Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16528 results about "Injection molding machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

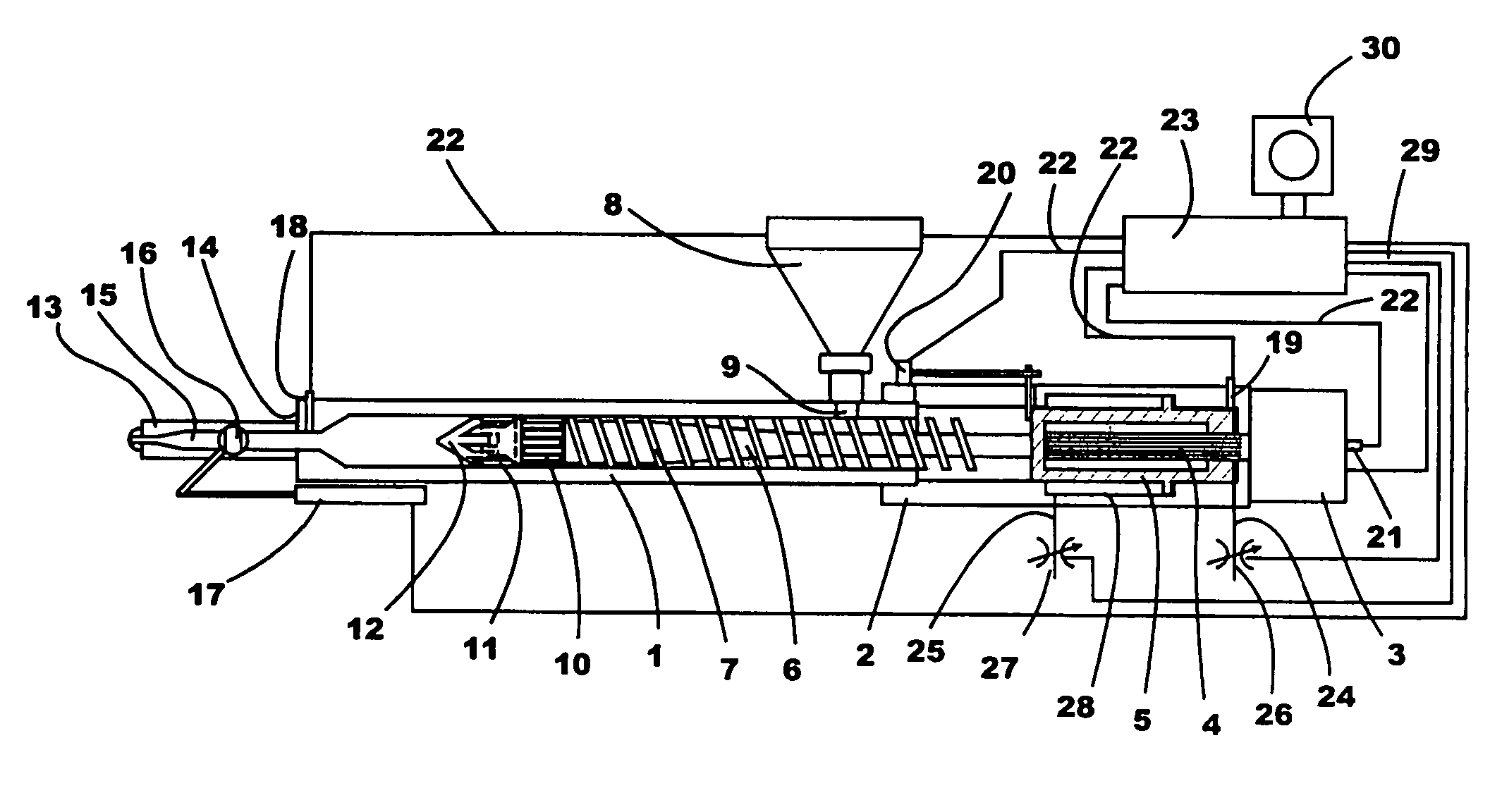

An Injection molding machine, or (Injection moulding machine BrE), also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. It consists of two main parts, an injection unit and a clamping unit.

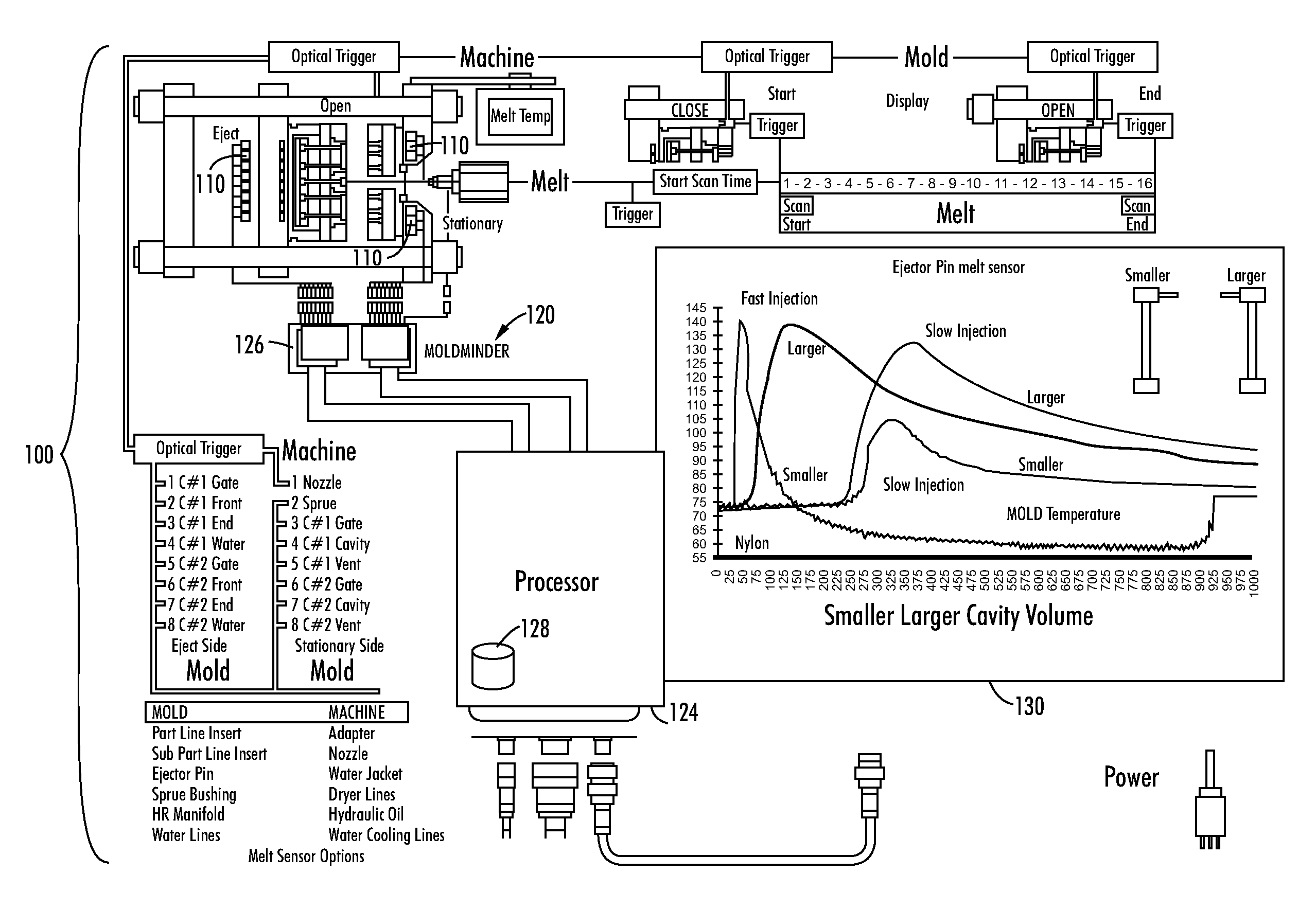

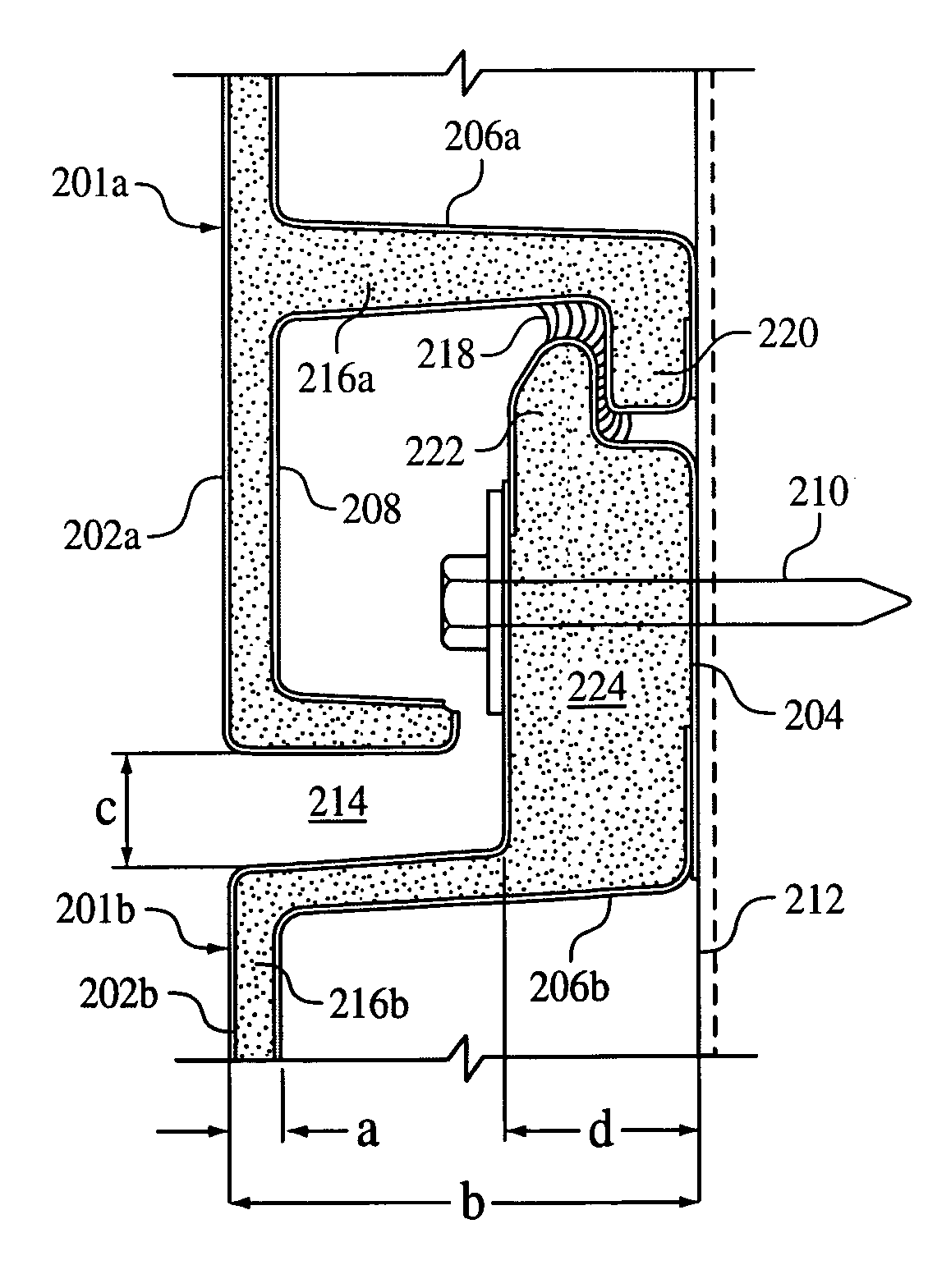

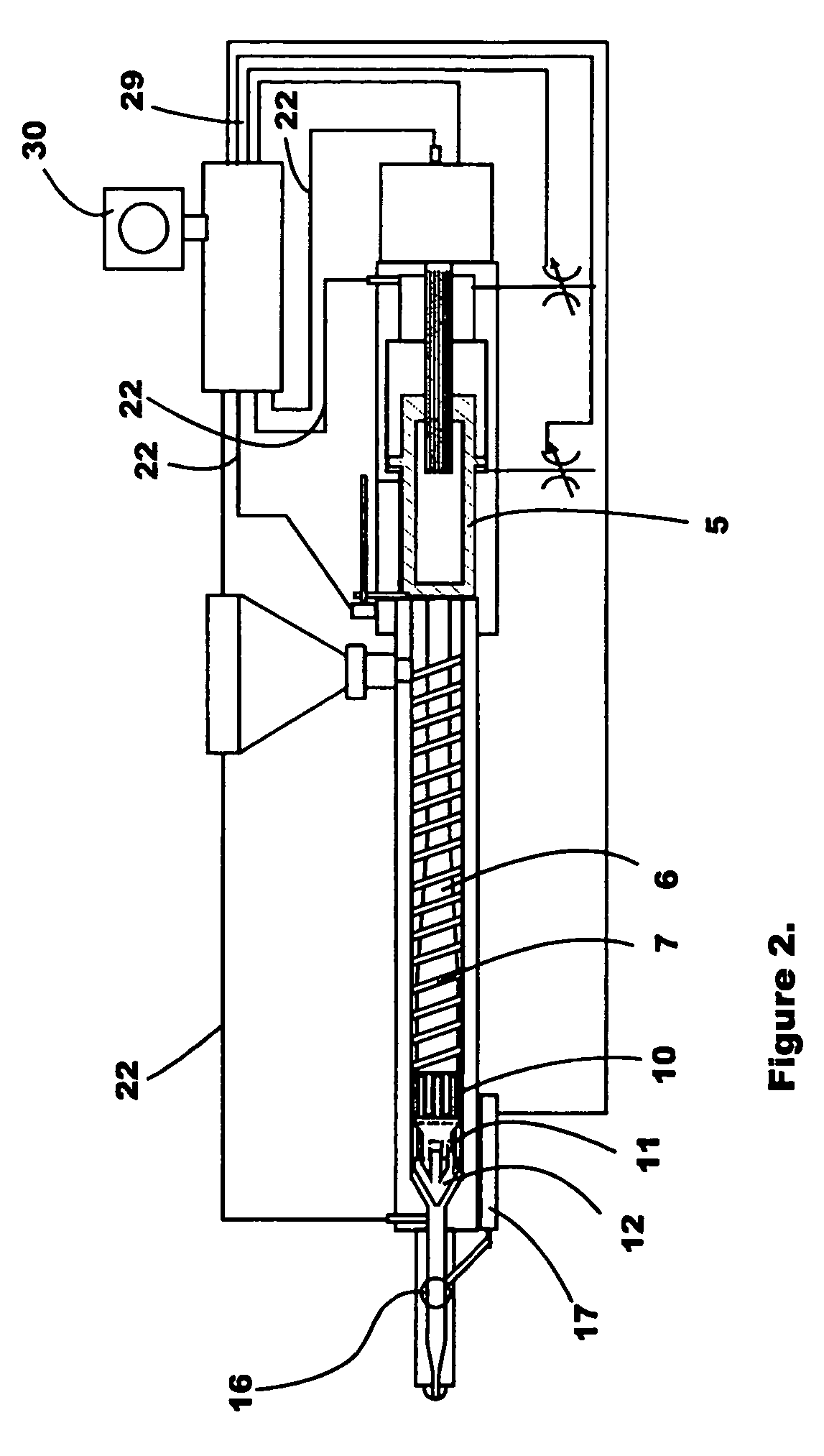

System for monitoring temperature and pressure during a molding process

Disclosed are systems and methods for the use of a micro-bead EMF junction in the sensing and control of an injection molding process, whereby the improved junction is able to reliably sense and indicate temperature and pressure changes in a molding process.

Owner:BUJA FREDERICK J

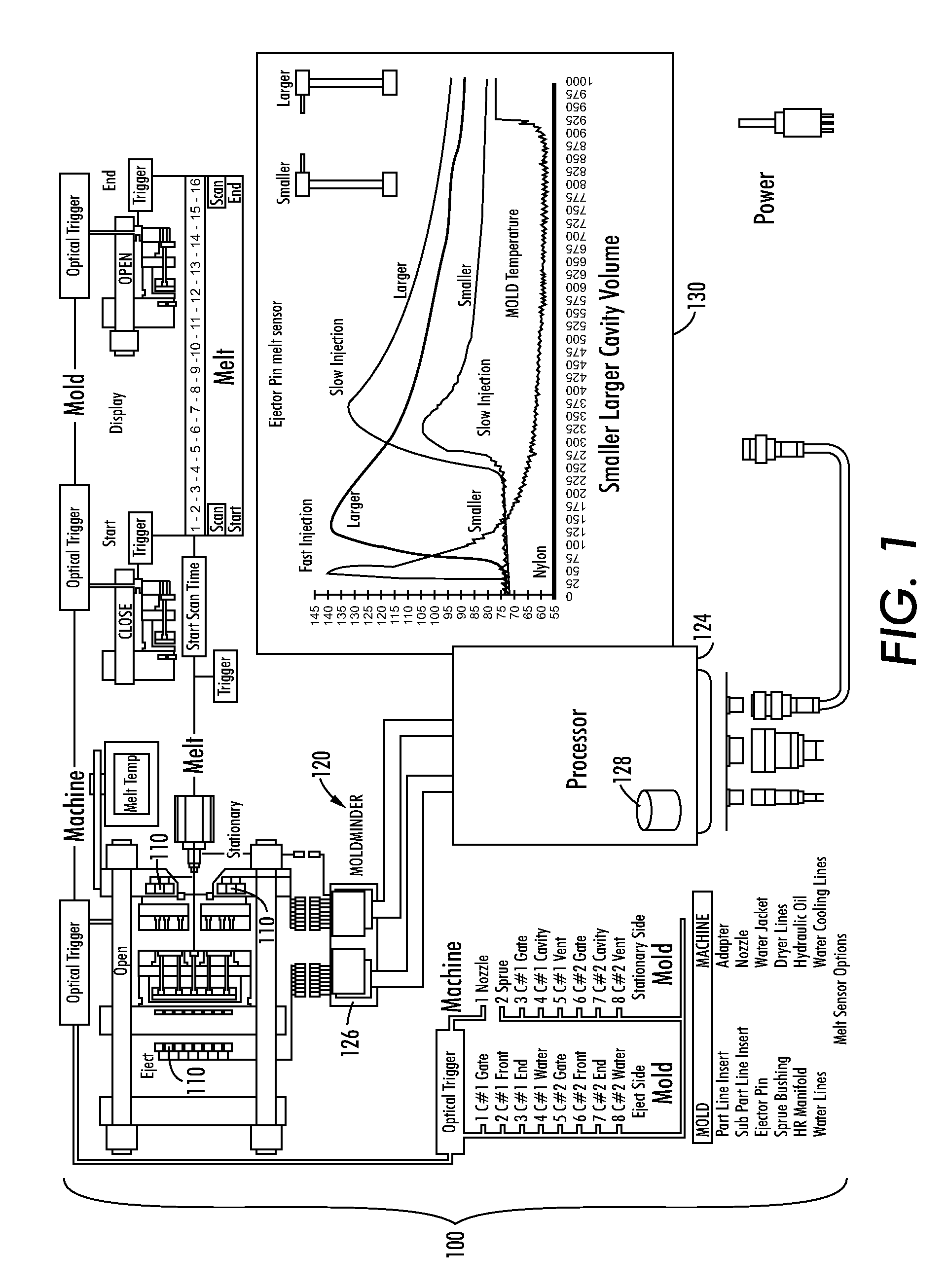

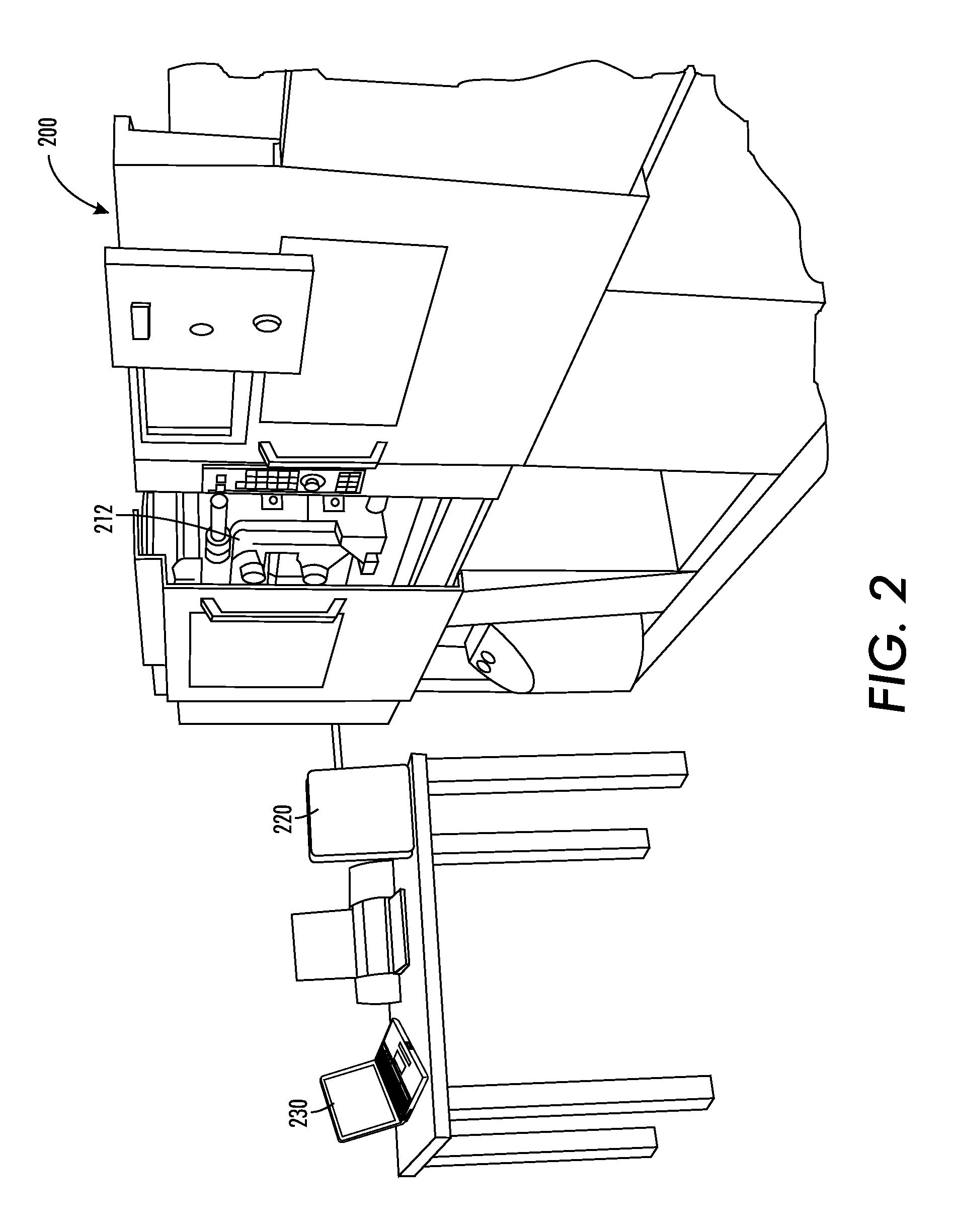

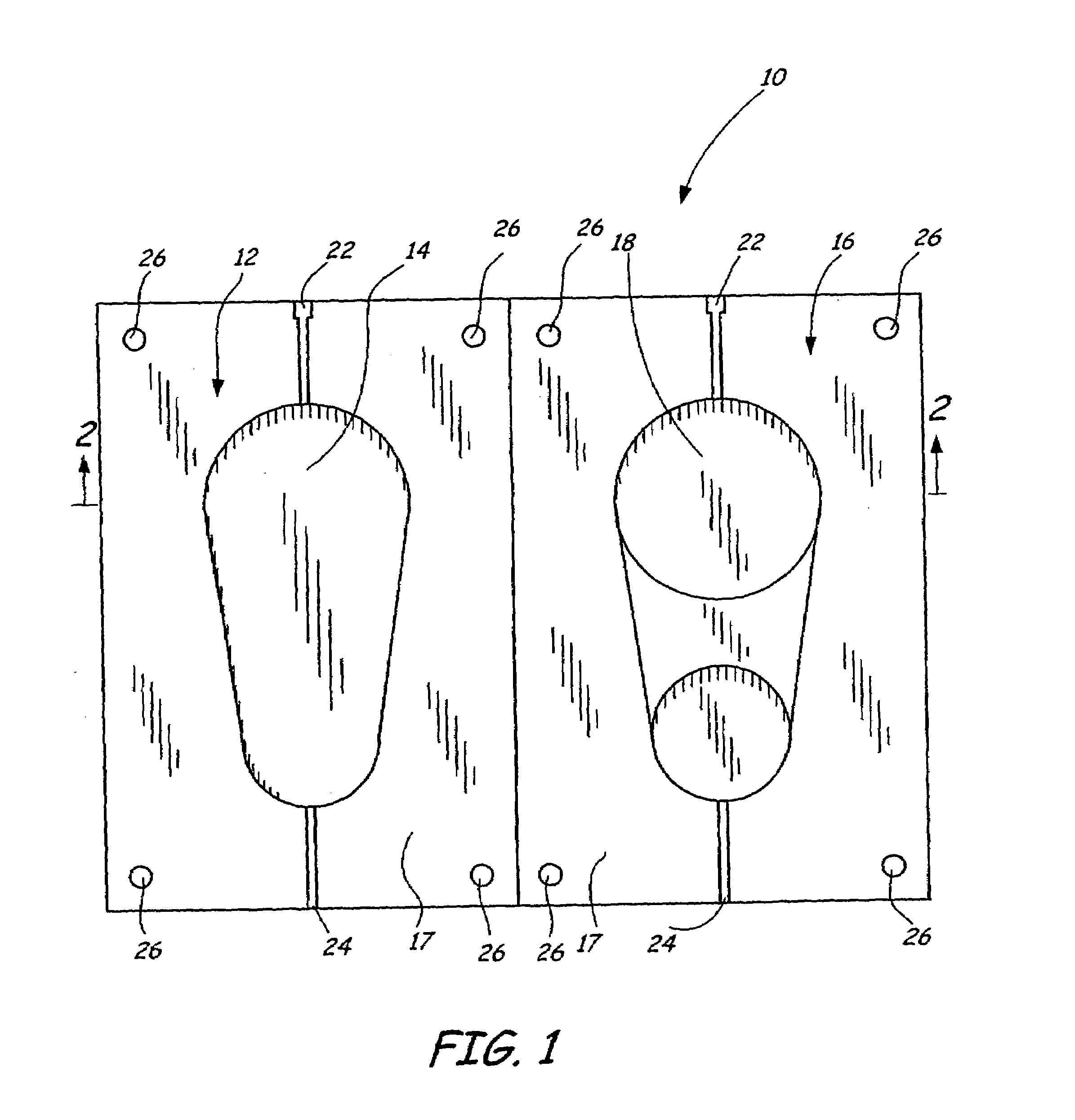

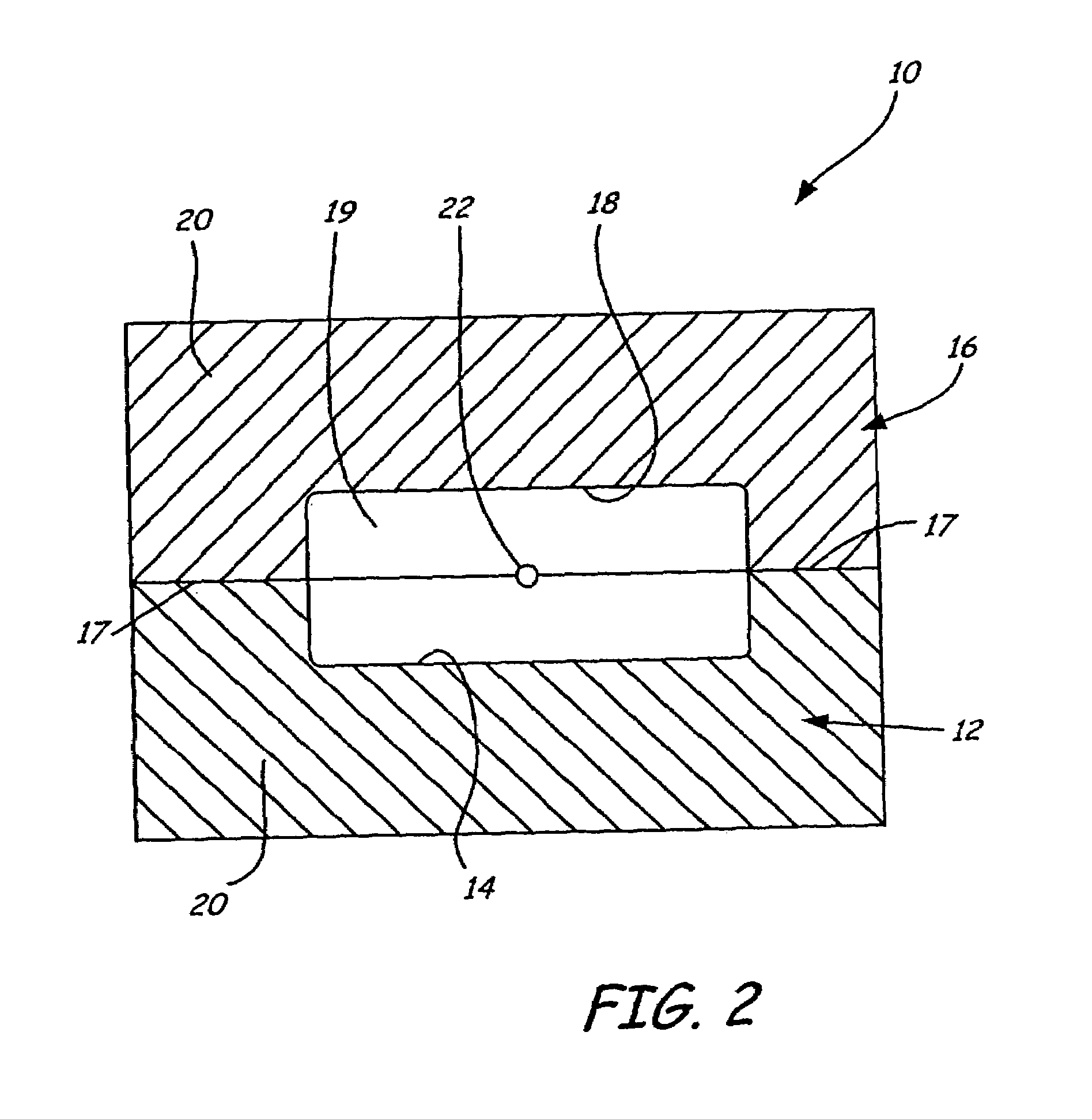

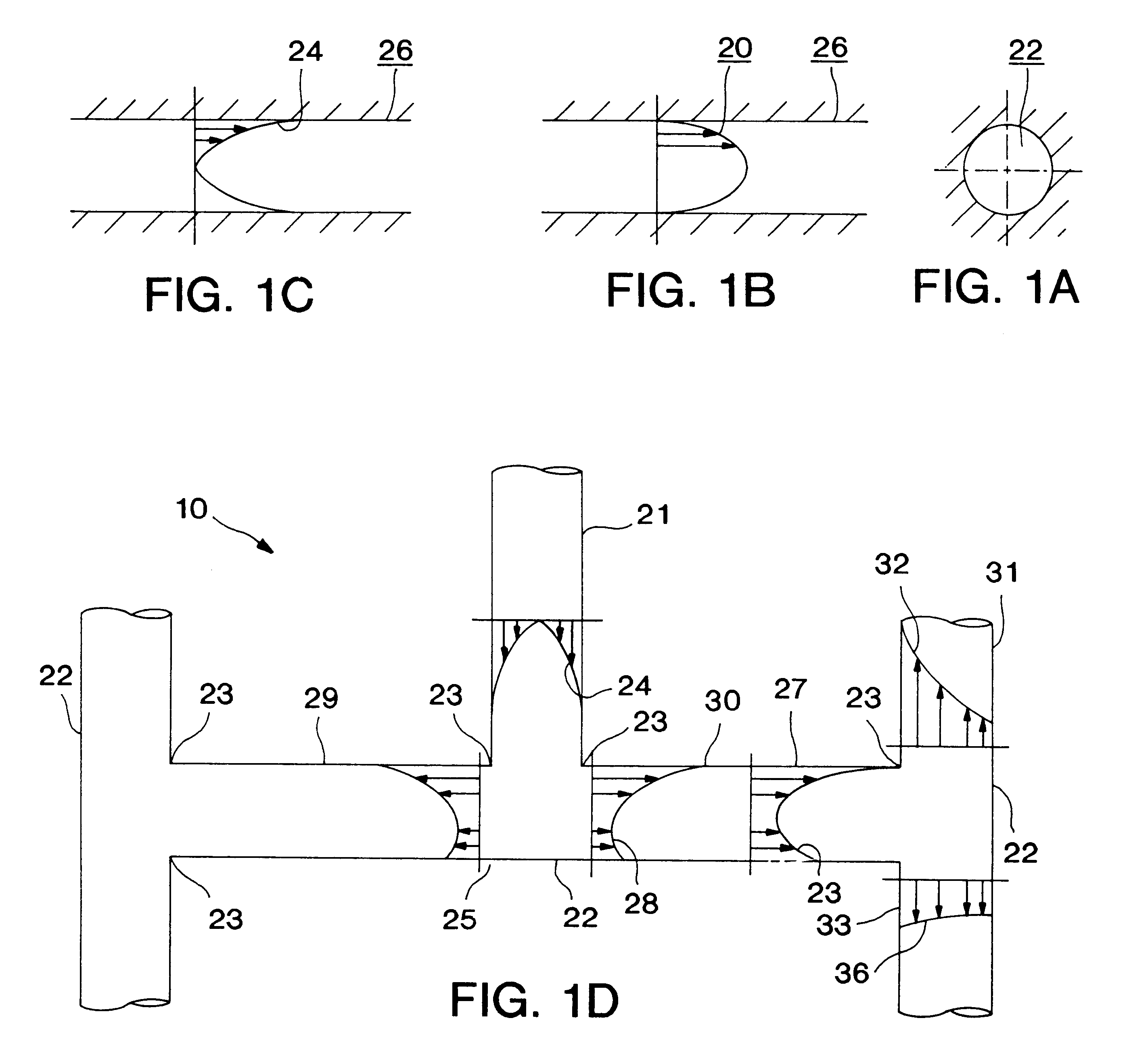

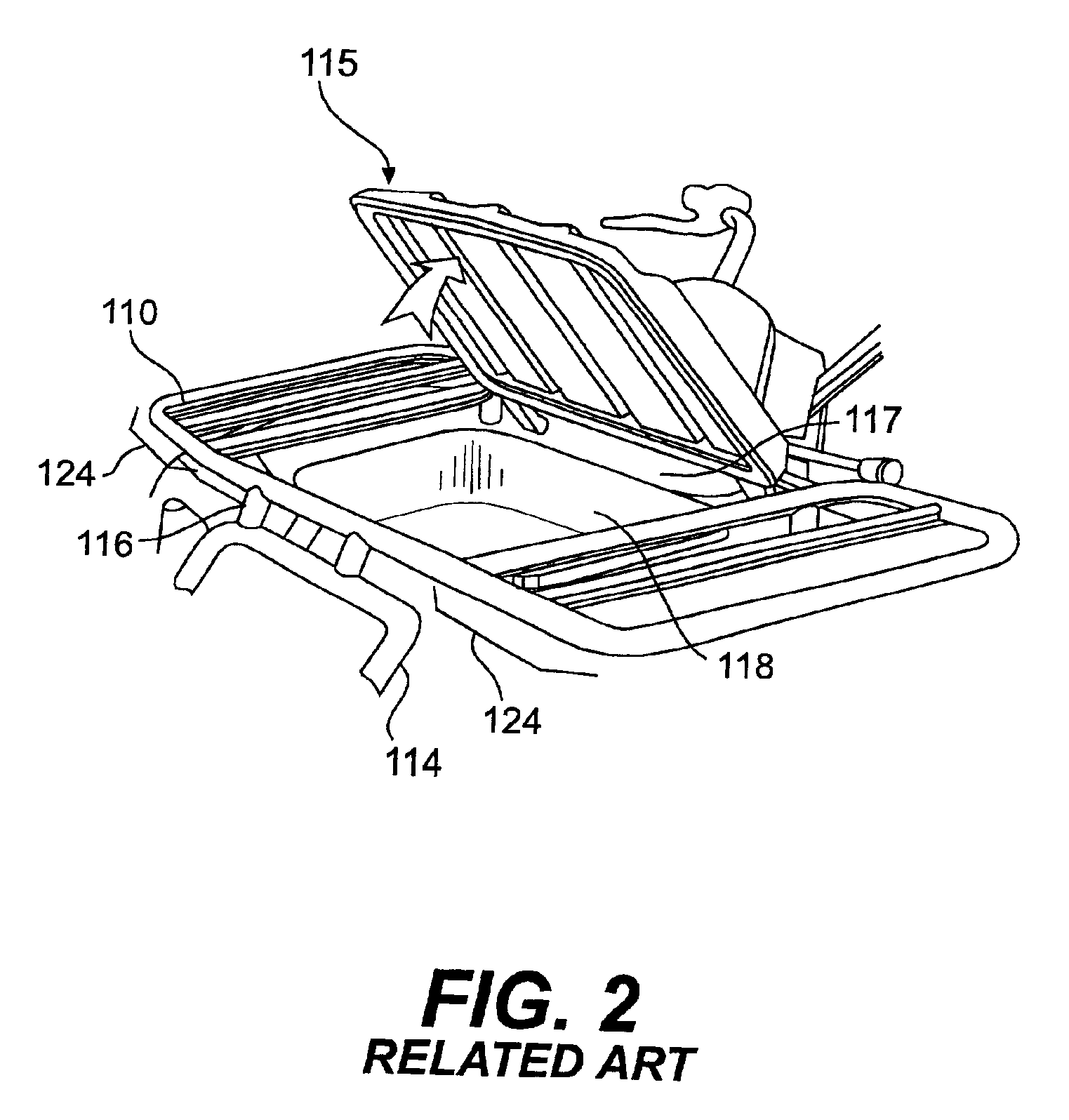

Layered deposition bridge tooling

InactiveUS7255821B2Additive manufacturing apparatusAdditive manufacturing with liquidsFilling materialsInjection molding machine

Disclosed is a method for making a prototype plastic injection molded part from a mold tool (10) built by fused deposition modeling. The mold tool (10) is built by depositing roads of a molten thermoplastic resin in layers in a predetermined pattern defined by computer file data representing the inverse of the desired prototype molded part, and is used in an injection molding machine without the addition of any reinforcement fill material or layers to create the prototype part. The disclosed method provides prototype plastic injection molded parts within a twenty-four hour time period.

