Spherical rhenium alloy powder as well as preparation method and application thereof

A rhenium alloy and powder technology, which is applied in the field of spherical rhenium alloy powder and its preparation, can solve the problems of unfavorable alloy processing and use, segregation of ammonium rhenate and ammonium paratungstate, etc., and achieve improved market utilization, good fluidity, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

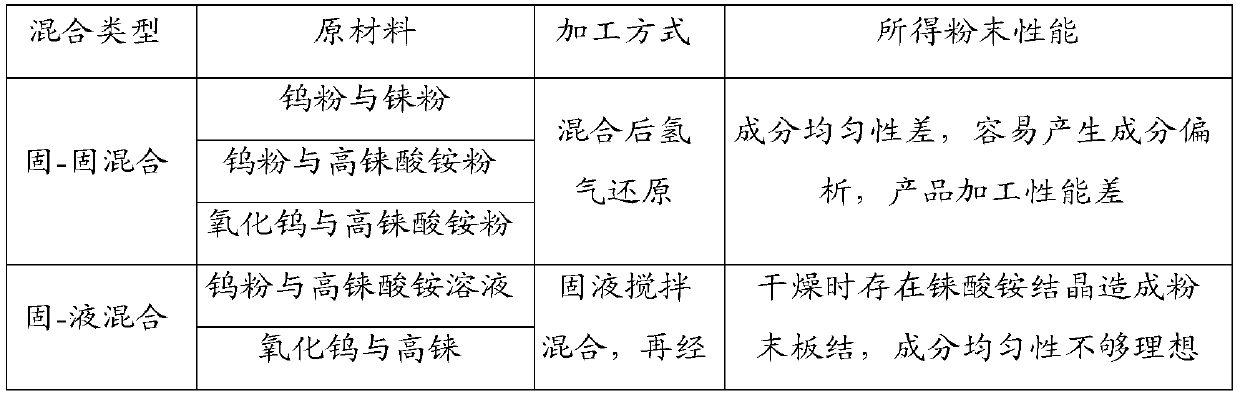

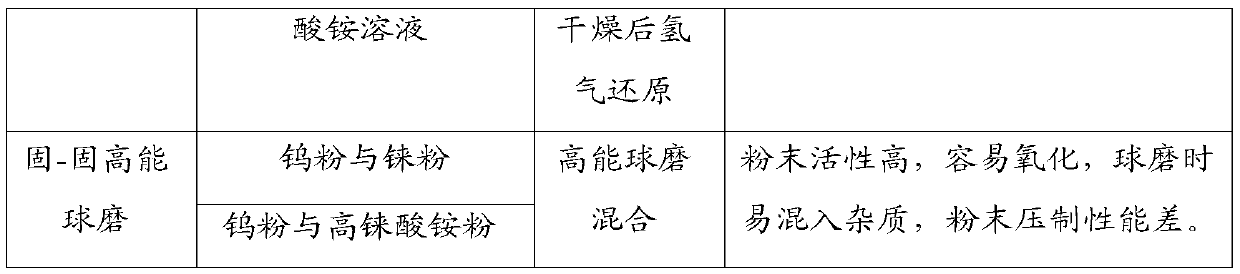

Problems solved by technology

Method used

Image

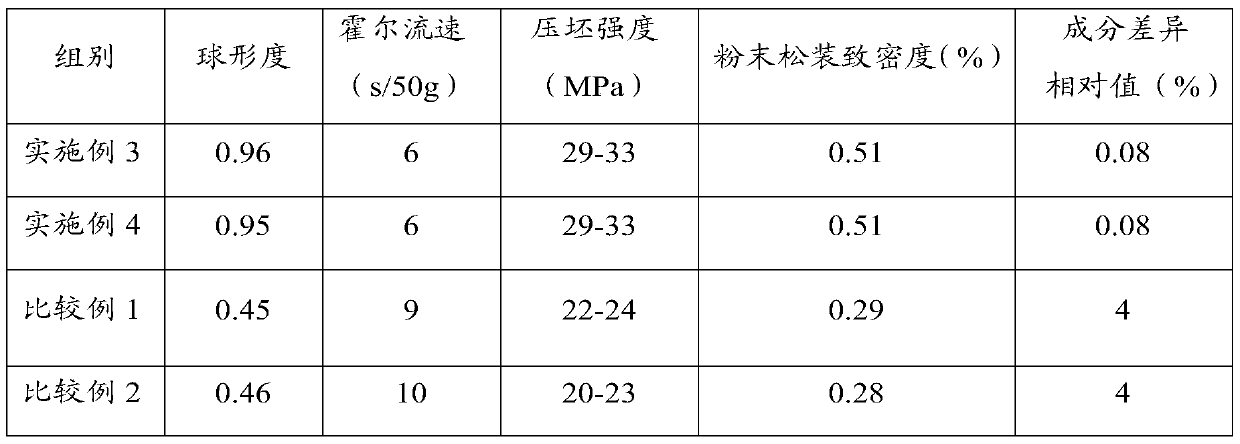

Examples

Embodiment 1

[0029] The preparation method of spherical rhenium alloy powder is as follows:

[0030] 1) Mix the ammonium paratungstate solution containing 20wt% tungsten with the ammonium rhenate solution containing 5wt% rhenium according to the weight of 36:1, and keep stirring;

[0031] 2) The mixed liquid is pumped to the centrifugal atomizer at the top of the spray drying tower by pumping 260g / min. The rotational speed of the centrifugal atomizer is 15000rad / min. The misty mixed liquid contacts with the hot air at 250°C in the tower and rapidly evaporates and crystallizes. The final mixed powder of ammonium paratungstate and ammonium rhenate falls into the collection tank at the bottom of the tower due to gravity, and a small part of the powder is pumped to the cyclone separation equipment for collection along with the induced draft equipment;

[0032] 3) The crystalline powder of ammonium paratungstate and ammonium rhenate is reduced once. The specific reduction process is as follows:...

Embodiment 2

[0036] 1) Mix the ammonium paratungstate solution containing 10wt% tungsten with the ammonium rhenate solution containing 8wt% rhenium according to the weight of 6:5, and keep stirring;

