Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Metallate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallate is the name given to any complex anion containing a metal ligated to several atoms or small groups. The spelling metalate is almost as common. Typically, the metal will be one of the transition elements and the ligand will be oxygen or another chalcogenide or a cyanide group (though others are known). The chalcogenide metallates are known as oxometallates, thiometallates, selenometallates and tellurometallates; the cyanide metallates are known as cyanometallates.

Conversion coating compositions

InactiveUS6764553B2Reduce the smellExcellent characteristicsOther chemical processesSolid state diffusion coatingVanadium CompoundsHydrophilic coating

Owner:HENKEL KGAA

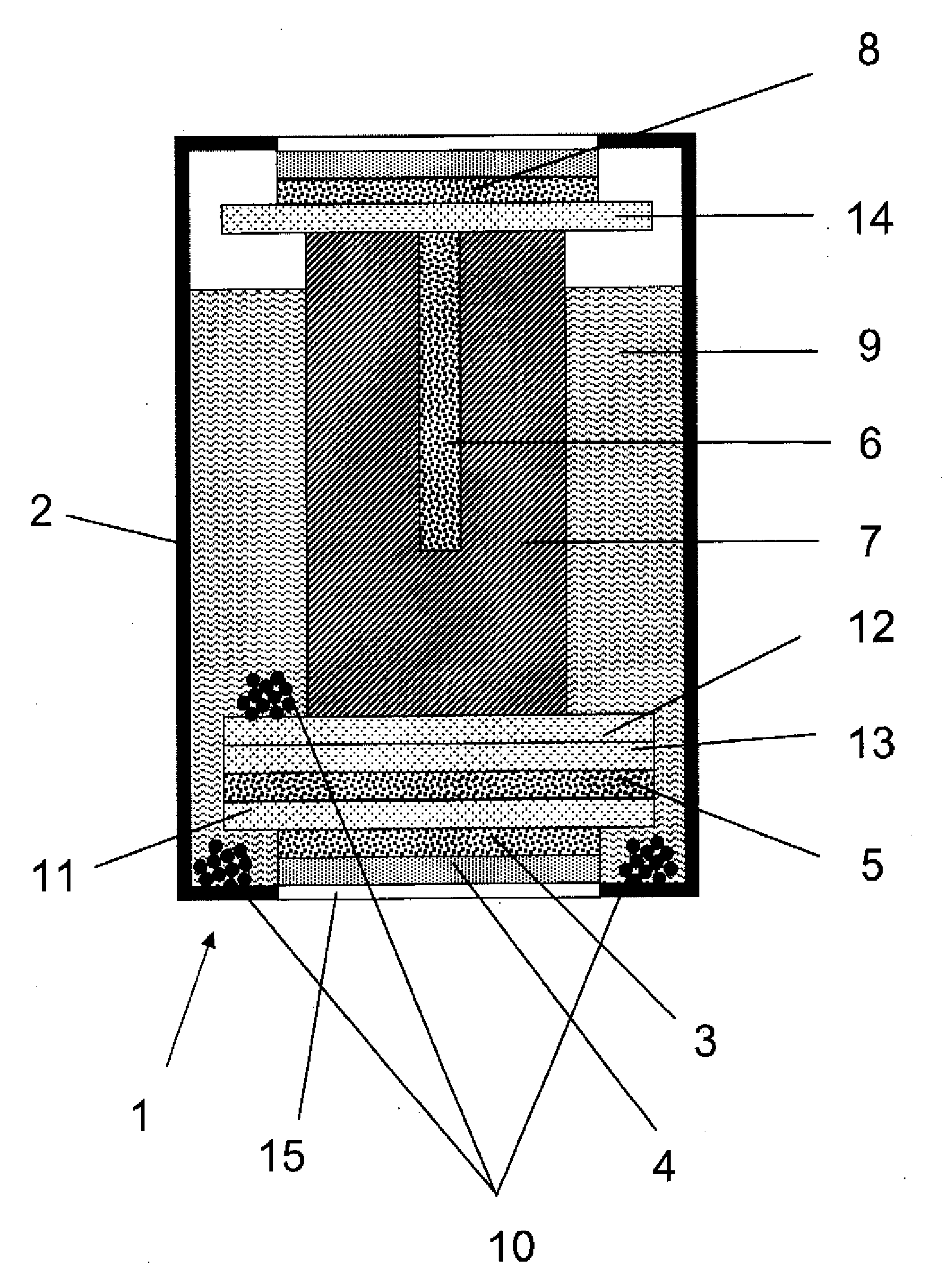

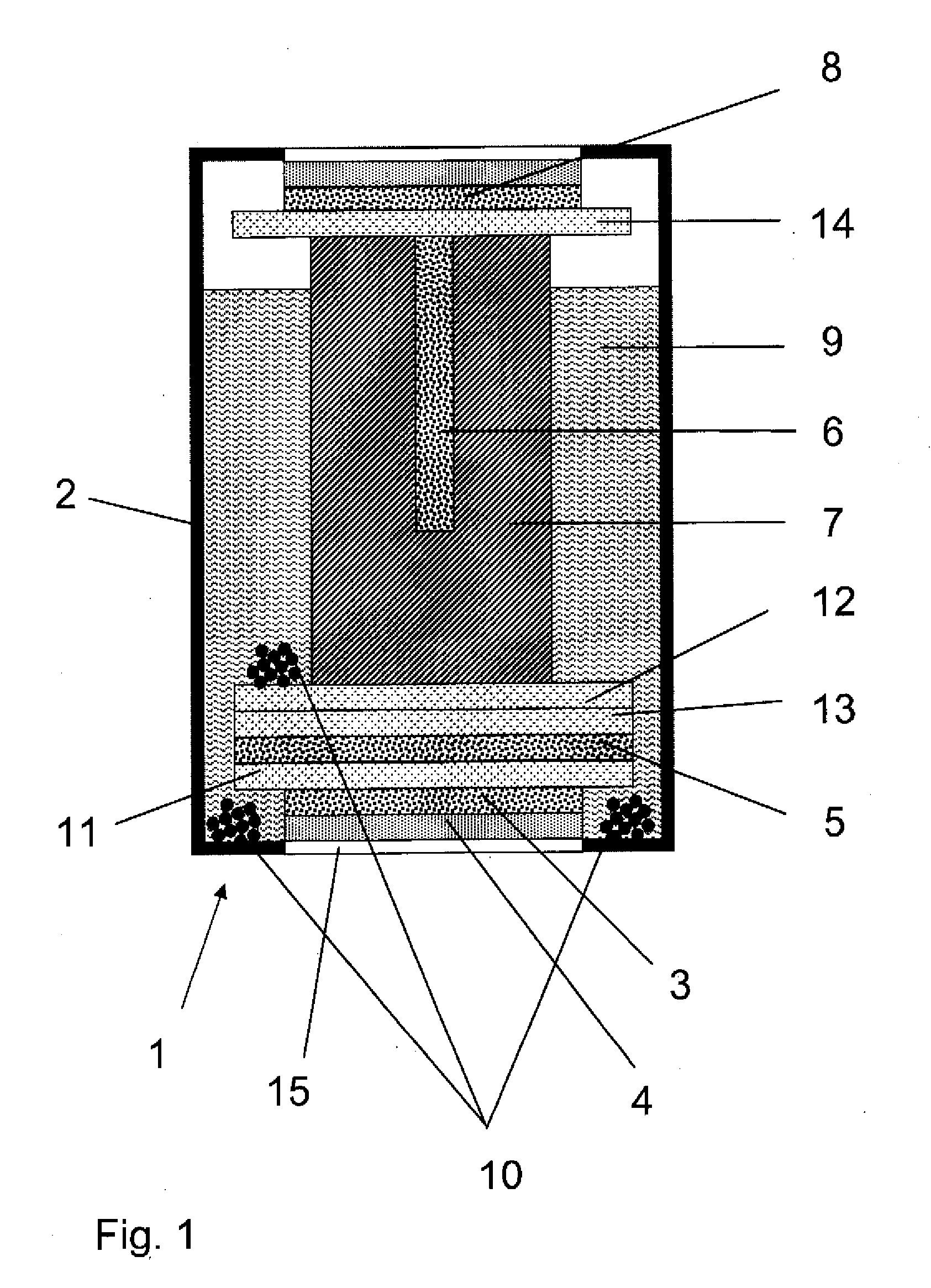

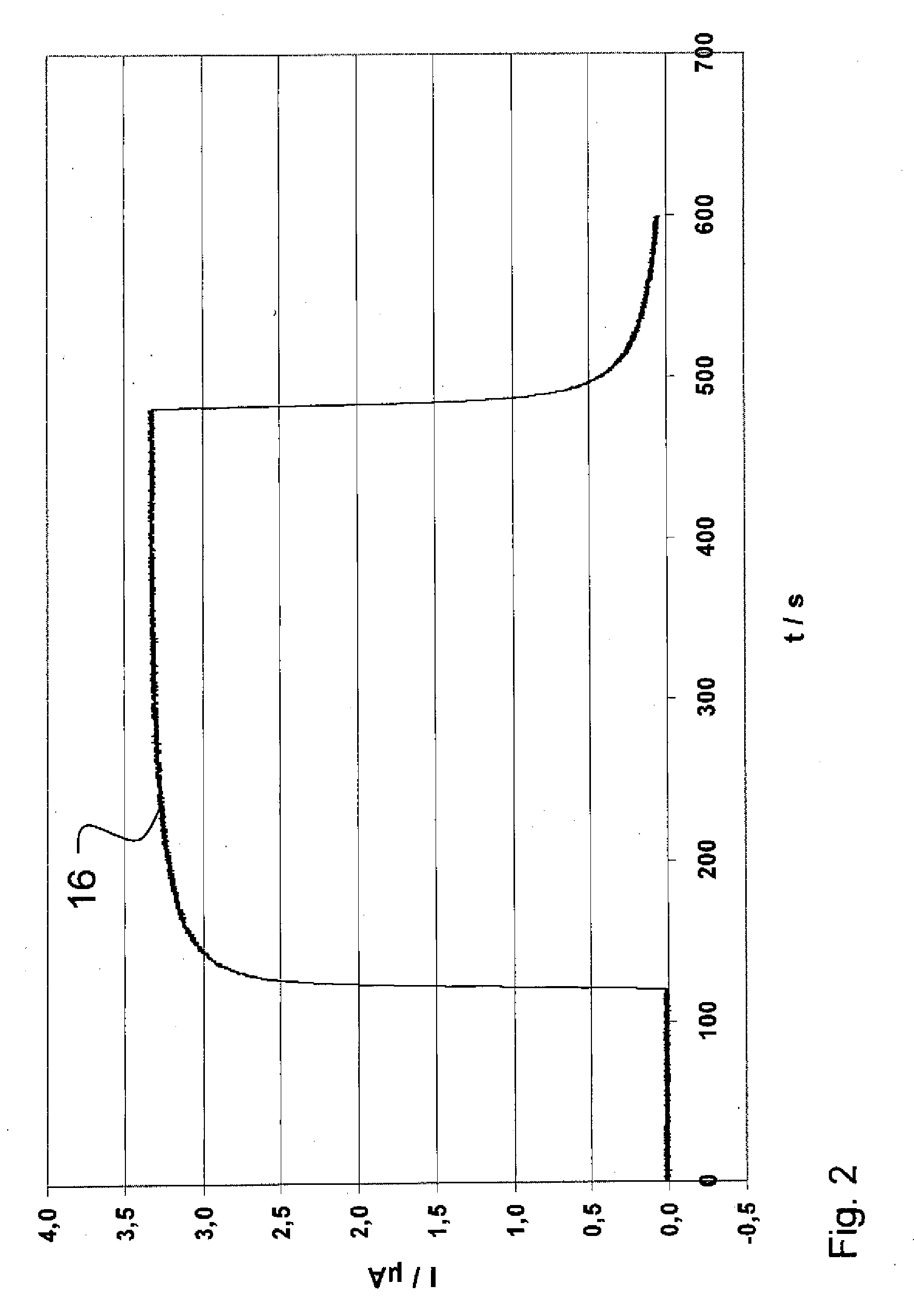

Electrochemical gas sensor

ActiveUS20100012494A1Stabilizing pH valueHigh sensitivityWeather/light/corrosion resistanceVolume/mass flow measurementElectrochemical gas sensorPhysical chemistry

A mediator-based electrochemical gas sensor reacts selectively with hydrogen sulfide. The gas sensor has an electrolyte solution (9), which contains a mediator compound in the form of metallates of transition metals.

Owner:DRAGER SAFETY

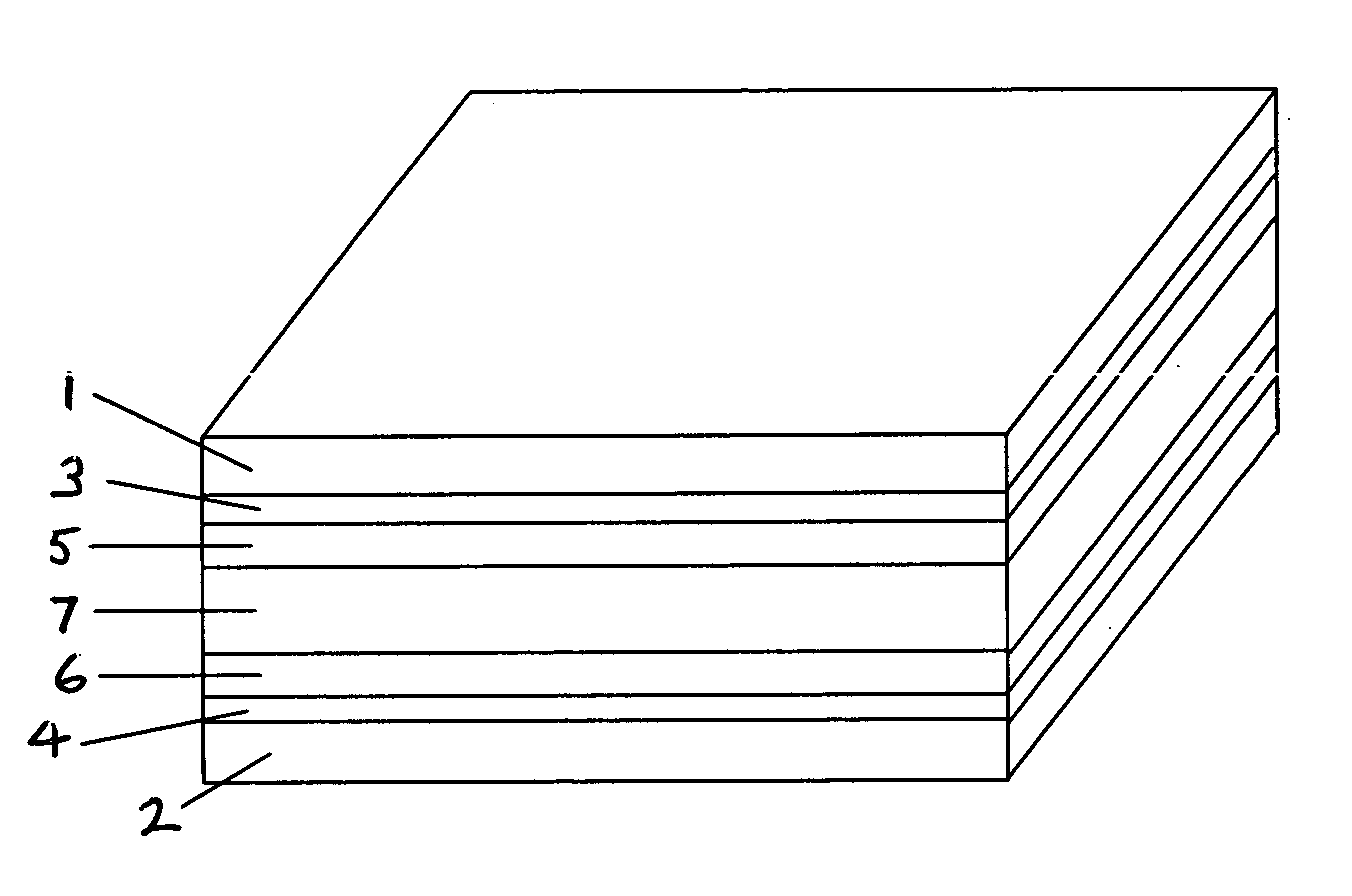

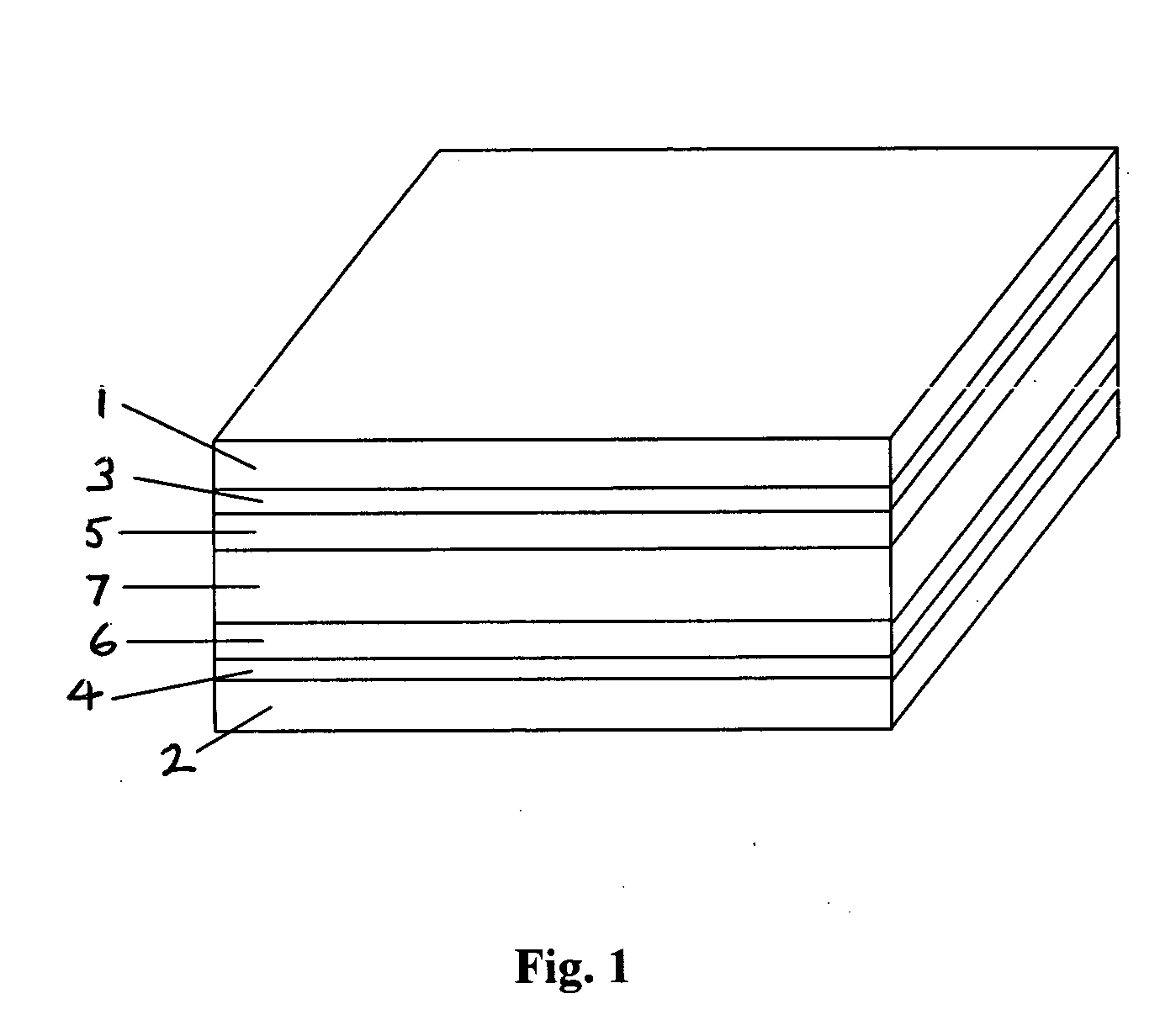

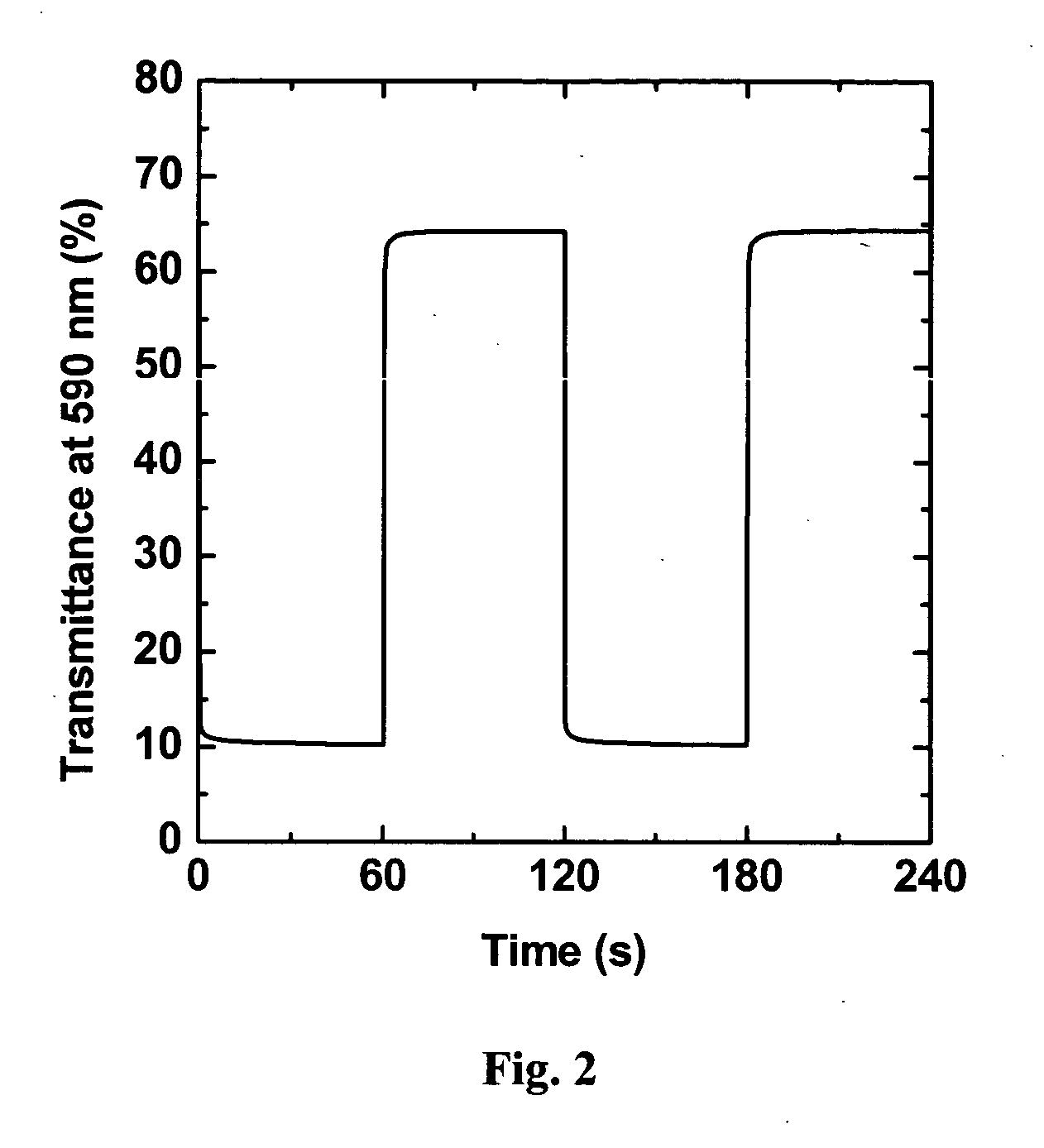

Electrochromic device using poly(3,4-ethylenedioxythiophene) and derivatives thereof

The present invention relates to complementary electrochromic devices comprising poly(3,4-ethylenedioxythiophene) and derivatives thereof as a cathodically coloring layer and an indium hexacyanometallate or transition metal hexacyanometallate as an anodically coloring layer.

Owner:TROPICS ENTERPRISE

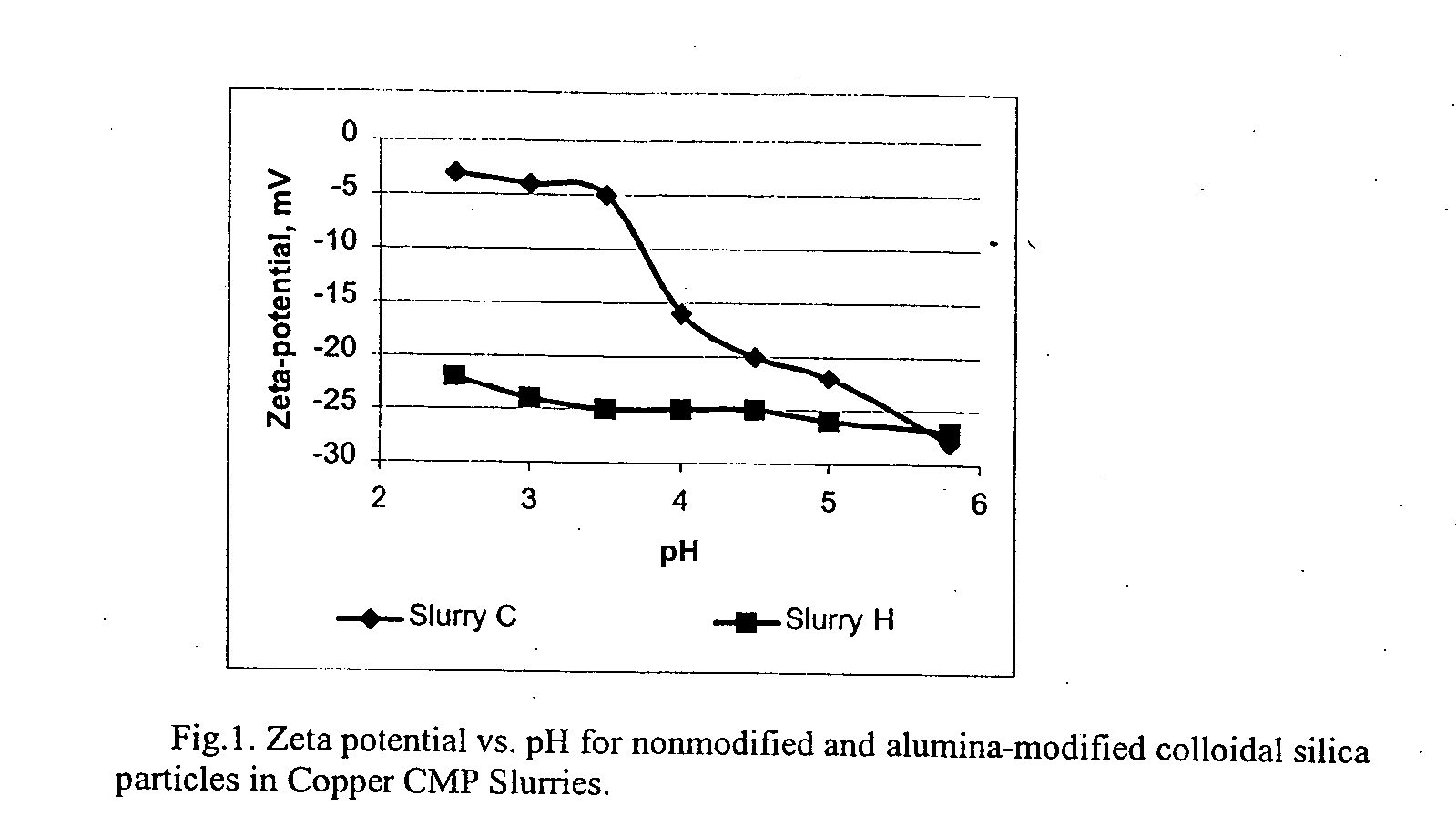

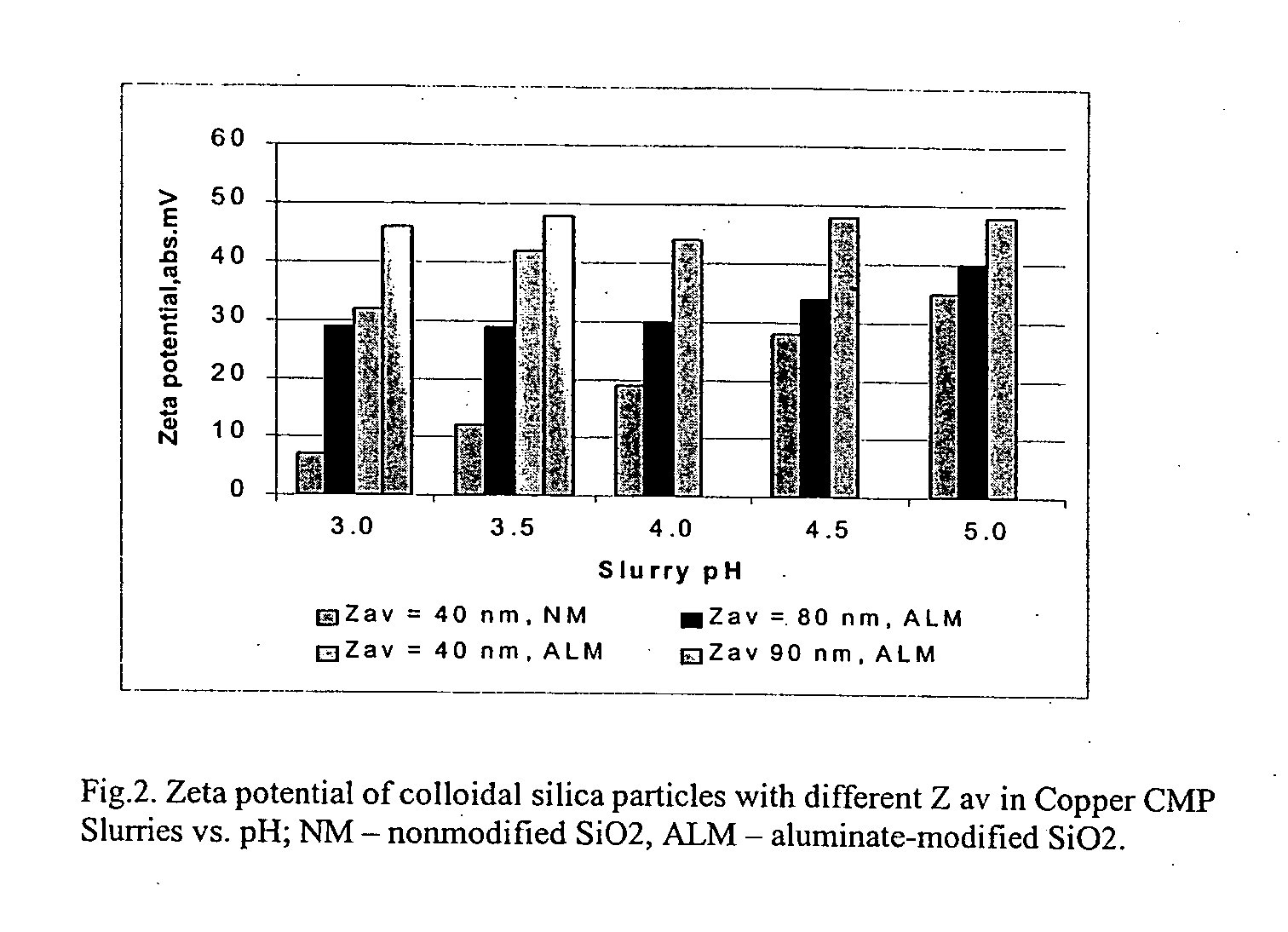

Aqueous slurry containing metallate-modified silica particles

InactiveUS20070037892A1Improve stabilityIncrease surface chargePigmenting treatmentOther chemical processesAluminateSilica particle

