Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1365 results about "Investment casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

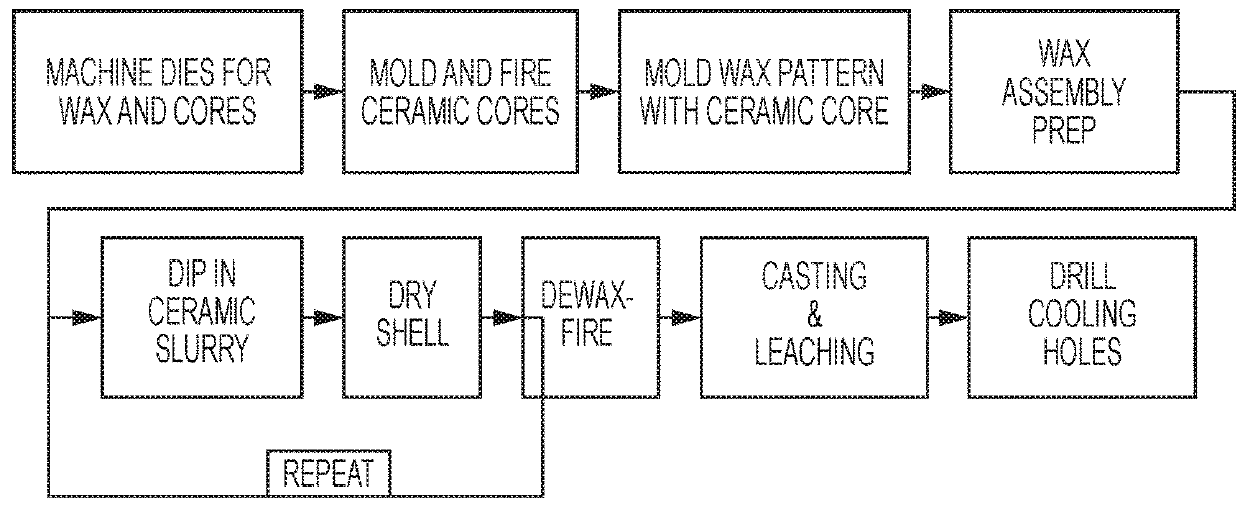

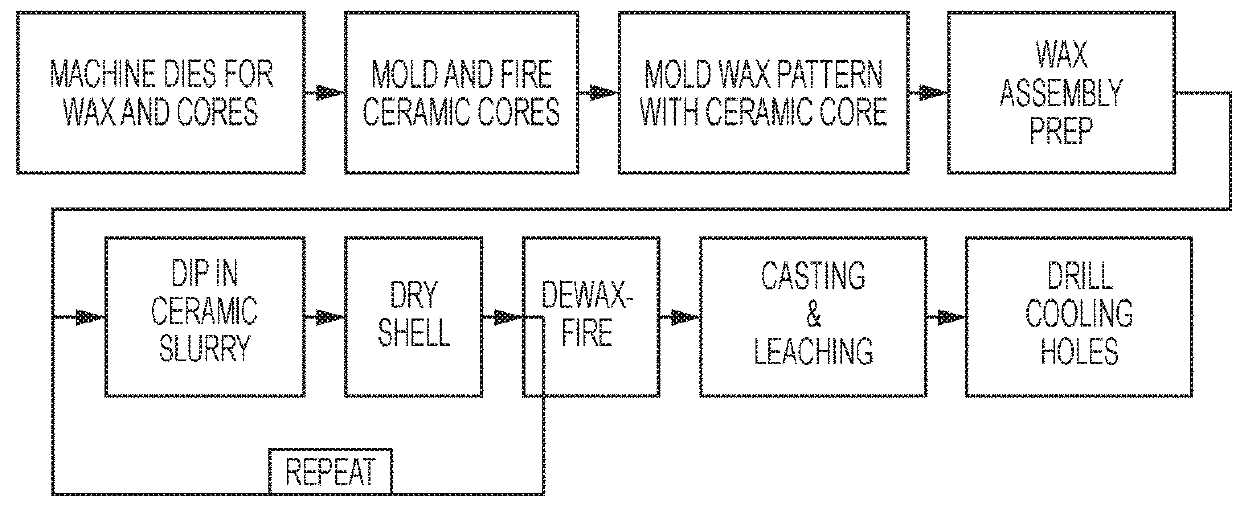

Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques. The term "lost-wax casting" can also refer to modern investment casting processes.

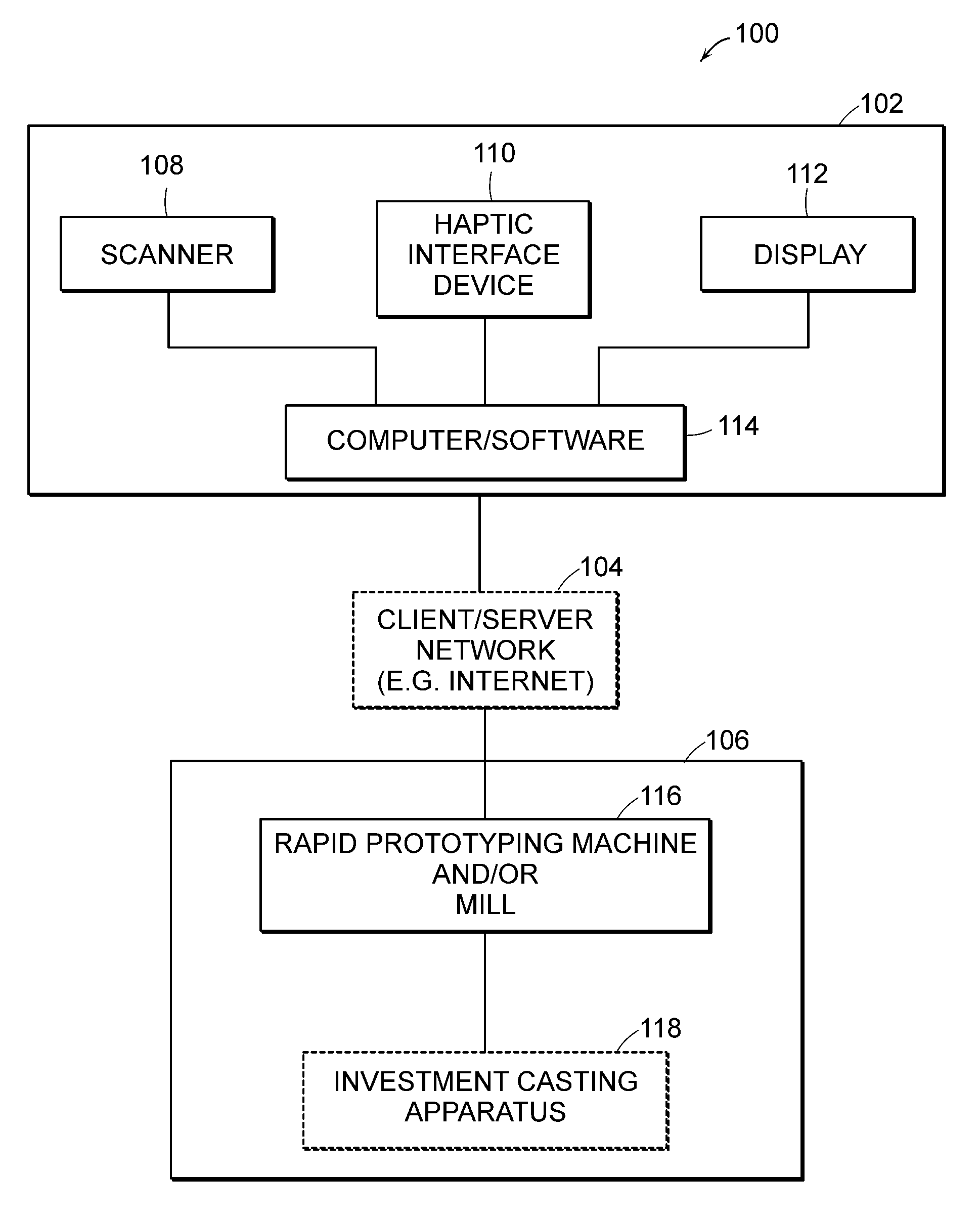

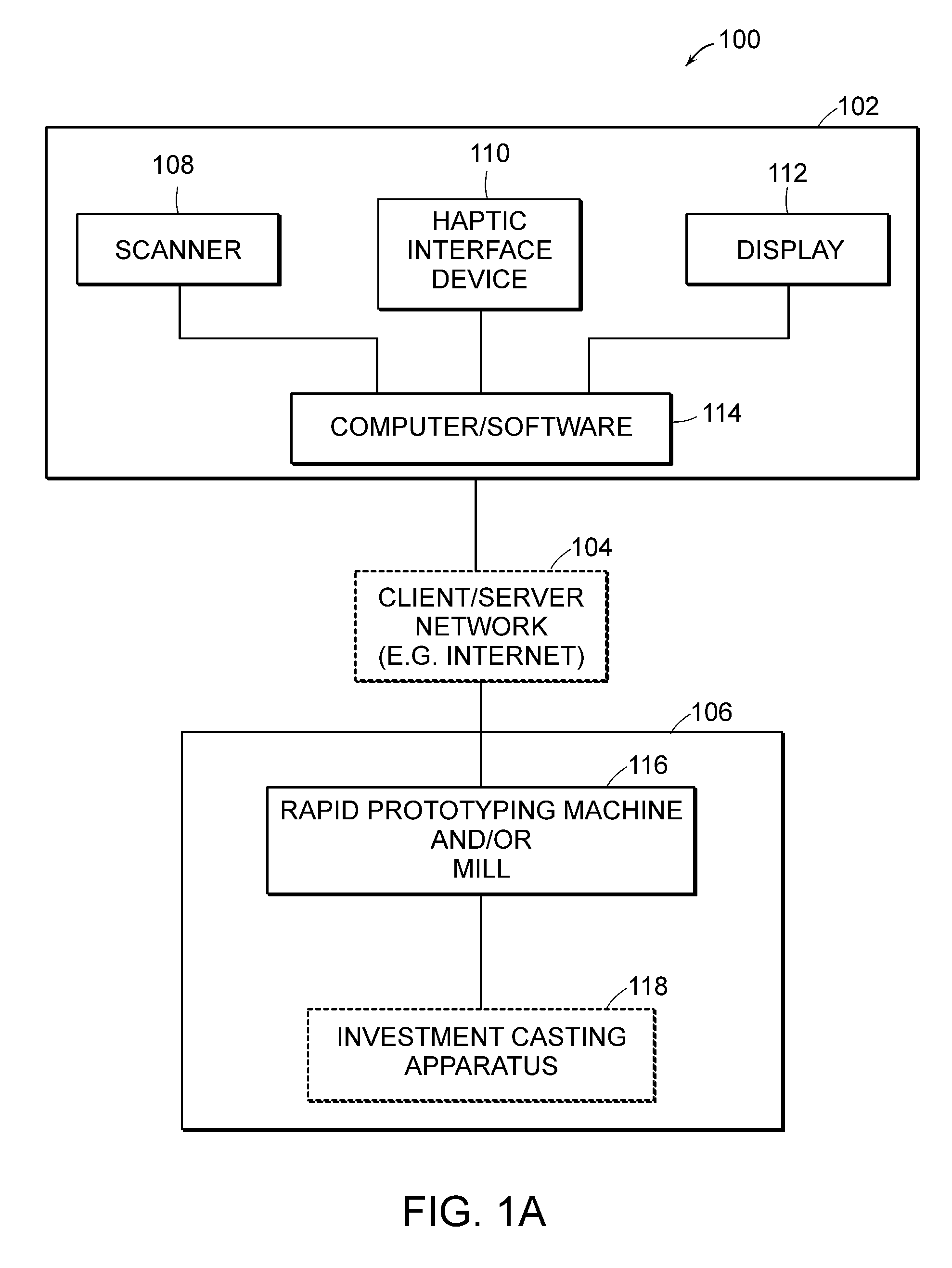

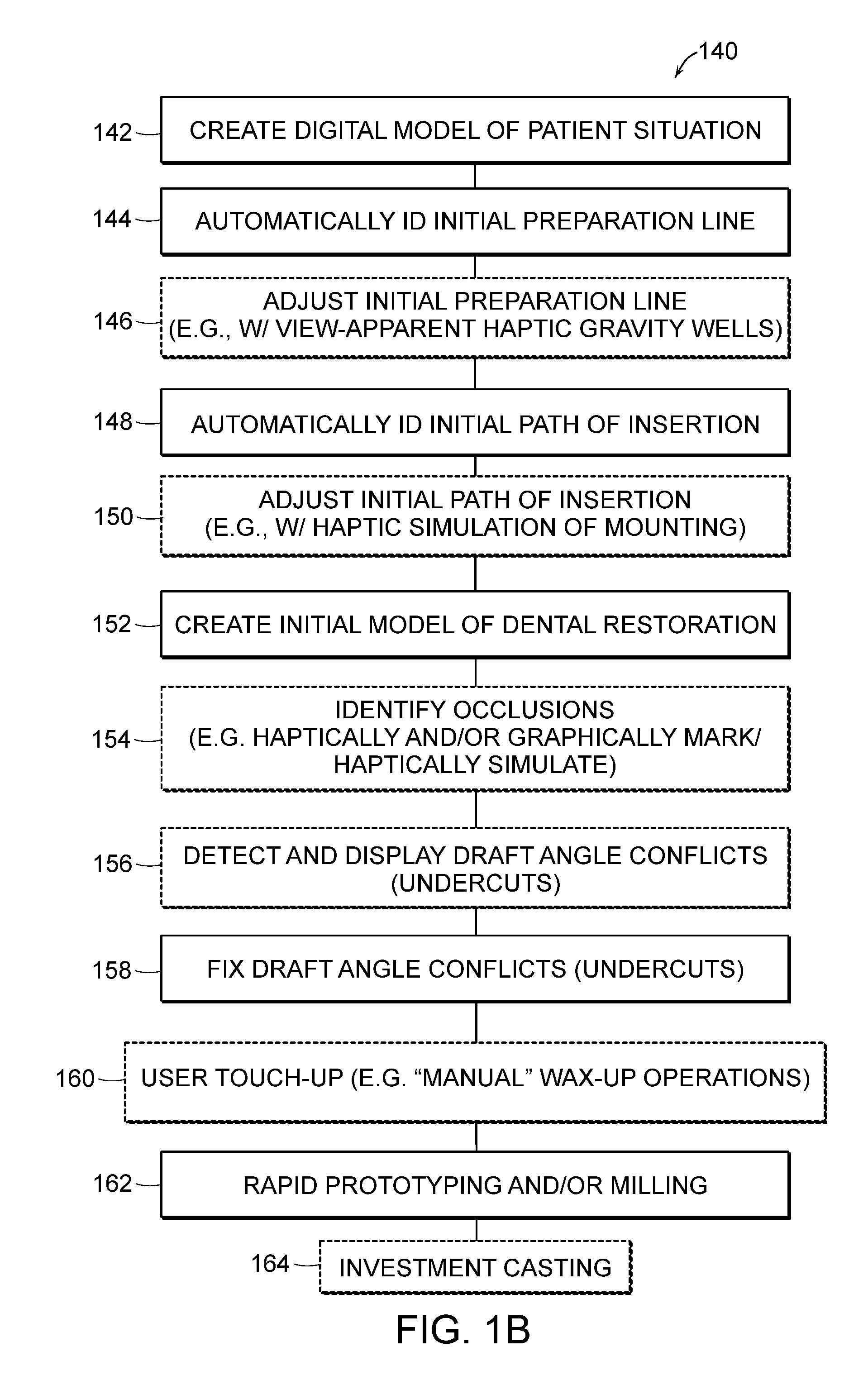

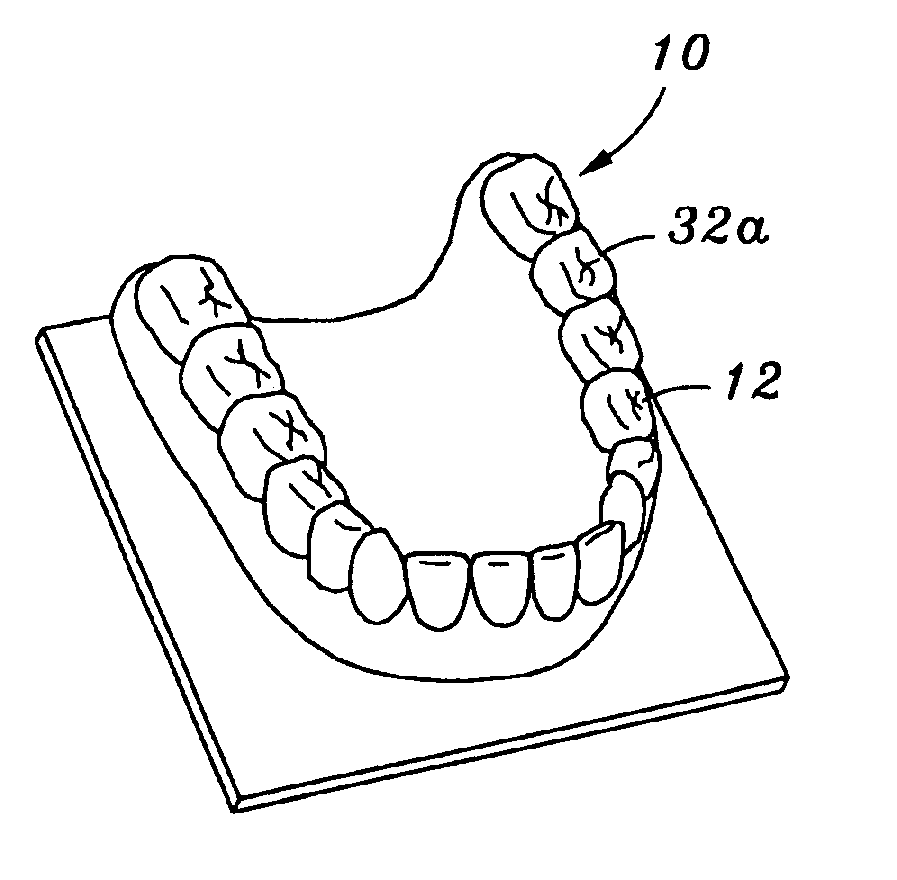

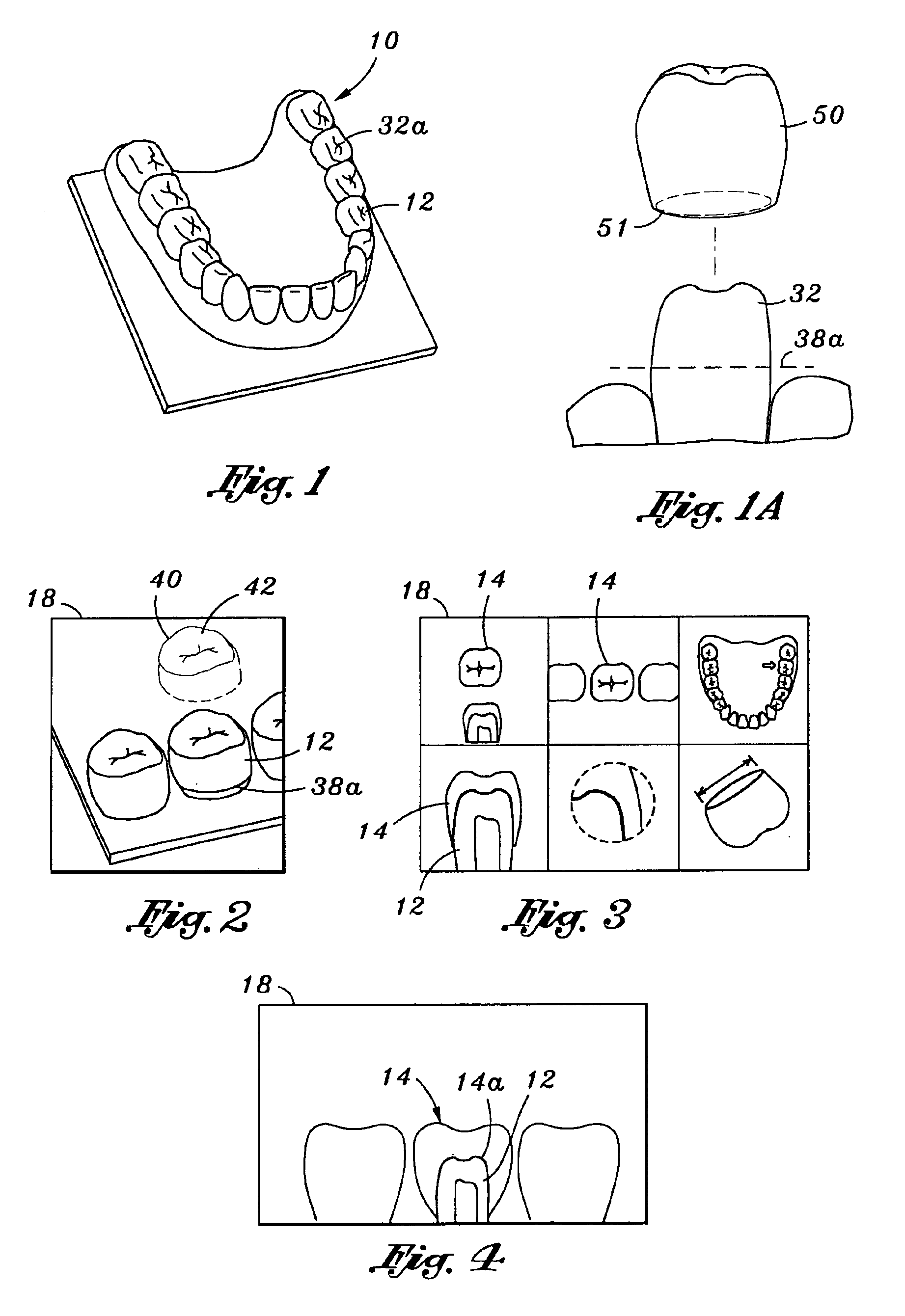

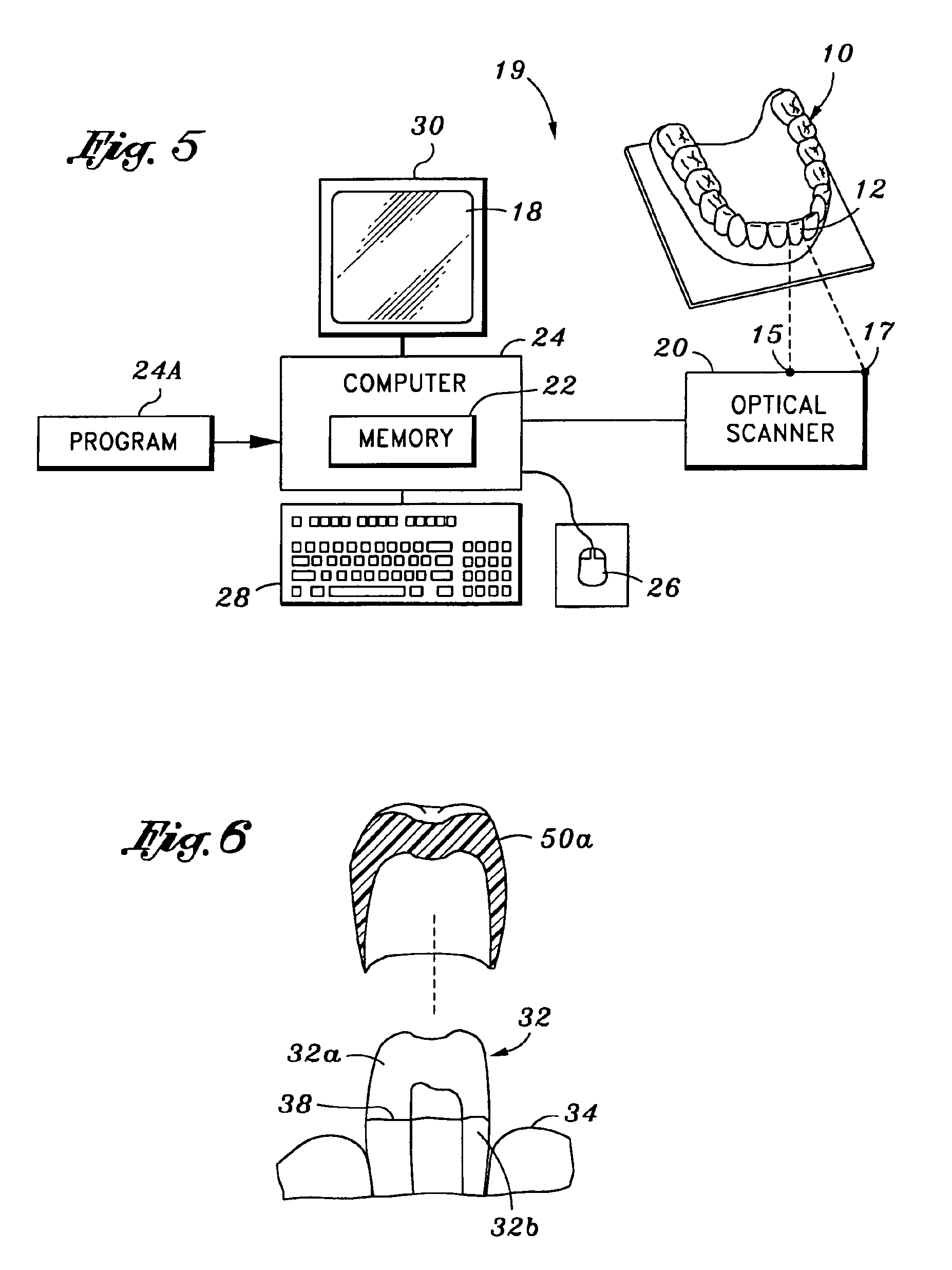

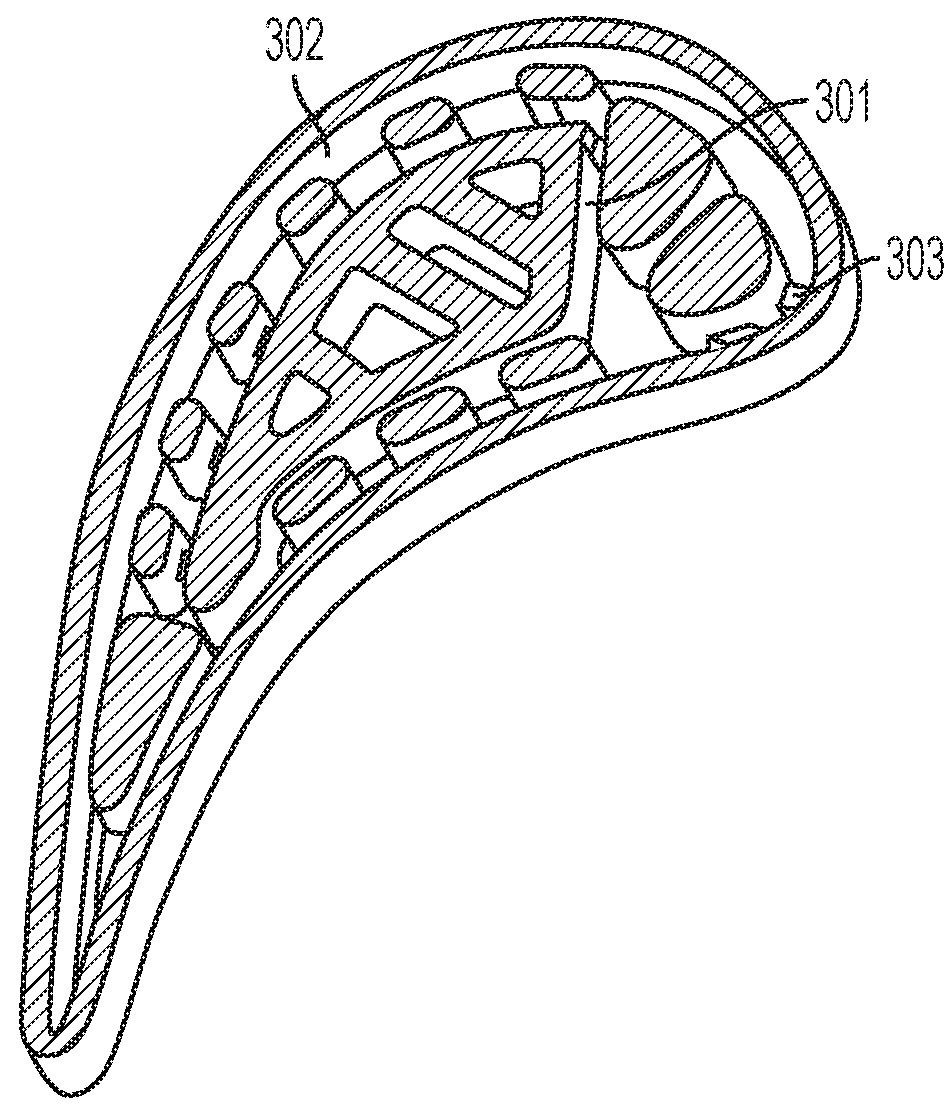

Systems for haptic design of dental restorations

InactiveUS20080261165A1Big advantageEasy to useAdditive manufacturing apparatusOthrodonticsVoxelInvestment casting

The invention provides systems for integrated haptic design and fabrication of dental restorations that provide significant advantages over traditional practice and existing computer-based systems. The systems feature technical advances that result in significantly more streamlined, versatile, and efficient design and fabrication of dental restorations. Among these technical advances are the introduction of voxel-based models; the use of a combination of geometric representations such as voxels and NURBS representations; the automatic identification of an initial preparation (prep) line and an initial path of insertion; the ability of a user to intuitively, haptically adjust the initial prep line and / or the initial path of insertion; the automatic identification of occlusions and draft angle conflicts (e.g., undercuts); the haptic simulation and / or marking of occlusions and draft angle conflicts; and coordination between design output and rapid prototyping / milling and / or investment casting.

