Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1237 results about "Laterite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laterite is a soil and rock type rich in iron and aluminium and is commonly considered to have formed in hot and wet tropical areas. Nearly all laterites are of rusty-red coloration, because of high iron oxide content. They develop by intensive and prolonged weathering of the underlying parent rock. Tropical weathering (laterization) is a prolonged process of chemical weathering which produces a wide variety in the thickness, grade, chemistry and ore mineralogy of the resulting soils. The majority of the land area containing laterites is between the tropics of Cancer and Capricorn.

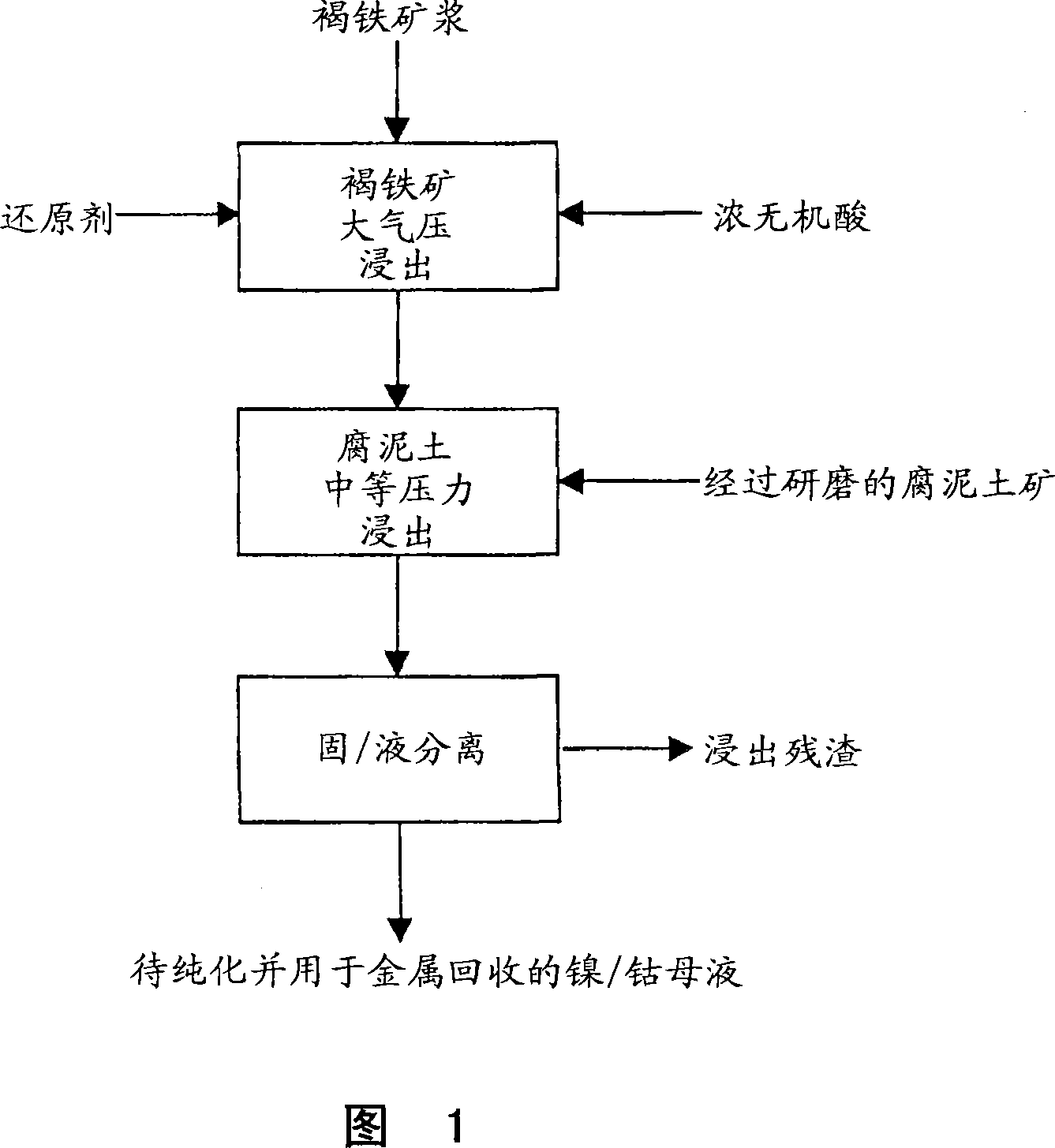

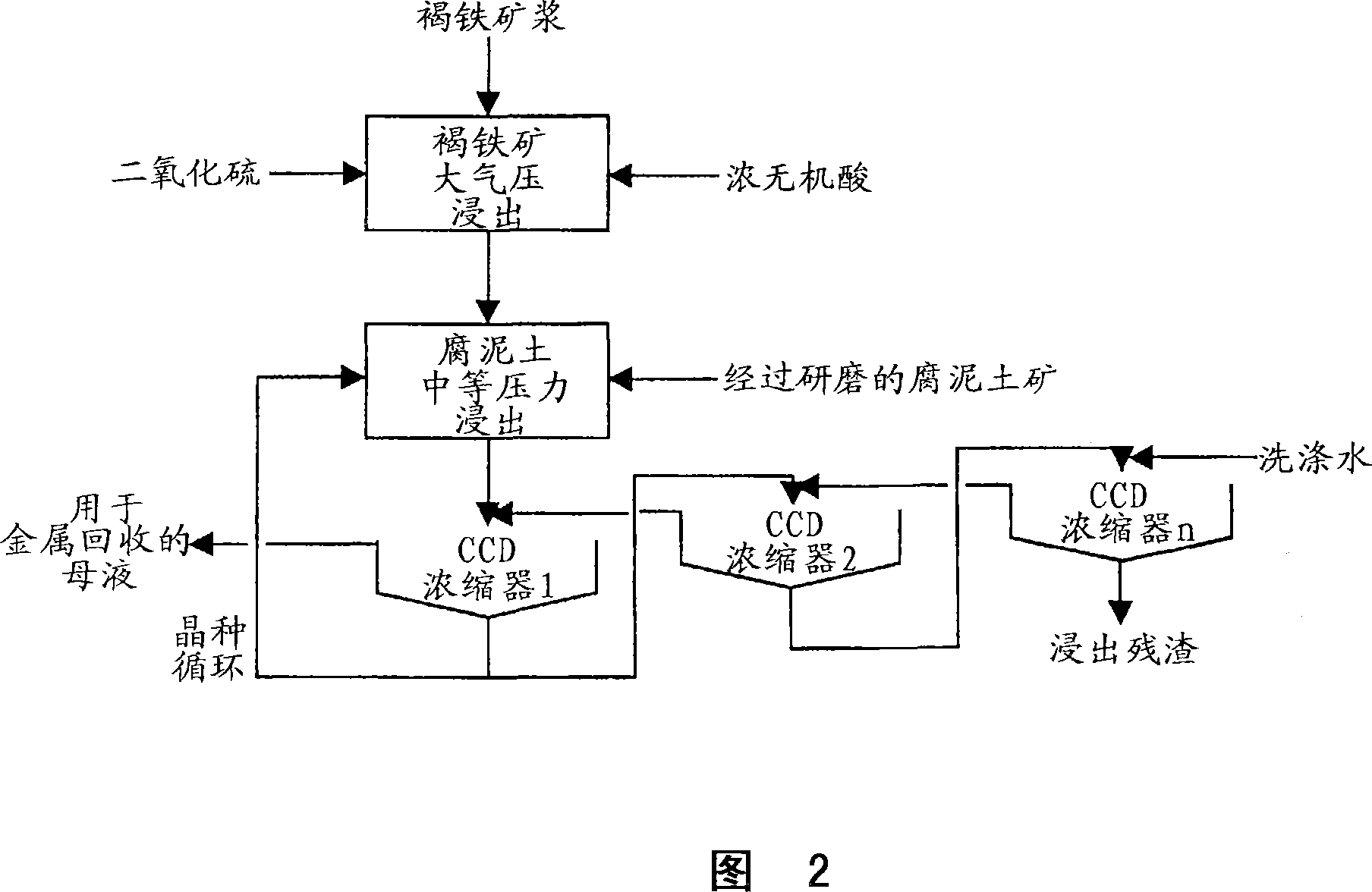

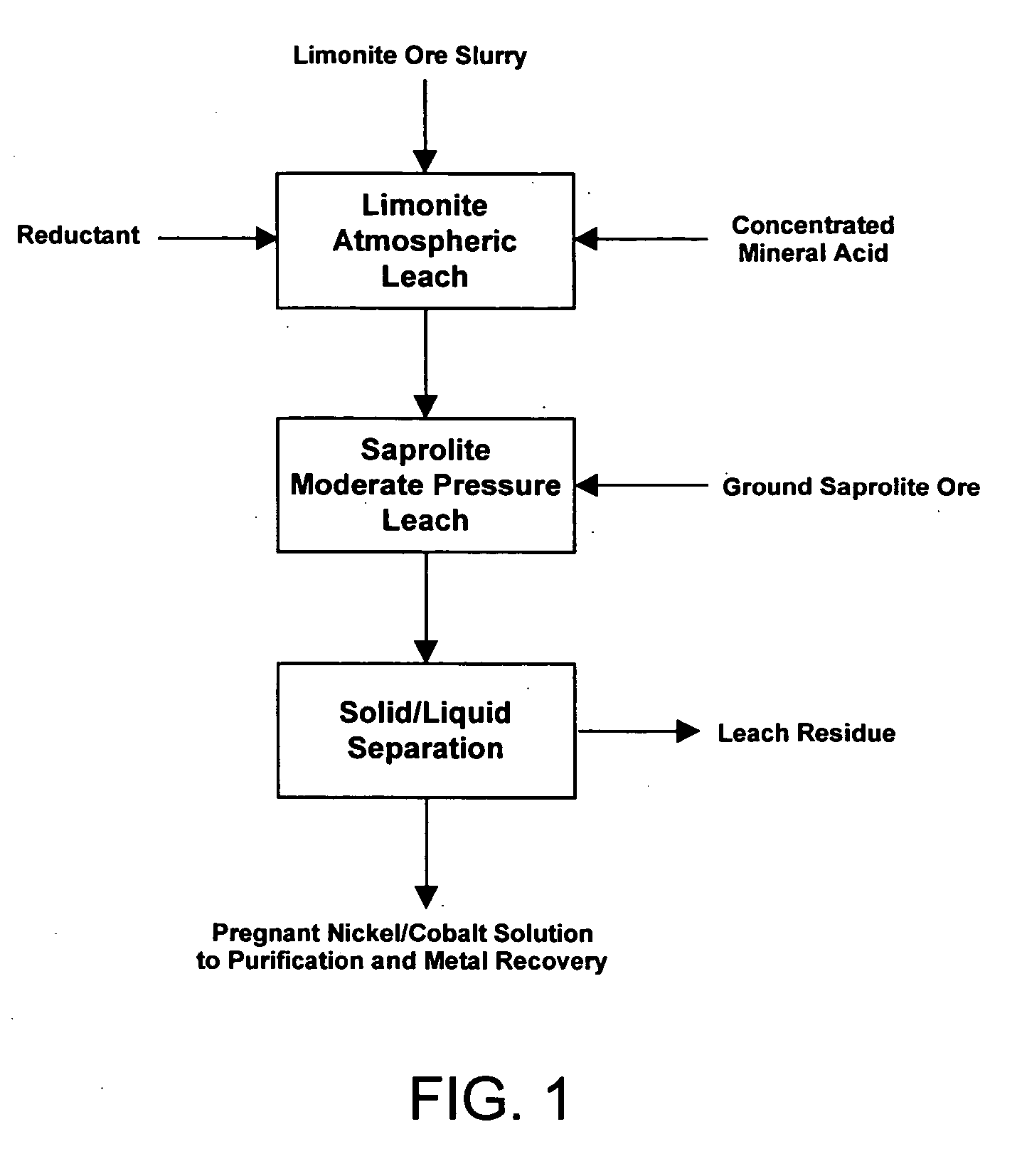

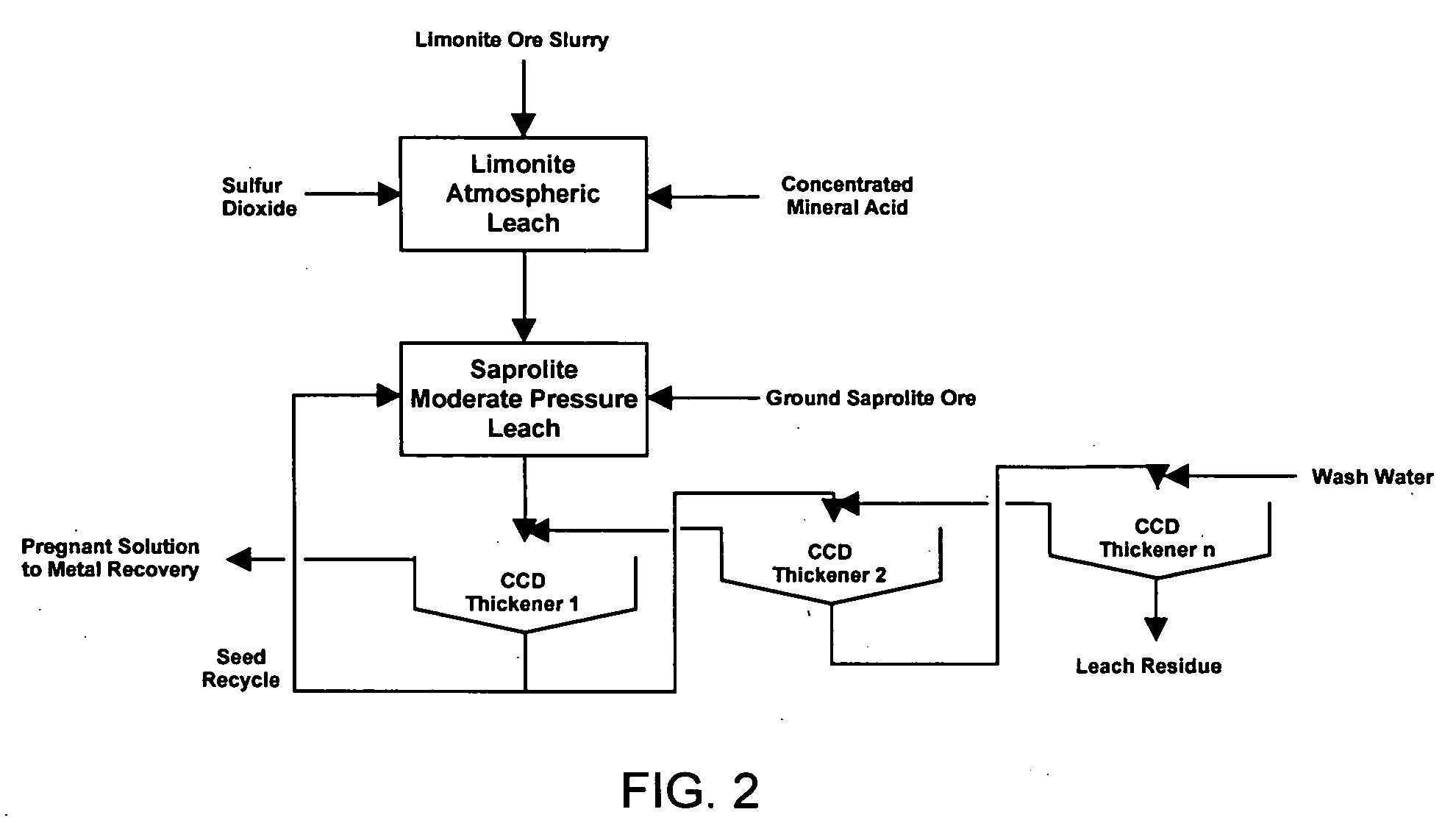

Method for nickel and cobalt recovery from laterite ores by combination of atmospheric and moderate pressure leaching

InactiveCN101001964AHigh extraction rateAvoid environmental unfriendlinessProcess efficiency improvementRecovery methodIon exchange

A process for leaching laterite ores containing limonite and saprolite. Sufficient mineral acid is added to a slurry of limonite which is leached at atmospheric pressure to dissolve most of the soluble non-ferrous metals and soluble iron. After adding saprolite the slurry is further leached at a temperature above the normal boiling point and at a pressure above atmospheric pressure for a time sufficient to leach most of the contained nickel in the saprolite and to precipitate most of the iron in solution. The pressure of the slurry is then reduced, and nickel and / or cobalt is subsequently recovered from the leach solution by solvent extraction, resin-in-pulp or other ion exchange, sulfide or hydroxide precipitation, or other recovery method.

Owner:SKYE RESOURCES

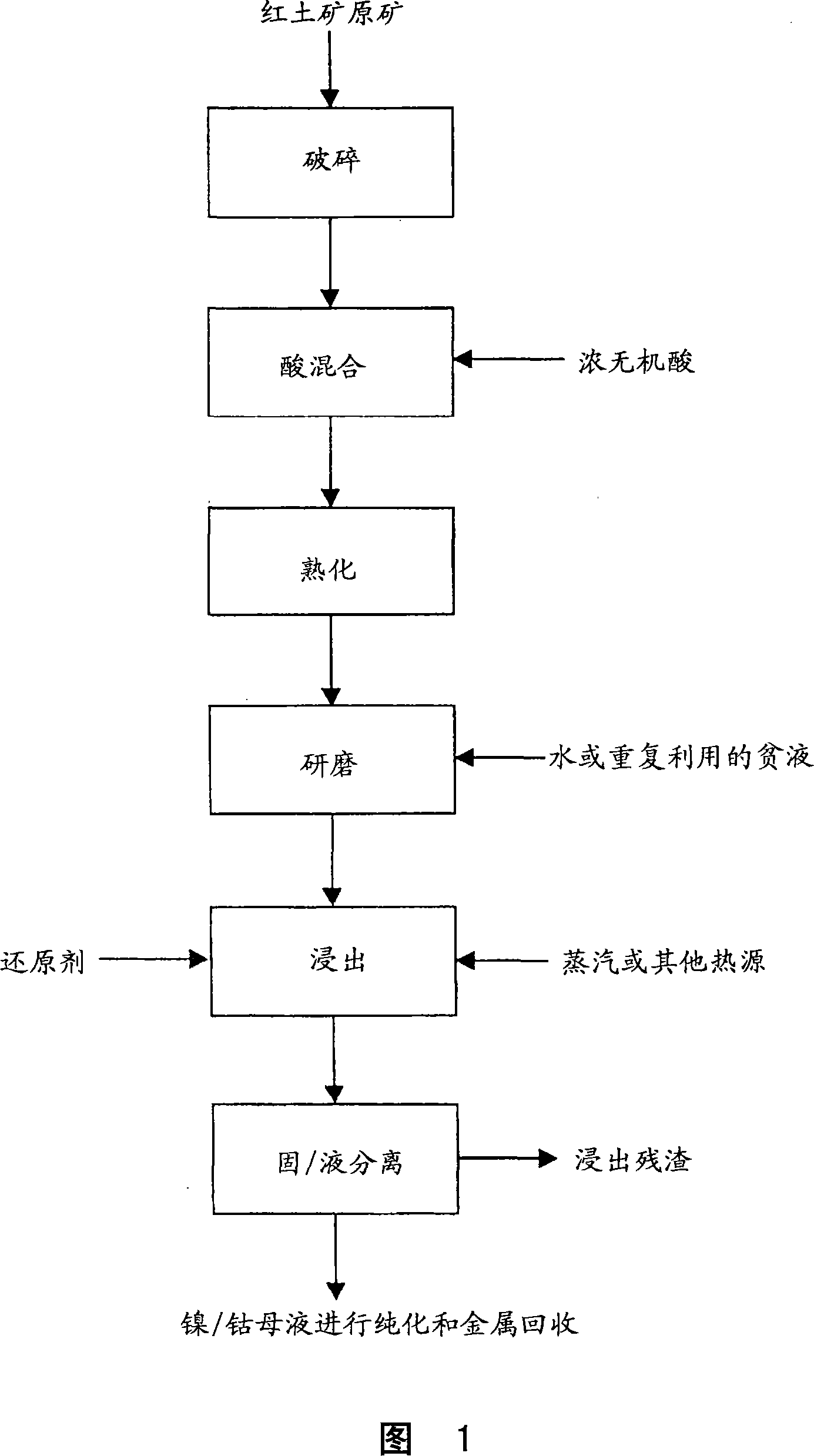

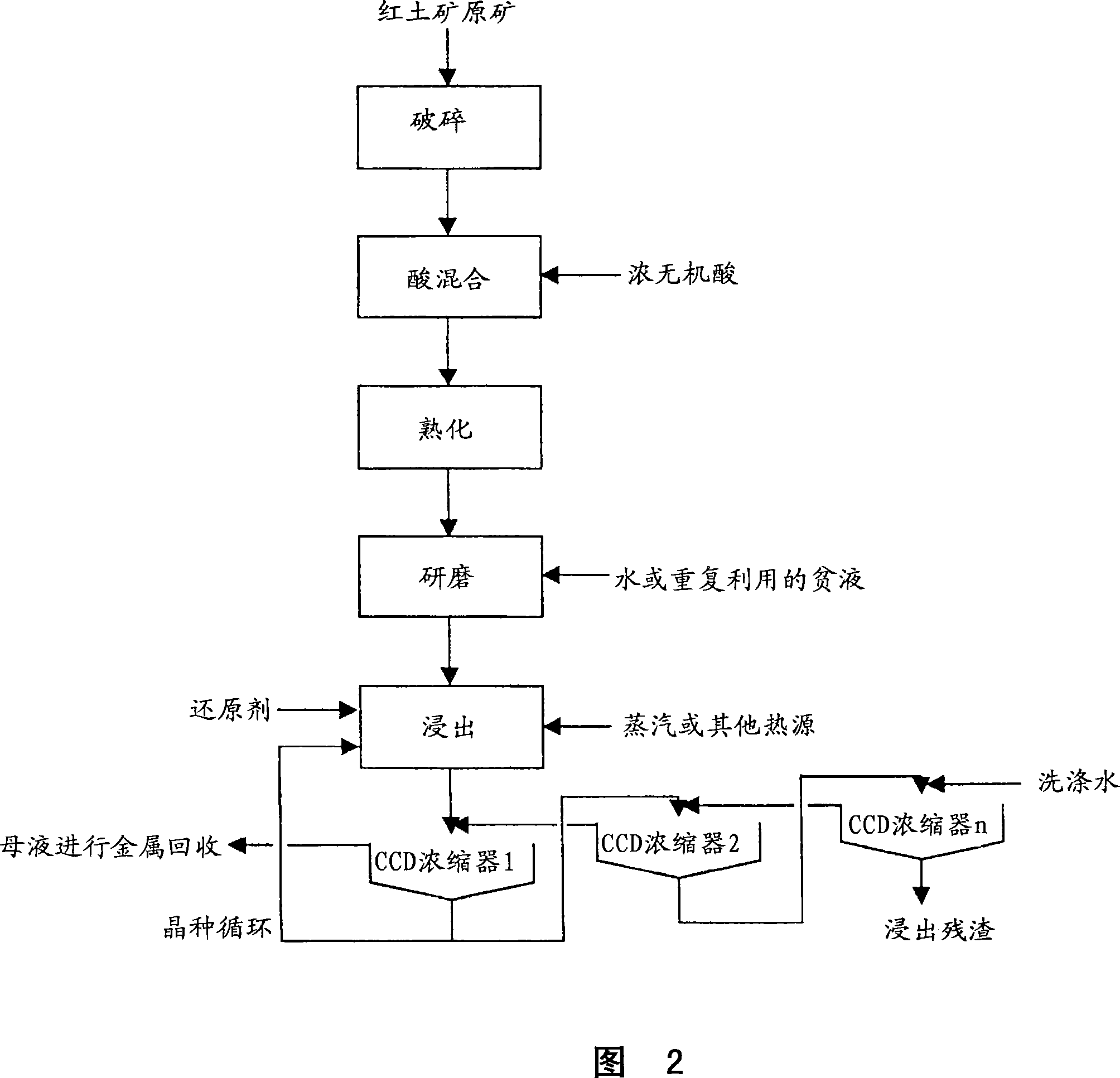

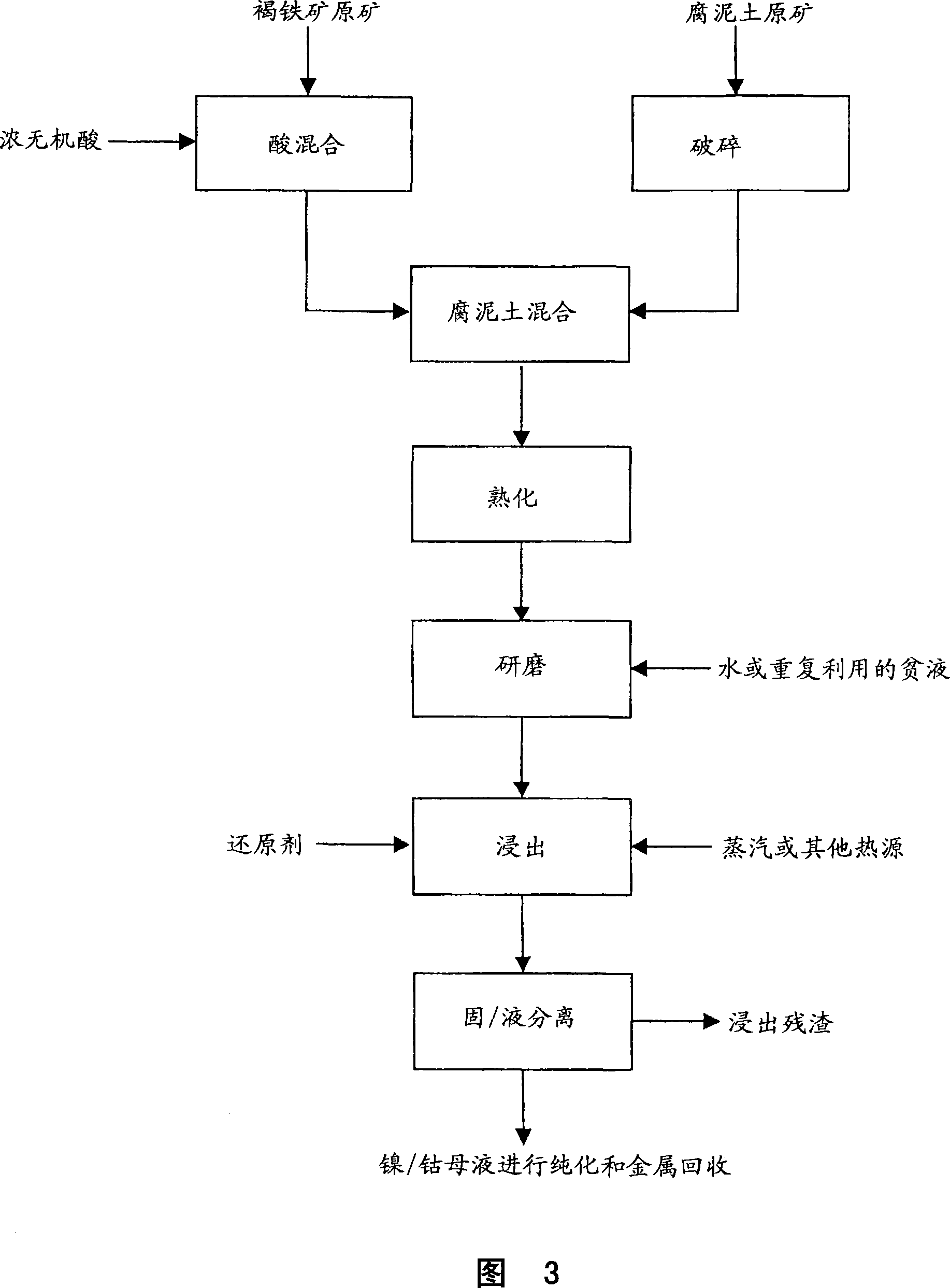

Method for nickel and cobalt recovery from laterite ores by reaction with concentrated acid and water leaching

