Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1776 results about "Bag filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

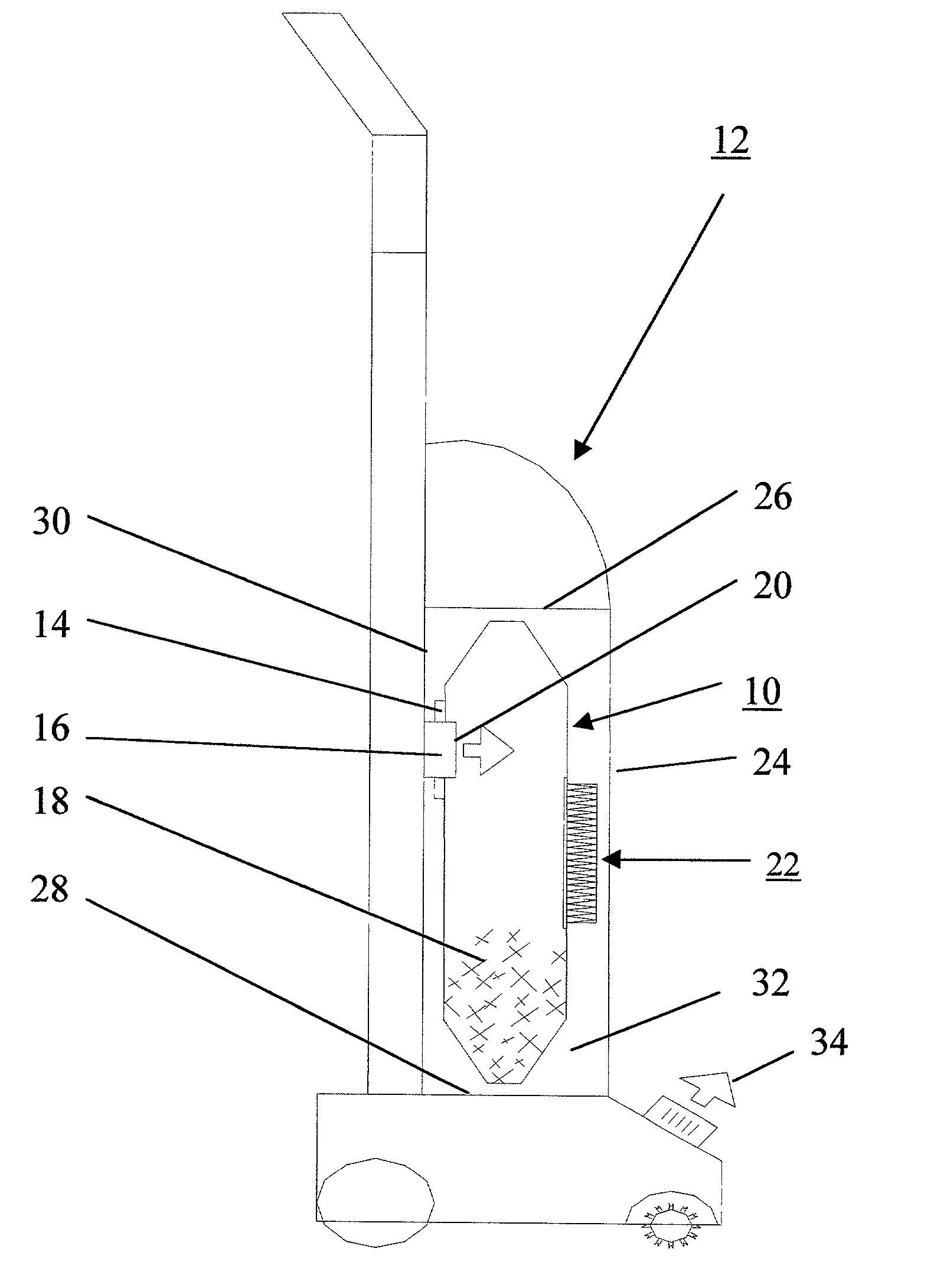

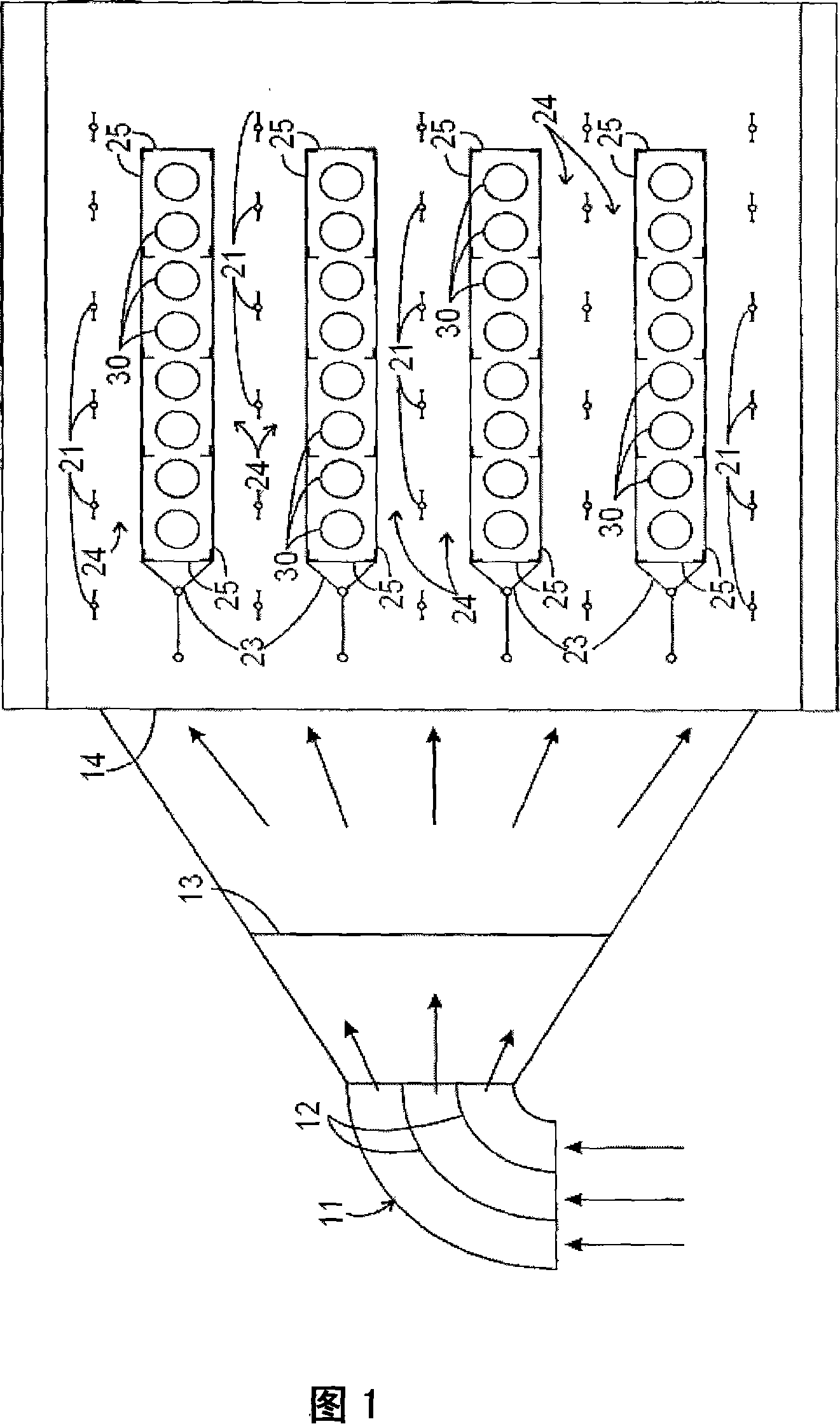

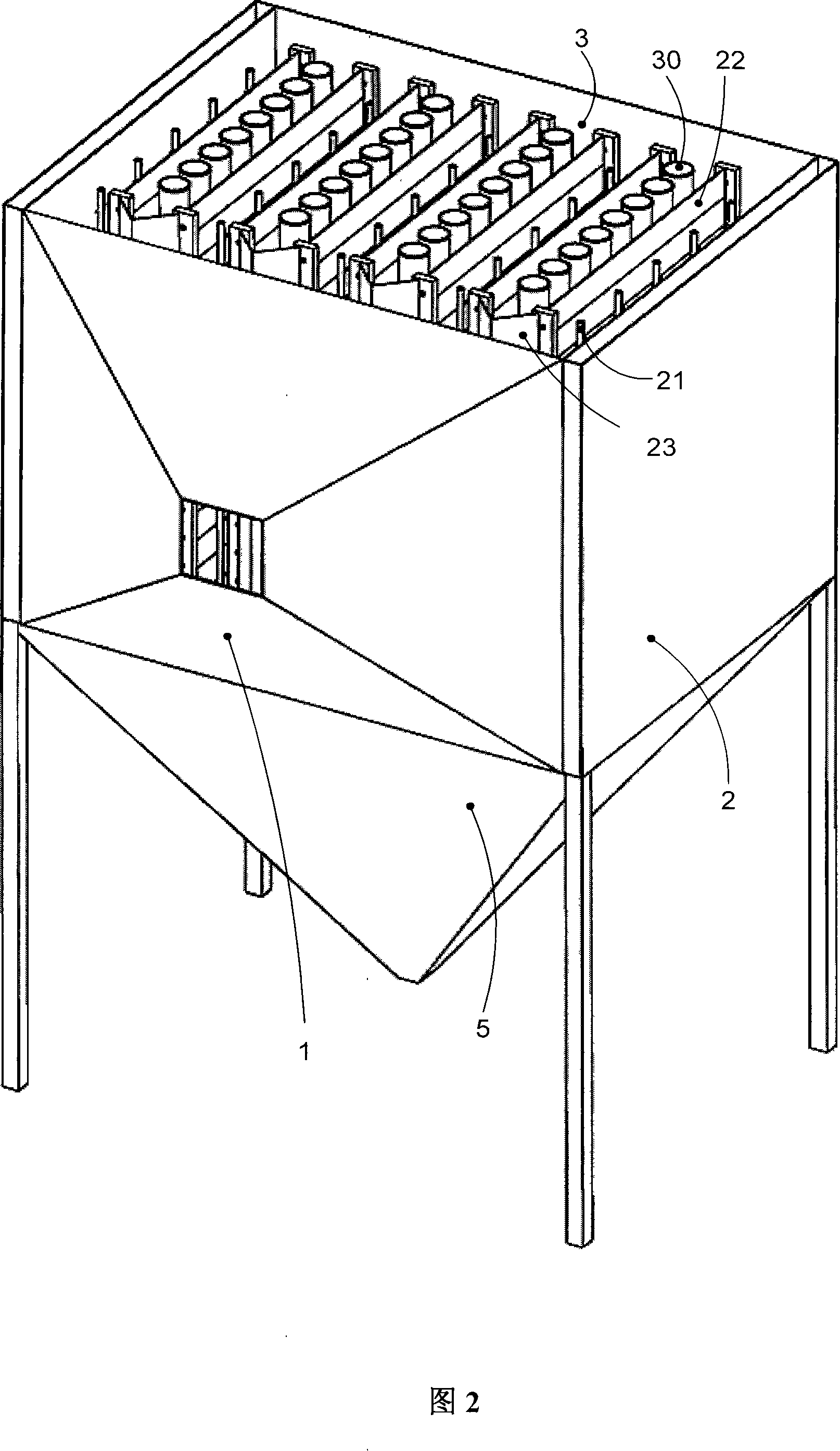

High efficiency air filter device and operating method thereof

PendingUS20190091619A1Improve efficiencyReduce energy consumptionDispersed particle filtrationTransportation and packagingAir filtrationAir filter

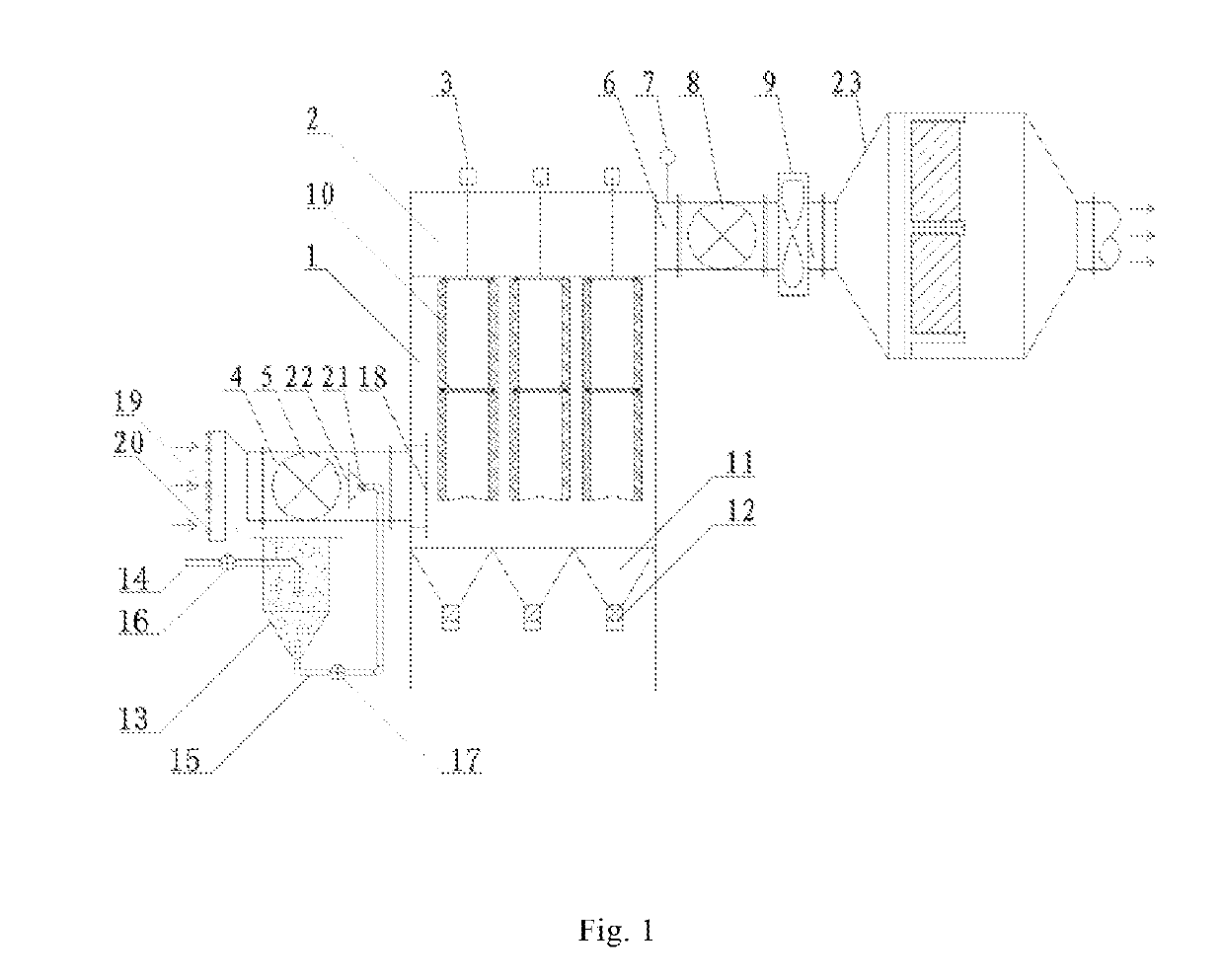

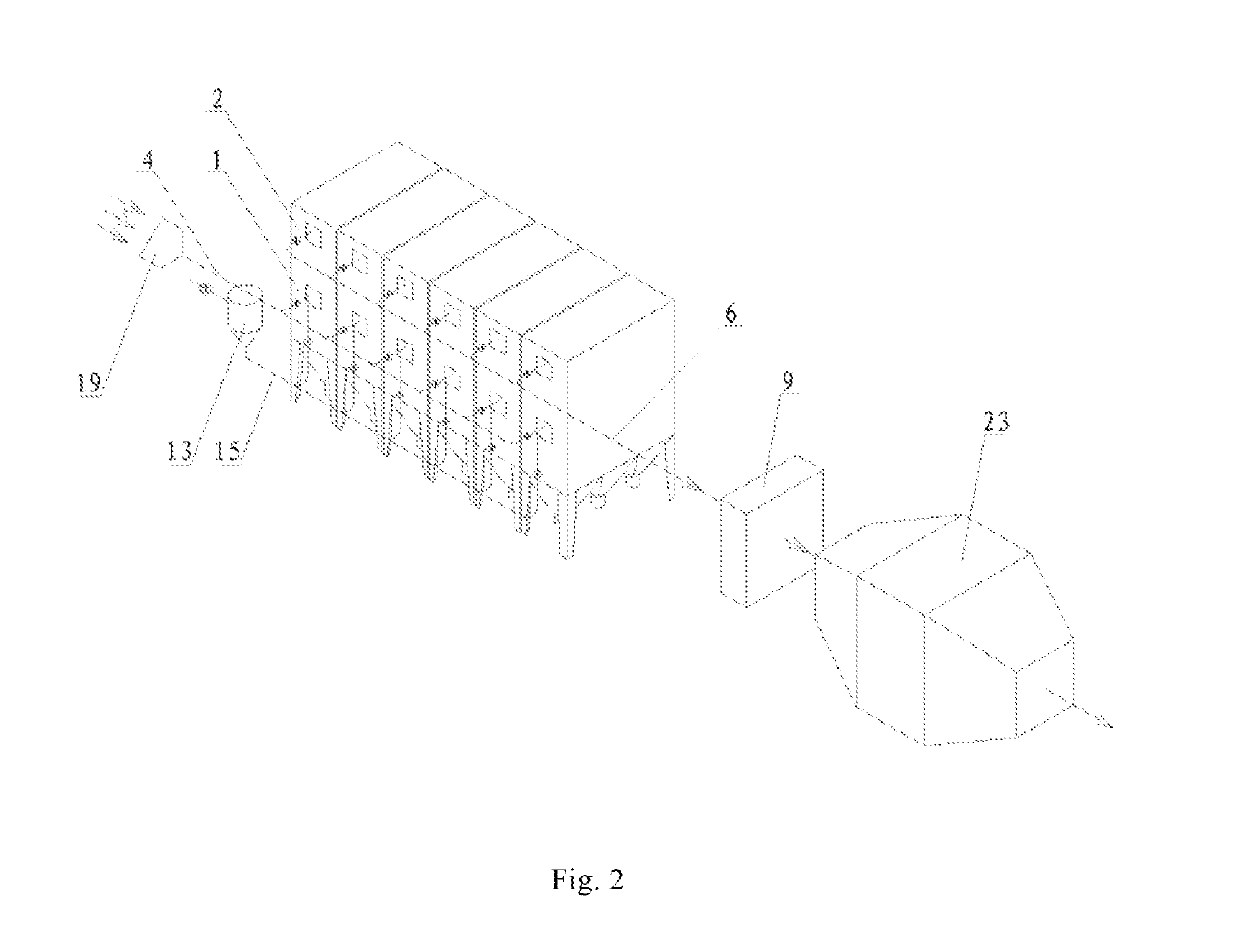

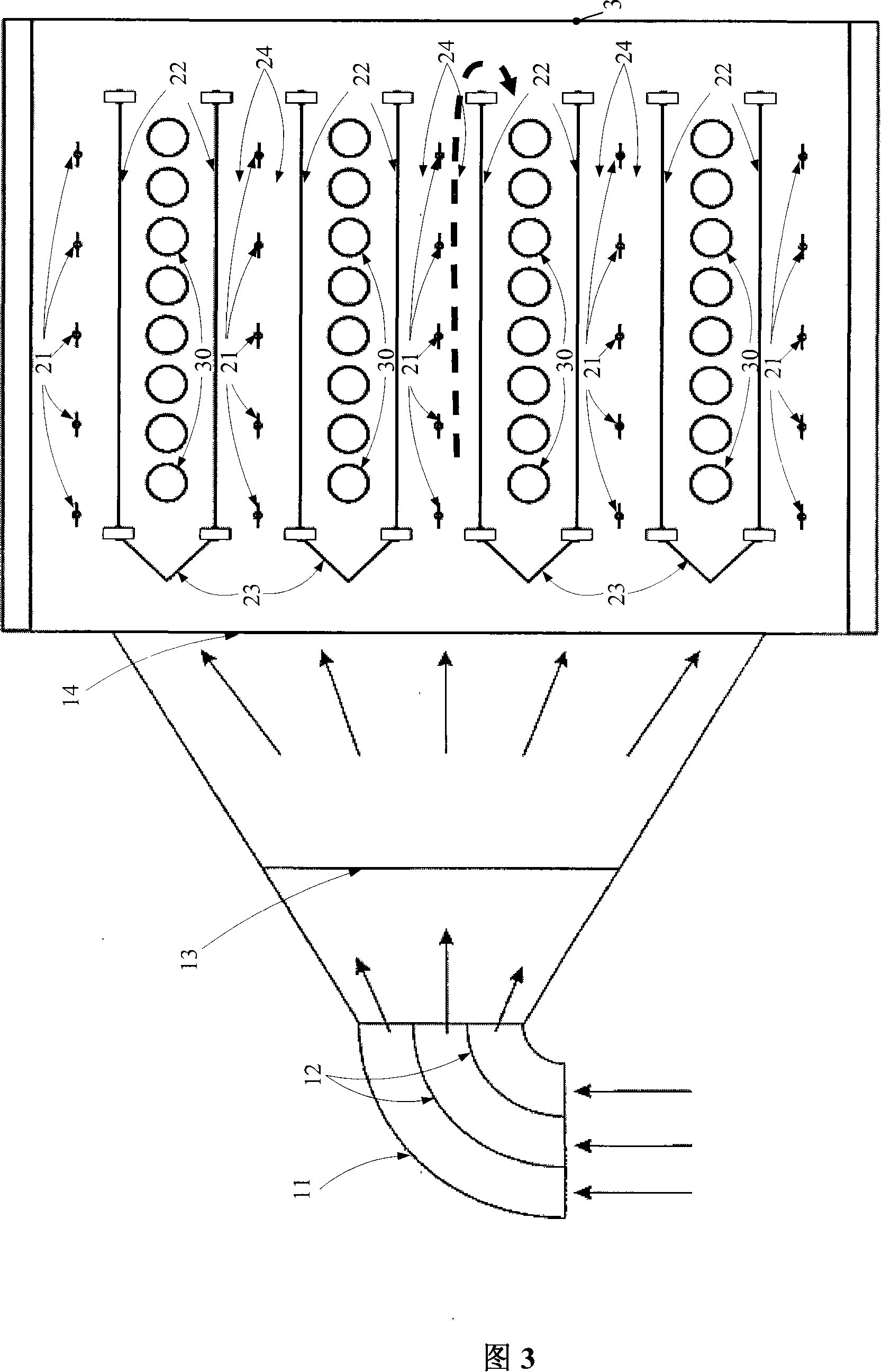

An air filter device and an operating method thereof. The air filter device comprises an air filter system and a powder distribution system. The air filter system comprises an air filter chamber (1), a clean air chamber (2), and a high-pressure jet pulse powder cleaning device (3). An entrance of the air filter chamber (1) is in communication with an air inlet pipe (4); an exit of the clean air chamber (2) is in communication with an air outlet pipe (6), and the air outlet pipe (6) is in communication with an exhaust fan (9). A plurality of bag filters or filter cartridges (10) are disposed in the air filter chamber (1). An opening end of each of the bag filters or filter cartridges (10) is in communication with the clean air chamber (2), and high-pressure jet pulse powder cleaning devices (3) are disposed above the opening end of the corresponding bag filters or filter cartridges (10). The powder distribution system includes a powder storage tank (13), which is in communication, via a powder delivery tube (15), with the air inlet pipe (4) of the air filter chamber (1). The operating method comprises a first powder distribution step and a second powder distribution step, which are respectively performed according to pressure detection status of the air filter chamber (1).

Owner:FOSHAN HUMAN HABITAT ENVIRONMENTAL PROTECTION ENG

Flue gas control system of coal combustion boiler and operating method thereof

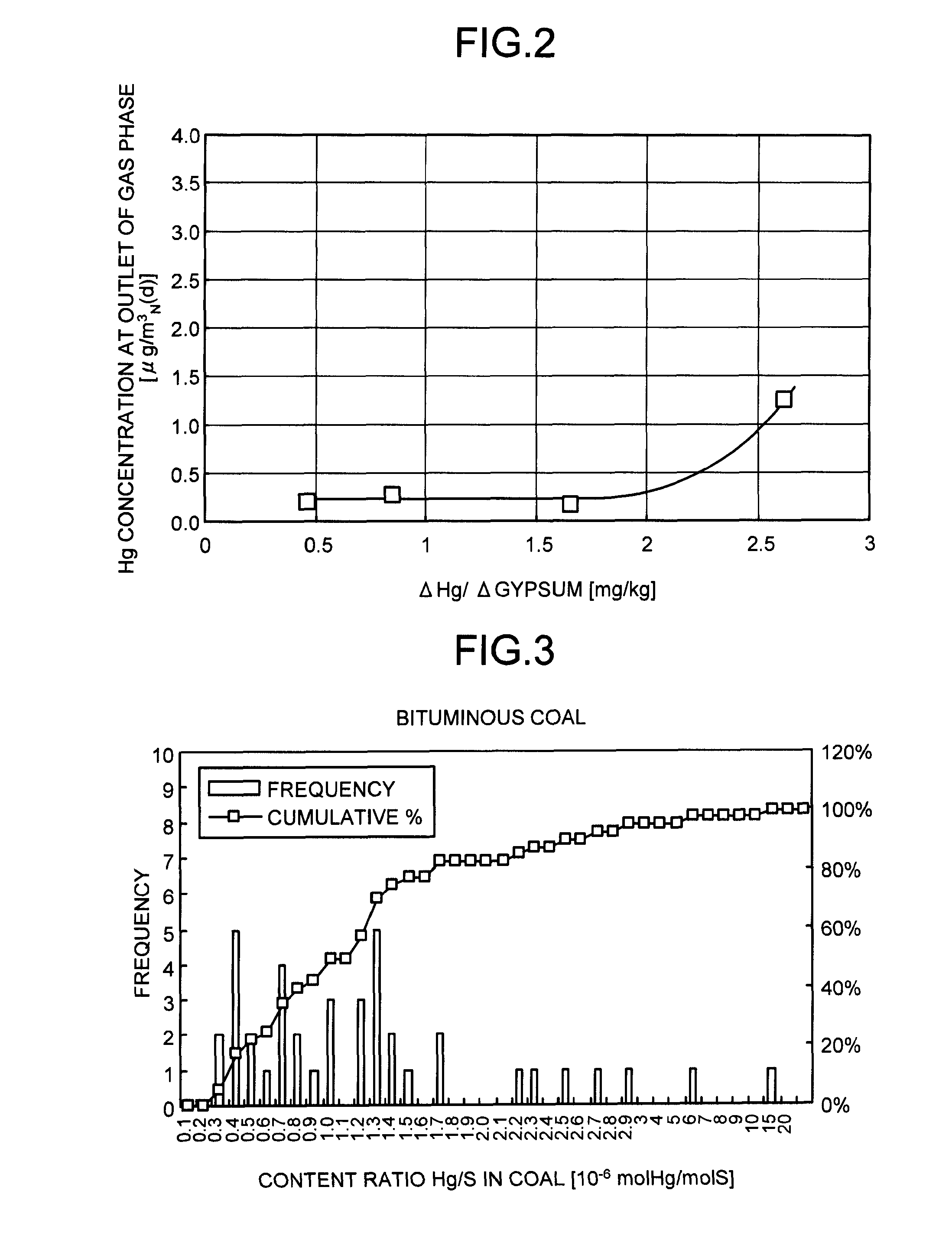

ActiveUS8071060B2Reduce operating costsCombination devicesNitrogen compoundsAir preheaterParticulates