Owner:SENSABLE TECH

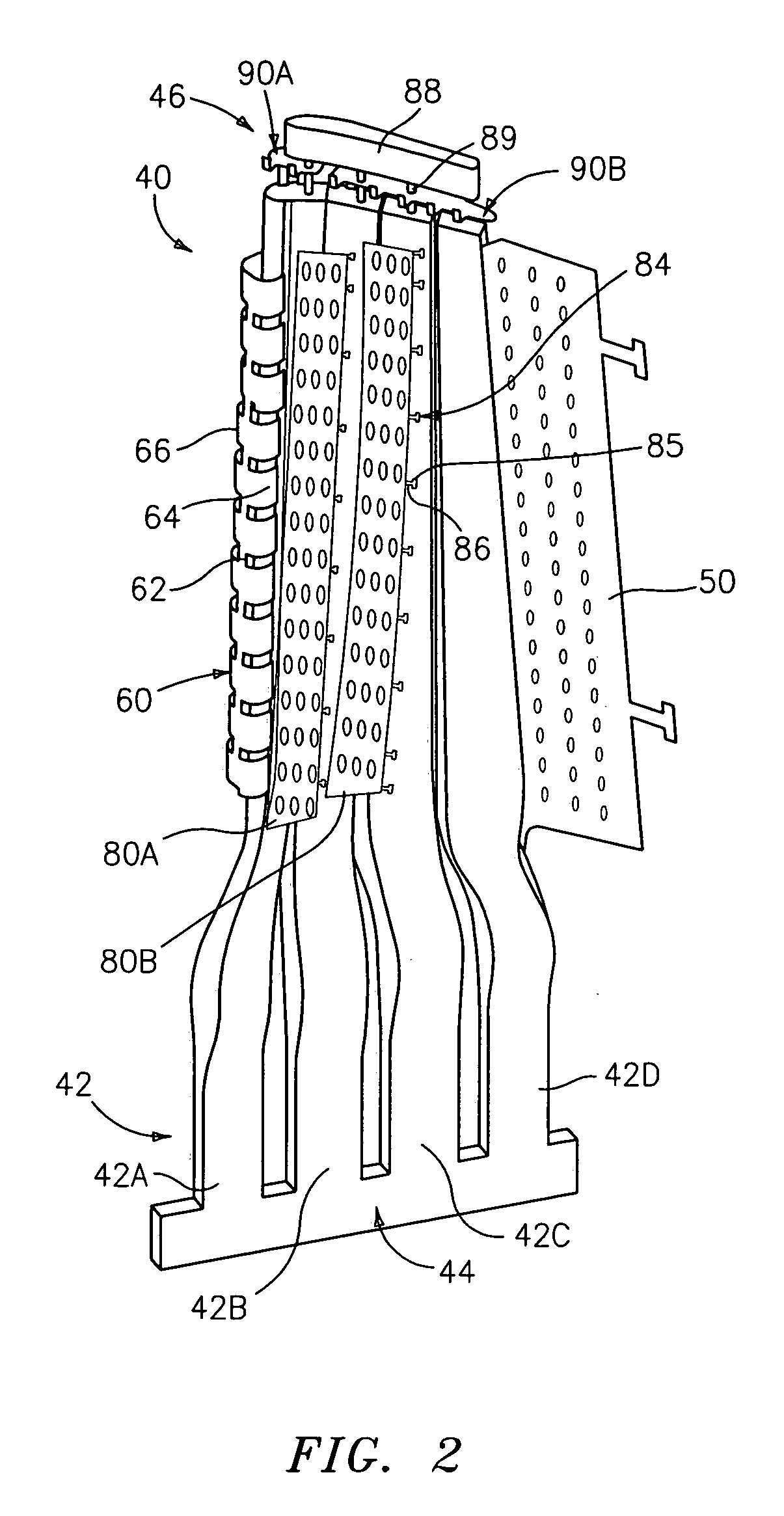

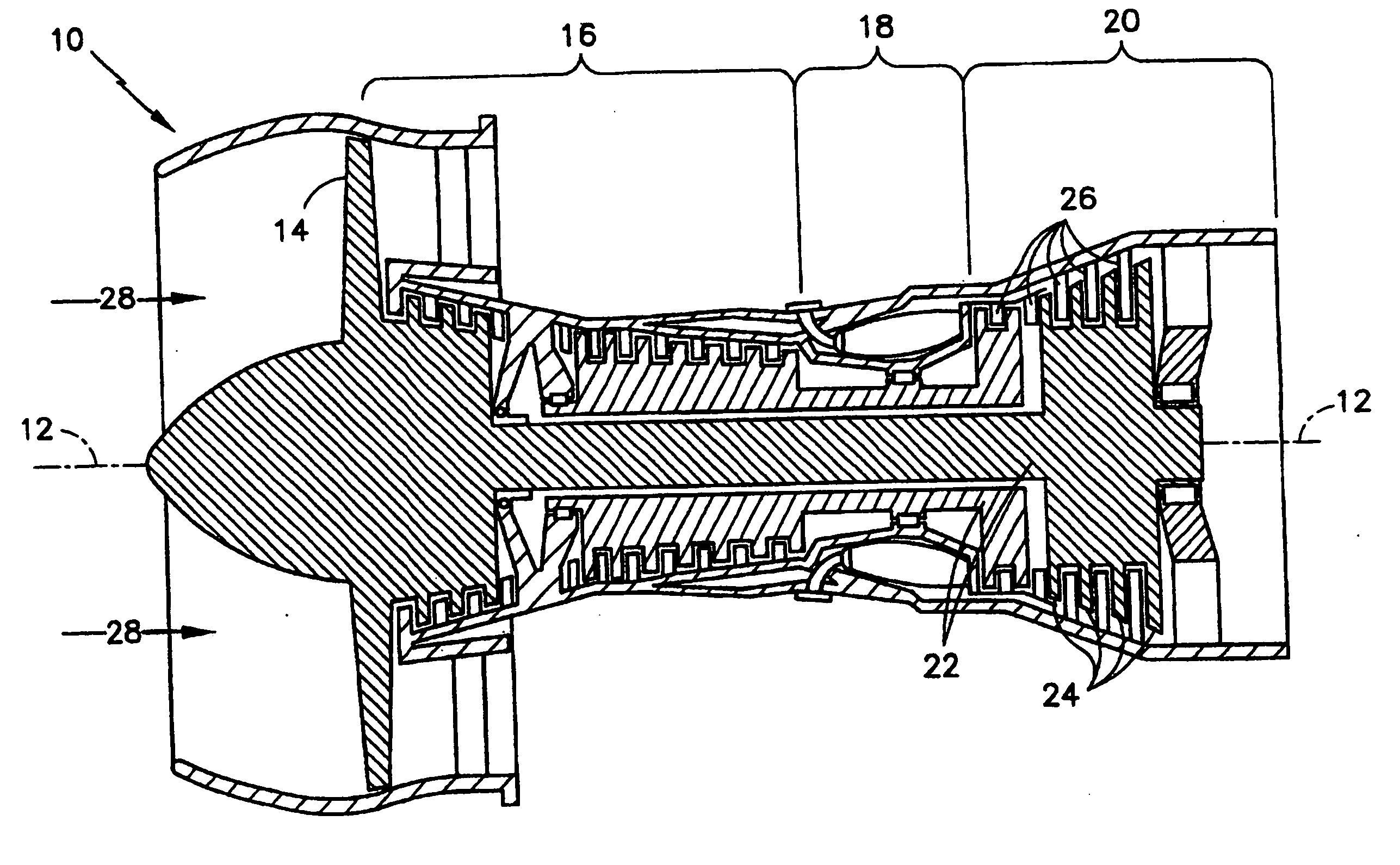

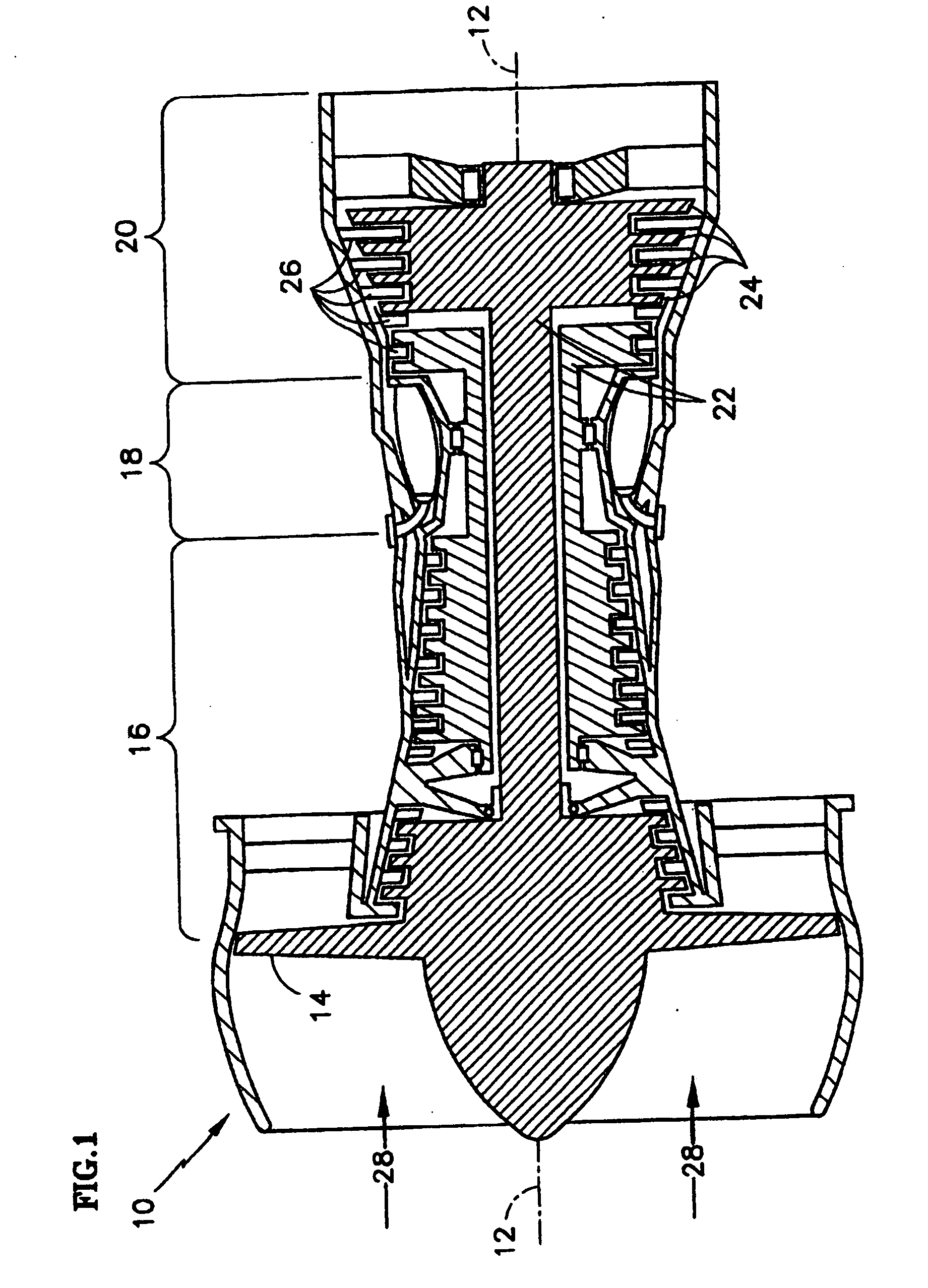

Investment casting cores

Owner:RTX CORP

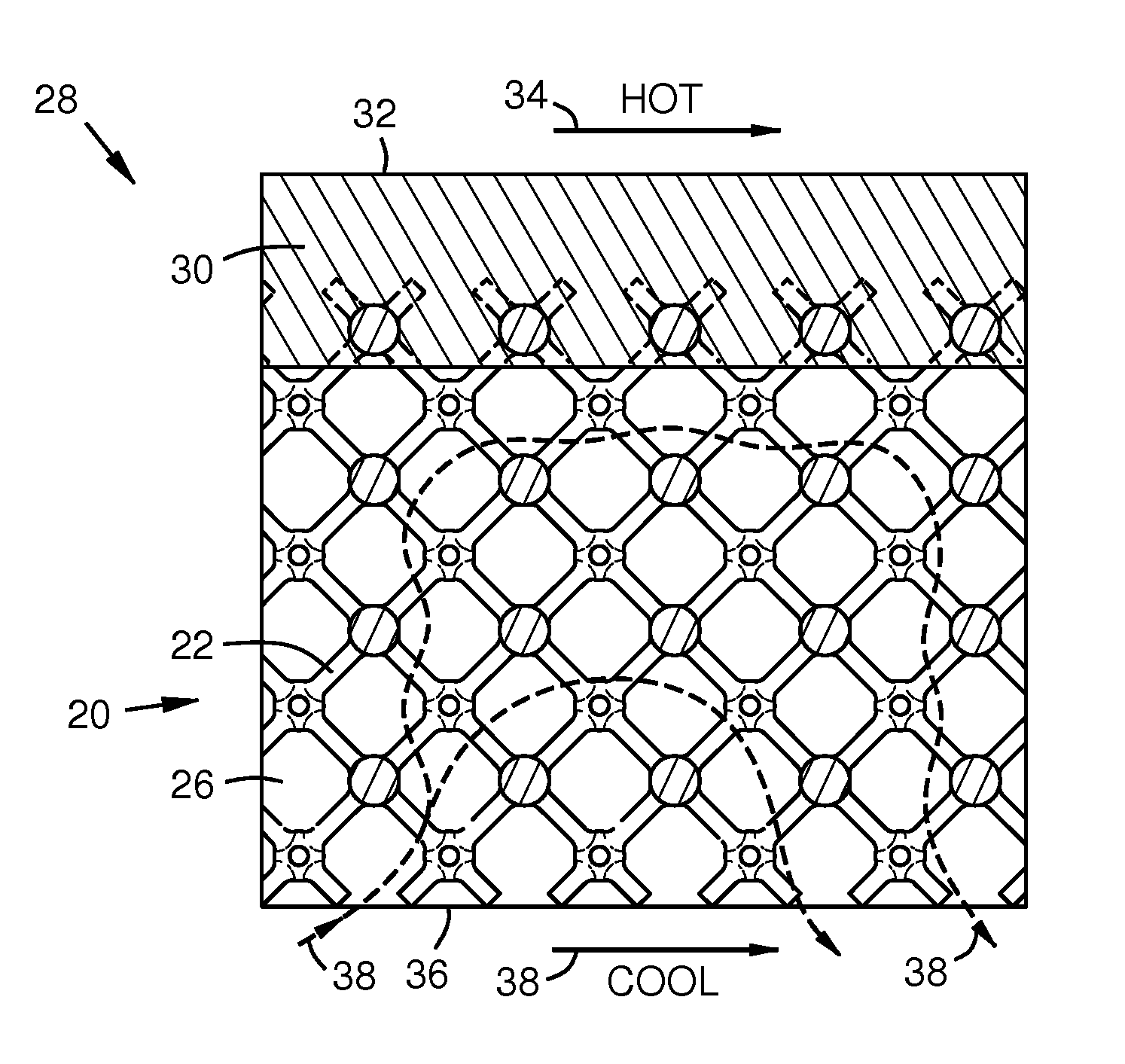

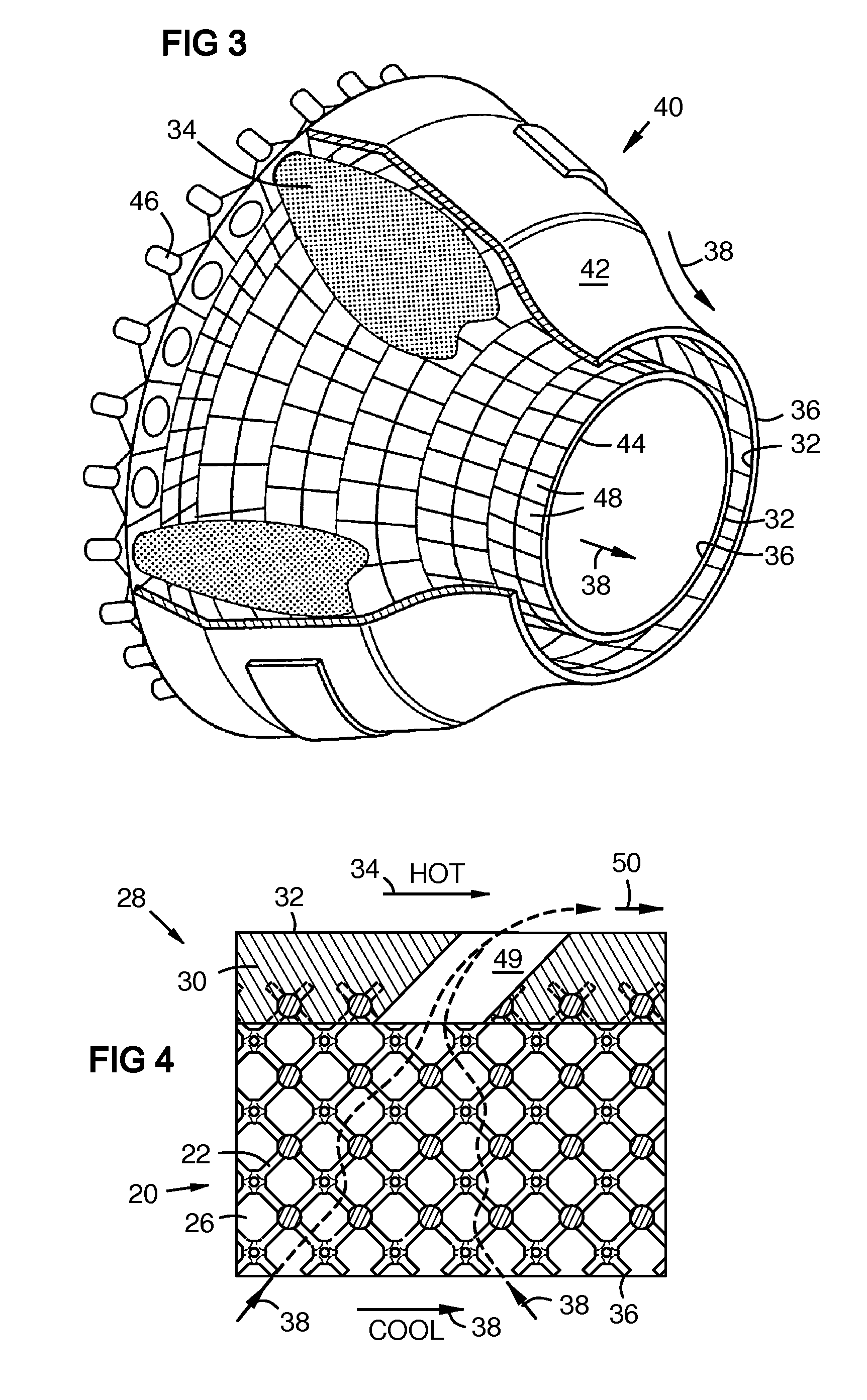

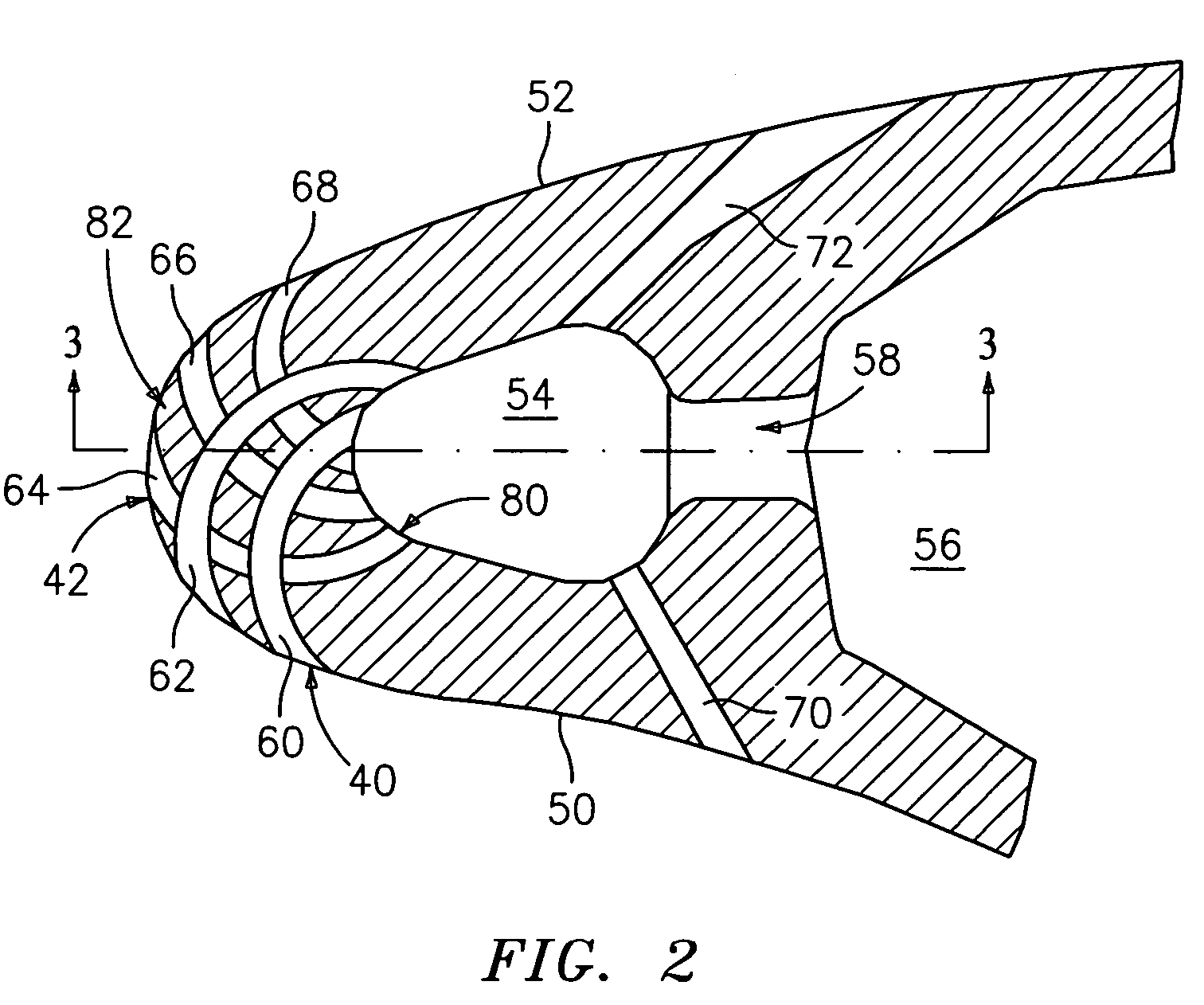

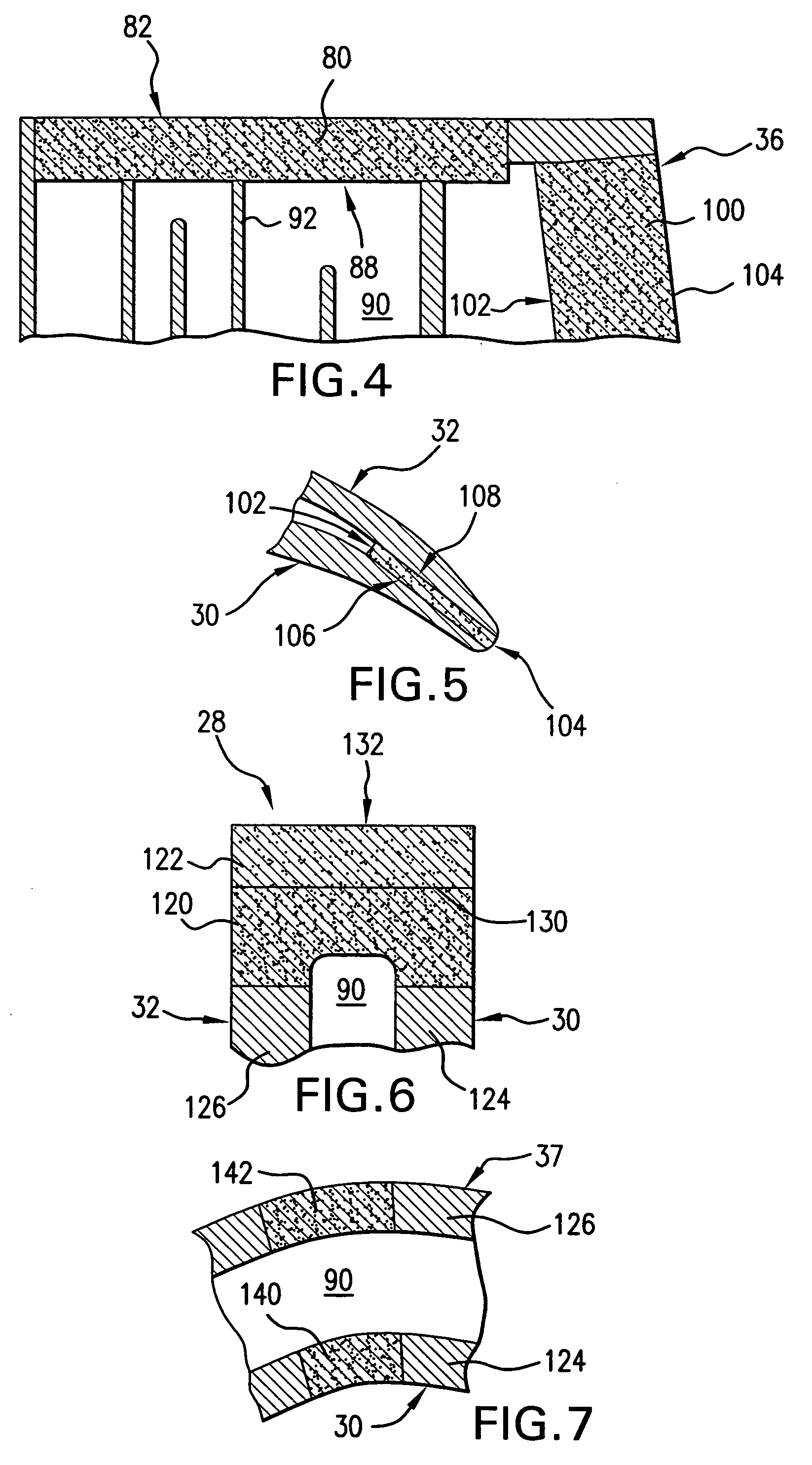

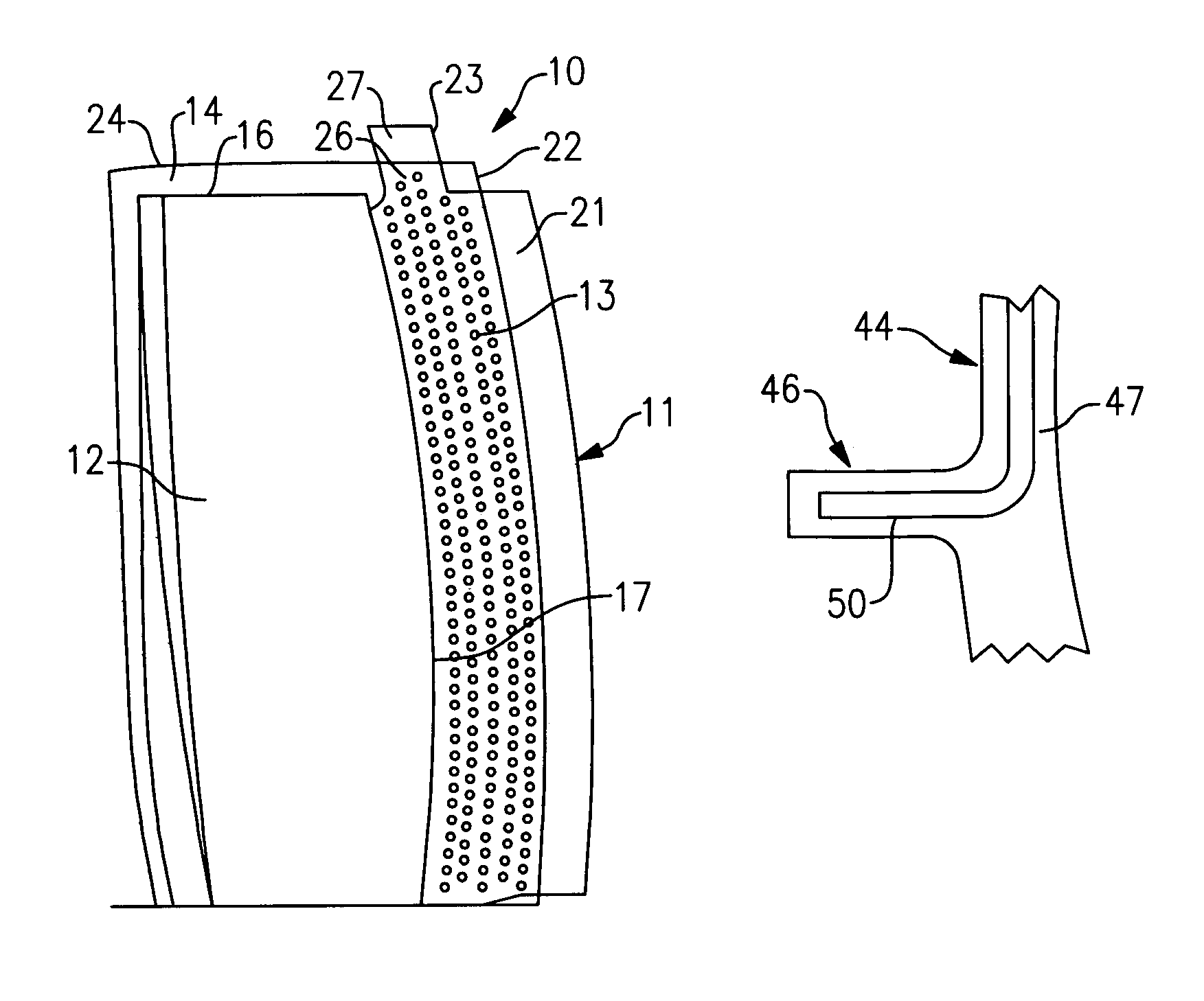

Process for making a wall with a porous element for component cooling

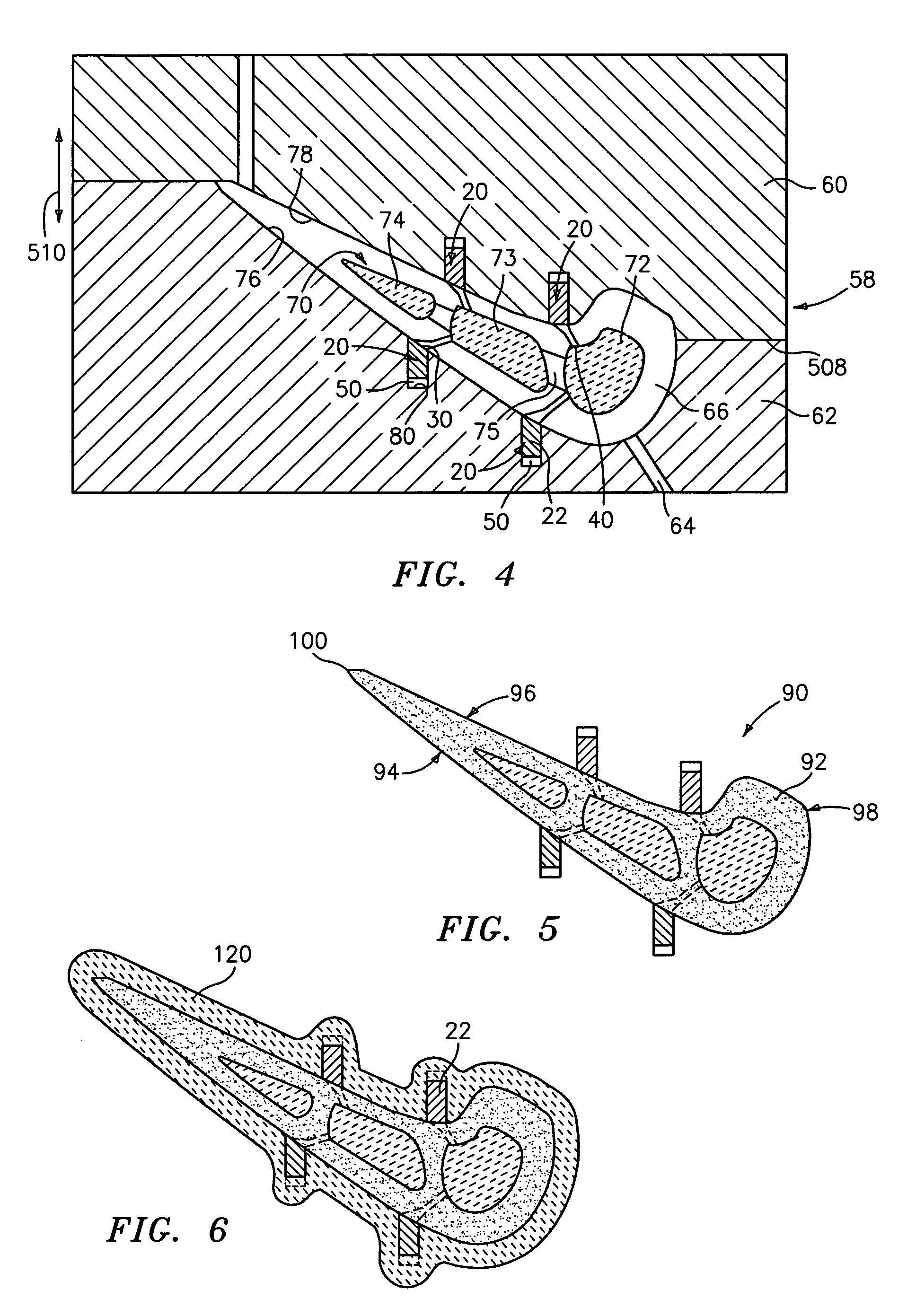

A structural layer (30) may be bi-cast onto ligaments (62) extending from a porous cooling construction (20). The material of the structural layer may be optimized for high-temperature strength, while the material of the porous construction may be optimized for high thermal conductivity. A fugitive material (56) such as wax may be formed on the ligaments of the porous construction. A second fugitive material (58) such as ceramic may fill the remaining part of the porous construction. An investment casting shell (60) may be disposed around the porous construction and the fugitive materials. The first fugitive material may then be replaced with the material of the structural layer (30), and the second fugitive material may be removed to provide coolant paths (26). A second structural layer (52) may be bi-cast onto further ligaments (62) on a second side of the porous construction.

Owner:SIEMENS ENERGY INC

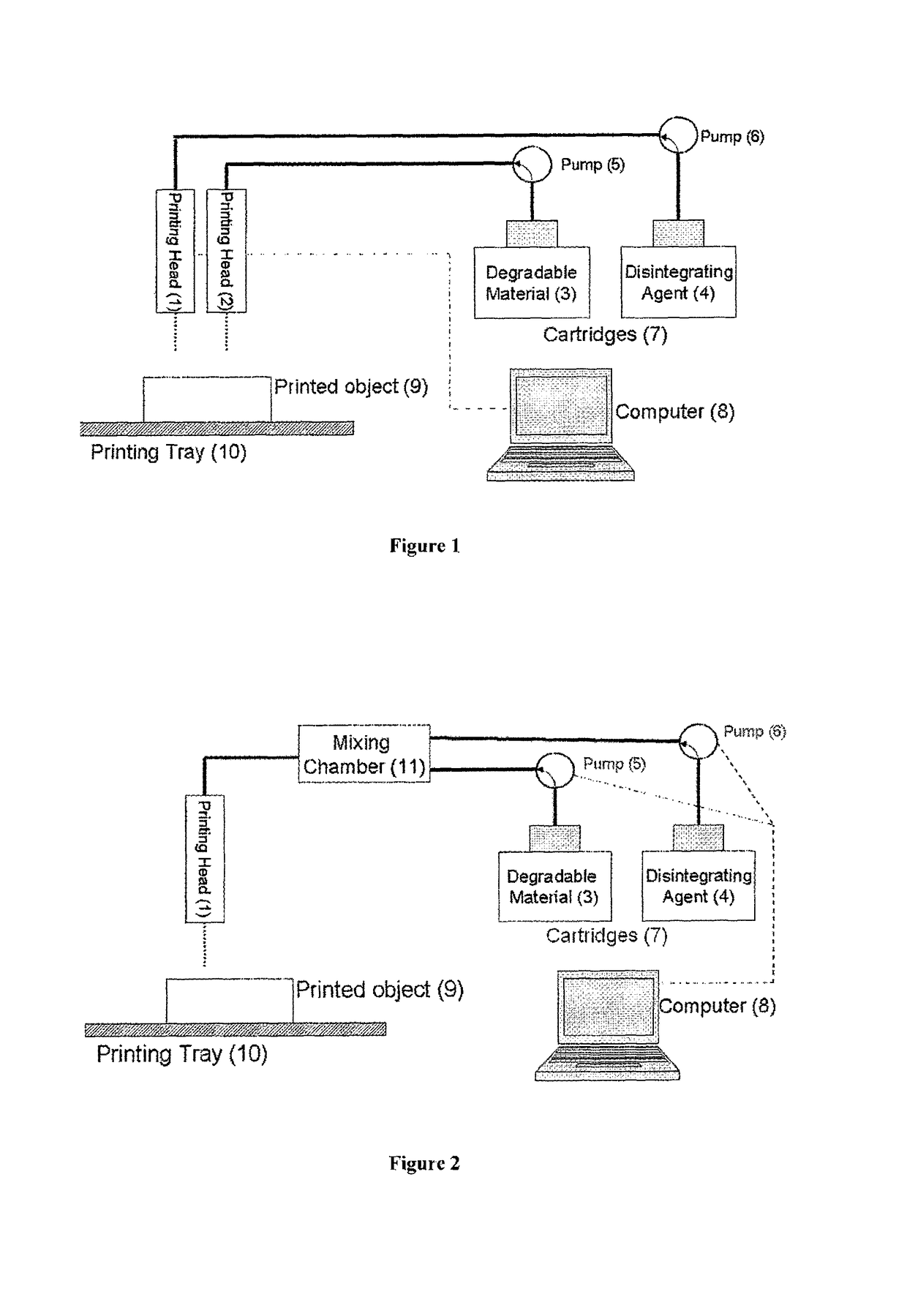

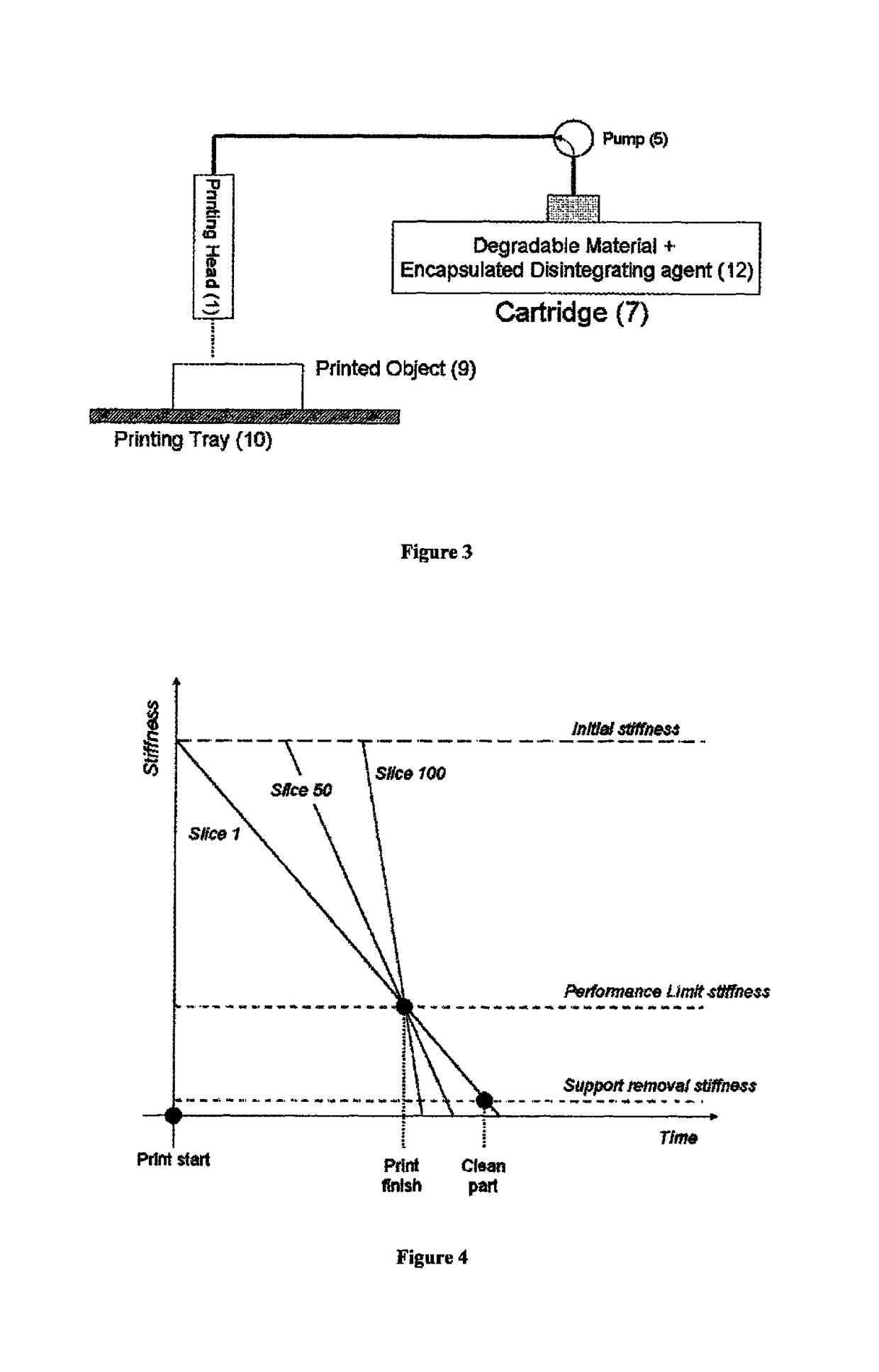

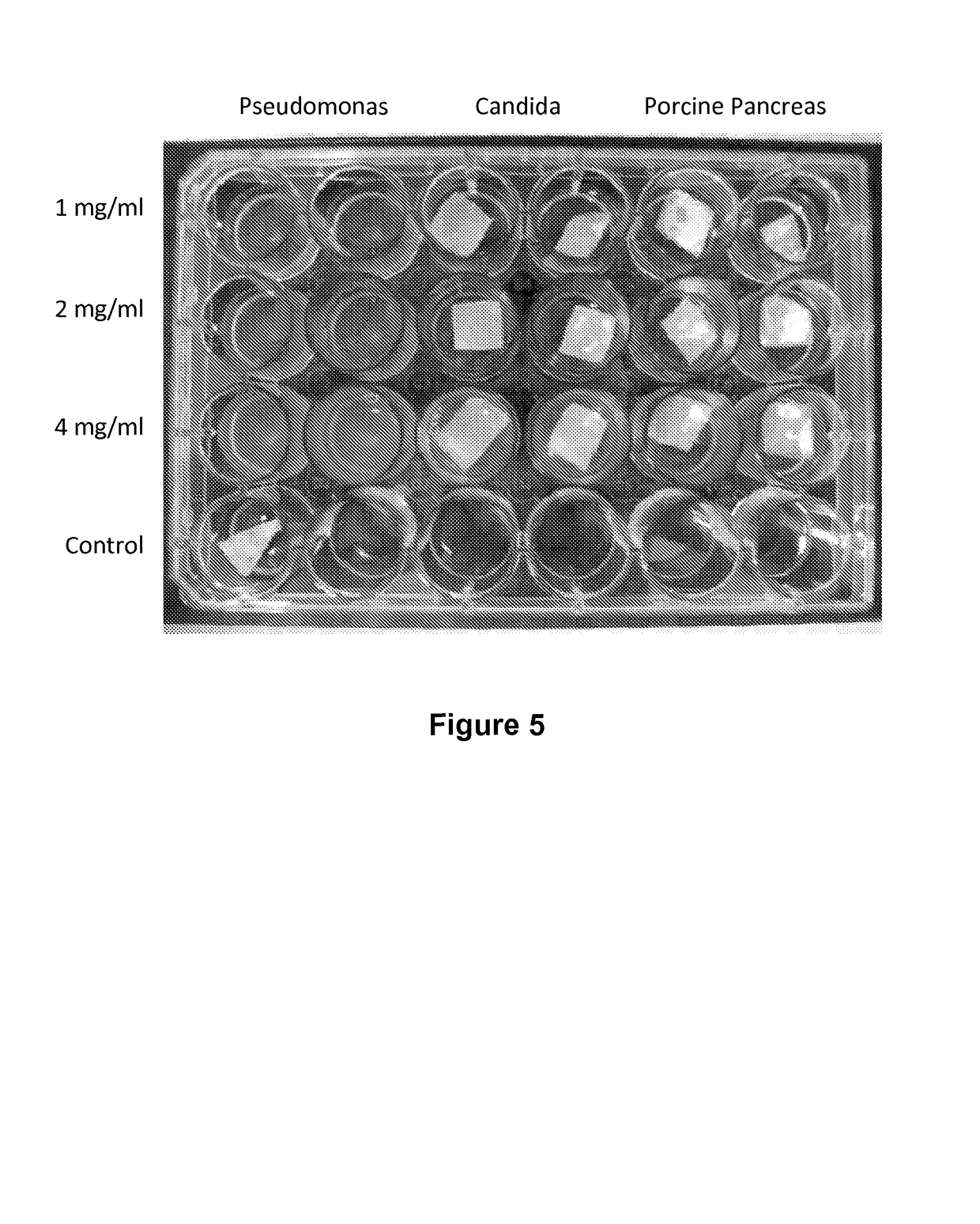

Three-dimensional printing process for producing a self-destructible temporary structure

ActiveUS8470231B1Additive manufacturing apparatusCeramic shaping apparatusInvestment castingSupport materials

The invention relates to additive manufacturing (AM) and in particular to a degradable material for use in applications that require temporary structure stability, such as in investment casting or biomedical applications or as a temporary support material.

