Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72 results about "Ammonium dimolybdate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium dimolybdate (ADM) is the inorganic compound with the formula (NH₄)₂Mo₂O₇. It is a white, water-soluble solid. ADM is an intermediate in the production of molybdenum compounds from its ores. Roasting typical ore produces crude molybdenum(VI) oxides, which can be extracted into aqueous ammonia, affording ammonium molybdate. Heating solutions of ammonium molybdate gives ADM. Upon heating, solid ammonium dimolybdate decomposes to molybdenum trioxide...

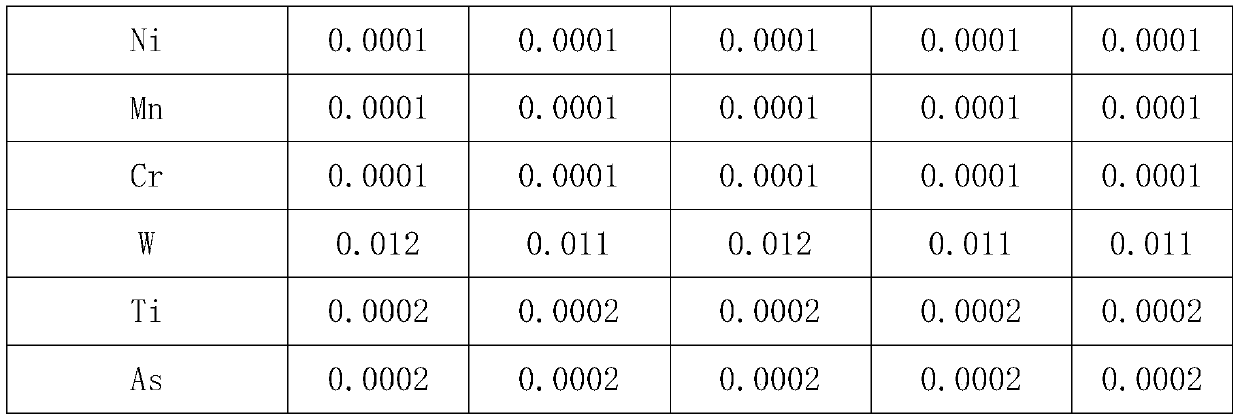

Method for preparing high-purity molybdenum titanium sputtering target

InactiveCN101956159AHigh purityHigh densityVacuum evaporation coatingSputtering coatingImpurityElectron

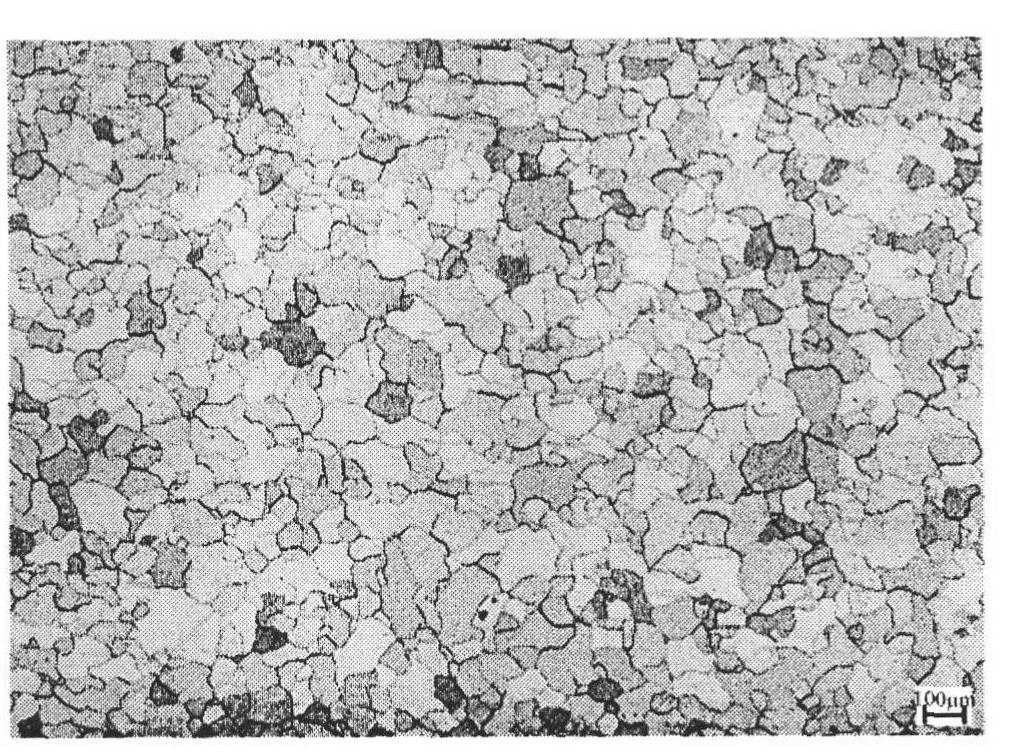

The invention discloses a method for preparing high-purity molybdenum titanium sputtering targets, and relates to a method for preparing molybdenum titanium sputtering targets used in the electronic and photovoltaic field, which is characterized in that the preparation process comprises the following steps: taking ammonium dodecamolybdate as a raw material, preparing high-purity molybdenum powder through two sections of a hydrogen reductive method; carrying out cold isostatic pressing on the high-purity molybdenum powder to press into a molybdenum plate green body; presintering in vacuum; sintering into a molybdenum plate at high temperature at the atmosphere of hydrogen; processing the sintered molybdenum plate into a molybdenum target body by adopting a pressure processing manner of firstly forging and then rolling; vacuum annealing to process into the finished product of molybdenum titanium sputtering target according to a specific specification machine. The preparation method of the invention has low cost, simple operation and low equipment requirements; the prepared molybdenum titanium sputtering target has high purity, low impurity content, high density, uniform particle size and specific crystallization orientation.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Continuous single stage process for the production of molybdenum metal

Molybdenum trioxide or ammonium dimolybdate is reduced to molybdenum metal as it passes through an atmosphere of hydrogen in a multi-zoned thermally profiled rotating tube furnace.

Owner:HARPER INT CORP

Preparation of rare earth ammonium bimolybdate

InactiveCN1644512AReduce microhardnessEasy to processMolybdeum compoundsRare earth metal compoundsCerium nitrateNitrate

Production of rare earth ammonium dimolybdate is carried out by adding ammonium tetramolybdate with ammonium tetramolybdate : soft water: ammonia water = 1kg: 4-5L: 1L, heating agitating, forming mother liquid, regulating the pH value of mother liquid between 7-8.5, adding the cerium nitrates, lanthanum nitrates or illinium nitrates into the mother liquid, heating evaporating for 2.0-6.0hrs with heating temperature 100deg.C-130deg.C until the solution transparent, discharging the materials, pumping filtering, drying with temperature 110-150deg.C for 6-8hrs, and obtaining the rare earth ammonium dimolybdate. It achieves low cost, higher material processing and using performance and no environmental pollution.

Owner:临沂市科创材料有限公司

Production of pure molybdenum oxide from low grade molybdenite concentrates

InactiveUS20050019247A1High purityValue maximizationOxide/hydroxide preparationMolybdeum compounds preparationProcess chemistryFiltration