InactiveCN101006190AHigh extraction rateLow extraction rateProcess efficiency improvementPotassiumSlurry

A process for leaching laterite ores containing limonite and saprolite in a two stage process. The first stage consisting of mixing and reacting the ore with concentrated mineral acid, and the second stage consisting of preparing a slurry of the acid / ore mixture in water and leaching the mixture to dissolve nickel and cobalt. Iron is efficiently separated from nickel and cobalt in the solid leach residue primarily as an oxide or hydroxide of ferric iron other than jarosite.

Owner:SKYE RESOURCES

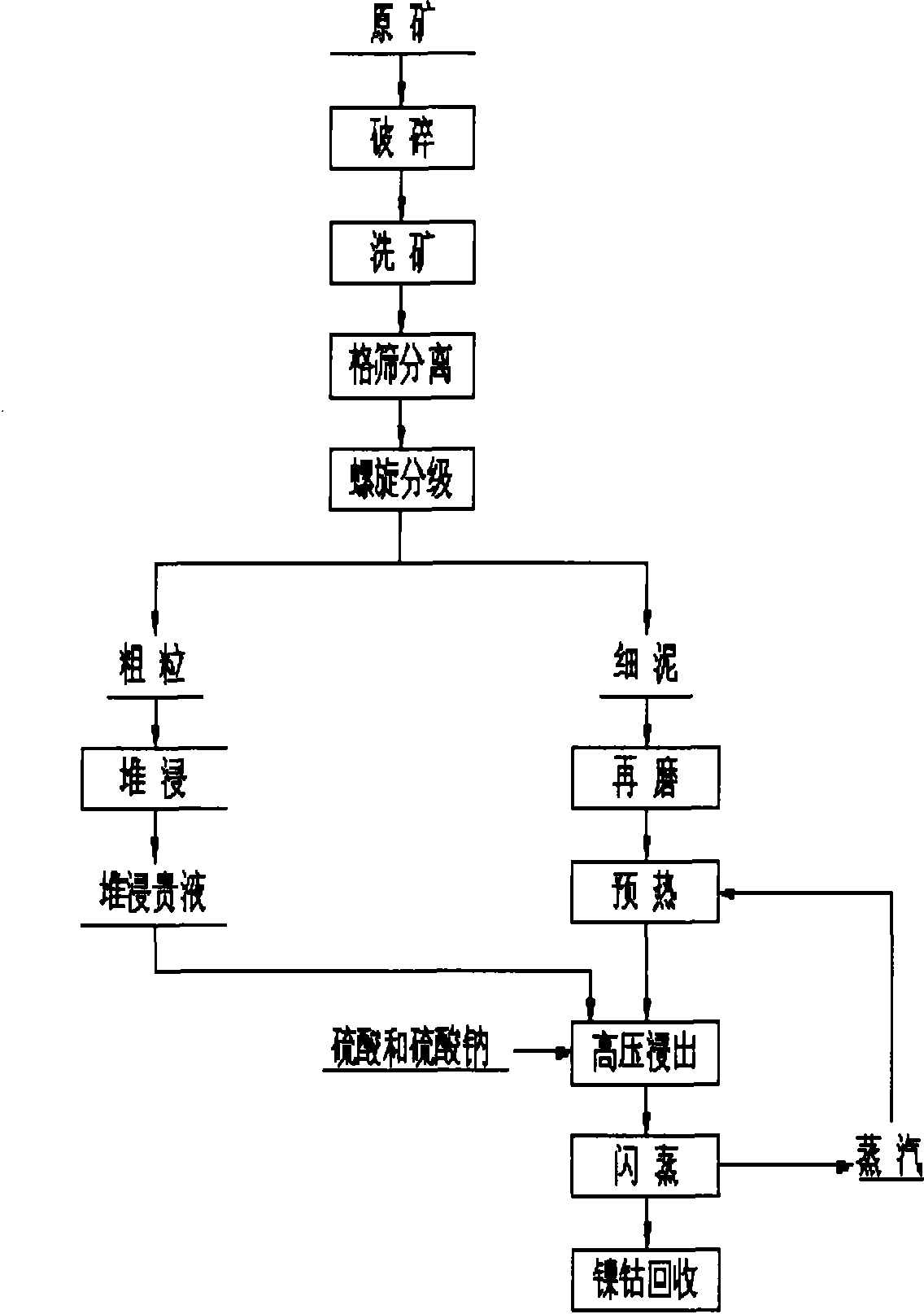

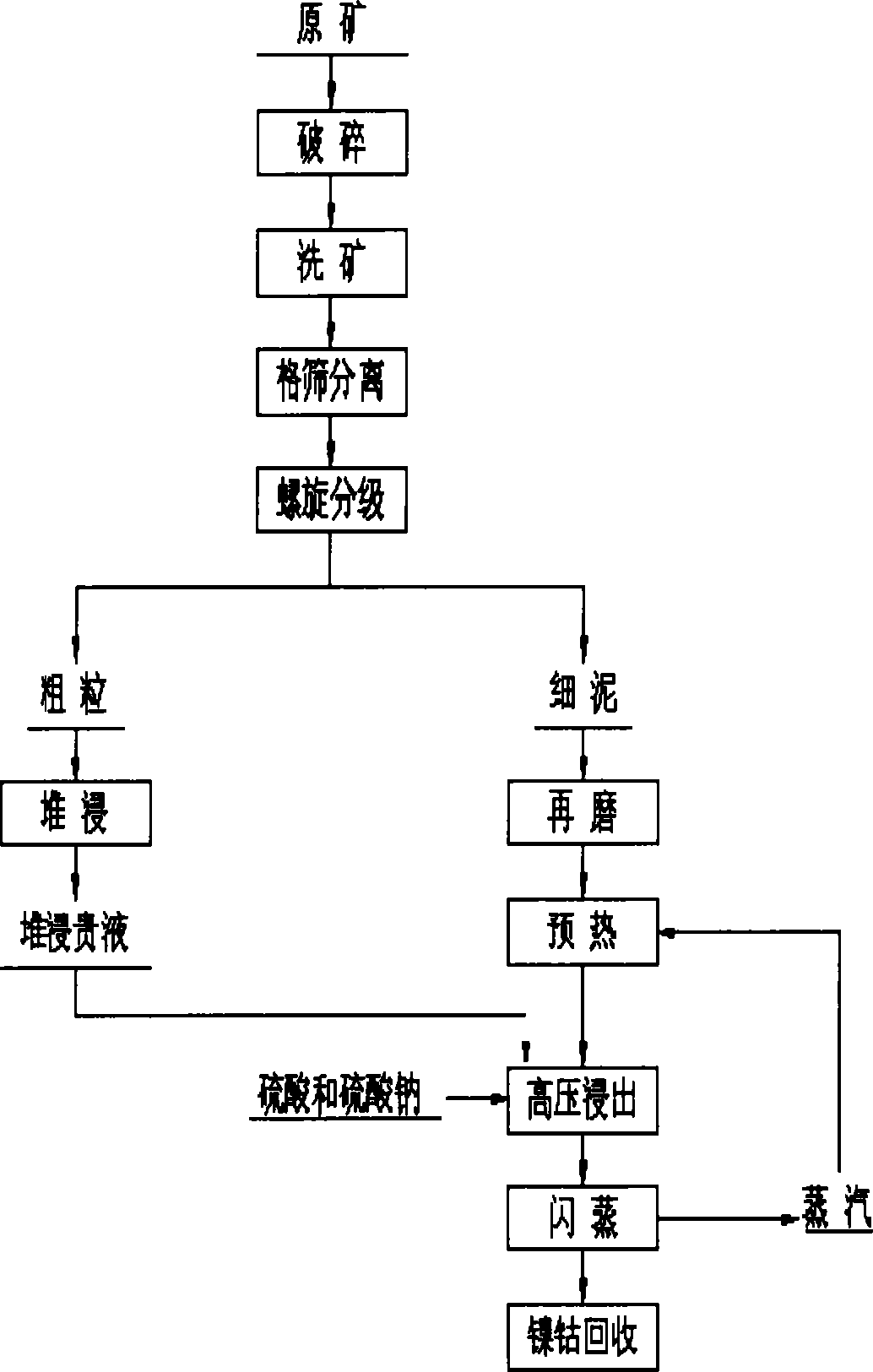

Method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore

InactiveCN101768665AReduce acid consumptionReduce consumptionProcess efficiency improvementHigh pressureLaterite

The invention discloses a method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore, which combines the heap leaching technology with the high-pressure leaching technology to reduce acid consumption during the treatment of nickel laterite ore; residual sulfuric acid in coarse particle immersion of limonite heap is sufficiently utilized and sodium sulfate is added during the stage of high-pressure leaching so that sulfuric acid is generated while yellow natrojarosite is formed, thereby further reducing the consumption of sulfuric acid during the stage of high-pressure leaching.

Owner:厦门紫金矿冶技术有限公司

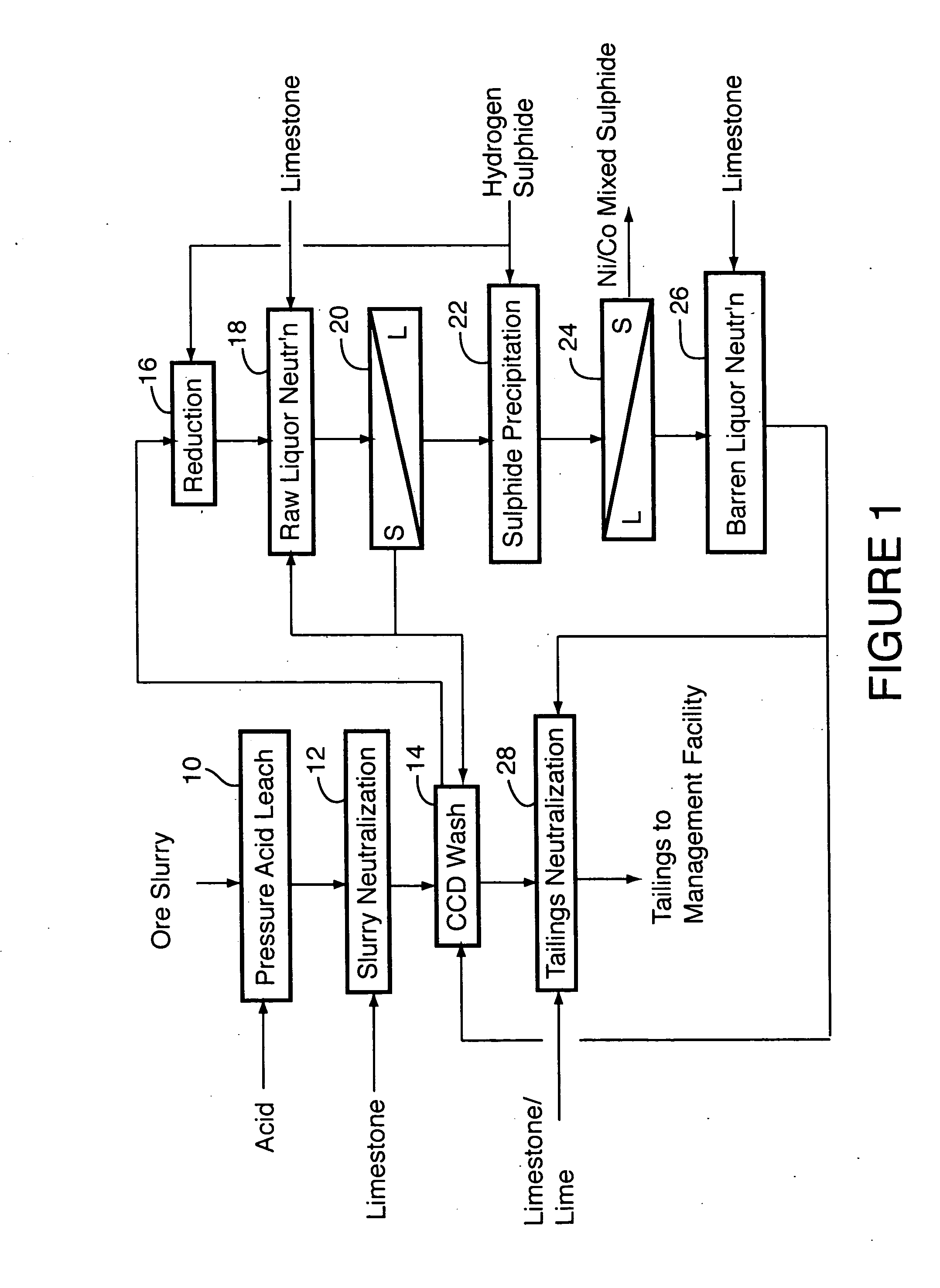

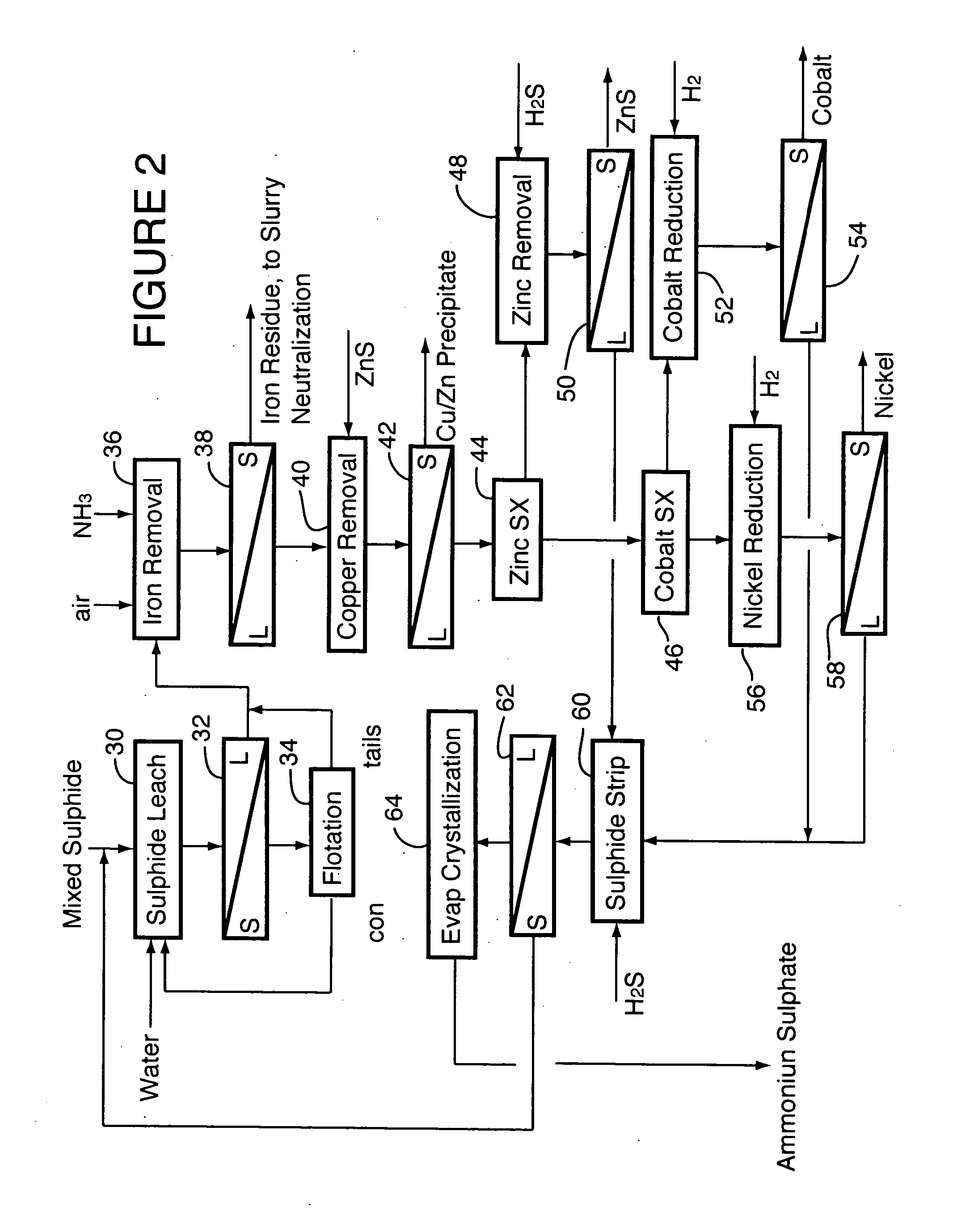

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

Recycling method for treating stainless steel pickling acid pickle and wastewater

ActiveCN104310647AHigh operating costsSimple processWater treatment compoundsWaste water treatment from metallurgical processWash waterLaterite

The invention relates to a recycling method for treating stainless steel pickling acid pickle and wastewater, belonging to the field of treatment of industrial acid pickle and wastewater in iron and steel and metallurgy industries. The acid pickle and wash wastewater generated during stainless steel pickling are collected according to quality and category and the acid pickle is subjected to acid recycling. The acid pickle and wash wastewater are treated through fractional precipitation by adopting lime as a neutralizing agent. Calcium sulfate or calcium fluoride or a mixture of calcium sulfate and calcium fluoride is obtained through precipitation under the acidic condition (the pH value is equal to 3.0+ / -0.5) and can serve as a cement filler or a material for brickmaking or a building material after heavy metal polluted calcium salt is removed. A metal hydroxide is obtained through precipitation under the alkaline condition (the pH value is not more than 9.0) and can serve as a stainless steel smelting raw material as the quality of the product is better than that of the imported laterite-nickel ores in China. The calcium nitrate containing wastewater obtained after the acid pickle is treated is not needed to be discharged or treated and can be recycled. After being treated, the wash wastewater can be reused as production line wash water.

