Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243 results about "Zincate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

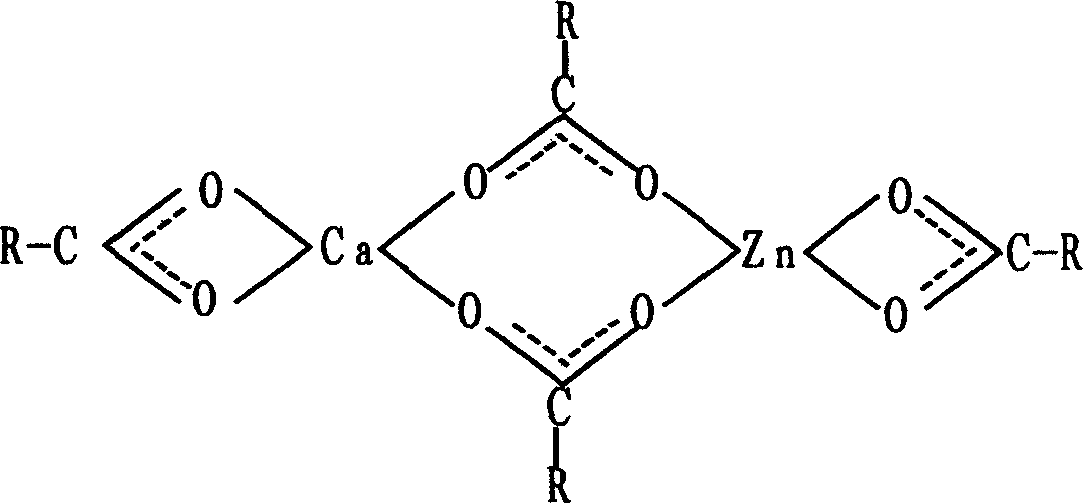

In chemistry the term zincate may refer to a salt containing Zn(OH)₄2−,also called the tetrahydroxozincate ion. It is an ore of Zinc. Examples include calcium zincate CaZn(OH)₄.2H₂O or Na₂Zn(OH)₄ or the polymeric anion [Zn(OH)₃−] in for example NaZn(OH)₃· H₂O an alkali solution prepared from dissolving zinc metal, zinc hydroxide or zinc oxide which contains various anionic species such as Zn(OH)₄2−. Such solutions are used in the plating industry. an oxide containing zinc and a less electronegative element e.g. Na₂ZnO₂. a commercially available zinc supplement formulated as zinc sulfate.

Aqueous slurry containing metallate-modified silica particles

InactiveUS20070037892A1Improve stabilityIncrease surface chargePigmenting treatmentOther chemical processesAluminateSilica particle

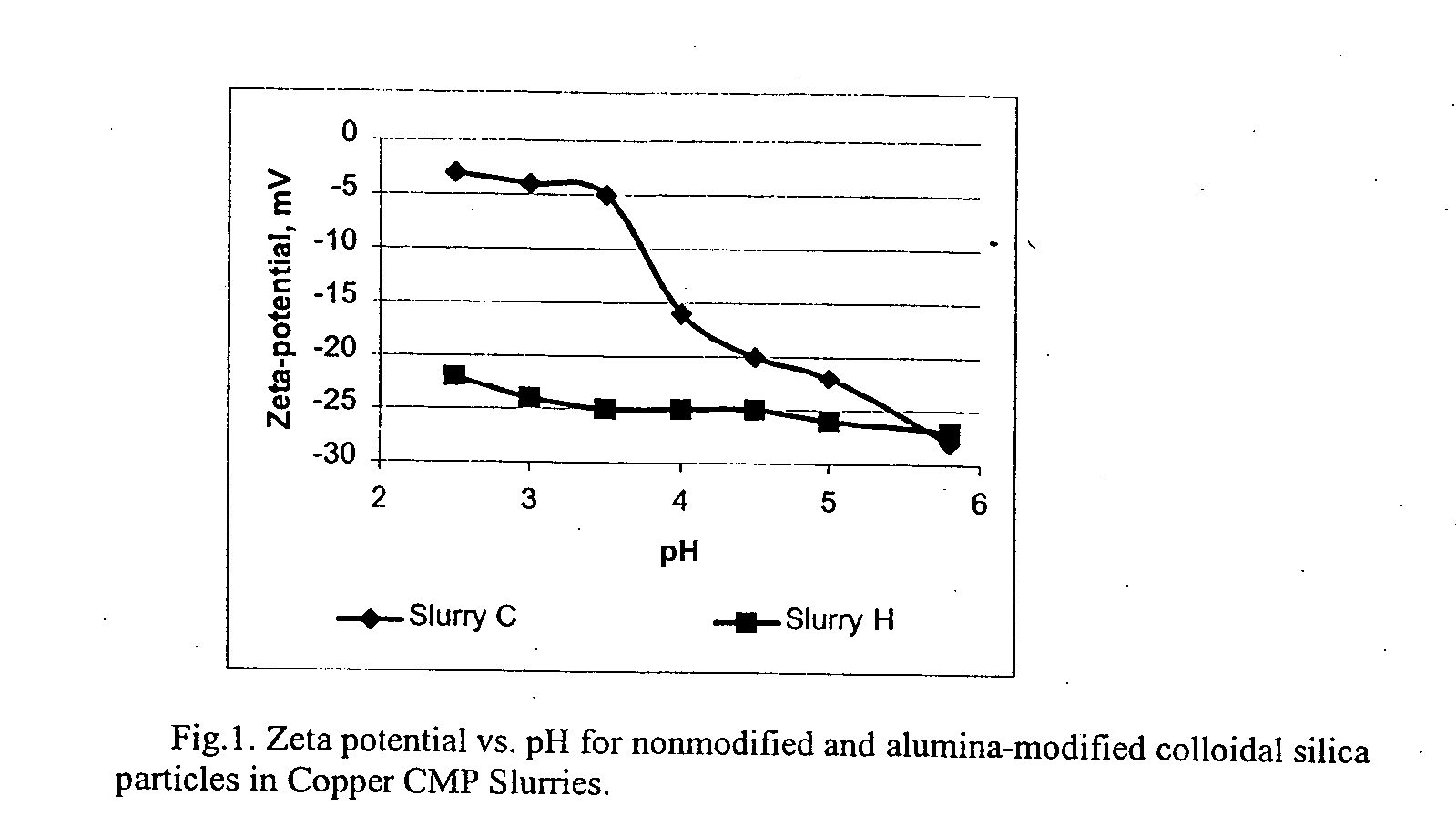

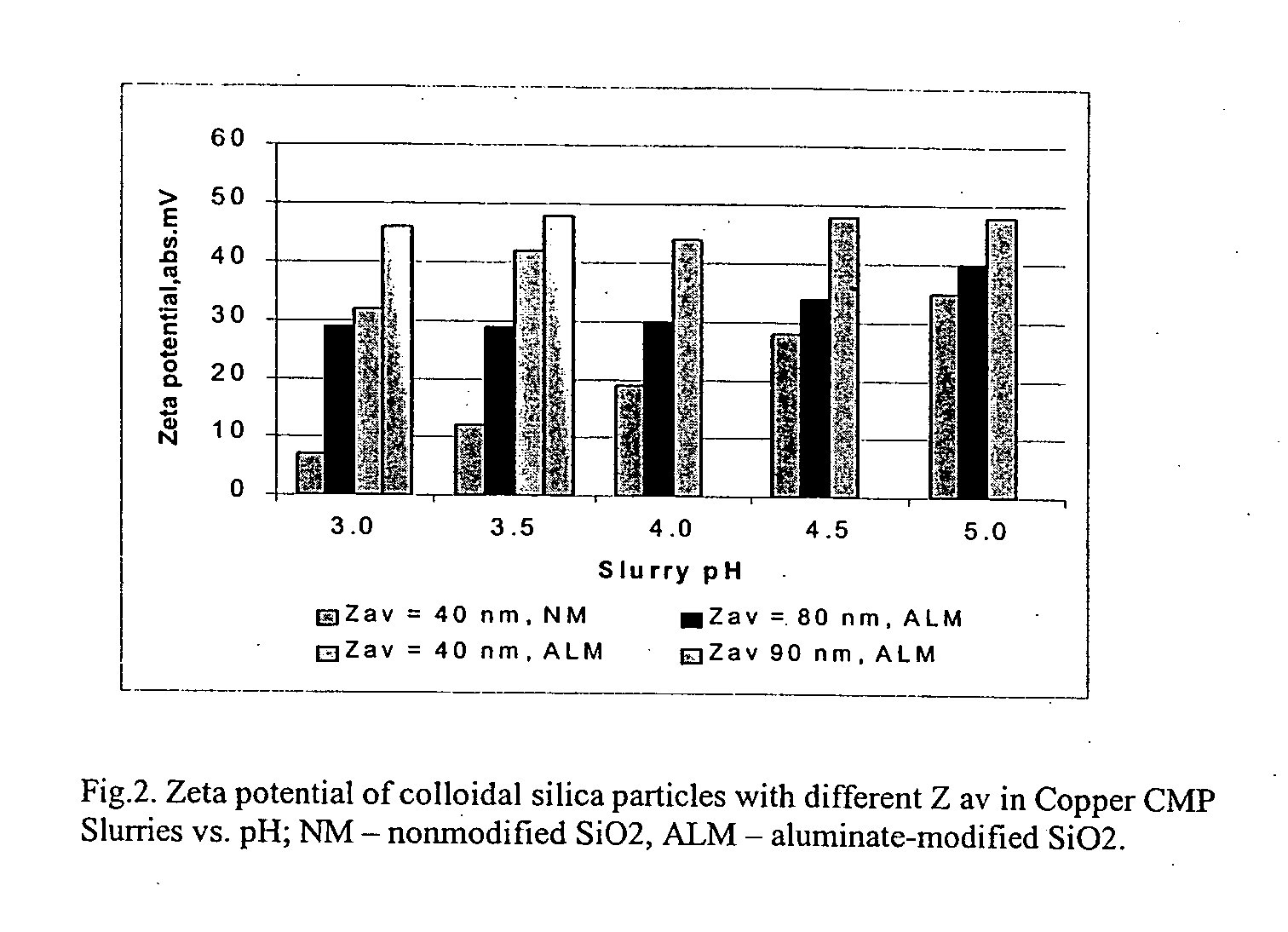

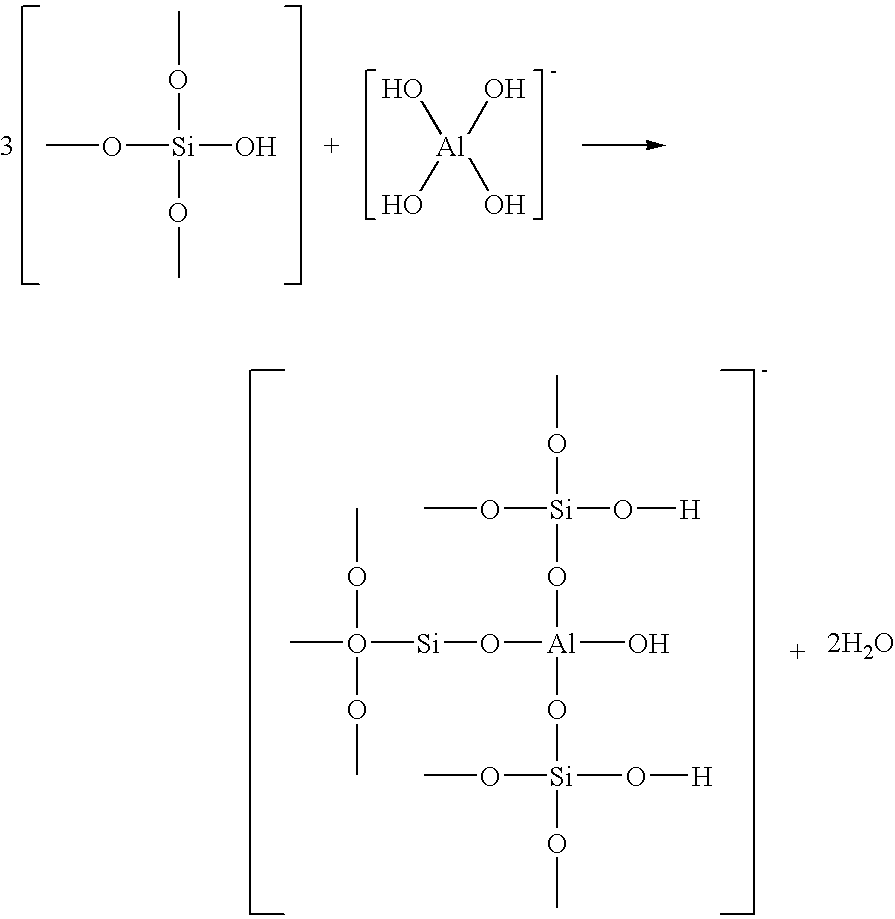

Provided is a novel aqueous slurry composition for polishing / planarization of a substrate. The composition includes silicon dioxide abrasive particles wherein the abrasive particles are anionically modified / doped with metallate anions selected from the group consisting of aluminate, stannate, zincate and plumbate, thereby providing a high negative surface charge to the abrasive particles and enhances the stability of the slurry composition.

Owner:PRAXAIR TECH INC

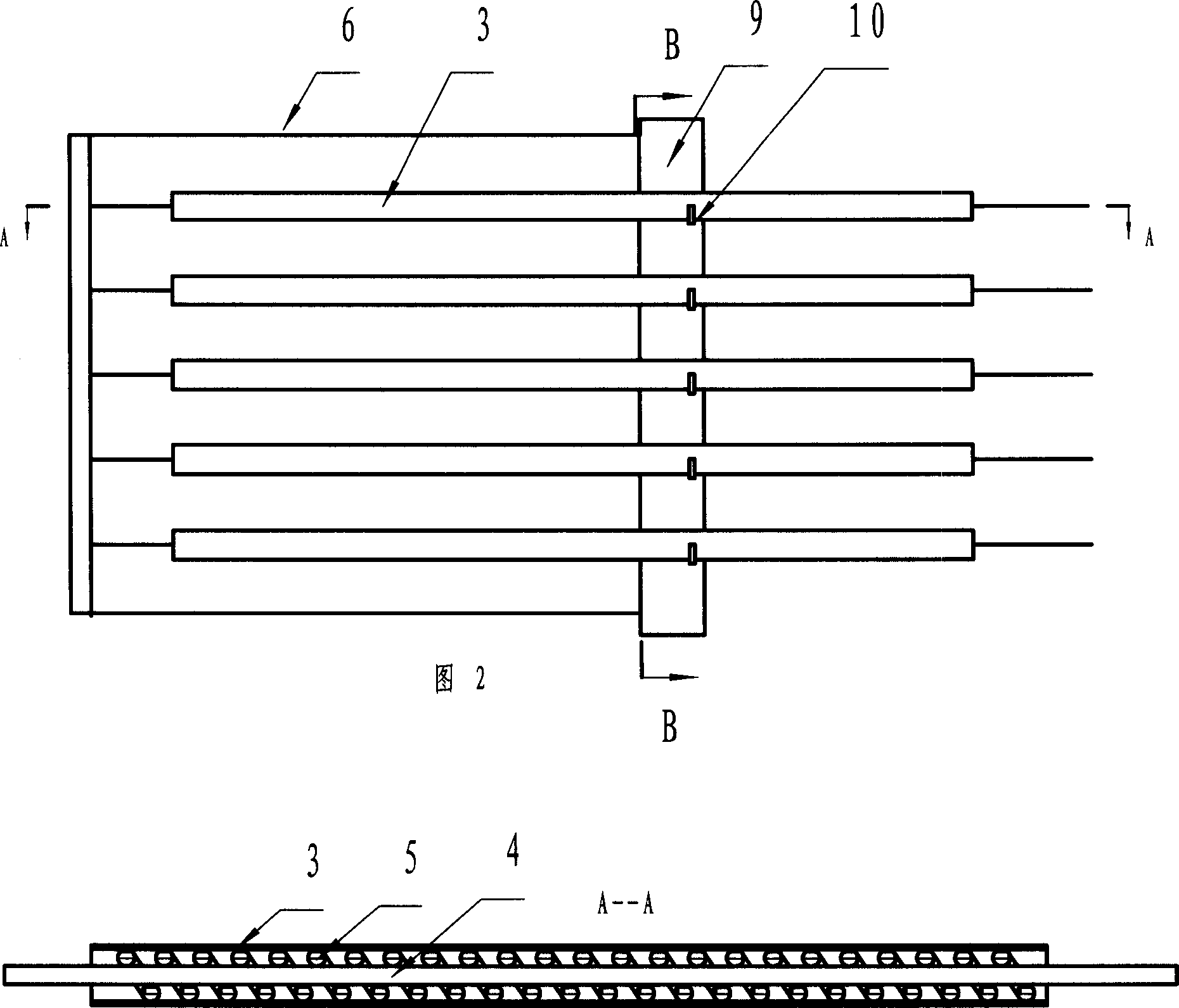

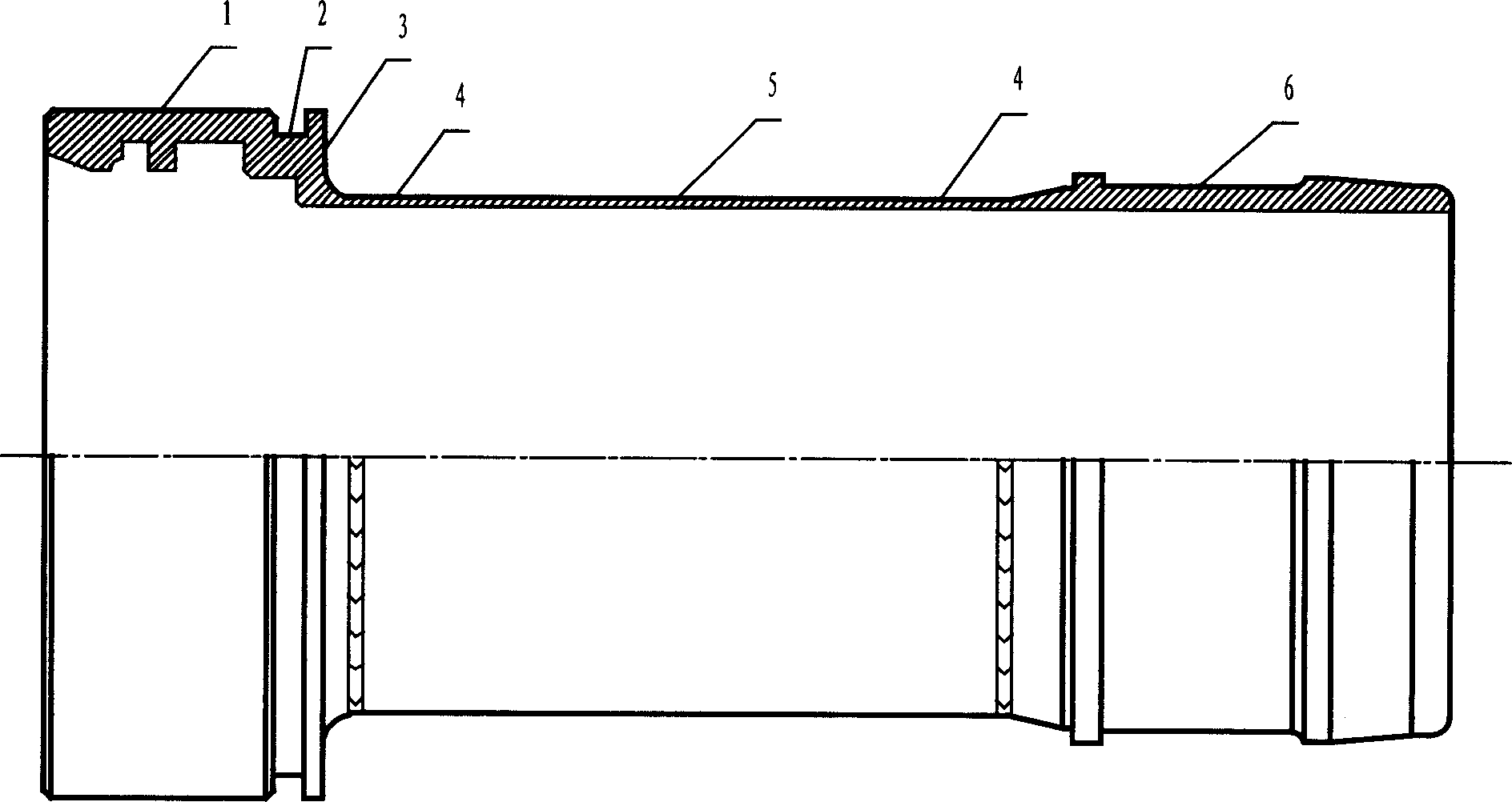

Process and special apparatus for electrogalvenizing inner and outer walls of steel pipe

