Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Guaranteed removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

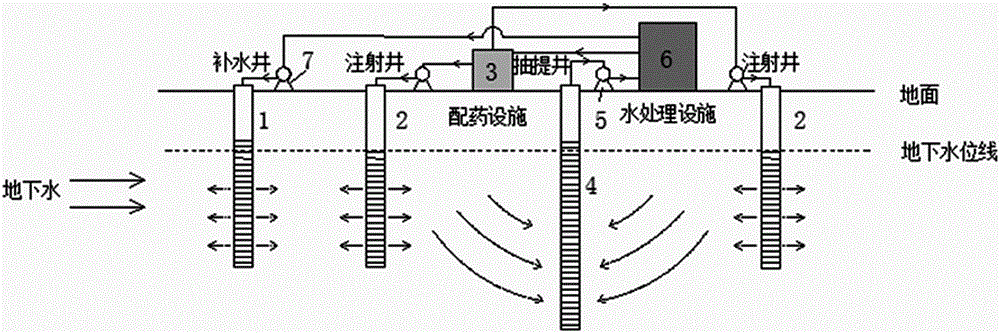

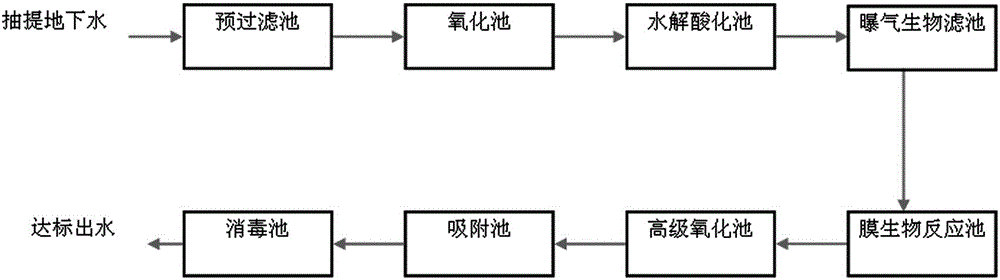

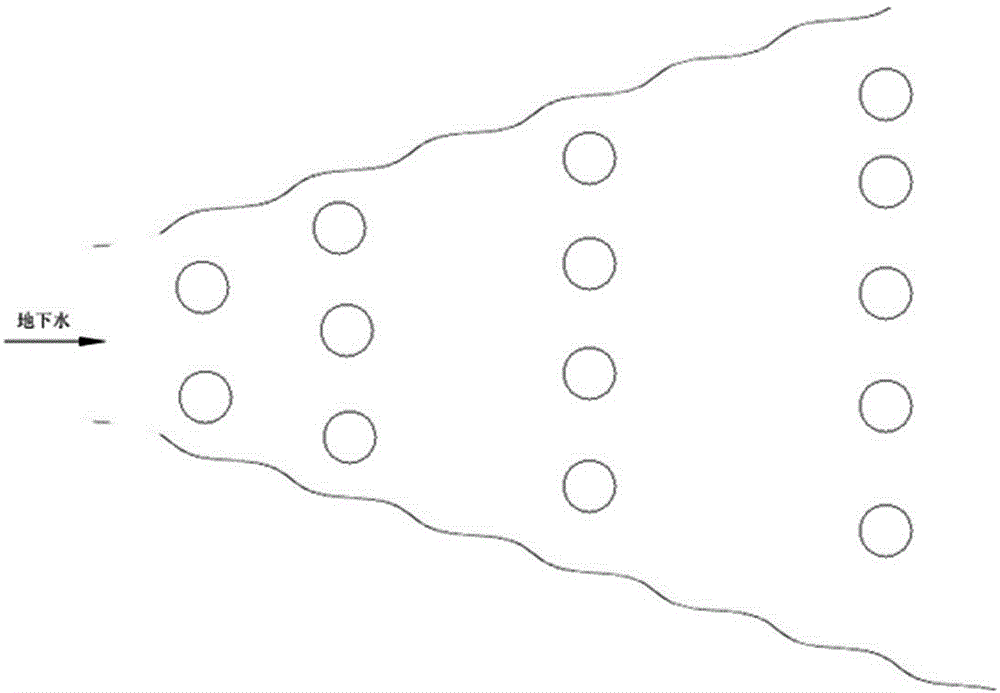

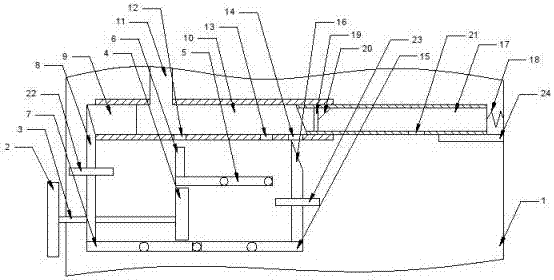

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

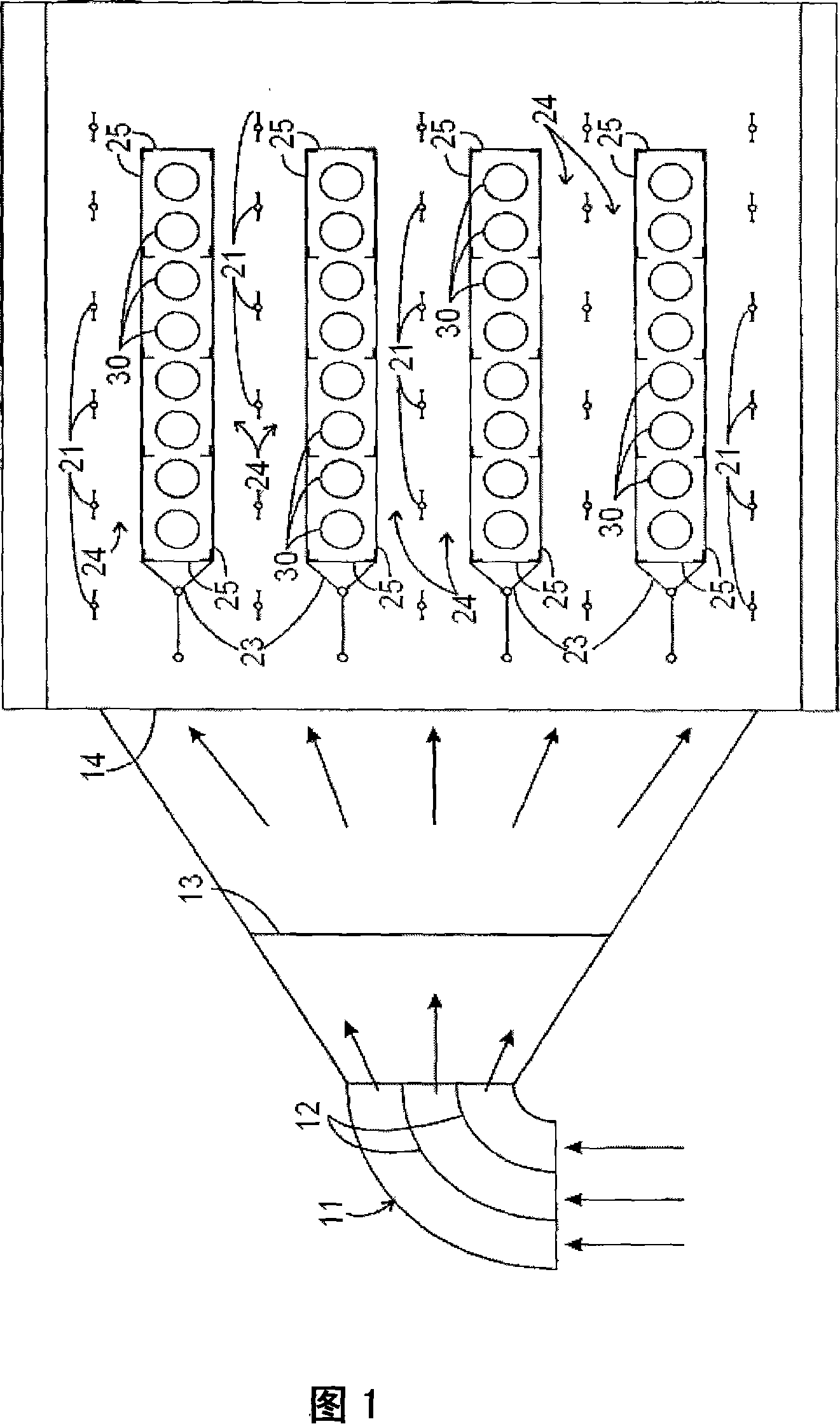

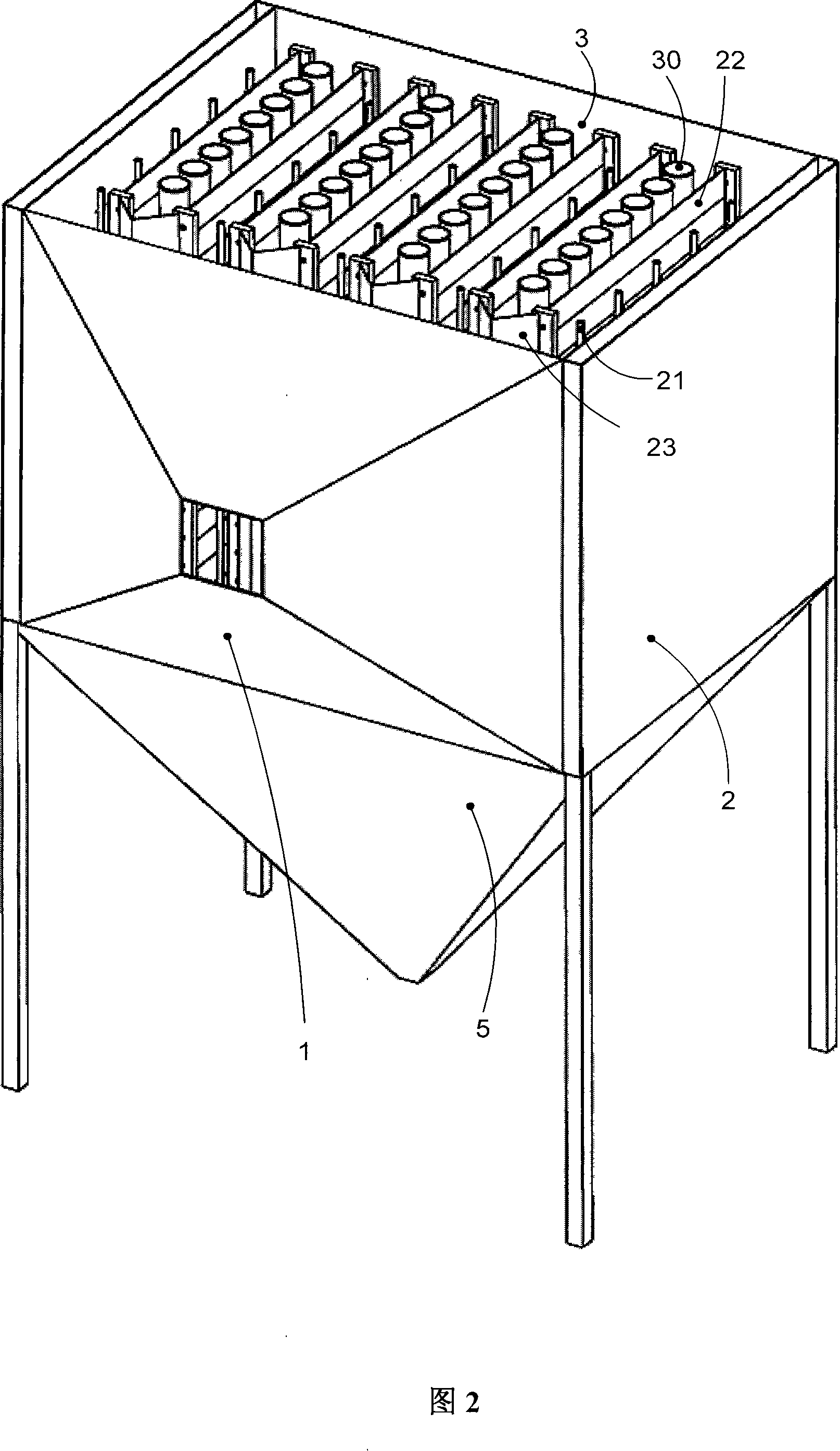

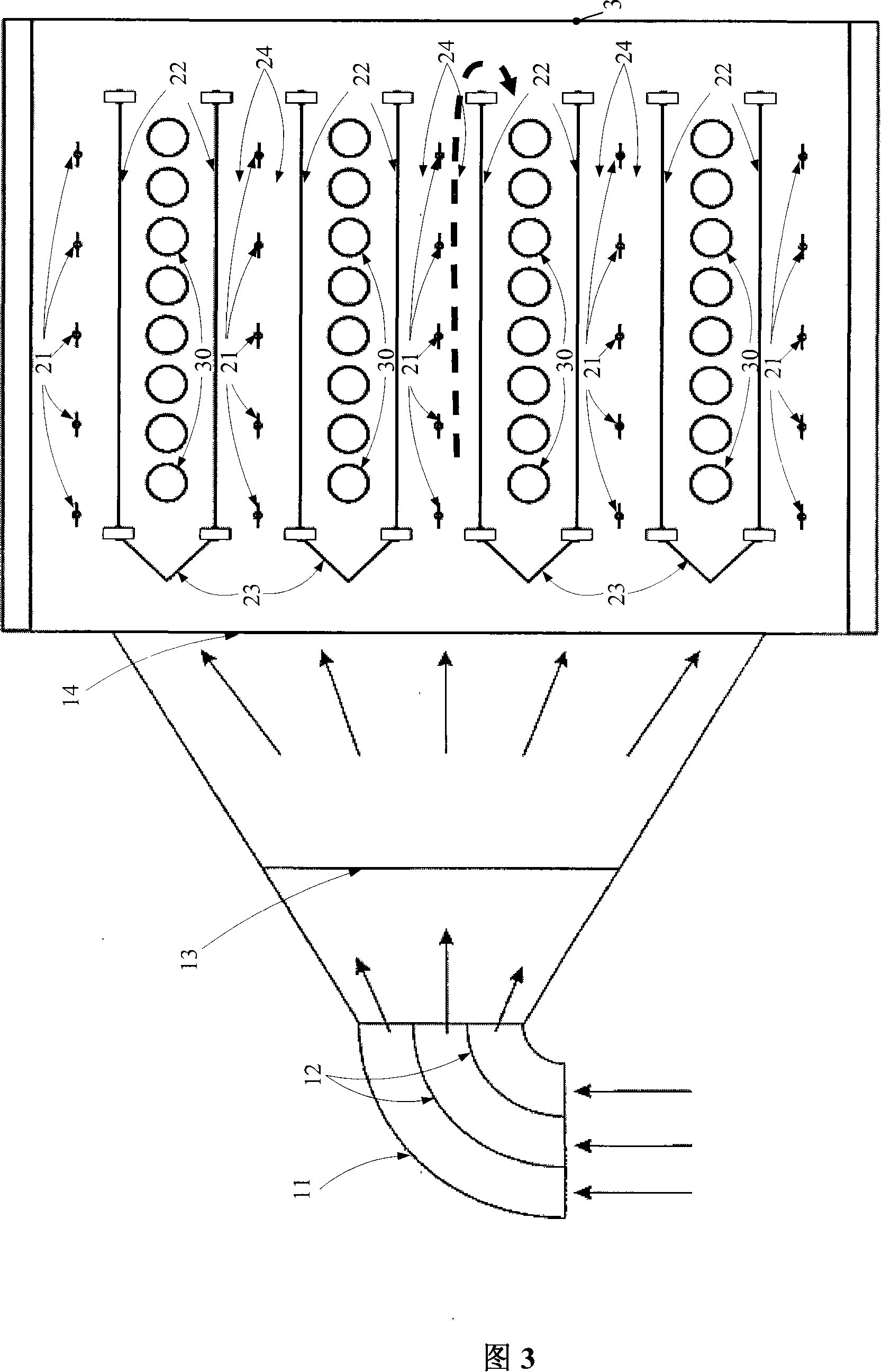

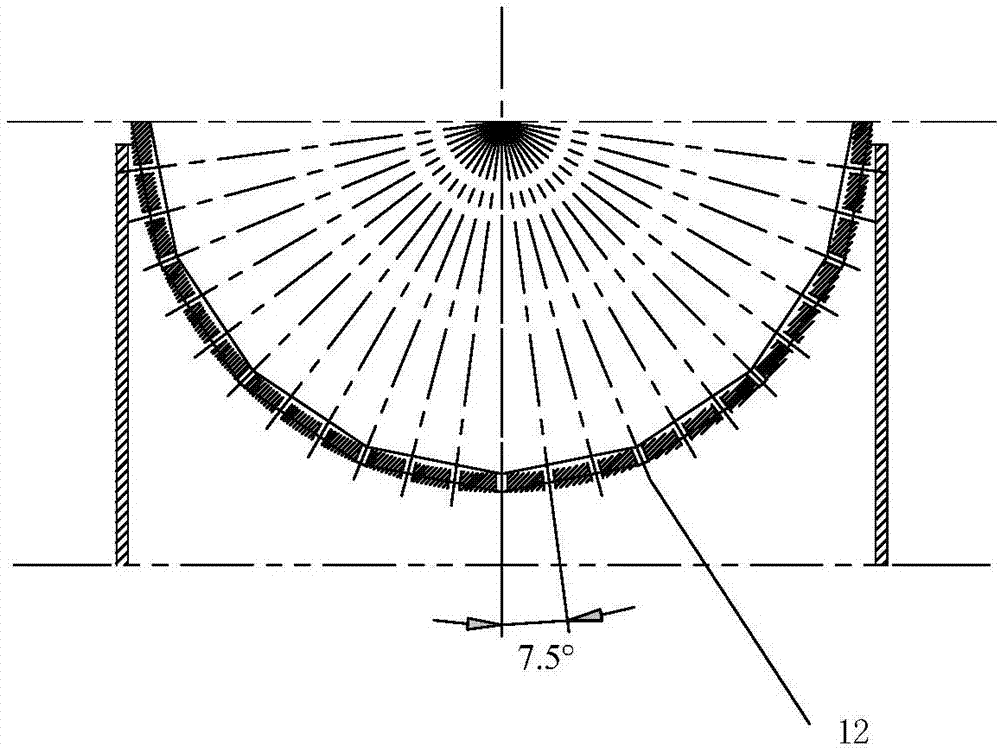

Static electric cloth bag compact mixed type dust remover and its running method

InactiveCN101121152AGuaranteed efficiencyGuaranteed removalCombination devicesElectrode constructionsFlue gasEngineering

An electrostatic bag closely hybrid dust remover and the operation method are mainly used for the flue gas disposal in a power plant etc. A grounding collecting plate is placed between a high voltage discharge electrode and the bag inside a dust removing room. An electrostatic dust removing area is formed by two sides of the high voltage discharge electrode and the grounding collecting plate; a filtering and dust removing area is formed by two sides of the bag and the grounding collecting plate. When the bag filters, the grounding collecting plate is closed, and the flue gas enters into the dust removing room and goes through the electrostatic dust removing area to arrive at the end of the grounding collecting plate and then enters into the filtering and dust removing area. When the bag reversely blows and cleans ash, the grounding collecting plate opens, the gas and dust for reverse blowing and ash cleaning pass through the grounding collecting plate directly and reach the electrostatic dust removing area, and the dust for reverse blowing and ash cleaning is collected by static electricity. Compared with the prior invention, the dust removal is separated into two steps: when the bag filters, an electrostatic dust remover is completely used to greatly reduce a dust-containing concentration of the flue gas which enters into the bag; when the bag reversely blows and cleans ash, the electrostatic dust remover is used to effectively remove the dust for ash cleaning.

Owner:TSINGHUA UNIV +1

Method for preparing foamed TiAl intermetallic compound

The invention discloses a method for preparing a foamed TiAl intermetallic compound. The method comprises the following steps of: adding 15 to 35 percent of low-temperature decomposition temperature pore-forming agent, 10 to 40 percent of moderate-temperature decomposition temperature pore-forming agent and 5 to 35 percent of high-temperature decomposition temperature pore-forming agent according to the total volume of 100 percent of mixed powder of TiAl powder and the pore-forming agents; uniformly mixing and performing compression molding; heating under vacuum; preserving heat at a low-temperature stage, a moderate-temperature stage and a high-temperature stage respectively; removing the pore-forming agents in turn; and sintering to obtain a high-porosity foamed TiAl intermetallic compound material with certain strength. The prepared TiAl intermetallic compound porous material has the porosity of over 80 percent, certain structural strength, high porosity, a simple and controllable process, stable quality and high repeatability, contributes to large-scale production and is suitable for the field of high-temperature heat insulation.

