Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

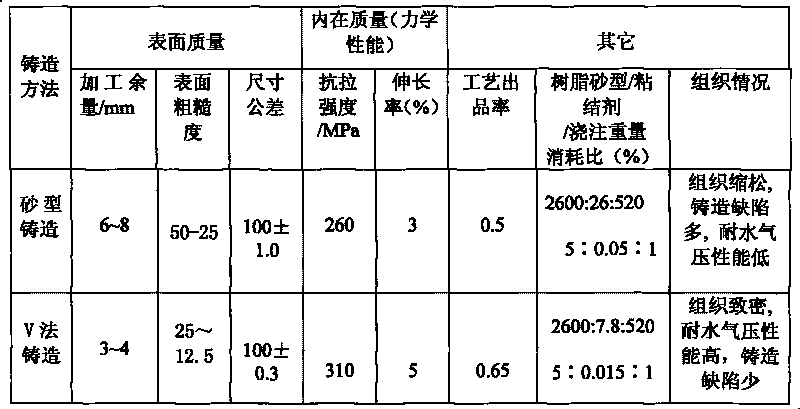

An aluminum alloy tank body and casting production technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., to achieve good economic benefits, reduce cleaning workload, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

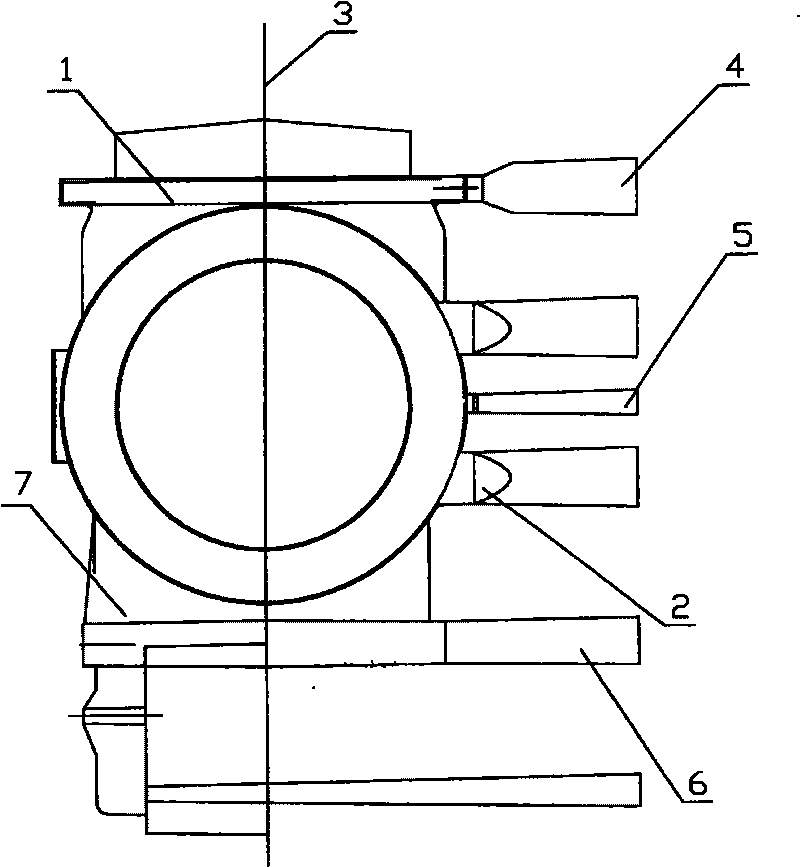

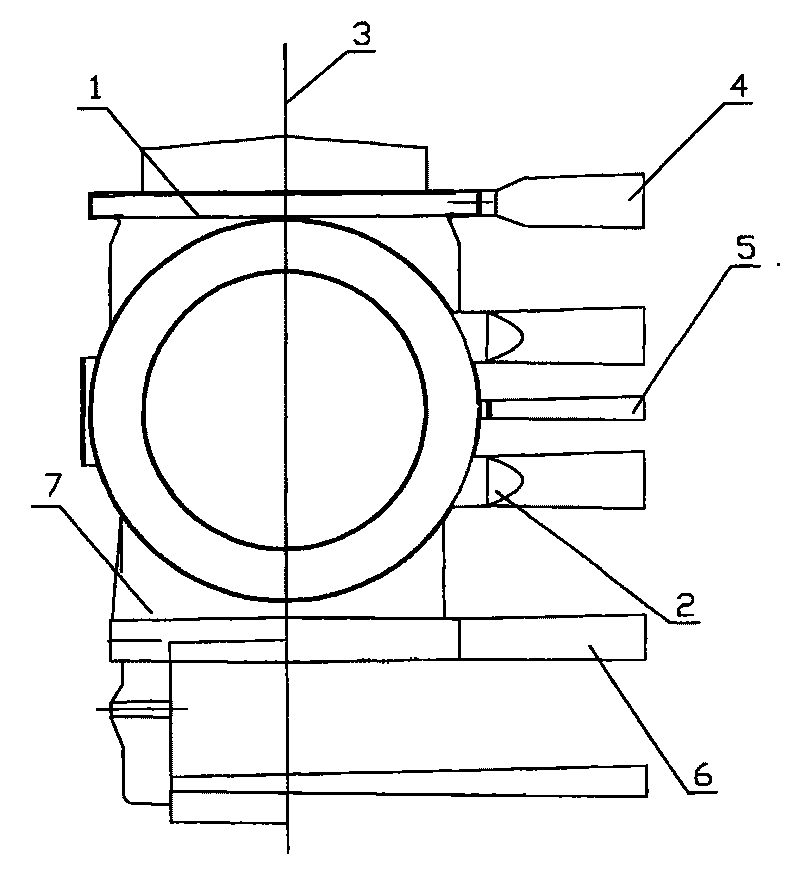

[0028] The method of the present invention will be further described in conjunction with the accompanying drawings.

[0029] The casting system includes an upper mold 2 and a lower mold 1 divided by a parting surface 3 , the upper mold 2 is provided with a stomach 4 , a ventilation hole 5 and a vertical tube 6 ; the lower mold is provided with an ingate 7 . The material of the produced pressure-resistant tank is aluminum alloy ZL101A-T6, the overall size of the tank is 1272mm×862mm×720mm, the weight of the casting is 167kg, and the Ra value of the surface roughness of the inner cavity is required to be no greater than 6.3μm. Design pressure: 0.6Mpa (20°C gauge pressure); withstand pressure: 1.2Mpa (20°C gauge pressure); burst pressure: 3Mpa (20°C gauge pressure); routine test: filled with SF6 or helium 0.4 Mpa (20°C gauge pressure) quantitative leak detection, the air leakage rate is not more than 0.5Pa.cm 3 / 3.

[0030]The size of the casting is large, and the wall thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com