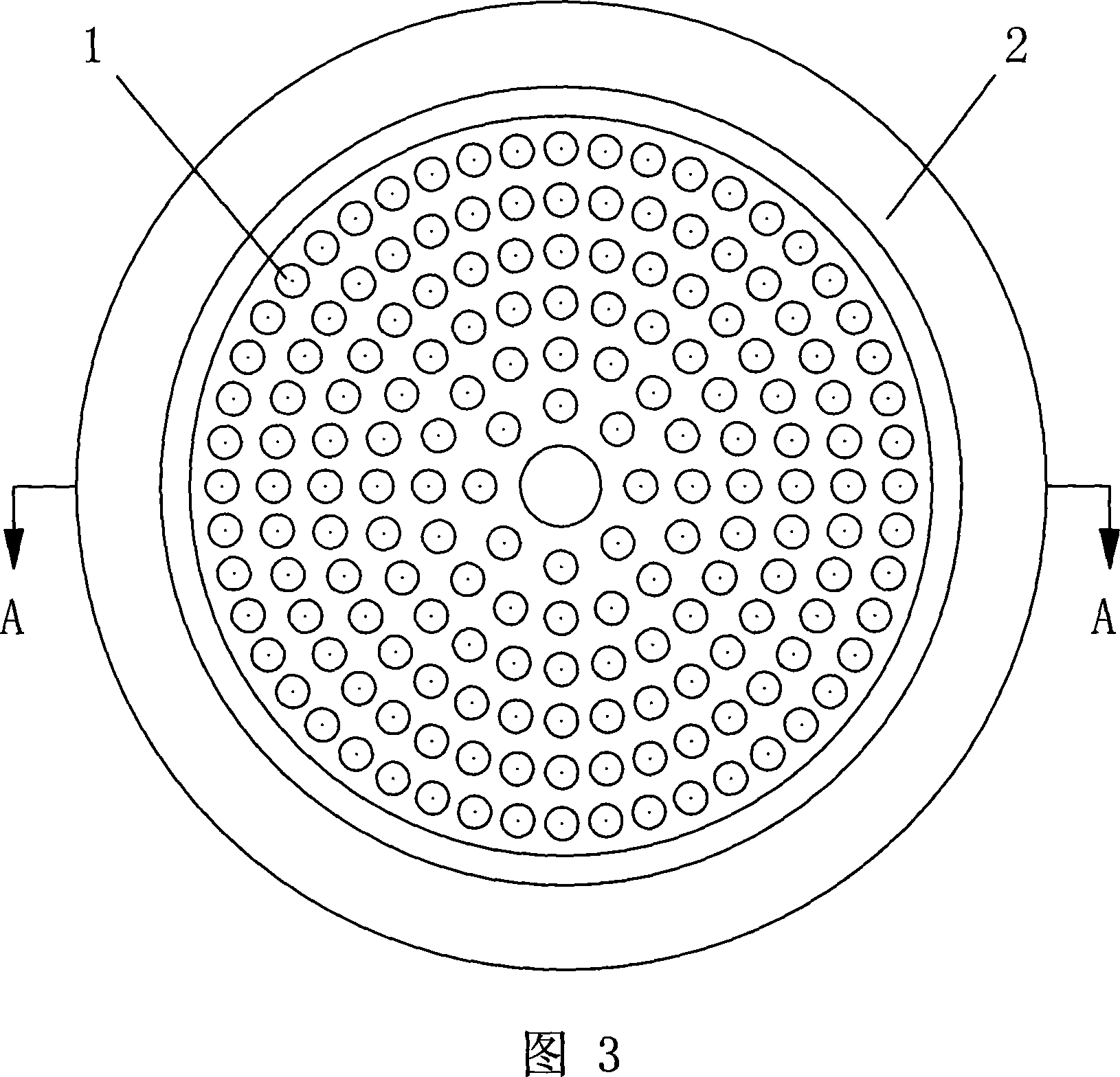

The invention is concerned with simulation diamond end face polishing-grinding machining method and the expert polishing-grinding machining. Set stuff and put molding plastics-absorption tray on fixture tray and make the concave face of plastics-absorption tray upside, and the simulation diamond adsorbs on the convexity of the bottom to plastics-absorption tray. Set plastics-absorption tray on the polishing-grinding machining and mill the tine end of simulation diamond on calm millstone. The polishing-grinding machining relates rack with a level millstone at its middle, and there are two level trays. They are centrosymmetric to the axis of millstone on top of millstone and have plastics-absorption tray on them. There is up and down equipment for tray on top of level tray which connecting with two turning axes on two sides of millstone with level rack, and the other end of turning axis has running equipment of turning axis. It has large machining amount of each time, high produce efficiency, good ratio to excellent stuff, long work time, easy operation without waste of material.

Owner:虞雅仙

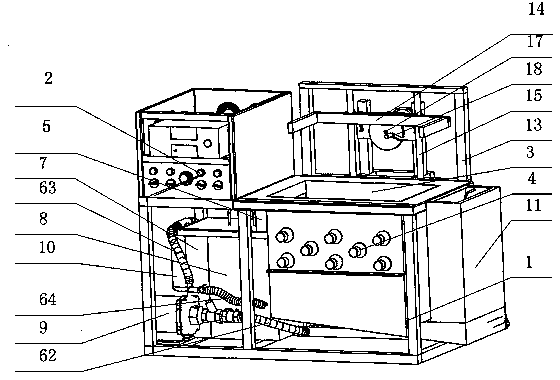

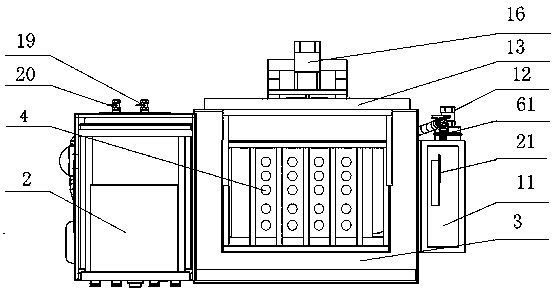

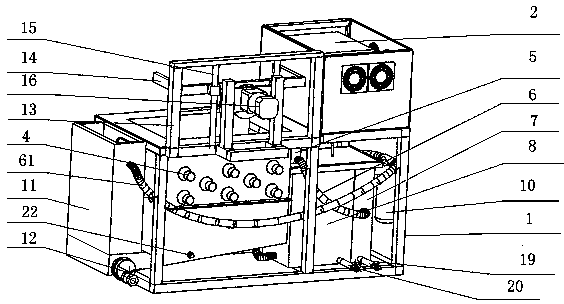

Hydraulic cylinder surface shot blasting, paint spraying and drying system and shot blasting, paint spraying and drying process thereof

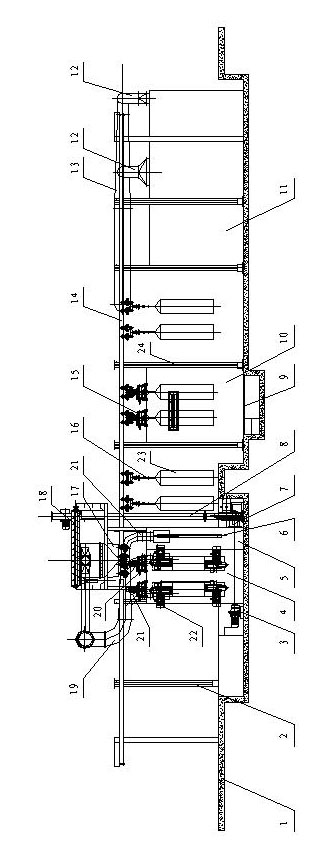

InactiveCN101972726AIncrease productivityImprove cleanlinessSpraying apparatusPretreated surfacesHydraulic cylinderLacquer

The invention relates to a hydraulic cylinder surface shot blasting, paint spraying and drying system and a shot blasting, paint spraying and drying process thereof, and the hydraulic cylinder surface shot blasting, paint spraying and drying system consists of a hanging chain conveying system, a shot blasting working position, a paint spraying working position, a drying working position, an overhauling working position, an unloading working position, a loading working position, a paint mixing room, an air compressor and an operating room. The shot blasting, paint spraying and drying process comprises the following process steps: loading of a piece, shot blasting, derusting and cleaning (10-15min), automatic paint spraying (3-5min), paint refinishing, leveling (5min), drying at 60-80 DEG C (30min), natural cooling and unloading of the piece. The hydraulic cylinder surface shot blasting, paint spraying and drying system has the advantages of high degree of mechanical and electrical automation, small occupied area, good safety performance, and high production efficiency, is not affected by weather and can ensure the cleanliness, the temperature, the illumination and the safety and sanitation standard required by the paint spraying environment; and the shot blasting, paint spraying and drying process is simple, safe, time-saving, environment-friendly and high in working efficiency and can obtain the good appearance quality of a paint film.