InactiveCN1401823AFacilitates automatic cycle updatesImprove corrosion resistanceElectrolysis componentsElectrogalvanizationCyanide

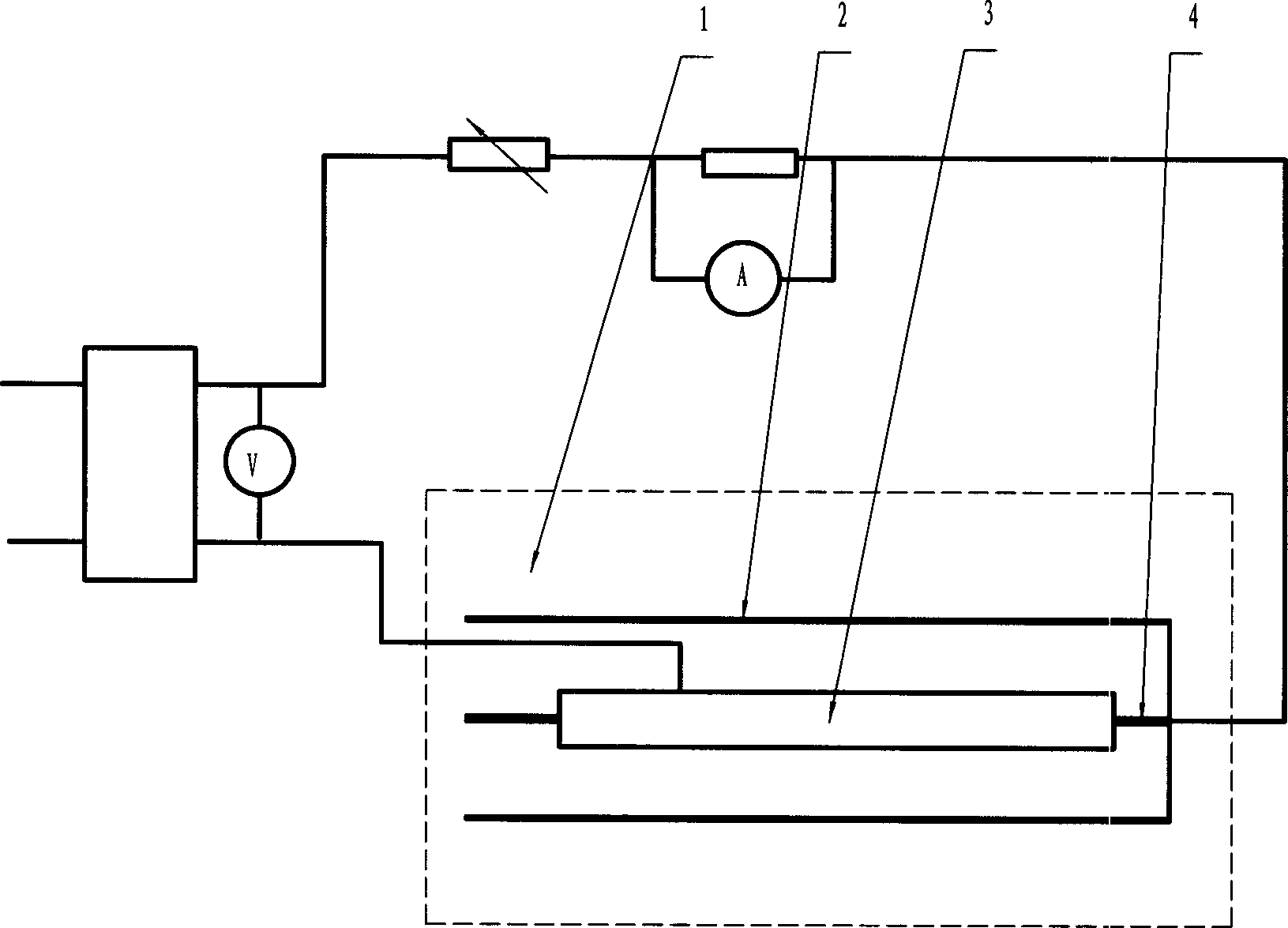

A process for electroplating the inner and outer surfaces of steel tube with Zn is disclosed. It is characterized by that its electroplating liquid has the merits of both alkaline zincate and cyanide used for plating zinc. Its apparatus is characterized by that an auxiliary anode is additionally used inside the steel tube to be plated, that is, its hanger plays the roles of both cathode and anodes. Its advantages are high anticorrosion power of its plated layer and enough thickness of internal plated layer.

Owner:山东鲁宏塑窗机械集团总公司五金电镀厂

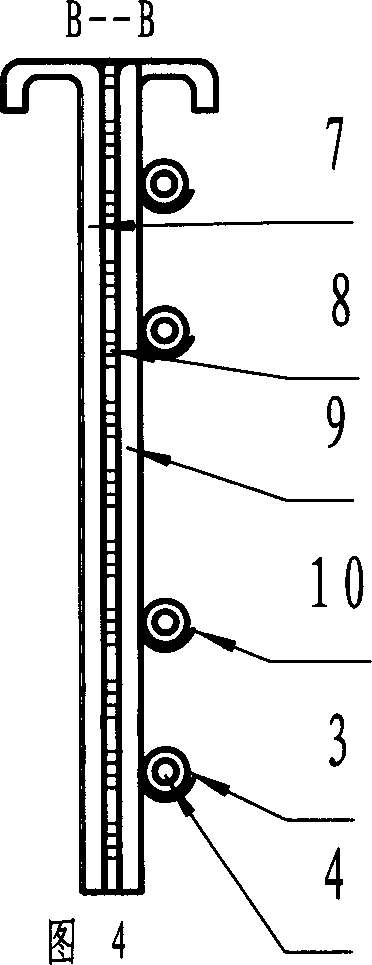

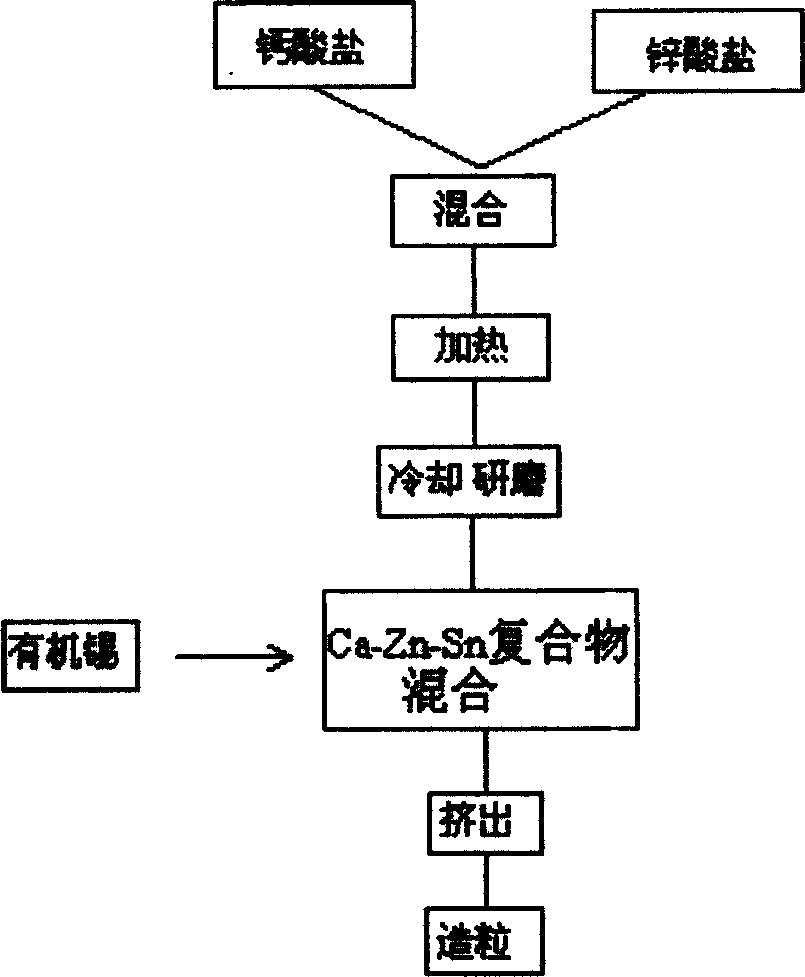

Ca-Zn-Sn composite stabilizer for polyvinyl chloride and method for preparing same

The invention relates to a Ca-Zn-Sn compound thermal stabilizer for stabalizer and its preparing method, which is based on Ca St2 / ZnSt2, comprised of angxiliary stabalizer and orgnic tin, with the main components: Ca / Zn compound of zincate and polyvinyl chloride-stabalizer portion and orgic tin 0.1-0.3 portion. The invention has outstanding thermal stabalization and processcable performance, increases thermal stabalization effect of thermal stabalizer, anlarge its application range, reduce the quantity of organic tin and decreases the productive cost.