Owner:上海博士高环保科技有限公司

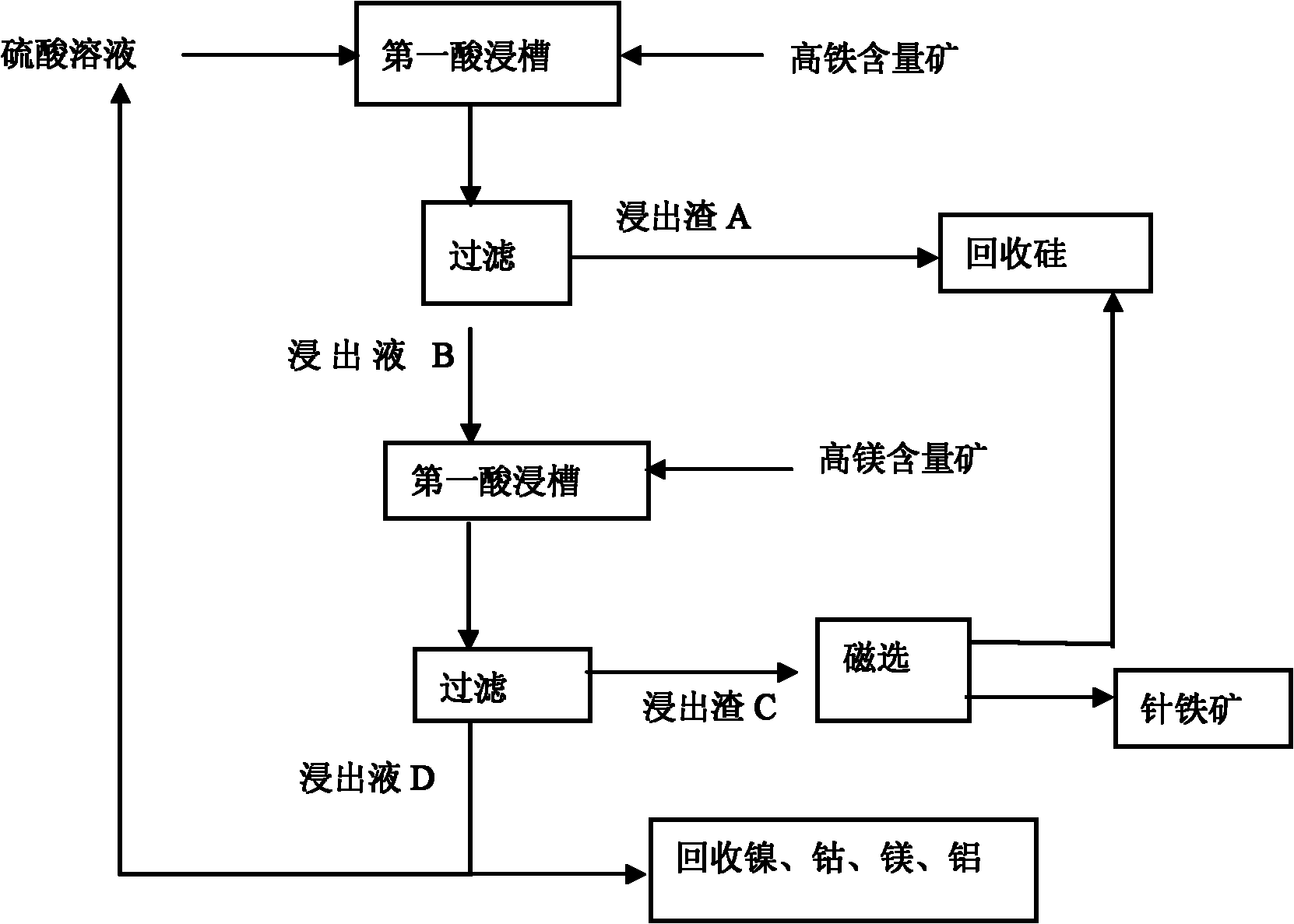

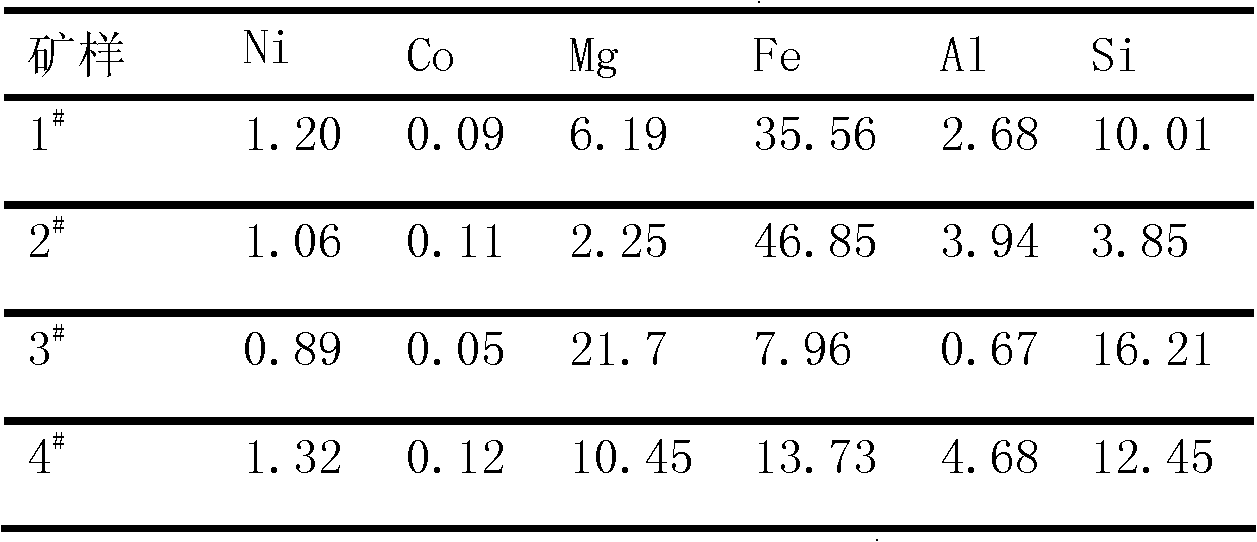

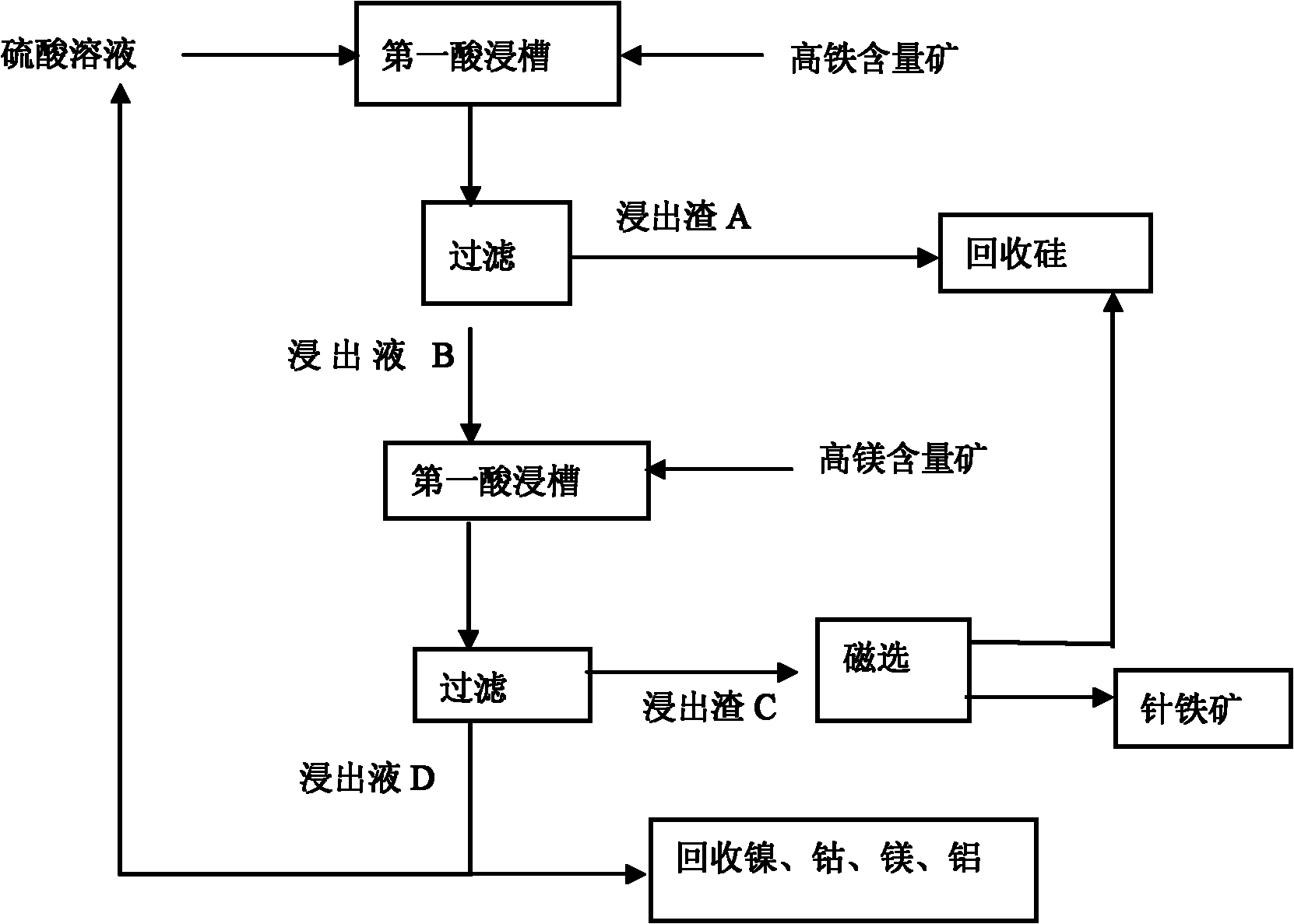

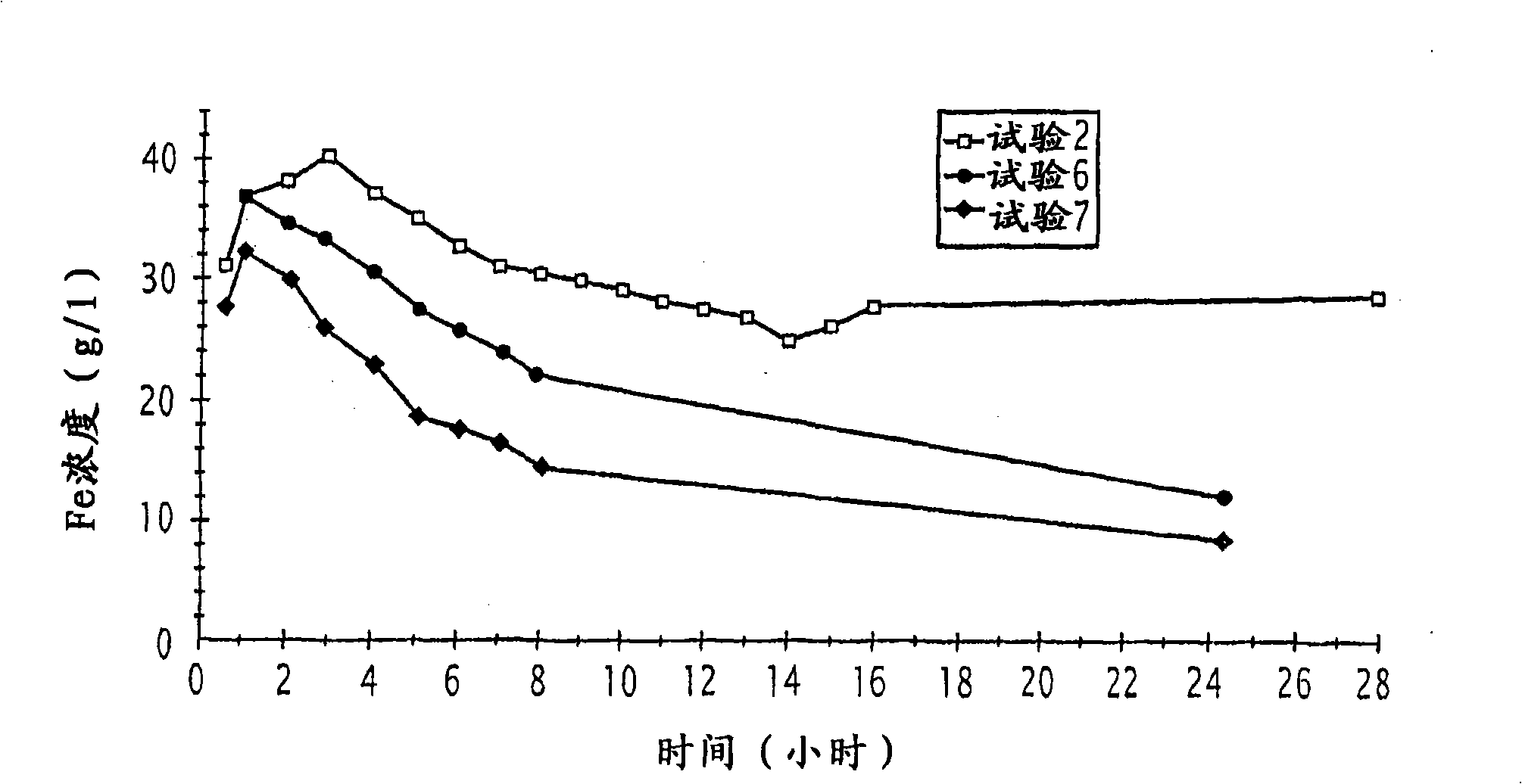

Normal-pressure leaching method for simultaneously processing laterites with high iron content and high magnesium content

InactiveCN102206749AOvercoming the disadvantage of requiring autoclave leachingOvercome the drawbacks of leachingIron oxides/hydroxidesProcess efficiency improvementLateriteNon magnetic

The invention discloses a normal-pressure leaching method simultaneously processing laterites with high iron content and high magnesium content, comprising the following steps of: screening the laterites with high iron content and high magnesium content; adding sulfuric acid to the laterite with high iron content for leaching so as to obtain leaching residue A and a leaching solution B; adding the laterite with high magnesium content to the leaching solution B, leaching to obtain leaching residue C and a leaching solution D; carrying out magnetic separation on the leaching residue C, wherein a magnetic part E is recovered as an iron product, and a non-magnetic part F and the leaching residue A are mixed to be used for recovering silicon products; delivering a part of the leaching solutionD into a purifying and recovering process, and returning the other part of the leaching solution D into the leaching process of the laterite with high iron content, and carrying out a next leaching period; repeating the leaching period for 4-5 times, and completely delivering a leaching solution I obtained from a last leaching period into the recovering processes of nickel, cobalt, aluminum and magnesium. The normal-pressure leaching method has the advantages of low cost and acid consumption and high leaching efficiency of the nickel and the cobalt and realizes the efficient separation and the recycling of iron, silicon, the nickel and the cobalt and the discharge without acid liquor.

Owner:GUANGXI NORMAL UNIV

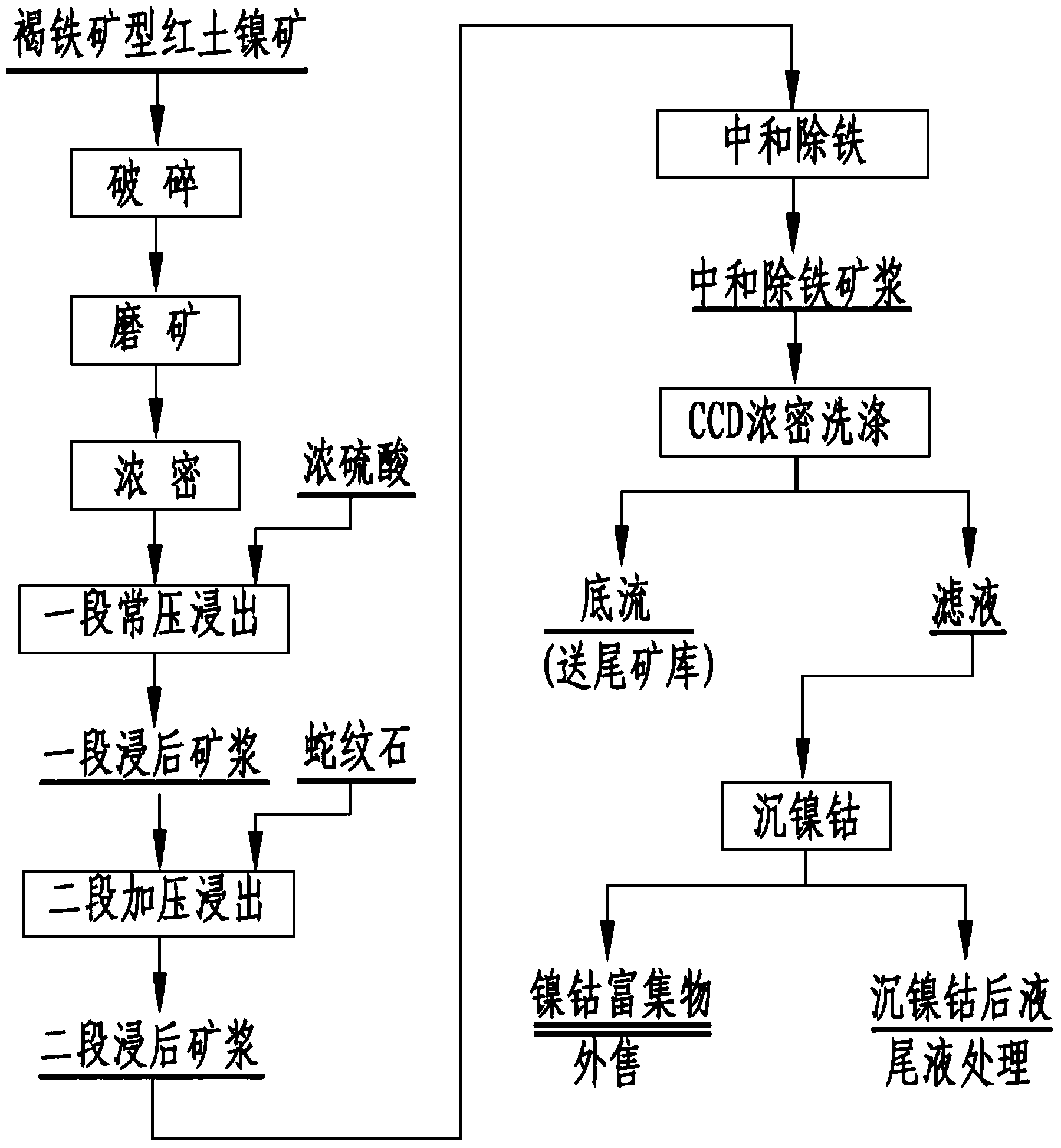

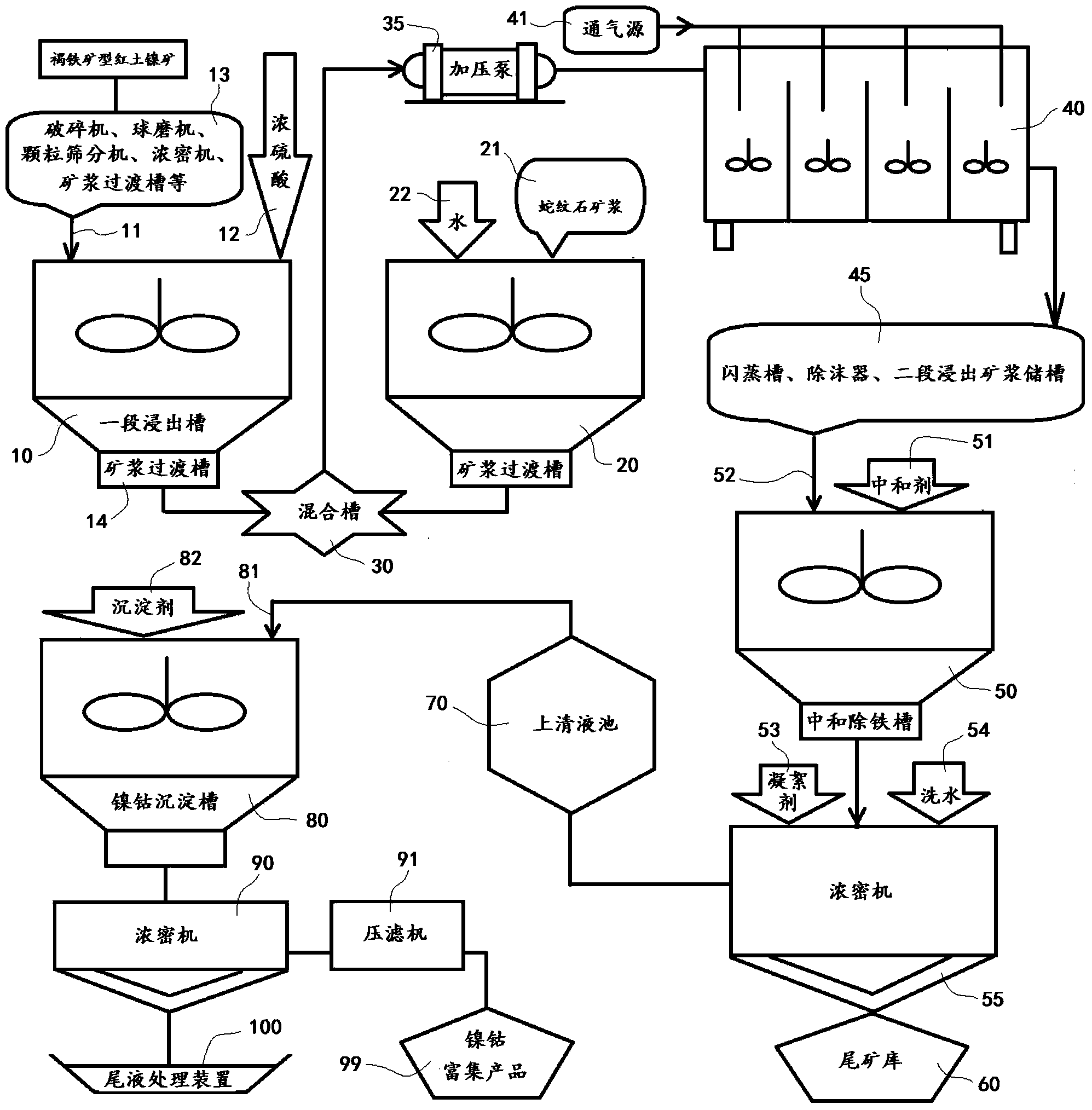

Laterite-nickel ore combination leaching process

InactiveCN103614571AWide adaptabilityImprove leaching rateProcess efficiency improvementMagmaHigh pressure

The invention relates to a laterite-nickel ore combination leaching process, which comprises that: limonite type laterite-nickel ore is subjected to crushing grading, and then is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring self-heating leaching, serpentine type laterite-nickel ore is subjected to crushing grinding, the obtained serpentine type laterite-nickel ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and serpentine is leached by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle, or mixing type laterite-nickel ore is subjected to grading, the obtained fine particle-grade ore is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring leaching, ore on the sieve is subjected to crushing grinding, the grinded ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and coarse particle-grade ore leaching is performed by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle. According to the invention, the process has characteristics of no special requirements on ore types and grades, wide raw material adaptability, investment reduction, energy consumption reduction, production cost reduction, and simple process, wherein the Ni recovery rate and the Co recovery rate of the whole process of the present invention are respectively more than 90% and 88%, and are higher than the Ni recovery rate and the Co recovery rate of the treatment method in the existing non-high-pressure acid leaching technology.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

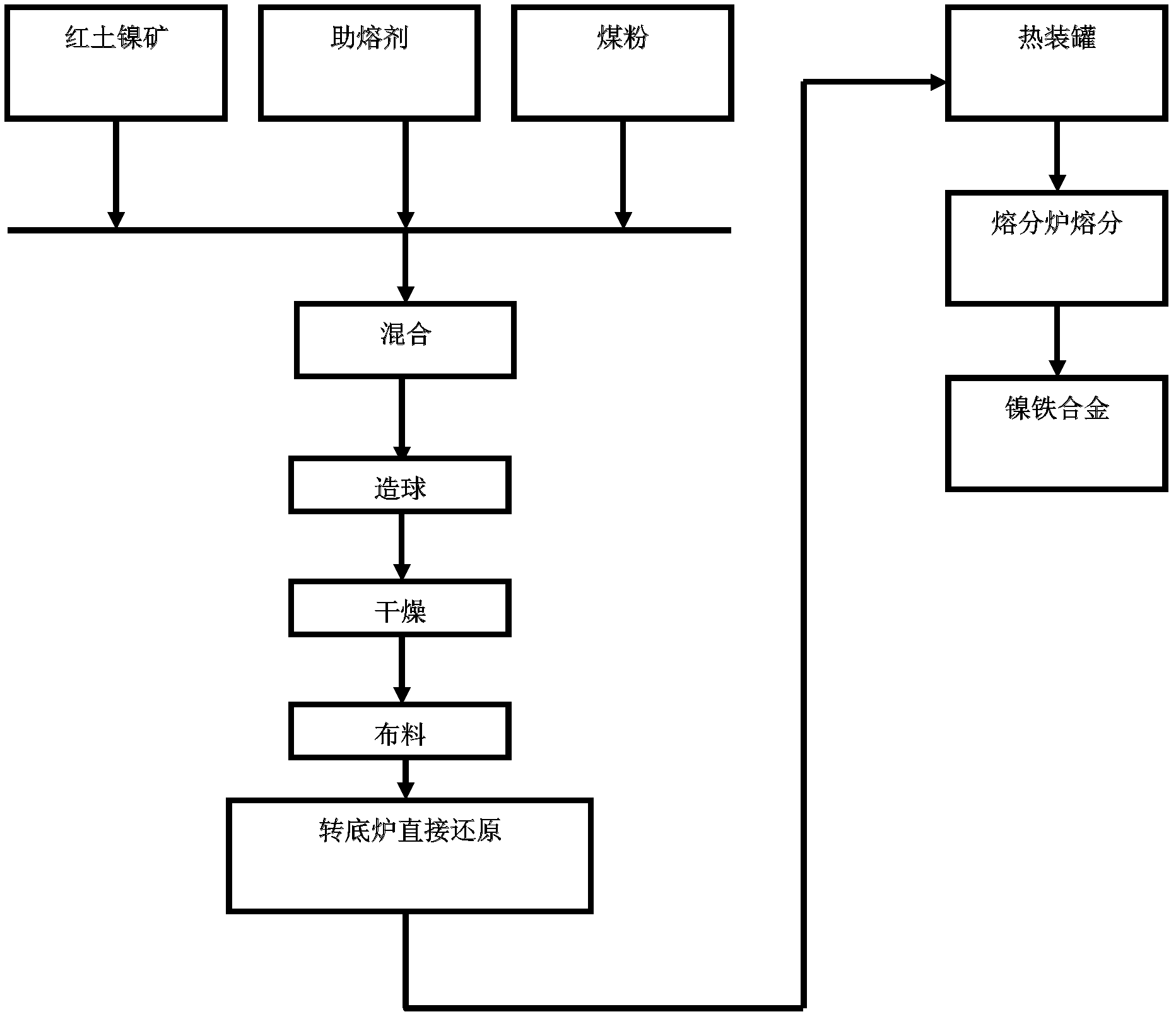

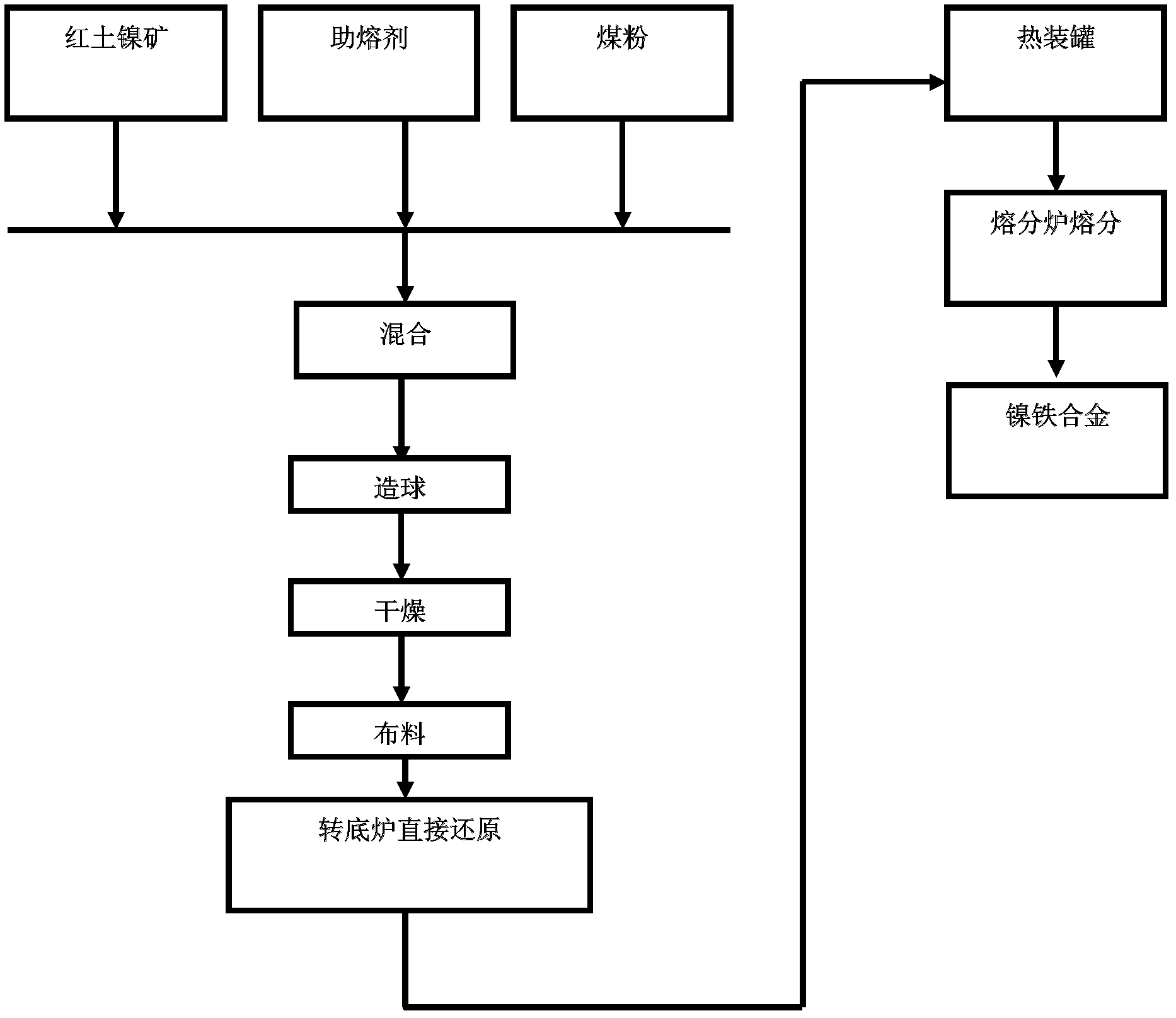

Iron-making method by performing coal-based direct reduction in rotary hearth furnace and melting in gas melting furnace on lateritic-nickel ore