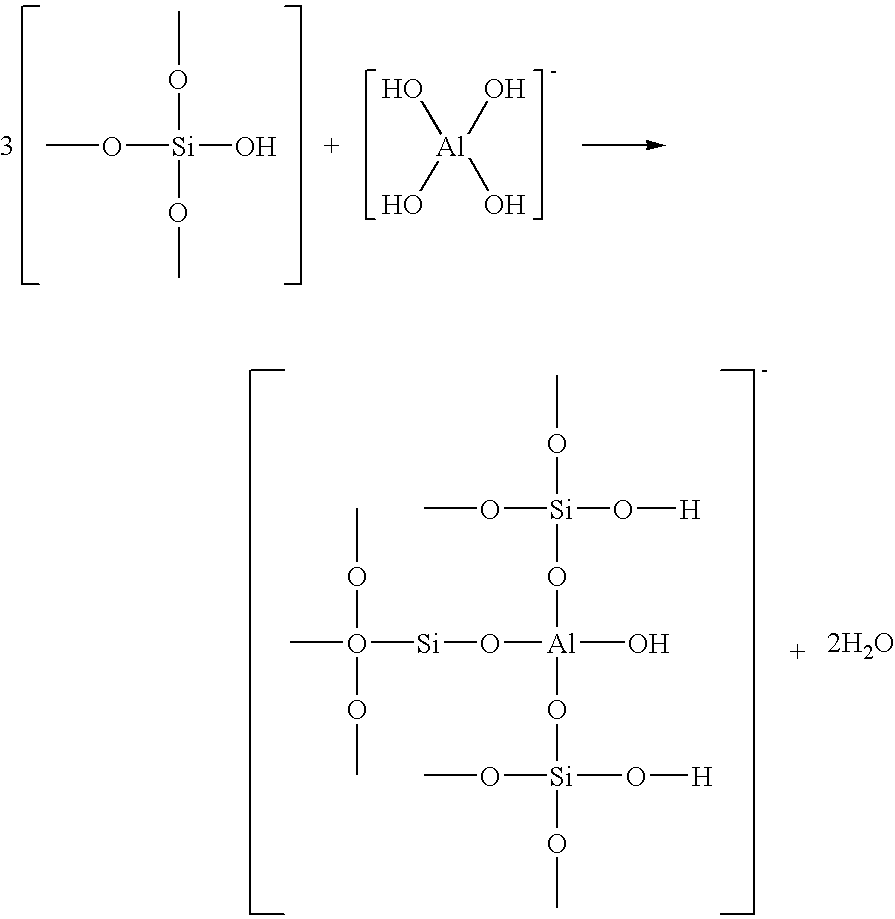

Provided is a novel aqueous slurry composition for polishing / planarization of a substrate. The composition includes silicon dioxide abrasive particles wherein the abrasive particles are anionically modified / doped with metallate anions selected from the group consisting of aluminate, stannate, zincate and plumbate, thereby providing a high negative surface charge to the abrasive particles and enhances the stability of the slurry composition.

