Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20077results about "Foundry patterns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

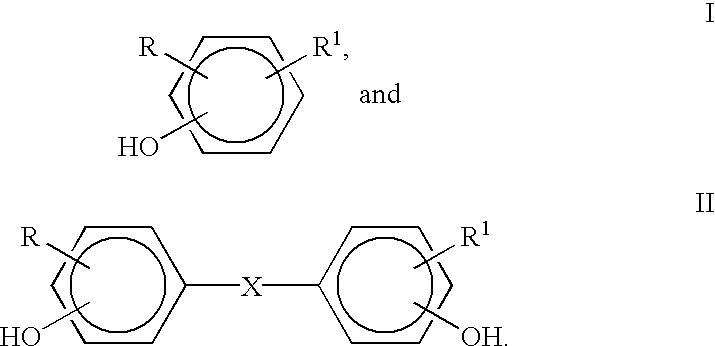

Composite proppant, composite filtration media and methods for making and using same

InactiveUS6632527B1Avoid condensationReduce molecular weightPretreated surfacesGlass/slag layered productsFiberFiltration

Composite particles made of a binder and filler material are provided for use in subterranean formations. The filler is finely divided mineral and optional fiber. The particles are proppants useful to prop open subterranean formation fractures. The particles are also useful for water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.< / PTEXT>

Owner:HEXION INC

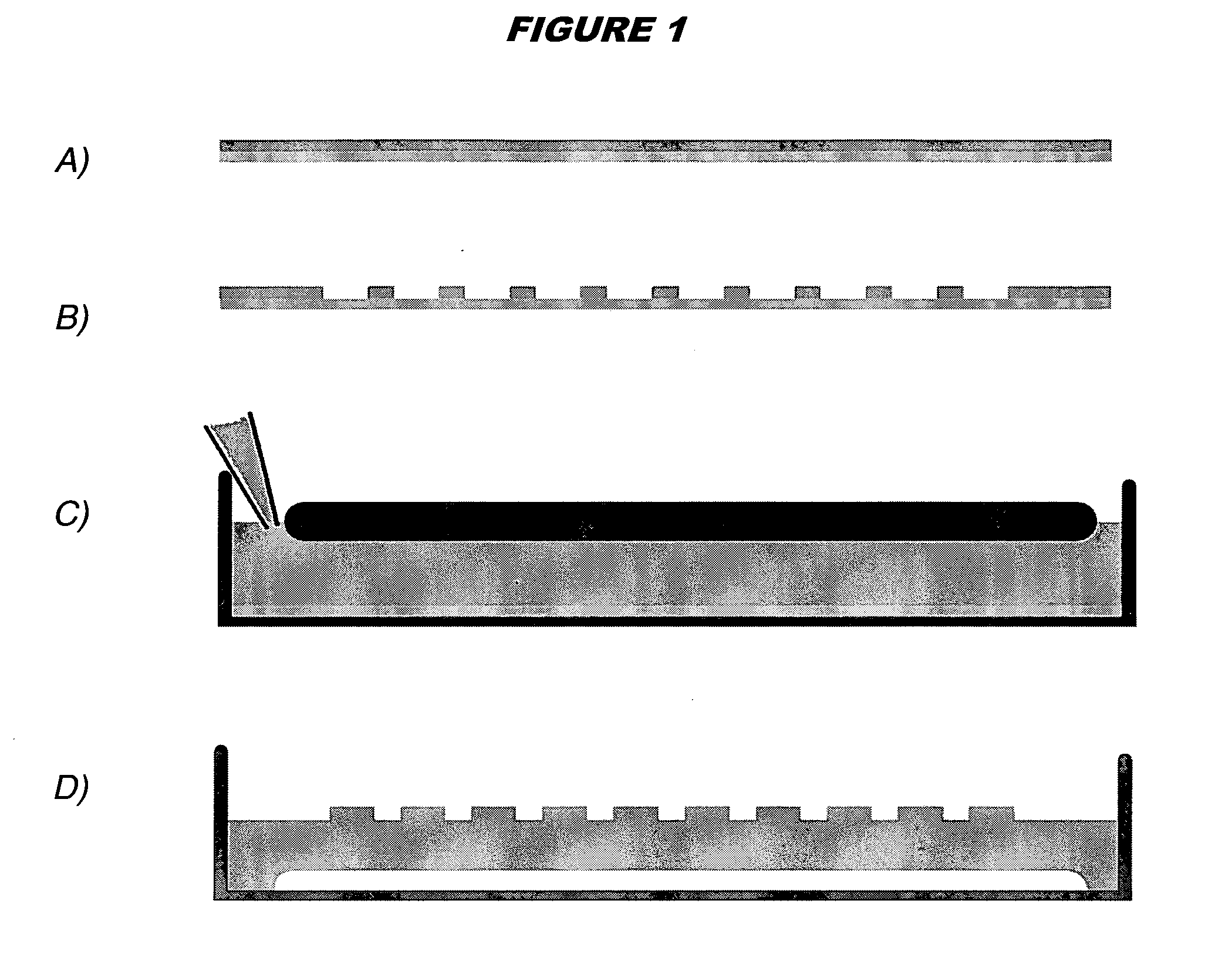

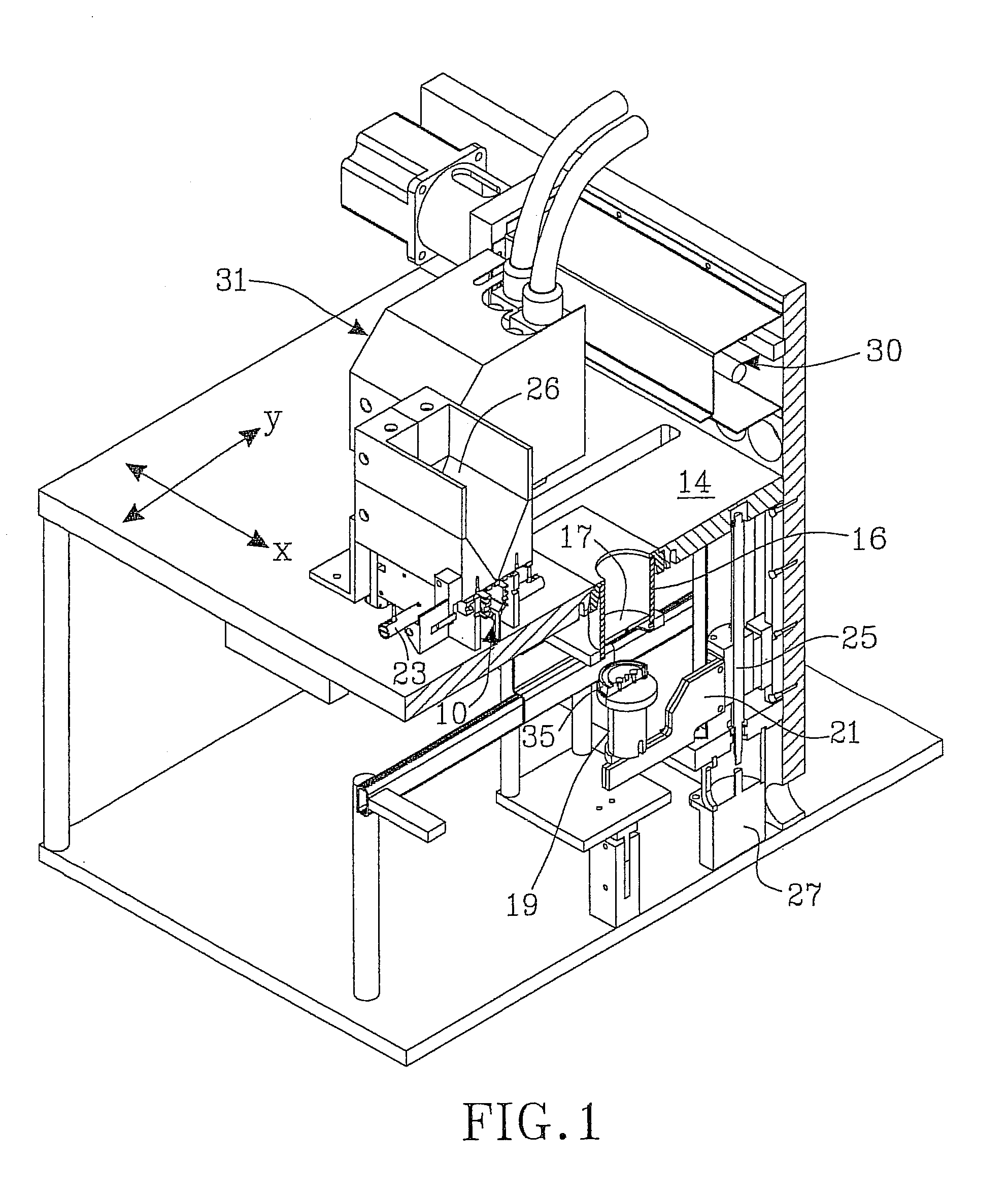

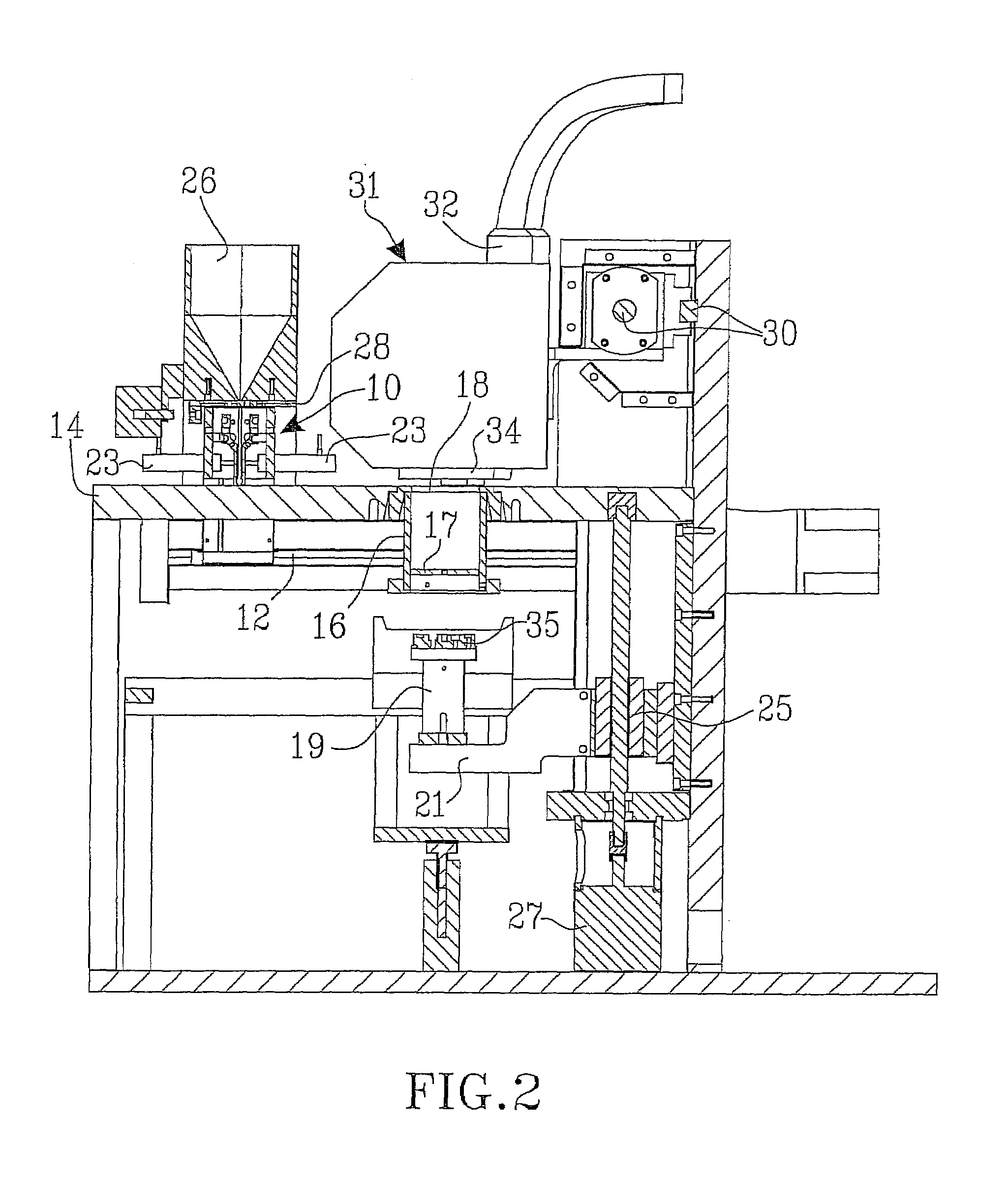

Methods and systems for the manufacture of layered three-dimensional forms

ActiveUS20050017394A1Lower potentialEasy to controlConfectionerySweetmeatsParticulatesBiological activation

