Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

443results about How to "Improve leaching efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective leaching agent and recycling method for metal components in positive electrode material

ActiveCN107230811ASelective leaching achievedImprove leaching efficiencyWaste accumulators reclaimingBattery recyclingSelective leachingLithium carbonate

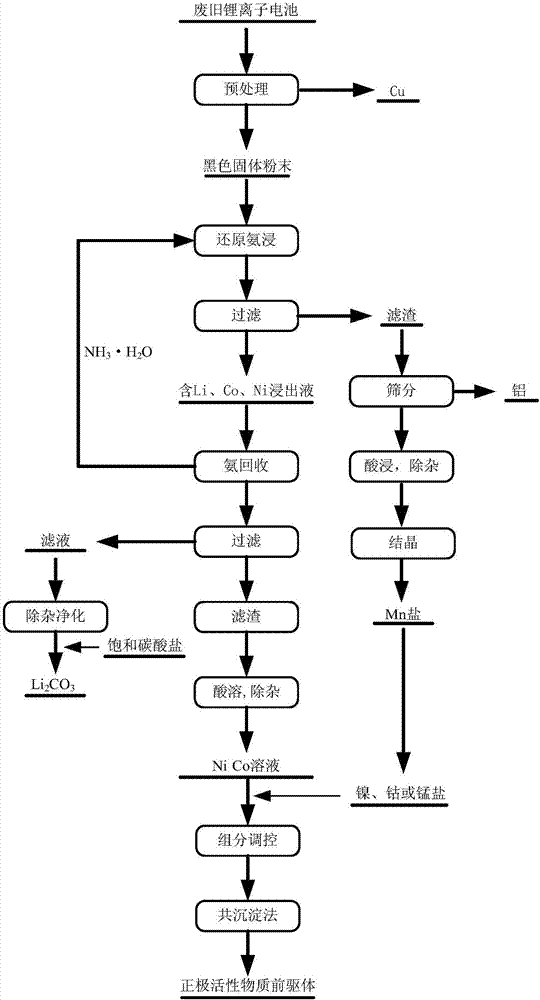

The invention provides a selective leaching agent and recovery method for metal components in positive electrode materials. The leaching agent is a solution containing a reducing agent, ammonium salt and ammonia water, and the reducing agent is a reducing substance under alkaline conditions. , the concentration of ammonia water in the leaching agent is 0-10 mol / L, the concentration of ammonium ion is 0-8 mol / L, and the concentration of reducing agent is 0-2 mol / L. The leaching agent provided by the invention has a wide range of sources, cheap raw materials, high leaching selectivity and leaching rate (up to 90%), and the prepared lithium carbonate has a purity of 99%, which is used to reclaim Li, Co and Ni in positive electrode materials. The introduction of hetero ions in the existing acid leaching process is avoided, the separation and purification process is simplified, the recycling of the leaching agent is realized, the treatment cost is reduced, and the method is suitable for large-scale industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for recycling value metal from lithium cell slag containing Co, Ni, Mn

ActiveCN101509071AIncrease contact areaIncrease the areaPhotography auxillary processesWaste accumulators reclaimingPregnant leach solutionSlag

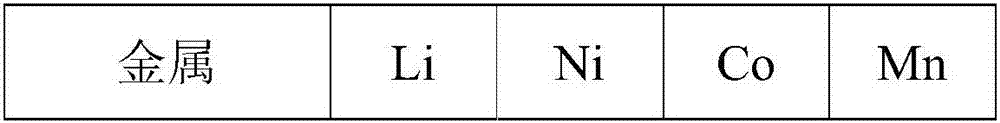

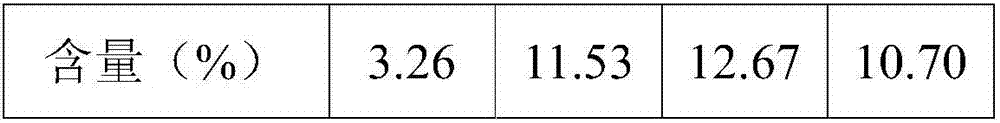

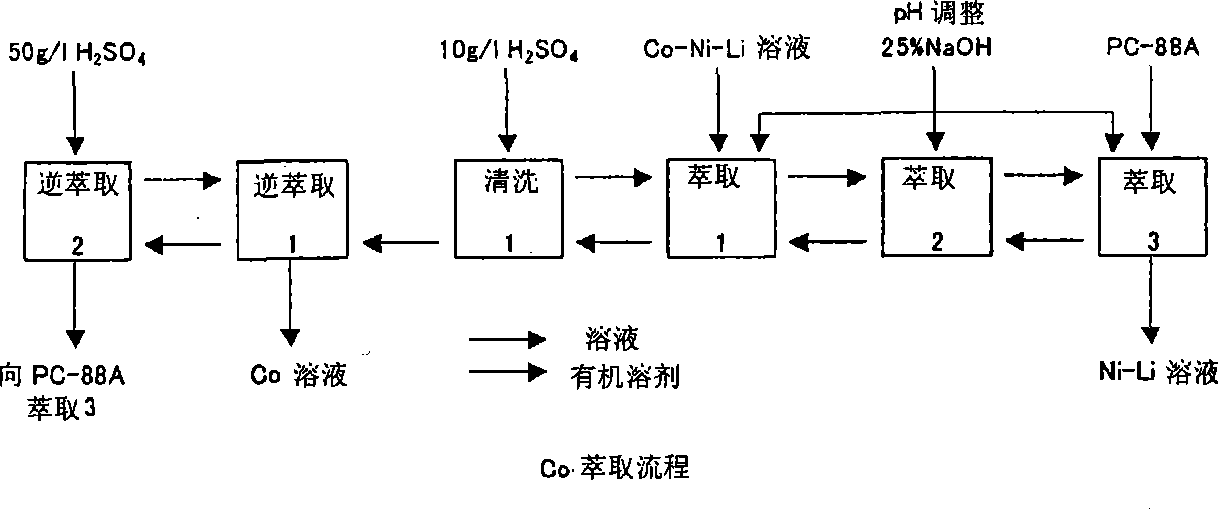

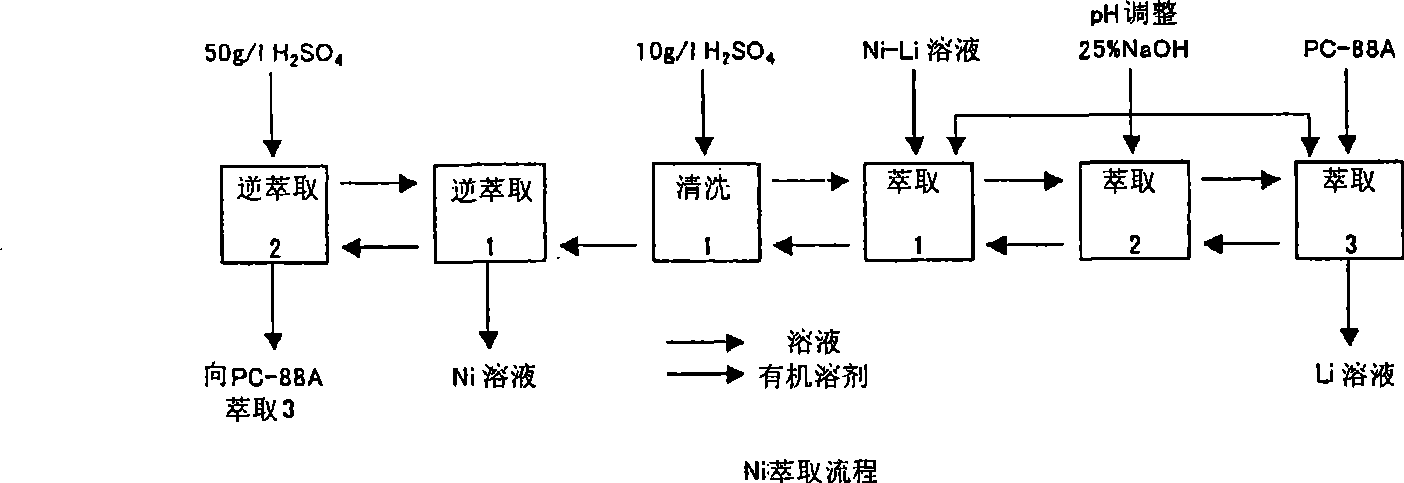

The invention relates to a method for recycling valuable metals from lithium battery residues containing Co, Ni and Mn. Valuable metals such as Mn, Co, Ni and Li are recycled from ternary system Li metal salt of lithium battery residues. The lithium battery residues containing generally equivalent lithium acid metal salt of Co, Ni and Mn are stirred and dipped with hydrochloric acid solution in the concentration of more than 250g / l, or stirred and dipped with sulfuric acid solution in the concentration of more than 200g / l while heating till the temperature of 65 to 80 DEG C, or stirred and dipped for processing with the solution mixed with sulfuric acid solution in the concentration of more than 200g / l and hydrogen peroxide solution in the concentration of more than 20g / l. More than 98% of the three metals of Mn, Co and Ni are extracted with acidic extractant solvent from leach liquor so that the solution containing each metal is produced; therefore, the valuable metals such as Mn, Co, Ni and Li are recycled from these solutions and remaining liquid containing Li after extraction.

Owner:JX NIPPON MINING & METALS CO LTD

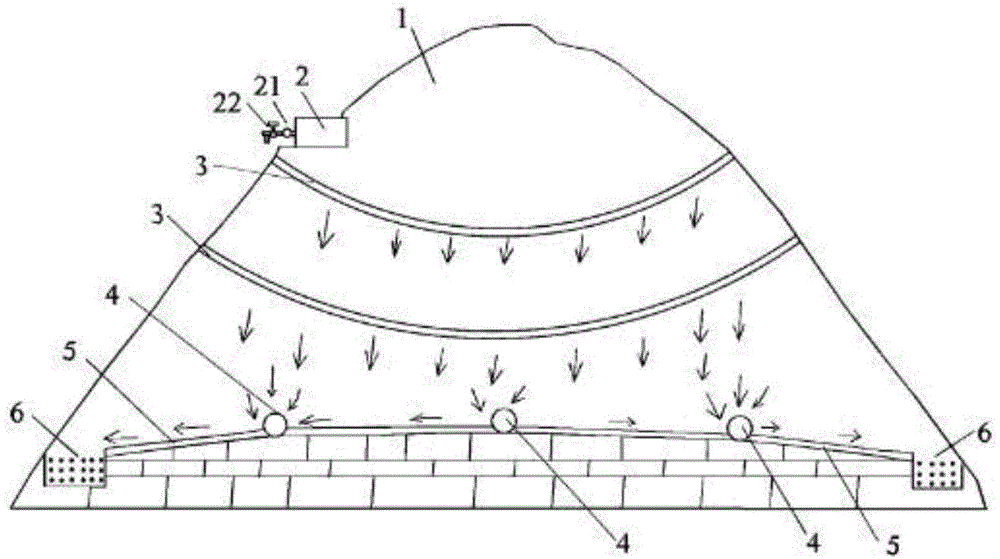

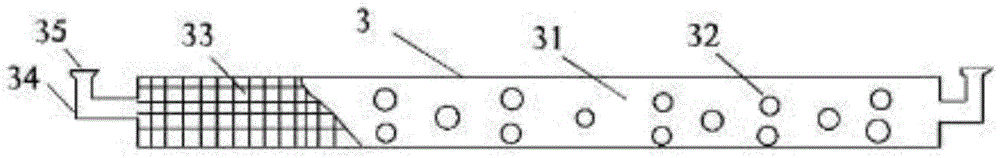

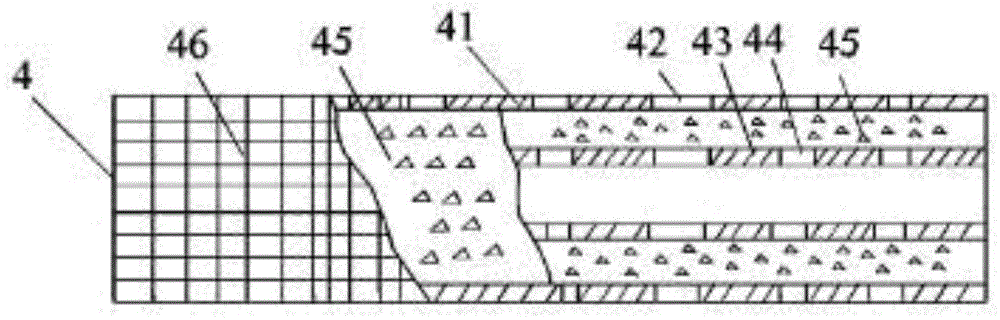

Ion-adsorption-type rare earth in-situ leaching method and leaching system thereof

ActiveCN104694746AEliminate the effects ofPreventing Induced Landslide DisastersProcess efficiency improvementEcological environmentSoil science

The invention belongs to the technology of in-situ leaching mining, and particularly relates to an ion-adsorption-type rare earth in-situ leaching method and a leaching system thereof. A non-excavation directional drilling machine is used for carrying out mechanical drilling of injection wells and liquid-collecting roadways instead of using manual excavation, The quantity of the injection wells is decreased, the injection wells are changed into curved pipes and are buried in a mine body. Therefore, the phenomenon that rainwater infiltrates into channels is reduced, a landslide triggered by the in-situ leaching is prevented, the construction is simple, the construction cycle is short, the cost is low, the safety performance is improved, the waste earth discharge is reduced, and the ecological environment is protected.

Owner:JIANGXI UNIV OF SCI & TECH

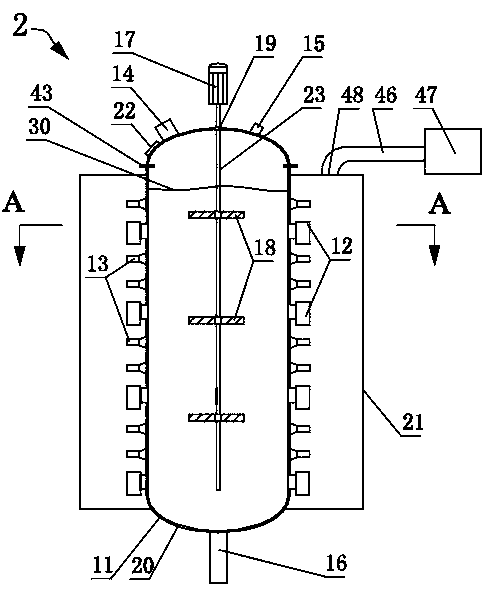

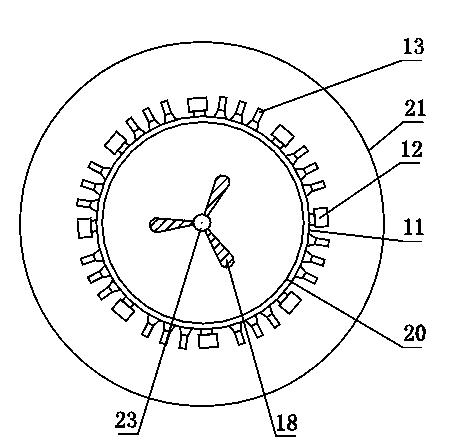

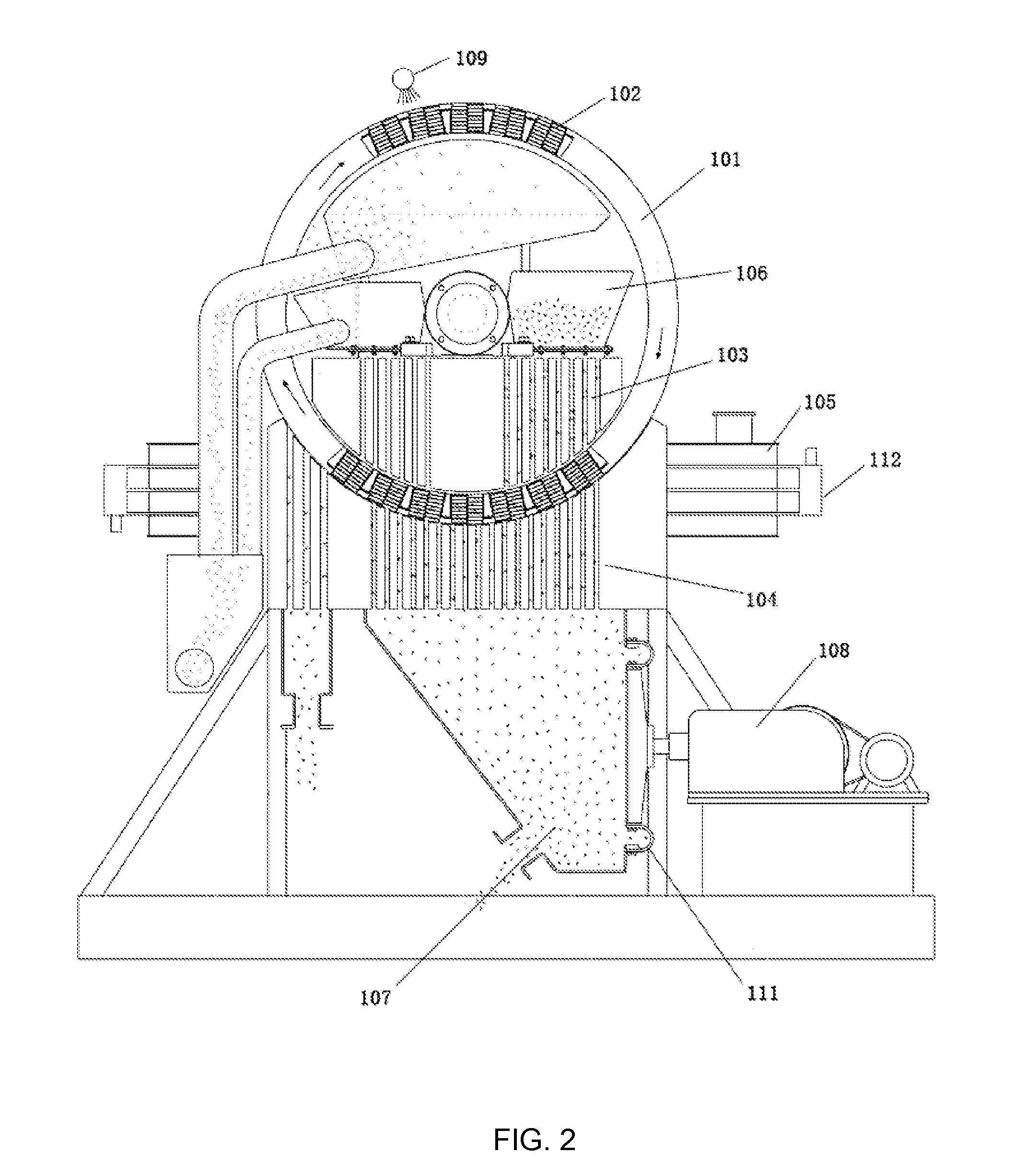

Industrial microwave ultrasonic reaction kettle

InactiveCN103418323ASave operating timeImprove work efficiencyChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesMicrowaveEngineering

Disclosed is an industrial microwave ultrasonic reactor. The inner wall of the reactor is provided with a liner; a microwave generation device is composed of microwave units distributed over the outer sidewall of the reactor in a spaced manner, or of a microwave pipe provided outside the reactor and microwave units distributed over the microwave pipe in a spaced manner. One end of the microwave pipe is in communication with the bottom of the reactor via a connecting pipe I and the other end is in communication with the top of the reactor via a return pipe. A shield is provided outside the microwave generation device to space the microwave units apart from the outer space, with a heat removal device being provided outside the shield. The microwave generation device is composed of ultrasonic pulse units provided along the outer sidewall of the reactor in a spaced manner; there are 10 - 30 sets of ultrasonic pulse units provided from top to bottom, each set having 10 - 50 members and being distributed along the circumferential direction of the reactor, and a stirring shaft of a stirring device is fixed below a stirring motor and extends into the reactor. The present reactor can shorten the time for chemical leaching, improve the purity of a product extracted and increase operation efficiency.

Owner:SONGXIAN EXPLOITER MOLYBDENUM

Method for continuously leaching sulfide ore by using synergy of autotrophic ore leaching bacteria and heterotrophic ore leaching bacteria

ActiveCN102329957AEliminate static clingImprove leaching efficiencyPregnant leach solutionSulfidation

The invention discloses a method for continuously leaching sulfide ore by using the synergy of autotrophic ore leaching bacteria and heterotrophic ore leaching bacteria, which comprises two main steps of preparing a compound ore leaching strain and leaching ore by using the compound strain. The step of preparing the compound ore leaching strain comprises the steps of selecting a strain, preparing a culture medium, compositely culturing the strain and domesticating the compound ore leaching strain. The step of leaching ore by using the compound strain comprises the steps of pretreating an ore sample, preparing an ore leaching culture medium, leaching the ore by using the compound ore leaching strain, selecting and adding semiconductor sulfide ore and extracting metals in the leaching liquids. In the method, the characteristic of the semiconductor sulfide ore to provide electrons to promote the ore leaching action of microbes in the electron transition process is utilized, so that the operating cost of the whole process is lowered, the ore leaching efficiency of the process is improved, and the method has broad application prospect in the field of metallurgy.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Composite mineral-leaching bacteria colony and use of same in biological metallurgy

ActiveCN101538540AImprove efficiencyBroaden the scope of ore processingBacteriaMicroorganism based processesIonLaboratory culture

The invention relates to a composite mineral-leaching bacteria colony and use of the same in biological metallurgy. The composite mineral-leaching bacteria colony has a preserving number of CGMCC No.2395 in the Common Micro-organism Center of China General Microbiological Culture Collection Center. The composite mineral-leaching bacteria colony has strong oxidative activity within a temperature range from 30 to 52 DEG C as well as a working pH value of between 0.8 and 2.25 and an arsenic ion tolerance of 0 to 20 g / L. The composite mineral-leaching bacteria colony is used for extracting and recovering gold or copper, and greatly expands the use range of biological metallurgy in gold mines. Meanwhile, due to the wide temperature adaptation range, the composite mineral-leaching bacteria colony improves the oxidation speed and reduces production cost. Therefore, the composite mineral-leaching bacteria colony has a significant application prospect in biological metallurgy industry.

Owner:CHINA NAT GOLD GROUP CORP TECH CENT +1

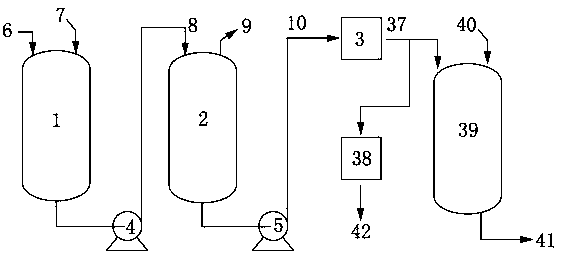

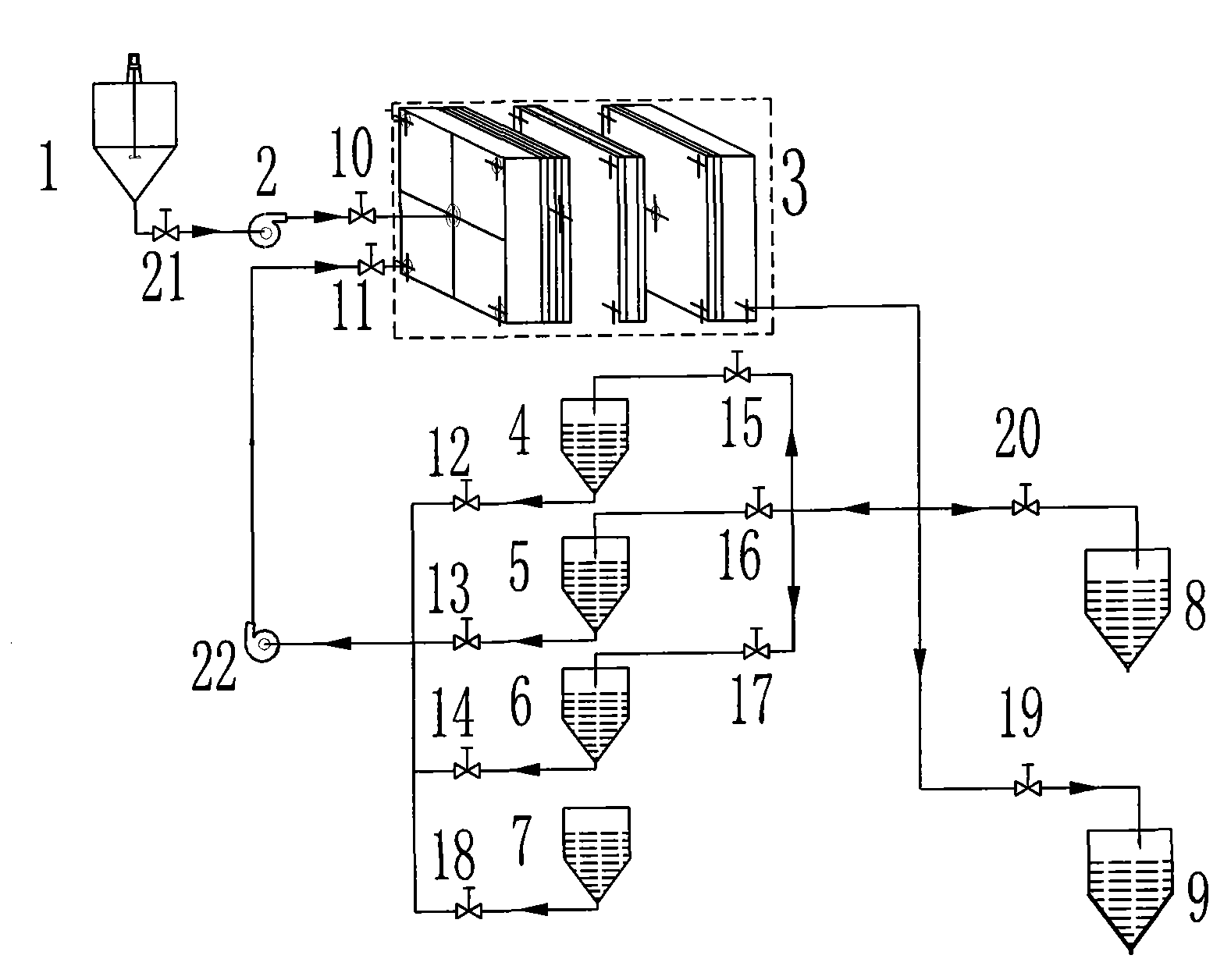

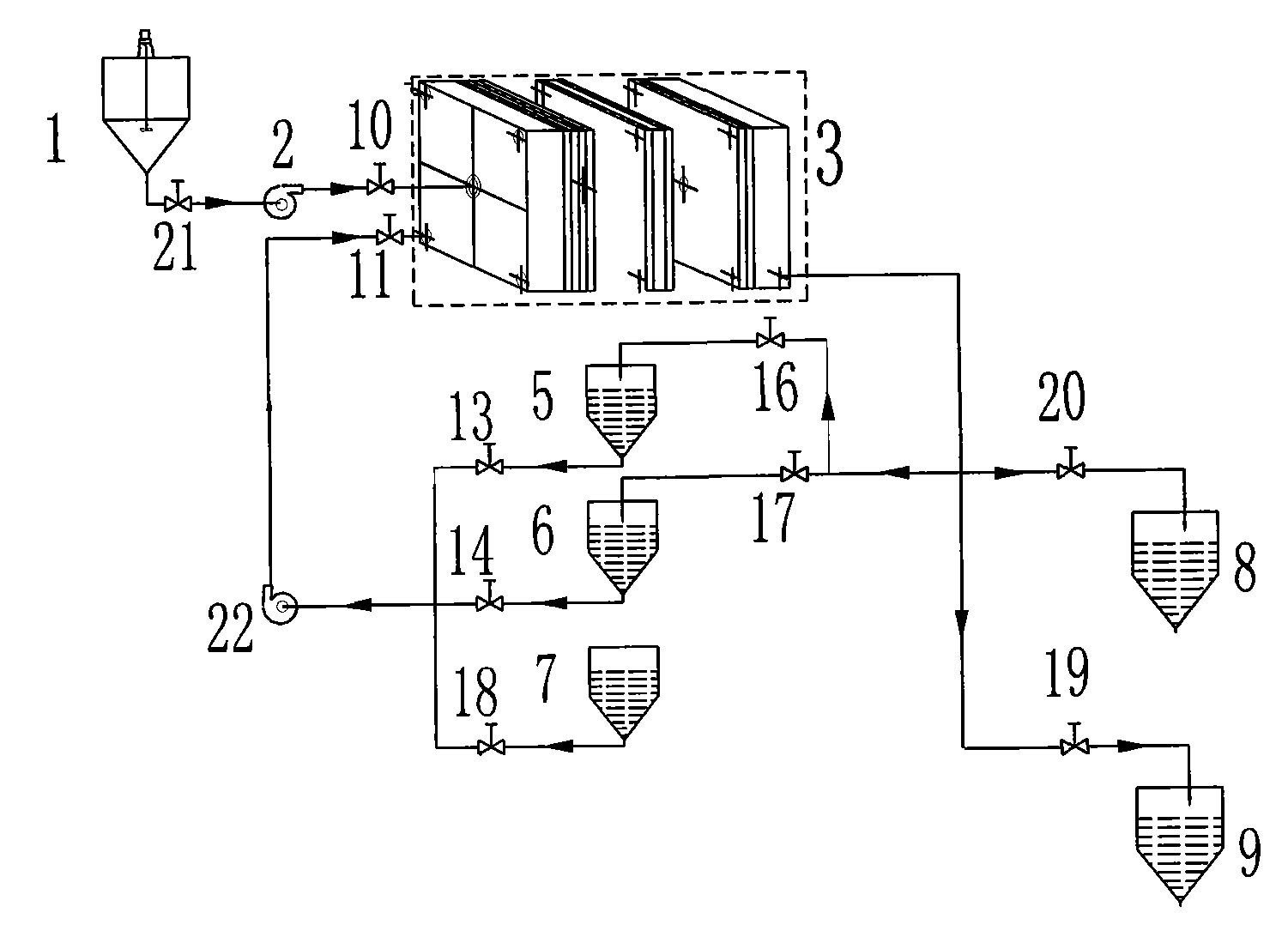

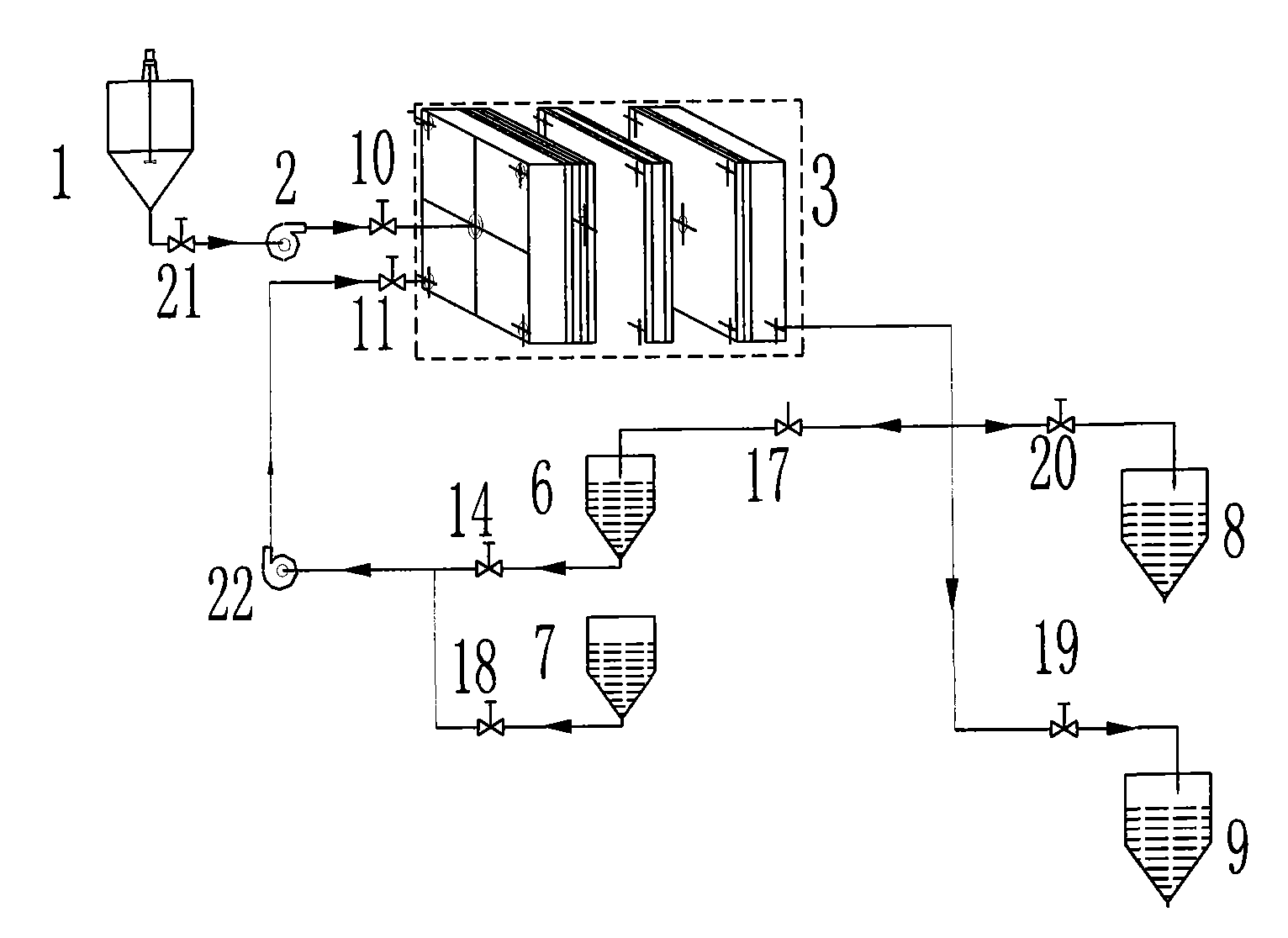

Multisection acid leaching, multistage countercurrent washing and filter pressing integrated system and method