Owner:SICHUAN UNIV

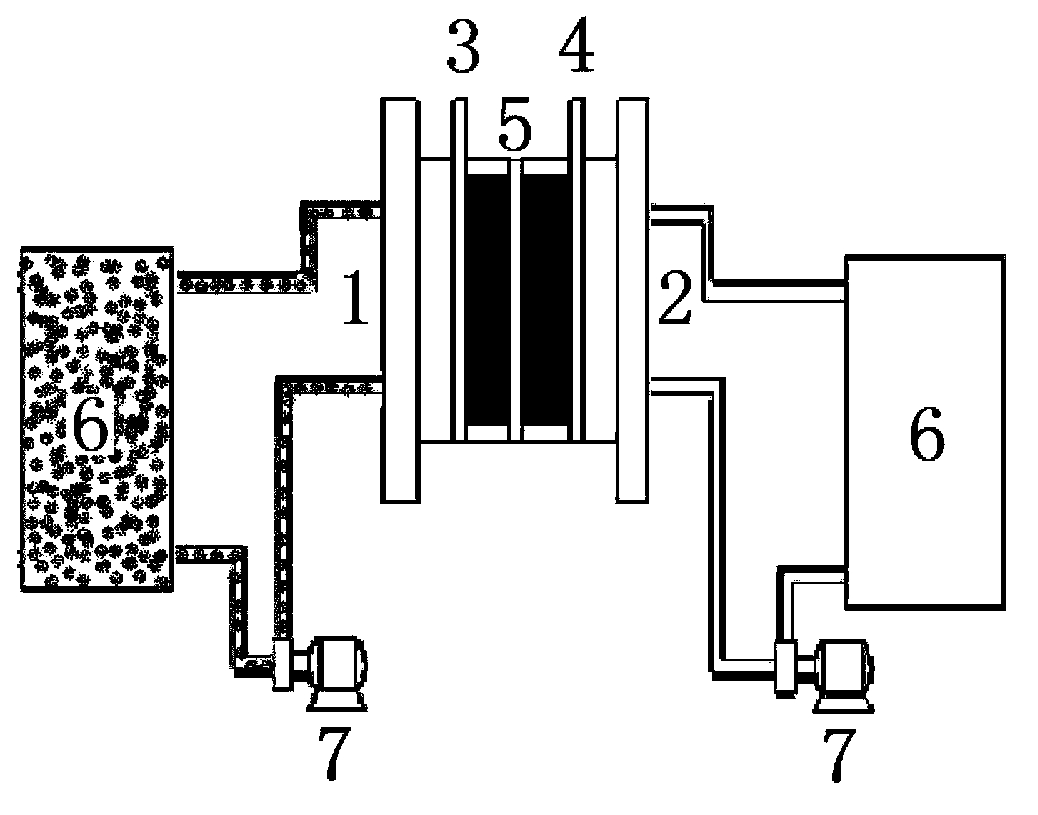

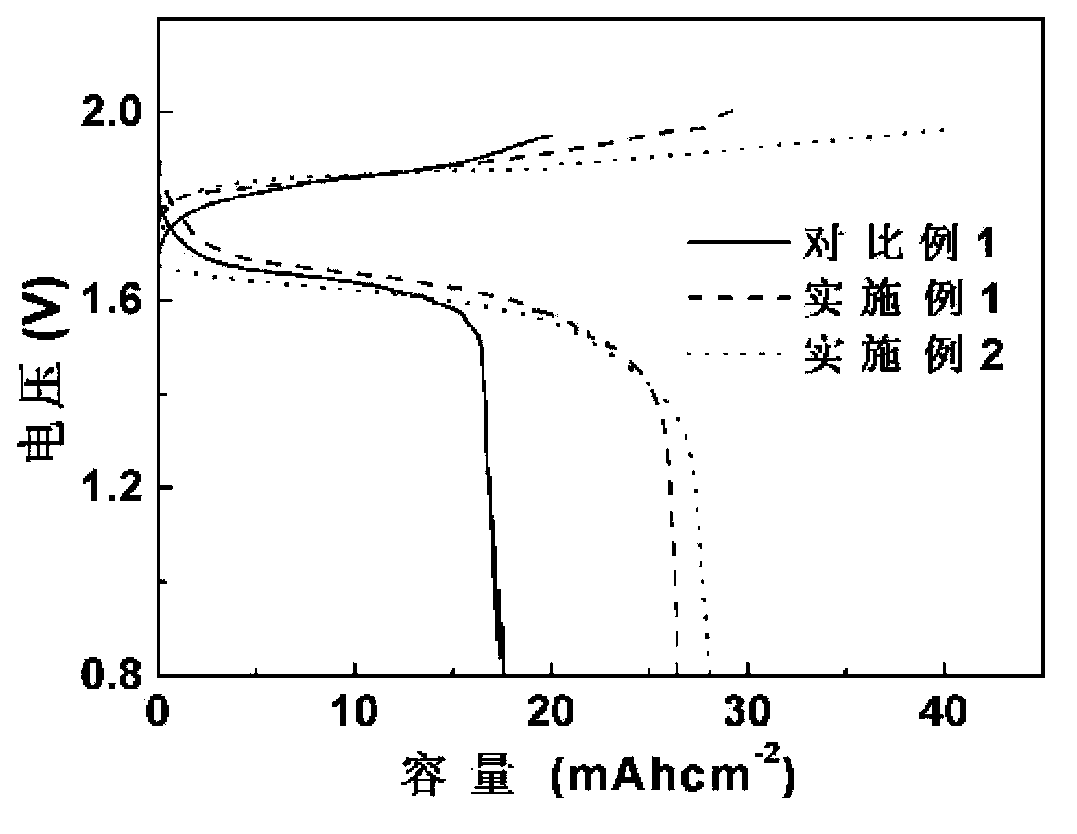

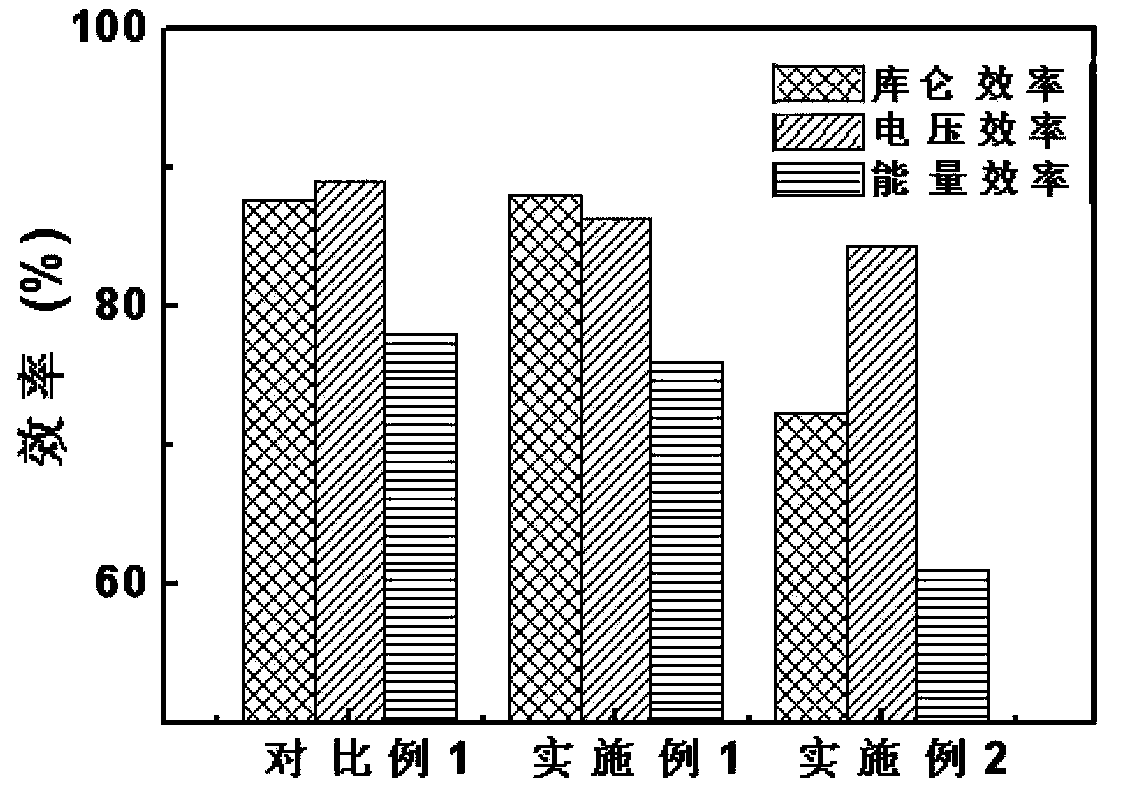

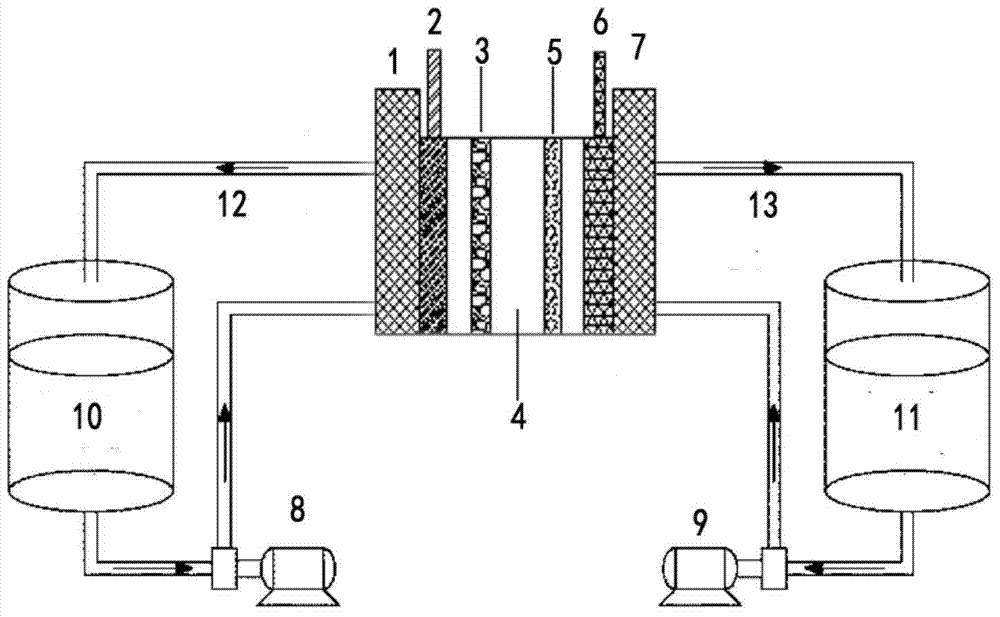

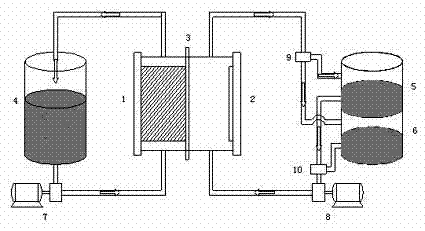

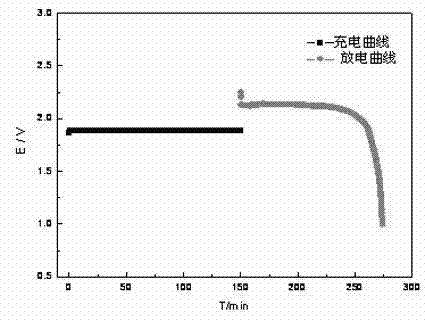

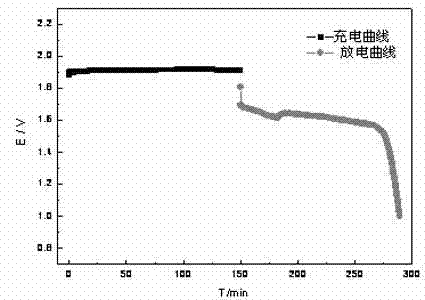

Semi-solid-state zinc nickel flow cell

InactiveCN103840187AIncrease capacityImprove securityFuel cells groupingFinal product manufactureZincateHigh energy

The invention provides a semi-solid-state zinc nickel flow cell. A single cell is composed of positive and negative electrode end plates, a positive electrode, a negative electrode, a diaphragm, fluid storage tanks, a pipeline and a pump, wherein the positive electrode is a porous electrode, the negative electrode is a deposition type electrode, an active material-nickelous hydroxide in the positive electrode is suspended and dispersed in a positive electrode electrolyte, and a negative electrode electrolyte is a high-consistency alkaline zincate solution. In the charging process, the electrolytes are respectively conveyed to the positive electrode and the negative electrode from the fluid storage tanks by the pump, and the active material-nickelous hydroxide in the positive electrode electrolyte is oxidized into nickel oxide hydroxide; zinc ions in the negative electrode electrolyte is directly deposited in the negative electrode in a zinc elementary substance form. In the discharging process, the nickel oxide hydroxide in the positive electrode fluid storage tank is reduced to nickel hydroxide; a zinc elementary substance is oxidized to zinc ions which return to the negative electrode fluid storage tank by the pump. According to the semi-solid-state zinc nickel flow cell disclosed by the invention, a solid active material-nickel hydroxide involving in the reaction with the positive electrode is stored in the corresponding electrolyte, so that the power and energy can be singly designed, and the cell has the characteristics of high energy storage capacity, high safety, long circulation service life, low cost and simple structure and manufacturing process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

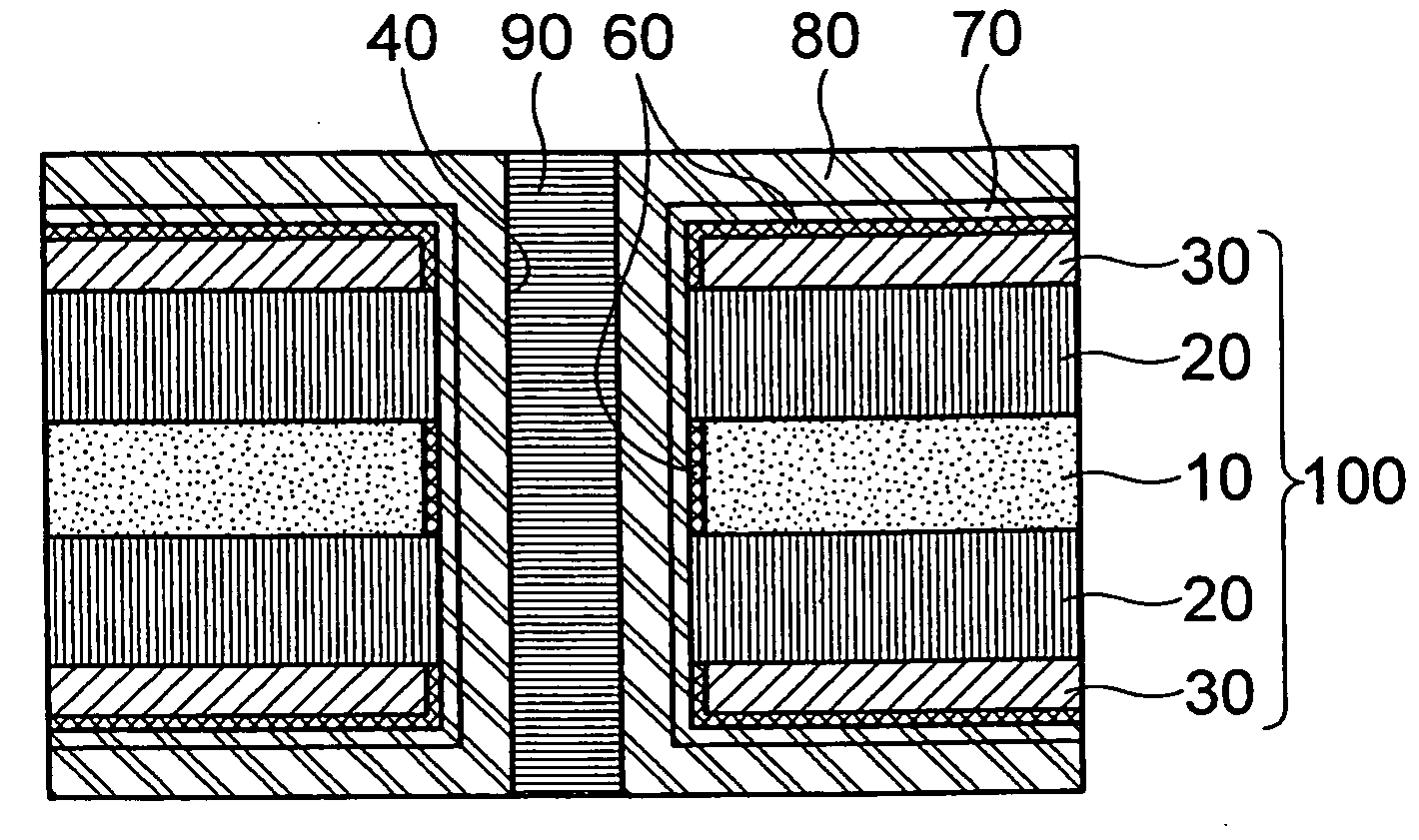

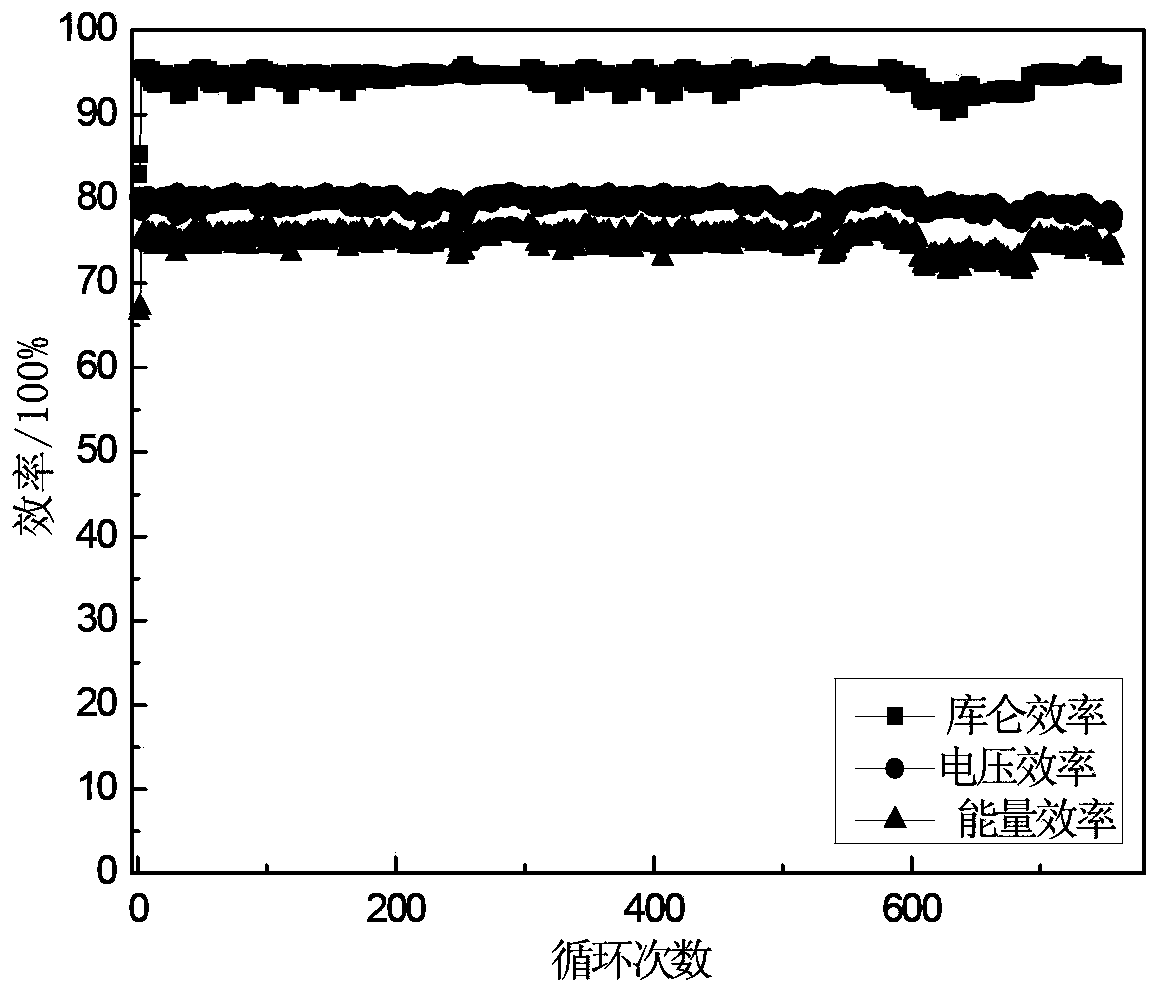

Zinc-nickel double-fluid flow battery

ActiveCN104716304ASolve the disadvantages of corrosionThere is no obvious attenuation in the charge-discharge cycle performanceAlkaline accumulator electrodesHigh concentrationAlkalinity

The invention relates to a zinc-nickel double-fluid flow battery. A single battery sequentially comprises a nickel electrode anode, a cation exchange membrane, an annular frame, an anion exchange membrane and a cathode that are superimposed in order. Both sides of the annular frame are respectively attached to the cation exchange membrane and the anion exchange membrane, two side opening ends of the annular frame are sealed by the cation exchange membrane and the anion exchange membrane, and the central cavity of the annular frame is enclosed into an electrolyte solution storage cavity. A third solution is loaded in the electrolyte solution storage cavity to conduct ions so as to form an ion conducting loop. Two different ion exchange diaphragms are used between the anode and cathode of the battery, by introducing the annular frame into the center, acidity and alkalinity of the electrolyte solutions at the anode and cathode are designed separately and independently, so that the anode electrolyte solution of the zinc-nickel fluid flow battery can use a low concentration alkali fluid, and the cathode electrolyte solution can use a zinc ion containing neutral aqueous solution, thus effectively solving the corrosion defect caused by the need of conventional nickel-zinc fluid flow batteries for a high concentration alkaline zincate aqueous solution.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of manufacturing PCB and PCB manufactured by the same

InactiveUS20090277679A1Inhibition of attachmentImprove product reliabilityPrinted circuit aspectsElectrical connection printed elementsZincateElectroplating

Provided is a method of manufacturing a PCB, the method comprising: providing a substrate including an aluminum core; forming a via hole passing through the substrate; substituting the surface of the aluminum core with a zinc film by performing a zincate treatment on the inner surface of the via hole; substituting the zinc film with a metal film by performing substitution plating on the zinc film; forming a first plated film on the surface of the via hole, where the metal film is formed, through electroless plating; and forming a second plated film on the first plated film through electroplating.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

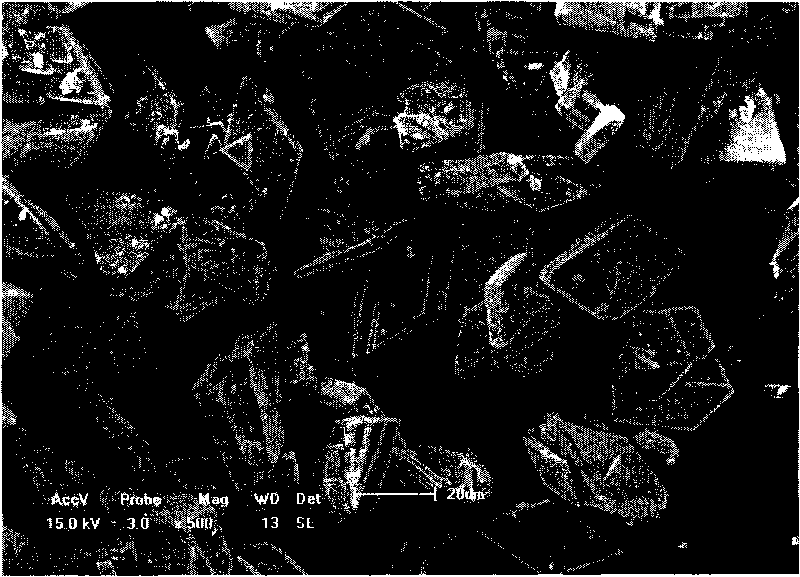

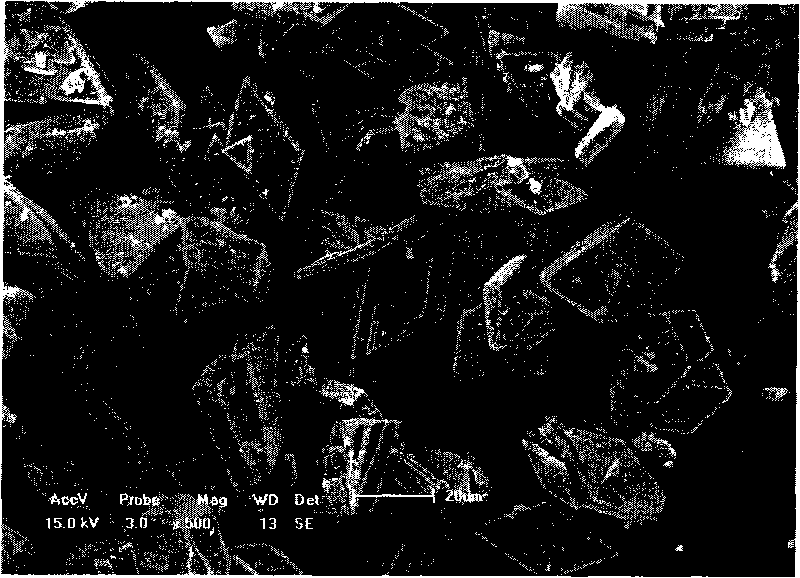

Melt method for growing sosoloid monocrystal of lead lead-titanate niobium-zincate