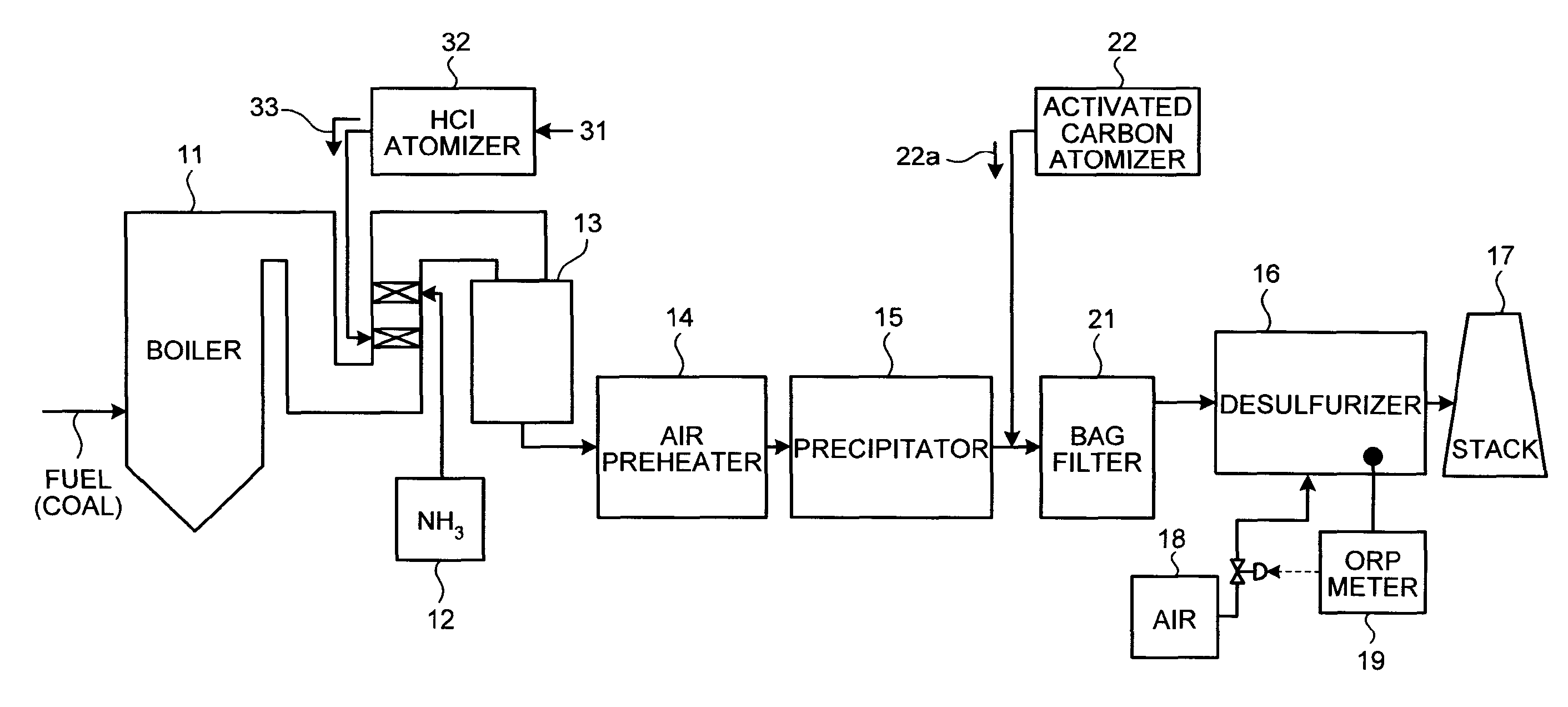

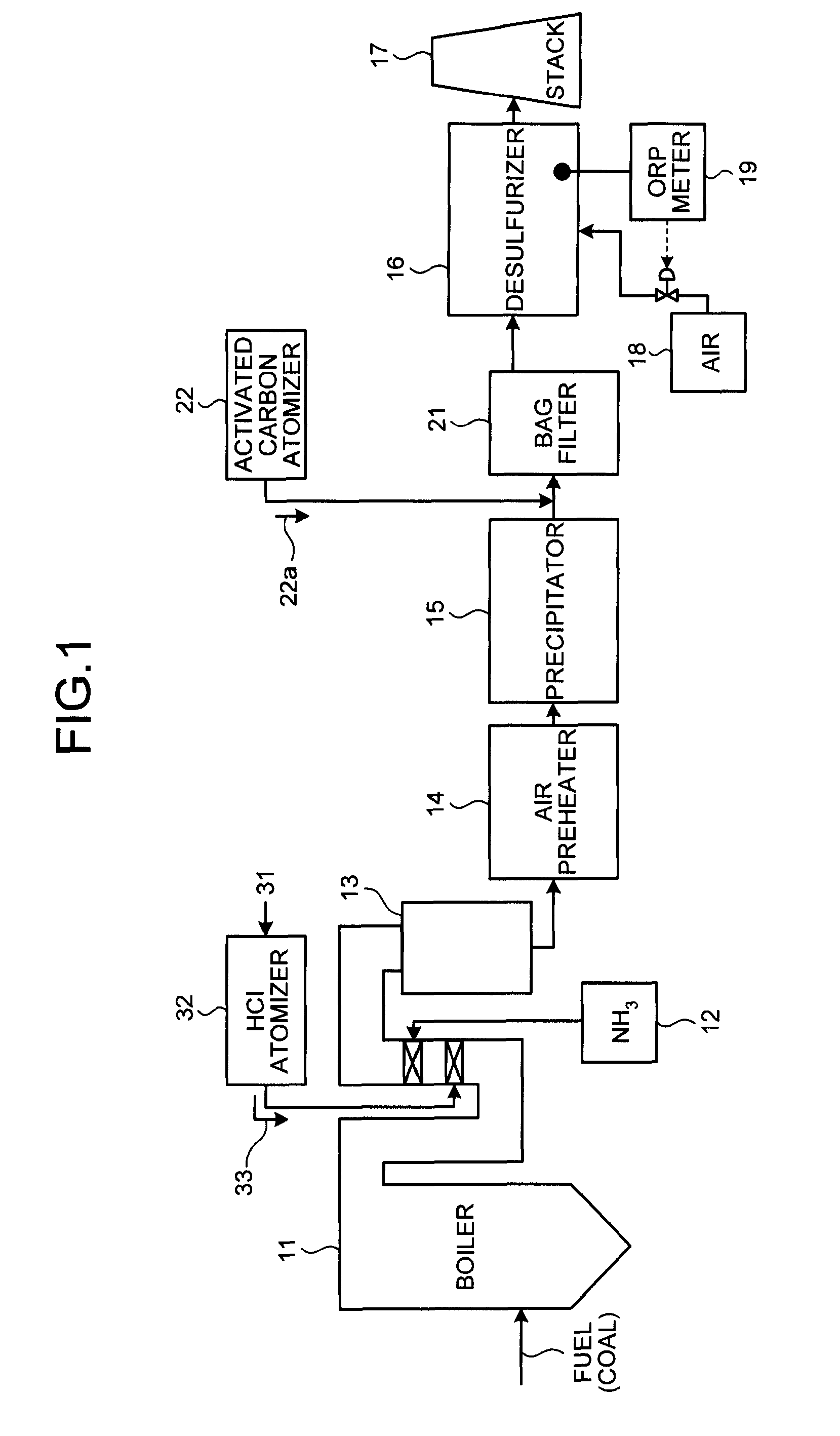

A flue gas control system of a coal combustion boiler comprises an HCl atomizer that sprays hydrogen chloride to flue gas from a coal combustion boiler that uses coal as a fuel; NOx removing apparatus that removes nitrogen oxides by ammonia denitration by adding ammonia to the flue gas after spraying hydrogen chloride and oxidizes mercury; an air preheater that recovers heat in the gas after removal of nitrogen oxides; a precipitator that removes particulates in the gas; an activated carbon atomizer that sprays activated carbon into the gas after particulate collection; a bag filter that collects activated carbon having adsorbed mercury; a desulfurizer that removes sulfur oxides in the flue gas after removal of activated carbon; a stack that discharges the gas which has undergone desulfurization to outside; and an ORP meter that measures an oxidation reduction potential for feeding air to a slurry absorbent in the desulfurizer.

Owner:MITSUBISHI HEAVY IND LTD

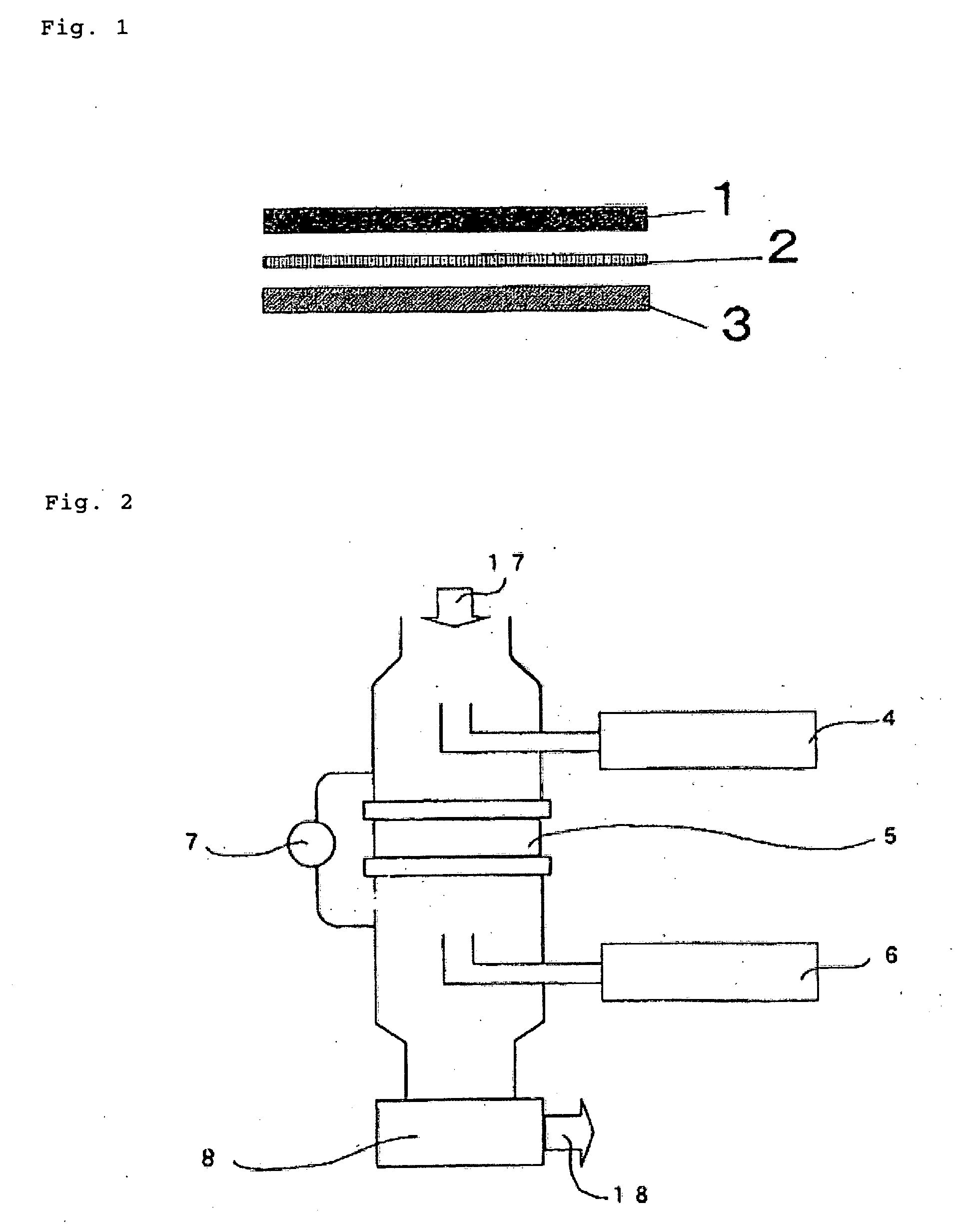

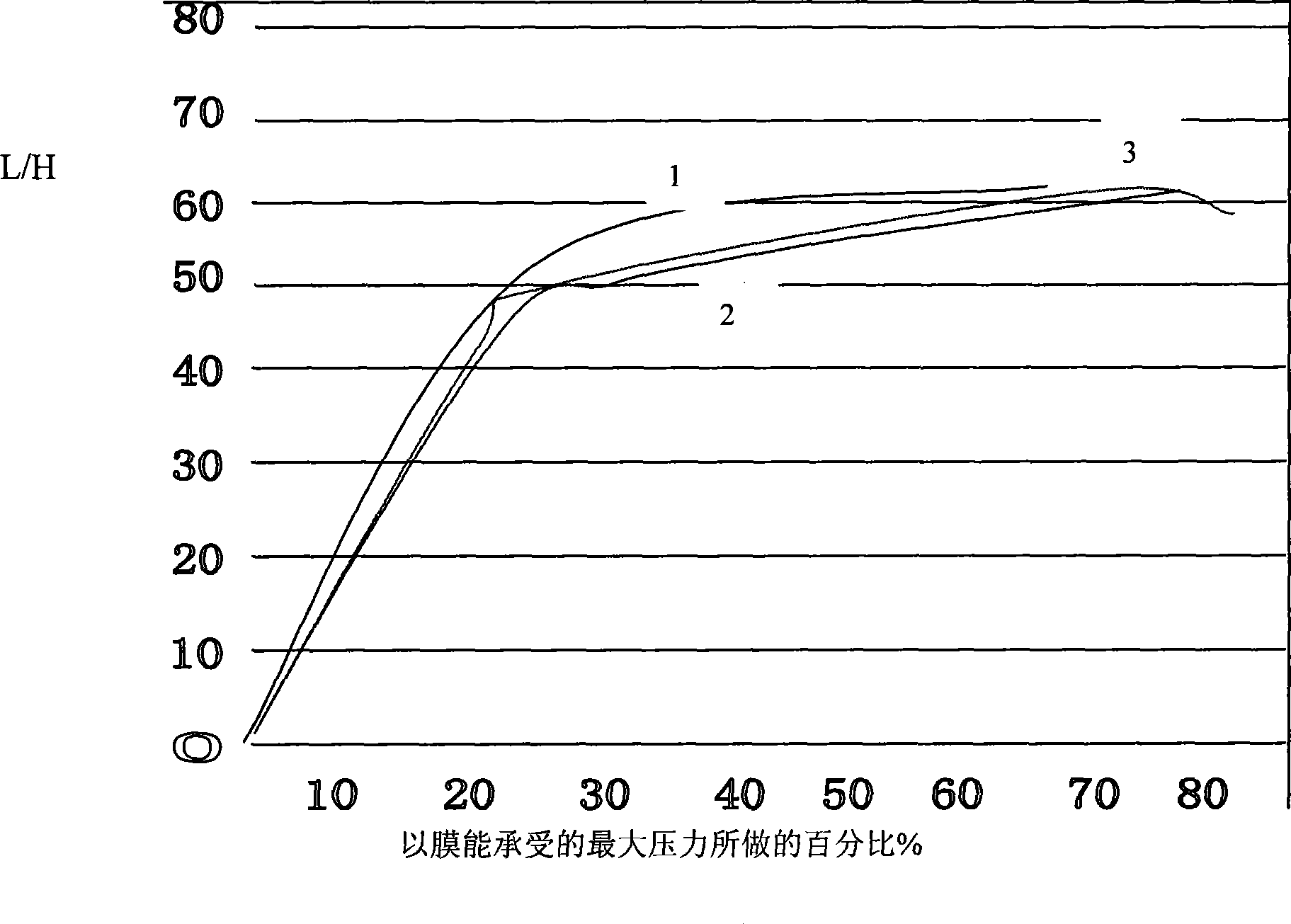

Nonwoven fabric for cylindrical bag filter, process for producing the same, and cylindrical bag filter therefrom

InactiveUS20100180558A1Excellent characteristicsImprove rigidityElectric discharge heatingDispersed particle filtrationEngineeringNonwoven fabric

The present invention provides a nonwoven fabric for cylindrical bag filter, wherein a long-fiber nonwoven fabric made of a synthetic fiber is used and the long-fiber nonwoven fabric is a long-fiber nonwoven fabric which is made of a thermoplastic continuous filament and is partially thermocompression-bonded. It is preferable that the circular arc flexural rigidity per basis weight is 0.050 to 1.000 ((cN / 2 cm) / (g / m2)) and the air permeation rate per basis weight is 0.010 to 0.500 ((cc / cm2 / sec) / (g / m2)). Further, there is provided a method for producing a nonwoven fabric for cylindrical bag filter including the steps of: melt-extruding a thermoplastic polymer through a spinneret; sucking and drawing the extrudate with an air sucker to form a thermoplastic continuous filament; allowing the filament to be subjected to electrification opening and to be piled on a moving collection surface to form a fiber web; and allowing the fiber web to be subjected to pressure welding treatment with a flat roll and partially thermocompression-bonding the fiber web with hot embossing rolls to form a long-fiber nonwoven fabric.

Owner:TORAY IND INC

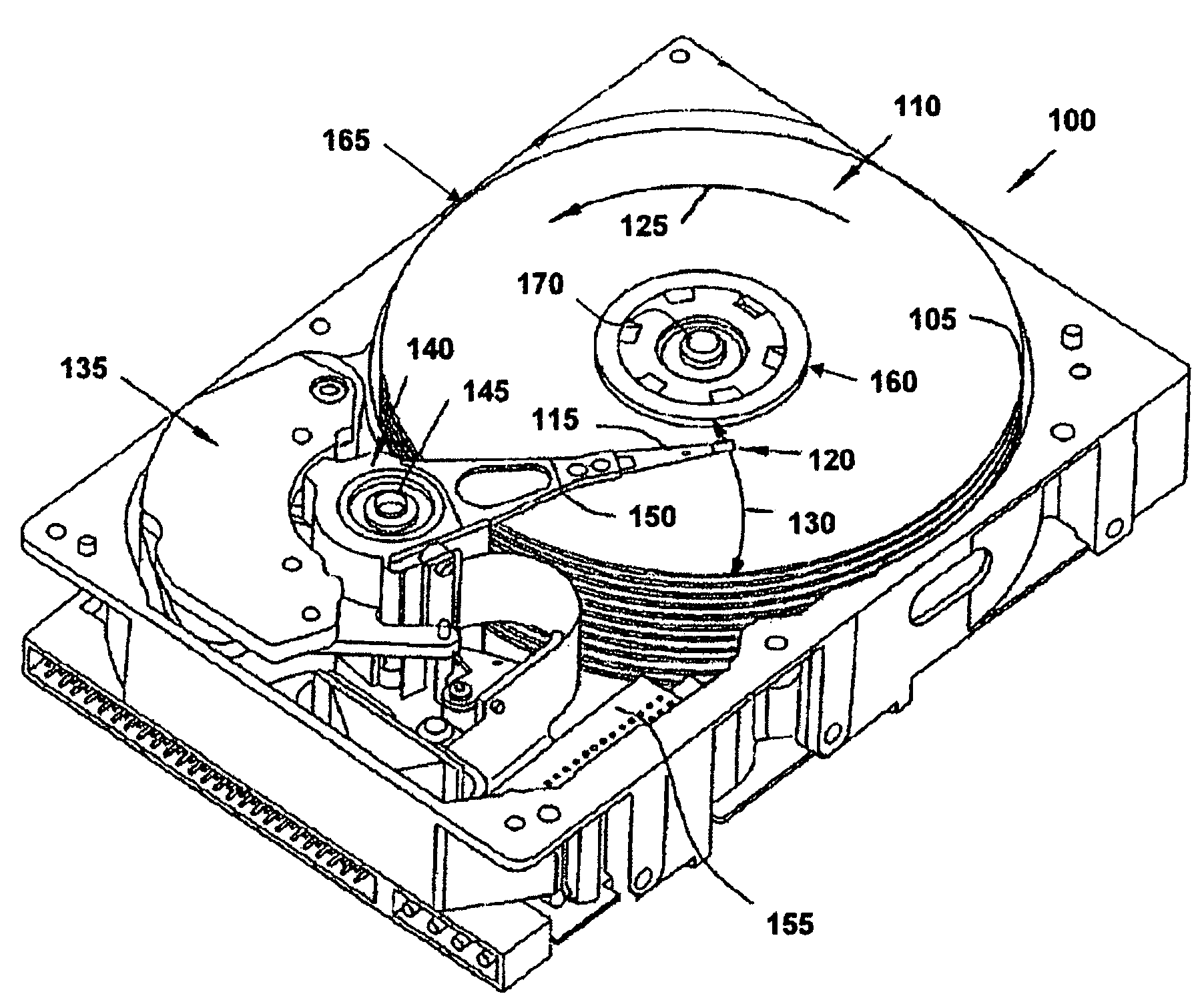

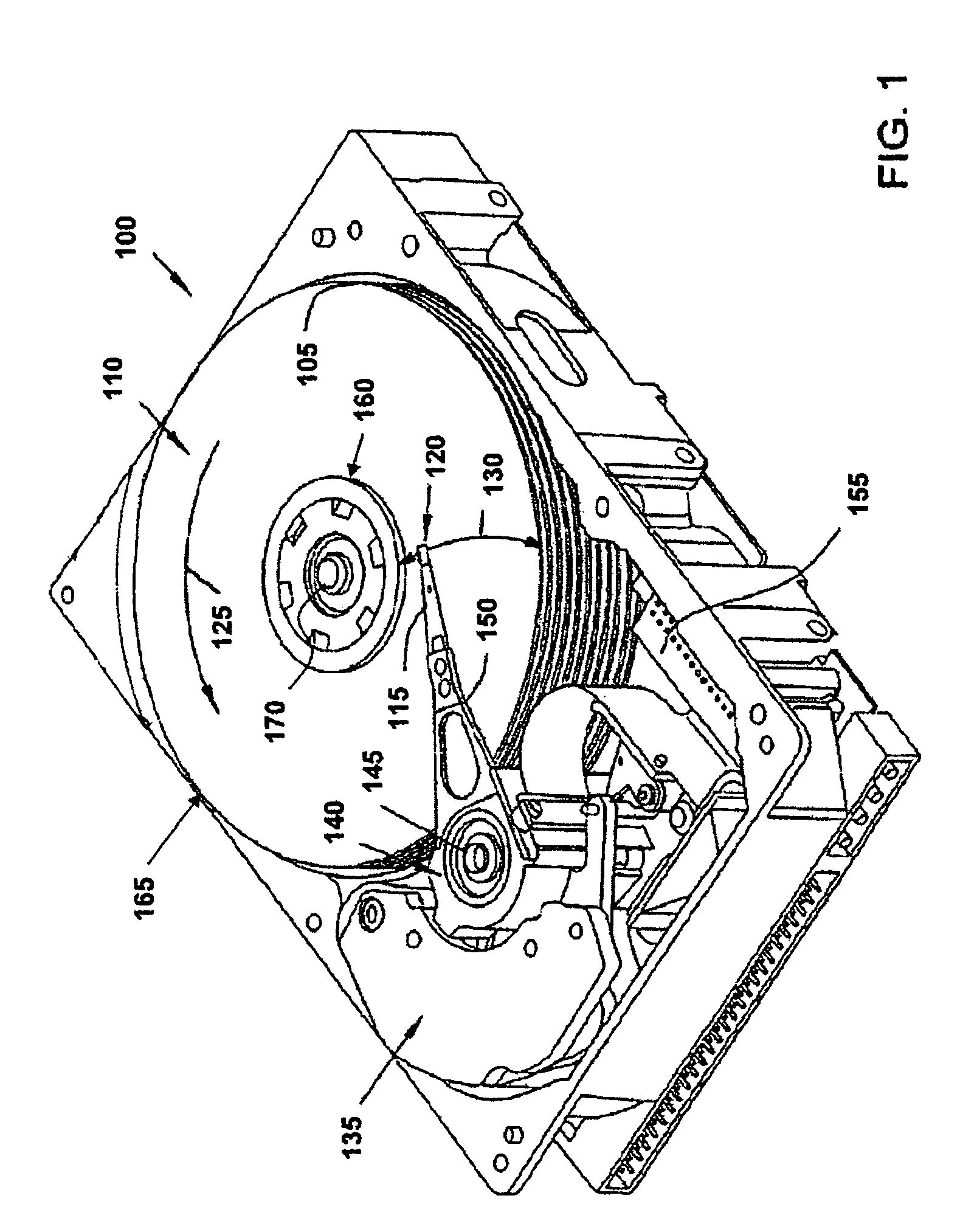

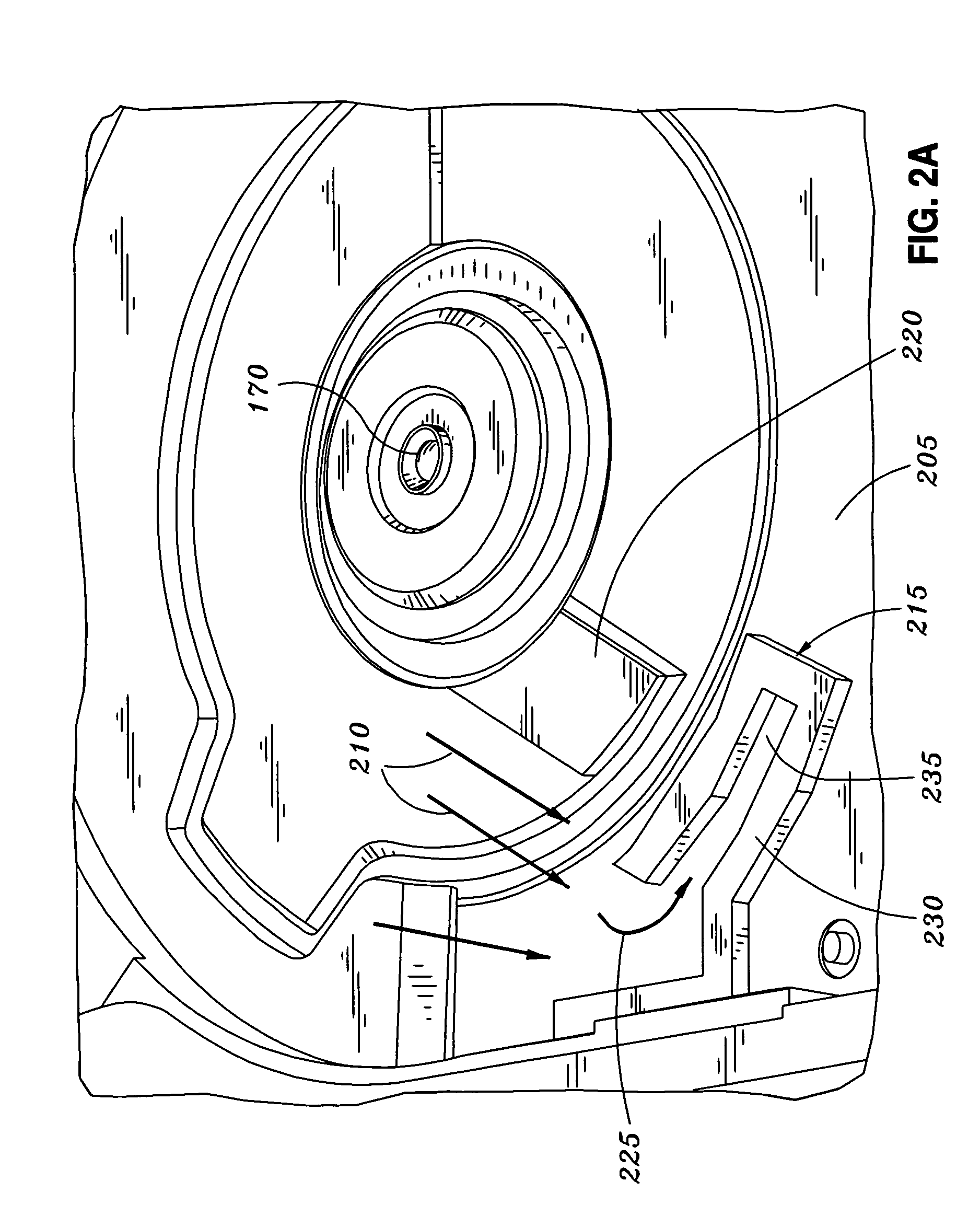

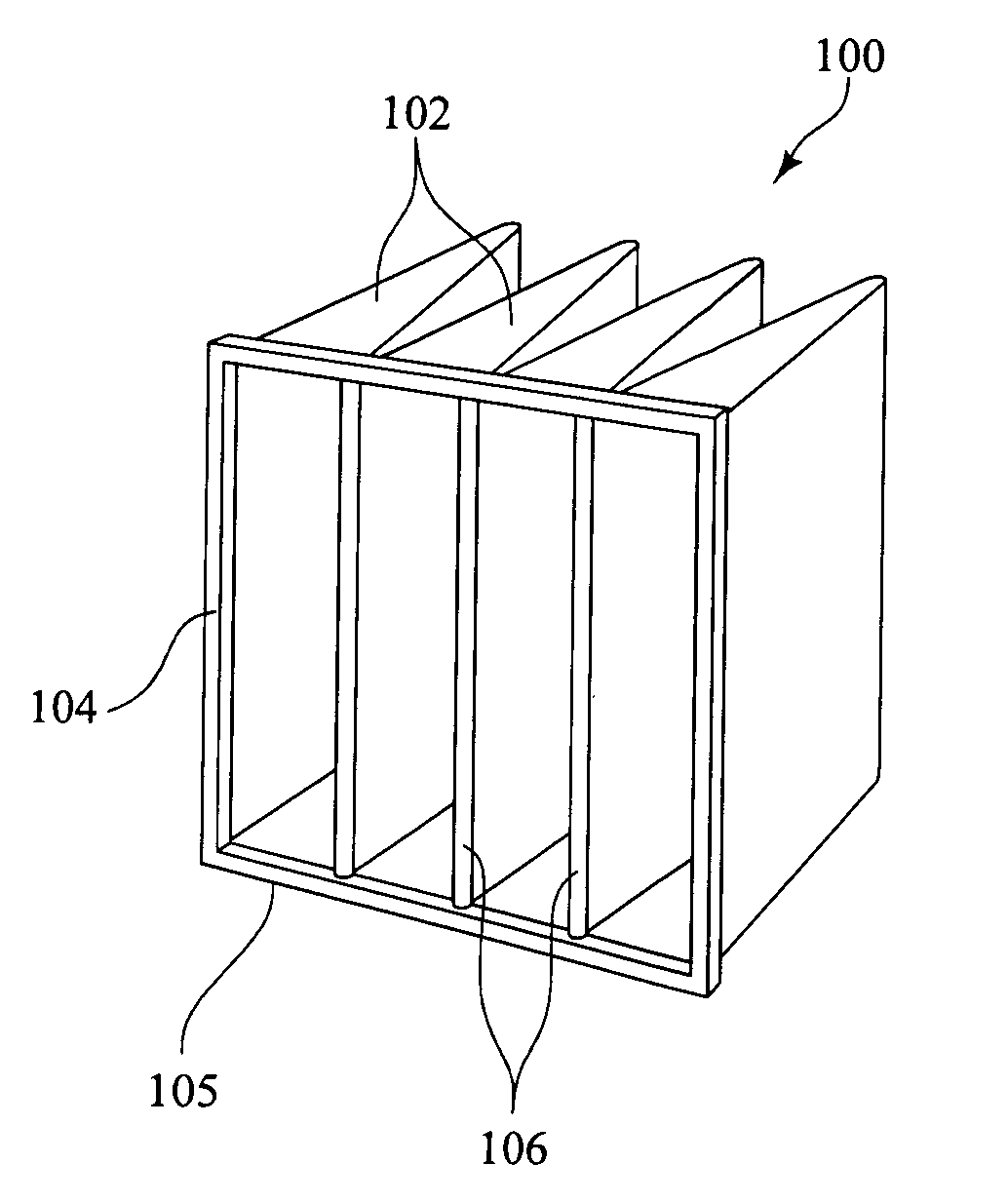

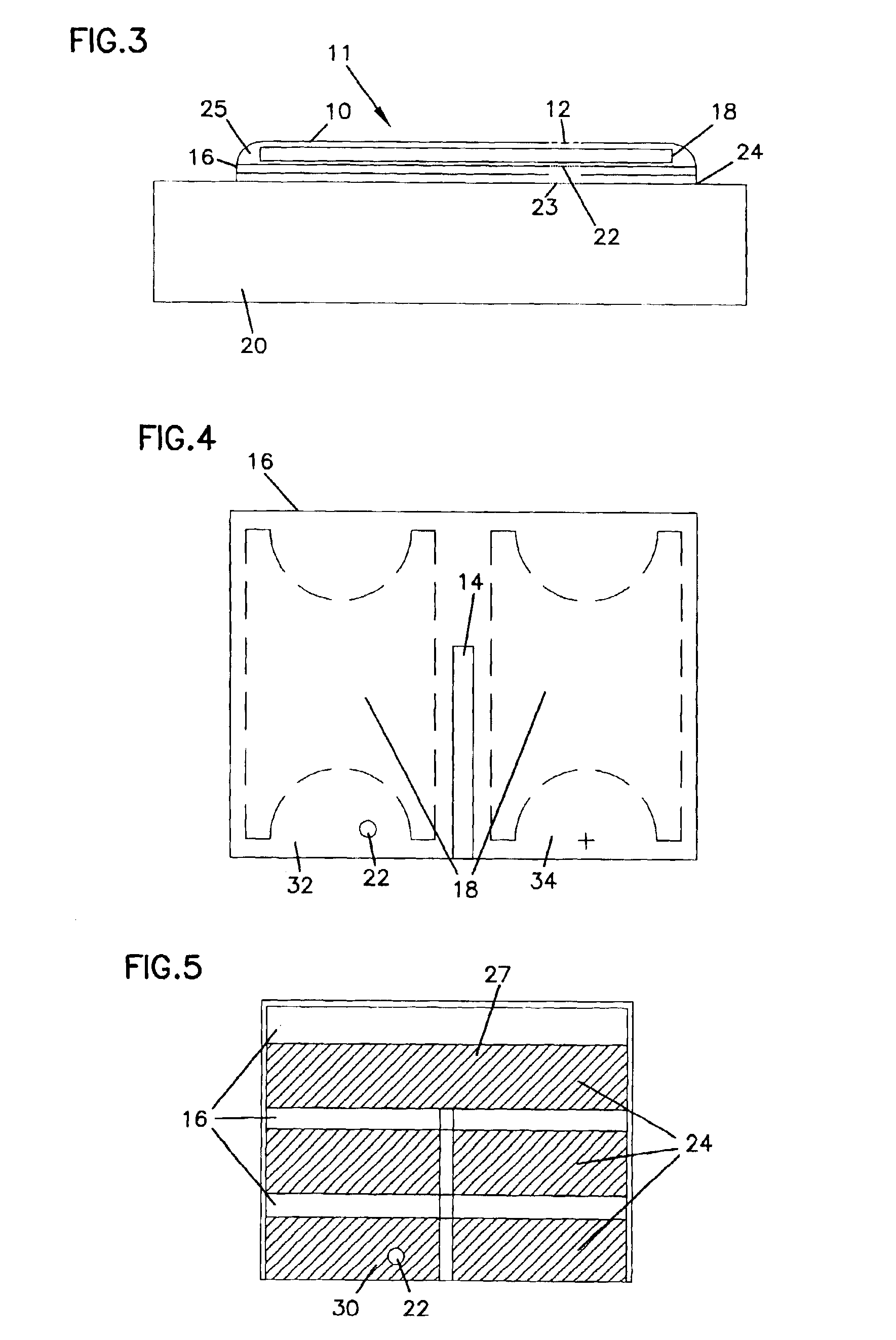

Hard disk drive recirculation air filter

ActiveUS7388731B1Undesired vibrations/sounds insulation/absorptionRecord information storageHard disc driveAir filter

A hard disk drive recirculation filter is disposed on a housing surface of a disk drive assembly oriented adjacent to one or more disk surfaces. In one embodiment, the recirculation filter is a pocket filter having a filter support component and a filter element. The filter support includes an inlet, a top surface and a bottom surface, where the bottom surface is used to adhere the pocket filter to the housing surface. The top surface is adapted to adhere the filter element thereto, thereby forming a pocket into which rotationally-induced airflow may enter.