Owner:STRATSYS INC

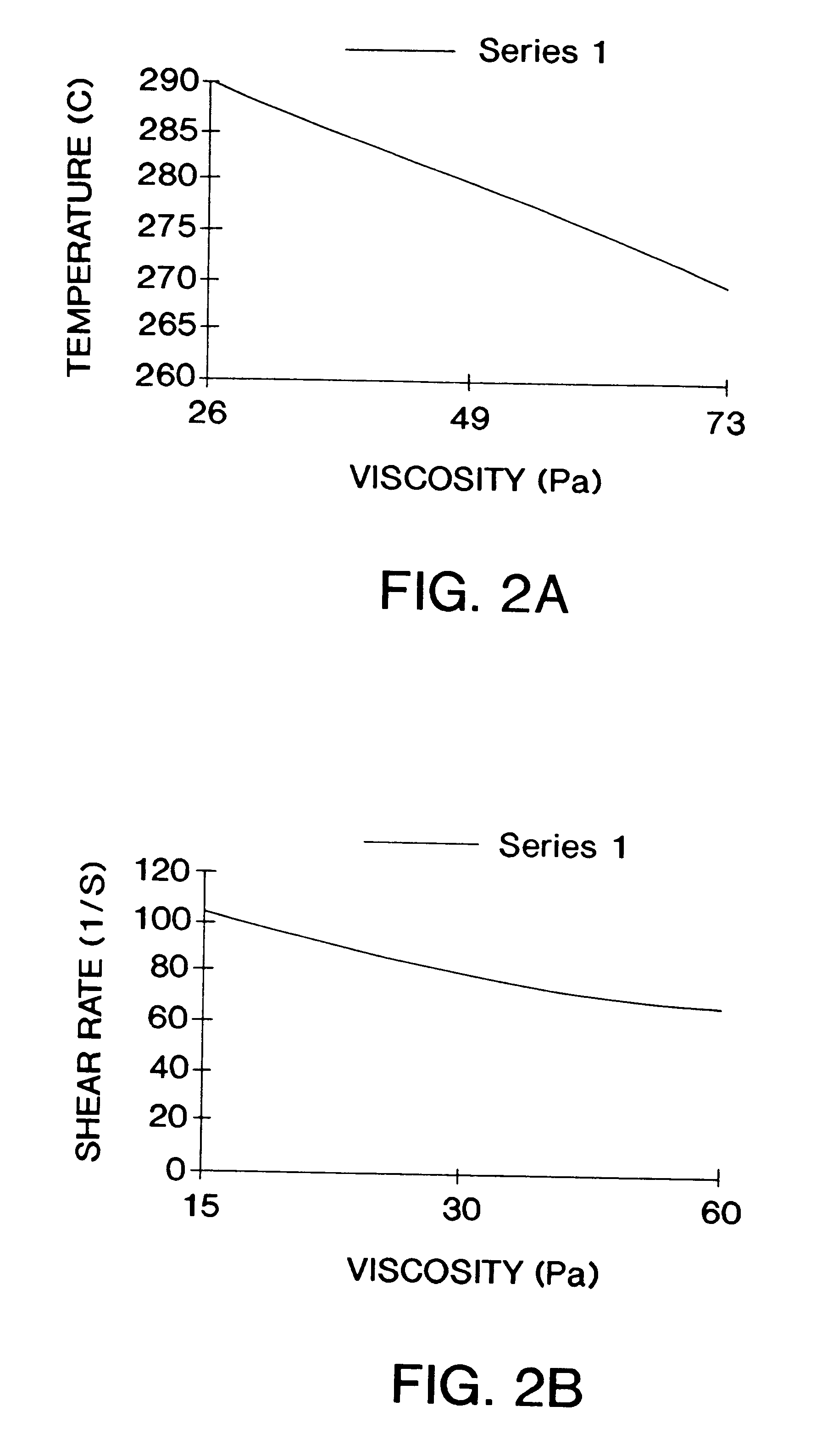

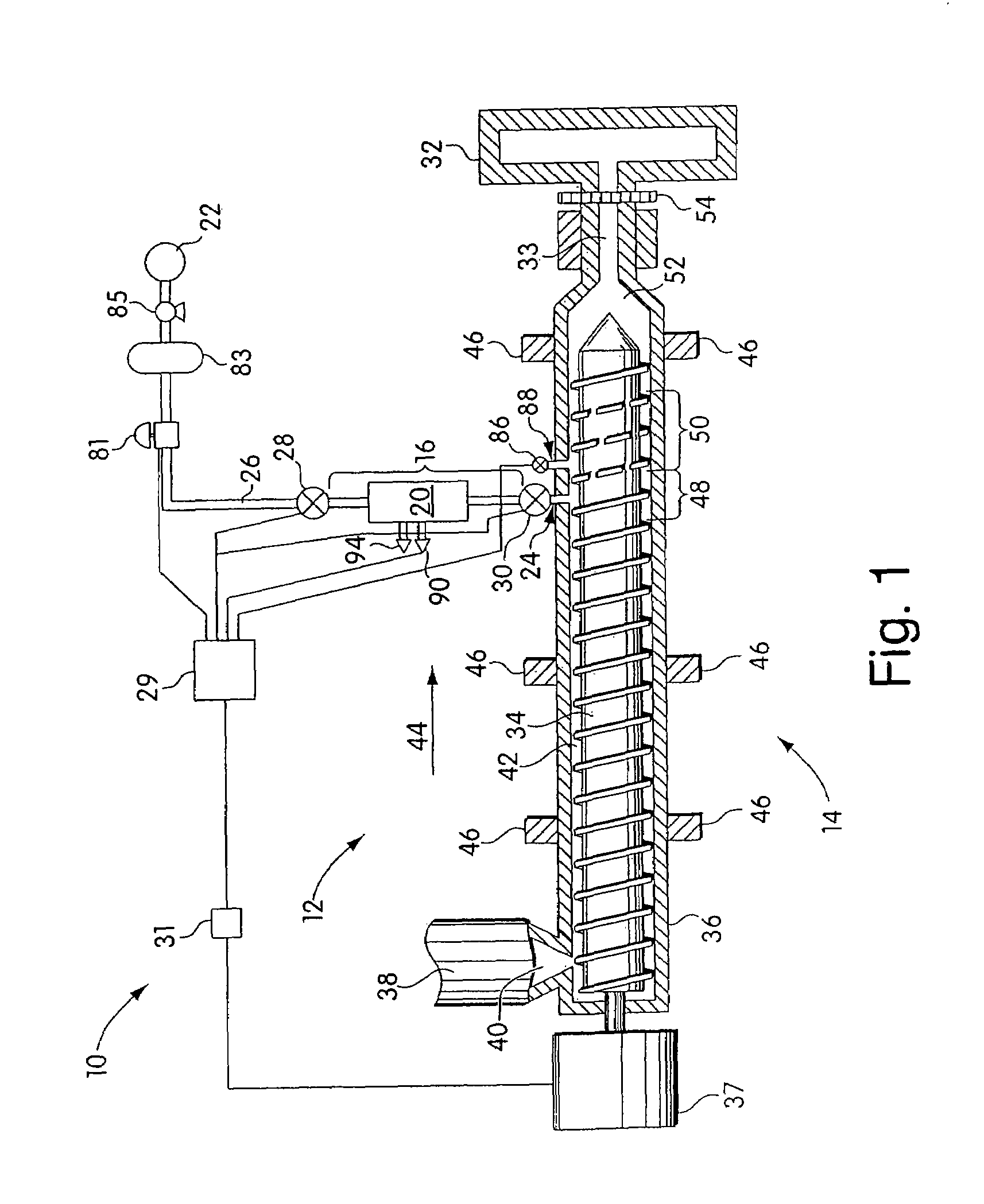

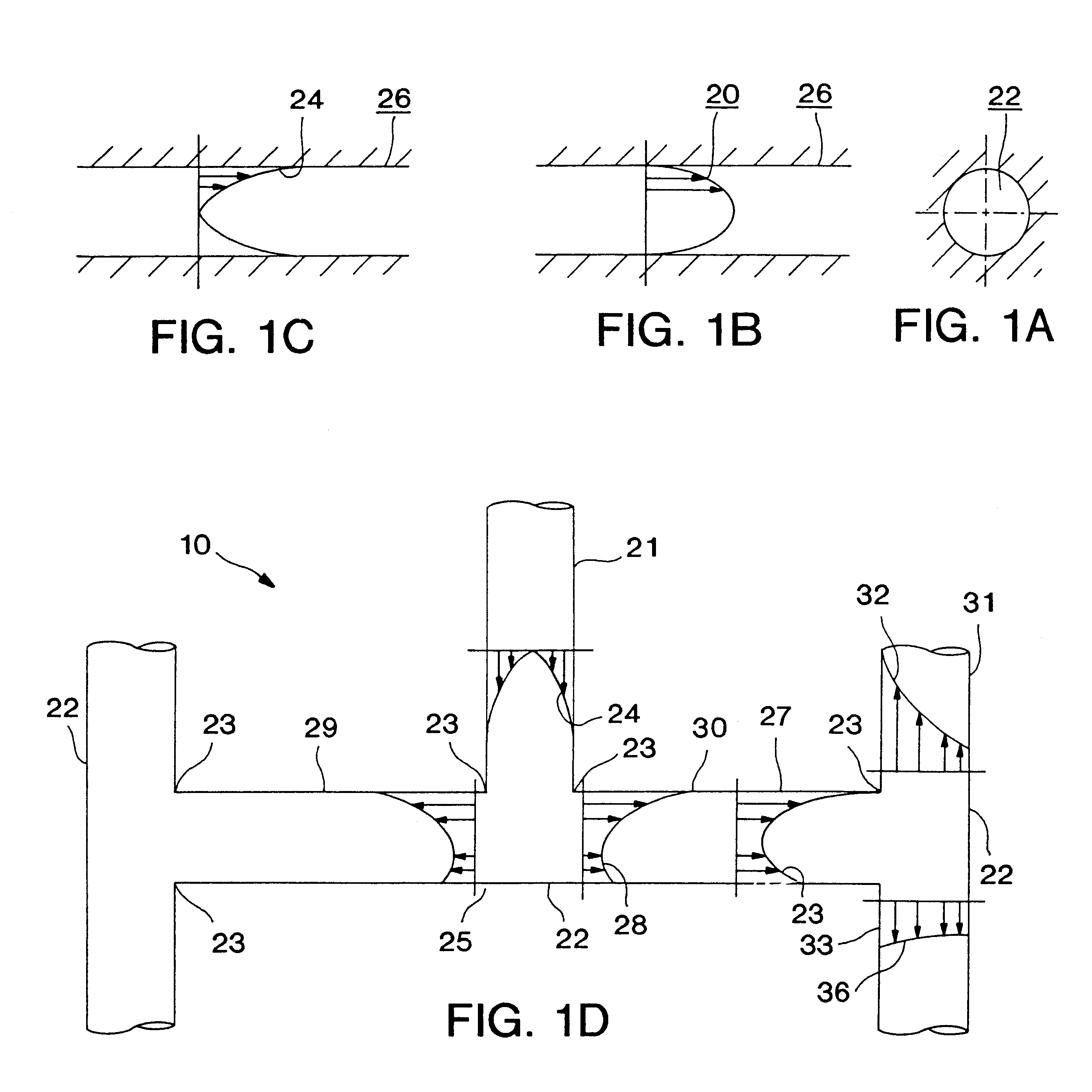

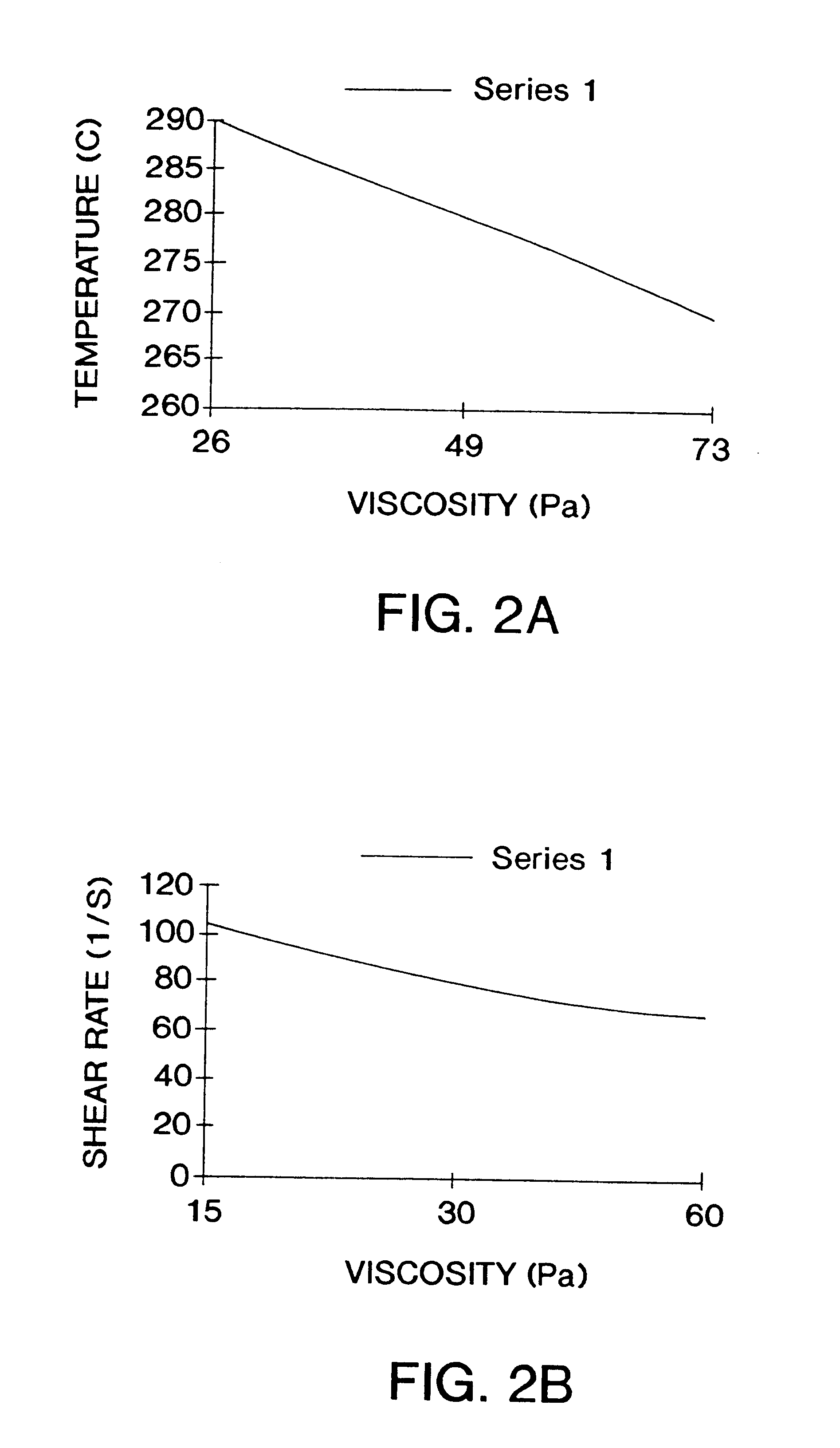

Injection molding of polymeric material

Injection molding systems and methods useful for making microcellular foamed materials are provided as well as microcellular articles. Pressure drop rate and shear rate are important features in some embodiments, and the invention provides systems for controlling these parameters in an injection molding system. Another aspect involves an injection molding system including a nucleator that is upstream of a pressurized mold. Another aspect involves an extrusion system with the reciprocating screw for forming a single phase solution of non-nucleated blowing agent and polymeric material. Another aspect involves very thin walled microcellular material and very thin walled polymeric material. Another aspect provides a method for producing high weight reductions in very thin-walled parts with surfaces that have no noticeable differences from non-foamed parts.

Owner:TREXEL

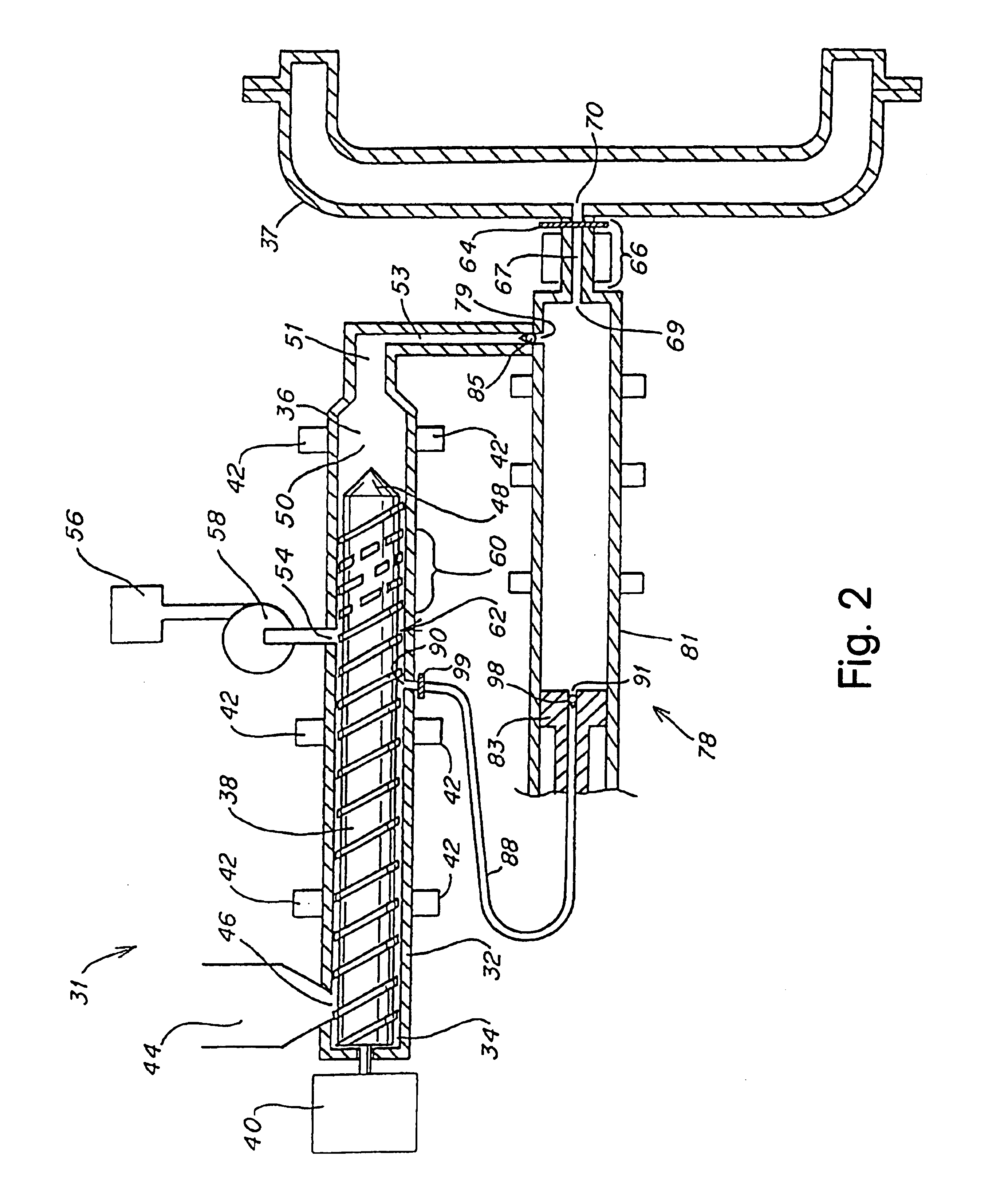

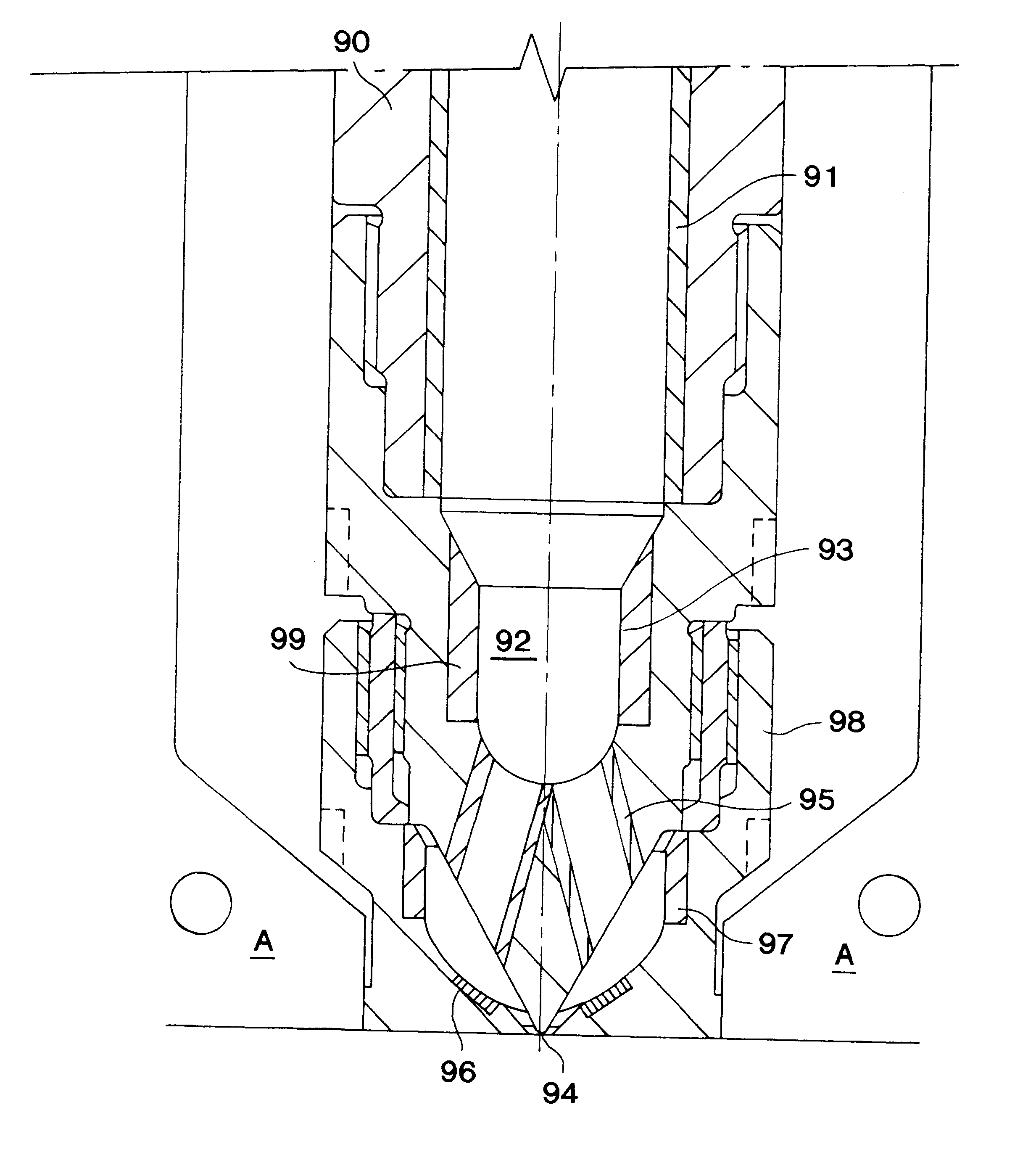

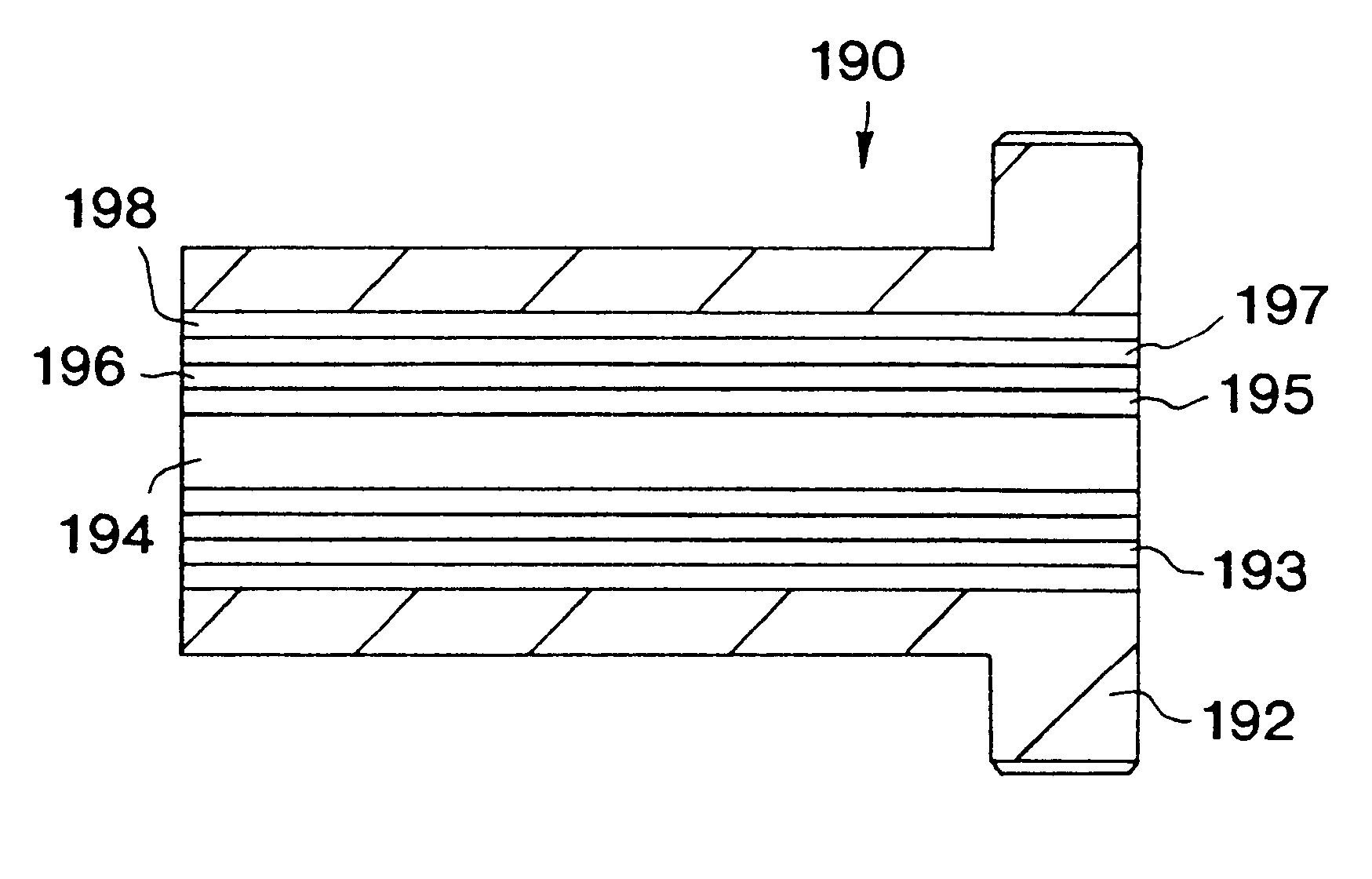

Molding system using film heaters and/or sensors

Improved mold manifold and hot runner nozzle using thin film elements include at least one active or passive thin film element disposed along a melt channel between the manifold inlet and the hot runner nozzle. Preferably, the thin film element may comprise a thin film heater in direct contact with the molten resin and position to aid in the heat and flow management of the resin within the melt channel. Thin film temperature sensors, pressure sensors, and leak detectors may also be provided in the vicinity of the melt channel to enhance process control in the injection molding machine.

Owner:HUSKY INJECTION MOLDING SYST LTD

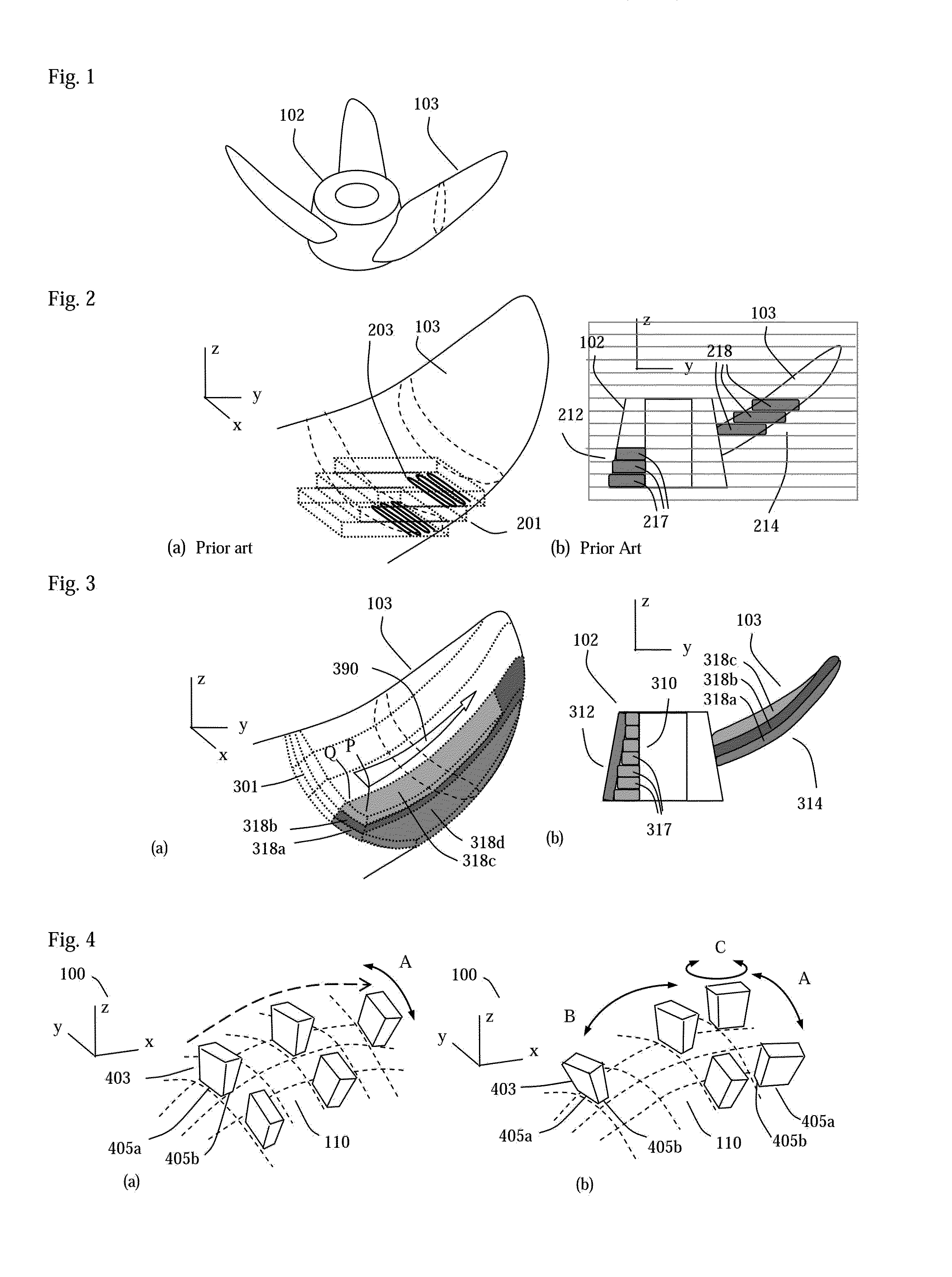

Flexible 3D Freeform Techniques

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

Thermoplastic composite material, and preparation method and application thereof

The invention belongs to the field of polymer composite materials, and discloses a thermoplastic composite material, and a preparation method and an application thereof. The composite material is composed of the components of, by weight: 1-99 parts of a prepreg and 1-99 parts of a thermoplastic composition or thermoplastic resin. The preparation method comprises the steps that: the 1-99 parts of thermoplastic composition or thermoplastic resin is added into a feeding hopper of an injection molding machine, and is mixed with the 1-99 parts of prepreg already in an injection mold; and injection molding is carried out. The invention also discloses an application of the thermoplastic composite material in car bumpers, car door inner panels, car bumper beams, cars toe-boards, car hood, car rear lift door, building templates, biogas digesters, train sidings, train wall panels, or train roof panels. The composite material provided by the invention has the advantages of smooth outer surface, high gloss, good appearance, excellent mechanical performance, high strength, and good impact resistance.