Owner:STRATASYS LTD

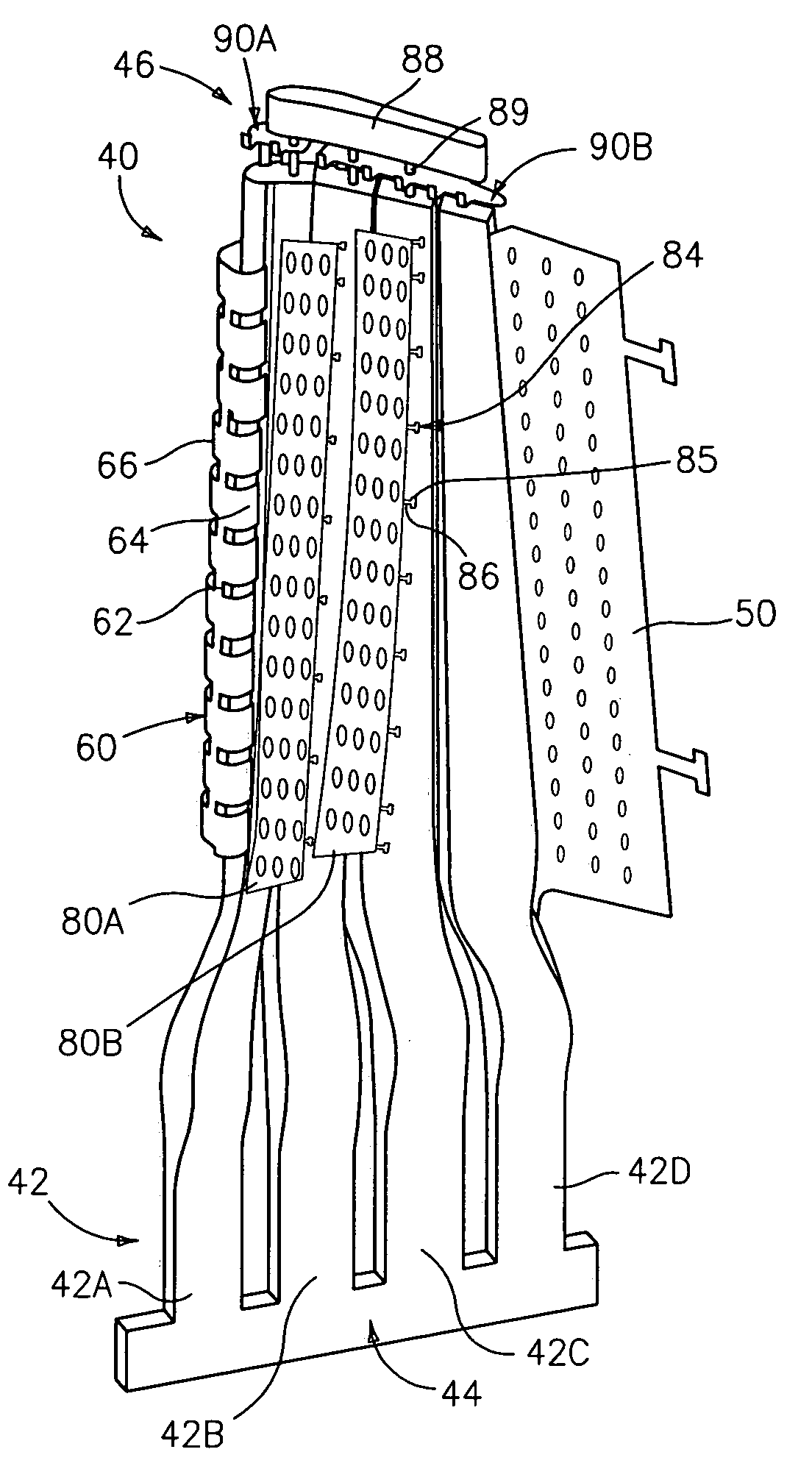

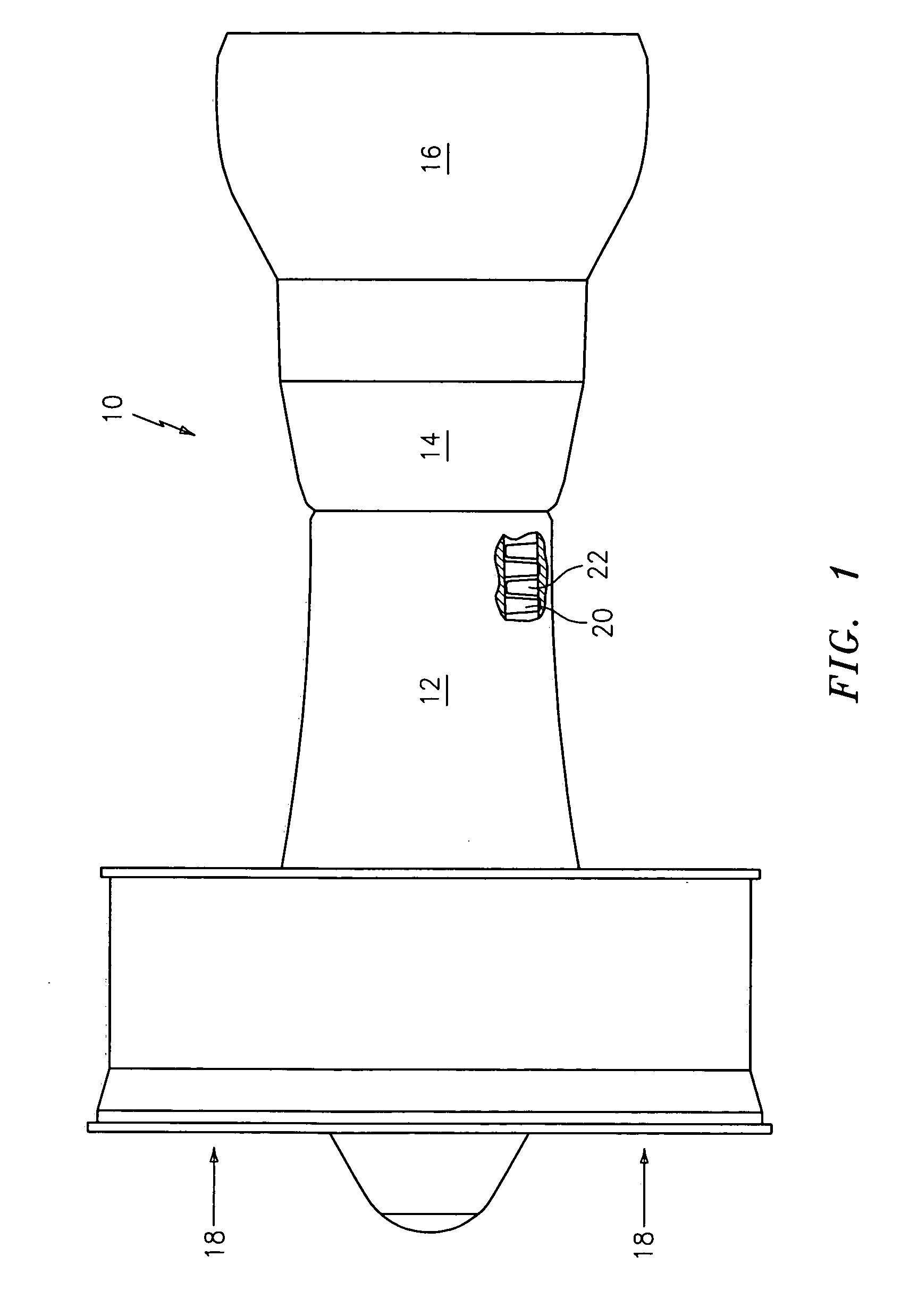

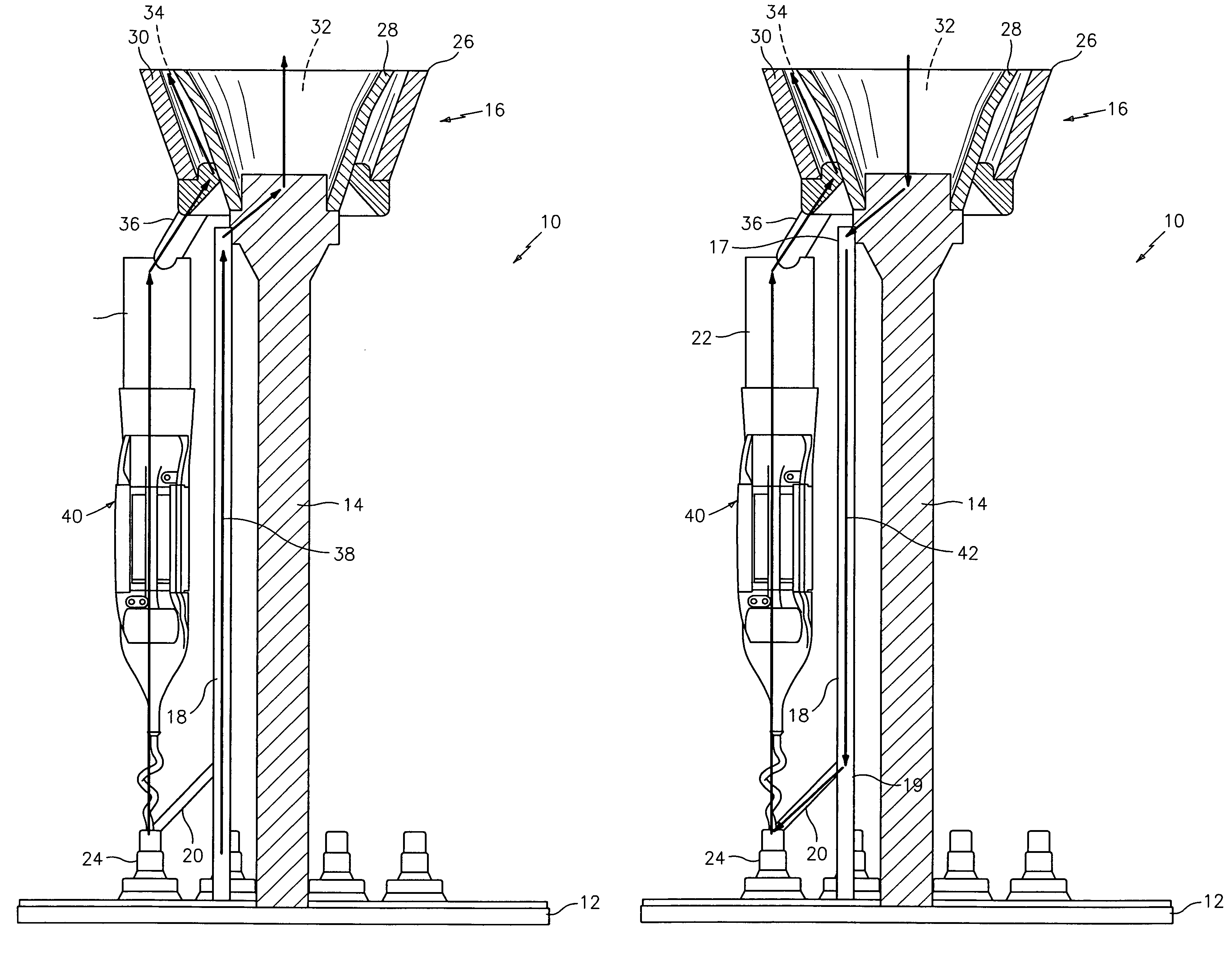

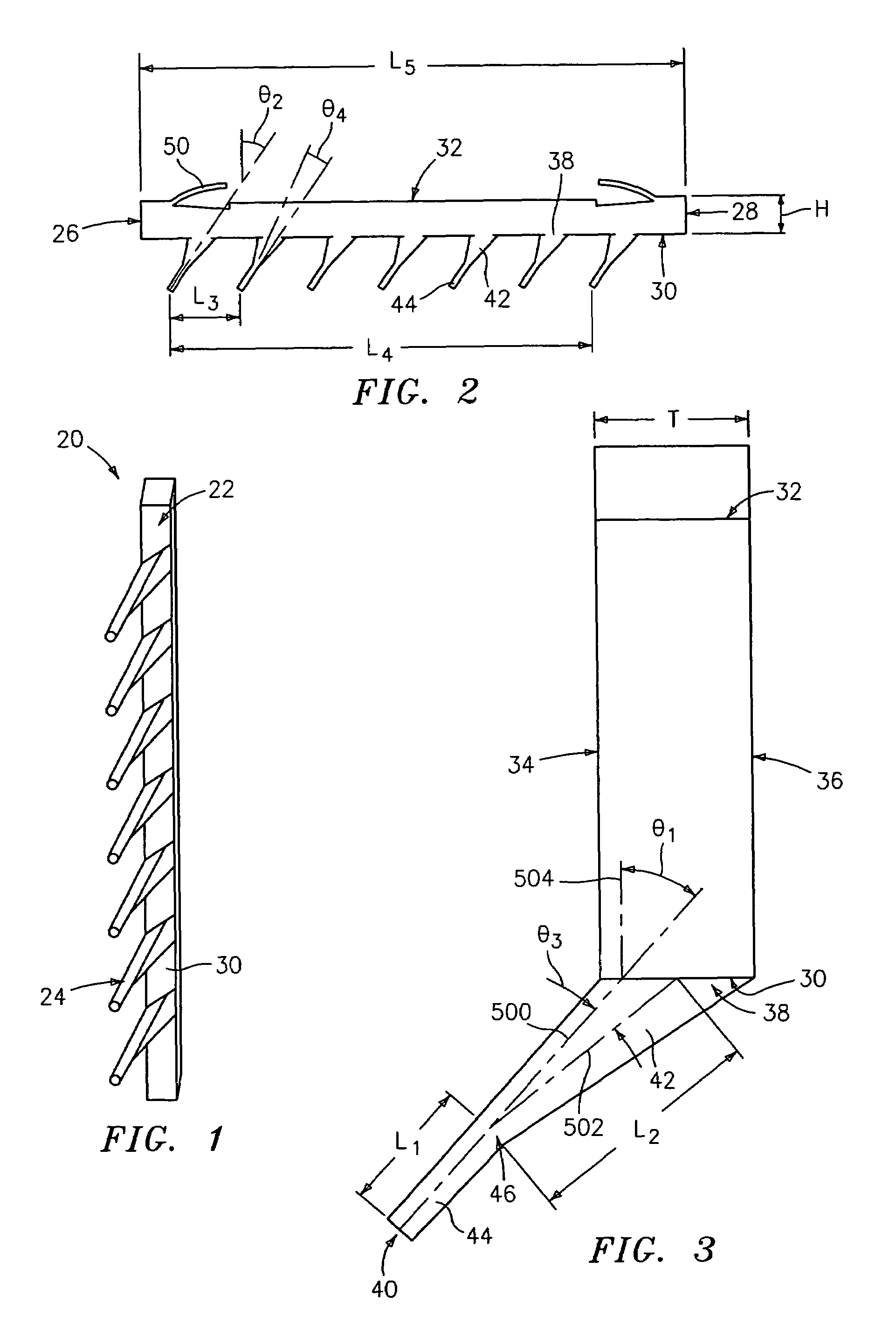

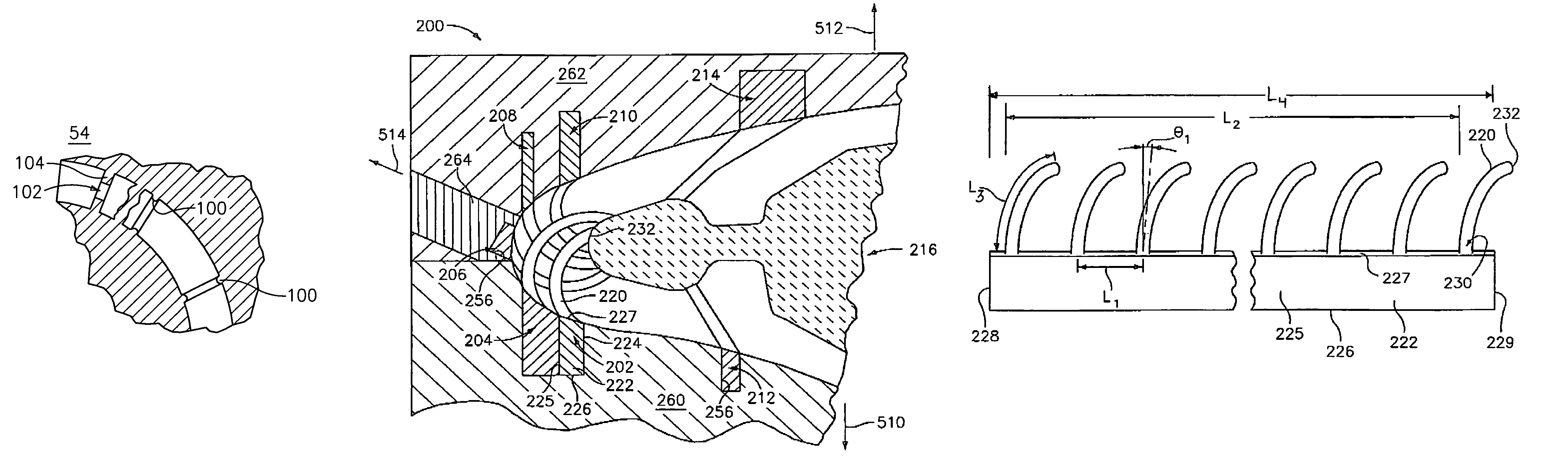

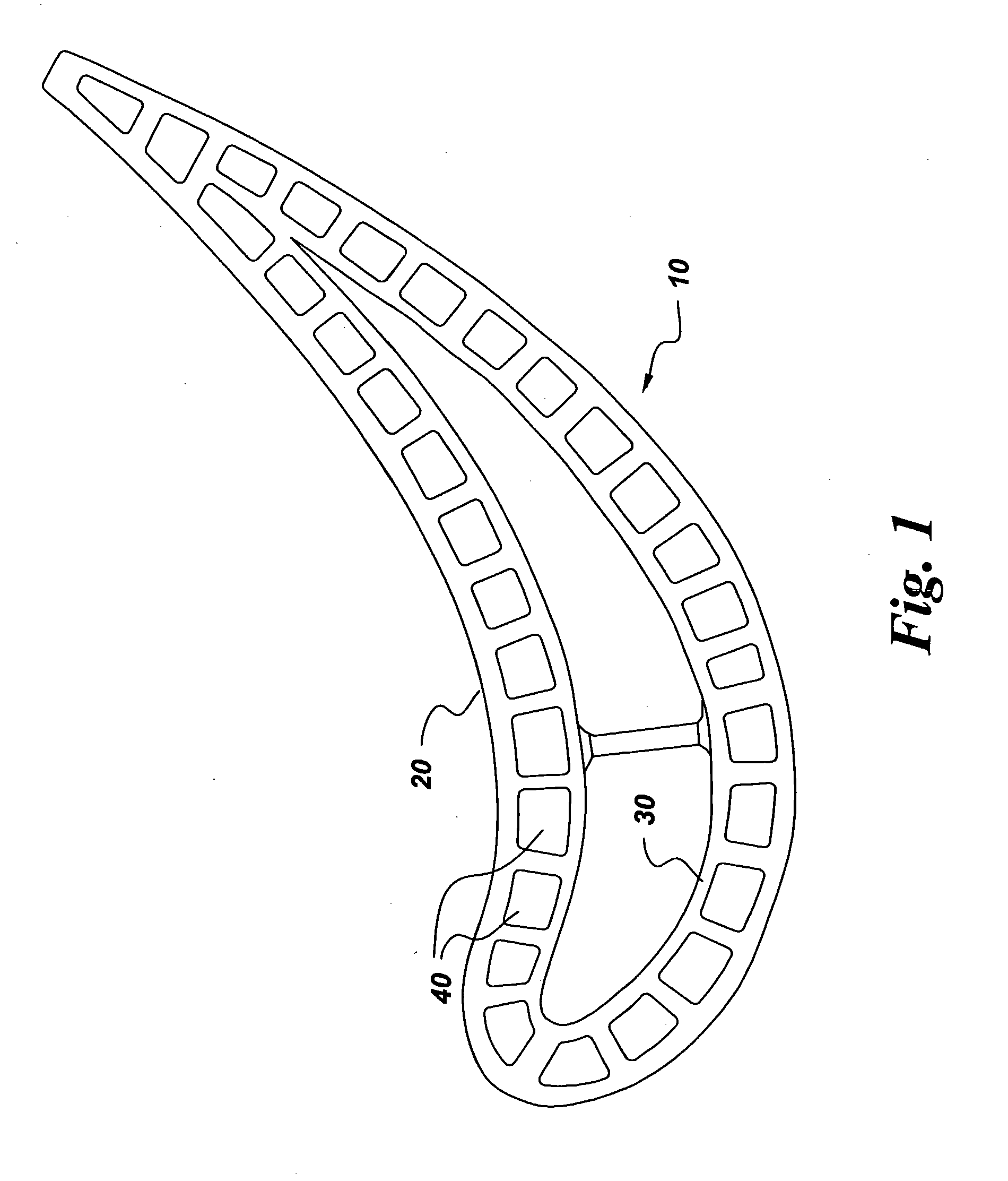

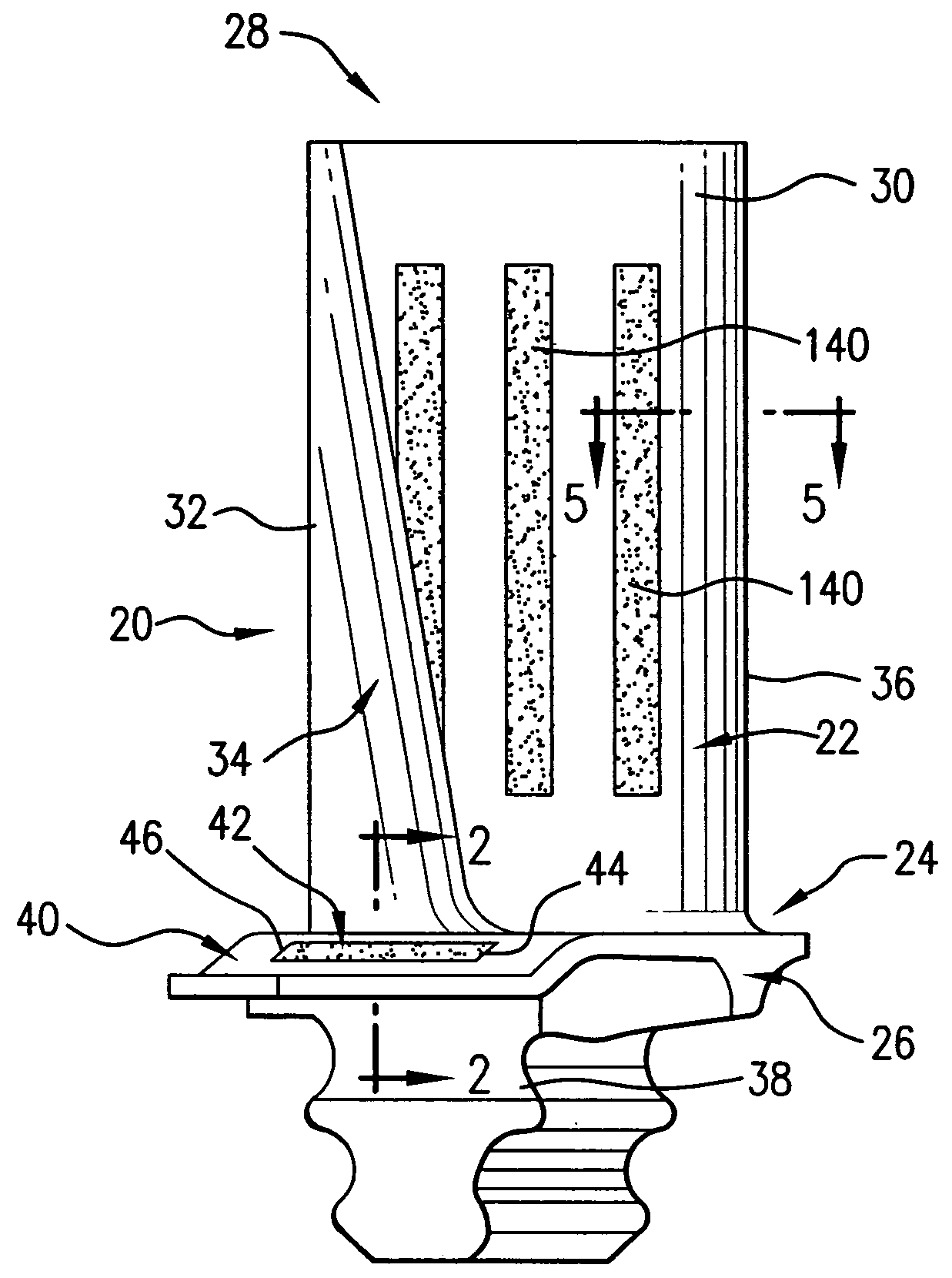

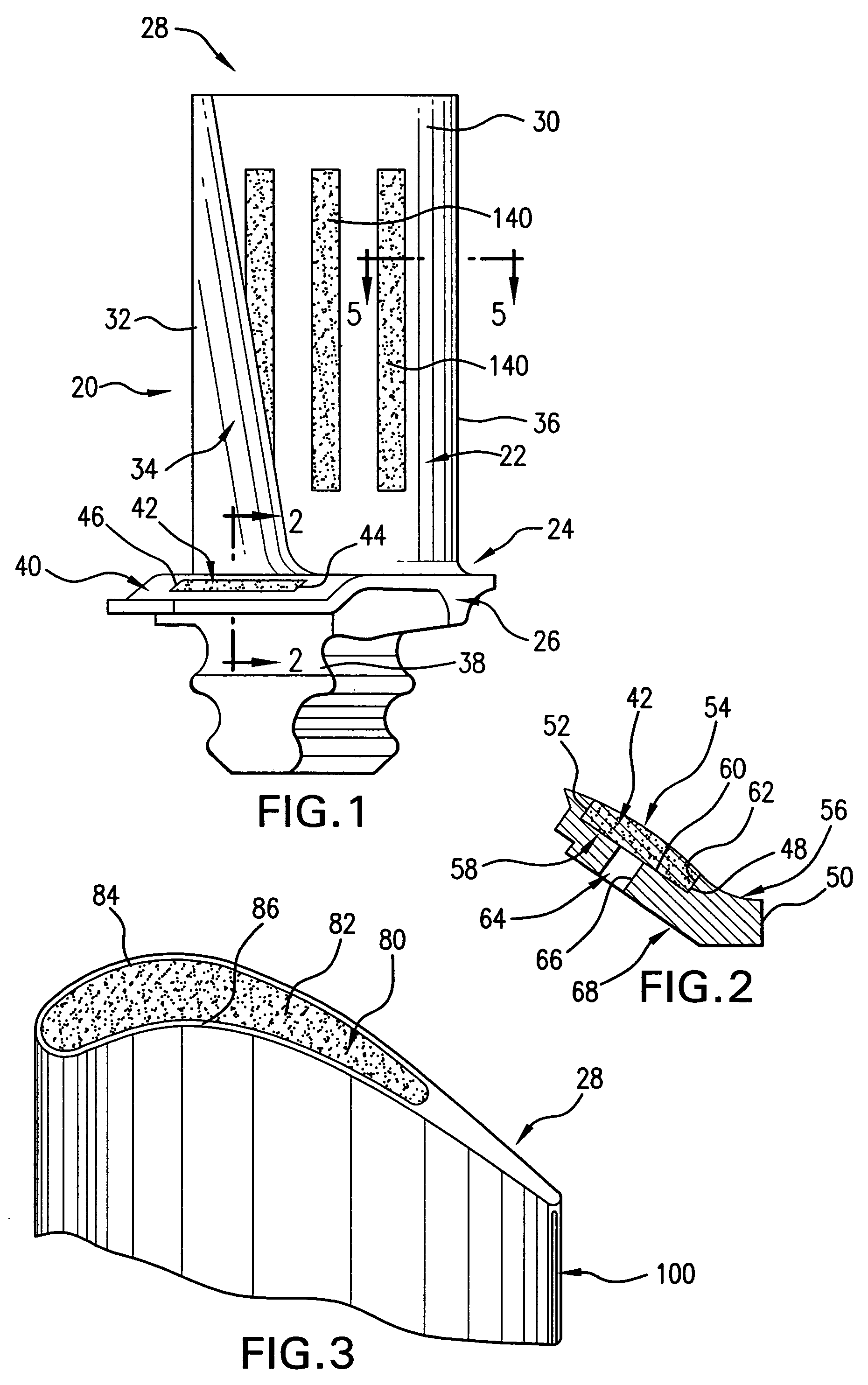

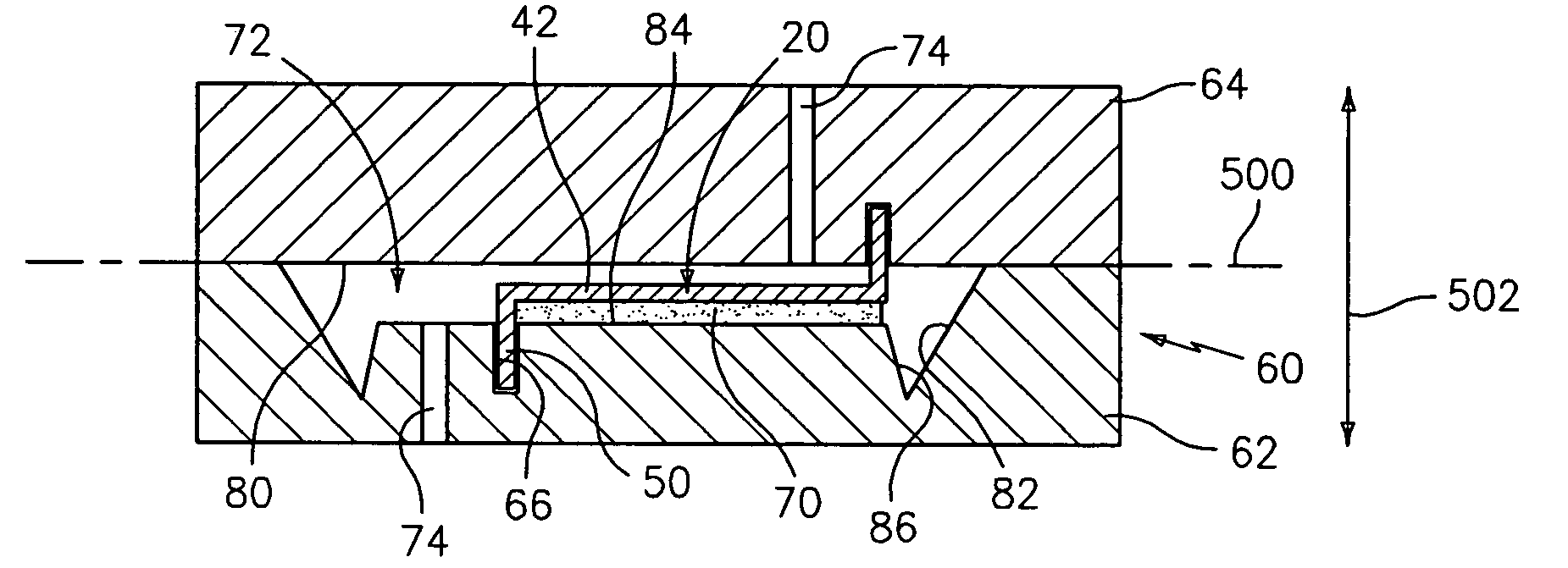

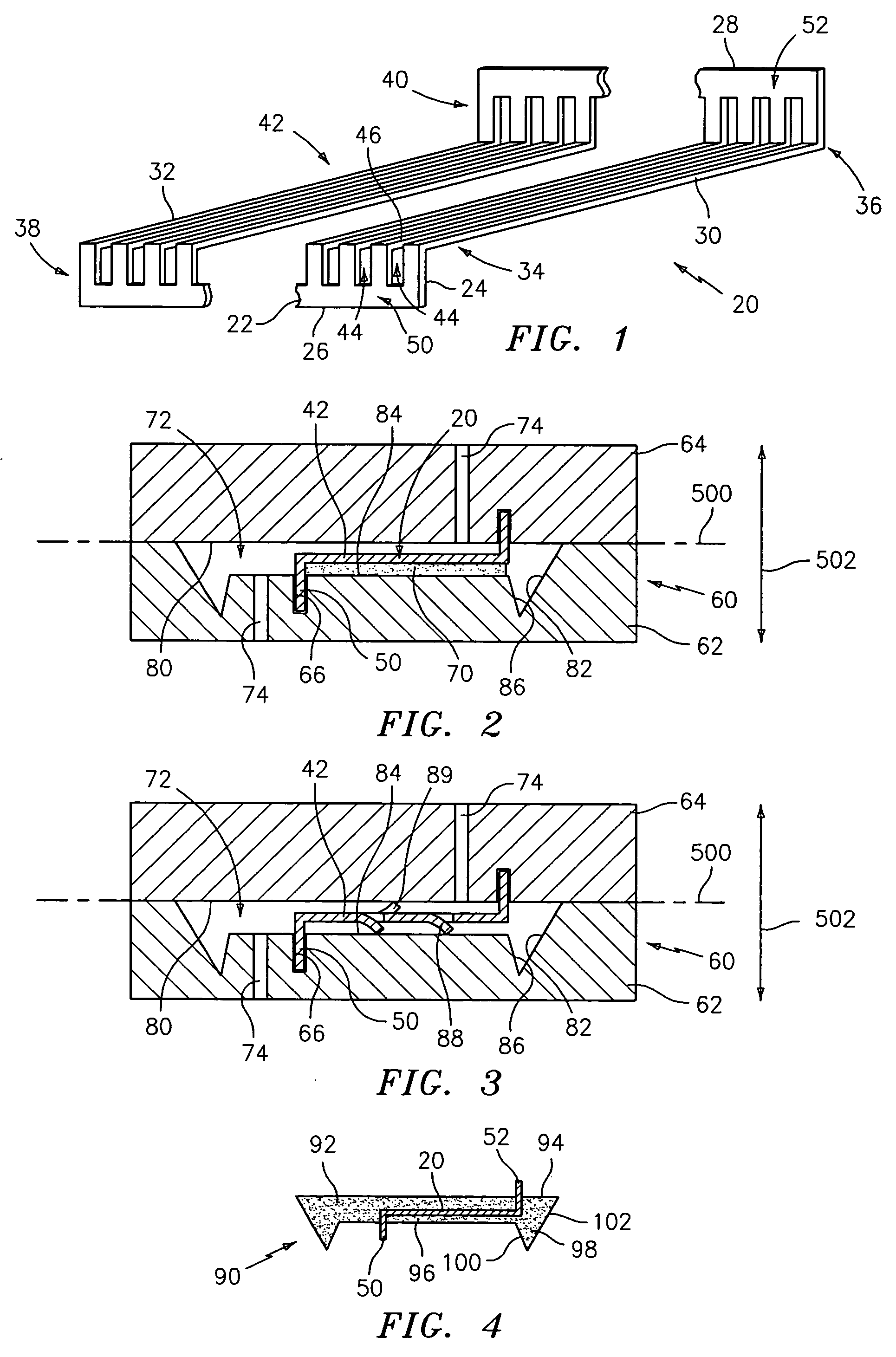

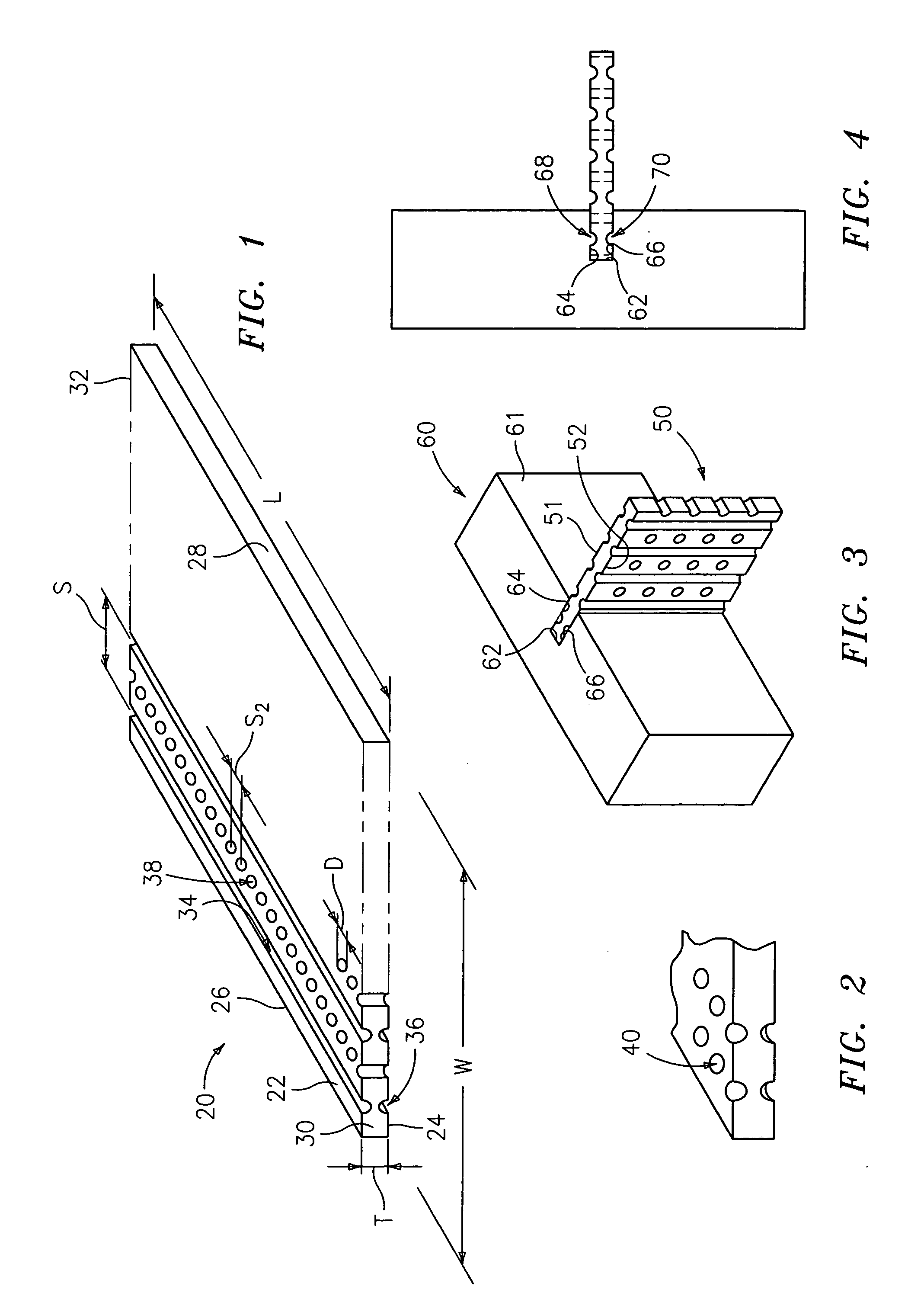

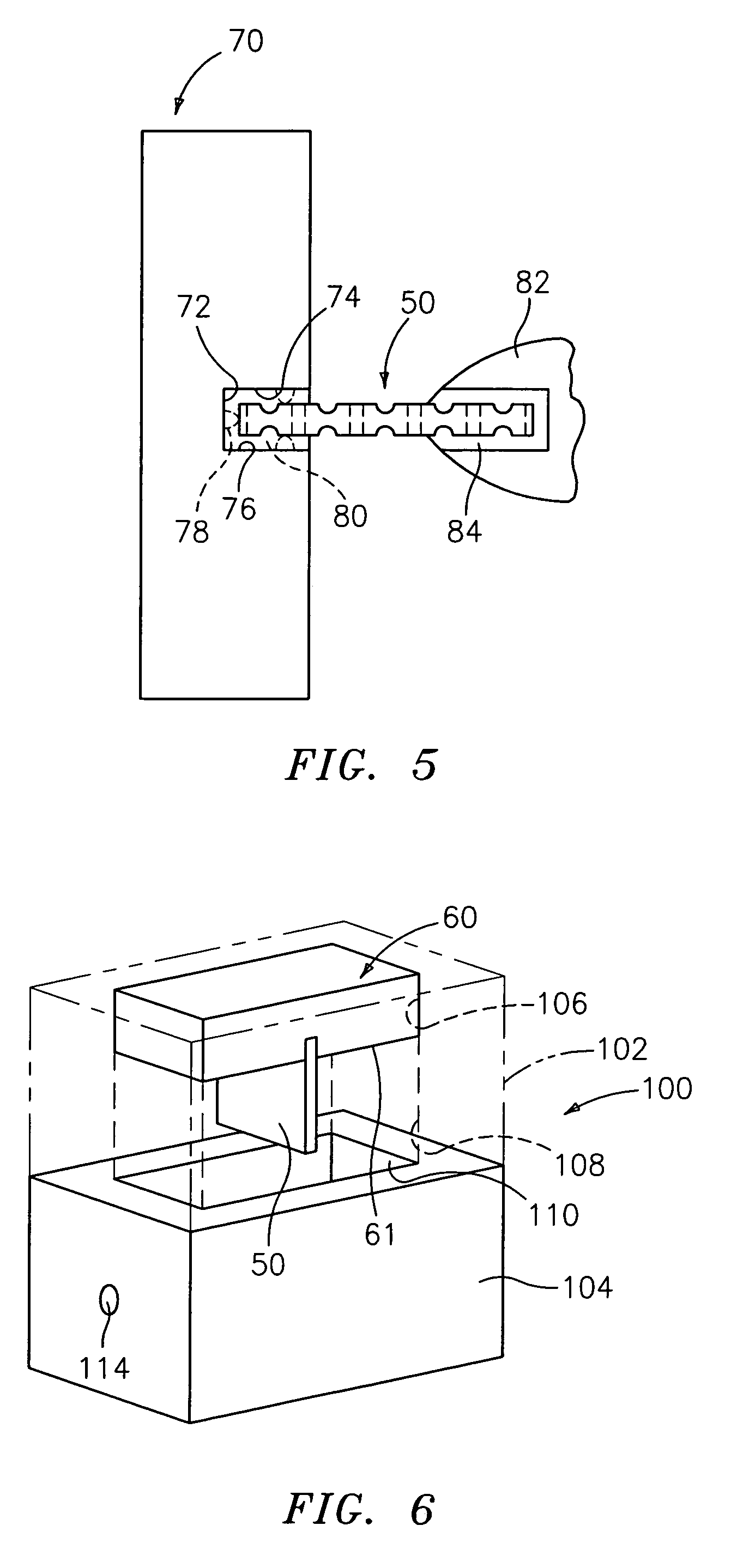

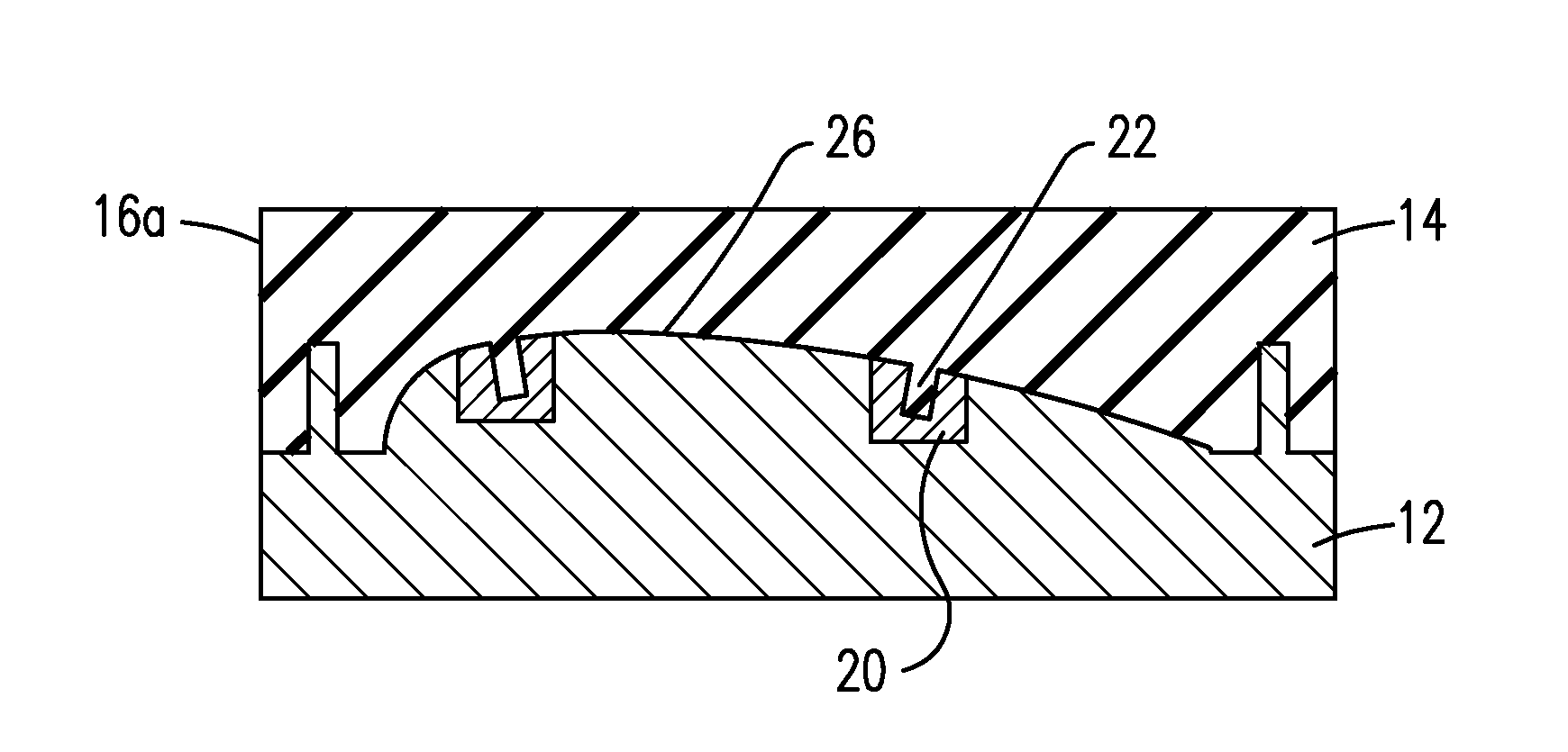

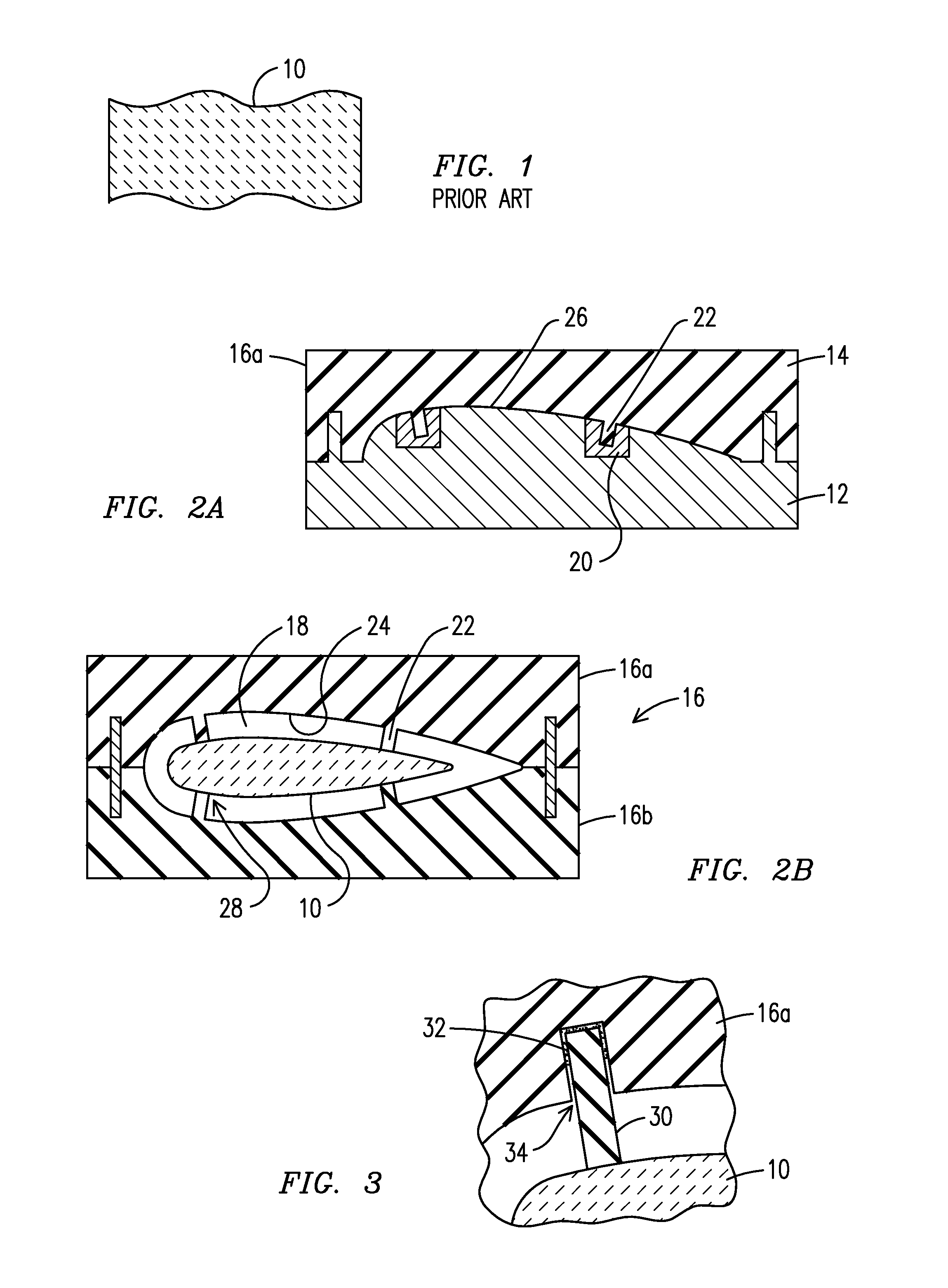

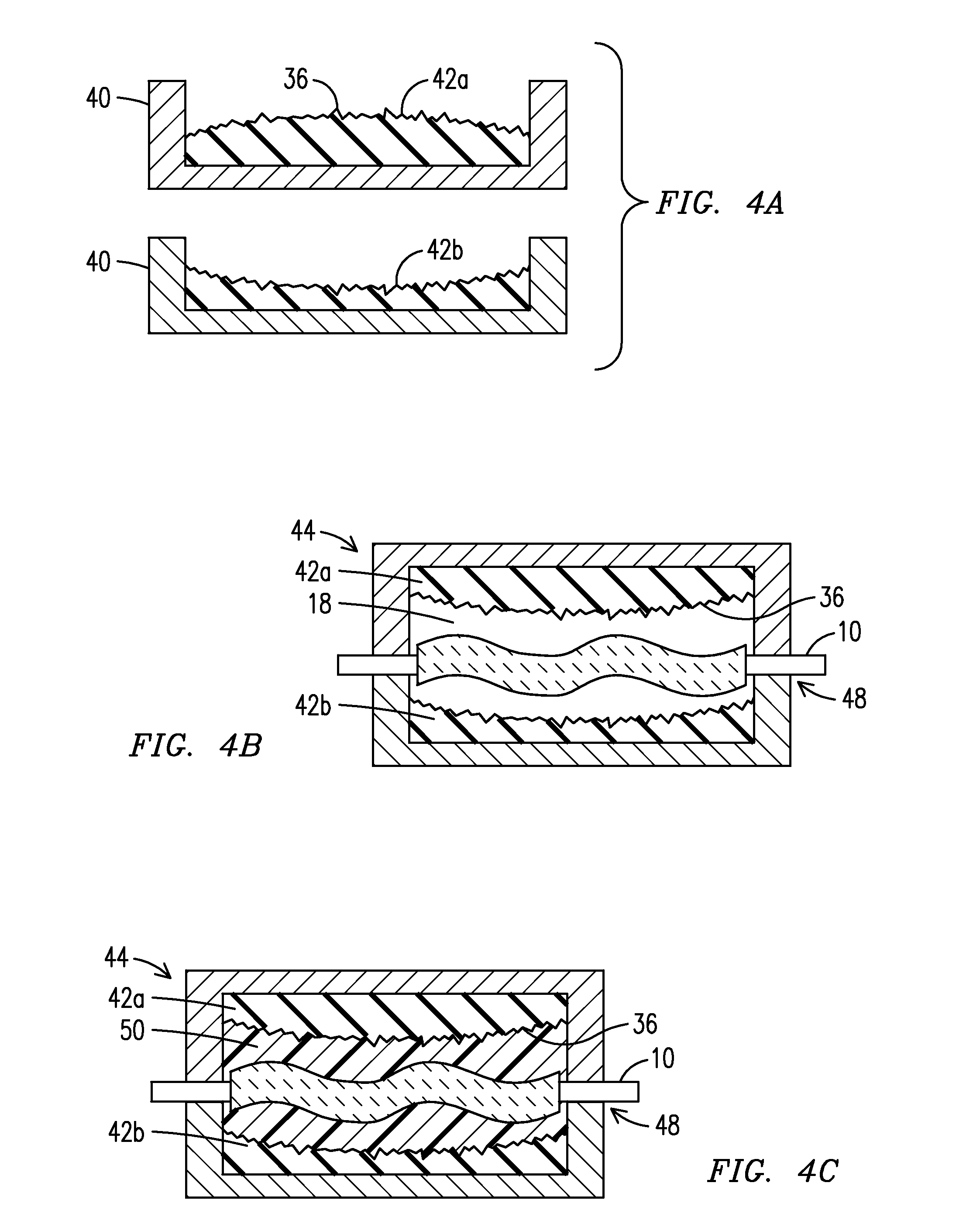

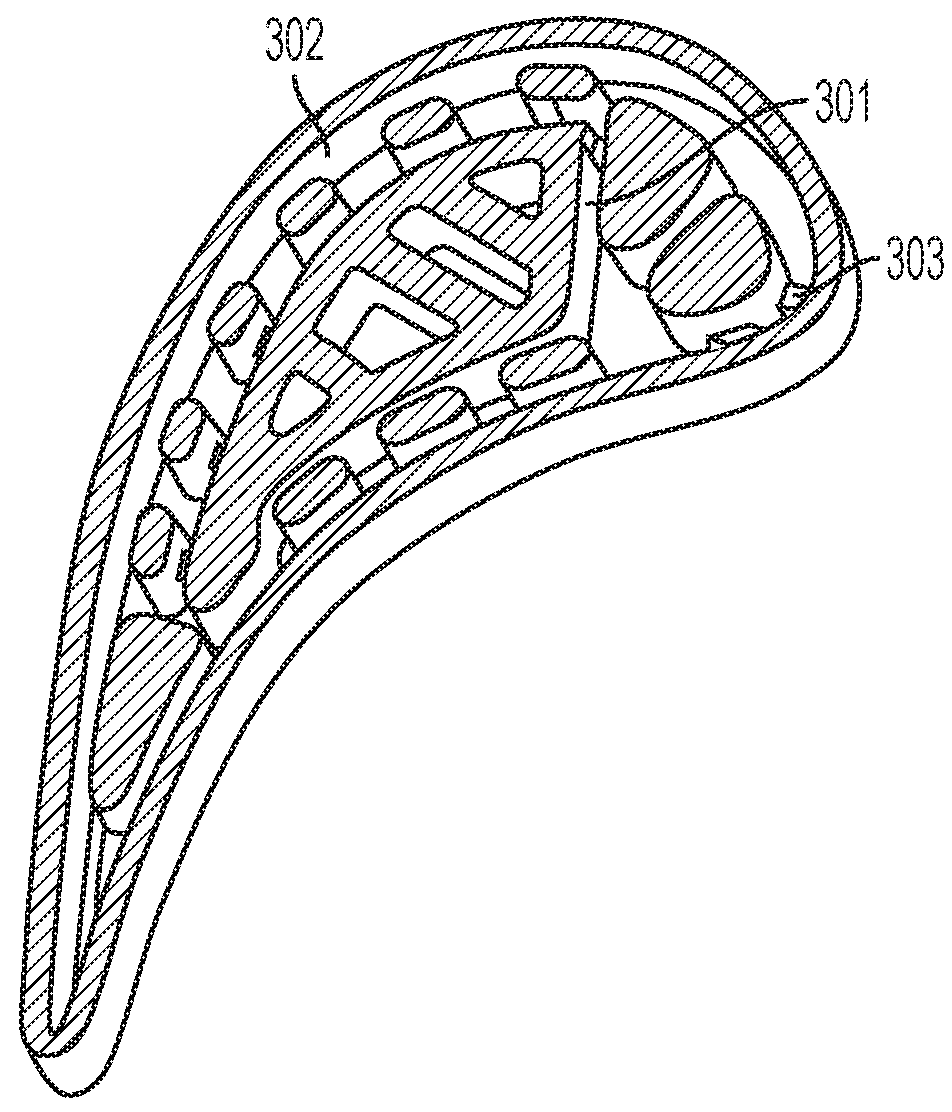

Investment casting utilizing flexible wax pattern tool for supporting a ceramic core along its length during wax injection

InactiveUS20130333855A1Reducing incidence of damage and movementIncrease pressureFoundry mouldsFoundry coresInjection pressureInvestment casting

An investment casting process wherein the wax pattern tool (42) is flexible to provide compliant support for an enclosed ceramic core (10) and to facilitate removal of the tool from the cast wax pattern (52) even when the cast shape would otherwise require multiple pull planes. Positioning pins (106) may extend from the flexible tool to make compliant contact against the core during the wax injection step. The pins may cooperate with a pedestal (128) formed on the core to support the core along multiple axes during wax injection, thereby allowing a higher wax injection pressure without damage to the core.

Owner:MIKRO SYSYTEMS INC +1

Investment casting mold design and method for investment casting using the same

