Investment casting method and cores and dies used therein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

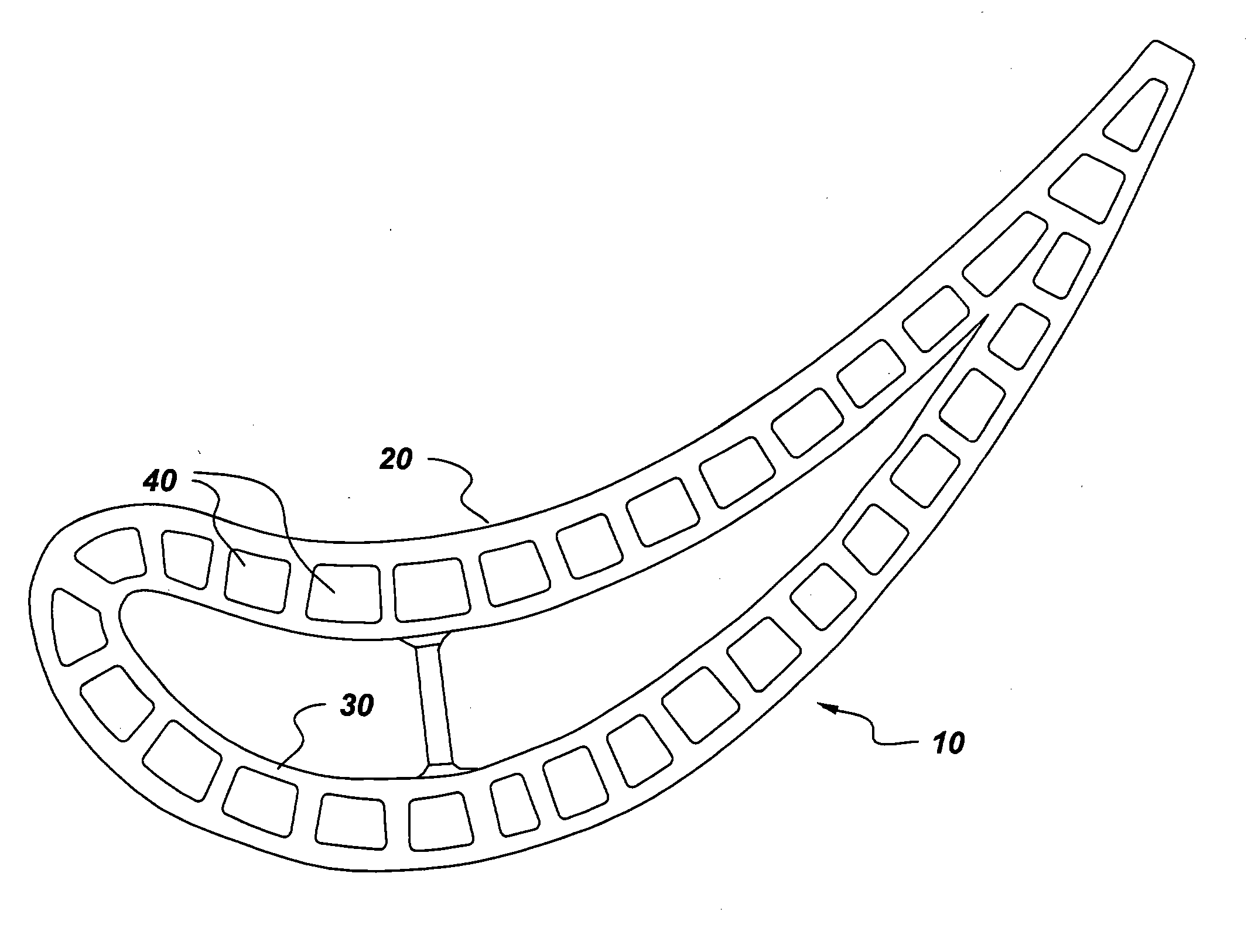

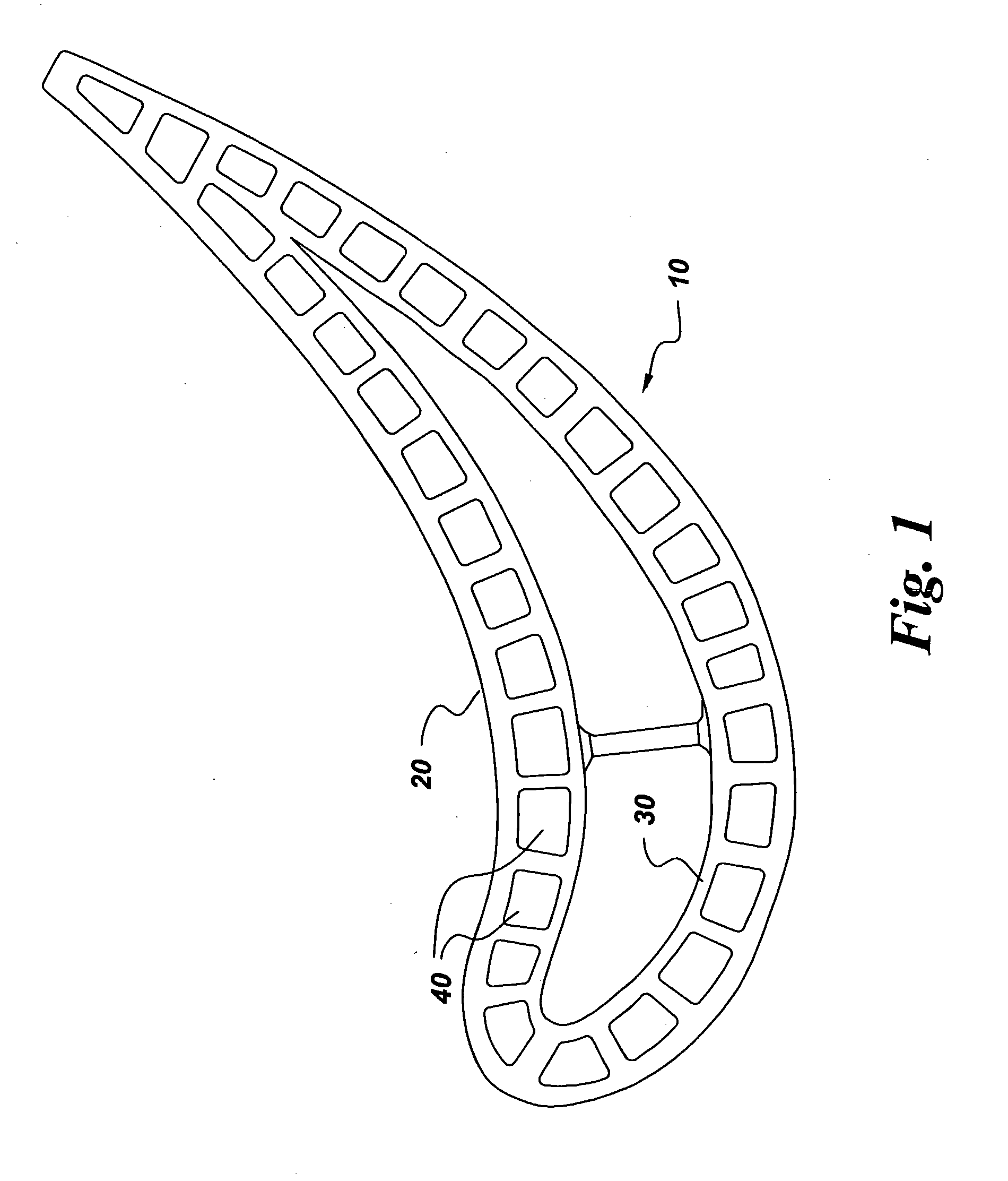

[0012] Referring to FIG. 1, a component 10 is made according to method embodiments of the present invention. In particular embodiments, component 10 comprises an external wall 20 and at least one internal wall 30 disposed in a spaced-apart relationship with external wall 20. Such components are referred to herein as “multi-wall components.” In the method of the present invention, a single-piece sacrificial die is provided. Conventional dies are generally constructed to be used multiple times and are usually two-piece designs, but the complicated geometry of the cooling circuits used in multi-wall components 10 makes the use of dies having two pieces very difficult and often impossible, requiring in conventional methods additional time and effort for multiple injected cores to be formed and assembled into a composite core. The single-piece sacrificial die comprises at least one internal cavity. As used hereinafter, the singular term “cavity” will be used to refer to the at least one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com