Owner:HEFEI GENIUS NEW MATERIALS

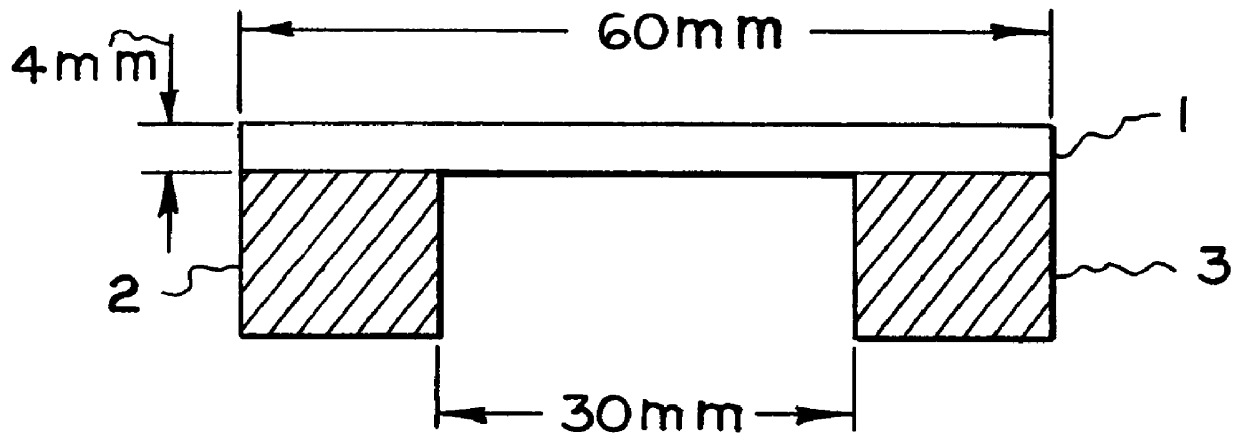

Features for thin composite architectural panels

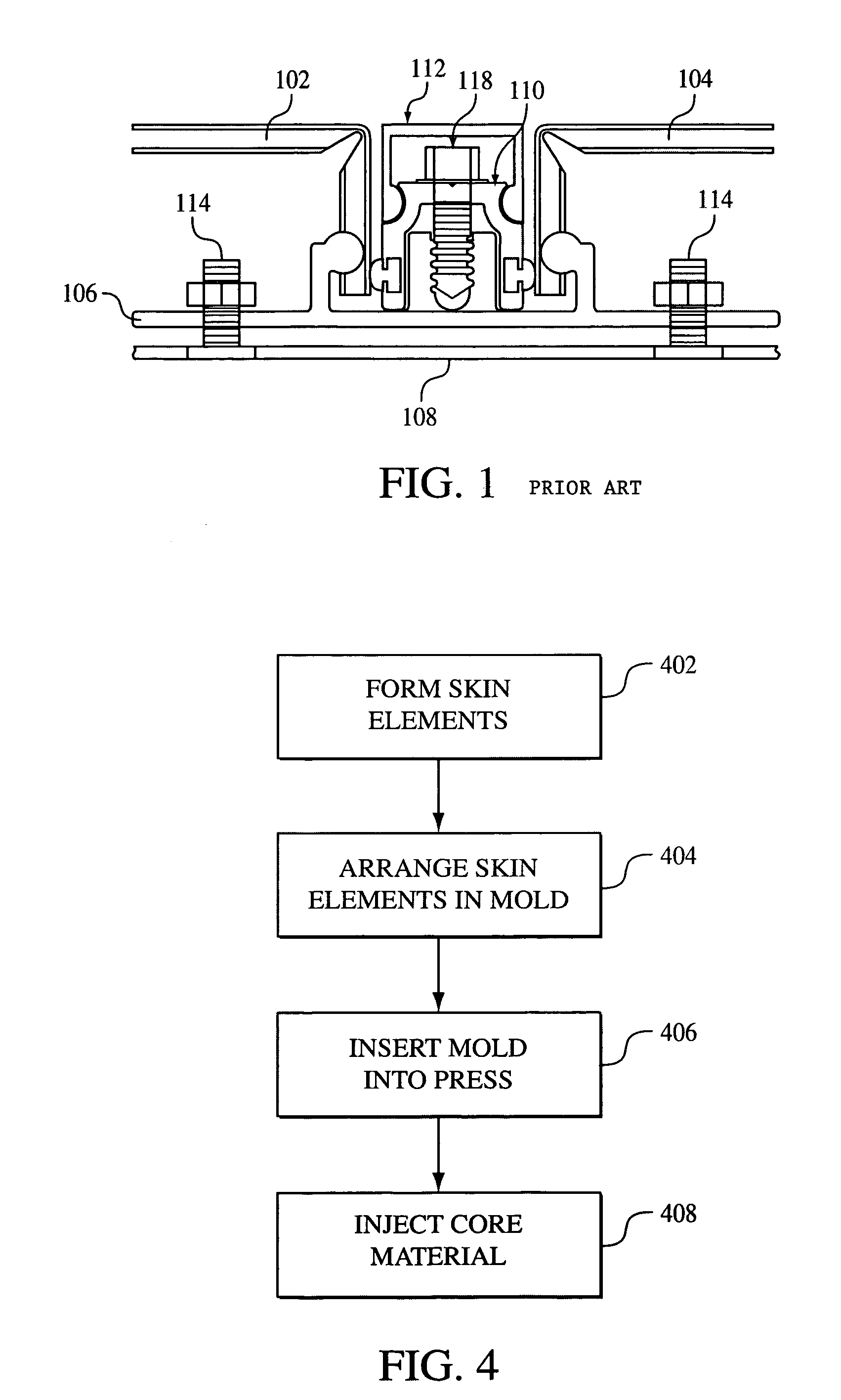

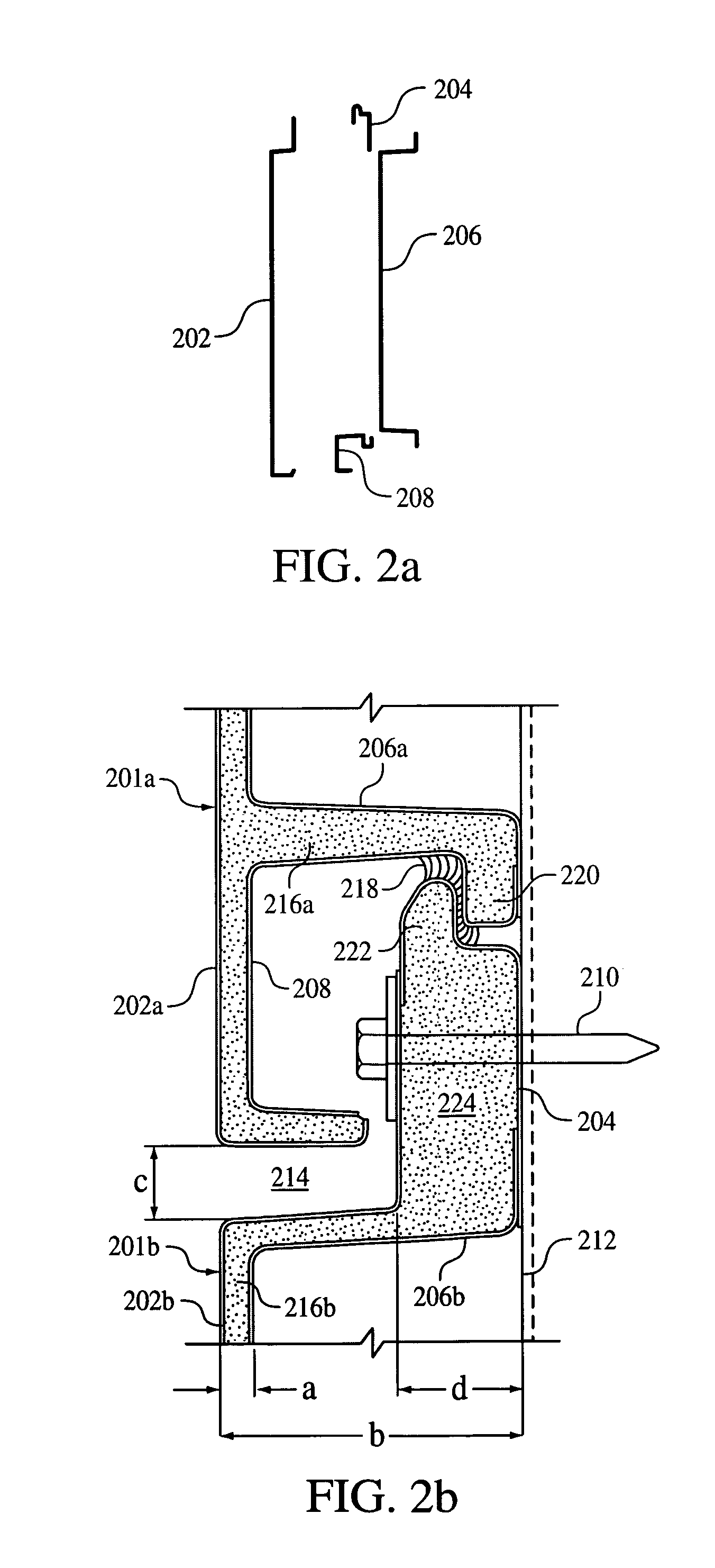

InactiveUS7007433B2Altering coloringAltering other visual featureCovering/liningsWallsInterconnectionComposite plate

Thin composite panels with interconnection schemes that are unitized with the panels, i.e., formed integrally and substantially simultaneously with the panels. Further contemplated is the application of an injection molding technique, such as reaction injection molding, in establishing a foam or polymeric core between laminates in thin composite panels. Additionally contemplated is the use of interchangeable laminate components in affording the capability of altering the coloring or other visual features of a reveal in a panel or panels.

Owner:CENTRIA

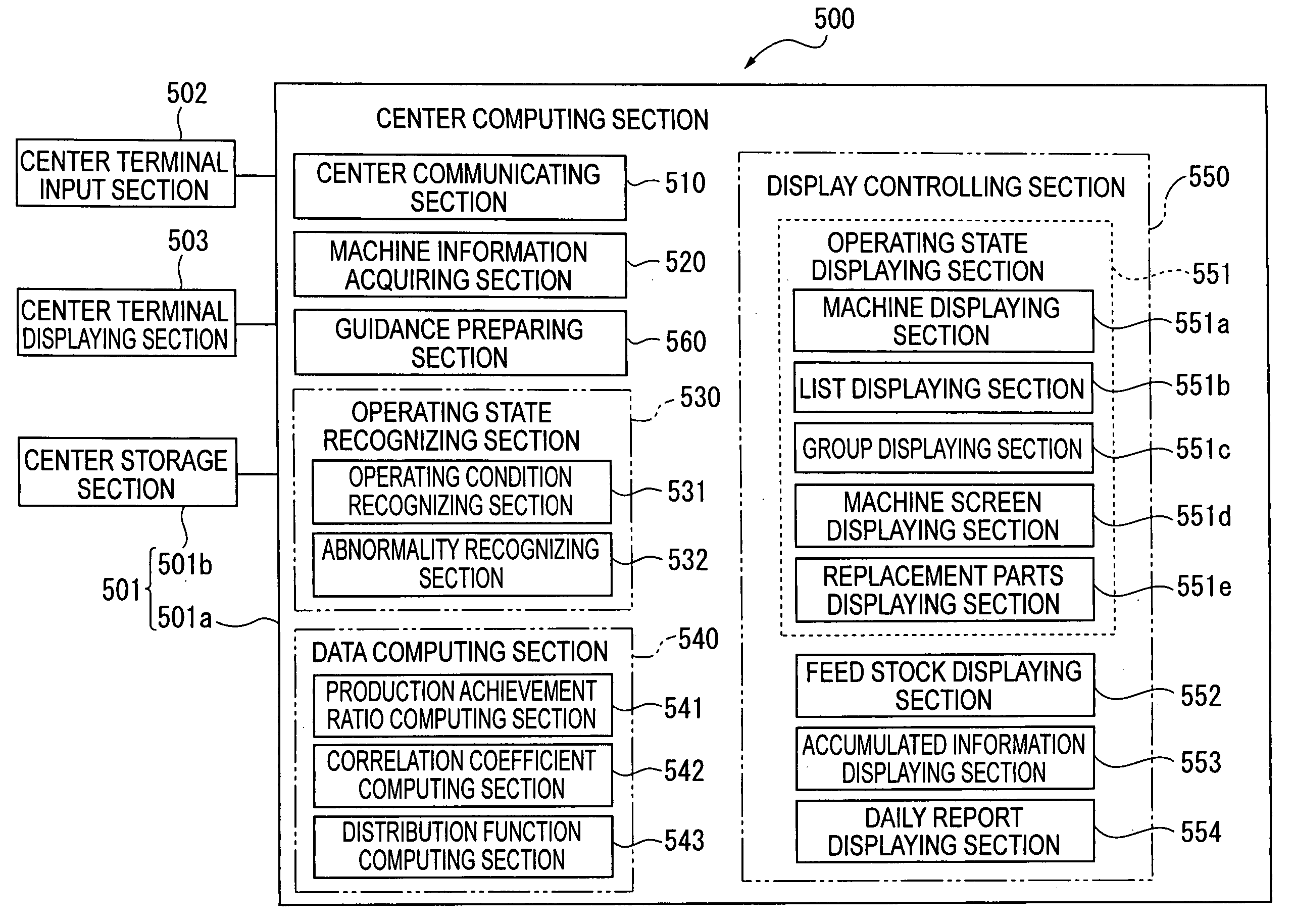

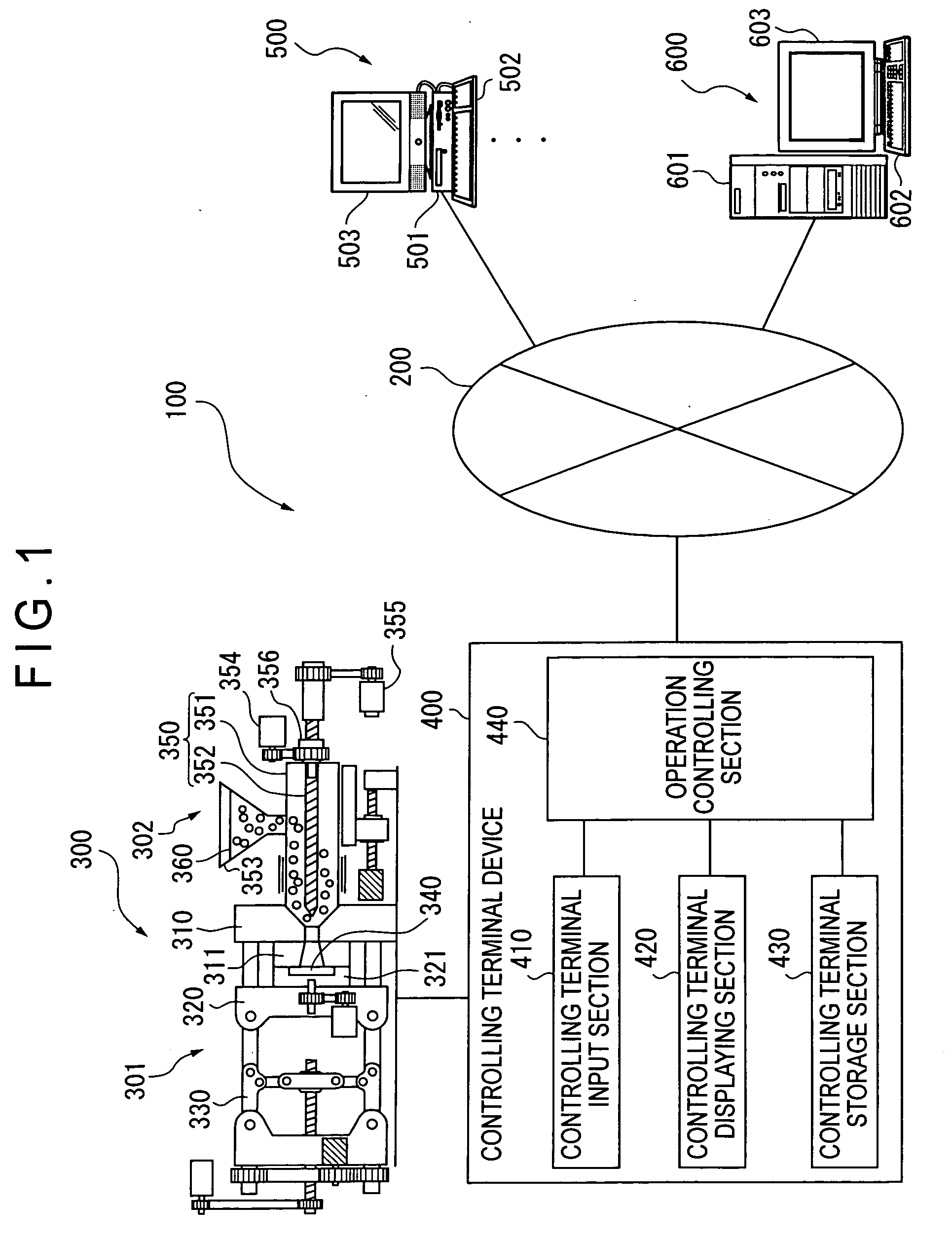

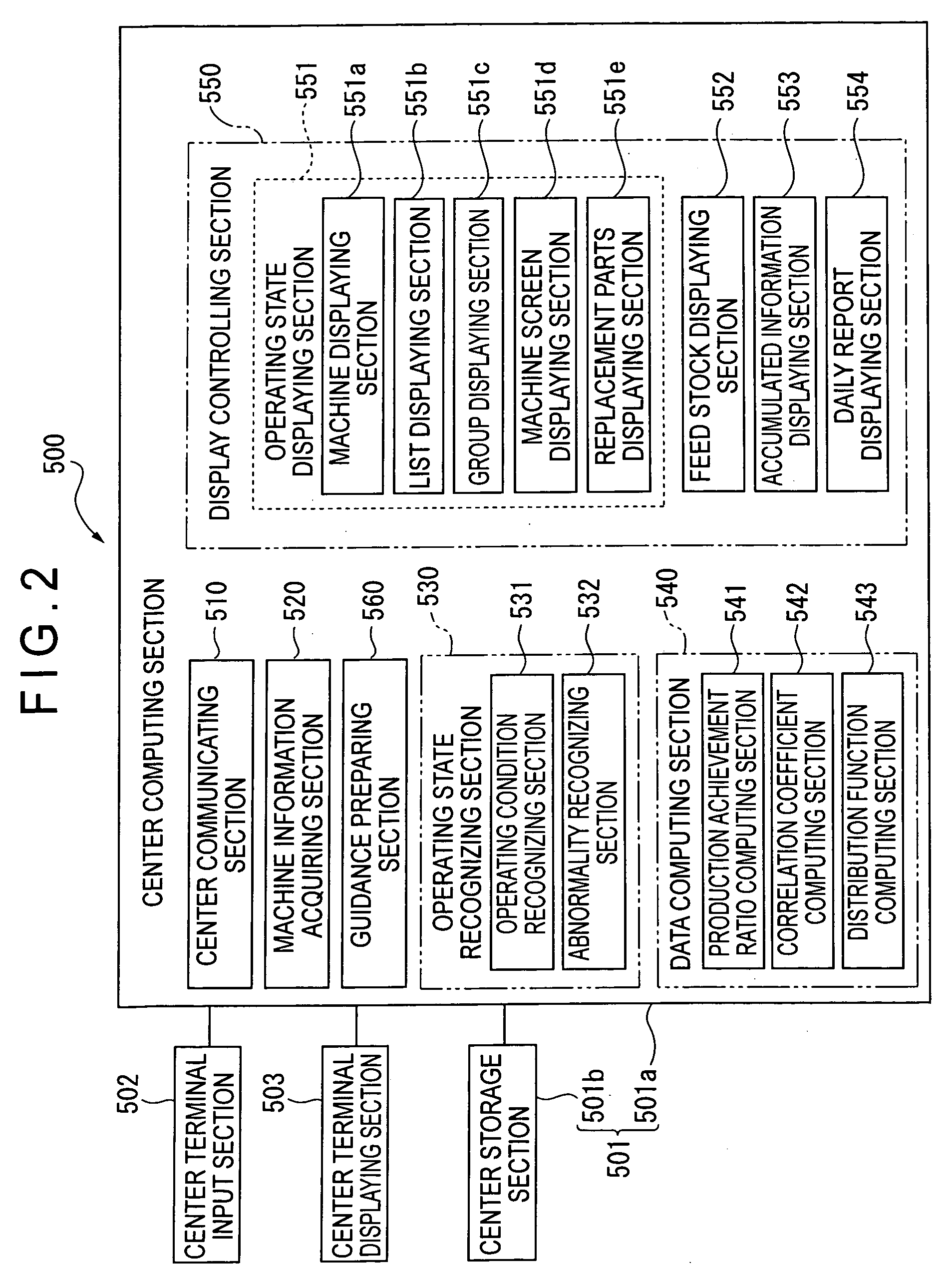

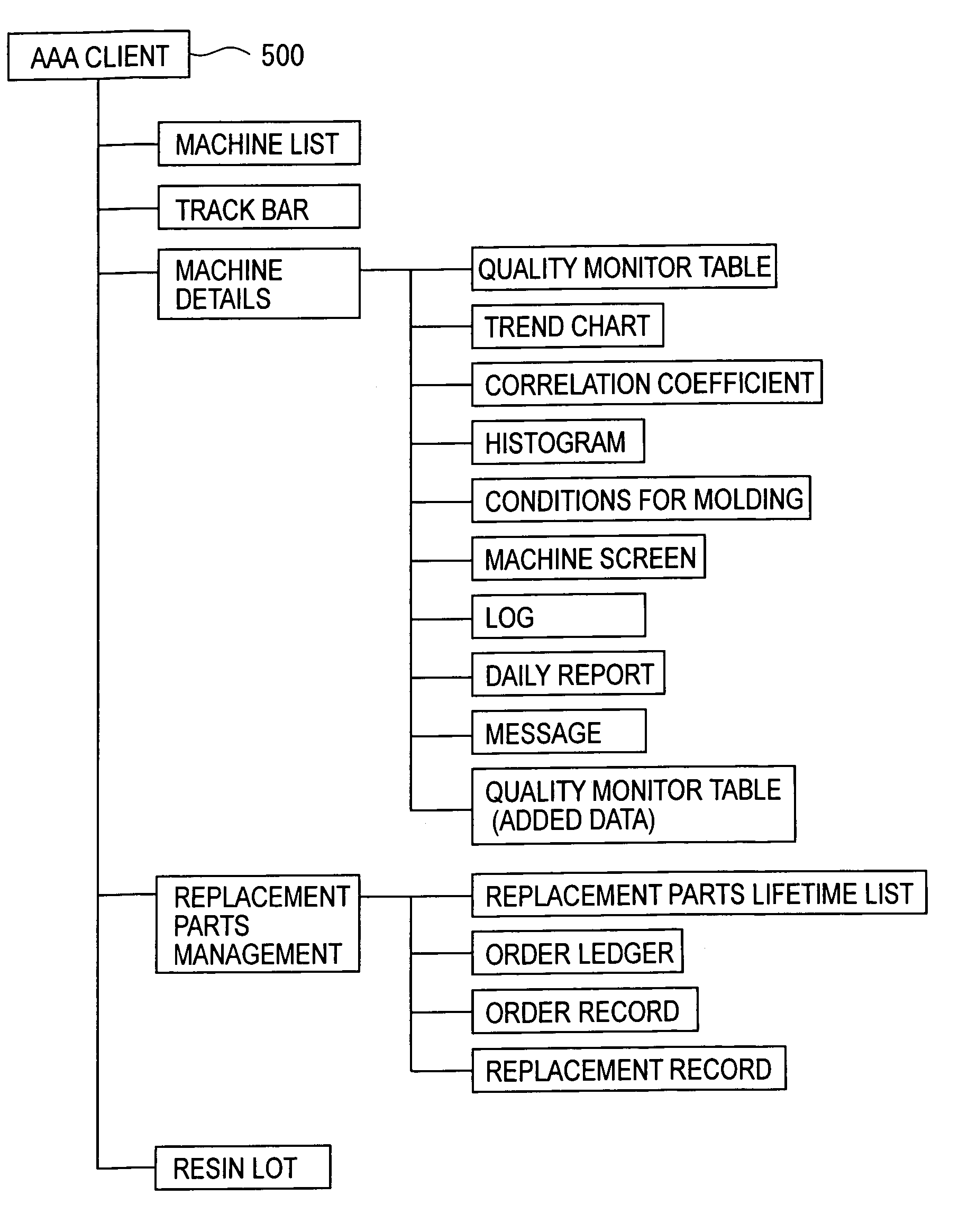

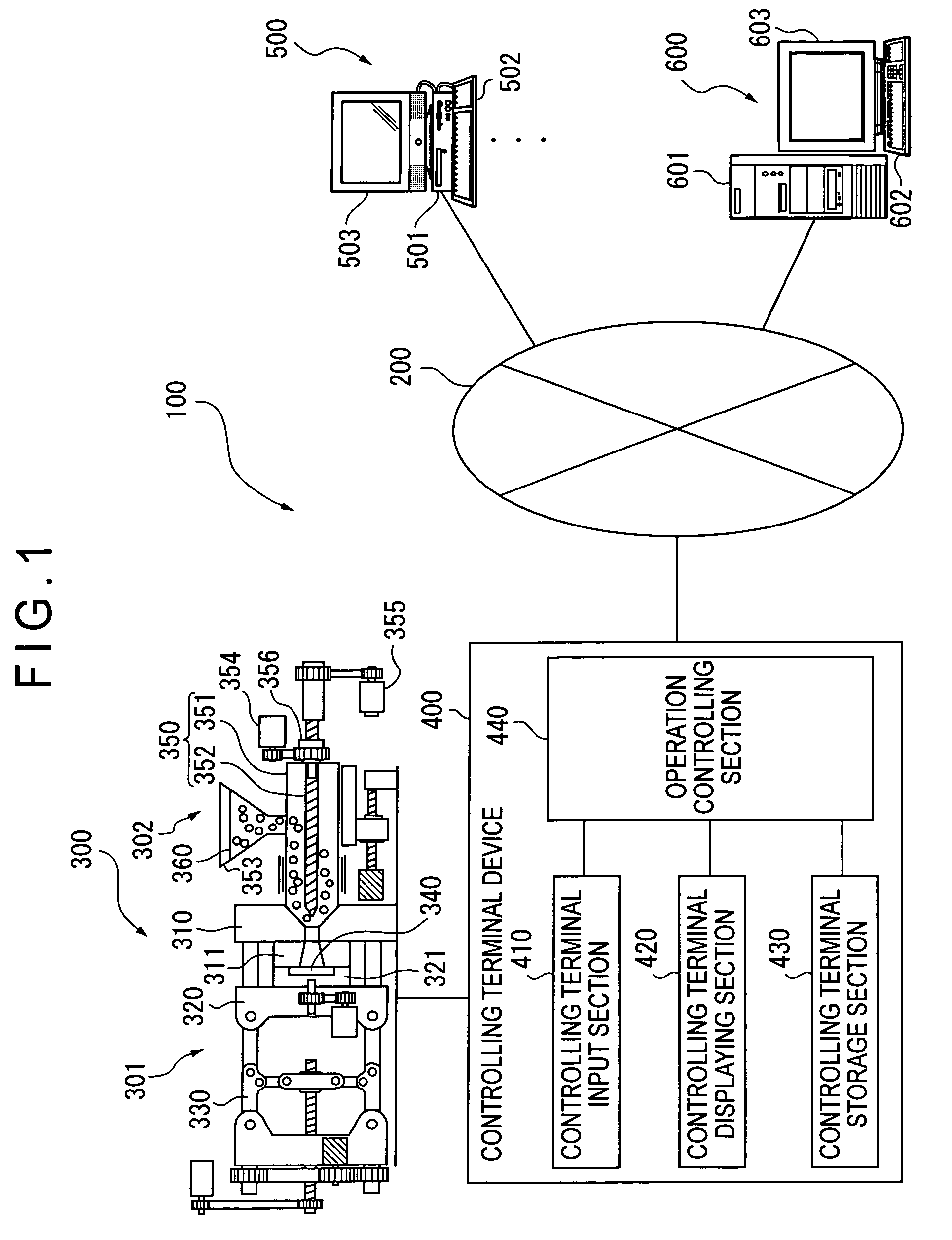

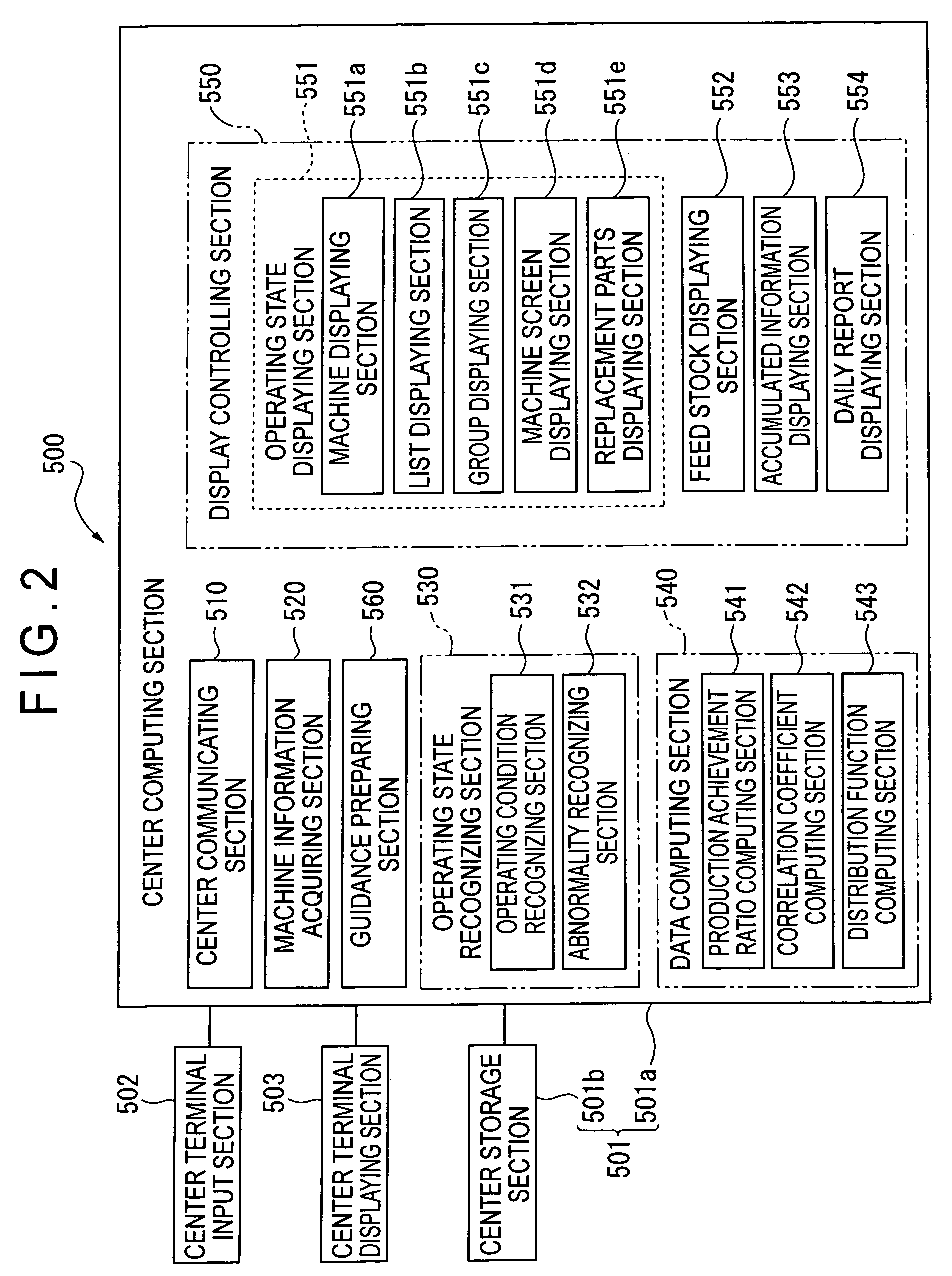

Management supporting apparatus, management supporting system, management supporting method, management supporting program, and a recording medium with the program recorded therein

ActiveUS20040148136A1Efficient replacementEasy to manageProgramme controlComputer controlSupporting systemManagement support systems

Operation state information for each cycle of manufacturing operations of each of injection molding machines 300 is acquired by a center management terminal device 400 via a network from a plurality of controlling terminal device 400 for controlling the injection molding machines 300. Cumulative utilization of replacement parts of each injection molding machine 300 put into practical operation is recognized by the operating condition recognizing section of the center management terminal device 400 based on the parts state information for the replacement parts of each injection molding machine 300 included in the operating state information. Based on the cumulative utilization, availability of the parts is recognized with reference to lifetime information concerning lifetime of the parts previously stored in the center storage section, and situation of the availability is displayed with a different display format on the center terminal displaying section 503.