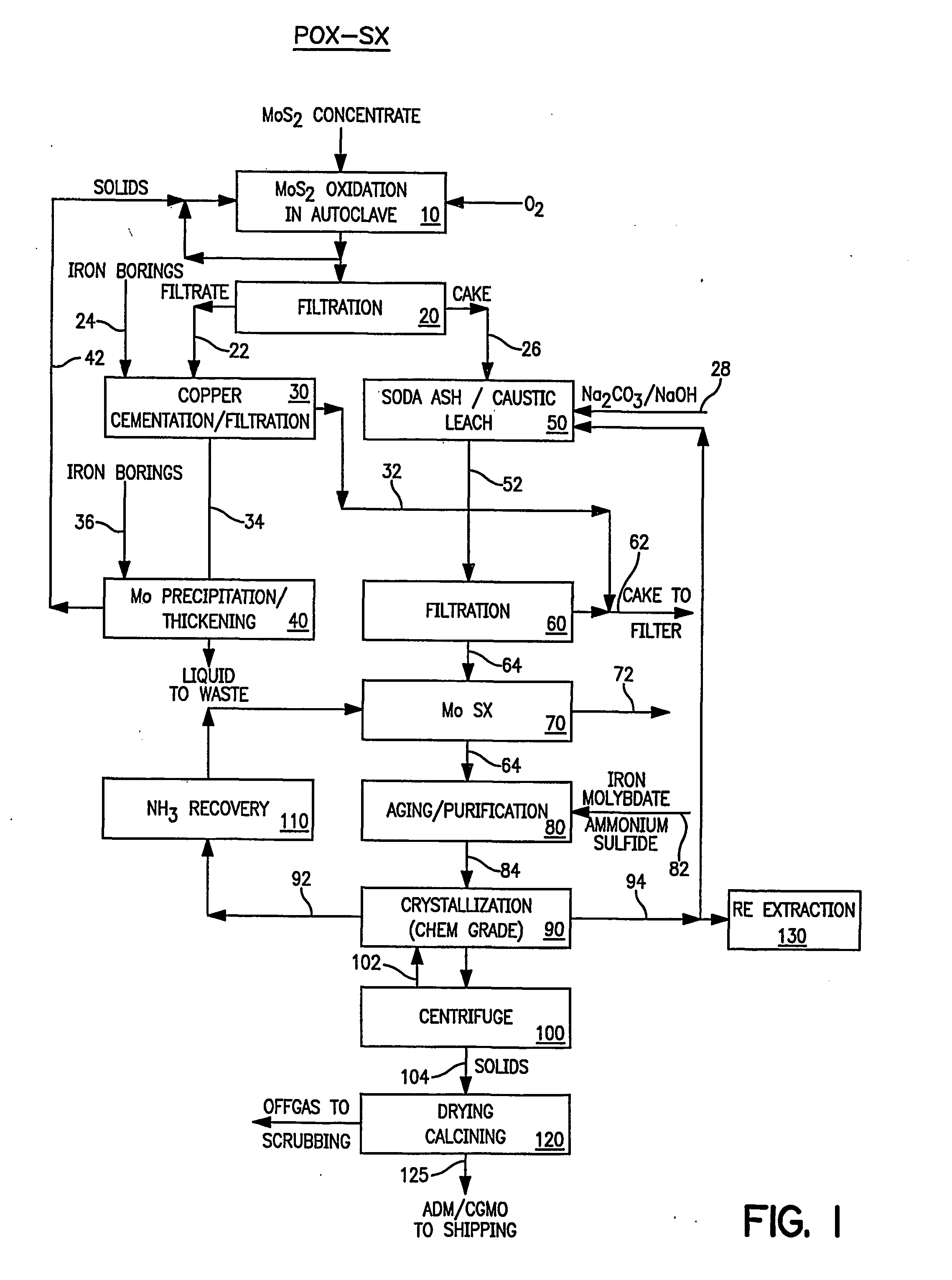

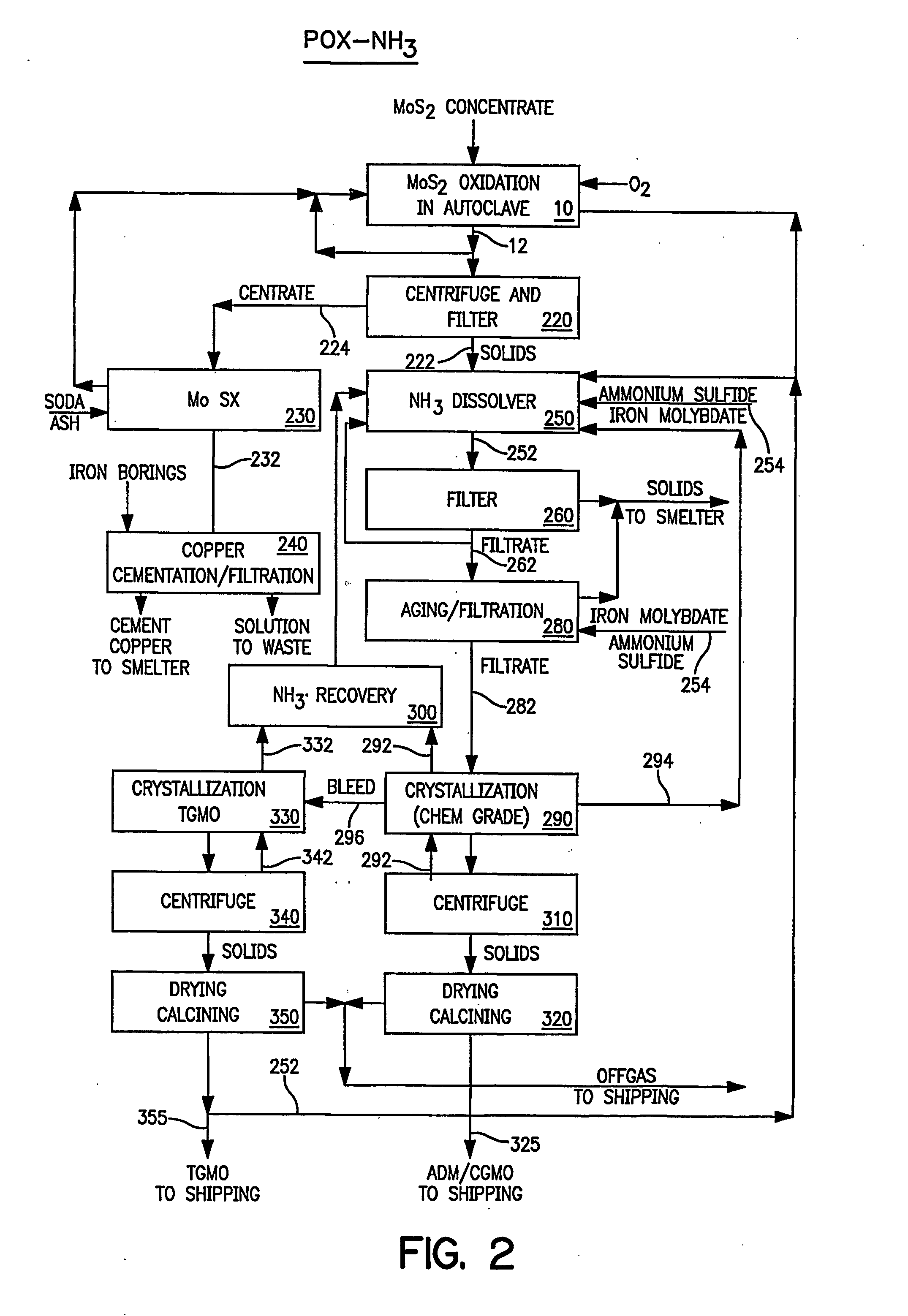

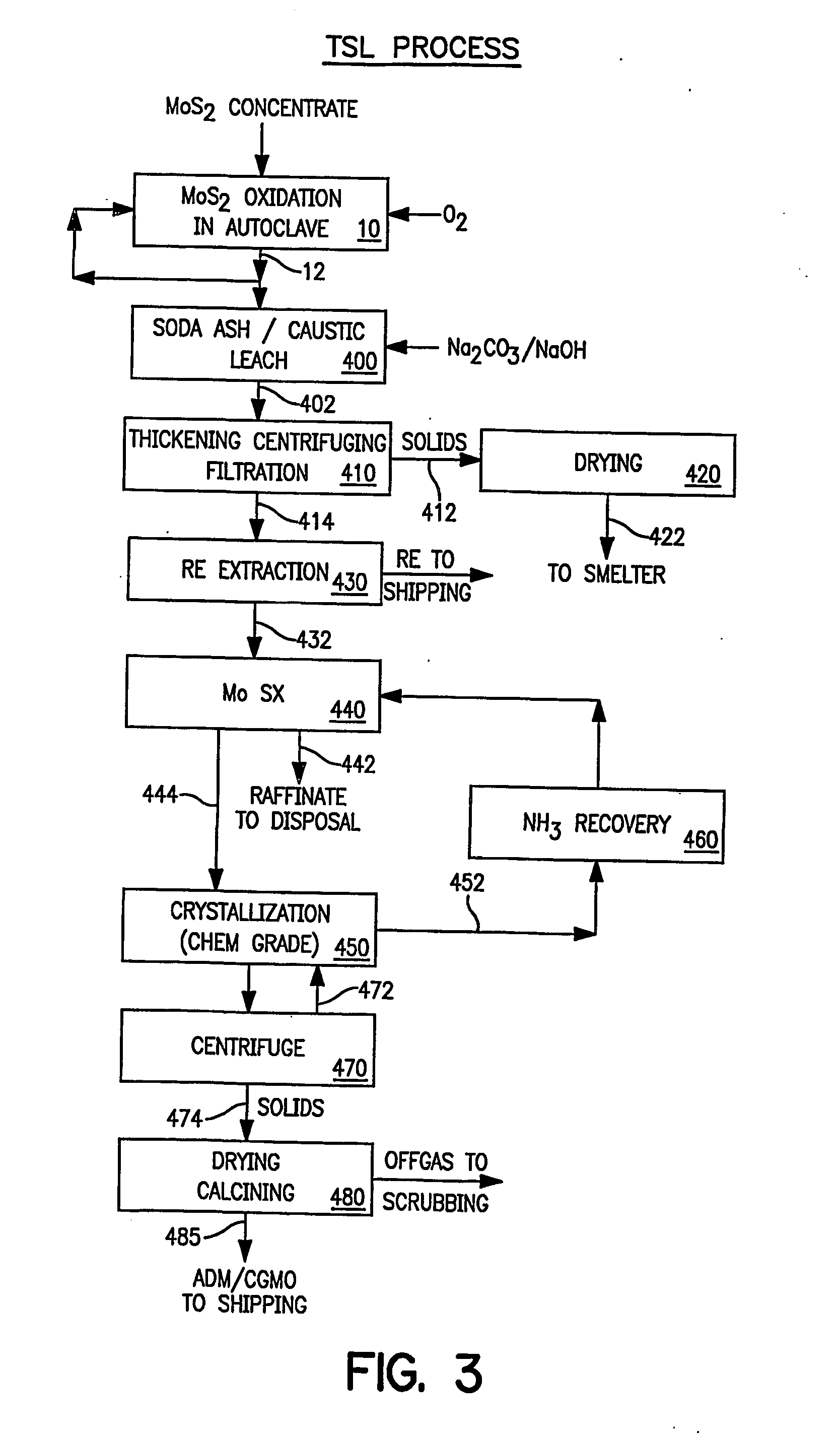

High purity ammonium dimolybdate or molybdenum oxide is produced by the pressure oxidation of low grade molybdenite concentrates or molybdenum intermediates. The process entails nearly complete oxidation of the sulfide minerals while optimizing the process chemistry and autoclave conditions to solubilize as little of the molybdenum values as possible. The autoclave discharge 12 is then subjected to a leaching step, either an alkaline leach 50, 400 or ammonium leach 250 process, before or after a liquid / solid separation step 20, 220, 410. The solution is then subjected to (a) filtration 60, 410, solvent extraction 70, 440, crystallization 90, 450, and calcination 120, 480 or (b) filtration 260, 280, crystallization 290, and calcination 320 to produce a product suitable for chemical-grade molybdenum oxide 125, 325, 485.

Owner:BALLIETT ROBERT W +6

Method for preparing nano molybdenum carbide (Mo2C) flake powder with regular-hexagon structure

ActiveCN105217633AAchieve synthesisWell mixedMaterial nanotechnologyTungsten/molybdenum carbideSucroseMetallurgy

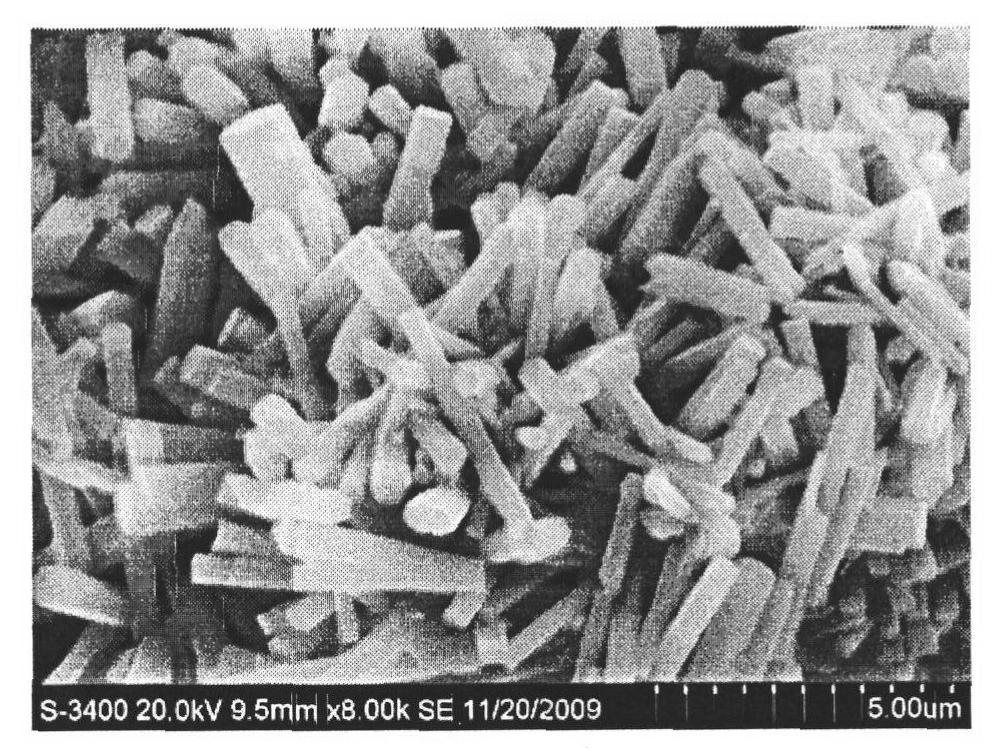

The invention relates to a method for preparing nano molybdenum carbide (Mo2C) flake powder with a regular-hexagon structure. According to the method, water-soluble ammonium dimolybdate (or ammonium heptamolybdate) and glucose (or saccharose) are respectively adopted as a molybdenum source raw material and a carbon source raw material; and through precursor solution drying, molecular-level uniform mixing of all elements in a reactant system is realized, the temperature for carbothermal reduction reaction is lowered, the reaction time for the carbothermal reduction reaction is shortened, and the synthesis of nano Mo2C is realized. In addition, during the reaction, a molten halogenating agent provides a uniformly-heated stable-state system for a reaction system, so that the homogeneous growth of regular-hexagonal nano flaky Mo2C is promoted.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

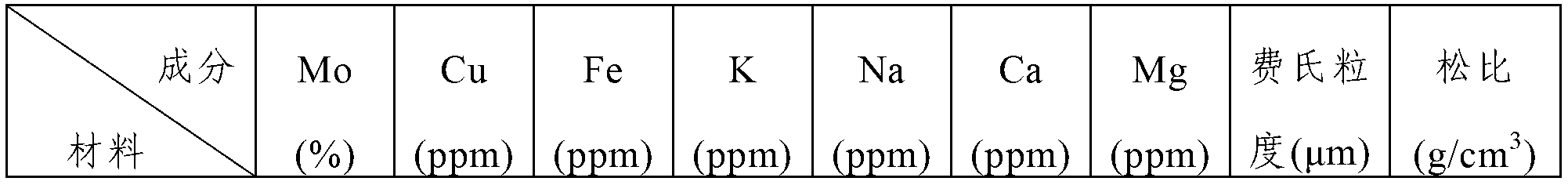

Method for manufacturing molybdenum powder

The invention discloses a method for manufacturing molybdenum powder. The method includes performing thermal decomposition for washing ammonium dimolybdate to obtain gray and white molybdenum trioxide; and performing para-hydrogen reduction for the molybdenum trioxide to obtain semi-finished products and uniformly mixing the semi-finished products to obtain the molybdenum powder. The method for manufacturing the molybdenum powder has the advantages that the washing ammonium dimolybdate is used as a raw material, accordingly, environmental pollution is prevented, the gray and white molybdenum trioxide is obtained by means of low-temperature calcination, energy consumption is reduced, and the productivity is improved; the molybdenum trioxide is reduced to form molybdenum dioxide, and the molybdenum dioxide is heated in four temperature zones of a horizontal four-tube reduction furnace and then is naturally cooled, so that energy consumption is reduced, the production cost is lowered, and the molybdenum dioxide can be assuredly dispersed; the method for manufacturing the molybdenum powder is simple, safe and reliable in operation and suitable for batch production; and the manufactured molybdenum powder is dispersed uniformly without being calcined, the Fisher particle size of the manufactured molybdenum powder ranges from 3.2 micrometers to 4.5 micrometers, the apparent density of the manufactured molybdenum powder ranges from 1.0g / cm<3> to 1.3g / cm<3>, and the yield reaches 90% at least after the manufactured molybdenum powder is screened by 200-mesh screen cloth.