Owner:CENT SOUTH UNIV

Catalytic ceramic filter tube and preparation method

ActiveCN105107310AEfficient removalExtended service lifeSemi-permeable membranesDispersed particle filtrationActive componentElemental mercury

The invention provides a catalytic ceramic filter tube which is high in dust collection efficiency, can efficiently oxidize elemental mercury, can also efficiently reduce NOx, and achieves simultaneous dust removal and SCR denitration and a preparation method. The catalytic ceramic filter tube comprises a ceramic filter tube substrate, and a catalytic active component layer and a separation membrane which sequentially coat the ceramic filter tube substrate. The preparation method comprises the following steps: step 1. preparing the ceramic filter tube substrate by isostatic pressing molding; step 2. coating the ceramic filter tube substrate with a catalytic active component membrane to obtain a catalytic ceramic filter tube substrate; and step 3. preparing the separation membrane on the catalytic ceramic filter tube substrate. The catalytic ceramic filter tube provided by the invention can achieve integrated efficient removal of dust, NOx and elemental mercury in high-temperature flue gas (>300 DEG C), the service life of the catalyst can be prolonged through protection for the catalyst by the separation membrane and the substrate, and the structure arrangement of the ceramic filter tube can reduce the occupied area and running cost of equipment.

Owner:HUANENG POWER INTERNATIONAL +2

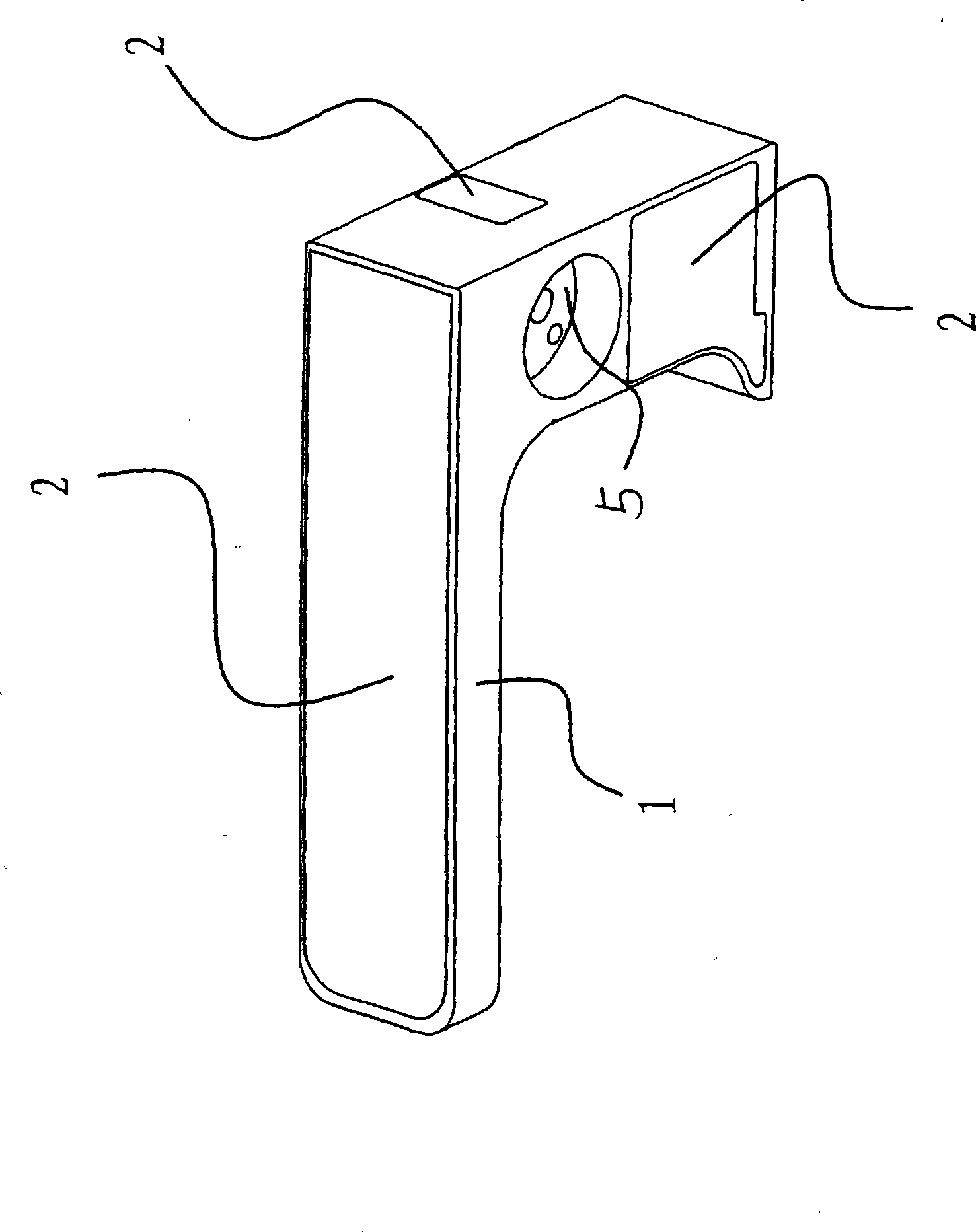

Method for producing stainless steel tap

InactiveCN101462224AEasy to disassembleGuaranteed removalFoundry mouldsFoundry coresWaxWater leakage

The invention provides a method for manufacturing a stainless steel water faucet for solving the process problem that articles with complex structures and thin walls such as a die cavity and the like are hard to be made from stainless steel at domestic, which comprises the following steps: using a finish cast die to manufacture a wax mould same as the blank of a water faucet valve body; after dipping slurry and adhering to sand on the wax mould, forming a sand mould in a through dewaxing in a dewaxing kettle; casting the stainless steel on the sand mould; and when the stainless steel is solidified, desanding the stainless steel through vibration to manufacture the blank of the water faucet valve body, wherein the outer wall of a water passage formed in the blank of the valve body is reserved with an opening; and after the blank of the water faucet valve body is formed, welding a cover plate to form the valve body which is then polished and assembled. The method for manufacturing the stainless steel water faucet has the advantages of simple process, high finished product ratio, economization of stainless steel materials and low cost, solves the process problem that the articles with the complex structures and the thin walls such as the die cavity and the like are hard to be made from stainless steel at domestic, and prevents the problem that the water faucet made from the stainless steel is easy to generate perforation and water leakage so that the finished product ratio is low because of the complex structure and the thin wall of the die cavity of the water faucet.