The invention discloses an iron-making method by performing coal-based direct reduction in a rotary hearth furnace and melting in a gas melting furnace on lateritic-nickel ore. The method comprises the following steps: firstly mixing a certain quantity of coal, lateritic-nickel ore and a fluxing agent and then pelletizing, spreading green pellets in a rotary hearth furnace after the pellets are dried, and heating to the temperature of 1200-1300 DEG C and maintaining the temperature for 30-40 minutes to obtain high-temperature metallized pellets; hot-packing the high-temperature metallized pellets at 600-1100 DEG C from the rotary hearth furnace, and then transferring the packed pellets into a heat-accumulating gas melting furnace for melting at the temperature of 1420-1500 DEG C for 30 minutes, wherein the heat-accumulating gas melting furnace utilizes coal gas as fuel; and removing slag to finally obtain high-nickel ferronickel alloy. The iron-making method has the advantages of simple process, short flow, high efficiency, high nickel recovery rate and no need of coking coal and is applicable to the treatment of lateritic-nickel ore.

Owner:吴道洪 +1

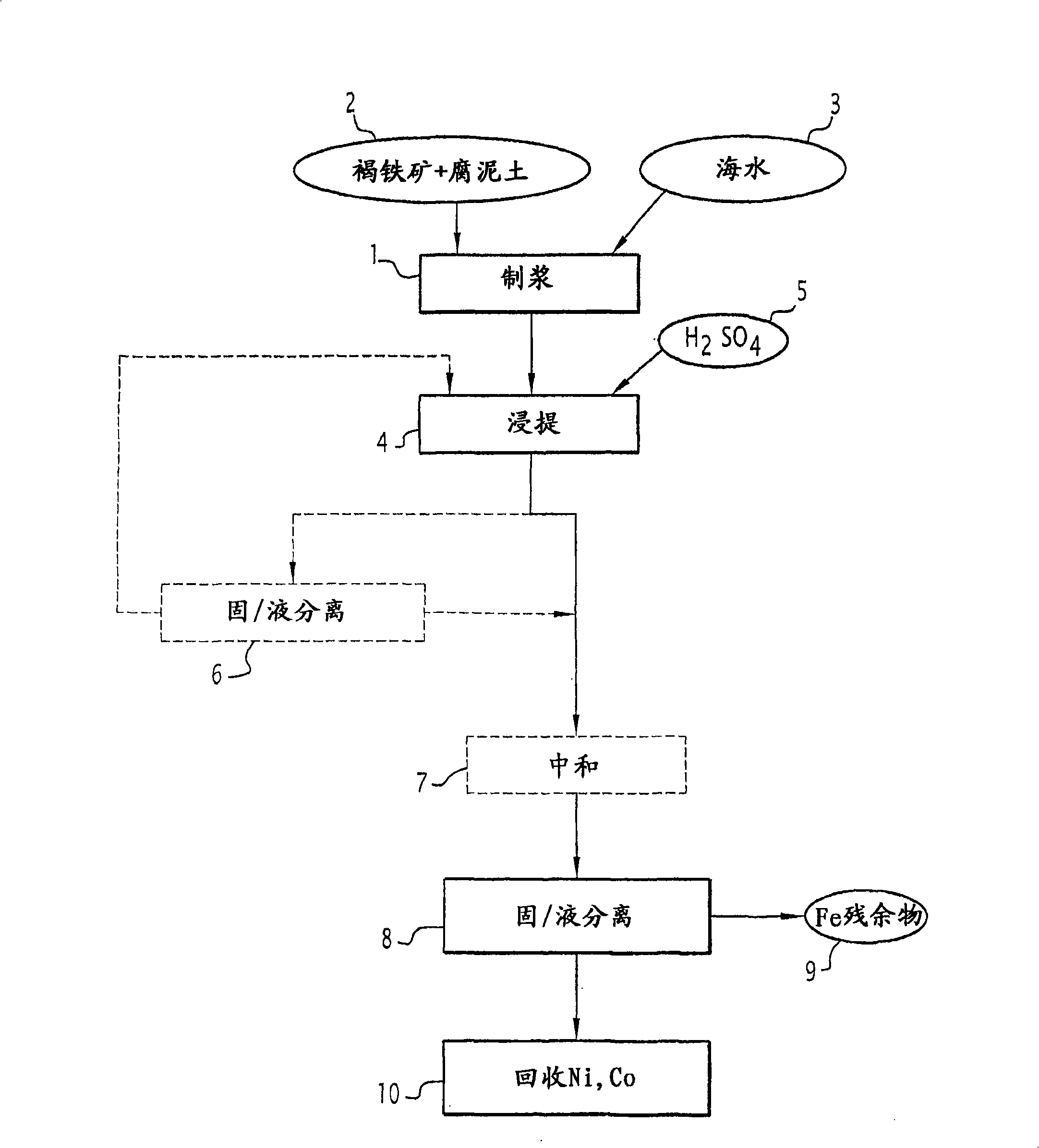

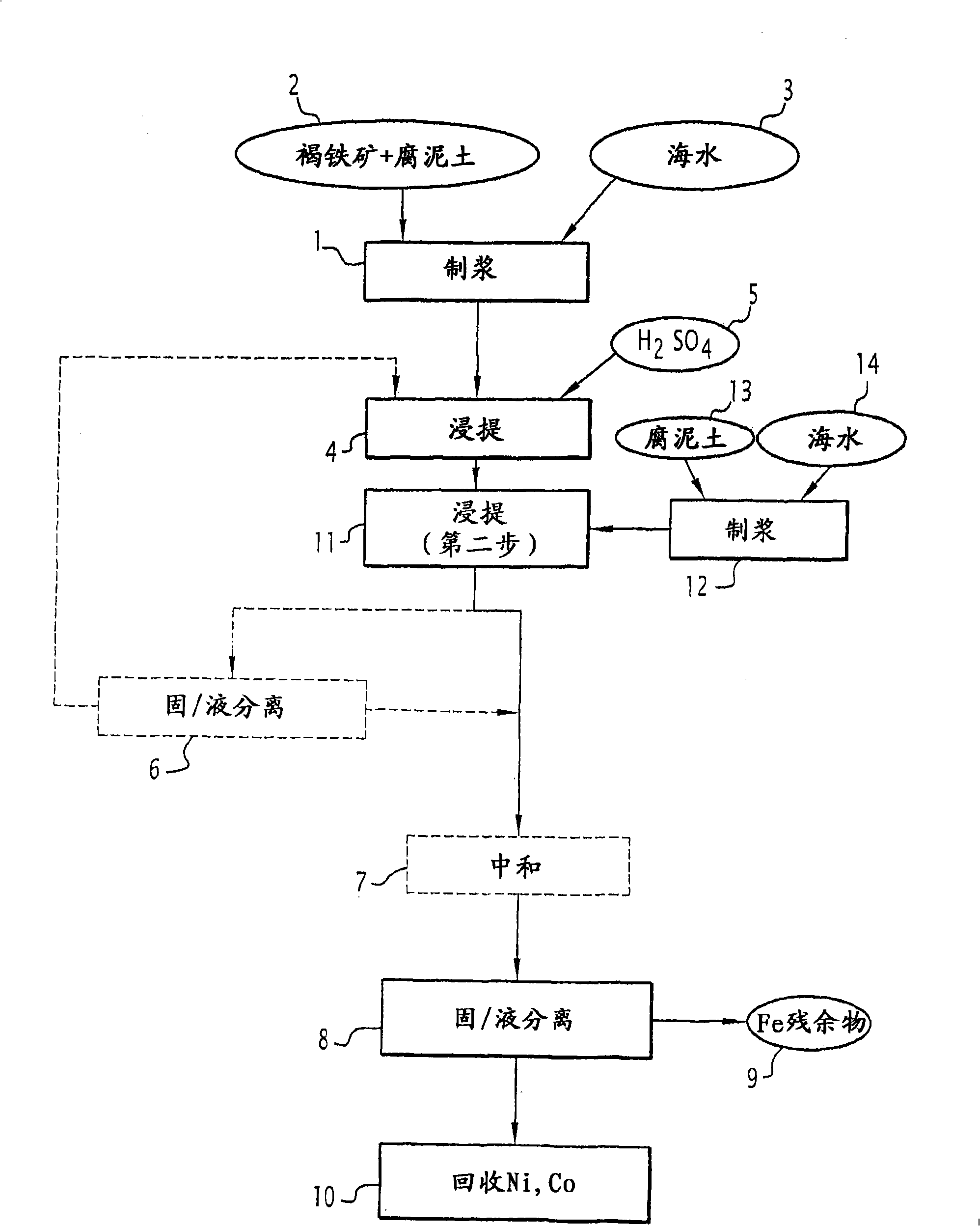

Process for the hydrometallurgical treatment of a lateritic nickel/cobalt ore and process for producing nickel and/or cobalt intermediate concentrates or commercial products using it

ActiveCN101541985ASimple structureShorten the durationProcess efficiency improvementBoiling pointHydrometallurgy

Process for the treatment of a lateritic nickel / cobalt ore consisting of a mixture (2) of limonite and saprolite, characterized in that: the mixture (2) in the presence of an iron-precipitating agent is made into a pulp (1), having a solids content of between 10 and 40% by weight; the pulp undergoes a leaching operation (4) with sulphuric acid (5), at a temperature between 70 DEG C and the boiling point and at atmospheric pressure; and a solid-liquid separation (8) is carried out so as to obtain an iron-containing solid residue (9) and a solution containing nickel and cobalt ions. Process for producing nickel and / or cobalt intermediate concentrates or commercial products using the above process.

Owner:ERAMET

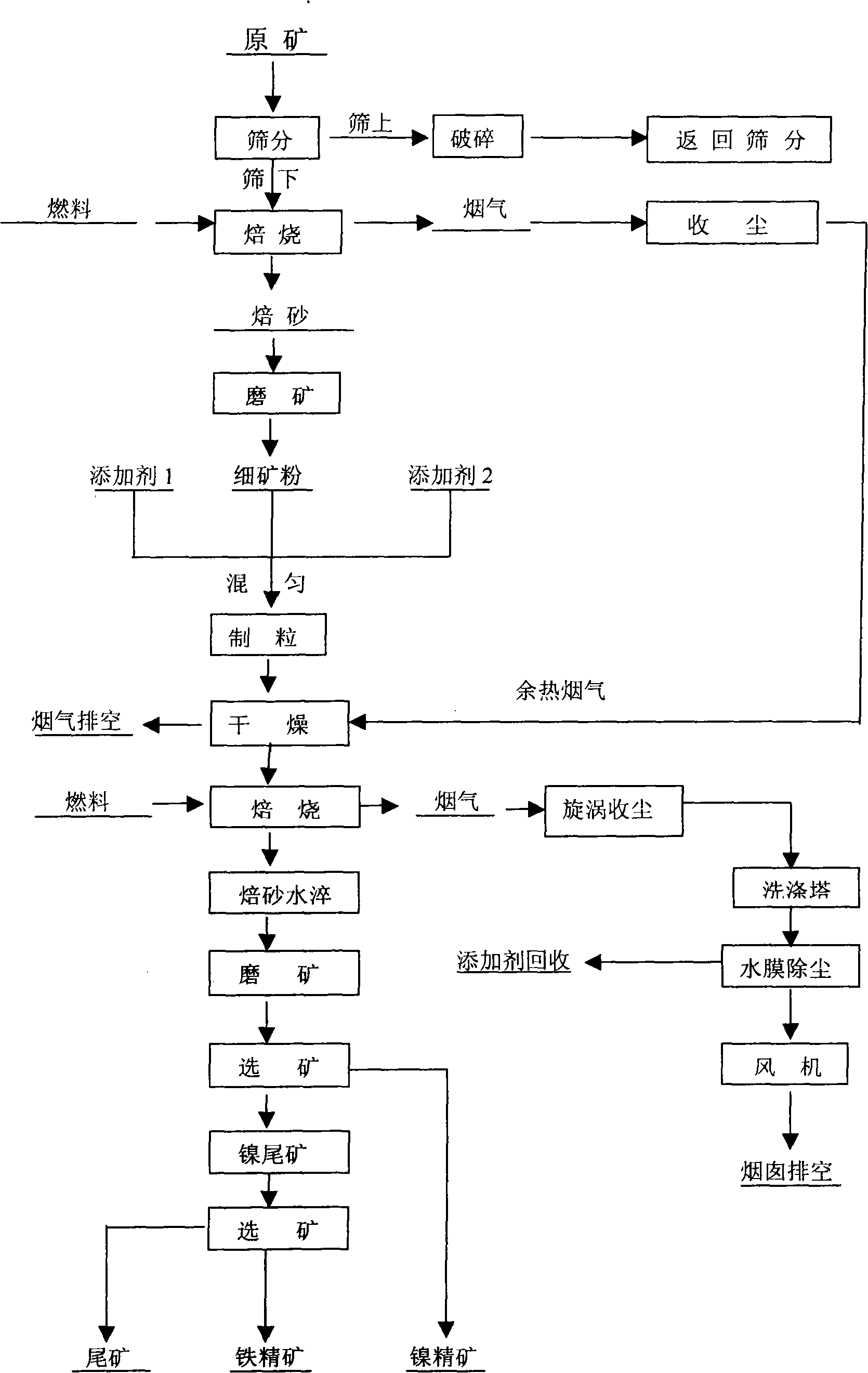

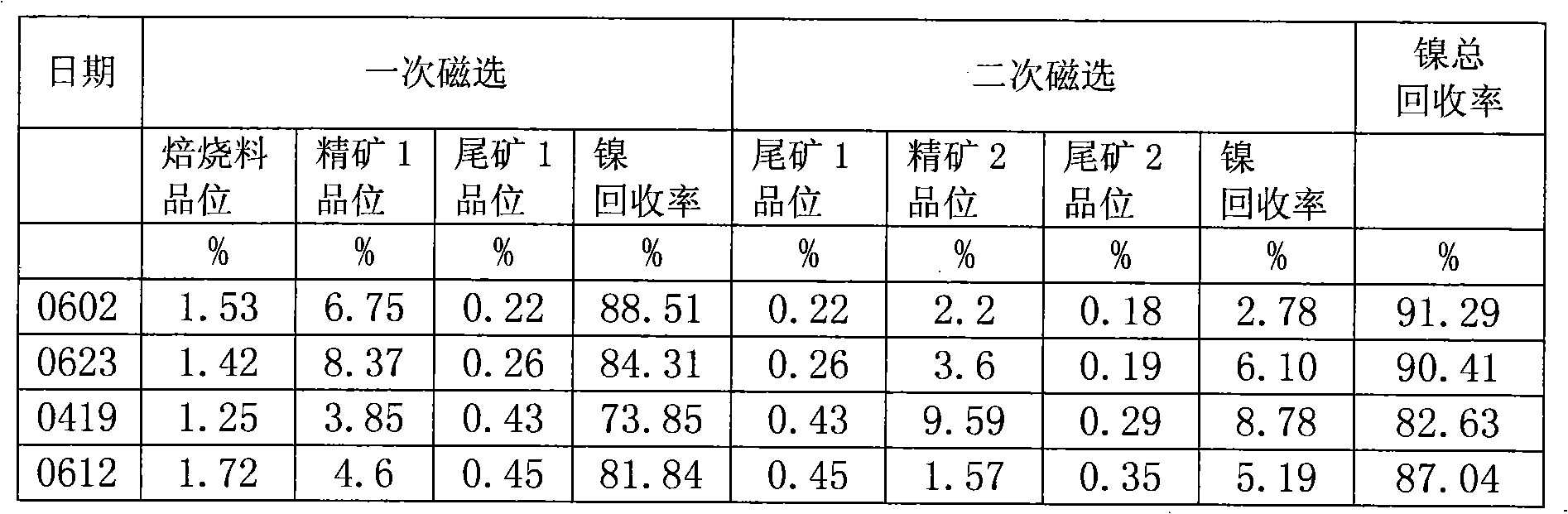

Technique for roasting and dressing laterite nickel ore

InactiveCN101538645APromote reductionAvoid excessive reductionProcess efficiency improvementLateriteCobalt

The invention relates to a technique for roasting and dressing laterite nickel ore. The technique comprises the following steps that: raw ore is crushed, sieved and then roasted for the first time by use of a kiln; cold roasted sand powder is ground into fine powder; the fine powder is mixed well with carbonaceous additives and chlorinating agents and then pelletized to be pellets in a disk pelletizer; the pellets are dried by use of afterheat flue gas of the kiln and then enter a second kiln so as to be roasted; neutral or weak reducing atmosphere is adopted in the roasting process to inhibit the reduction of iron in laterite ore; roasting temperature is controlled below soft melting temperature; the roasted pellets are quenched with water under an airtight condition; water-quenched roasted sand is ground and then dressed so as to obtain nickel-cobalt concentrate; iron in tailings is recovered through high intensity magnetic separation and gravity separation; tail gas of a pellet-roasting kiln is subjected to vortex dust collection, neutralized with lime mortar and concentrated and then passes through a washing tower; and most of chlorinating agents are recovered after water-film dust removal. The technique is characterized by strong raw-material adaptability, simple process flow, low cost, environment-friendly property and the like.

Owner:张建宏 +6

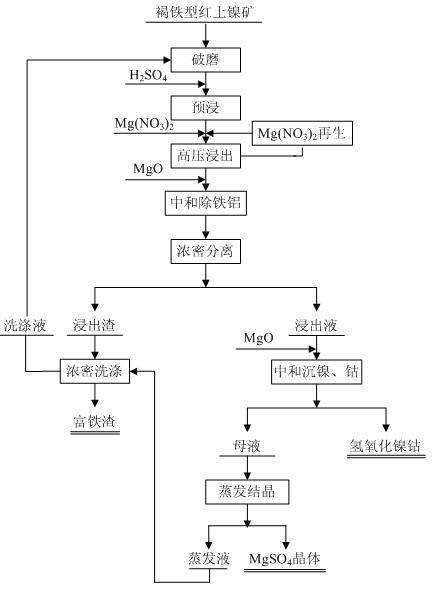

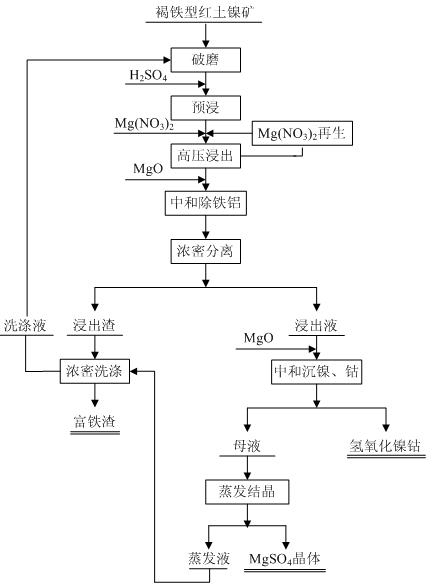

Method for leaching limonitic laterite nickel ore

InactiveCN102534206AReduce consumptionEasy to operate and controlProcess efficiency improvementSlagSlurry

The invention discloses a method for leaching limonitic laterite nickel ore and relates to a process method for recovering nickel, cobalt and iron through treatment of laterite nickel ore by wet process. The method is characterized in that the technical process comprises: (1) grinding raw limonitic laterite nickel ore into fine powder, making slurry, adding sulfuric acid, heating the slurry and leaching the slurry; (2) adding Mg(NO3)2 into the pre-leached slurry, heating with stirring, pressurizing the slurry and leaching the slurry; 3) at the end of leaching, neutralizing the slurry, removing iron and aluminum from the slurry, and separating to obtain a leaching solution and a leaching residue; and 4) washing the leaching residue to obtain washing liquid and iron-enriched slag, neutralizing the leaching solution, precipitating nickel and cobalt, obtaining nickel and cobalt hydroxides, evaporating a mother solution from which nickel and cobalt are separated to crystallize magnesium sulfate and comprehensively recovering magnesium sulfate. The method realizes the high-efficiency selective leaching of nickel and cobalt, the leaching rate reaches over 90 percent, the iron leaching rate is lower than 0.8 percent and iron-enriched slag with an iron content of over 55 percent is obtained.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

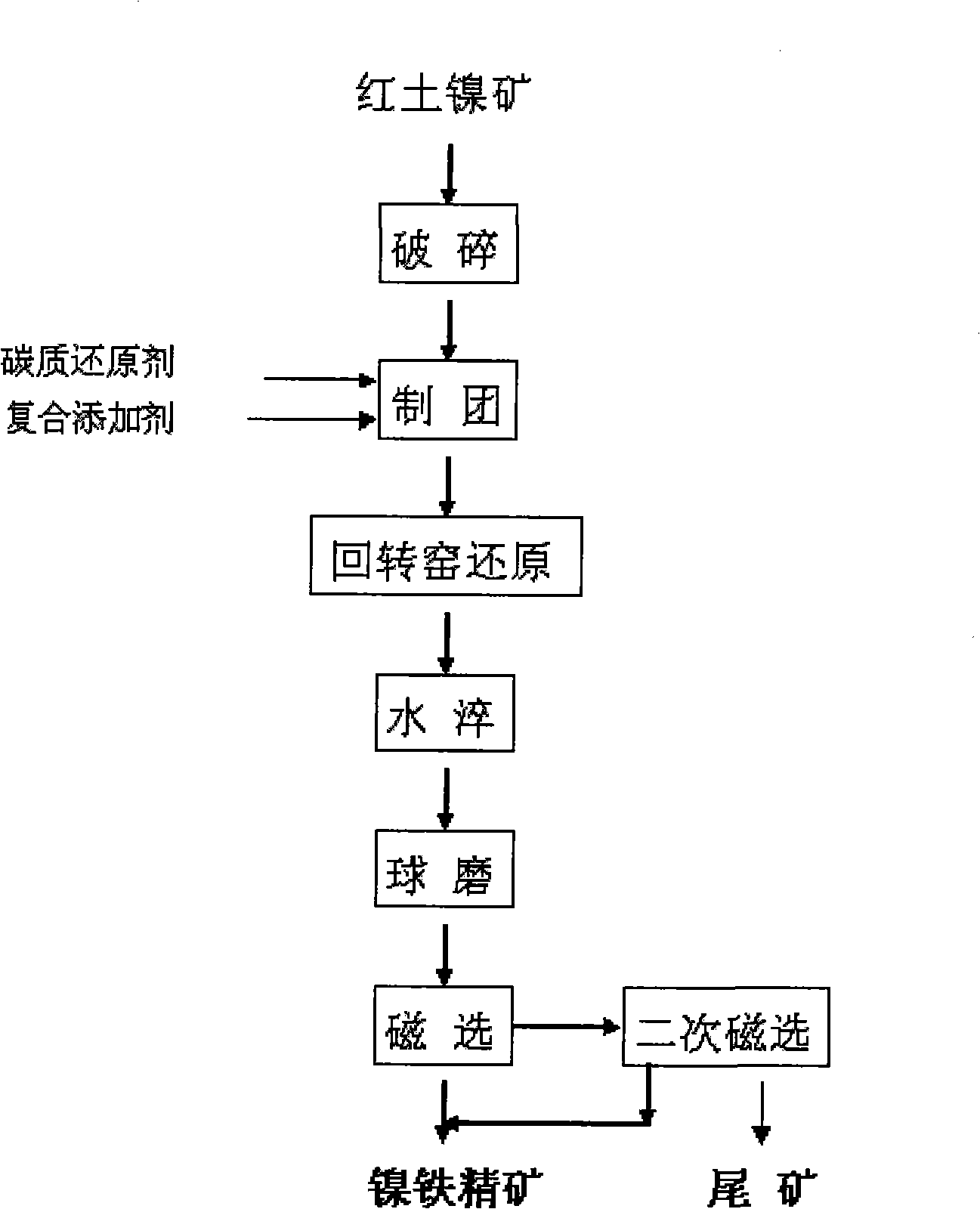

Method for enriching nickel iron ore concentrate from laterite type nickel ore by means of rotary kiln

InactiveCN101323904ANo pollution in the processSimple processRotary drum furnacesMagnetic separatorLaterite

The invention relates to a method for collecting ferronickel concentrate from lateritic nickel ores by a rotary kiln. The lateritic nickel ores are crushed, stirred and mixed with a carbonaceous reducing agent and a compound additive, made into pellets by a ball press or a marble machine and put into the rotary kiln for reducing and roasting; waste heat at the front part of the rotary kiln is used for carrying out the drying and preheating of the pellets; the high-temperature area of the rotary kiln is 9 to 10 meters away from a kiln outlet; the temperature of the high-temperature area is controlled to be 1000 to 1300 DEG C; roasting time is 0.5 to 2 hours; the dried pellets enter the high-temperature area of the rotary kiln for reducing and roasting; a magnetic separator with a magnetic field intensity of 3000 to 5000 gauss is adopted to sort roasted material obtained after water quenching and wet ball milling, thus obtaining high-content ferronickel concentrate; the method can realize the simultaneous recycling of nickel and iron and obtain the high-content ferronickel concentrate; the content of nickel is 5 to 13 percent and the recycling rate of nickel is 85 to 93 percent; the content of iron is 30 to 75 percent and the recycling rate of nickel is 60 to 85 percent; the reasonable utilization of the waste heat during process procedure achieves the purposes of saving energy and reducing discharge and greatly reduces pollution to the environment.