Owner:TOSHIBA MASCH CO LTD

Method for preparing magnetic filling with biological affinity, hydrophilicity and activity for water treatment

InactiveCN1522972AEasy to grow and compactGood compatibilitySustainable biological treatmentBiological water/sewage treatmentInjection molding machineInjection moulding

The present invention relates to a preparation method of biological affinity hydrophilic active magnetic seed filling material for treating water. It is characterized by that said method includes the following steps: mixing biological affinity substance, hydrophilic substance, magnetic powder and active carbon or magnetic powder and calcium carbonate in the high-molecular base material, and adding dispersion lubricating agent, uniformly stirring them, placing them into injection moulding machine, utilizing filling mould to make extrusion moulding and magnetizing, so as to obtain the invented filling material. It has biological affinity and hydrophilicity, at the same time can induce microbial activity and enzyme activity, and can raise oxygen utilization rate in water and water treatment efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Management supporting apparatus, management supporting system, management supporting method, management supporting program, and a recording medium with the program recorded therein

ActiveUS7117050B2Easy to manageProgramme controlComputer controlSupporting systemManagement support systems

Operation state information for each cycle of manufacturing operations of each of injection molding machines 300 is acquired by a center management terminal device 400 via a network from a plurality of controlling terminal device 400 for controlling the injection molding machines 300. Cumulative utilization of replacement parts of each injection molding machine 300 put into practical operation is recognized by the operating condition recognizing section of the center management terminal device 400 based on the parts state information for the replacement parts of each injection molding machine 300 included in the operating state information. Based on the cumulative utilization, availability of the parts is recognized with reference to lifetime information concerning lifetime of the parts previously stored in the center storage section, and situation of the availability is displayed with a different display format on the center terminal displaying section 503.

Owner:TOSHIBA MASCH CO LTD

Bamboo powder filling biodegradable compound material and preparation method thereof

The invention relates to a bamboo powder filling biodegradable compound material and a preparation method thereof. The bamboo powder filling biodegradable compound material comprises the following raw materials in part by mass: 30 to 80 parts of biodegradable resin, 20 to 70 parts of bamboo powder, 1 to 19 parts of plasticizer, 0.6 to 6 parts of interface modifier and 4 to 12 parts of aids. The preparation method comprises the following steps of: uniformly mixing the biodegradable resin, bamboo powder, plasticizer, interface modifier and auxiliary agent by using a mixer according to formula proportion; performing melt blending and granulation of the obtained mixture by using a screw extruder to obtain particles; and processing the particles by using an injection molding machine, a sheet extrusion forming machine, a blow molding machine or a film blowing machine, and molding in molds of different shapes to obtain the bamboo powder filling biodegradable compound materials of different shapes. The method has the advantages of high production efficiency and low cost; and the powder filling biodegradable compound material prepared by the method has the advantages of high environmentally-friendly property and economy and excellent usability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nutrition slow-release type biofiller for water treatment and its preparation method

InactiveCN100999361AIncrease roughnessIncrease specific surface areaSustainable biological treatmentWater/sewage treatment by substance additionPlastic injection moldingInjection molding machine

This invention discloses a nourishing slow-released type organic bulking agent for processing water and its preparation. This bulking agent includes 60-100 parts of high polymer basis material, 1-15 parts of nutrient substance, 1-10 parts of slow-releasing control substance, and 1-10 parts of dispersing lubricant. When prepare, lubricate slow-releasing control substance with 0.5-3 parts of dispersing lubricant; lubricate high polymer basis material with remaining dispersing lubricant, add in stirring machine, mix with above mixture, mix uniformly, transfer mixture into stirring dipper of plastic injection molding machine, extrude and form by bulking agent tooting. Organic bulking agent prepared by this invention slow-releases nutrient substance that is required for microbes forming biofilm. It has characteristics of fast forming biofilm, more microbial biomass, and activity. It is especially suitable for oxygen degrading process of waste water that contains difficult degraded toxic pollutant.

Owner:SOUTH CHINA UNIV OF TECH

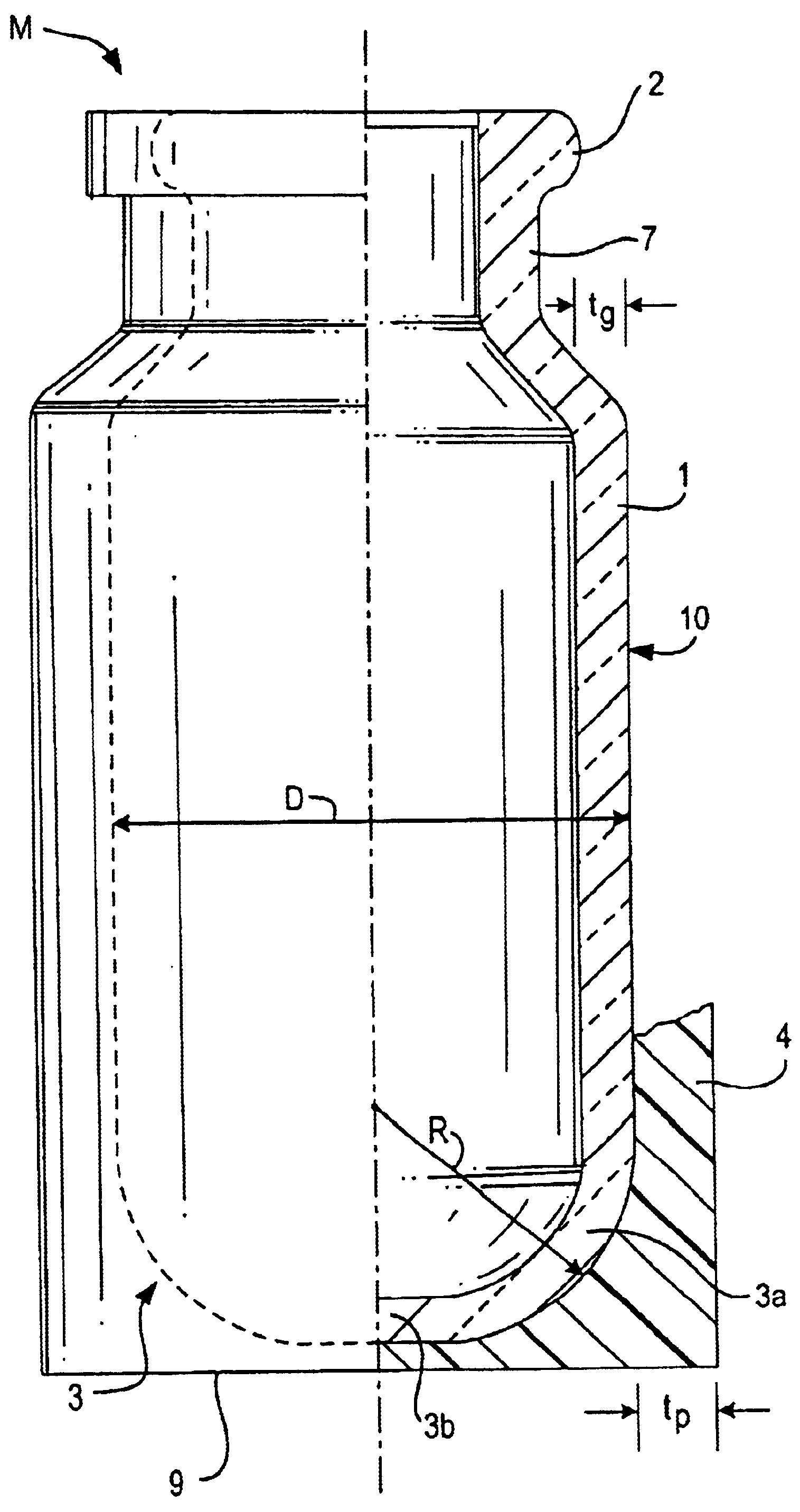

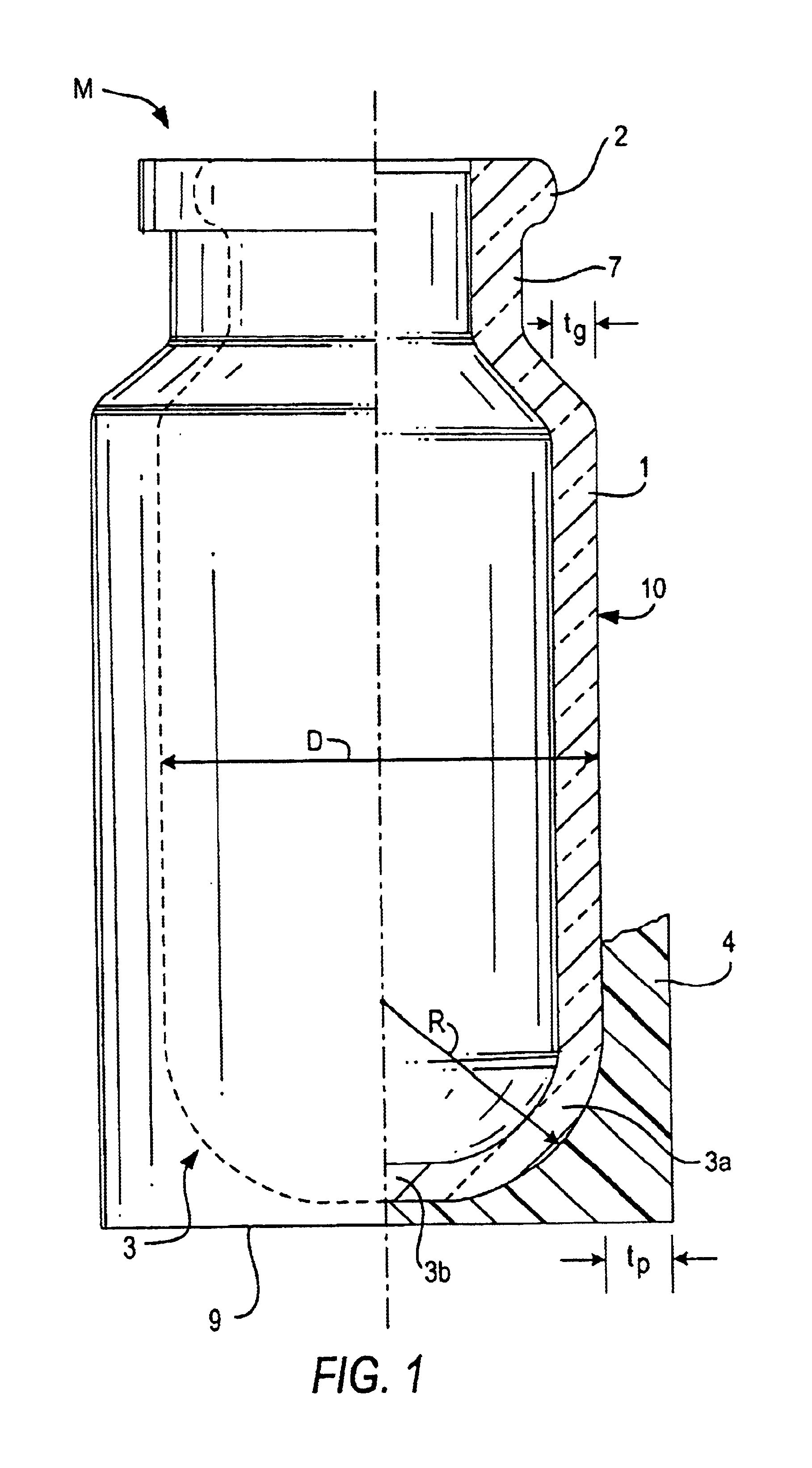

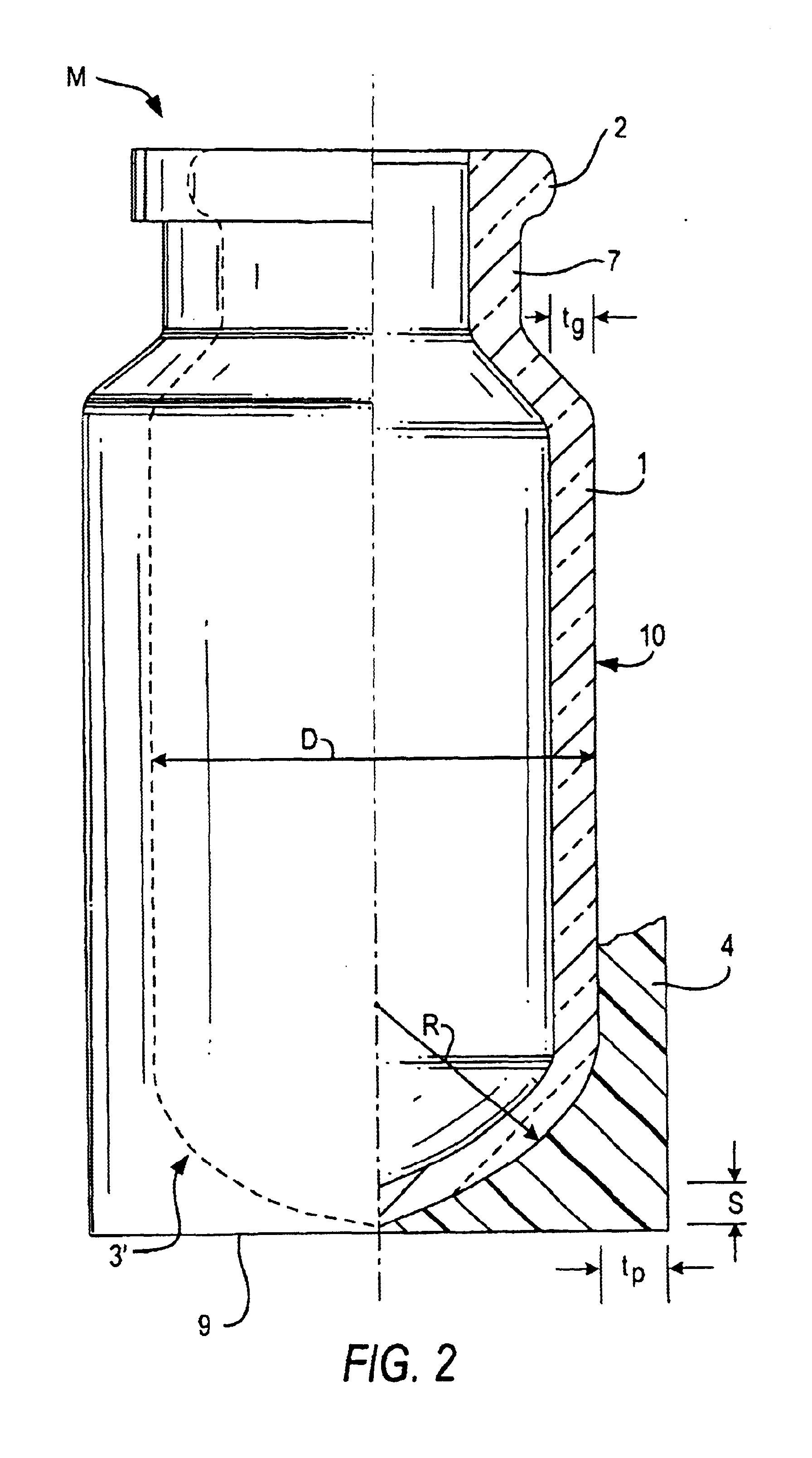

Closeable glass container comprising a plastic coating applied by injection molding and method for the production thereof

InactiveUS6866158B1Reduce wasteProduce some attenuationBottlesNon-pressured vesselsEngineeringBottle

The container is a glass bottle (10) encased with a plastic coating (4) from its base section (3) to a sealing rim (2) around its mouth (M) in order to protect against shattering or explosive failure. The glass bottle, preferably a glass inlet, is fillable under pressure with a sprayable medically active substance and a propellant and provided with a delivery element attached to the sealing rim. To facilitate lower injection molding temperatures and pressures and to permit autoclaving at high temperatures the glass bottle with the plastic coating (4) is made by a method which includes injecting at least one reactively cross-linkable plastic capable of being heat-softened into a mold surrounding the glass bottle and forming the plastic coating (4) by a reaction injection molding (RIM) method.

Owner:SCHOTT AG

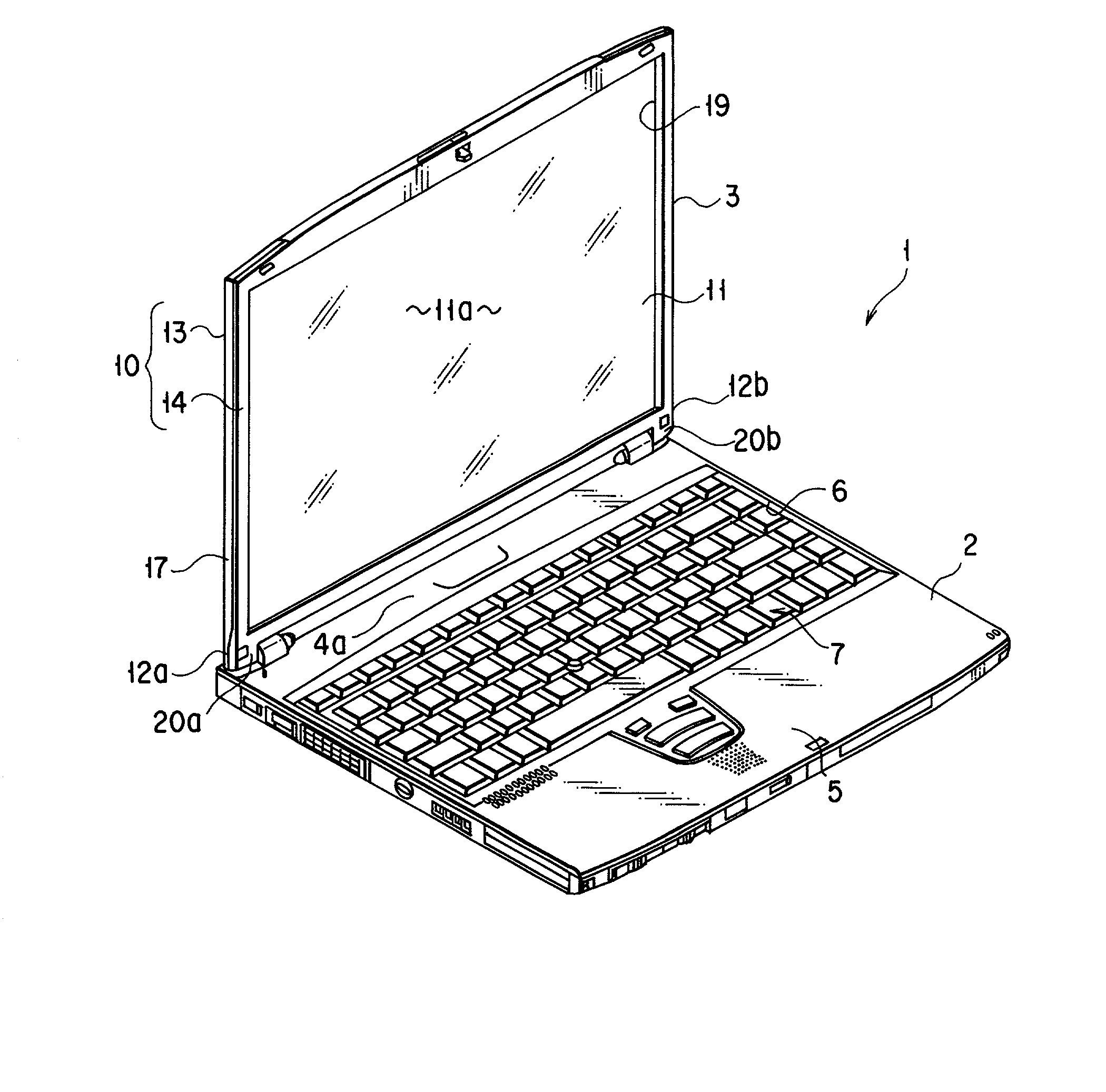

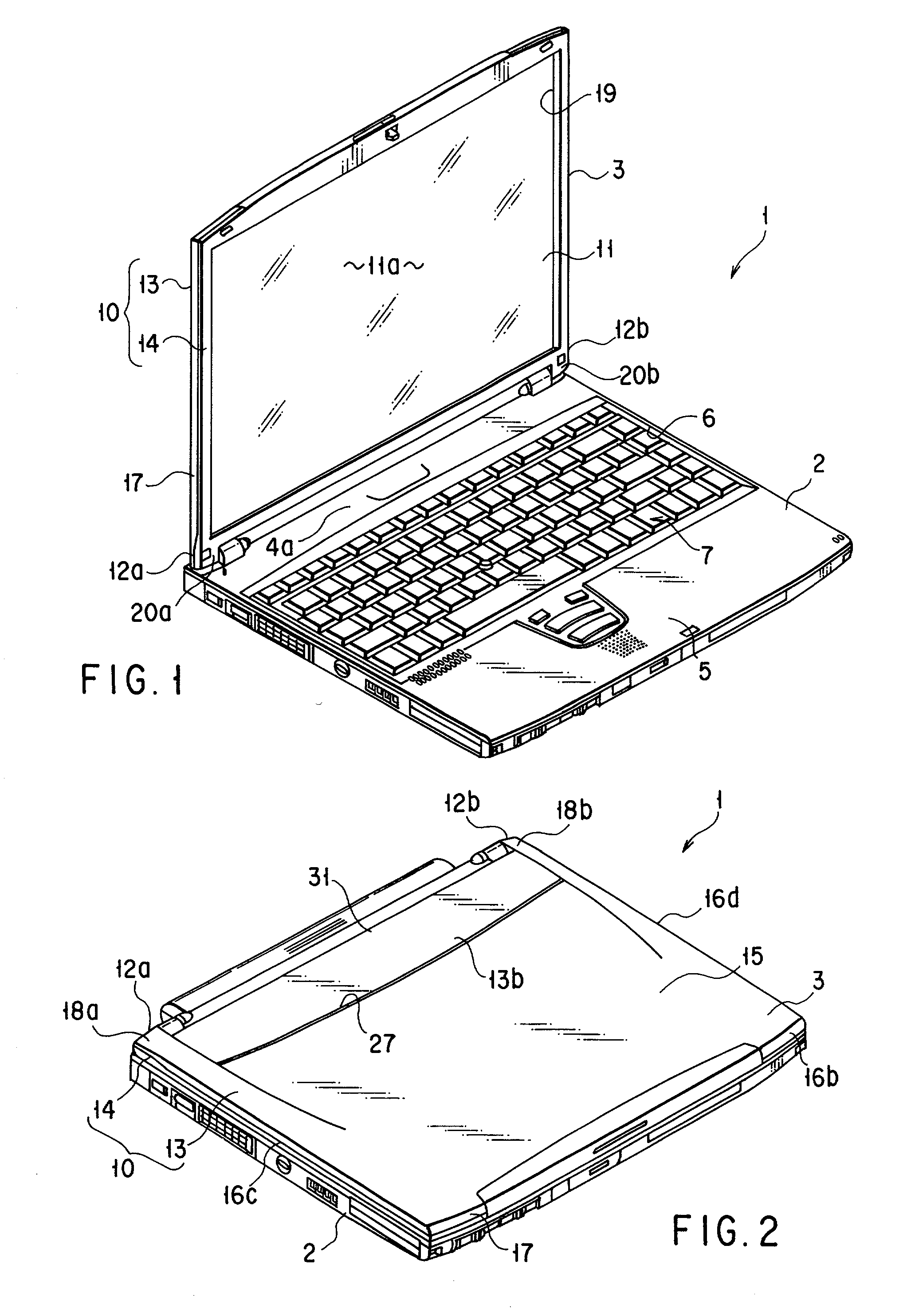

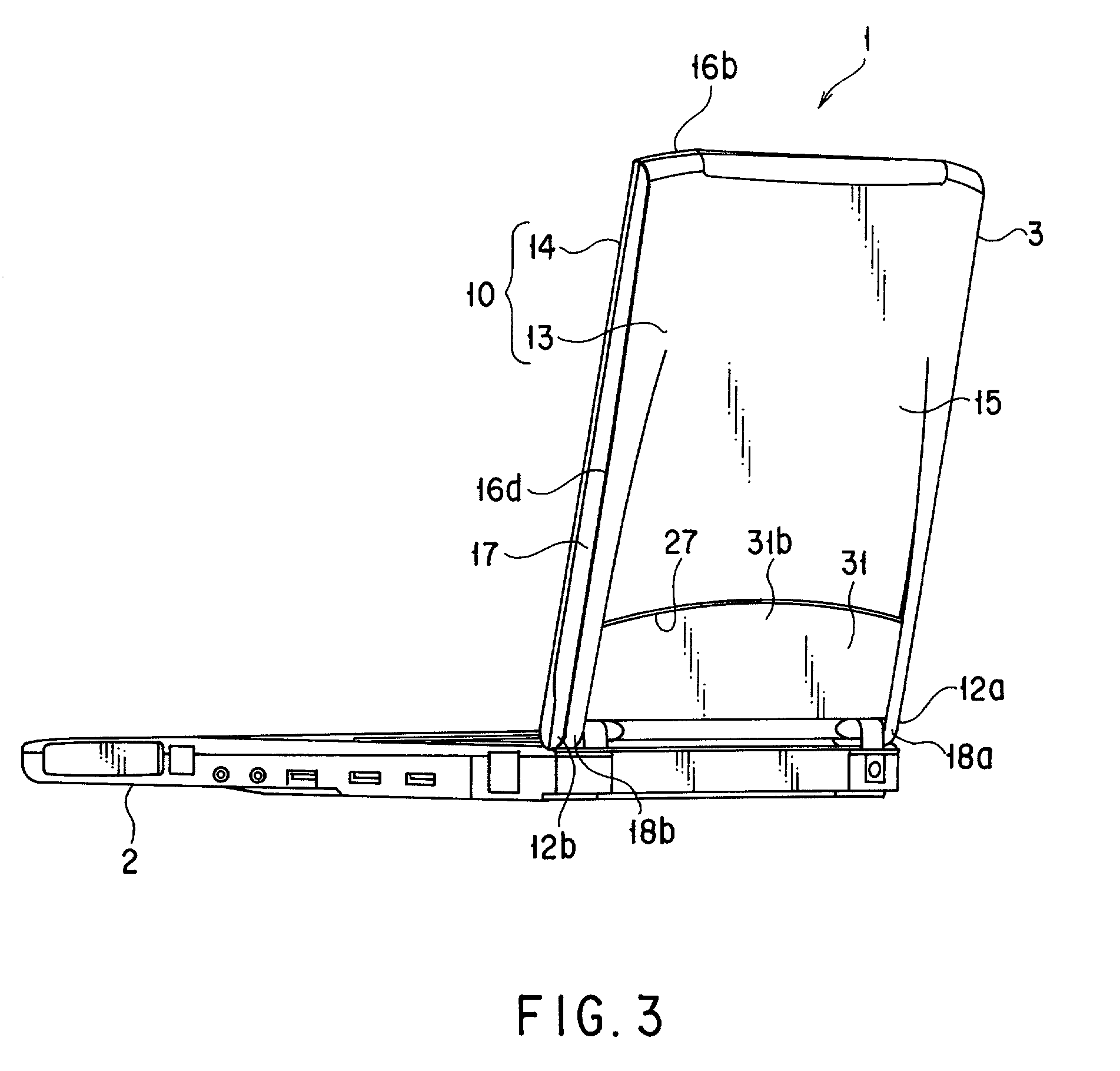

Housing for electronic apparatus having outer wall formed by injection molding

InactiveUS20020126445A1Improve productivityLow production costMetal rolling stand detailsFoundry mouldsMetallic materialsInjection molding machine

The housing used in the electronic apparatus has an outer wall. The outer wall is formed by injecting a metal material from a plurality of gates into a molding space in a metal die. The outer wall includes a first end portion situated on an upstream end along a flowing direction of the metal material, a second end portion situated on a downstream end of the flowing direction of the metal material, and an injection portion formed on the first end portion where the plurality of gates of the metal die are situated, forming a space between the first end portion and the injection portion.