Owner:浙江苏泊尔卫浴有限公司

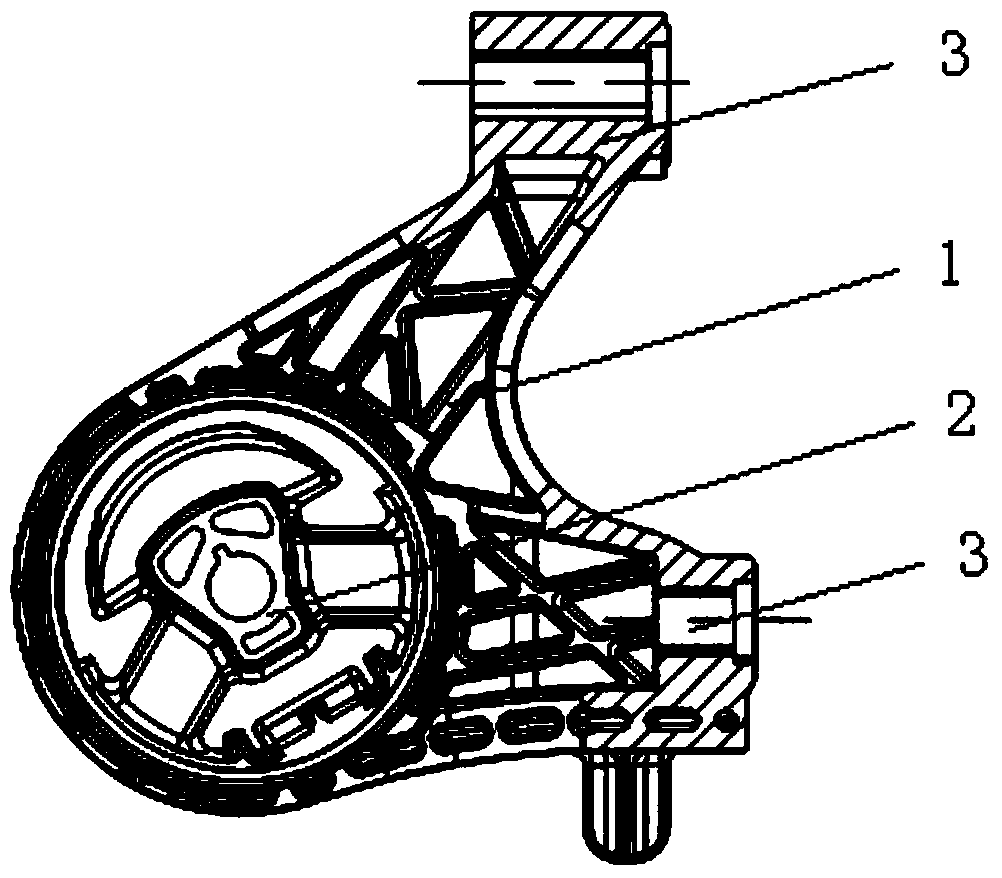

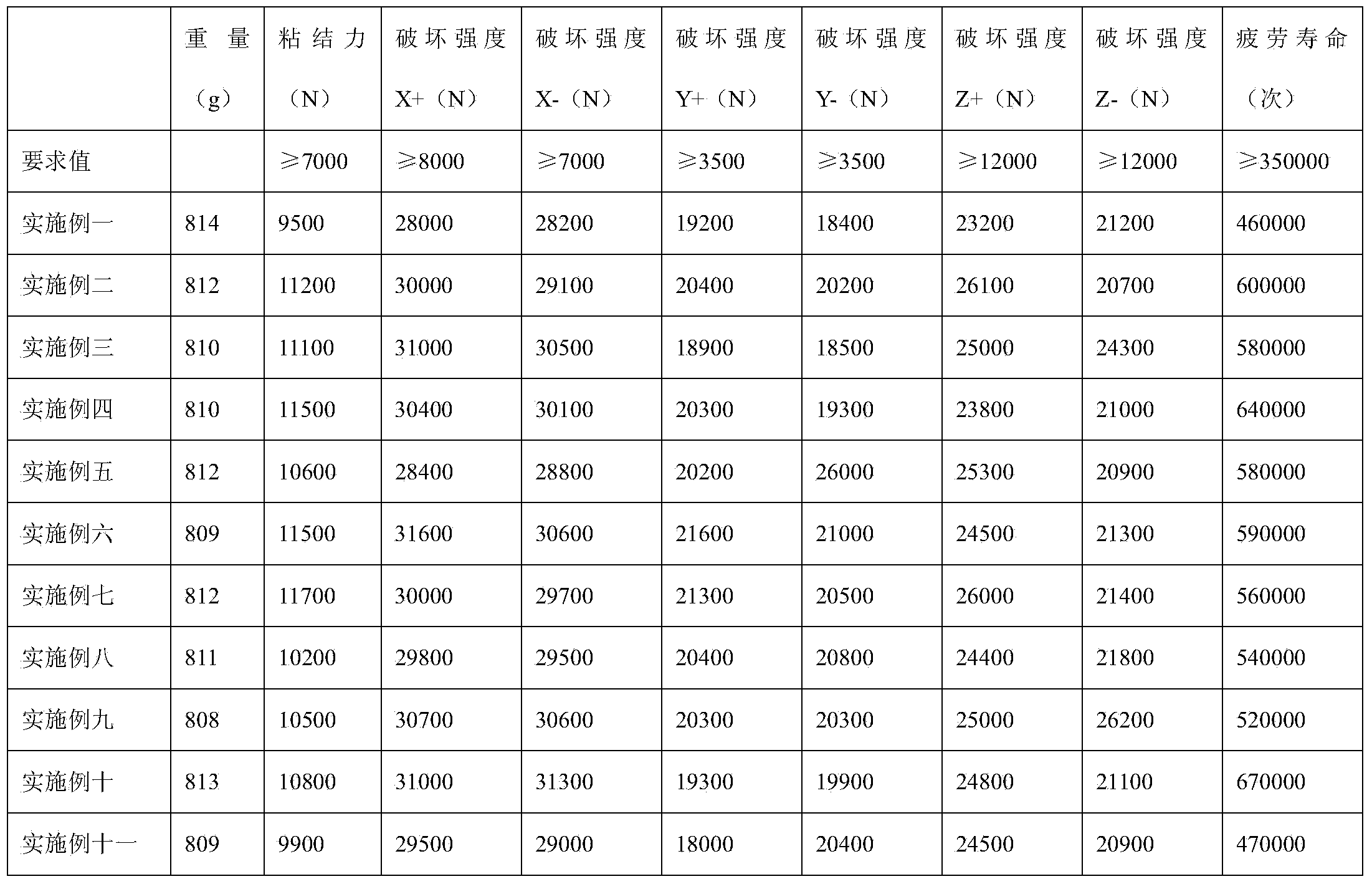

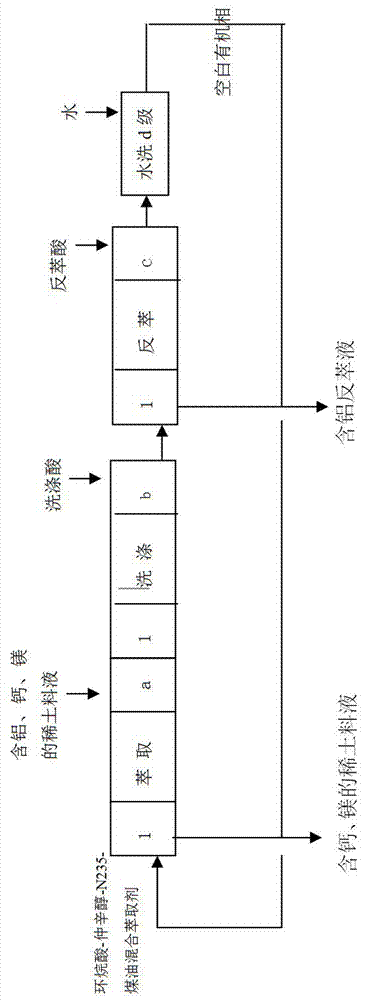

Making method of lightweight rubber shock absorption member for automobile

ActiveCN103640143AAvoid degradationAvoid morphological changesDomestic articlesVulcanizationEngineering

The invention discloses a making method of a lightweight rubber shock absorption member for an automobile. The rubber shock absorption member is characterized in that the rubber shock absorption member is composed of a rubber mainspring, a plastic support and a metal insert, and the making method comprises the steps of vulcanization, gluing, drying, assembling, injection molding, cooling and moisture absorption. The method has the advantages of simple technology and low cost, and the lightweight rubber shock absorption member made through the method has a good performance and a long service life.

Owner:NINGBO TUOPU GROUP CO LTD

Coal dry distillation technology employing indirect heat exchange

ActiveCN104130790AAvoid enteringGuaranteed removalIndirect heating destructive distillationSpecial form destructive distillationCombustionWater source

The invention provides a coal dry distillation technology employing indirect heat exchange. Glue gas subjected to heat exchange at a dry distillation stage is employed for direct heat exchange on raw coal at a drying stage, so that dewatering drying is realized. Then at the dry distillation stage, combustion of coal gas and air is realized and a high-temperature flue gas of 800-1200 DEG C is generated, and the high-temperature flue gas is used to perform indirect heat exchange on coal. After the dry distillation step is finished, cooling of semicoke employs direct spraying cooling at the upper part combined with indirect water cooling at the lower part, and indirect water cooling gives play to main effect, so that semicoke with relatively high quality is relatively easily obtained, and also no wastewater discharge is generated, water source is saved and environmental pollution is reduced. The coal dry distillation technology employing indirect heat exchange helps to improve the calorific value of coal gas, reduce the dust content in the coal gas and improve the tar yield, the prepared semicoke is high in quality, and the technology is applicable to both dry distillation of lump coal and small-granularity coal.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

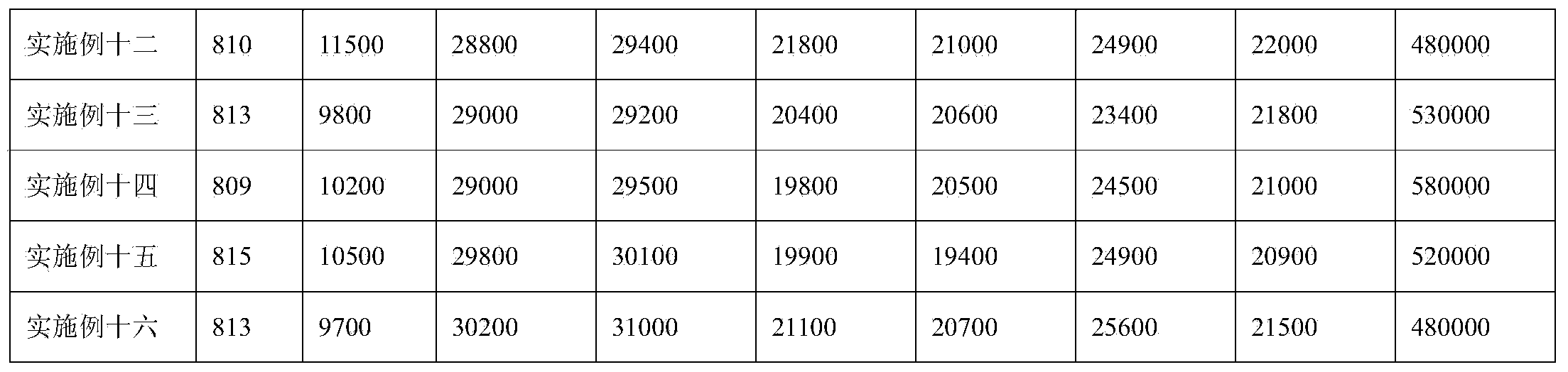

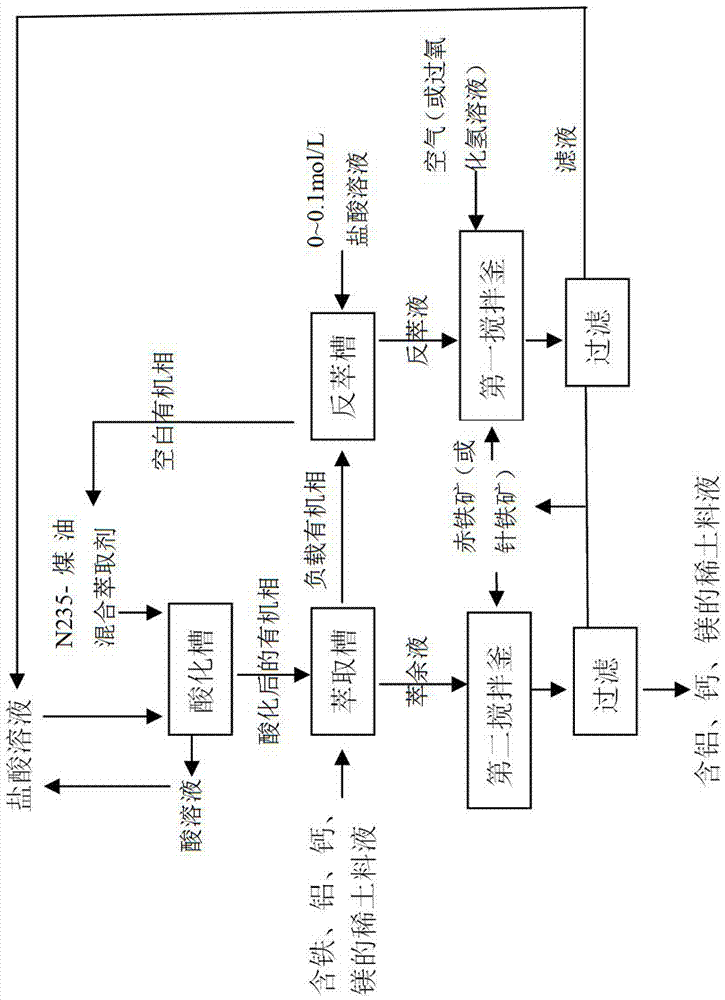

Non-rare earth impurity and rare earth element extraction and separation method

ActiveCN107130120AAvoid consumptionElimination of ammonia nitrogen wastewaterProcess efficiency improvementRare-earth elementYttrium

The invention discloses a non-rare earth impurity and rare earth element extraction and separation method. The method comprises the steps that at first, N235 is adopted for extracting and separating iron in rare earth feed liquid, then a sediment iron removing method is used for eliminating the iron in the rare earth feed liquid completely further, and then unsaponifiable naphthenic acid is adopted for extracting and separating aluminum in the feed liquid; the rare earth feed liquid obtained after the iron and aluminum are separated is extracted and grouped by adopting an extraction agent P507-N235, heavy rare earth elements are separated from light and medium rare earth elements, for feed liquid containing the heavy rare earth elements, unsaponifiable naphthenic acid is adopted for separating yttrium and other heavy rare earth elements, for feed liquid containing the light rare earth elements, the extraction agent P507-N235 is adopted for extracting, grouping and separating calcium, magnesium and the light rare earth elements, and the extraction agent P507-N235 continues to be used for separating other rare earth elements one by one. According to the method, non-rare earth impurities such as iron, aluminum, calcium, magnesium and the rare earth elements are separated completely, acid is utilized comprehensively, the adopted extraction agent does not need to be saponified and can be used directly and circularly, an acid reagent and an alkaline reagent do not need to be added in the extraction process, and the separation cost is very low.

Owner:GUANGXI NORMAL UNIV

Apparatus for carrying cooling water away from the narrow sides of a slab

InactiveUS7905271B2Reduce falling speedAvoid damagePipe supportsFluid dynamicsEngineeringContinuous casting

The invention relates to an apparatus (100) for carrying cooling water away from the narrow sides (210) of a slab (200) passed essentially vertically through a secondary cooling device after casting in a continuous casting installation. In order to prevent partial overcooling of the slab at its edges, the apparatus (100) according to the invention comprises a plurality of water drainage devices (110-n), which are arranged such that they are distributed in a vertical direction over the length of the narrow side of the slab. This plurality of water drainage devices (110-n) is carried by a vertically arranged collecting downpipe (120). The collecting downpipe additionally serves for collecting the cooling water that is drained by the plurality of water drainage devices (110-n) and carrying it away in a decentralized manner.