InactiveCN1382841AGrowth inhibitionInhibition of spontaneous nucleationPolycrystalline material growthBy pulling from meltZincateUltrasonic sensor

A melt method for growing the sosoloid monocrystal of lead lead-titanate niobium-zincate, (1-x)Pb(Zn1 / 3Nb2 / 3)O3-xPbTiO3 where x=0.05-0.2, features that the raw material is pretreated by two steps andther PZNT monocrystal is grown by heterosyntectonic crucible lowering method, where PMNT sosoloid monocrystal is used as seed, temp is 1380-1420 deg.C, the temp gradient at growth interface is 40-80 deg.C and lowering speed is 0.5-1 mm / hr.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

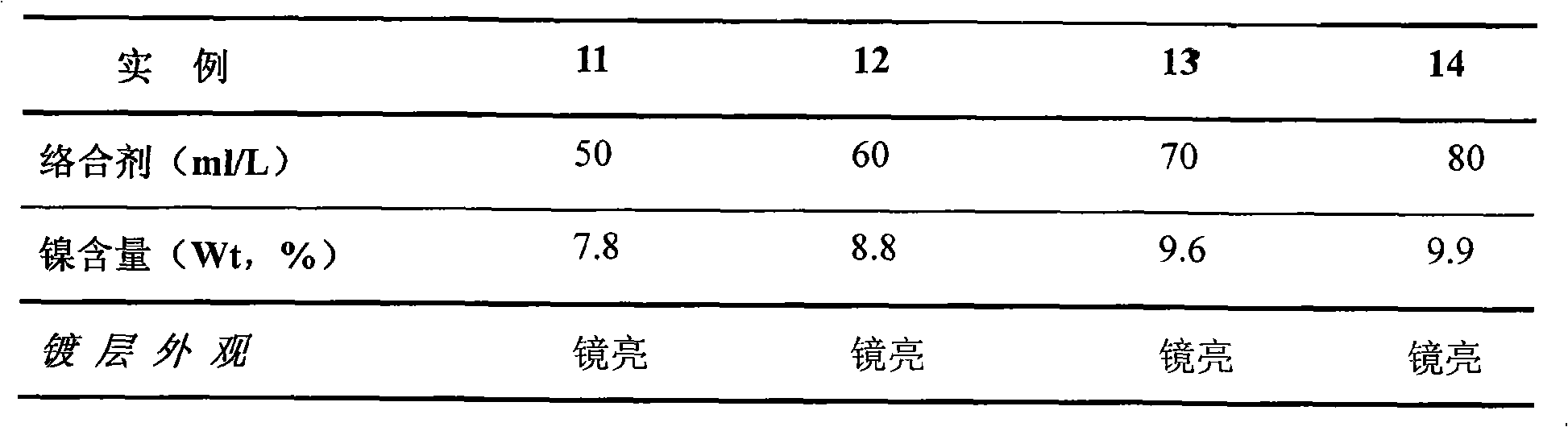

Plating process for low-nickel non-cyanogen alkalescent zinc-nickel alloy

The invention relates to a plating technology of alkaline zinc nickel alloy without cyanogen with low nickel content. The technology comprises the steps as follows: nickel retention agent is synthesized in the water medium through the reaction between divinyl triammonium and epoxy chloropropane in the temperature of 60 to 70 DEG C, wherein, the mol ratio between the divinyl triammonium and the epoxy chloropropane is 1:1; nickel composition is obtained after sufficient complexation between the nickel complexing agent and the nickel ions; the nickel composition is dissolved in alkaline zincate basic liquid, and then the mixed solution is mixed well; plating additive is added and then the mixed solution is mixed well; the plating is processed according to the plating technology demands. The plating technology has the beneficial effects that: the plating solution has excellent dispersive capacity; cladding alloying component is homogeneous in a wilder ampere density range; the thickness of a cladding layer is homogeneous; the equipment and the workpiece are corrupted slightly; the technology is steady, the operation is simple, and the cost is lower; a zinc plate or a nickel plate can be adopted as an anode; the plating technology has the advantages that the technology is stable, the dispersive capacity is good, the high temperature is endured and the nickel content is steady in the cladding layer, etc.; the industrial application is convenient.

Owner:杭州东方表面技术有限公司

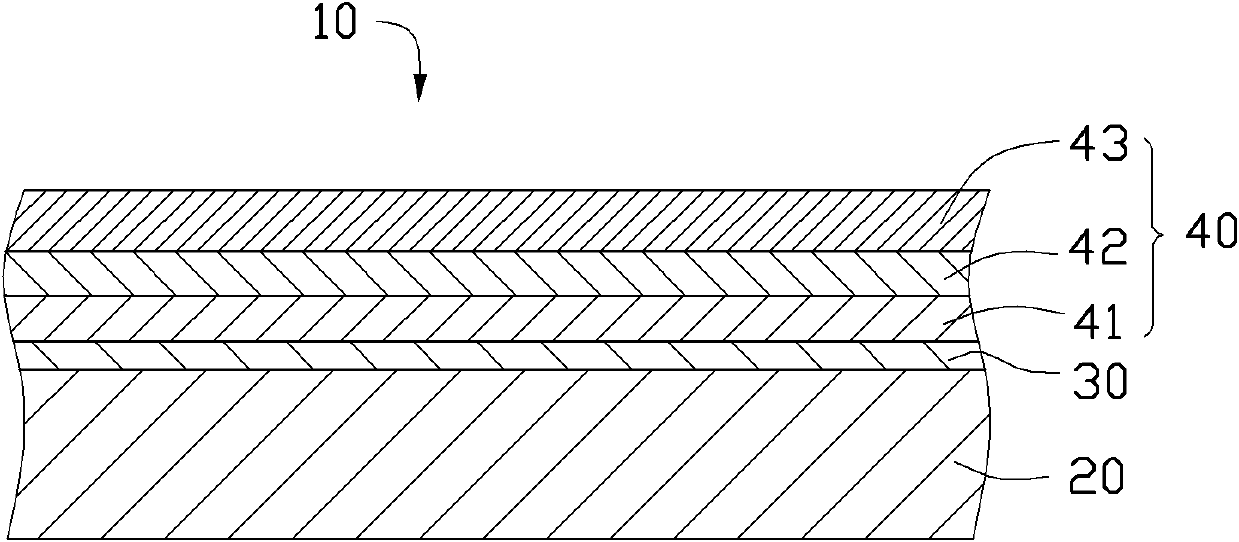

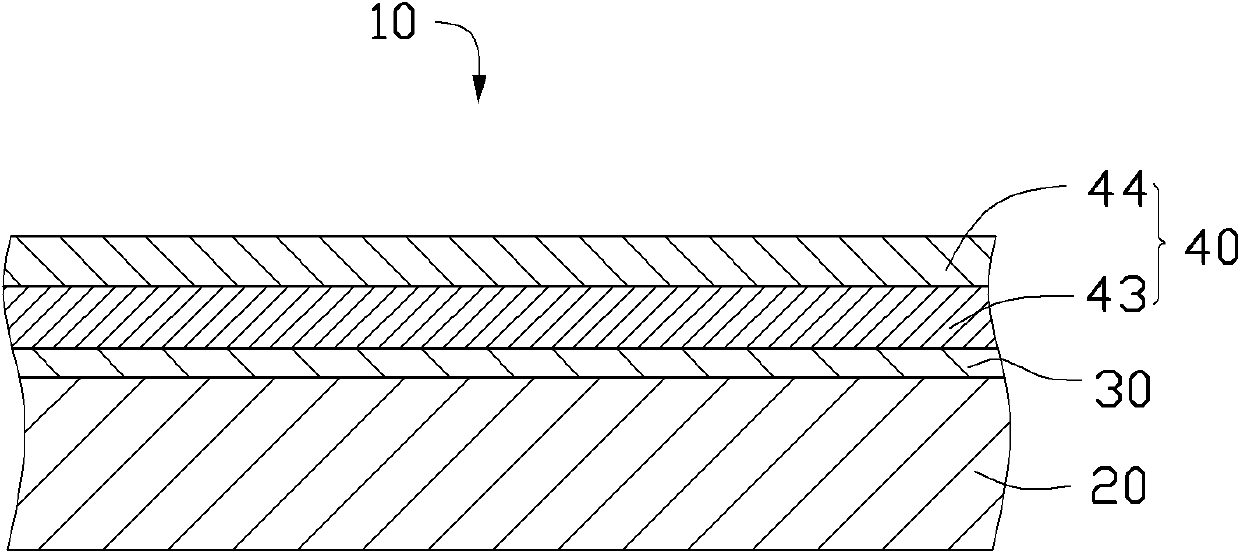

Aluminium and aluminium alloy surface antiseptic treatment method and product prepared by same

InactiveCN102560483AImprove bindingImprove corrosion resistanceSuperimposed coating processThin material handlingZincateCeramic coating

The invention provides an aluminium and aluminium alloy surface antiseptic treatment method which comprises the following steps of: providing an aluminium matrix; carrying out chemical degreasing on the aluminium matrix; carrying out zincate treatment on the aluminium matrix to form a zinc layer on the aluminium matrix; and forming a ceramic coating consisting of a refractory compound on the zinc layer by a vacuum plating method. The invention provides an aluminium product prepared by the antiseptic treatment method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

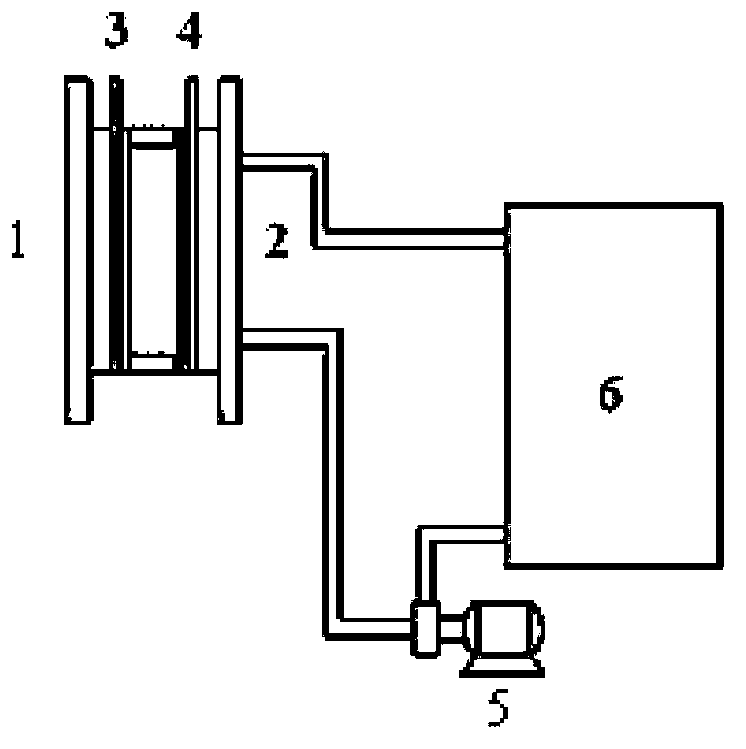

Electrogalvanizing method of neodymium iron boron magnet

The invention discloses an electrogalvanizing method of a neodymium iron boron magnet. A first electroplating solution adopted in primary electrogalvanizing treatment is a zinc sulfate solution, the zinc sulfate solution is prepared by mixing 200-400 g / L of zinc sulfate, 20-50 g / L of boric acid and water, the pH value of the zinc sulfate solution is 3.5-5.5, and the temperature of the zinc sulfate solution is 20-40 DEG C; and a second electroplating solution adopted in secondary electrogalvanizing treatment is an alkaline zincate solution, the alkaline zincate solution is prepared by mixing 6-20 g / L of zinc oxide, 80-140 g / L of sodium hydroxide and water, the pH value of the alkaline zincate solution is greater than 12, and the temperature of the alkaline zincate solution is 20-40 DEG C. The method has the following advantages: the zinc sulfate solution does not corrode the neodymium iron boron magnet, the combination consistence of a first galvanizing layer and the neodymium iron boron magnet is good, a second galvanizing layer does not corrode the neodymium iron boron magnet, the combination force consistence of the second galvanizing layer and the neodymium iron boron magnet is good, and the obtained neodymium iron boron magnet has good anticorrosive performance.

Owner:NINGBO YUNSHENG +2

Zinc-iron single flow battery

ActiveCN103682407AImprove cross-contamination problemsLow costRegenerative fuel cellsZincateEngineering

The invention relates to a zinc-iron single flow battery comprising a battery module formed by a single battery or more than two single batteries connected in series, an electrolyte storing tank, a circulating pump and a circulating pipeline, wherein the single battery comprises positive and negative end plates, a positive electrode and a negative electrode; the electrolyte is an alkaline zincate solution; the positive electrode and the negative electrode adopt the same electrolyte; the positive reaction is the solid phase conversion of FeO and Fe2O3. The zinc-iron single flow battery disclosed by the invention is capable of overcoming the cross contamination problem of a traditional zinc-iron flow battery and has the characteristics of long cycle life, low cost and simple structure and simplicity in manufacturing process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

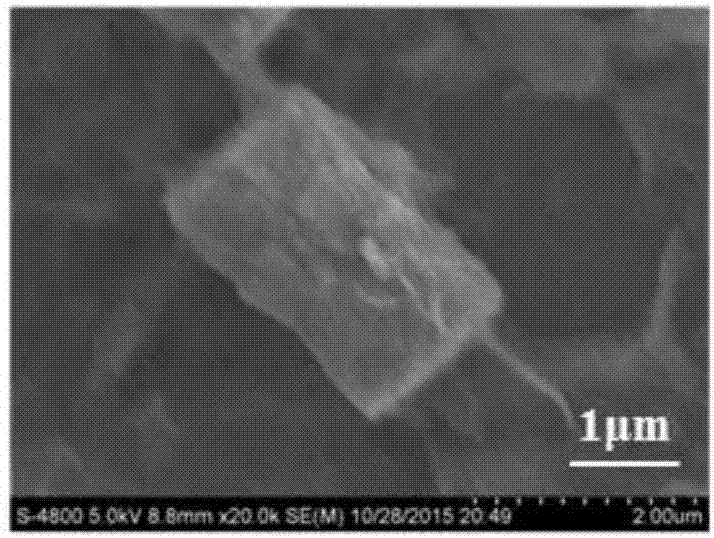

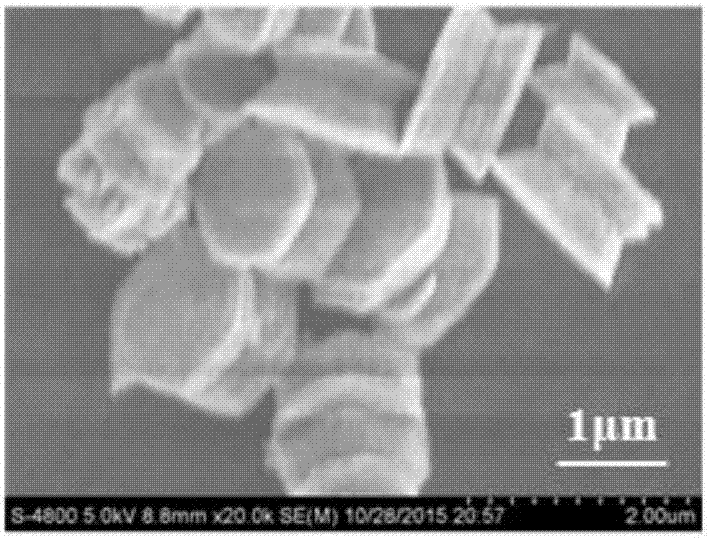

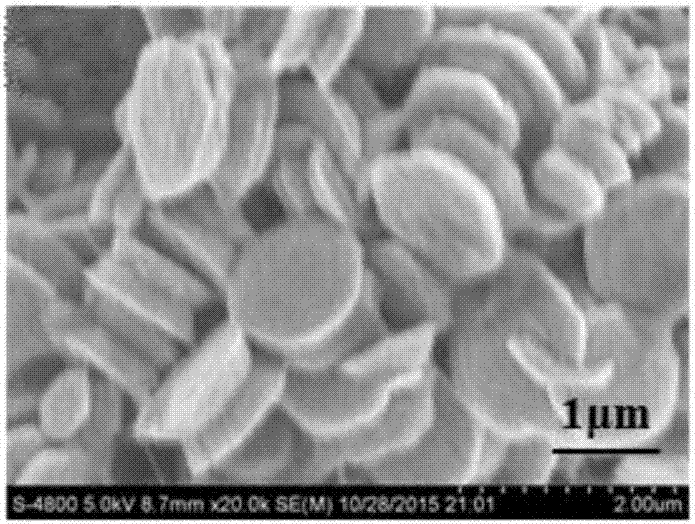

Zinc oxide nanoparticle preparation method based on silk fibroin bio-template regulation

ActiveCN107089677AHigh surface energyImprove antibacterial propertiesZinc oxides/hydroxidesNanotechnologyZincateNanoparticle

The invention relates to the technical field of biomedical materials, and in particular to a zinc oxide nanoparticle preparation method based on silk fibroin bio-template regulation, which includes the following steps: (S1) after being degummed, silkworm cocoons are dissolved, so that aqueous silk fibroin solution is prepared; (S2) zincate solution and alkaline solution are blended, so that mixed solution is obtained; (S3) the aqueous silk fibroin solution obtained step S1 is added into the mixed solution in step S2 to sufficient react; (S4) after solution after the reaction in step S3 is washed and dried, zinc oxide nanoparticles are obtained. Silk fibroin is adopted as a bio-template to regulate the size and morphology of the zinc oxide nanoparticles, the grain size of the obtained zinc oxide nanoparticles is small, the morphology is irregular, the antibacterial property is enhanced, moreover, the operation method is simple, and the cost is low.