InactiveCN102071311AWater-soluble zinc content is reducedReduce environmental risksFiltration separationProcess efficiency improvementElectrolysisSlag

The invention relates to a multisection acid leaching, multistage countercurrent washing and filter pressing integrated system and method which are applicable to industries such as the metallic zinc electrolysis industry, hydrometallurgy and the like. The system provided by the invention comprises a membrane filter press, wherein the feed port end of the membrane filter press is connected with a zinc calcine acid leaching liquor feed pool, and the discharge port end of the membrane filter press is respectively connected with a filtrate pool and a collection liquor pool; and a waste electrodeposit liquor circulation pool, a circulation washing pool and a clean washing water pool are connected in parallel between the feed port end and discharge port end of the membrane filter press. The method provided by the invention comprises the following steps: (1) feeding materials; (2) carrying out multisection acid leaching by using the waste electrodeposit liquor at different temperature gradients; (3) carrying out multistage countercurrent washing by using zinc-containing washing water of different concentrations; and (4) carrying out filter pressing on the filter cake. According to the invention, the content of water-soluble zinc (in terms of Zn) in zinc waste slag in the mainstream technique in metallic zinc electrolysis industry at present can be reduced from 3.5-6.0% to below 0.5%; and the acid leaching and washing efficiency are greatly enhanced, and the acid leaching recovery rate of zinc ore can be higher than 97%.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for mixed acid leaching and recovery of positive pole materials of waste and old lithium ion batteries

ActiveCN106848471AWide range of sourcesImprove leaching efficiencyWaste accumulators reclaimingBattery recyclingAluminium hydroxideFiltration

The invention provides a method for mixed acid leaching and recovery of metal components of positive pole materials of waste and old lithium ion batteries. The method comprises carrying out coarse crushing on wastes, drying the crushed wastes, pre-leaching the wastes through a mixed acid containing a reduction agent to obtain pre-separated residues, carrying out ball milling, carrying out primary and secondary leaching, mixing the primary and secondary leachates and the pre-leachate, adjusting pH of the mixture, carrying out suction filtration to obtain aluminum hydroxide and raffinate containing cobalt and lithium, adjusting pH of the raffinate containing cobalt and lithium at a high temperature, carrying out suction filtration to obtain cobalt hydroxide and raffinate containing lithium, carrying out concentration on the raffinate containing lithium at a high temperature, adding a saturated sodium carbonate solution into the concentrate to obtain high purity lithium carbonate, and recovering aluminum foil. The method utilizes a mixed acid leaching agent, has high leaching efficiency, can gradually acquire high purity aluminum, aluminum hydroxide, cobalt hydroxide and high purity lithium carbonate (having purity of 99.9%), realizes efficient recovery, overall recovery and collaborative recovery of high-value metals in the waste and old lithium-ion batteries and has a good application prospect.

Owner:BOTREE CYCLING SCI &TECH CO LTD

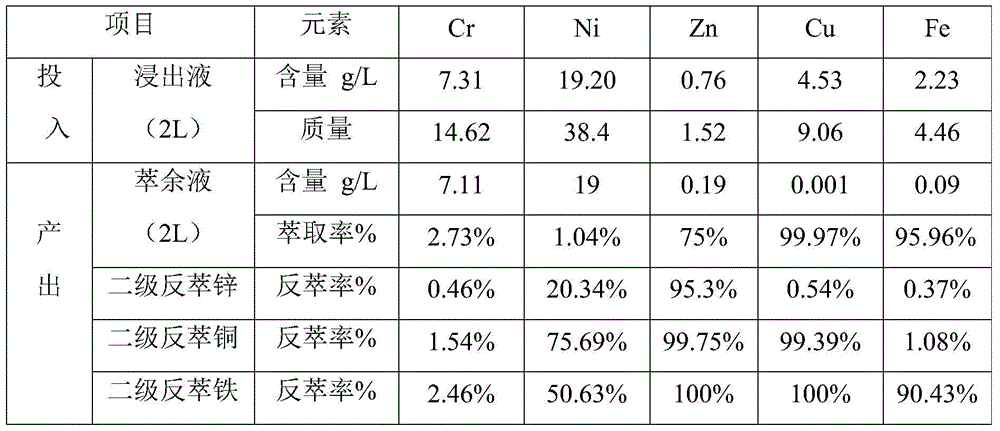

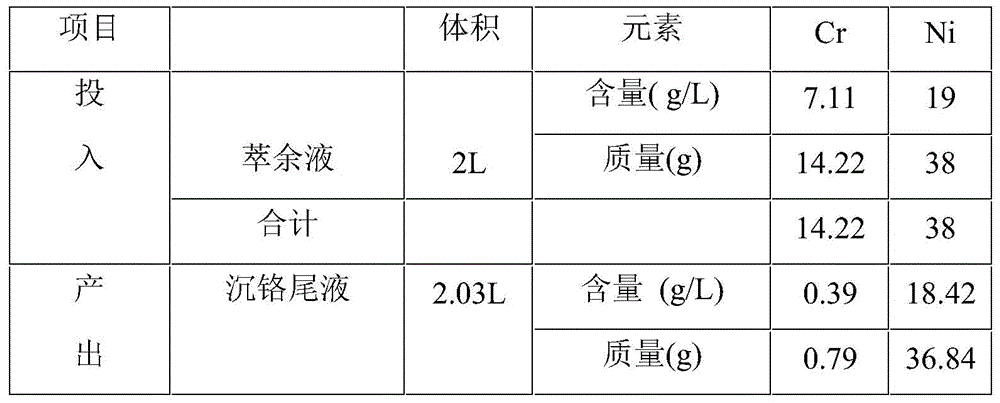

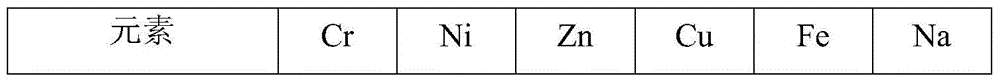

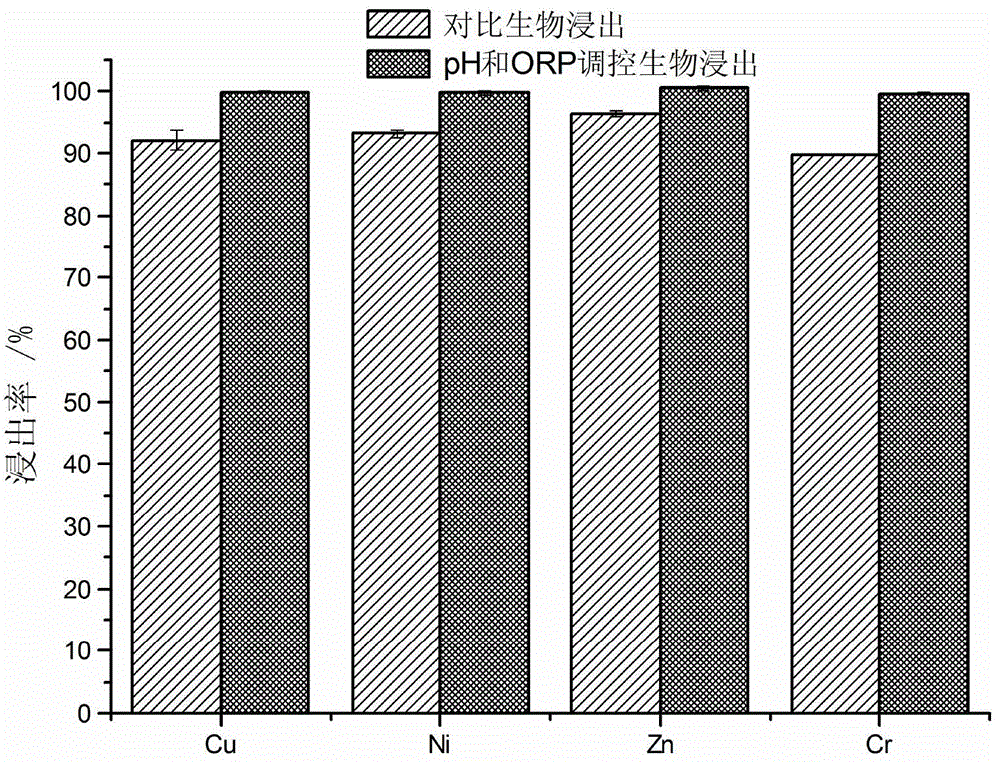

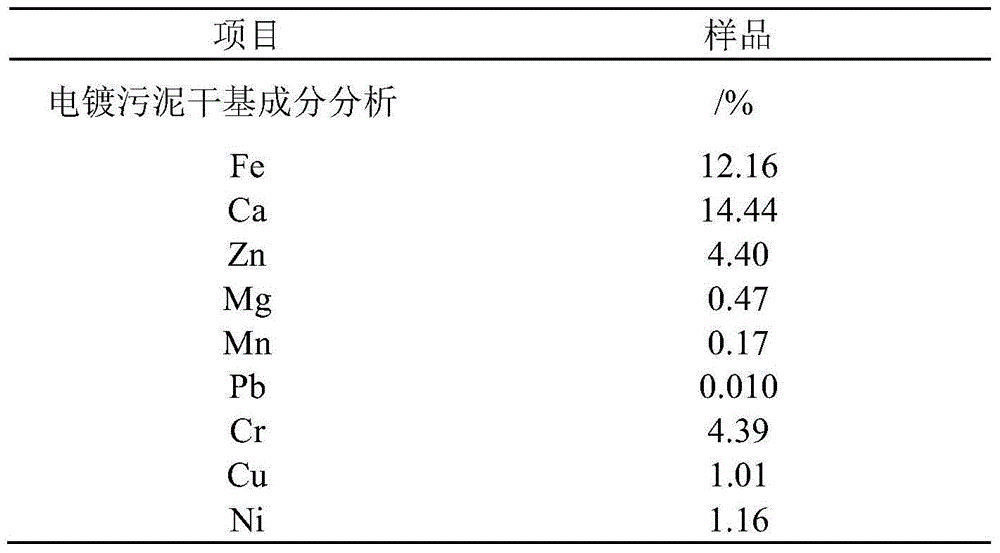

Harmless disposal and resource utilization method for electroplating sludge

InactiveCN105734294ADetoxify thoroughlyAdaptableProcess efficiency improvementResource utilizationSludge

The invention provides a harmless disposal and resource utilization new technology for electroplating sludge and particularly for complex electroplating sludge rich in copper, iron, nickel, zinc and chromium. Selected microorganisms are high in adaptation to the electroplating sludge and good in leaching performance; one-step extraction is adopted to extract copper, iron and zinc, follow-up nickel and chromium separation and purification are facilitated, in the whole technology, the iron cannot form any solid phase, and the problem that according to an existing reported technology, during iron separation, entrainment is serious or iron precipitation is not thorough is solved; a metallurgical method is adopted to carry out separating and recycling on extraction raffinate, the separation effect is good, and an obtained product is high in purity; and according to the technological process, cleaning and efficient high-value recycling of valuable metal in the electroplating sludge are achieved, the method is high in adaptation to various kinds of electroplating sludge, the electroplating sludge meets the harmless requirement, and the method extremely has the industrialized utilization value.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for efficiently and intensively leaching metals in waste lithium ion batteries

InactiveCN102703705AReduce dosageImprove leaching efficiencyWaste accumulators reclaimingProcess efficiency improvementElectrical batteryLithium-ion battery

The invention relates to a method for efficiently and intensively leaching metals in waste lithium ion batteries. In the method, lithium cobaltate powder is added in dilute acid solution, solid-to-liquid ratio is controlled to be less than 1:10 g / mL; then ferrous sulfate is added, dosage of ferrous sulfate is more than lithium cobaltate powder by less than 1.5 times; next, direct voltage of 0.4-0.7 V passes through; an iron electrode is used as a cathode; graphite, titanium plate or platinum is used as an anode; and rotating speed of a stirrer is 200-500 r / min. Compared with traditional acid leaching, the method can greatly reduce dosage of acids, operate at constant temperature, greatly shorten time when lithium cobaltate is leached and greatly increase leaching efficiency of lithium cobaltate. A high-efficiency, energy-saving, high-leaching-efficiency technical method is provided for recovery of valuable metals in waste lithium ion batteries.