ActiveUS7231955B1Molten metal pouring equipmentsMolten metal supplying equipmentsInvestment castingCasting mold

A method for investment casting includes the steps of positioning a base plate relative to a die; molding a first material between the die and at least a first surface portion of the base plate; securing one or more patterns to the base plate, the one or more patterns comprising a second material; applying one or more coating layers over at least portions of the one or more patterns and at least a portion of the first material; substantially removing the first material through an interior receptacle of a manifold body and the second material through an exterior receptacle of the manifold body to leave one or more shells formed by the coating layers; removing said base plate; introducing molten metal to the one or more shells through the interior receptacle of the manifold body; permitting the molten metal to solidify; and destructively removing one or more investment casting molds.

Owner:RTX CORP

Investment casting

An investment casting pattern is formed by installing a first core to a first element of a molding die to leave a first portion of the first core protruding from the first element. After the installing, the first element is assembled with a feed core and a second element of the molding die so that the first portion contacts the feed core and is flexed. A material is molded at least partially over the first core and feed core.

Owner:RTX CORP

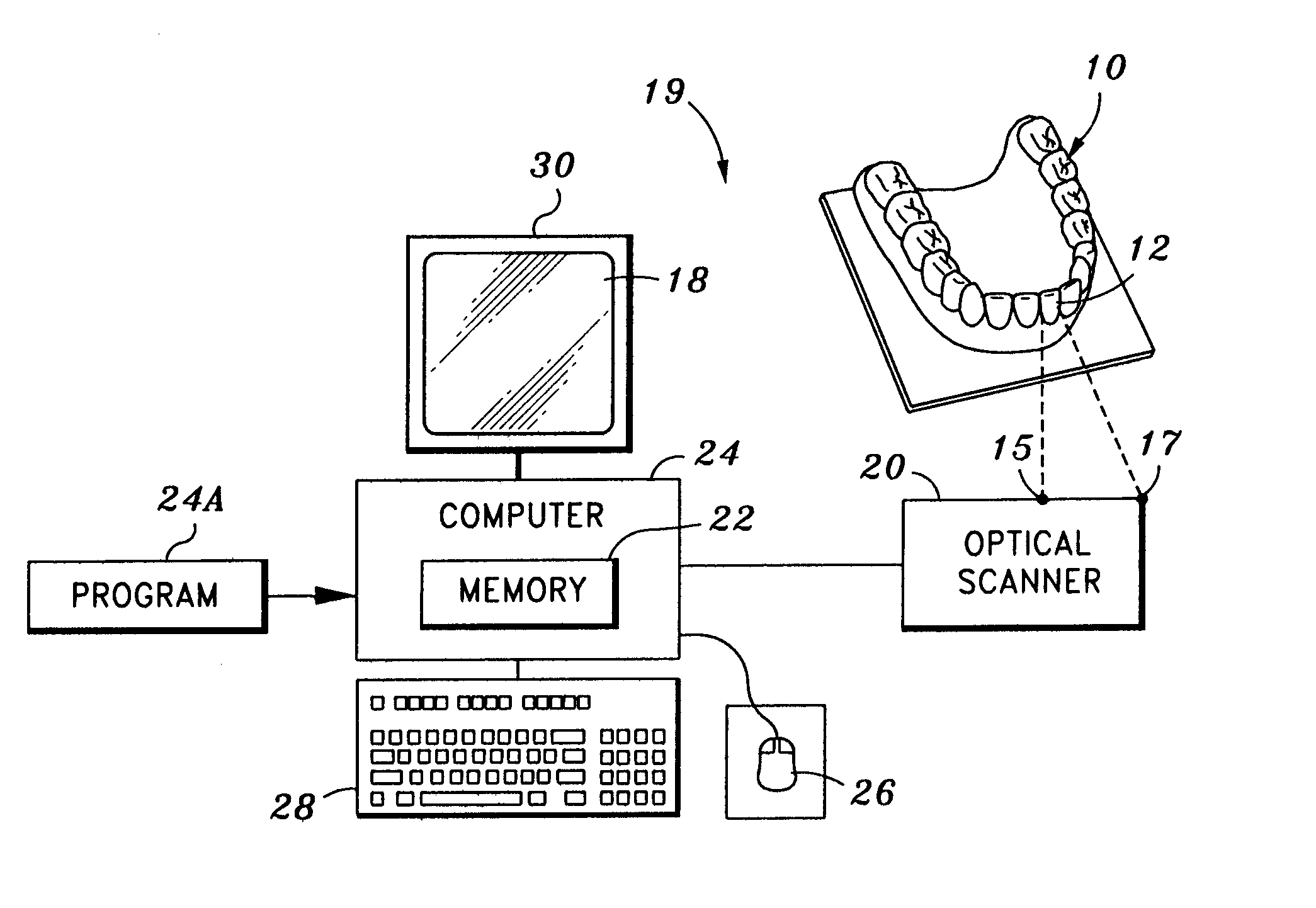

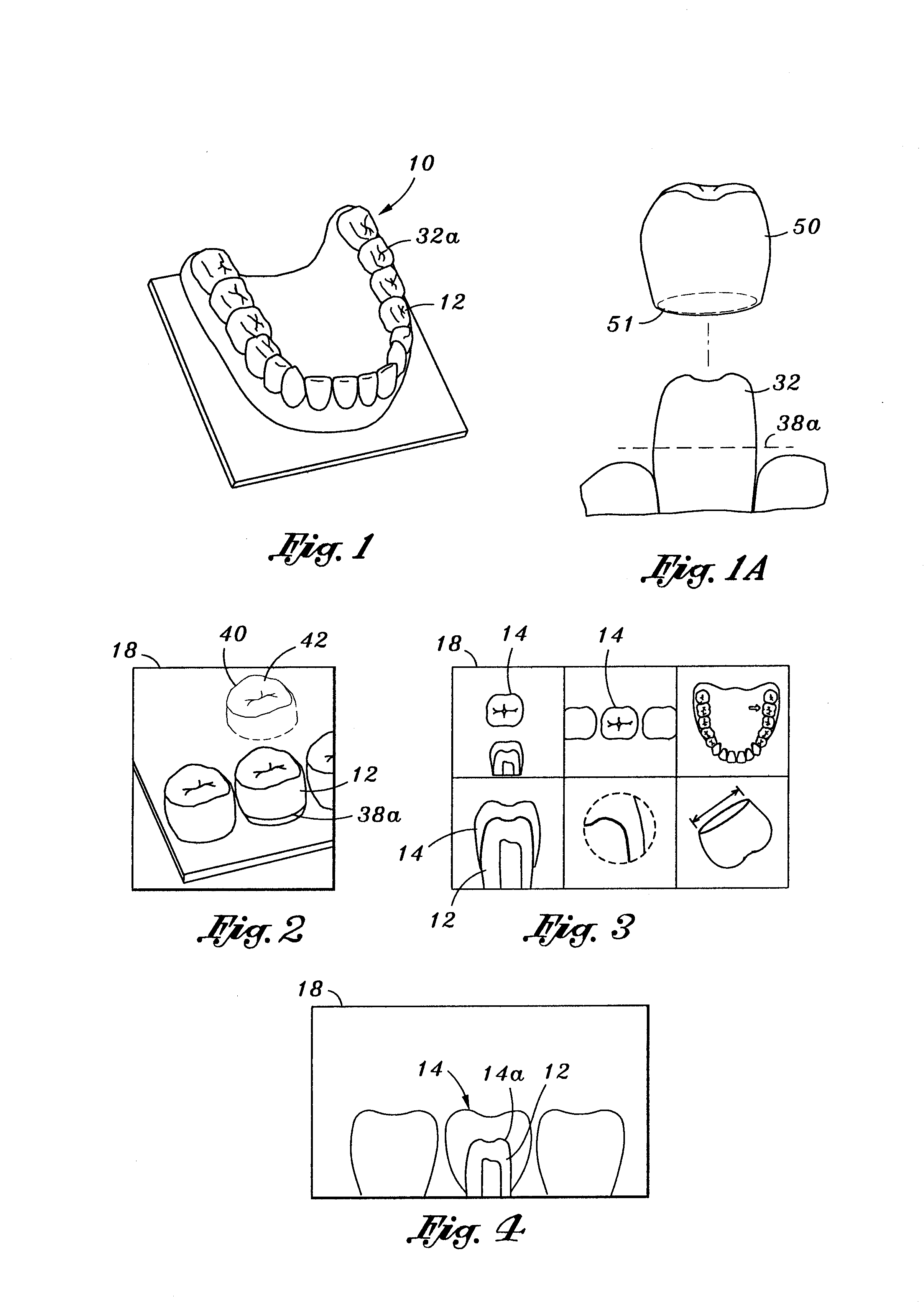

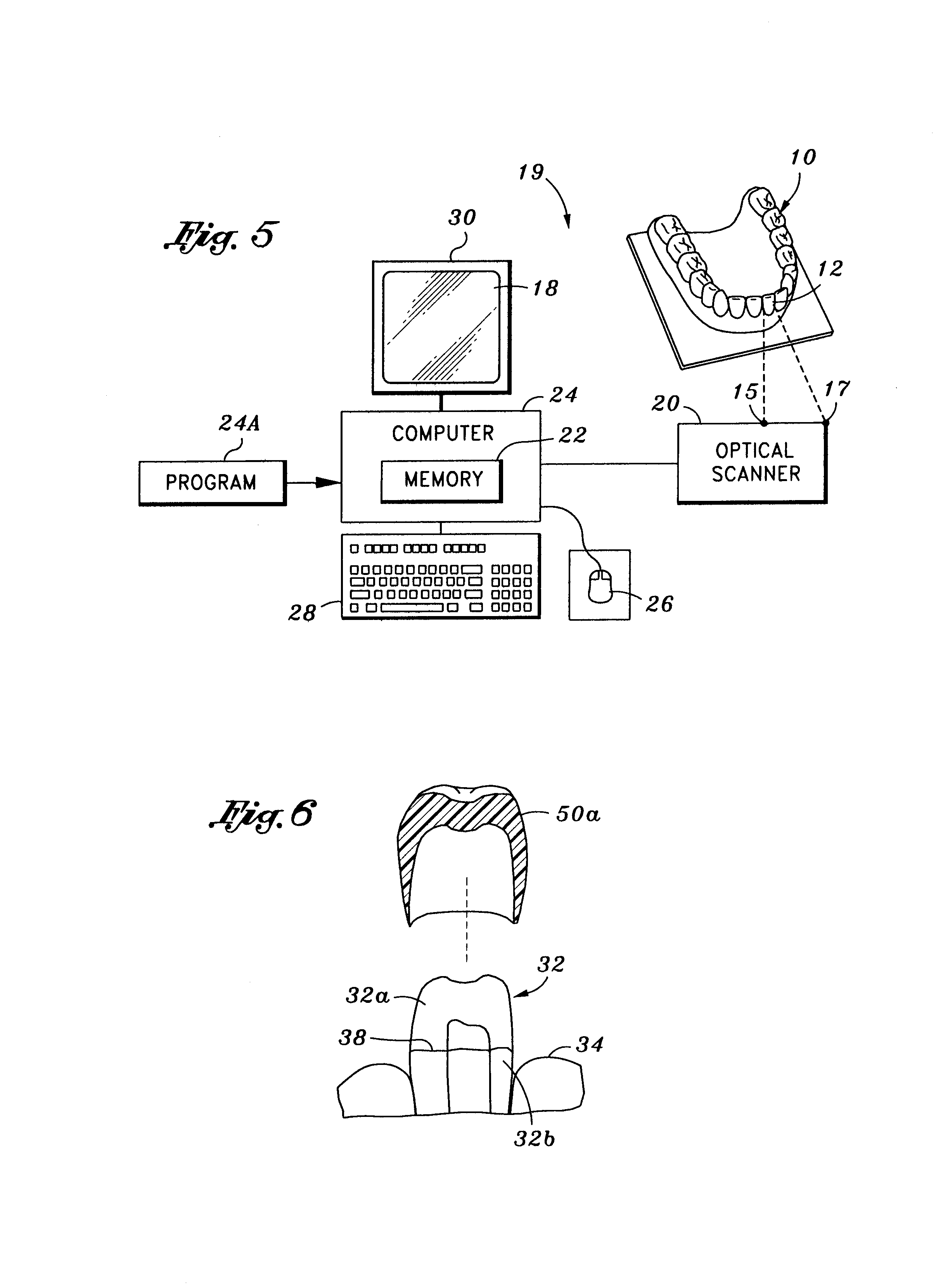

Dental prosthesis manufacturing process, dental prosthesis pattern @$amp; dental prosthesis made thereby