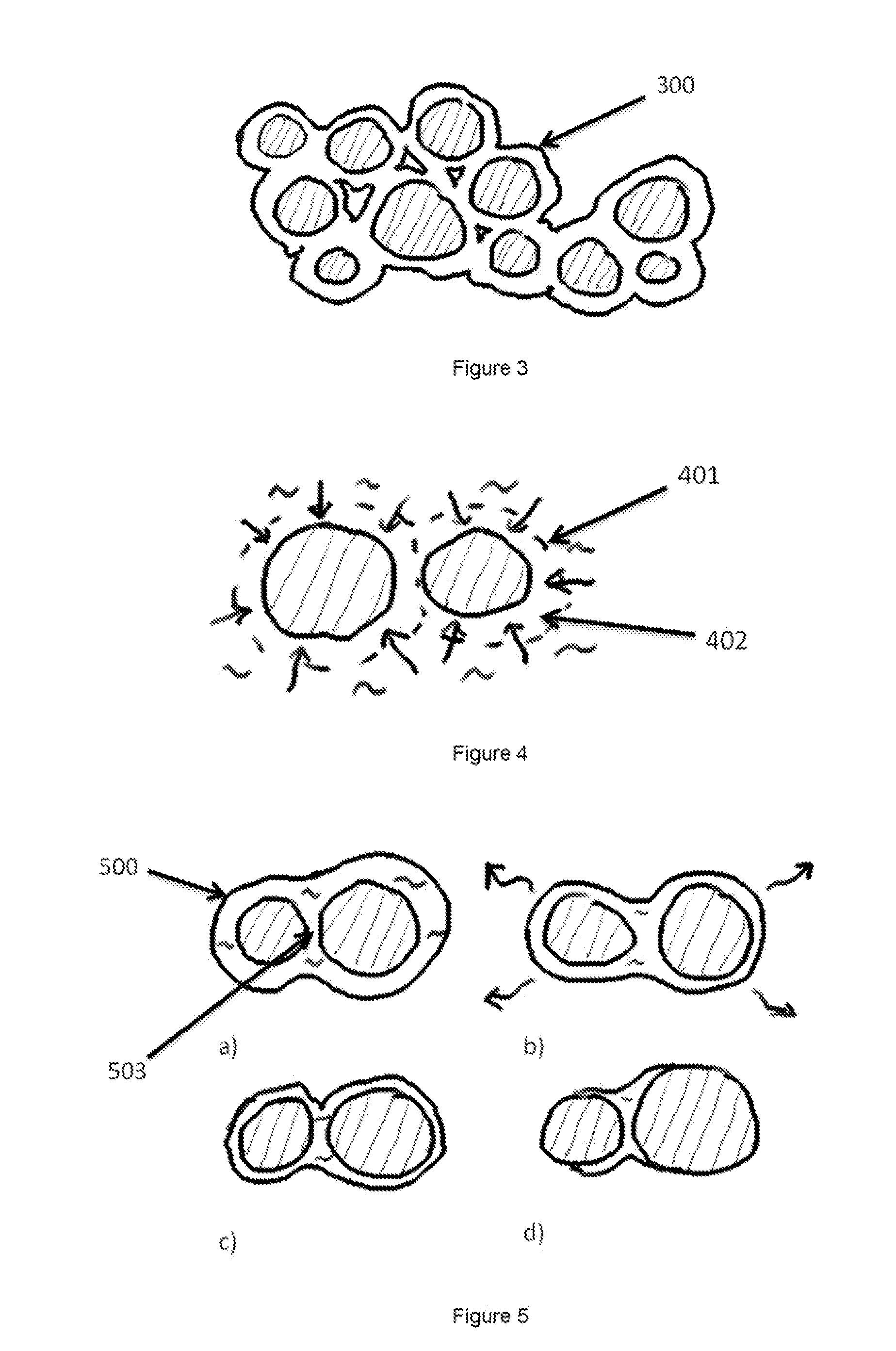

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

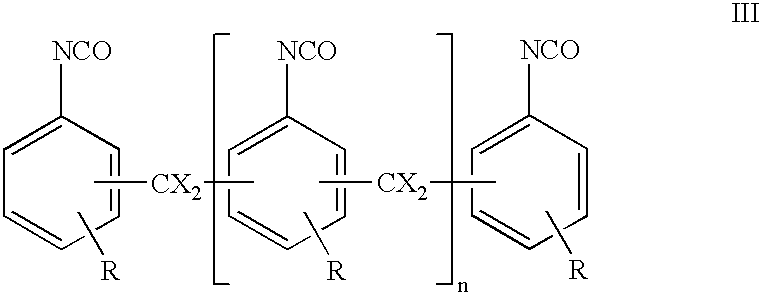

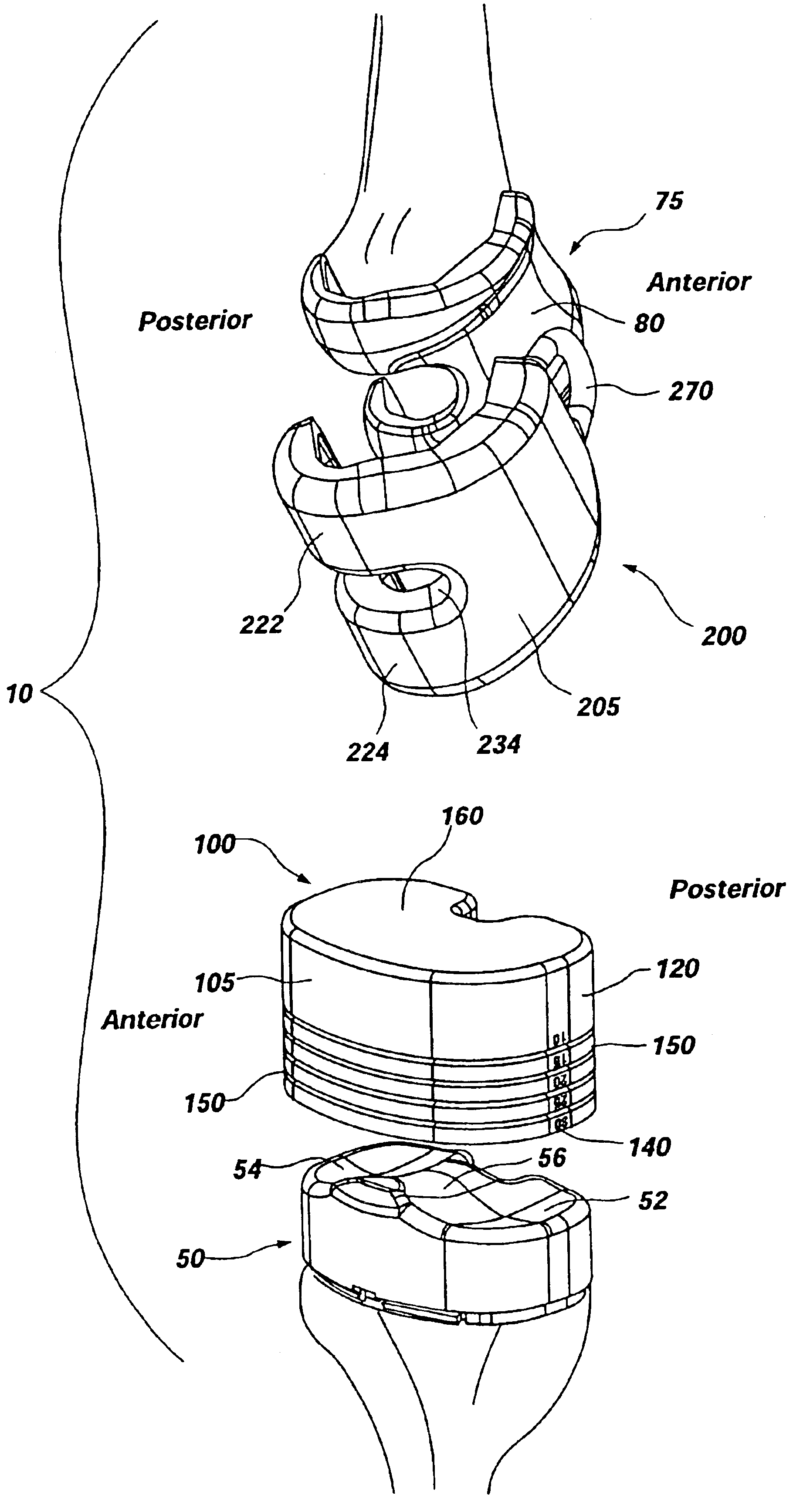

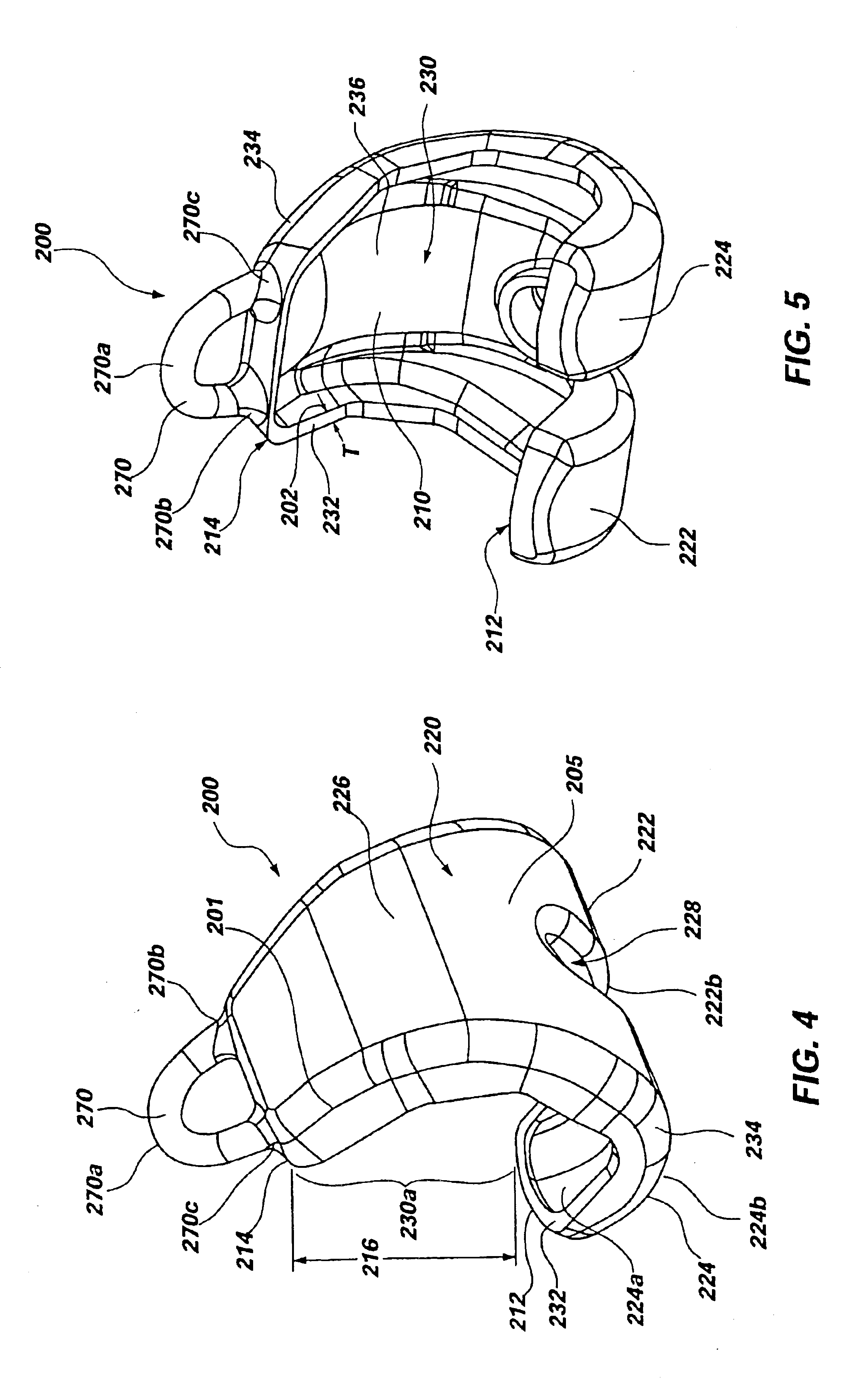

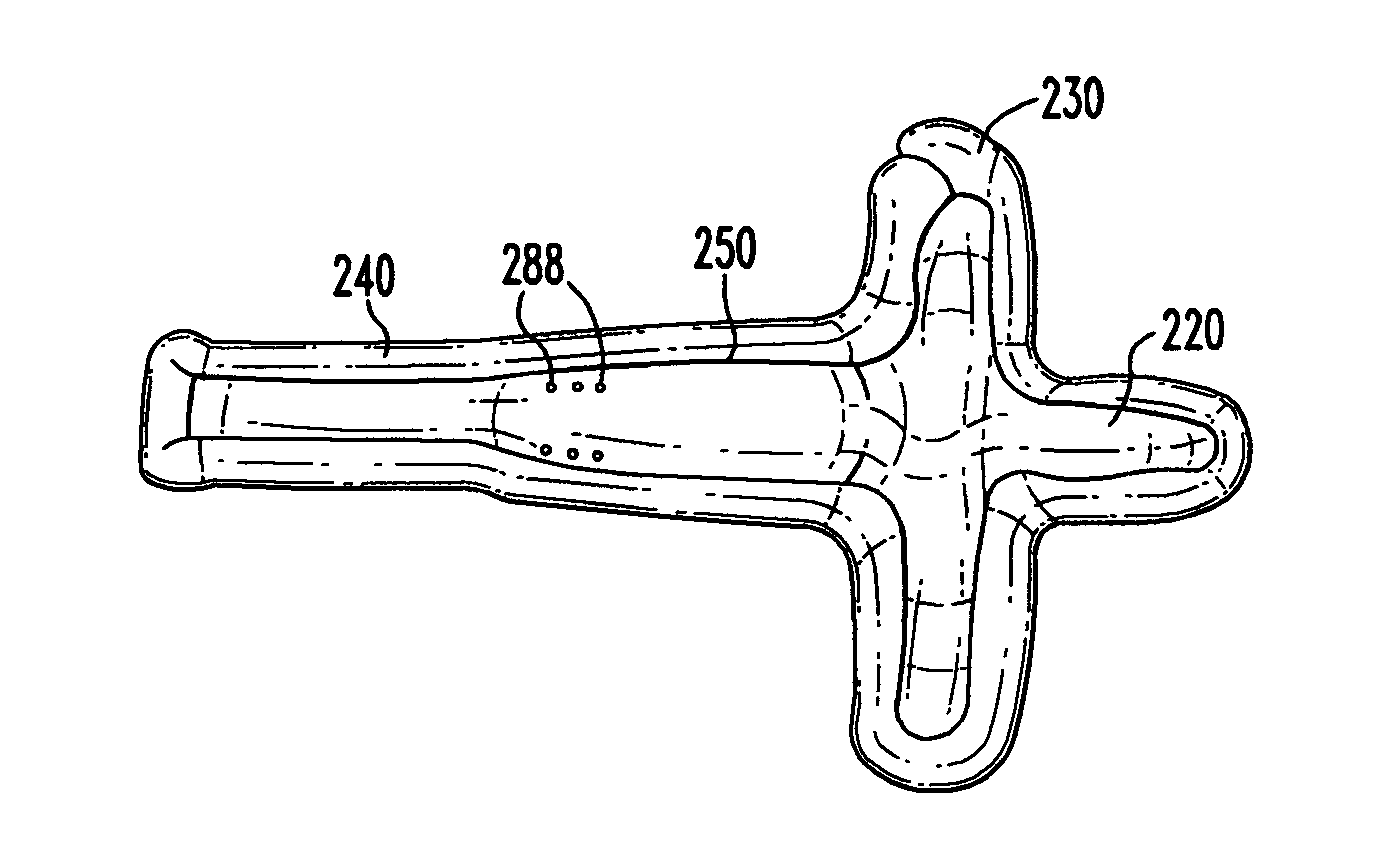

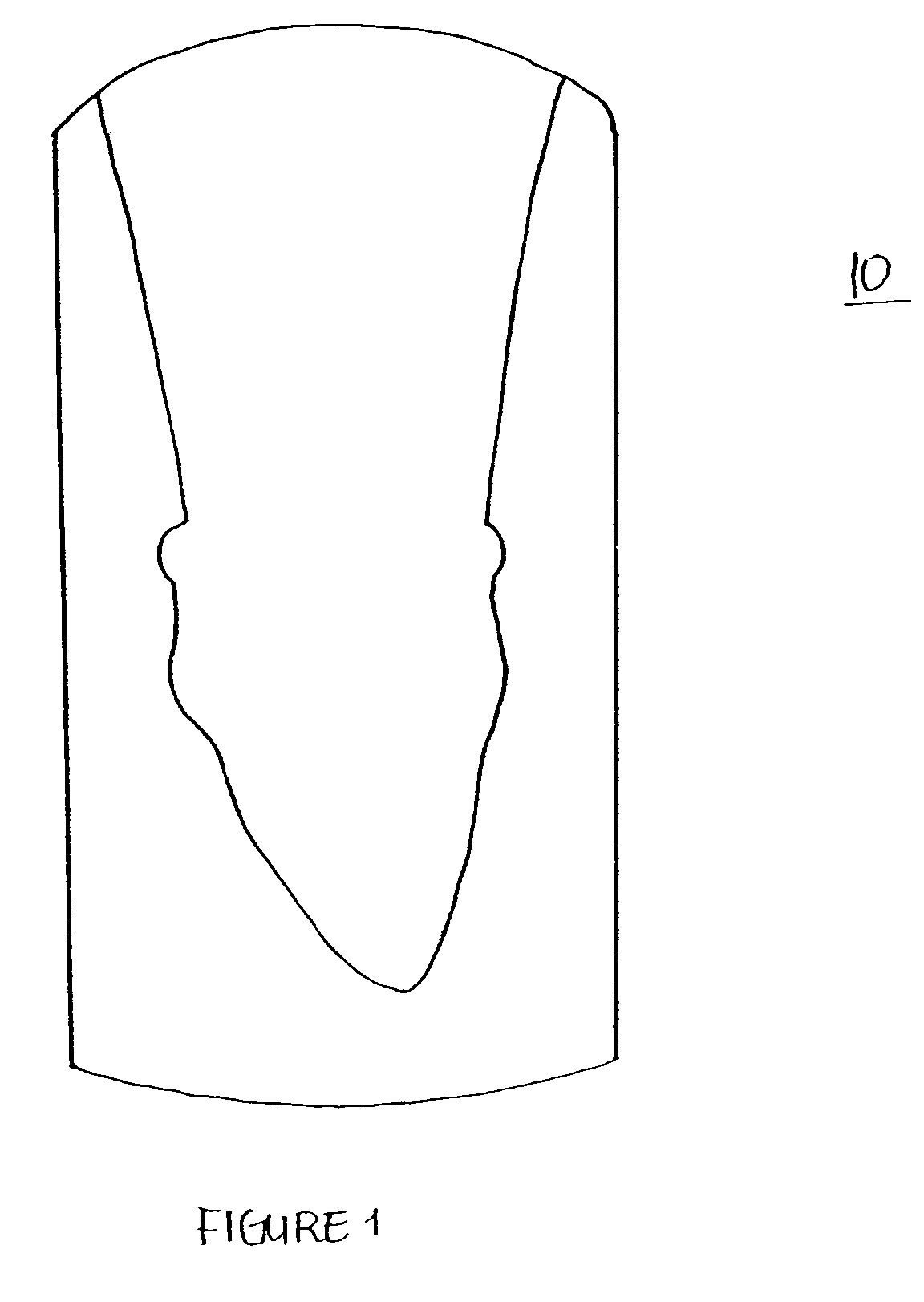

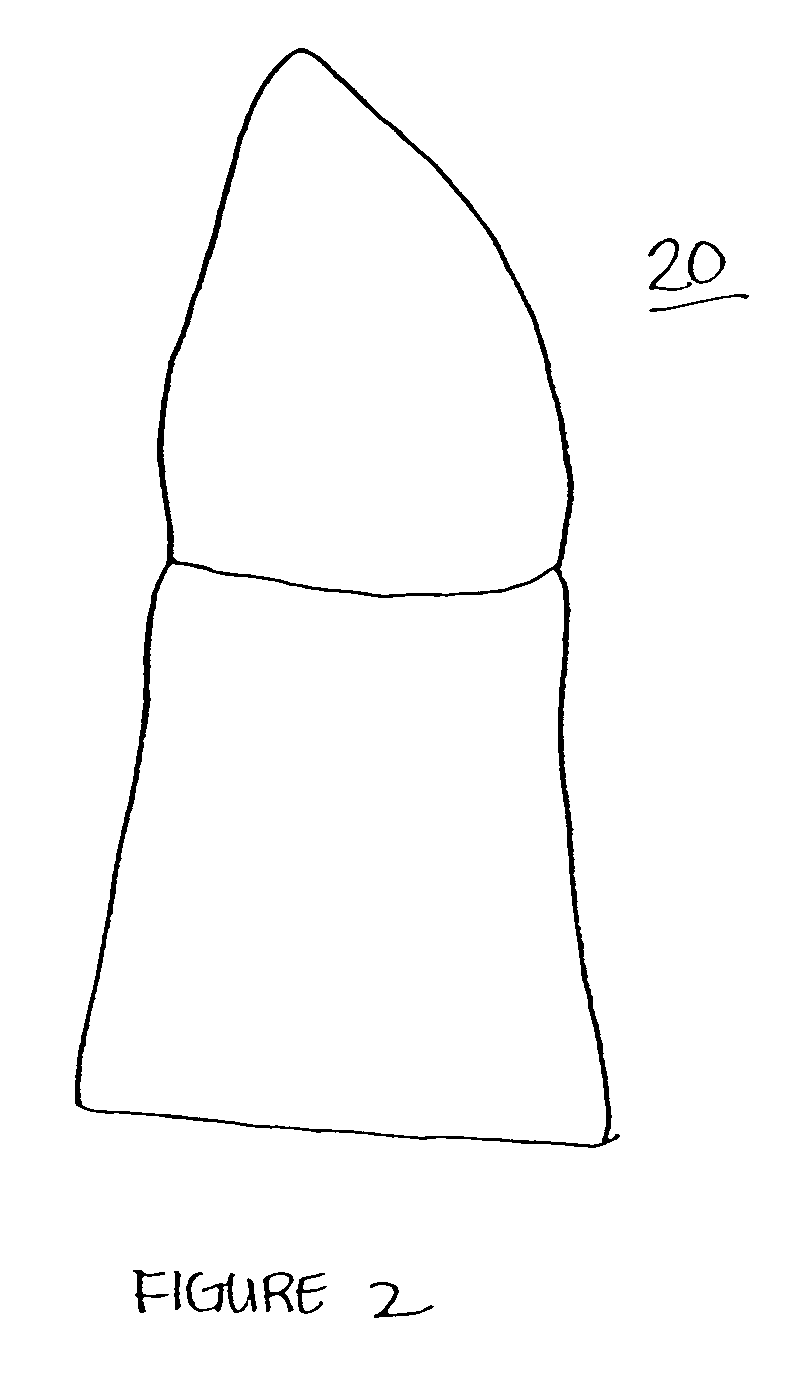

Disposable knee mold

An orthopedic implant device and method is disclosed. Specifically, a knee mold system is disclosed, including elastic tibial and femoral molds, each of which may be configured and dimensioned as a unitary mold for in situ placement during a surgical procedure. Each mold may be manufactured from an elastic material that may be disposable. The tibial mold may further comprise a sidewall forming a cavity, markings for relative depth measurement, and depth rings for use as a guide for scoring, cutting, and / or trimming and tearing away an excess portion of the tibial mold. The femoral mold may further comprise a sidewall defining a cavity, two legs extending from a body of the femoral mold for forming the artificial condyles, and an eyelet for aiding in placement and removal of the femoral mold. The resulting prosthetic tibial and femoral components may form an articulation surface that mimics, at least in part, the natural articulation surface of the knee.

Owner:ORTHO DEV CORP

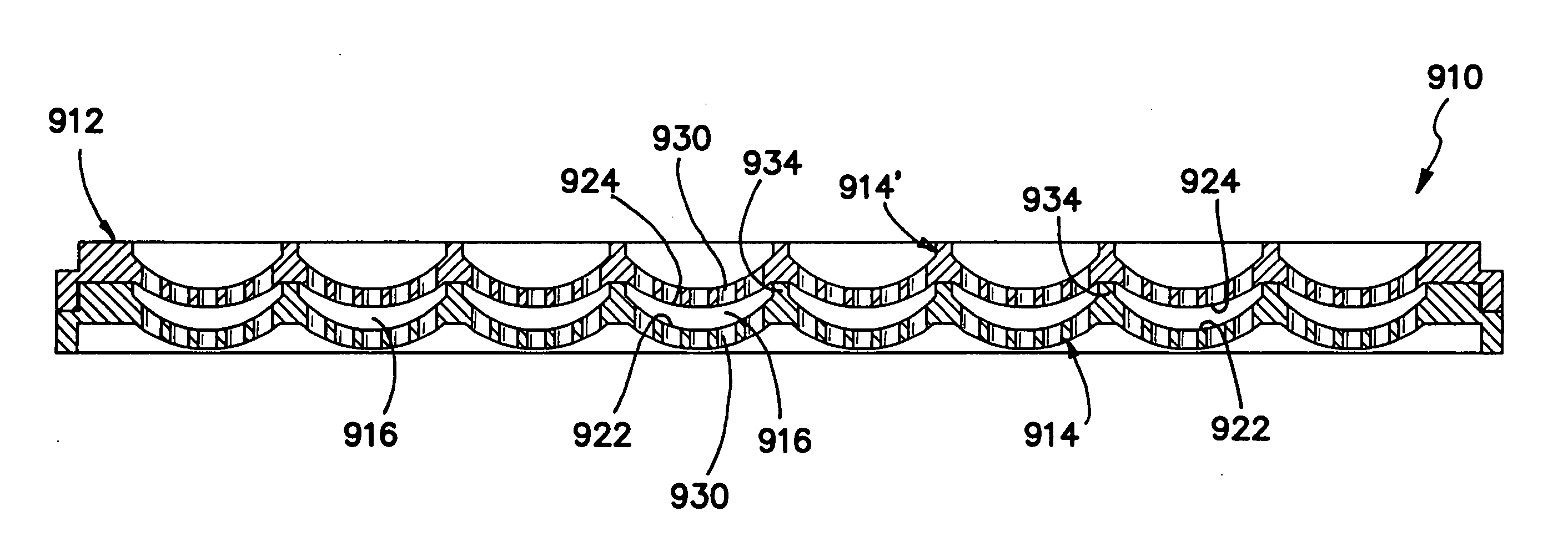

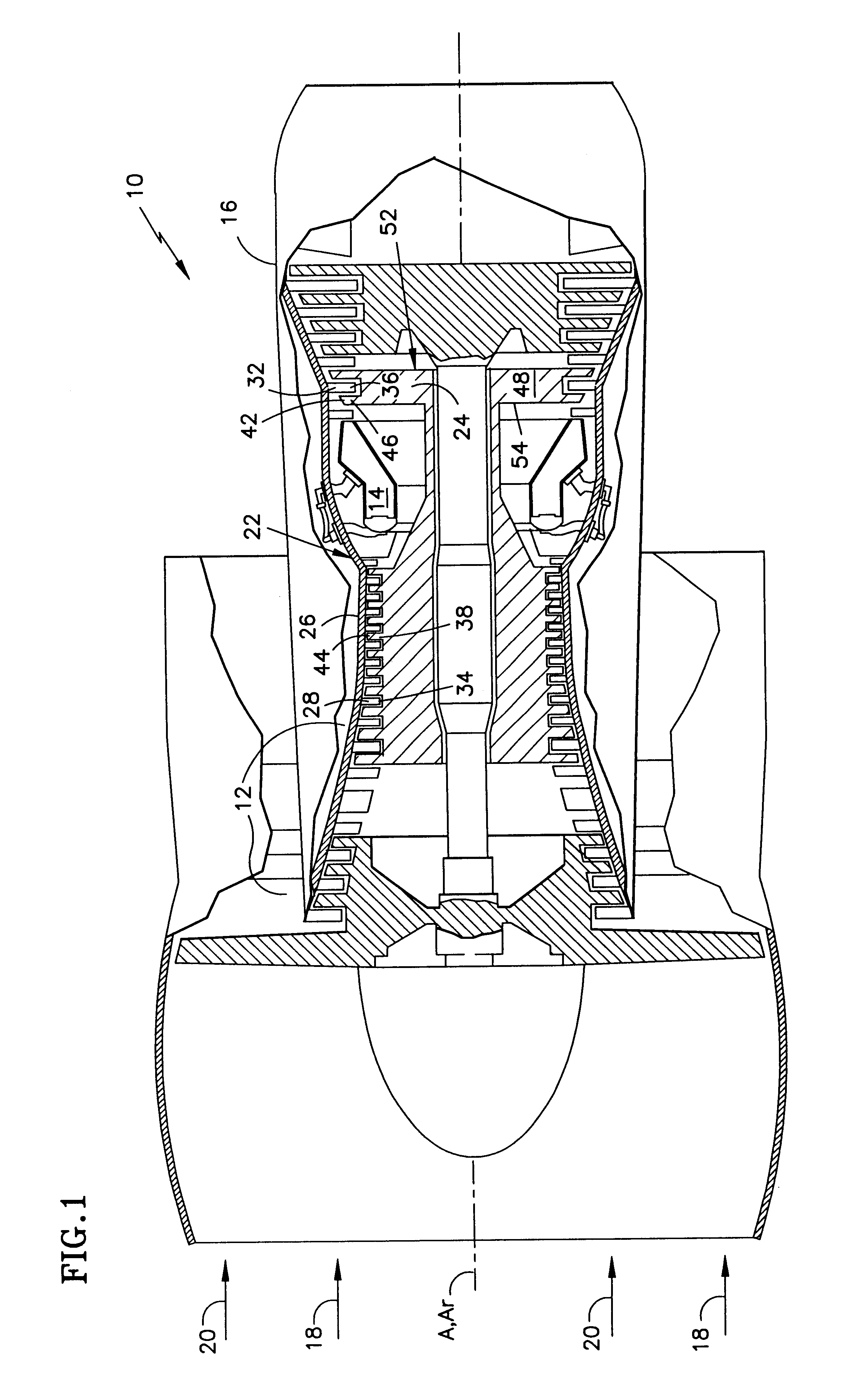

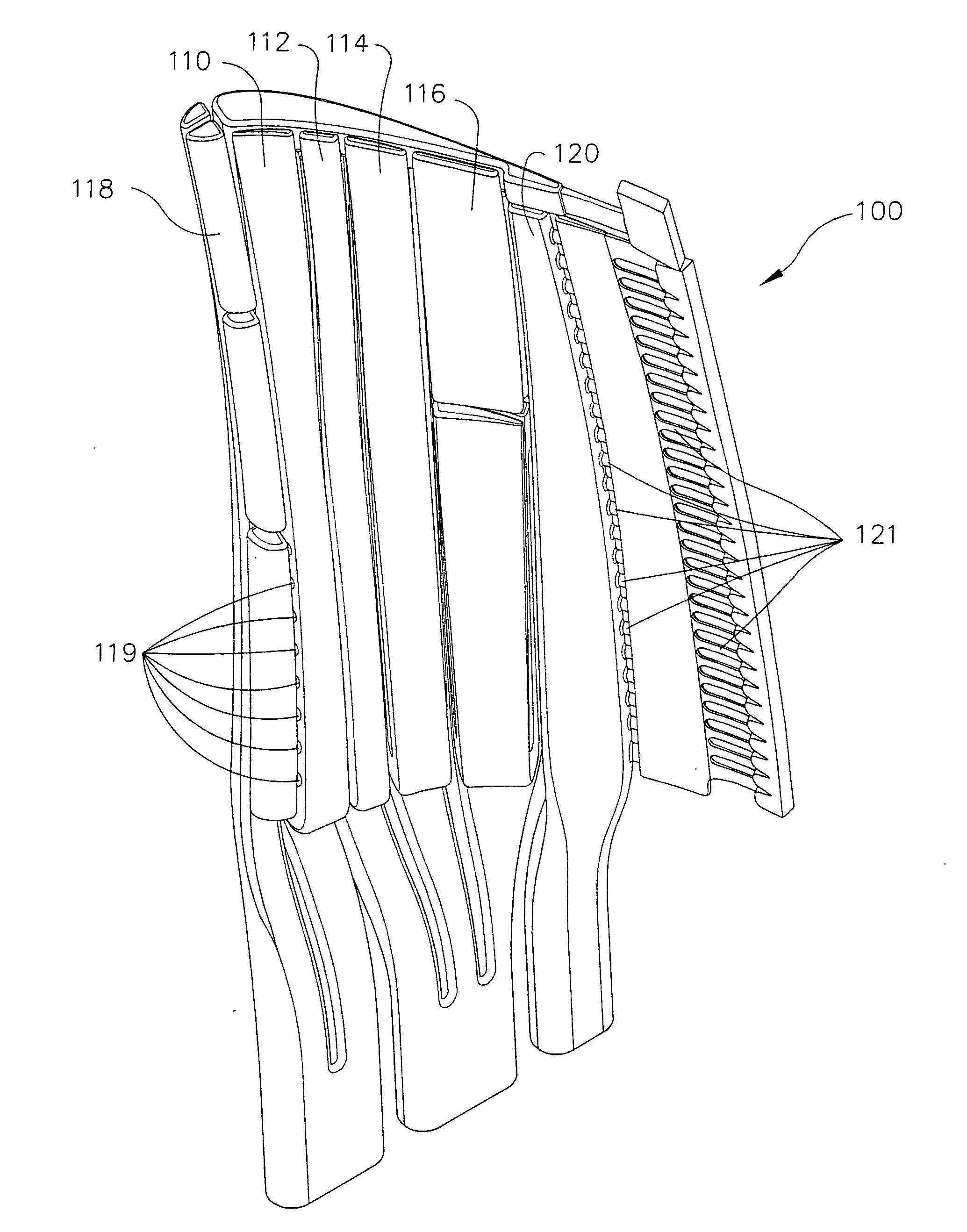

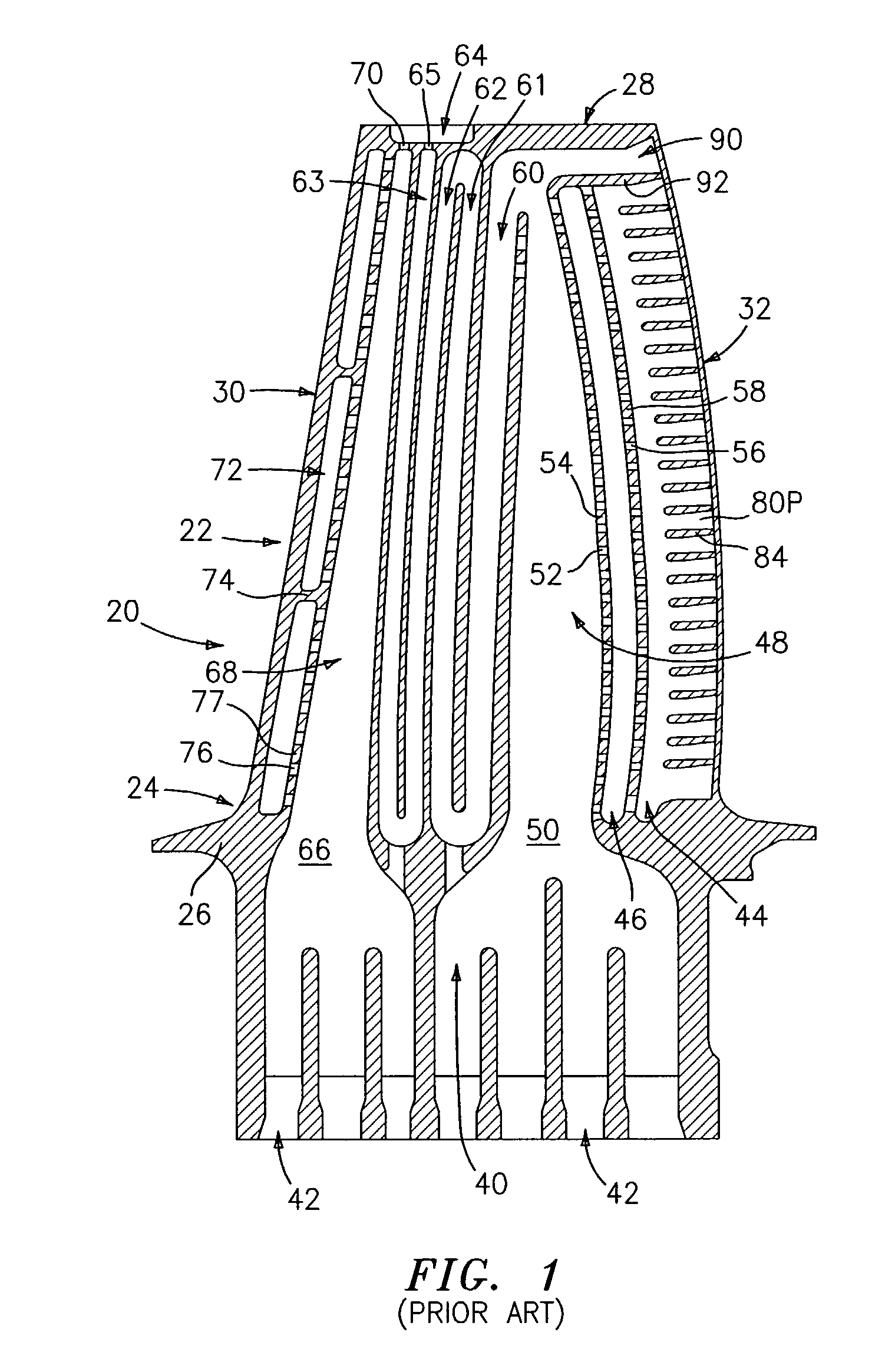

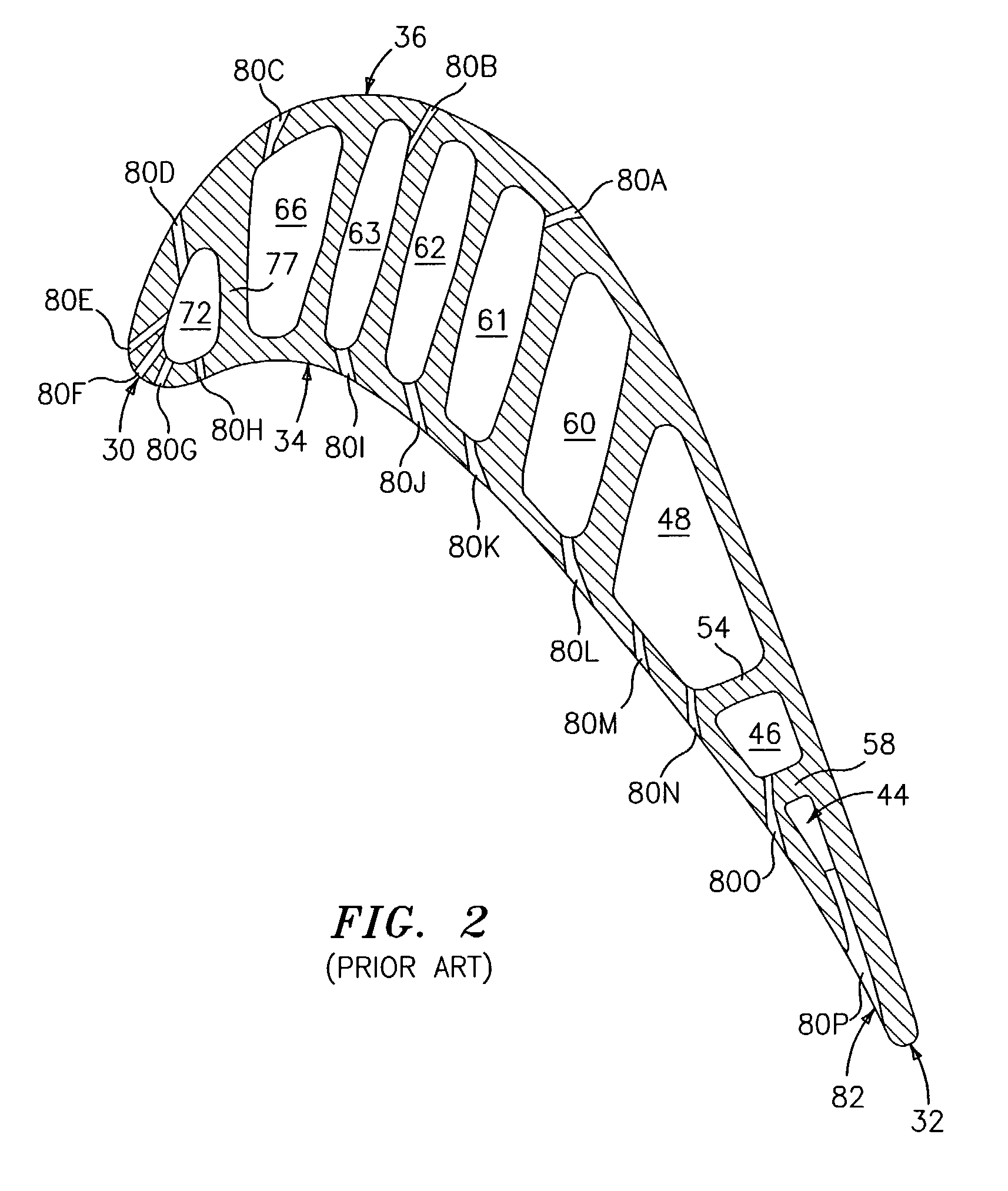

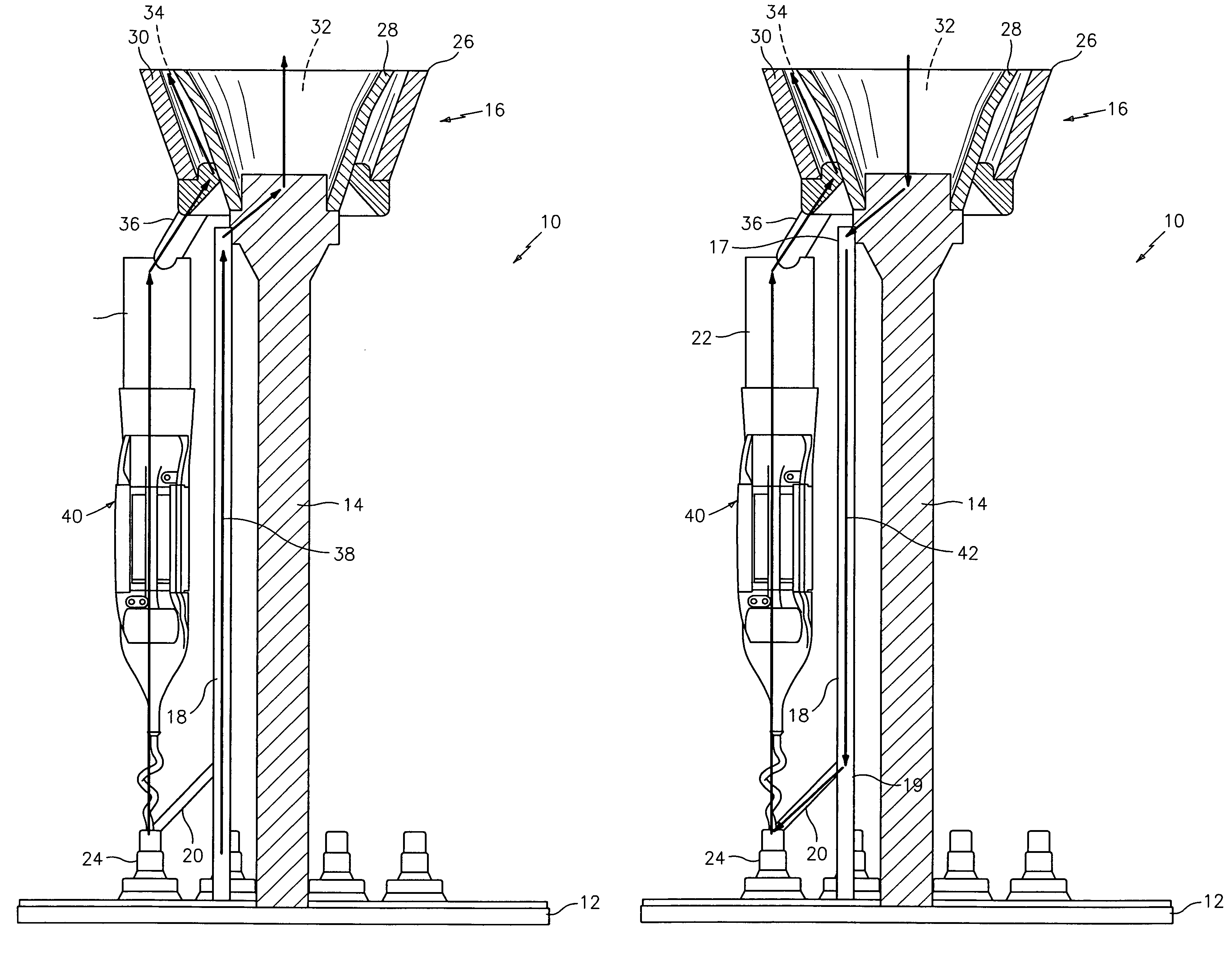

High effectiveness cooled turbine vane or blade

InactiveUS6974308B2Improve cooling efficiencyEasy to manufacturePump componentsEngine fuctionsSuction stressConventional casting

A robust multiple-walled, multi-pass, high cooling effectiveness cooled turbine vane or blade designed for ease of manufacturability, minimizes cooling flows on highly loaded turbine rotors. The vane or blade design allows the turbine inlet temperature to increase over current technology levels while simultaneously reducing turbine cooling to low levels. A multi-wall cooling system is described, which meets the inherent conflict to maximize the flow area of the cooling passages while retaining the required section thickness to meet the structural requirements. Independent cooling circuits for the vane or blade's pressure and suction surfaces allow the cooling of the airfoil surfaces to be tailored to specific heat load distributions (that is, the pressure surface circuit is an independent forward flowing serpentine while the suction surface is an independent rearward flowing serpentine). The cooling air for the independent circuits is supplied through separate passages at the base of the vane or blade. The cooling air follows intricate passages to feed the serpentine thin outer wall passages, which incorporate pin fins, turbulators, etc. These passages, while satisfying the aero / thermal / stress requirements, are of a manufacturing configuration that may be cast with single crystal materials using conventional casting techniques.