Owner:WESTERN DIGITAL TECH INC

Bag house filters and media

A bag filter having a support structure clothed in a filter bag. The cloth of the filter bag is a composite of at least one substrate layer and at least one nanoweb bonded thereto in a face-to-face relationship. The nanoweb is positioned at the surface of the filter bag first exposed to the hot particle laden gas stream and can have a basis weight of greater than about 2 gsm.

Owner:EI DU PONT DE NEMOURS & CO

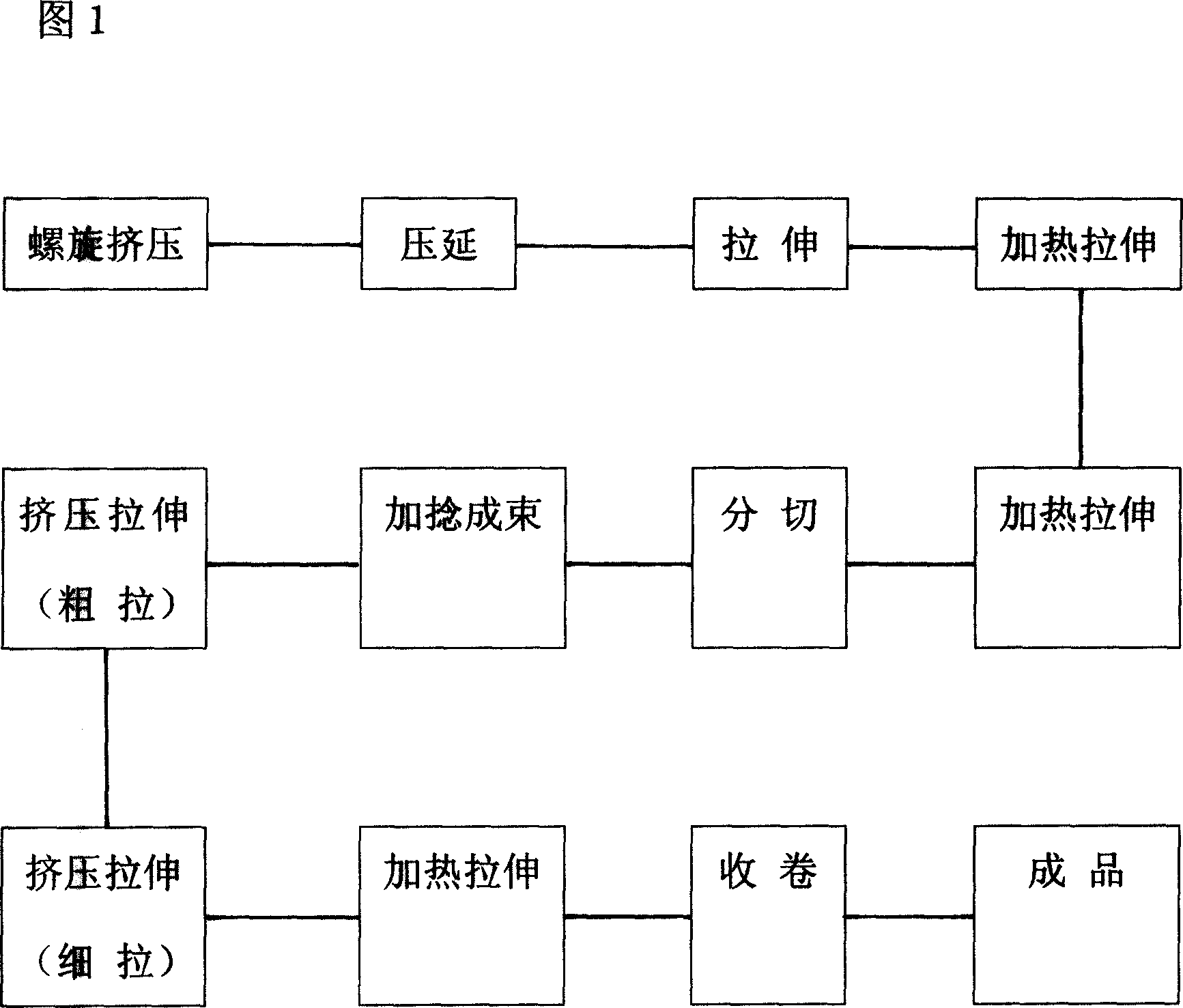

Method for producing polytef amosite

ActiveCN101074499AAchieve preparationExtended service lifeMelt spinning methodsMonocomponent halogenated hydrocarbon artificial filamentFiberProcess equipment

This invention provides one method for producing PTFE long fiber. The raw materials for this invention is 100% PTFE, the use of processing equipment includes spiral extrusion machine, calendar, stretching machine, heating tensile machine, Slitter, twisting machines, extrusion tensile machine, and roll-up. Firstly put the PTPE into spiral extruder and crash, secondly put into heating tensile machine to heat and stretch, do it once more, thirdly cut through slitter, twist into beam by twisting Machine, fourthly roughly stretch by squeeze tensile machine, and then stretch finely by squeeze tensile machine, finally put into heating tensile machine to heat and stretch, roll up by the roll-up machine, after which the production of PTFE long fiber is done. The PTFE long fiber in this invention can produce the monofilament long fiber and multi long fiber which can be used as the fabric filter substrate of bag filter as well as high-intensity industrial sewing thread which longer the durability of the filter bag for Teflon bag.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

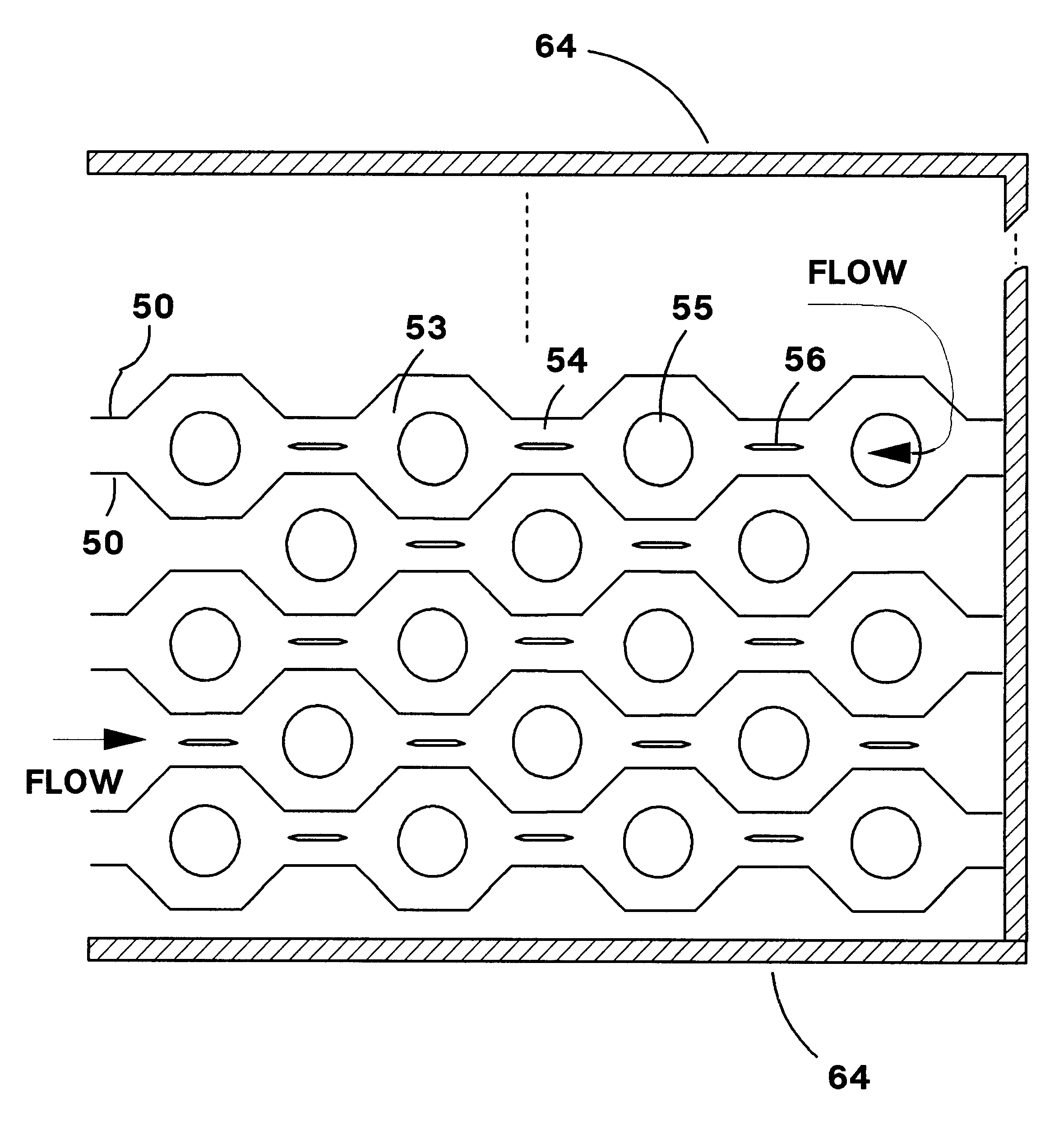

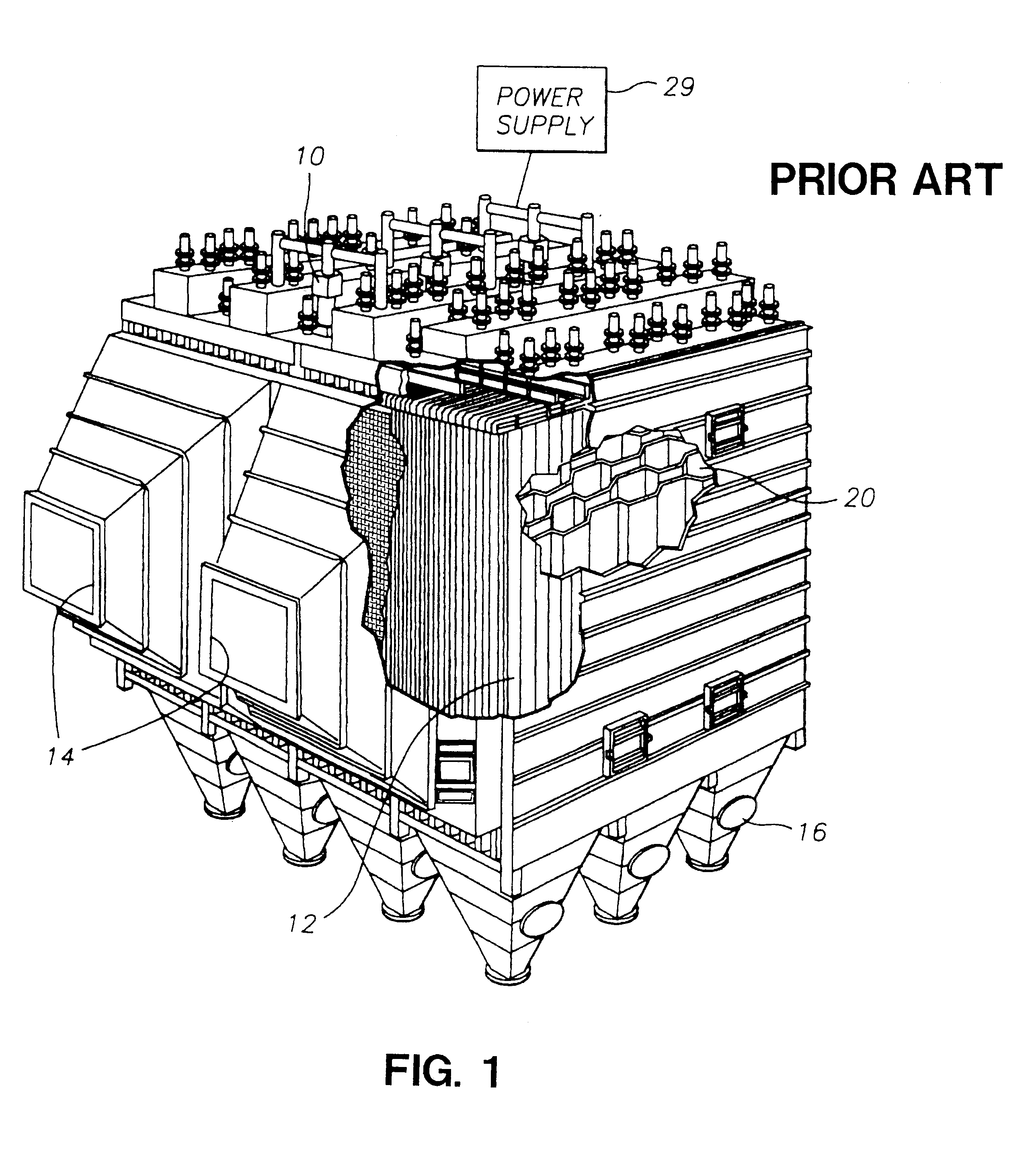

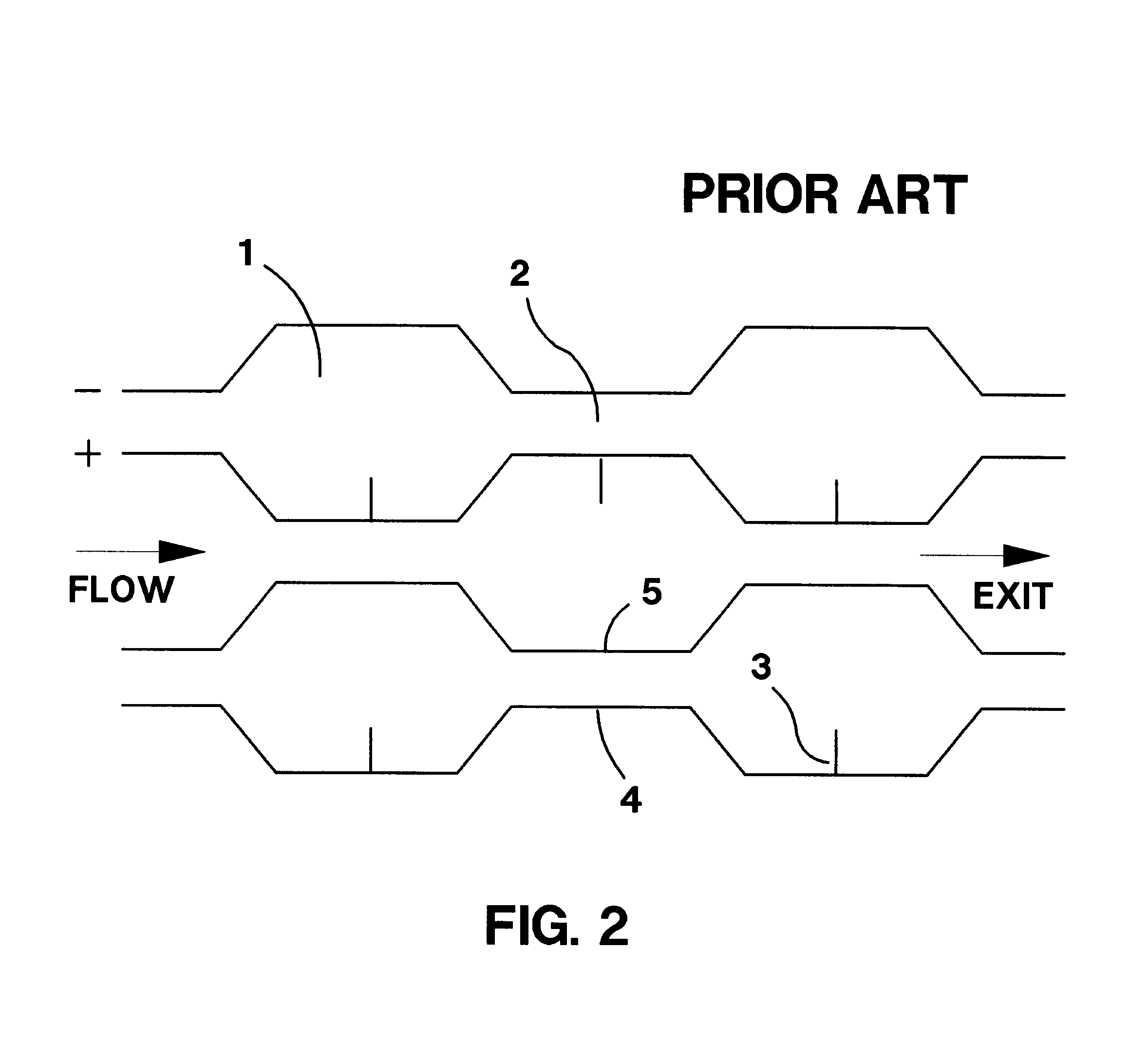

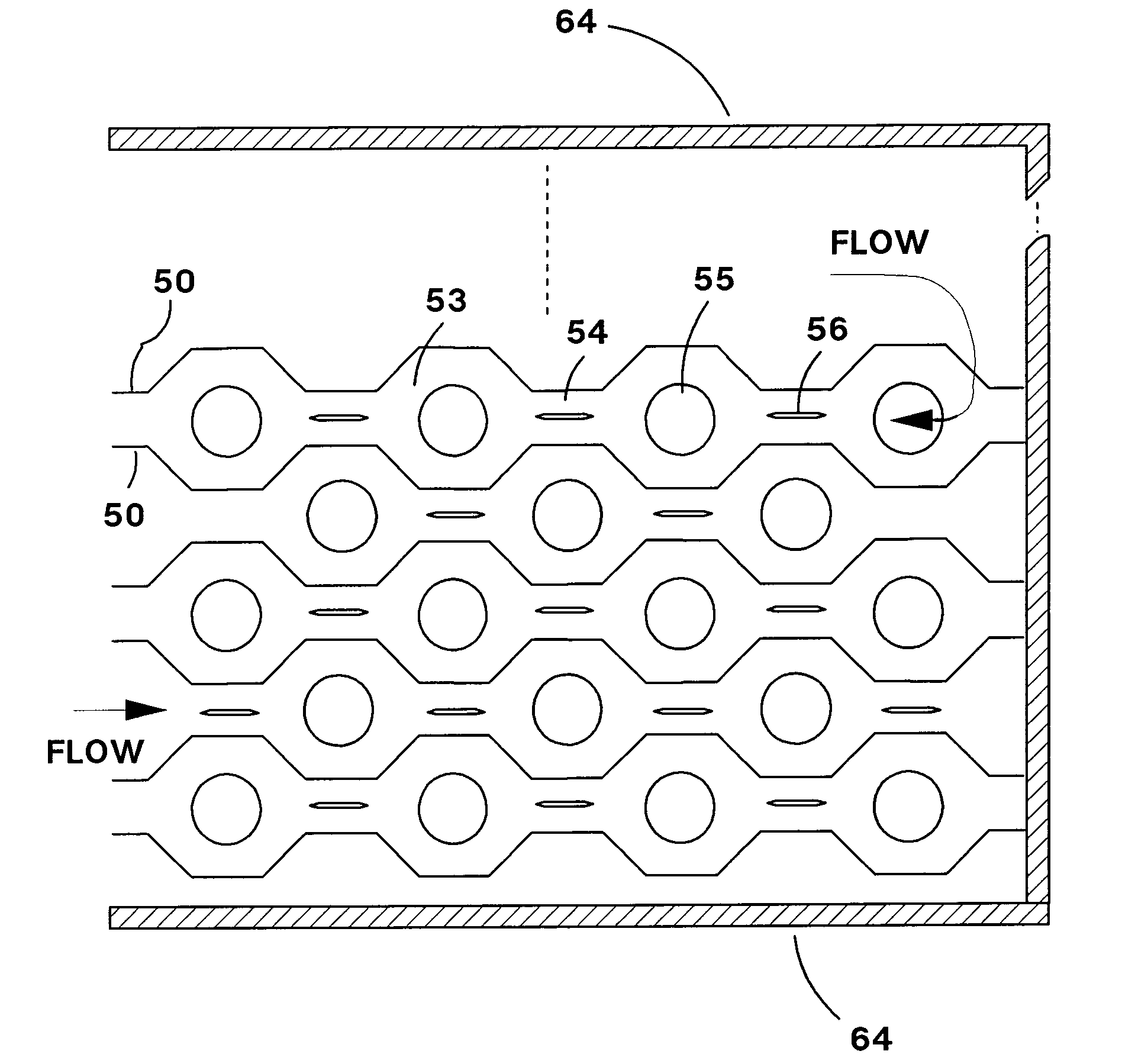

Multi-stage particulate matter collector

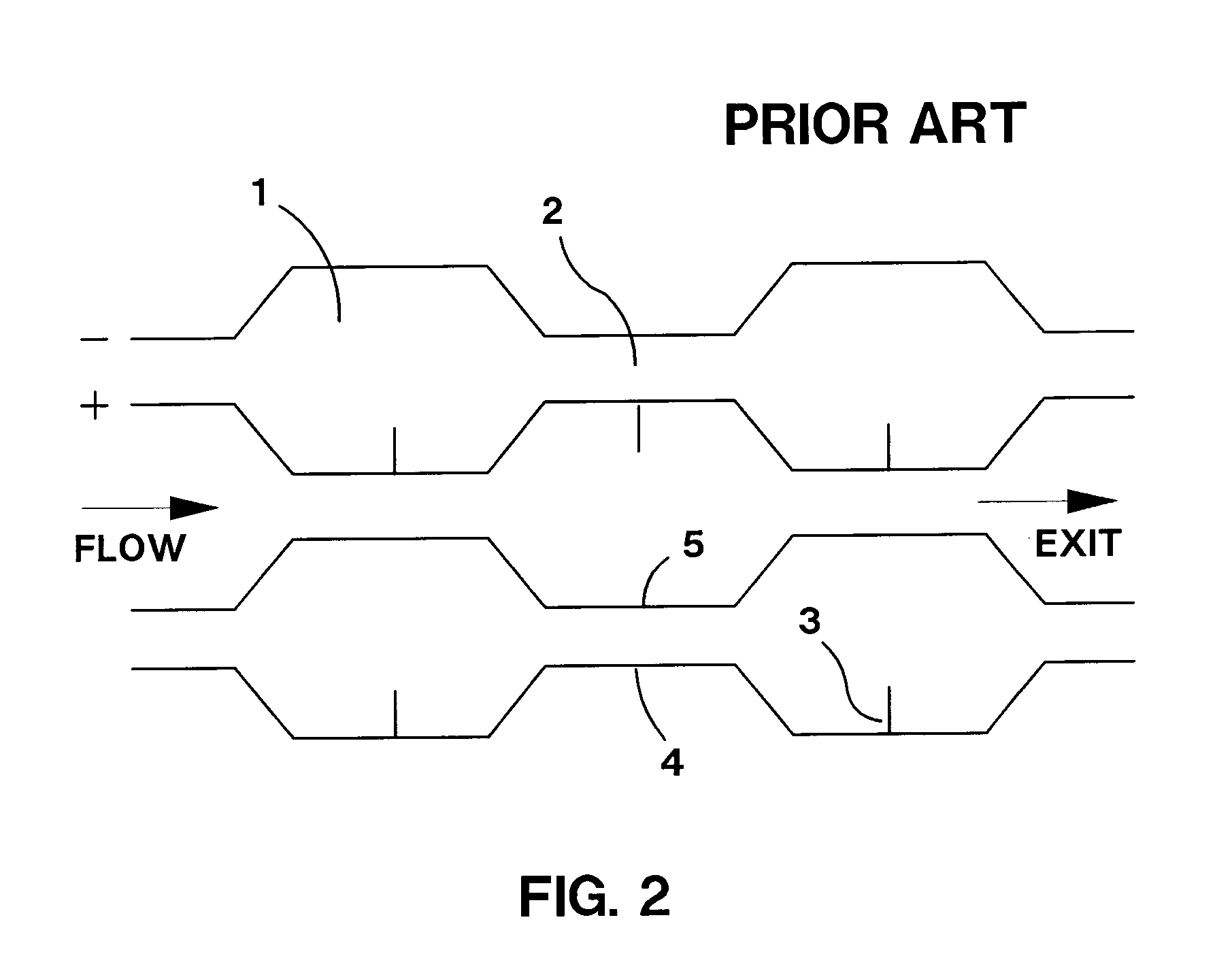

InactiveUS6524369B1Improve collection efficiencyIncrease the areaDispersed particle filtrationParticle charging/ionising stationsParticulatesParallel plate

A multi-stage particulate matter collector of the type used to collect particles from waste industrial gas. The collector can contain multiple narrow and wide zones formed by a plurality of parallel corrugated plates. Contained in the narrow zones are elongated electrodes with sharp leading and / or trailing edges. These electrodes provide a non-uniform electric field near their sharp edges leading to corona discharge. The corona discharge causes particulate matter in the gas flow to become charged. The region in narrow zones away from the sharp edges of the electrodes resembles a parallel plate capacitor with relatively uniform electric field. In this region, particles can be collected on the plates and on the electrode. Wide regions can contain barrier filters (bag filters) with conductive surfaces. The electric field is also relatively uniform in this region causing electrostatic collection on the plates and filter surface. Gas exits the array through the sides of the barrier filters which provides additional highly efficient filtering.