Owner:KK TOSHIBA

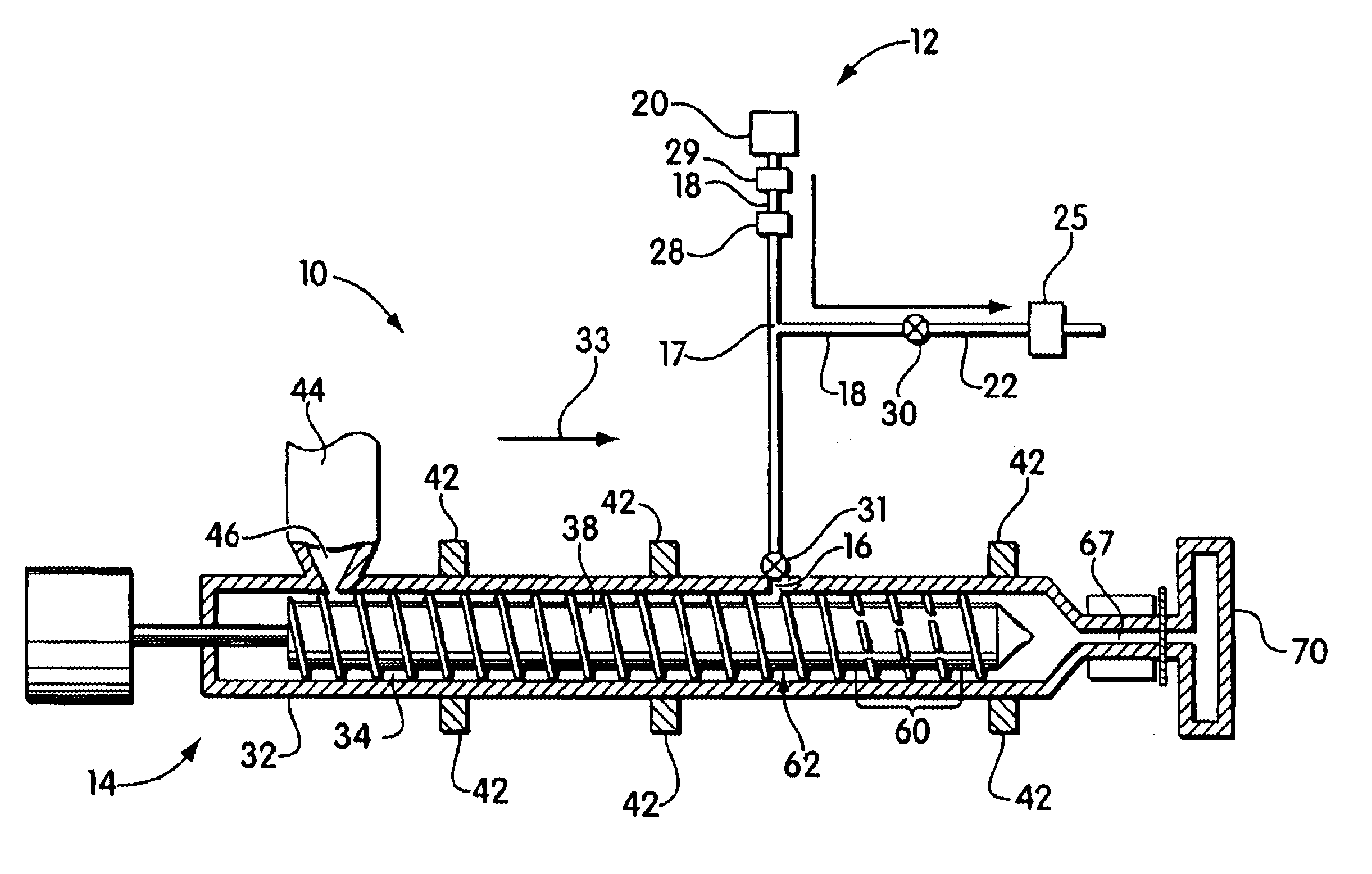

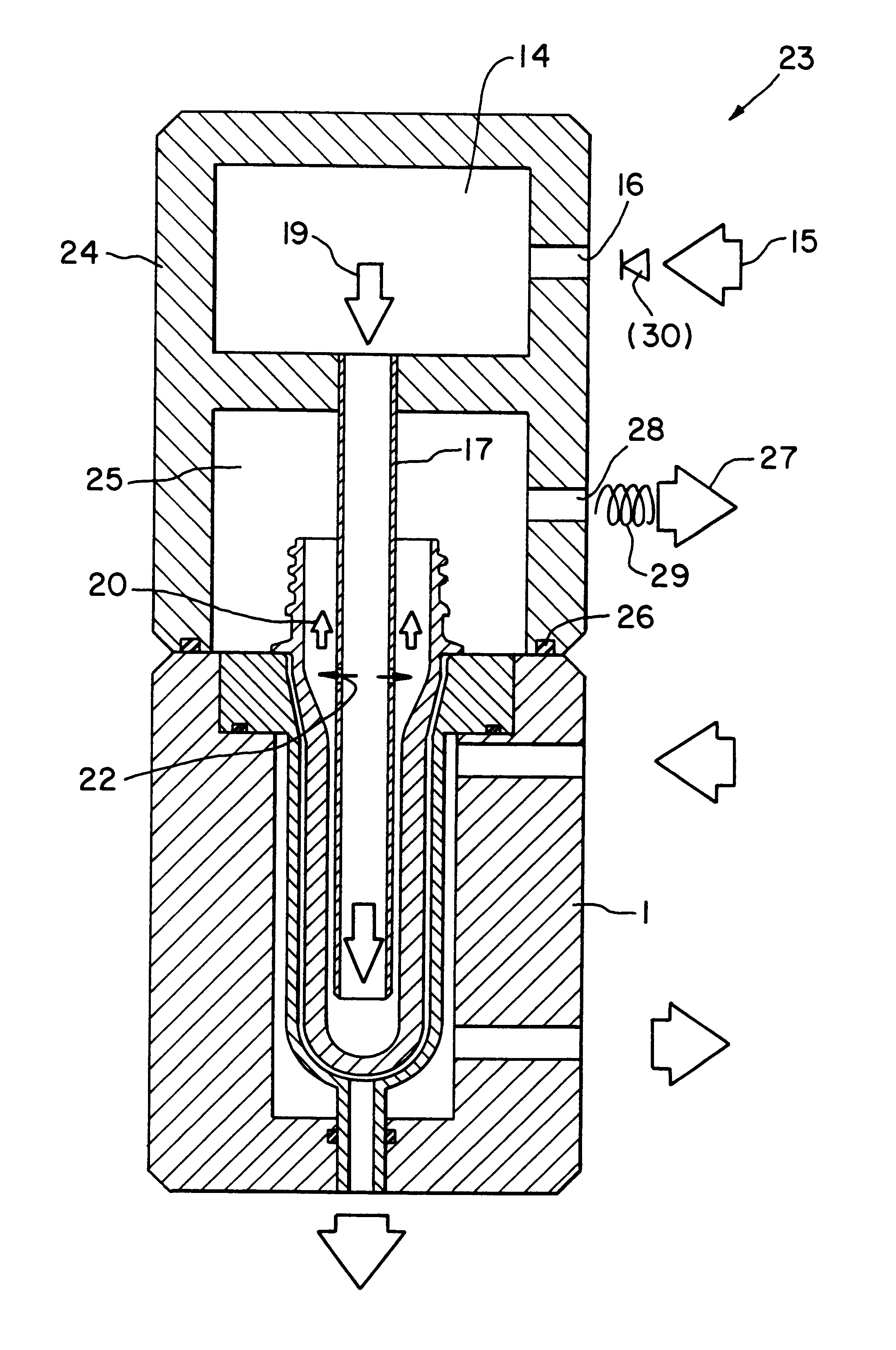

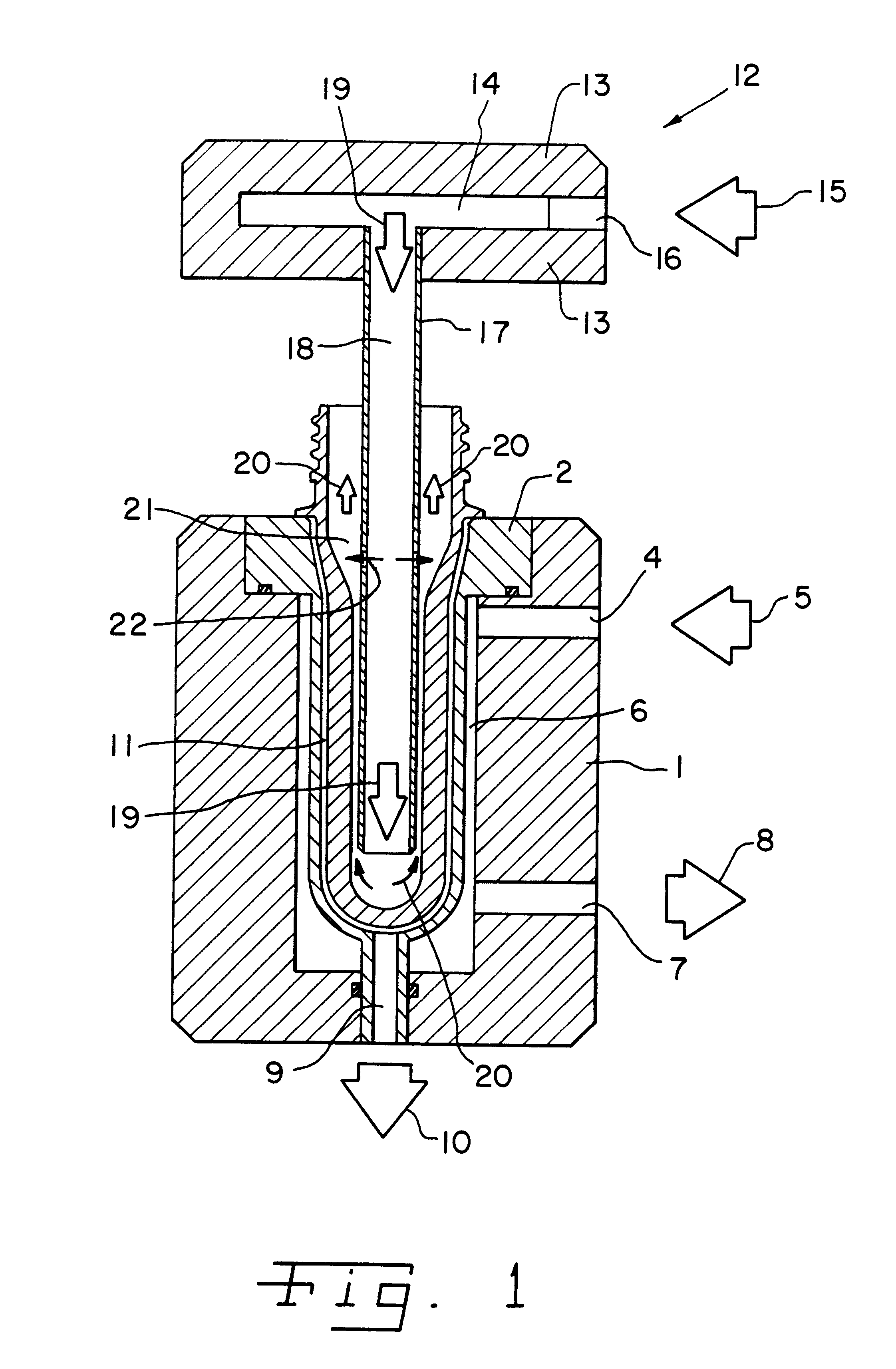

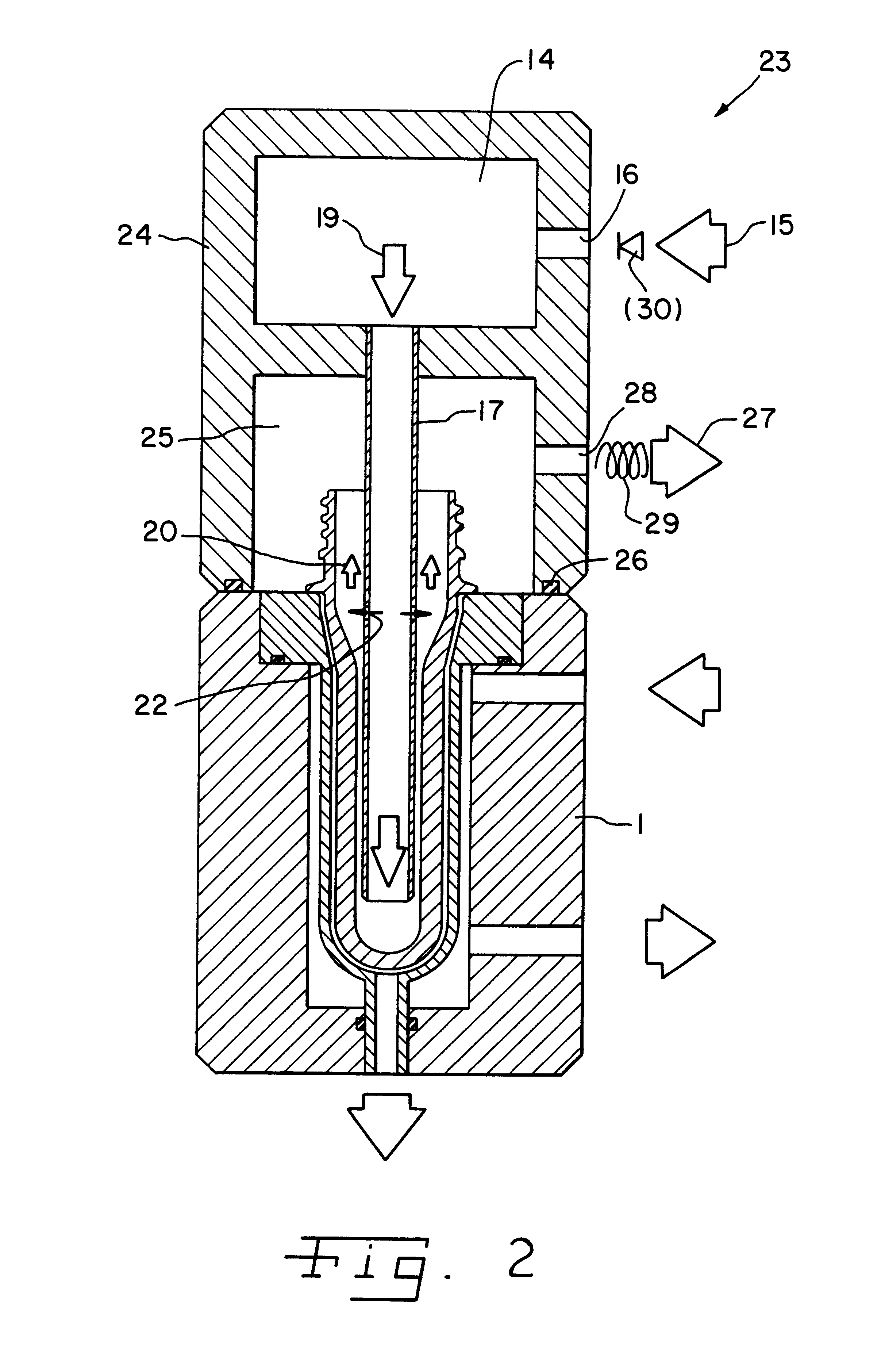

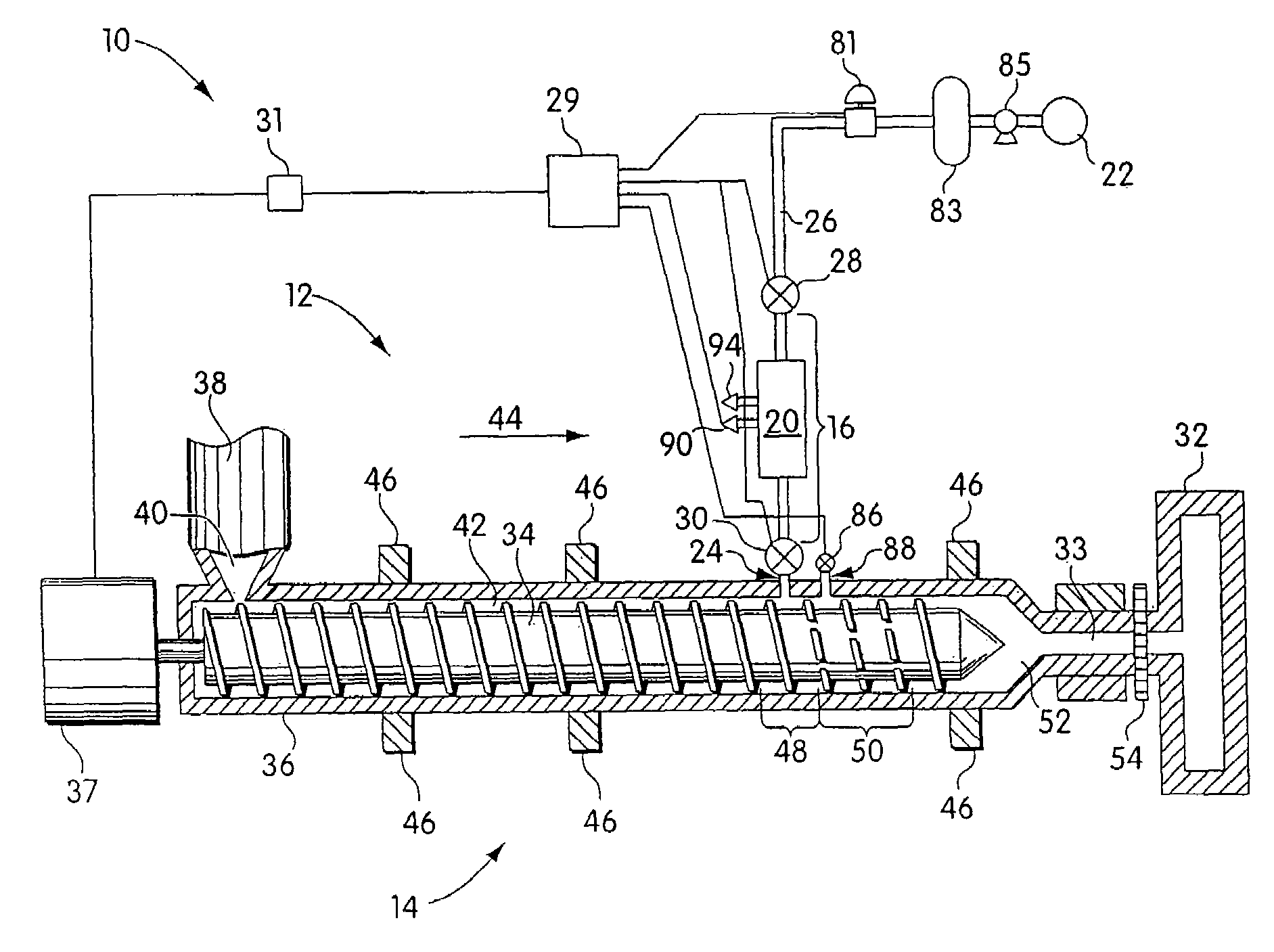

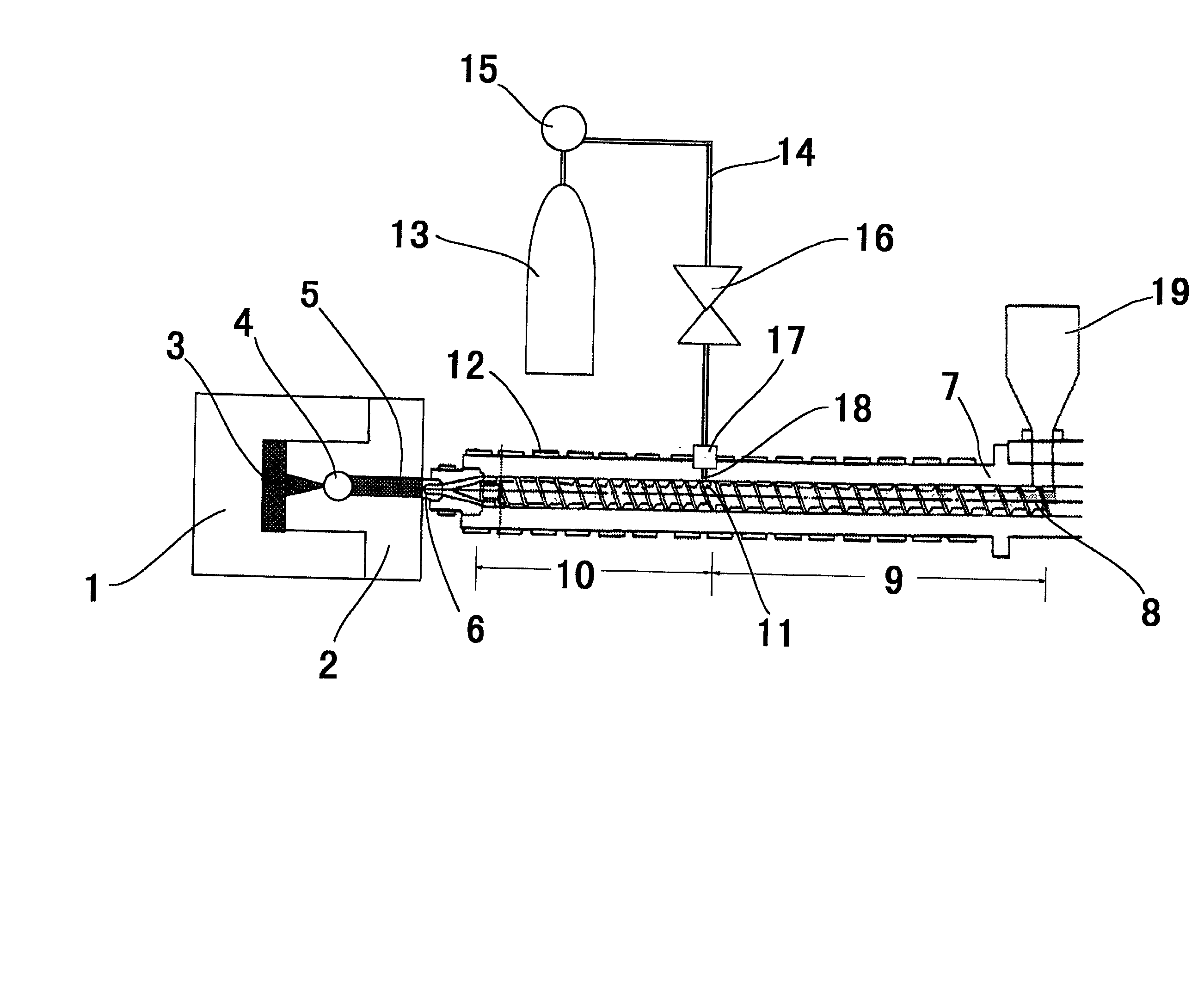

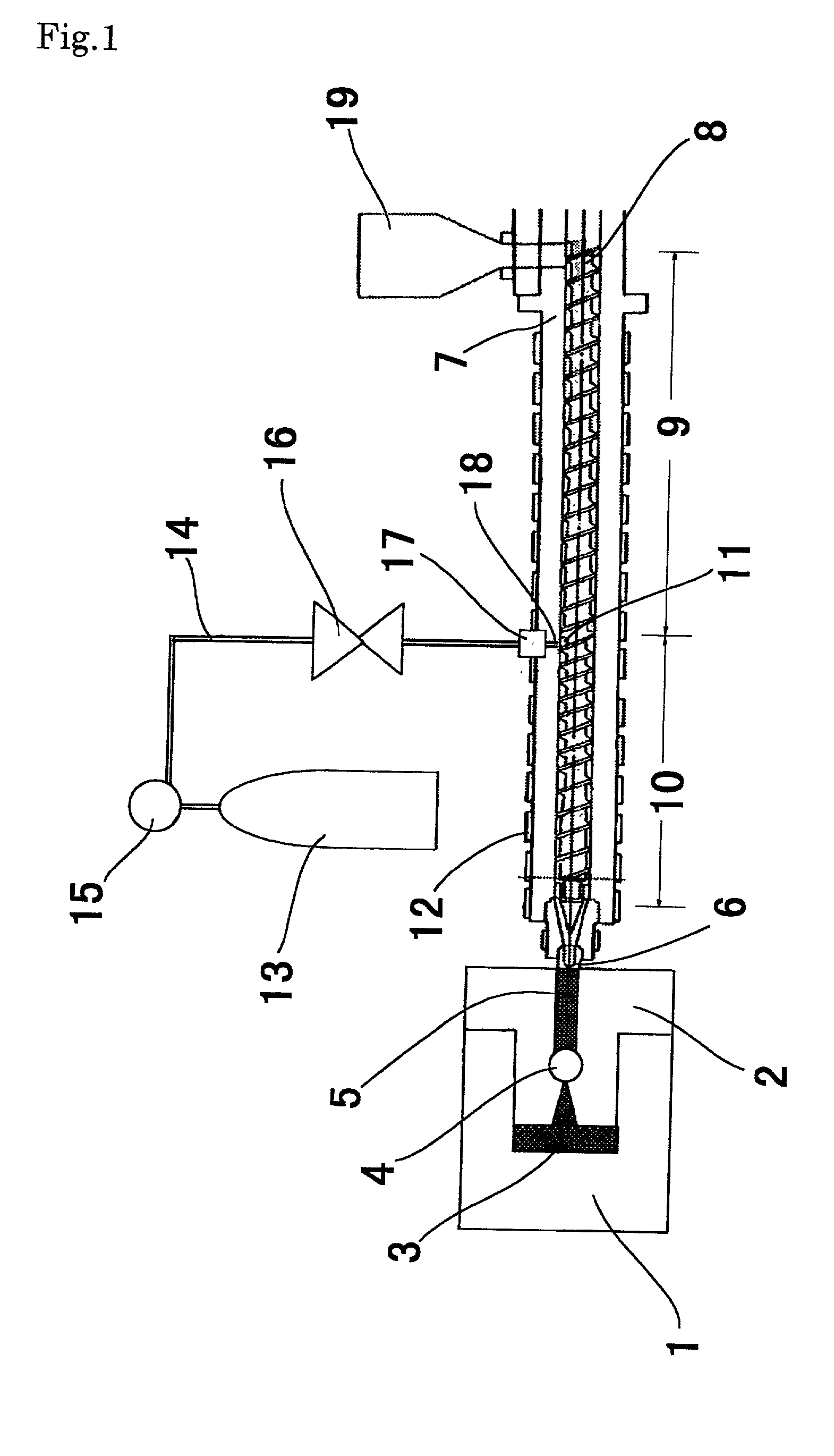

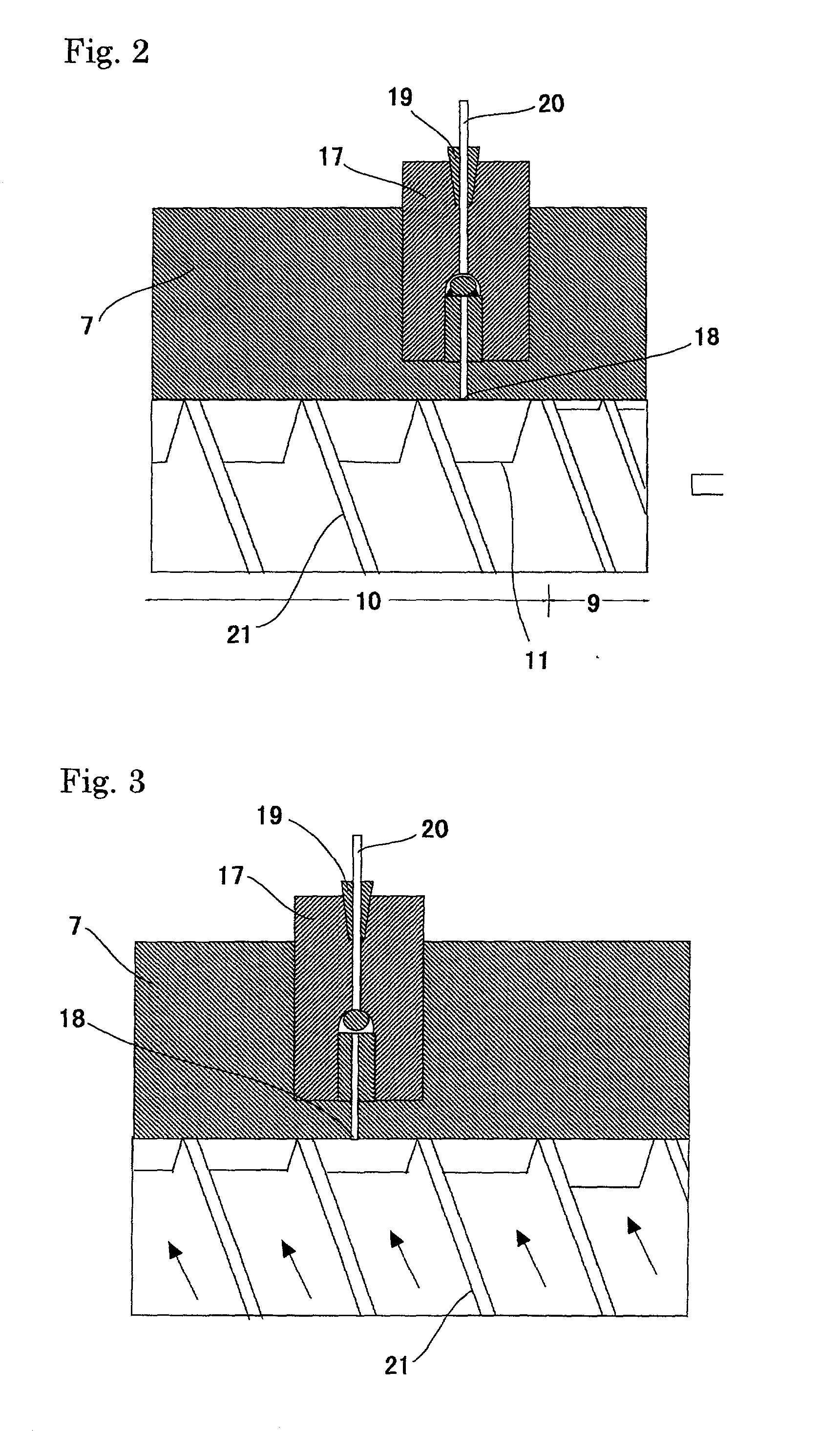

Blowing agent delivery system

InactiveUS6926507B2Easy to controlPrevents output inconsistencyAuxillary shaping apparatusFood shapingBlow moldingInjection molding machine

The invention provides a blowing agent delivery system for introducing a blowing agent into a polymeric foam processing system. The delivery system is designed to discontinuously introduce blowing agent from a continuous source into polymeric material within an extruder. The system, thus, may improve control over blowing agent delivery in discontinuous polymer processing systems such as injection molding or blow molding. In some embodiments, the blowing agent delivery system selectively directs blowing agent flow from the source to the extruder barrel, or through a bypassing passageway. In this manner, blowing agent may be continuously supplied by the source but discontinuously injected into the extruder barrel. During use, the delivery system may cause blowing agent to flow through the bypassing passageway, for example, when the screw stops plasticating polymeric material.

Owner:TREXEL

Method and device for the after-cooling of a preform in the injection molding process

InactiveUS6223541B1Avoid vibrationUndesired vibrationLighting and heating apparatusFood shapingInjection mouldingInjection molding machine

The present invention relates to improving the after-cooling process of preforms from the injection molding process in respect to its efficiency and its economy.

Owner:FARRAG RAINER

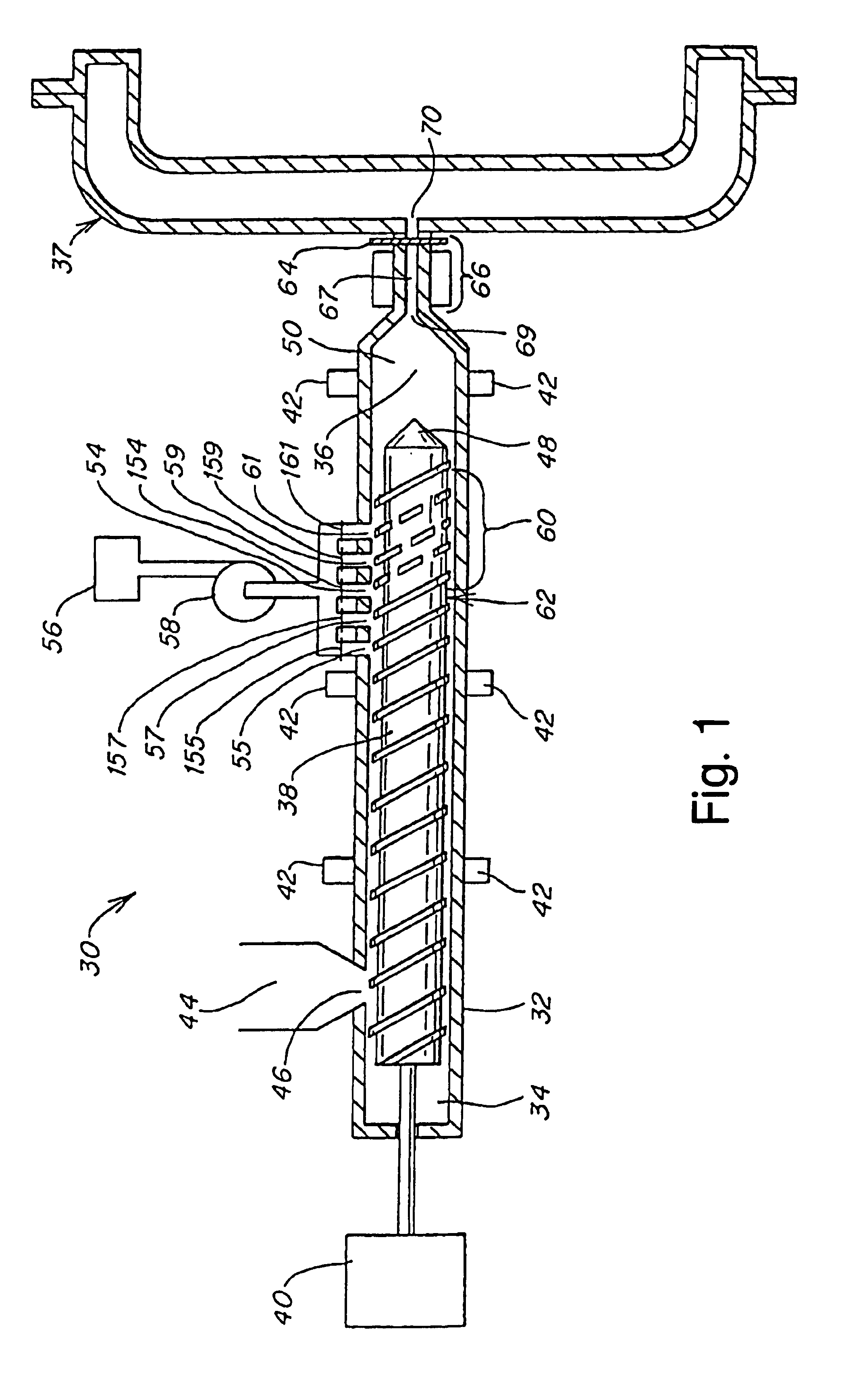

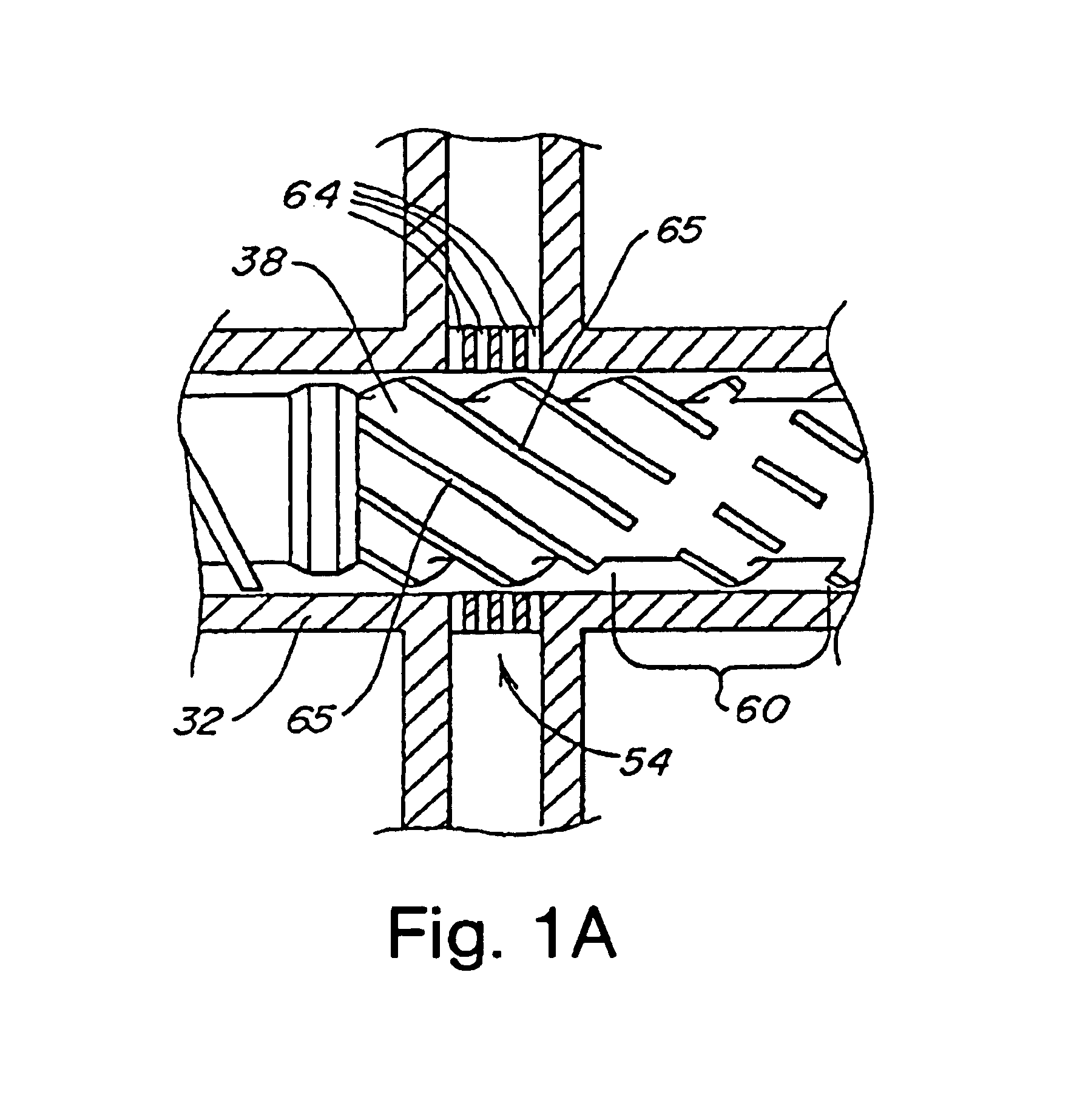

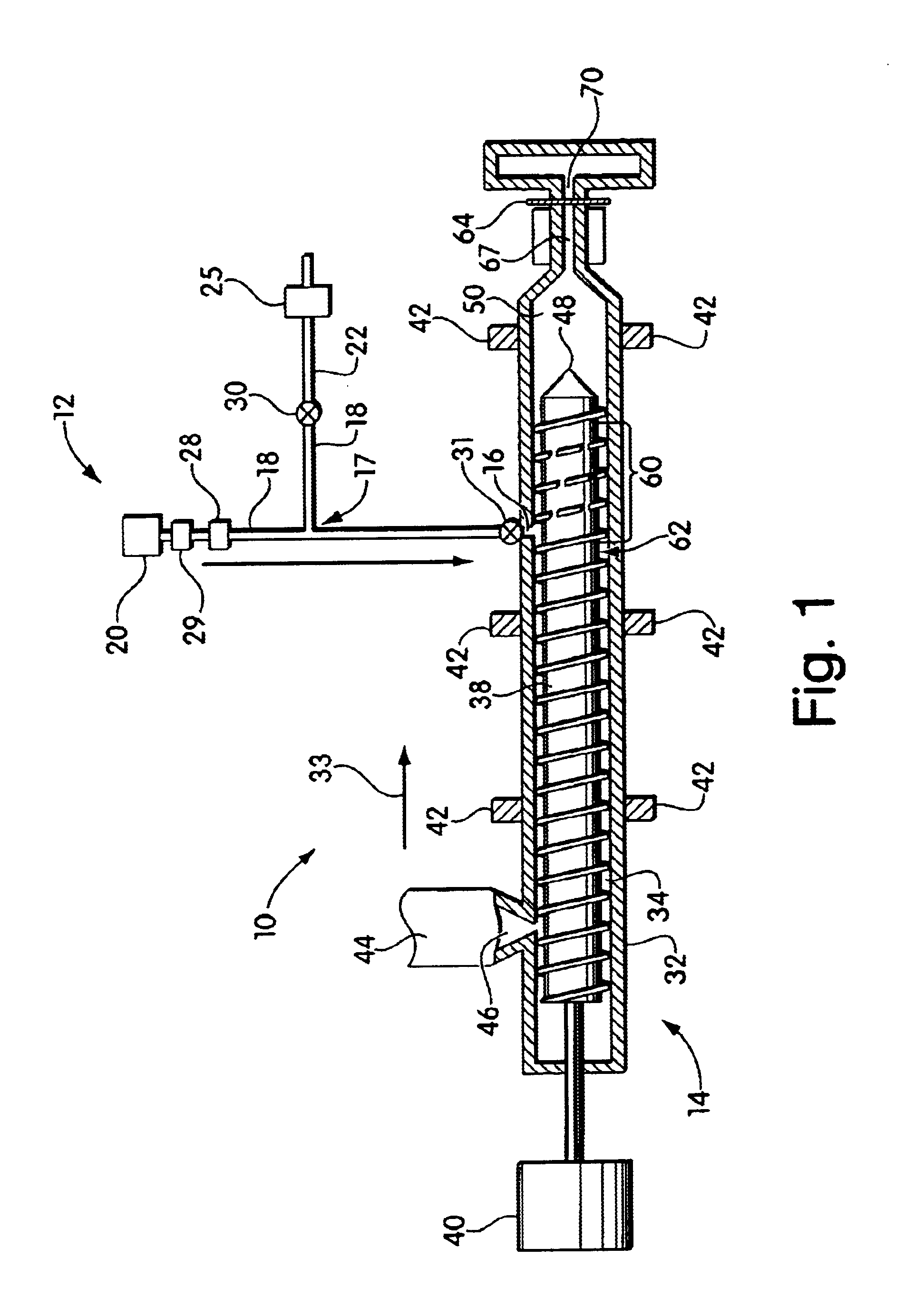

Blowing agent introduction systems and methods

The present invention provides blowing agent introduction systems and methods for introducing blowing agent into polymeric foam processing systems. The methods may involve introducing one or more doses of blowing agent into polymeric material in an extruder during a plastication period of a molding cycle. Prior to introduction, a dose is confined in an accumulator which, for example, has a volume defined between an inlet valve and an outlet valve. A control system may receive inputs related to system parameters (e.g., pressure of polymeric material in extruder, axial position of screw in barrel, whether screw is rotating, and the like) and based on the inputs coordinates operation of the valves to confine and introduce the blowing agent dose(s). The introduction systems may be used in discontinuous plasticating processes, such as injection molding and blow molding, and can be particularly useful in processes that use precise quantities of blowing agent.

