Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

495 results about "Limonite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Limonite (/ˈlaɪmənaɪt/) is an iron ore consisting of a mixture of hydrated iron(III) oxide-hydroxides in varying composition. The generic formula is frequently written as FeO(OH)·nH₂O, although this is not entirely accurate as the ratio of oxide to hydroxide can vary quite widely. Limonite is one of the three principal iron ores, the others being hematite and magnetite, and has been mined for the production of iron since at least 2500 BCE.

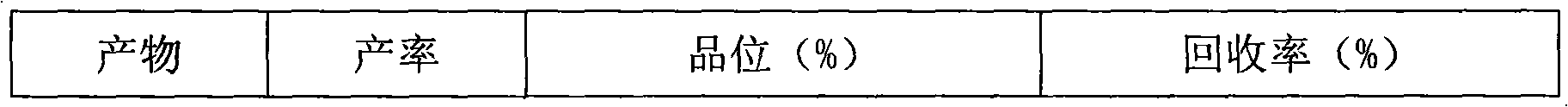

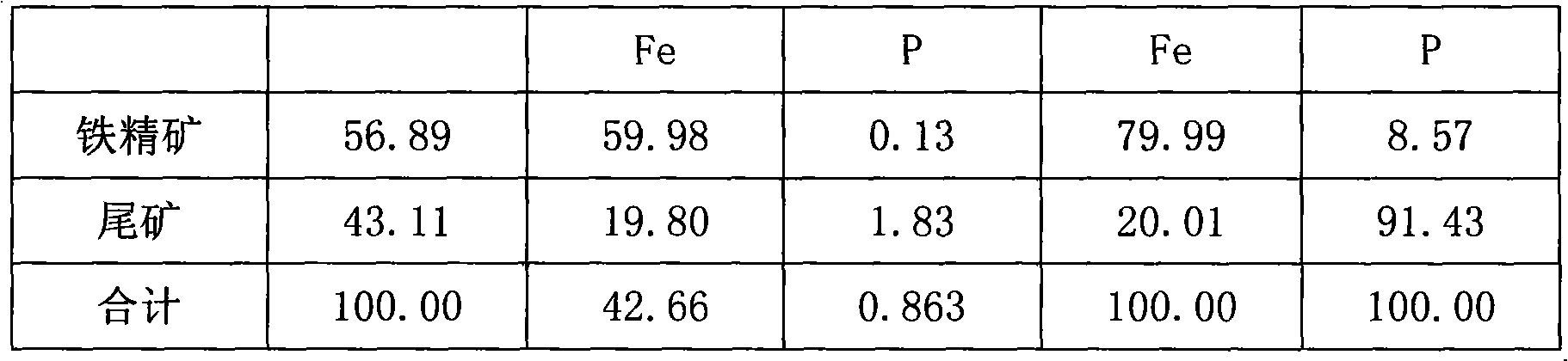

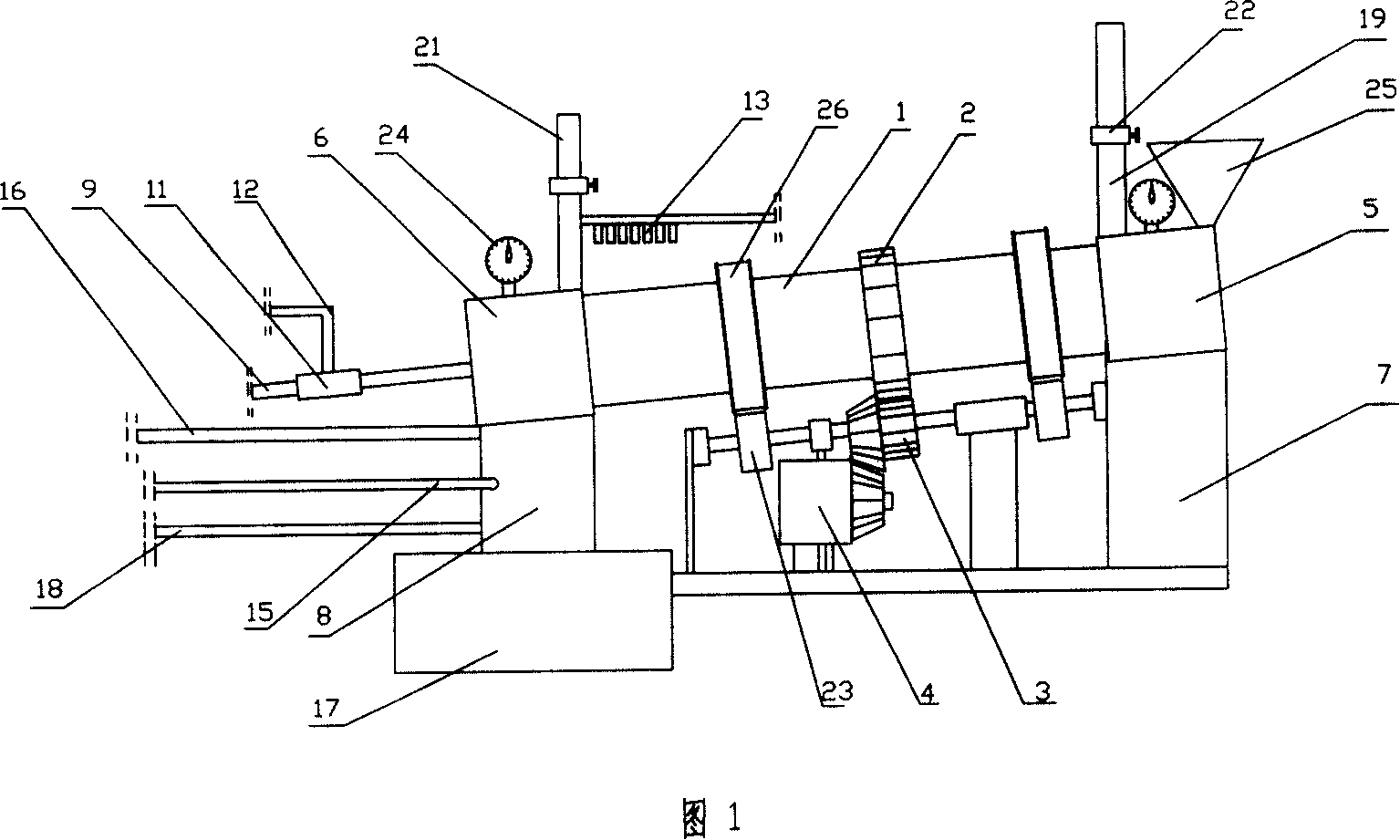

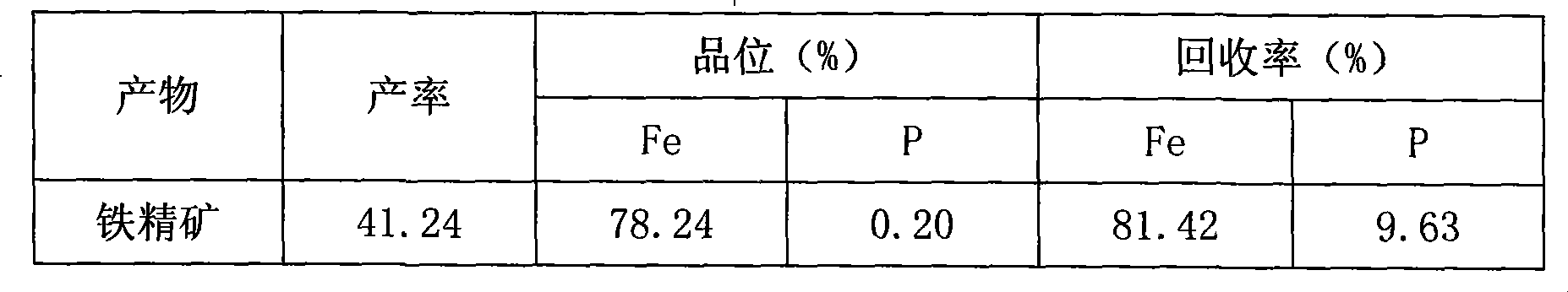

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

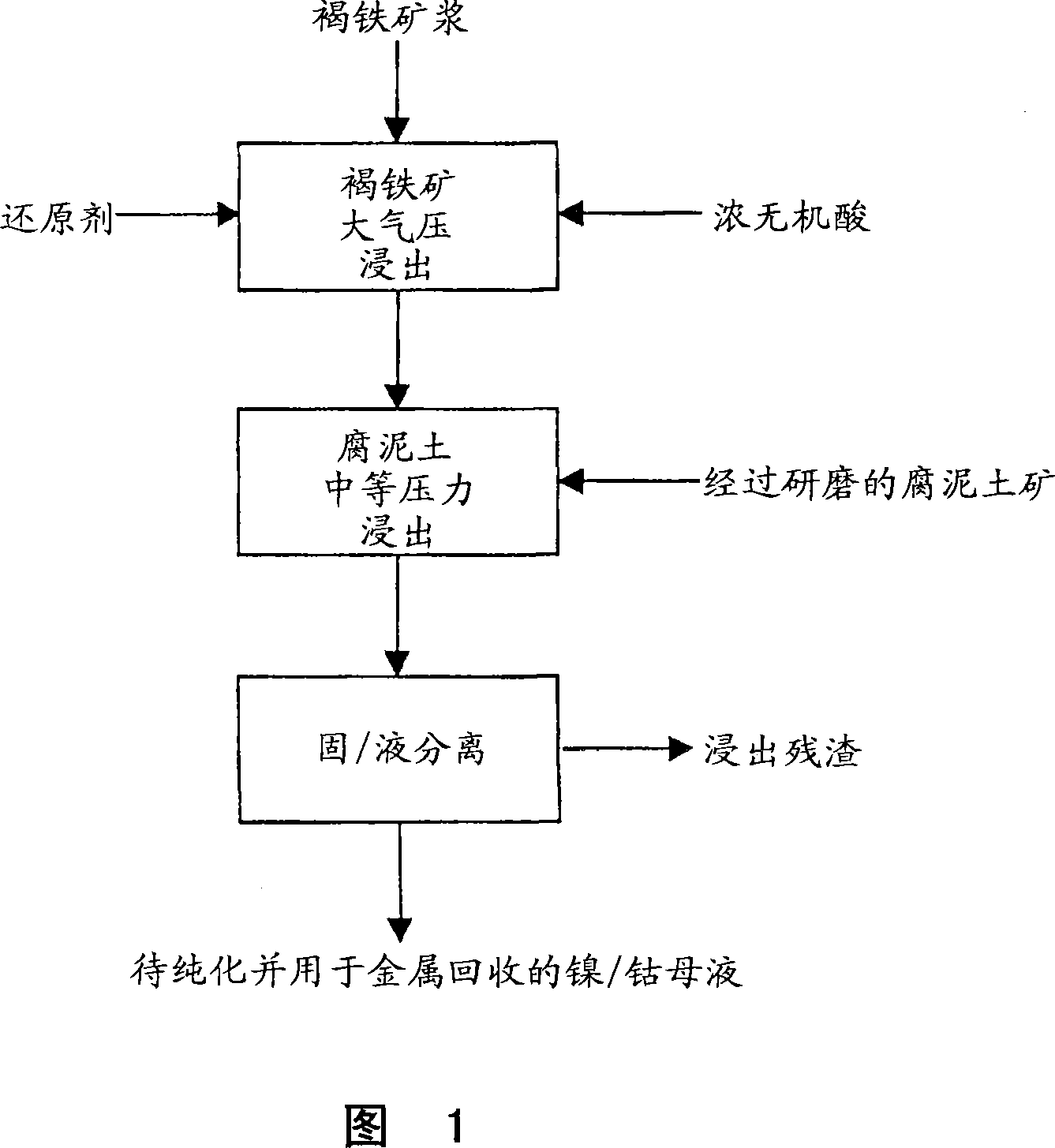

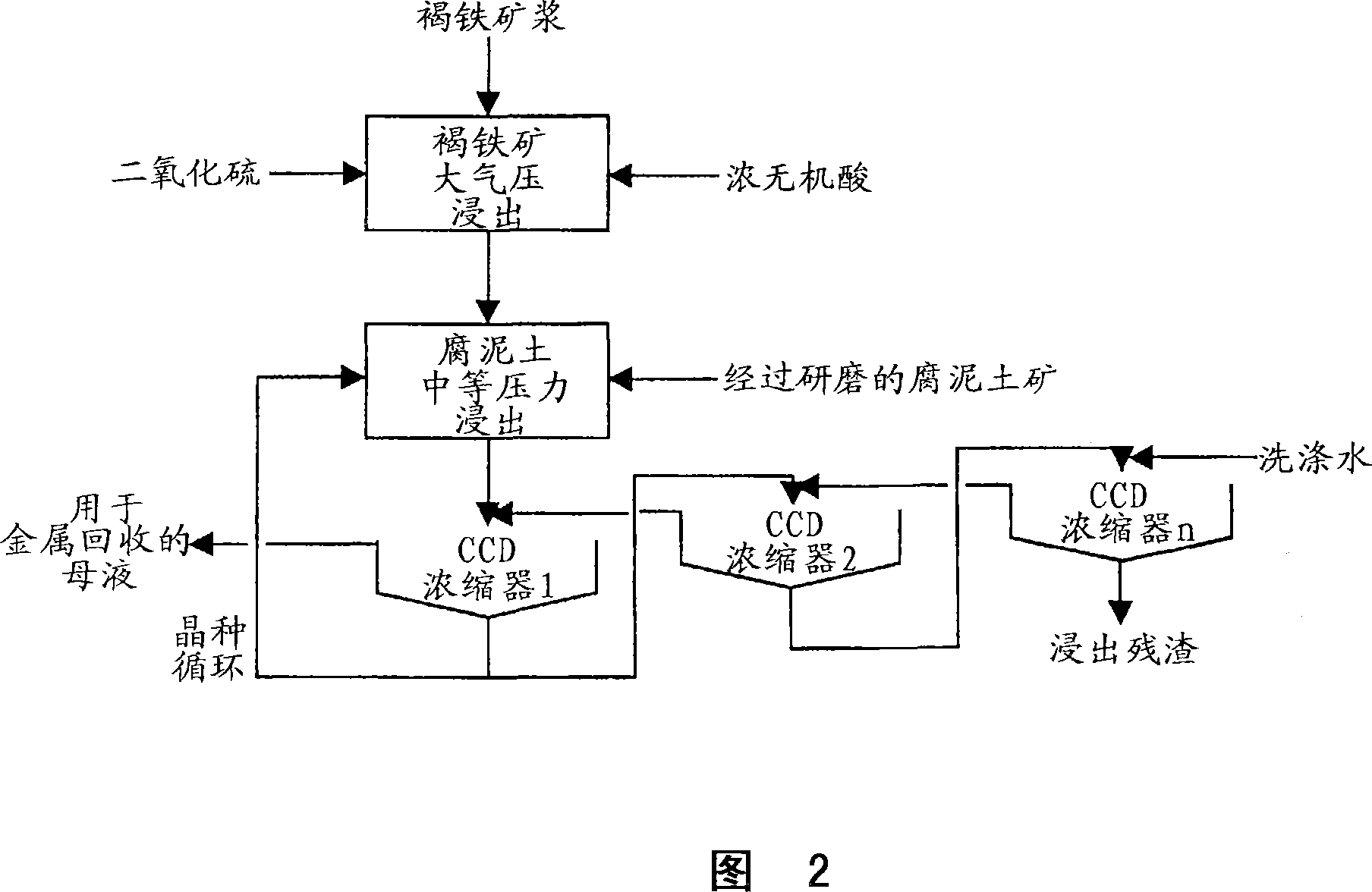

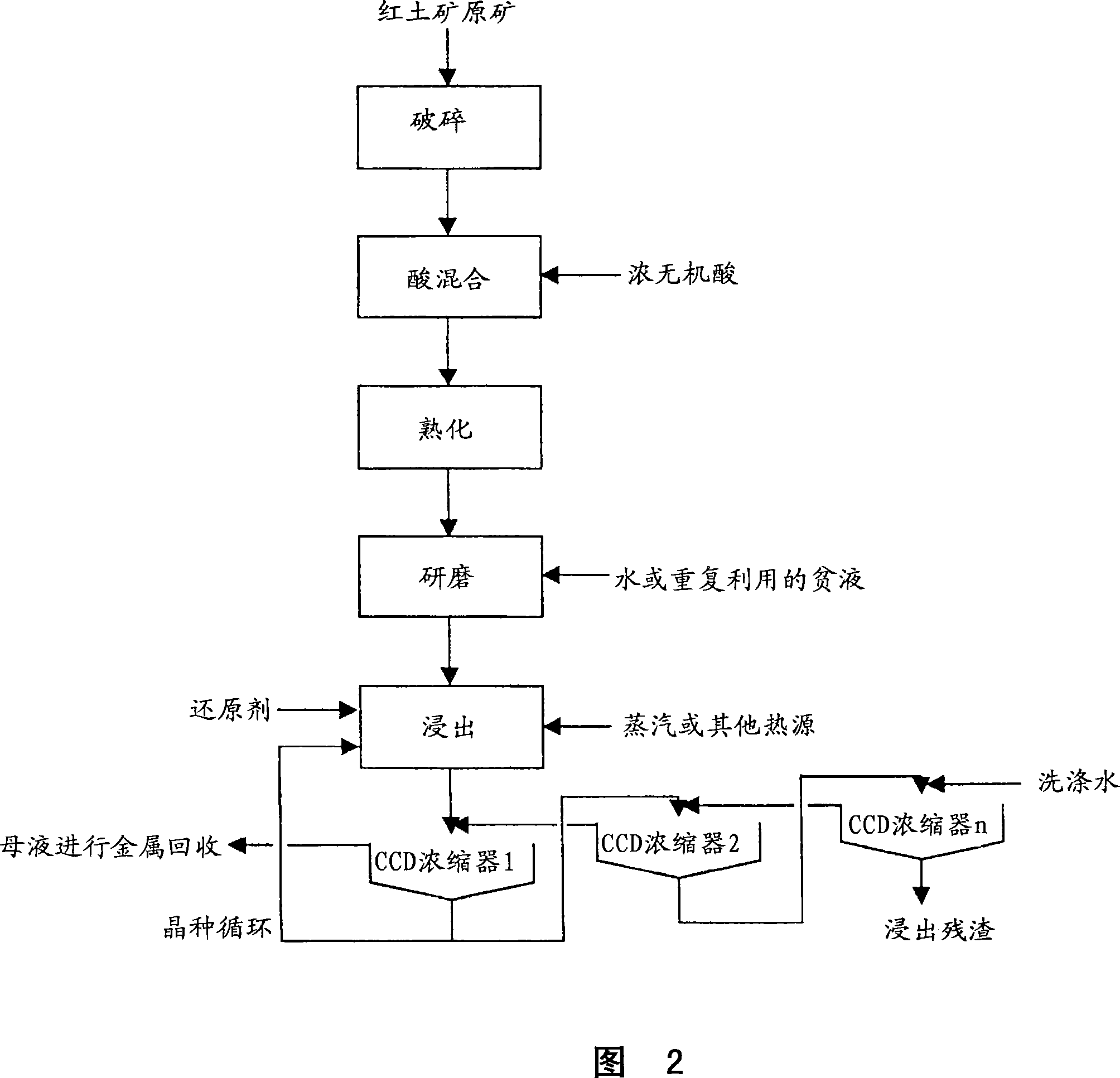

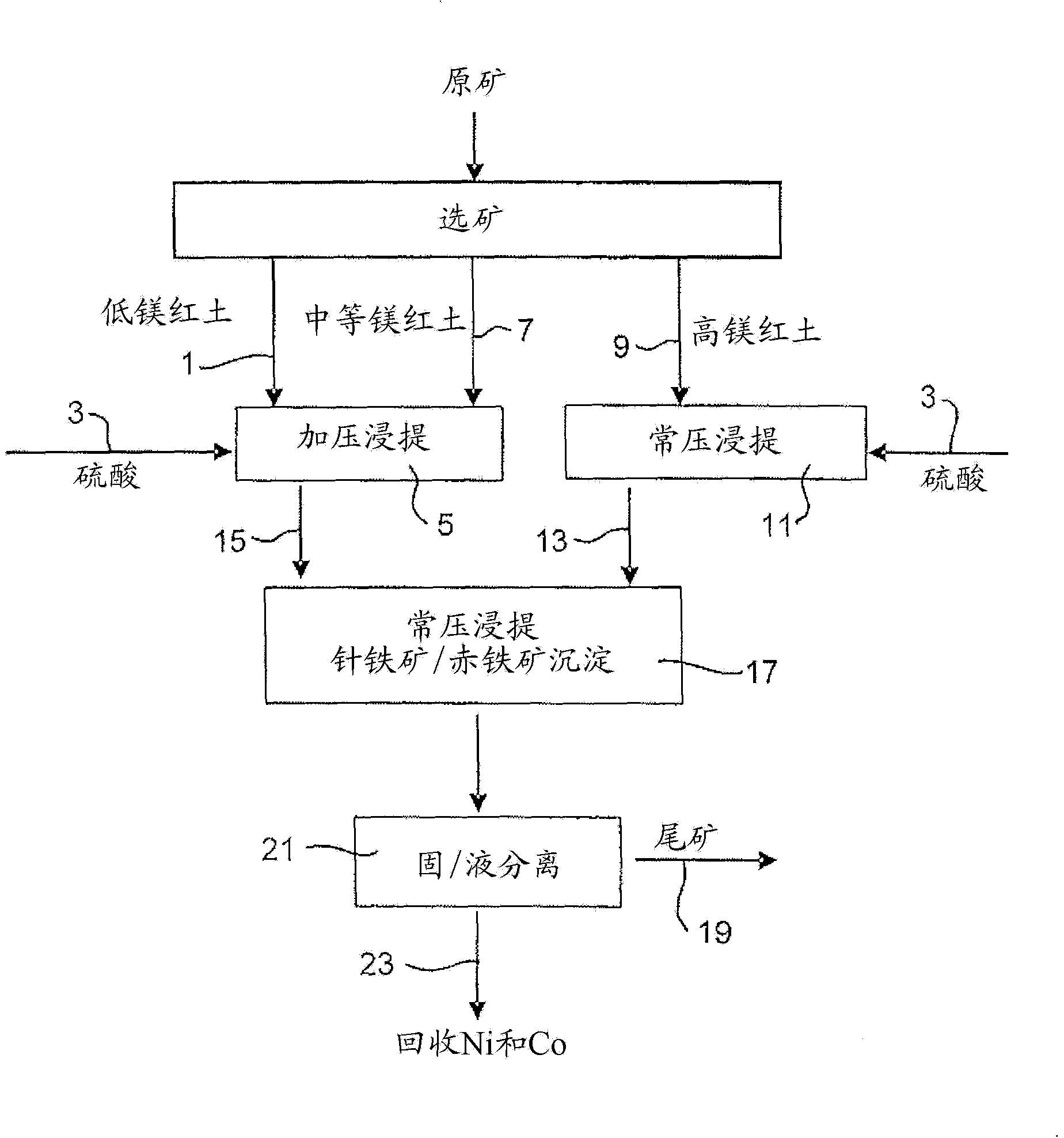

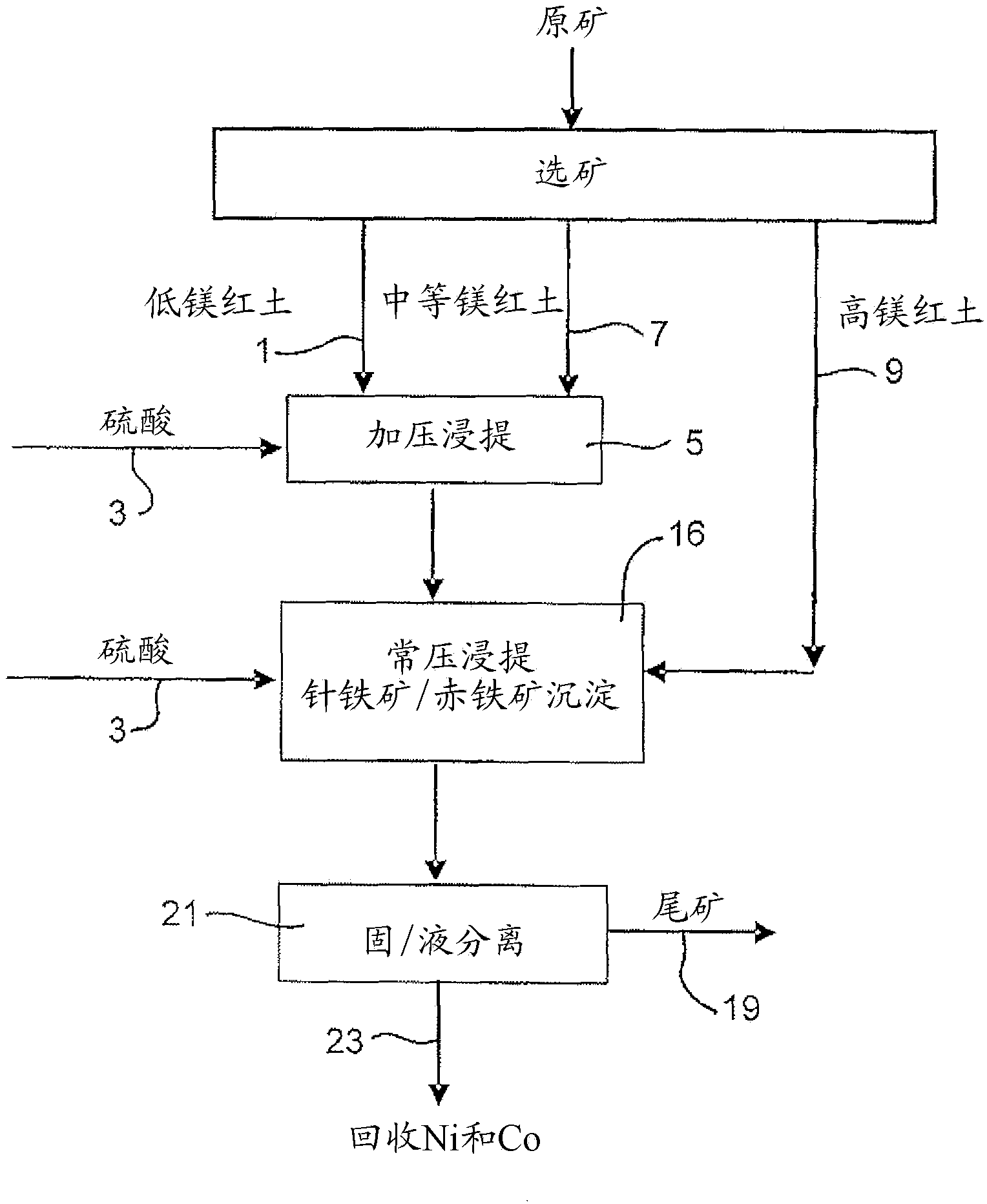

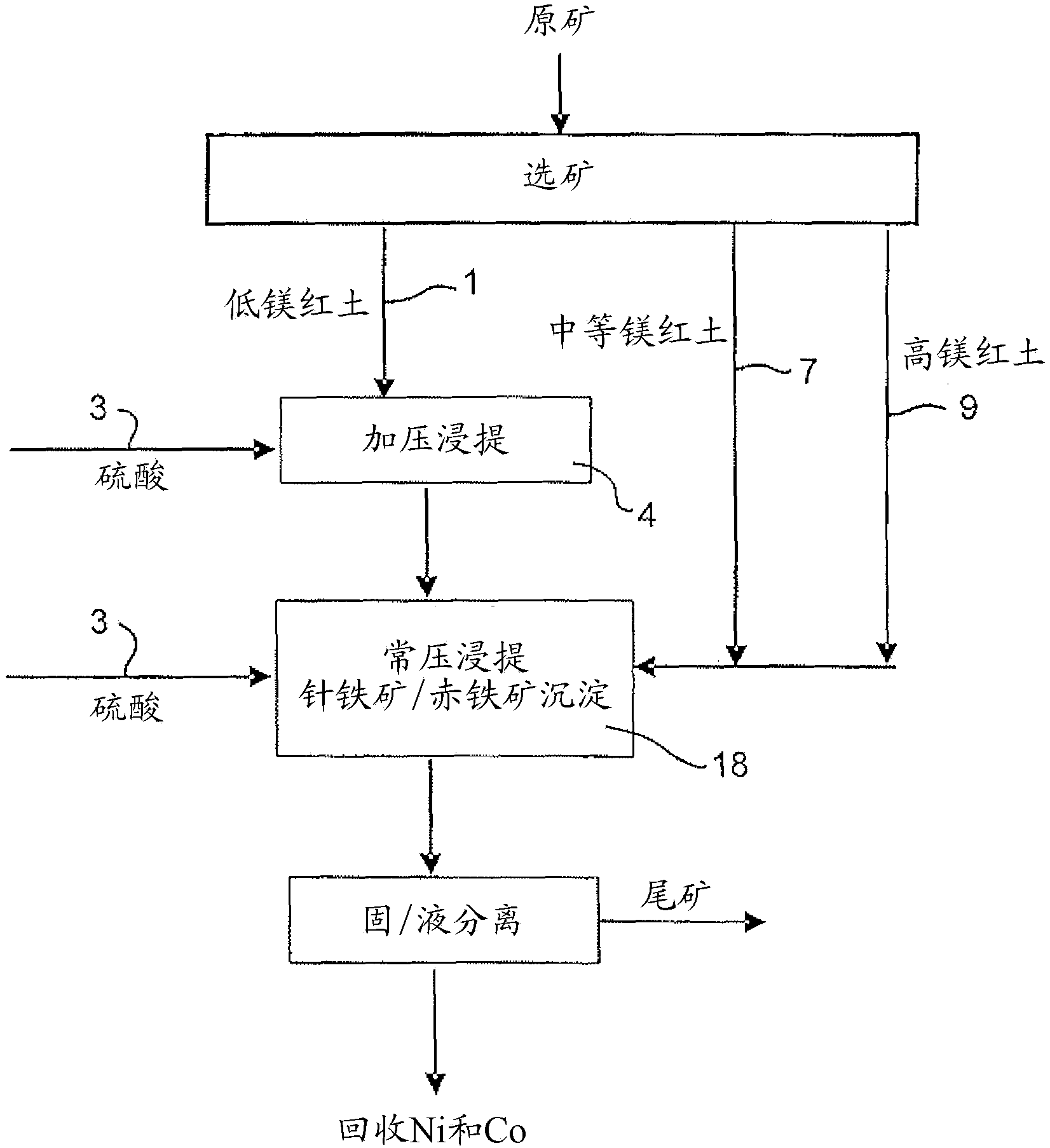