Owner:PRAXAIR TECH INC

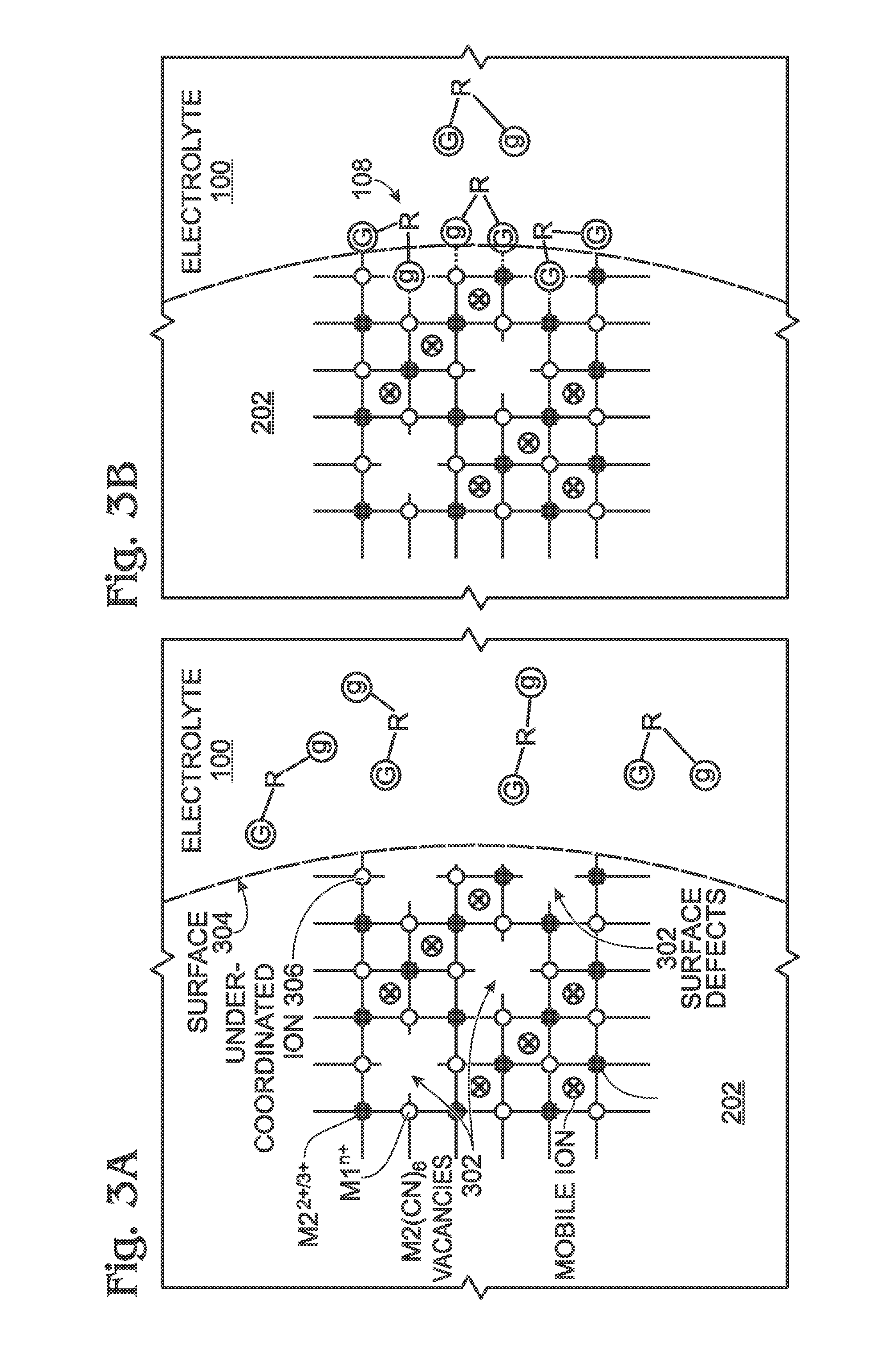

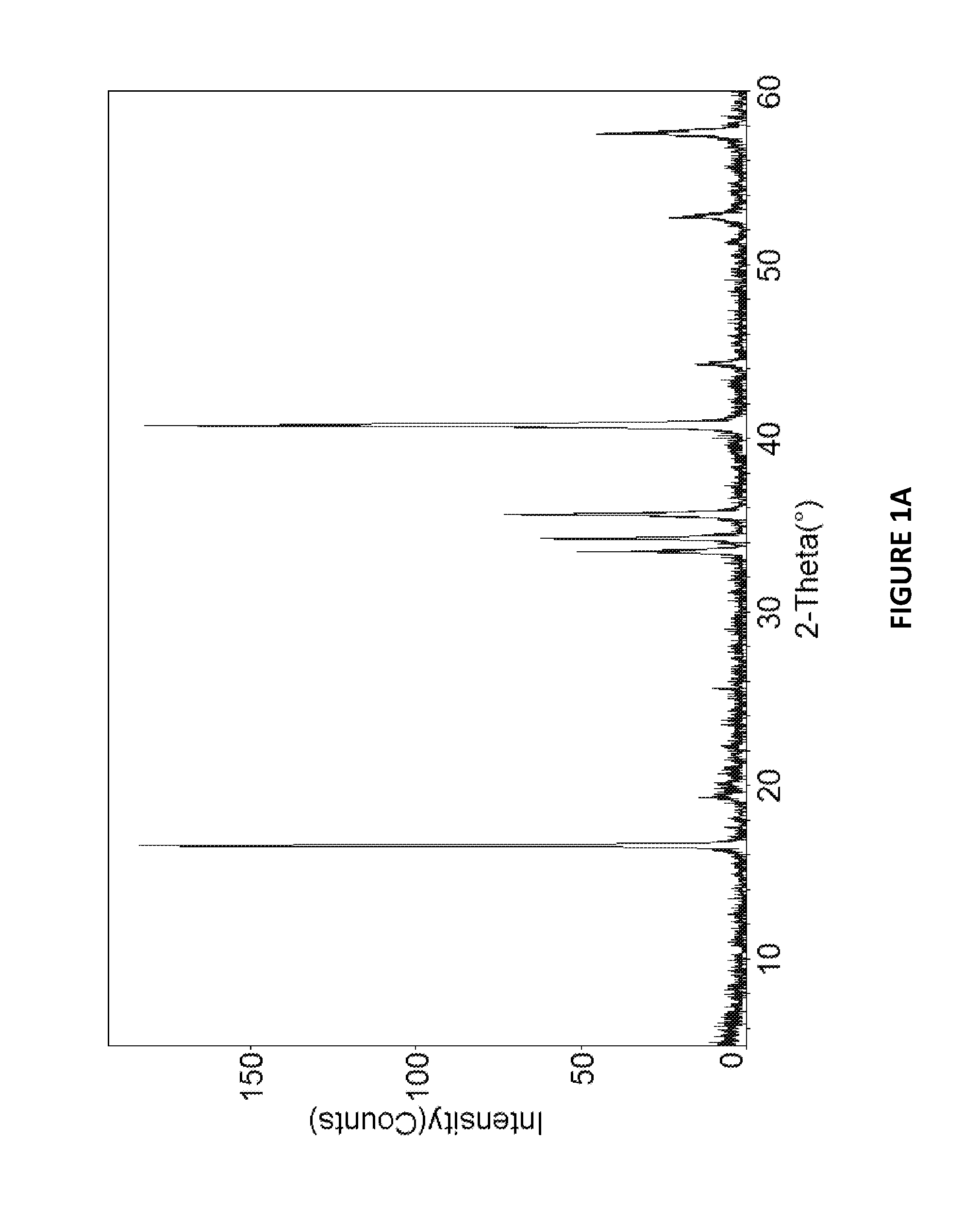

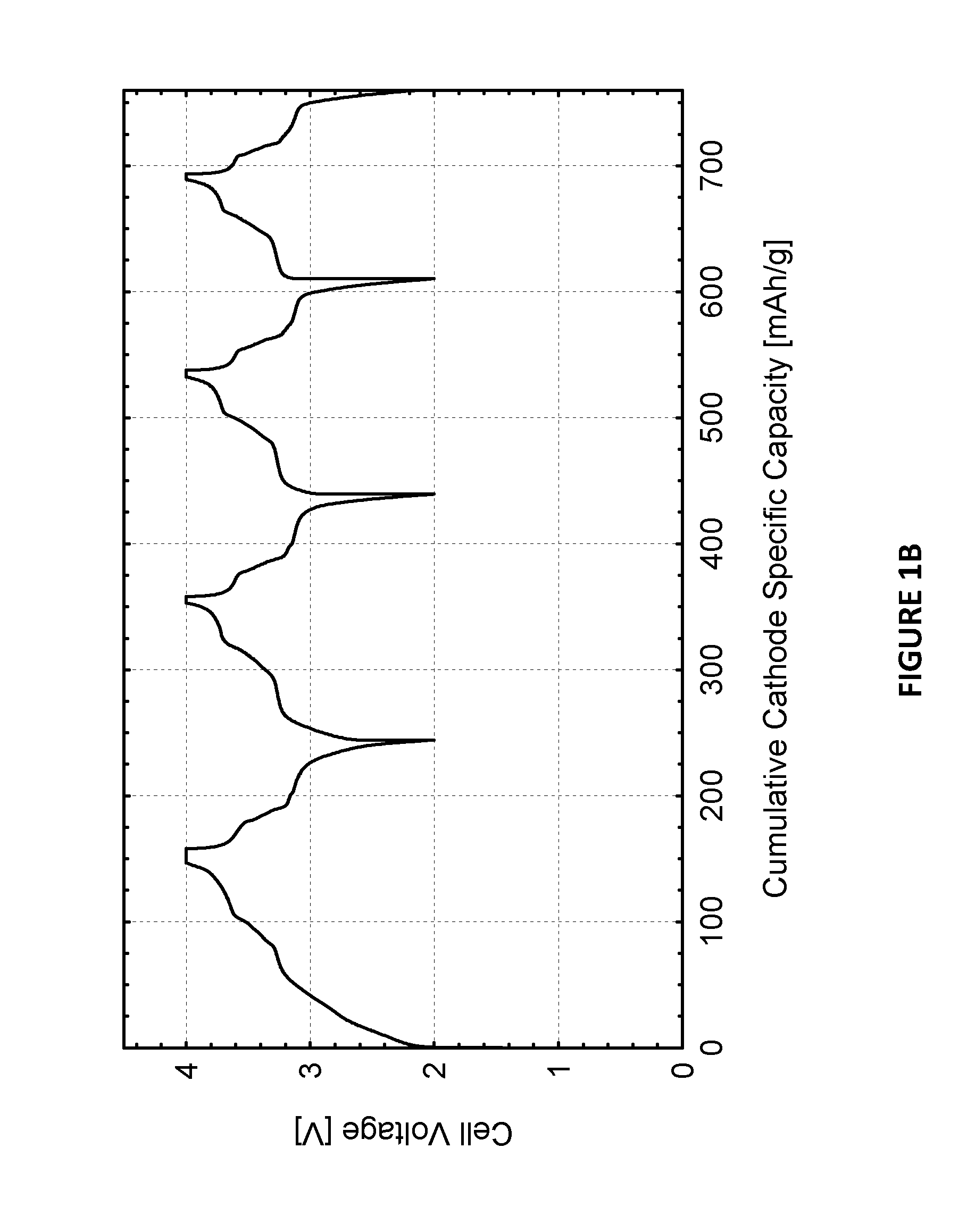

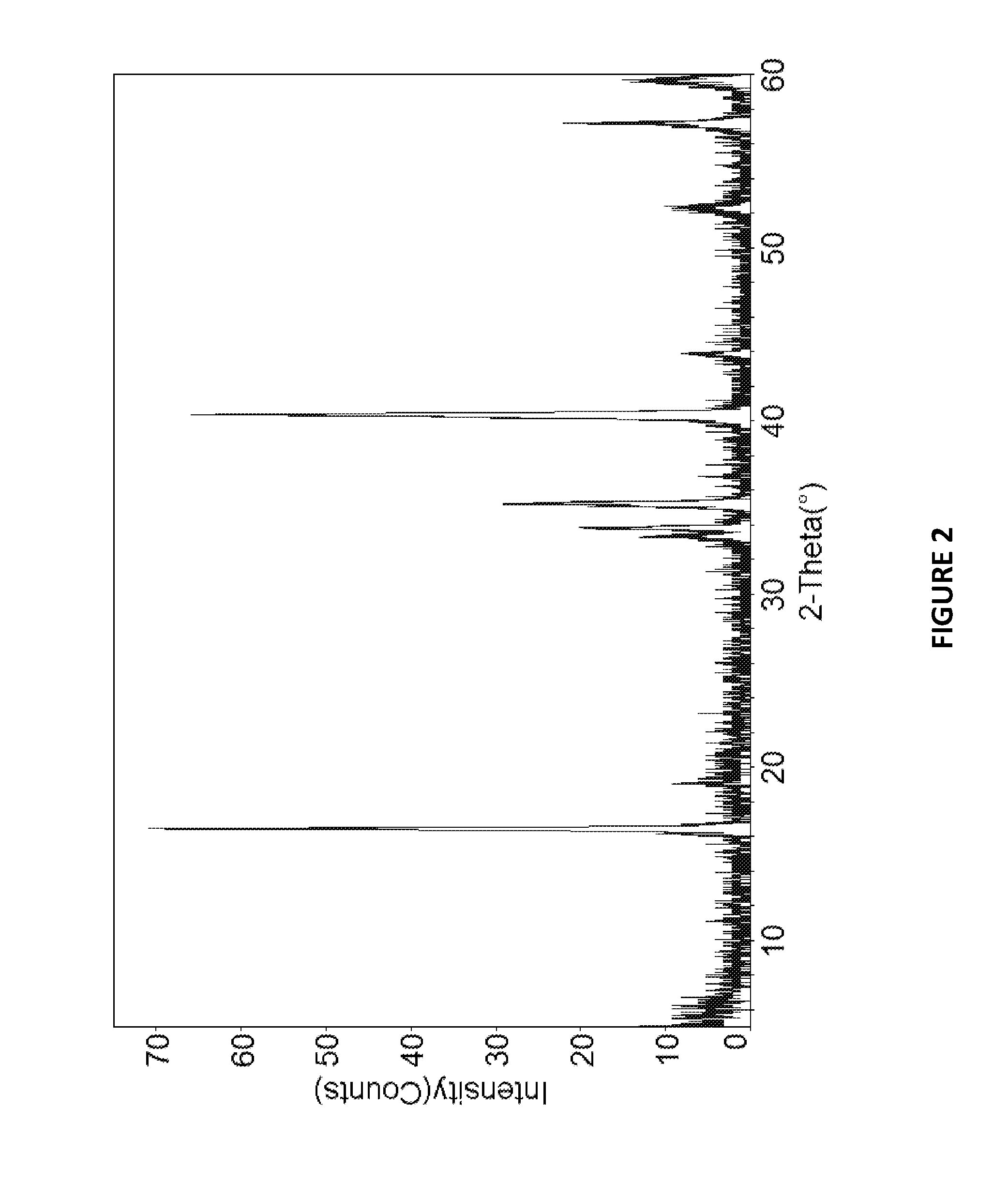

Prussian Blue Analogue Electrodes without Zeolitic Water Content

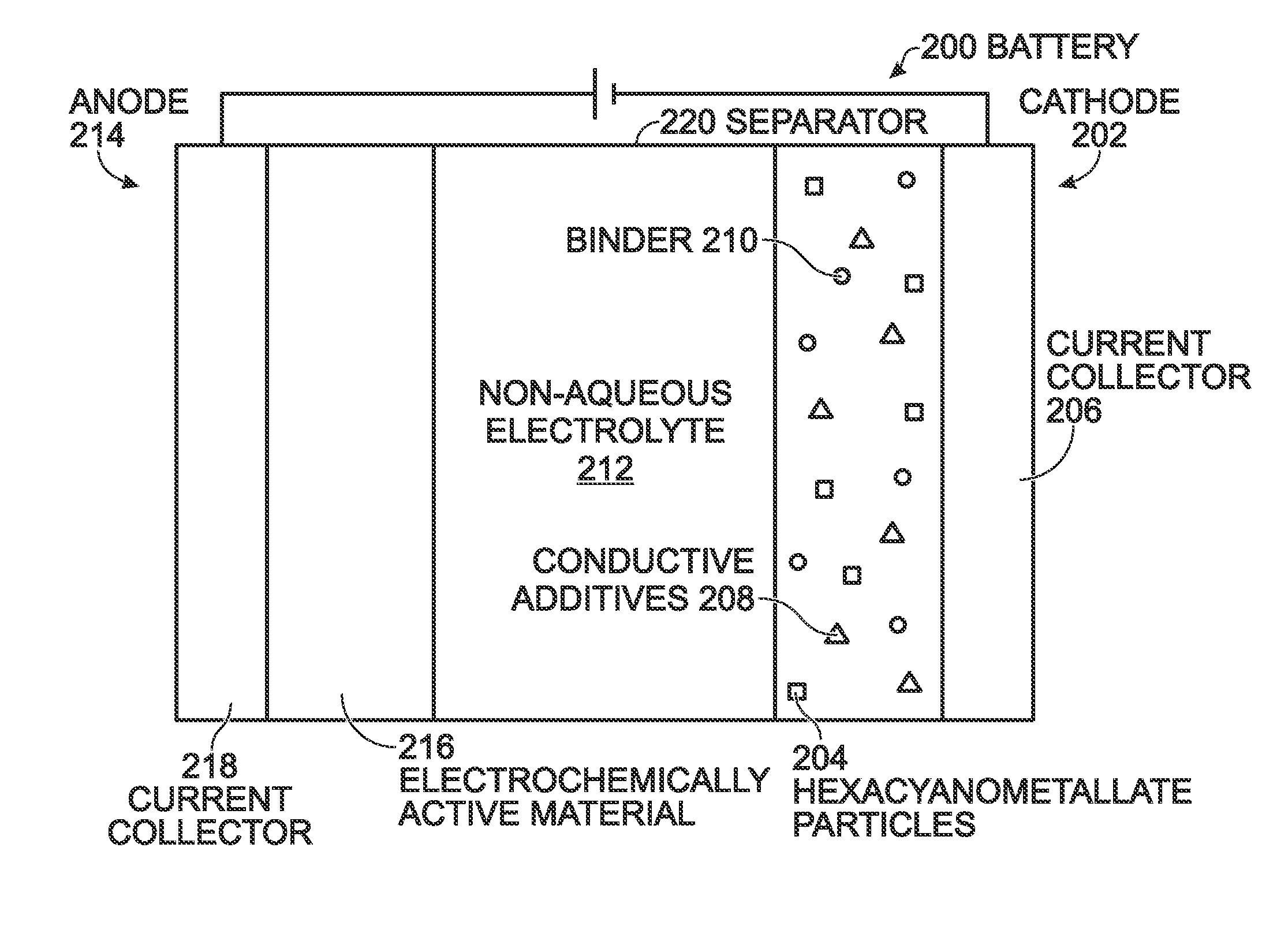

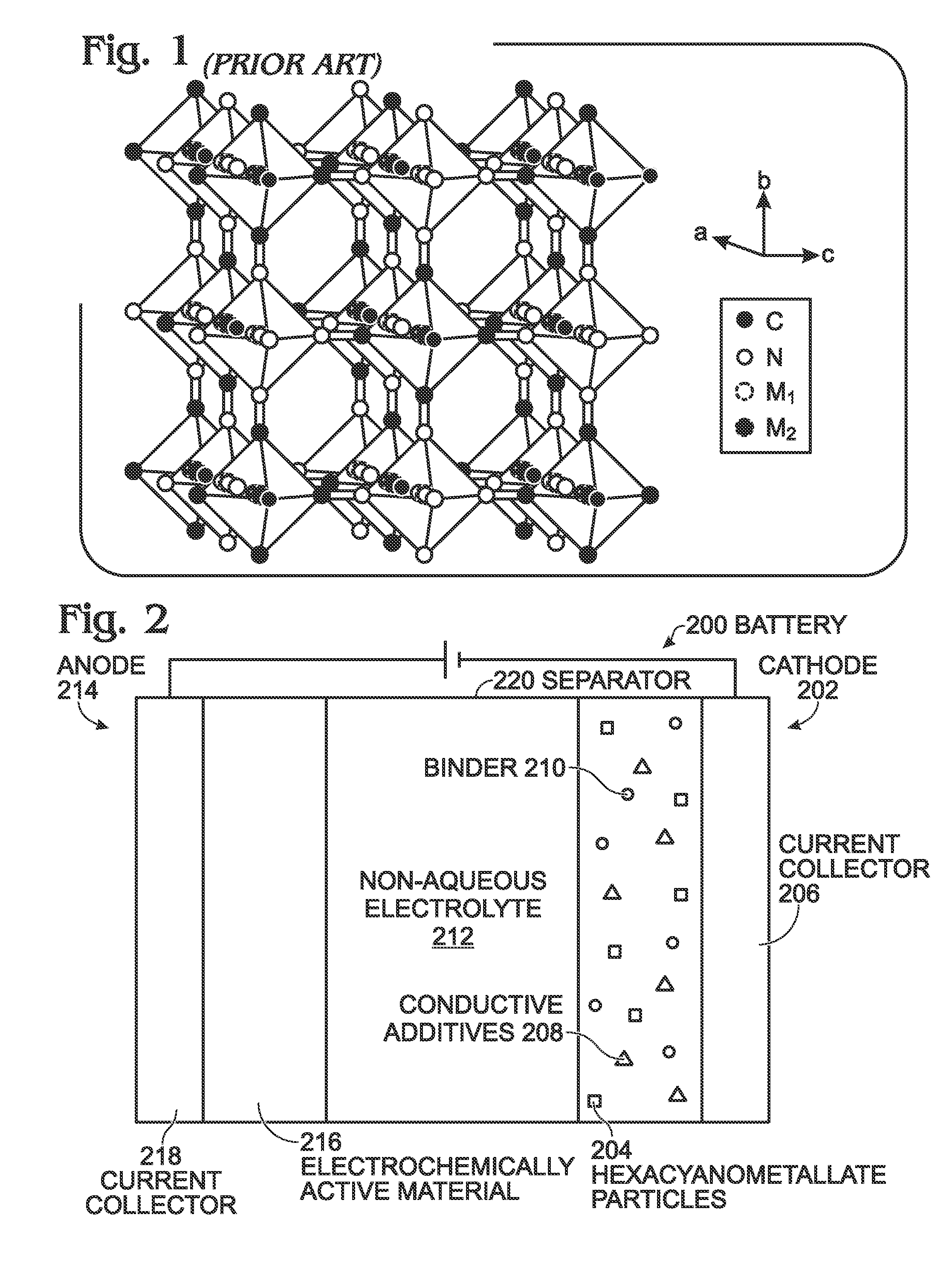

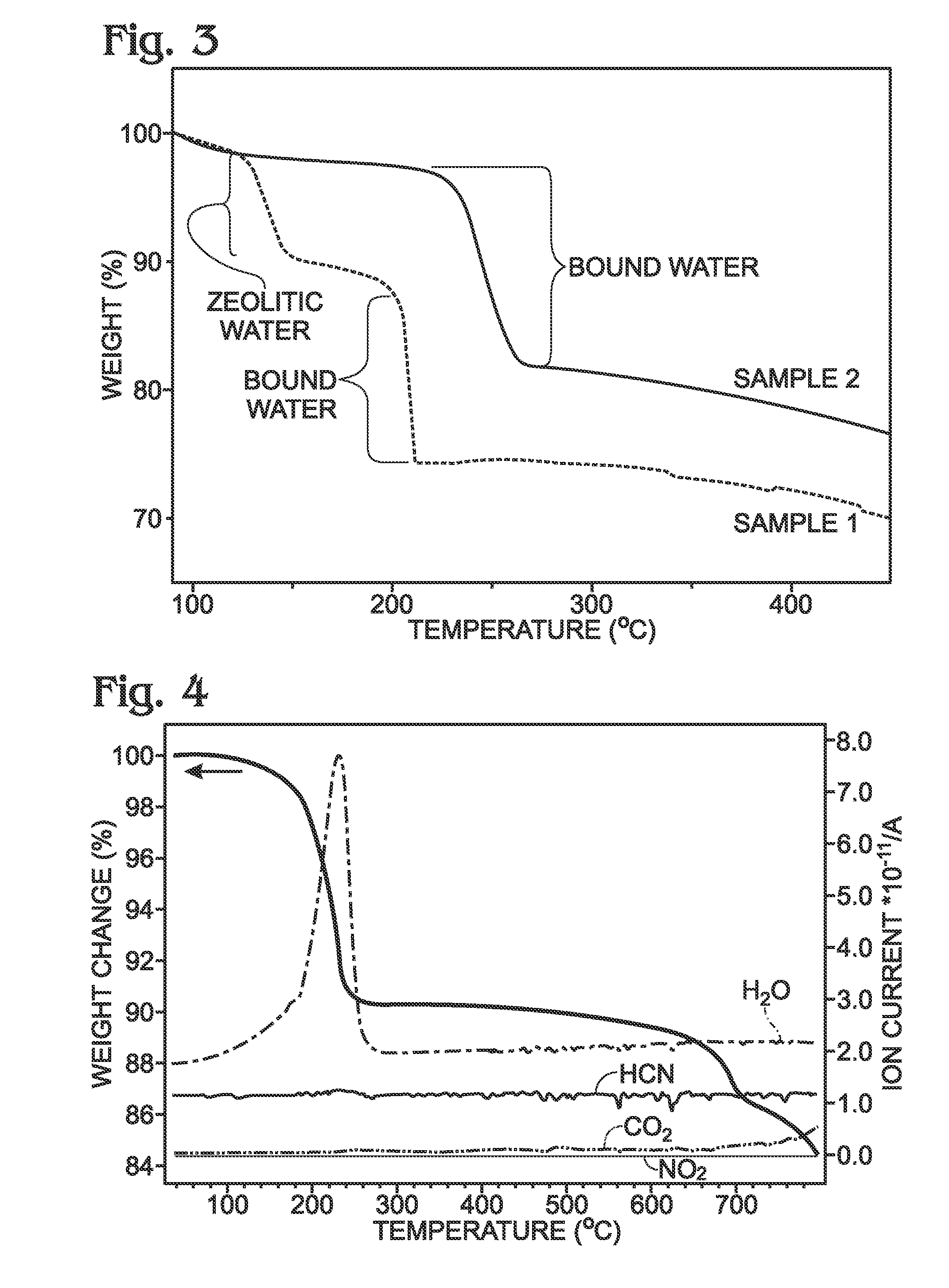

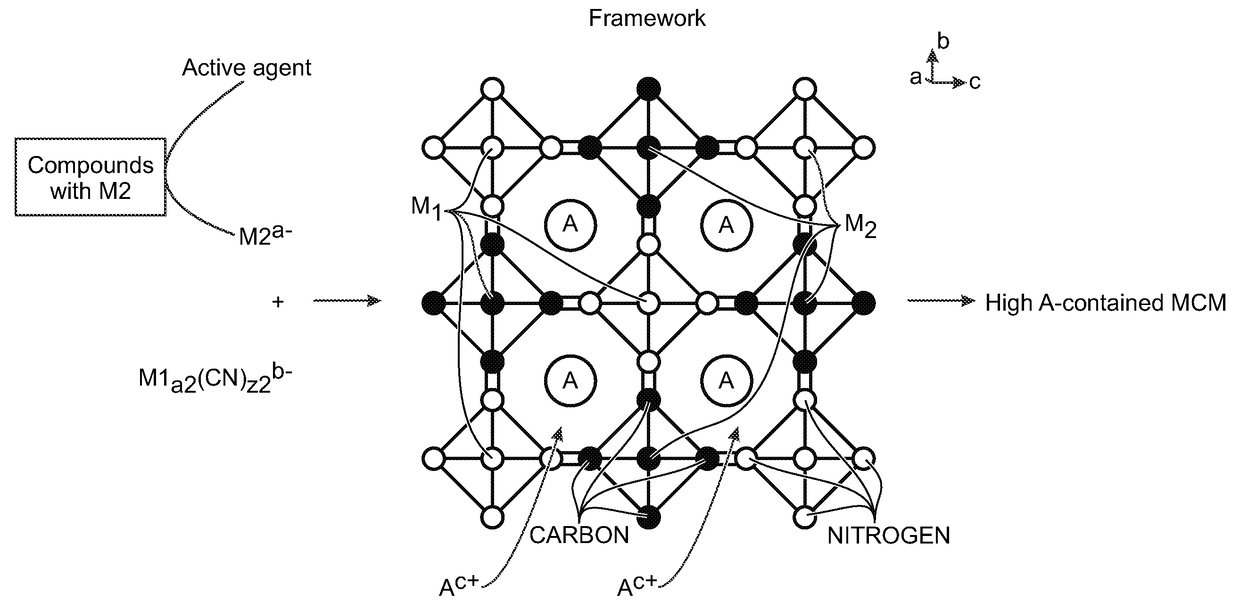

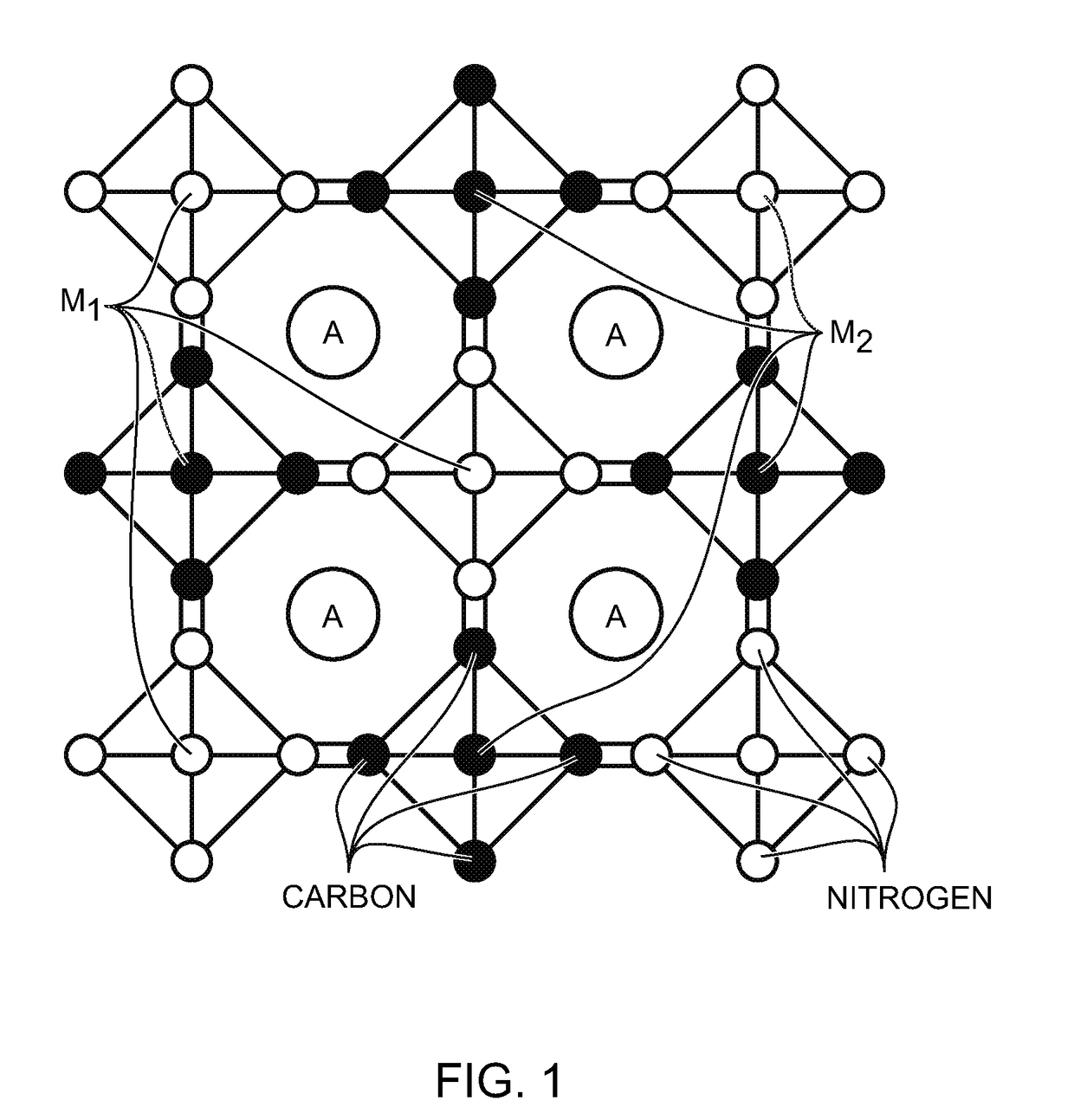

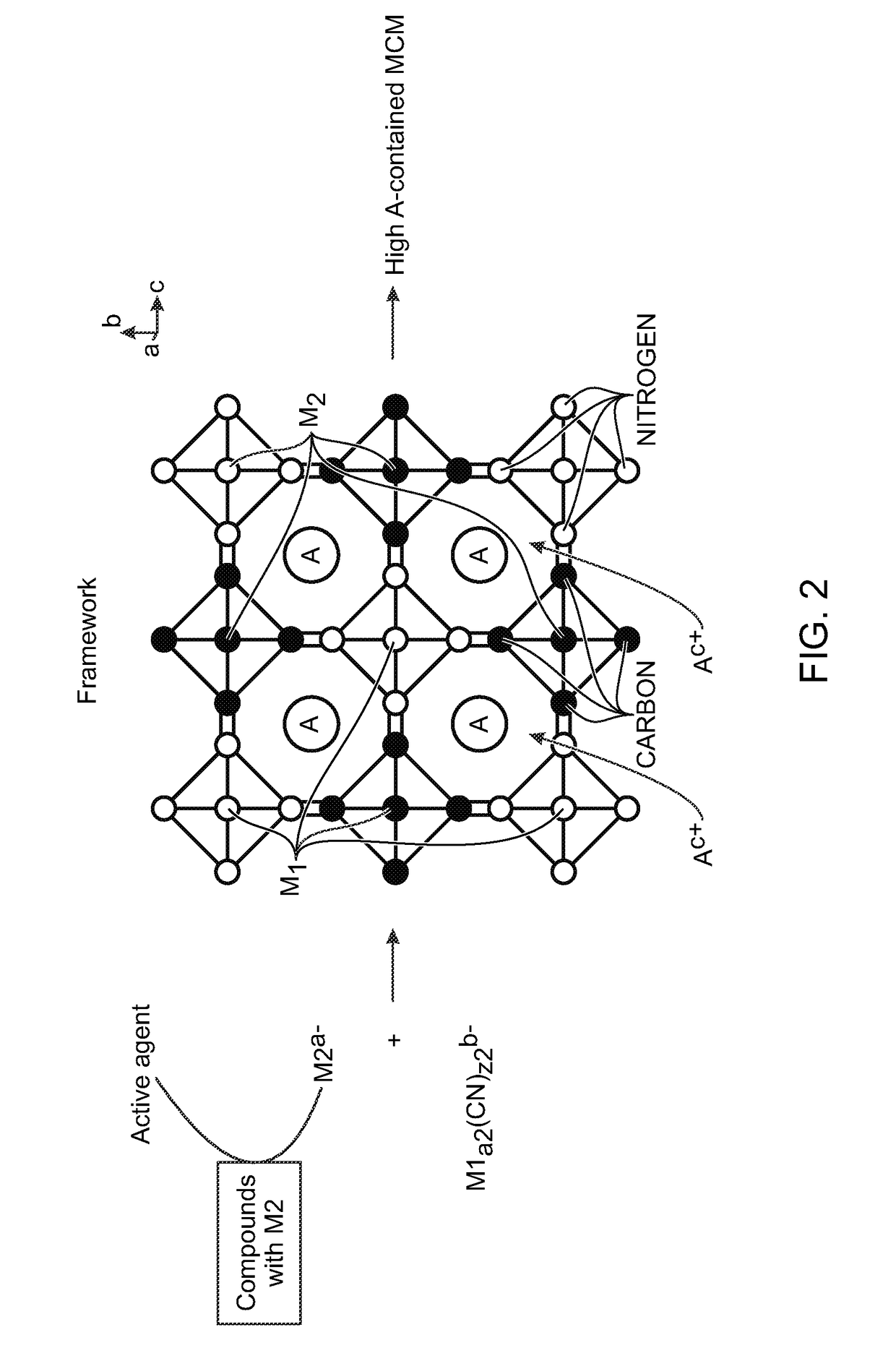

A battery is provided with a hexacyanometallate cathode. The battery cathode is made from hexacyanometallate particles overlying a current collector. The hexacyanometallate particles have the chemical formula AXM1MM2N(CN)Z.d[H2O]ZEO.e[H2O]BND. where A is a metal from Groups 1A, 2A, or 3A of the Periodic Table, where M1 and M2 are each a metal with 2+ or 3+ valance positions, where “ZEO” and “BND” indicate zeolitic and bound water, respectively, where d is 0, and e is greater than 0 and less than 8. The anode material may primarily be a material such as hard carbon, soft carbon, oxides, sulfides, nitrides, silicon, metals, or combinations thereof. The electrolyte is non-aqueous. A method is also provided for fabricating hexacyanometallate with no zeolitic water content in response to dehydration annealing at a temperature of greater than 120 degrees C. and less than 200 degrees C.