Owner:HONEYWELL INT INC

Investment casting cores

Owner:RTX CORP

Picowell capture devices for analysing single cells or other particles

InactiveUS20120156675A1Easy to adaptCompared rapidly and convenientlyBioreactor/fermenter combinationsBiological substance pretreatmentsIndividual analysisBiopolymer

Owner:OXFORD GENE TECH IP

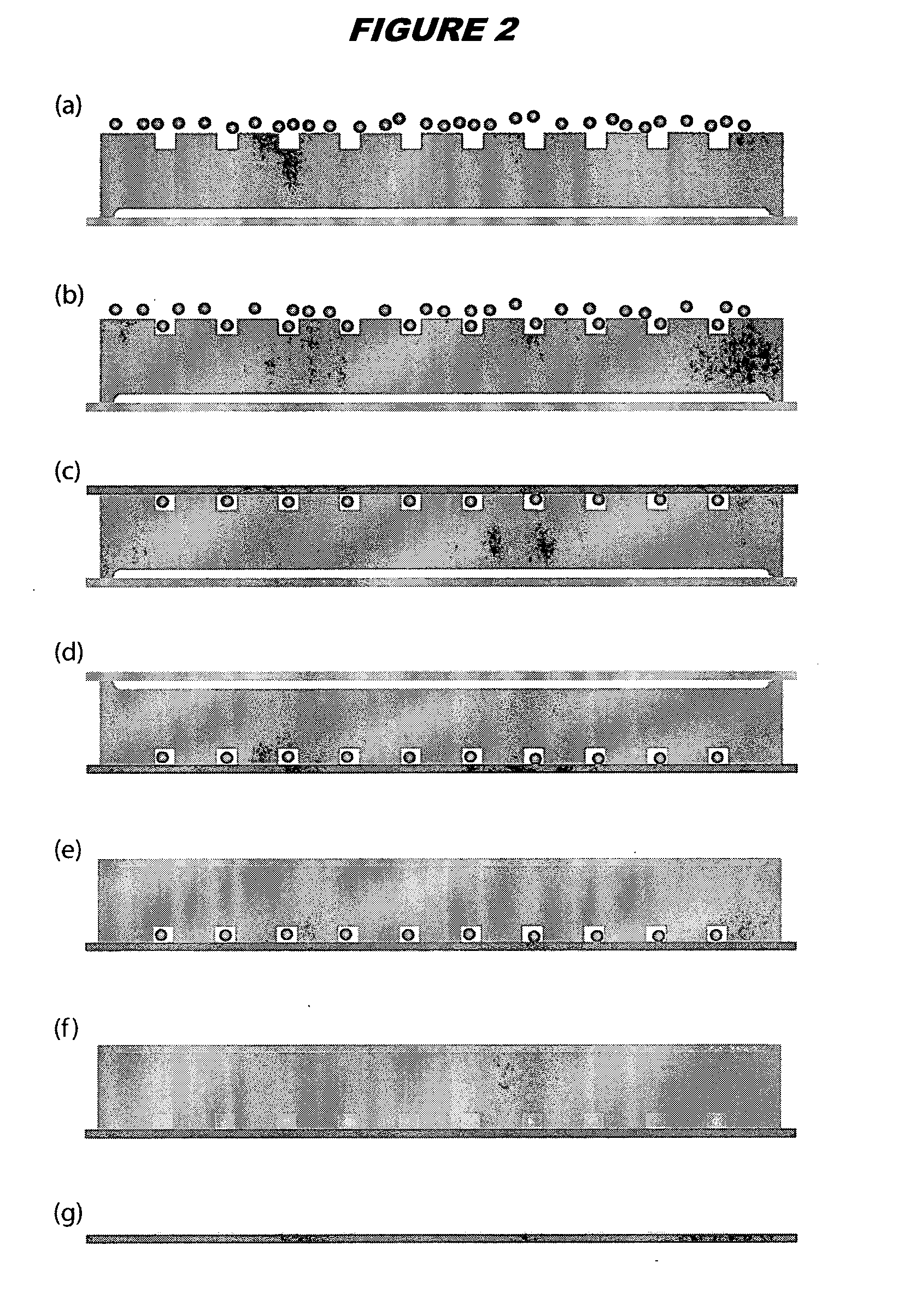

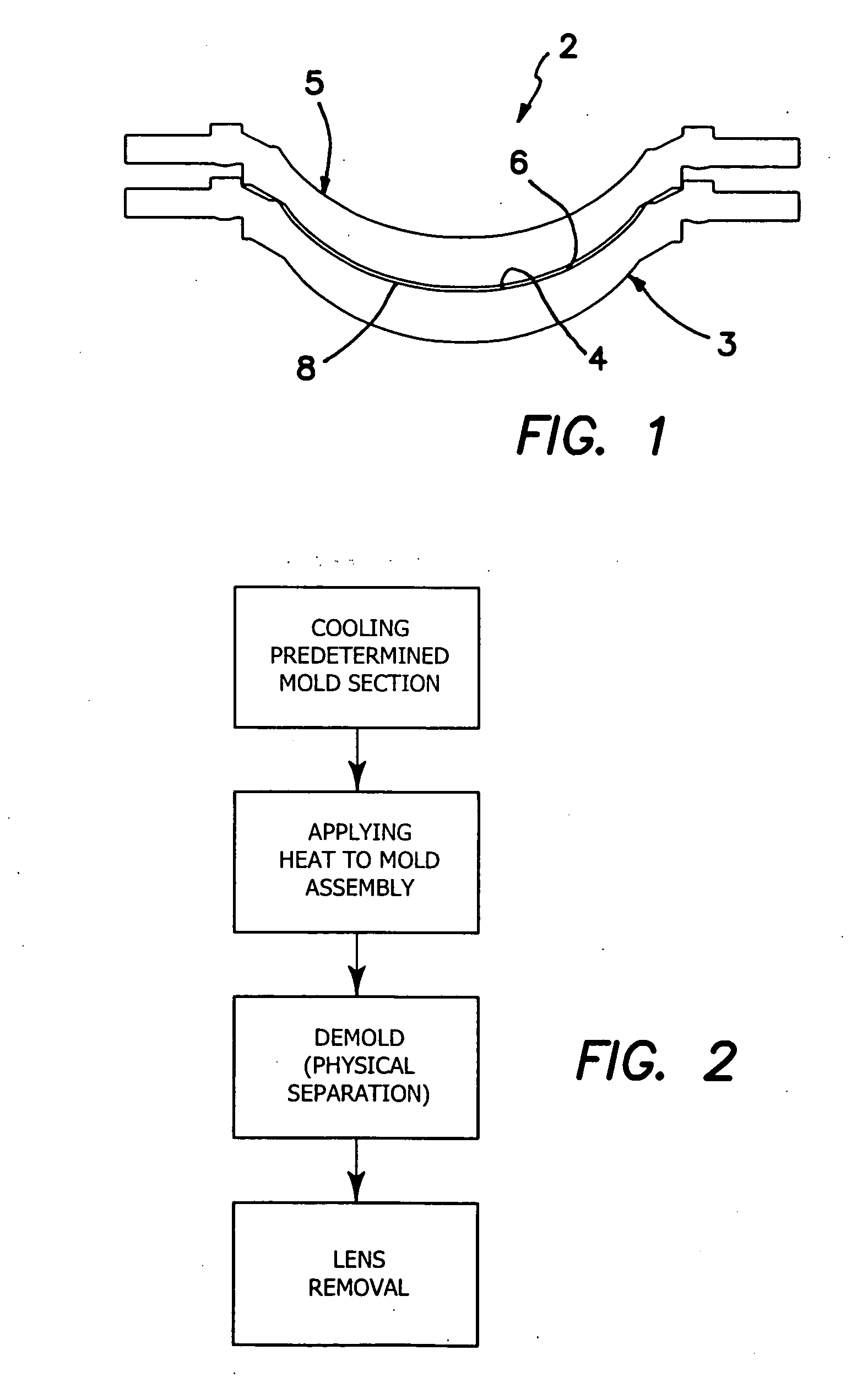

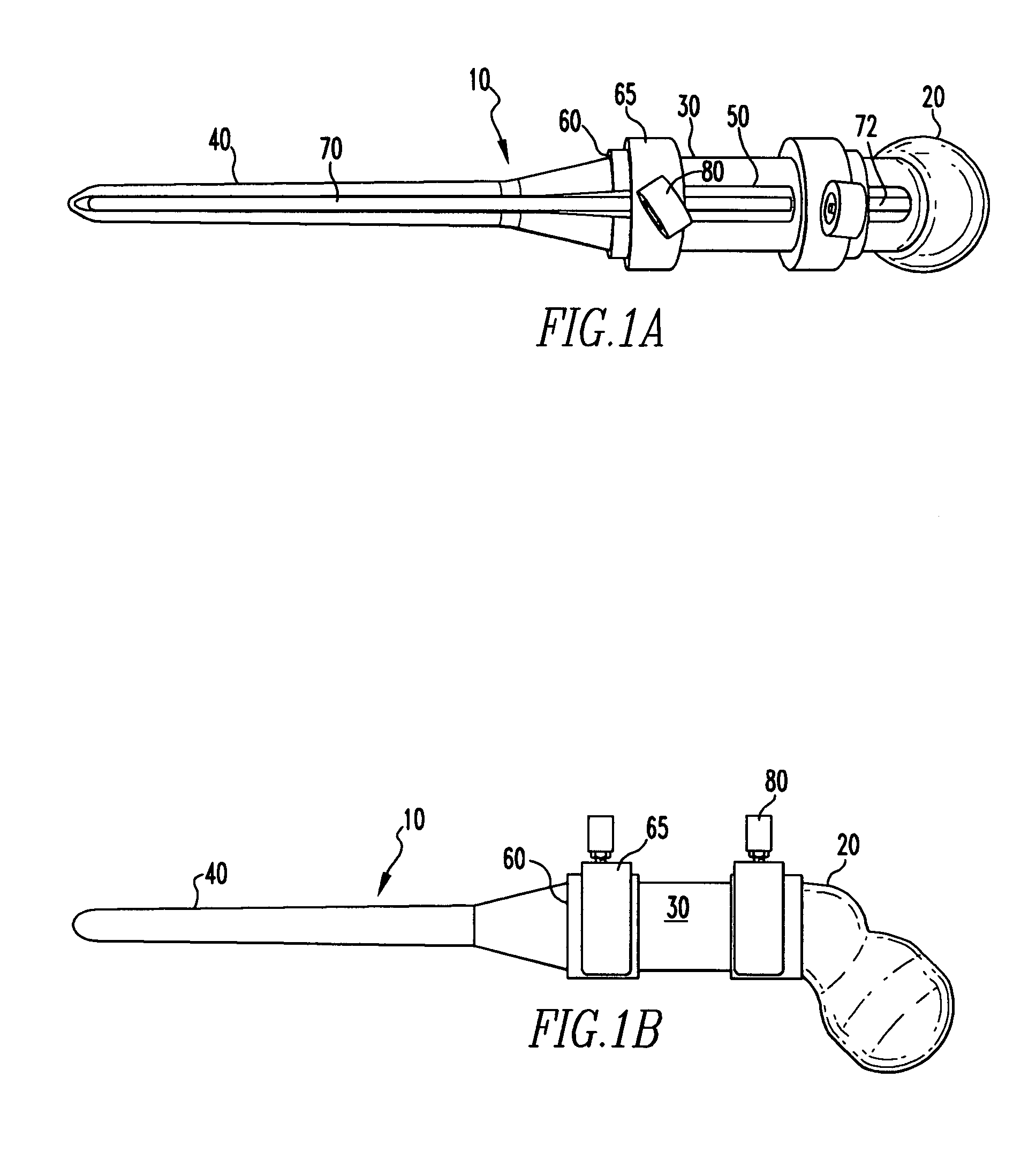

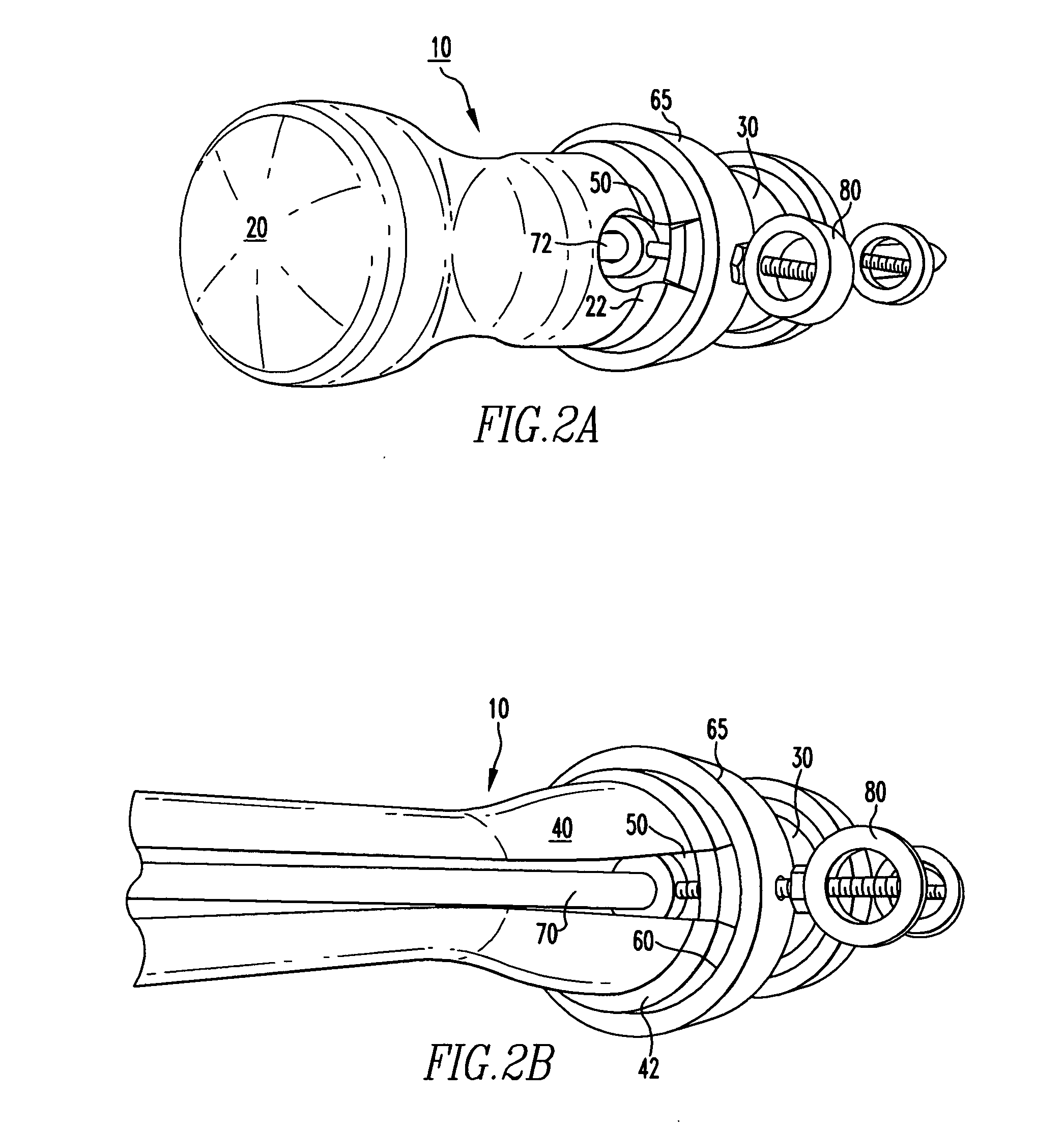

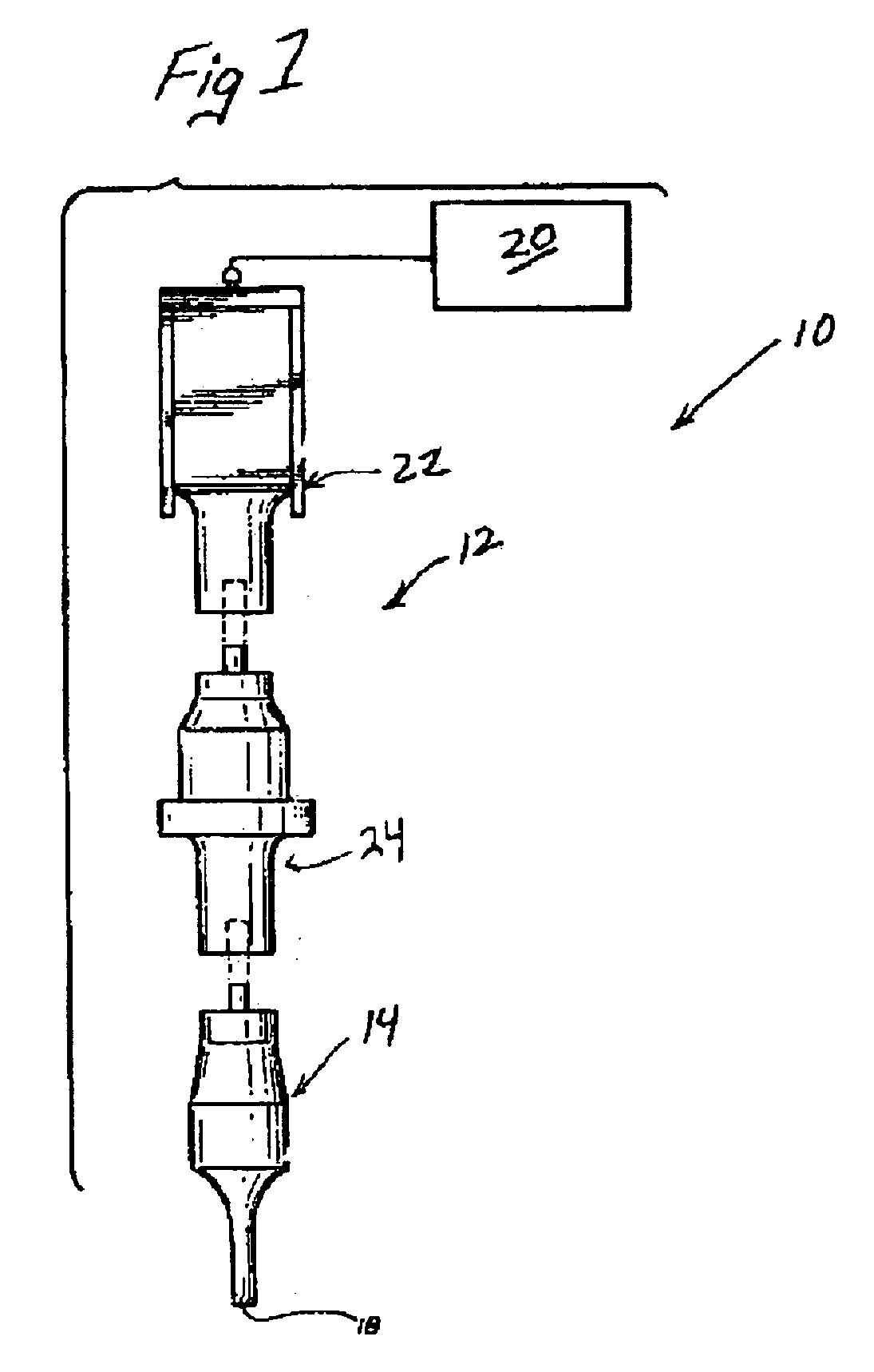

Systems and methods for removing lenses from lens molds

ActiveUS20070035049A1Efficient heatingFacilitate agitationMould separation apparatusConfectioneryEngineeringWedge shape

Methods and apparatus for separating mold sections, removing a lens product from the separated mold sections, and transferring the lens product to a processing tray are provided and include contacting assembled mold sections with a warm fluid to break fused portions between the mold sections, and using one or more wedge shaped elements to pry apart and separate the mold sections, one from the other. A vacuum head having multiple vacuum ports is employed for lifting the newly molded lens product from a mold section and for releasing the lens from the vacuum head into a processing tray. A cylinder of flowing air directed around the circumference of the lens is effective to maintain the lens in an unfolded position as the lens is being released into the processing tray. A tray set including multiple trays holding multiple lenses is provided and includes features for enabling visual and / or mechanical distinction of the trays and lenses held thereby.

Owner:COOPERVISION INT LTD

Anti-seepage burnon casting paint made from alcohol base or aqueous sand powder

InactiveCN1666828AExcellent anti-seepage and sticky sand effectSmall specific surface areaFoundry mouldsFoundry coresWater basedAlcohol

The invention relates to the melting coating of alcohol-base or water-base anti-penetrating sands, which uses the fireproofing bone materials, the floating agent, the felting agent, the reinforcing agent and the carrier as the preparing coating. The weight shares of the said coating are: 100,3-8,3-7,0.2-1.0 and 30-40. The invention uses chrome iron minerals as the main materials and is prior to any kinds of the traditional coating.