InactiveUS20020013636A1Improve accuracyShorten the timeSpecial data processing applicationsDental prostheticsDigital dataWax

<heading lvl="0">Abstract of Disclosure< / heading> A dental prosthesis is made by first forming a model of a patient's dentition. A three dimensional digital data corresponding to the surfaces of the model is then created. Based on this data, a three dimensional digital data file is then created substantially corresponding to the dental prosthesis to be manufactured. The three dimensional digital data of the dental prosthesis to be manufactured is next transmitted to automated prototyping equipment, and using the automated prototyping equipment, a wax pattern of the dental prosthesis is manufactured based upon this three dimensional digital data of the dental prosthesis. Finally, using this wax pattern in the lost wax investment casting process, the dental prosthesis is made. Prior to investment casting, marginal edges of the wax pattern are adjusted manually.

Owner:NAT DENTEX LLC

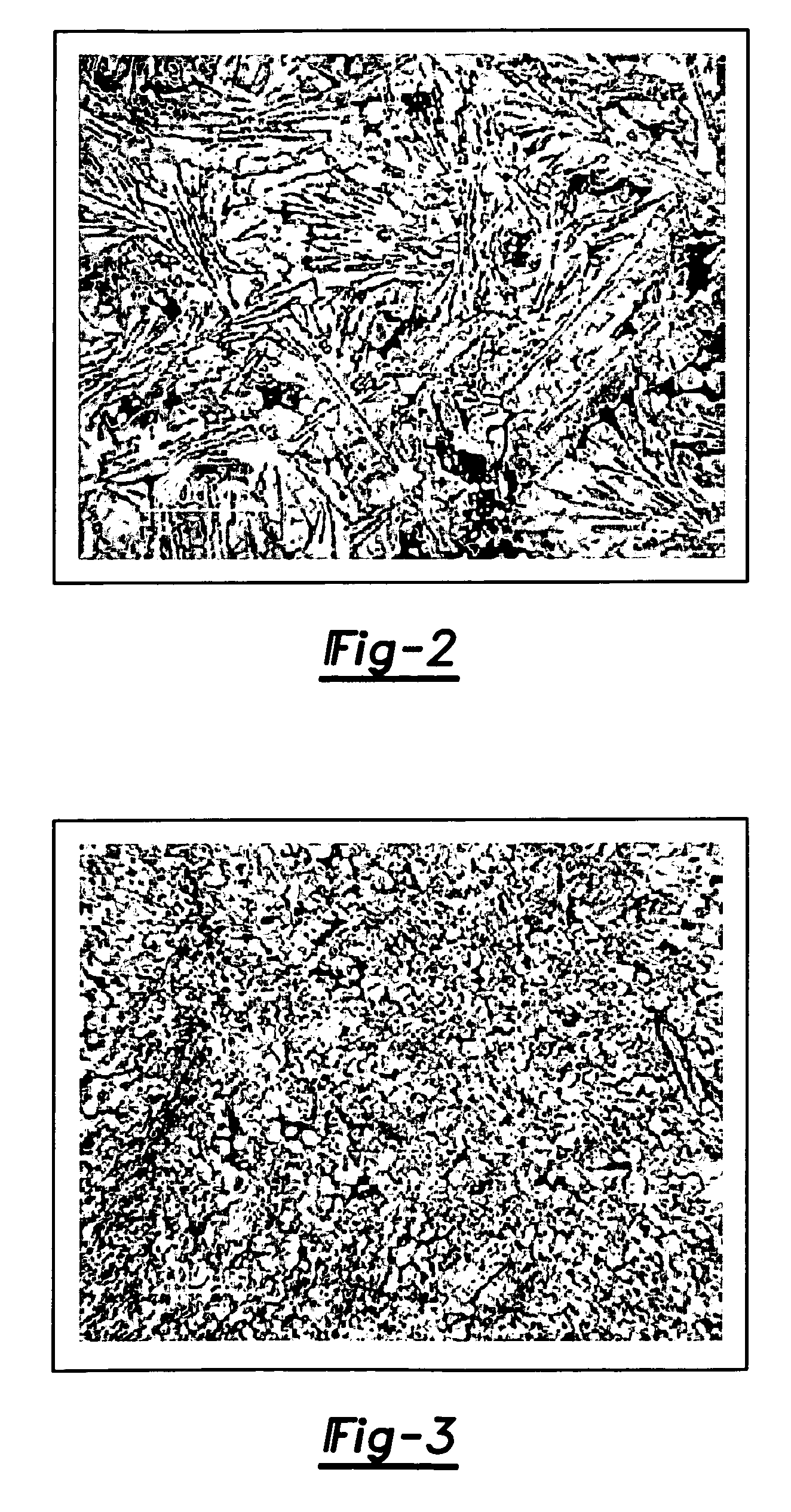

Method of producing a castable high temperature aluminum alloy by controlled solidification

ActiveUS20070062669A1Increase the speed of solidificationFoundry mouldsAerodynamics improvementRare-earth elementInvestment casting

Owner:RAYTHEON TECH CORP

Dental prosthesis manufacturing process, dental prosthesis pattern & dental prosthesis made thereby

InactiveUS6915178B2Improved accuracy of the marginal edges of the dental prosthesisShorten the timeMedical simulationAdditive manufacturing apparatusDigital dataWax

A dental prosthesis is made by first forming a model of a patient's dentition. A three dimensional digital data corresponding to the surfaces of the model is then created. Based on this data, a three dimensional digital data file is then created substantially corresponding to the dental prosthesis to be manufactured. The three dimensional digital data of the dental prosthesis to be manufactured is next transmitted to automated prototyping equipment, and using the automated prototyping equipment, a wax pattern of the dental prosthesis is manufactured based upon this three dimensional digital data of the dental prosthesis. Finally, using this wax pattern in the lost wax investment casting process, the dental prosthesis is made. Prior to investment casting, marginal edges of the wax pattern are adjusted manually.

Owner:NAT DENTEX LLC

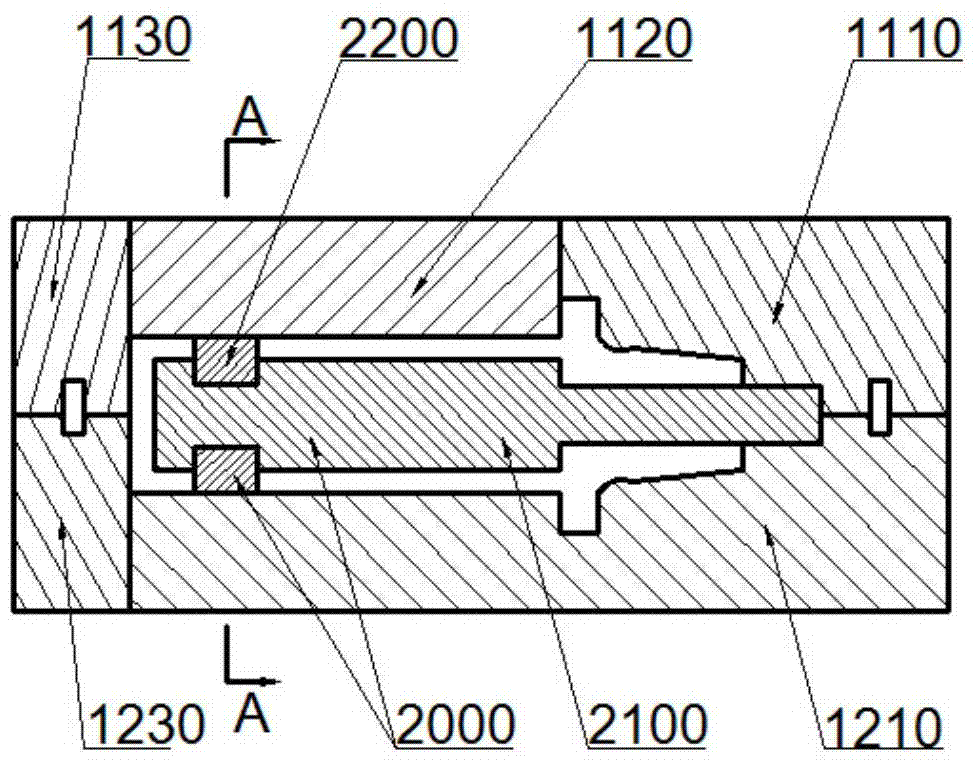

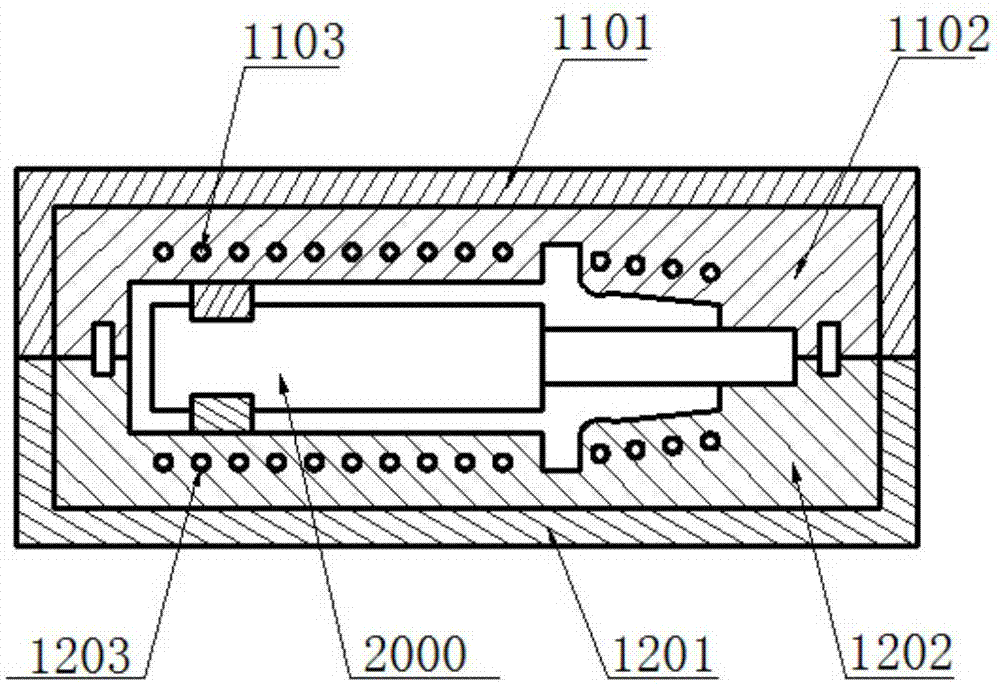

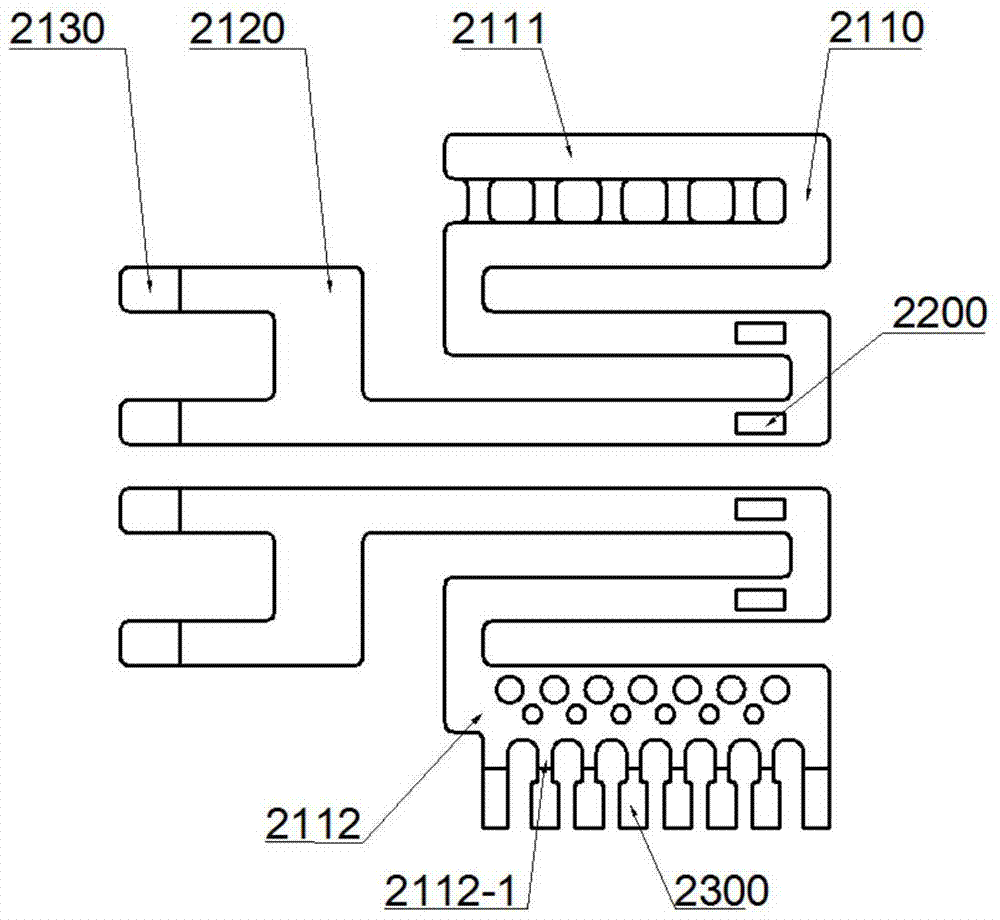

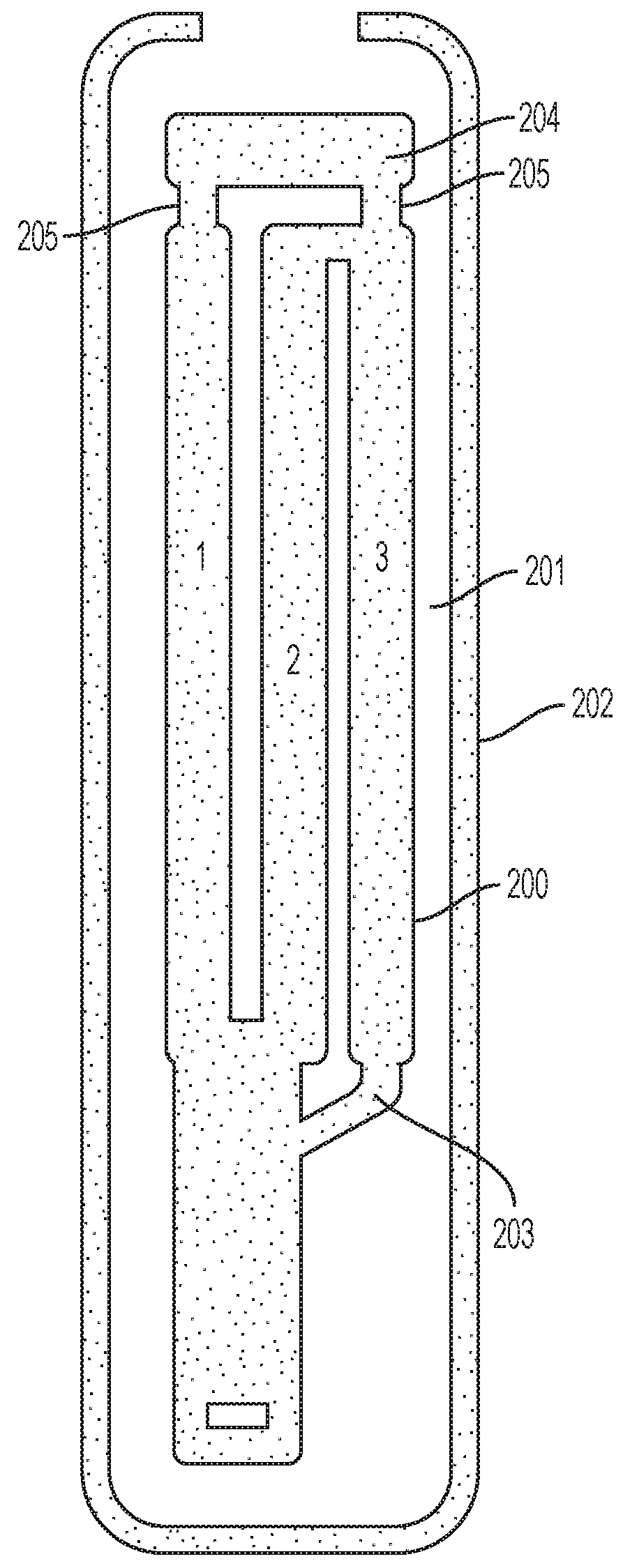

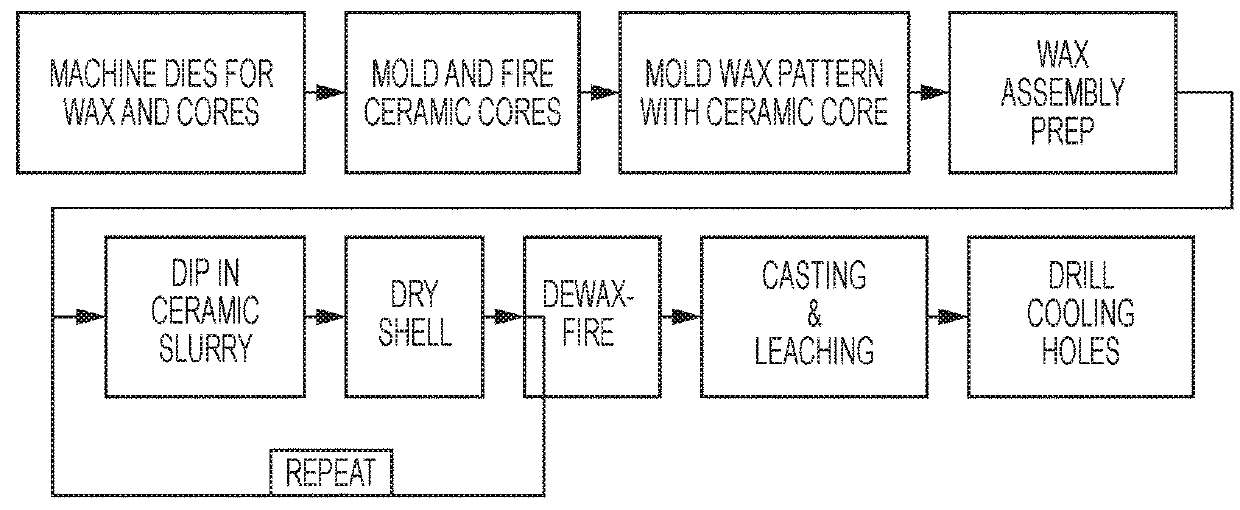

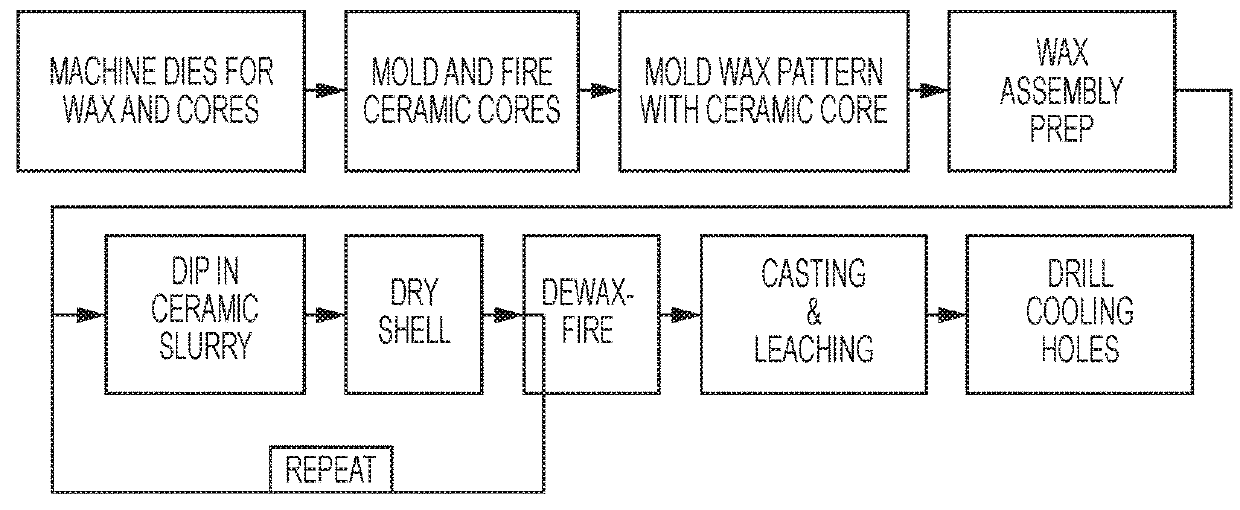

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

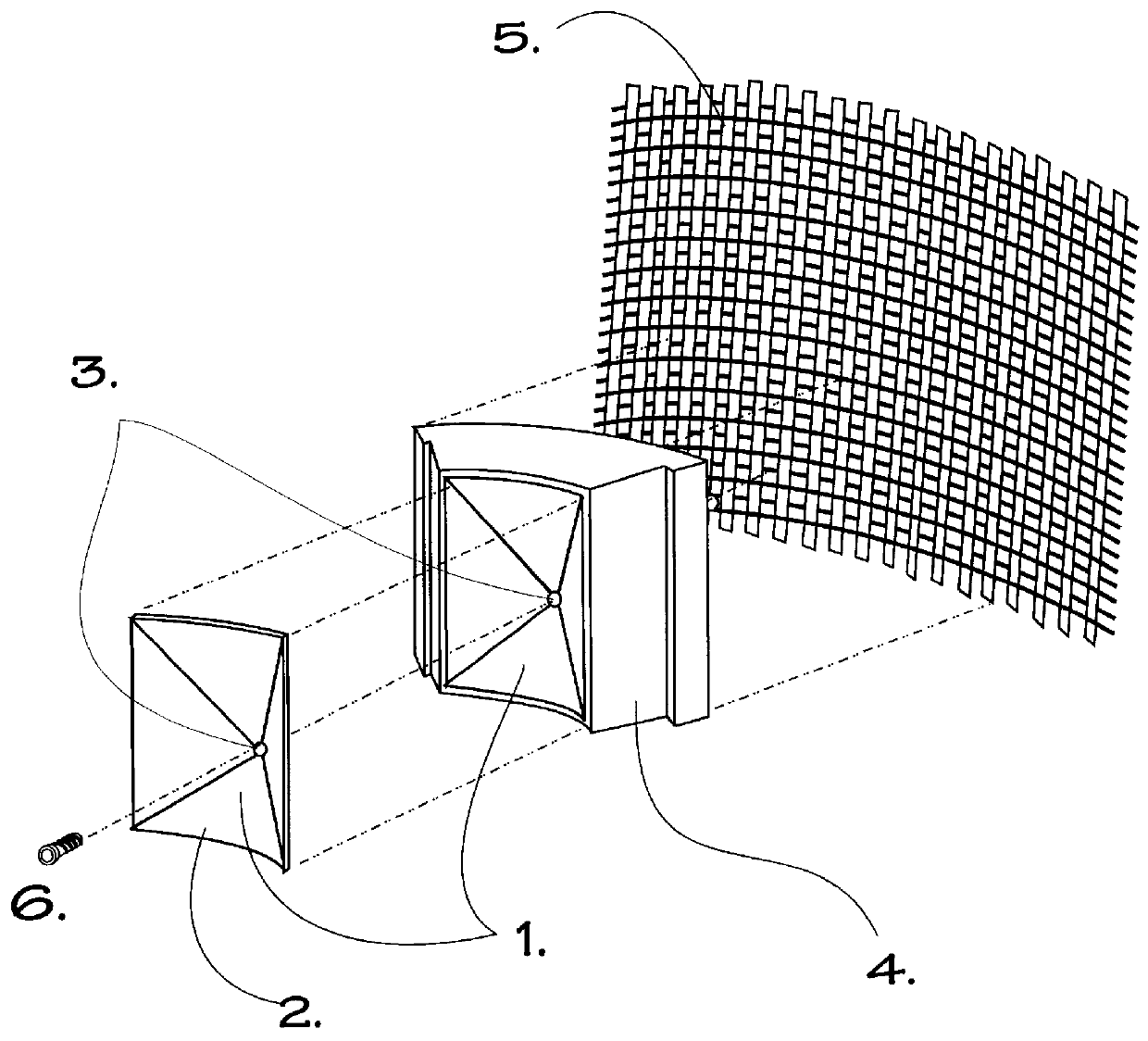

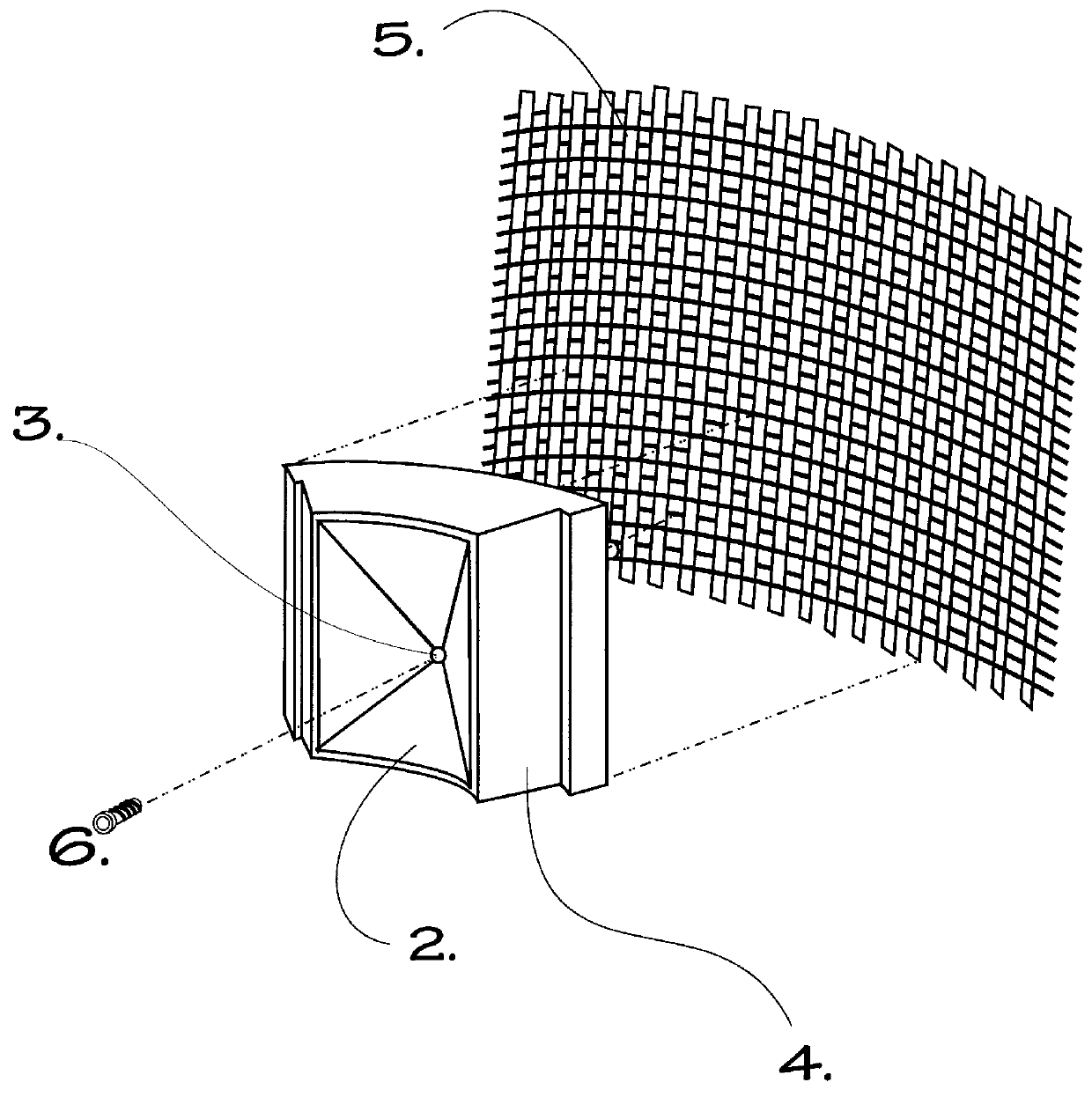

Method of construction for density screening outer transport walls

InactiveUS6033564AThin and inexpensiveReduced toleranceRotary centrifugesCeramic shaping apparatusBursting strengthDynamic balance

A method for combining three different means of constructing the concentric layers of the outer collecting wall for industrial size centrifuges, whereby treating the inward-facing elements of easily cast or stamped materials using processes such as Physical Vapor Deposition, Chemical Vapor Deposition or metal plating, transforms them into an innermost member with superior hardness and durability, and whereby said wear surface member or deposited layer is physically supported by a middle composite layer made up of one or more investment castings designed to optimally transfer centrifugally-induced compression loads from the innermost wear surface toward the outer surface of the composite wall, such castings being of ceramic, metals or other materials, and whereby the outer surface of said composite wall is comprised of a filament-wound hoop strength reinforcement layer, using aramid, graphic, carbon or such fibers mixed and embedded in resin, such that all highly desirable characteristics for a centrifuge outer, heavies-collecting wall are provided, including interior hardness and wear abrasion, incompressibility and intrinsic dynamic balance, and substantially higher hoop or bursting strength, than can be attained through any metal-crafted centrifuge outer wall, and, model for model, for substantially lower design and fabrication costs.

