Metallic crucibles and methods of forming the same

A metal and non-metal technology, applied in the field of powder metallurgy technology, can solve the problems of expensive toughness, high vapor pressure, pollution of growing sapphire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

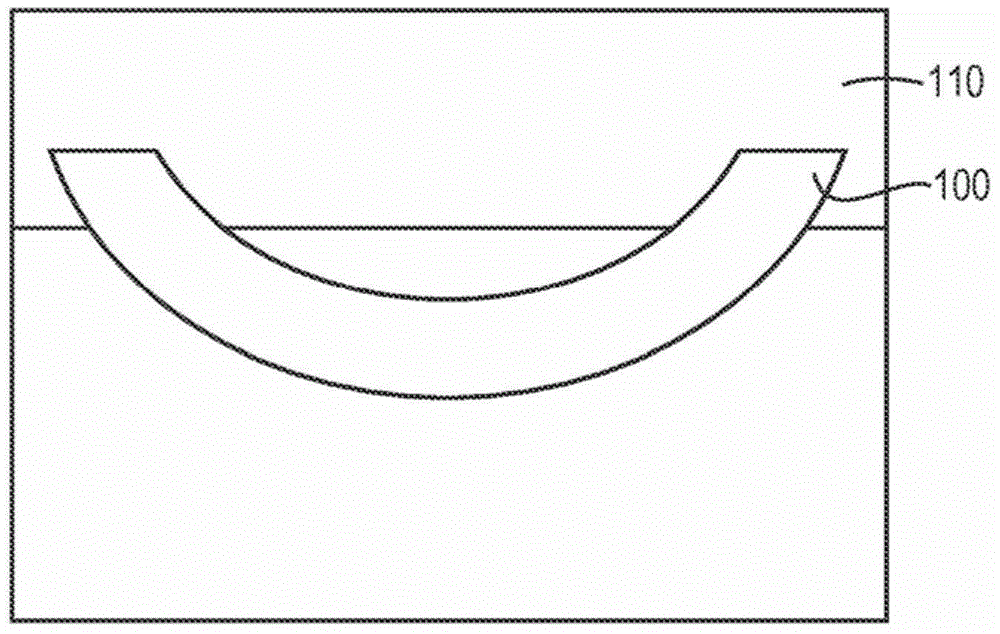

[0027] refer to figure 1 Shown in cross-section, particles of one or more metal precursor powders 100 are collected and pressed into a desired shape (eg, the cup-like shape of a crucible) according to various embodiments of the invention. For example, precursor powder 100 may be cold isostatically pressed into mold 110 . During cold isostatic pressing, mold 110 is generally flexible and fluid pressure (eg, at a level of 15,000 psi to 40,000 psi) is applied to the mold at about room temperature to compress precursor powder 100 into a molded shape. Precursor powder 100 generally includes, or consists essentially of, compounds of, for example, one or more metals (eg, refractory metals such as Mo and / or W), oxygen, and / or other elements. Precursor powder 100 is formed into a shape that generally conforms to an internal shape defined by mold 110 that is generally larger in size than the desired size of the finished article, as embodiments of the present invention allow for sinter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com