Method for nickel and cobalt recovery from laterite ores by combination of atmospheric and moderate pressure leaching

InactiveCN101001964AHigh extraction rateAvoid environmental unfriendlinessProcess efficiency improvementRecovery methodIon exchange

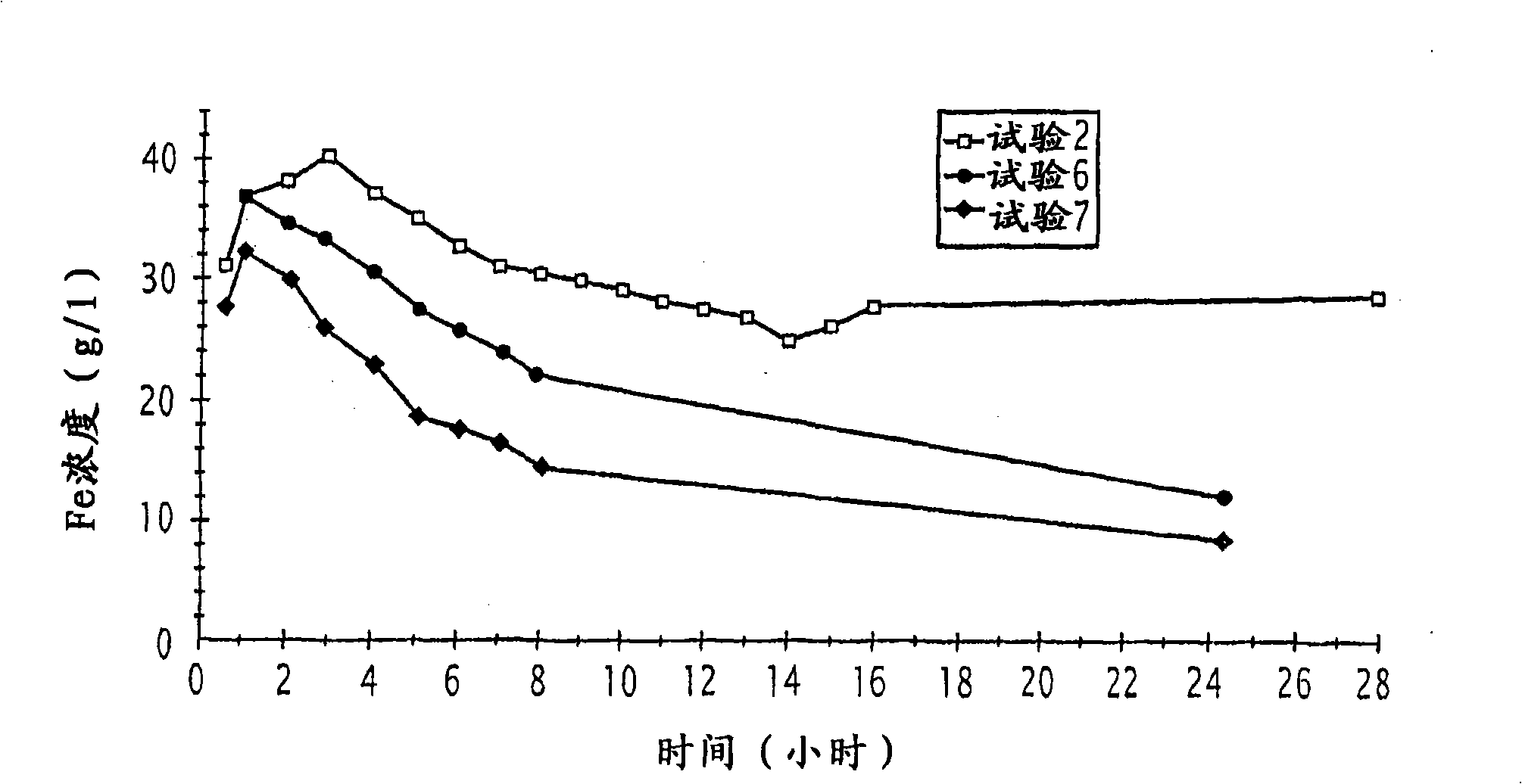

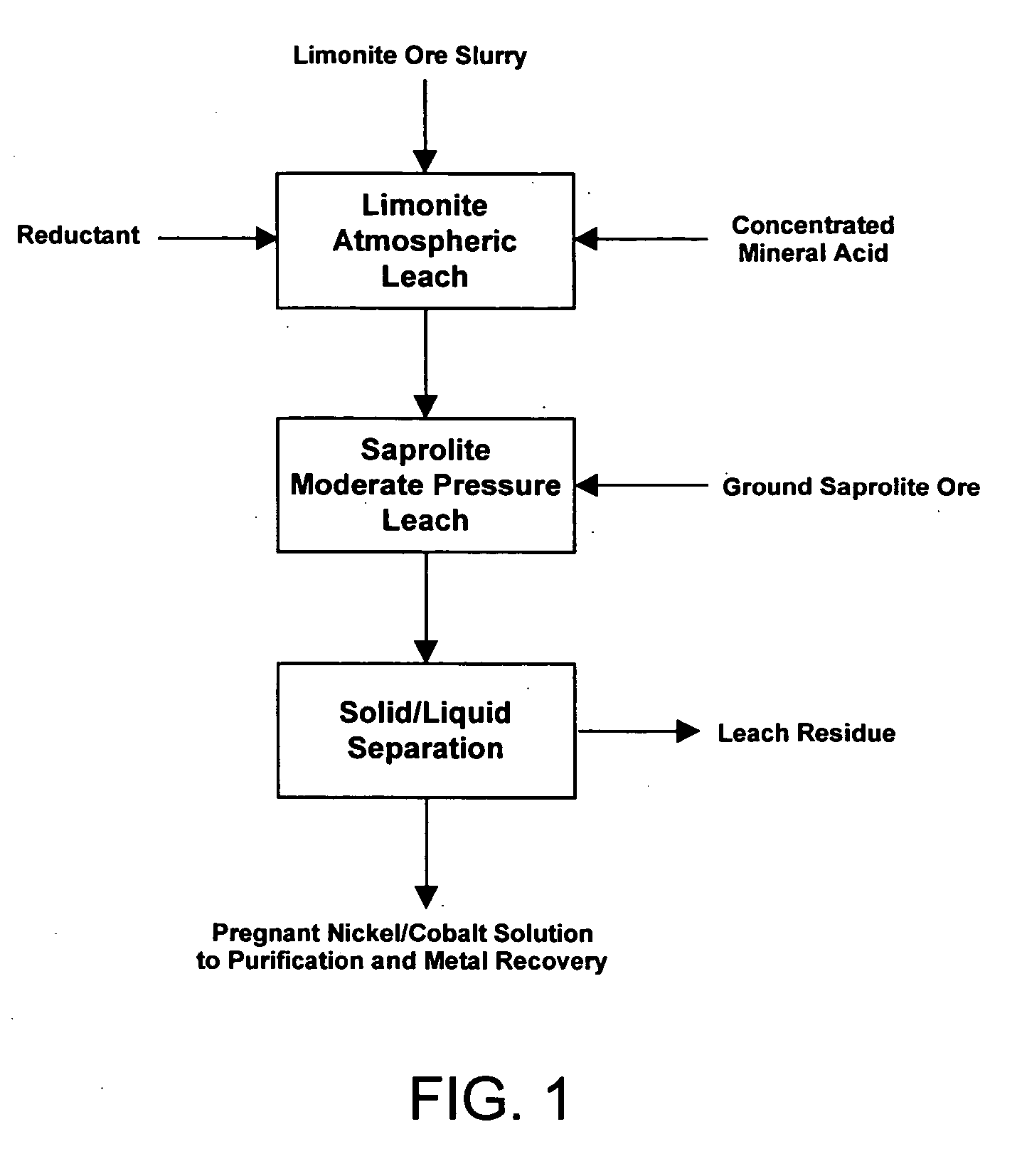

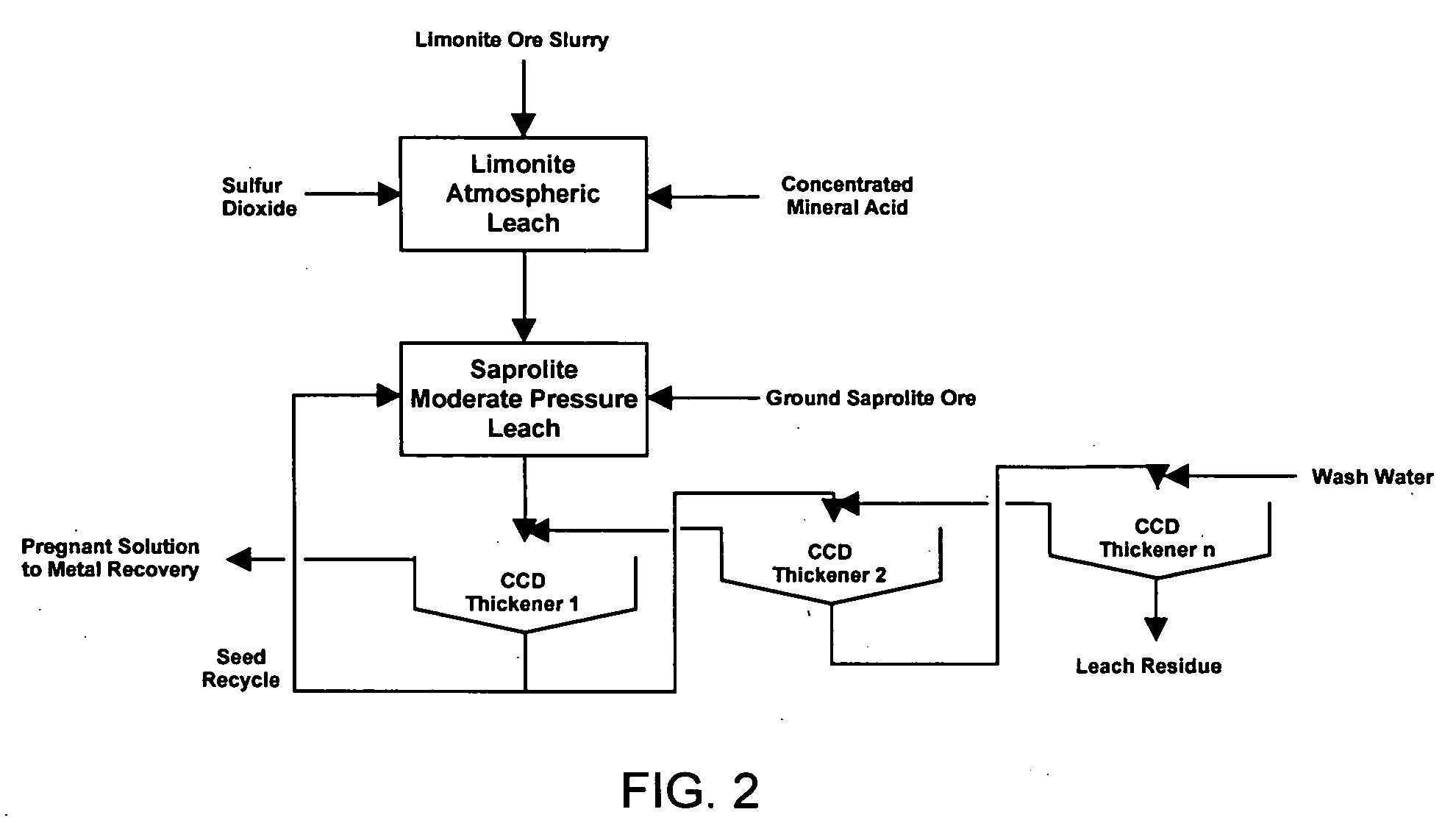

A process for leaching laterite ores containing limonite and saprolite. Sufficient mineral acid is added to a slurry of limonite which is leached at atmospheric pressure to dissolve most of the soluble non-ferrous metals and soluble iron. After adding saprolite the slurry is further leached at a temperature above the normal boiling point and at a pressure above atmospheric pressure for a time sufficient to leach most of the contained nickel in the saprolite and to precipitate most of the iron in solution. The pressure of the slurry is then reduced, and nickel and / or cobalt is subsequently recovered from the leach solution by solvent extraction, resin-in-pulp or other ion exchange, sulfide or hydroxide precipitation, or other recovery method.