Owner:NANCHANG HANGKONG UNIVERSITY

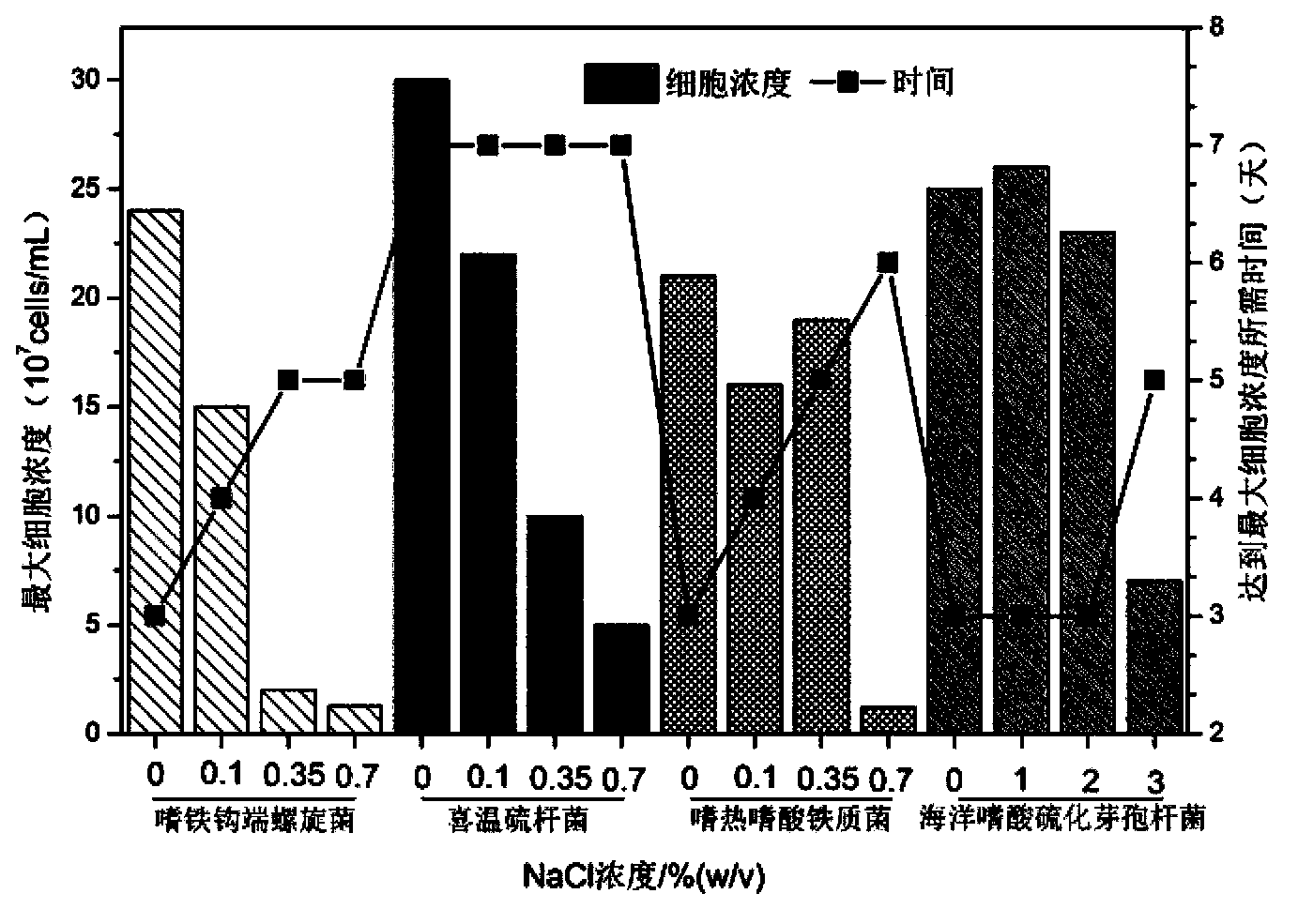

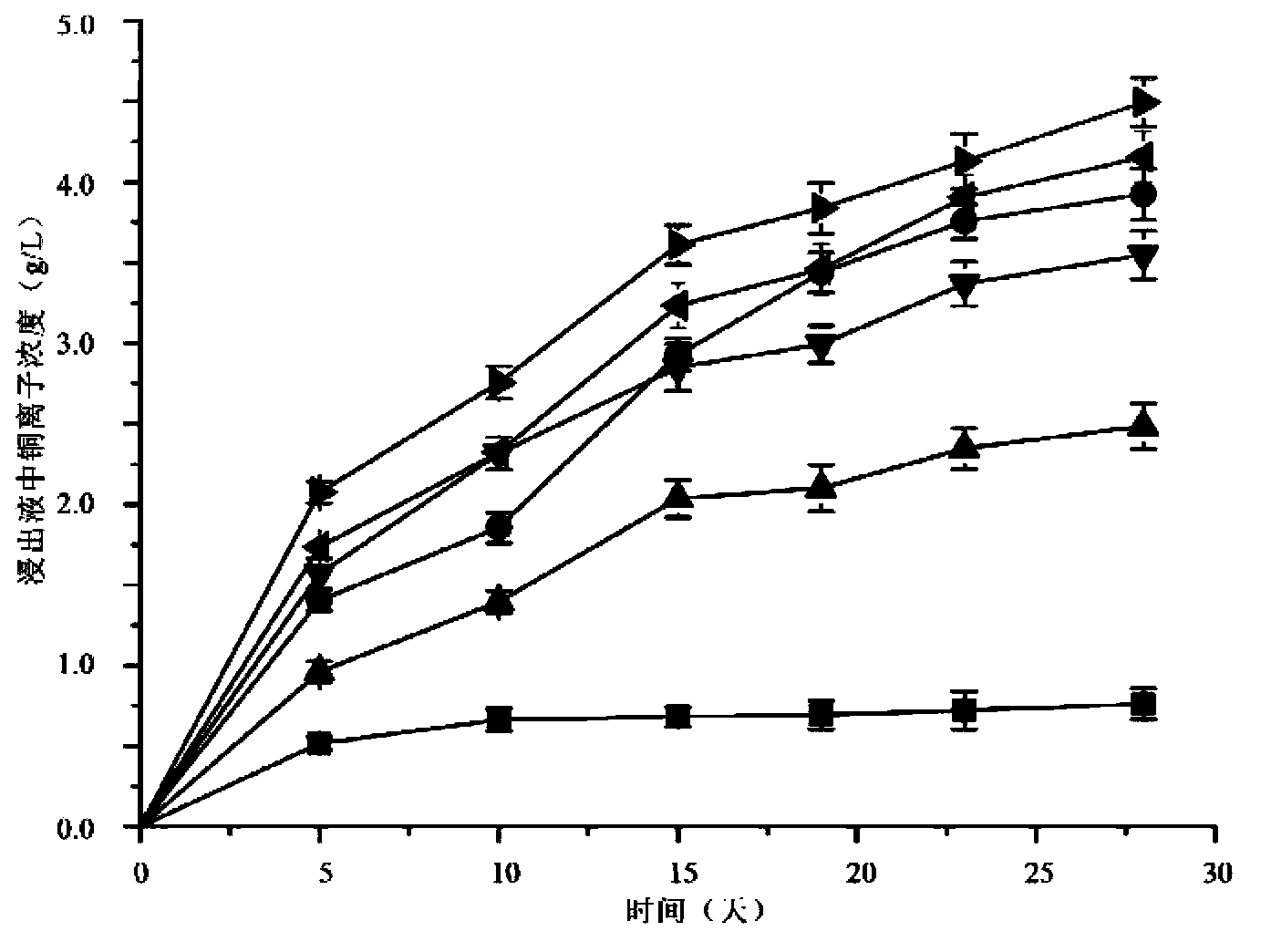

Compound bacterium community capable of efficiently leaching sulphide ore, and compounding method and application method thereof

ActiveCN103396964AIncrease resistanceImprove leaching efficiencyBacteriaMicroorganism based processesChemical reactionEngineering

The invention discloses a compound bacterium community capable of efficiently leaching a sulphide ore, and a compounding method and an application method thereof, and belongs to the technical filed of wet-process metallurgy. Aiming at a biological leaching mechanism of the sulphide ore and the physiological-biochemical characteristics of microorganisms, a community capable of efficiently leaching the sulphide ore is compounded by a plurality of mineral leaching microorganisms, wherein the mineral leaching microorganisms comprise marine bacteria which come from deep-sea hydrothermal vents and are capable of enduring high concentration sodium chloride, sulfur-oxidized bacteria, iron-oxidized bacteria and archaea which are from a freshwater environment, autotrophic bacteria and facultative heterotrophic bacteria. Not only can the difficult problem that the mineral leaching microorganisms from the freshwater environment are intolerance of sodium chloride be solved, but also microorganisms required by oxidation and dissolution of the sulphide ore and diversity of chemical reactions are guaranteed. The compound bacterium community can obviously increase leaching efficiency and leaching rate of the sulphide ore such as copper pyrites and can be applied in a leaching process and a dump leaching process of a stirring tank. A certain basis for popularization and application of biological metallurgy of the sulphide ore is provided by the invention.

Owner:CENT SOUTH UNIV +1

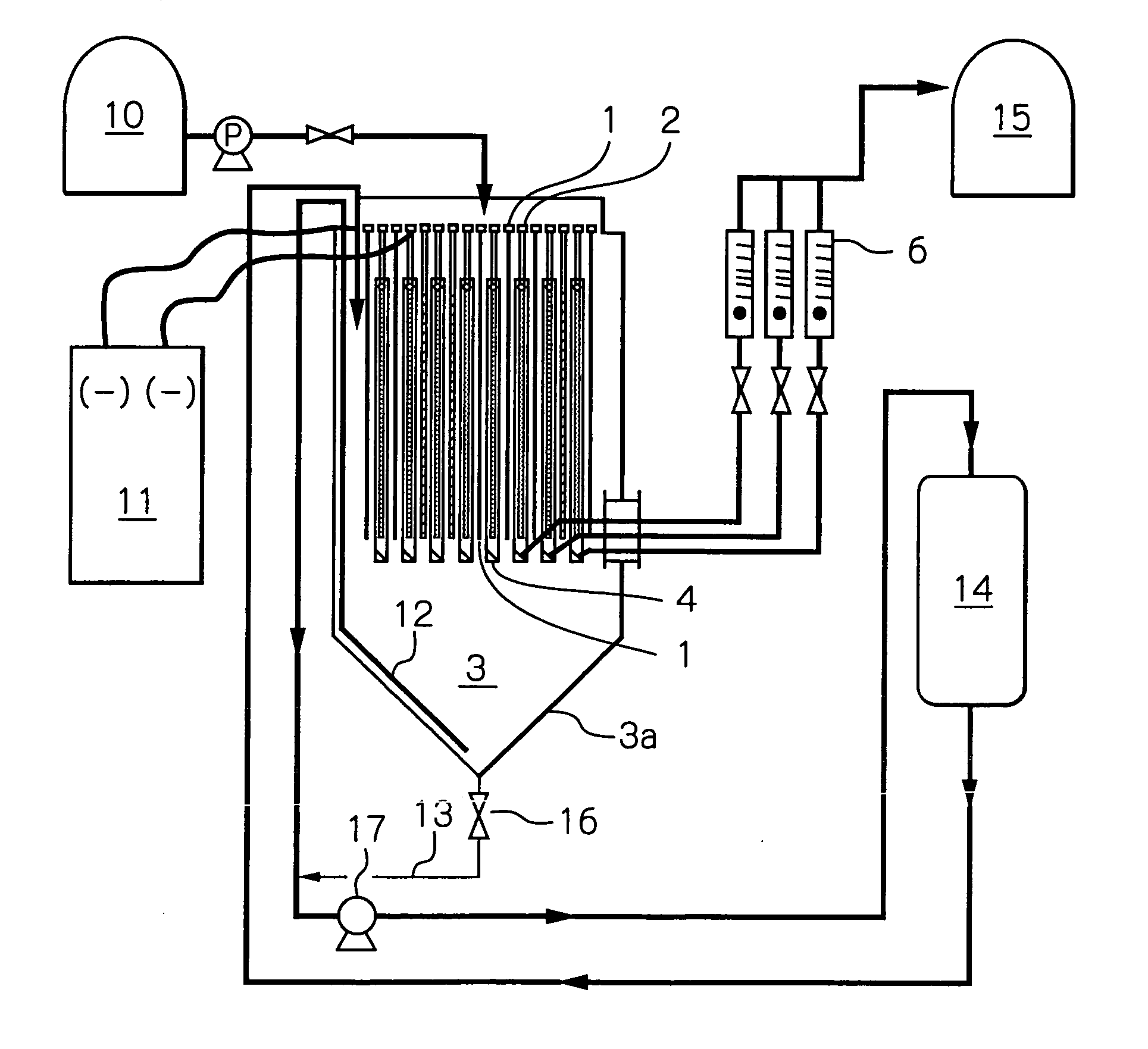

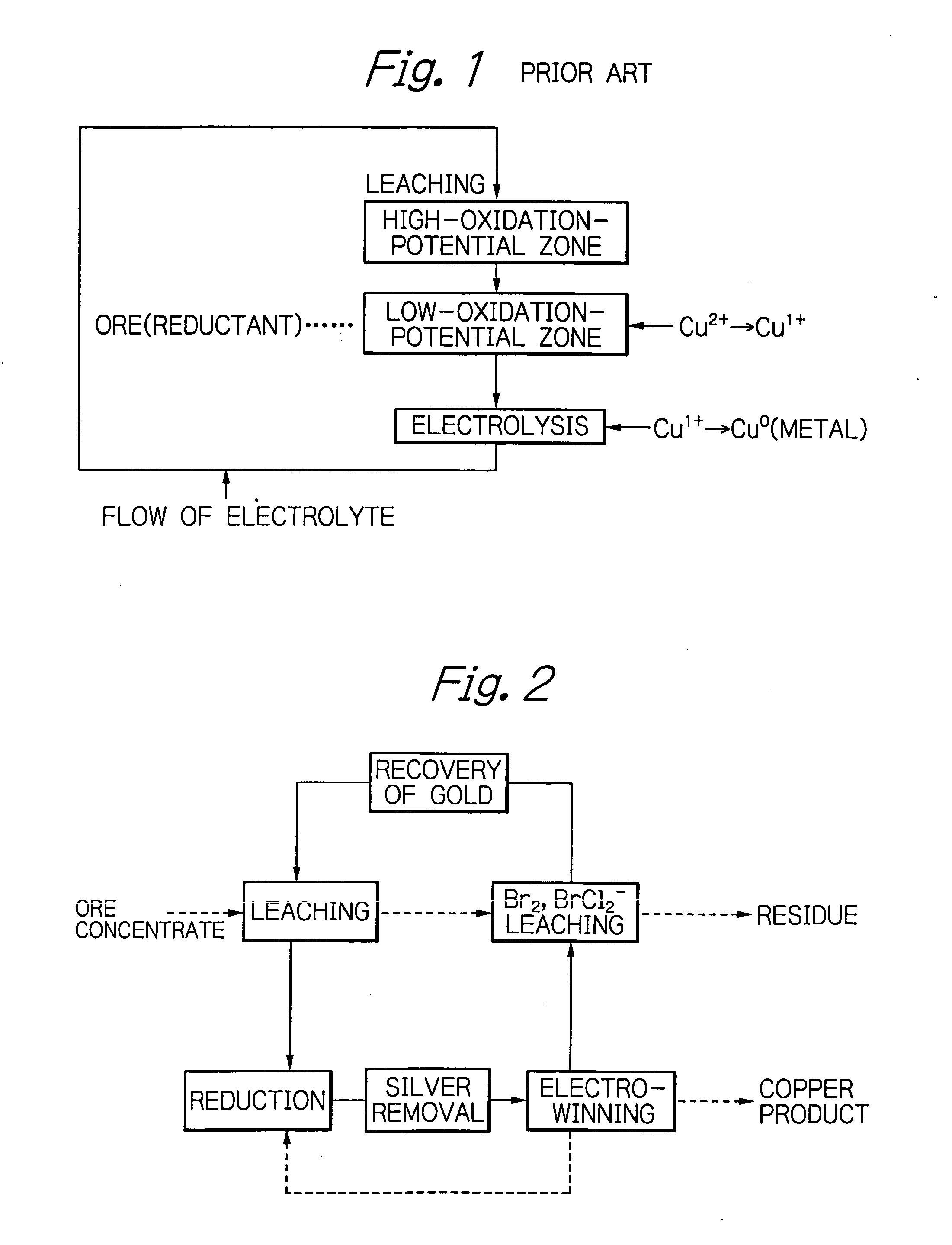

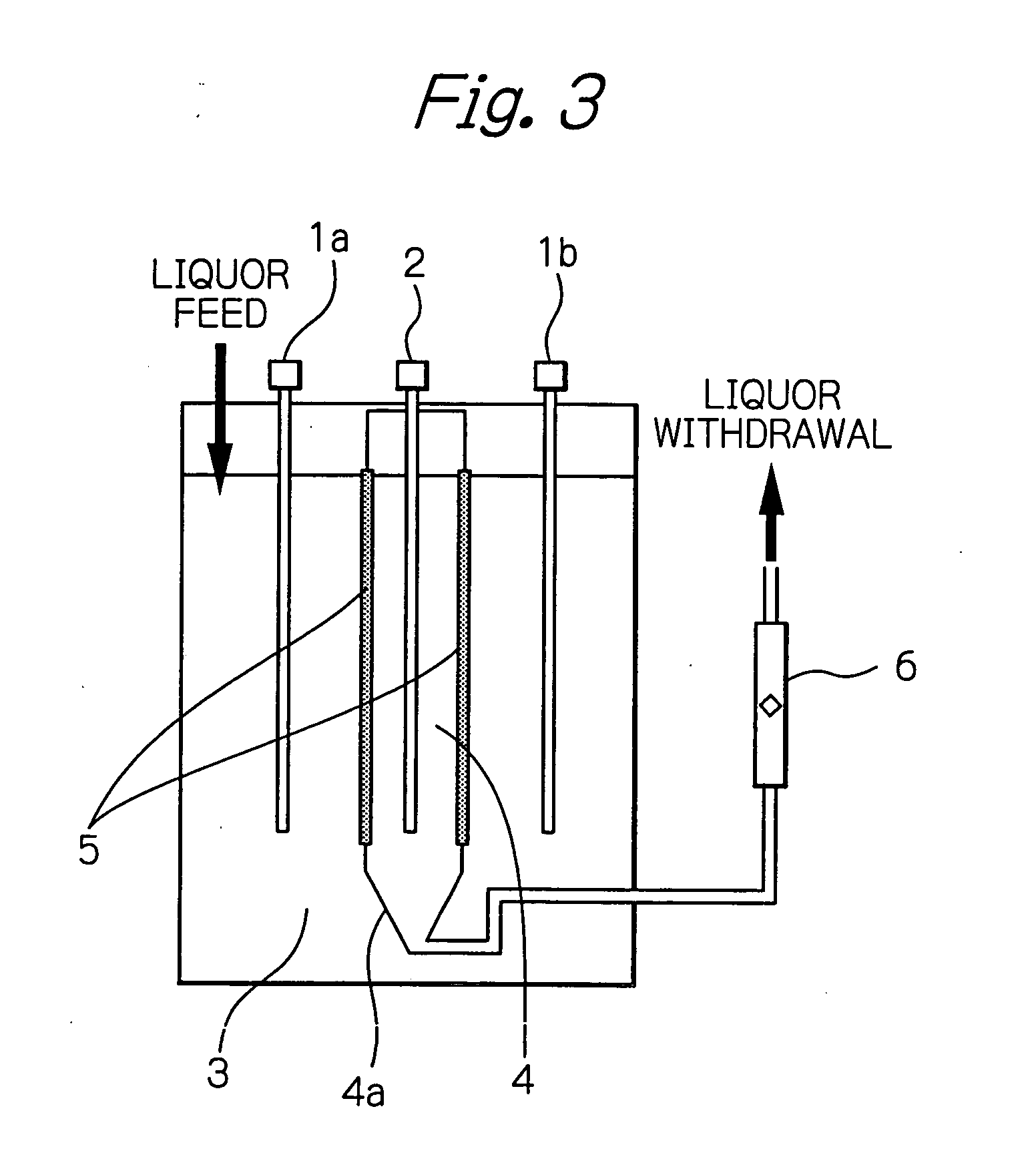

Electrolytic method in diaphragm-type cell

InactiveUS20050067299A1Improve leaching efficiencyReduce reaction efficiencyPhotography auxillary processesElectrolysis componentsPregnant leach solutionChloride electrolytes

In a metal-winning method, copper ore or copper-ore concentrates is effectively hydraulically leached in a chloride leach liquor and the resultant leached liquor is diaphragm-electrolyzed. A chloride electrolyte containing Br− ions and the leached metals is subjected to a diaphragm-electrolysis in an electrolytic cell comprising an anode compartment (4) and a cathode compartment (3). A portion of the electrolyte in the anode compartment (4) is withdrawn from below an anode (2) of the anode compartment (4) and is returned to the leaching step so as to increase the oxidation potential of the chloride leach liquor.