Owner:HUBEI UNIV OF TECH

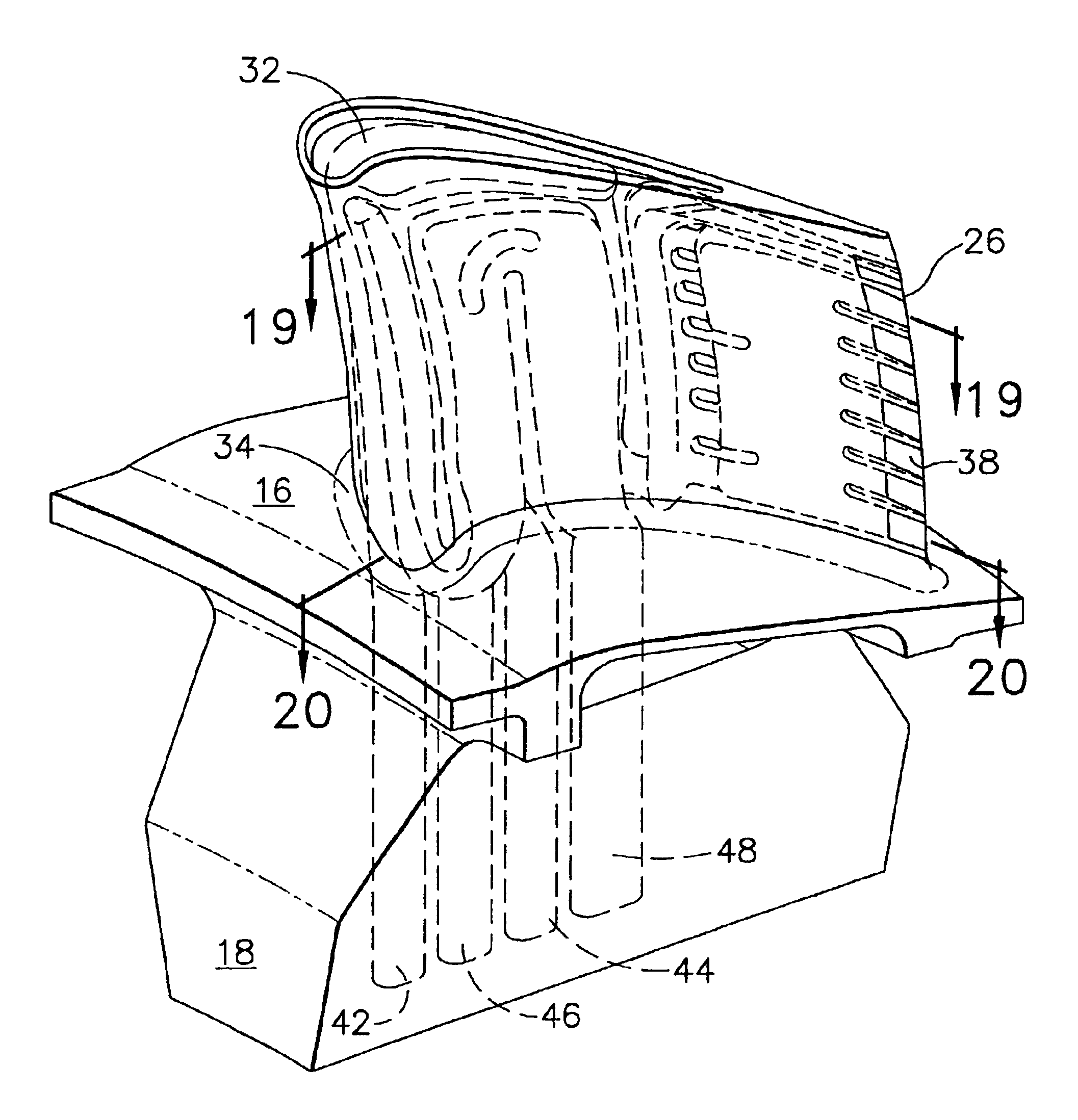

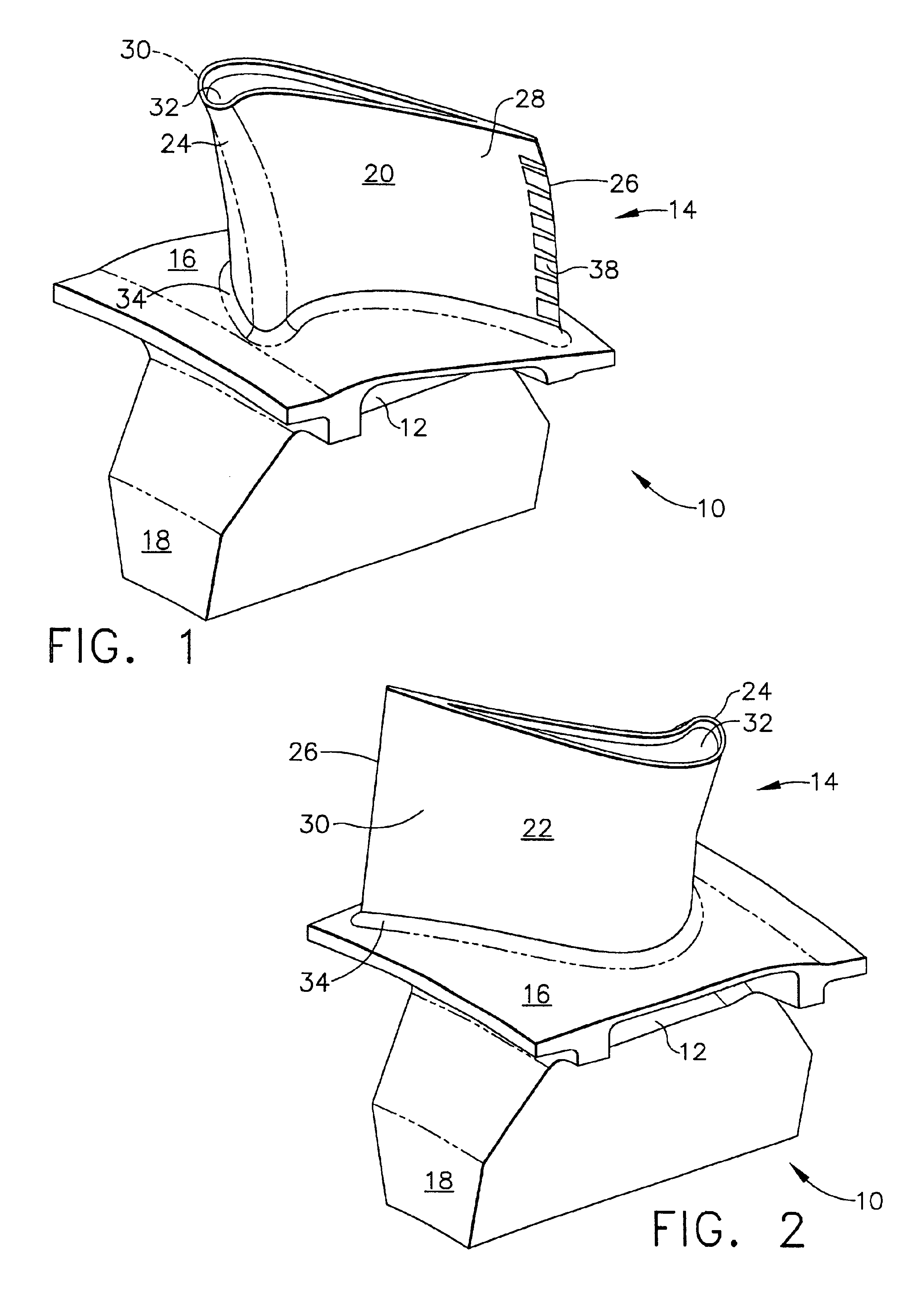

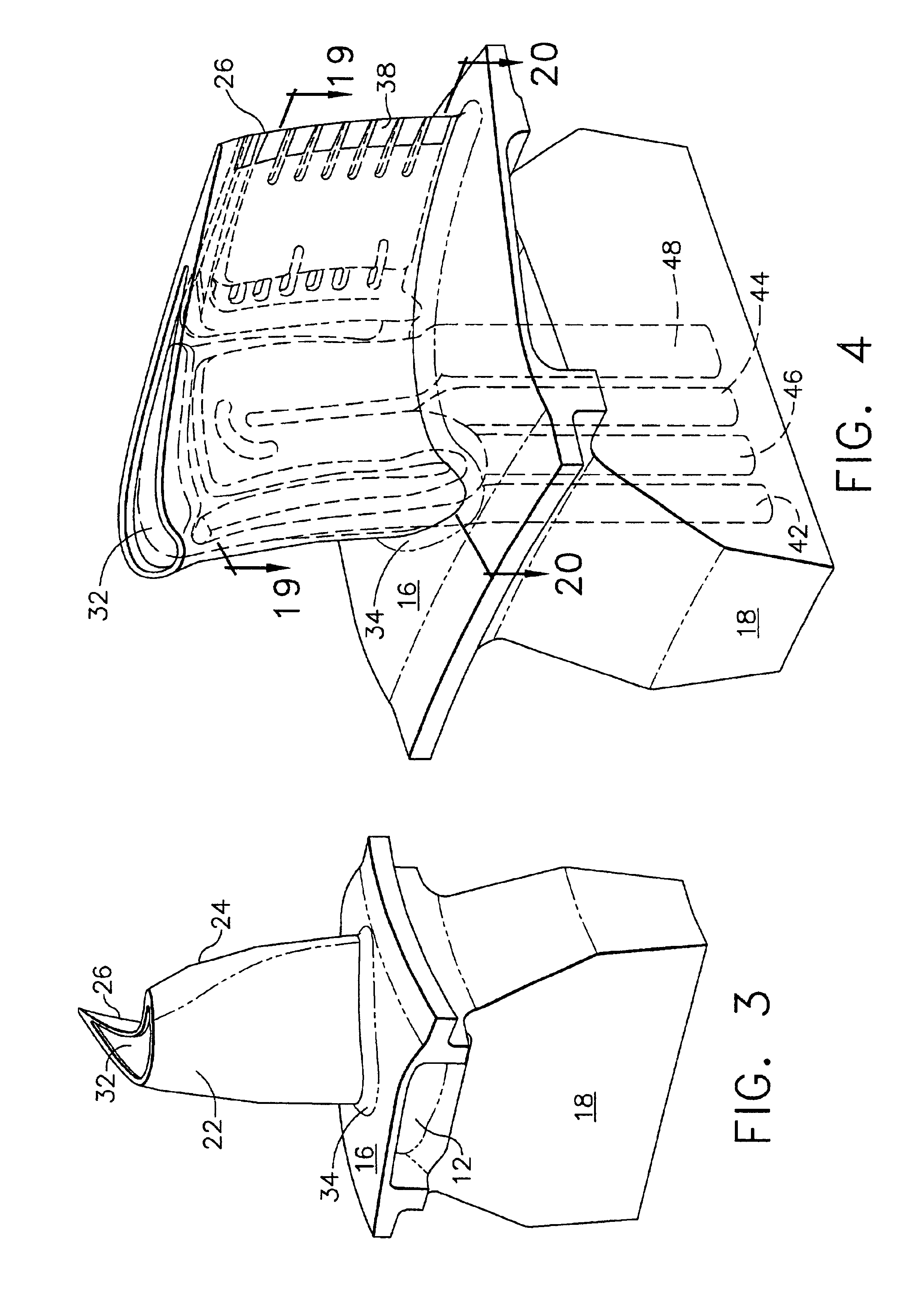

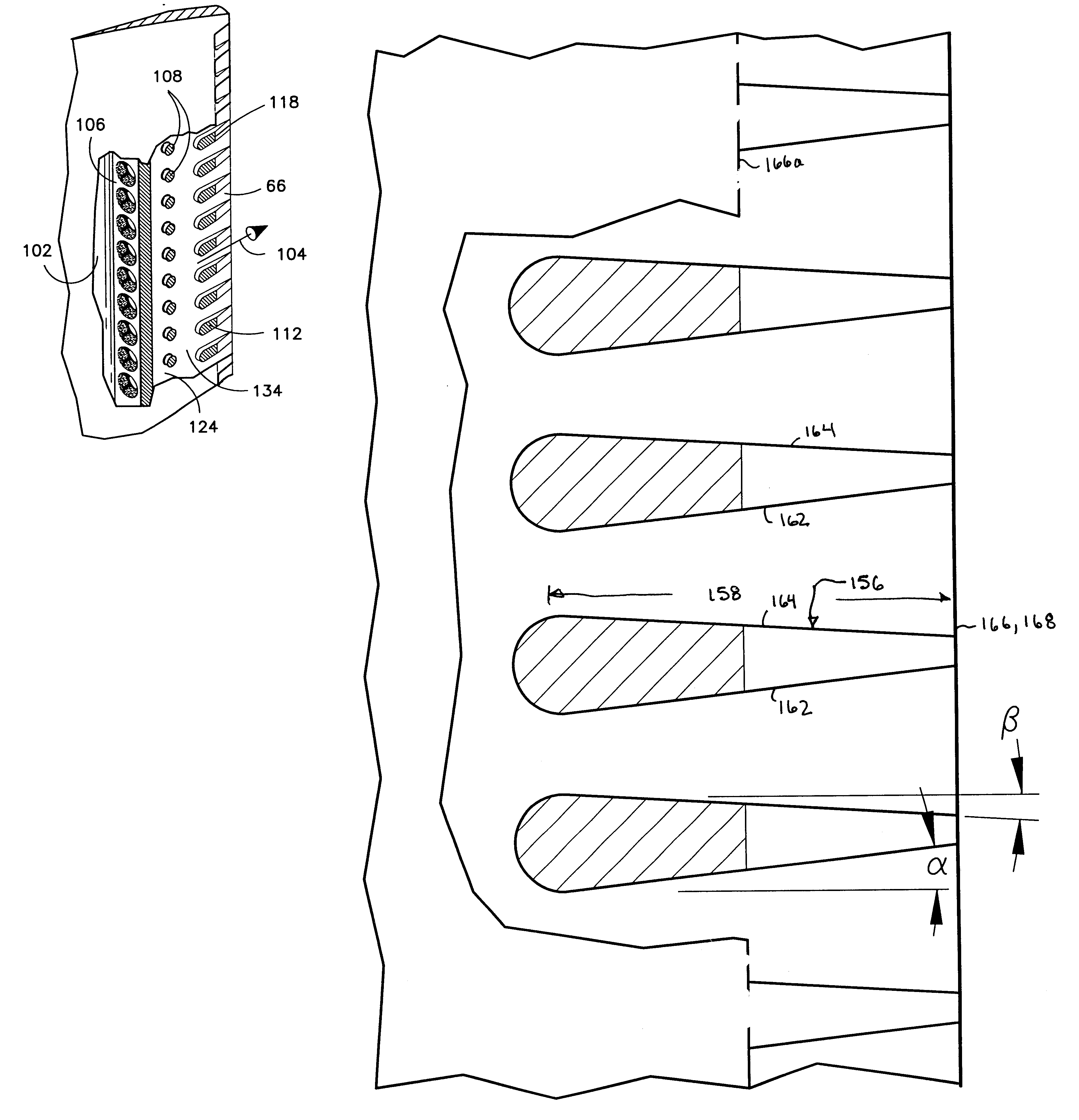

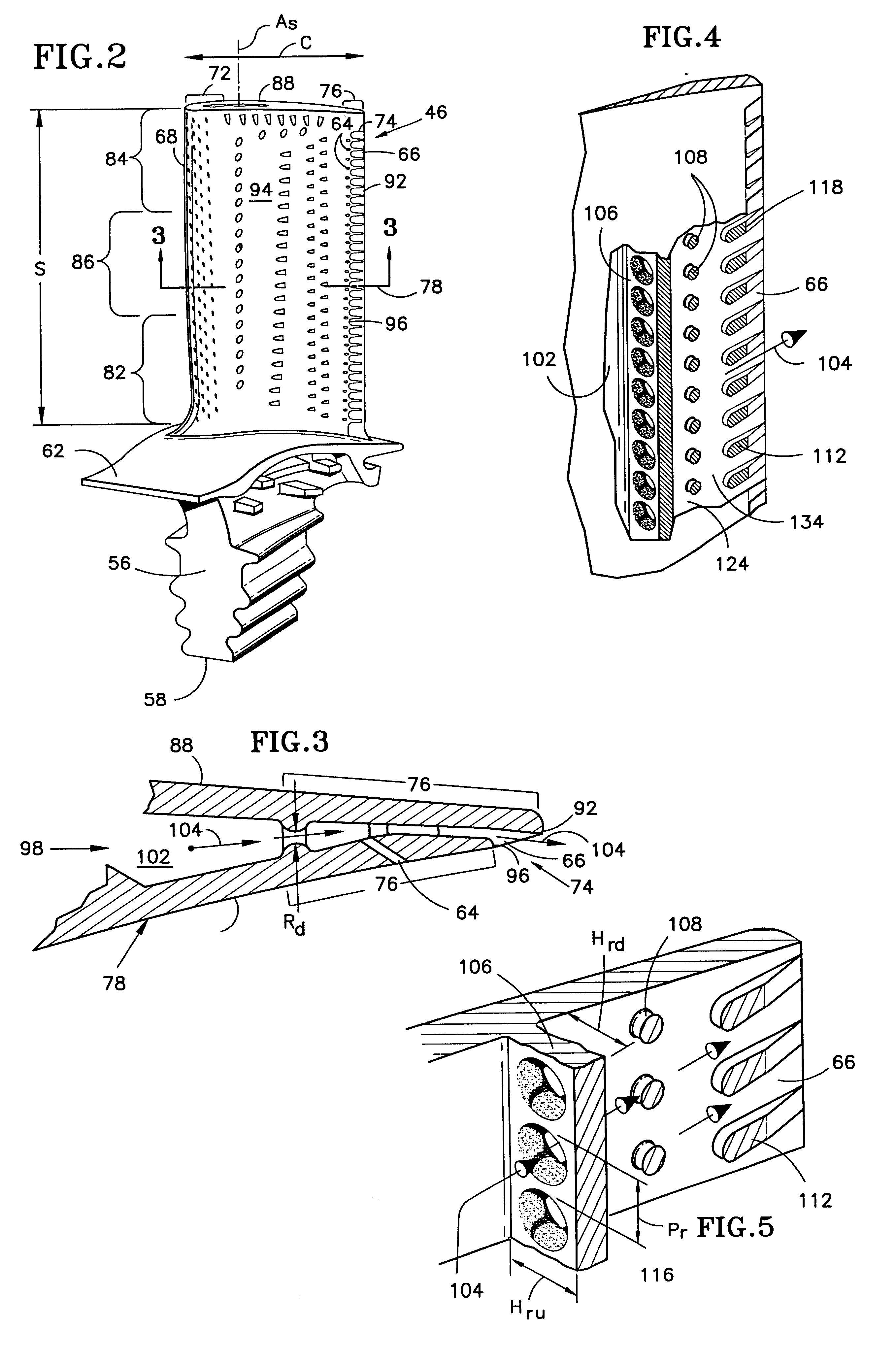

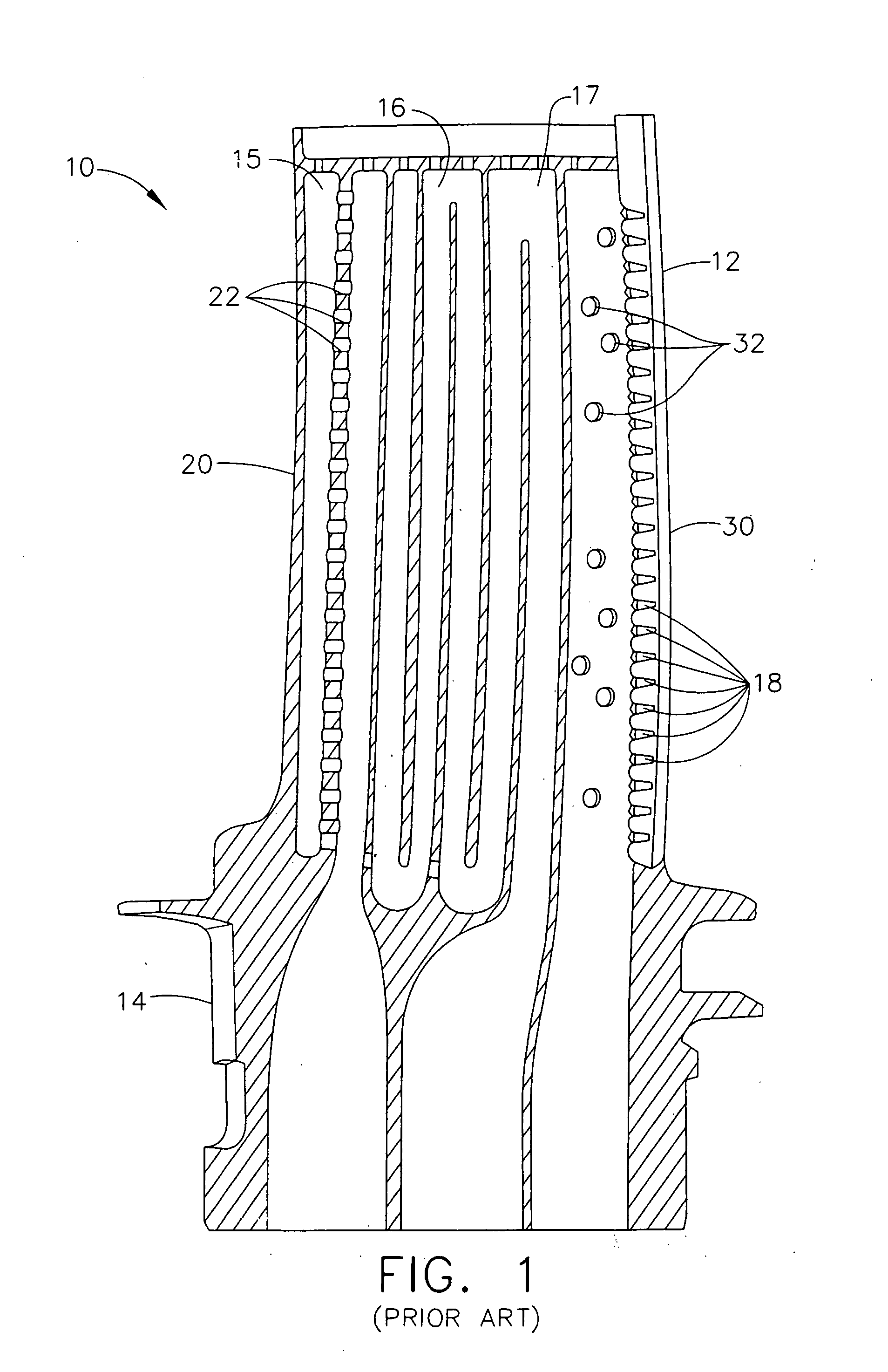

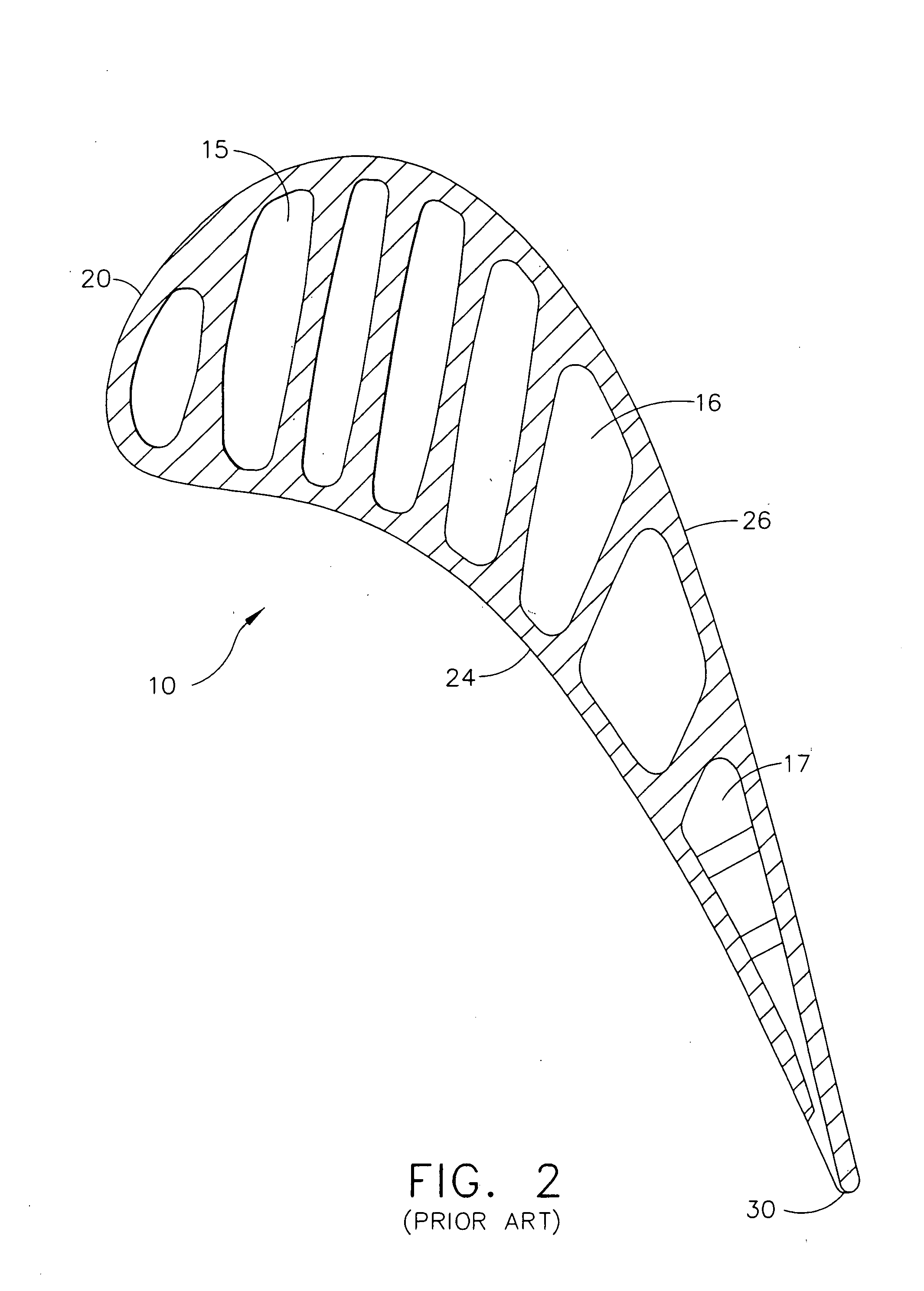

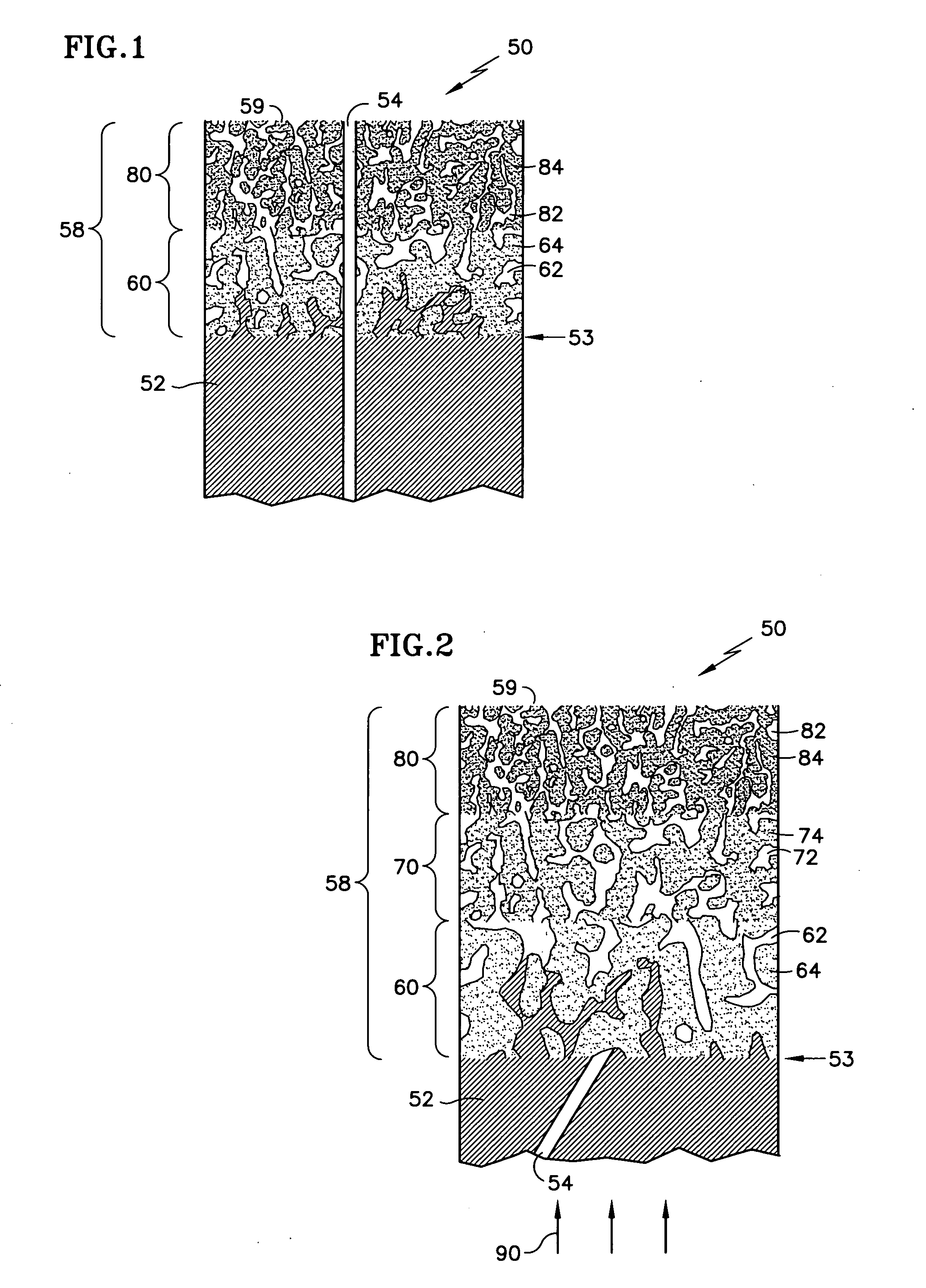

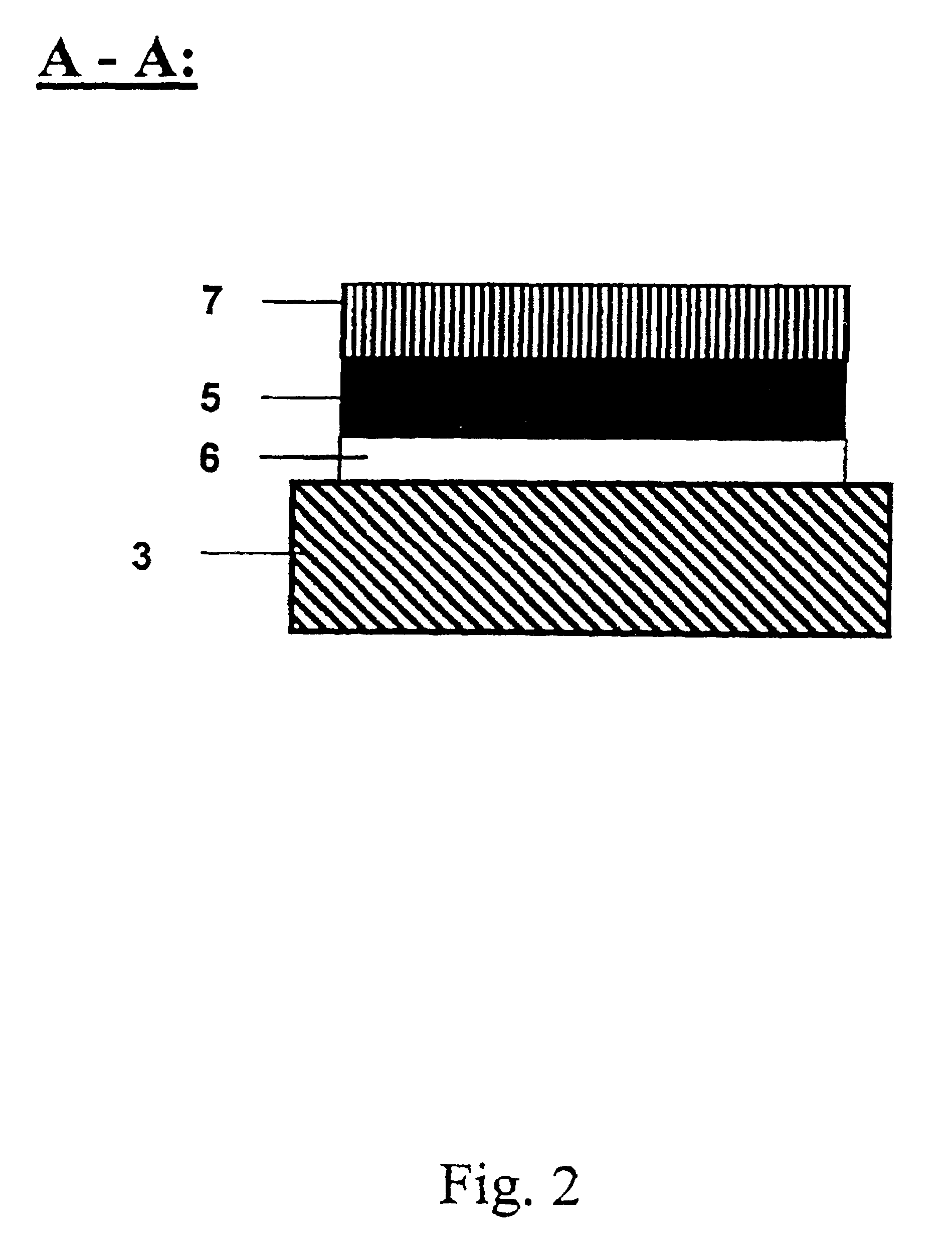

Coolable airfoil structure

InactiveUS6234754B1Durability and thermomechanical performanceIncreased durabilityPump componentsEngine fuctionsCastabilityInternal heat transfer

A coolable airfoil structure having internal heat transfer features through which cooling air is flowed under operative conditions is disclosed. Various construction details and features are developed which affect the castability and core strength during manufacture and strength and cooling effectiveness of the airfoil after manufacture. In one particular embodiment, the airfoil has a plurality of heat transfer members disposed in the rearmost section of the trailing edge region which comprises a single impingement rib, a single row of pedestals and a single row of chordwisely extending flow dividers.