Owner:SKYE RESOURCES

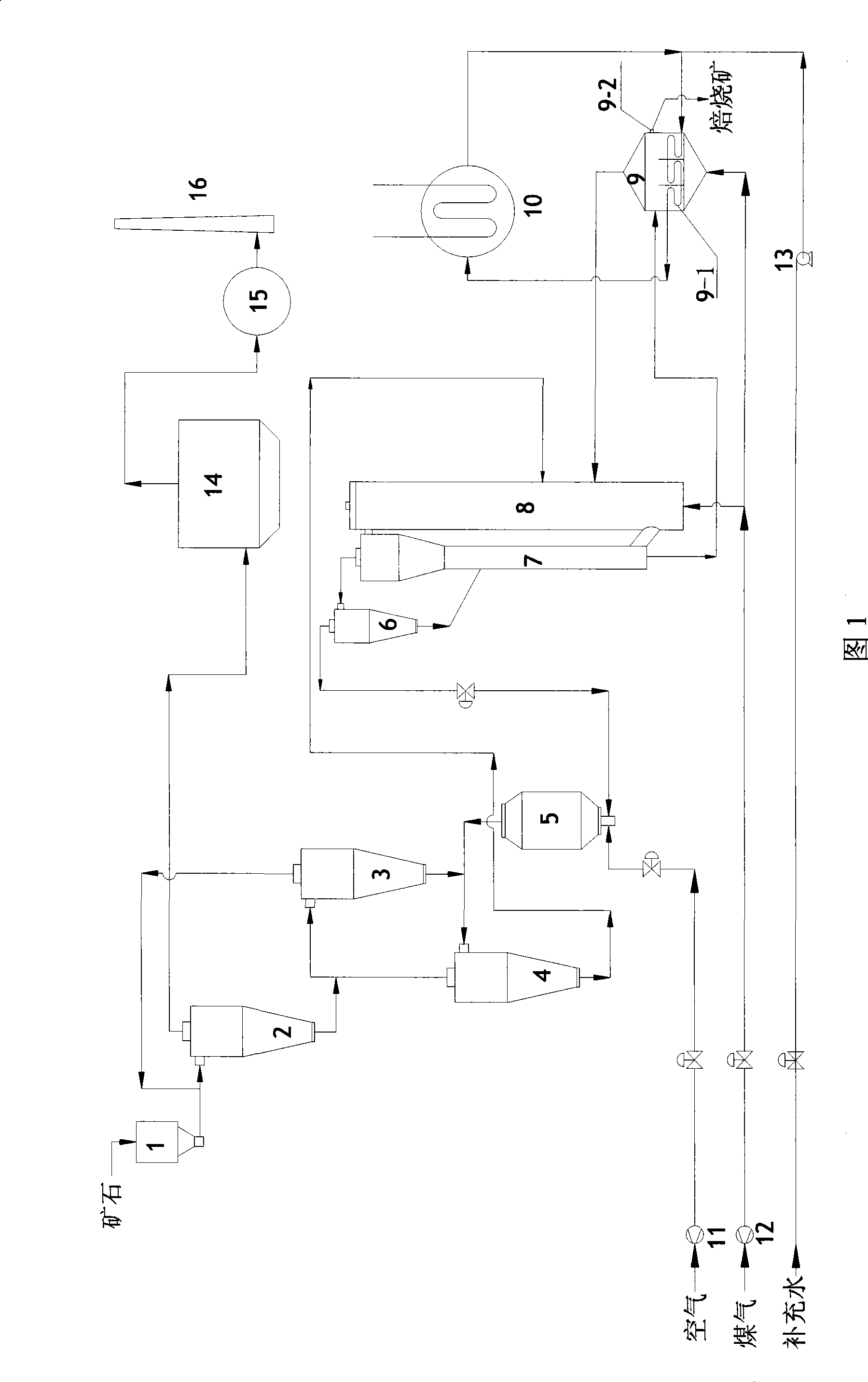

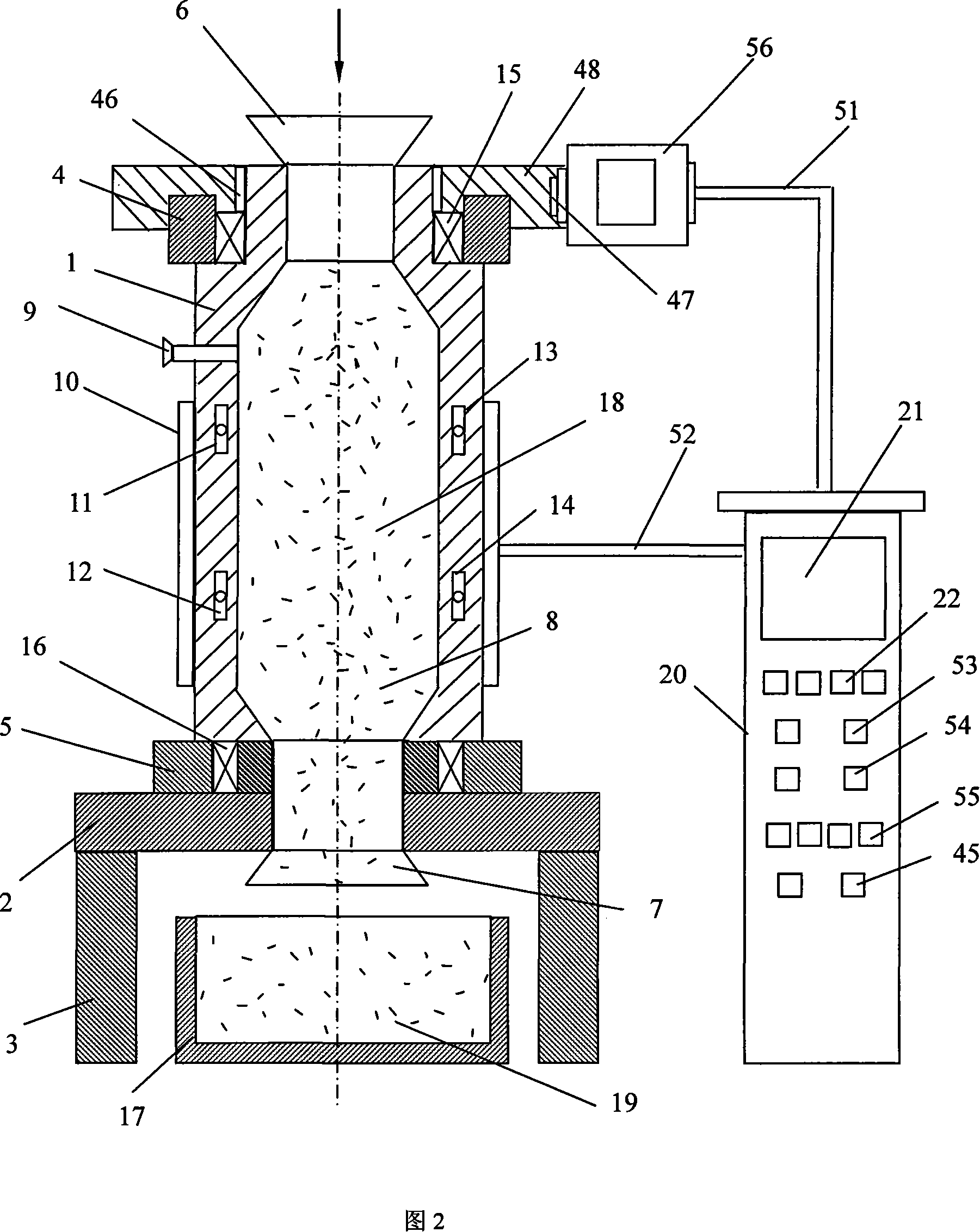

Magnetization roasting technique system for refractory iron ore powder and roasting technology

The invention belongs to the fields of chemical engineering and metallurgy and in particular relates to a process system which adopts a circulating fluid bed to carry out magnetization roasting on limonite, siderite, sedimentary hematite and other refractory iron ore powder bodies. The process system adopts a high-efficiency low-resistance reactor of the circulating fluid bed to carry out the magnetizing roasting to the iron ore powder body; firstly, roasted tail gas in a combustion chamber releases latent heat of unreacted reducing gas through combustion; secondly, the roasted tail gas exchanges heat with the cold iron ore powder body through a multilevel cyclone preheater to reclaim heat; and finally a fluidizing cooler is adopted to reclaim sensible heat of high-temperature roasting ore. The process system has the advantages of high magnetizing roasting efficiency and full heat reclaiming and utilization in the roasting process and the like, can reduce energy consumption of the refractory iron ore powder body in the process of magnetizing roasting and improve the economical efficiency of the refractory iron ore in the process of magnetizing roasting.

Owner:深圳市中科九台资源利用科技产业股份有限公司

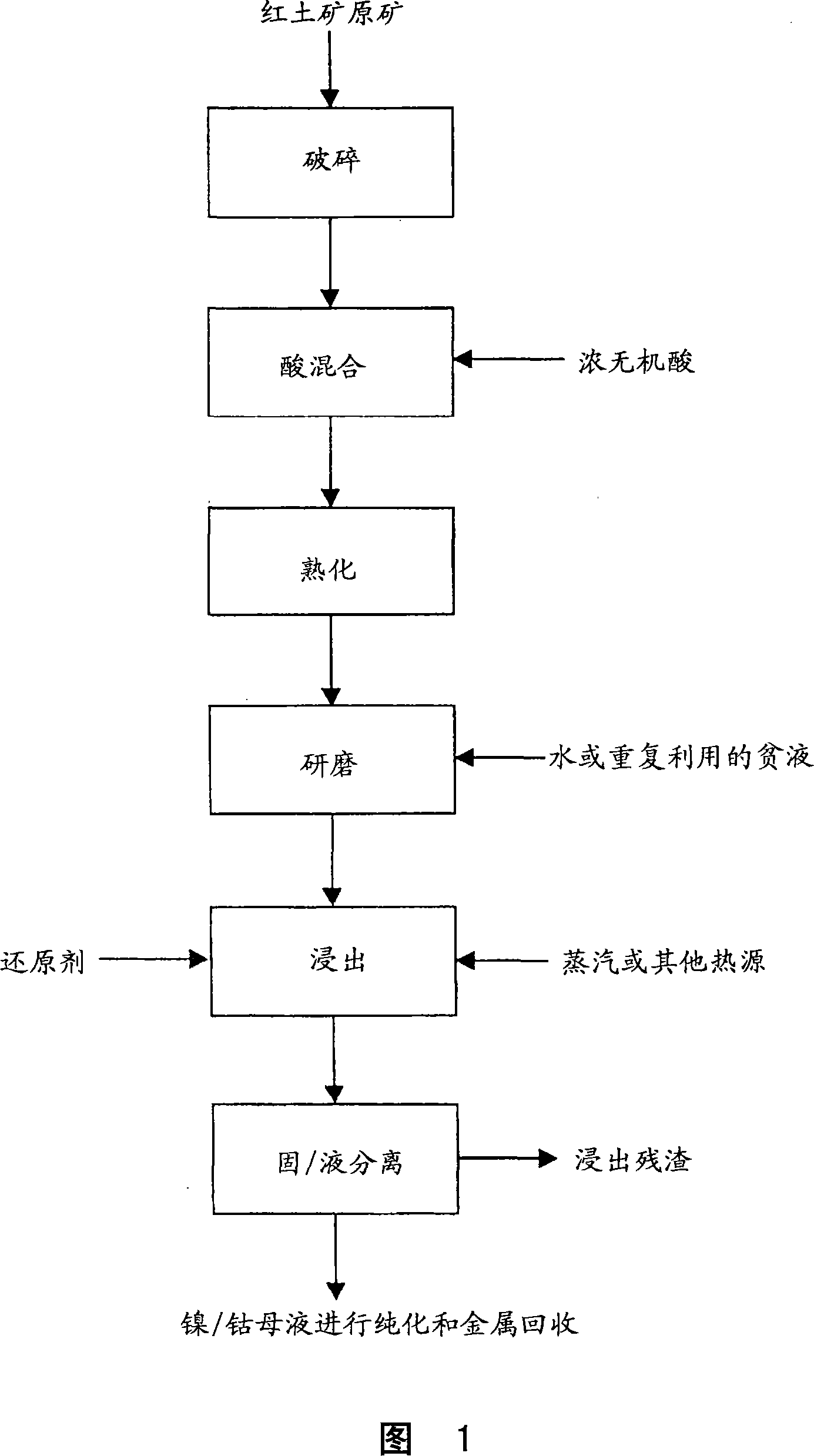

Method for nickel and cobalt recovery from laterite ores by reaction with concentrated acid and water leaching

InactiveCN101006190AHigh extraction rateLow extraction rateProcess efficiency improvementPotassiumSlurry

A process for leaching laterite ores containing limonite and saprolite in a two stage process. The first stage consisting of mixing and reacting the ore with concentrated mineral acid, and the second stage consisting of preparing a slurry of the acid / ore mixture in water and leaching the mixture to dissolve nickel and cobalt. Iron is efficiently separated from nickel and cobalt in the solid leach residue primarily as an oxide or hydroxide of ferric iron other than jarosite.