Owner:BERKELEY F FULLER

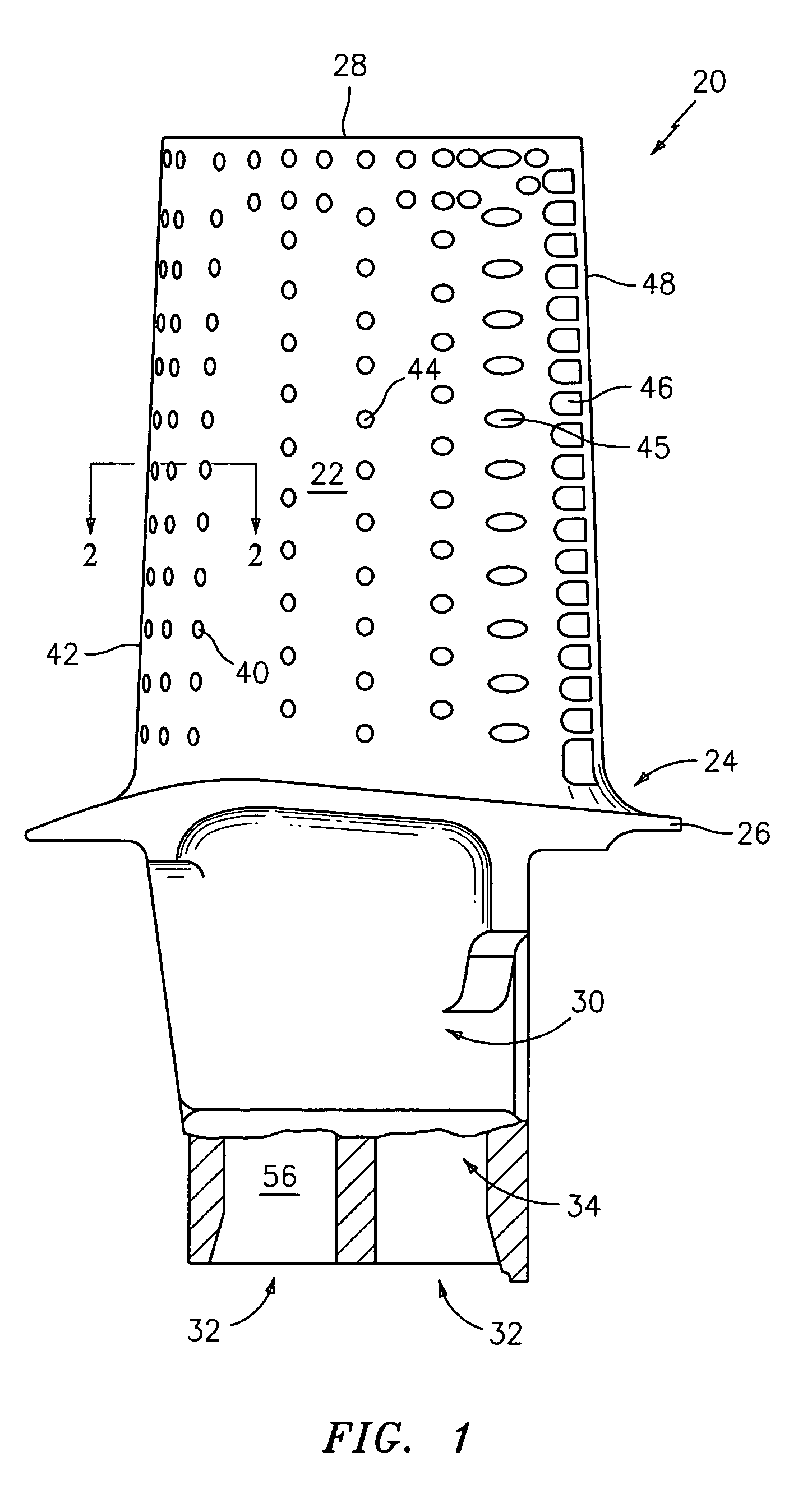

Cooled turbine airfoils and methods of manufacture

An investment casting pattern is formed by installing a first core to a first element of a molding die to leave a first portion of the first core protruding from the first element. After the installing, the first element is assembled with a feed core and a second element of the molding die so that the first portion contacts the feed core. A material is molded at least partially over the first core and the feed core. The first portion has one or more surface area enhancements.

Owner:RTX CORP

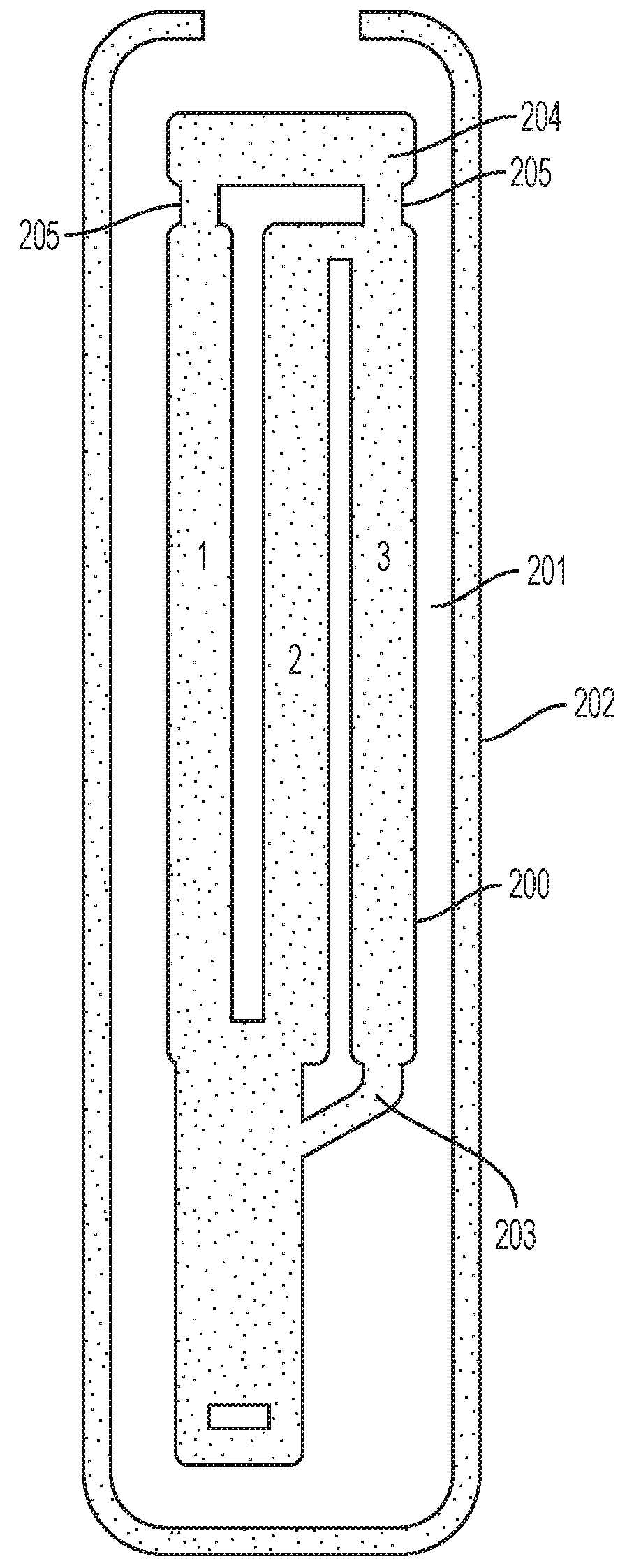

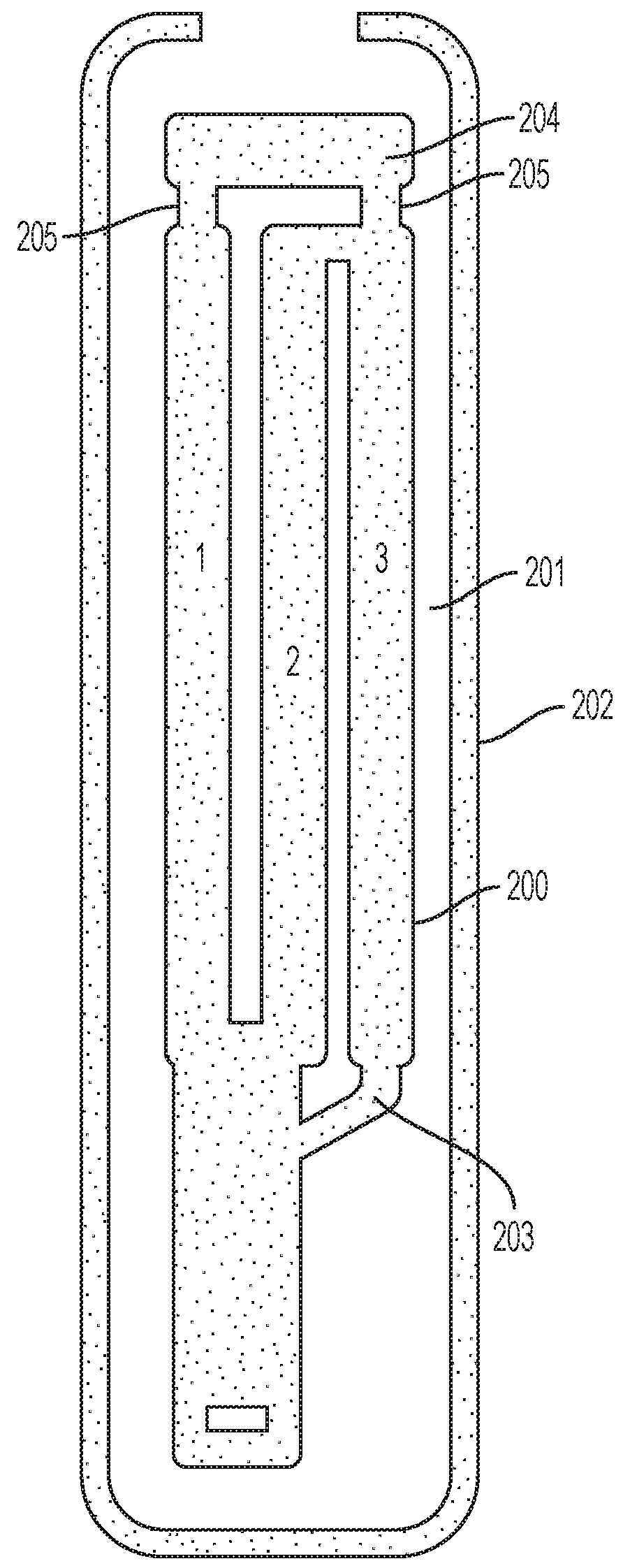

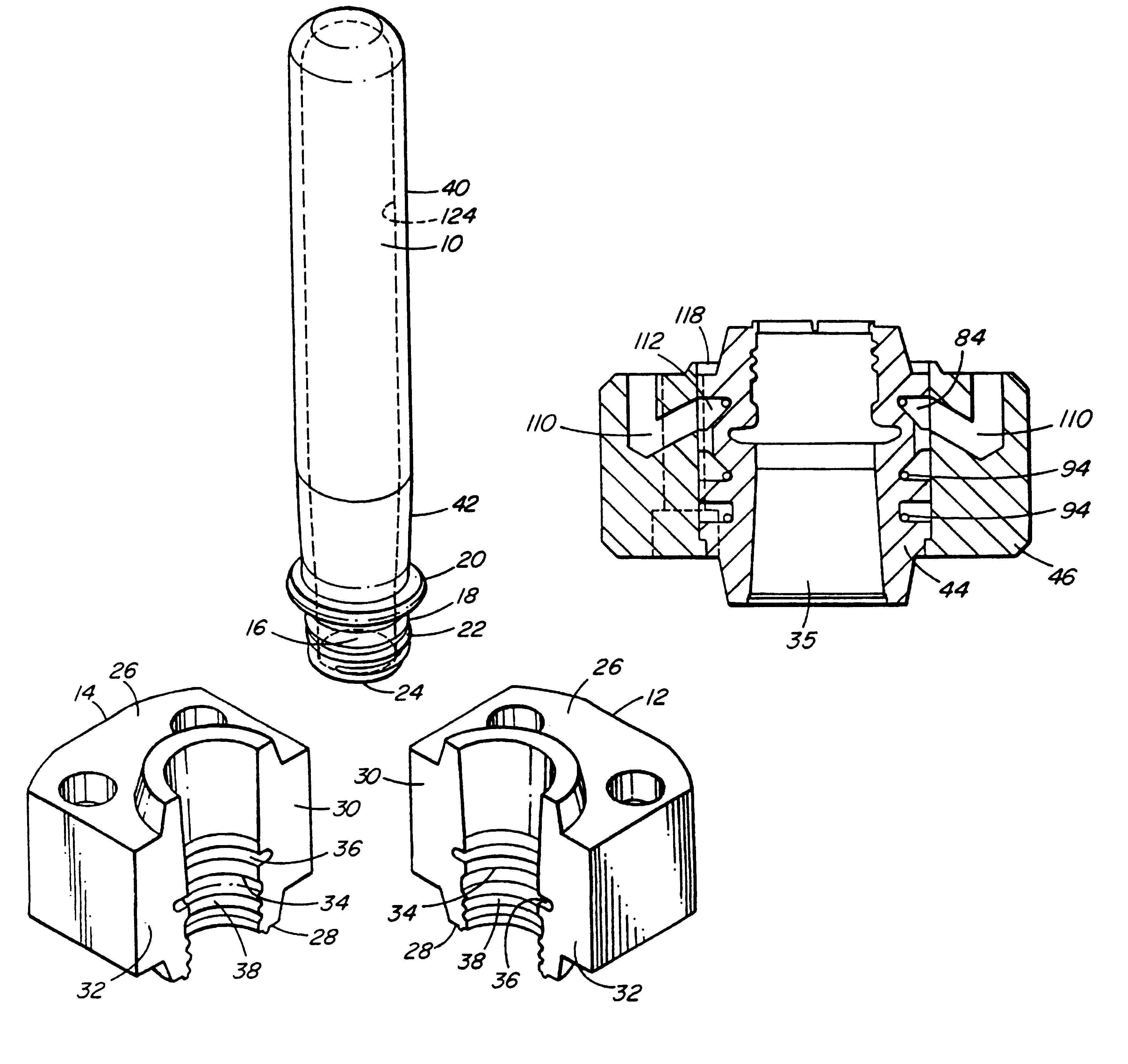

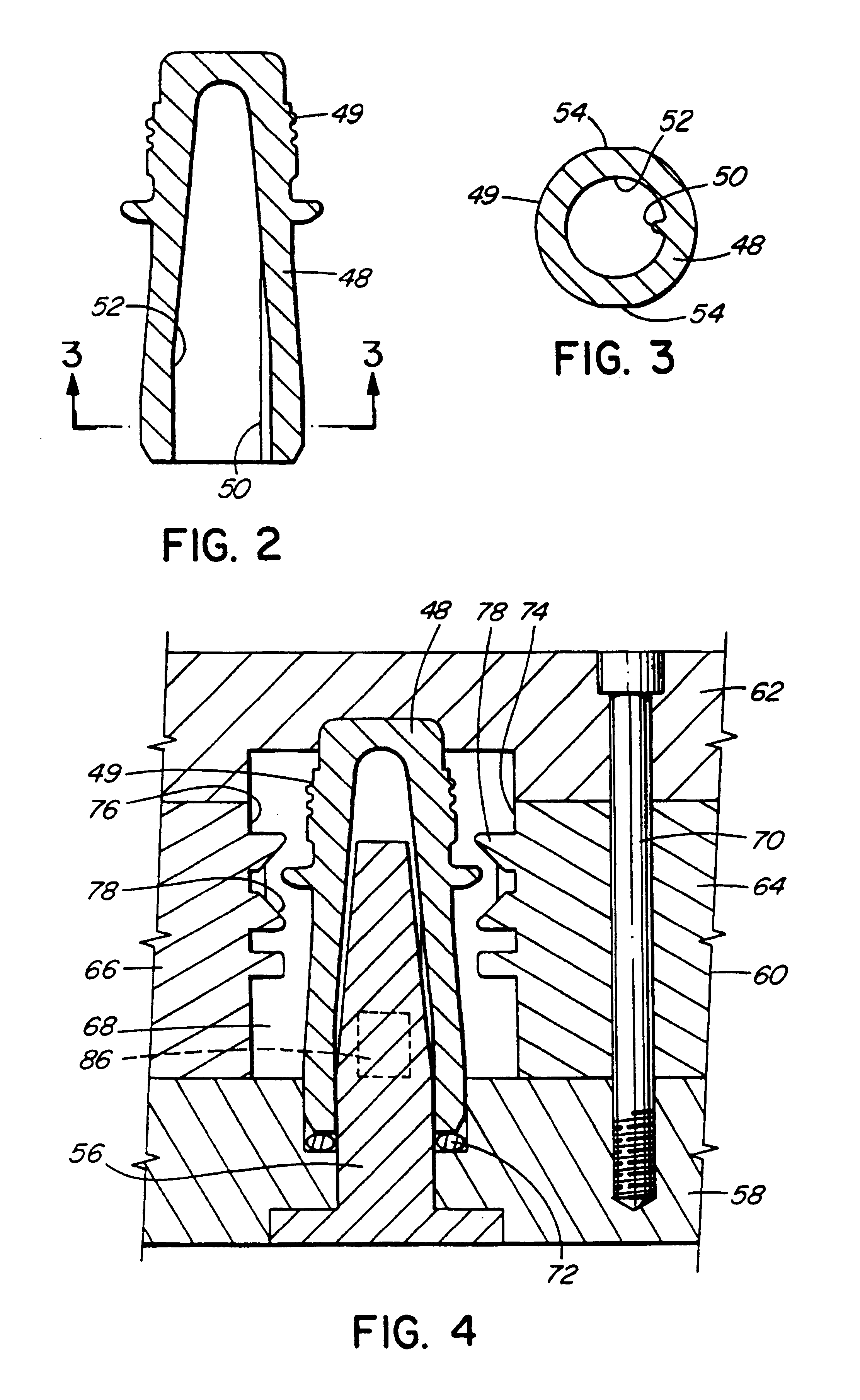

Investment casting method and cores and dies used therein

InactiveUS20050006047A1Additive manufacturing apparatusFoundry mouldsInvestment castingInternal cavity

A method for making an article by an investment casting process is presented, along with a method for making casting cores, the casting cores made by this method, and dies for making such cores. The method for making a component comprises providing a single-piece sacrificial die, the die comprising at least one internal cavity; introducing a ceramic slurry into the at least one cavity of the die, the slurry comprising a ceramic and a carrier fluid; curing the slurry to form a ceramic casting core; removing the sacrificial die by exposing the die to an environment adapted to destroy the die while leaving the ceramic casting core intact; and performing an investment casting process using the ceramic casting core as part of a mold-core assembly to form the component.

Owner:GENERAL ELECTRIC CO

Investment casting

An article may be manufactured by providing a reticulate core element in a mold shell having a shape at least partially corresponding to a shape of the article. The molten metallic material is introduced to the shell so as to at least partially infiltrate into the reticulate core element. The molten metallic material is permitted to solidify. The shell and the reticulate core element are destructively removed. The removal leaves the article with one or more gas-permeable porous regions.

Owner:RTX CORP

Investment casting

Pre-molding of wax or similar sacrificial material over one or more cores facilitates a subsequent molding over a core assembly. Individual cores or groups thereof may be pre-molded in a wax body. One or more such wax bodies may be assembled with other bodies and / or other cores to facilitate a main wax molding of such assembly.

Owner:RTX CORP

Investment casting cores and methods

An investment casting pattern is formed by forming a metallic first core element including at least one recess. The first core element is engaged to at least a mating one of an element of the die and a second core element. The recess serves to retain the first core element relative to the mating one. The die is assembled and a sacrificial material is introduced to the die to at least partially embed the first core element. The recess may be pre-formed prior to cutting the first core element from a larger sheet of material.

Owner:RTX CORP

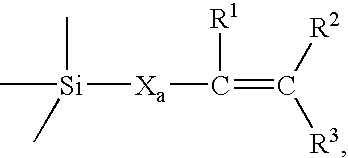

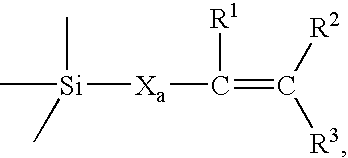

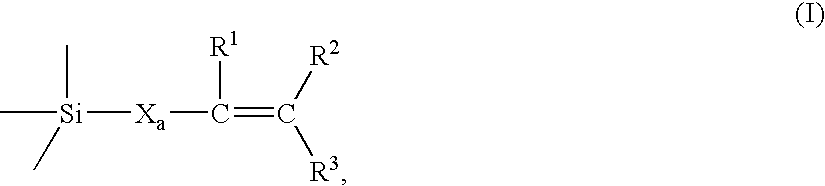

Silicone binders for investment casting

A green product for use in fabricating a ceramic article comprises a ceramic powder immobilized within a silicone matrix, wherein the silicone matrix comprises one or more cross linked or polymerized silicone monomers and / or oligomers, wherein the one or more cross linked or polymerized silicone monomers and / or oligomers have a alkenyl reactive functional group and a hydride reactive functional group. Processes for forming a green product and a ceramic core with the silicone monomers and / or oligomers are also disclosed.

Owner:GENERAL ELECTRIC CO

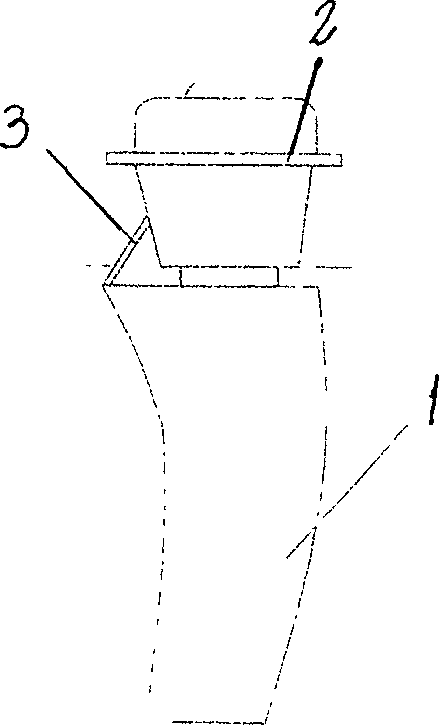

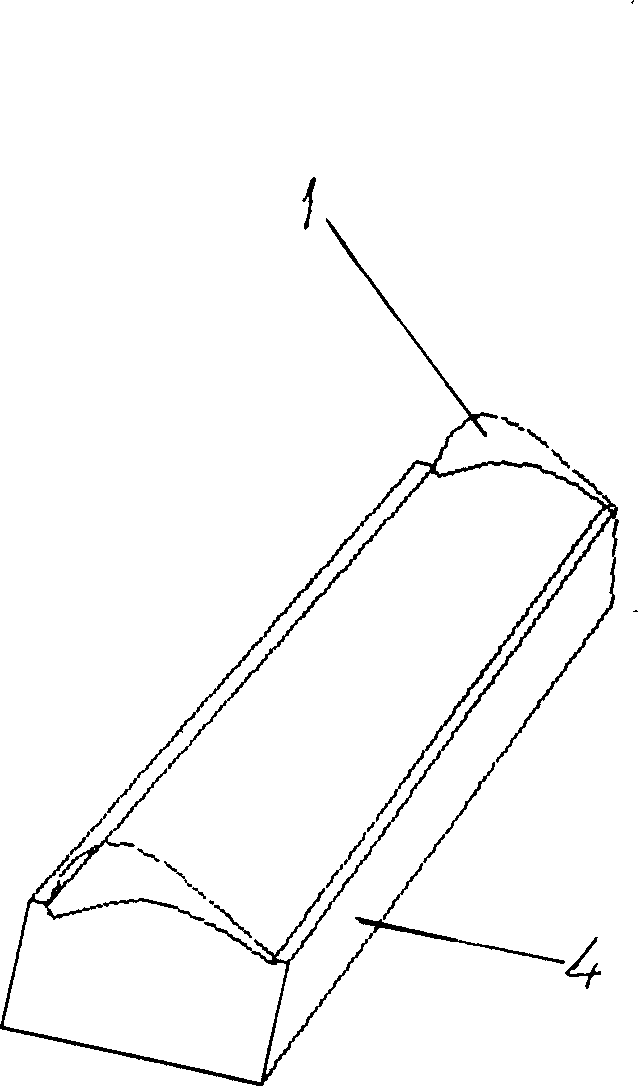

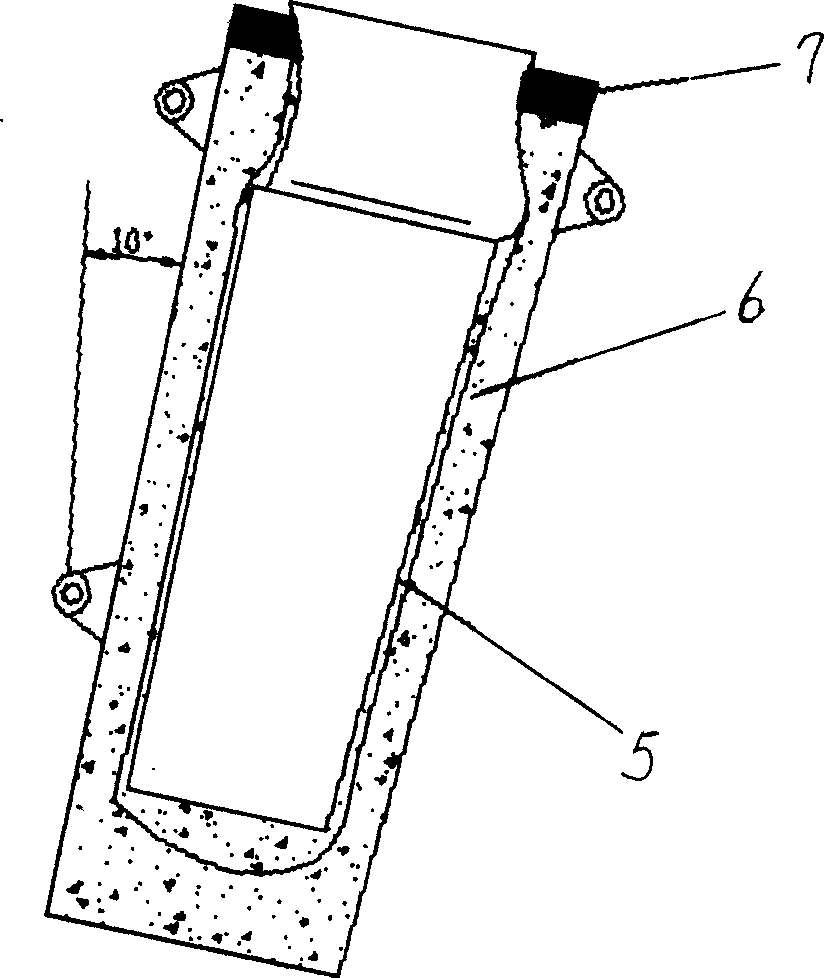

Fine casting method for super long lower pressure partition guide blade of turbine in stainless steel investment mold

The present invention discloses precise investing process of super long low pressure partition guide blade of stainless steel for turbine. Crankled stainless steel guide blade with length up to 960 mm and weight up to 42 kg may be manufactured through investing process. The present invention adopts pre-deforming profiling design and improved investing process and the produced guide blade for 600 KW steam turbo generator has high performance. The investing process includes making wax mold, making shell, smelting and casting, and heat treatment.

Owner:HARBIN XINRUN IND

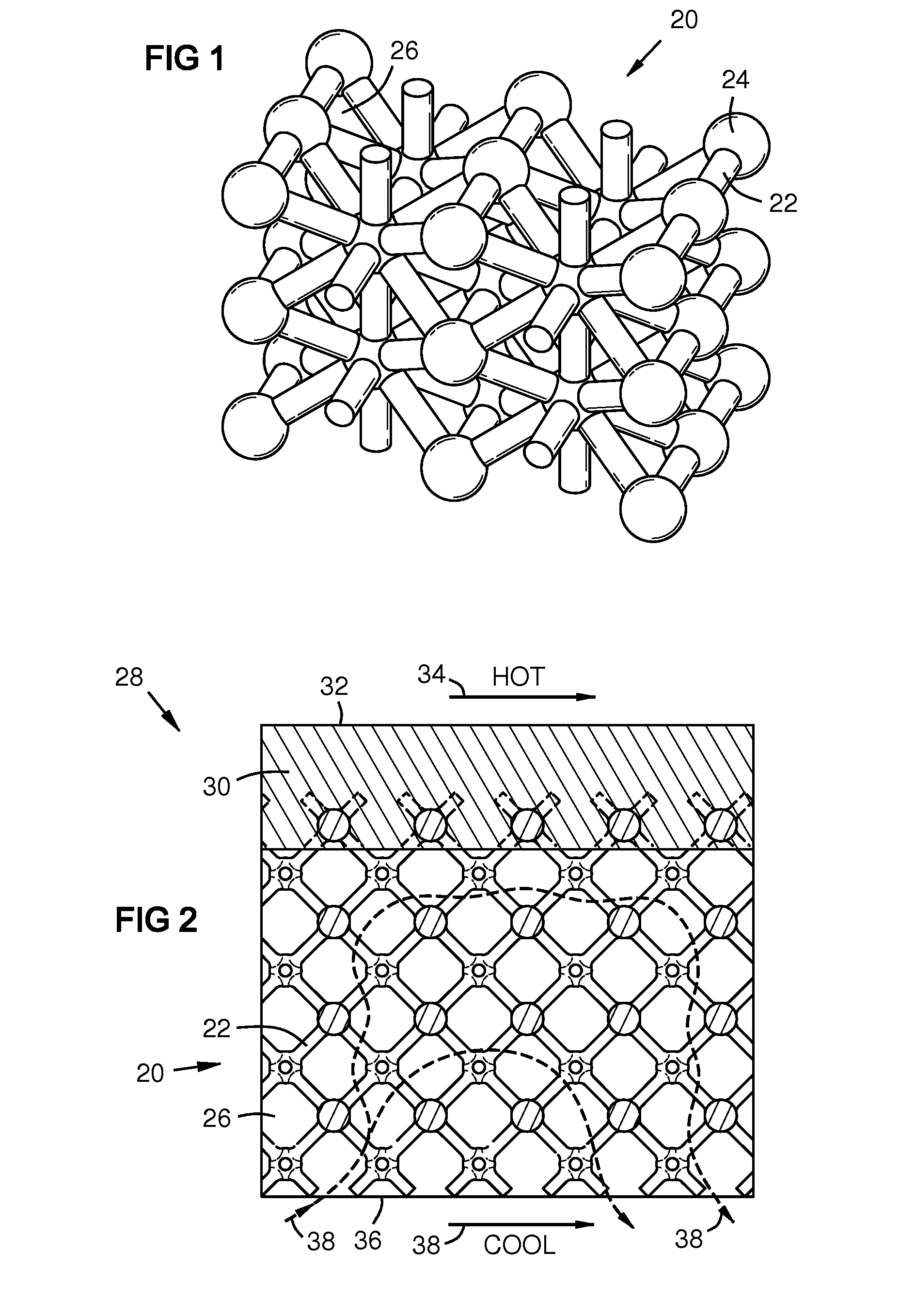

Aluminum-based dot matrix material based on 3D printing technology and preparation method thereof

InactiveCN105033188ARich configurationAdjustable structureFoundry mouldsFoundry coresGratingDot matrix

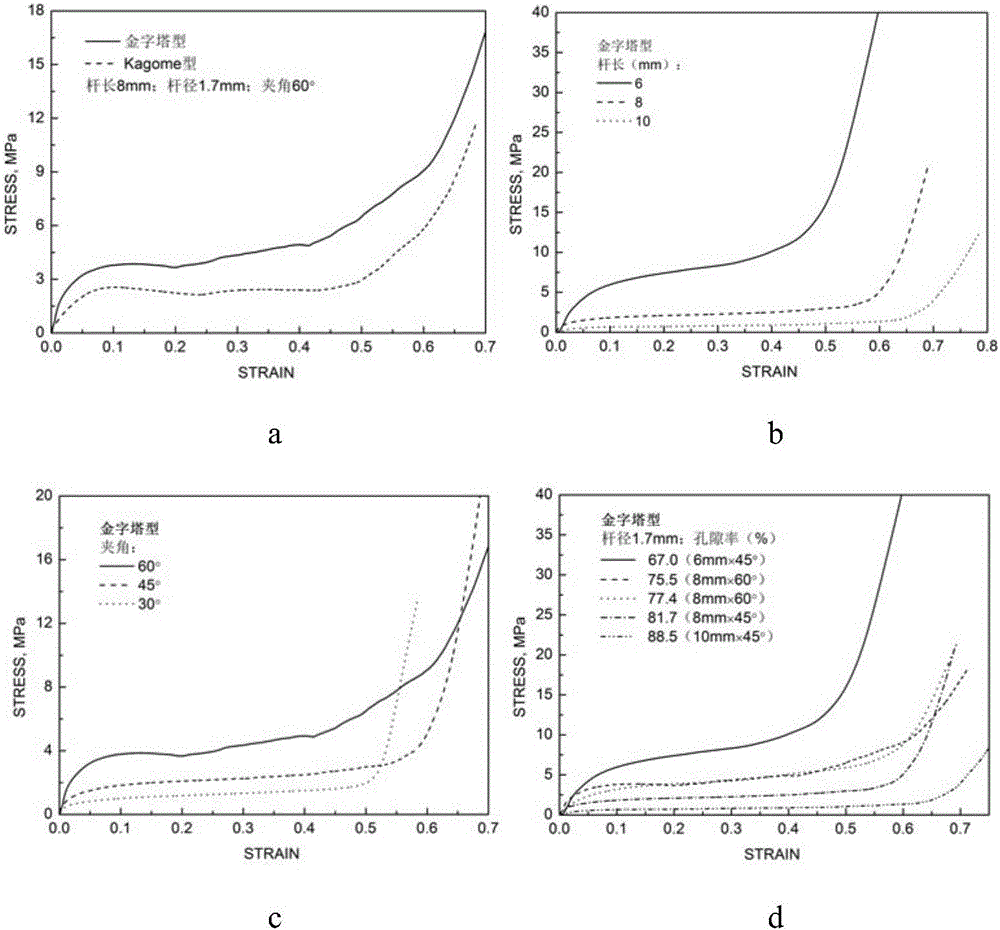

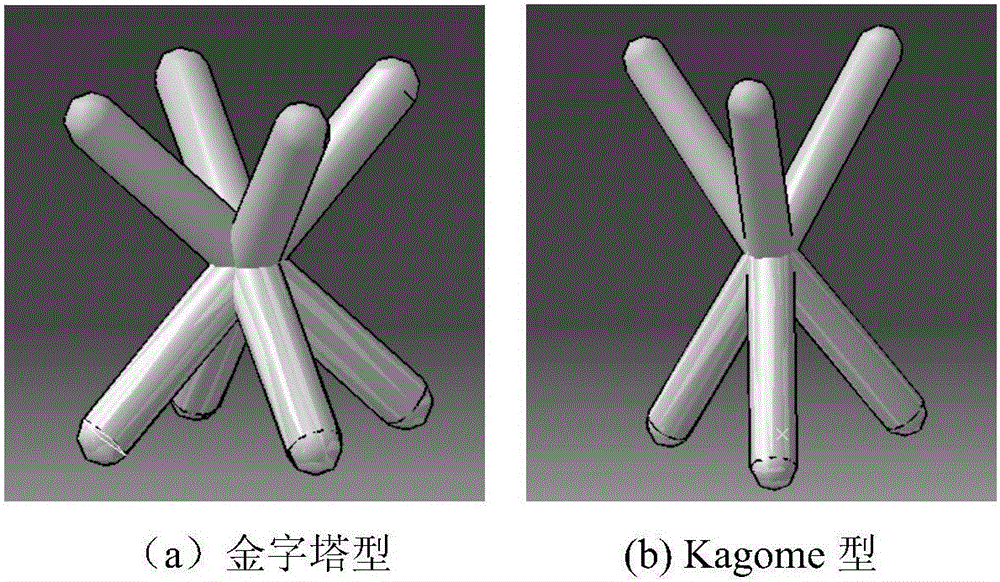

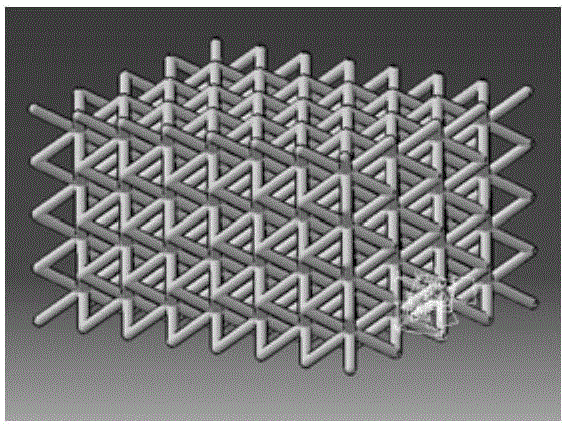

The invention discloses an aluminum-based dot matrix material based on 3D printing technology. In the dot matrix material, industrial pure aluminum or any aluminum alloy is employed as a base body. Unit cell configuration and a periodic structure thereof are modeled and designed with CATIA software and the model is produced from high-molecular materials through the 3D printing technology. An investment casting shell mould is prepared from soluble gypsum and the aluminum-based dot matrix material is prepared through an air-pressure seepage process. The aluminum-based dot matrix material can be in a pyramid type, a Kagome type and a grating type in the unit cell configuration. The invention also provides a sandwiched plate composite structure composed of the dot matrix material and a compact surface plate. The diameter of a unit cell bar is 0.5-5.0 mm, the length of the unit cell bar is 0.5-15.0 mm, and an included angle between the unit cell bar and a protective surface is 30-70 degrees. The compact surface plate is made from industrial pure aluminum, aluminum alloy, iron alloy or high-molecular materials. The dot matrix material with the industrial pure aluminum as the base body can reach higher than 5 MPa / g*cm<-3> in specific compressive strength.