Owner:中煤邯郸煤矿机械有限责任公司

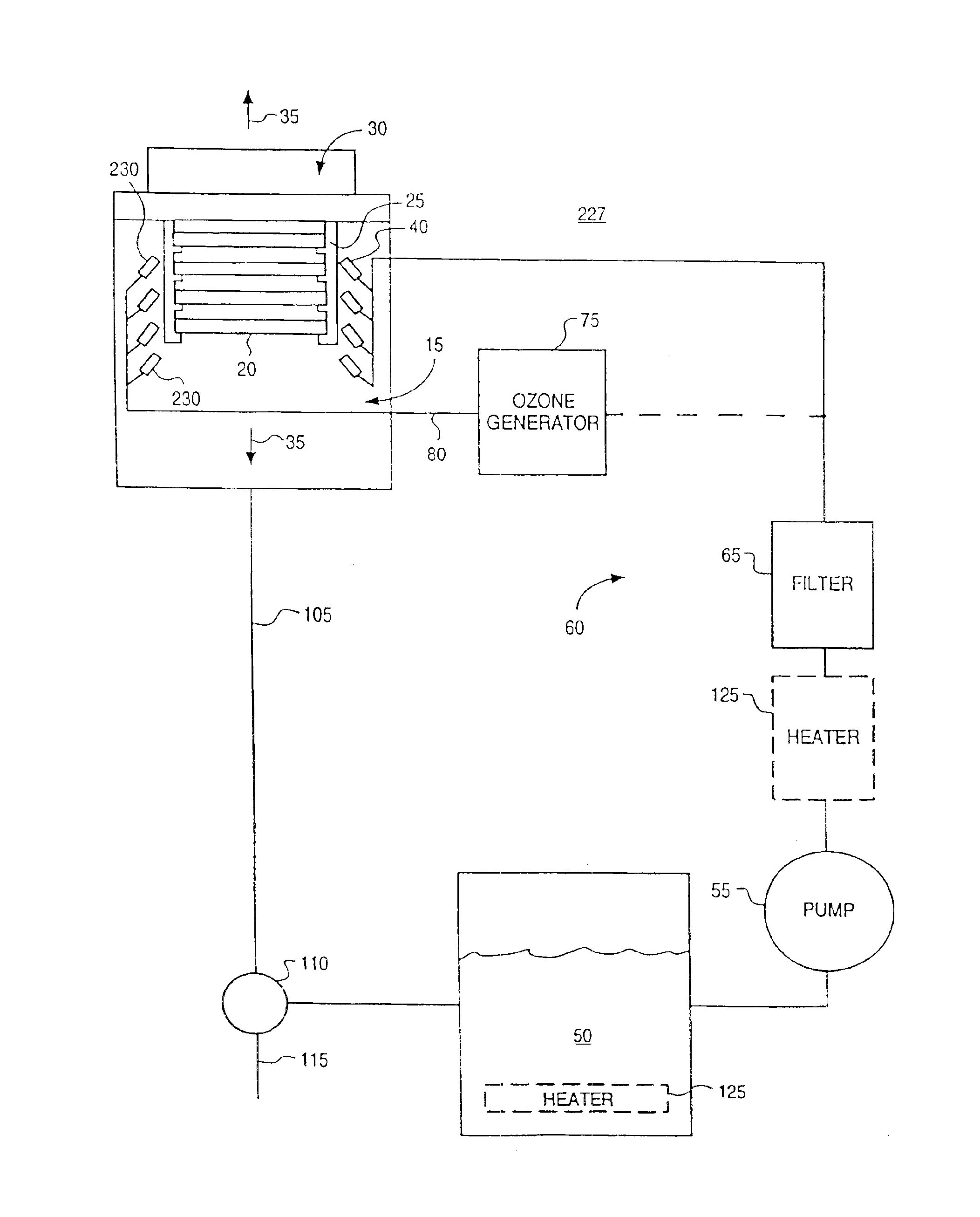

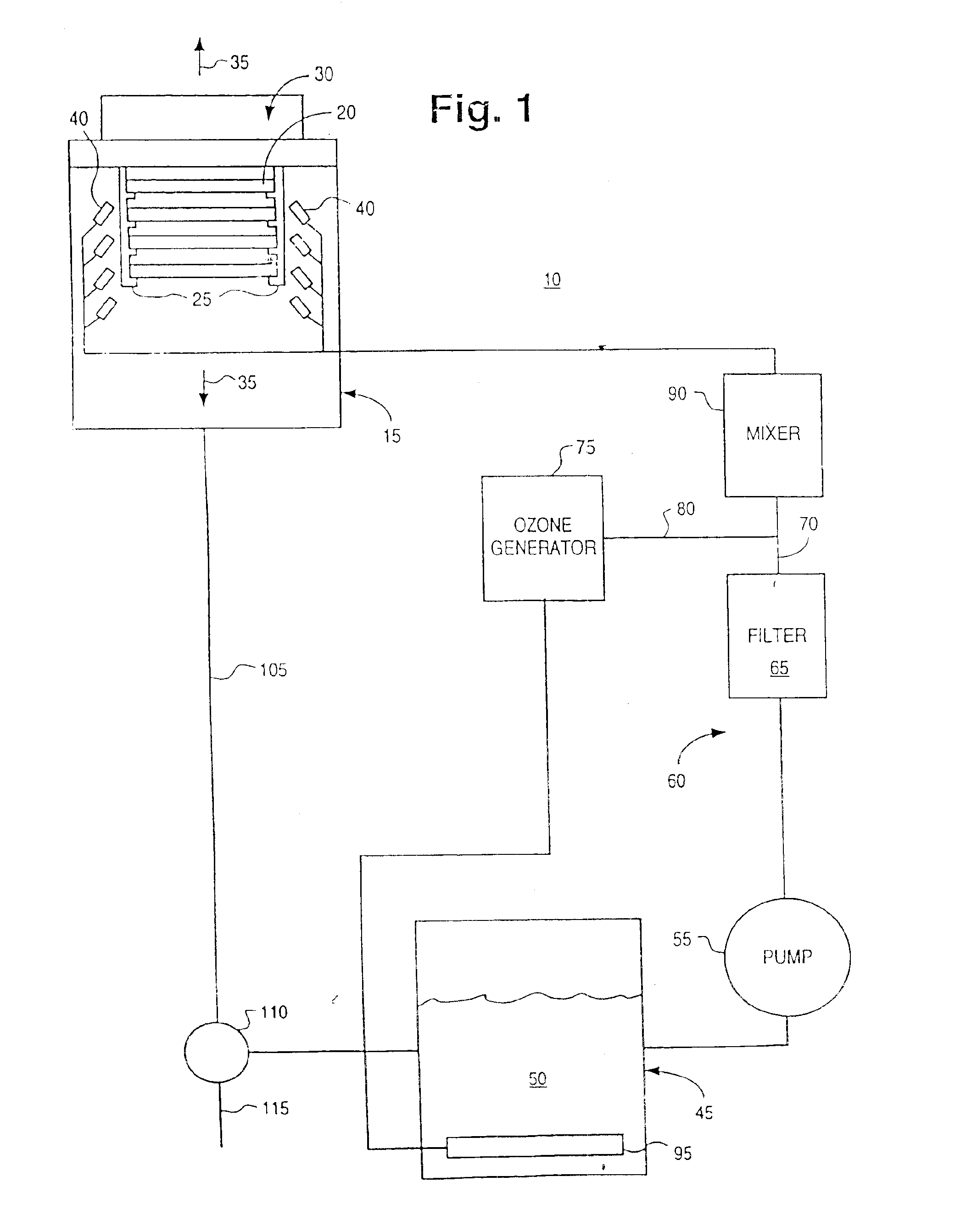

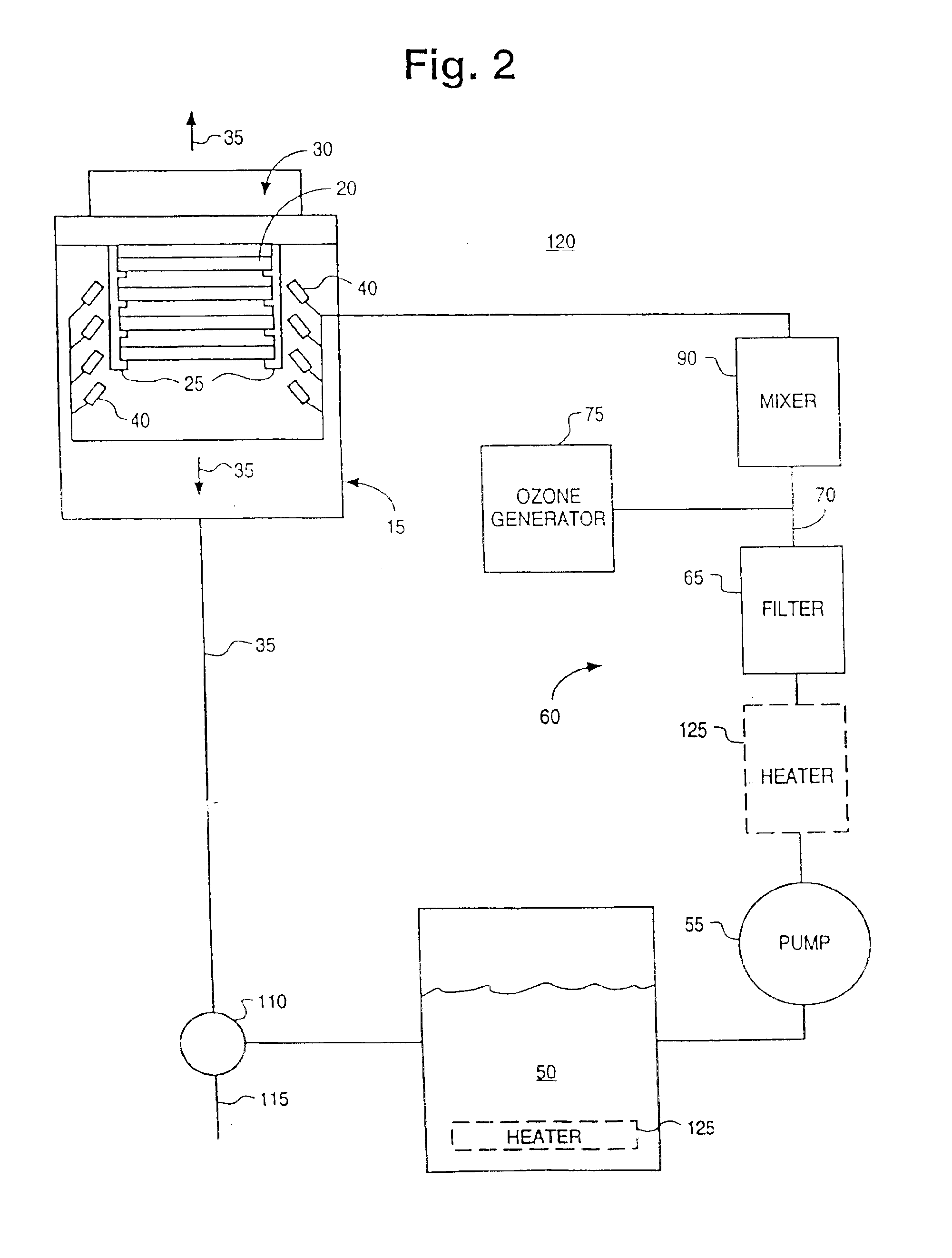

Process and apparatus for treating a workpiece such as a semiconductor wafer

InactiveUS6869487B1Reduce pollutionProcessing speedPrinted circuit assemblingLighting and heating apparatusOzone generatorCompound (substance)

A novel chemistry, system and application technique reduces contamination of semiconductor wafers and similar substrates and enhances and expedites processing. A stream of liquid chemical is applied to the workpiece surface. Ozone is delivered either into the liquid process stream or into the process environment. The ozone is preferably generated by a high capacity ozone generator. The chemical stream is provided in the form of a liquid or vapor. A boundary layer liquid or vapor forms on the workpiece surface. The thickness of the boundary layer is controlled. The chemical stream may include ammonium hydroxide for simultaneous particle and organic removal, another chemical to raise the pH of the solution, or other chemical additives designed to accomplish one or more specific cleaning steps.