Owner:SKYE RESOURCES

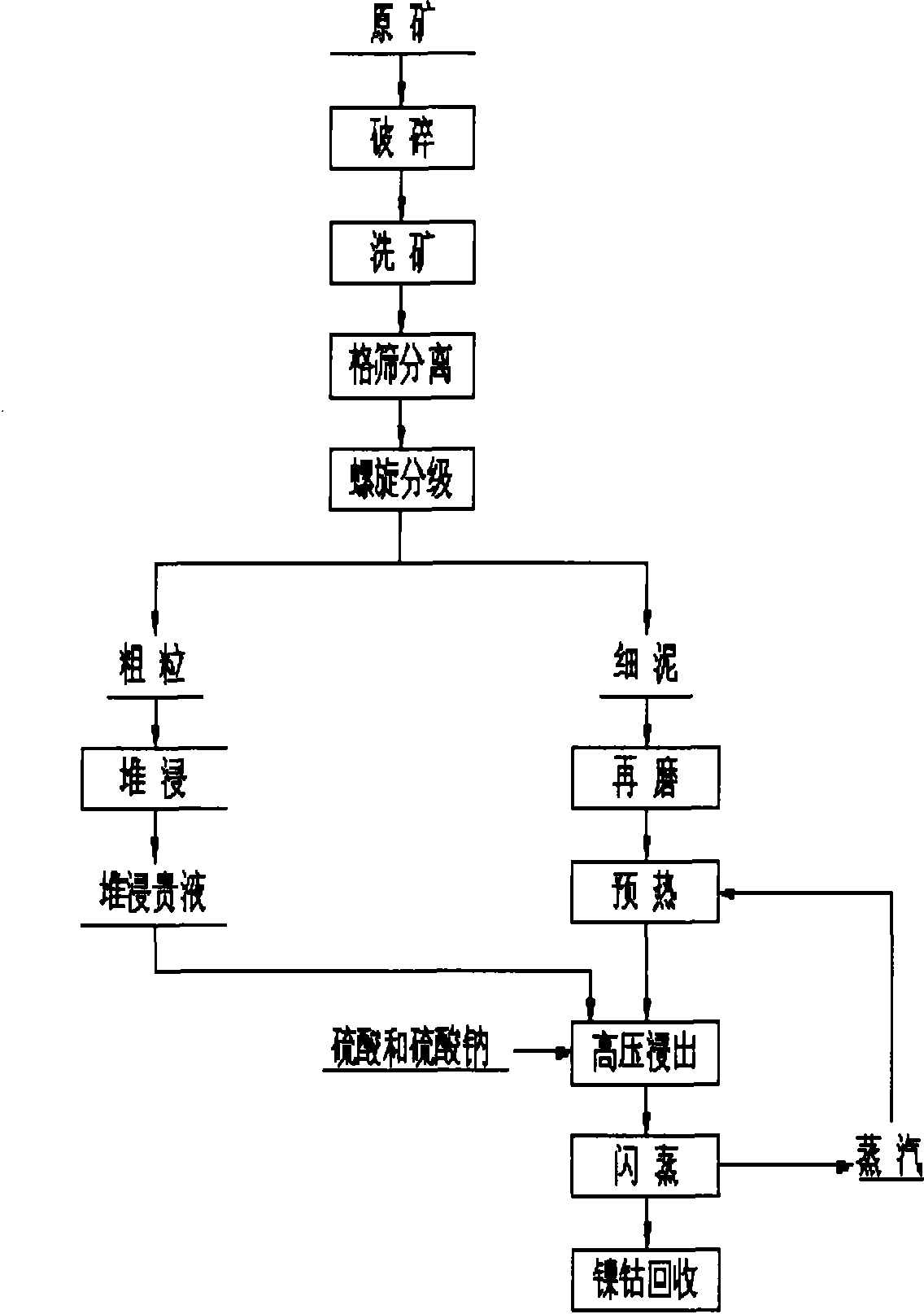

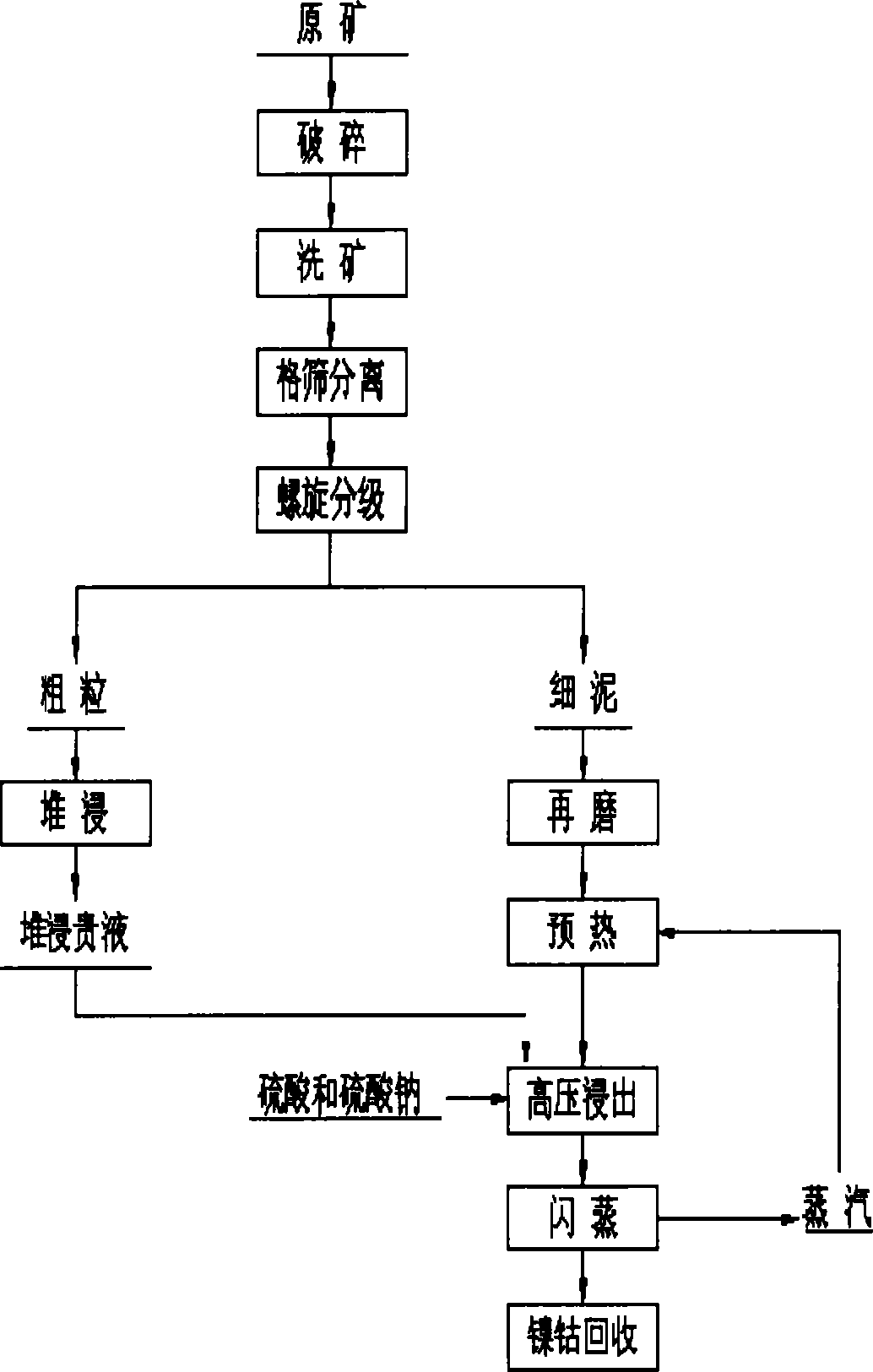

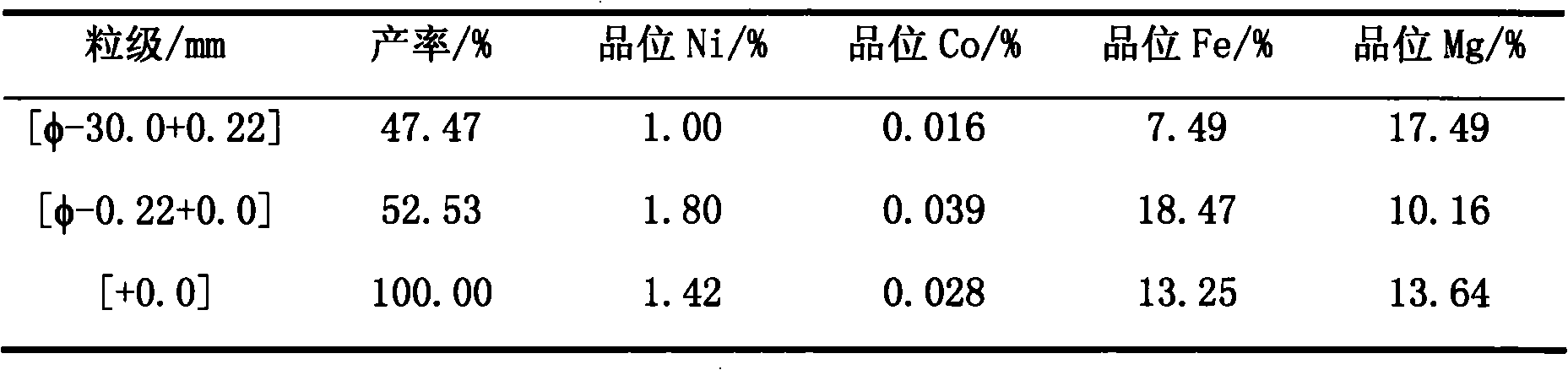

Method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore

InactiveCN101768665AReduce acid consumptionReduce consumptionProcess efficiency improvementHigh pressureLaterite

The invention discloses a method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore, which combines the heap leaching technology with the high-pressure leaching technology to reduce acid consumption during the treatment of nickel laterite ore; residual sulfuric acid in coarse particle immersion of limonite heap is sufficiently utilized and sodium sulfate is added during the stage of high-pressure leaching so that sulfuric acid is generated while yellow natrojarosite is formed, thereby further reducing the consumption of sulfuric acid during the stage of high-pressure leaching.

Owner:厦门紫金矿冶技术有限公司

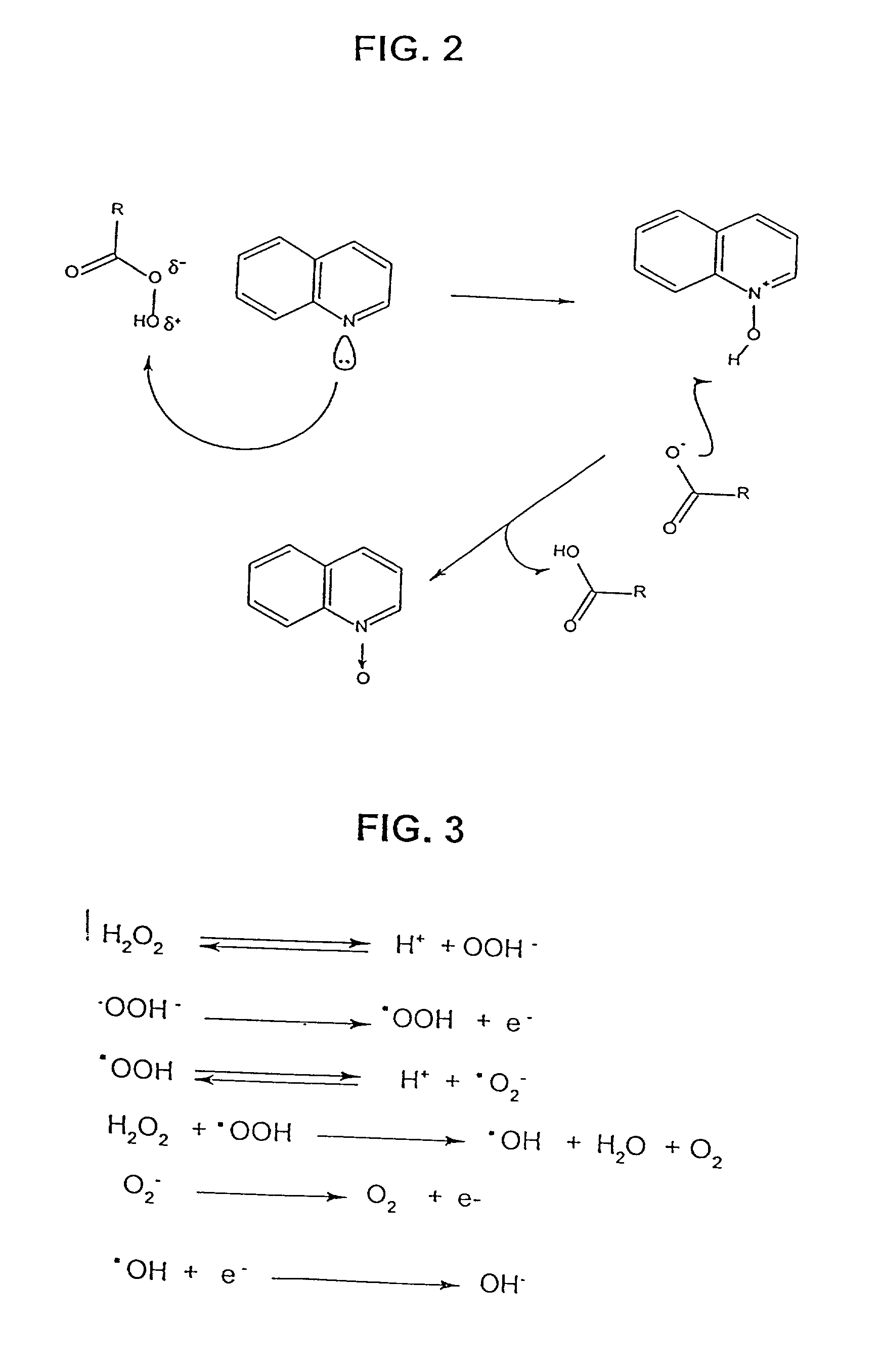

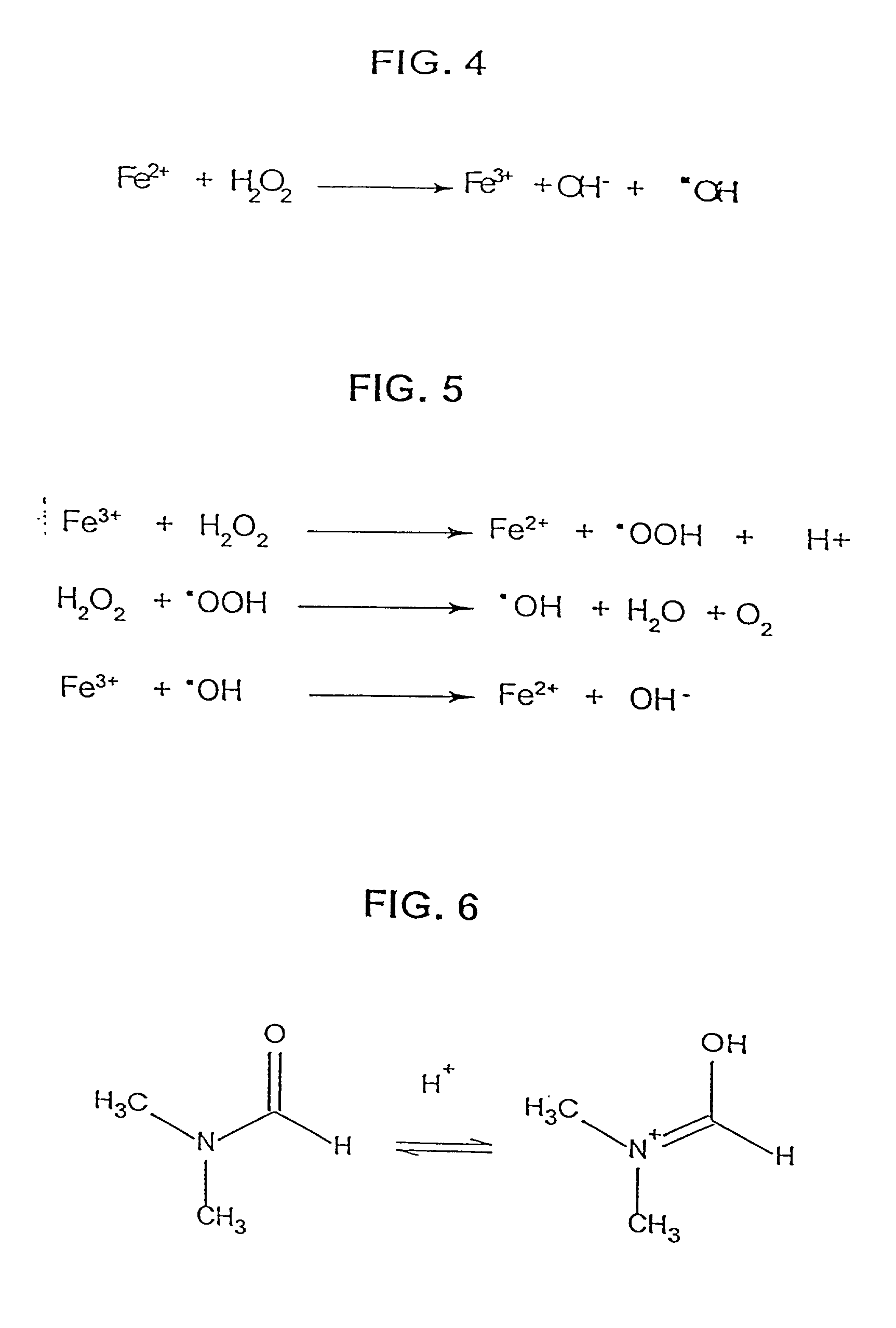

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

InactiveUS20020189975A1Refining with metalsRefining with oxygen compoundsCatalytic oxidationPeroxy acid

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxy-acid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

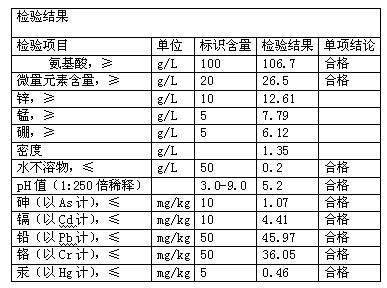

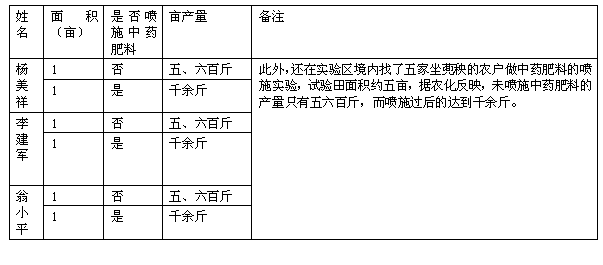

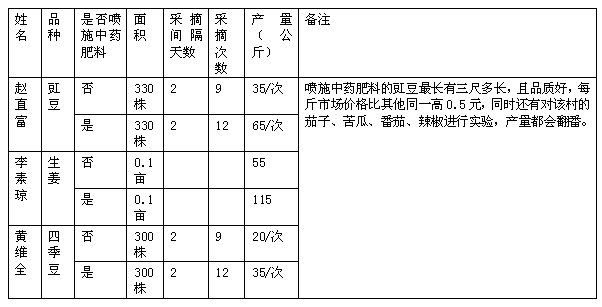

Disease and insect resistant fertilizer produced by traditional Chinese medicines and preparation technology thereof

ActiveCN103319282AAntibacterial and anti-pest functionsRich in nutrientsFertilizer mixturesOysterRhizome

The invention relates to a?fertilizer,?in particular to a?fertilizer produced by the adoption of traditional Chinese medicines and a production method?thereof. The fertilizer comprises the following raw materials: artemisia capillaris, Tripterygium wilfordii,?radix stemonae,?Scutellaria,?coptis,?Phellodendron amurense,?Chinese rhubarb 1, honeysuckle,?Salvia miltiorrhiza,?safflower,?astragalus membranaceus,?bighead atractylodes rhizome, Paris polyphylla,?Poria cocos, Polygonum bistorta L.,?kelp, Chinese angelica, Polygonum multiflorum, root of chinese barberry, radix polygonati officinalis, Manis pentadactyla, gypsum, keel, oysters, limonite, cuttlebone and silkworm excrement. The fertilizer is extracted from pure organic raw materials, causes no pollution to the environment, has no residue, and is safe and environmentally friendly. Nutritive elements such as amino acid, synthetase, polysaccharide and the like contained in the fertilizer can be rapidly absorbed and utilized by plants, not stimulating or damaging plants. Due to diversity of the raw materials, nutrient composition of the fertilizer is more comprehensive, thus meeting the nutritive element diversity requirement of crops. Alkaline substances and other active substances in the traditional Chinese medicines can destroycell membrane so as to inhibit germs well. Meanwhile, the fertilizer has effects of repelling insects and inhibiting breeding of insects.