Owner:HONGHE HENGHAO MINING

Method for nickel and cobalt recovery from laterite ores by combination of atmospheric and moderate pressure leaching

InactiveUS20060024224A1Efficient leachingEfficient separationIron compoundsCobalt compoundsRecovery methodIon exchange

A process for leaching laterite ores containing limonite and saprolite. Sufficient mineral acid is added to a slurry of limonite which is leached at atmospheric pressure to dissolve most of the soluble non-ferrous metals and soluble iron. After adding saprolite the slurry is further leached at a temperature above the normal boiling point and at a pressure above atmospheric pressure for a time sufficient to leach most of the contained nickel in the saprolite and to precipitate most of the iron in solution. The pressure of the slurry is then reduced, and nickel and / or cobalt is subsequently recovered from the leach solution by solvent extraction, resin-in-pulp or other ion exchange, sulfide or hydroxide precipitation, or other recovery method.

Owner:SKYE RESOURCES

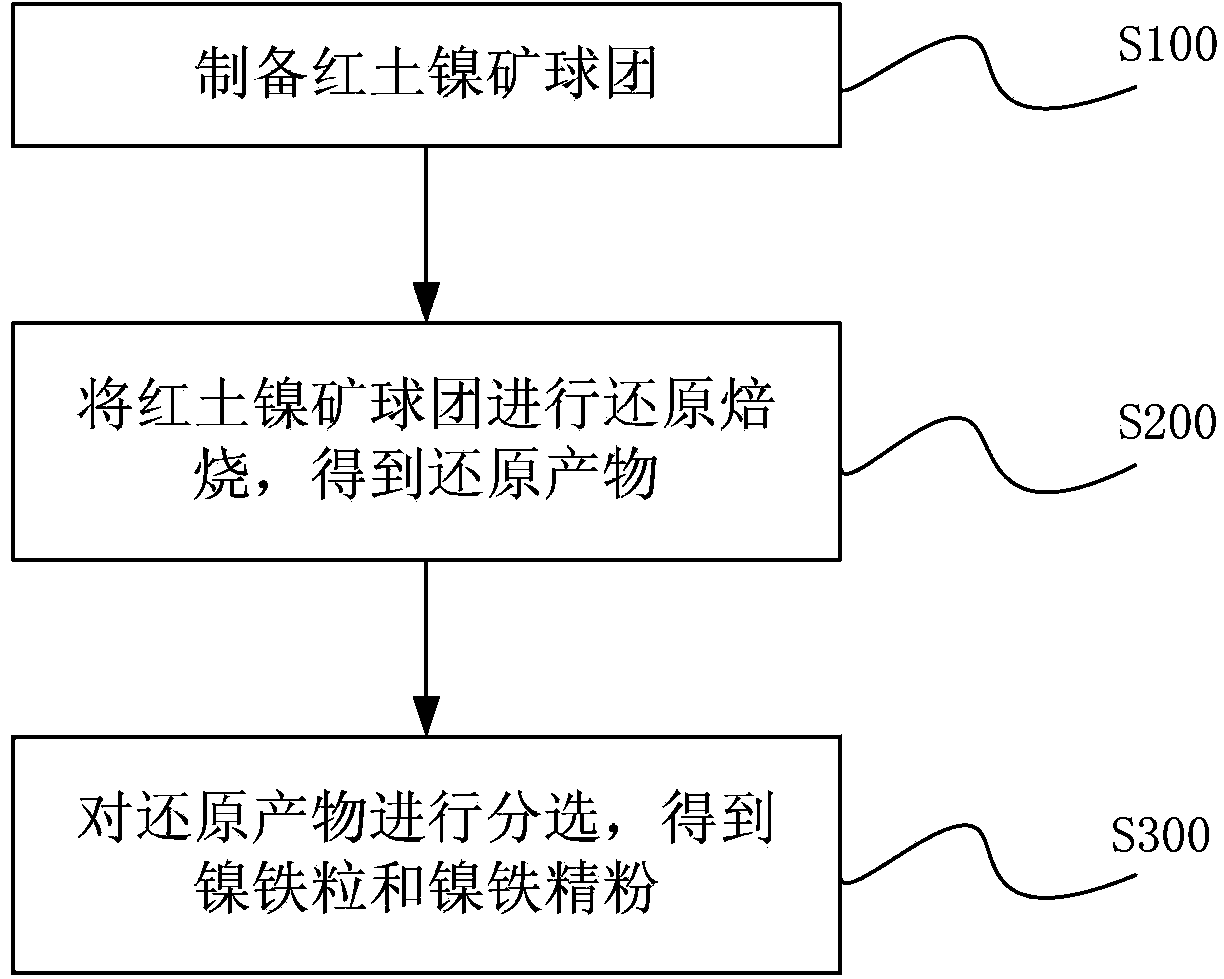

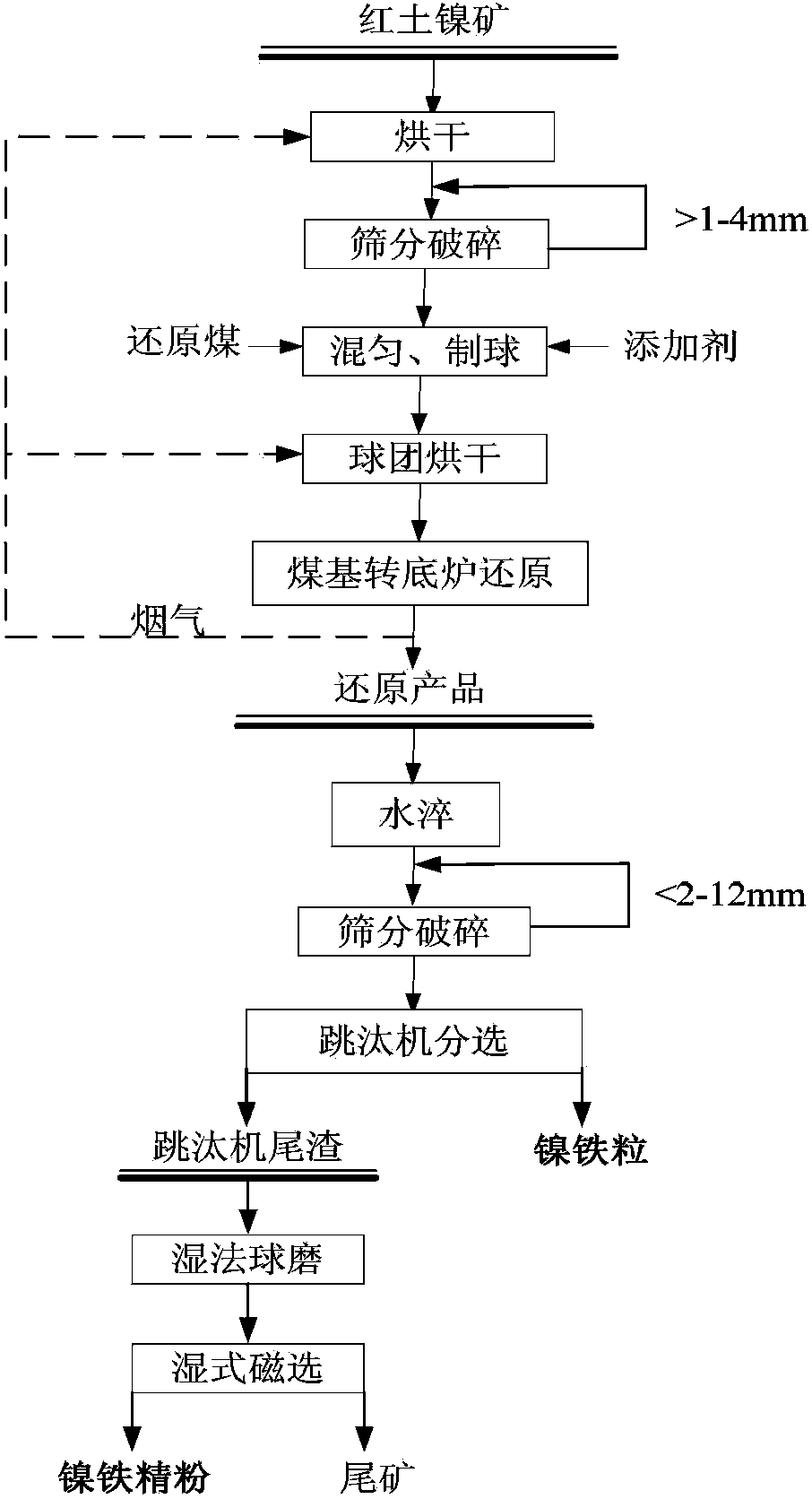

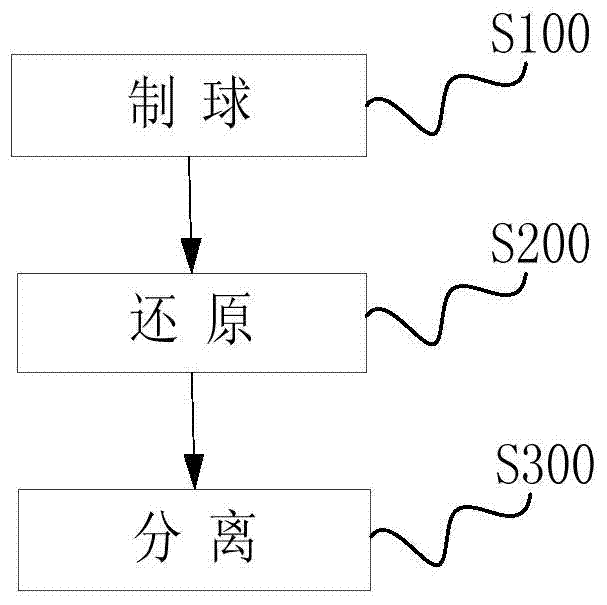

Treatment method of laterite-nickel ore

InactiveCN103667675AFully effective separationIncrease productionRotary drum furnacesWet separationReducerLaterite

The invention provides a treatment method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, a reducer and additives to obtain laterite-nickel ore pellets; carrying out reducing roasting on the laterite-nickel ore pellets in a rotary hearth furnace to obtain a reduction product; quenching the reduction product with water; crushing the quenched reduction product; carrying out separation on the crushed reduction product by using a jigging machine to obtain nickel iron granules and tailings; and carrying out wet ball milling and wet magnetic separation on the obtained tailings to obtain nickel iron refined powder and tailings. The method can be utilized to obviously enhance the yield and quality of the product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

