Static electric cloth bag compact mixed type dust remover and its running method

A hybrid dust collector technology, which is applied in the field of electrostatic precipitator, bag filter, and particle removal equipment, can solve the problems of reduced electrostatic dust removal efficiency, consumption of cleaning gas, and accelerated bag aging, so as to achieve full utilization and performance improvement , Reduce the effect of dust collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

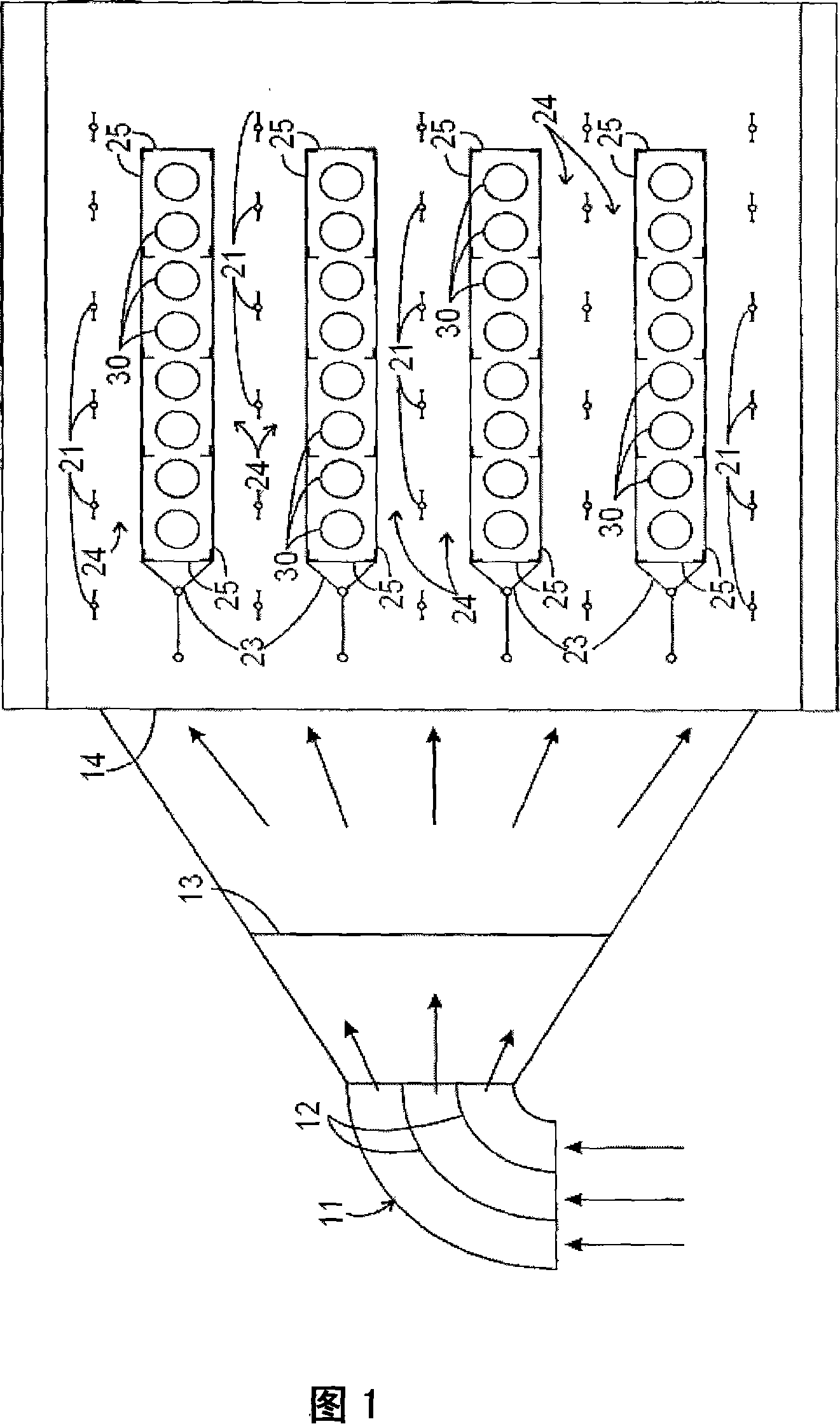

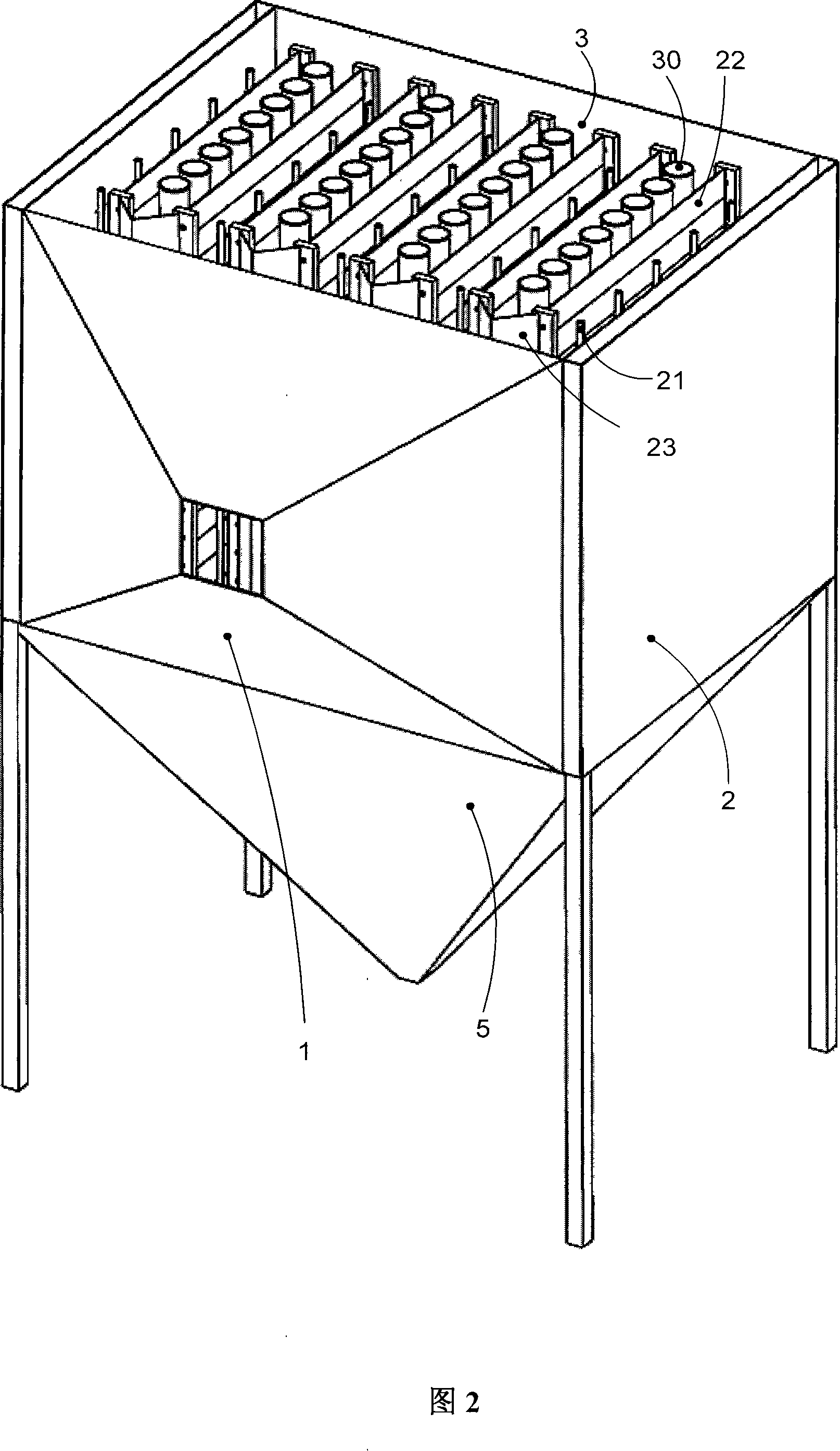

[0030] Fig. 2 is an electrostatic bag close-mixing dust collector for implementing the method proposed by the present invention, which adopts a horizontal louver as a grounded dust collection plate that can be opened and closed. In the figure, the flower board at the outlet of the cloth bag, the clean air chamber above, and the electrode power supply, insulation, vibration, and the dust cleaning auxiliary system of the cloth bag are not drawn. The flue gas enters the dust removal chamber composed of the inlet gradual expansion section 1 of the dust collector, the dust collector side plate 2 and the dust collector rear end plate 3 through the inlet gradual expansion section 1. The air chamber (not shown) is then vented.