Owner:韦文礼

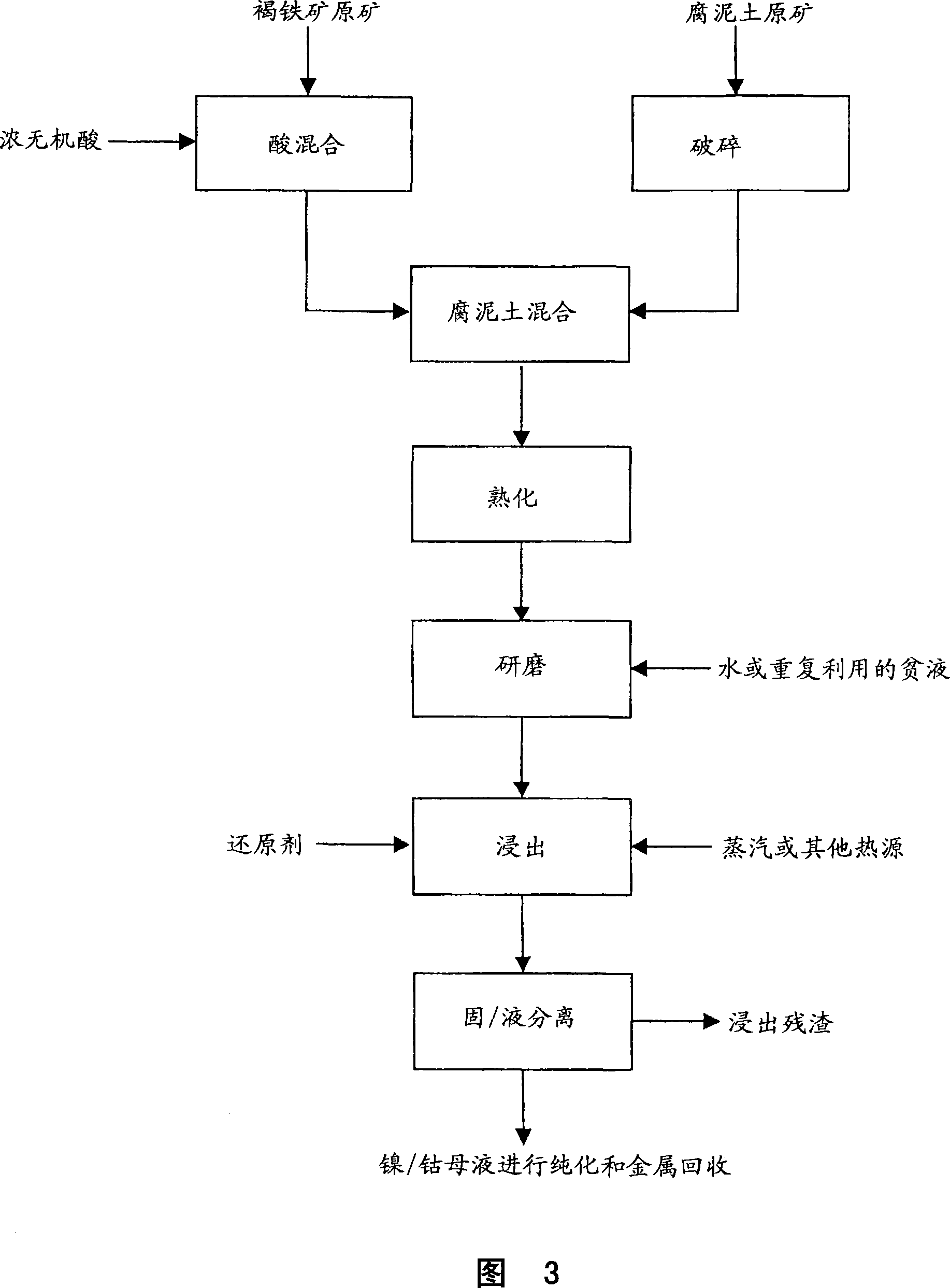

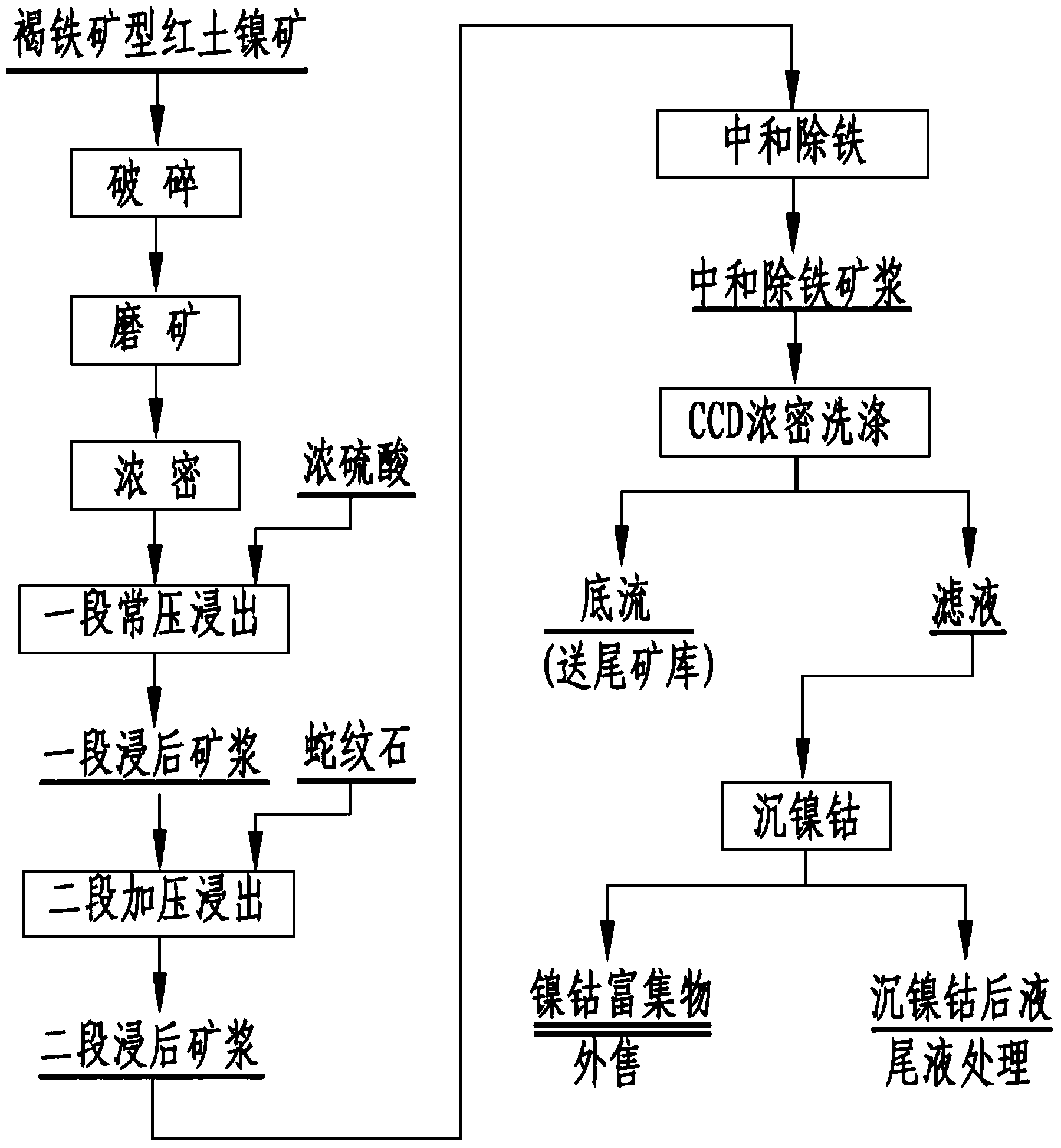

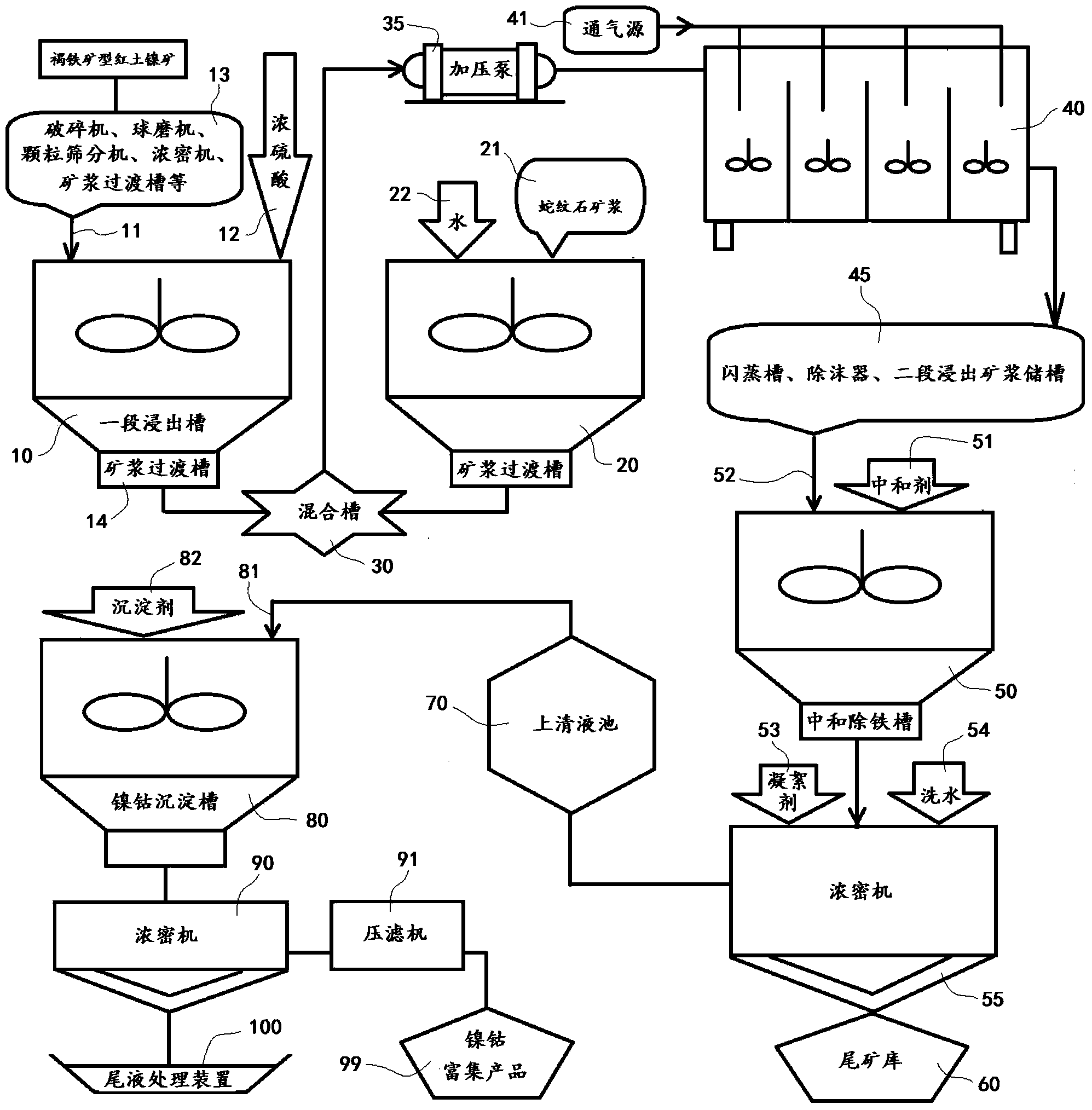

Laterite-nickel ore combination leaching process

InactiveCN103614571AWide adaptabilityImprove leaching rateProcess efficiency improvementMagmaHigh pressure

The invention relates to a laterite-nickel ore combination leaching process, which comprises that: limonite type laterite-nickel ore is subjected to crushing grading, and then is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring self-heating leaching, serpentine type laterite-nickel ore is subjected to crushing grinding, the obtained serpentine type laterite-nickel ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and serpentine is leached by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle, or mixing type laterite-nickel ore is subjected to grading, the obtained fine particle-grade ore is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring leaching, ore on the sieve is subjected to crushing grinding, the grinded ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and coarse particle-grade ore leaching is performed by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle. According to the invention, the process has characteristics of no special requirements on ore types and grades, wide raw material adaptability, investment reduction, energy consumption reduction, production cost reduction, and simple process, wherein the Ni recovery rate and the Co recovery rate of the whole process of the present invention are respectively more than 90% and 88%, and are higher than the Ni recovery rate and the Co recovery rate of the treatment method in the existing non-high-pressure acid leaching technology.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

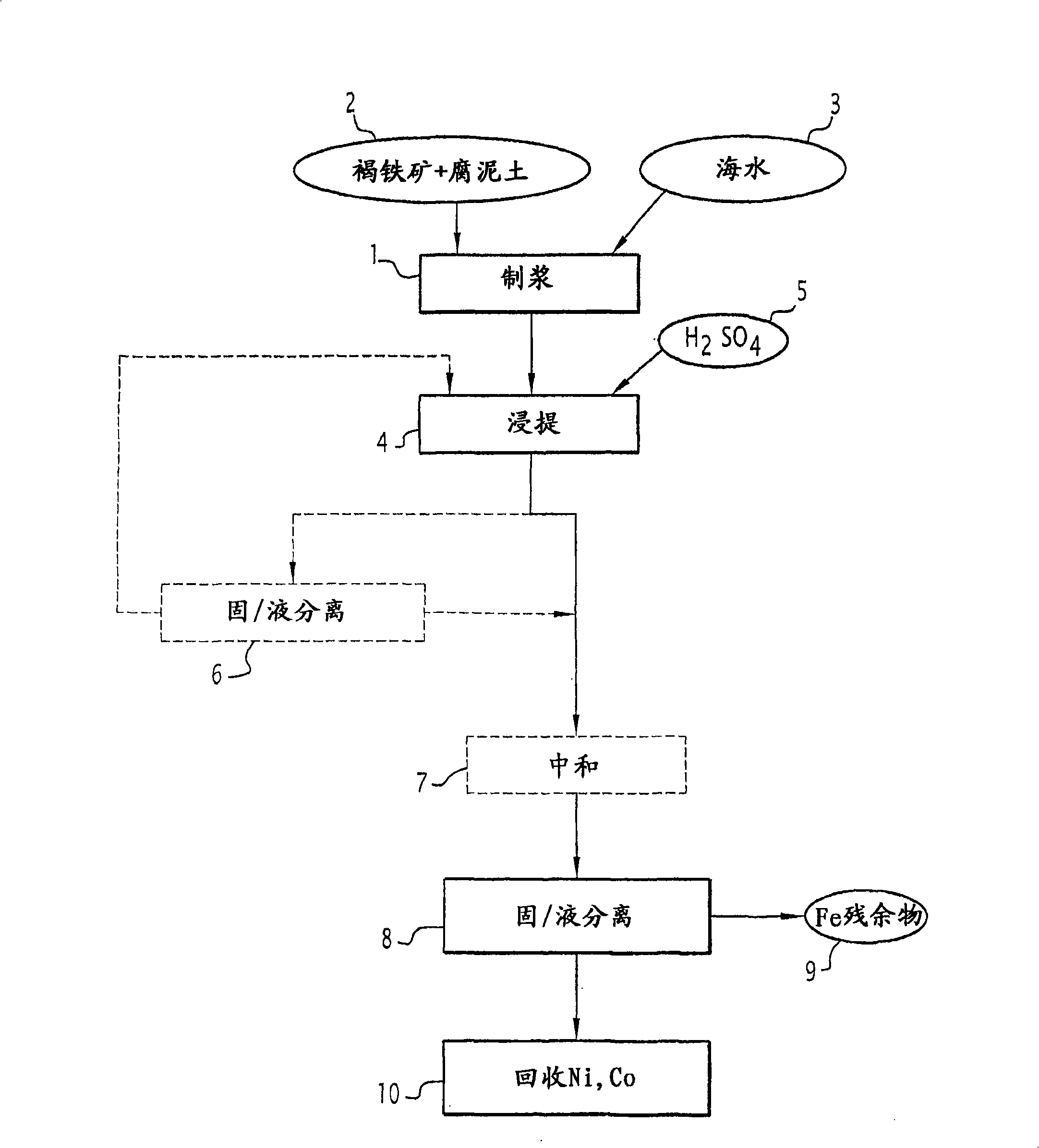

Process for the hydrometallurgical treatment of a lateritic nickel/cobalt ore and process for producing nickel and/or cobalt intermediate concentrates or commercial products using it

ActiveCN101541985ASimple structureShorten the durationProcess efficiency improvementBoiling pointHydrometallurgy

Process for the treatment of a lateritic nickel / cobalt ore consisting of a mixture (2) of limonite and saprolite, characterized in that: the mixture (2) in the presence of an iron-precipitating agent is made into a pulp (1), having a solids content of between 10 and 40% by weight; the pulp undergoes a leaching operation (4) with sulphuric acid (5), at a temperature between 70 DEG C and the boiling point and at atmospheric pressure; and a solid-liquid separation (8) is carried out so as to obtain an iron-containing solid residue (9) and a solution containing nickel and cobalt ions. Process for producing nickel and / or cobalt intermediate concentrates or commercial products using the above process.

Owner:ERAMET

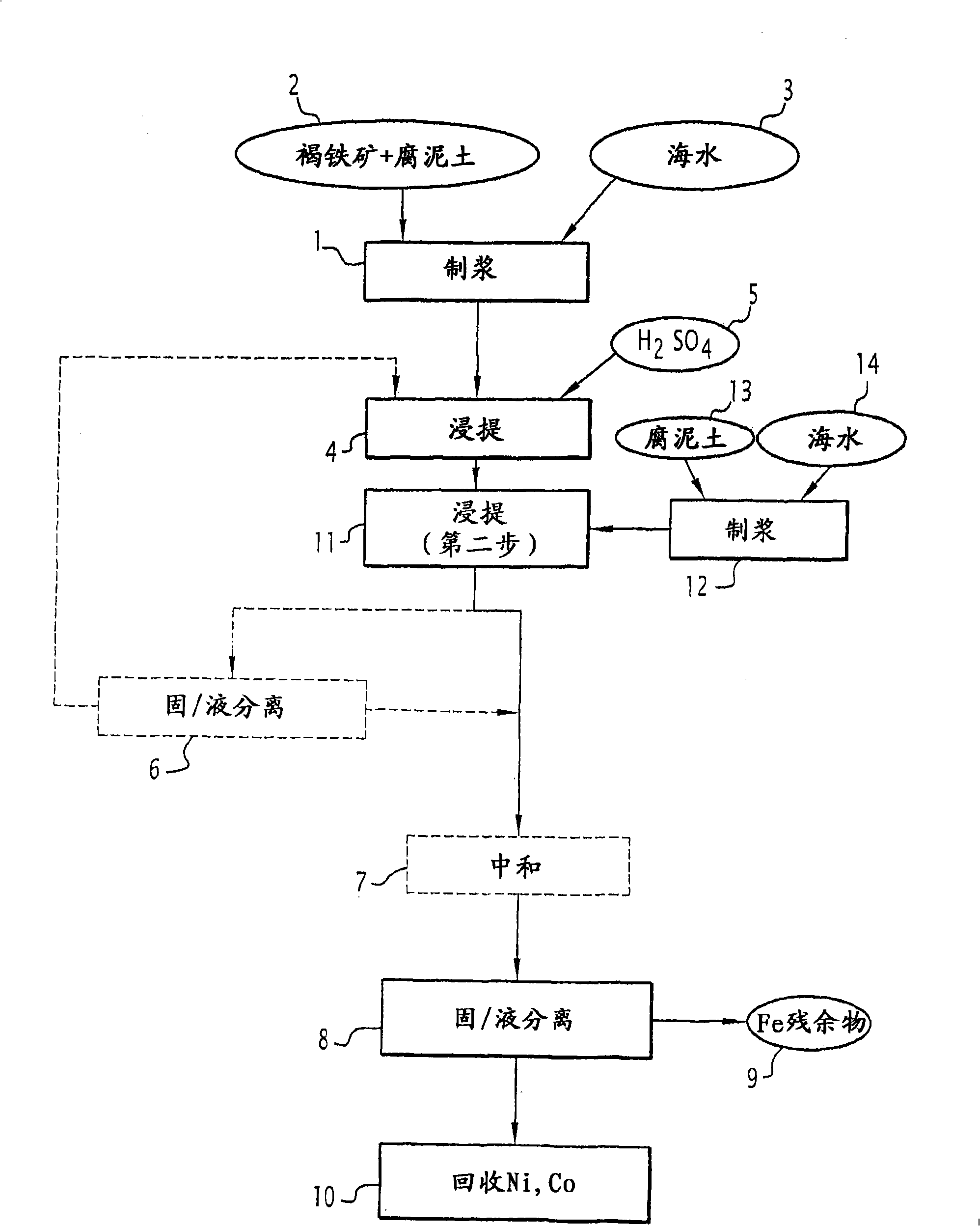

Method for nickel and cobalt recovery from laterite ores by combination of atmospheric and moderate pressure leaching

InactiveUS20060024224A1Efficient leachingEfficient separationIron compoundsCobalt compoundsRecovery methodIon exchange

A process for leaching laterite ores containing limonite and saprolite. Sufficient mineral acid is added to a slurry of limonite which is leached at atmospheric pressure to dissolve most of the soluble non-ferrous metals and soluble iron. After adding saprolite the slurry is further leached at a temperature above the normal boiling point and at a pressure above atmospheric pressure for a time sufficient to leach most of the contained nickel in the saprolite and to precipitate most of the iron in solution. The pressure of the slurry is then reduced, and nickel and / or cobalt is subsequently recovered from the leach solution by solvent extraction, resin-in-pulp or other ion exchange, sulfide or hydroxide precipitation, or other recovery method.

Owner:SKYE RESOURCES

Method for reducing phosphorus in high phosphorus haematite or hematite and limonite ore by magnetization roasting-leaching method

InactiveCN101338361AReduce phosphorus contentProcess efficiency improvementMagnetic separationIronstoneMagnetization

The invention relates to a high phosphorus hematite-hematite-limonite magnetic roasting-extraction phosphorous reduction method, in particular applicable for an extraction phosphorous reduction method for the iron ores which mainly include the hematite-hematite and the limonite and accompany with magnetite, pyrrhotite, iron pyrites, etc. The method of the invention adopts magnetic roasting-wet extraction to reduce phosphorous; after carrying out modifying on high phosphorus iron ore, muriatic acid or vitriol is selected to carry out extraction phosphorous reduction on the iron concentrate obtained by a weak electromagnetic separator which not only can obtain the iron concentrate with an iron grade to be larger than 56 percent; simultaneously the content of the phosphorous in the iron concentrate is lower than 0.30 percent.

Owner:昆明晶石矿冶有限公司

Ru agate glaze and processing method and application thereof

The invention discloses a Ru agate glaze, which contains the following components by weight parts: 6 to 26 parts of agate, 40 to 65 parts of feldspar, 10 to 23 parts of calcite, 13 to 28 parts of black limestone, 3 to 8 parts of limonite, 2 to 4 parts of talcum and 5 to 10 parts of chestnut ash. The invention also discloses a processing method for the Ru agate glaze and the application of the Ru agate glaze on Ru porcelains, and also discloses a Ru porcelain. The basic tones of the glaze of the Ru porcelain fired with the Ru agate glaze are green and blue, and therefore the glaze can present the deep colors of azure, cyan and bluish white as well as the bright, transparent colors of pea green, light green and light greenish blue; the texture of the porcelain body is fine and dense, the porcelainizing degree is high, the water absorption does not exceed 1.2 percent, and the sound is silvery when the product is knocked; the thermostability is good, and defects, such as through cracks and leakage, do not exist.