Owner:TREXEL

Metal powder injection moldable composition, and injection molding and sintering method using such composition

InactiveUS6051184AHigh strengthAvoid deformationTransportation and packagingMetal-working apparatusPolyoxymethyleneInjection molding machine

A metal powder injection moldable composition which hardly causes debinding deformation is obtained. This composition consists of a metal powder and an organic binder. The components which constitute the organic binder are: a. polyoxymethylene having a Vicat softening temperature A> / =150 DEG C., b. polypropylene having a Vicat softening temperature B> / =130 DEG C., c. an organic compound whose viscosity at said Vicat softening temperature A ( DEG C.) is not more than 200 mPaxs, and d. a thermoplastic resin whose Vicat softening temperature is not higher than said B ( DEG C.).

Owner:IHI CORP

Process for manufacturing an electromagnetic interference shielding metallic foil cladded plastic product

The present invention provides a process and apparatus for manufacturing an electromagnetic interference shielding metallic foil cladded plastic product. The process comprises (a) coating one side of a superplastic alloy plate with a coupling agent or a hot melt adhesive; (b) placing the coupling agent- or hot melt adhesive-coated superplastic alloy plate in a mold, and superplastically forming the superplastic alloy plate to a superplastic alloy foil with a predetermined shape, such that another side of the superplastic alloy foil is attached to the mold and the coupling agent- or hot melt adhesive-coated side of the superplastic alloy foil is spaced apart from the mold to form a mold cavity, wherein an injection machine is attached to the mold cavity, and wherein the injection machine is capable of injecting softened plastic into the mold cavity; (c) introducing softened plastic from the injection machine to the mold cavity, such that plastic adheres on the coupling agent- or hot melt adhesive-coated side of the superplastic alloy foil, and an electromagnetic interference shielding metallic foil cladded plastic product is formed; and (d) removing the plastic product from the mold. The final metallic plastic product can not only have as intricate a shape as an ordinary plastic product, but also has a shielding effectiveness as high as an ordinary metallic shield.

Owner:NAT SCI COUNCIL

Metal-like engineering plastic composite material and preparation method thereof

The invention discloses a metal-like engineering plastic composite material and a preparation method thereof, and relates to a polymer composite material. The invention provides the metal-like engineering plastic composite material which combines plastic with metal and simultaneously keeps the advantages of the two and the preparation method thereof. The composite material comprises thermoplastic engineering plastic, high-density packing, mineral powder, glass fiber, toughener, coupling agent, lubricant and antioxidant. The metal-like engineering plastic composite material has high density, high mechanical properties, excellent thermal deformation temperature and good injection molding property. The preparation method adopts the method of being combined with the coupling agent and the optimized granulation conditions, the process is simple and easy to operate, extrusion and granulation can be carried out by adopting an ordinary twin-screw granulator, and injection molding can be carried out by adopting an ordinary injection machine.

Owner:XIAMEN RUNNER IND CORP

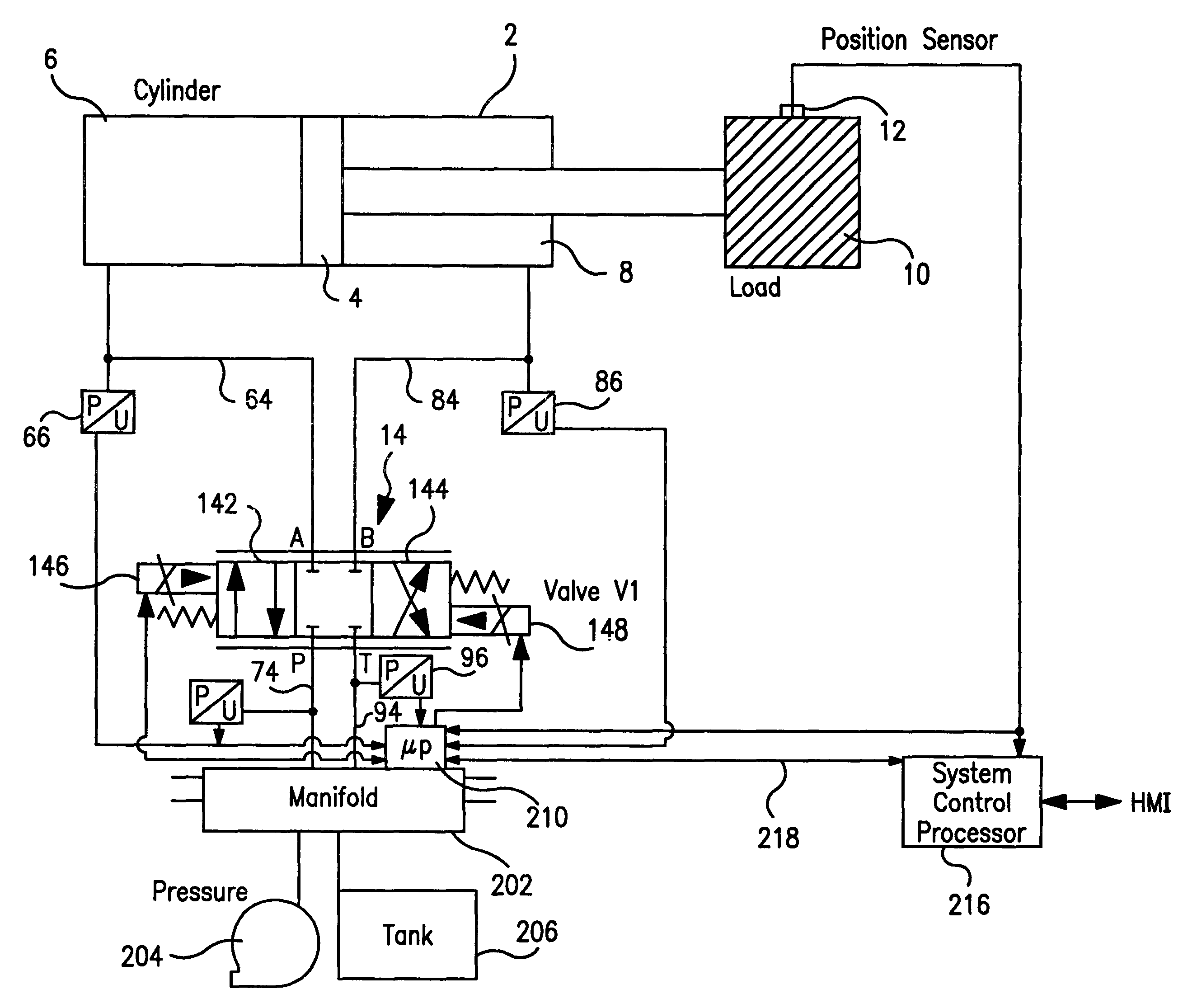

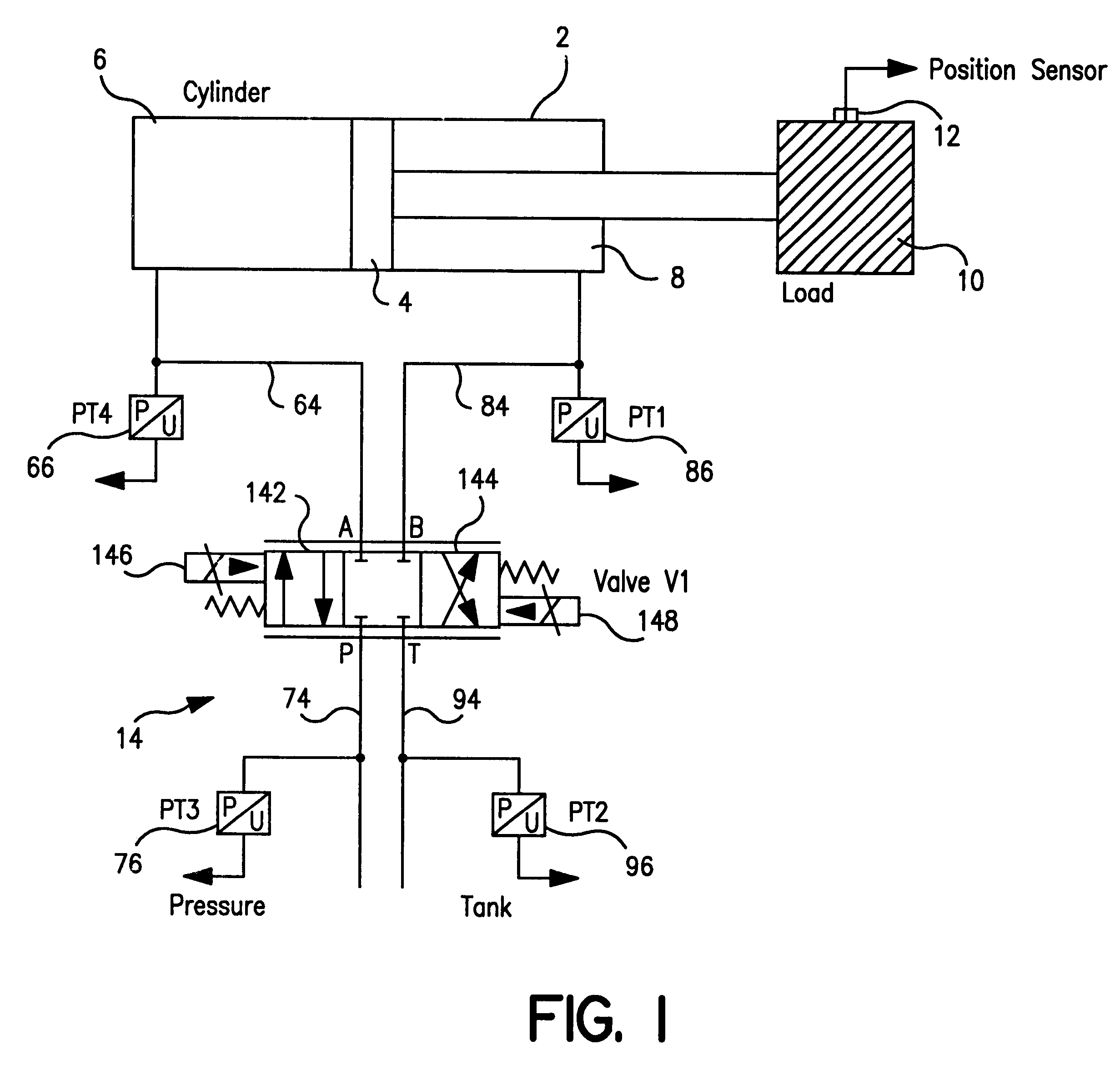

Intelligent hydraulic manifold used in an injection molding machine

Apparatus and method for controlling a hydraulic actuator in an injection molding machine, where the hydraulic actuator moves in a linear or rotary manner to effect movement of an injection molding device, such as a mold clamp. A microcontroller is locally disposed adjacent to the actuator or the hydraulic fluid distribution manifold to cause the actuator to drive the device. The microcontroller is electrically coupled to the system control processor. This distributed control architecture increases system processing throughput, enhances reliability, and permits easier upgrades / repair. Preferably, the microcontroller is mounted on the manifold and controls all of the actuators supplied from that manifold.

Owner:HUSKY INJECTION MOLDING SYST LTD

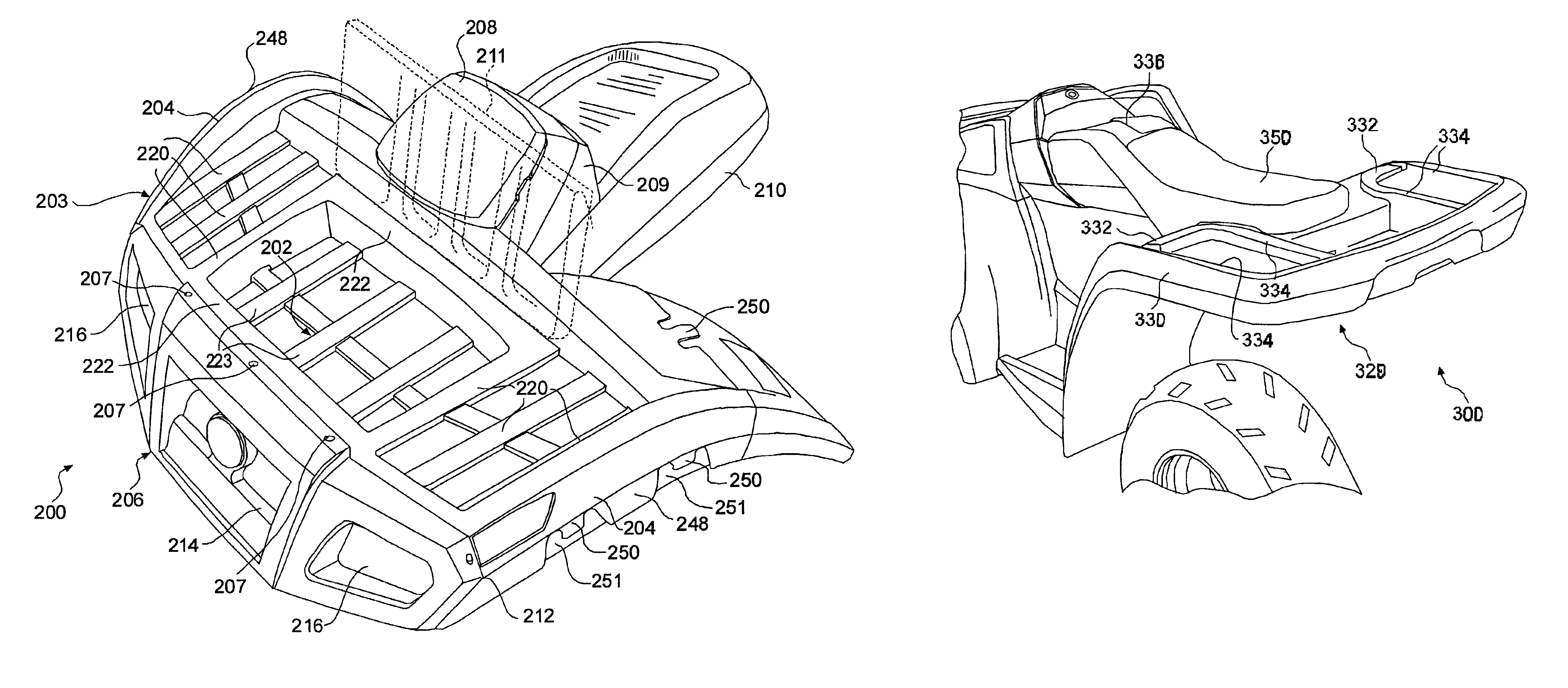

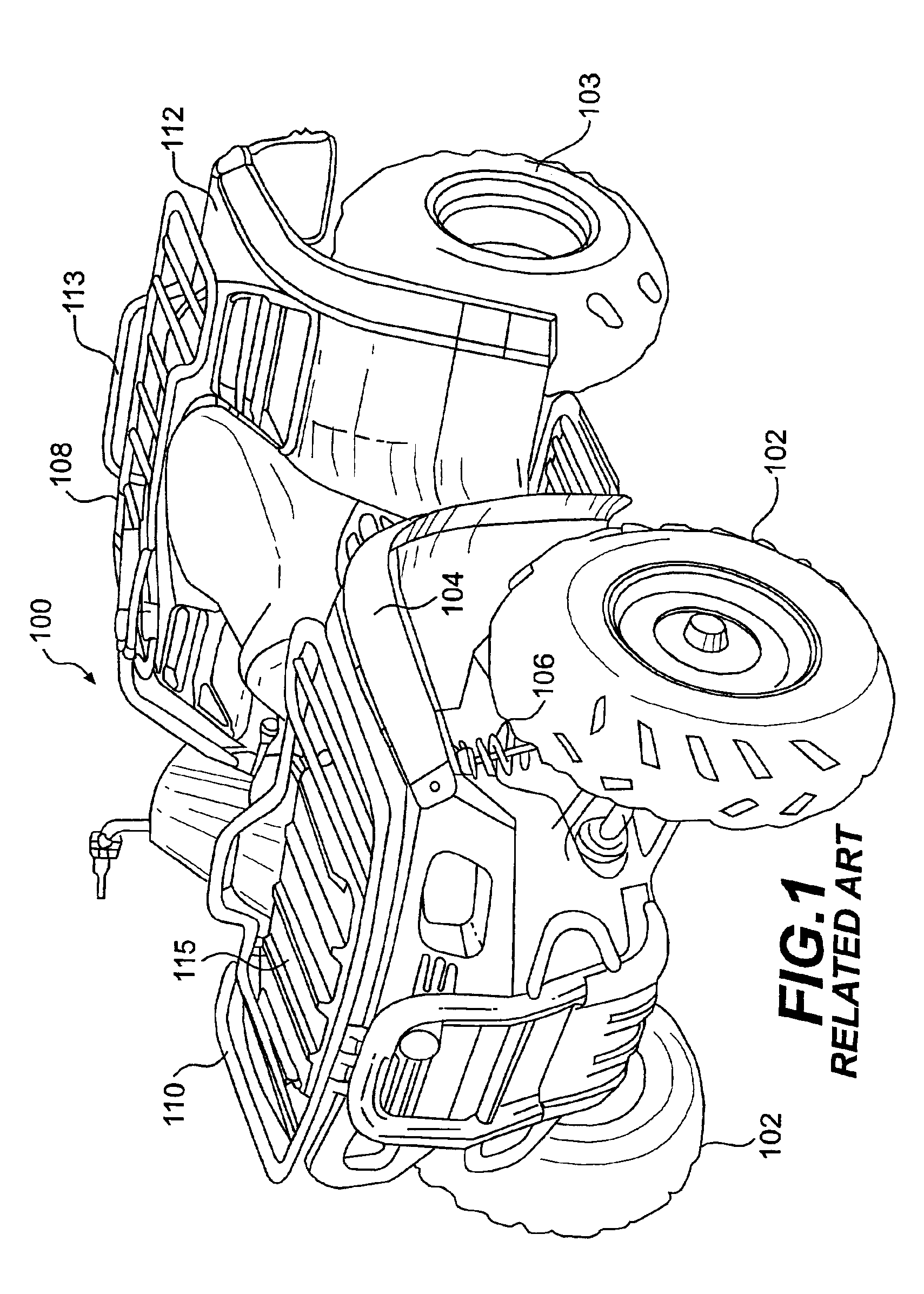

Fender structure for an all terrain vehicle

An all terrain vehicle (ATV) includes a plurality of wheels and a fender structure positioned over the wheels having a support portion designed as and defining a load-bearing surface. The fender structure may include a plurality of raised support portions that increase rigidity and load capacity. Additionally, it is not necessary to support either the fender structure or the support portion using the bumper of the ATV. The fender structure may be formed with plastic material, such as polyethylene, polypropylene or fiberglass-charged polyethylene, and may be manufactured using a blow-molding technique or an injection molding technique. The ATV may also include mud guards and a floor board that extends between the mud guards. The mud guards and the floor board may be formed as an integral or one piece unit with the fender structure. The mud guards can be injection molded or blow-molded while the fender structure can be blow-molded.