Owner:UNITED TECH CORP

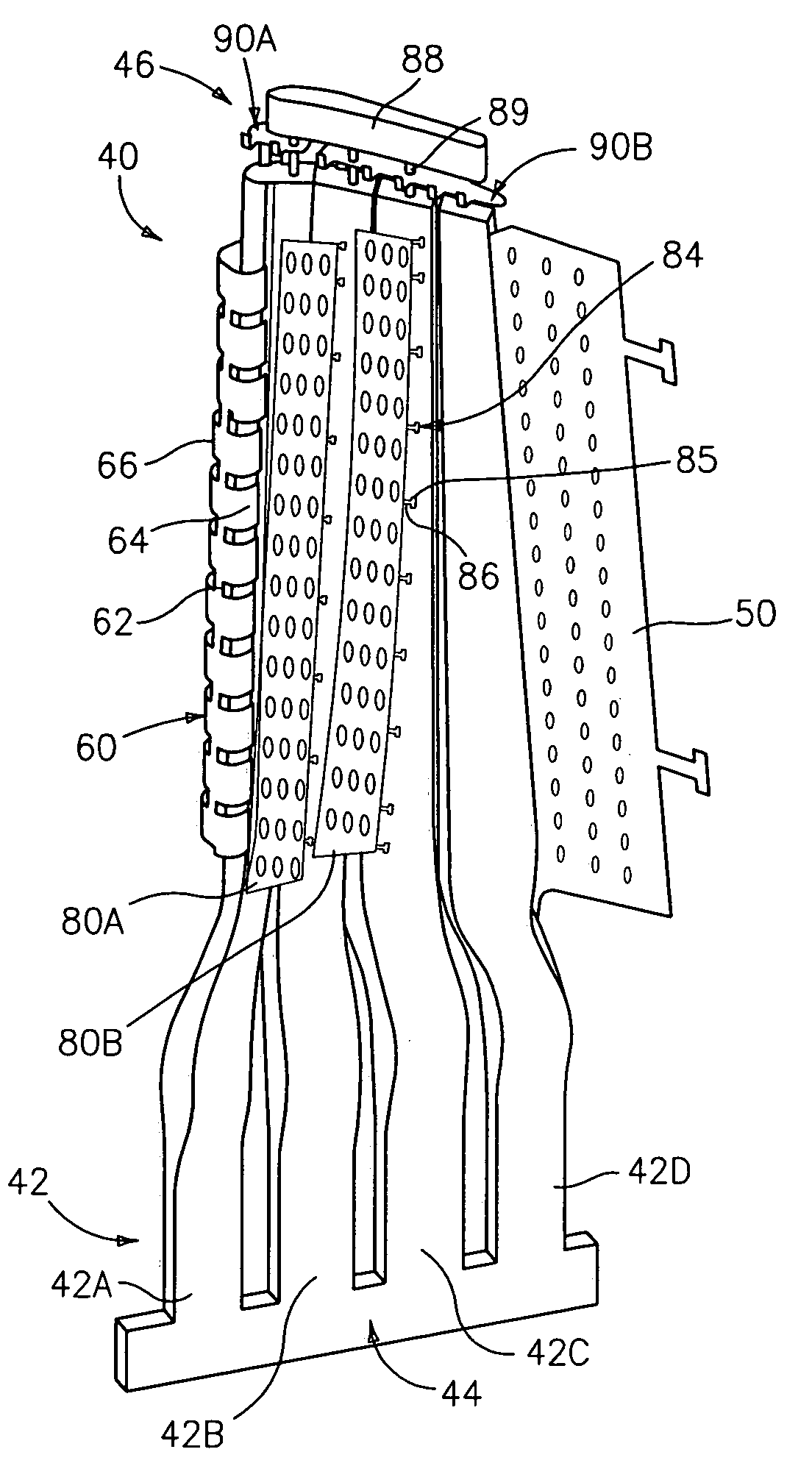

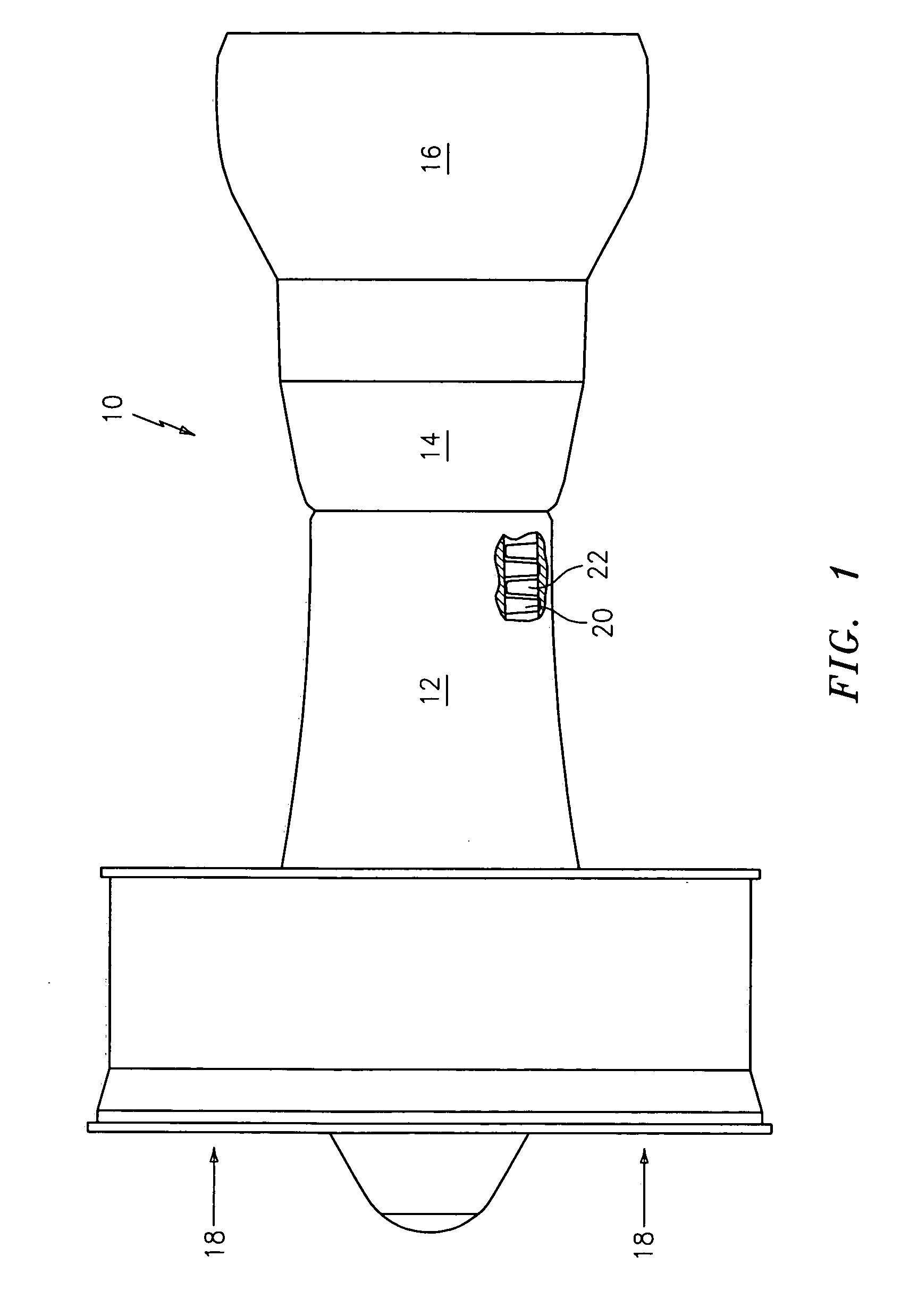

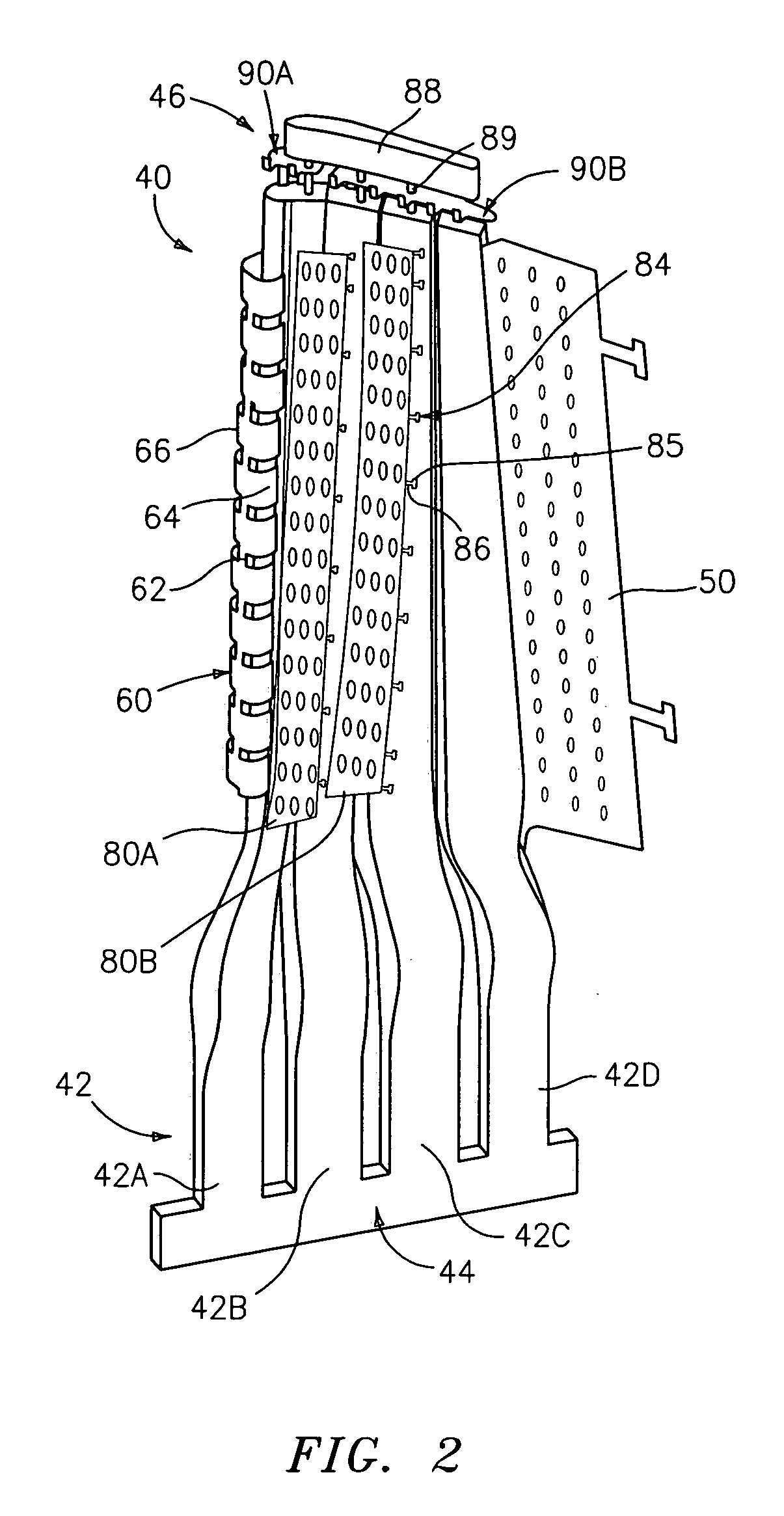

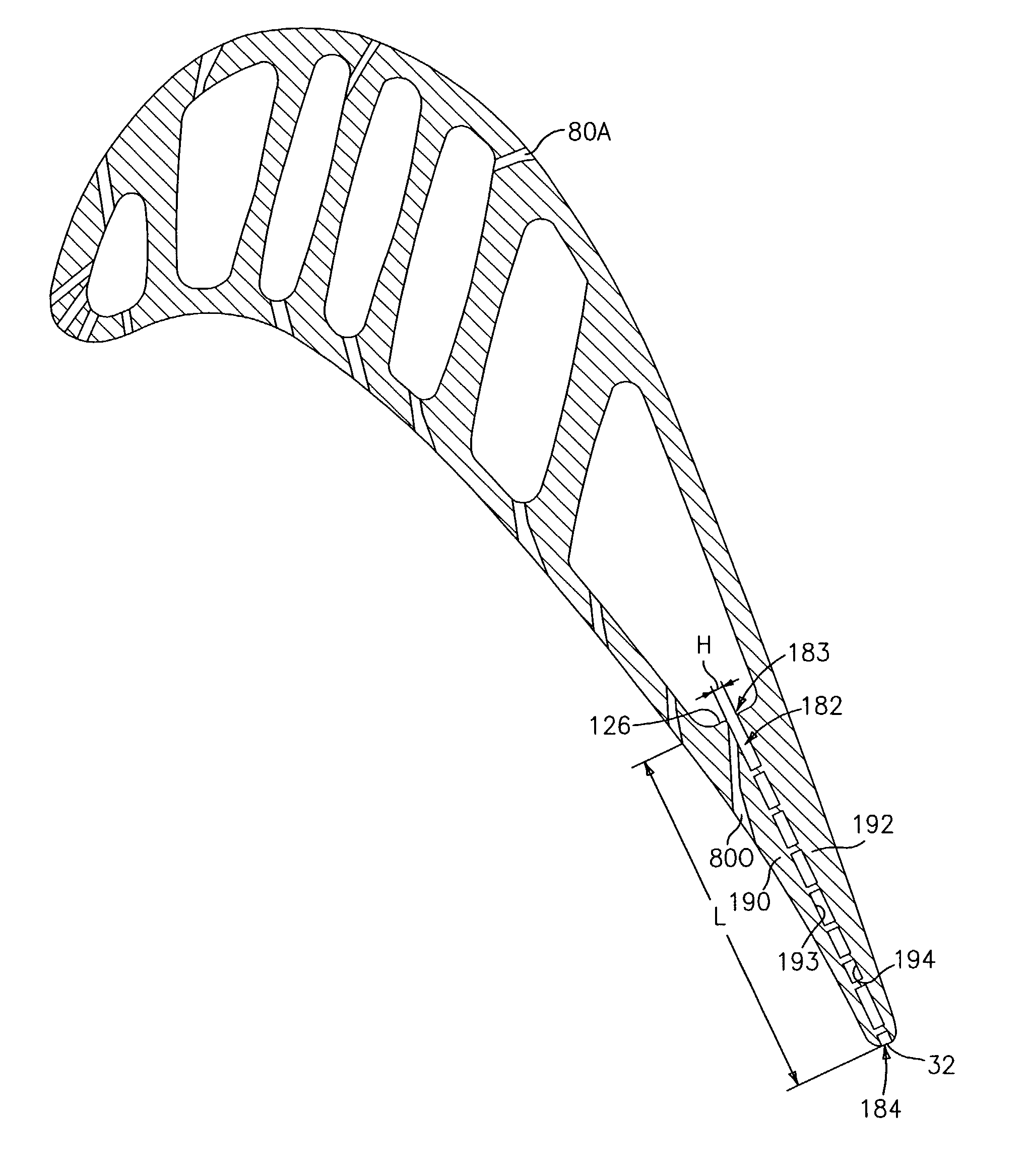

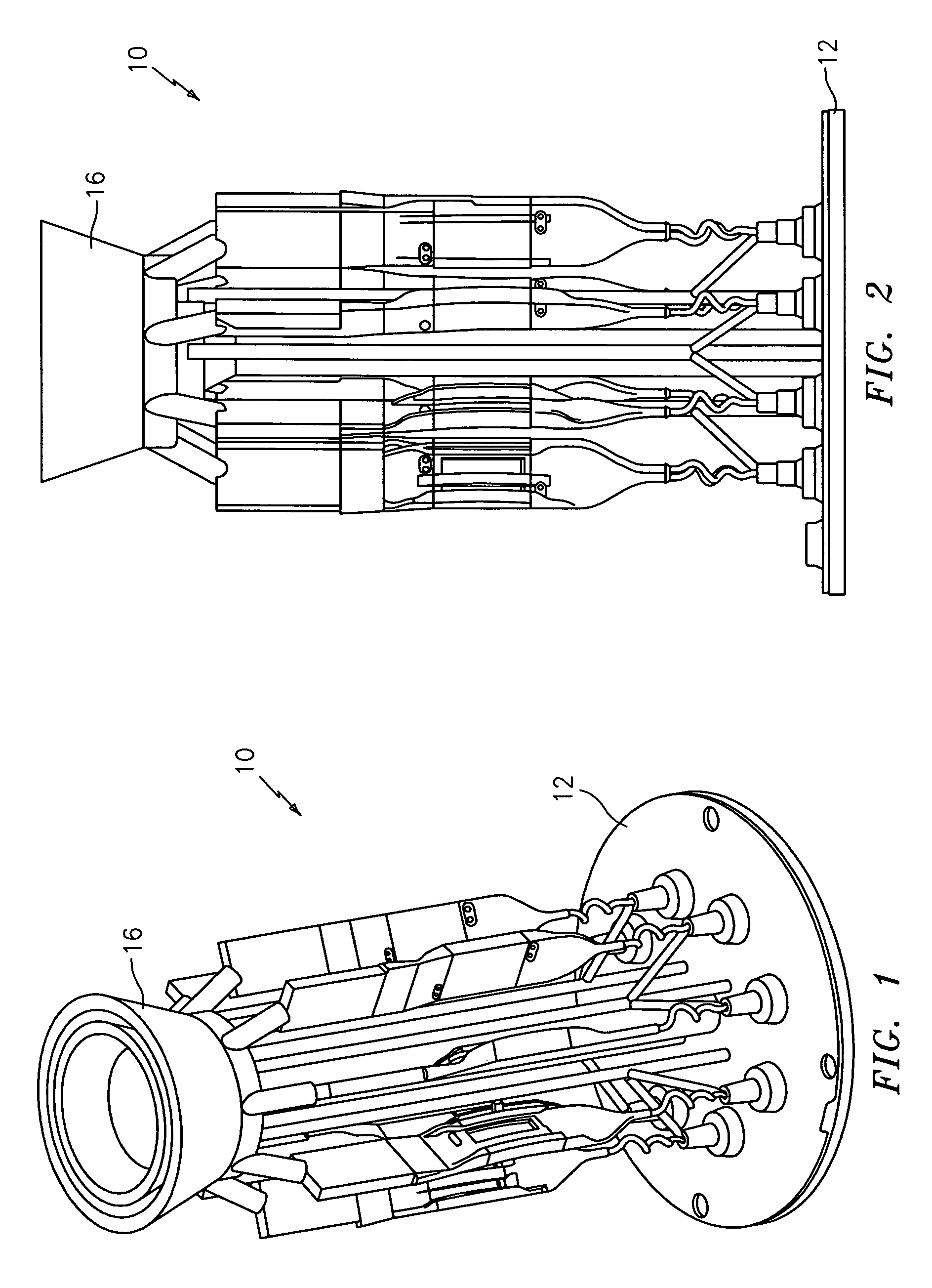

Airfoil cooling circuits and method

InactiveUS20080080979A1Pump componentsBlade accessoriesElectrical and Electronics engineeringAirflow

An airfoil is disclosed having at least first and second cast, axially-stacked internal airflow cooling circuits. Each circuit defines multiple air flow passages positioned laterally between a pressure sidewall side and a suction sidewall side of respective ones of the circuits. Each of the circuits is formed by a separate casting core. Methods of forming a axially-stacked core and an airfoil are also disclosed.

Owner:GENERAL ELECTRIC CO

Turbine element

A turbine element airfoil has a cooling passageway network with a slot extending from a trailing passageway toward the trailing edge. A number of discrete posts span the slot between pressure and suction sidewall portions.

Owner:RTX CORP

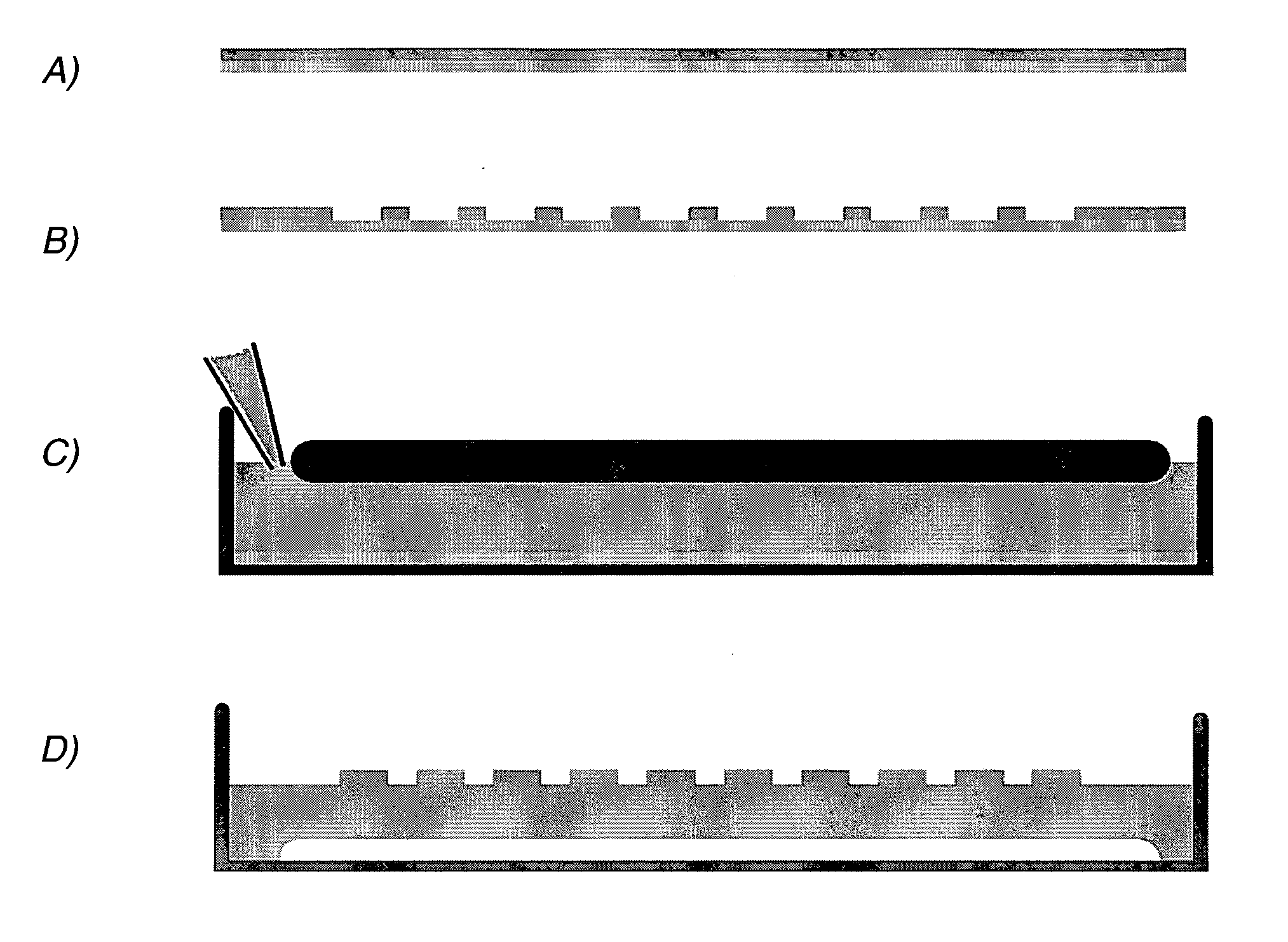

Method for constructing patterns in a layered manner

A process to produce models in layers is described, whereby a first material and then selectively a second material is applied in layers on a building platform and these two application stages are repeated until a desired pattern is achieved. The two materials form a solid if a suitable mixture ratio is used and the first material is a material mixture. The material mixture is at least partially prepared prior to each application stage.

Owner:EXONE

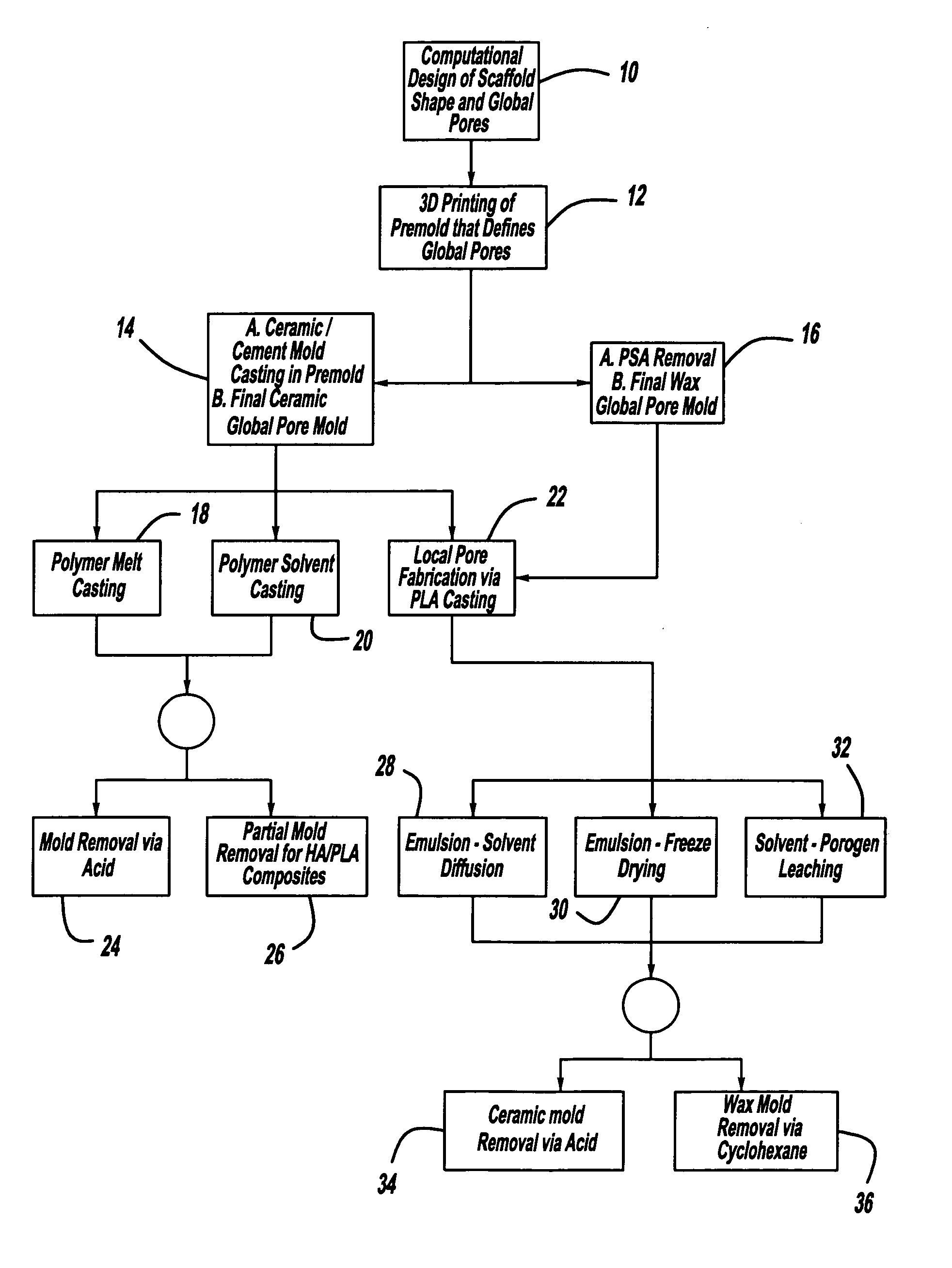

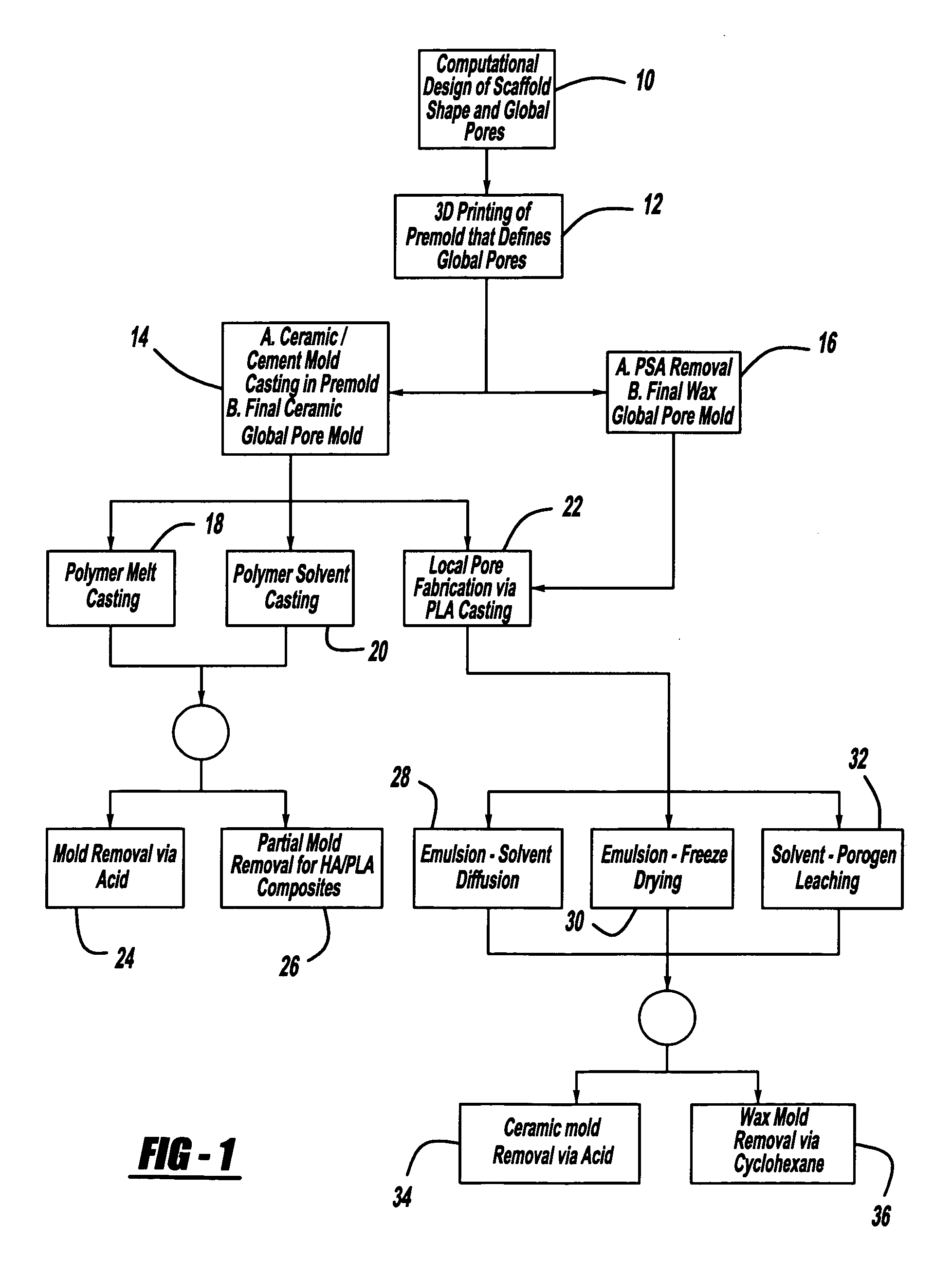

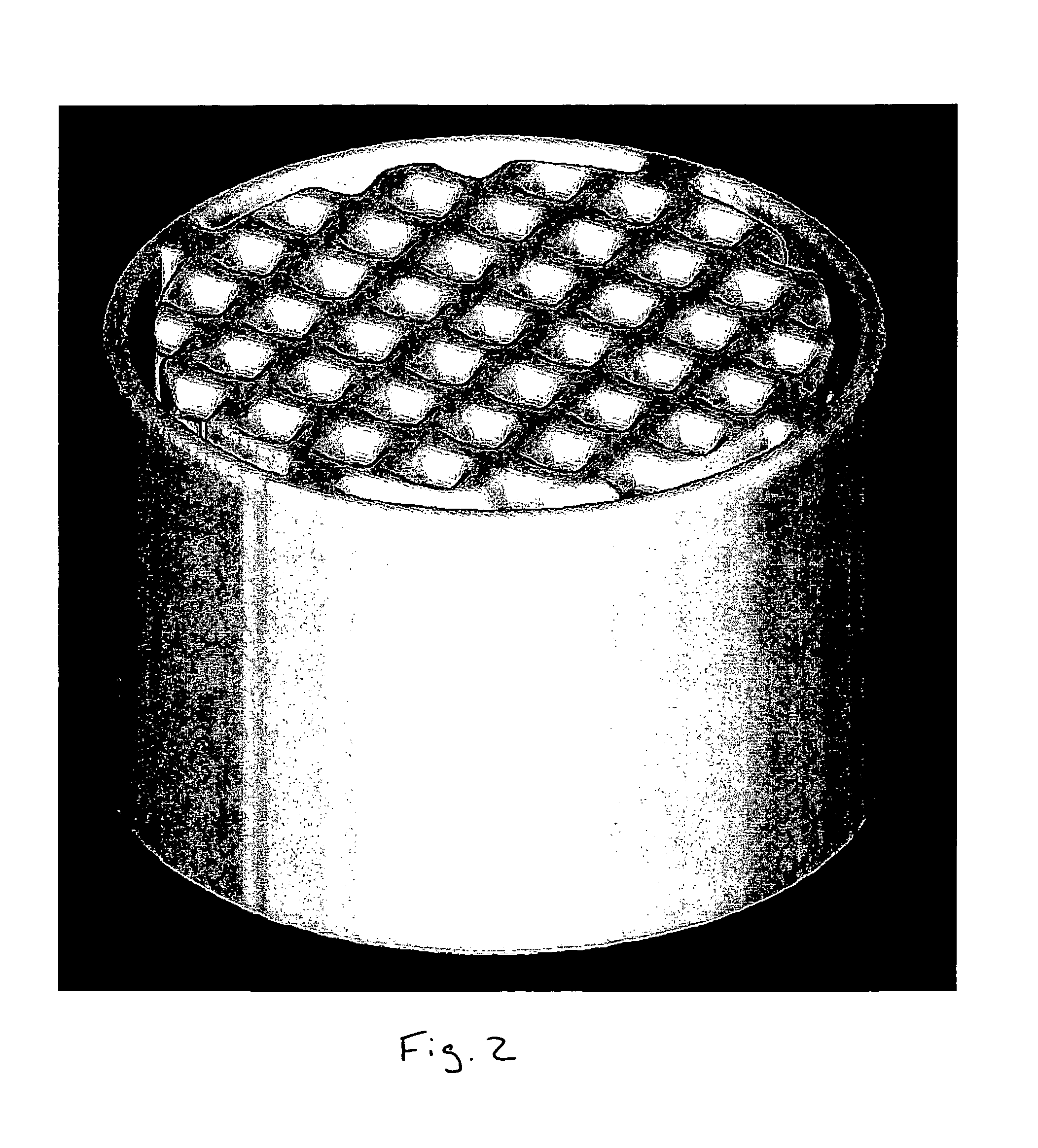

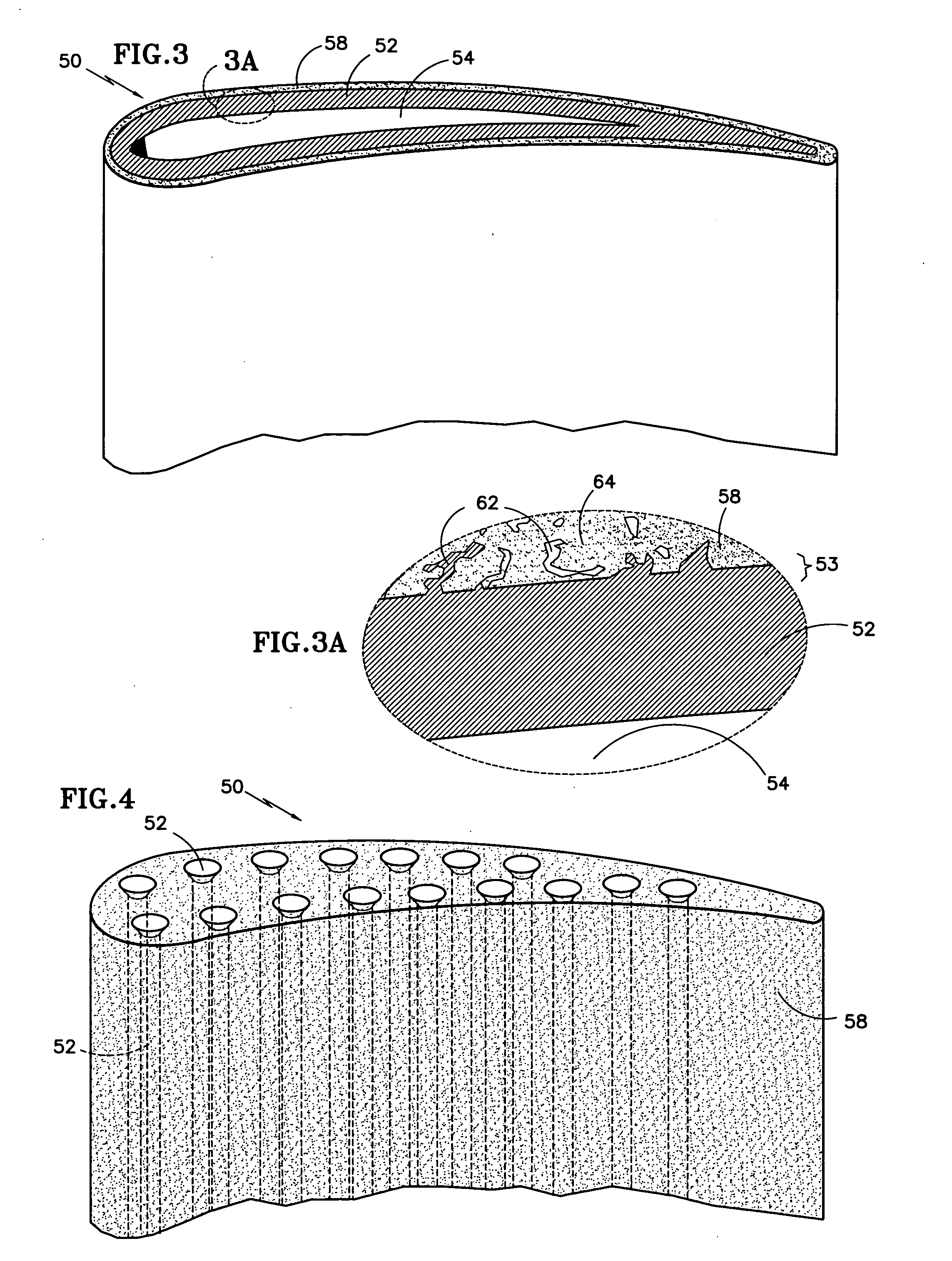

Controlled local/global and micro/macro-porous 3D plastic, polymer and ceramic/cement composite scaffold fabrication and applications thereof

InactiveUS7087200B2Easy to controlImprove interconnectivityMouldsJoint implantsManufacturing technologyFree form

An indirect solid free form scaffold manufacturing technique is provided. More particularly, the present invention provides a set of molds, casting methods, mold removals, and surface modification techniques that are compatible with image-based design methods and with solvent, melt, and slurry casting of polymers and ceramics.

Owner:RGT UNIV OF MICHIGAN

Method of forming a temporary implant and mold assembly for same

InactiveUS20070222114A1Risk of separationArtificial flowers and garlandsJoint implantsBone cementMaterials science

A mold assembly and method of forming a surgical implant from bone cement. The method has the steps of connecting a plurality of mold segments to approximate the size of a patient implant. Each mold segment has an open channel. The method may further include aligning the channels of connected mold segments, positioning a centralizing holder on a reinforcement member, mixing bone cement, pouring at least some bone cement through the channels and into connected mold segments, fitting the reinforcement member into the mold segments, curing the bone cement; and removing the cured surgical implant.

