Preparation method of denitration-catalyst-supported polyphenylene sulfide (PPS) filter material

A technology of denitrification catalyst and polyphenylene sulfide, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low NOx adsorption and removal rate, achieve long service life, high denitrification rate, Good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

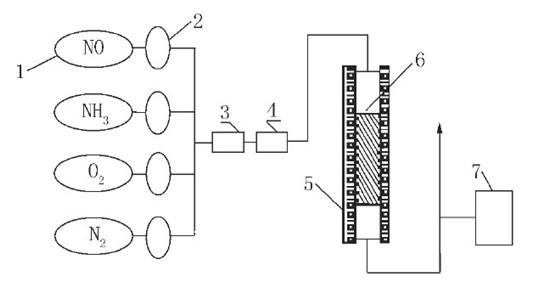

Image

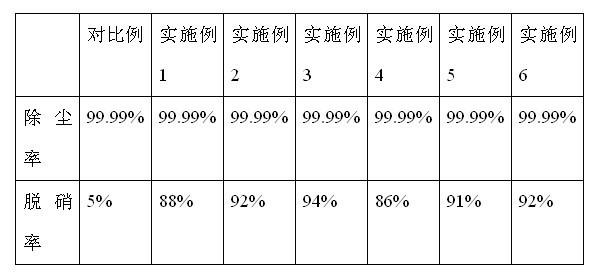

Examples

Embodiment 1

[0040] Take 2g of PPS filter material and immerse in 30% nitric acid at 80°C for 1 hour to acidify, and use 500ml of deionized water to neutralize it to obtain PPSN with a volume of 15mL; dry it in air at 105°C for 5 hours; Manganese acetate and 0.042g citric acid were prepared into a 15mL aqueous solution, and magnetically stirred at room temperature for 1 hour; PPSN was immersed in manganese acetate and citric acid solution for 2 hours; dried in a water bath at 60°C, and then dried in air at 65°C for 5 hours , and finally dried in air at 105°C for 12 hours; calcined in nitrogen atmosphere at 350°C for 6 hours to obtain loaded MnO x Polyphenylene sulfide (PPS) filter material.

Embodiment 2

[0042] Take 2g of PPS filter material and immerse in 30% nitric acid at 80°C for 1 hour to acidify, and wash with 500ml of deionized water until neutral to obtain PPSN with a volume of 15mL; dry in air at 105°C for 5 hours; dissolve 0.245g of tetrahydrate Manganese acetate and 0.210g citric acid were mixed into 15mL aqueous solution, and magnetically stirred at room temperature for 1 hour; PPSN was immersed in manganese acetate and citric acid solution for 2 hours; dried in a water bath at 60°C, and then dried in air at 65°C for 5 hours , and finally dried in air at 105°C for 12 hours; calcined in nitrogen atmosphere at 350°C for 6 hours to obtain loaded MnO x Polyphenylene sulfide (PPS) filter material.

Embodiment 3

[0044] Take 2g of PPS filter material and immerse in 30% nitric acid at 80°C for 1 hour to acidify, and wash with 500ml of deionized water until neutral to obtain PPSN with a volume of 15mL; dry in air at 105°C for 5 hours; dissolve 0.49g of tetrahydrate Manganese acetate and 0.42g of citric acid were prepared into 15mL aqueous solution, and magnetically stirred at room temperature for 1 hour; PPSN was immersed in manganese acetate and citric acid solution for 2 hours; dried in a water bath at 60°C, and then dried in air at 65°C for 5 hours , and finally dried in air at 105°C for 12 hours; calcined in nitrogen atmosphere at 350°C for 6 hours to obtain loaded MnO x Polyphenylene sulfide (PPS) filter material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com