Owner:KRIGMONT HENRY V

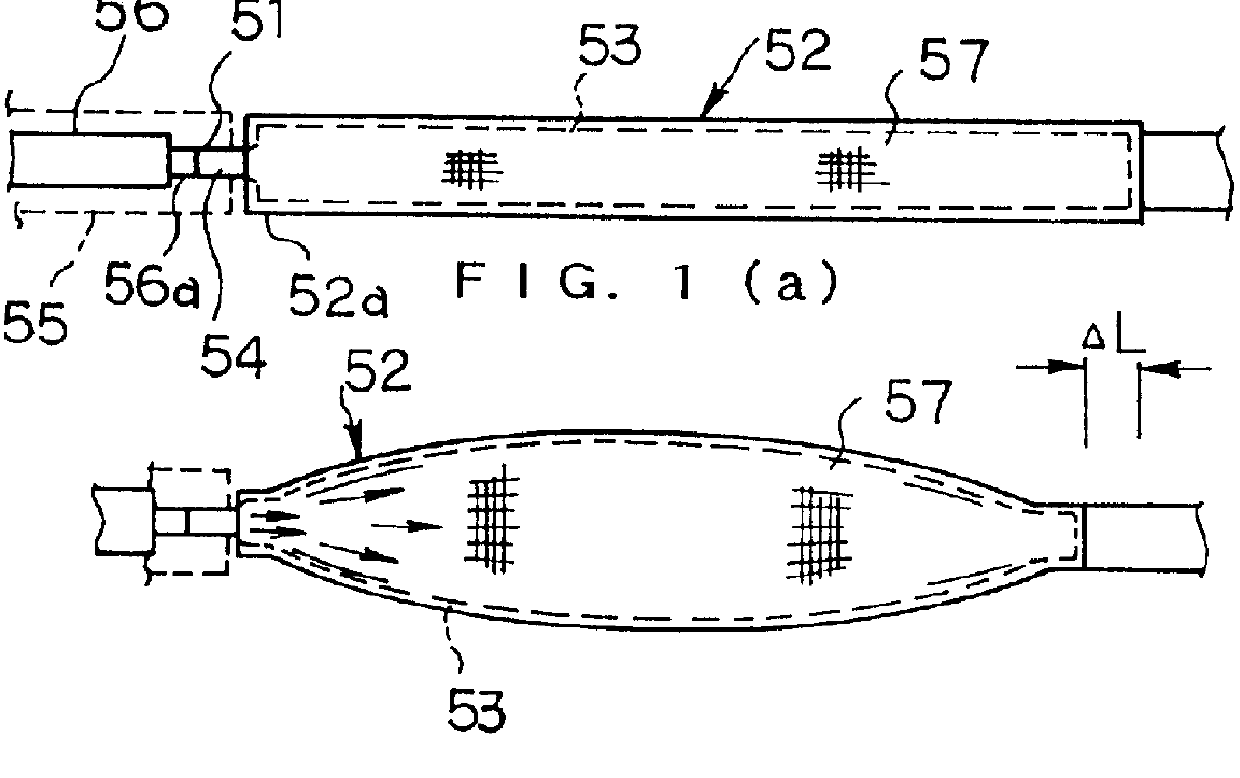

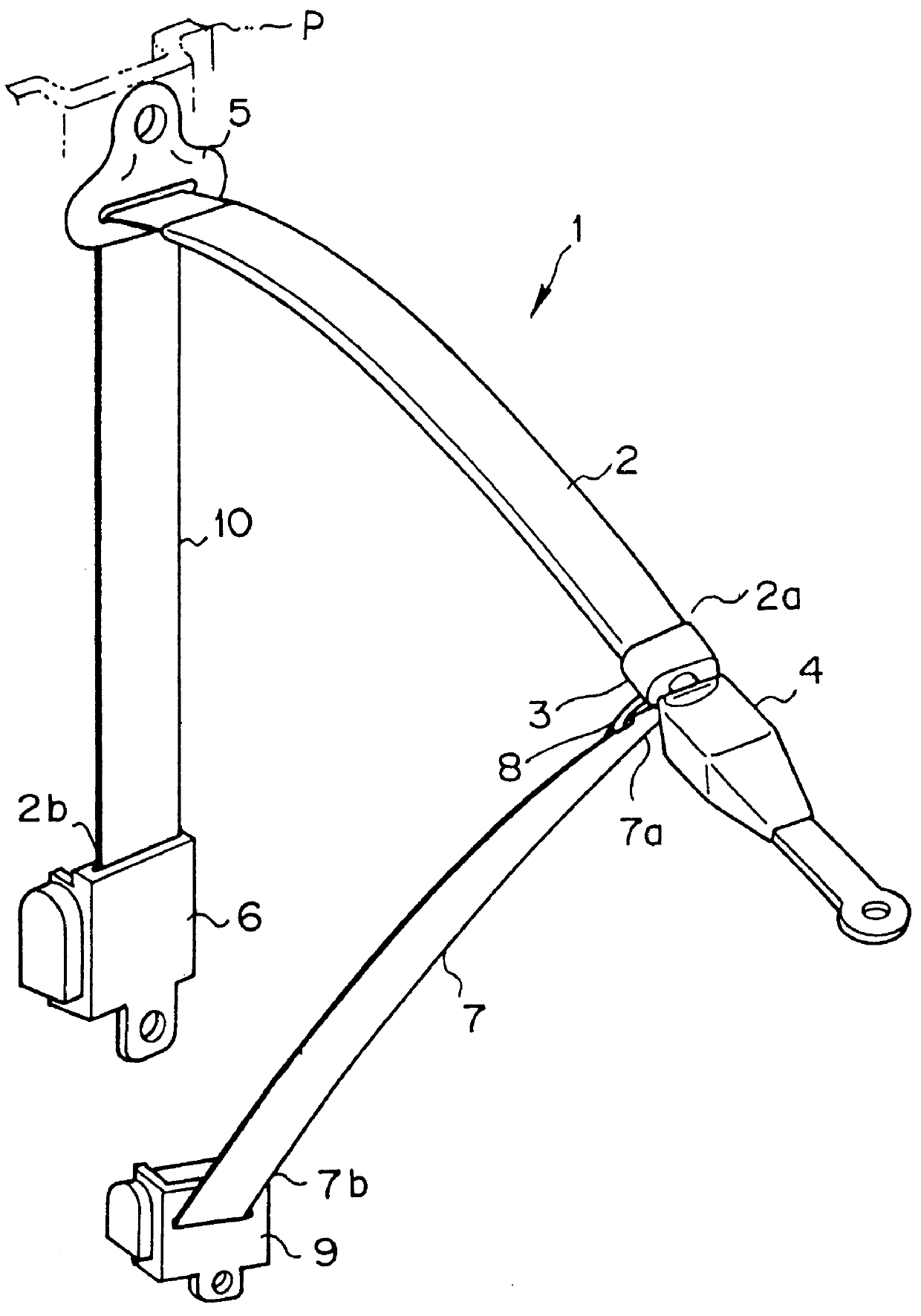

Inflatable seat belt having bag filter

InactiveUSRE36587E1Improve securityIncrease pressureWeft knittingOrnamental textile articlesSeat beltBand shape

An inflatable seat belt apparatus is formed of an inflatable portion which is usually maintained in a band shape and has an envelope part inflated and deployed in a spindle shape by introducing gas generated by a gas generating device, the gas generating device acting in case of exceeding a predetermined threshold, a webbing having the inflatable portion extending over at least a range directly contacting with an occupant, a tongue fixed to an end of the inflatable portion and having a gas path from the gas generating device and a buckle to which the tongue is detachably engaged. The inflatable portion has an elastic inflatable unit inserted into the envelope part and is inflated and deployed by introducing the gas generated by the gas generating device into the elastic inflatable unit via a filter.

Owner:TAKATA CORPORATION

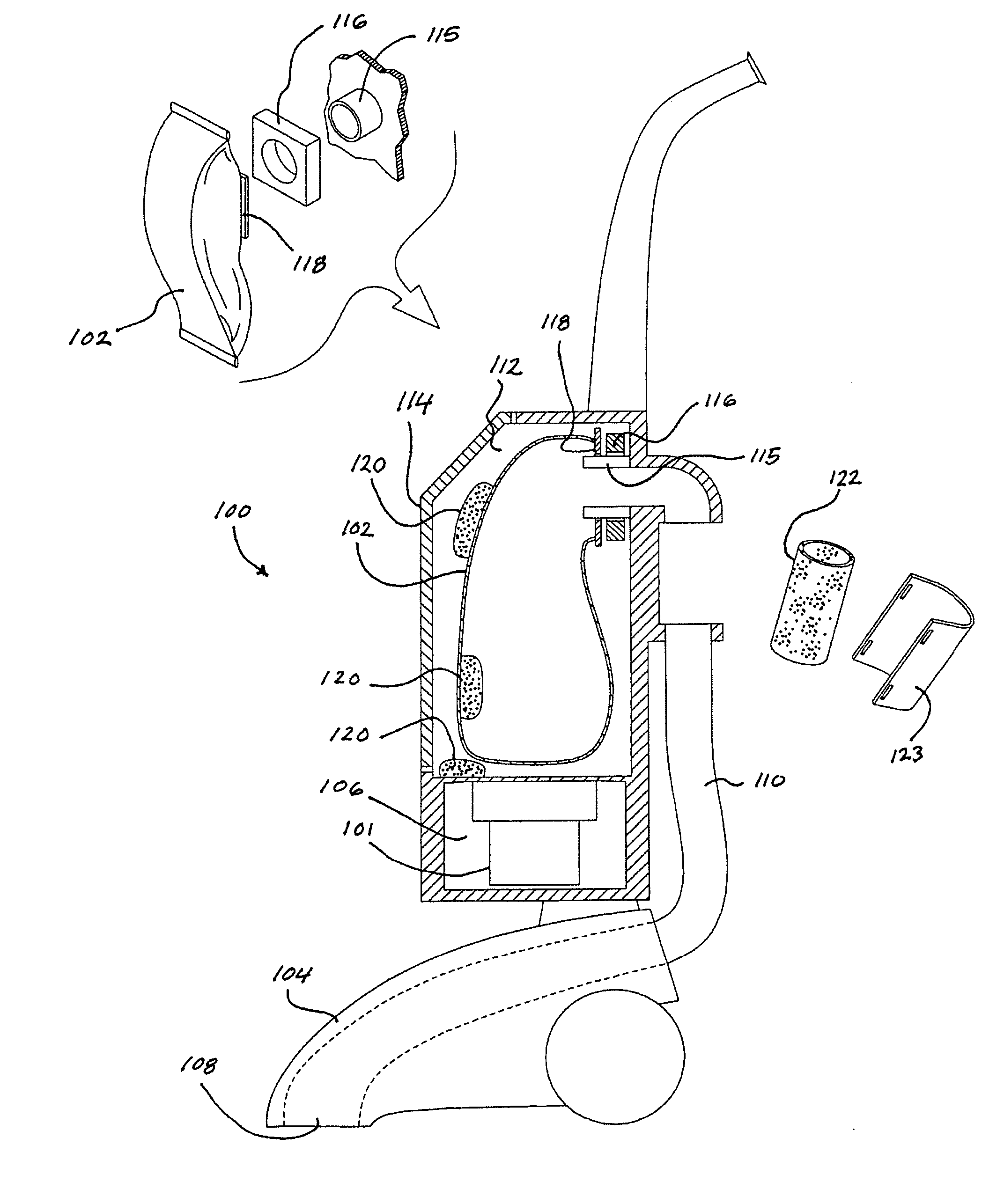

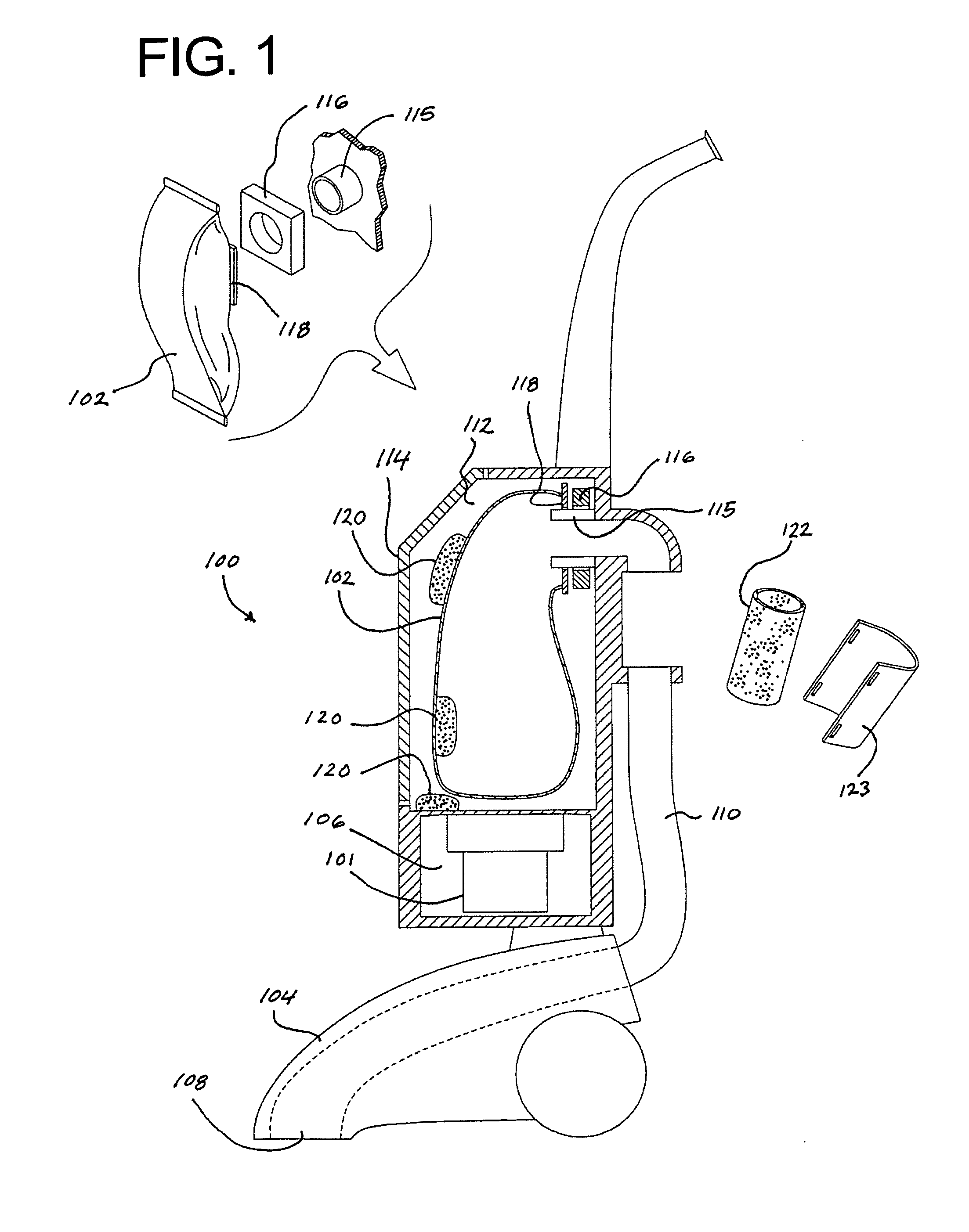

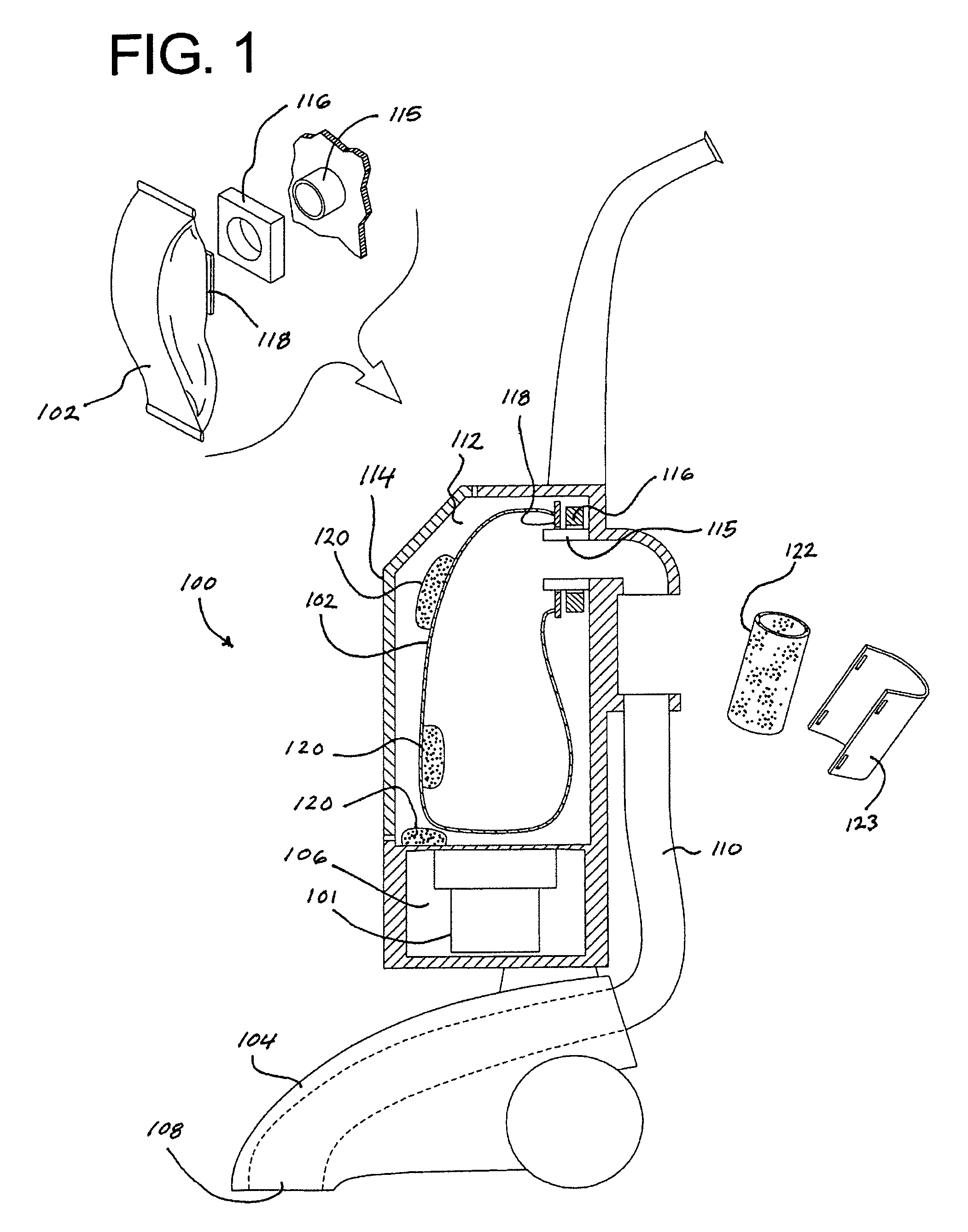

Sodium bicarbonate vacuum bag inserts

A vacuum cleaner bag filter with one or more filter walls forming a generally air permeable enclosure having a bag opening through it, and a flange attached to the one or more filter walls to cover the bag opening. The filter walls have a working surface area through which air can pass during use, and the flange is a relatively rigid structure having an air inlet passing into the air permeable enclosure. One or more deodorizing sheets are attached to an inner surface of the one or more filter walls. The deodorizing sheets include a first sheet layer, and sodium bicarbonate particles operatively associated with the first sheet layer. The deodorizing sheets may cover less than about 30% of the working surface area, a single deodorizing sheet may be provided, and the deodorizing sheets may be attached to the filter walls by an air impermeable adhesive that covers at least about 5% of the surface area of the deodorizing sheets. Also provided is a vacuum cleaner filter having a filter and a deodorizing sheet attached thereto by an air-impermeable adhesive.

Owner:ELECTROLUX HOME CARE PRODS

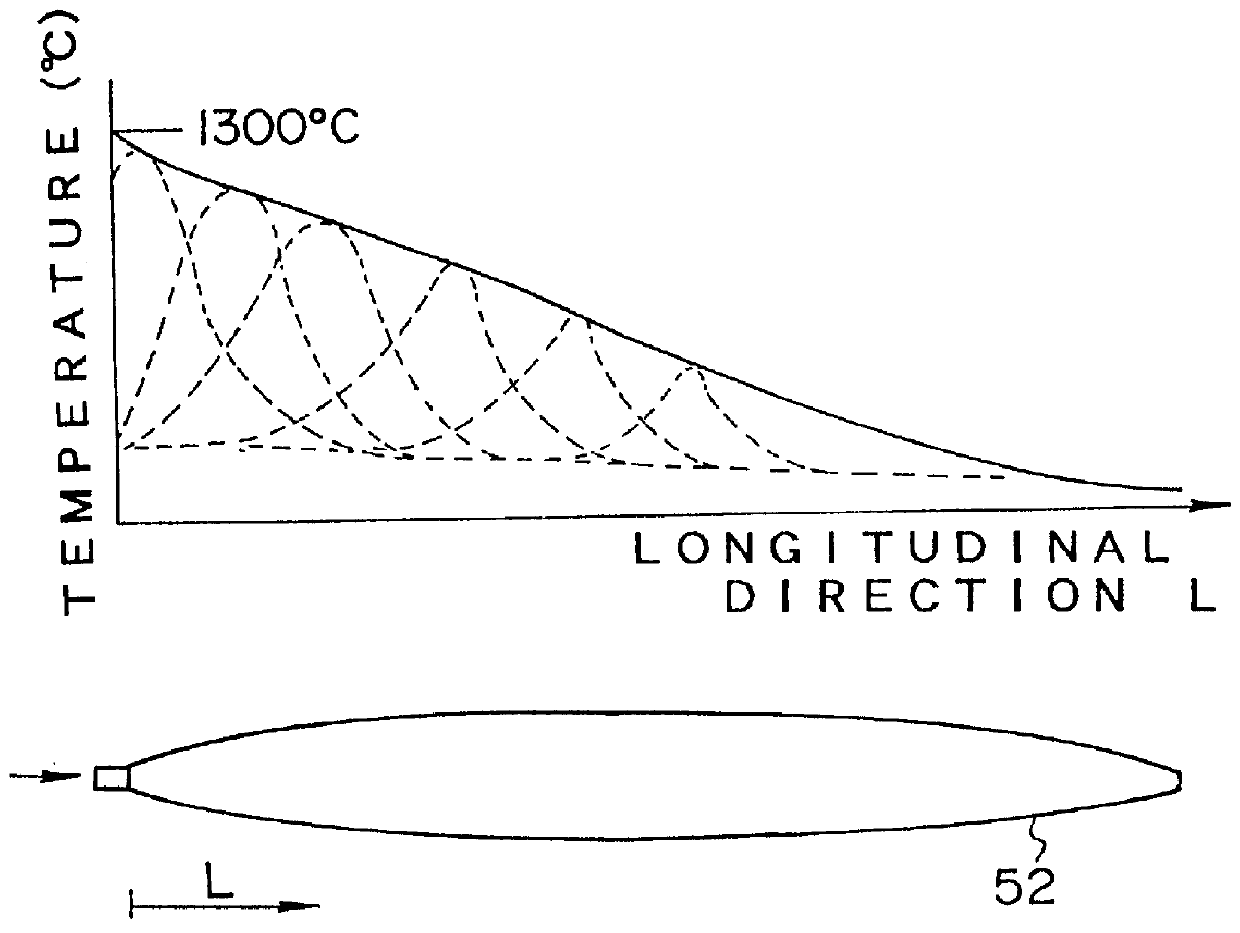

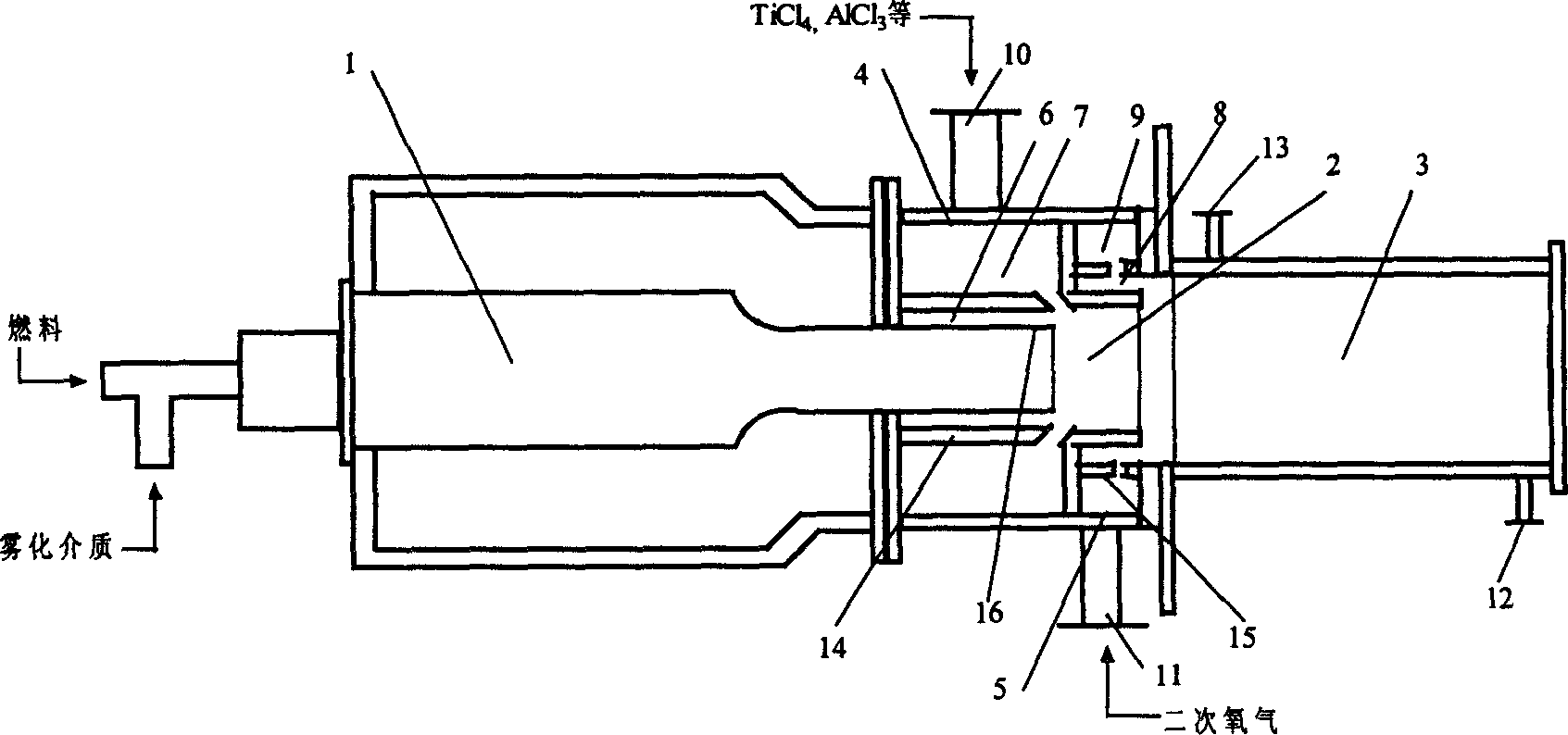

Method and apparatus for preparing titanium dioxide by oxidation reactor

InactiveCN1609001AHigh crystal conversion rateSpeed up the flowPigmenting treatmentTitanium dioxidePositive pressureHeating furnace

The present invention is a two-stage heating process and apparatus for preparing titanium dioxide. The reactant material TiCl4 and O2 is prepared 400-600 deg.c and 800-1000 deg.c in the pre-heating furnace and then led into the oxidizing reactor, where atomized fuel and crystal form converting agent AlCl3 are introduced and the material is heated to 1500-1800 deg.c directly under positive pressure condition, with the product being collected with bag filter. The apparatus includes burning area, mixing reaction area with feeding ring, cooling area, material feeding pipes, cooling water inlet and outlet and cylindrical rings. The present invention his the advantages of high product quality, less scaling and long life of reactor.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