Owner:JINDUICHENG MOLYBDENUM CO LTD

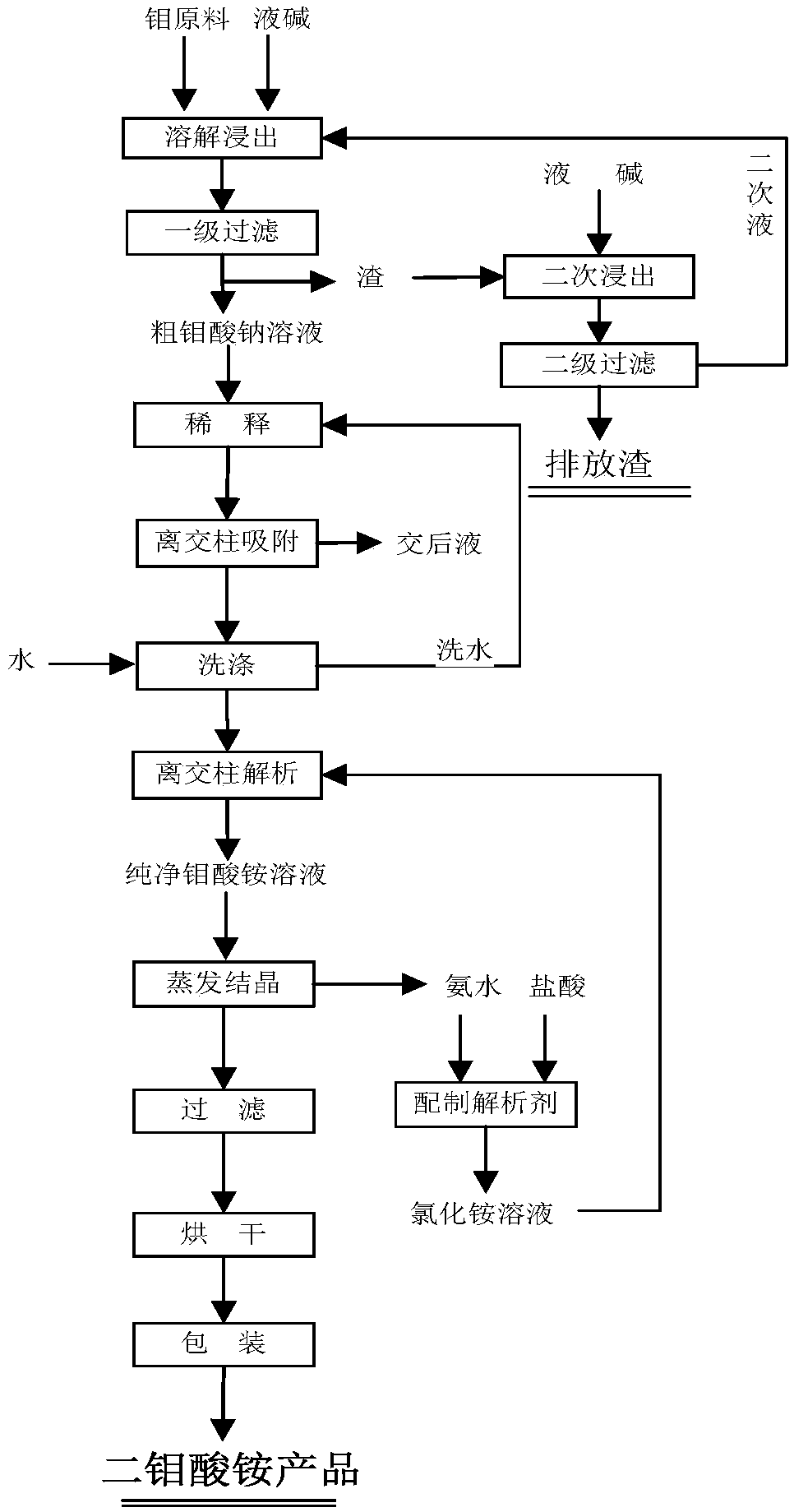

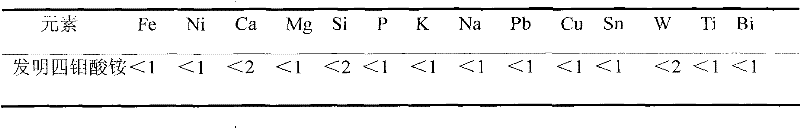

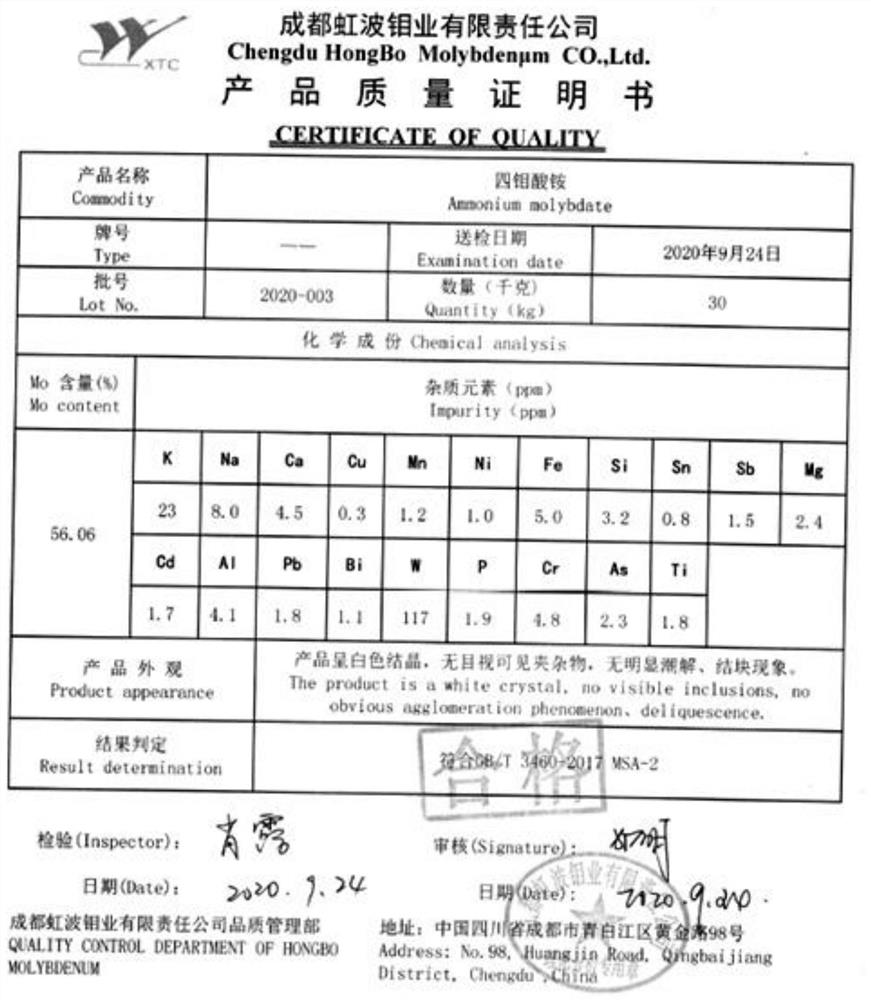

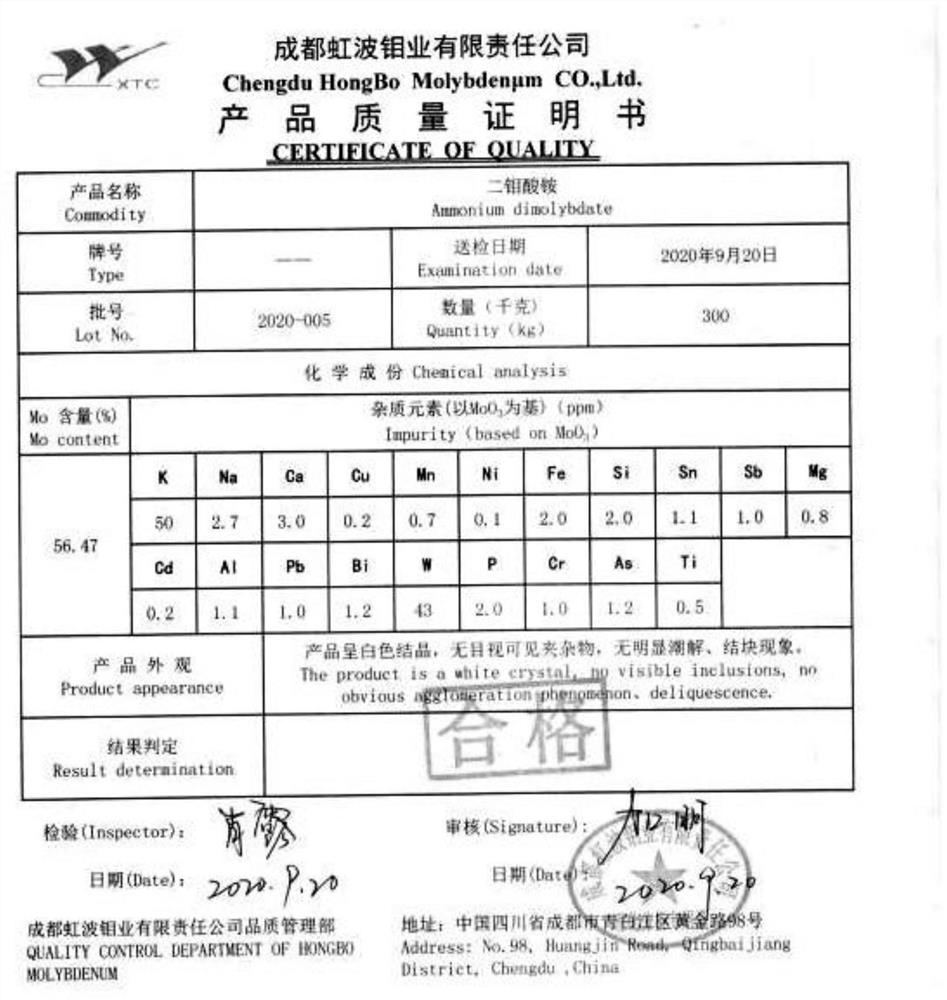

Process for producing high-purity ammonium dimolybdate through ion exchange method

InactiveCN108083335AAchieve recyclingSatisfy recyclingMolybdeum compoundsEnvironmental resistanceAutomatic control

The invention discloses a process for producing high-purity ammonium dimolybdate through an ion exchange method. The process comprises the following steps: I, preparing a sodium molybdate solution, (I) dissolving and (II) filtering and secondary leaching; II, performing ion exchange: (I) adsorbing and (II) resolving; and III, crystallizing and drying. The process adopts the ion exchange method toprepare ammonium molybdate, has the environment-friendly advantages, realizes recycling use, in process, of ammonia nitrogen, and meets process requirements of clean production; moreover, the processis simple and short, the impurity removal effect is good, the process controlled degree is high, and the product quality is stable; needed auxiliary material varieties are fewer, ion exchange resin can be repeatedly used, and material movement is less; automatic control is easily performed, labor productivity is favorably improved and labor intensity is favorably reduced, the working environment is friendly, and social benefits are better; and the raw material adaption is strong, and a metal recovery rate is high, and low-grade calcined products and various other molybdenum-containing raw materials can be treated.