Owner:XUANWU HOSPITAL OF CAPITAL UNIV OF MEDICAL SCI

Recovering and utilizing method for waste alkaline zinc-manganese battery

InactiveCN1716666AReduce addSolve environmental pollutionSolid waste disposalReclaiming serviceable partsElectrolysisZincate

The recovering and utilizing method of waste alkaline zinc-manganese battery includes the following technological steps: 1. separating and extracting the positive pole and negative pole material; 2. soaking in alkali solution at room temperature; 3. separating zincate; 4. electrolysis to prepare zinc; 5. preparing potassium manganate; and 6. electrolysis to prepare potassium permanganate. The said technological process is simple and low in cost, produces few secondary pollution, and is favorable to reducing environmental pollution caused by waste battery.

Owner:SOUTH CHINA NORMAL UNIVERSITY

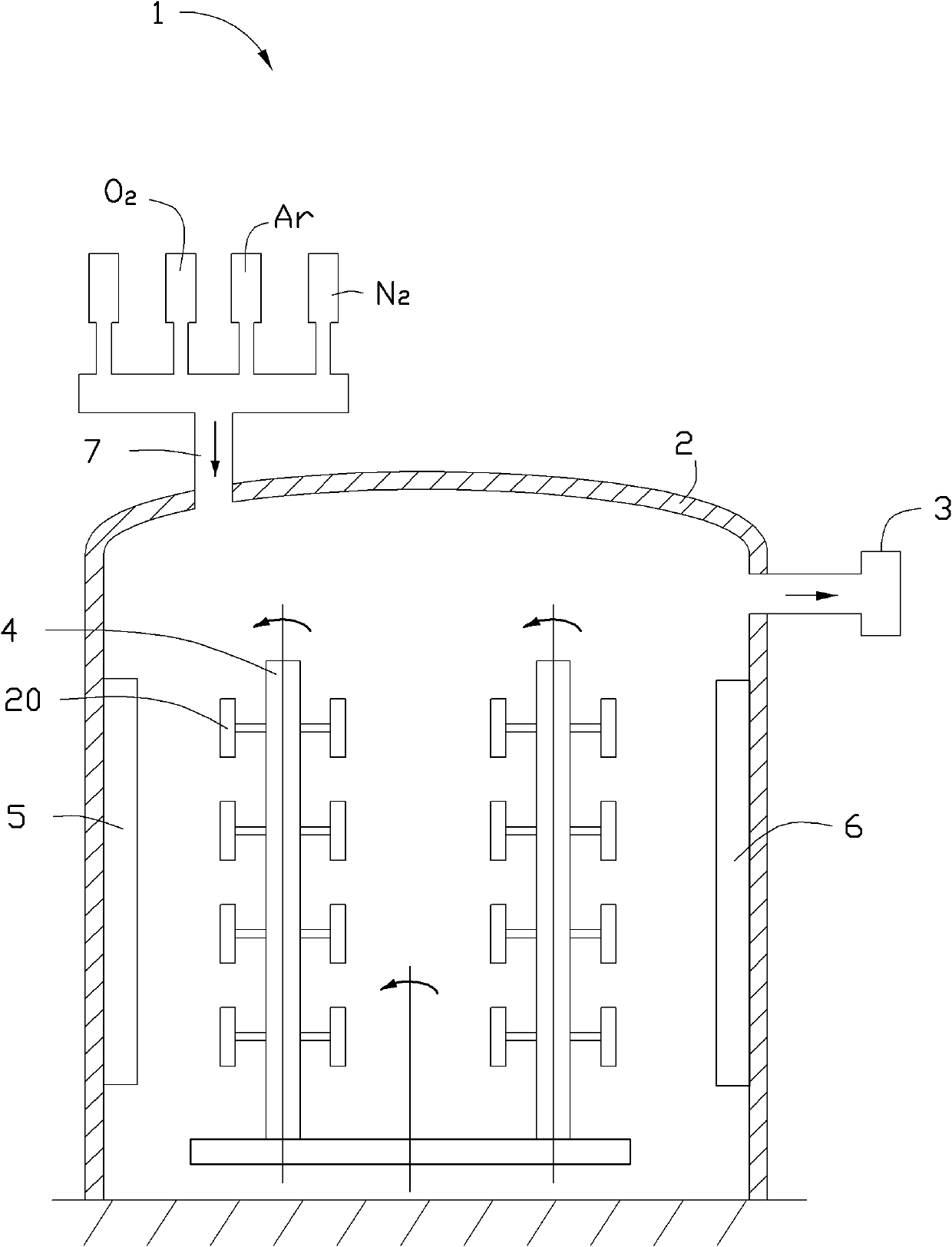

Basic zincic acid salt plating liquor, its electroplating method and long steel-pipe with electroplated zinc nickel alloy

The invention is about the alkali zincate plating liquid which contain: 8-12g / L ZnO; 80-140g / L NaOH; 8-10g / L NiSO4íñ6H2O; 4-6mL / L N2-918A; 2-4mL / L of N2-918B; 50-70mL / L of N2-918C.Also the invention provided the process to plate Zn-Ni alloy to steel pipe which concludes de-oiling, washing, installing endo-anode, plating, unloading endo-anode, washing and airing. The process is used to the complex long steel pipe especially. The Ni content is 10% and the erosion resistance is 2.8 times than the others, the rigidity is 1.9 times.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

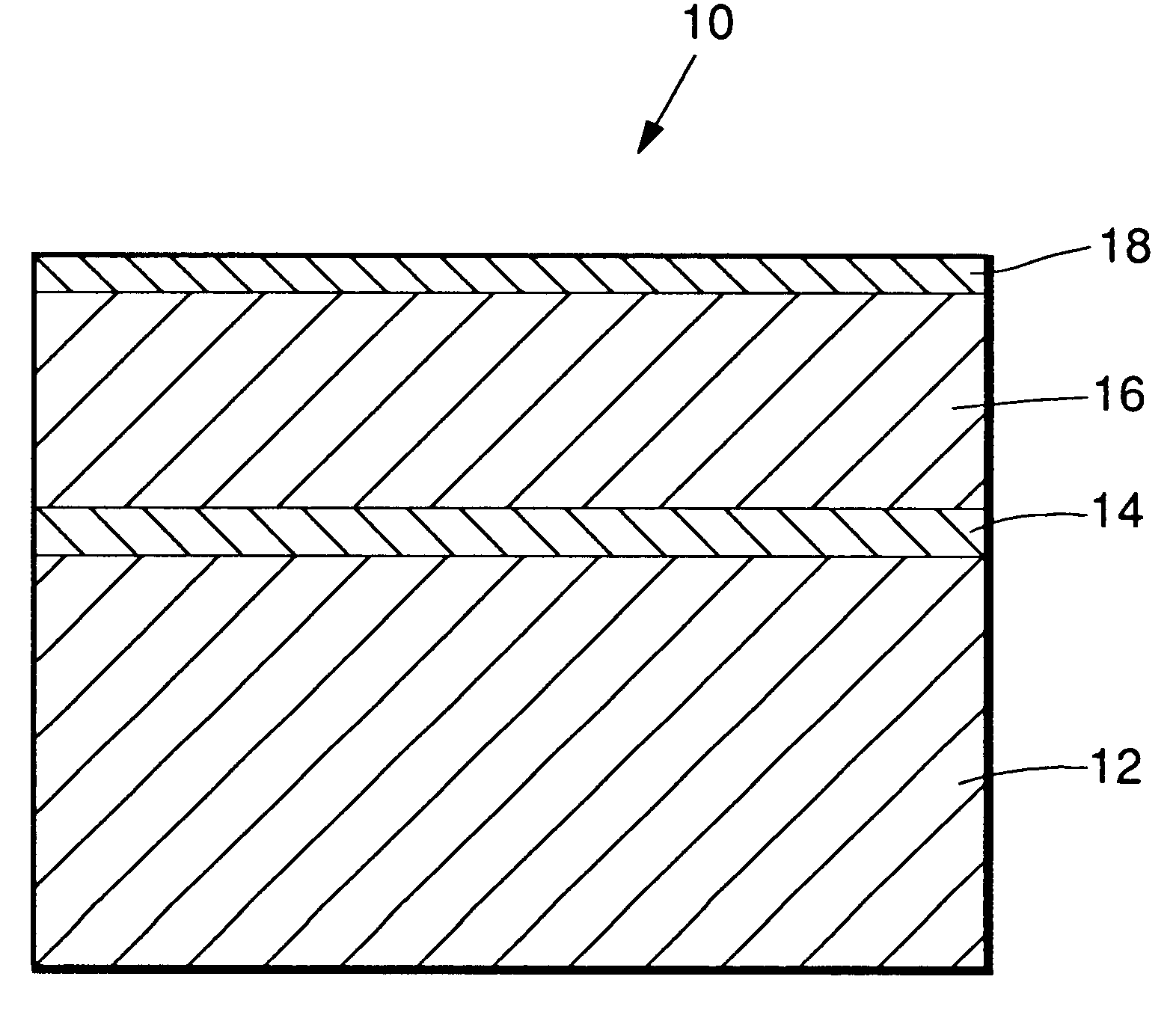

Iron-plated aluminum alloy parts and method for planting same

InactiveUS6258415B1Hot-dipping/immersion processesLiquid surface applicatorsElectroless nickelAlloy substrate

A process for plating aluminum alloy substrates (10), such as 390 aluminum alloy pistons (12), with iron comprises (a) plating on the aluminum substrate a layer of zincate from a zincate bath; (b) plating on the zincate layer a layer (14) of nickel from an electroless nickel bath; (c) plating on the nickel layer a layer (16) of iron from an iron ammonium sulfate bath; and (d) plating on the iron layer a layer (18) of tin from an alkaline tin bath. During the electroless plating, the zincate layer, which protects the underlying aluminum against oxidation, is sacrificed. All of these baths are environmentally much safer than cyanide and chloride. They are also cost effective and can be utilized in a totally closed loop plating system.

Owner:HUGHES ELECTRONICS

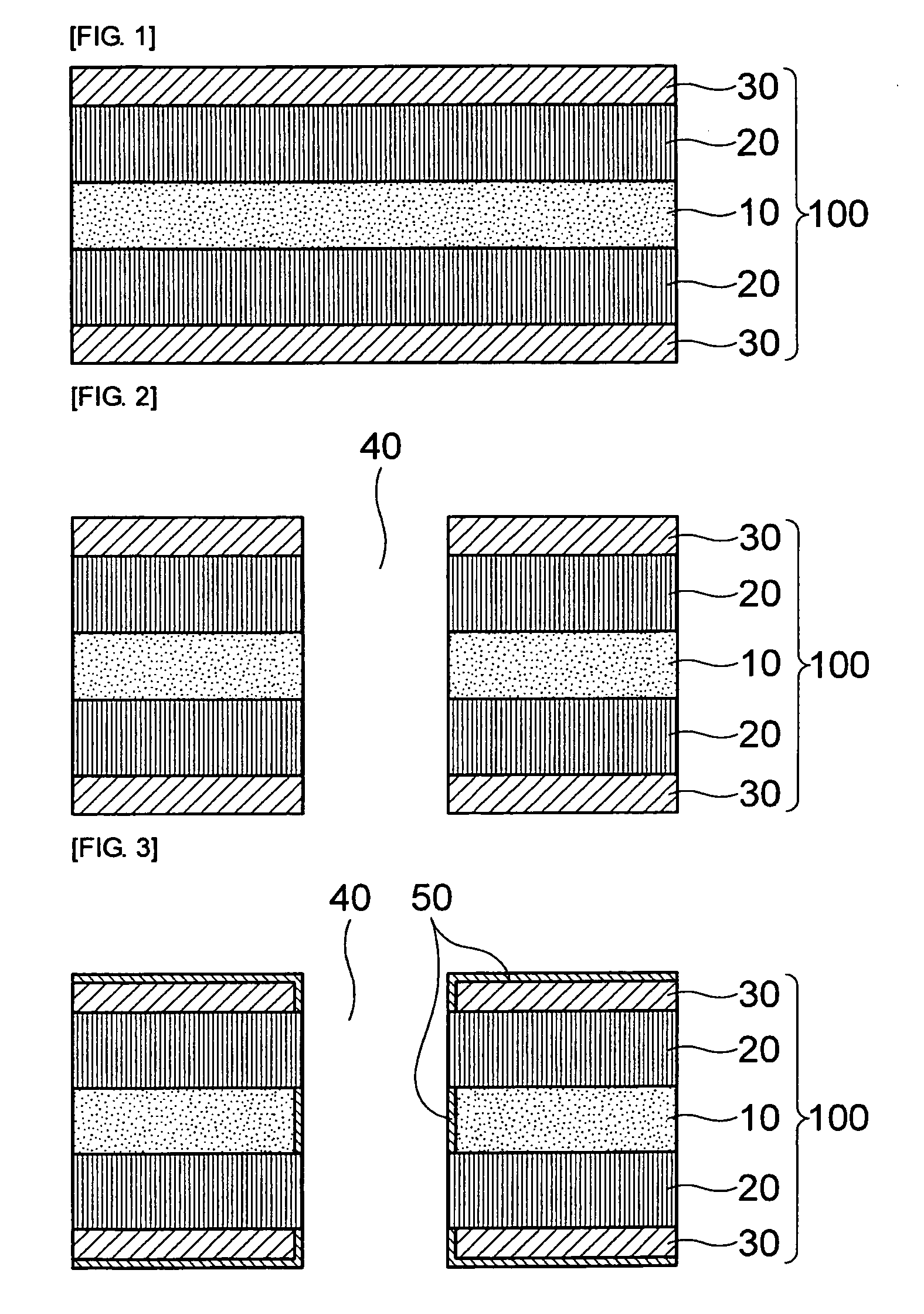

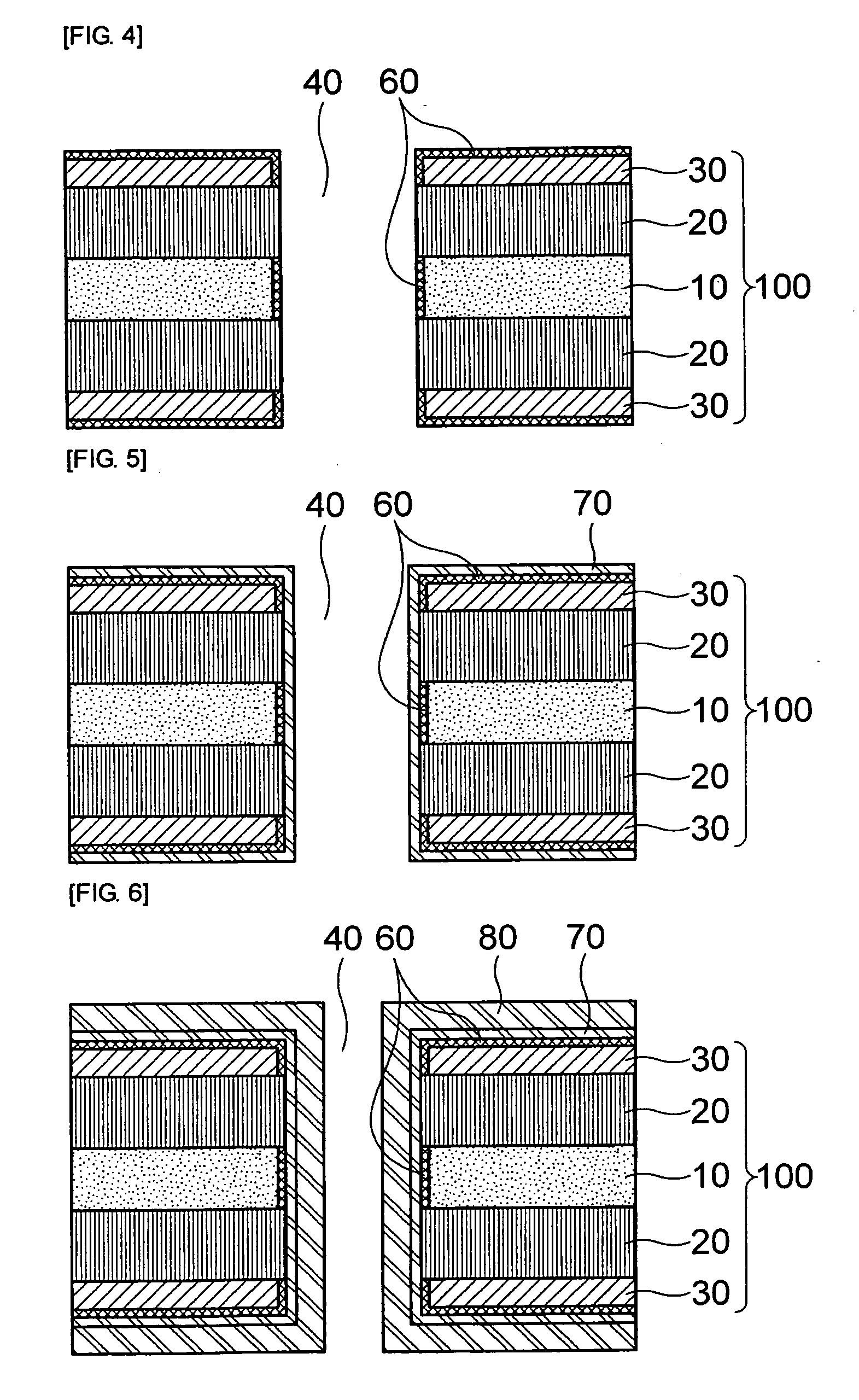

Method for producing polarizer, prolarizer, polarization sheet and video display

The present invention provides a method of producing a polarizer with good durability, dyeing the polarizer with iodine, and boric acid treatment, and making the polarizer without defects caused by boric acid or zinc deposits Contains Zinc. The production method comprises the steps of: dyeing the unstretched polyvinyl alcohol film with iodine; performing uniaxial stretching treatment and boric acid treatment; then performing zinc immersion treatment; and then performing iodide ion immersion treatment.