[0037] 2) Pump the mixed liquid at 100g / min to the centrifugal atomizer at the top of the spray drying tower. The rotational speed of the centrifugal atomizer is 18000rad / min. The misty mixed liquid contacts with the hot air at 320°C in the tower and rapidly evaporates and crystallizes. The final mixed powder of ammonium paratungstate and ammonium rhenate falls into the collection tank at the bottom of the tower due to gravity, and a small part of the powder is pumped to the cyclone separation equipment for collection along with the induced draft equipment;

[0038] 3) The crystalline powder of ammonium paratungstate and ammonium rhenate is reduced once. The specific reduction process is as follows: the loading capacity of the boat is 2kg, the speed of pushing the boat is 40min / boat, and the ...

Embodiment 3

[0042] 1) Mix the ammonium dimolybdate solution containing 12wt% molybdenum with the ammonium rhenate solution containing 6wt% rhenium in a weight ratio of 4:9, and keep stirring.

[0043] 2) Pump the mixed liquid at 200g / min to the centrifugal atomizer at the top of the spray drying tower. The final mixed powder of ammonium dimolybdate and ammonium rhenate falls into the collection tank at the bottom of the tower due to gravity, and a small part of the powder is pumped to the cyclone separation equipment for collection along with the induced draft equipment;

[0044] 3) The crystalline powder of ammonium dimolybdate and ammonium rhenate is reduced once. The specific reduction process is as follows: the loading capacity of the boat is 1kg, the speed of pushing the boat is 35min / boat, and the amount of hydrogen is 25m 3 / h, the reduction temperature is 920°C;

[0045] 4) Powder spheroidization: Using plasma as a heat source, molybdenum-rhenium alloy powder is fed into the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com