Owner:SHARP KK

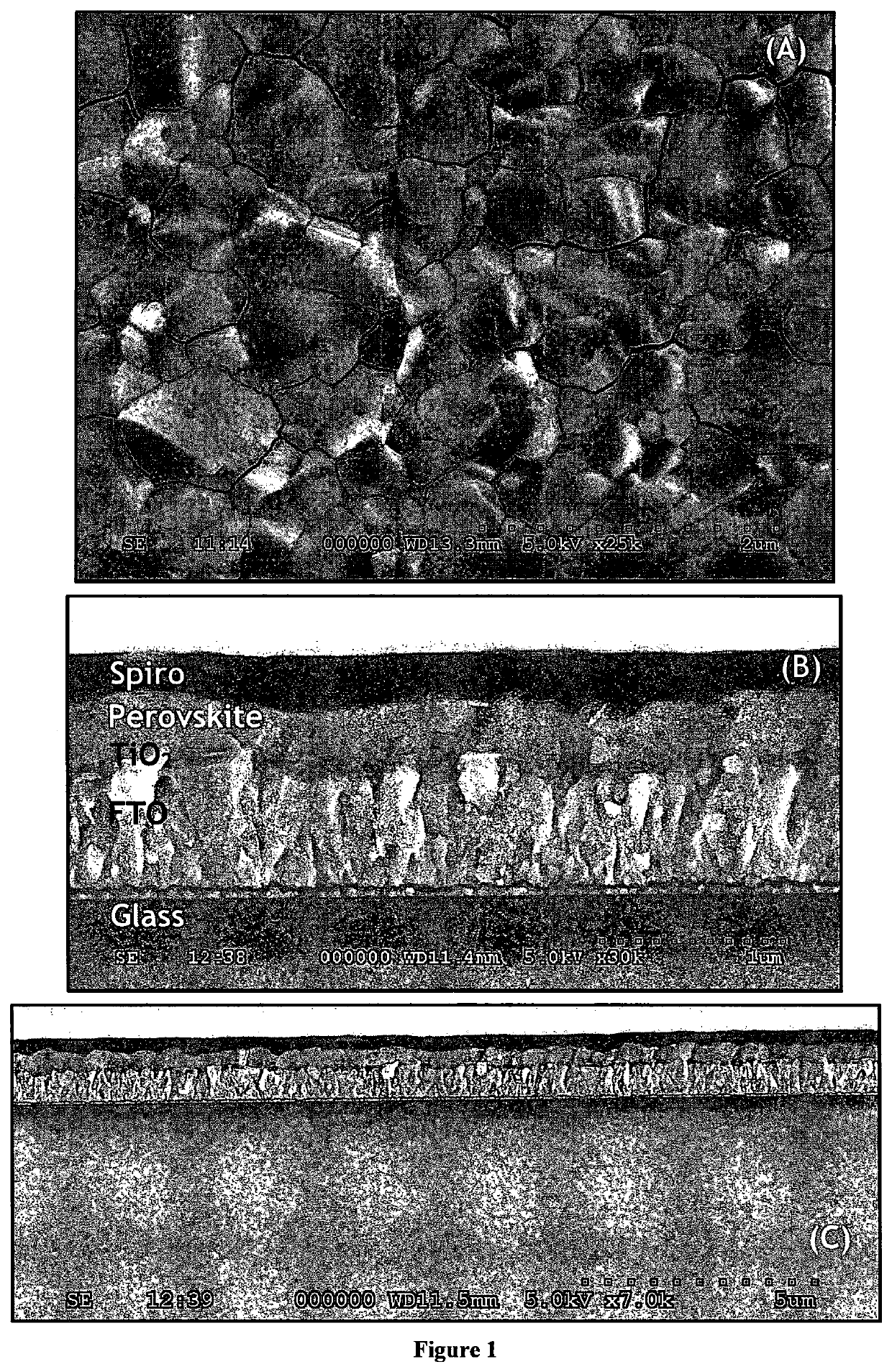

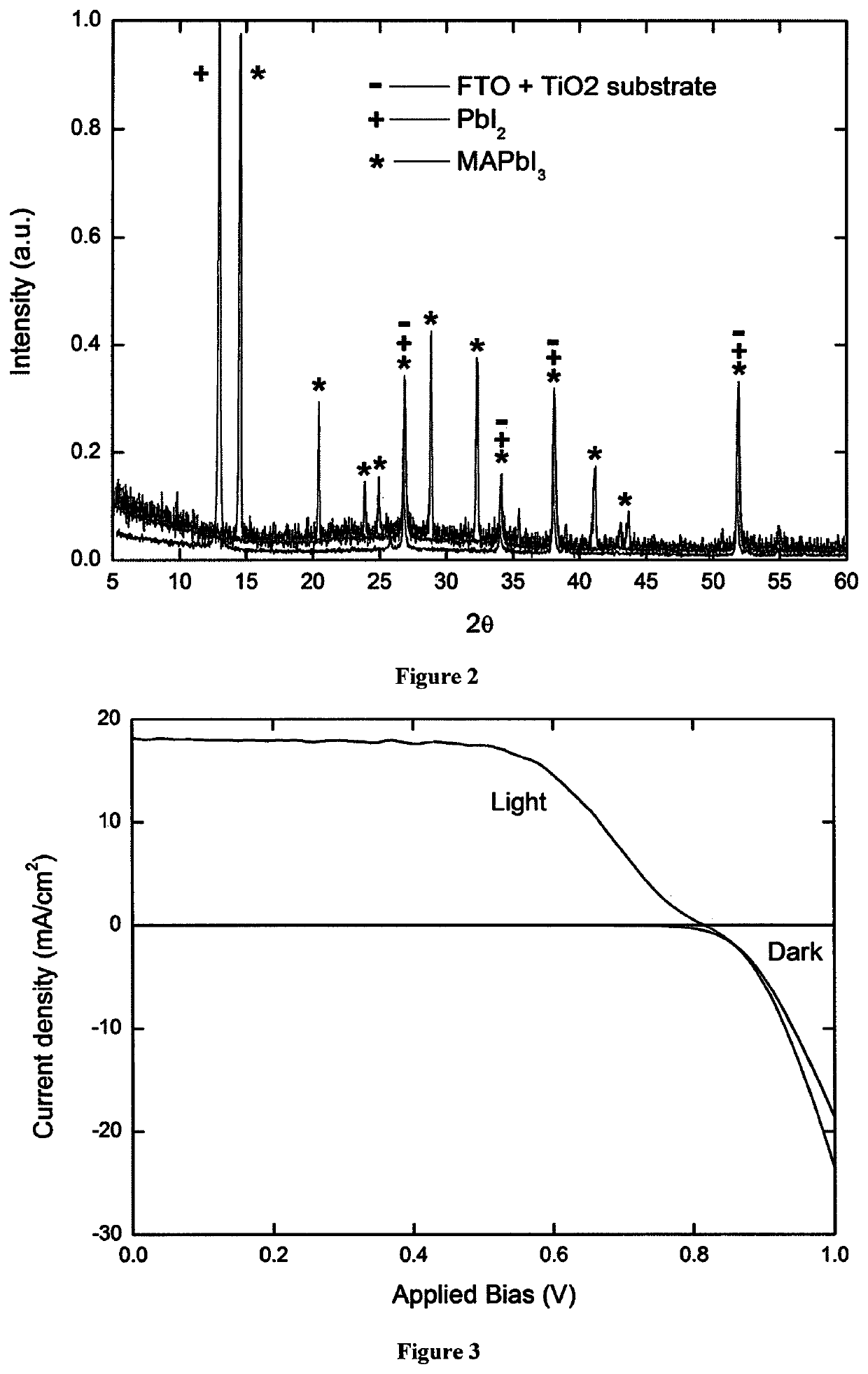

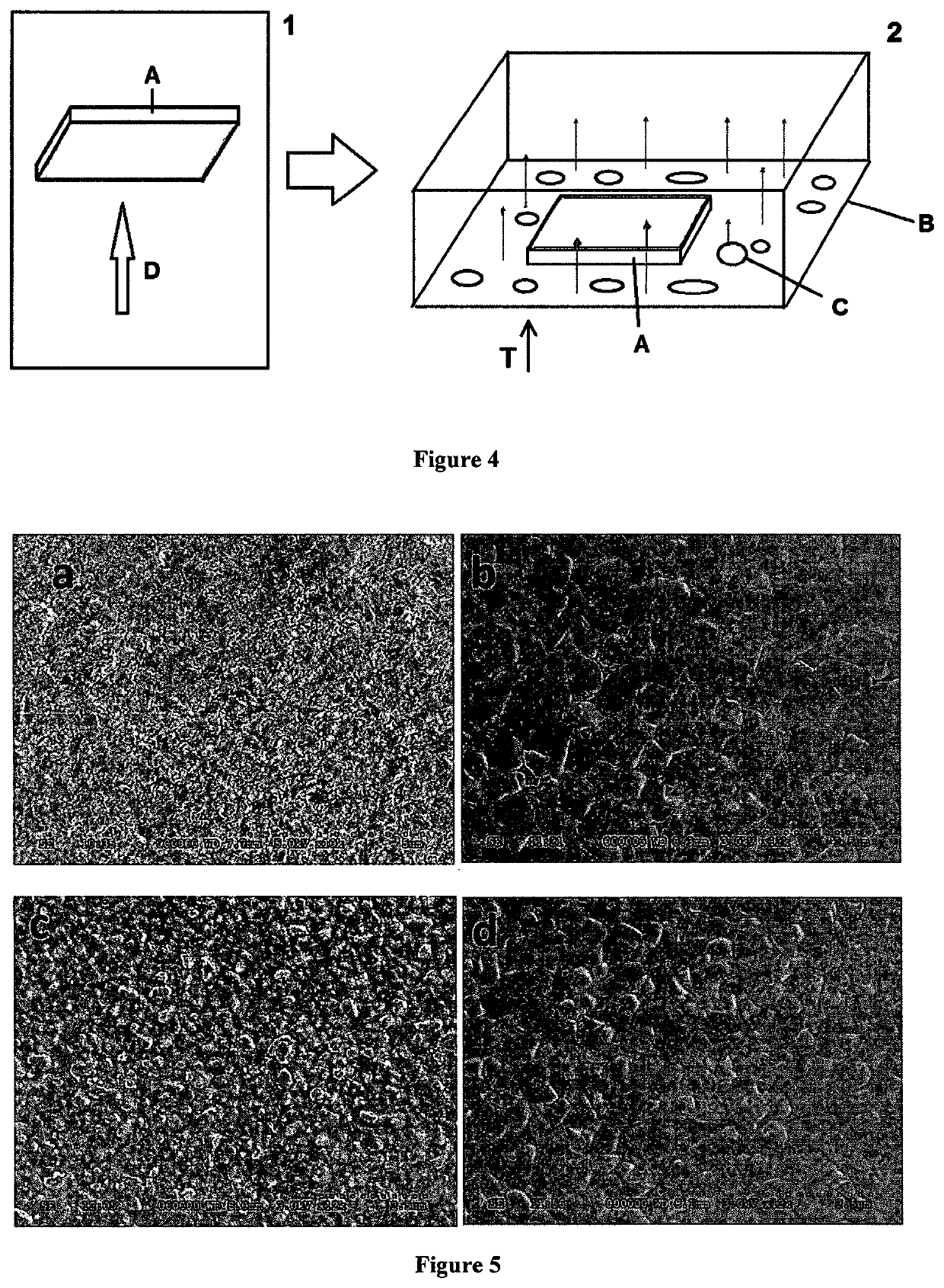

Two-step deposition process

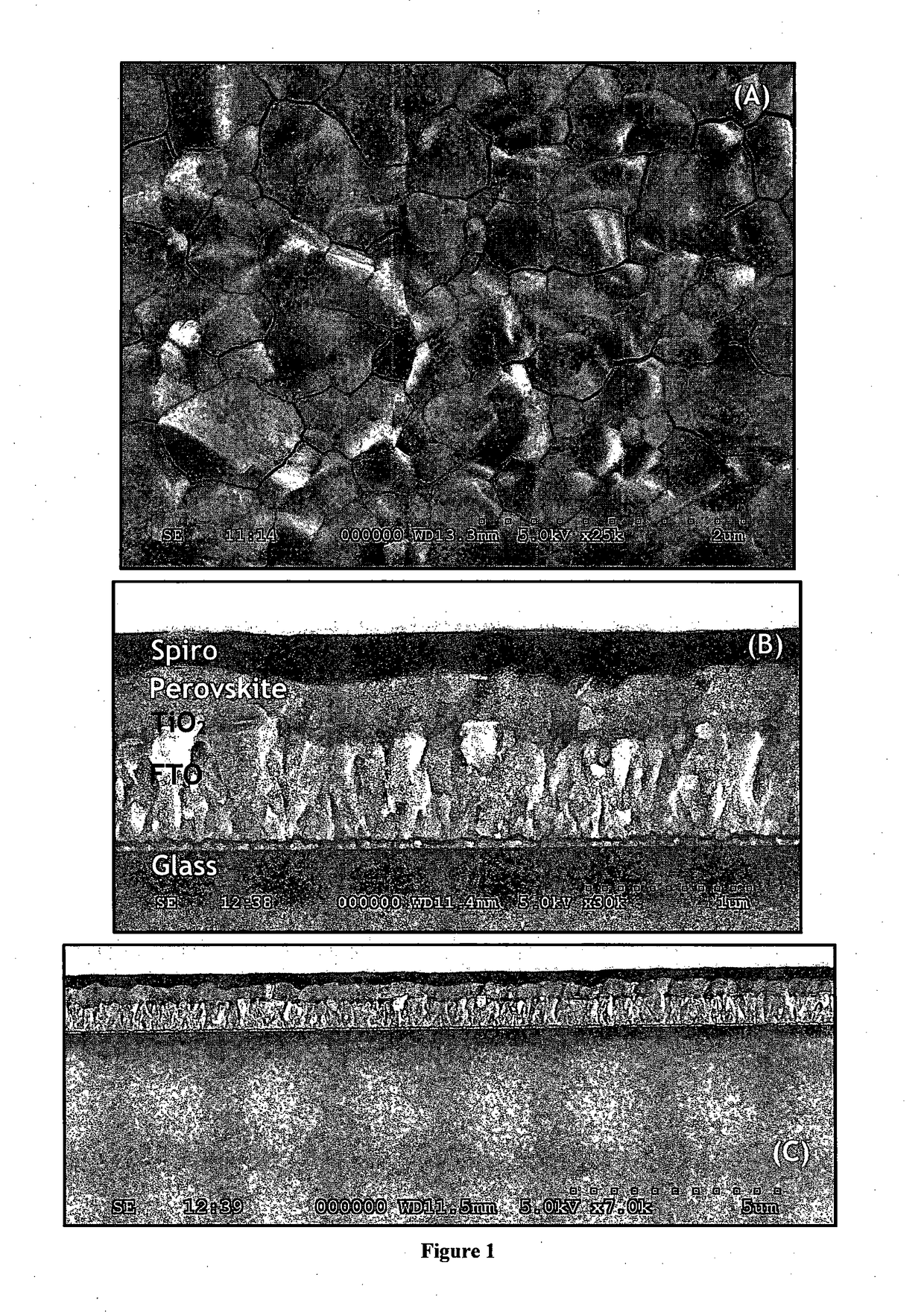

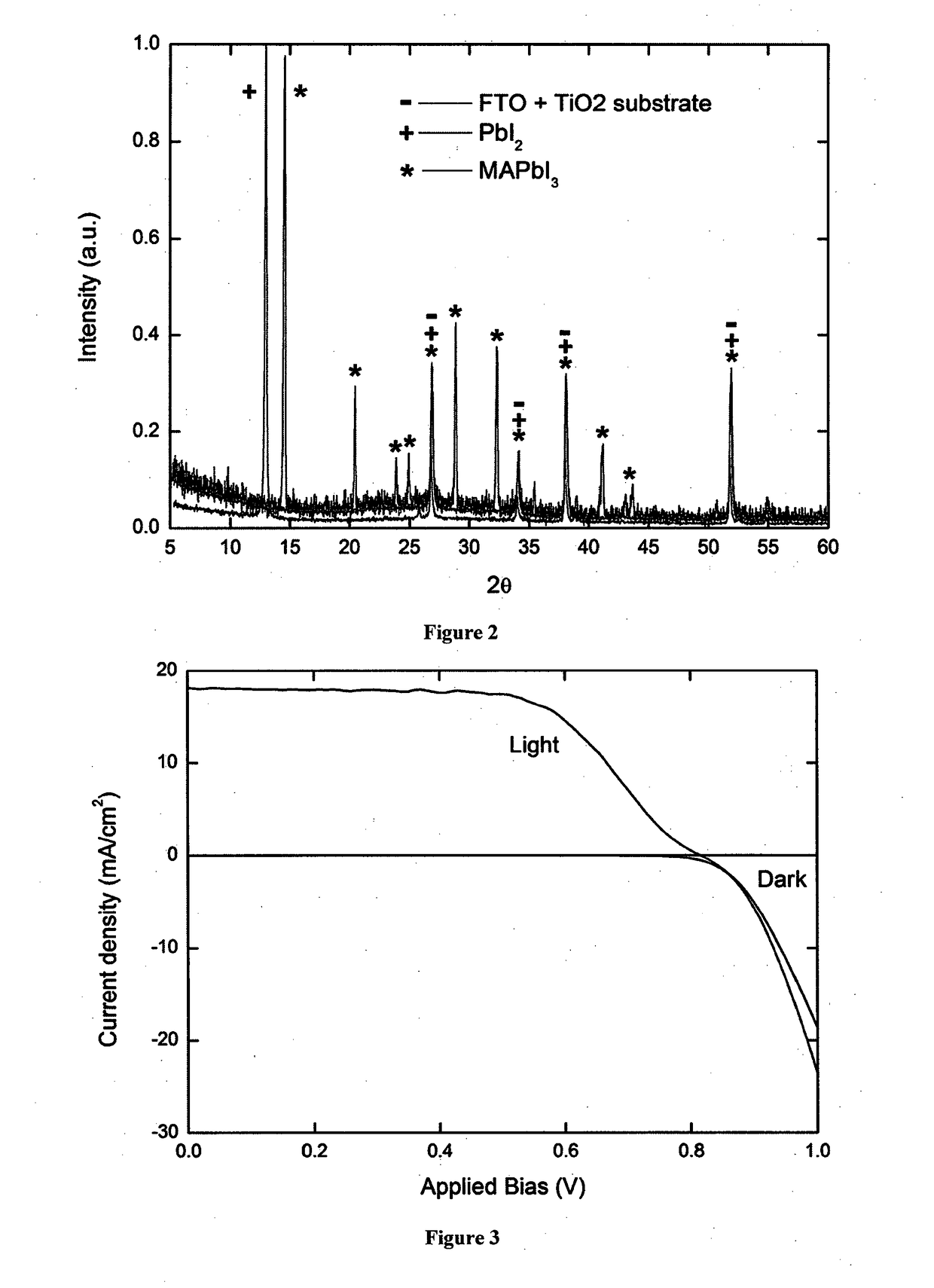

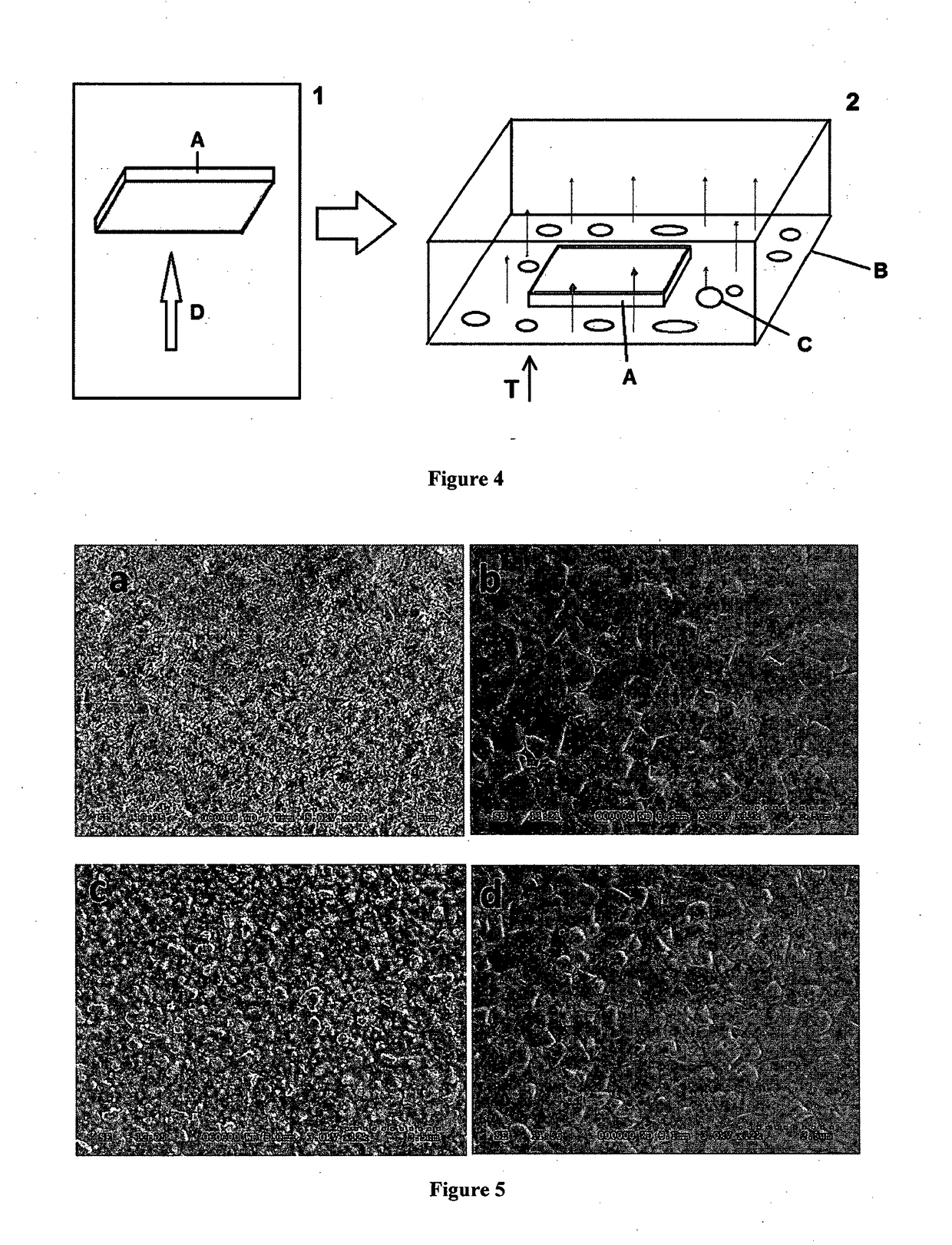

ActiveUS20170148579A1High purityImprove film qualityLight-sensitive devicesFinal product manufactureCrystallographyCrystalline materials

The present invention provides a process for producing a layer of a crystalline material comprising a perovskite or a hexahalometallate, which process comprises: (i) exposing a substrate to a vapour comprising a first precursor compound in a first chamber to produce a layer of the first precursor compound on the substrate; and (ii) exposing the layer of the first precursor compound to a vapour comprising a second precursor compound in a second chamber to produce the layer of a crystalline material, wherein the pressure in the second chamber is above high vacuum. The invention also provides a process for producing a layer of a crystalline material comprising a perovskite or a hexahalometallate, which process comprises exposing a layer of a first precursor compound on a substrate to a vapour comprising a second precursor compound in a chamber to produce the layer of a crystalline material, wherein the pressure in the chamber is greater than high vacuum and less than atmospheric pressure. The invention also provides a process for producing a semiconductor device comprising a layer of a crystalline material, which process comprises producing said layer of a crystalline material by a process as according to the invention.

Owner:OXFORD UNIV INNOVATION LTD

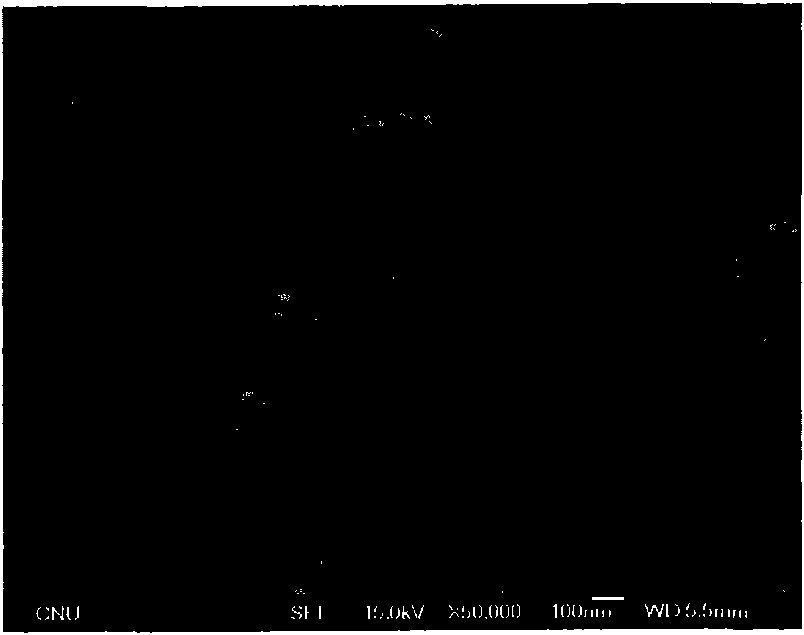

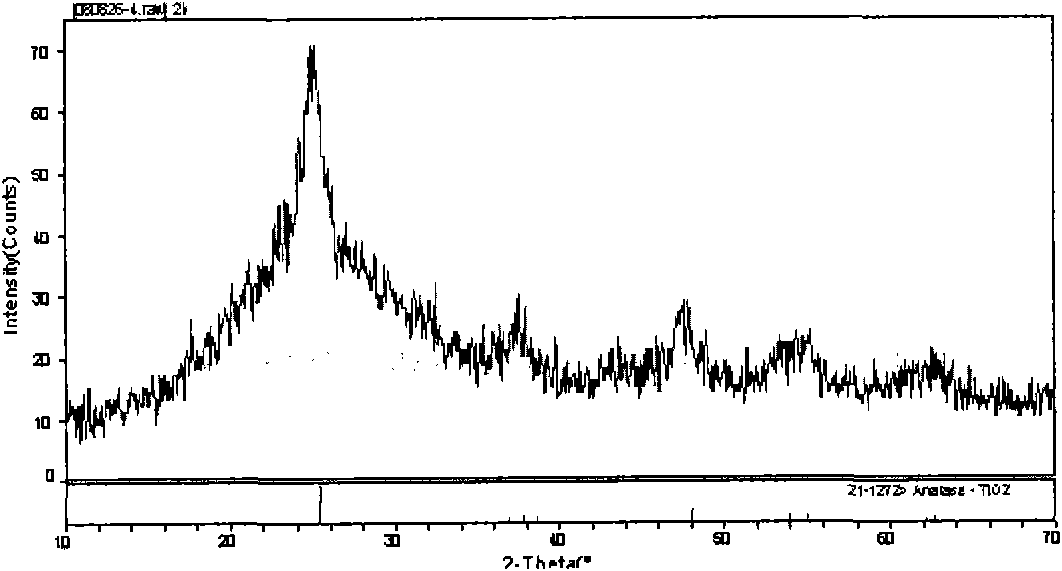

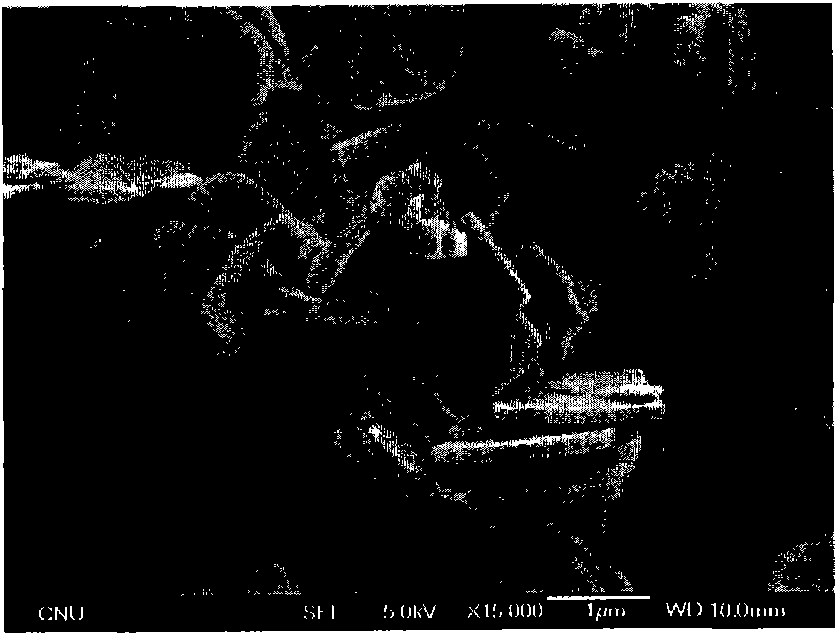

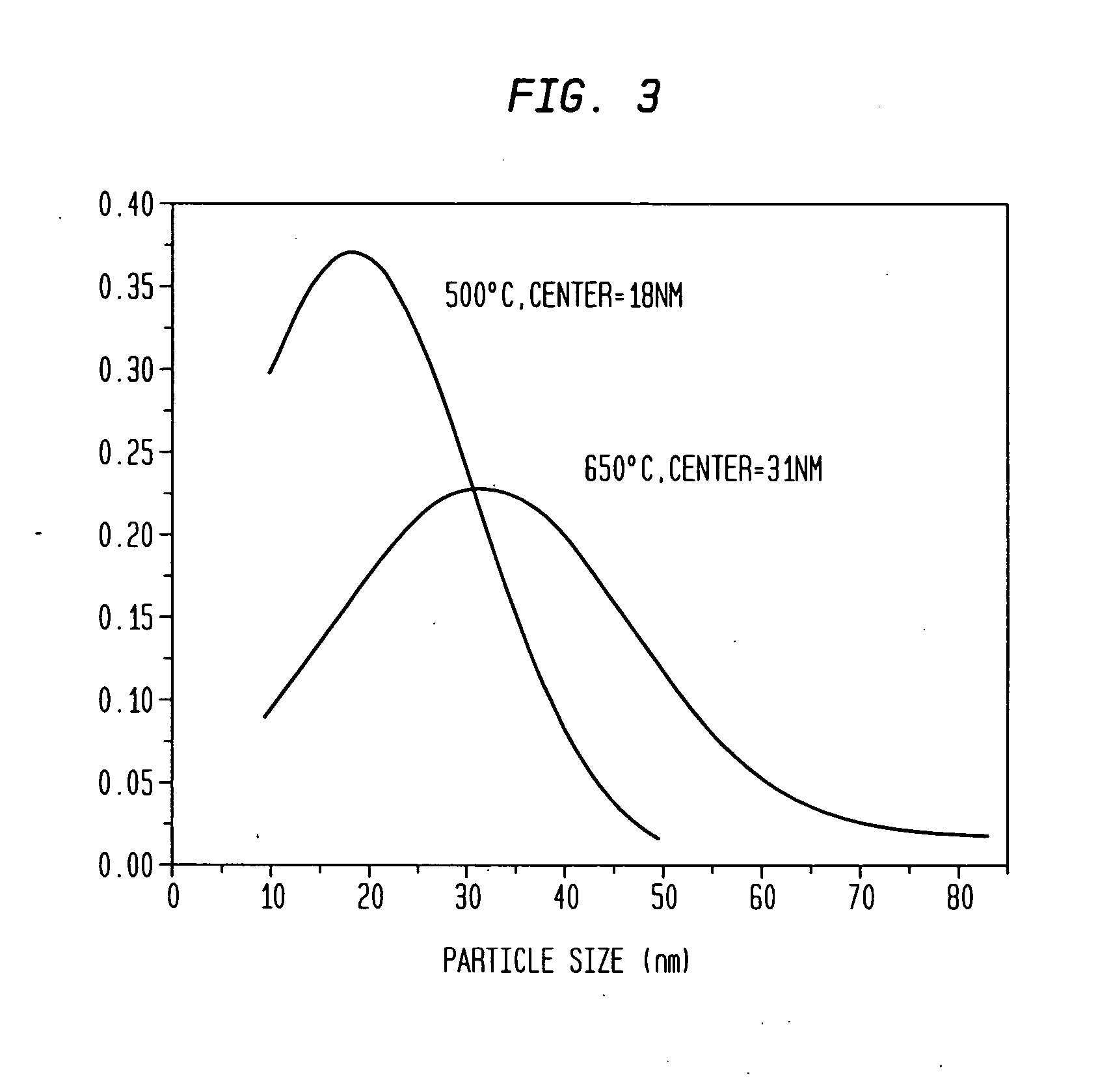

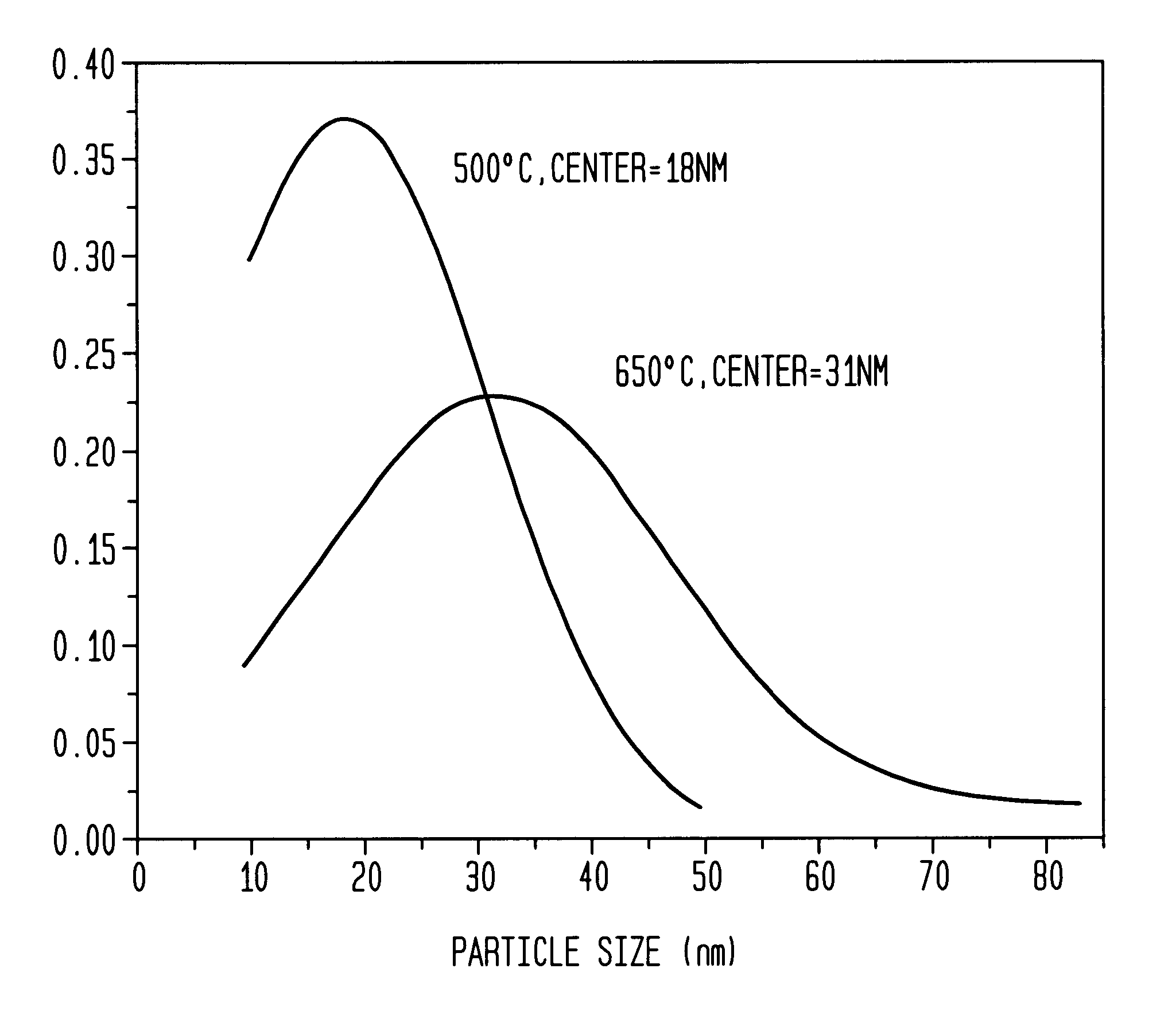

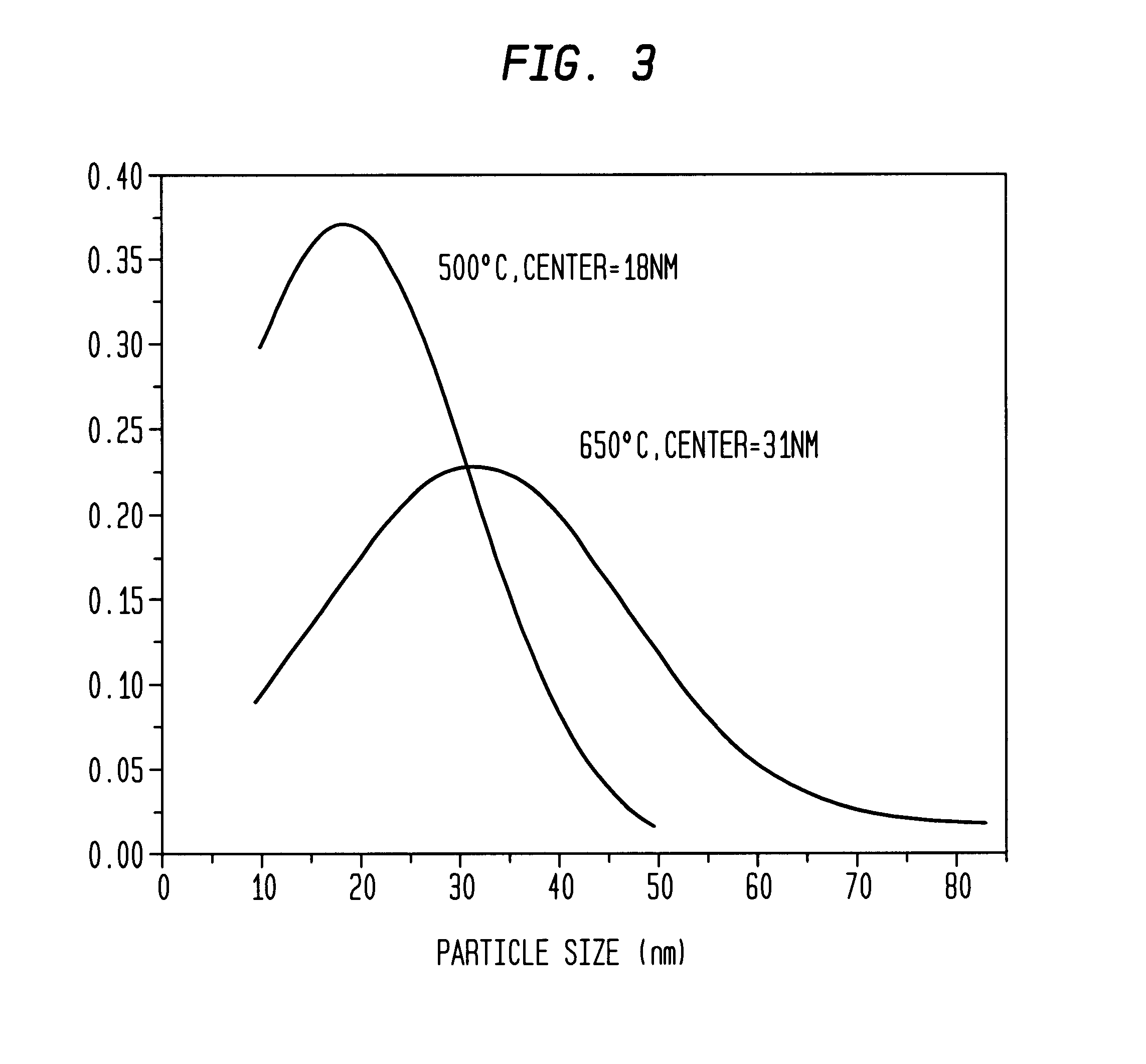

Method of preparing transition metal oxide nano-particles

ActiveCN101830496AEasy to manufactureEasy to handleNanostructure manufactureTantalum compoundsAlcoholMetallate

Provided is a method for preparing transition metal oxide nano-particles from a transition metal as a reactant. The method includes dissolving the transition metal into aqueous hydrogen peroxide to provide peroxi-metallate solution, and then adding a reactive solution containing an alcohol, water and an acid thereto to perform hydrothermal reaction. More particularly, the method for preparing transition metal oxide particles includes: dissolving transition metal powder as a reactant into aqueous hydrogen peroxide to provide a peroxi-metallate solution with a molar concentration of transition metal of 0.001-0.2 M; adding a reactive solution containing an alcohol, water and an acid to the peroxi-metallate solution to provide a mixed solution; and subjecting the mixed solution to hydrothermal reaction to provide transition metal oxide nano-particles.