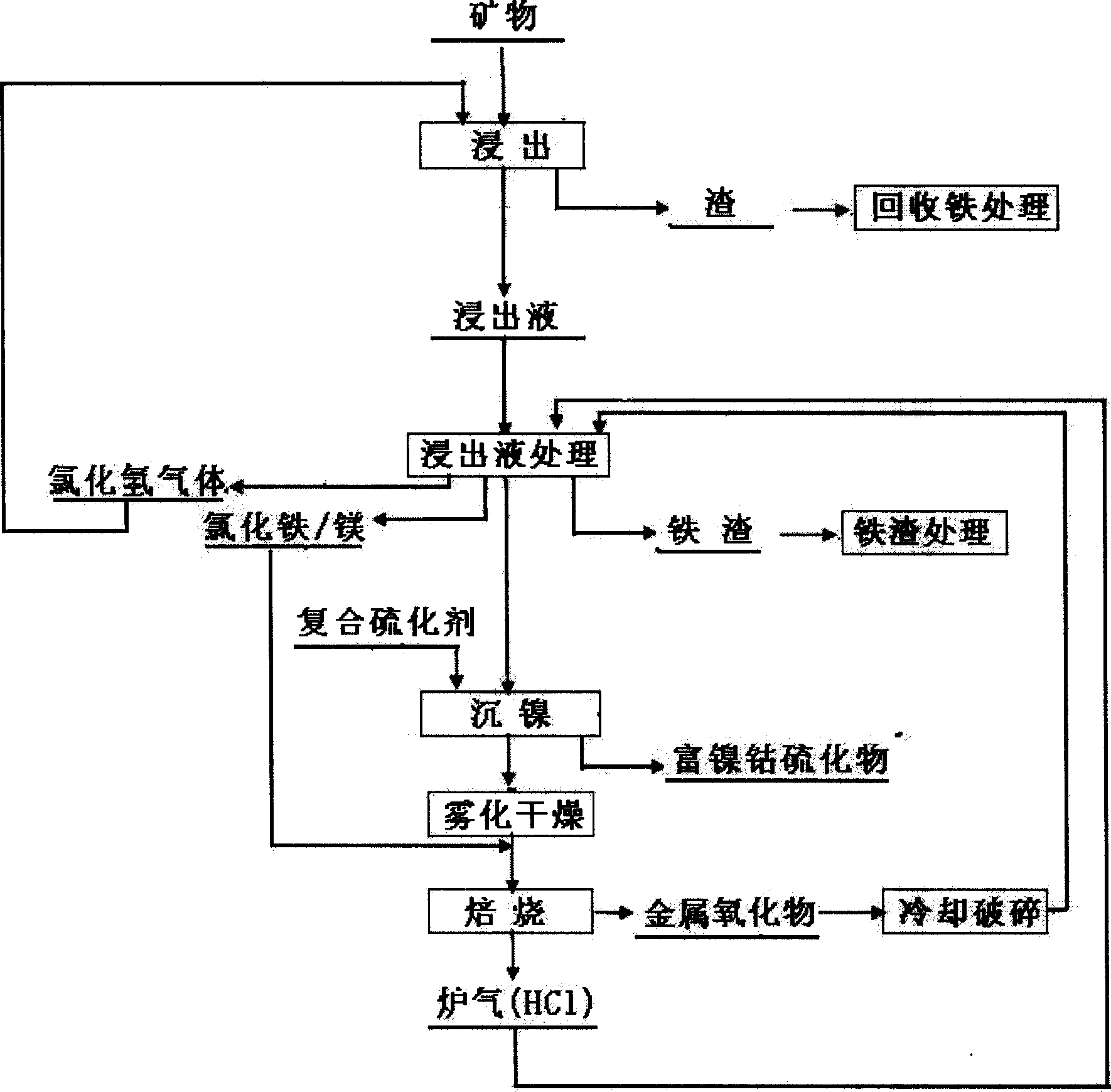

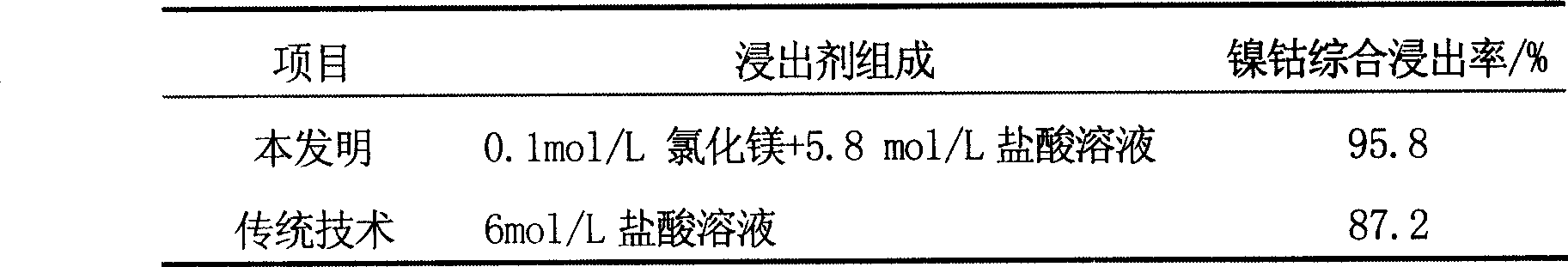

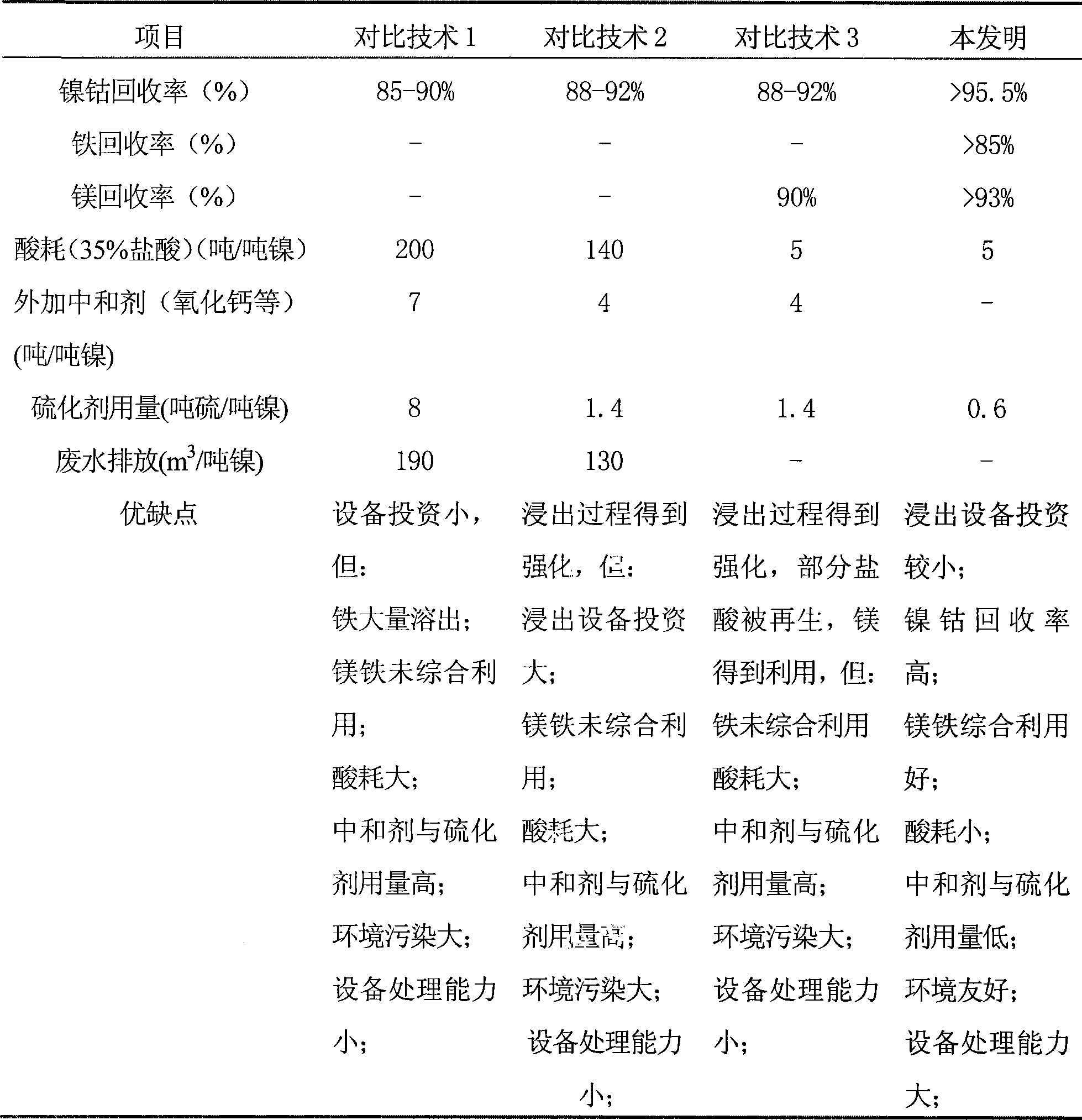

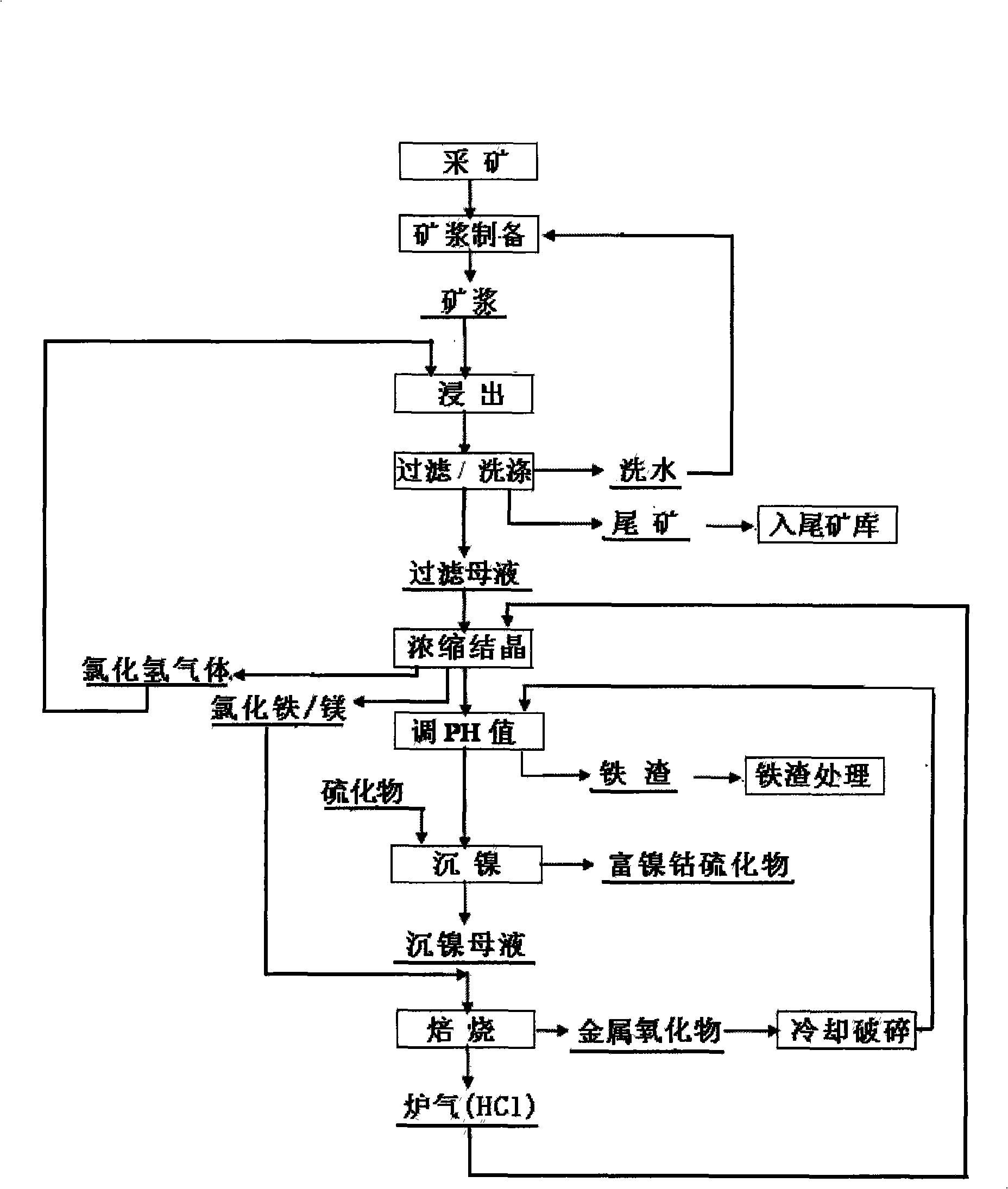

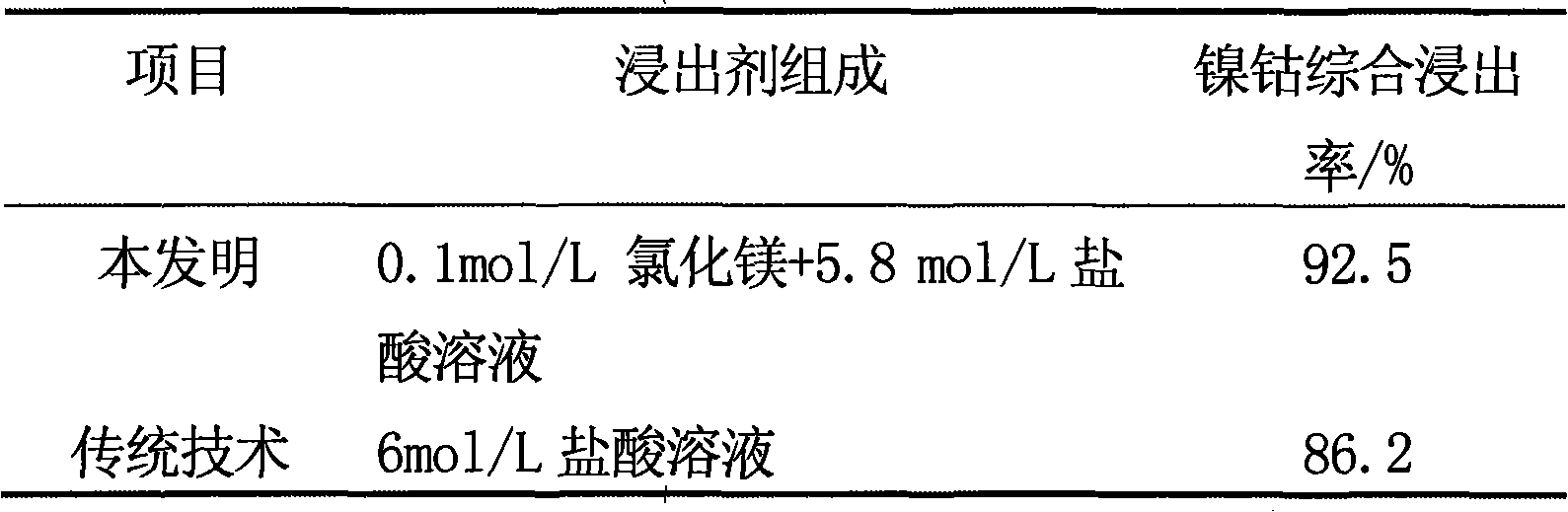

Method for extracting valuable metals from laterite nickel mine with hydrochloric acid full-closed circulation method

ActiveCN101509072AImprove leaching efficiencyIncrease profitMagnetic separationProcess efficiency improvementMetal chlorideWastewater

A method for extracting valuable metals from laterite nickel ore on the basis of the hydrochloric acid fully-closed circulation method belongs to the field of non-ferrous metallurgy. Crushed laterite nickel minerals are taken as raw material and the technique comprises the following technological steps: chlorination-leaching; recovering iron (Fe) from leaching residue; extracting nickel (Ni) and cobalt (Co); spray-drying the mother liquor; and calcining. By leaching the laterite nickel minerals with a mixed solution of hydrochloric acid and metal chlorides as a leaching agent under the proper conditions of heating and pressurizing and further precipitating nickel and cobalt with a compound vulcanizing agent, the overall recovery rate of nickel and cobalt is high; the closed circulation of hydrochloric acid is realized while processing the laterite nickel minerals with water and hydrochloric acid, therefore, the method is environment-friendly by realizing the zero discharge of waste water; comprehensive utilization of the resources, such as Ni, Co, Fe and Mg, in the laterite nickel ore can be realized; and the resources can be efficiently utilized and the clean production can be realized by recovering and reutilizing the waste heat and the residue acid during the production.

Owner:CENT SOUTH UNIV

Treating method for high magnesium laterite nickel mine

InactiveCN101289704AEfficient extractionEfficient leachingProcess efficiency improvementPregnant leach solutionHigh magnesium

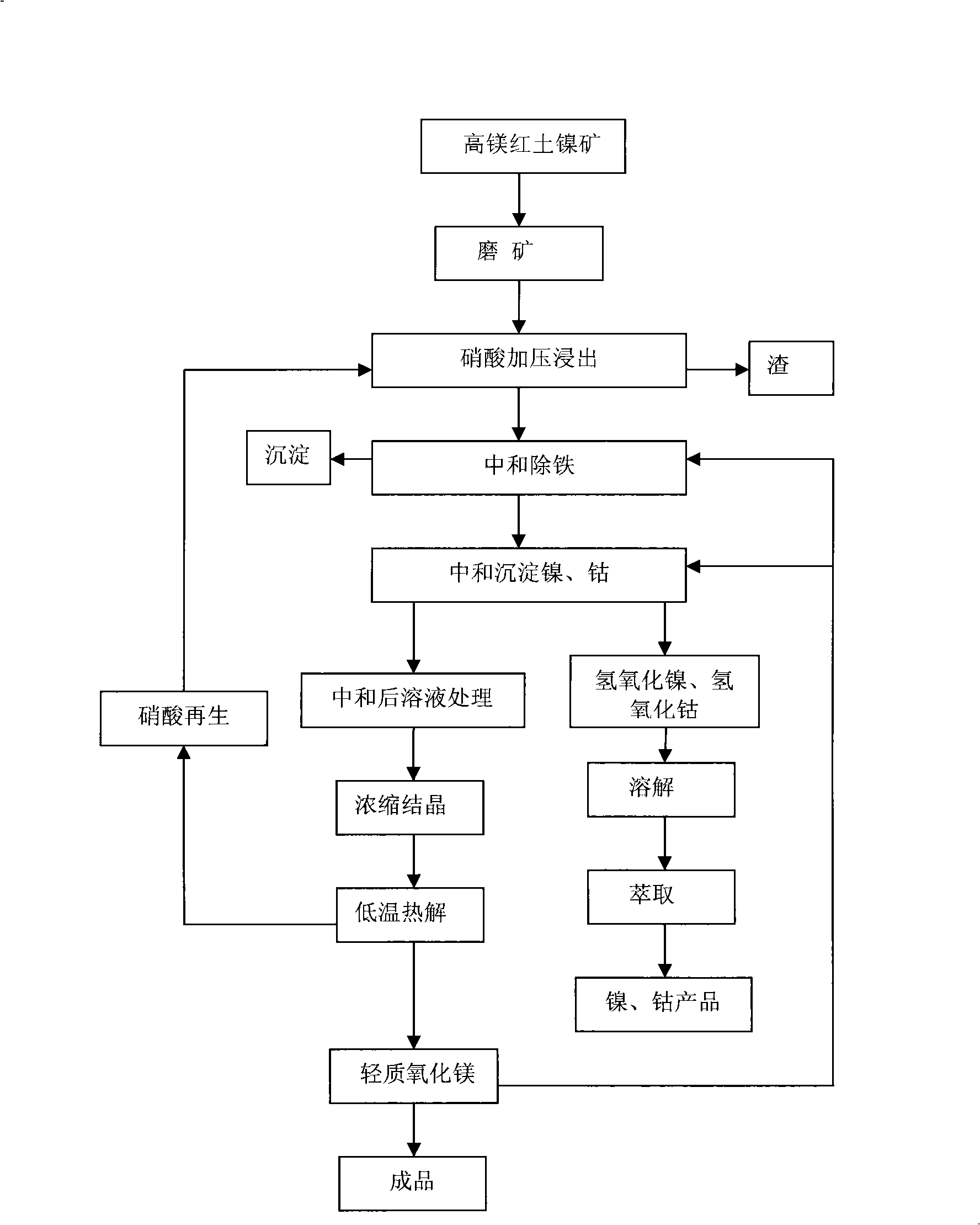

The invention discloses a method for treating high magnesium laterite-nickel ores. The method comprises the following steps of preliminary treatment of ore, pressurized leaching, iron purification of leach solution, deposition of nickel and cobalt, condensation and crystallization, production of light magnesium oxide by low-temperature thermal decomposition of crystals and regeneration of nitric acid. Under mild conditions of low temperature and pressure, leaching ratios of nickel and cobalt both reach 95 percent, the leaching ratio of magnesium reaches 98 percent, the iron content in the leach solution is less than 1g / L, and no silicon dioxide is leached out. The method can fully recover nickel, cobalt and magnesium, and the magnesium is generated in the form of light magnesium oxide, and the leaching agent-nitric acid can be recovered and regenerated for n, thereby better resolving the problems of highly efficient leaching-out of nickel and cobalt and reasonable utilization of magnesium; moreover, the technical flow is simple and has low requirements on equipment, and in the process of leaching out, the scab phenomenon does not occur in a high-pressure pan, so that the method is applied to the large-scale industrial production.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for collecting nickel and cobalt from laterite-nickel ore lixivium

ActiveCN101298638AHigh extraction rateReduce energy consumptionProcess efficiency improvementPregnant leach solutionSlag

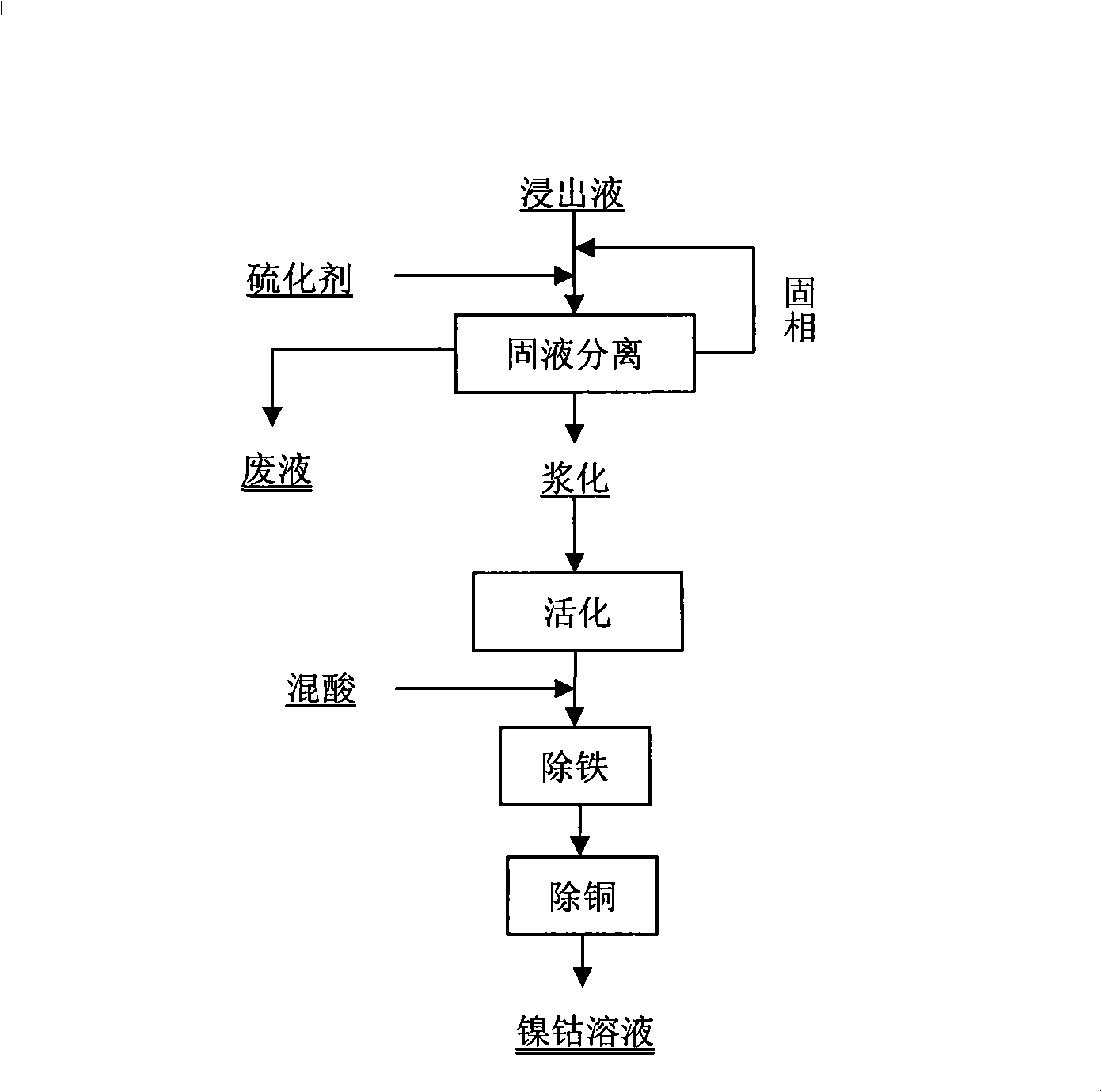

The invention discloses a method for separating enriched nickel and cobalt from a laterite nickel ore lixivium, which comprises the following steps: after solid and liquid separation between the laterite nickel ore lixivium and ore slag is implemented, a vulcanizing agent is added into the lixivium, the solid and the liquid are separated after reaction precipitation, and precipitated solid is washed by a new lixivium, thus obtaining sulfide precipitate; after the sulfide precipitate is pulpified, sulphuric acid and solution of nitric acid and mixed acid are added so as to implement oxidizing leaching; the goethite method is adopted for removing iron from a superior pickle liquor; a sodium thiosulfate solution is added so as to implement copper removing; a filtering liquor that is the enriched nickel and cobalt solution is obtained. Compared with the prior art, the method for separating enriched nickel and cobalt from the laterite nickel ore lixivium is implemented at normal temperature and normal pressure, does not need a high-pressure caldron, has less device investment, low running cost, simple technical path, short process and controllable production scale; the vulcanizing agent and acids that are used in the technique can be recycled to the utmost extent and do not have emissions and environment pollution; the extraction yield of nickel and cobalt can achieve over 95 percent, and the method for separating enriched nickel and cobalt from the laterite nickel ore lixivium has low production cost and easy industrialization.

Owner:福建常青新能源科技有限公司

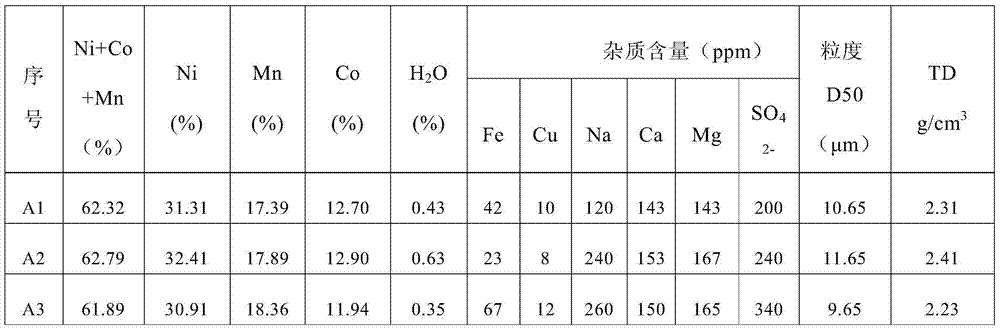

Preparation method of ternary anode material precursor

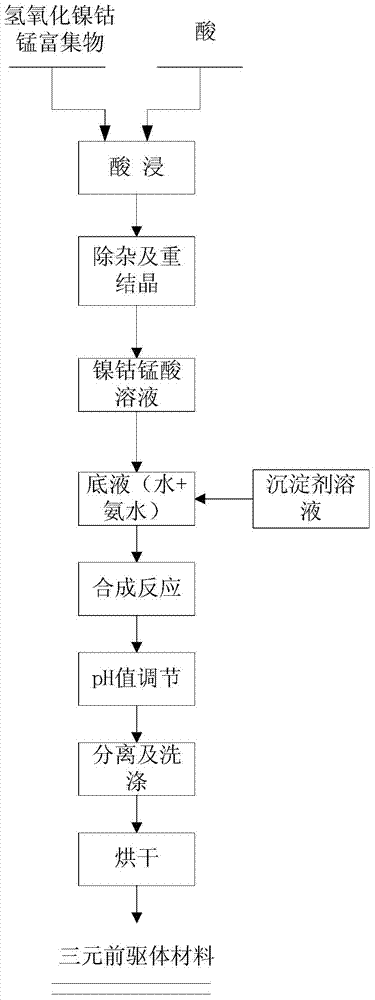

ActiveCN103545504AReduce manufacturing costLow costCell electrodesSecondary cellsNickel oxide hydroxideManganese

The invention discloses a preparation method of a ternary anode material precursor. According to the preparation method, an intermediate product namely nickel-manganese-cobalt hydroxide concentrate generated by producing electrolytic nickel from laterite, and the preparation process comprises the following process flows: A, acid leaching; B, impurity removal and recrystallization; C, preparation of a mixed salt; D, preparation of a precipitant; E, synthetic reaction; F, adjustment of the pH value; G, separation and washing; H, drying. The ternary anode material precursor prepared by the preparation method disclosed by the invention is uniform in particle size distribution, high in activity, high in density, high in specific capacity and low in cost.