Owner:BOMBARDIER RECREATIONAL PROD INC

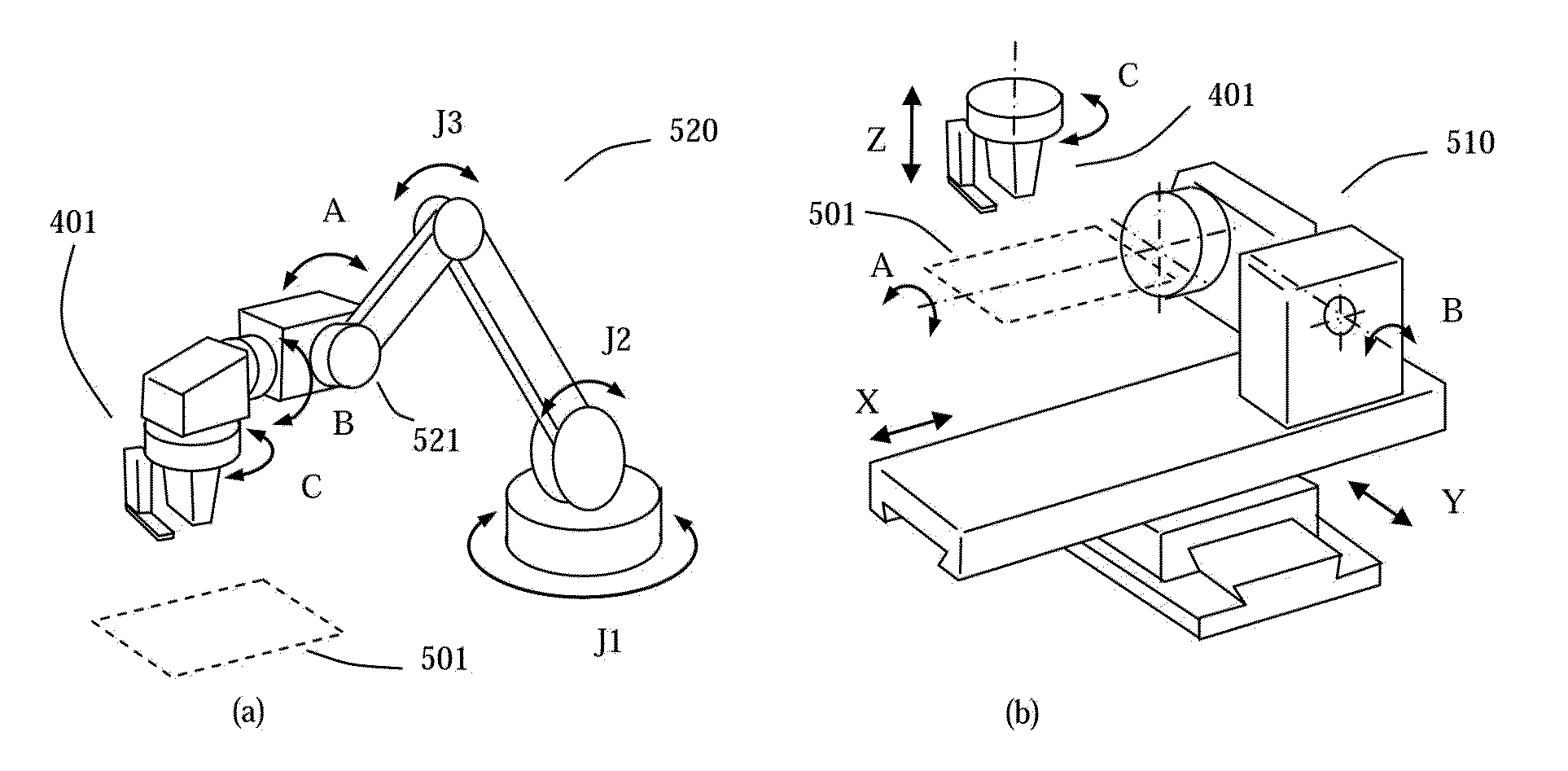

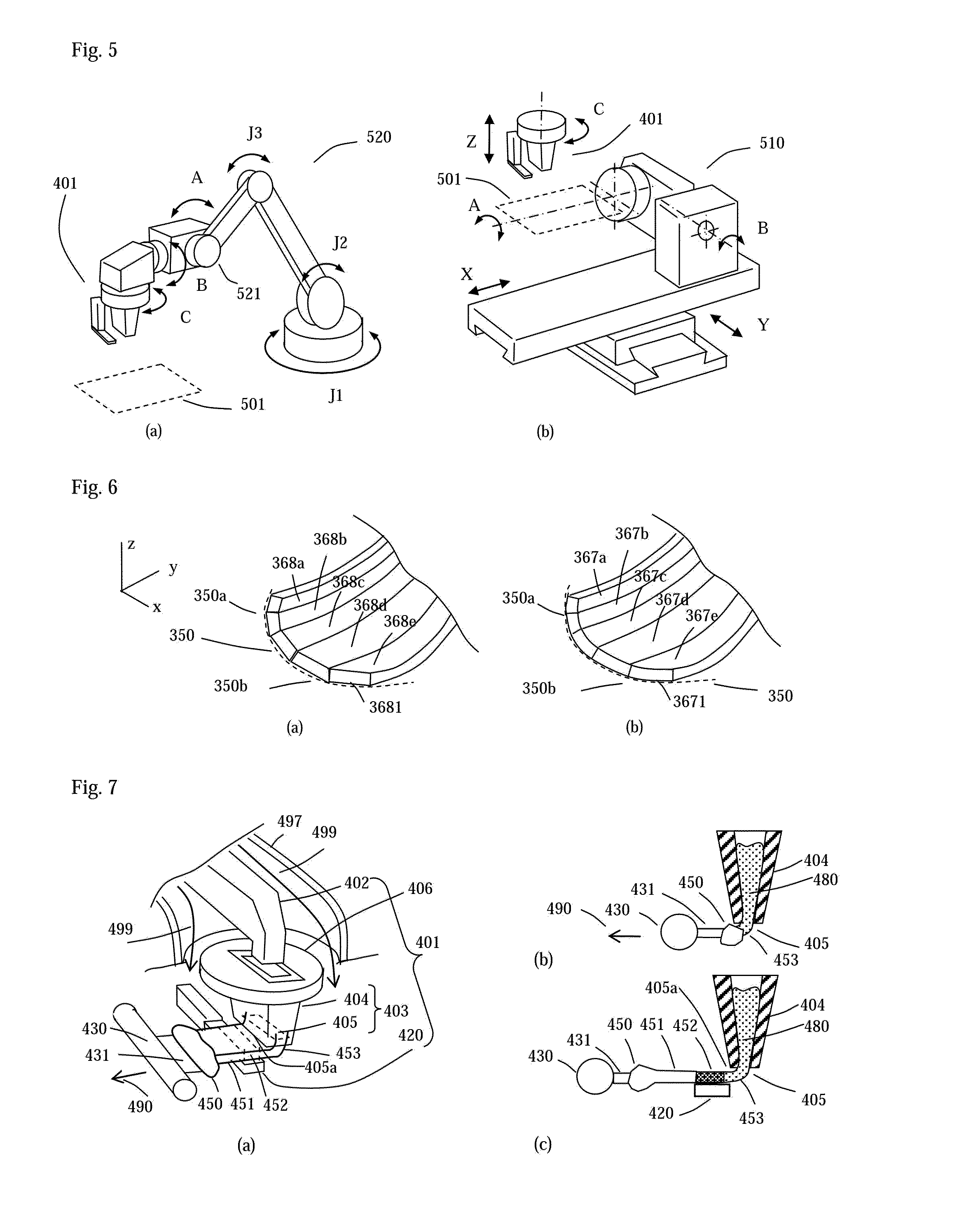

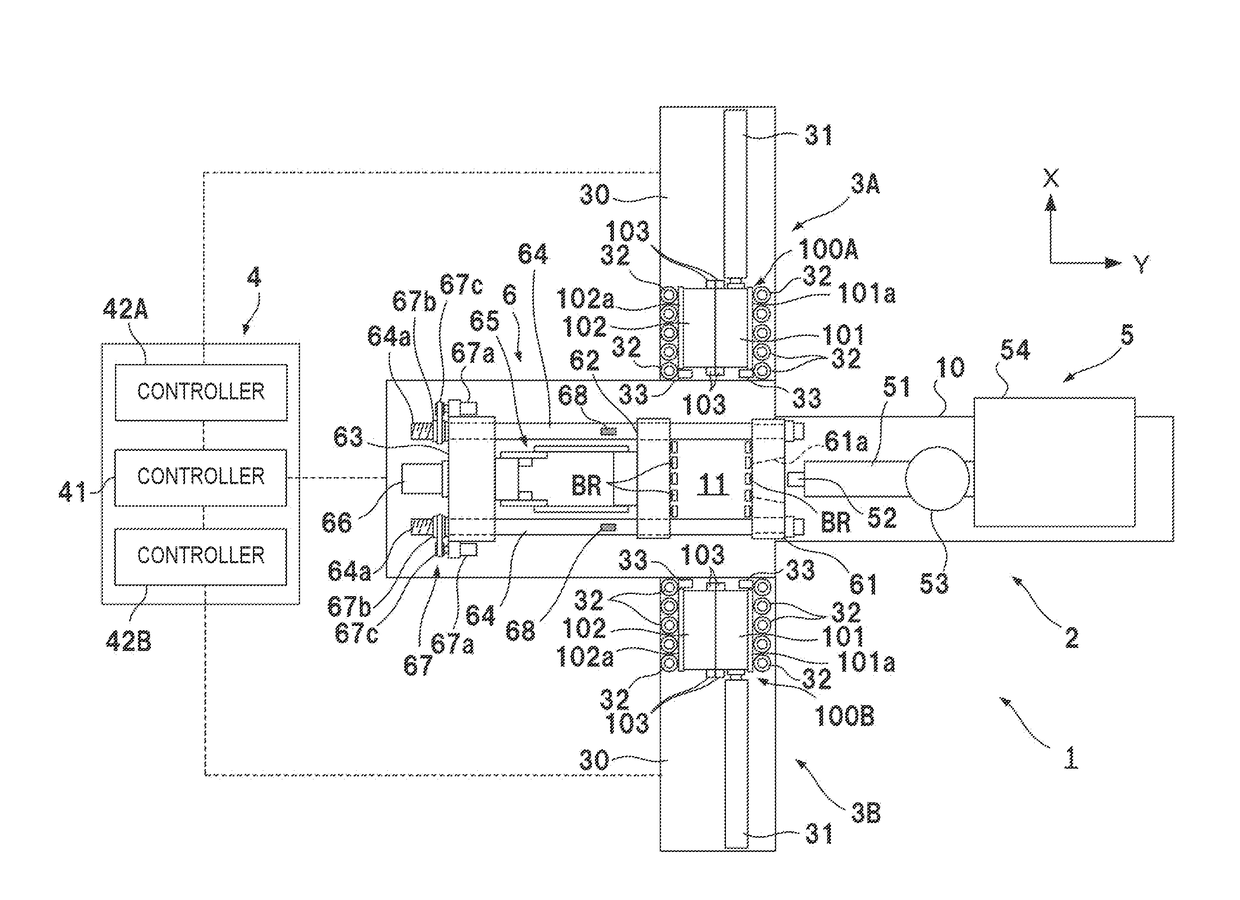

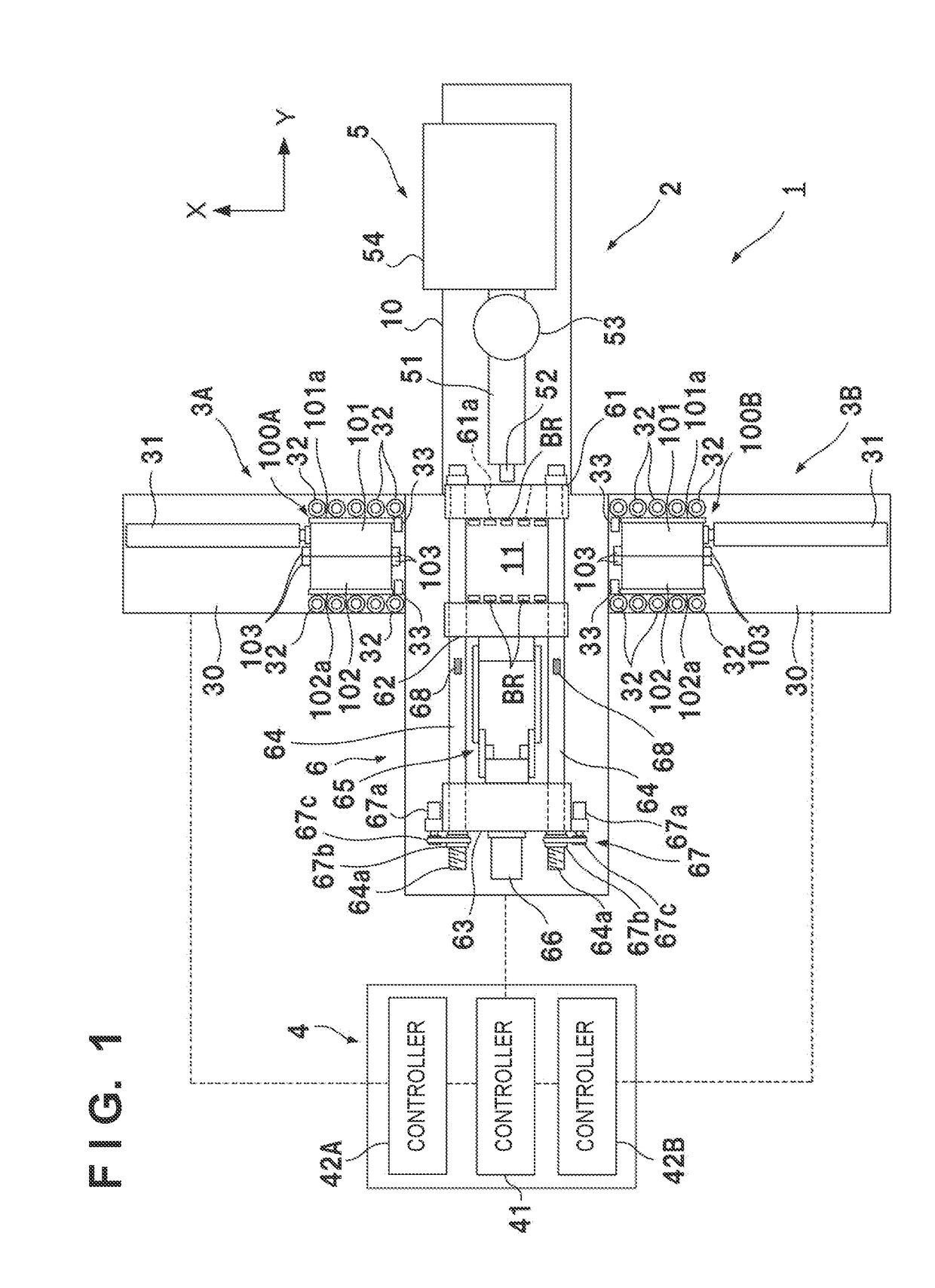

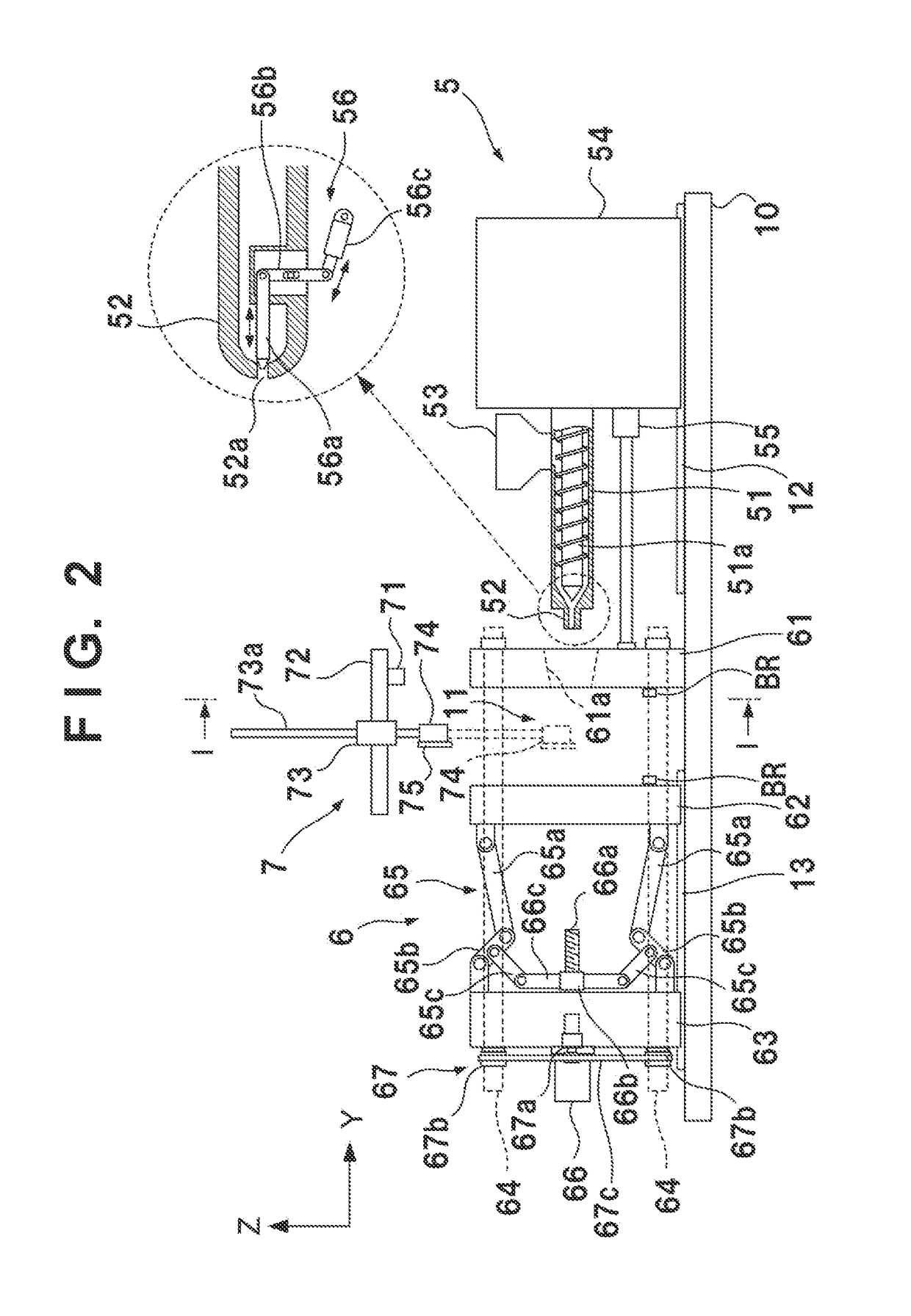

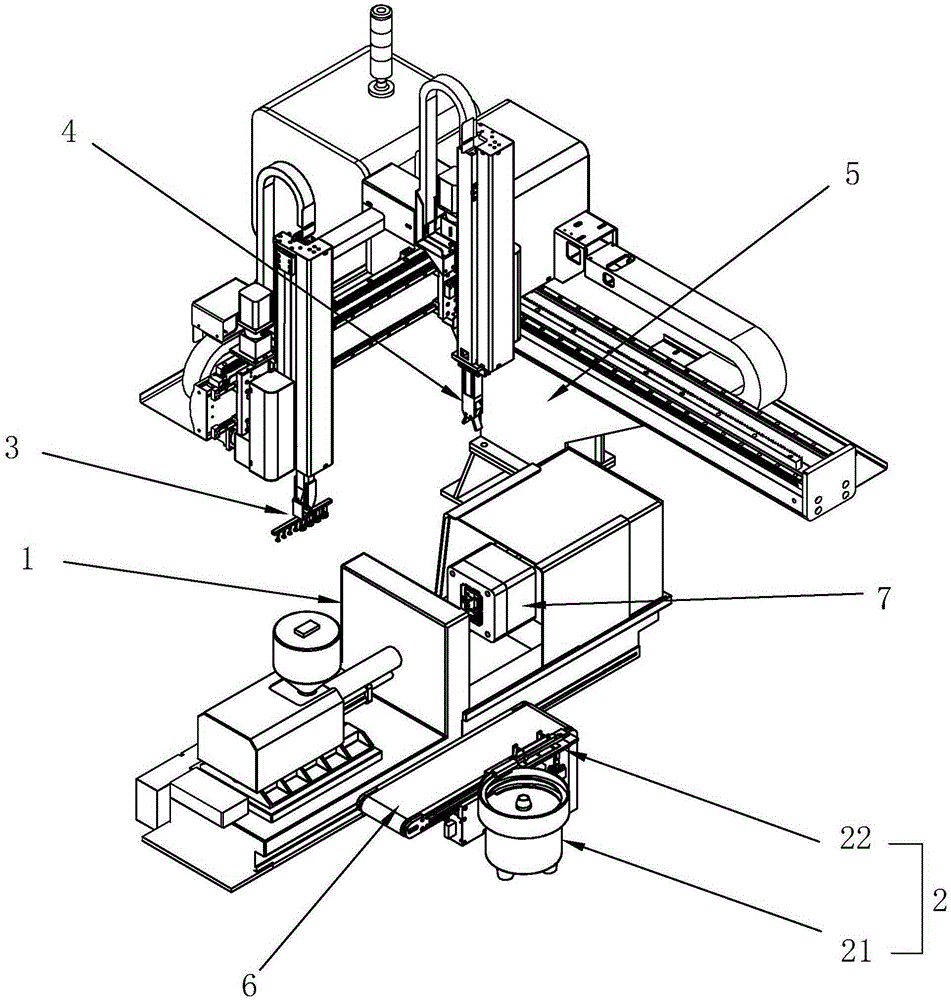

Manufacturing method and injection molding system

ActiveUS20180009146A1Improve productivityIncrease equipment costInjection molding machineMechanical engineering

A method including a first step of performing clamping of a mold, injection and dwelling in an injection molding machine, a second step of performing a conveyance and a cooling of the mold outside of the machine, and a third step of performing a conveyance of the mold into the machine, an opening of the mold and an ejection of a molded part in the machine. The second step is performed for a first mold, the third step and the next first step are performed for a second mold. The first mold is conveyed by a first conveyance apparatus which is arranged on one lateral side of the machine. The second mold is conveyed by a second conveyance apparatus which is arranged on the other lateral side and is independently driven from the first conveyance apparatus.

Owner:CANON KK

Molding system using film heaters and/or sensors

Improved mold manifold and hot runner nozzle using thin film elements include at least one active or passive thin film element disposed along a melt channel between the manifold inlet and the hot runner nozzle. Preferably, the thin film element may comprise a thin film heater in direct contact with the molten resin and position to aid in the heat and flow management of the resin within the melt channel. Thin film temperature sensors, pressure sensors, and leak detectors may also be provided in the vicinity of the melt channel to enhance process control in the injection molding machine.

Owner:HUSKY INJECTION MOLDING SYST LTD

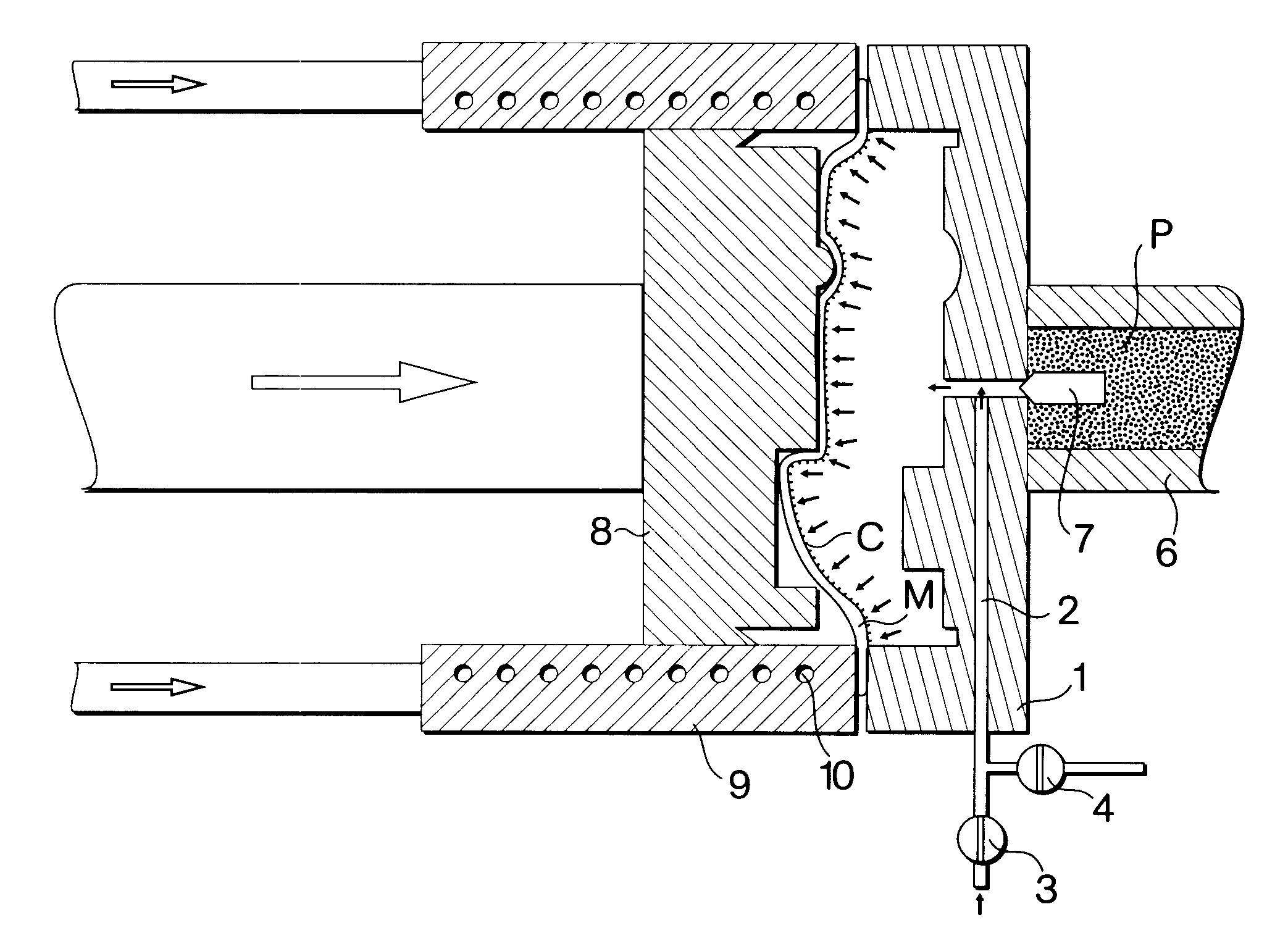

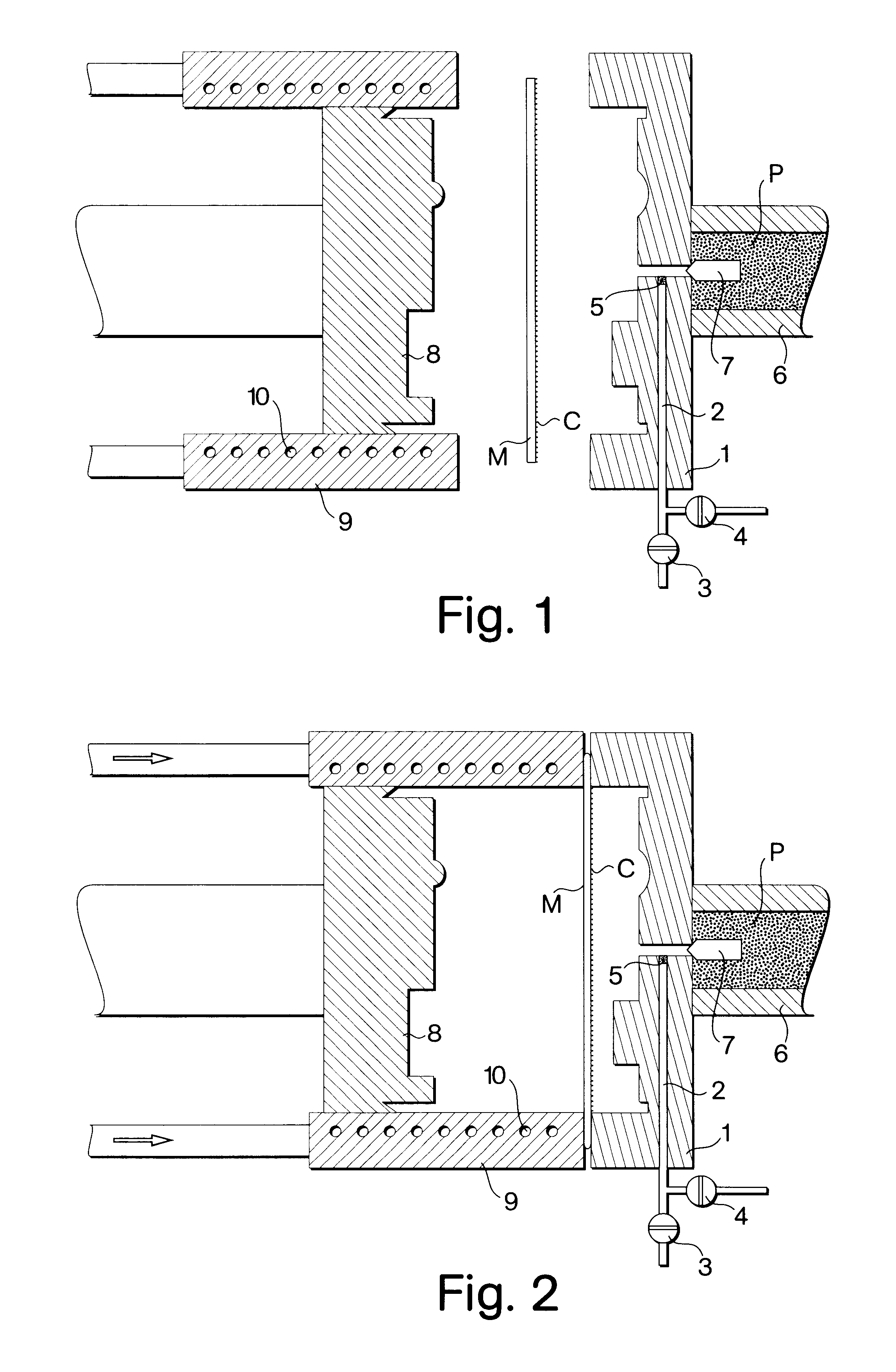

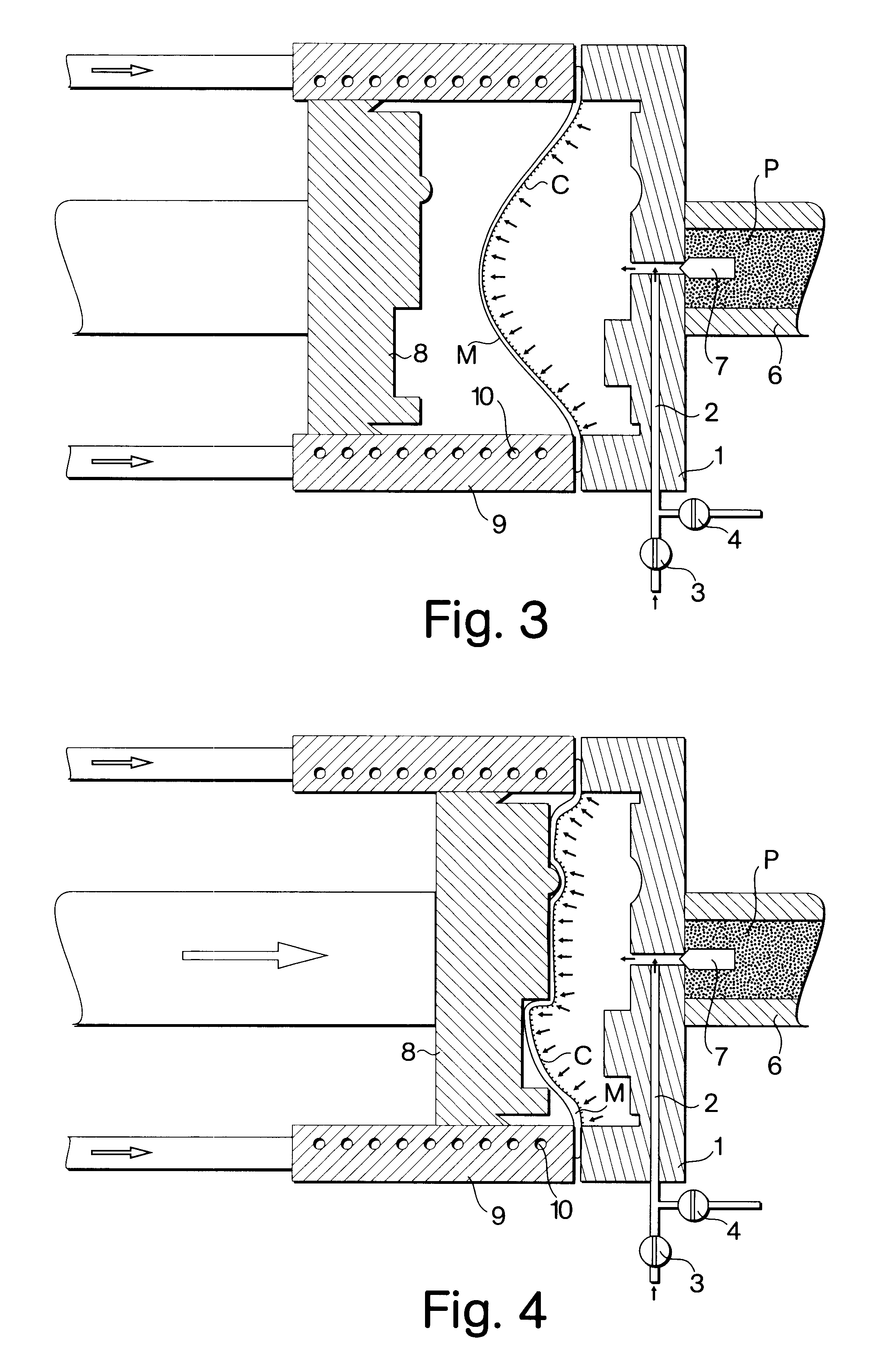

Process for injection foaming, and machine and composition therefore

A process for injection-foaming a thermoplastic resin by using an injection molding machine with a two-stage-compression screw, injecting a physical foaming agent into the cylinder of the machine at a pressure lower than the storage pressure of the physical foaming agent, mixing it with a melted resin and expanding the volume of the cavity of the mold at the time of injection, and an injection molding machine and resin composition suitable therefore.

Owner:MITSUI CHEM INC

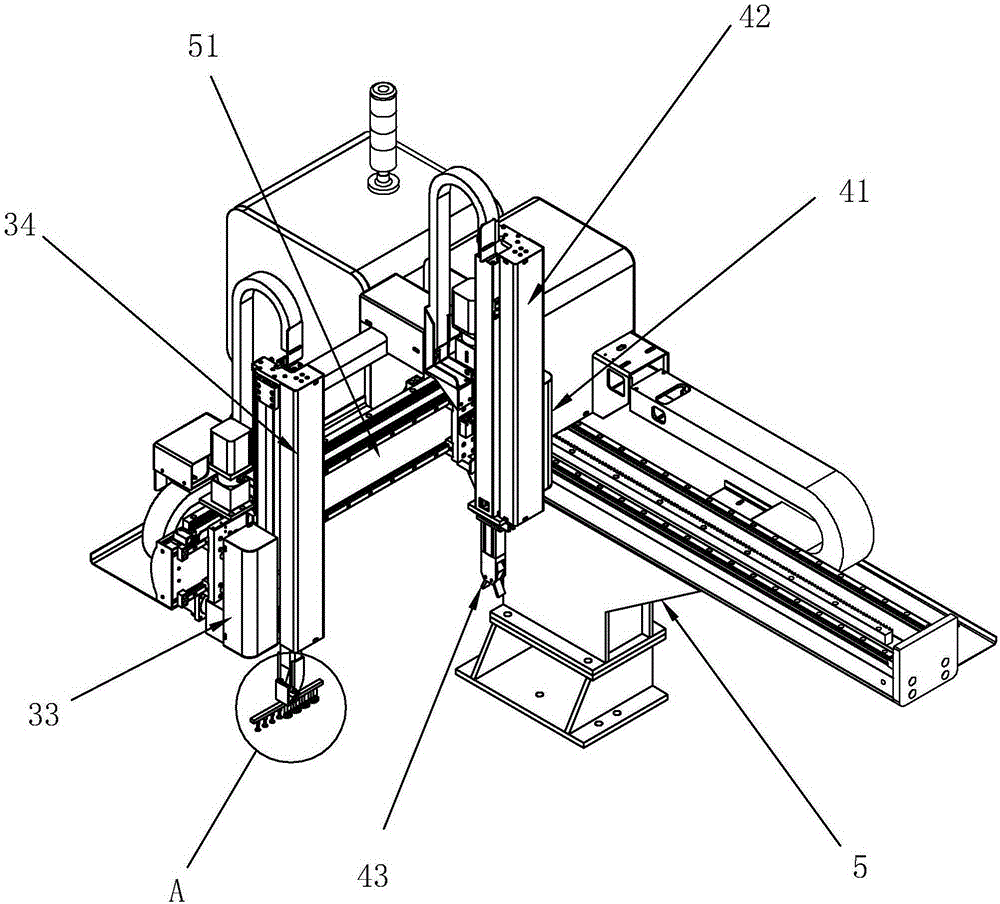

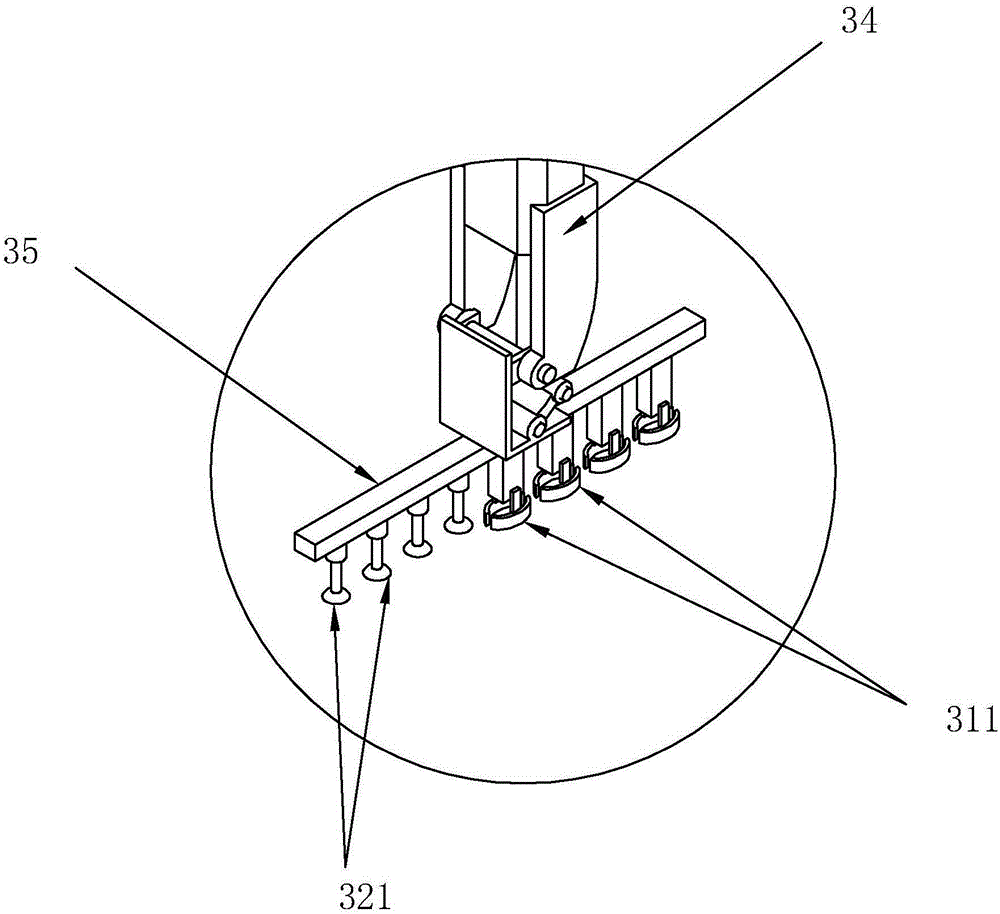

Automatic insert injection molding machine

The invention discloses an automatic insert injection molding machine. The automatic insert injection molding machine comprises an injection molding machine body and is characterized in that the injection molding machine body comprises a machine frame; a movable arm is connected to the machine frame, and a taking and placing mechanism and a waste clamping mechanism are connected to the movable arm; a feeding mechanism is further arranged on one side of the injection molding machine body and comprises a vibrating tray used for screening materials and a candidate collecting mechanism used for storing an insert temporarily; the taking and placing mechanism is provided with a grabbing assembly and an adsorbing assembly and used for grabbing the insert on the candidate collecting mechanism and adsorbing and taking out a finished injection molded product. The waste clamping mechanism is used for clamping waste generated during injection molding of the insert. According to the automatic insert injection molding machine, automatic feeding and collecting are achieved, automatic machining is completed, risks and a high error rate of manual operation are avoided, and damage to a die is reduced; in addition, the quality of products is guaranteed and made uniform, production efficiency is greatly improved, labor is reduced, and cost is reduced.