Owner:NITTO DENKO CORP

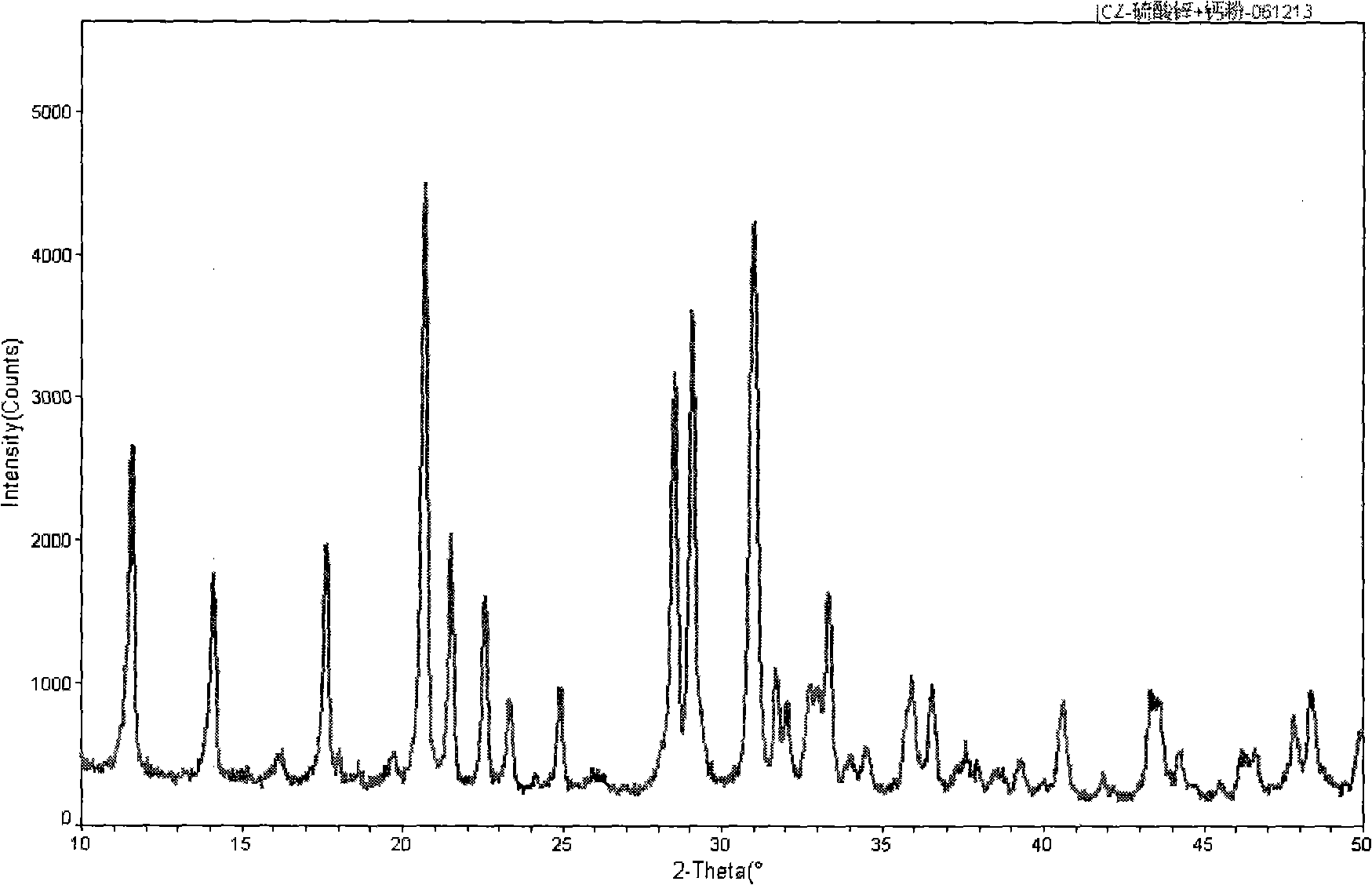

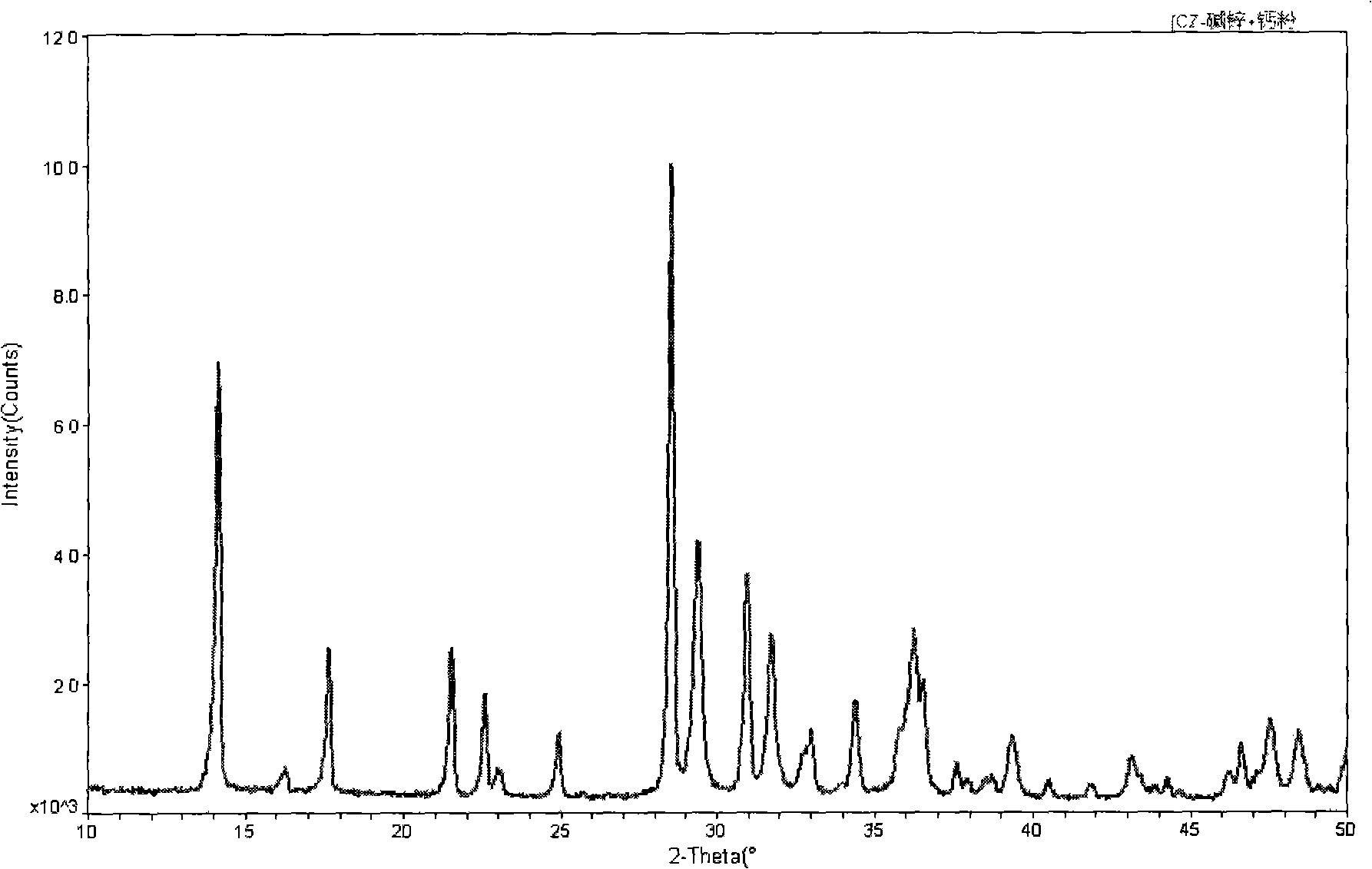

Preparation method of calcium zincate and calcium zincate reclaiming agent at normal temperature

ActiveCN101288821AHigh sulfur capacityLow costDispersed particle separationAdsorption purification/separationZincateSulfur

The invention provides a calcium zincate and a method for preparing normal-temperature desulfurizer of the calcium zincate. The calcium zincate preparation method provided by the invention requires no crystal seeds, is directly formed, has simple operation, high yield and low cost and can be used for large-scale industrialized production. The desulfurizer provided by the invention consists of calcium zincate structural promoter. The desulfurizer of the invention reduces the cost and improves the production safety; furthermore, the desulfurization effect of the desulfurizer is much better than that of traditional normal-temperature desulfurizer and the sulfur capacity can reach 35.2%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing power type columnar sealed zinc-nickel alkaline accumulator zinc negative pole

Said invention refers to power type column sealed zinc nickel alkaline accumulator zinc cathode manufacturing method. It contains using zinc powder, calcium zincate and zinc oxide as zinc cathodal primary material, indium oxide, yellow lead, bismuth oxide, and titanium oxide as auxiliary materials, using it with adhesive mixture composed of sodium carboxymethylcellulose, polyoxyethylene, polyvinyl alcohol and hydroxypropyl cellulose water solution to form cathode syrup, using punching copper strip as frame penetrating said cathode syrup, both sides uniformly stuck on pulp, through drying rolling to reach the specified thickeness, then coated single-layer graphite or active carbon, after drying coated single-layer organic matter, finally cut into zinc cathode piece with given size. Said invention can fully meet power main-supply requirement in different multiplying factor current charge and discharge process without electrolyte and gas leakage.