Owner:SMS DEMAG AG

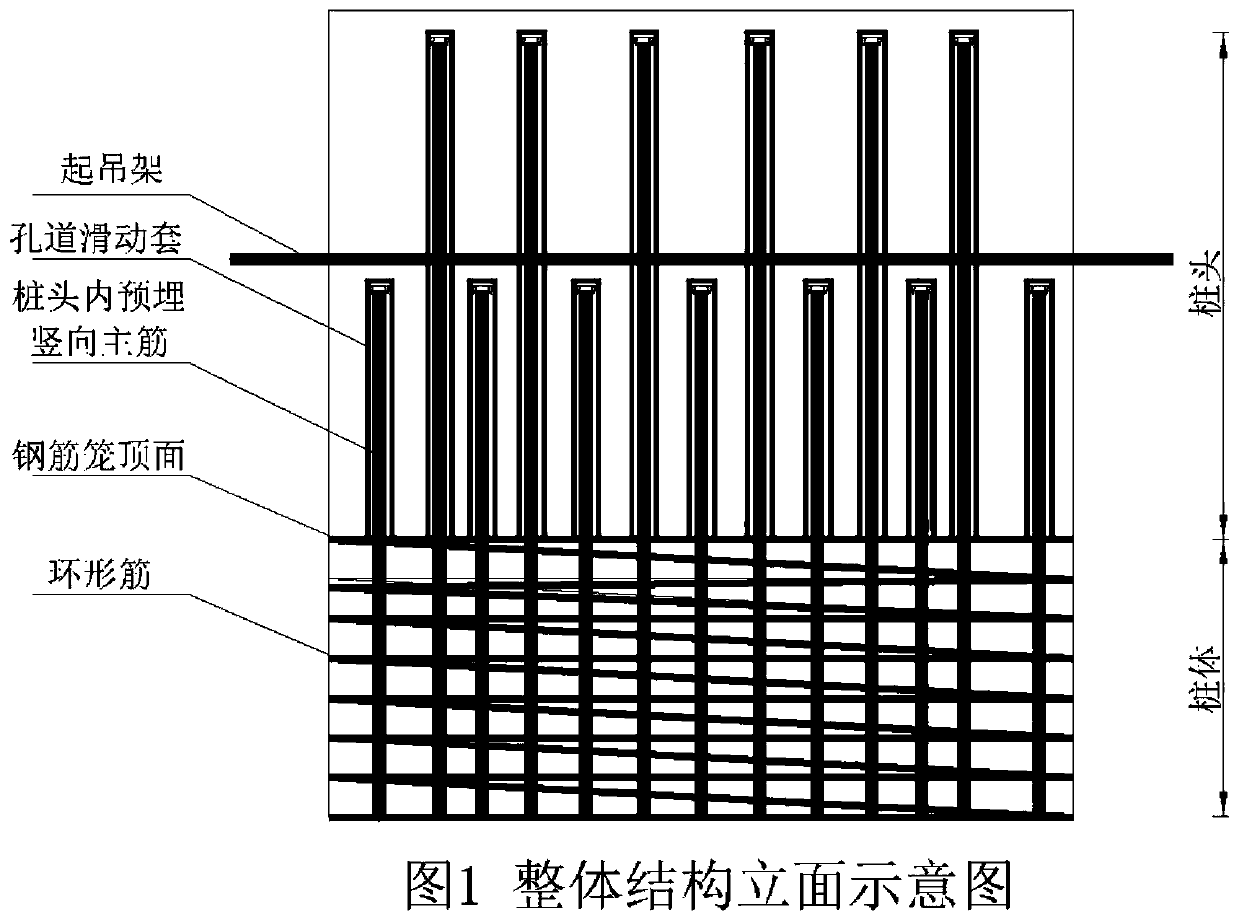

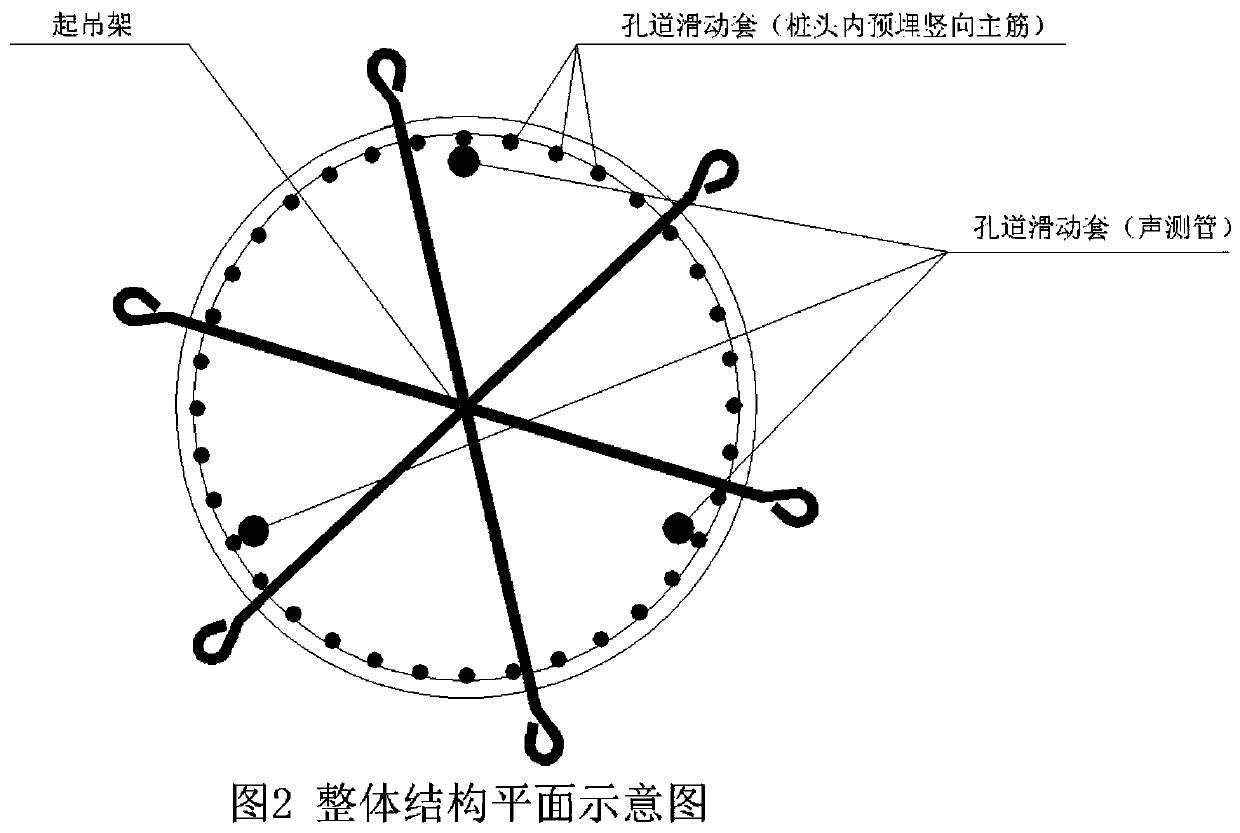

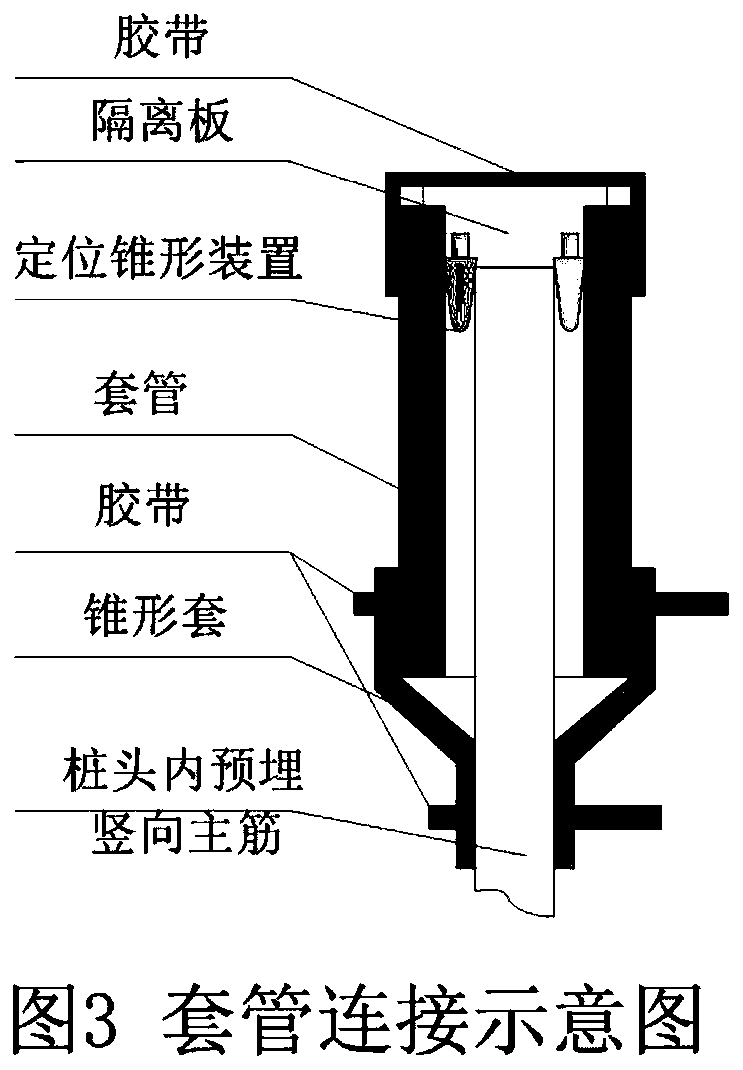

Construction method for quickly and non-destructively breaking pile heads

InactiveCN111218936AEasy to removeGood for guaranteed removalBulkheads/pilesAdhesive beltArchitectural engineering

The invention discloses a construction method for quickly and non-destructively breaking pile heads. In the construction method, a pile body is included. A reinforced cage is arranged inside the pilebody; vertical main reinforcements are reserved in a pile head of the reinforced cage; a pore passage sliding sleeve is arranged on the outer surface of a sound measuring pipe; an isolation plate anda tapered sleeve are separately arranged at the upper and lower ends of the pore passage sliding sleeve; the upper and lower ends of the pore passage sliding sleeve are bonded and sealed with an adhesive tape; a lifting frame (the whole pile head is used as a marking rod before lifting) is arranged at a position where the vertical main reinforcements reserved in the pile head of the reinforced cage are not smaller than 30 cm from the top surface of the reinforced cage; and a concrete pouring pile head is within the range of the vertical main reinforcements reserved in the pile head of the reinforced cage. After the construction of the pile head is completed, a high-pressure water jet technology (also known as hydraulic breaking technology) is used for properly removing concrete from the lifting frame to the top surface of the reinforced cage, and finally the pile head is integrally hoisted by a crane, thereby completing the quick and non-destructive breaking of the whole pile head.

Owner:SHANDONG LUQIAO CONSTR

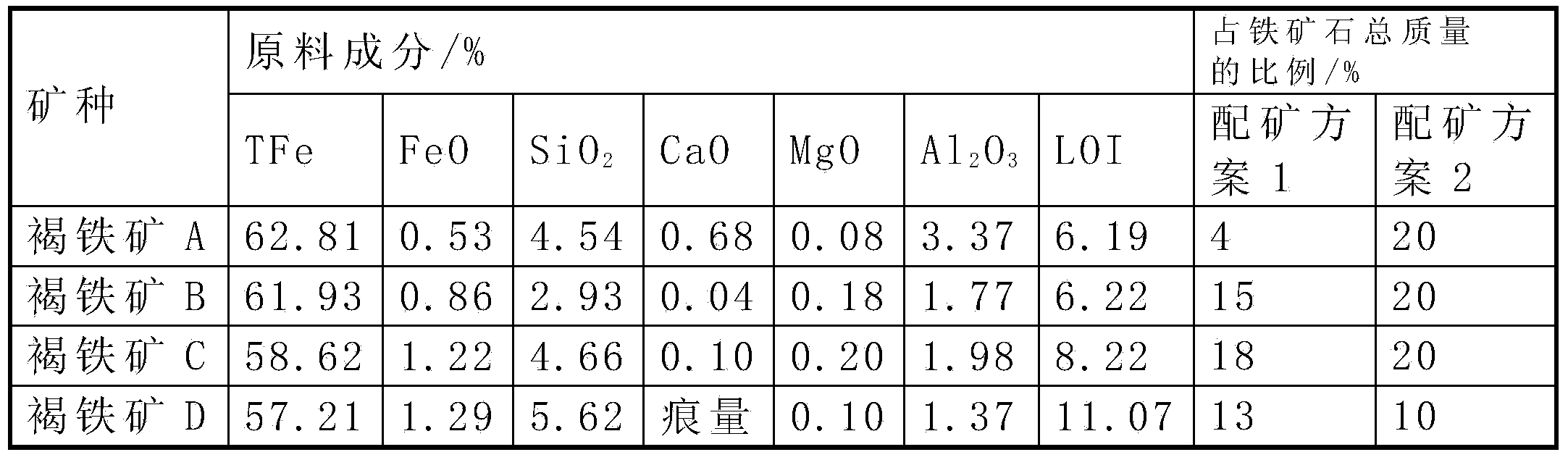

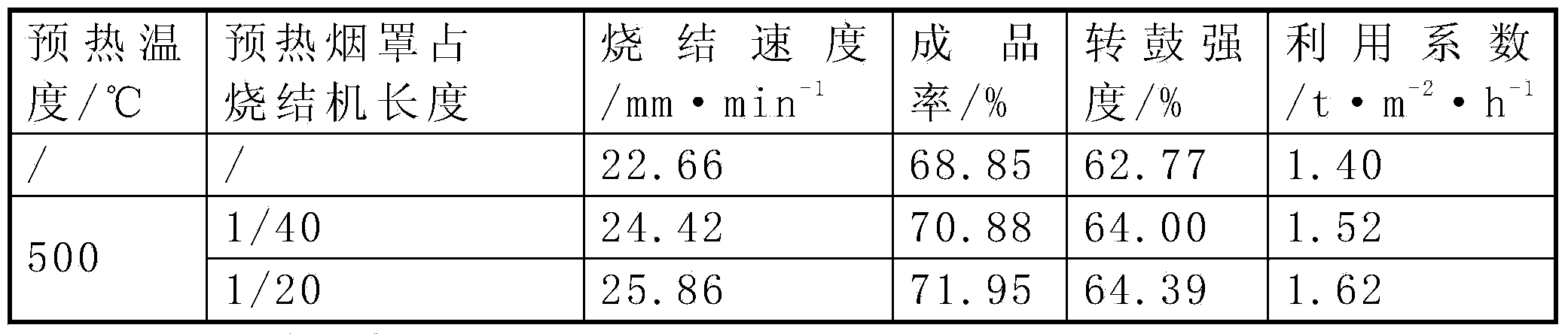

Method for enhancing sintering of high-proportion limonite by utilization of waste heat of exhaust gas

ActiveCN103484661AImprove the quality index of sintering outputRaise the sintering temperatureEvaporationSmoke hood

The invention discloses a method for enhancing the sintering of high-proportion limonite by the utilization of waste heat of exhaust gas. According to the high-proportion limonite, limonite accounts for 50-70% of the total mass of iron ore, the content of crystal water in the limonite is 5-15%, after distribution of a mixture and before sintering ignition, a sealed smoke hood is additionally arranged, high temperature exhaust gas from a sintering ring cooler or high temperature exhaust gas at the tail portion of a sintering machine is guided in to be used for heating the mixture, crystal water and free water in the mixture at the surface layer of a bed of material are removed, thermal decomposition of the crystal water of the material on the surface layer in the sintering process and thermal emission of evaporation of water are reduced, the sintering temperature of the surface layer of the bed of material is increased, accordingly, the sintering yield and quality index of the high-proportion limonite are improved, and energy consumption for sintering is reduced.