Owner:成都虹波钼业有限责任公司

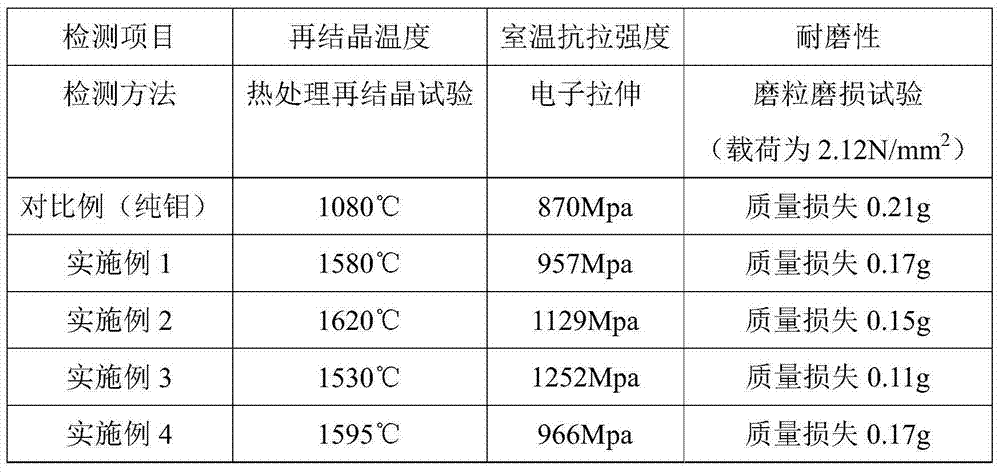

Preparation method of nanometer rare earth oxide-doped molybdenum alloy plate

The invention provides a preparation method of a nanometer rare earth oxide-doped molybdenum alloy plate, and relates to a production processing method of a molybdenum alloy sheet. The method is characterized by comprising the following steps: taking rare earth ammonium dimolybdate as a raw material, and carrying out hydrogen reduction on the rare earth ammonium dimolybdate; pressing molybdenum alloy powder into a molybdenum plate blank under cold isostatic pressing; sintering the molybdenum alloy plate blank; forging and cogging the molybdenum alloy plate blank; alternately rolling for multiple passes; annealing followed by cold rolling into the molybdenum plate; alkali-cleaning the molybdenum plate; and annealing the molybdenum plate after alkali-cleaning. The molybdenum alloy plate prepared by the method has higher strength and higher ductility; and a molybdenum alloy pontoon formed by punching the molybdenum alloy plate has fewer defects and longer service life. The preparation method proposed in the invention has simple process, a small quantity of working procedures and easy realization of industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

ZrO2 ceramic particle reinforced molybdenum-based composite material and preparation method thereof

The invention discloses ZrO2 ceramic particle reinforced molybdenum-based composite material and a preparation method thereof. The ZrO2 ceramic particle reinforced molybdenum-based composite material is mainly prepared from the following raw materials by weight: 1-14 parts of zirconium nitrate, 80-92 parts of ammonium dimolybdate and 120-138 parts of citric acid. The ZrO2 ceramic particle reinforced molybdenum-based composite material takes zirconium nitrate, ammonium dimolybdate and citric acid as raw materials; in the obtained molybdenum-based composite material, the particle size of the reinforcement phase ZrO2 ceramic particles is small, the particle size is on a nano or submircro level; the distribution of the ceramic particles is uniform; and the content of impurities is low. The ZrO2 ceramic particle reinforced molybdenum-based composite material has good high-temperature mechanical properties, processability and high usage temperature.

Owner:HENAN UNIV OF SCI & TECH

Preparation of nano rare-earth oxide doping molybdenum alloys

The invention discloses a method for preparing a nano rare earth oxide doped molybdenum alloy. In the method, by taking rare earth ammonium dimolybdate crystals as raw materials and adopting the roasting and hydrogen reduction method, molybdenum alloy powder is obtained, the powder after reduction is in press-forming by the isostatic cool pressing with a pressure of between 180 and 200 Mpa, the formed blank materials are presintered in a muffle furnace with a temperature of between 1, 100 and 1, 300 DEG C, and sintered in a vacuum intermediate frequency induction sintering furnace at a temperature of between 1, 600 and 1, 900 DEG C for 10 to 24 hours; the materials sintered can be made by the prior mechanical processing methods into materials and products with different shape such as molybdenum alloy bar materials or plate materials, etc. as required. The molybdenum alloy containing nano rare earth oxide, prepared by the method of the invention, has the advantages of high intensity, ductility and toughness and wide application.

Owner:临沂明华管业有限公司

Method for preparing high-purity ammonium tetramolybdate mainly by using ammonium molybdate transformation process

The invention relates to a method for preparing high-purity ammonium tetramolybdate, which comprises the steps of: mixing raw ammonium tetramolybdate with pure water and concentrated ammonia water to dissolve the raw ammonium tetramolybdate, then using pure water to adjust density and filtering to obtain filtrate 1; using concentrated nitric acid to adjust the density of the filtrate 1 at room temperature, then adding FeCl3, agitating and filtering to obtain filtrate 2; conducting evaporation and crystallization and filtering to obtain filtrate 3 and a filter cake 1; after the filtrate 3 is cooled, filtering to obtain a filter cake 2; after the filter cake 1 and the filter cake 2 are mixed with pure water, are agitated and are dissolved, adding concentrated nitric acid to obtain solution with H+ concentration being 3-8 mol / L, agitating, heating, preserving heat, cooling and filtering to obtain a filter cake 3, and using nitric acid aqueous solution to wash the filter cake 3 to obtain ammonium dodecamolybdate; adding pure water and concentrated ammonia water to mix and dissolve, heating, evaporating, regulating pH, cooling and then using pure water to adjust density; and adding concentrate nitric acid to regulate pH, agitating, heating, preserving heat, filtering to obtain a filter cake 4, washing the filter cake 4 and drying the filter cake 4 to an extent with the water content being less than or equal to 1.0g / cm<3> to obtain ammonium tetramolybdate with the purity being more than or equal to 99.998 percent. Therefore, the content of impurities in the raw ammonium tetramolybdate is effectively reduced.

Owner:西部鑫兴金属材料有限公司

Method for producing industrial-grade ammonium dimolybdate by combination method

InactiveCN102010007AIncrease crystallization rateHigh recovery rateMolybdeum compoundsNational levelAmmonia

The invention relates to a method for producing industrial-grade ammonium dimolybdate by a combination method. The method comprises the following steps: adding pure water and ammonia water into industrial ammonium molybdate which is taken as a raw material, dissolving ammonium and evaporating, aging and crystallizing to separate out ammonium dimolybdate, wherein the crystallization rate is more than 87%; and separating solid from liquid for crystallization mother liquor, and carrying out acid precipitation to obtain ammonium polymolybdate, wherein the comprehensive recovery of molybdenum can be up to more than 99%. By using the invention, the purity of the ammonium dimolybdate is greatly improved, the product quality can reach the national level, the operation is simple and convenient, and the equipment is simple, therefore, the method has very good application value.

Owner:CENT SOUTH UNIV

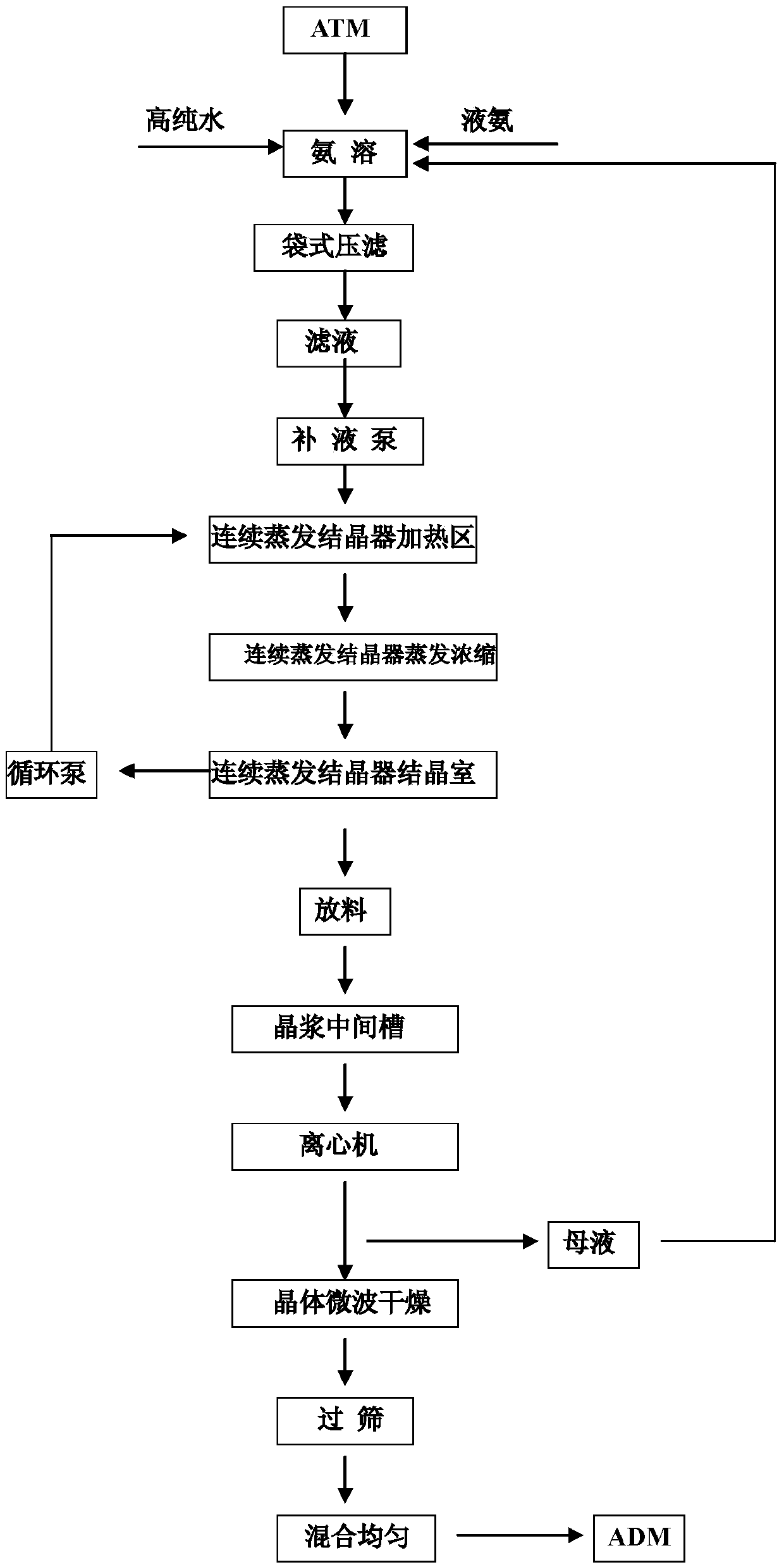

Ammonium dimolybdate automatic continuous crystallization production process

ActiveCN105502501AImprove performanceWide variety of sourcesMolybdeum compoundsFiltrationEvaporation

An ammonium dimolybdate automatic continuous crystallization production process comprises the following steps: solution density, a pH value and temperature in an ammonia dissolution process in a stirring reaction still are adjusted; an ammonia dissolution solution is pumped into a precision filter for filtration, then the filtered ammonia dissolution solution enters a continuous evaporating crystallizer with a constant feed liquid feeding amount in a circulating manner, and the heating, the evaporation and the crystallization of the solution are carried out in three independent working areas, namely, a heating area, an evaporation concentration area and a crystallization chamber separately, wherein the three areas work simultaneously; crystal slurry density is controlled, after crystallization, a crystal slurry enters a crystal slurry intermediate tank so as to enter a centrifuger for solid-liquid separation, after separation, an ammonium dimolybdate crystal drops in a microwave dryer to be dried, then the product (the dried ammonium dimolybdate crystal) is conveyed to a sieving machine to be subjected to sieving through a bucket elevator, and then the sieved ammonium dimolybdate crystal enters a cantilever tapered mixer to be mixed. The production process has the advantages that not only is the ammonium dimolybdate automatic continuous crystallization production realized, but also the single crystal, large particle size and high loose ratio ammonium dimolybdate is obtained through selection of a domestic crystallizer and control of a crystallization condition.