Owner:INST OF SOLID PHYSICS ACAD SINICA

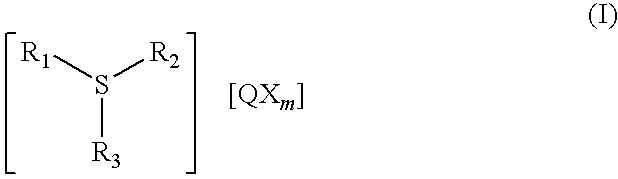

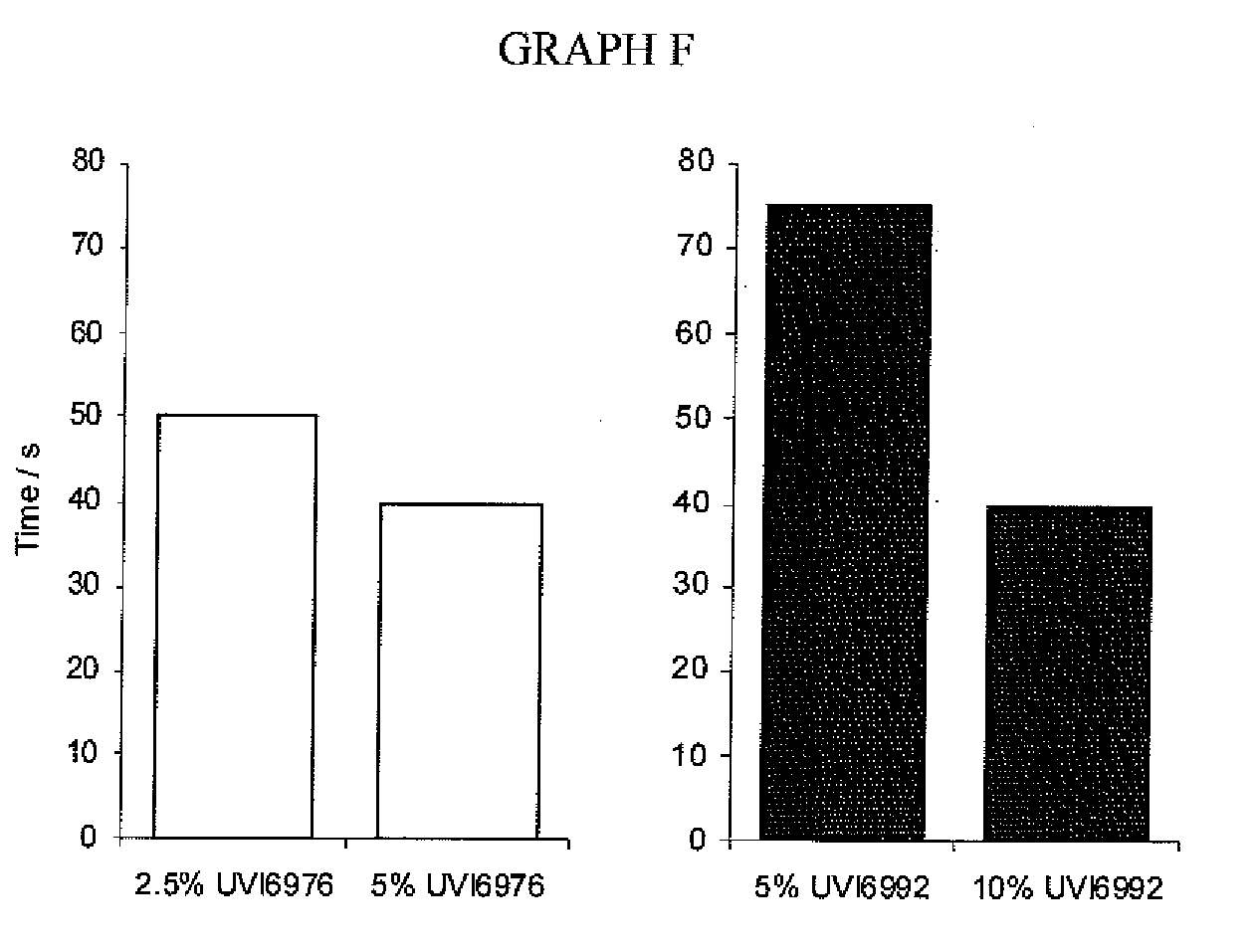

Antimony-free photocurable resin composition and three dimensional article

ActiveUS20100015408A1Fast curingLiquid surface applicatorsOrganic chemistryInvestment castingActive component

The present invention provides a low viscosity photocurable composition including (i) a cationically curable component (ii) a free radically active component (iii) an antimony-free cationic photoinitiator (v) a free radical photoinitiator, and (vi) a toughening agent. The photocurable composition can be cured using rapid prototyping techniques to form three-dimensional articles which can be used in various aerospace and investment casting applications.

Owner:3D SYST INC

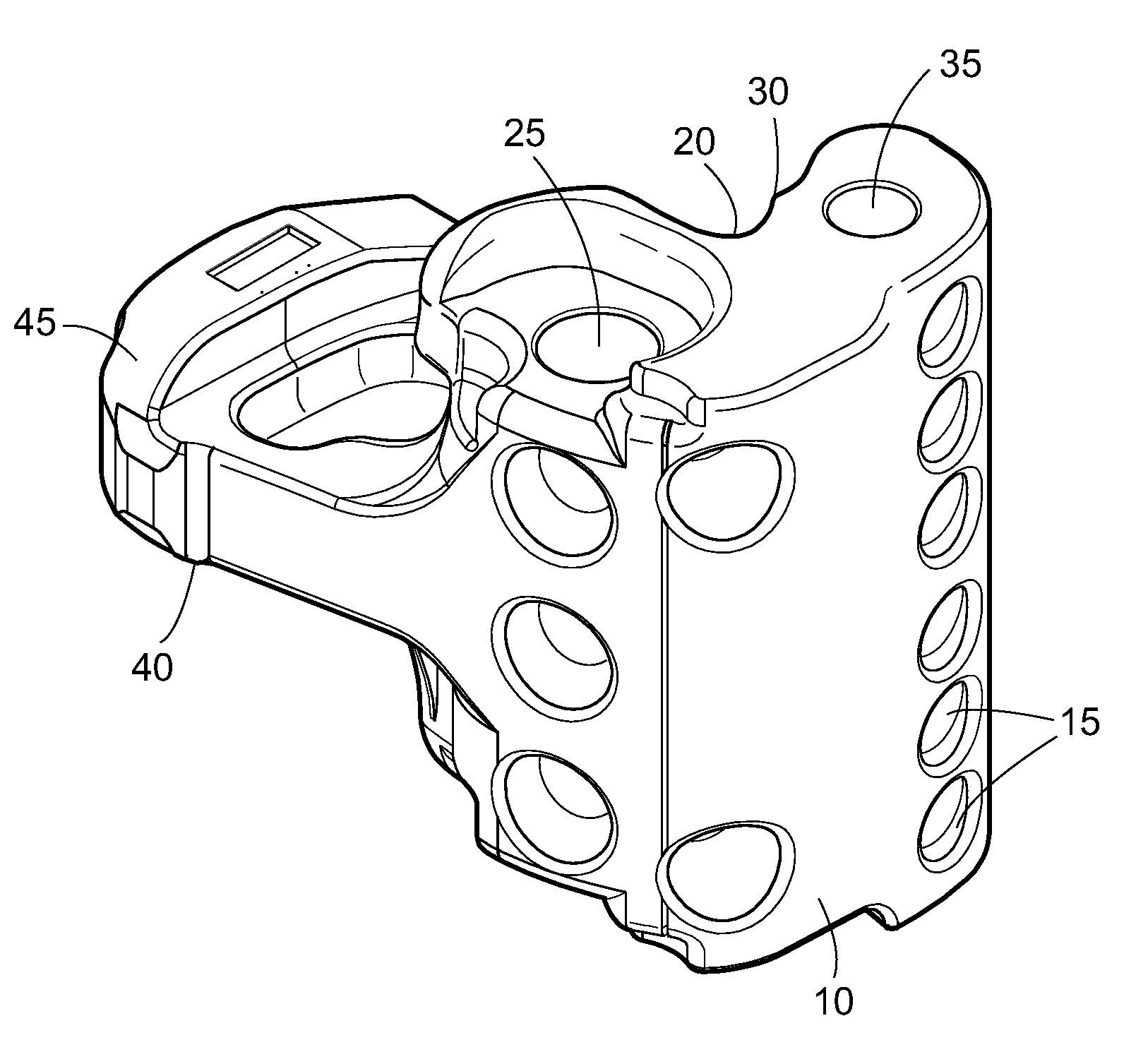

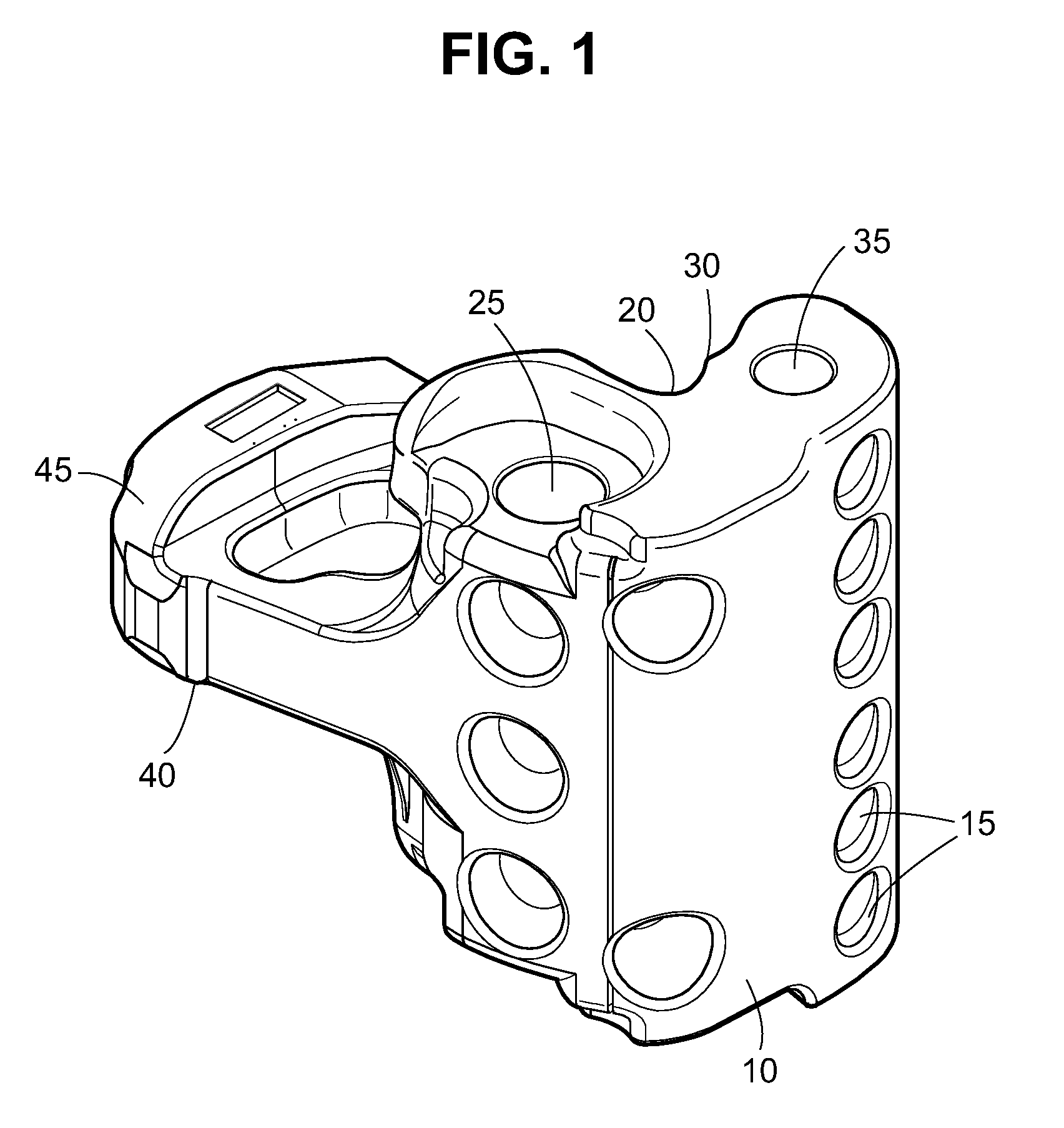

Knuckle for a railway car coupler

A knuckle for a railway coupler system is made without internal voids or cores. Instead, external pockets are formed on the front face and tail portion surface to reduce weight. The knuckle is formed by investment casting, which permits a pulling face to be provided without a draft angle or parting line typical of a cast part. As a result of these innovations, the knuckle according to the invention has an improved fatigue life.

Owner:STRATO AG

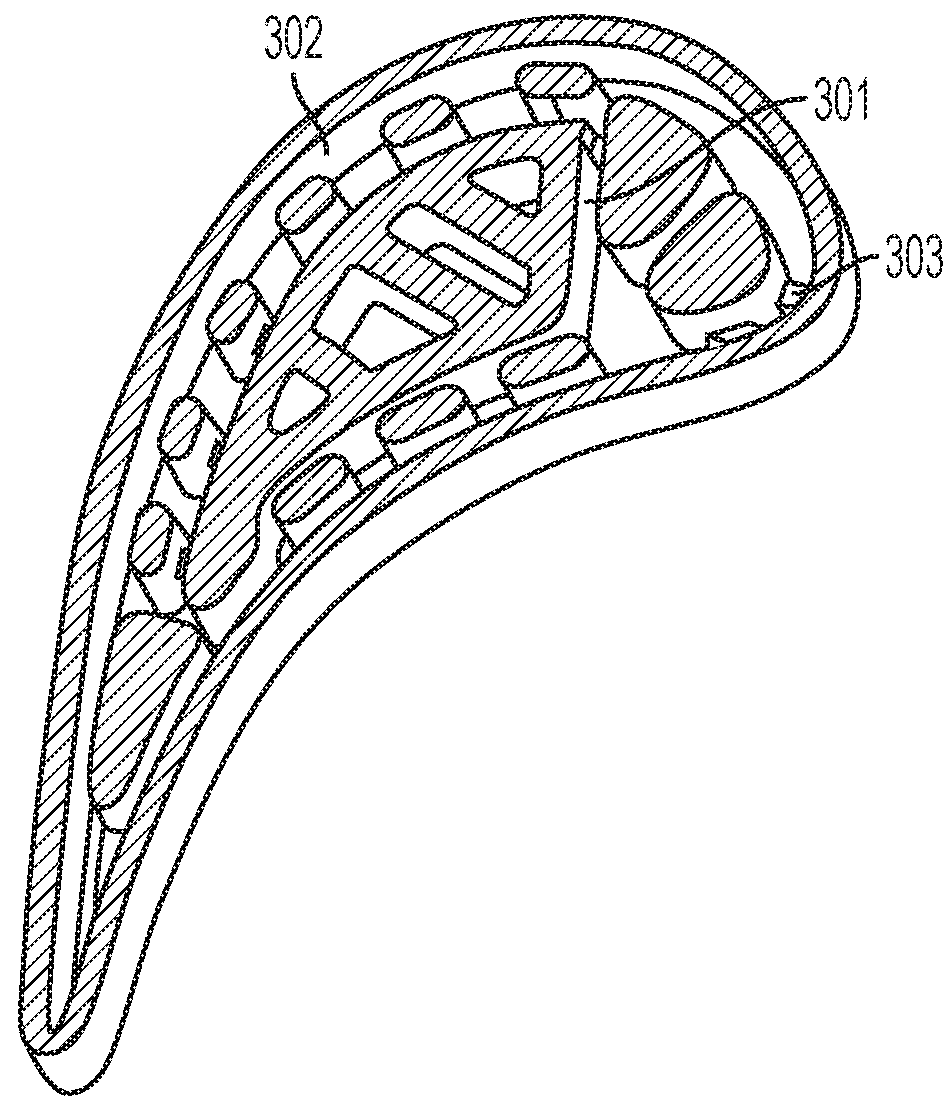

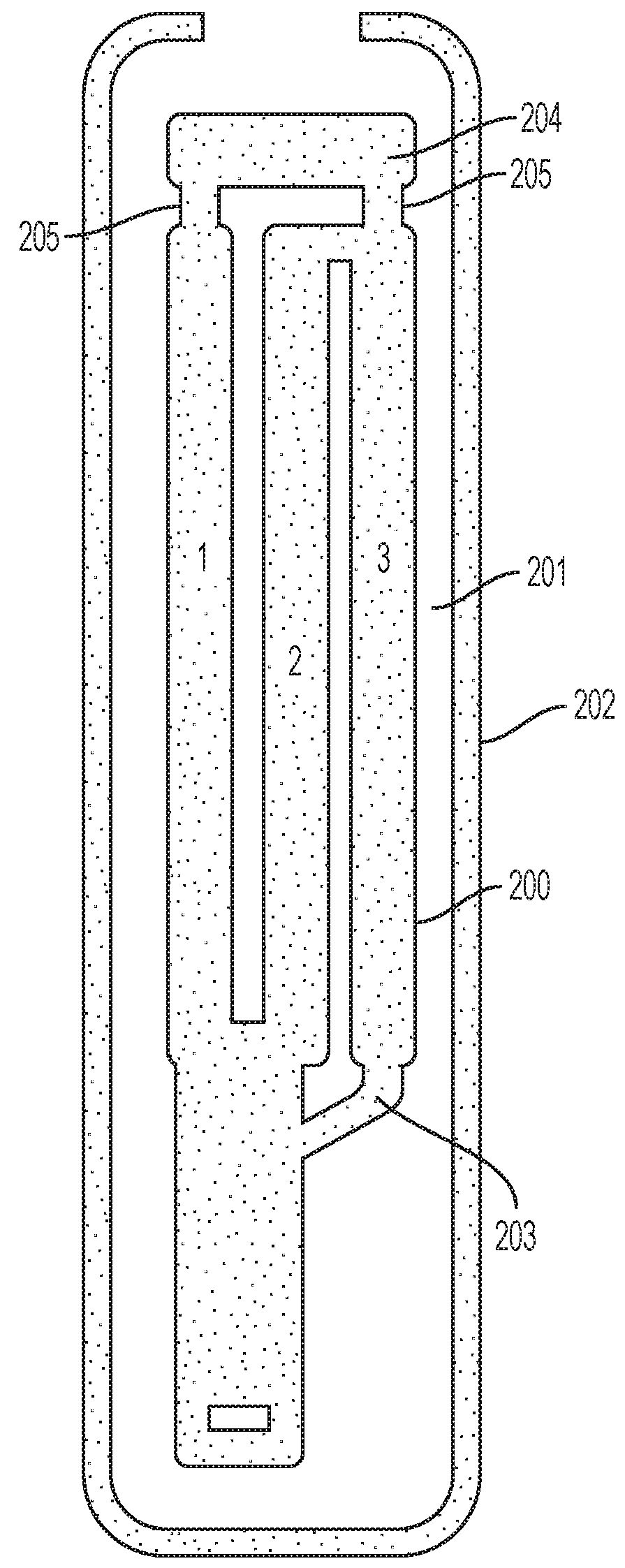

Integrated casting core-shell structure with printed tubes for making cast component

InactiveUS20180161852A1High strengthAvoid the needAdditive manufacturing apparatusFoundry mouldsTurbine bladeInvestment casting

The present disclosure generally relates to integrated core-shell investment casting molds that provide filament structures corresponding to cooling hole patterns on the surface of the turbine blade or stator vane, which provide a leaching pathway for the core portion after metal casting. The invention also relates to core filaments that can be used to supplement the leaching pathway, for example in a core tip portion of the mold.

Owner:GENERAL ELECTRIC CO

Integrated casting core-shell structure for making cast component with non-linear holes

InactiveUS20180161859A1High strengthAvoid the needEngine manufactureEngine fuctionsTurbine bladeInvestment casting

The present disclosure generally relates to integrated core-shell investment casting molds that provide filament structures corresponding to cooling hole patterns in the surface of the turbine blade or stator vane, which provide a leaching pathway for the core portion after metal casting. These filament structures may be linear or non-linear. The invention also relates to core filaments that can be used to supplement the leaching pathway, for example in a core tip portion of the mold.

Owner:GENERAL ELECTRIC CO

Multi-piece integrated core-shell structure for making cast component

InactiveUS20180161866A1High strengthAvoid the needCeramic shaping apparatusMachines/enginesTurbine bladeInvestment casting

The present disclosure generally relates to partial integrated core-shell investment casting molds that can be assembled into complete molds. Each section of the partial mold may contain both a portion of a core and portion of a shell. Each section can then be assembled into a mold for casting of a metal part. The partial integrated core-shell investment casting molds and the complete molds may be provided with filament structures corresponding to cooling hole patterns on the surface of the turbine blade or the stator vane, which provides a leaching pathway for the core portion after metal casting. The invention also relates to core filaments that can be used to supplement the leaching pathway, for example in a core tip portion of the mold.

Owner:GENERAL ELECTRIC CO

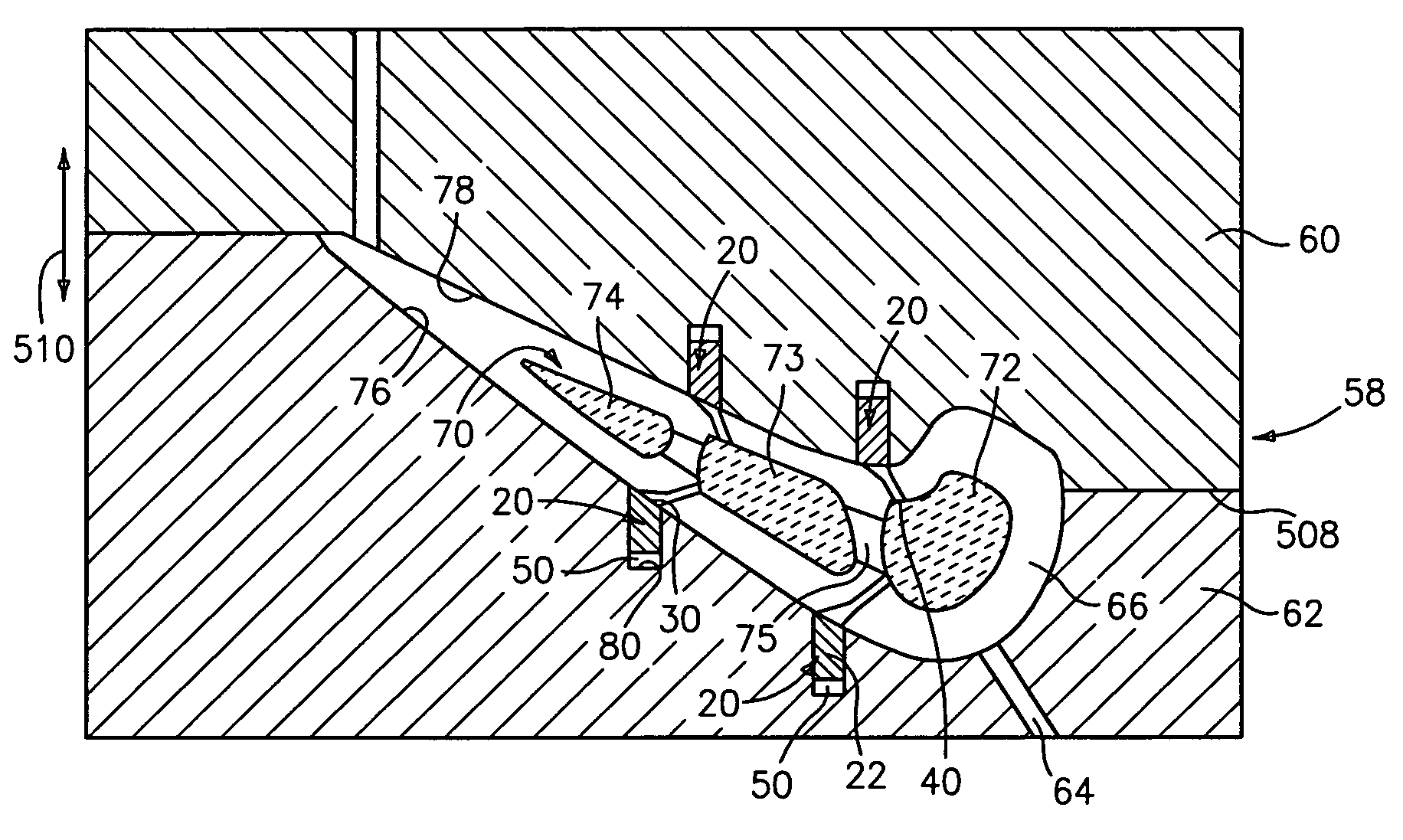

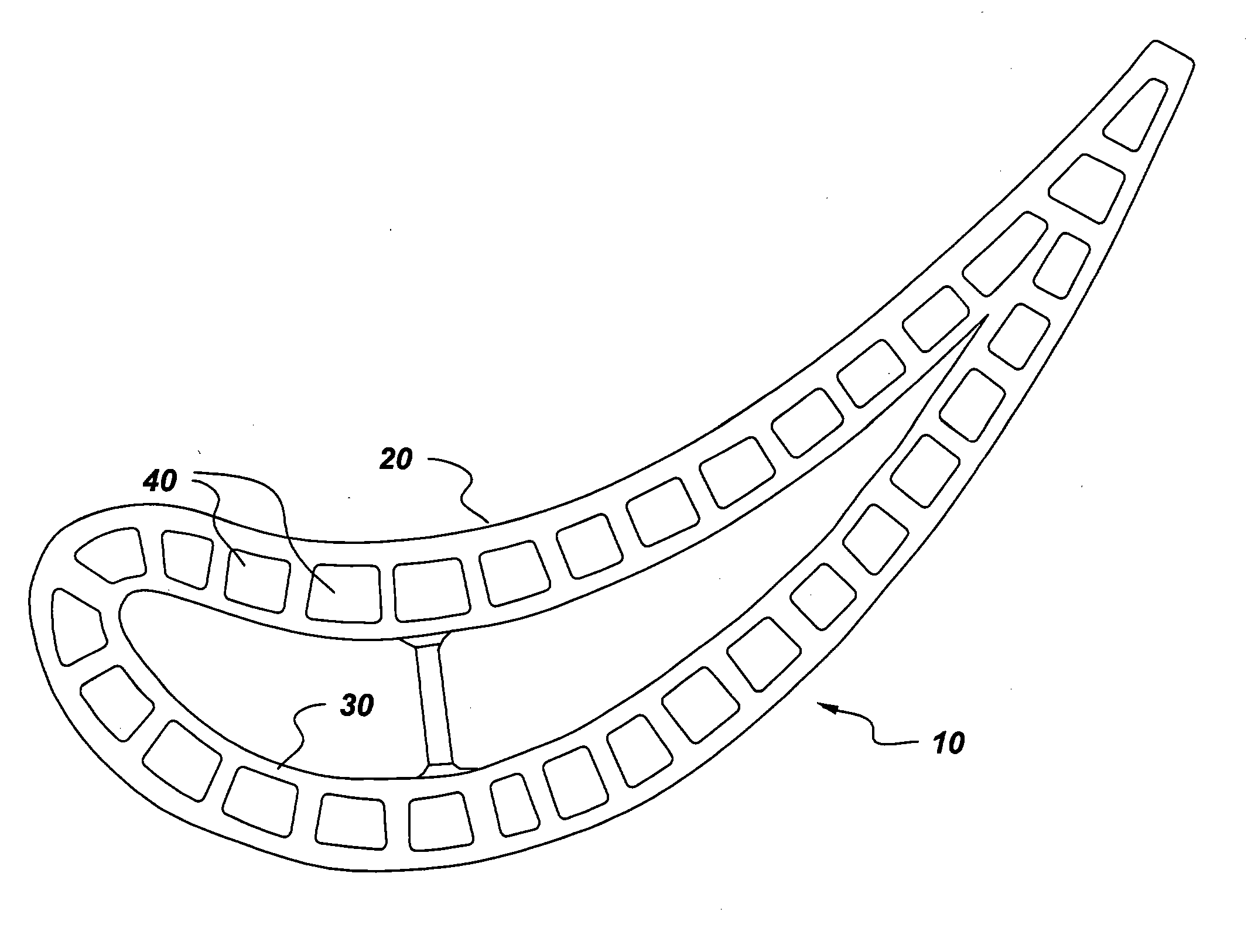

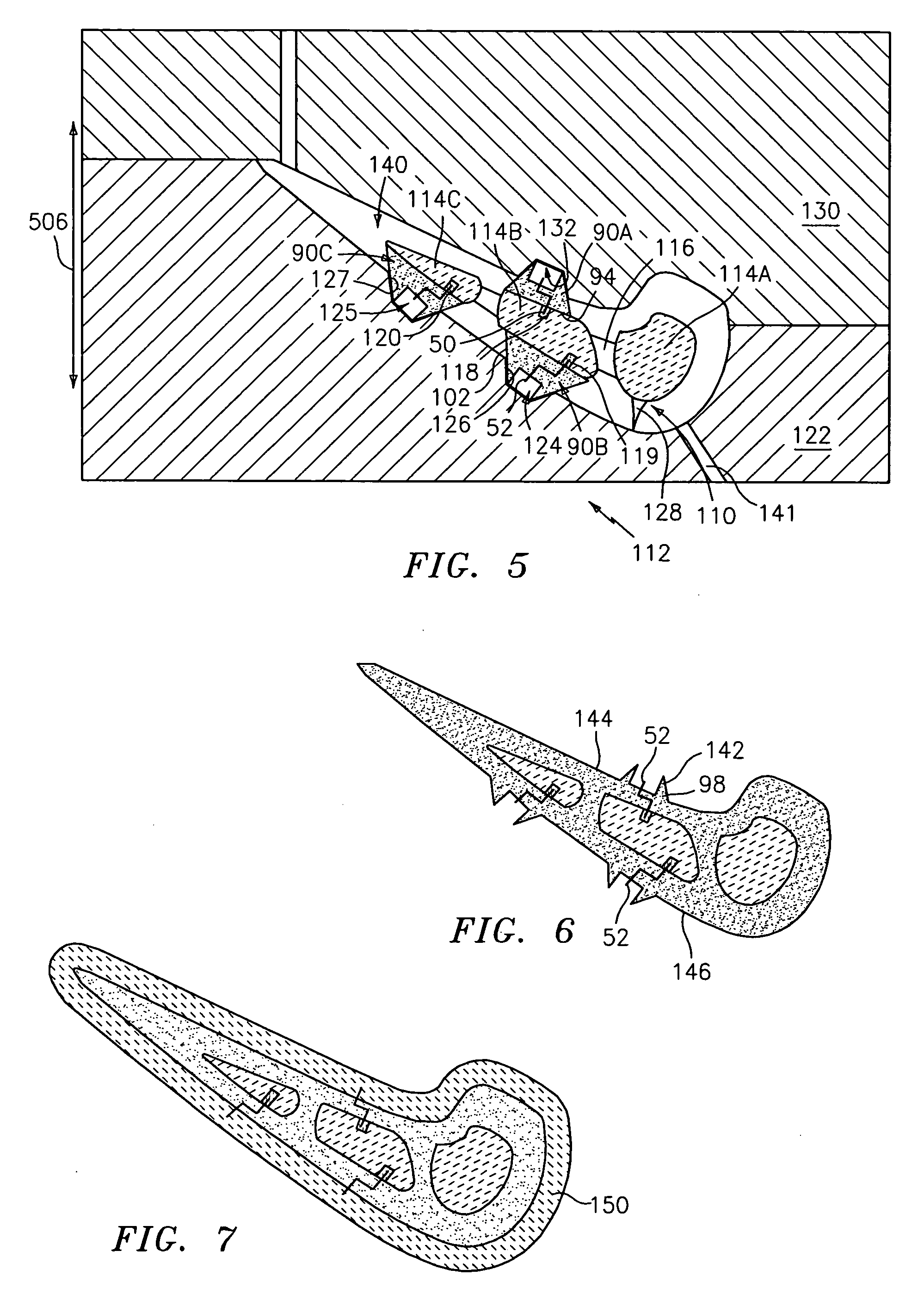

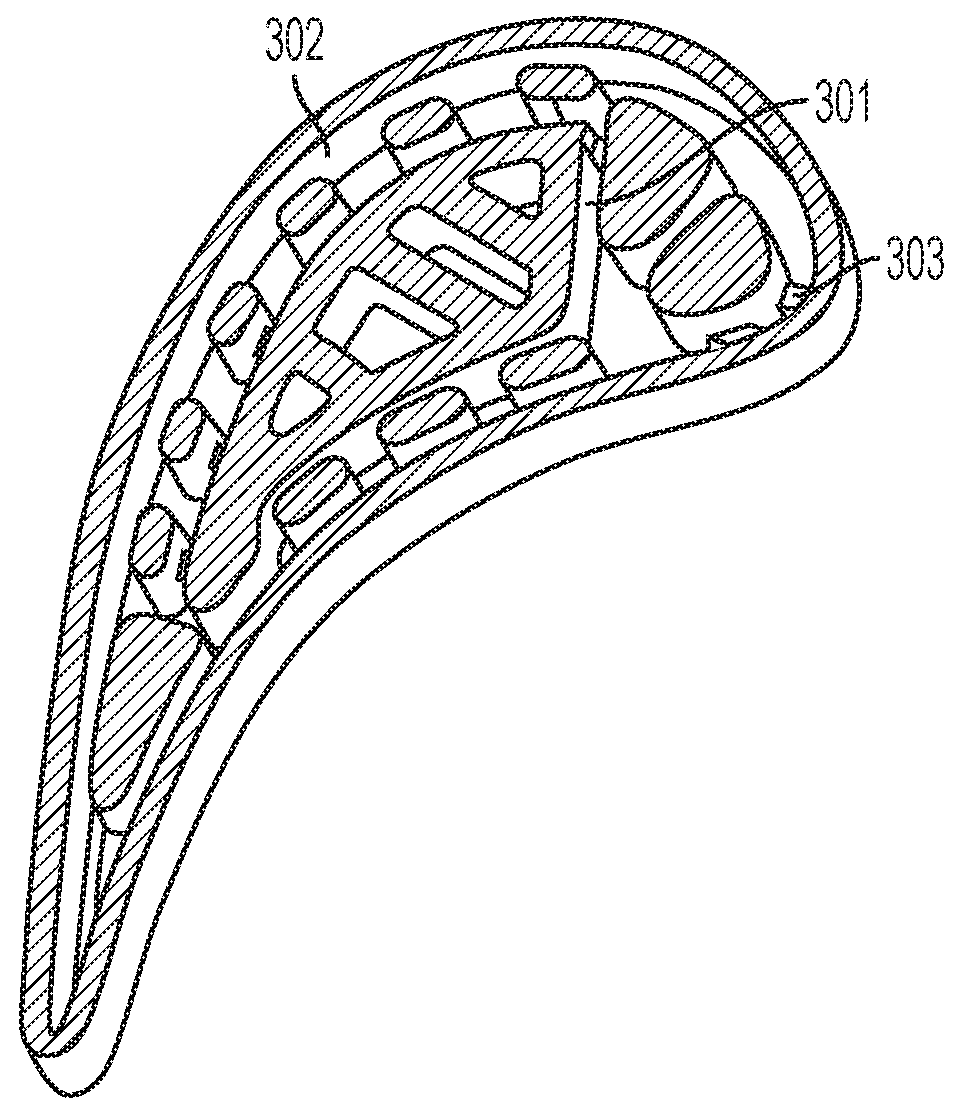

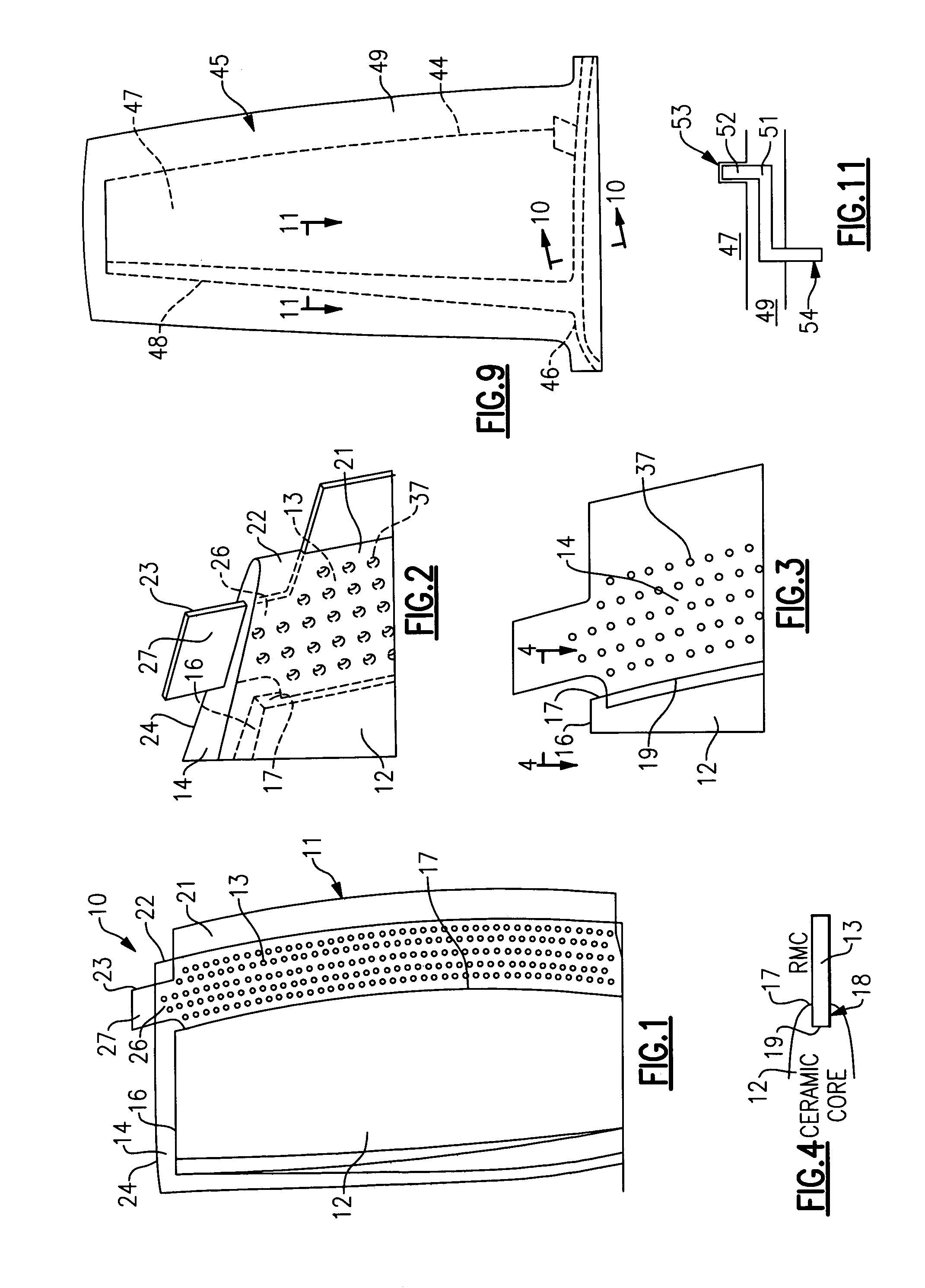

Composite core for use in precision investment casting

ActiveUS7108045B2Reduce in quantityReduce manufacturing costFoundry mouldsFoundry coresWaxInvestment casting