Owner:THE IND & ACADEMIC COOPERATION & CHUNGNAM NAT UNIV

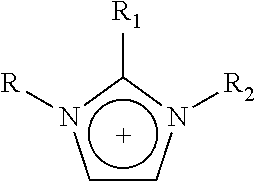

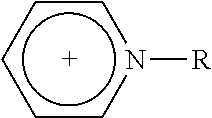

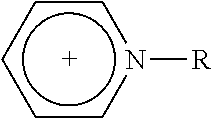

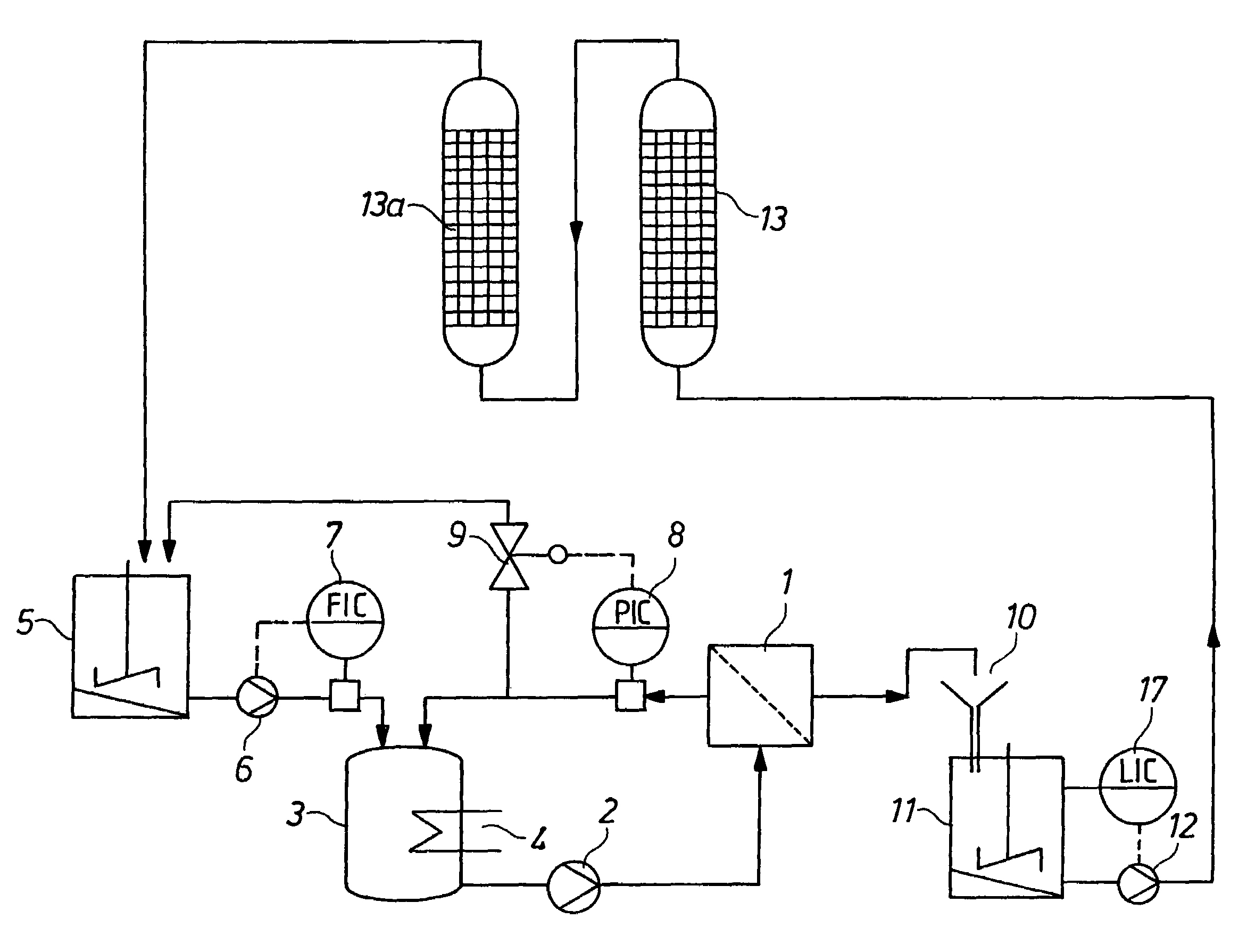

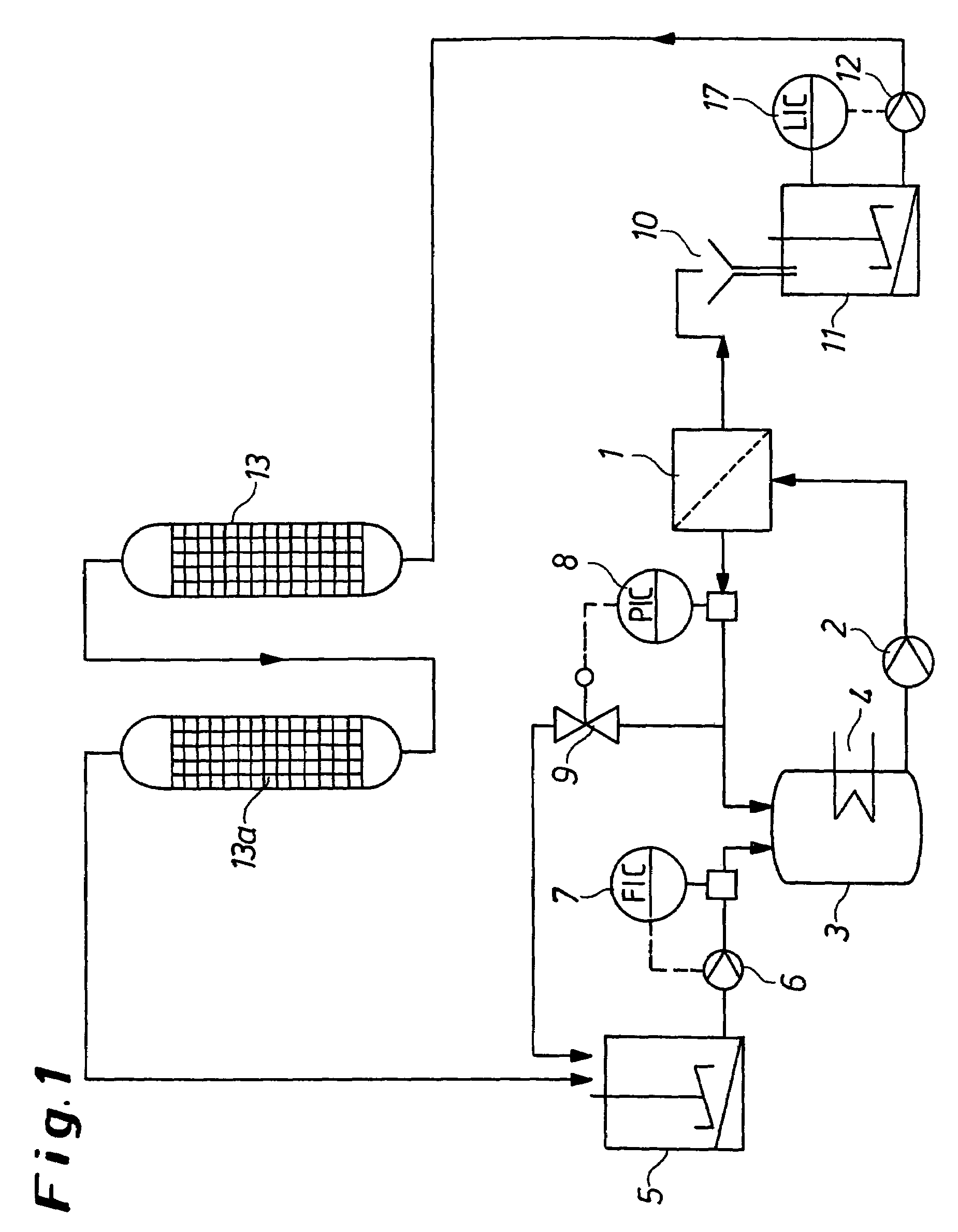

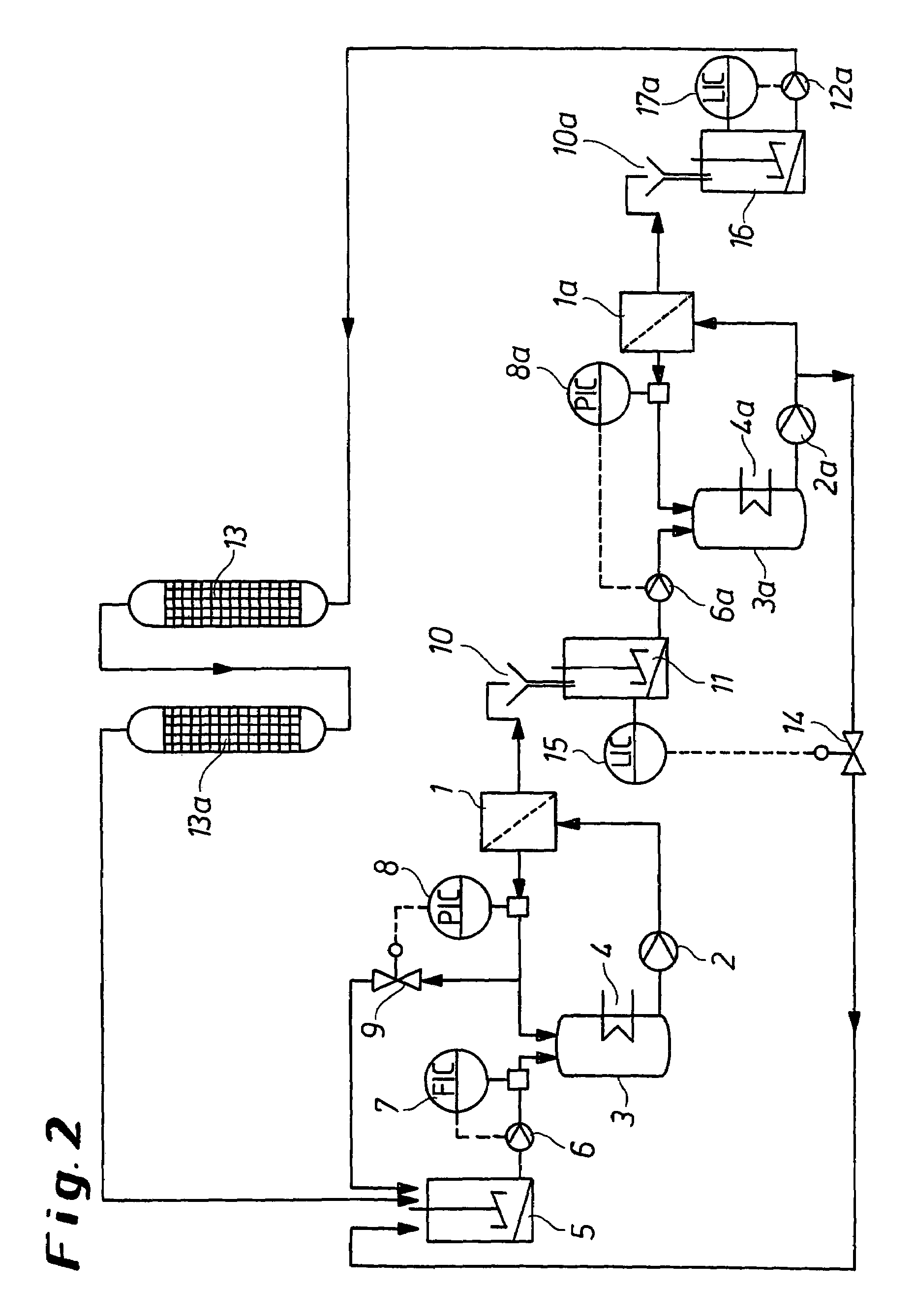

Process of recovery of exhausted ionic liquids used in the extractive desulfurization of naphthas

InactiveUS20110215052A1Low toxicitySedimentation separationDifferential sedimentationOrganic solventHalogen

A process for recovering ionic liquids comprising the steps of: providing a first ionic liquid mixture, the first ionic liquid having a halogen metallate anion, the mixture containing an organic solvent; adjusting the pH of the mixture to pH 7-10 by the addition of a base to form a first precipitate; separating the first precipitate from the mixture; removing the organic solvent from the first mixture to form a second precipitate and separating the second precipitate from the first mixture; acidifying the resulting mixture to pH 2-7 by the addition of an acid; and drying the mixture to obtain a second ionic liquid having a halogen anion.

Owner:INST MEXICANO DEL GASOLINEEO

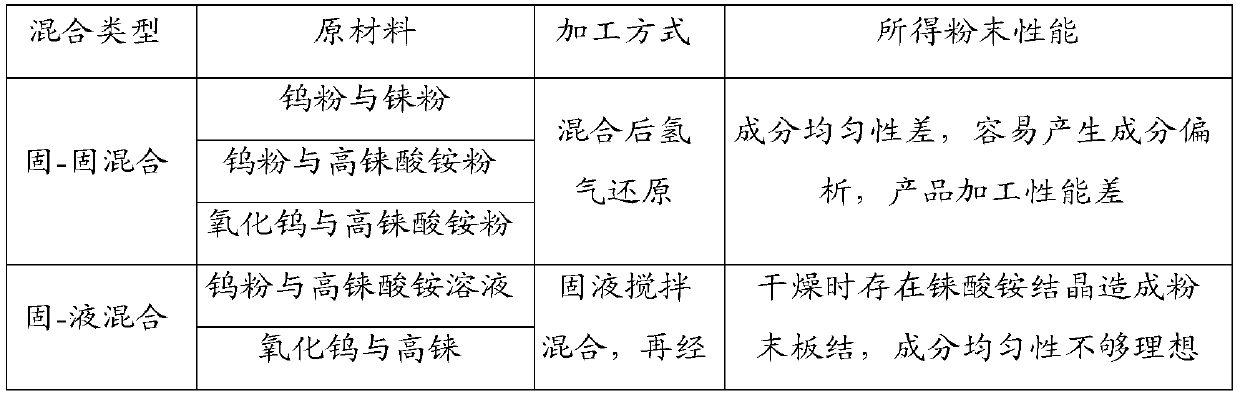

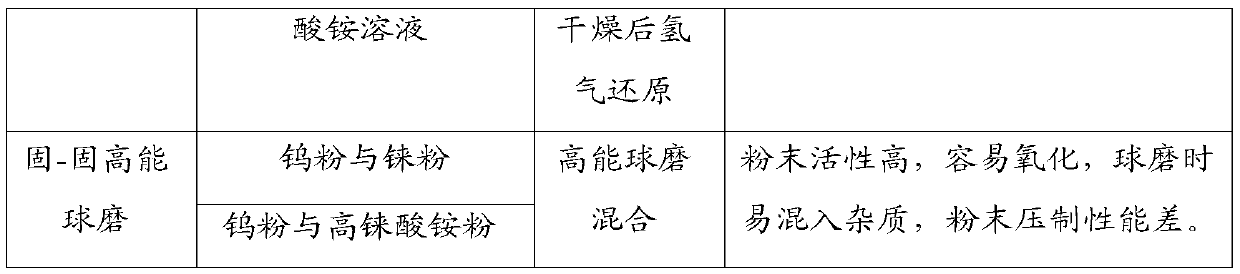

Spherical rhenium alloy powder as well as preparation method and application thereof

ActiveCN105499558AImprove liquidityImproves ingredient uniformityTransportation and packagingMetal-working apparatusRheniumCerium

The invention provides a preparation method of spherical rhenium alloy powder. The preparation method comprises the following steps: (A) mixing an ammonium rhenate solution with one or more types of ammonium metallates including cerium, molybdenum and tungsten to form a mixed solution; (B) centrifuging and atomizing the mixed solution at the speed of 15000rad / min-18000rad / min to form an atomized solution, and evaporating moisture at a high temperature to obtain alloy powder; and (C) after carrying out hydrogenation reduction on the alloy powder, heating and melting by adopting plasmas and balling to obtain the spherical rhenium alloy powder. The spherical rhenium alloy powder prepared by the method provided by the invention has good mobility and high component uniformity; after being detected by an instrument, the spherical rhenium alloy powder has high sphericity degree and high intensity, and excellent performances in all aspects; and the spherical rhenium alloy powder is widely applied to the aspects of steel die pressing, isostatic pressing, hot spraying, injection molding, 3D (Three Dimensional) printing and the like, particularly 3D printing.

Owner:株洲铼因材料技术有限公司

Corrosion Resistant Metallate Compostions

A composition for application to a metal substrate comprising at least one metallate compound comprising hexafluorzirconate, zirconyl nitrate, and / or yttrium nitrate is provided. The composition may further comprise additives that promote corrosion resistance of the metal substrate, or the adhesion of subsequent coatings, such as one or more rare earth element salts; allontoin, polyvinylpyrrolidone, surfactants, and other additives and co-inhibitors. A metal substrate such as an aluminum or an aluminum alloy substrate coated with a metallate composition according to the present invention is also provided. A process for preparing a coating on a metal substrate to improve the corrosion resistance of the substrate or improve the adhesion of a subsequent coating is also provided. The process comprises treating the metal substrate with an aqueous solution comprising a metallate compound. The process may further comprise one or more pre-treating the substrate, coating the metal substrate with an oxidizing agent and / or coating the metal substrate with one or more rare earth element salts. A process for preparing the metallate coatings of the invention is also provided.

Owner:PRC DE SOTO INT INC

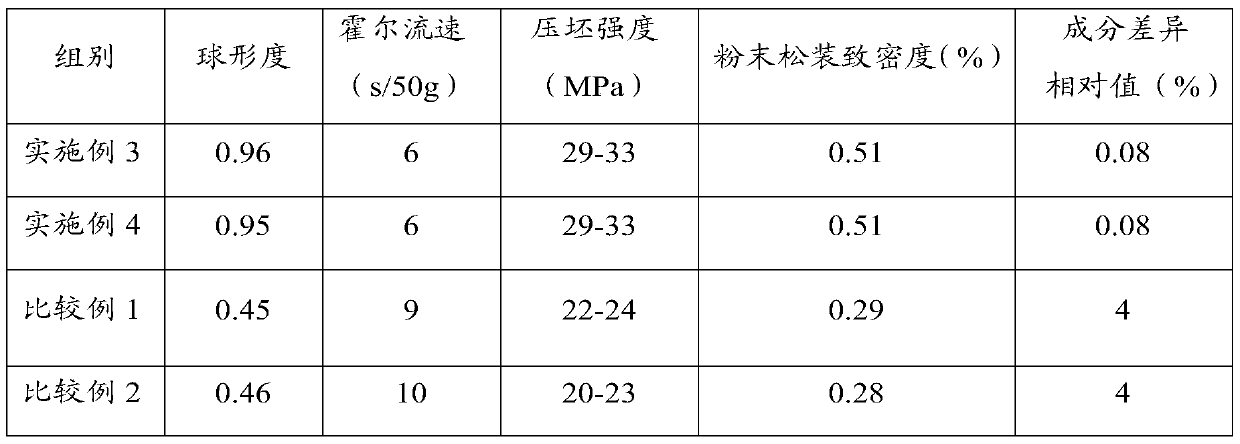

Environmentally benign bismuth-containing spin-on precursor materials

InactiveUS6303804B1Low toxicityLess capitol intensiveAntimony compoundsFixed capacitorsEngineeringMetallate

Metal acid salt complexes are provided comprising (1) a first metal ion consisting essentially of bismuth, and optionally, at least one second metal ion selected from the group consisting of barium, calcium, strontium, lead, titanium, tantalum, and niobium, and (2) a polyether acid. The metal acid salt complexes are prepared by combining (1) bismuth ion, and optionally, at least one second metal ion and (2) at least one of a polyether acid and a polyether acid anhydride prepared from the polyether acid. In particular, the use of a mixture of bismuth, strontium, and niobium and / or tantalum salts of the hydrophilic acid 3,6-dioxaheptanoic acid salt is described for production of ceramic thin films, such as for use in ferroelectric devices, using non-toxic solvents. As a consequence, improved electronic devices are formed from less toxic and easier handled precursors and solvents. The present invention provides soluble spin-on precursors which are compatible and soluble in non-toxic and environmentally benign solvents.

Owner:RAYTHEON CO

Release on demand corrosion inhibitor composition

ActiveUS20100291307A1Avoid corrosionLow corrosion rateOther chemical processesPretreated surfacesProtonationMetallate

Owner:HENKEL KGAA

Process of recovery of exhausted ionic liquids used in the extractive desulfurization of naphthas

A process for recovering ionic liquids comprising the steps of: providing a first ionic liquid mixture, the first ionic liquid having a halogen metallate anion, the mixture containing an organic solvent; adjusting the pH of the mixture to pH 7-10 by the addition of a base to form a first precipitate; separating the first precipitate from the mixture; removing the organic solvent from the first mixture to form a second precipitate and separating the second precipitate from the first mixture; acidifying the resulting mixture to pH 2-7 by the addition of an acid; and drying the mixture to obtain a second ionic liquid having a halogen anion.

Owner:INST MEXICANO DEL GASOLINEEO

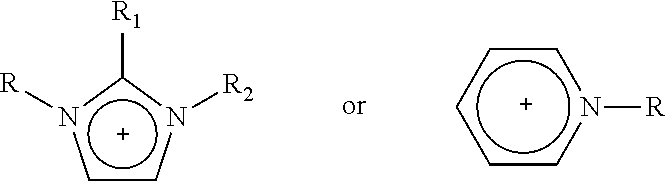

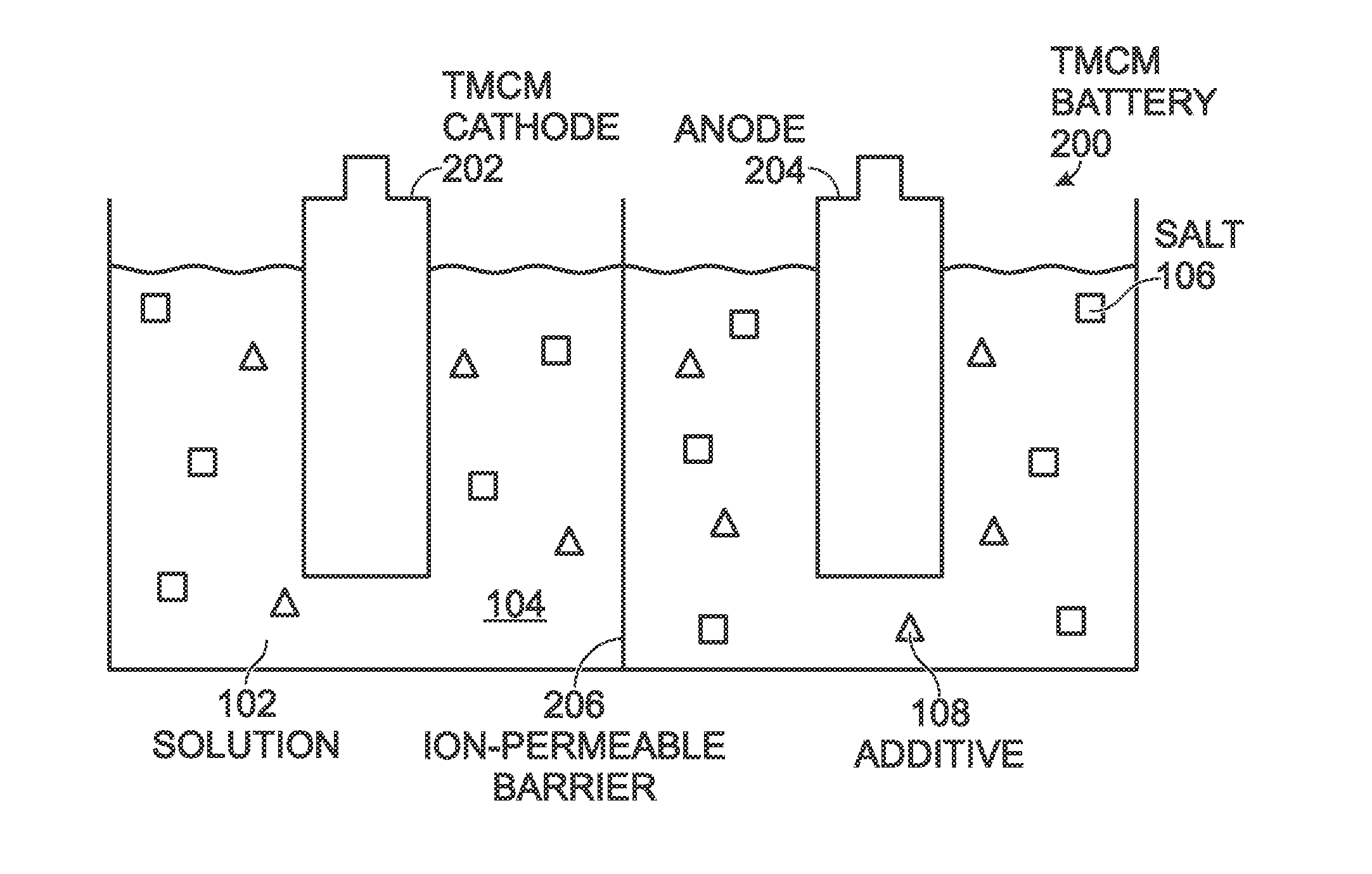

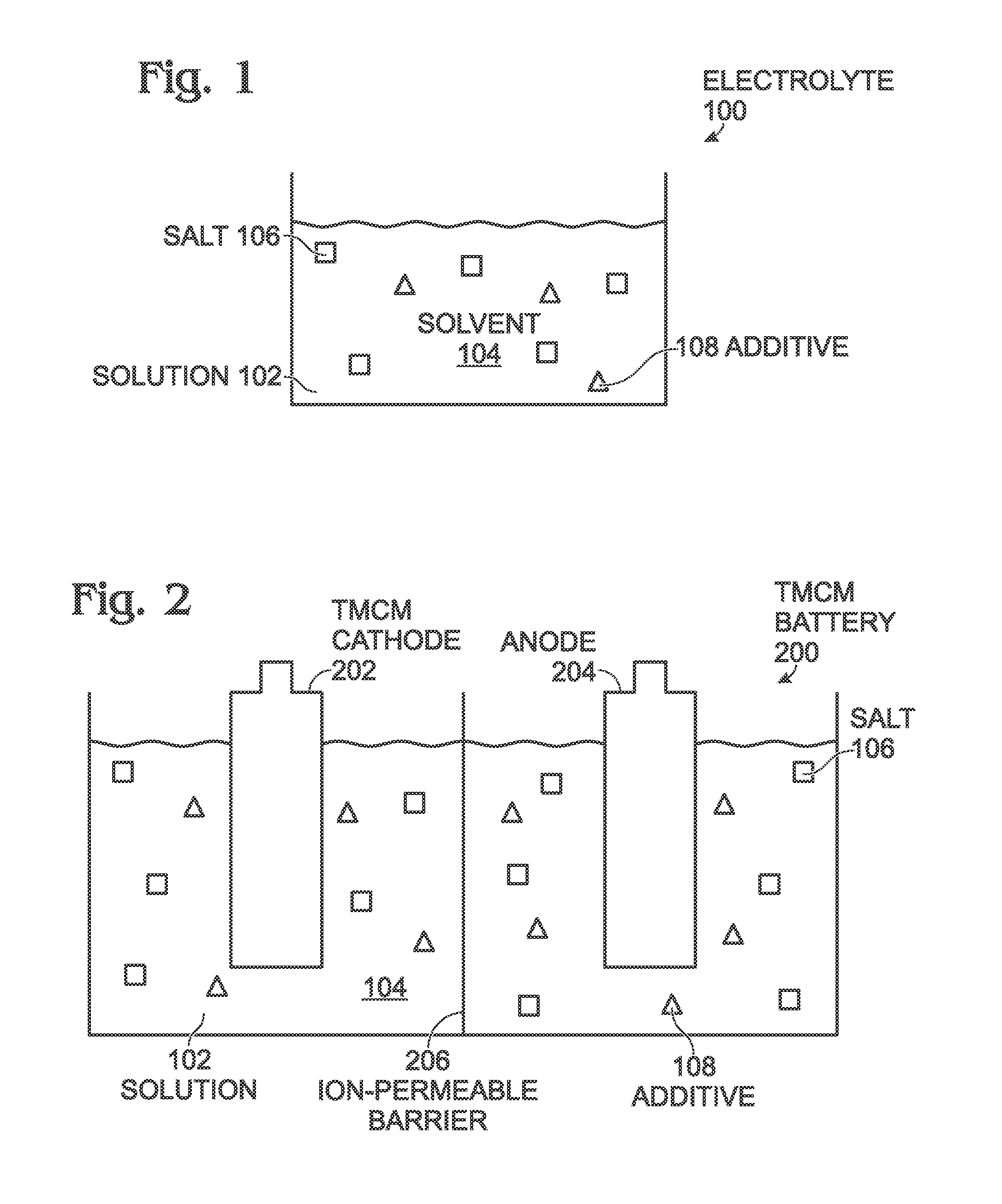

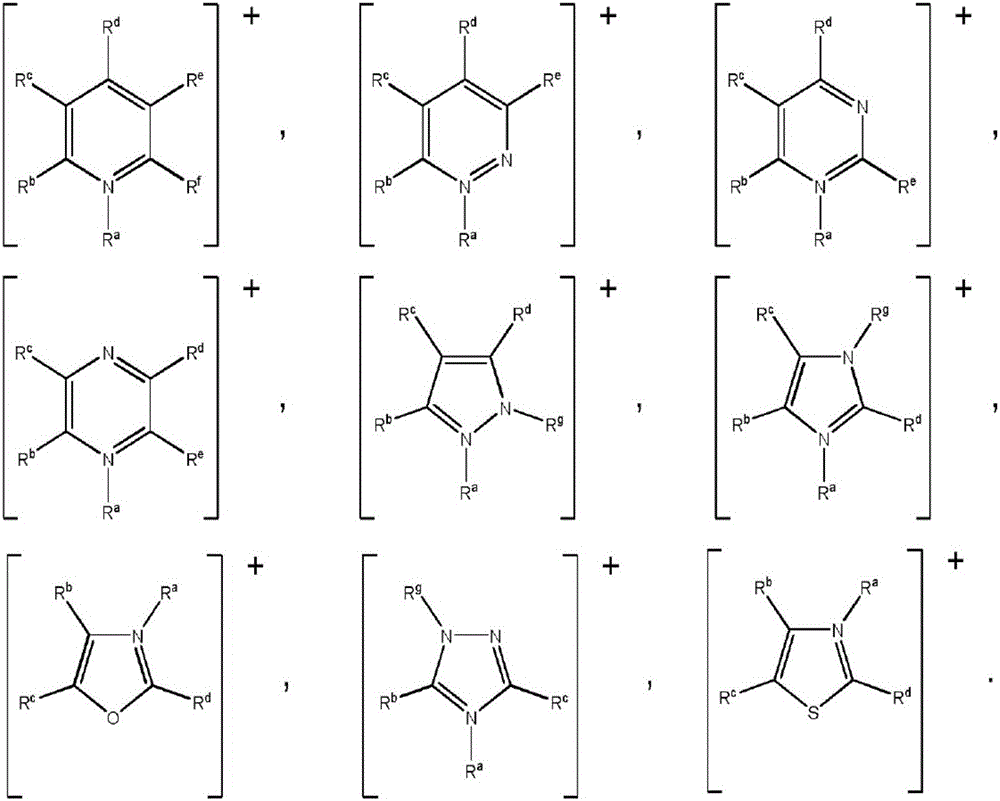

Electrolyte Additives for Transition Metal Cyanometallate Electrode Stabilization

ActiveUS20150263383A1Improve performanceImprove power densityBatteries circuit arrangementsCell electrodesAlkaneAlkaline earth metal

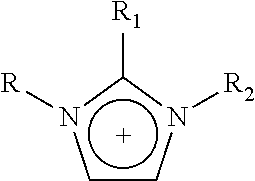

A method is provided for the self-repair of a transition metal cyanometallate (TMCM) battery electrode. The battery is made from a TMCM cathode, an anode, and an electrolyte including solution formed from a solvent and an alkali or alkaline earth salt. The electrolyte includes an additive represented as G-R-g: where G and g are independently include materials with nitrogen (N) sulfur (S), oxygen (O), or combinations of the above-recited elements; and where R is an alkene or alkane group. In response to charging and discharging the battery in a plurality of cycles, the method creates vacancies in a surface of the TMCM cathode. Then, the method fills the vacancies in the surface of the TMCM cathode with the electrolyte additive. An electrolyte and TMCM battery using the above-mentioned additives are also provided.