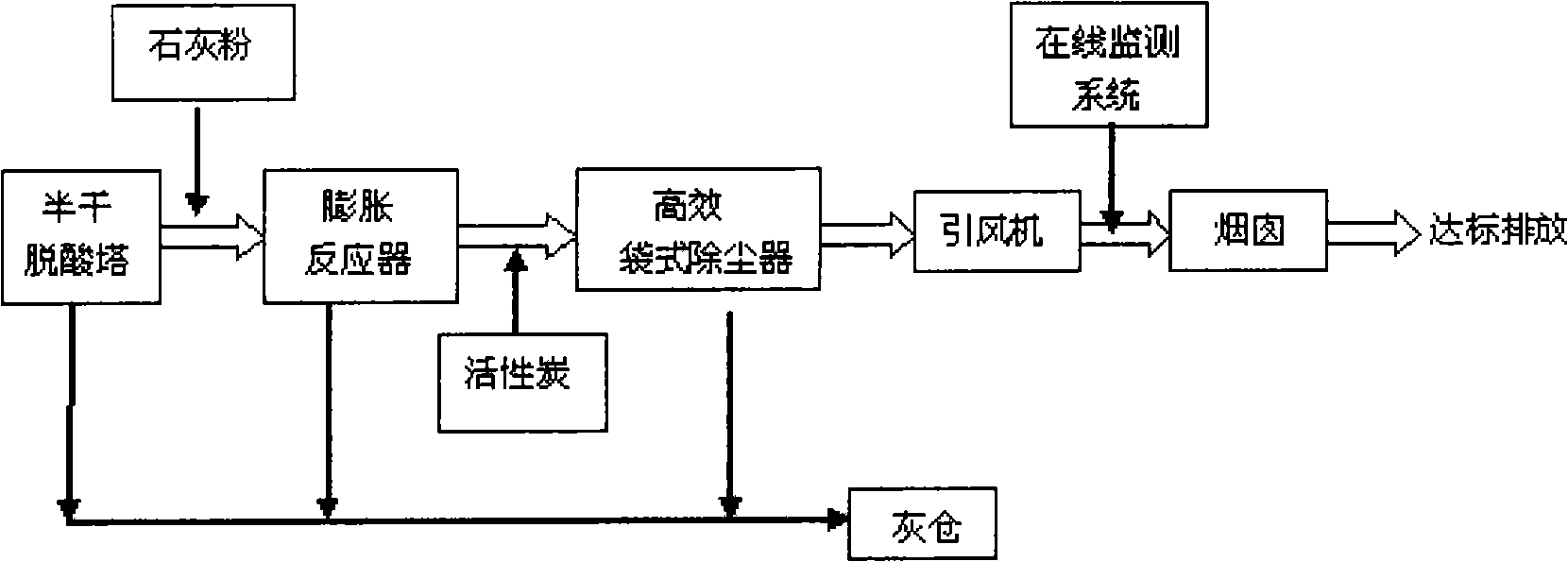

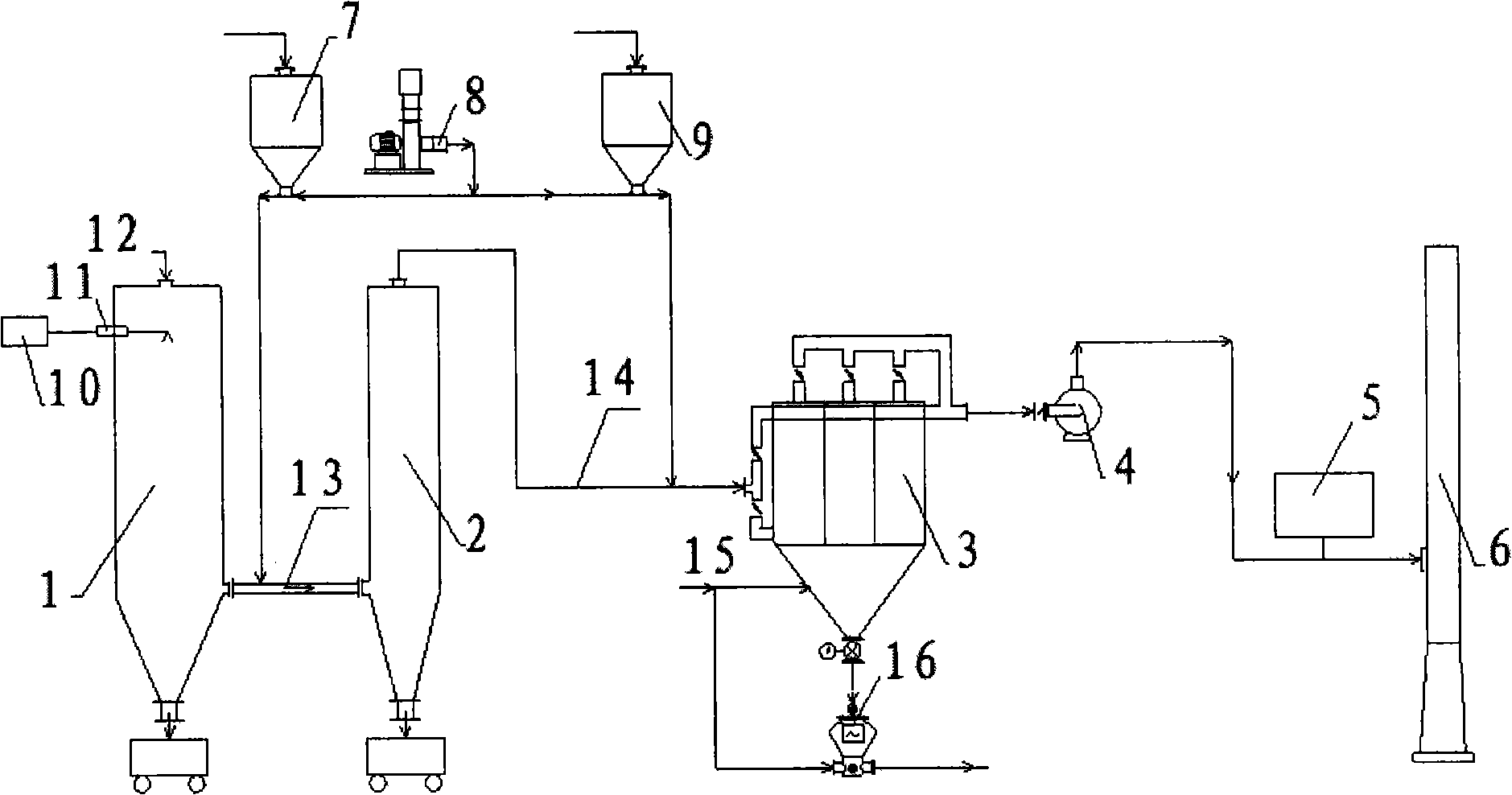

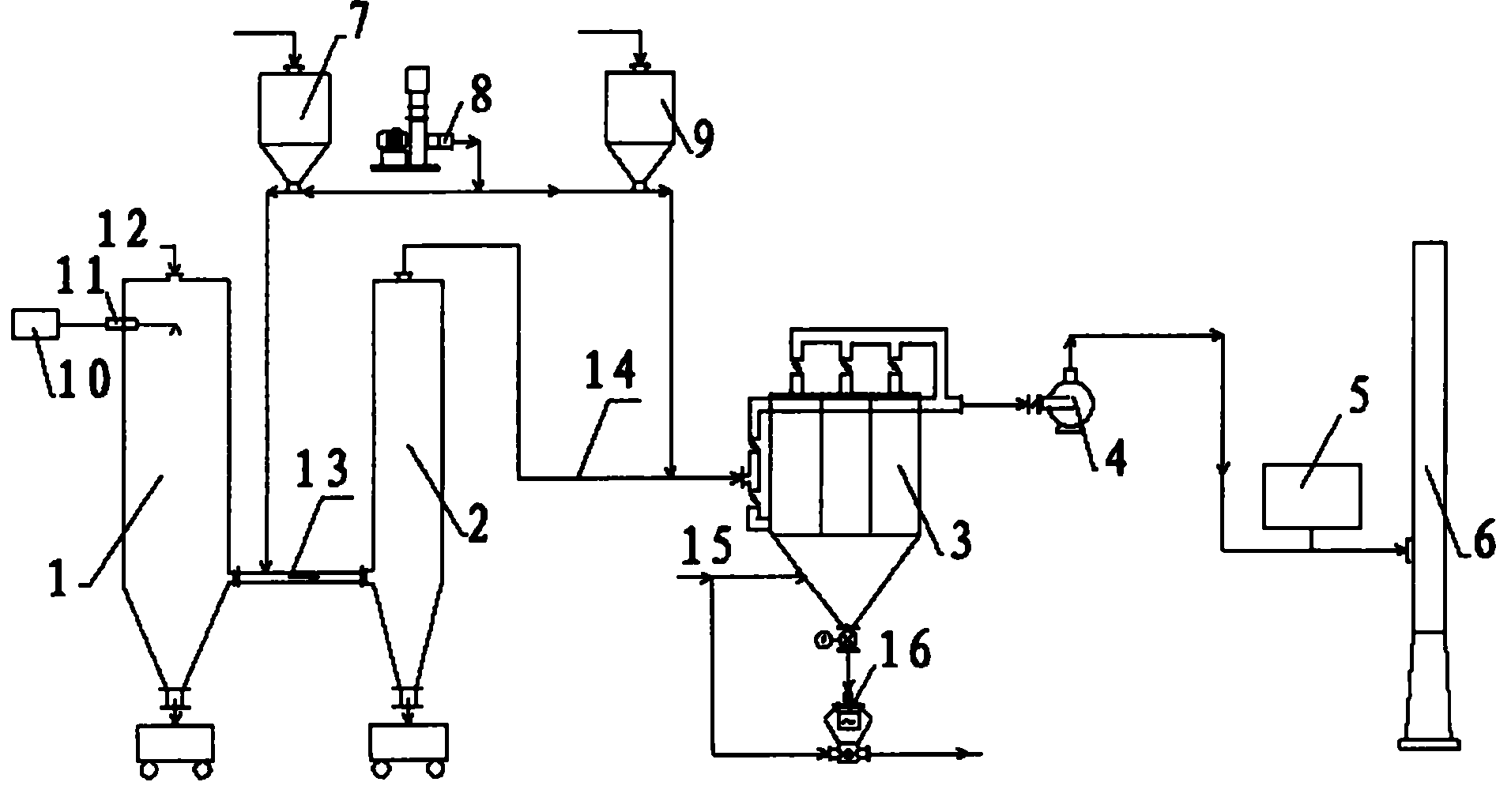

Complete set of device and method for treating tail gas from sludge incineration through semidry method

ActiveCN102120130AHigh removal rateEmission reductionDispersed particle separationChemical reactionSorbent

The invention relates to a device and a method for treating tail gas from sludge incineration through a semidry method, belonging to the field of solid wastes. The incineration tail gas passes through a semidry deacidification tower, thus the removing efficiency can reach about 90%, the use amount of chemicals is less, and sewage discharge is avoided; a flue in front of an expanded reactor is provided with a lime powder inlet, and the lime powder and the acid gas in the flue gas are subjected to full chemical reaction, thus the residue acid gas is removed; activated carbon serving as an adsorbent is injected, thus the removal rate of heavy metal and dioxin is further increased; an efficient bag filter is added to collect the Ca(OH)2 and powder of incomplete reaction, thus the removal rates of the heavy metal, dioxin and acid gas in the powder are effectively improved, the removal rate of the heavy metal (except mercury) reaches 99%, the emission of various pollutants can meet the environmental requirements, and the secondary pollution caused by incineration of the tail gas to the environment can be effectively solved.

Owner:BMEI

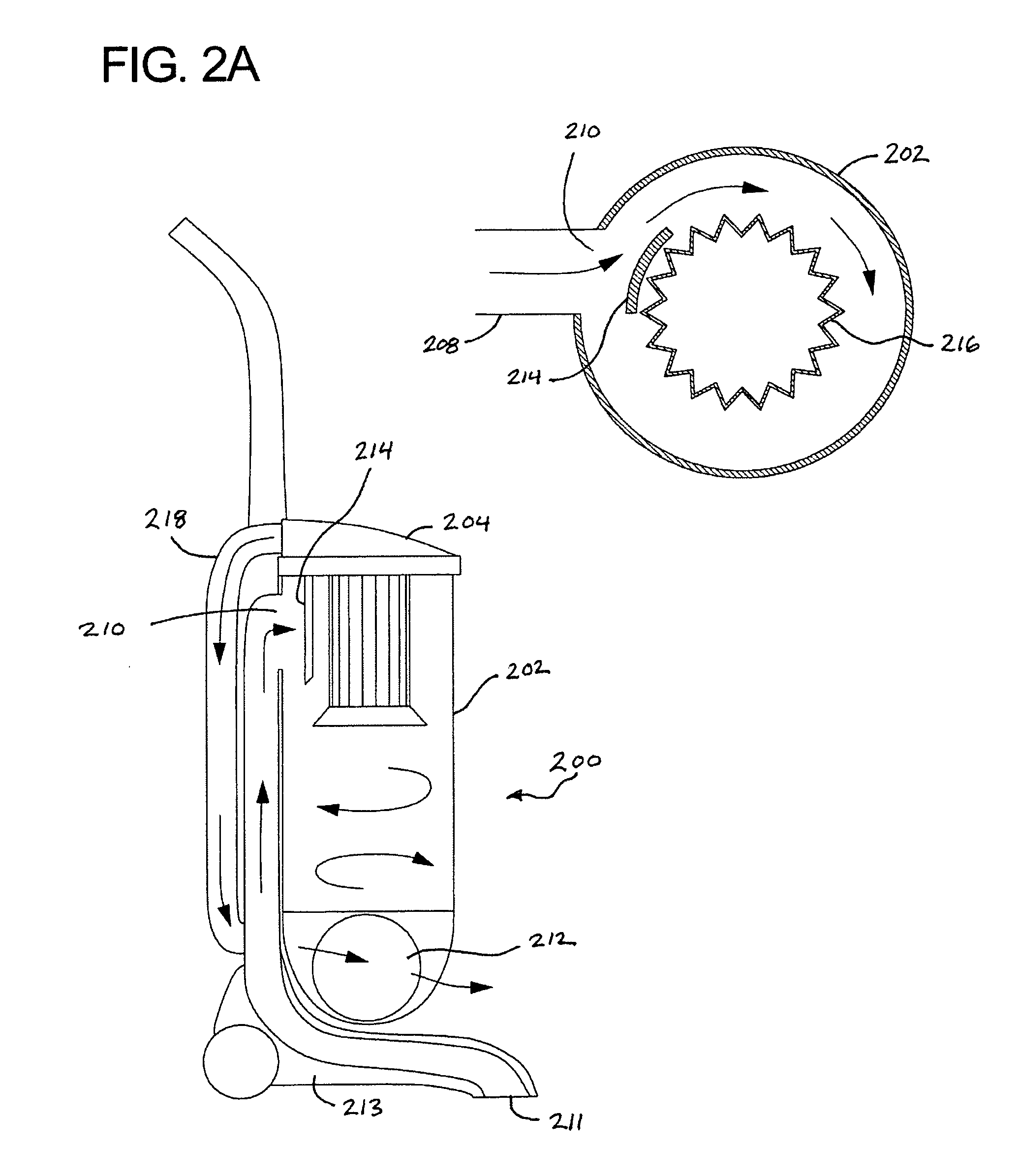

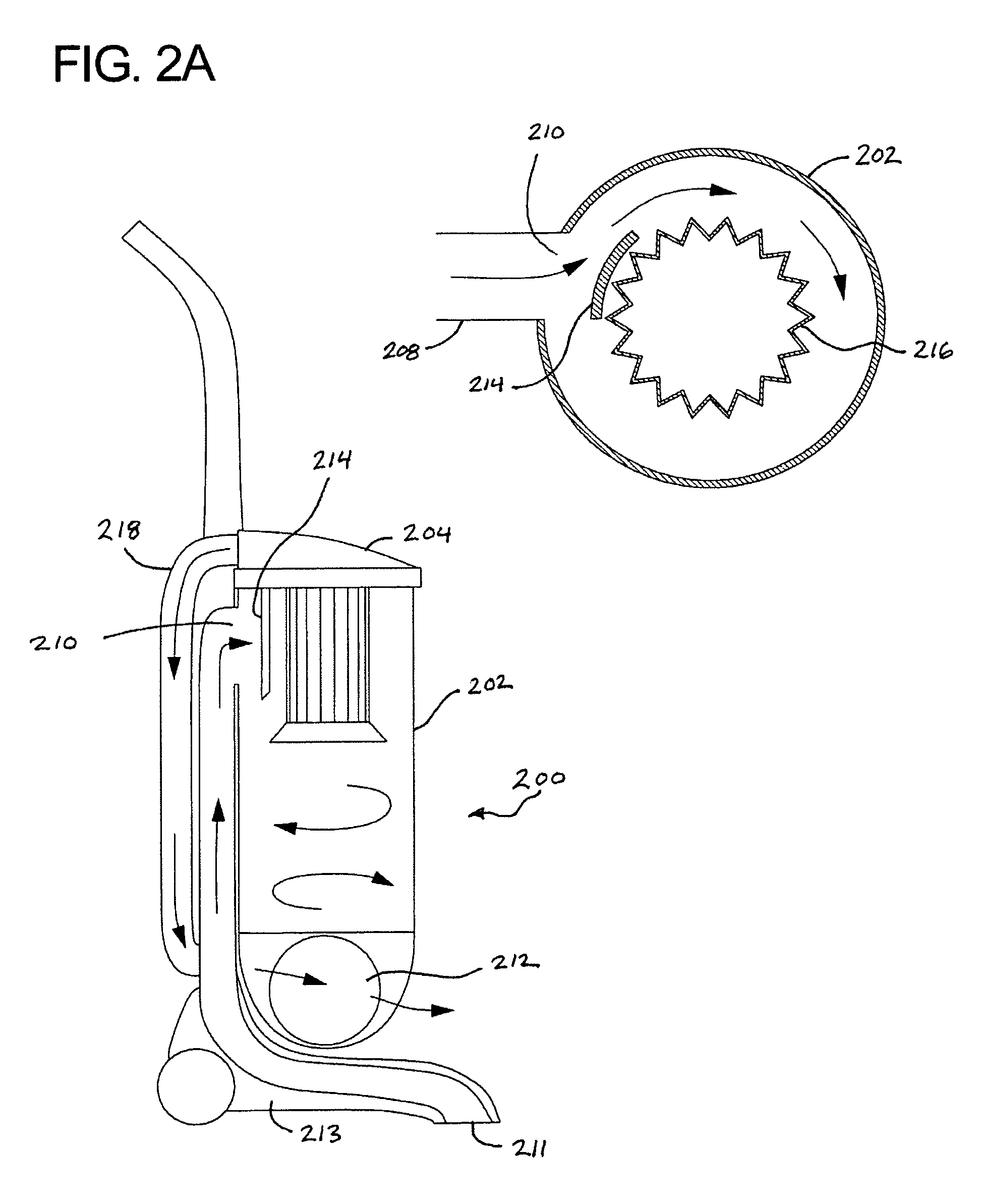

Vacuum collection bag and method of operation

InactiveUS20020166449A1Low costEasy to cleanCombination devicesEnvelopes/bags making machineryFiltrationPulp and paper industry

The present invention is an improved vacuum collection bag for vacuum cleaners and other appliances. By employing an impermeable bag and an air-permeable particle separator together with a tight seal against a vacuum system dirt tube in place of a conventional paper bag filter, it has been determined that the vacuum cleaner bag can be reused and significantly improve the filtration performance of the vacuum system.

Owner:WL GORE & ASSOC INC

Method for producing superconducting carbon black with high specific surface area

ActiveCN102174277AHigh strengthReduce usagePigmenting treatmentChemical industryElectricityAir preheater

The invention relates to a method for producing superconducting carbon black with high specific surface area, and aims to make a production process simple and product performance stable. The method comprises the following steps of: completely combusting gas in a combustion section of a reaction furnace, mixing the gas, air and raw oil, adding into a throat pipe section of the reaction furnace, and making the temperature of a reaction section of the reaction furnace reach 1,300 to 1,600 DEG C under the action of a K2CO3 catalyst; performing thermal cracking and thermal polycondensation on the gas and the raw oil rapidly to generate the superconducting carbon black; continuously reacting the superconducting carbon black with a CO2 catalyst in a rapid cooling section of the reaction furnace,and performing catalytic activation on the superconducting carbon black to form a developed pore structure and improve the specific surface area of the superconducting carbon black; exchanging the flue gas of the superconducting carbon black with cold air by using an air preheater in a retention section of the reaction furnace to reduce the temperature to be lower than 600 DEG C; and when reaction for preparing a product from raw materials is finished, cooling the superconducting carbon black to 320-350 DEG C by using a tubular rapid cooling boiler, slowly cooling, adding into a bag filter, and collecting, wherein recycled heat is used for generating electricity.

Owner:山西永东化工股份有限公司

Multi-stage collector and method of operation

InactiveUS6932857B1Improve collection efficiencyIncrease the areaDispersed particle filtrationParticle charging/ionising stationsLeading edgeIndustrial gas

A multi-stage collector of the type used to collect particles from industrial gas. The collector can contain multiple narrow and wide zones formed by a plurality of parallel corrugated plates. Contained in the narrow zones can be elongated electrodes with sharp leading and / or trailing edges. These electrodes can provide a non-uniform electric field near their sharp edges leading to corona discharge. The corona discharge causes particulate matter in the gas flow to become charged. The region in narrow zones away from the sharp edges of the electrodes resembles a parallel plate capacitor with relatively uniform electric field. In this region, particles can be collected on the plates and on the electrode. Wide regions can contain barrier filters (bag filters) with conductive surfaces. The collector can also be used to clean inlet gas in gasification plants and to collect re-usable materials from a gas stream.