Owner:HANGZHOU ZHENHUA COSMETIC GLASS

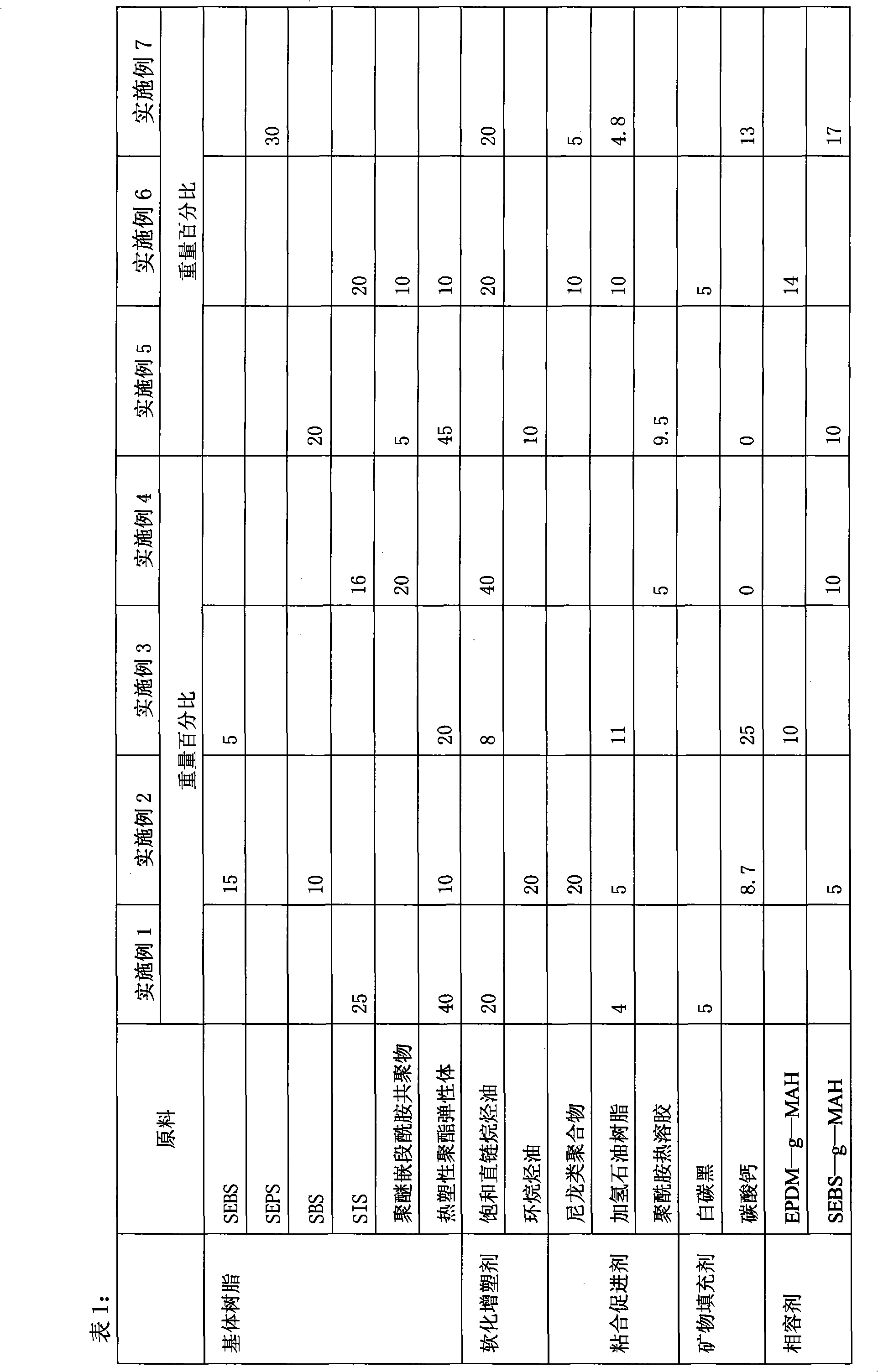

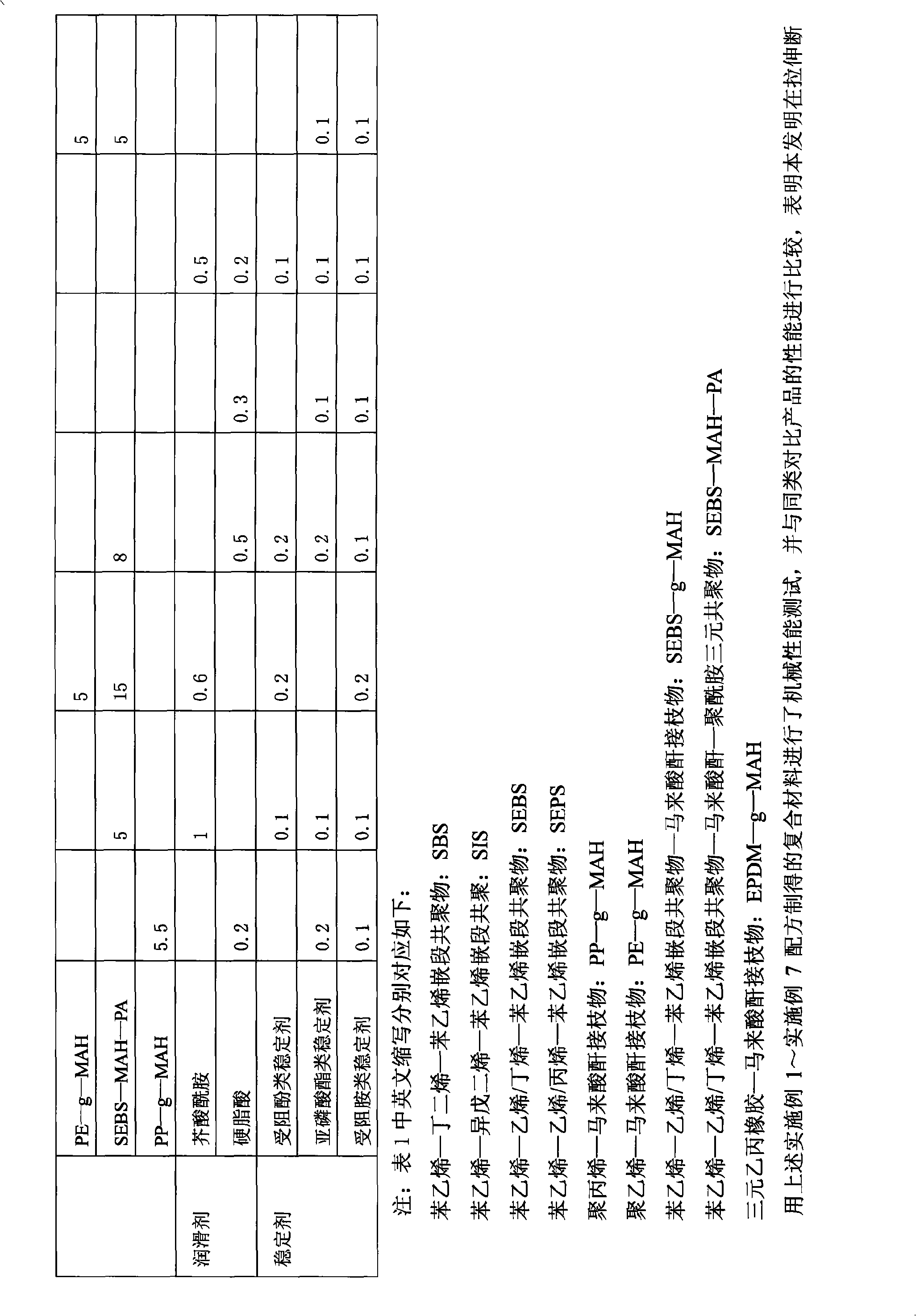

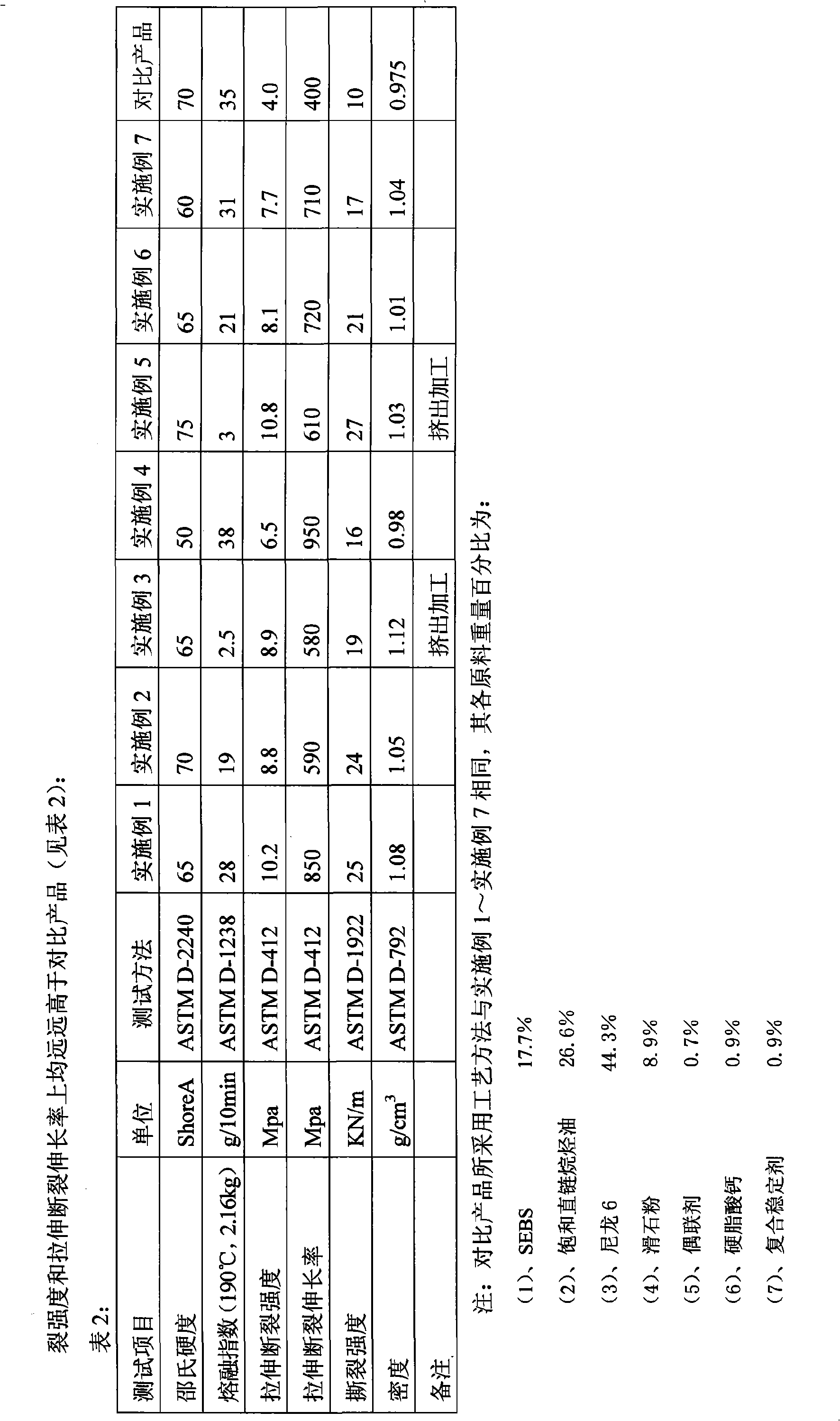

Thermoplastic elastomer capable of coating and bonding with nylon

The invention provides a thermoplastic elastomer coated and bonded by nylon, comprising matrix resin, softened plasticizer, adhesion promotor, mineral filler, lubricant and stabilizer, wherein the weight percentage of the material is as follow: resin 20-75%, softened plasticizer 5-45%, adhesion promoter1-30%, mineral filler 0-3%, compatiblizing agent 5-35%, lubricant 0-2%, stabilizer 0-2%. The matrix resin also comprises: thermoplasticity polyurethane elastomer or polymerized silica block amide copolymer, which makes the thermoplastic elastomer with good physical property, in addition a great variety of compatiblizing agents are used, therefore each component fully and mutually dissolves with each other to reduce the occurence of delamination, and the solubility of the composite material to the other engineering plastics, so that the thermoplastic elastomer is firmly adhesive on the surface of the nylon material without any bonding agent by twice injection of plastic jetting-moulding machine or extruder, and coating adhesive on the material such as ABC, PC. The market prospect is increased.

Owner:NINGBO SHIP PLASTIC CO LTD

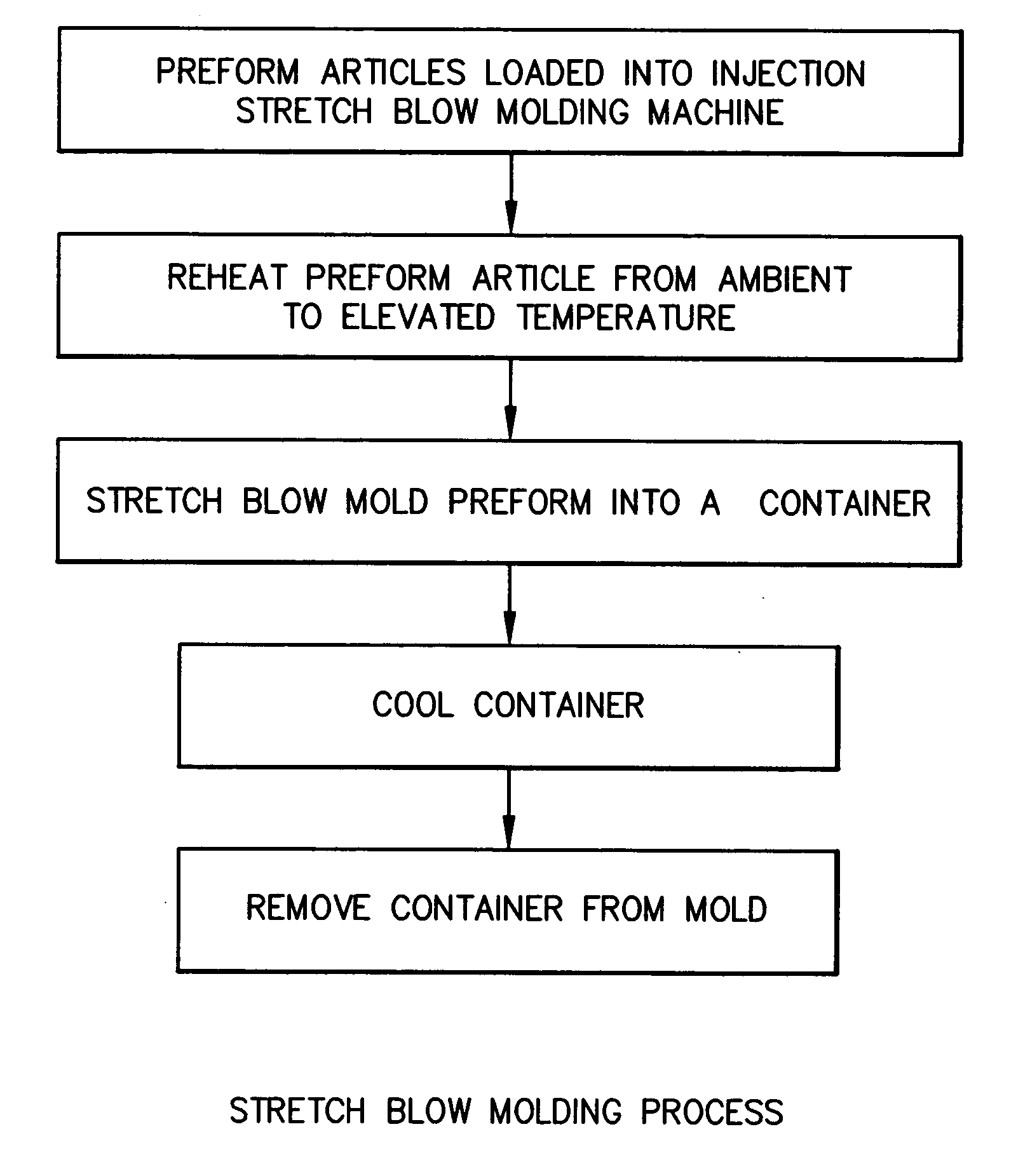

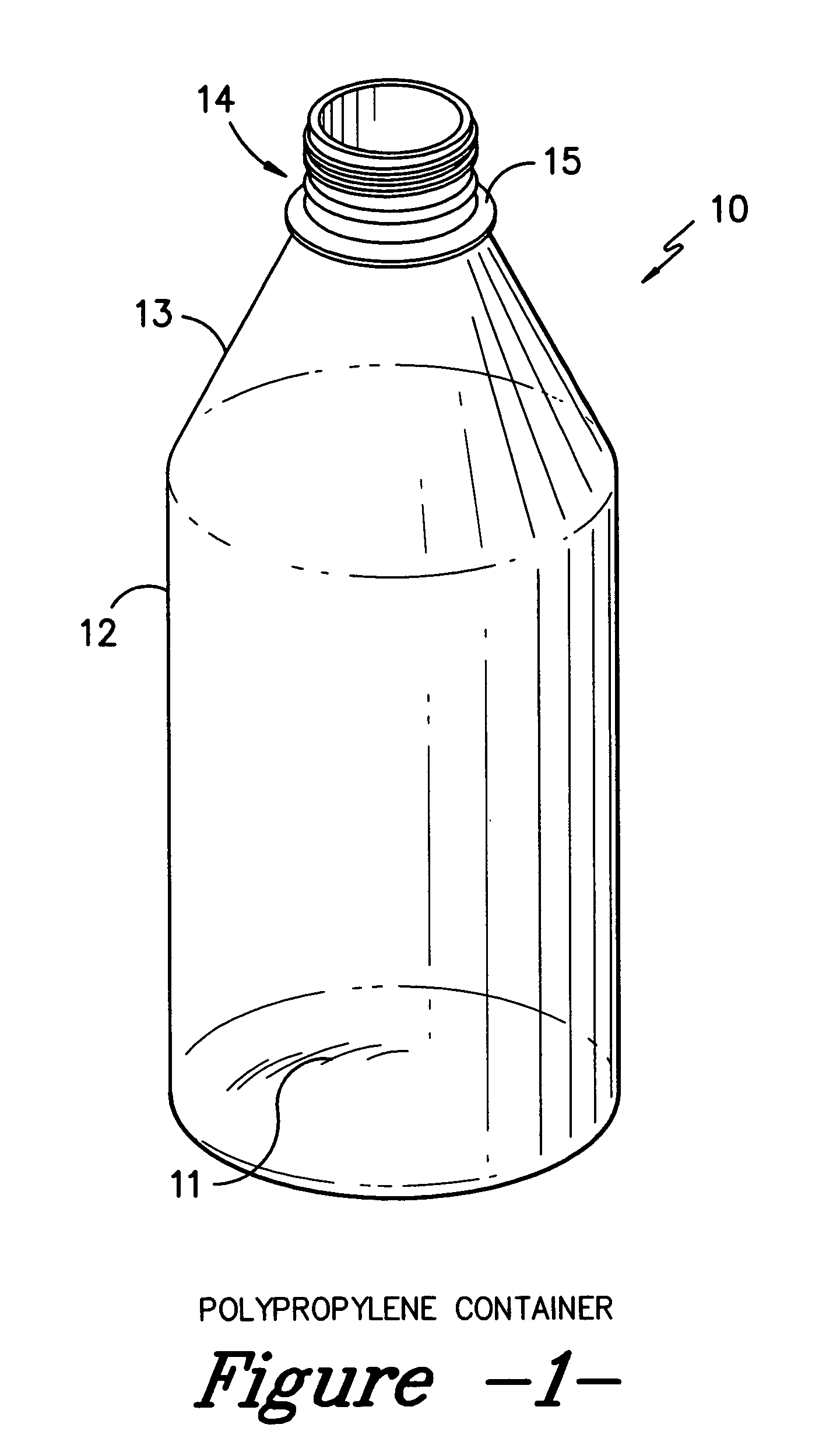

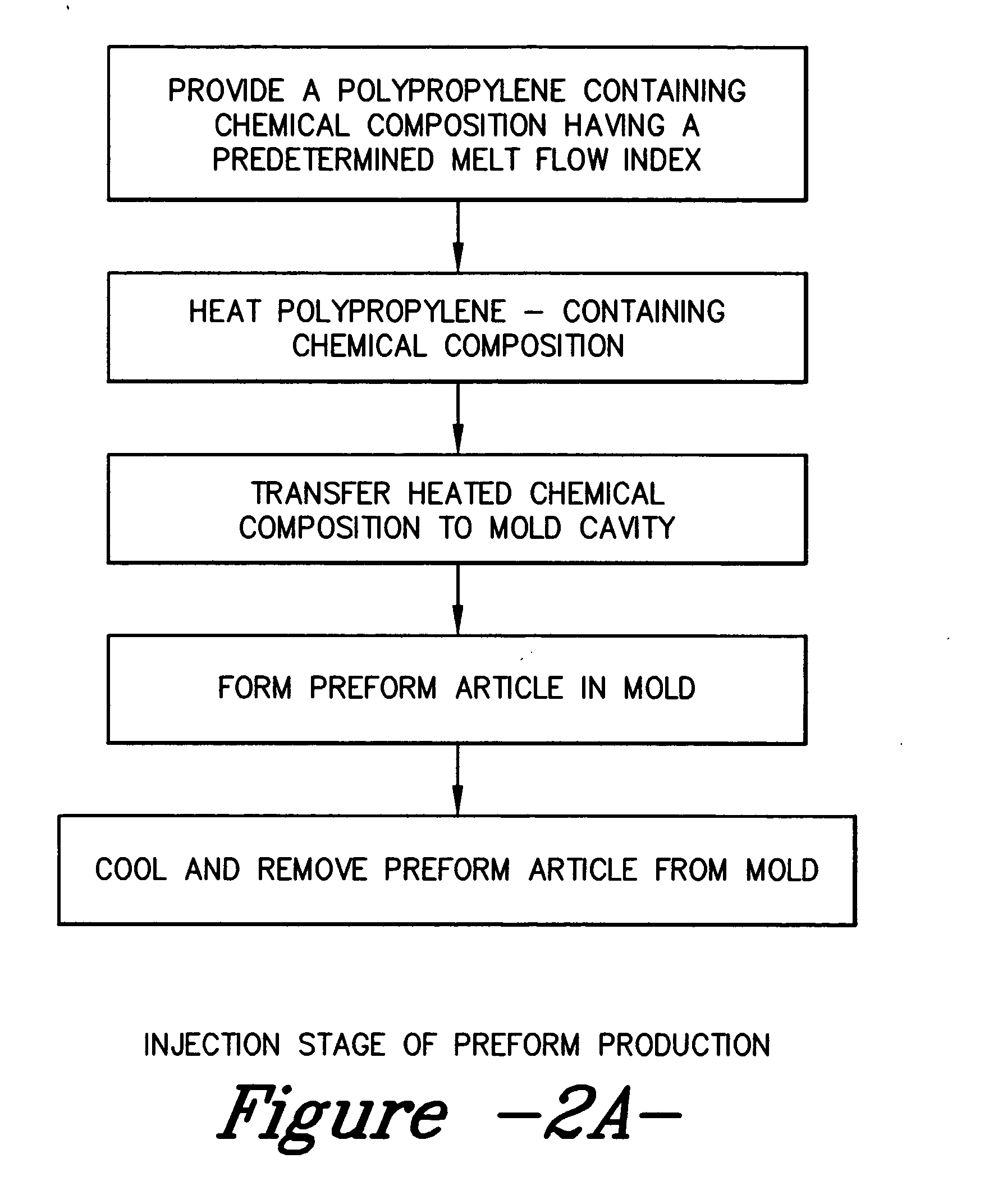

Process of making two-stage injection stretch blow molded polypropylene articles

The two stage production of clear, low-haze, injection stretch blow molded polypropylene container articles is disclosed. In the first processing stage, a preform article is manufactured on an injection molding machine. In a second and subsequent step, which may occur remotely from apparatus used in the first step, the preform article is heated and stretch blown into a container. The process may employ the selection of processing parameters to produce preform articles that facilitate stretch blow molding at relatively high rates of speed, while still maintaining an appropriate polypropylene polymer morphology that results in clear, low haze containers.

Owner:MILLIKEN & CO

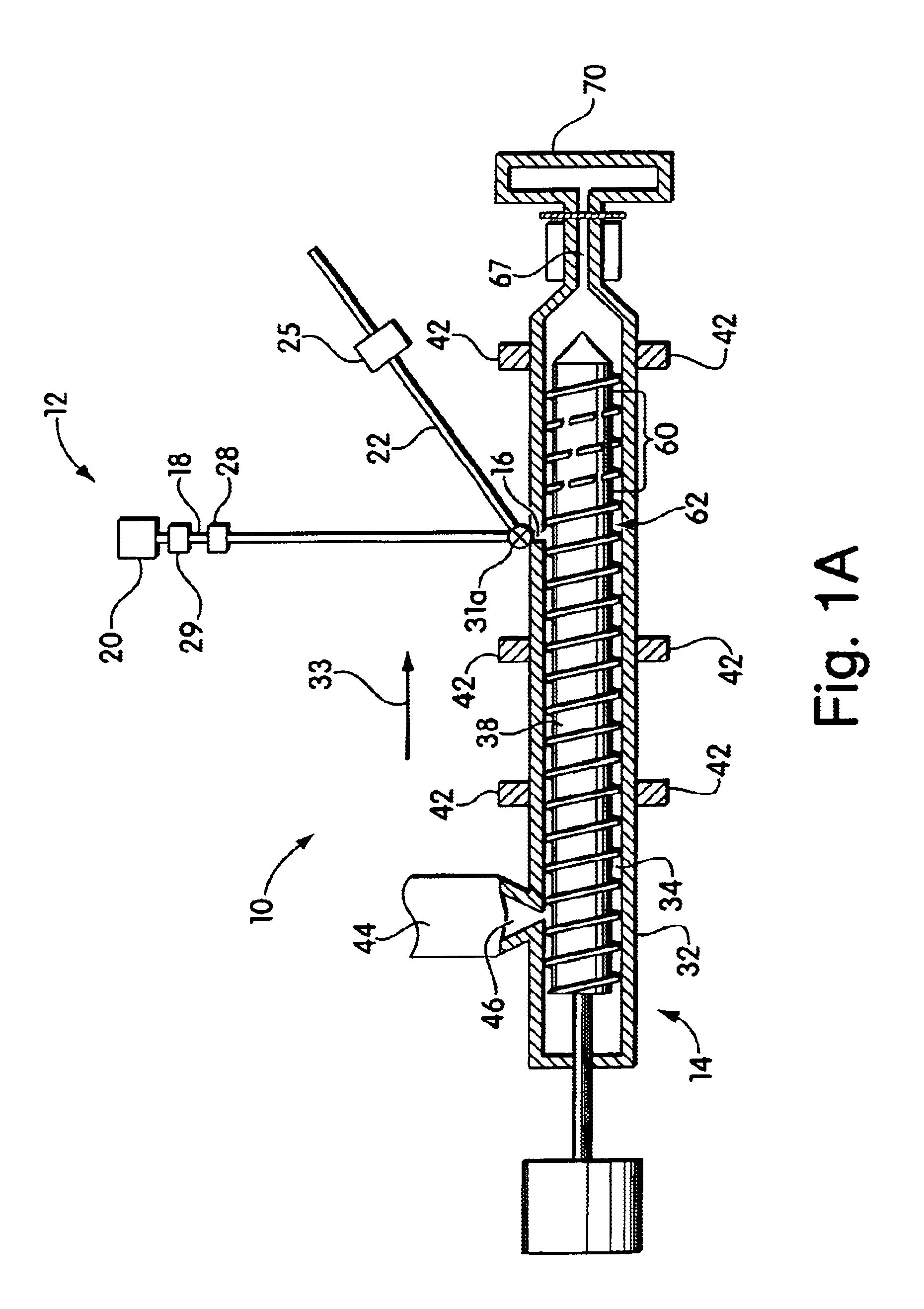

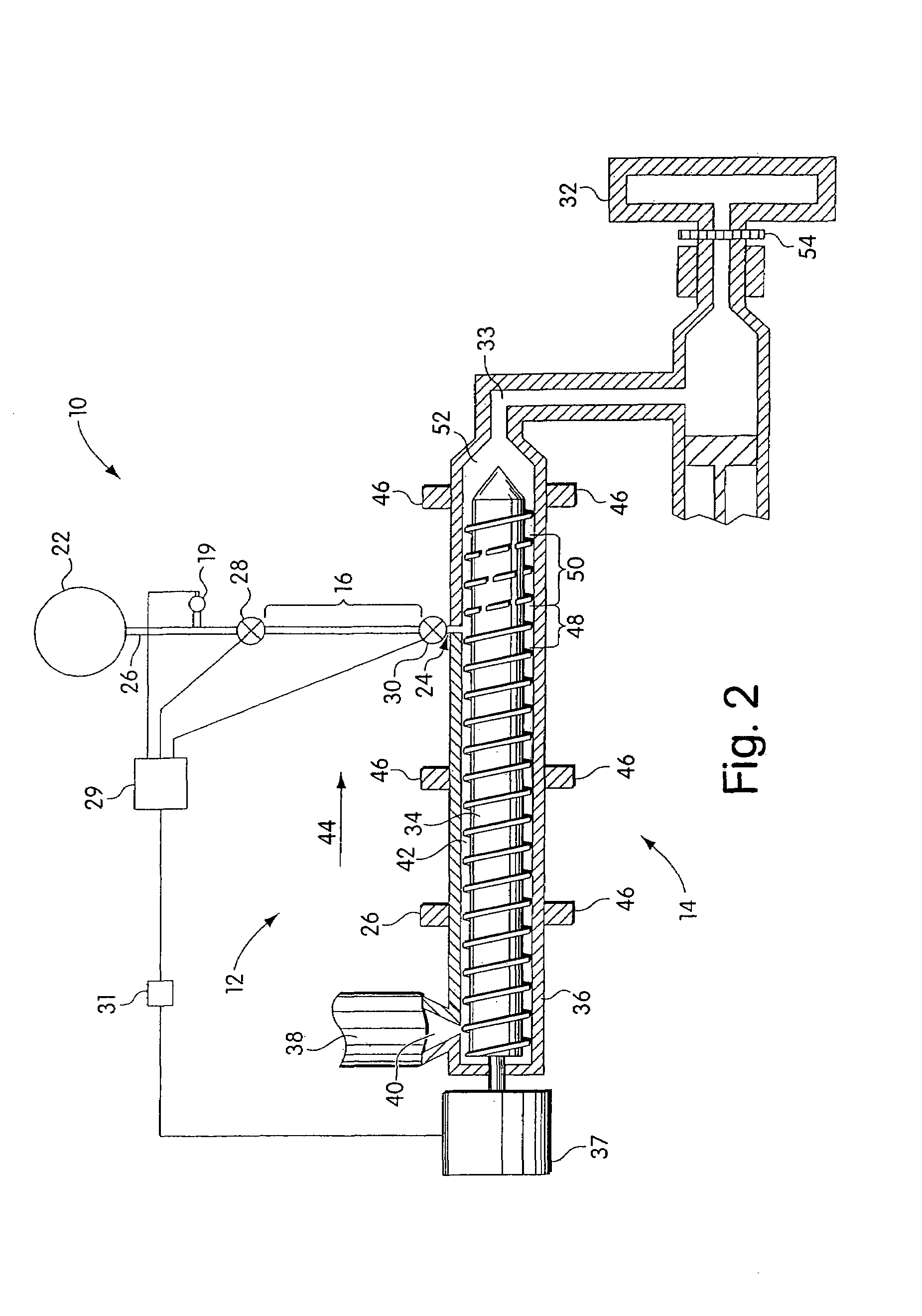

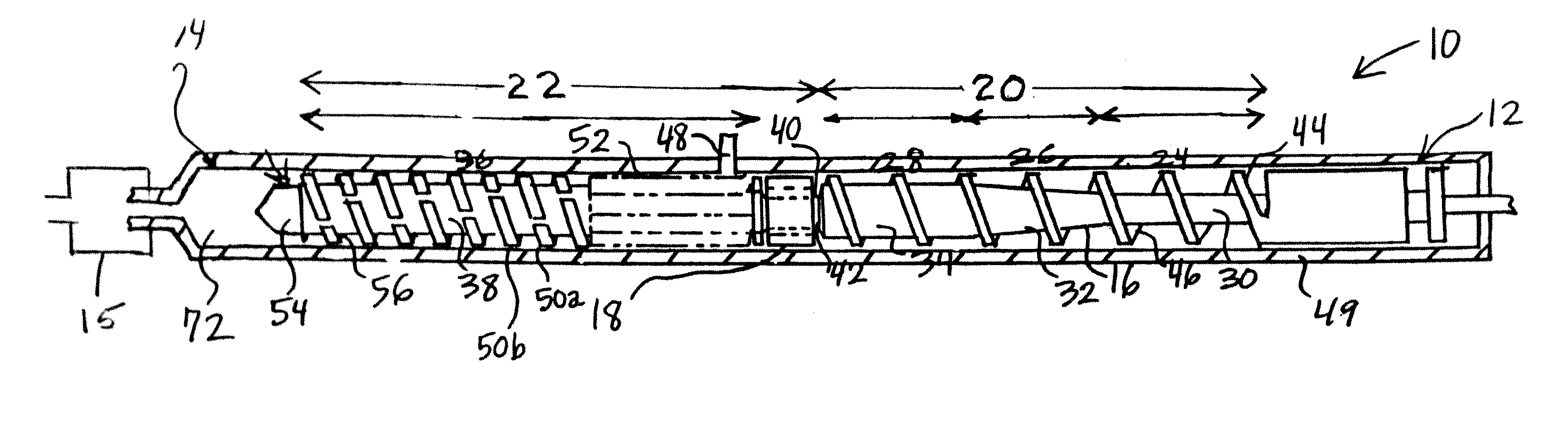

Injection molding method and apparatus for continuous plastication

InactiveUS7291297B2Improve output efficiencyLower energy requirementsAuxillary shaping apparatusFood shapingReflux valveEngineering

In a reciprocating (RS) injection unit environment, as shown in FIG. 1, a controller of the injection unit is arranged to continuously rotate the screw during both conventional plasticizing operation and shot injection. In this way the RS unit is more efficient, utilizing less energy and producing greater resin output. The injection unit includes a non-return valve adjacent a nozzle, which non-return valve is either configured to rotate with the screw to reduce wear or presented as a ball check style noon-return valve. In an injection molding environment, the rotating screw includes flights that allow granules of resin to melt and mix in spaces between adjacent flights, but the flights are arranged substantially to inhibit excessive displacement of resin around the flights.

Owner:HUSKY INJECTION MOLDING SYST LTD

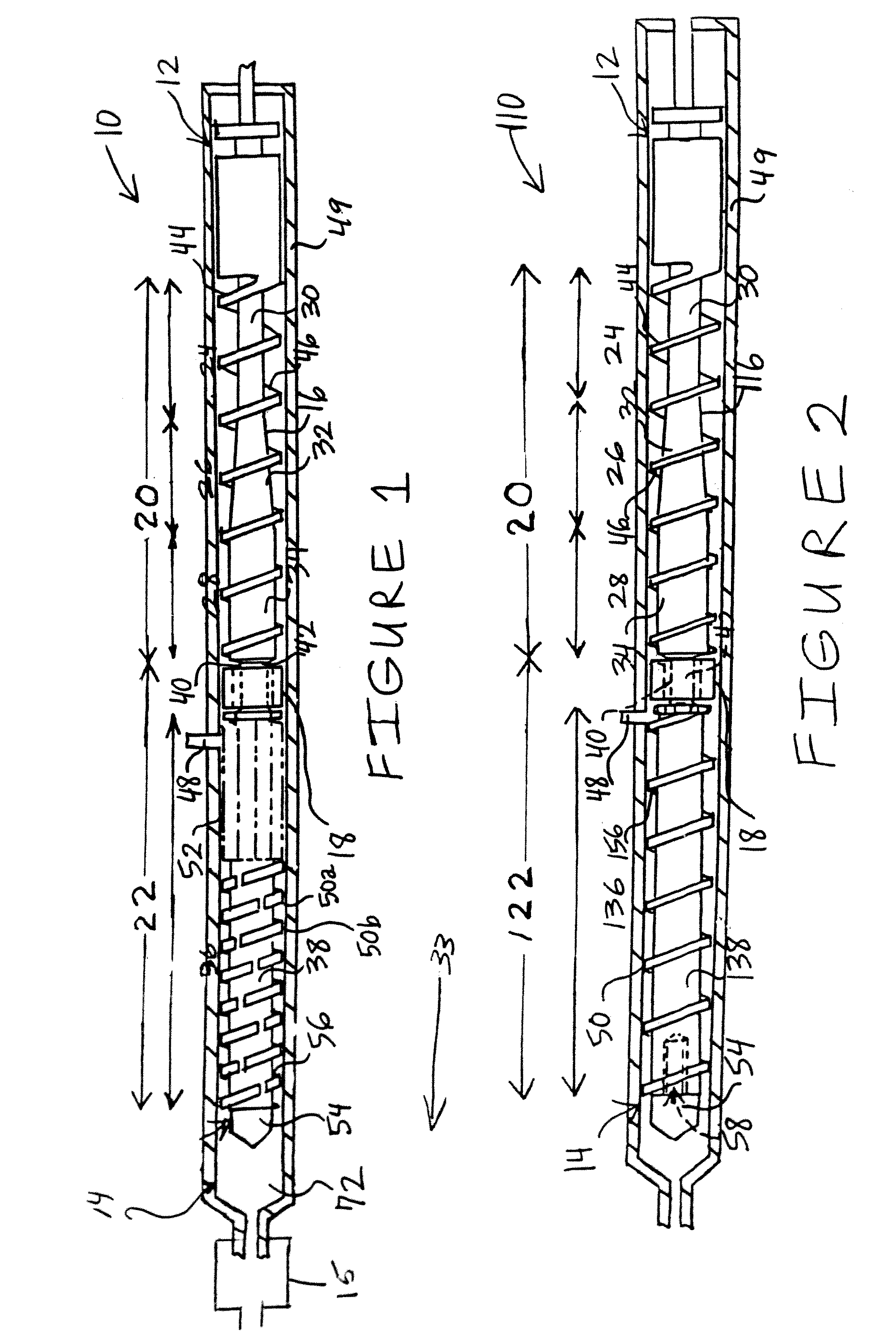

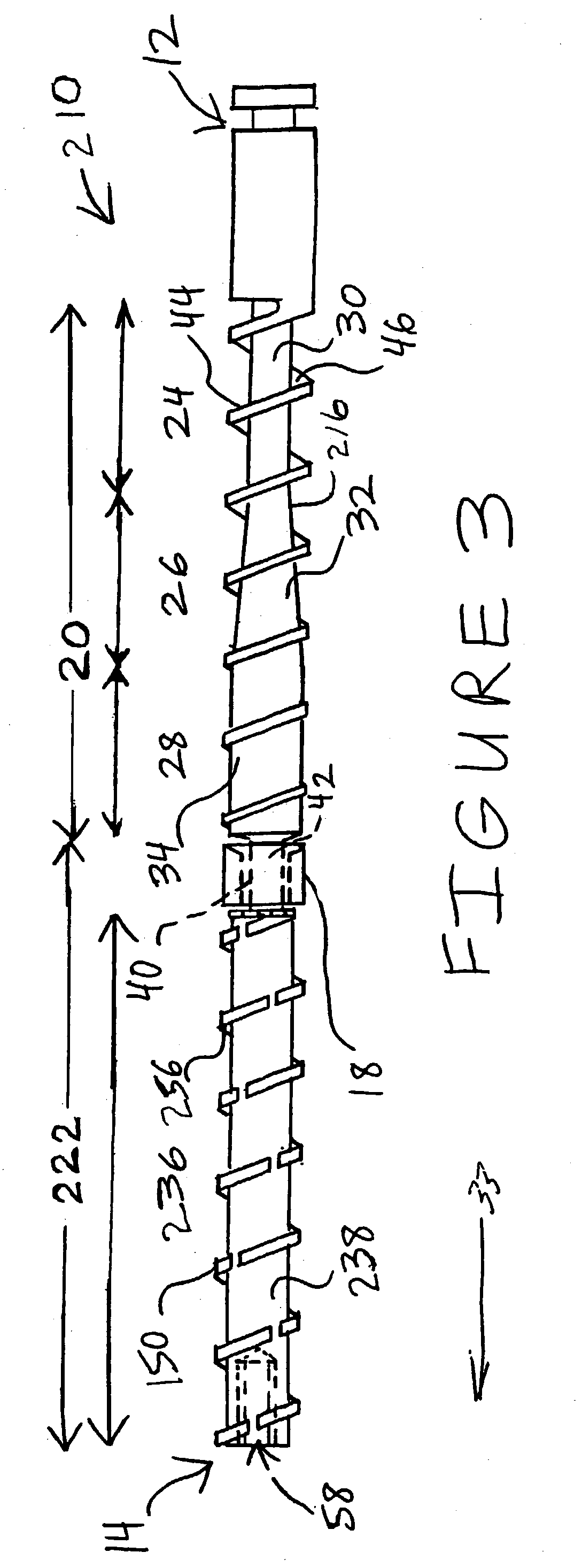

Injection molding screw

InactiveUS7172333B2Minimized pressure lossRotary stirring mixersFrozen sweetsEngineeringInjection molding machine

An injection molding screw for metal injection molding includes a first end, a second end, a longitudinal body with a first stage and a second stage extending axially along a length of the screw between the ends, a pressure retention device, and optionally, a screw tip. The pressure retention element minimizes loss of pressure in the second stage portion.

Owner:SOUTHCO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com