Owner:SHARP KK

Metallate electrodes

The invention relates to electrodes that contain active materials of the formula: AaMbXzOy wherein A is one or more alkali metals selected from lithium,sodium and potassium; M is selected from one or more transition metals and / or one or more non-transition metals and / or one or more metalloids; X comprises one or more atoms selected from niobium, antimony, tellurium, tantalum, bismuth and selenium; and further wherein 0<a≦̸6; b is in the range: 0<b≦̸4; x is in the range 0<x≦̸1 and y is in the range 2≦̸y≦̸10. Such electrodes are useful in, for example, sodium and / or lithium ion battery applications.

Owner:FARADION

Method for producing a solid nanocomposite material based on hexa- and octa-cyanometallates of alkali metals

ActiveUS20170260083A1Easy extractionMaterial nanotechnologySemi-permeable membranesChemical ligationNanoparticle

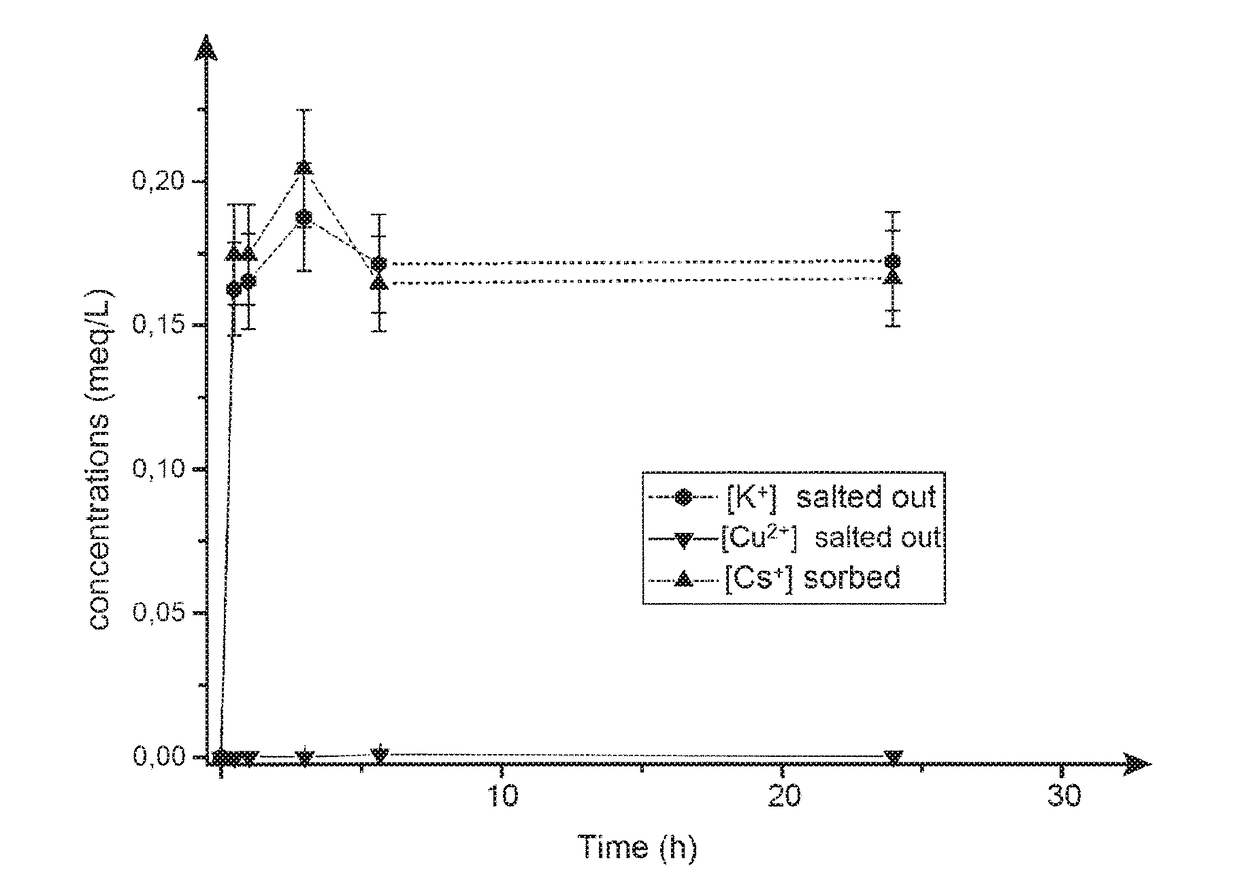

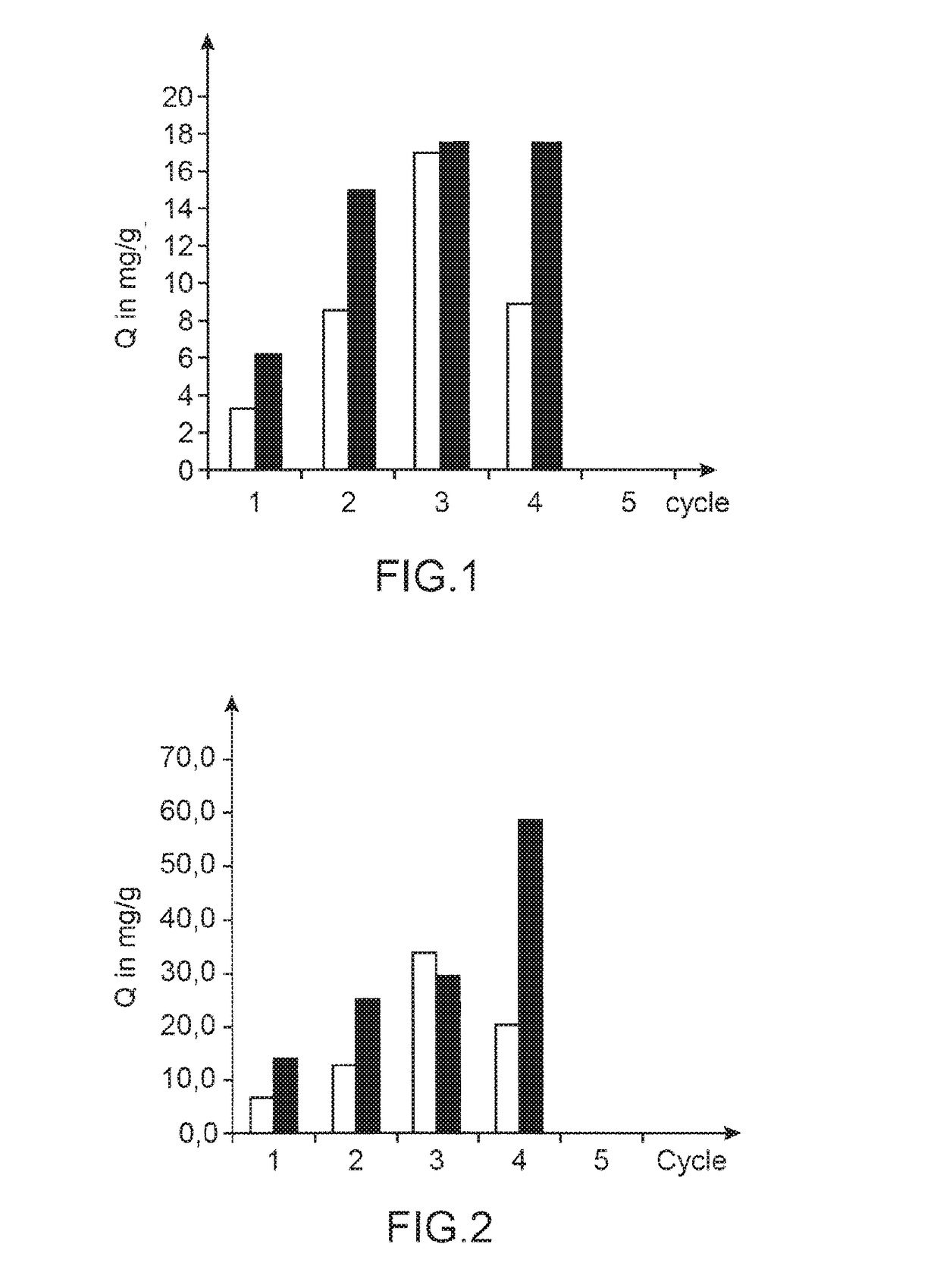

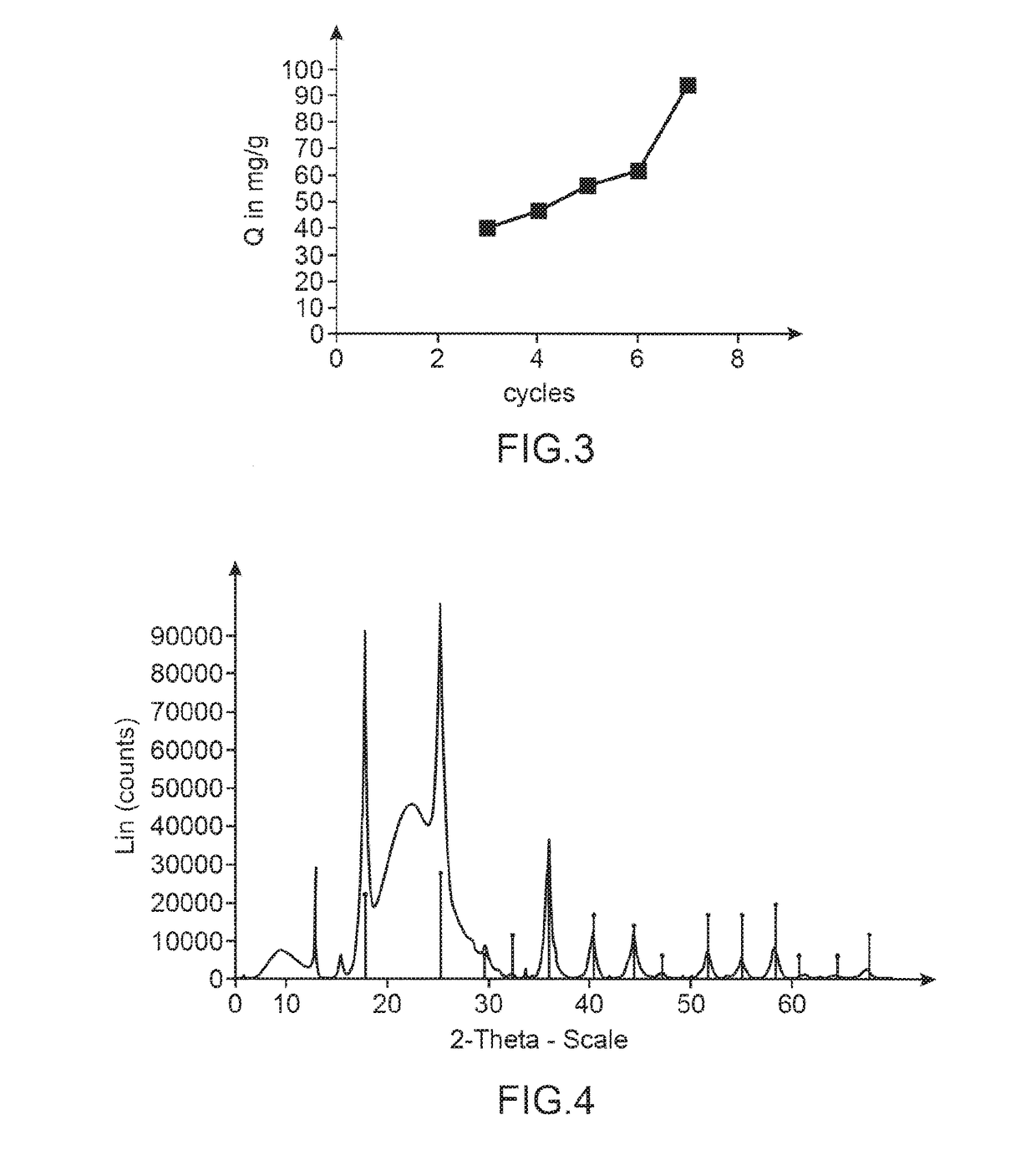

The invention relates to a method for producing a solid nanocomposite material comprising nanoparticles of a metal coordination polymer with ligands CN, said nanoparticles satisfying the formula [Alk+x]Mn+[M′(CN)m]z− where Alk is an alkali metal, x is 1 or 2, M is a transition metal, n is 2 or 3, M′ is a transition metal, m is 6 or 8, and z is 3 or 4; said Mn+ cations of the coordination polymer being bound by an organometallic bond or a coordination bond to an organic group R2 of an organic graft, and said organic graft furthermore being chemically attached, preferably by a covalent bond, to at least one surface of a solid support, by reaction of a group R1 of said graft with said surface.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

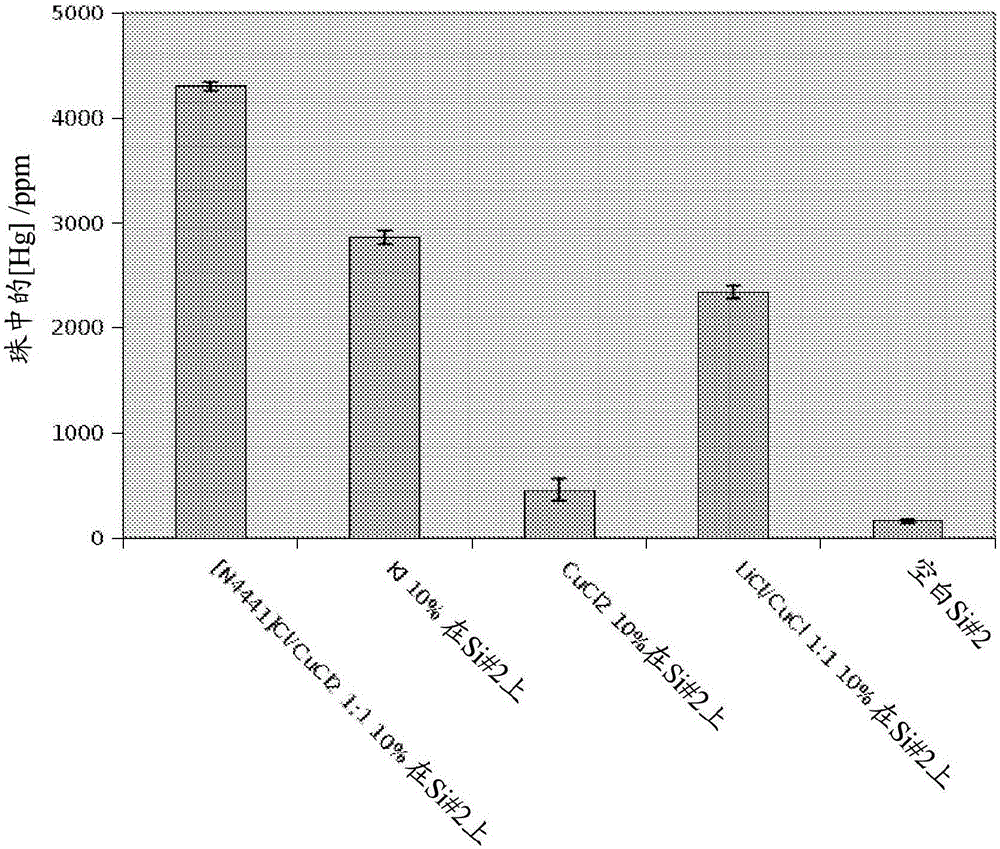

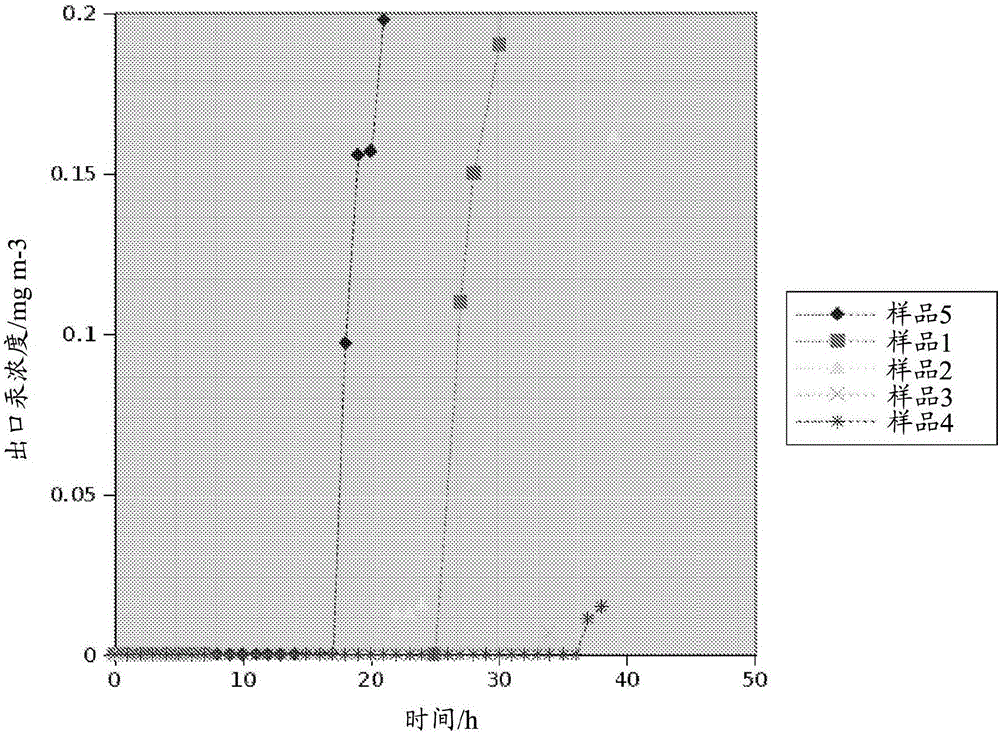

Process for removing metals from hydrocarbons

The invention relates to a process for the removal of metals (especially mercury) from a mercury-containing hydrocarbon fluid feed using specifically selected ionic liquids, comprising contacting the mercury-containing hydrocarbon fluid feed with an ionic liquid having the formula [Cat+][M+][X-] and separating from the ionic liquid a hydrocarbon fluid product having a reduced mercury content compared to the mercury-containing fluid feed. An alternative process involves the use of a metallate salt of the following formula [Q+][(Mx+)m(Ly-)m](nx-my) For the meanings of the above symbols, please see the specification.

Owner:QUEENS UNIV OF BELFAST

Two-step deposition process

ActiveUS10580585B2Quality improvementHigh purityLight-sensitive devicesVacuum evaporation coatingCrystallographyDevice material

Owner:OXFORD UNIV INNOVATION LTD

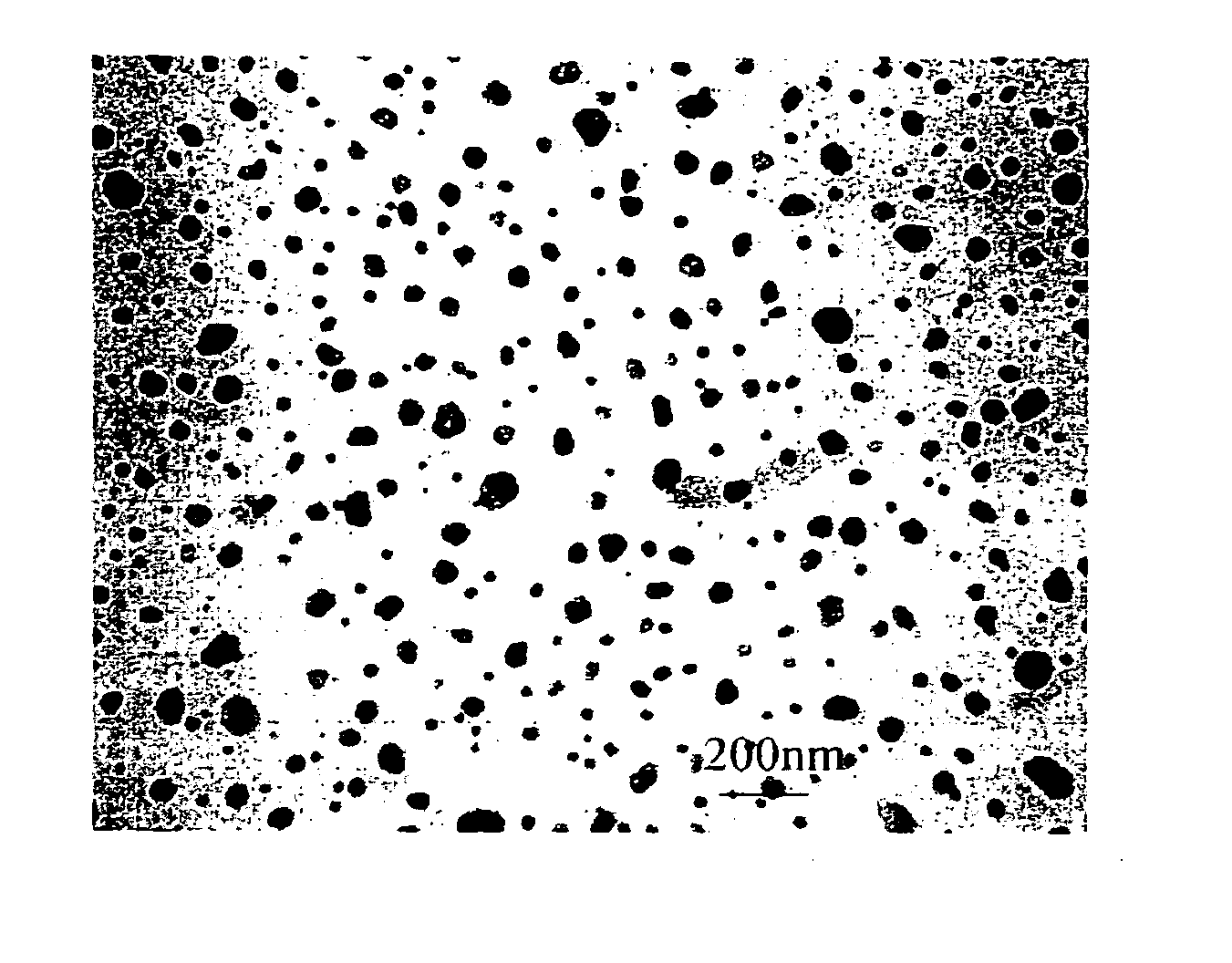

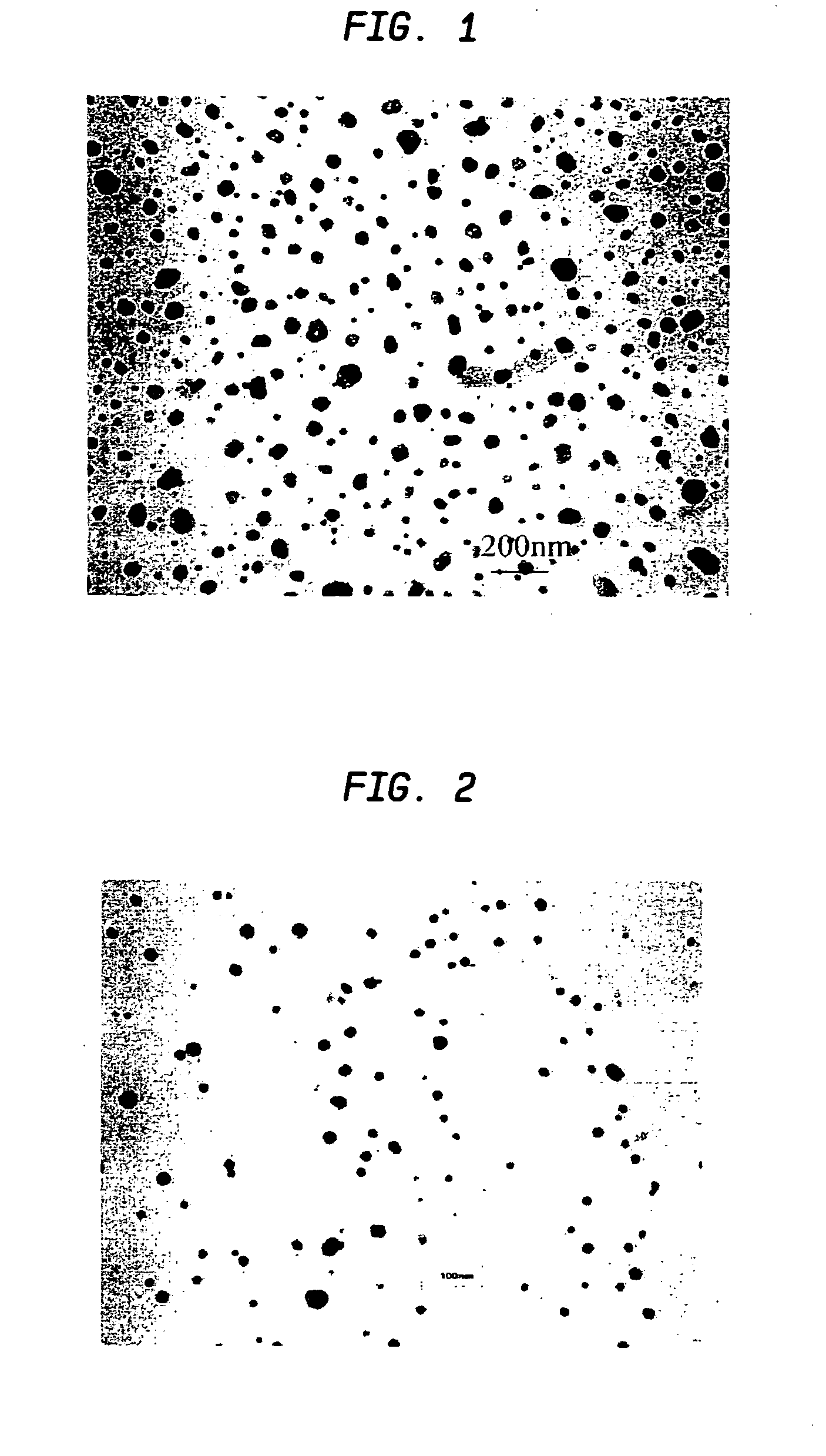

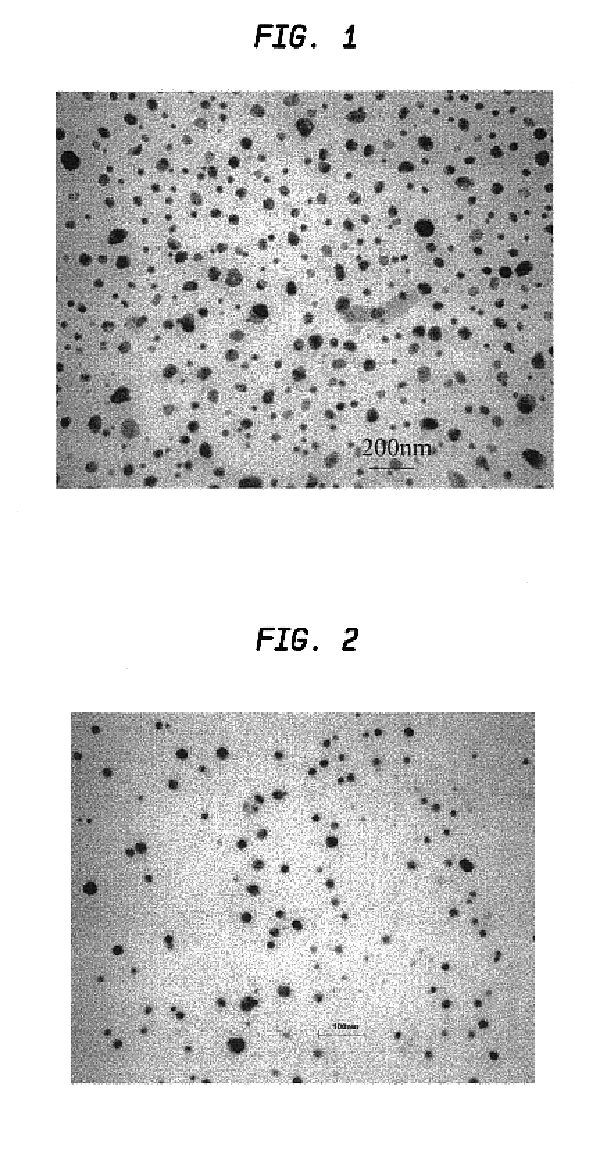

Methods for the preparation of metallic alloy nanoparticles and compositions thereof