A composite core for an investment casting process, the core including both a ceramic portion and a refractory metal portion, with the refractory metal portion being so disposed as to perform the function of a plurality of such refractory metal elements. In particular, a refractory metal element attached to a trailing edge of a ceramic element extends beyond the plane of a tip end of the ceramic element so as to replace the refractory metal element otherwise extending from the ceramic tip edge. The refractory metal element also extends beyond the space to be occupied by the wax casting, both in the direction of the tip end and the trailing edge such that improved placement and securing of the core is facilitated during the casting process. A further embodiment uses a single refractory metal element that extends into both the airfoil portion and an orthogonal extending platform portion thereof.

Owner:RTX CORP

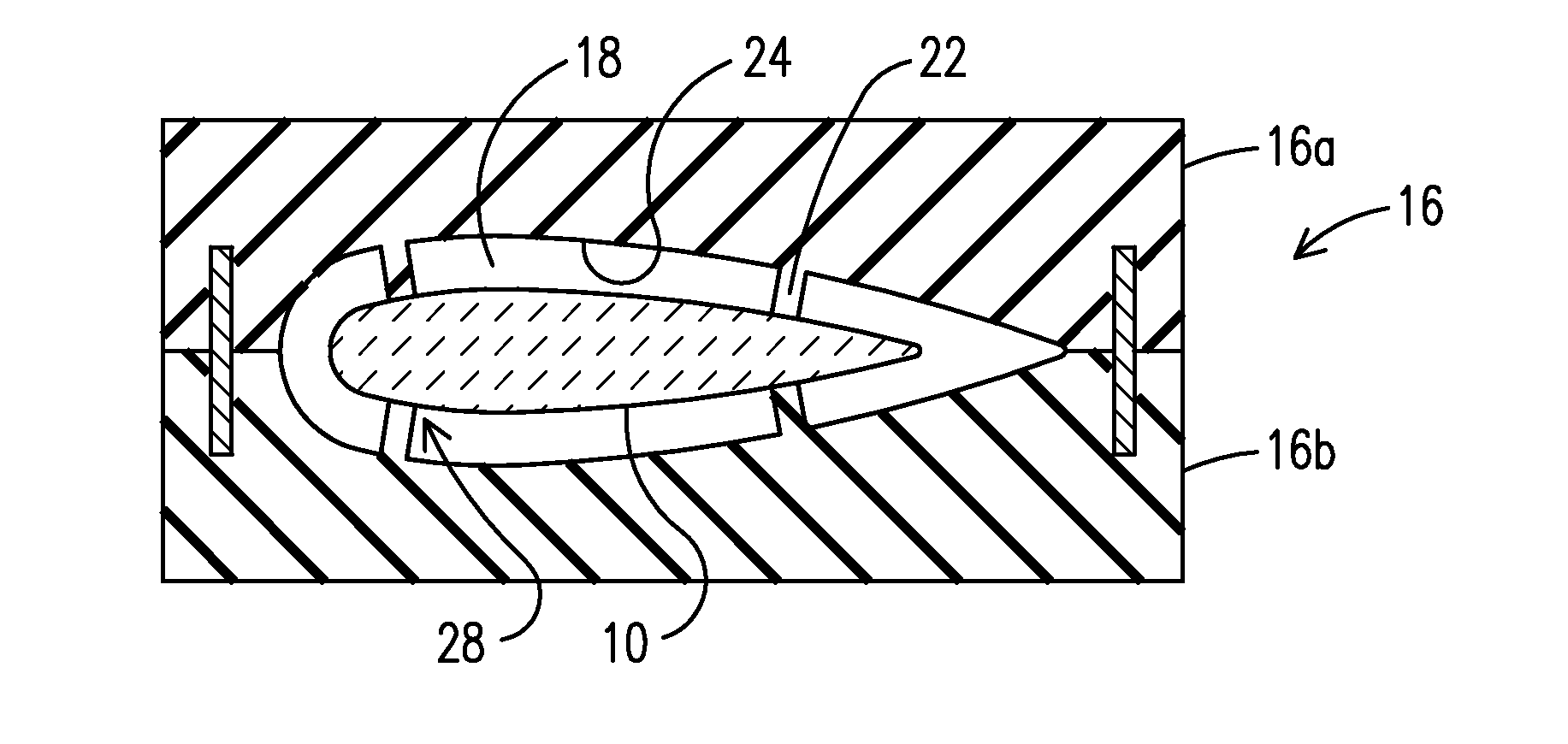

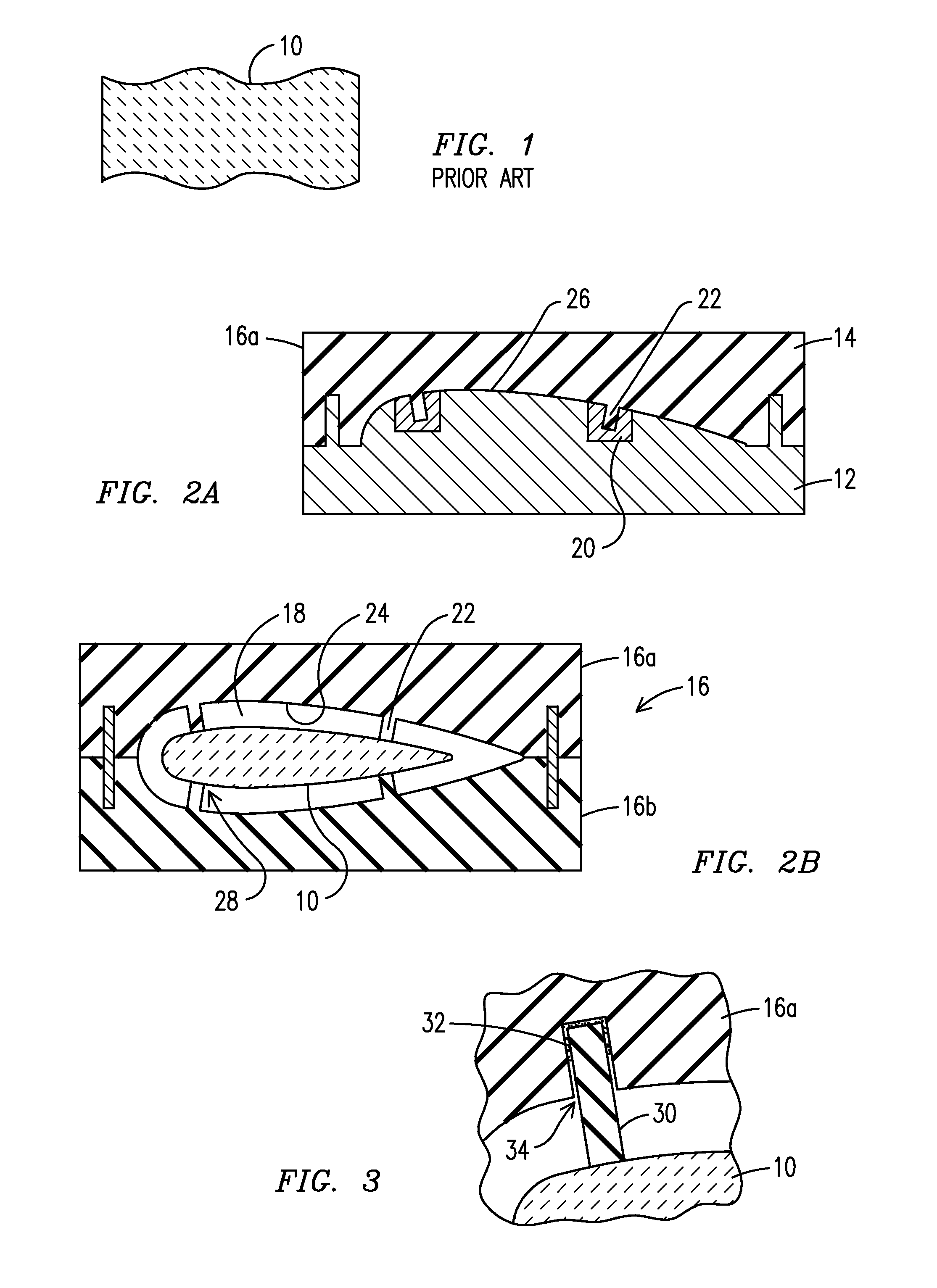

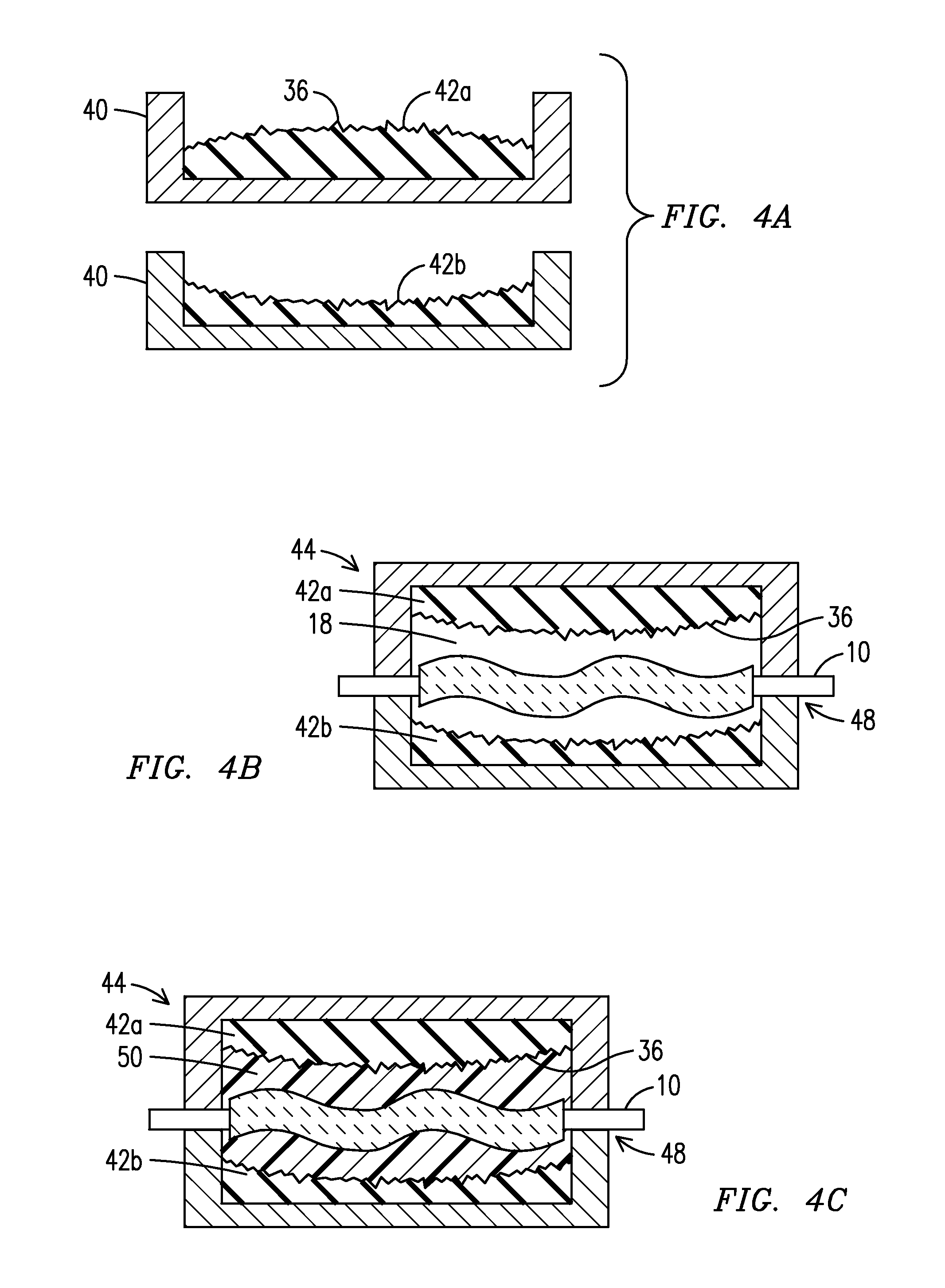

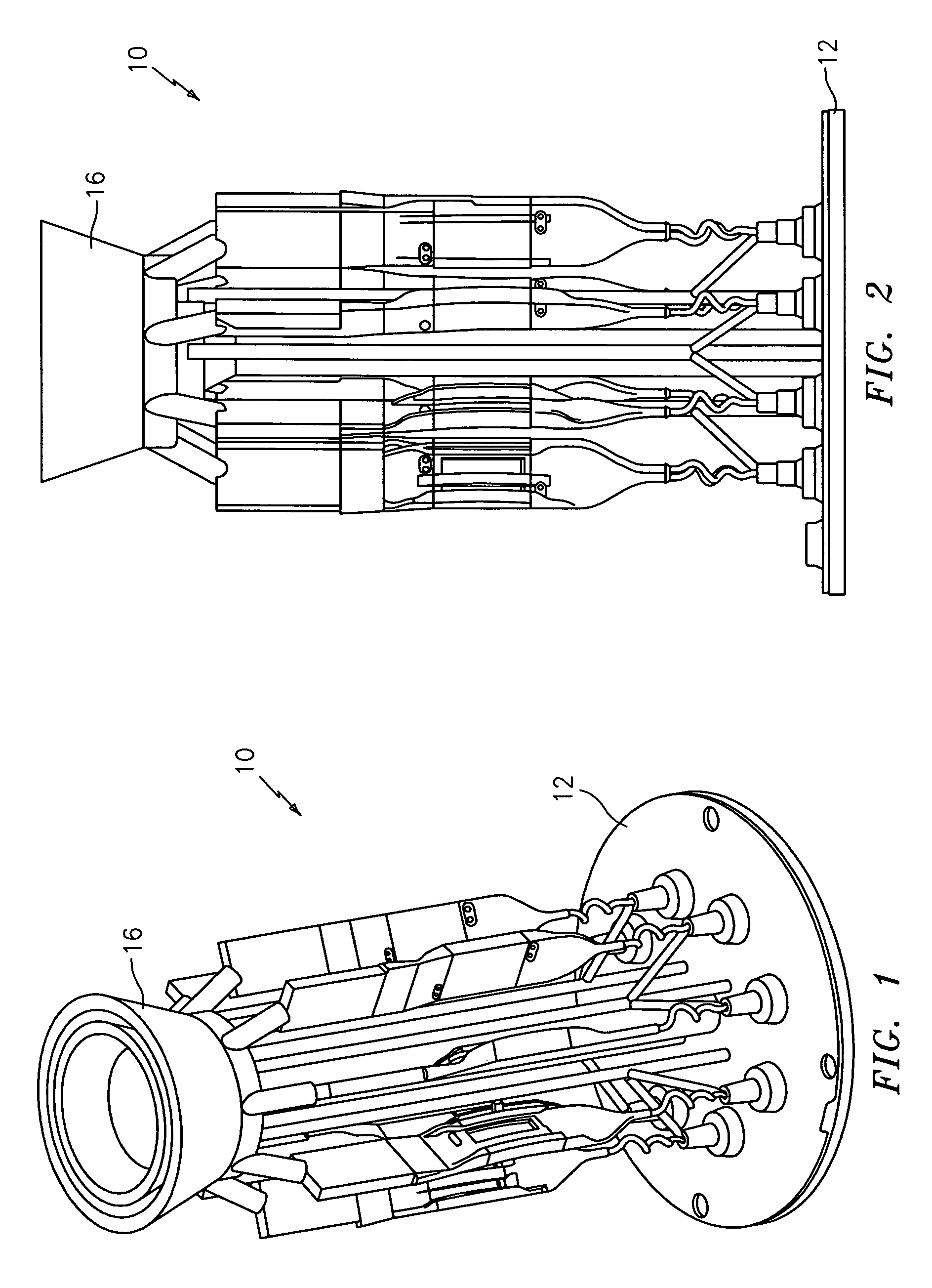

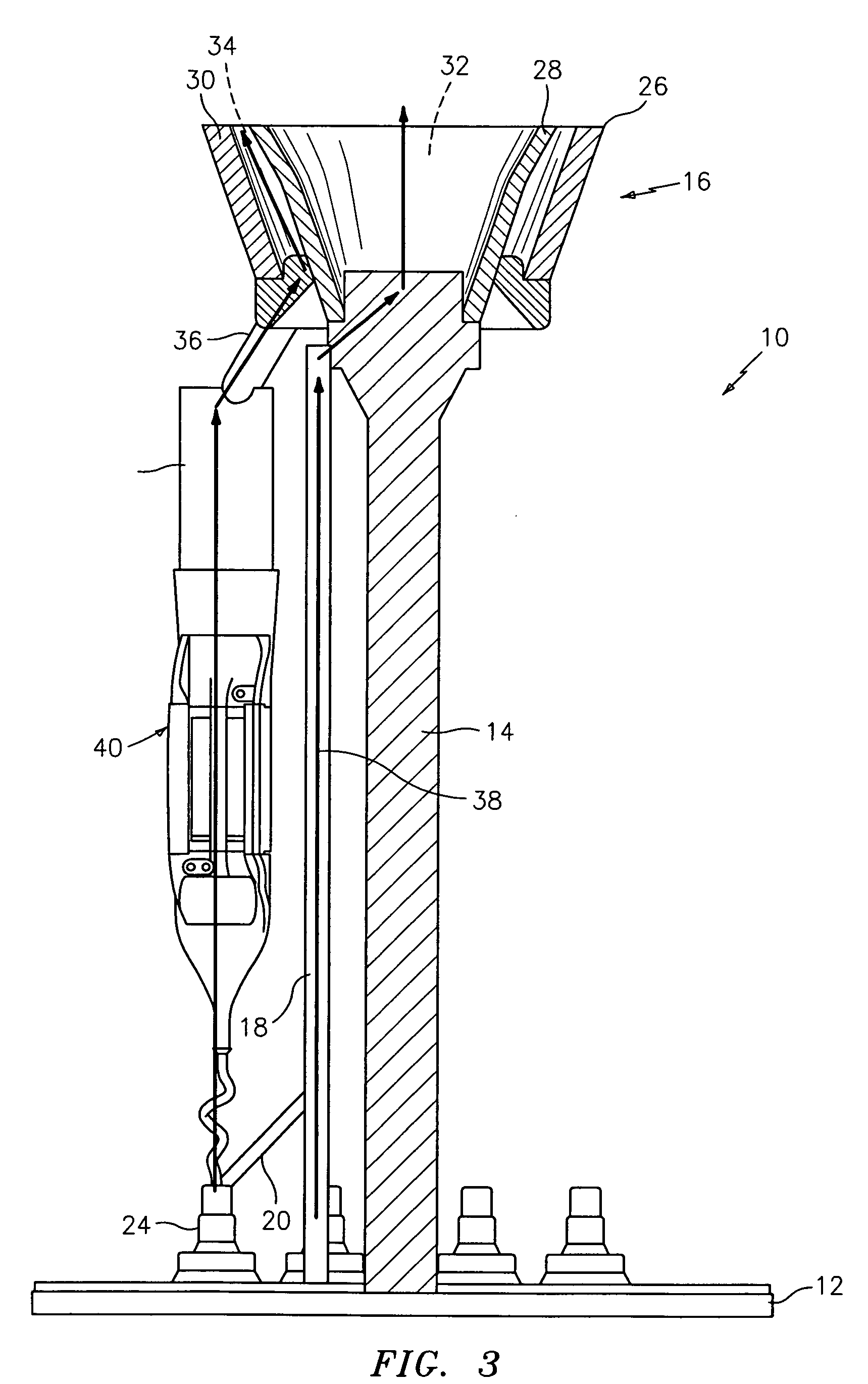

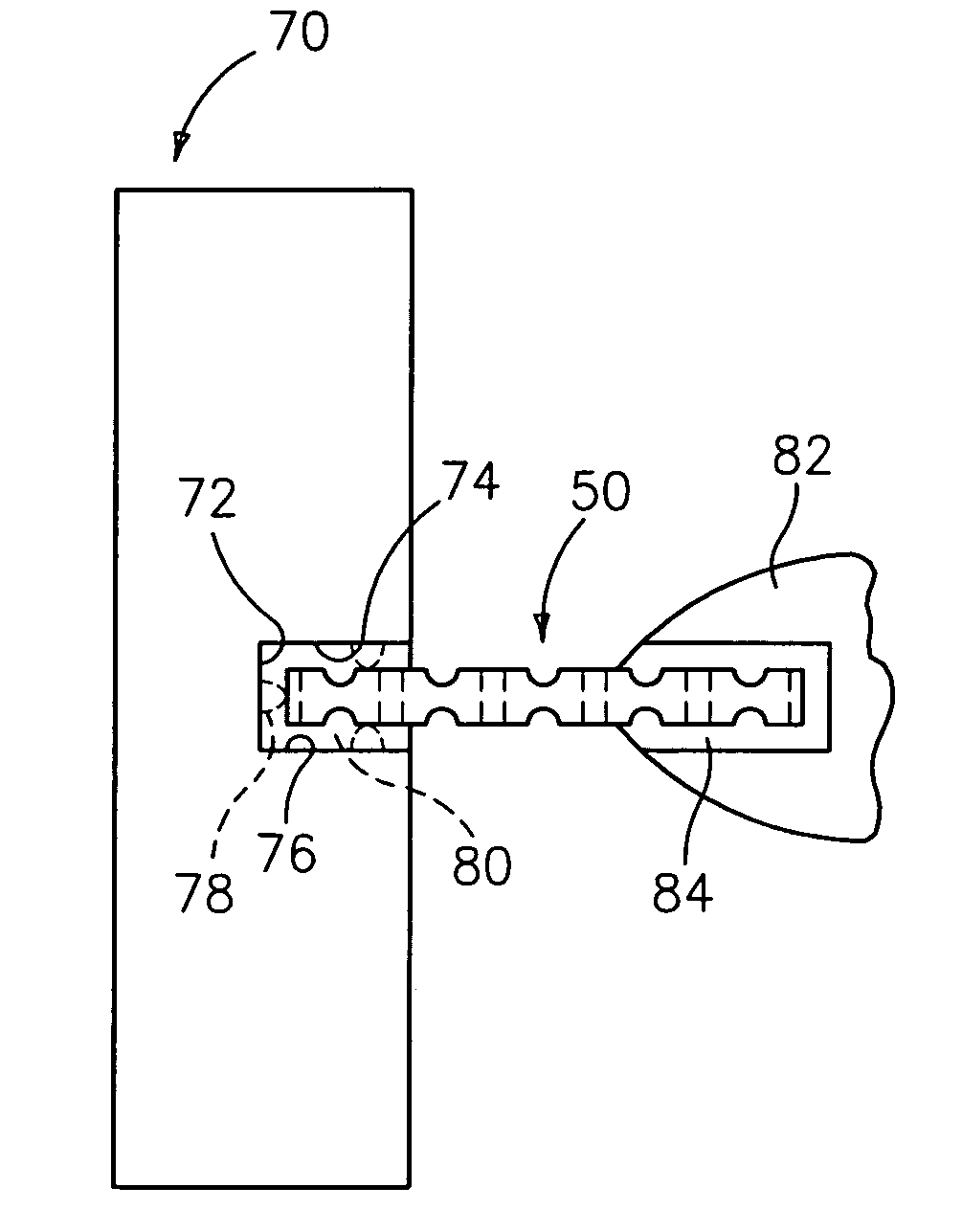

Investment casting utilizing flexible wax pattern tool

An investment casting process wherein the wax pattern tool (44) is flexible to facilitate removal of the tool from the cast wax pattern (52) even when the cast shape would otherwise require multiple pull planes. The flexible tool may include a flexible insert (42) precisely indexed to a surrounding coffin mold (40), and thereby to an enclosed ceramic core (10). Positioning pins (106) may extend from the flexible tool to make compliant contact against the core prior to a wax injection step. The surface of the resulting wax pattern may contain an engineered topography (36) replicated through the flexible surface from a master tool (12). The flexible tool may encase thermally conductive or magnetic particles (92), or other active device (96) such as a sensor or vibrator which is operable during wax injection.

Owner:MIKRO SYSYTEMS INC +1

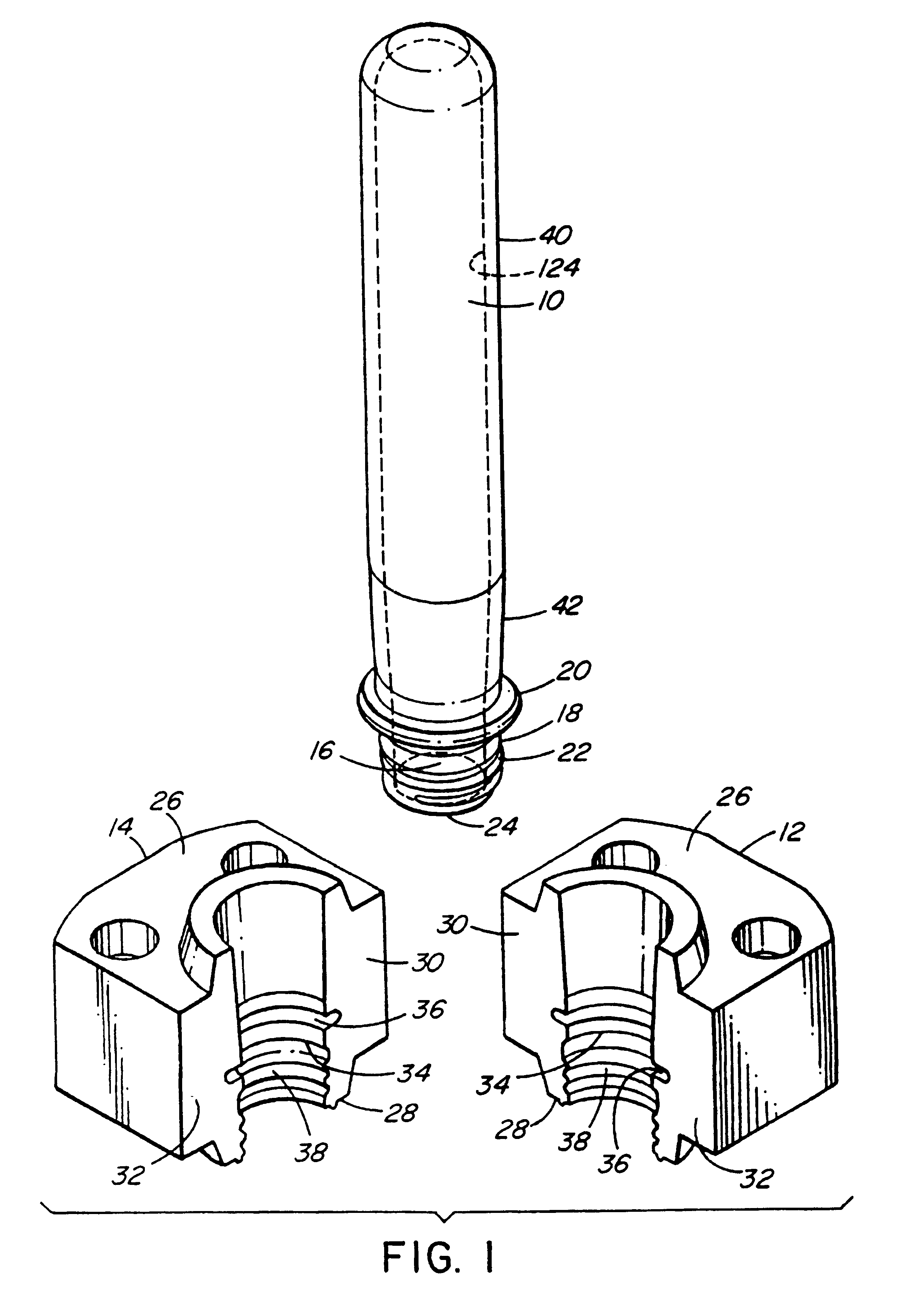

Method of making injection molding cooled thread split inserts

InactiveUSRE38396E1Metal rolling stand detailsFood shapingInvestment castingInjection molding machine

A method of making pairs of thread splits inserts used to injection mold bottle preforms. Machining a hollow outer part of the pair of thread split inserts with an opening therethrough and outer portions of two cooling conduits extending from the opening therethrough to respective inlets and outlets. Making an inner part of the pair of thread split inserts by injection molding a ceramic core with the required shape and investment casting the inner part around the ceramic core. The outer surface of the inner part having grooves to partially form inner portions of the two cooling fluid conduits. Then machining the cast inner part to fit in the opening through the outer part. Mounting the outer part around the inner part with the inner and outer portions of the two cooling fluid conduits aligned. Applying brazing material between the inner and outer parts and heating them in a vacuum furnace to integrally braze them together. Finally, cutting the integral inner and outer parts in half to form the pair of thread split inserts with each of the thread split inserts having one of the cooling fluid conduits therein.

Owner:MOLD MASTERS 2007

Integrated casting core-shell structure

InactiveUS20180161854A1High strengthAvoid the needAdditive manufacturing apparatusFoundry mouldsTurbine bladeInvestment casting

The present disclosure generally relates to integrated core-shell investment casting molds that provide a filament structure corresponding to a cooling hole pattern in the surface of the turbine blade or stator vane, which provide a leaching pathway for the core portion after metal casting. The invention also relates to core filaments that can be used to supplement the leaching pathway, for example in a core tip portion of the mold.

Owner:GENERAL ELECTRIC CO

Method for preparing TiAl-based alloy formwork by precision-investment casting

InactiveCN101462151AFast moisture absorptionGood hygroscopicityFoundry mouldsFoundry coresWaxOxide ceramic

The invention discloses a method for preparing a shuttering for a precision investment casting TiAl-based alloy, and relates to a method for preparing an oxide ceramic shuttering. The method solves the problems of slow drying for making the shuttering, longer production period for cast and high cost during production of a TiAl-based alloy precise cast. The preparation method comprises: firstly, adopting SLS technology to prepare a fusible pattern; secondly, coating polyvinyl alcohol on the surface of bauxite and grinding the bauxite into granules; thirdly, smearing a shuttering surface layer; fourthly, smearing a shuttering back layer; fifthly, removing wax from the shuttering, and roasting the shuttering; and sixthly, casting the TiAl-based alloy in vacuum to obtain the TiAl-based alloy cast. The method only needs 13 to 15 days to obtain the TiAl-based alloy precise cast from CAD design, but the prior method at least needs 45 to 60 days, so the method saves nearly two thirds of production period, and the manufacturing cost is correspondingly lowered.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com