Owner:CENT SOUTH UNIV

A catalytic ceramic filter tube and its preparation method

ActiveCN105107310BEfficient removalExtended service lifeSemi-permeable membranesDispersed particle filtrationPtru catalystFlue gas

The invention provides a catalytic ceramic filter tube which is high in dust collection efficiency, can efficiently oxidize elemental mercury, can also efficiently reduce NOx, and achieves simultaneous dust removal and SCR denitration and a preparation method. The catalytic ceramic filter tube comprises a ceramic filter tube substrate, and a catalytic active component layer and a separation membrane which sequentially coat the ceramic filter tube substrate. The preparation method comprises the following steps: step 1. preparing the ceramic filter tube substrate by isostatic pressing molding; step 2. coating the ceramic filter tube substrate with a catalytic active component membrane to obtain a catalytic ceramic filter tube substrate; and step 3. preparing the separation membrane on the catalytic ceramic filter tube substrate. The catalytic ceramic filter tube provided by the invention can achieve integrated efficient removal of dust, NOx and elemental mercury in high-temperature flue gas (>300 DEG C), the service life of the catalyst can be prolonged through protection for the catalyst by the separation membrane and the substrate, and the structure arrangement of the ceramic filter tube can reduce the occupied area and running cost of equipment.

Owner:HUANENG POWER INT INC +2

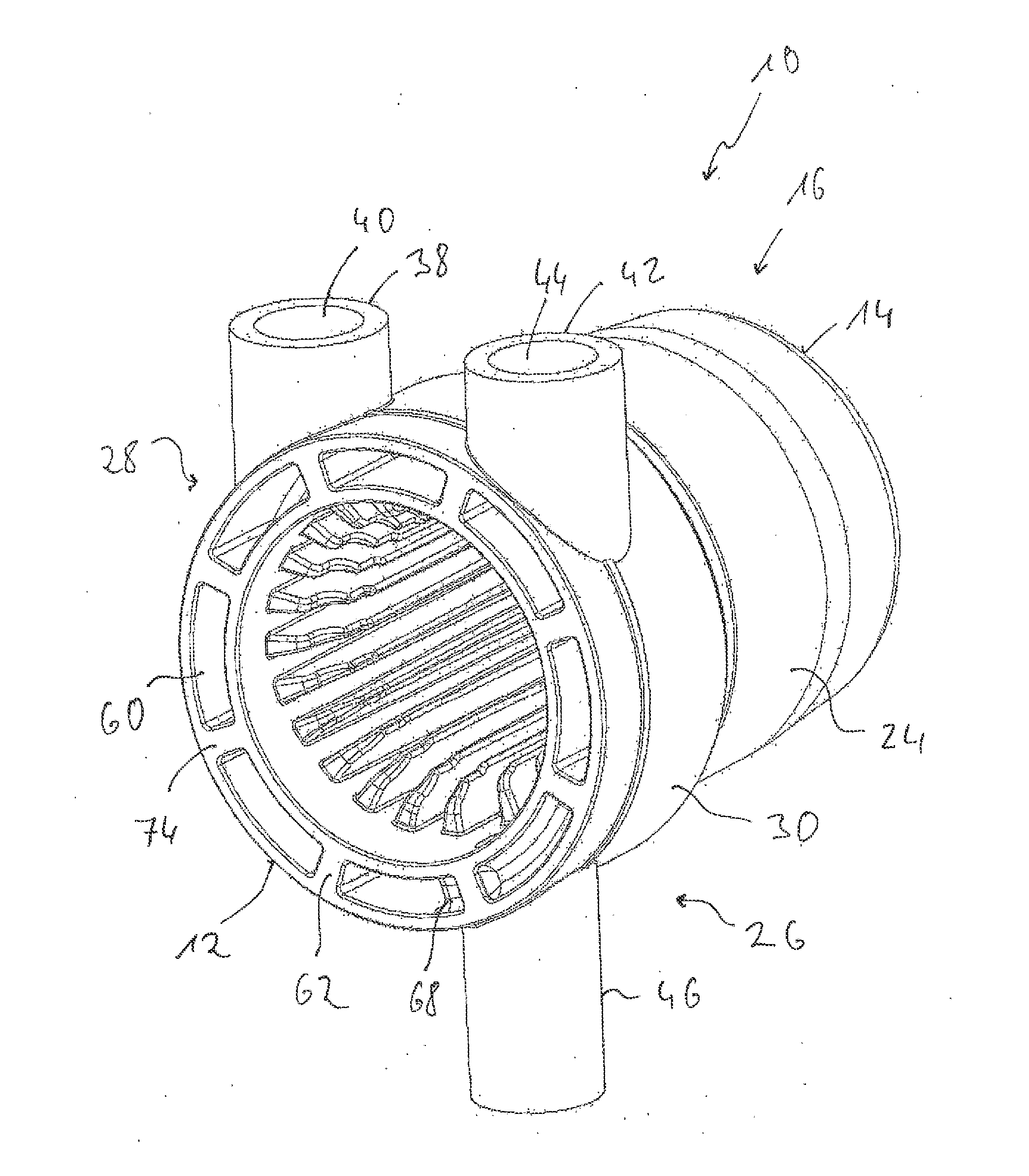

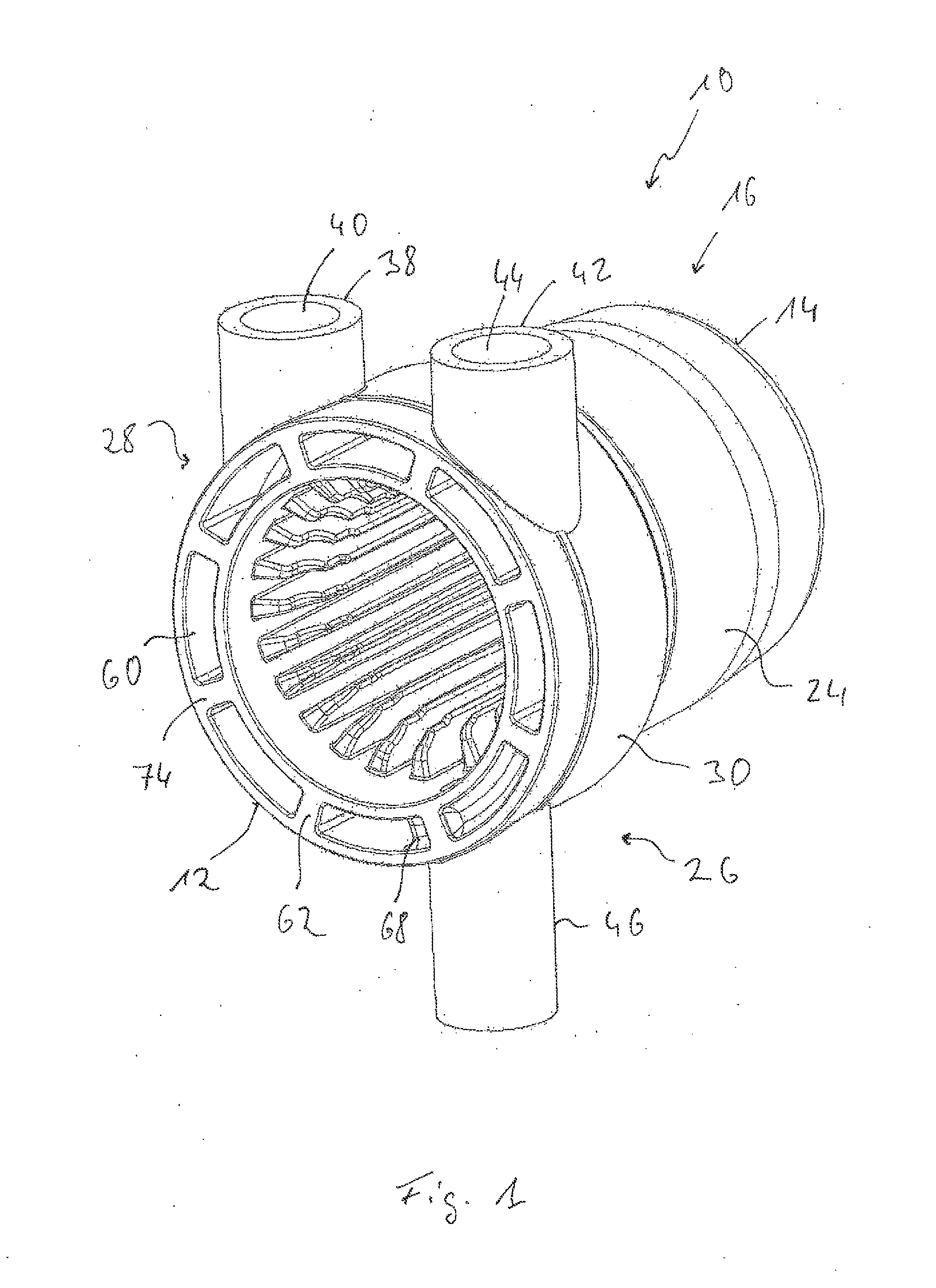

Heat exchanger arrangement, especially for a vehicle heater

ActiveUS20160023535A1Reduce lossReduce heat lossAir-treating devicesRecuperative heat exchangersEngineeringHeat exchanger

A vehicle heater heat exchanger arrangement (10) includes: a pot-like heat exchanger housing (12) with a first bottom wall (18) in a first axial end area (16) and with a first circumferential wall (20) adjoining the first bottom wall and enclosing a longitudinal axis (L); and a pot-like outer heat exchanger housing (14) with a second bottom wall (22) in the first axial end area and with a second circumferential wall (24) adjoining the second bottom wall and enclosing the longitudinal axis. The inner heat exchanger housing and the outer heat exchanger housing are connected to one another in a second axial end area (26) and a fluid flow space (34) is formed between the inner heat exchanger housing and the outer heat exchanger housing. The second axial end area has an outwardly open recess (60) defined by the inner heat exchanger housing or / and by the outer heat exchanger housing.

Owner:EBERSPACHER CLIMATE CONTROL SYST GMBH

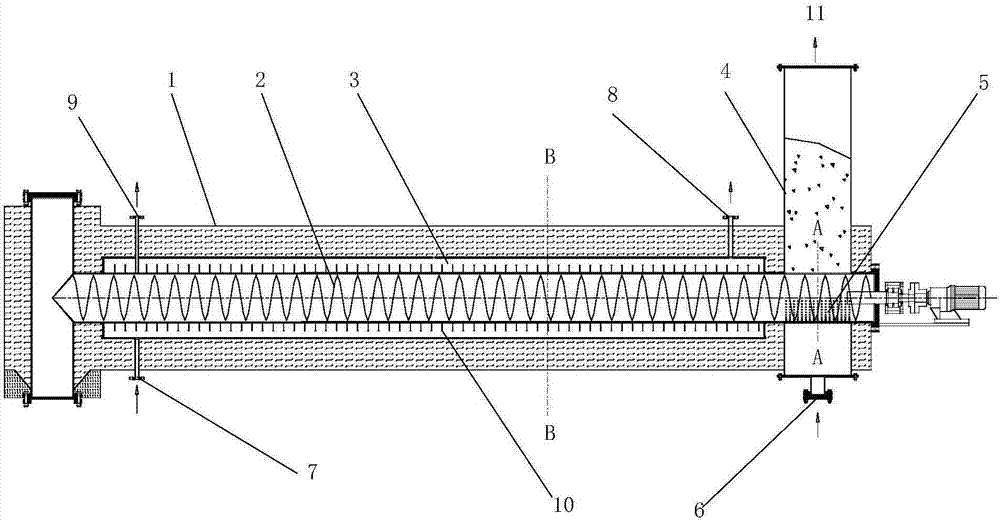

Two-stage feeding and drying device, biomass gasifier, and two-stage feeding and drying method

ActiveCN107976010AReduce moistureRaise the combustion temperatureProductsGasifier feeding meansFlue gasProcess engineering

The invention discloses a two-stage feeding and drying device, a biomass gasifier, and a two-stage feeding and drying method. The two-stage feeding and drying device comprises a drying cylinder, a feed bin and a spiral conveyer, wherein the feed bin is arranged on one end of the drying cylinder; a drying cylinder jacket with a hollow structure is coaxially and annularly arranged in the drying cylinder; an inner wall surface of the drying cylinder jacket surrounds to form a hollow conveying space; the spiral conveyer transversely penetrates through the bottom part of the feed bin and is coaxially welded into the hollow conveying space; a first high temperature flue gas inlet and a first high temperature flue gas outlet are formed in the bottom part and the top part of the feed bin; a secondhigh temperature flue gas inlet and a second high temperature flue gas outlet are formed in a lower bottom surface of one end, far away from the feed bin, of the drying cylinder, and an upper top surface of one end, close to the feed bin, of the drying cylinder; and the second high temperature flue gas inlet and the second high temperature flue gas outlet penetrate to an outer wall surface of thedrying cylinder jacket from an outer surface of the drying cylinder. The two-stage feeding and drying device and a gasifier are integrally designed, and meanwhile, conveying and drying are realized at the same time, so that the energy consumption is reduced, and the gasification gas quality is improved.