Owner:OEM GRP LLC

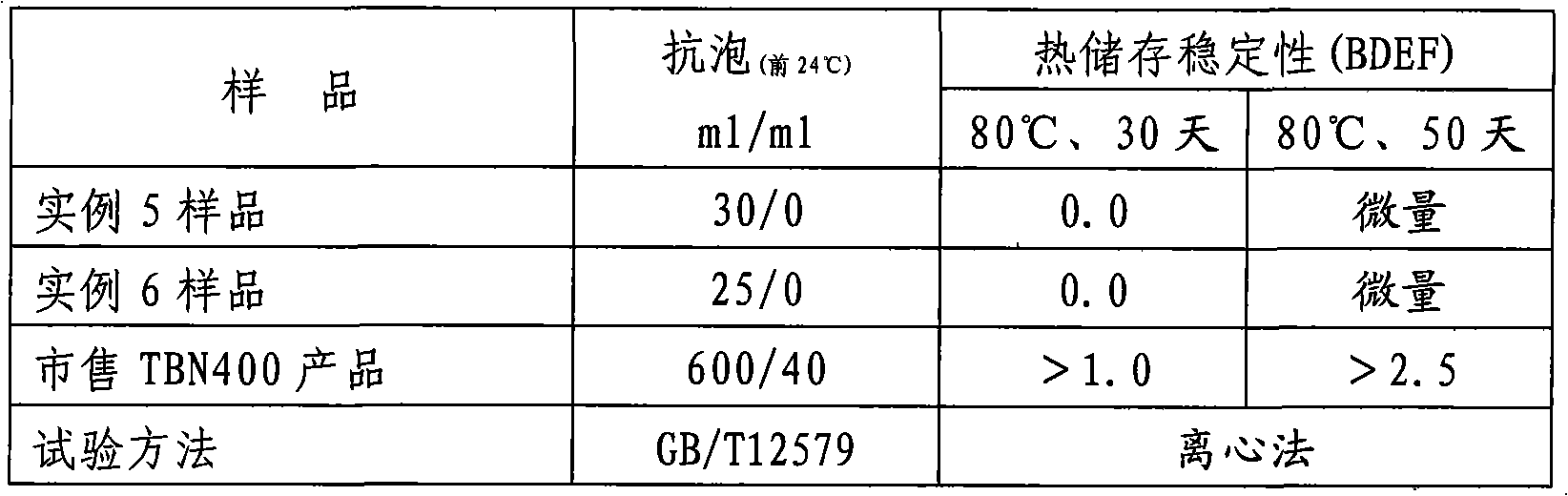

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

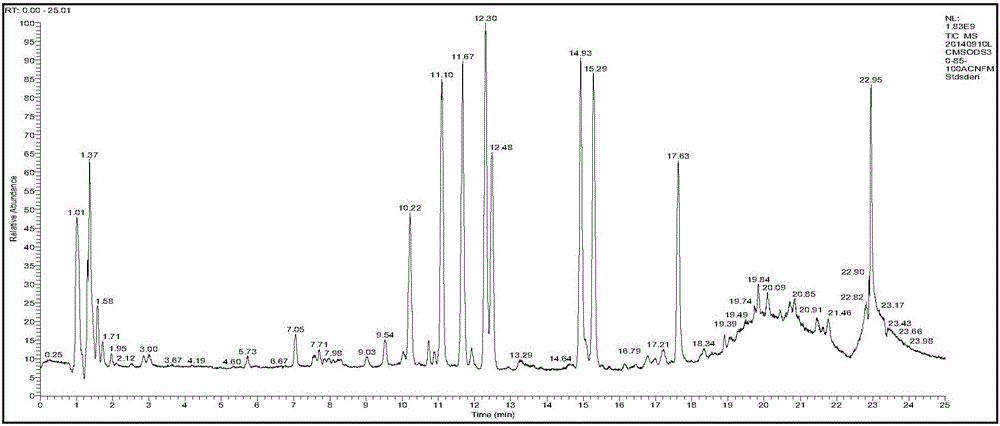

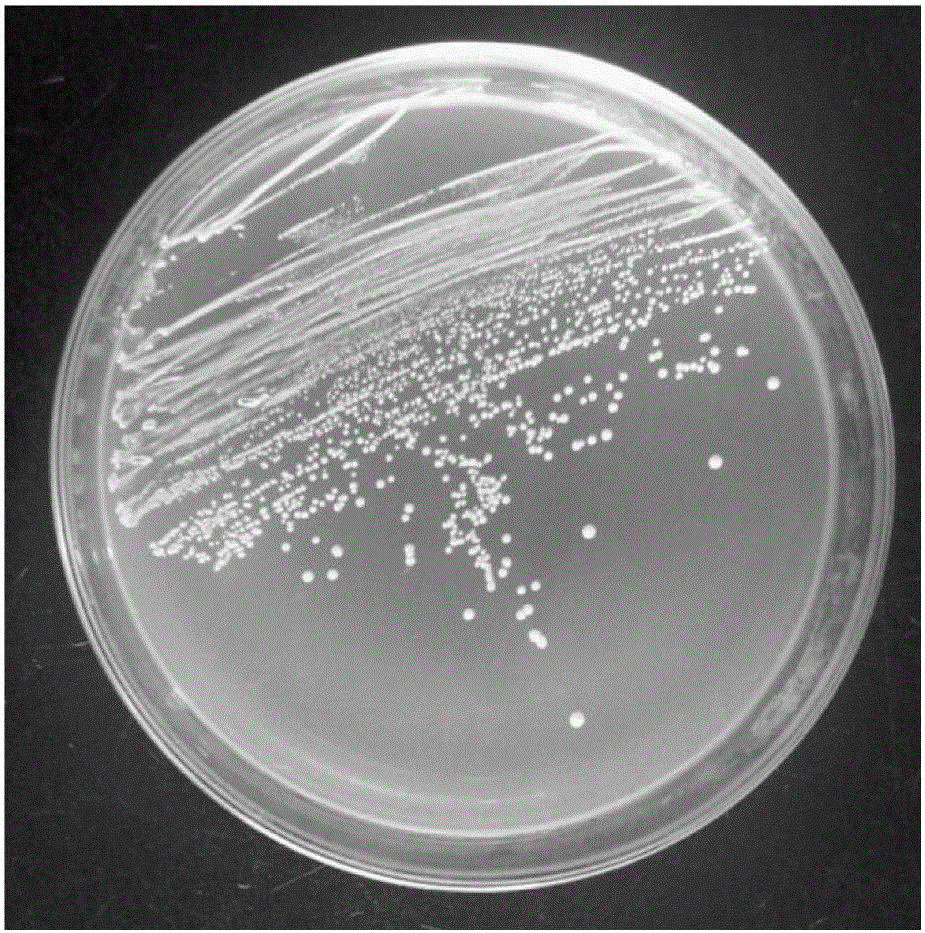

Lactobacillus plantarum with function of reducing contents of biogenic amines in foods and application of lactobacillus plantarum

ActiveCN105132308AAcid resistantHas the ability to clearBacteriaMicroorganism based processesBiotechnologyFermentation

The invention belongs to the technical field of microorganisms and discloses lactobacillus plantarum with a function of reducing contents of biogenic amines in foods and application of the lactobacillus plantarum. The lactobacillus plantarum is resistant to acids and capable of strongly removing eight types of biogenic amines (including tryptamine, phenethylamine, putrescine, cadaverine, histamine, tyramine, spermidine and spermine) in vitro. After 1*1010CFU / ml of the lactobacillus plantarum and the eight types of biogenic amines are co-cultured for 24h, wherein the concentration of each type of the biogenic amines is 100mg / L, and the total amine concentration is 800mg / L, the total amine content is reduced by 70% approximately, the content of each type of the biogenic amines is reduced by 30%-100%, and the removal rate of histamine highest in toxicity is up to 96.69%. Further, the lactobacillus plantarum is capable of lowering pH to 4 in eight hours owing to quickness in acid generation, thereby having favorable fermentation potential. The lactobacillus plantarum is used for degradation of the biogenic amines in foods, especially in fermented foods and extensive in application prospect.

Owner:JIANGNAN UNIV

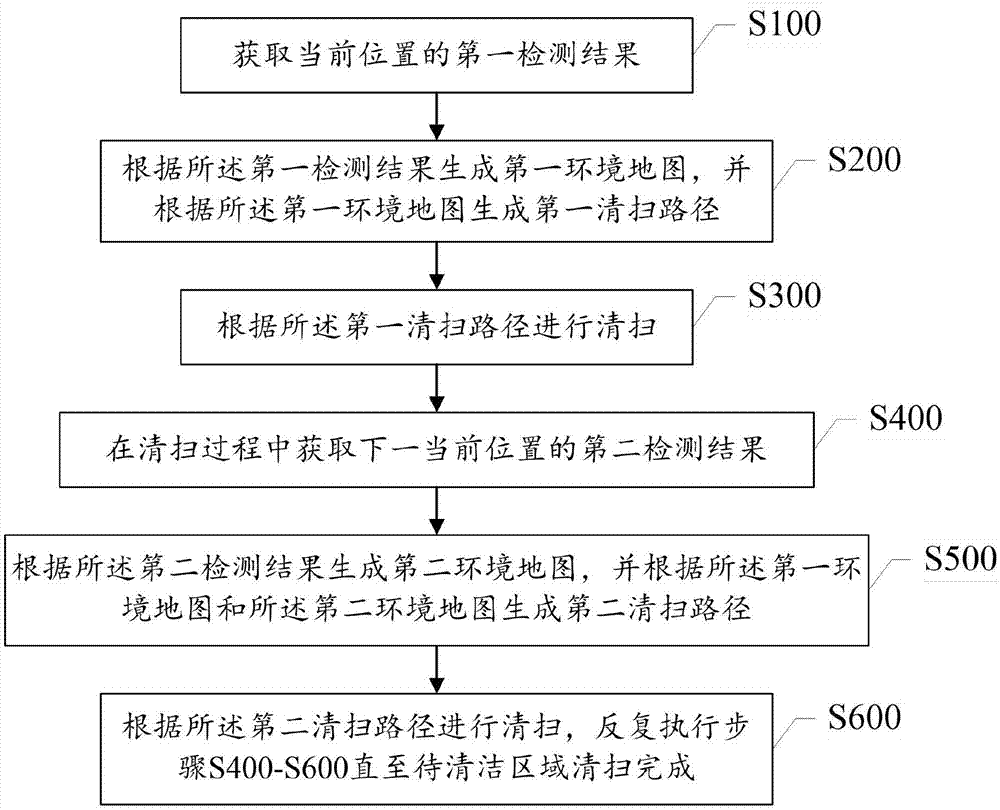

Ultrasonic cleaner

ActiveCN103878143AConsistent cleanlinessReduce replacement cycleCleaning using liquidsFiltrationWater storage tank

The invention discloses an ultrasonic cleaner and belongs to the field of mechanical equipment cleaning. The ultrasonic cleaner solves the problems that cleaning fluid in an existing ultrasonic cleaner cannot remove impurities in time, and the cleaning fluid is wasted. The ultrasonic cleaner comprises a rack (1), an ultrasonic generator (2), a cleaning tank (3) and ultrasonic vibrators (4). A water circulation device is arranged on the outer side of the cleaning tank (3) and comprises an overflow tank (5) arranged on one side of the cleaning tank (3). The water circulation device further comprises the overflow tank, an oil contamination tank (7), a water storage tank (8), a water pump (9), a filter (10) and a water injection tank (11). The bottom of the water injection tank (11) is communicated with the cleaning tank (3). The bottom of the cleaning tank (3) is an inclined plane. The ultrasonic cleaner integrates the functions of heating, ultrasonic waves, circulating filtration, oil-water separation and article movement, the cleaning speed is high, and the cleaning effect is good; besides, the ultrasonic cleaner is multifunctional, low in energy consumption and capable of prolonging the replacement cycle of the cleaning fluid and reducing environmental pollution, thereby being wide in application range.