Owner:郭秀贞

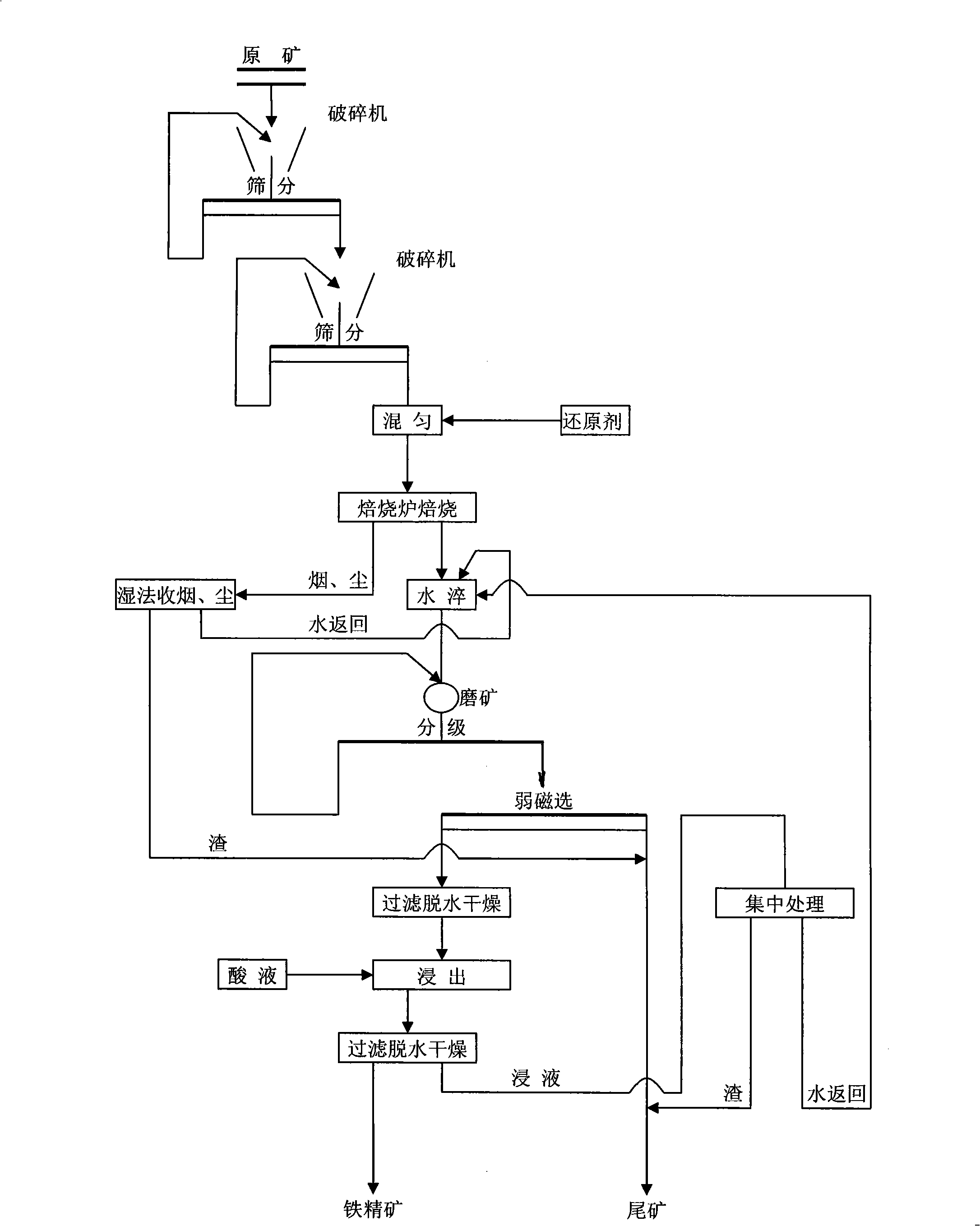

Method for producing iron concentrate by brown hematite and siderite and reduction roaster

The present invention discloses a method for adopting the limonite and the siderite to produce iron powder and a reduction roaster. The material adopts the limonite and the siderite or the specularite, the hematite, and the sulphuric acid slag, the inclined rotary reduction roaster is used, the pressure of the furnace chamber is 250 to 350 Pa, under the deoxidizing atmosphere, the inert solid is rotated and moved to 650 to 900 DEG C from the low temperature, and is cooled and magnetized, and lastly become the iron powder through the dressing by magnetic separation. The present invention is adopted to produce the iron powder, the resources is rich and the production cost is low, and through the utilization of the powder metallurgy art, the iron content of the iron powder is controlled and the activation energy of the iron powder is reduced, and the chemical reaction ability is increased, thereby the output of iron powder is high, the quality is good, the iron powder is loose and porous, the specific surface is big, the apparent density is large, the manufacture cost of pellets sinter and steel smelting can be reduced greatly, and the iron powder can use directly to produce iron oxide red as well as H and N synthetic iron catalyst, or produce ultrapure iron powder.

Owner:郭元杰

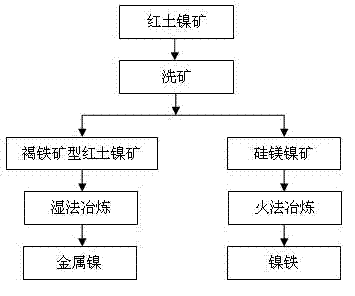

Method for processing laterite-nickel ore

InactiveCN102226232AHigh recovery rateReduce energy consumptionProcess efficiency improvementLateriteMaceral

The invention discloses a method for processing laterite-nickel ore. The method provided by the invention is characterized in that laterite-nickel ore undergoes an ore-washing treatment; noumeite and limonite-type laterite-nickel ore are separated; separated noumeite is melted by the pyrometallurgical process to generate ferronickel; and metallic nickel is extracted from the separated limonite-type laterite-nickel ore by the wet process. According to the method provided by the invention, based on the different mineral compositions of different laterite-nickel ore particle fractions, limonite-type laterite-nickel ore containing high content of iron and low content of magnesium is melted by the wet process to extract metallic nickel, thus leading to low acid consumption; noumeite containing low content of iron and high content of magnesium is melted by the pyrometallurgical process to extract ferronickel, thus leading to high quality of the produced ferronickel, high recovery rate of nickel, low energy consumption and simultaneous recovery of iron.

Owner:广西银亿新材料有限公司

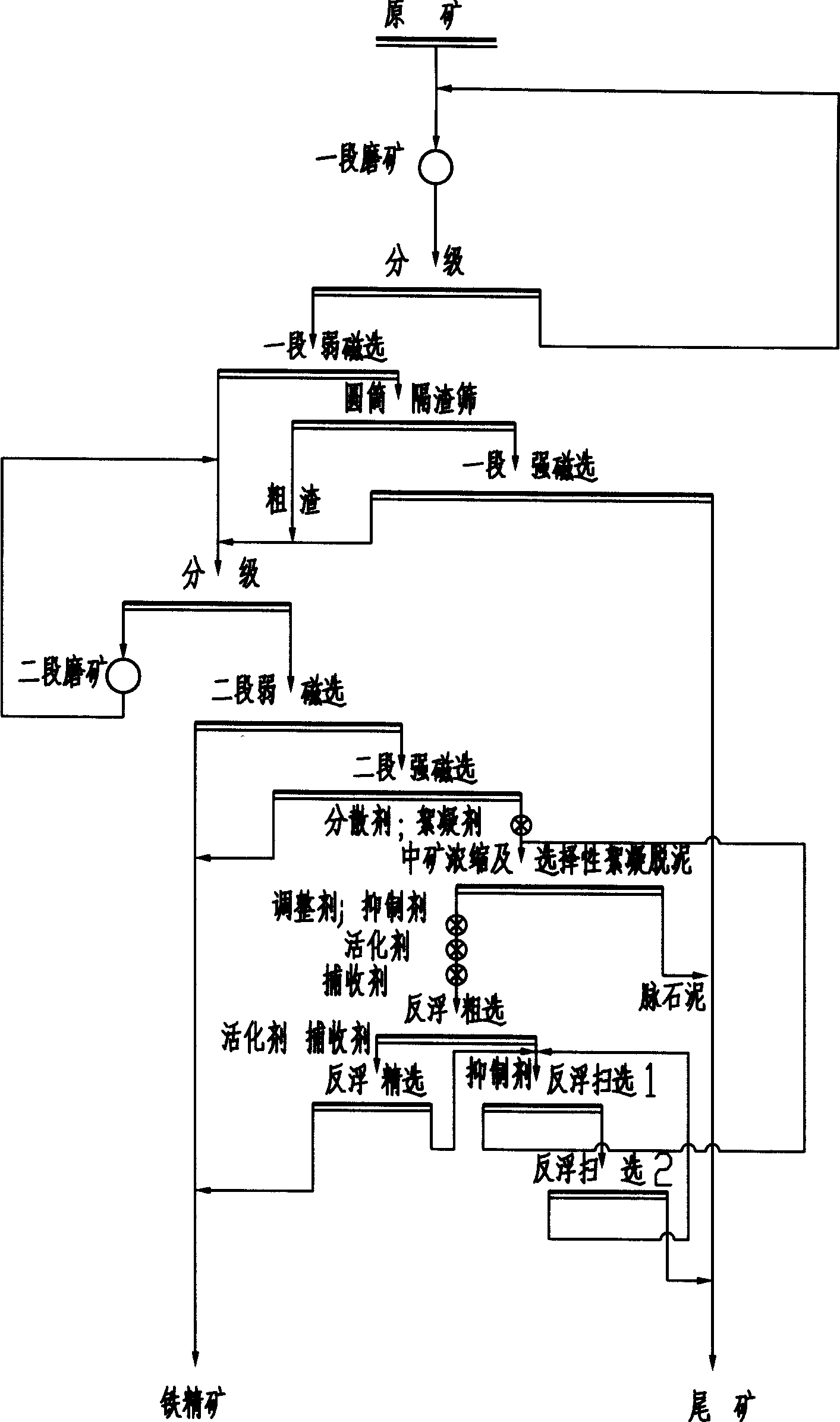

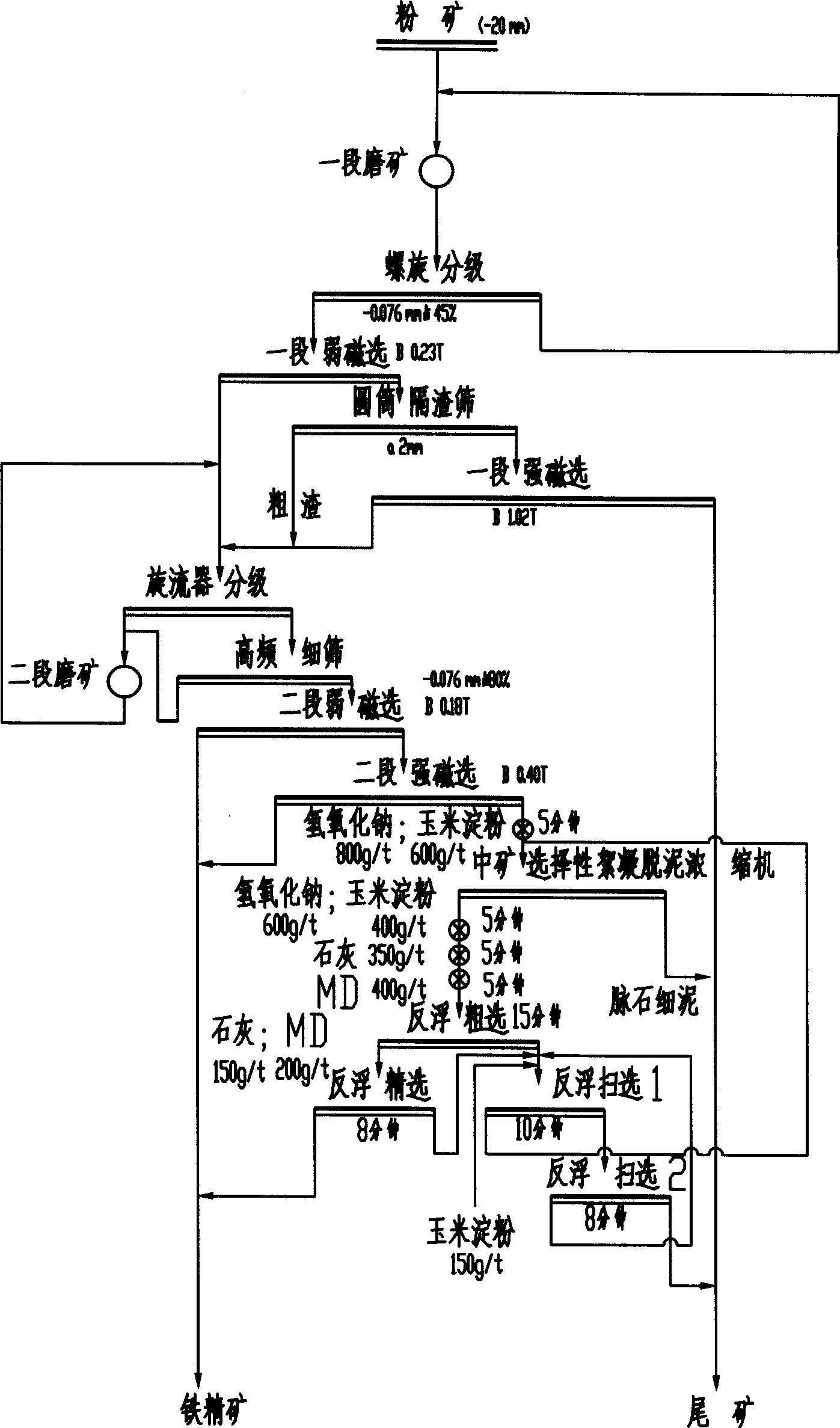

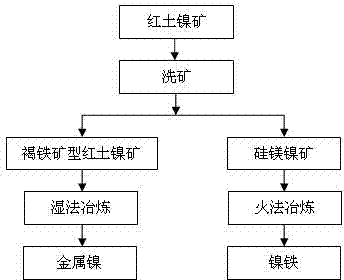

Mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore

The invention relates to a mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore. The mineral processing process comprises steps as follows: raw ore containing the mixed ore of the magnetic iron ore and the hematite-limonite ore is smashed and then subjected to two-stage continuous ore grinding; overflowing ore of a secondary classifying cyclone is subjected to two-stage low-intensity magnetic separation and one-stage fine screening and separation in combination of a single magnetic separation, fine screening and regrinding process for processing magnetic ore; under the condition of rougher ground ore particles, a part of undersize qualified magnetite concentrate products are firstly obtained, the other part of oversize products are combined with one-stage high-intensity magnetic separator concentrate and two-stage low-intensity magnetic separator tailings to serve as middlings, and the middlings are subjected to three-stage ore grinding classification operation for regrinding and separation; and overflowing ore of a tertiary classifying cyclone is subjected to three-stage low-intensity magnetic separation and high-intensity magnetic separation, fine-grain qualified tailings are thrown again, three-stage low-intensity magnetic concentrate and two-stage high-intensity magnetic concentrate are combined to obtain mixed magnetic concentrate, the mixed magnetic concentrate is subjected to a reverse flotation process for separation, and a qualified flotation concentrate product is obtained. According to the mineral processing process, the mixed ore of the magnetic iron ore and the hematite-limonite ore with different dissemination particle sizes is reasonably processed, the qualified iron ore concentrate product is obtained, and the mineral processing process is economical, energy-saving and environment-friendly.

Owner:ANSTEEL GRP MINING CO LTD

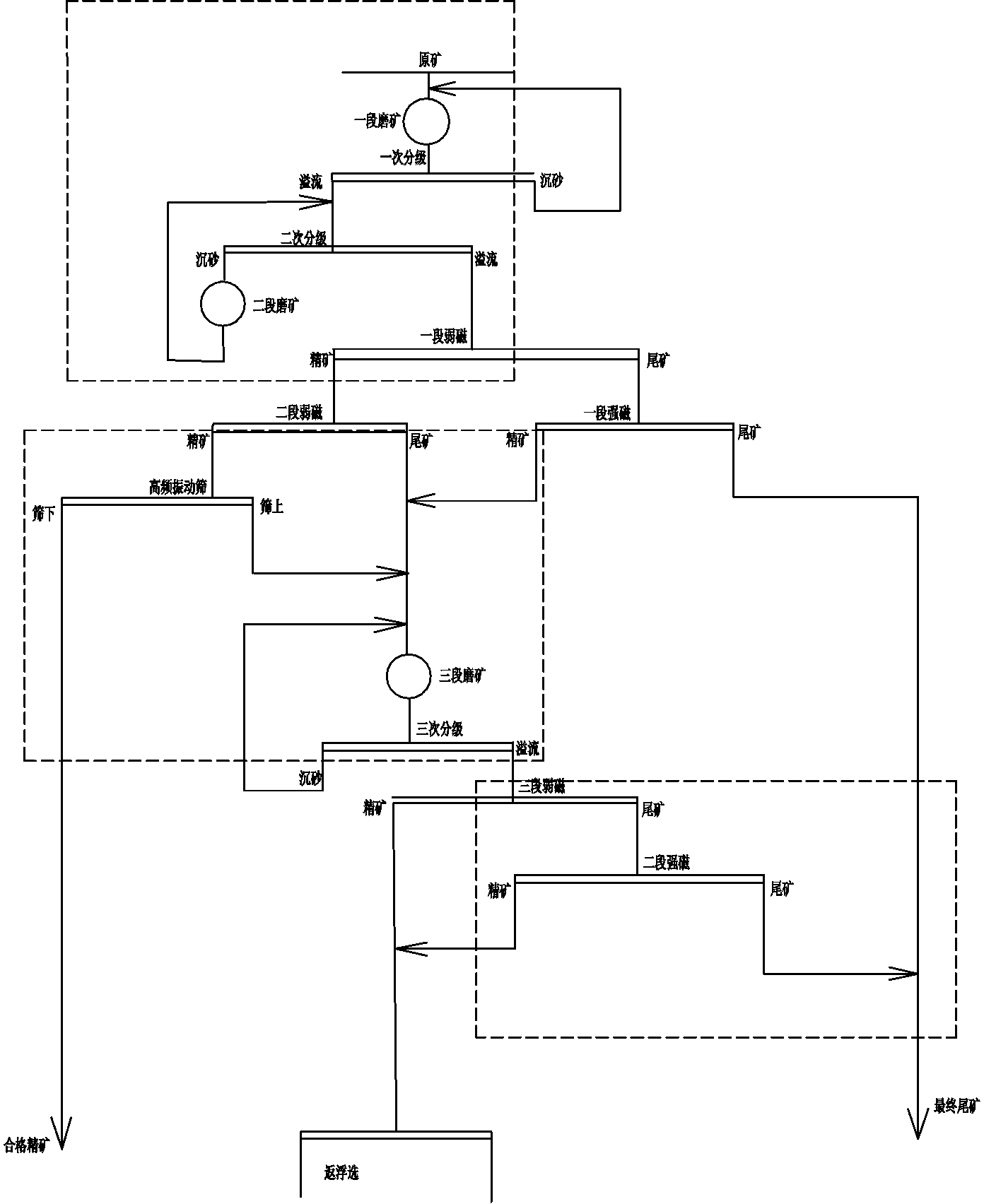

Ultra-high performance concrete mixed with hybrid fibers

The invention belongs to the technical field of building materials, and particularly relates to ultra-high performance concrete mixed with hybrid fibers. The concrete is prepared from ordinary Portland cement, silica fume, floating bead fly ash, slag powder, HP-CSA, quartz sand, limonite ore, titanium alloy sand, water reducing agent, defoaming agent, steel fiber, basalt fiber, cellulosic fiber and water. The ultra-high performance concrete mixed with the hybrid fibers has the advantages that the problems that the water-binder ratio is low, the usage amount of cementing material is large, andthe incorporation of the high-performance water reducing agent increases the shrinkage of the concrete can be solved, the constraint problem caused by the shrinkage on the application of the ultra-high performance concrete fabricated precast unit can be overcome, and the toughness of products is drastically improved. The ultra-high performance concrete mixed with the hybrid fibers is applicable tovarious concrete projects with special structures such as long span and super high-rise, and is suitable for various types of fabricated buildings.