Owner:SHANGHAI ELECTRICGROUP CORP

Disinfection device for gynecological manipulator

PendingCN112717175AFully disinfectedComprehensive disinfectionLavatory sanitoryChemicalsAssistive device/technologyDisinfectant

The invention discloses a disinfection device for an obstetrics and gynecology department manipulator, and relates to the technical field of medical auxiliary equipment. The disinfection device comprises two support bodies, wherein an upper support body is arranged between the two support bodies, an upper disinfection assembly is arranged at the bottom of the upper support body, lower disinfection assemblies are arranged in the two support bodies, the upper disinfection assembly comprises a first front-back moving assembly, the first front-back moving assembly is connected with a left-right moving assembly, the left-right moving assembly is connected with a first disinfection mechanism, the lower disinfection assembly comprises a second front-and-back moving assembly, the second front-and-back moving assembly is connected with an up-and-down moving assembly, the up-and-down moving assembly is connected with a rotating mechanism, the rotating mechanism is connected with a second disinfection mechanism, the rotating mechanism is used for controlling the second disinfection mechanism to retract into the support body or extend into a disinfection channel, and a disinfection detection unit is also arranged in the disinfection channel and is used for detecting the spraying degree of a disinfectant. The disinfection device has the advantages that the disinfection effect and the disinfection efficiency are improved.

Owner:JILIN UNIV FIRST HOSPITAL

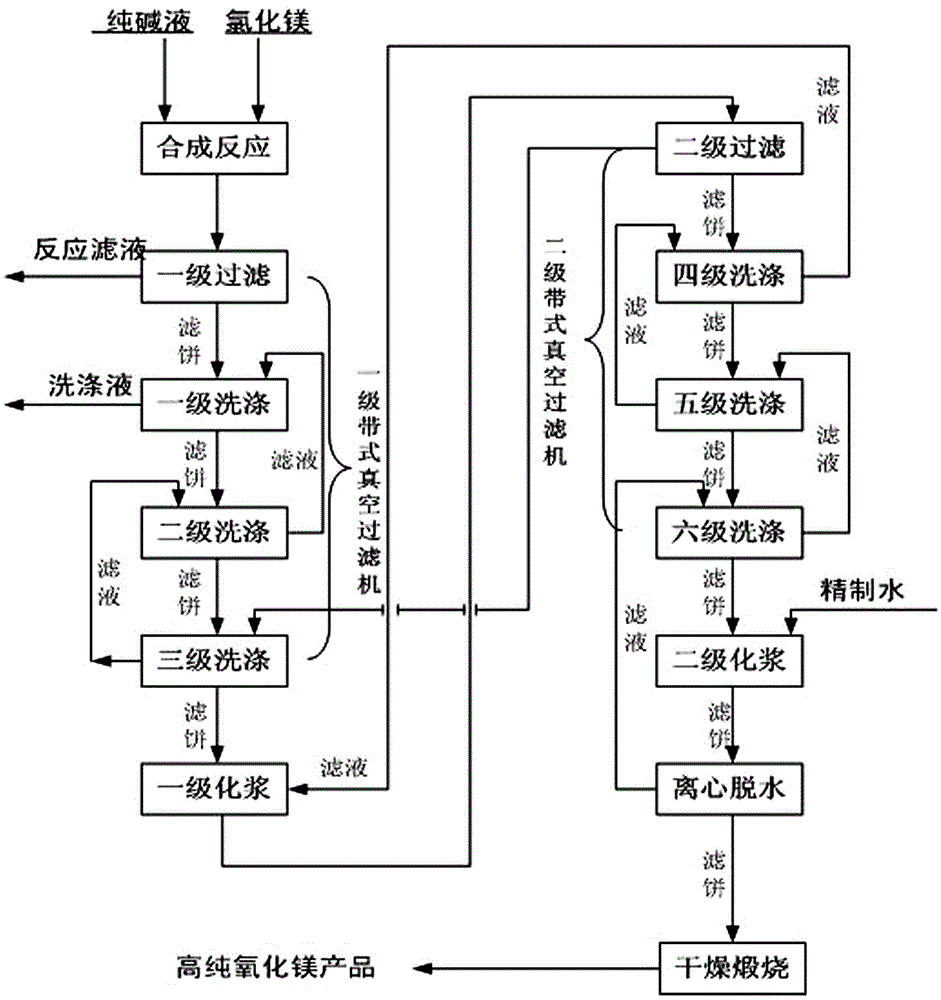

Method for producing low chlorine high purity magnesia by soda ash method

The present invention discloses a method for producing low chlorine high purity magnesia by taking hydrated magnesium chloride or a magnesium chloride solution and soda ash as raw materials. The method includes utilizing two filter devices (belt vacuum filter machine) having best washing effect as a washing device, at the same time performing slurrying washing twice, and using a filter device (a centrifugal machine) with best dehydrating effect for dehydration treatment. When the water content is reduced to less than 65%, basic magnesium carbonate is obtained, and then dried and calcined to get the high purity magnesia product with Cl less than 0.07% (by mass percentage). The method enables the magnesia product to reach the class of national superior products, and helps to reduce the amount of washing water and the energy consumption for drying.

Owner:桐柏兴源化工有限公司

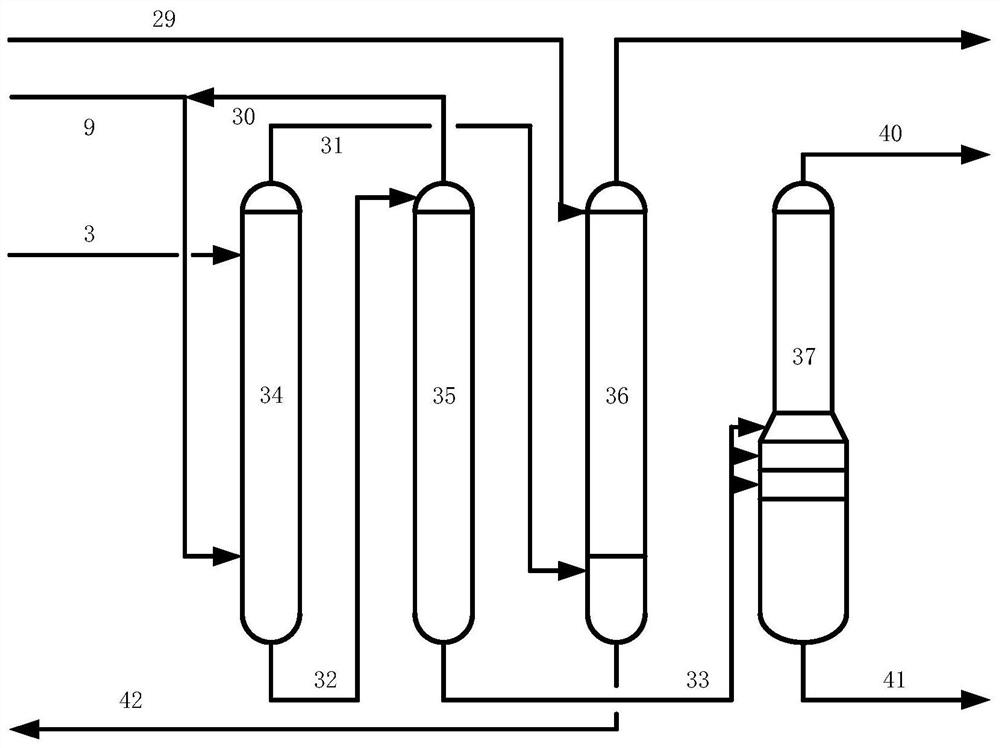

Multi-technology integrated separation process for producing high-purity helium from liquefied tail gas of helium-rich natural gas

PendingCN113144821AHigh purityTake advantage ofSolidificationGas treatmentCatalytic oxidationDehydrogenation

The invention relates to a multi-technology integrated separation process for producing high-purity helium from helium-rich liquefied natural gas tail gas, which comprises the following steps: helium-containing tail gas from a natural gas liquefaction device enters a multi-stage circulating membrane separation unit for preliminary enrichment after being subjected to cold energy recovery and pressurization; crude helium obtained through membrane separation enters a catalytic oxidation dehydrogenation unit after being pressurized, then enters a compression condensation and temperature swing adsorption dehydration unit and finally enters a low-temperature pressure swing adsorption purification unit, and high-purity helium is obtained; and desorbed gas of the adsorption unit returns to a membrane separation unit. Through multi-technology gapless matching and synergistic interaction, it is guaranteed that each impurity is removed in a proper mode, high-purity helium with the purity being 99.99 vol% is obtained, the helium recovery rate is remarkably increased, and meanwhile purification energy consumption is reduced. The natural gas with a helium concentration of 4.60vol% liquefies tail gas , the simulation result shows that the recovery rate of the multi-technology integrated process can reach 84.0% or above, and the purification unit consumption (electricity) does not exceed 4.0 kWh / Nm <3> of helium.

Owner:DALIAN UNIV OF TECH

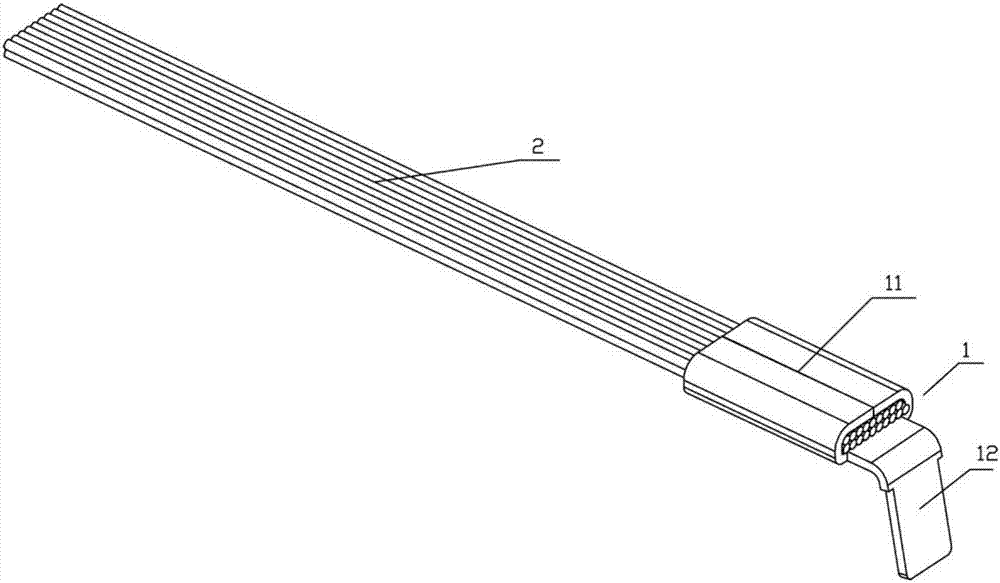

Wiring method of wiring terminal

ActiveCN107394553AImprove conduction performanceEmission reductionLine/current collector detailsEngineeringElectrical and Electronics engineering

The invention relates to a wiring method of a wiring terminal. The wiring method comprises the following steps of S1, putting a varnished wire into a crimping and fixing groove of the wiring terminal, and performing at least one time of normal-temperature extrusion on the side wall of the crimping and fixing groove to enable the varnished wire to be fixedly connected with the wiring terminal; and S2, performing at least one time of high-temperature extrusion on the side wall of the crimping and fixing groove to enable the varnished wire to be electrically conducted with the wiring terminal. Compared with the conventional process, normal-temperature extrusion for fixation and high-temperature extrusion for conduction are carried out by the wring method disclosed in the invention, so that the varnished film of the varnished wire can be molten through high-temperature extrusion, and the conduction effect between the varnished wire and the wiring terminal can be reinforced; and in addition, production efficiency is improved, production cost is lowered, emission of gases and powder with pungent smell can be reduced, and damage to the environment and harm to the body of an operator can be avoided.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Preparation and application methods of calcium zirconate ceramic core

InactiveCN109574662AImprove room temperature strengthHigh temperature strengthFoundry mouldsFoundry coresAlcoholTurbine blade

The invention relates to the technical field of ceramic cores, particularly to preparation and application methods of a calcium zirconate ceramic core. The preparation method of the calcium zirconateceramic core comprises the following steps of mixing acrylamide, crosslinking agent and absolute ethyl alcohol to obtain a premixed solution; mixing the premixed solution, dispersion, calcium zirconate and mineralizer to obtain a calcium zirconate pulp; mixing the calcium zirconate pulp, initiator and catalysts for mold casting to obtain a calcium zirconate ceramic core blank; powder-sintering thecalcium zirconate ceramic core blank to obtain the calcium zirconate ceramic core. The calcium zirconate ceramic core prepared through the method is high in strength and more applicable to at high temperature casting Nb-Si-based alloy turbine blades, and meanwhile, achieves high-temperature chemical stability, avoids sharp reaction with chemical elements of Nb-Si-based alloy and effectively ensures the quality of the inner cavity of Nb-Si alloy hollow blades.