Owner:ZIRAN BRUCE H +1

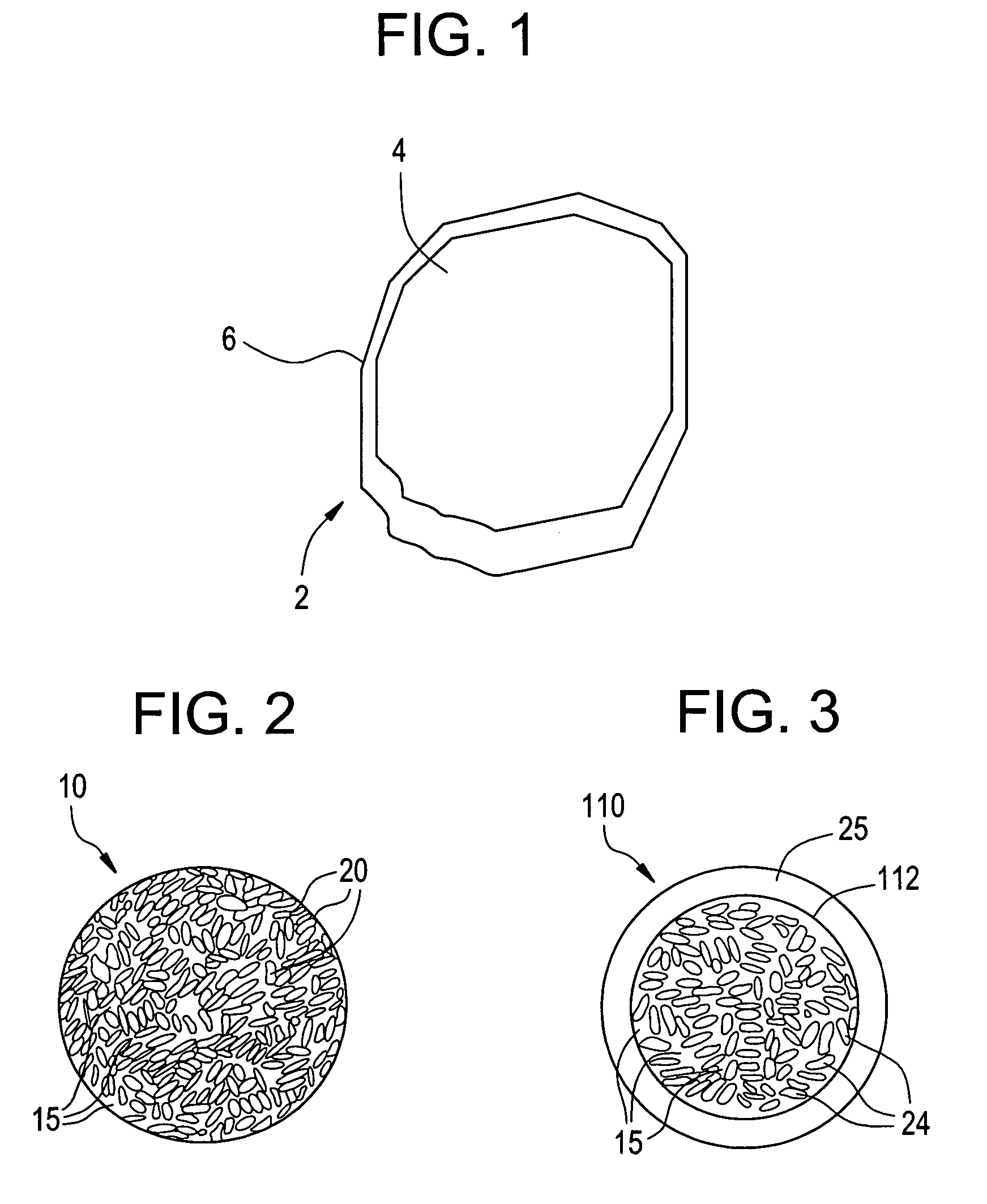

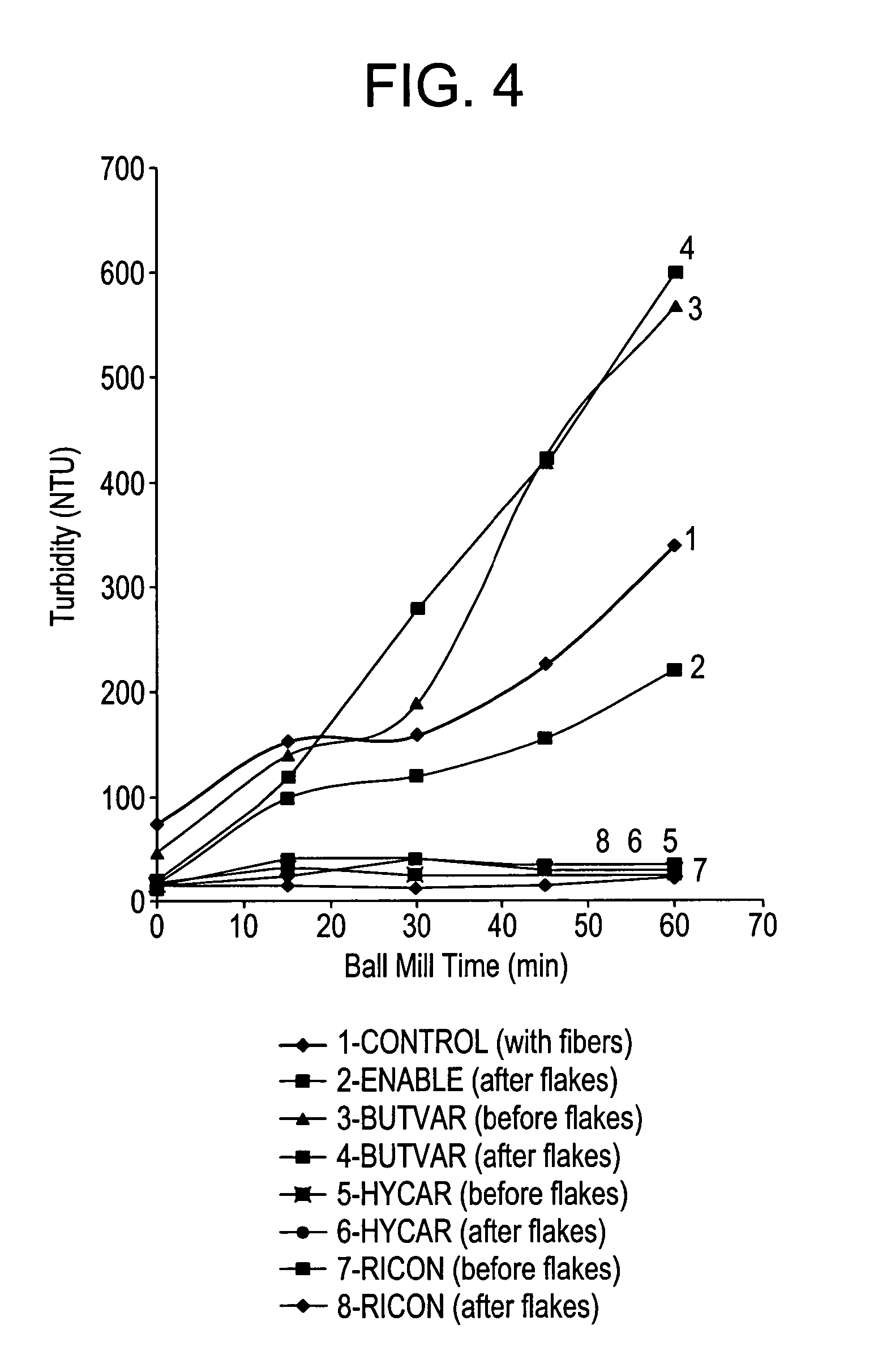

Particulate material containing thermoplastics and methods for making and using the same

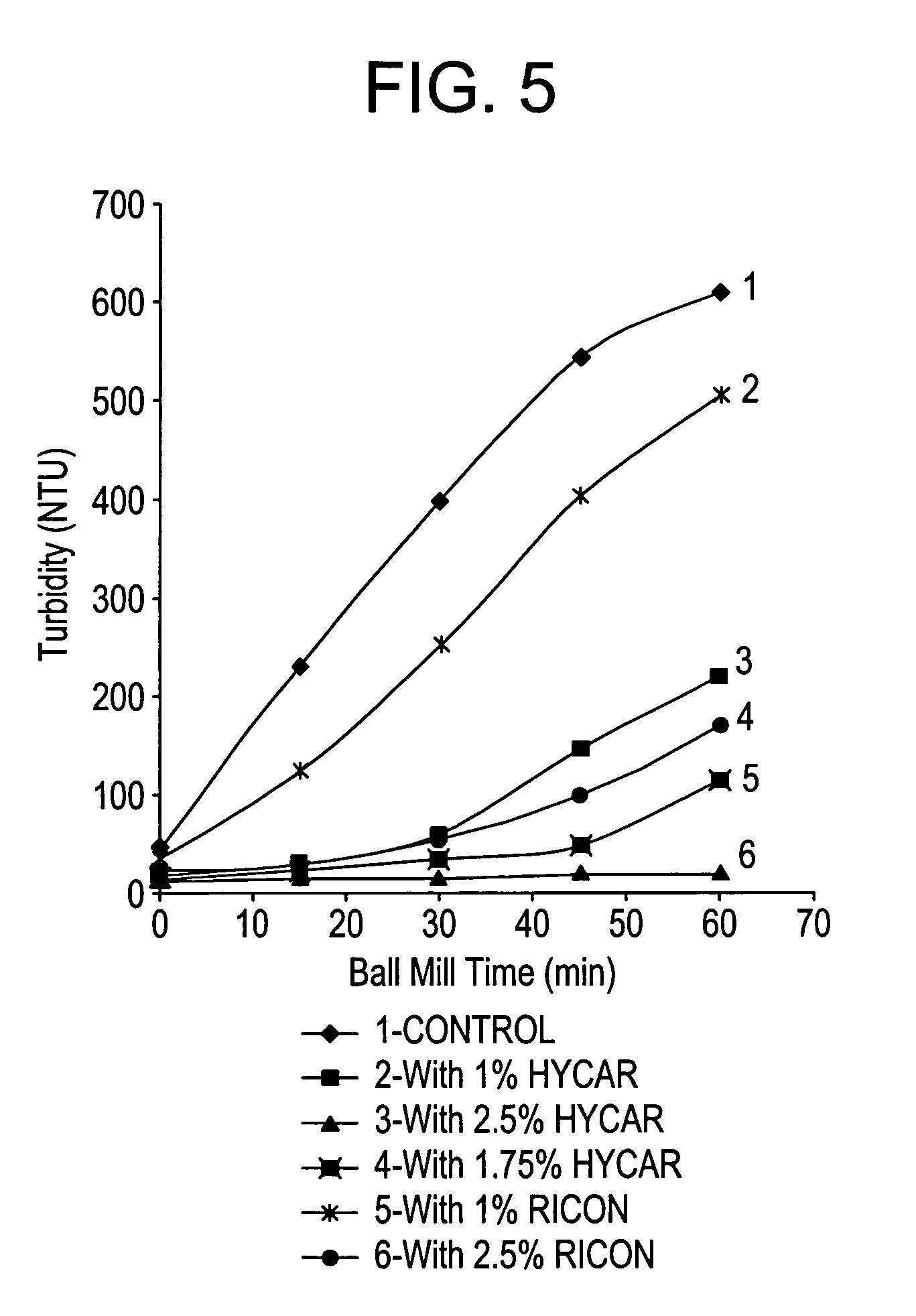

ActiveUS7270879B2Trend downImprove abilitiesPretreated surfacesGlass/slag layered productsParticulatesThermoplastic

Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer present on or in the substrate as an amount sufficient to improve the dust suppression of the particle above that which would occur if the thermoplastic elastomer was absent. Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer, wherein the particle has a compressive strength retention of greater than about 50% as measured by a UCS test and a turbidity of about 10 to 200 NTU after a one hour ball mill test.

Owner:HEXION INC

Contact lens mold assemblies and systems and methods of producing same

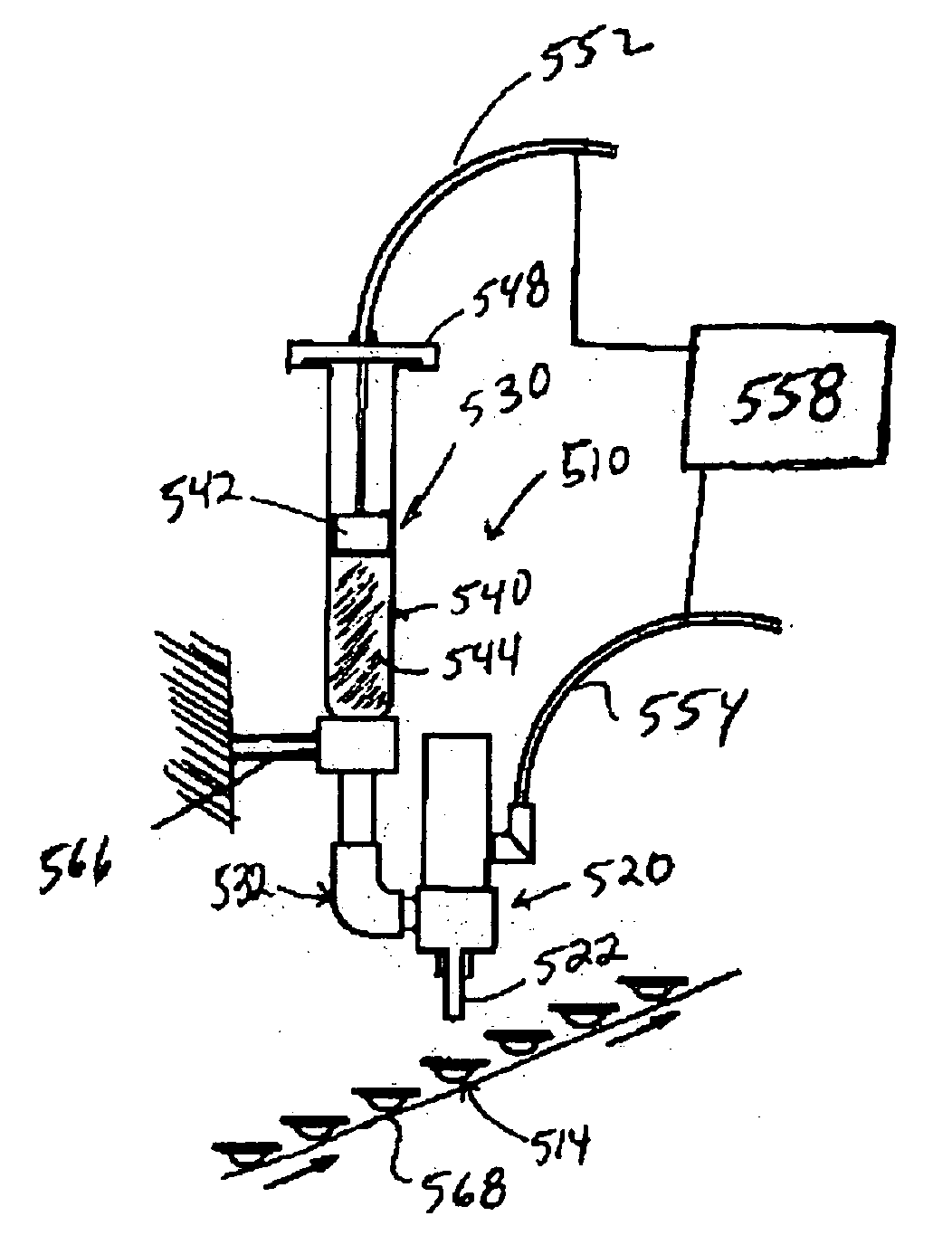

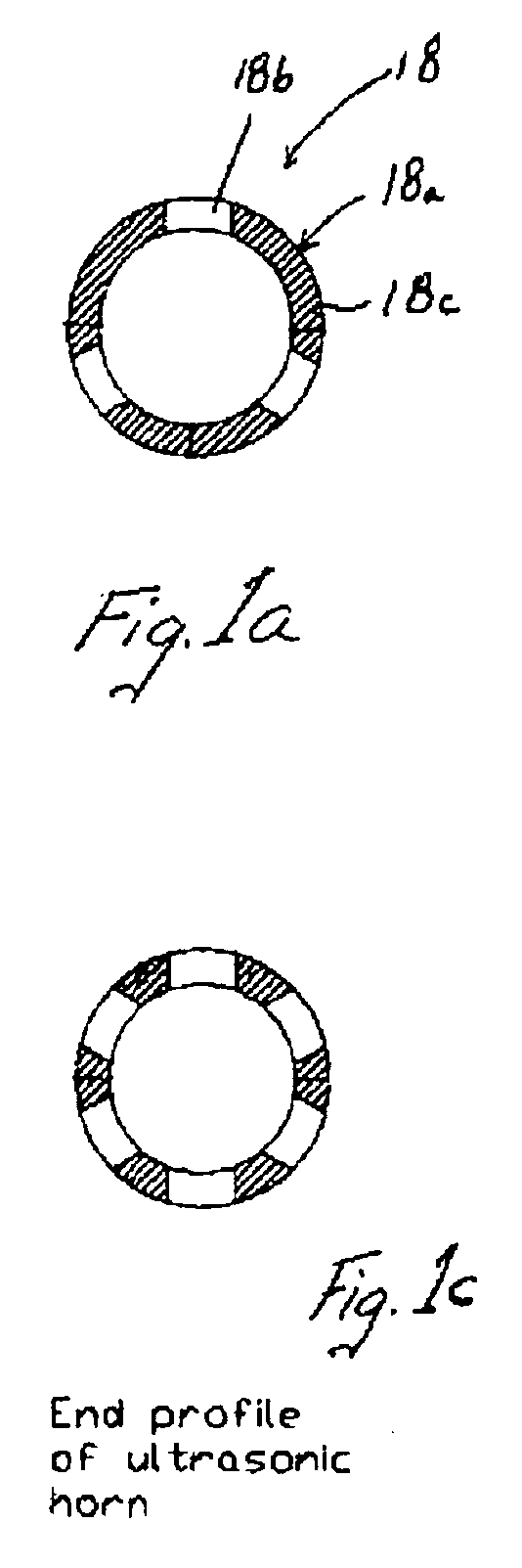

ActiveUS20070035051A1Prevent materialEnhanced cavitationOptical articlesStereotype platesEngineeringContact lens

Methods and apparatus are provided for making an ophthalmic lens. Apparatus are provided for filling contact lens shaped cavities of contact lens molding assemblies. Methods of coupling and fusing contact lens mold sections are also provided and generally include providing first and second mold sections which when coupled together are effective to form a lens-shaped cavity and contact regions between the mold sections. One or both of the mold sections may include one or more recessed regions or projections which provide areas of non-fusion and areas of fusion, respectively, when the mold sections have been filled with a contact lens precursor material and are fused together, for example, by means of focused ultrasound energy.

Owner:COOPERVISION INT LTD

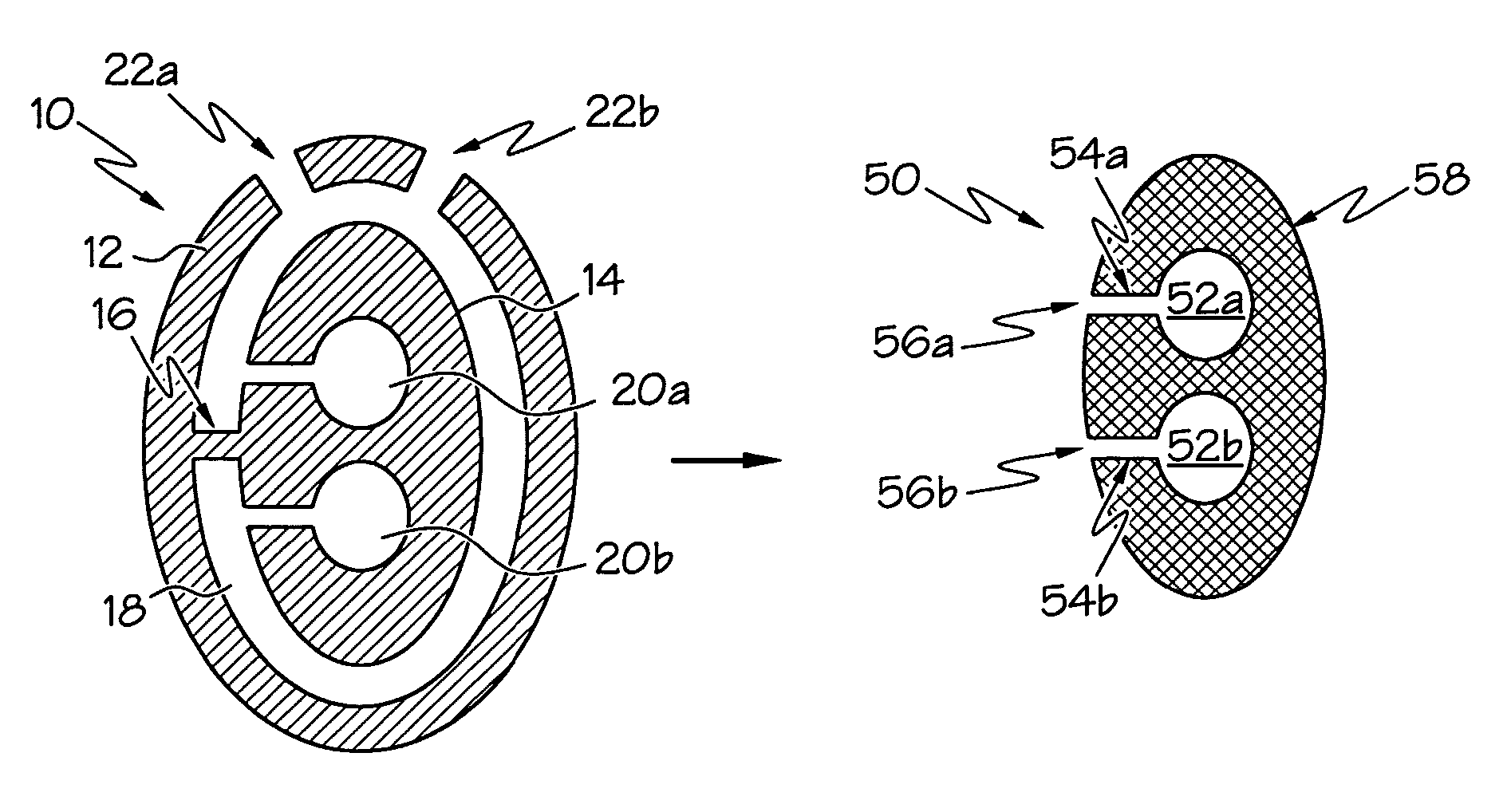

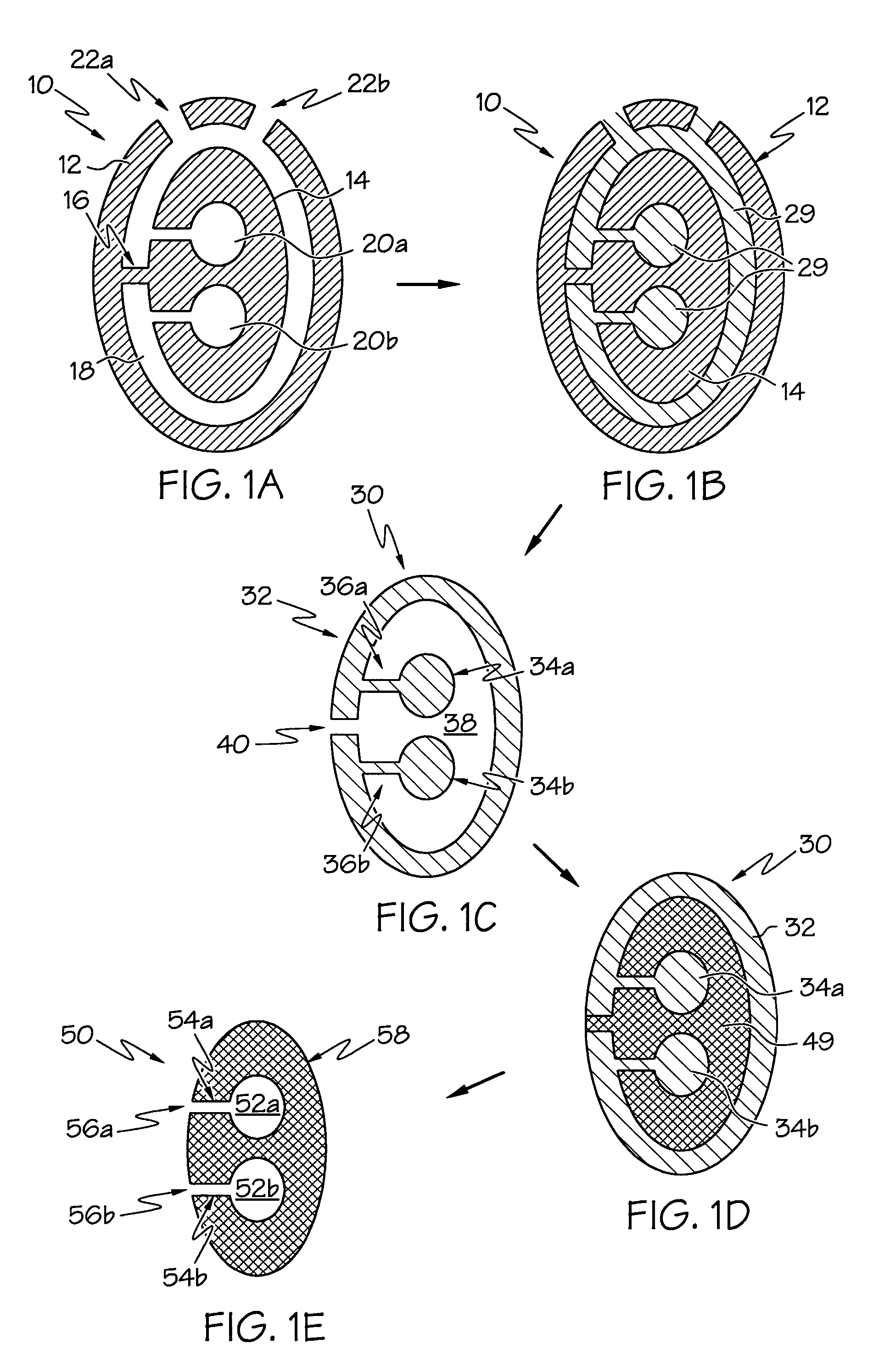

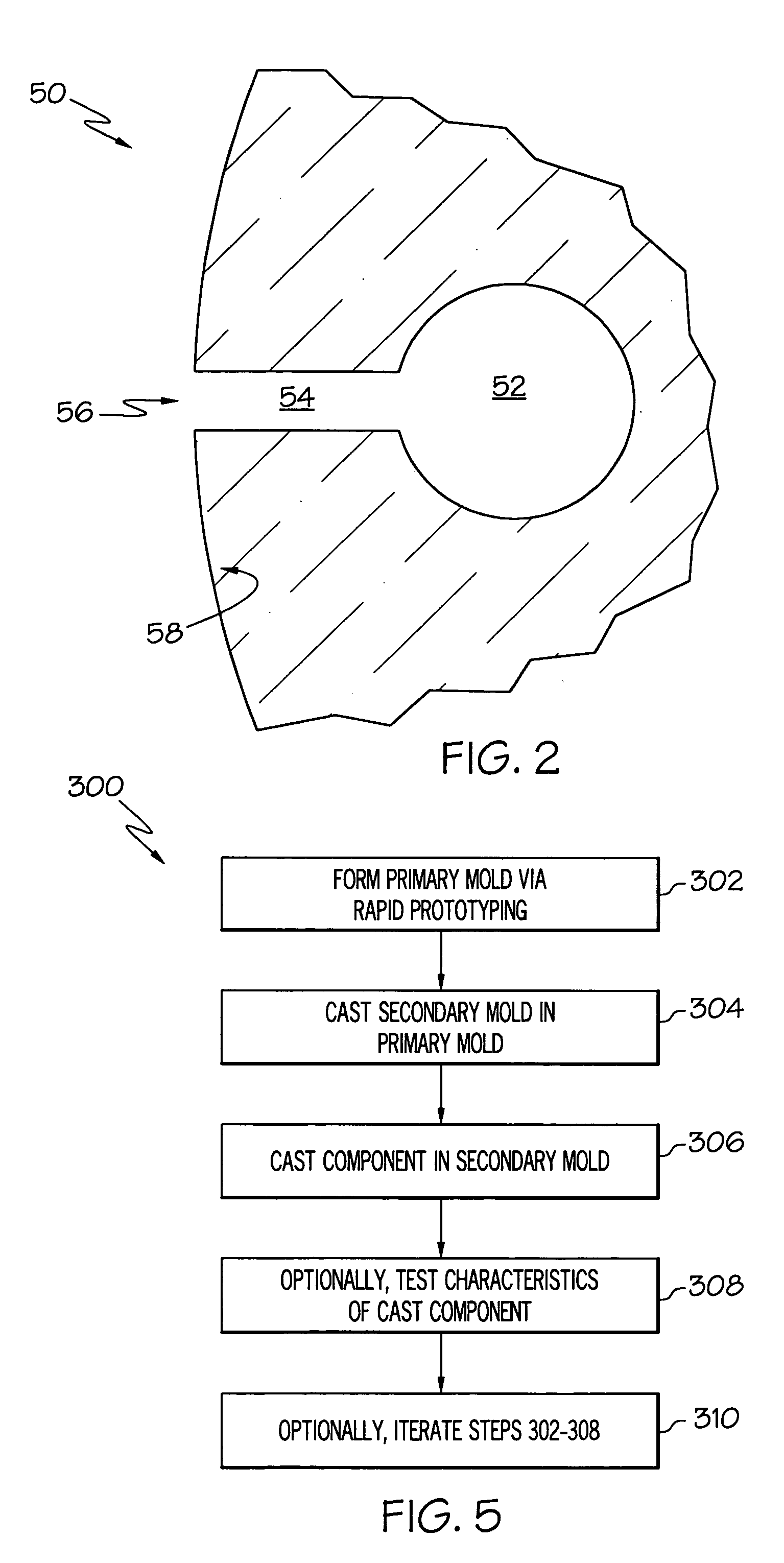

Rapid prototype casting

Methods for rapid prototype casting metal components, wherein the metal components are cast in a secondary ceramic mold, the secondary ceramic mold is cast in a primary mold, and the primary mold is formed by rapid prototyping or rapid manufacturing. The secondary ceramic mold may comprise a one-piece integral shell and core(s), and the metal components may have at least one hollow portion or void therein, such as a hollow airfoil for a gas turbine engine.

Owner:HONEYWELL INT INC

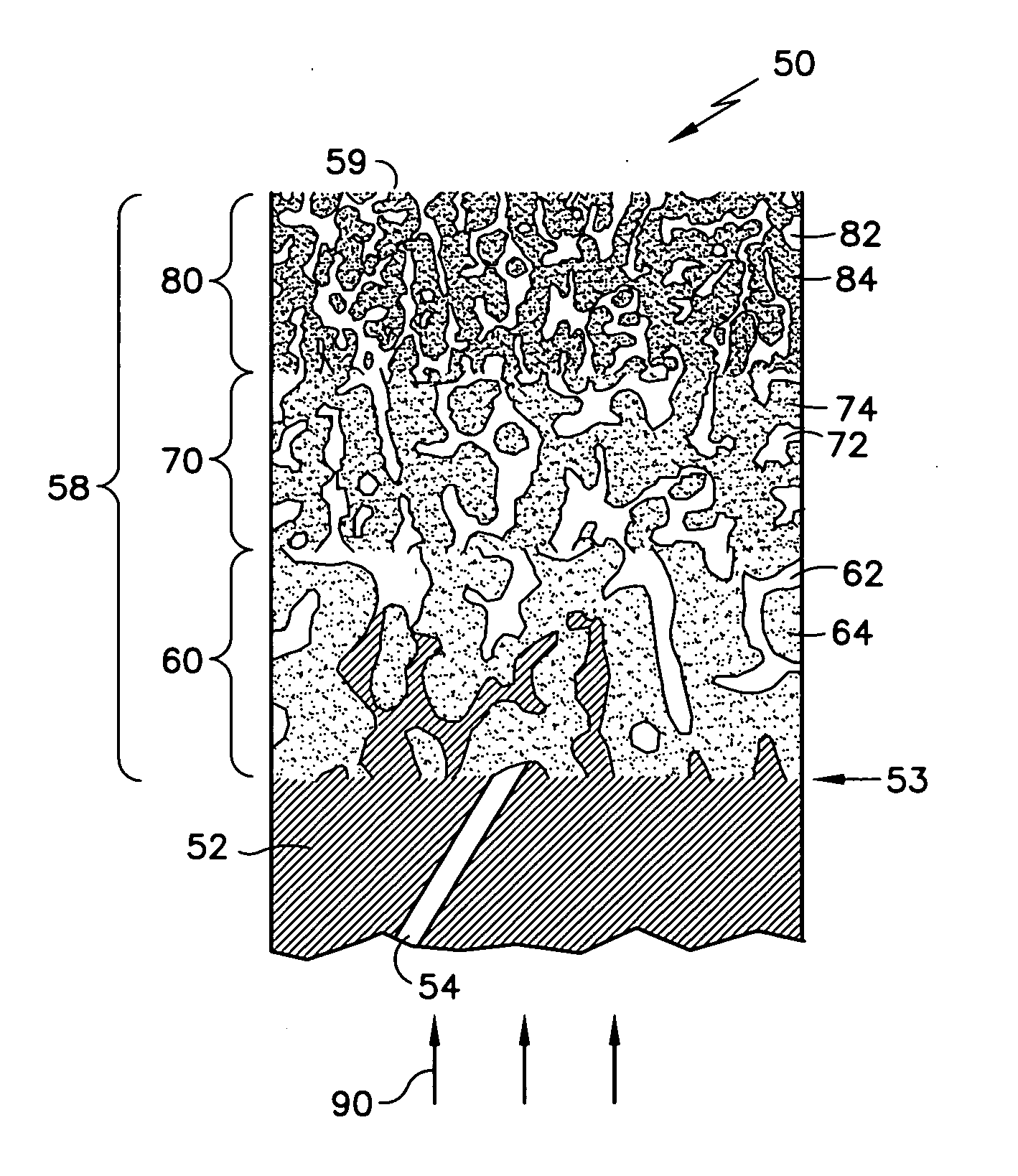

Integrated ceramic/metallic components and methods of making same

Integrated ceramic / metallic components and methods of making same are described herein. Embodiments of these integrated ceramic / metallic components comprise a metallic non-foam region; and a ceramic foam region comprising a gradient porosity therein, wherein the ceramic foam region and the metallic non-foam region are integrally formed together to create the integrated ceramic / metallic component. Embodiments of these integrated ceramic / metallic components comprise a metallic region; and a single piece ceramic foam construction comprising a plurality of ceramic foam regions therein, each ceramic foam region comprising a predetermined pore size and a predetermined volume percent porosity, wherein the single piece ceramic foam construction is integrally joined to the metallic region to form the integrated ceramic / metallic component. These components may be utilized in gas turbine engines.