Owner:THE TRUSTEES FOR PRINCETON UNIV

Methods for the preparation of metallic alloy nanoparticles and compositions thereof

InactiveUS6932851B2Easily produceEasy to produceNanomagnetismTransportation and packagingNanometreNanoparticle

Owner:THE TRUSTEES FOR PRINCETON UNIV

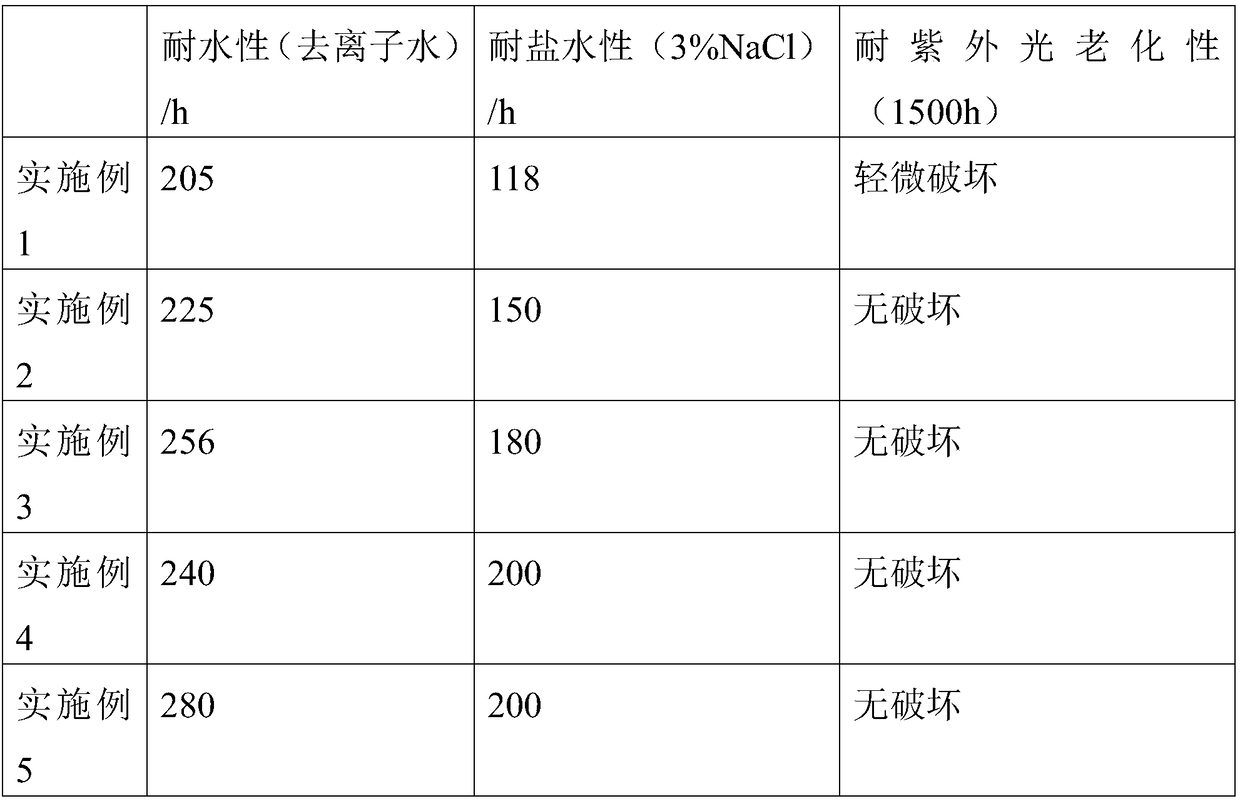

High-stability antifouling automobile coating and preparation method thereof

InactiveCN109161333AImprove corrosion resistanceImprove aging resistanceAntifouling/underwater paintsPaints with biocidesMetallatePolymethylhydrosiloxane

The invention provides a high-stability antifouling automobile coating and a preparation method thereof, and belongs to the field of coatings. The high-stability antifouling automobile coating provided by the invention is prepared from modified organosiloxane, bismuth metallate salt and an amine curing agent, wherein the organosiloxane is prepared from a modifier and polymethylhydrogensiloxane; the modifier is selected from diallyl phthalate, diallyl-o-phthalate and diallyl terephthalate; the amine curing agent is selected from N, N-diethylcyclopentane-1, 2-diamine, 1-N-morpholino-2-amino-cyclopentane and 2-(4-methyl-1-piperazine) cyclopentylamine. The automobile coating provided by the invention has good corrosion resistance, aging resistance and antibacterial property.

Owner:安徽康瑞高科新材料技术工程有限公司

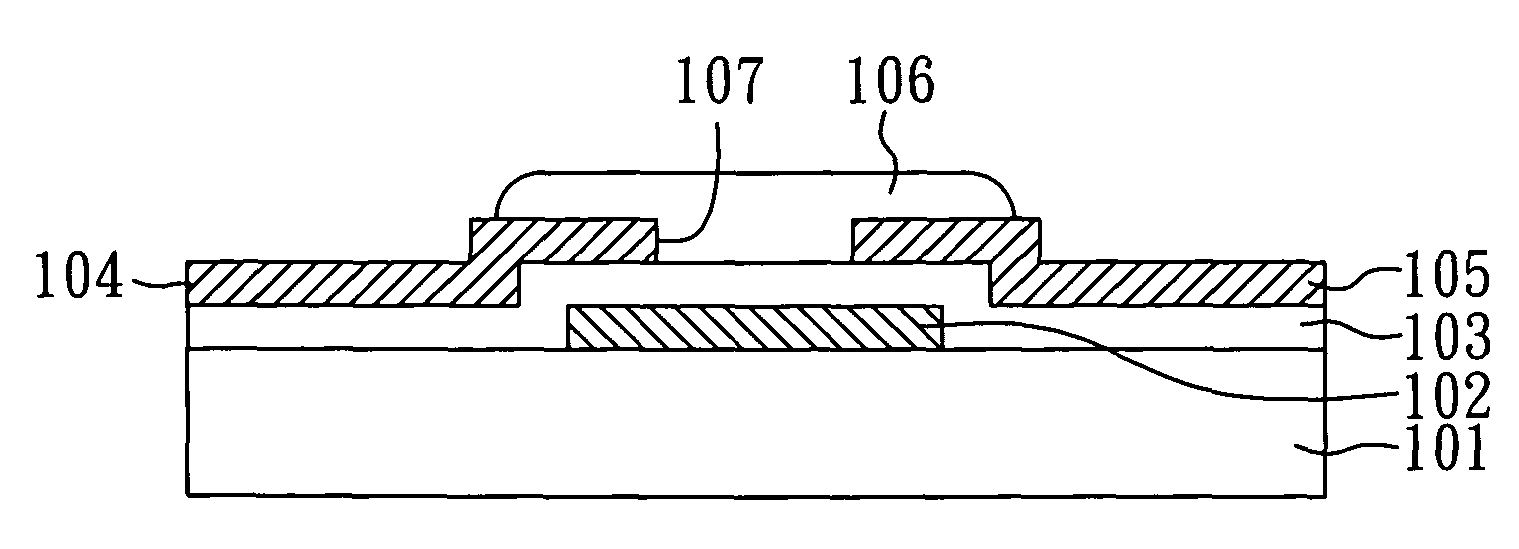

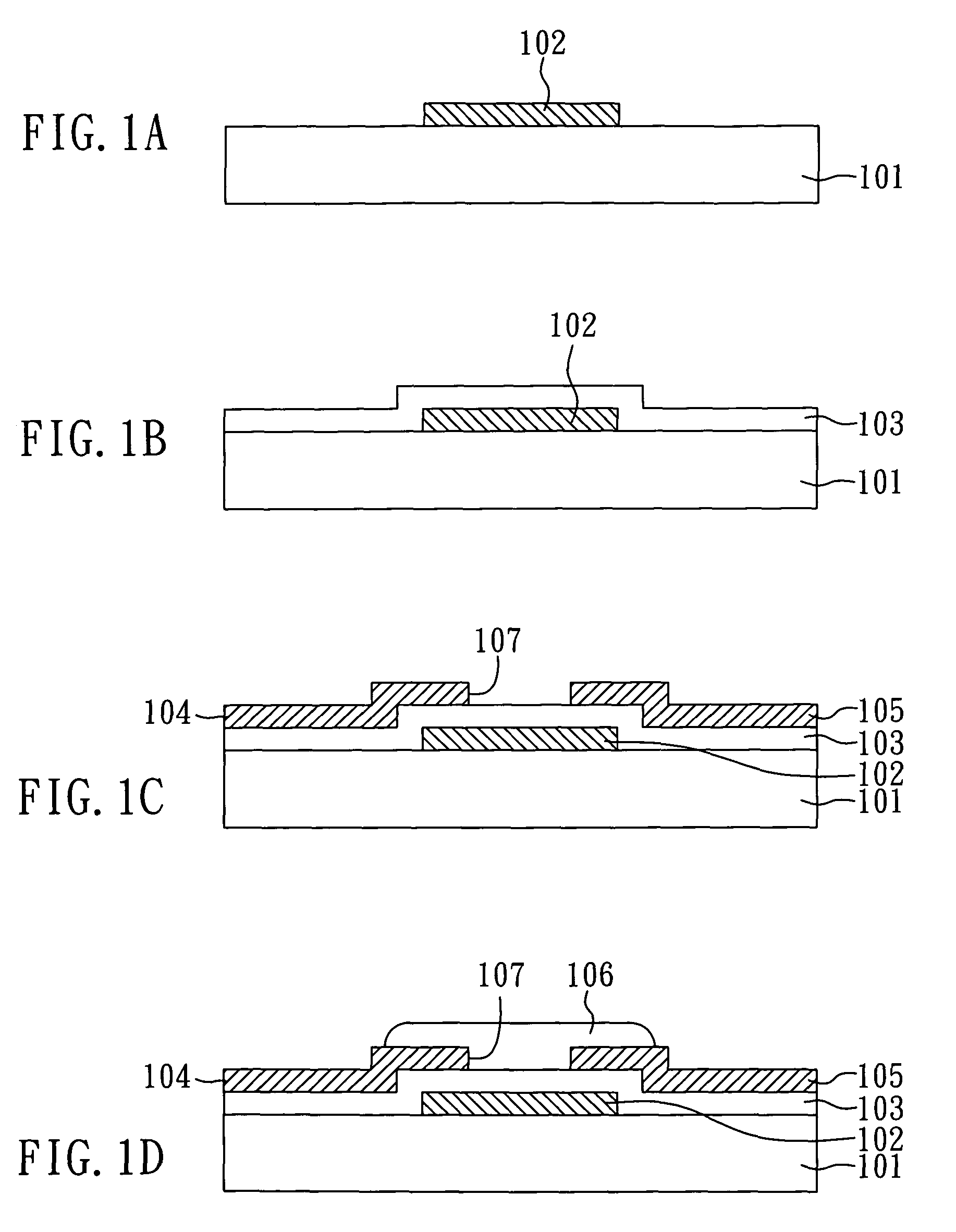

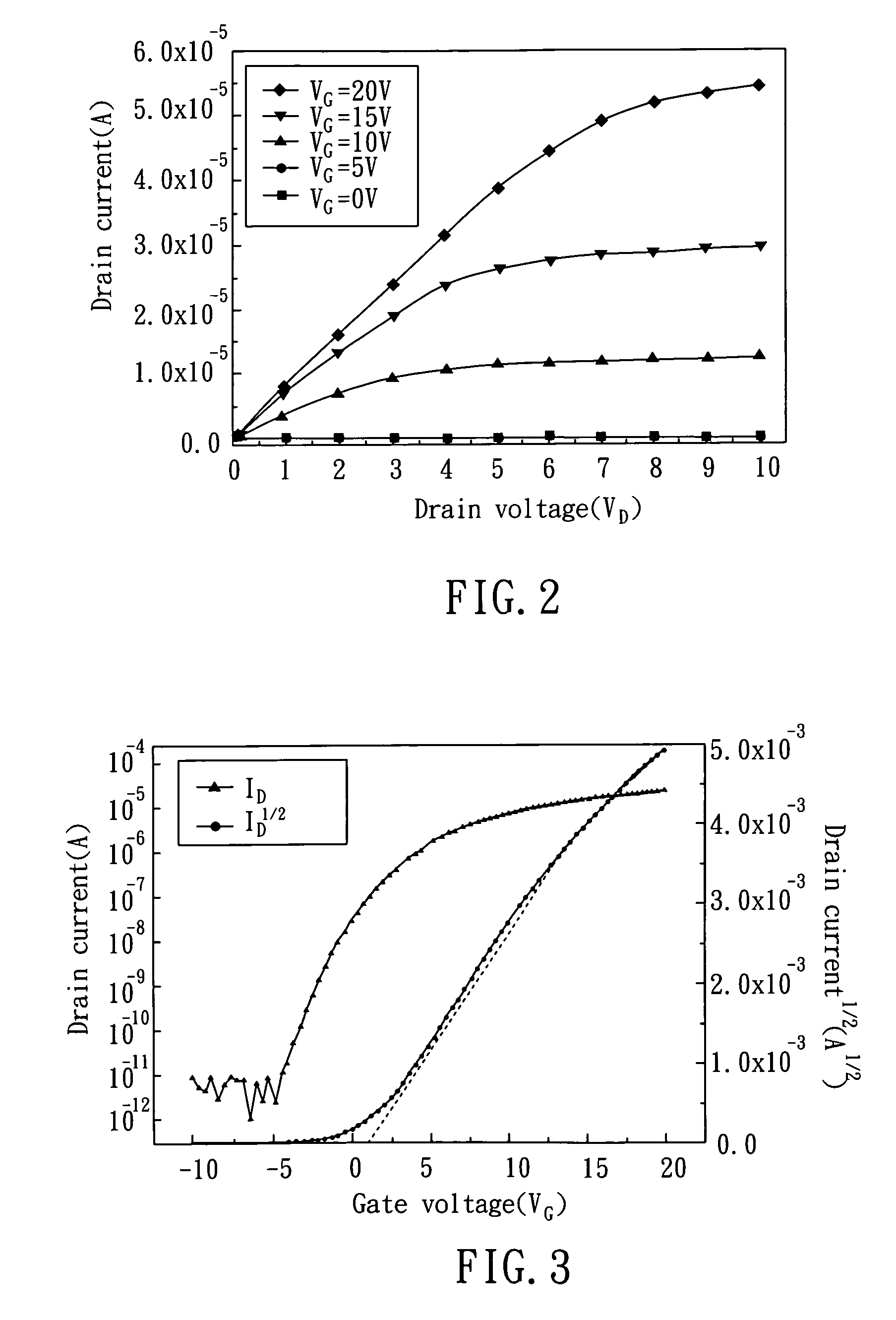

Method for preparing IGZO particles and method for preparing IGZO film by using the IGZO particles

ActiveUS8278140B2More eco-friendlyThe process is simple and lowMaterial nanotechnologyZinc oxides/hydroxidesIndiumMetallate

A method for preparing IGZO particles and a method for preparing an IGZO thin film by using the IGZO particles are disclosed. The method for preparing the IGZO particles comprises the following steps: (A) providing a solution of metal acid salts, which contains a zinc salt, an indium salt, and a gallium salt; (B) mixing the solution of the metal acid salts with a basic solution to obtain an oxide precursor; and (C) heating the oxide precursor to obtain IGZO particles.

Owner:NATIONAL TSING HUA UNIVERSITY

Corrosion resistant metallate compositions

A composition for application to a metal substrate comprising at least one metallate compound comprising hexafluorzirconate, zirconyl nitrate, and / or yttrium nitrate is provided. The composition may further comprise additives that promote corrosion resistance of the metal substrate, or the adhesion of subsequent coatings, such as one or more rare earth element salts; allontoin, polyvinylpyrrolidone, surfactants, and other additives and co-inhibitors. A metal substrate such as an aluminum or an aluminum alloy substrate coated with a metallate composition according to the present invention is also provided. A process for preparing a coating on a metal substrate to improve the corrosion resistance of the substrate or improve the adhesion of a subsequent coating is also provided. The process comprises treating the metal substrate with an aqueous solution comprising a metallate compound. The process may further comprise one or more pre-treating the substrate, coating the metal substrate with an oxidizing agent and / or coating the metal substrate with one or more rare earth element salts. A process for preparing the metallate coatings of the invention is also provided.

Owner:PRC DE SOTO INT INC

Metal cyanometallate synthesis method

Owner:SHARP KK +1

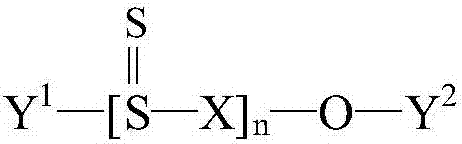

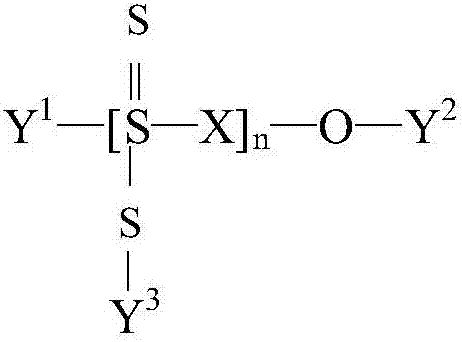

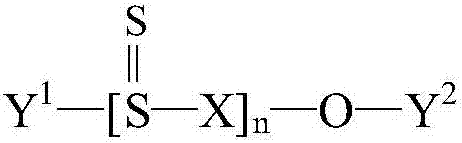

Inhibitor through select flotation of disulfo-nonmetal acid salt and oligomer of disulfo-nonmetal acid salt and preparation and using method

ActiveCN107971140ALower pHIncrease pulp concentrationFlotationProcess efficiency improvementOligomerIron sulfide

Disclosed is an inhibitor through select flotation of disulfo-nonmetal acid salt and oligomer of the disulfo-nonmetal acid salt and a preparation and using method. The inhibitor is formed by the disulfo-nonmetal acid salt and the oligomer of the disulfo-nonmetal acid salt and inhibits zinc sulfide ore of select flotation by iron sulfide ore in a natural pH condition. The disulfo-nonmetal acid saltand the oligomer of the disulfo-nonmetal acid salt comprises two molecular structure forms. The two molecular structure forms have the structural characteristics of the disulfo-nonmetal acid salt andthe oligomer. The disulfo-nonmetal acid salt is non-metallic oxygen-containing acid salt. By means of the inhibitor, the zinc sulfide ore of select flotation by the select flotation process can be achieved through a slight inhabiting method that lime cannot be added in the select flotation process, the pH value of ore pulp of operation of the zinc sulfide ore of select flotation in a 6-9 neutralrange is different from the pH value of more than 12 of ore pulp of operation of the zinc sulfide ore of select flotation by using a known method that lime is used as an inhibitor of the iron sulfideore significantly.

Owner:HUNAN HUAQI RESOURCES ENVIRONMENT SCI & TECH DEV CO LTD

Purification of ammonium metallate solutions

A process for reducing the content of alkali metal impurities (e.g., potassium) in ammonium metallate solutions is described. The process involves subjecting a feed solution containing ammonium metallate and alkali metal impurities to membrane filtration. The membrane filtration results in the formation of a retentate having a reduced level alkali metal relative to the feed solution, and a permeate containing substantially the balance of alkali metal. The permeate may also be further treated, to remove alkali metal there from, by passage through a cation exchange column, thereby forming a cation exchange treated permeate that may be combined with the retentate of the membrane filtration step.

Owner:H C STARCK GMBH

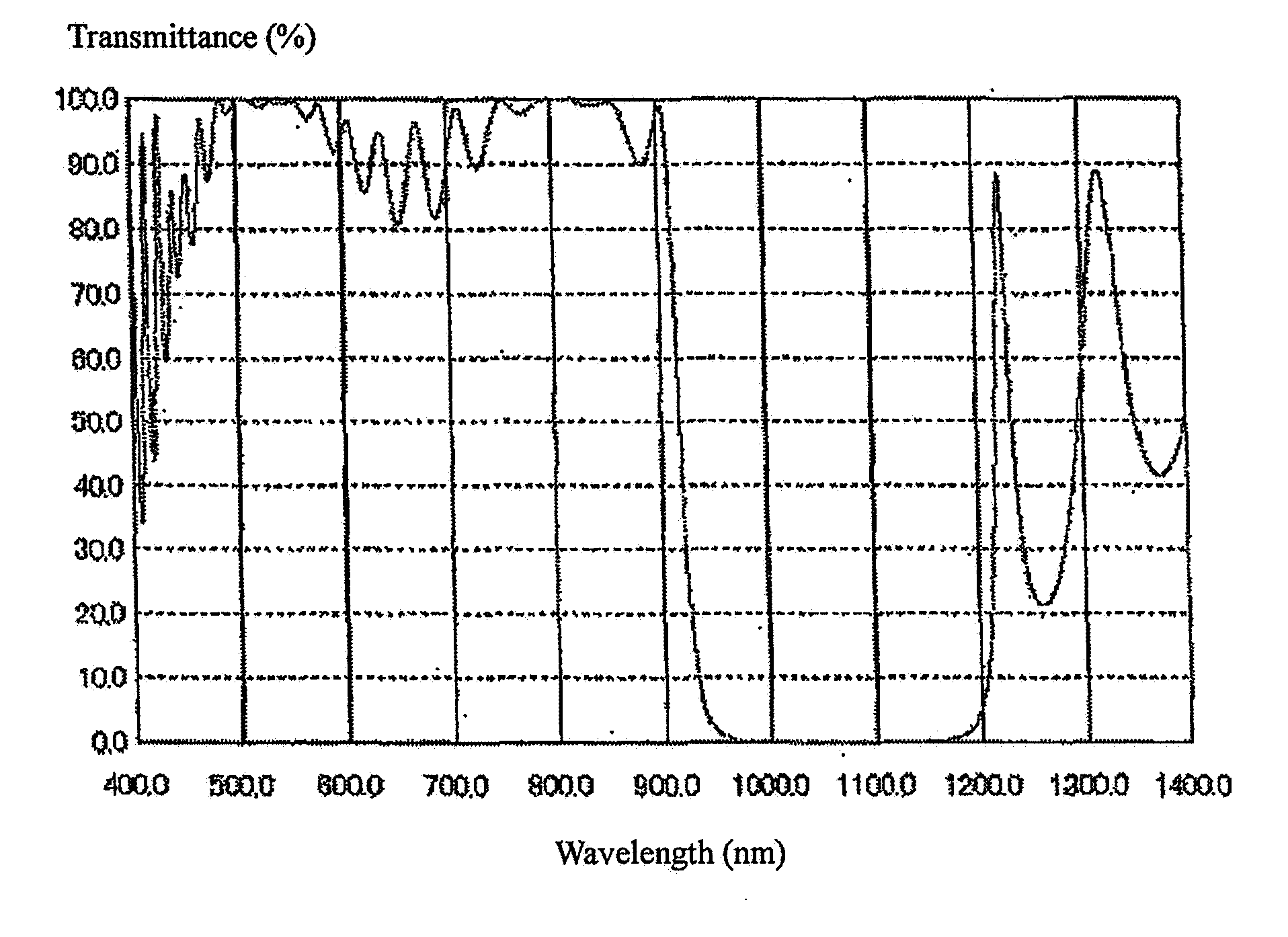

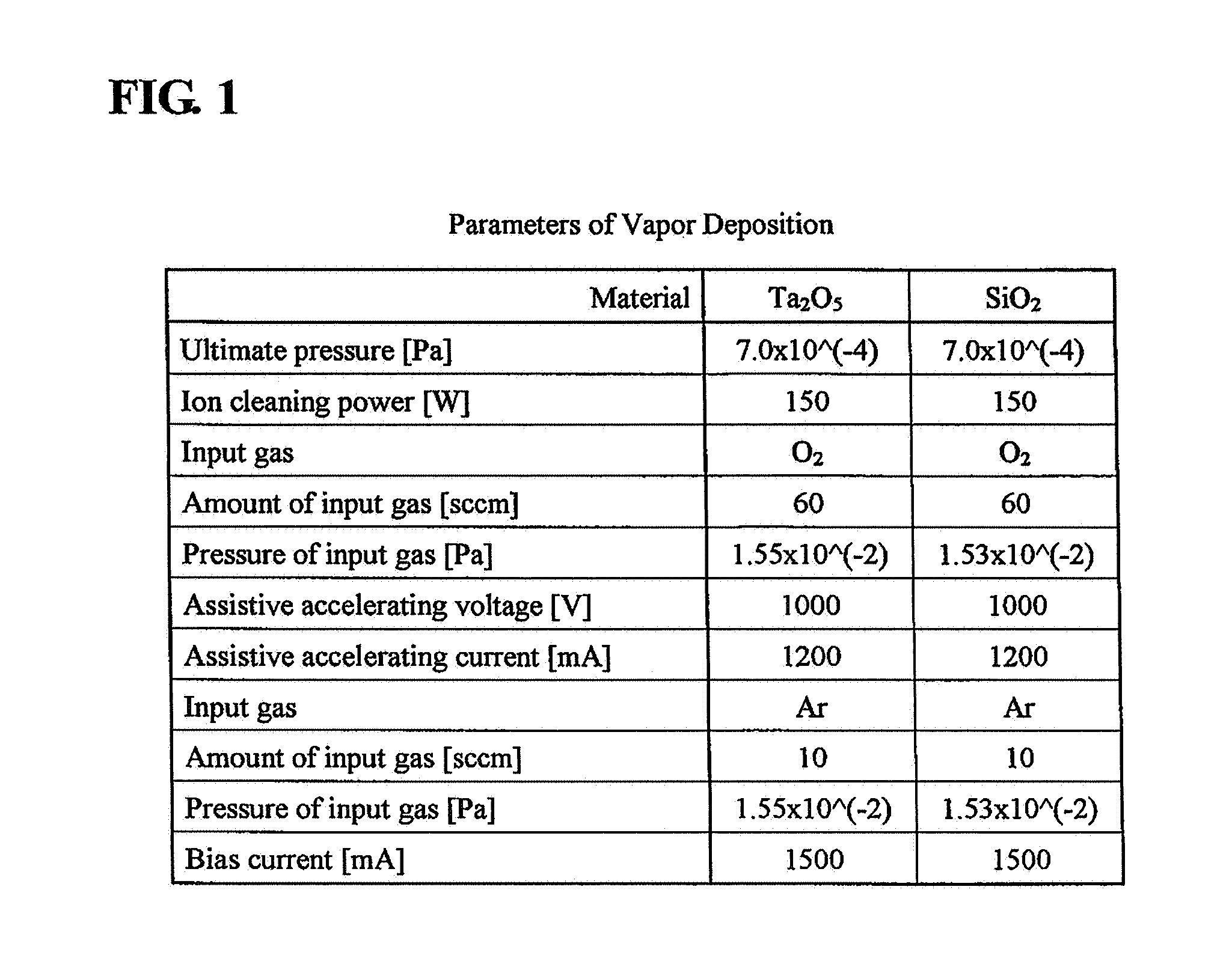

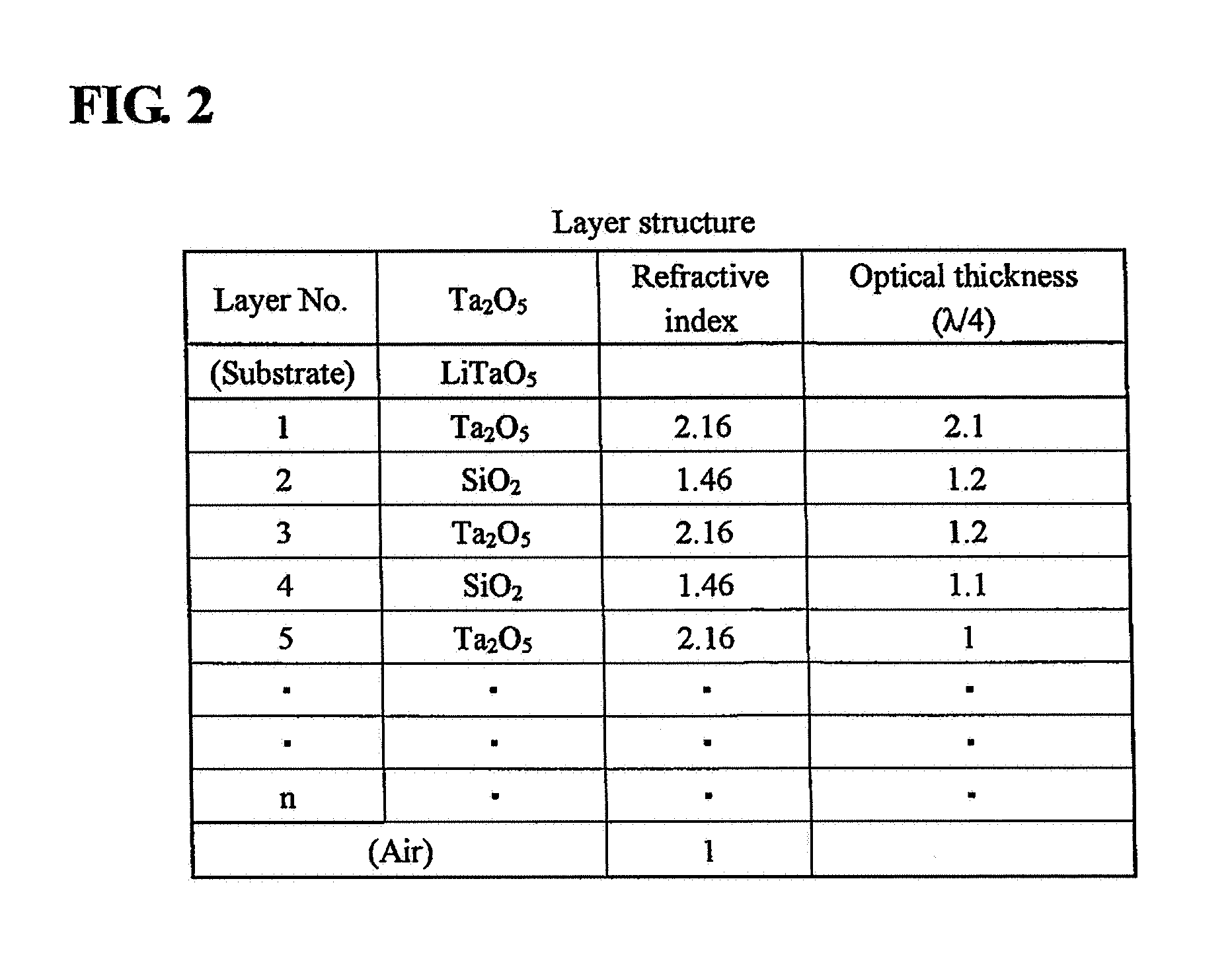

Multilayer coating for quasi-phase-matching element

InactiveUS20080160329A1Reduce riskReduce the temperatureVacuum evaporation coatingSputtering coatingLithiumNiobium

Disclosed is a multilayer coating for a quasi-phase-matching (QPM) element having a substrate made of lithium metallate. The multilayer coating comprises a first layer which is in contact with the substrate and made of an oxide of a metal constituting the metallate in the lithium metallate. Specifically, when the substrate is made of lithium tantalate (LiTaO5), the first layer may be made of tantalum pentoxide (Ta2O5). When the substrate is made of lithium niobate (LiNbO3), the first layer may be made of niobium trioxide (Nb2O3). The multilayer coating of the present invention can provide a high-performance quasi-phase-matching element on the basis of consideration of a relationship between the substrate and the first layer of the multilayer coating.