Owner:沃尔曼科技张家港有限公司

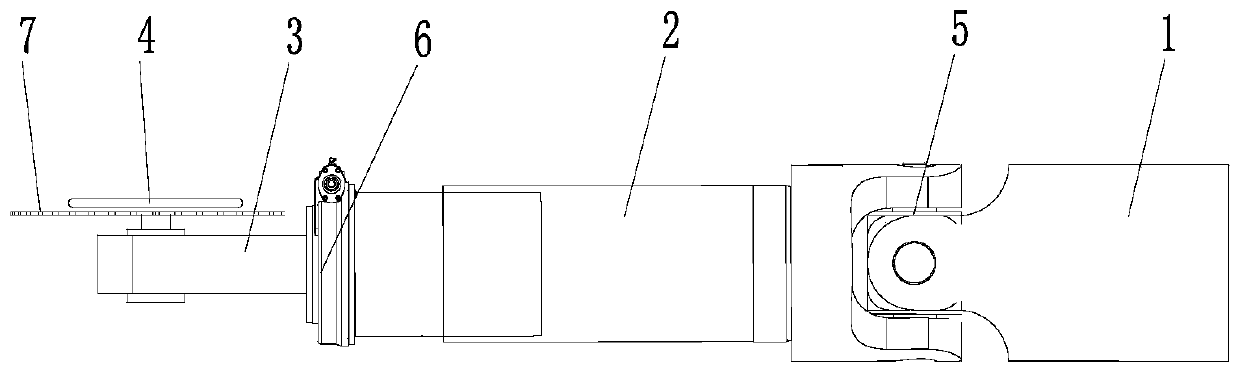

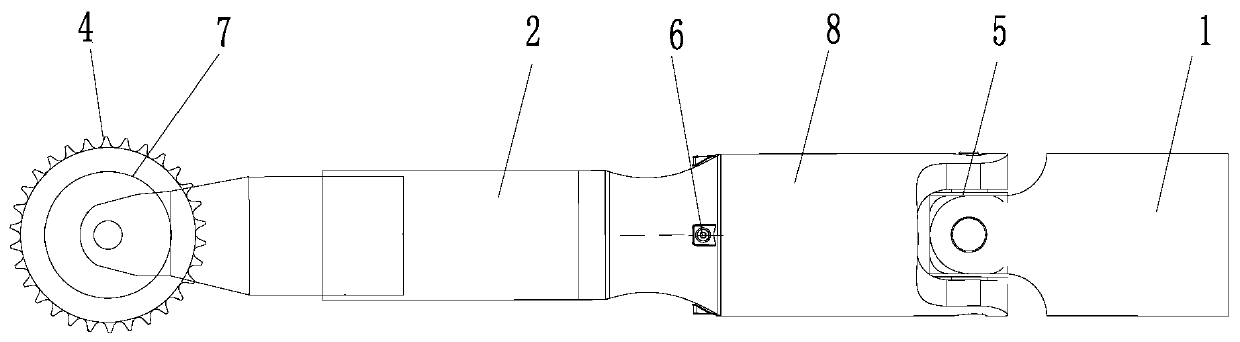

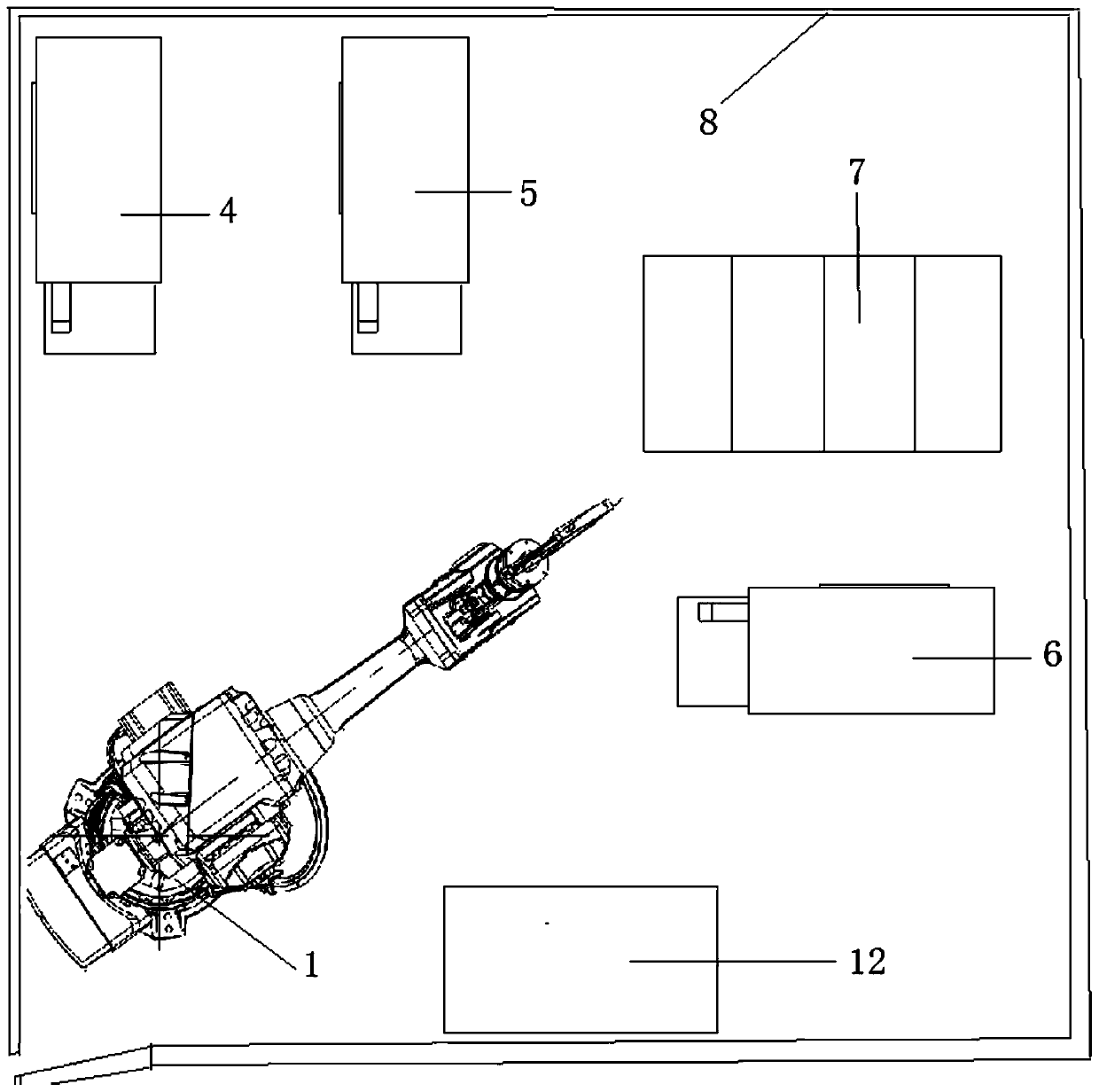

Tunnel secondary-lining concrete and rock cutting mechanism, device and method

ActiveCN110065167AGuaranteed removalRealize cutting requirementsWorking accessoriesStone-like material working toolsSpatial OrientationsUniversal joint

The invention discloses a tunnel secondary-lining concrete and rock cutting mechanism, device and method. The mechanism comprises a large arm, a telescopic arm and a cutting arm, wherein the front endof the large arm and the rear end of the telescopic arm are hinged together through a universal joint, so that the telescopic arm is capable of swinging vertically and horizontally relative to the large arm; the front end of the telescopic arm and the rear end of the cutting arm are connected through a rotary support; a cutting circular saw is arranged on the front end of the cutting arm; and thecutting circular saw is provided with a depth control wheel for controlling the cutting depth. The mechanism is installed on a modified excavator, a crane, a rock drilling trolley or a drilling machine through the large arm. According to the mechanism, the device and the method, 360 degrees of cutting in any spatial orientation is achieved, the demolition efficiency of the tunnel second-layer concrete or rock is effectively improved, and the construction cost is saved.

Owner:中铁十一局集团第五工程有限公司 +1

Preparation and application methods of barium zirconate ceramic core

InactiveCN109574661AHigh strengthImprove high temperature stabilityFoundry mouldsFoundry coresDie castingRoom temperature

The invention relates to the technical field of ceramic cores, particularly to preparation and application methods of a barium zirconate ceramic core. The preparation method of the barium zirconate ceramic core comprises the following steps of mixing barium zirconate, beewax and paraffin to obtain a barium zirconate ceramic paraffin pulp; die-casting the barium zirconate ceramic paraffin pulp to obtain a barium zirconate ceramic core blank; sintering the barium zirconate ceramic core blank to obtain the barium zirconate ceramic core. The barium zirconate ceramic core prepared through the method is high in room temperature strength and high-temperature stability, maintains high size stability before and after being sintered, is applicable to at high temperature casting Nb-Si-based alloy turbine blades, avoids sharp reaction with chemical elements of Nb-Si-based alloy and ensures the quality of the inner cavity of Nb-Si alloy hollow blades.

Owner:沃尔曼科技张家港有限公司

Pulse diversion cavitation generator

ActiveCN105396719ANot dangerousEnsure safetySpray nozzlesLiquid spraying apparatusCavitationThroat neck

The invention relates to a pulse diversion cavitation generator. The pulse diversion cavitation generator comprises a pulse cavitation nozzle, an abrasion-resistant throat neck, an abrasion-resistant protecting sleeve and a flow stabilizing pipe. The abrasion-resistant throat neck is of a hollow cylindrical structure and internally provided with riflings. The abrasion-resistant protecting sleeve is arranged outside the abrasion-resistant throat neck in a sleeving mode and fixedly connected with the abrasion-resistant throat neck. The pulse cavitation nozzle is fixedly connected with one end of the abrasion-resistant protecting sleeve. The other end of the abrasion-resistant protecting sleeve is fixedly connected with the flow stabilizing pipe. The pulse cavitation nozzle, the abrasion-resistant throat neck and the flow stabilizing pipe are communicated in sequence. According to the pulse diversion cavitation generator, the pressure of cleaning jet flow is small and only is 10-16 MPa; the generator is not dangerous for a user, and the safety of personnel and dirt removing can be ensured; meanwhile, it is ensured that oil paint and an antifouling and anticorrosion coating on a processed surface cannot be damaged.

Owner:CHINA OCEAN ENG CORP

Method of cumulative helium mass spectrometric combination test by using argon as gross-leak tracer gas

ActiveUS20150073726A1Extension of timeAdapted and convenient and applicableParticle separator tubesFluid-tightness measurementHeminLeakage test

The present invention discloses a method of cumulative helium mass spectrometric combination test by using argon gas as gross-leak tracer gas, and specifically gives the procedure for this gross-leak and fine-leak combination test, comprising steps and methods of selecting helium-argon prefilling method or helium-argon pressuring method, fixed or flexible scheme and the criterion RAr0max for argon measured leak rate of gross-leak test according to the rigour grade THemin, cavity volume, leak rate of surficially absorbed helium and argon and the history of the test of a component under test; designing time for pressuring of helium-argon pressuring method, the maximum test-waiting time of fine-leak test and the criterion for helium measured leak rate, helium-argon prefilling and helium-argon pressuring, removing absorbed helium and argon gas, gross-leak test, fine-leak test and complementally testing bigger gross leak, which enhances the sensitivity of gross-leak test, lengthens the maximum test-waiting time of fine-leak test, tremendously expands the range of adapted cavity volume and criterion for measured leak rate of fine-leak test, thus making the cumulative helium mass spectrometric combination test more applicable, convenient and practical.

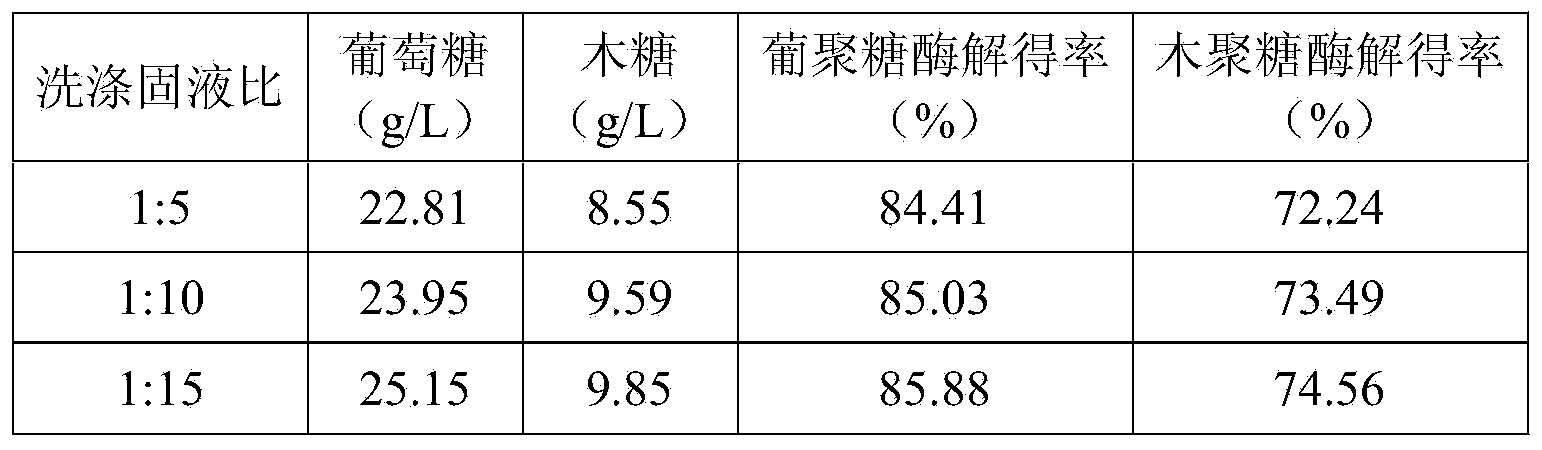

Method for preparing fermentable sugar from water-washed alkaline pretreated plant fiber raw material

The invention discloses a method for preparing fermentable sugar from a water-washed alkaline pretreated plant fiber raw material, which comprises the steps of raw material pretreatment, washing and enzyme hydrolysis, wherein in the washing step, after filtering the pretreated plant fiber raw material, neutralizing with acid, washing a small amount of water to obtain a substrate susceptible to enzyme hydrolysis, and carrying out enzyme hydrolysis to prepare the fermentable sugar. According to the method, the plant fiber raw material is pretreated by green liquor and filtered, neutralized by acid and subjected to batch section washing according to a solid-to-liquid ratio of 1:(2-20), and the substrate with the concentration (w / v) of 5-15% is subjected to cellulase batch hydrolysis for 48-72 hours to obtain the fermentable sugar. The method recovers chemicals and heat energy by using the existing mature technique in pulping paper technology, reduces the consumption of washing water and the generation of wastewater, lowers the environmental pollution, and implements the clean production of fermentable sugar.