Owner:JINZHOU TIANQIAO REFRACTORY METAL

Method for producing high-solubility ammonium heptamolybdate

The invention discloses a method for producing high-solubility ammonium heptamolybdate. The method comprises the following steps of: in a sealed reaction kettle, dissolving ammonium tetramolybdate or ammonium dimolybdate in ammonia water with concentration of 14%-16%, and applying a certain gas pressure during dissolving; then, filtering and cooling liquor, carrying out high-speed centrifugal dehydration while cooling to 18-20 DEG C to obtain granulate ammonium heptamolybdate crystals; finally, drying. Compared with the existing production technology, environmental pollution is reduced as the method is carried out in the sealed reaction kettle; during dissolving, quality of ammonium heptamolybdate is improved by applying a certain pressure, so that produced ammonium heptamolybdate has solubility of over 80g. Meanwhile, when ammonium heptamolybdate is dissolved in water, light transmittance can reach 95% that of the pure water. Finally, ammonium heptamolybdate produced by the method disclosed by the invention does not need a crushing step, so that production efficiency is improved.

Owner:JIANGSU DONGTAI FENGFENG TUNGSTEN & MOLYBDENUM MATERIAL

Method for preparing molybdenum alloy powder containing nano rare-earth oxides

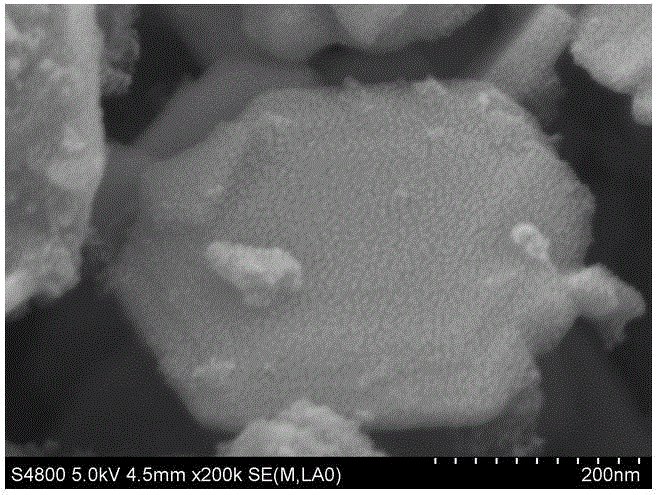

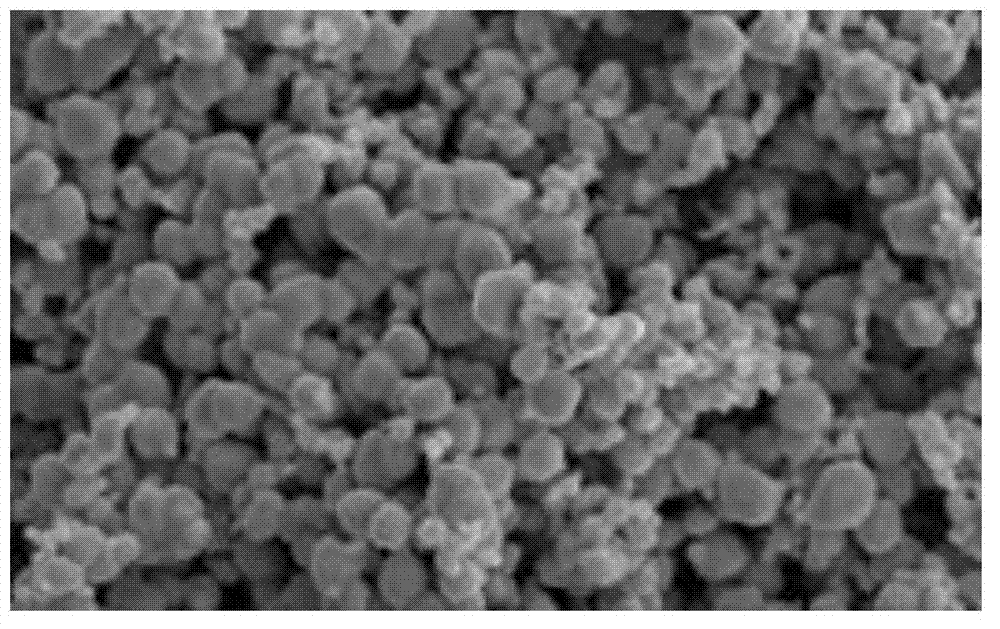

The invention discloses a preparation method of molybdenum alloy powder containing nanometer rare earth oxides. The method uses rare earth ammonium dimolybdate crystals as the material, and adopts the methods of roasting and hydrogen reduction to produce powder mixture containing nanoscale rare earth oxides and molybdenum metal, wherein, the scale range of the rare earth oxides in the molybdenum alloy powder is from 30 to 80 nanometers, and the rare earth oxides are all evenly dispersed on molybdenum powder matrix; the molybdenum granules are very fine, wherein, the Fisher particle size of the crystals is 1.0 to 4.0 um. The invention to prepare molybdenum alloy powder containing nanometer rare earth oxides has the characteristics of simple structure, low cost, small particle size and even distribution of the rare earth oxides, etc, and ensures the high strength and high flexibility of the molybdenum alloy material prepared in the method.

Owner:临沂明华管业有限公司

Preparation method of carbon/carbon-copper composite material

The invention discloses a preparation method for a carbon / carbon-copper composite material. The preparation method comprises the following steps of: (1) cleaning a carbon / carbon-copper composite material sample in absolute ethyl alcohol and drying, wherein the density of the carbon / carbon-copper composite material sample is 0.6-1.6g / cm<3>; (2) uniformly mixing one or more than one of MoO3, ammonium orthomolybdate, ammonium paramolybdate, ammonium dimolybdate and ammonium tetramolybdate with one or more than one of alkali chlorides, wherein the mass percentage of Mo in the mixed salt is 5-20%; (3) embedding a green body obtained in the step (1) into the mixed salt obtained in the step (2), preserving heat for 0.5-5 hours at the temperature of 900-1100 DEG C, and cooling to the room temperature in the furnace; and (4) maintaining the temperature of the green body obtained in the step (3) for 0.5-2 hours at the temperature of 1100-1300 DEG C, and carrying out copper infiltration. The preparation method has the advantages that the mechanical and frictional wear properties of the material are improved on the premise that the high conductivity of the composite material is guaranteed; and requirement on equipment is low, the process is simple, and process conditions are easy to control.

Owner:CENT SOUTH UNIV +1

Method for preparing high-purity molybdenum trioxide

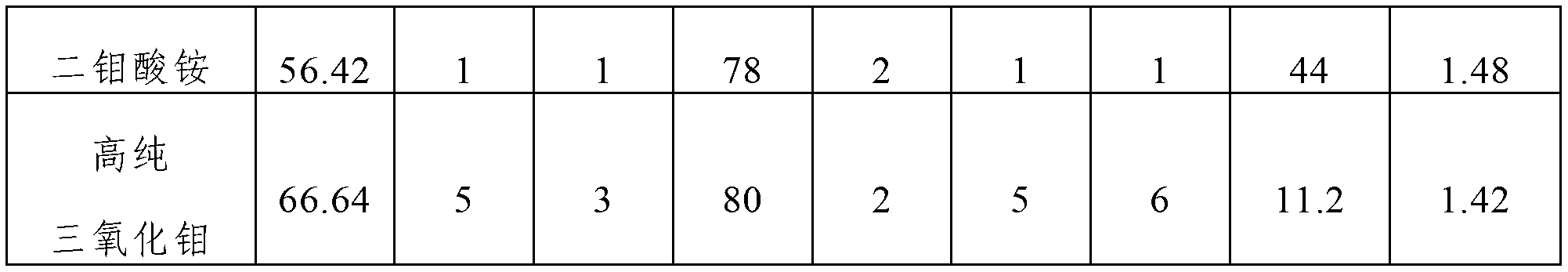

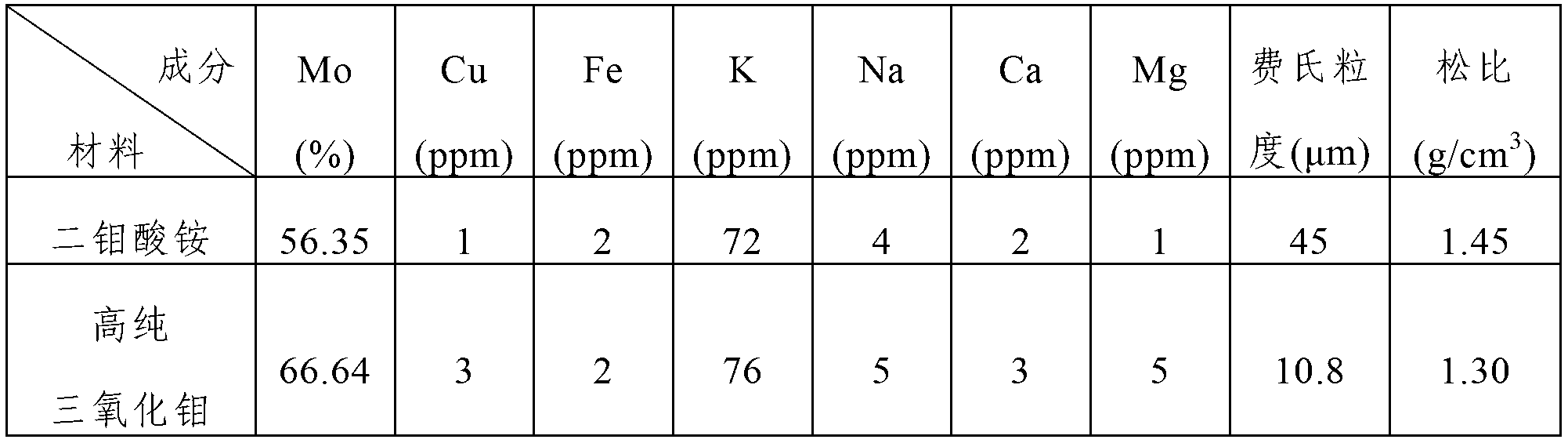

ActiveCN103194624AUniform particle size distributionQuality improvementChemical industryFree cooling

The invention provides a method for preparing high-purity molybdenum trioxide. The method comprises the steps that 1) ammonium dimolybdate is screened; 2) the screened ammonium dimolybdate is put into a muffle furnace and precalcined by heat insulation for 1-1.5 hours under the condition of 245-255 DEG C; 3) ammonium dimolybdate is screened by a 20-mesh sieve to obtain screening powders; 4) the screening powders are put in the muffle furnace and calcined by heat insulation for 1.5-2 hours under the condition of 430-460 DEG C, and high-purity molybdenum trioxide with the molybdenum mass content of not less than 66.63 percent is obtained after natural cooling. The method has simple preparation technology, and has high reproducibility; the high-purity molybdenum trioxide prepared according to the method has stable quality, uniform size and high molybdenum content, meets the requirements of molybdenum powders, molybdenum products, molybdenum materials and the like in molybdenum metallurgy and molybdenum chemical industry; and the method is suitable for large-scale industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