Owner:TONGJI UNIV

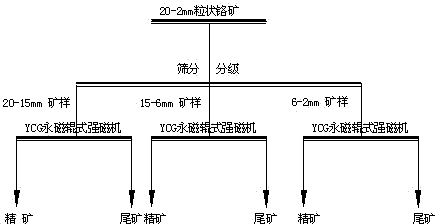

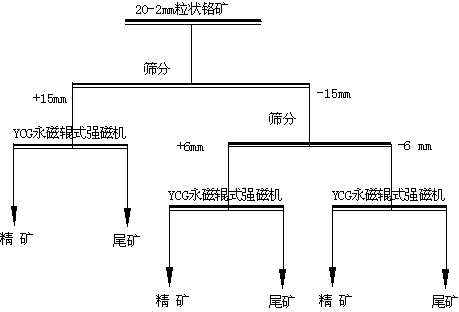

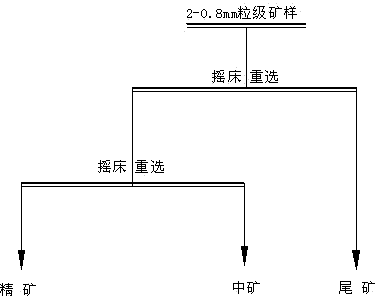

Novel beneficiation technology of high-grade ferrochrome ore

The invention discloses a novel beneficiation technology of high-grade ferrochrome ore. The novel beneficiation technology includes the following technological processes that ferrochrome ore is broken and is screened and classified into the ore of +20 mm fraction and the ore of -20 mm fraction. The ore of the +20 mm fraction receives manual back picking or hotching, large waste ore is thrown, and block concentrate is obtained. The narrow grade of the -20 mm fraction is screened and classified into four fractions, namely the 20-15 mm fraction, the 15-6 mm fraction, the 6-2 mm fraction and the 2-0 mm fraction. For the 20-15 mm fraction, the 15-6 mm fraction and the 6-2 mm fraction, a permanent magnet roller type intensity magnetic separator is used for performing dry intense magnetic separation. The 2-0 mm fraction is further screened and classified into the 2-0.8 mm fraction and the 0.8-0 mm fraction. For the 2-0.8 fraction, a shaker is selected again to obtain shaker gravity concentrate, and for the 0.8-0 mm fraction, a spiral chute and the shaker are used and a united procedure is selected again to obtain the thin-particle gravity concentrate. The novel beneficiation technology can be used for obtaining the concentrate and removing tailings in advance and has the advantage of being lower in energy consumption compared with other technologies. The technology can be used for grading chrome ore and can also be used for grading other weak magnetic iron minerals such as manganese ore, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Reverse flotation iron increase and silicon removing method for refractory limonite

InactiveCN101234366AImprove mineral processing recovery rateReduce typesFlotationIron increasedRefractory

The invention discloses an reverse flotation iron extracting and desiliconizing method of rebellious limonite. The procedure of the invention is as following: finely grinding, dispersing and desliming ore; adding sulphuric acid to stir the ore power into paste; adding a certain amount of starch or modified starch, lignosulfonate sulphonic acid and their salt and polyacrylamide with the molecular weight about 10,000 or polyacrylamide inhibitory iron-bearing mineral; adopting cation collector quaternary ammonium salt to reverse flotation and separate ore with silicon range or iron ore in a method of adding a little amount of medicine for many times. The reverse flotation iron extracting and desiliconizing method has the advantages of simple process, few medicine agent varieties, able to obtain high grade iron ore concentrate and good effect of raising ore dressing recovery percentage of limonite.

Owner:CENT SOUTH UNIV

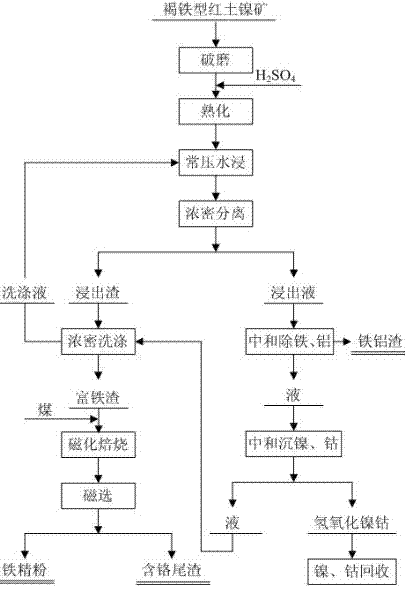

Method for processing limonite lateritic nickel

The invention discloses a method for processing limonite lateritic nickel, which comprises the following steps of: (1) curing raw ores, i.e. crushing and grinding the raw ores of the limonite lateritic nickel, adding concentrated sulfuric acid, uniformly mixing the concentrated sulfuric acid and the crushed and ground raw ores and carrying out curing roasting to obtain cured materials, wherein the processed ores have the water content of 5 to 30 percent; (2) carrying out selective normal-pressure leaching on the curing materials, i.e. directly carrying out normal-pressure leaching on the cured materials obtained in the step (1) at a stirring rotating speed of 200 to 600rpm, carrying out thickening separation on the leached ore pulp to obtain leachate and leached residues, carrying out thickening washing on the leached residues to obtain washing solution and high-iron residues and returning the washing solution to the water leaching process; and (3) carrying out magnetizing roasting and magnetic separation on the high-iron residues, i.e. adding the high-iron residues obtained in the step (2) into coal of which the weight is 3 to 20 percent of a dry basis of the high-iron residues to carry out magnetizing roasting and carrying out water quenching, ball milling and magnetic separation on the obtained calcine to obtain the iron concentrate with the iron content of over 63 percent.The method has strong process operability, good leaching selectivity and high comprehensive utilization rate of iron.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

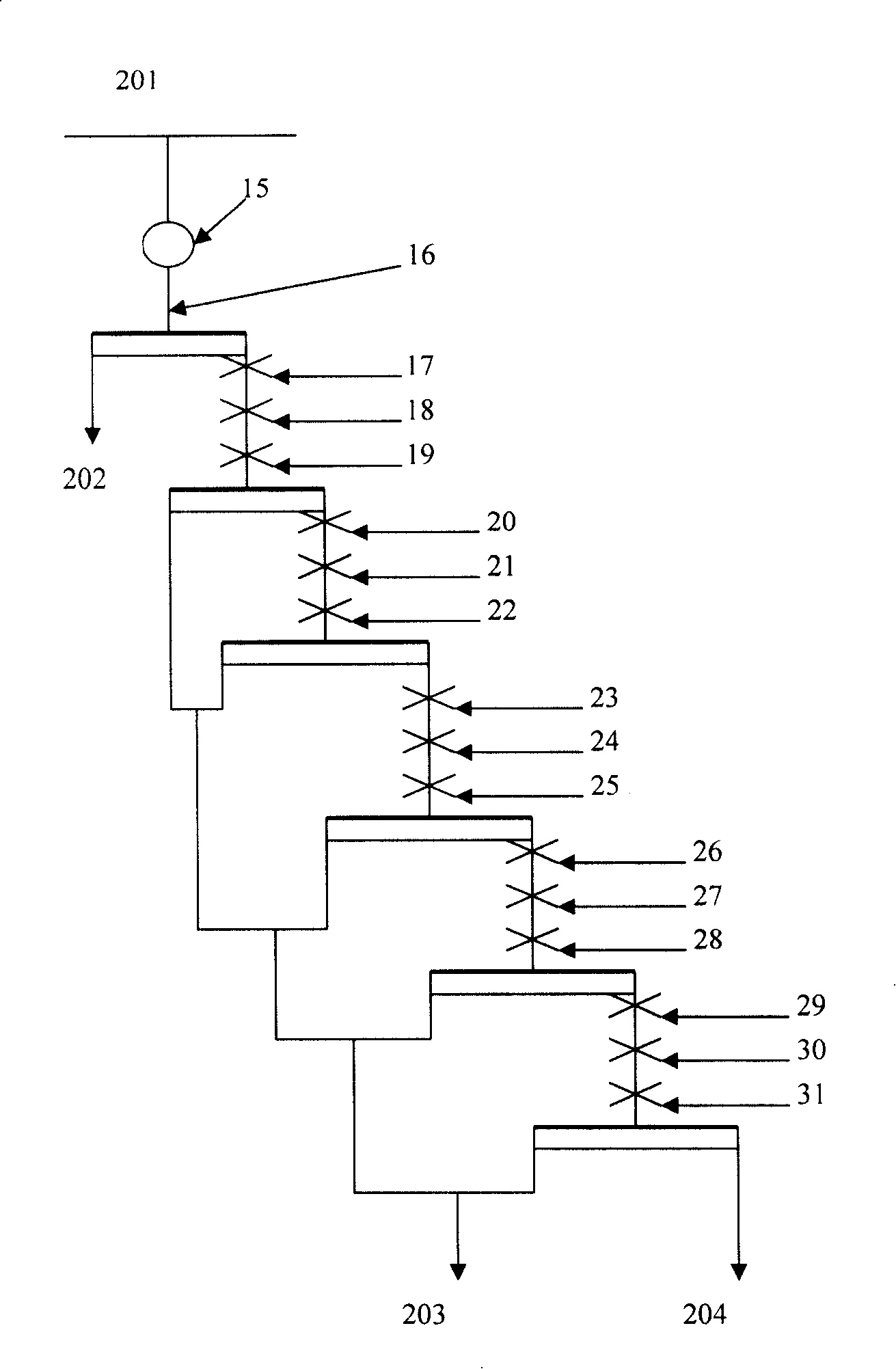

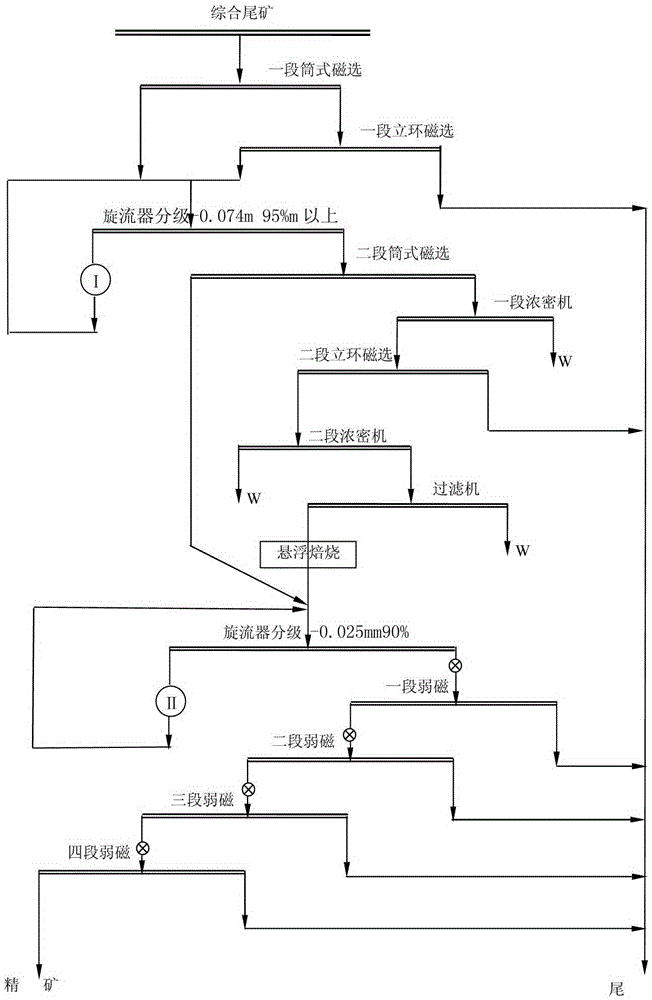

Tailing recovery process adopting preconcentration-roasting-regrinding and magnetic separation method

ActiveCN105233976AEfficient recyclingReduce the processing volume of subsequent grinding and sorting operationsMagnetic separationProcess efficiency improvementMagnetic separatorReducing atmosphere

The invention relates to a tailing recovery process adopting a preconcentration-roasting-regrinding and magnetic separation method. The tailing recovery process is characterized by comprising the following steps: concentrate extraction and tailing discarding are carried out by virtue of a preconcentration process which sequentially comprises first-section drum magnetic separation, first-section vertical ring magnetic separation, ore grinding, second-section drum magnetic separation and second-section vertical ring magnetic separation, so that a rough concentrate grade is increased, and a subsequent operation treatment amount is reduced; suspension roasting is adopted, so that a rotational-flow suspension state of rough concentrate materials in a suspension magnetization roasting furnace under the conditions of a high temperature of 500 DEG C and a reducing atmosphere can be ensured, and micro-and fine-grained hematite, siderite and limonite in the rough concentrate materials are converted to magnetic iron minerals; and meanwhile, multi-section continuous fine separation is carried out by virtue of a regrinding and fourth-section low-intensity magnetic separation machine, thus the good indexes of a concentrate grade of more than 65% and a metal recovery rate of 48-55% are obtained.

Owner:ANSTEEL GRP MINING CO LTD

Method for smelting base metal of low phosphorous stainless steel by using low-grade limonite of containing nickel-chromium

ActiveCN101092656ARich sourcesLow priceBlast furnace detailsManufacturing convertersAdhesiveHigh pressure

This invention relates to a method for smelting low-phosphorus stainless steel base material from nickel and chrome-containing low-grade limonite. The method comprises: (1) pre-treating nickel and chrome-containing low-grade limonite via sieving, pulverizing and drying to obtain ore powder and ore blocks with different particle sizes, and mixing with fuel and flux to obtain sinter ore; (2) mixing various dedusted ashes, sintered return fines, and ore powder with an adhesive and a reductant, and passing into cold-pressed balls or carbon-containing balls under high pressure; (3) drying the carbon-containing balls, adding into a converter, and reducing to obtain pre-reduced balls; (4) mixing the sinter ore with partial ore blocks, the cold-pressed balls, the carbon-containing balls, the pre-reduced balls, the fuel, the flux and auxiliary materials, and smelting in a blast furnace to obtain molten nickel and chrome-containing alloy or molten iron; (5) mixing with the cold-pressed balls, the carbon-containing balls and the pre-reduced balls, and smelting in an electric furnace or a converter to reduce, decarbonizes, dephosphorize and obtain clean molten stainless steel base material that can be directly used in steel making; (6) casting with a continuous caster to obtain solid stainless steel base material that can be directly used in steel making. The method has such advantages as low cost, little pollution, abundant raw materials, high recovery rate of alloy elements, and few harmful elements.

Owner:前海索新发展科技(深圳)有限公司

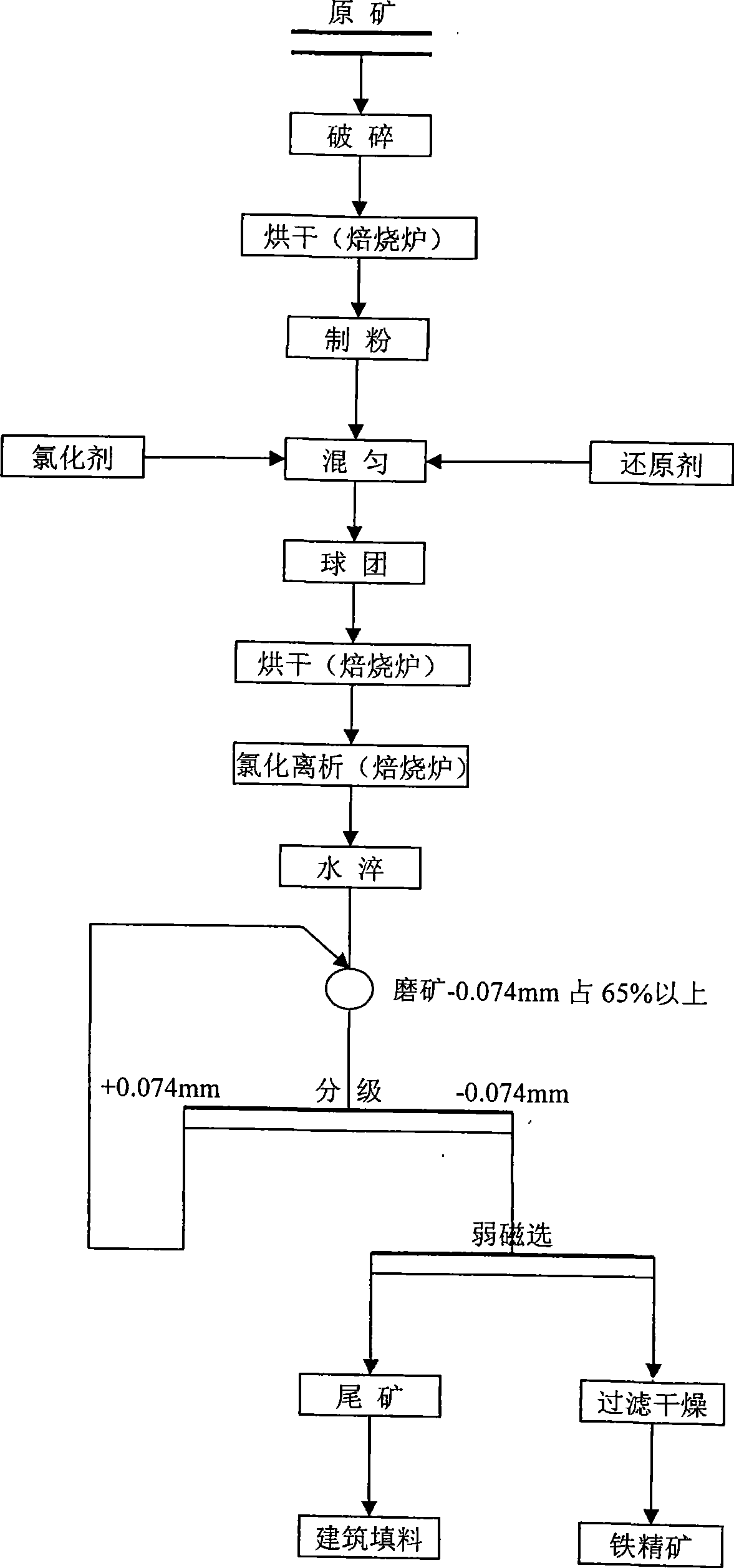

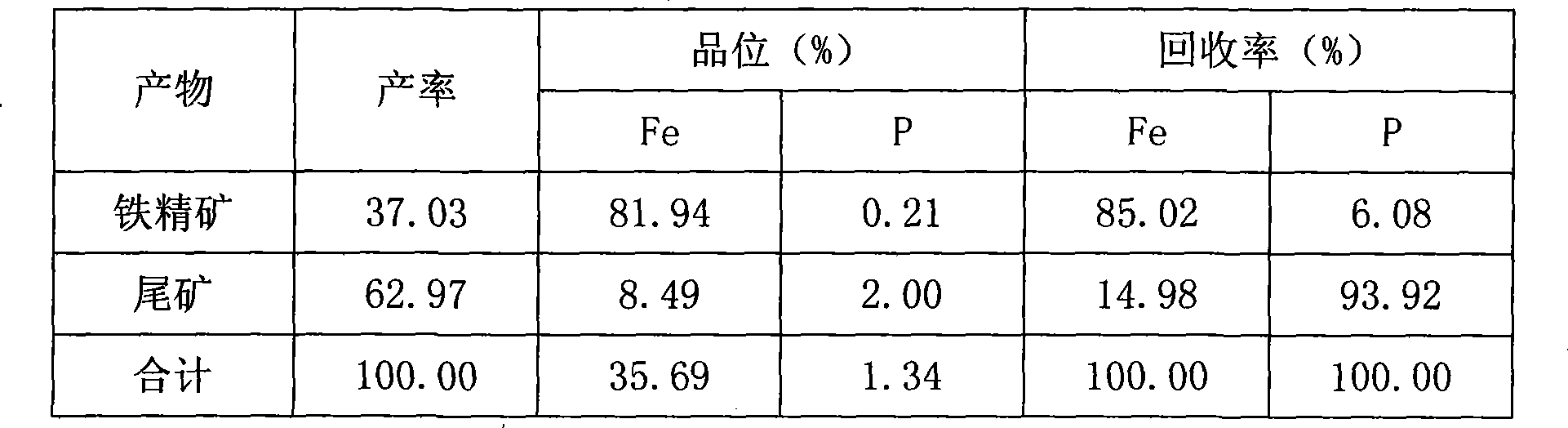

Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

InactiveCN101457288AReduce phosphorus contentGood beneficiation indexMagnetic separationWet separationIronstoneIron increased

The invention relates to a chloridizing segregation-low-intensity magnetic separation method for reducing phosphorus of a high phosphorus iron ore. A chloridizing segregation-low intensity magnetic separation process is adopted to realize iron increase and phosphorous reduction in the method. A chlorinating agent and a reducing agent coke are added to the high phosphorus iron ore and mixed evenly, then chloridizing segregation roasting is carried out in a roasting furnace; the roasted product is water quenched and ball milled, and then separated by a low-intensity magnetic field magnetic separator, thus being capable of obtaining an iron ore concentrate with the iron grade more than 80%, the iron recovery rate more than 85% and the phosphorous content less than 0.20%. The iron ore concentrate powder can be taken as a raw material for smelting pig iron after being pelletized. Additionally, with regard to high phosphorus iron ores which contain sulfur or contain sulfur and arsenic at the same time, such as hematite, hematite-limonite ore, oolitic hematite-limonite ore, hematite, siderite and the like, the product iron ore concentrate with the sulfur content less than 0.20% and the arsenic content less than 0.04% can also be obtained.