Owner:NANJING FORESTRY UNIV

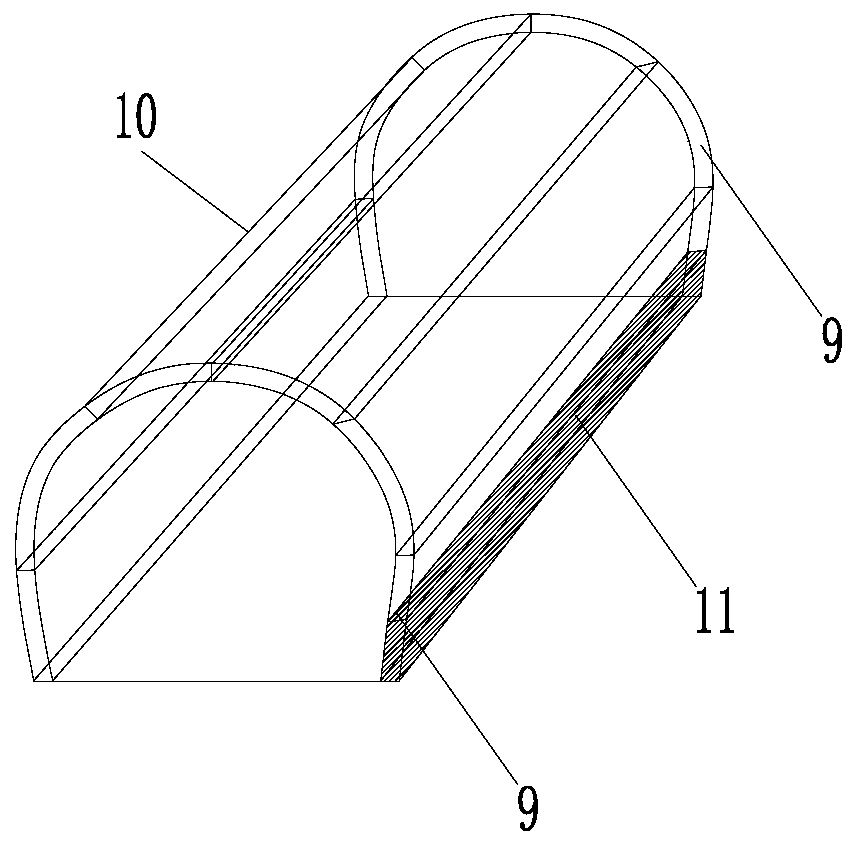

Seed husking device for green beans

The invention discloses a seed husking device for green beans. The seed husking device comprises a machine frame, wherein a power mechanism, a pushing mechanism and a cutting mechanism are arranged on the machine frame; the power mechanism comprises a fan blade, a rotating shaft, a cam, a first hinge arm and a cutting knife; the pushing mechanism comprises a second hinge arm, a first tapered wedge block, a pushing rod and a transport pipe, wherein a feed pipe is arranged on the transport pipe; a cutting opening, a waste opening and a spacing hole are sequentially formed in one end, away from the pushing rod, of the transport pipe, and the cutting opening and the cutting knife are arranged oppositely; the cutting mechanism comprises a third hinge arm, a second tapered wedge block in sliding connection with the spacing hole, and a hollow cutting pipe; a first pressure spring is arranged between one end, away from the second tapered wedge block, of the cutting pipe and the machine frame; and a movable plate is hinged to the inner wall of the cutting pipe, a first pressure spring is arranged between one end, away from the second tapered wedge block, of the cutting pipe, and the machine frame, and a discharge opening is also formed in the cutting pipe. According to the seed husking device disclosed by the invention, the problems that an artificial seed husking manner for green beans is low in efficiency, and fingers easily suffer from chimatlon due to being exposed to cold environment are mainly solved.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Production equipment and process of high-quality low-sulfur biodiesel

ActiveCN105694999BLow sulfur content in fats and oilsReduce the color numberBiofuelsLiquid carbonaceous fuelsBiodieselWater source

Disclosed is high-quality low-sulfur-content biodiesel production equipment.An aeration reaction pool is connected with a salt solution supply source and a raw oil supply source through pipelines respectively.The aeration reaction pool is connected with a butterfly type centrifugal machine through a pipeline.The butterfly type centrifugal machine is connected with an ultrasonic box through a pipeline.The ultrasonic box is connected with an oil-water separation tank through a pipeline.The ultrasonic box is further connected with a clean water source through a pipeline.The oil-water separation tank is connected with an atmospheric distillation tower through a pipeline.The atmospheric distillation tower is connected with a raw material storage tank through a pipeline.The raw material storage tank is connected with an esterification reactor through a pipeline and connected with the upper portion of the atmospheric distillation tower through a pipeline to form a low-boiling point material outlet.The esterification reactor is connected with a vacuum distillation tower through a pipeline.

Owner:TANGSHAN JINLIHAI BIODIESEL

Extraction method of auricularia auricula polysaccharide

The invention discloses an extraction method of auricularia auricula polysaccharide. The extraction method comprises specific steps as follows: auricularia auricula is subjected to superfine grindingand superfine auricularia auricula powder is obtained; water, dodecanoic acid and L-lactic acid are added to the superfine auricularia auricula powder, ultrasonic reinforced subcritical water extraction is performed, centrifugation is performed after the extraction, and a liquid supernatant is an auricularia auricula polysaccharide extraction liquid; protease is added to the auricularia auricula polysaccharide extraction solution for enzymolysis, centrifugation is performed, the liquid supernatant is subjected to deproteinization with a Sevage method, and a deproteinized polysaccharide liquidis obtained; the deproteinized polysaccharide liquid is concentrated, polysaccharide is precipitated with ethanol, centrifugation, precipitation and freeze-drying are performed, and the auricularia auricula polysaccharide is obtained. The extraction method is simple and feasible, takes a short time, facilitates industrial mass production and has good application value and market potentials, and the auricularia auricula polysaccharide has high extraction rate, purity and antioxidant activity.

Owner:金华市艾力生物科技有限公司

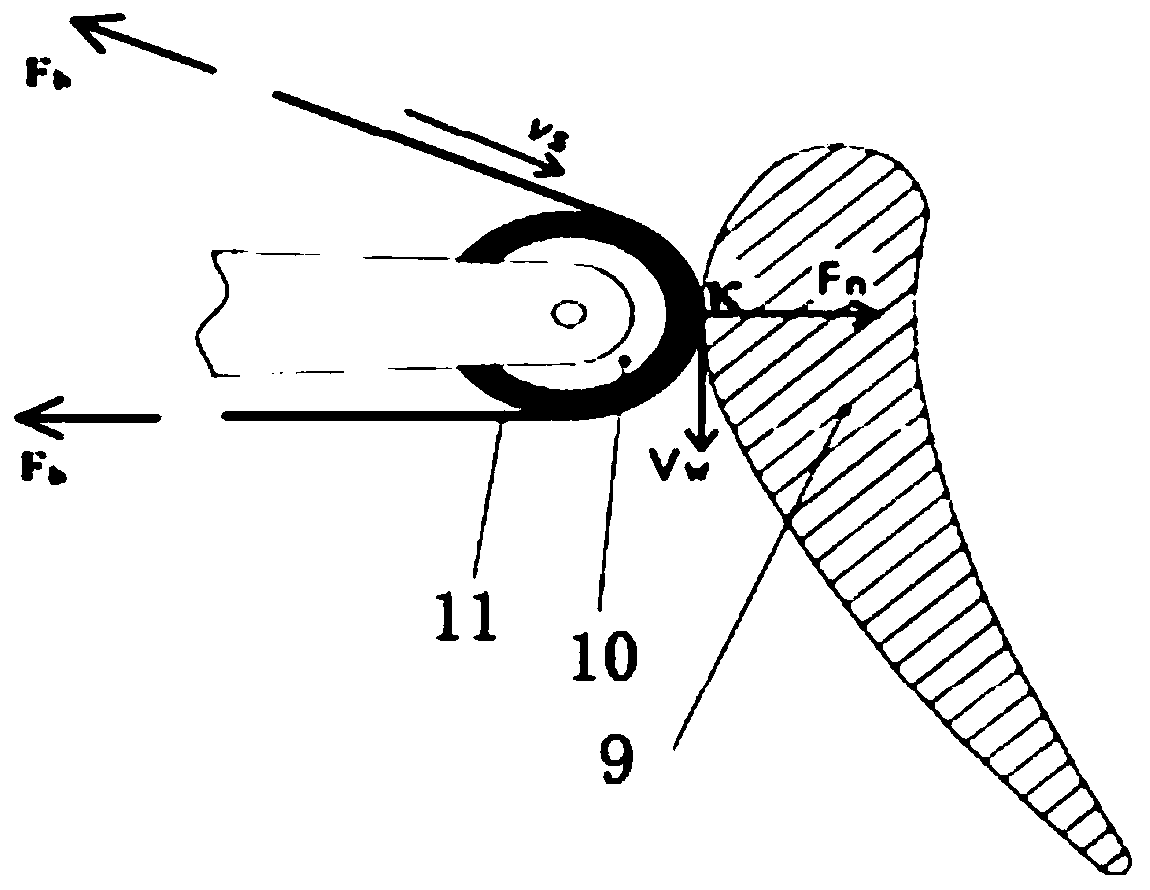

Blade polishing device and method

ActiveCN110814983AReduce surface roughnessEliminate surface microscopic defectsPolishing machinesBelt grinding machinesPhysicsEngineering

The invention discloses a blade polishing device and method. The blade polishing device comprises an industrial robot, a force control device, a clamping tool, a first polishing machine, a second polishing machine and a third polishing machine, wherein the force control device is installed at the end part of a mechanical arm of the industrial robot; the clamping tool is connected with the force control device; the first polishing machine, the second polishing machine and the third polishing machine are distributed around the industrial robot; the clamping tool is used for clamping a blade; theforce control device is used for adjusting the contact pressure between the blade and the polishing machines; the first polishing machine is used for polishing the profile of the blade; the second polishing machine is used for polishing the air inlet edge and the air outlet edge of the blade; and the third polishing machine is used for polishing the edge plate of the blade and is used for polishing the profile of the blade, the air inlet edge and the air outlet edge of the blade. The force control device sets the contact pressure between the blade and the polishing machines, and ensures the removal amount of different blade sections in the polishing process, and the requirements of different positions and precision of the blade are met by different stations of the polishing machines.

Owner:AECC AVIATION POWER CO LTD

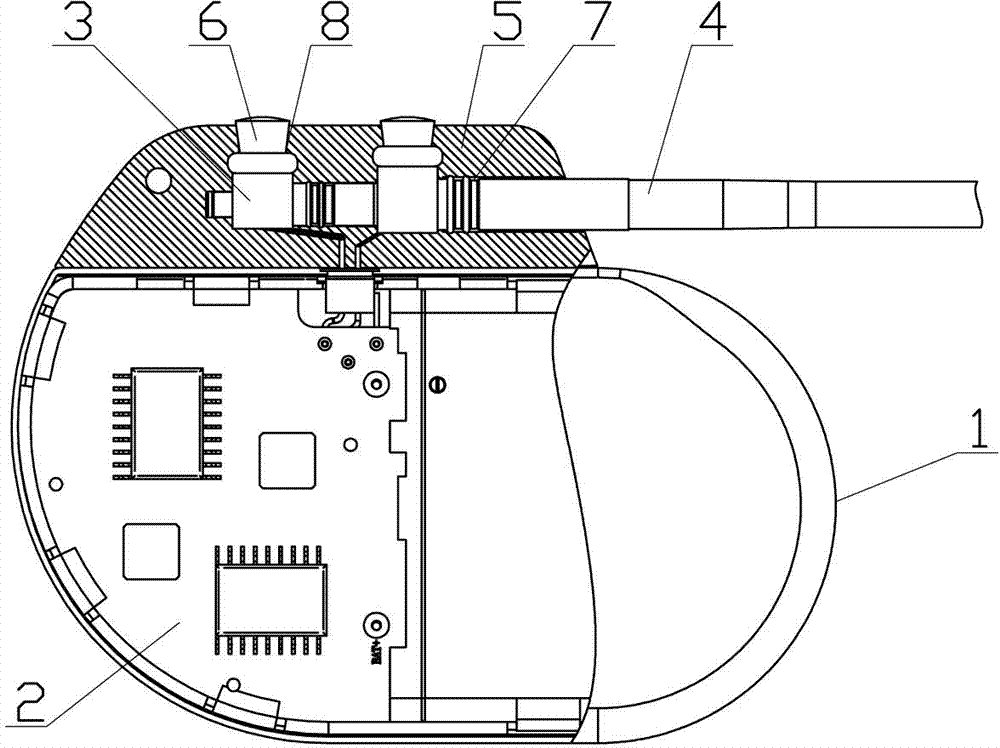

Implantable heart pacemaker packaging device and implantable heat pacemaker packaging method

InactiveCN102641555BQuality improvementEasy to demouldArtificial respirationVolume variationCardiac pacemaker electrode

The invention relates to an implantable heart pacemaker packaging device. The packaging device comprises a packaging mould, a sealing plug cavity forming mould, a positioning rod for fixing the sealing plug cavity forming mould and an electrode positioning mandrel for forming a pace-making electrode cavity and for controlling and determining a position of an electrode square block, wherein a titanium shell holding cavity, a top cover forming cavity, a positioning rod connection hole, an electrode positioning mandrel connection hole, a feeding port and a vent port are arranged inside the packaging mould. Since the packaging device is ingeniously adopted, the top cover forming an implantable heart pacemaker is packaged to the top part of a titanium shell through a filling and sealing way, not only easiness in filling and sealing is achieved, but also positions of all parts forming the packaging device are relatively stable and accurately positioned; and meanwhile, a reasonable packaging method is adopted, so that the material forming the top cover is free from having the problems such as volume variation, bubbles and the like during the entire solidification process, the stability of the shape and the size of the top cover and cavities on the top cover can be guaranteed, and the strength, transparency performance and completion of the top cover also can be guaranteed.

Owner:GUANGDONG PROV MEDICAL INSTR INST

Catalytic cracking light product desulfurization method, and method and device for catalytic cracking production of low-sulfur light oil product

ActiveCN112745936AReduce lossesReduce consumptionTreatment with hydrotreatment processesGaseous mixture working upGasolineProcess engineering

The present invention provides a catalytic cracking light product desulfurization method and device. The method comprises the following steps: (1) introducing crude gasoline from a fractionating tower of a catalytic cracking device into a first desulfurization reactor, carrying out contact desulfurization on the crude gasoline and a desulfurization adsorbent in the presence of hydrogen, and enabling the crude gasoline to flow upwards; and enabling one part of the sulfur-loaded adsorbent separated by gas-solid separation to enter the upper part of the second desulfurization reactor, and roasting, regenerating and recycling the other part of the sulfur-loaded adsorbent and oxygen-containing gas in an adsorbent regenerator, wherein the separated reaction oil gas is desulfurized crude gasoline; (2) carrying out countercurrent contact adsorption desulfurization reaction on the desulfurization adsorbent in the second desulfurization reactor and rich gas, and returning the desulfurization adsorbent to the first desulfurization reactor after the reaction; and (3) respectively feeding the desulfurized rich gas and the desulfurized crude gasoline to an absorption and stabilization unit for further separation to obtain desulfurized dry gas, liquefied gas and stable gasoline. The method provided by the invention is suitable for treating rich gas and crude gasoline obtained by a catalytic cracking fractionating tower, and the obtained refined gasoline is high in yield and low in octane number loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com