Owner:JX NIPPON MINING& METALS CORP +1

Process for recycling copper through electrodeposition by treating scrap copper materials by adopting cyclone electrolysis technology

ActiveCN102534656ATo achieve the purpose of high efficiency and environmental protectionImprove leaching efficiencyPhotography auxillary processesProcess efficiency improvementHigh current densityCyclone

The invention provides a process for recycling copper through electrodeposition by treating scrap copper materials by adopting a cyclone electrolysis technology, belonging to the technical field of recycling copper from wastes containing copper. The process is characterized by taking various purchased wastes containing copper as raw materials, preliminarily screening and grinding the wastes, adding the materials to a dissolved copper leaching bath device to undergo continuous copper dissolving to obtain a copper sulfate solution, then filtering the solution with precision filter equipment, decoppering the obtained filtrate through cyclone electrolysis, scalding an obtained copper pipe with weak acid and then feeding the copper pipe into a product processing unit to process a standard copper plate. The process has the following beneficial effects: through portable or module assembly, the cyclone electrolysis bath and support equipment are convenient to install, dismantle and move; the solution circulates in a closed loop, thus avoiding emission of harmful gases; electrolytic deposition is carried out on the metals selectively and the copper can be better purified by applying the cyclone electrolysis technology; higher current density and current efficiency are ensured, fewer reagents are consumed, the production cost is lowered and the enterprise revenue is improved; and high efficiency and high purity electrolytic extraction is carried out on the solution, the recycled copper is the standard cathode copper and the total recycling rate is above 96%.

Owner:浙江科菲科技股份有限公司

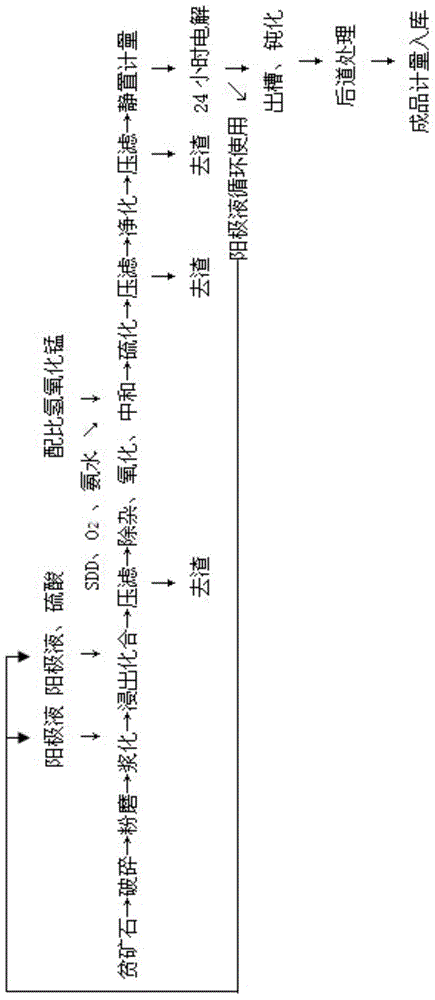

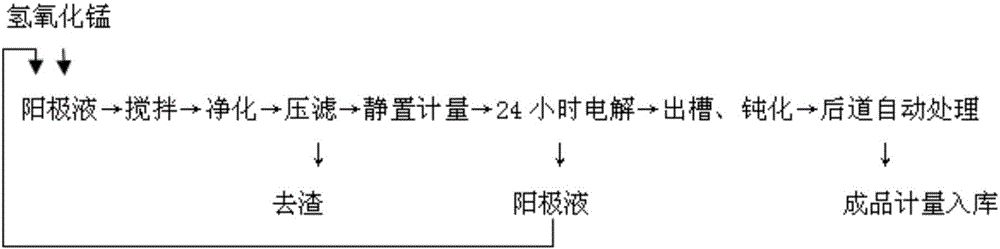

Brand new method of producing electrolytic manganese metal

ActiveCN104018184AImprove leaching rateImprove total manganese recoveryPhotography auxillary processesElectrolysis componentsElectrolysisSlag

The invention discloses a brand new method of producing electrolytic manganese metal. The method comprises the following steps: (1) grinding lean manganese ore powder, adding an anode liquor of electrolytic manganese and then adding the anode liquor of electrolytic manganese to be reacted with sulfuric acid to obtain a reaction leachate; (2) carrying out press filtering on the reaction leachate so as to remove slags, adding SDD (Sodium Dimethyl Dithiocarbamate) to remove impurites, introducing oxygen to oxidize, then adding manganese hydroxide to react, supplementing ammonium water to neutralize, and then adding a vulcanizing agent to further remove impurities; (3) after further carrying out press filtering so as to slags, carrying out deep purification and press filtering so as to remove slags, standing and metering to obtain an electrolyte; (4) electrolyzing the electrolyte to obtain the electrolytic manganese metal, wherein the anode liquor of electrolytic manganese is recycled. The invention further discloses a method of producing electrolytic manganese metal by fully replacing manganese ores by manganese hydroxide. The two methods disclosed by the invention can be used for improving the manganese leaching efficiency, saving the use level of auxiliary materials, lowering the production cost, simplifying the production flow and reducing the amount of waste residues, is free from influence on electrolysis and is mature, simple and practical in process.

Owner:张安良 +1

Method for processing cobalt copper alloy

The invention discloses a method for processing the cobalt copper alloy, which comprises the following steps: 1) machine activating program: sending the cobalt copper alloy to the ball crusher to do cruse milling, sending it to the pipe crusher to do correct grinding, then the cobalt copper alloy powder has high internal energy, surface energy and rate surface area so that it has high reacting activity; 2) extracting process: adding the cobalt copper alloy powder in the reacting extraction groove and adding water and muriatic acid by a certain ratio to heat stir on catalyzed oxidation condition so that the cobalt and copper mental 90%-99% extracting of the cobalt copper alloy enters into the solution; 3) Magnetic separating program: separating the residual cobalt copper alloy of the extracting slip and the slip by the magnetic separator, dosing filter solid-liquid separation to the magnetic separated slip to obtain the solution with cobalt and copper.

Owner:浙江盈联科技有限公司

Hydrometallurgical gold cyanide leaching optimization method

ActiveCN104597755ASolve the insufficient additionSolve problems such as blindly adding too muchAdaptive controlProcess optimizationData acquisition

The invention discloses a hydrometallurgical gold cyanide leaching optimization method. By using the traditional hydrometallurgical gold cyanide leaching process and based on stable production and production index, the production cost is minimized. The method comprises the following process steps of: (1), data collection; (2), selection and data processing of auxiliary variables; (3), establishment of an optimization model; (4), solution of the optimization model; and (5), determining of operation guidance of the leaching process optimization. According to production requirements and production site conditions, additive amount of raw materials in the guidance production process is optimized, a reasonable production plan is developed, problems of insufficient additive amount of the raw materials and excessive additive amount in the production process are solved, the production requirements are ensured, and waste of the raw materials is avoided.

Owner:NORTHEASTERN UNIV

Method for extracting fresh bamboo juice

InactiveCN1792272AReduce filterThe process steps are simplePlant ingredientsFood scienceEngineeringVALVE PORT

Owner:刘兴

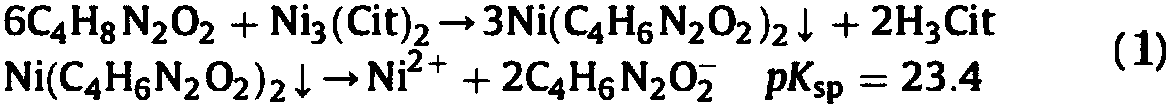

Method for recycling high-value-added metals from waste nickel-cobalt-manganese lithium ion batteries

InactiveCN108913873AConducive to enhanced leachingParticle refinementWaste accumulators reclaimingProcess efficiency improvementAdhesiveManganese

The invention relates to a method for recycling high-value-added metals from waste nickel-cobalt-manganese lithium ion batteries and belongs to the technical field of recovery of lithium batteries. The method comprises the following steps: (1) thoroughly discharging waste nickel-cobalt-manganese batteries, disassembling and sorting out positive powder, and carrying out heat treatment on the positive powder to remove impurity components such as conductive agents and adhesives in the positive powder; (2) mixing the positive powder subjected to heat treatment with active additive according to a ratio, then mechanically and finely grinding so as to carry out machine-chemical synergistic activation of the positive powder; and (3) mixing the activated positive powder with citric acid-D glucose leachate leaching agent, then carrying out leaching reaction and precipitating nickel, cobalt, manganese and lithium in the filtrate to obtain the high-value-added metals. According to the method, citric acid in the citric acid-D glucose leachate can be recycled after extracting the metal elements; high consumption of the leachate is avoided; the leaching efficiency is improved; the recycling costis reduced.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

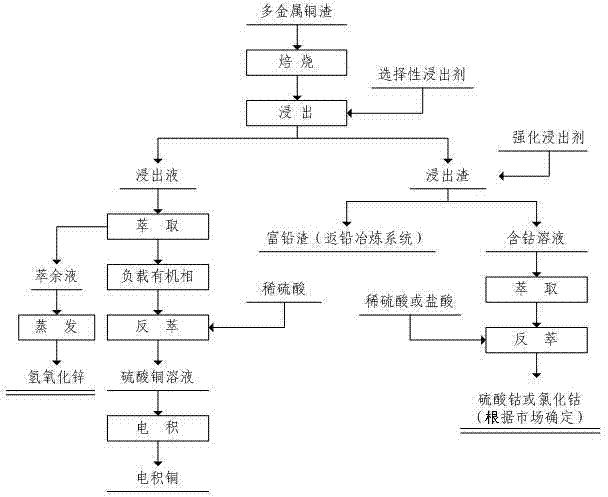

Method for producing electrodeposited copper from polymetallic copper slag

ActiveCN104846202AImprove leaching efficiencyHigh recovery ratePhotography auxillary processesProcess efficiency improvementZinc hydroxideLead smelting

The invention discloses a method for producing electrodeposited copper from polymetallic copper slag, which includes the following steps: the polymetallic copper slag is roasted to oxidize, so that the complex states of valuable metals in the polymetallic copper slag are transformed into oxides, changed into a state which can be selectively leached; leaching first adopts selective leaching agent to leach copper and zinc, the leachate is extracted, reextracted and electrodeposited, so that electrodeposited copper is obtained, and raffinate is vaporized and crystallized, so that zinc hydroxide is obtained; mechanical intensified leaching agent is then used for intensely leaching leaching residue, so that cobalt, nickel and the like in the leaching residue are leached, lead, iron and the like are enriched into the slag, the lead-rich slag is adopted as material for lead smelting, the leachate is extracted and reextracted, so that cobaltous sulfate or cobalt chloride is obtained, and if the nickel content in the leachate is overhigh, multi-stage extraction can be carried out to separate cobalt and nickel, so that nickel sulfate or nickel chloride is produced. The method can comprehensively recover a variety of metals, the leaching efficiency is high, the recovery rate is high, the method is environment-friendly, and is easy to implement, the method ensures that all the valuable metals in the polymetallic copper slag can be effectively separated and recycled, and the solid waste utilization rate can reach more than 99 percent.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for preparing lithium cobaltate by directly using spent lithium ion batteries

InactiveCN105322247AReduce dispersionHigh purityWaste accumulators reclaimingBattery recyclingHydrazine compoundPotassium hydroxide

A method for preparing lithium cobaltate by directly using spent lithium ion batteries comprises crushing spent lithium ion batteries or waste leftover materials generated during lithium cobaltate battery production by using a machinery crusher at normal temperature, adding one or more of water, acetic acid, sulfuric acid, hydrochloric acid and nitric acid, so as to prepare an aqueous solution of a mixture of the battery crushed materials and the acid, putting in an enclosed pressure reaction kettle, controlling the kettle internal temperature to be 50-150 DEG C, introducing or adding one of leaching additives sulfur dioxide and hydrogen, or adding hydrazine hydrate, stirring for leaching, then cooling and filtering, adding one of sodium carbonate, potassium carbonate and ammonium carbonate precipitating agents into the filtrate, or adding a composite precipitating agent composed of one of sodium carbonate, potassium carbonate and ammonium carbonate and one of sodium hydroxide and potassium hydroxide, so as to obtain a mixture of lithium carbonate, cobalt carbonate and cobalt hydroxide, and performing drying and high-temperature roasting, so as to obtain the lithium cobaltate product. The method is especially suitable for the processing scale of middle and small-sized enterprises, and is an effective method for direct material formation of cobalt-containing sources.