Owner:SHIMADZU CORP

Preparation method of pyridine-3-formaldehyde

InactiveCN102627599ALow costSimple preparation processOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsGas phaseFixed bed

The invention discloses a preparation method of pyridine-3-formaldehyde. The preparation method mainly comprises the following steps: preparing a supported catalyst by treating ammonium molybdate, bismuth nitrate and a transition metallate as active component precursors and titanium dioxide as a carrier and adjusting by an acid adjusting agent and an organic complexing agent; and carrying out a gas phase catalytic oxidation reaction on 3-methylpyridine, oxygen and water which are used as raw materials in a fixed bed at 290-390DEG C to generate crude pyridine-3-formaldehyde, and extracting, distilling and rectifying the crude pyridine-3-formaldehyde to obtain a product containing above 98% of pyridine-3-formaldehyde. The preparation method of the invention, which has the advantages of simple preparation process, high catalytic reaction activity and selectivity, and low cost, is suitable for industrialized production.

Owner:ZHEJIANG UNIV

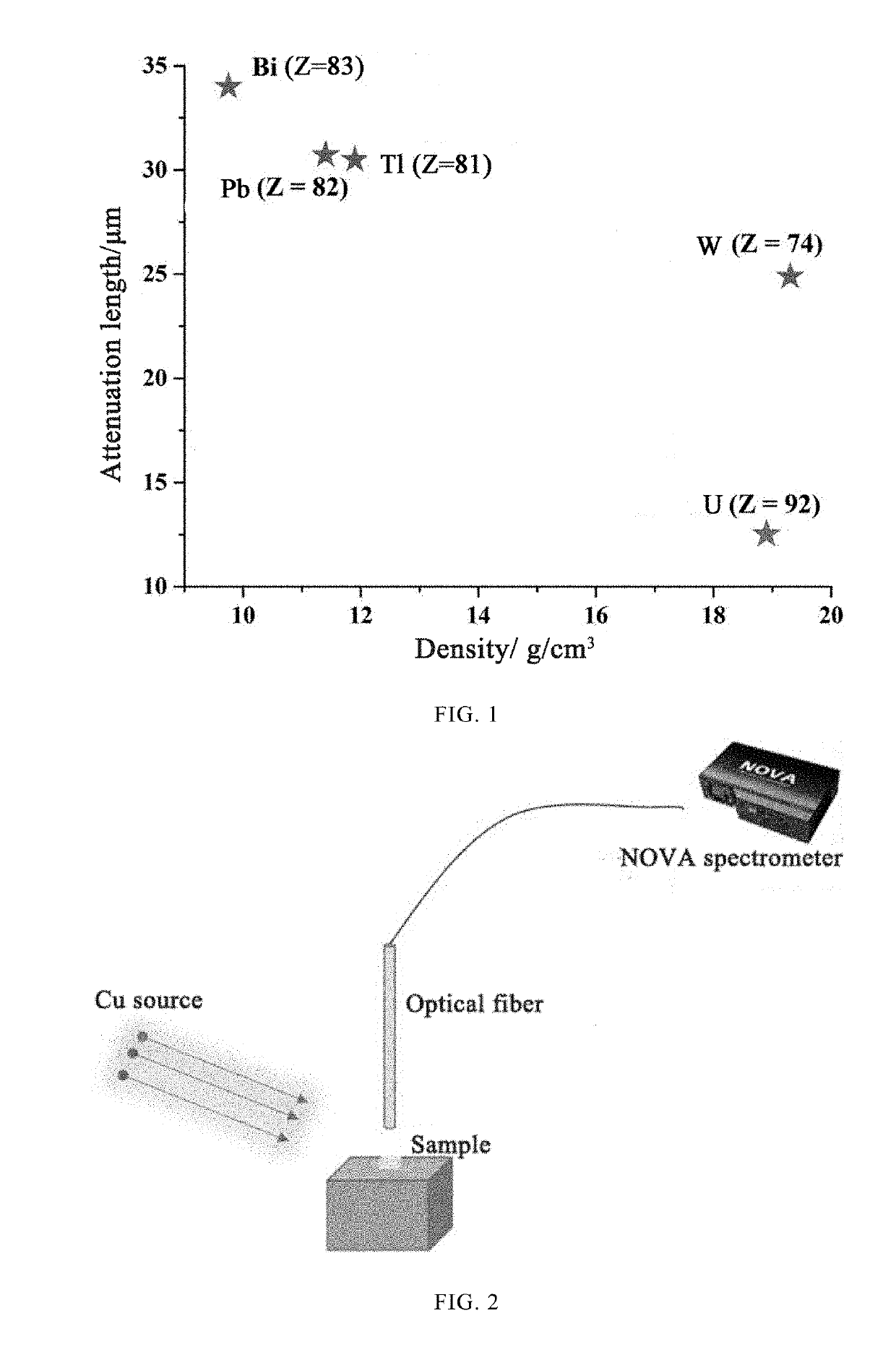

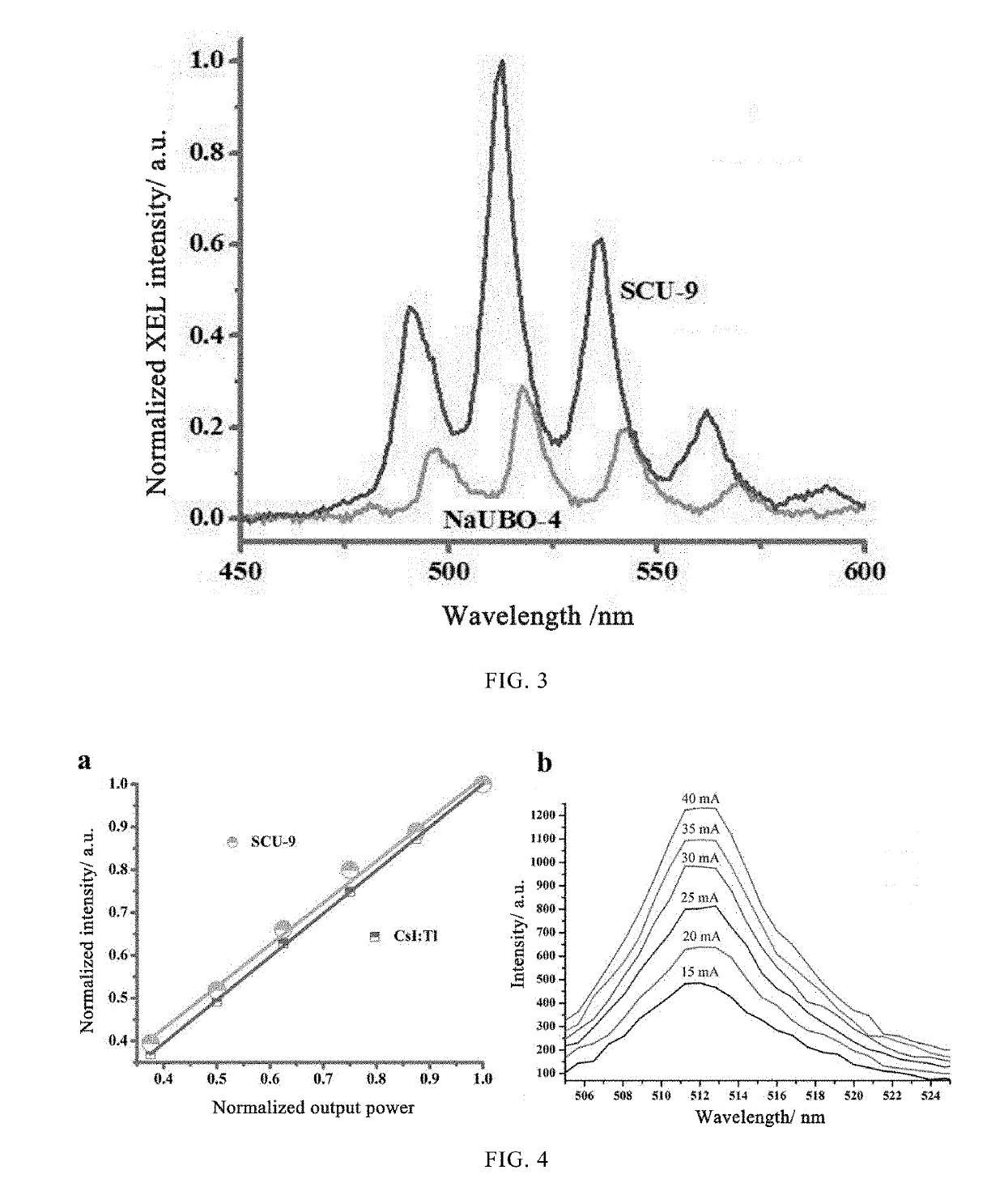

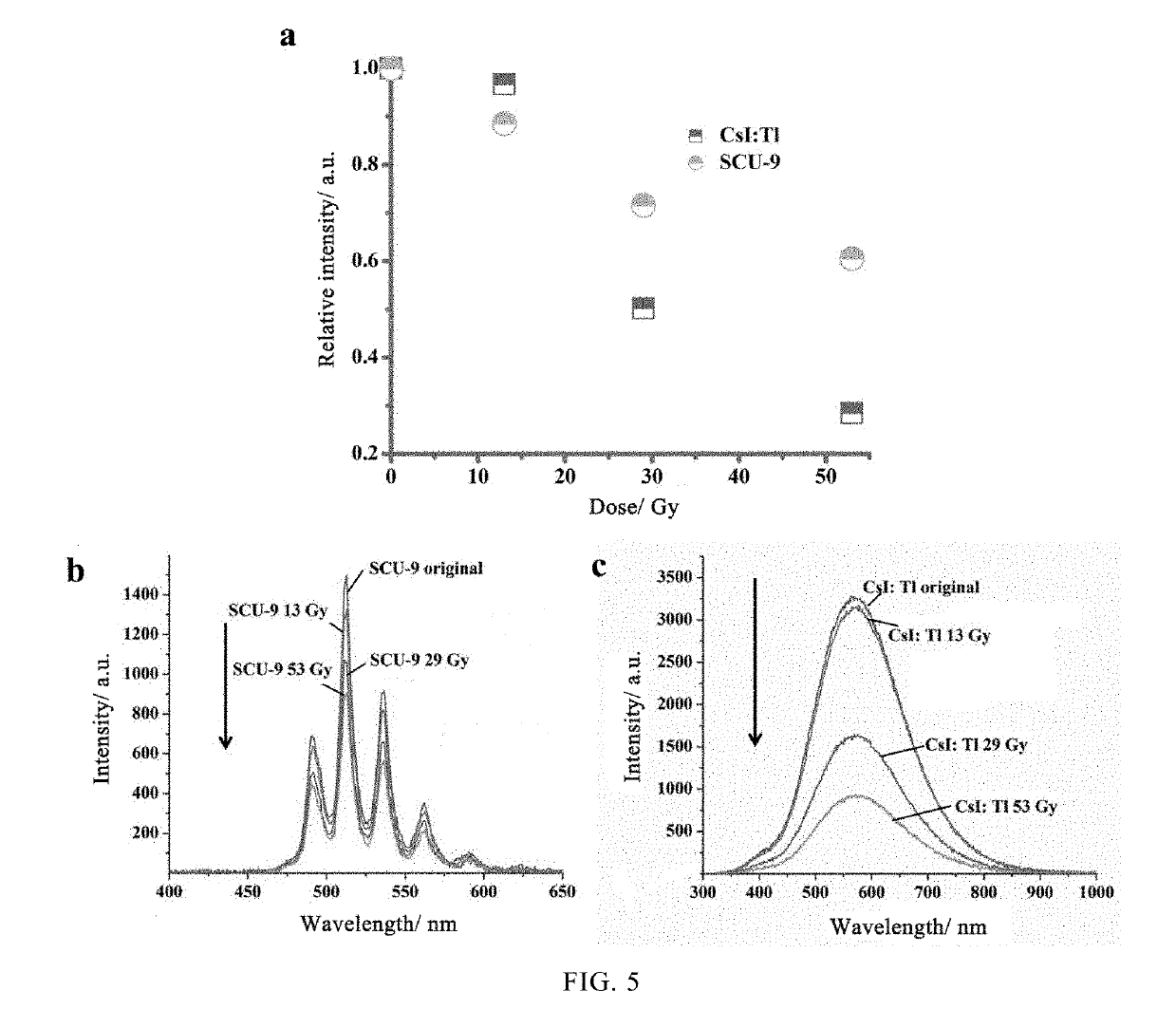

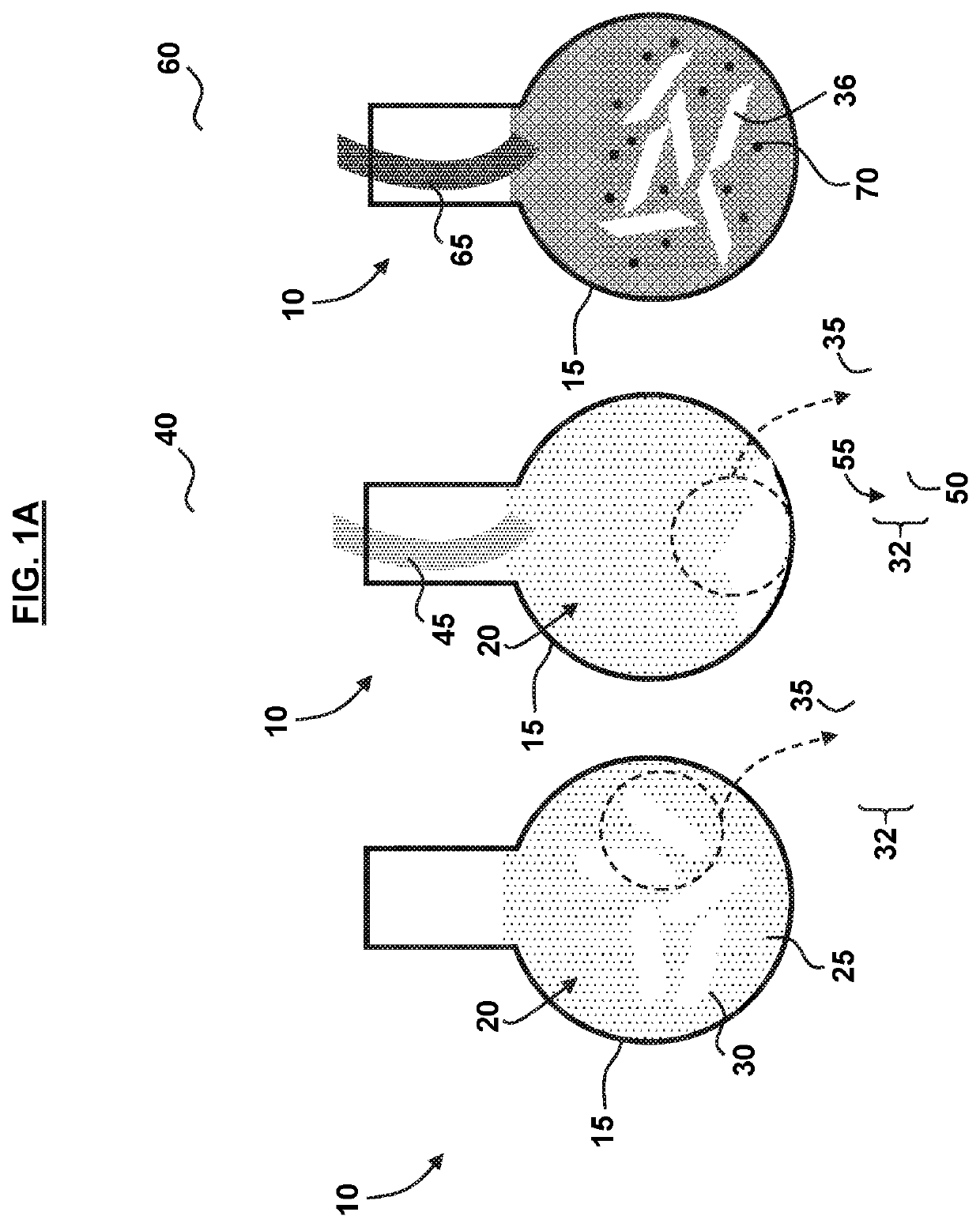

Use of uranium-containing compound as scintillator

ActiveUS20190300787A1Improve performanceLarge design spaceLuminescent compositionsUranium compoundsHybrid compoundCarboxylic salt

The invention discloses use of a uranium-containing compound as a scintillator. The uranium-containing compound is a uranium-containing organic-inorganic hybrid compound or a uranium-containing inorganic compound. The uranium-containing organic-inorganic hybrid compound is a uranium-containing organic carboxylate or a uranium-containing organophosphate. The uranium-containing inorganic compound is a uranium-containing non-metallate, a uranium-containing metal salt, or a uranium-containing halide. The invention discloses the uranium-containing organic-inorganic compound or the uranium-containing inorganic compound having intrinsic scintillating ability, and provides a new concept and method for the development of (organic-inorganic, inorganic) scintillators of various chemical compositions and configurations with the uranium element.

Owner:SUZHOU UNIV

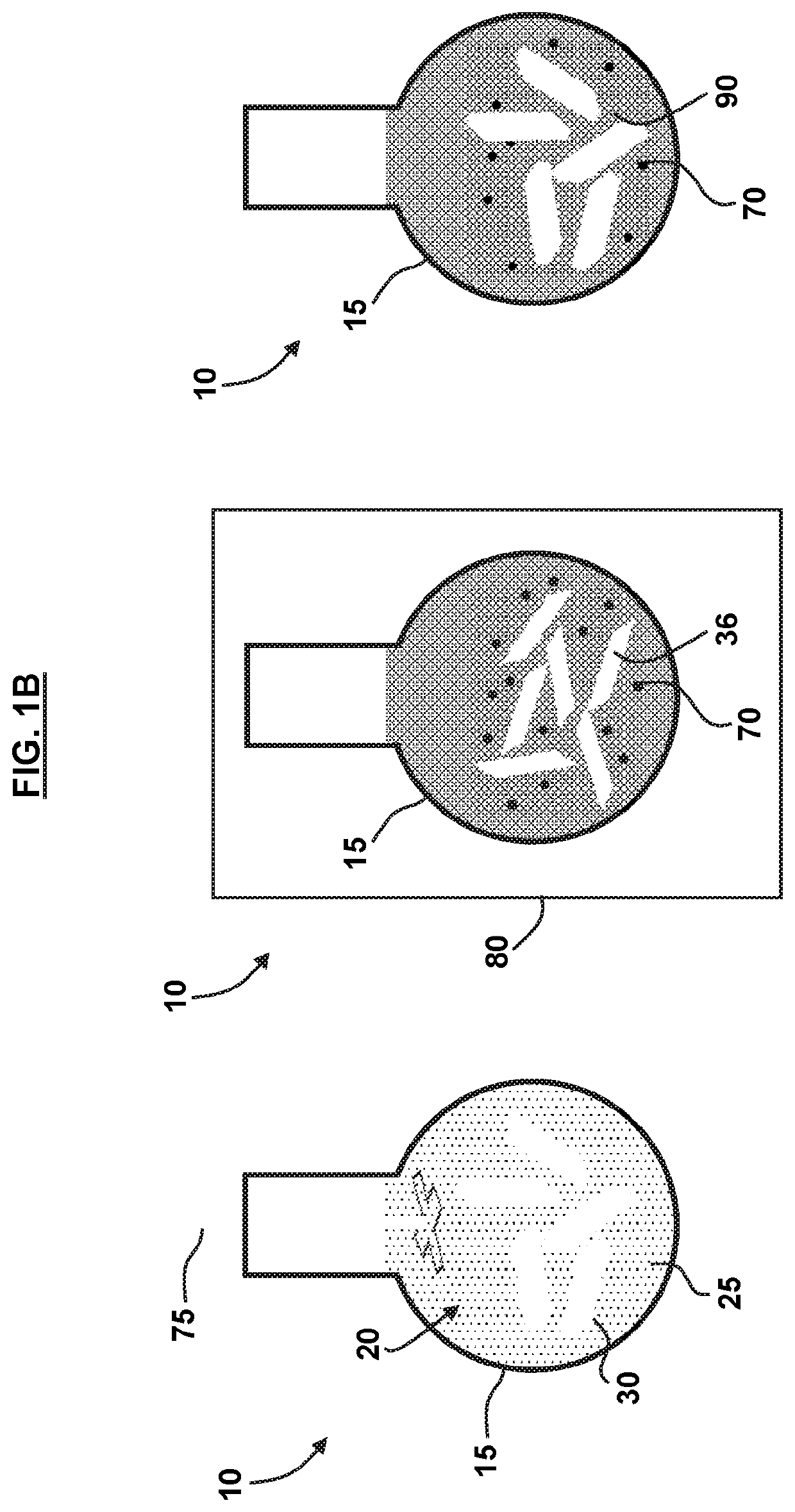

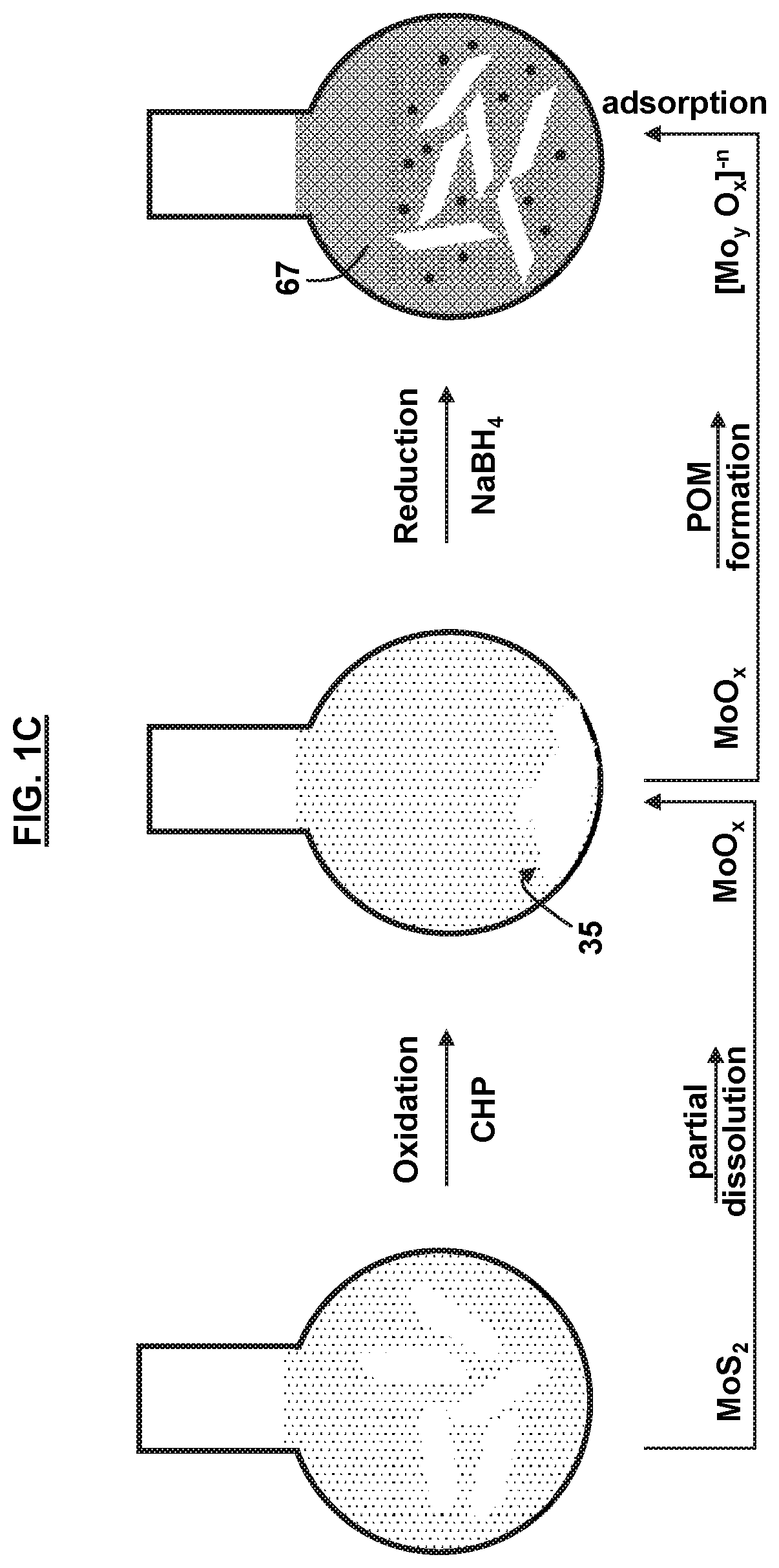

Exfoliating layered transition metal dichalcogenides

A technique for exfoliating a transition metal dichalcogenide material to produce separated nano-scale platelets includes combining the transition metal dichalcogenide material with a liquid to form a slurry, wherein the transition metal dichalcogenide material includes layers of nano-scale platelets and has a general chemical formula MX2, and wherein M is a transition metal and X is sulfur, selenium, or tellurium. The slurry of the transition metal dichalcogenide material is treated with an oxidant to form peroxo-metalate intermediates on an edge region of the layers of nano-scale platelets of the transition metal dichalcogenide material. The peroxo-metalate intermediates is treated with a reducing agent to form negatively charged poly-oxo-metalates to induce separation of the transition metal dichalcogenide material into the separated nano-scale platelets of the transition metal dichalcogenide material.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com