Owner:KRIGMONT HENRY

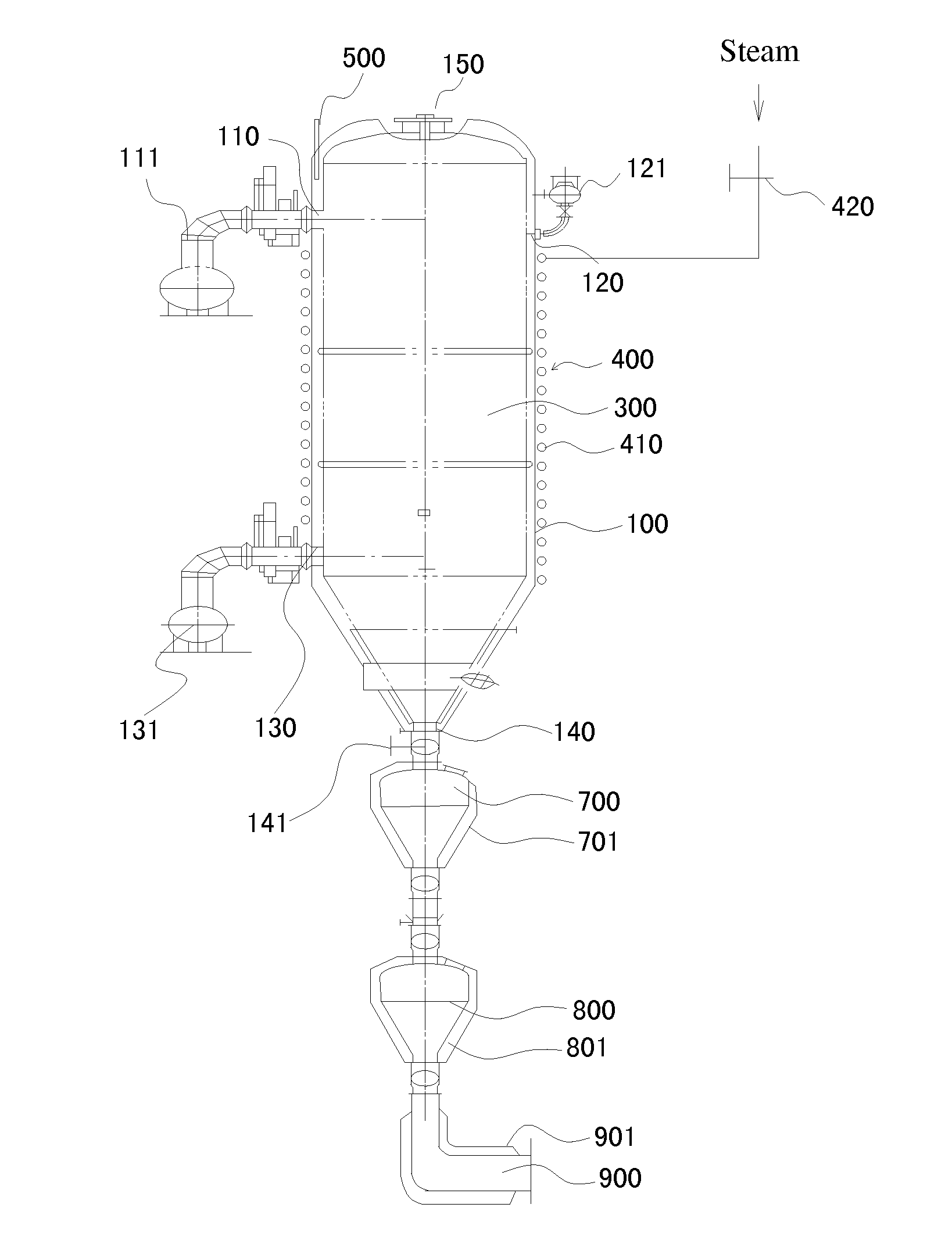

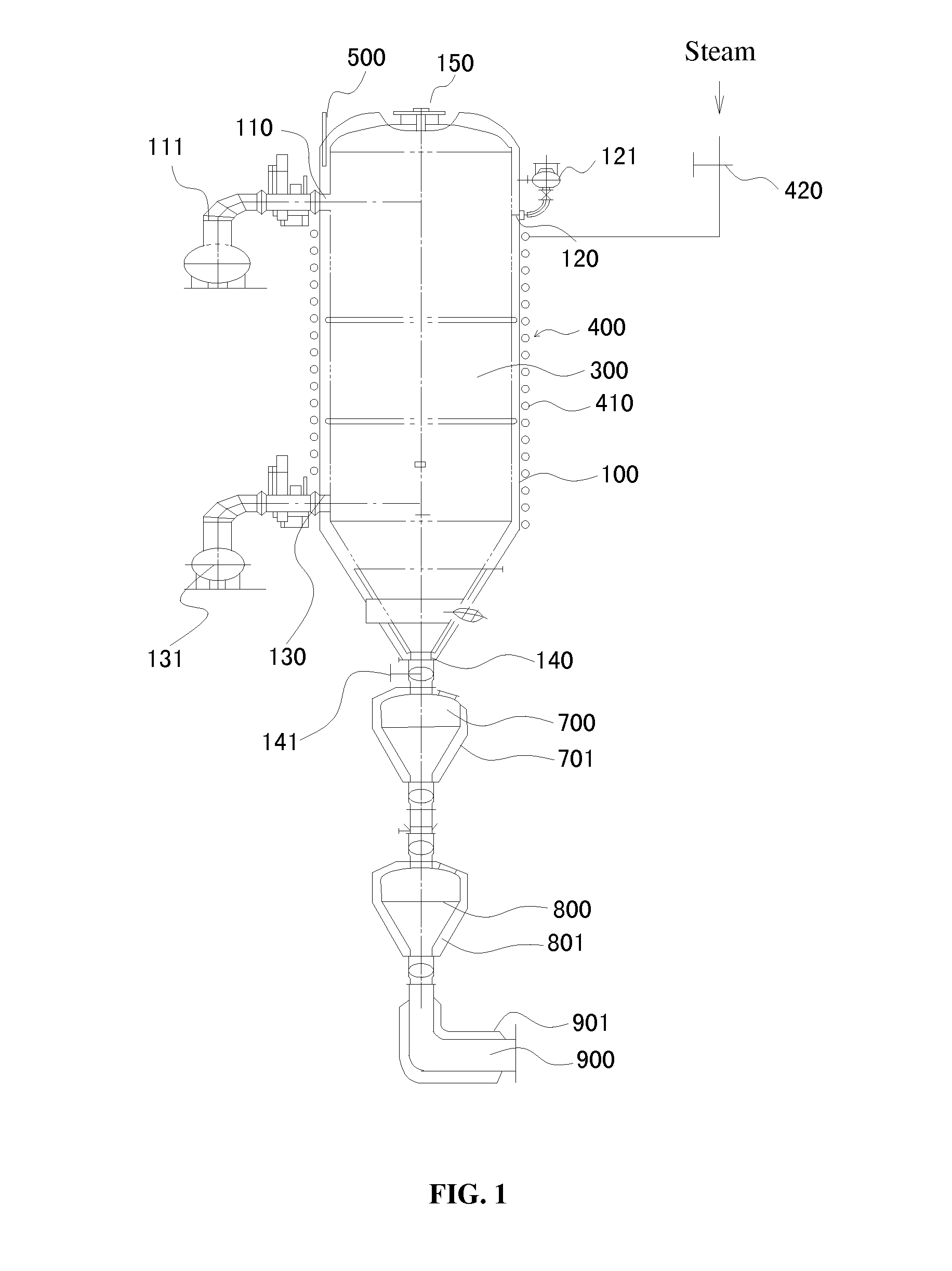

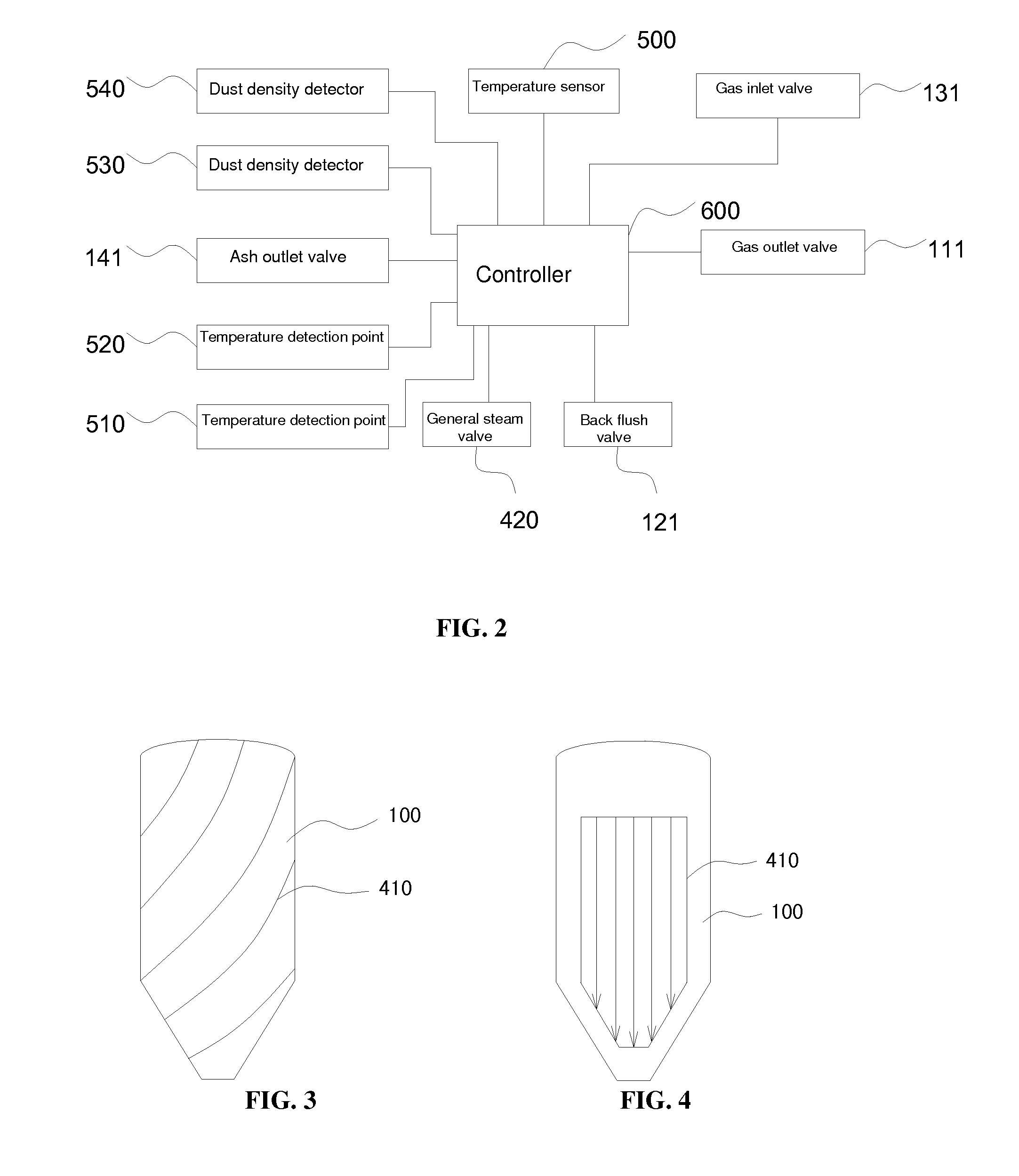

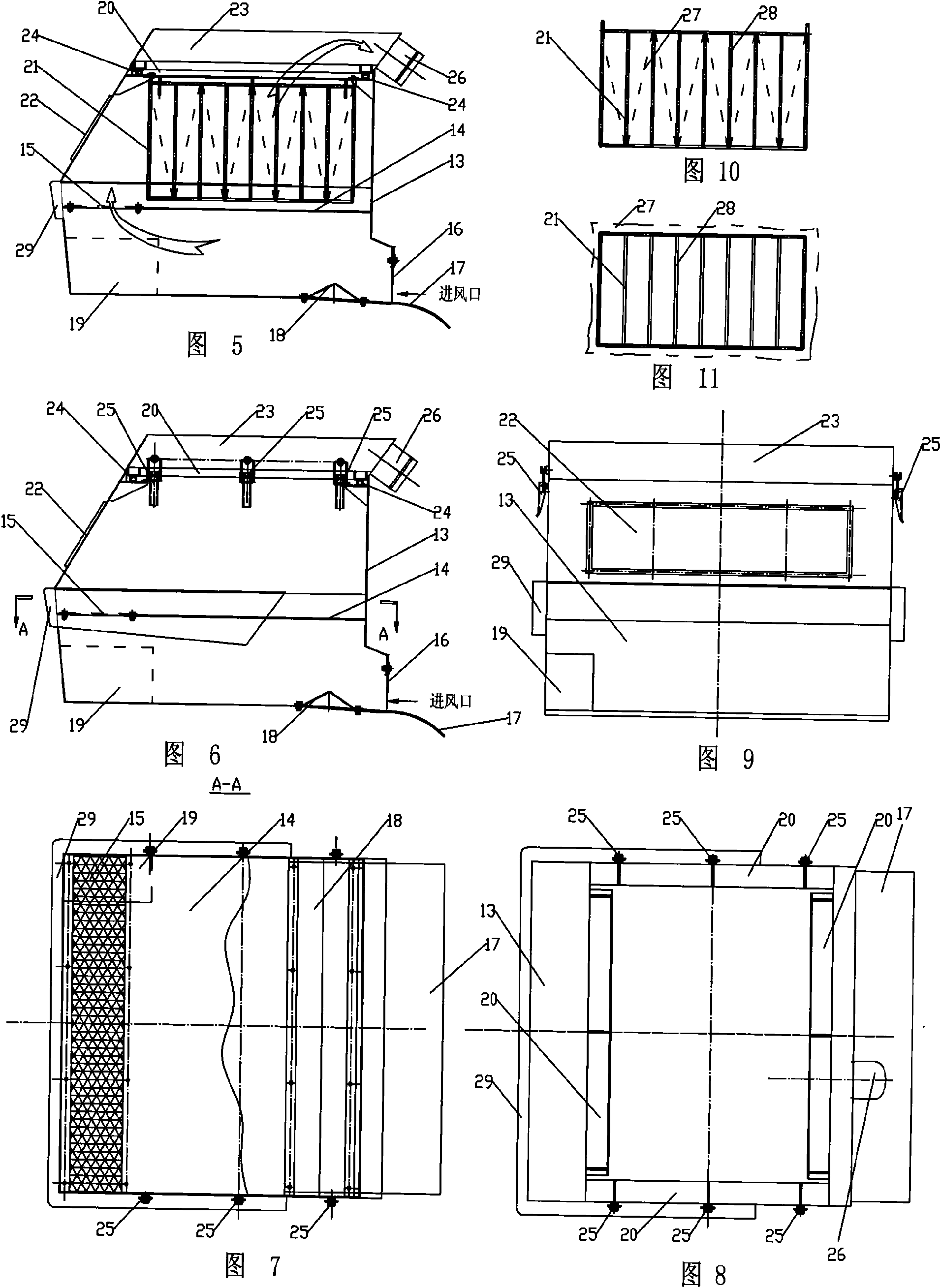

Dust Removal Method Using Baghouse Filters And Dust Removal Apparatus Therefor

ActiveUS20110265652A1Reduce in quantityImprove air tightnessCombination devicesAuxillary pretreatmentPresent methodFluidized bed

A dust removal method using baghouse filter to process raw syngas from fluidized bed coal gasifier, wherein temperature in the baghouse (300) is maintained at 180° C.-250° C., pressure difference between the gas inlet (130) of the baghouse (300) and the gas outlet (110) of the baghouse (300) is controlled at 1000-5000 Pa, the raw syngas from the fluidized bed coal gasifier enters the gas inlet under the pressure of 0.2-3.0 Mpa. The present method effectively solves the technical problems of condensation and baghouse block due to high steam and ash content in the raw syngas from the fluidized bed coal gasifier and the present method is also applicable to remove dusts from the raw syngas produced by the fluidized bed coal gasifier under the conditions of high water-gas ratio (the water-gas ratio is up to 37%), high dust content (15-100 g / Nm3 dusts) and 0.2-3.0 Mpa pressure. The present invention also discloses a baghouse dust collector and a dense phase pneumatic conveying apparatus for the method.

Owner:GAS TECH INST

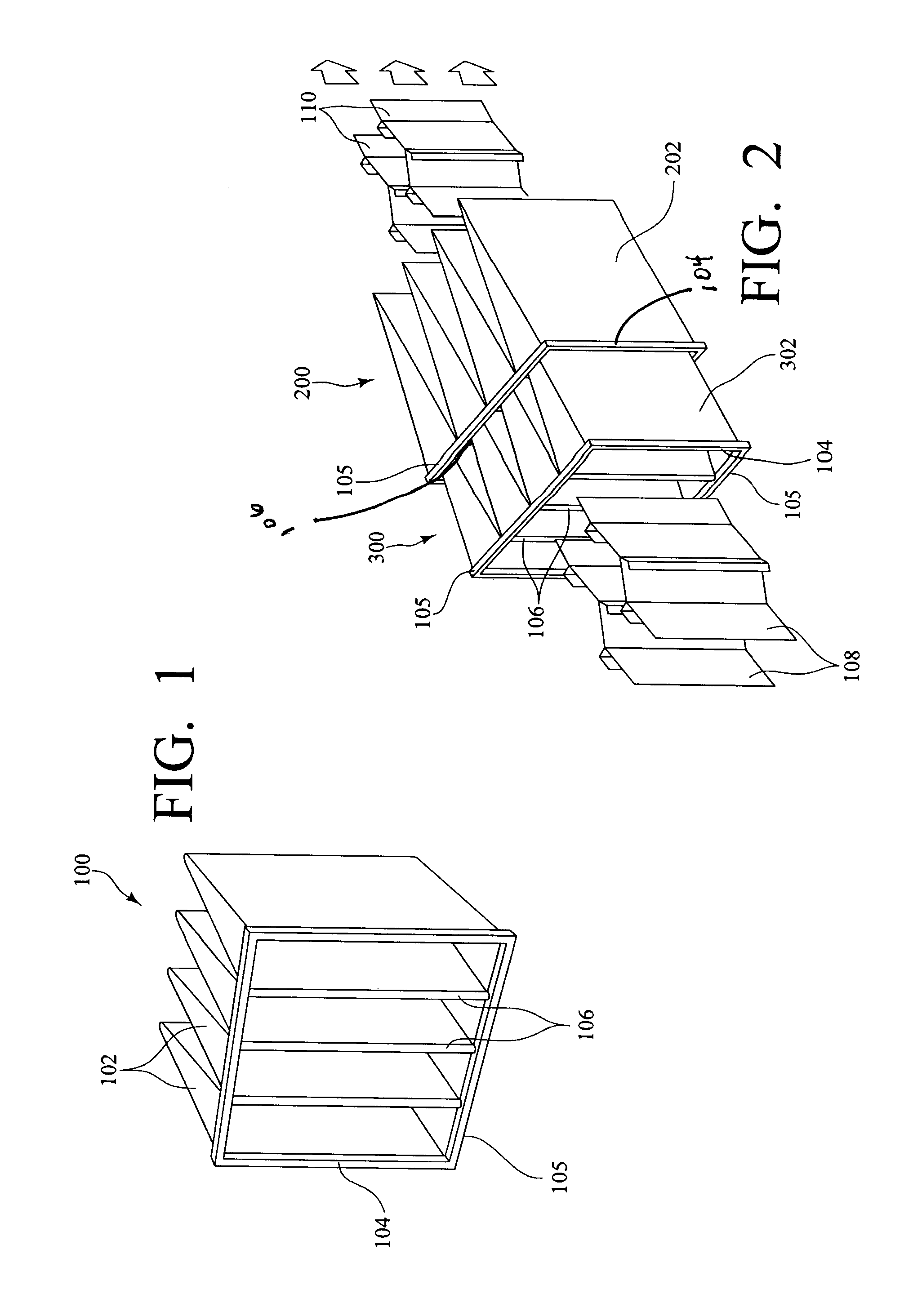

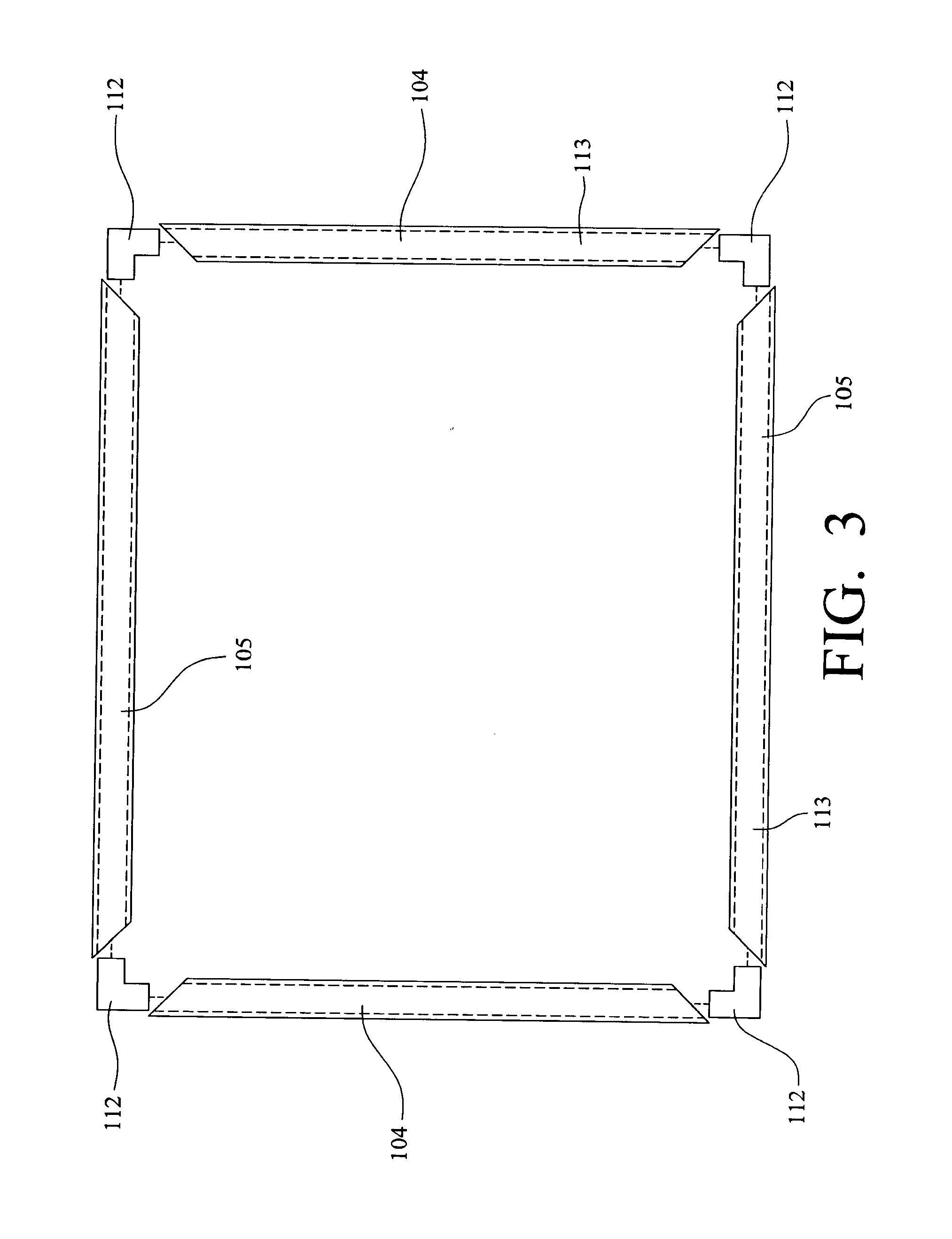

Method of Making a Marine Gas Turbine Filter

A method for making a pocket filter assembly is provided. Two side and two end header elements each having a pair of longitudinally extending side walls and a longitudinally extending bottom wall forming a longitudinally extending channel are joined at ends forming a rectangular header with two opposing sides and two opposing ends. The bottom wall and side walls of each of the opposing sides and the bottom walls and said side walls of each of said opposing ends become adjacent forming a rectangular header with a continuous bottom wall and continuous inner and outer side wall having a continuous channel therein. An upstream perimeter portion of a pocket filter element is inserted in the continuous channel and a liquid polymeric material is placed therein. The polymeric material is solidified forming a header frame having the upstream perimeter portion of the filter element unitary therewith.

Owner:AAF MCQUAY INC

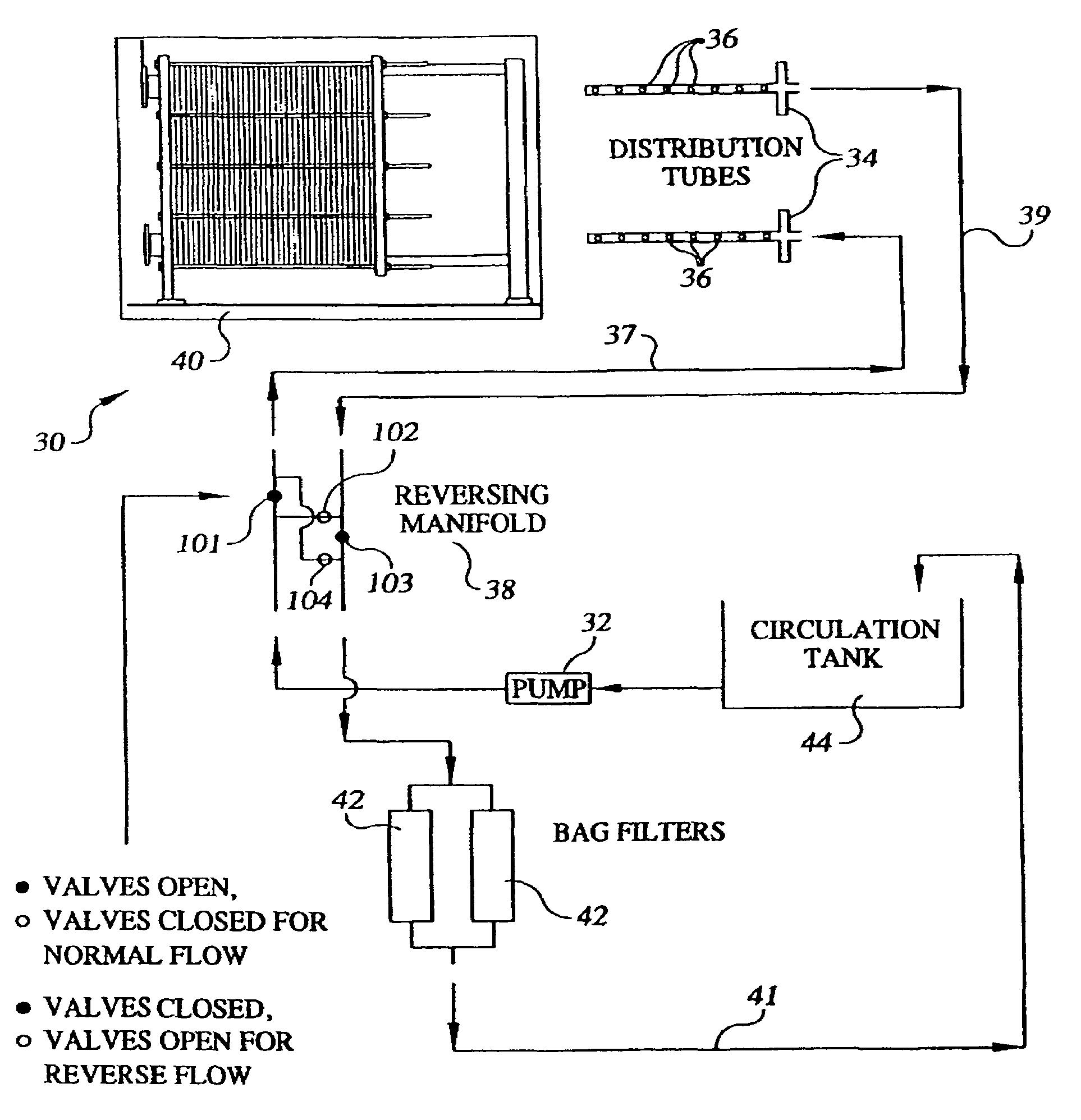

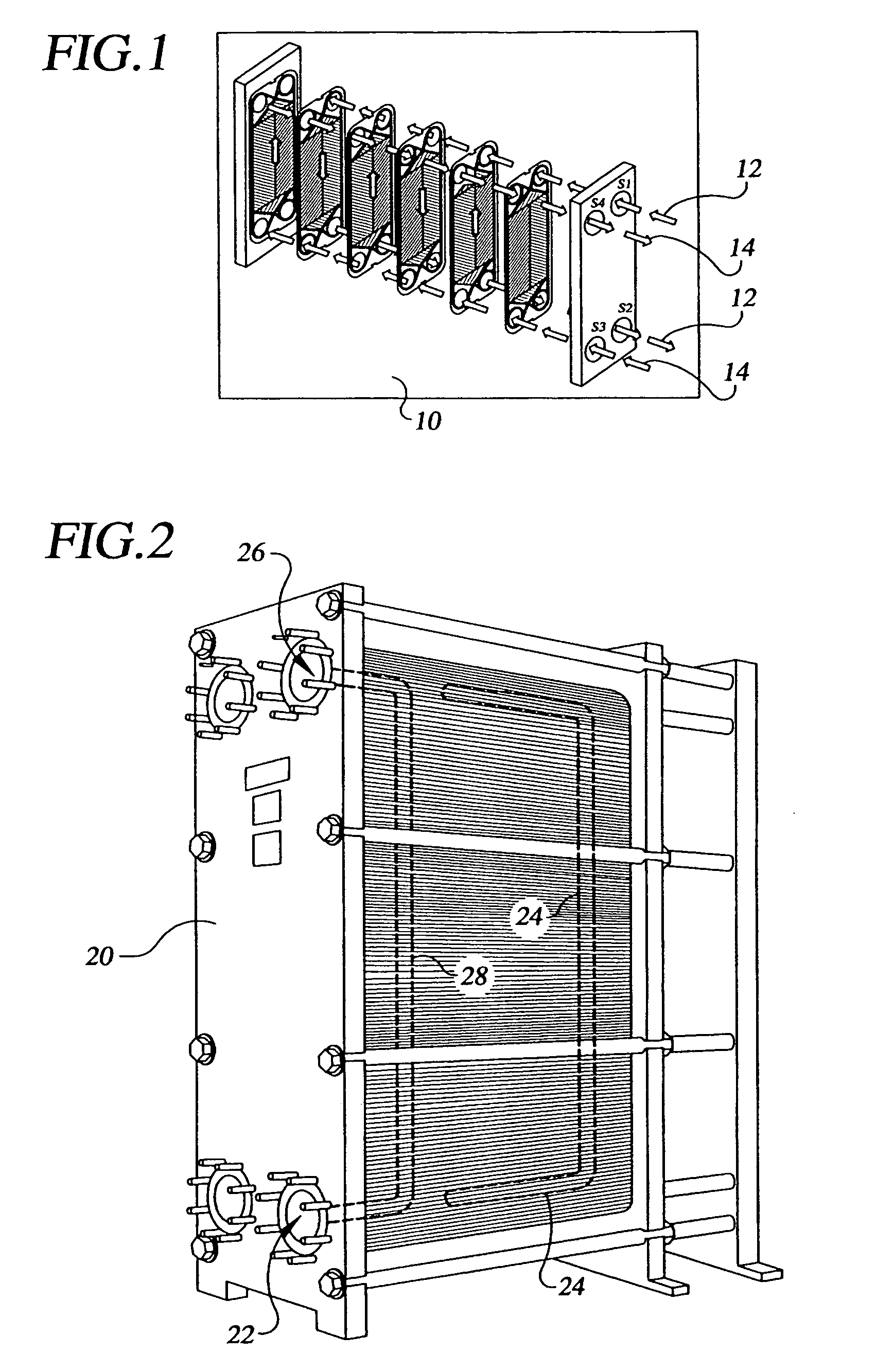

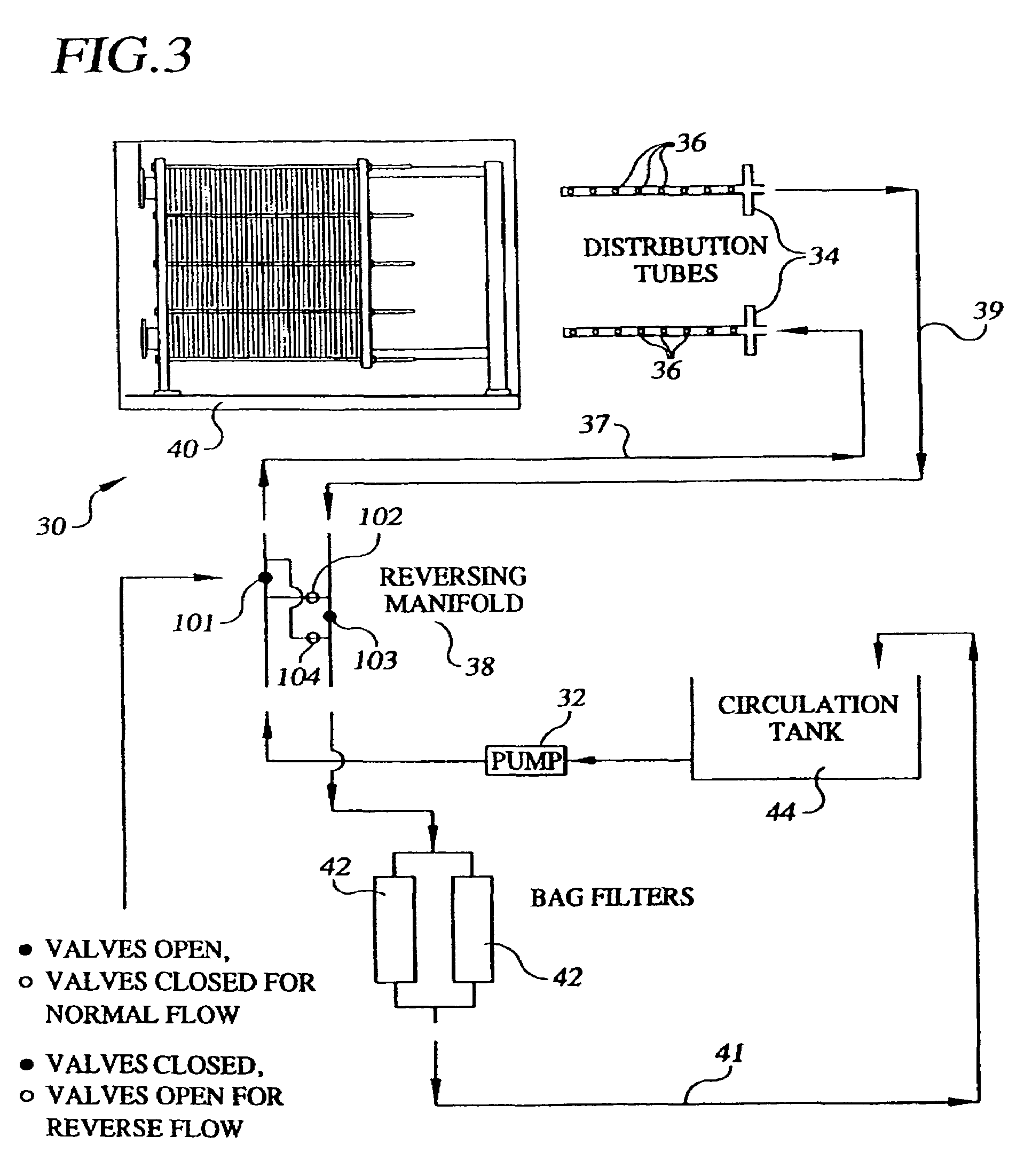

Portable cleaning apparatus and method for single pass plate and frame heat exchangers

InactiveUS6978793B1Reduce the amount requiredEasy extractionCombustion processHollow article cleaningParticulatesWorking fluid

A portable apparatus and method for chemically cleaning a single pass plate and frame heat exchanger allows the cleaning solution to be uniformly distributed across the plate pack. This portable system of one pump of preferably 10-horsepower, capable of 300 gallons per minute flow through a discharge port; at least two distribution / collection tubes with apertures of predetermined diameter and predetermined placement; one reversing manifold; two bag filters; and one circulation tank with a capacity at least on the order of 150 to 200 gallons; attaches to a single pass plate and frame heat exchanger. The single pass plate and frame heat exchanger is configured with at least two removable flanges that, once removed, allow for the installation of the distribution / collection tubes. The apertures in the distribution / collection tubes are placed facing downwards depending upon the direction of the operational fluid to enhance a vacuuming effect for particle and debris removal during cleaning. The distribution / collection tubes are skewed off-center of the flanges, with an ability to be rotated in at least four different directions off-center, and generally located towards the bottom of the single pass plate and frame heat exchanger to facilitate particulate removal and uniform distribution of cleaning solution.

Owner:PHEX

Process for tinting plastic articles

Owner:COVESTRO LLC

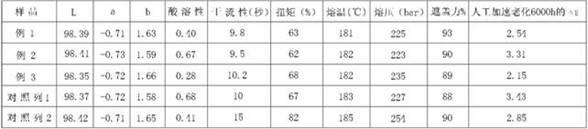

Method for preparing special titanium dioxide pigment for plastic sectional materials by chlorination method

ActiveCN102070921APrevent chalkingGood weather resistancePigment treatment with organosilicon compoundsPigment physical treatmentPhosphateSlurry

The invention provides a method for preparing special titanium dioxide pigment for plastic sectional materials by a chlorination method, which comprises the following steps that: the chlorination method is adopted for preparing titanium dioxide primary products into slurry, and the pH value of the slurry is regulated to 4.0 to 5.0; phosphate dispersing agents are added; grinding treatment is carried out, then, grinding media is removed, and the temperature is raised; water-soluble silicate solution is added, the pH value of the slurry is maintained between 3.5 and 4.5, amorphous silicon oxide is formed, curing is carried out, and a first covering layer is formed; the pH value of the slurry is regulated to 6.0 to 7.0, curing is carried out, and a second covering layer is formed; aluminum salt solution is added, the pH value is controlled between 7.0 and 9.0, curing is carried out, a third covering layer is formed, the pH value of the slurry is regulated to 6.0 to 7.0, and curing is carried out; the slurry is washed by de-ionized water until the conductivity of filter cake is higher than 15000 ohm*cm, and then, drying and air powder treatment are carried out; modified polysiloxane is added in the air powder process, and a fourth organic covering layer is formed; and materials are recovered through a bag filter. The titanium dioxide pigment prepared by the method provided by the invention has the advantages of high weatherability, high shielding capability, high non-transparency and excellent processing performance in the field of plastic sectional materials.

Owner:中信钛业股份有限公司

Filter medium

ActiveUS20060172639A1Excellent in dust-collecting efficiencySmall in rise of pressure lossHuman health protectionDispersed particle filtrationPolymer scienceFilter media

The filter fabric containing polyphenylene sulfide fibers, characterized in that the following (1) and / or (2) is satisfied is used to provide a filter fabric and a bag filter composed of the filter fabric excellent in dust-collecting efficiency and high in mechanical strength: (1) Containing at least two webs, one of which on the dust side contains 50 wt % or more of heat resistant fibers with a fiber, diameter of 15 μm or less, while the other web on the clean side contains 50 wt % or more of heat resistant fibers with a fiber diameter of 20 μm or more (2) Containing a web containing polyphenylene sulfide staple fibers with their fineness kept in a range from 1 to 3 dtex and fluorine-based staple fibers with their fineness kept in a range from 2 to 4 dtex.