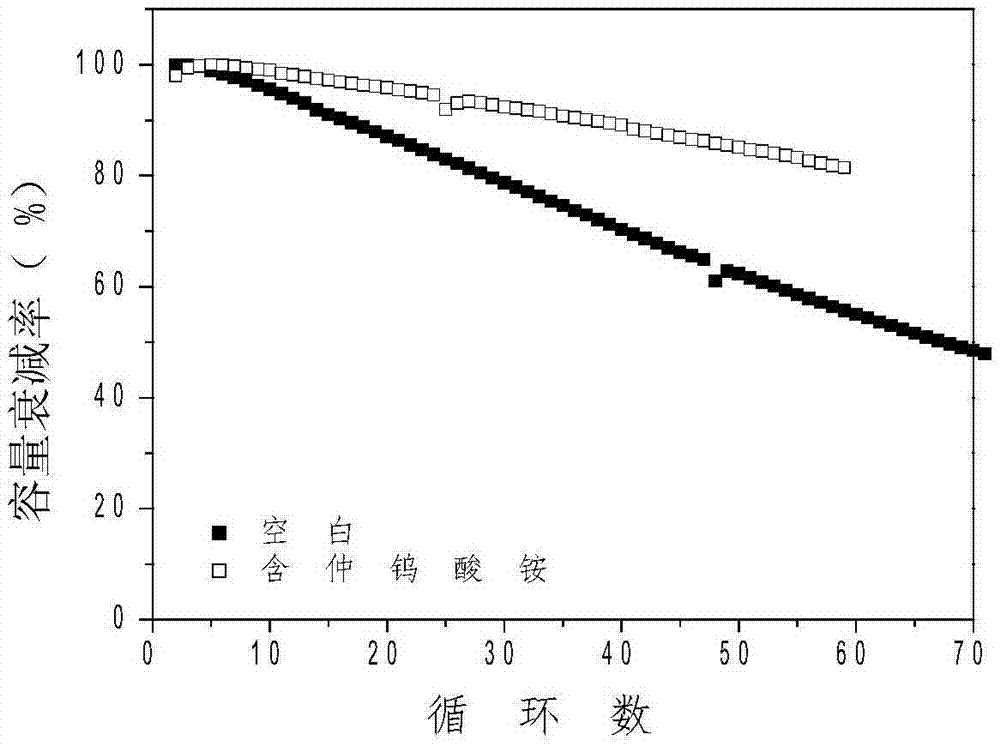

All-vanadium redox flow battery cathode electrolyte containing additive

ActiveCN106876767AImprove high temperature thermal stabilityImprove coordination environmentCell electrodesRegenerative fuel cellsTungstateAmmonium paratungstate

The invention relates to an all-vanadium redox flow battery cathode electrolyte containing additive. The additive is one or more than two of ammonium tungstate, ammonium molybdate, ammonium niobate, ammonium tantalite, ammonium paratungstate, ammonium paramolybdate, ammonium paraniobate, ammonium metatungstate, ammonium metamolybdate, ammonium metaniobate, ammonium dimolybdate, ammonium tetramolybdate and ammonium fluoroniobate. The concentration of the additive is 0.01mol / L-0.5mol / L. According to the electrolyte, salt is taken as the cathode electrolyte additive, so the capacity fading problem generated when a battery operates under a high temperature condition can be effectively suppressed, and the stable operation of the battery is realized. The electrolyte is simple in preparation technology operation and low in cost, is energy-saving and environment-protective and can operate in the battery stably.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Production technology of non agglomeration state ammonium dimolybedate

The production process of ammonium dimolybdate of non-agglomeration state comprises 1) preparing ammonium molybdate solution, and then adding the solution into evaporation crystallization kettle, heating to boiling and continuing to heat; 2)adding minicrystal of ammonium dimolybdate when the PH of ammonium molybdate solution is 6.9-7.5; 3)determining vaporization rate curve; 4) crystal growth; 5) filtering, drying at 100-110 degree. The invention solve the techinical problems such as bad phsical index of background techinic and bad product performance. The crystallization course is improved and fine controled to improve the crystallographic form and grain size of ammonium dimolybdate. The original agglomeration state is changed into single crystal of non-agglomeration state to make the process of product and handling property good. The improvement of the crystallographic form and grain size of ammonium dimolybdate can be realized by adding crystal seed, eliminating cryptomere, controling vaporization rate to make the physical property index achieve to advanced world standard.

Owner:JINDUICHENG MOLYBDENUM GROUP CO LTD

A kind of method of producing high solubility ammonium heptamolybdate

The invention discloses a method for producing high-solubility ammonium heptamolybdate. The method comprises the following steps of: in a sealed reaction kettle, dissolving ammonium tetramolybdate or ammonium dimolybdate in ammonia water with concentration of 14%-16%, and applying a certain gas pressure during dissolving; then, filtering and cooling liquor, carrying out high-speed centrifugal dehydration while cooling to 18-20 DEG C to obtain granulate ammonium heptamolybdate crystals; finally, drying. Compared with the existing production technology, environmental pollution is reduced as the method is carried out in the sealed reaction kettle; during dissolving, quality of ammonium heptamolybdate is improved by applying a certain pressure, so that produced ammonium heptamolybdate has solubility of over 80g. Meanwhile, when ammonium heptamolybdate is dissolved in water, light transmittance can reach 95% that of the pure water. Finally, ammonium heptamolybdate produced by the method disclosed by the invention does not need a crushing step, so that production efficiency is improved.

Owner:JIANGSU DONGTAI FENGFENG TUNGSTEN & MOLYBDENUM MATERIAL

Method for crystallizing ammonium molybdate

InactiveCN110127761AEliminate the conversion preparation processReduce process stepsMolybdeum compoundsEvaporationIon-exchange resin

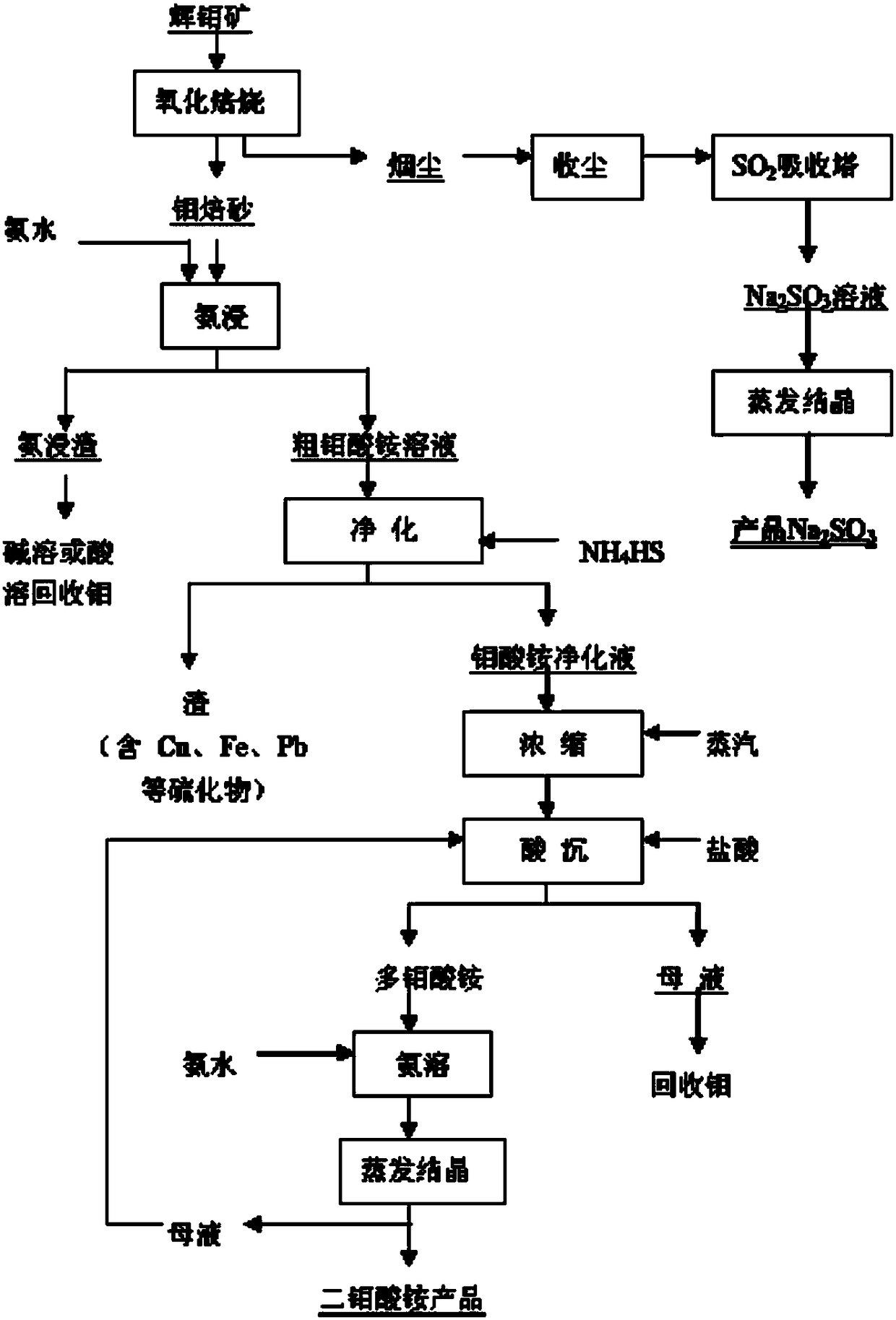

A method for crystallizing ammonium molybdate relates to that field of ammonium molybdate preparation, in particular comprises the follow steps: ammonia leaching is carried out after molybdenum calcine is pickled to obtain ammonia leaching solution; ammonia leaching solution enters into a cationic exchange resin to remove calcium, magnesium, aluminum, iron and copper and other metal ions; the treated liquid enters a cross-flow three-effect evaporation crystallization system and crystallizes continuously to obtain ammonium dimolybdate; centrifugal drying and screening are performed to obtain ammonium dimolybdate finished product. The ammonium molybdate crystallization method uses the ion exchange resin to remove impurity from ammonia leaching solution, the liquid directly enters the evaporation crystallization system, continuously crystallizes to obtain ammonium dimolybdate product, eliminates the acid precipitation crystallization step in the traditional process, simplifies the processflow, simultaneously reduces the use of acid solution, reduces the environmental pollution, and uses the ion exchange resin impurity removing step to compound the evaporation crystallization purification step to obtain the product with high purity.