Owner:台州鸿辰机械制造有限公司

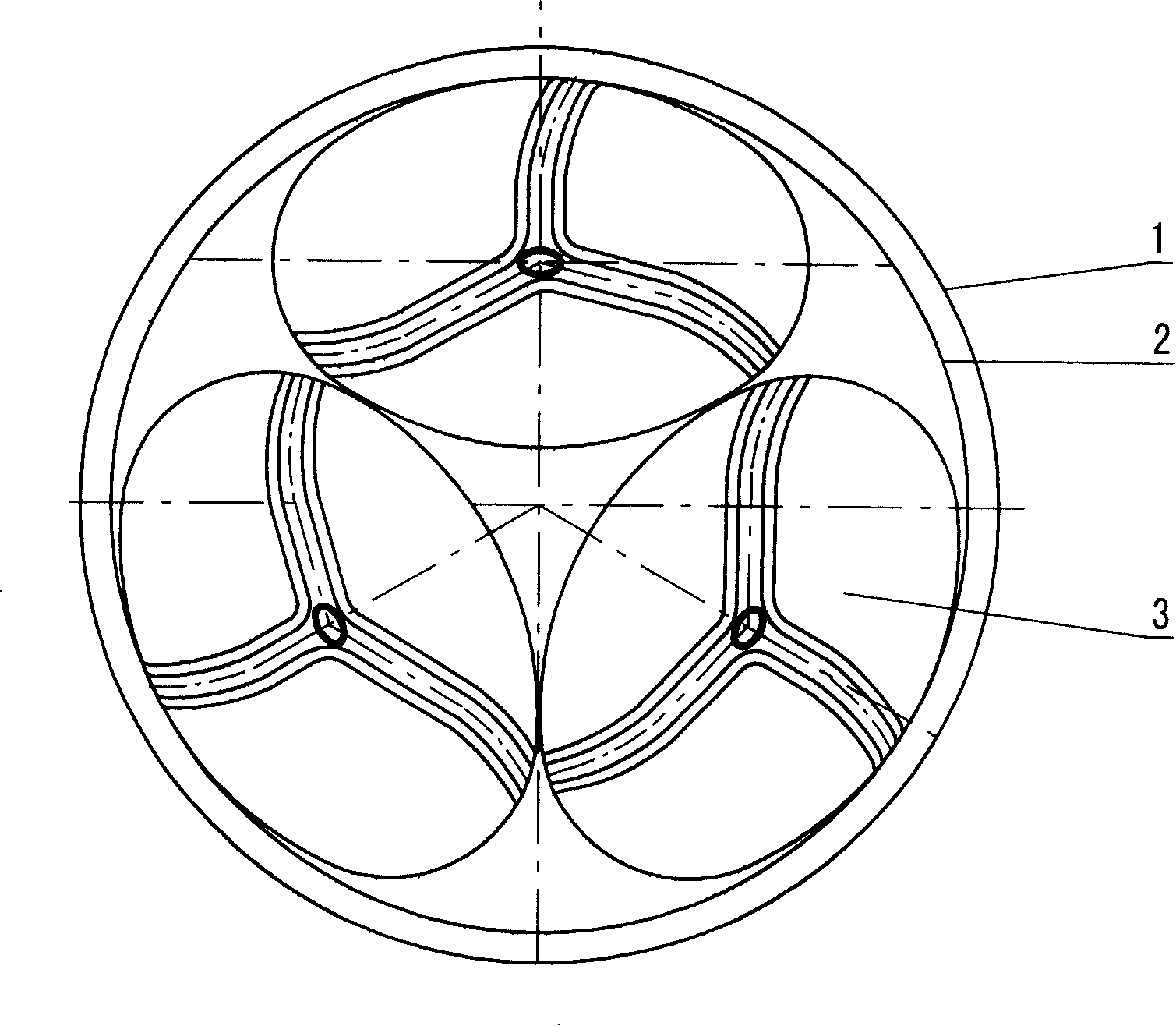

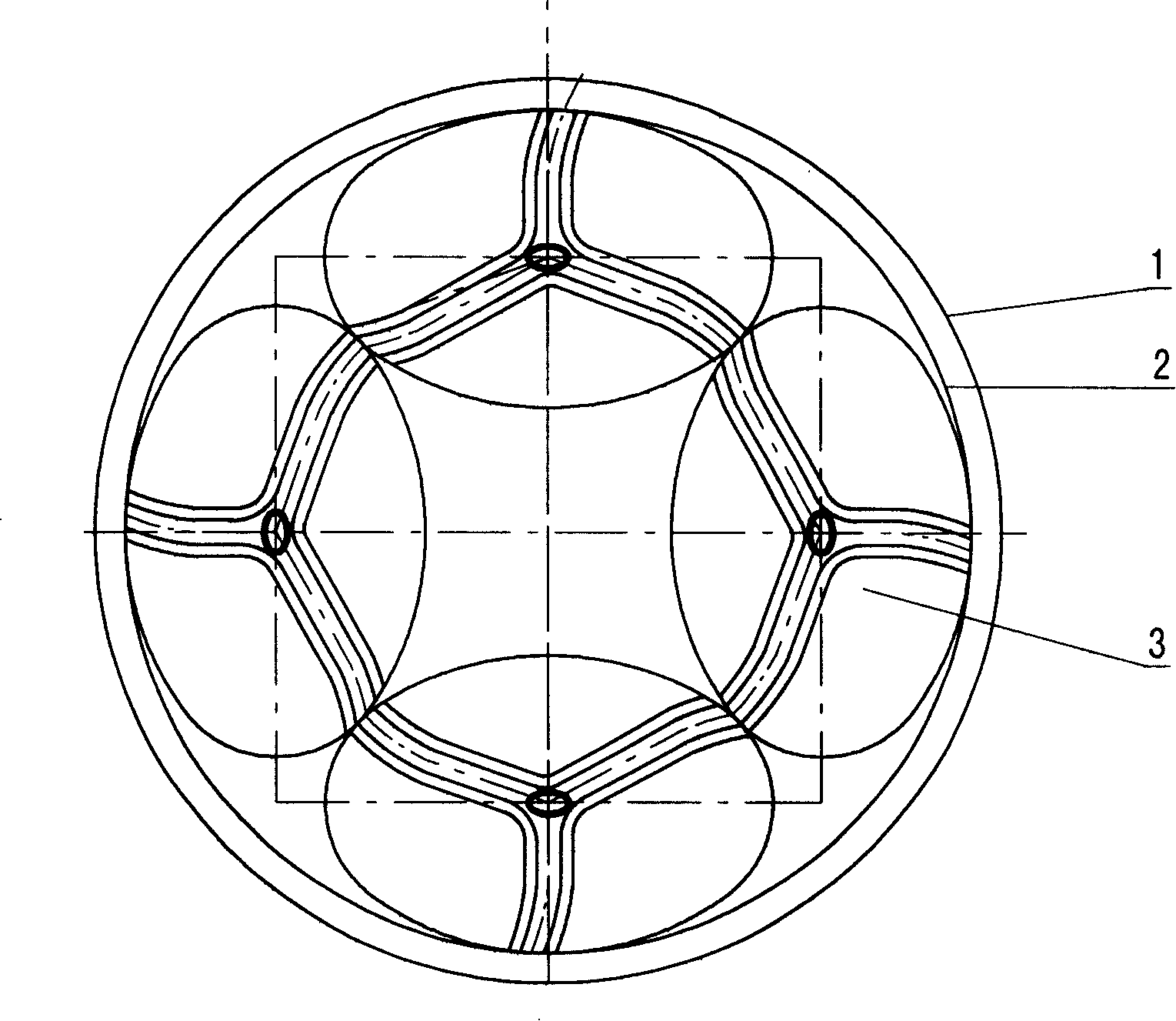

Vertical multi-impeller washing machine and washing method

InactiveCN101191285ASolve the entanglementImprove cleanlinessWashing machine with receptaclesTextiles and paperImpellerEngineering