Owner:TORAY IND INC

Method for producing hexamethylene tetramin by formaldehyde-containing wastewater

ActiveCN101497617AEfficient use ofHigh purityOrganic chemistryUltrafiltrationSolid componentViscous liquid

The invention relates to a method for producing urotropine by utilizing wastewater containing formaldehyde. Ammonia is added into the wastewater containing the formaldehyde, and the mixture is stirred to react for 3 to 15 hours to obtain a dilute solution of the urotropine under the condition that the pH value is controlled to be between 7 and 12 and the reaction temperature is between 10 and 90 DEG C; one or more devices of a filter press, a bag filter and a precision filter are adopted to remove solid components of the dilute solution of the urotropine, then an activated carbon filter is used to remove a viscous liquid of the dilute solution of the urotropine, then a microporous filter membrane with a pore diameter of between 0.2 and 1mu m is used to remove micron and submicron impurities and floccules in the solution, an ultrafiltration membrane is used to remove soluble macromolecular impurities, and the pollution index of the solution is less than or equal to 5; and the treated solution enters a first-order film for separation, a first-order thin solution is directly discharged or is used for industrial circulating water, a first-order thick solution is collected and stored in a tank when the mass fraction of the urotropine in the first-order thick solution is more than or equal to 6 percent, the first-order thick solution enters a second-order film for the separation, a second-order thin solution returns to the first-order film for the separation, and a second-order thick solution is collected and stored in the tank when the mass fraction of the urotropine in the second-order thick solution reaches more than 10 percent.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

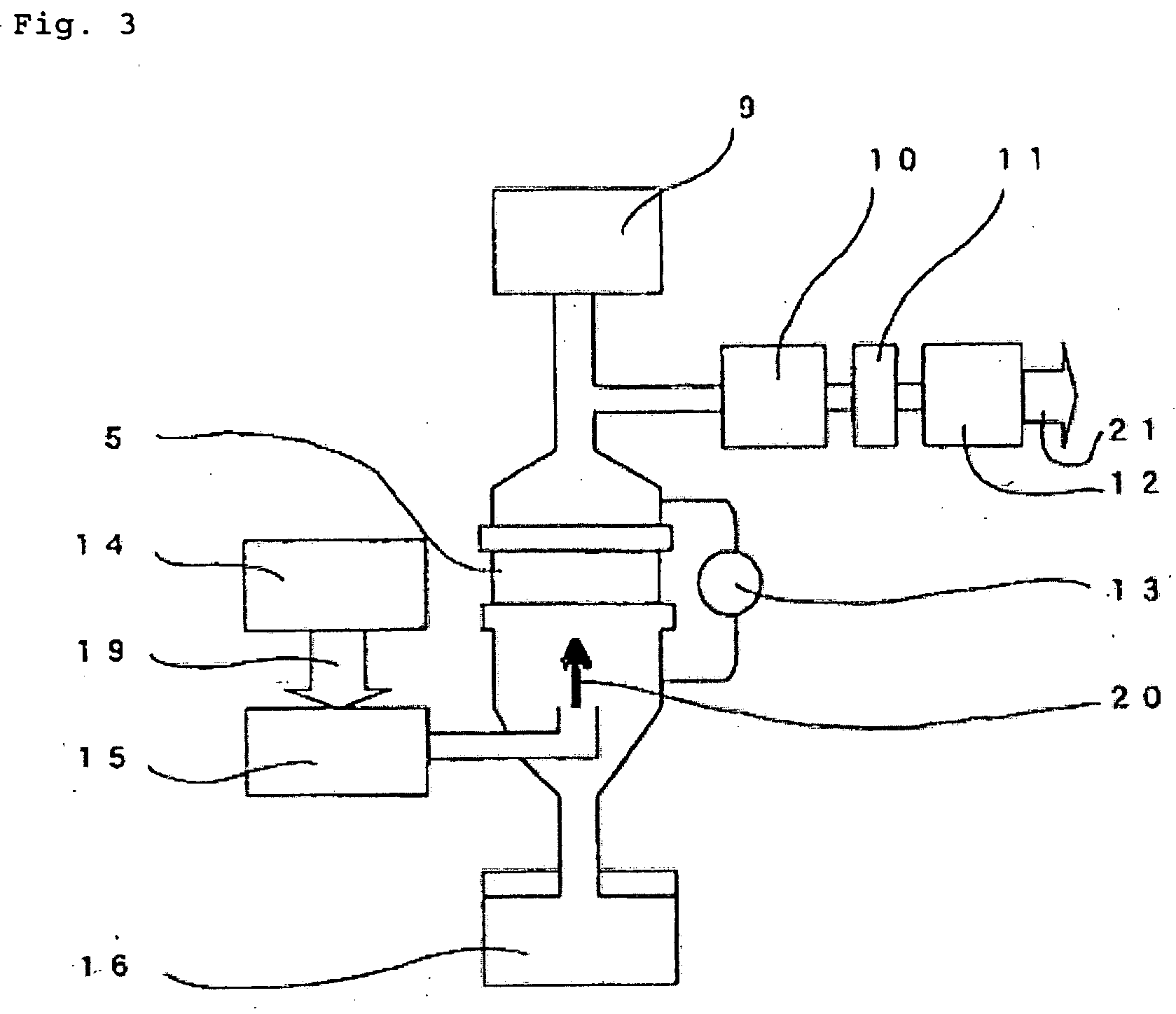

Technique for cooling titanic chloride burner gas

ActiveCN101462766AHigh yieldEmission reductionChemical industryDispersed particle separationEcological environmentAtmospheric air

The invention provides a process for cooling titanium tetrachloride furnace gas, which comprises the following steps: furnace gas discharged sequentially enters a cyclone dust extractor (1) for dust removal, a first cooler (2) for cooling, a spray condensing tower (3) for cooling, a bag filter (4) for filtering, a front leaching tower (5), a rear leaching tower (6), a second cooler (7) for further condensation and a cooling drum (8); waste gases discharged from the cooling drum enter a tail gas washing system and are discharged into the air after meeting discharge standards; and liquid enters a coarse titanium tetrachloride tank (9). The process reasonably uses the heat of the high-temperature titanium tetrachloride furnace gas, improves the recovery rate of TiCl4, reduces the discharge of harmful gases in the tail gas, contributes to environment production, and meets the requirements for establishing an industrial structure which is energy and resource-saving and ecological environment-friendly.

Owner:GUIYANG AL-MG DESIGN & RES INST

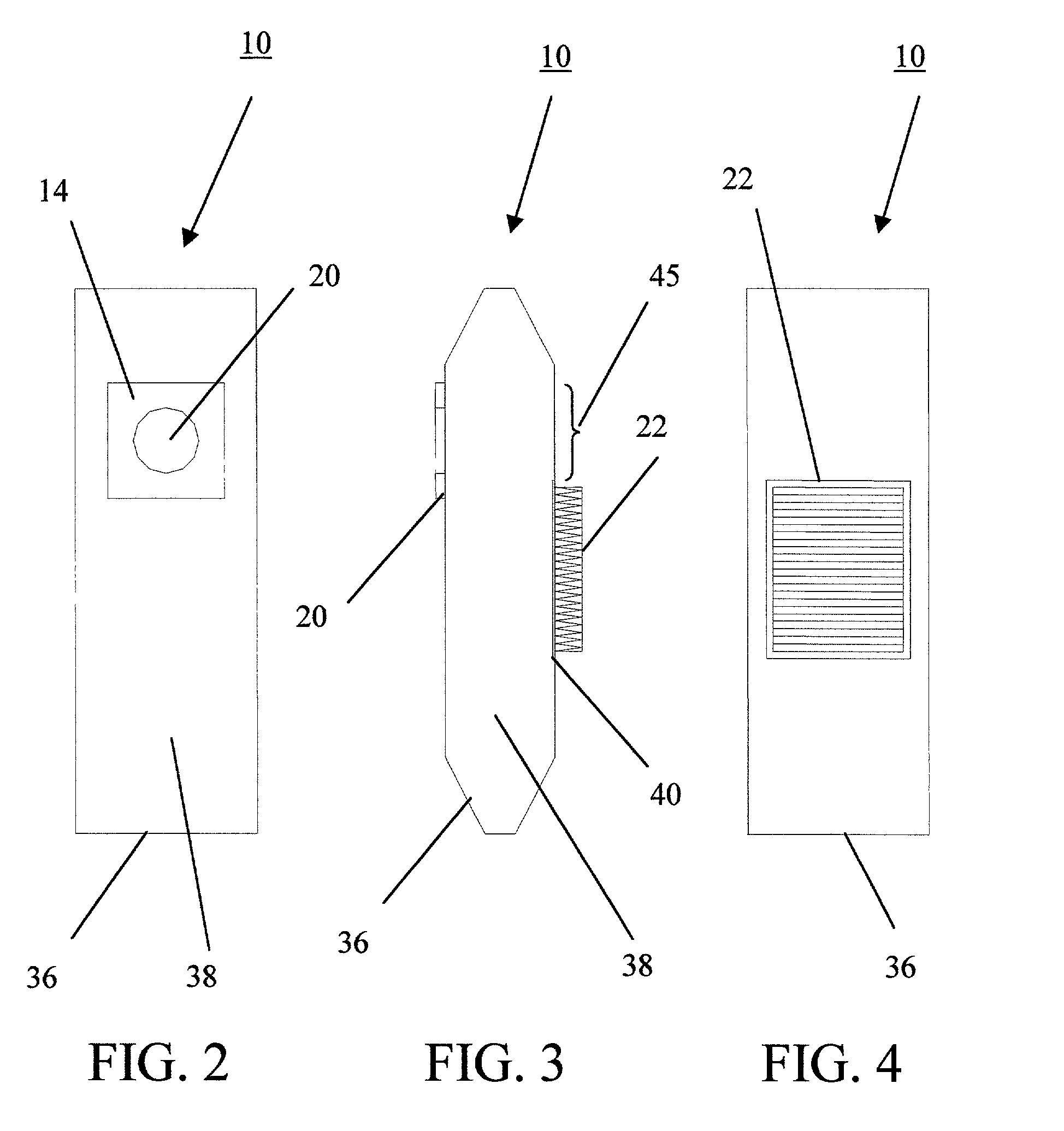

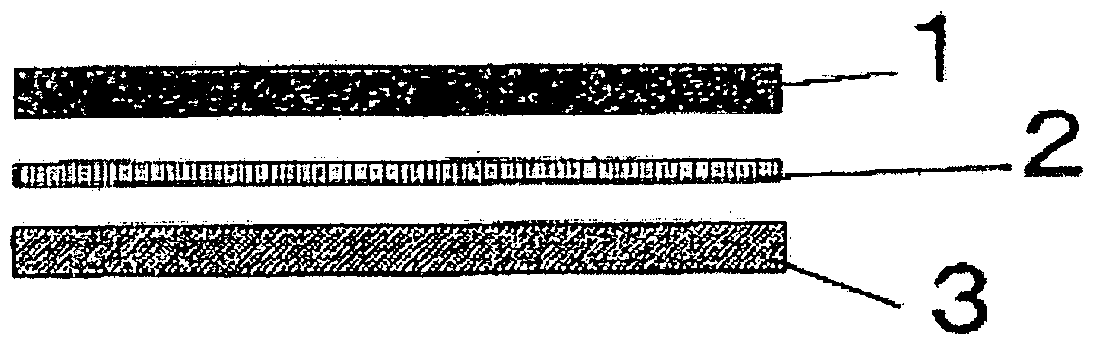

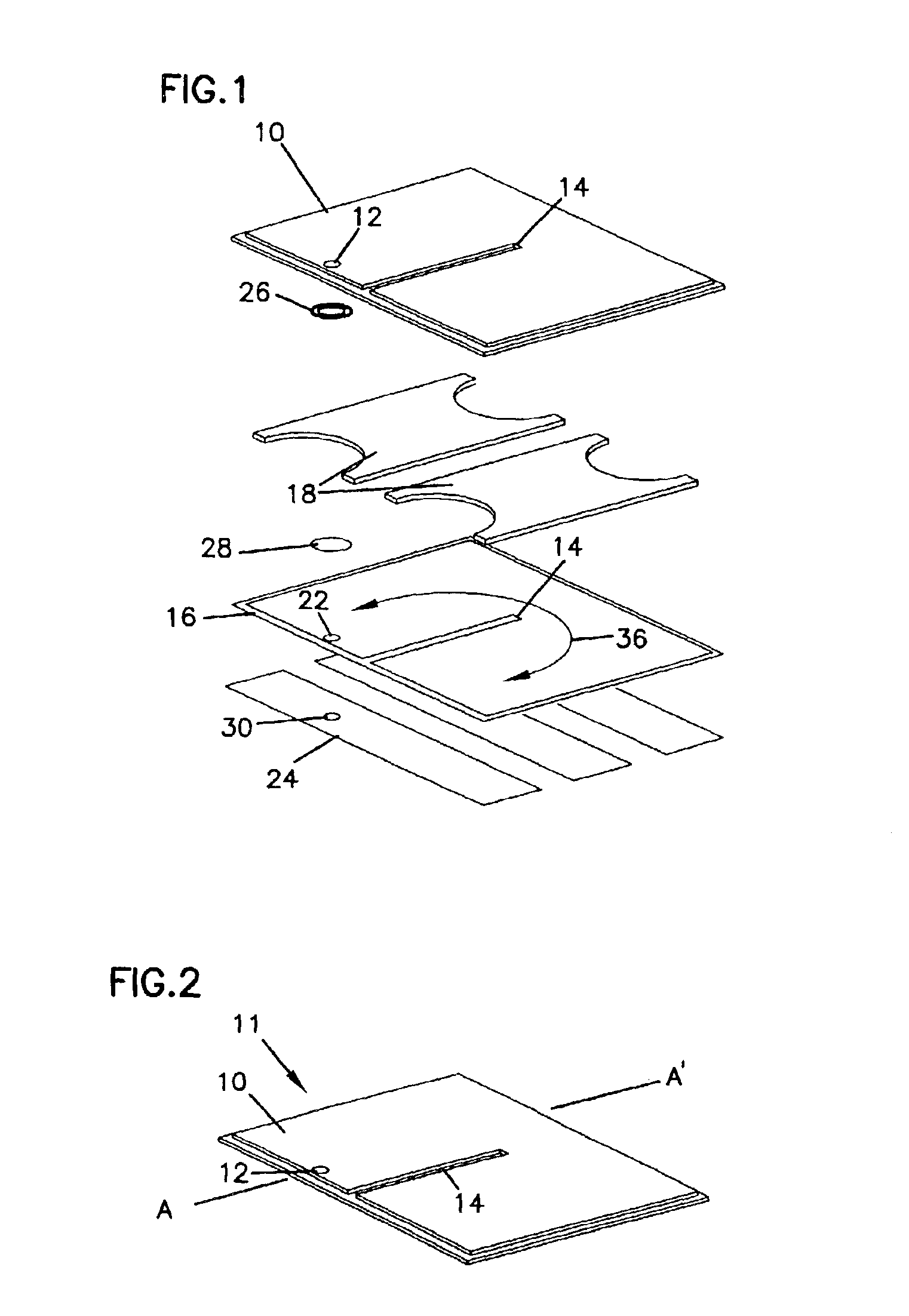

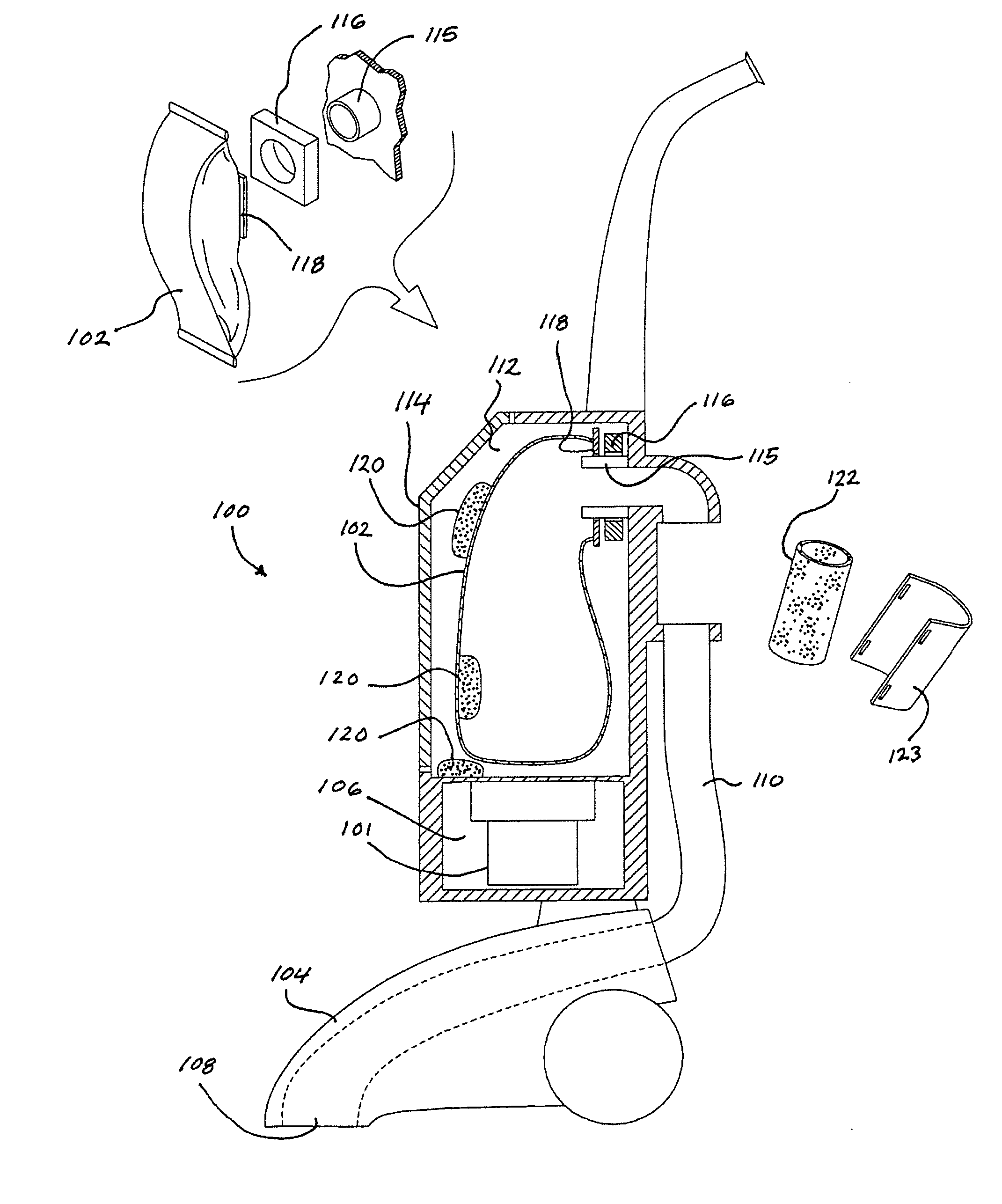

Electronic breather bag filter

A breather bag filter assembly for use with an electronic enclosure, such as a hard disk drive enclosure containing a rotating disk, is disclosed. The filter assembly provides filtration of air entering and exiting an electronic enclosure through a breather hole. The filter assembly is a deformable sealed cavity that exchanges air with the drive enclosure as the air pressure inside the drive enclosure fluctuates. In one implementation of the invention the filter assembly contains three layers of material. Two layers of material form the exterior of the filter assembly surrounding a third layer that is composed of an adsorbent material.

Owner:DONALDSON CO INC

Storm drain grate and filter apparatus and method

ActiveUS20190226193A1Improve permeabilityLess debrisSewerage structuresStationary filtering element filtersResistFiltration

A storm water capture and filtration system may secure in a catch basin or other area subject to flows of water from streets, channels, and the like as a result of run off from storms. A filter system may include a capture portion including attachment mechanisms, a funnel, various supports, and a filter hanger designed and calculated to capture all water entering a storm water inlet and directing it toward a bag filter. A gap is provided between a funnel and filter hanger in order to provide accommodation for overflow, while an anti-backflow skirt on the filter bag resists flushing of captured pollution out of the bag in overflow condition.

Owner:FROG CREEK PARTNERS LLC

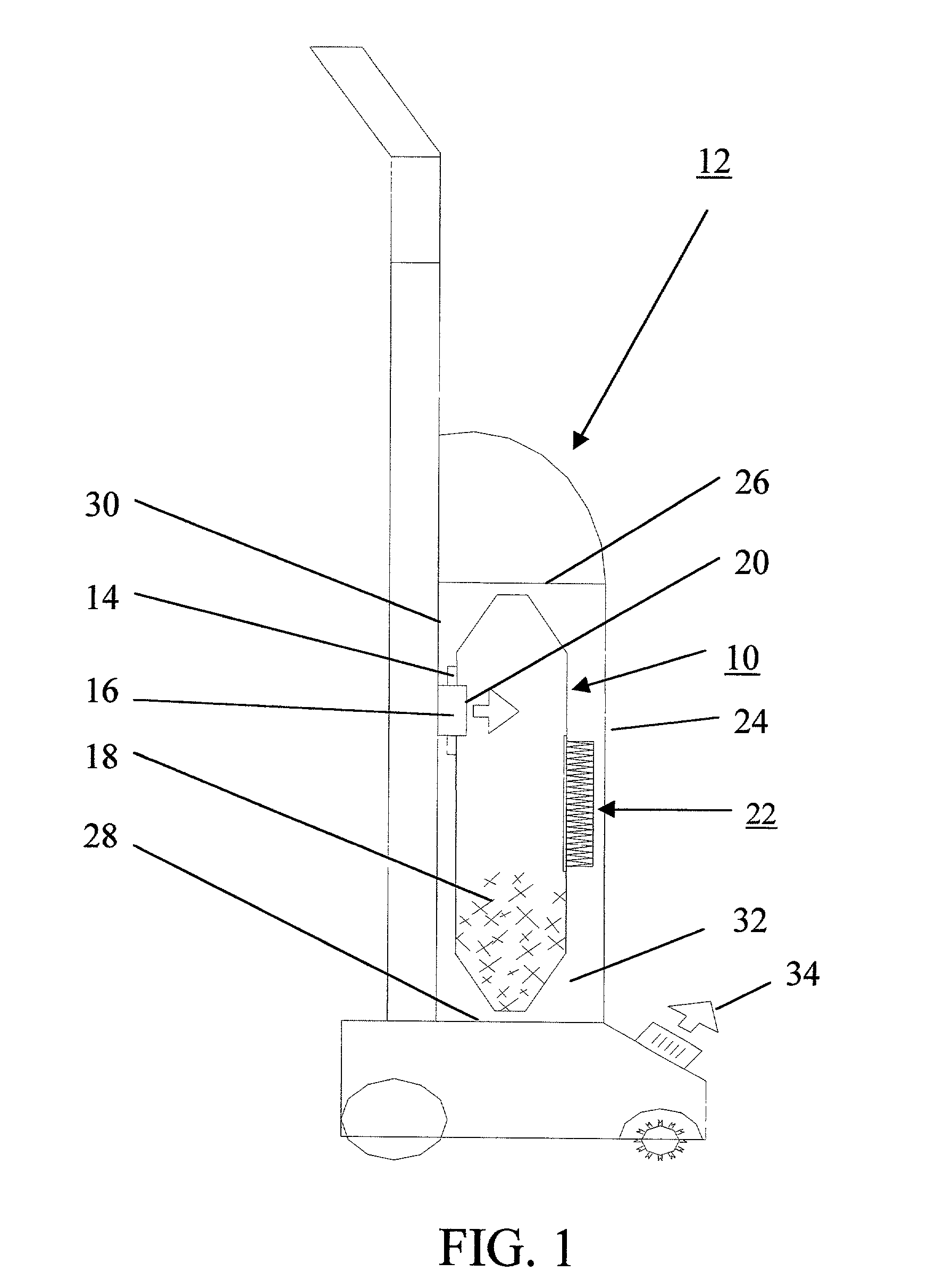

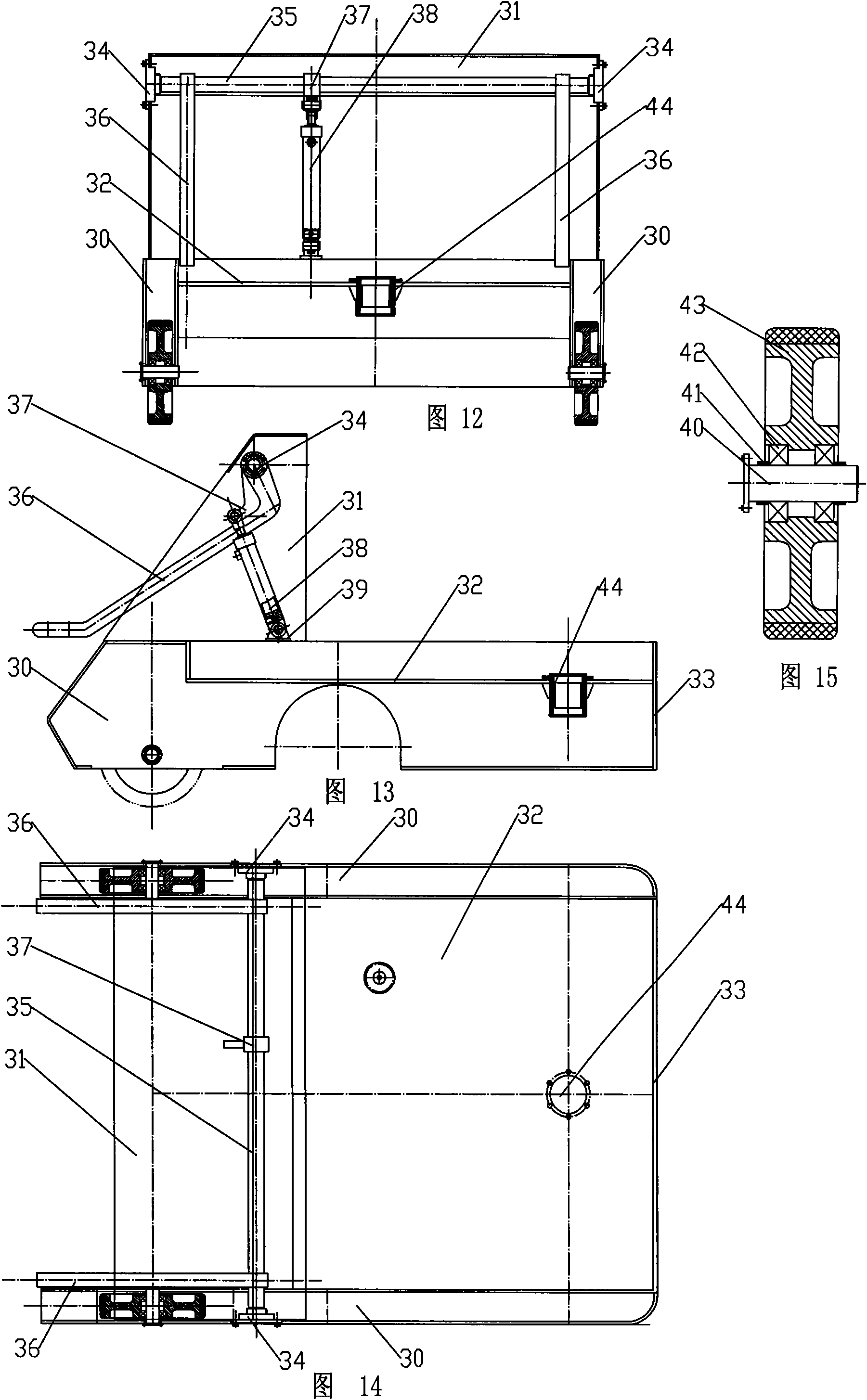

Hydraulic self-tipping type road sweeping machine driven by solar energy

InactiveCN101666072AImprove cleaning efficiencyAvoid dustBatteries circuit arrangementsPhotovoltaicsVehicle frameLarge capacity

The invention relates to a hydraulic self-tipping type road sweeping machine driven by solar energy, and because a sweeping and negative pressure mechanism with large capacity is utilized, dust pollution can not generate completely. According to the technical scheme provided by the invention, a negative pressure tank is arranged in front of a vehicle frame, and a rolling sweeping mechanism is arranged at the bottom of the vehicle frame; the upper part of the front end of the vehicle frame is hinged with a crank mechanism, and the crank mechanism is connected with the negative pressure tank atthe same time; a bag type filter is arranged in the negative pressure tank; an induced draft fan, a walking mechanism and a steering system used for controlling the walking direction of the sweeping machine are arranged on the vehicle frame, and the steering system is connected with the walking mechanism; the air inlet of the induced draft fan is connected with the air outlet of the negative pressure tank, and the air inlet of the negative pressure tank is near the rolling sweeping mechanism; a top protection rack is arranged at the upper part of the vehicle frame, a solar panel is arranged onthe top protection rack, and the solar panel is used for charging a battery on the vehicle frame through a controller; and the battery is used for providing power for the induced draft fan, the rolling sweeping mechanism and the walking mechanism.

Owner:缪慰时

Sodium bicarbonate vacuum bag inserts

A vacuum cleaner bag filter with one or more filter walls forming a generally air permeable enclosure having a bag opening through it, and a flange attached to the one or more filter walls to cover the bag opening. The filter walls have a working surface area through which air can pass during use, and the flange is a relatively rigid structure having an air inlet passing into the air permeable enclosure. One or more deodorizing sheets are attached to an inner surface of the one or more filter walls. The deodorizing sheets include a first sheet layer, and sodium bicarbonate particles operatively associated with the first sheet layer. The deodorizing sheets may cover less than about 30% of the working surface area, a single deodorizing sheet may be provided, and the deodorizing sheets may be attached to the filter walls by an air impermeable adhesive that covers at least about 5% of the surface area of the deodorizing sheets. Also provided is a vacuum cleaner filter having a filter and a deodorizing sheet attached thereto by an air-impermeable adhesive.

Owner:ELECTROLUX HOME CARE PRODS

Static electric cloth bag compact mixed type dust remover and its running method

InactiveCN101121152AGuaranteed efficiencyGuaranteed removalCombination devicesElectrode constructionsFlue gasEngineering

An electrostatic bag closely hybrid dust remover and the operation method are mainly used for the flue gas disposal in a power plant etc. A grounding collecting plate is placed between a high voltage discharge electrode and the bag inside a dust removing room. An electrostatic dust removing area is formed by two sides of the high voltage discharge electrode and the grounding collecting plate; a filtering and dust removing area is formed by two sides of the bag and the grounding collecting plate. When the bag filters, the grounding collecting plate is closed, and the flue gas enters into the dust removing room and goes through the electrostatic dust removing area to arrive at the end of the grounding collecting plate and then enters into the filtering and dust removing area. When the bag reversely blows and cleans ash, the grounding collecting plate opens, the gas and dust for reverse blowing and ash cleaning pass through the grounding collecting plate directly and reach the electrostatic dust removing area, and the dust for reverse blowing and ash cleaning is collected by static electricity. Compared with the prior invention, the dust removal is separated into two steps: when the bag filters, an electrostatic dust remover is completely used to greatly reduce a dust-containing concentration of the flue gas which enters into the bag; when the bag reversely blows and cleans ash, the electrostatic dust remover is used to effectively remove the dust for ash cleaning.