Owner:安庆市月铜钼业有限公司

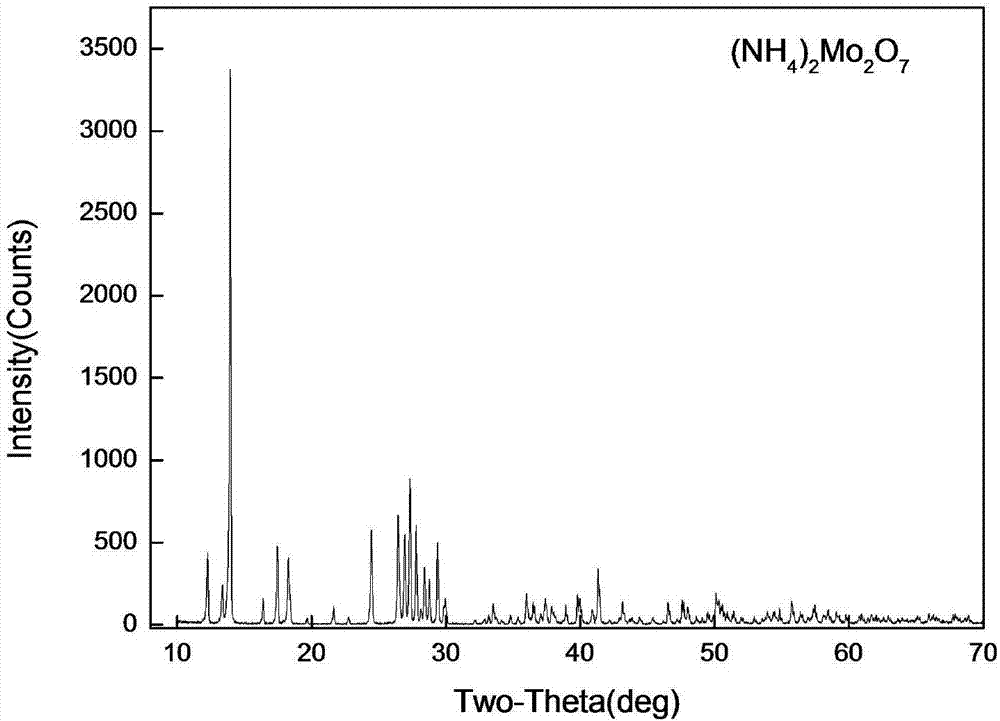

Preparation method of ammonium dimolybdate

The invention provides a preparation method of ammonium dimolybdate. The preparation method comprises the following step of carrying out complex decomposition reaction on a molybdenum source and an ammonium source to obtain the ammonium dimolybdate. According to the preparation method, ammonium tetramolybdate and / or molybdic acid is used as the molybdenum source and one or more of ammonia water, ammonium hydrogen carbonate and ammonium carbonate are used as the ammonium source; a lot of solvents and water are not needed so that the preparation method is environmentally friendly and economical. The result of the embodiment shows that the preparation method provided by the invention can be used for successfully preparing the ammonium dimolybdate and the purity of the ammonium dimolybdate is more than 99 percent.

Owner:CENT SOUTH UNIV

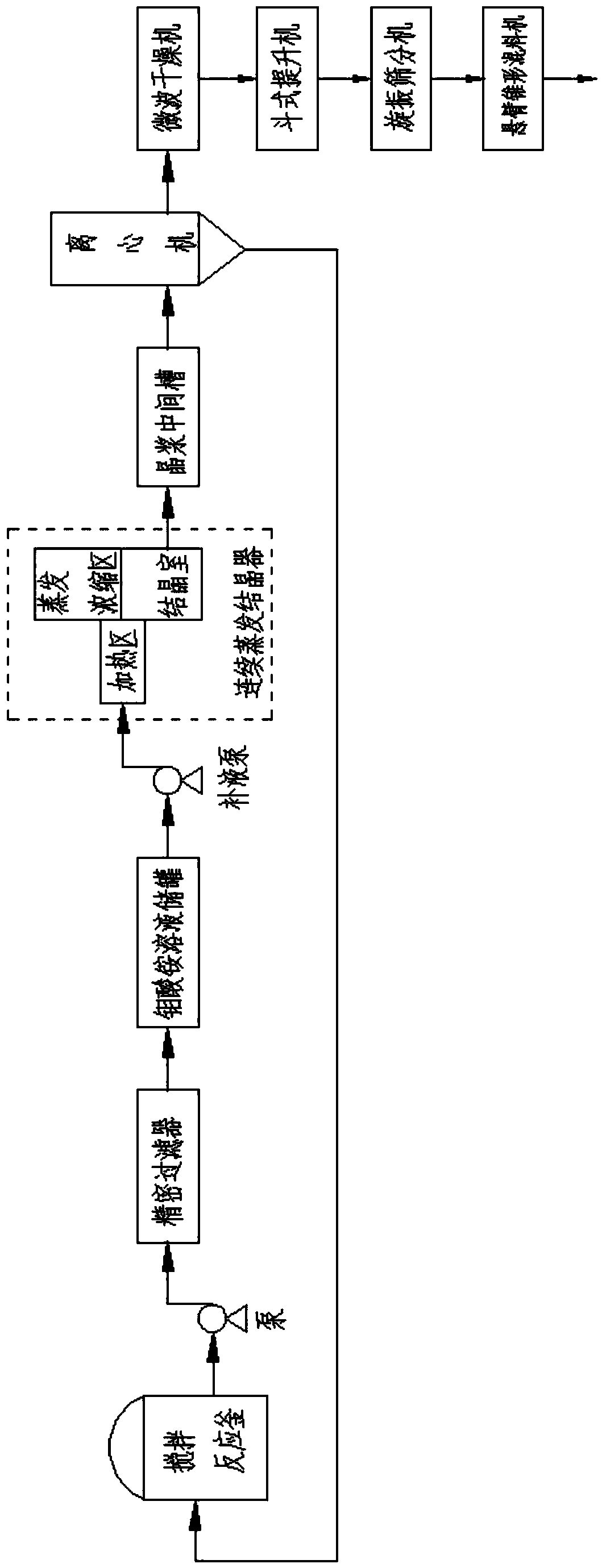

Process for preparing ammonium dimolybdate crystal by using sulfuric acid and molybdenum calcine

InactiveCN102417207AThe preparation process is continuousSimple manufacturing processMolybdeum compoundsFiltrationMetal impurities

The invention provides a process for preparing ammonium dimolybdate crystal by using sulfuric acid and molybdenum calcine. The method comprises steps of: (1) mixing molybdenum calcine, ammonium sulfate, ammonium persulfate and water and carrying out a pretreatment by sulfuric acid; (2) carrying out ammonia leaching by ammoniacal liquor to obtain an ammonium molybdate solution; (3) adding ammoniumsulphide for purification and removing metal impurity ions in the ammonium molybdate solution; (4) evaporating, concentrating and crystallizing a clean fluid to a certain solution proportion and pH value, adding ammoniacal liquor, regulating and control quantity of nucleus to promote crystal growth, carrying out hot pumping filtration and drying to obtain the ammonium dimolybdate crystal. The invention has continuous technology, simple process, and increased efficiency and needs no seed addition; nitric acid is substituted by sulfuric acid to lower cost; a product crystal has an average Fsss of 337 mum, an average particle size distribution d0.5 of 412 mum and an average loose specific weight of 1.329g.cm<-3>.

Owner:HENAN UNIV OF SCI & TECH

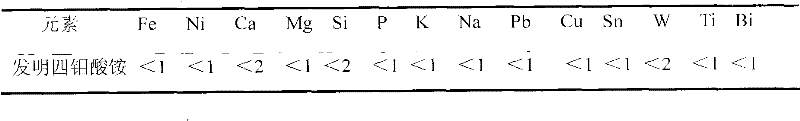

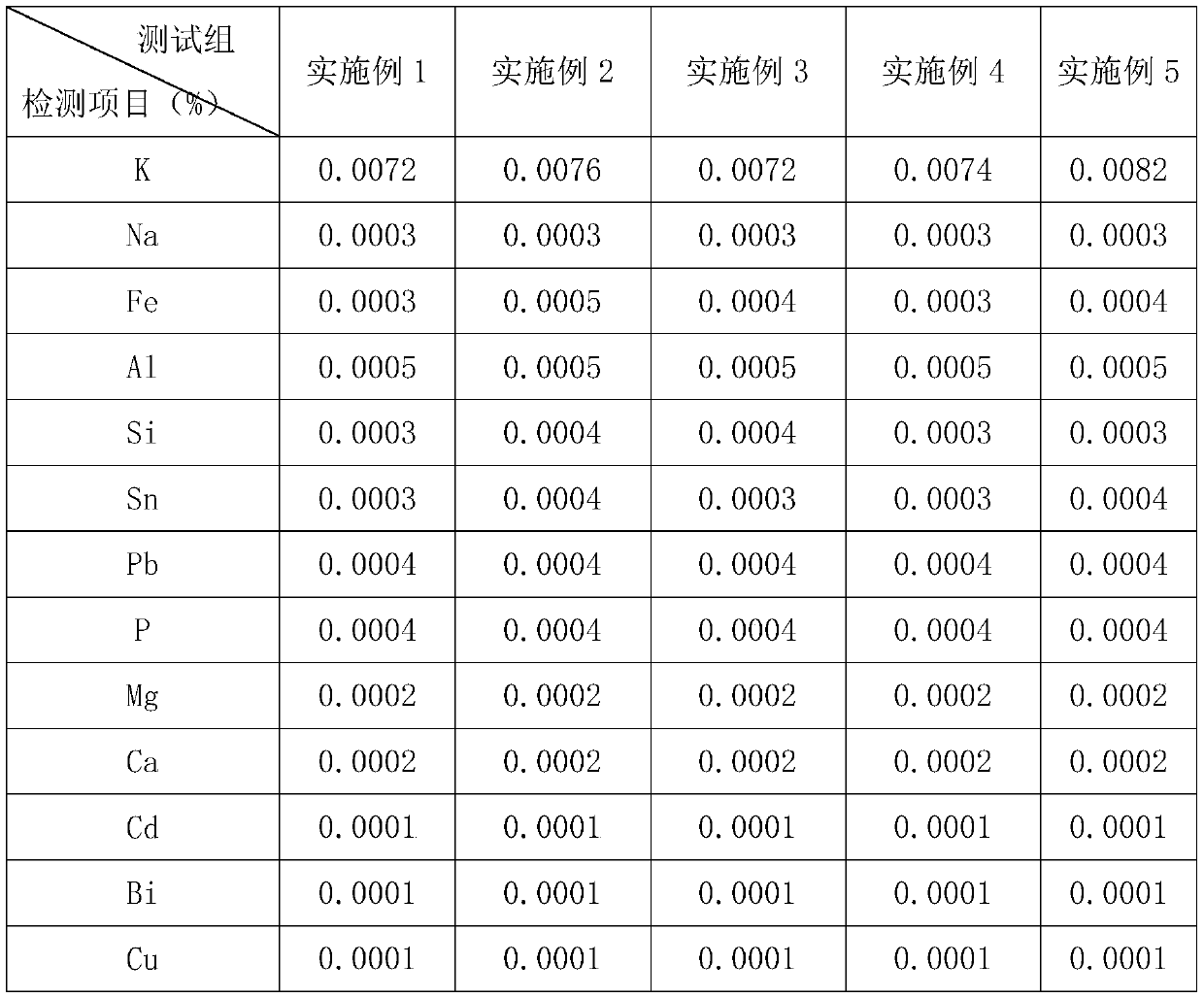

Preparation method for ultrapure ammonium molybdate

The invention provides a preparation method for ultrapure ammonium molybdate. The method comprises the following steps of: adding pure water and liquid ammonia (or ammonia water) into molybdenum oxide, ammonium dimolybdate, ammonium tetramolybdate, ammonium polymolybdate and the like serving as raw materials, dissolving ammonia at the normal temperature and stirring for uniformly mixing; extracting and purifying with a special extracting agent, and adding a super acid under the normal pressure for performing acid precipitation and crystallization; performing solid-liquid separation after acid precipitation is completed; and drying the separated ammonium molybdate till the moisture in the ammonium molybdate is lowered to be less than or equal to 1.0 g / cm<3>, wherein during ammonia dissolving burdening, the concentration of molybdenum ions in a solution main body is controlled at 50-200 g / L, and the pH is kept at 7.0-10.0; acid precipitation is performed after extraction and purification with the special extracting agent; and the pH of an acid precipitation end point is controlled at 4.5-6.5. Due to the adoption of the preparation method, the purity of an ammonium molybdate product is greatly increased, surpasses the first class of the national standard of ammonium molybdate, and meets the index requirements of the electronics industry and the catalyst industry. The preparation method disclosed by the invention is easy to operate, novel equipment is not required to be provided, the quality of the obtained ammonium molybdate product is stable, and the crystallization rate can be over 97 percent.

