Vertical multi-impeller washing machine and washing method

A pulsator washing machine and pulsator technology, applied in the field of washing, can solve the problems such as the coaxial winding of the laundry, and achieve the effects of low wear rate, less time consumption and high cleaning degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

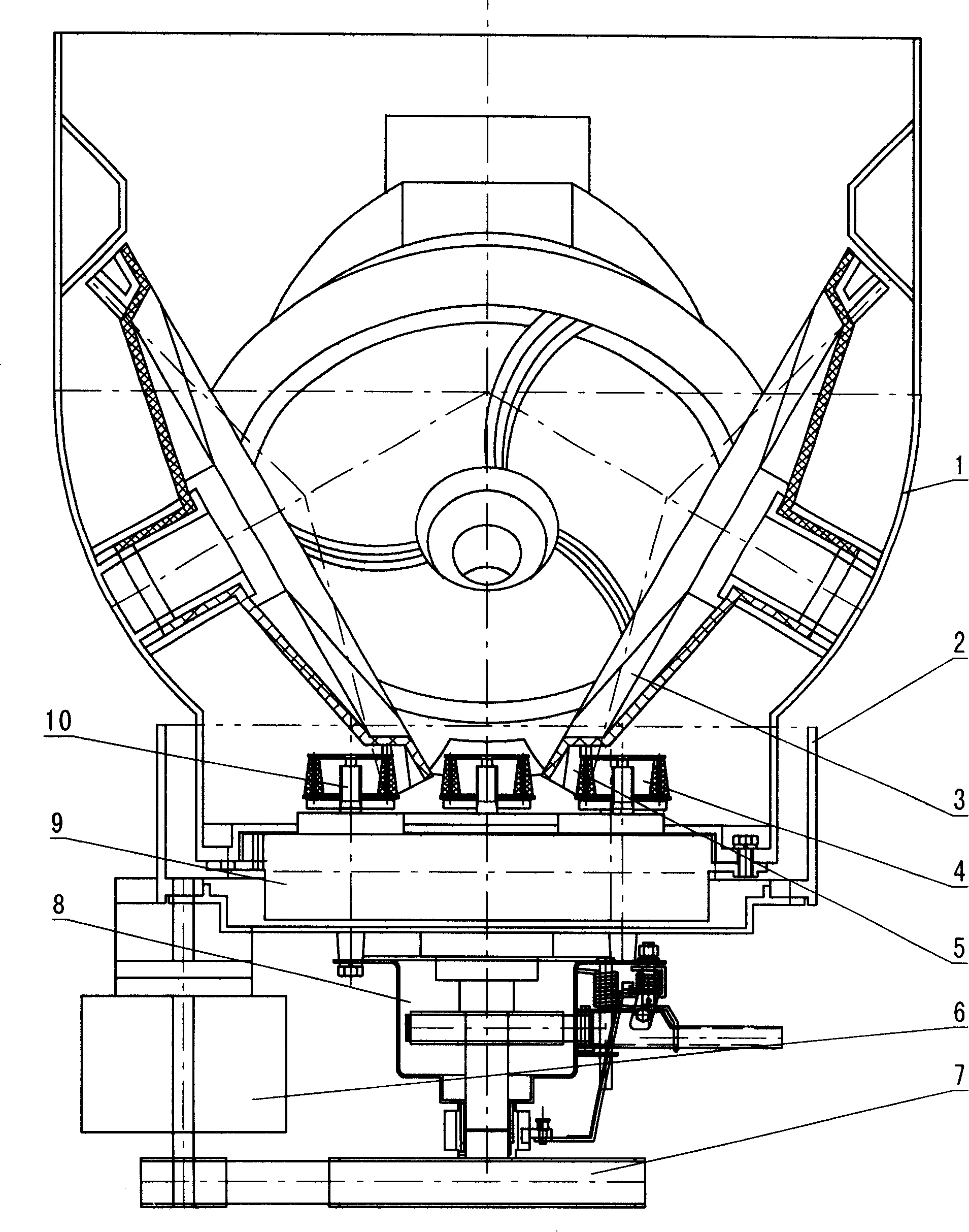

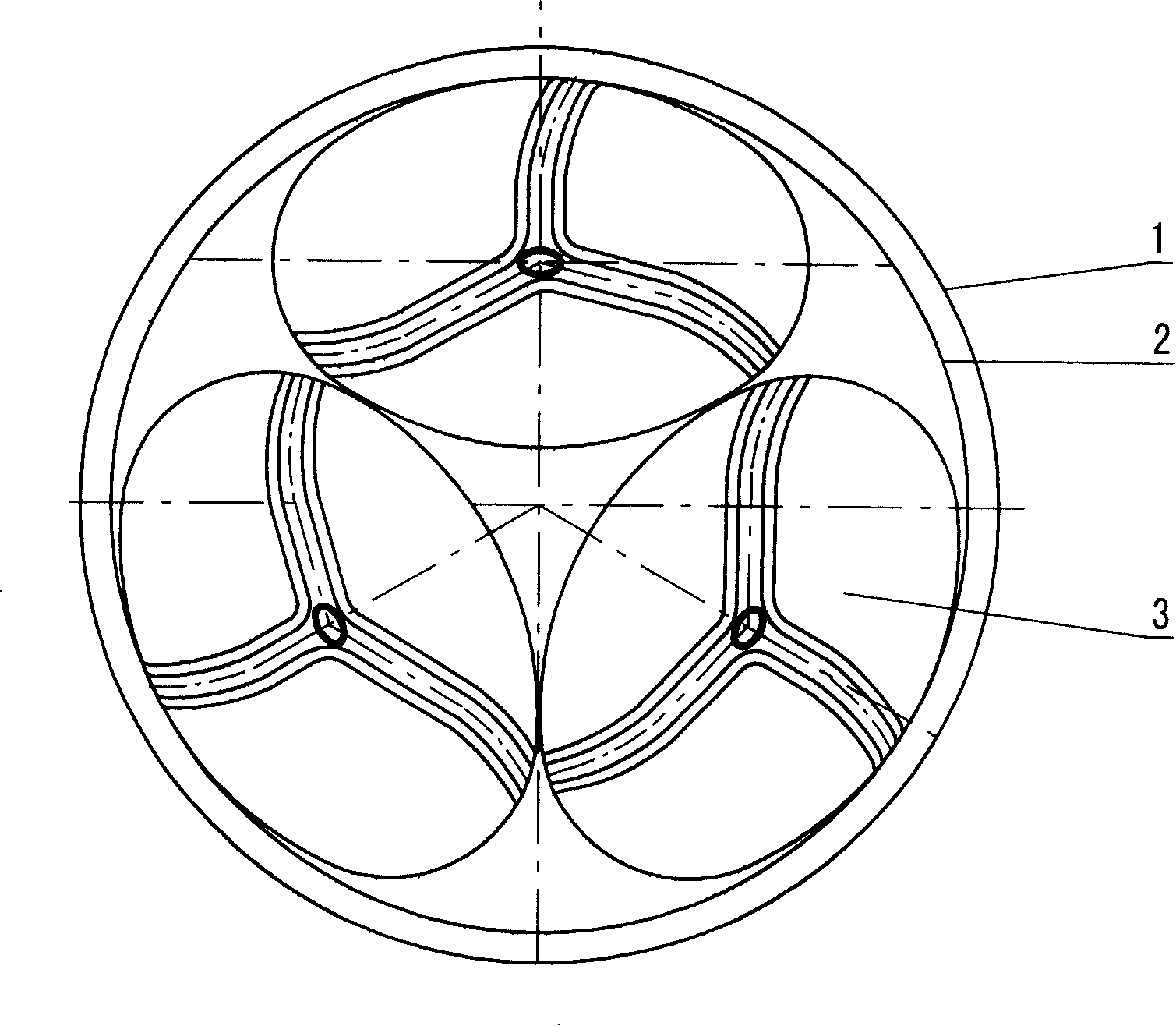

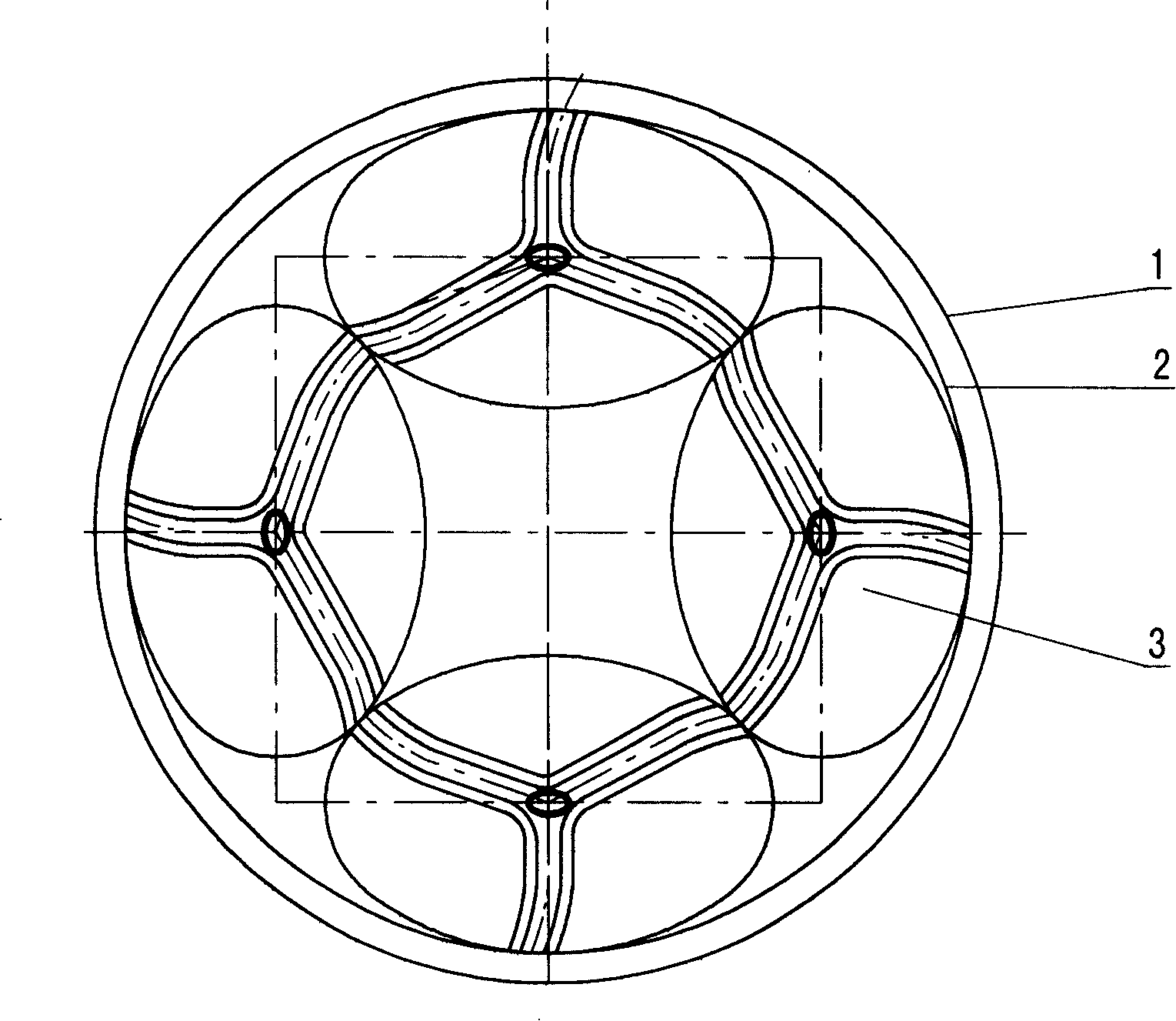

[0025] combine figure 1 , a vertical washing machine with three or four pulsators, including an inner tub 1, an outer tub 2, a pulsator 3, a motor 4, a reducer 8 and a transmission 9, the reducer 8 is connected to the transmission 9 through a shaft. The transmission device 9 has three or four output shafts 10 on which the pulsators 3 are installed. The pulsator 3 of the vertical three-wave-wheel washing machine is pivoted at 120 degrees around the inner wall of the inner tub (refer to figure 2 ). The pulsator 3 of the vertical four-wave-wheel washing machine is pivoted at 90 degrees around the inner wall of the inner tub (refer to image 3 ). The pulsator 3 is basin-shaped, and is provided with smooth arc ribs 11 (referring to Figure 4 ), the back is provided with ring gear 5. The transmission device 9 is arranged at the bottom of the inner tub 1 . Corresponding inner barrel 1 and outer barrel 2 at the fixed position of the pulsator 3 are all in the shape of a basin wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com