Owner:TSINGHUA UNIV +1

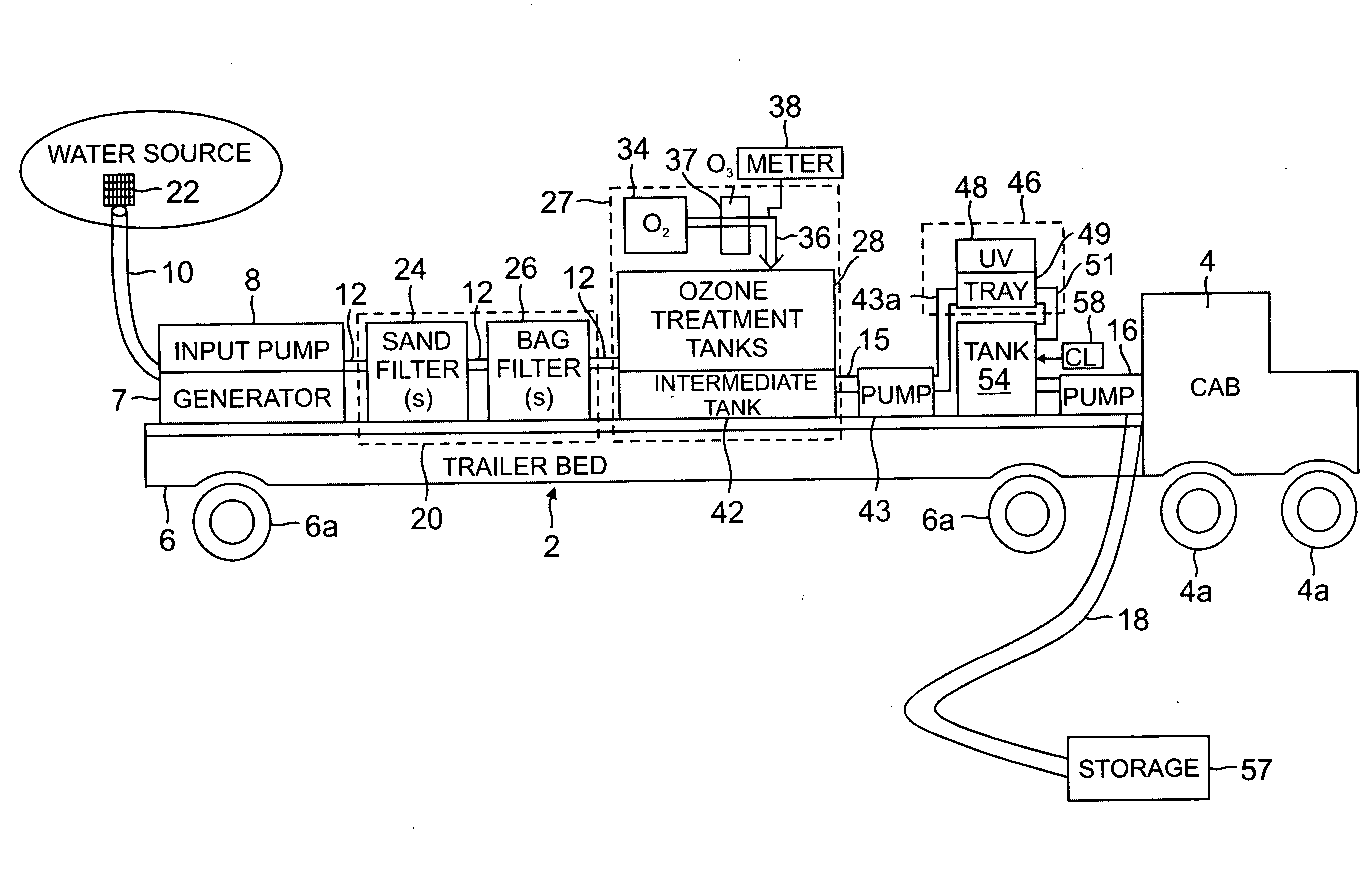

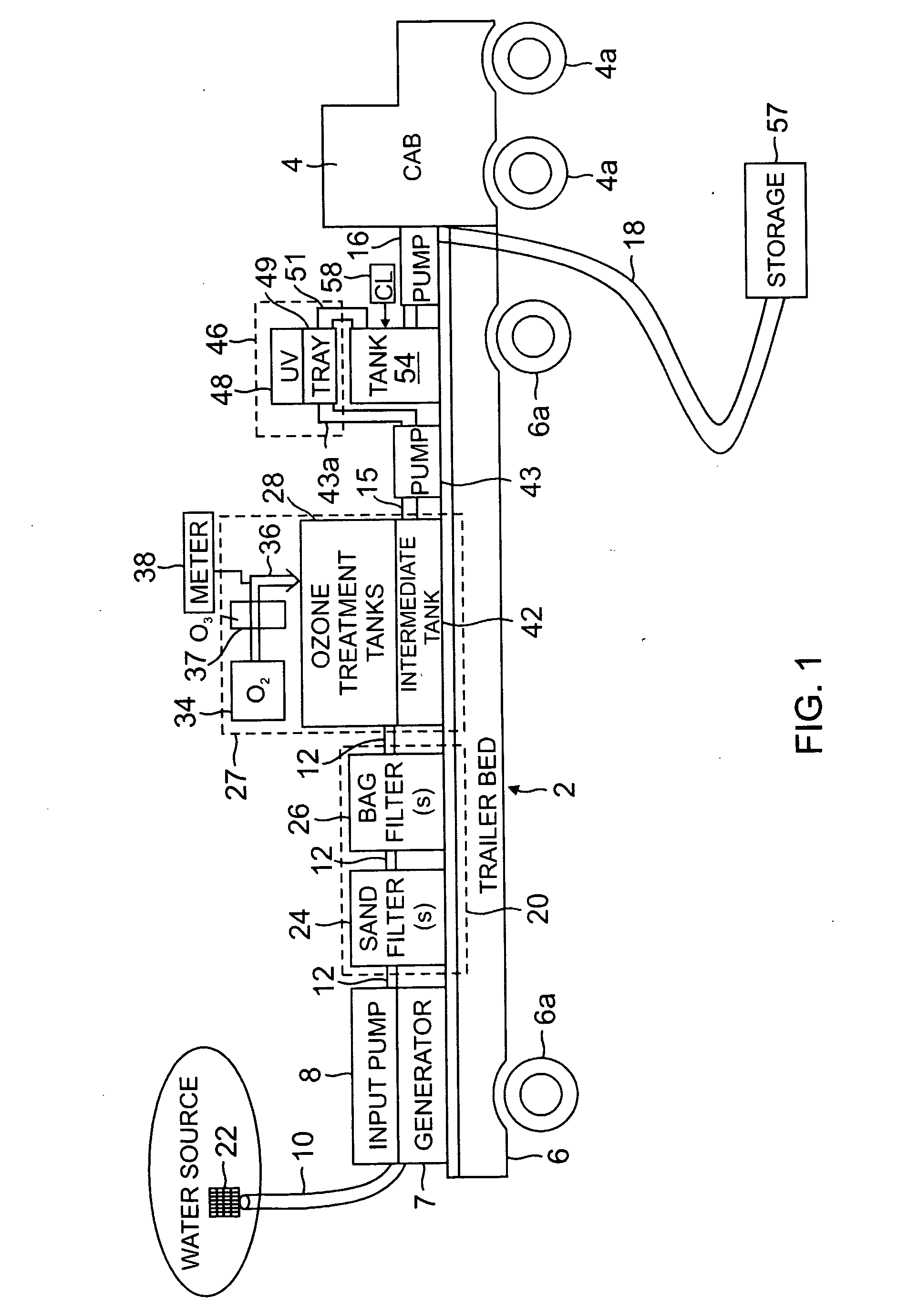

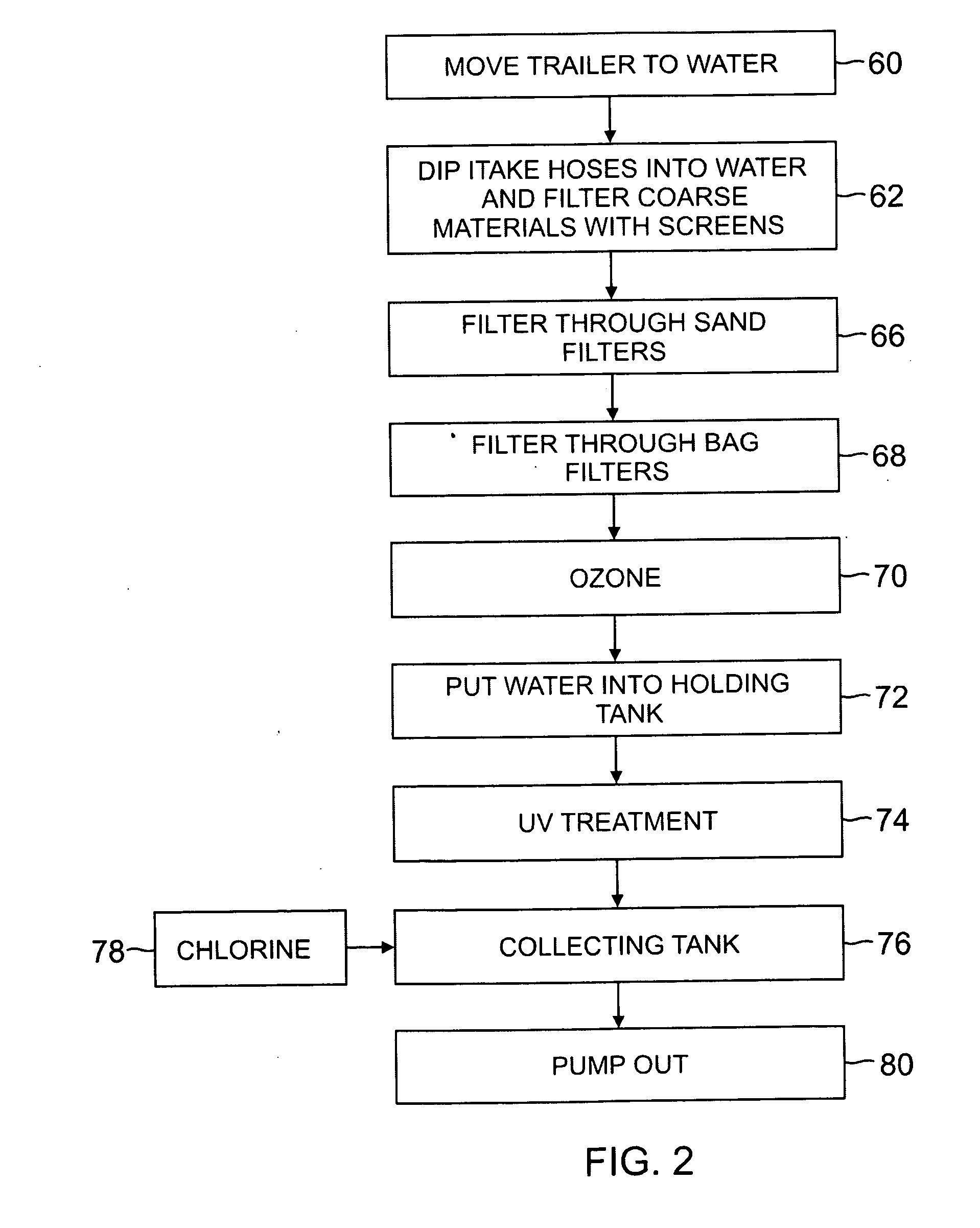

System and method of water treatment

InactiveUS20090250407A1Maximize transportMinimize ozone breakdownGeneral water supply conservationTransportation and packagingWater useHolding tank

A mobile water treatment system is disposed on a trailer of a truck. There is an intake filter, an intake hose, a pump or multiple pumps for water intake and sending water throughout the system, a filtering section that may include sand and / or bag filter or other types of filters, an ozone treatment section after the filters, a holding tank after the ozone section, a UV treatment section after the holding tank, and a chlorination tank. The water may then be sent to a water storage facility or other place as desired. The system includes a generator for power to run the system, and a controller for the system. The ozone section makes use of a misting nozzle in order to increase ozone contact time, and decrease ozone breakdown. The UV section makes use of a slightly downward tilted table with UV bulbs and reflectors above it, and preferably is mounted on a leveling system. A method of treating water uses the mobile system.

Owner:NEOS INT LLC

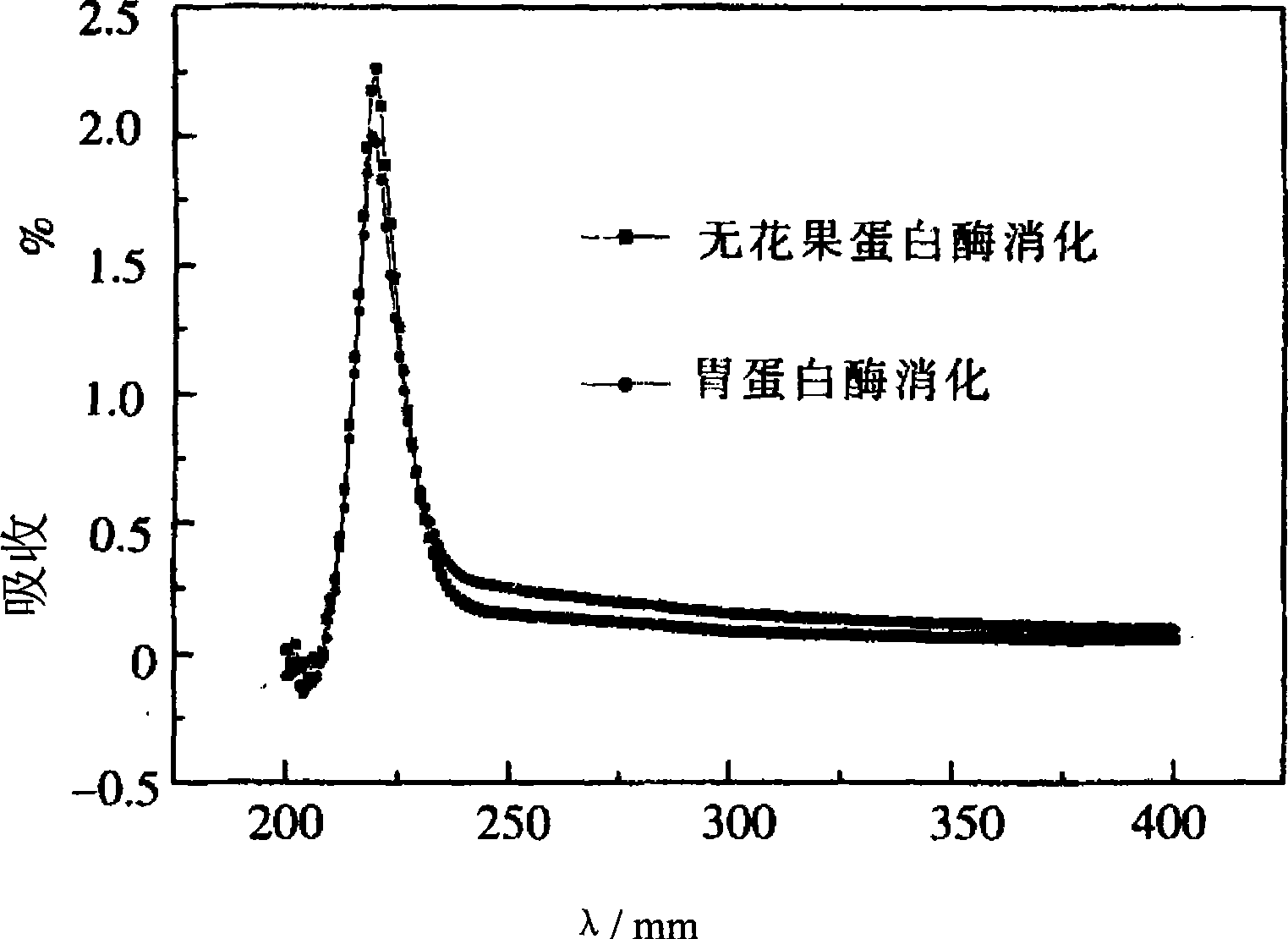

Method for preparing collagen protein

InactiveCN101363040AComplete triple helixComplete bioactive structurePeptide preparation methodsFermentationCollagen VIAponeurosis

A method for preparing collagen comprises the steps: 1) preliminary treatment of materials: body fat and aponeurosis of fresh beef tendon are removed, and then the beef tendon is soaked in 0.1 plus or minus 0.05% of sodium carbonate solution for 4 plus or minus 2h and is rinsed by distilled water for a plurality of times for airing; 2) pretreated beef tendon is added with proteolytic enzyme according to the mass mixture ratio of 0.3 plus or minus 0.1wt% and is added with acetic acid solution to be slowly stirred for 3-5d at the temperature of 1-12 DEG C; and then, the mixture is centrifugated by a high speed freezing centrifuge, and supernatant fluid is taken out and extracted crudely to obtain collagen solution; 3) the purification of the collagen: the crude extracted collagen solution is added with H2O2 solution with the mass percentage of 1 plus or minus 0.5% to be evenly mixed in a rest state for 4 plus or minus 2h, and the pH value is adjusted by 5 plus or minus 1 by trisodium citrate solution; after centrifugation, certain quantity of sodium chloride is added into the residual solution for salting out, and then the precipitate is filled into a bag filter to be dialyzed by acetic acid solution for 1 plus or minus 0.5d and by distilled water for 3 plus or minus 1d; dialysate is changed for 2-3 times every day, and collagen liquid is obtained.

Owner:无锡贝迪生物工程股份有限公司

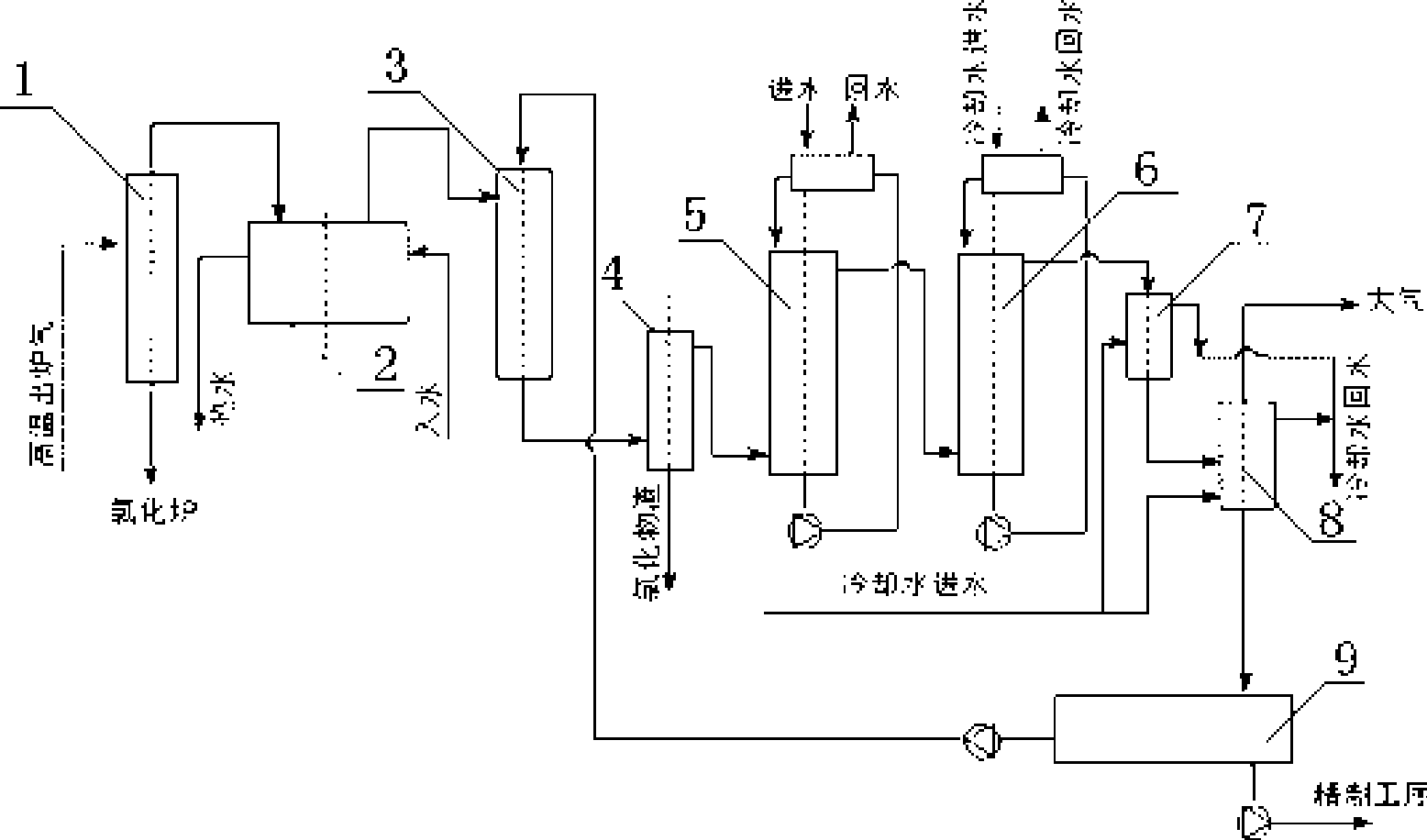

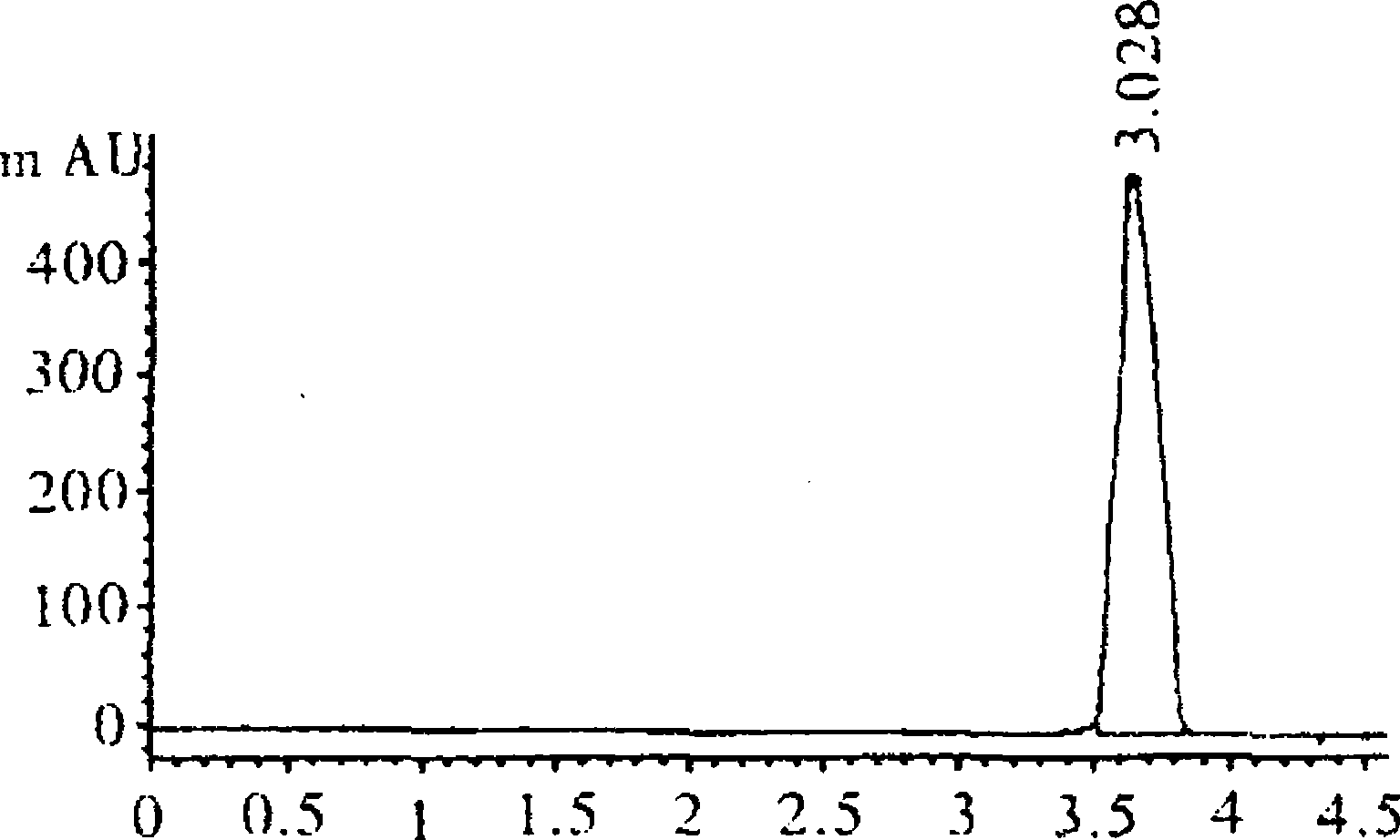

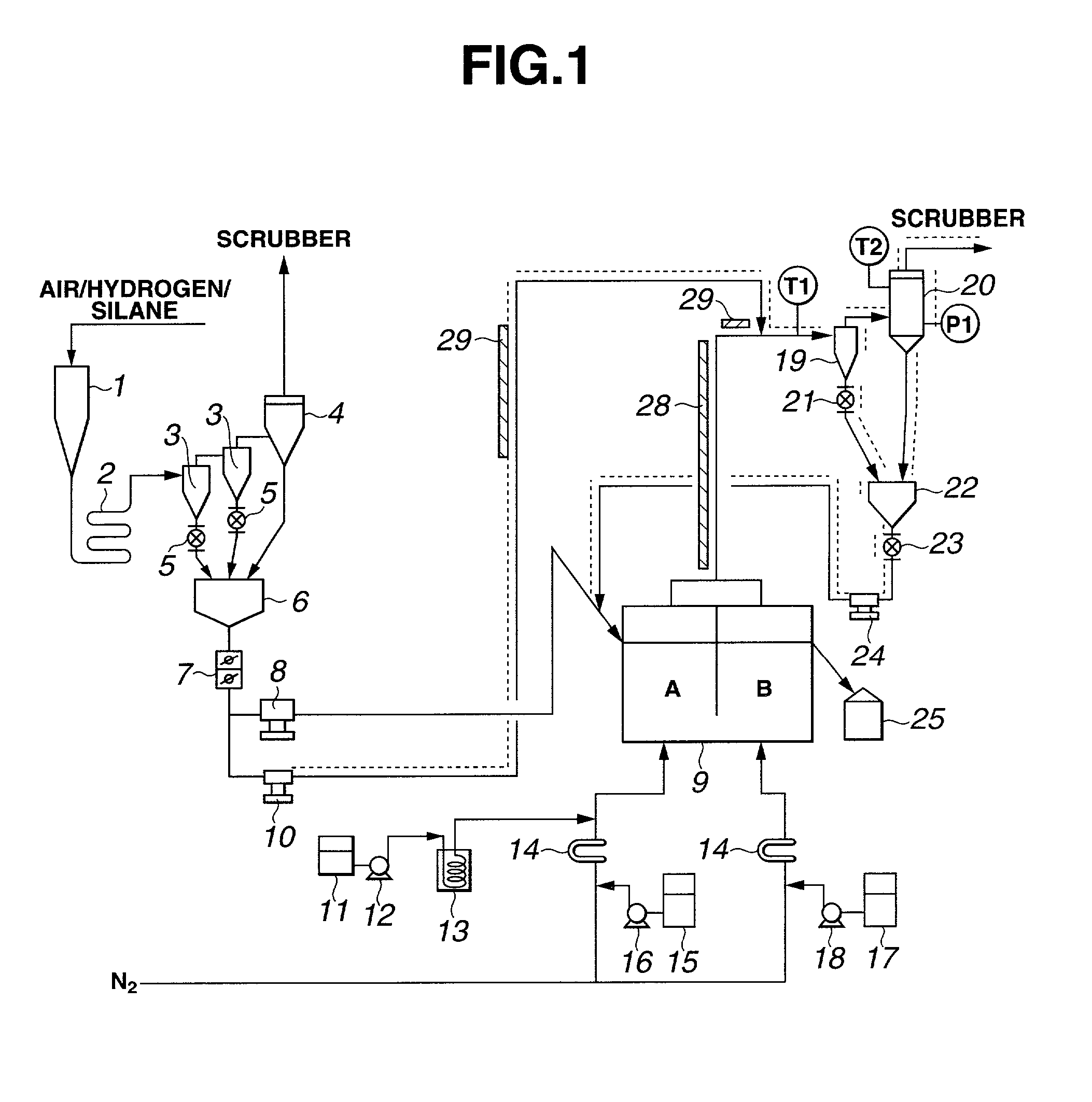

Method for producing hydrophobic silica fine powder

InactiveUS20020025288A1Reduce the amount requiredImprove responseSilicaSemiconductor/solid-state device testing/measurementSilane compoundsHydrophobic silica

Hydrophobic silica fine powder is produced by pyrolyzing a silane compound to form a silica fine powder and hydrophobizing the silica fine powder with an organohalosilane as hydrophobizing agent in a fluidization vessel. A portion of the silica fine powder is bypassed to a waste gas line from the fluidization vessel and collected with a cyclone and bag filter, and the collected powder is fed to the fluidization vessel where it is hydrophobized. The amount of unreacted organohalosilane in the waste gases is reduced, alleviating the burden on waste gas treatment. The silica having the unreacted organohalosilane borne thereon is fed back to the fluidization vessel, increasing the reaction efficiency of organohalosilane.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com