Owner:高龙飞

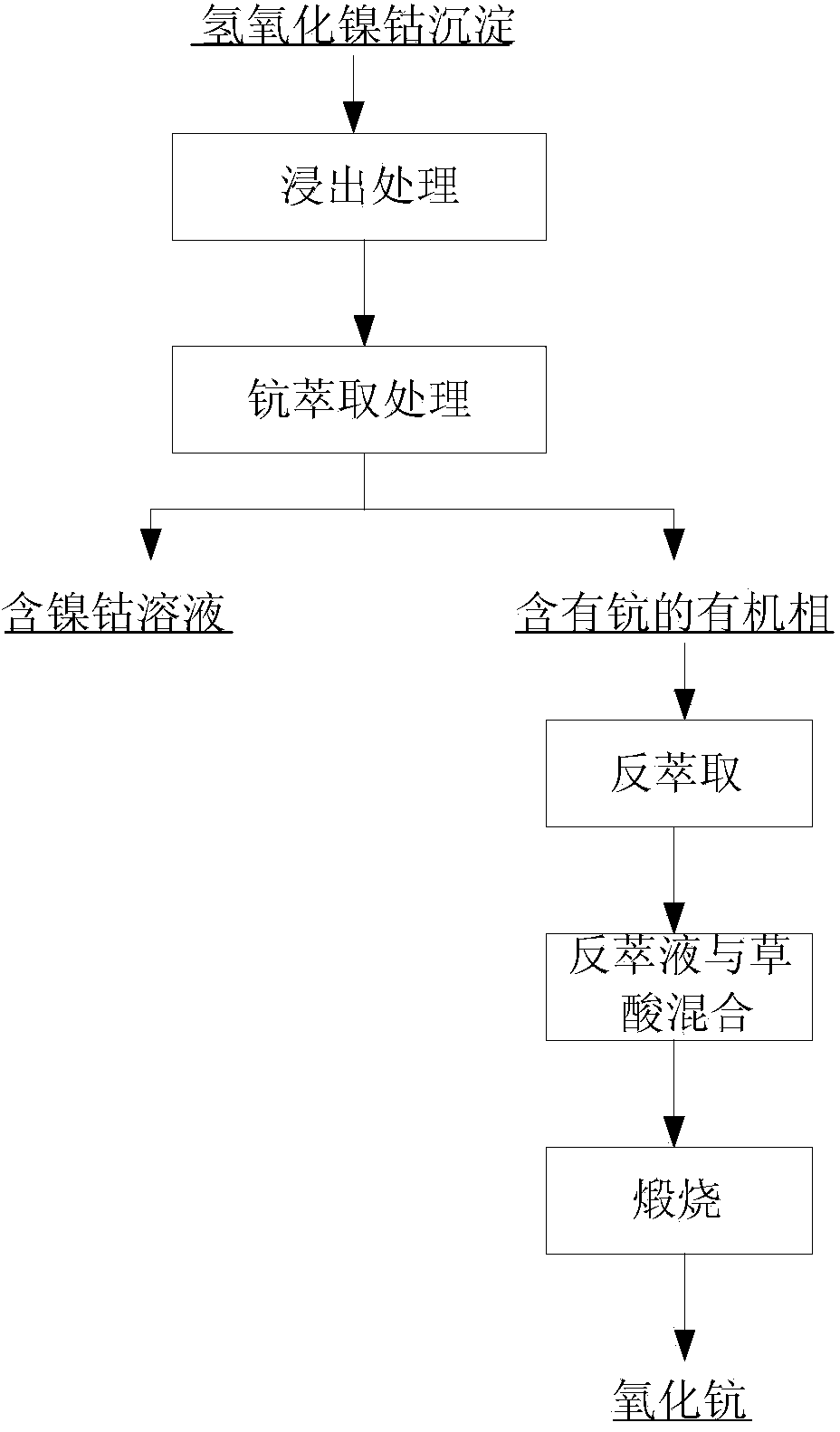

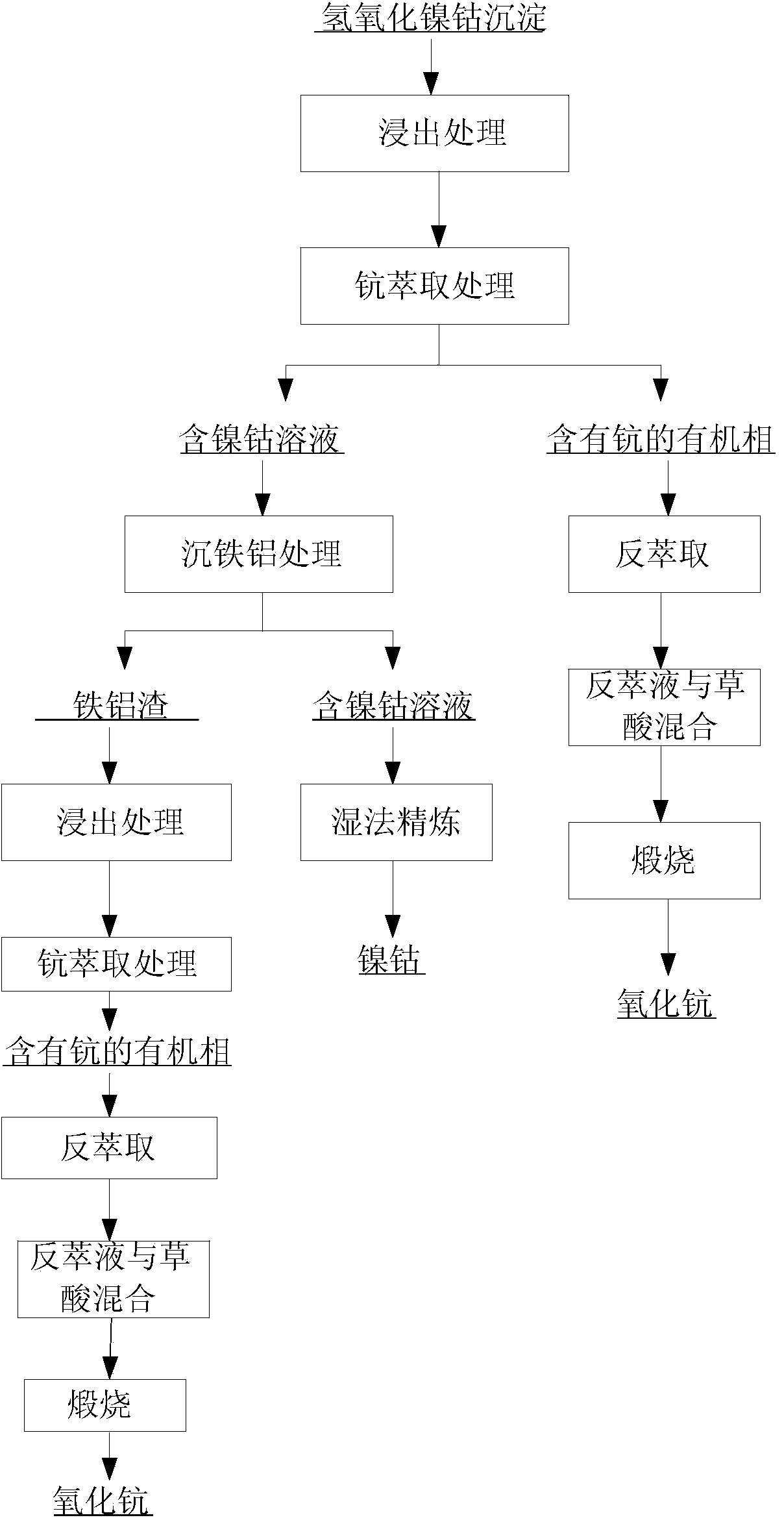

Treatment method for scandium-containing cobalt nickel hydroxide

ActiveCN103468949AImprove processing efficiencyImprove leaching efficiencyProcess efficiency improvementProcess engineeringSulfuric acid

The invention provides a treatment method for scandium-containing cobalt nickel hydroxide. The method includes the steps: carrying out leaching treatment of a cobalt nickel hydroxide precipitation by utilizing sulfuric acid, so as to obtain a nickel cobalt leaching solution; carrying out scandium extraction treatment of the nickel cobalt leaching solution by utilizing an organic extractant, so as to obtain a nickel-cobalt-containing solution and a scandium-containing organic phase; recycling nickel cobalt from the nickel-cobalt-containing solution; and recycling scandium from the scandium-containing organic phase. With the utilization of the method, scandium can be effectively extracted from the scandium-containing cobalt nickel hydroxide precipitation.

Owner:中冶瑞木新能源科技有限公司

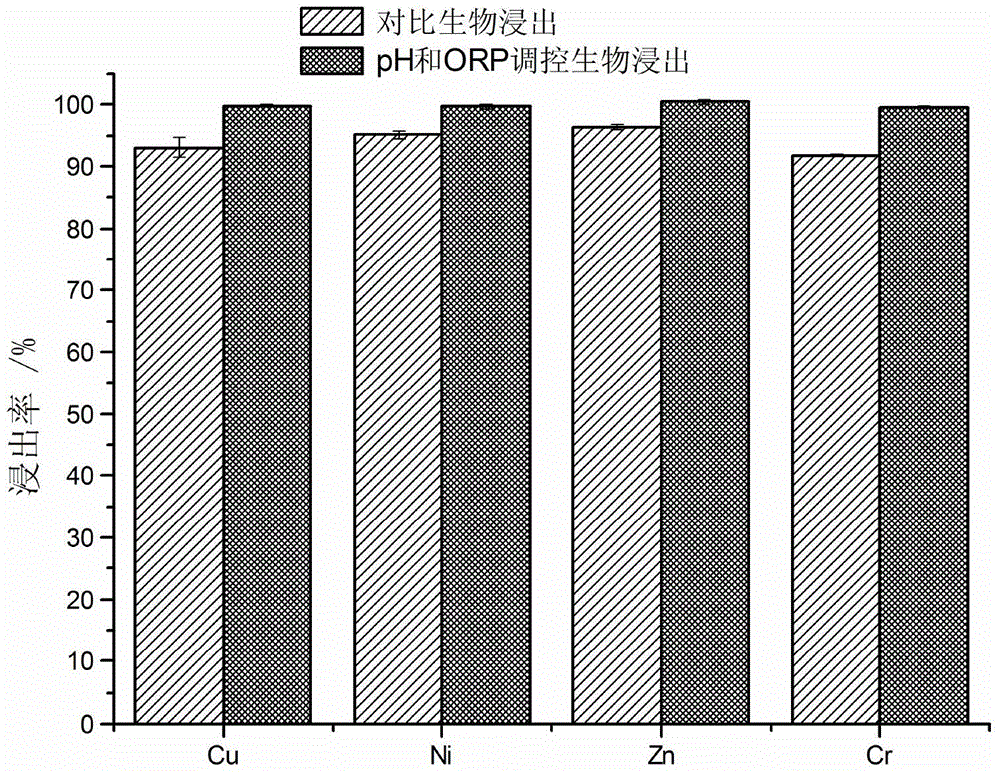

Method for biologically leaching heavy metal from heavy metal-contained waste based on pH and potential co-regulation

ActiveCN104862474AAvoid interactionEfficient DissolutionProcess efficiency improvementCo-regulationSludge

The invention discloses a method for biologically leaching heavy metal from a heavy metal-contained waste based on pH and potential co-regulation. The method comprises the following steps: in a process of leaching out the heavy metal-contained waste by an acidophilic iron oxide microbial agent, the pH value of the leaching system is controlled within 1.0-4.0 in the whole process; meanwhile, an oxidizing agent is combined with a reducing agent to regulate the redox potential of the leaching system, so that the redox potential of the leaching system is controlled within 420-650 mV; the pH value of the leaching system is gradually increased phase by phase in the leaching process; the redox potential of the leaching system is gradually increased phase by phase; the total leaching time is within 8 hours; and finally, the efficient leaching of the heavy metal from the heavy metal-contained waste by the acidophilic iron oxide microbial agent is realized. The method can accelerate biologic leaching of metal from sludge to shorten the leaching time and to reduce the acid consumption, and can greatly improve the biologic leaching efficiency.

Owner:厦门资生环保科技有限公司

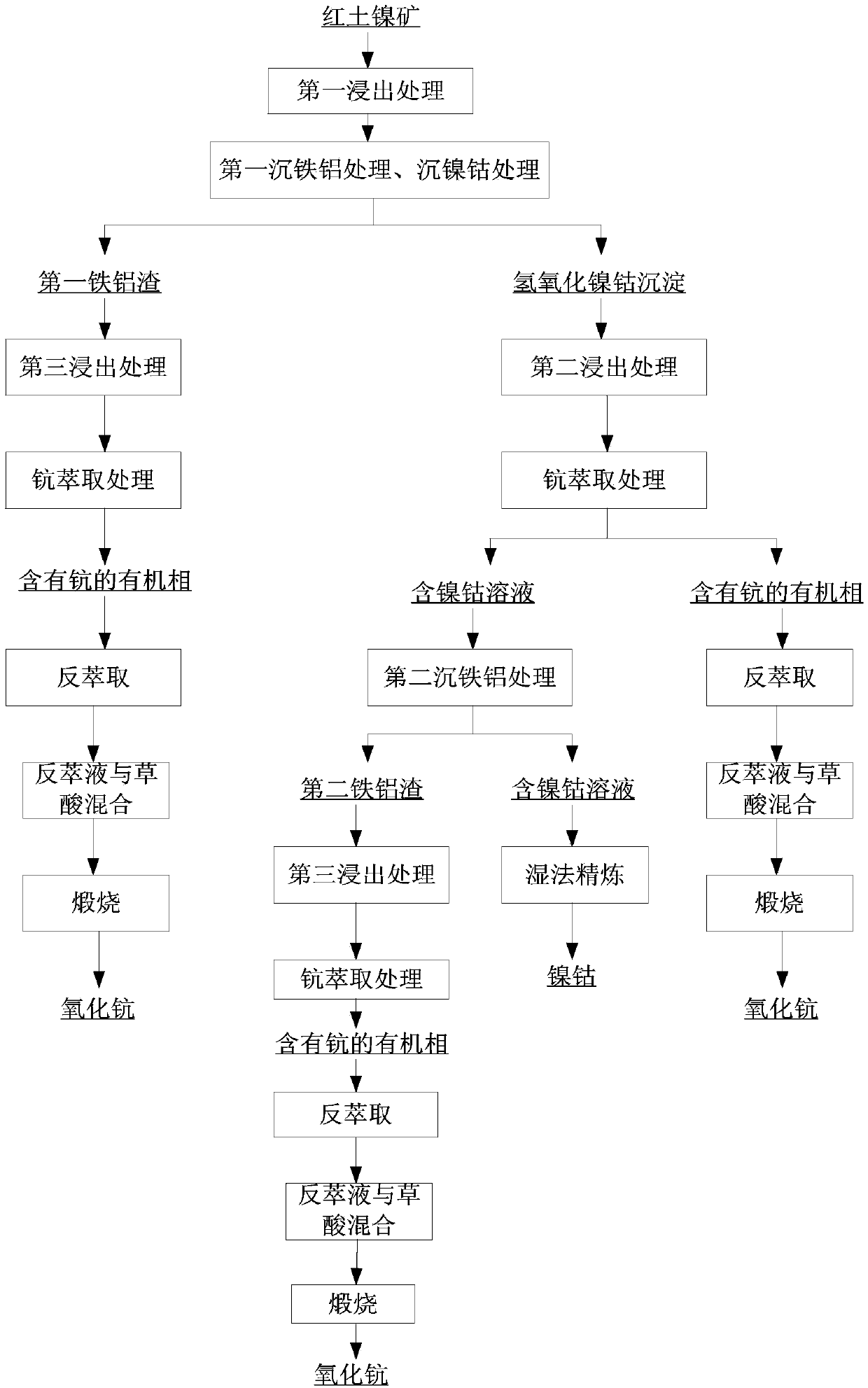

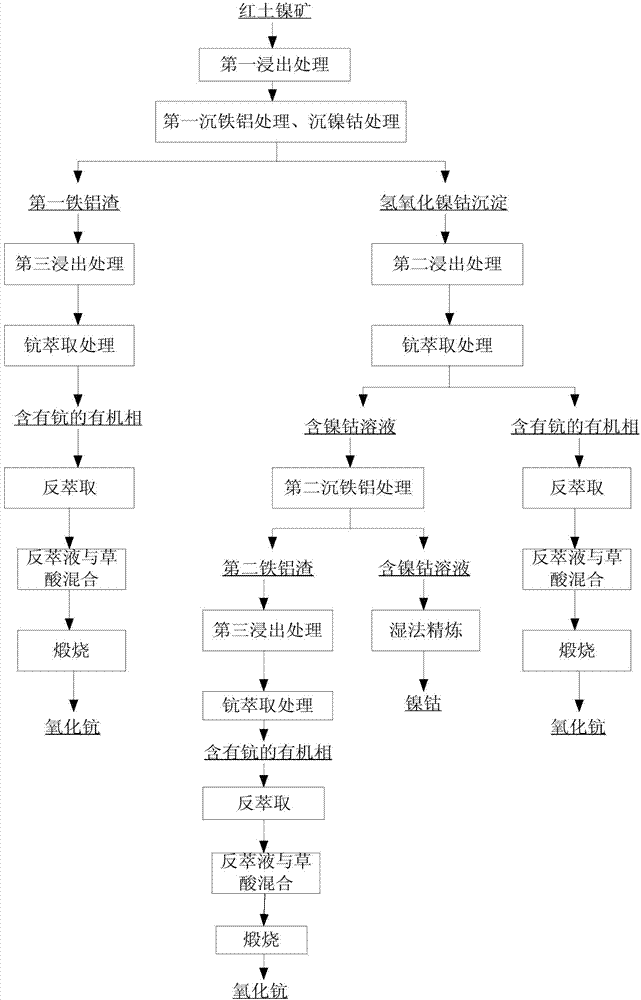

Treatment method for comprehensively recovering valuable elements from laterite-nickel ore

ActiveCN103484695AImprove processing efficiencyImprove leaching efficiencyProcess efficiency improvementPregnant leach solutionNickel oxide hydroxide

The invention provides a treatment method of laterite-nickel ore, particularly a treatment method for comprehensively recovering valuable elements from laterite-nickel ore. The treatment method comprises the following steps of: carrying out first leaching treatment on laterite-nickel ore by utilizing sulphuric acid so as to obtain laterite-nickel ore leachate; carrying out first iron-aluminium precipitating treatment and nickel-cobalt precipitating treatment on the laterite-nickel ore leachate so as to respectively obtain first iron-aluminium resides and cobalt nickel hydroxide precipitation; carrying out secondary leaching treatment on the cobalt nickel hydroxide precipitation by utilizing sulphuric acid so as to obtain nickel-cobalt leachate; carrying out scandium extracting treatment on the nickel-cobalt leachate by utilizing an organic extracting agent so as to obtain nickel-cobalt-containing solvent and scandium-containing organic phase; recovering nickel-cobalt from the nickel-cobalt-containing solvent; and recovering scandium from the scandium-containing organic phase. Scandium can be effectively extracted from laterite-nickel ore by utilizing the method disclosed by the invention.