Owner:昆明晶石矿冶有限公司

Process for enhanced acid leaching of laterite ores

A process is described for the recovery of nickel and cobalt from a nickeliferous laterite ore including the steps of: a) providing a nickeliferous laterite ore and separating that ore into its low magnesium limonite fraction and high magnesium saprolite fraction; b) treating the limonite fraction in acid solution in a primary high pressure leach step to produce a primary leach slurry; c) adding the saprolite fraction to the primary leach slurry to initiate precipitation of iron as goethite and / or hematite, while simultaneously releasing further acid from the iron precipitation, to effect a secondary atmospheric leach step, producing a secondary leach slurry; wherein all water used to prepare the ore slurries and / or acid solutions has an ionic composition that substantially avoids jarosite formation.

Owner:BHP BILLITON SSM TECH PTY LTD

Negative-ion water purification ceramic ball and method for preparing same

The invention discloses a negative-ion water purification ceramic ball. The negative-ion water purification ceramic ball comprises, by weight, 55-76 parts of Gui mineral, 32-54 parts of elbaite, 28-49 parts of basalt, 11-17 parts of potassium feldspar, 9-17 parts of zeolite, 8-14 parts of germanite, 12-17 parts of kaolin, 6-11 parts of indianite, 14-20 parts of bryozoatum, 7-14 parts of shell powder, 17-22 parts of pebble, 12-19 parts of pearl powder, 30-35 parts of pi-mineral balls, 11-15 parts of tourmaline balls, 14-18 parts of selenium-rich mineralized balls, 4-7 parts of negative-potential balls, 65-90 parts of limonite balls, 38-47 parts of medical stone balls, 3-5 parts of activated carbon, 68-83 parts of tourmaline, 12-20 parts of far-infrared powder, 50-88 parts of clay, 13-22 parts of sepiolite, 40-60 parts of inorganic nano-selenium mineral powder, 40-58 parts of negative-potential mineral powder, 45-63 parts of adhesive, other 45-50 parts of kaolin and 20-40 parts of medical stone. The negative-ion water purification ceramic ball has the advantages that high-concentration efficient and durable negative ions can be released by the negative-ion water purification ceramic ball, electrolytic actions can be carried out between the negative-ion water purification ceramic ball and water, accordingly, hydroxide ions with negative electricity can be generated, macromolecule groups in the water can be diminished, and the dissolving capacity and the permeability of the water can be improved.

Owner:GUANGXI UNIV

Method for manufacturing sintering ore from limonite with high content of crystal water

The invention provides a method for manufacturing sintering ore from limonite with high content of crystal water. The method is characterized by comprising the following steps: taking limonite with high content of physical water and crystal water as the raw material; and subjecting the limonite to material proportioning, stirring granulation, pallet-feeding, sintering ignition and CaCl2 solution spraying to obtain the sintering ore. The method can effectively overcome the shortcomings that the strength of the sintering ore is reduced and thus the output of the sintering ore is influenced, for the limonite with high content of crystal water is prone to shrink to form thin-wall large pores due to the high burning loss rate in the sintering process; particularly, the method can inhibit the crystal transition of the sintering ore and improve the low-temperature reduction degradation performance by adding SYP sintering promoting agent; in addition, the method can inhibit the sintering ore from undergoing the reduction degradation within the temperature range of 450 to 550 DEG C and effectively reduce the amount of secondary powder generated in the reducing atmosphere within the temperature range of 450 to 550 DEG C; and the method is beneficial to improve the ventilation property of stock columns of a blast furnace and improve the smooth operation of furnace practice thereof, and the method can solve the problem of the shortage of iron ore resources in the long run and offer a guarantee to the industrial popularization and application of limonite.

Owner:红河钢铁有限公司

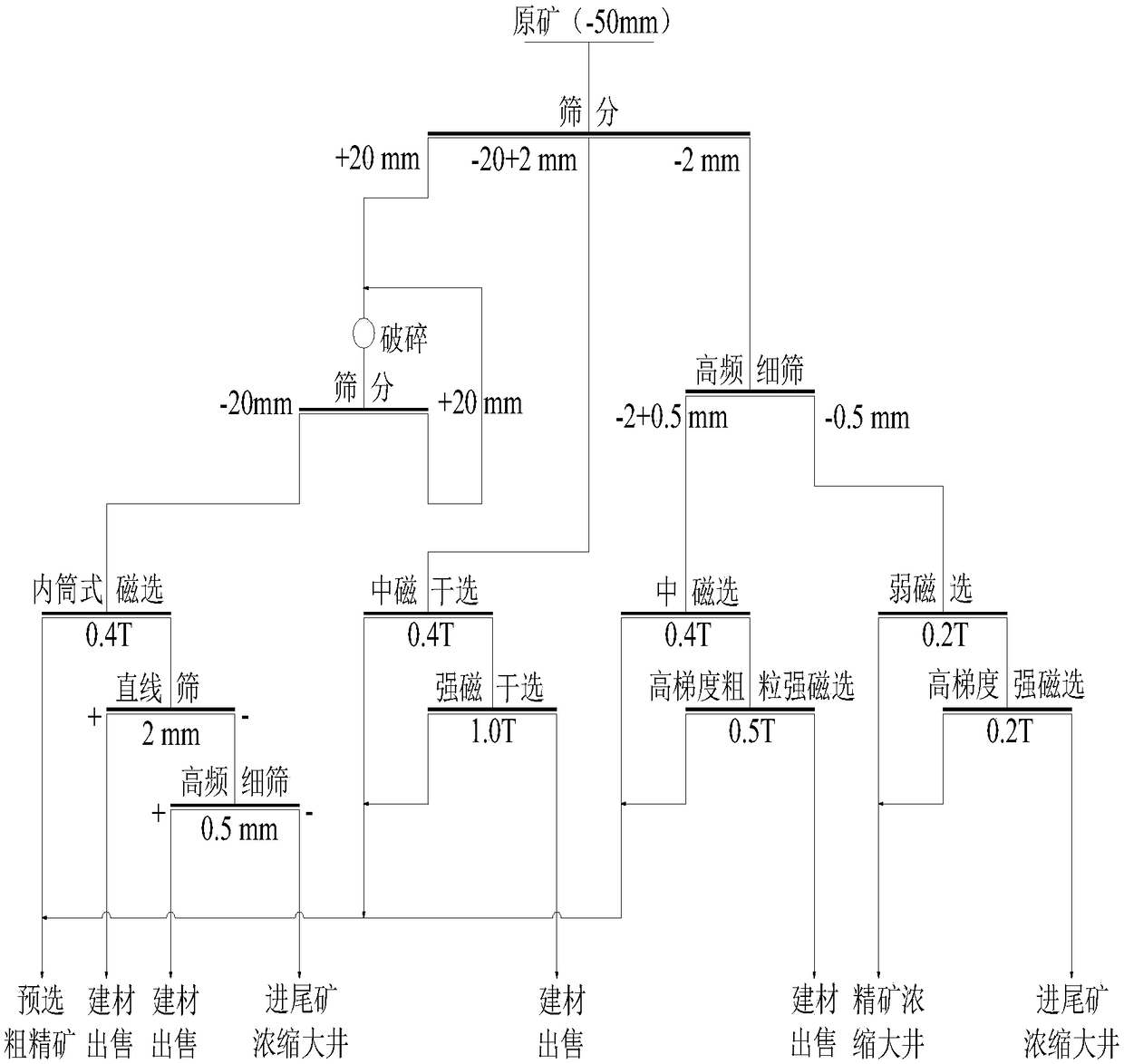

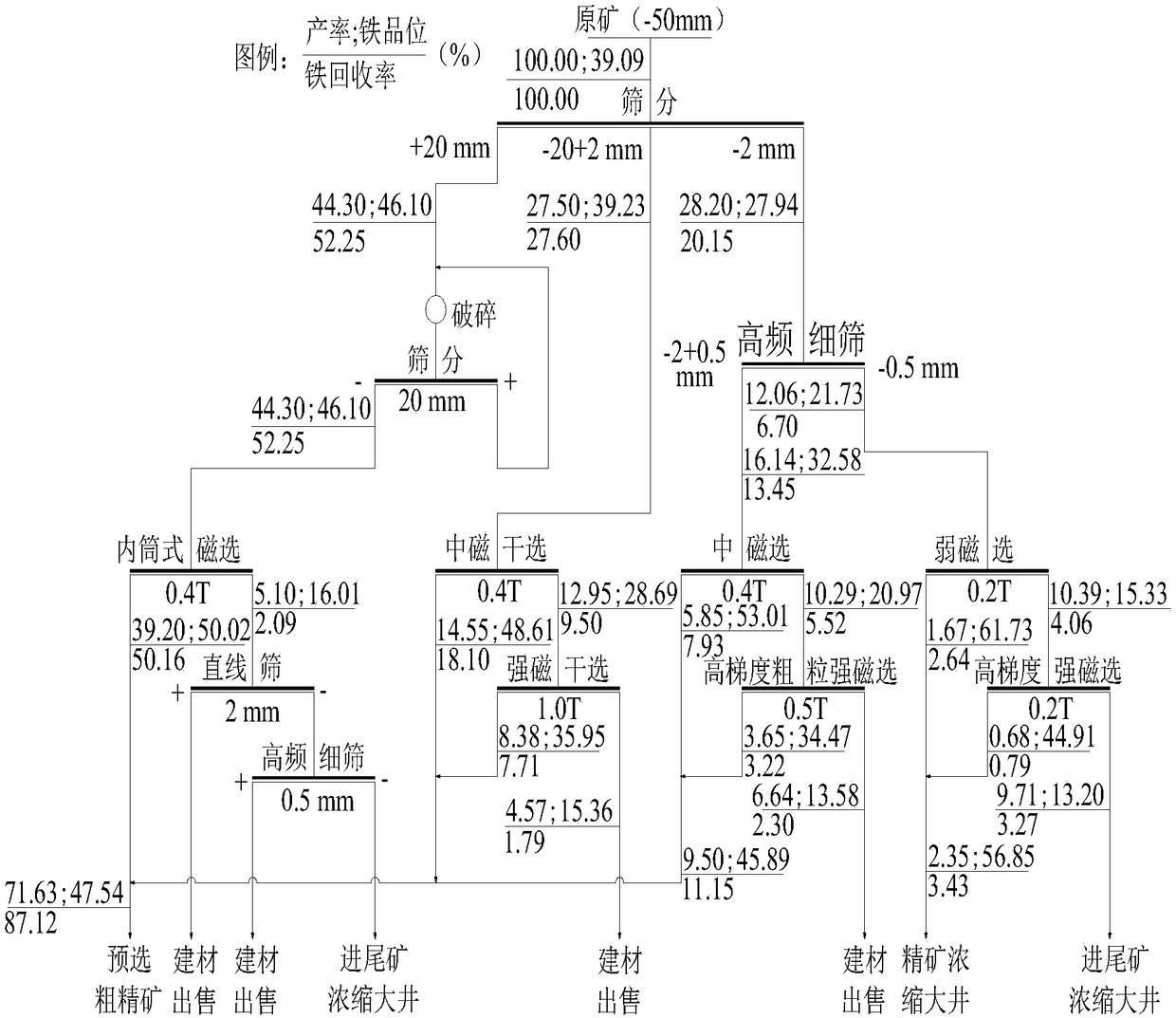

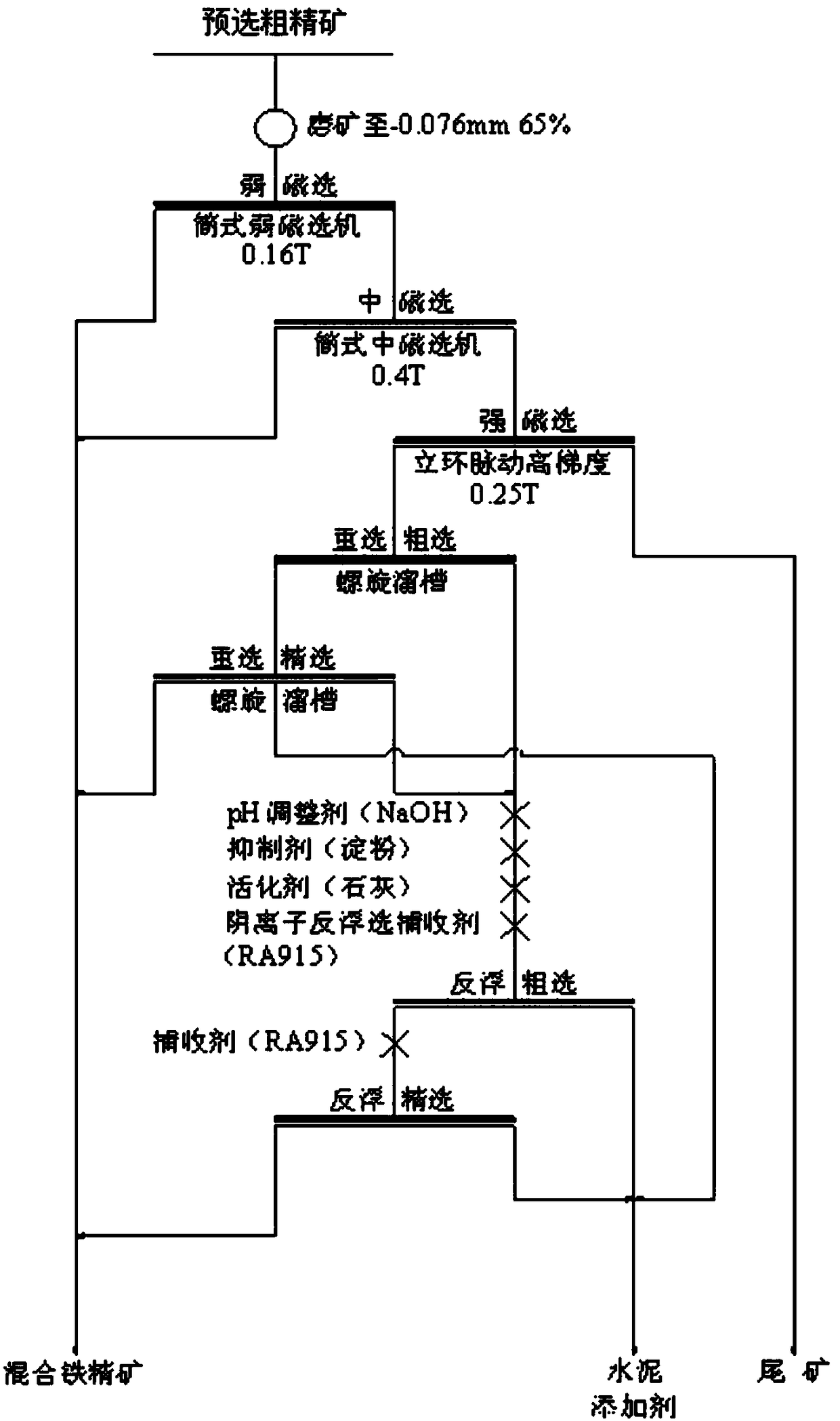

Novel grading prescreening precise separation method for mixed iron ore including magnetic iron ore, hematite and siderite

The invention discloses a novel grading prescreening precise separation method for mixed iron ore including magnetic iron ore, hematite and siderite. Intermediate smashed products with the particle size being -50 mm are subjected to grading prescreening at first, prescreened rough concentrate, prescreened fine-particle iron ore concentrate and building material products with different particle grades are obtained; the prescreened rough concentrate is subjected to ore grinding and grading closed loop operation after being precisely smashed, low intensity magnetic separation concentration (C1),intermediate intensity magnetic separation concentration (C2), gravity concentrate (3) and reverse flotation iron ore concentrate (C4) are obtained, and a cement additive product is obtained. The novel grading prescreening precise separation method has the advantages that the adaptability is high, the energy saving effect is good, economic benefits are large, the separation precision and the resource comprehensive utilization rate are high, and the discharging amount of tailings is small, the method is especially suitable for screening of the mixed iron ore including the magnetic iron ore, thehematite and the siderite, wherein the TFe grade is 35.0%-42.0%, the hematite / limonite difficult to screen accounts for 19-25% of the total amount of the mixed iron ore, and the siderite accounts for17-23% of the total amount of the mixed iron ore.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Tungsten-bearing limonite processing method

ActiveCN103611633AImprove resource utilization efficiencyEfficient separationFlotationMagnetic separationEquipment useMaterials science

The invention discloses a tungsten-bearing limonite processing method. The method includes: subjecting the tungsten-bearing limonite to flotation to remove silicon-bearing ore so as to obtain tungsten-bearing limonite concentrate; mixing the tungsten-bearing limonite with coke and reduction roasting enhancer, performing reduction roasting, grinding a product of reduction roasting, and performing neutral leaching to obtain tungstate solution and leaching residue; subjecting the leaching residue to magnetic separation in magnetic field so as to obtain iron concentrate and valuable metal tailing. The equipment used in the method is simple, the process flow is short, operation is simple, and the method is economical and reliable; efficient enrichment and selective separation of valuable elements in the low-grade tungsten-bearing limonite can be achieved, and comprehensive utilization rate of the tungsten-bearing limonite resources is increased effectively.

Owner:CENT SOUTH UNIV

Method for wet-leaching lateritic-nickel ore at transition layer

ActiveCN102212684AImprove leaching rateReduce consumptionProcess efficiency improvementSlurryImpurity

The invention discloses a method for wet-leaching lateritic-nickel ore at a transition layer. The method comprises the following steps: firstly washing lateritic-nickel ore at a transition layer so as to separate out limonite type lateritic-nickel ore and garnierite type lateritic-nickel ore; crushing and grading garnierite, sorting out ore with size fraction of 1-10mm for heap leaching to lixiviate metallic nickel, and mechanically grinding ore with particle size of less than 1mm into garnierite pulp with particle size of -100 meshes; adding concentrated sulfuric acid to limonite pulp for high-acid leaching under normal pressure; adding the garnierite pulp and nickel-containing solution subjected to heap leaching to the high-acid leaching pulp so as to neutralize residual acid; adding lime milk or limestone slurry for removing iron; and carrying out preliminary solid-liquid separation on the slurry without iron by utilizing a thickener, then finely filtering the slurry by utilizing apress filter, and further treating the obtained nickel-containing solution. The method has the advantages of simple flow, no need of ore pretreatment, the adoption of conventional leaching equipment,low acid consumption, good impurity removal effect, high nickel recovery rate and the like.

Owner:广西银亿新材料有限公司

Microwave roasting dry type wind magnetic selection method for hematite powder

The invention relates to a method of microwave roasting dry wind magnetic separation of hematite powder, which is a technology of rotary microwave oven roasting, dry wind magnetic separation and mineral processing and purification adopted to solve the deficiencies of wet mineral separation. The collected hematite powder, along with anthracite powder and under the condition of water-free, is crushed, finely ground, sieved, mixed, stirred, carbon reduced and roasted in a microwave oven at 700DEG C, and finally powder is obtained; afterwards, with the processes of cooling, fine grinding and magnetic separation, the hematite powder with high iron content and high purity is obtained. The method of roasting and wind magnetic separation does not require water washing and filtration, which is characterized by water saving and environmental protection. The method is in particular suitable for mineral dressing of the mining area without water source featuring short process flow, wherein microwave oven roasting, computer-controlled combined type dry wind magnetic separator, liquid crystal display, and sensor for displaying temperature information are clean beneficiation technologies. The method can bring 93-95 percentage yield rate and manufacture the powder with 71 percent iron content. The method can also be used for beneficiation of limonite and siderite.

Owner:TAIYUAN UNIV OF TECH

Resource recycling method of industrial phosphogypsum waste residues

ActiveCN104211099AResource conservationHigh chemical puritySulfate/bisulfate preparationCalcium/strontium/barium oxides/hydroxidesHydrogen SulfateSilicic acid

The invention discloses a resource recycling method of industrial phosphogypsum waste residues and relates to the technical field of inorganic chemical industry. The method comprises the following steps: carrying out a reaction on gypsum calcium sulfate and concentrated sulfuric acid to generate calcium hydrogen sulfate; carrying out a reaction on calcium hydrogen sulfate which is 1 time and a sodium hydroxide NaOH or potassium hydroxide KOH aqueous solution which is 4 times; filtering or precipitating and separating to recover calcium hydroxide, limonite, silicic acid and calcium fluoride and CaHPO4; and obtaining sodium sulfate / potassium sulfate, sodium aluminate or potassium aluminate and calcium acetate Ca(CH3COO)2. The method is mainly applied to resource recycling of industrial phosphogypsum waste residues.

Owner:济宁理工思源商务服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com