Process for the hydrometallurgical treatment of a lateritic nickel/cobalt ore and process for producing nickel and/or cobalt intermediate concentrates or commercial products using it

A technology of hydrometallurgy and laterite ore, which is applied in the direction of improving process efficiency, etc., can solve problems such as affecting costs, ineffective separation of various ores, and difficulties in the separation process, so as to achieve the effect of improving performance and shortening the total duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] At the outset it should be noted that in the following the following definitions are applied to certain terms whose exact meanings are not always agreed in the technical literature:

[0046] - Limonite: 50-70% Fe 2 o 3 and an ore fraction up to 5% MgO;

[0047] - Saprolite: 7-27% Fe 2 o 3 and an ore fraction of at least 10% MgO.

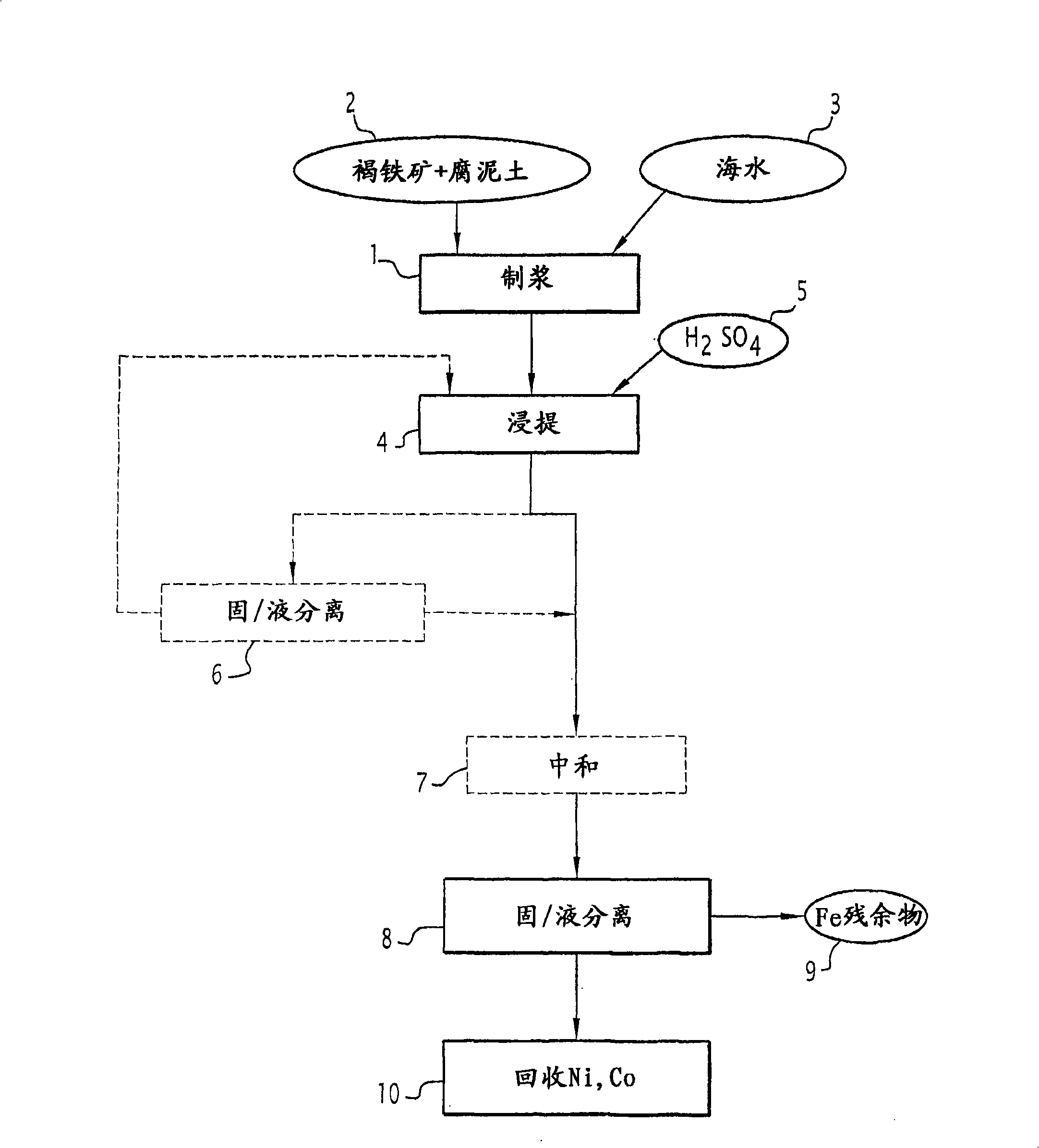

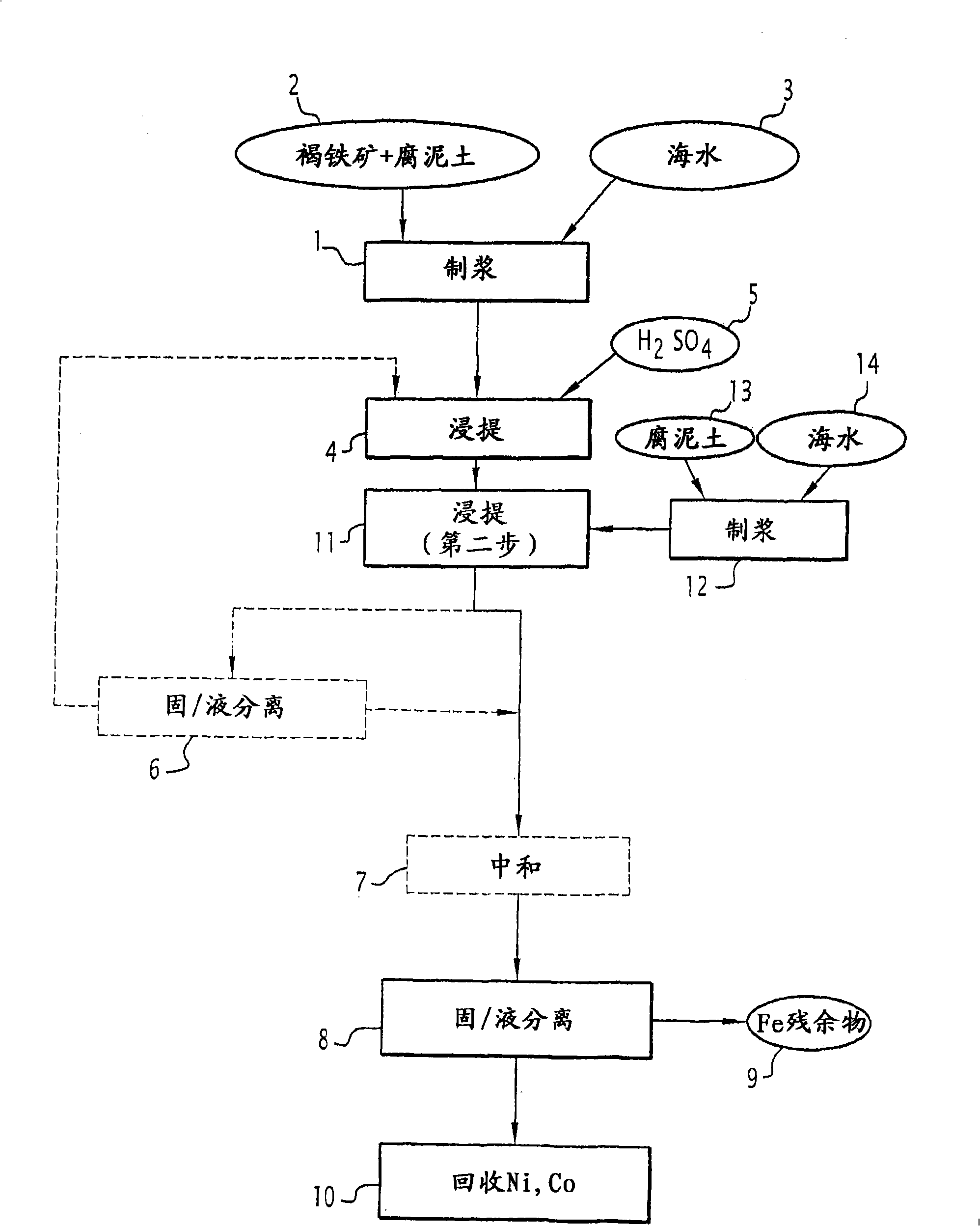

[0048] figure 1 The basic form of the method of the present invention, which will be referred to as "Format 1" hereinafter, is shown.

[0049] In a first step, a mixture 2 of limonite and saprolite is slurried with seawater 3 . This mixture 2 of limonite and saprolite is optimally a lateritic nickel ore with no separation of the magnesium-rich and low-magnesium fractions. The saprolite / limonite ratio is preferably 0.5-3. This pulping process makes it possible to obtain solids contents of 10-40% by weight, preferably 20-30% by weight.

[0050] In the second step 4, the slurry obtained in the first step 1 is leached with sulfuric acid 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com