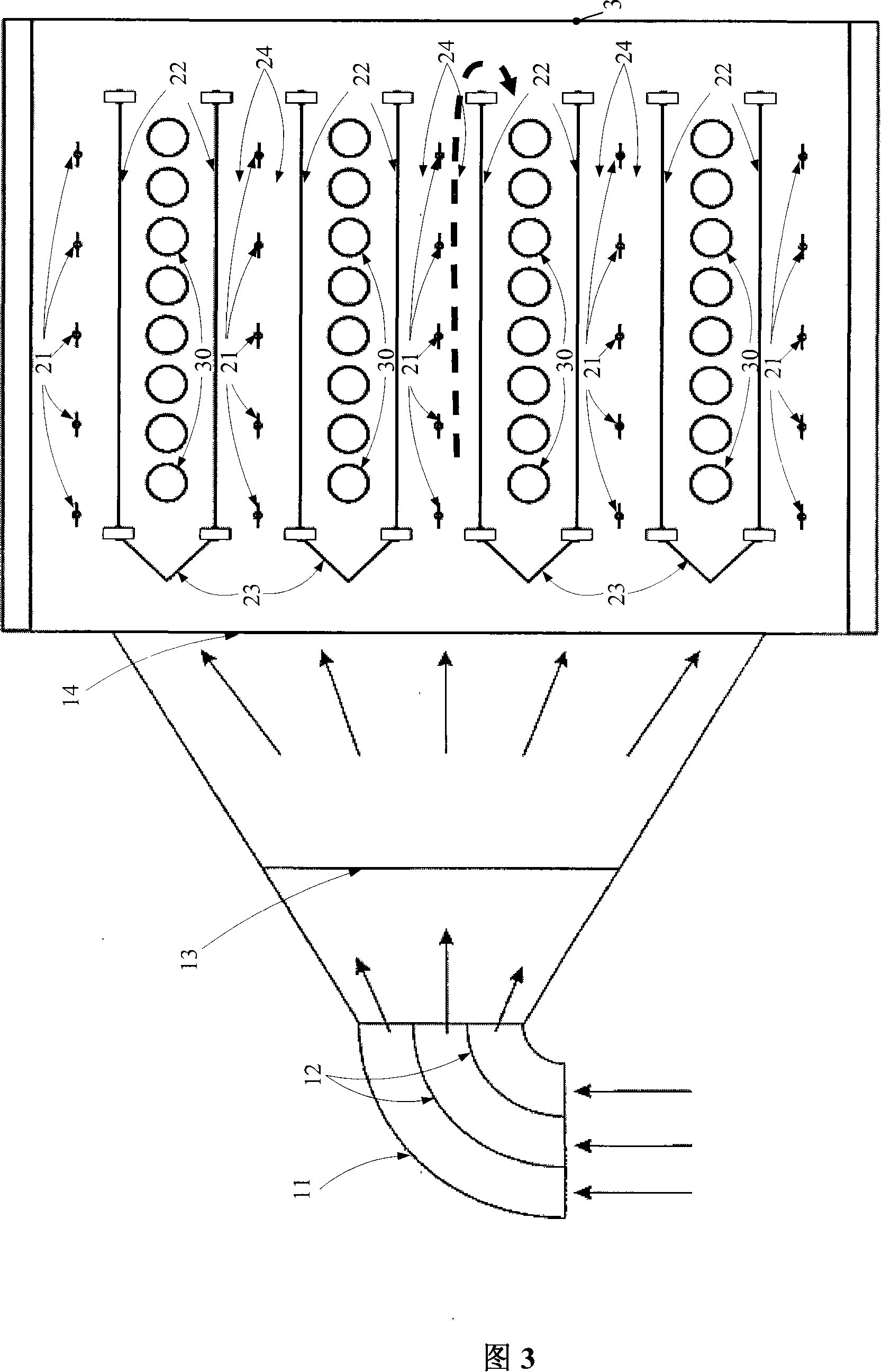

[0031] Fig. 3 is a plan view from the top of Fig. 2, and the bag of the electrostatic bag close-mixing dust collector is in the working condition of filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com