The invention relates to a vertical multi-impeller washing machine which comprises an inner barrel, an outer barrel, impellers, a motor, a speed reducer and a transmission gear. The invention is characterized in that: the impellers are three or four impellers which are pivotally arranged on the periphery of the inner wall of the inner barrel and correspondingly arranged at 120 DEG or 90 DEG; the impellers take the shape of a basin and are provided with convex ribs with smooth edges; gear rings are arranged on reverse surfaces of the impellers; the transmission gear is provided with three or four output shafts on which the impellers are arranged. A washing method of the invention is characterized in that: during the washing process, washing can be carried out when water inlet quantity only reaches one third of impeller height, and all the impellers can rotate positively or reversely simultaneously for washing clothes. Due to adoption of multi-impeller structure, the clothes can be overturned and thrown in the three-dimensional direction, thereby effects of non winding, high cleanliness and low abrasion are realized. Because the inner barrel and the outer barrel are designed into the shape of a basin and the size of the bottom part of the outer barrel is small, the aim of water conservation is reached.

Owner:HEFEI GOOLU TECH WASHER

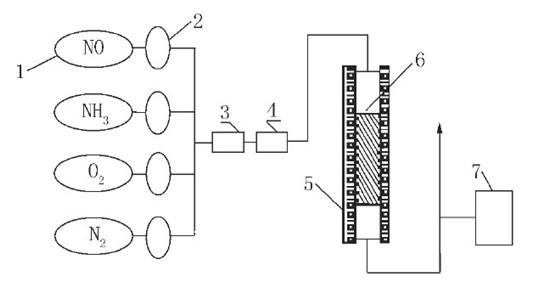

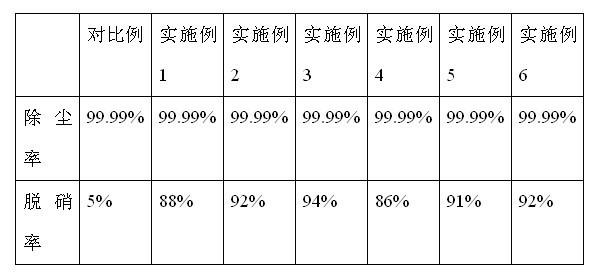

Preparation method of denitration-catalyst-supported polyphenylene sulfide (PPS) filter material

InactiveCN102145241AImprove denitrification rateImprove water resistanceDispersed particle filtrationOrganic-compounds/hydrides/coordination-complexes catalystsFiberPtru catalyst

The invention provides a supported polyphenylene sulfide (PPS) filter material which belongs to the field of filter materials. The supported PPS filter material is prepared by the following method: making a PPS fiber into a PPS filter material; performing water bath acidification in nitric acid, and washing with deionized water to neutrality; drying to obtain acidified polyphenylene sulfide nitride (PPSN); preparing a catalyst into a solution and stirring; soaking PPSN in the solution; performing water bath baking, and drying in air; and calcining in a nitrogen atmosphere to obtain the supported PPS filter material with denitration function. The denitration-catalyst-supported PPS filter material provided by the invention can be used as a dedusting agent and a denitration agent at the sametime, is prepared by simple steps, realizes dedusting and denitration functions as well, and has the advantages of high denitration rate, high temperature resistance, acid-base resistance, good waterresistance, long service life and the like; and a new application field of the filter-bag catalytic denitration is created.