Owner:范传景

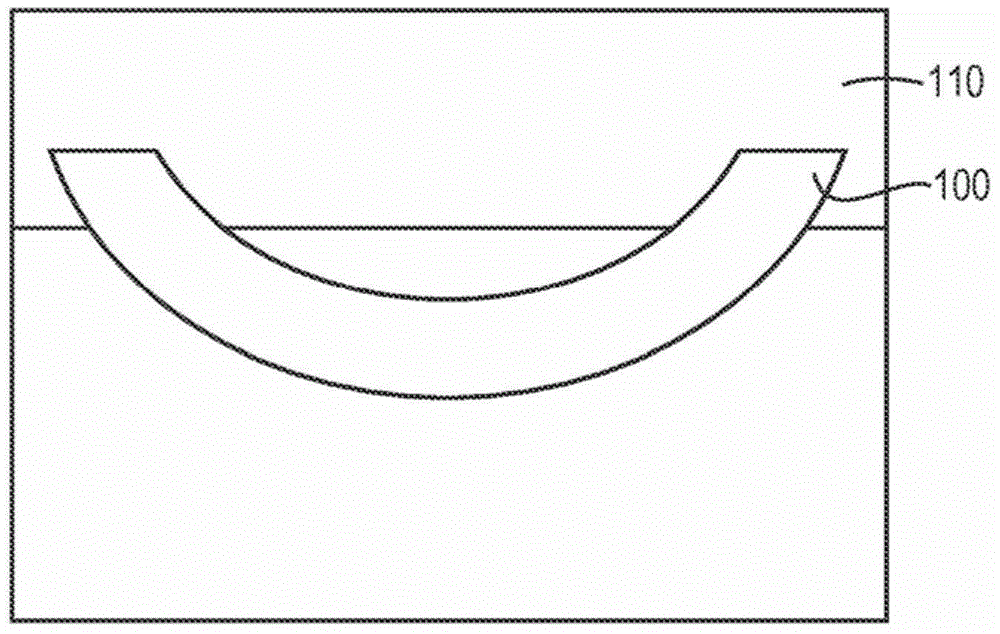

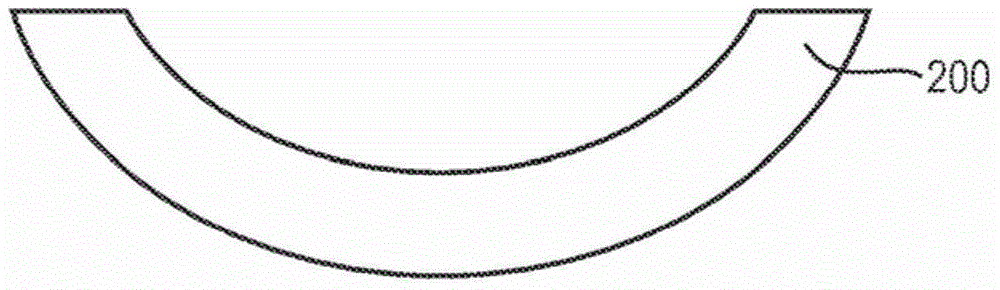

Metallic crucibles and methods of forming the same

In various embodiments, a precursor powder is pressed into an intermediate volume and chemically reduced, via sintering, to form a metallic shaped article. In a further embodiment the invention concerns a method of fabricating a shaped article having a target set of final dimensions and consisting essentially of molybdenum, the method comprising the pressing of an ammonium-based molybdenum-precursor powder, in particular ammonium dimolybdate, and a stepwise sintering process, defining four different temperature levels. In a further aspect, embodiments of the invention feature a method of treating a shaped article. An additive is disposed on at least one surface of a shaped article including or consisting essentially of one or more metals. In yet a further aspect, embodiments of the invention feature a crucible that includes or consists essentially of an inner layer consisting essentially of an alloy of molybdenum and tungsten, an outer layer consisting essentially of molybdenum, and therebetween, a zone consisting essentially of a graded concentration of molybdenum and tungsten.

Owner:H C STARCK GMBH +2

Production process of ammonium molybdate

InactiveCN112607777AHigh yieldEmission reductionMolybdeum compounds preparationSodium molybdateMolybdic acid

The invention discloses a production process of ammonium molybdate, which relates to the technical field of ammonium molybdate production, and comprises the following steps: (1) washing and filter-pressing molybdenum calcine, mixing the filter-pressed molybdenum calcine with a leaching agent, adjusting the pH value to 10-11.5, and keeping the temperature for 2-3 hours under the conditions of oxygen partial pressure of 20 atm and temperature of 150-170 DEG C to obtain a sodium molybdate solution; (2) adding quaternary ammonium salt into the ammonium molybdate solution, extracting molybdenum under an alkaline condition, and adding ammonium bicarbonate into the extracting solution to obtain an ammonium molybdate solution; (3) adding calcium oxide into the extracting solution; (4) evaporating and crystallizing the ammonium molybdate solution to obtain ammonium dimolybdate; and (5) adding acid into the crystallization mother liquor after the ammonium dimolybdate is prepared for precipitation to obtain ammonium tetramolybdate, adjusting the pH value of the ammonium tetramolybdate solution to 1.5-2.0 by using nitric acid, and separating out ammonium tetramolybdate crystals. The method has the beneficial effects that the method has the advantages of short process flow, low consumption of chemical reagents and high resource adaptability.

Owner:安庆市月铜钼业有限公司

Method of preparing ammonium dimolybdate from a molybdenum-containing solution

ActiveCN108622938ANo pollution in the processShort processMolybdeum compoundsIon exchangeCrystallization

The invention belongs to the technical field of chemical separation and particularly relates to a method of preparing ammonium dimolybdate from a molybdenum-containing solution. The method includes the steps of: (1) stirring the molybdenum-containing solution and adding ammonium sulfide to regulate the color of the solution from blue into colorless status, and allowing the solution to stand, feeding a supernatant through a paperboard filter to obtain a filtrate, which serves as a raw material for the next acid precipitation step; (2) stirring the filtrate by means of anchor-type blades, addingindustrial concentrated sulfuric acid, regulating pH value to 2.5-2.8, stirring the mixture for 30 min and performing ion exchange column adsorption to prepare crude ammonium tetramolybdate; (3) heating pure water to boiling, adding the crude ammonium tetramolybdate, regulating the pH value to 6.5-7.0, filtering the liquid while hot, feeding a filtrate into a crystallization kettle, performing vacuum evaporation concentration, and filtering the liquid when 55% of water is evaporated, feeding a mother liquid to the step (2) for acid precipitation again, and drying crystals to prepare ammoniumdimolybdate. The method is short in process and low in cost, is high in recovery rate, is free of environmental pollution, and is far better than other preparation processes of ammonium dimolybdate.

Owner:安徽华西稀有金属材料有限公司

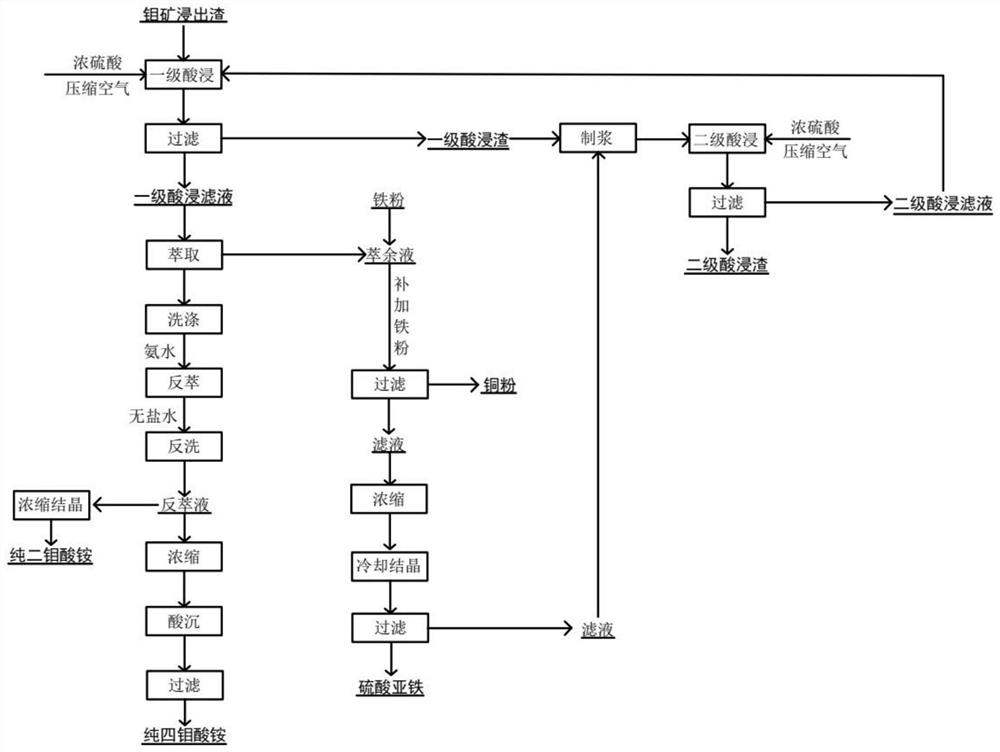

Molybdenum ore leaching residue comprehensive utilization process

ActiveCN112831660AImprove leaching rateShort processAlkaline-earth metal silicatesIron sulfatesMining engineeringSulfate

The invention provides a molybdenum ore leaching residue comprehensive utilization process. According to the molybdenum ore leaching residue comprehensive utilization process, sulfuric acid is used as a leaching agent, a two-stage countercurrent leaching mode is adopted, the fact that the leaching rates of molybdenum and iron are both higher than 98% is realized, the leaching rate of copper is higher than 75%, and a wollastonite byproduct is produced; molybdenum is extracted from an acid leaching solution by extracting, and reverse extraction with ammonia water is performed to finally obtain a pure ammonium tetramolybdate or ammonium dimolybdate product; and iron and copper in raffinate are separated to respectively obtain elemental copper and ferrous sulfate. By means of the molybdenum ore leaching residue comprehensive utilization process, waste residue cyclic utilization is realized, existing resources are further recycled, pollution of valuable metal to the environment is also avoided, and the molybdenum ore leaching residue comprehensive utilization process is safer and more environmentally friendly; and meanwhile, the molybdenum ore leaching residue comprehensive utilization process is simple in principle, reasonable in process, high in yield and product grade and low in cost.

Owner:成都虹波钼业有限责任公司 +1

Method for preparing molybdenum alloy powder containing nano rare-earth oxides

The invention discloses a preparation method of molybdenum alloy powder containing nanometer rare earth oxides. The method uses rare earth ammonium dimolybdate crystals as the material, and adopts the methods of roasting and hydrogen reduction to produce powder mixture containing nanoscale rare earth oxides and molybdenum metal, wherein, the scale range of the rare earth oxides in the molybdenum alloy powder is from 30 to 80 nanometers, and the rare earth oxides are all evenly dispersed on molybdenum powder matrix; the molybdenum granules are very fine, wherein, the Fisher particle size of the crystals is 1.0 to 4.0 um. The invention to prepare molybdenum alloy powder containing nanometer rare earth oxides has the characteristics of simple structure, low cost, small particle size and evendistribution of the rare earth oxides, etc, and ensures the high strength and high flexibility of the molybdenum alloy material prepared in the method.

Owner:临沂明华管业有限公司

a zro 2 Ceramic particle reinforced molybdenum-based composite material and preparation method thereof

The invention discloses ZrO2 ceramic particle reinforced molybdenum-based composite material and a preparation method thereof. The ZrO2 ceramic particle reinforced molybdenum-based composite material is mainly prepared from the following raw materials by weight: 1-14 parts of zirconium nitrate, 80-92 parts of ammonium dimolybdate and 120-138 parts of citric acid. The ZrO2 ceramic particle reinforced molybdenum-based composite material takes zirconium nitrate, ammonium dimolybdate and citric acid as raw materials; in the obtained molybdenum-based composite material, the particle size of the reinforcement phase ZrO2 ceramic particles is small, the particle size is on a nano or submircro level; the distribution of the ceramic particles is uniform; and the content of impurities is low. The ZrO2 ceramic particle reinforced molybdenum-based composite material has good high-temperature mechanical properties, processability and high usage temperature.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com