Owner:UNITED TECH CORP

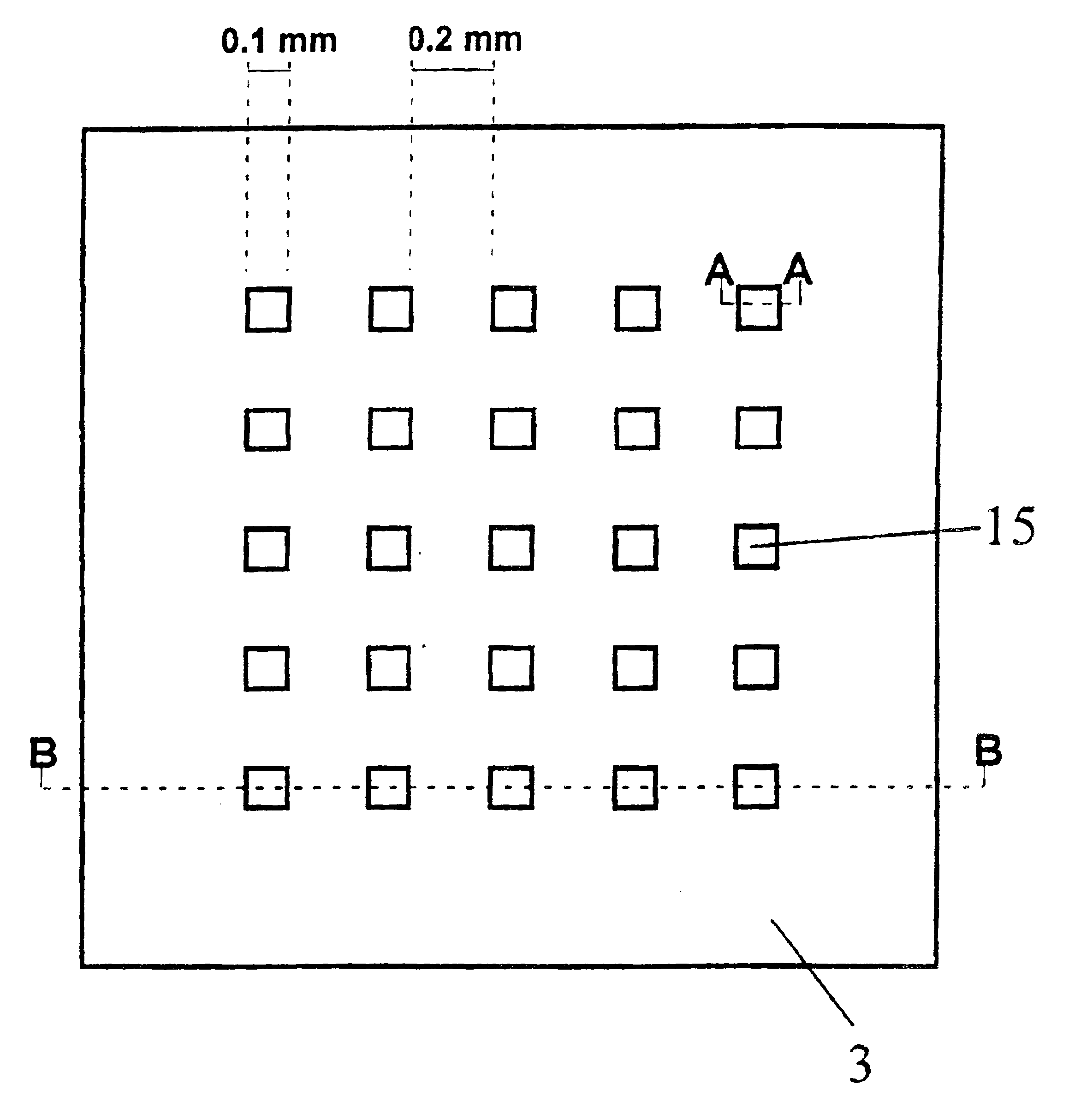

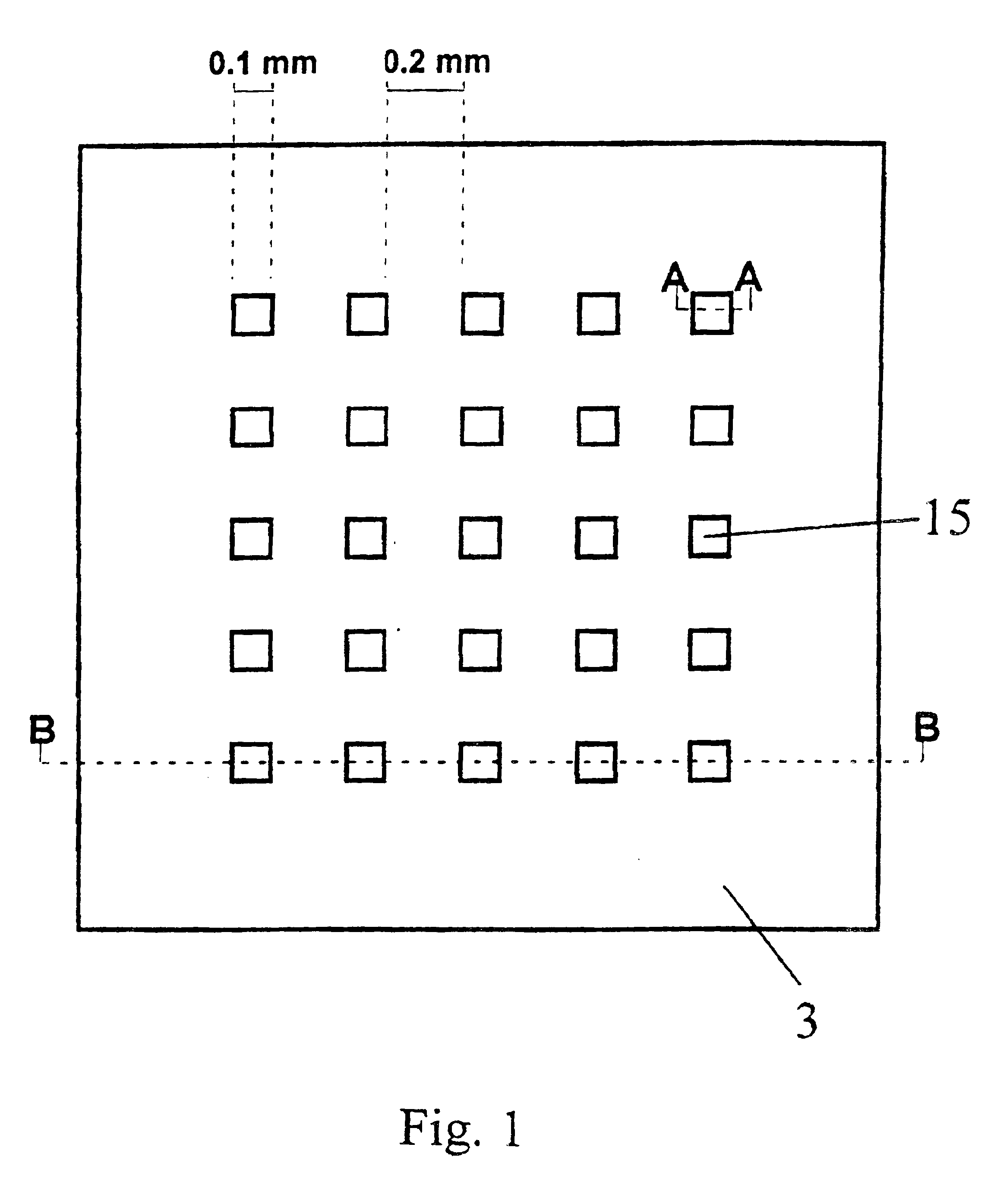

Non-specific binding resistant protein arrays and methods for making the same

InactiveUS6897073B2Effective resistanceMaterial nanotechnologyBioreactor/fermenter combinationsBiological bodyCell biology

Arrays of protein-capture agents useful for the simultaneous detection of a plurality of proteins which are the expression products, or fragments thereof, of a cell or population of cells in an organism are provided. A variety of antibody arrays, in particular, are described. Methods of both making and using the arrays of protein-capture agents are also disclosed. The invention arrays are particularly useful for various proteomics applications including assessing patterns of protein expression and modification in cells.

Owner:ZYOMYX

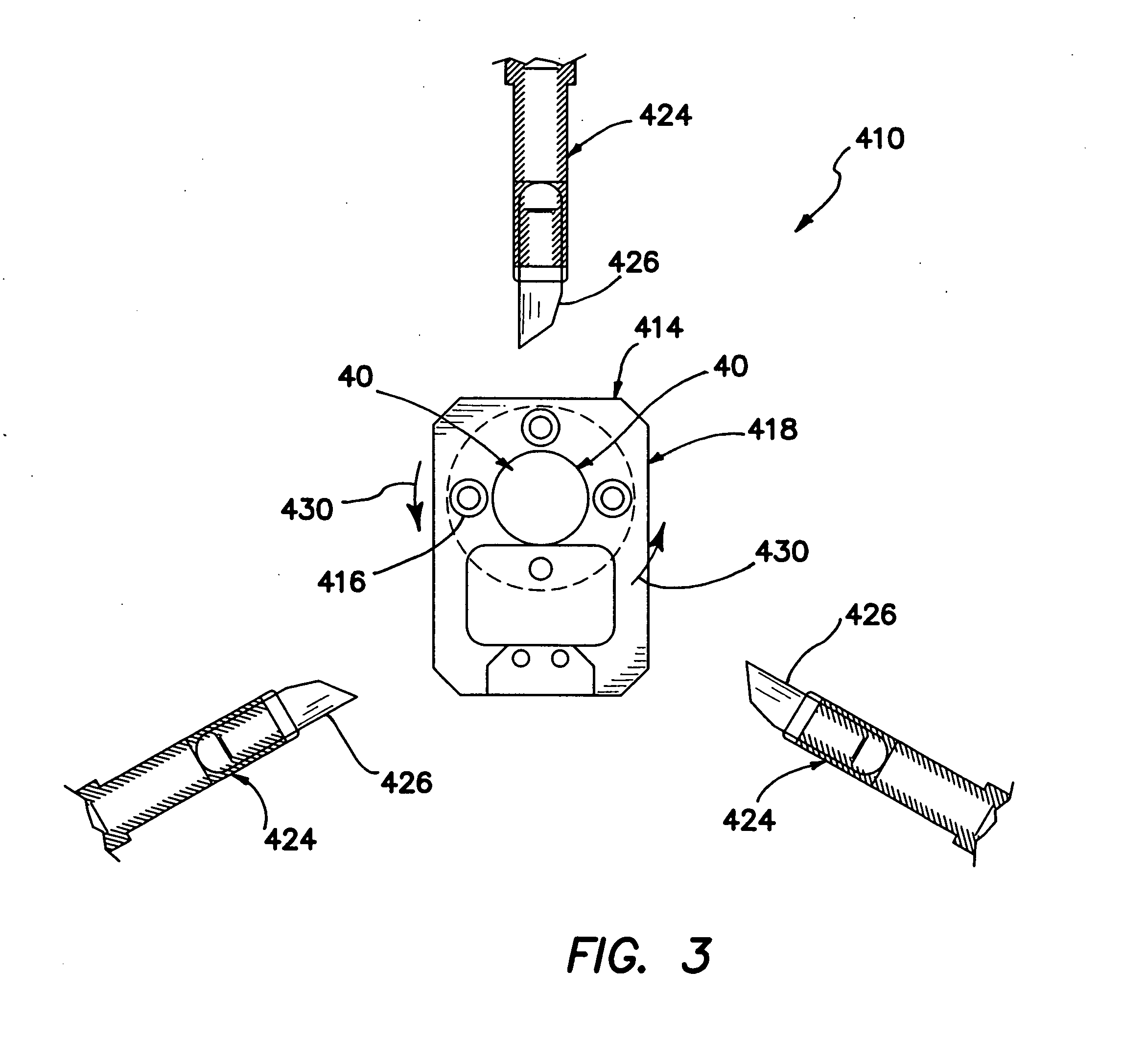

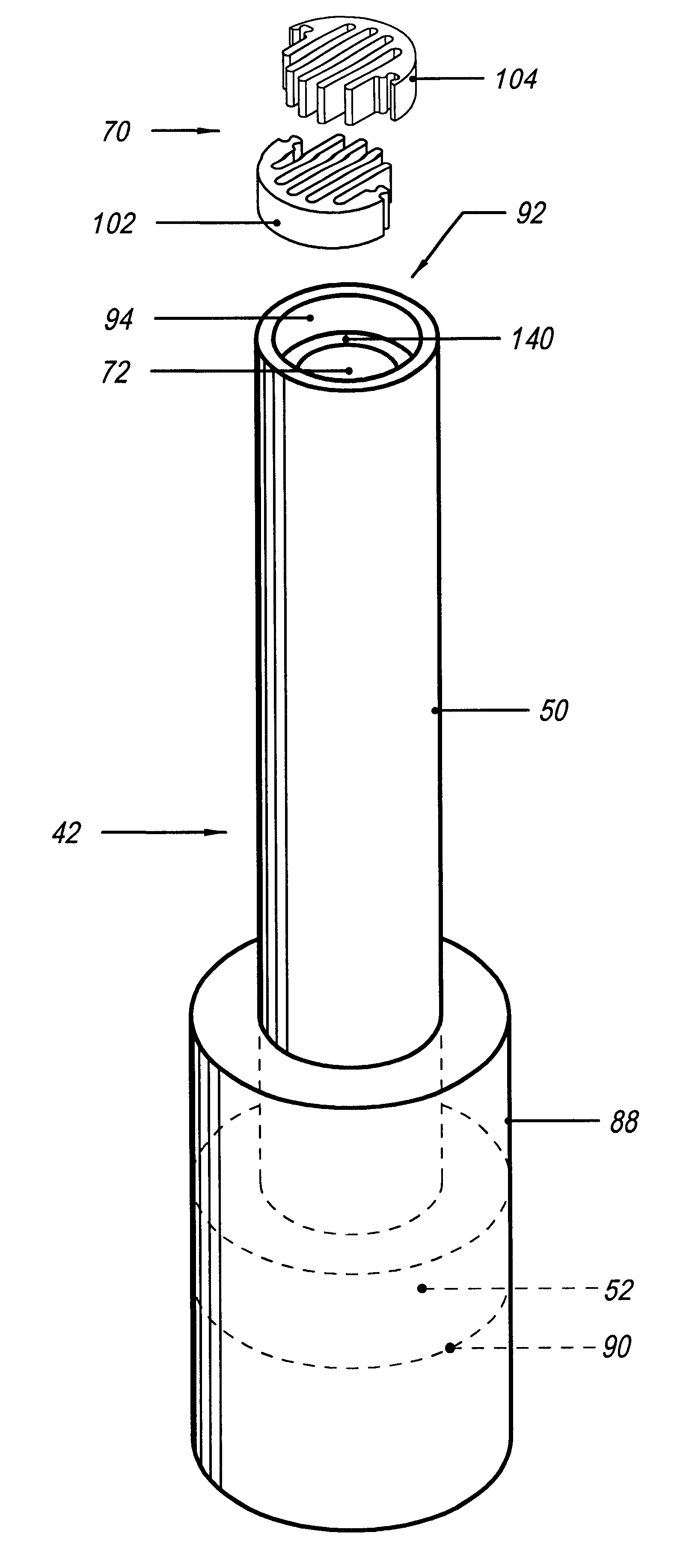

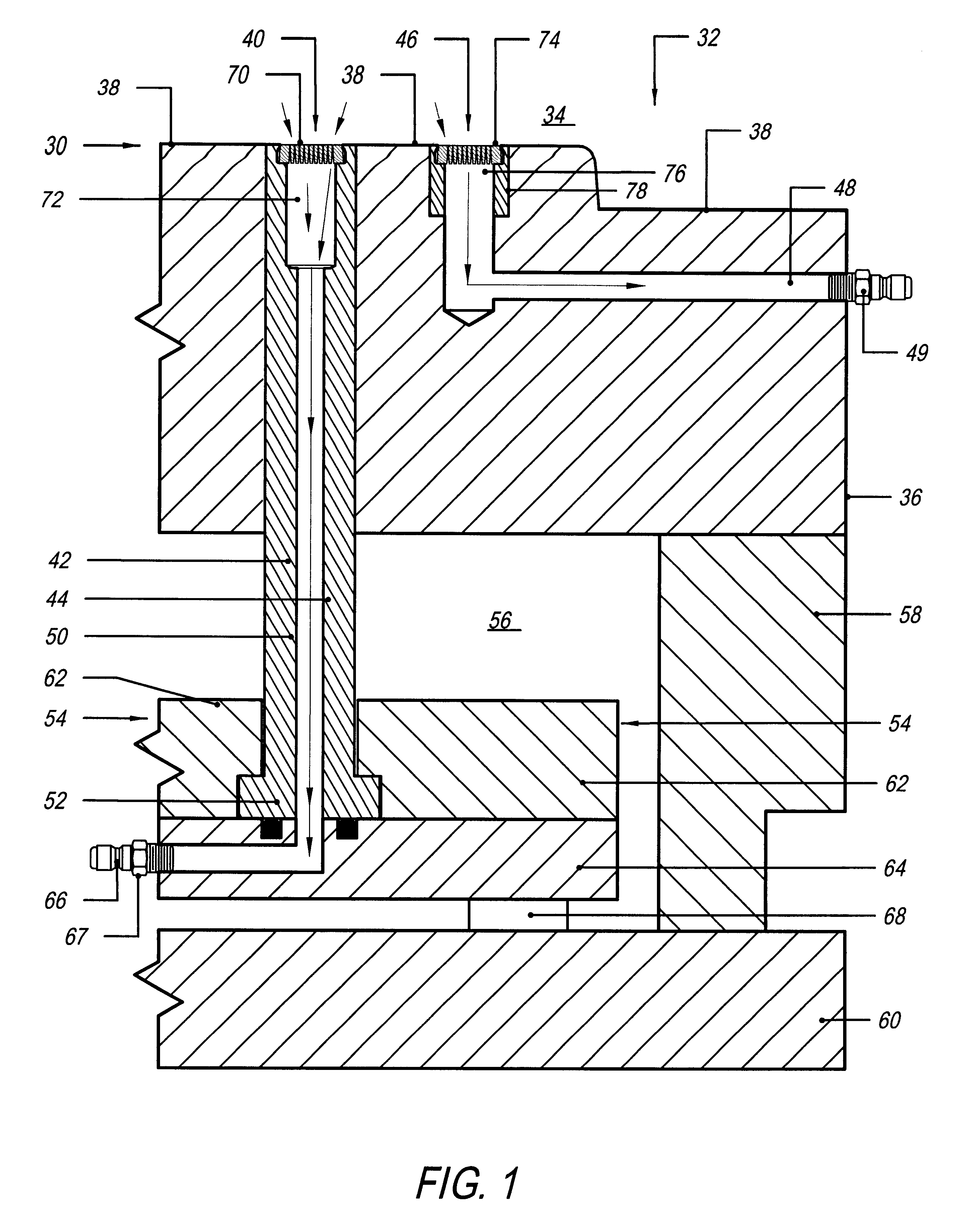

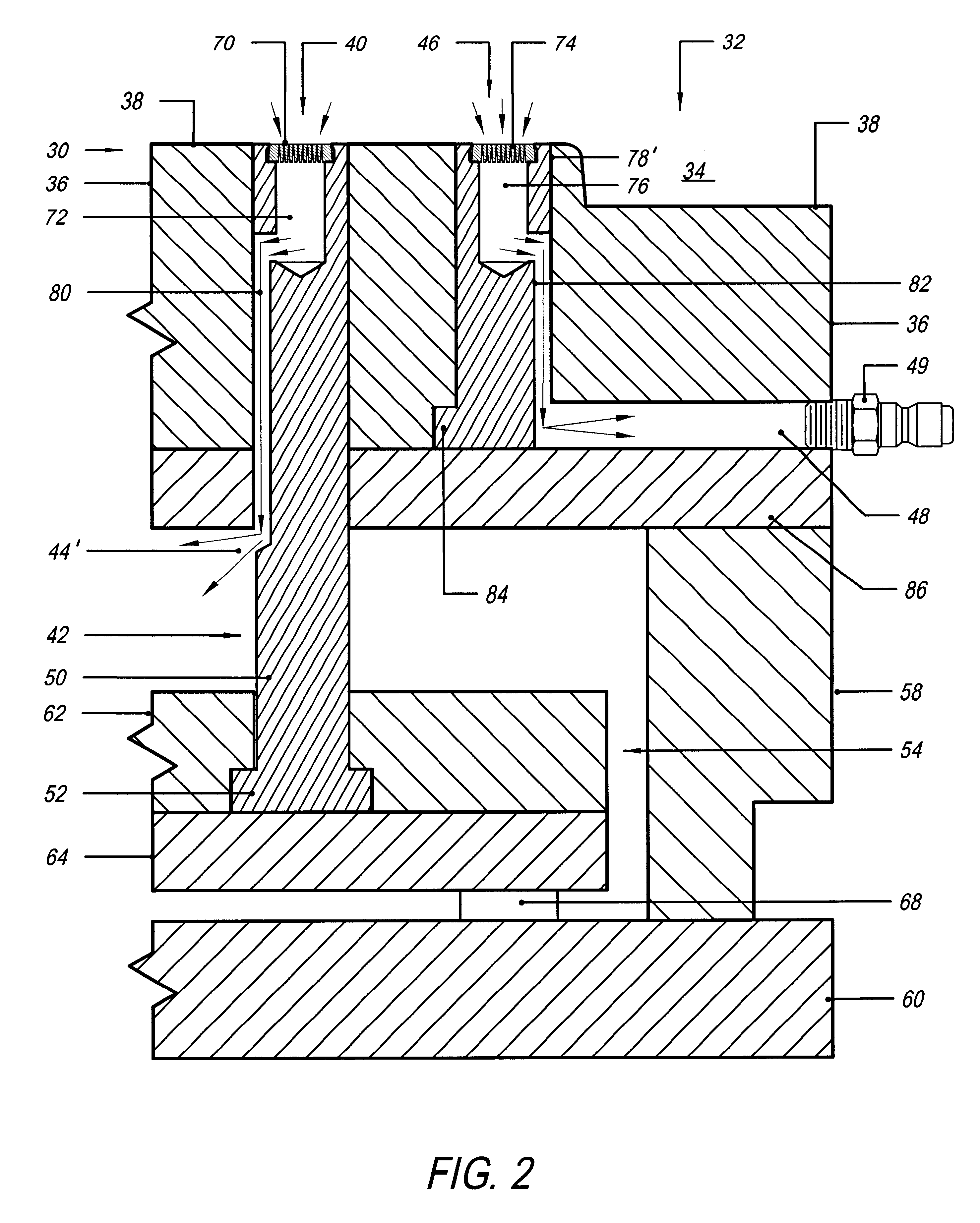

Mold vent

InactiveUS6367765B1Avoid flowIncrease surface areaConfectioneryFoundry mouldsEngineeringMechanical engineering

A vent, system and method for controlling flow of fluid into and out of a mold cavity. The vent has a plurality of passages that each have narrow oblong slot-shaped openings in the mold cavity and which each expand in size in a direction leading away from its opening. The vent preferably is an insert that comprises a grate with at least a plurality of vent slots. The grate preferably is formed of two halves with fingers that interleave to form the slots when assembled. The grate preferably is discharge machined from disc-shaped blanks cut from elongate stock made a material that preferably is non-porous and smooth. The grate can be mounted in a pocket in the mold cavity or carried by a movable pin. A system uses valving and a source of fluid and, if needed, a source of vacuum to help facilitate venting by drawing atmosphere out of the cavity during molding. The system can also be used to introduce fluid through a vent such as for foaming moldable material in the cavity. The system can also be used to introduce a heat transfer medium into the mold cavity. The system can also be used to accelerate venting during one part of a mold cycle and then introduce fluid into the cavity during the same cycle.