Owner:HENAN HUANYU GROUP

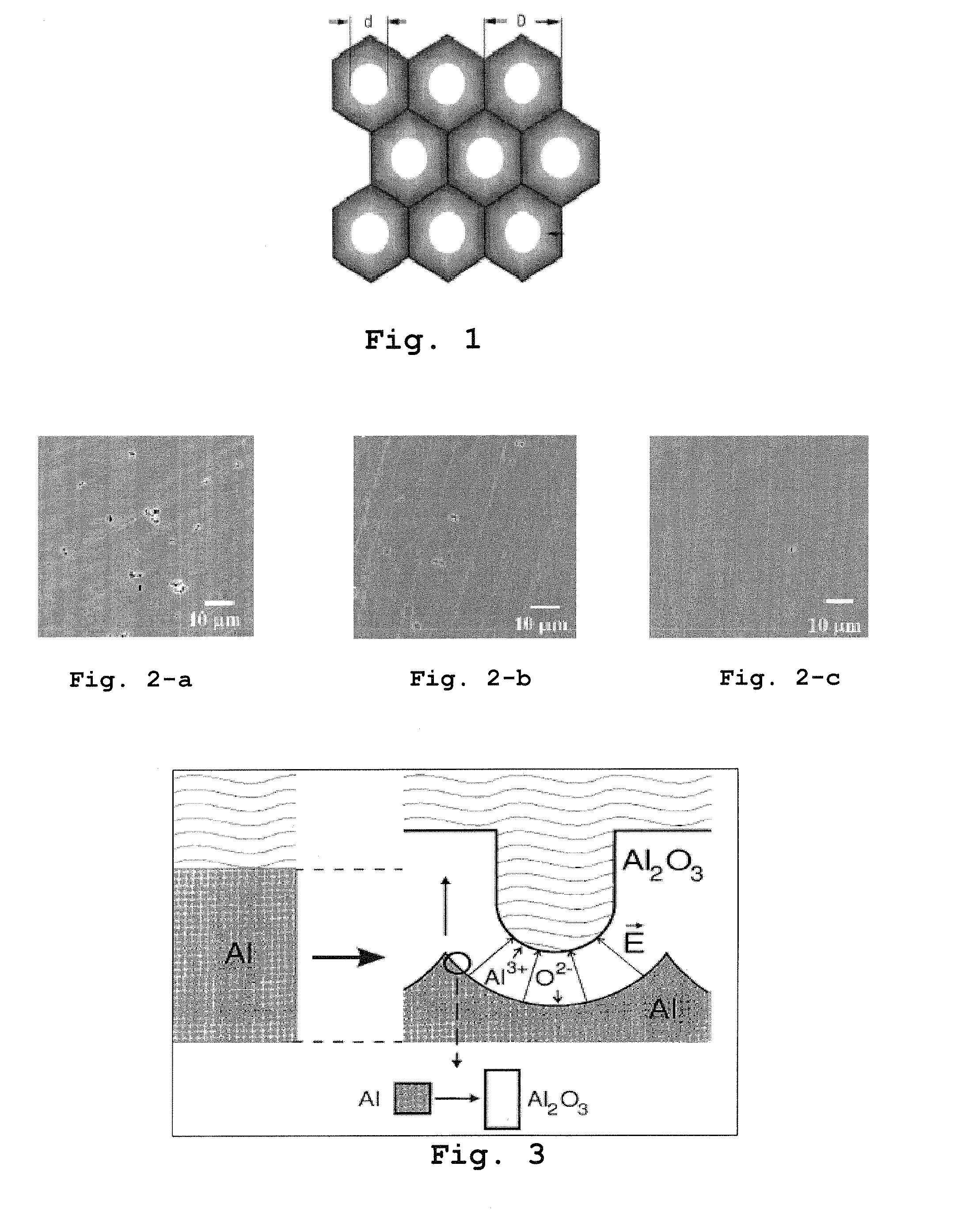

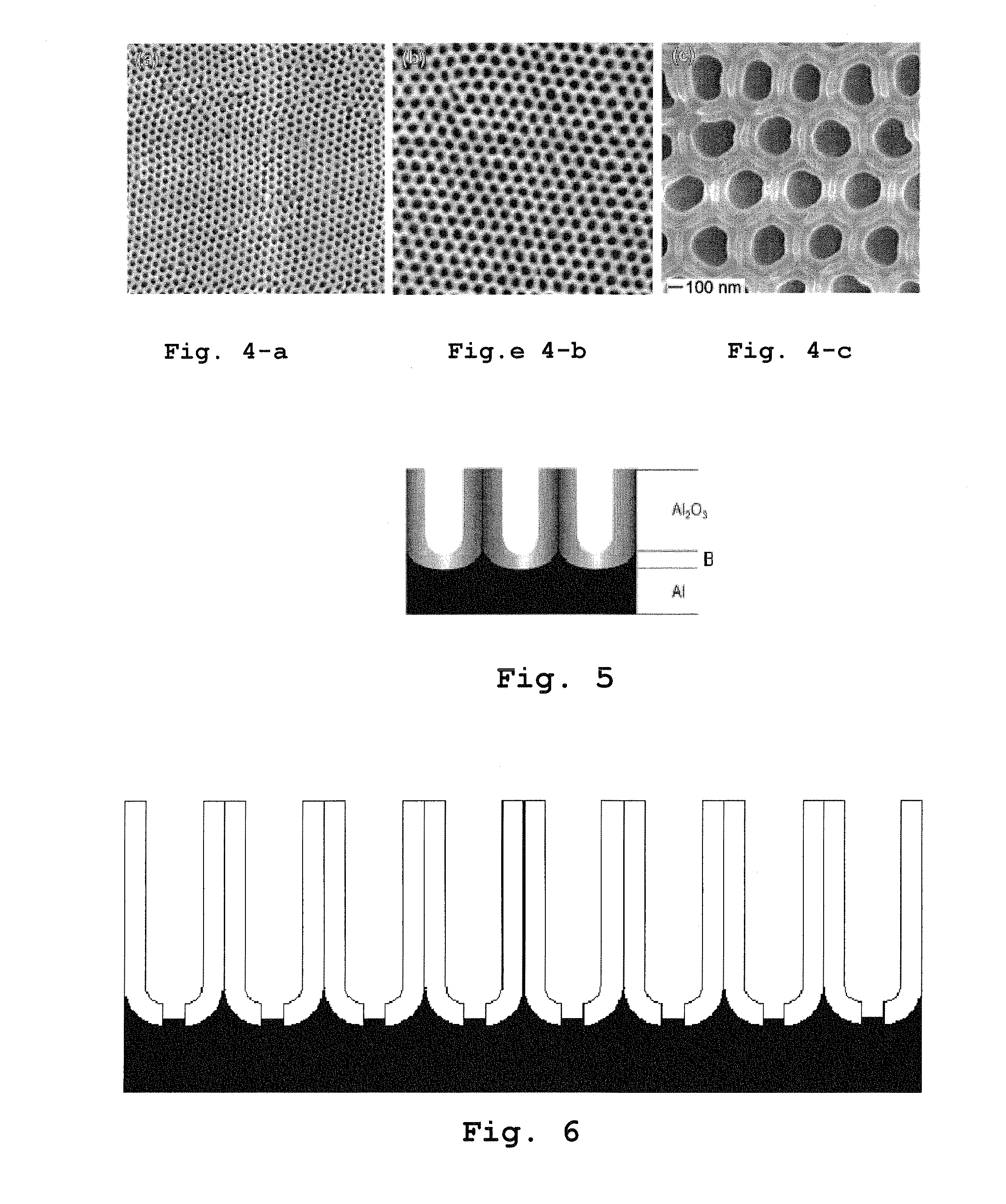

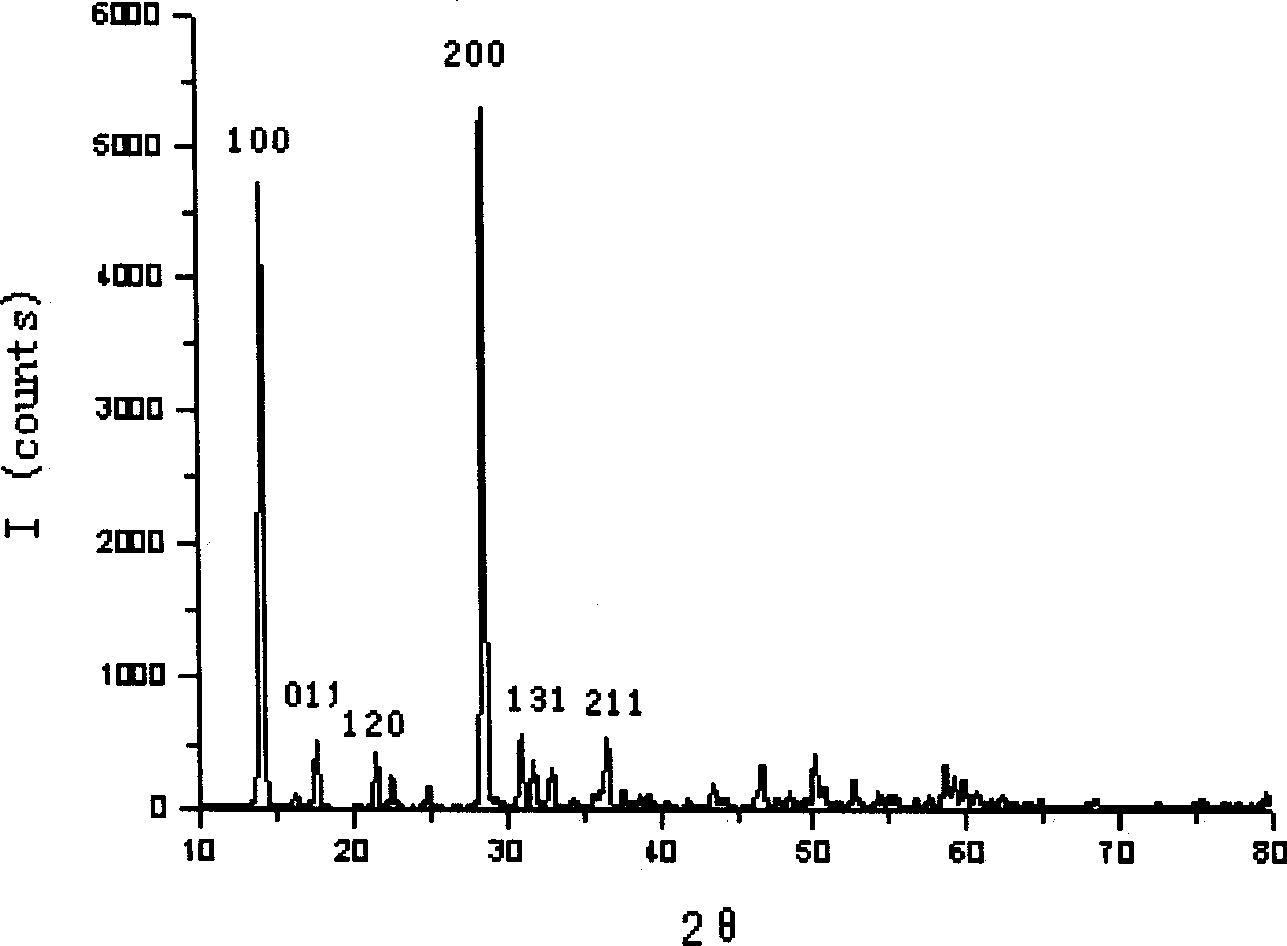

Method for the preparation of nanostructures and nanowires

A process for producing porous nanostructures suitable for the manufacture of nanowires and processes for manufacturing of the nanowires by using said nanostructure are disclosed. The process for obtaining the nanostructure of the invention comprises the steps of cleaning and polishing the surface of an aluminum metal substrate, forming a porous oxide layer bearing nanoholes on said aluminum substrate, immersing the porous structure into a basic zincate solution for etching the bottoms and walls of the nanoholes and depositing a thin and substantially pure Zn film extending from the bottom of the nanoholes through the aluminum substrate. Nanowires can be fabricated by the step of utilizing so obtained etched nanostructure as an electrode and subjecting the same to a metal electro-deposition operation.

Owner:ISTANBUL TEKNIK UNIVSI

Non-cyanide electroplating process for zinc alloy die casting

The non-cyanide electroplating process for zinc alloy die casting includes first pre-plating with zincate and then subacid chemical nickel plating. In the pre-plating with zincate, the plating solution comprising zinc oxide, sodium hydroxide and brightener is used, the electroplating temperature is 10-40 deg.c, electroplating current is 1-7 A / sq dm and electroplating time is 15-25 min. In the subacid chemical nickel plating, the plating solution comprising nickel sulfate, sodium citrate, sodium hypophosphorite, ammonia water and hydrogen ammonium fluoride and with pH 6.5-7.5 is used, the solution temperature is 75-85 deg.c and the electroplating time is 20-30 min. The technological process of the present invention is used to replace cyanide copper-plating process and has no pollution caused by cyanide and low waste water treating cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

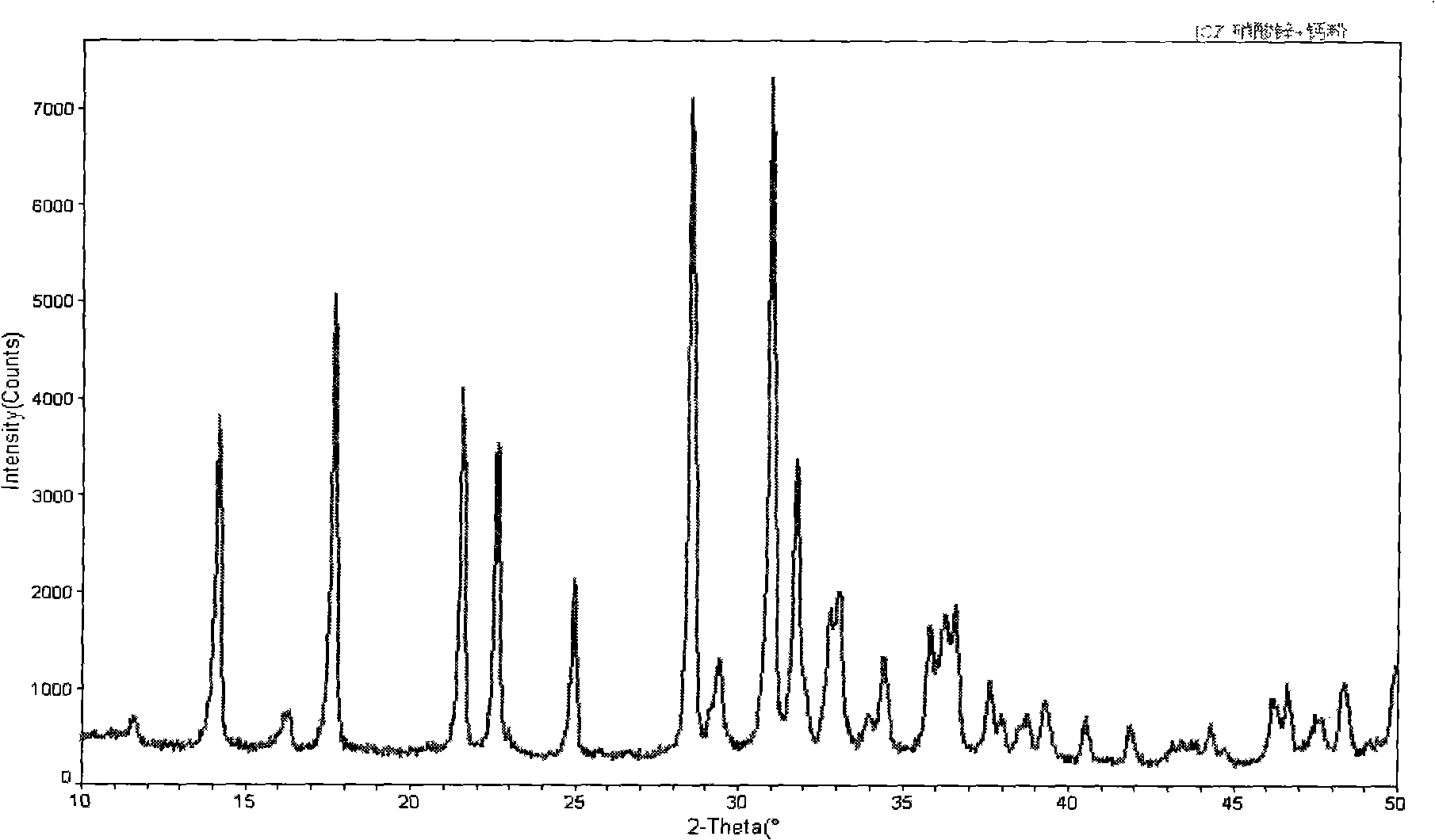

Method for preparing secondary basic zinc electrode material

InactiveCN1482698AImprove performanceGood reversibilityElectrode manufacturing processesAlkaline accumulator electrodesPotassium hydroxideZinc nitrate

The invention discloses a process for the manufacture of secondary alkaline zinc electrode material calcium zincate, composed of zinc oxide, zinc acetate, zinc nitrate, or zinc chloride and calcium oxide, calcium hydroxide, calcium acetate, calcium nitrate or calcium chloride, in potassium hydroxide or aqueous medium, reaction for 6-24 hours at room temperature through rolling ball grinding, filtering, washing and seasoning using deionized water for production, the calcium zincate is synthesized through ball milling, the equipment and process required by the invention are simple and reliable,thus easy for realizing mass production. íí

Owner:WUHAN UNIV

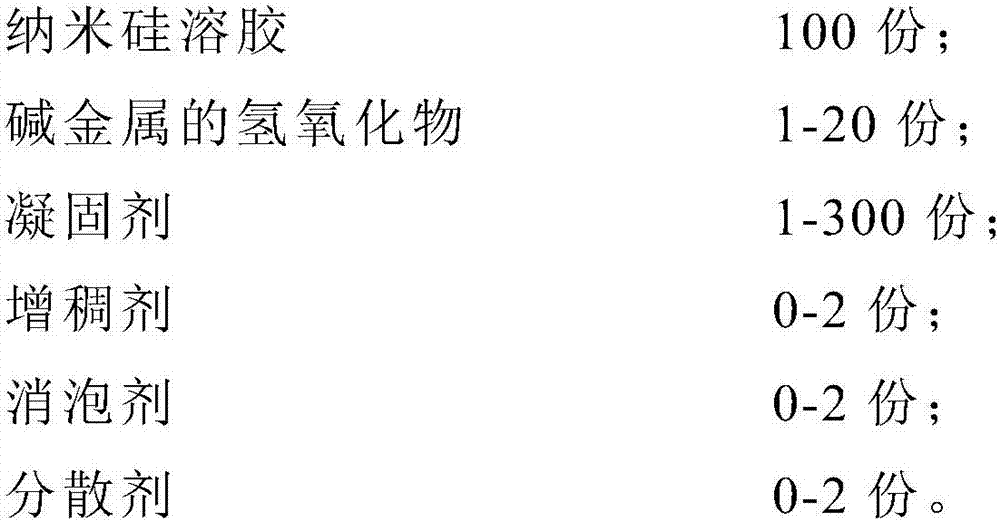

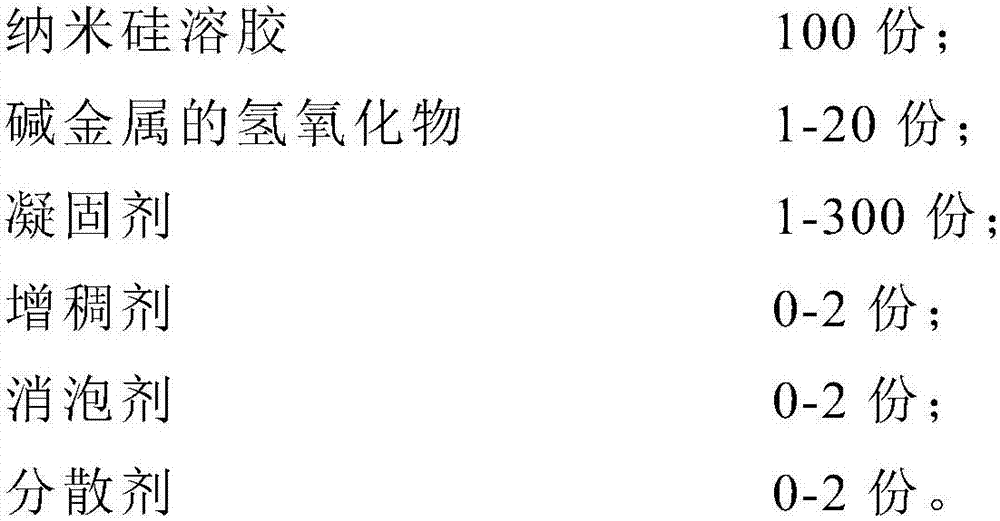

Inorganic bonding agent and manufacturing method thereof

InactiveCN107151466AImprove permeabilityHigh solid contentNon-macromolecular adhesive additivesAlkali metal silicate coatingsAluminateDissolution

The invention belongs to the technical field of a bonding agent, and relates to an inorganic bonding agent and a manufacturing method thereof. According to the manufacturing method, alkali metal hydroxides are added into nanometer silica sol; the continuous ultrasonic stirring is performed until the pH is stable; a silicate solution is obtained; coagulators, thickening agents, defoaming agents and dispersing agents are added into the silicate solution; high-shearing mixing and reaction are performed to obtain the inorganic bonding agent. The silicon sol is used as raw materials; alkali metal is added for improving the seepage performance and shortening the curing time; zinc-containing or aluminum-containing inorganic materials are added for generating meta-zincate or meta-aluminate, so that the characteristic of water re-dissolution avoidance after the water loss curing is realized; inorganic filling materials can be added for improving the solid content.