Owner:江西赣锋循环科技有限公司

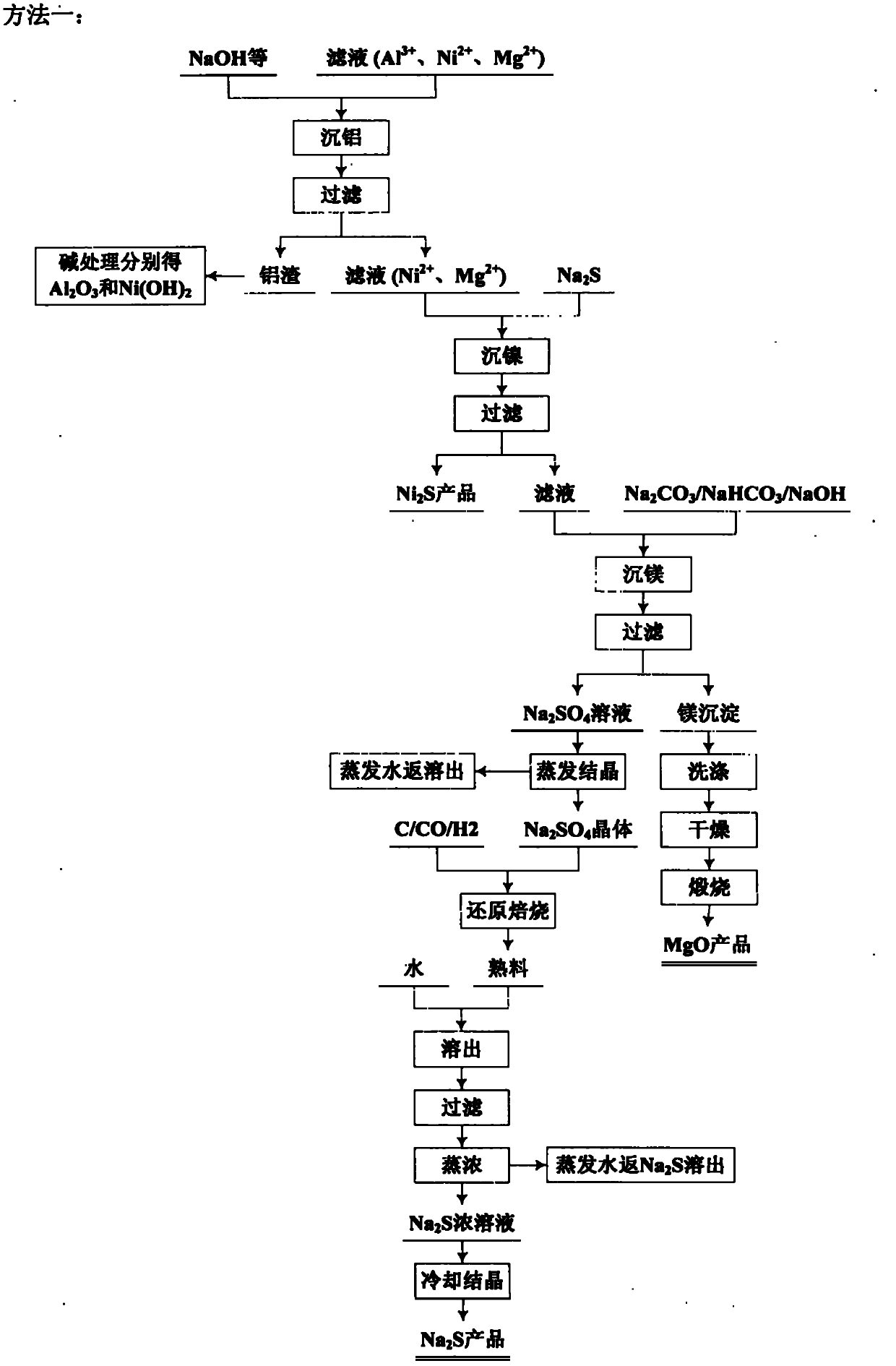

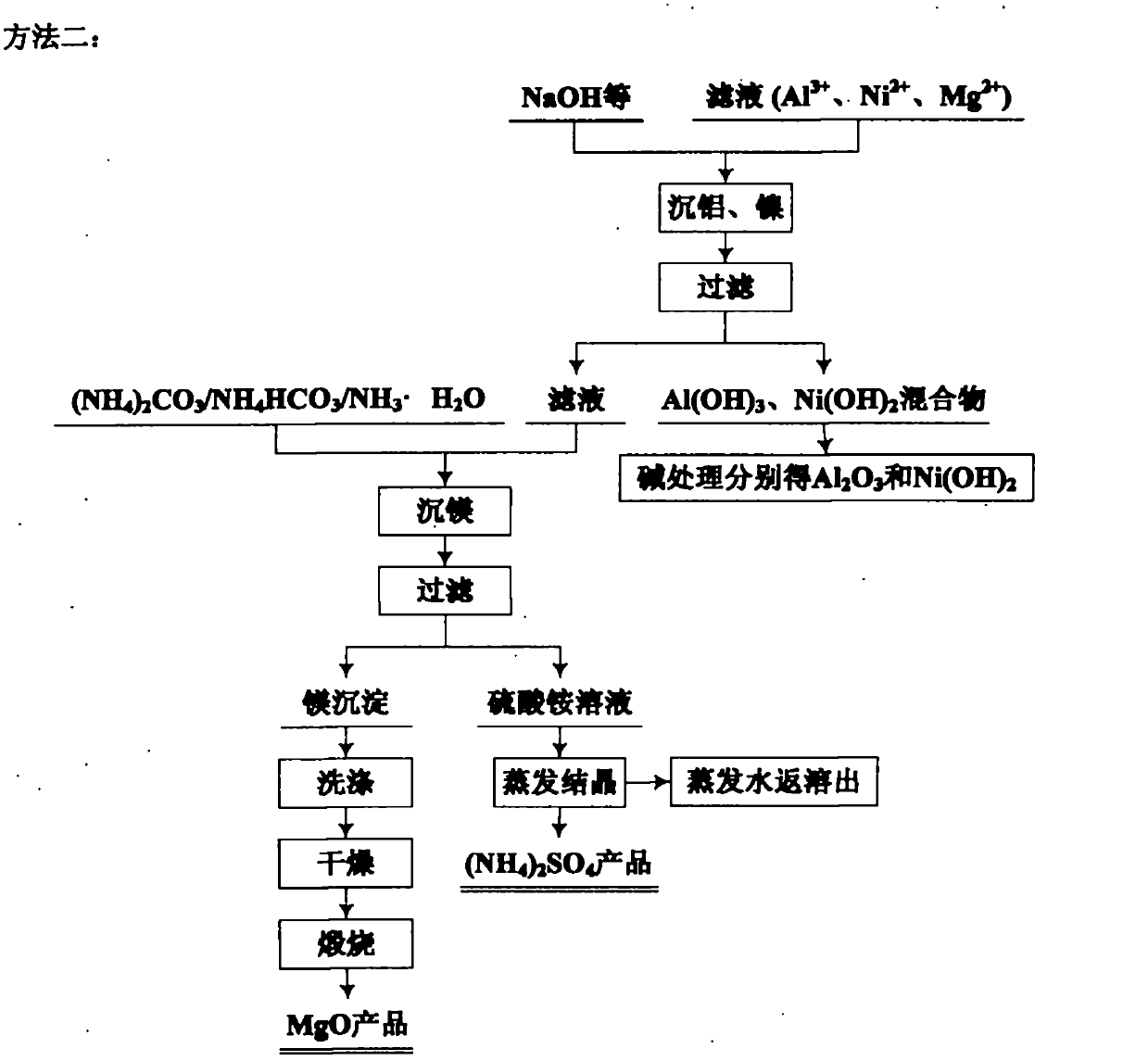

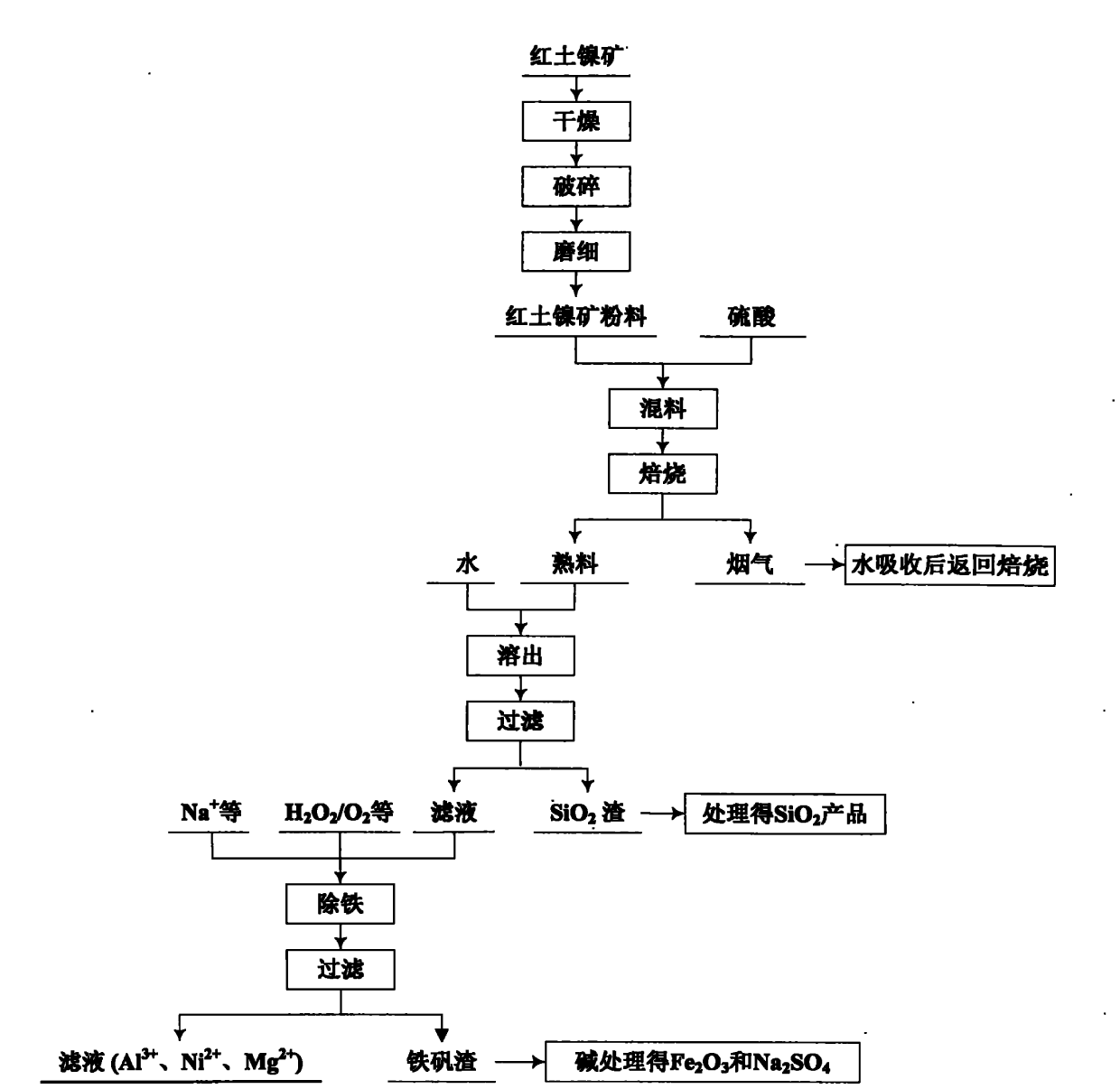

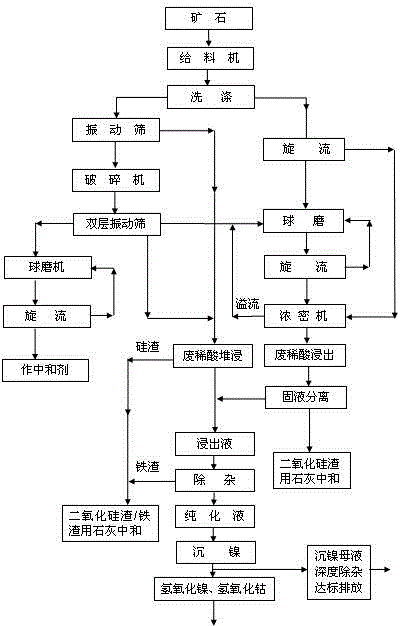

Comprehensive utilization method for laterite-nickel ore

The invention relates to an environmental-friendly comprehensive utilization method for a laterite-nickel ore, which comprises the following steps of: (1) grinding the laterite-nickel ore, mixing with sulfuric acid, roasting, dissolving out roasted clinker and filtering to obtain silicon dioxide and dissolution liquid; (2) deironing the dissolution liquid to obtain liquid No.2 and filter residue (iron compounds), wherein the liquid No.2 comprises aluminum, nickel and magnesium and can be treated by the step (3) or (4); (3) precipitating the aluminum in the liquid No.2 by using alkali, filtering, precipitating the nickel in filtrate by using sodium sulfide, filtering, precipitating the magnesium by using the alkali, and treating filter residue to obtain aluminum oxide, nickel hydroxide, nickel sulfide and magnesium oxide respectively; and (4) precipitating the aluminum and the nickel in the liquid No.2 by using the alkali, treating mixed slag containing the aluminum and the nickel by using the alkali to obtain aluminum hydroxide and nickel hydroxide products, and precipitating the magnesium in filtrate subjected to aluminum and nickel precipitation by using ammonia or ammonium saltto obtain a magnesium oxide product. The method is suitable for treating various laterite-nickel ores, three wastes (waste gas, waste water and waste residue) are not generated, and valuable components magnesium, nickel, iron, aluminum and silicon in the laterite-nickel ore are separated and extracted.

Owner:NORTHEASTERN UNIV

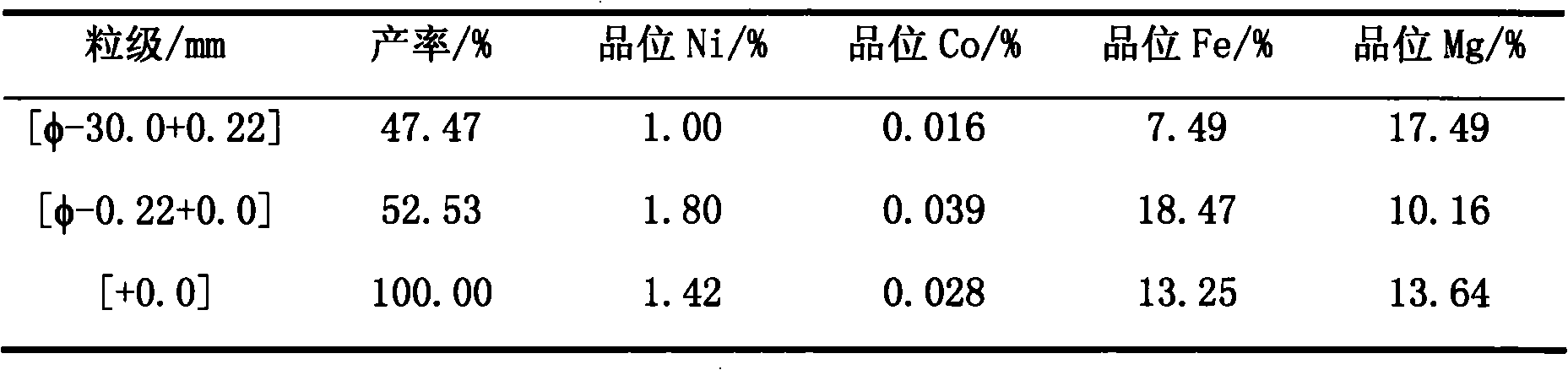

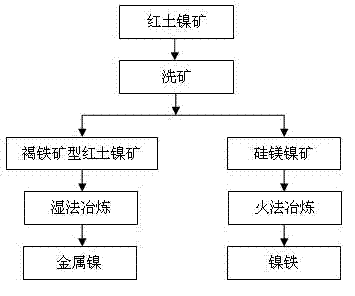

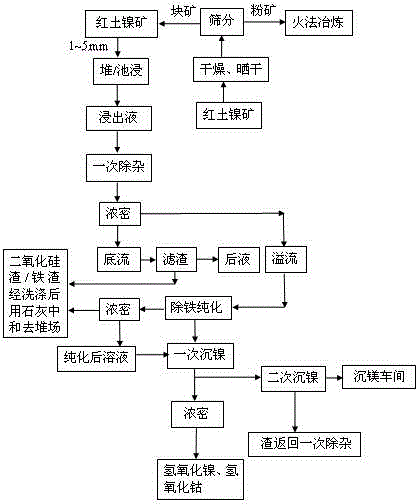

Method for processing laterite-nickel ore

InactiveCN102226232AHigh recovery rateReduce energy consumptionProcess efficiency improvementLateriteMaceral

The invention discloses a method for processing laterite-nickel ore. The method provided by the invention is characterized in that laterite-nickel ore undergoes an ore-washing treatment; noumeite and limonite-type laterite-nickel ore are separated; separated noumeite is melted by the pyrometallurgical process to generate ferronickel; and metallic nickel is extracted from the separated limonite-type laterite-nickel ore by the wet process. According to the method provided by the invention, based on the different mineral compositions of different laterite-nickel ore particle fractions, limonite-type laterite-nickel ore containing high content of iron and low content of magnesium is melted by the wet process to extract metallic nickel, thus leading to low acid consumption; noumeite containing low content of iron and high content of magnesium is melted by the pyrometallurgical process to extract ferronickel, thus leading to high quality of the produced ferronickel, high recovery rate of nickel, low energy consumption and simultaneous recovery of iron.

Owner:广西银亿新材料有限公司

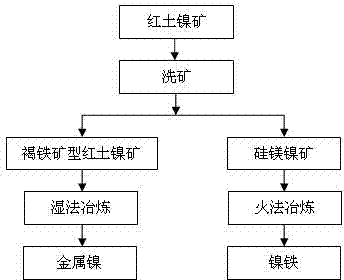

Method for deep reduction and magnetic separation of nickel and iron in lateritic nickel ore carbon-containing pellets

The invention discloses a method for deep reduction and magnetic separation of nickel and iron in lateritic nickel ore carbon-containing pellets. The method aims at realizing deep reduction calcination and magnetic separation, and has obvious nickel and iron enrichment effects. The method comprises the following steps of carrying out crushing and abrasive cleaning of lateritic nickel ores by a jaw crusher and a ball mill, removing soil, carrying out dehydration and drying by an oven, adding a reducing agent, CaO as a flux and a composite binder into the dried lateritic nickel ore particles, feeding the mixture into a damp mill to obtain the uniform mixture, feeding the uniform mixture from the damp mill into a disc-shaped pelletizer for pelletizing, respectively carrying out drying, preheating and calcination by a grate and a rotary kiln, throwing the calcined pellets into a sealed channel of a cooling water tank, wherein an annular air cooler is arranged around the sealed channel, feeding heat carried by the calcined pellets back to the grate for use by the annular air cooler, carrying out water quenching of the calcined pellets falling into the cooling water tank so that the calcined pellets are crushed automatically, dragging nickel, iron and slag in the cooling water tank by a slag dragging machine and feeding them into the ball mill for fine grinding, directly feeding theobtained nickel and iron ore powder into a magnetic separator for separation, drying the separated nickel and iron ore powder by an oven, packaging the dried nickel and iron ore powder, warehousing the packaged nickel and iron ore powder, drying the separated nonmagnetics by an oven, and warehousing the dried nonmagnetics as magnesium raw materials.

Owner:王号德

Method for smelting nickel-iron alloy from laterite nickel oxide ore

ActiveCN101481753ALow SiLess slagProcess efficiency improvementMagnetic separationSmelting processAlloy

A method for smelting ferronickel alloy from laterite nickel oxide ore belongs to the ferronickel alloy smelting technical field. A direct reduction technique of carbon-bearing pellets in a rotary hearth furnace is adopted to reduce the nickel oxide in nickel ores to iron and nickel; then iron and nickel are smelted; the solid solutions of nickel and iron are agglomerated, cooled, shattered and subjected to magnetic selection, so that the granular ferronickel alloy with high sulfur content is obtained; and the ferronickel alloy is melted and desulphurized, so that the purified ferronickel alloy is obtained. The invention has the advantages that compared with the traditional process without separation in advance, the follow-up smelting process of the method can save a great amount of energy source for the greatly reduced quantity of slag; and the crude ferronickel obtained through smelting contains relatively low Si content.

Owner:SHOUGANG CORPORATION

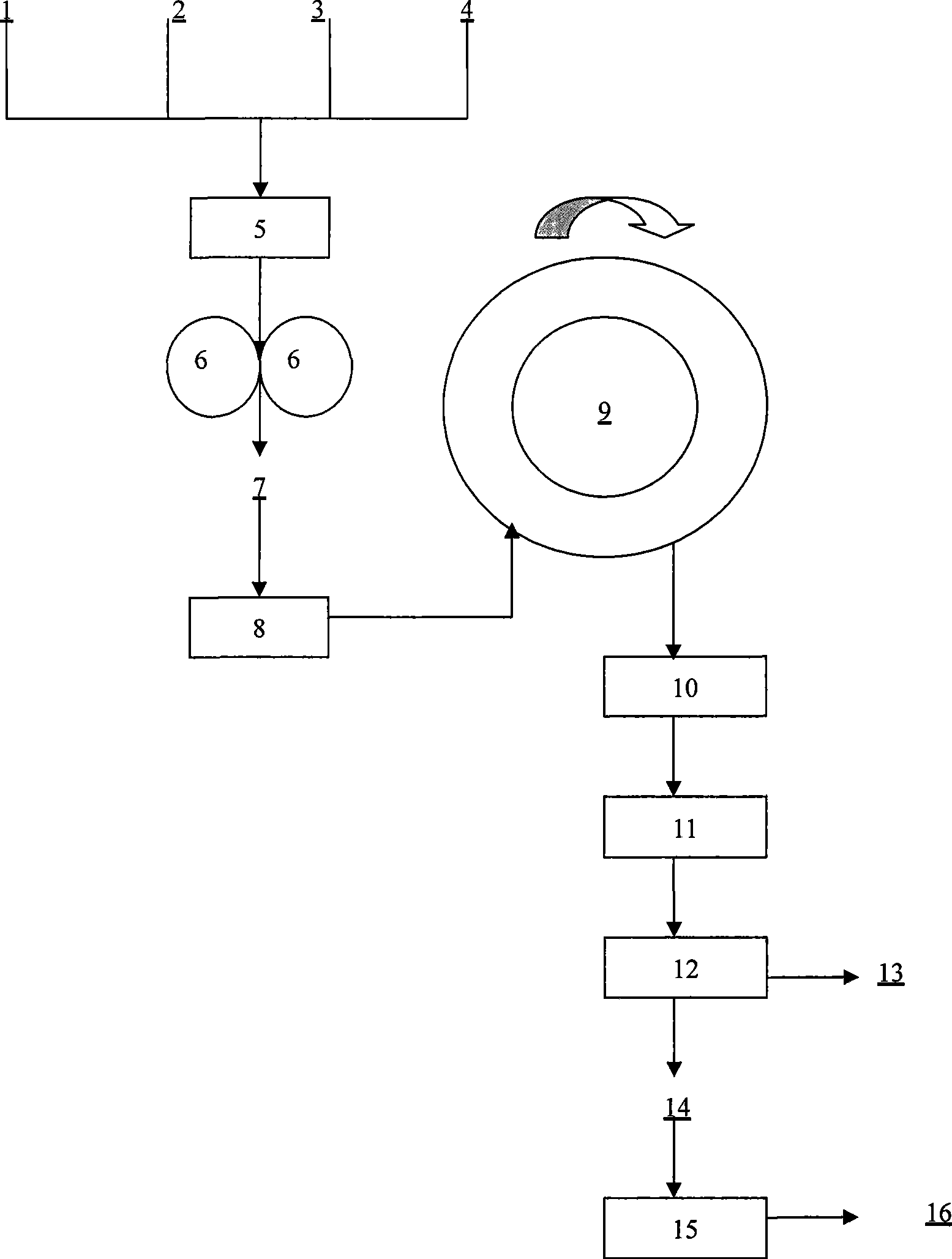

Method for treating red soil nickel ore leaching liquid

The invention discloses a method for separating nickel, magnesium and cobalt from red soil nickel ore leaching liquid based on a solvent extraction technology. The method is characterized by comprising the following steps of: adjusting the pH value of the leaching liquid to be between 3.5 and 5.5; extracting impurities by using diisooctyl acid phosphate, and adding into an organic phase; extracting the cobalt and the magnesium by using 2-ethylhexyl phosphonic acid single 2-ethylhexyl ester; making the nickel left in a water phase to separate the nickel from the cobalt and the magnesium; performing multi-stage reverser flow magnesium washing on the organic phase from which the cobalt and the magnesium are extracted by using sulfuric acid solution at slightly low concentration; adding the magnesium into the water phase, and making the cobalt left in the organic phase to separate the cobalt from the magnesium; and reversely extracting the cobalt by using sulfuric acid solution at slightly high concentration to obtain cobalt sulfate solution with high purity. In the method provided by the invention, a process is simple, a relatively expensive reagent is not required to be consumed, the nickel, the magnesium and the cobalt can be effectively separated from the red soil nickel ore leaching liquid, nickel sulfate solution and the cobalt sulfate solution which have high purity are produced, the nickel and the cobalt have high recovery rates and the magnesium can be recycled.

Owner:广西银亿新材料有限公司

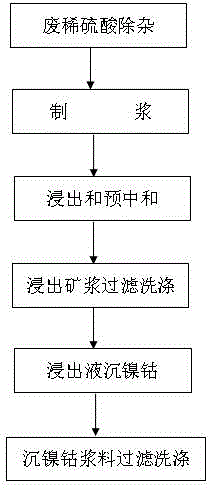

Method for leaching nickel and cobalt form low-iron and high-magnesium and high-iron and low-magnesium laterite-nickel ore by using waste dilute sulphuric acid

The invention provides a method for leaching nickel and cobalt from low-iron and high-magnesium and high-iron and low-magnesium laterite-nickel ore by using waste dilute sulphuric acid. Nickelous hydroxide, cobaltous hydroxide and the like are directly extracted by leaching the laterite-nickel ore with non-concentrated decolored and desalinated waste dilute sulphuric acid. The method specially comprises the steps of: removing impurities out of the waste dilute sulphuric acid, slurrying, leaching and pre-neutralizing, filtering and washing leached ore pulp, settling nickel and cobalt from leachate, filtering and washing nickel and cobalt settled slurry, electrically depositing nickel, and post-treating and recycling iron, magnesium, manganese and the like. The method provided by the invention overcomes the technical difficulty, ensures that a technology of a direct dilute sulphuric acid atmospheric pressure leaching process route operates stably, is greatly lowered in cost, is high in production efficiency, and is high in recycling rate of nickel, cobalt, iron, magnesium, manganese and other metals. The waste dilute sulphuric acid which is an byproduct in industries such as dye industry and is difficult to treat is effectively recycled, the method is environmental-friendly, any harmful gas is not emitted, waste slag is solid materials, trees can be planted on the waste slag for greening, the waste slag can be recycled, and waste water can completely reach the standard for emission.