Owner:WIEDER KLAUS A

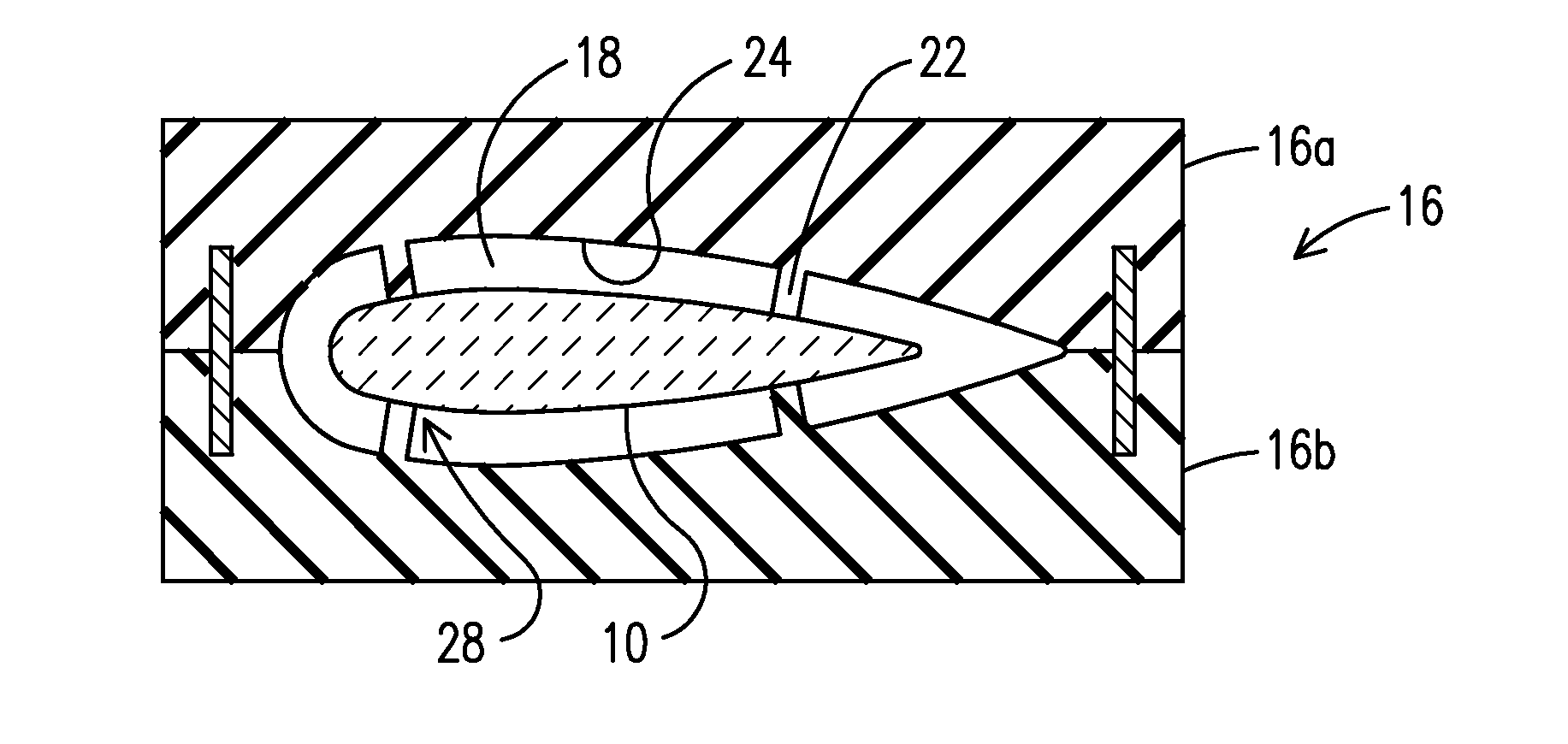

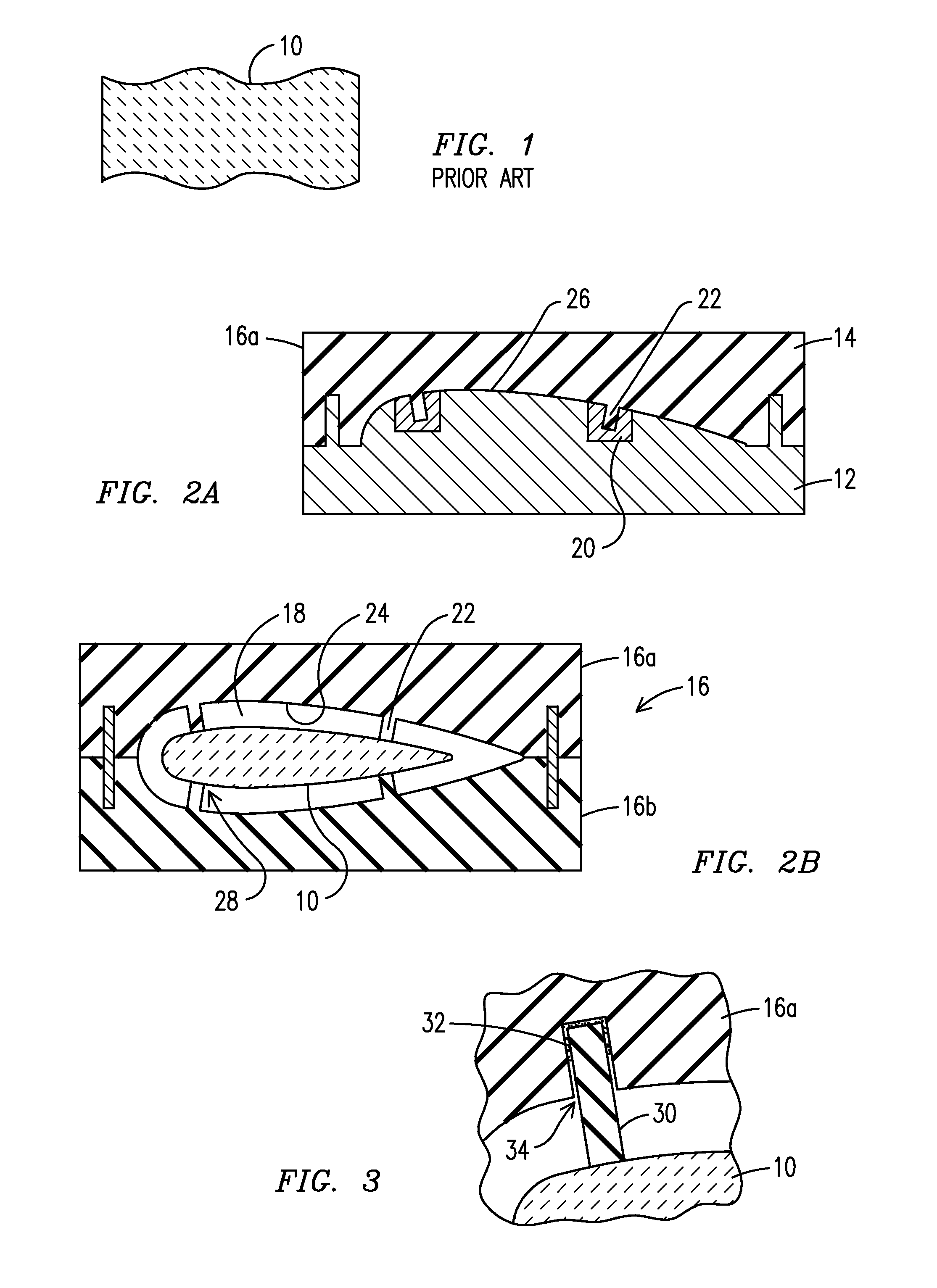

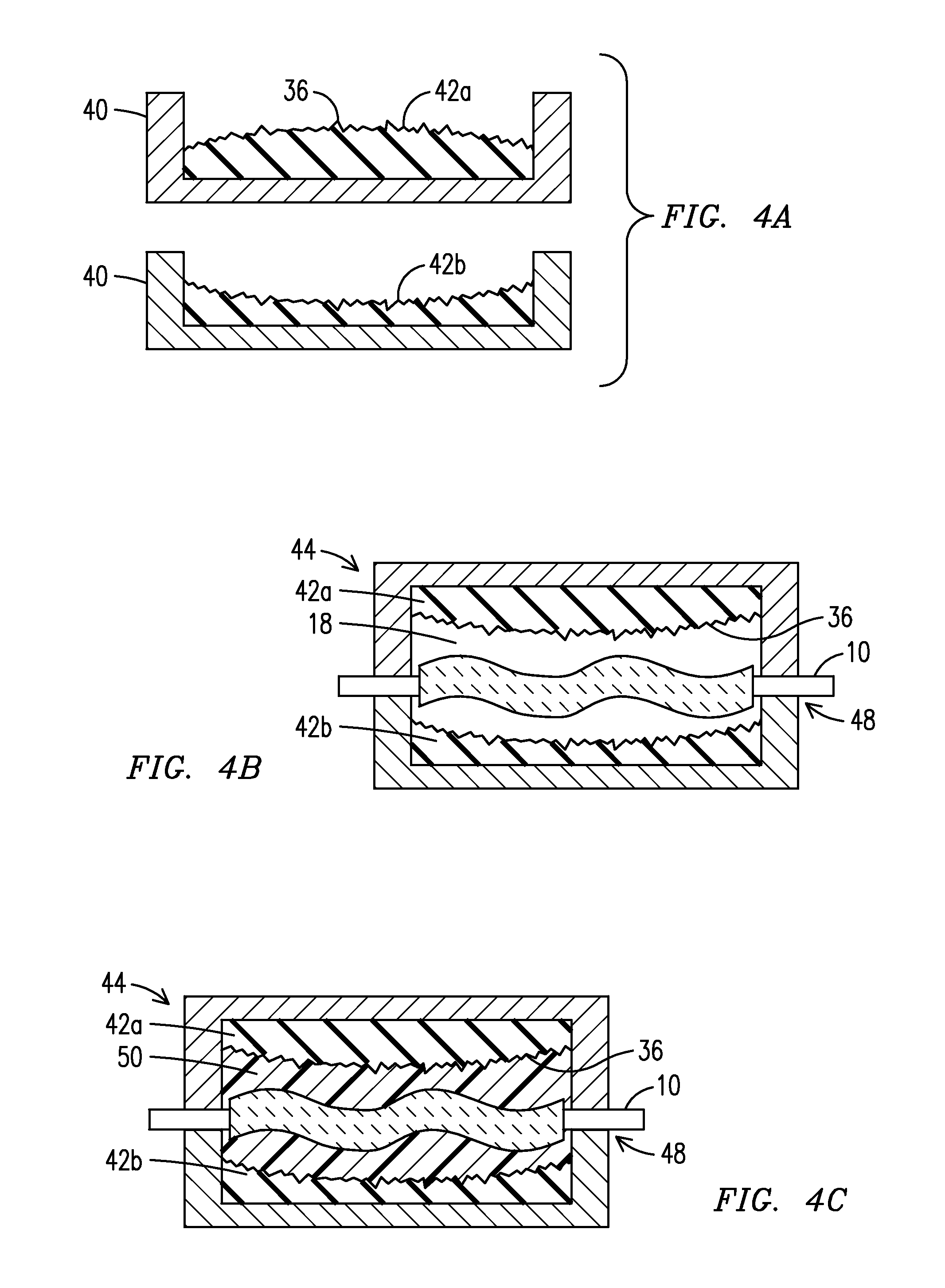

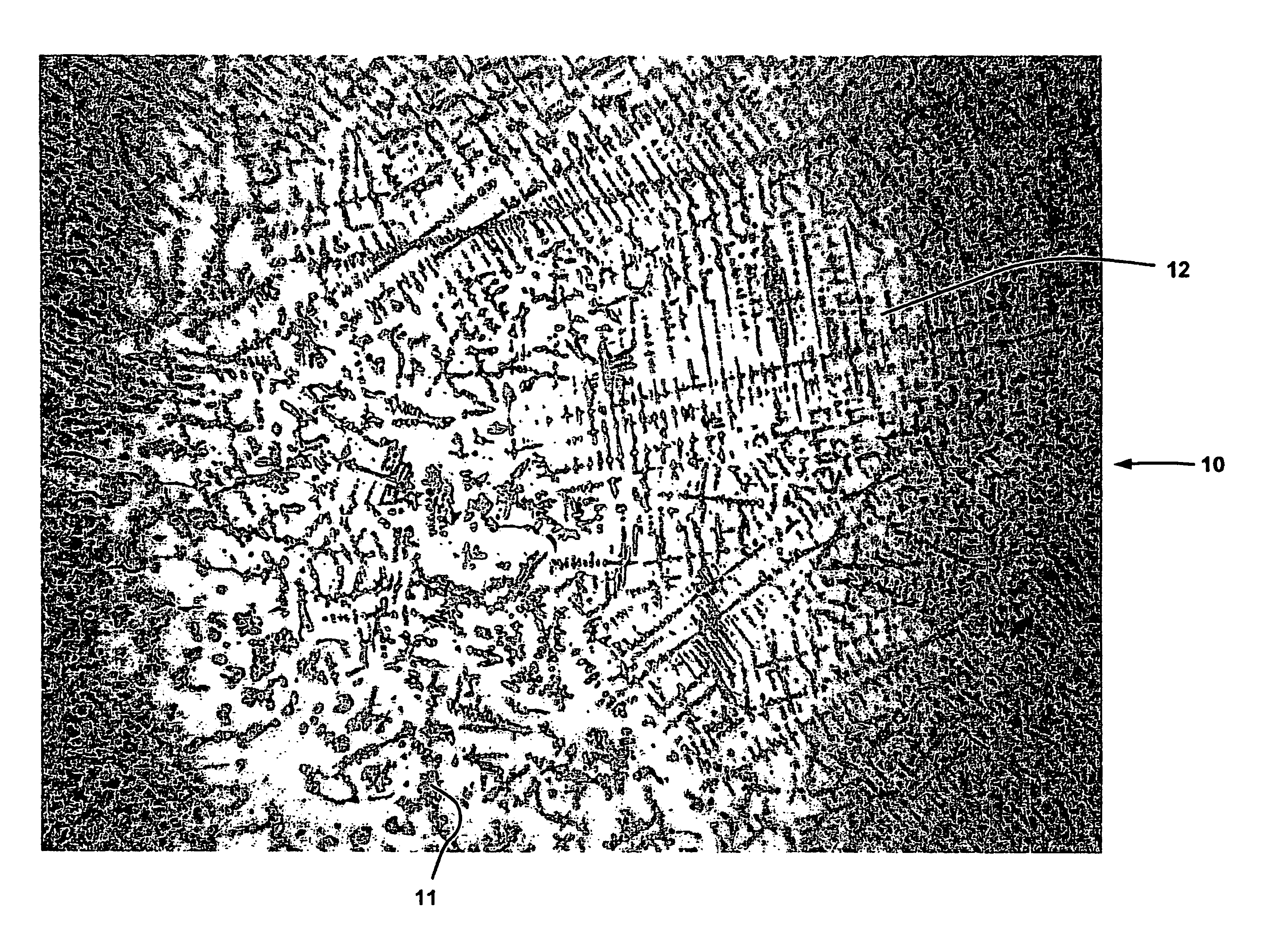

Investment casting utilizing flexible wax pattern tool for supporting a ceramic core along its length during wax injection

InactiveUS20130333855A1Reducing incidence of damage and movementIncrease pressureFoundry mouldsFoundry coresInjection pressureInvestment casting

An investment casting process wherein the wax pattern tool (42) is flexible to provide compliant support for an enclosed ceramic core (10) and to facilitate removal of the tool from the cast wax pattern (52) even when the cast shape would otherwise require multiple pull planes. Positioning pins (106) may extend from the flexible tool to make compliant contact against the core during the wax injection step. The pins may cooperate with a pedestal (128) formed on the core to support the core along multiple axes during wax injection, thereby allowing a higher wax injection pressure without damage to the core.

Owner:MIKRO SYSYTEMS INC +1

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

Method for producing metal fibers

Owner:ATI PROPERTIES

3D multi-stage method

ActiveUS20150273572A1Reduce or entirely avoid time-consuming and cost-intensive manual workFacilitate machine- or robot-assisted unpackingAdditive manufacturing apparatusFoundry mouldsThermal energyMaterials science

The present invention relates to a multi-stage method for producing one or multiple molded bodies, the method comprising the following steps: a) constructing one or multiple molded bodies in layers by repeatedly applying particulate material by the 3D printing method; b. a presolidification step for achieving a presolidification of the molded body; c. an unpacking step, wherein the unsolidified particulate material is separated from the presolidified molded body; d. a final solidification step, in which the molded body receives its final strength due to the action of thermal energy. The invention also relates to a device which may be used for this method.

Owner:VOXELJET AG

Solid free-form fabrication methods for the production of dental restorations

Solid free form fabrication techniques such as fused deposition modeling and three-dimensional printing are used to create a shell or die used in the manufacture of a dental restoration. Three-dimensional printing includes ink-jet printing a binder into selected areas of sequentially deposited layers of powder. Each layer is created by spreading a thin layer of powder over the surface of a powder bed. Instructions for each layer may be derived directly from a CAD representation of the restoration. The area to be printed is obtained by computing the area of intersection between the desired plane and the CAD representation of the object. All the layers required for an aesthetically sound shell can be deposited concurrently slice after slice and sintered / cured simultaneously.

Owner:PENTRON LAB TECH

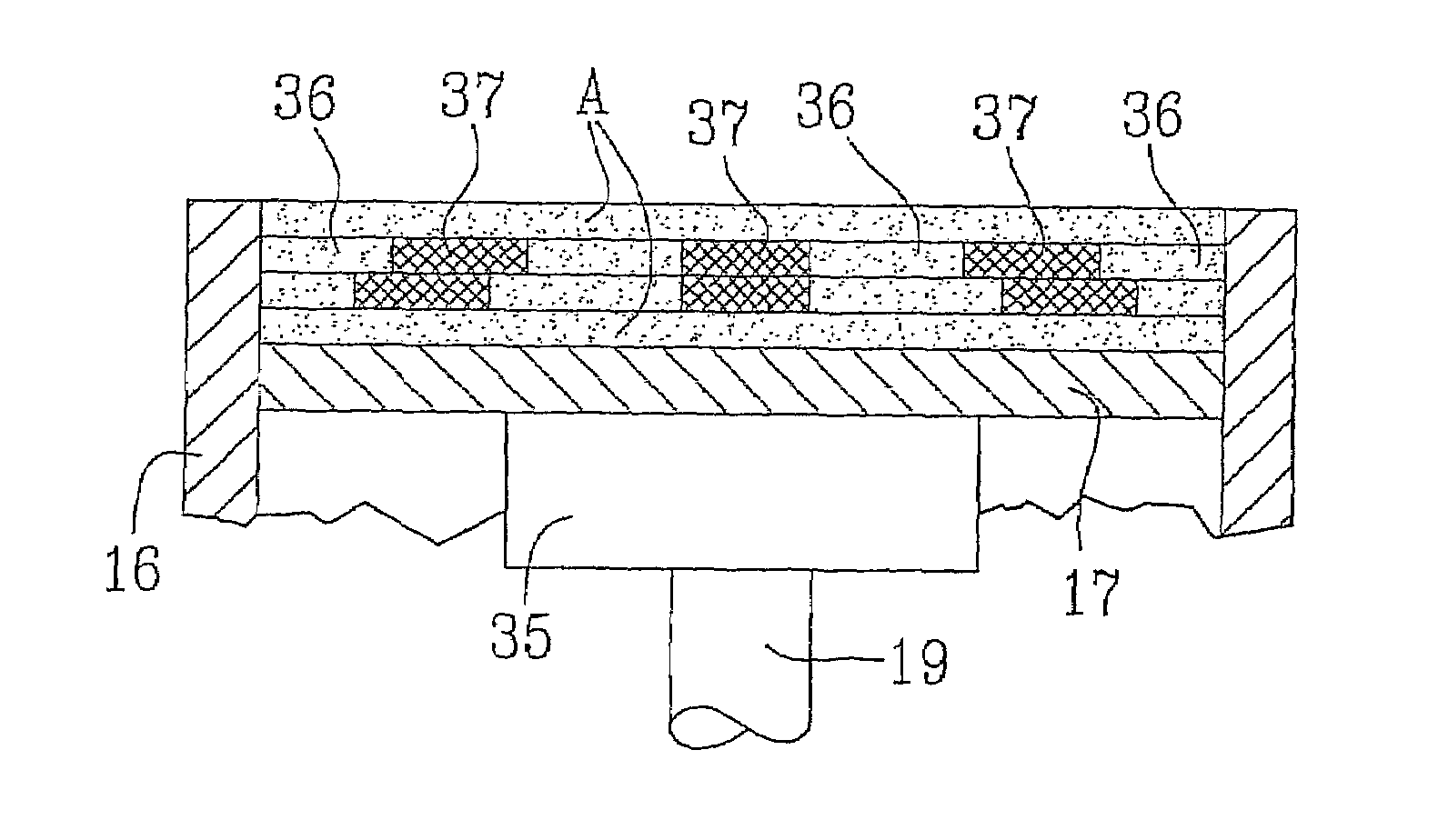

Methods and systems for the manufacture of layered three-dimensional forms

ActiveUS7807077B2Efficiently reclaim and re-useEfficient use ofAdditive manufacturing apparatusFoundry mouldsChemistryComposite material

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

Investment casting mold design and method for investment casting using the same

ActiveUS7231955B1Molten metal pouring equipmentsMolten metal supplying equipmentsInvestment castingCasting mold

A method for investment casting includes the steps of positioning a base plate relative to a die; molding a first material between the die and at least a first surface portion of the base plate; securing one or more patterns to the base plate, the one or more patterns comprising a second material; applying one or more coating layers over at least portions of the one or more patterns and at least a portion of the first material; substantially removing the first material through an interior receptacle of a manifold body and the second material through an exterior receptacle of the manifold body to leave one or more shells formed by the coating layers; removing said base plate; introducing molten metal to the one or more shells through the interior receptacle of the manifold body; permitting the molten metal to solidify; and destructively removing one or more investment casting molds.

Owner:RTX CORP

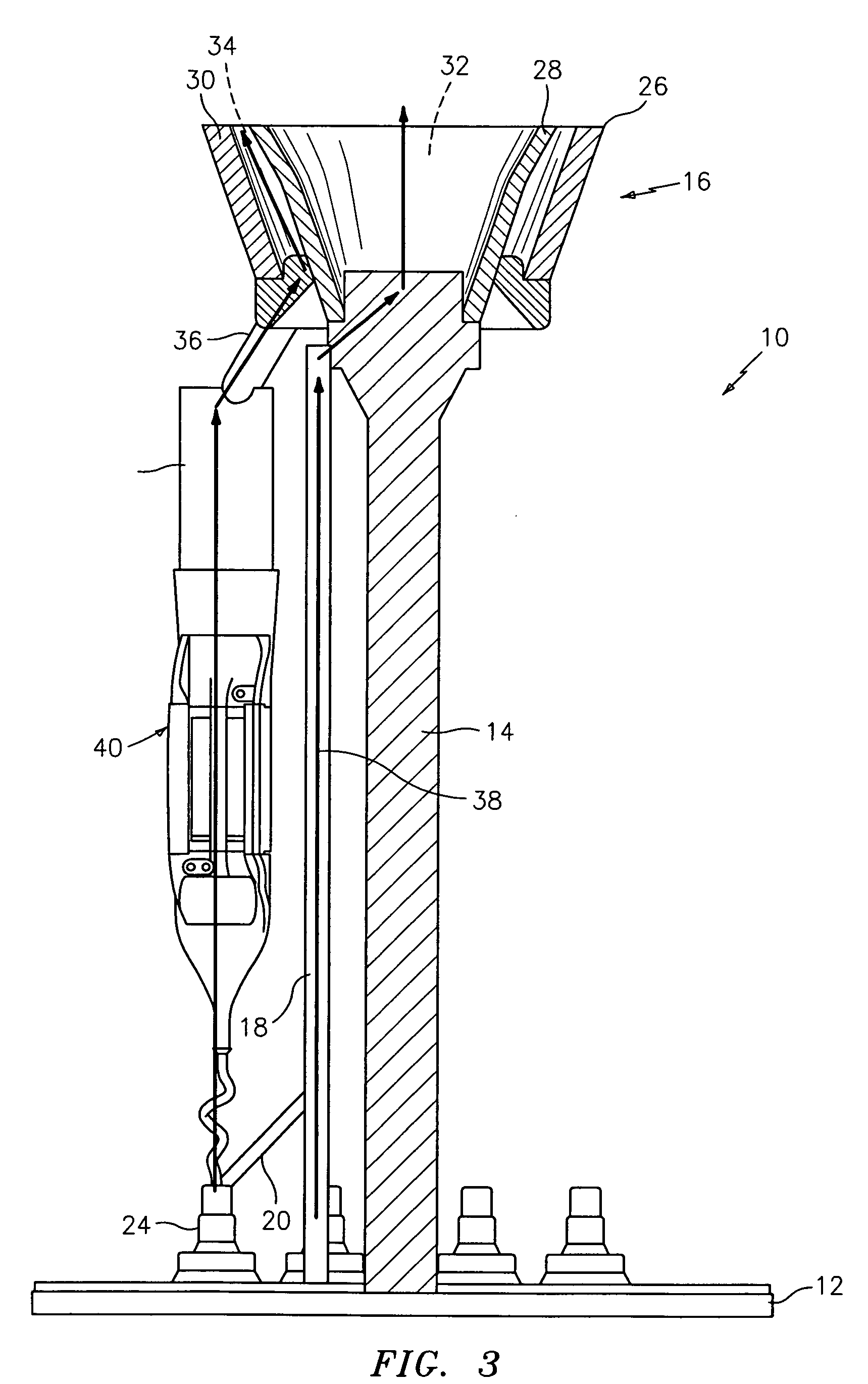

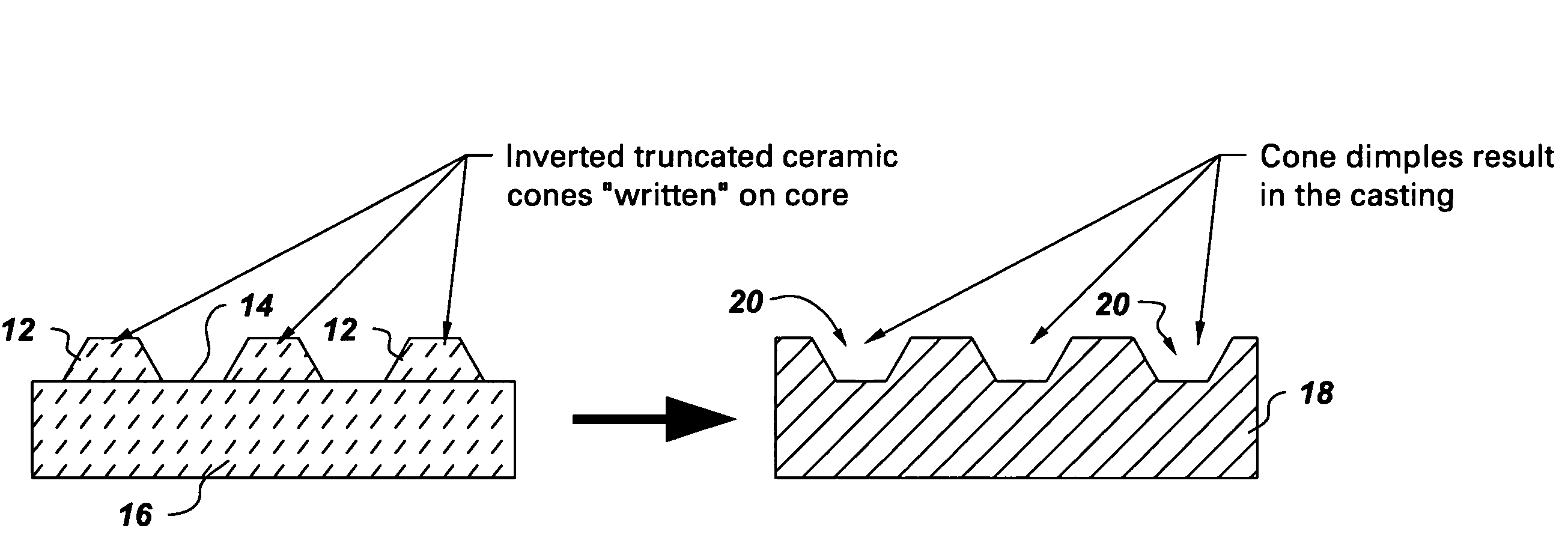

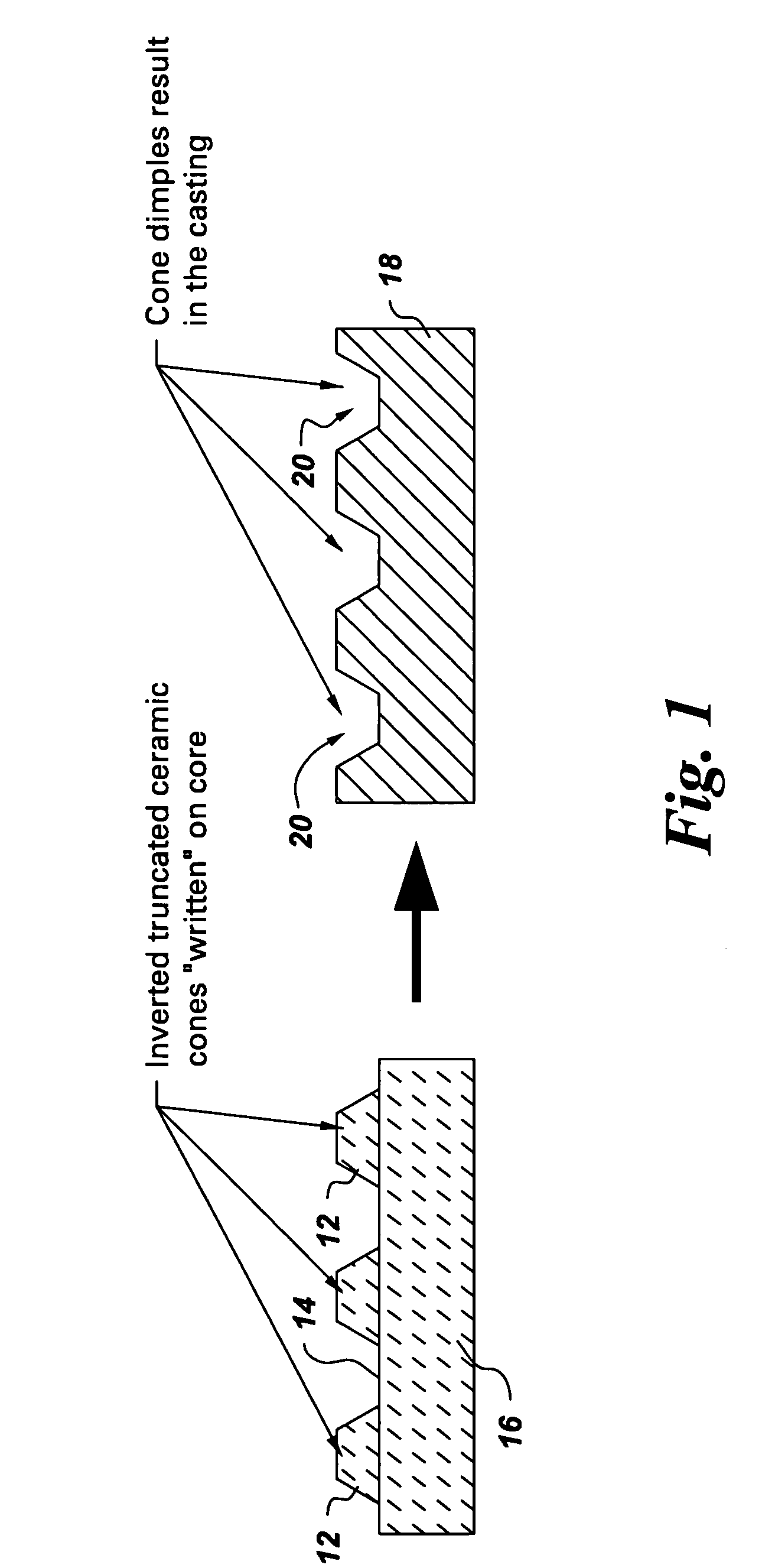

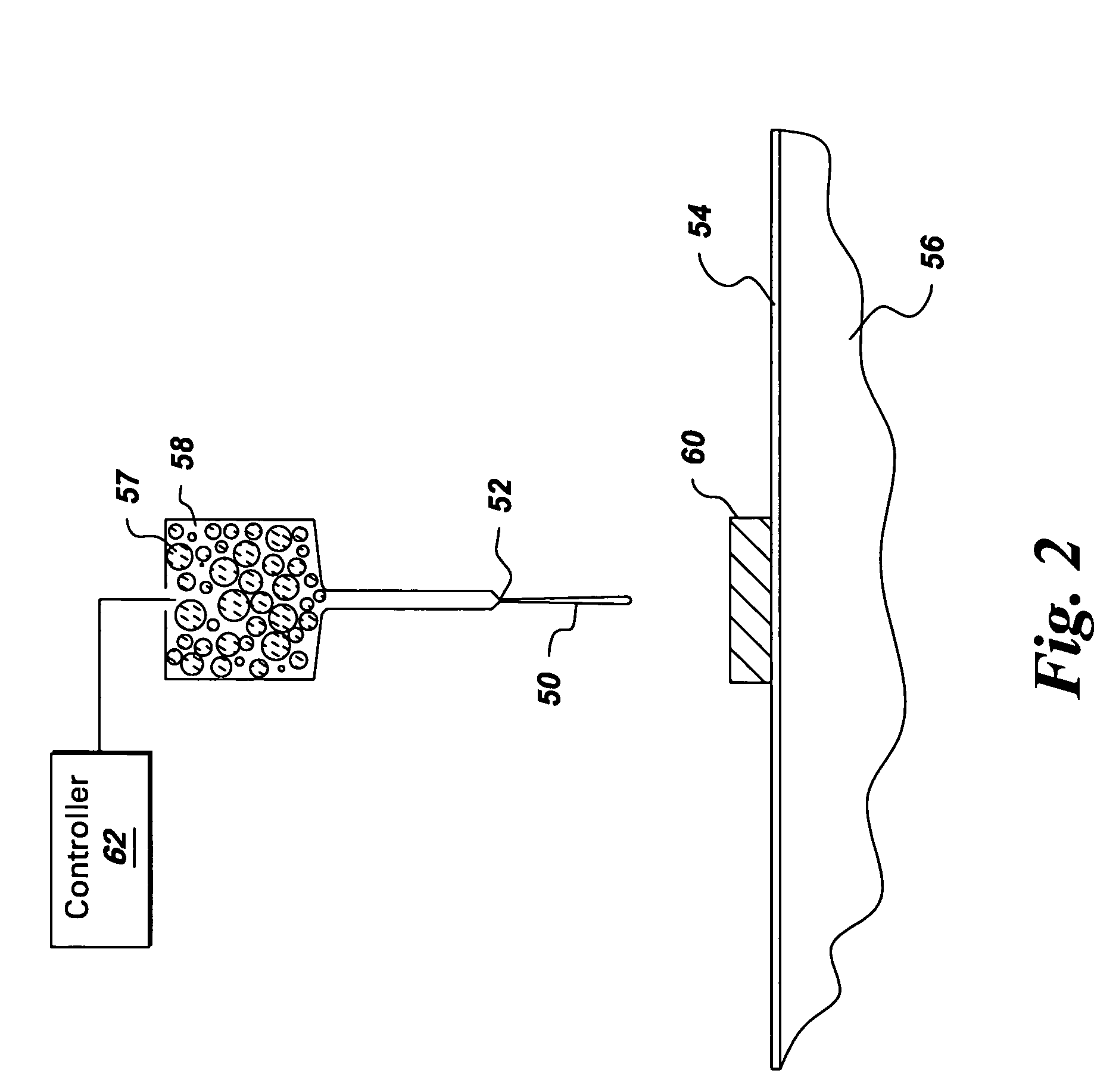

Method of forming concavities in the surface of a metal component, and related processes and articles

ActiveUS7302990B2Forming accuratelyAdditive manufacturing apparatusMolten spray coatingHeat treatedMetal

A method of forming at least one concavity of a selected size and shape within a surface of an internal passageway of a metallic component comprises: depositing a ceramic-based material by a direct-write technique onto a ceramic core which is suitable for forming the internal passageway during a casting process to form the metallic component, wherein the ceramic-based material is deposited as a positive feature; heat-treating the deposited ceramic-based material; forming the metallic component by a casting process in which the ceramic core is incorporated into the casting, in a position selected as a desired position for the internal passageway; and then removing the ceramic core from the metal component after the casting process is complete, thereby forming the internal passageway, with the concavity contained within the surface of the passageway, said concavity formed by removal of the positive feature of the ceramic-based material.

Owner:GE INFRASTRUCTURE TECH INT LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com