Owner:FUZHOU UNIV

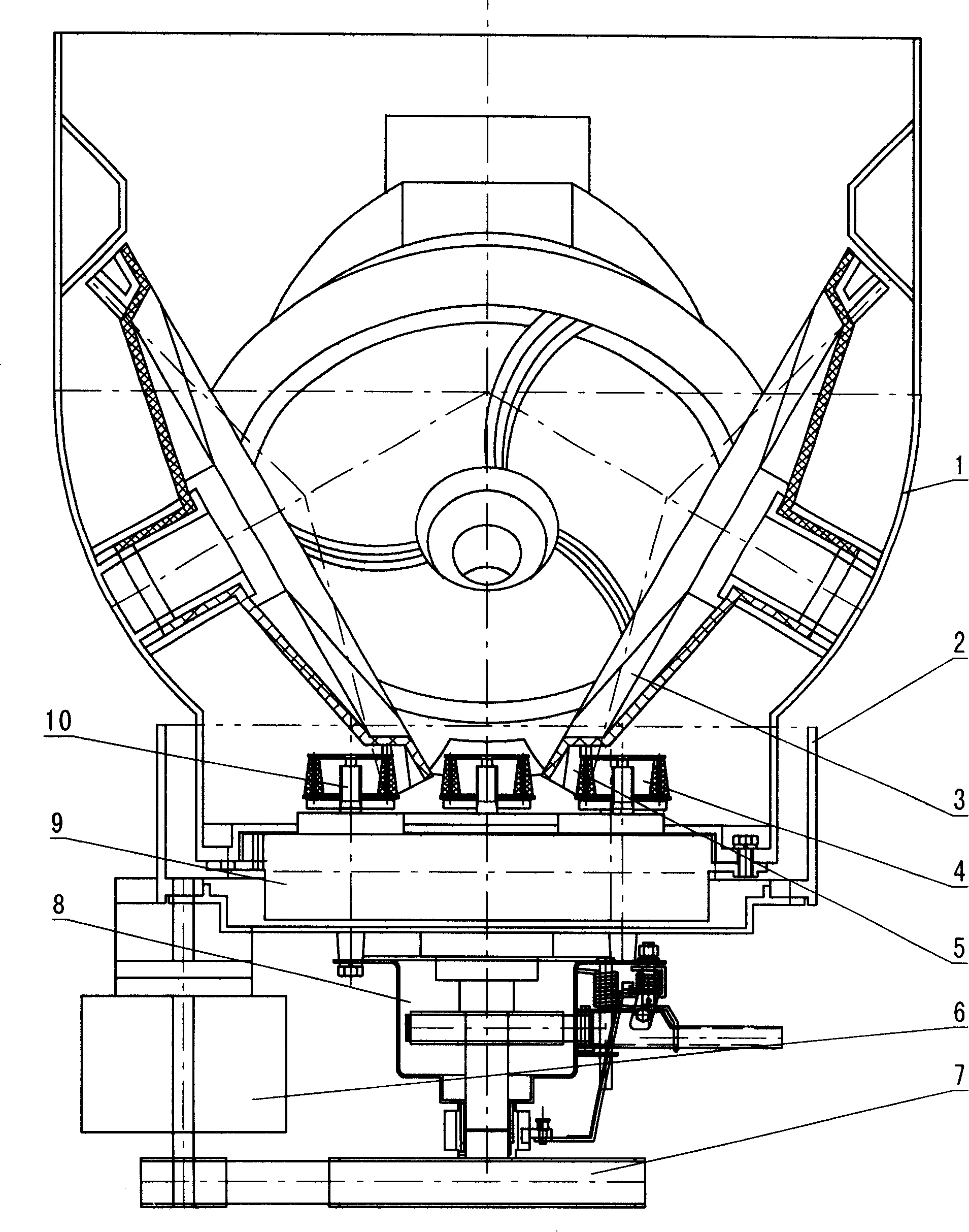

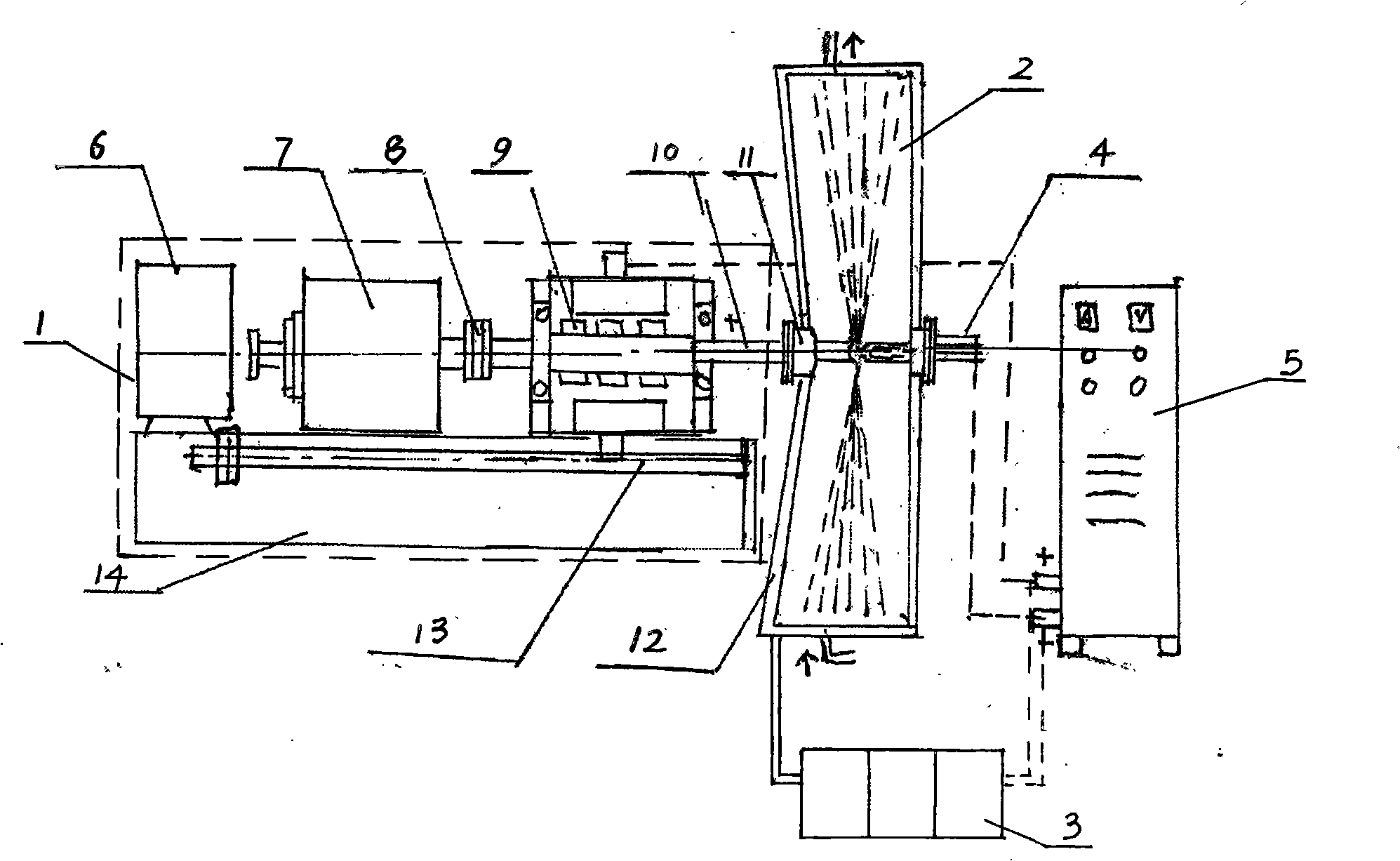

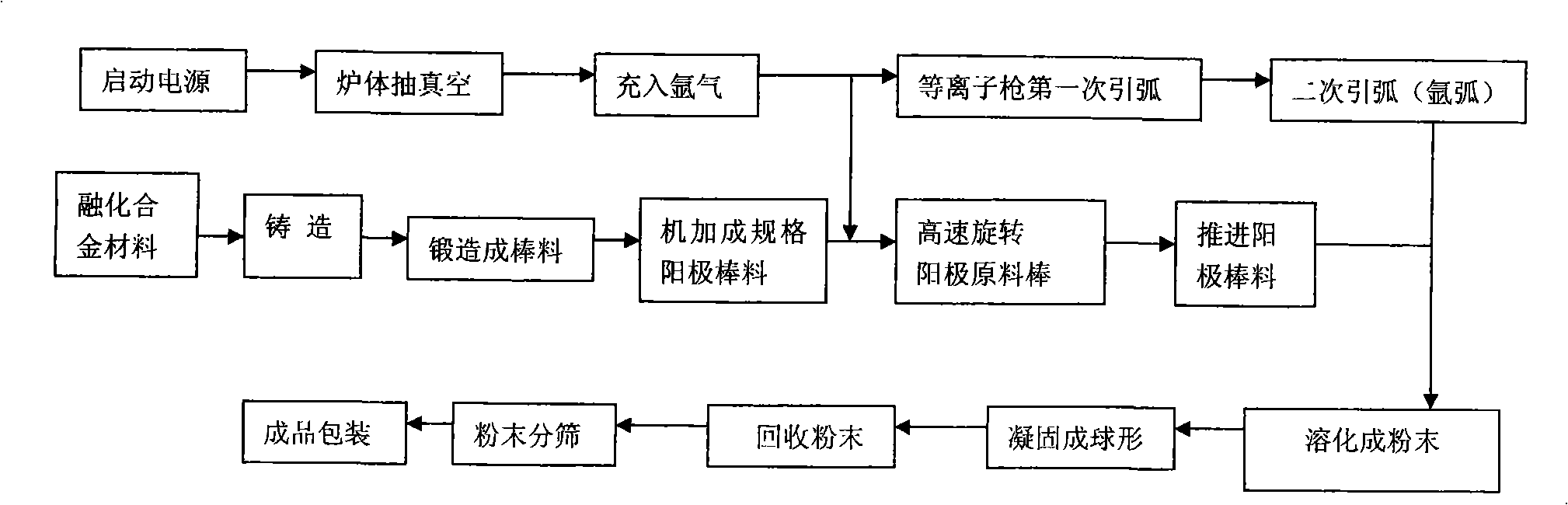

Plasma rotating electrode milling machine group and technique

The invention relates to a plasma rotary electrode powder milling set and a process thereof, relating to the technical field of powder metallurgy. The milling set comprises a rotating feeding mechanism, a vacuum furnace, a vacuum unit, a plasma gun device and an electrical source. The rotating feeding mechanism is arranged at the exterior of one side of the vacuum furnace; the plasma gun device is arranged at the interior of the other side of the vacuum furnace; the vacuum unit is communicated with the vacuum furnace through a ventilation pipe, wherein, the vacuum furnace body has a double-decker sandwich structure, and cooling circulating water is injected into the sandwich structure; a receiving mechanism is arranged at the bottom part of the vacuum furnace, wherein, the receiving mechanism comprises two cut-off valves connected in series. The process includes the following steps: metal is processed into electrode bars; low-voltage heavy current is applied to the electrode bars to melt the electrode bars in a highly vacuumized melting chamber through the high temperature produced by the cathode arc of the plasma gun, and to eject the molten metal instantly by the strong centrifugal force produced through the high-speed rotation of the electrode bars to produce fine metal powders. The invention is characterized in that the yield of perfect spherical metal powders is up to 97 percent, and the powders are free from the contamination of any microelement.