Owner:杭州蓝普水务有限公司

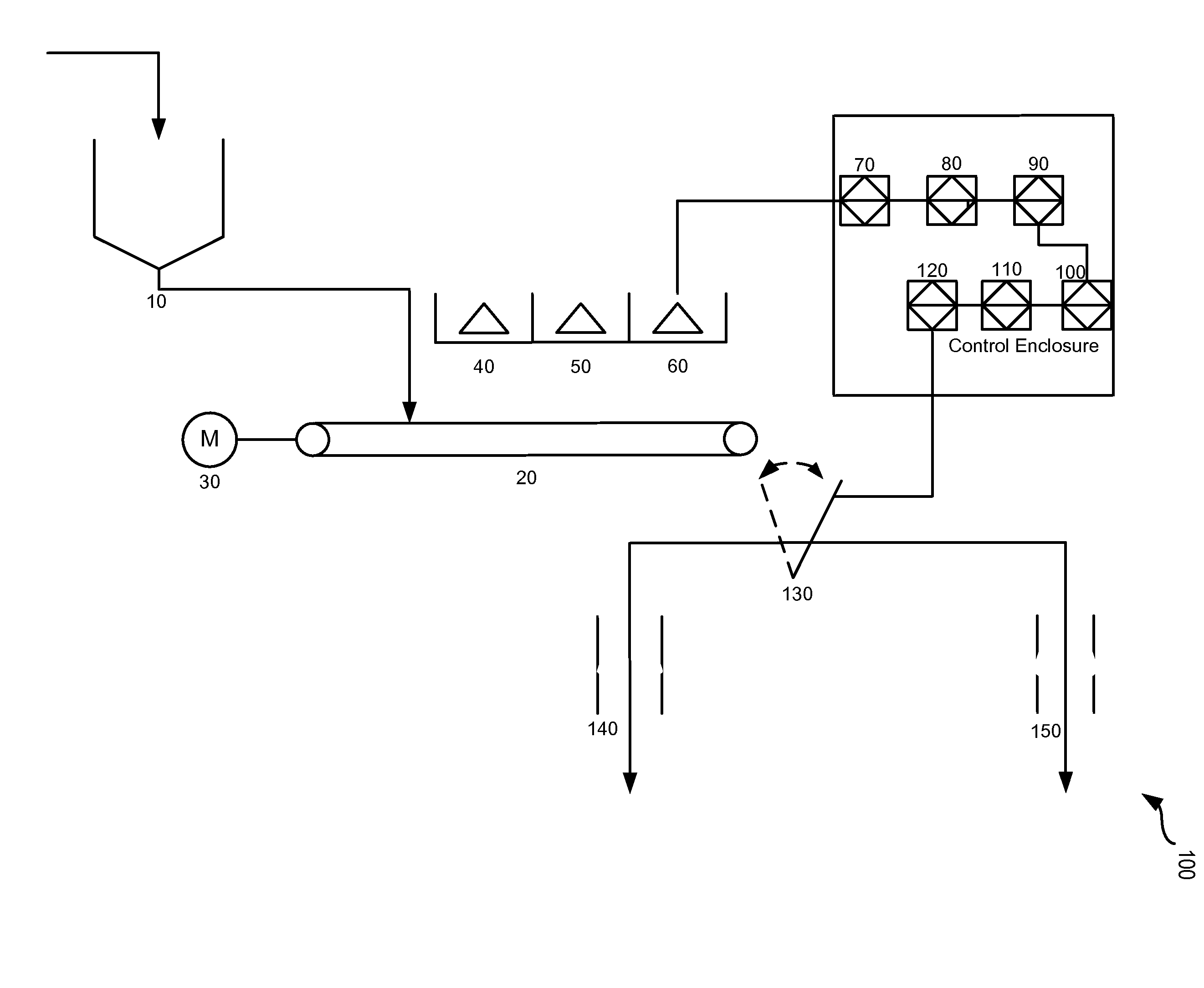

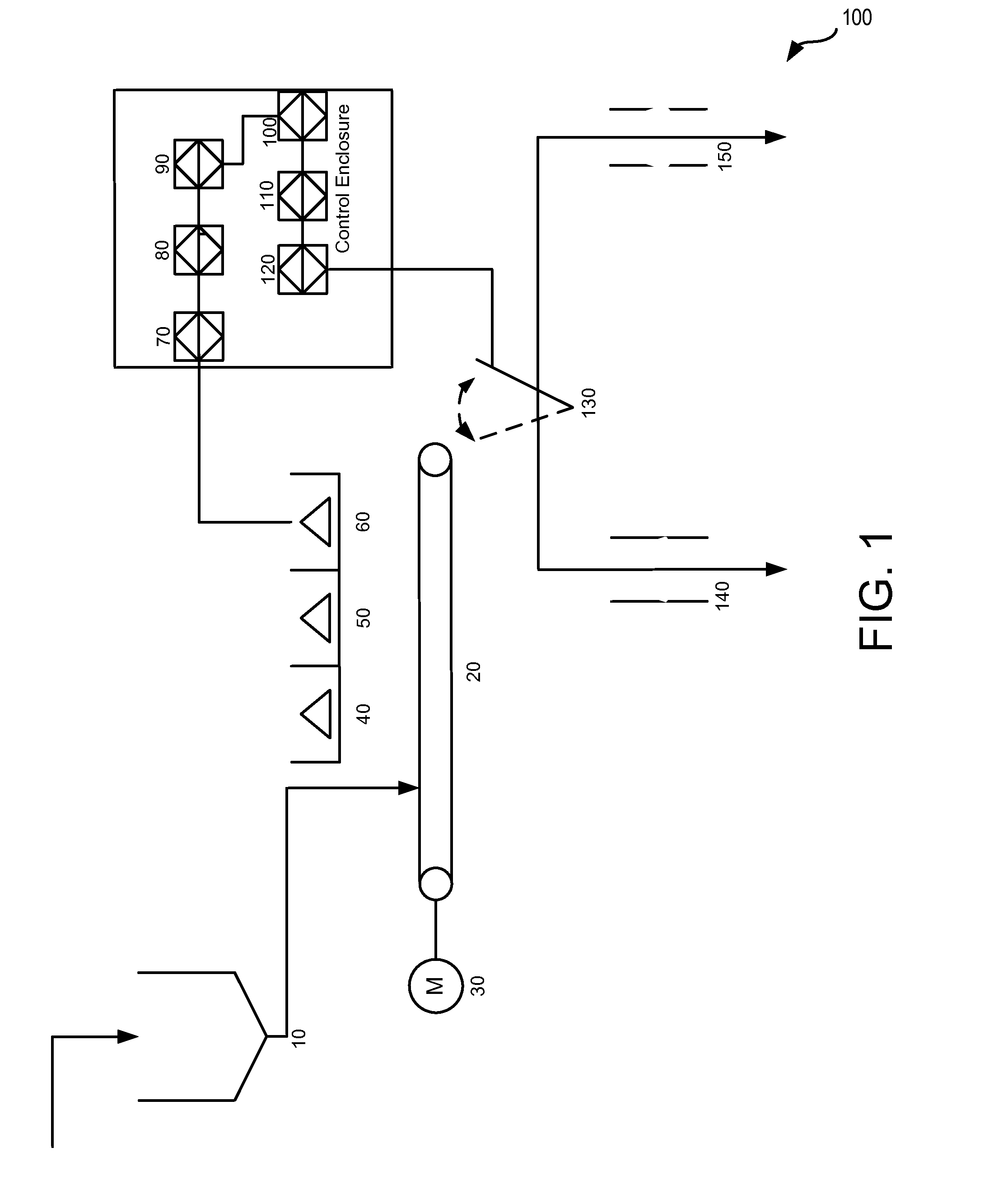

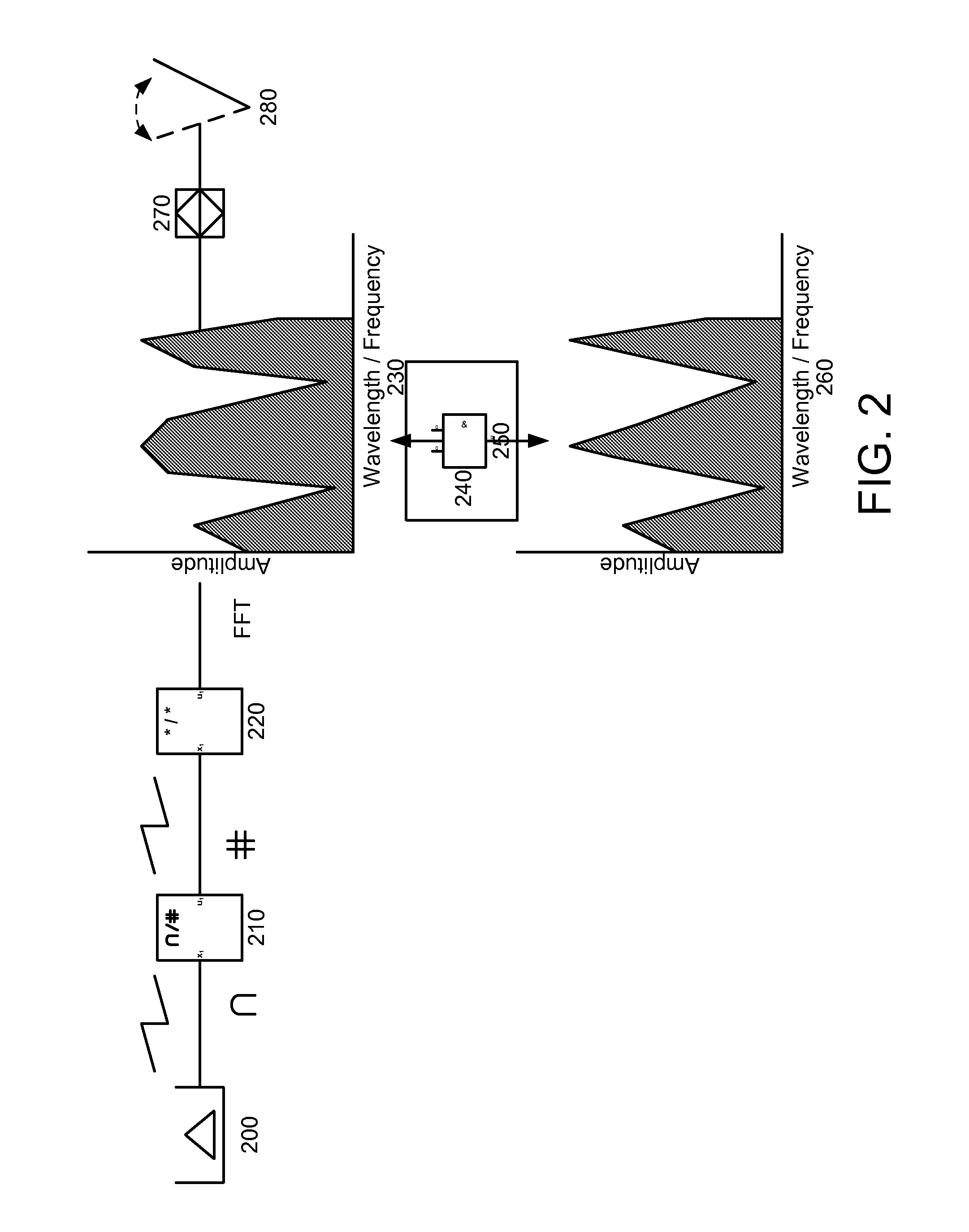

Sorting materials using pattern recognition, such as upgrading nickel laterite ores through electromagnetic sensor-based methods

ActiveUS20130201481A1Radiation pyrometryColor measuring devicesWaste streamElectromagnetic shielding

A system and method of sorting mineral streams, for example laterite mineral ores, into appropriately classified valuable and waste streams for maximum recovery of value from the mineral stream, e.g., a stream of minerals includes receiving response data indicating reflected, absorbed or backscattered energy from a mineral sample exposed to a sensor, where the mineral sample is irradiated with electromagnetic energy. The system determines spectral characteristics of the mineral sample by performing spectral analysis on the response data of the mineral sample and identifies a composition of the mineral sample by comparing the spectral characteristics of the mineral sample to previously developed spectral characteristics of samples of known composition. The system then generates a sort decision for the mineral sample based on the comparison, where the sort decision is used in diverting the mineral sample to a desired destination e.g. pyrometallurgical treatment stages, or to a waste stream.

Owner:MINESENSE TECH

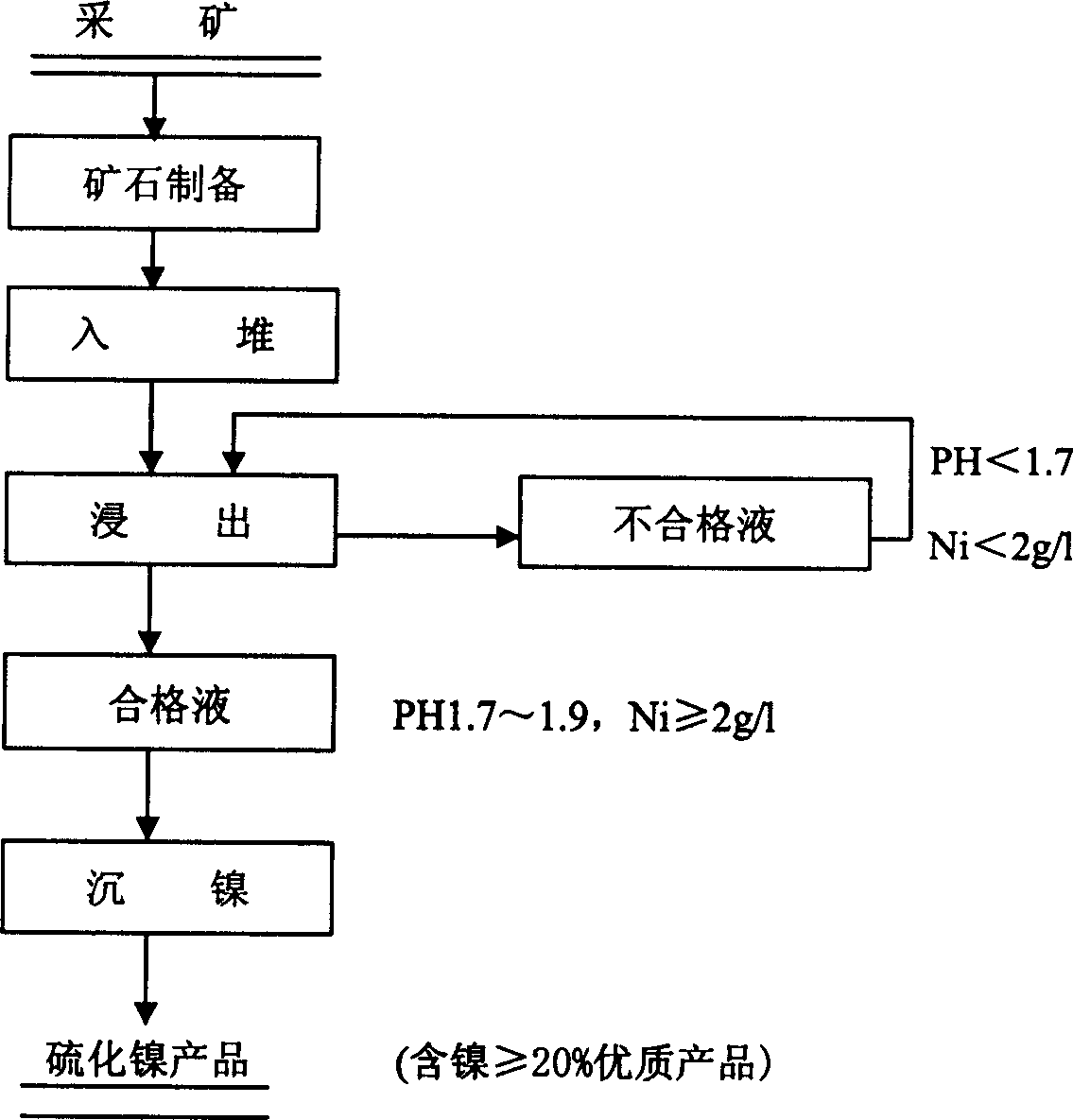

Method of bulk infusion extracting nickel cobalt from low grade red soil nickel ore

InactiveCN1718787AImprove leaching rateNo pollutionProcess efficiency improvementPregnant leach solutionGranularity

A process for extracting Ni and Co from the low-grade Ni-contained laterite ore includes such steps as crushing to make its average granularity less than 2 cm, stacking the ore particles with granularity of 100 mesh-1.5 cm, proportionally mixing others, adding them to the stack, shrinkling acidic extracting liquid, collecting the extracting liquid, and concentrating until the concentration of Ni ions is 2-4g / L.

Owner:广西赛可昱新材料科技有限公司

Method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite

InactiveCN101525690AImprove leaching rateHigh dissolution rateProcess efficiency improvementSlagLaterite

A method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite is disclosed; nickel, cobalt, magnesium and iron therein are leached out by using high-temperature peracid, leachate is pre-neutralized via serpentine powder, after the pre-neutralization, the leachate is neutralized by magnesite powder for de-ironing, and the scum is delivered for ironmaking after being dewatered by smoke gases in a fluidized bed furnace for making sulfuric acid, the de-ironed clear nickel liquid uses magnesite powder to precipitate nickel carbonate, and the precipitated liquid is concentrated and crystallized to obtain magnesium sulfate heptahydrate. The leached slag mainly contains silicon and can be used for making white carbon black. The invention can sufficiently recover and utilize nickel, cobalt, magnesium, iron and silicon in the nickel-bearing laterite, and the invention is simple in technology, low in energy consumption and pollution-free on environment.

Owner:广西冶金研究院有限公司 +1

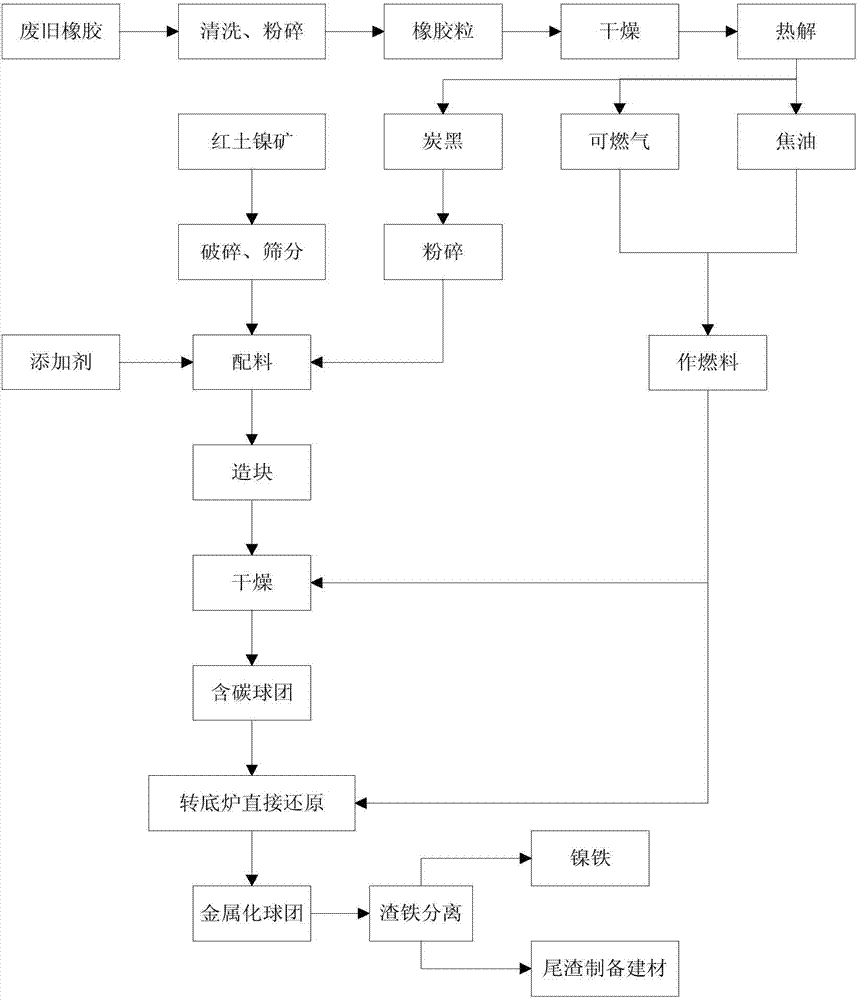

Treatment method of laterite-nickel ore

ActiveCN103667742AEffectively madeImproving the Efficiency of Reduction Roasting Laterite Nickel OreHearth type furnacesSlagHearth

The invention discloses a smelting method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, carbon black and additives; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; and carrying out slag-iron separation on the metalized pellets to obtain nickel iron and tailings. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Process for abstracting nickel and cobalt by using wet method to chloridize laterite-nickel ore

InactiveCN101285127AImprove leaching efficiencyIncrease profitProcess efficiency improvementMetallic sulfideLaterite

The invention relates to a method for extracting nickel and cobalt from a laterite-nickel ore, comprising the following steps of mineral preparation, chloride leaching, solid-liquid separation, leaching liquid concentration, sulfide precipitation, solid-liquid separation and hydrochloric acid recovery of the laterite-nickel ore. A chloride leaching agent is mixing solution of metal chloride and hydrochloric acid; the leaching liquid is concentrated by heating; ferric chloride and magnesium chloride are crystallized and separated out so that Fe / Ni ratio is reduced below 1 / 5 of Fe / Ni ratio before the concentration; the magnesium oxide or the ferric oxide generated in the hydrochloric acid recovery process is used as neutralizer; polysulfide, just precipitated metal sulfide and metal sulfide are used as sulfuration precipitator; mother liquor with precipitated nickel is roasted with the ferric chloride and the magnesium chloride which are obtained by concentrating the leaching liquid; the metal chloride in the mother liquor and the metal chloride obtained from the concentration are hydrolyzed into chlorine hydride and metal oxide; and the obtained acid is recycled to use. The method for extracting nickel and cobalt from the laterite-nickel ore improves the leaching rate of valuable metals such as nickel, cobalt and so on in the leaching process of the laterite-nickel ore, reduces the energy consumption and is environment friendly.

Owner:CENT SOUTH UNIV

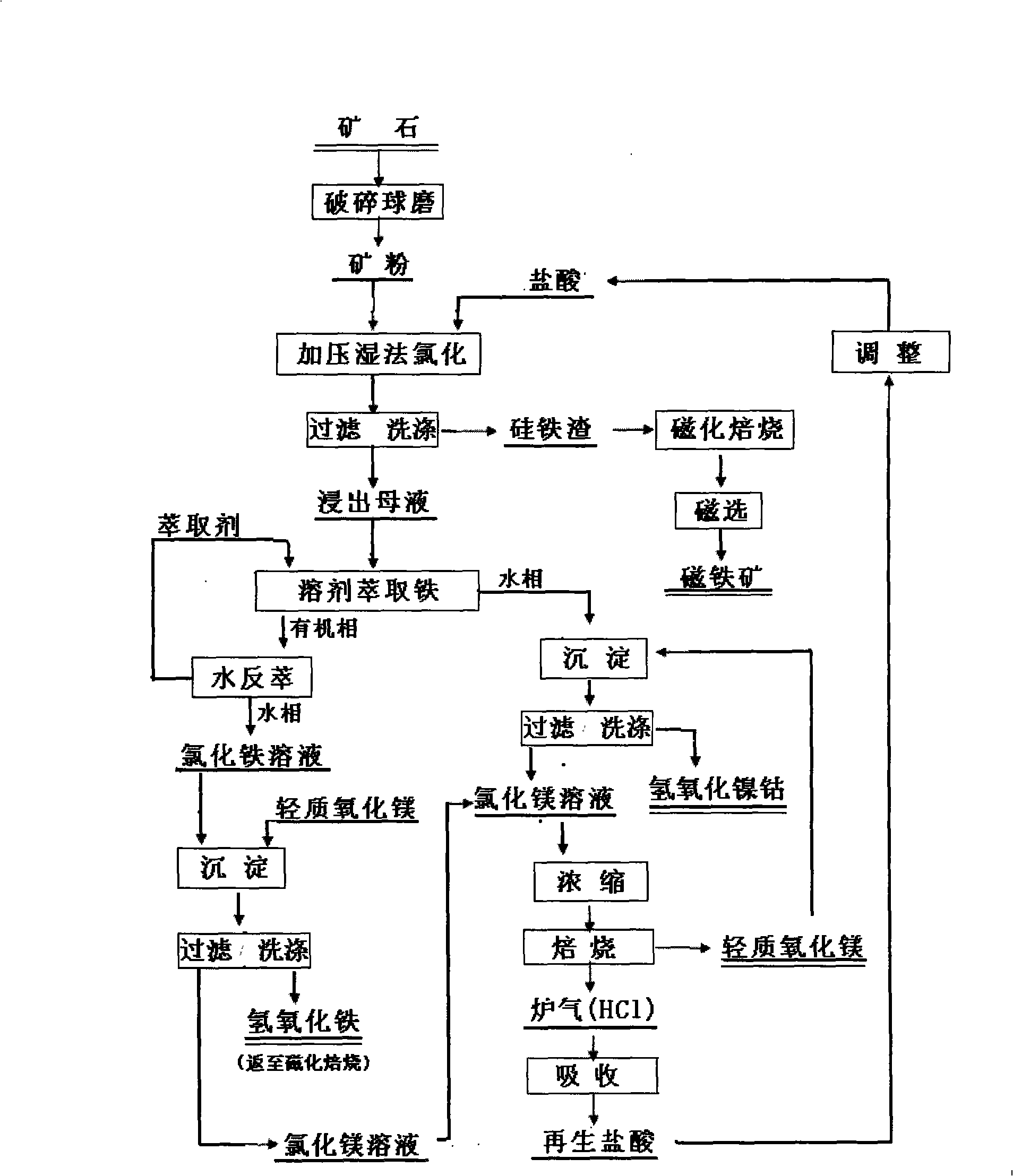

Process for comprehensively developing and utilizing nickel, cobalt, iron and magnesium from laterite-nickel ore

The invention relates to a method for compressively developing and utilizing nickel and cobalt in a lateritic nickel ore. The lateritic nickel ore is used as the raw material; the technical flows of mining, defibrination and ore preparation, pressurizing and wet chlorinating extraction, separating the nickel (cobalt) and iron by extraction, hydrolyzing magnesium chloride with a high temperature, magnetizing and roasting the extracted slag, magnetically separating, etc., and the like, are adopted to extract the middle product of the nickel and cobalt, recycle the light magnesium chloride and the materials used for pudding. The invention is mainly characterized in that the nickel and cobalt in the lateritic nickel ore is firstly and selectively dissolved and extracted by using the pressurized muriatic acid; a depositing method is used on the nickel and cobalt in a liquid to obtain the middle product; the mother liquid after the nickel is deposited is hydrolyzed by high temperature to obtain the light magnesium chloride and the chlorine hydride is recycled to obtain the muriatic acid; a material used for pudding is obtained after the extracted slag is reduced, magnetized, roasted and weakly separated in a magnetic way; the recycling muriatic acid enters the working period of extraction, thereby leading the muriatic acid to closely circulate. The method of the invention comprehensively recycles nickel and cobalt, magnesium and iron and has the advantages of high nickel and cobalt extraction rate, low cost, less investment and closed muriatic acid circulation. The whole technique is simple, clean, environmental friendly and is applicable for industrial production with large scale in particular.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com