Owner:CHINA ENFI ENGINEERING CORPORATION

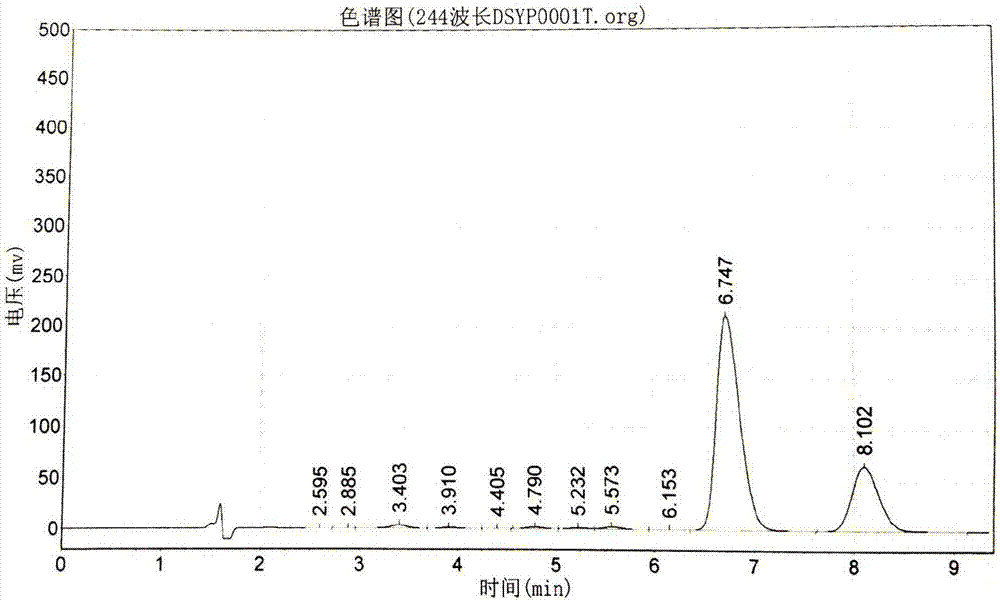

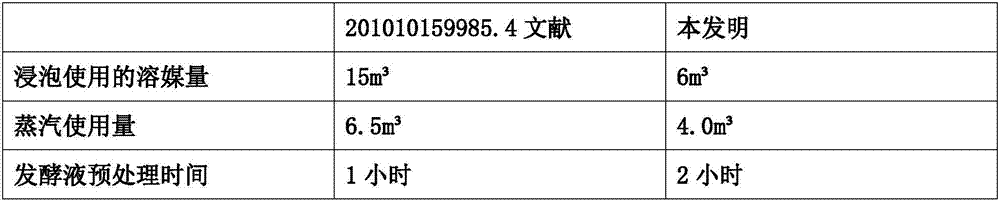

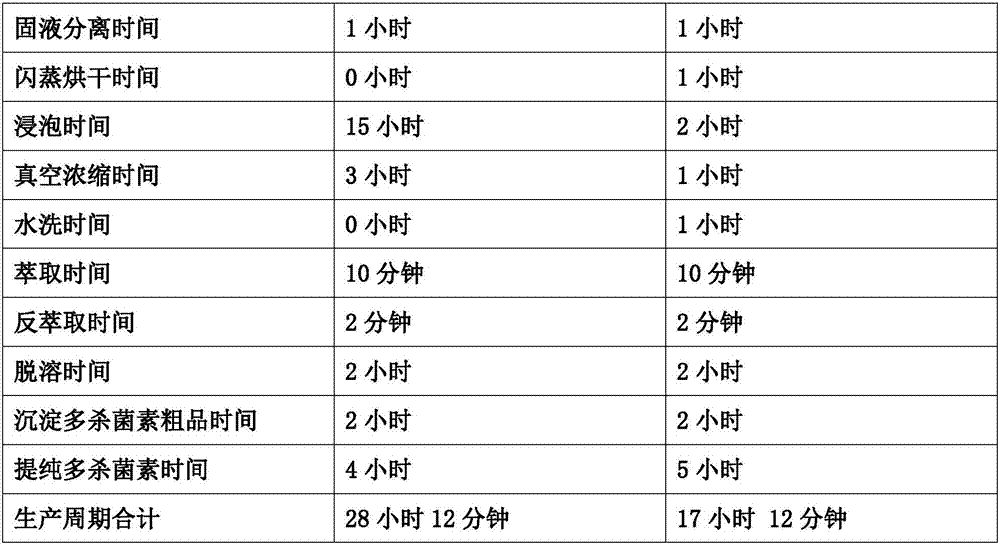

Extraction process for industrial mass production of spinosad

ActiveCN107474088AReduce usageImprove leaching efficiencySugar derivativesSugar derivatives preparationFiltrationSolvent

The invention relates to an extraction process for industrial mass production of spinosad. The process includes the steps of: fermentation broth pretreatment, frame and plate filtration, and flash drying; mycelium soaking in methanol; concentration of extract liquid, phase inversion washing; back extraction with tartaric acid; adjustment of pH and centrifugation to obtain a spinosad crude product; and recrystallization with methanol to obtain a spinosad fine product. The process provided by the invention extracts spinosad by means of mycelium separation, drying and extraction, and has the characteristics of high extraction efficiency, small solvent dosage, which is only half of that of fermentation broth direct solvent extraction, relatively low energy consumption, and shortened production cycle. In addition, the equipment needed by frame and plate filtration, flash drying, extraction, concentration, washing, back extraction and refining is general, therefore industrial production can be realized easily. The obtained product has high yield up to 85%-90%, after purification of spinosad coarse crystals by solvent recrystallization, the quality of spinosad is improved, and the product content reaches 95%-98%.

Owner:QILU PHARMA INNER MONGOLIA

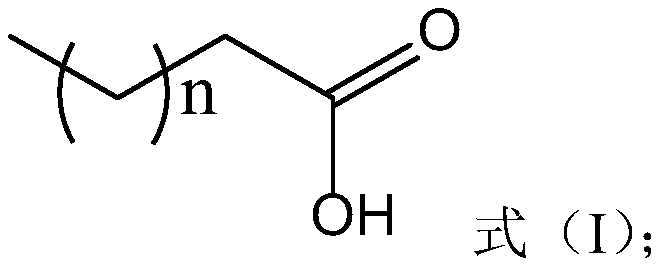

Method for extracting metal ions from fatty acids

ActiveCN110408777ABalanced utilizationImprove leaching efficiencyProcess efficiency improvementRare earthFatty acid

The invention relates to the field of enrichment of metal ions, and discloses a method for extracting metal ions from fatty acids. The method comprises the following steps that (1) saponification is carried out on a fatty acid extraction agent through alkali; (2) the saponification-treated fatty acid extraction agent and an extraction mother solution are mixed, react with each other, are stirred uniformly and precipitated and are then subjected to solid-liquid separation to obtain a metal precipitate, and rare-earth metal ions or non-rare-earth metal ions in the mother solution are extracted;and (3) the metal precipitate is eluted through an acid liquid, and a metal-enriched solution and a regenerative fatty acid extraction agent are obtained after liquid separation. The fatty acid extraction agent used in the method can be directly extracted from animals and plants, can be acquired from numerous sources at low price, is convenient to convey and store, good in biological compatibilityand easy to degrade and causes less pollution to water bodies, the precipitates formed in the precipitation process are large in particle size, solid-liquid separation is easy, the recovery rate of metal ions is high, the enrichment factor is large, and the fatty acids can be recycled.

Owner:厦门熙途科技有限公司

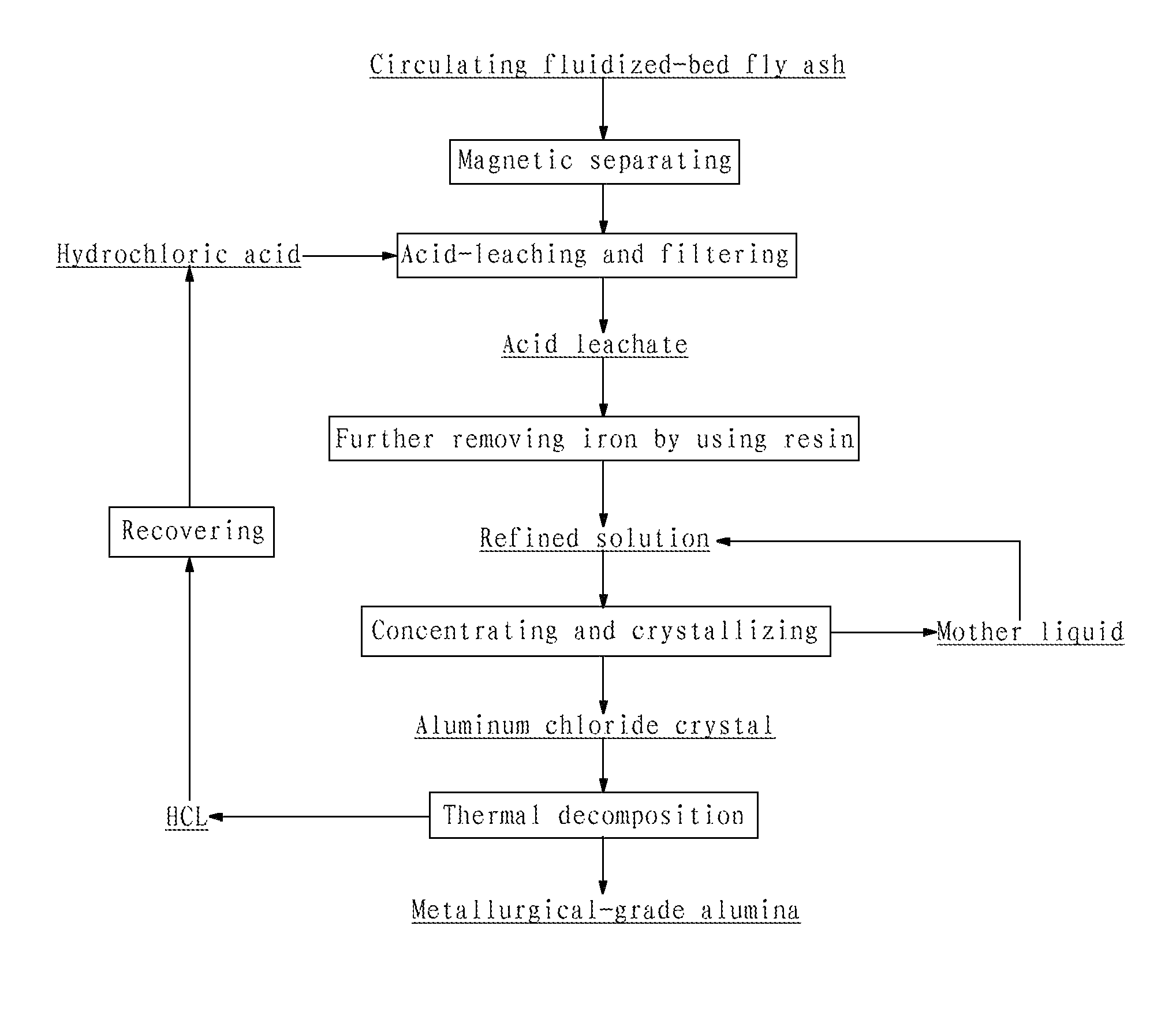

Method for preparing metallurgical-grade alumina by using fluidized bed fly ash

ActiveUS8568671B2Simple methodLow production costSolvent extractionSolid waste disposalFluidized bedChloride

Provided a method for preparing metallurgical-grade alumina by using fluidized-bed fly ash, comprising: a) removing iron by wet magnetic separation after crushing the fly ash; b) reacting the fly ash after magnetic separation with hydrochloric acid to obtain a hydrochloric leachate; c) passing the hydrochloric leachate through macro-porous cationic resin to deeply remove iron to obtain a refined aluminum chloride solution; d) concentrating and crystallizing the refined aluminum chloride solution to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal to obtain the metallurgical-grade alumina. The method is simple, the procedure is easy to be controlled, the extraction efficiency of alumina is high, the production coast is low, and the product quality is steady.

Owner:CHINA SHENHUA ENERGY CO LTD

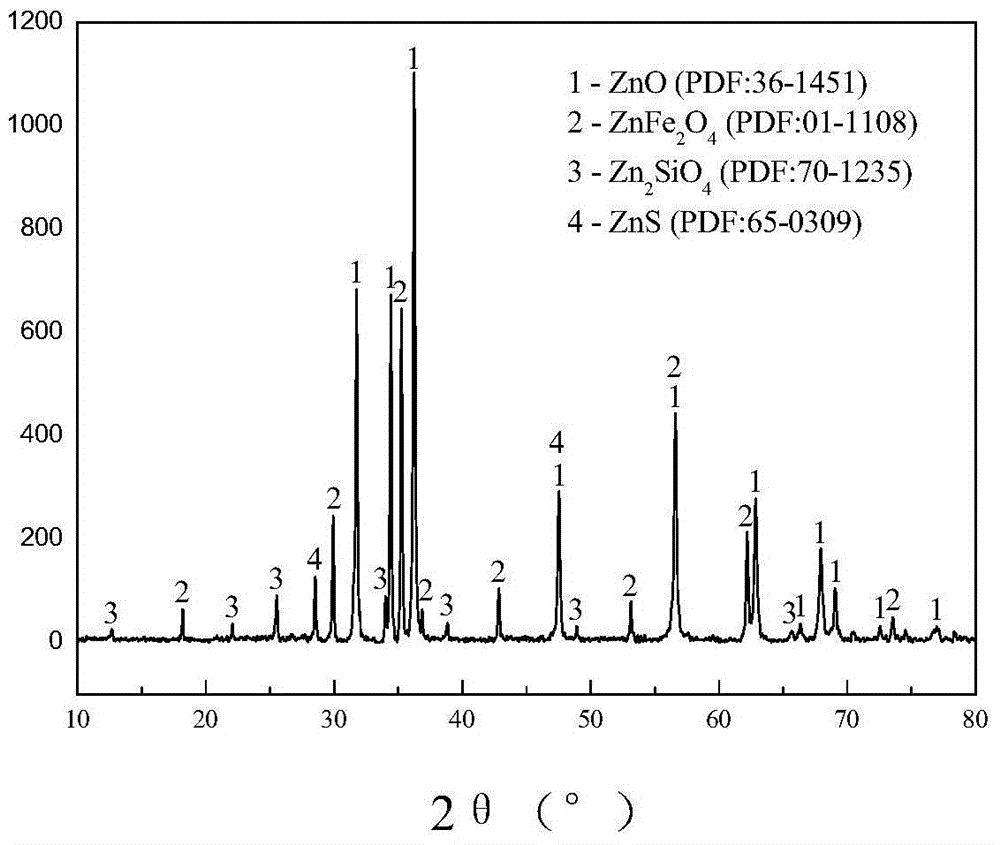

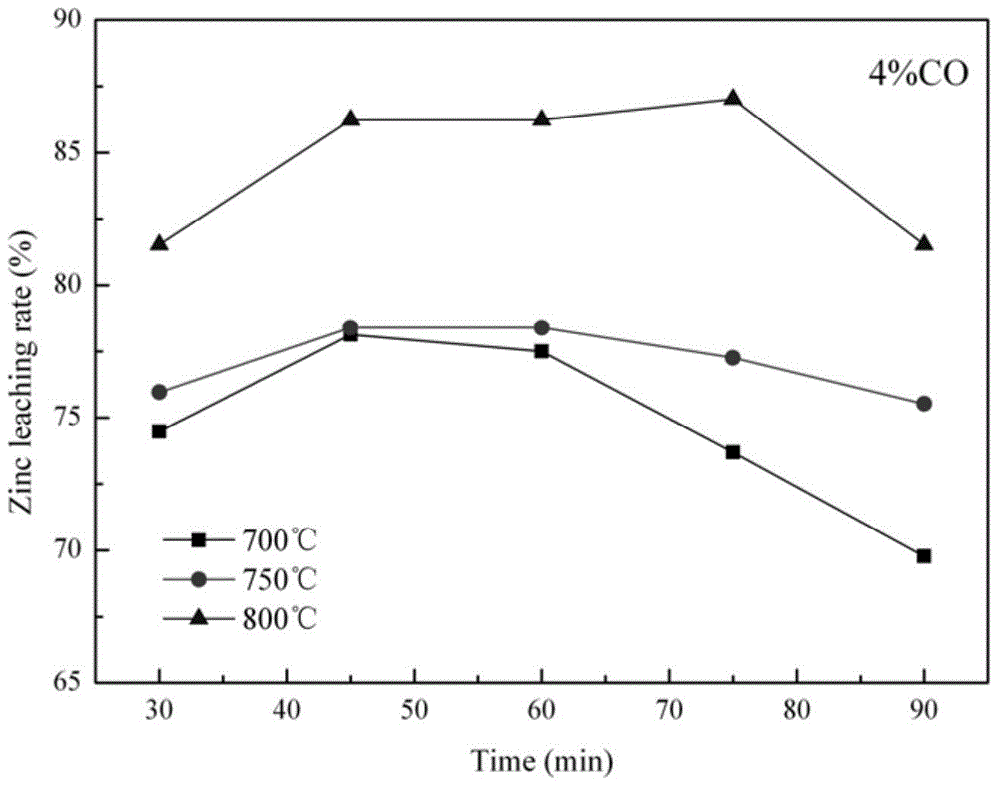

Method for recovering metal resource from zinc calcine through reduction roasting-leaching-zinc sinking

InactiveCN104946903AEfficient separationImprove leaching rateProcess efficiency improvementSodium zincateSlag

The invention discloses a method for recovering a metal resource from zinc calcine through reduction roasting-leaching-zinc sinking. High-iron zinc calcine containing zinc ferrite is reduced and roasted under the CO atmosphere, so that the zinc ferrite is decomposed to zinc oxide and iron oxide; the alkaline leaching is performed for the roasting product by sodium hydroxide solution to obtain sodium zincate solution containing few impurity ions; and iron, lead and silver enter the leaching slag for enriching and recovering to realize high-efficiency separation of zinc and iron. The neutralization, the adjustment and the zinc sinking are performed for the leaching liquid by waste electrolyte in conventional zinc wet smelting; the leaching liquid is calcined by a muffle after the precipitation; and the zinc resource is recovered in a form of active zinc oxide. The method prevents the complicated iron sinking flow in the conventional zinc wet smelting procedure, is excellent in zinc-iron separation effect, and achieves the purpose of comprehensively recovering the metal resource.