Owner:张建利

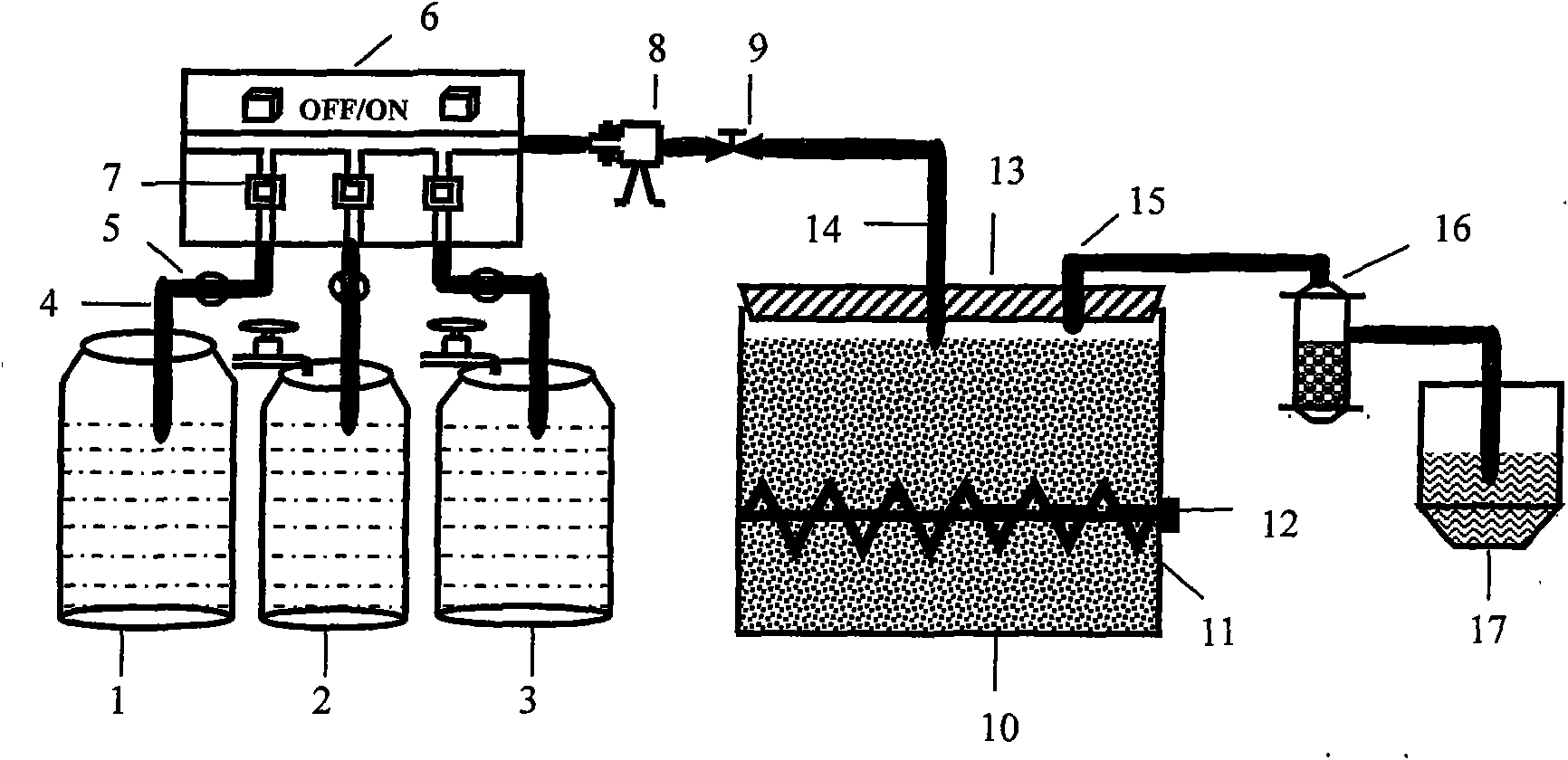

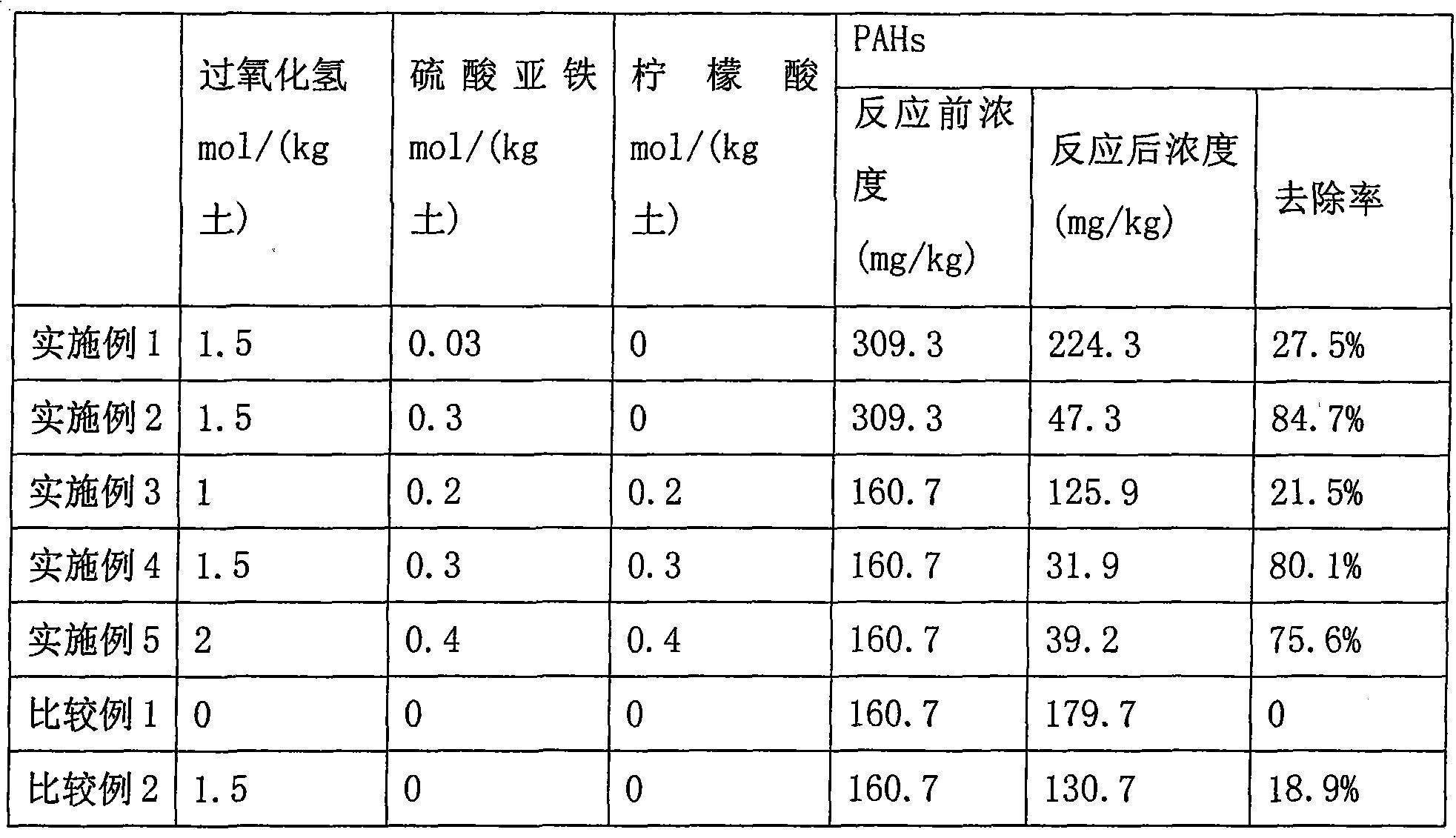

Chemical oxidation remediation method for organism-contaminated soil and remediation device

ActiveCN101648207AIncrease contactAvoid secondary pollutionContaminated soil reclamationContaminated soilsSoil remediation

The invention relates to a chemical oxidation remediation method for organism-contaminated soil and a remediation device. The device comprises an oxidant pot, a catalyst pot, a chelating agent pot, aflexible pipe, an electric valve, a control apparatus, a valve switch, a pump, a flow valve, a reactor, a stirrer, a stirrer switch, a sealing cover, a liquid inlet pipe, an exhaust pipe, a gas-liquidseparating apparatus and a tail gas treating apparatus. The method comprises the following steps: placing contaminated soil into the reactor; firstly injecting 0.03-0.4mol / (kg soil) of citric acid into the reactor through the chelating agent pot; then adding 0-0.4mol / (kg soil) of catalyst ferrous sulfate in the catalyst pot, and adding water to be dissolved to prepare 0.5mol / l of catalyst; injecting the catalyst into the reactor by the pump; pumping 1-2mol / (kg soil) of oxidant hydrogen peroxide into the reactor; and fully stirring the three preparations and the contaminated soil by the stirrer in the reactor to oxidize and degrade polycyclic aromatic hydrocarbon in the soil, and the removal rate of pollutants in the soil exceeds 80 percent. The invention has high efficiency on organics-contaminated soil remediation and can not cause secondary pollution to the soil.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com