Owner:ZHEJIANG TRANSFER PAINT CO LTD

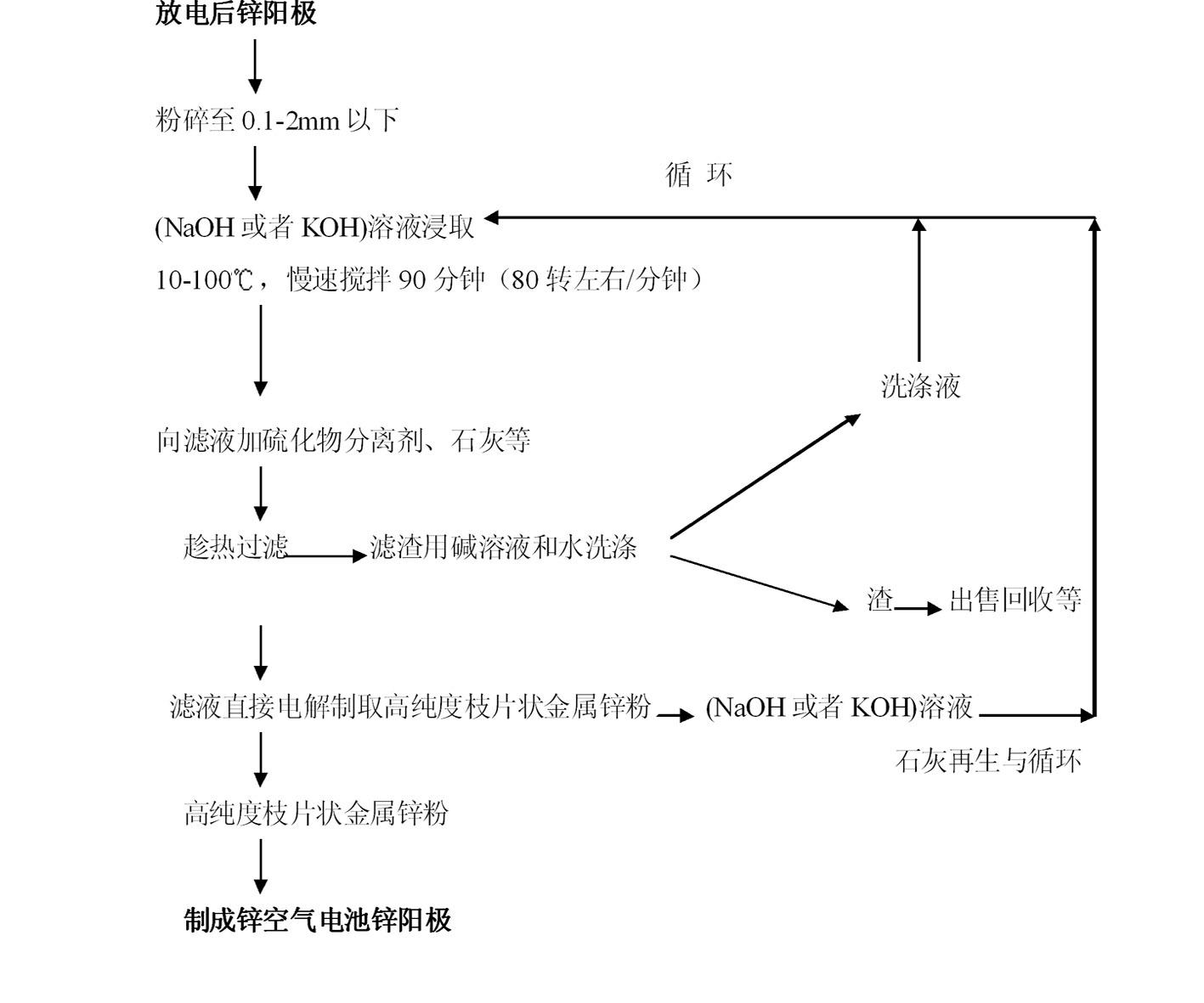

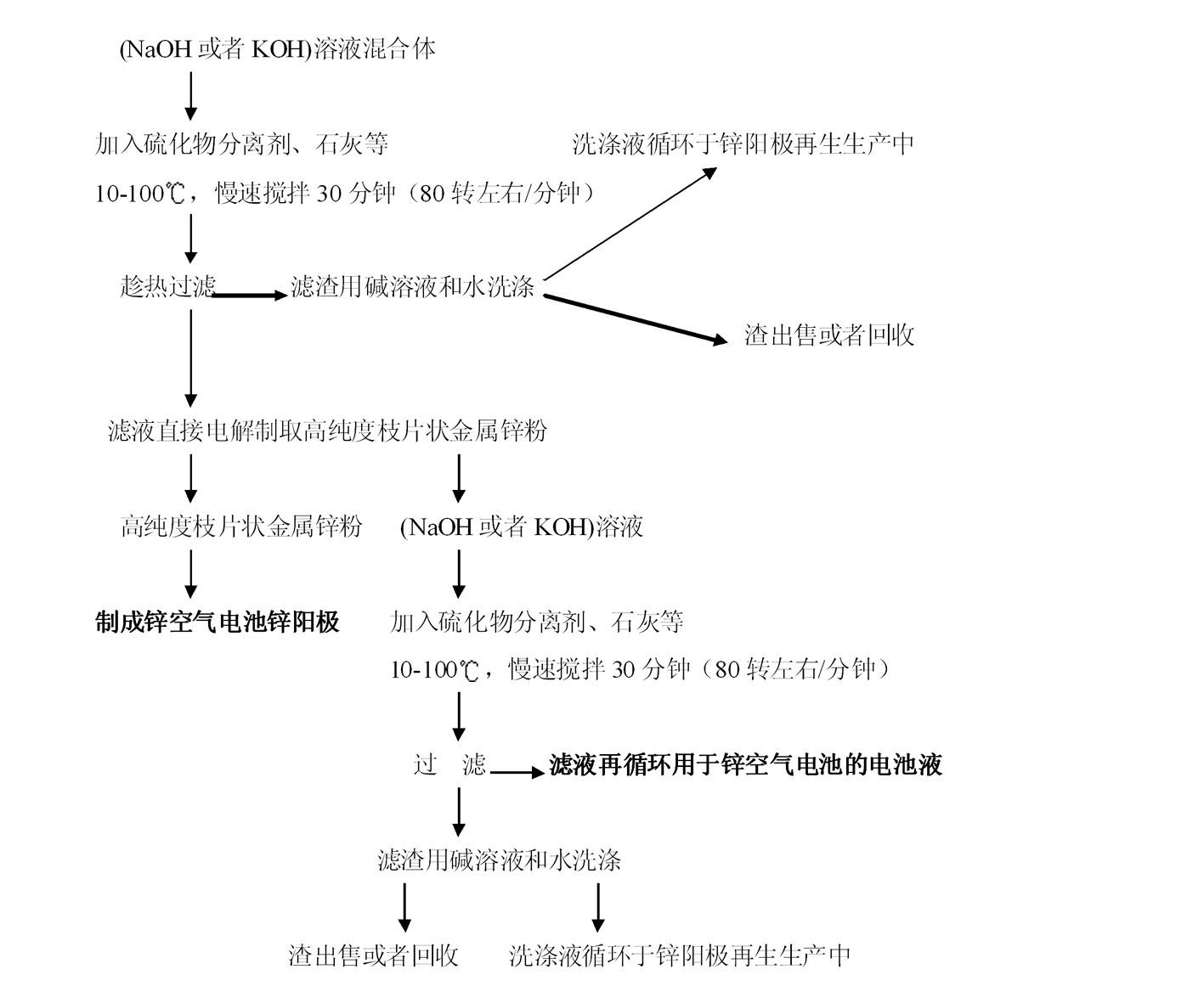

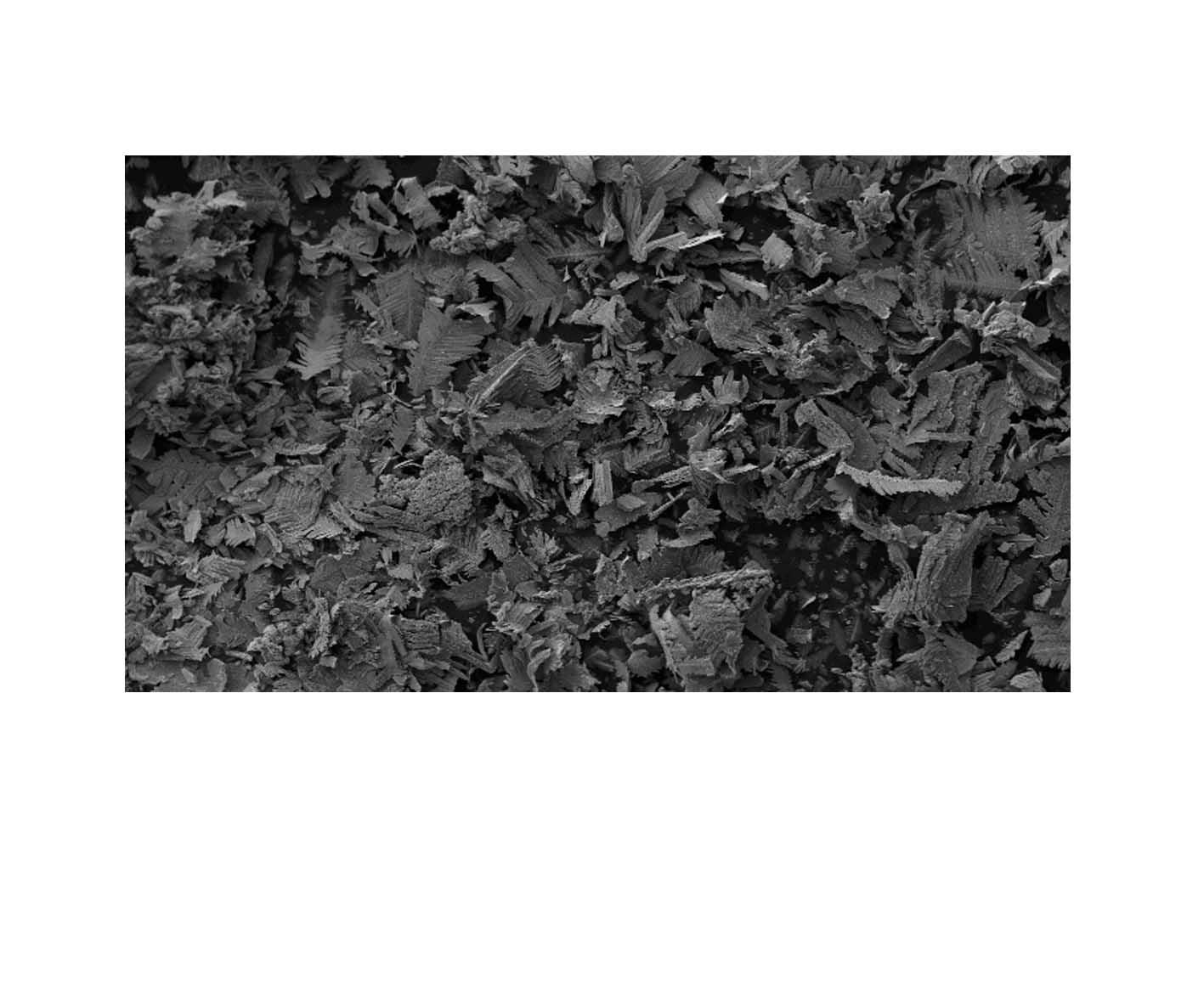

Method for producing zinc powder and battery fluid from battery zinc anode waste and battery waste fluid

InactiveCN102505076AIncrease surface areaStable running costPhotography auxillary processesProcess efficiency improvementSodium zincateElectrolysis

The invention discloses a method for producing zinc powder and battery fluid from battery zinc anode waste and battery waste fluid, which relates to the technical field of waste resource regeneration and processing. The method comprises the following steps: (a) 1-99 parts of NaOH and 99-1 parts of KOH are mixed to obtain a strong alkaline solution according to a proportion by weight; (b) NaOH / KOH mixed solution is uniformly mixed at a solid-to-liquid ratio of 1:(2-10) to obtain a leaching material; (c) the leaching material is mixed with zinc-air battery waste fluid to obtain zinc-air battery integrated mixed fluid; (d) sulfide is used for purifying and separating iron, copper and lead to obtain a sulfide purified solution; (e) lime regenerated alkali is used to react with the sulfide purified solution to obtain sodium zincate and potassium zincate solution suitable for electrolysis; (f) the sodium zincate and potassium zincate solution suitable for electrolysis obtained in step (e) is electrolyzed to obtain metal zinc powder; and (g) the lean solution is recycled after the electrolysis. The method of the invention sufficiently utilizes waste resources, and does not cause secondary pollution during the whole production process.

Owner:昆明同越科技开发有限公司

Zinc-deposition type liquid flow energy-storage battery system and running way thereof

ActiveCN102544563AIncrease energy densityImprove energy efficiencyRegenerative fuel cellsFuel cell auxillariesElectrolytic agentZincate

The invention relates to a liquid flow energy-storage battery system which consists of a deposition-type zinc negative pole, negative electrolyte, a negative pole storage tank, a positive pole, positive electrolyte, a positive pole storage tank, a liquid pump, a pipeline and a control system. The negative electrolyte is charging state electrolyte and discharging state electrolyte; an acid solution containing zinc ions can be adopted in charging, and an alkaline zincate solution is adopted in discharging; the electrolytes can be sent into the battery from the storage tanks through the pipeline by the liquid pump; and the liquid flow battery system has the advantage that the actual voltage efficiency is more than 100%.

Owner:DALIAN RONGKE POWER

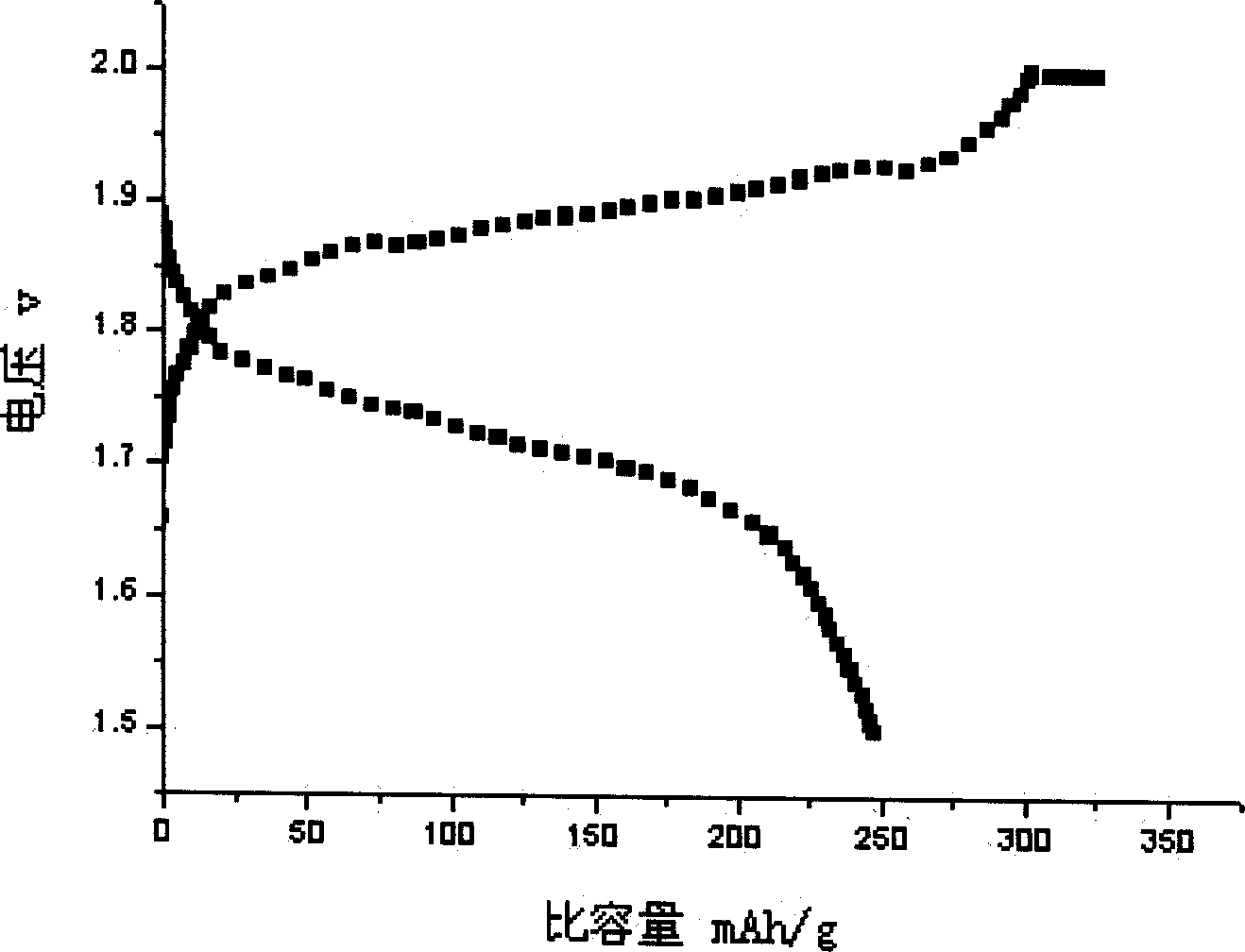

Process for preparing basic secondary Zn battery negative electrode active compound

InactiveCN1521876AElectrode manufacturing processesAlkaline accumulator electrodesZincateChemical computing

The present invention discloses a process for preparing zinc negative electrode active calcium zincate, wherein ZnO anc Ca(OH)2 are weighed by stoichiometric calculation and added into KOH solution for stirring, the temperature is controlled between the range of 70-100 degree C., stirring uninterruptedly for more than 72hrs, ageing for over 60 hrs in the environment of 70-95 degree C., cooling, filtering, washing to neutral, drying at the temperature of 105-110 degree C., grinding, screening by 300 mesh to obtain calcium zincate which can be used as the negative pole active compound for the Zn-Ni secondary cell.

Owner:江苏海四达集团有限公司

Method for preparing battery cathode active substance calcium zincate

InactiveCN101746810AControl granularityControl reaction speedCell electrodesZinc compoundsZincateElectrical battery

The invention relates to a method for preparing a battery cathode active substance calcium zincate. The calcium zincate is prepared by adopting a microemulsion method; the calcium zincate is generated through the reaction of zinc chloride or other soluble zinc salts, calcium chloride or other soluble calcium salts and hydroxide; n-hexyl alcohol, OP-10 emulsifying agent, cyclohexane or other dispersant and emulsifying agent are used as emulsifying materials; the speed of the reaction and the granularity and apparent density of the generated calcium zincate are effectively controlled by adopting fixed flow injection technology; and the granularity and the apparent density of the generated calcium zincate serving as a reaction product can be adjusted by adjusting the adding amount of the emulsifying agent, concentration and reaction speed and can reach nano scale at least. The method can be used for producing zinc electrodes of zinc series batteries such as square and cylindrical zinc-silver batteries, zinc-nickel batteries and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Recycle process for alkaline and carbon zinc batteries

ActiveUS8911696B1Value maximizationLow costPrimary cell maintainance/servicingZinc oxides/hydroxidesZincateManganese oxide

High purity MnO and zinc oxide may be efficiently recovered from alkaline and / or carbon zinc batteries using a process involving the treatment of the crushed batteries with an alkali hydroxide to produce insoluble manganese oxides and an alkali zincate solution. Zinc oxide is obtained by reacting the zinc solution with carbon dioxide or an acid such as a mineral acid and furnacing. The manganese oxides are converted to MnO by furnacing under an inert atmosphere.

Owner:RETRIEV TECH

Electrodeposition process of a cobalt-chromium film on aluminum alloys for magnetic recording

InactiveUS6187461B1Enhanced magnetizationClear signalBase layers for recording layersMagnetic layer production by platingPhosphateMagnetization

A cobalt-chromium (Co-Cr) magnetic film electrodeposited on the surface of an aluminum alloy. A process for making an aluminum alloy electrodeposited a cobalt-chromium (Co-Cr) magnetic film comprises the steps of chemically polishing an aluminum alloy substrate, pretreating either with phosphate or with zincate and electrodepositing in a plating bath containing cobalt and chromium ions to prepare the cobalt-chromium thin film on the aluminum alloy. Chromium content in the film can be designed by adjusting the parameters of pretreatment and electroplating. The produced cobalt-chromium film can flexibly adjust the magnetic characteristics (e.g. coercive force (Hc) and ramanence magnetization (Mr)) and is suitable for use in a magnetic recorder. The chemical composition, adhesion, microhardness, magnetic properties of the deposits indicate that the Co-Cr films produced are satisfactory for magnetic recording service.

Owner:NAT SCI COUNCIL

Preparation method of alkaline secondary zinc battery negative electrode active substance

InactiveCN1462083AGood formabilityImprove formingAlkaline accumulatorsZinc compoundsZincateChemical computing

An active substance (calcium zincate) for the negative electrode (Zn) of secondary alkaline battery is prepared from ZnO and Ca(OH)2 through proportioning, adding them to KOH solution, stirring at 75-95 deg.C for at least 72 hr. ageing at 75-95 deg.c for at least 60 hr, cooling, filtering, washing, baking at 105-110 deg.c, grinding and sieving by 300 meshes.

Owner:江苏海四达集团有限公司

Copper-alkaline storage battery

InactiveCN104934611AThe stubborn problem of bad customer serviceImprove conductivityAlkaline accumulatorsElectrode carriers/collectorsPotassium hydroxidePotassium

The invention discloses a copper-alkaline storage battery, and can be widely applied to the technical field of electrochemical storage batteries. The copper-alkaline storage battery comprises a cathode plate, an anode plate and alkaline electrolyte. A copper sheet is used as a matrix of the cathode plate, the anode plate comprises grids and active substances, copper sheets are punched or subjected to copper casting to form the grids, the active substances which include copper oxide and acetylene black are coated on the grids, the grids are packaged in a copper shell by the aid of alkali-proof paper, meshes are formed in two sides of the copper shell, the alkaline electrolyte is mixed liquid of potassium zincate and potassium hydroxide, zinc oxide is dissolved in aqueous liquor of the potassium hydroxide to obtain the mixed liquid, the potassium zincate can be reduced to obtain the potassium hydroxide and zinc when the copper-alkaline storage battery is charged, and zinc molecules can be deposited on a cathode; the zinc and the potassium hydroxide react to each other to generate the potassium zincate and hydrogen when the copper-alkaline storage battery is discharged, the hydrogen is oxidized by the copper oxide to obtain water, the copper oxide is turned into cuprous oxide due to oxygen loss, and the same reversible reaction can be repeatedly carried out and is permanently reversible. The copper-alkaline storage battery has the advantages that a process for manufacturing the copper-alkaline storage battery is simple, the battery is high in capacity and reliability, low in cost, free of pollution and long in service life, and is environmental friendly.

Owner:陈尚发

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com