Owner:CENT SOUTH UNIV

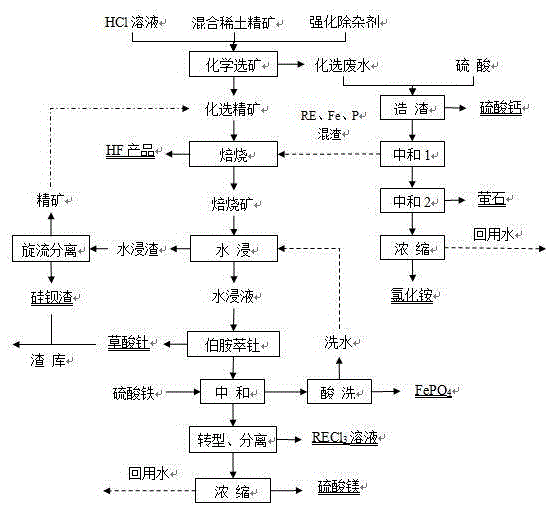

Method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid

InactiveCN105568006AImprove dissolution rateIncrease dissolution rateProcess efficiency improvementResource recoveryWastewater

The invention relates to a method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid. The method is characterized by comprising the following steps of chemically selecting and gathering mixed rare earth concentrate by use of a hydrochloric acid solution and a reinforced impurity remover, mixing the chemically-selected concrete with the concentrated sulfuric acid to roast at a low temperature, carrying out water leaching on roasted concentrate, carrying out resource recovery on a water leaching fluid, carrying out tail gas absorption, and recycling chemical-selected wastewater resources. The method has the advantages that the source of three wastes of a current concentrated sulfuric acid high-temperature roasting process is solved at the front end of concentrate treatment, so that various problems in a low-temperature acid method are solved, the follow-up three-waste treatment difficulty is greatly reduced, the rare earth direct recovery rate is increased, and the purpose of comprehensively recycling various resources in the concentrate and auxiliary materials is finally realized.

Owner:BAOTOU RES INST OF RARE EARTHS

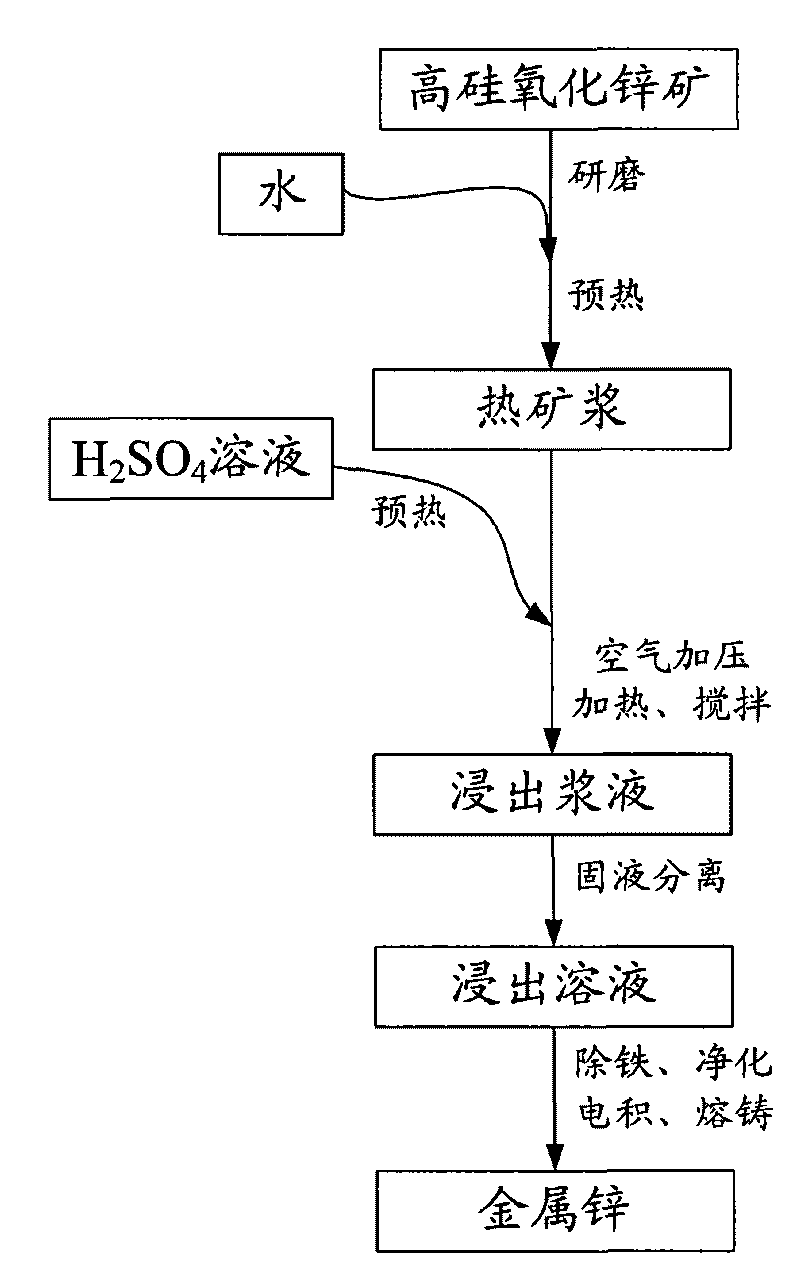

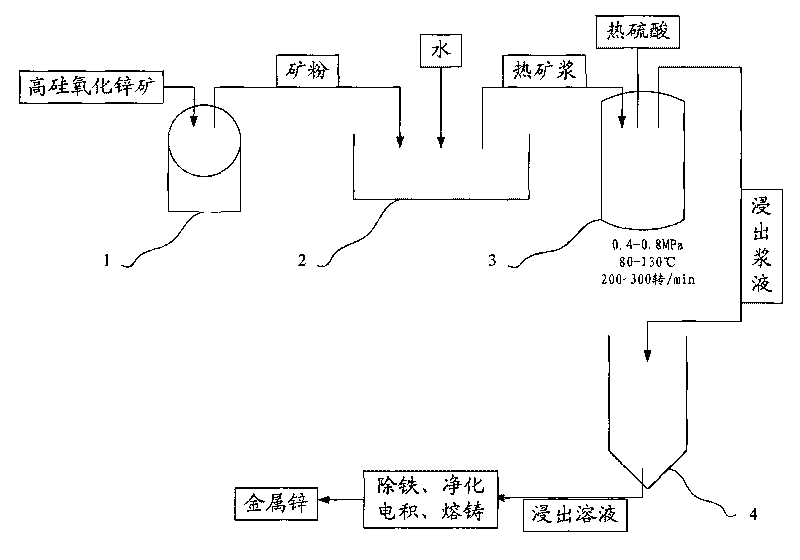

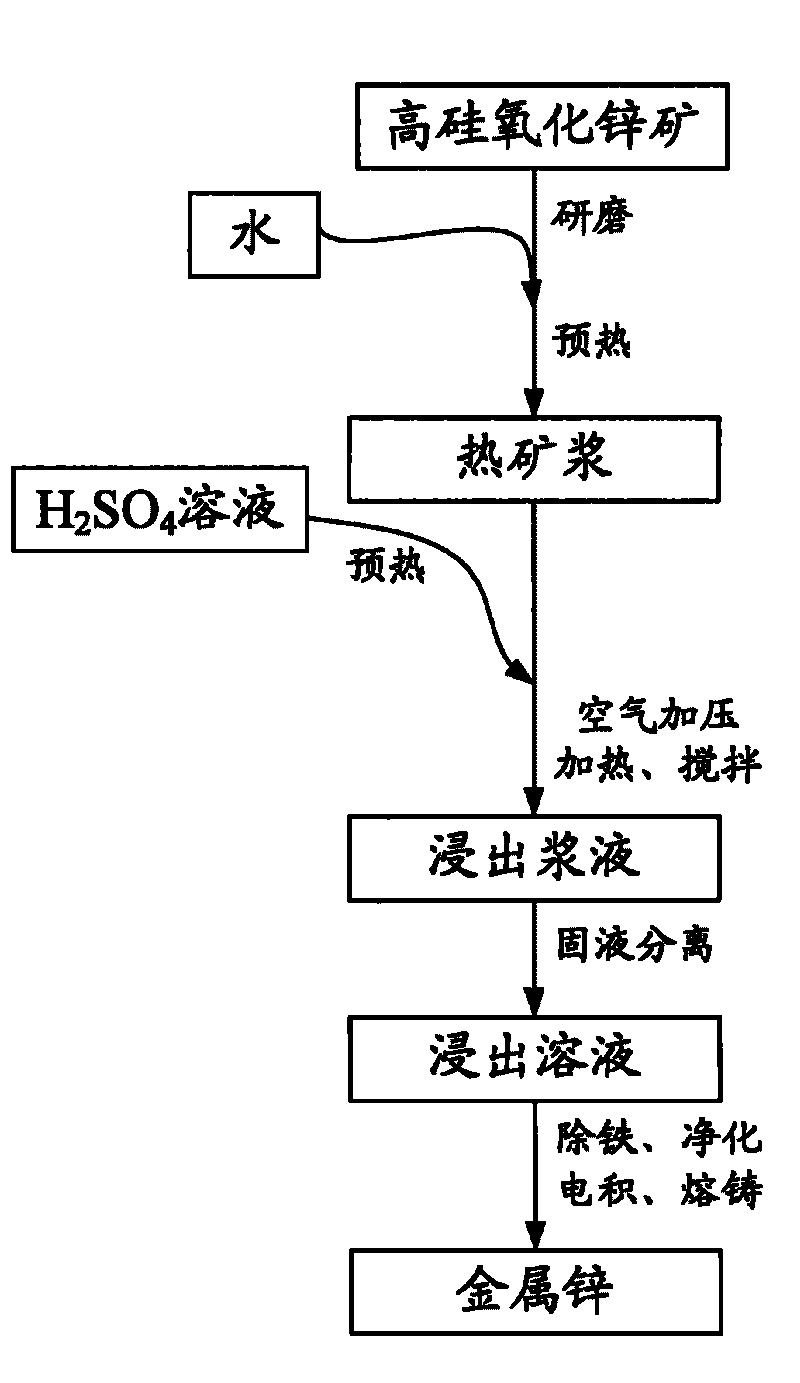

Method for producing zinc by use of high-silicon zinc oxide ore

InactiveCN101709386ARelieve pressureImprove securityProcess efficiency improvementMass ratioHydrometallurgy

The invention provides a method for producing zinc by use of high-silicon zinc oxide ore. The method comprises the following steps: grinding high-silicon zinc oxide ore and mixing the obtained product with water in a mass ratio of 0.7-0.8:1; heating the mixture to 40 to 60 DEG C and preparing hot ore pulp; preheating H2SO4 solution in a concentration of 150 to 220 g / L to 40 to 90 DEG C; continuously conveying the hot ore pulp and hot sulfuric acid solution in a volume ratio of 1:3-5 into a reaction container; supplying air to ensure that the pressure in the reaction container is 0.4 to 0.8 MPa; performing reaction for 30 to 180 minutes at a temperature kept between 80 and 130 DEG C at a stirring speed of 200 to 300 revolutions per minute so as to leach zinc; forming leaching solution from leaching slurry discharged from the reaction container through liquid-solid separation; adopting a conventional zinc hydrometallurgy process to treat the leaching solution; and producing the zinc through iron removal, purification, electrowinning and melt casting. The method for producing zinc has the characteristics of high leaching efficiency, high safety, reaction conditions easy to realize, low production cost and the like.

Owner:YUNNAN METALLURGICAL GROUP

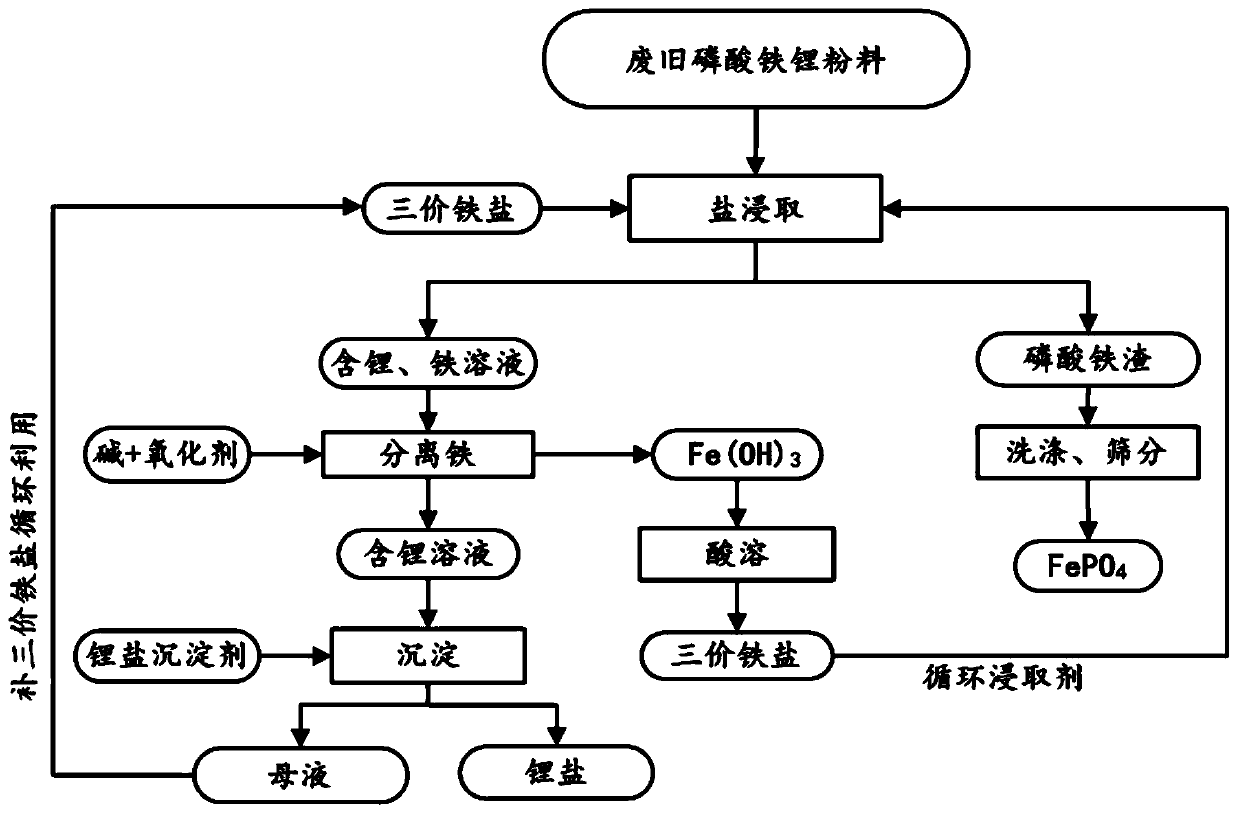

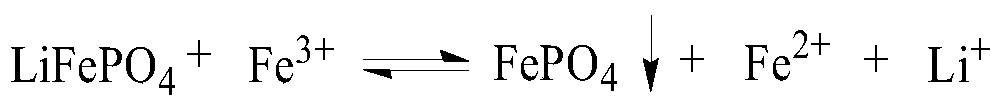

Method for comprehensive recycling waste lithium iron phosphate battery cathode material

ActiveCN110474123AAchieve recyclingFast and efficient leachingPositive electrodesWaste accumulators reclaimingRecovery methodLithium iron phosphate

The invention belongs to the technical field of waste lithium battery resource recycling and particularly relates to a method for comprehensive recycling a waste lithium iron phosphate battery cathodematerial, comprising the following steps of (1) putting a pulverized and sieved waste lithium iron phosphate battery cathode material into a ferric salt solution, and performing filtration after a reaction to obtain a first filtrate and a first filter cake; (2) adding a base and an oxidizing agent to the first filtrate, and performing filtration after a reaction to obtain a second filtrate and asecond filter cake; (3) adding a lithium salt precipitant to the second filtrate, and performing filtration after a reaction to obtain a third filtrate and a coarse lithium salt, and supplementing thethird filtrate with ferric ions and then cyclically utilizing the third filtrate for the step (1). The method of the present invention uses the ferric salt as a leaching reagent, causes no pollutionand achieves high lithium leaching efficiency (>96%).

Owner:贵州红星电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com